Preparation method and device for multilayered embedded particles

A particle and equipment technology, which is applied in the field of equipment for preparing the particle, can solve the problems of uneven particle distribution, low embedding rate of core materials, unstable active ingredients, etc. The effect of solvent residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A method for preparing multilayer embedded microparticles, comprising the steps of:

[0042] a) a step of dispersing the active ingredient in a protective colloid solution to form an active ingredient suspension;

[0043] b) a step of forming the suspension in step a) into droplets with a particle size distribution of 100-1000 μm;

[0044] c) attaching a second layer of embedding material to the surface of the droplet in step b), and obtaining bead-shaped particles after solidification; and

[0045] d) Further drying the bead-like particles, the step of embedding microparticles in multiple layers.

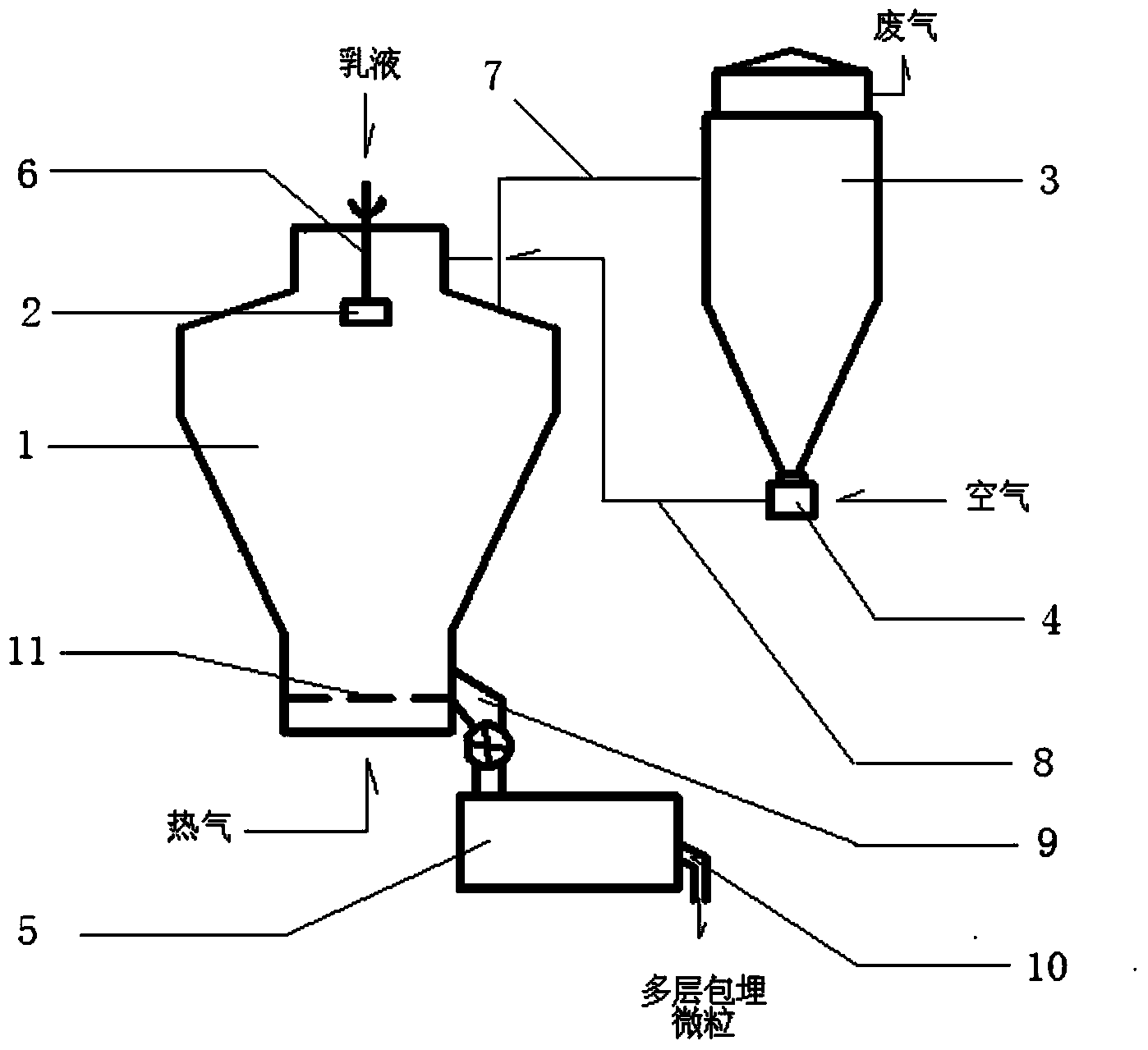

[0046] Attached below figure 1 The multilayer embedding particle device shown in exemplifies the preparation method of the above-mentioned multilayer embedding particle.

[0047] The multi-layer embedded particle device ( figure 1 ) includes a forming tower 1, an atomizer 2, a silo 3, a conveying device 4 and a drying device 5, wherein the atomizer 2 is arranged in the f...

Embodiment 1

[0052] Put 110g of sodium caseinate and 890g of sucrose in 2000ml of water, heat up to 60°C, stir until they are evenly mixed and dissolved to obtain a protective colloid solution. Then slowly add 1000g fish oil (EPA / DHA: 18 / 12) into the protective colloid solution, stir evenly, and homogenize the obtained suspension twice under 40MPa pressure to obtain an emulsion; send the emulsion into centrifugal atomization At the same time, the edible cornstarch (powder) in the silo is sent to the atomization tower by the wind, and the atomized droplets are wrapped; the particles of the wrapped cornstarch are collected, and the remaining starch is screened out to obtain bead-shaped granules. The particle size is 40 mesh to 120 mesh, and the particles are further dried in a fluidized fluidized bed until the water content is less than 5.0%, and 1890g of fish oil particles are obtained. The mass percentage of Omega3 in the particles is 12%, and the bulk density of the particles is 0.63g / ml...

Embodiment 2

[0054] Put 400g of gum arabic and 390g of corn syrup in 980ml of water, heat up to 55°C, stir until evenly mixed and dissolved to obtain a protective colloid solution; mix 50g of mixed tocopherols, 160g of lutein crystals (mass percentage of lutein 80%, from Dalian Yinuo Biological Co., Ltd. ) slowly added to the protective colloid solution. And through emulsification homogenization 2 times, homogenization pressure 60Mpa. The above-mentioned emulsion is sent to the centrifugal atomizer for atomization, and at the same time, food-grade modified starch (the amount of silicon dioxide added is 5%) is sent into the atomization tower by the air, and the atomized droplets are wrapped. Collect the wet granules wrapped with modified starch, then sieve the remaining starch to obtain bead-shaped granules with a particle size of 20 mesh to 140 mesh, and further dry the granules in a vibrating fluidized bed until the water content is 3.0%, to obtain 935g leaves Lutein microparticles (10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com