Reddish brown ceramic color glaze and preparation method thereof

A technology of ceramic color and reddish brown, applied in the field of colored ceramic glaze and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

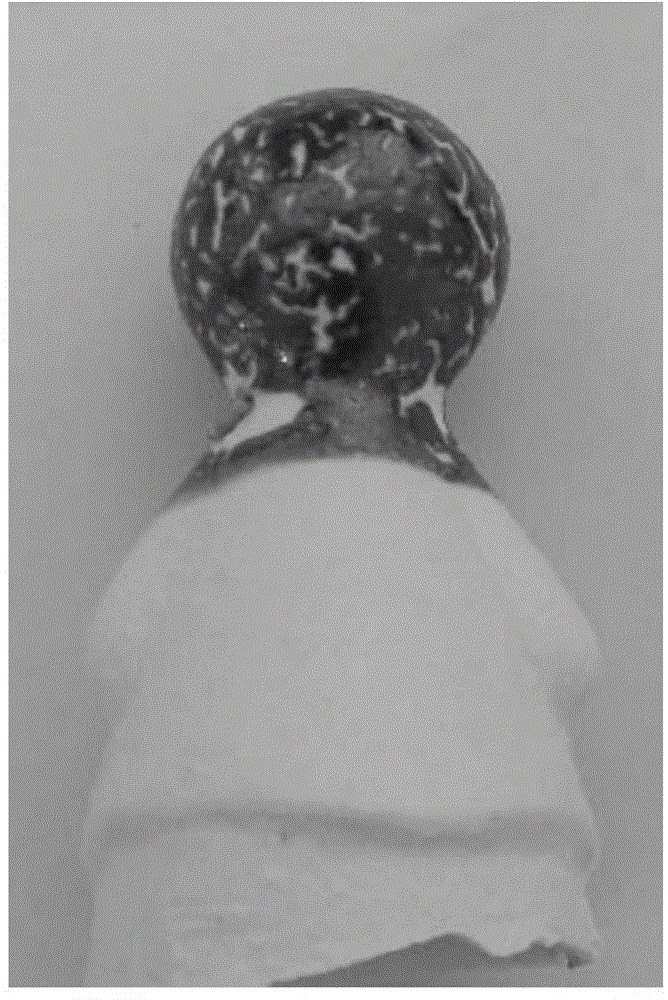

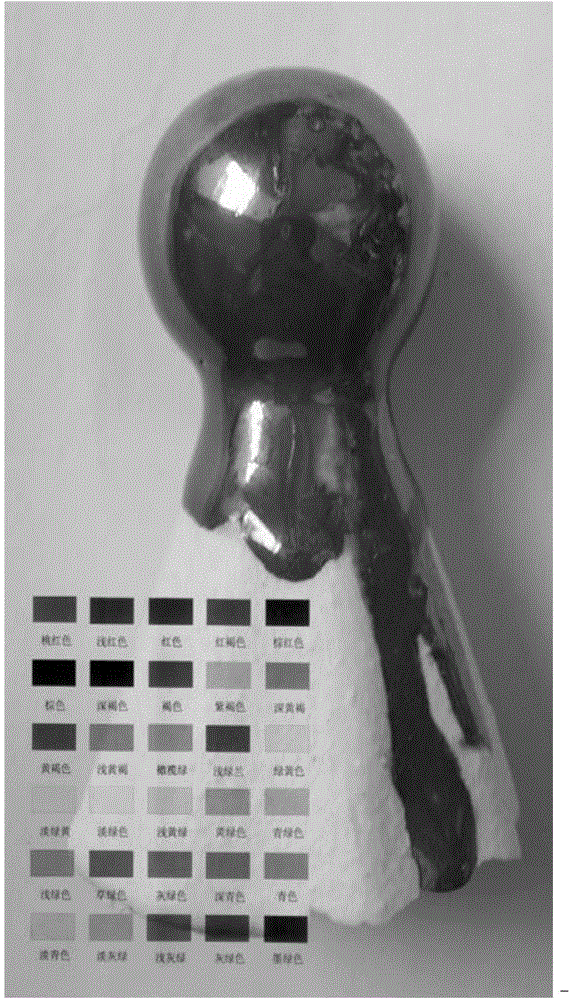

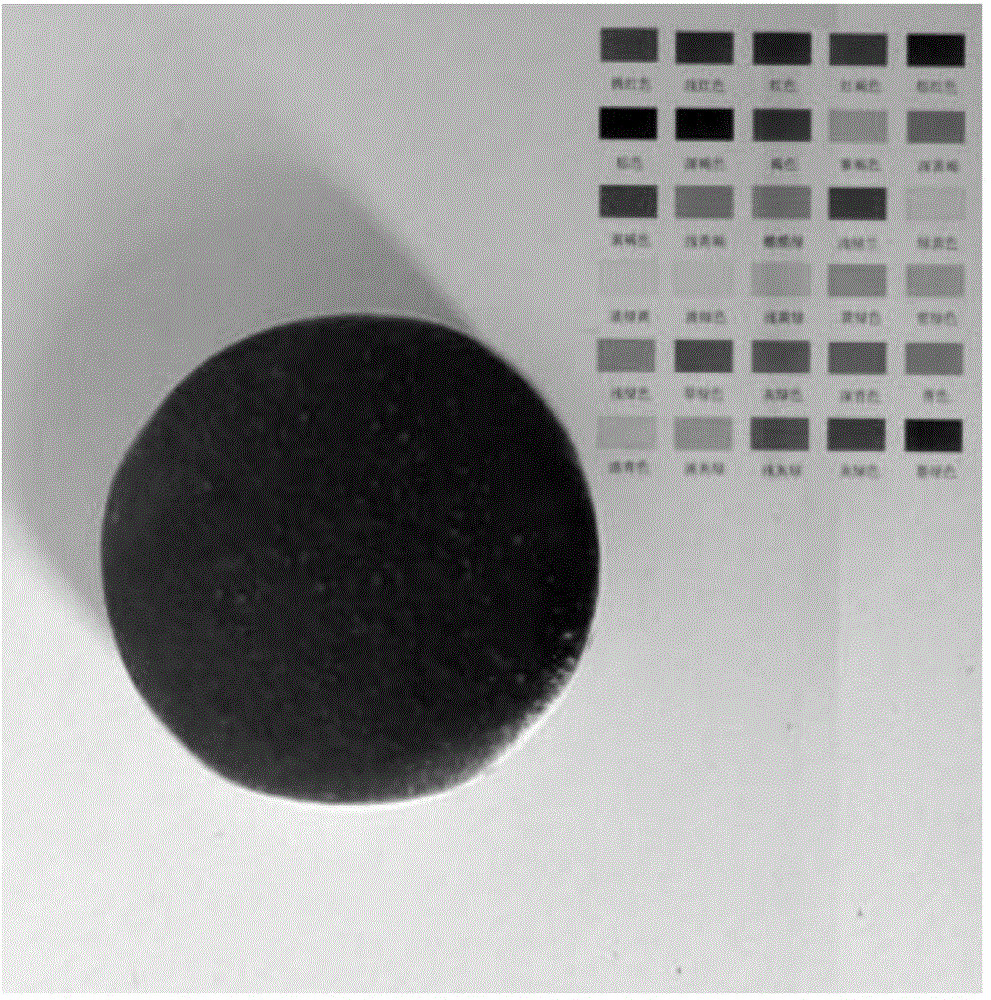

Image

Examples

specific Embodiment approach 1

[0043] Specific embodiment one: the reddish-brown ceramic colored glaze of this embodiment is made by 65%~75% volcanic mud and 25%~35% albite by weight percentage; Or reddish-brown ceramic colored glaze is made by weight percentage %~10% kaolin and 90%~95% volcanic rock ore.

[0044] This embodiment uses volcanic slime or volcanic rock ore as the main raw material. The glaze prepared in this embodiment can be evenly distributed on the ceramic body when the glaze layer is in a molten state during the high-temperature firing process, and the glaze formula does not contain Gas raw materials (such as calcite, limestone, etc.); therefore, the glaze surface made by this embodiment will not produce pinholes and bubbles due to the escape of gas, and avoid glaze defects.

[0045] The complex composition of existing glazes inevitably contains components that affect the color of the glaze surface, so there are strict requirements on the kiln temperature and kiln position during the firin...

specific Embodiment approach 2

[0046] Specific embodiment two: In this embodiment, the reddish-brown ceramic color glaze is made of 68%-73% volcanic mud and 27%-32% albite by weight percentage.

specific Embodiment approach 3

[0047] Embodiment 3: In this embodiment, the reddish-brown ceramic colored glaze is made of 70% volcanic mud and 30% albite by weight percentage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com