Patents

Literature

205 results about "Bead shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-channel microfluidic chip capable of detecting various subtype swine influenza viruses simultaneously

InactiveCN102478582AImprove diagnostic efficiencyReduce diagnostic costsMaterial electrochemical variablesSurface layerGold Colloid

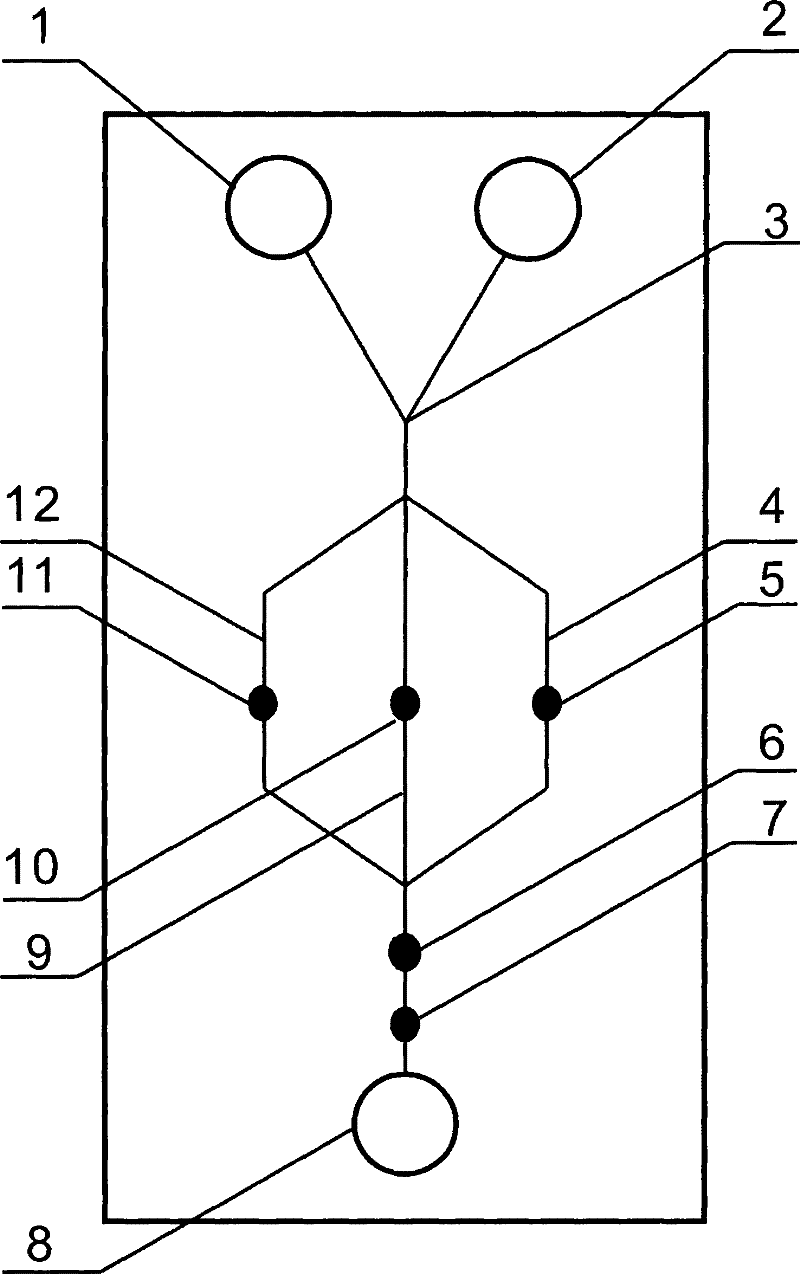

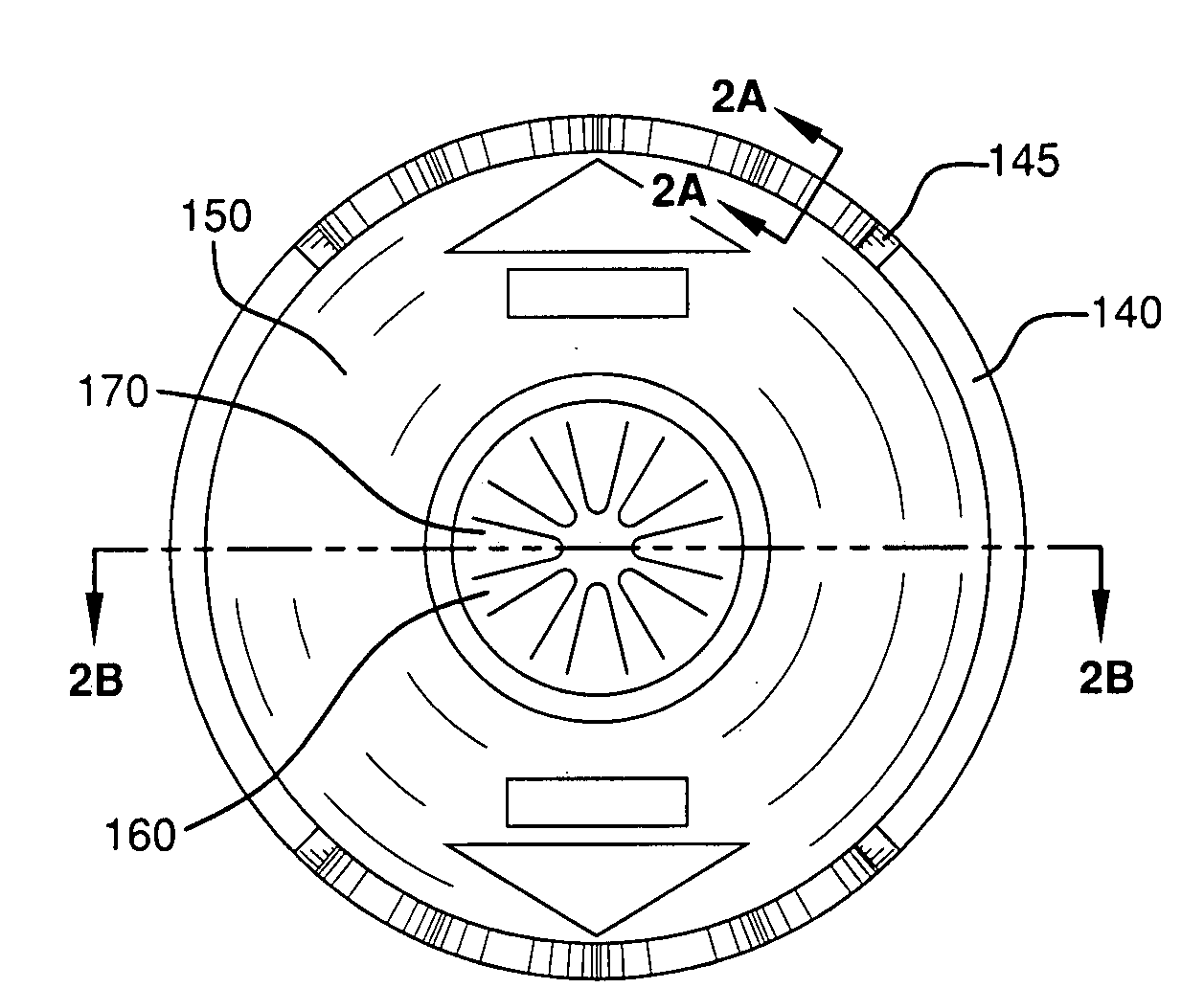

The invention relates to the fields of analysis and test, in particular to a multi-channel microfluidic chip capable of detecting various subtype swine influenza viruses (SIV) simultaneously. One of the aims of advancing the related diagnosis and treatment technology is to diagnose the SIV quickly and cheaply. The invention provides a diagnosis device, which can fulfill the aims. The key point of the scheme is that: the device, namely the microfluidic chip, comprises pipelines with a parallel structure, wherein the parallel structure comprises three branched pipelines arranged in parallel; three beads-shaped working electrodes are arranged in the three branched pipelines respectively; each beads-shaped working electrode consists of a conductive electrode and a gold colloid sensitive film; the gold colloid sensitive film is attached to the conductive electrode and embeds different subtypes of SIV specific antibodies; the gold colloid sensitive films on the surface layers of the three beads-shaped working electrodes embed three different subtypes of SIV specific antibody substances respectively; and the three different subtypes of SIV specific antibody substances are the subtype H1N1, the subtype H3N2 and the subtype H1N2 SIV specific antibody substances respectively.

Owner:NINGBO UNIV

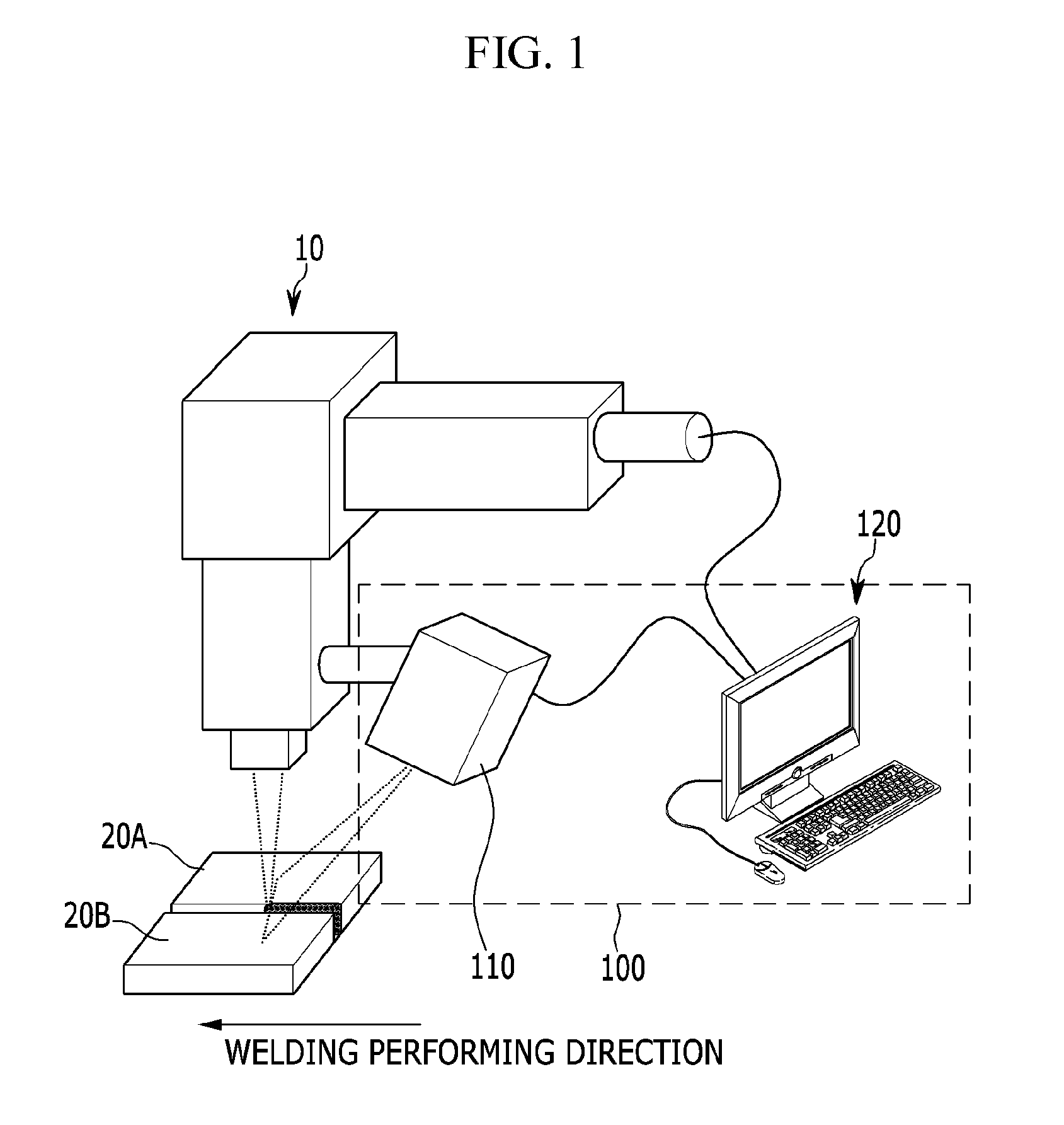

Apparatus and Method for Determining Shape of End of Welding Bead

InactiveUS20120048838A1Improve accuracySimple processUsing optical meansLaser beam welding apparatusImage extractionBead shape

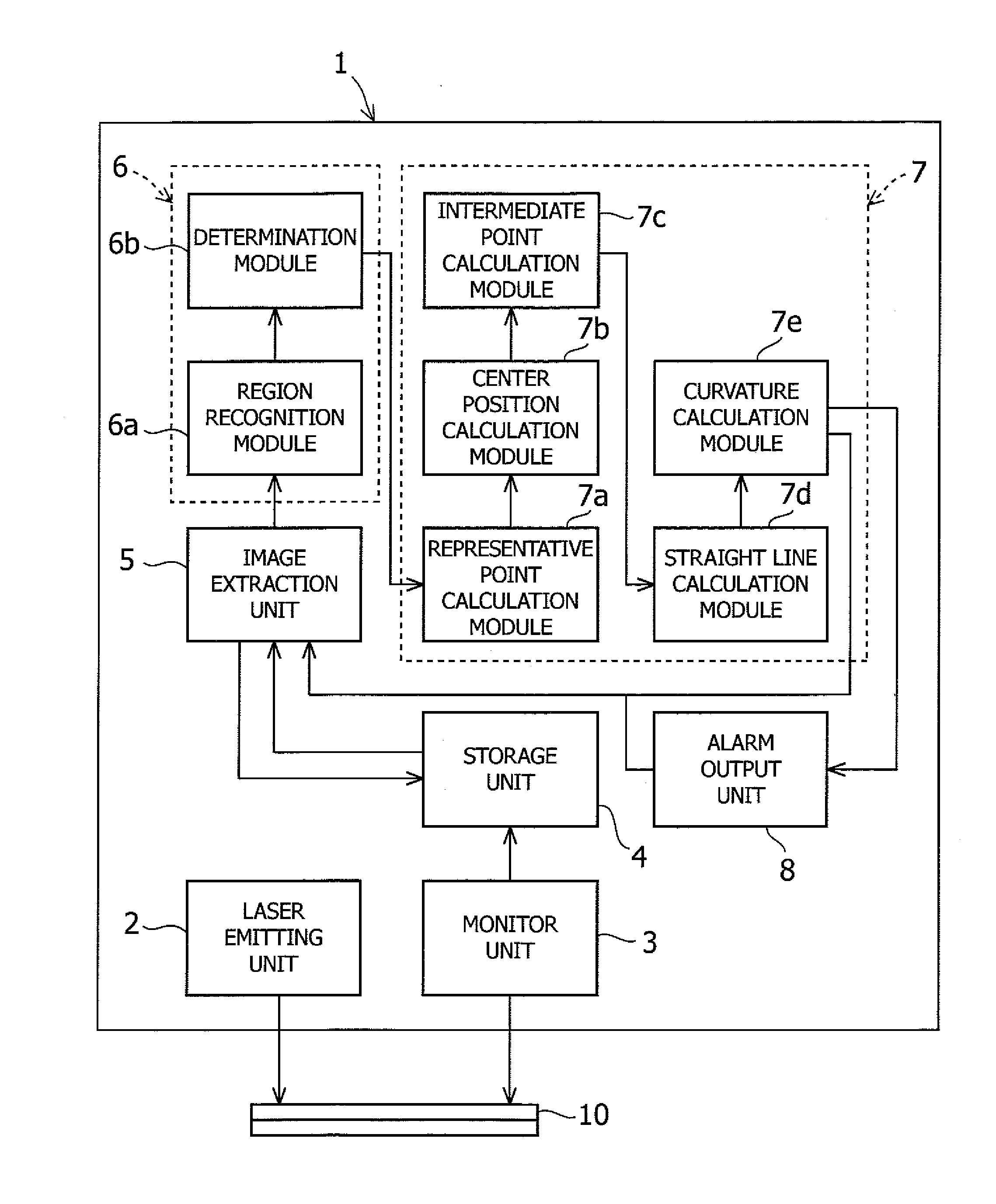

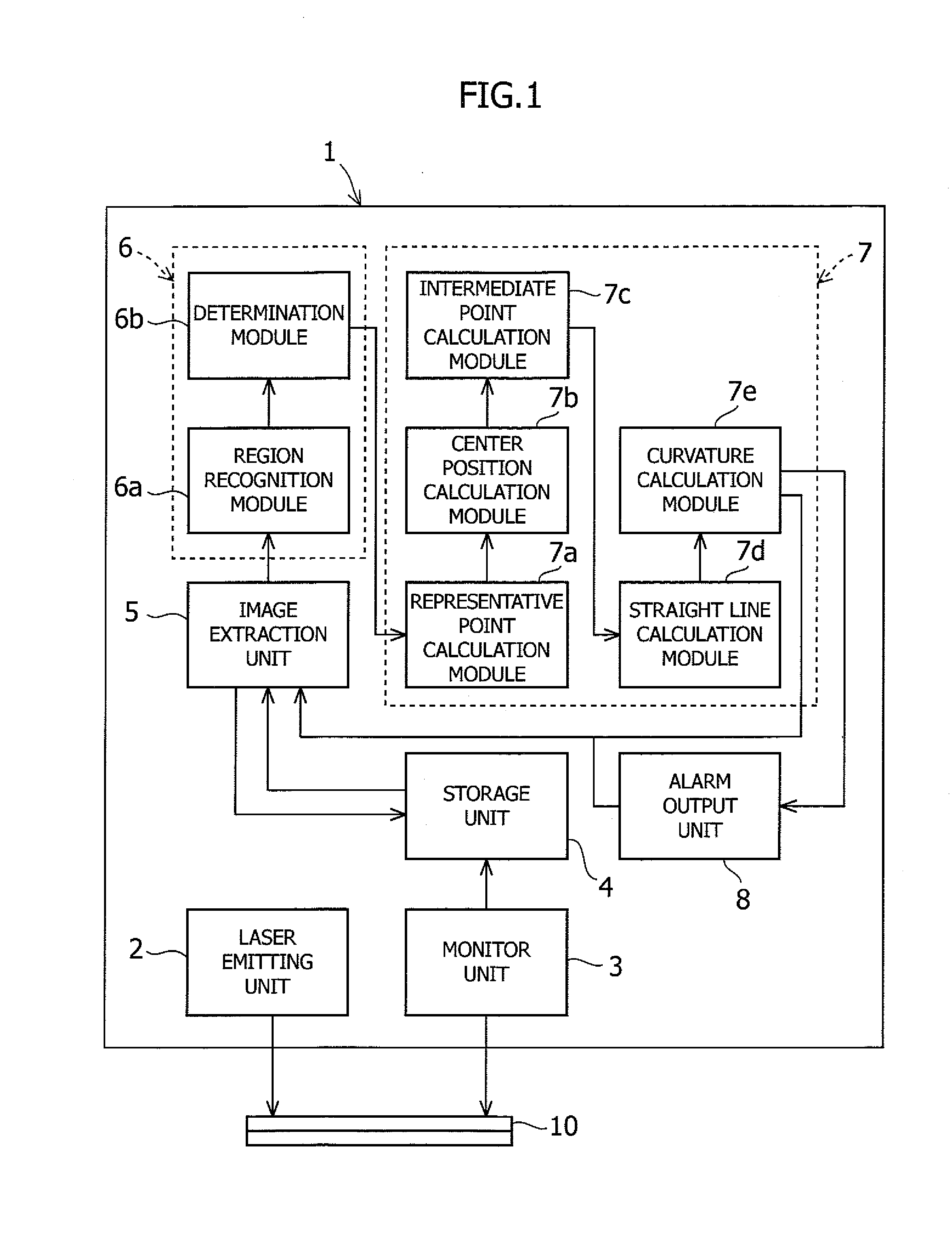

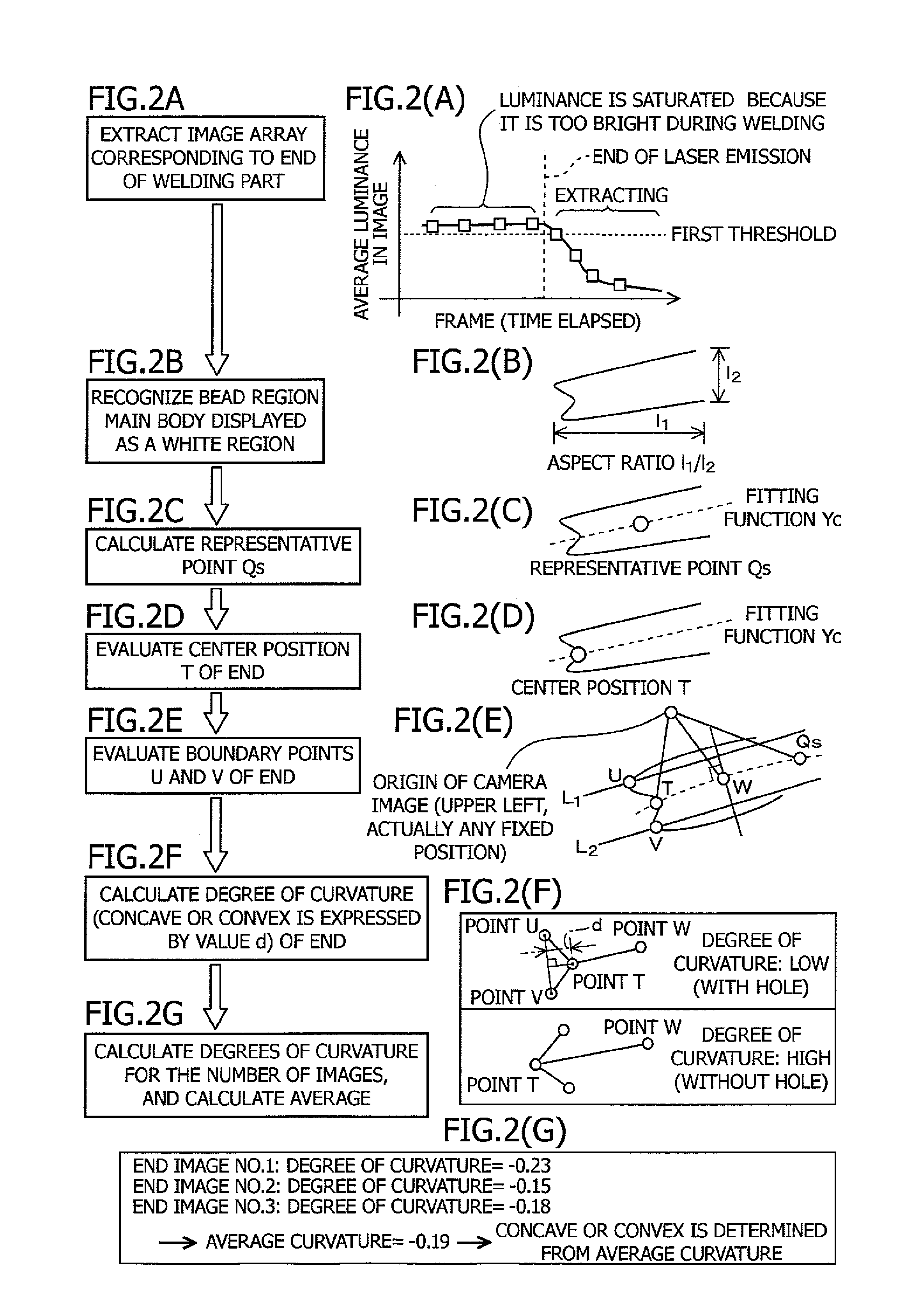

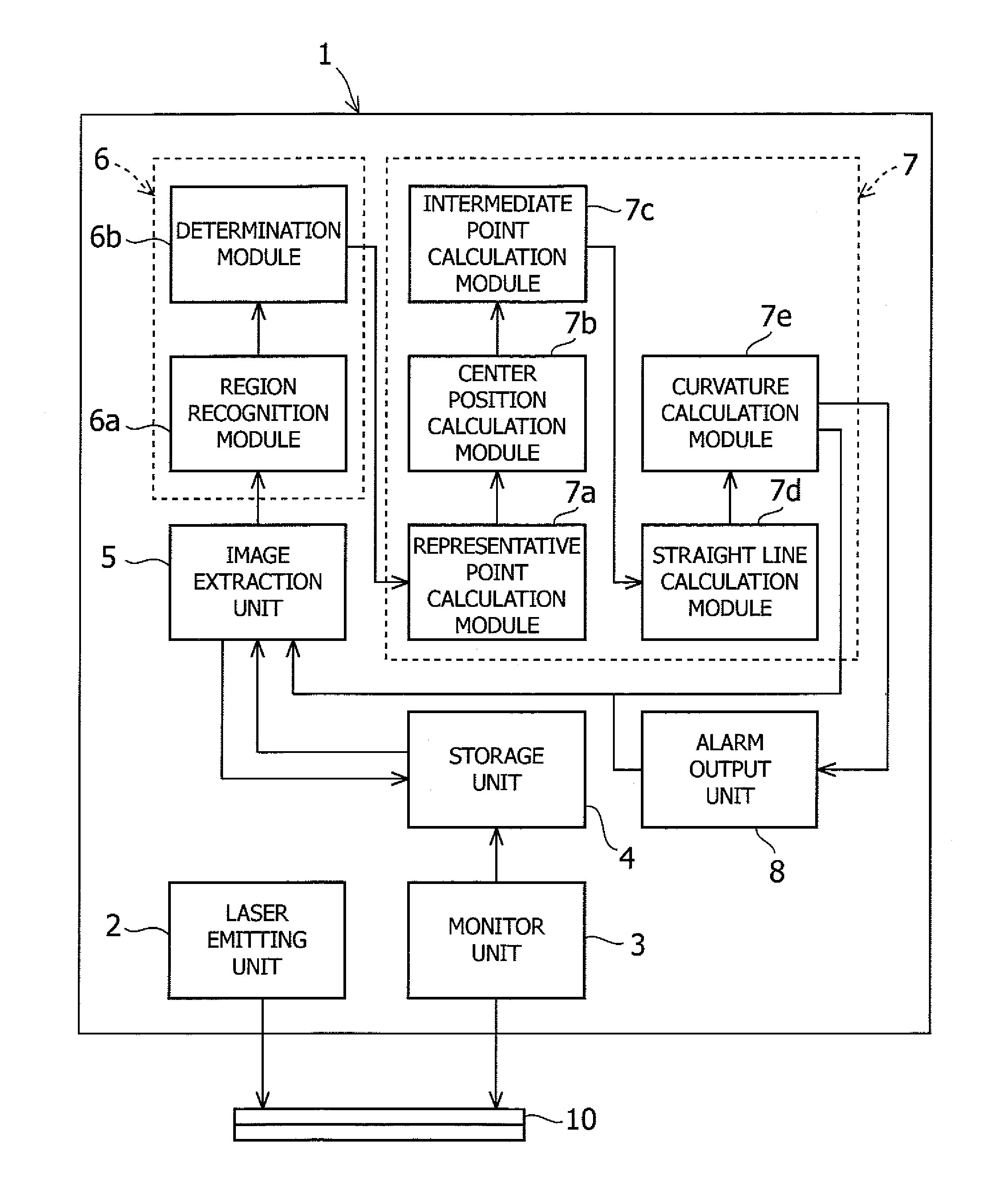

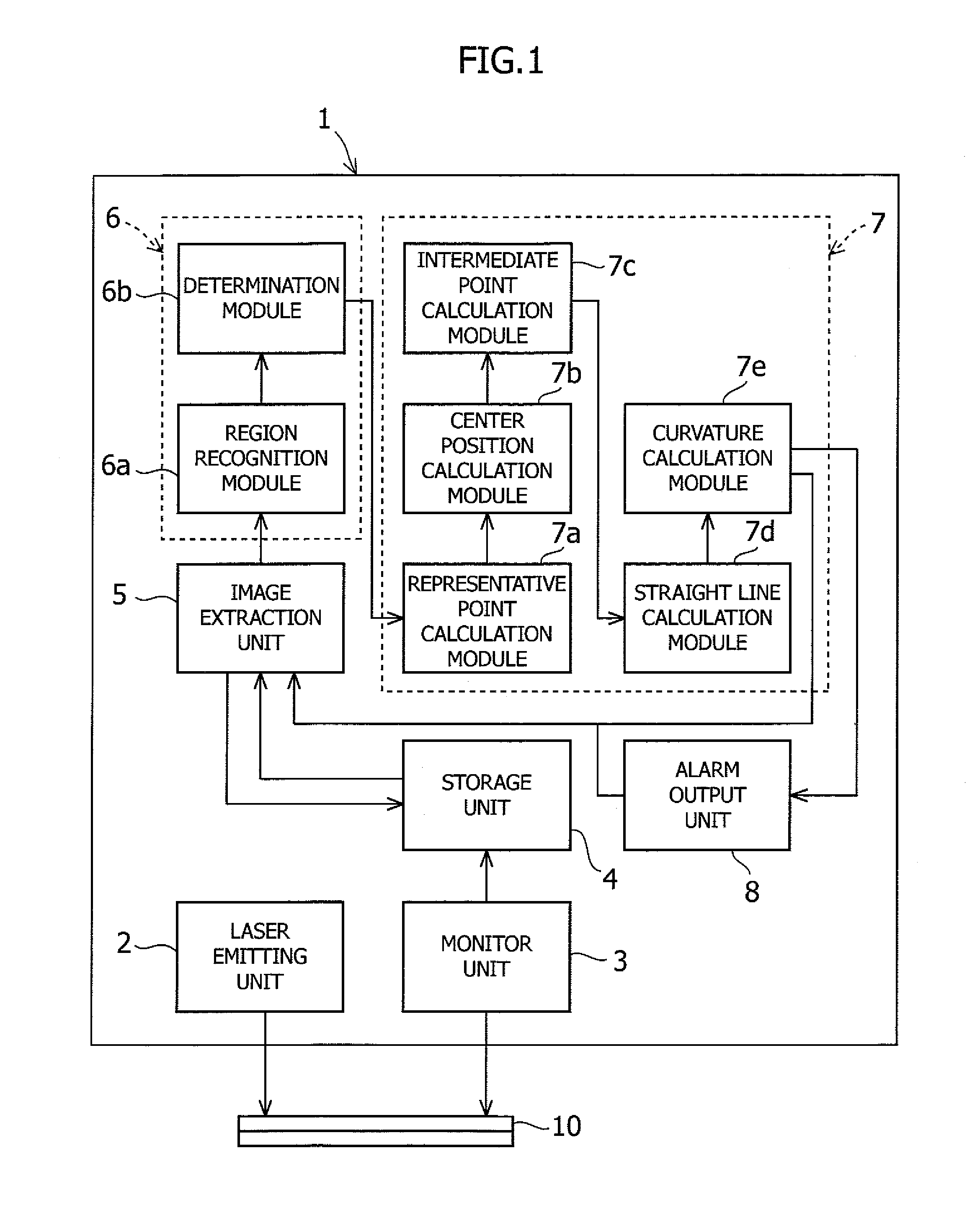

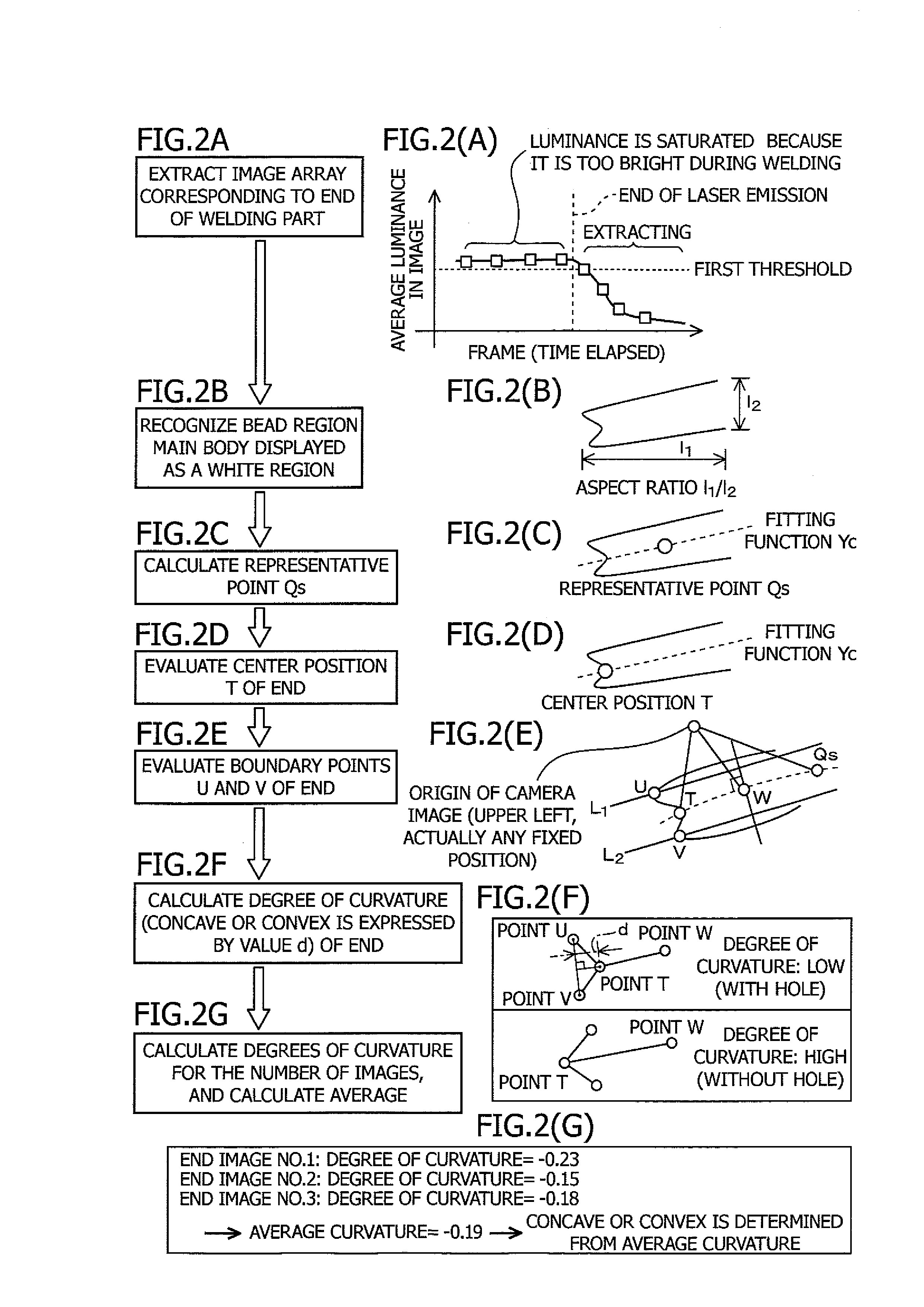

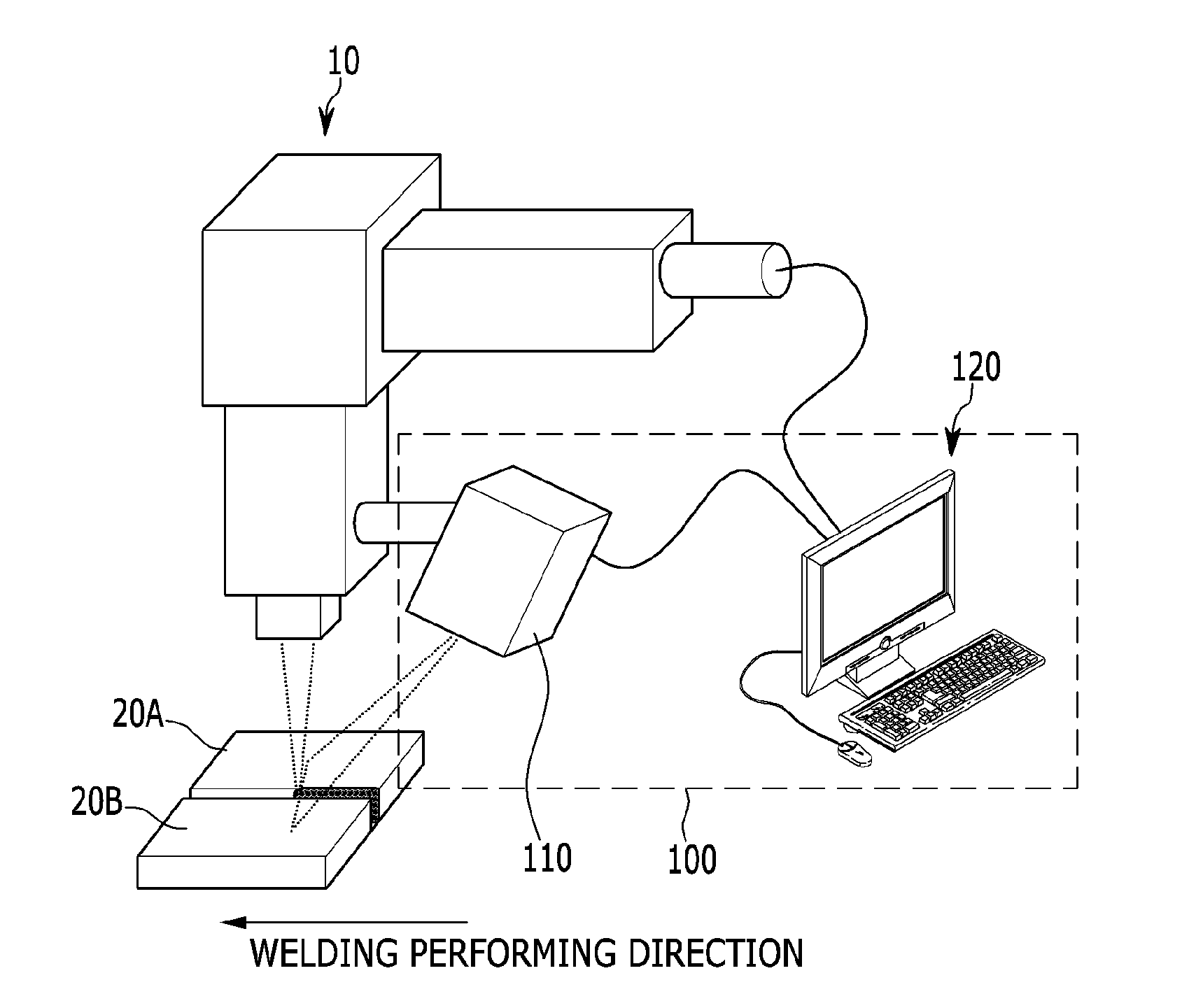

An apparatus 1 of the present invention includes a laser emitting unit 2, a monitor unit 3, a storage unit 4, an image extraction unit 5, a bead recognition unit 6, and a bead shape determination unit 7. The bead shape determination unit 7 is configured to calculate the position of the end of a bead region based on the bead region recognized by the bead recognition unit 6, and to determine whether the shape of the end of the bead region is convex or concave in the extending direction of the bead region.

Owner:SUZUKI MOTOR CORP

Steel wire for carbon dioxide shielded arc welding and welding process asing the same

InactiveCN1533315AAchieve Jet TransitionGood effectArc welding apparatusWelding/cutting media/materialsRare-earth elementBead shape

In carbon dioxide arc welding by use of shielding gas comprised of carbon dioxide as main component, a welding wire that enables spray transfer of globules, and provides an excellent bead shape in addition to reduction of amount of spatters even in a high-speed welding, and a welding method using the welding wire are proposed. As the specific means, a welding steel wire for use in carbon dioxide arc welding in DC-electrode negative, comprising a bar steel having a composition that contains 0.003 to 0.20% by mass of C, 0.05 to 2.5% by mass of Si, 0.25 to 3.5% by mass of Mn, 0.015 to 0.100% by mass of REM (rare-earth elements), 0.001 to 0.05% by mass of P, and 0.001 to 0.05% by mass of S, or further contains 0.0100% by mass or less of O, or further contains one or two or more of 0.02 to 0.50% by mass of Ti, 0.02 to 0.50% by mass of Zr, and 0.02 to 3.00% by mass of Al, or further contains 0.0001 to 0.0150% by mass of K, or further contains 3.0% by mass or less of Cr, 3.0% by mass or less of Ni, 1.5% by mass or less of Mo, 3.0% by mass or less of Cu, 0.015% by mass or less of B, 0.20% by mass or less of Mg, 0.5% by mass or less of Nb, 0.5% by mass or less of V, and 0.020% by mass or less of N, and contains Fe and unavoidable impurities as residue is used.

Owner:JFE STEEL CORP

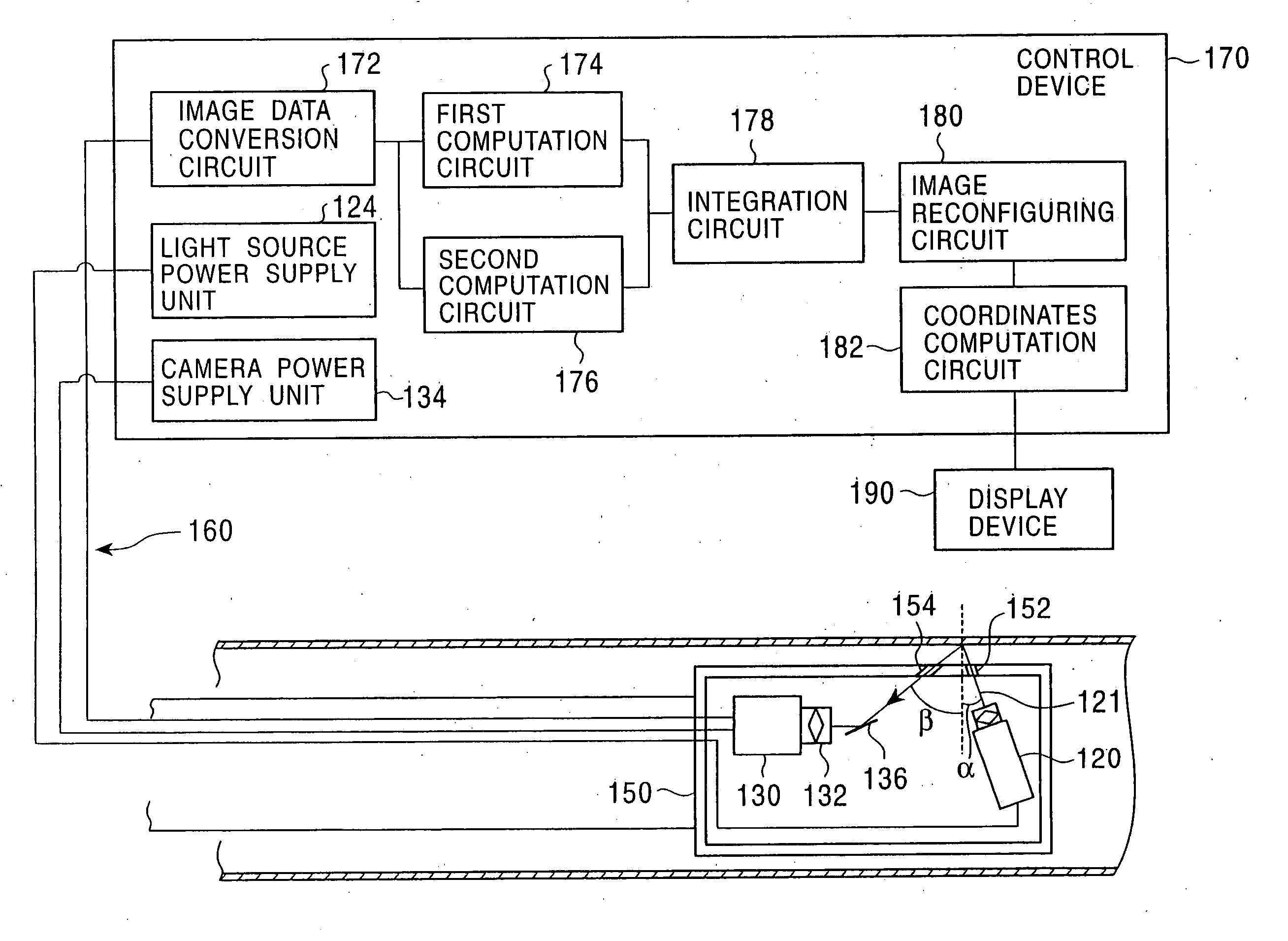

Apparatus and method for determining shape of end of welding bead

InactiveUS8946595B2Improve accuracyReduce transmittanceUsing optical meansLaser beam welding apparatusImage extractionBead shape

Owner:SUZUKI MOTOR CORP

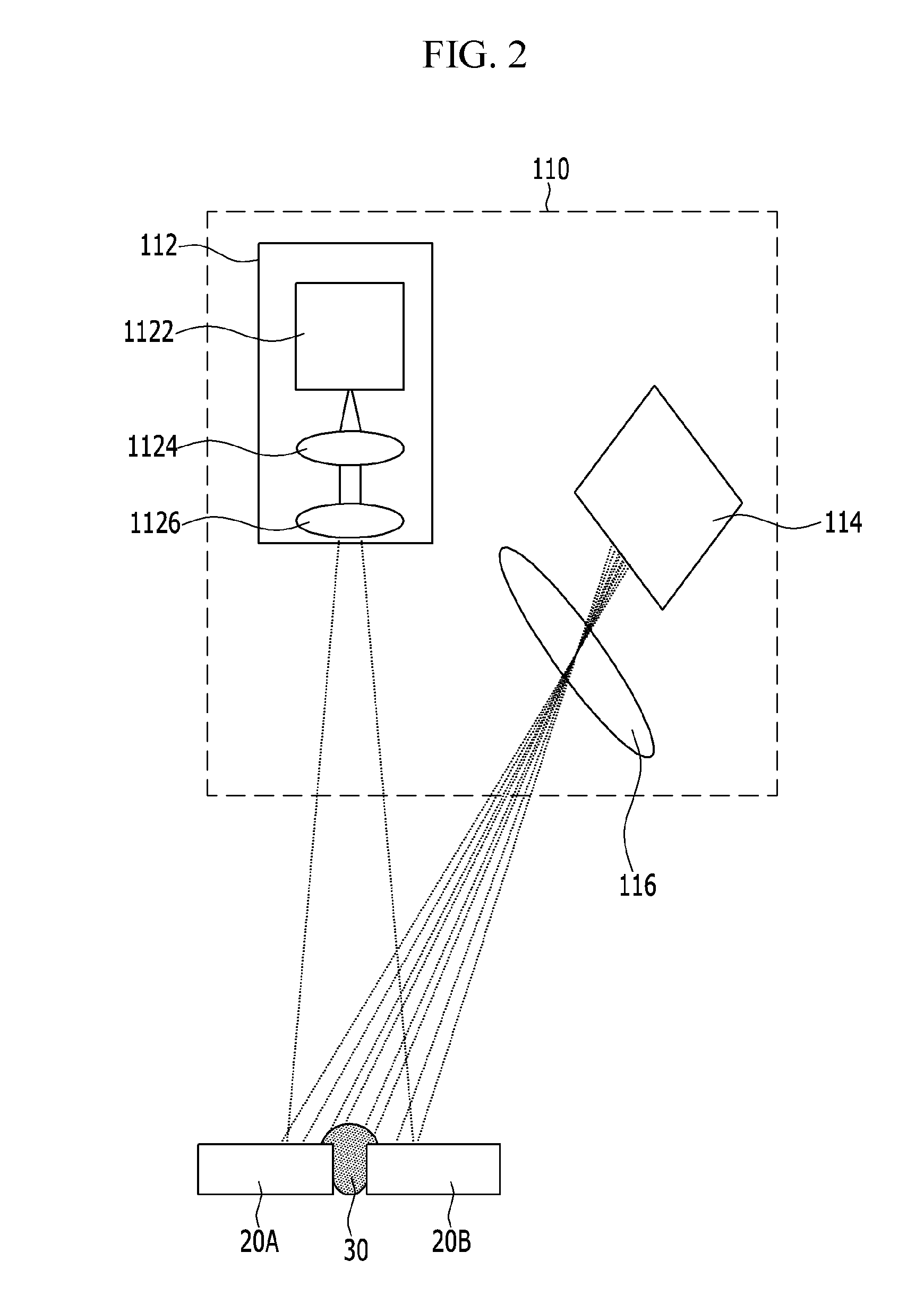

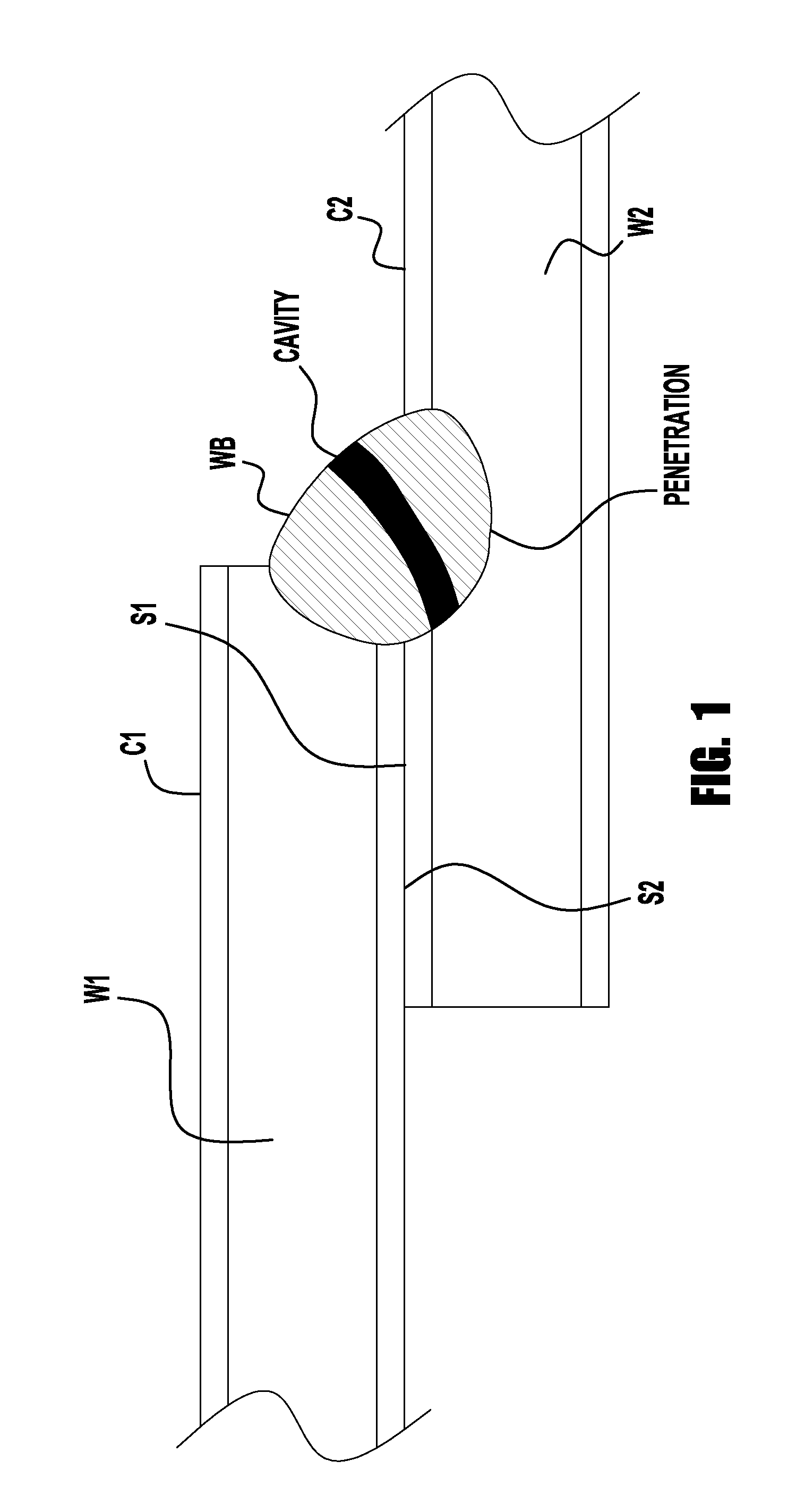

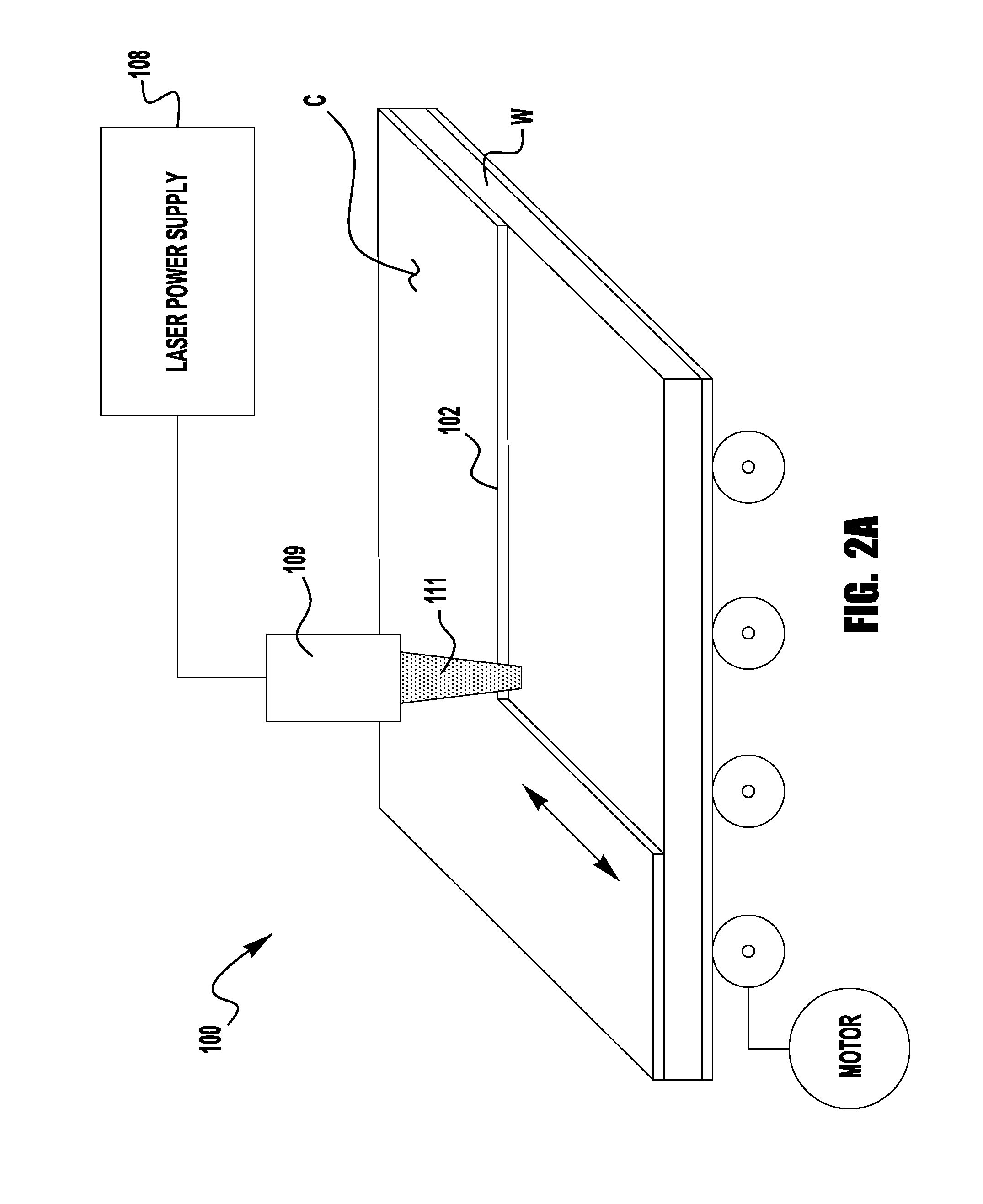

Apparatus and method for monitoring laser welding bead

ActiveUS20150001196A1Easy to manageWelding/soldering/cutting articlesLaser beam welding apparatusBead shapeEngineering

An apparatus for monitoring a laser welding bead irradiates a laser to a surface of a welding bead when welding with a laser welding machine, collects a signal reflected from the surface of the welding bead as an image signal, and then extracts at least one feature variable of a bead shape using the collected image signal. Then, the apparatus for monitoring the laser welding bead determines welding defects using the at least one feature variable, and controls an operation of the laser welding machine according to whether or not the welding defects are generated.

Owner:ELECTRONICS & TELECOMM RES INST

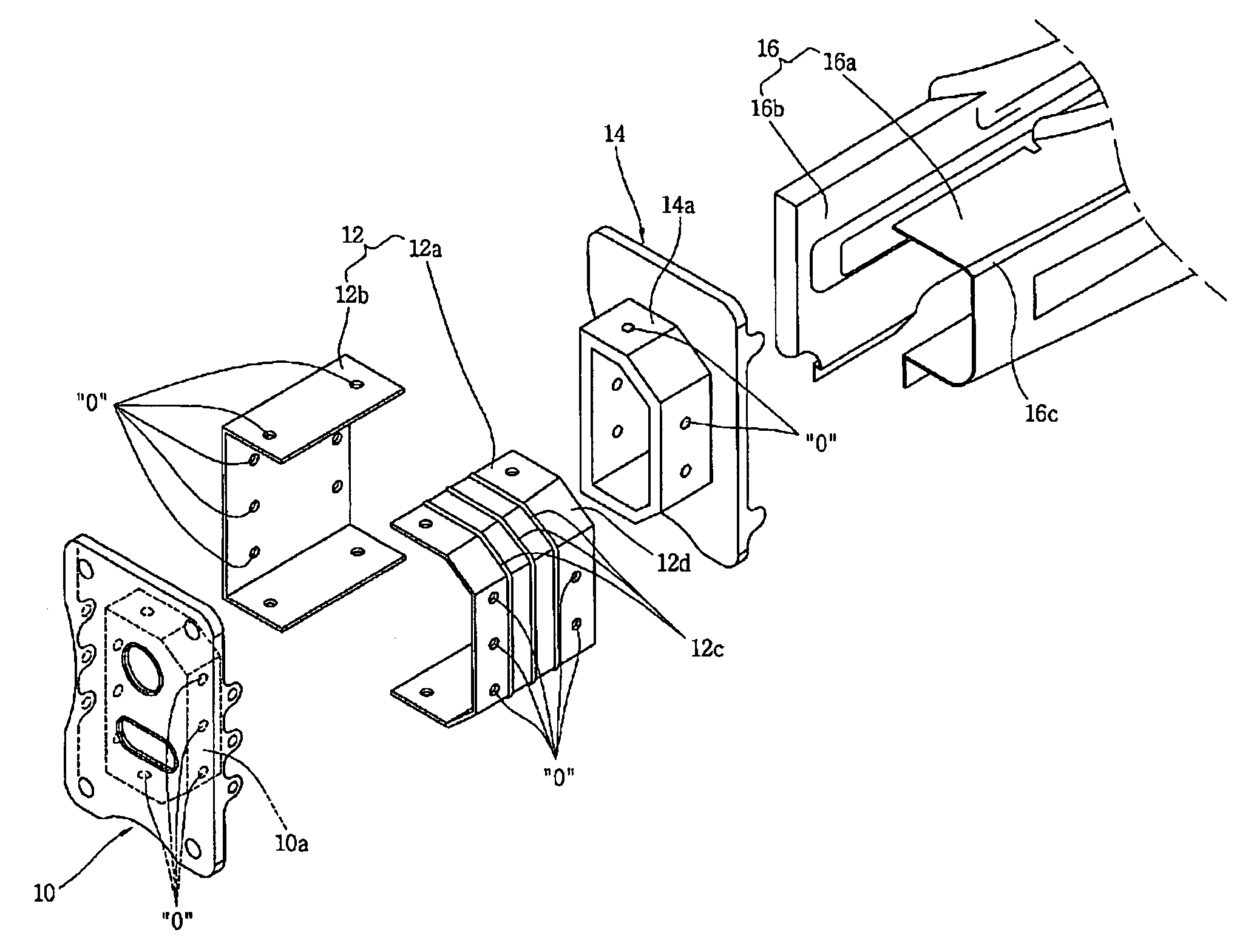

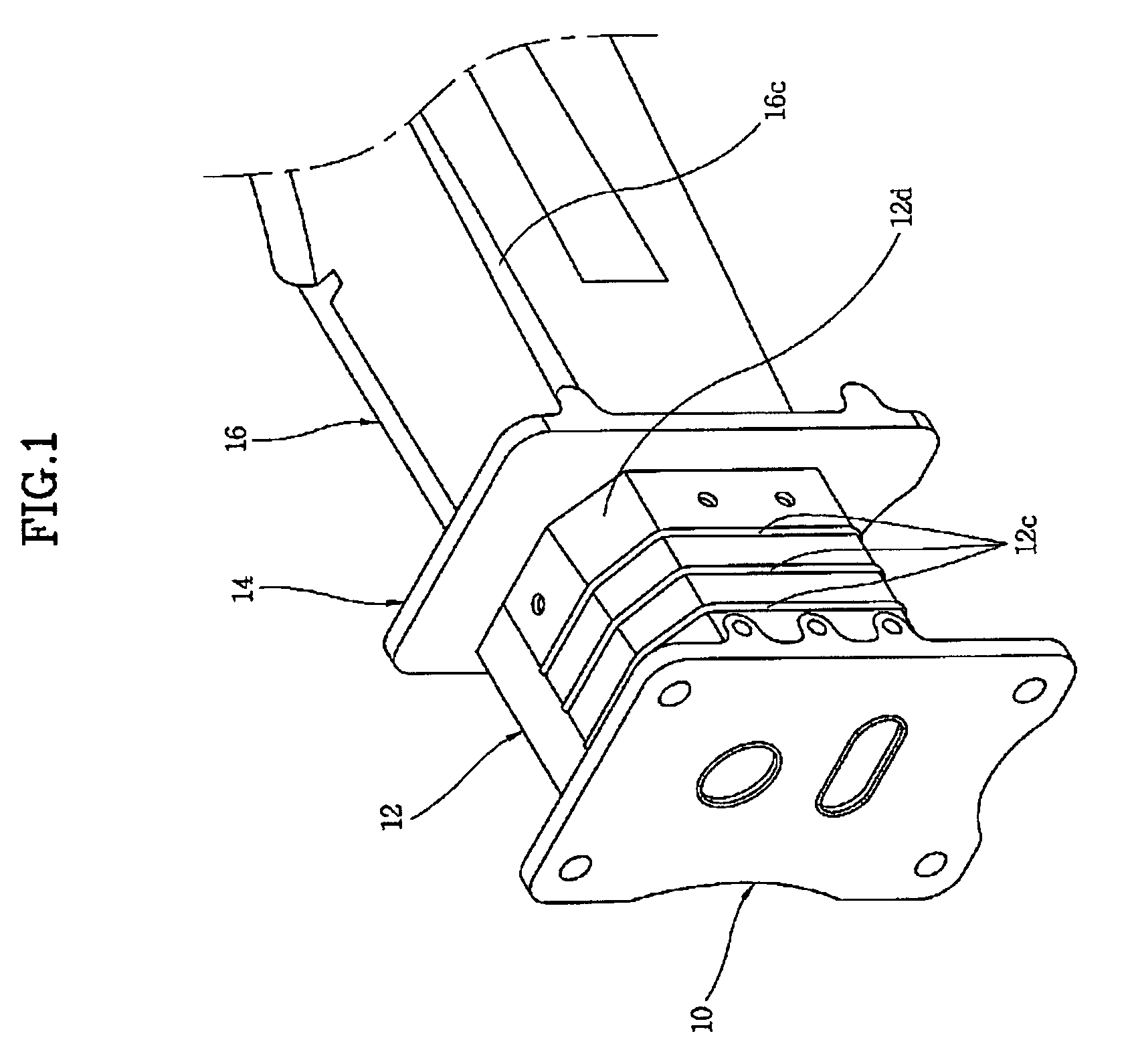

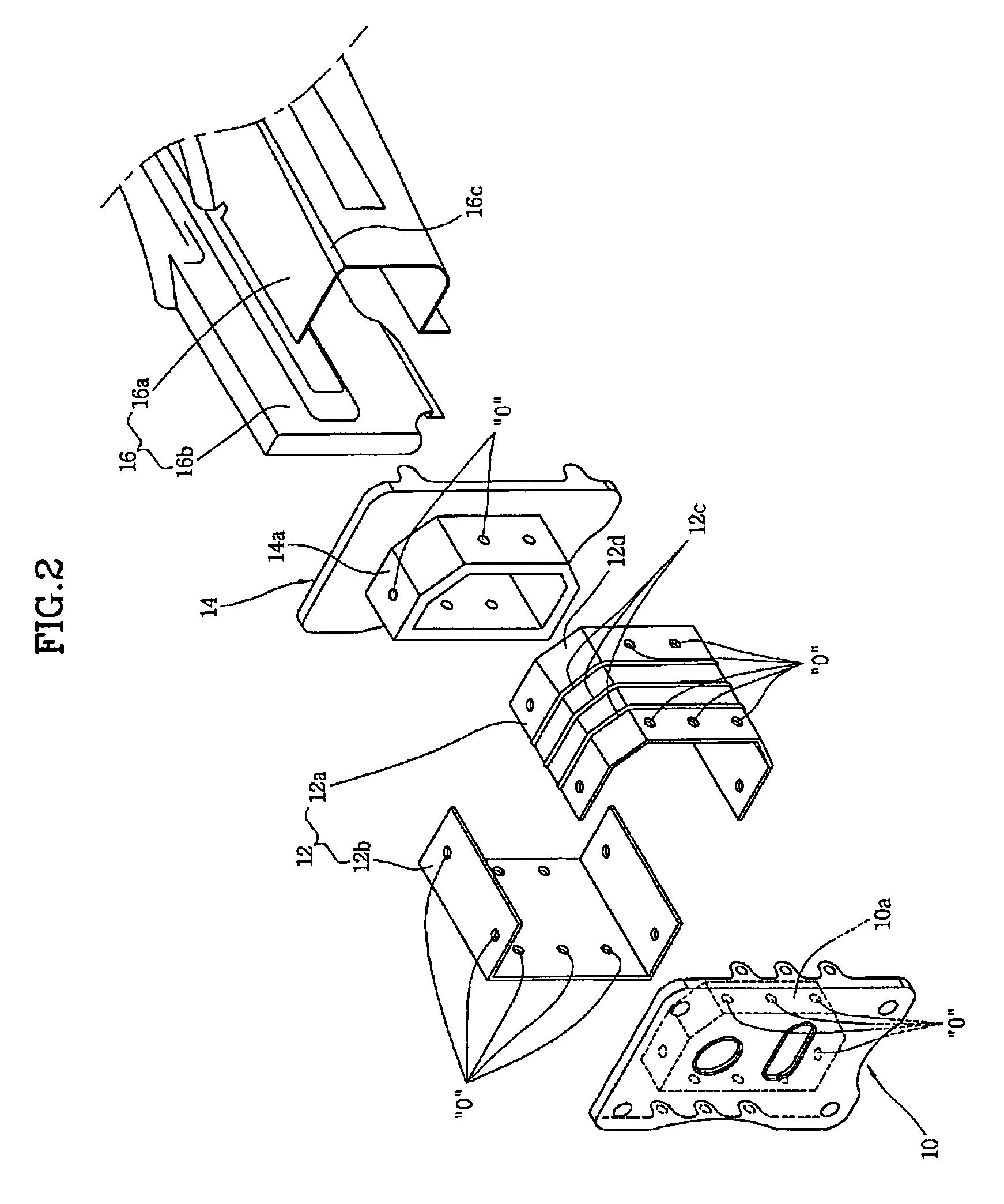

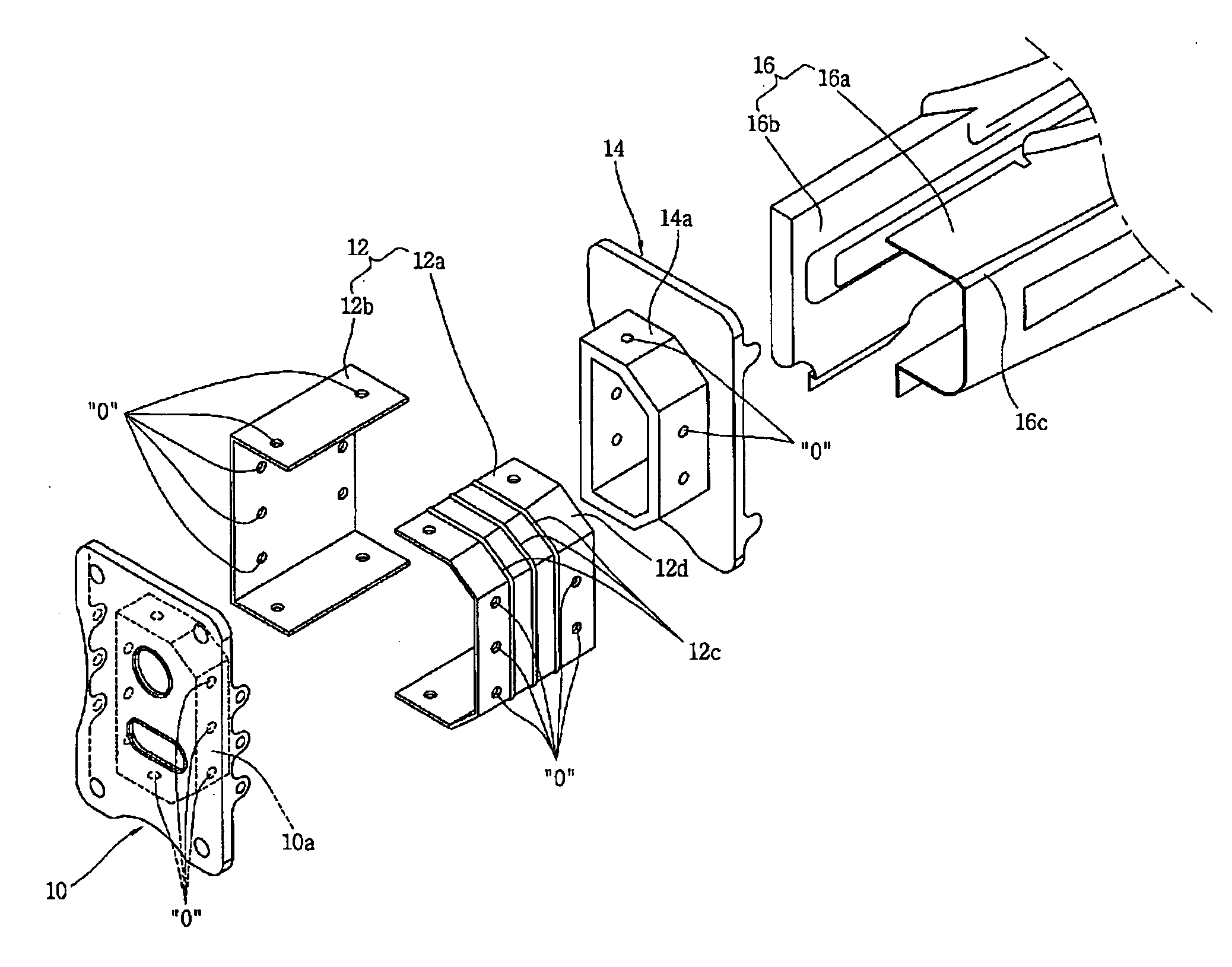

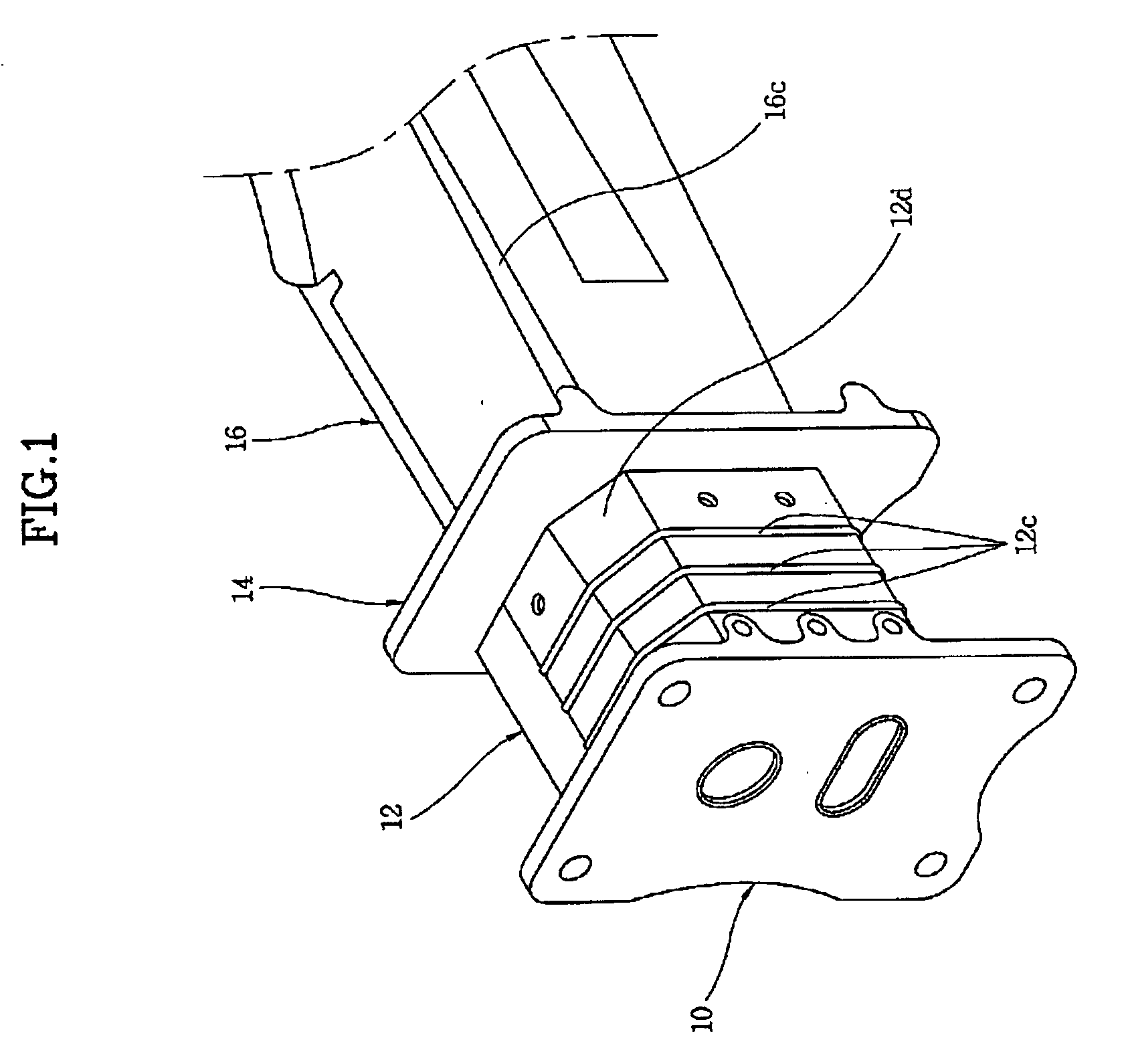

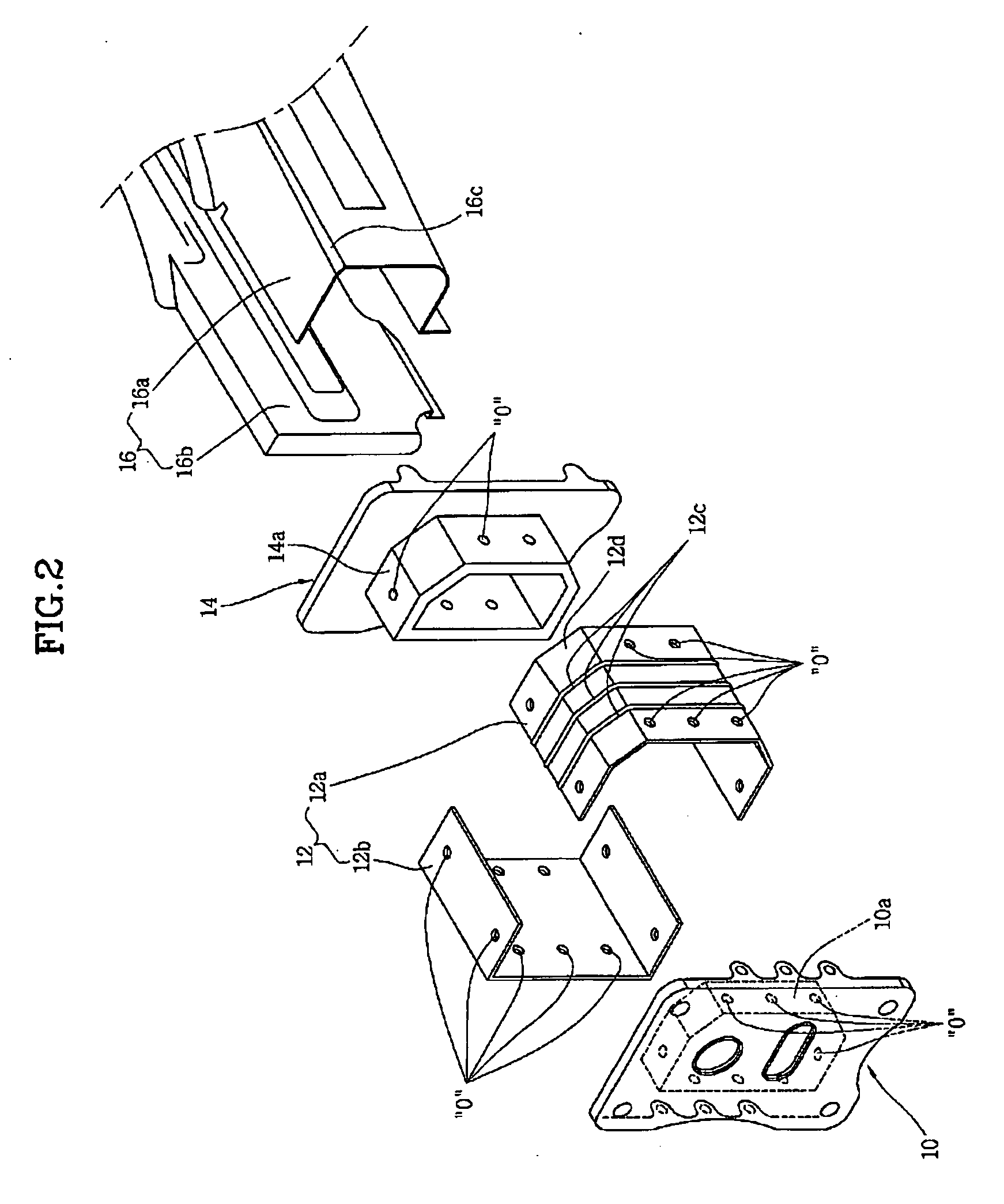

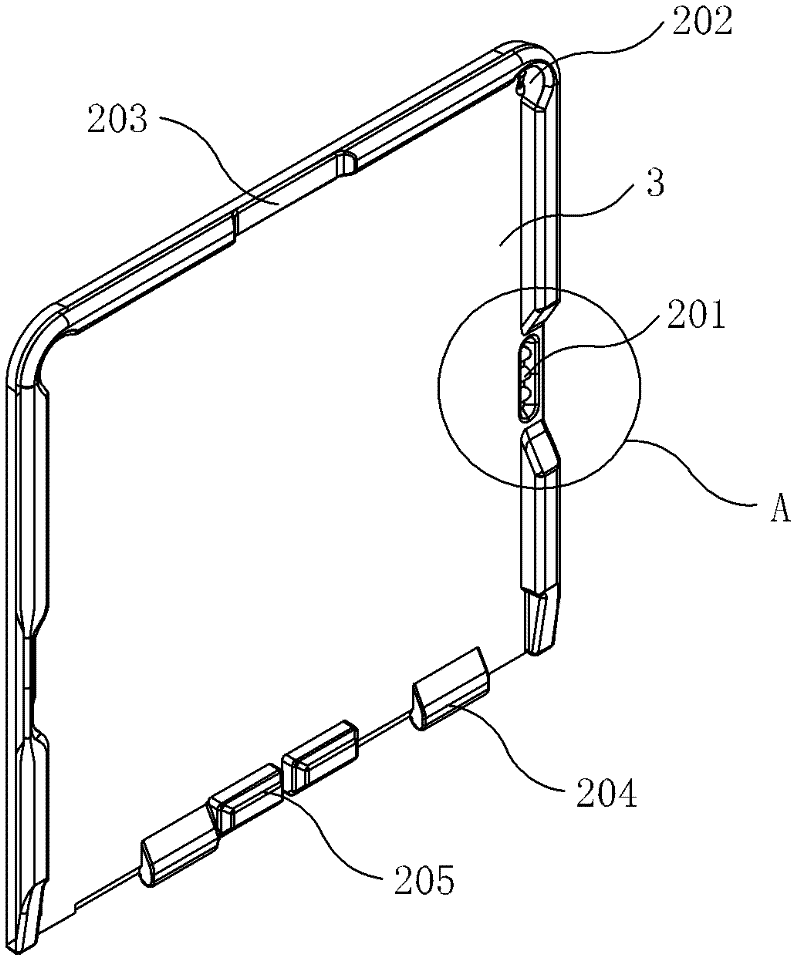

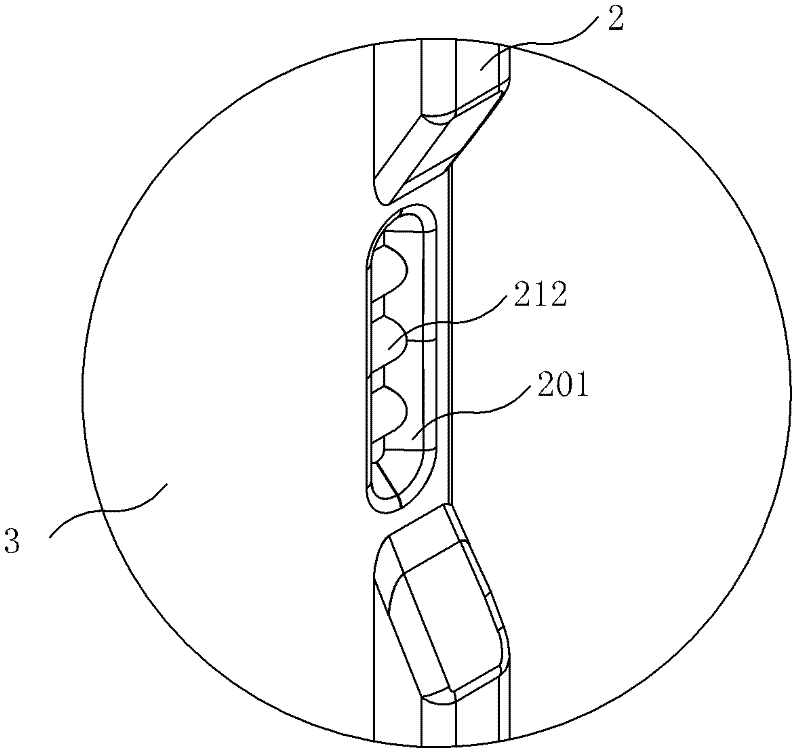

Front structure for car body

A front structure for a car body that reduces time and cost to repair a car body after a collision by localizing damage in low-speed collisions to a crash box mounted in a space between a front bumper and a side member and making the car body deform always in a predetermined mode in the collisions. A front structure for a car body may include a first connecting bracket supporting the left and right rear of a front bumper, a crash box joined to the rear of the first connecting bracket, a second connecting bracket joined to the rear of the crash box, and a front side member joined to the rear of the second connecting bracket. The crash box includes an inner member and an outer member, which are curved and separated from each other, so as to extend in the longitudinal direction of the vehicle and have a closed cross section. The inner member has a plurality of bead-shaped protrusions that are formed across the inner member and longitudinally spaced from each other.

Owner:HYUNDAI MOTOR CO LTD

Front structure for car body

A front structure for a car body that reduces time and cost to repair a car body after a collision by localizing damage in low-speed collisions to a crash box mounted in a space between a front bumper and a side member and making the car body deform always in a predetermined mode in the collisions. A front structure for a car body may include a first connecting bracket supporting the left and right rear of a front bumper, a crash box joined to the rear of the first connecting bracket, a second connecting bracket joined to the rear of the crash box, and a front side member joined to the rear of the second connecting bracket. The crash box includes an inner member and an outer member, which are curved and separated from each other, so as to extend in the longitudinal direction of the vehicle and have a closed cross section. The inner member has a plurality of bead-shaped protrusions that are formed across the inner member and longitudinally spaced from each other.

Owner:HYUNDAI MOTOR CO LTD

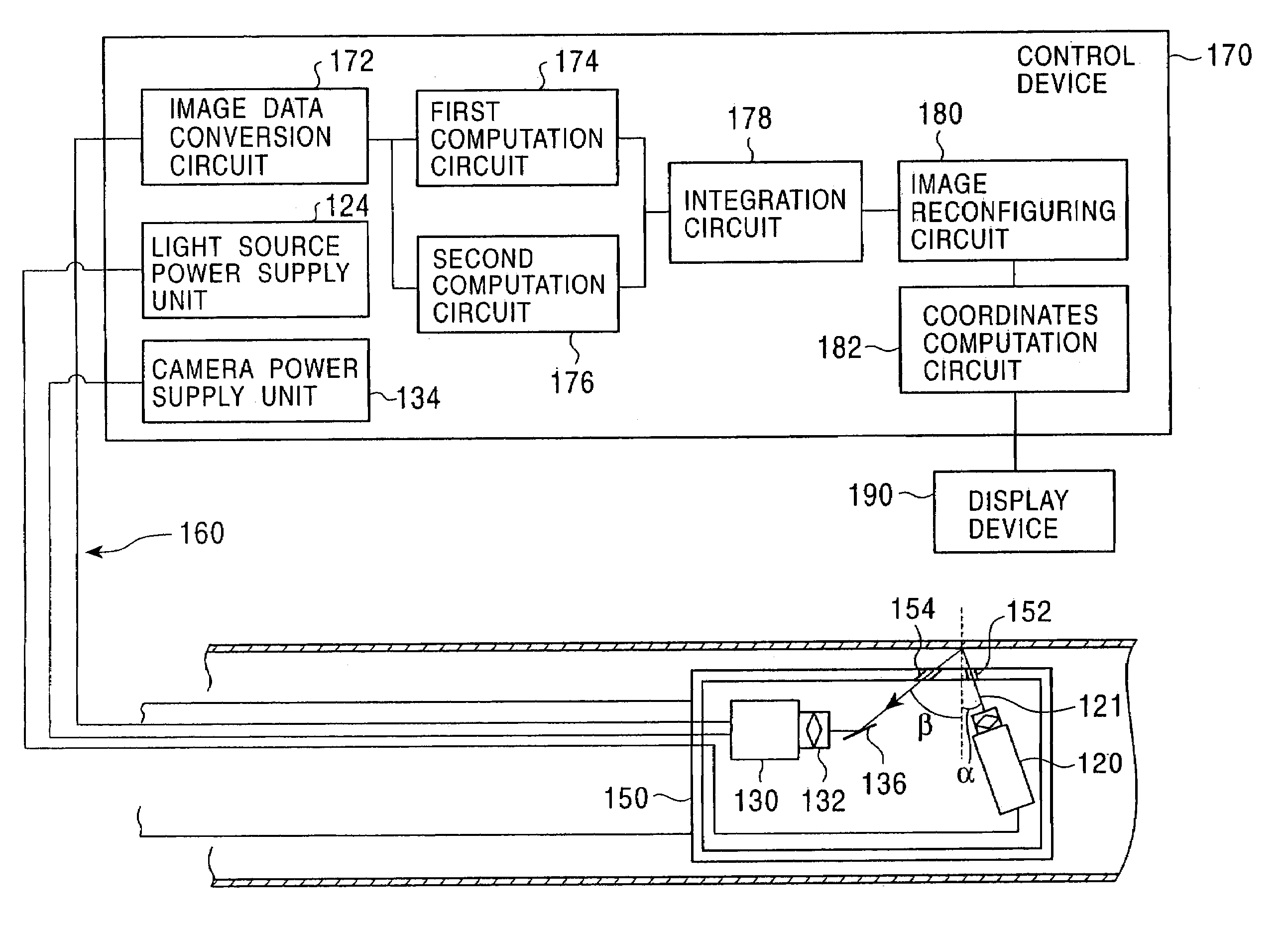

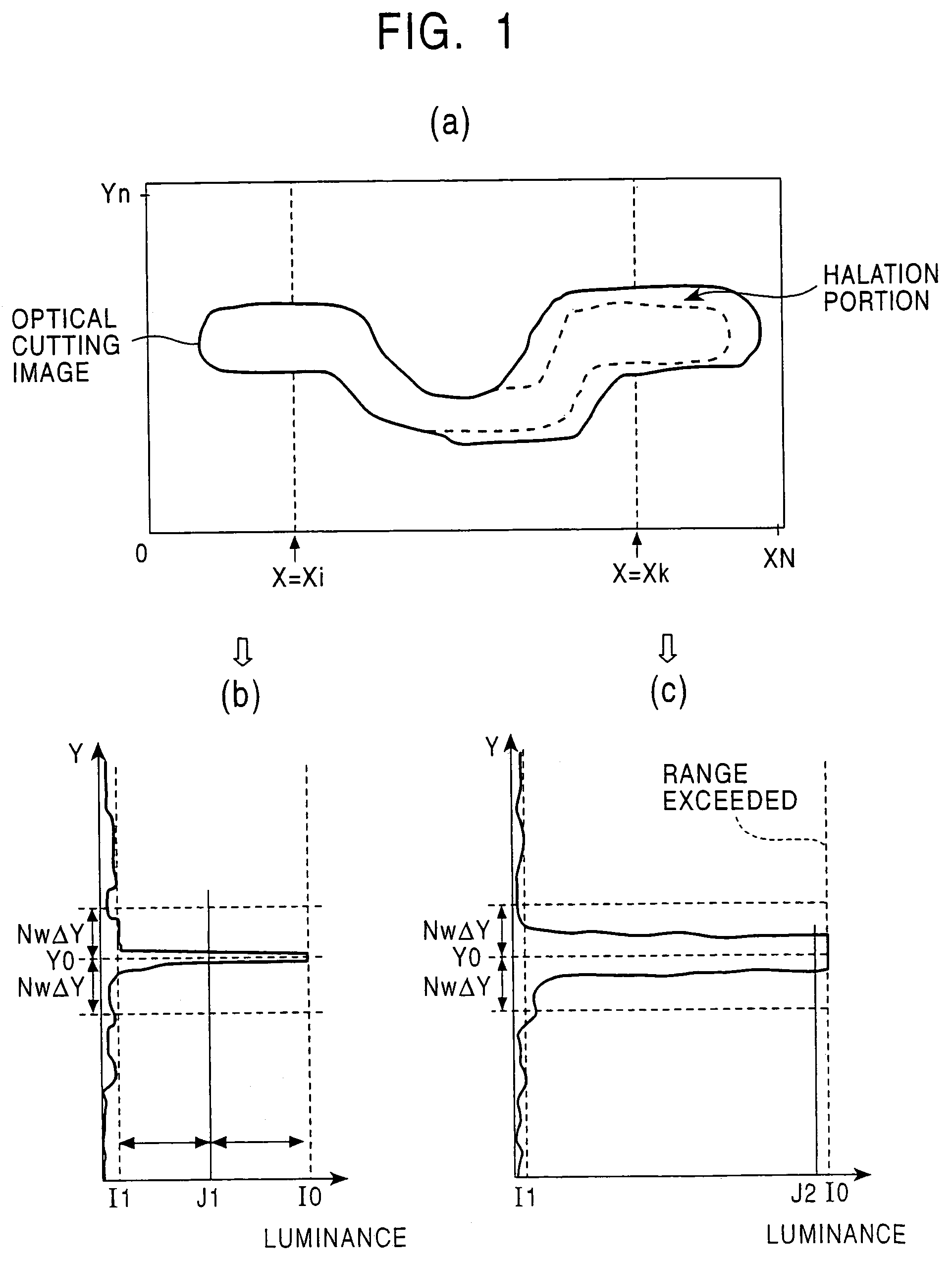

Method and instrument for measuring bead cutting shape of electric welded tube

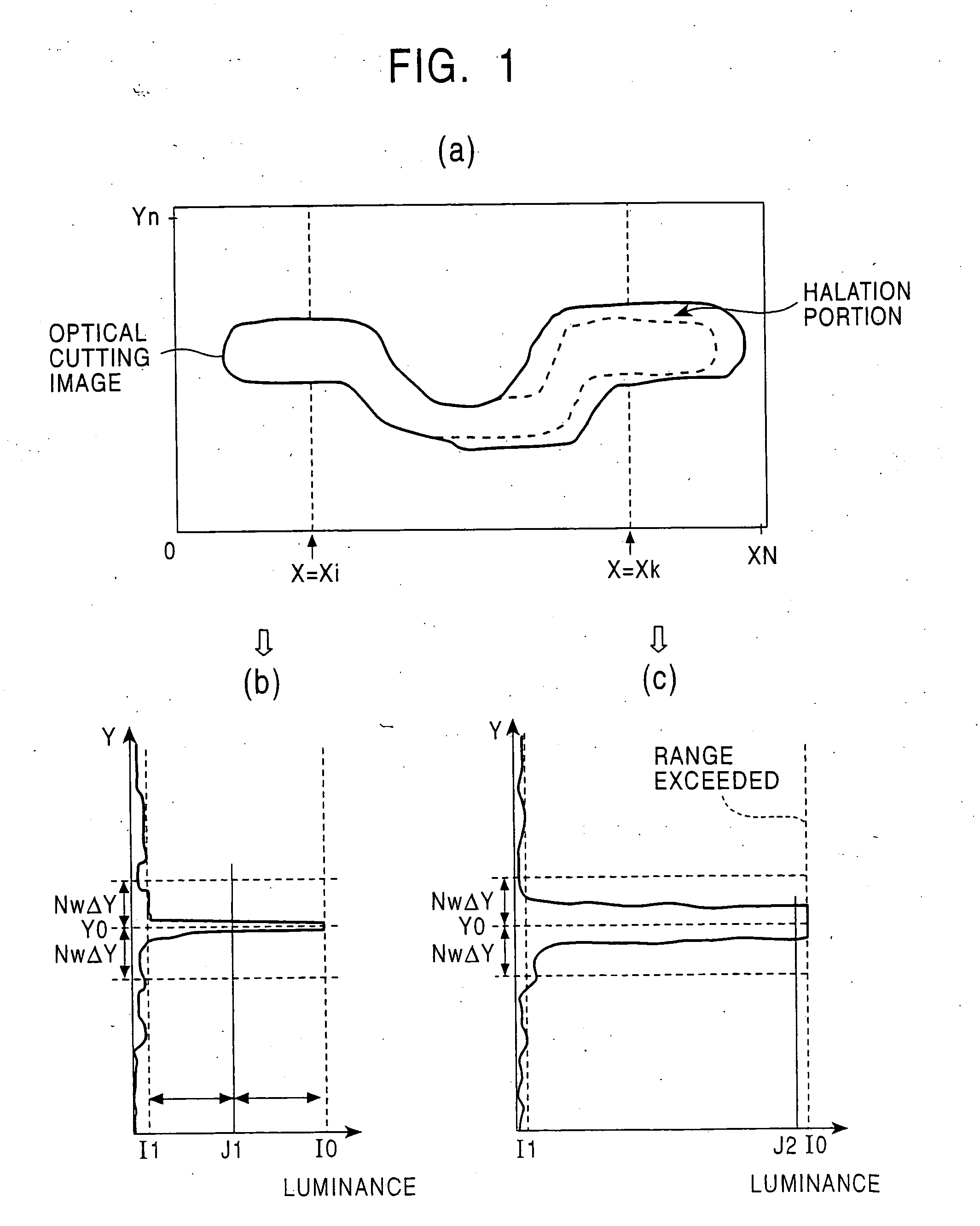

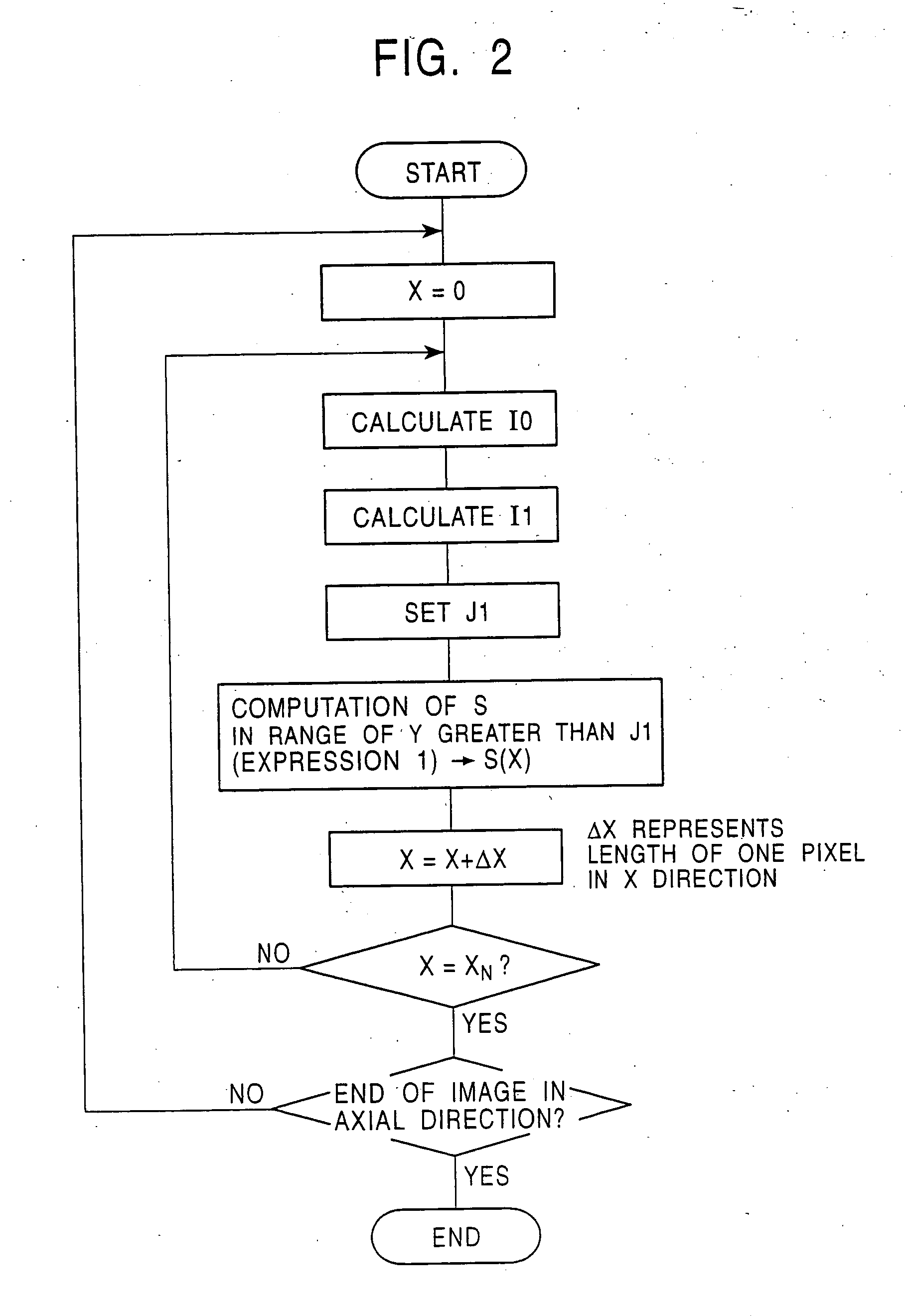

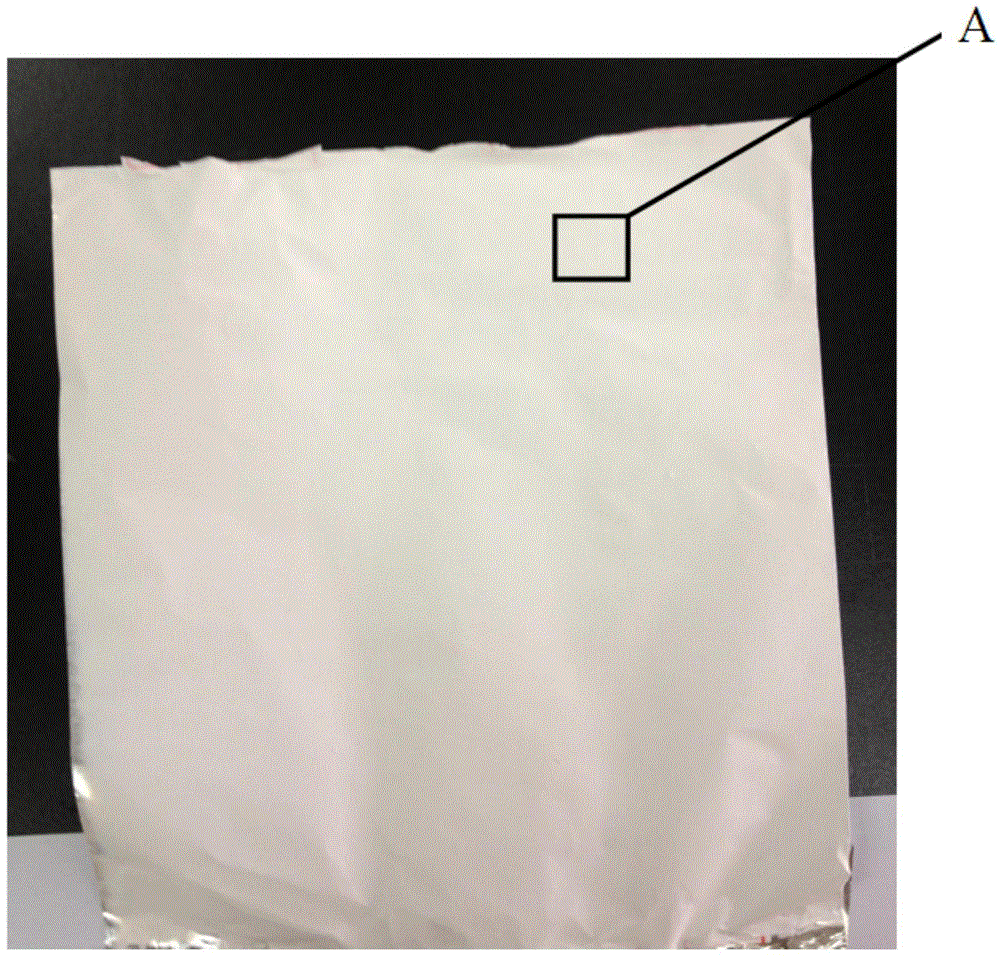

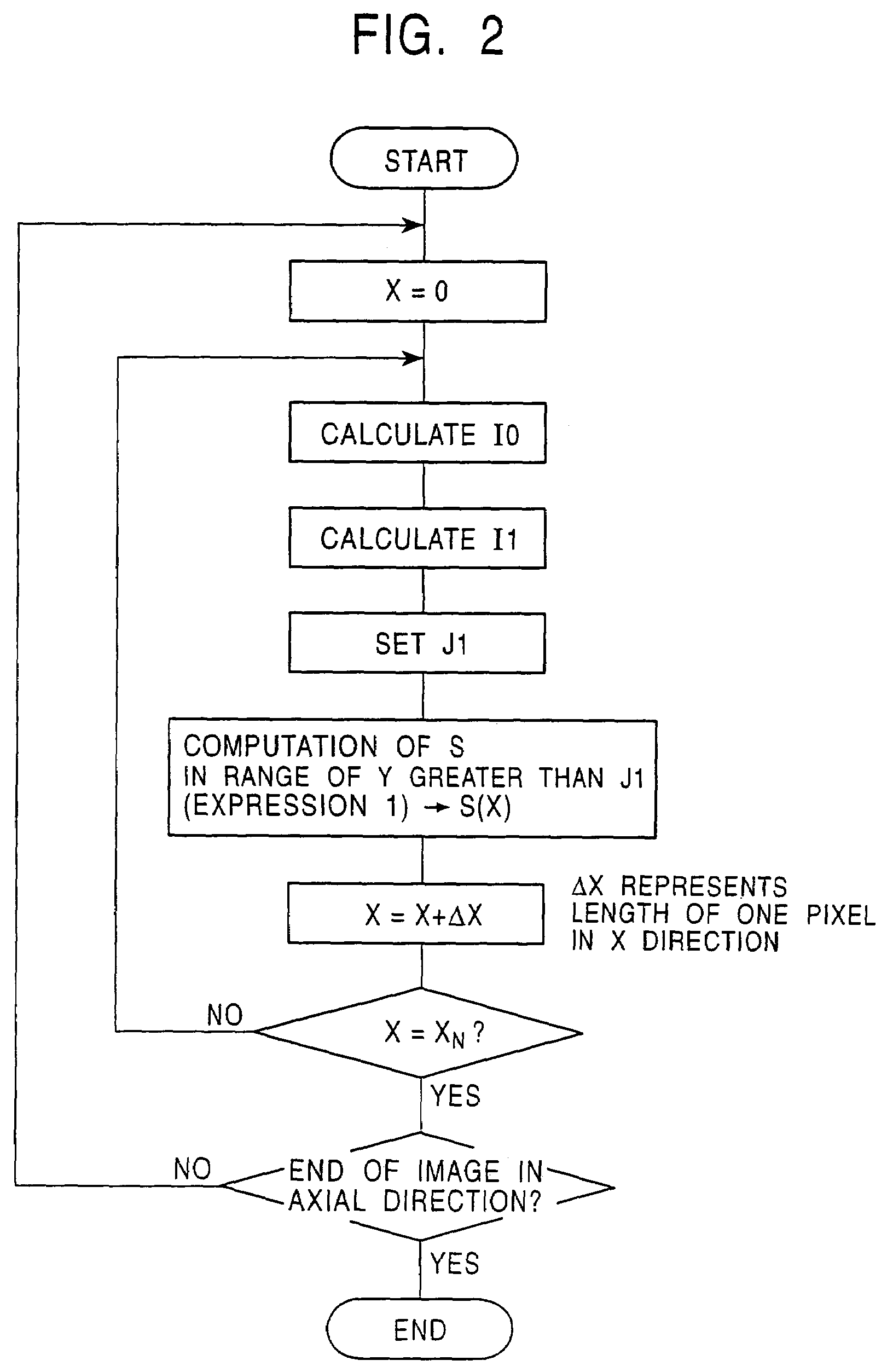

InactiveUS20050147289A1Accurate detectionAccurate measurementMaterial analysis using sonic/ultrasonic/infrasonic wavesCharacter and pattern recognitionElectrical resistance and conductanceApproximation function

To precisely measure bead cutting shapes of electric resistance welded pipes without being affected by difference in luminance level between cut and uncut portions in optical cutting images, an image is obtained by overlaying an optical cutting image with the optical cutting image subjected to thinning processing. A profile of the welded pipe is approximated with a quadratic function and a region containing the bead apex coordinates is identified as the bead. Shape data of the pipe surface at the portion corresponding to the bead portion is obtained from the preset left and right boundaries of the bead portion and the apex position of the separately-calculated bead portion, and bead width, height, slope angle, and unevenness at the left and right boundaries between the bead portion and base pipe portion, are each calculated, based on the left and right bead shape approximation functions and base pipe shape approximation function.

Owner:JFE STEEL CORP

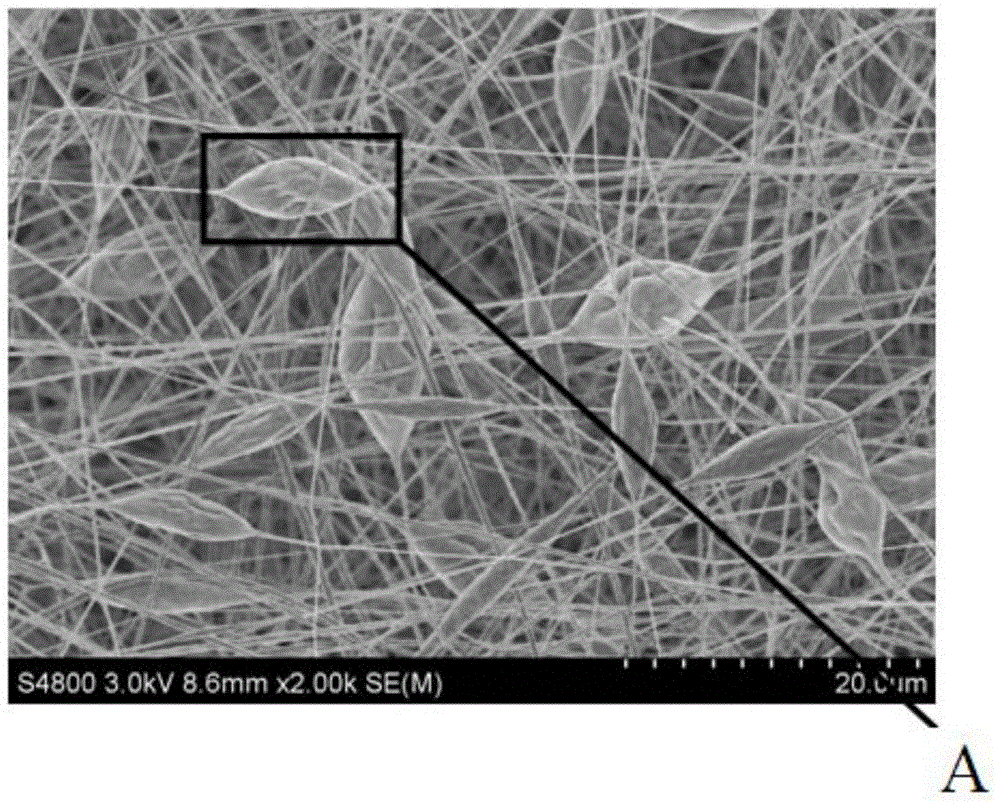

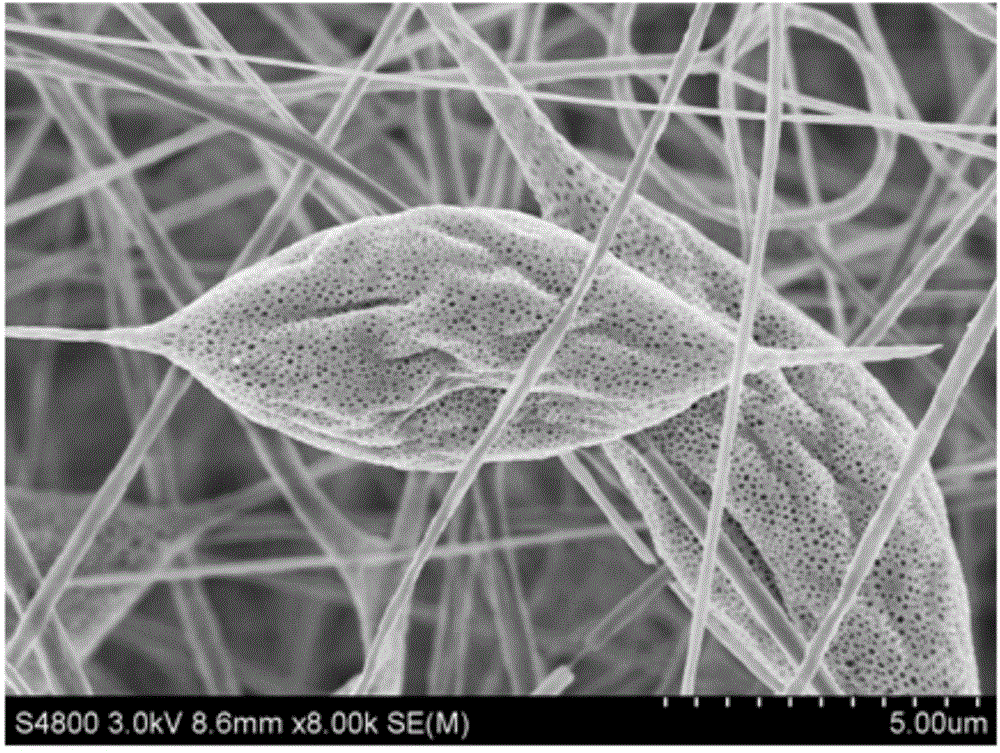

Bead-like porous PLA (Poly Lactic Acid) nano fiber as well as preparation method and application thereof

ActiveCN103952783AReduce fill rateImprove air filtration efficiencySemi-permeable membranesDispersed particle separationFiberAir filtration

The invention discloses a bead-like porous PLA (Poly Lactic Acid) nano fiber which is characterized in that pearls in the bead-like porous PLA nano fiber accounts for 8.0-22% of the area of the bead-like porous PLA nano fiber and the geometrical dimensions of stringed beads are as follows: the pearls have the mean area of 10-80mu m <2> and the length-width ratio of 2-4; the average diameter of fibers for connecting the beads is 100-800nm; the surface pore coverage rate of the beads is 3-30%. Due to the bead-shaped porous structure and the nano porous fibers for connecting the beads, the bead-like porous PLA nano fiber has high specific surface area, and high surface energy is provided for absorbing micro particles; meanwhile, the bead-like porous PLA nano fiber is beneficial to gas circulation, the air filtration resistance is reduced, especially the air filtratione efficiency for micro particles with the mass median diameter of 75nm is 99.9-99.999%, and the average filtration resistance is 120-360 Pa. The invention also provides a preparation method of the bead-like porous PLA nano fiber and application of the bead-like porous PLA nano fiber serving as an air filtration film.

Owner:江苏正大易方科技有限公司

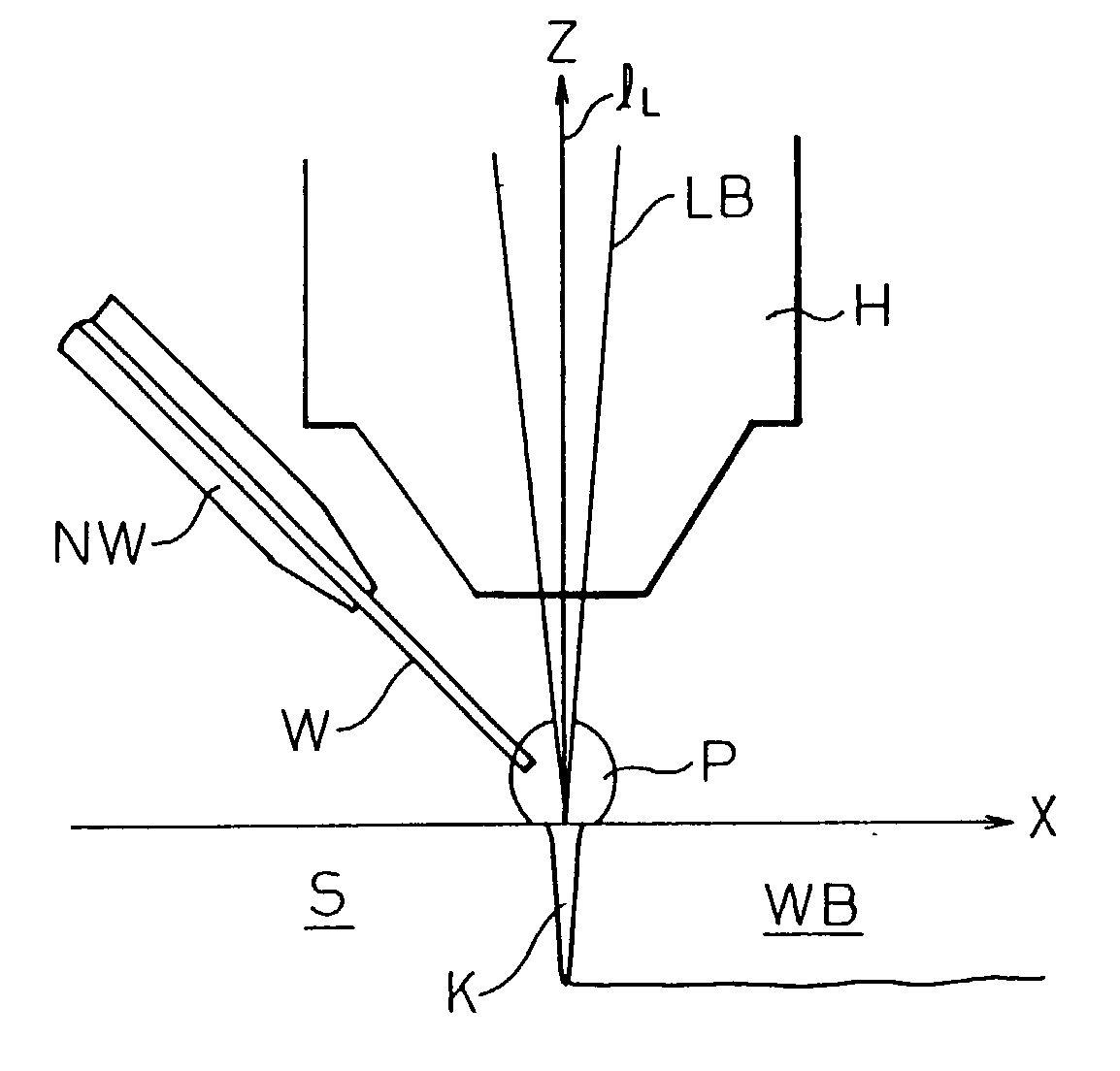

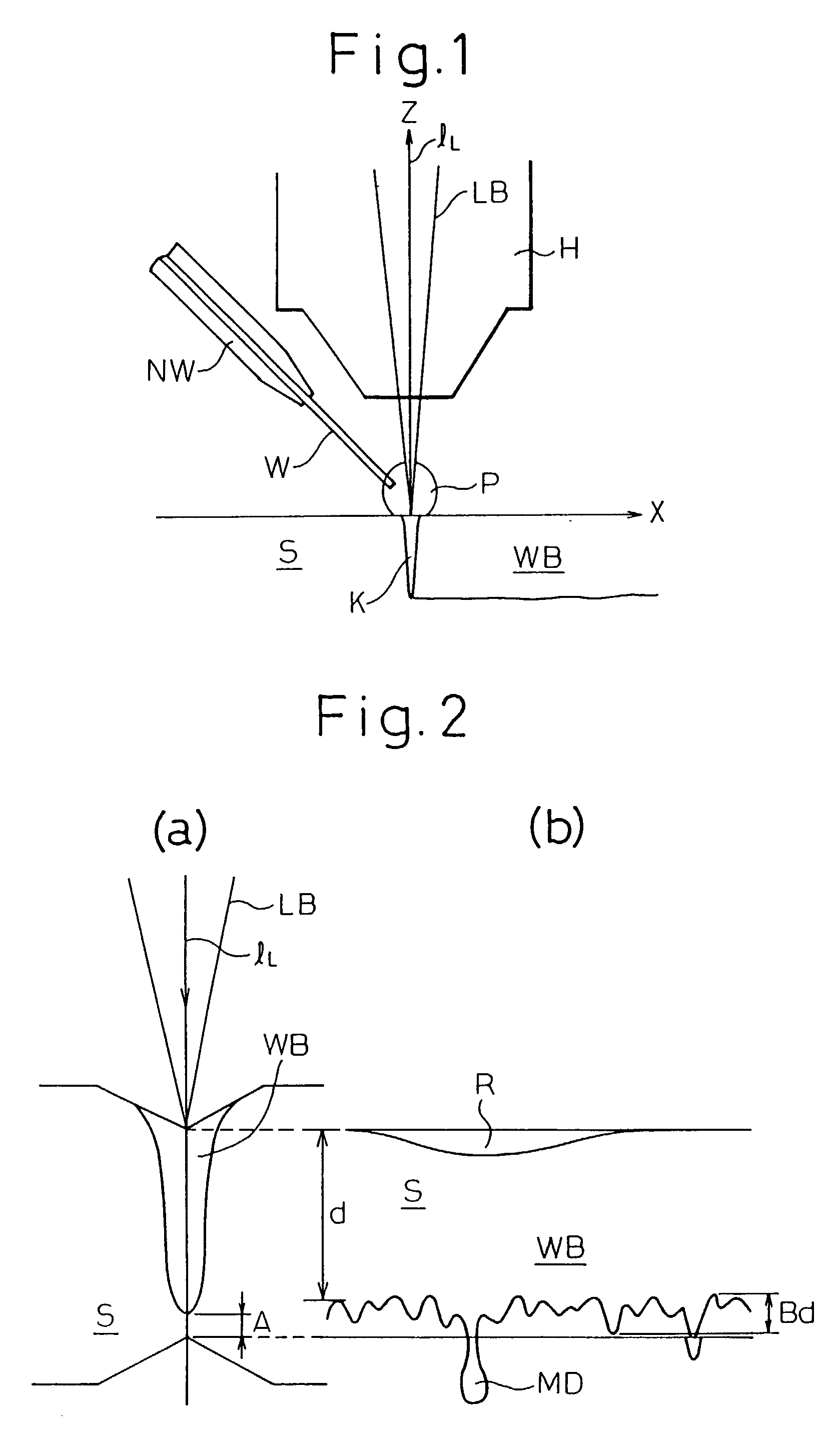

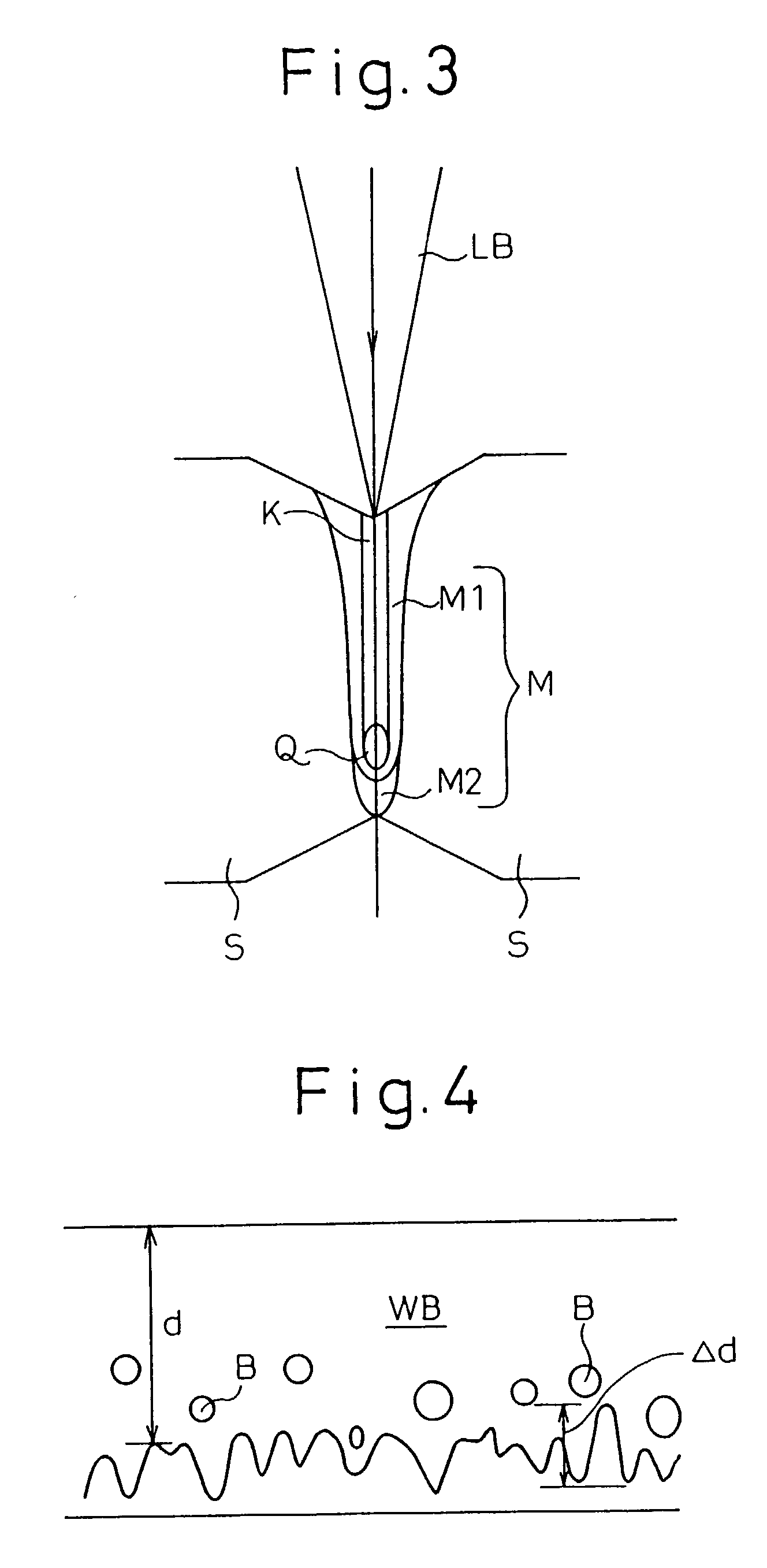

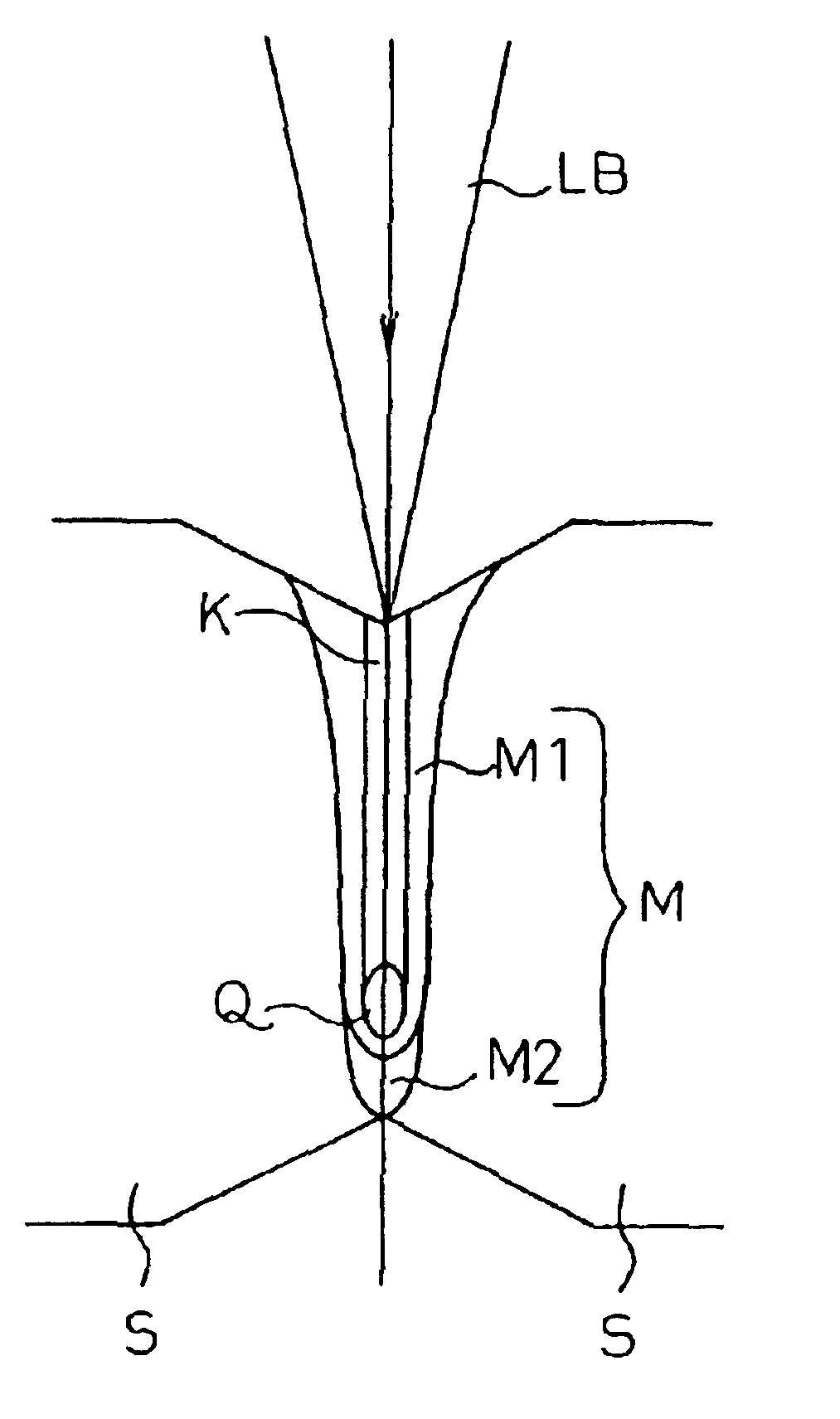

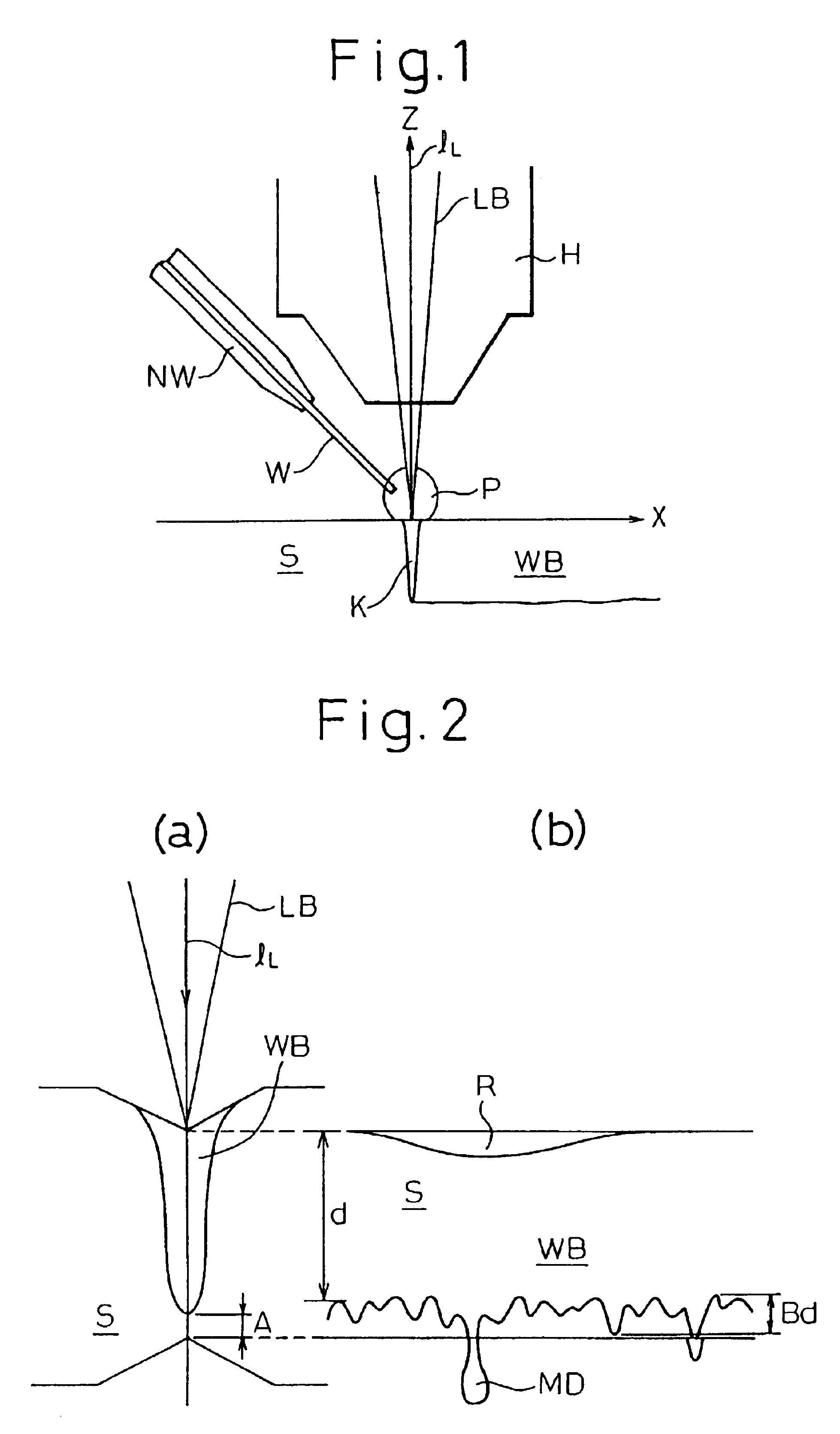

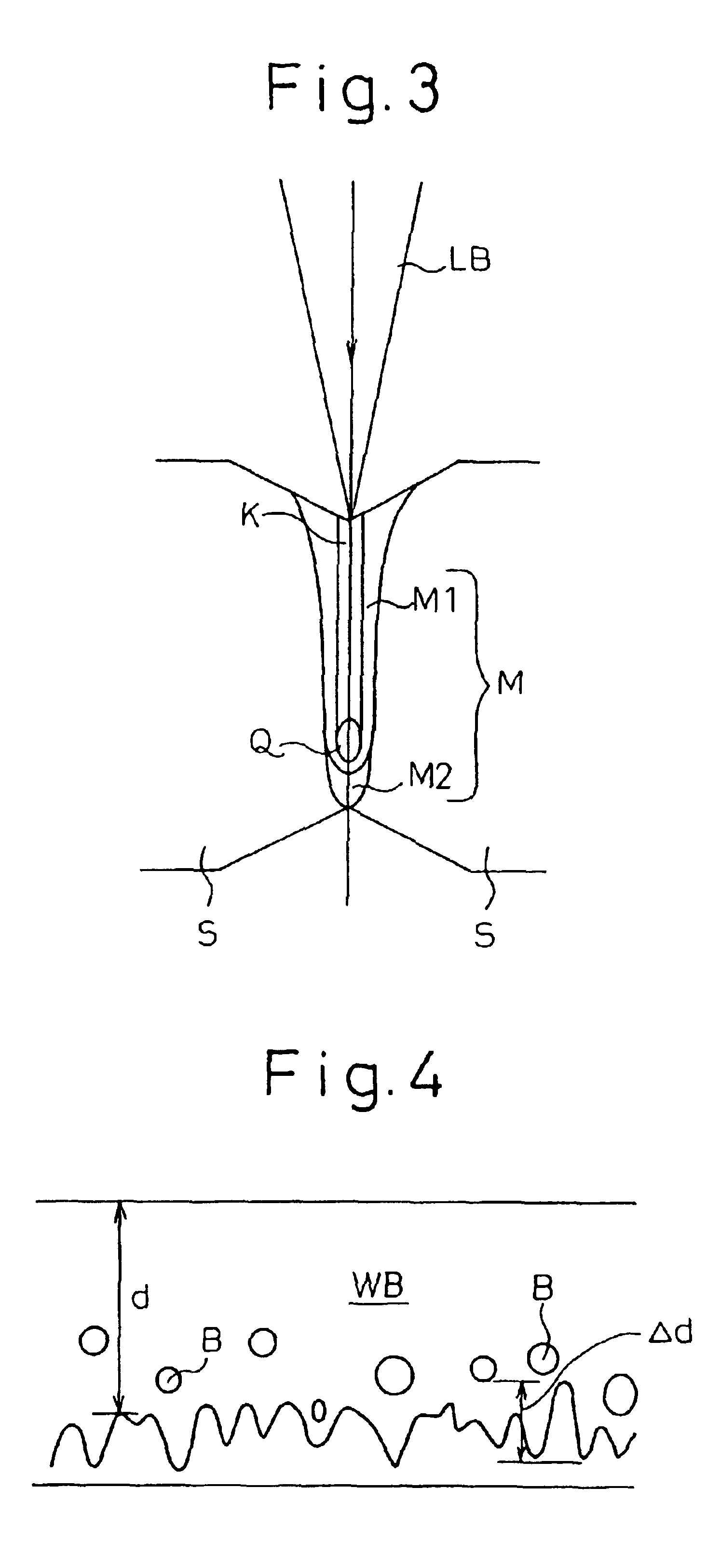

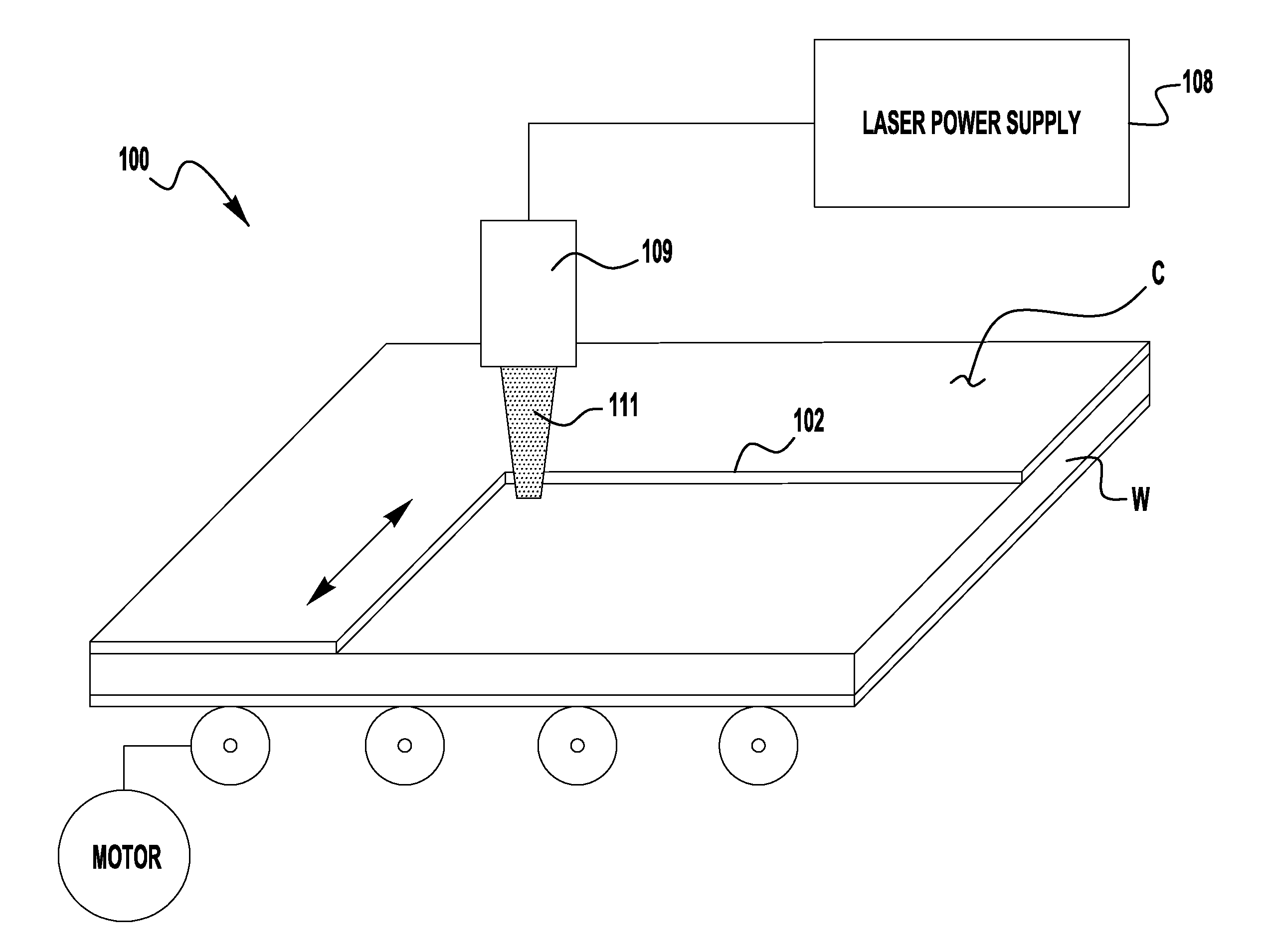

Method of butt-welding hot-rolled steel materials by laser beam and apparatus therefor

InactiveUS20030038120A1Inhibition formationSufficient reducing abilityWelding/cutting media/materialsWelding/soldering/cutting articlesButt weldingManganese

In order to make the depth of penetration in the weld bead portion uniform and obtain a bead shape having a flat bottom without spiking and meltdown during continuous hot rolling by bonding a plurality of hot-rolled steel materials using a laser beam, the following methods are employed: (A) a method of butt welding wherein center gas is blown against the welding portion symmetrically to the optical axis of the laser beam while side gas is being blown thereagainst from the side, the method comprising conducting welding while the center of laser-induced plasma is shifted in the welding direction from the center of the laser beam by a distance 0.2 to 0.5 times as much as a reference plasma diameter determined from the laser output and the beam diameter, and the type and flow rate of the center gas; or (B) a method comprising scanning the butt line with the laser beam during the laser welding at a speed of 2 to 10 m / min, and simultaneously oscillating the laser beam in the direction vertical to the butt line at a frequency of 40 to 80 Hz at an amplitude of 0.4 to 1.0 mm. Alternatively, (C) in order to prevent formation of blow holes in the weld bead, to make the depth of penetration in the weld bead portion uniform, and to obtain a bead shape having a flat bottom without spiking and excessive penetration, laser welding is conducted while a filler wire of an iron series base material, containing from 0.05 to 3% of one or at least two elements selected from aluminum, silicon, titanium and manganese, is being supplied to the welding portion. Moreover, (D) in order to stably supply a filler wire to the butt portion with high supply accuracy, the filler wire W is passed through a wire supply nozzle having a curved portion, and the filler wire is supplied toward the welding point along the welding line.

Owner:NIPPON STEEL CORP

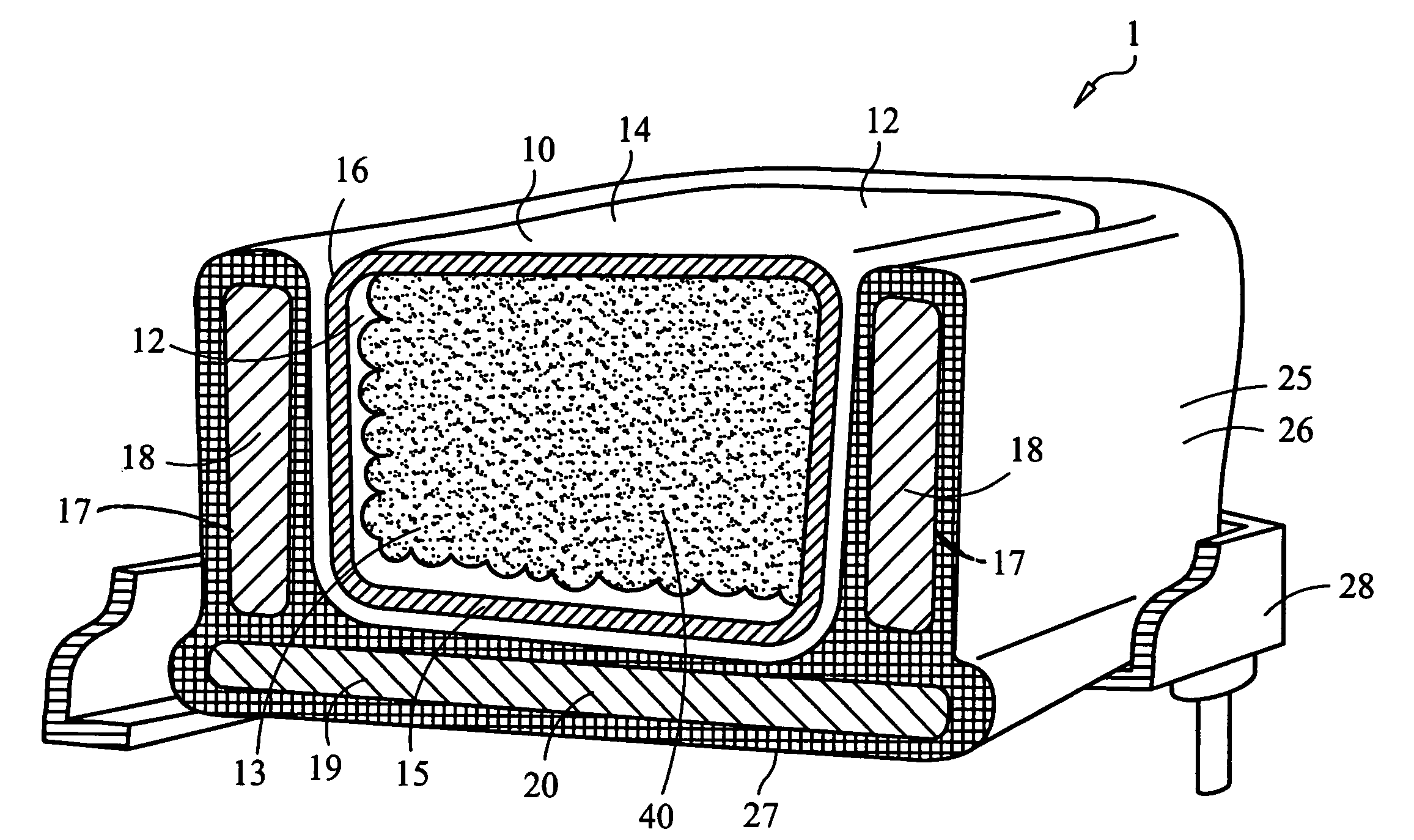

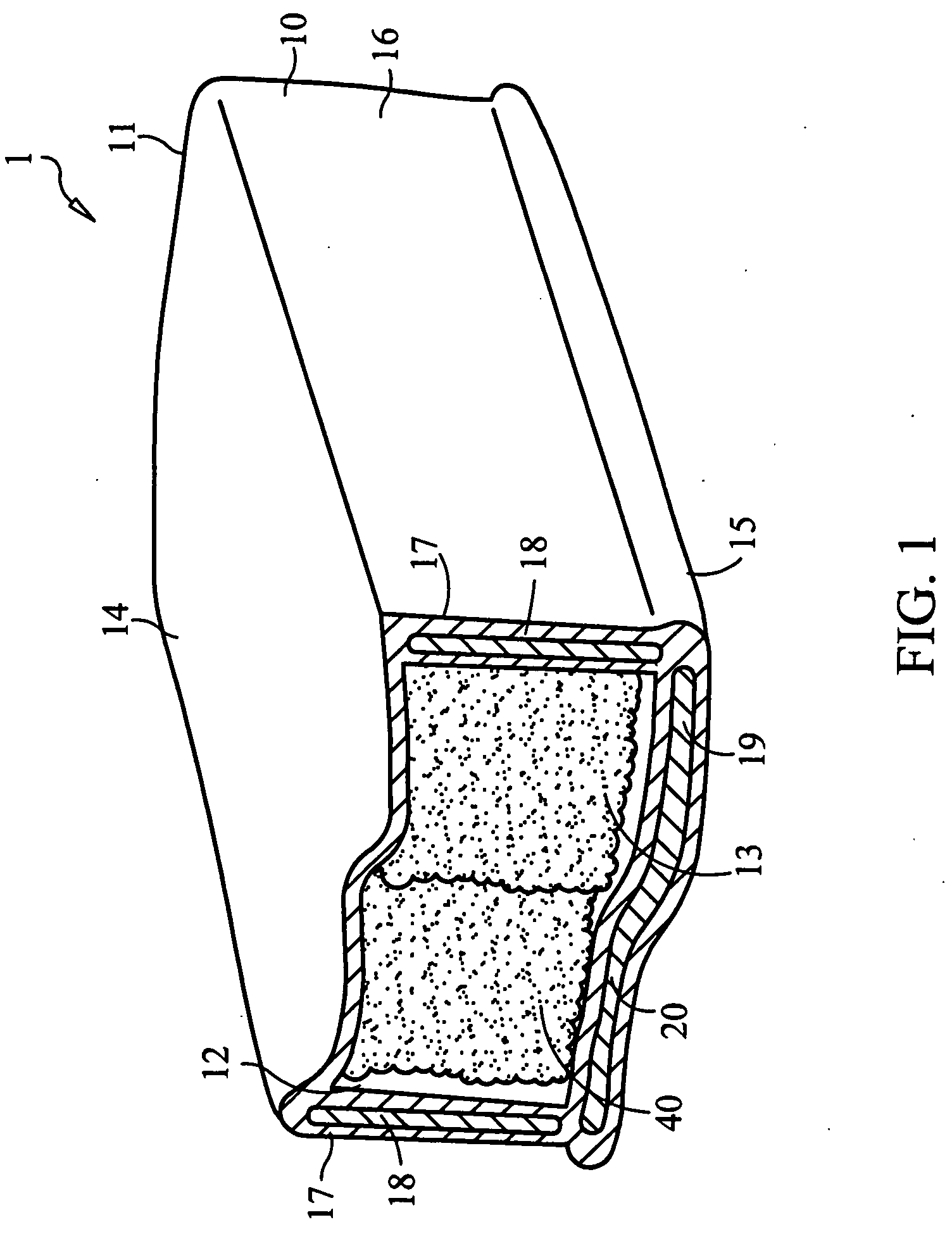

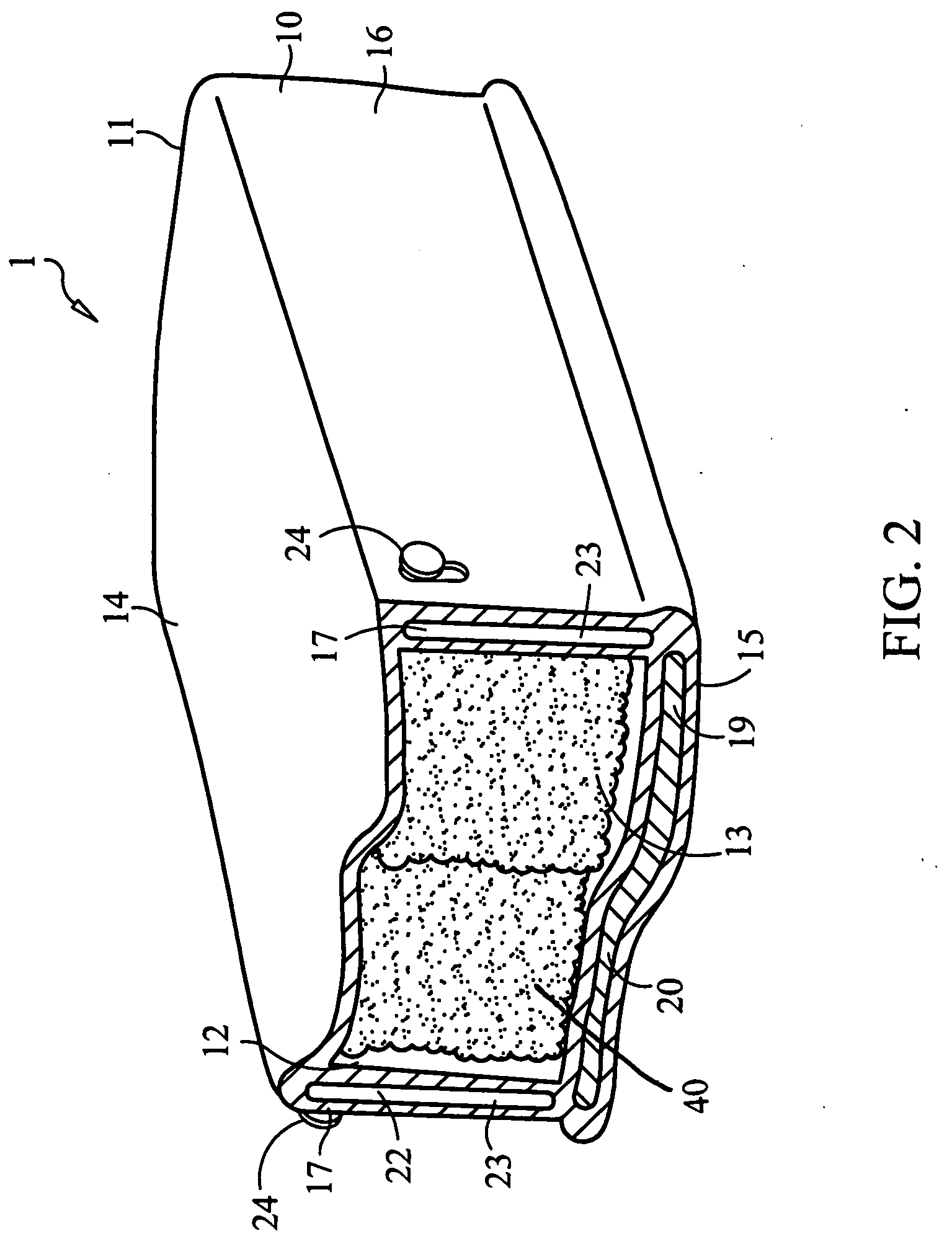

Particulate filler mattress

One possible embodiment of the invention could be a particulate filler mattress, which may be comprised of an outer envelope, a fire resistant liner envelope, a particulate matter filler envelope, and a foam pad. The foam pad could be made of a foam top and foam base, each layer generally having a different type of foam with corresponding essentially different qualities. The foam top could be essentially affixed to the foam bottom. The particulate matter filler envelope, generally affixed to the top of the foam base, could be made from elastic and sheer materials to essentially contain particulate matter filler, which could be bead-shaped and made from material such as, but not limited to, oats, Latex, Viscoelastic, Polyurethane, polystyrene or other materials. The fire resistant liner envelope essentially encompasses the particulate matter filler envelope and the foam pad. The outer envelope essentially encompasses the fire resistant liner envelope.

Owner:WILLIAMS CARLA M

Filter media containing powered cellulose and immobilized lipase for swimming pool and spa water filteration

A composition is provided containing powdered cellulose and at least one water insoluble, immobilized water treatment additive. Preferably, a filter media composition is provided containing powdered cellulose and at least one water insoluble, immobilized enzyme such as lipase for filtration of swimming pool and spa water. The lipase may be recombinantly produced, and lipases having 1,3 positional or non-positional specificity are used. The immobilized lipase may be in the form of bead-shaped particles, and immobilization can be on a macroporous acrylic resin. Moisture may be added to the composition to provide a pre-moistened composition that is dustless and provides for improved dispersement and even filter grid coating. In a filtering system, the filter media absorbs oils contained in pool or spa water, and the lipase hydrolyzes the oils.

Owner:PURIFIBER LLC +1

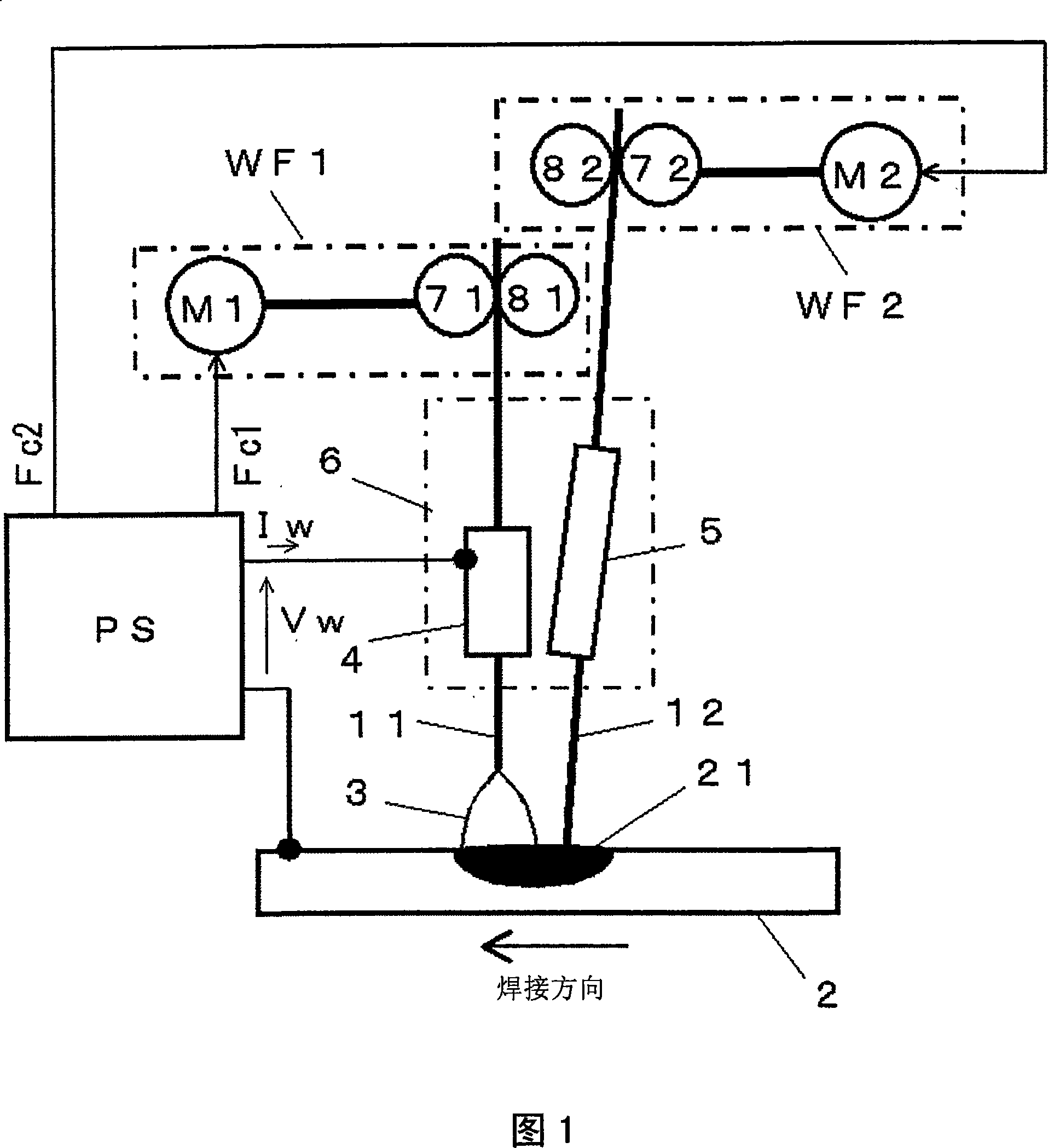

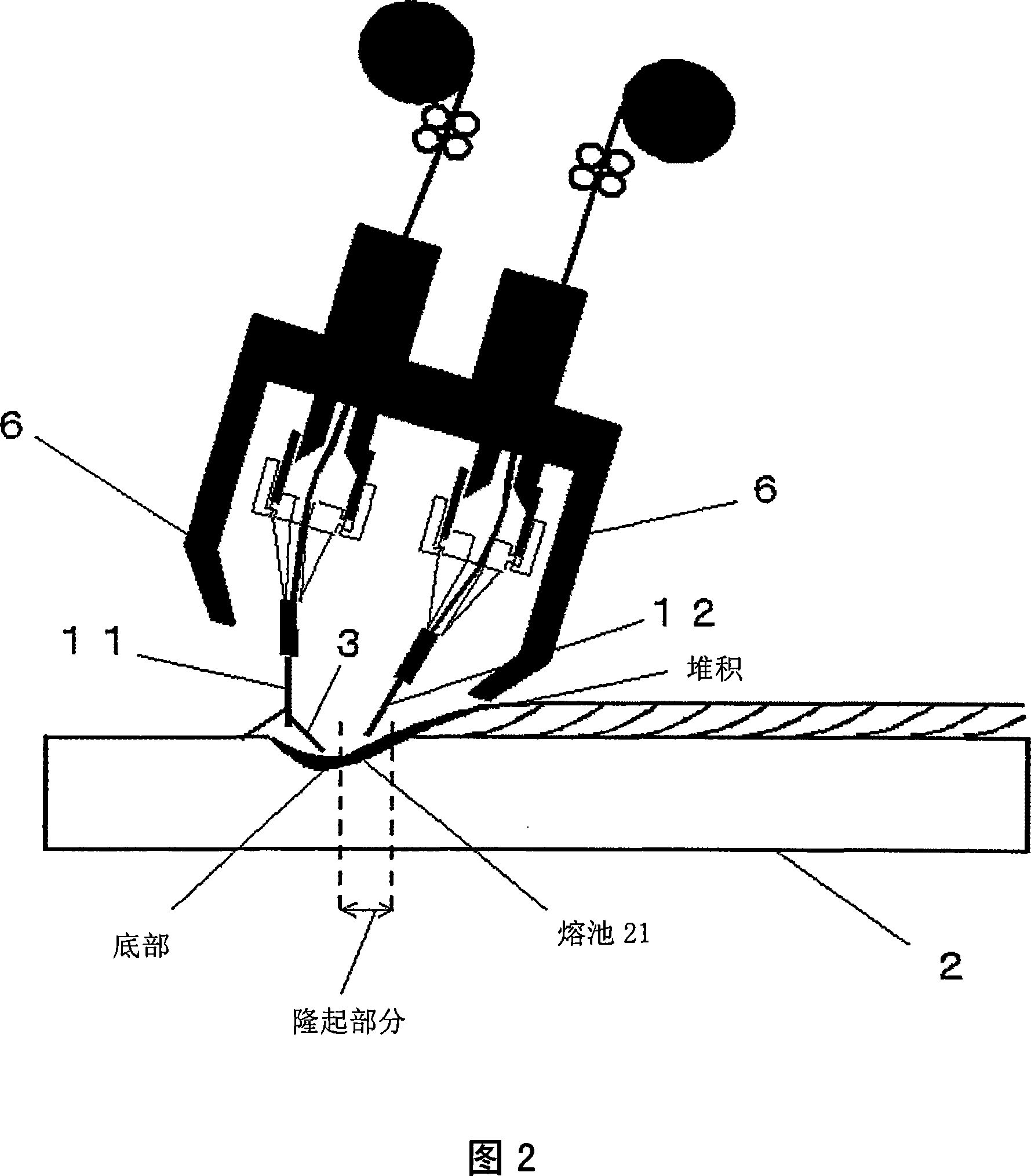

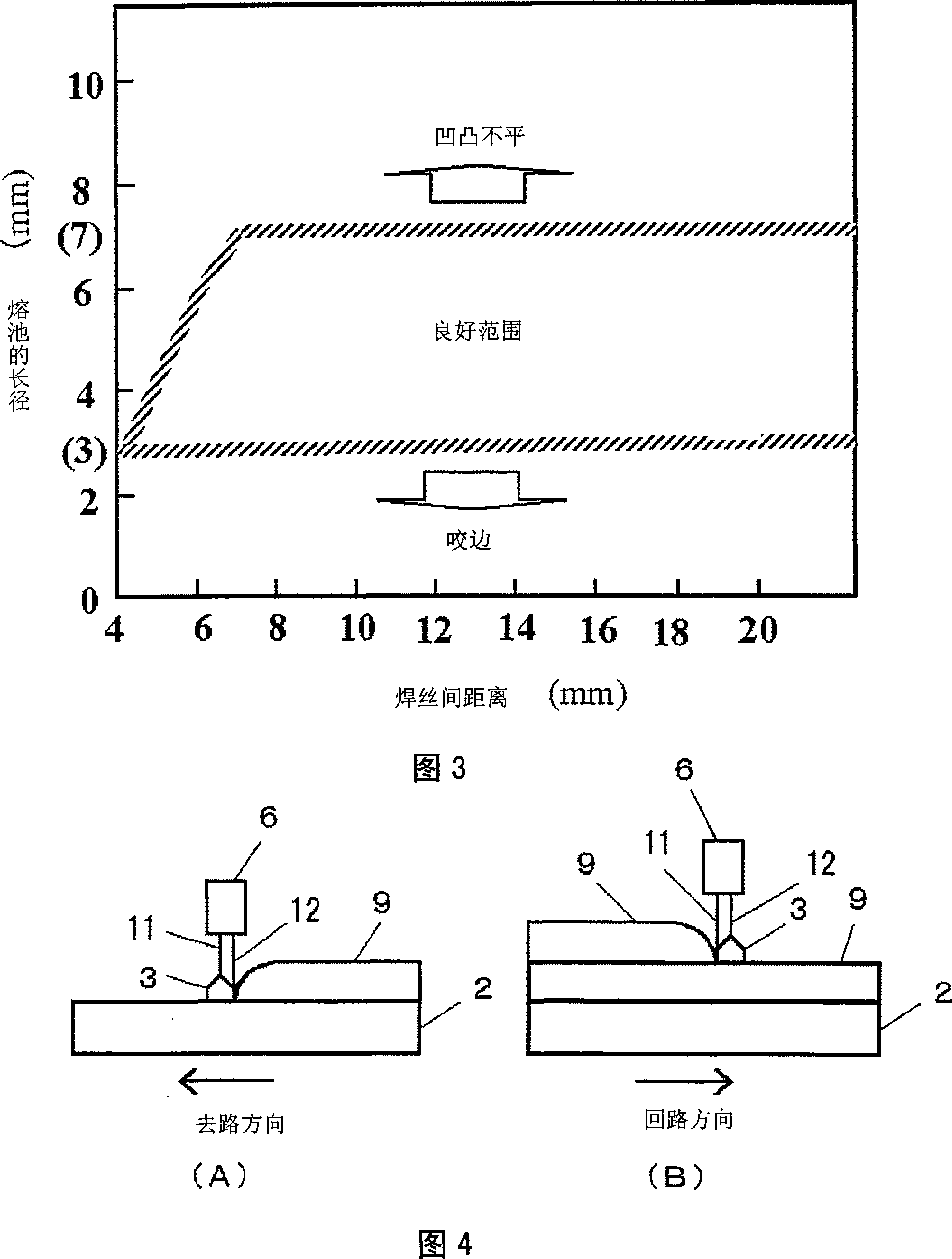

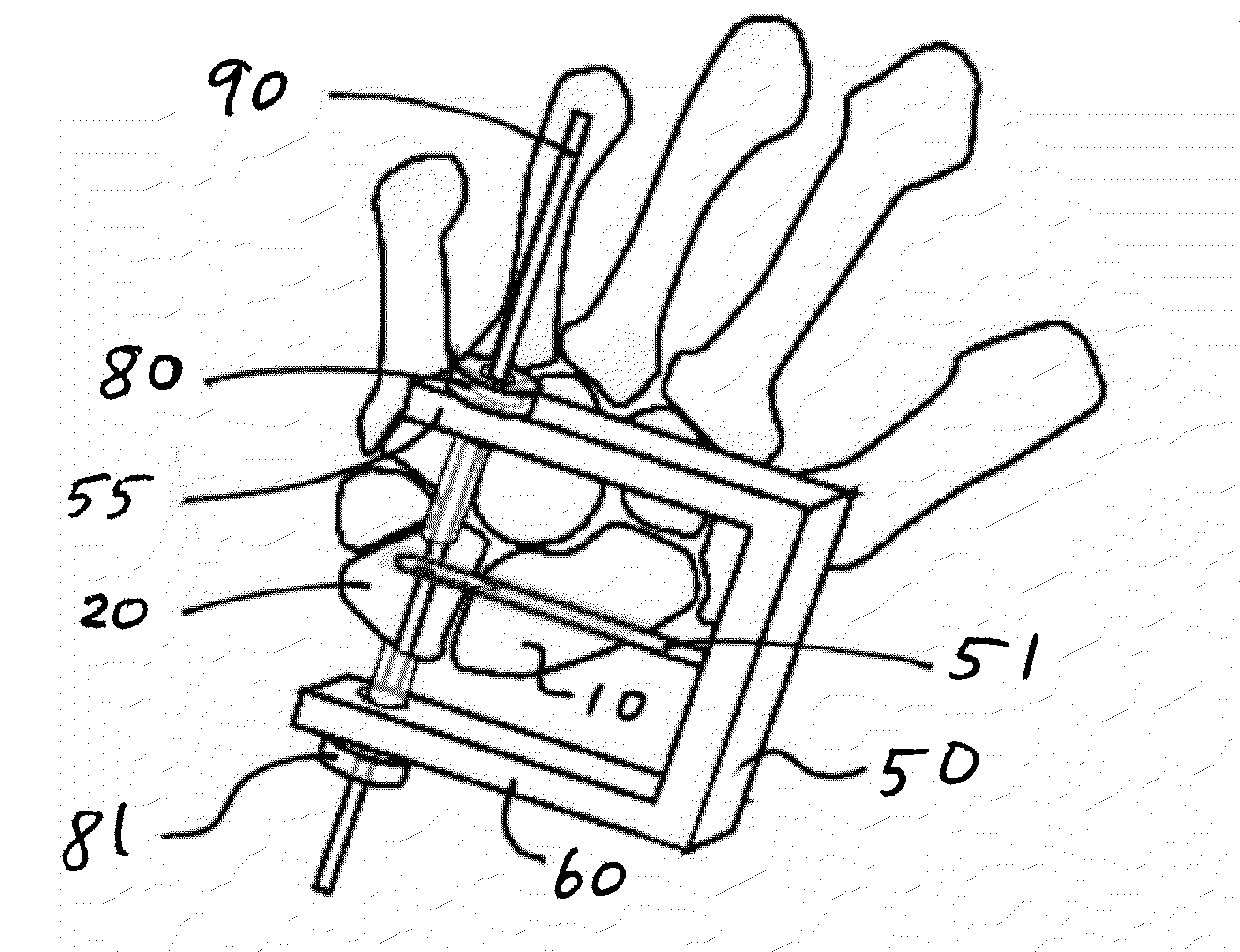

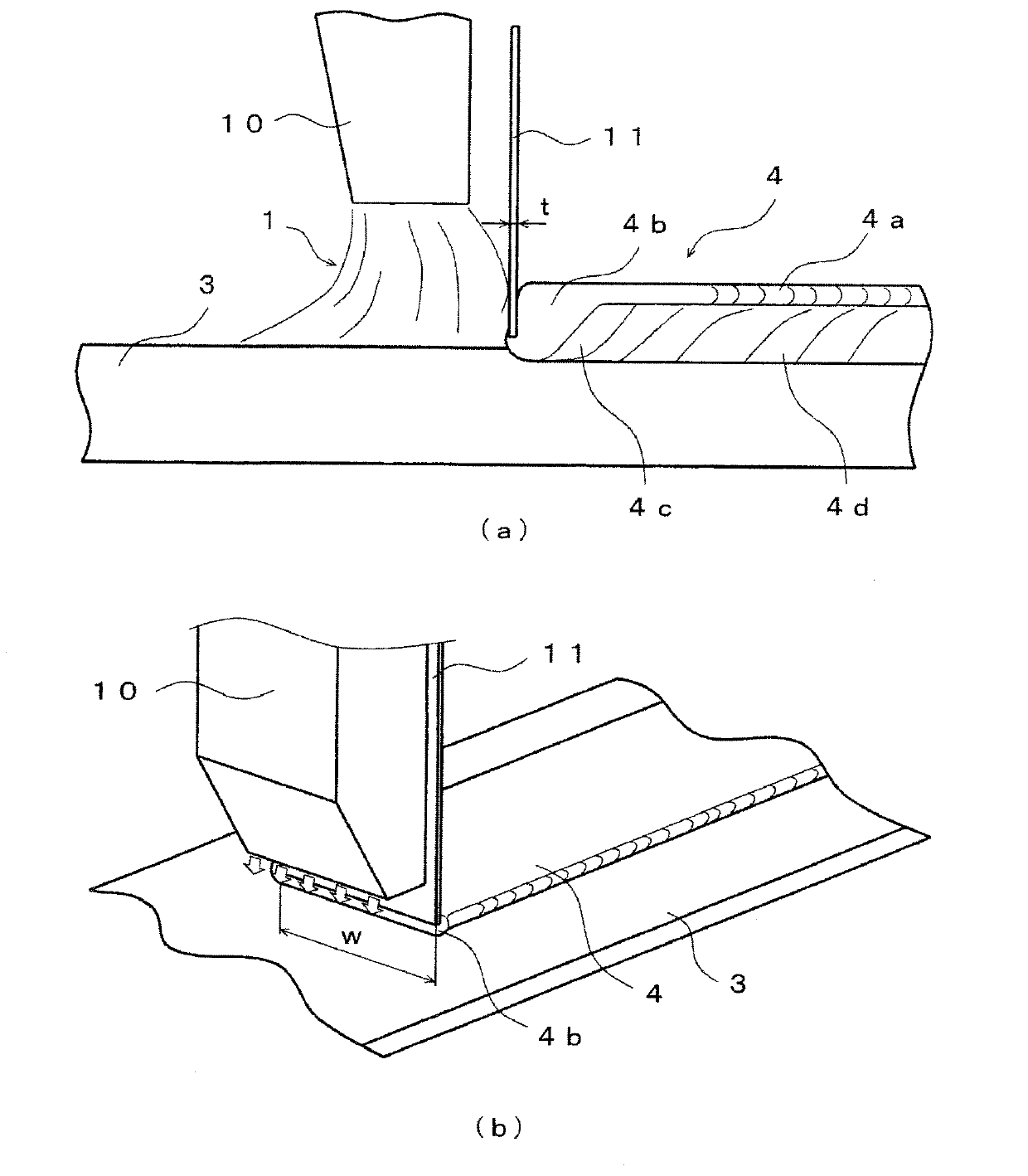

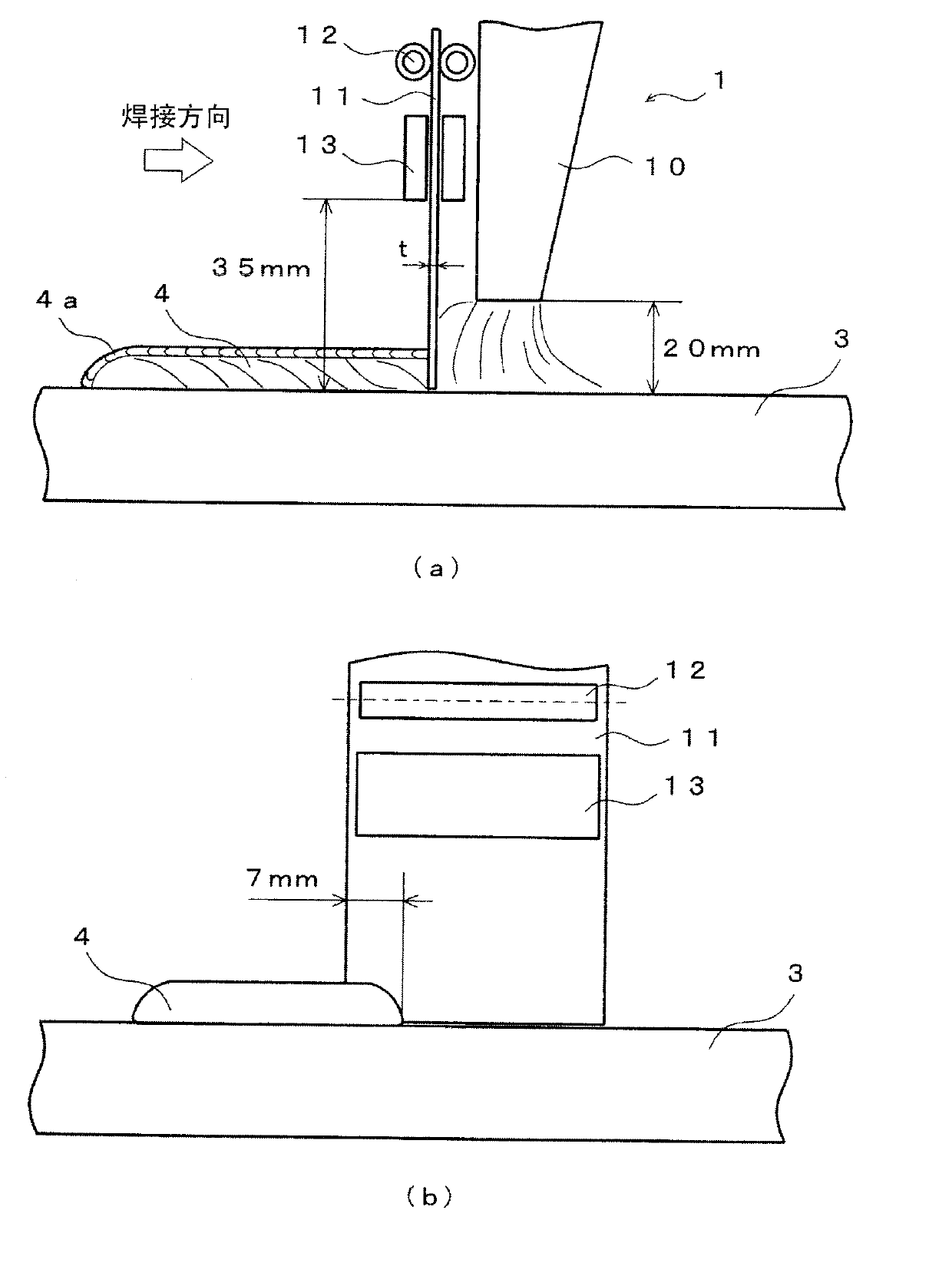

Double-wire feeding arc welding method and multi-layer surfacing method

ActiveCN101116925AReduce the temperatureIncrease surface tensionArc welding apparatusBead shapeEngineering

In the double-wire feeding arc welding method of the present invention, the first (leading) welding wire (11) and the second (backward) welding wire (12) that are insulated from each other are fed from the welding nozzle (6) at the front end of the welding torch, and the molten metal Welding the low-viscosity iron and steel materials, the welding current (Iw) is energized in the above-mentioned leading welding wire, and the arc (3) is generated to form a molten pool (21). The above-mentioned molten pool (21) under the pressure of the electric arc (3) is excavated to the raised position. Therefore, when welding iron and steel materials with low molten metal viscosity, a good bead shape without unevenness, undercut, and underfill can be obtained.

Owner:DAIHEN CORP

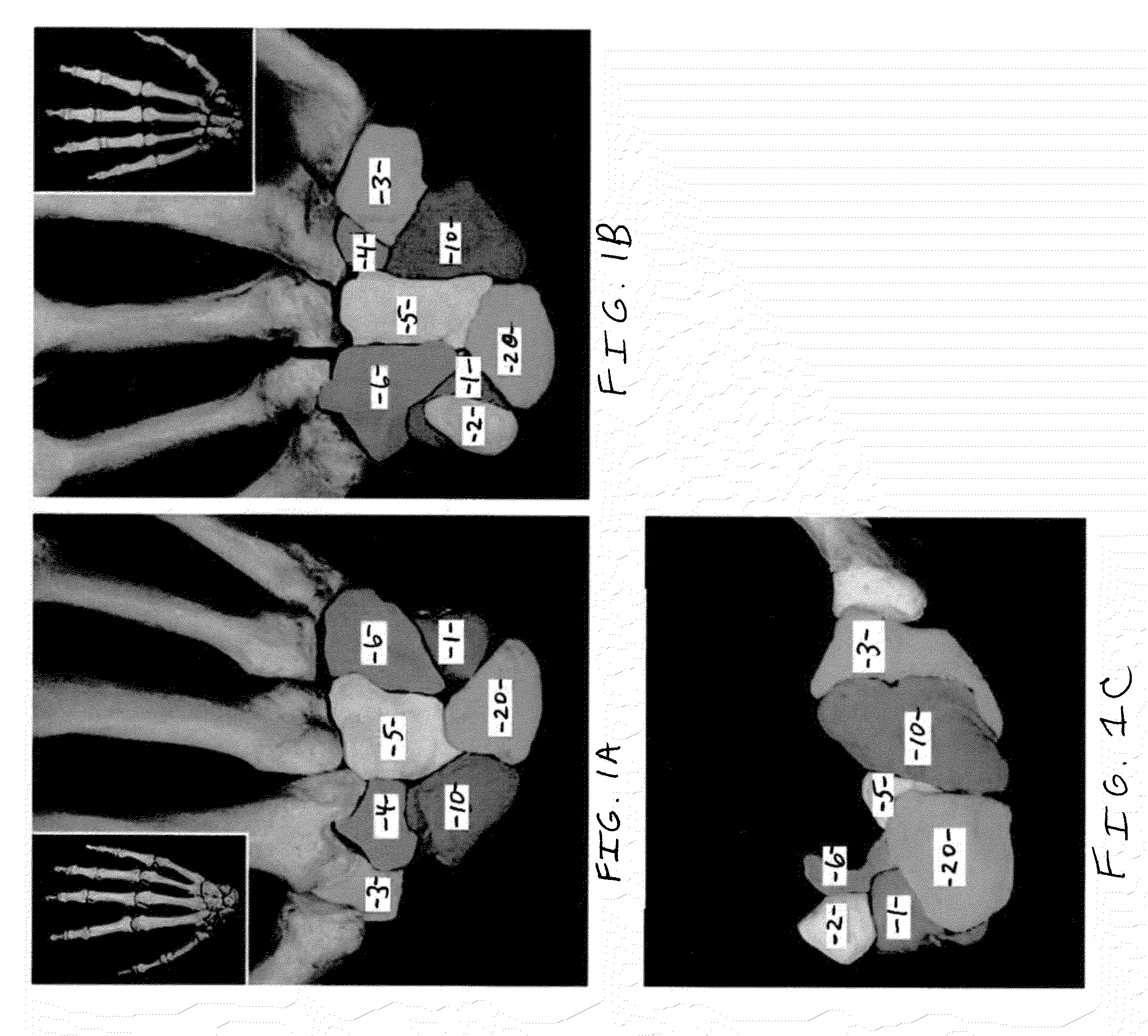

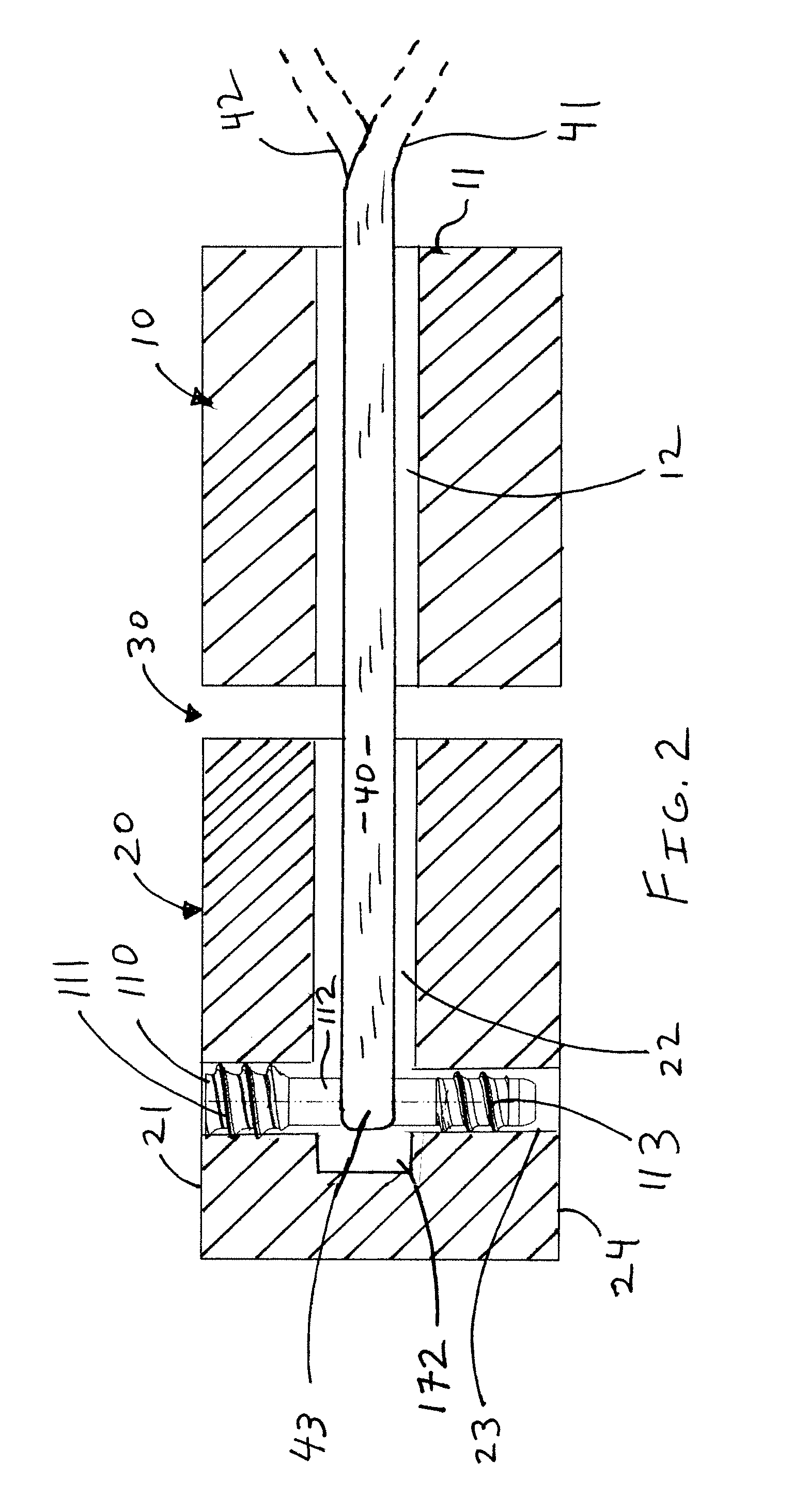

Method and apparatus for articular scapholunate reconstruction

InactiveUS20090234396A1Broad surgicalImprove performanceSuture equipmentsFinger jointsScapholunate jointBead shape

A reconstructive procedure for addressing instability of the scapholunate articulation between a scaphoid and a lunate of the hand. A graft is obtained. At least a portion of the graft is positioned intramedullary to the scaphoid. At least another portion of the graft is positioning intramedullary to the lunate. The graft crosses directly through the scapholunate joint. A plurality of instruments and implements, including an E-shaped drill guide, a cannulated lunate screw, and suture anchors in the form of button-shaped or bead-shaped anchors, are provided to facilitate the surgeon's performance of the scapholunate ligament reconstruction. A kit is provided, including a plurality of instruments and implements for performing the reconstructive procedure.

Owner:TELLMAN LARS G +1

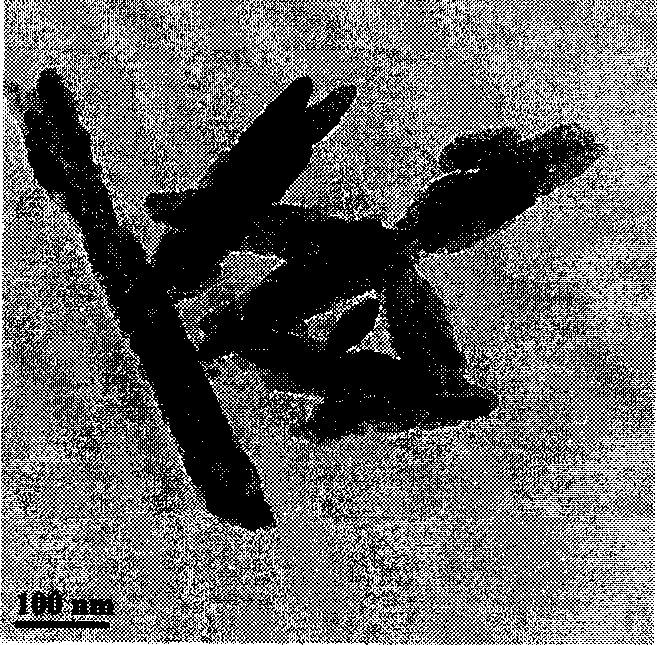

Industrial preparation of calcium carbonate nano bead string

InactiveCN101475199AImprove mechanical propertiesImprove the blocking effectCalcium/strontium/barium carbonatesCarbonizationComposition B

The invention discloses an industrial preparation method for calcium carbonate nanometer beads, which is an industrial preparation method for nanometer calcium carbonate with a bead-shaped structure, and comprises the following steps that: (1) natural limestone is crushed and calcined, then is added with hot water for digestion, and passes through a sieve for refining to be prepared into a refined calcium hydroxide material liquid; (2) the calcium hydroxide slurry is sent into a reactor system, proper kiln gas is aerated for carbonization reaction, the concentration of carbon dioxide in the kiln gas is between 10 and 50 percent, and a crystal control agent composition A and a crystal control agent composition B are added before the carbonization or at an initial carbonization stage; and (3) an obtained product is filtered, dried and crushed to obtain the bead-shaped nanometer calcium carbonate. The diameter of the bead-shaped nanometer calcium carbonate is between 20 and 50nm, the slenderness ratio is between 10 and 30, and the BET specific surface area is larger than 30m / g. The bead-shaped nanometer calcium carbonate has good dispersivity, improves the mechanical property of materials, and improves the barrier property of the materials to various gases and liquids, so the bead-shaped nanometer calcium carbonate can be widely applied to industries such as rubber, plastic, coating, printing ink, paper making, sealing gum and the like.

Owner:山东海泽纳米材料有限公司

Method of butt-welding hot-rolled steel materials by laser beam and apparatus therefor

InactiveUS6770840B2Inhibition formationAvoid reactionWelding/cutting media/materialsWelding/soldering/cutting articlesButt weldingManganese

In order to make the depth of penetration in the weld bead portion uniform and obtain a bead shape having a flat bottom without spiking and meltdown during continuous hot rolling by bonding a plurality of hot-rolled steel materials using a laser beam, the following methods are employed: (A) a method of butt welding wherein center gas is blown against the welding portion symmetrically to the optical axis of the laser beam while side gas is being blown thereagainst from the side, the method comprising conducting welding while the center of laser-induced plasma is shifted in the welding direction from the center of the laser beam by a distance 0.2 to 0.5 times as much as a reference plasma diameter determined from the laser output and the beam diameter, and the type and flow rate of the center gas; or (B) a method comprising scanning the butt line with the laser beam during the laser welding at a speed of 2 to 10 m / min, and simultaneously oscillating the laser beam in the direction vertical to the butt line at a frequency of 40 to 80 Hz at an amplitude of 0.4 to 1.0 mm. Alternatively, (C) in order to prevent formation of blow holes in the weld bead, to make the depth of penetration in the weld bead portion uniform, and to obtain a bead shape having a flat bottom without spiking and excessive penetration, laser welding is conducted while a filler wire of an iron series base material, containing from 0.05 to 3% of one or at least two elements selected from aluminum, silicon, titanium and manganese, is being supplied to the welding portion. Moreover, (D) in order to stably supply a filler wire to the butt portion with high supply accuracy, the filler wire W is passed through a wire supply nozzle having a curved portion, and the filler wire is supplied toward the welding point along the welding line.

Owner:NIPPON STEEL CORP

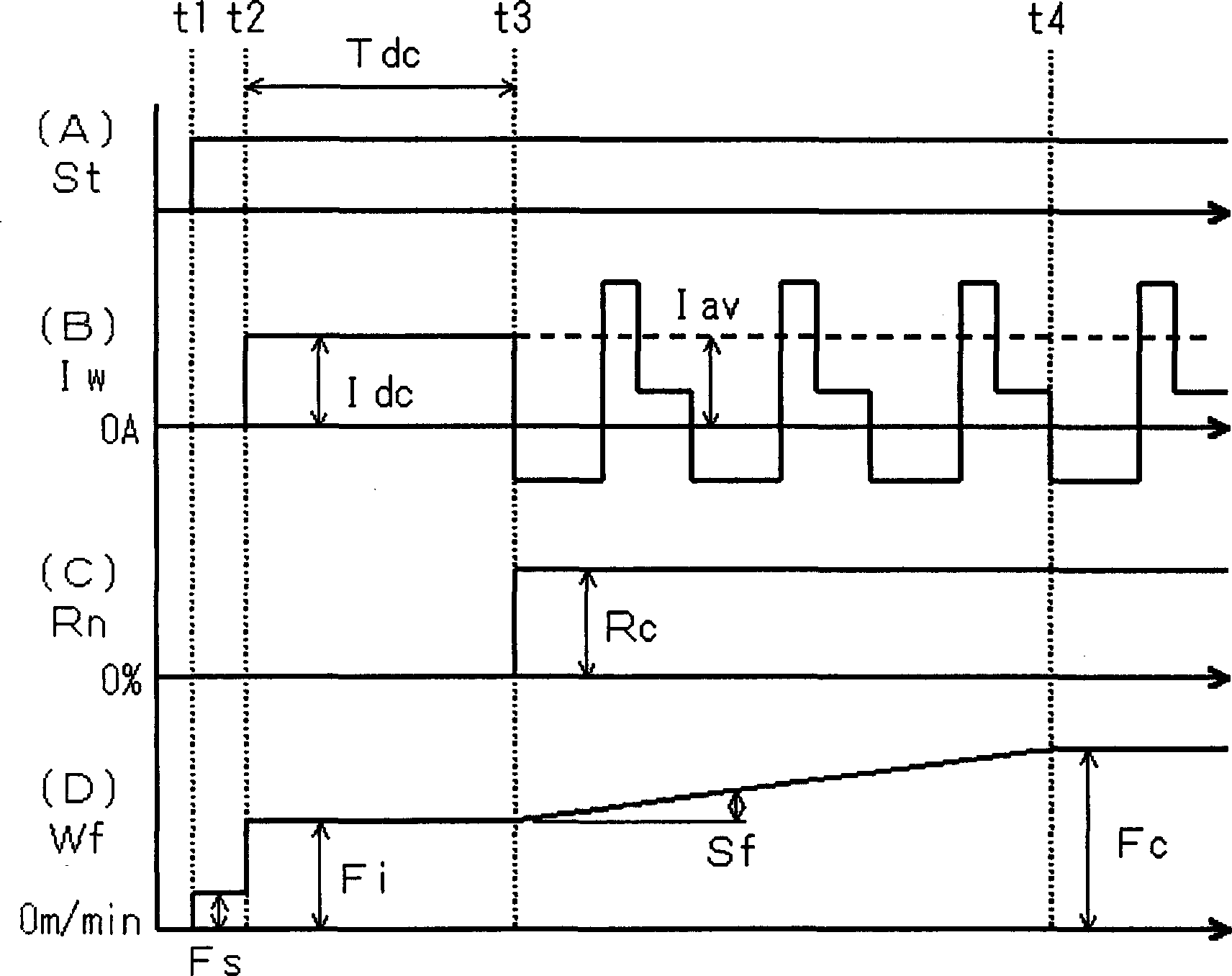

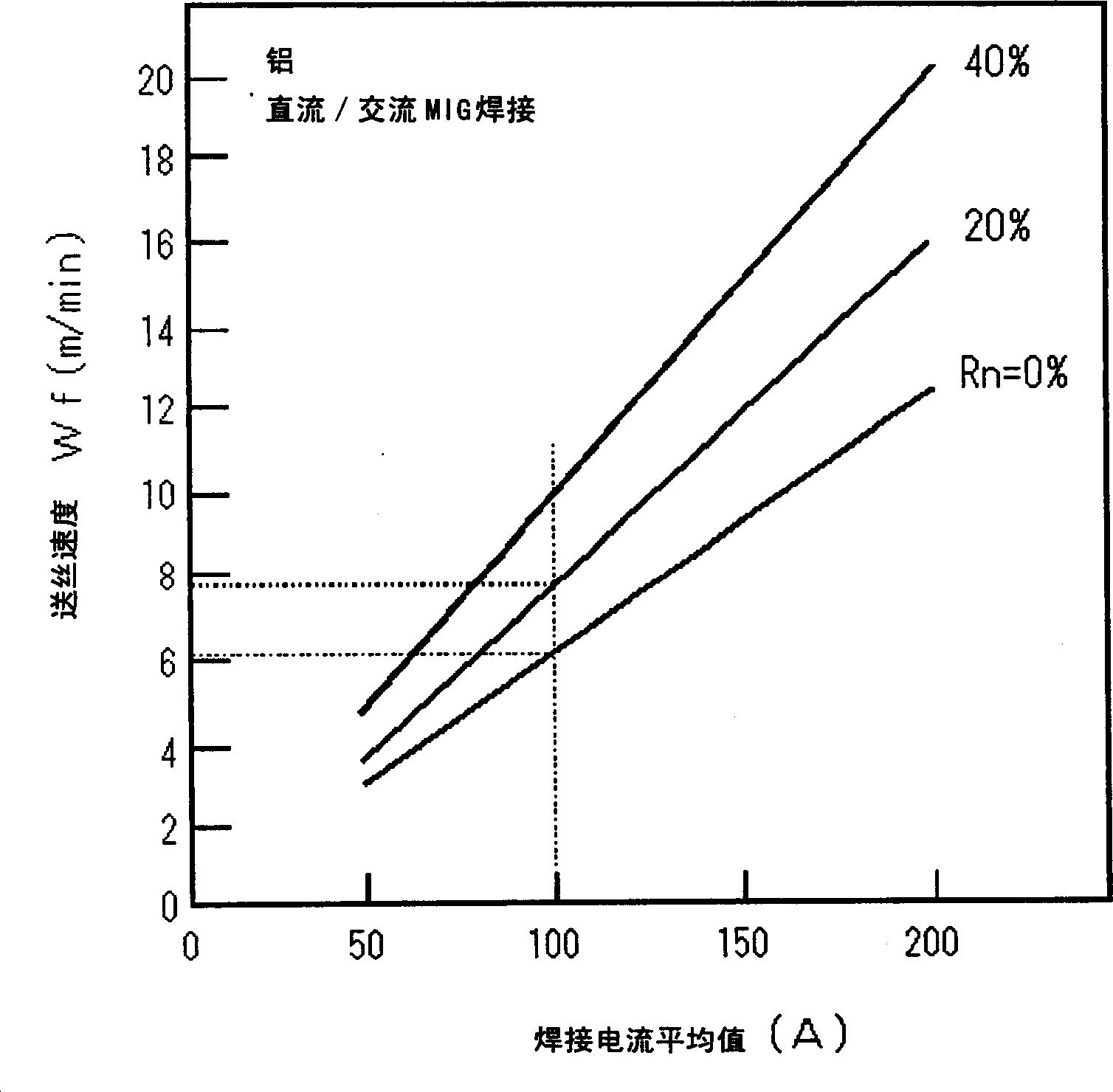

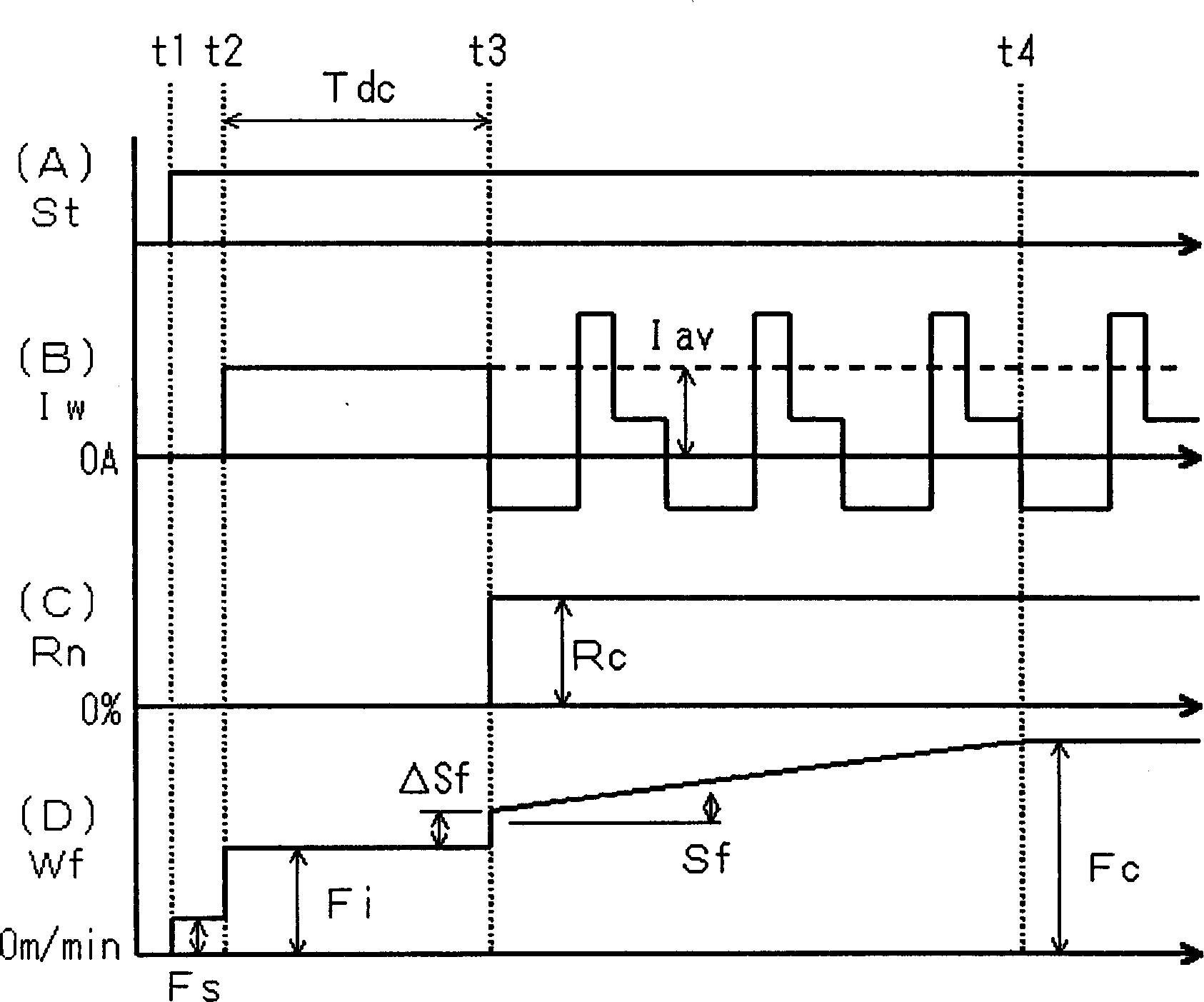

Arc start control method for AC arc welding

An arc start control method for AC arc welding is provided. In accordance with the method, upon arc start, a welding wire (1) is supplied at an initial feeding speed (Fi), and DC arc welding with electrode-positive polarity is performed during an initial period (Tdc) of hundreds of milliseconds by applying a DC welding current (Idc) with electrode-positive polarity (EP). Then, the welding is switched to AC arc welding based on an AC welding current, and the wire feeding speed (Wf) is varied from the initial feeding speed (Fi) to a steady-state feeding speed (Fc) with a slope (Sf). The initial feeding speed (Fi) is set so that the DC welding current (Idc) is substantially equal to the average (Iav) of the AC welding current. Also, the initial period (Tdc) is set so that the bead shape by the DC arc welding is substantially the same as the bead shape by the AC arc welding. Further, the slope (Sf) is determined so as to be substantially proportional to the rate of change in the wire welding speed observed when the DC welding current (Idc) is switched to the AC welding current.

Owner:DAIHEN CORP

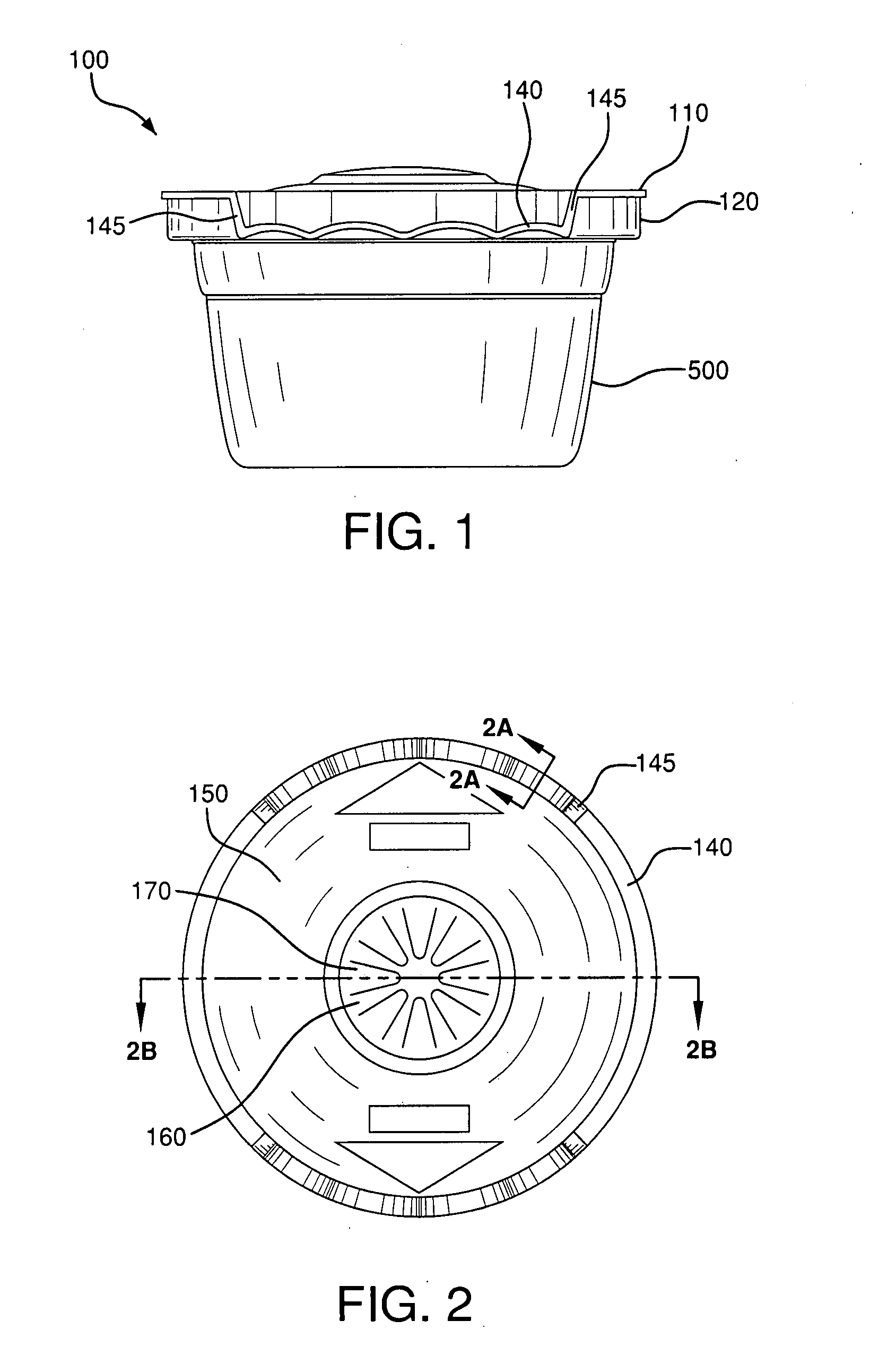

Removable locking container lid with outer skirt

A container lid for use with a container with a neck. The lid includes a top and bottom, a skirt extending downward from the circumference of the lid, and a circumferential flange extending radially outward from the lid. The skirt preferably includes at least one integral bead shaped to engage the neck or rim of the container. The lid preferably includes a convex center section including at least one vent. The at least one vent is preferably integral with the lid, and is opened by the steam pressure buildup inside the container when the contents are heated. When the cover is locked on the container, the skirt provides a seal against the outside of the container neck.

Owner:MRP NEW JERSEY LLC

A prepared tea combined by oolong tea with green tea or white tea

InactiveCN101006813AImprove taste qualityA fly in the ointment to cover up miscellaneous flavorsPre-extraction tea treatmentDigestive systemFlavorBead shape

The invention discloses prepared tea containing complementation combination of oolong and green tea or white tea, and belongs to the tea field. The invention is a kind of dominant complementation with one tea modifying another tea. The invention reinforces the synergy of the two kinds of tea. The invention is characterized in: preparing the tea to a combination with bead shape, clamping green or white tea in oolong (Tieguanyin is the best) leaves to prepare to bead shape, or packaging separately into lovers tea for keeping the advantages of the tow kinds of tea and overcoming the light and bitter flavor in common green or white tea, and foreign flavor in oolong. The invention can still have perfume after being soaked for several times, has the special characters of green tea and oolong, can be drunk in all seasons, and increases new product to the development of fine tea.

Owner:吴卫清

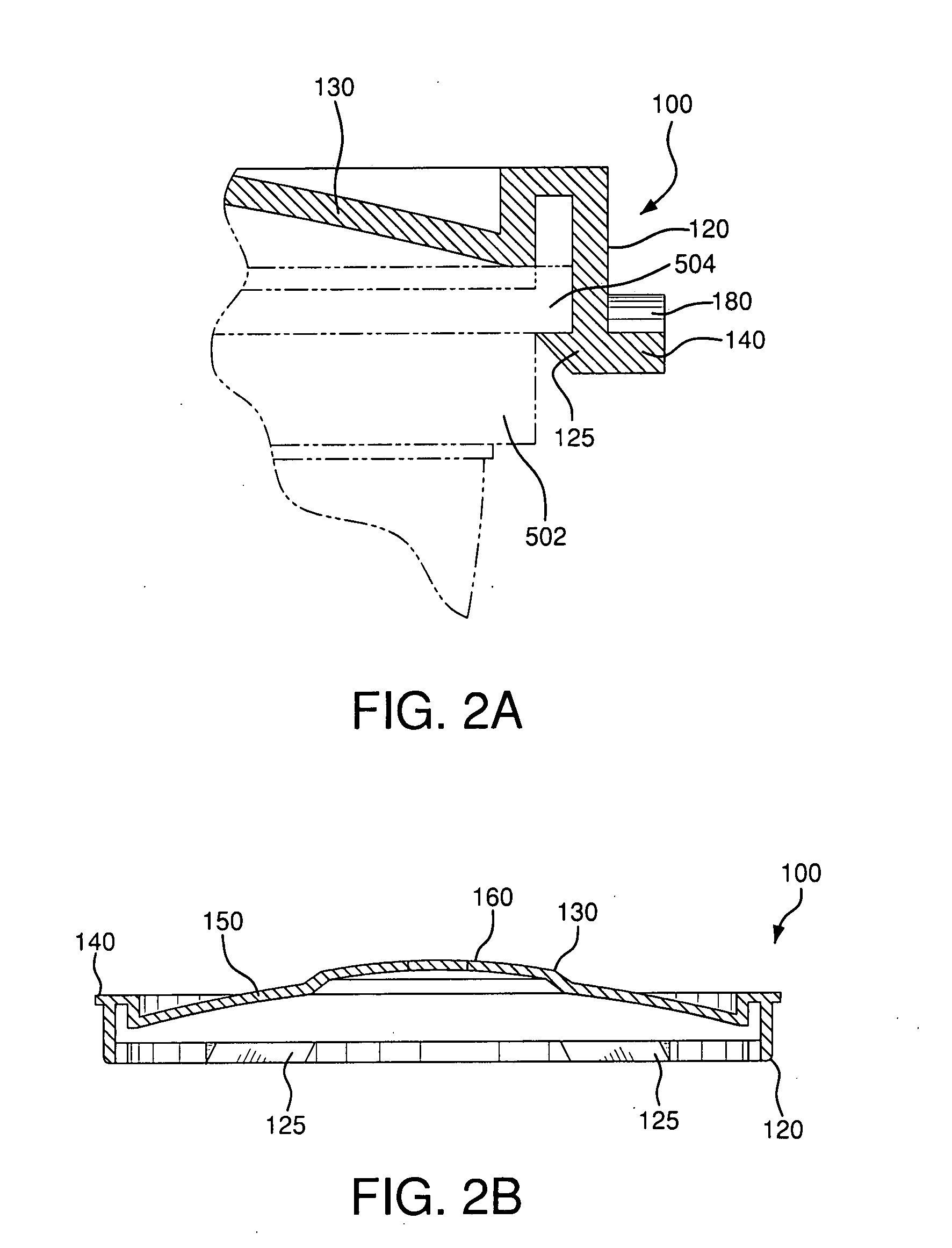

Preparation method and device for multilayered embedded particles

ActiveCN103404955ASolve the real problemProcess environmental protectionFood shapingHard CapsuleActive component

The invention provides a preparation method and device for multilayered embedded particles. The preparation method comprises the following steps of: dispersing active components into a protective colloidal solution to form an active component mixed suspension solution; processing the mixed suspension solution into liquid drops with the grain diameter in a range of 100-1000 microns; enabling second-layer embedding materials to be attached to the surfaces of the liquid drops and curing to obtain bead-shaped grains; and further drying the bead-shaped grains to obtain the multilayered embedded particles. The preparation method provided by the invention is simple in device and easy to operate. The multilayered embedded particles provided by the invention have high stability, narrow grain diameter distribution, good flowability and high mechanical strength, and can be widely applied to fields of tablets, hard capsules, diet supplementing foods, health-care foods, medicines and the like.

Owner:INNOBIO CORP LTD

Bead shaped vine tea

InactiveCN1871927ARich varietyRich choicePre-extraction tea treatmentPlant ingredientsBead shapeVine

Owner:HUAZHONG AGRI UNIV

Hollow desktop board and its hollow blow molding process

The invention relates to a hollow desktop board and a hollow blow molding process thereof, which is designed for the technical problem of poor structure of similar products. The desktop board is composed of two groups of desktop board monomers connected by hinges to form a folding table board. The desktop board is composed of a group of desktop board monomers. It is connected with the back side by reinforcing ribs, and is blow-molded at one time; the main point is that the reinforcing ribs are in the shape of a vertical surface, and the vertical-shaped reinforcing ribs are located inside the desktop board, and both the front and the negative sides are flat; the reinforcing ribs are multi-dimensional The ribs are arranged adjacent or intersecting; the distance between adjacent and intersecting ribs is less than or equal to ten times the distance between the front and back. It has high strength, large bearing weight, simple production process, and feasible hollow blow molding process; it is suitable for the production and use of hollow blow molding desktop boards and other similar hollow board products.

Owner:TAIZHOU LANGQING PLASTIC

Method and instrument for measuring bead cutting shape of electric welded tube

InactiveUS7236255B2Accurate detectionAdvanced electric resistance welded pipe manufacturing operationsAngles/taper measurementsMaterial analysis using sonic/ultrasonic/infrasonic wavesElectrical resistance and conductanceApproximation function

Owner:JFE STEEL CORP

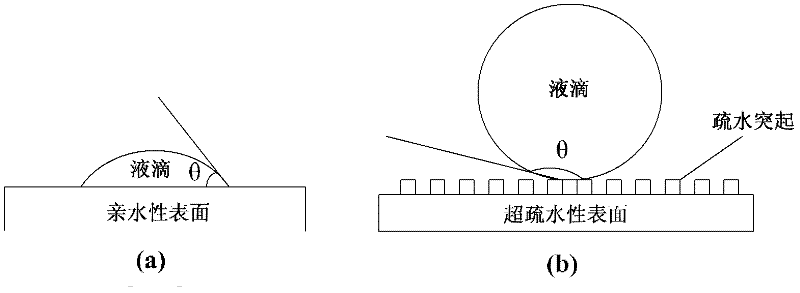

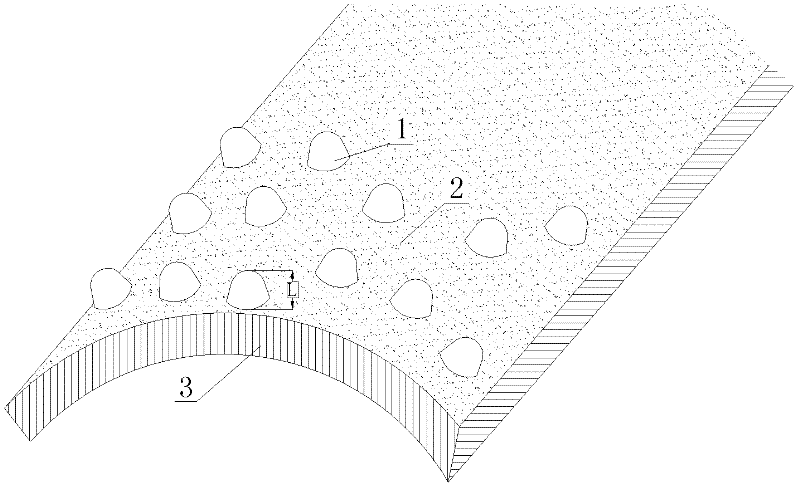

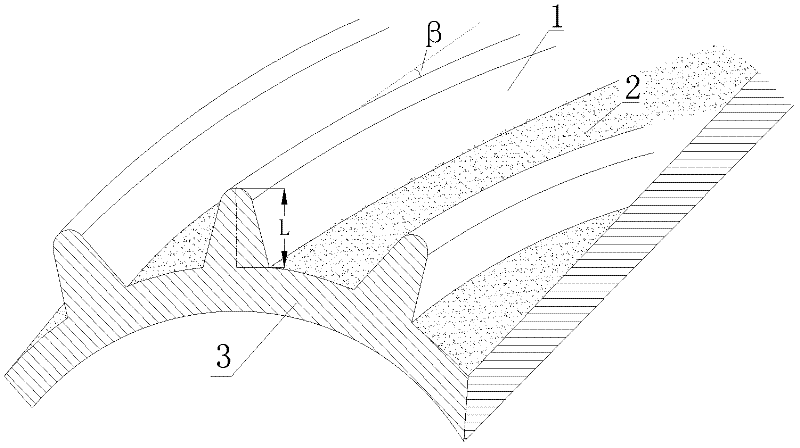

Flue gas condensation-type heat transfer pipe with bionic structure

InactiveCN102538542AGuaranteed safety and reliabilityReduce rolling resistanceHeat transfer modificationTubular elementsWater vaporPolymerization

The invention discloses a flue gas condensation-type heat transfer pipe with a bionic structure. The surface of the conventional flue gas condensation-type heat transfer pipe is prepared into a bionic structure surface which is characterized in that hydrophilic protrusions are distributed on an ultra hydrophobic base. When flue gas passes through the heat transfer pipe, water vapor in the flue gas is subjected to the condensation process comprising three links, namely absorption, polymerization growing and falling off, on the bionic structure surface. The flue gas condensation-type heat transfer pipe with the bionic structure can deeply intensify the condensation link of the water vapor in the flue gas, and bead-shaped condensate can be stably formed on the surface of the heat transfer pipe. According to the invention, waste heat and water resources in the industrial flue gas can be recycled efficiently, the energy resource utilization ratio is improved, and low-temperature corrosion can be prevented to a certain extent. The flue gas condensation-type heat transfer pipe with the bionic structure provided by the invention is quite suitable for the low-temperature-difference heat transfer in the industrial field.

Owner:XI AN JIAOTONG UNIV

Method for preparing defoaming, dehumidifying and drying mother stock for ABS(acrylonitrile- butadiene-styrene copolymer) plastic processing

The related preparation method for defoaming and dehumidifying masterbatch used in ABS plastic process comrpises: using CaO as the defoaming and dehumidifying agent, stearate as disperser for CaO, and both random copolymeric polypropylene and EPT rubber as surface modifier; blending, dispersing, and preparing the bead-shaped particles. This invention eliminates heat and dehumidification to reduce opposite investment and consumption even the comprehensive process cost greatly, and has bright application future in ABS process field.

Owner:SHANGHAI LINDA PLASTIC CHEM CO LTD

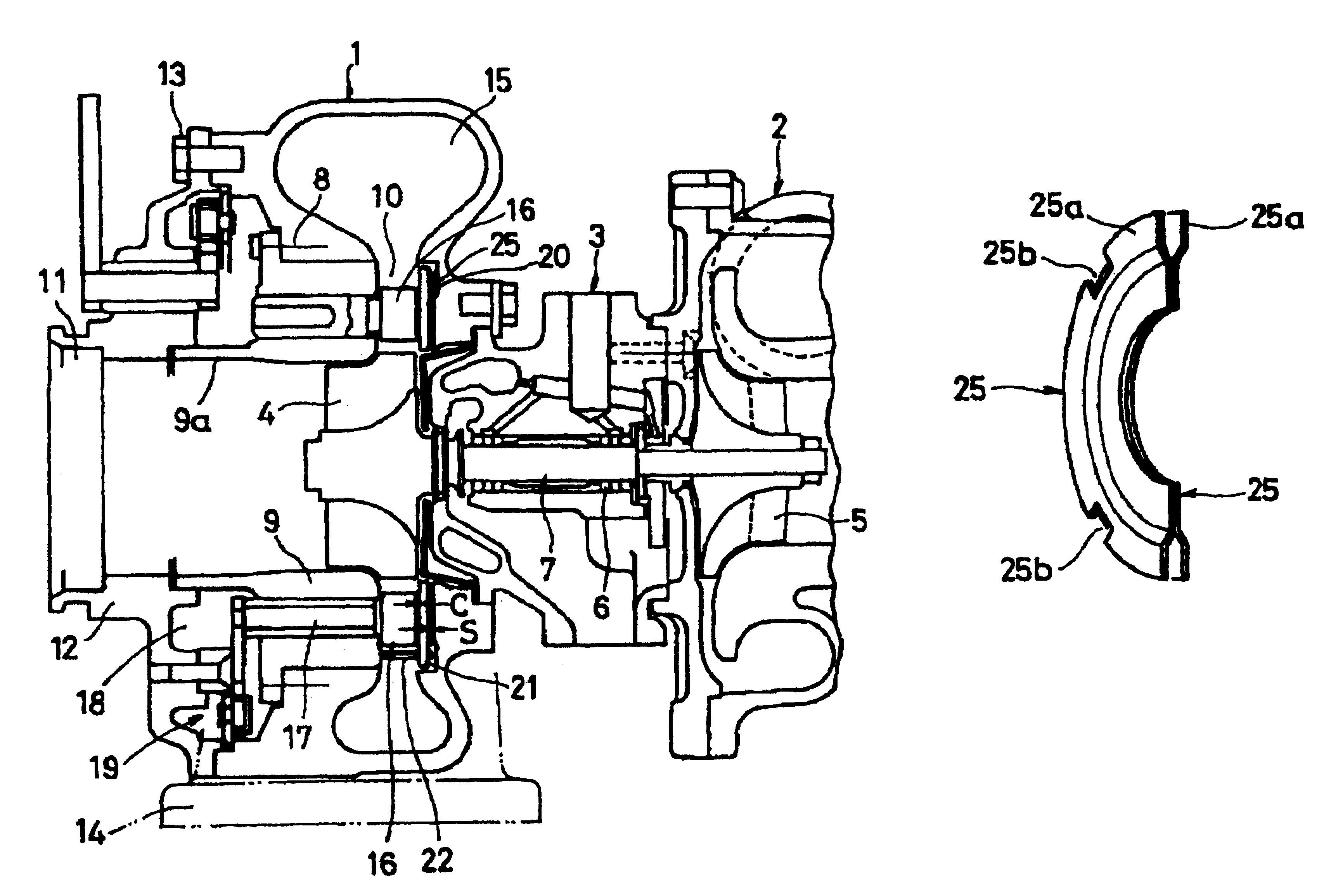

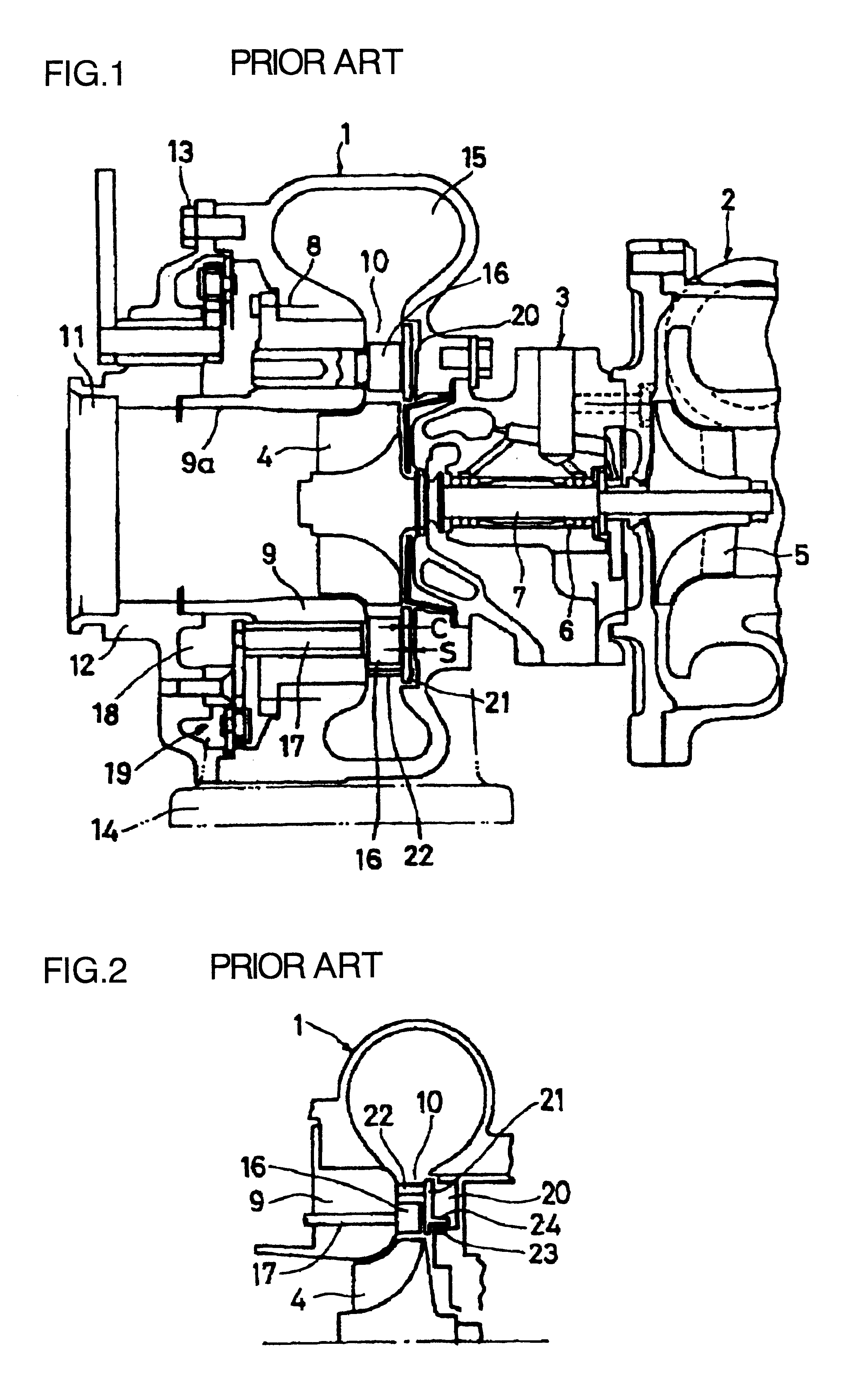

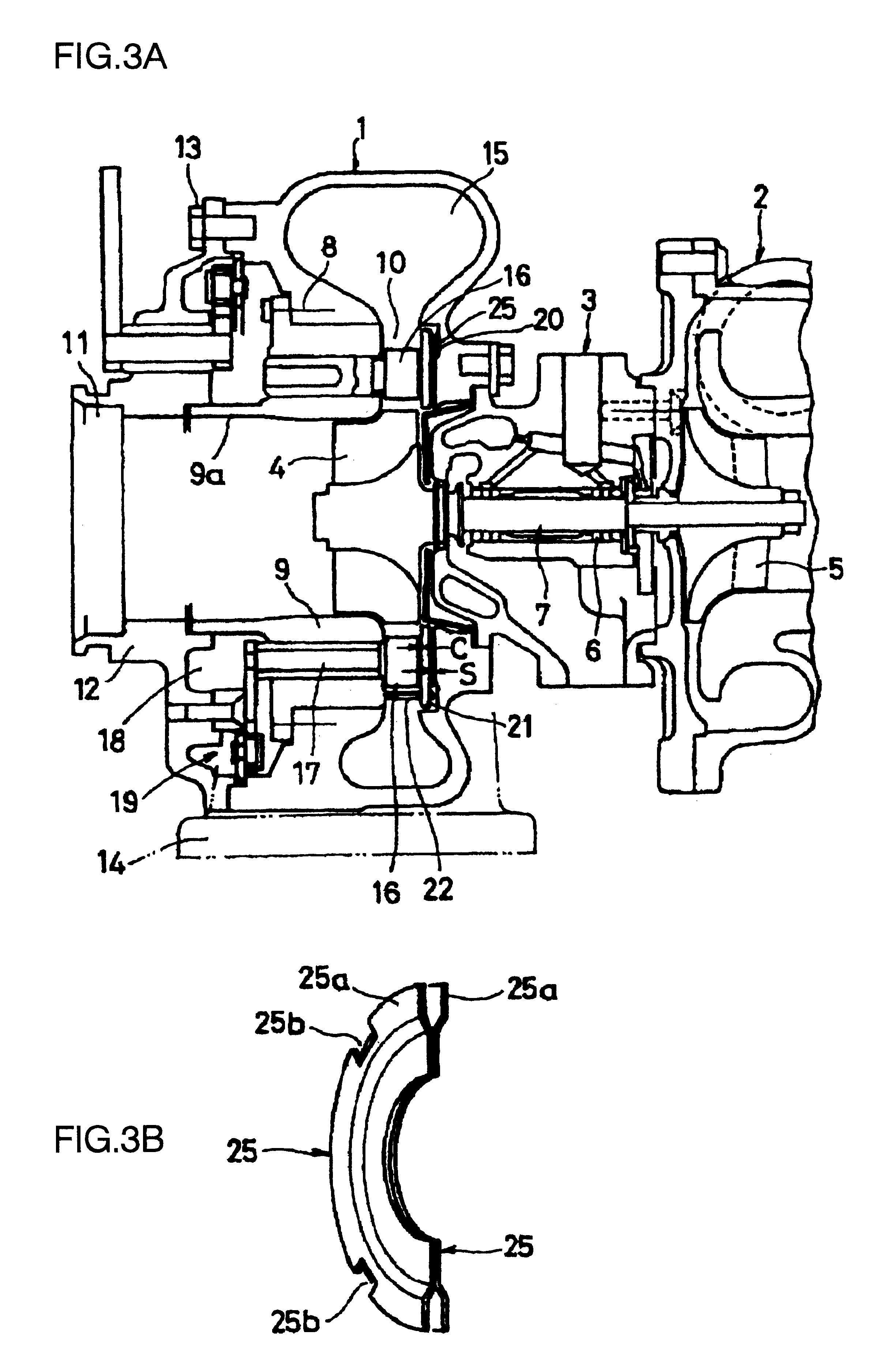

Gas sealing apparatus for variable capacity supercharger

A large number of nozzle vanes 16 are arranged in an annular channel 10 formed between opposed surfaces of turbine housing 1 and turbine shroud 9. A recess 20 is constructed on the formation surface of the annular channel 10 of the turbine housing 1, and in this recess, a clearance control plate 21 is disposed so that the clearance C between the plate and nozzle vanes 16 becomes constant. Two gaskets 25 whose outer rims are formed in a bead shape are laid in a gap S on the rear side of clearance control plate 21, in such a manner that outer rims of the gaskets separate from each other. In this configuration, outer rims widen when gas pressure is applied, and gas can be sealed stably without leakage.

Owner:IHI CORP

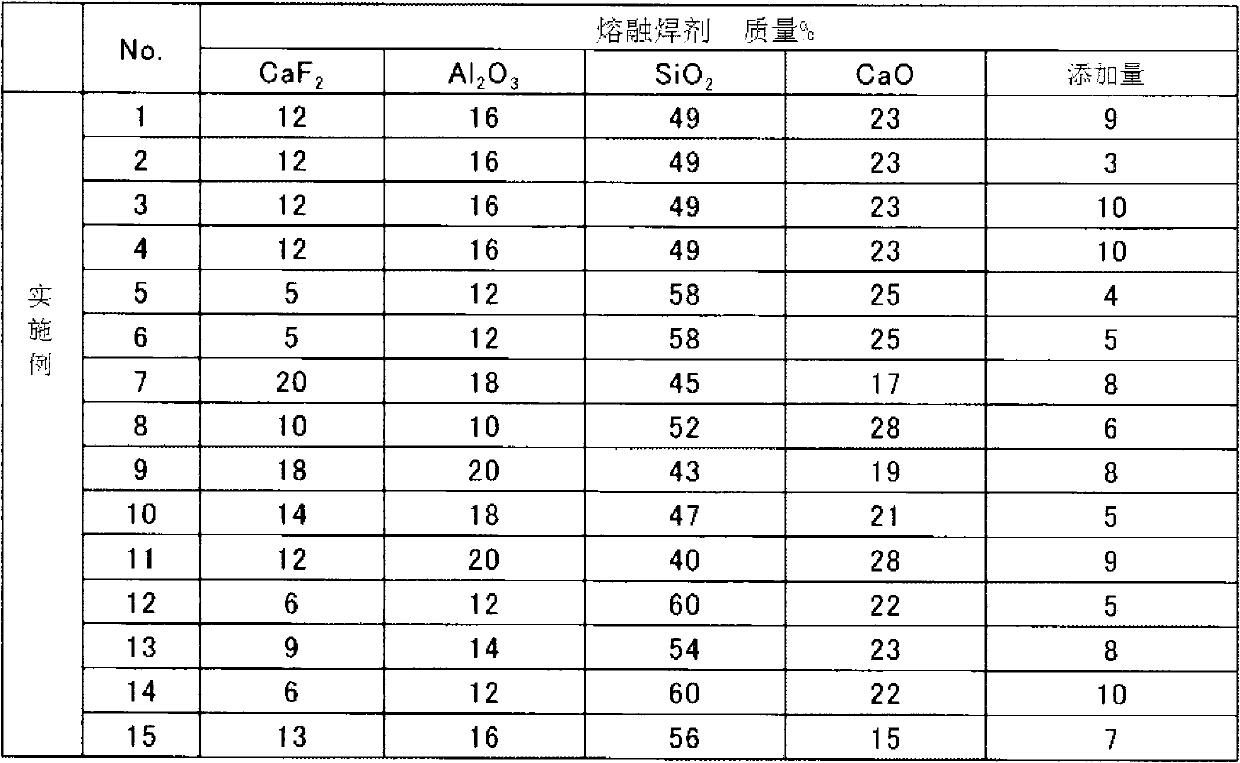

Flux for electroslag overlay welding

ActiveCN102990251AExcellent peelabilityImprove melting abilityArc welding apparatusWelding/cutting media/materialsElectroslag weldingBead shape

The invention provides a flux for electroslag overlay welding. The flux is advantageous in that, in electroslag overlay welding for which band steel formed by a Ni-based alloy is used, even under the condition of small heat input amount in welding, stability of welding is excellent, and good welding bead shape and welding bead appearance can be obtained. The flux (1) is used for the electroslag overlay welding for which the band steel formed by the Ni-based alloy is used. The flux (1) is a sintered flux obtained by mixing and sintering, in total mass percent of the flux, 3-10 mass% of a molten flux as a part of raw materials for the sintered flux, wherein the molten flux comprises CaF2: 5-20 mass%, Al2O3: 10-20 mass%, SiO2: 40-60 mass%, and CaO: 15-30 mass%. In addition, whole composition of the flux is optimized.

Owner:KOBE STEEL LTD

Novel ampelopsis grossedentata processing technology

The invention belongs to the technical field of health-care tea science, and relates to a novel ampelopsis grossedentata product and a manufacturing method thereof. The method is characterized by carrying out spread-cooling, de-enzyming, spread-cooling, twisting, deblocking, initial drying, secondary spread-cooling, twisting and forming, secondary drying, spread-cooling, drum-roasting, storage of semi-finished products, drying, grading, packaging and the like on the picked fresh ampelopsis grossedentata stem leaves, thus producing the bead-shaped ampelopsis grossedentata. Compared with the prior art, bitter materials in the ampelopsis grossedentata product can be reduced because carbureted hydrogen can be effectively removed by low-temperature, high-temperature and alternating treatment, and rime, stems and green taste on the traditionally processed ampelopsis grossedentata do not exist due to the utilized mechanical stem separation and grading stem-removal technology. The ampelopsis grossedentata processed by the novel technology is blackish green (like green tea), is in a tight and bent shape, and has bright liquor color and sweet flavor. The active ingredient of ampelopsis grossedentata has high flavones content (25%-40%). The technology provided by the invention is applicable to modern tea mechanical processing, can be used for batched production and meets market requirements.

Owner:郁建平 +1

Apparatus and method for post weld laser release of gas build up in a gmaw weld

InactiveUS20130087543A1Additional heat energyArc welding apparatusWelding/cutting media/materialsPorosityBead shape

A system and method is provided where a work piece is welded at high speeds with minimal porosity and spatter. In embodiments, the work piece is welded with an arc welding process to create a weld puddle and the weld puddle is irradiated by a energy beam downstream of the arc welding operation, such that high welding speeds are attained. The high energy heat source is positioned downstream of the welding operation to input energy into the weld puddle to change its shape or characteristics to optimize bead shape and / or bead quality.

Owner:LINCOLN GLOBAL INC

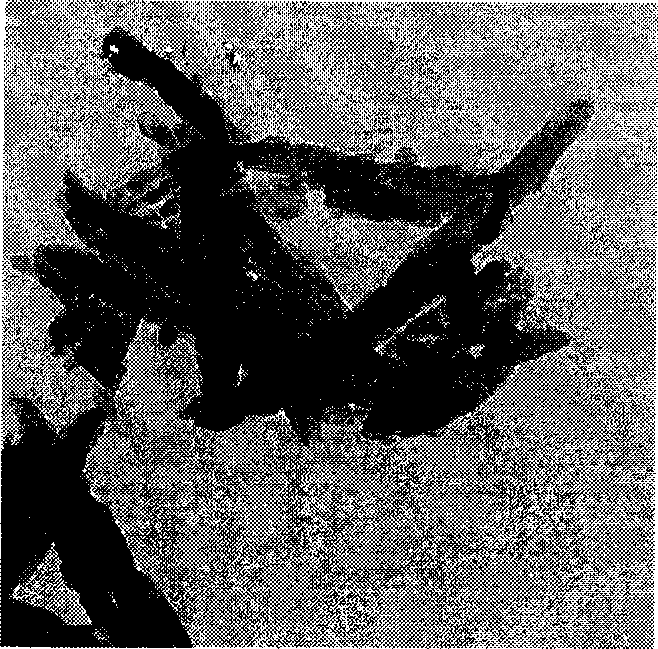

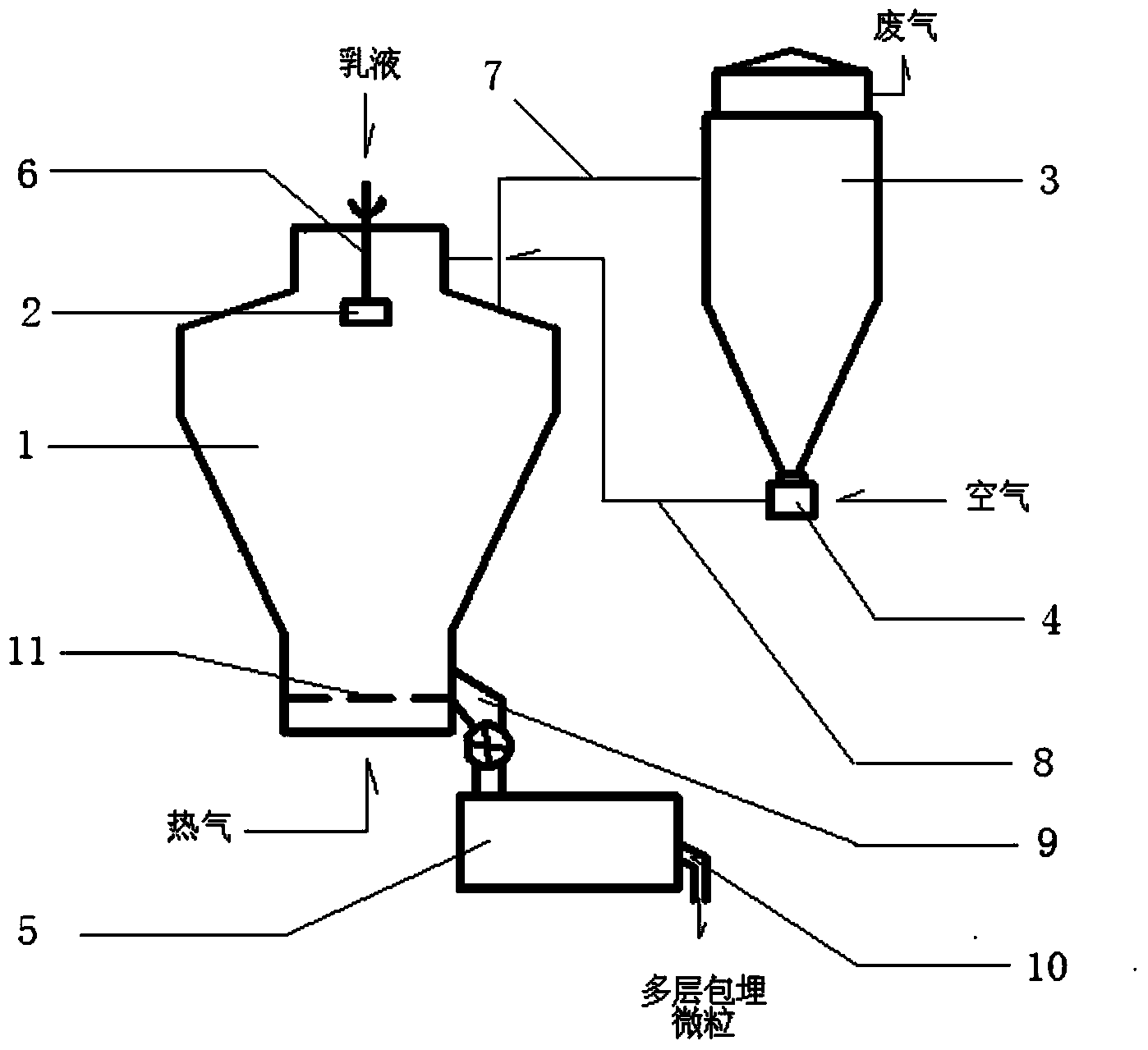

Hollow bead shaped nano-cerium oxide and its preparation method

ActiveCN1948157ALarge specific surface areaLower catalytic temperatureIndividual molecule manipulationRare earth metal compoundsSpherical granuleOrganic solvent

The present invention relates to a hollow pearl nano cerium oxide and its preparation method. The invented nano cerium oxide is a spherical granule whose diameter is 80-200 nm and centre has a through hole whose diameter is 10-60 nm. Said invention utilizes organic solvent to make the cerium salt be dissolved, and further utilizes solvent heat to make the hollow pearl nano cerium oxide be formed on the surface of carbon nano tube, then the template is removed, so that the correspondent hollow pearl nano cerium oxide can be obtained.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com