Stripping glaze, ceramic tile without glaze defects and preparation method of ceramic tile

A technology for peeling off glaze and ceramic tiles, applied in the field of architectural ceramics, can solve the problems of air bubbles and pinholes, yellow edges of finished products, and reduce the quality of finished products, so as to reduce the defective rate, avoid economic losses, and improve the qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

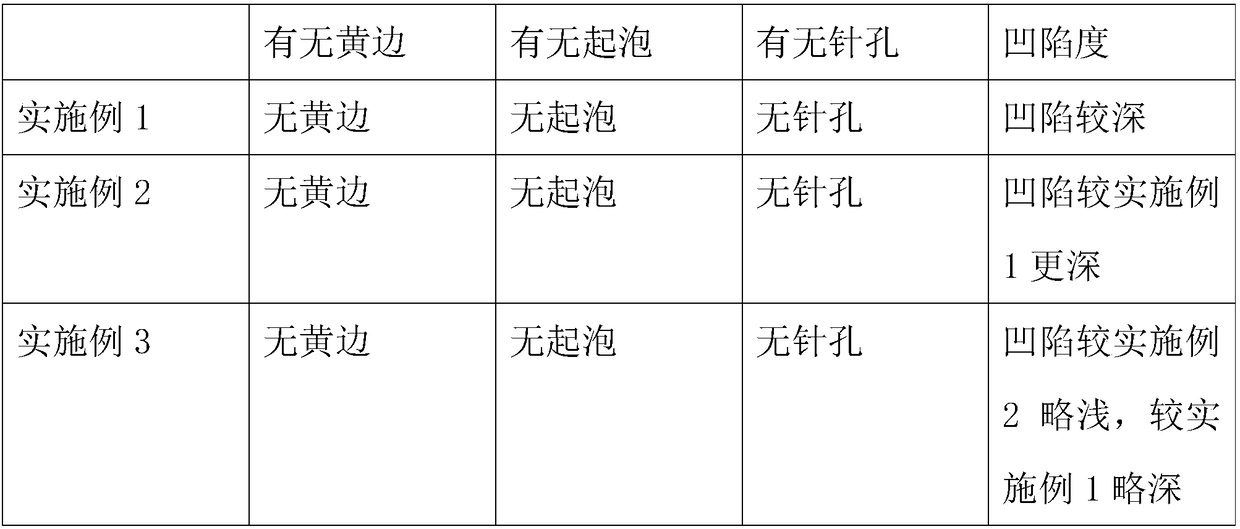

Embodiment 1

[0024] A peeling glaze, in parts by weight, comprising the following raw materials: 8.2 parts of silicon dioxide, 6.7 parts of aluminum oxide, 3.3 parts of zinc oxide, 2.2 parts of corundum, in parts by weight, which also includes 0.6 parts of calcined talc and water-washed balls 1.2 parts of soil, 8.2 parts of silicon dioxide, 6.7 parts of aluminum oxide, 3.3 parts of zinc oxide, 2.2 parts of corundum, 0.6 part of calcined talc and 1.2 parts of washed ball clay are spherical dry particles.

[0025] The present invention also provides a ceramic tile without glaze defects, which includes a brick embryo, the exterior of which is provided with a peel-off glaze layer made of the above formula, and the thickness of the peel-off glaze layer is set at 0.2-0.3mm.

[0026] The present invention also provides a method for preparing ceramic tiles without glaze defects, which specifically includes the following steps:

[0027] Step 1: Use electrostatic spraying equipment to spray the peel...

Embodiment 2

[0032] What is different from Example 1 is that a kind of peeling glaze comprises the following raw materials in parts by weight: 9.4 parts of silicon dioxide, 7.3 parts of aluminum oxide, 4.2 parts of zinc oxide, and 2.8 parts of corundum, in parts by weight, wherein Including 0.7 parts of calcined talc and 1.4 parts of washed ball clay, 9.4 parts of silicon dioxide, 7.3 parts of alumina, 4.2 parts of zinc oxide, 2.8 parts of corundum, 0.7 parts of calcined talc and 1.4 parts of washed ball clay are spherical dry particles .

[0033] The present invention also provides a ceramic tile without glaze defects, which includes a brick embryo, the exterior of which is provided with a peel-off glaze layer made of the above formula, and the thickness of the peel-off glaze layer is set at 0.2-0.3 mm.

[0034] The present invention also provides a method for preparing ceramic tiles without glaze defects, which specifically includes the following steps:

[0035] Step 1: Use electrostati...

Embodiment 3

[0040] What is different from Example 2 is: a peeling glaze, characterized in that, in parts by weight, comprising the following raw materials: 10.5 parts of silicon dioxide, 8.8 parts of aluminum oxide, 5.2 parts of zinc oxide, 3.4 parts of corundum, in parts by weight 10.5 parts of silicon dioxide, 8.8 parts of aluminum oxide, 5.2 parts of zinc oxide, 3.4 parts of corundum, 0.8 parts of calcined talc and 1.6 parts of washed ball clay are all spherical dry grain.

[0041] The present invention also provides a ceramic tile without glaze defects, which includes a brick embryo, the exterior of which is provided with a peel-off glaze layer made of the above formula, and the thickness of the peel-off glaze layer is set at 0.2-0.3 mm.

[0042] The present invention also provides a method for preparing ceramic tiles without glaze defects, which specifically includes the following steps:

[0043] Step 1: Use electrostatic spraying equipment to spray the peeling ink on the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com