Steel and steel tube for high- temperature use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

Tests on Experimental Heat

[0121] A 100 kg laboratory heat formed from the steel of the invention was produced under vacuum (F).

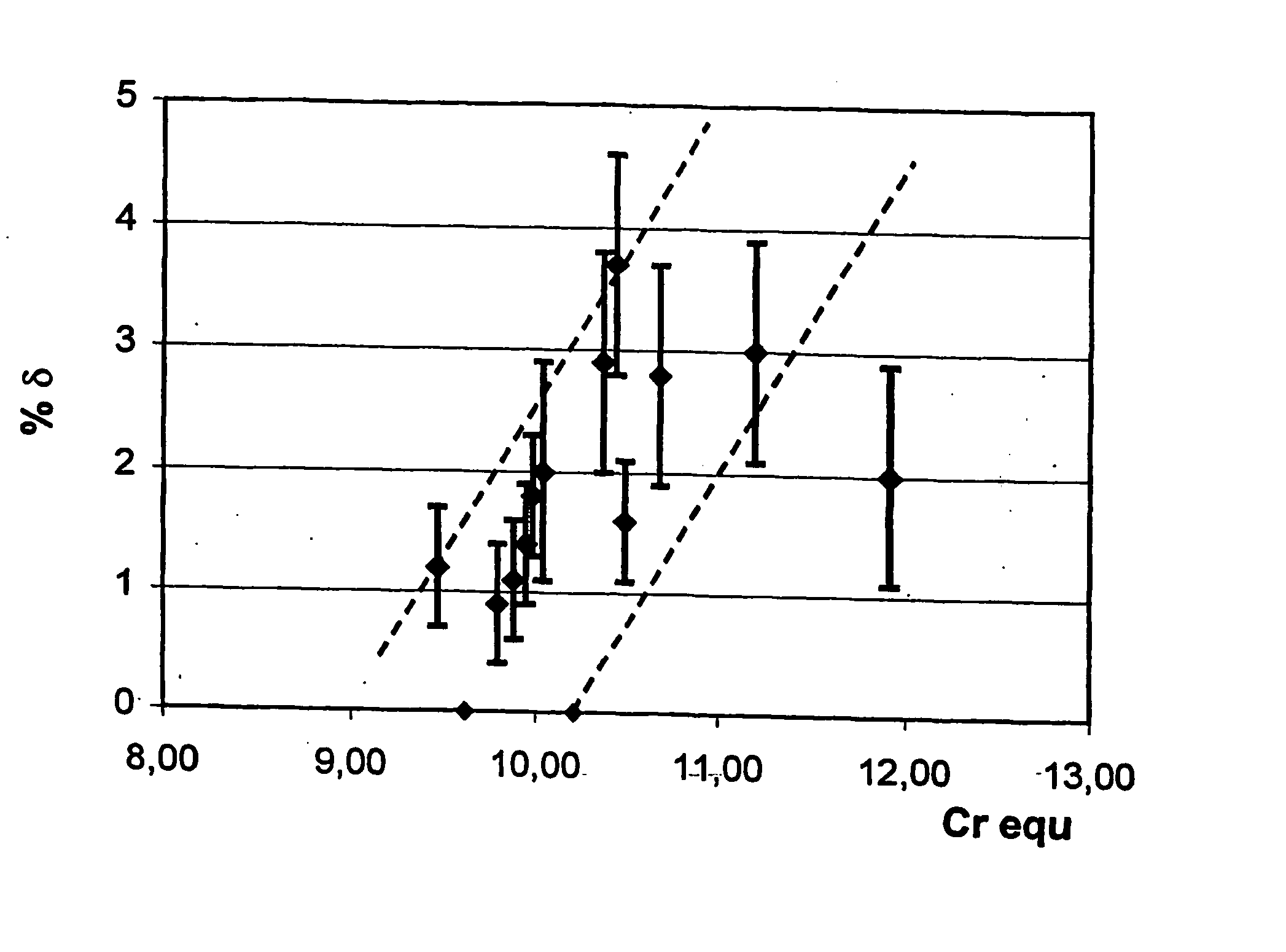

[0122] FIG. 1 shows the relationship between an equivalent chromium parameter (Cr.sub.equ) derived from the chemical composition and the .delta. ferrite content:

Cr.sub.equ=Cr+6Si+4Mo+1.5W+11V+5Nb+8Ti-40C-30N-2Mn-4Ni-2Co-Cu

[0123] The parameter Cr.sub.equ derives from studies by Patriarca et al (Nuclear Technology, 28 (1976), p 516).

[0124] In FIG. 1, we show the .delta. ferrite content measured by image analysis in the optical microscope for a certain number of heats of T91, P91, T92 and X20 as a function of the parameter Cr.sub.equ.

[0125] FIG. 1 provides analytical evidence that the amounts of elements in heat F lie within the ranges given in the chemical composition defined in claim 1. We aimed to obtain a Cr.sub.equ content of 10.5% or less and if possible 10.0% or less to seek to remain substantially free of .delta. ferrite (less than 2% and preferably les...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com