Patents

Literature

1816results about How to "Improve polishing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oily diamond grinding liquid and preparation method thereof

InactiveCN103013345AImprove polishing efficiencyImprove matchPolishing compositions with abrasivesStable stateEnvironmental resistance

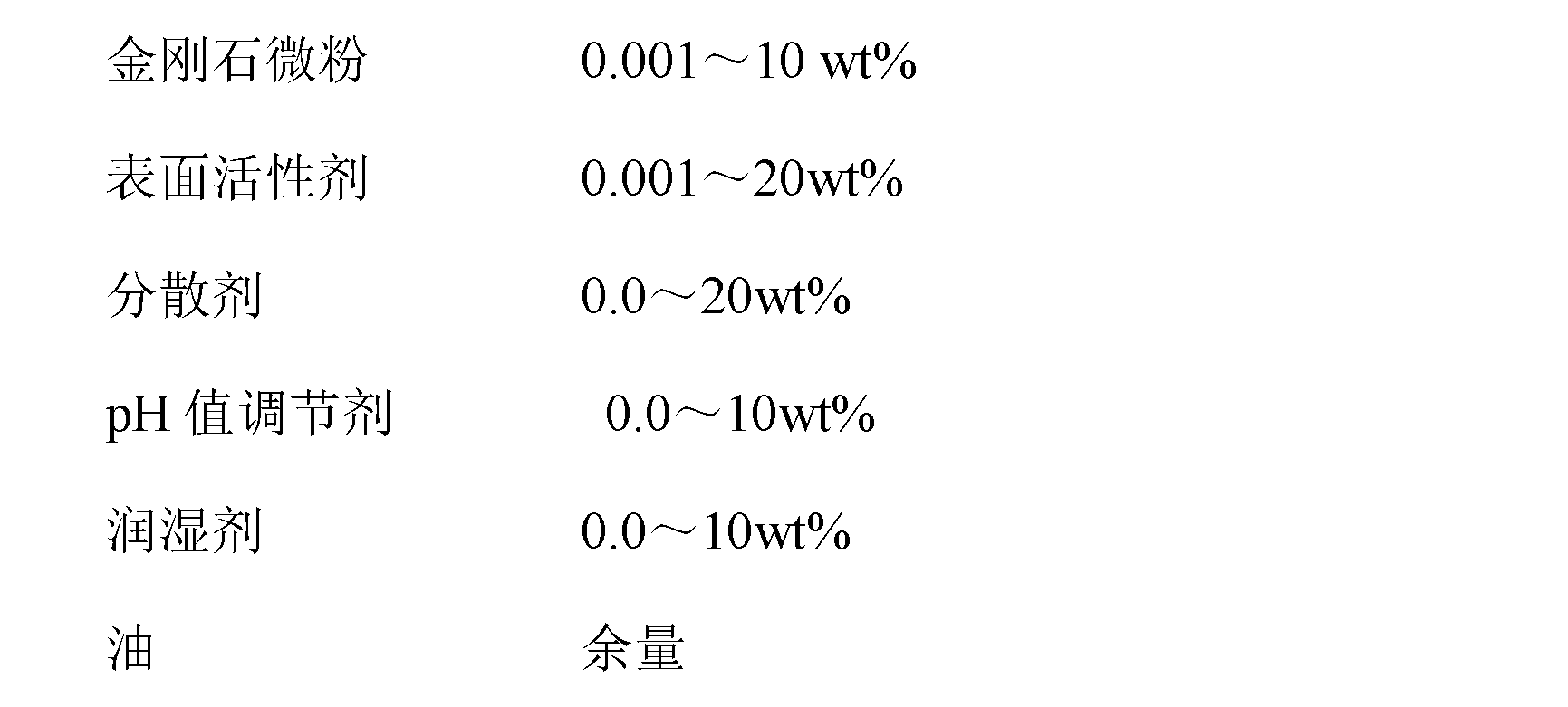

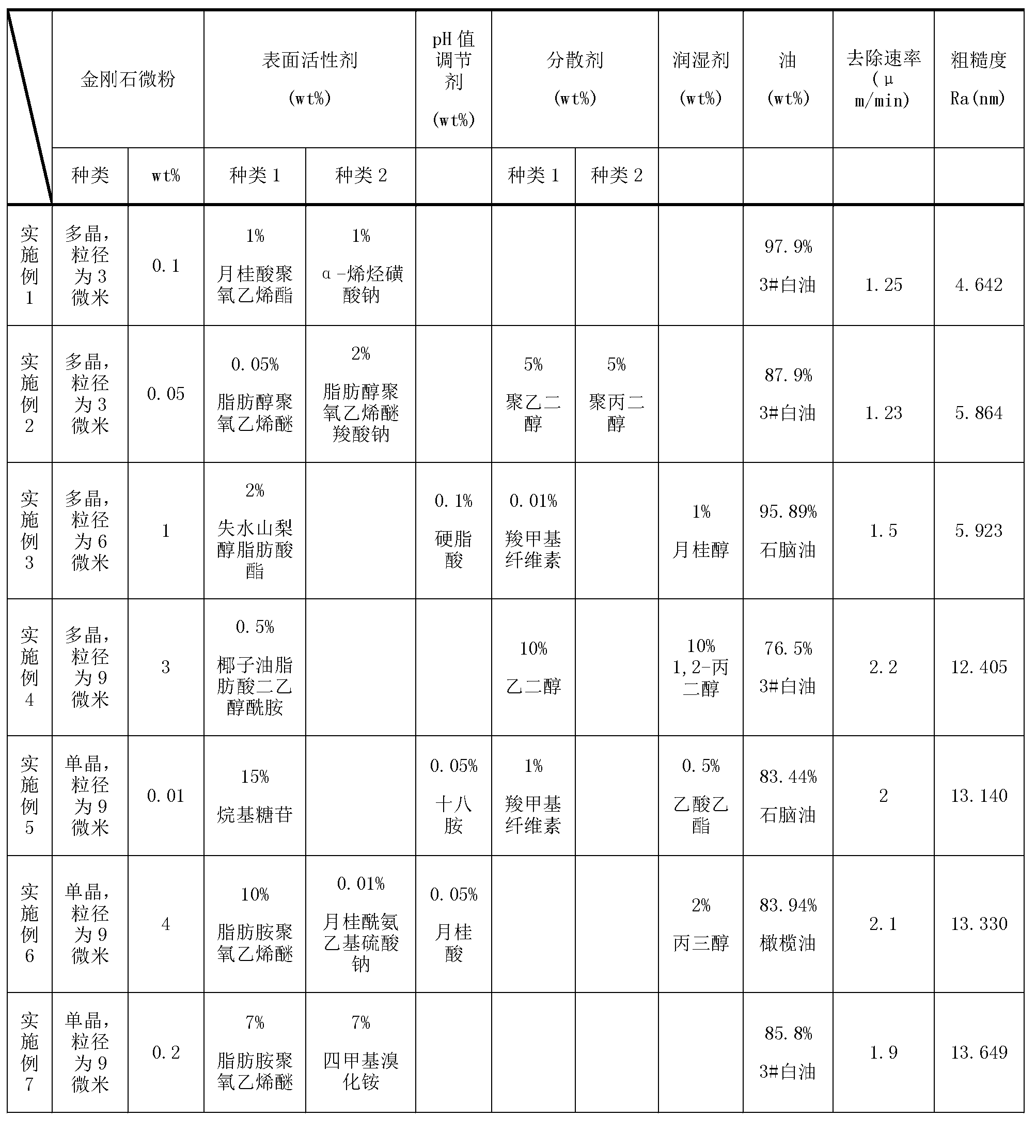

The invention discloses an oily diamond grinding liquid and a preparation method thereof, and belongs to the technical field of surface superfine grinding. The grinding liquid comprises the following components by weight percent: 0.001%-10% of diamond micro powder, 0.001%-20% of surface active agent, 0-20% of dispersant, 0-10% of pH value regulator, 0-10% of wetting agent and oil in balancing amount. The oily diamond grinding liquid is mainly applied to surface grinding and polishing of silicon carbide wafers, LED sapphire substrate slices, ceramic, optical fiber, dies, semi-conductor compound wafers and the like. By the use of the oily diamond grinding liquid provided by the invention, the polishing efficiency can be greatly improved; the dispersing performance is good; a uniform and stable state can be kept for a long time; the degree of finish of products polished with the oily diamond grinding liquid is high; the polishing effect is good; no ingredient harmful to human body is contained; the cleaning is easy; and the environmental protection is facilitated.

Owner:TSINGHUA UNIV +2

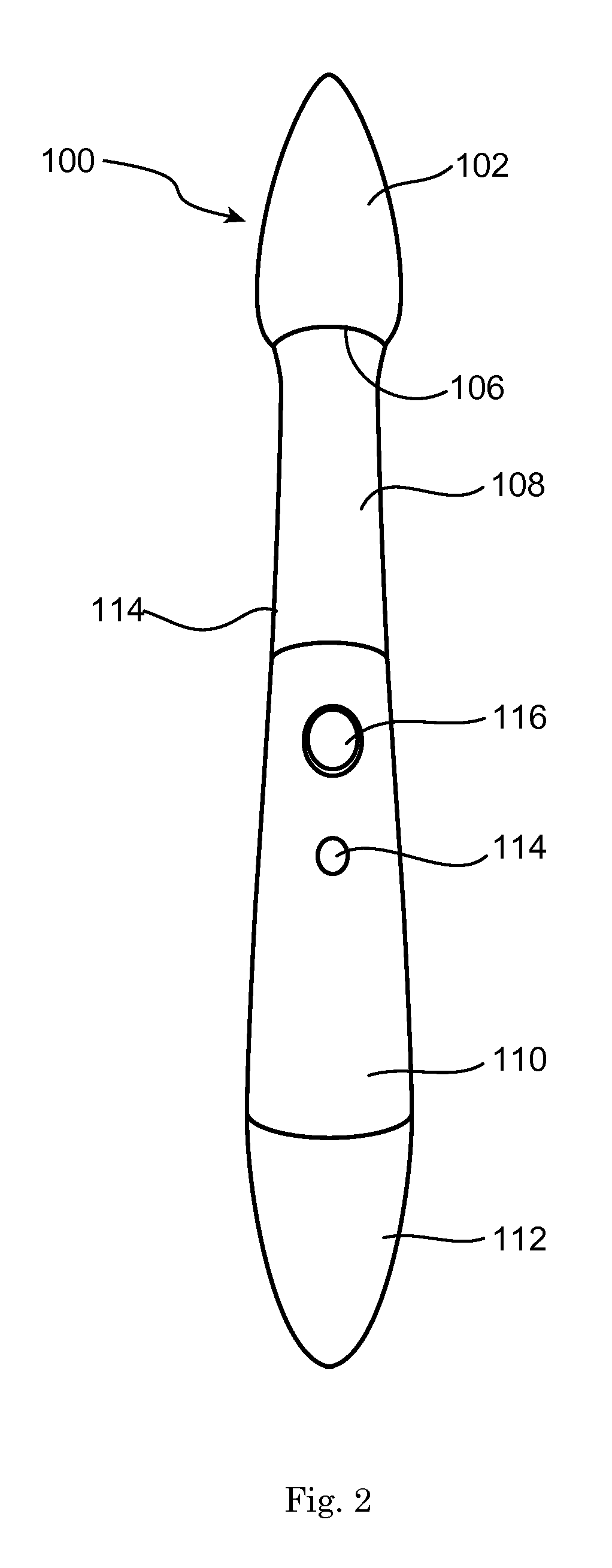

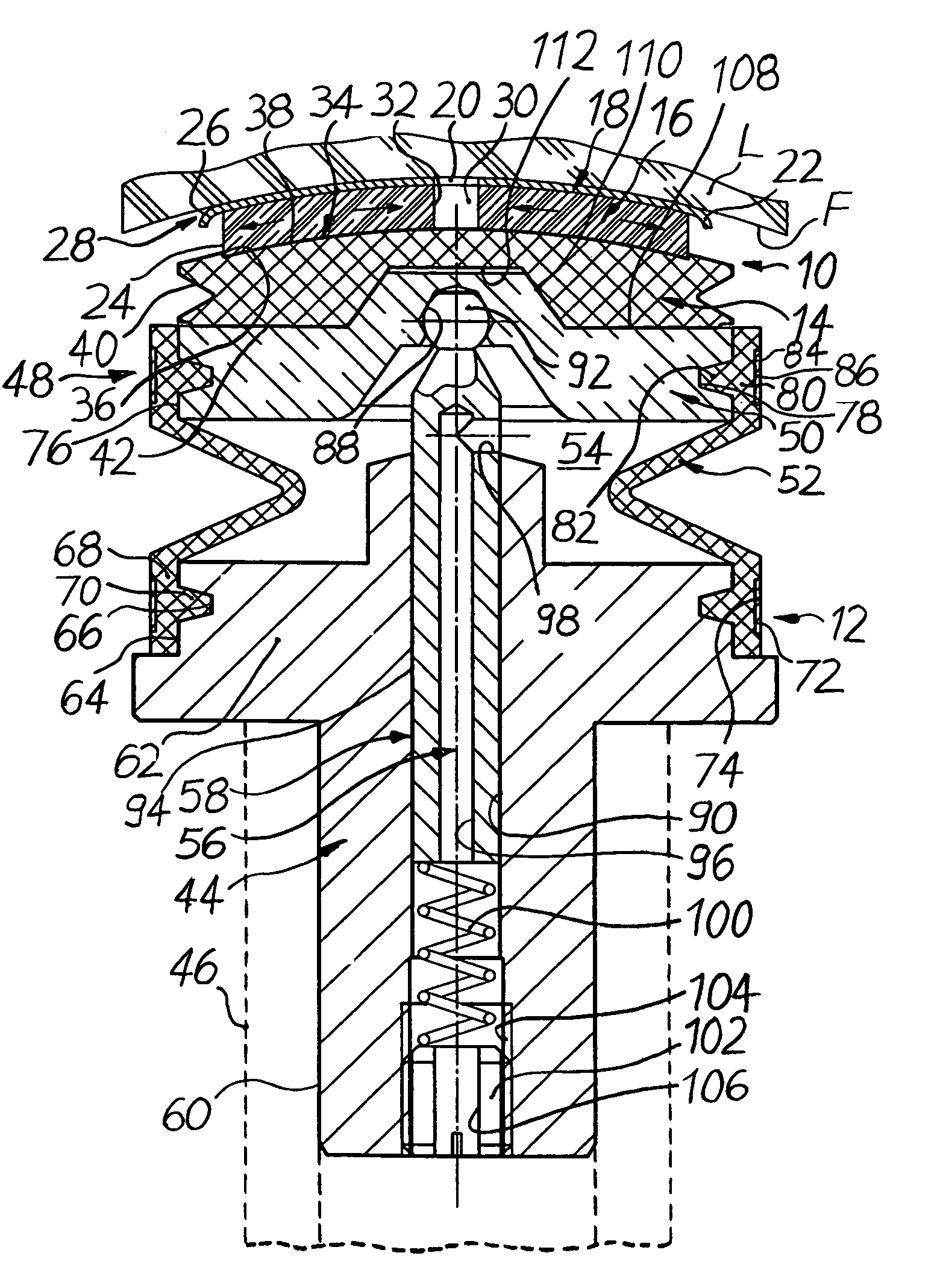

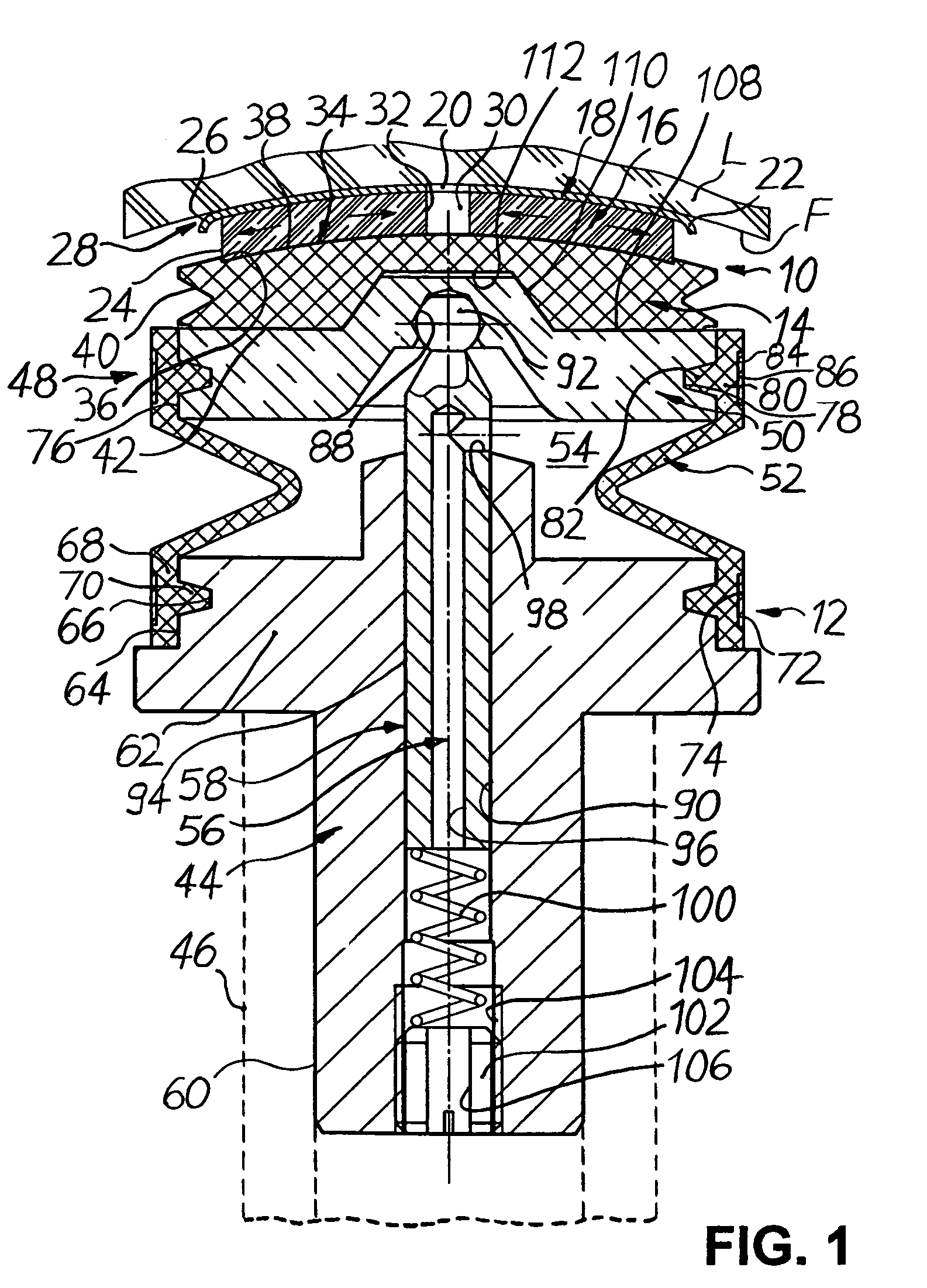

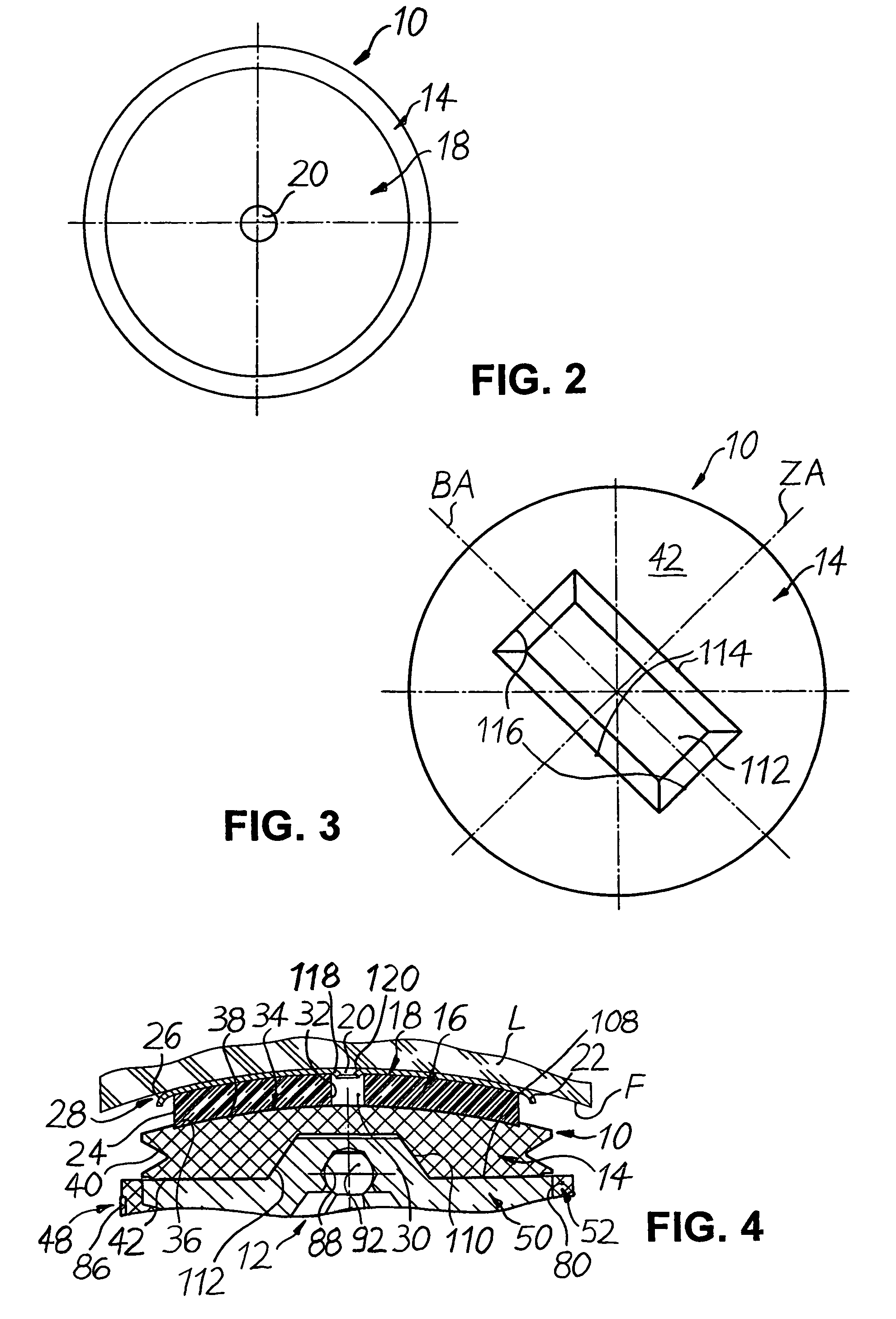

Skin treatment device

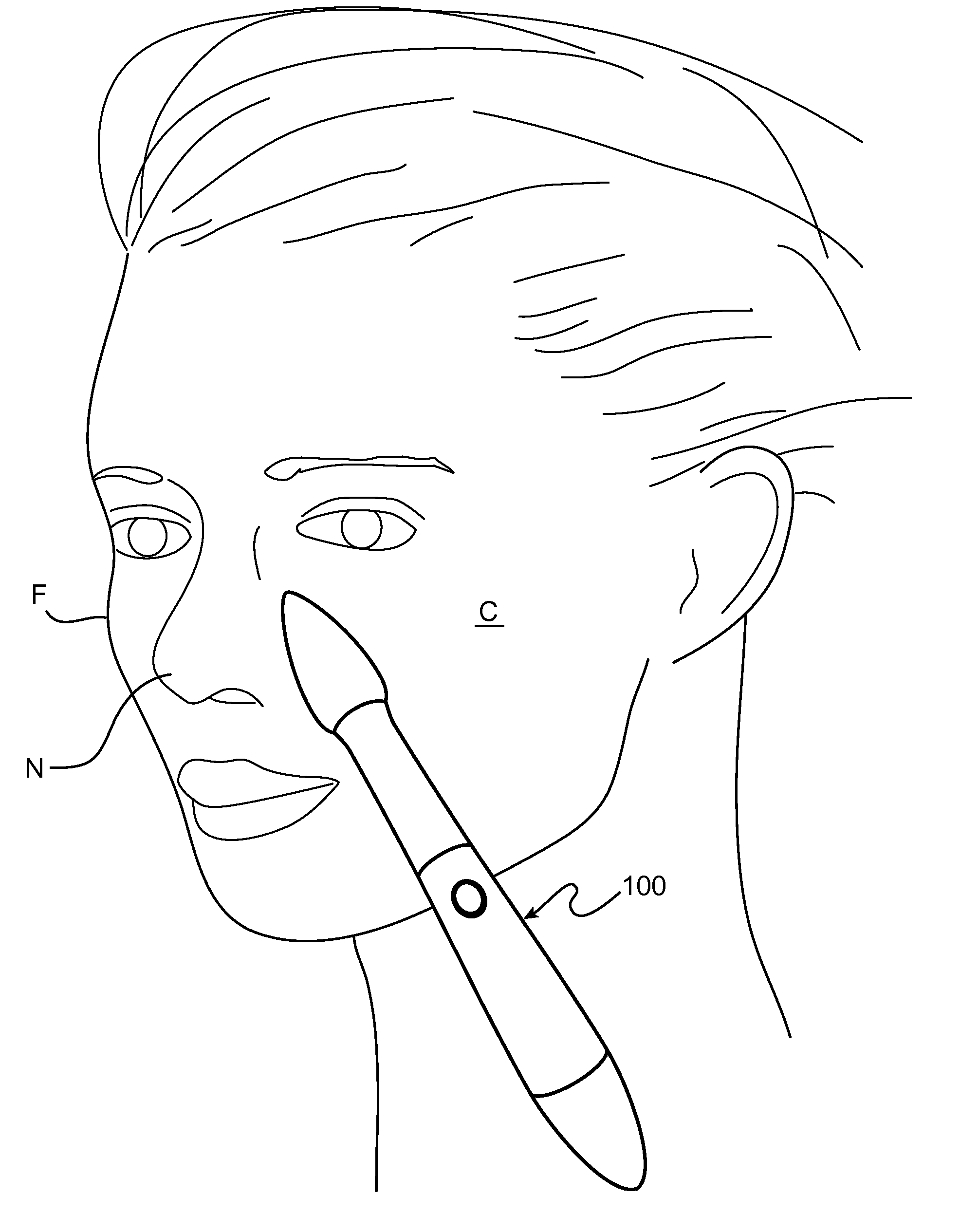

ActiveUS20090124985A1Great motionEnhance skin polishing effectCosmetic preparationsToilet preparationsPorosityPersonal care

A personal skin polishing or microdermabrasion device having a convenient form factor with a applicator attached to a contoured housing with a handle portion. The housing contains a battery, a cordless motor and a gear box to provide an appropriate rotational velocity to the output shaft that is coupled to the applicator. The applicator may be a foam material selected to cushion the skin from excessive abrasion to the particles in a personal care composition to be used with device, and to have a porosity that will enable the foam to interact with the particles and enhance the skin polishing effect.

Owner:THE PROCTER & GAMBLE COMPANY

Water diamond lapping liquid and its preparation method and use

InactiveCN101186804AEnvironmentally friendlyAccelerated corrosionPolishing machinesOther chemical processesAlloySuspending Agents

The invention provides aqueous diamond polishing liquid, process for preparation and purpose. The main components are diadust, dispersion stabilizer, suspending agent, pH modifying agent, antiseptic agent, organic solvent and deionized water. The preparing technique of the invention is that organic solvent, diadust, prior prepared suspending agent, deionized water and dispersion stabilizer are mixed, then the mixture is stirred or supersonically dispersed uniformly, finally pH modifying agent and antiseptic agent are added, and the preparation is accomplished after shaking up. The lapping liquid can be widely used in grinding and polishing in various departments and areas of optical instruments, glasses, ceramics, rigid alloy, diamonds, artificial lens, optical fiber, LED display, integrated circuit, semiconductor, hard disk and the like. The lapping liquid can be kept in uniform and stable state, generates no precipitation, delamination or invalidation.

Owner:BEIJING GRISH HITECH

Processing method allowing lower broken rice rate

The invention relates to a processing method allowing lower broken rice rate and belongs to the technical field of rice processing. The processing method includes the steps of rice screening, stone removal, magnetic separation, moisture measurement and drying or atomizing, hulling, husked rice separation, thickness classification, moisture measurement and drying or atomizing, rolling, white rice classification, cooling, polishing, color sorting, water content detection, and sterilizing and packaging. The rice processed by the processing method is low in broken rice rate, long in shelf life and good in glossiness, and flavor of the rice is rarely lost.

Owner:GUIZHOU FENGGANG COUNTY SHENNONG RICE IND

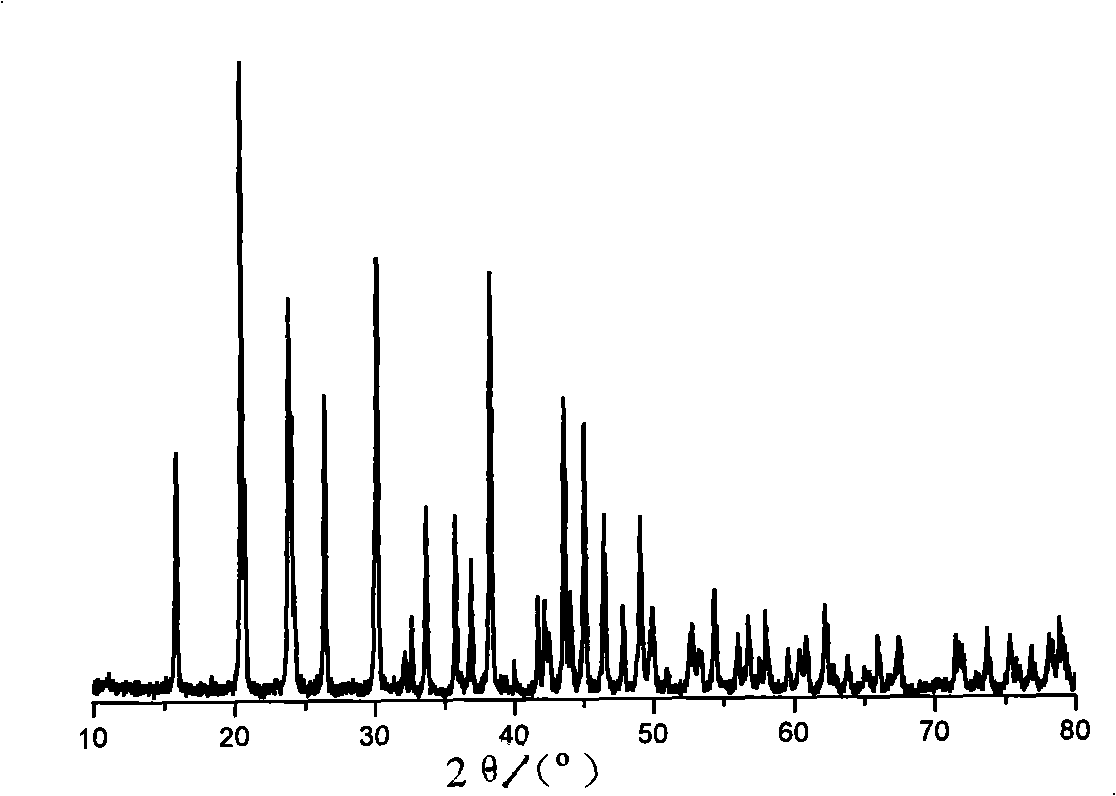

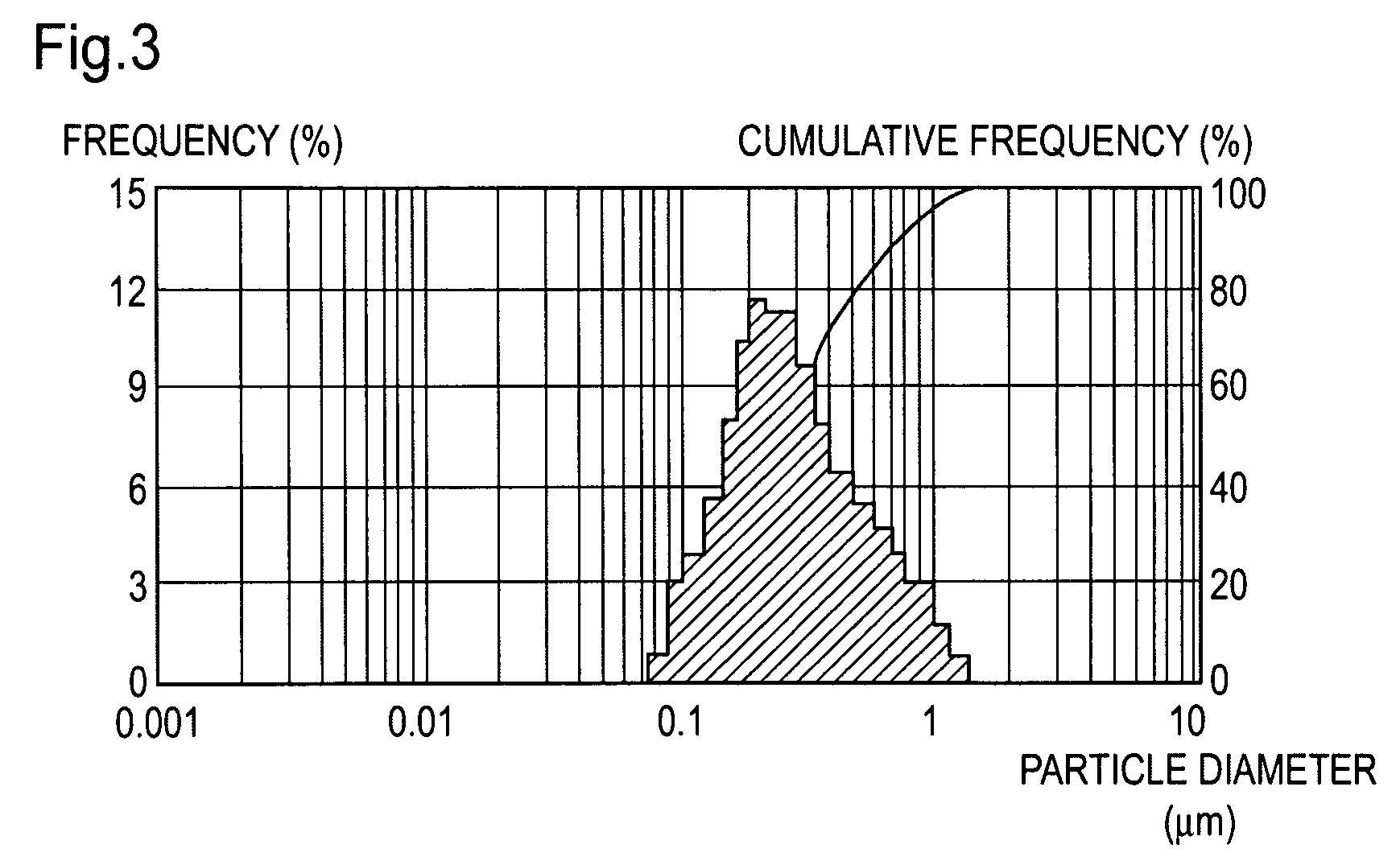

Superfine and spheroidizing rare-earth polish and preparing process thereof

ActiveCN101284983AIncrease ionic strengthIncrease surface chargeOther chemical processesIonDiammonium carbonate

The invention provides ultrafine spheroidized rare earth polishing powder and a process for making the same. The process comprises the following steps that: one of or the mixture of ammonia water, ammonium bicarbonate and ammonium carbonate is used as precipitant; ammonium salt and fluoride ions are added into precipitated slurry to adjust the ionic strength in mother liquid, so as to increase the surface electrical property of solid particles in the slurry; after high temperature aging, the ultrafine rare earth polishing powder with good dispersity and high spheroidization degree can be obtained by filtering the slurry, drying, burning, ball-milling and sieving filter cakes. The average particle size of the obtained polishing powder is between 0.02 mu m and 2.0 mu m, wherein the specific surface area BET is more than 0 and less than 10 m<2> / g, and the powder is in a well-dispersed spherical shape. The powder is used for polishing optical glass, crystal, display screens, etc., strong in cutting force, few in scratch and long in service time.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Method for forming a porous polishing pad

ActiveUS20060226567A1Improve polishing effectAbrasion apparatusLaminationMicrosphereMaterials science

The present invention provides a method of forming a chemical mechanical polishing pad comprising providing a polymeric matrix with fluid-filled unexpanded microspheres, curing the polymeric matrix and heating the polymeric matrix and the microspheres to expand the microspheres.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

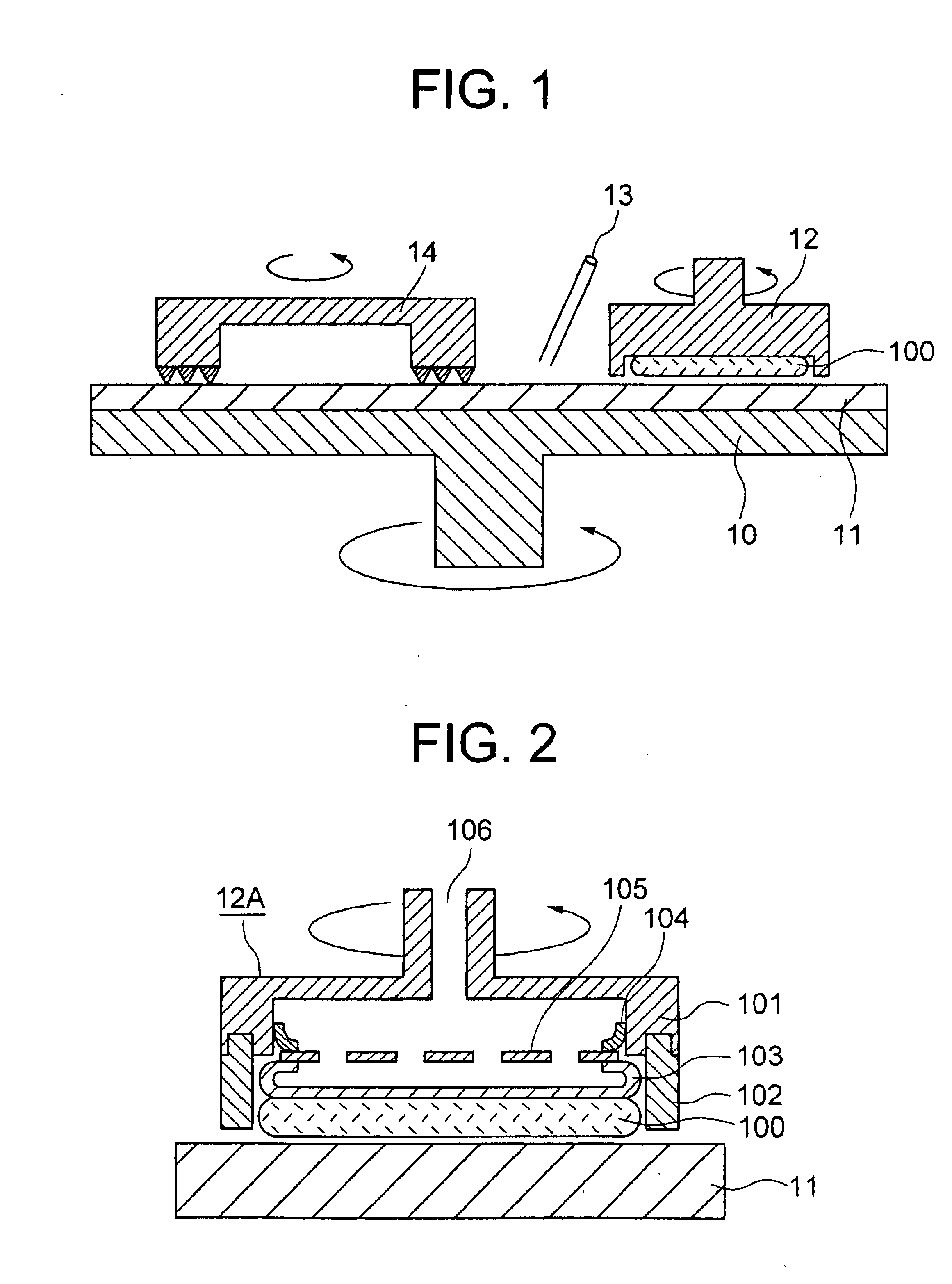

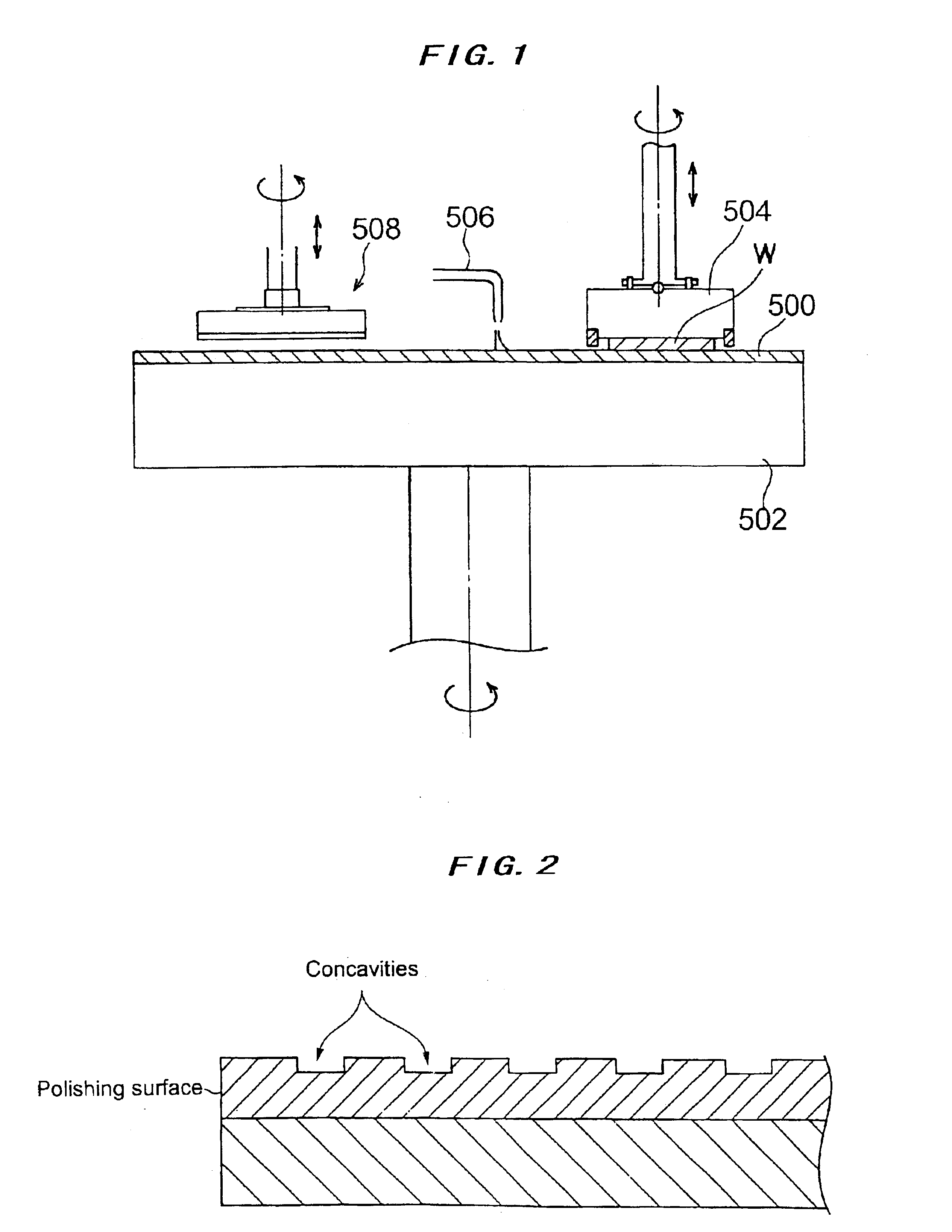

Polishing apparatus

InactiveUS6899603B2Reduce the possibilityAvoid instabilityPolishing machinesRevolution surface grinding machinesEngineering

In a polishing apparatus having a cover body with fluid pressing mechanism, during polishing, vibration and migration of sticking portion between a retainer and a membrane generated in downstream of rotation of a polishing platen is prevented by reducing sticking force between the retainer and the membrane to less than force needed to wafer polishing with rotation of the cover body.

Owner:RENESAS TECH CORP

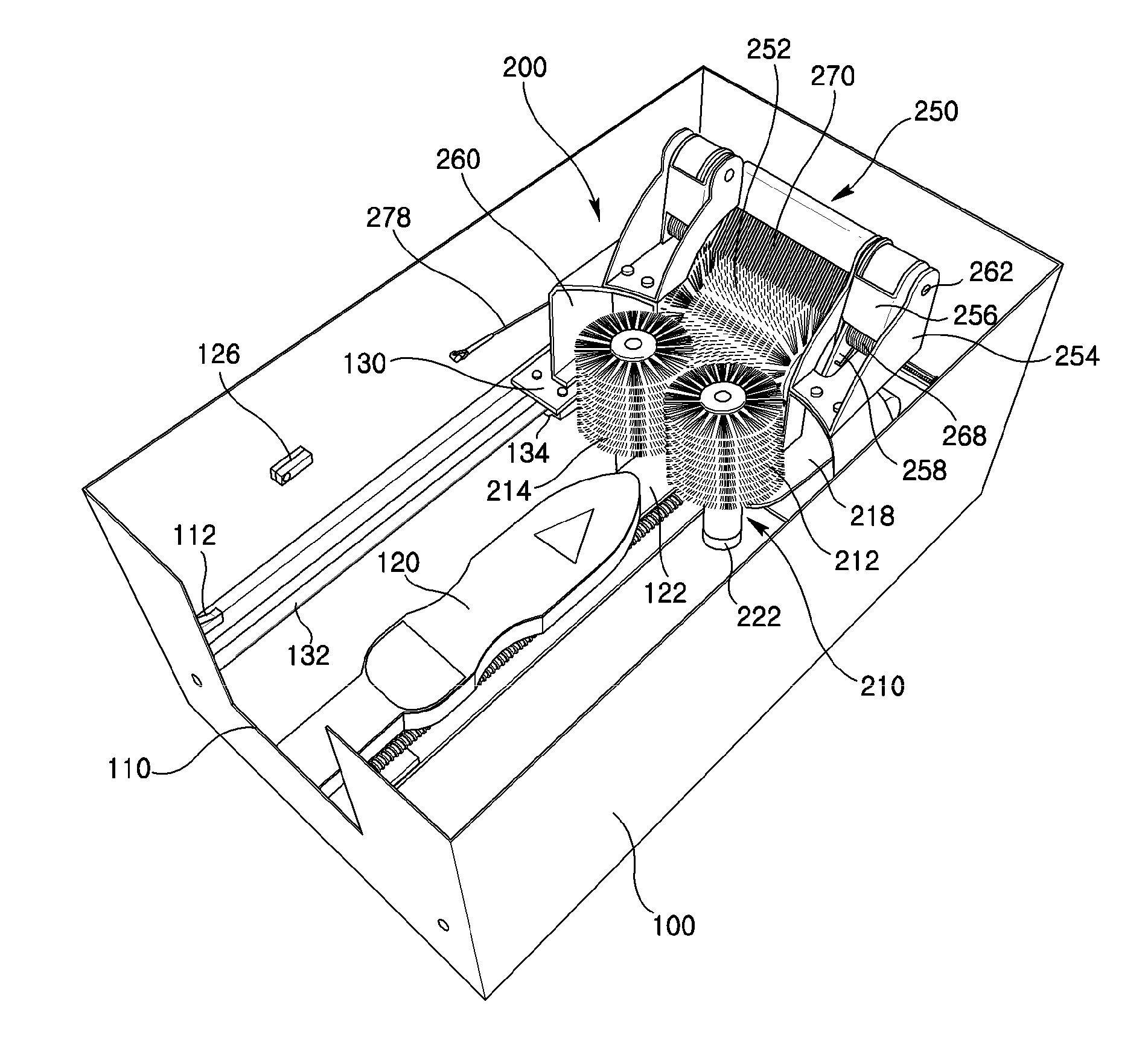

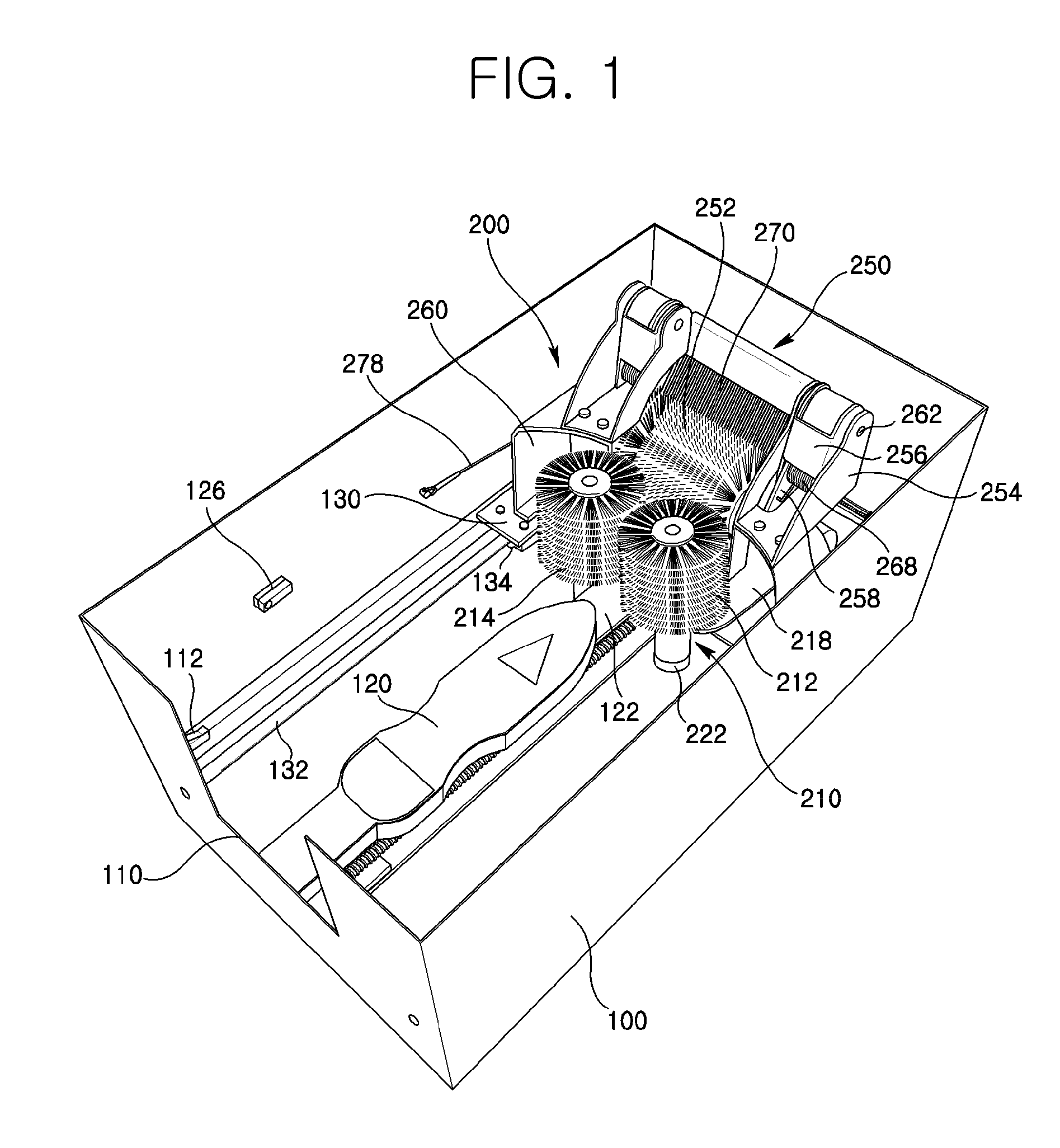

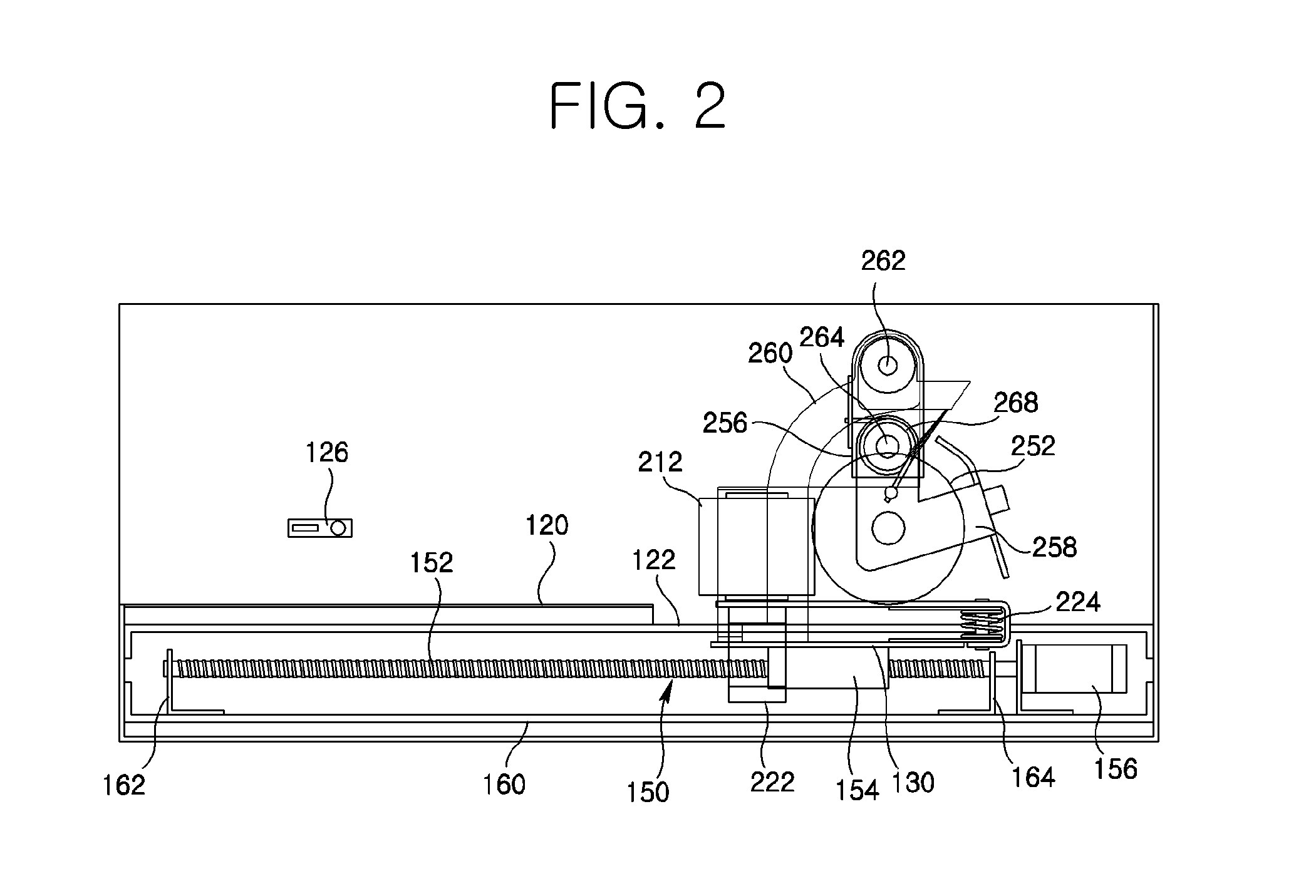

Automatic shoe cleaning device

InactiveUS20110252585A1Uniform applicationImprove polishing effectFootwear cleanersShoe polishEngineering

The present invention relates to an automatic shoe cleaning device, which includes: a housing having a shoe inlet through which a foot with a shoe is inserted and a foot plate where the shoe is placed; a base frame disposed linearly movably inside the housing; a first brush assembly having a pair of side brushes polishing both sides of the shoe at both sides ahead of the base frame and a first spring supplying elastic force to the side brushes; and a second brush assembly having an upper brush polishing the top of the shoe behind the first brush assembly and a second spring supplying elastic force to the upper brush; and a shoe polish supply unit supplying shoe polish to the upper brush, in which as the upper brush moves backward and contacts the pair of side brushes, the shoe polish supplied to the upper brush is transferred to the pair of side brushes, whereas as the upper brush move forward to polish the shoe, the upper brush is separated from the pair of side brushes by the elastic force of the second spring, whereby it is possible to uniformly apply the shoe polish over the entire surface of the shoe and prevent the shoe polish from sticking to the pants.

Owner:LEE SEUNG HO

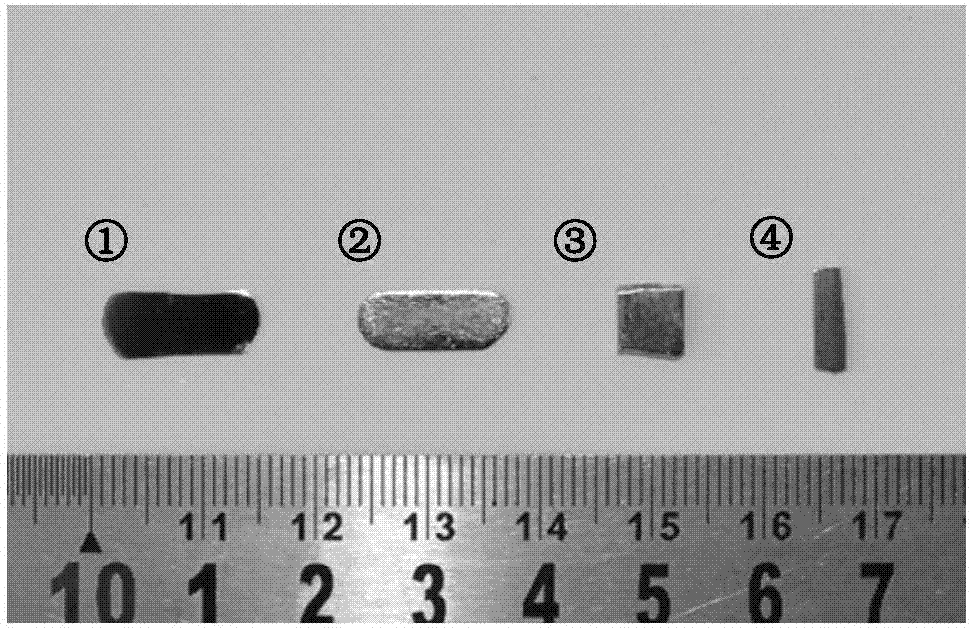

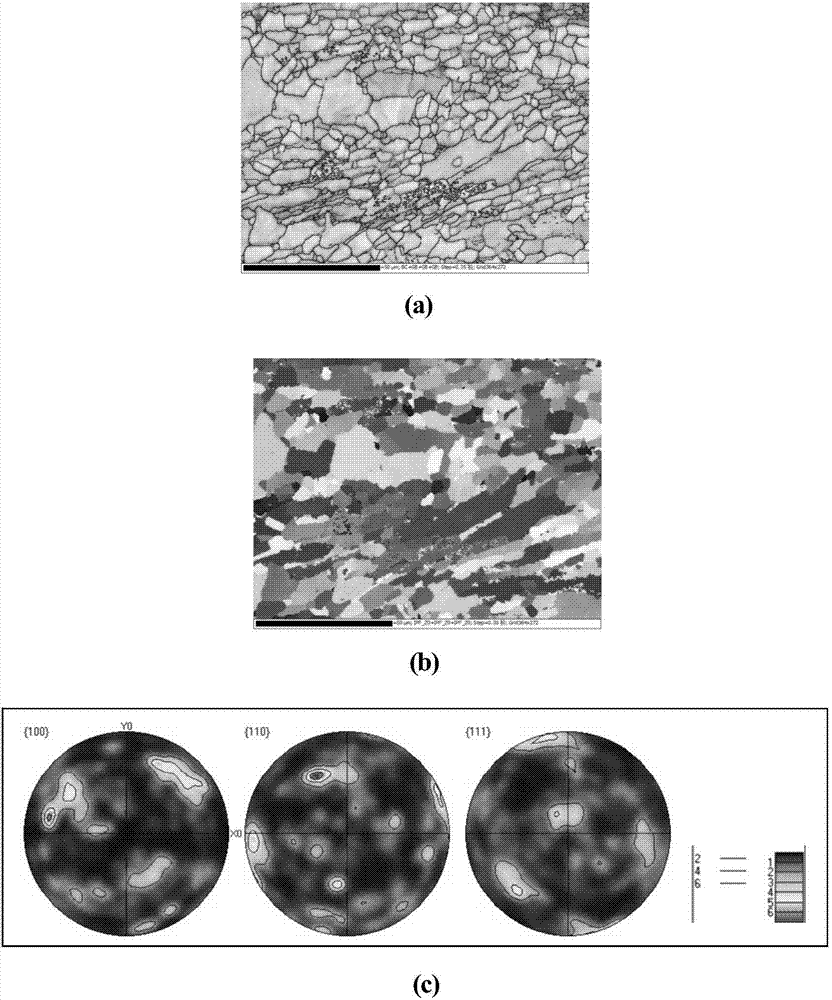

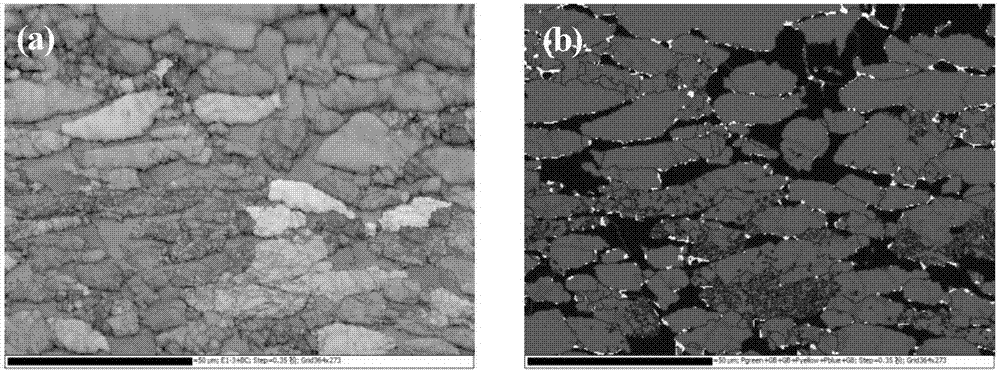

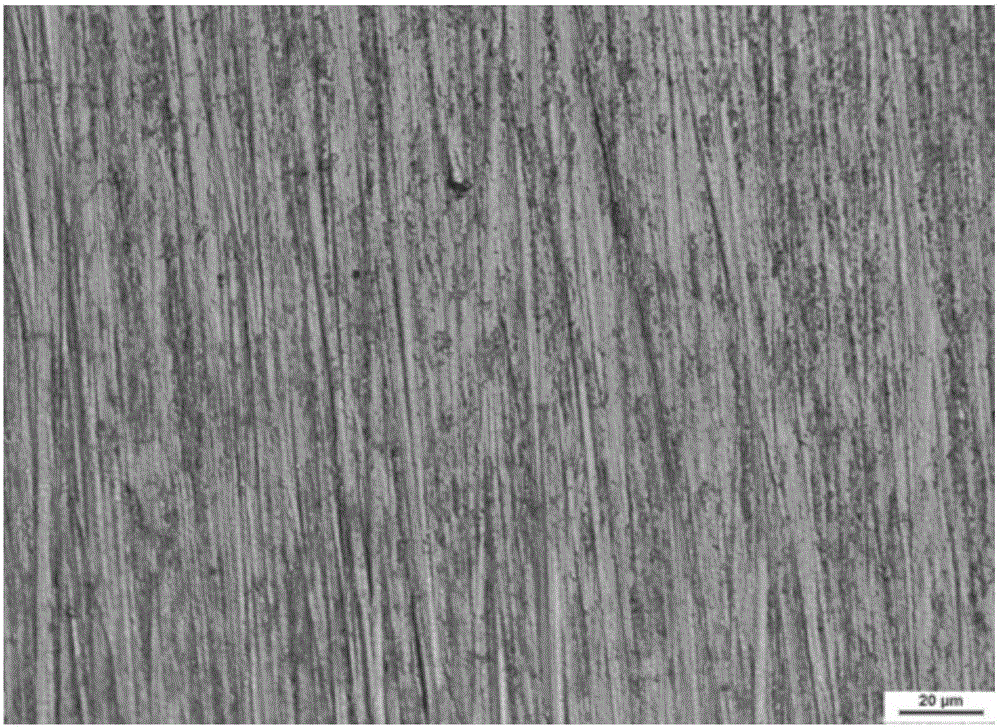

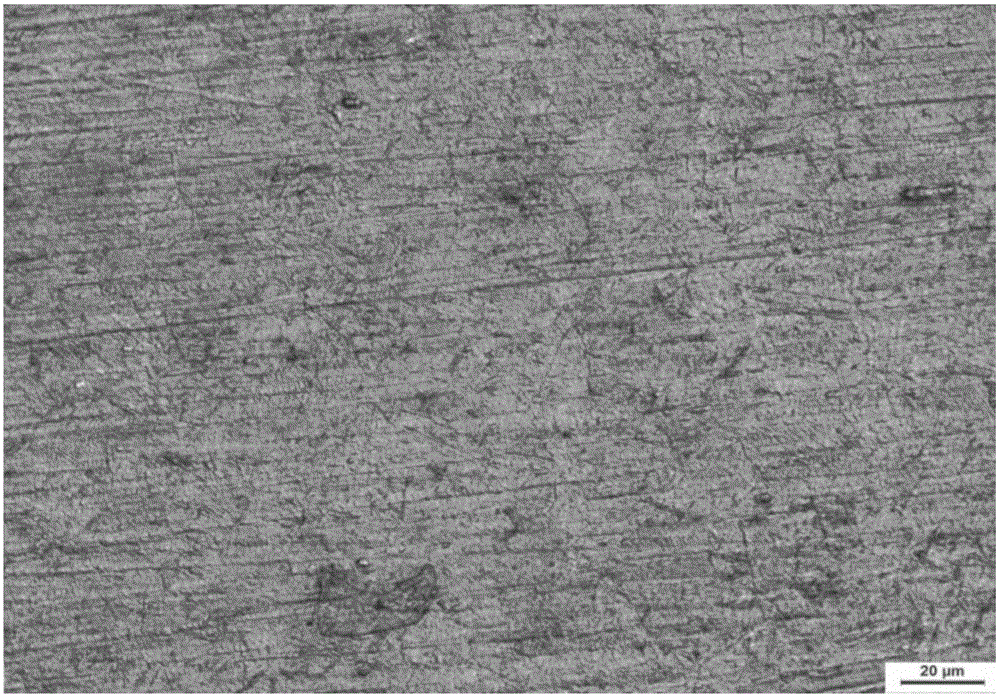

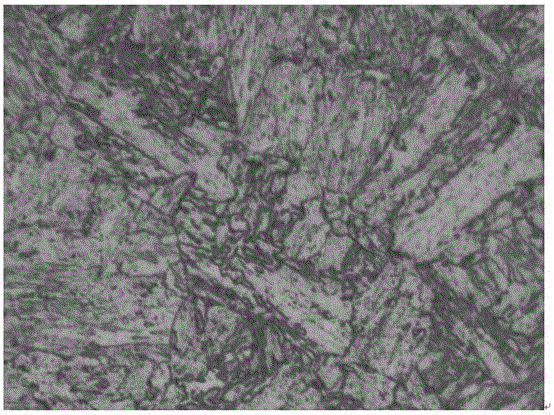

Electropolishing preparation method of sample for EBSD (Electron Back-Scattered Diffraction) analysis of titanium-aluminum alloy

InactiveCN107402150AIncrease the areaEasy and flexible operationPreparing sample for investigationElectrolysisHigh rate

The invention belongs to the technical field of non-ferrous metal analysis and particularly relates to an electropolishing preparation method of a sample for EBSD (Electron Back-Scattered Diffraction) analysis of a titanium-aluminum alloy. The electropolishing preparation method comprises the following steps: firstly, carrying out earlier stage treatment on the sample: determining the size of the sample to be smaller than 7mm*6mm*4mm, and carrying out standard metallographic treatment and mechanical polishing on the testing surface; secondly, setting up a portable device: connecting the sample with a positive pole of a power supply, connecting a stainless steel plate with a negative pole of the power supply and matching the bottom end of electrolyte with a magnetic stirrer; thirdly, preparing the electrolyte: selecting 4 to 12 percent of perchloric acid, 55 to 65 percent of methyl alcohol and the balance of n-butyl alcohol according to the volume ratio, wherein the total amount of the electrolyte is 700ml; putting the electrolyte into a beaker with the volume of 1L; fourthly, carrying out electrolysis treatment, washing and drying: controlling the temperature to be 30 DEG C below zero to 20 DEG C below zero, controlling the voltage to be 25 to 35V and controlling the polishing time to be 40 to 55 seconds. The electropolishing preparation method disclosed by the invention has the advantages of large surface area for treating the sample and suitability for preparing titanium-aluminum alloy samples with various components and various test purposes, which are prepared by different processing method. In addition, the electropolishing preparation method has the advantages of easiness and flexibility in operation, no restriction from site facilities and the like, good polishing effect and high rate of finished products; the device has the characteristics of high mobility, low cost, easiness in promotion and wide application prospect.

Owner:NORTHEASTERN UNIV

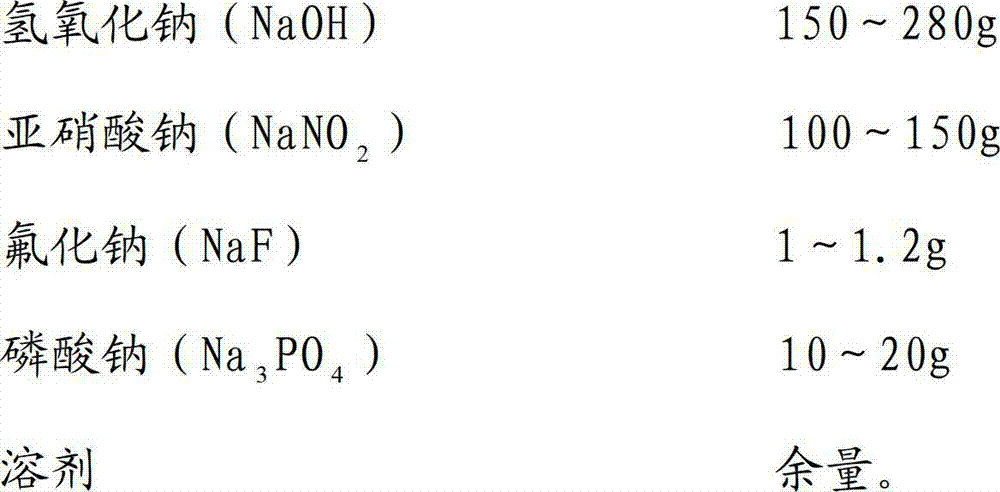

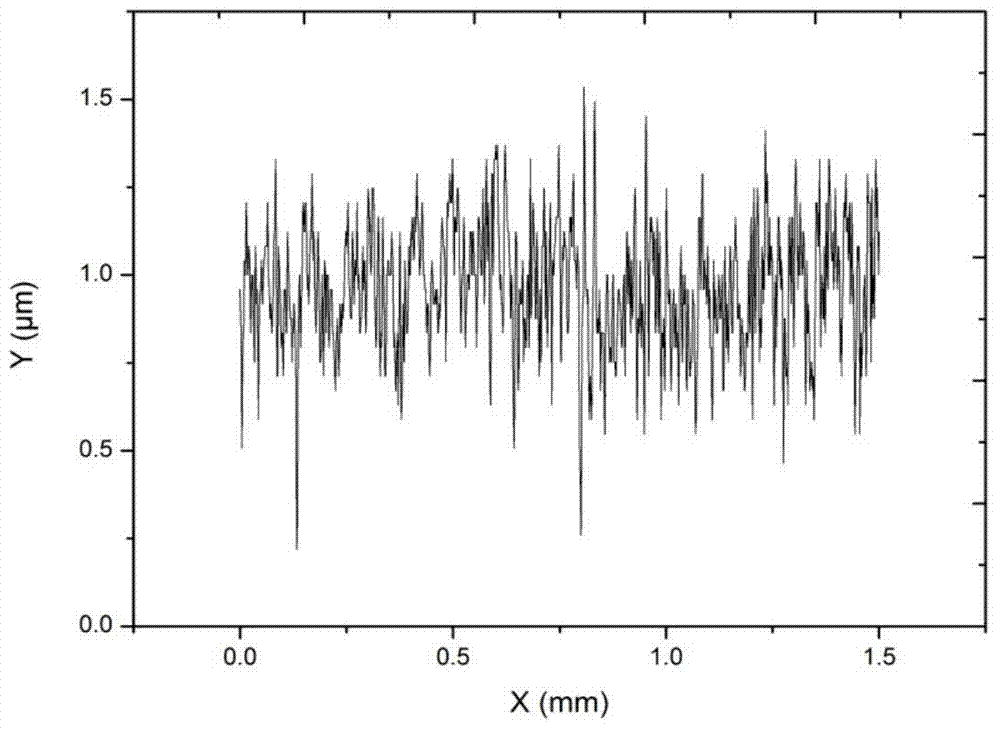

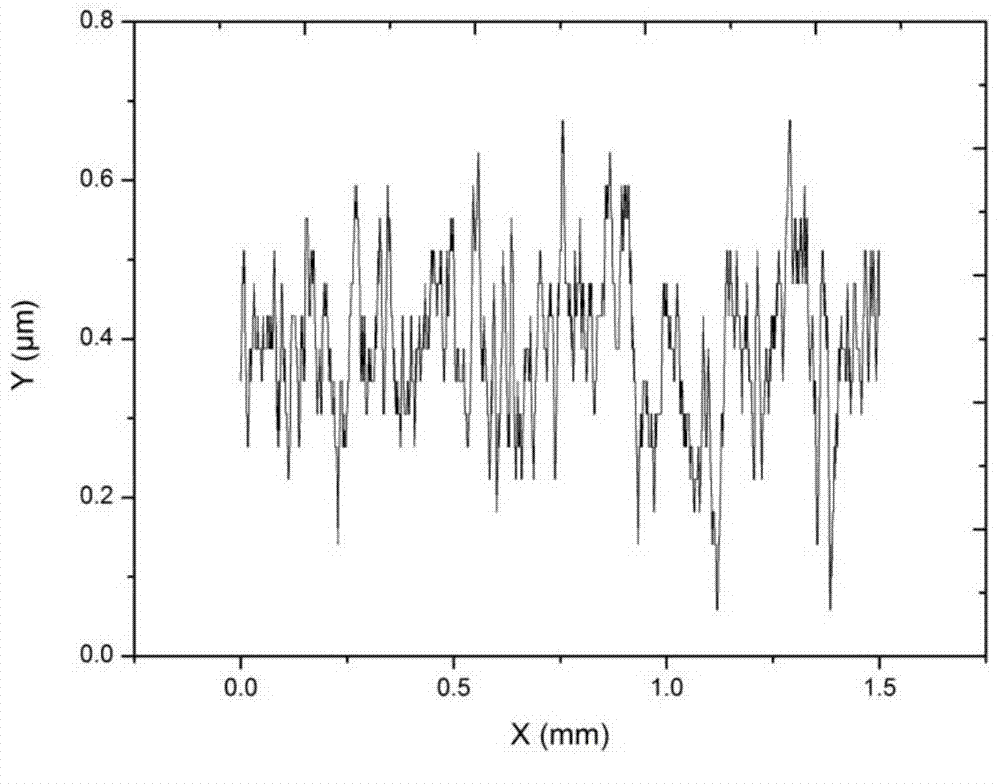

Alkaline chemical polishing solution and alkaline chemical polishing method

The invention discloses an alkaline chemical polishing solution and an alkaline chemical polishing method. Each 1 L of alkaline chemical polishing solution comprises components of 150-280 g of sodium hydroxide, 100-150 g of sodium nitrite, 1-.1.2 g of sodium fluoride, 10-20 g of sodium phosphate, and the balance of a solvent; and meanwhile, the alkaline chemical polishing solution is utilized for alkaline chemical polishing. The alkaline chemical polishing solution and the alkaline chemical polishing method, disclosed by the invention, have the beneficial effects of solving the problems of scratching and impacting of aluminum alloy parts, improving surface roughness of parts, lowering production cost and avoiding environment pollution as a selective self-dissolution function of aluminum and an aluminum alloy is utilized in an alkaline solution to flatten and polish the surface of the aluminum.

Owner:GUIZHOU AEROSPACE LINQUAN MOTOR CO LTD

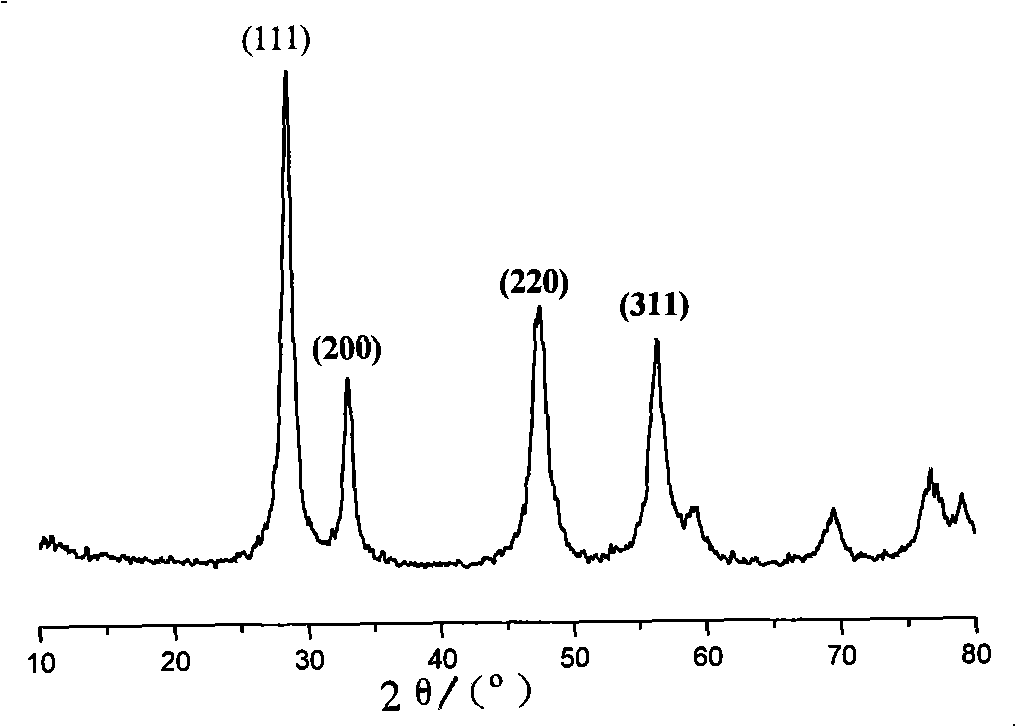

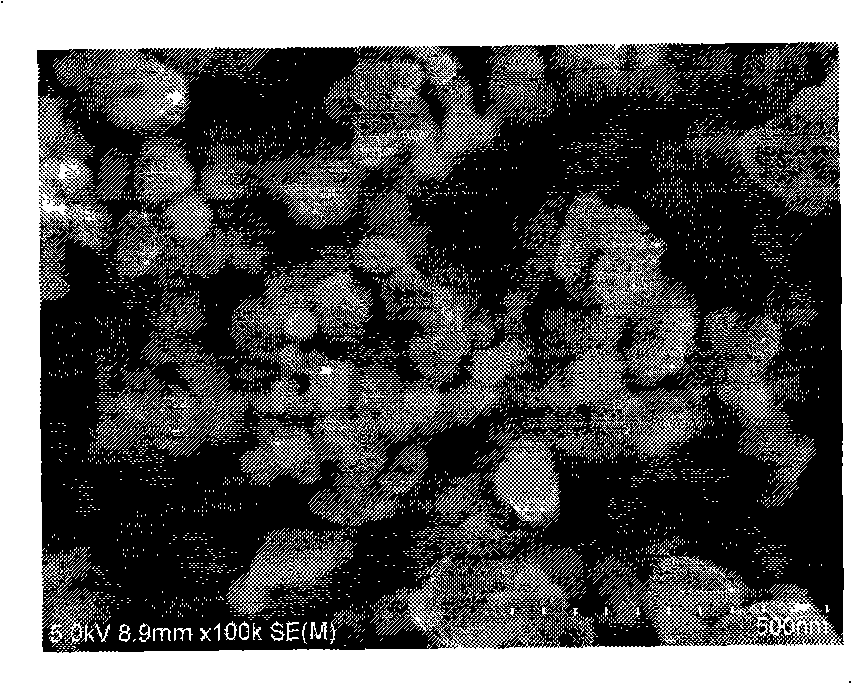

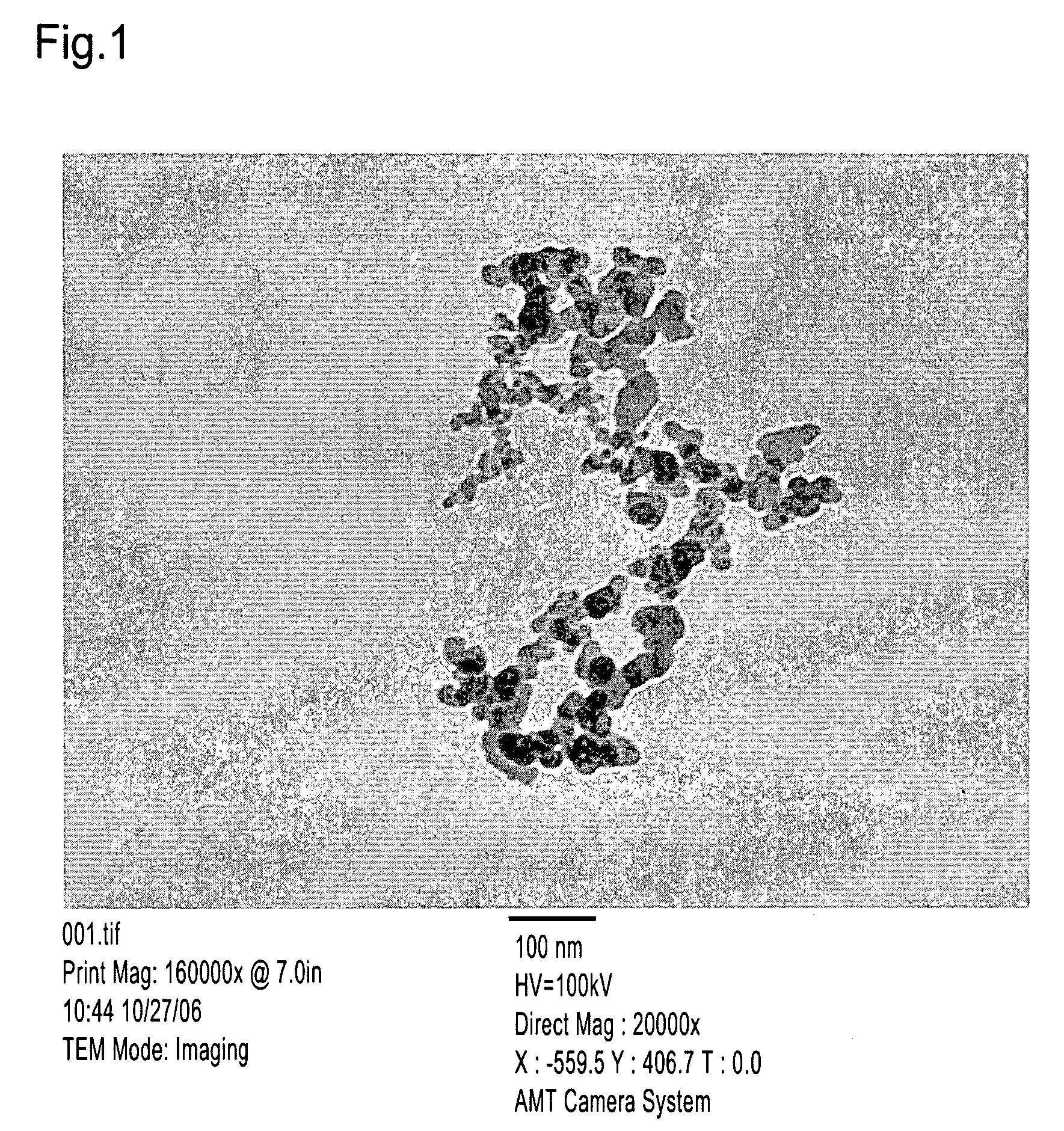

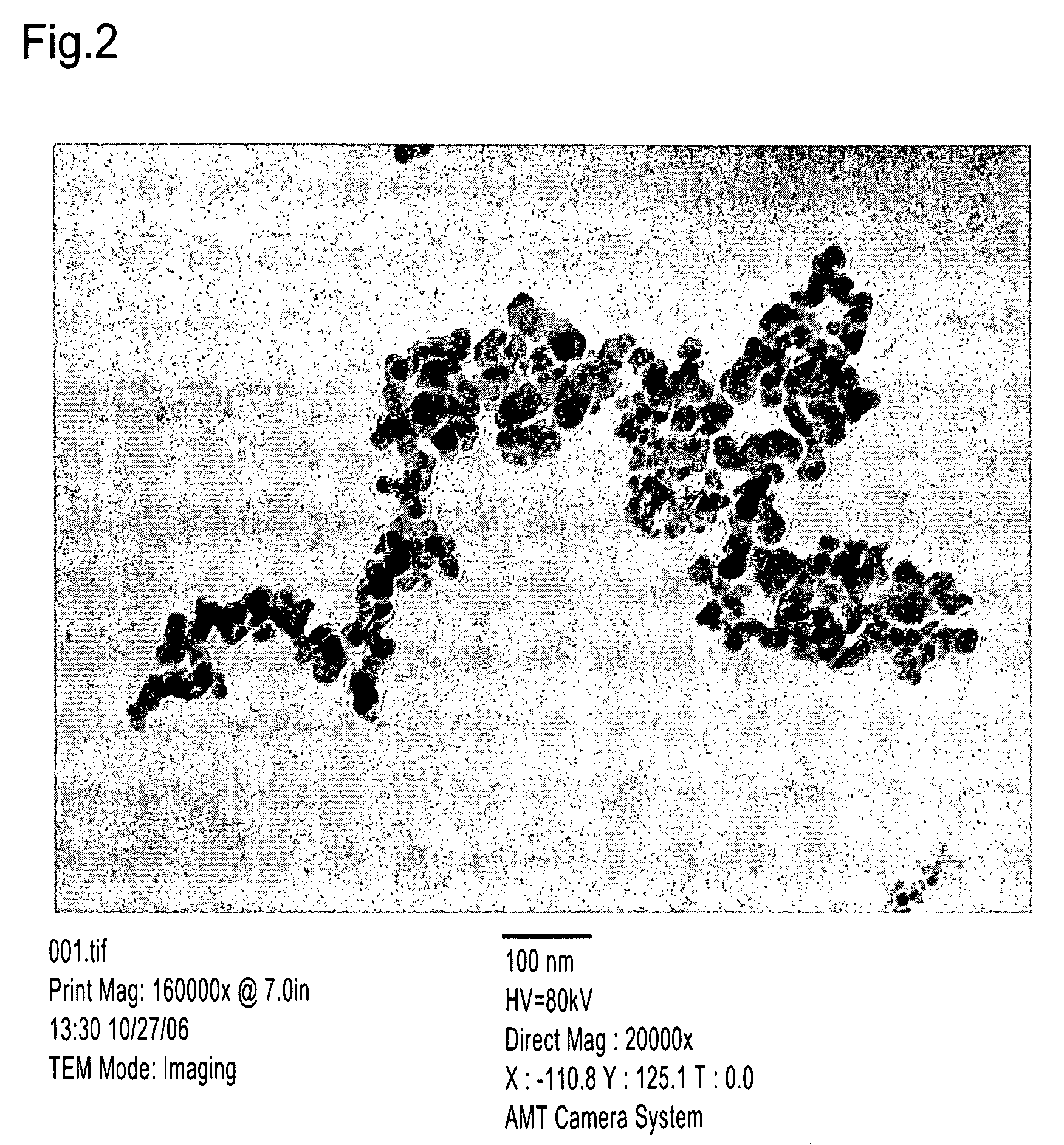

Nodular Silica Sol and Method of Producing the Same

InactiveUS20100146864A1Easy to getImprove polishing effectPigmenting treatmentOther chemical processesMaterials scienceNitrogen absorption

A novel nodular silica sol adapted to use as a polishing material for polishing, for instance, CMP.The nodular silica sol has a ratio of an average particle diameter (r) measured by the dynamic light scattering method versus a particle diameter (r′) converted to that of an equivalent sphere computed from an average specific surface area measured by means of the nitrogen absorption method (r / r′, referred to as “association ratio”) in a range from 1.2 to 10, the particle diameter (r′) in a range from 5 to 200 nm, and the specific surface area in a range from 13 to 550 m2 / g. The nodular silica particles have heterogeneous forms, and contents of Ca and Mg contained in the nodular silica particles are below 1000 ppm against SiO2 respectively.

Owner:JGC CATALYSTS & CHEM LTD

Composition for polishing semiconductor wafer, and method of producing the same

InactiveUS20080237535A1Improve polishing effectBig advantagePigmenting treatmentOther chemical processesSilica particleGas phase

A composition for polishing a semiconductor wafer contains fumed silica particles that are produced by wet grinding using a grinding medium and that have characteristics (A) to (C):(A) a specific surface area in the range of 50 to 200 m2 / g measured by a BET method;(B) an average particle diameter in the range of 10 to 50 nm measured by a laser light-scattering method; and(C) an average ratio A / B of the major axis A to the minor axis B of the fumed silica particles in the range of 1.2 to 2.0 measured by TEM observation,wherein the concentration of silica particles containing the fumed silica particles is in the range of 0.5 to 50 weight percent relative to the total weight of an aqueous dispersion.

Owner:NIPPON CHECMICAL IND CO LTD +1

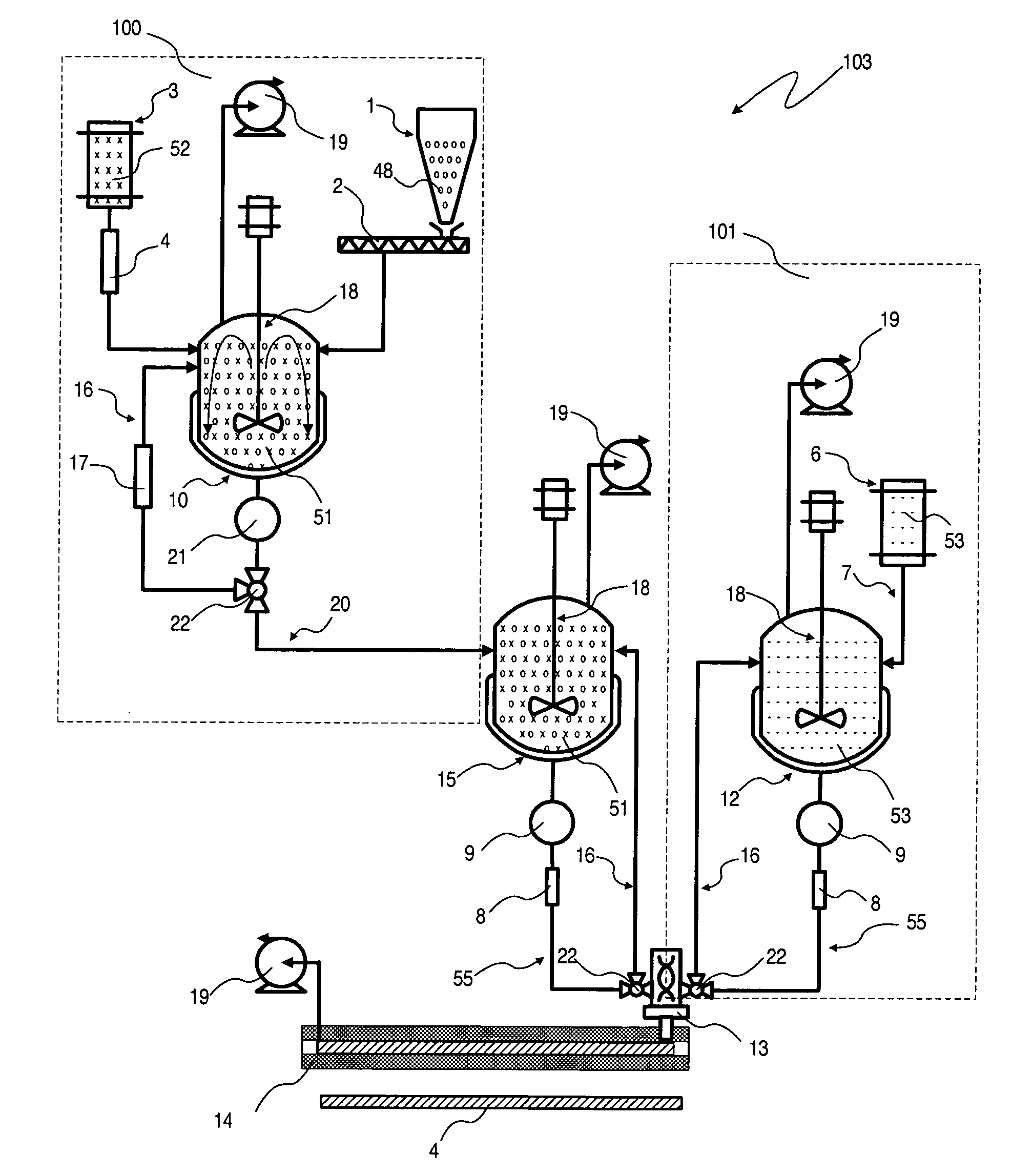

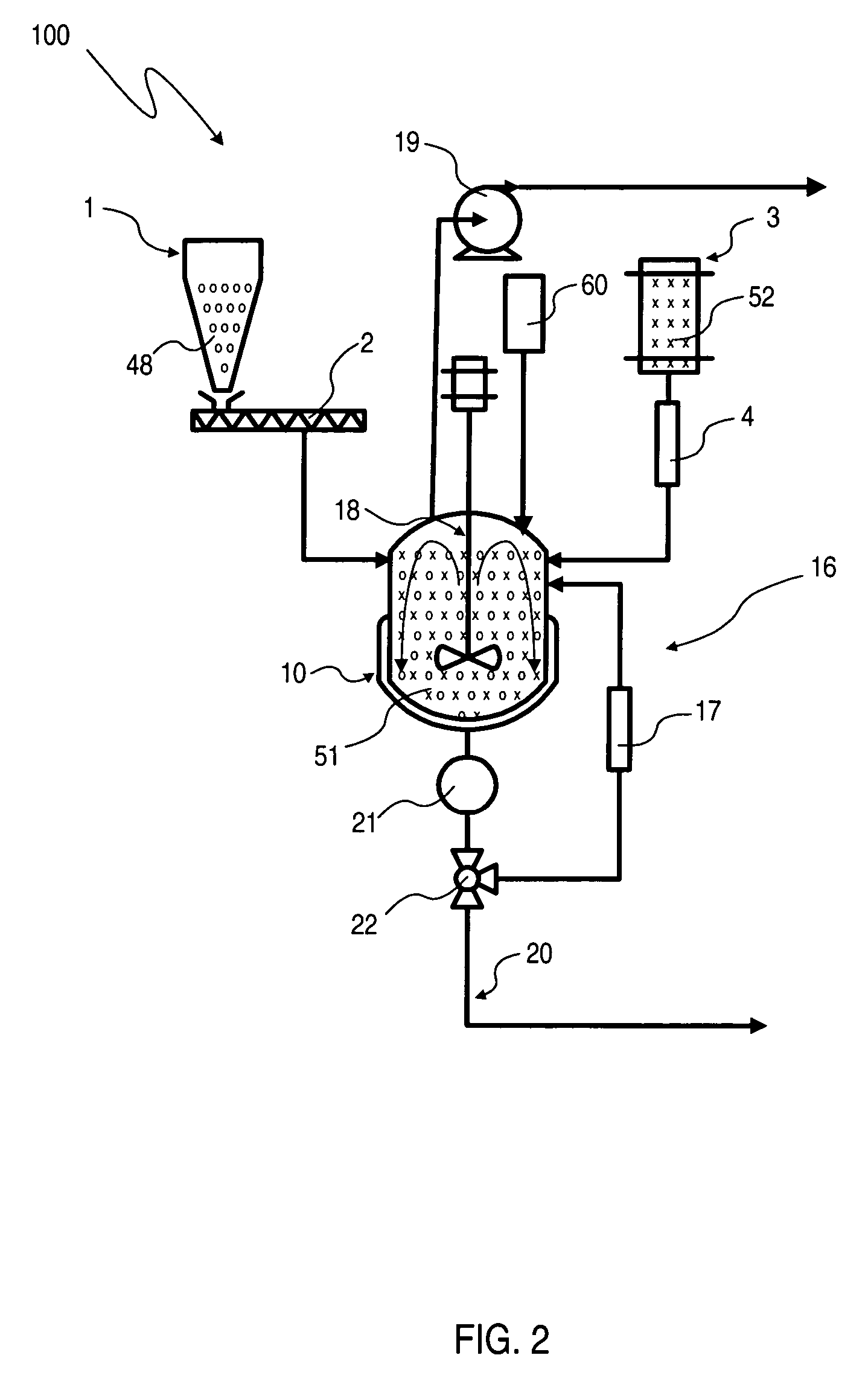

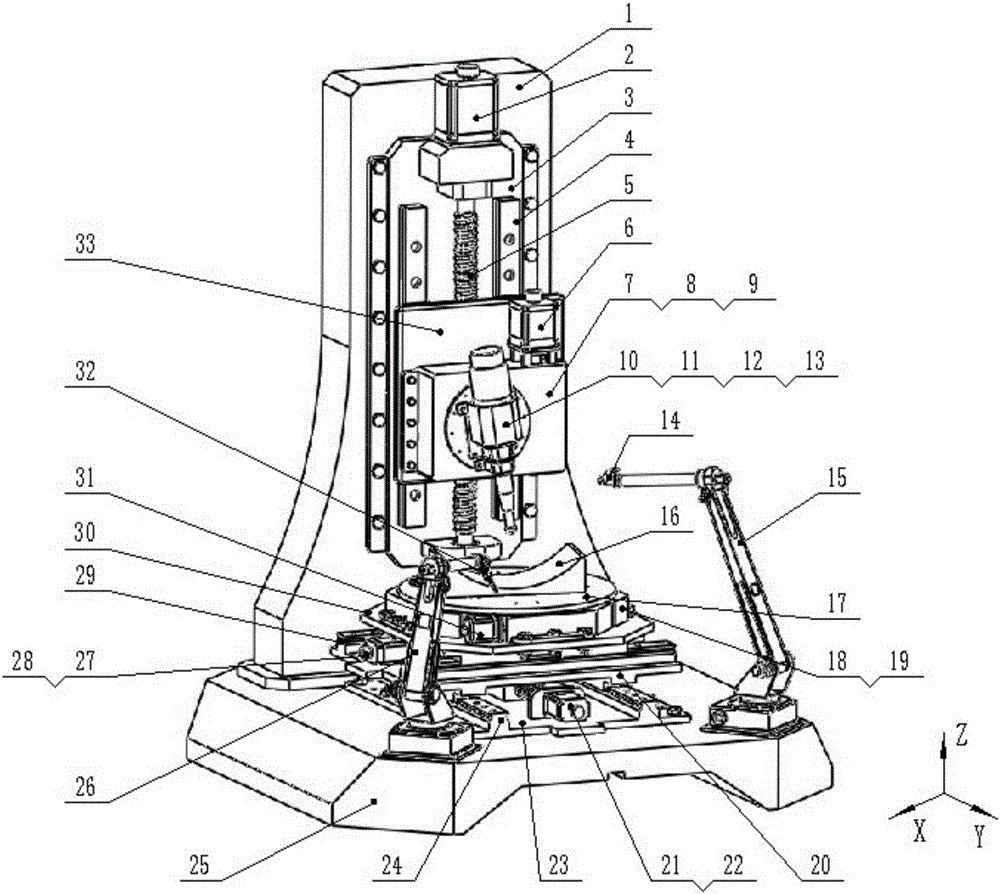

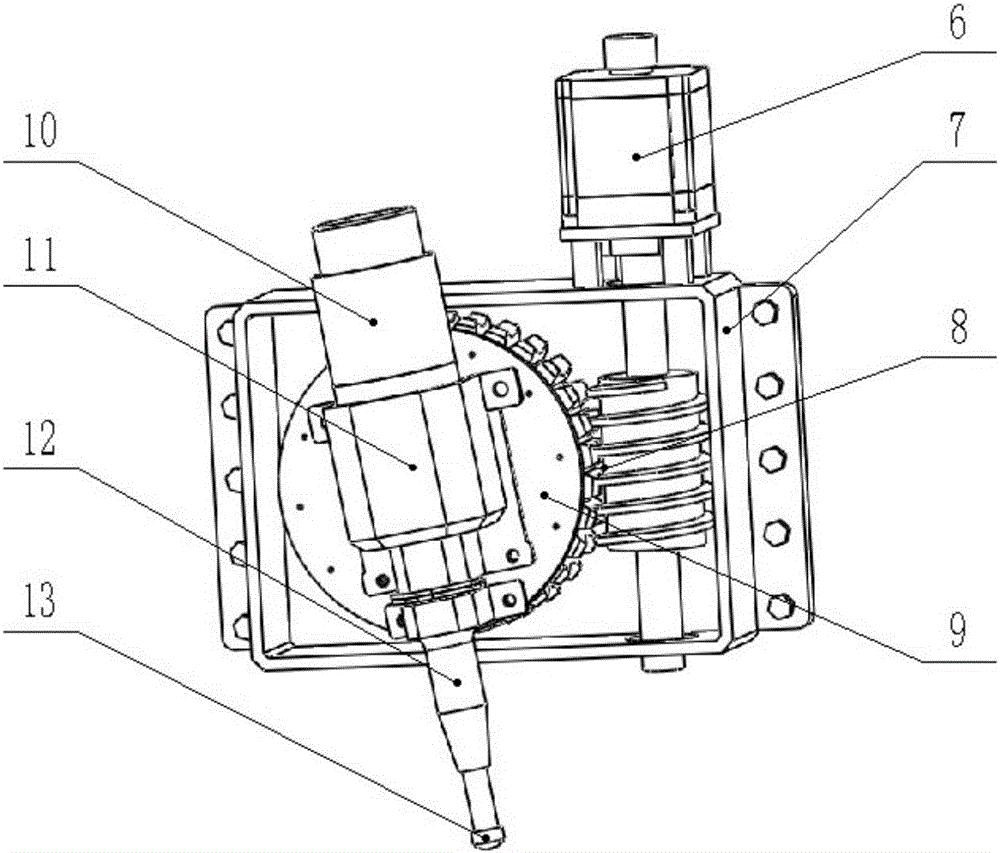

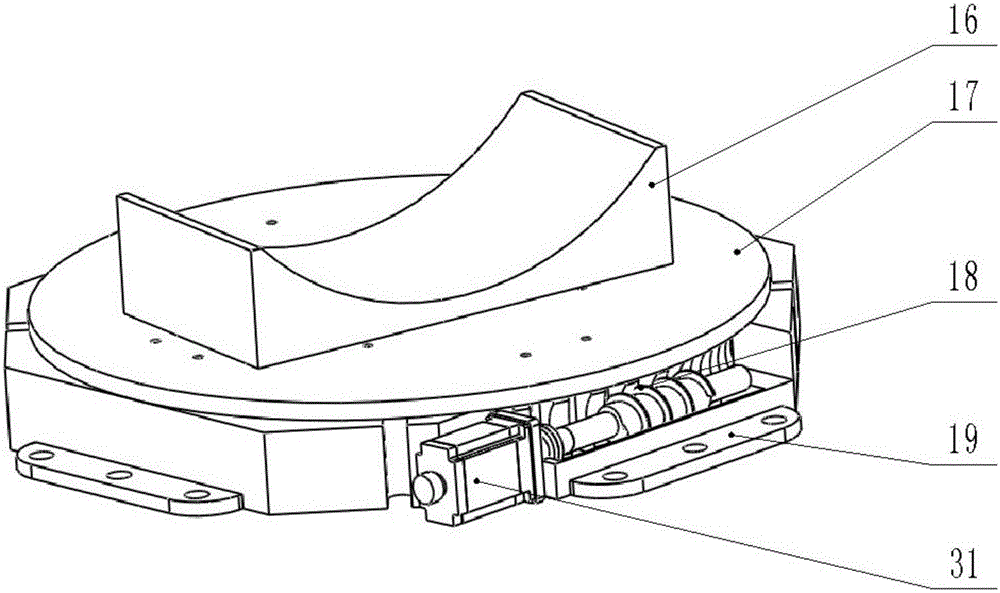

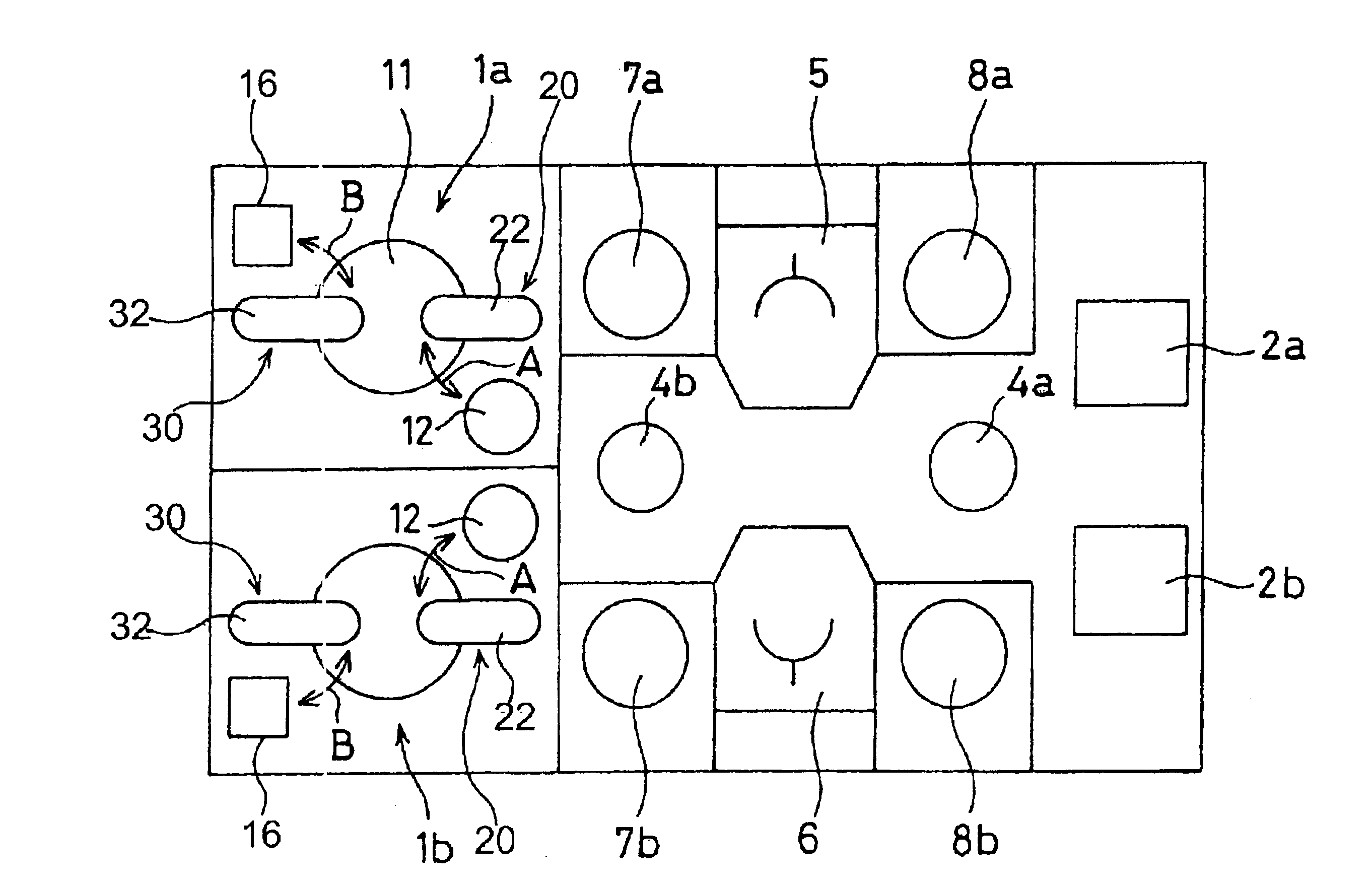

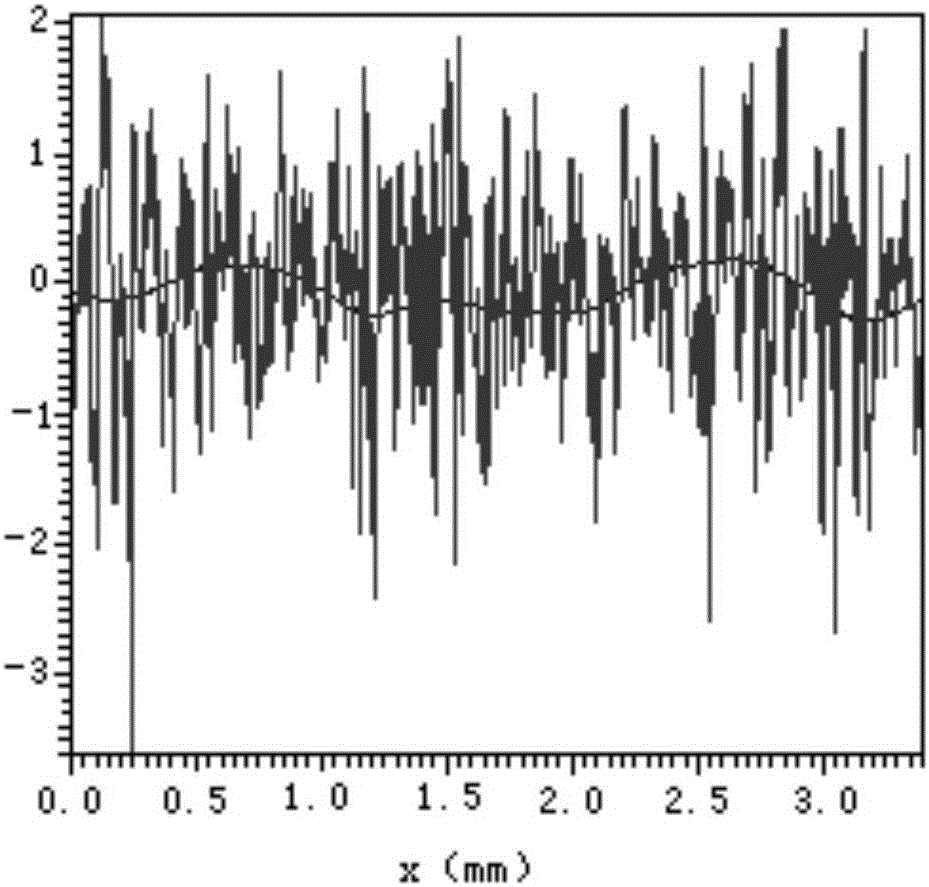

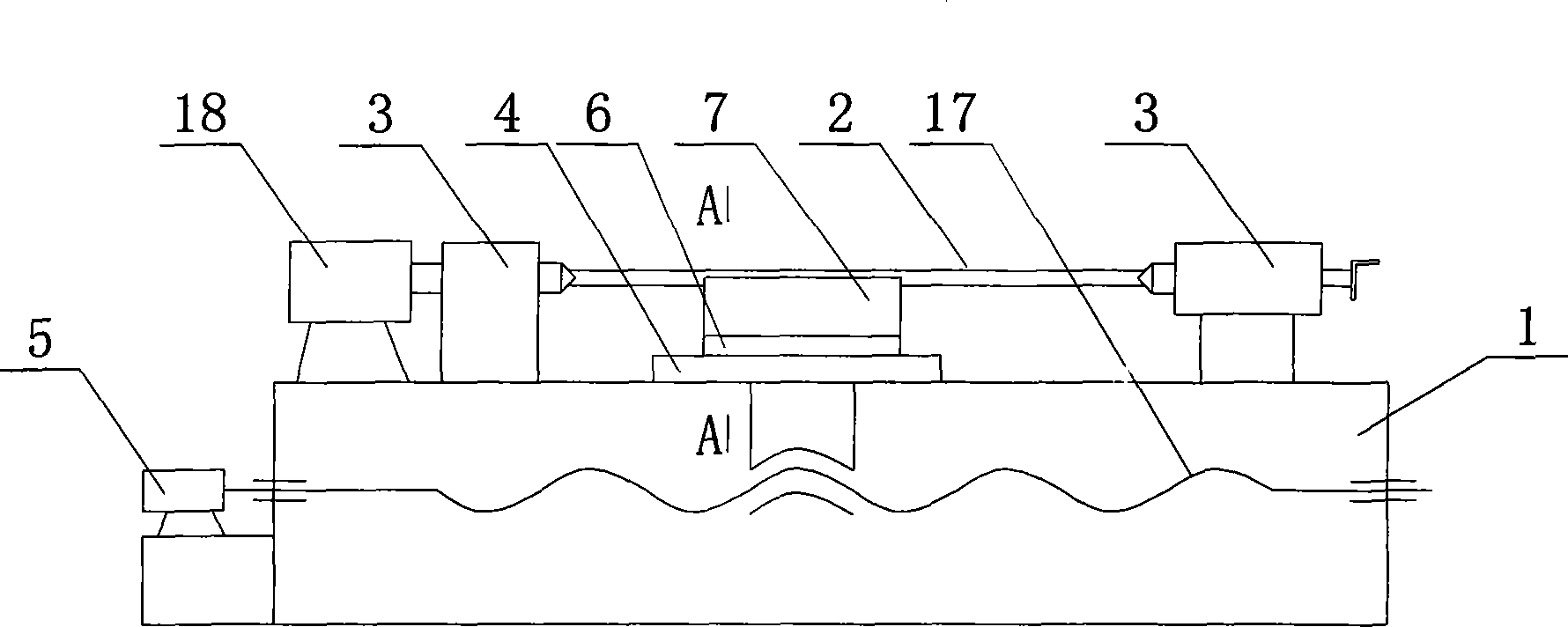

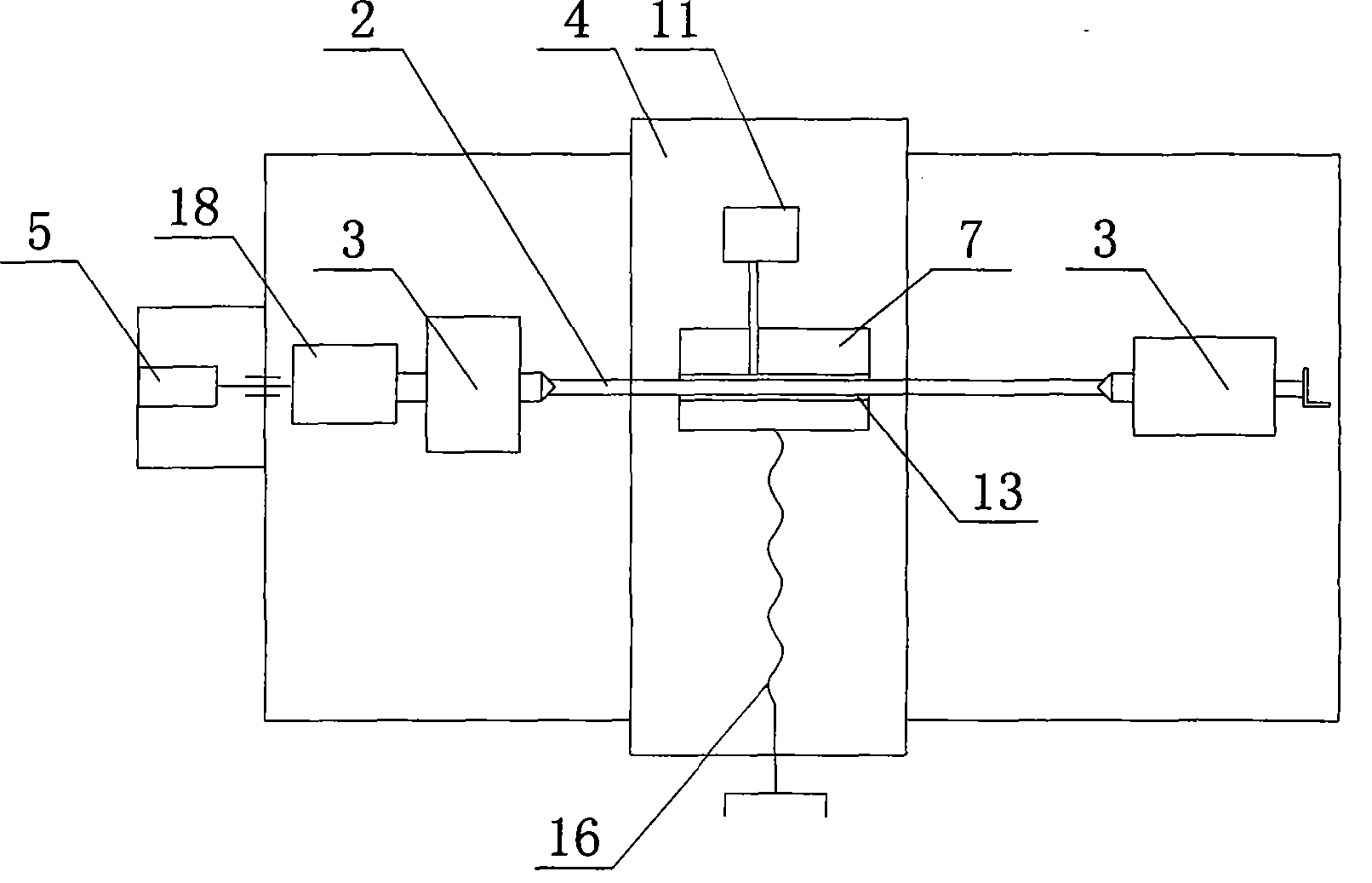

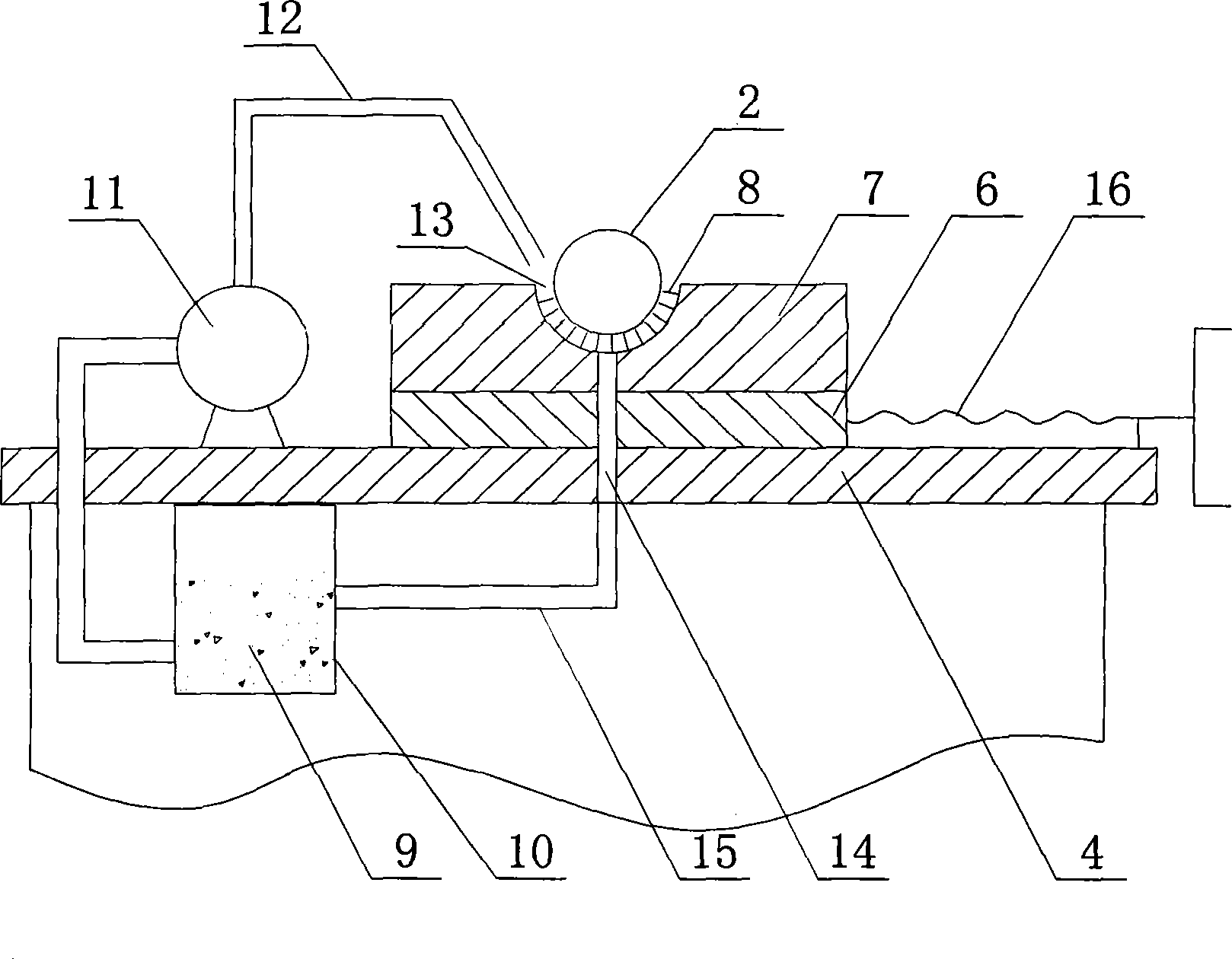

Five-axis two-dimensional ultrasonic polishing machine tool for optical curved face machining and using method thereof

ActiveCN106475868AUniform contact stressHigh polishing precisionGrinding carriagesOptical surface grinding machinesUltrasonic vibrationEngineering

The invention discloses a five-axis two-dimensional ultrasonic polishing machine tool for optical curved face machining. The machine tool is composed of a rack, a three-dimensional moving device, a rotary ultrasonic vibration polishing device, a rotary workbench, a polishing liquid ultrasonic atomizing and applying device and an on-line workpiece detection device. When the machine tool is used, the amplitude of the ultrasonic vibration polishing device is obtained according to the calculation formula (please see the formula in the description); five-axis linkage is achieved through a program control system, and the axis of a polishing head is made to always coincide with the normal line of a workpiece polishing point; a 45-degree included angle is kept between the jetting direction of polishing liquid and the normal line of the polishing point. The polishing machine tool has the advantages that ultrasonic energy transmission is concentrated, the contact stress between the surface of the polishing head and the surface of a workpiece is uniform, the polishing precision is high, the removal rate in the polishing process is high, the utilization rate of the polishing liquid is high, and the polishing precision of the workpiece can be detected on line.

Owner:NORTHEASTERN UNIV

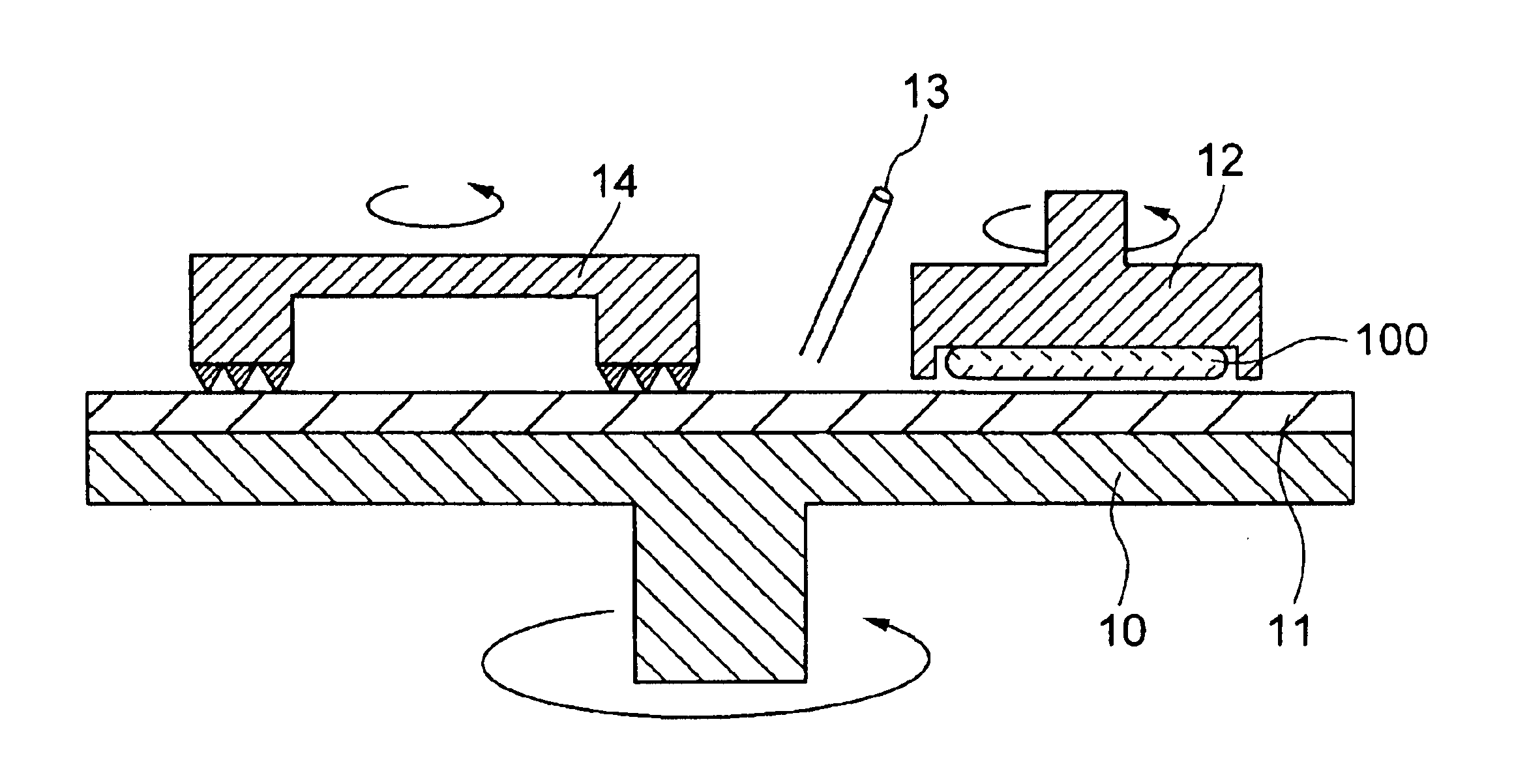

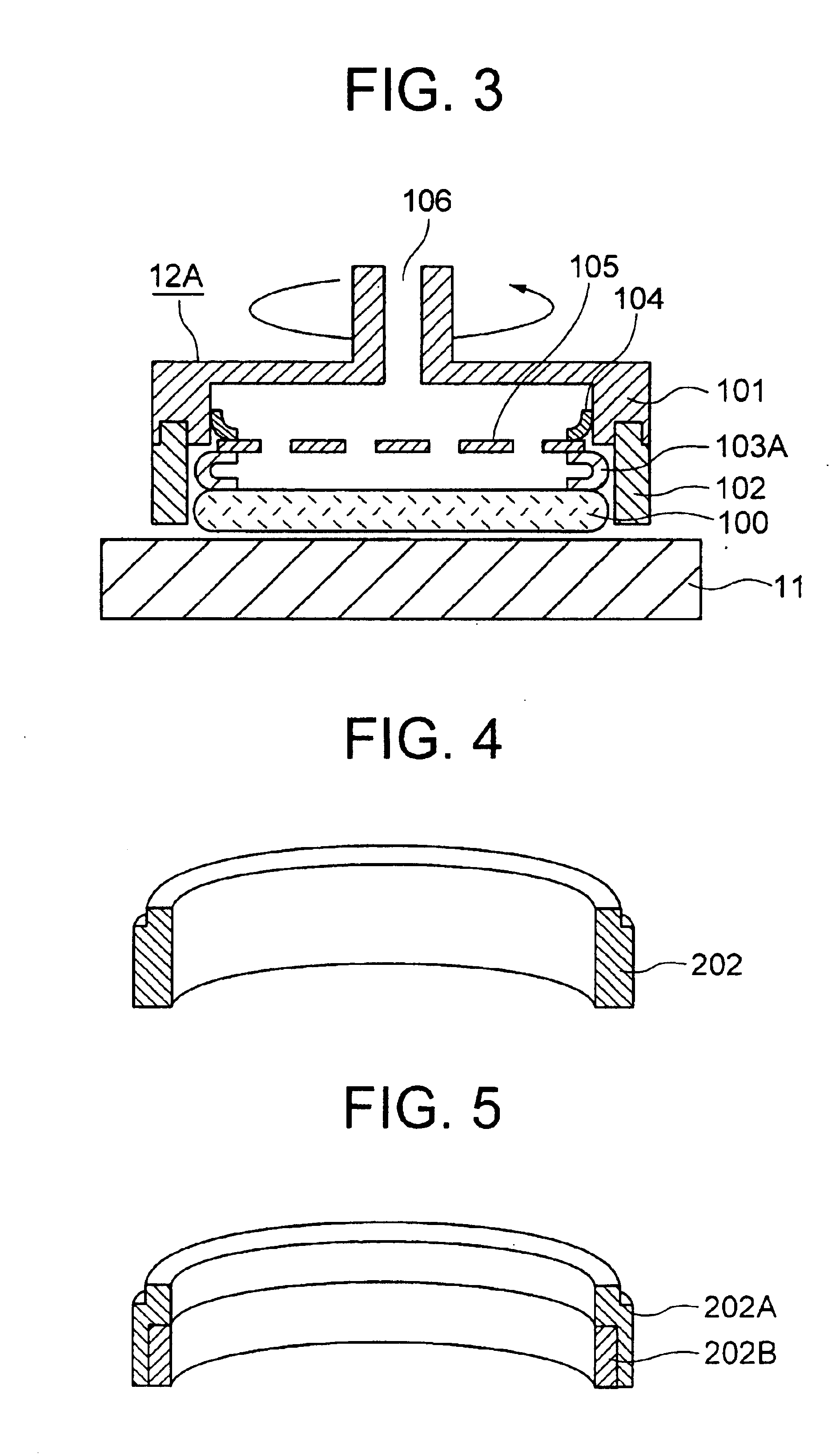

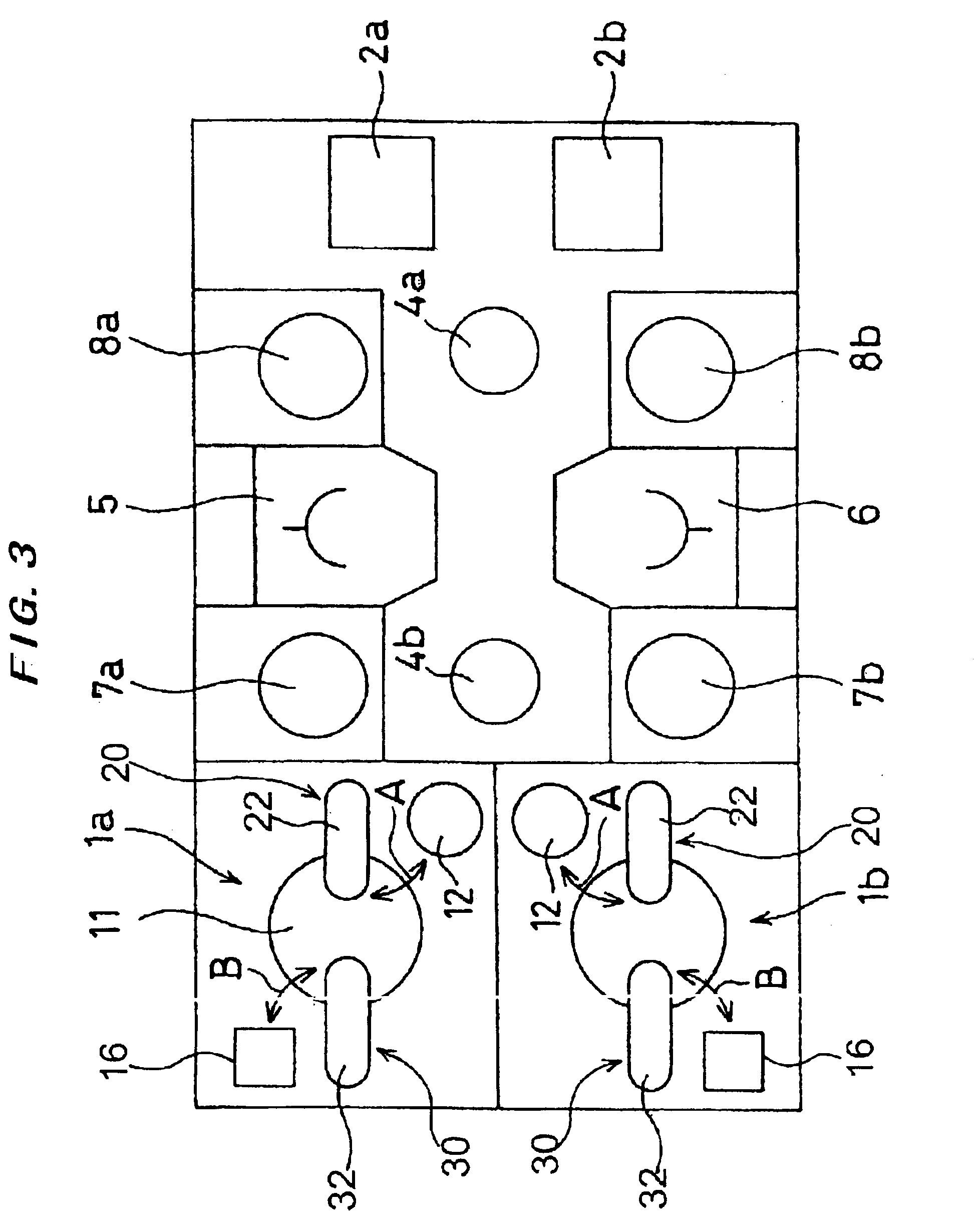

Polishing apparatus

InactiveUS6953390B2Efficient removalImprove polishing effectPolishing machinesRevolution surface grinding machinesForeign matterEngineering

A polishing surface is conditioned by pressing a diamond dresser against the polishing surface to thinly shave a surface of the polishing surface. Foreign matter clogging concavities formed in the polishing surface is scraped by pressing a brush dresser against the polishing surface in a state such that a polishing liquid is not supplied to the polishing table. A liquid composed of a mixture of a liquid or inert gas with pure water or a chemical liquid is ejected onto the polishing surface to clean the polishing surface.

Owner:EBARA CORP

High comprehensive performance composite grinding piece and manufacturing method thereof

ActiveCN105500225AImprove polishing efficiencyReduce internal stressNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWeather resistanceCerium

The invention discloses a high comprehensive performance composite grinding piece which comprises a base material, grinding particles and an adhesion agent, wherein the surface of the base material is divided into a plurality of areas; the grinding particles attached to the identical areas have identical sizes; the grinding particles attached to the different areas have different sizes; the sizes of the grinding particles attached to the various areas of the base material increase gradually from the center of the base material to the edge of the base material; the grinding particles are composite grinding particles formed by compositing nano cerium dioxide particles and silicon dioxide particles; and the adhesion agent consists of a component A and a component B. The invention also provides a manufacturing method of the high comprehensive performance composite grinding piece. The manufacturing method comprises the following steps of a gluing procedure, a sand planting procedure, a post curing procedure, a flexing water carrying procedure, a laser cutting procedure, a base material deformation prevention treatment procedure and a storage procedure. The manufacturing method is simple and convenient, and is low in manufacturing cost, and the manufactured composite grinding piece has weather resistance, fatigue resistance, high temperature resistance and abrasion resistance, and is long in service life and high in polishing efficiency.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

Chemical polishing liquid used for metal and polishing technology

The invention belongs to the technical field of metal surface treatment and discloses chemical polishing liquid used for metal and a polishing technology. The polishing liquid includes 60 g / L-90 g / L of nitrate, 60 g / L-90 g / L of hydrochloric acid, 120 ml / L-180 ml / L of medium-strong acid, 20 g / L-50 g / L of a viscosity modifier, 1 g / L-10 g / L of a corrosion inhibitor, 2 g / L-6 g / L of a brightening agent and water. The polishing technology includes the steps that a metal workpiece is subjected to degreasing and activating pretreatment, the obtained metal workpiece is placed in the polishing liquid to be soaked for 2.5 min-4 min at the temperature ranging from 60 DEG C to 100 DEG C for being polished, after polishing is completed, the metal workpiece is subjected to neutralization aftertreatment, and therefore a flat and smooth metal surface can be obtained. The chemical polishing liquid is safe, environment-friendly, high in polishing efficiency, low in cost and suitable for industrial application.

Owner:SOUTH CHINA UNIV OF TECH

Polishing disk for a tool for the fine machining of optically active surfaces on spectacle lenses in particular

ActiveUS7278908B2Promote wettingUniform filmEdge grinding machinesPolishing machinesEngineeringHigh surface

A polishing disk for a tool for the fine machining of optically active surfaces on spectacle lenses in particular is disclosed, which comprises a support body, to which a foam layer is attached, wherein a polishing film bears against the foam layer. The polishing film is provided with at least one opening in a central region. During machining, the opening ensures pressure equalization and makes liquid polishing agent available from inside the foam layer, as a result of which better rinsing and cooling of otherwise disadvantaged regions of the polishing disk is achieved. As a result, a polishing disk of simple and cost-effective design is proposed, which is much more durable than the prior art while achieving high surface qualities.

Owner:SATISLOH GMBH

Method for preparing sheet alumina powder

ActiveCN101182017AGood crystal uniformityImprove polishing effectAluminium oxides/hydroxidesPolyvinyl alcoholPolyethylene glycol

The invention relates to a preparation method of flaky Alpha-alumina, in particular to the preparation method of flaky Alpha-alumina powder applied to grinding and polishing materials. The method is characterized in that aluminum hydrous oxide and aqueous solutions with organic matters of polyethylene glycol, polyvinyl alcohol, etc., are mixed, with the amount of the organic matters accounting for 0.5 percent to 2 percent of the weight of the aluminum hydrous oxide, and then are calcined for 30-240 minutes under the temperature of 300-1000 DEG C after being dried so as to obtain the alumina which is then mixed with the aqueous solution containing fluoride salts to be calcined for 0.5-12 hours under the temperature of 1200-1700 DEG C after the fluoride is absorbed to the alumina and dried to obtain the flaky Alpha-alumina powder. The flaky Alpha-alumina powder prepared by the invention after being grinded can be used as the flaky Alpha-alumina of the grinding and polishing materials.

Owner:中铝郑州有色金属研究院有限公司

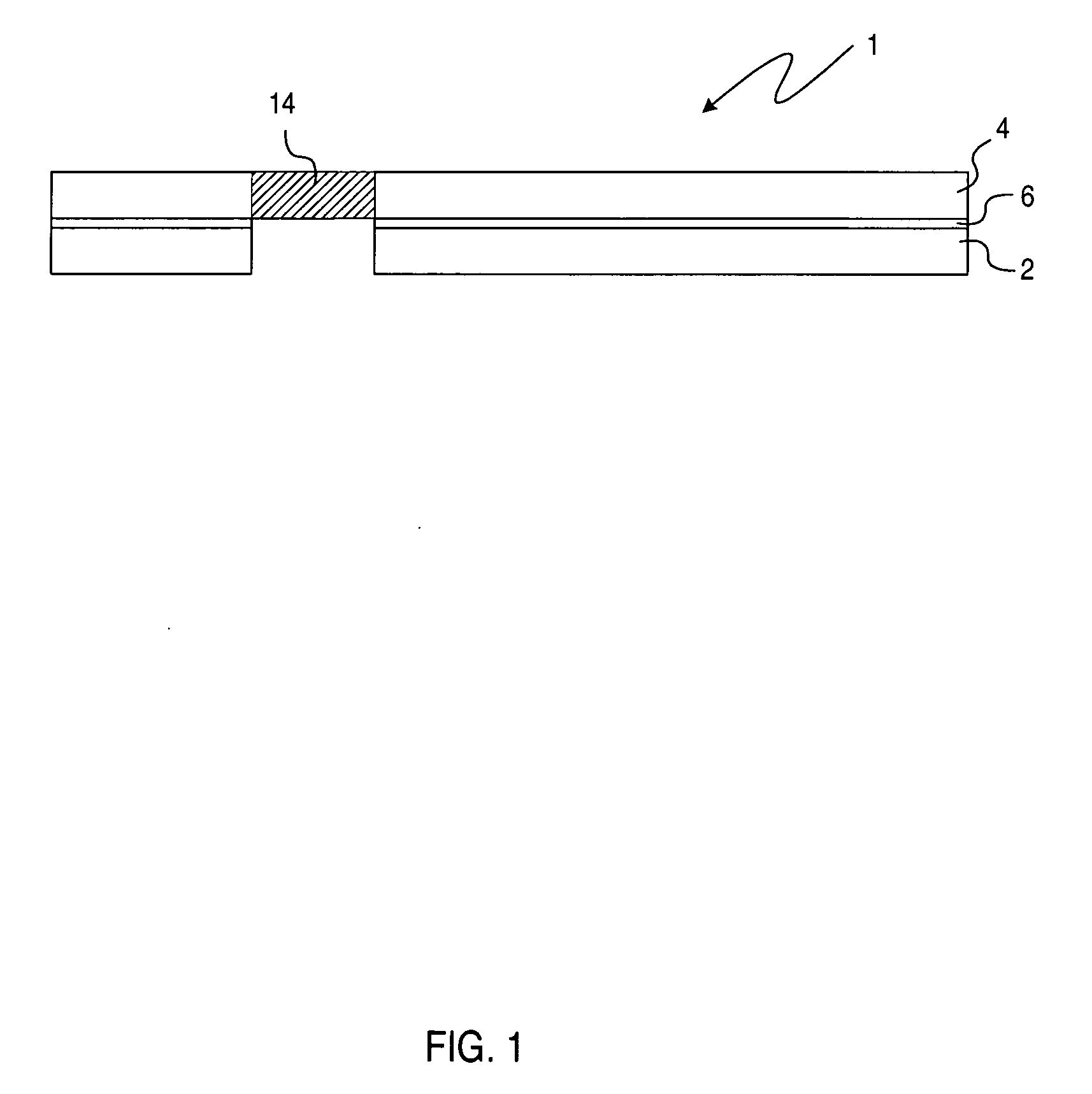

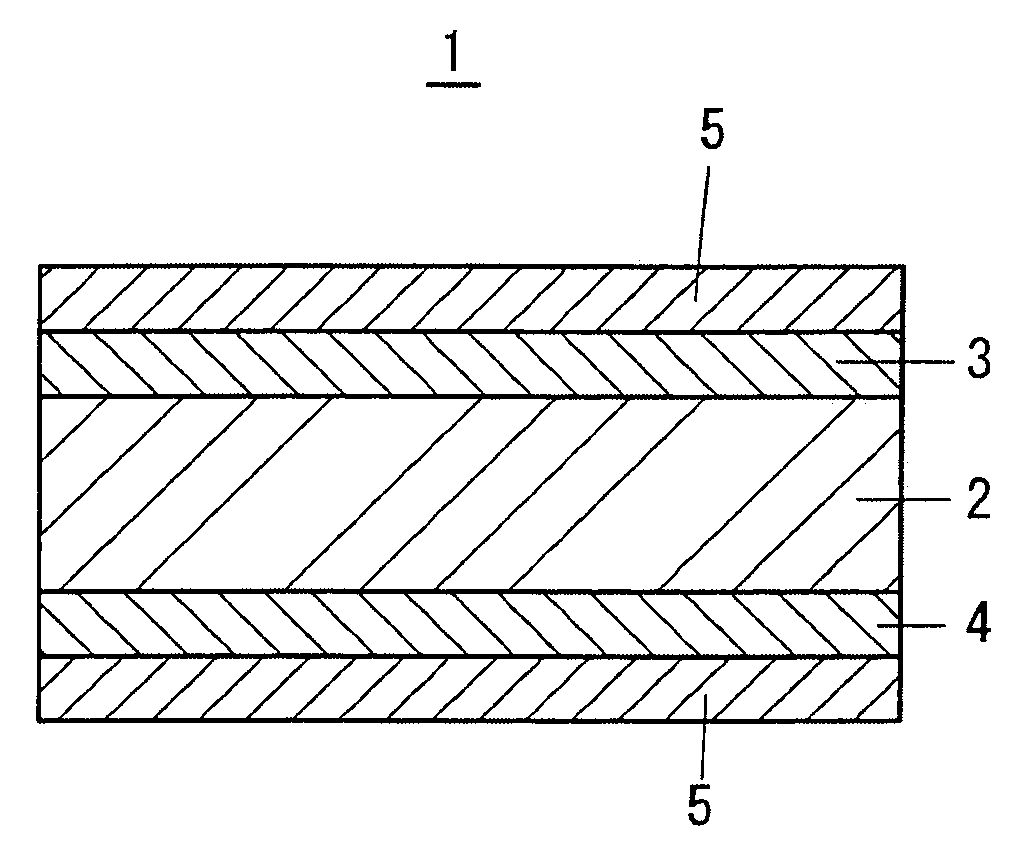

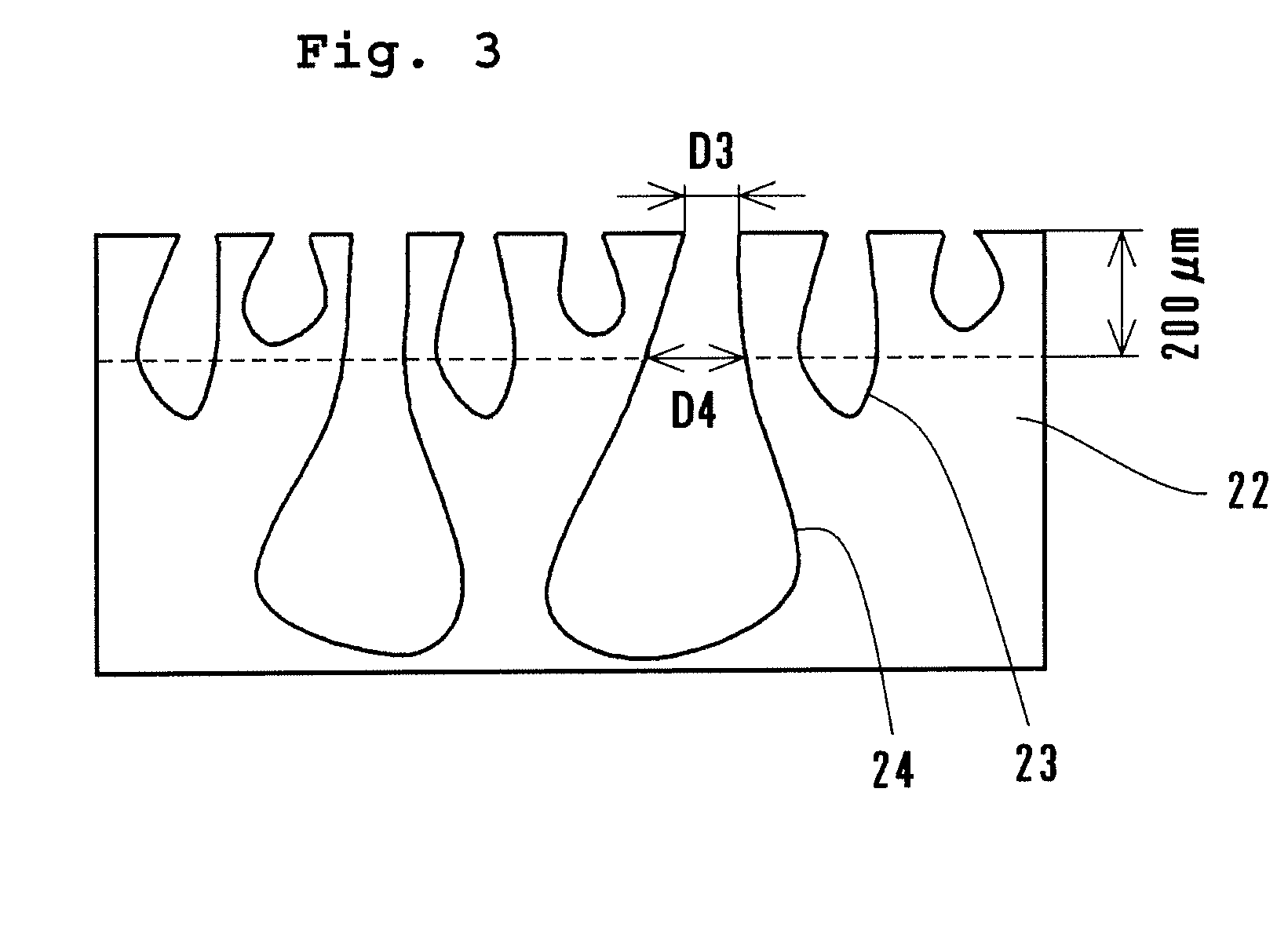

Double-Sided Adhesive Tape for Securing Polishing-Pad

InactiveUS20090098376A1High precisionReduce adverse effectsSynthetic resin layered productsLapping machinesPolyethylene terephthalateSolvent based

To provide a double-sided adhesive tape for securing a polishing-pad, the tape being capable of improving precision in polishing using a polishing-pad.The double-sided adhesive tape 1 for securing the polishing-pad includes a substrate 2 and adhesive layers 3 and 4, which are provided on both sides of the substrate 2, respectively. The substrate 2 is formed of a polyethylene terephthalate resin-film having a thickness of 150 to 300 μm, one of the adhesive layer 3 is formed of a synthetic rubber pressure sensitive adhesive, and the other adhesive layer 4 is formed of an acrylic solvent-based pressure sensitive adhesive.

Owner:SEKISUI CHEM CO LTD

Flexible magnetic fluid brush polishing shaping machine for round tube

The invention discloses a flexible magnetic fluid brush polishing shaping machine for a round tube. The polishing shaping machine comprises a machine body, a top frame arranged on the machine body and used for fixing the round tube, a rotary motor driving the round tube to rotate, a supporting plate arranged on the machine body in a sliding manner, a main motor driving the supporting plate to horizontally move, a magnetic driver arranged on the supporting plate, a magnetic brush body fixed on the magnetic driver, a brush fixed on the magnetic brush body and being in contact with the round tube; the polishing shaping machine further comprises magnetorheological finishing liquid consisting of a magnetorheological fluid and abrasive grains and a jet bubbler which sprays the magnetorheological finishing liquid on the brush. The polishing shaping machine provided by the invention has the advantages as follows: the structure is simple, the use is convenient and the polishing effect is good, so that the finishing of the round tube can be achieved without dead angles and no damage is caused to the product; material removal ratio and the final surface roughness can be adjusted by adjusting the proportion of ingredients of the magnetorheological fluid and the abrasive grains in the magnetorheological finishing liquid as well as the density of the brush; moreover, automatic operation is convenient to realize, zero waste gas and waste liquor are produced in the polishing process and the polishing shaping machine saves energy and is environment friendly.

Owner:ZHEJIANG NORMAL UNIVERSITY

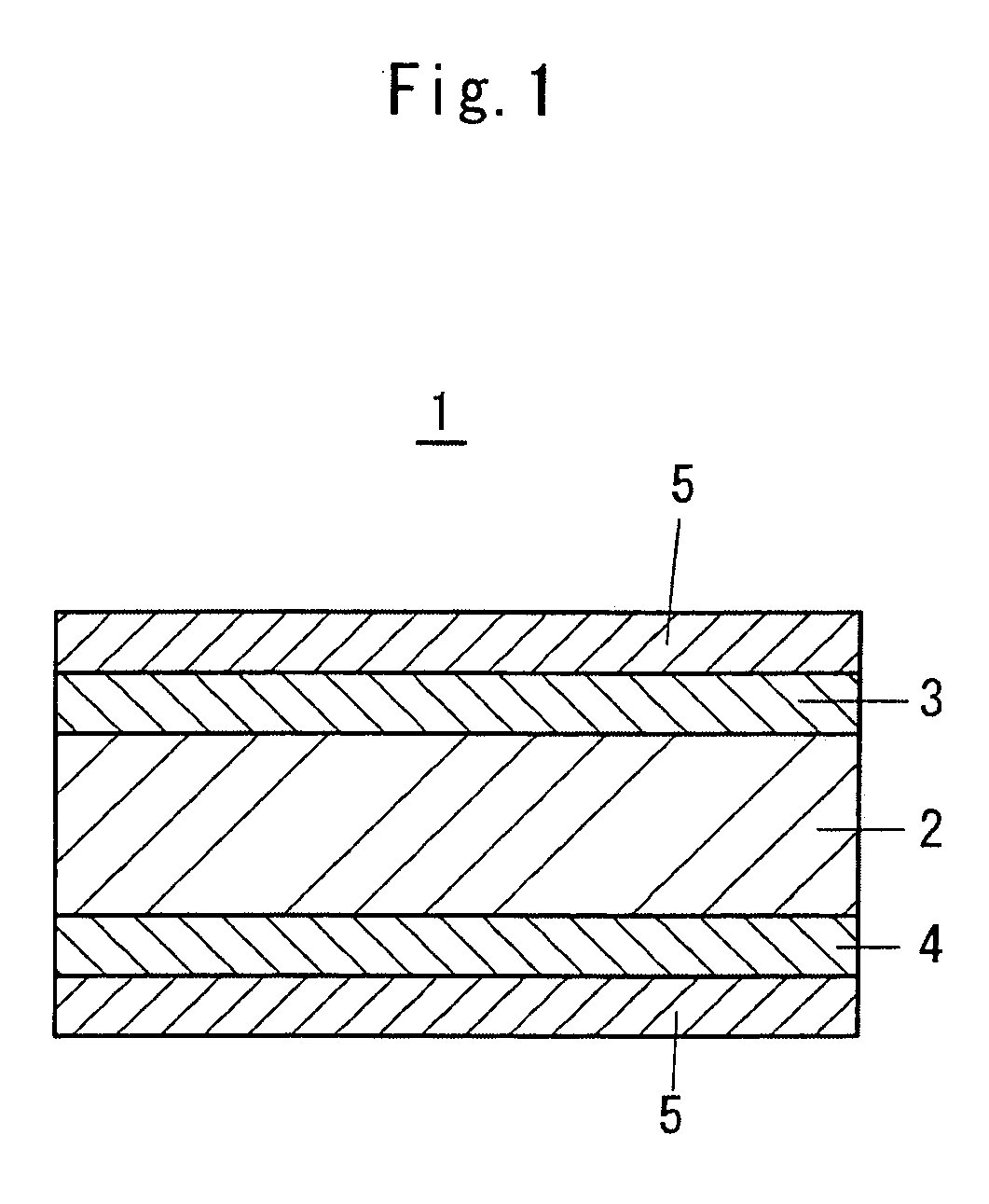

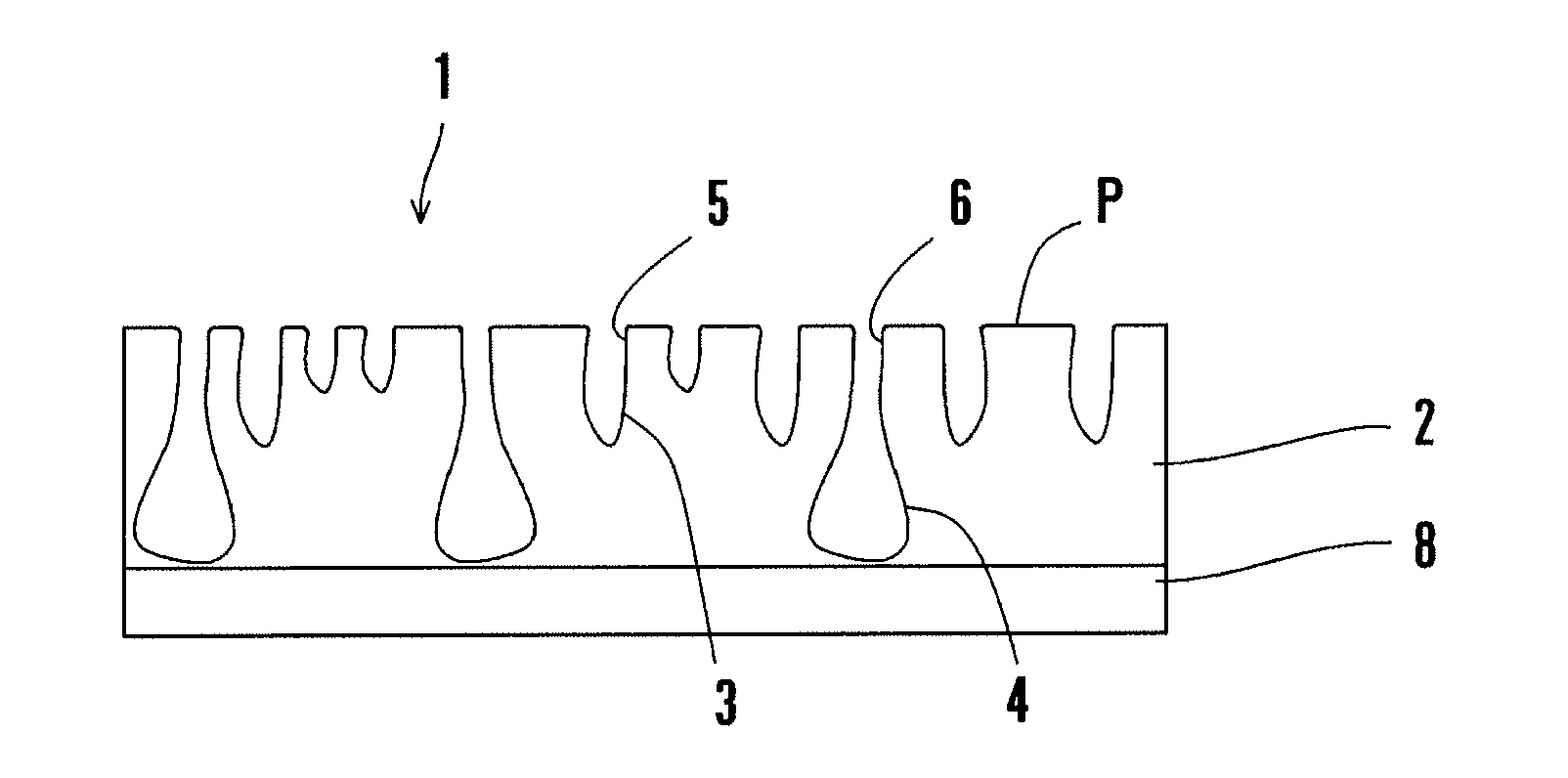

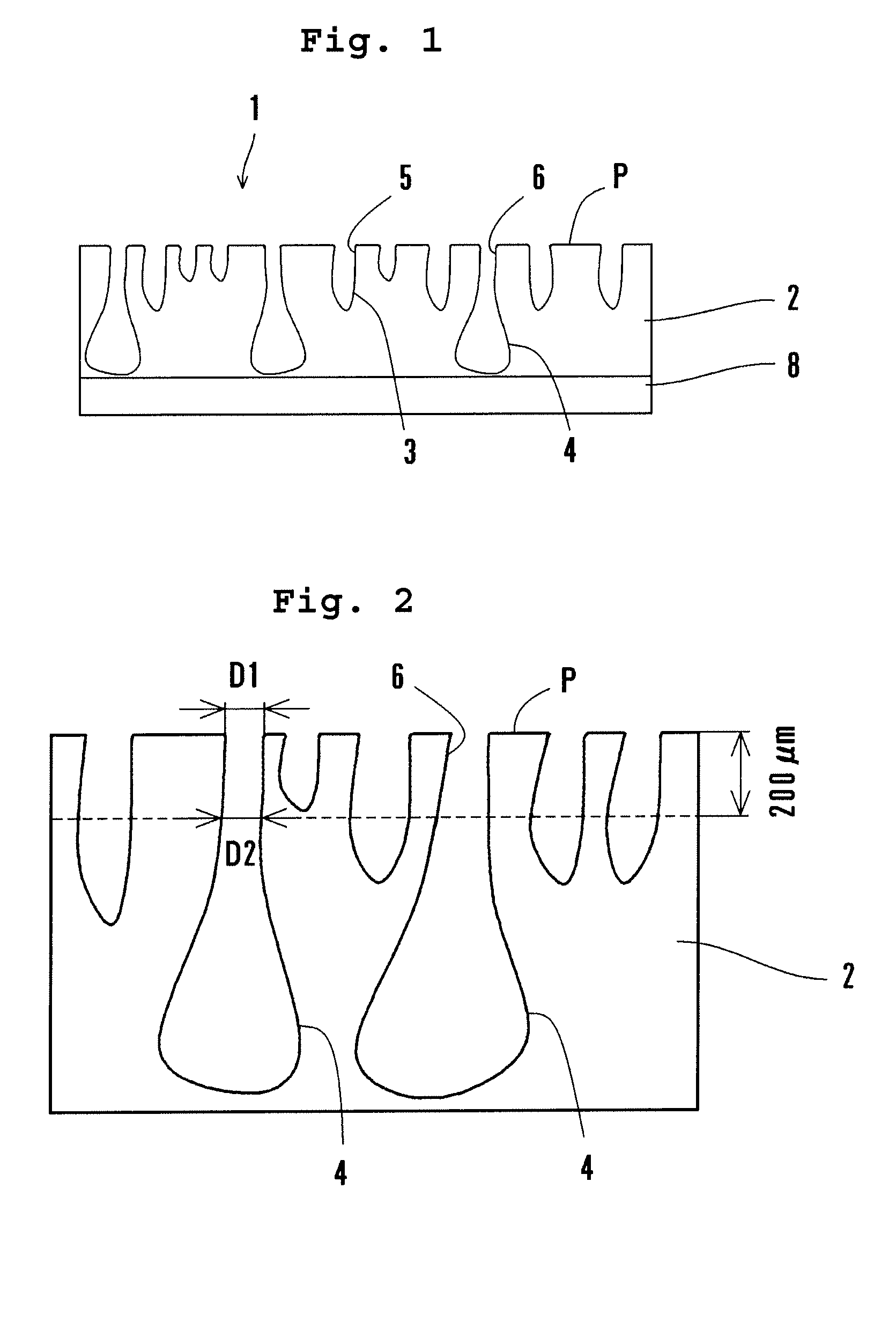

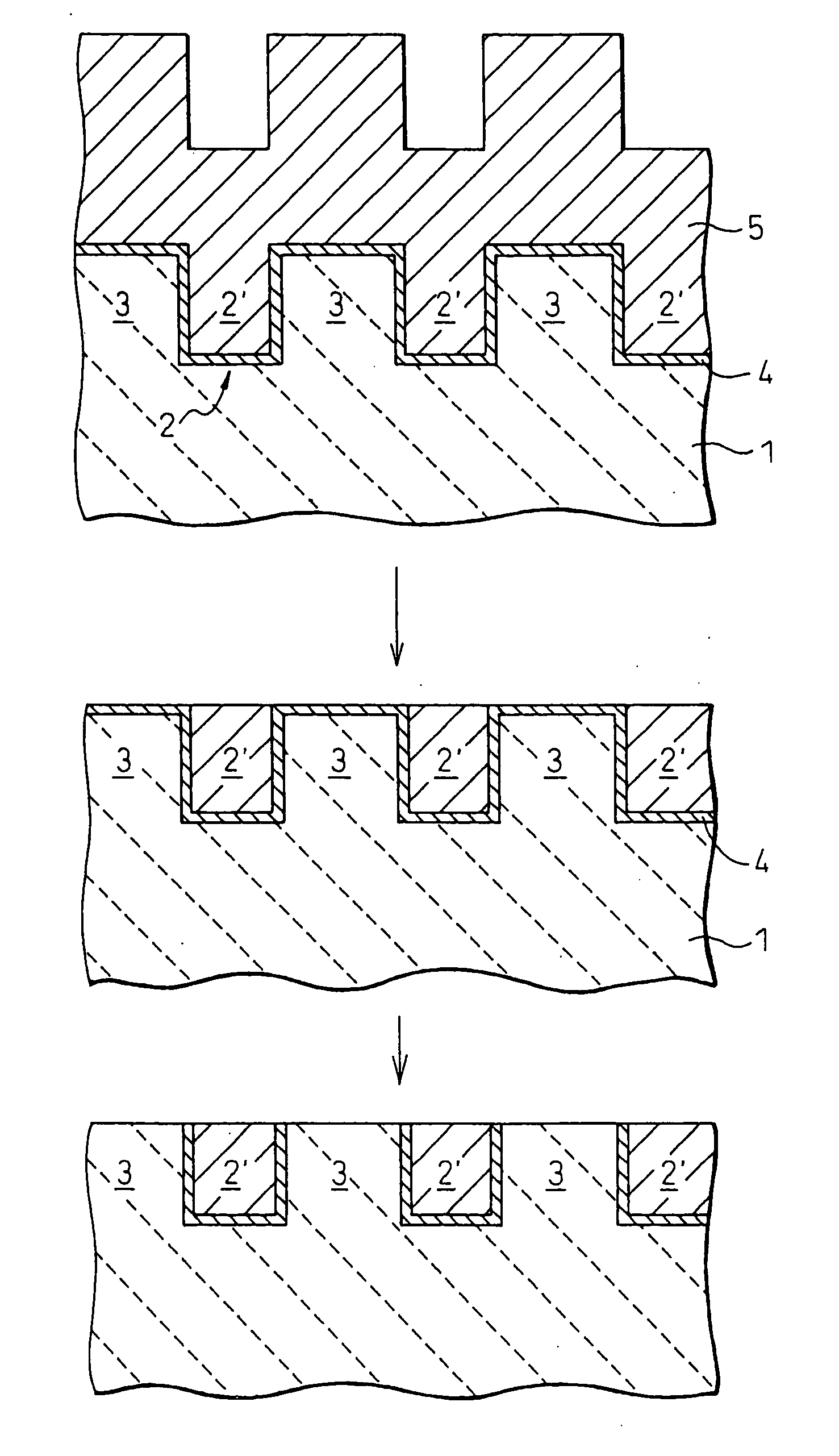

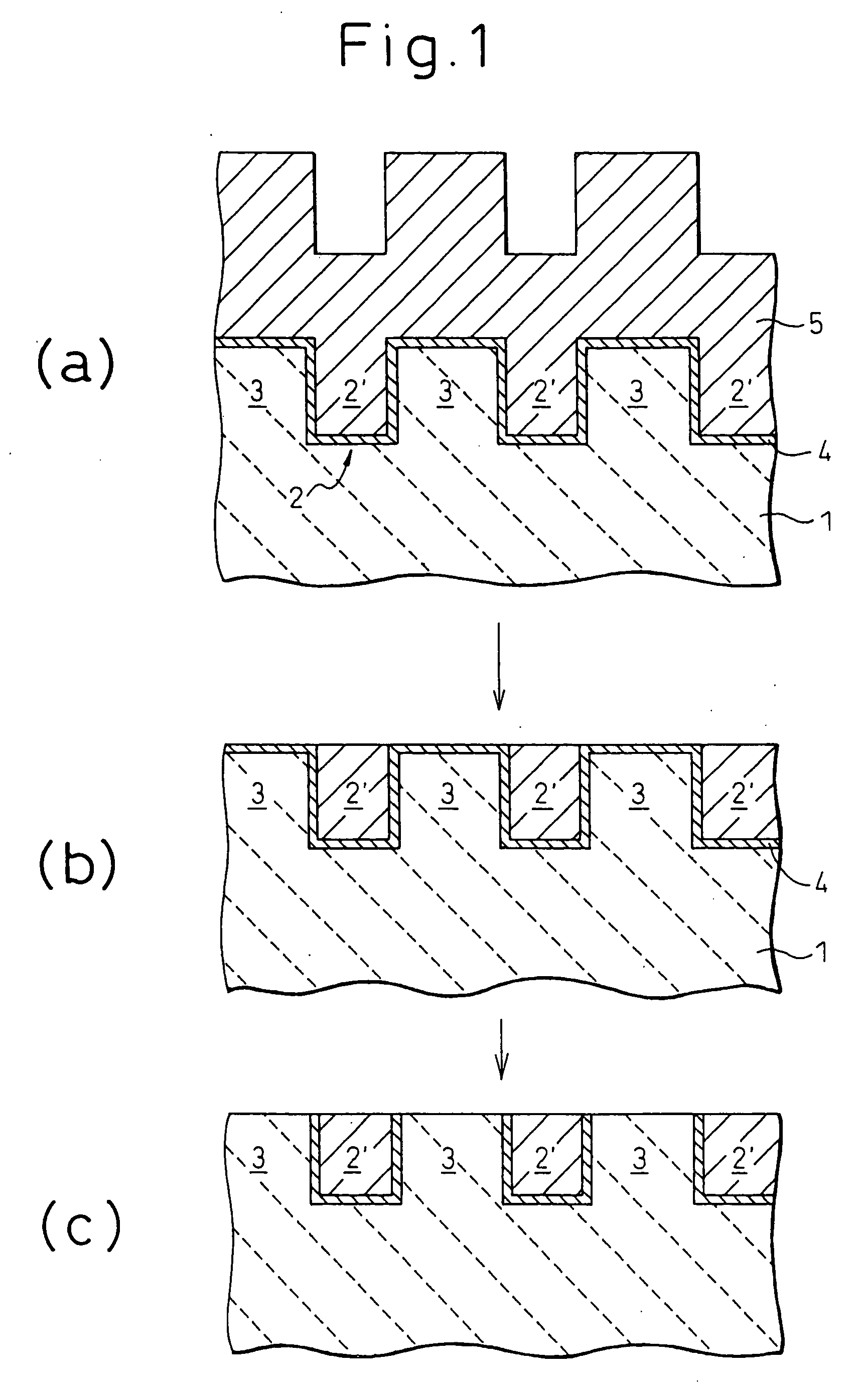

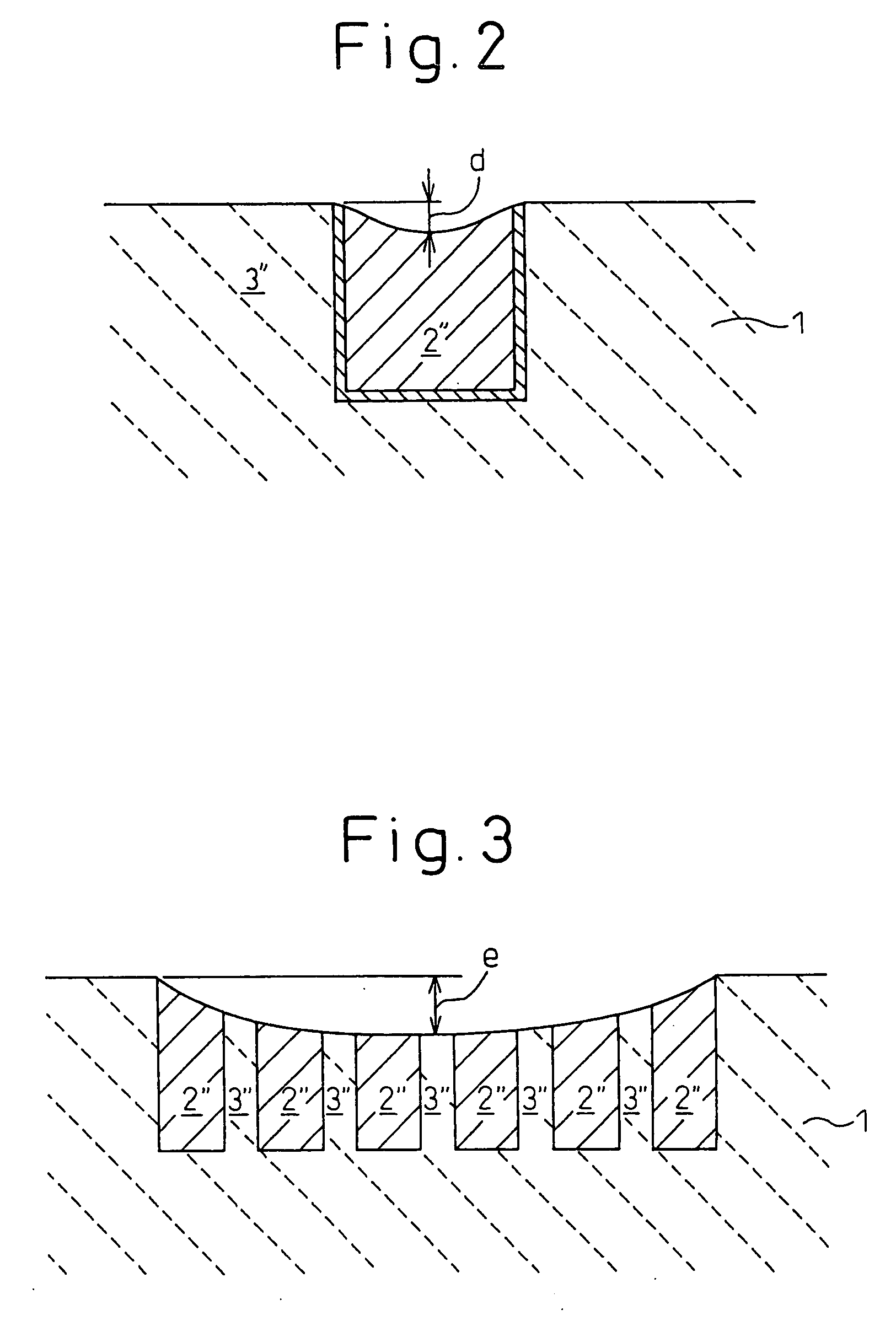

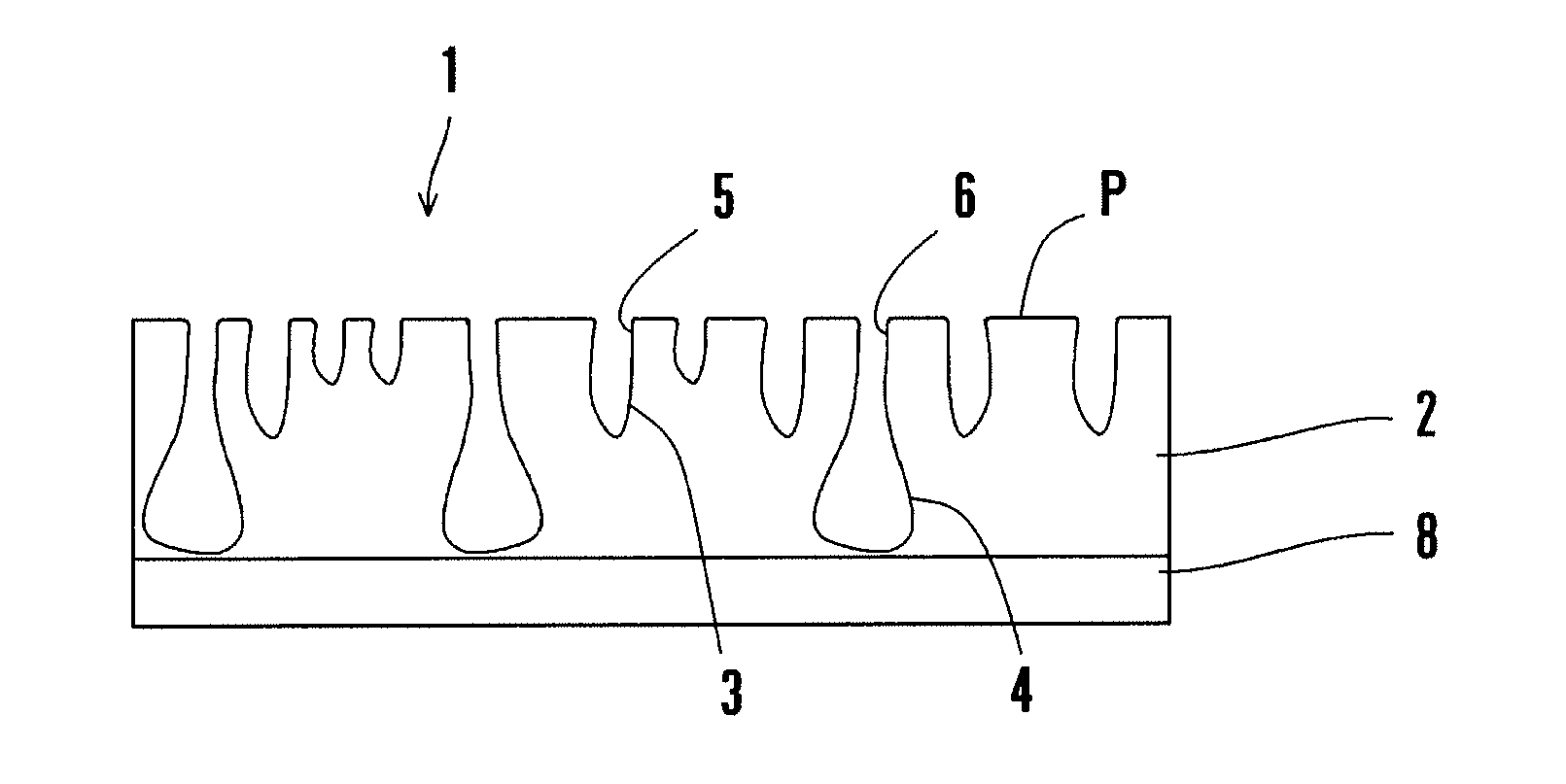

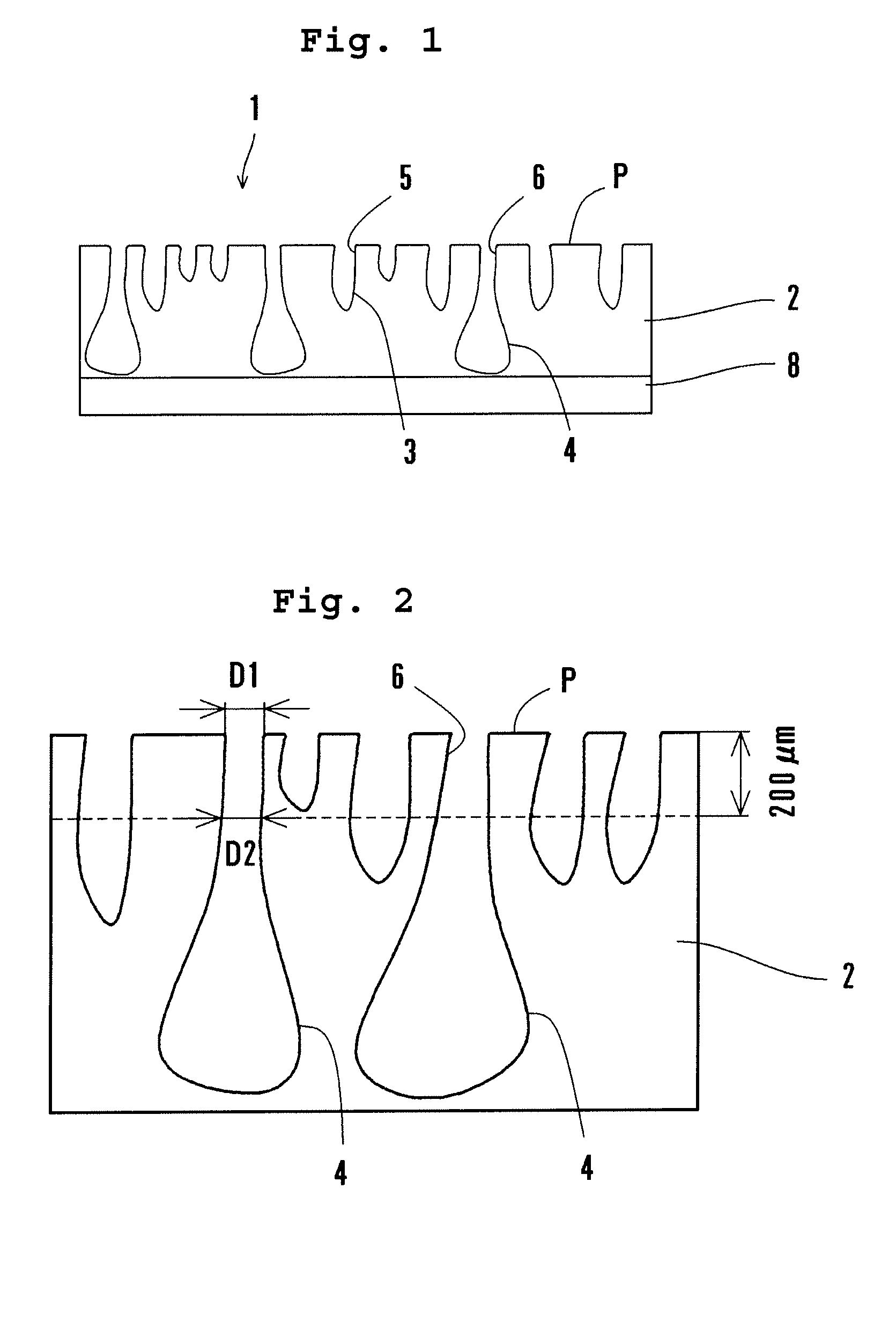

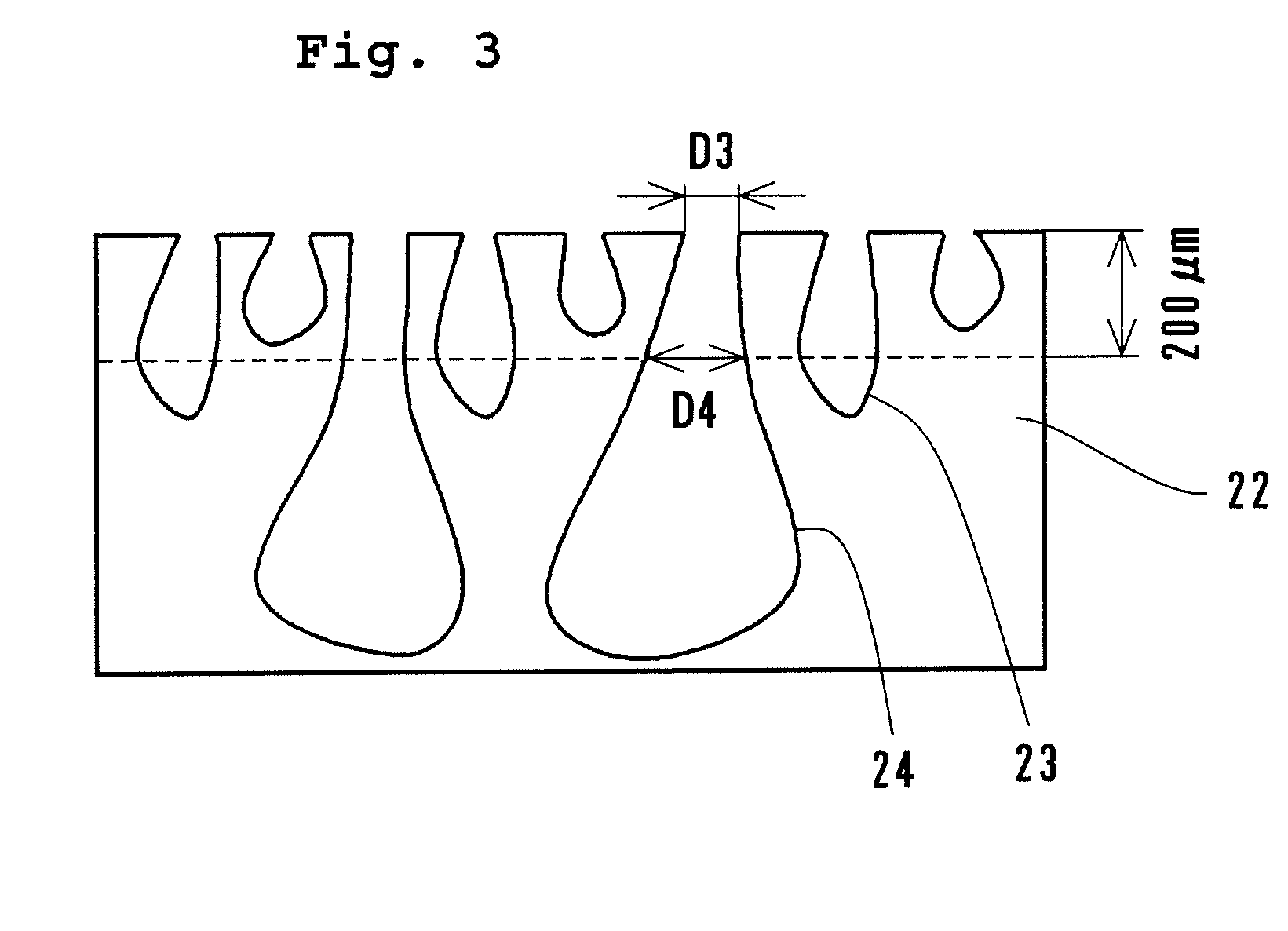

Polishing pad

ActiveUS20090093200A1Raise densitySuppress occurrenceLayered productsAbrasion apparatusEngineeringPore diameter

The present invention provides a polishing pad whose unevenness in thickness hardly occurs and whose life can be improved. A polishing pad 1 is provided with a polyurethane sheet 2. Foams 3 having lengths of about ½ of the length of the polyurethane sheet 2 in its thickness direction and elongated foams 4 having lengths of at least 70% of the length of the polyurethane sheet 2 in the thickness direction are formed in the polyurethane sheet 2. The foams 3 and the elongated foams 4 are opened by buffing processing so that opened pores 5 and opened pores 6 are formed at a polishing face P, respectively. Regarding the opened pores 5, 6, the total number of opened pores having opened pore diameters falling in a range of from 30 to 50 μm occupies at least 50% of the number of all opened pores. The total number of the opened pores 5, 6 per 1 mm2 of the polishing face P is set in a range of from 50 to 100. An average value of ratio of an opened pore diameter D1 of the opened pore 6 of the elongated foam 4 to an opened pore diameter D2 of the opened pore 6 at a depth position of at least 200 μm from the polishing face P is set in a range of from 0.65 to 0.95.

Owner:FUJIBO HLDG

Method for producing cerium-based abrasive and cerium-based abrasive produced thereby

InactiveUS6901684B2High-accuracy polished surfaceImprove wear resistancePigmenting treatmentDrying using combination processesCeriumCe element

This invention is a method for producing a cerium-based abrasive which includes: a step of grinding raw material for the cerium-based abrasive; a step of roasting the ground raw material; and a step of subjecting the roasted raw material to wet processing, the method being characterized in that it further includes a lower-temperature re-roasting step of heating the wet-processed raw material at 200 to 700° C. In the invention disclosed in this application, an abrasive with particularly preferable properties can be produced by fully drying the wet-processed raw material in a drying step, and subsequently subjecting the dried raw material to the lower-temperature re-roasting step.

Owner:MITSUI MINING & SMELTING CO LTD

Polishing Composition And Polishing Method

ActiveUS20080087644A1Suppressing dishingSuppressing erosionPigmenting treatmentOther chemical processesInter layerCompound (substance)

The present invention aims to provide a polishing composition which allows high-speed polishing of a barrier film and an inter-layer dielectric film along with a wiring metal at the same time, while preventing dishing and erosion, and particularly maintaining the flatness of metal film. The chemical-mechanical polishing composition of the present invention comprises a dicarboxylic acid having 7 to 13 carbon atoms, an oxidizing agent, an abrasive and water.

Owner:RESONAC CORP

Polishing solution for sapphire substrate

ActiveCN103450812AImprove removal rateThe preparation method is simple and easyPolishing compositions with abrasivesPhysical chemistryBULK ACTIVE INGREDIENT

The invention discloses a polishing solution for a sapphire substrate, and relates to the technical field of preparation of polishing materials. The polishing solution is prepared from the following active ingredients in percentage by weight: 90-95% of silica sol, 0.05-2% of polishing accelerator, 0.05-3% of complexing agent, 0.05-3% of pH regulator, and the balance of deionized water. The polishing solution has the characteristics of being high in removal rate, good in polishing effect, easy to clean, low in cost and the like, and is applicable to the polishing of sapphire substrate materials.

Owner:HUNAN HAOZHI TECH

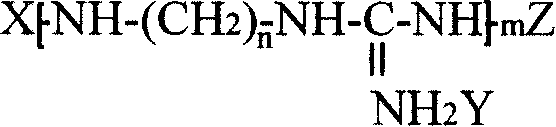

Antibiotic polymer material

The invention discloses an antibacterial polymer material which is polymerized by a plurality of components including antibacterial oligomer. The specific components comprise 30-99.5wt percent of unsaturated double bond monomer, 0.01-50wt percent of unsacturated double bond antibacterial oligomer, 0-10wt percent of hydrophilic monomer, 0.01-5.0wt percent of polymerization initiator and 0-80wt percent of fillings. The antibacterial polymer material of the invention is safe to the health of people and has long antibacterial performance and the antibacterial rates of the invention to staphyloccocus aureus rosenbach and escherichia coli are both more than 99percent. The invention is applicable for medical treatment and hygiene industries, including the wound dressing material, dental recovery materials used in dentistry (such as tooth bonder, tooth recovery coating, tooth recovery substrate and tooth filling materials, etc.), surgery seam and materials for daily use, etc.

Owner:EAST CHINA UNIV OF SCI & TECH

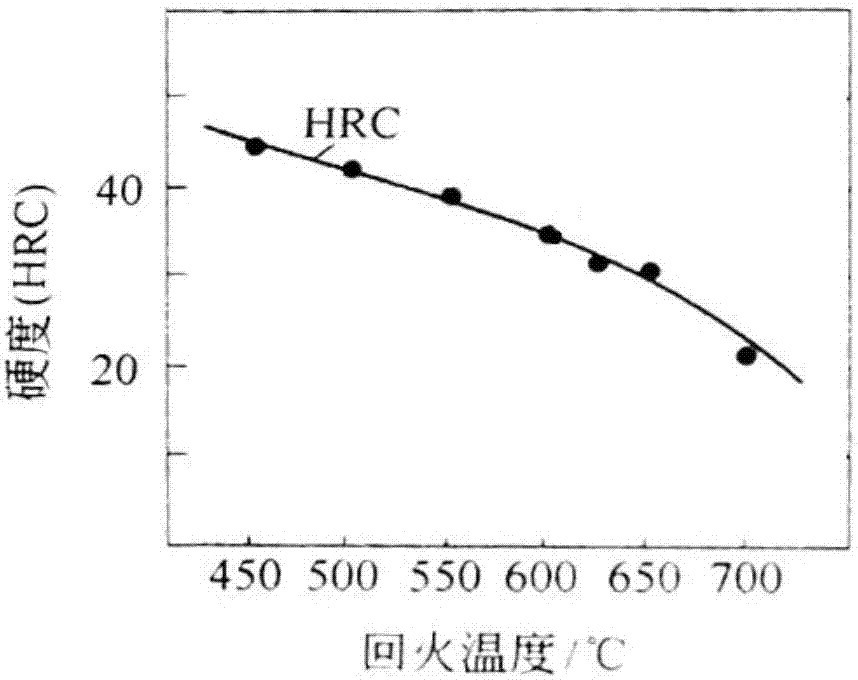

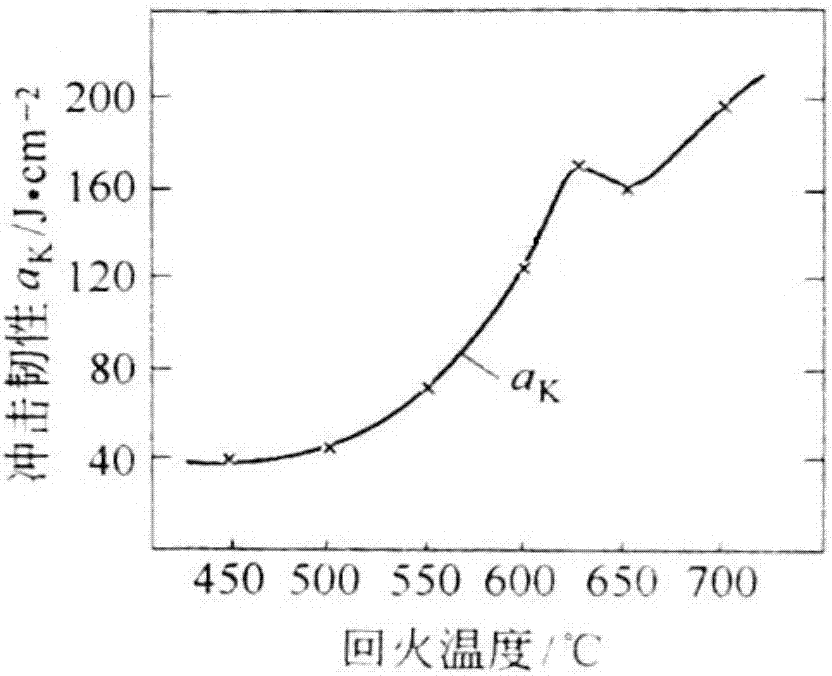

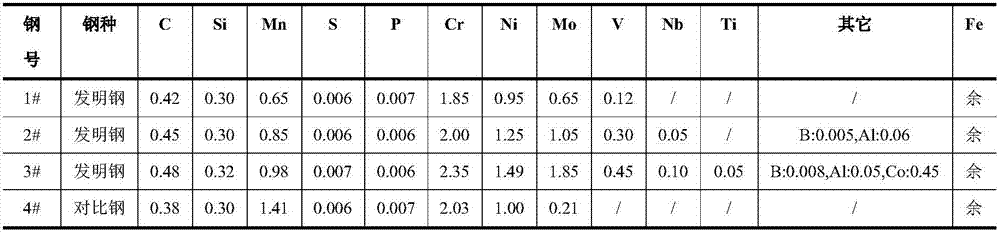

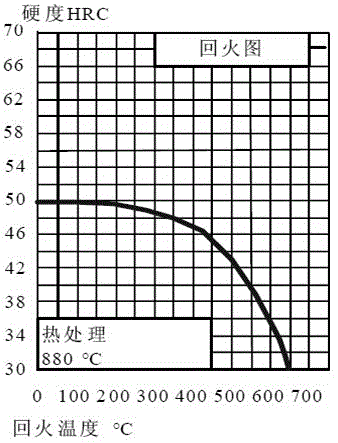

High-hardness high-hardenability pre-hardening plastic mould steel and preparation method thereof

The invention discloses a high-hardness high-hardenability pre-hardening plastic mould steel and a preparation method thereof and belongs to the technical field of tool and mould steels. To be specific, the steel comprises, by weight percentage, 0.40-0.50% of C, 0.2-0.5% of Si, less than or equal to 0.030% of S, less than or equal to 0.030% of P, 0.6-1.0% of Mn, 0.8-1.5% of Ni, 0.6-2.0% of Mo, 1.6-2.5% of Cr, 0.1-0.5% of V and the balance Fe and inevitable impurities. The high-hardness high-hardenability pre-hardening plastic mould steel has the beneficial effects that compared with the priorart, the steel is higher in pre-hardening hardness, toughness and hardenability; the comprehensive performance is more excellent; and the steel can be used for producing a high-hardness large-size pre-hardening plastic mould steel module more easily, so that user requirements are met.

Owner:CENT IRON & STEEL RES INST

Polishing pad

The present invention provides a polishing pad whose unevenness in thickness hardly occurs and whose life can be improved. A polishing pad 1 is provided with a polyurethane sheet 2. Foams 3 having lengths of about ½ of the length of the polyurethane sheet 2 in its thickness direction and elongated foams 4 having lengths of at least 70% of the length of the polyurethane sheet 2 in the thickness direction are formed in the polyurethane sheet 2. The foams 3 and the elongated foams 4 are opened by buffing processing so that opened pores 5 and opened pores 6 are formed at a polishing face P, respectively. Regarding the opened pores 5, 6, the total number of opened pores having opened pore diameters falling in a range of from 30 to 50 μm occupies at least 50% of the number of all opened pores. The total number of the opened pores 5, 6 per 1 mm2 of the polishing face P is set in a range of from 50 to 100. An average value of ratio of an opened pore diameter D1 of the opened pore 6 of the elongated foam 4 to an opened pore diameter D2 of the opened pore 6 at a depth position of at least 200 μm from the polishing face P is set in a range of from 0.65 to 0.95.

Owner:FUJIBO HLDG

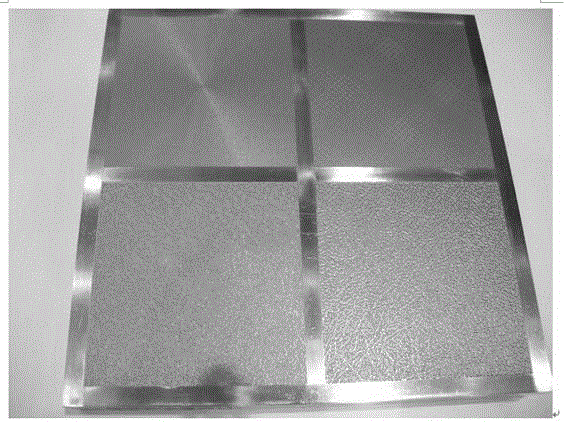

Boron microalloyed die steel and preparation process thereof

The invention relates to boron microalloyed die steel and a preparation process thereof and belongs to the technical field of alloy steel preparation processes. The main alloy elements in alloy chemical components of the die steel comprise, by mass, 0-0.20% of C, 0-0.20% of Si, 1.20-1.60 of Mn, 1.10-1.50% of Cr, 0-0.30% of Ni, 0.20-0.35% of Mo, 0-0.10% of V, less than 0.015% of P, less than 0.005% of S, 0.005-0.01% of B, and the balance Fe. The preparation process of the steel includes the following steps of conducting burdening, smelting, casting and hot delivery; conducting high temperature diffusion heat treatment, multi-directional forging hot working and post-forging hydrogen diffusion tempering treatment; and finally conducting quenching-and-tempering heat treatment so as to obtain a tempered martensite structure with the hardness being 32-38 HRC. The boron microalloyed die steel and the preparation process thereof have the advantages that the prepared die steel has low cost, high hardenability, high hardness, high polishing performance and high skin grain etching performance.

Owner:RUGAO HONGMAO HEAVY FORGING

Chemical polishing solution and alloy surface polishing treatment method

The invention discloses a chemical polishing solution and an alloy surface polishing treatment method. The polishing solution per liter contains 30-100g of persulfate, 300-500ml of concentrated sulfuric acid, 10-40g of viscosity modifier, 2-14g of brightener and the balance of water. The alloy surface polishing treatment method comprises the following steps: orderly performing deoiling, cleaning, acid pickling and activation and cleaning on an alloy workpiece, dipping the alloy workpiece pretreated previously in the chemical polishing solution, and after the completion of polishing, orderly cleaning, passivating, cleaning and drying the alloy workpiece. The chemical polishing solution is characterized in that sodium persulfate is taken as the oxidizing agent, and no yellow smoke is generated in the polishing process, which is green and environmental friendly. The polishing solution is simple in components, and easy to control. The obtained chemically polished surface is bright and flat, and capable of achieving the mirror polishing effect. The polishing solution can be widely applied to polishing the surface of the copper alloy.

Owner:SOUTH CHINA UNIV OF TECH

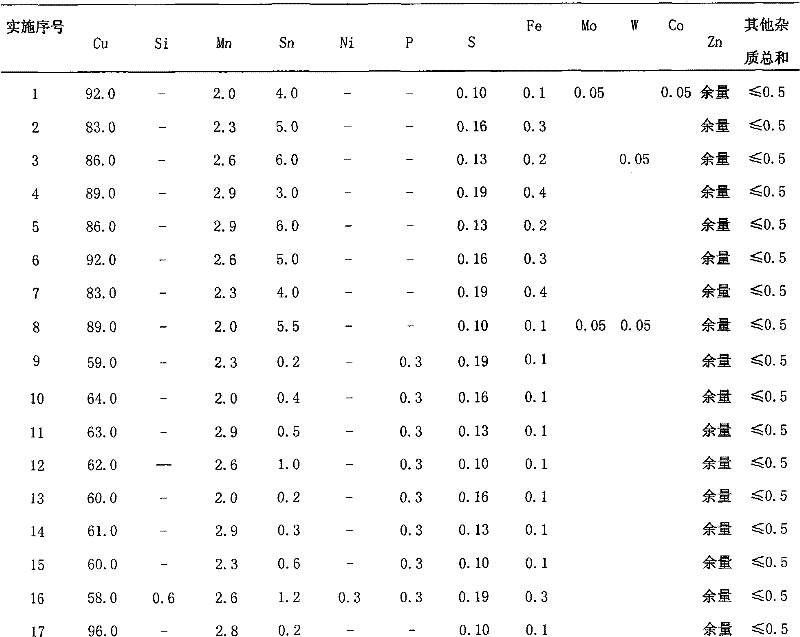

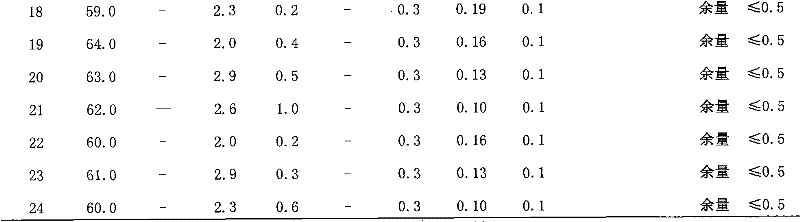

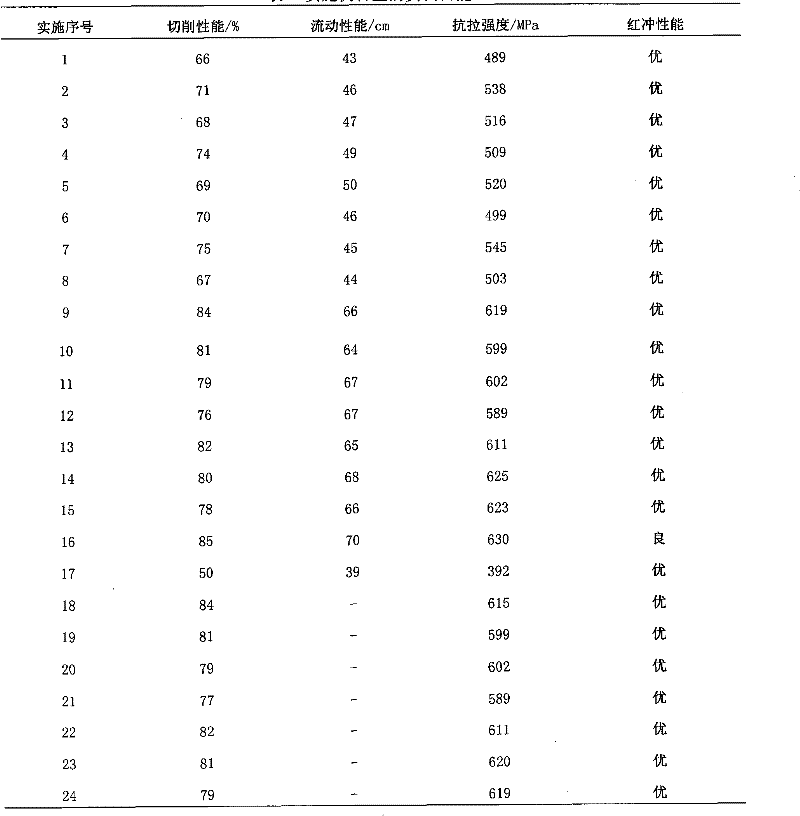

Leadless free-cutting copper alloy and preparation method

A leadless free-cutting copper alloy and a preparation method. The copper alloy comprises the following elements by mass: 58.0%-96.0% of copper, 2.0%-2.9% of manganese, 0.2%-6.0% of tin, not more than 0.3% of phosphor, not more than 0.3% of nickel, 0.10%-0.19% of sulfur, 0.1%-0.9% of the sum of 1-3 elements selected from silicon, iron, molybdenum, tungsten, and cobalt, and the balance of zinc. In the alloy, the mass ratio of manganese and sulfur is more than 10 and less than 30; the other elements are impurities, and the mass fraction of any one of the impurities is not more than 0.03%; the sum of the mass fractions of all the impurities is not more than 0.5%. The preparation method comprises the following steps: melting and alloying the base metal element of copper and the important metal element of manganese, adding other alloy elements and performing homogenization, performing refining, adding sulfide or sulfur, performing homogenization and adding zinc rapidly, immediately casting into a ingot casting or performing atomization to obtain powder. The leadless free-cutting copper alloy and the preparation method of the invention are applicable to cutting processing, hot forging processing, and polishing processing of copper alloy.

Owner:HUNAN TERRY NEW MATERIALS COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com