Patents

Literature

37results about How to "Restrict form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

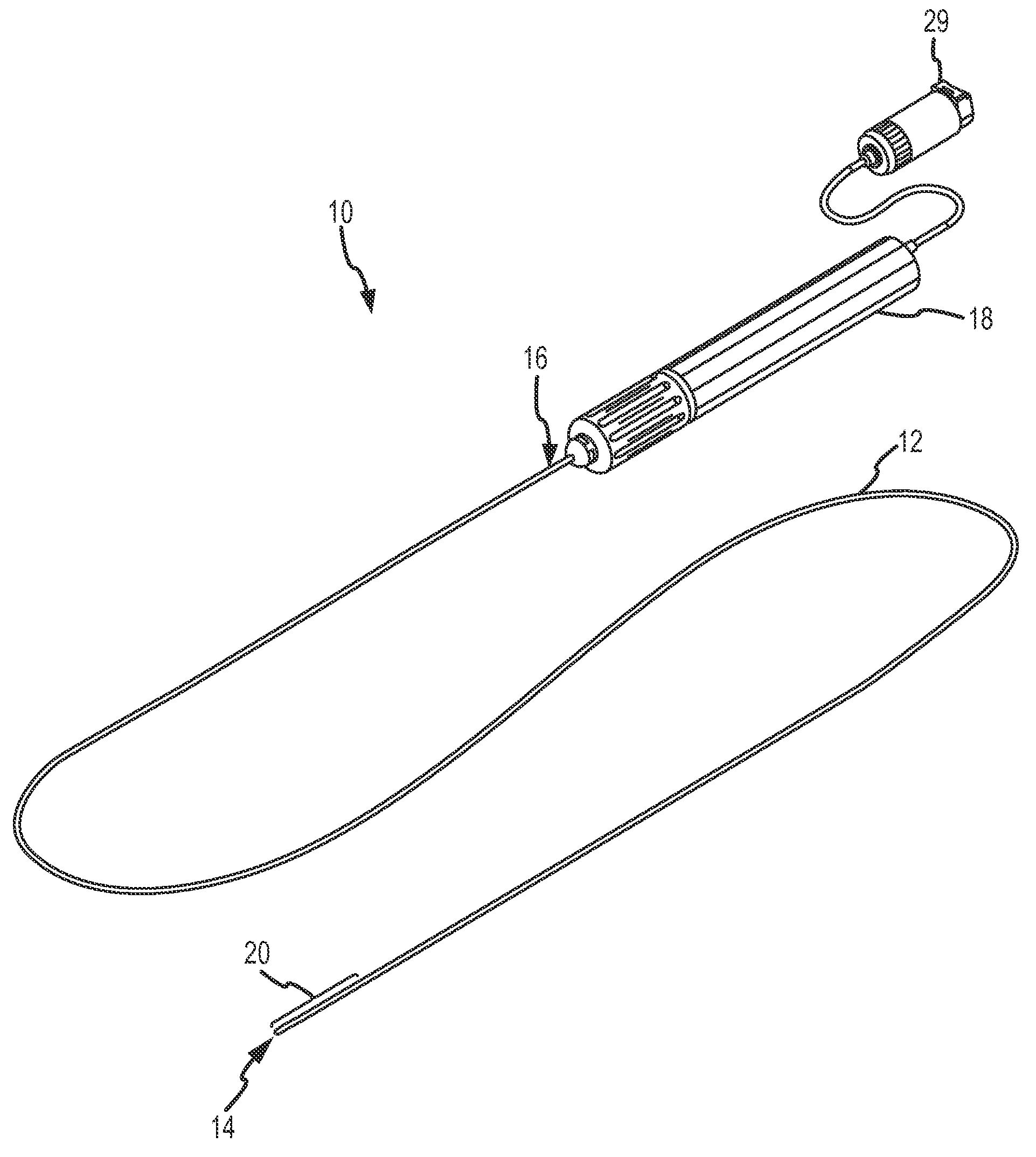

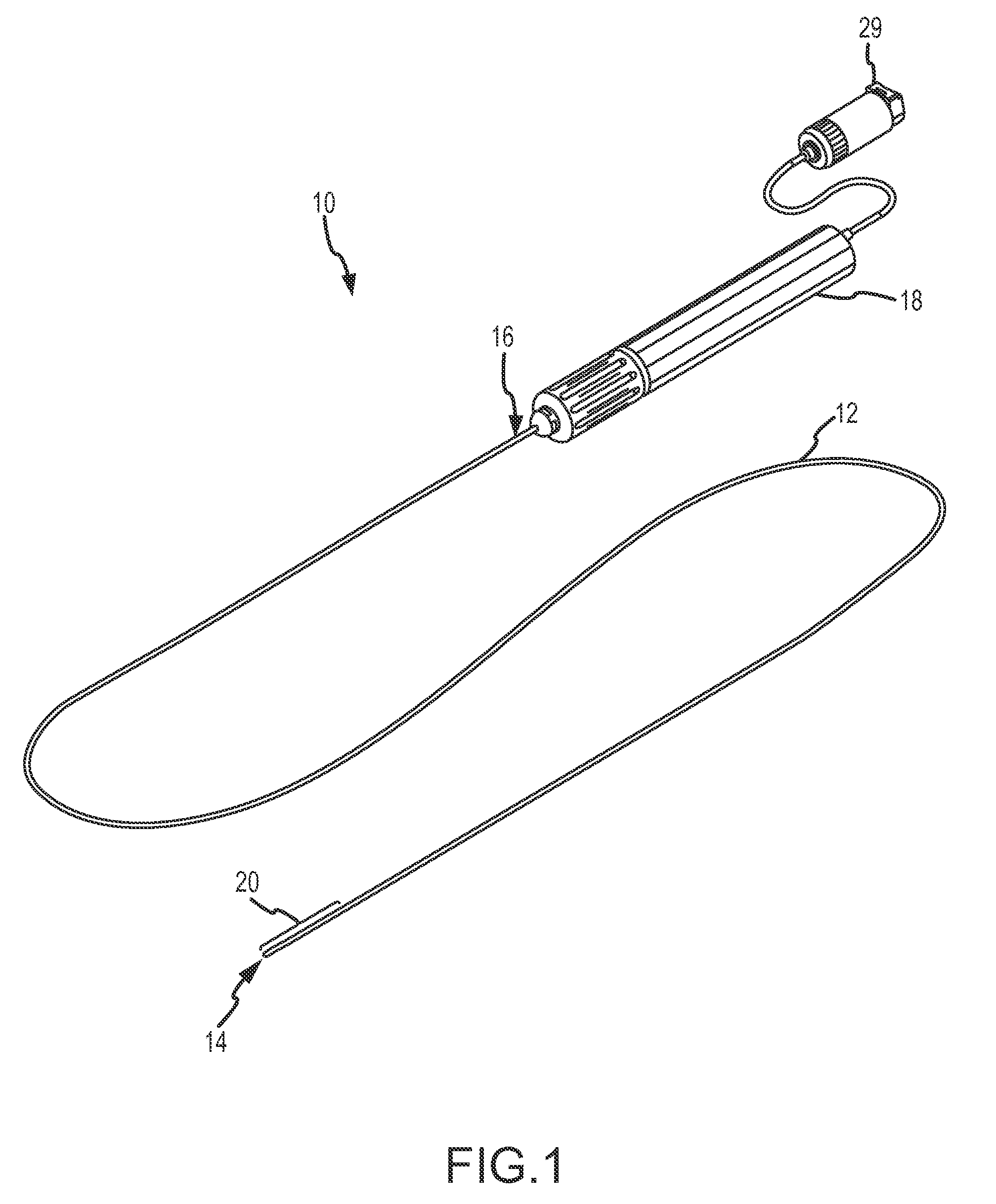

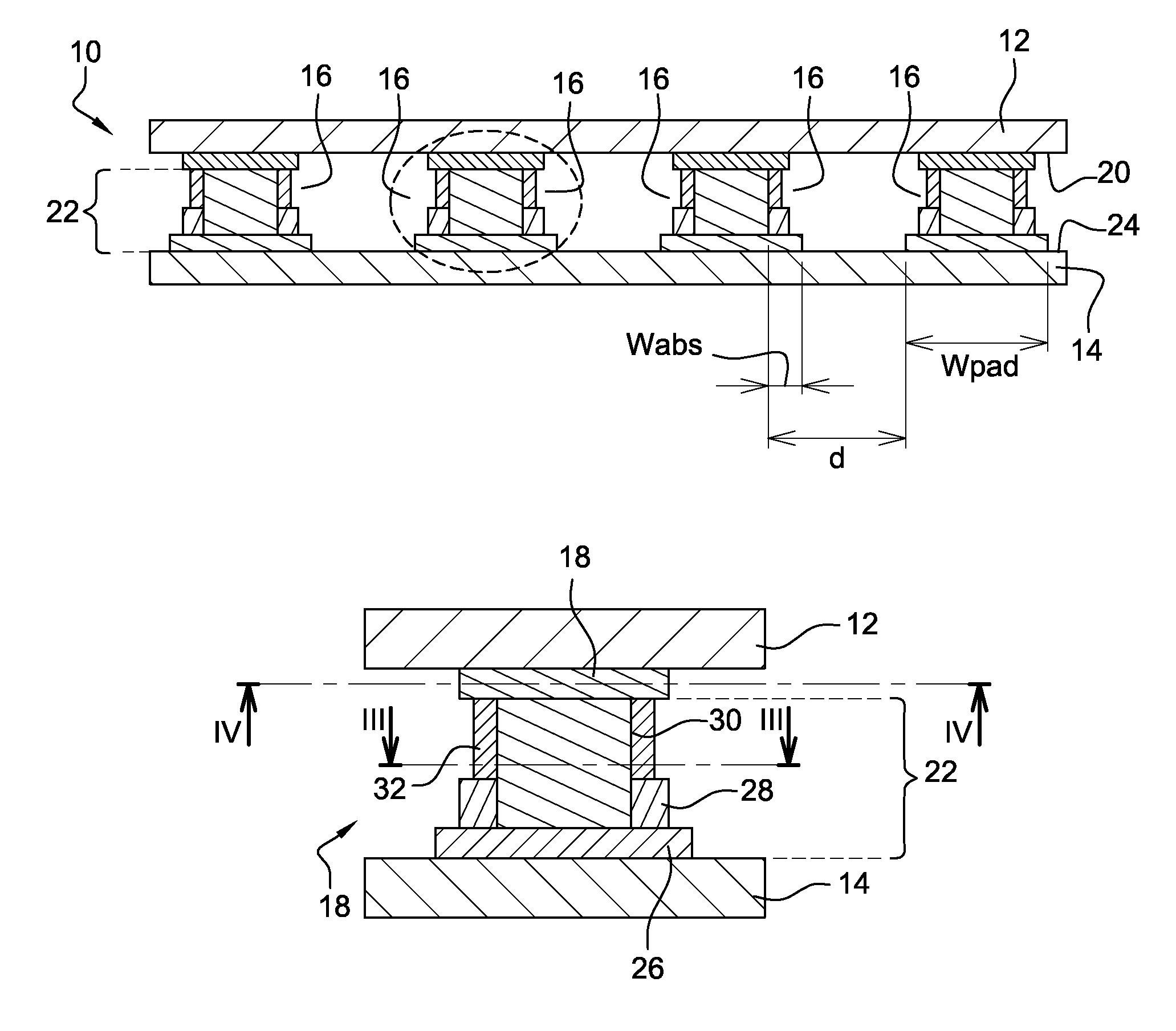

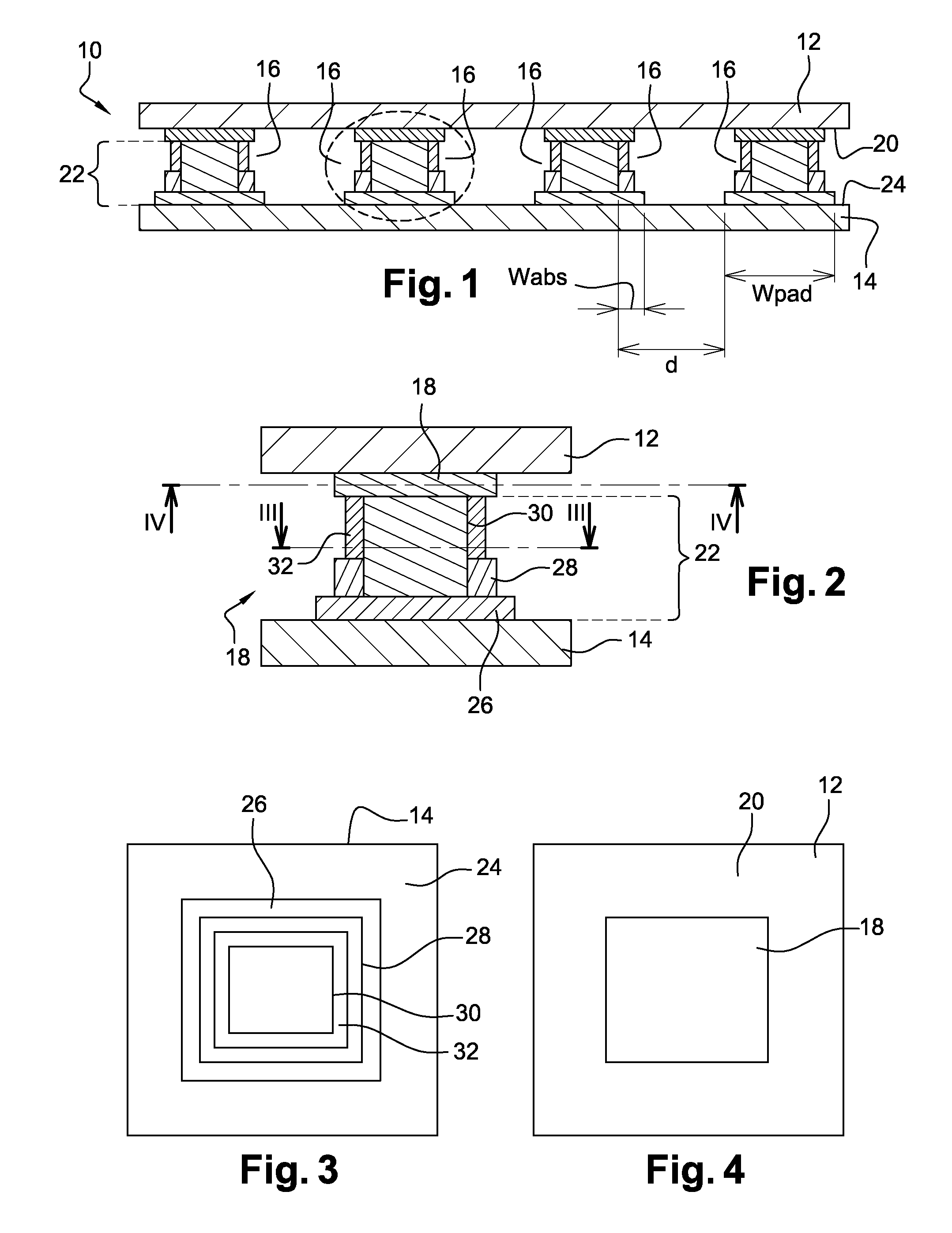

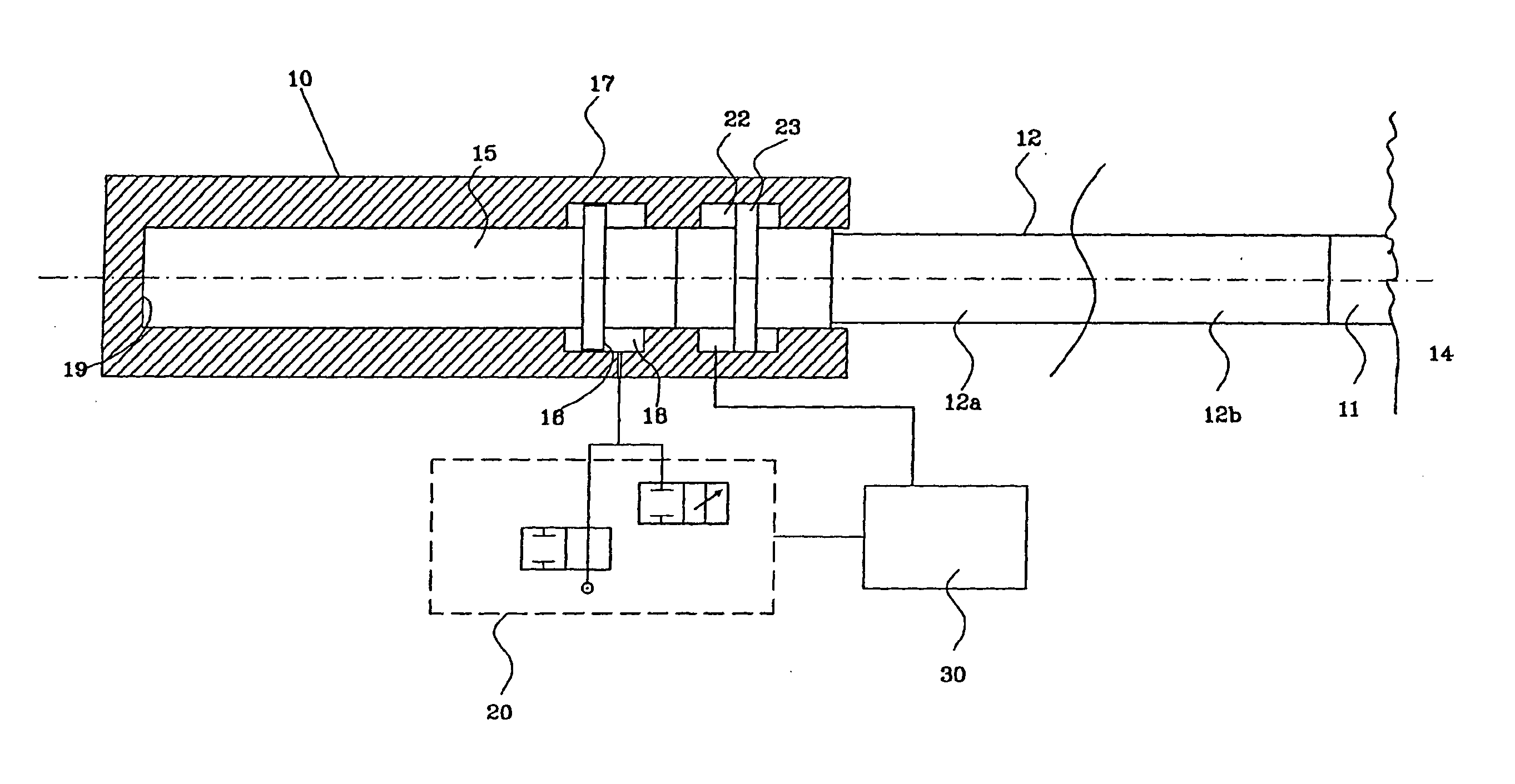

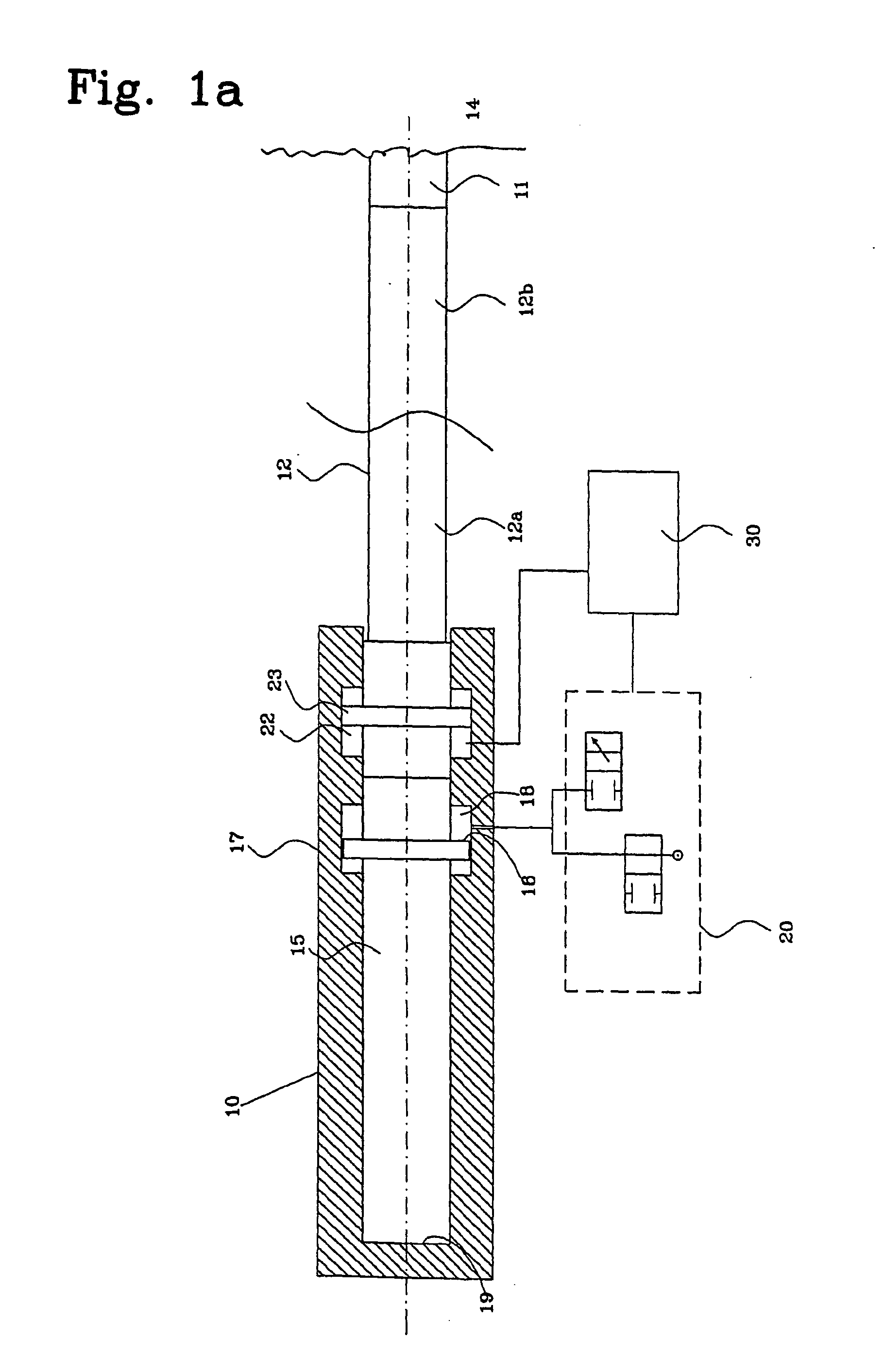

Apparatus and Methods for Acoustic Monitoring of Ablation Procedures

InactiveUS20100168572A1Easy to collectFacilitates presentationUltrasonic/sonic/infrasonic diagnosticsAuscultation instrumentsContact forceInterface position

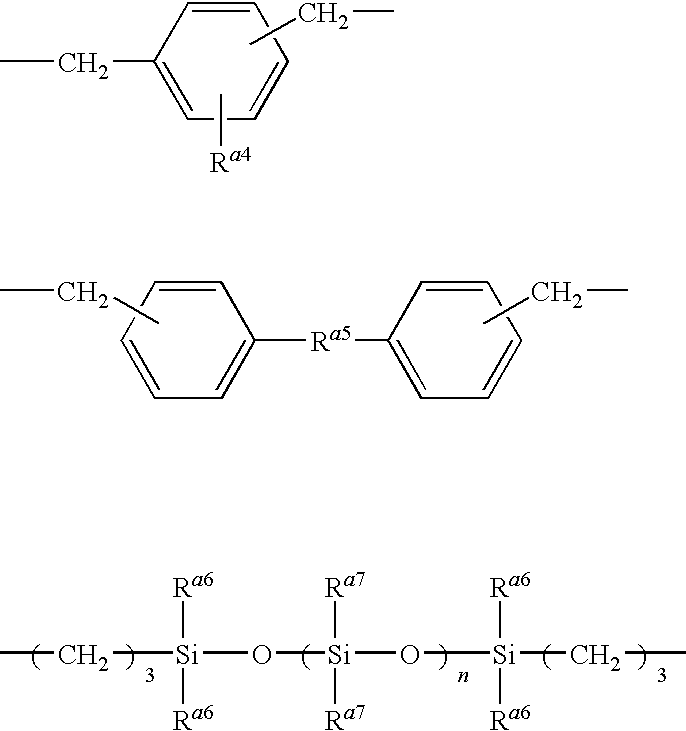

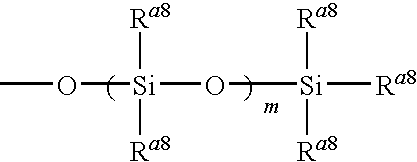

A system for ablating tissue includes a catheter having an elongate body, with at least one ablation element (e.g., RF electrode) and at least one acoustic transducer located within the body's tip region. The transducer receives acoustic signals from proximate the tip region. The system also includes a monitoring unit coupled to the transducer to interpret the received acoustic signals as data regarding at least one therapeutic parameter (e.g., pre-pop detection, lesion making progress, tissue interface detection, tissue contact force, tissue contact establishment, bubble spatial distribution, bubble depth, bubble size, bubble size distribution, tissue interface distance, tissue interface position, tissue attenuation, tissue thickness, lesion spectral fingerprint). The monitoring unit is operable to provide feedback to a practitioner, such as graphical, audible, and / or haptic output of sensed data, and may also be operable to control operation of the at least one ablation element in response thereto.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

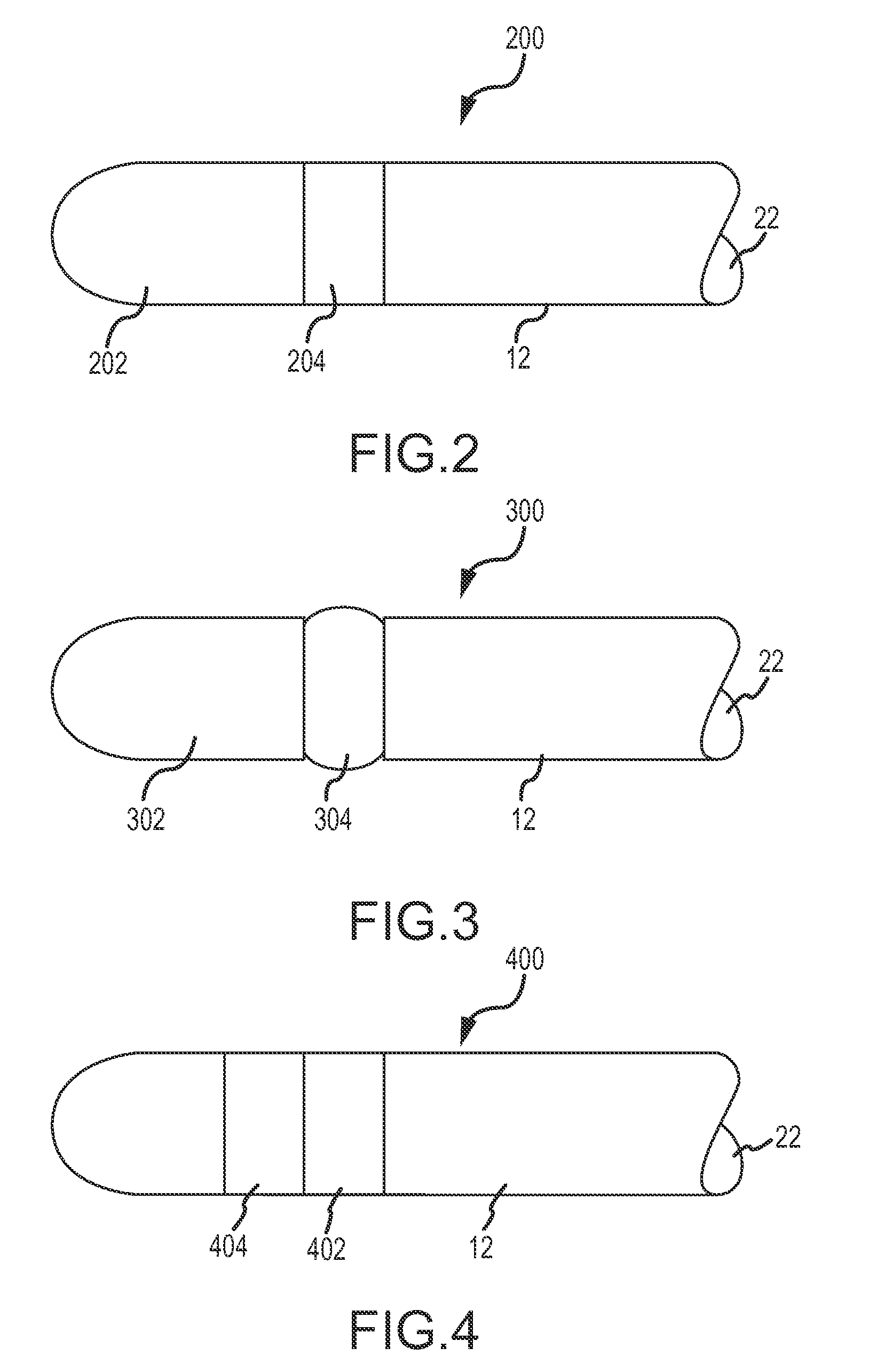

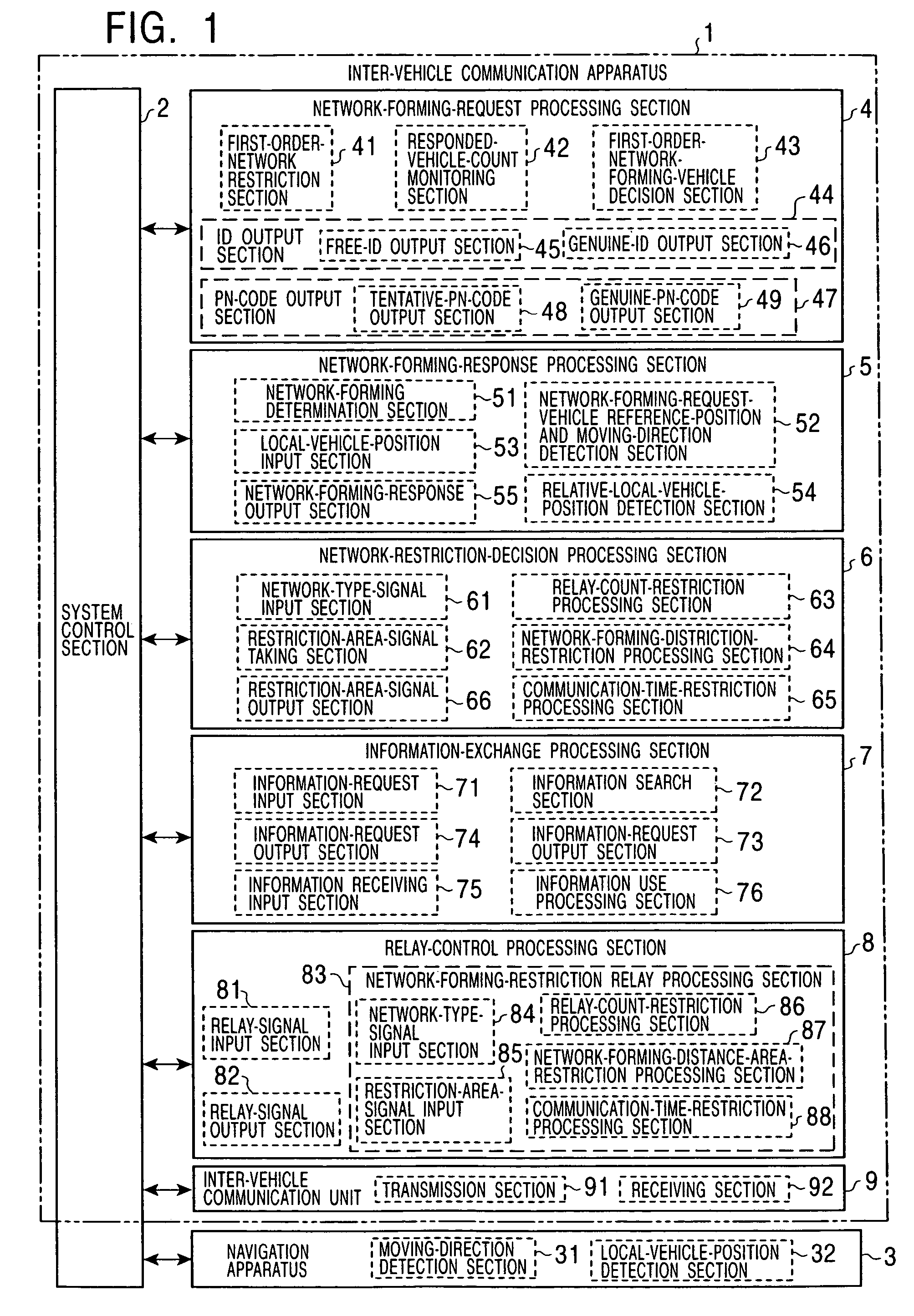

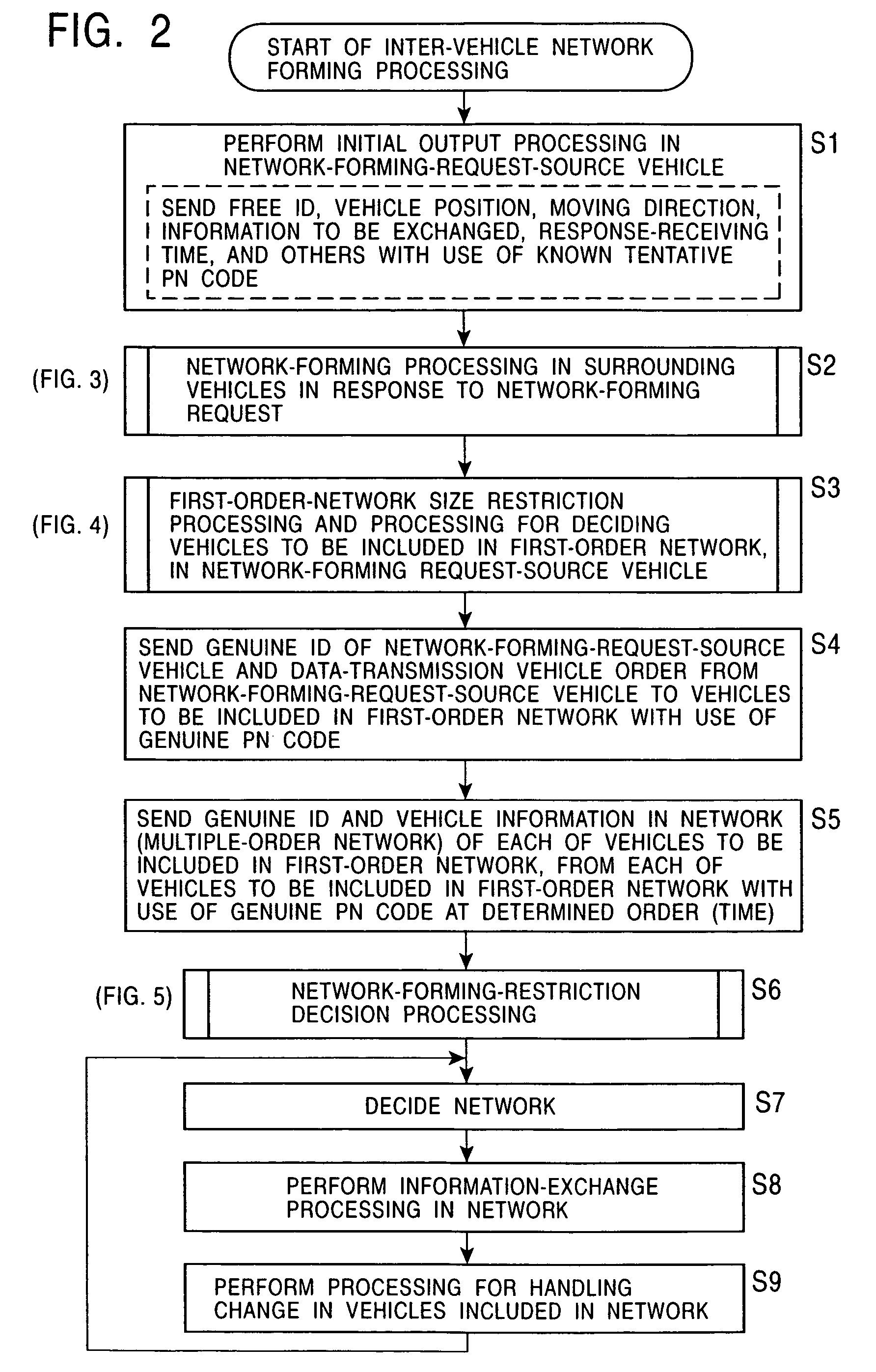

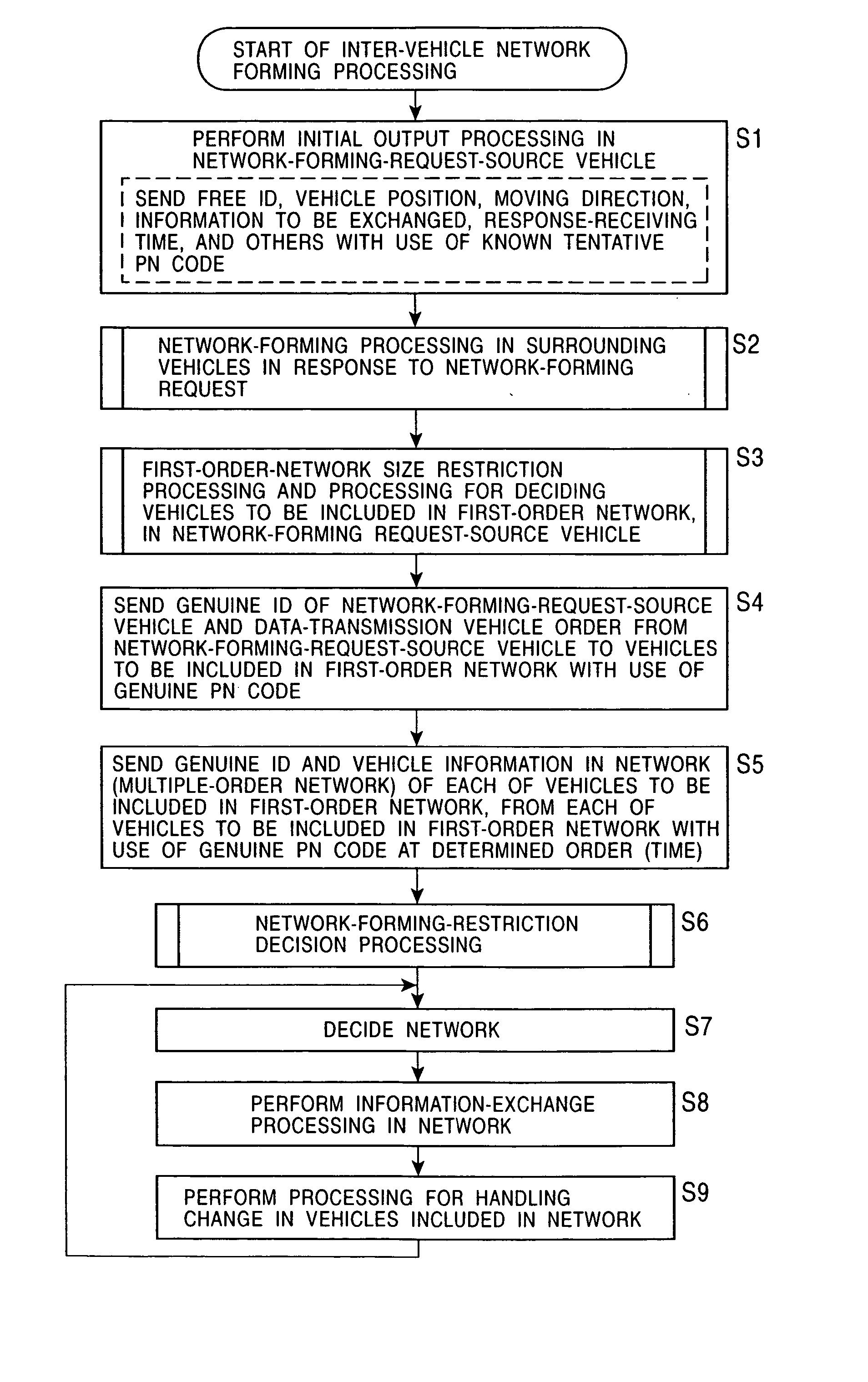

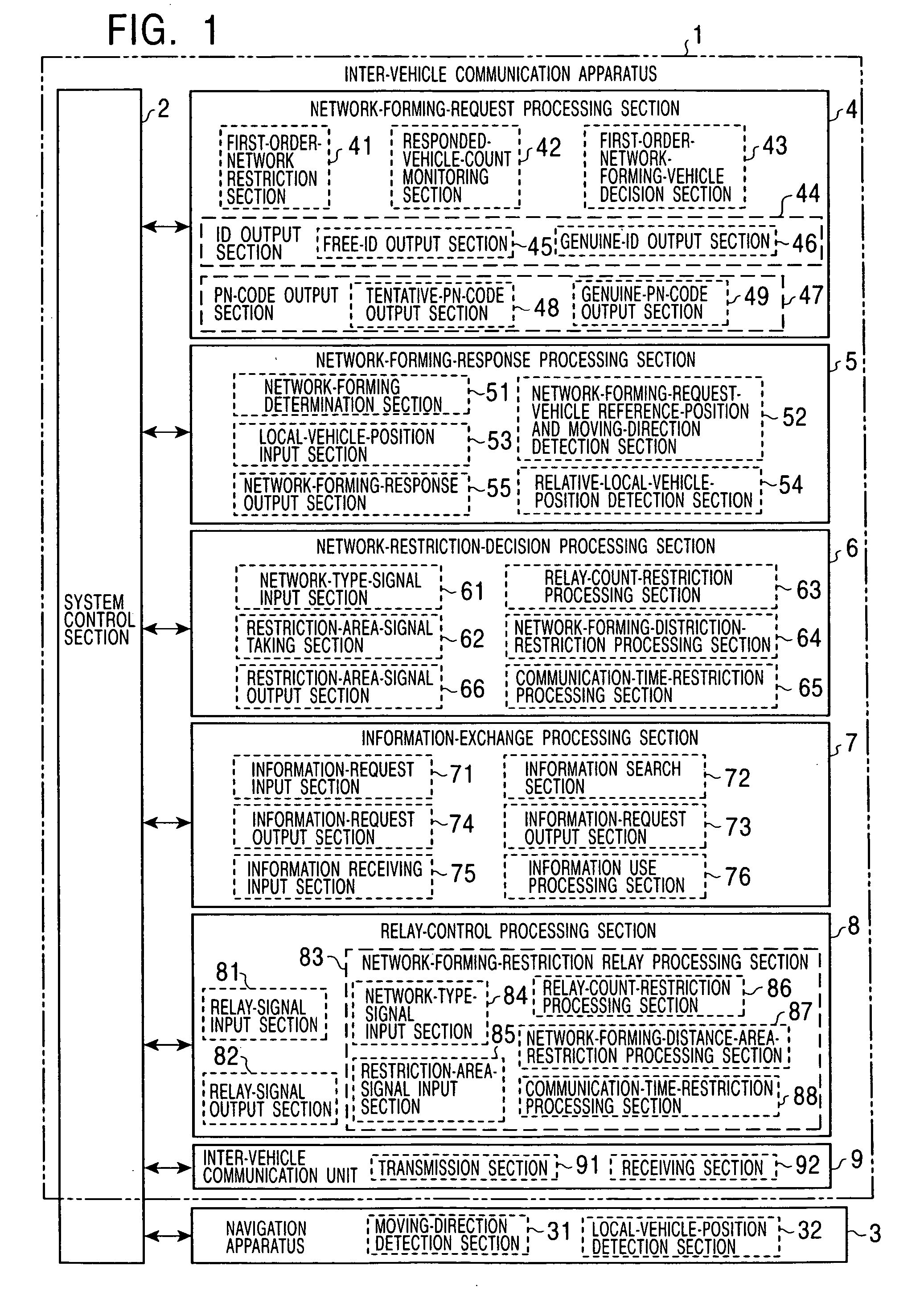

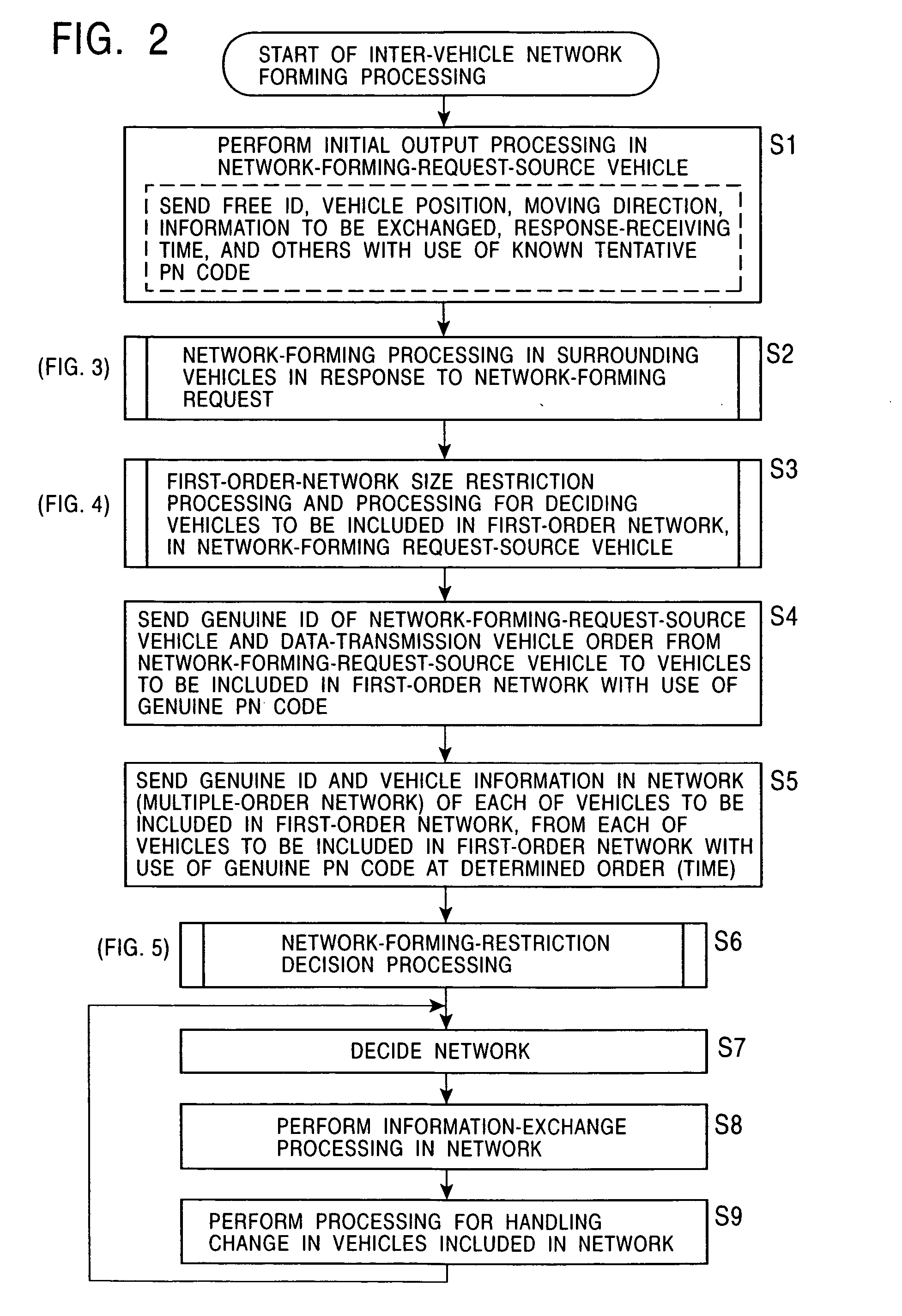

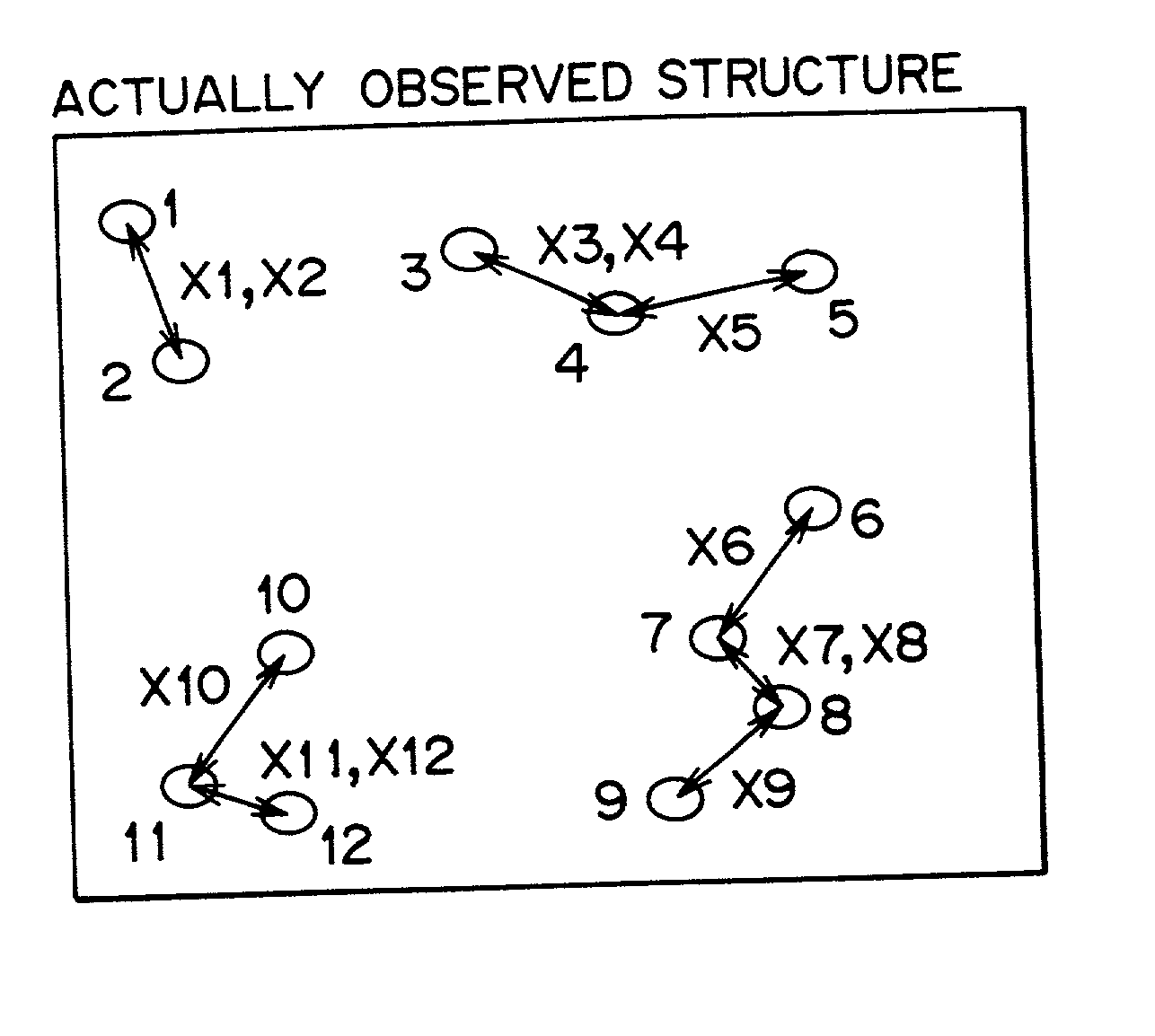

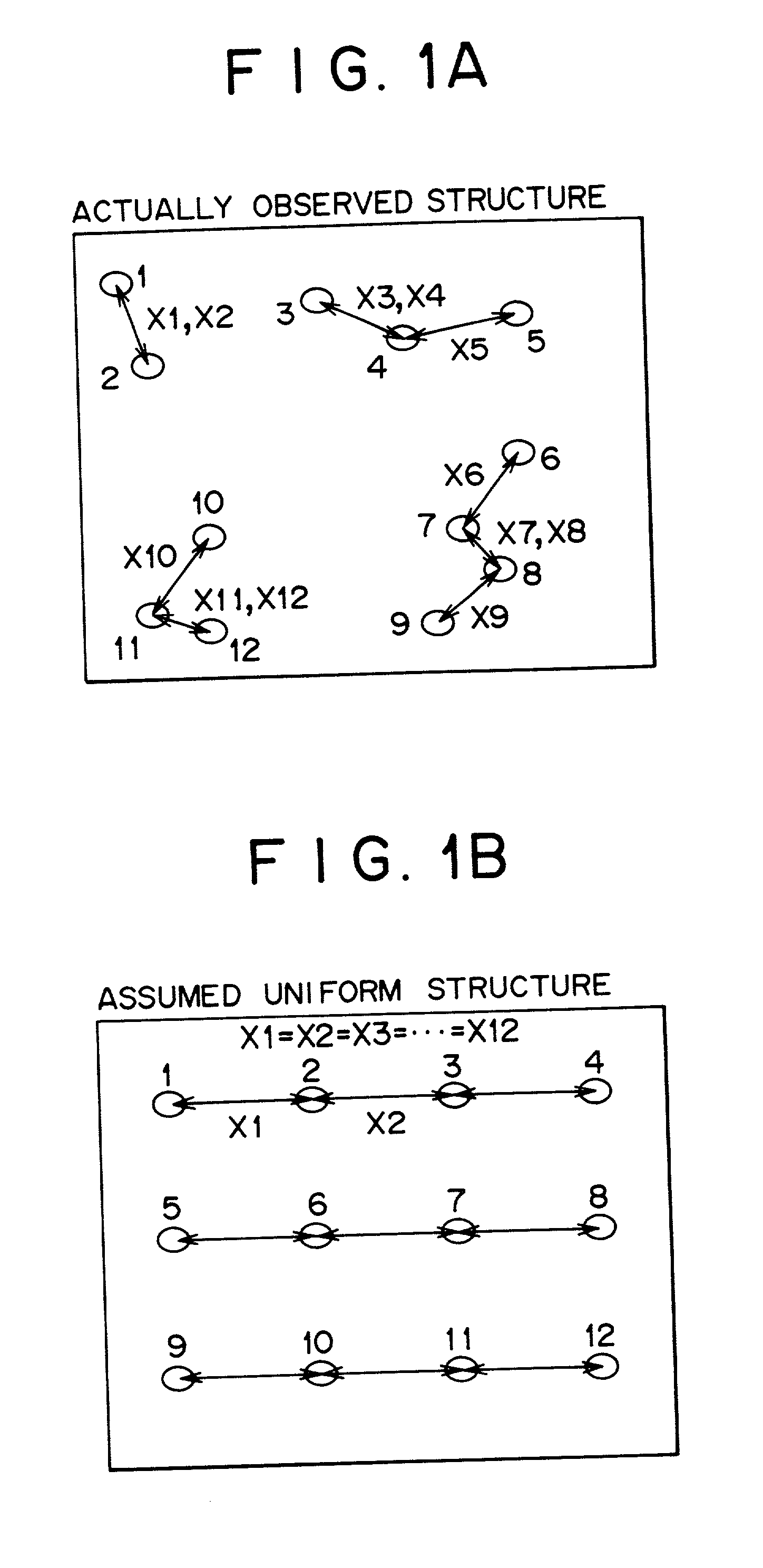

Inter-vehicle communication apparatus and method with restrictions on size of network

InactiveUS7272357B2Avoid interferenceRestrict formArrangements for variable traffic instructionsAssess restrictionArea networkInter vehicle communication

Owner:ALPINE ELECTRONICS INC

Inter-vehicle communication apparatus

InactiveUS20050003844A1Easily apply appropriate restrictionPrevent PN codeArrangements for variable traffic instructionsAssess restrictionArea networkTrunking

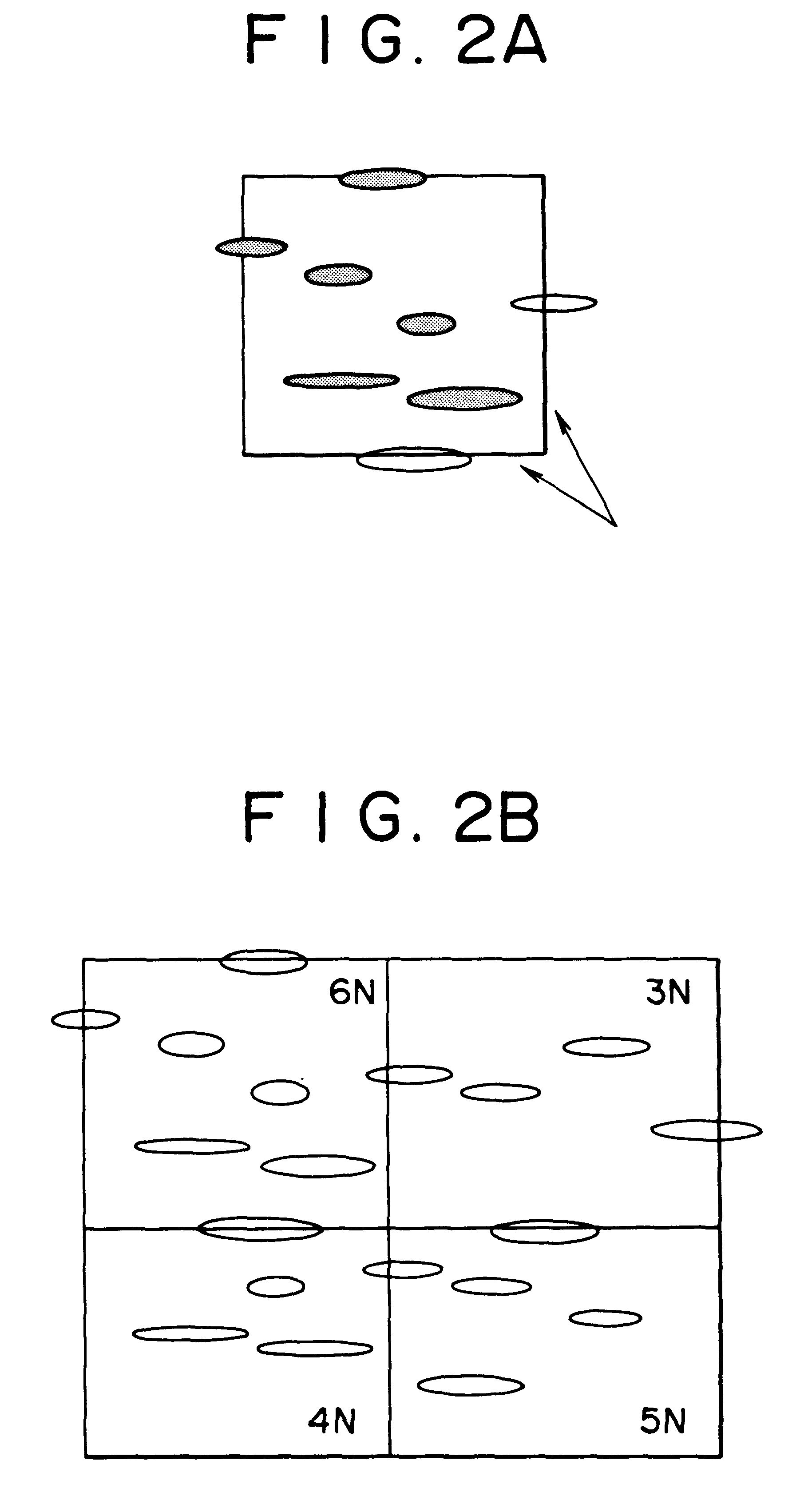

When a network is formed among vehicles with the use of inter-vehicle communication units, a network-forming-request-source vehicle sends its position serving as a reference position, its moving direction, and requested information to surrounding vehicles by the use of a free ID. Among the surrounding vehicles, vehicles which are to subscribe to the network receive the position, the moving direction, and the requested information, determine where the vehicles are positioned among positions specified in advance relative to the reference position, and respond at a timing corresponding to their positions by the use of free IDs. The network-forming-request-source vehicle receives the responses, stops receiving responses when the number of responded vehicles reaches an appropriate number of vehicles, and sends its genuine ID and a vehicle communication order. Then, a restriction, such as a restriction based on the number of times relay processes are allowed, a restriction based on a predetermined-distance area from the center of balance or the center, or a restriction based on a communication period equal to a predetermined time or shorter from when the network is formed, all of which correspond to the type of network, is applied to form an appropriate-area network.

Owner:ALPINE ELECTRONICS INC

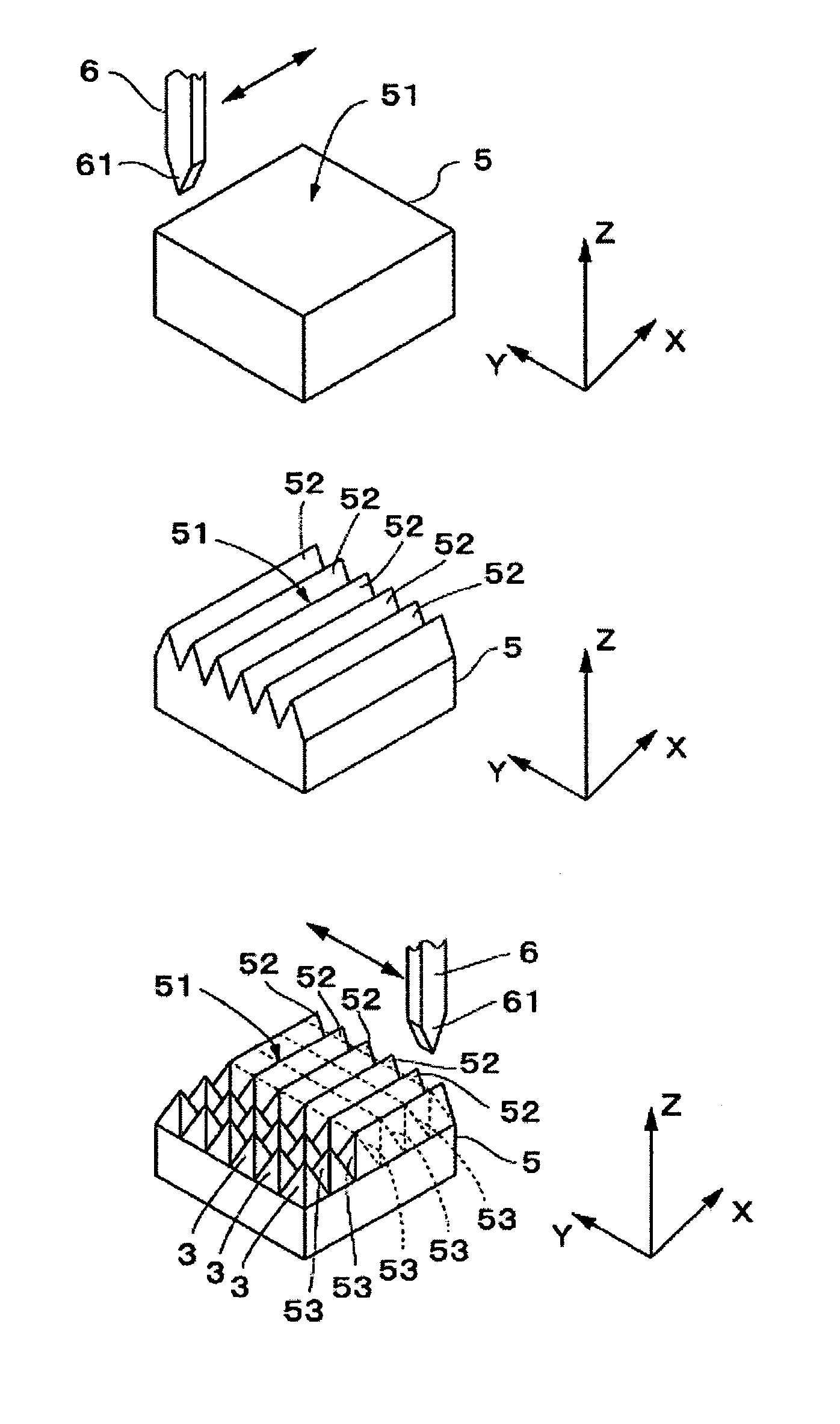

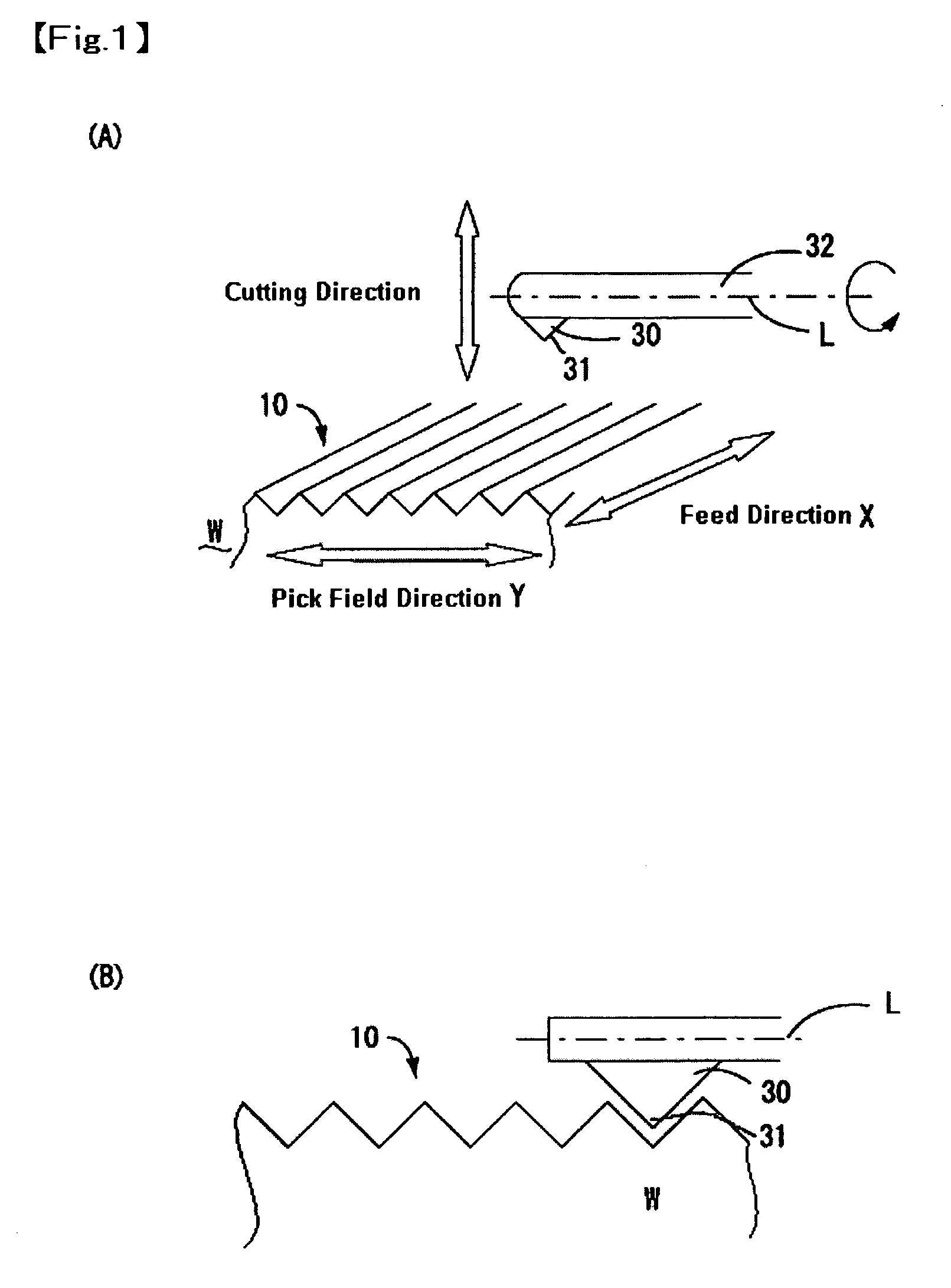

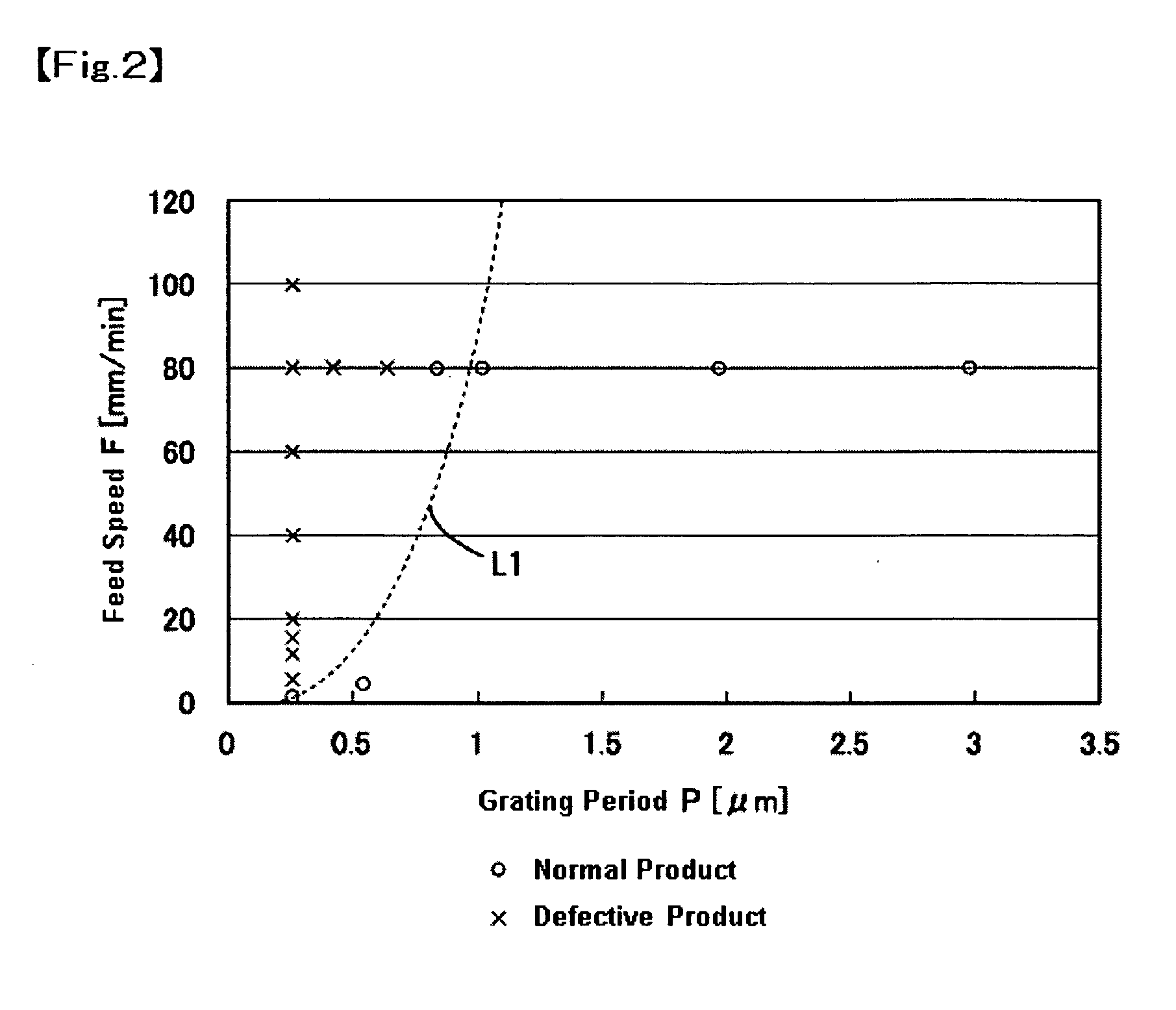

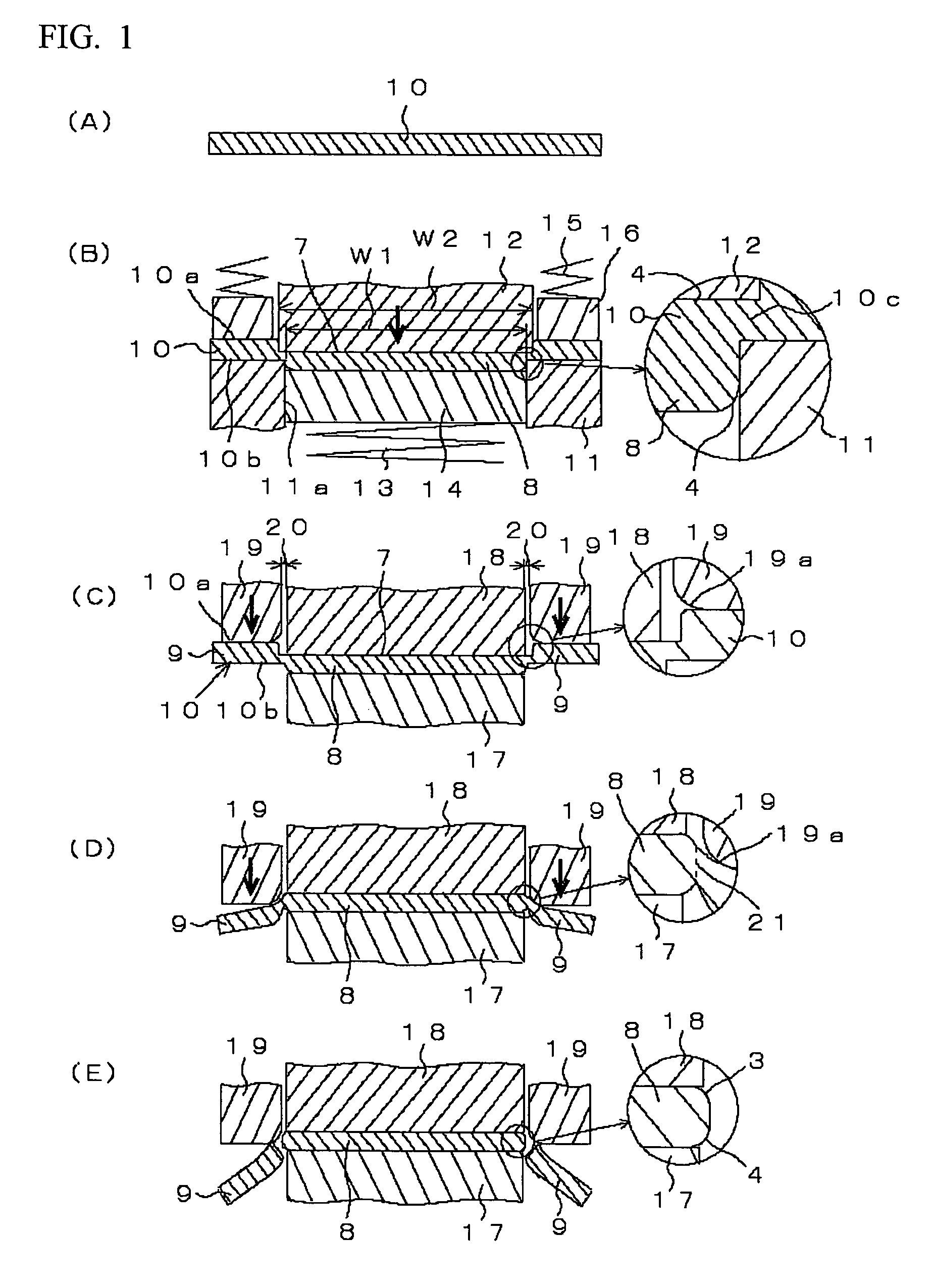

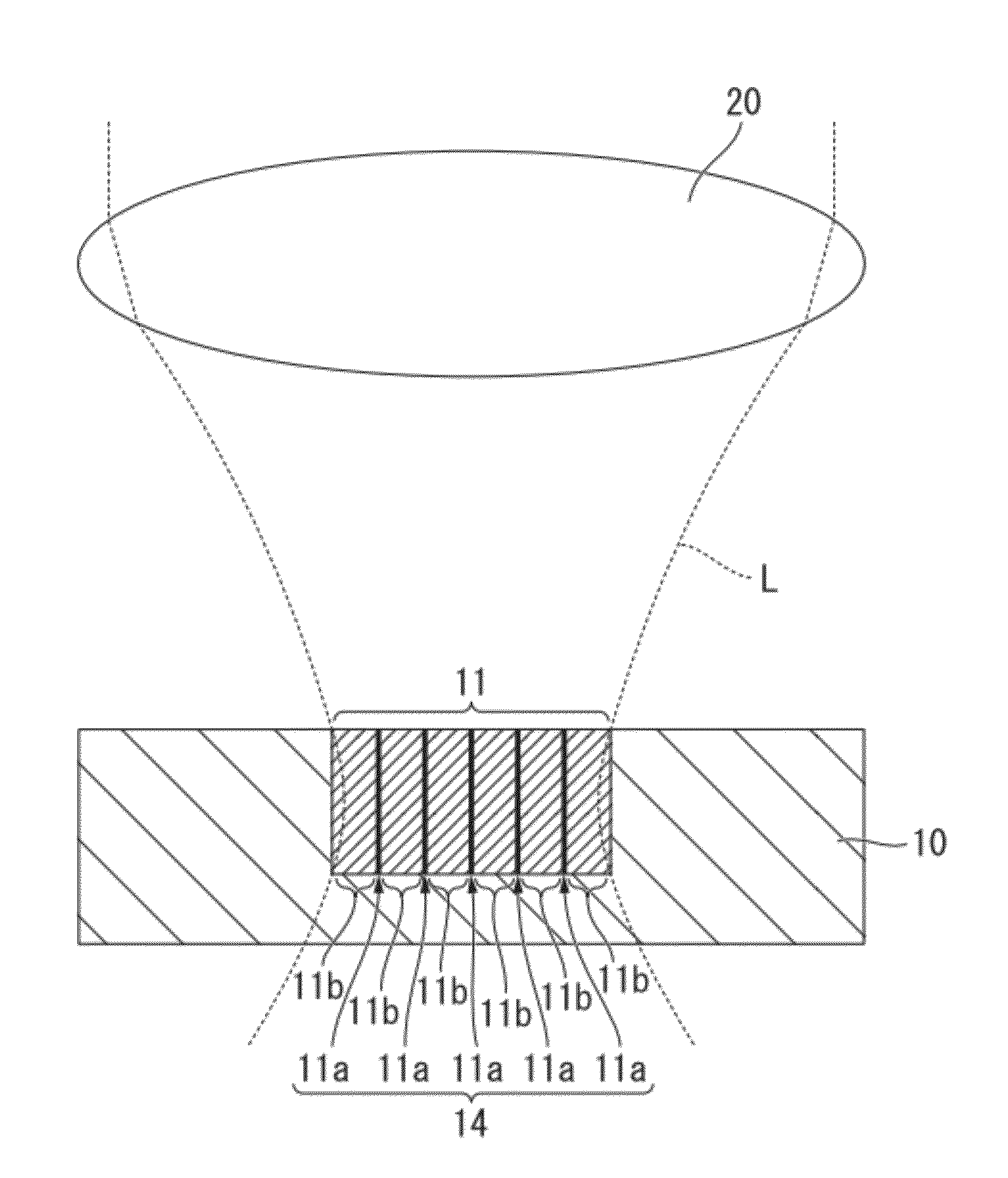

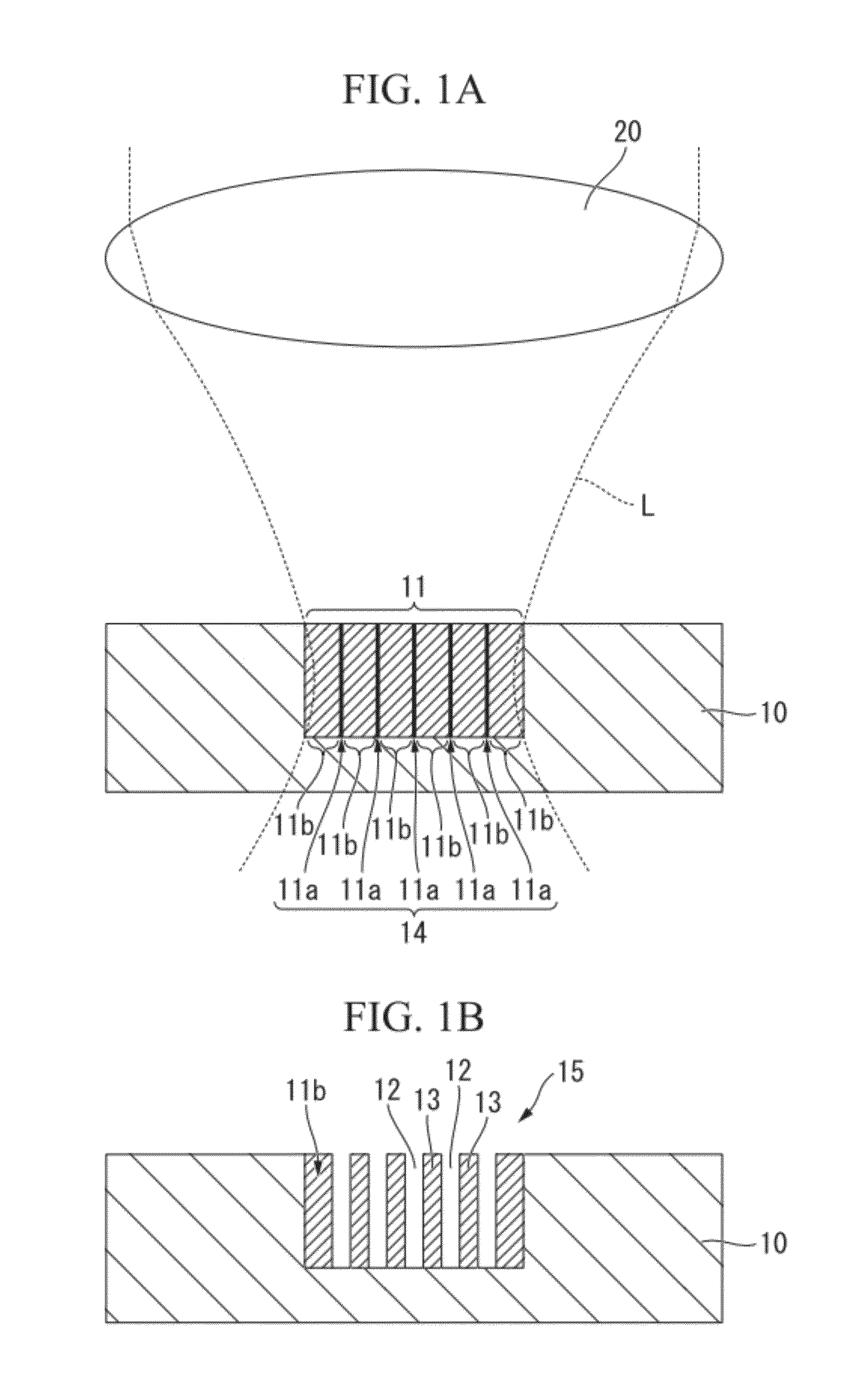

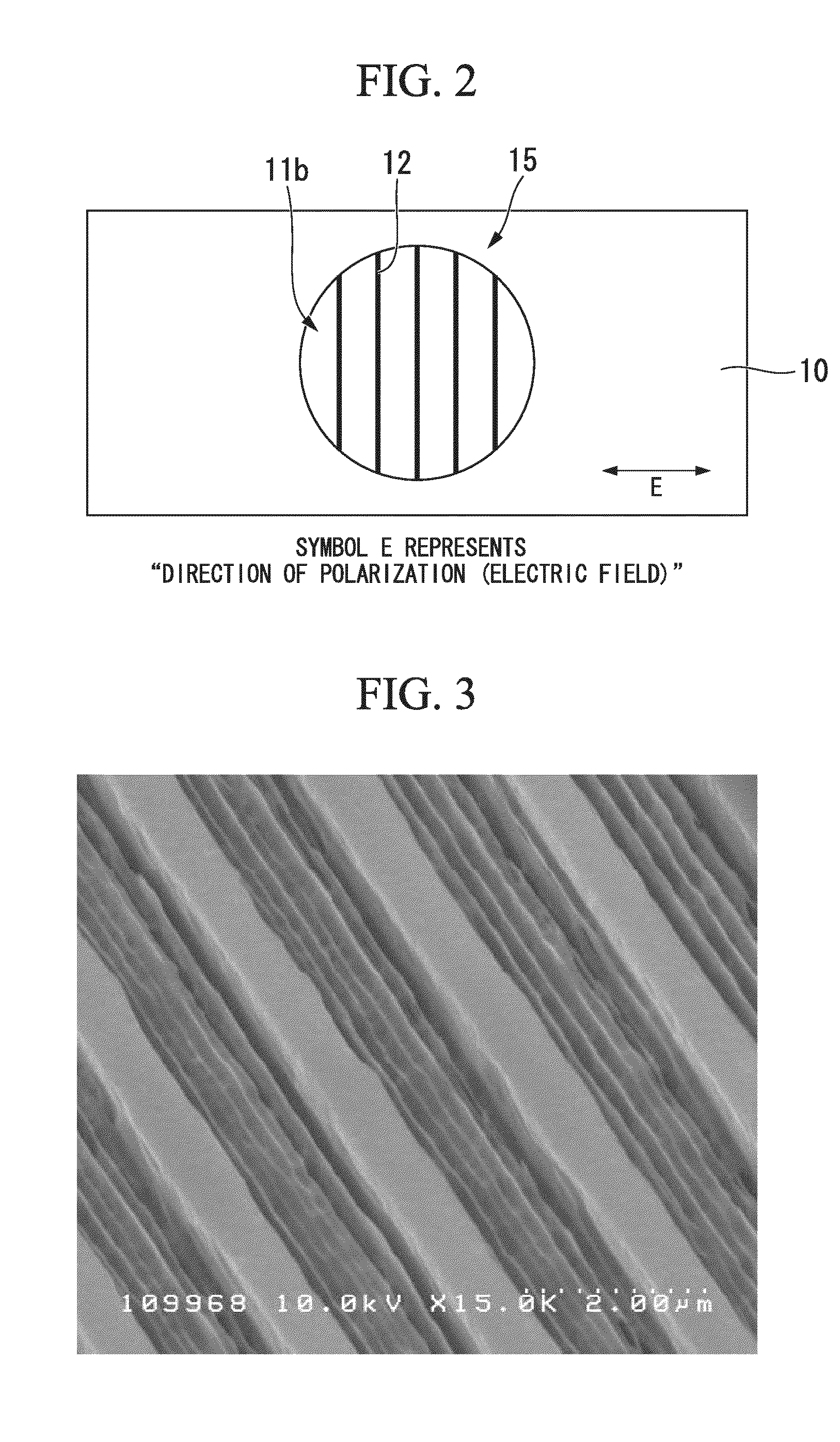

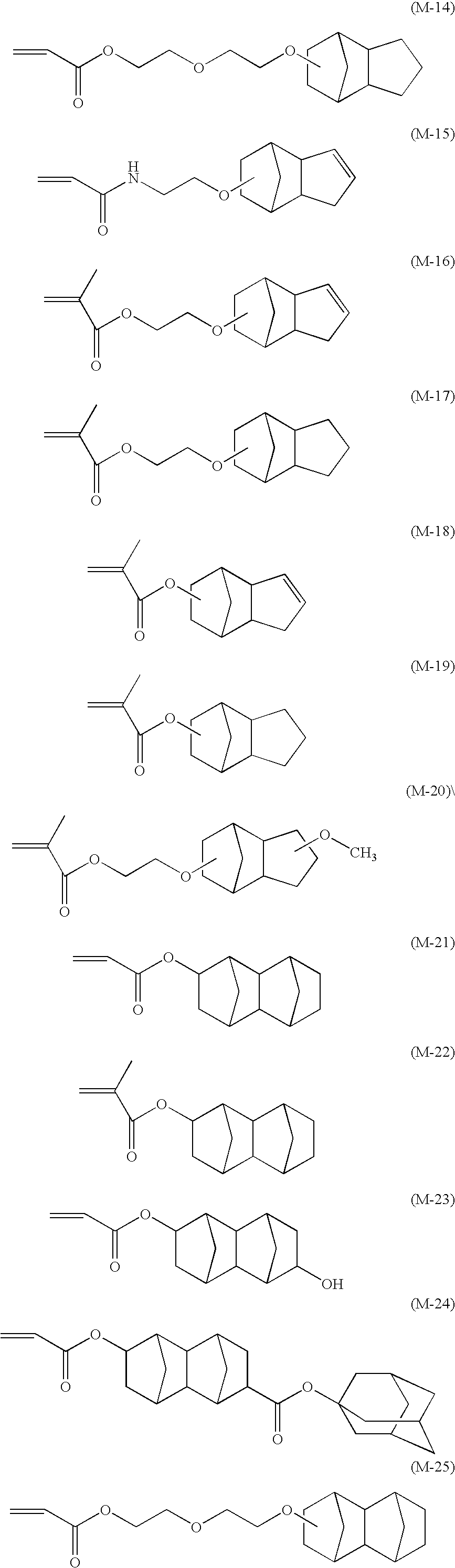

Grating forming method, molding die, molded product and manufacturing method for master member for manufacturing molding die

InactiveUS20050025423A1Reducing roughness and swellingRestrict formDiffraction gratingsCoupling light guidesDiamond cuttingVibration amplitude

A grating forming method for forming a fine grating with a grating period of 1 μm or less on a surface of a blank material including cutting the surface of the blank material with a blade tip part of a diamond cutting tool. When the fine grating with the grating period of “P”μm is formed and the feed speed of the diamond cutting tool is set to be “F” mm / min, the feed speed “F” is set to satisfy the conditional expression: F<1 0 0 P3. The vibration amplitude of the diamond cutting tool in a perpendicular direction to the surface of the blank material is set to be “A”μm, the vibration amplitude “A” is set to satisfy the following conditional expression: A<0. 0 1 8 P2. The feed amount per revolution of the diamond cutting tool is set to be “S”μm, the feed amount per revolution “S” is set to satisfy the following conditional expression: S<2. 9 P3. These conditional expressions are applied to a blank material, a molding die, a molded product, and a master member for manufacturing a molding die.

Owner:SANKYO SEIKI MFG CO LTD

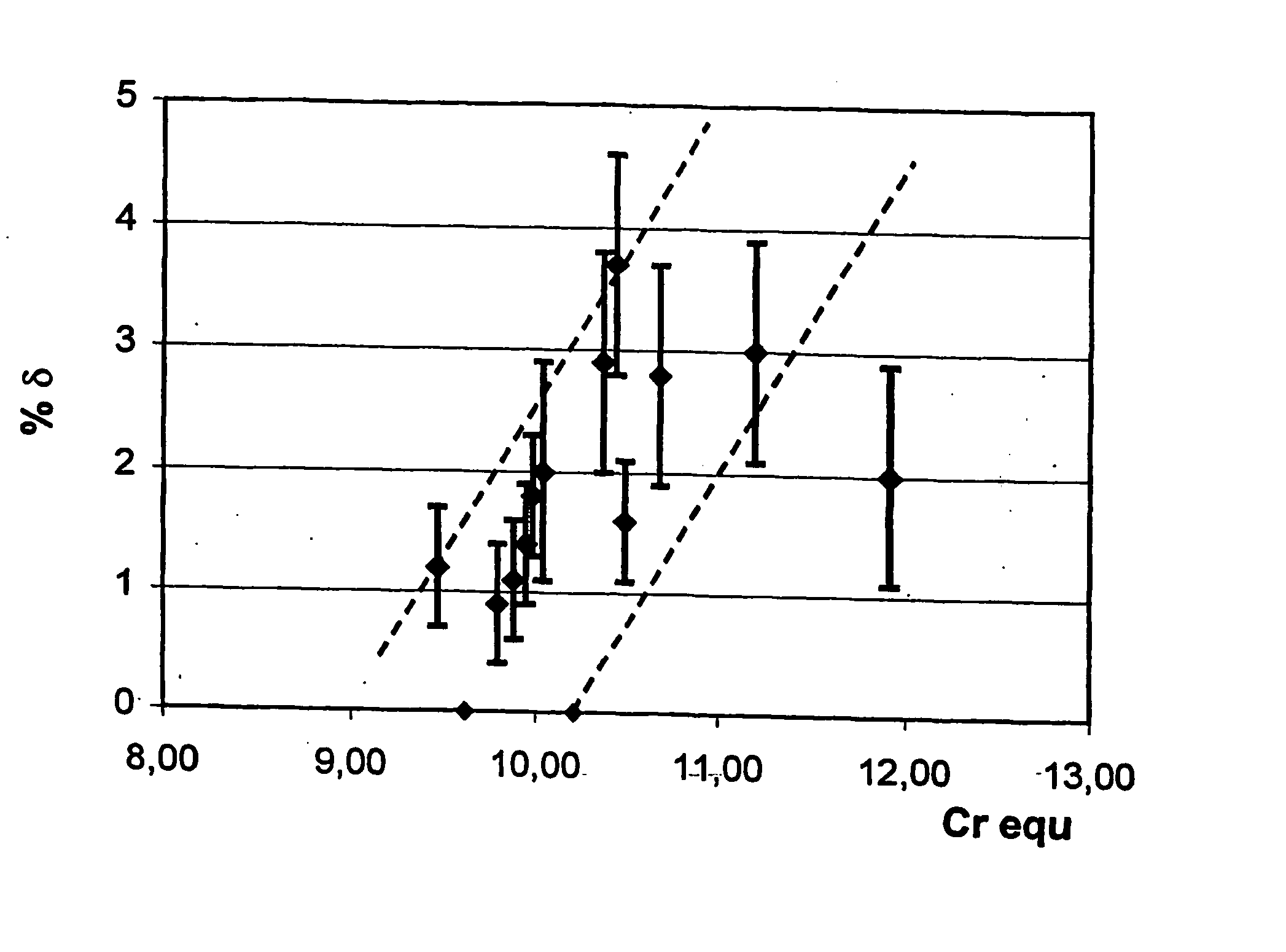

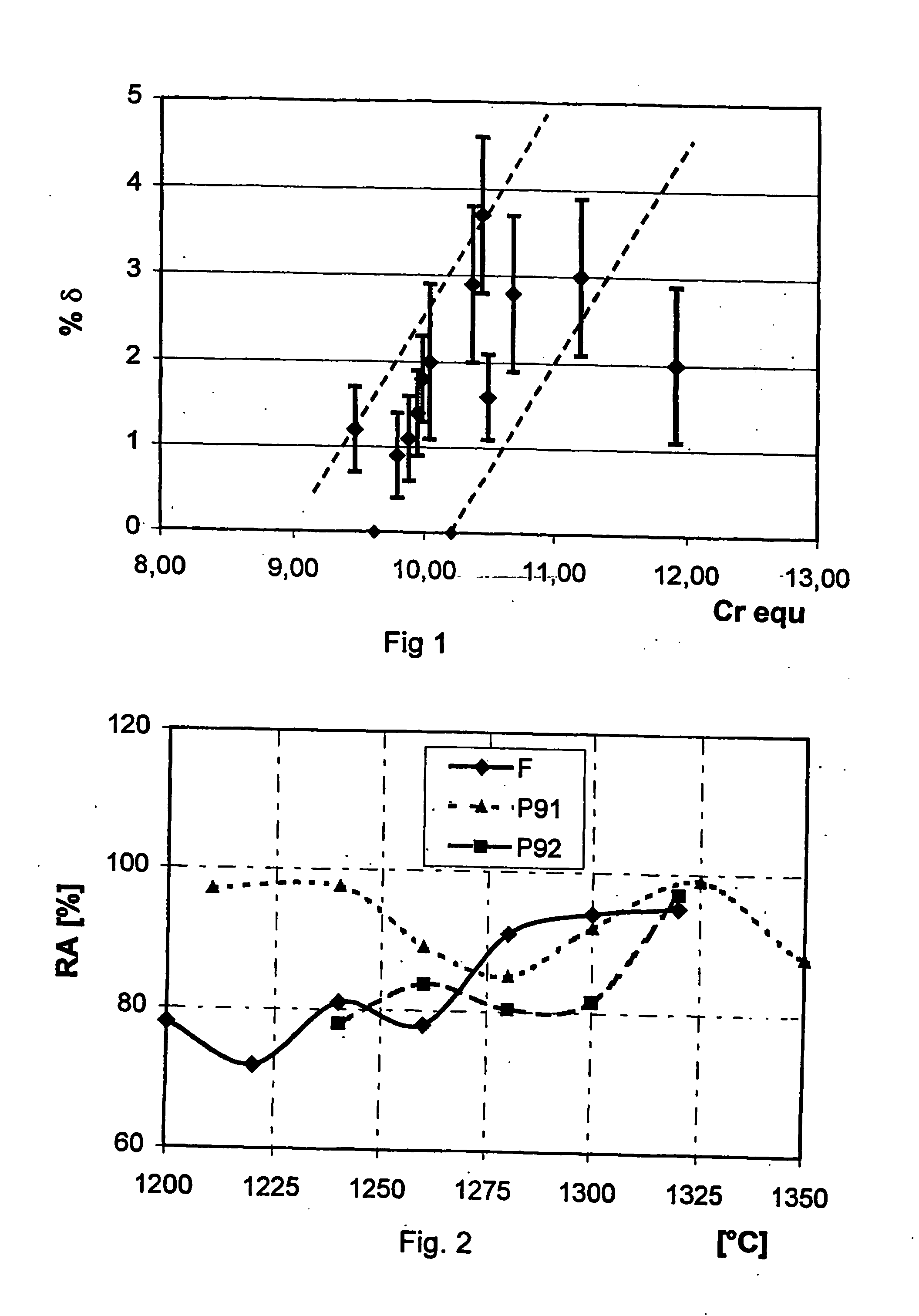

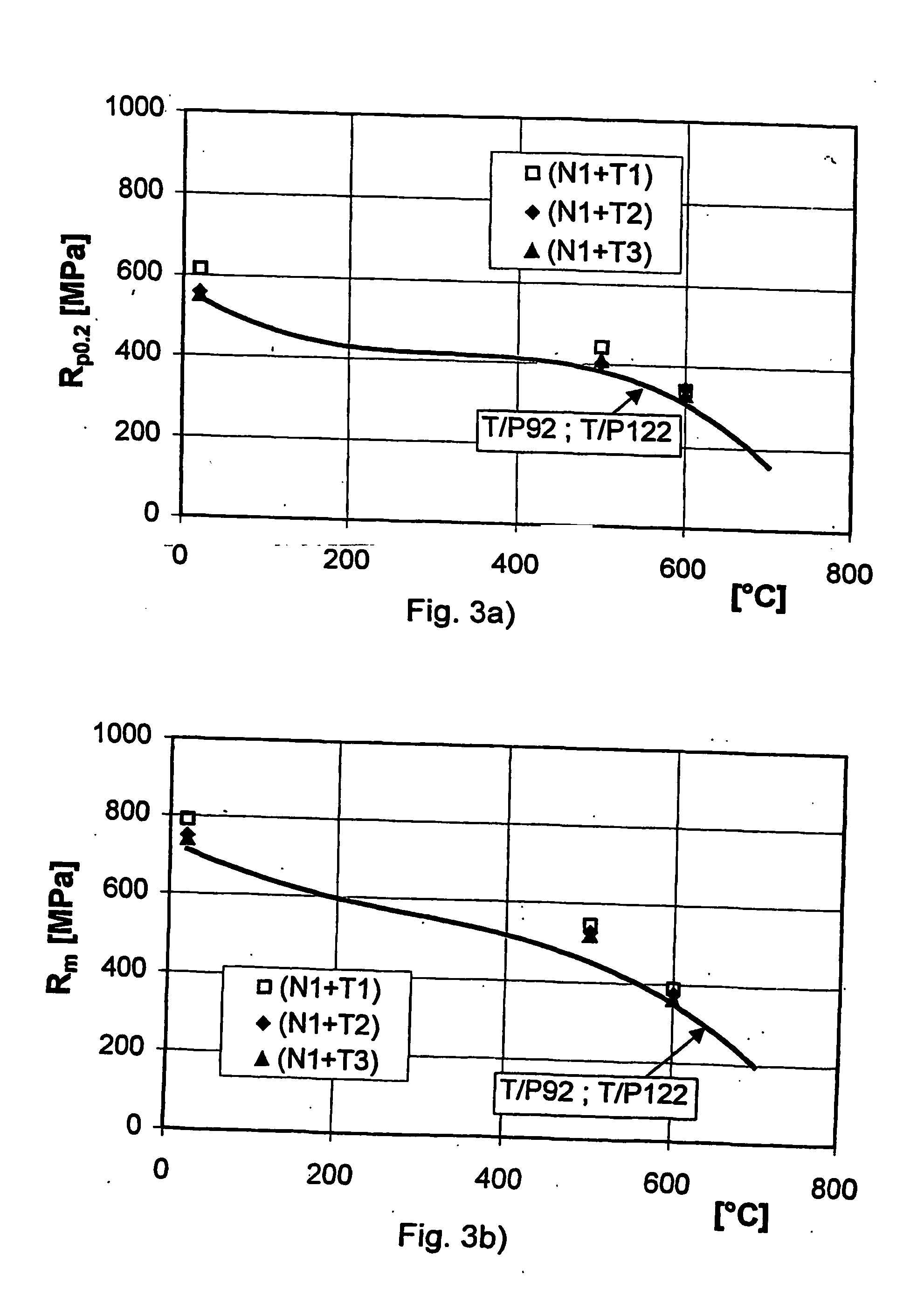

Steel and steel tube for high- temperature use

InactiveUS20040109784A1Reduce formationGood castabilityFurnace typesProcess efficiency improvementSteel tubeChemical composition

Owner:V & M FRANCE

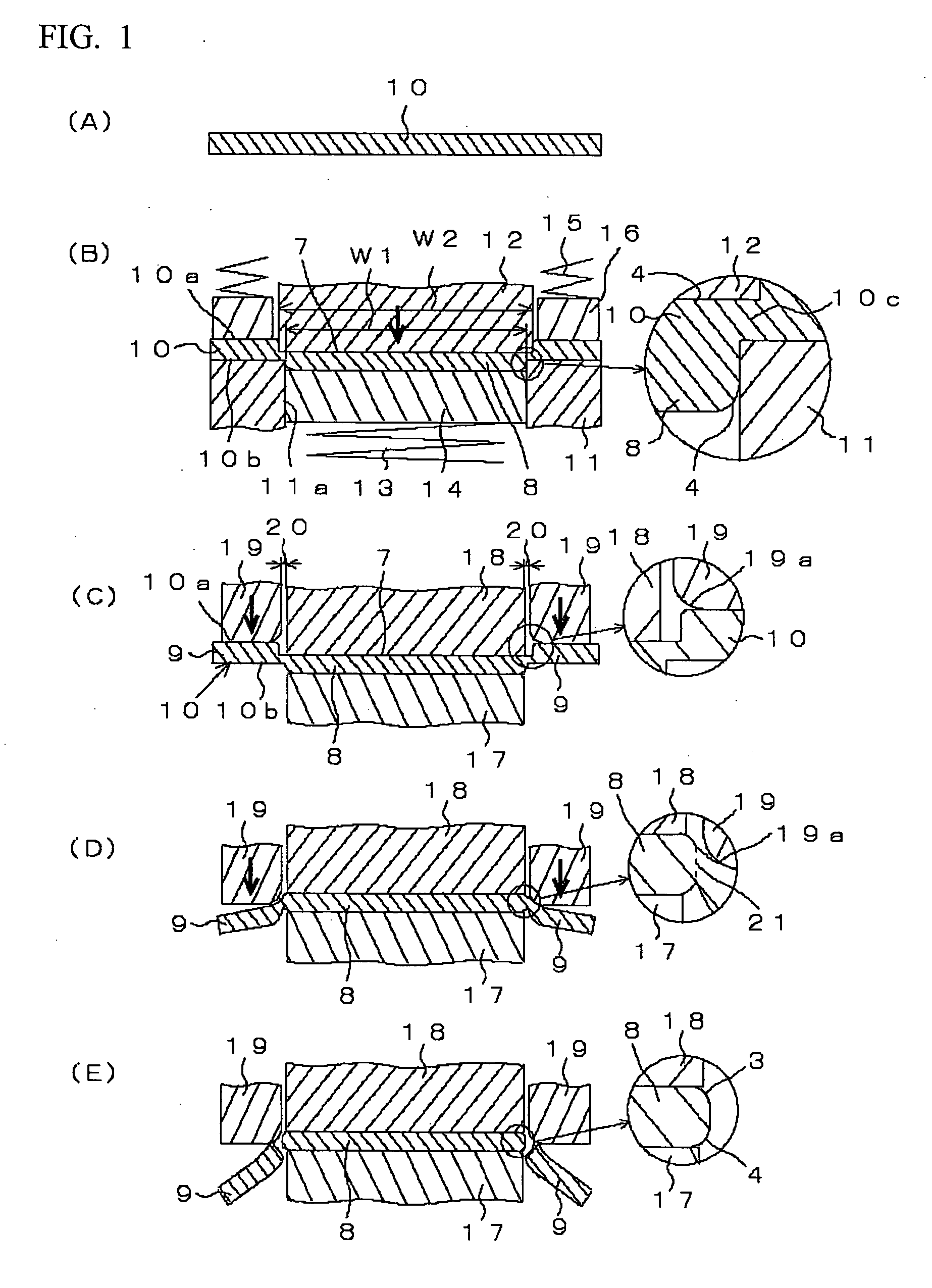

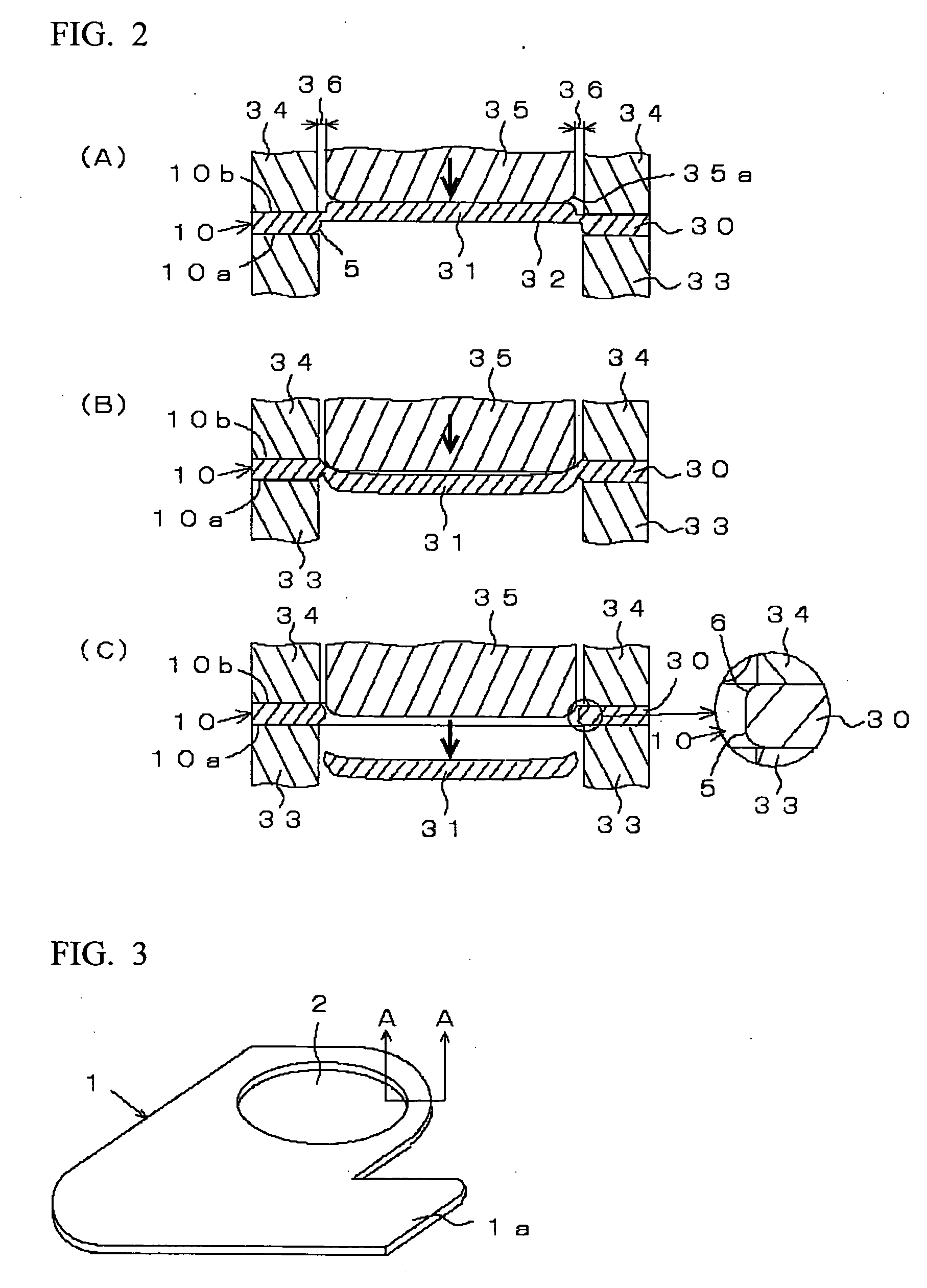

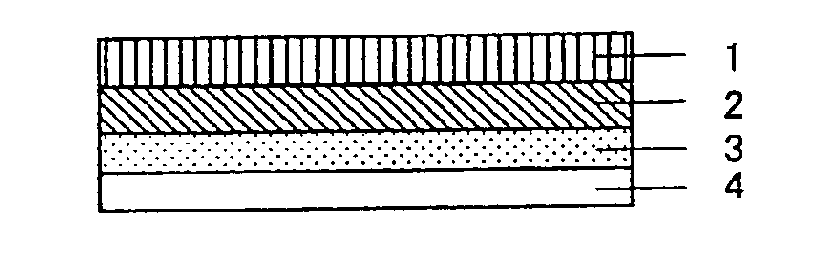

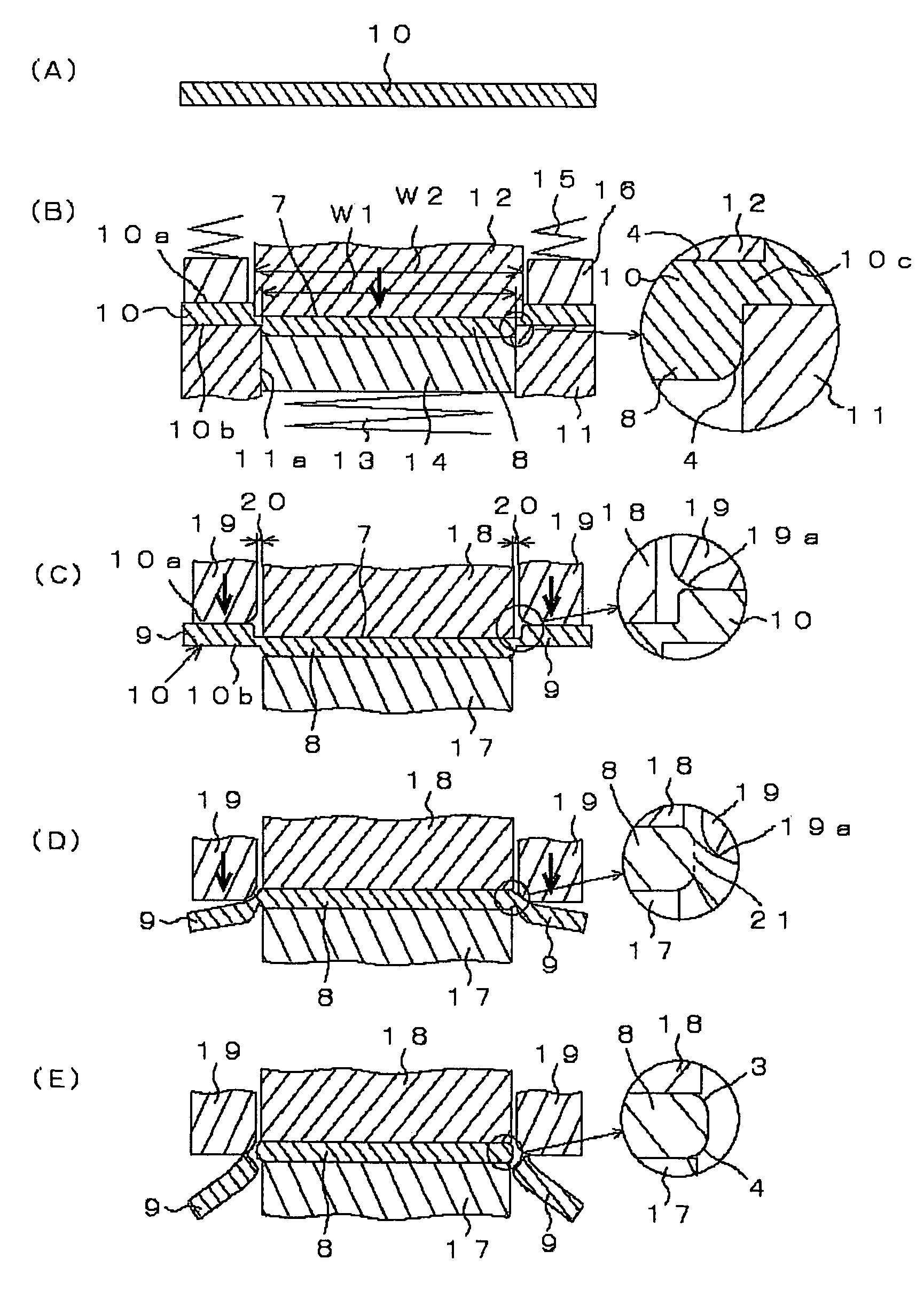

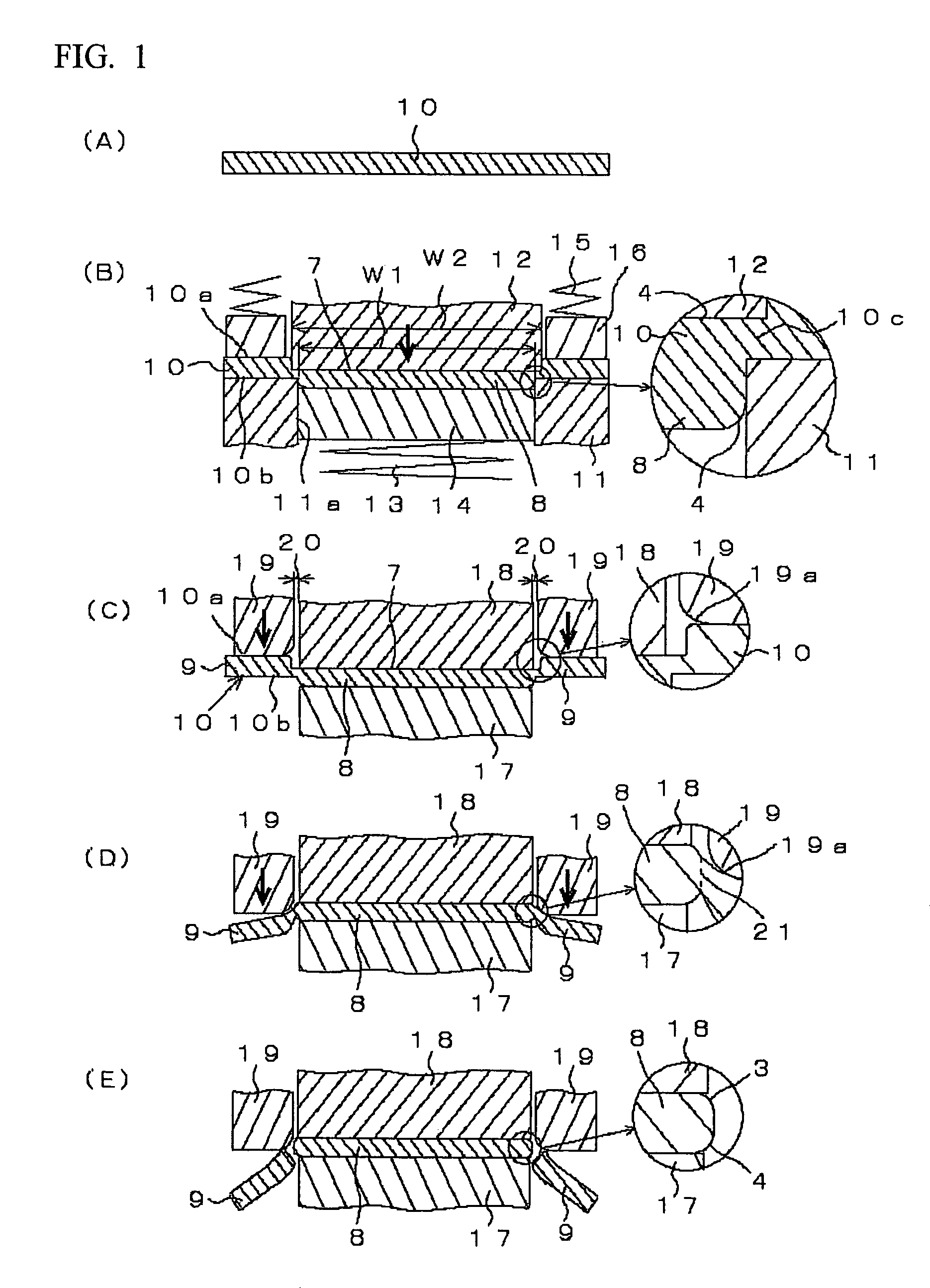

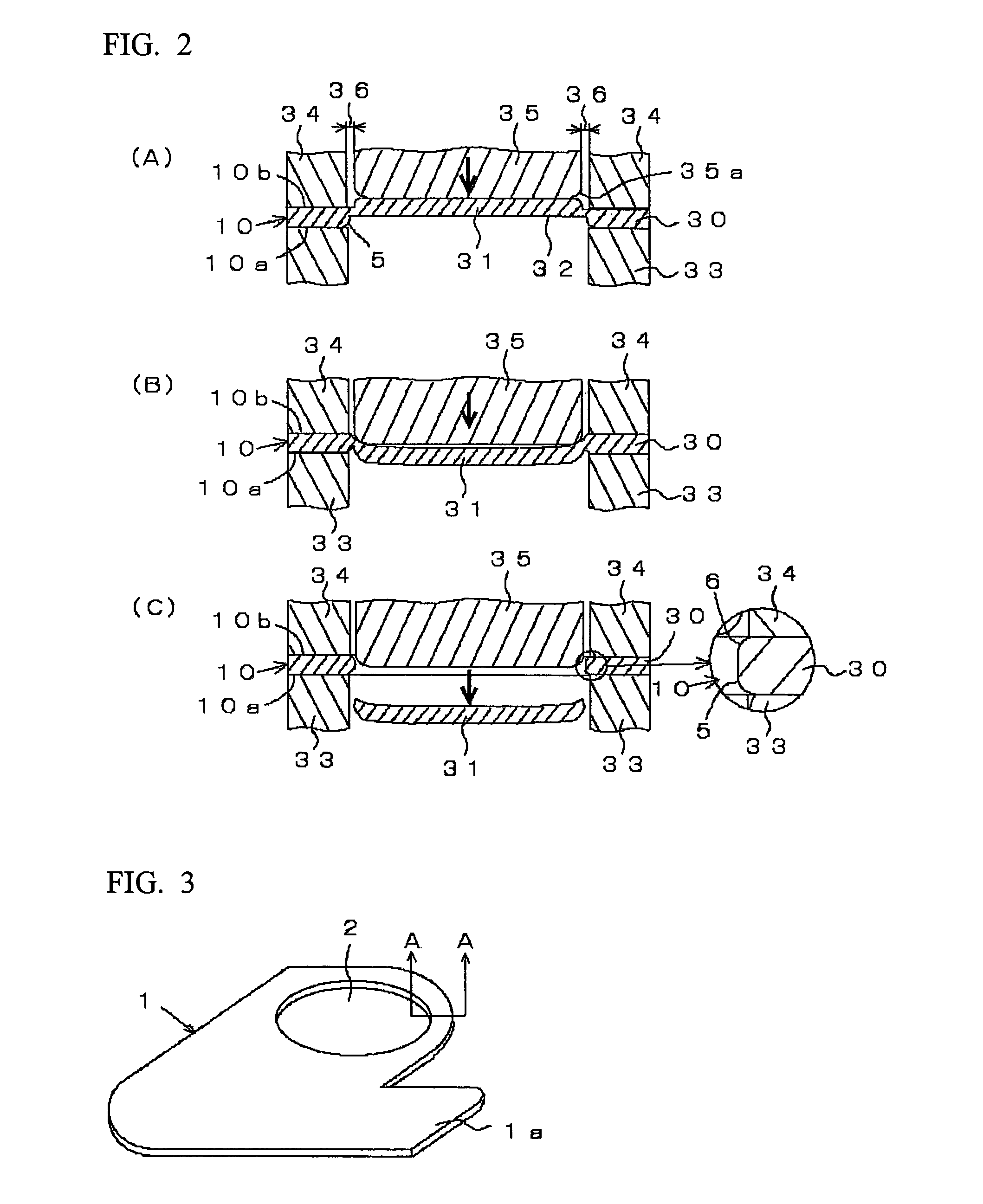

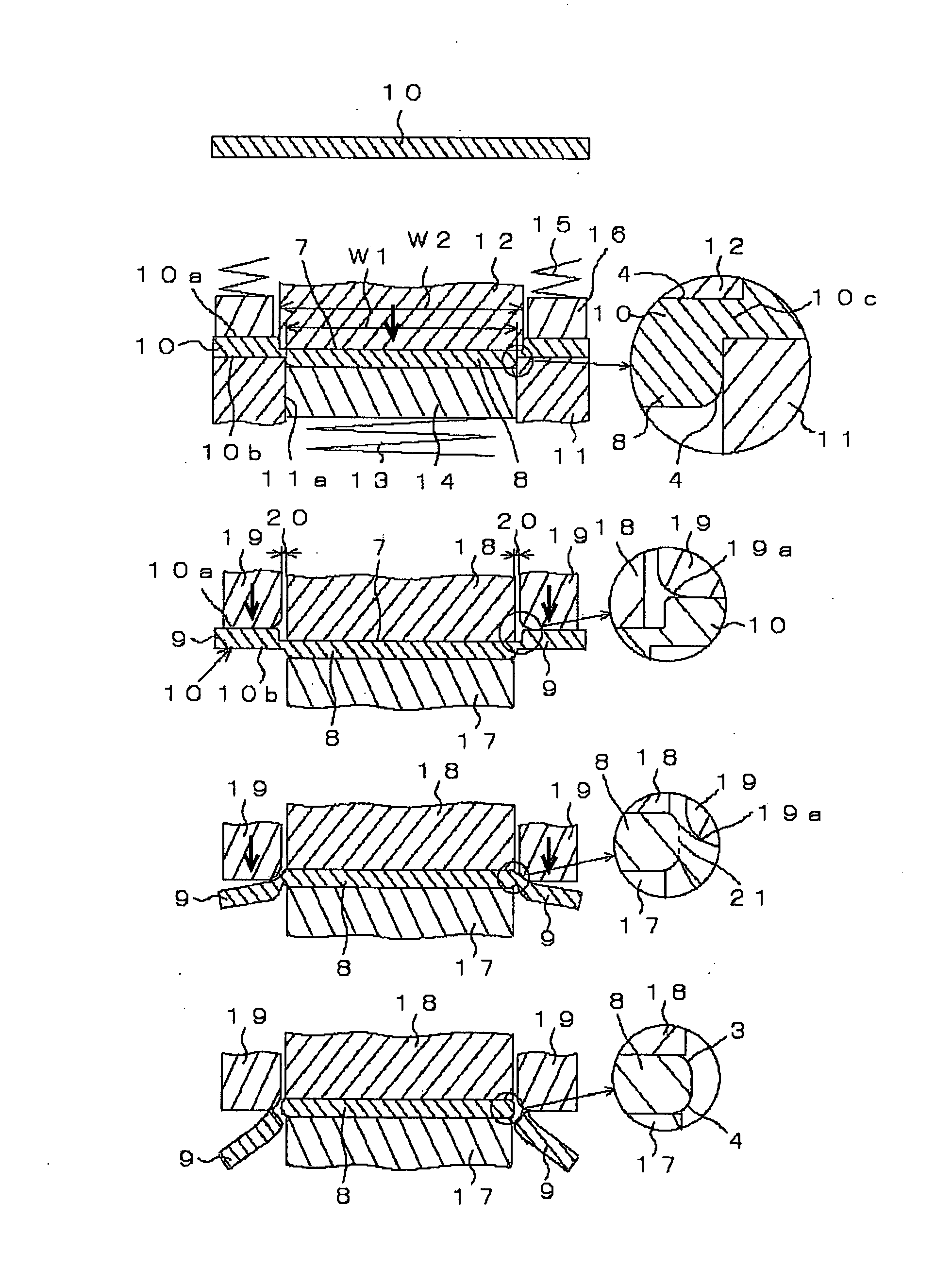

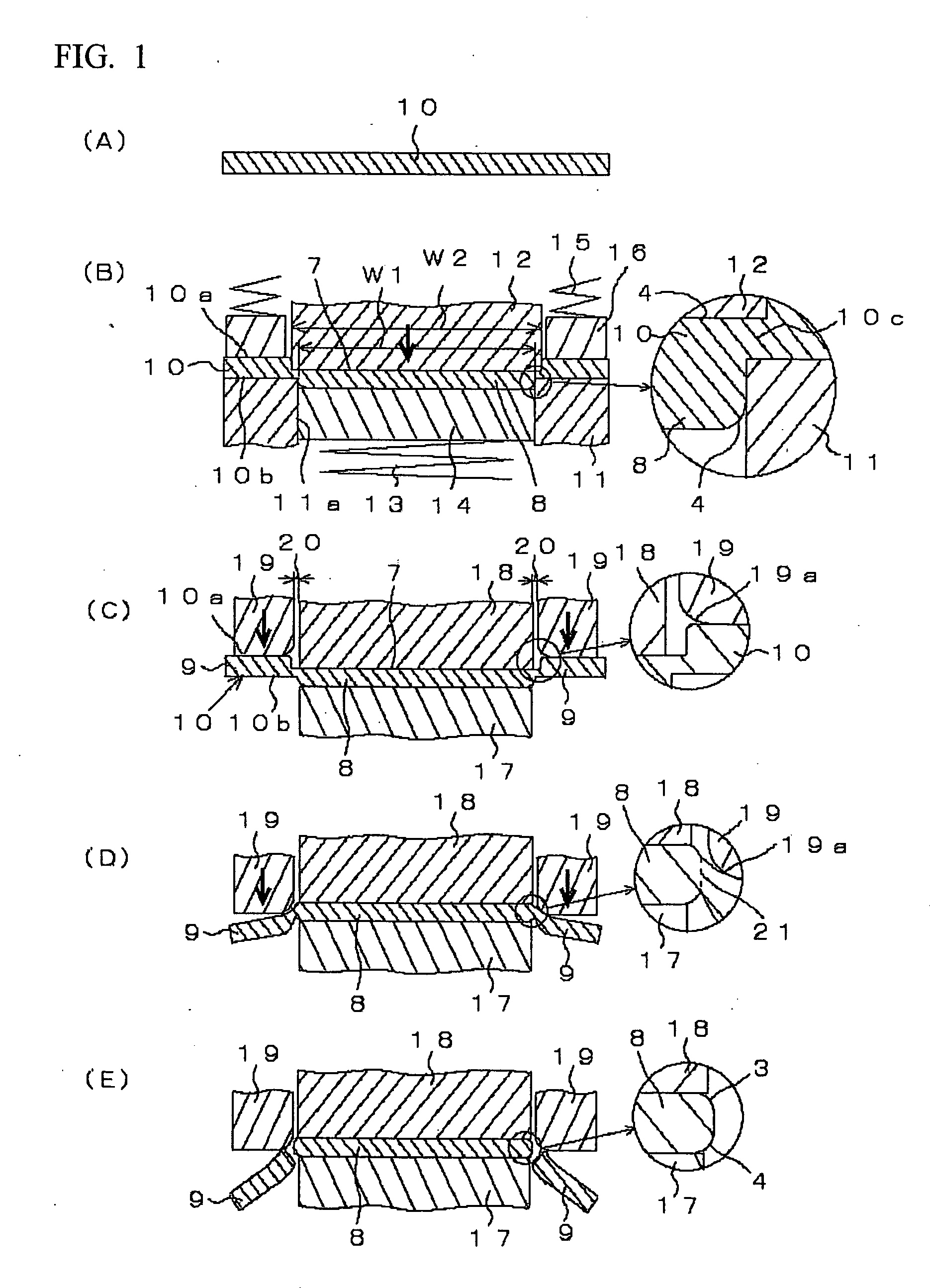

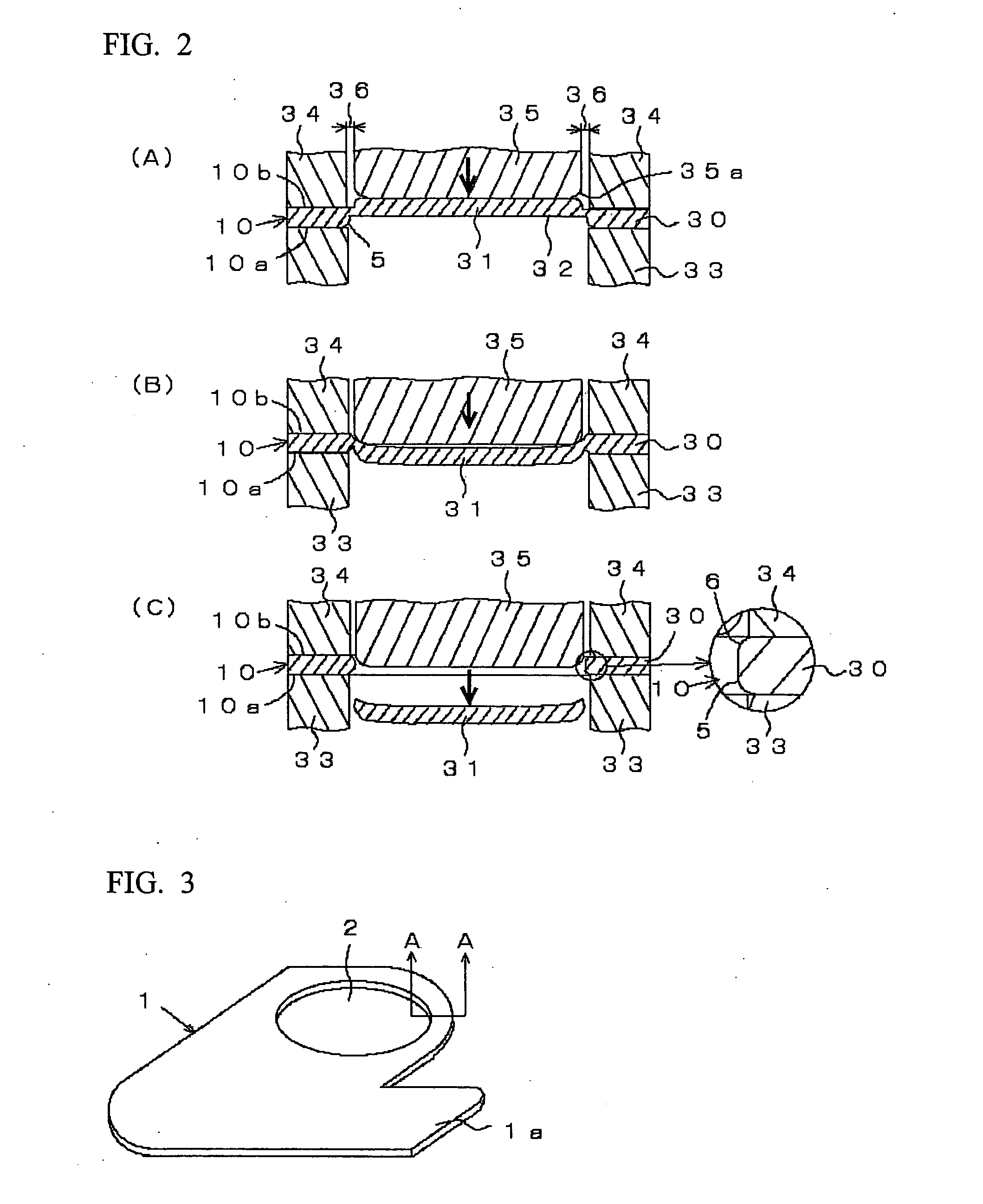

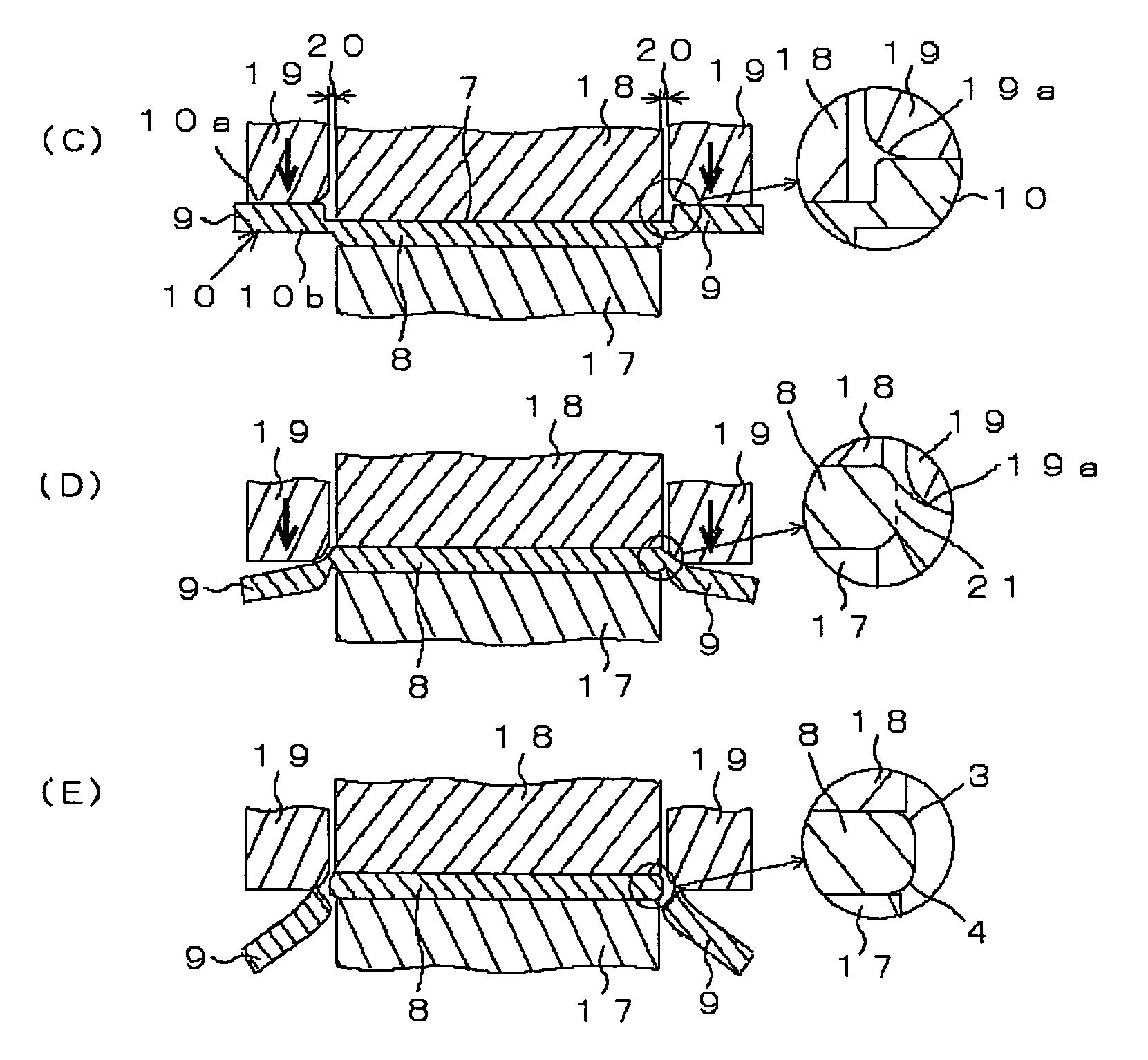

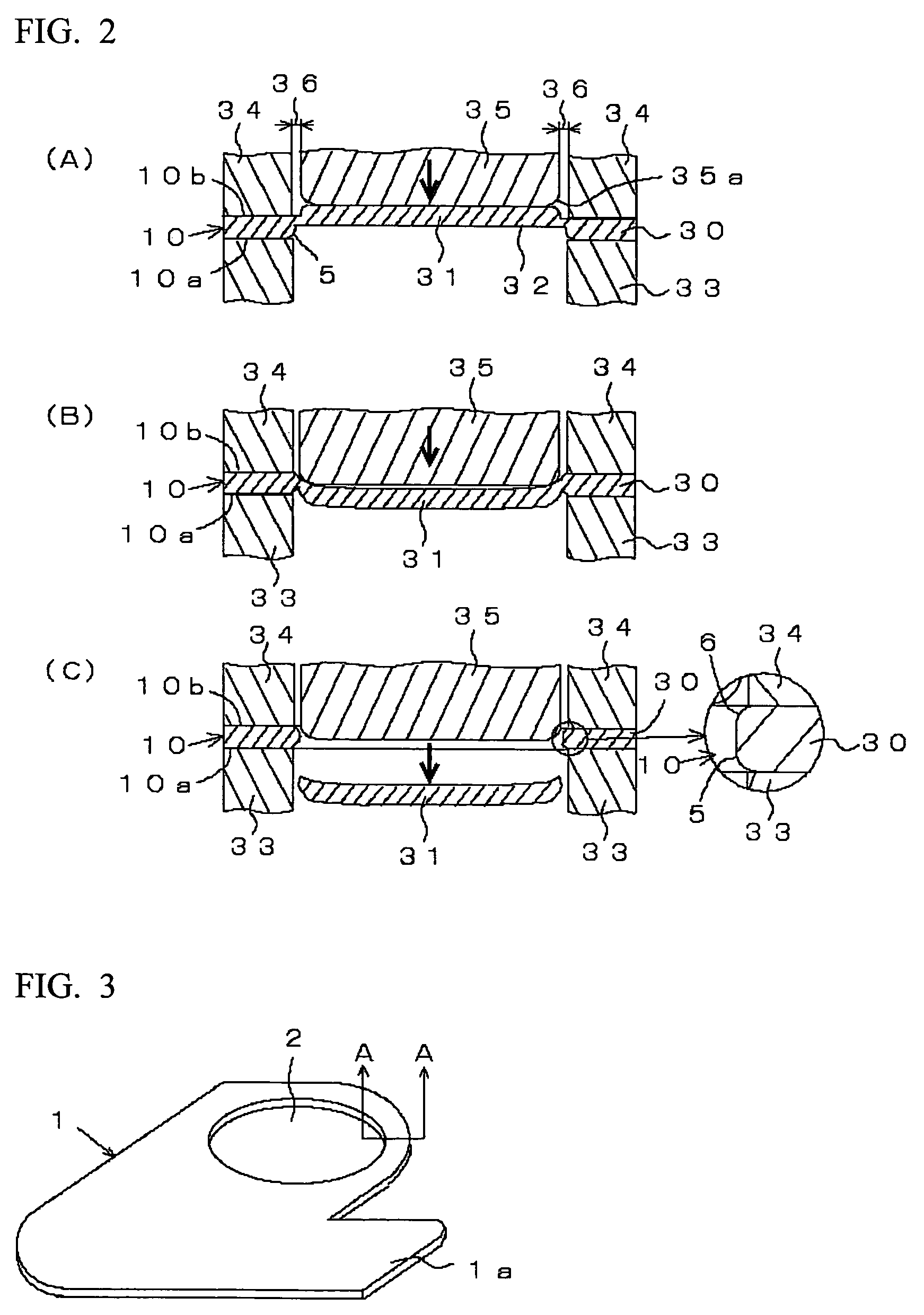

Shearing method for thin plate

A shearing method for a thin plate including forming a protruded product part having a first sagging part when the thin plate with a thickness of not more than approximately 0.3 mm is performed with a half die cutting by pressing the half die cutting punch slightly larger than the half die cutting hole to form a shallow recessed part, fixing the product part by a fixing member, forming a second sagging part at an edge portion of the thin plate by pressurizing a scrap part by moving a pressure punch which is provided with a gap between the fixing member and the pressure punch and by being bent between the scrap part and the product part, and then separating the scrap part from the product part.

Owner:NAKAMURA IND MFG CO LTD

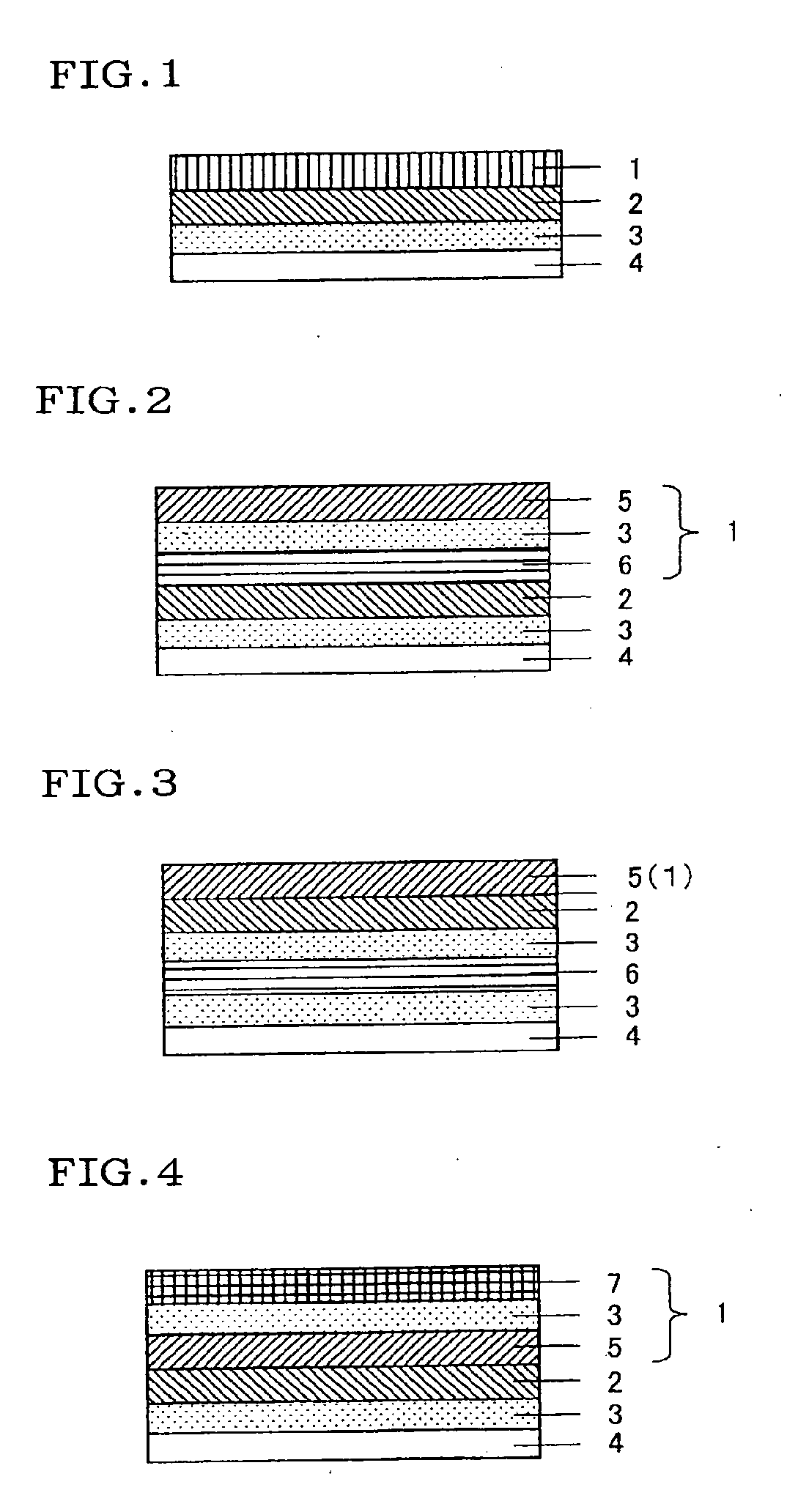

Antistatic optical film, method for manufacturing the same and image viewing display

ActiveUS20080274272A1Reduce manufacturing costExcels in productivitySolid-state devicesSemiconductor/solid-state device manufacturingWater dispersibleConductive polymer

An antistatic optical film comprising an antistatic layer laminated on at least one side of an optical film, wherein the antistatic layer comprises a water soluble or a water dispersible conductive polymer, has excellent antistatic effect, optical characteristics and appearance.

Owner:NITTO DENKO CORP

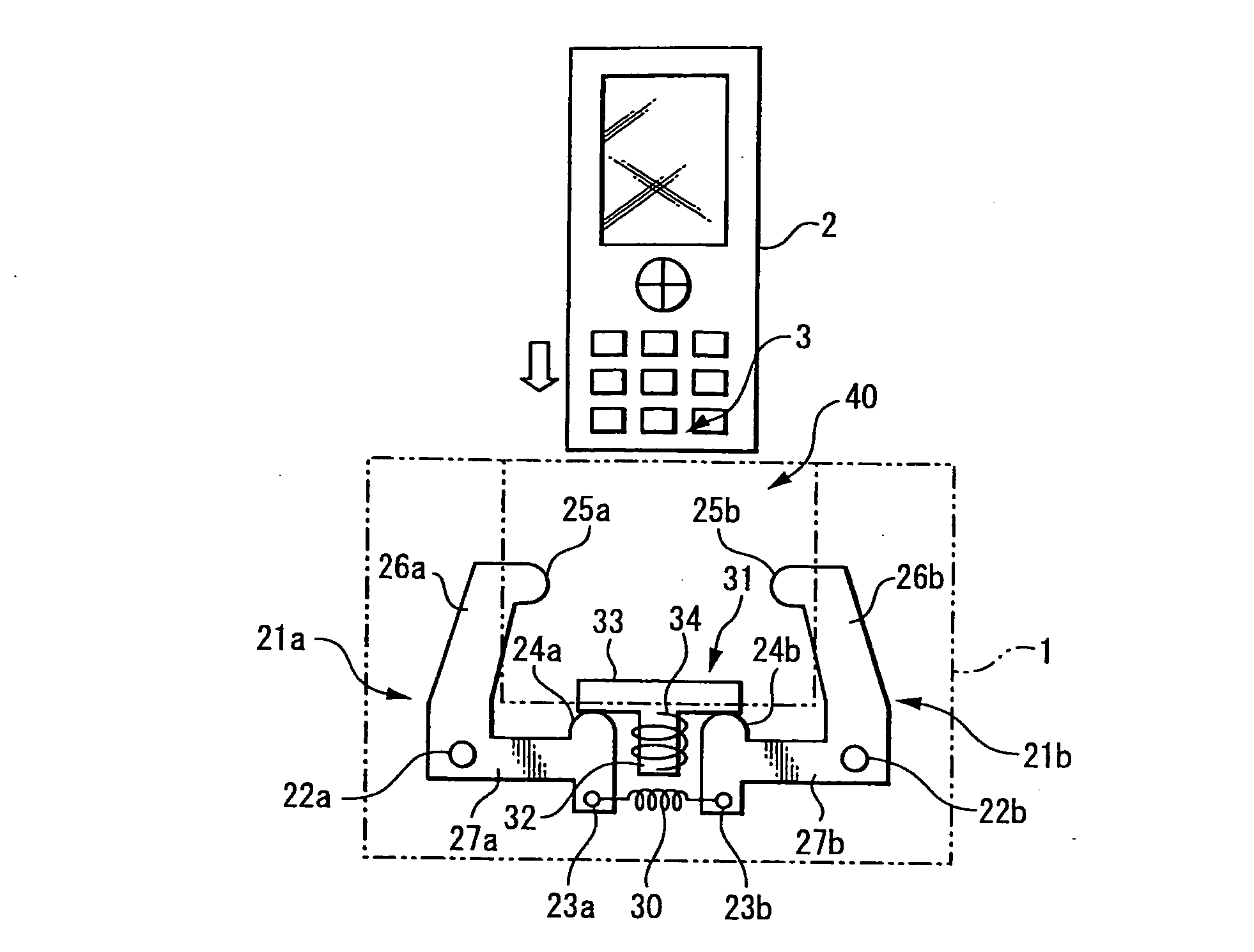

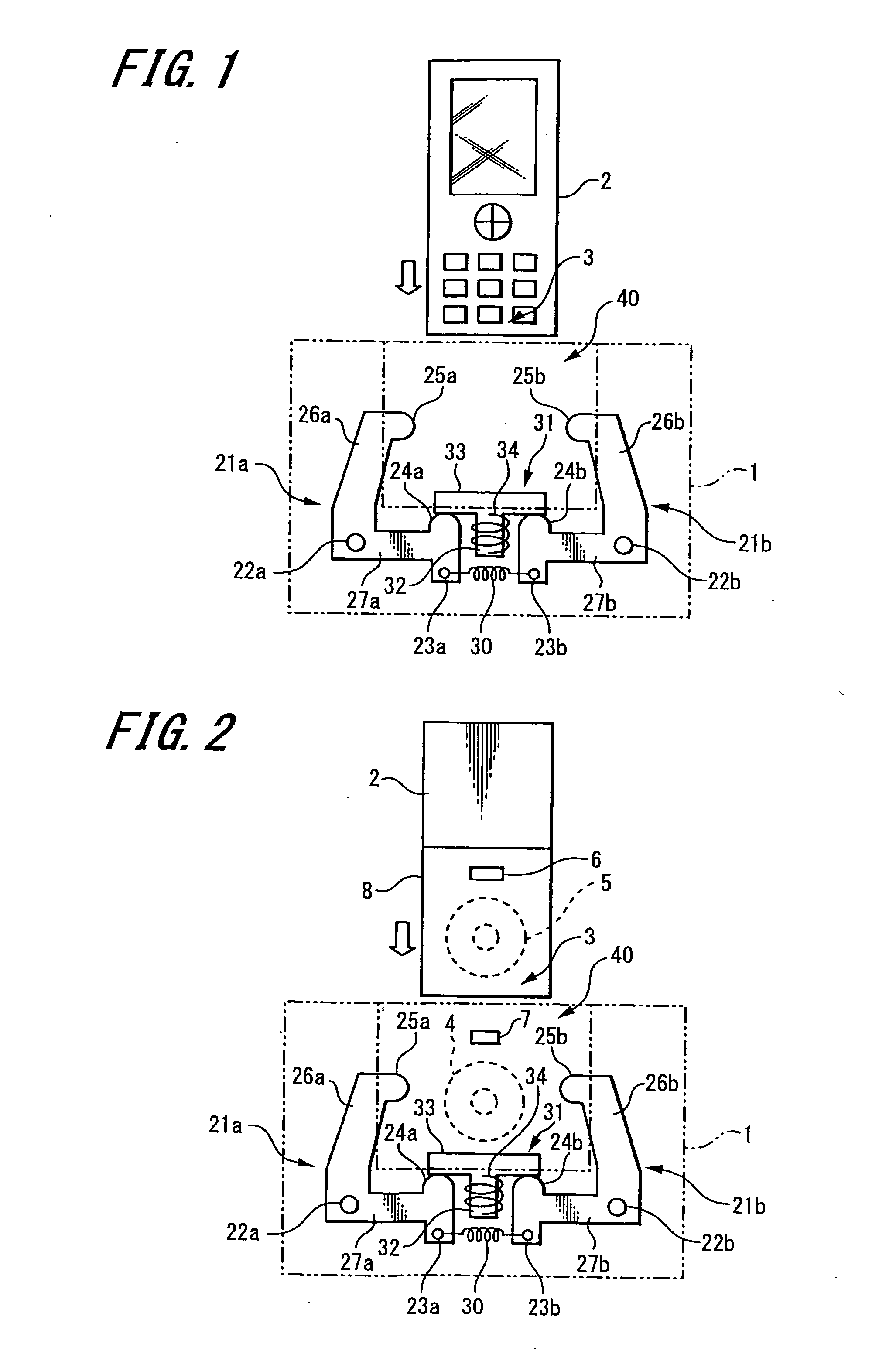

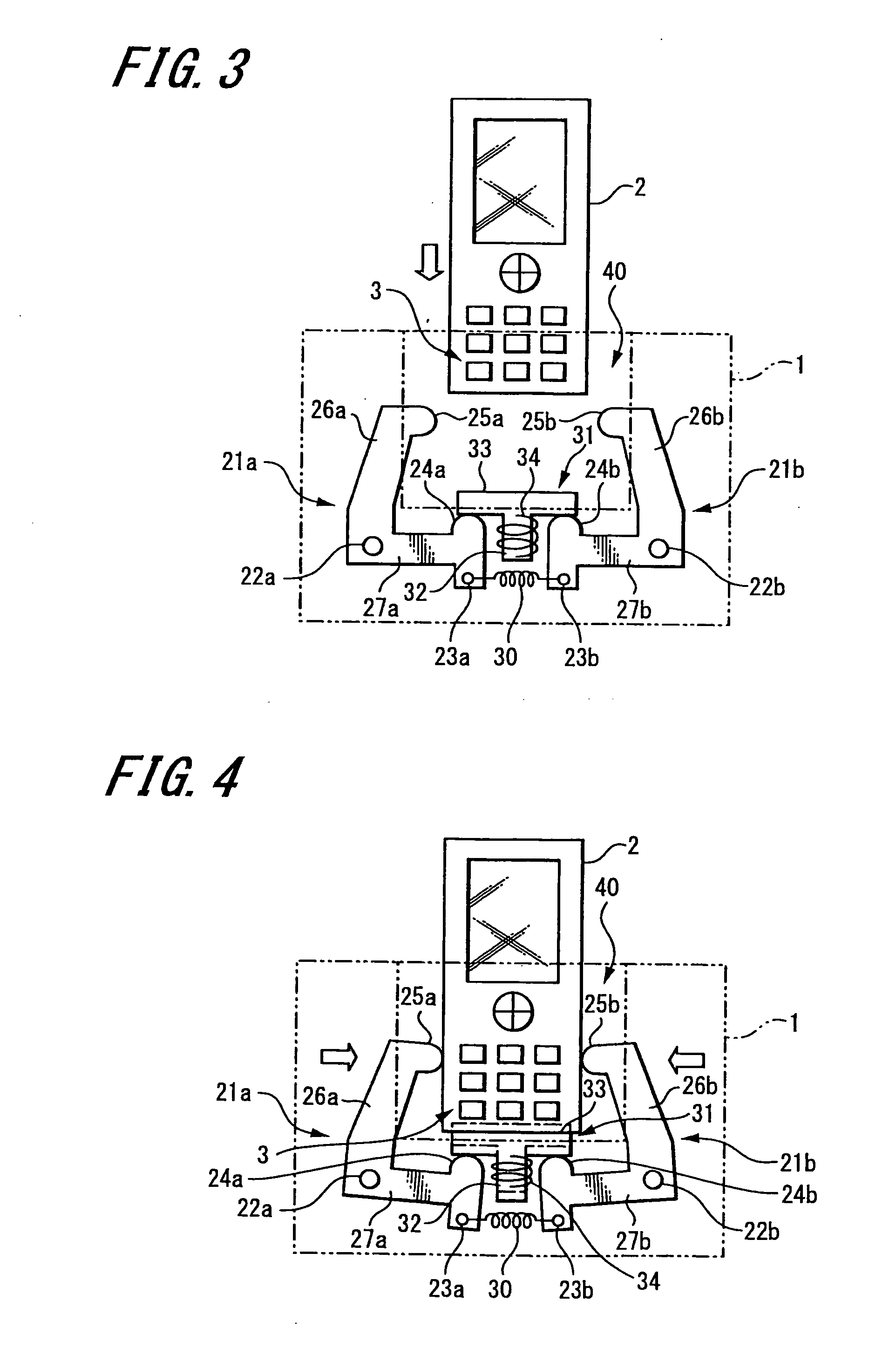

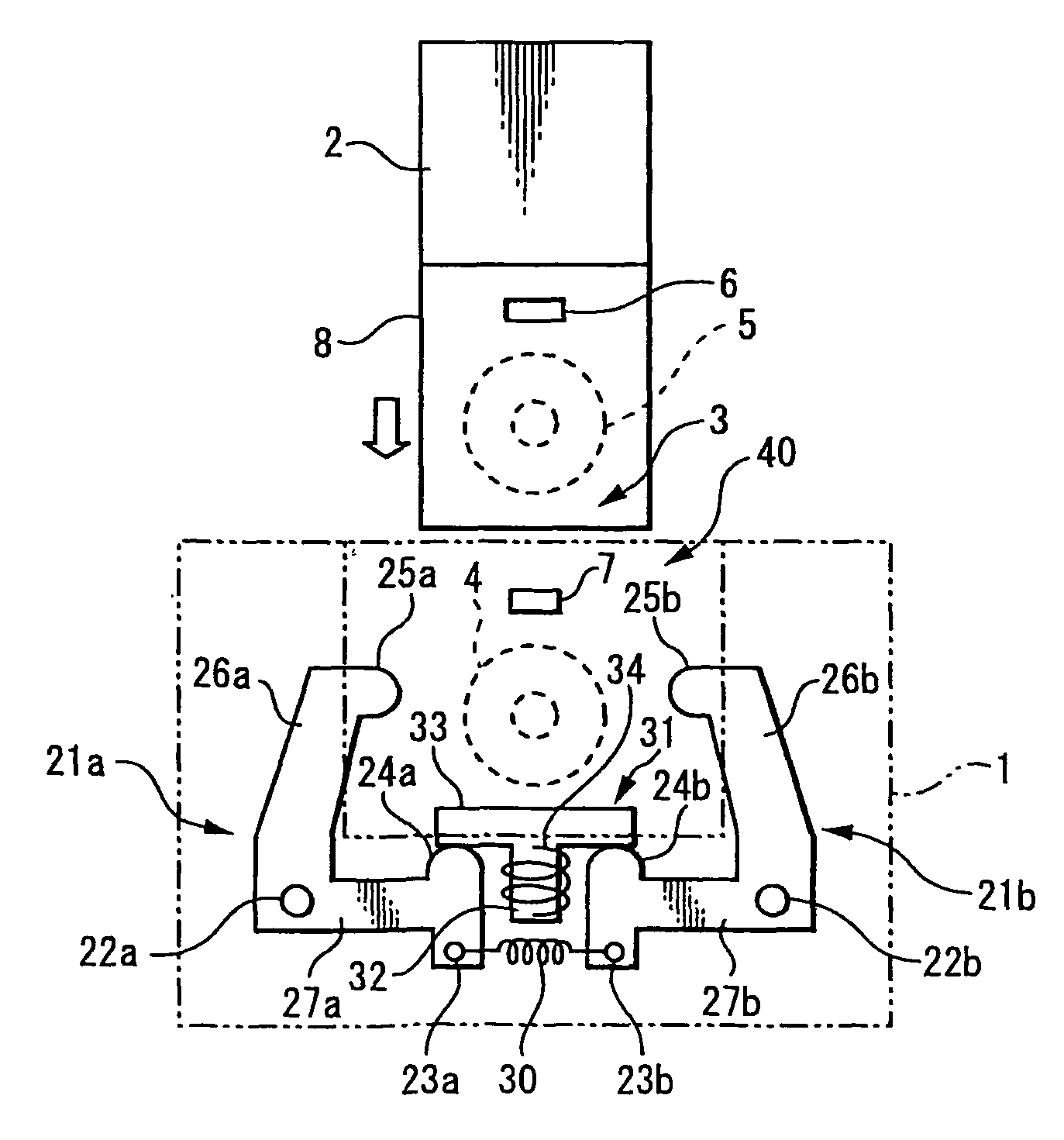

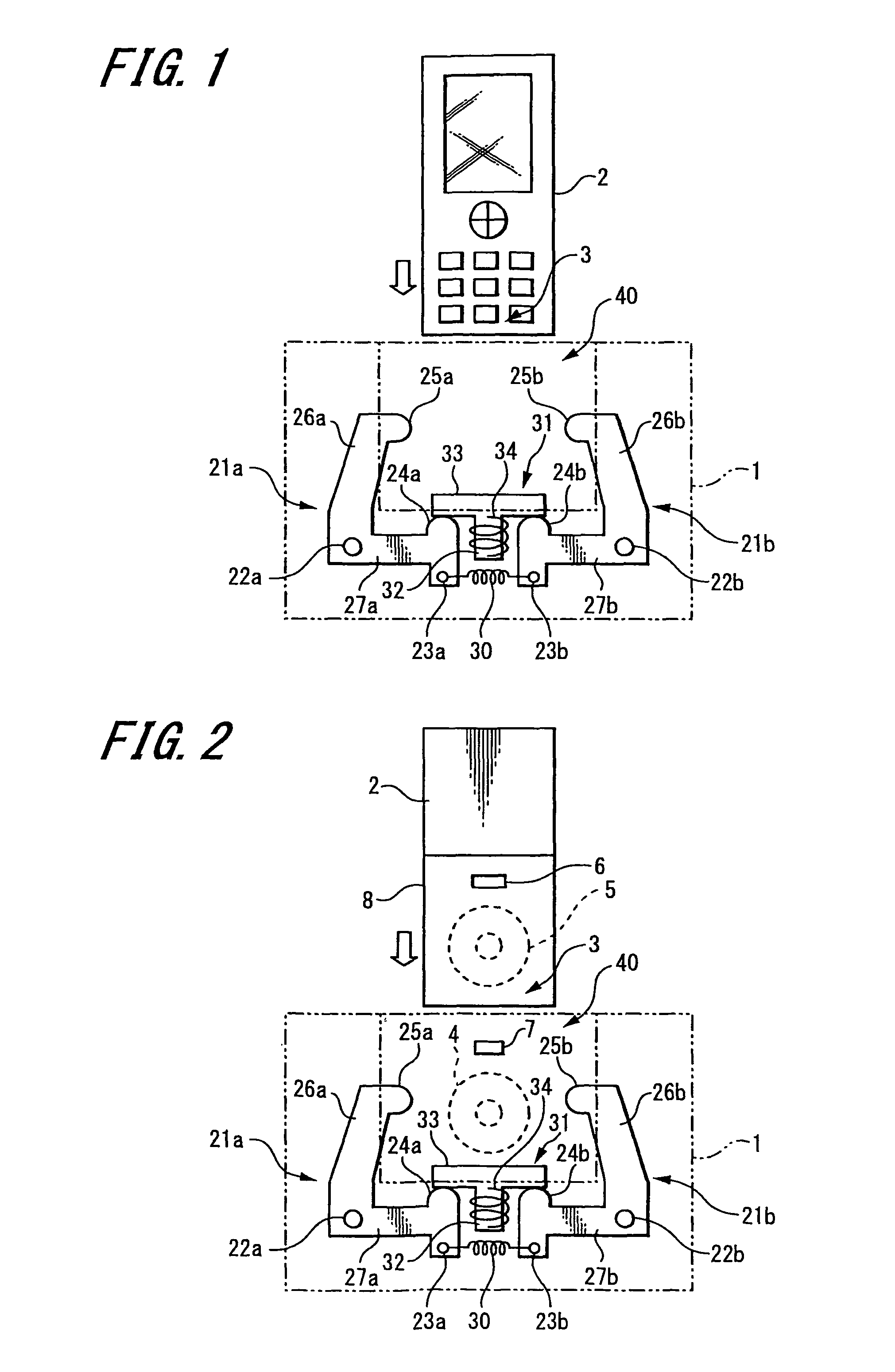

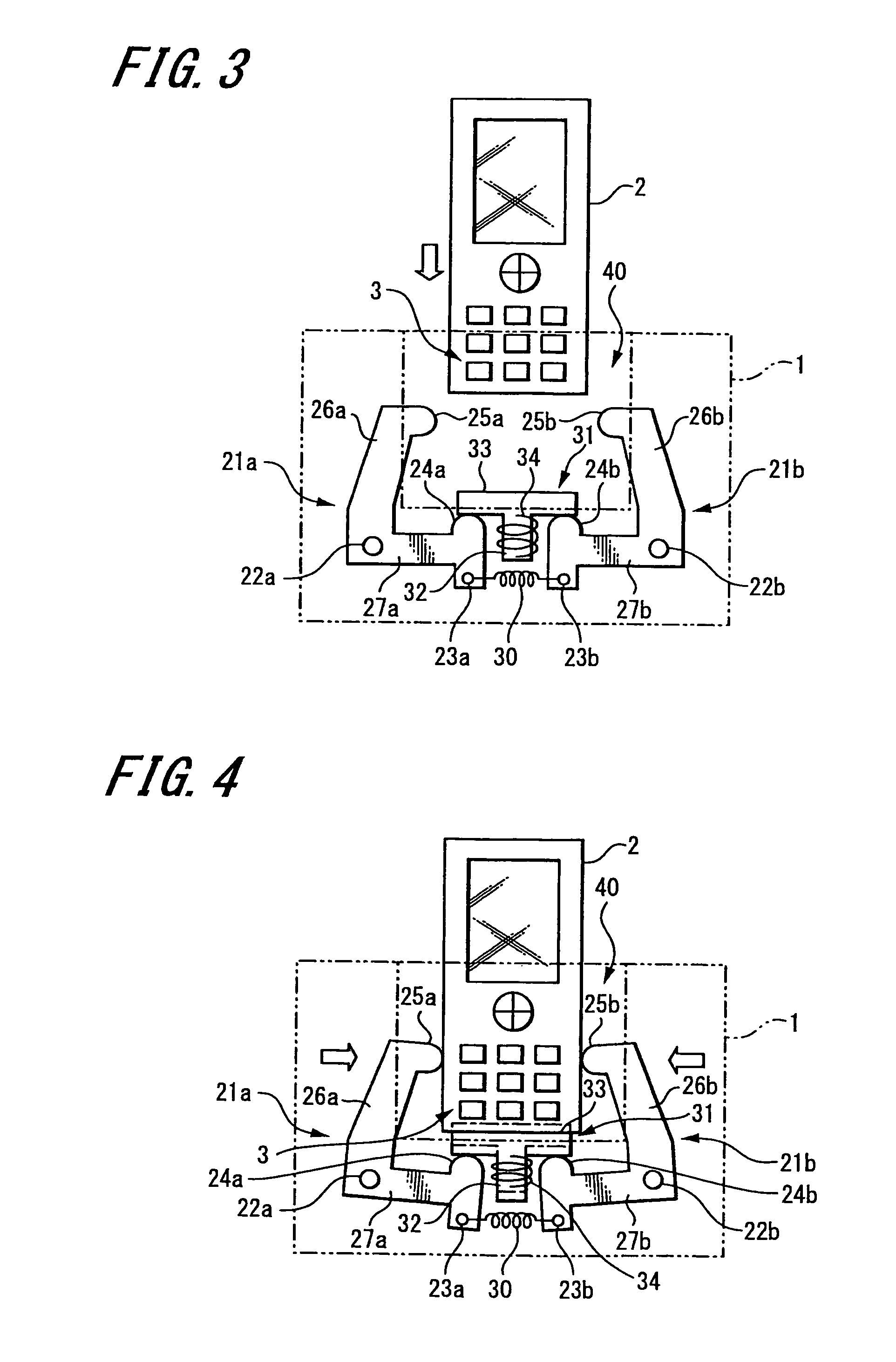

Contactless power transferring apparatus

ActiveUS20080296979A1Large openingSmall sizeBatteries circuit arrangementsElectromagnetic wave systemElectric power transmissionEngineering

A contactless power transferring apparatus includes a terminal loading portion, a primary coil, an up-down-direction pressing portion, a width direction pressing portion and a thickness direction pressing portion. The terminal loading portion has an opening through which a mobile terminal is inserted and loaded. The primary coil transfers power using electromagnetic induction to a secondary coil incorporated in the mobile terminal. When the mobile terminal is inserted inside the terminal loading portion, the pressing portions operate in an up-down direction, in a left-right direction and in a width direction, to press and support the mobile terminal respectively from below to position the coils in the up-down direction, from the width direction to position the coils in the left-right direction and from the thickness direction to dispose the coils a predetermined distance apart.

Owner:SONY MOBILE COMM INC +1

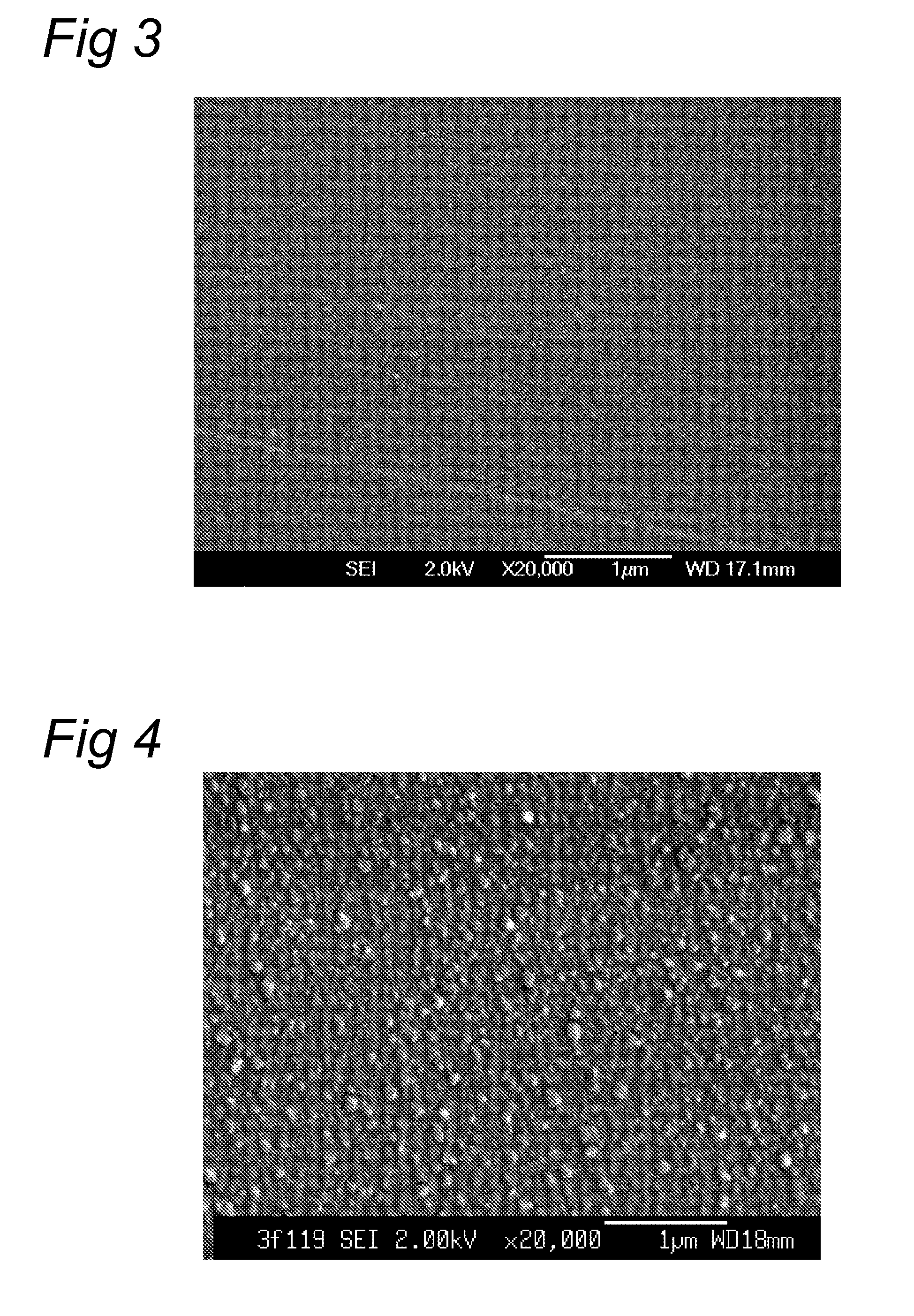

High-Purity Copper or High-Purity Copper Alloy Sputtering Target, Process for Manufacturing the Sputtering Target, and High-Purity Copper or High-Purity Copper Alloy Sputtered Film

ActiveUS20110163447A1High resistanceReduce percent defectCellsSemiconductor/solid-state device detailsSputteringNon-metallic inclusions

Provided is a high-purity copper or high-purity copper alloy sputtering target of which the purity is 6N or higher and in which the content of the respective components of P, S, O and C is 1 ppm or less, wherein the number of nonmetal inclusions having a particle size of 0.5 μm or more and 20 μm or less is 30,000 inclusions / g or less. As a result of using high-purity copper or high-purity copper alloy from which harmful inclusions of P, S, C and O system have been reduced as the raw material and controlling the existence form of nonmetal inclusions, the present invention addresses a reduction in the percent defect of wirings of semiconductor device formed by sputtering a high-purity copper target so as to ensure favorable repeatability.

Owner:JX NIPPON MINING & METALS CO LTD

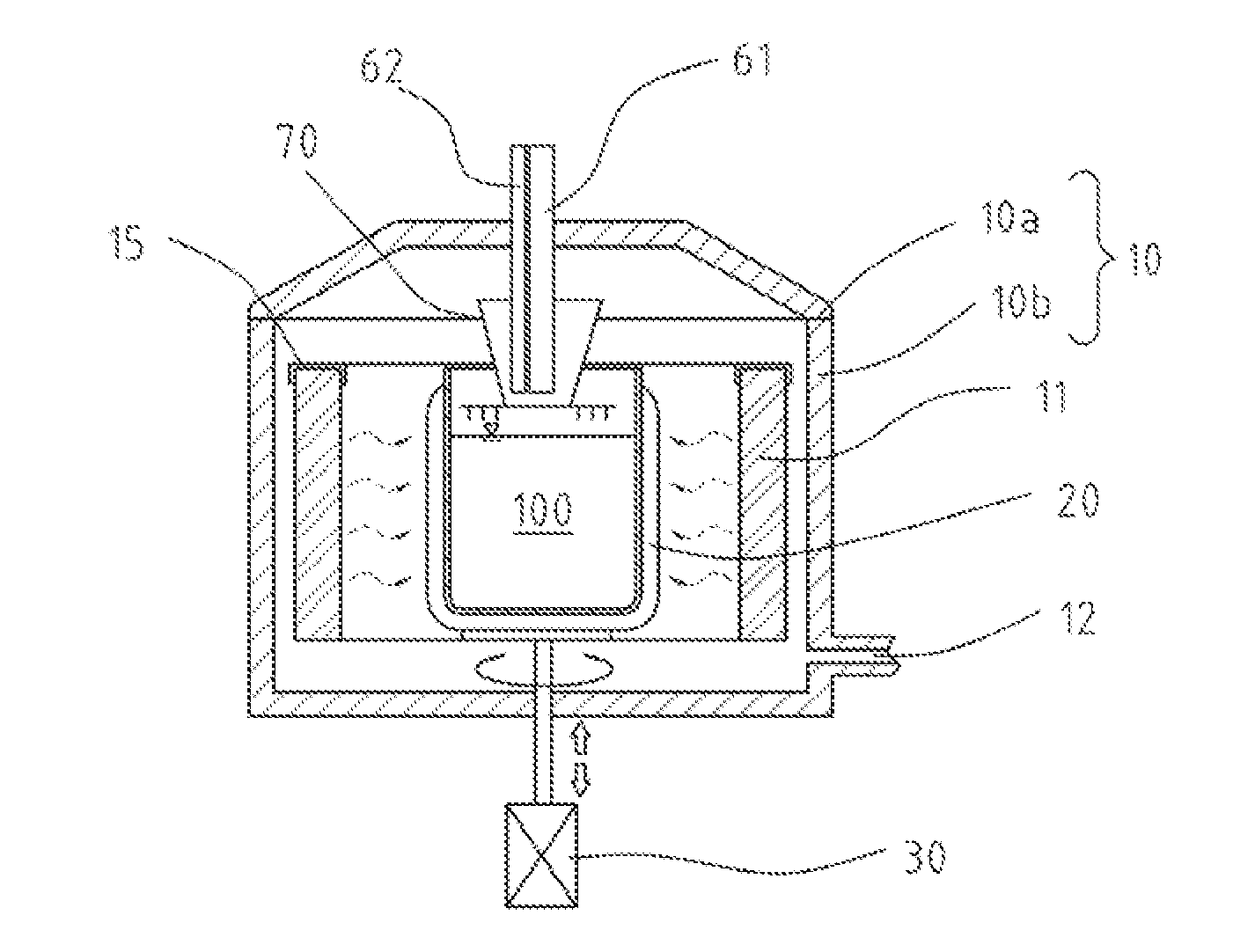

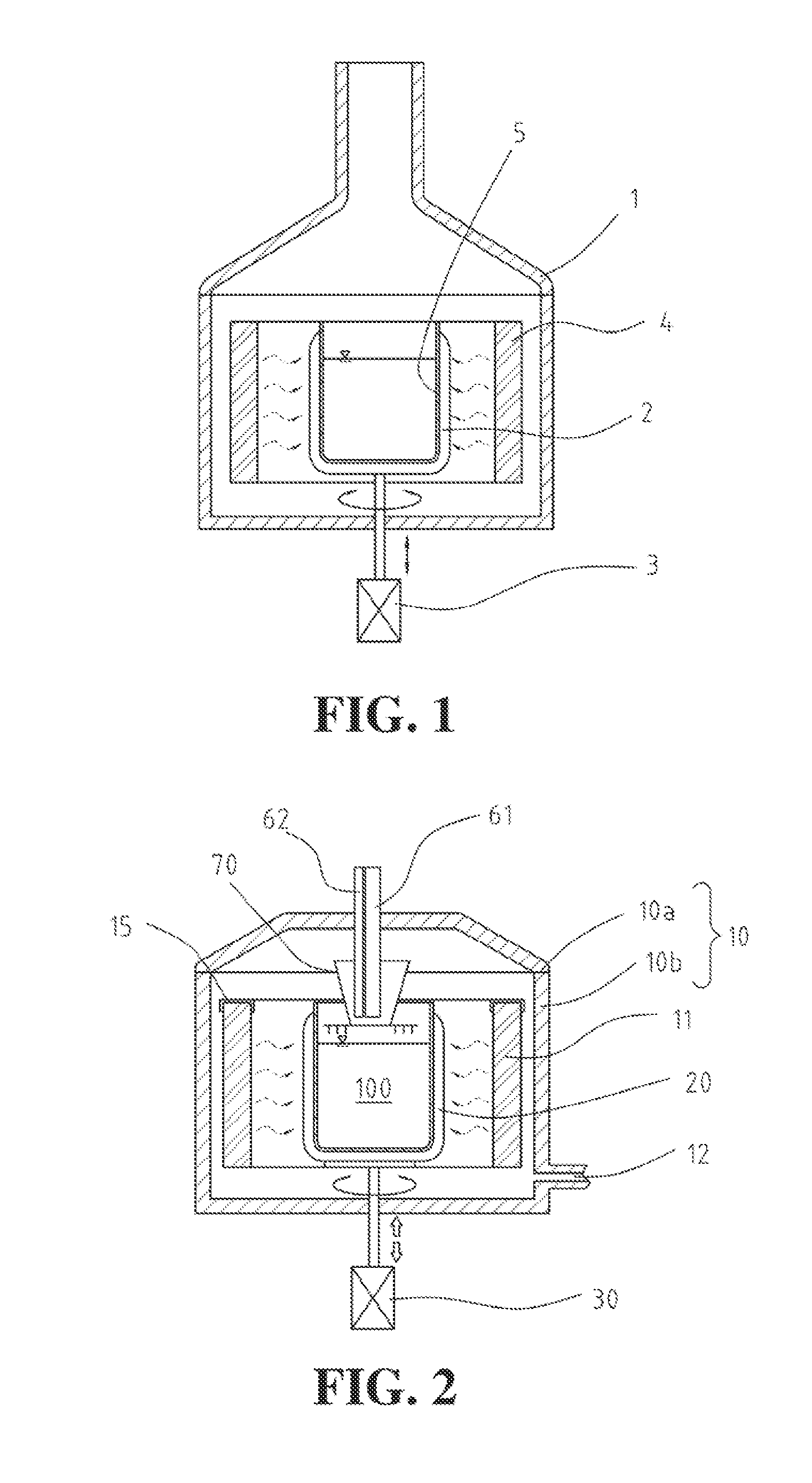

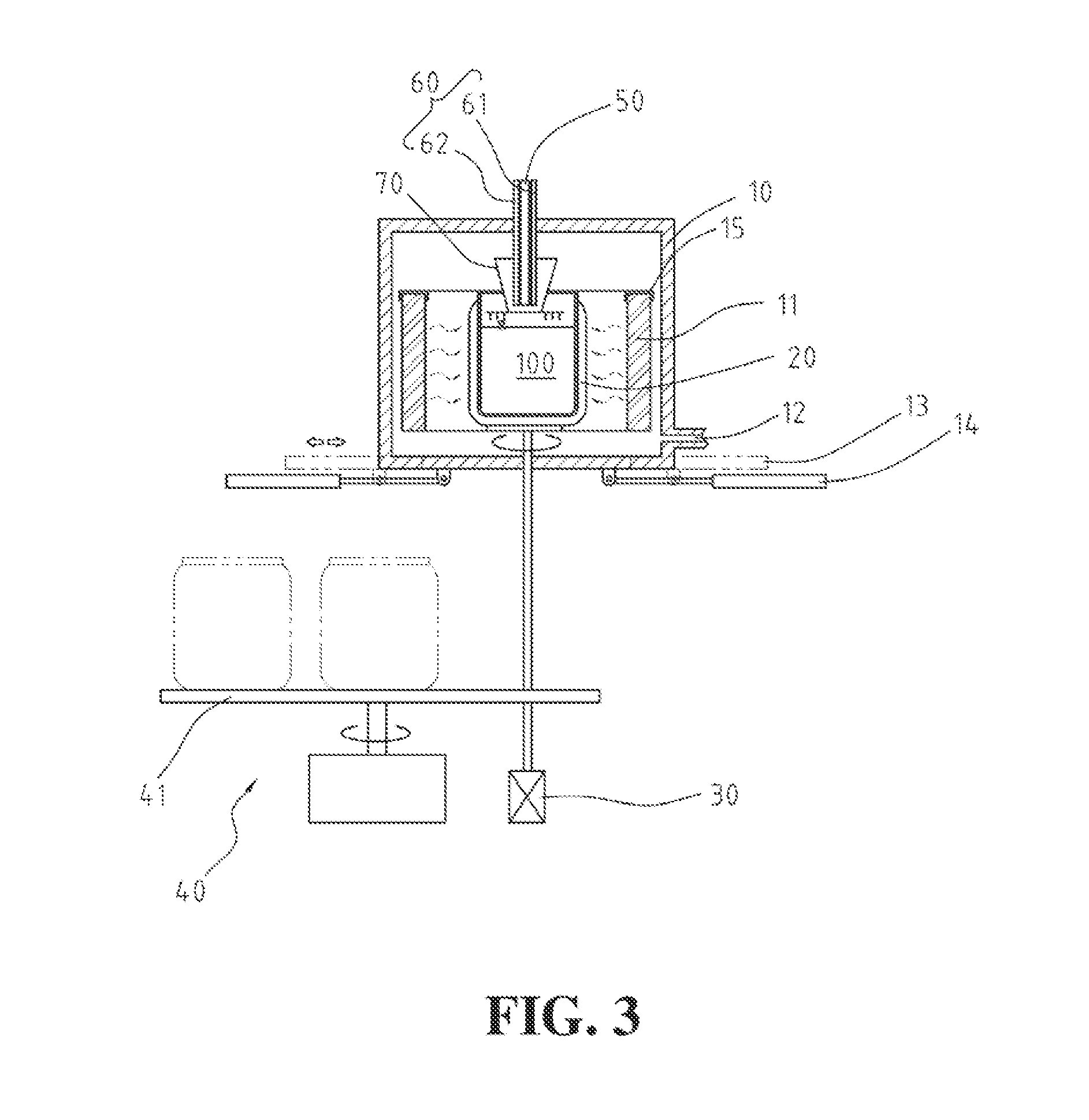

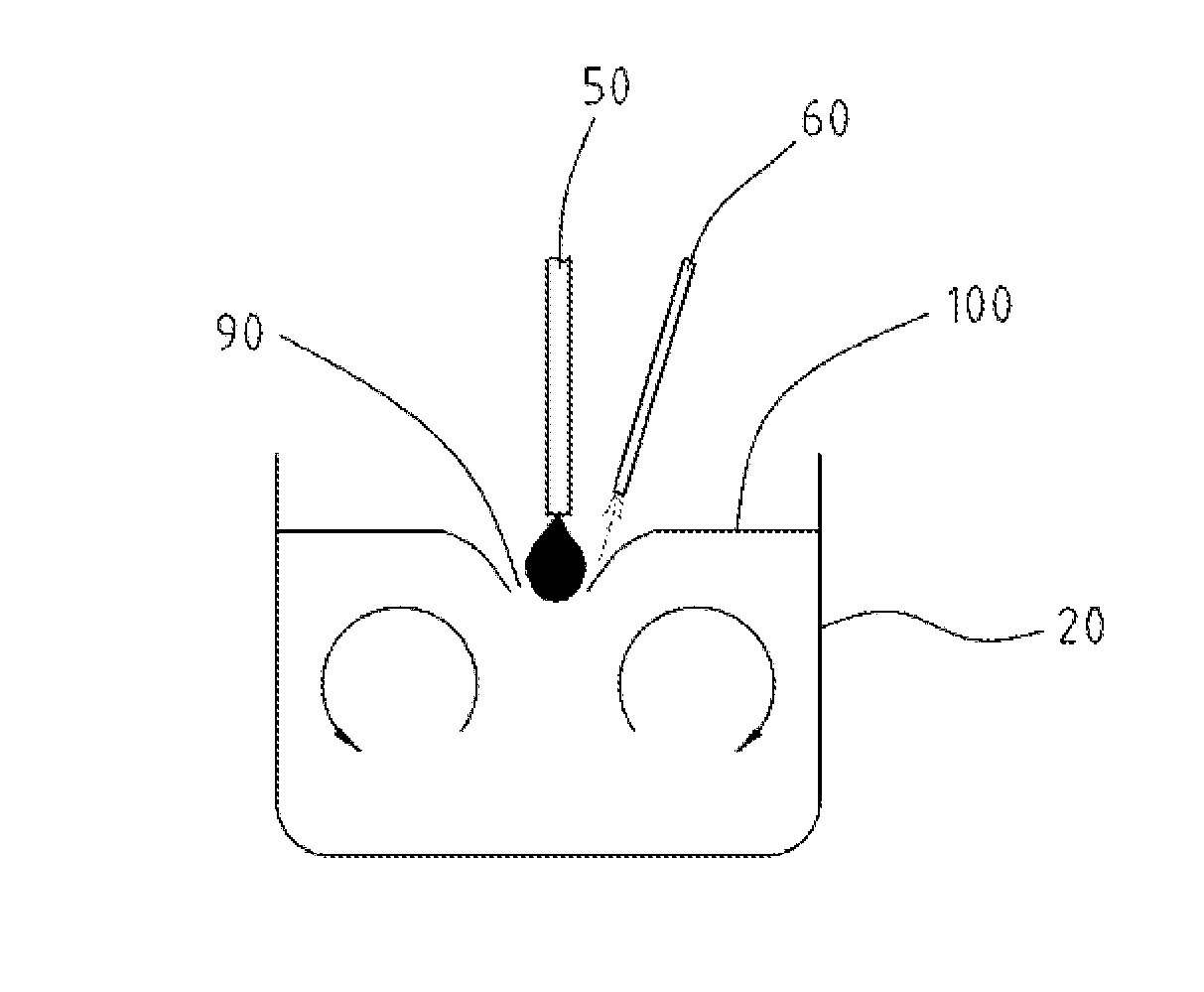

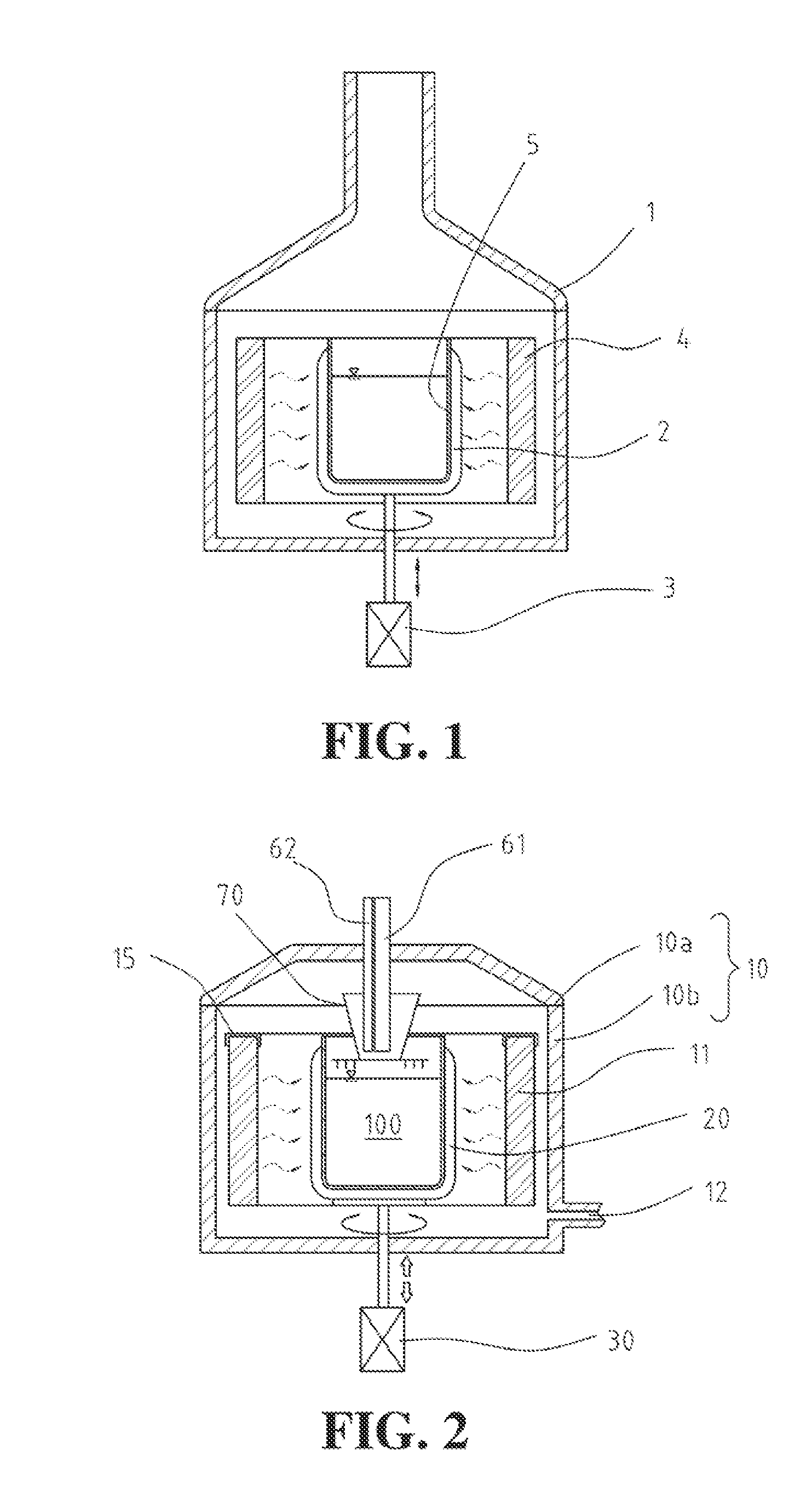

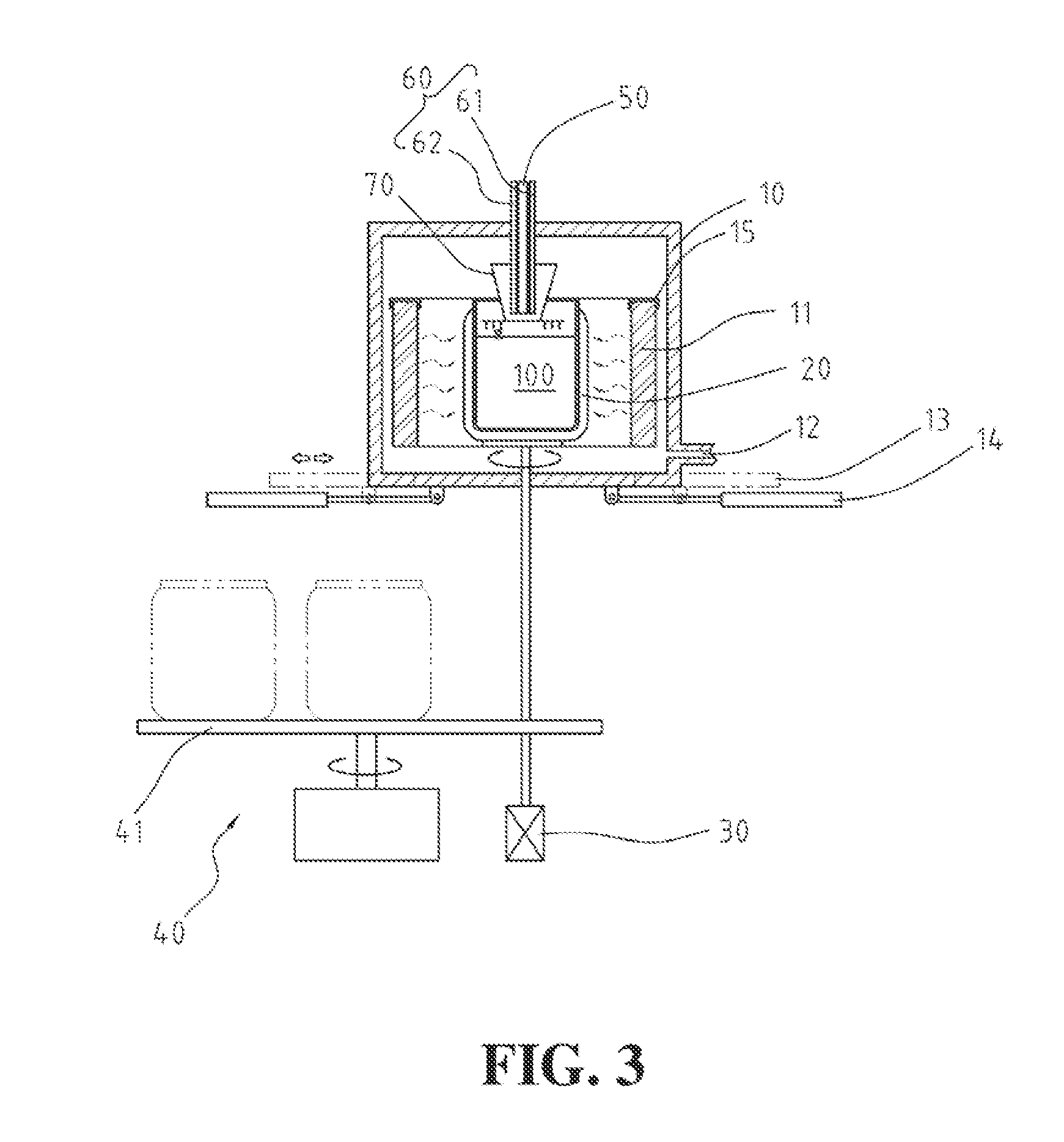

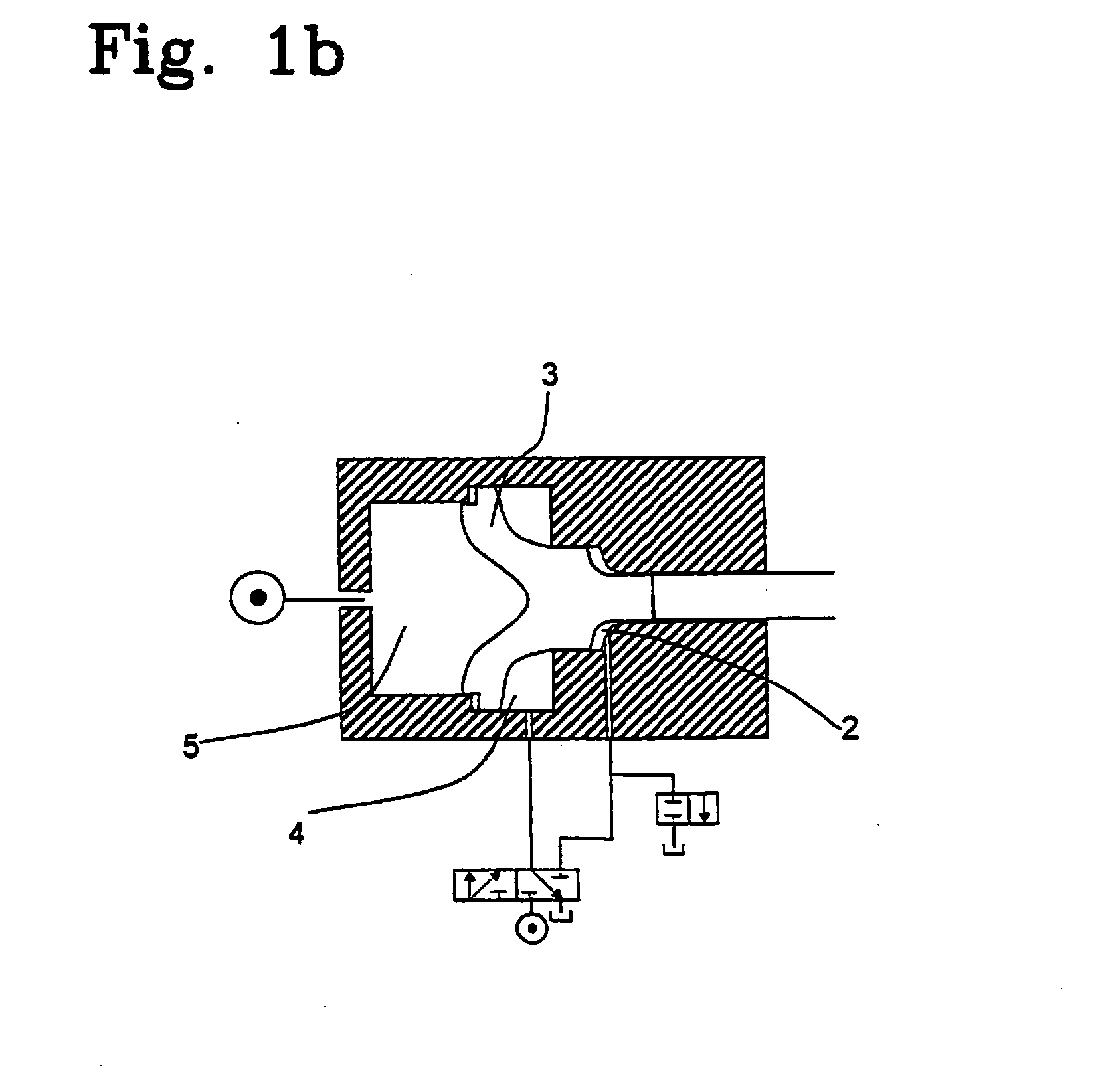

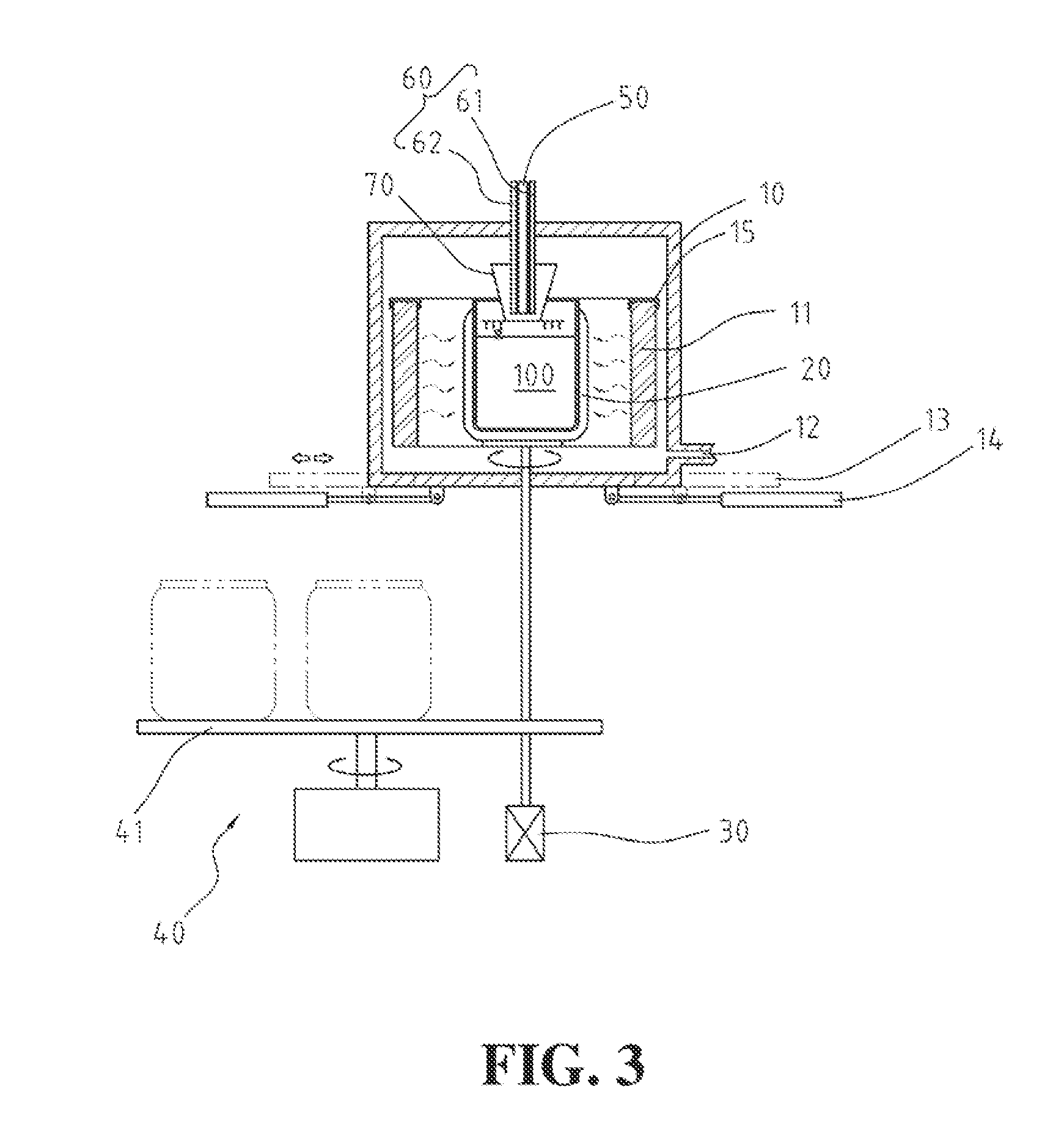

Apparatus for purifying metallurgical silicon for solar cells

InactiveUS20110198336A1Ensure safetyImprove purification efficiencyPolycrystalline material growthElectric discharge heatingCelsius DegreeCrucible

A system for forming high quality silicon material, e.g., polysilicon. In a specific embodiment, the melted material comprises a silicon material and an impurity, e.g., phosphorous species. The system includes a crucible having an interior region. In a specific embodiment, the crucible is made of a suitable material such as a quartz material or others. The quartz material is capable of withstanding a temperature of at least 1400 Degrees Celsius for processing silicon. In a specific embodiment, the crucible is configured in an upright position and has an open region to expose a melted material. In a specific embodiment, the present system has an energy source. Such energy source may be an arc heater or other suitable heating device, including multiple heating devices, which may be the same or different. The arc heater is configured above the open region and spaced by a gap between the exposed melted material and a muzzle region of the arc heater to cause formation of a determined temperature profile within a vicinity of a center region of the exposed melted material while maintaining outer regions of the melted material at a temperature below a melting point of the quartz material of the crucible. In a specific embodiment, the system produces a melted material comprising a resulting phosphorous species of 0.1 ppm and less, which is purified silicon.

Owner:HOSHINO MASAHIRO +1

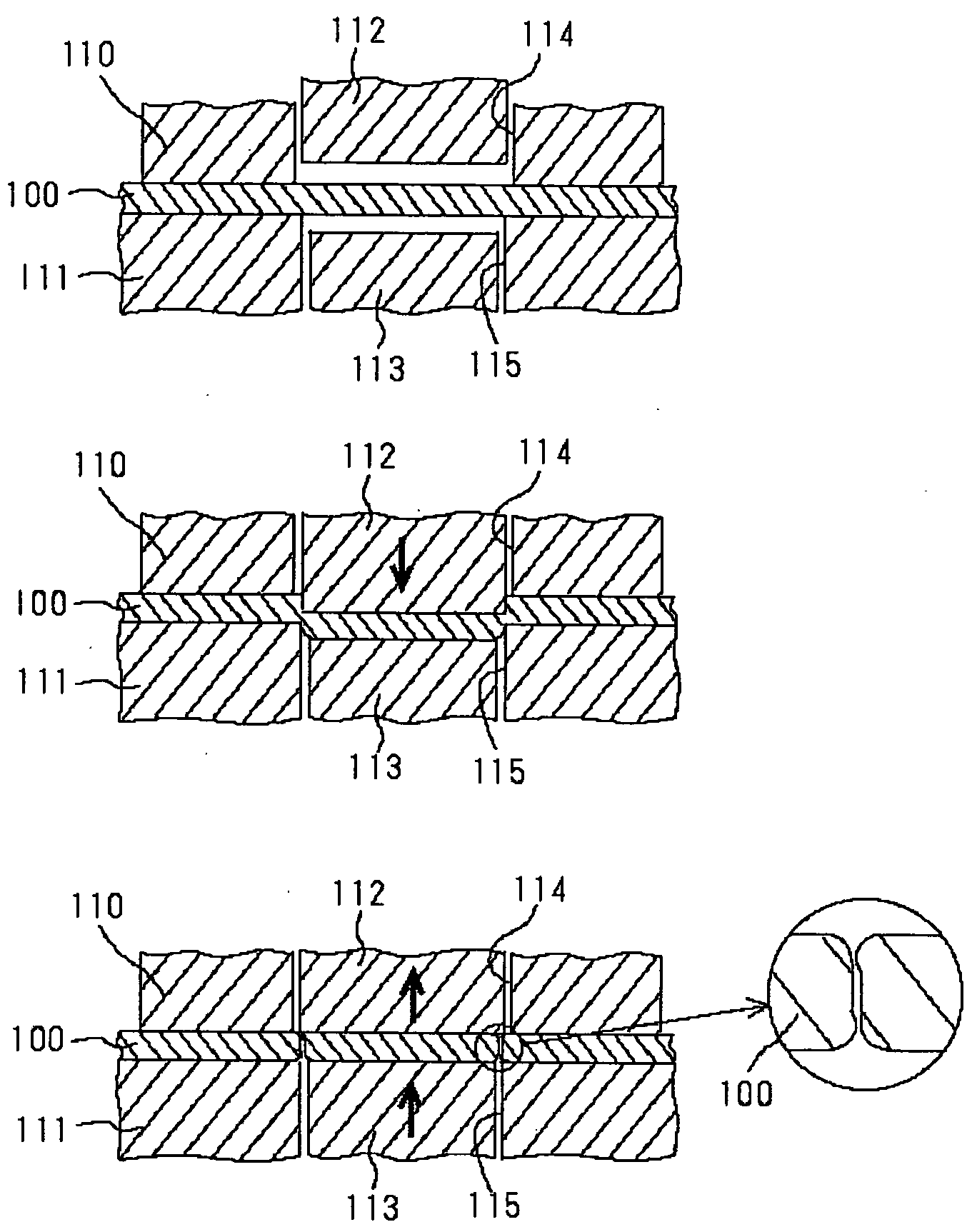

Shearing method for thin plate

A shearing method for a thin plate including forming a protruded product part having a first sagging part when the thin plate with a thickness of up to approximately 5 mm is performed with a half die cutting by pressing the half die cutting punch slightly larger than the half die cutting hole to form a shallow recessed part, fixing the product part by a fixing member, forming a second sagging part at an edge portion of the thin plate by pressurizing a scrap part by moving a pressure punch which is provided with a gap between the fixing member and the pressure punch and by being bent between the scrap part and the product part, and then separating the scrap part from the product part.

Owner:NAKAMURA SEISAKUSHO KK

Shearing method for thin plate

InactiveUS20060277961A1Low costReduce manufacturing stepsMetal working apparatusEngineeringProduct Part

A shearing method for a thin plate including forming a protruded product part having a first sagging part when the thin plate with a thickness of up to approximately 5mm is performed with a half die cutting by pressing the half die cutting punch slightly larger than the half die cutting hole to form a shallow recessed part, fixing the product part by a fixing member, forming a second sagging part at an edge portion of the thin plate by pressurizing a scrap part by moving a pressure punch which is provided with a gap between the fixing member and the pressure punch and by being bent between the scrap part and the product part, and then separating the scrap part from the product part.

Owner:NAKAMURA IND MFG CO LTD

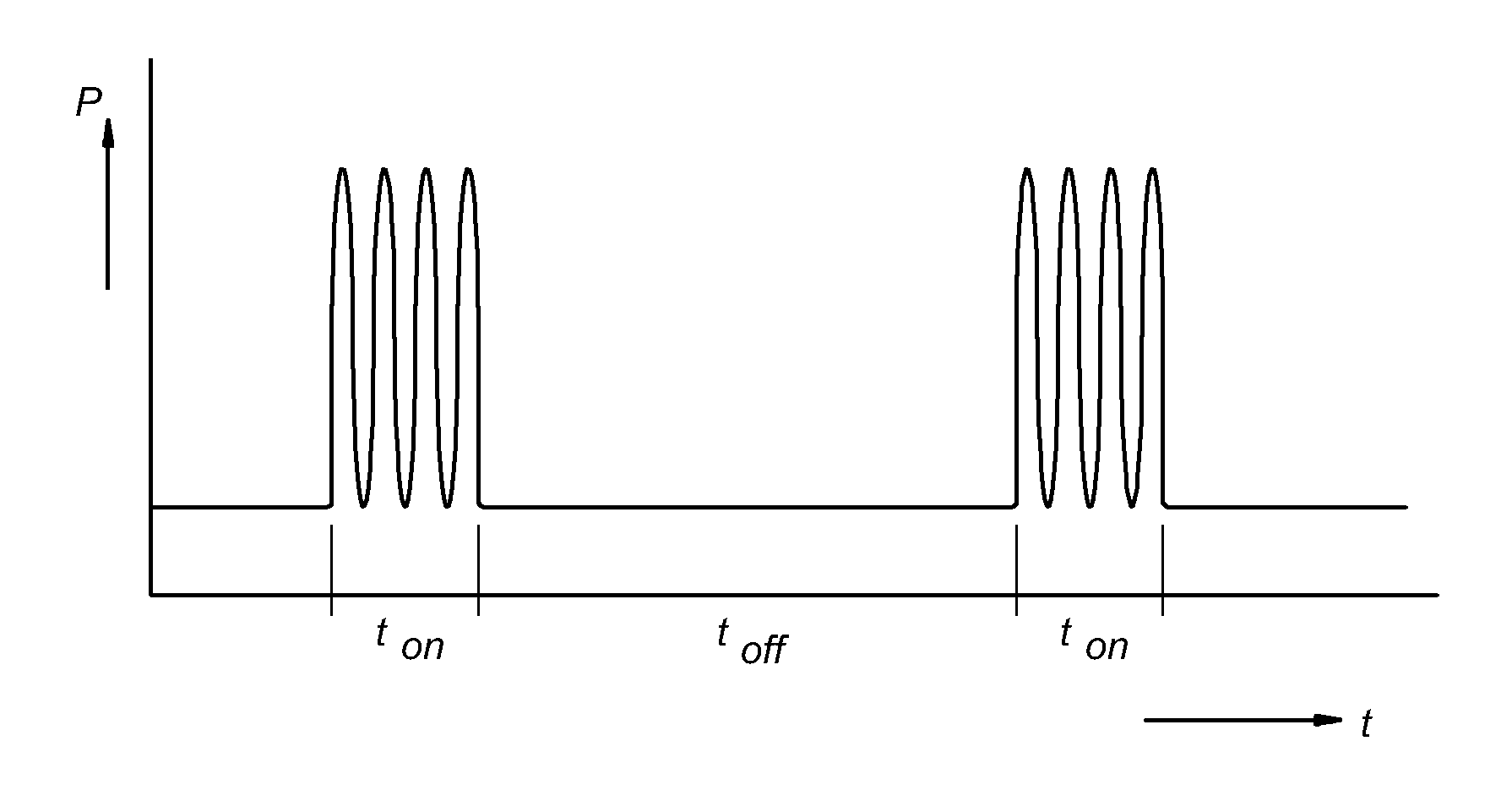

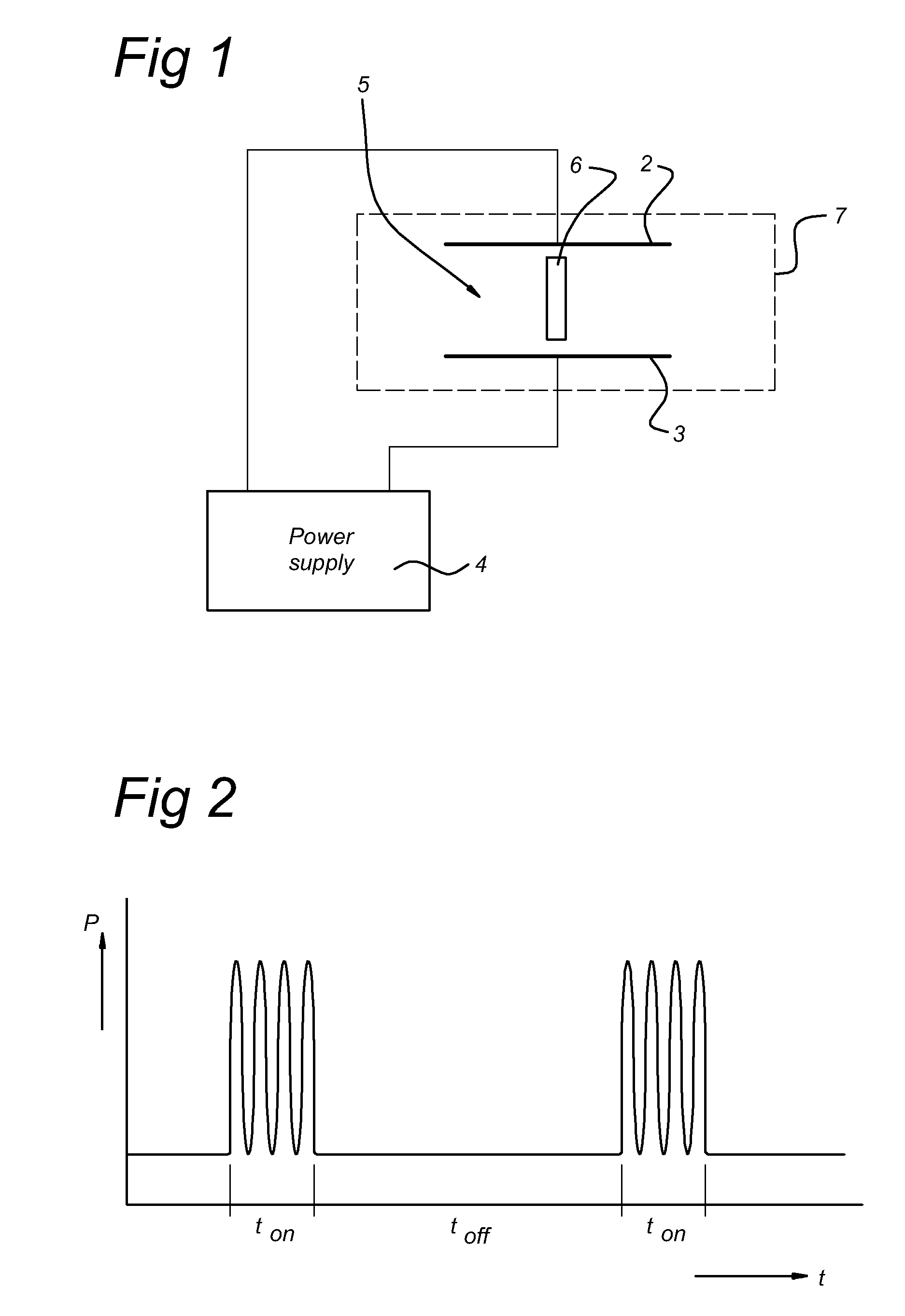

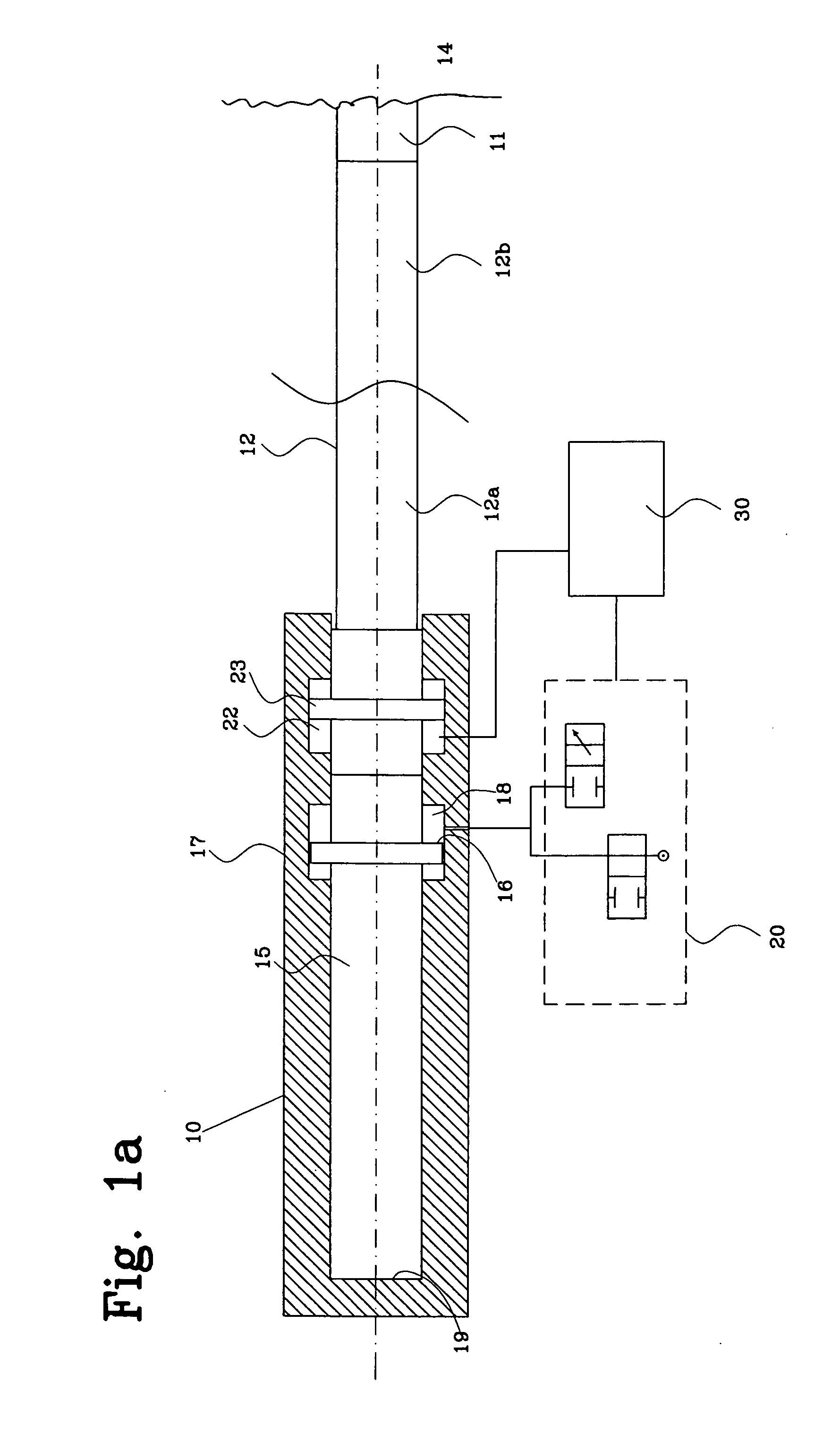

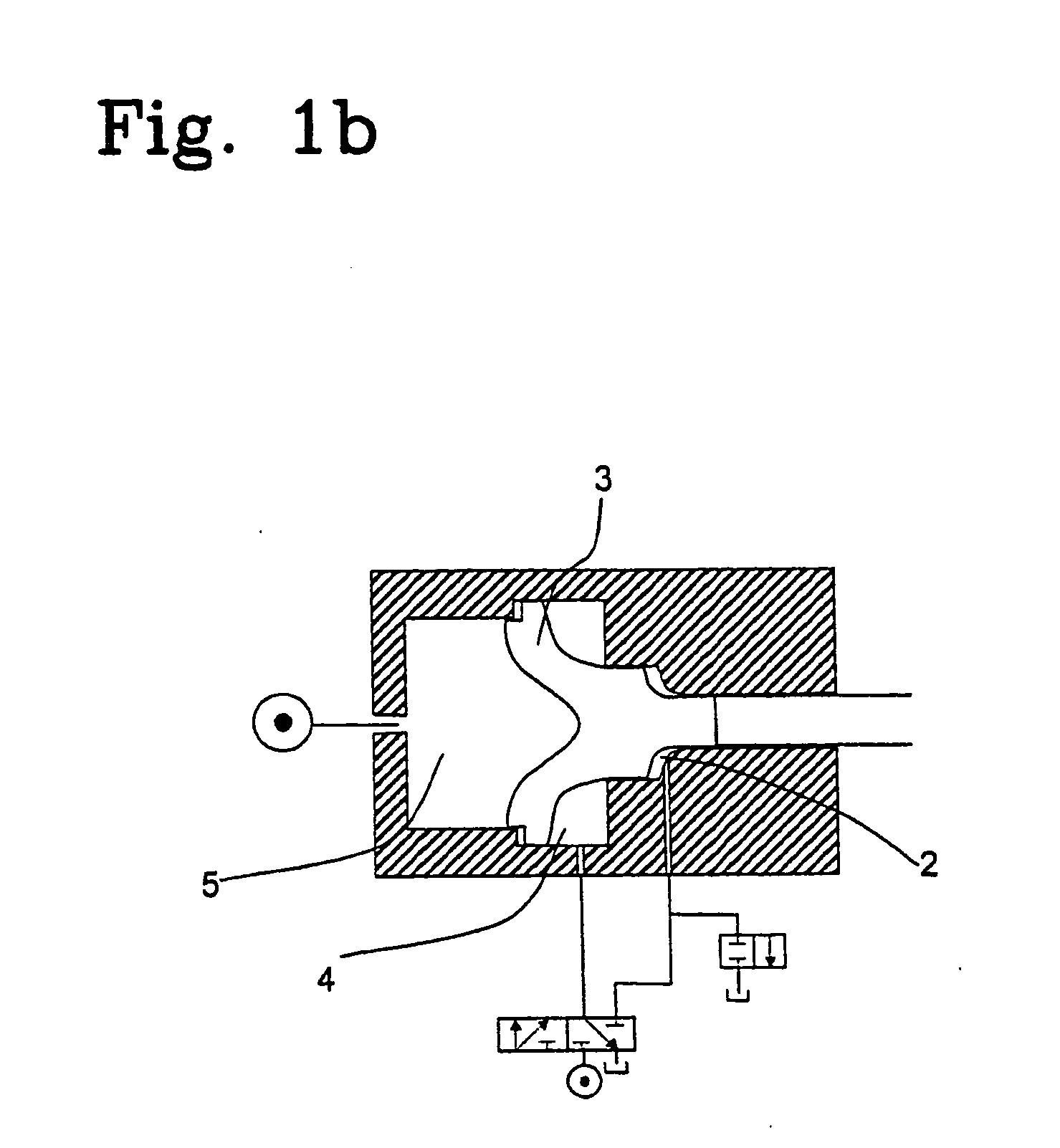

Short pulse atmospheric pressure glow discharge method and apparatus

InactiveUS20090304949A1Restrict formEnhance layeringElectric discharge tubesChemical vapor deposition coatingGas compositionProduct gas

Method and plasma generating apparatus for generating an atmospheric pressure glow discharge plasma in a treatment space (5) filled with a gas composition. Two electrodes (2, 3) are connected to a power supply (4) for providing electrical power during an on-time (ton). The power supply (4) is arranged to provide a periodic signal with an on-time (ton) which is shorter than a predetermined time period, the predetermined time period corresponding substantially to the time necessary for a dust coagulation center from the gas composition to become a cluster in the treatment space (5). This method and apparatus may be used for depositing a layer of material on a substrate (6) in the treatment space (5).

Owner:FUJIFILM MFG EURO

Shearing method for thin plate

Owner:NAKAMURA SEISAKUSHO KK

Contactless power transferring apparatus

ActiveUS7750508B2Prevent fallingDesign freedom is reducedBatteries circuit arrangementsTransformersElectric power transmissionEngineering

A contactless power transferring apparatus includes a terminal loading portion, a primary coil, an up-down-direction pressing portion, a width direction pressing portion and a thickness direction pressing portion. The terminal loading portion has an opening through which a mobile terminal is inserted and loaded. The primary coil transfers power using electromagnetic induction to a secondary coil incorporated in the mobile terminal. When the mobile terminal is inserted inside the terminal loading portion, the pressing portions operate in an up-down direction, in a left-right direction and in a width direction, to press and support the mobile terminal respectively from below to position the coils in the up-down direction, from the width direction to position the coils in the left-right direction and from the thickness direction to dispose the coils a predetermined distance apart.

Owner:SONY MOBILE COMM INC +1

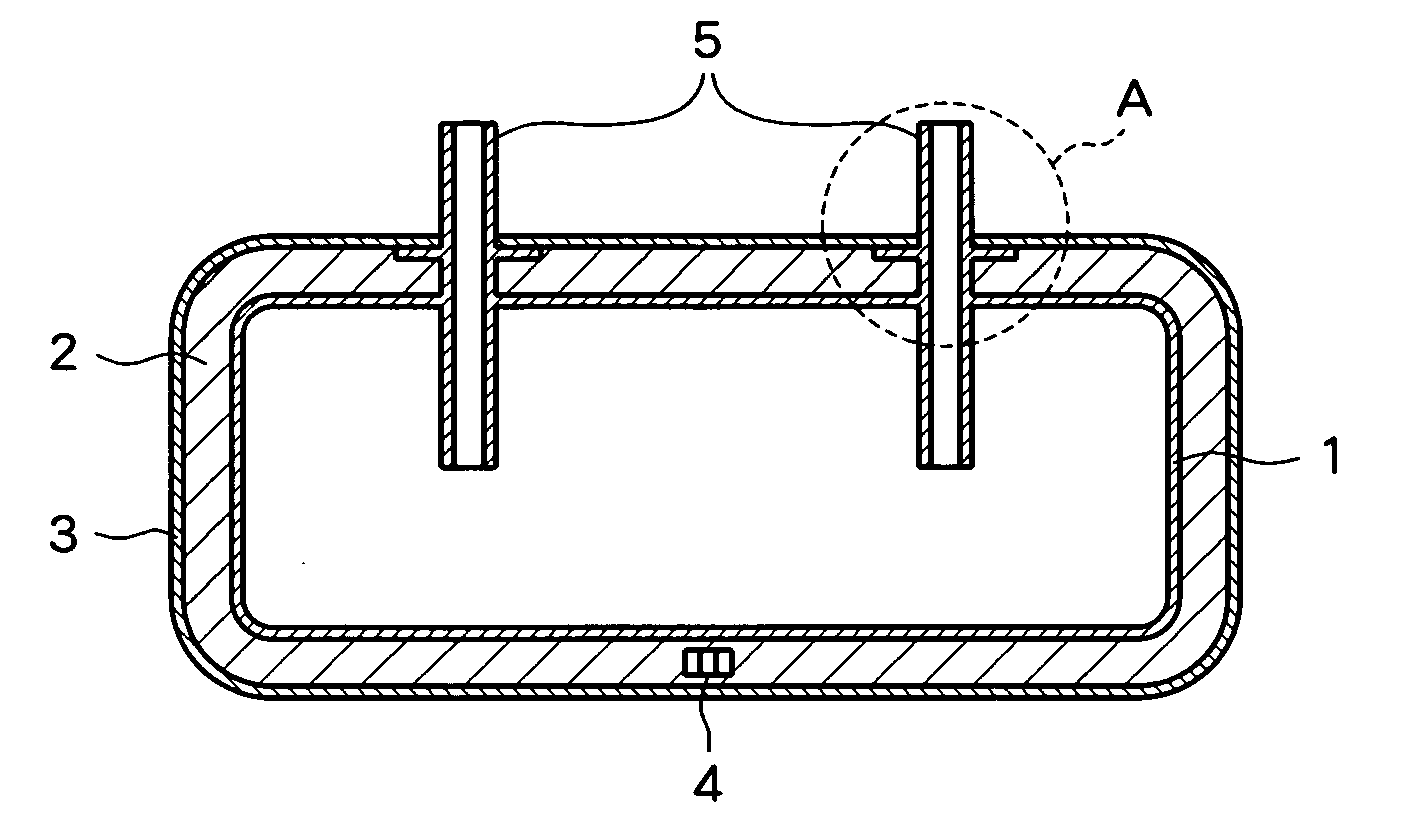

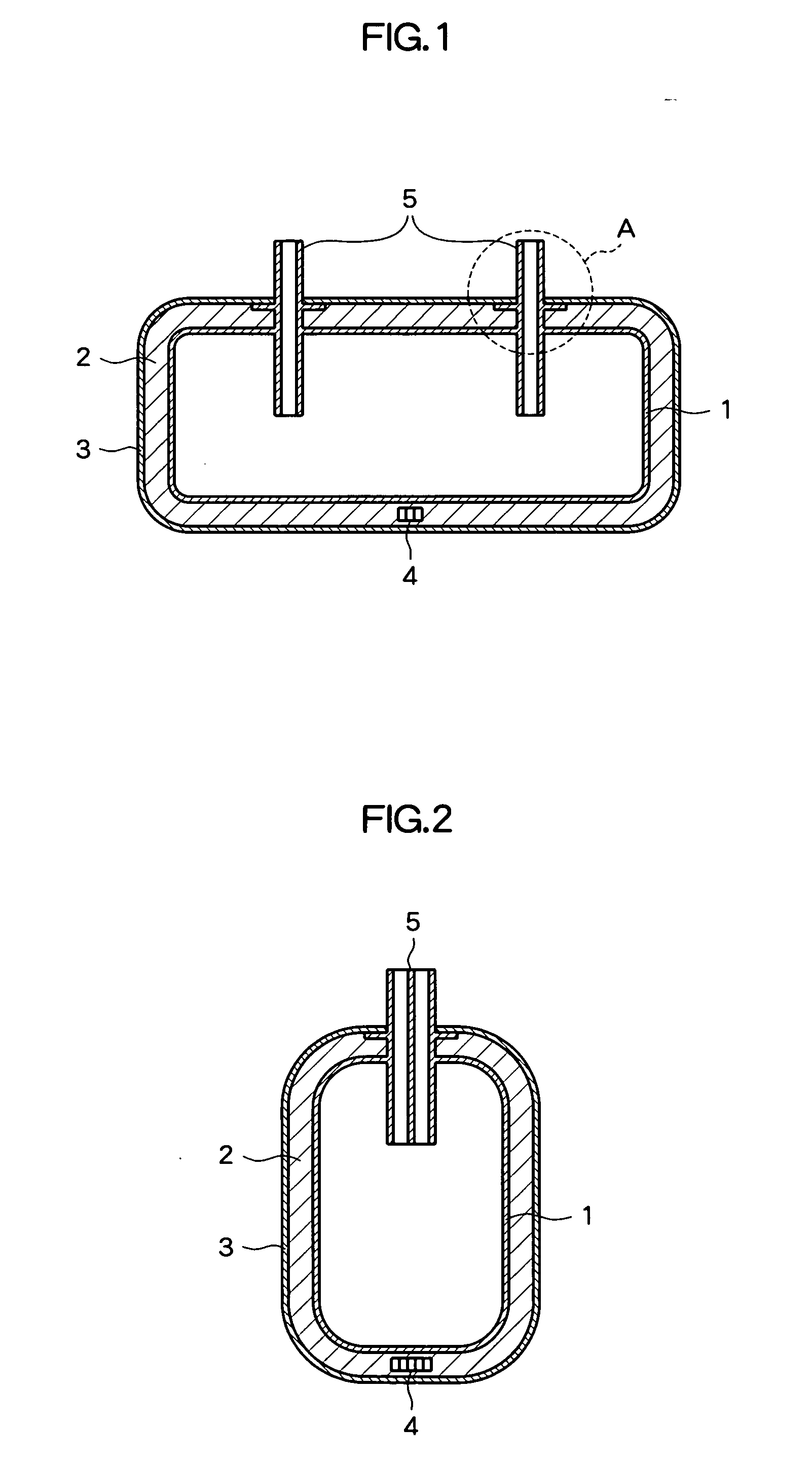

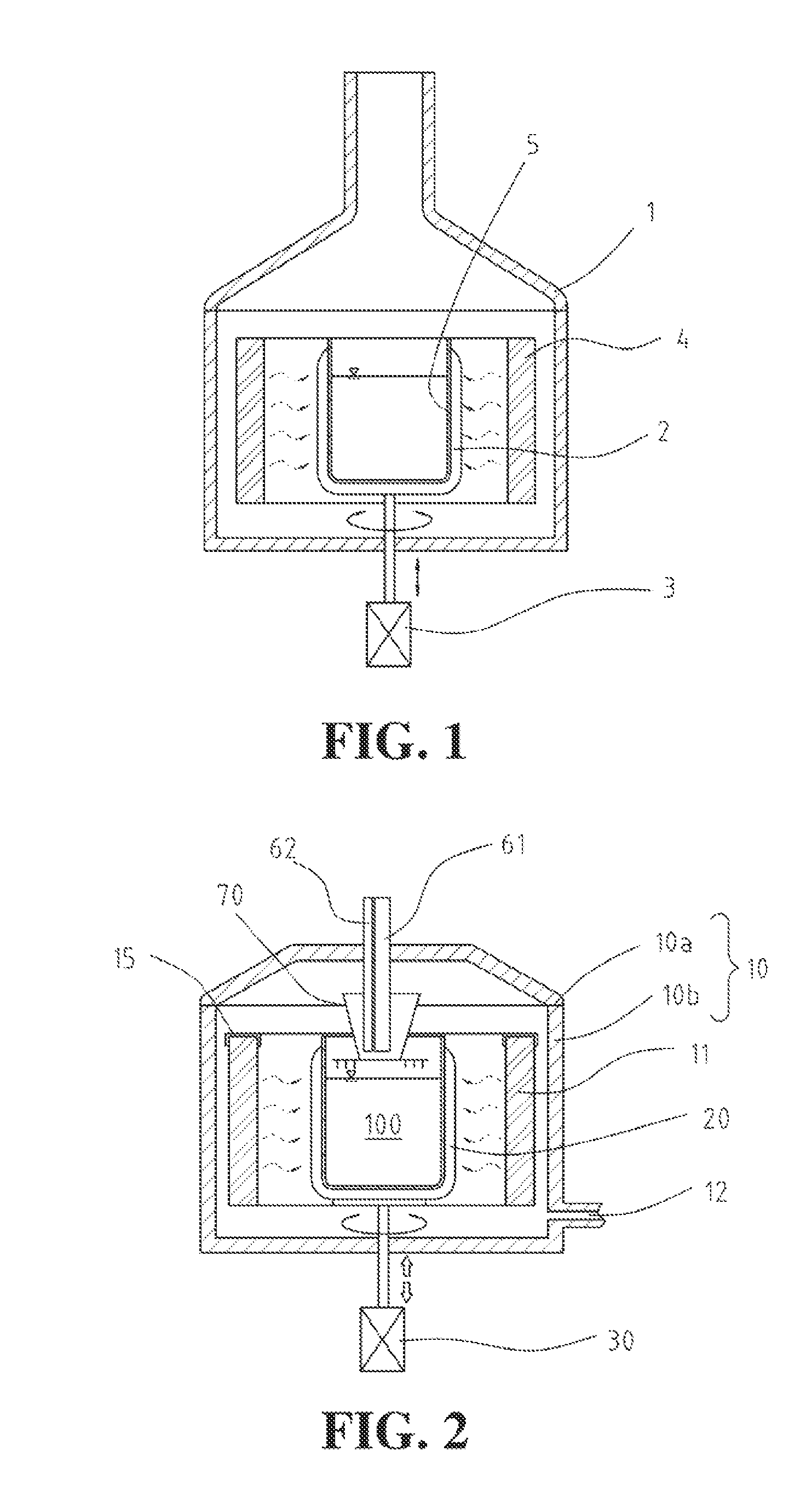

Heat-insulating container and method for manufacturing same

InactiveUS20080237244A1Reduce pressureExcellent heat insulating propertyDomestic cooling apparatusPaper-makingEngineeringFlange

The present invention provides a heat-insulating container and a method for manufacturing the same which make it possible to lower manufacturing costs, and to obtain a sufficient heat-insulating effect, and which are also suitably used in a limited installation space such as an engine compartment or the like. The present invention is a heat-insulating container for storing and maintaining a temperature of a liquid, comprising an inside container (1) having inlet and outlet opening part (5) for the liquid, and a sheet-form outer covering (3) which accommodates the inside container (1). A heat-insulating material (2) is sealed between the outer covering (3) and the inside container (1), and a heat-insulating space in a state of reduced pressure is formed between the outer covering (3) and the inside container (1), flange parts are formed on the liquid inlet and outlet openings of the inside container (1), the outer covering (3) and the inside container (1) are joined by the flange parts. The resulting heat-insulating container has exceptional heat-insulating properties and can be used in a limited space.

Owner:NICHIAS CORP

Method for purifying metallurgical silicon for solar cells

ActiveUS20110200514A1Ensure safetyImprove purification efficiencyPolycrystalline material growthElectric discharge heatingThermal energyCelsius Degree

The present invention provides a method for forming high quality silicon material, e.g., polysilicon. The method includes transferring a raw silicon material in a crucible having an interior region. The crucible is made of a quartz or other suitable material, which is capable of withstanding a temperature of at least 1400 Degrees Celsius. The method includes subjecting the raw silicon material in the crucible to thermal energy to cause the raw silicon material to be melted into a liquid state to form a melted material at a temperature of less than about 1400 Degrees Celsius. Preferably, the melted material has an exposed region bounded by the interior region of the crucible. The method also includes subjecting an exposed inner region of the melted material to an energy source comprising an arc heater configured above the exposed region and spaced by a gap between the exposed region and a muzzle region of the arc heater to cause formation of determined temperature profile within a vicinity of an inner region of the exposed melted material while maintaining outer regions of the melted material at a temperature below a melting point of the quartz material of the crucible. Preferably, the method removes one or more impurities from the melted material to form a higher purity silicon material in the crucible.

Owner:HOSHINO MASAHIRO +1

Surface nanostructure forming method and base having surface nanostructure

InactiveUS20120295066A1High aspect ratioRestrict formMaterial nanotechnologyLayered productsPeriodic nanostructuresLaser light

A surface nanostructure forming method includes: preparing a substrate having an appropriate processing value; a first process of irradiating a part which is close to a surface of the substrate with laser light having a pulse duration of picosecond order or shorter at an irradiation intensity being close to the appropriate processing value of the substrate, or greater than or equal to the appropriate processing value and less than or equal to an ablation threshold and forming periodic nanostructures in which first modified portions and second modified portions are periodically arranged in a self-assembled manner at a focus at which the laser light is concentrated and in a region being close to the focus; and a second process of performing an etching treatment on the surface of the substrate having the periodic nanostructures formed thereon to form an uneven structure having the first modified portions as valleys.

Owner:THE FUJIKURA CABLE WORKS LTD +2

Free machining steel for use in machine structure of excellent mechanical characteristics

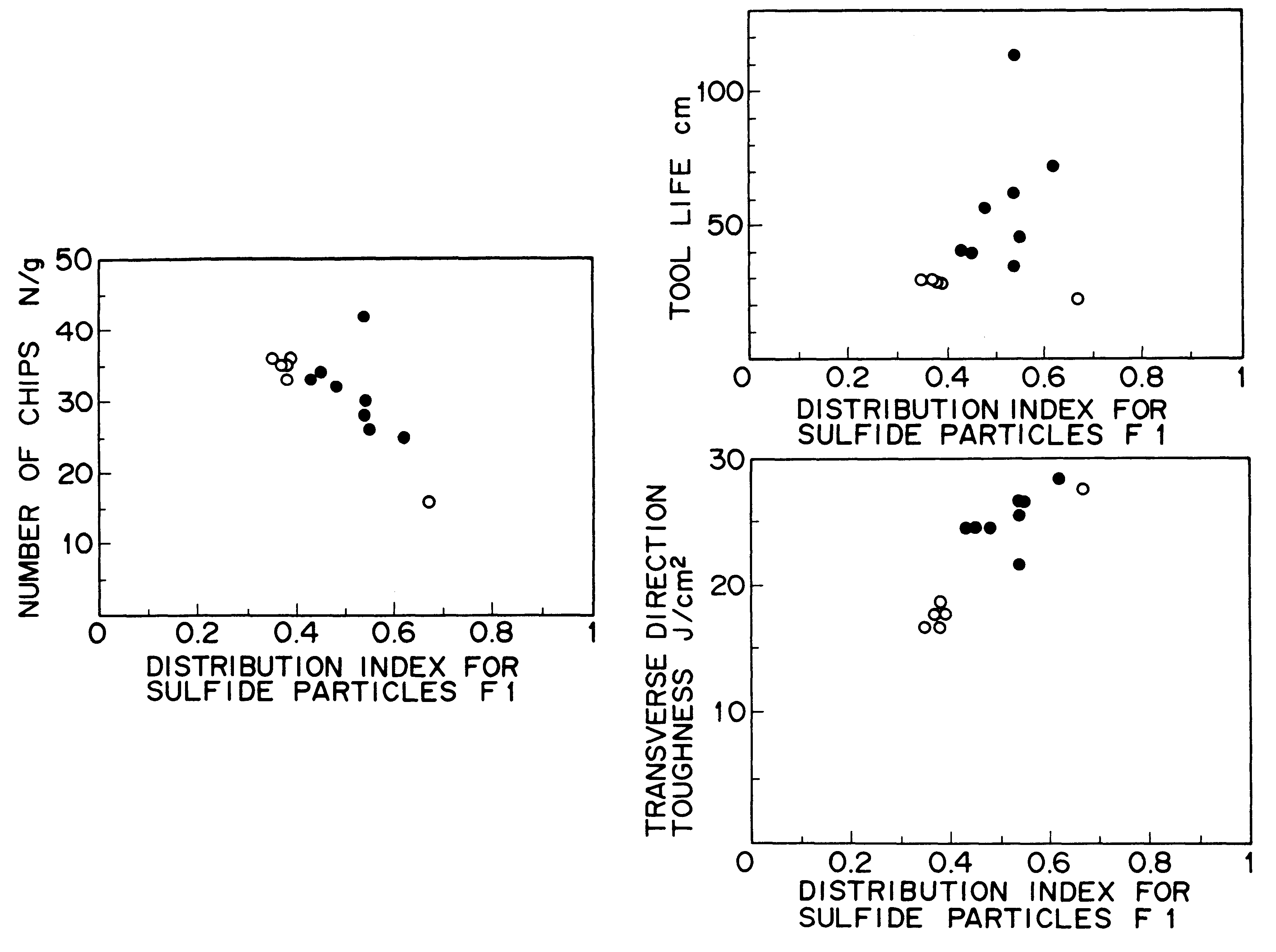

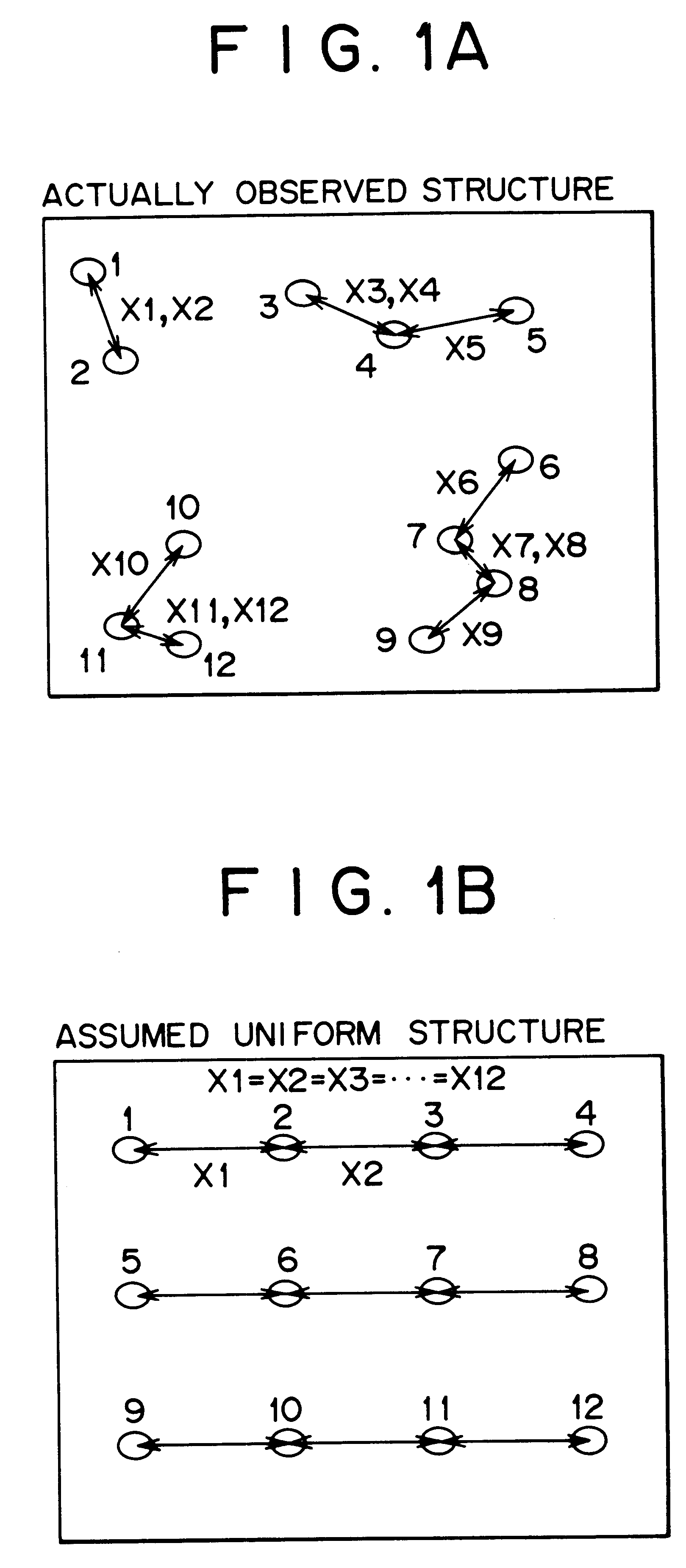

Free machining steel for use in machine structures capable of stably and reliably providing excellent machinability (chip disposability and tool life) and mechanical characteristics (transverse direction toughness) comparable, in a Pb free state, with existent Pb-added steels the machining steel being manufactured so as to contain 0.0005 to 0.02 mass % of Mg and provide a distribution index F1 for the sulfide particles defined by the following equation (1) of 0.4 to 0.65 or a distribution index for the sulfide particles defined by the following equation (2) of 1 to 2.5: <paragraph lvl="0"><in-line-formula>F1=X1 / (A / n)½ (1), or < / in-line-formula><paragraph lvl="0"><in-line-formula>F2=sigmaF / X2 (2) < / in-line-formula>as described in the specification.

Owner:KOBE STEEL LTD

Free machining steel for use in machine structure of excellent mechanical characteristics

Free machining steel for use in machine structures capable of stably and reliably providing excellent machinability (chip disposability and tool life) and mechanical characteristics (transverse direction toughness) comparable, in a Pb free state, with existent Pb-added steels the machining steel being manufactured so as to contain 0.0005 to 0.02 mass % of Mg and provide a distribution index F1 for the sulfide particles defined by the following equation (1) of 0.4 to 0.65 or a distribution index for the sulfide particles defined by the following equation (2) of 1 to 2.5:as described in the specification.

Owner:KOBE STEEL LTD

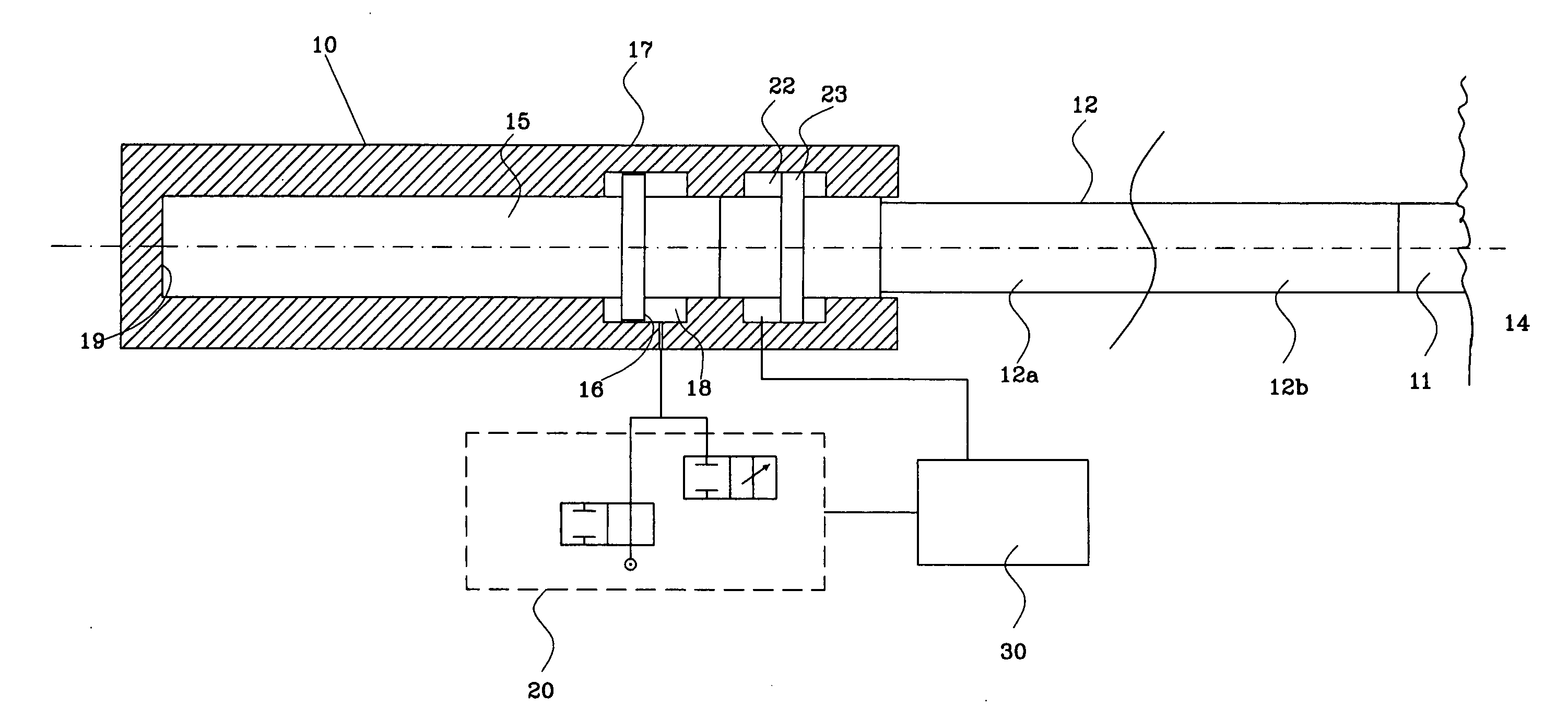

Method and device

InactiveUS20100258326A1Restrict formEasy to controlConstructionsReciprocating drilling machinesShock waveEngineering

The present invention relates to a method for controlling a rock drilling process, in which an impulse-generating device comprising an impact element transmits a shock wave to a tool connected to the impulse-generating device, whereby a portion of the energy of the shock wave is transmitted to the rock by means of the tool and a portion of the energy of the shock wave is reflected and brought back to the impulse-generating device as reflected energy. The method comprises steps of generating at least one parameter value representing the reflected energy, and regulating the interaction of said impact element with said tool at least partially based on said value or values to control the rise time and / or length of said shock wave. The invention also relates to a regulation device, an impulse-generating device and a drilling rig.

Owner:ATLAS COPCO ROCK DRILLS

Method for purifying metallurgical silicon for solar cells

ActiveUS8236265B2Quality improvementFlexible productionPolycrystalline material growthElectric discharge heatingThermal energyCelsius Degree

The present invention provides a method for forming high quality silicon material, e.g., polysilicon. The method includes transferring a raw silicon material in a crucible having an interior region. The crucible is made of a quartz or other suitable material, which is capable of withstanding a temperature of at least 1400 Degrees Celsius. The method includes subjecting the raw silicon material in the crucible to thermal energy to cause the raw silicon material to be melted into a liquid state to form a melted material at a temperature of less than about 1400 Degrees Celsius. Preferably, the melted material has an exposed region bounded by the interior region of the crucible. The method also includes subjecting an exposed inner region of the melted material to an energy source comprising an arc heater configured above the exposed region and spaced by a gap between the exposed region and a muzzle region of the arc heater to cause formation of determined temperature profile within a vicinity of an inner region of the exposed melted material while maintaining outer regions of the melted material at a temperature below a melting point of the quartz material of the crucible. Preferably, the method removes one or more impurities from the melted material to form a higher purity silicon material in the crucible.

Owner:HOSHINO MASAHIRO +1

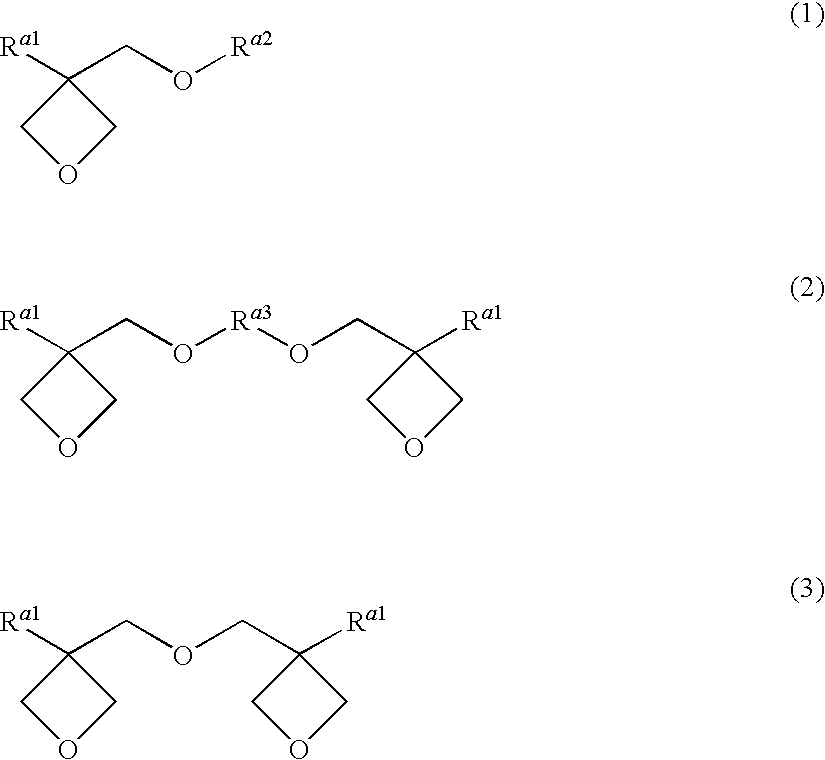

Nonaqueous ink, image-recording method, image-recording apparatus and recorded article

InactiveUS20100196680A1Good dispersionGood effectMaterial nanotechnologyLayered productsImage recordingDistribution function

A nonaqueous ink, having: colorant particles, the colorant particles having an average particle diameter of 1 nm or more and less than 50 nm, and the value (D90-D10) of being 100 nm or less, a dispersant; and a radical-polymerization compound; wherein D90-D10 is a value obtained by subtracting D10 from D90; D90 and D10 represent respectively the particle diameters at cumulative colorant particle numbers of 0.9 (90 number %) and 0.1 (10 number %) in an integral value of the distribution function dG=F(D)dD; and G represents the number of the pigment particles; and D represents the diameter of the particles.

Owner:FUJIFILM CORP

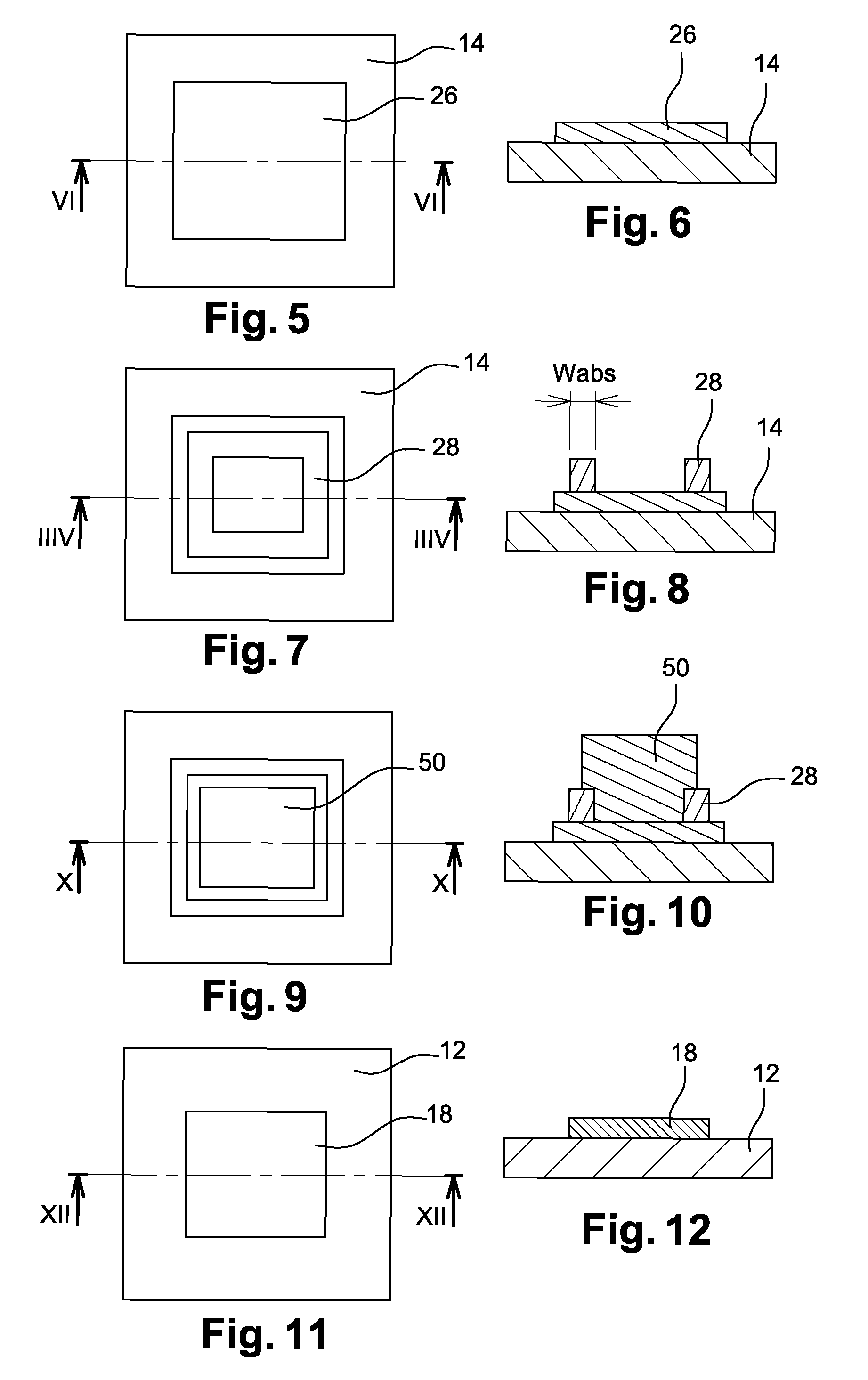

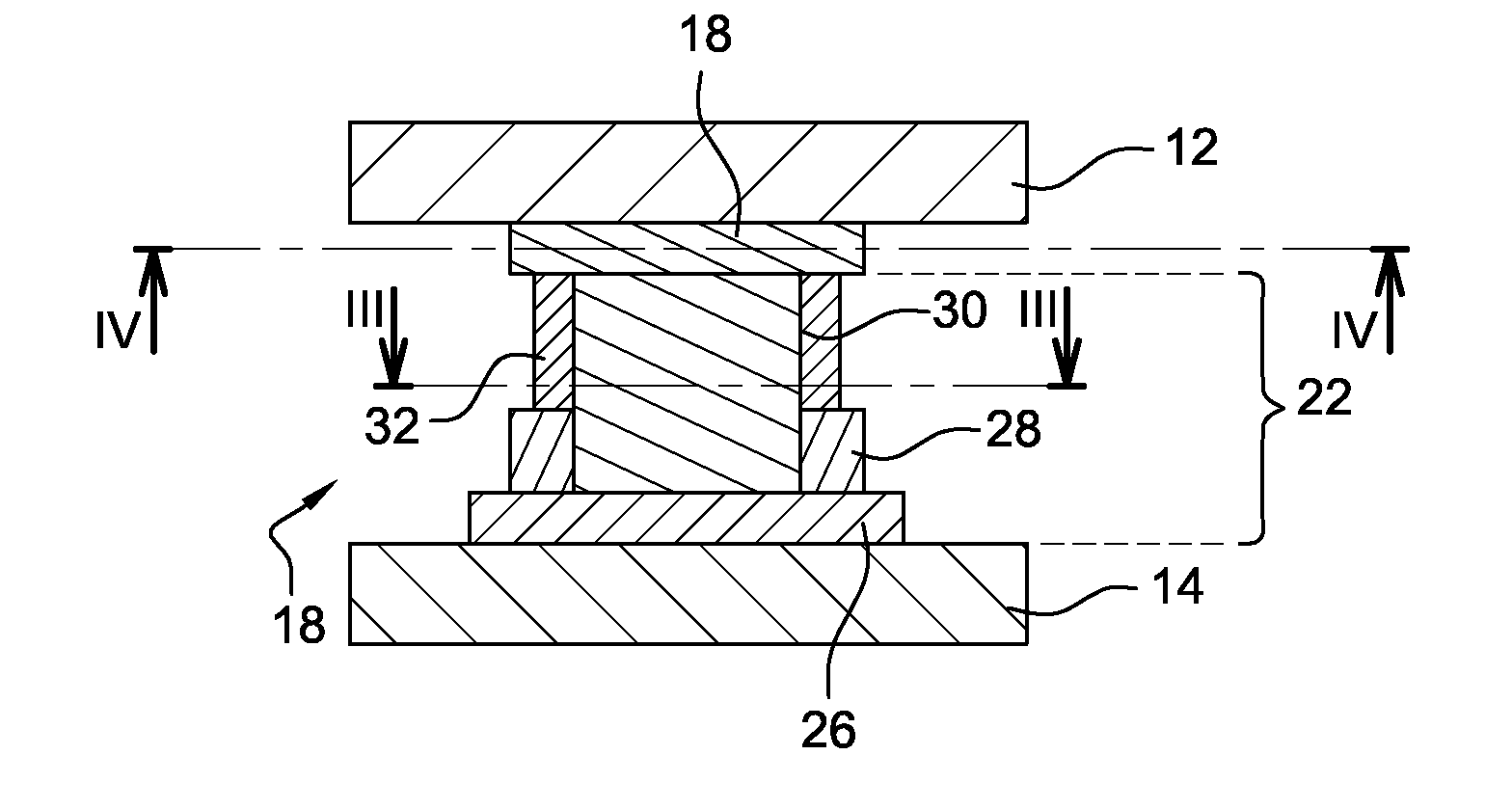

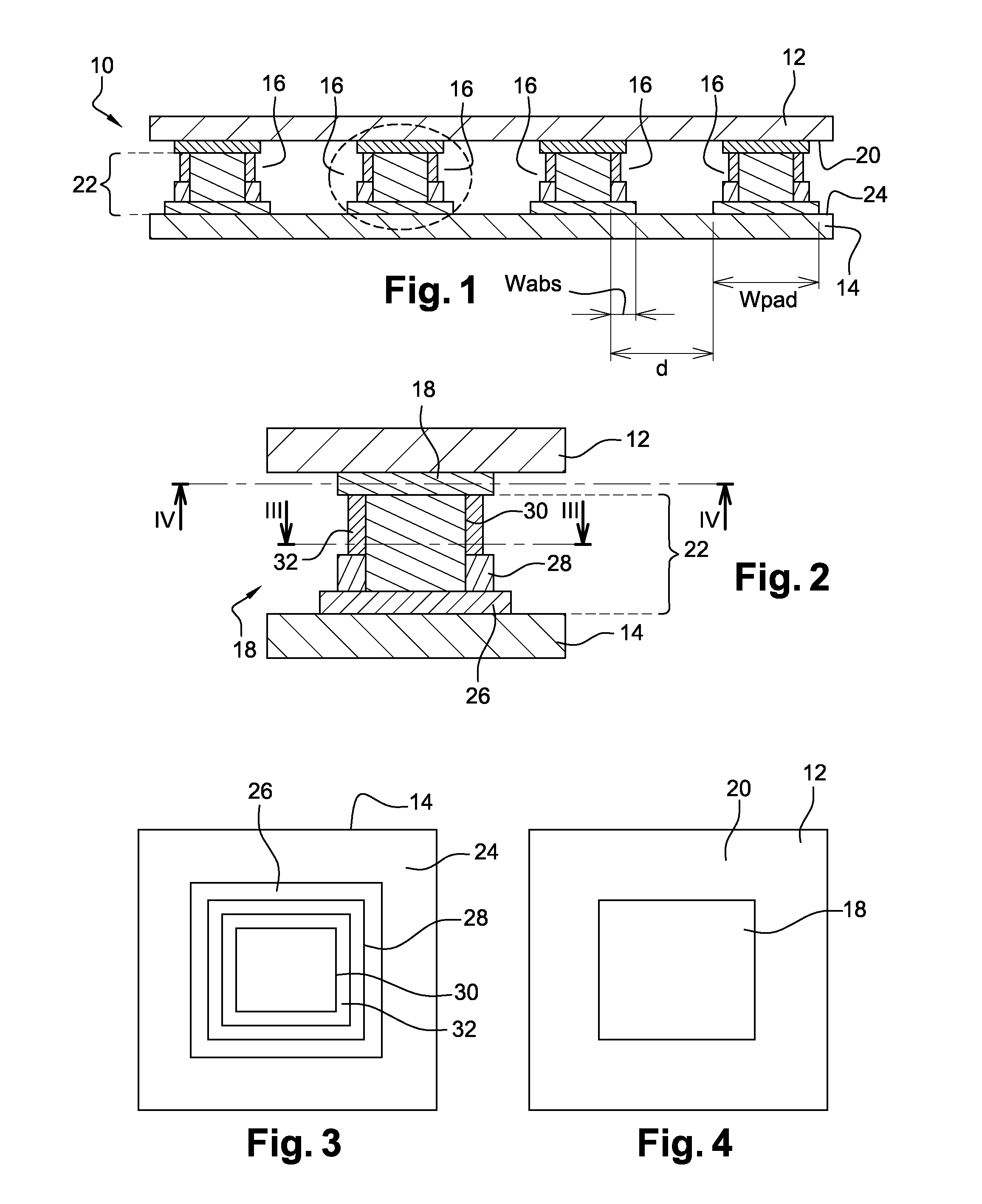

Flip-chip hybridisation of two microelectronic components using a UV anneal

ActiveUS9318453B2Restrict formSemiconductor/solid-state device detailsSolid-state devicesElectricityInterconnection

A method of manufacturing a microelectronic device including a first component hybridized with a second component via electric interconnects, involves the steps of: (i) forming the first and second components, the second component being transparent to ultraviolet radiation at least in line with locations provided for the interconnects; (ii) forming interconnection elements including copper oxide on the second component at the locations provided for the interconnects; (iii) placing the first and second components on each other; and (iv) applying the ultraviolet radiation through the second component on the elements including copper oxide to implement an ultraviolet anneal converting copper oxide into copper.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Flip-Chip Hybridisation Of Two Microelectronic Components Using A UV Anneal

ActiveUS20150221602A1Restrict formSemiconductor/solid-state device detailsSolid-state devicesElectricityInterconnection

A method of manufacturing a microelectronic device including a first component hybridized with a second component via electric interconnects, involves the steps of: (i) forming the first and second components, the second component being transparent to ultraviolet radiation at least in line with locations provided for the interconnects; (ii) forming interconnection elements including copper oxide on the second component at the locations provided for the interconnects; (iii) placing the first and second components on each other; and (iv) applying the ultraviolet radiation through the second component on the elements including copper oxide to implement an ultraviolet anneal converting copper oxide into copper.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Process for producing betaine/amine oxide mixtures

InactiveUS6281176B1Restrict formLow viscosityCosmetic preparationsHair cosmeticsLiquid mediumBetaine

This invention provides a process for producing a betaine / amine oxide mixture. This process comprises reacting, in a liquid medium, an alkali metal omega-halocarboxylate with a first tertiary amine of the formula Ra2RbN, wherein each Ra group is a hydrocarbyl group which independently has from 1 to about 4 carbon atoms, and wherein the Rb group is a hydrocarbyl group which has from about 8 to about 24 carbon atoms, to produce a betaine product solution. To the betaine product solution is added a second tertiary amine of the formula Ra2RbN, wherein each Ra group is a hydrocarbyl group which independently has from 1 to about 4 carbon atoms, and wherein the Rb group is a hydrocarbyl group which has from about 8 to about 24 carbon atoms, to produce an amine / betaine mixture. The first and second tertiary amines can be separate portions of the same amine. Preferably, however, the first and second tertiary amines differ from each other. In a carbon dioxide atmosphere, the amine / betaine mixture is mixed with hydrogen peroxide to yield a betaine / amine oxide mixture.

Owner:ALBEMARLE CORP

Nonaqueous ink, ink set, image-forming method, image-forming apparatus and recorded article

InactiveUS20100247772A1Good dispersionGood effectMaterial nanotechnologyLayered productsDistribution functionColoring agents

A nonaqueous ink, having: colorant particles, the colorant particles having an average particle diameter of 1 nm or more and less than 50 nm, and the value (D90−D10) of being 100 nm or less, a dispersant; and a cationically-polymerizable compound; wherein D90−D10 is a value obtained by subtracting D10 from D90; D90 and D10 represent respectively the particle diameters at cumulative colorant particle numbers of 0.9 (90 number %) and 0.1 (10 number %) in an integral value of the distribution function dG=F(D)dD; and G represents the number of the pigment particles; and D represents the diameter of the particles.

Owner:FUJIFILM CORP

Method and device

InactiveUS20100025106A1Solve problemsRestrict formSurveyPortable percussive toolsShock waveEngineering

The present invention relates to a method for controlling a rock drilling process, in which an impulse-generating device comprising an impact element transmits a shock wave to a tool connected to the impulse-generating device, whereby a portion of the energy of the shock wave is transmitted to the rock by means of the tool and a portion of the energy of the shock wave is reflected and brought back to the impulse-generating device as reflected energy. The method comprises steps of generating at least one parameter value representing the reflected energy, and regulating the interaction of said impact element with said tool at least partially based on said value or values to control the rise time and / or length of said shock wave. The invention also relates to a regulation device, an impulse-generating device and a drilling rigg.

Owner:ATLAS COPCO ROCK DRILLS

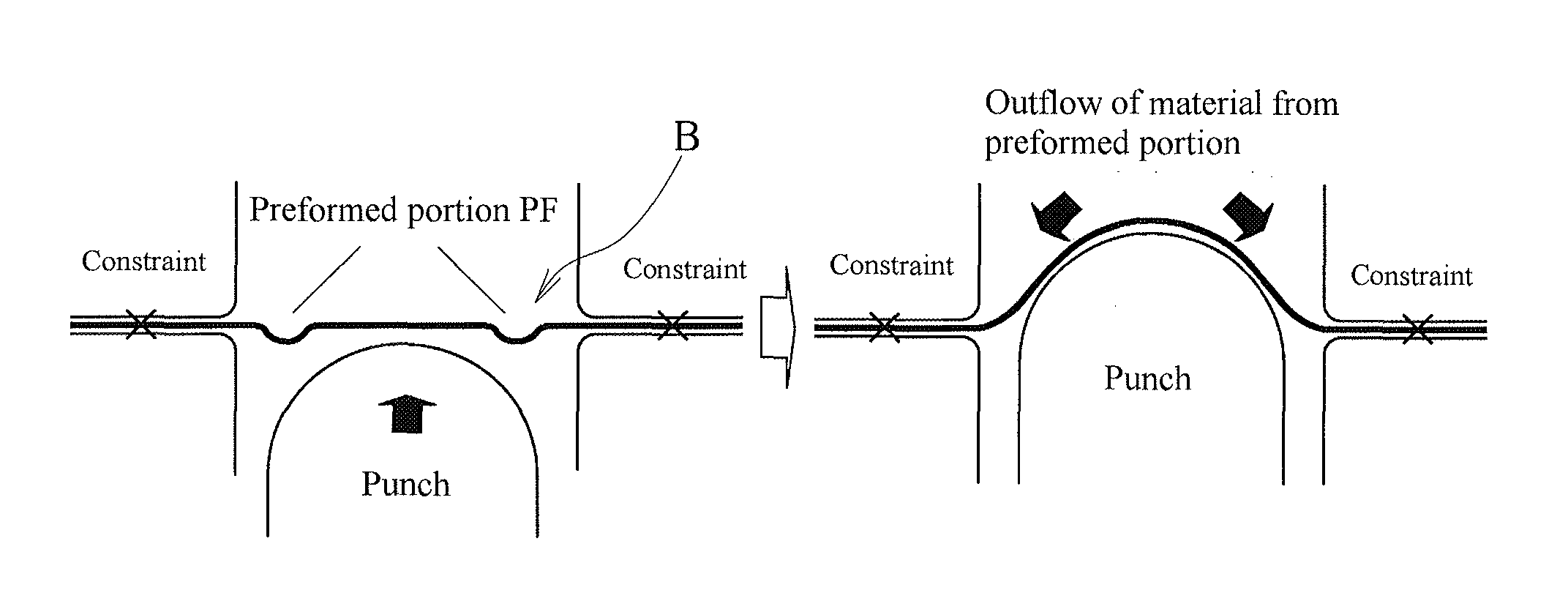

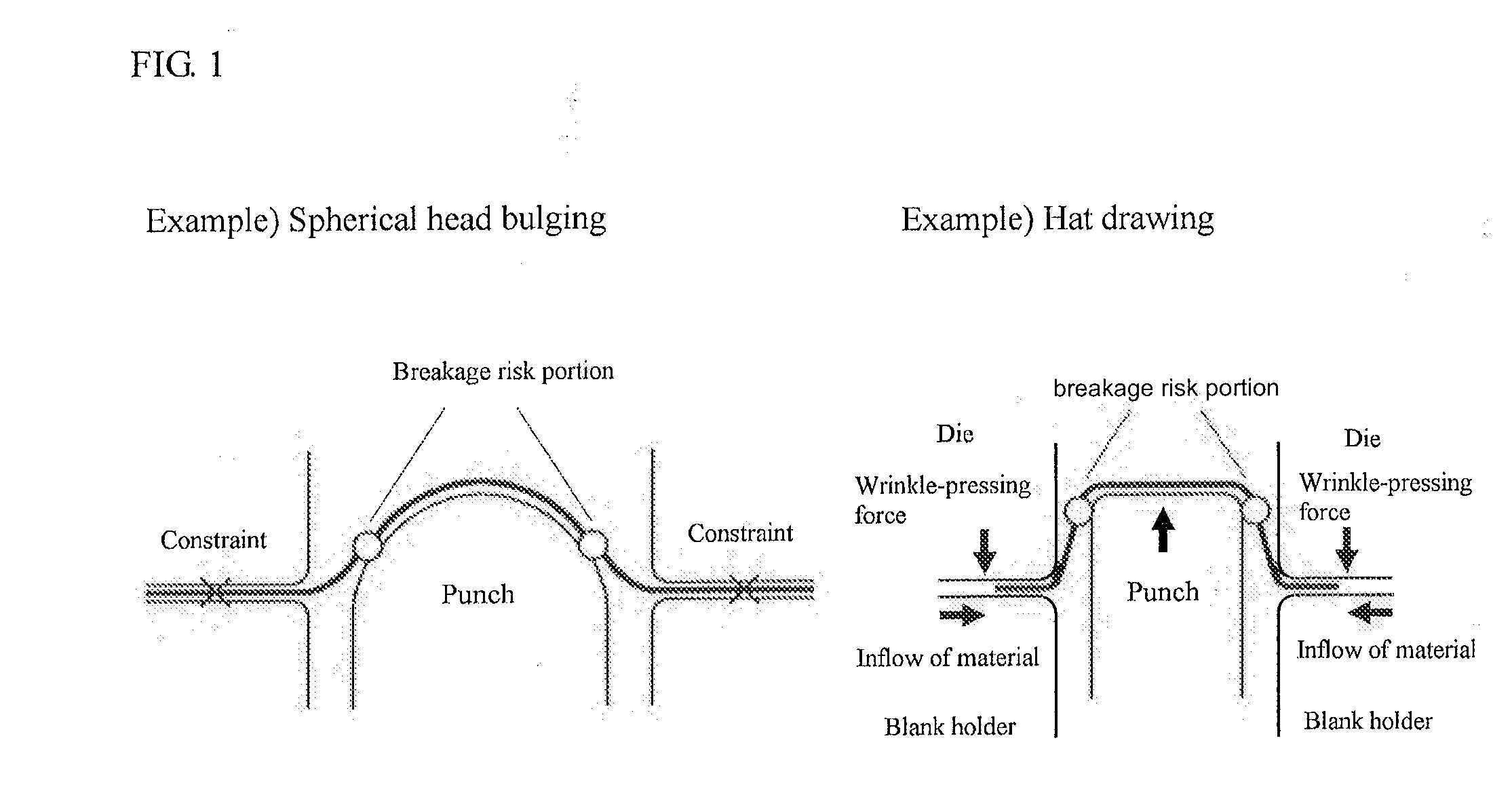

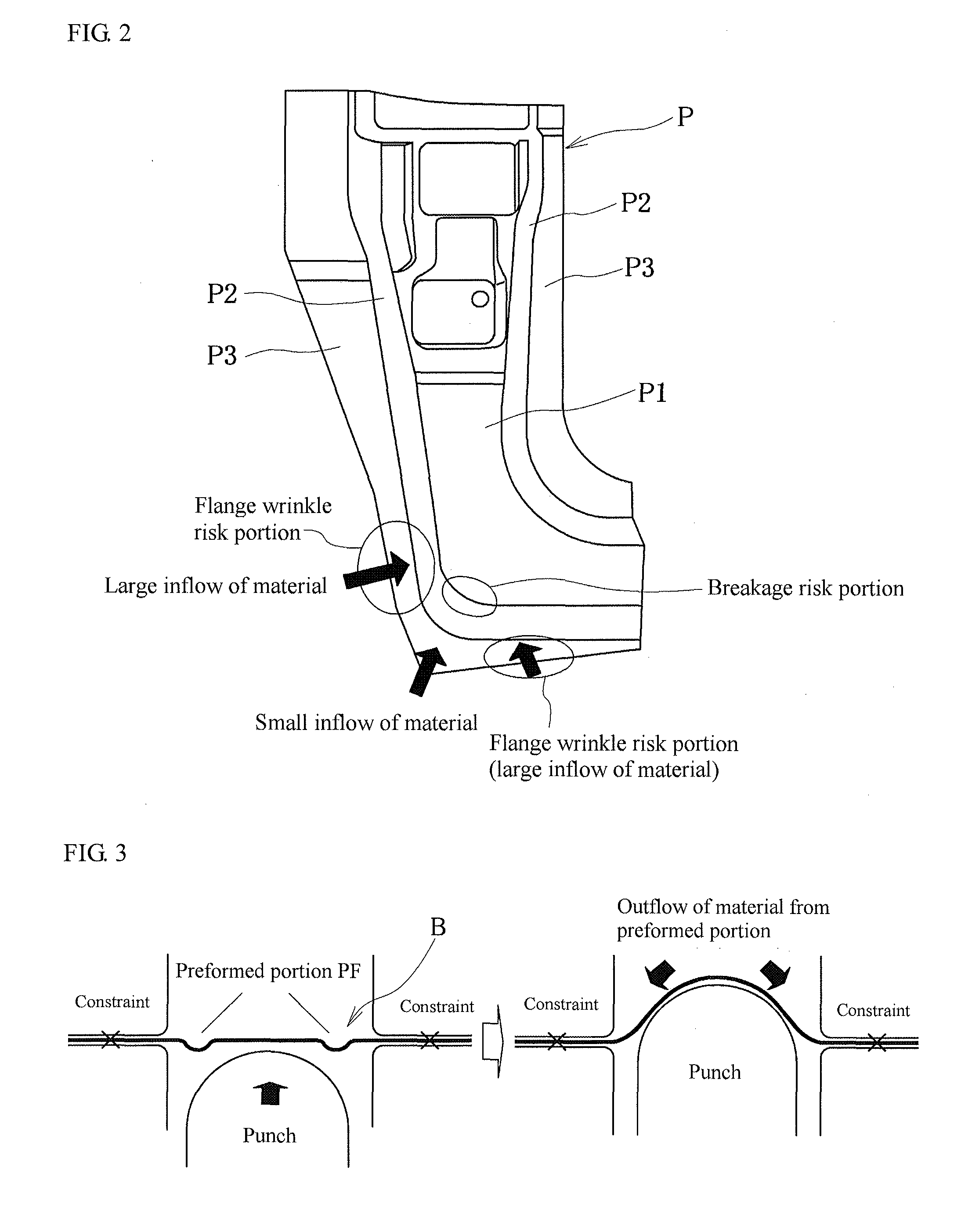

Press molding method, manufacturing method for press-molded component, and method for determining preform shape for use in said methods

ActiveUS20160354825A1Avoid it happening againComplex structureVehicle componentsBead shapeEngineering

A method is provided for press forming a product having a shape of a top board portion, a vertical wall portion continuously formed from the top board portion and a flange portion continuously formed from the vertical wall portion at a press process of two or more stages, wherein a convex or concave bead shape is preformed in a position of a flat metal sheet as a raw material corresponding to a neighborhood of a position generating breakage or flange wrinkles when the raw material is formed into a product shape, and thereafter a product shape is press formed from the raw material having the preformed bead shape.

Owner:JFE STEEL CORP

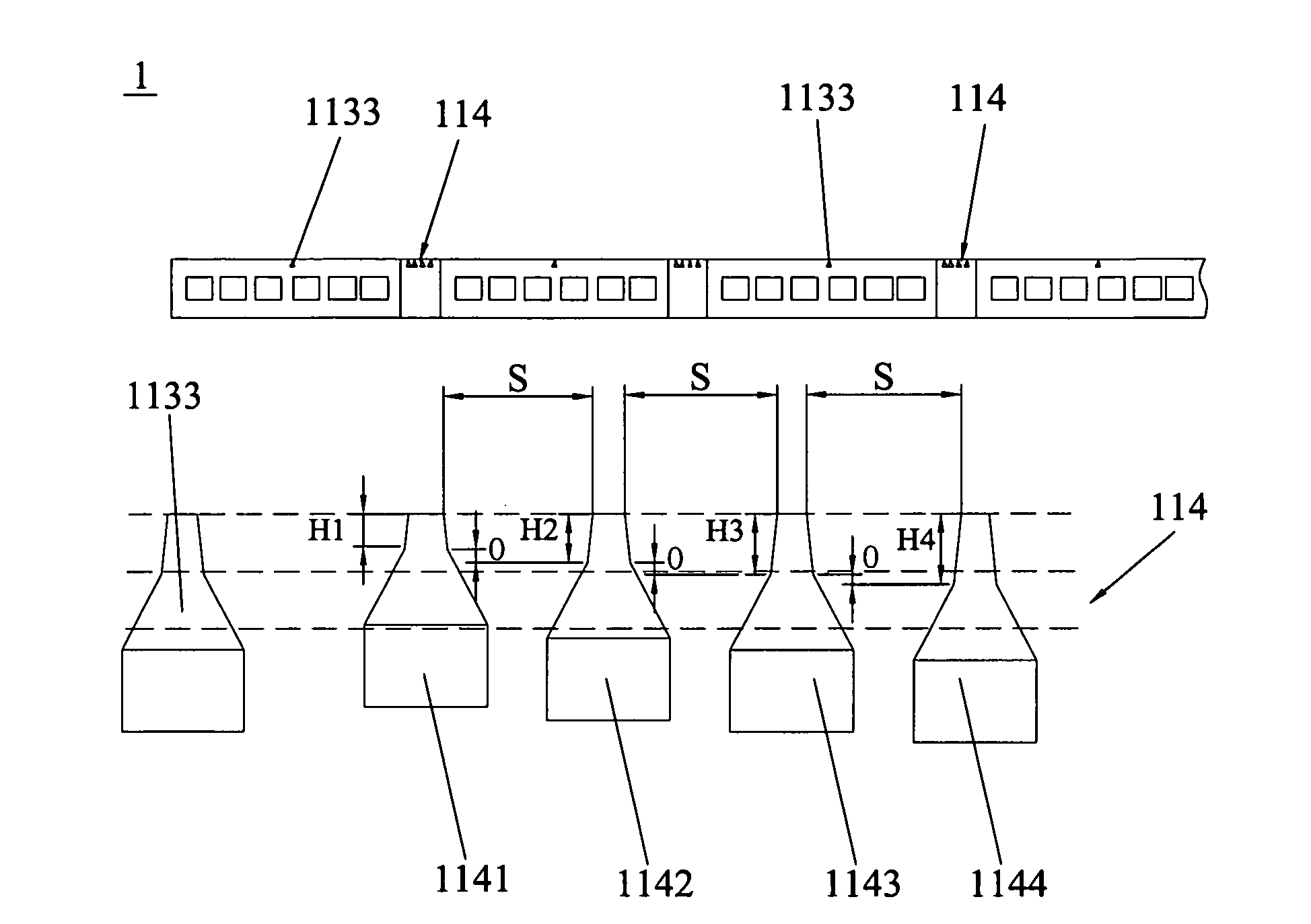

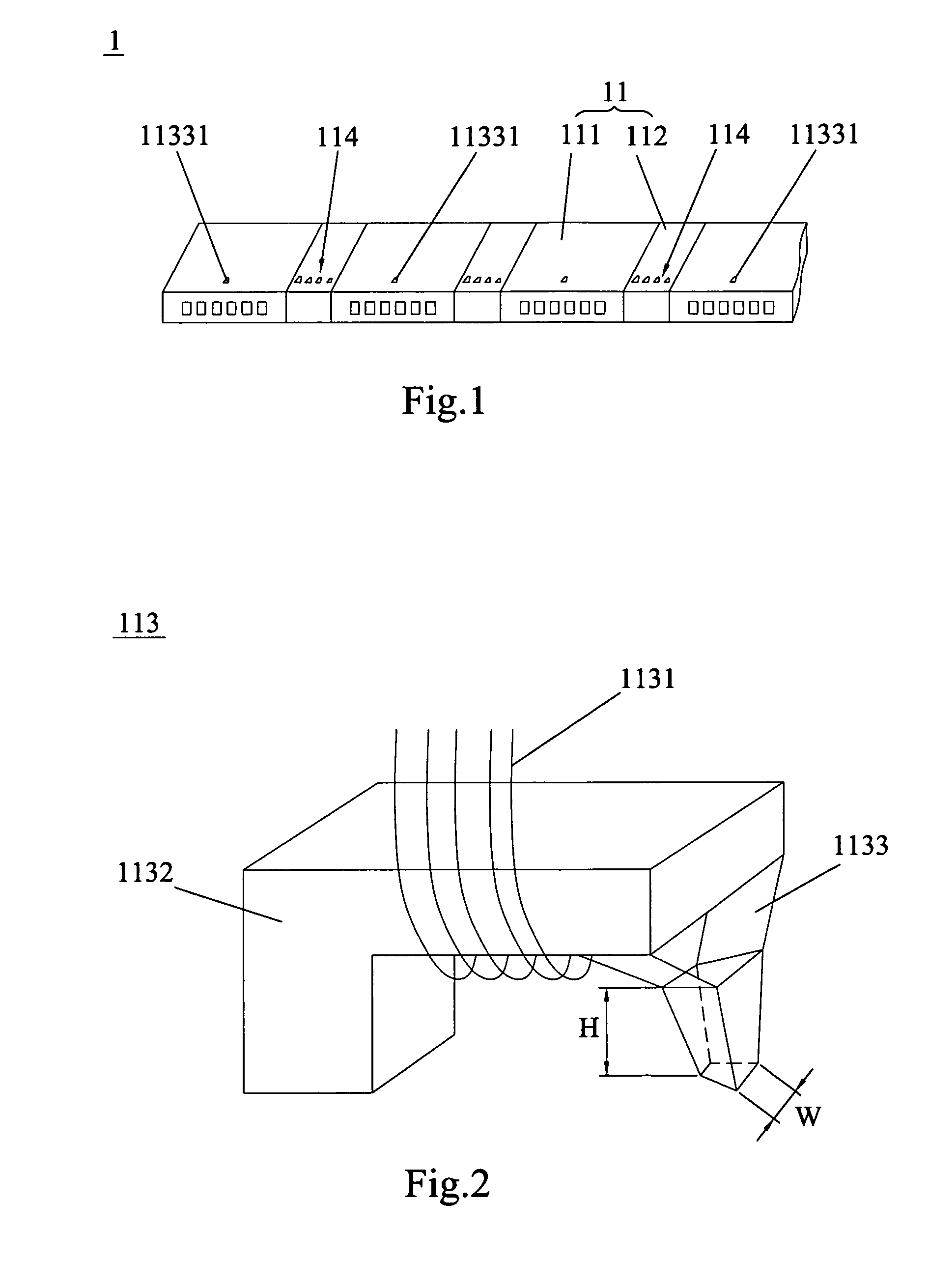

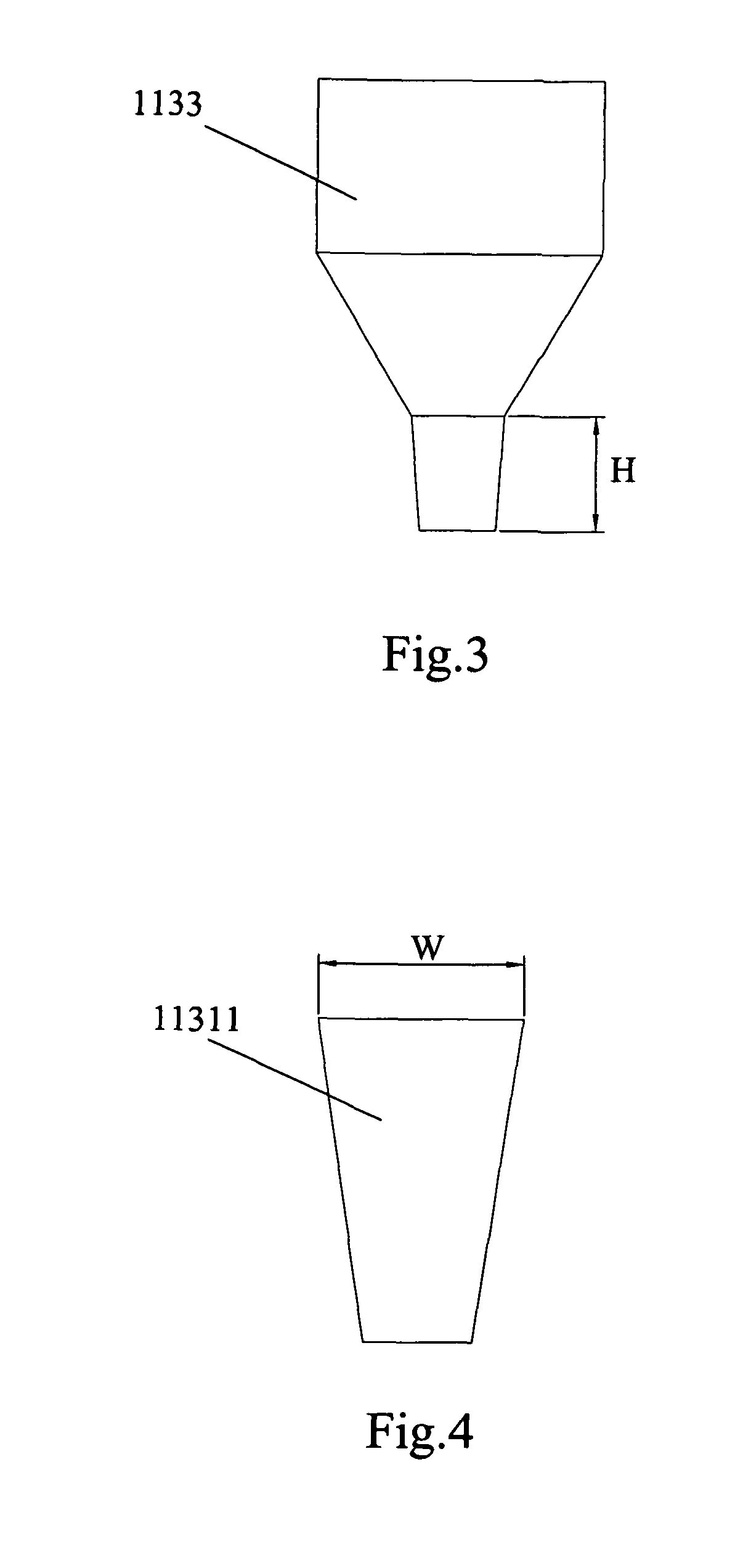

Row bar with smart sensor for forming sliders and method of manufacturing slider

ActiveUS8614863B2Restrict formImprove performanceFluid-dynamic spacing of headsRecord information storageEngineeringMechanical engineering

A row bar with smart sensor for forming sliders, which comprises a row of slider forming portions, each slider forming portion comprising a slider to be cut from the row bar and a medial region adjacent the slider; each slider comprises a slider body and a magnetic writer disposed in the slider body, with the magnetic writer having a main pole which includes a pole face for being lapped, and all the main poles are arranged in a row; the row bar has at least one smart sensor disposed therein, with the smart sensor having at least three dummy poles, whose structure is identical to that of said main pole, arranged in the row of the main poles, there is a space between every two adjacent dummy poles of said smart sensor, and there is a offset in the direction vertical with the pole face between every two adjacent dummy poles of said smart sensor. The invention also discloses a method of manufacturing the slider.

Owner:SAE MAGNETICS (HK) LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com