PET (Polyethylene Terephthalate) composite packaging material and preparing method thereof

A composite packaging material and composite film technology, which is applied in the field of PET composite packaging materials and its preparation, can solve the problems of non-environmentally friendly residual solvents, numerous processes, and the need for glue, etc., achieve a clean peeling interface, meet safety and hygiene requirements, and reduce waste of resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0117] For preparing the PET composite packaging material that is provided with the composite film of above-mentioned preferred embodiment, adopt following preparation method, comprise:

[0118] (1) forming a molten adhesive layer by an extruder A;

[0119] The technical details of the adhesive layer are consistent with the above, and will not be repeated here.

[0120] (2) forming the functional layer in molten state by extruder B;

[0121] The thickness of the functional layer is preferably 3-80 μm. More preferably, the thickness of the functional layer is preferably 5-70 μm.

[0122] The functional layer can be a PE layer, an easy-to-tear layer, or a barrier layer, or it can be a nylon layer that increases the puncture resistance of the film, or it can be any layer between the PE layer, barrier layer, nylon layer, and easy-to-tear layer. combination, and is not limited to this. Wherein, the barrier layer is an EVOH barrier layer or a PVDC barrier layer, and the barrier ...

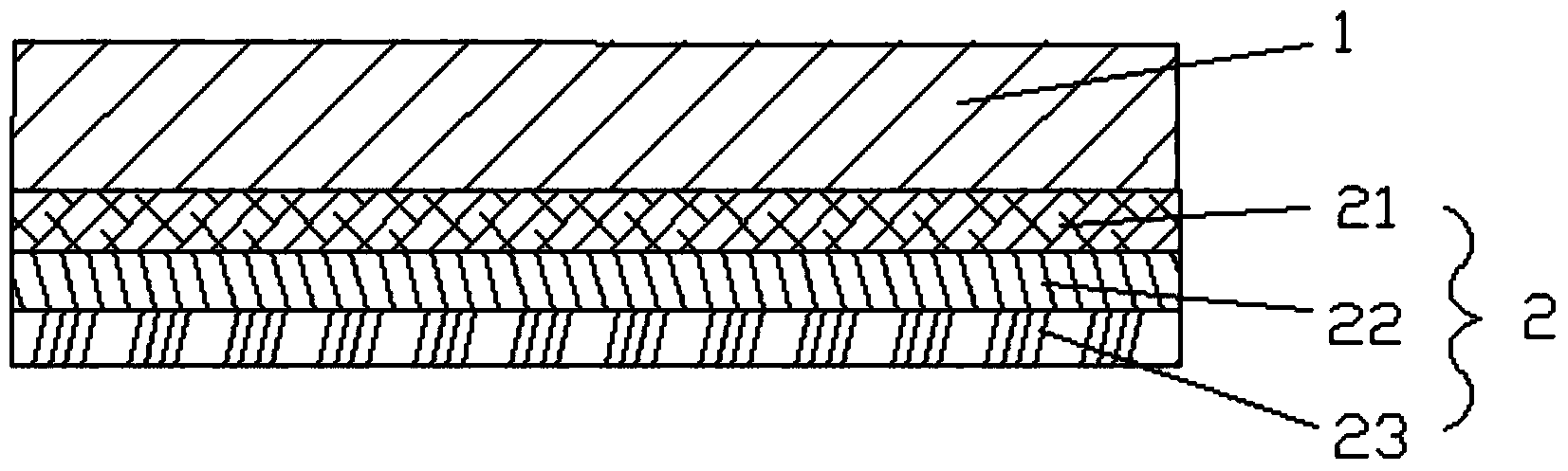

Embodiment 1

[0139] see figure 1 , the present invention provides a first embodiment of a PET composite packaging material, which includes a PET sheet 1 and a composite film 2 compounded on the surface of the PET sheet 1 from top to bottom, the thickness of the PET sheet 1 is 400 μm, and the composite film 2 has a thickness of 50 μm, wherein the composite film 2 includes an adhesive layer 21, a functional layer 22, and a heat-sealing layer 23, the adhesive layer 21 is composed of ethylene-ethyl acetate copolymer (EVA), and the thickness is 10 μm, and the functional layer 22 It is a PE layer with a thickness of 25 μm, and the thickness of the heat-sealing layer 23 is 15 μm.

[0140] Its preparation process is as follows:

[0141] 1. Prepare a composite film consisting of an adhesive layer, a functional layer and a heat-sealing layer

[0142] The molten adhesive layer, PE layer and heat-sealing layer are respectively formed by the extruders A, B, and C, and the molten adhesive layer, PE la...

Embodiment 2

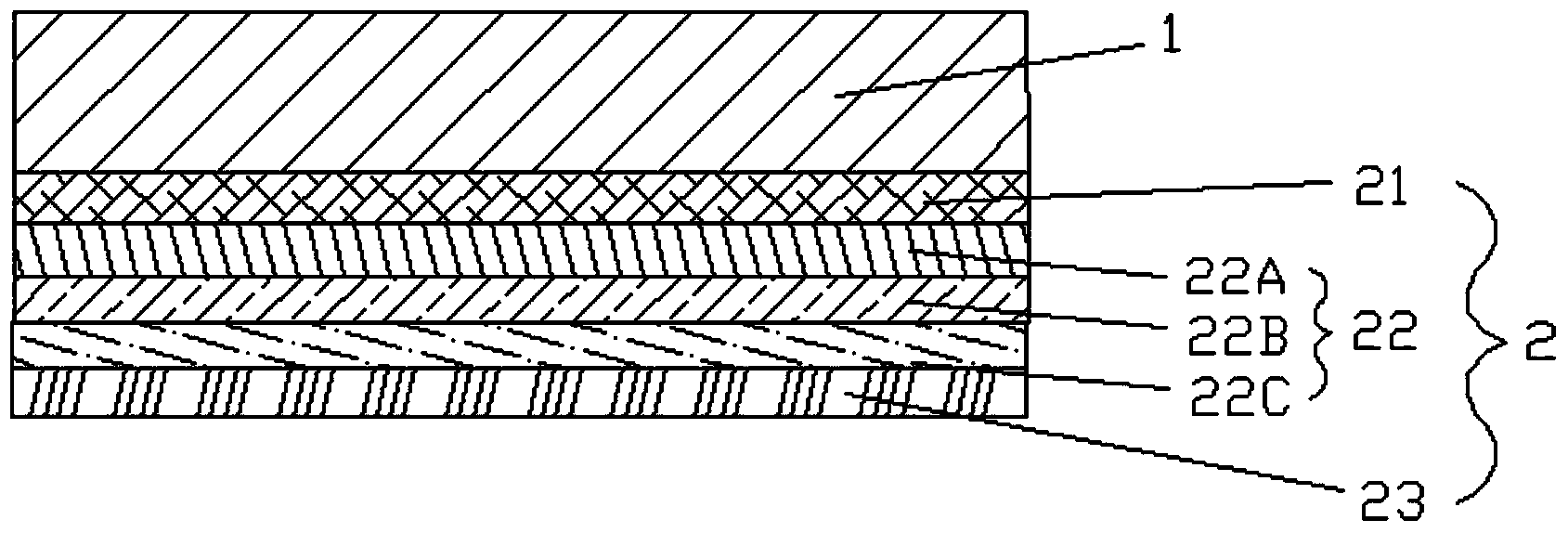

[0148] see figure 2 , the present invention provides a second embodiment of a PET composite packaging material, which includes a PET sheet 1 and a composite film 2 compounded on the surface of the PET sheet 1 from top to bottom, the thickness of the PET sheet 1 is 300 μm, and the composite film 2 has a thickness of 50 μm, wherein the composite film 2 includes an adhesive layer 21, a functional layer 22 and a heat-sealing layer 23, the adhesive layer 21 is composed of ethylene-ethyl acetate copolymer (EVA), and the thickness is 5 μm, and the functional layer 22 It includes an adhesive layer 22A, a barrier layer 22B and an adhesive layer 22C, the thickness of which is 25 μm, and the thickness of the heat-sealing layer 23 is 20 μm.

[0149] Its preparation process is as follows:

[0150] 1. Prepare a composite film consisting of an adhesive layer, a functional layer and a heat-sealing layer

[0151]The adhesive layer 21, adhesive layer 22A, barrier layer 22B, adhesive layer 22...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com