Patents

Literature

155results about How to "No solvent residue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting and refining paeonia rockii seed oil

InactiveCN101649246AImprove oil yieldNo solvent residueCosmetic preparationsToilet preparationsAdditive ingredientAntioxidant

The invention relates to a method for extracting and refining paeonia rockii seed oil. The method comprises the following steps: collecting seeds, unshelling, baking and frying, carrying out screw press, filtering, deacidifying, degumming, drying, decoloring, deodorizing in vacuum, adding an antioxidant and filling. After solid impurities and residues obtained by the screw press are broken up, ethylacetate is added, then refluxing extraction is carried out, and a solvent is recovered so as to obtain the paeonia rockii seed oil for cosmetics. A two-step method is used for extracting the paeonia rockii seed oil, wherein in the first step: primary pressed oil used for eating is obtained by physical pressing, and the produced paeonia rockii seed oil has higher oil recovery rate and no residual solvents and can be securely eaten; in the second step, the ethyl acetate is adopted for extraction, and ingredients for antioxidation, inflammation resistance, sun block, and the like in the paeonia rockii seed oil can be extracted and used for producing the cosmetics. The invention not only improves the oil recovery rate of paeonia rockii seeds, but also ensures that the effective ingredients in the paeonia rockii seeds are sufficiently utilized.

Owner:兰州牡丹园艺开发公司

Method for preparing lignin nanoparticles by taking papermaking black liquid as raw material

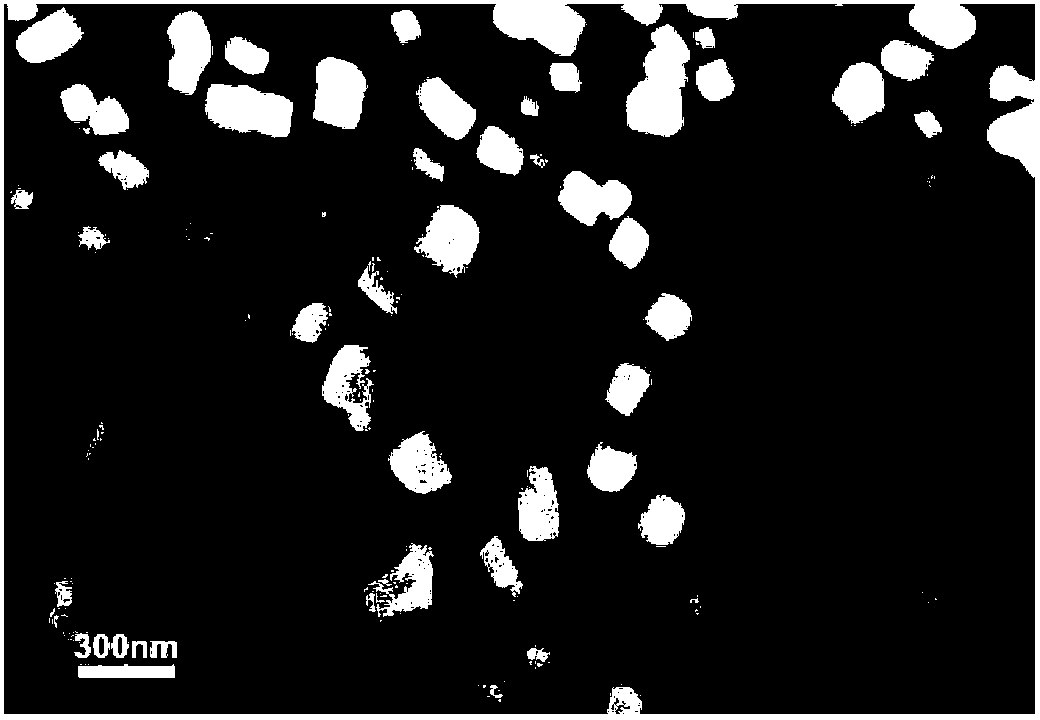

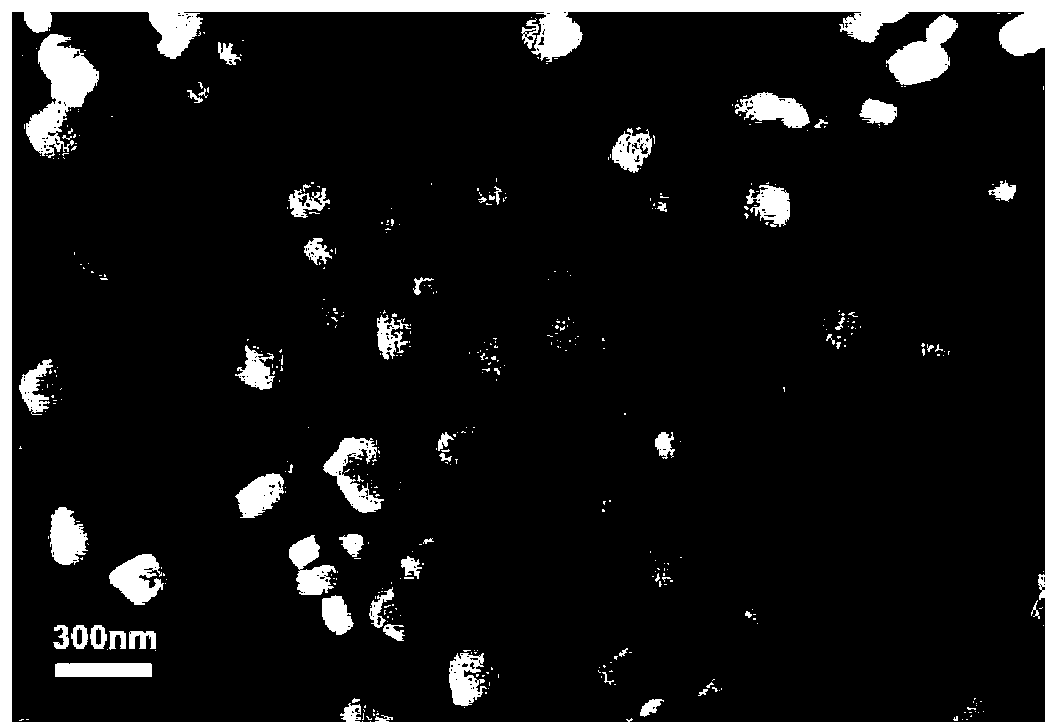

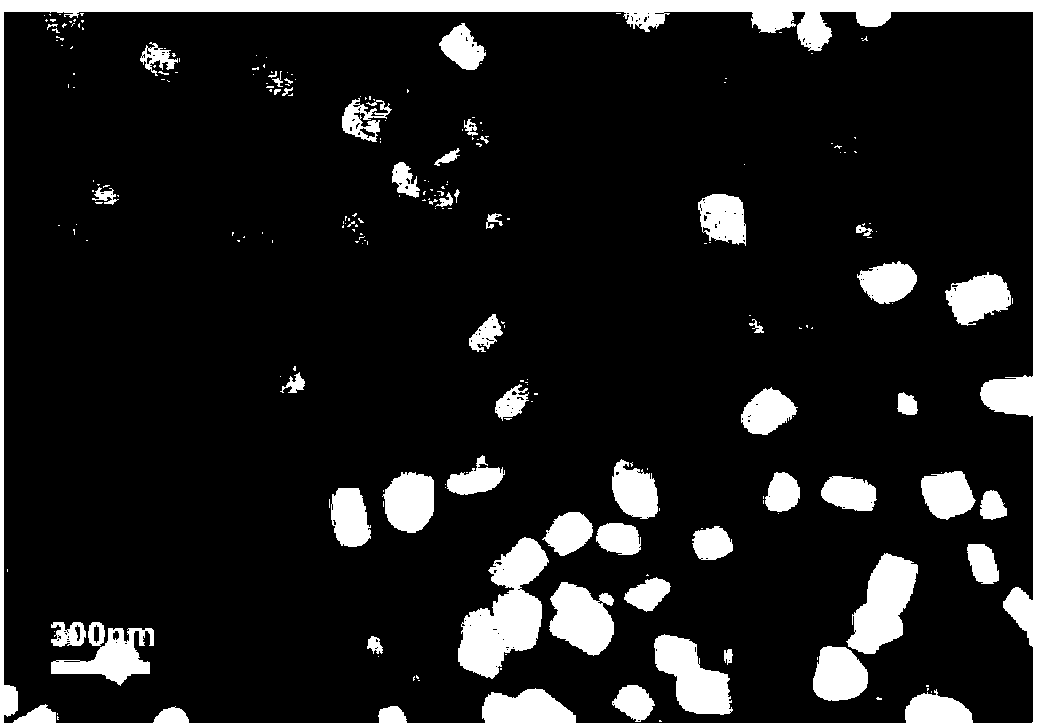

The invention discloses a method for preparing lignin nanoparticles by taking papermaking black liquid as a raw material and belongs to the field of nanometer material chemistry. The preparation method comprises the following steps of: carrying out acidification or ultra-filtration purification on the papermaking black liquid taken as the raw material so as to remove insoluble impurities and a lower molecular compound; dissolving purified lignin in an alkaline solution; adding sulfuric acid, nitric acid or hydrochloric acid at a certain speed so as to form lignin colloid; and carrying out freeze drying to obtain the lignin nanoparticles, wherein the particle sizes of the lignin nanoparticles are in the range being 50-280 nm. The obtained lignin nanoparticles have good dispersion property and absorption property and are expected to be applied to a dispersing agent for wastewater treatment and systems such as dyes, pesticides and coal-water slurry. The preparation method disclosed by the invention is simple and practicable and has good application prospect; and a solvent used in the method is water which has no negative effect on environments.

Owner:GUANGXI UNIV

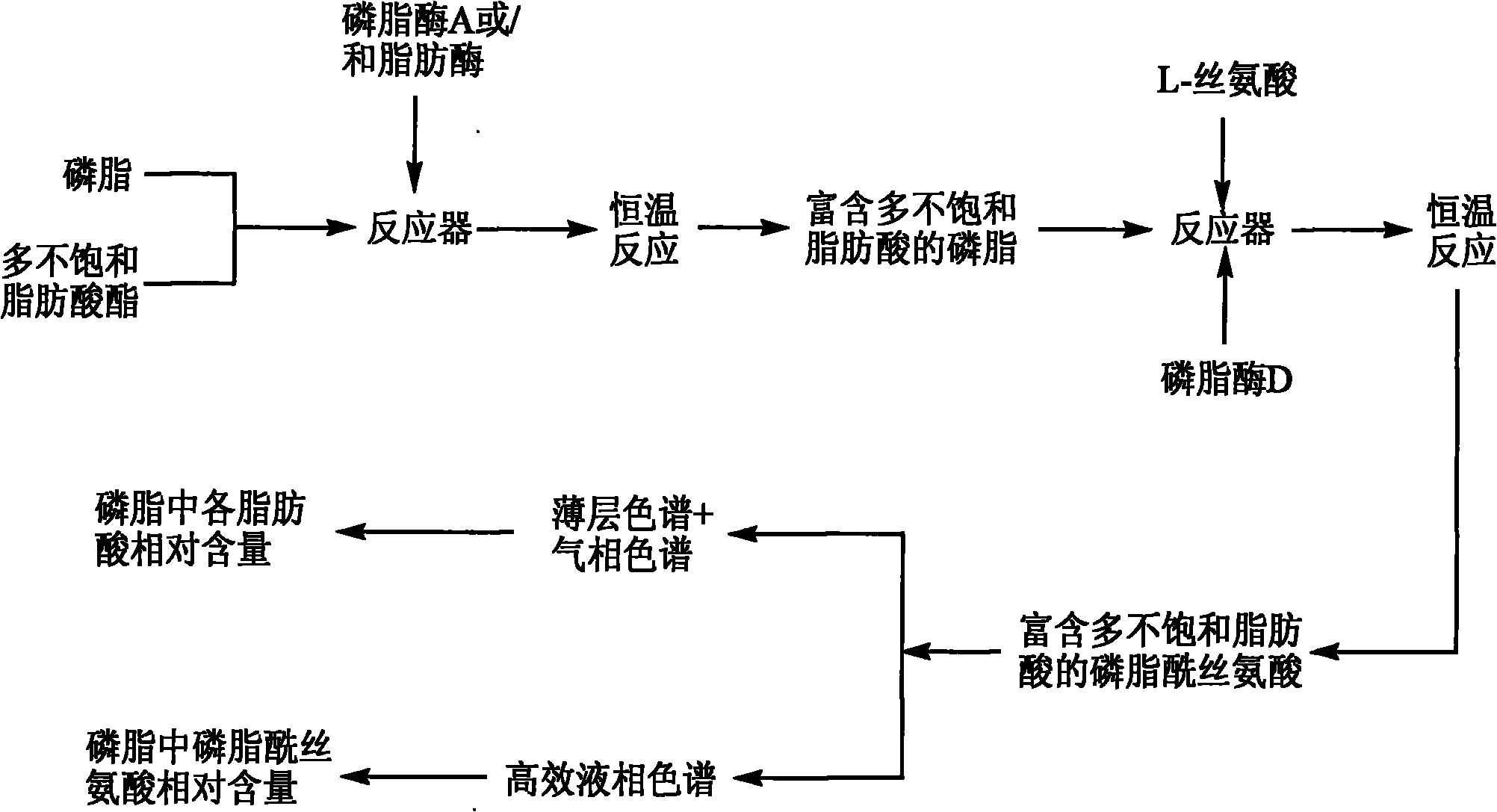

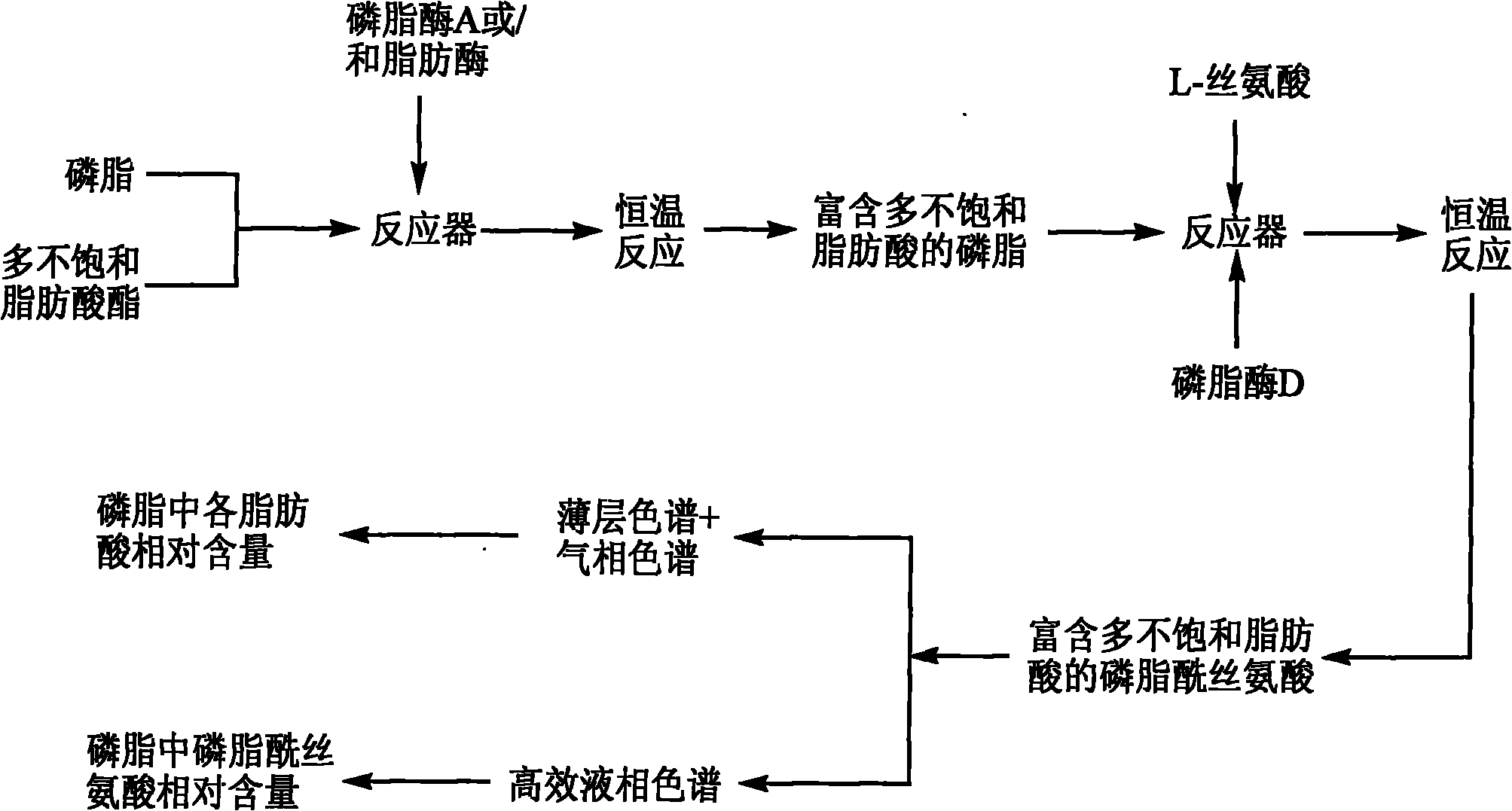

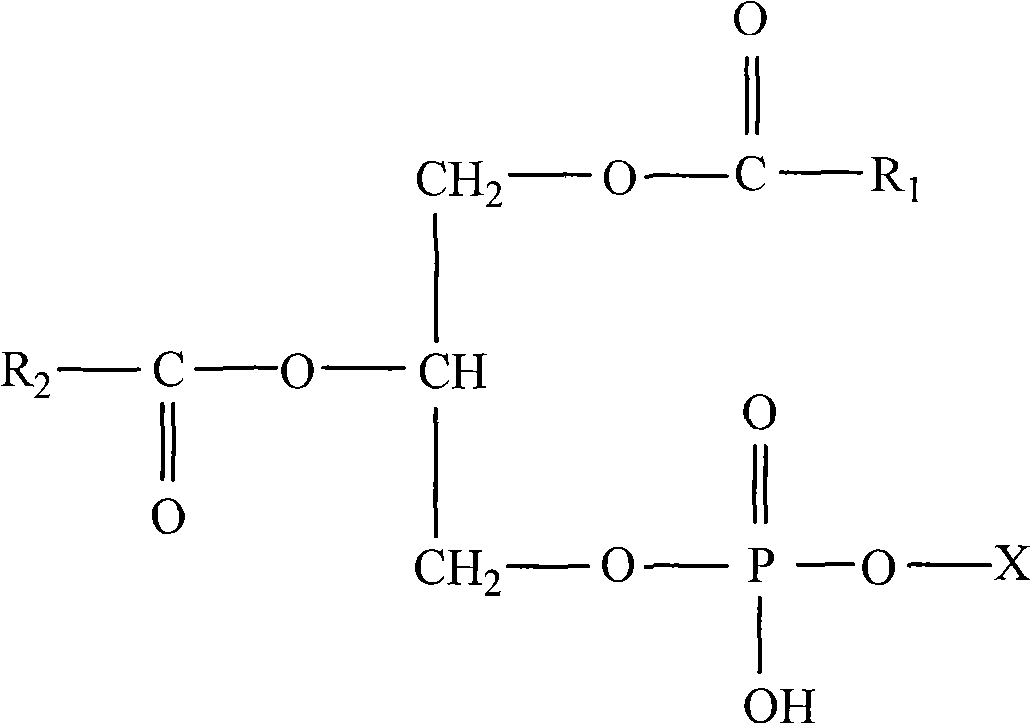

Method for preparing phosphatidylserine abundant in polyunsaturated fatty acid

InactiveCN101818179ANo emissionsImprove product qualityMicroorganism based processesFermentationUnsaturated fatty acid esterPhospholipid

The invention relates to a method for preparing phosphatidylserine abundant in polyunsaturated fatty acid and belongs to the technical field of bioengineering. The method is characterized by comprising the following steps of: firstly, catalyzing ester exchange reaction between phosphatide and polyunsaturated fatty acid ester by utilizing one or a mixture of phosphatidase A and lipase to generate phosphatide abundant in polyunsaturated fatty acid; and then catalyzing phosphor-transfer esterification reaction between the phosphatide abundant in the polyunsaturated fatty acid and L-serine by utilizing phosphatidase D to generate the phosphatidylserine abundant in the polyunsaturated fatty acid. The method has the advantages of no discharge of waste water, good product quality, no solvent residue, safe process operation, few reaction byproducts, no waste generation, cost reduction, simple production process and easy realization of scale production because of utilizing two enzymes to perform sub-step catalysis and perform reaction in the same reactor, and completing the reaction process in a non-solvent system. Therefore, the invention provides a good and feasible method for preparing the phosphatidylserine abundant in the polyunsaturated fatty acid.

Owner:DALIAN UNIV OF TECH

Process for preparing coix seed oil

InactiveCN101036761ANo lossEasy extractionFatty-oils/fats productionAntineoplastic agentsOrganic solventCoix

The invention relates to a preparation method of coix seed oil. The characteristics are as follows, 1 ultrafine grinding: the dry coix seeds being coarsely cracked and then attrited until the grain size of micropowder is 1-5micron; 2 wetting and puffing: adding 0.1-1.5 times amount of water to the micropowder, and after wetting and puffing for 12-36 hours, slightly dried; 3 supercritical extraction of carbon dioxide: the temperature of extraction kettle being 25-45 degree, at the pressure of 35-40MPa, the flow rate of carbon dioxide being 50-100kg / h.kg; the temperature of separation column being 25-45 degree, at the pressure of 5-6MPa; the temperature of separator being 25-45 degree, at the pressure of 2-6MPa, the extration time being 2-5 hours. The said preparation method has features comprising high yield rate, low cost, no pollution, no organic solvent residue and so on, without any entrainers in addition, convenient for industrialized extraction of coix seed oil.

Owner:福建拓天生物科技有限公司

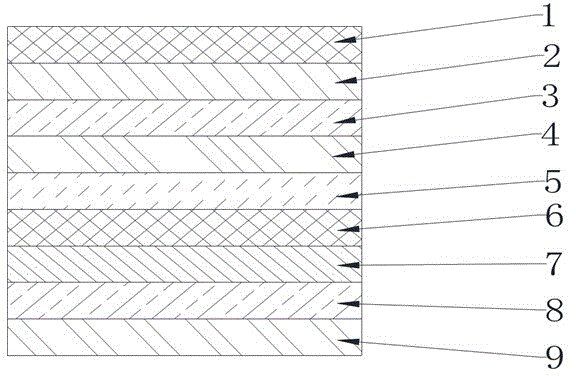

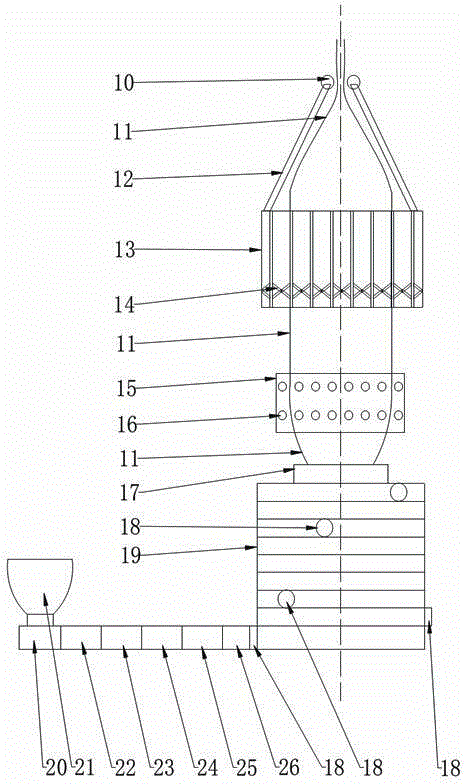

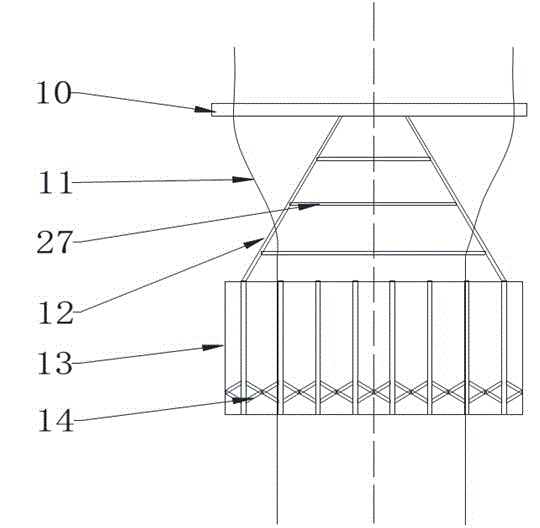

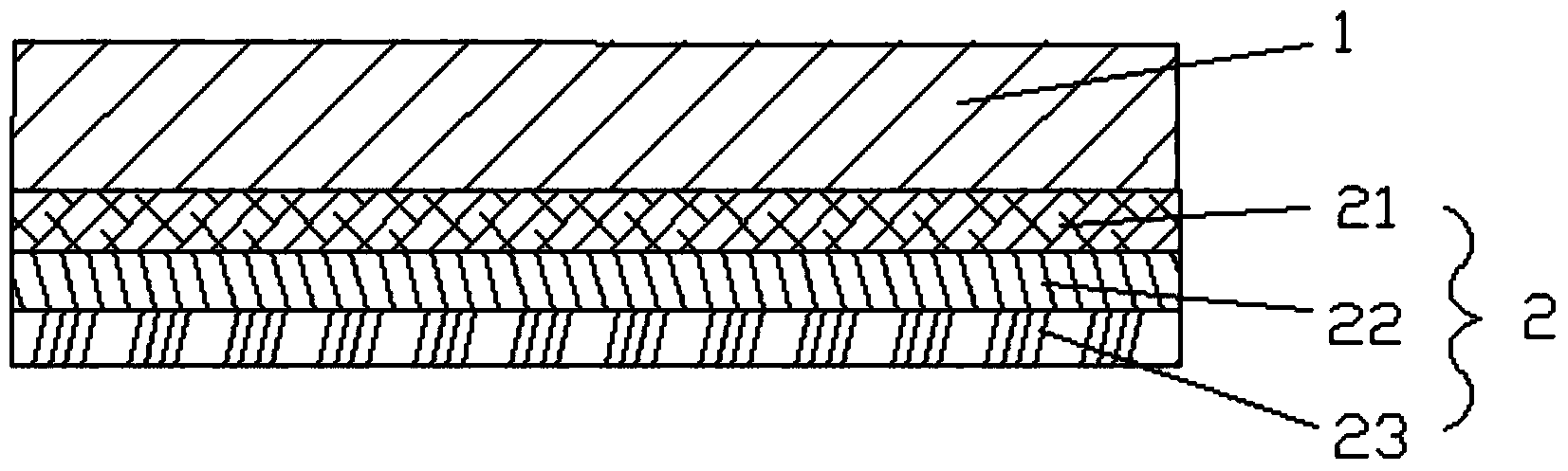

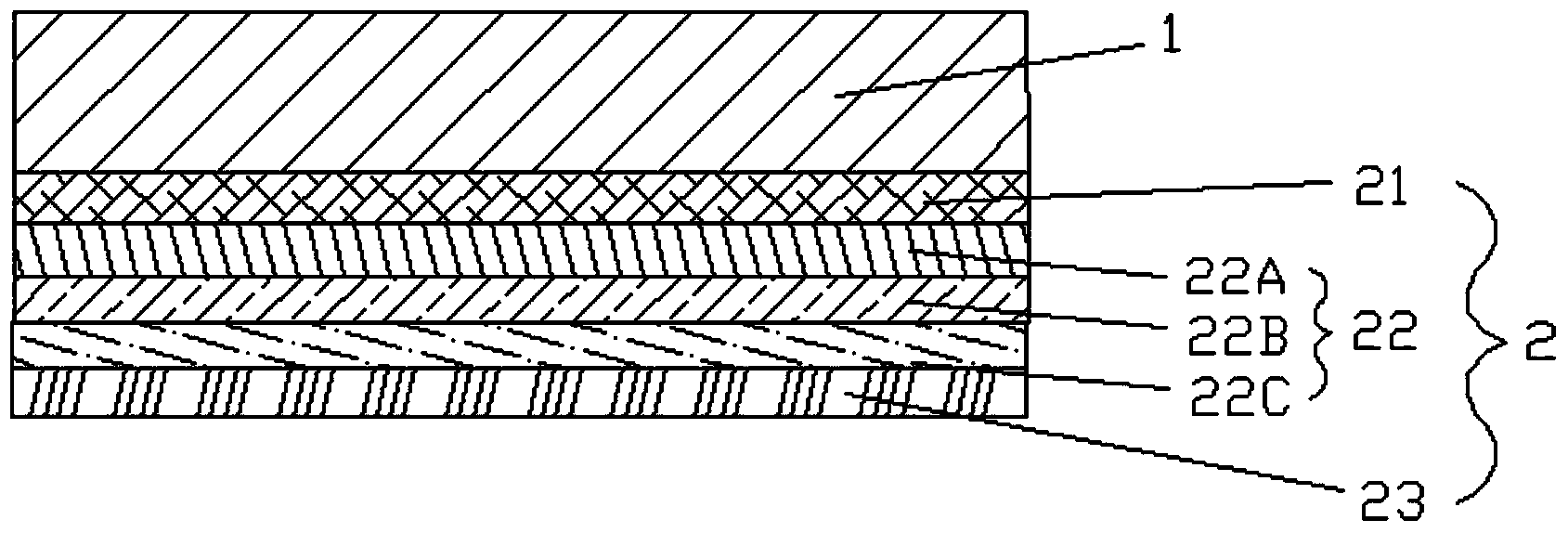

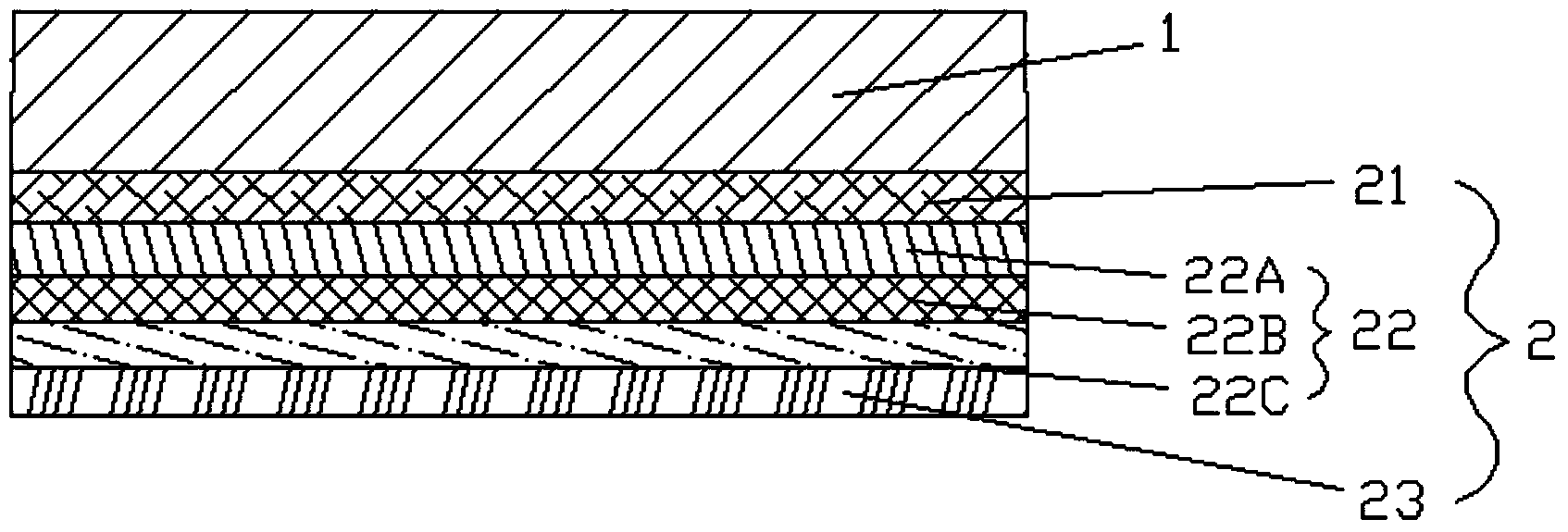

Multilayer co-extrusion high-barrier film and preparation method thereof

ActiveCN104476753AGood oxygen barrier performanceGood stretchabilitySynthetic resin layered productsMolten stateSolvent free

The invention discloses a multilayer co-extrusion high-barrier film, a preparation method of the film and production equipment used by the preparation method. The multilayer co-extrusion high-barrier film has excellent oxygen barrier properties, tensile strength and high strength, the gradation is distinct, solvent residues are avoided, and the requirements on industrial products and food package can be met. According to the preparation method, a co-extrusion form is adopted, different materials are co-extruded in a molten state by virtue of a die head of a film blowing machine, the barrier film with distinct gradation is prepared, a composite processing technology is reduced, the problems such as solvent residues caused by compounding are solved, and the barrier film has the advantages of high efficiency and high yield. Moreover, the production equipment can be matched with the production method so as to perform high-efficiency production process, so that the barrier film has uniform film thickness, and high production efficiency and product quality are guaranteed.

Owner:朝阳佛瑞达科技有限公司

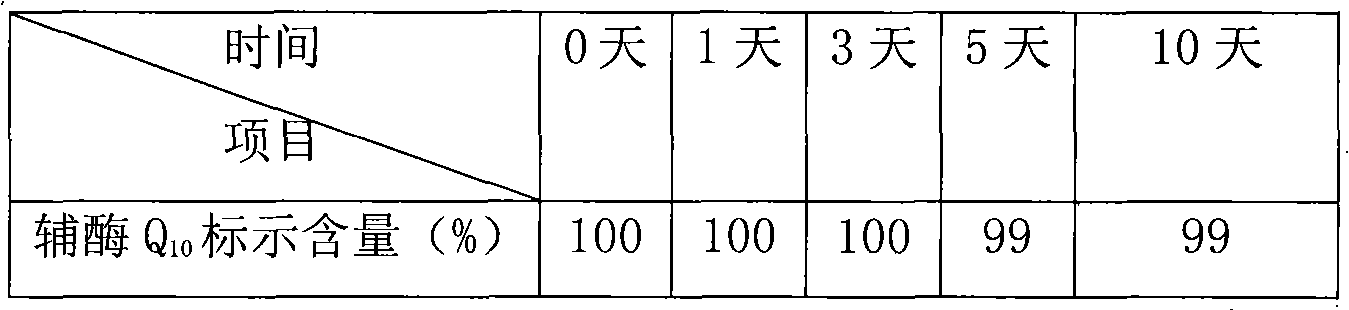

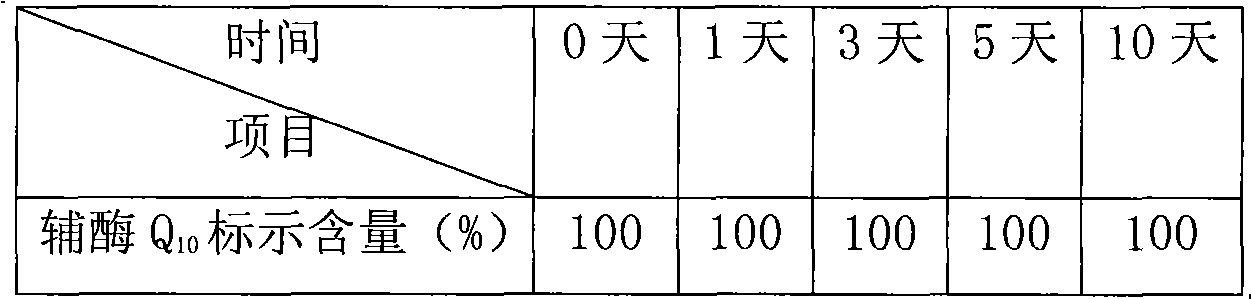

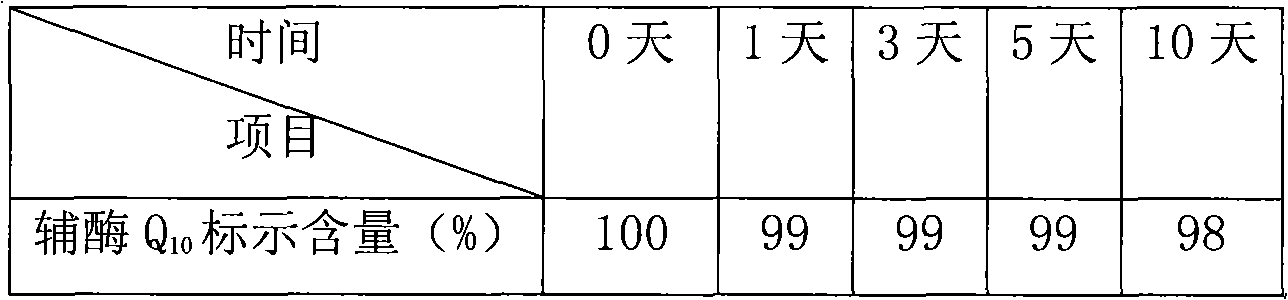

Coenzyme Q10 composite soft capsule and preparation method thereof

ActiveCN101897440AGuaranteed qualityAnti-Aging ProtectionFood preparationWater bathsAdditive ingredient

The invention relates to a coenzyme Q10 composite soft capsule and a preparation method thereof, belonging to the technical field of health-care foods. The coenzyme Q10 composite soft capsule comprises a capsule shell and capsule content, wherein the capsule content comprises the following raw materials in proportions by weight: coenzyme Q10: zinc lactate: sodium selenite: vitamin E: corn oil =1:(0.8-1.6):(0.001-0.005):(1.5-3.5):(15-25); and the soft capsule shell comprises the following ingredients of gelatin, glycerol and pure water. The preparation method comprises the following steps of: preparing the capsule materials: heating the gelatin, the glycerol and the water in water bath to 50-95 DEG C for dissolving according to the proportions of (0.5-2):(0.2-0.8):(0.5-1.5) , and preserving the temperature at 45-80 DEG C; taking the zinc lactate and the sodium selenite according to the formula amount, evenly mixing in an equivalent progressive-increase way, then evenly mixing with the coenzyme Q10, and carrying out ultramicro crushing; putting the natural vitamin E and the corn oil in and stirring in 500-2000rpm to obtain mixed oil, adding fine mixed powder and evenly stirring; and preparing the coenzyme Q10 composite soft capsule by using an auto-rotating capsule rolling machine. the invention has the advantage of greatly increasing the stability of the coenzyme Q10.

Owner:BEIJING DAWN AEROSPACE BIO TECH

Anti-yellowing water-based coating agent and preparation method and coating technology thereof

The invention discloses an anti-yellowing water based coating agent. The anti-yellowing water based coating agent is prepared by the matching of the following components by weight: 90-97 parts of an acrylic ester modified polyurethane water solution, 0.5-1 part of a nanometer ZnO, 0.5-1 part of a flatting agent, 0.5-2 part(s) of a cross-linking agent, and 0.5-2 part(s) of a thickening agent. The anti-yellowing water based coating agent has the advantages of aquosity and environmental protection, non-pollution and the like, belongs to a resource-saving product, is low in cost, meanwhile can be mixed with other raw materials, and is an ideal coating adhesive product.

Owner:DRAGON CLAN CHINA

Marigold lutein supercritical CO2 extraction method

ActiveCN1800325AStrong selectivityActive ingredients less damageOrganic non-active ingredientsFatty-oils/fats productionHealth foodTagetes

The invention relates to a method for using above-critical carbon dioxide to extract Tagetes lutein in the field of chemical, foods and health food process applied technology. It also relates to a new type of green entrainer: vegetable oil which can improve the lutien extracting ratio without the organic solvent residual.

Owner:GUANGZHOU LEADER BIO TECH

Process of extracting effective component from plant

InactiveCN101019894AChange microscopic propertiesEasy extractionAnimal feeding stuffFood preparationMechanical crushingOrganic solvent

The process of extracting effective component from plant material includes crushing solid plant material mechanically, mixing with proper amount of chemical assistant, and extracting the effective component with water or ethanol. In the process, mechanical crushing of solid plant material produces micro shearing in the material interface and breaks cell wall to expose fresh cut surface, and the chemical assistant produces mutual adsorption with effective component, so that the process can alter the microscopic performance of the effective component and raise the leaching rate to 80-400 %. The present invention has shortened extraction period, high extraction efficiency, high extraction specificity, high selectivity, minimized organic solvent consumption and environment friendship.

Owner:周婕

Yunnan black tea essential oil and preparation method thereof

ActiveCN103087828ANo solvent residueNo environmental pollutionEssential-oils/perfumesSolventSupercritical fluid extraction

The invention relates to a Yunnan black tea essential oil and a preparation method thereof. The essential oil is prepared by a supercutical fluid extraction-molecular distillation combination technique. The preparation method comprises the following steps: carrying out supercritical extraction on Yunnan black tea, and carrying out molecular distillation to obtain the Yunnan black tea extract. Compared with the traditional extraction method, the invention adopts the newest supercutical fluid extraction-molecular distillation combination technique, has the advantage of high extraction efficiency, does not introduce any harmful organic reagent, and obtains the Yunnan black tea essential oil with no solvent residue and with good scent and quality under the conditions of low temperature and low pressure. The method is simple to operate, has the advantages of high extraction rate and no pollution, and provides an efficient green environment-friendly extraction separation method for preparing Yunnan black tea essential oil.

Owner:云南天宏香精有限公司

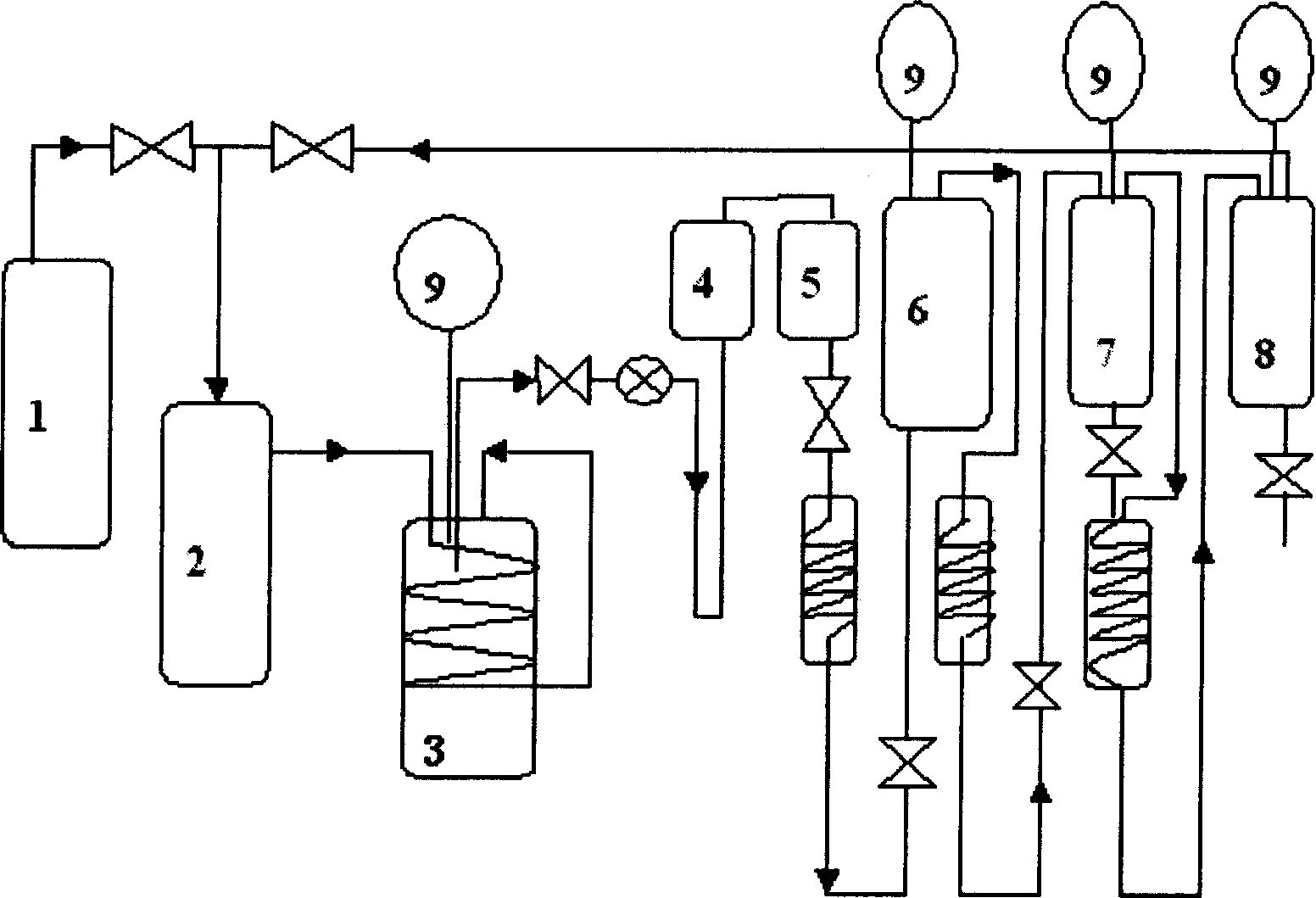

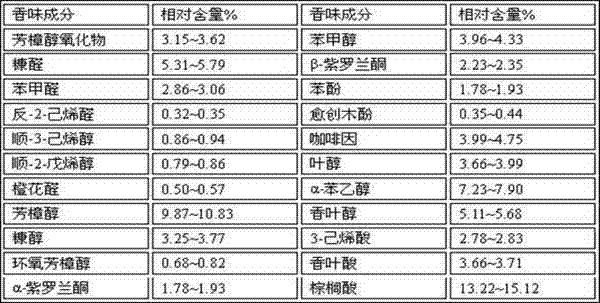

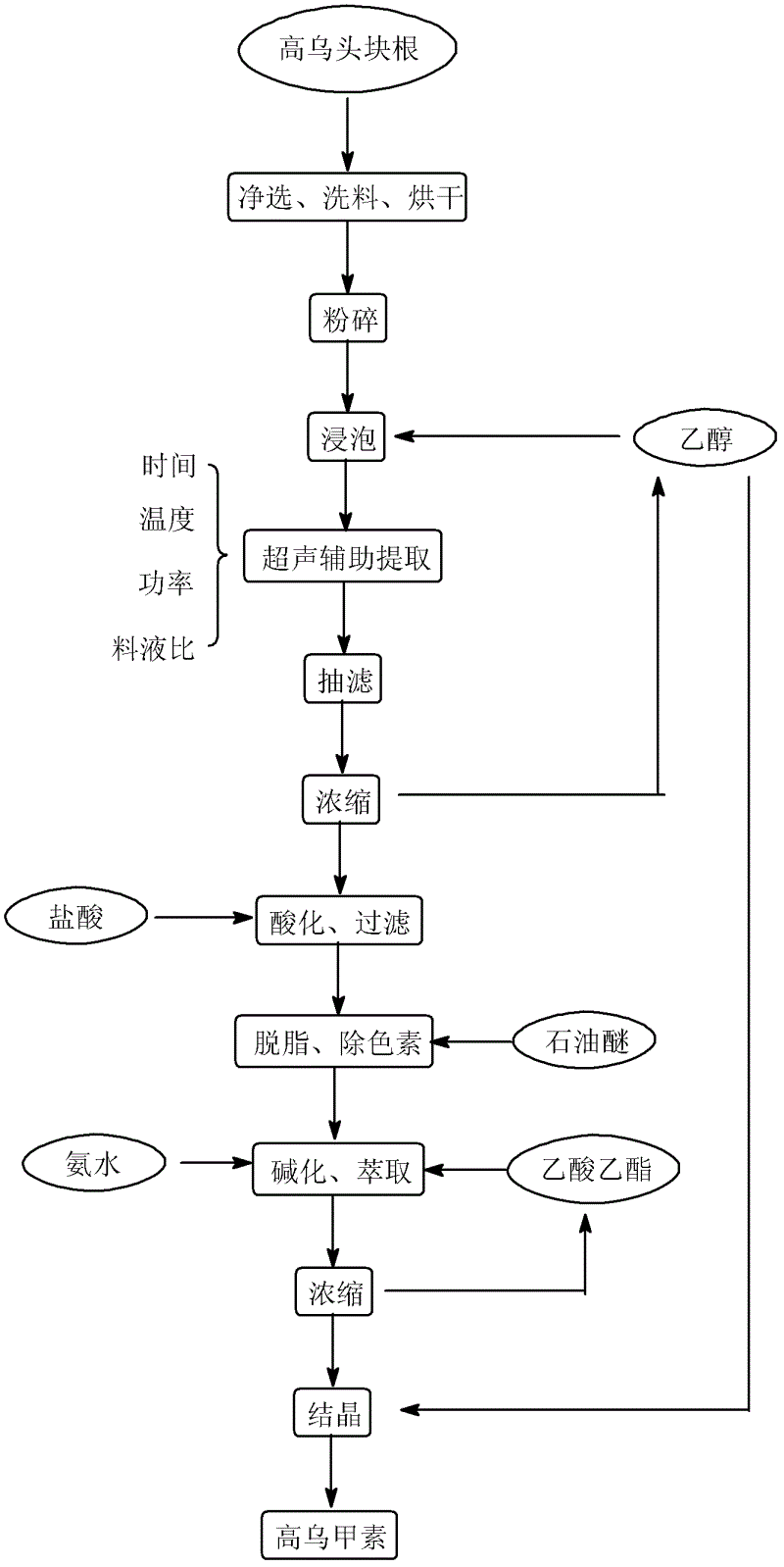

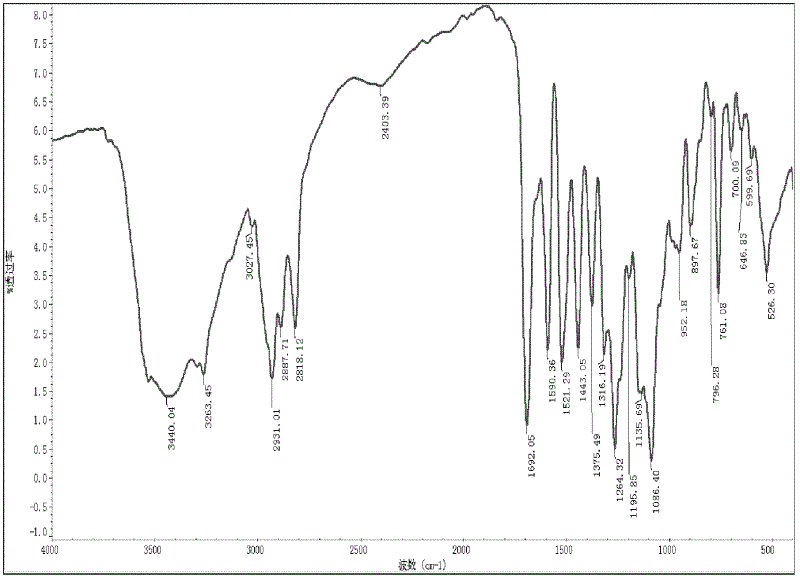

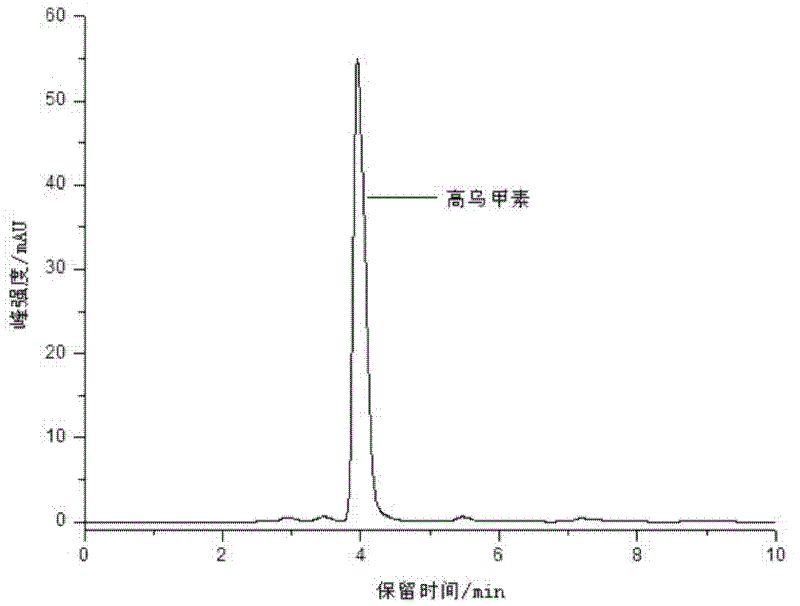

Method for ultrasound-assisted extraction of lappaconitine

The invention discloses a method for ultrasound-assisted extraction of lappaconitine, belonging to the technical field of preparation of traditional Chinese medicine. The preparation method comprises the following steps of: (1) herb pretreatment; 2) ultrasound extraction; 3) preparation of acidic solution; (4) extraction; and (5) crystallization. The lappaconitine is extracted from aconitum sinomontanum via high-speed and intense cavitation and mixing effects produced by ultrasonic waves. The method has the advantages of simple process, convenience in operation, high efficiency, energy conservation, short production cycle, low cost, high yield and easiness in industrialization, no toxic solvents such as chloroform and benzene are used in the operating process, the method is environment-friendly, and the lappaconitine cannot be polluted.

Owner:NORTHWEST NORMAL UNIVERSITY

Preparation method of edible sea-buckthorn dietary fiber

The invention relates to a preparation method of an edible sea-buckthorn dietary fiber. The method comprises the following steps of: mixing sea-buckthorn seed residual after supercritical carbon dioxide degreasing treatment with water, adding a neutral protease into the resulting product, preserving heat and stirring for 2 hours, filtering the resulting product, washing the filter residue with deionized water, deactivating enzyme, cooling the resulting product, adding cellulase into the cooled product, stirring for 2 hours so as to carry out enzymolysis, carrying out vacuum concentration on enzymatic hydrolysate, carrying out spray-drying on the resulting product, and ultra-finely crushing the resulting product to obtain the sea-buckthorn seed dietary fiber powder. The edible sea-buckthorn dietary fiber prepared by the method provided by the invention is fine in particles, the total dietary fiber content reaches more than 80%, wherein the soluble dietary fiber content reaches more than 30%, and the edible sea-buckthorn dietary fiber can be applied to the fields of various beverages, foods and healthcare foods.

Owner:内蒙古宇航人高技术产业有限责任公司

Method for preparing shikimic acid from folium ginkgo extraction waste liquor

ActiveCN109593034AReasonable process designHigh purityCarboxylic compound separation/purificationOrganic solventHydrolysate

The invention relates to the field of extraction and purification of plant effective components, in particular to a method for preparing shikimic acid from folium ginkgo extraction waste liquor. The method comprises the following steps: carrying out enzymolysis on the folium ginkgo extraction waste liquor; and collecting an enzymatic hydrolysate, filtering by an organic membrane, carrying out adsorption elution by an anion exchange resin column, concentrating, crystallizing and drying. The method is simple to operate, economical and practical and proper to popularize, and does not need an organic solvent. Moreover, the obtained shikimic acid is high in purity and good in appearance condition, and the mass content is greater than 99%.

Owner:GUILIN NATURAL INGREDIENTS CORP

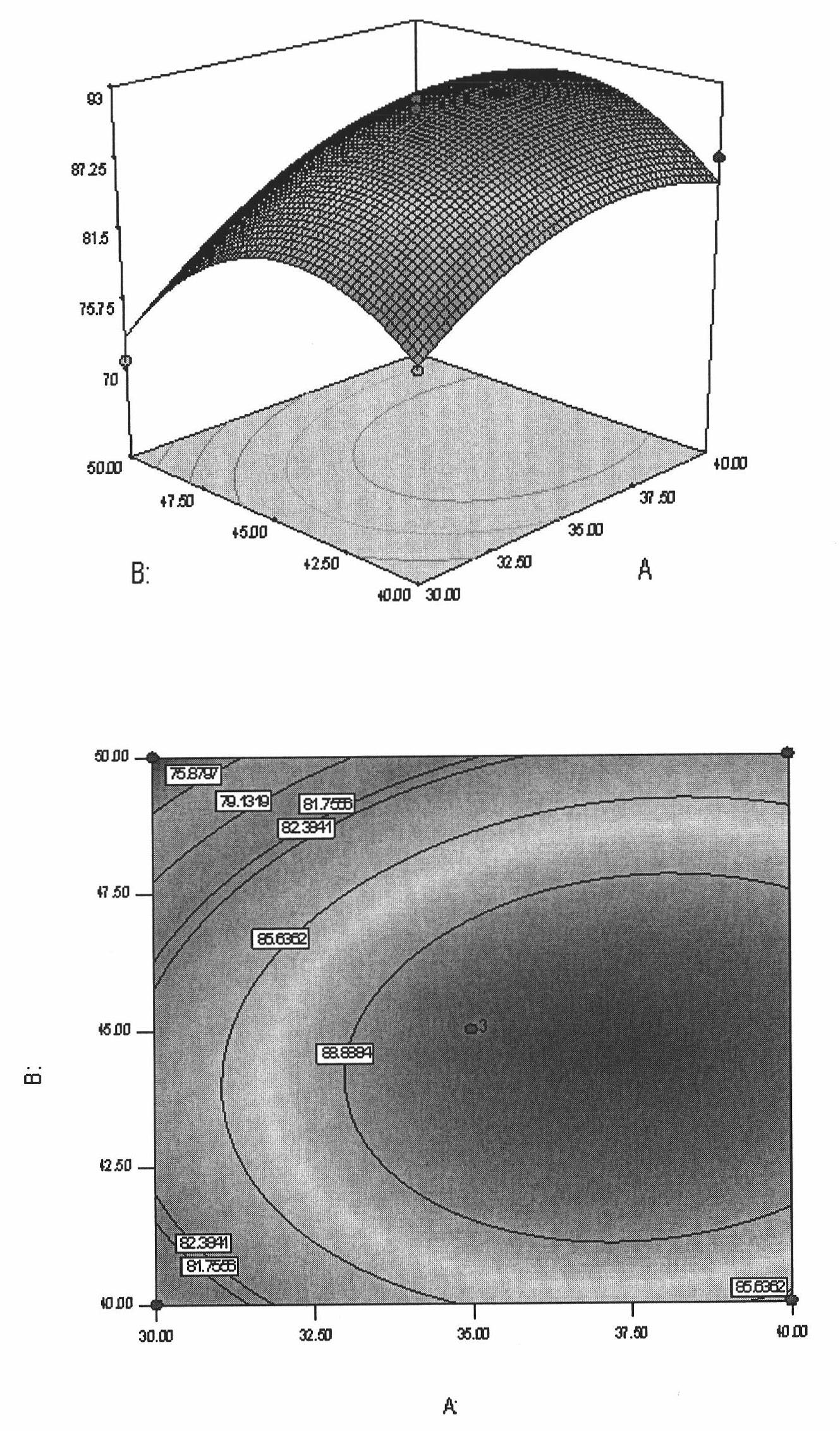

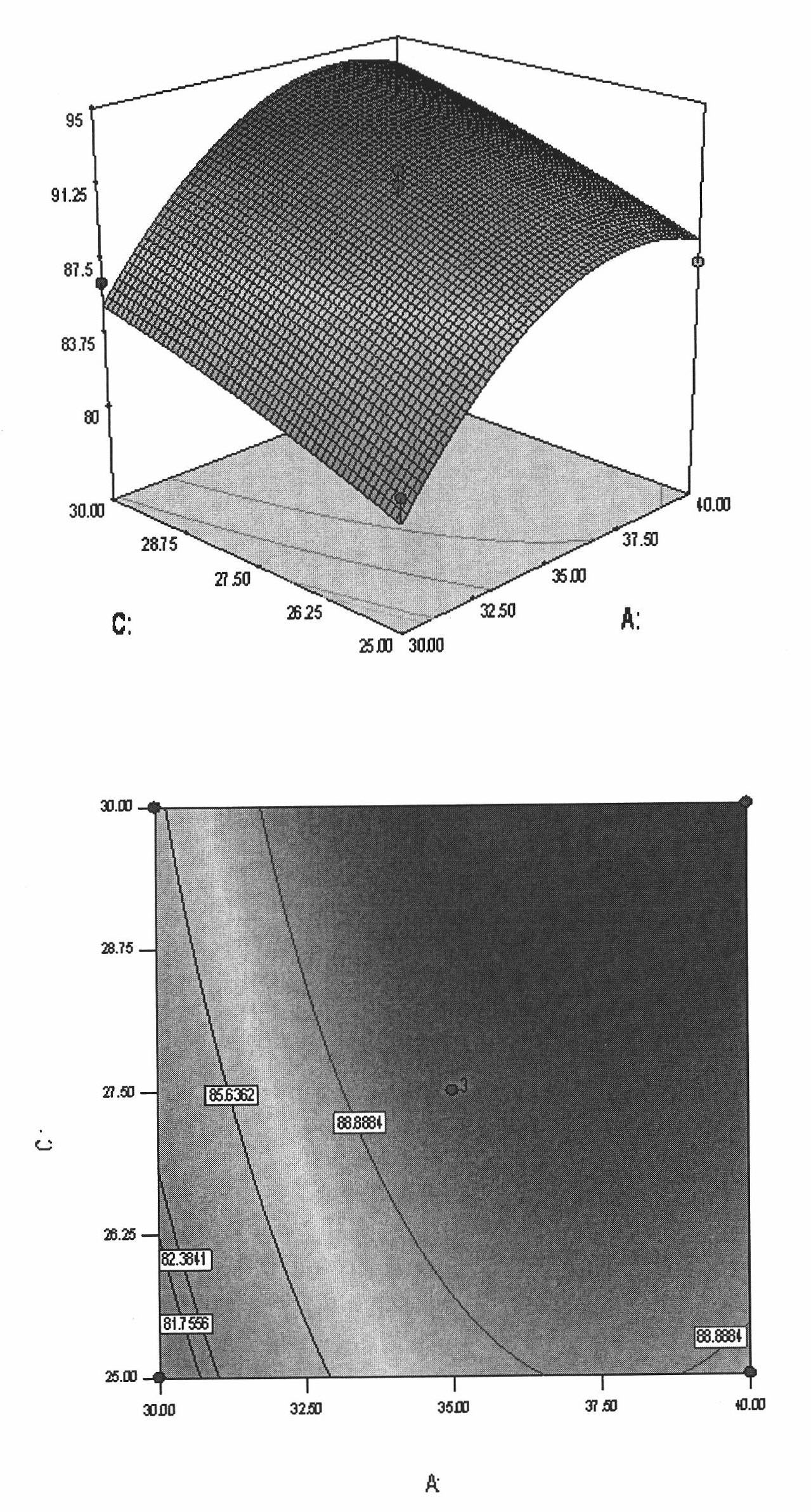

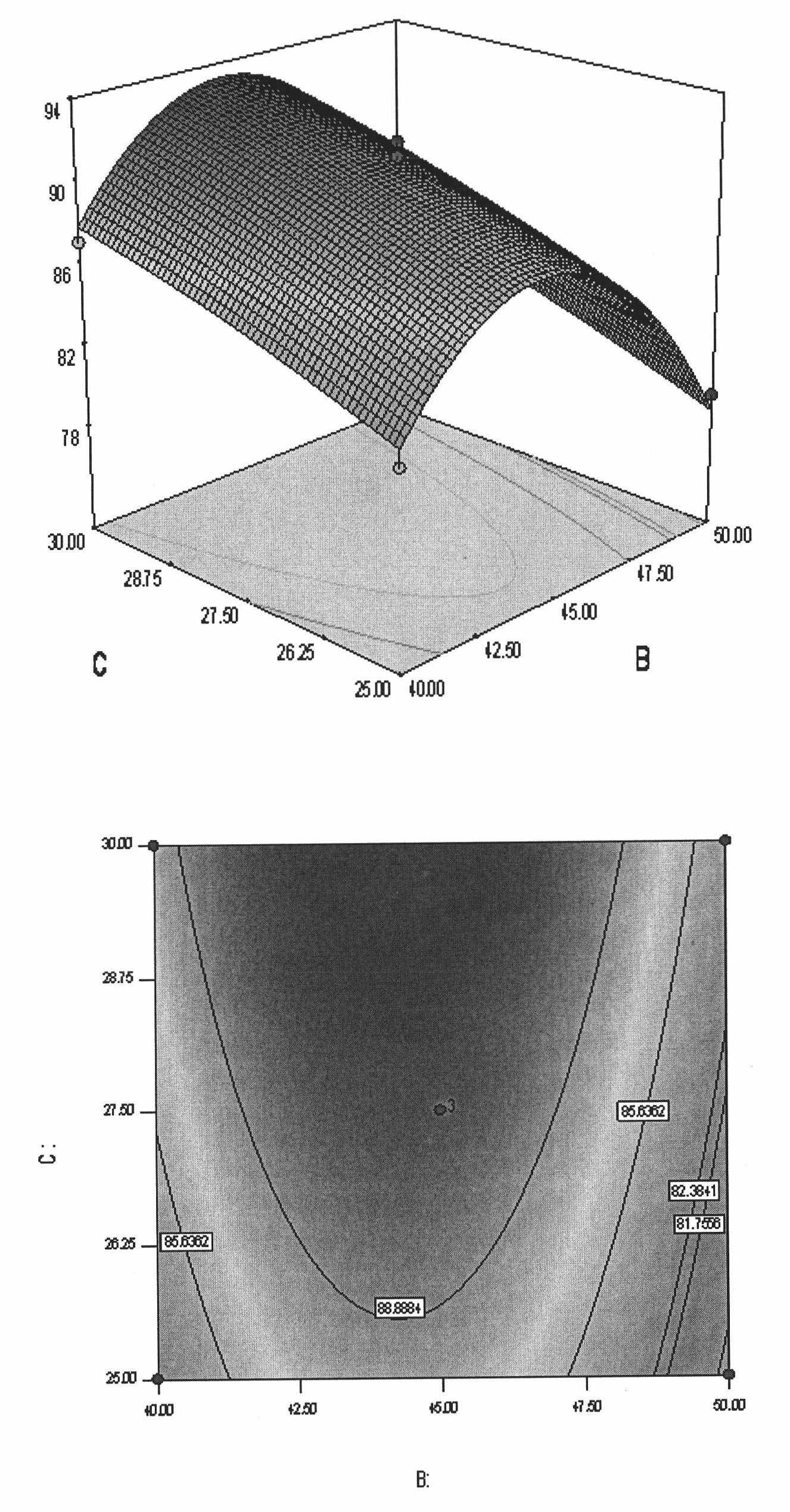

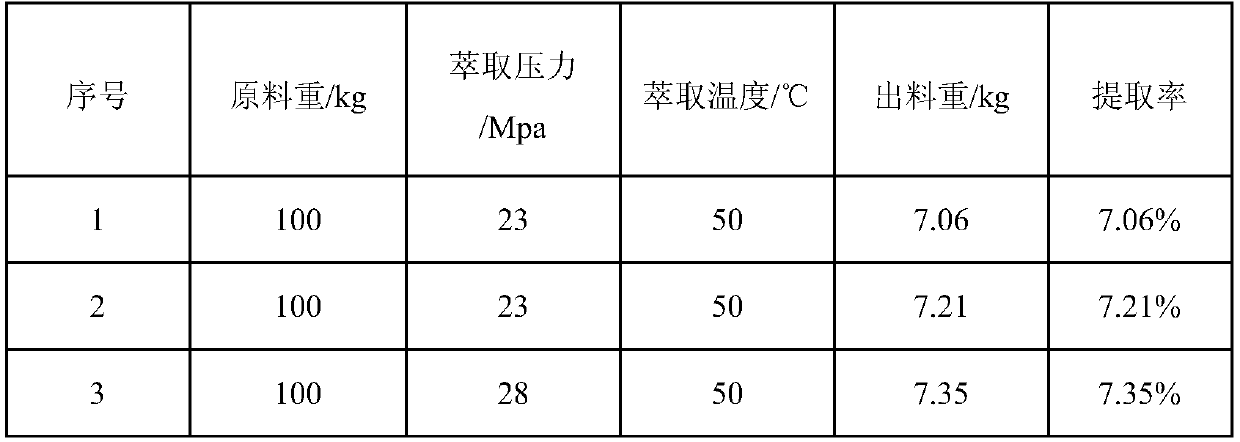

Supercritical CO2 method for extracting barbadosnut seed oil and product thereof

InactiveCN101775333ASimple extraction methodEasy to operateFatty-oils/fats productionOperabilityDeep processing

The invention discloses a method for extracting barbadosnut seed oil by supercritical CO2 extraction technology. The method comprises the following raw materials and processes: decladding barbadosnut seed, grinding and sieving, wherein the extraction ratio of barbadosnut seed oil is 93.13-94.41% under the condition that the particle size of raw materials is 20 mesh, the extracting pressure is 37.73 MPa, the extracting temperature is 44.53 DEG C, the CO2 flow rate is 30 L / h, the extraction time is 120min, the usage of entrainer is 40%, the separation pressure is 6.5-7.0 MPa, and the separation temperature is 50 DEG C. By adopting the supercritical CO2 technology for extracting barbadosnut seed oil, a new method for the deep processing of the barbadosnut seed is provided, thereby being capable of effectively developing the research on supercritical CO2 extraction of extracting the barbadosnut seed oil. The invention has the advantages of strong operability, good safety, high oil extraction ratio, good repeatability, simple process, no pollution and the like, and can be used for extracting the barbadosnut seed oil during production.

Owner:SICHUAN AGRI UNIV

Method for extracting cannabidiol by using microbial fermentation

InactiveCN109776275AHigh extraction rateImprove qualityOrganic chemistryOrganic compound preparationTrichoderma koningiiPenicillium bilaiae

The invention discloses a method for extracting cannabidiol by using microbial fermentation, and belongs to the technical field of chemical drug intermediate extraction. The method comprises the stepsof drying, smashing and sieving flowers and flower leaves of industrial hemps to obtain industrial hemp powder; adding water into the industrial hemp powder to obtain a mixed solution, and inoculating mixed bacteria of paecilomyces hepiali, trichoderma koningii and aspergillus niger into the mixed solution for fermentation to obtain a fermentation solution; adopting a three-phase separation machine for conducting three-phase separation on the fermentation solution to obtain an aqueous phase, a residue and an oil phase; concentrating the oil phase under reduced pressure to obtain a CBD-enriched extract. The method is high in extraction rate and suitable for industrial production.

Owner:黑龙江阳光工业大麻研究院

PET (Polyethylene Terephthalate) composite packaging material and preparing method thereof

InactiveCN104249525AAvoid pollutionNo solvent residueFlexible coversWrappersPolyethylene terephthalate glycolPolymer science

The invention discloses a PET (Polyethylene Terephthalate) composite packaging material specially used for food packaging. The PET composite packaging material comprises a PET sheet material and a composite film compounded on the surface of the PET sheet material, wherein the composite film comprises a bonding layer, and the PET sheet material is bonded with the bonding layer; the bonding layer is made from an ethylene copolymer, and the comonomer of the ethylene copolymer is ethyl acetate, acrylate or maleic anhydride. Correspondingly, the invention further discloses a method for preparing the PET composite packaging material. The bonding layer is directly bonded with the PET sheet material, so that the glue laminating procedure is reduced, no solvents are left, the cost is lowered, resource wastes are reduced, and environmental pollution caused by glue laminating is further avoided.

Owner:SEALED AIR CHINA

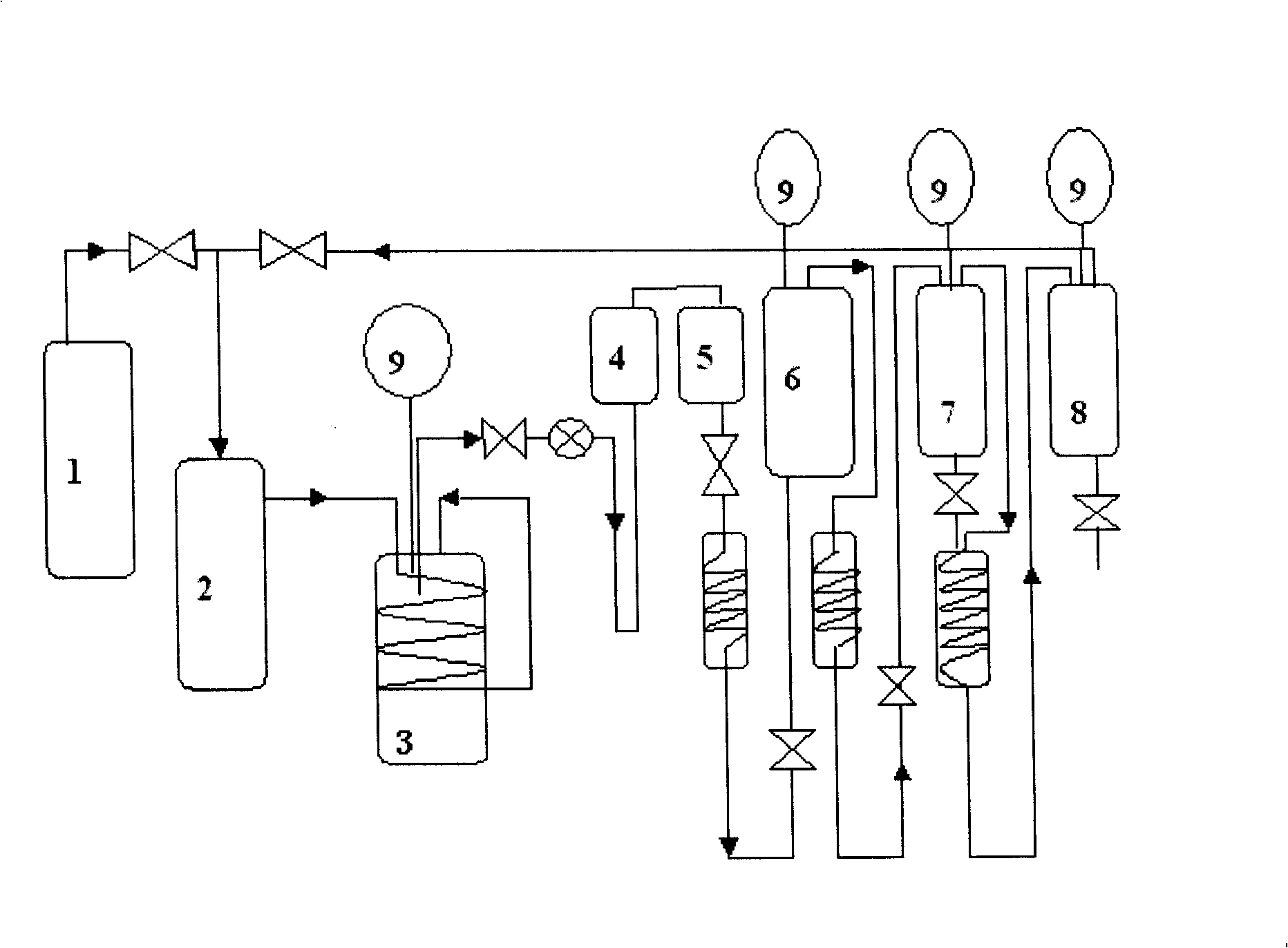

Wall-breaking abstraction melissa powder oil and fat method with supercritical carbonic anhydride

InactiveCN101269093ASimple processIncrease productivityAnthropod material medical ingredientsAntinoxious agentsExhaust valveEnergy consumption

The invention relates to the applied technology field of medicine, foodstuff and health-care food processing and belongs to a method of extracting bee pollen oil from broken bee pollens by supercritical carbon dioxide. The method adopts a continuous process of breaking bee pollens by supercritical carbon dioxide and extracting bee pollen oil subsequently. The process is simple and includes the following steps: firstly, bee pollens are put into the extracting kettle of an extracting device of supercritical carbon dioxide, the temperature and pressure of the extracting kettle are controlled, an exhaust valve is opened and carbon dioxide is rapidly emptied after the pressure is maintained; secondly, carbon dioxide is continuously passed into the extracting kettle, the extraction temperature, pressure, the flow rate of carbon dioxide and the pressure and temperature of the two-stage separation are adjusted, and then bee pollen oil is collected in a separation pot after a certain period of extraction. Compared with the prior extracting method, the method of extracting bee pollen oil from broken bee pollens by supercritical carbon dioxide has the advantages of short extraction duration, high production efficiency, low energy consumption and contamination absence. The obtained product can be directly used as a high-quality material for foodstuff, health-care food and pharmaceutical products, and has a good development prospect.

Owner:BEE RES INST CHINESE ACAD OF AGRI SCI

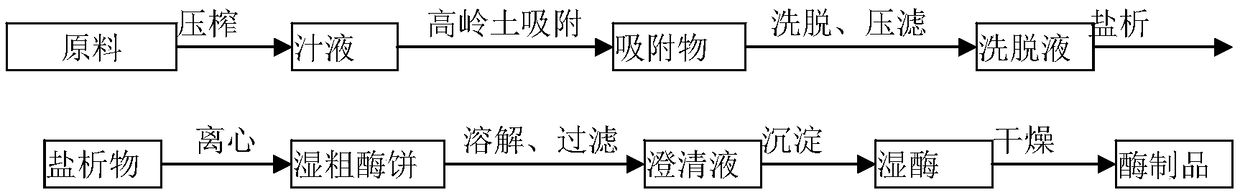

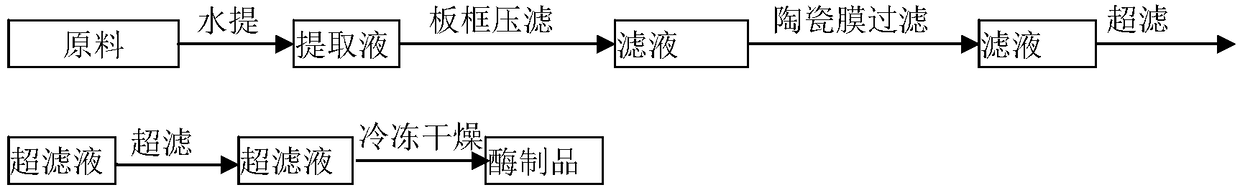

Plant proteinase extraction method and obtained plant proteinase

The invention relates to a plant proteinase extraction method and obtained plant proteinase. The method comprises the following steps: mixing slurry or a crushed material of plants with water in a solid-liquid ratio of 1:(5-20), then carrying out water extraction, and collecting an extracting solution; filtering the obtained extracting solution by virtue of a plate-and-frame filter press and a ceramic membrane sequentially, wherein the pore size of filter cloth of the plate-and-frame filter press is 100-150 meshes, and the pore size of the ceramic membrane is 50-200nm; carrying out primary ultrafiltration treatment on a filtrate by using an ultrafiltration membrane with the molecular weight cutoff of 30-100KDa, collecting the filtrate, carrying out secondary ultrafiltration treatment on the filtrate by using an ultrafiltration membrane with the molecular weight cutoff of 5-15KDa, and collecting trapped fluid; and concentrating the trapped fluid to obtain a concentrated solution, and carrying out freeze drying on the concentrated solution, so that the plant proteinase is obtained. The method provided by the invention has the advantages of simple technology, no pollution to the environment, the feasibility of large-scale industrial production and high proteinase activity and purity. The plant proteinase has the advantages of good activity, high purity and no solvent residue and meets usage requirements of the food, daily chemical and medicine industries.

Owner:XIAN HERB REFINE BIOLOGIC PRODS

Novel propolis soft capsule and preparation method thereof

InactiveCN104873546AImprove purityAvoid wastingOrganic active ingredientsNervous disorderPropolisMedicine

The invention discloses a novel propolis soft capsule which comprises a capsule content and a capsule shell, wherein the capsule content consists of the following components in parts by weight: 25-35 parts of a propolis supercritical CO2 extract, 77-95 parts of a mixed oil agent, 13-25 parts of vitamin E and 12-24 parts of beeswax; and the capsule shell consists of the following components in parts by weight: 75-95 parts of gelatin, 49-65 parts of glycerol and 88-105 parts of purified water. The propolis, which is extracted through supercritical carbon dioxide, is higher in purity; some components low in boiling point are reserved, and the soft capsule is free from solvent residue, safe, non-toxic and reliable; and by virtue of a soft capsule preparation process of covering the content with a glue solution, the waste of the content is avoided.

Owner:JIANGSU JIANGDAYUAN ECOLOGICAL BIOLOGICAL TECH

Method for extracting and purifying natural volatile oil from sophora flower by using supercritical CO2 fluid extraction process

InactiveCN1380380ASolve the need to keep freshSolve the problem that dried petals can still be used equallyEssential-oils/perfumesSolventSophora

The supercritical CO2 fluid extraction method for extracting and purifying essential oil from sophora flower includes the following steps: firstly, cleaning sophora flower, drying by airing, using dried sophora flower and fresh sophora flower as raw material, using supercritical CO2 as extraction solvent, making extraction at 10-40 MPa and 15-65 deg.C, progressively reducing pressure under the condition of 15-65 deg.c and extracting for 2-10 hr., so that the sophora flower oil and CO2 can be naturally separated, the CO2 can be reused. Its essential oil recovering can be up to 90%.

Owner:DALIAN UNIV OF TECH

Aquosity lacquer used for cigarette lining paper and method of manufacturing the same

ActiveCN101109163ANo pollutionNo pollution in the processNon-fibrous pulp additionFlexible coversBenzoyl peroxideLacquer

The invention discloses a water varnish for inner liner paper of cigarette and the preparing way for the varnish. The water varnish is obtained by synthesizing through taking acrylic acid, vinylacetate, butyl acrylate, ethyl acrylate, methyl methacrylate and styrene as reaction monoblock, n-butyl alcohol, isopropyl alcohol and ethyl alcohol as solution, benzoyl peroxide as initiator, and ammonia or ethanolamine as neutralizer. Further, the water varnish got is mixed evenly with essence for cigarettes, and water varnish with fragrance is obtained. The product takes water as solution, has no organic solution volatimatter during the production and use, no pollution on the environment and no harm on one's body. The invention has a low cost, easy process, needs no changing existing process and equipment, and can adjust the fragrance formula depending upon user's demand, so that the product can coordinate with fragrances of cigarettes of different makes, the safety of cigarettes can be improved, quality of cigarettes can be increased comprehensively. The invention is of a good application prospect.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD +1

Extraction method of passionflower seed oil

The invention discloses an extraction method of passionflower seed oil from passionflowers. The extraction method comprises the following steps: raw material treatment; compound enzyme treatment; supercritical CO2 fluid extraction; and vacuum drying to obtain a finished product. Compared with the prior art for directly carrying out supercritical CO2 fluid extraction on a passionflower raw material, the extraction method disclosed by the invention has the advantage of high content.

Owner:GUILIN TECH ENTERPRISE DEV CENT

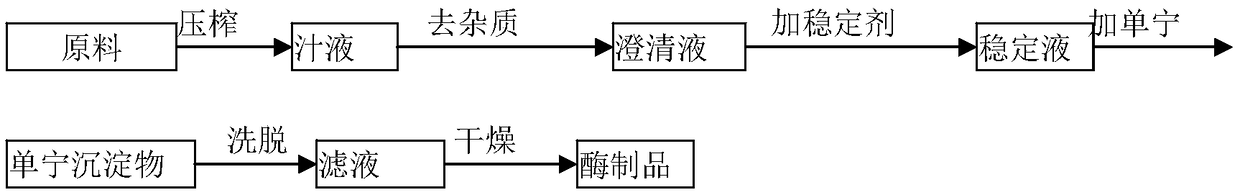

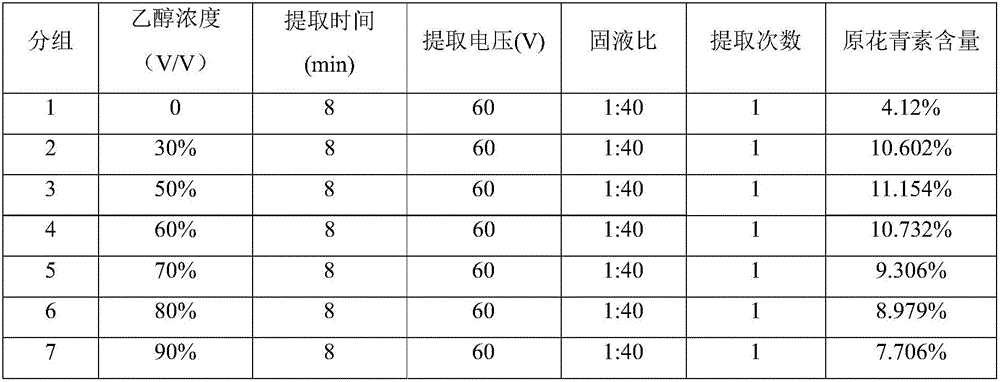

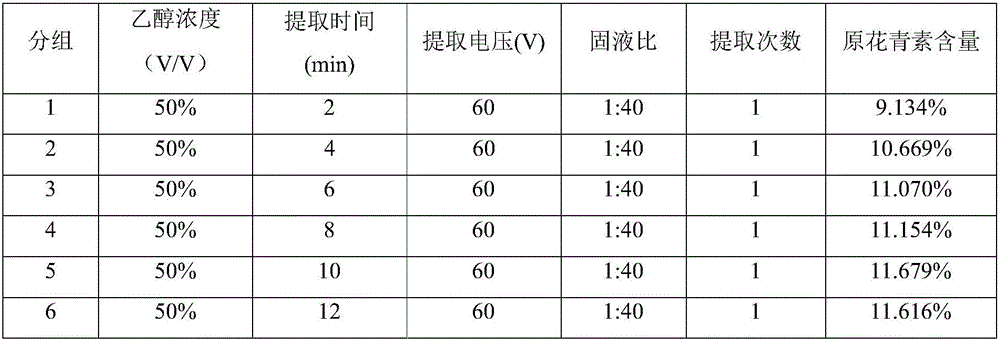

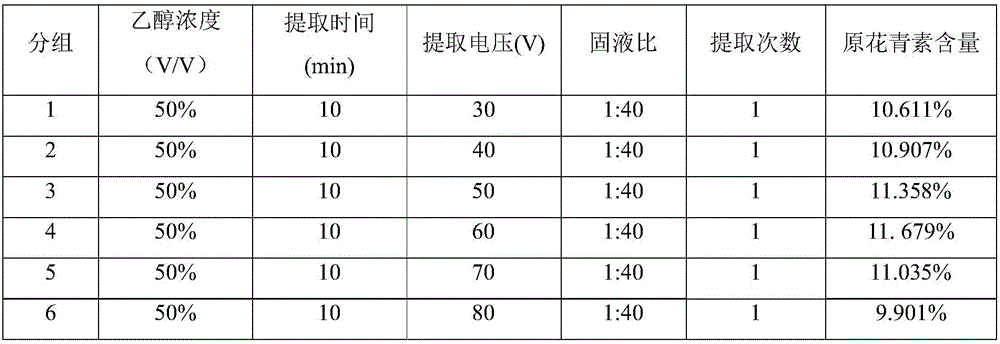

Method for extracting procyanidine from fruit or pomace of aronia melanocarpa elliot

ActiveCN106674185AAvoid decompositionAvoid lostOrganic chemistryUltra Low Temperature FreezerFiltration

The invention relates to a method for extracting procyanidine from fruit or pomace of aronia melanocarpa elliot. The method comprises the steps of dipping the fruit or pomace of the aronia melanocarpa elliot into an organic solvent, conducting Flash extraction for 0.5-30 minutes by using a Flash extractor, carrying out suction filtration and centrifugation to obtain a procyanidine extract solution of the aronia melanocarpa elliot; concentrating the procyanidine extract solution of the aronia melanocarpa elliot by using a negative pressure rotary evaporation device to obtain procyanidine extract concrete of the aronia melanocarpa elliot; and after pre-freezing the procyanidine extract concrete of the aronia melanocarpa elliot by using an ultra-low temperature refrigerator, carrying out freeze drying on the procyanidine extract concrete by using a freeze drying device to obtain the freeze-dried powder of a procyanidine extract of the aronia melanocarpa elliot. According to the method disclosed by the invention, low temperature in the whole course can be realized, procyanidine disintegration caused by high temperature can be avoided, the loss of anthocyanin in the extracting process effectively can be effectively avoided, the operation is simple and the cost is low, and promotion in enterprises can be achieved by forming an automatic production line, so that the method has a relatively high commercial value.

Owner:LIAONING UNIVERSITY

Supercritical extracting method of ginger oil

The invention discloses a supercritical extracting method of ginger oil. The ginger oil is extracted from ginger by adopting supercritical carbon dioxide fluid. Before extracting, ginger is selected,washed, dried and pulverized, the extracting temperature is 25-65 DEG C, and the pressure is 15-28 MPa; the flow of carbon dioxide gas passing through an extracting kettle is 1.0-1.3 t / h, and the extracting time is 2-4 h. The carbon dioxide fluid under the supercritical state is used as an extracting solvent, the solvent is recycled in the same system, the solvent consumption is small, the price is cheap, and thus the extracting cost is low. The carbon dioxide fluid is green pollution-free solvent, the extracted ginger oil has the advantages of being high in quality and purity, good in color,free of peculiar smell, solvent residue and environmental pollution and the like, the extracting cycle is short, residues after the ginger oil is extracted also contain effective components like starch and dietary fiber, and the ginger can be comprehensively utilized. The technology is simple, and the energy consumption is low.

Owner:GUIZHOU AEROSPACE WUJIANG MACHINERY & ELECTRICITYEQUIP

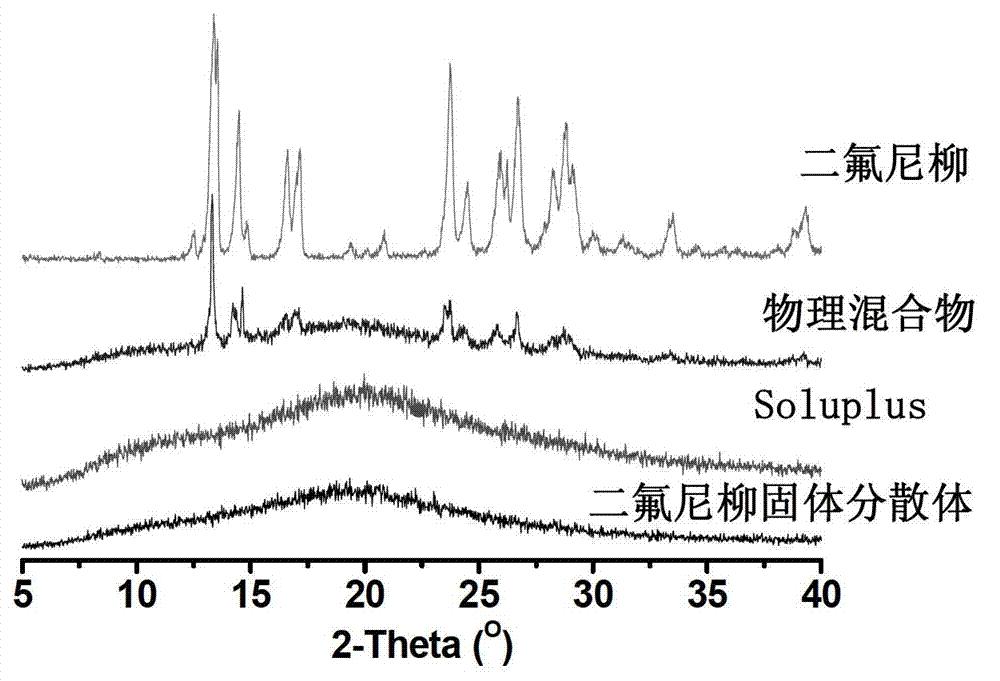

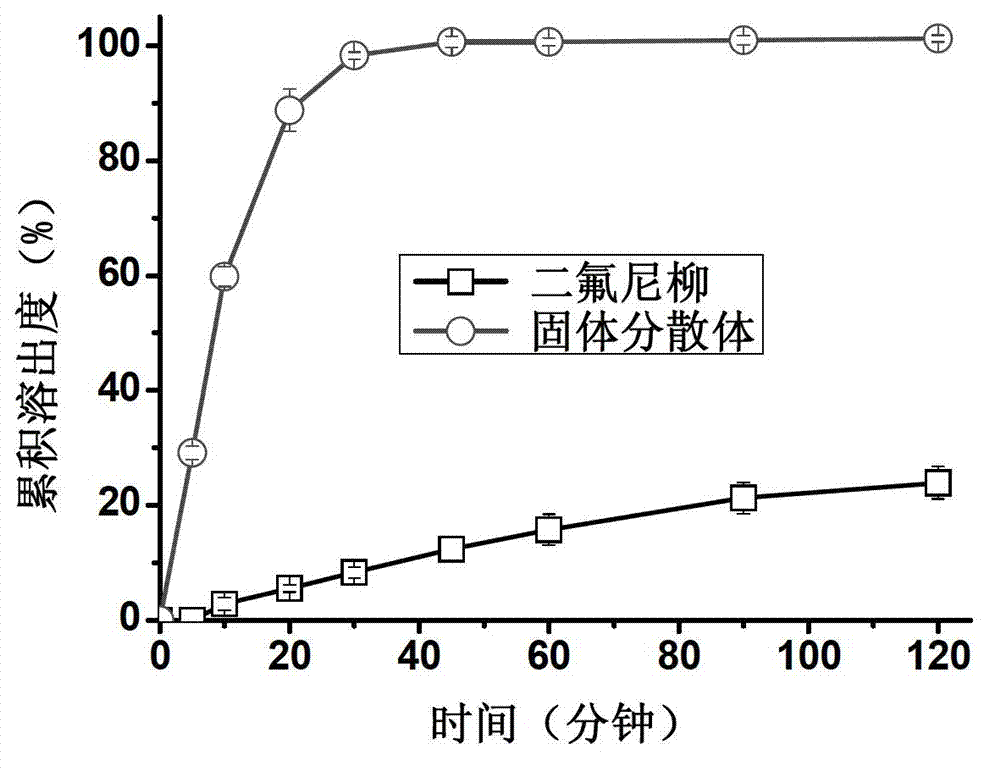

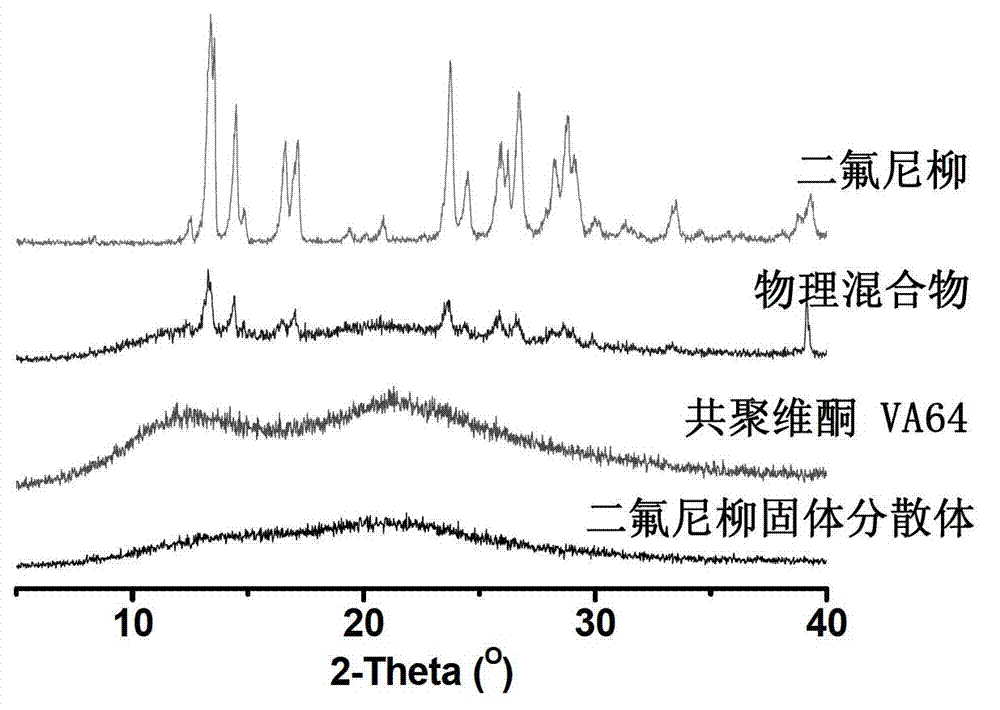

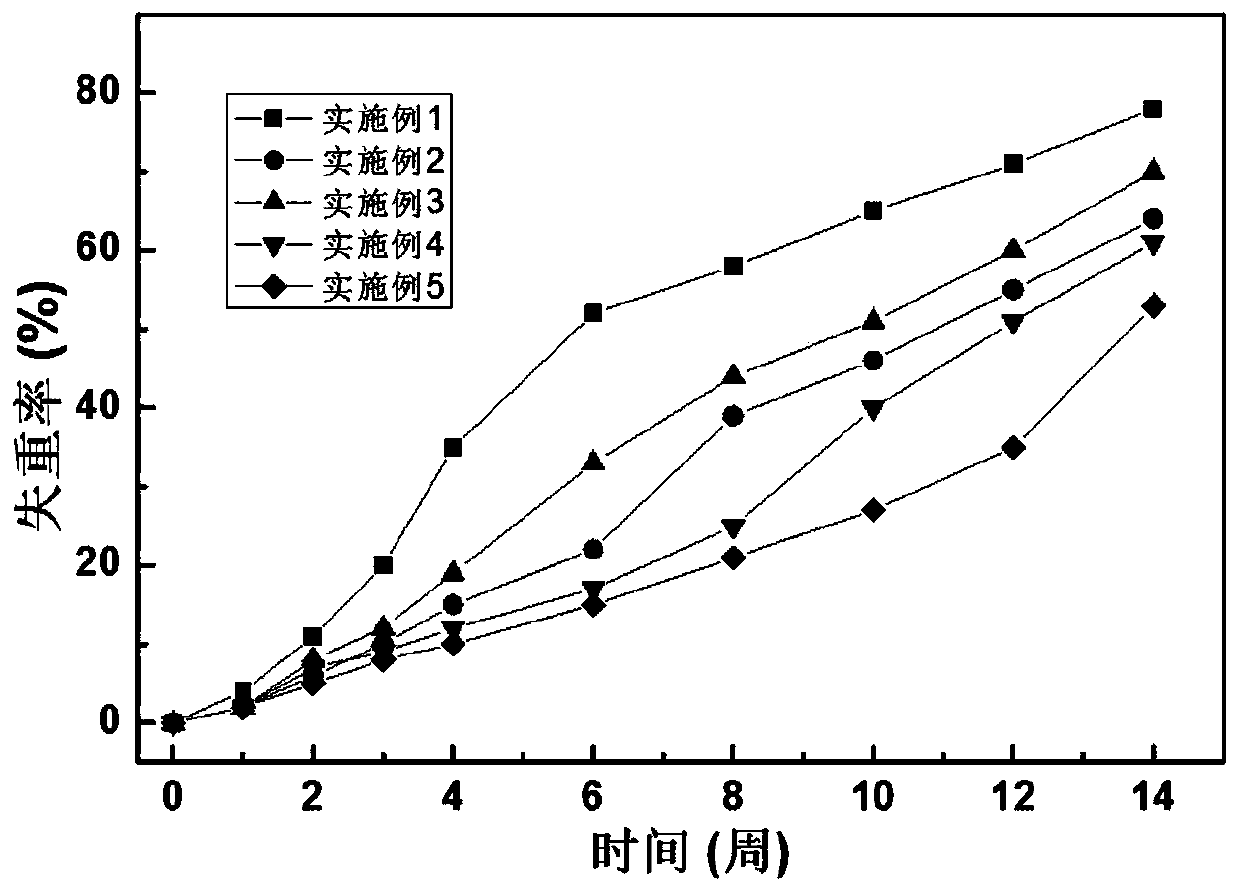

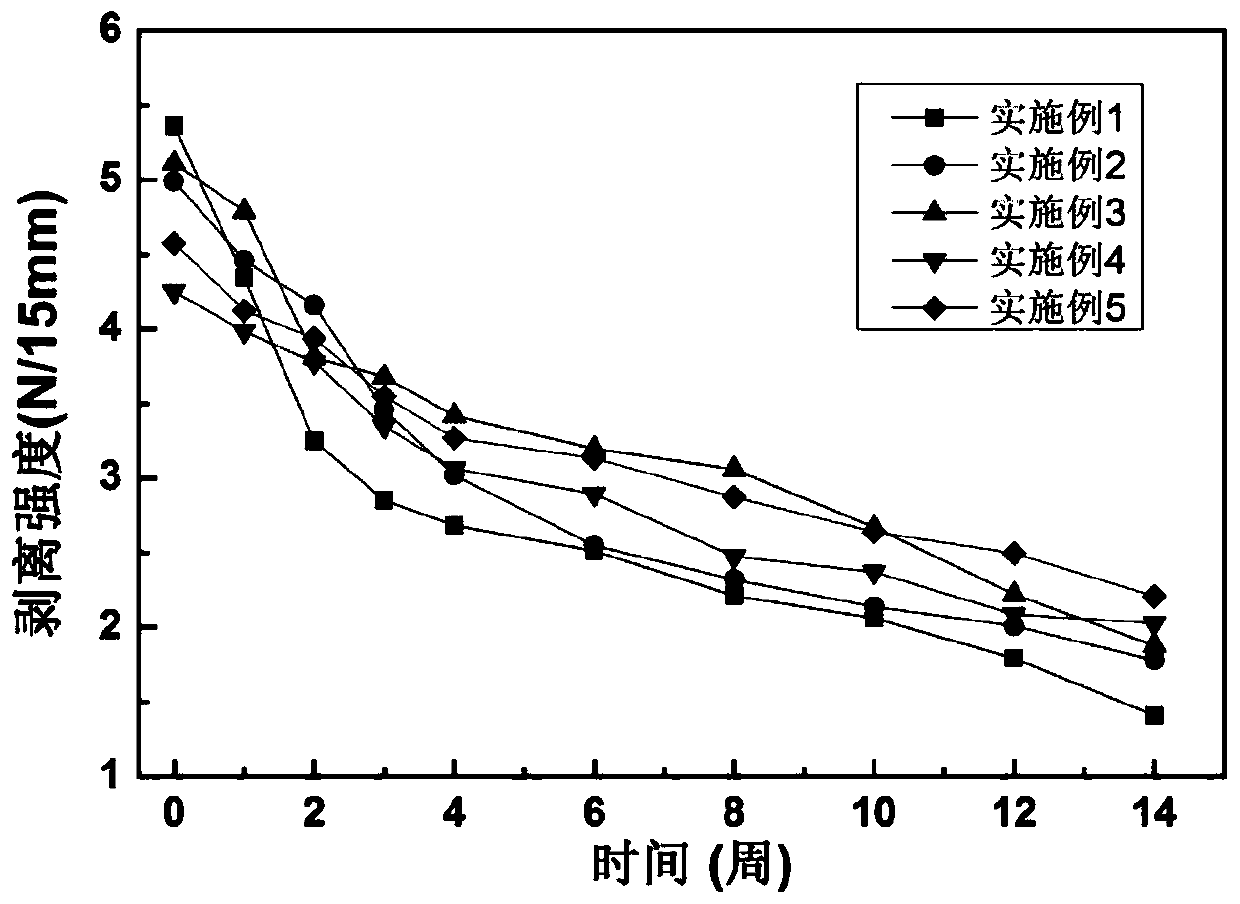

Diflunisal solid dispersion and preparation method thereof

ActiveCN103202811AReduce adverse reactionsNo solvent residueOrganic active ingredientsPowder deliverySolubilityPolyethylene glycol

The invention discloses a diflunisal solid dispersion and a preparation method thereof. The solid dispersion is composed of diflunisal as active components and high-polymer carrier materials. The high-polymer carrier materials are 40-90% of the diflunisal in total and selected from povidones, copovidones, and polyethylene glycol / vinyl caprolactam / vinyl acetate copolymer or hydroxypropyl methylcellulose. The preparation method adopts a hot-melting extrusion method. The diflunisal solid dispersion obtained is higher in solubility and quick and high in dissolving, bioavailability of indissolvable drugs is improved, drug dosage is reduced, and adverse drug reaction is reduced.

Owner:SUN YAT SEN UNIV

Preparation method of high purity sulforaphene

ActiveCN105294525AImprove degradation yieldIncrease productionOrganic chemistryHazardous substanceEvaporation

The invention discloses a preparation method of high purity sulforaphene and belongs to the field of sulforaphene preparation. High purity sulforaphene is prepared from radish seed meal as a raw material by ethanol extraction, enzyme film reaction, chromatogram preparation and vacuum thin film evaporation. The preparation method has the characteristics of continuous production technology, simpleness, stability, high extraction and purification efficiency, high yield, high resource comprehensive utilization rate and no harmful substance discharge. In production, two enzymes are used as catalysts so that a sulforaphene enzymolysis yield is greatly improved. The preparation method of high purity sulforaphene has high purifying efficiency, realizes product purity of 98% or more and does not produce solvent residues. The high purity sulforaphene can be widely used in industries of medicines and health products.

Owner:BEIKE HUAXIA BIOMEDICAL TECH CO LTD

Method for extracting swertiamarin with supercritical fluid

InactiveCN102558131AGood reproducibilityLow extraction temperatureOrganic chemistryBulk chemical productionSilica gelSolvent

The invention belongs to the technical field of extraction of Chinese medicinal active ingredients, and particularly relates to a method for extracting swertiamarin with a supercritical fluid. The method comprises the following steps of: soaking swertiamarin with an ethanol solution; putting into an extracting kettle; extracting by taking supercritical CO2 as an extracting agent and taking ethanol as an entrainer; decompressing, separating and discharging; and purifying and separating an extract through column chromatography, and eluting with an eluent, wherein the extracting pressure is 25-45 MPa, the temperature is 30-60 DEG C, the extracting time is 1-5 hours, and the resolution pressure is 4-8 MPa; silica gel is taken as a column chromatography filler; and a petroleum ether-ethyl acetate mixed solvent, ethanol or methanol is taken as the eluent. Through supercritical CO2 extraction, the obtained swertiamarin has good quality and high purity; and the entire method has short operating time and a simple process.

Owner:苏州宝泽堂医药科技有限公司

Polyurethane adhesive with degradation features and preparation method thereof

ActiveCN109810666AHas degradative propertiesGood adhesionPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

The invention discloses a polyurethane adhesive with degradation features. The polyurethane adhesive comprises an ingredient A and an ingredient B, wherein the ingredient A is NCO terminated polyurethane prepolymers; the ingredient B is OH terminated polyol compounds; the mol ratio of the NCO in the ingredient A to the OH in the ingredient B conforms to a formula of n(NCO) / n(OH)=(1.2 to 3.0):1; the ingredient A is prepared from the following raw materials of oligomer resin and polyisocyanates; the ingredient B is prepared from the following raw materials of polyhydric alcohols, polyisocyanatesand anti-foaming agents; the oligomer resin is prepared through polyesterification reaction on polyatomic acid, degradable polyol and polyhydric alcohol; the adhesive has degradable characteristics;meanwhile, in the reaction and preparation process, no organic solvent is contained; no VOCs emission and no solvent residue exist; the green and environmental-friendly effect and safety are realized.The invention also discloses a preparation method of the polyurethane adhesive.

Owner:中山市康和化工有限公司

Preparation method of silymarin

ActiveCN105503843AAvoid influenceSimple manufacturing methodOrganic chemistrySilybum Marianum SeedAlcohol

The invention relates to a preparation method for extracting high-purity silymarin from silybum marianum seed husk. The preparation method comprises the following steps: separating silybum marianum seeds from seed husk, radiating by ultraviolet, carrying out the enzymolysis, extracting by absolute ethyl alcohol, volatilizing a solvent in an extracting solution, and washing solids to obtain a silymarin crude product; dissolving in absolute ethyl alcohol, obtaining supernatant, treating by adopting the reversed phase partition chromatography, carrying out the gradient elution by using water-ethyl alcohol, collecting eluate of the absolute ethyl alcohol part, concentrating the eluate, and vacuum-drying by virtue of microwaves to obtain a product. The method is simple in process, high in production efficiency and simple to operate, the product purity can reach up to 93 percent or more, and basically no solvent remains.

Owner:内蒙古昶辉生物科技股份有限公司

Angelica sinensis health care oil, preparation method and application of angelica sinensis health care oil

InactiveCN102144677AEnsure that the structure does not alienateSimple processing methodEdible oils/fatsEdible oilAngelica archangelica

The invention relates to angelica sinensis health care oil, a preparation method and an application of the angelica sinensis health care oil. The angelica sinensis health care oil is composed of angelica sinensis oil and edible plant oil, The angelica sinensis health care oil provided by the invention has good aroma and better taste, and has health care function, so that the angelica sinensis health care oil can be used as health care edible oil.

Owner:北京本草通汇科技中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com