Patents

Literature

30 results about "Glaze defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glaze defects are any flaws in the surface quality of a ceramic glaze, its physical structure or its interaction with the body.

Stripping glaze, stripping-glaze marble ceramic tile without glaze defects and preparation process of marble ceramic tile

Owner:FOSHAN DONGPENG CERAMIC +2

Black ink-jet ceramic tile and manufacturing method thereof

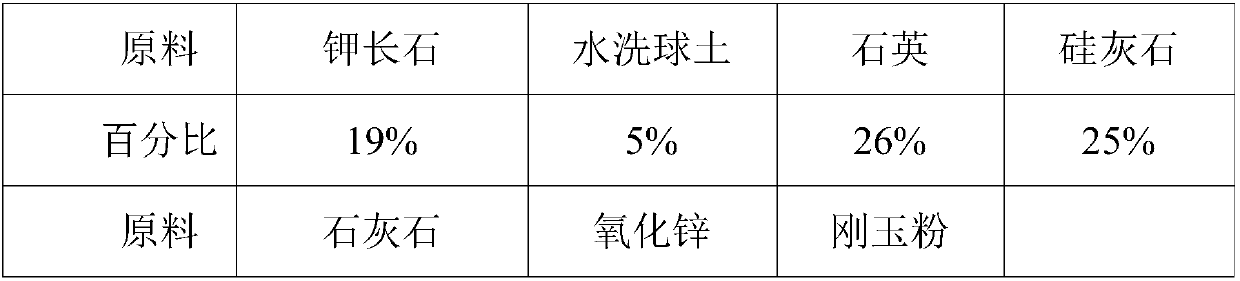

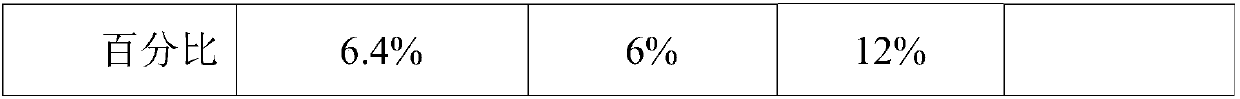

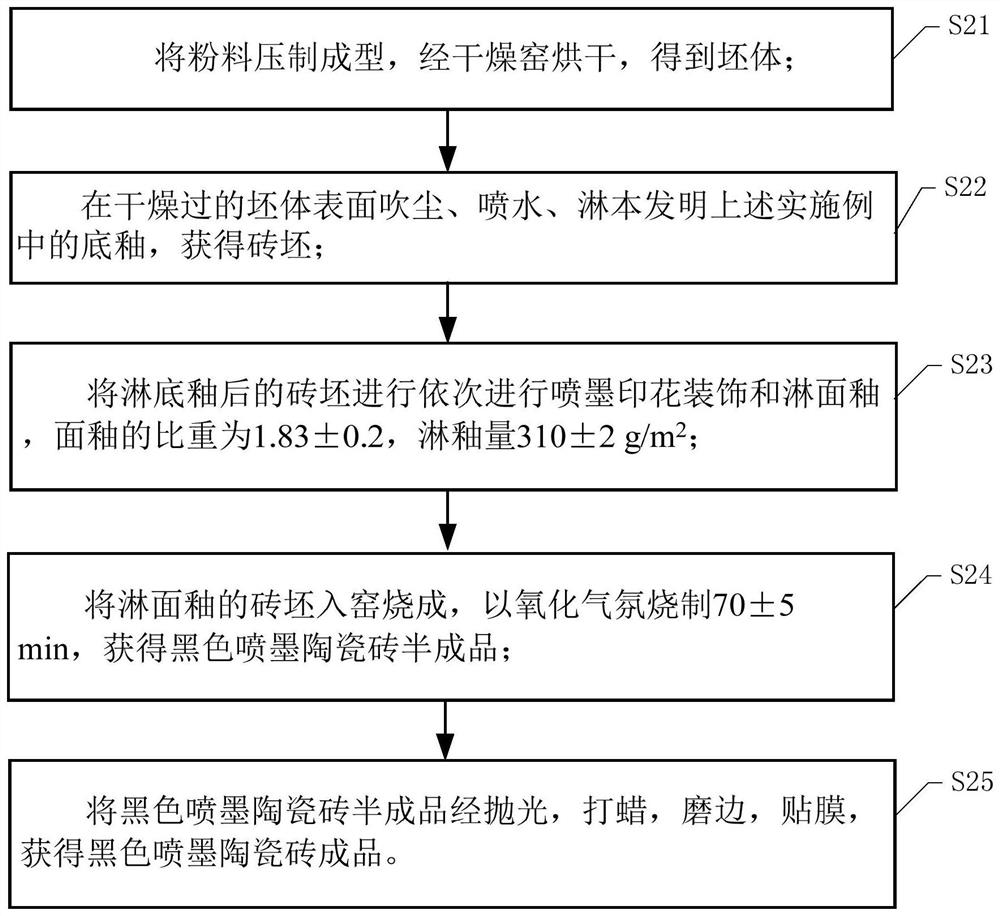

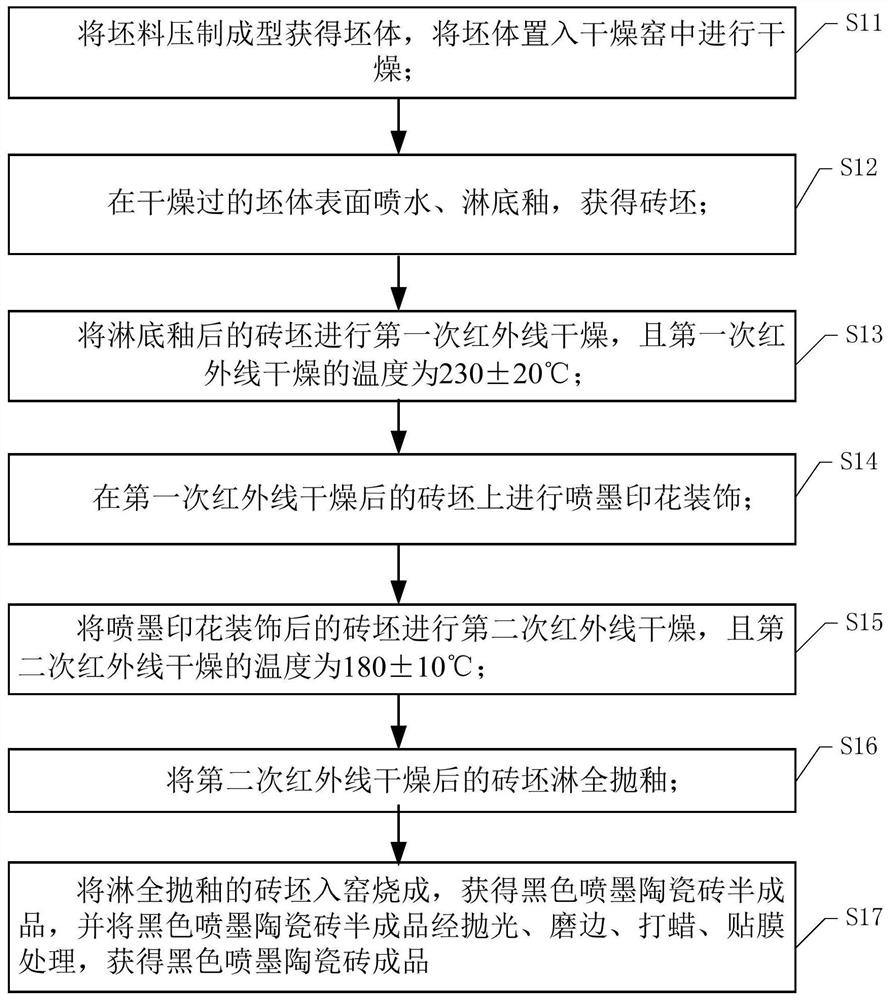

The invention discloses a black ink-jet ceramic tile and a manufacturing method thereof. The method comprises: carrying out pressing molding on a billet material to obtain a billet, placing the billetinto a drying kiln, and drying; spraying the surface of the dried billet with water, and leaching with a bottom glaze to obtain a brick billet; carrying out first infrared drying on the leached brickbillet, wherein the temperature is controlled at 230+ / -20 DEG C; carrying out ink-jet printing decoration on the surface of the leached brick billet; carrying out second infrared drying on the obtained brick billet, wherein the temperature is controlled at 180+ / -10 DEG C; and spraying the surface of the dried brick billet with a full-polished glaze, firing in a kiln, polishing, edging, waxing, and laminating to obtain the black ink-jet ceramic tile finished product. According to the invention, through the infrared drying, the drying efficiency of the glaze and the ink is improved, the glaze avoiding defect of the dark ink-jet product is overcome, the labor intensity of workers is reduced, and the quality and the production efficiency of black ink-jet ceramic tiles are remarkably improved.

Owner:CHONGQING WONDERFUL CERAMICS CO LTD +2

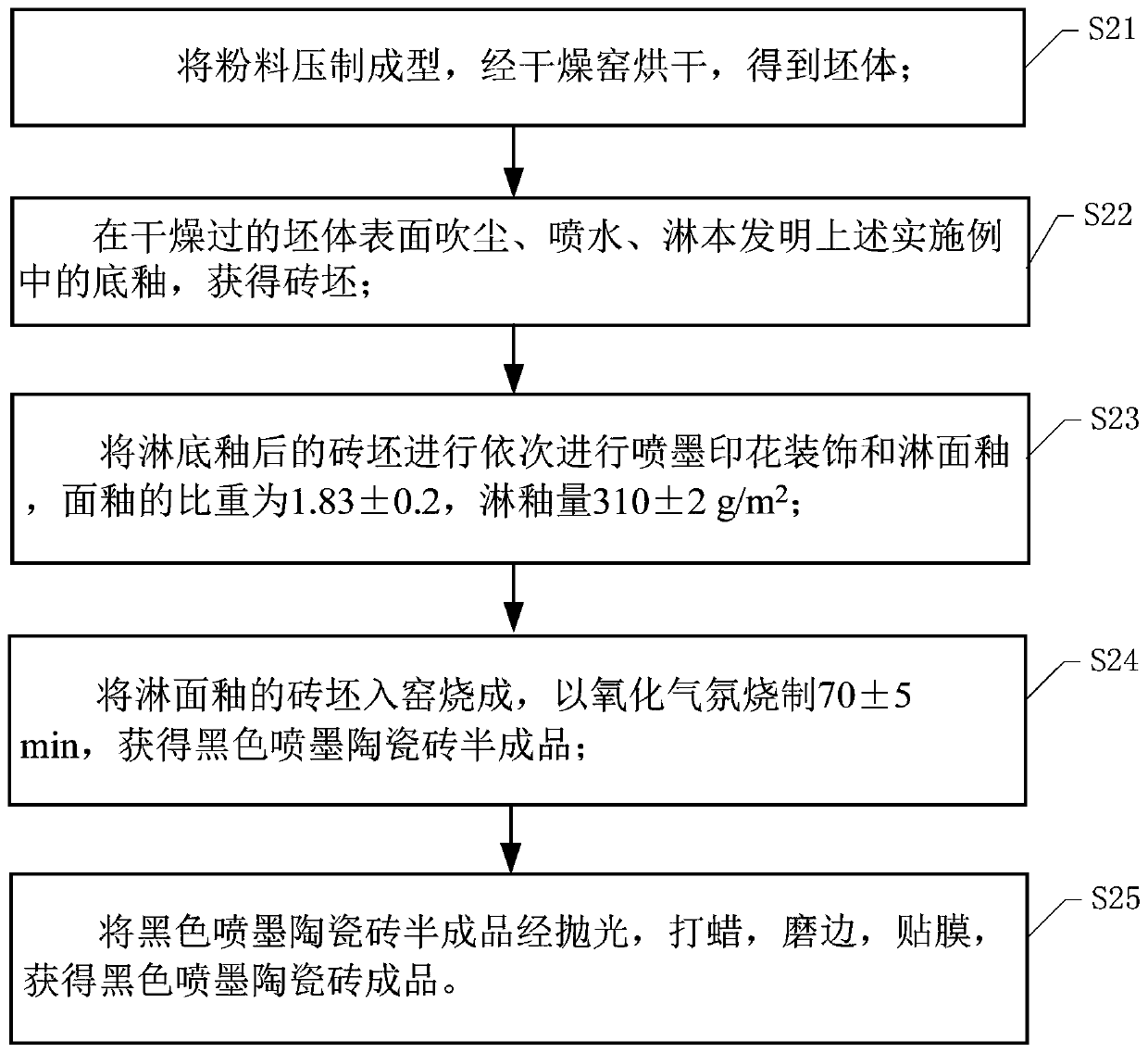

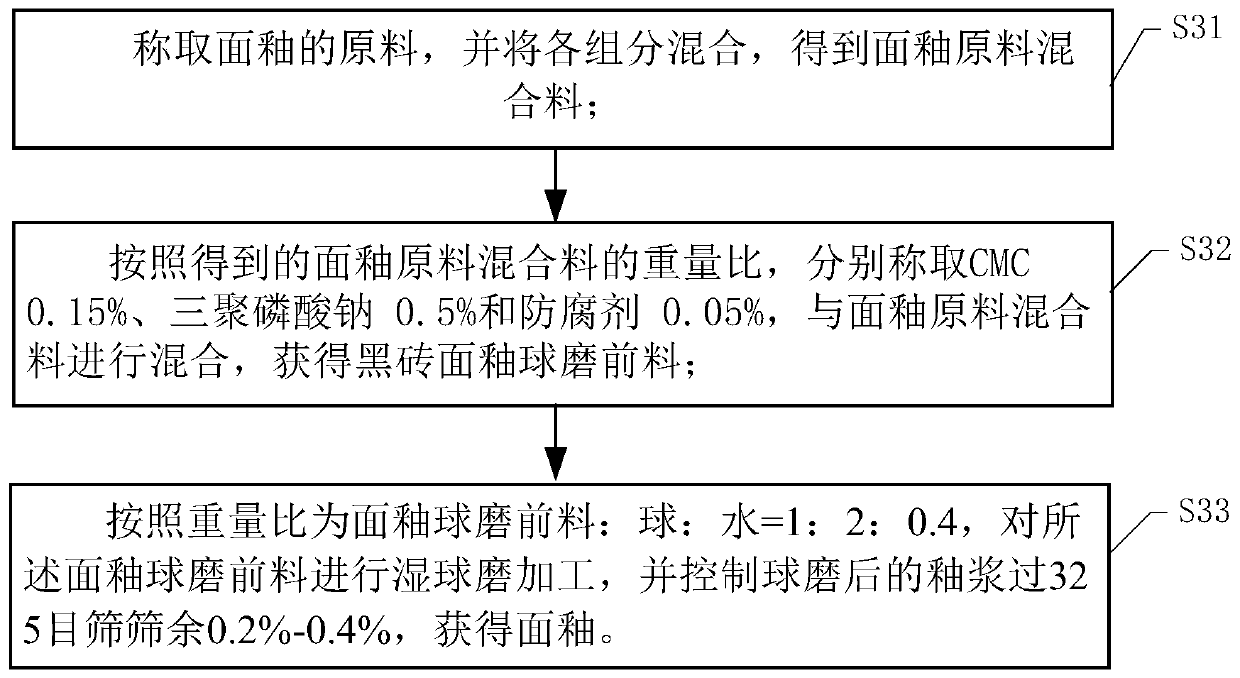

Ground glaze and preparation method thereof, as well as black ink-jet ceramic tile and manufacturing method thereof

ActiveCN110790507AGood appearance consistencyIncrease infiltration depthTextile printerChemical composition

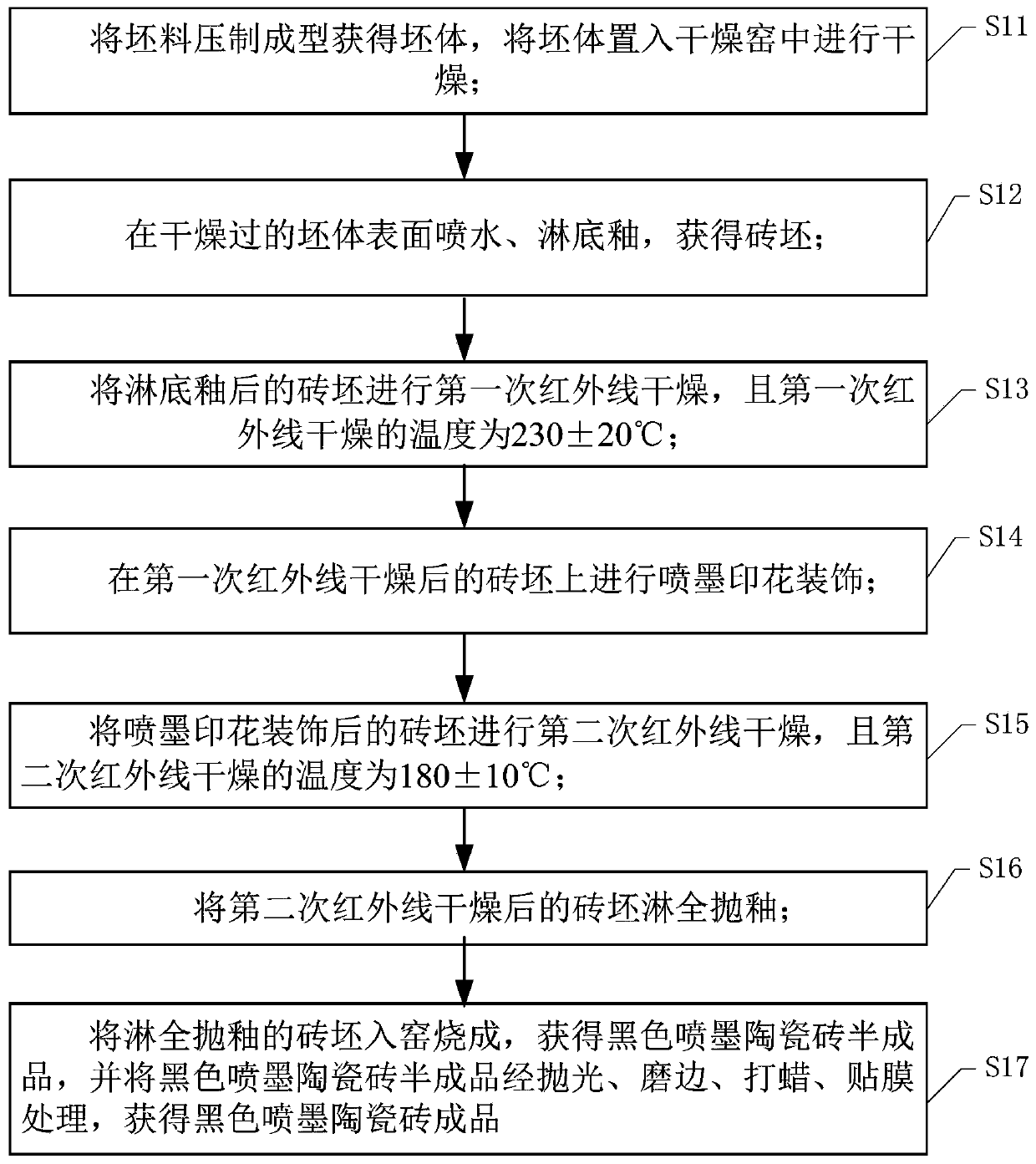

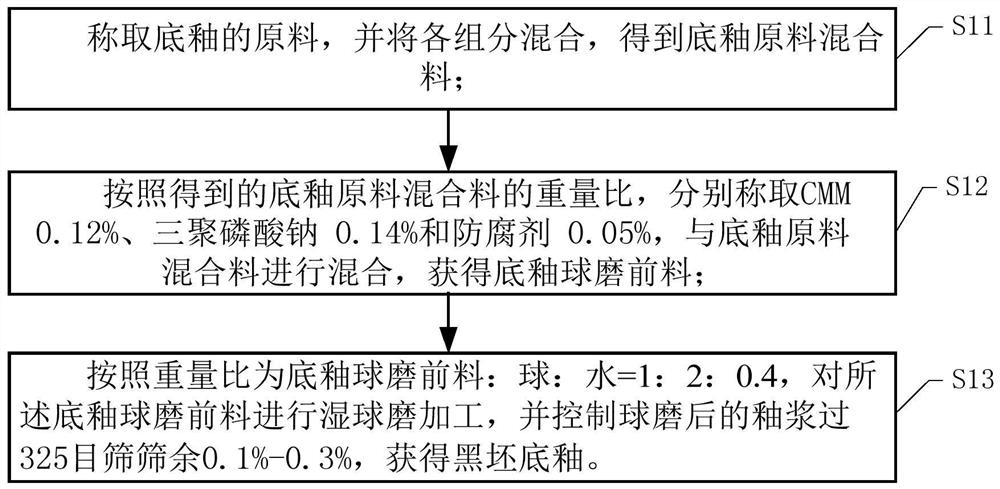

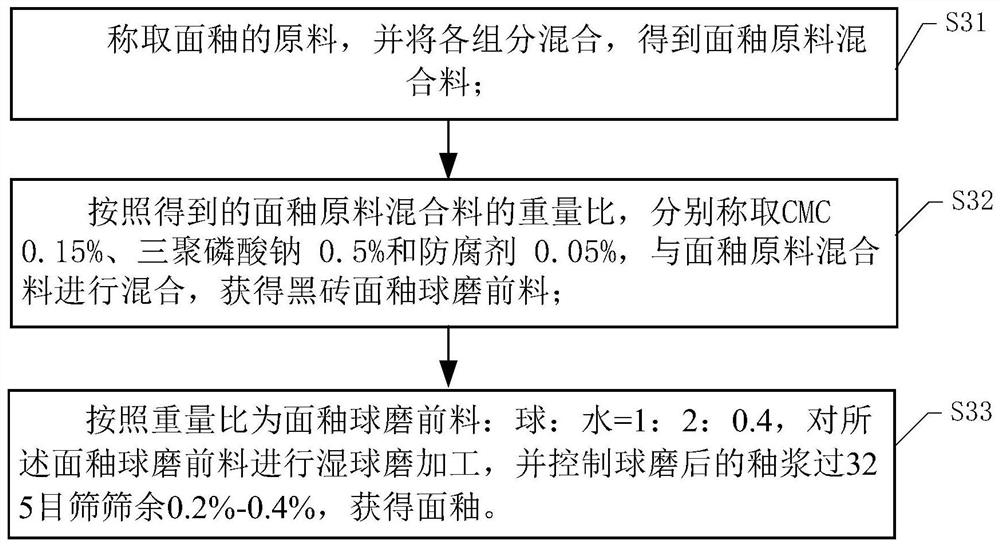

The invention discloses a ground glaze and a preparation method thereof, as well as a black ink-jet ceramic tile and a manufacturing method thereof. The ground glaze is prepared from the raw materialcompositions in parts by mass: 5 parts of kaolin, 33 parts of potassium feldspar, 28 parts of albite, 10 parts of quartz powder, 10 parts of zirconium silicate, 7 parts of talcum powder and 7 parts ofa 965 frit. The 965 frit is prepared from the chemical compositions in percentage by mass: 49.97% of SiO2, 16.96% of Al2O3, 0.14% of Fe2O3, 0.05% of TiO2, 12.71% of CaO, 1.41% of MgO, 4.03% of K2O, 12.57% of Na2O, 0.37% of ZnO, 0.18% of B2O3, 0.83% of BaO and 0.78% of losses on ignition. By controlling the adding amount of the kaolin, the penetration depth of ink is increased, the drying efficiency of the ink is improved, and the defect of avoiding glazes after ink-jet printing is overcome.

Owner:CHONGQING WONDERFUL CERAMICS CO LTD +2

Satin glaze, satin glazed tile and preparation method of satin glazed tile

ActiveCN113912294ASuitable for various application occasionsImprove the decorative effectCeramic shaping apparatusCeramic materials productionAlkali metal oxideGlaze defects

The invention discloses satin glaze, a satin glazed tile and a preparation method of the satin glazed tile. The satin glaze comprises the following chemical components in percentage by mass: 43-48% of SiO2; 14-17% of Al2O3; 16-21% of alkaline earth metal oxide; 6.1-7.2% of an alkali metal oxide; 5.2-6.6% of ZnO; and 1.2-1.5% of ZrO2. According to the satin glaze, the high-temperature matte frit and the raw glaze are combined for use, so that the requirements of luster, hand feeling, transparency, wear resistance, glaze texture and the like of the satin glaze are better met. The satin glazed tile solves the problems of low glaze glossiness and poor transparency, and hardly has glaze defects; besides, the luster of the satin glaze surface is not influenced by kiln temperature or raw material fluctuation, and the luster of the glaze surface is stable.

Owner:广东清远蒙娜丽莎建陶有限公司

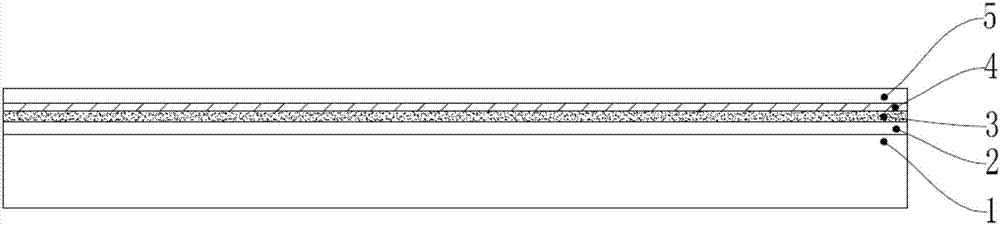

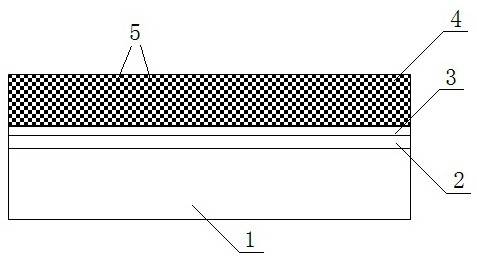

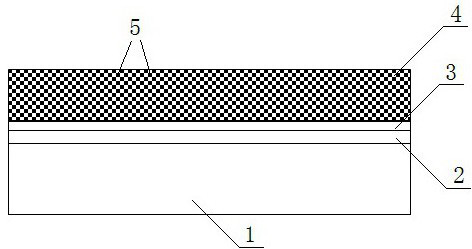

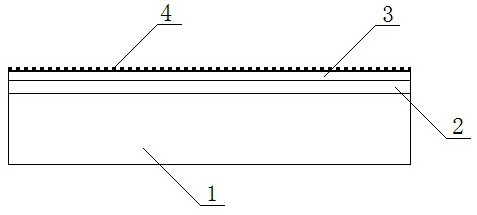

Ceramic brick with super-flat glaze without glaze defect and preparation process of ceramic brick

The invention discloses a ceramic brick with a super-flat glaze without glaze defects and a preparation process of the ceramic brick. The ceramic brick comprises a blank body, a bottom glaze layer, a pattern layer, an insulating layer and a transparent glaze layer from bottom to top in sequence, wherein the insulating layer is made of a printing paste with an aqueous tackifying resin in a silk-screen printing manner; and the viscosity of the printing paste is 2000-3000MPa.S. The ceramic brick with the super-flat glaze without glaze defects, which is disclosed by the invention, is high in glaze flatness and clear and fine in glaze pattern, and glaze defects such as glaze pouring orange peel, pinholes and concave glazes are effectively solved.

Owner:FOSHAN DONGPENG CERAMIC +2

Porcelain archaized brick with golden glittering effect and preparation method of porcelain archaized brick

The invention relates to a porcelain archaized brick with golden glittering effect and a preparation method of the porcelain archaized brick, 880 stamp-pad ink accounting for a large proportion in thegolden glittering glaze can provide a good printing effect, agglomeration of a glittering material is reduced, glaze defects are reduced, the antifouling property is improved, and the glaze melting effect is enhanced; a flashing material A can adjust the flashing effect of the composite glaze; a glittering material B is mainly used for adjusting the high-temperature firing temperature of the composite glaze besides adjusting the glittering effect of the composite glaze, so that complete fusion of the golden glittering glaze and the transparent polished glaze is guaranteed, the smoothness of aglaze surface is kept, and a prepared porcelain archaized brick finished product has antifouling, wear-resisting and durable properties; the porcelain archaized brick has the following characteristics that the printing glittering golden color is combined with the product color and texture, the product has more impact force in level and vision, the pattern level is richer, the texture is more natural, the stereoscopic impression is stronger, and a newly fused glazed product has more transparent three-dimensional stereoscopic impression.

Owner:广西蒙娜丽莎新材料有限公司

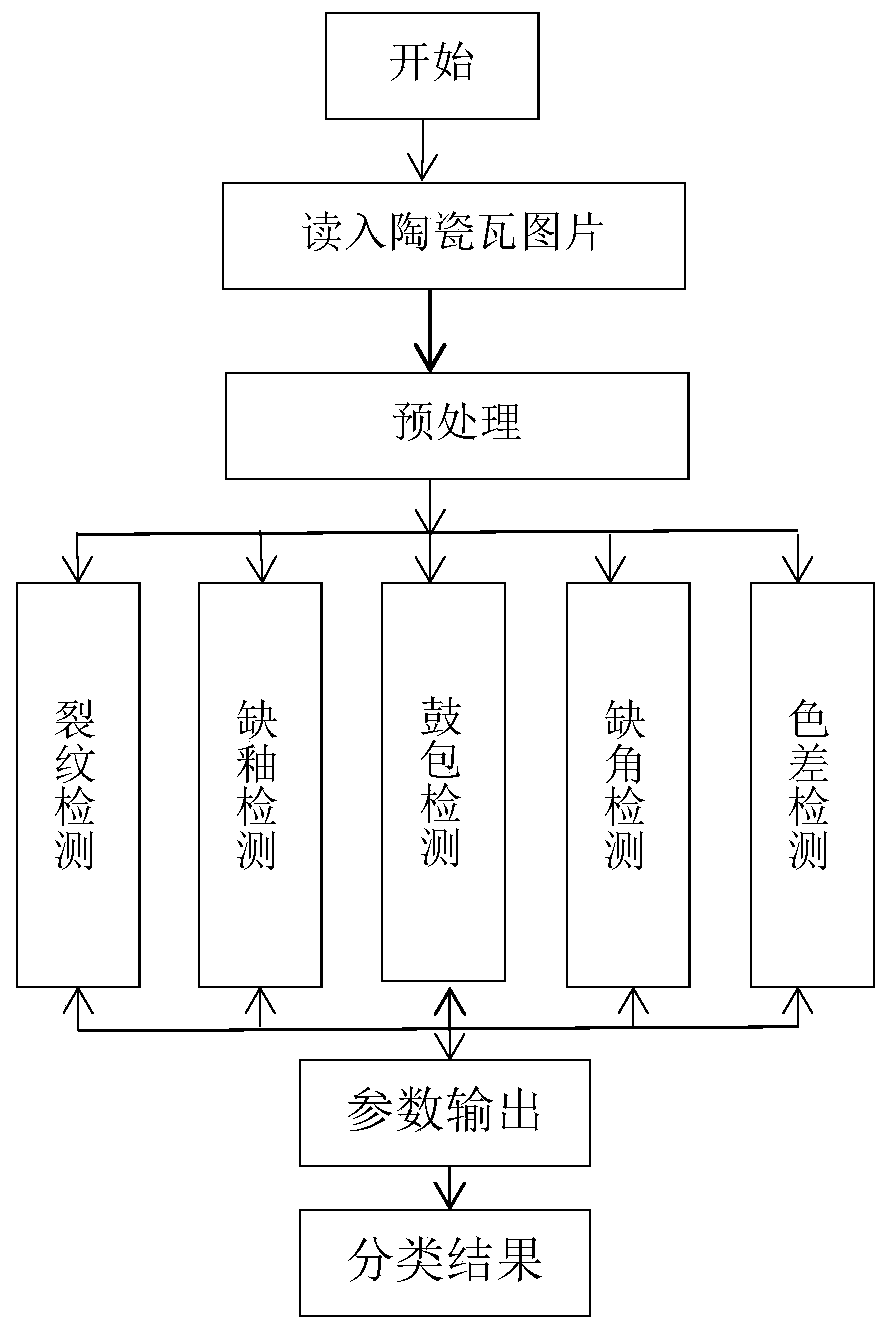

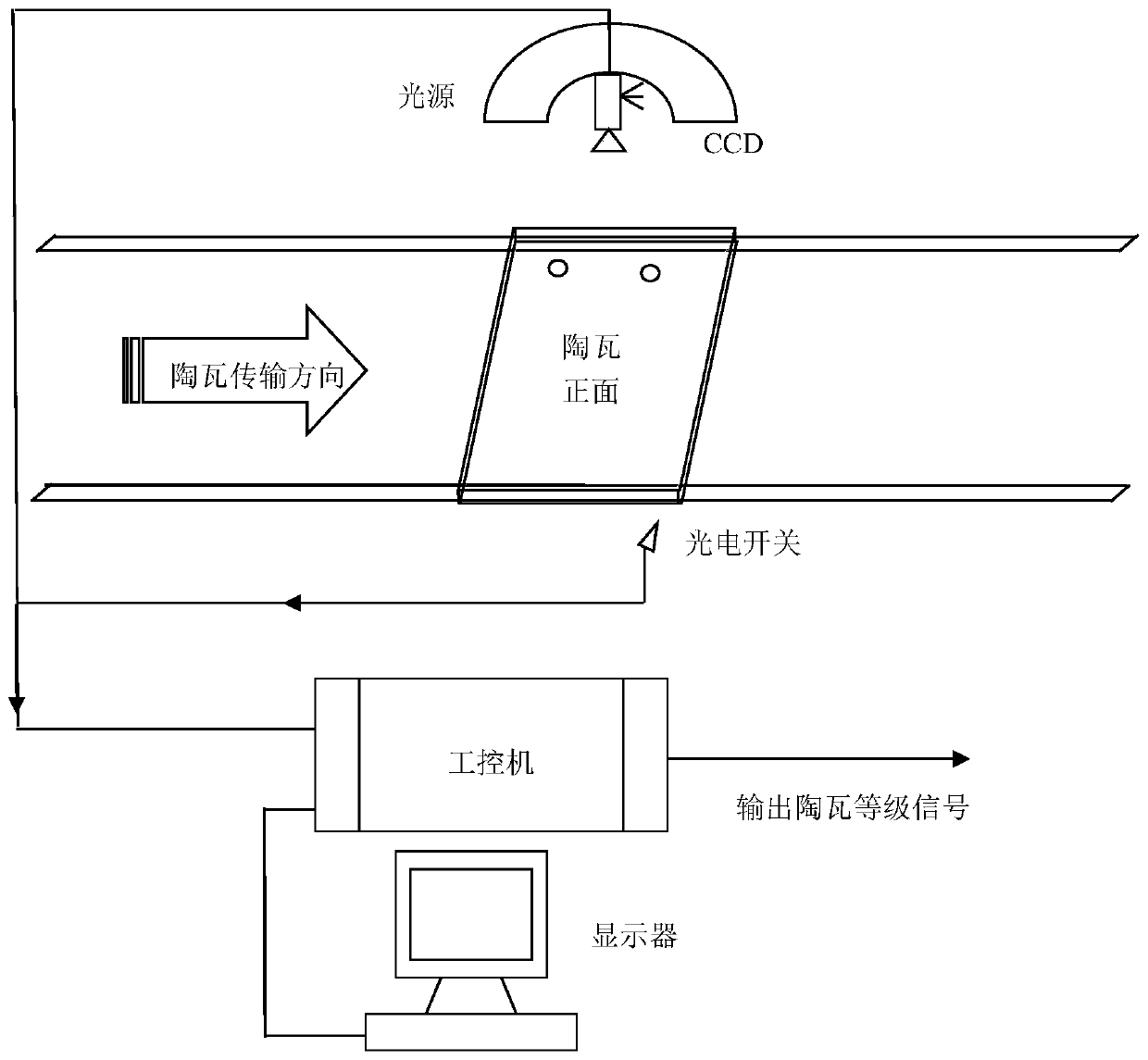

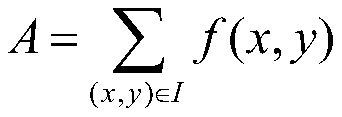

Intelligent online detection and automatic grading method and system for pottery tiles

ActiveCN110687121AFast and efficient detection one by oneImprove pass rateImage enhancementImage analysisFeature extractionGlaze defects

The invention discloses an intelligent online detection and automatic grading method and system for pottery tiles. The method comprises the steps of acquiring image data of a to-be-detected pottery tile, respectively carrying out crack defect detection, unfilled corner defect detection, chromatic aberration defect detection, glaze lack defect detection and bulge defect detection on the image data,obtaining the grade of the to-be-detected pottery tile according to the defect detection results, respectively carrying out first pretreatment or second pretreatment on the acquired image according to the detection requirements, adopting different filtering and defect extraction modes at the same time, carrying out color discrimination during glaze lack detection in particular, and carrying out image pretreatment, image segmentation, feature extraction and corresponding defect grades on to-be-detected pottery tiles with different colors by adopting different algorithms, so that the detectionof various defects can be realized, and the detection and intelligent grading of pottery tiles of various complex shapes and structures can be realized.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

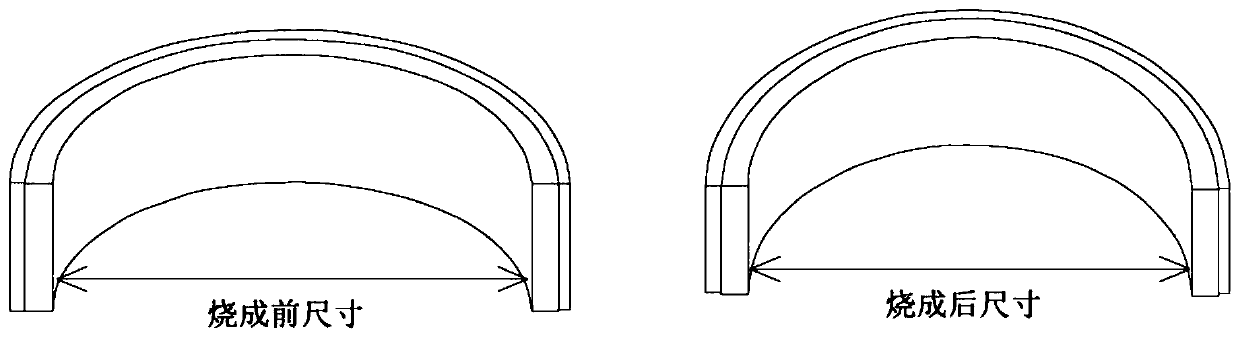

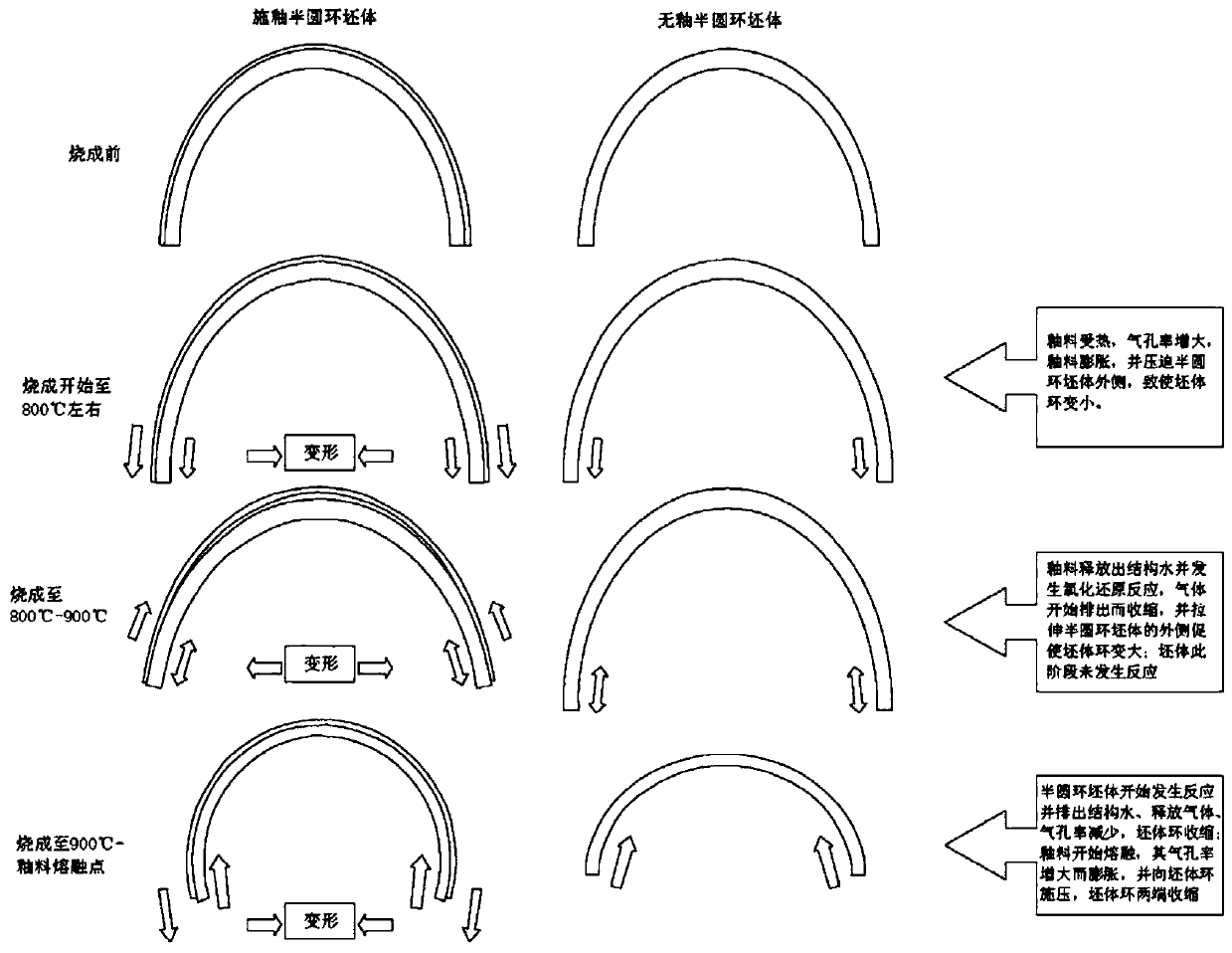

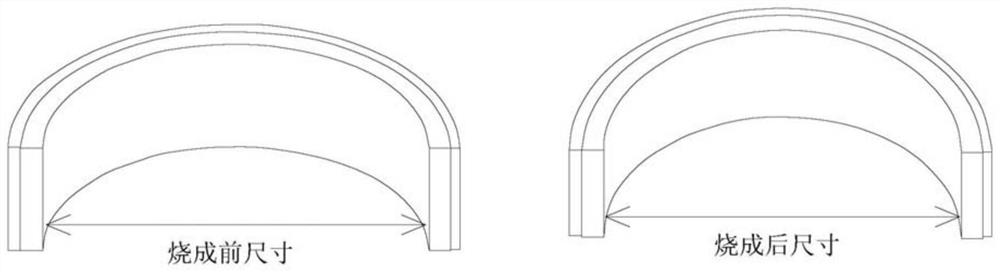

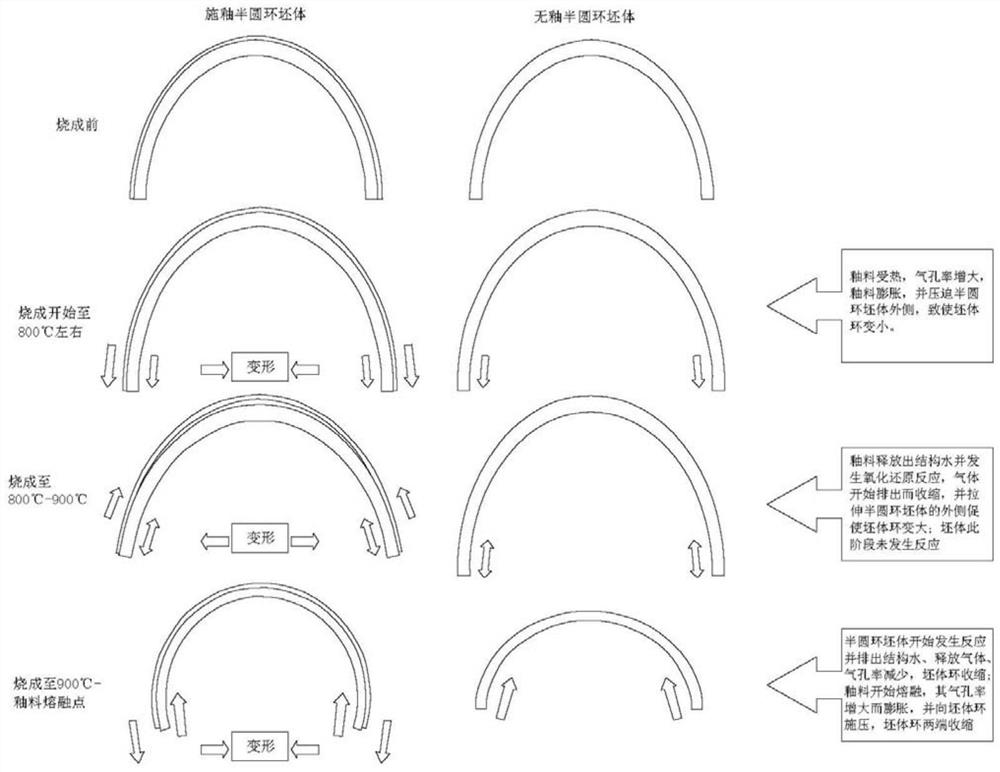

Method for detecting glaze shrinkage defect of sanitary ceramic product

ActiveCN110736825AThe effect of sintering shrinkage reachesAvoid situations where glaze shrinkage defects cannot be reflected normallyMaterial testing goodsMechanical solid deformation measurementsGlaze defectsSintering shrinkage

The invention discloses a method for detecting a glaze shrinkage defect of a sanitary ceramic product. According to the method, change of the distance, between the two ends, before and after sinteringof a glazed fan-shaped ring green body is compared with change of the distance, between the two ends, before and after sintering of an unglazed fan-shaped ring green body to evaluate influence of glazing on sintering shrinkage of the green body. The problem in evaluating influence of glazing on the sintering shrinkage of the green body in the ceramic green body production process can be solved, deformation caused by a difference between a deformation stress generated by a glaze layer and that of the green body itself can be recorded faithfully by means of a fan-shaped green body, influence ofglazing on green body sintering in practical production can be fit to larger degree, matching of a glaze formula and performance with reaction of the green body in the sintering temperature-rise stage can be determined, possible defect of the glaze formula in the design and manufacture stages can be detected, and the risk can be avoided.

Owner:JOMOO KITCHEN & BATHROOM

Glazing method for reducing glaze shrinkage defects on ceramic surfaces

The invention discloses a glazing method for reducing glaze shrinkage defects on ceramic surfaces. The glazing method comprises the following steps: 1) mixing magnesia, aluminum oxide, chromium oxide,titanium oxide and ceramic blank raw materials, grinding, and carrying out slip casting to obtain ceramic blanks; 2) coating a slurry obtained by ball-milling molybdenum silicide, tantalum silicide,glass powder, silicon boride, ethanol and carboxymethyl cellulose on the surfaces of the ceramic blanks, drying and then carrying out heat treatment; 3) immersing the ceramic blanks into a nano iron oxide dispersion liquid, taking out the ceramic blanks, and irradiating the ceramic blanksby using an ultraviolet lamp; and 4) spraying a glaze on the surfaces of the ceramic blanks for glaze sintering. According to the invention, conventional ceramic blank raw materials and glaze are improved; the surfaces of the green bodies are treated, so that sintered glaze surfaces are uniform in corrugation,high in glossiness and good in thermal stability, meanwhile, the defects of wavy lines, cracks, pinholes, even deglazing and the like of the glaze surfaces can be well eliminated, the integrity of the glaze surfaces is improved, and the product quality is obviously improved.

Owner:界首市伟盛古窑彩陶制作发展有限公司

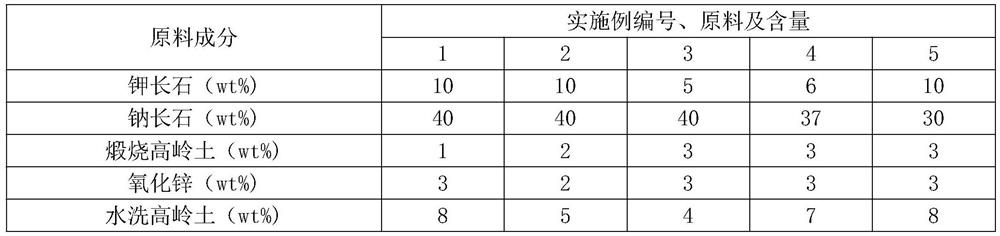

Protective glaze suitable for firing in low-temperature fast firing kiln, ceramic tile and preparation method thereof

PendingCN114516722AIncrease contentAvoid unqualifiedCeramic materials productionChemical compositionGlaze defects

The invention discloses a protective glaze suitable for firing in a low-temperature fast firing kiln and a ceramic tile and a preparation method thereof, and the protective glaze comprises the following chemical components of raw materials in percentage by weight: SiO2, Al2O3, CaO, MgO, K2O, Na2O and ignition loss; the firing temperature of the protective glaze in a low-temperature fast firing kiln is 1199-1230 DEG C, and the firing time is 50-55 minutes; the tension of the protective glaze effectively prevents bubbles generated in the cover glaze layer, the ink jet layer and the pressed green body from breaking through the glaze layer; according to the ceramic tile fired in the low-temperature fast firing kiln, the protective glaze is applied above the ink jet layer between the cover glaze and the polished glaze, the thickness is small, bubbles can be effectively prevented from rising, and the effect of protecting the ink jet layer and the glaze surface from generating air holes and concave glaze defects is achieved; the preparation method of the protective glaze suitable for firing in the low-temperature fast-firing kiln is simple in process and does not cause obvious increase of the manufacturing cost of the product.

Owner:FOSHAN DONGPENG CERAMIC +3

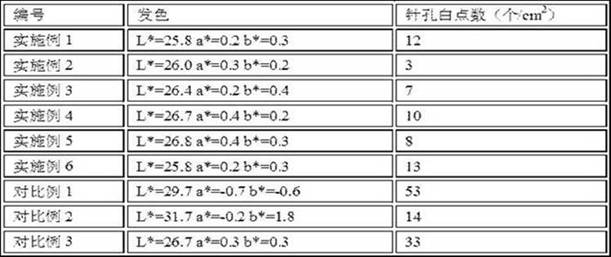

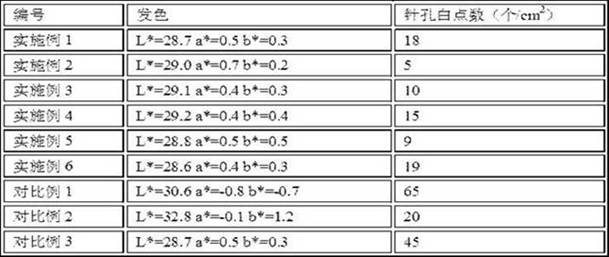

Black pigment for ceramic ink-jet printing and preparation method and application thereof

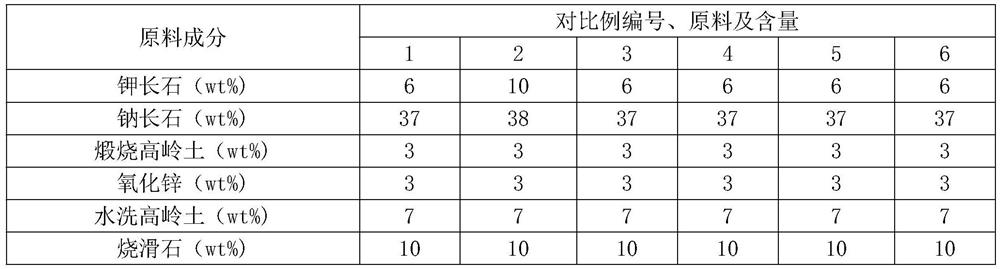

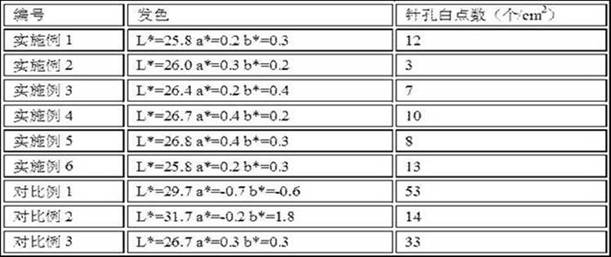

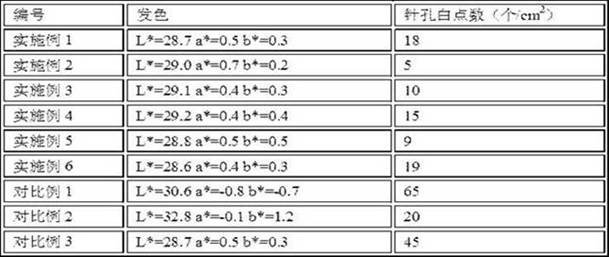

The invention belongs to the technical field of ceramic pigments, and particularly relates to a black pigment for ceramic ink-jet printing and a preparation method and application thereof. The black pigment is prepared from the following raw materials in parts by weight: 17-35 parts of a pre-sintered material, 25-36 parts of Co3O4, 30-45 parts of NiO, 0-5 parts of MnO2, 0-4 parts of Al2O3, 0-3 parts of SrCO3, 0-2 parts of Bi2O3 and 0.5-1.5 parts of MoO3, wherein the pre-sintered material is a material formed by sintering a mixed material of Cr2O3 and Fe2O3. Through cooperation of the raw materials, the problems of unstable color development and glaze defects (such as chromatic aberration, color shading, pinholes and white dots) after ink is prepared from the existing black pigment can be solved, the color development performance of black ceramic ink can be improved, and glaze defects can be reduced.

Owner:FOSHAN SANSHUI CREATE TIDE

A mosaic ceramic tile and its preparation device and method

ActiveCN103350560BSimple structureEasy to installTypewritersCeramic shaping apparatusTextile printerScreen printing

A mosaic ceramic tile and its preparation device and method, the device includes a positioning baffle, a baffle support, a conveyor belt, an inkjet printer and a screen printing machine. The steps of using the device to prepare mosaic ceramic tiles include: A. Press the ceramic powder to form adobe, and pour the bottom glaze; B. The adobe after step A is positioned through the positioning baffle; C. The adobe after step B enters the inkjet printer for light-color inkjet printing decoration to form an inkjet printing decoration area; D. The adobe after step C enters the screen printing machine for dark-color overcolor screen printing decoration to form a screen printing decoration area; E. Firing into shape. The mosaic ceramic tile prepared by using the device and method of the present invention avoids the defects of poor product integrity, easy damage, and large waste caused by the bonding and splicing of different products after water jet cutting, and also avoids the use of multiple products. The production of mosaic ceramic tiles by sub-screen printing brings about poor controllability and many glaze defects. At the same time, glaze is saved, the product has high repeatability, the design and color are easy to adjust, and the production change is fast.

Owner:FOSHAN DONGPENG CERAMIC +2

Colored glaze rough blank grinding process

InactiveCN107470986AImprove qualitySimple processPolishing machinesGrinding machinesWarm waterSand blasting

The invention discloses a glaze grinding process, which comprises the following steps: (1), rough grinding, (2), fine repairing, using a fine repairing pen to replace the nib according to the size and shape of the glaze defect; ( 3), sandblasting, (4), cleaning, and after sandblasting, first remove the sand on the surface of the glass with a water gun, then soak the glass in warm water at 70-80°C, take the glass out of the warm water, and wash it with (5), fine grinding, (6), grinding, using a grinder to polish the surface of the glass 2-4 times, after each grinding, the powder on the glass should be wiped clean; (7) Polishing. Mix the polishing powder with 8‑10 times of water, and then use a polishing machine and a polishing powder solvent to polish the colored glaze. After polishing, the glazed work is finished. The invention provides a glaze rough grinding process with simple process, fast processing speed, good grinding effect, safety and reliability, and high product quality.

Owner:太仓市科教新城琉璃艺术策划中心

A peeled marble tile with peeled glaze and no glaze defects and its preparation process

Owner:FOSHAN DONGPENG CERAMIC +2

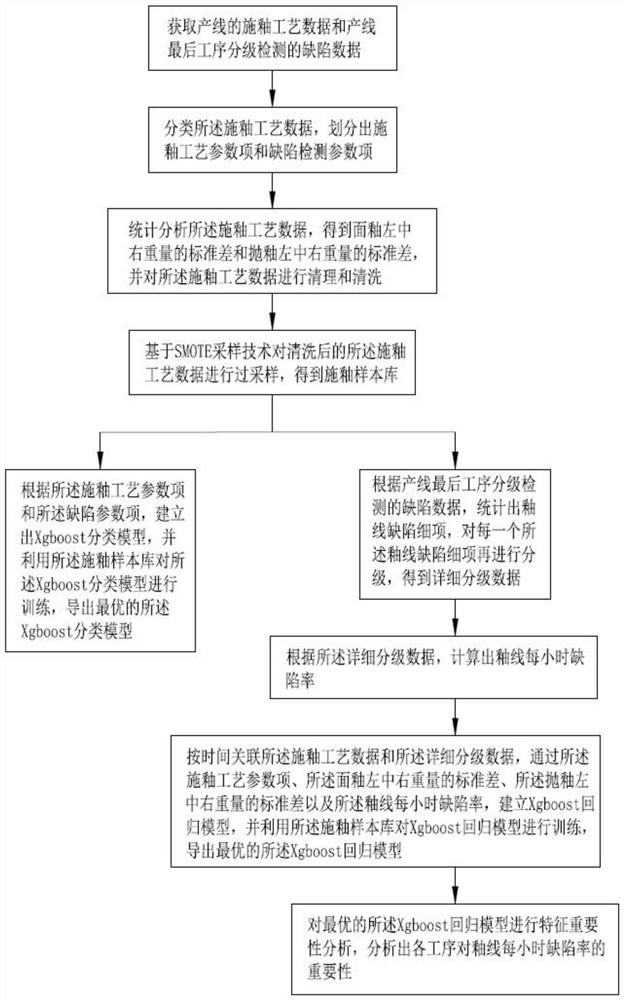

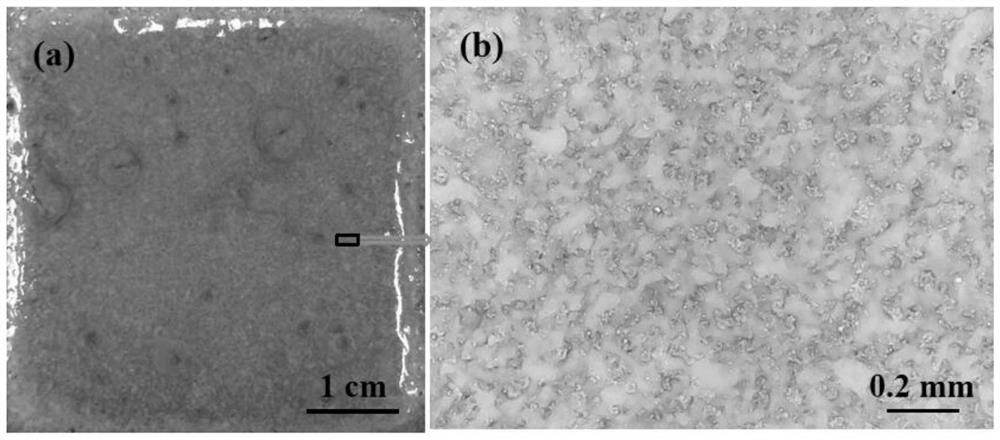

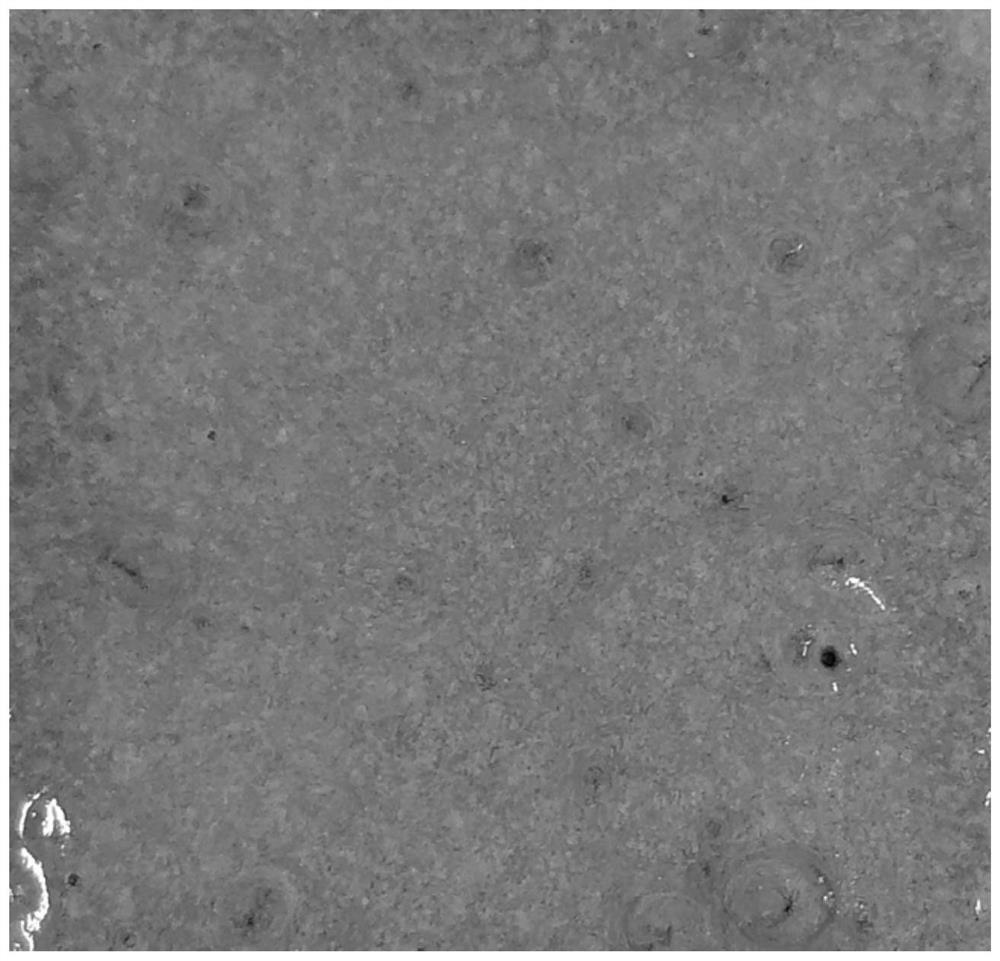

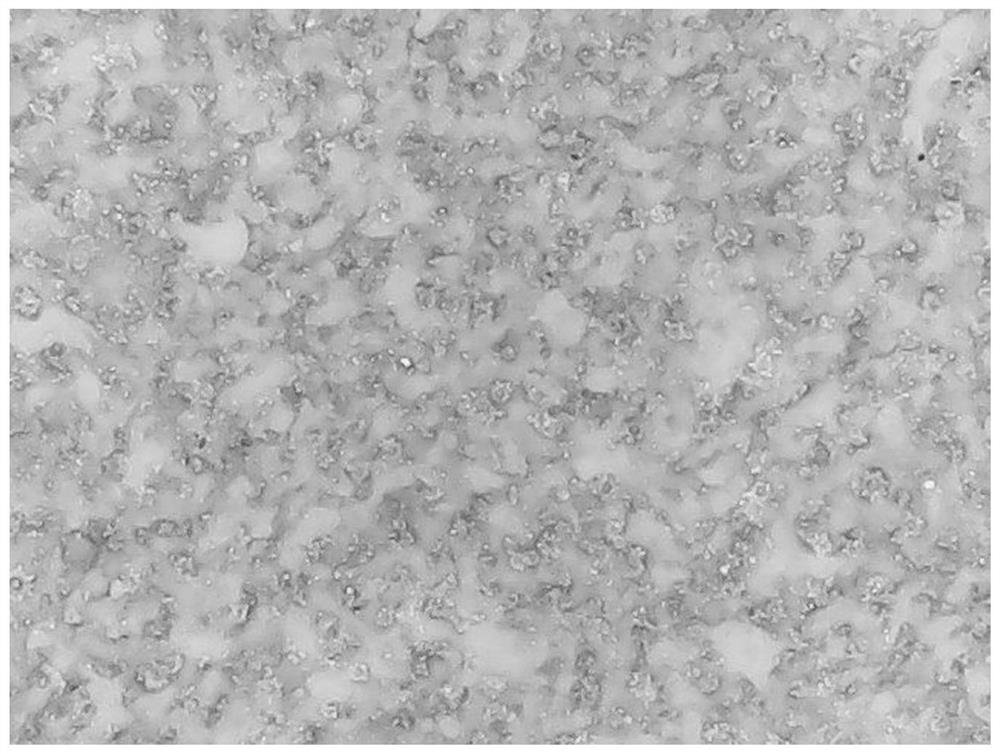

Building ceramic tile surface decoration glazing data analysis and prediction method and system

ActiveCN113554240AGlazing process parameters can be adjusted at any timeShorten the timeDigital data information retrievalForecastingGlaze defectsPolishing

The invention discloses a building ceramic tile surface decoration glazing data analysis and prediction method and system, and relates to the technical field of the ceramic surface glazing process. The method is characterized in that: glazing process parameter items of a current glaze line are input into a classification model to predict glazing defects, therefore, workers are reminded to adjust the glazing process parameters of the glaze line at any time, defects are reduced the time for searching the glazing process parameters by glazing workers can be shortened, the working efficiency is improved, and a better glazing effect is achieved; glazing process parameter items of the current glaze line, a standard deviation of the left, middle and right weights of a cover glaze, and a standard deviation of the left, middle and right weights of a polishing glaze are input into the classification model to predict the influence of defects generated in the glazing process on the overall quality of ceramic tiles, therefore, workers can correspondingly modify and adjust the related processes of the glaze line. The simulation prediction generated by a computer is used for replacing an actual experiment, so that the test cost is saved, the test period is shortened, and the overall glaze line defect rate is reduced.

Owner:西藏众陶联供应链服务有限公司

A kind of golden yellow ceramic glaze and preparation method thereof

The present invention relates to the technical field of ceramic glaze preparation, specifically a golden yellow ceramic glaze and a preparation method thereof. The specific process is to prepare the glaze according to a certain proportion of micronano silver powder, albite, quartz, talc and calcite, The glaze is made into a glaze slurry by planetary ball milling, and the glaze is applied to the surface of the ceramic biscuit by the glaze dipping method. After the glazed biscuit is dried, it is placed in a program-controlled high-temperature furnace and fired in an air atmosphere to obtain a golden yellow color. Ceramic glaze products with color effects. The present invention utilizes the phenomenon of synergistic reaction, diffusion effect and condensation of micro-nano silver and other components in the glaze formula and oxygen in the air during the high-temperature glaze firing process, and is prepared by using a program-controlled high-temperature furnace under air atmosphere conditions. It has a uniform golden yellow color on the glaze surface, good glossiness of the glaze layer, smooth enamel, ceramic glaze with a certain jade texture, and a ceramic glaze product without pinholes and orange glaze defects. The preparation method is simple and easy to operate, and has a wide range of applications prospect.

Owner:禹州市神后镇孔家钧窑有限公司

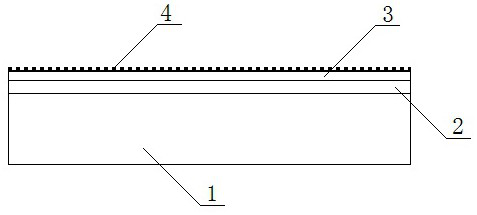

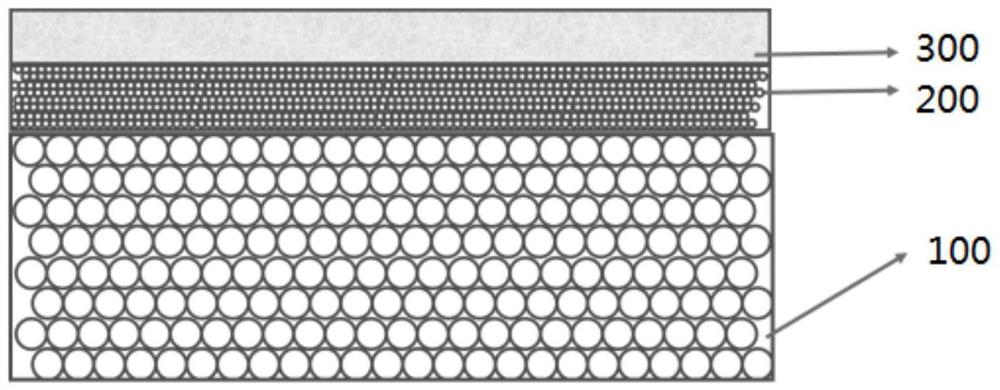

Foamed ceramic with high sunlight reflection performance and thermal insulation and preparation method thereof

ActiveCN114262210AGood antifoulingSolve the closed porosity is not highCeramic materials productionCeramicwarePorosityFoaming agent

The invention belongs to the technical field of ceramics, and discloses a foamed ceramic with high sunlight reflection performance and heat insulation and a preparation method thereof. The foamed ceramic comprises a foam layer, a compact layer and a functional glaze layer from bottom to top, the foam layer comprises the following components: glass powder, potassium-sodium feldspar, borax and a foaming agent; the functional glaze layer comprises the following components: mica and tungsten trioxide. Through combination and component adjustment of the foam layer, the compact layer and the functional glaze layer, the problems that the closed porosity of a conventional foam ceramic formula system is not high and the high-temperature viscosity of a ceramic glaze with sunlight reflection performance is too low are solved, so that the foam ceramic has the advantages of heat preservation and heat insulation of a base material and sunlight reflection of a glaze surface; glaze defects such as pinholes, foaming and the like cannot be generated, and meanwhile, acid and alkali corrosion resistance and antifouling performance are good.

Owner:FOSHAN OCEANO CERAMICS

A detection method for glaze shrinkage defects of sanitary ceramic products

ActiveCN110736825BThe effect of sintering shrinkage reachesAvoid situations where glaze shrinkage defects cannot be reflected normallyMaterial testing goodsMechanical solid deformation measurementsGlaze defectsSintering shrinkage

Owner:JOMOO KITCHEN & BATHROOM

FFC slurry for ceramic production

The invention relates to the technical field of manufacturing of sanitary ceramics, in particular to FFC slurry for ceramic production, which is specifically applied to large basin type water tank products. On the basis of the original imported FFC mud raw material, other mud materials are added, and the technical key points are as follows: the raw material dry material comprises the following components: 8%-11% of imported FFC-A material, 6%-12% of imported FFC clinker, 55%-61% of kaolin 1 # material, 10%-15% of kaolin 2 # material and 12%-14% of quartz. The FFC slurry provided by the invention retains the advantages of low buckling deformation rate, low shrinkage rate and good regularity of the original FFC ceramic, reduces the risks of wind frightening and glaze defects, and greatly reduces the production cost.

Owner:TANGSHAN MONOPY CERAMIC

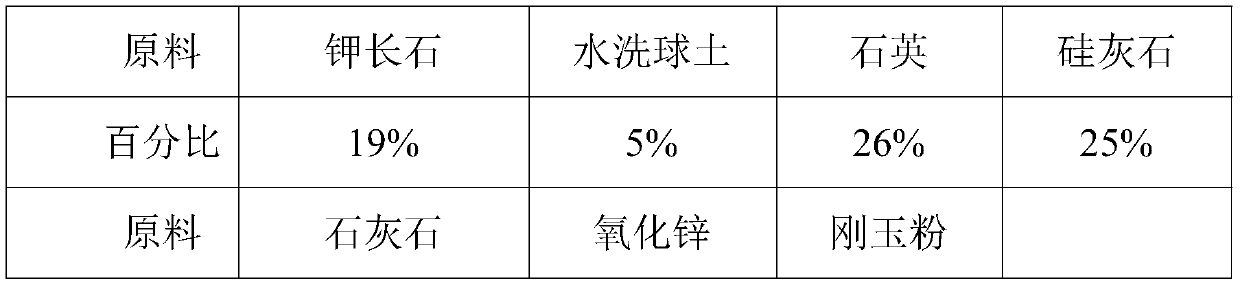

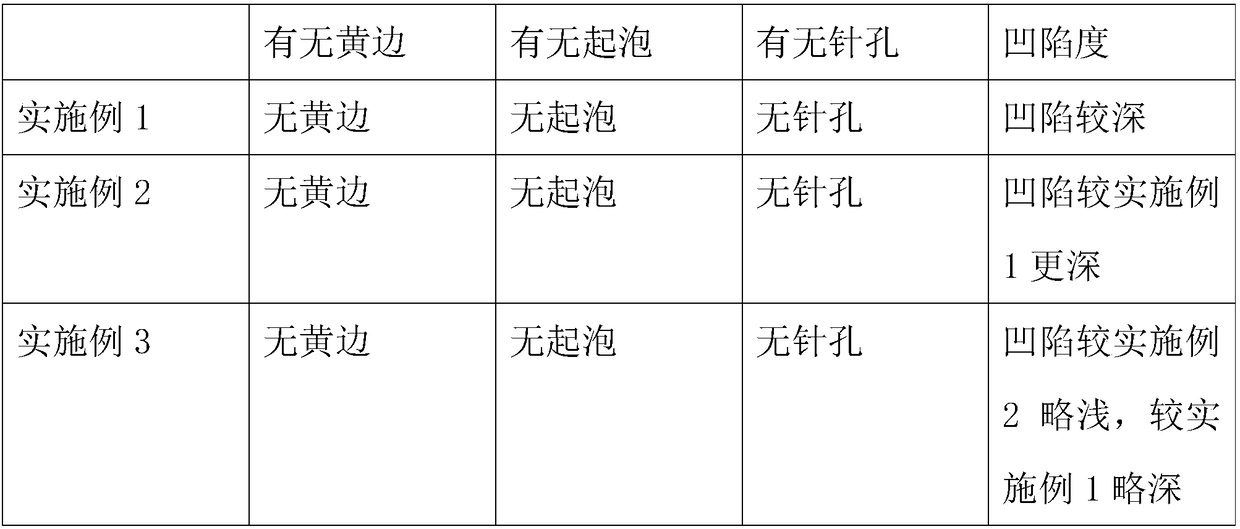

Stripping glaze, ceramic tile without glaze defects and preparation method of ceramic tile

The invention discloses stripping glaze. The stripping glaze comprises the following raw materials in parts by weight: 8.2-10.5 parts of silicon dioxide, 6.7-8.8 parts of aluminum oxide, 3.3-5.2 partsof zinc oxide, and 2.2-3.4 parts of corundum; and the stripping glaze also comprises the following components in parts by weight: 0.6-0.8 part of calcined talc and 1.2-1.6 parts of water-washed ballclay, wherein 8.2-10.5 parts of the silicon dioxide, 6.7-8.8 parts of the aluminum oxide, 3.3-5.2 parts of the zinc oxide, 2.2-3.4 parts of the corundum, 0.6-0.8 part of the calcined talc and 1.2-1.6parts of the water-washed ball clay are spherical dry particles. According to a method disclosed by the invention, the silicon dioxide and the aluminum oxide are directly introduced, so that impurities in the raw materials of the stripping glaze are reduced; and compared with the prior art, the stripping glaze prepared by data provided by the invention has no glaze defects such as yellow edges, bubbles and pinholes during firing, at the same time, sunken parts are deeper, the stripping glaze has higher quality, so that a qualification rate of the product is improved, a defective rate is reduced, and unnecessary economic loss is avoided.

Owner:NANAN CHUANGPEI ELECTRONICS TECH CO LTD

A glazing method for reducing glaze shrinkage defect on ceramic surface

The invention discloses a glazing method for reducing glaze shrinkage defects on ceramic surfaces. The glazing method comprises the following steps: 1) mixing magnesia, aluminum oxide, chromium oxide,titanium oxide and ceramic blank raw materials, grinding, and carrying out slip casting to obtain ceramic blanks; 2) coating a slurry obtained by ball-milling molybdenum silicide, tantalum silicide,glass powder, silicon boride, ethanol and carboxymethyl cellulose on the surfaces of the ceramic blanks, drying and then carrying out heat treatment; 3) immersing the ceramic blanks into a nano iron oxide dispersion liquid, taking out the ceramic blanks, and irradiating the ceramic blanksby using an ultraviolet lamp; and 4) spraying a glaze on the surfaces of the ceramic blanks for glaze sintering. According to the invention, conventional ceramic blank raw materials and glaze are improved; the surfaces of the green bodies are treated, so that sintered glaze surfaces are uniform in corrugation,high in glossiness and good in thermal stability, meanwhile, the defects of wavy lines, cracks, pinholes, even deglazing and the like of the glaze surfaces can be well eliminated, the integrity of the glaze surfaces is improved, and the product quality is obviously improved.

Owner:界首市伟盛古窑彩陶制作发展有限公司

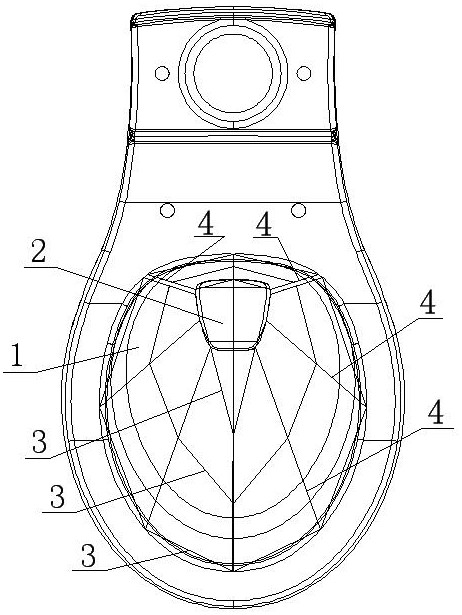

Robot glaze spraying process for pedestal pan products

The invention relates to ceramic glaze spraying, in particular to a robot glaze spraying process for pedestal pan products. The process comprises the following steps: A, teaching a pedestal pan inner glaze spraying program: 1) drawing a line in a pedestal pan product, 2) setting parameters, and 3) conducting teaching along the drawing line in the pedestal pan product; and B, conducting glazing: 1) positioning a green blank semi-finished product at a workpiece position specified by teaching, and 2) confirming an equipment state and various parameters, and conducting glazing by a robot. The glaze quality of a pedestal pan product is improved, the orange glaze defect is avoided, the yield is improved, and the production cost is reduced.

Owner:TANGSHAN MONOPY CERAMIC +1

A kind of high hardness wear-resistant ceramic tile and preparation method thereof

The invention discloses a high-hardness wear-resistant ceramic brick, which comprises a body, an underglaze layer, a decorative layer and a high-hardness wear-resistant polished glaze layer from bottom to top, and the chemical composition of the high-hardness wear-resistant polished glaze layer is as follows: Contains 68-75% SiO in weight percentage 2 , 10-13% Al 2 o 3 , 0.05~0.1% Fe 2 o 3 , 0.01~0.03% TiO 2 , 1-3% CaO, 2-4% MgO, 2-5% K2O, 1.5-3% Na 2 O, 0.1-0.3 Li 2 O, 1-2.5% BaO and 2.5-4% loss on ignition. The invention obtains high-silicon glaze by controlling the chemical components in the glaze, so as to ensure the formation of a high-hardness wear-resistant polished glaze layer in the later stage. The invention also discloses a preparation method of the ceramic tile, which solves the defects of the glaze surface such as glaze shrinkage when the glaze layer is formed in the later stage through the nanometerization process of the raw material and the particle size and thickness matching of the high-silicon glaze, thereby greatly improving the glaze surface of the ceramic tile. hardness and wear resistance.

Owner:FOSHAN OCEANO CERAMICS +1

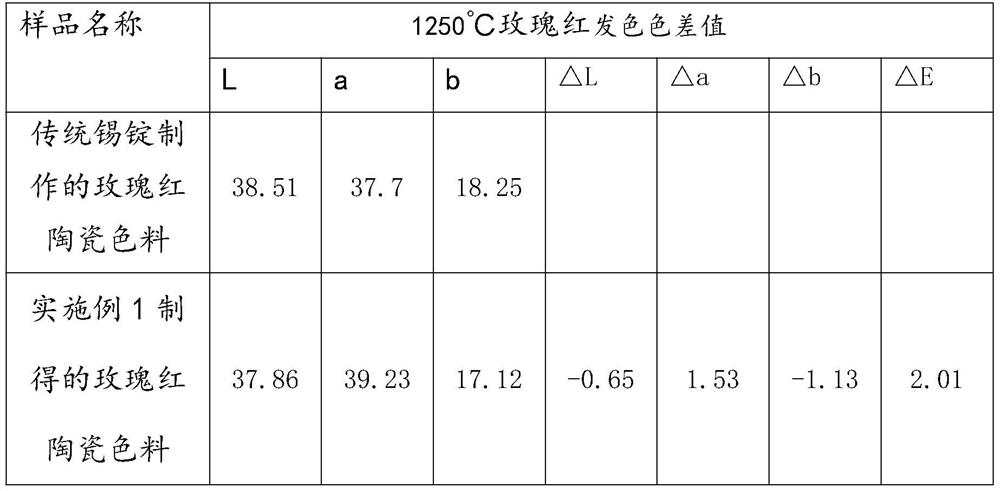

Production method of rose-bengal ceramic pigment

PendingCN114752231ASatisfy the hair color effectMeet needsPigmenting treatmentCalcium silicateMetallurgy

The invention relates to the technical field of production methods of ceramic pigments, in particular to a production method of a rose-bengal ceramic pigment which comprises the following components in parts by mass: 50-60 parts of calcium silicate, 40-50 parts of tin oxide and 1-3 parts of potassium dichromate. According to the present invention, the raw material is the by-product generated during the electric melting zirconia production process, such that the waste material is recycled, the advantages of low cost and easy obtaining are provided, the rose-bengal ceramic pigment is synthesized at the low temperature through the grinding, the aging, the drying screening, the calcining, the grinding, the cleaning and the drying process, and compared with the existing rose-bengal ceramic pigment, the high temperature resistance can be improved; high-temperature glaze defects are reduced, the color is full, and the color development effect and color matching requirements of ceramic products are met.

Owner:SANXIANG ADVANCED MATERIALS

A kind of bottom glaze and preparation method thereof, black inkjet ceramic tile and preparation method thereof

ActiveCN110790507BGood appearance consistencyIncrease infiltration depthTextile printerGlaze defects

The invention discloses a bottom glaze and a preparation method thereof, a black ink-jet ceramic tile and a production method thereof. The raw material composition of the bottom glaze includes, in terms of mass fractions, 5 parts of kaolin, 33 parts of potassium feldspar, 28 parts of albite, 10 parts of quartz powder, 10 parts of zirconium silicate, 7 parts of talcum powder, and 7 parts of 965 frit; the chemical composition of the 965 frit includes: SiO 2 49.97%, Al 2 o 3 16.96%, Fe 2 o 3 0.14%, TiO 2 0.05%, CaO 12.71%, MgO 1.41%, K 2 O 4.03%, Na 2 O 12.57%, ZnO 0.37%, B 2 o 3 0.18%, BaO 0.83%, loss on ignition 0.78%. By controlling the addition of kaolin, the penetration depth of the ink is increased, the drying efficiency of the ink is improved, and the glaze avoidance defects after inkjet printing are avoided.

Owner:CHONGQING WONDERFUL CERAMICS CO LTD +2

A kind of black pigment for ceramic inkjet printing and its preparation method and application

ActiveCN113583513BImprove temperature resistanceHigh crystallinityInksCeramic colorantsGlaze defects

The invention belongs to the technical field of ceramic pigments, and in particular relates to a black pigment for ceramic inkjet printing and its preparation method and application; the parts by weight of each raw material in the black pigment are: 17-35 parts of pre-fired material, Co 3 o 4 25-36 parts for NiO, 30-45 parts for NiO, MnO 2 0-5 parts, Al 2 o 3 0‑4 parts, SrCO 3 0-3 copies, Bi 2 o 3 0‑2 parts and MoO 3 Is 0.5-1.5 part; Wherein, described calcined material is Cr 2 o 3 and Fe 2 o 3 Mixed and fired materials. Through the combination of the above-mentioned raw materials, the black pigment can solve the problems of unstable color development and glaze defects (such as color difference, yin and yang, pinholes, and white spots) after the existing black pigment is made into ink. Effectively improve the color development of black ceramic inks and reduce glaze defects.

Owner:FOSHAN SANSHUI CREATE TIDE

A kind of black ink-jet ceramic brick and its manufacturing method

The invention discloses a black ink-jet ceramic tile and a manufacturing method thereof. The method comprises pressing the blank to obtain a green body, putting the green body into a drying kiln for drying; The base glaze is obtained to obtain bricks; the first infrared drying is carried out on the bricks after the base glaze is applied, and the temperature is controlled at 230±20°C; the inkjet printing decoration is carried out on the surface of the bricks coated with the base glaze; the second Secondary infrared drying, and the temperature is controlled at 180±10°C; the surface of the dried bricks is fully glazed, fired in a kiln, polished, edged, waxed, and filmed to obtain finished black inkjet ceramic tiles. Through infrared drying, the drying efficiency of glaze and ink is improved, the glaze avoidance defect of dark inkjet products is solved, the labor intensity of workers is reduced, and the quality and production efficiency of black inkjet ceramic tiles are significantly improved.

Owner:CHONGQING WONDERFUL CERAMICS CO LTD +2

Preparation Technology of Nixing Jun Pottery

The invention provides a preparation process of Nixing Jun pottery, which includes preparing a blank, molding the blank, drying the blank, decorating the blank and firing the blank. The decoration of the blank is to apply a layer of low-temperature Glaze; the low-temperature glaze is made of the following raw materials in parts by weight: 50-60 parts of quartz, 6-10 parts of calcite, 8-15 parts of borax, 8-12 parts of feldspar, 2-5 parts of spodumene, cordierite 3 to 5 parts, 1 to 3 parts of copper oxide, 3 to 5 parts of zinc oxide, 2 to 3 parts of Dongni, and 1 to 2 parts of Xini. The sintering temperature of the glaze of the present invention is compatible with the green body, and the expansion coefficient is slightly lower than that of the green body, which can effectively avoid glaze cracking, deglazing and other phenomena. The three-stage firing process can also effectively promote the formation of the intermediate layer of the blank glaze, increase its thickness and density, and make the blank glaze tightly bonded, thereby avoiding defects such as glaze cracking and deglazing.

Owner:钦州狮岩斋文化科技有限公司

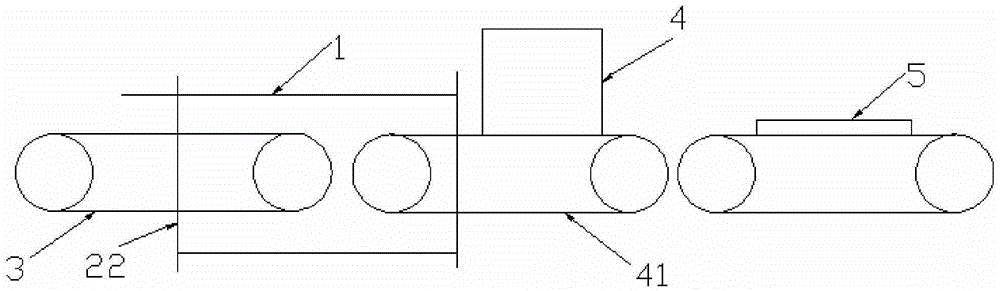

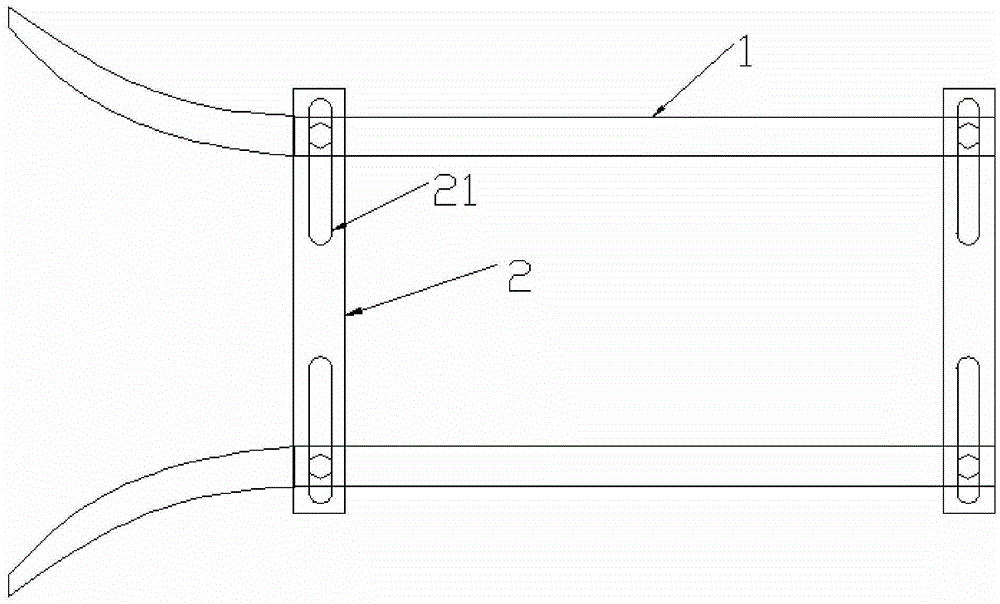

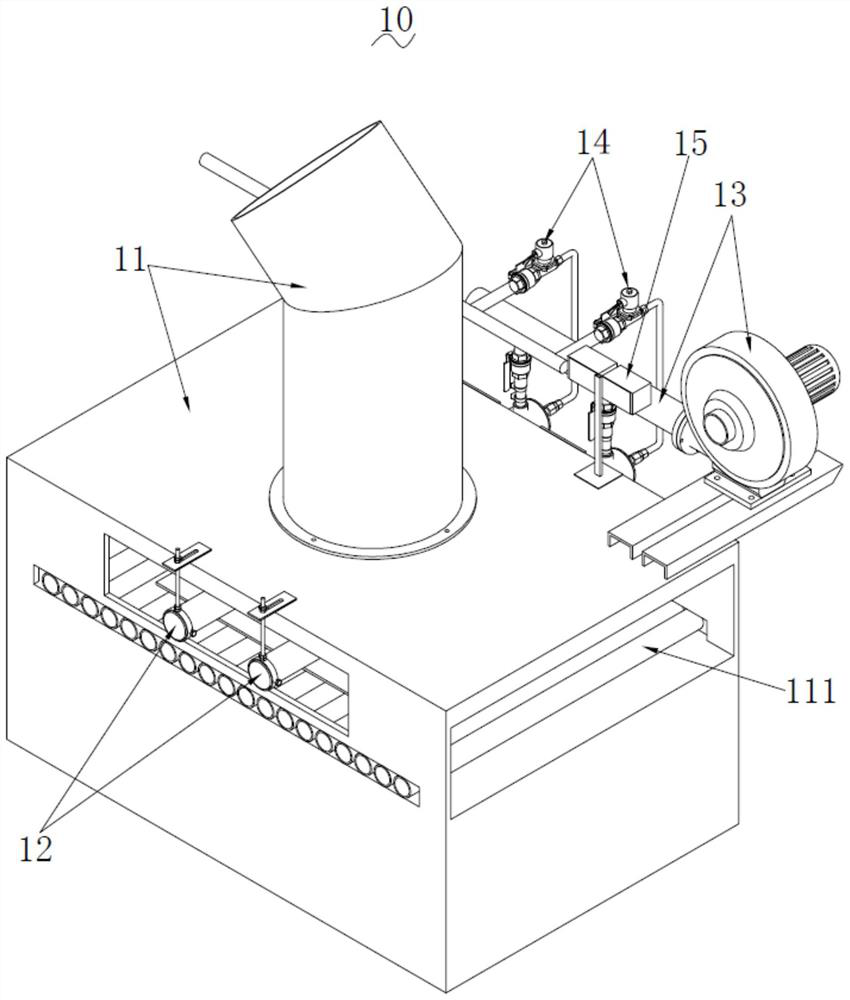

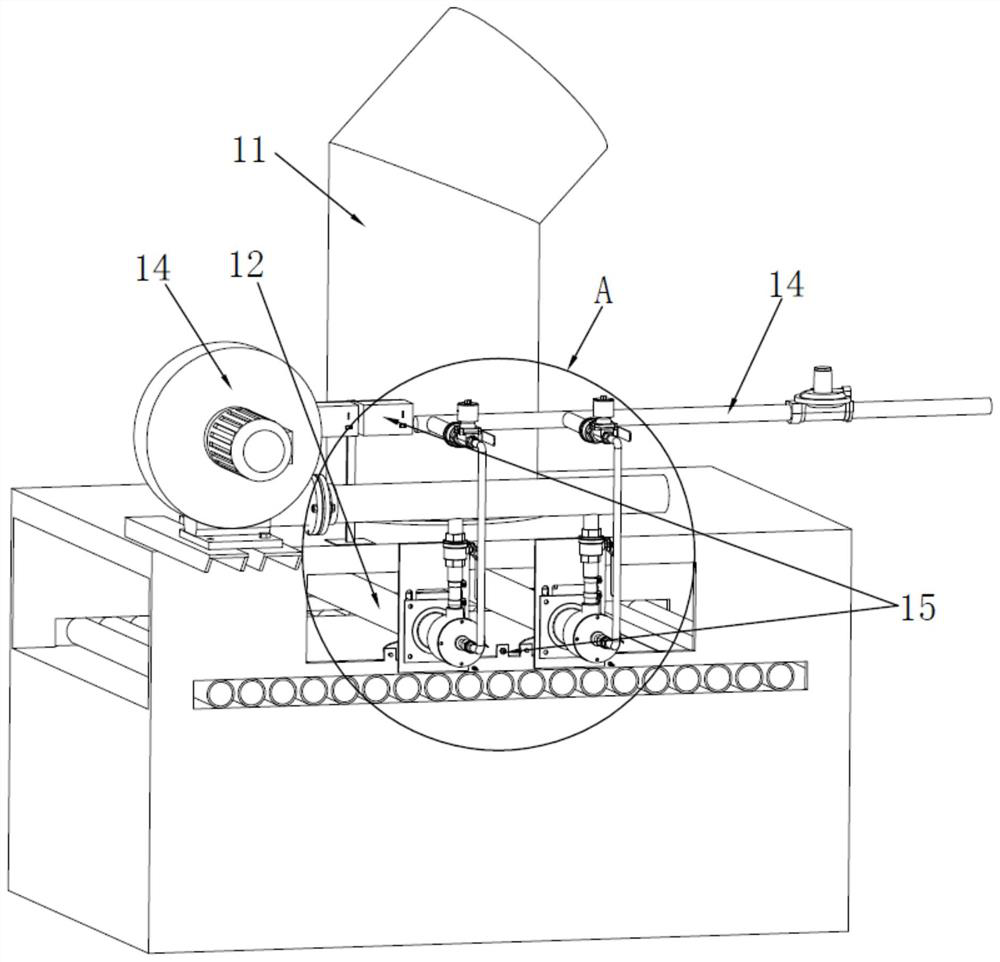

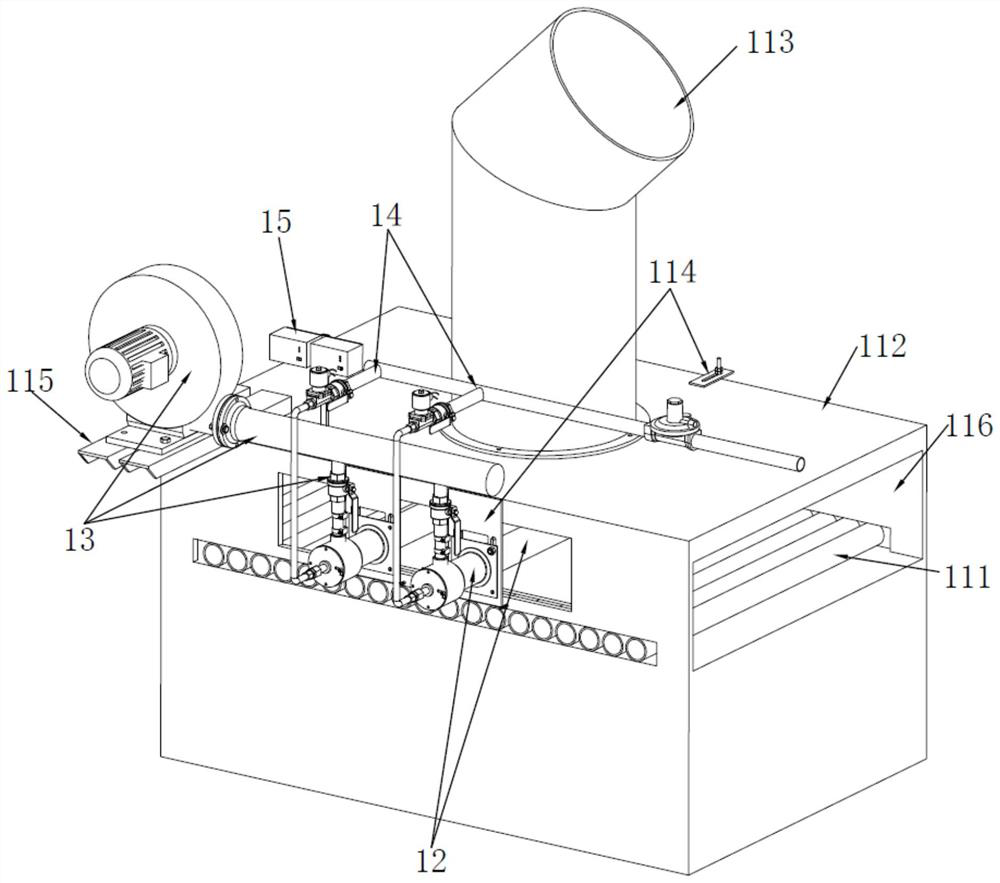

Device for overcoming glaze avoiding defect of ink-jet ceramic tiles

The invention provides a device for overcoming the glaze avoiding defect of ink-jet ceramic tiles. The device comprises a rack, a combustion mechanism, a combustion-supporting mechanism and a fuel gas conveying mechanism, wherein a conveying assembly used for conveying the ceramic tiles is arranged on the rack; the combustion mechanism is arranged on the rack, and the combustion mechanism is located at the upper end of the conveying assembly; the combustion-supporting mechanism is arranged on the rack, and the combustion-supporting mechanism communicates with the combustion mechanism; and the fuel gas conveying mechanism is arranged on the rack, and the fuel gas conveying mechanism communicates with the combustion mechanism; by arranging the rack, protection and support can be provided for the combustion mechanism, the combustion-supporting mechanism and the fuel gas conveying mechanism; and the conveying assembly is arranged on the rack, to-be-glazed ink-jet ceramic tiles are automatically conveyed to pass through the combustion mechanism, open fire generated by the combustion mechanism is used for baking the glaze surfaces of the ceramic tiles subjected to ink-jet printing, oil-soluble and lipid substances in ceramic ink are completely combusted, and substances capable of causing the glaze avoiding defect in the wet glaze pouring process in ceramic ink are removed, so that the glaze avoiding defect of the ink-jet ceramic tile is overcome.

Owner:JIANGXI HEMEI CERAMICS

Porcelain antique brick with golden glitter effect and preparation method thereof

The invention relates to a porcelain archaized brick with golden glittering effect and a preparation method of the porcelain archaized brick, 880 stamp-pad ink accounting for a large proportion in thegolden glittering glaze can provide a good printing effect, agglomeration of a glittering material is reduced, glaze defects are reduced, the antifouling property is improved, and the glaze melting effect is enhanced; a flashing material A can adjust the flashing effect of the composite glaze; a glittering material B is mainly used for adjusting the high-temperature firing temperature of the composite glaze besides adjusting the glittering effect of the composite glaze, so that complete fusion of the golden glittering glaze and the transparent polished glaze is guaranteed, the smoothness of aglaze surface is kept, and a prepared porcelain archaized brick finished product has antifouling, wear-resisting and durable properties; the porcelain archaized brick has the following characteristics that the printing glittering golden color is combined with the product color and texture, the product has more impact force in level and vision, the pattern level is richer, the texture is more natural, the stereoscopic impression is stronger, and a newly fused glazed product has more transparent three-dimensional stereoscopic impression.

Owner:广西蒙娜丽莎新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com