Patents

Literature

551results about How to "Good castability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper alloy with no lead

This invention relates to a Pb-free Cu alloy, especially a Pb-free machinable Cu alloy, which is composed of: Cu 55.0-89%, Zn 3.0-45%, Sn 0.1-10%, Ni 0.1-2.0%, Si 0-5.0%, Bi 0.1-5.0%, Se 0-3.0%, Al 0.01-1.0%, P 0.05-0.15%, and RE 0.01-0.5%. RE, Bi, Se and P are added respectively in the forms of RE-Cu intermediate alloy, Cu-Bi intermediate alloy, Cu-Se intermediate alloy and P-Cu intermediate alloy, or RE, Bi, Se and P are added respectively in the forms of Bi-Se alloy and P-Cu alloy. This invention can eliminate harmful effects on environment and human bodies caused by Pb during production and recovery process. The Cu alloy has good machinability, mechanical properties, processability and fluidity, and has no thermal splitting. The production method is simple, and can produce the Cu alloy by using the present apparatus for producing lead-brass alloy. Besides, the contents of Se, Bi and RE are low,.

Owner:JIANGXI UNIV OF SCI & TECH

Method for producing ultra-low-carbon steel

A method for producing ultra-low-carbon steel belongs to steel-making technology field. The process route is: molten iron desulfuration preprocess -converter smelting -RH vacuum process -slab continuous casting. The iron desulfuration preprocess applies blowing magnesium granules for desulfuration; the converter smelting terminal carbon content and oxygen activity of molten steel; applying slag dam operation when tapping without deoxidation; the ladle furnace proceeds operation of top slag modification and temperature controlling; RH vacuum processing to control the maximum vacuum; applying Al for deoxidation when the decarburization is finished, and alloying if the deoxidation is finished and assuring the deep vacuum processing time after the deoxidation; calming the molten steel when the vacuum is finished; applying non-carbon covering agent and non-carbon protection slag in the slab casting process; the continuous casting process uses full protection casting, and the casting process controls a reasonable pulling speed according to slab section. The advantages are: the invention resolves problem of nozzle clogging and improves castability of the ultra-low-carbon steel and implements multi-furnace continuous casting, and the components of carbon, phosphorus, sulphur and nitrogen of the completed product conforms smelting request of the ultra-low-carbon steel.

Owner:SHOUGANG CORPORATION

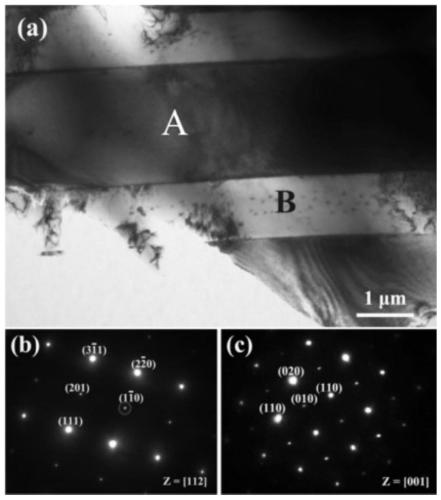

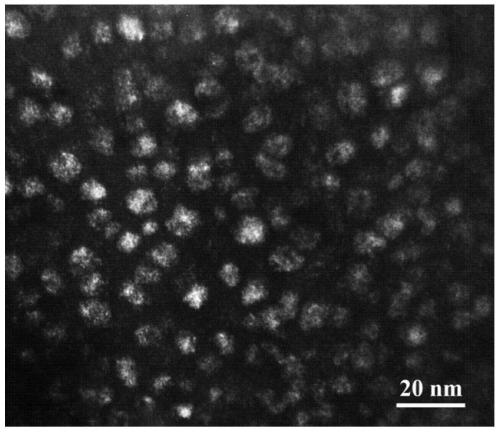

Nickel-base high-temperature alloy with low density and high melting point and preparation process thereof

The invention relates to high-temperature alloy technology, and in particular provides an isometrical cast nickel-base high-temperature alloy with low density, high incipient melting temperature and good casting property and a preparation process thereof, which can be used for floating tile materials of a combustion chamber. The alloy comprises the following compositions by mass percentage: 0.03 to 0.06 percent of C, 5 to 12 percent of Cr, 5.5 to 6.5 percent of Al, 3 to 8 percent of Co, 3 to 7 percent of W, 2 to 4 percent of Mo, 1.6 to 3.2 percent of Nb, 0.01 to 0.03 percent of B, 0.008 to 0.025 percent of Y and the balance of Ni. A vacuum induction furnace is adopted to smelt a master alloy, and a smelting crucible is a CaO crucible or a MgO crucible; and the operation process comprises the following steps: putting alloying elements such as carbon, chromium, cobalt, tungsten, molybdenum and niobium in proportion and a nickel plate into the crucible; melting the alloy when the vacuum degree reaches between 50 and 0.1 Pa; and after completion of the melting, refining for 30 to 300 seconds at a temperature of between 1,550 and 1,600 DEG C, cutting off electricity, forming a film, breaking the film to add Al and Al-Y and Ni-B interalloy for uniform stirring, and casting a master alloy pig at a temperature of between 1,450 and 1,500 DEG C. The invention solves the problems of low incipient melting temperature, poor plasticity and inoxidability and the like of the nickel-base high-temperature alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Nickel-base alloy

Owner:ATI PROPERTIES

Aluminium alloy and preparation method thereof

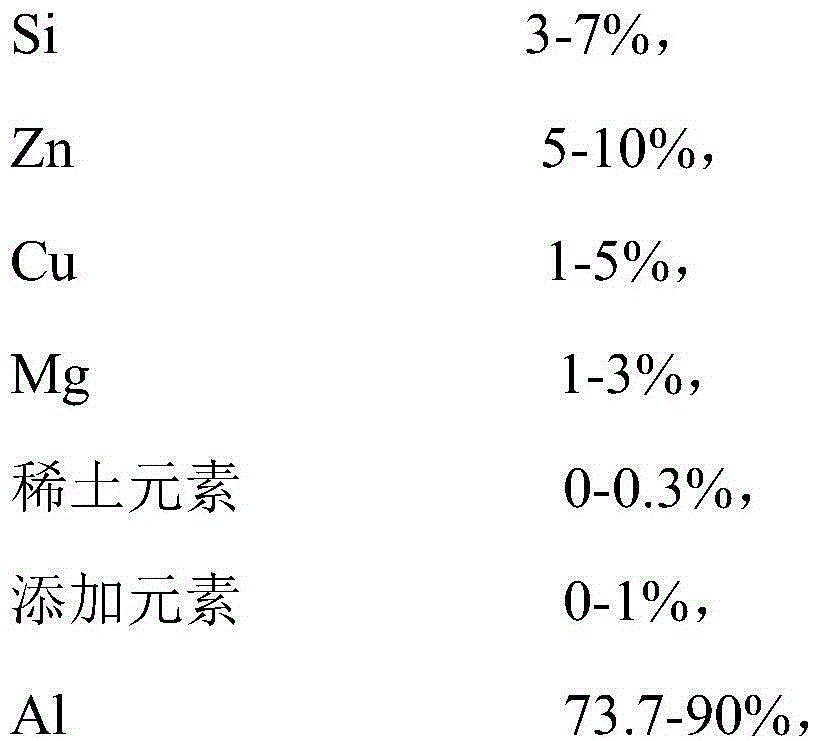

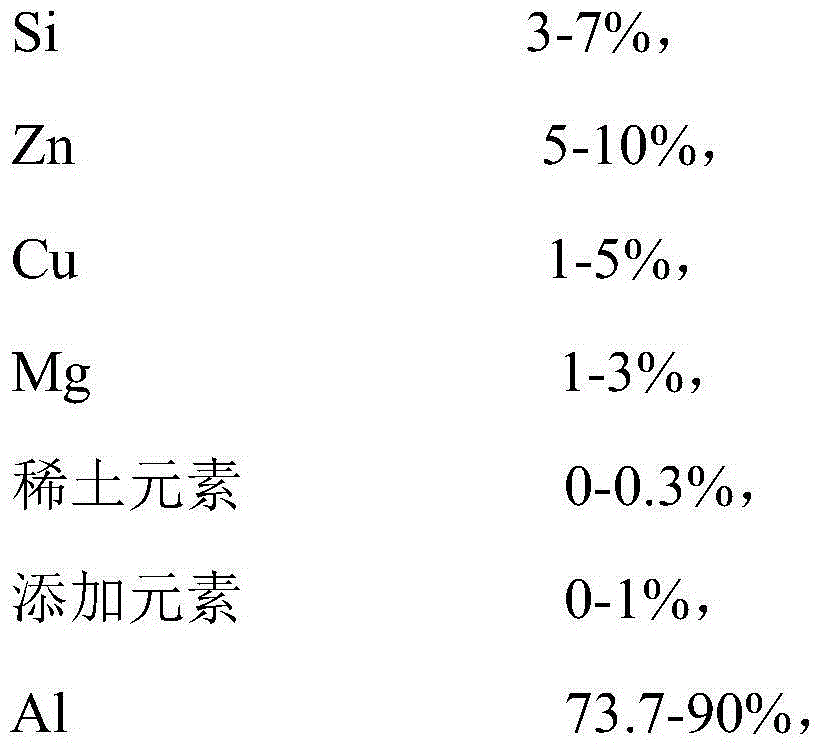

An aluminum alloy contains 3-7wt%of Si, 5-10wt%of Zn, 1-5wt%of Cu, 1-3wt%of Mg, 0-0.3wt%of a rare earth element, 0-1wt%of an additional element, and 73.7-90wt%of Al. The additional element is at least one selected from a group consisted of Ti, Zr, Mn, Fe, Cd, Cr, B, Bi, Ni and Sr. A method of preparing the aluminum alloy is also provided.

Owner:BYD CO LTD

High-plasticity cast aluminum alloy and extrusion casting preparation method thereof

The invention discloses a high-plasticity cast aluminum alloy and an extrusion casting preparation method thereof, belonging to the technical fields of metal materials and metallurgy. The alloy comprises the following components in percentage by weight: 7.5-13.5% of Si, 0.5-0.8% of Mg, 0.2-0.5% of Mn, 0.1-0.4% of Ti, 0.01-1.5% of RE, 0.6-1.3% of Fe, at most 100 ppm of P, 100-600 ppm of Sr and the balance of Al. The RE is one or more of Gd, Y, Nd, Sm, Er, Yb and La. After the high-plasticity cast aluminum alloy is subjected to extrusion casting and solid solution+artificial aging treatment, the elongation percentage delta of the alloy is greater than or equal to 22%. The alloy has the advantages of excellent casting performance and low cost. The method has the advantages of simple technique, high production efficiency and obvious progress, and widens the application range of the Al-Si cast aluminum alloy.

Owner:SHANGHAI JIAO TONG UNIV

Pressure cast rare earth aluminum alloy with high thermal conductivity and high electrical conductivity and preparing method thereof

The invention discloses pressure cast rare earth aluminum alloy with high thermal conductivity and high electrical conductivity and a preparing method thereof. The aluminum alloy comprises 0.5-2.0 wt% of Si, 0.001-0.05 wt% of Cu, 0.2-0.6 wt% of Fe, 0.001-0.50 wt% of Mn, 0.8-3.0 wt% of Mg, 0.07-0.15 wt% of Zn, 0.001-0.05 wt% of B, 0.05-0.20 wt% of La, 0.05-0.2 wt% of Y, 0.05-0.2 wt% of Ce, and the balance Al and less than 0.1 wt% of impurities. The aluminum alloy has high castability, excellent thermal conductivity and electrical conductivity, excellent corrosion resistance and medium mechanical performance and can be applied to 3C mobile phones, notebook computer shells, communication, illumination, rail transit, civil hardware and other fields.

Owner:GAOAN JINLIANGXUAN SCI & TECH

High-plasticity cast aluminum alloy and gravity casting preparation method thereof

The invention discloses a high-plasticity cast aluminum alloy and a gravity casting preparation method thereof, and belongs to the fields of metal materials and metallurgy. The high-plasticity cast aluminum alloy is prepared from the following components in percentage by weight: 7.5 to 13.5% of Si, 0.5 to 0.8% of Mg, 0.2 to 0.5% of Mn, 0.1 to 0.4% of Ti, 0.01 to 1% of RE, not greater than 0.4% of Fe, not greater than 100ppm of P, 100 to 600ppm of Sr, and the balance of Al, wherein RE is one or some of Gd, Y, Nd, Sm, Er, Yb and La. After gravity casting, solid solution treatment and artificial aging treatment, the high-plasticity cast aluminum alloy has the elongation delta of being not less than 18%. The prepared alloy is outstanding in casting performance, low in cost, simple in process, high in production efficiency, and obvious in progress, and the applicable scope of Al-Si cast aluminum alloy is expanded.

Owner:SHANGHAI JIAO TONG UNIV

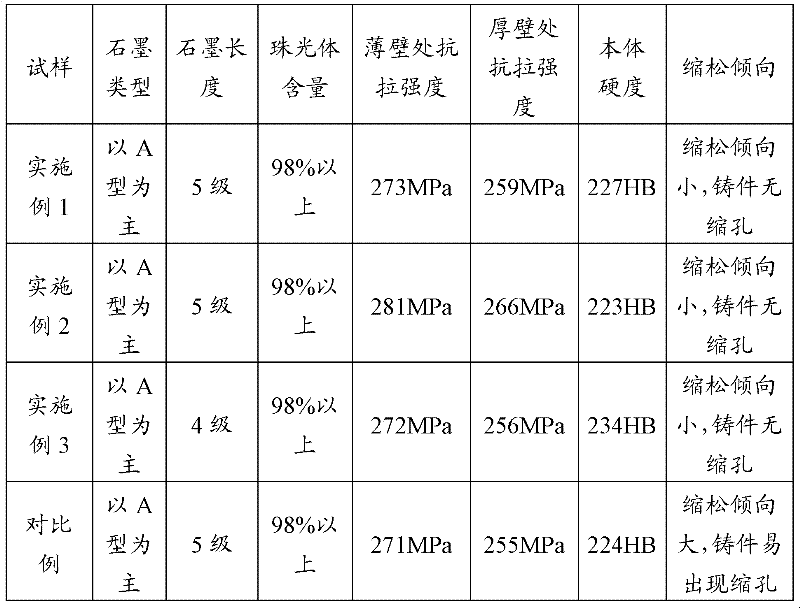

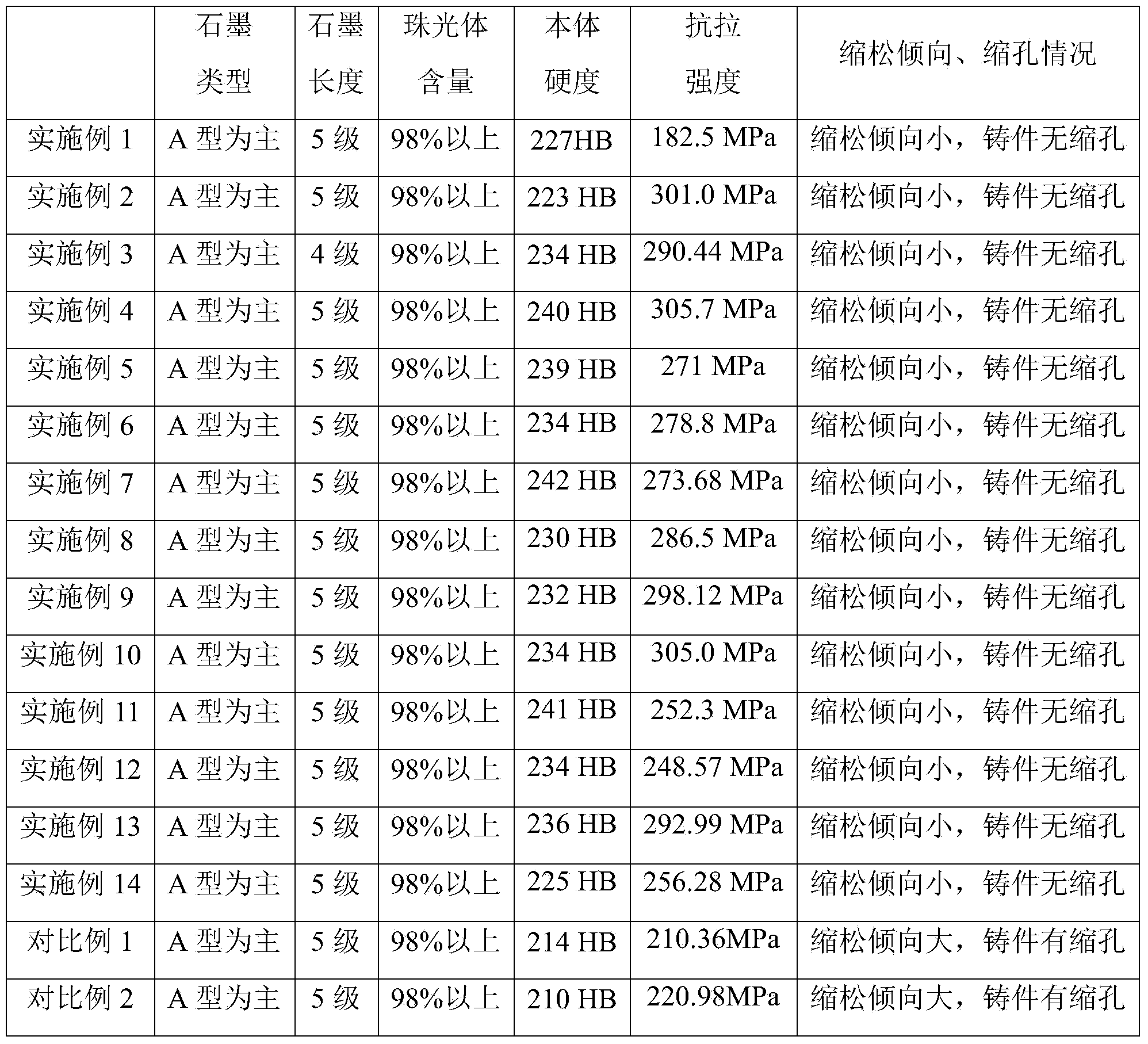

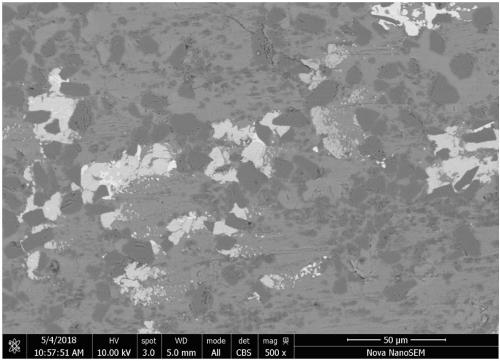

Gray pig iron and production process thereof

The invention provides a gray pig iron, which comprises the following elements in percentage by weight: 3.1 to 3.4 percent of C, 1.5 to 2.1 percent of Si, 0.5 to 0.8 percent of Mn, 0 to 0.06 percent of P, 0.05 to 0.15 percent of S, 0.15 to 0.50 percent of Cr, 0.3 to 0.8 percent of Cu, 0 to 0.12 percent of Sn, 0.20 to 0.60 percent of Ni, and the balance of Fe. In the production process of the gray pig iron, the Cu, the Cr, the Ni and the Sn are added into molten iron to perform alloying, so the defect of large shrinkage porosity tendency caused by using molybdenum to perform the alloying can be overcome, the obtained gray pig iron has excellent casting property, shrinkage cavities are not generated on casts, the requirements on materials of key casts of cylinder bodies and cylinder covers of high-performance engines at present can be met; and the price the Ni and the Sn is lower than that of the molybdenum, so the cost of the casts is low.

Owner:WEICHAI POWER CO LTD

Lead-free environmental silicon brass alloy bar or alloy ingot and preparation method thereof

The invention relates to a lead-free environmental silicon brass alloy bar or alloy ingot and the alloy material comprises the following chemical elements by weight percent: 60%-70% of copper, 0.7%-3.0% of silicon, 0.15% or less of aluminium, 0.25% or less of lead, 0.5% or less of iron, 0.3% or less of tin, 0.1% or less of phosphorus, 0.2% or less of nickel, 0.25% or less of antimony and the balance zinc and unavoidable impurities. The lead content of the silicon brass alloy material of the invention is greatly reduced, which corresponds to the demand of environmental protection and health; the alloy material has good casting property and is applicable to casting, in particular to large-scale gravity casting so as to have broad application prospect in health fittings industry.

Owner:浙江天申铜业有限公司

Multielement high-chromium wear-resisting cast-iron sieve-plate and production thereof

An antiwear multi-element screening plate made of high-Cr cast iron contains C (2.2-3.2 wt.%), Cr (18-28), Mn (0.6-1.5), Si (0.4-1.0), Mo (0.4-1.5), Ni (0.5-1.2), Nb (0.1-0.5), Ca (0.01-0.08), Zn (0.008-0.050), Mg (0.002-0.010), Ce (0.003-0.10), Ti (0.08-0.15) and Fe (rest). It is made up by electric furnace and cold hardened resin-sand mould. Its advantages are high bending strength, hardness, antiwear performance and impact toughness, and low cost.

Owner:XI AN JIAOTONG UNIV

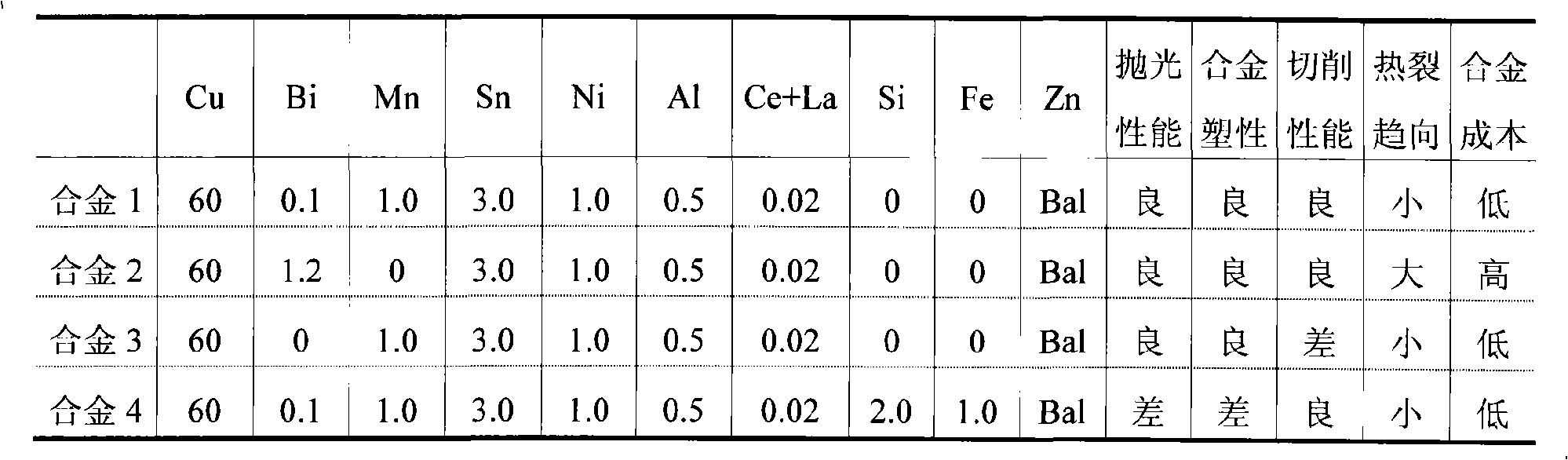

Rare earth manganese brass alloy and producing process thereof

The invention relates to a rare earth brass alloy with environment protection and easy cutting, which achieves the purpose of improving the easy cutting of the alloy by adding Bi and Mn to replace the lead in Pb brass. The alloy has the components of 55.0-65wt percent of Cu, 0.1-2.5wt percent of Bi, 0.1-1.0wt percent of Mn, 0-3.0wt percent of Sn, 0-1.0wt percent of Ni, 0.1-1.0wt percent of Al, 0.01-0.05wt percent of one or two of Ce and La, the rest of Zn and other inevitable impurities, wherein Bi, Si, Ce, La and Ce+La are added respectively in the form of master alloys of Cu-Bi, Cu-Si, Cu-Ce, Cu-La and Cu-Ce-La. The alloy has the advantages of favorable cutting performance, cold and hot working performances and cast performance, little thermal fragment trend, simple production process of supporting preparation in the existing Pb brass production equipment, low alloy cost, good polishing performance and welding performance, etc.

Owner:XIAMEN LOTA INT CO LTD

Environment-friendly manganese brass alloy and manufacturing method thereof

The invention provides an environment-friendly manganese brass alloy comprising 55-65 wt% of Cu, 1.0-6.5 wt% of Mn, 0.2-3.0 wt% of Al, 0-3.0 wt% of Fe, 0.3-2.0 wt% of Sn, 0.01-0.3 wt% of Mg, 0-0.3 wt% of Bi and / or 0-0.2 wt% of Pb, and the balance of Zn and other inevitable impurities. The alloy has favorable mechanical property, casting property, cutting property and corrosion resistance, particularly stress corrosion resistance, has the advantages of low manufacturing cost, simple production technology and the like, is suitable for parts processed by forging, casting, machining and other manufacturing methods, and is particularly suitable for a tap body and a valve processed by forging, casting and machining.

Owner:XIAMEN LOTA INT CO LTD

Heat-resistant cast aluminum alloy and extrusion casting method thereof

ActiveCN104561689AGood high temperature performanceHigh hardnessMetallic materialsSolution treatment

The invention relates to a heat-resistant cast aluminum alloy and an extrusion casting method thereof, and belongs to the fields of metallic materials and metallurgy. The alloy consists of the following elements in percentage by weight: Si, Cu, Ni, Mg, Ti, RE, Mn, Fe and Al. The heat-resistant cast aluminum alloy is prepared by virtue of extrusion casting, and after performing solution treatment and artificial aging treatment on the alloy, the room temperature tensile strength sigma b of the alloy is more than or equal to 420MPa, the tensile strength sigma b at 300 DEG C is more than or equal to 220MPa, the tensile strength sigma b at 350 DEG C is more than or equal to 140MPa, the room temperature extensibility delta is more than or equal to 2.5%, the extensibility delta at 300 DEG C is more than or equal to 6.5%, and the extensibility delta at 350 DEG C is more than or equal to 14.5%. According to the alloy and the extrusion casting method thereof provided by the invention, the casting performance is improved, the room-temperature and high-temperature mechanical properties of the alloy are greatly improved, and the application range of Al-Si series cast aluminum alloys is expanded.

Owner:SHANGHAI JIAO TONG UNIV

Ultra-fine grained eutectic high-entropy alloy and preparation method thereof

The invention relates to the technical field of alloys, in particular to an ultra-fine grained eutectic high-entropy alloy and a preparation method thereof. The invention discloses the ultra-fine grained eutectic high-entropy alloy. The general formula of the ultra-fine grained eutectic high-entropy alloy is Al<1.0>Cr<1.0>Co<x>Fe<y>Ni<Z>MnM<j>. The invention further provides the preparation method of the ultra-fine grained eutectic high-entropy alloy. The preparation method comprises the steps that 1, alloy raw materials are subjected to alkali washing and acid washing, thus a first alloy is obtained, and the raw materials comprises metals of Al, Co, Cr, Fe, Ni, Mn, W and V; 2, the Al metal and the Cr metal in the first alloy are placed on the bottommost part of a melting furnace crucible, the Co metal, the Fe metal and the Ni metal are placed at the middle and the upper part of the crucible, and the W metal and the V metal are placed at the uppermost part of the crucible; and 3, after the metals in the melting furnace crucible are totally melted, the Mn metal placed in a hopper in the melting furnace is mixed with the melted metals, and thus the ultra-fine grained eutectic high-entropy alloy is obtained. The invention provides the ultra-fine grained eutectic high-entropy alloy and the preparation method thereof, and the technical problems that in the prior art, the strengthand plasticity of the high-entropy alloy are low, and a macroscopic segregation phenomenon is prone to occurring are solved.

Owner:GUANGDONG UNIV OF TECH

High temperature resistant titanium and aluminum based alloy and manufacturing method thereof

The invention provides a high temperature resistant titanium-aluminium base alloy and a method for preparing the same, wherein, the alloy which belongs to gamma-TiAl alloy has components of Al of 44.0-48.0at%, Nb of 3.0-5.0at%, Cr of 0.2-2.0at%, Ni of 0.1-0.8at%, Si of 0-0.8at% and the rest are Ti and ineluctable impurity elements; the method comprises steps of using titanium sponge, AlNb alloy, AlCr alloy, Ni, Al and Si as the raw material, smelting, casting and shaping the raw material in a vacuum consumable electrode electrical arc skull crucible or a vacuum induction furnace, and when the casting process is performed, Ti-Al alloy casting ingot can be casted after vacuum melting or be casted after argon-filling smelting.The alloy of the invention has characteristics of favorable room-temperature plasticity, creep-resistance capability and anti-oxygenic property, can be used under a temperature of 800-900 DEG C, is suitable for the casting of parts with thin walls, can improve the use characteristics of aircraft engines and car engines, and has a wide market outlook.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

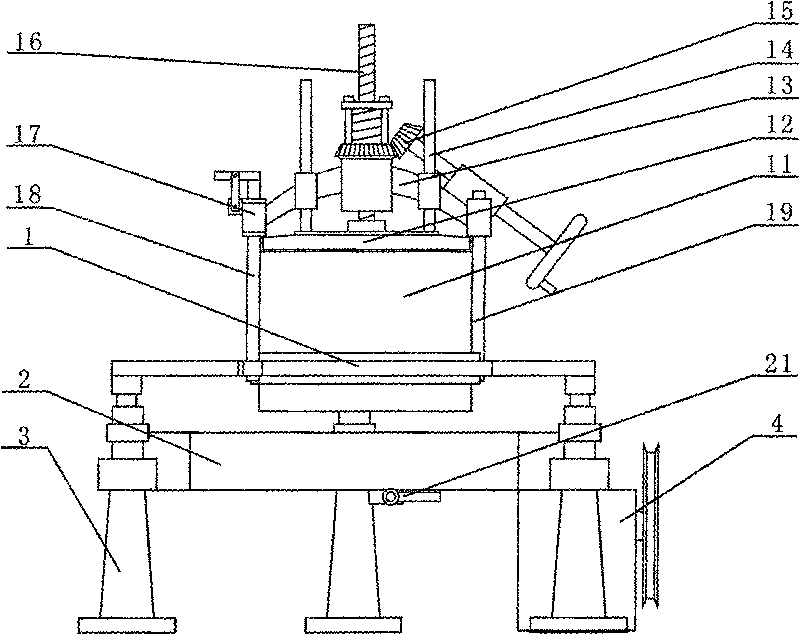

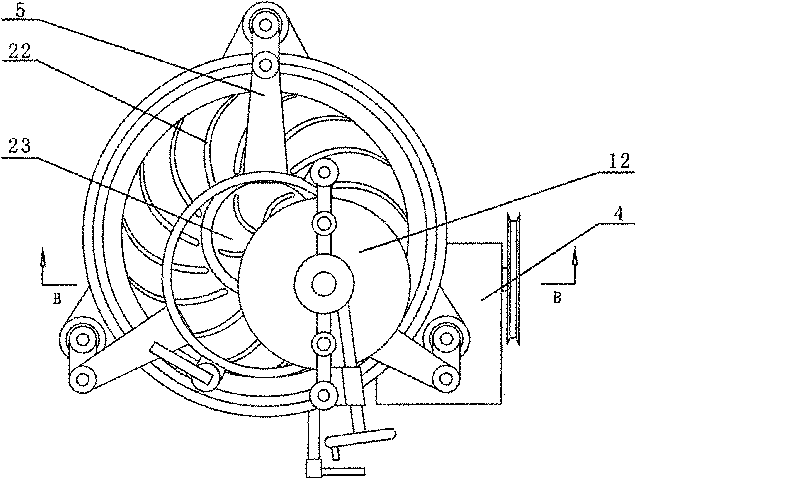

Novel tea knead entwist machine

The invention discloses a novel tea knead entwist machine and relates to tea processing machineries. The circular movement of the knead entwist device above the knead entwist plate can be realized by connecting the knead entwist device with a crank rocker mechanism; and the tailor-made knead entwist plate matches with the screw cover in the knead entwist device. The stripping tea rate of the tea is high, broken tea is little, and the broken tea generated in production can be separated from the mature tea automatically, thus improving tea grade and increasing production efficiency.

Owner:WUFENG TIANCHI TEA MACHINERY

High-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy and heat treatment method

The invention discloses a high-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy and a heat treatment method. The alloy comprises the following components by mass percentage: 6.5-8.3% of Zn, 2.3-3.0% of Mg, 0.8-1.2% of Cu, 0.1-0.2% of Zr, less than 0.15% of Fe, less than 0.1% of Si, and the balance of Al. A preparation method of the alloy comprises the steps of blending, smelting, semi-continuous casting, homogenizing, thermoplastic deformation, short time solid solution, and ageing heat treatment. For the high-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy prepared with the method, the hardness (HV) is 185-209, the tensile strength sigma b is greater than or equal to 650Mpa, the percentage elongation delta is greater than or equal to 7%, the pitting resistance is high, the cast ingot yield is high, and the stress corrosion resistance is further improved while the mechanical property is kept after multiple regression reageing treatment. The alloy and the heat treatment method solve the problems that the cast ingot yield in the existing high-copper Al-Zn-Mg-Cu ultrahigh-strength aluminium alloy is low, and the strength, toughness and corrosion resistance cannot be compromised. The heat treatment method is simple to operate, and the industrial production is facilitated.

Owner:CENT SOUTH UNIV

Leadless environment friendly bismuth brass alloy material suitable for gravity force cast and manufacture method thereof

The invention relates to a lead-free environment-friendly bismuth brass alloy material suitable for gravity casting. The alloy material comprises the following chemical elements: 57 to 63 percent of brass, 0.1 percent or less than 0.1 percent of lead, 0.2 to 0.65 percent of aluminum, 0.5 percent or less than 0.5 percent of iron, 0.1 to 3.0 percent of tin, 0.4 to 3.0 percent of bismuth, 0.5 percent or less than 0.5 percent of nickel, balance zinc and unavoidable impurities. The lead content of the brass alloy material of the invention is greatly reduced and conforms to the environmental protection and health requirements, and meanwhile the lead-free environment-friendly brass alloy material has excellent casing performance, is suitable for casting, in particular for larger-scale gravity casting, and has extensively application prospect in the sanitary-ware industry.

Owner:浙江中瀚智能控制股份有限公司

Leadless free-cutting copper alloy and preparation method

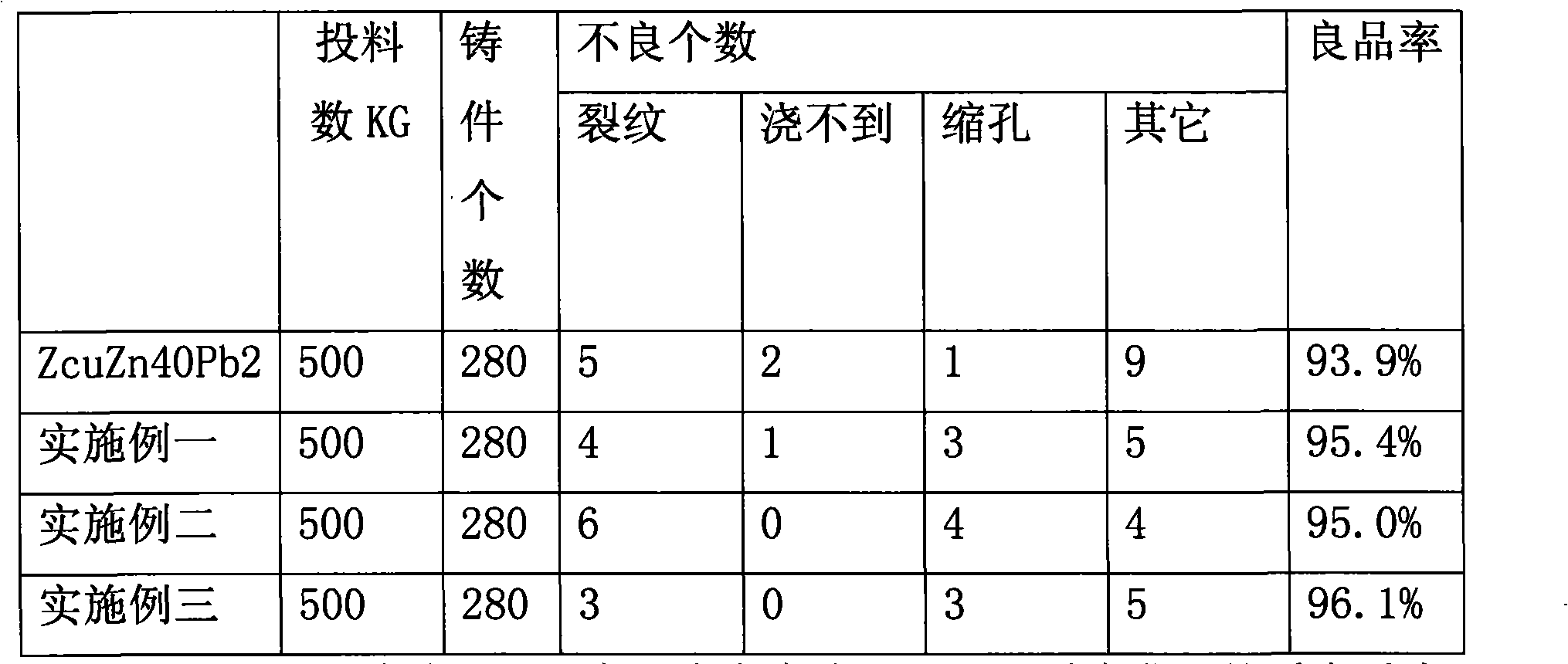

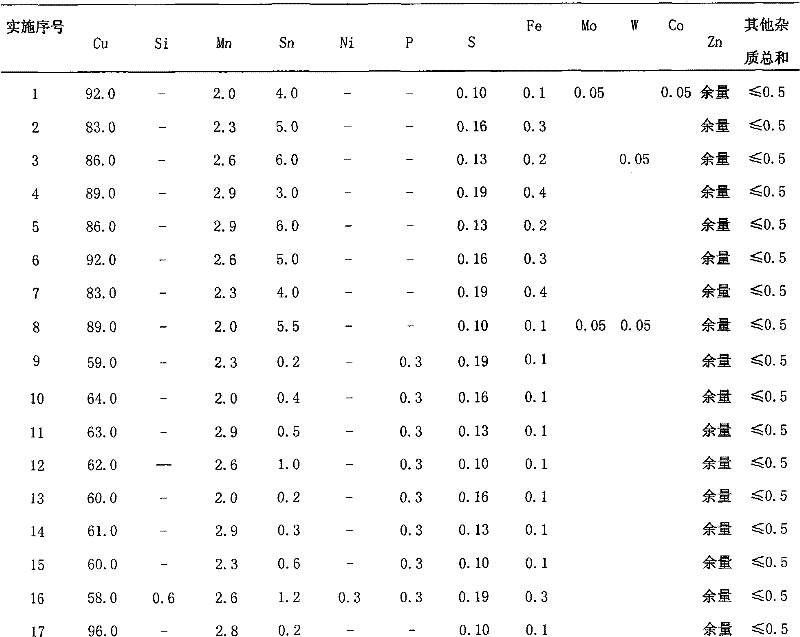

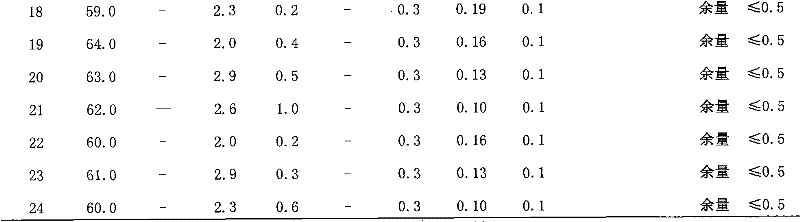

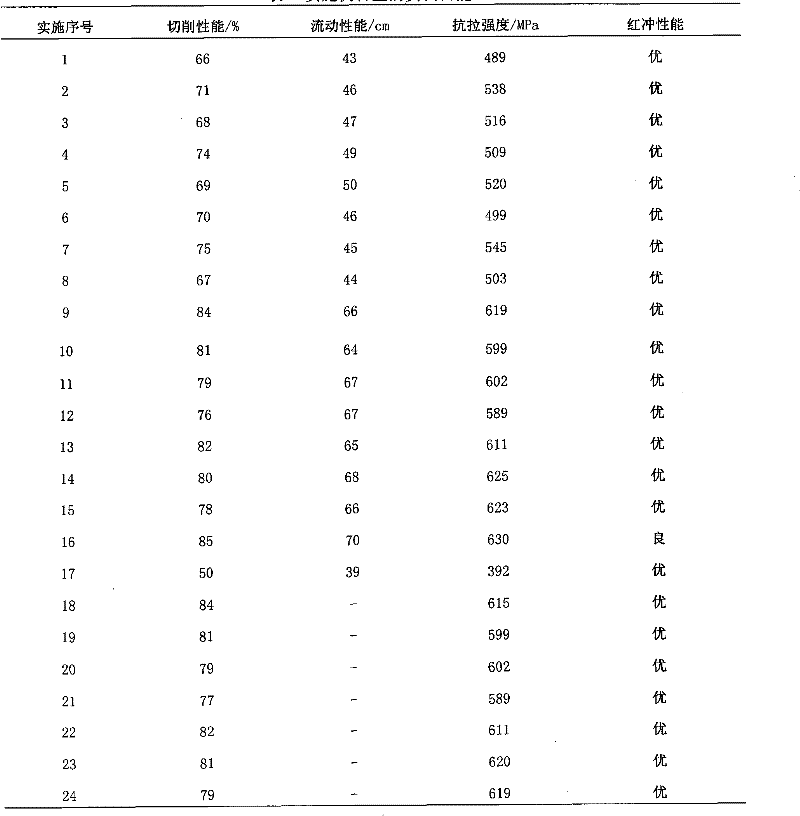

A leadless free-cutting copper alloy and a preparation method. The copper alloy comprises the following elements by mass: 58.0%-96.0% of copper, 2.0%-2.9% of manganese, 0.2%-6.0% of tin, not more than 0.3% of phosphor, not more than 0.3% of nickel, 0.10%-0.19% of sulfur, 0.1%-0.9% of the sum of 1-3 elements selected from silicon, iron, molybdenum, tungsten, and cobalt, and the balance of zinc. In the alloy, the mass ratio of manganese and sulfur is more than 10 and less than 30; the other elements are impurities, and the mass fraction of any one of the impurities is not more than 0.03%; the sum of the mass fractions of all the impurities is not more than 0.5%. The preparation method comprises the following steps: melting and alloying the base metal element of copper and the important metal element of manganese, adding other alloy elements and performing homogenization, performing refining, adding sulfide or sulfur, performing homogenization and adding zinc rapidly, immediately casting into a ingot casting or performing atomization to obtain powder. The leadless free-cutting copper alloy and the preparation method of the invention are applicable to cutting processing, hot forging processing, and polishing processing of copper alloy.

Owner:HUNAN TERRY NEW MATERIALS COMPANY

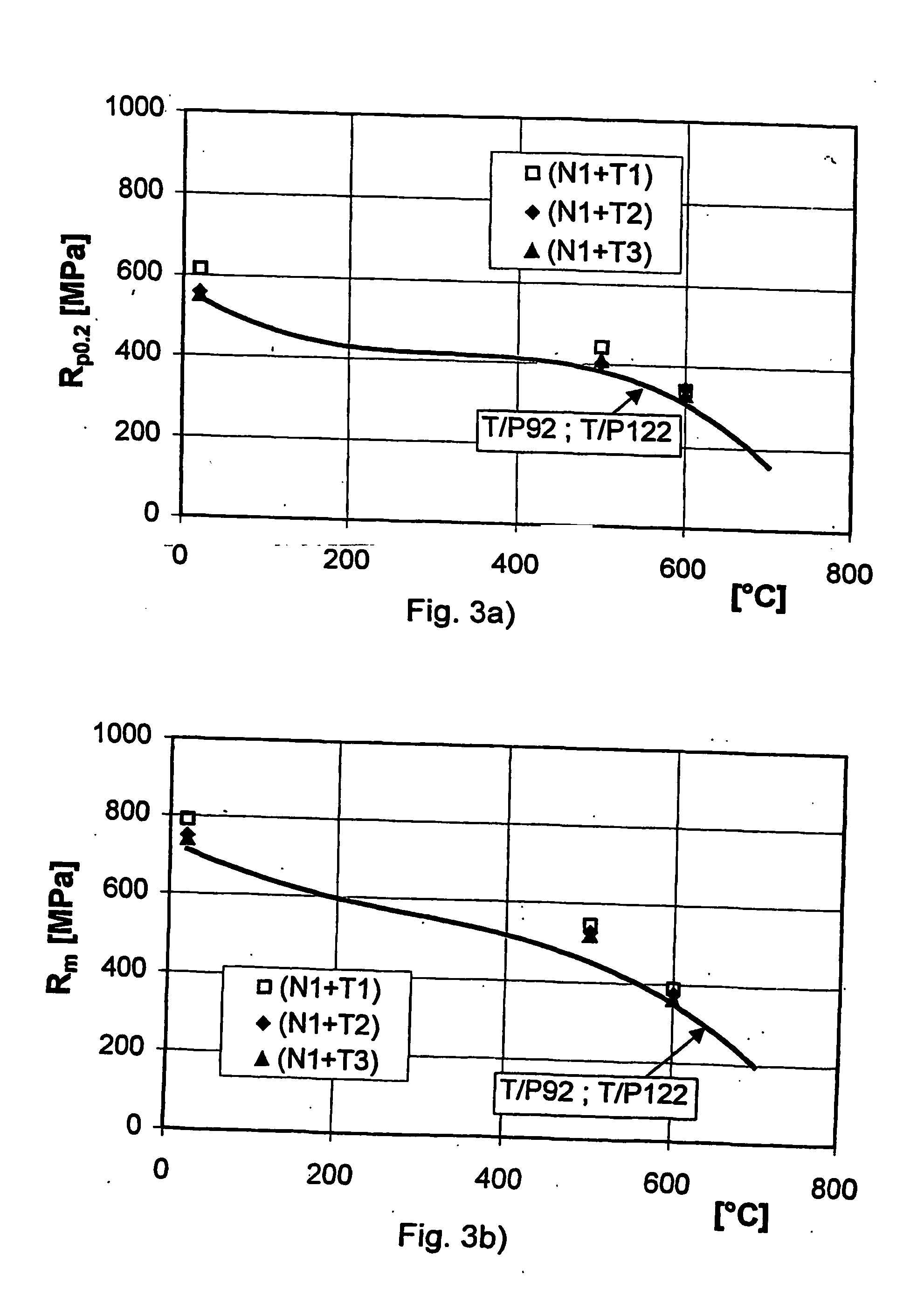

Steel and steel tube for high- temperature use

InactiveUS20040109784A1Reduce formationGood castabilityFurnace typesProcess efficiency improvementSteel tubeChemical composition

Owner:V & M FRANCE

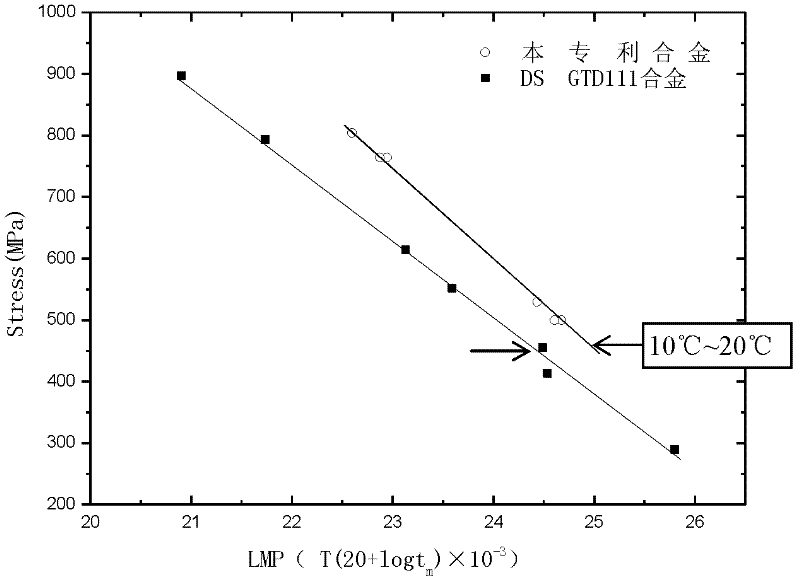

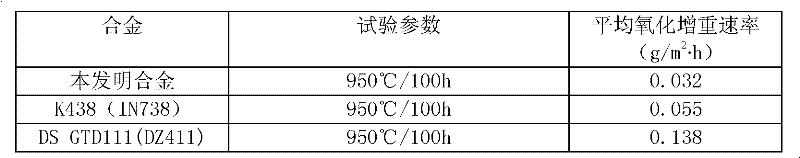

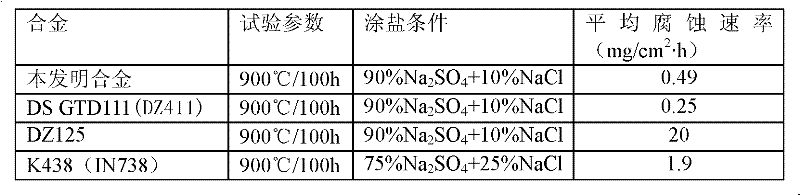

Novel directed nickel-base high temperature alloy

ActiveCN102653832AGuaranteed StrengthControl hot corrosion resistanceChemical compositionMetallic materials

The invention belongs to the field of metallic materials and relates to a novel directed nickel-base high temperature alloy for hold end parts and components of a gas turbine. The chemical ingredients of the alloy and mass percents of the chemical ingredients are as follows: 3.0-5.5% of Al, 0.5-4.0% of Ti, 9.0-12.0% of Cr, 5.0-7.0% of Ta, 7.0-10.0% of Co, 4.0-7.0% of W, 1.0-3.0% of Mo, 0-2.0% of Hf, 0-4% of Re, 0.02-0.15% of C, 0.002-0.02% of B, and the balance of nickel. The novel directed nickel-base high temperature alloy disclosed by the invention has good high temperature strength, tissue stability, casting performance and high temperature and hot corrosion resistance, no TCP phase is separated out after the alloy is aged at 900 DEG C for 50000h, the salt coated hot corrosion resistance of the alloy disclosed by the invention at 900 DEG C is close to that of a DS GTD111 alloy, and the temperature bearing capability of the alloy disclosed by the invention is 10-20 DEG C higher than that of the DS GTD111 alloy, so that the alloy disclosed by the invention is suitable for casting directed thin-walled hollow casting.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

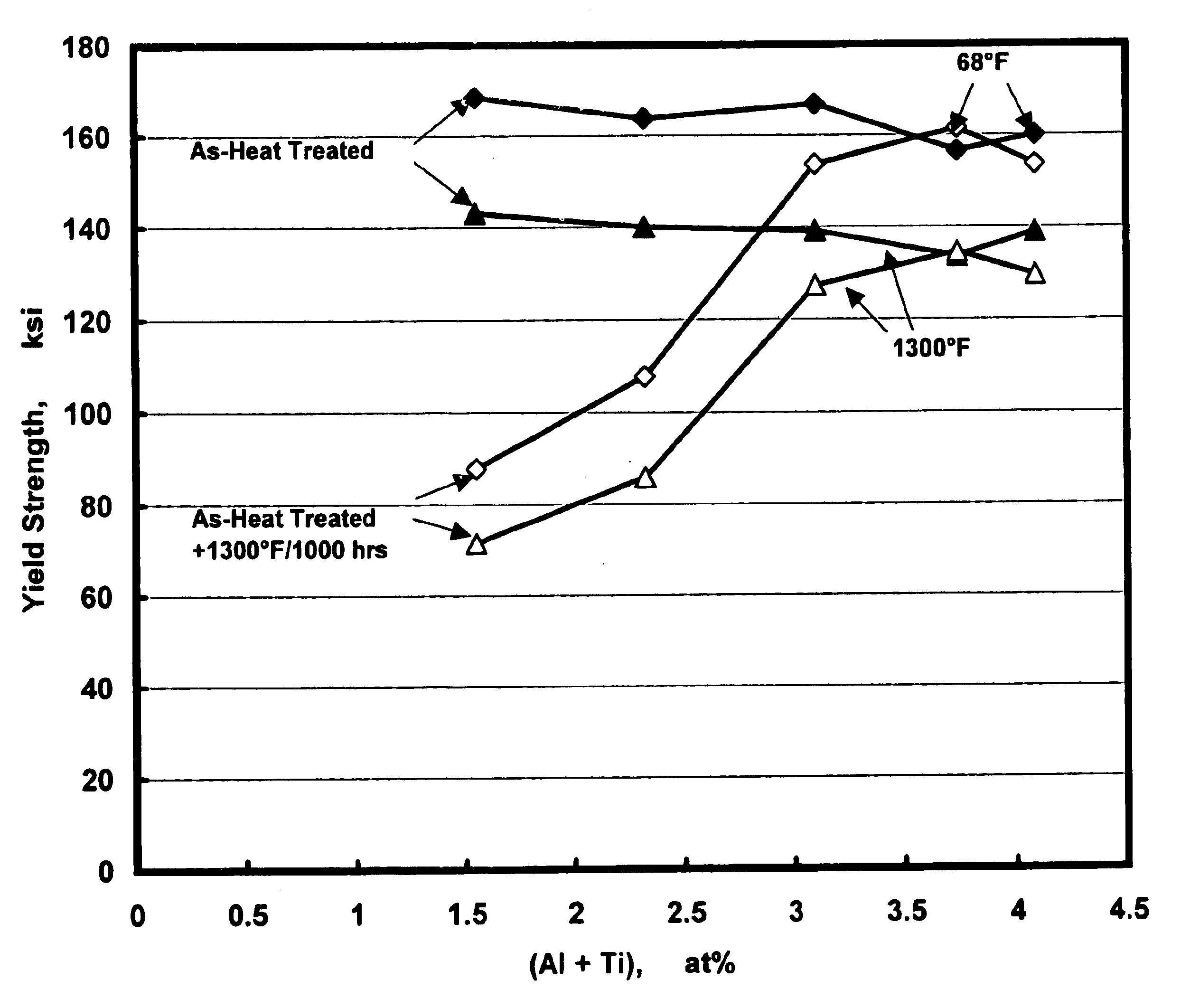

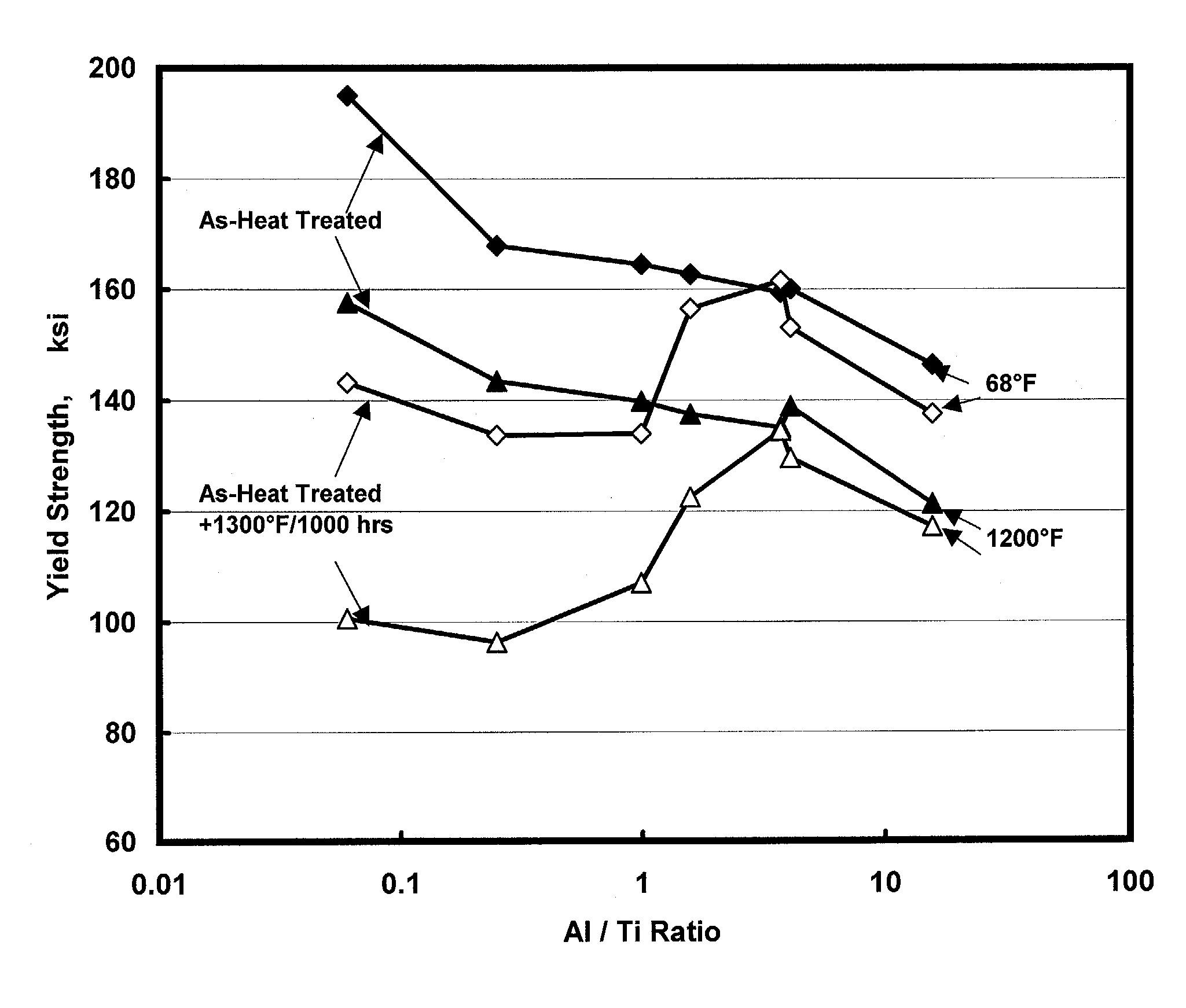

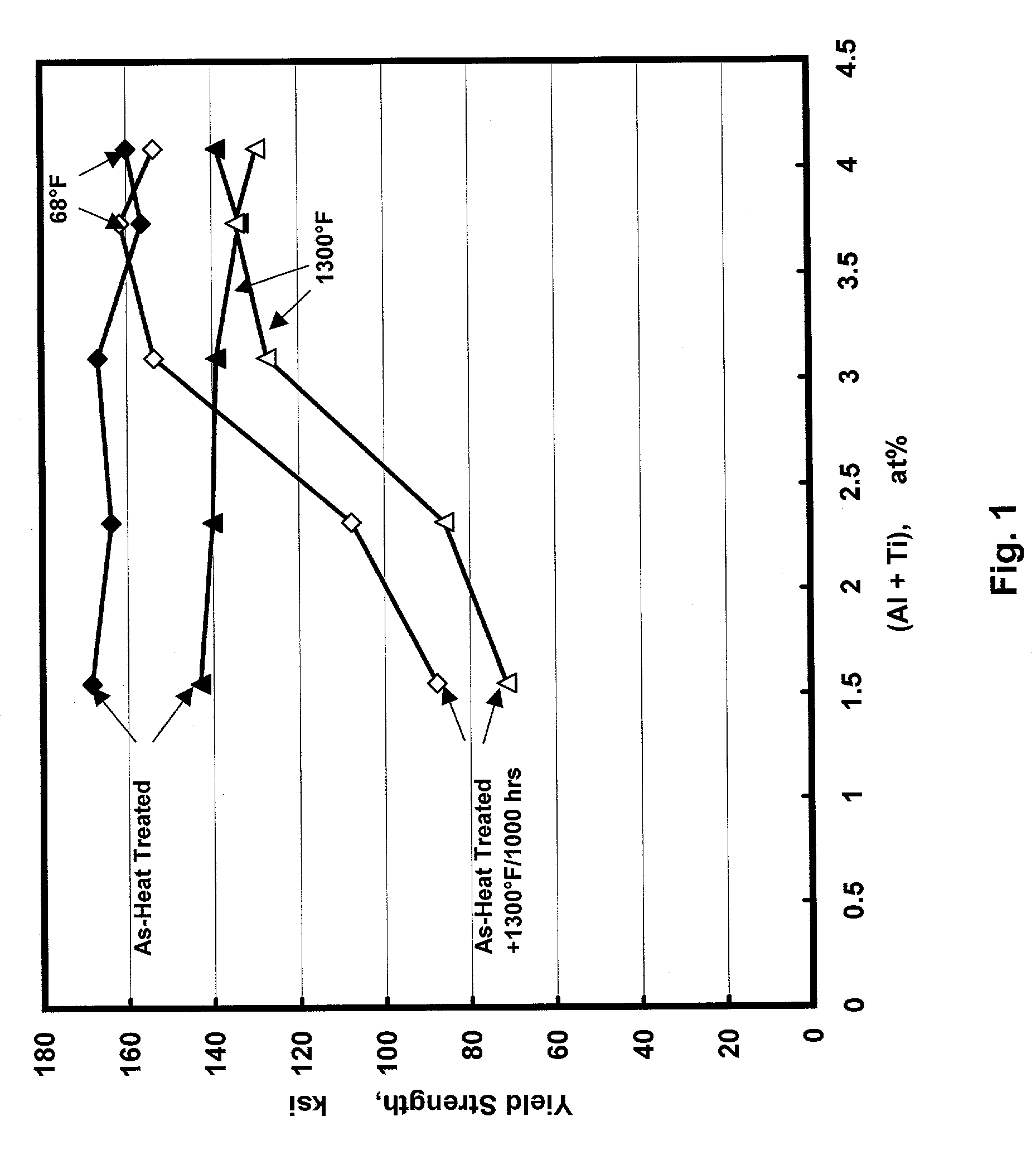

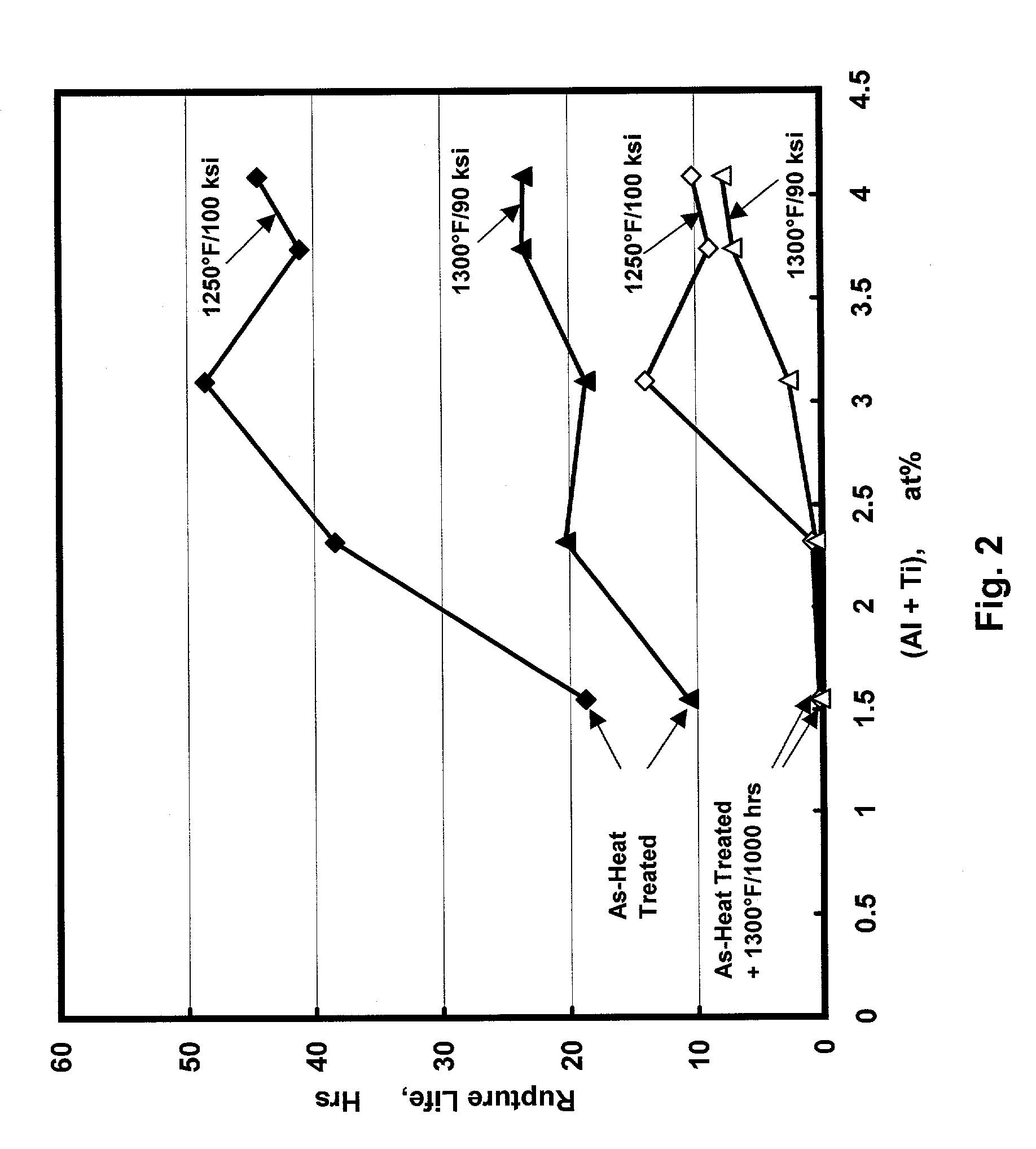

Nickel-base alloy

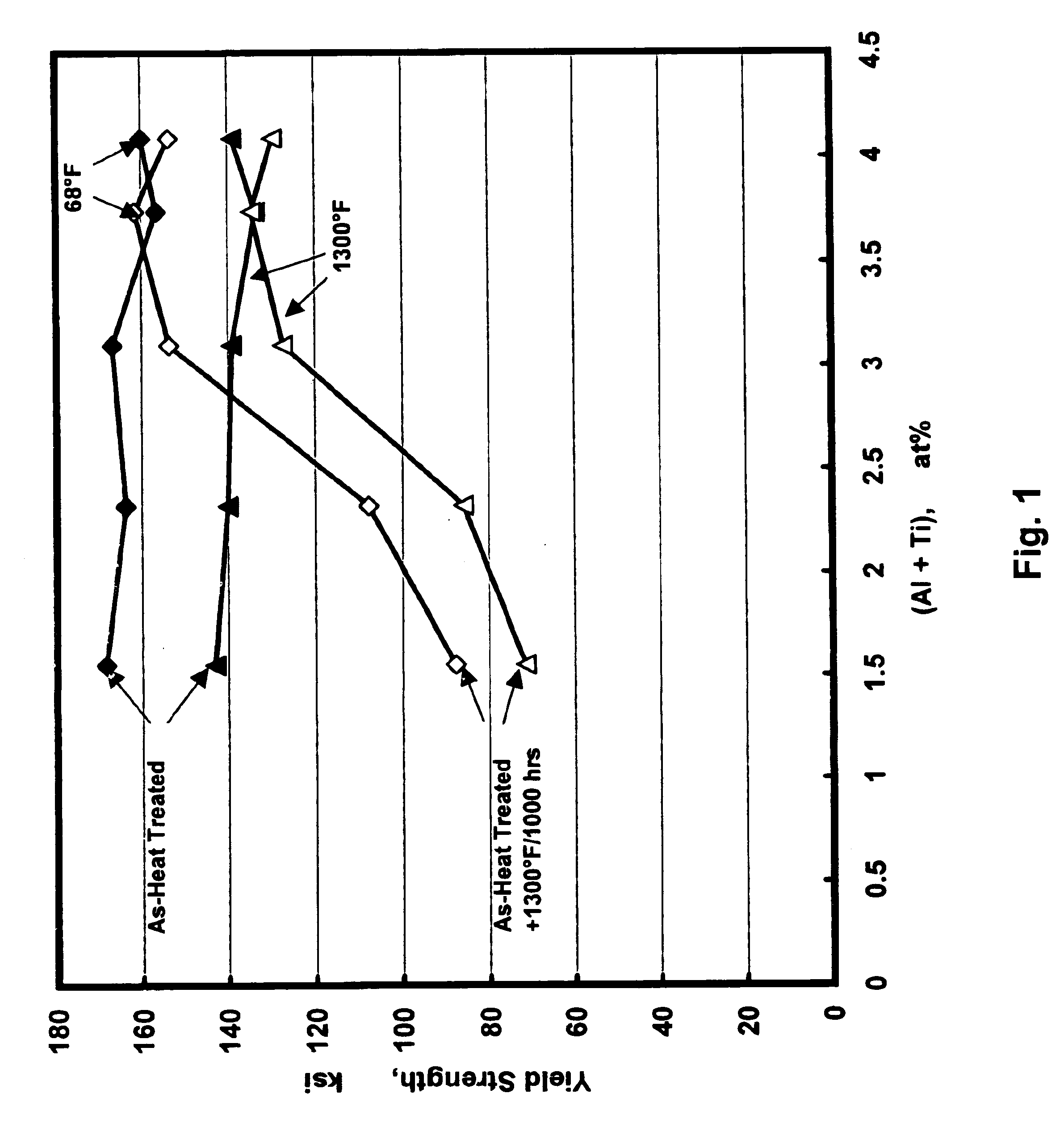

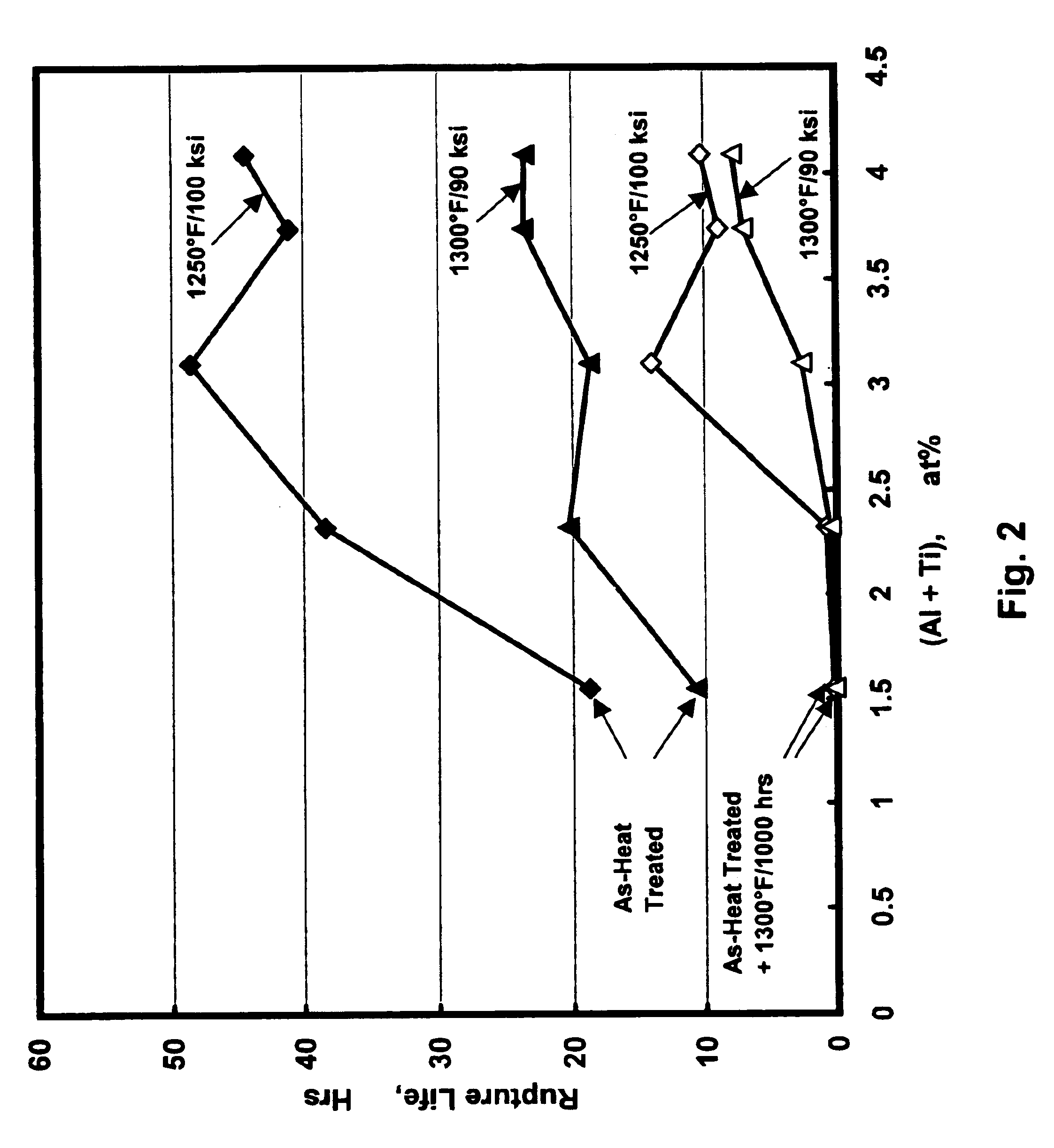

A nickel-base alloy includes, in weight percent, up to about 0.10 percent carbon; about 12 up to about 20 percent chromium; up to about 4 percent molybdenum; up to about 6 percent tungsten, wherein the sum of molybdenum and tungsten is at least about 2 percent and not more than about 8 percent; about 5 up to about 12 percent cobalt; up to about 14 percent iron; about 4 percent up to about 8 percent niobium; about 0.6 percent up to about 2.6 percent aluminum; about 0.4 percent up to about 1.4 percent titanium; about 0.003 percent up to about 0.03 percent phosphorous; about 0.003 percent up to about 0.015 percent boron; nickel; and incidental impurities. The sum of atomic percent aluminum and atomic percent titanium is from about 2 to about 6 percent, the ratio of atomic percent aluminum to atomic percent titanium is at least about 1.5, and the atomic percent of aluminum plus titanium divided by the atomic percent of niobium equals about 0.8 to about 1.3. The nickel-base alloy may be provided in the form of an article of manufacture, such as, for example, a disk, a blade, a fastener, a case, or a shaft. A method for making a nickel-base alloy also is disclosed. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:ATI PROPERTIES

Aluminum-magnesium-silicon series aluminum alloy material with middle and high intensity

The invention discloses an aluminum-magnesium-silicon series aluminum alloy material with middle and high intensity, comprising the following elements in percentage by weight: 0.50-1.0 percent of silicon, 0.20-0.40 percent of iron, 0.25-0.50 percent of copper, 0.9-1.4 percent of magnesium, 0.05-0.15 percent of manganese, not more than 0.10 percent of zinc, not more than 0.05 percent of titanium, 0.05-0.12 percent of chromium and the balance of aluminum. A process thereof comprises the following steps of burdening, furnace charging, slag skimming, magnesium adding, stirring, sampling, composition adjusting, refining, slag skimming, refining, standing and casting. The invention has the advantages of high intensity, high tenacity, high corrosion resistance and good shock absorption performance.

Owner:SHANGHAI UNISON ALUMINUM PRODS

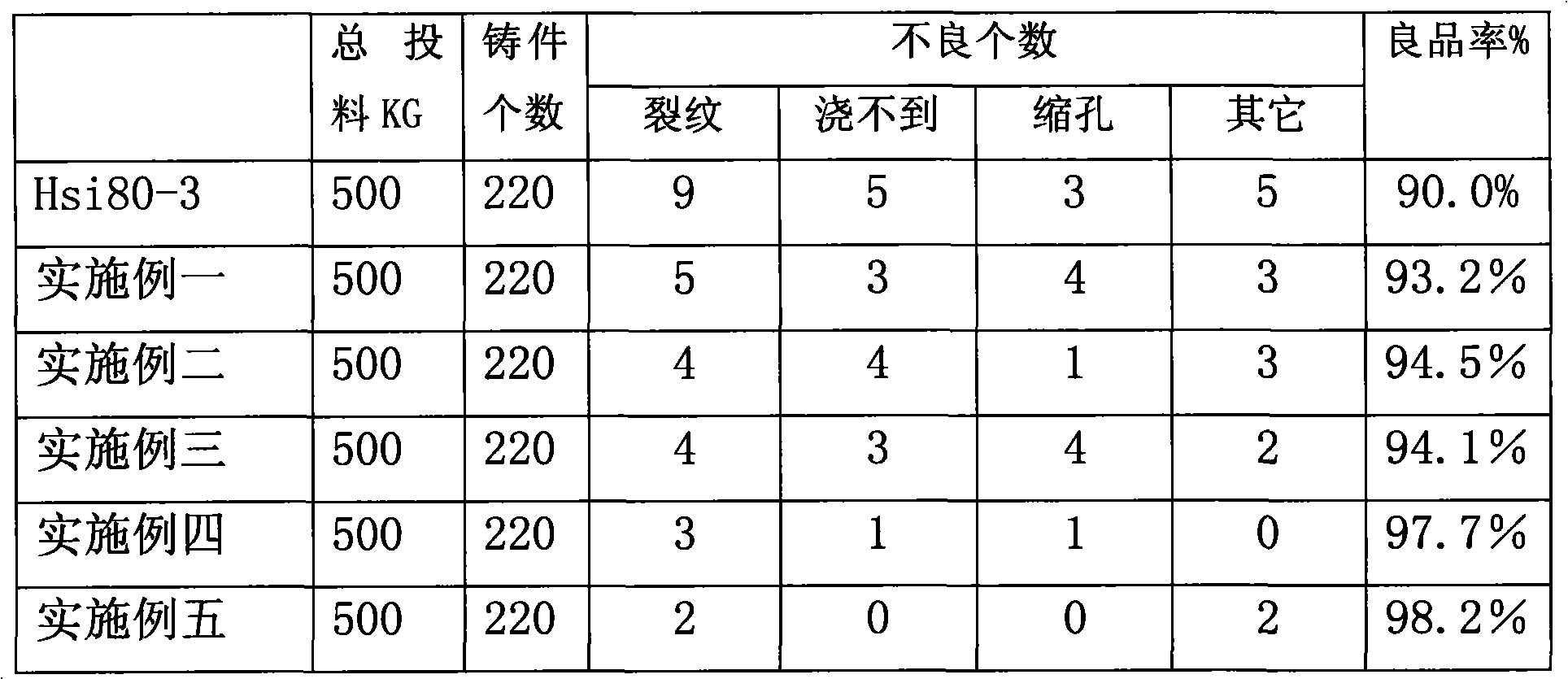

Gray cast iron and production method thereof

The invention discloses a gray cast iron and a production method thereof. The gray cast iron comprises the following chemical components in percentage by weight: 3.1-3.3% of C, 1.8-2.2% of Si, 0.5-0.8% of Mn, 0-0.04% of P, 0.05-0.1% of S, 0.1-0.4% of Cr, 0.3-0.5% of Cu, 0-0.06% of Sn, Sb less than 0.02%, and the balance amount of Fe. The gray cast iron disclosed by the invention is suitable for producing casting parts which easily shrunk, have thick walls, and have marks above HT300; according to the production method of the gray cast iron, the technical means of adding copper, chrome, antimony and tin in molten iron for alloying in the gray cast iron production process is adopted, so that molybdenum and nickel for alloying in the prior art are replaced, thereby solving the problem of high possibility of shrinkage and looseness of gray cast iron products, after the prepared gray cast iron is used for casting and forming, the casting parts have low possibility of shrinkage and looseness, have no shrinkage hole, have high yield and are low in production costs.

Owner:山东海之冠工贸有限公司

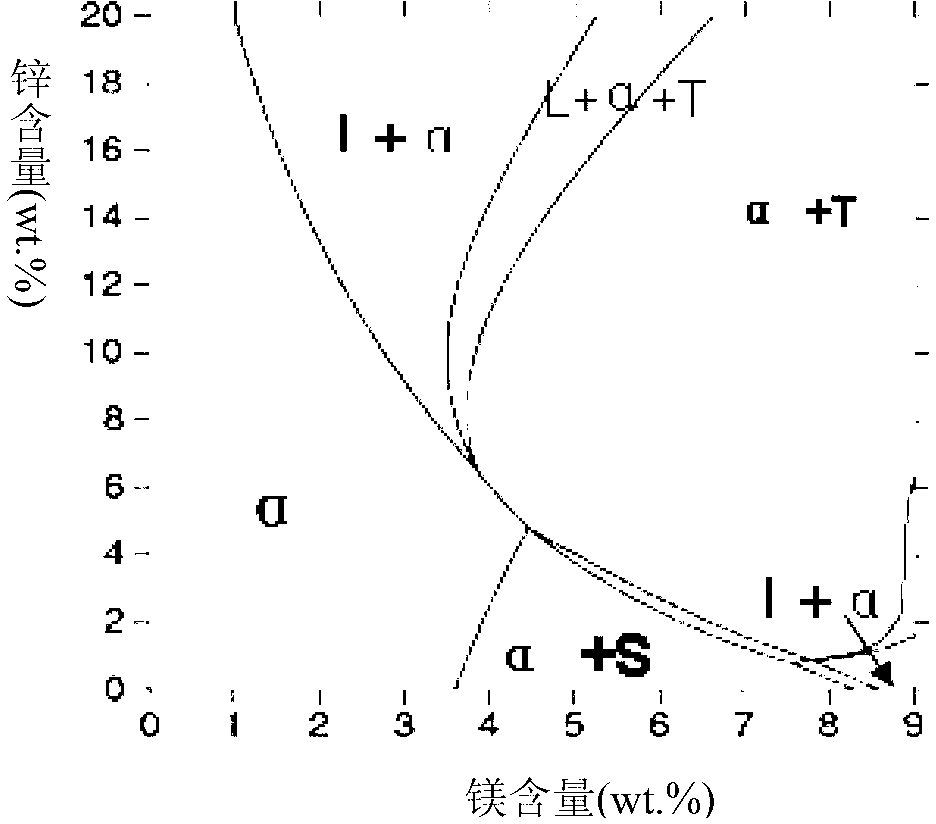

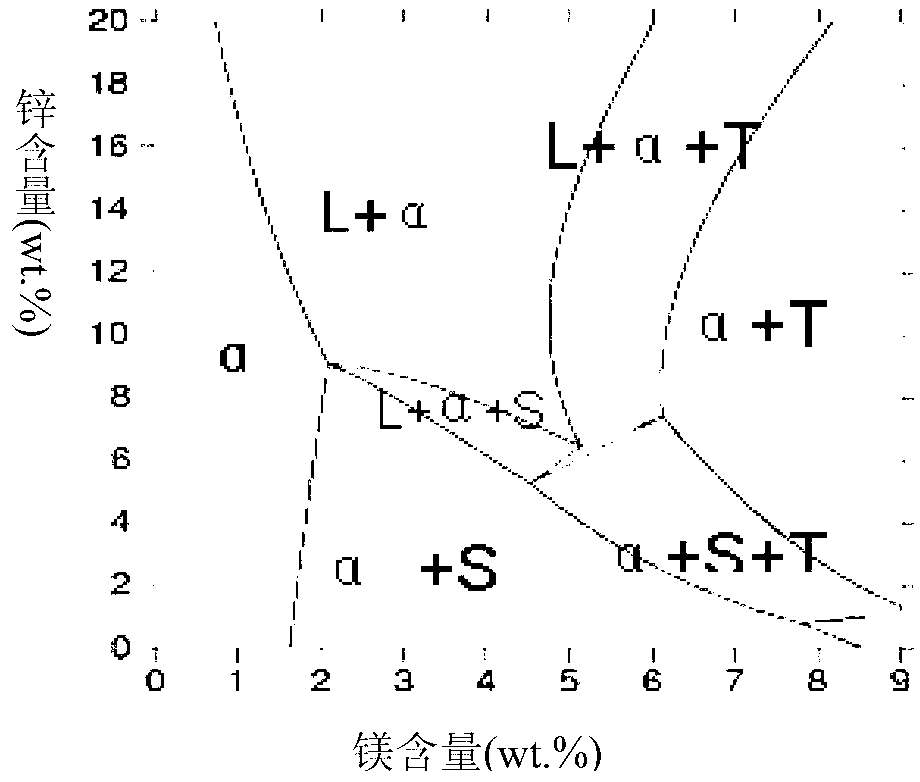

SiC particle-enhanced aluminum based composite with high-temperature wear resistance and preparation method of SiC particle-enhanced aluminum based composite

The invention provides a SiC particle-enhanced aluminum based composite with high-temperature wear resistance and a preparation method of the SiC particle-enhanced aluminum based composite and belongsto the field of aluminum alloy materials. The preparation method comprises the following steps of smelting industrial pure aluminum, aluminum-silicon alloy, aluminum-copper alloy, pure magnesium, thealuminum-copper alloy, aluminum-nickel alloy, aluminum-zinc alloy, aluminum-titanium alloy and aluminum-magnesium alloy at 700-800 DEG C according to a mass ratio; performing degassing refining; performing casting at 700-750 DEG C; using vacuum smelting, stirring and casting equipment to smelt a substrate at 700-800 DEG C; adding micron-size SiC particles; performing semi-solid state stirring at550-570 DEG C; performing casting at 700-750 DEG C; and performing T6 heat treatment. For the SiC particle-enhanced aluminum based composite with the high-temperature wear resistance and the preparation method, the substrate alloy components are designed self according to an alloy phase diagram, and a proper element content is selected, so that a high temperature resistant hard phase occurs aftersubstrate alloy heat treatment, and the substrate hardness at high temperature is ensured; and meanwhile, by adding an SiC-enhanced phase, the high temperature resistance of the composite is further improved.

Owner:TONGJI UNIV

High-strength cast aluminium-silicon alloy reinforced via cryogenic treatment, and preparation method thereof

InactiveCN106498245AImprove solubilityAdvantages of mechanical propertiesSolubilitySolution treatment

The invention discloses a high-strength cast aluminium-silicon alloy reinforced via cryogenic treatment, and a preparation method thereof, and belongs to the technical field of aluminium-silicon alloy. The invention also discloses chemical composition of the high-strength cast aluminium-silicon alloy reinforced via cryogenic treatment. The preparation method comprises steps of chemical composition controlling, melting process controlling, casting technology controlling, and cryogenic treatment. The step of cryogenic treatment comprises following steps: solution treatment is carried out for 5 to 6h at 470 to 490 DEG C, and then quenching in hot water of 60 to 90 DEG C is carried out; cryogenic thermal insulation is carried out for 24h at -145 to -165 DEG C, and the temperature of an obtained product is increased to room temperature in the air; aging treatment is carried out for 5 to 6h at 170 to 180 DEG C, and the processed product is cooled to room temperature in the air so as to obtain the high-strength cast aluminium-silicon alloy reinforced via cryogenic treatment. According to the preparation method, cryogenic treatment is capable of increasing solubility of alloy elements in cast aluminium-silicon alloy greatly, and more fine strengthening phases are formed by a plurality of added alloy elements, so that the mechanical properties of the high-strength cast aluminium-silicon alloy are much better than that of other cast aluminium-silicon alloy.

Owner:NANJING LONGHAO NEW MATERIAL TECH CO LTD

Heat-resistant cast aluminum alloy and pressure casting method thereof

The invention relates to a heat-resistant cast aluminum alloy and a pressure casting method thereof. The aluminum alloy consists of the following elements according to certain weight percentage: Si, Cu, Ni, Mg, Ti, RE, Mn, Fe and the balance of Al. After pressure casting of the heat-resistant cast aluminum alloy provided by the invention, the tensile strength (sigma)b of the alloy at room temperature is greater than or equal to 400MPa, the tensile strength (sigma)b at 300 DEG C is greater than or equal to 210MPa, and the tensile strength (sigma)b at 350 DEG C is greater than or equal to 130MPa; and the elongation delta at room temperature is greater than or equal to 2.0%, the elongation delta at 300 DEG C is greater than or equal to 6.0%, and the elongation delta at 350 DEG C is greater than or equal to 14.0%. By comparing the alloy and pressure casting preparation method thereof provided by the invention with the existing Al-Si cast aluminum alloy and the pressure casting preparation method thereof, the casting performance is improved, the room-temperature and high-temperature mechanical properties of the alloy are remarkably improved, and the application range of the Al-Si cast aluminum alloy is widened.

Owner:SHANGHAI JIAO TONG UNIV

Leadfree high-strength and corrosion-resistance silicon brass alloy easy to be cut and preparation method and application

The invention belongs to the technical field of alloy materials, and discloses a leadfree high-strength and corrosion-resistance silicon brass alloy easy to be cut and a preparation method and application. The alloy comprises the following components in percentage by mass: 56-60% of Cu, 38-42% of Zn, 0.003-0.01% of B, 0.03-0.06% of Ti, and 1.0-1.5% of Si and 0.5-0.9% of Al, or 0.5-0.8% of Si and 1-1.5% of Al; and the equivalent weight of zinc in all the components is within 48-50%. The contents of Si and Al elements are controlled, and B and Ti composite grain refiners are added to control the phase composition of the alloy and the distribution state thereof, so that the copper alloy with such excellent comprehensive performances as strength, machinability and dezincification resistance, high yield and low cost is obtained, the alloy can replace lead brass and bismuth brass for water heating, bathroom and various easy corrosion parts, and the alloy is excellent in promotion and application prospect.

Owner:SOUTH CHINA UNIV OF TECH +2

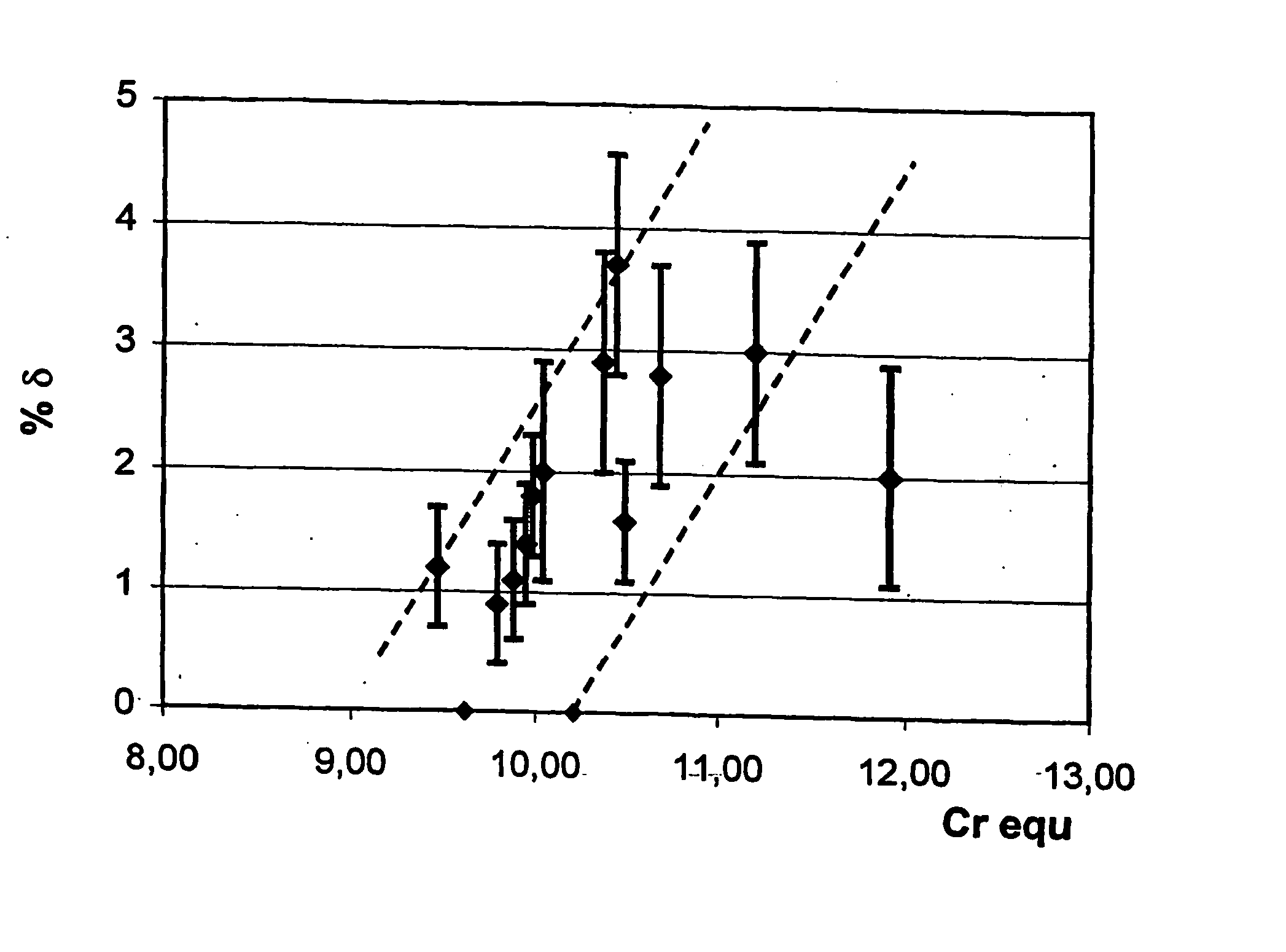

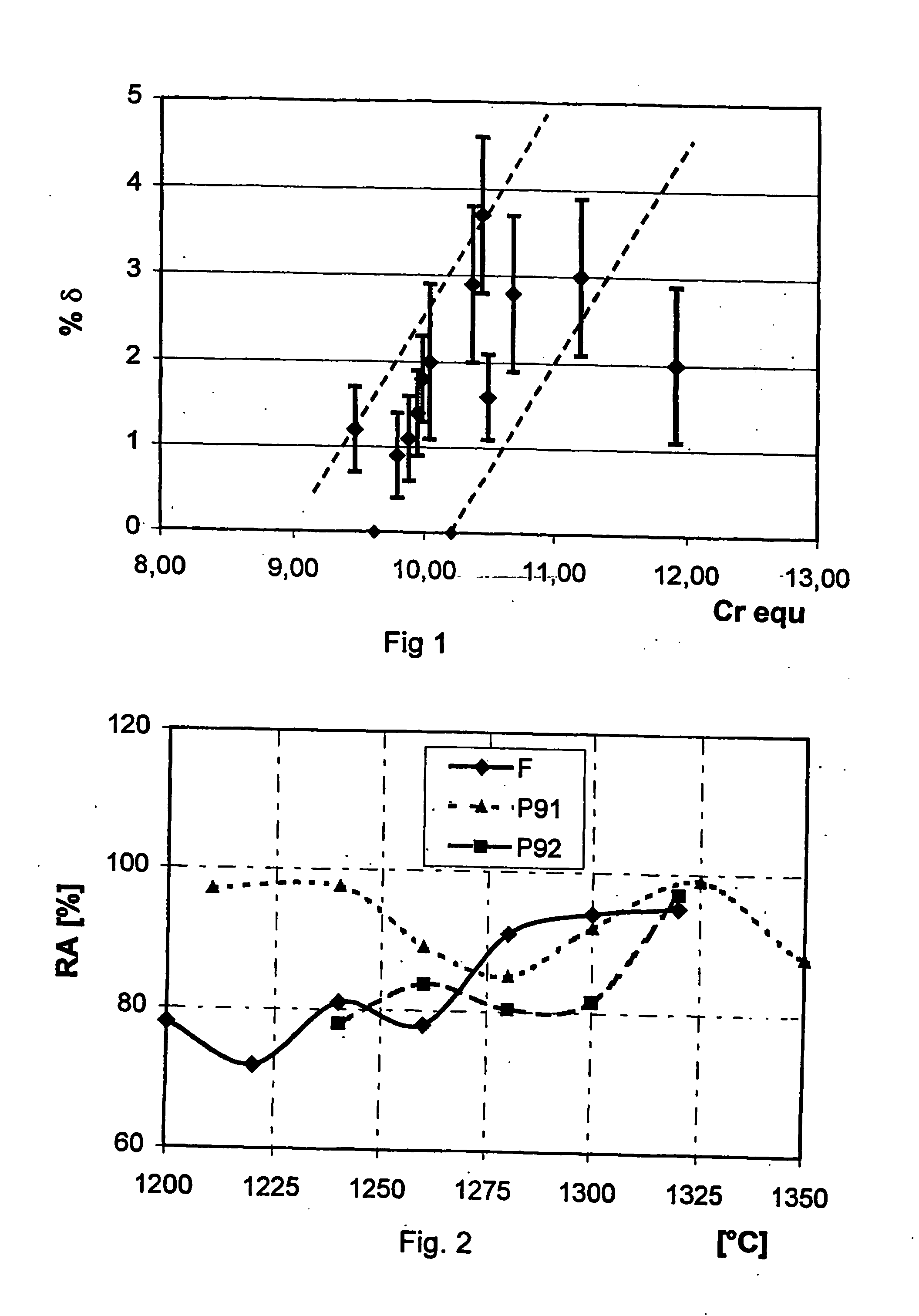

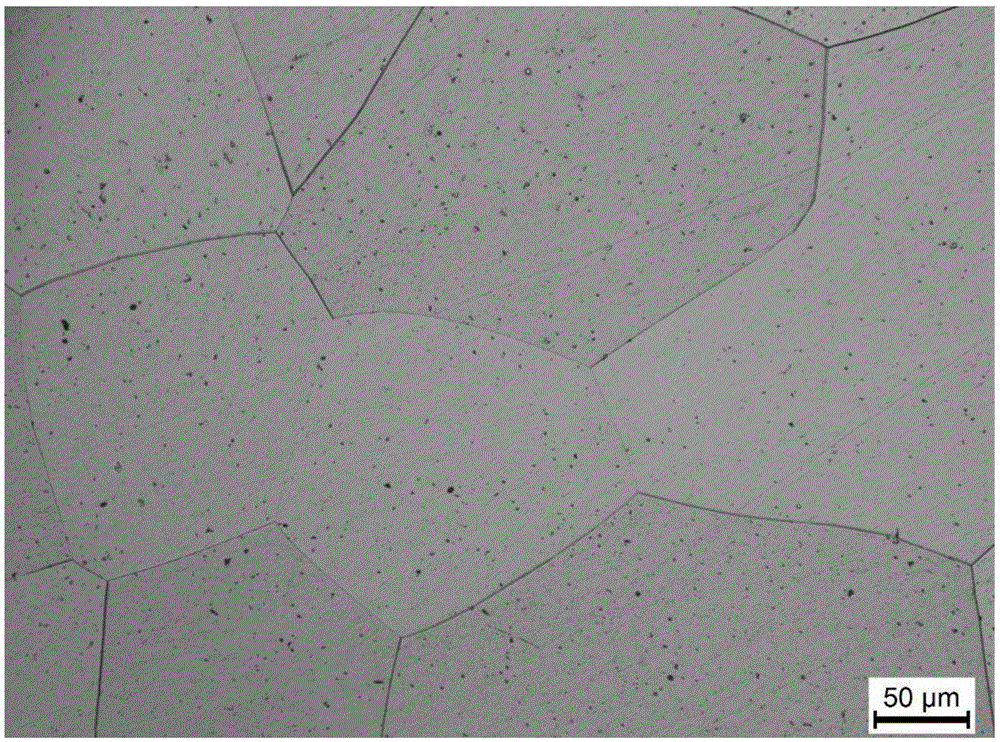

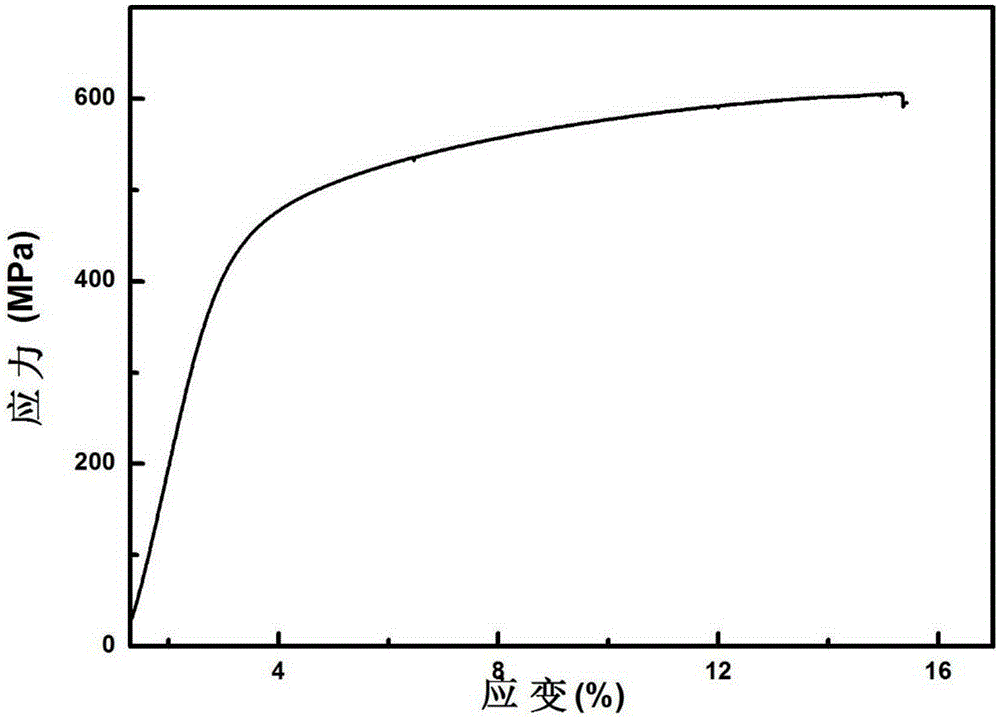

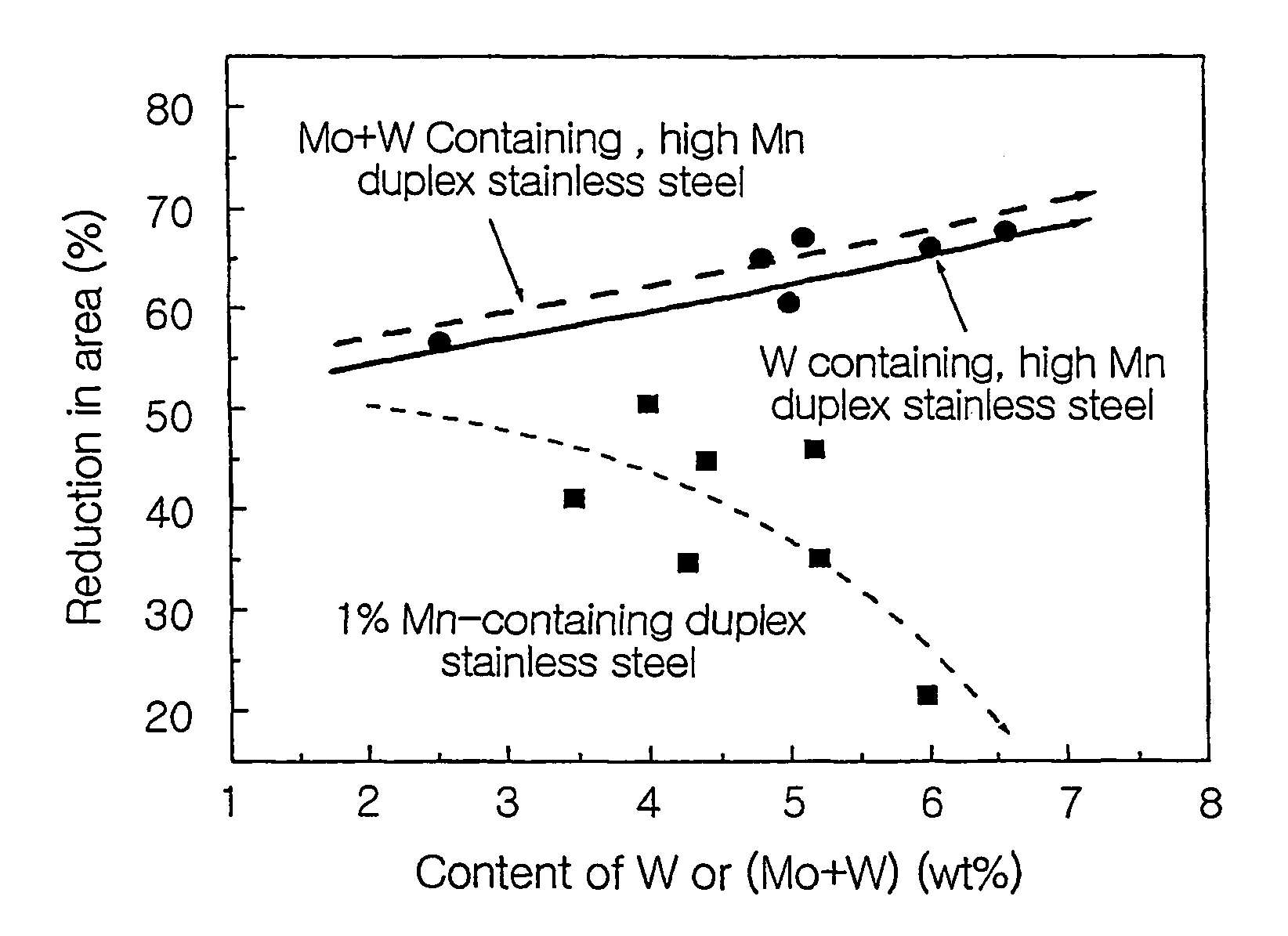

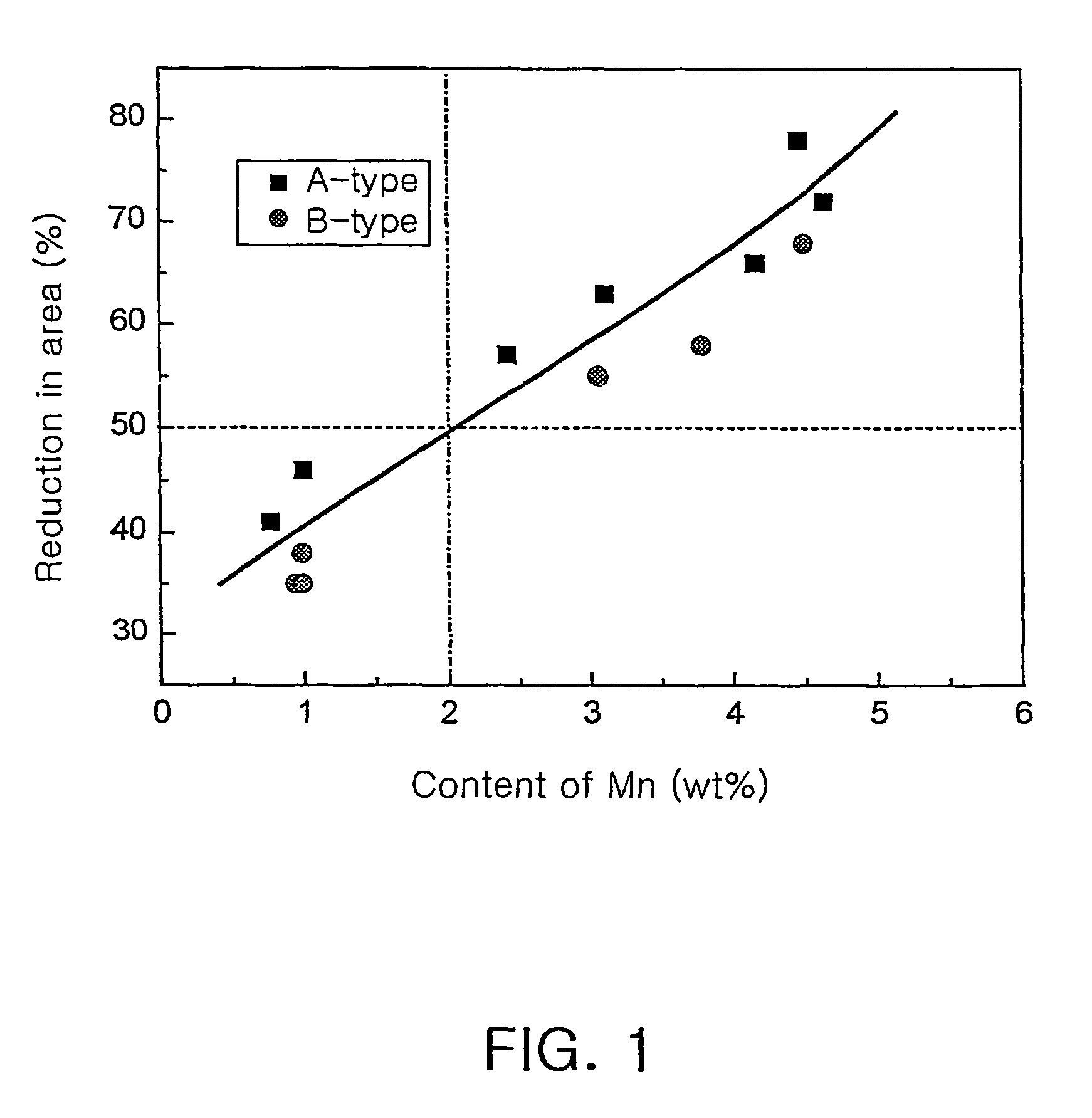

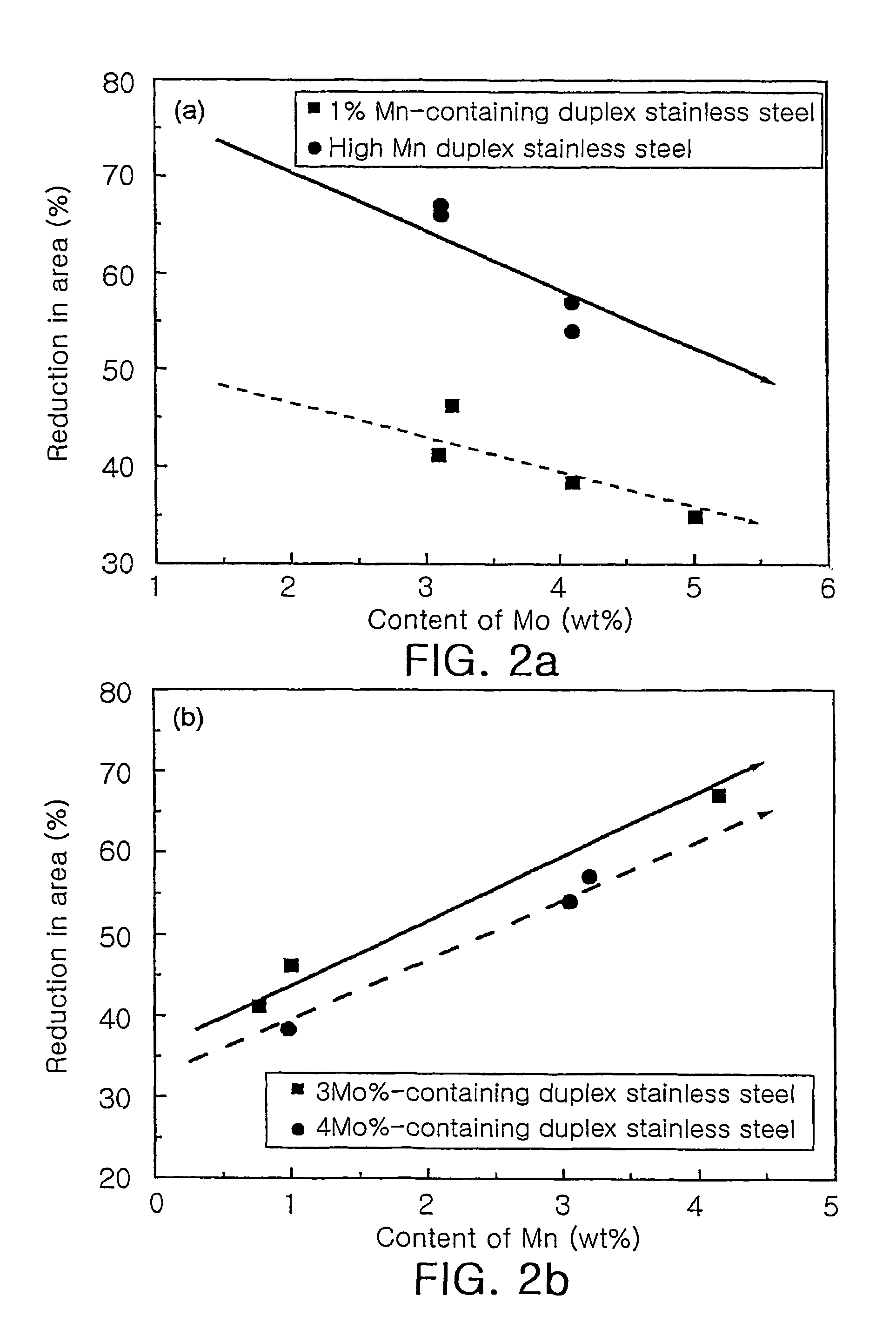

High manganese duplex stainless steel having superior hot workabilities and method for manufacturing thereof

A high manganese duplex stainless steel with excellent hot workability, comprising (in weight %): less than 0.1% of C; 0.05-2.2% of Si; 2.1-7.8% of Mn; 20-29% of Cr; 3.0-9.5% of Ni; 0.08-0.5% of N; less than 5.0% of Mo and 1.2-8% of W, alone or composite; the balance Fe and inevitable impurities; and a method for manufacturing the duplex stainless steel, comprising the steps of: solution heating the duplex stainless steel composition at a temperature of 1,050 to 1,250° C., hot working at a starting temperature of 1,130 to 1,280° C. and then ending at a temperature greater than 1,000° C., and then cooling within the temperature range from 1,000 to 700° C. at a cooling rate of more than 3° C. / min. The duplex stainless steel exhibits a reduction in area of more than 50% at 1,050° C., and possesses a yield strength of more than 400 MPa, and a corrosion rate of less than 0.36 mm / year, after solution heating.

Owner:RES INST OF IND SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com