Patents

Literature

143results about How to "Operation process security" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coking coal dust shaping technique

A process method of coking coal dust forming chiefly aims at settling the problem about a second dust emission in the course of transportation. First, the large quantity of small smut produced by a fluidized bed can be collected by a dust precipitator, be conveyed to a smut collecting storehouse, and constantly transmitted into a high pressure molding machine by an incessant closed conveyer. The feeding mouth of the high pressure molding machine is provided with a repressing screw to ensure the smut entering a high pressure rolling pair to be with certain pressure. Then the smut can be extruded into effigurate briquette, which at last is conveyed into a production coal conveying system after the molding. The process can prevent the production coal from producing the second dust emission during the transportation, thus reducing the engineering investment and environmental pollution with the advantages of less floor space and increasing the coke yield produced by coke oven.

Owner:SHANDONG IRON & STEEL CO LTD

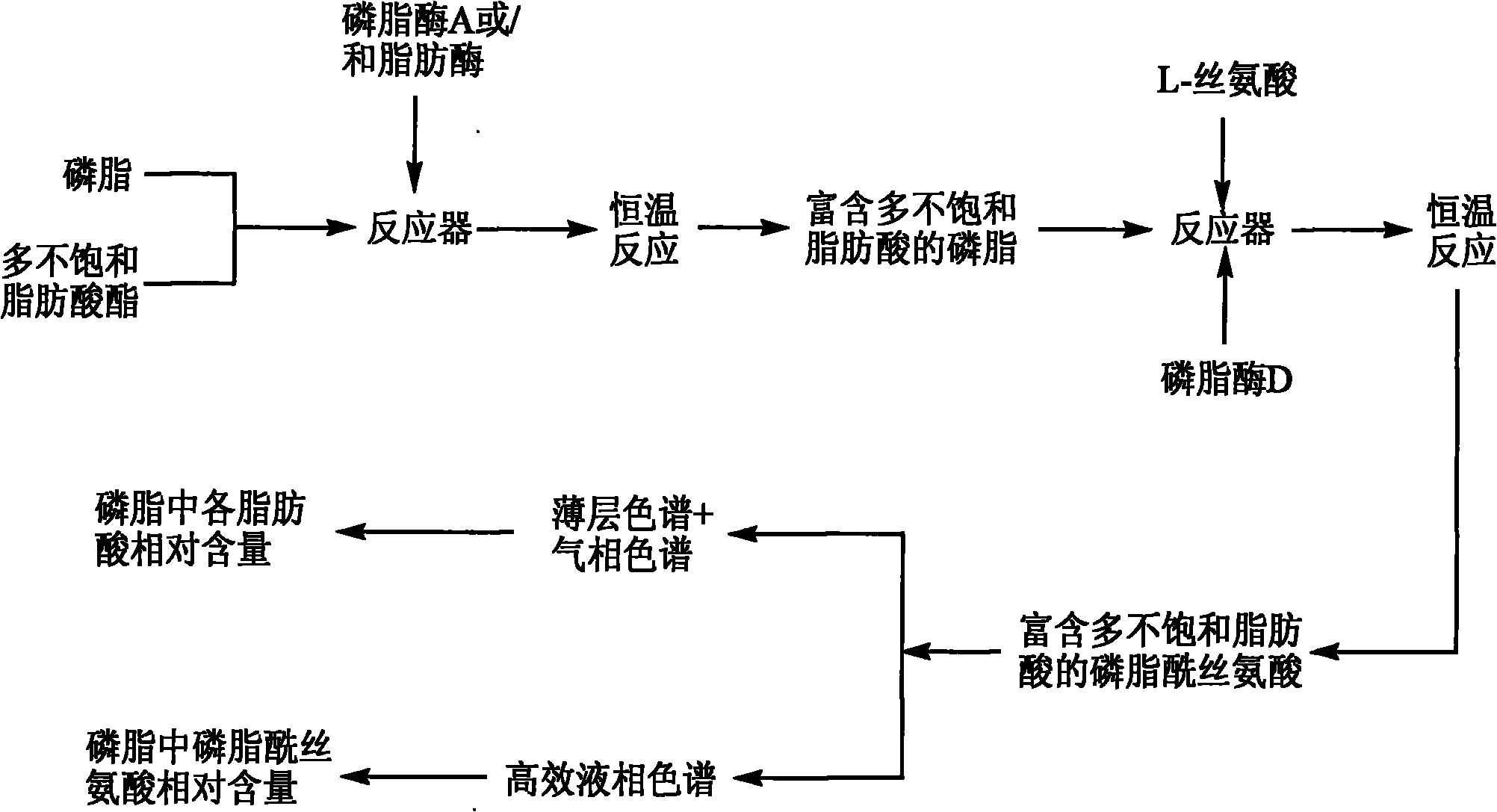

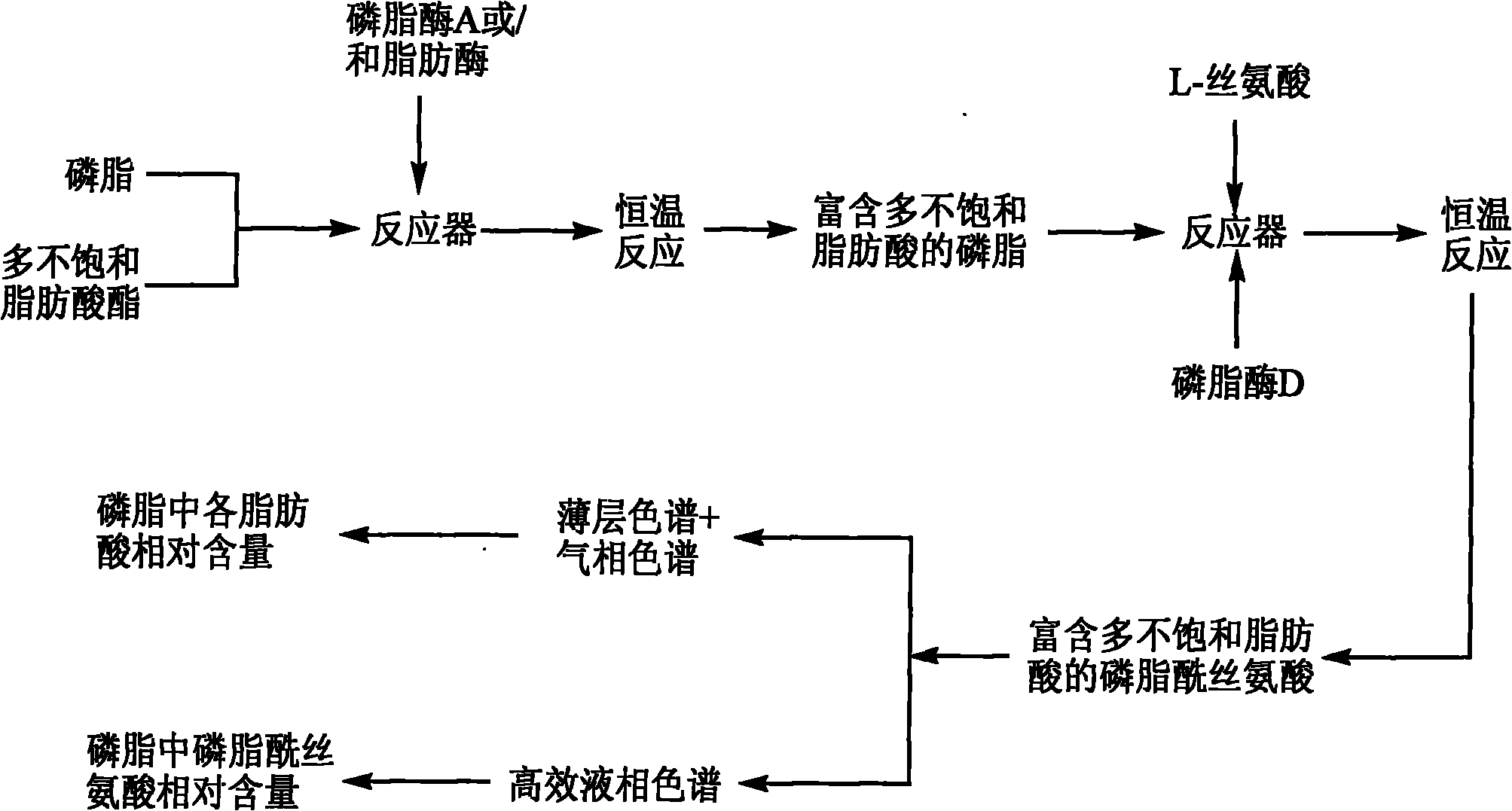

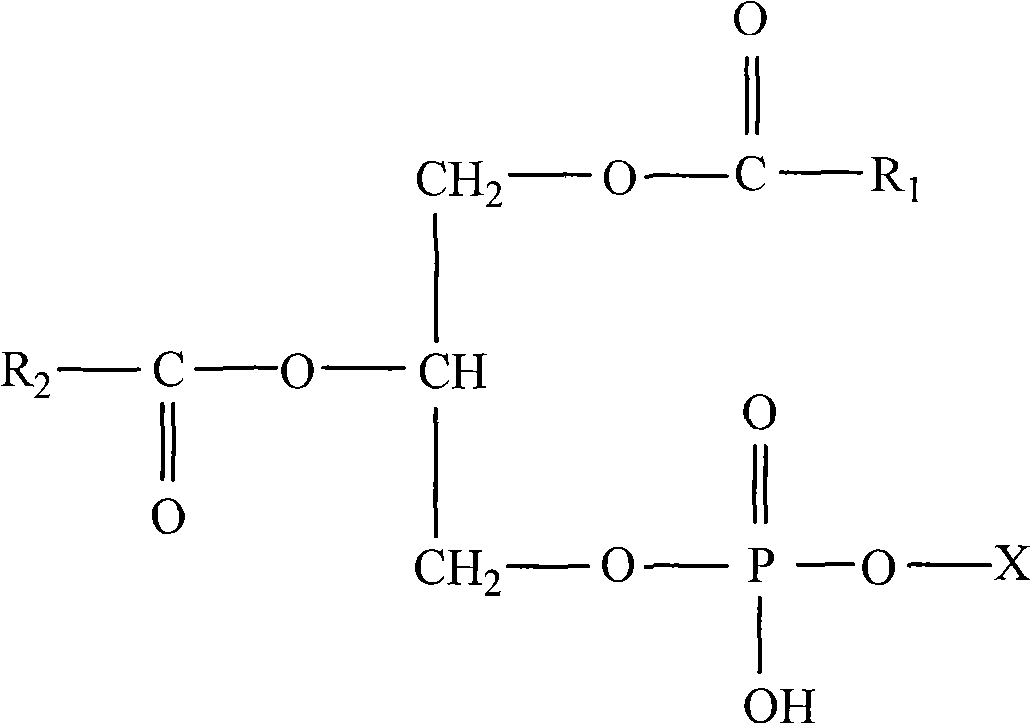

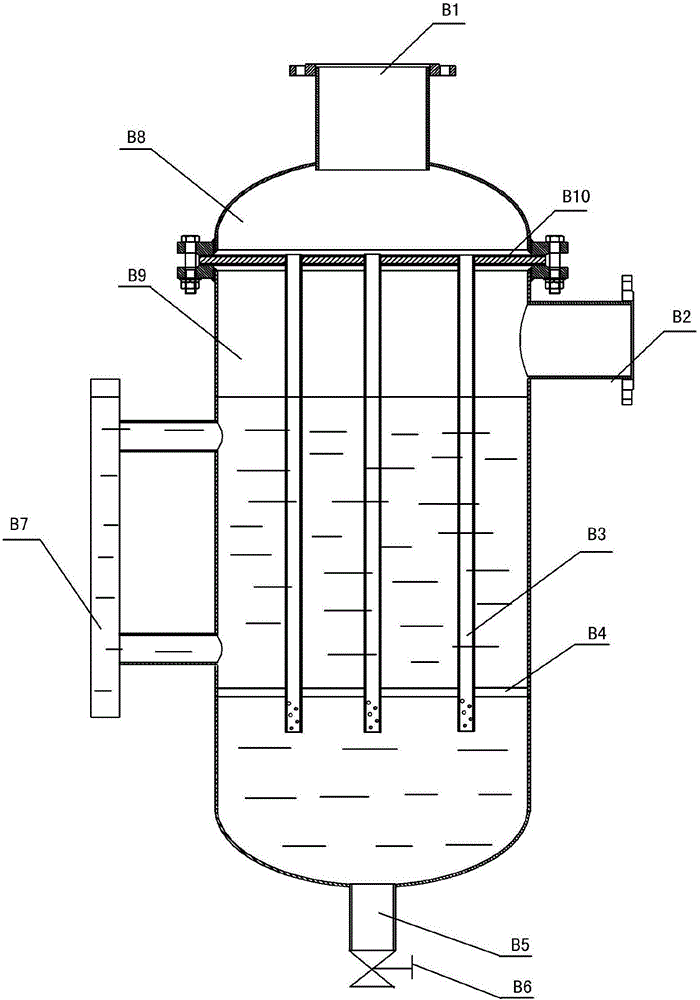

Method for preparing phosphatidylserine abundant in polyunsaturated fatty acid

InactiveCN101818179ANo emissionsImprove product qualityMicroorganism based processesFermentationUnsaturated fatty acid esterPhospholipid

The invention relates to a method for preparing phosphatidylserine abundant in polyunsaturated fatty acid and belongs to the technical field of bioengineering. The method is characterized by comprising the following steps of: firstly, catalyzing ester exchange reaction between phosphatide and polyunsaturated fatty acid ester by utilizing one or a mixture of phosphatidase A and lipase to generate phosphatide abundant in polyunsaturated fatty acid; and then catalyzing phosphor-transfer esterification reaction between the phosphatide abundant in the polyunsaturated fatty acid and L-serine by utilizing phosphatidase D to generate the phosphatidylserine abundant in the polyunsaturated fatty acid. The method has the advantages of no discharge of waste water, good product quality, no solvent residue, safe process operation, few reaction byproducts, no waste generation, cost reduction, simple production process and easy realization of scale production because of utilizing two enzymes to perform sub-step catalysis and perform reaction in the same reactor, and completing the reaction process in a non-solvent system. Therefore, the invention provides a good and feasible method for preparing the phosphatidylserine abundant in the polyunsaturated fatty acid.

Owner:DALIAN UNIV OF TECH

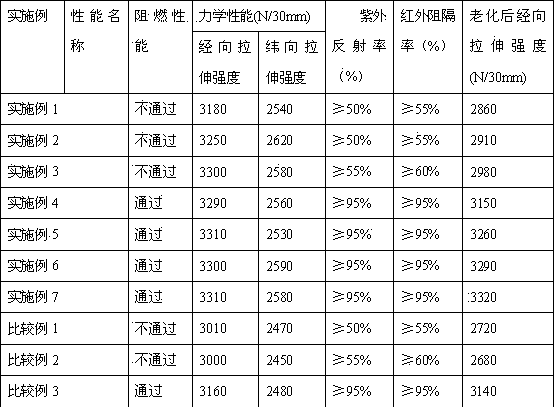

High-strength PVC (Polyvinyl Chloride) awning cloth

InactiveCN103741474AHigh tensile strengthHigh hardnessFibre typesPolyvinyl chlorideCarvacryl acetate

The invention discloses high-strength PVC (Polyvinyl Chloride) awning cloth which is formed by coating both sides of gridding cloth with PVC coatings. According to a raw material formula, each PVC coating comprises the following components in parts by weight: 80 parts of PVC paste resin, 70-90 parts of dioctyl phthalate, 55-65 parts of calcium carbonate, 3-6 parts of chlorinated paraffin, 3-6 parts of a stabilizer, 3-10 parts of de-aromatic solvent oil, 1-8 parts of a vinylpyridine bonding agent, 7-20 parts of flame retardant mortar, 3-8 parts of titanium dioxide, 0.1-0.8 part of an anti-UV (Ultraviolet) agent and 2-30 parts of heat insulation powder. The heat insulation powder is a mixture prepared from hollow glass beads and polyvinyl acetate according to the weight part ratio of 100: (1-5). Compared with the prior art, the awning cloth has the advantages that the tensile strength is up to 3,300N / 30mm, the ultraviolet reflectivity and infrared ray blocking rate are up to 95%, and the favorable mechanical property stability is kept after an ageing test is ended.

Owner:JIANGYIN DONGHENG NEW MATERIAL SCI TECH

Blueberry preserved fruit and preparation method thereof

ActiveCN103222530ARetain effective nutrientsNo pollution in the processConfectionerySweetmeatsNutritive valuesSugar

The invention provides a blueberry preserved fruit and a preparation method thereof. The method comprises using fresh blueberry as raw materials, cleaning the blueberry, pricking apertures, steaming, immersing in sugar under vacuum and suitable conditions, immersing in sugar under normal temperature and pressure, drying under suitable conditions, and then softening for several days after drying to obtain the blueberry preserved fruit. A technical scheme provided by the invention uses a vacuum sugar-immersing technology, is low in cost and non-polluted; and the produced blueberry preserved fruit reserves original nutrition values of the blueberry, and is sweet and sour in taste and moderate in hardness.

Owner:建昌县亿丰蓝莓饮料有限公司

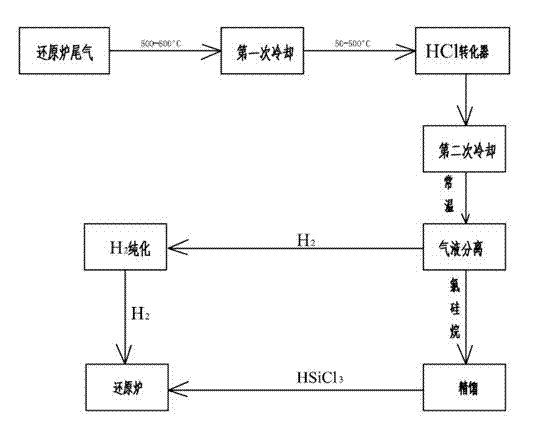

Novel process for recycling tail gas generated in polycrystalline silicon production

InactiveCN102923715AReduce power consumptionReduce utilizationHydrogen separationHalogenated silanesImpurityPolycrystalline silicon

The invention discloses a novel process for recycling tail gas generated in polycrystalline silicon production. The tail gas comprises H2, HCl, HSiCl3, SiCl4 and H2SiCl2; the novel process comprises the following steps of after cooling tail gas with temperature of 500-600 DEG C, which is output by a reducing furnace, for the first time, conveying the cooled tail gas to an HCl converter; completely reacting the tail gas with the HSiCl3 and the H2SiCl2 in the HCl converter so as to generate corresponding chlorosilane; after cooling the tail gas from the HCl converter for a second time, reducing the temperature of the tail gas to normal temperature; spraying SiCl4 refrigerating fluid to the tail gas; carrying out gas and liquid separation on the H2 and the chlorosilane; after adsorbing the H2 by an adsorbing column to remove impurities, recycling the H2; and after rectifying the chlorosilane liquid, recycling the separated HSiCl3. According to the invention, after the HCl is converted into the chlorosilane, the absorbing and desorbing process of the HCl is avoided, the separating process is simplified, raw materials are sufficiently recycled, consumption of steam and power is reduced, and the production cost of the polycrystalline silicon is reduced.

Owner:天威四川硅业有限责任公司

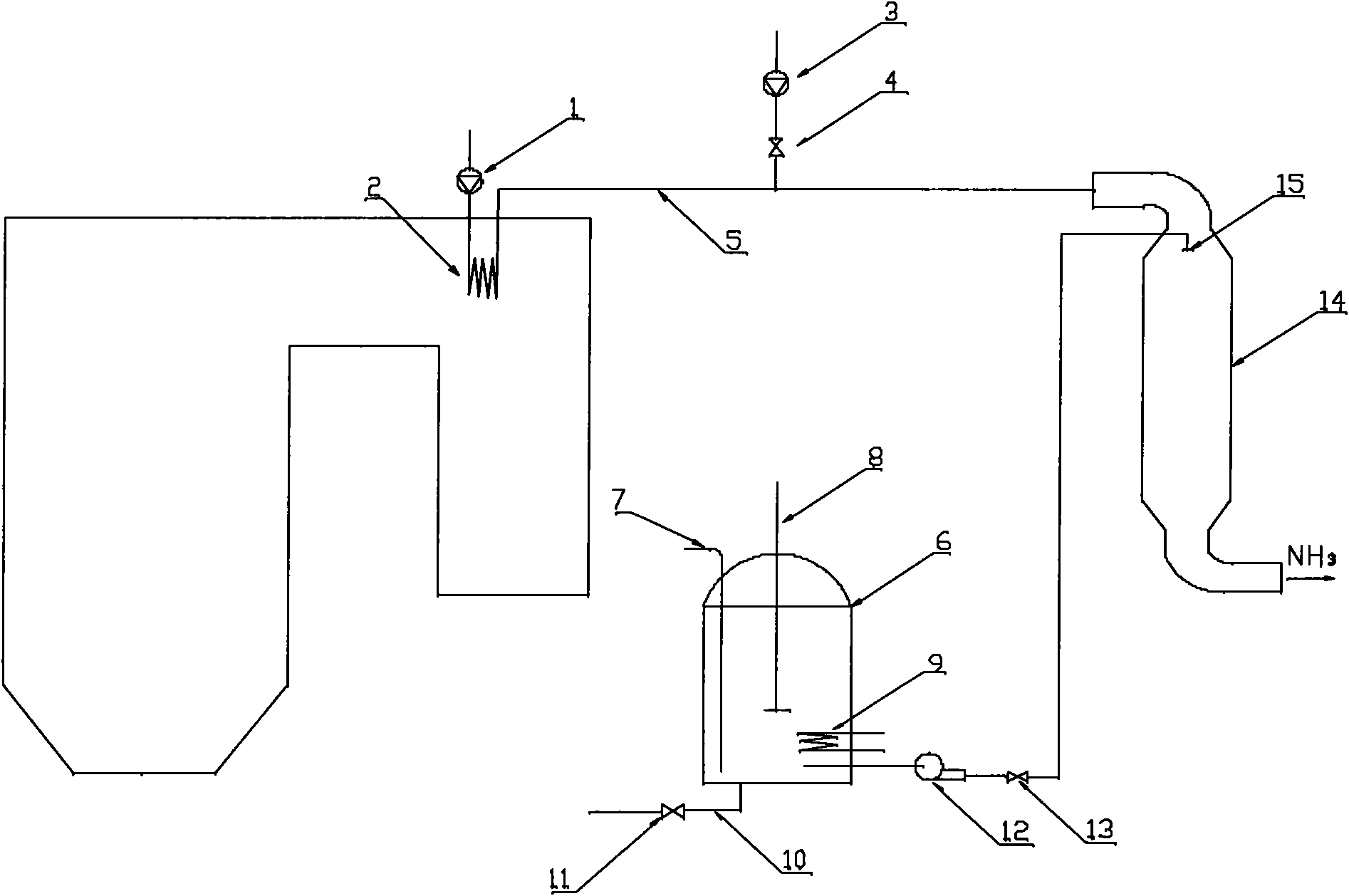

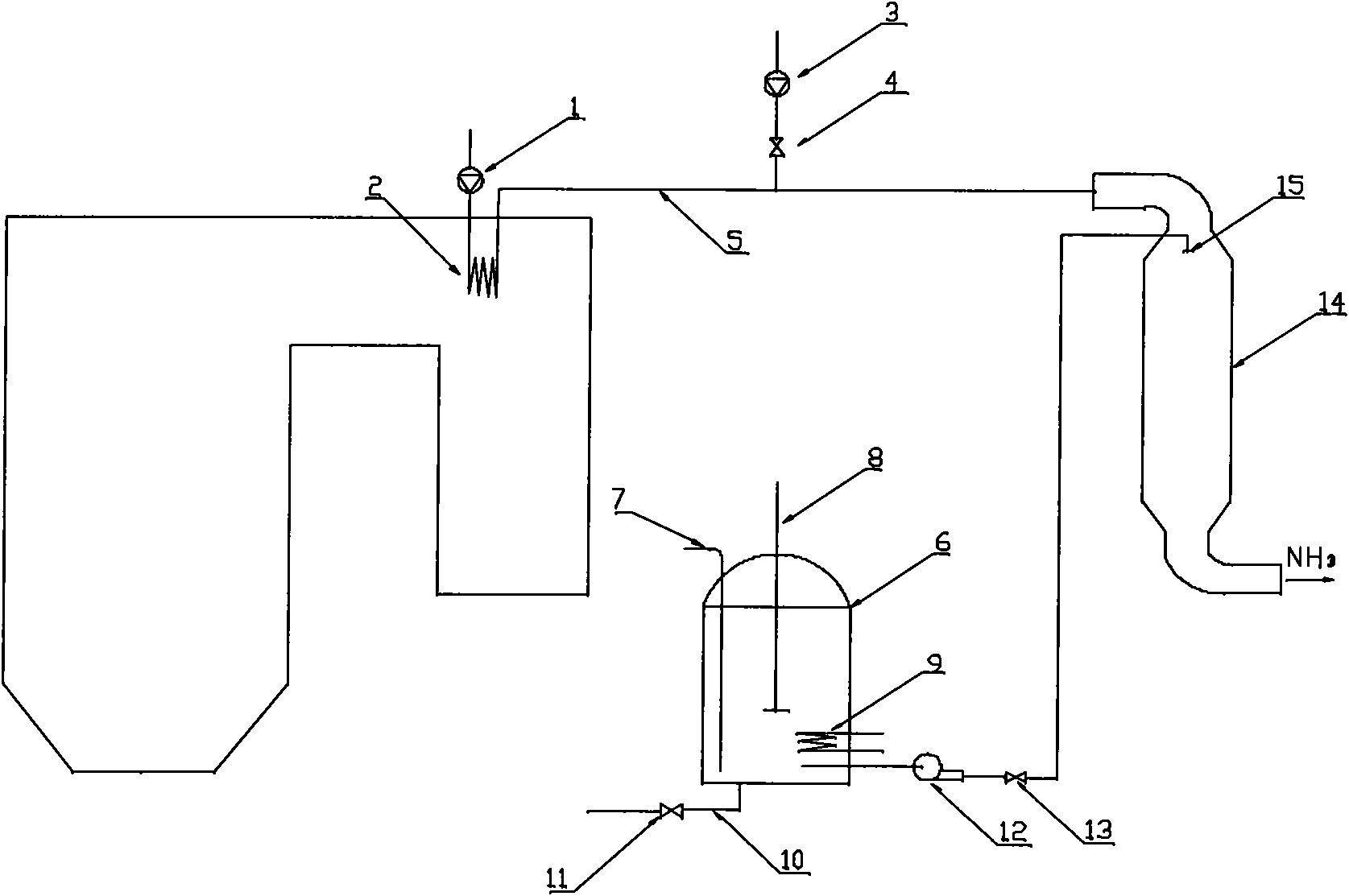

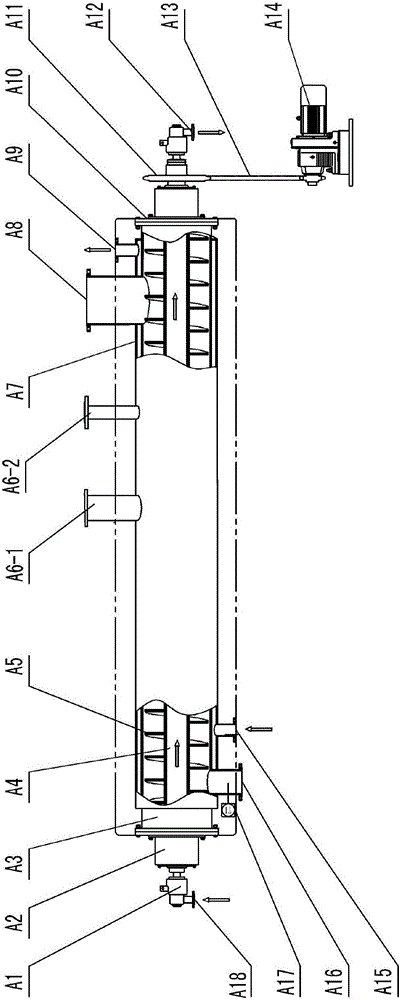

Process for producing ammonia from urea used for denitration of boiler smoke and system thereof

ActiveCN101928014AStable temperature conditionsSave energyChemical industryDispersed particle separationBoiler furnaceDecomposition

The invention discloses a process for producing ammonia from urea used for denitration of boiler smoke and a system thereof. The process has the following flow: feeding a urea solution into a decomposition chamber by a urea solution feeding system; and heating and decomposing the urea solution into ammonia in the decomposition chamber, wherein a heat source for heating the urea solution in the decomposition chamber is air heated by heat in a boiler. The invention adopts the heat in the boiler as the heat source instead of traditional diesel and gas fuel, thus saving the energy resources, greatly lowering the operation cost and improving the system economy, and the process in the invention has safer and more reliable operation compared with the process utilizing fuels such as diesel, gas and the like as the heat source.

Owner:北京洛卡环保技术有限公司

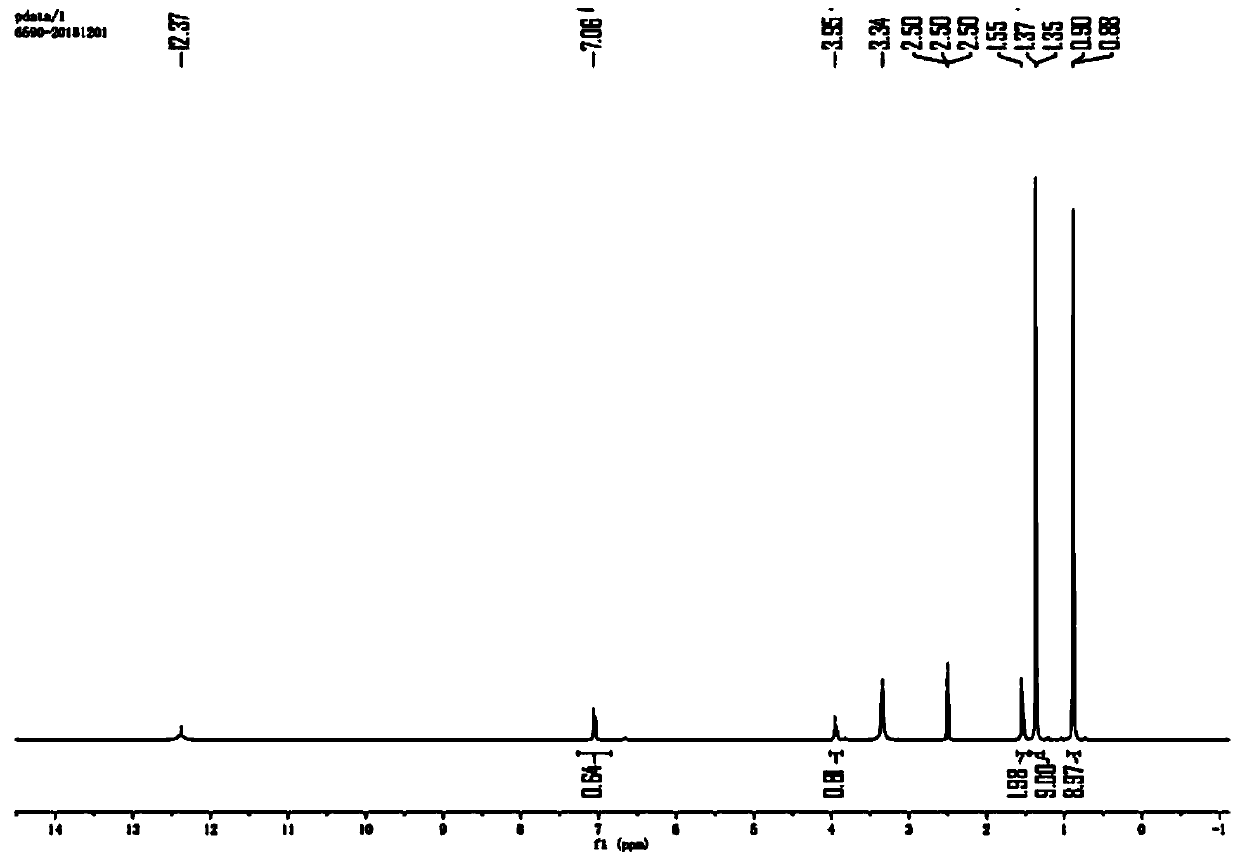

Preparation method of 3-guanidino propanoic acid

InactiveCN103288685AReduce use costReduce recycling costsOrganic chemistryOrganic compound preparationPropanoic acidIon exchange

The invention relates to a preparation method of 3-guanidino propanoic acid. The preparation method comprises the following steps of: adding 3-aminopropionic acid to methanol, thereby obtaining a solution a at 15 DEG C; putting monocyanamide into methanol, thereby obtaining a solution b; feeding the solution b to the solution a, thereby obtaining a solution c at a temperature within 15 DEG C and PH in the range from 7.5 to 8.0; performing vacuum concentration on the solution c and filtering at -5 DEG C, thereby obtaining a crude product of sodium 3-guanidine propionate; preparing the crude product into an aqueous solution of sodium 3-guanidine propionate, thereby obtaining a solution d2; filling H type weakly acidic cation exchange resin into an ion exchange column, and feeding the solution d2 into the ion exchange column and detecting no 3-guanidino propanoic acid; blending the exchange solution collected by the step e and performing decompression concentration on the exchange solution, feeding methanol, reducing the temperature to -10 DEG C for crystallization, thereby obtaining a crystalline mixed liquid f; and then filtering and drying the crystalline mixed liquid f to obtain 3-guanidino propanoic acid. The problem of removing sodium ions during the production of 3-guanidino propanoic acid is solved through exchange treatment of the weakly acidic cation exchange resin; as methanol is taken as a solvent, the utilization and recovery cost of the solvent is lower and the preparation method is safer to operate; side-reactions are few; the 3-guanidino propanoic acid is extracted by ion resin exchange; and the yield of the 3-guanidino propanoic acid is 76.0% and the purity of the 3-guanidino propanoic acid is 99.0%.

Owner:郭礼强

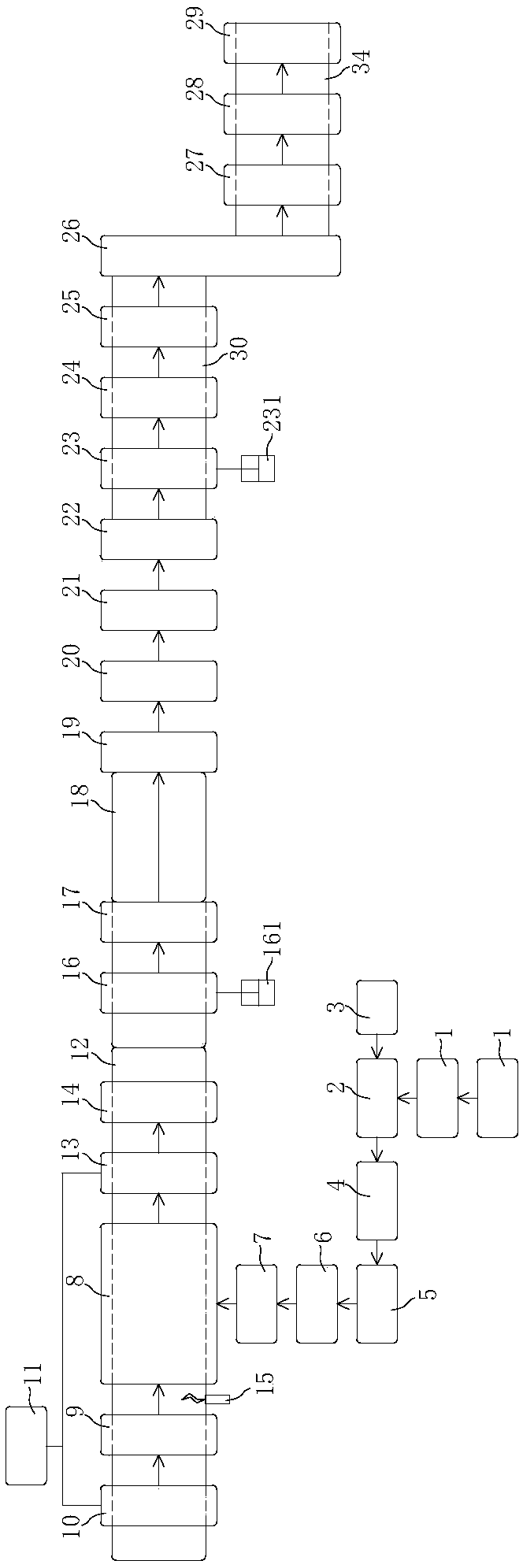

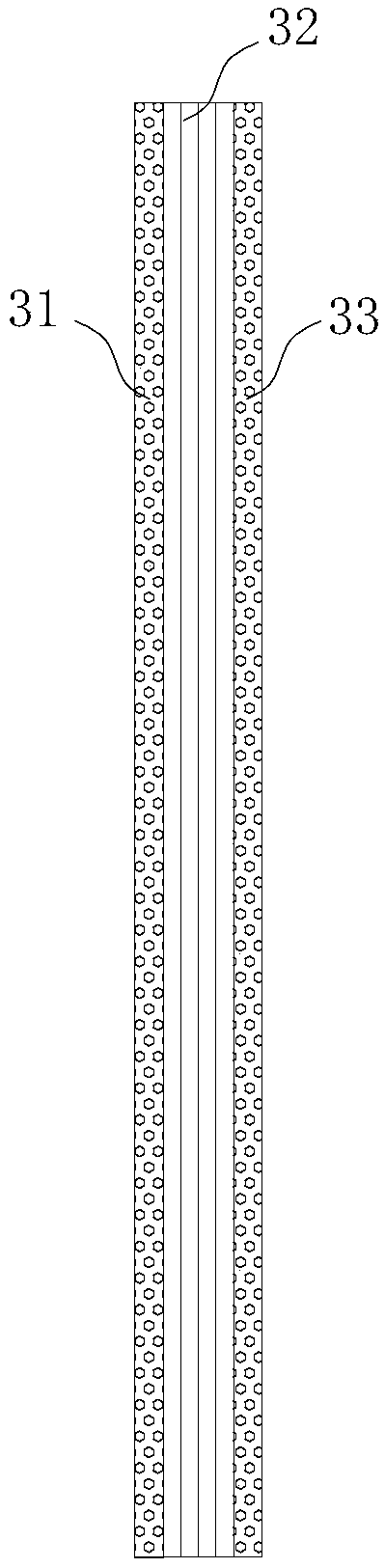

Manufacturing method and production line of composite panels

PendingCN108943210AFlat surfaceConducive to the subsequent veneer processOther plywood/veneer working apparatusProduction lineSurface layer

The invention belongs to the technical field of wood panel production and discloses a production line of composite panels. The production line comprises a lower surface layer paving working position,a first prepressing working position, a bonding working position, an upper surface layer paving working position, a second prepressing working position and a hot pressing working position, and furthercomprises a conveying device. The lower surface layer paving working position, the first prepressing working position, the bonding working position, the upper surface layer paving working position, the second prepressing working position and the hot pressing working position are sequentially arranged. The conveying device is used for conveying materials to each working position. The bonding working position is provided with two material inlets, wherein one material inlet of the bonding working position is connected with a material outlet of the first prepressing working position, and the other material inlet is provided with a glue applying working position. A manufacturing method comprises the following steps of: manufacturing raw materials for surface layers, gluing plywood, manufacturing the lower surface layer, bonding the lower surface layer, manufacturing the upper surface layer, hot pressing and stacking. The manufacturing method enables the production efficiency to be high through a specially designed one-time hot pressing molding, reciprocating plate feeding and paving process, and enables a plywood layer and the surface layers to be more tightly combined and protected against easy degumming and cracking.

Owner:成都市荣胜木业有限公司

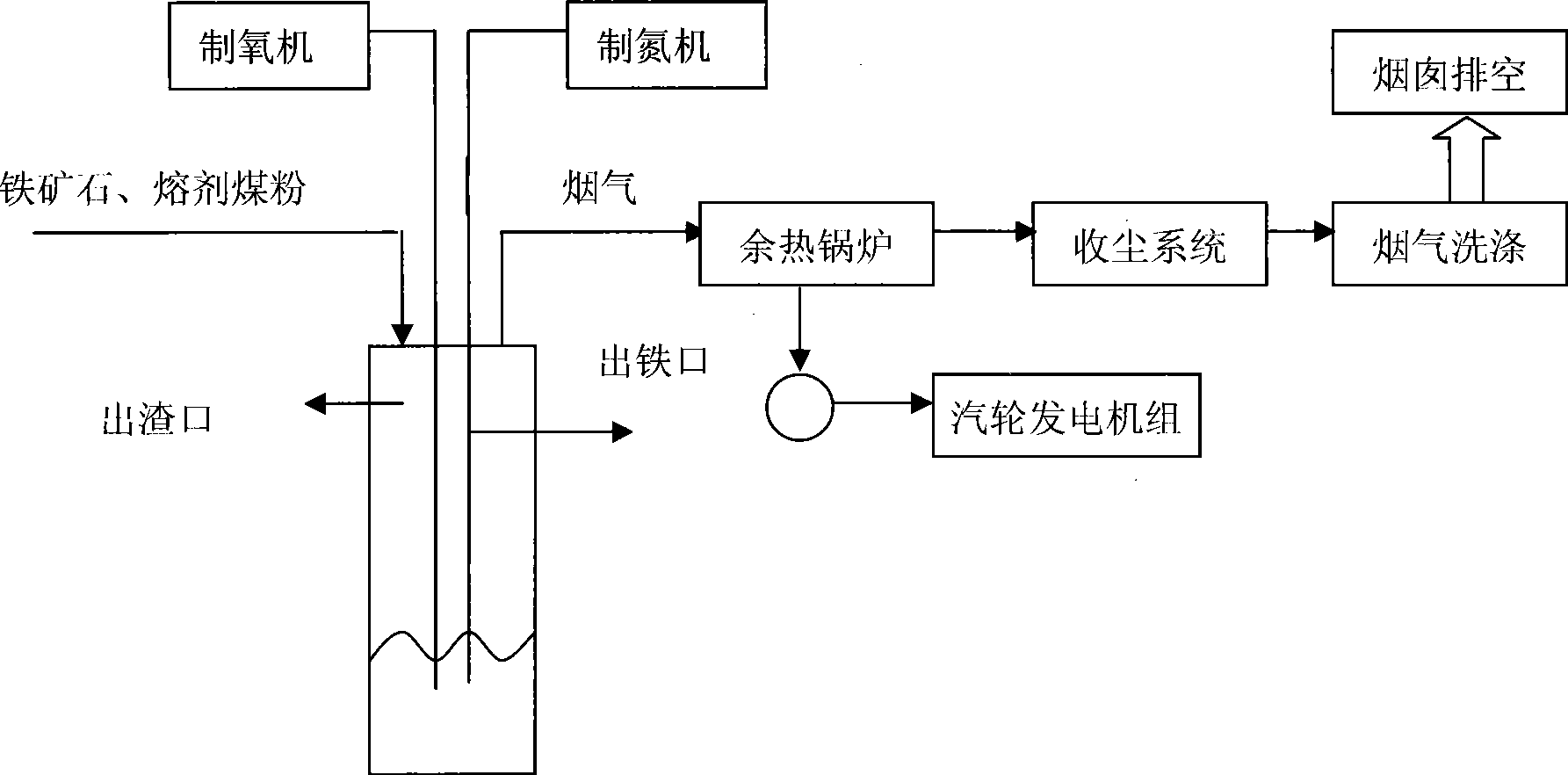

Method for preparing molten iron by utilizing oxygen top blown smelting reduction ironmaking

The invention relates to a method for producing molten iron by directly utilizing coal to deoxidize iron ore under smelting state, belonging to the technical field of energy source and metallurgy. The method comprises the following steps: charging iron ore, dolomite, lime and deoxidized coal are crushed, the crushed for materials are evenly mixed according to a certain proportion and added to a smelting reducing furnace from a material inlet at the top of the smelting reducing furnace; a central nitrogen pipe of a spray gun is inserted into a slag layer of a smelting pool to spray nitrogen to stir the slag layer, and one period of reaction, smelted high-temperature molten iron and slag are respectively discharged from an iron outlet and a slag outlet, wherein the oxygen jacket of the spray gun is higher than the smelting slag. In the method, raw materials do not need to be treated in advance so that a coking procedure is omitted and the environment pollution is reduced; coal of various levels can be used as fuel; the oxidizing atmosphere in the furnace is very strong so as to be very beneficial to dephophorization; and investment for the construction is low and can be recovered in a short time.

Owner:KUNMING UNIV OF SCI & TECH

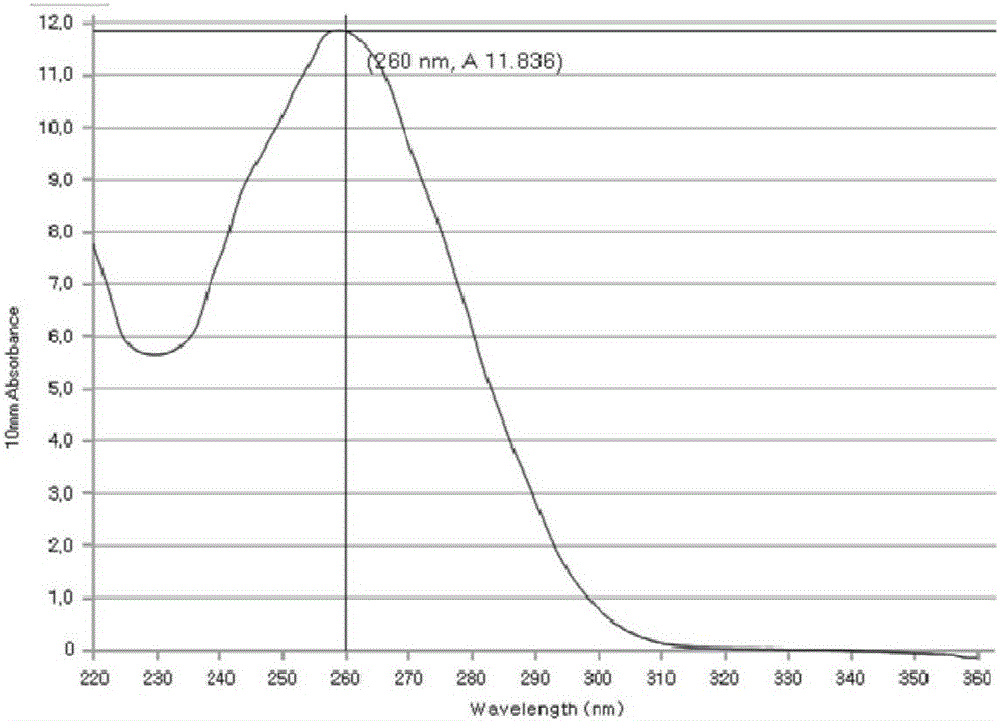

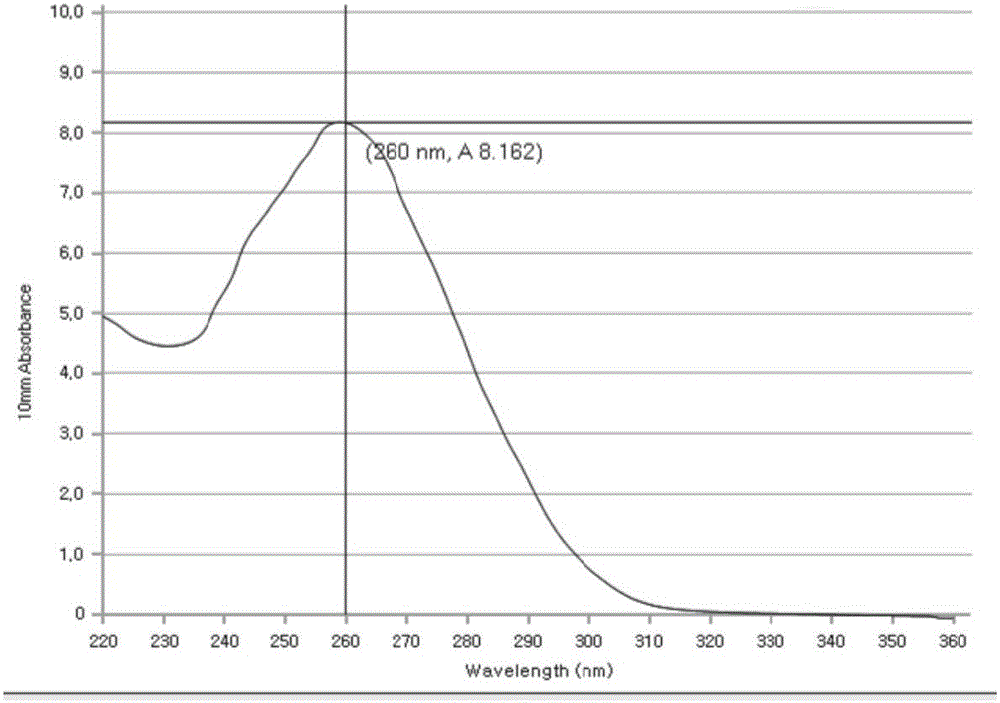

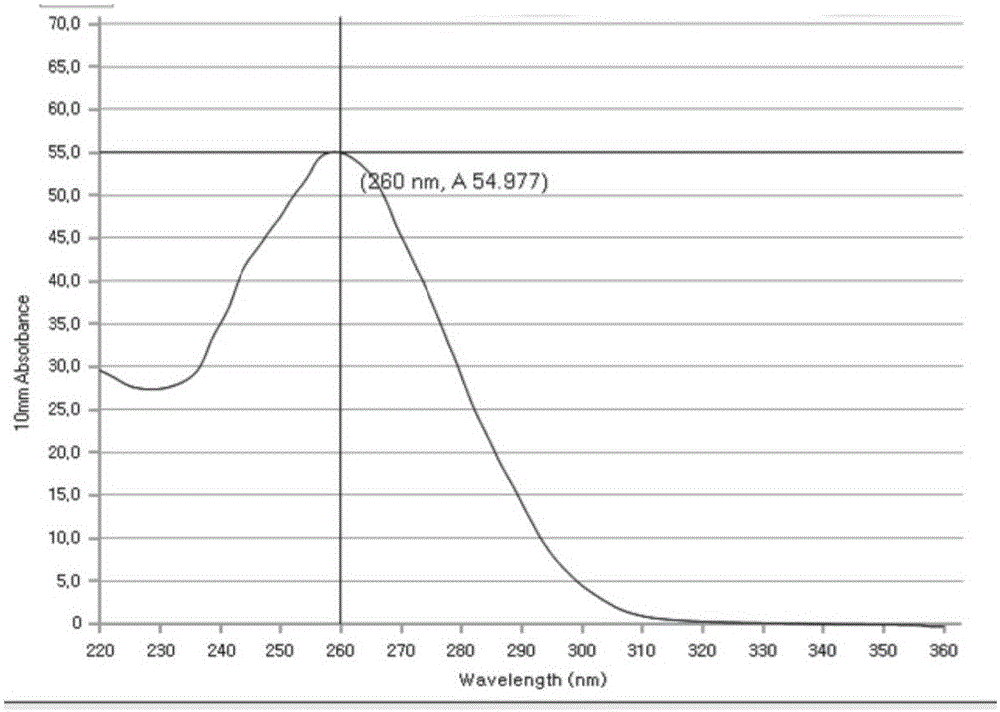

Method for extracting black chokeberry anthocyanin

The invention relates to a method for extracting black chokeberry anthocyanin. By using black chokeberries as raw materials, the method comprises the following steps: firstly, pulping and homogenating the black chokeberries and then carrying out ultrasonic-assisted extraction on anthocyanin by using an ethanol-acetic acid-aqueous solvent; after extraction, carrying out suction filtration in vacuum to remove filter residues; performing rotary evaporation on a crude extract for removing ethanol to obtain an anthocyanin concentrated liquid; removing impurities by using distilled water; then, eluting anthocyanin by using an ethanol solution; after ultrahigh pressure treatment on the eluant, extracting the impurities by using ethyl acetate; after performing standing and layering, collecting an aqueous phase; freezing and drying a black chokeberry anthocyanin water phase solution in vacuum to obtain anthocyanin powder. The method provided by the invention is simple in process operation, pollution-free and high in extraction amount, the purity of anthocyanin obtained is high, and the nutritional value of black chokeberries is given full play to, and moreover, macroporous resin is convenient and quick to activate and can be repeatedly used, so that the cost is lowered.

Owner:SHENYANG AGRI UNIV

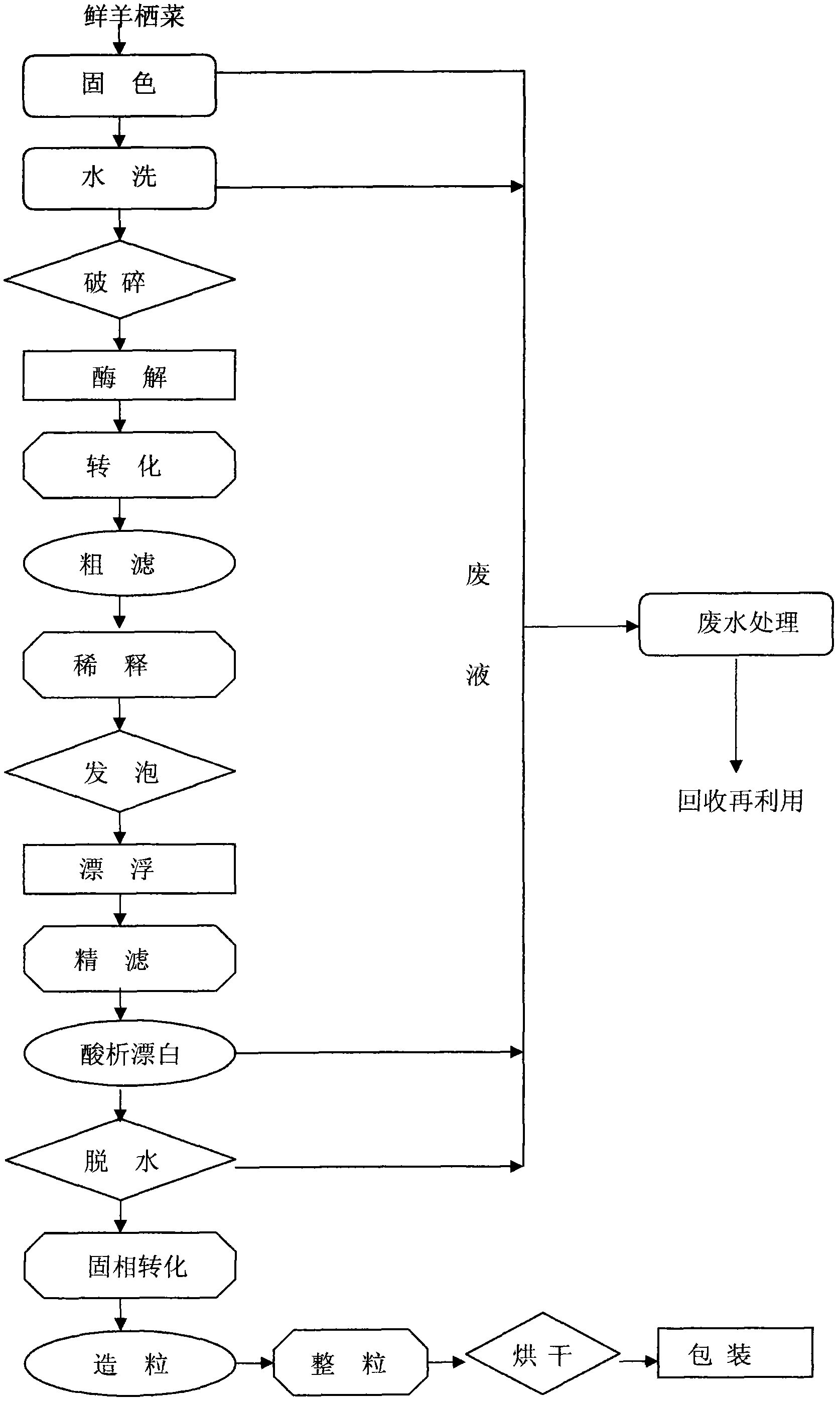

Method for extracting algin from fresh Sargassum fusiforme

ActiveCN102718884AExpand the range of raw materialsImprove high calcium contentSolid phasesSARGASSUM FUSIFORME

The invention relates to a method for extracting algin from fresh Sargassum fusiforme. The method comprises the following steps of dye fixation, water washing, fragmentation, enzymatic hydrolysis, transformation, coarse filtration, dilution, foaming and floating, fine filtration, acidification bleaching, dehydration, solid phase transformation, granulation, finishing and drying. The method provided by the invention has the advantages that 1, an enzymatic hydrolysis technology is adopted and thus the problem that algin is difficultly extracted from Sargassum fusiforme is solved; and fresh Sargassum fusiforme is used as a raw material for production of low-viscosity and ultralow-viscosity algin and thus a raw material source range of algin processing is widened; 2, an acidification technology replaces the traditional calcification technology and thus the problems of high calcium content, poor water-solubility and high insoluble substance content of the traditional algin are improved; and 3, a NaClO solution is dropwisely added into an extraction system during acidification to realize bleaching and thus the traditional bleaching technology characterized in that chlorine is fed into an algin solution subjected to fine filtration to realize bleaching is modified so that bleaching effects are better and technical processes are safer.

Owner:青岛聚大洋藻业集团有限公司

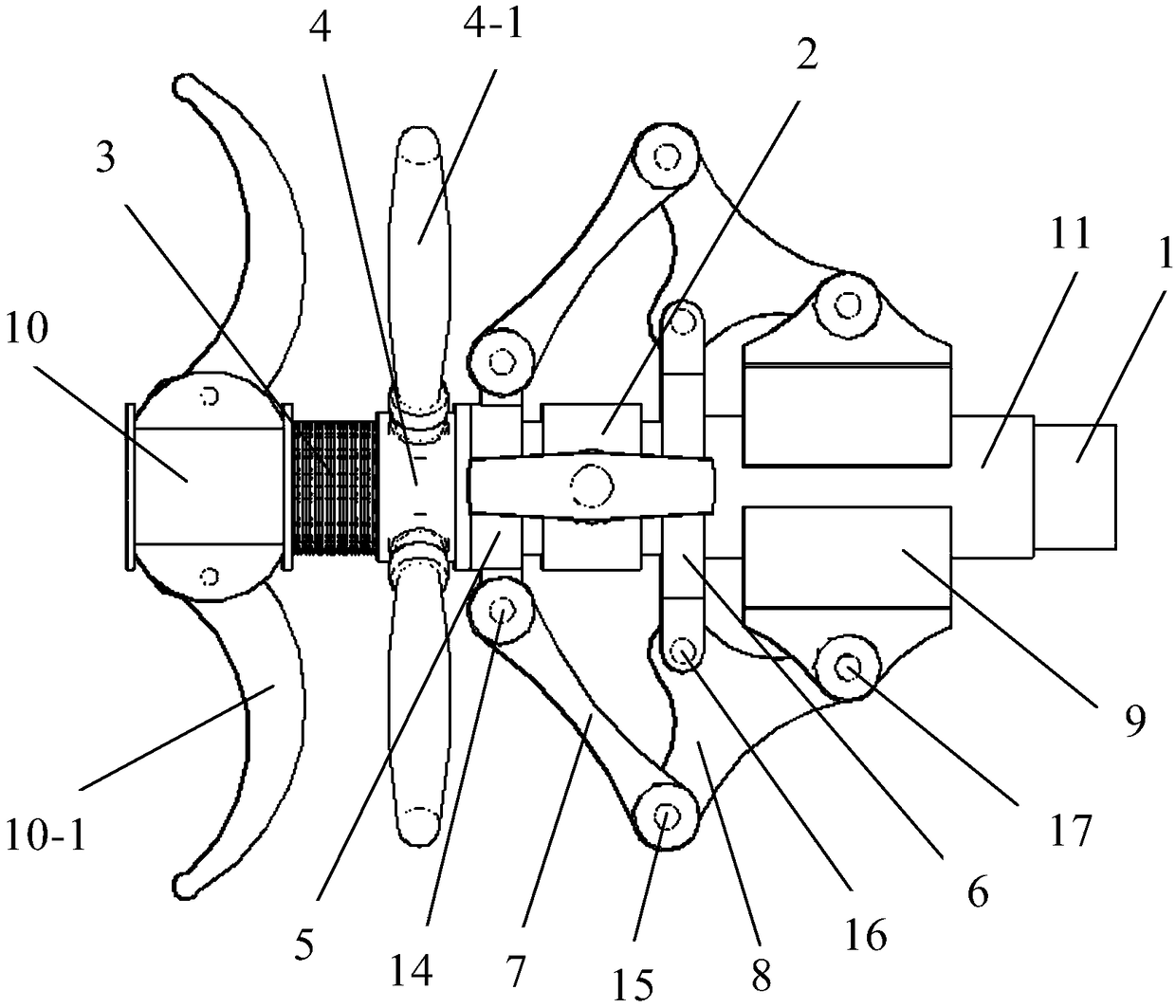

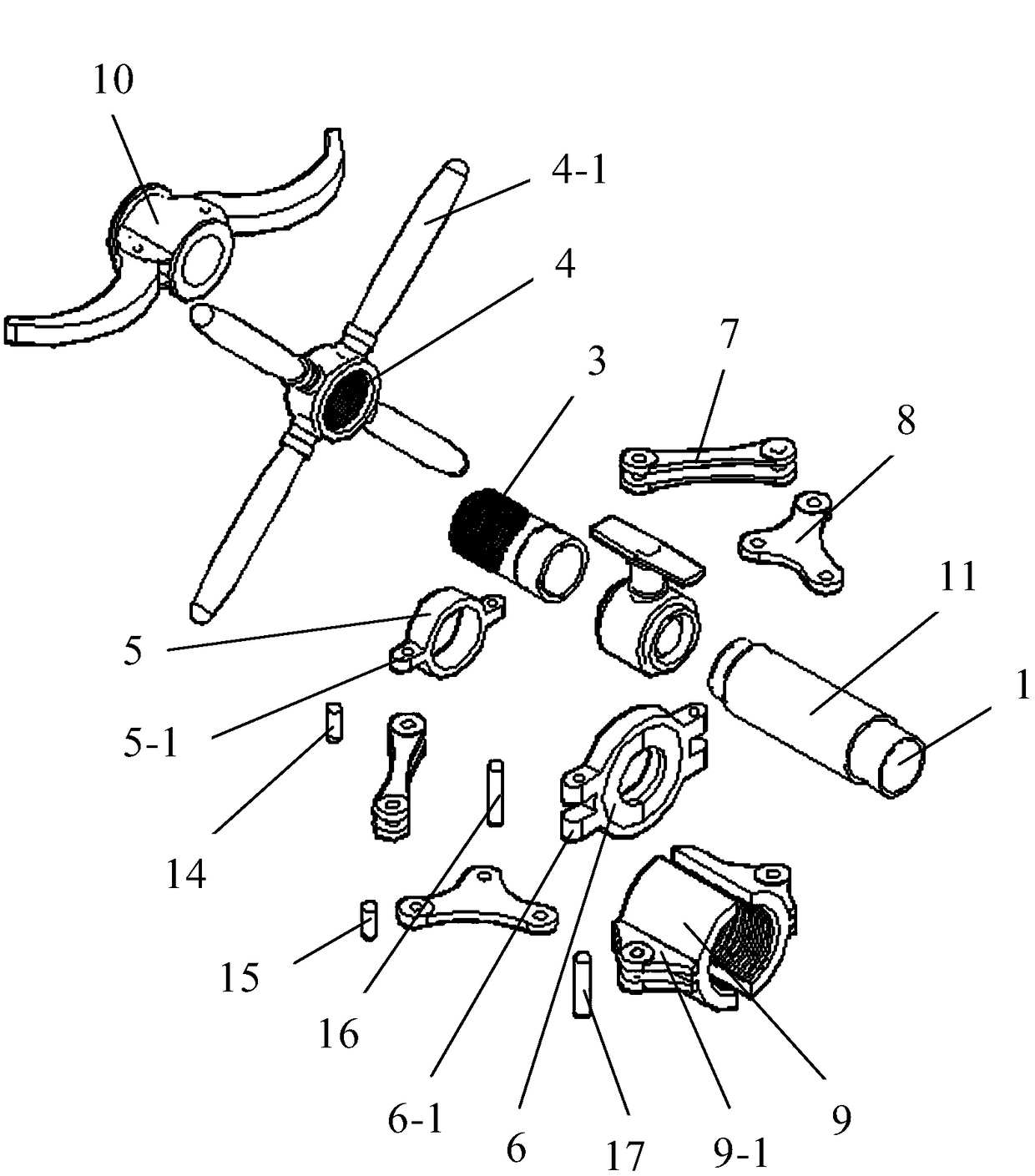

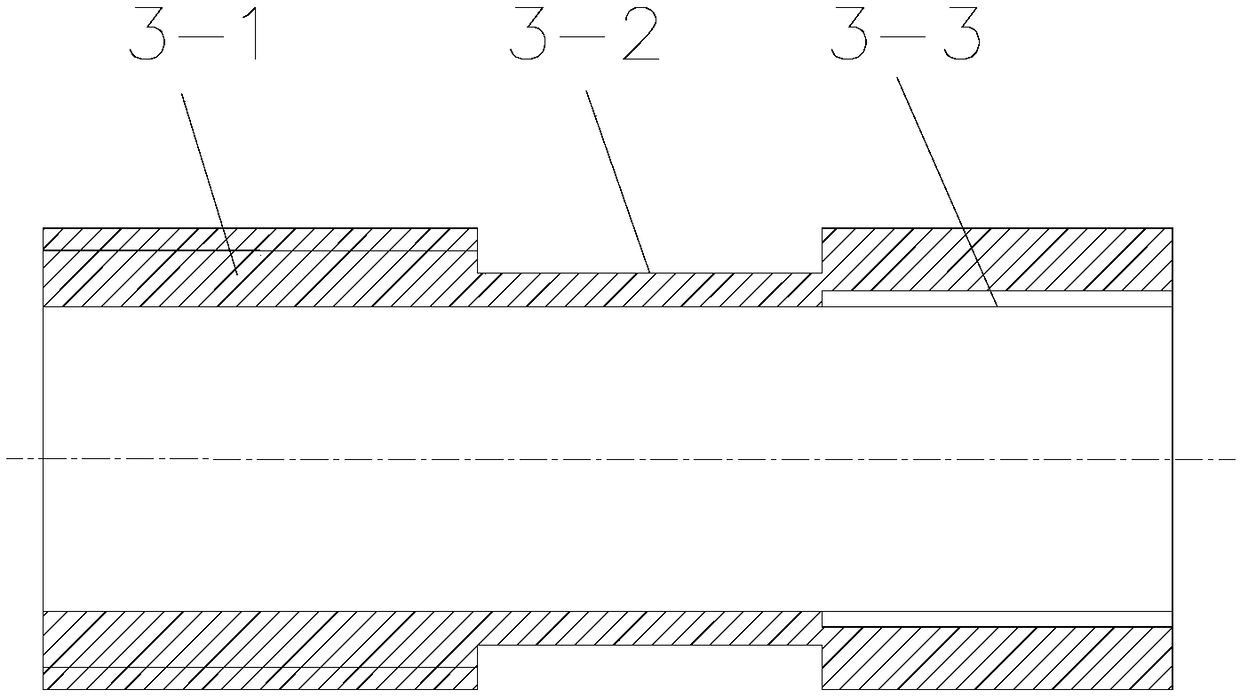

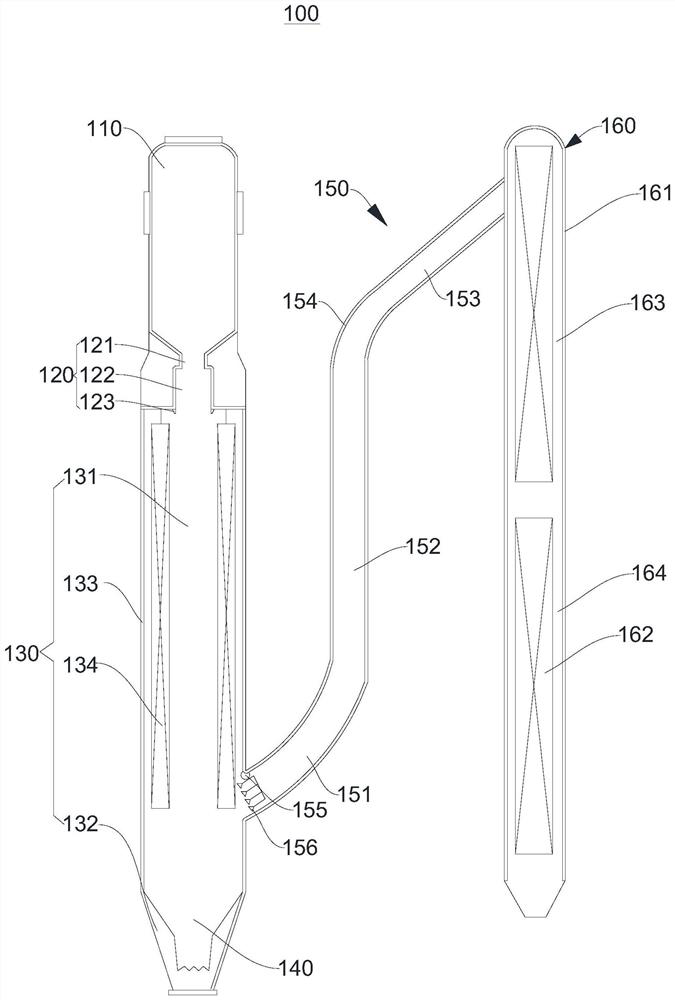

Rapid pipe joint mounting device and advanced small pipe construction method

ActiveCN109253337ALow input costOperation process securityUnderground chambersCouplingsArchitectural engineeringUltimate tensile strength

The invention discloses a rapid pipe joint mounting device and an advanced small pipe construction method. The rapid pipe joint mounting device comprises a pipe joint body, a clamping mechanism and arapid joint, and a front end pipe, a grout stop valve and a rear end pipe are sequentially connected to form the pipe joint body. The construction method includes the steps: first, mounting a plurality of advanced small pipes; second, mounting the rapid pipe joint mounting device at the end of one advanced small pipe; third, connecting a grouting pipe onto the rapid joint of the rapid pipe joint mounting device; fourth, starting grouting; fifth, stopping grouting and disconnecting the grouting pipe and the rapid joint; sixth, detaching the rapid pipe joint mounting device; seventh, repeating the second step to the sixth step more than once. The rapid pipe joint mounting device and the advanced small pipe are firmly and reliably connected, the rapid pipe joint mounting device and the grouting pipe are firmly and reliably connected, the rapid pipe joint mounting device is convenient to detach and simple to operate and can be recycled, the labor intensity of operators is reduced, construction progress is accelerated, and construction cost is reduced.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

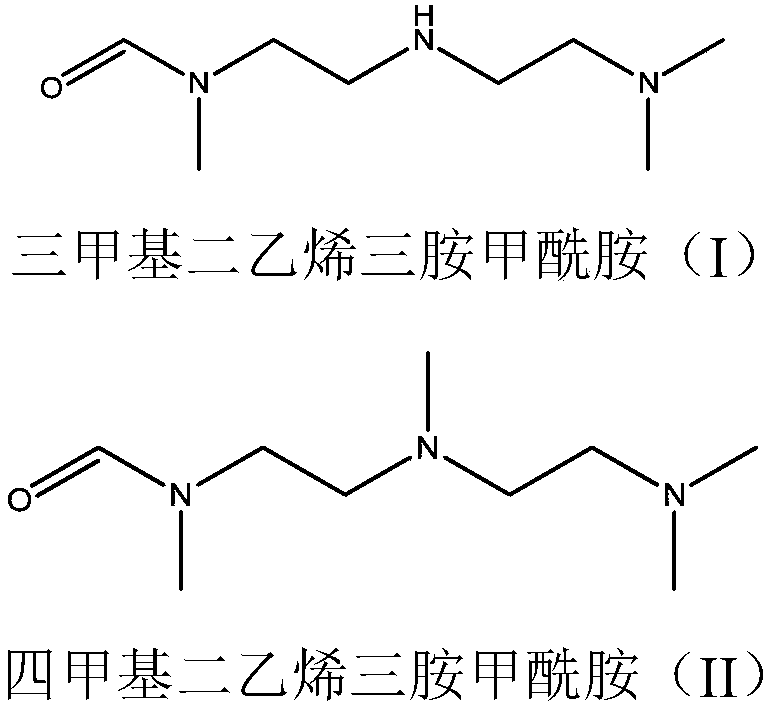

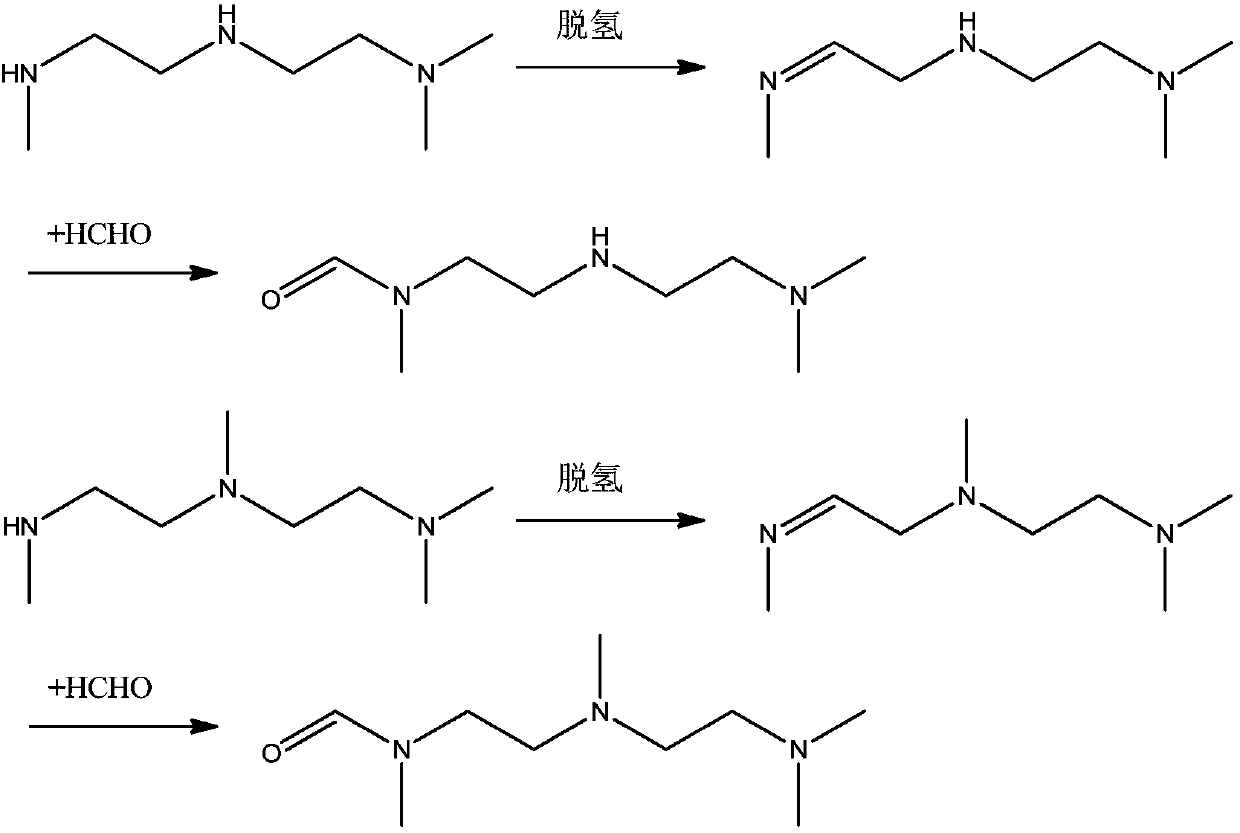

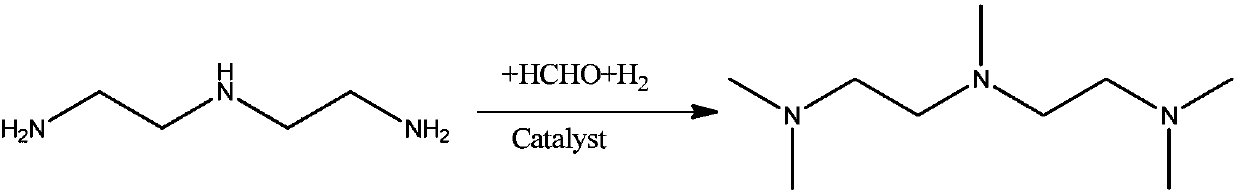

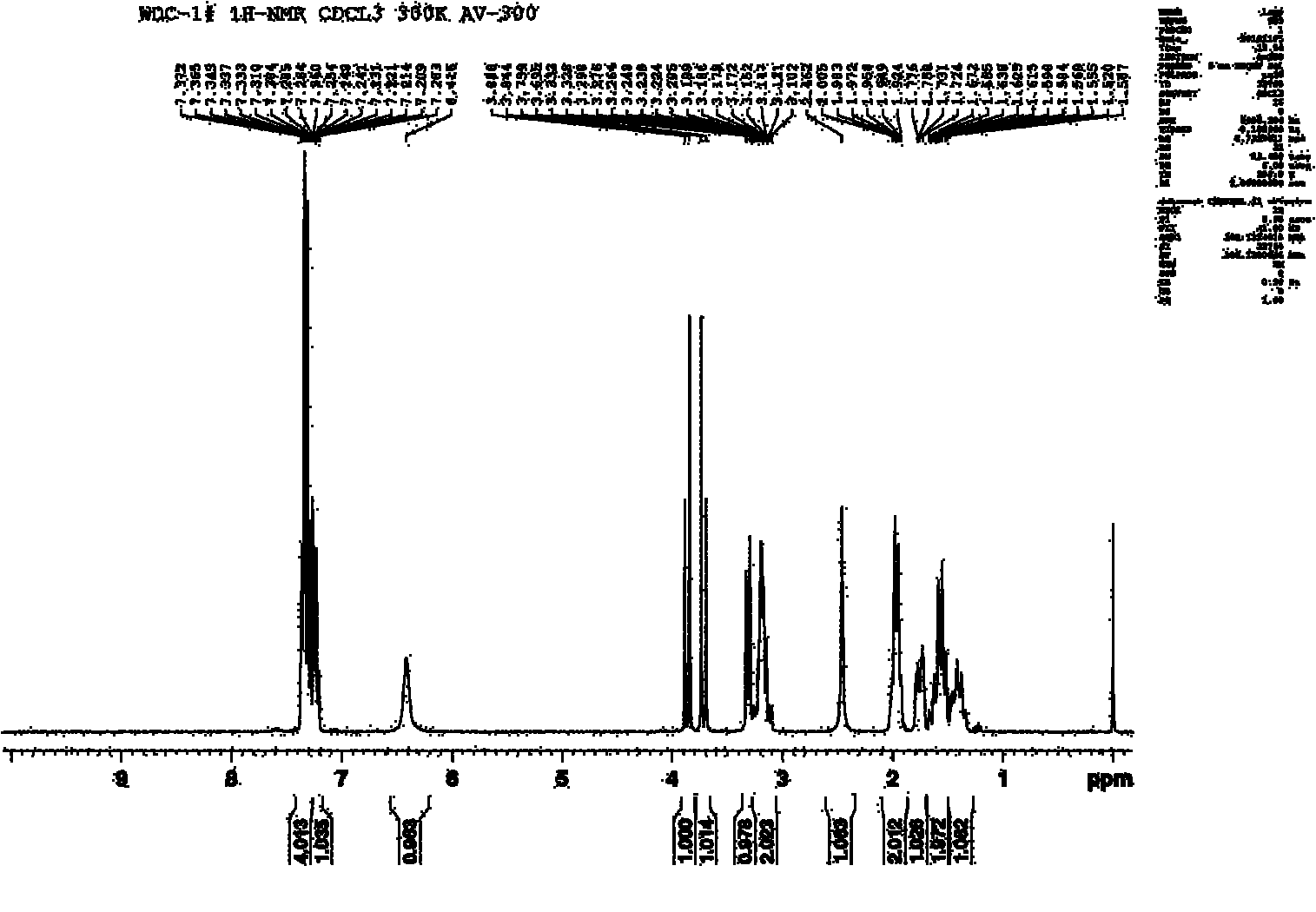

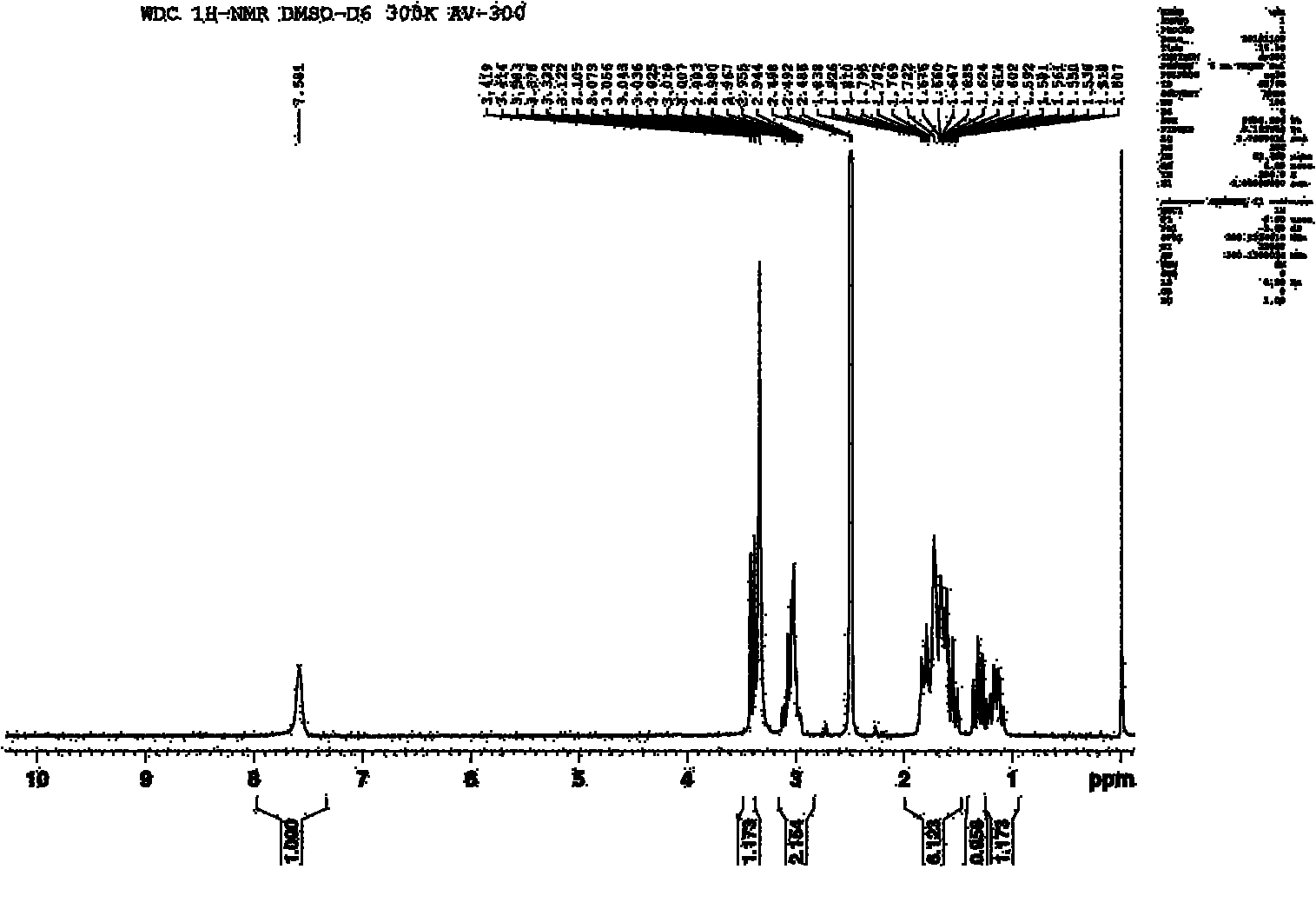

Method of continuously preparing pentamethyldiethylenetriamine and catalyst system for method

ActiveCN109574855AReduce generationHigh yieldAmino preparation from aminesOrganic compound preparationReaction temperatureDiethylenetriamine

The invention discloses a method of continuously preparing pentamethyldiethylenetriamine and a catalyst system for the method. The method includes: subjecting diethylenetriamine, a solvent, hydrogen and formaldehyde to reaction in a two-stage fixed-bed reactor under certain reaction temperature, pressure and space velocity to obtain pentamethyldiethylenetriamine reacted liquid; the first stage ofreactor is filled with a supported copper-based catalyst, with reaction temperature controlled to 60-100 DEG C; the second stage of reactor is filled with a supported palladium-based catalyst, with reaction temperature controlled to 100-130 DEG C. The different catalysts and different reaction conditions are employed to carry out two-stage reaction; amide byproducts can be effectively decreased; the yield of pentamethyldiethylenetriamine is increased accordingly. The fixed-bed continuous process is employed herein; serial problems due to the catalysts crushed and entering a reacted liquid post-treatment system can be avoided; the method herein has the advantages of high automation level, low labor intensity, good process operational safety, low production cost and the like, and is suitablefor industrial large-scale production.

Owner:WANHUA CHEM GRP CO LTD

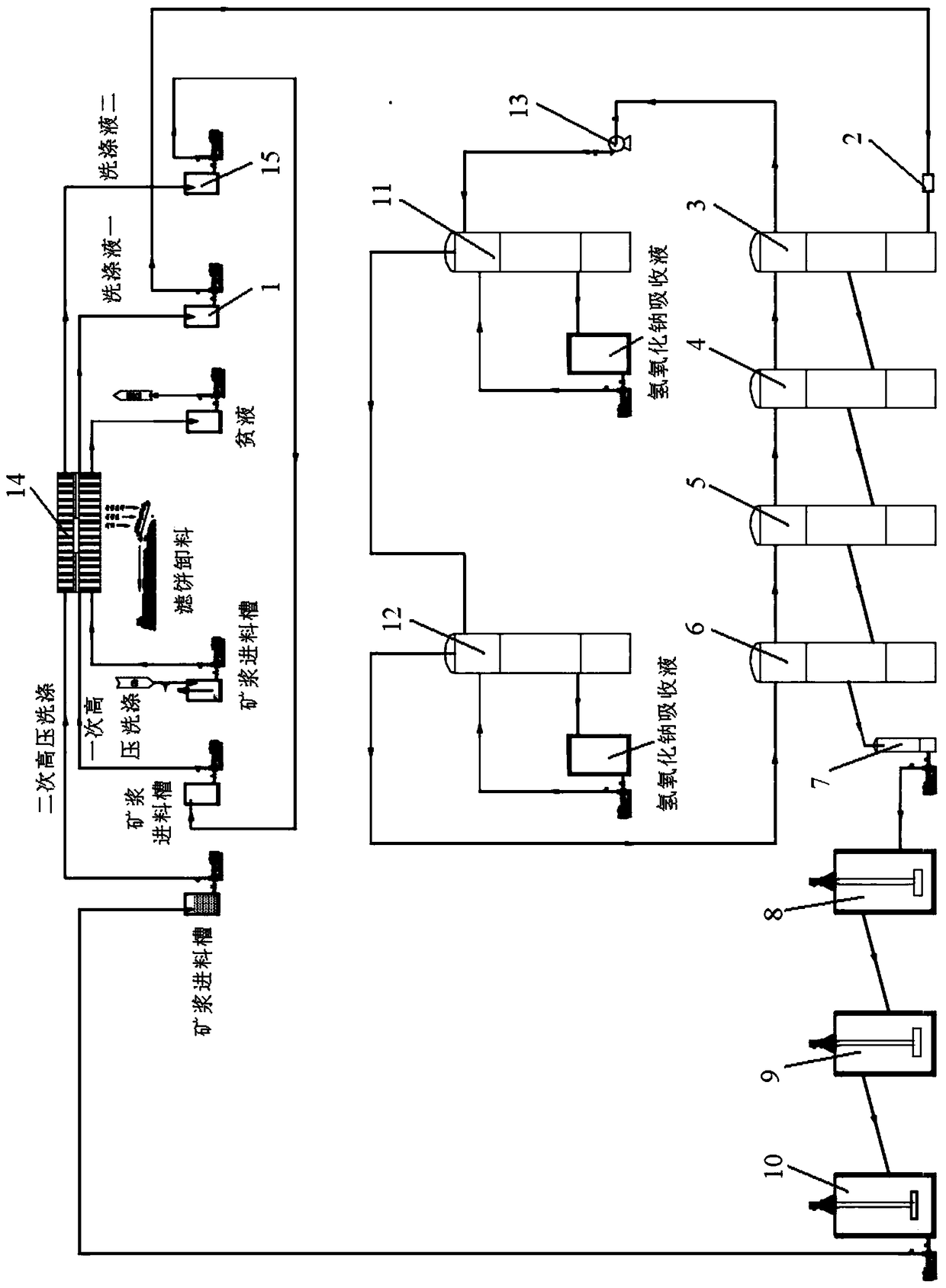

Method for recycling cyanide through high-pressure circulating countercurrent washing of cyanidation tailings

InactiveCN108793509ASimple processProcess operation safetyAlkali metal cyanidesDispersed particle separationEnvironmental resistanceHigh concentration

The invention relates to a method for recycling cyanide through high-pressure circulating countercurrent washing of cyanidation tailings and belongs to the field of environment protection. The methodcomprises the following steps: introducing high-concentration cyanogen-containing ore slurry into a compacted filter press and carrying out press filtering to form a filter cake; washing the filter cake under high pressure and conveying the filter cake into a buffering groove and a reactor; adding a proper amount of concentrated sulfuric acid into the reactor; introducing air with a certain flow into an absorption tower and the reactor by adopting a draught fan; taking a sodium hydroxide solution as an absorption solution and absorbing generated hydrogen cyanide gas to finally produce sodium cyanide; collecting at fixed period and recycling in a cyanidation technology. Aiming at the properties of the cyanidation tailings of gold concentrate smelting industries, an efficient, safe, green and environment-friendly, and economical and practical cyanidation tailing purification and cyanide recycling method is provided; significant environment protection problems of a gold industry are solved, and useful substances are recycled from being wasted; the wastes are changed into valuable things, and the environment, economic and social benefits are remarkable.

Owner:CHANGCHUN GOLD RES INST

Method for extracting tea polysaccharides by hydrothermal method

The invention discloses a method for extracting tea polysaccharides by a hydrothermal method. The method comprises the following steps: (1) raw material tea, tea branches, processing residues of tea or processing waste of tea are dried and pulverized to 40-60 mesh sieve; (2) extraction is carried out for pulverized raw materials whose mass unit is kg and water whose volume unit is L by a high-temperature high-pressure reaction vessel with stirring at 120-200 DEG C with a pressure of 0.1-2.5MPa for 0.5-2.0 hours, wherein the mass volume ratio between the raw materials and water is 1:10-1:30; (3) separation, condensation and drying are carried out for extract liquid, in order to obtain tea polysaccharide. Compared with the prior art, the method has the advantages of simple operation flow, safety without usage of organic solvents, and high yield.

Owner:NORTHWEST A & F UNIV

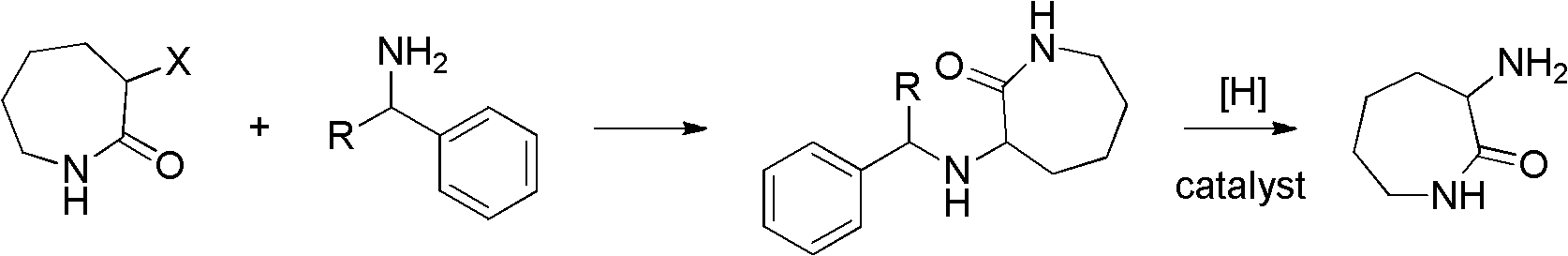

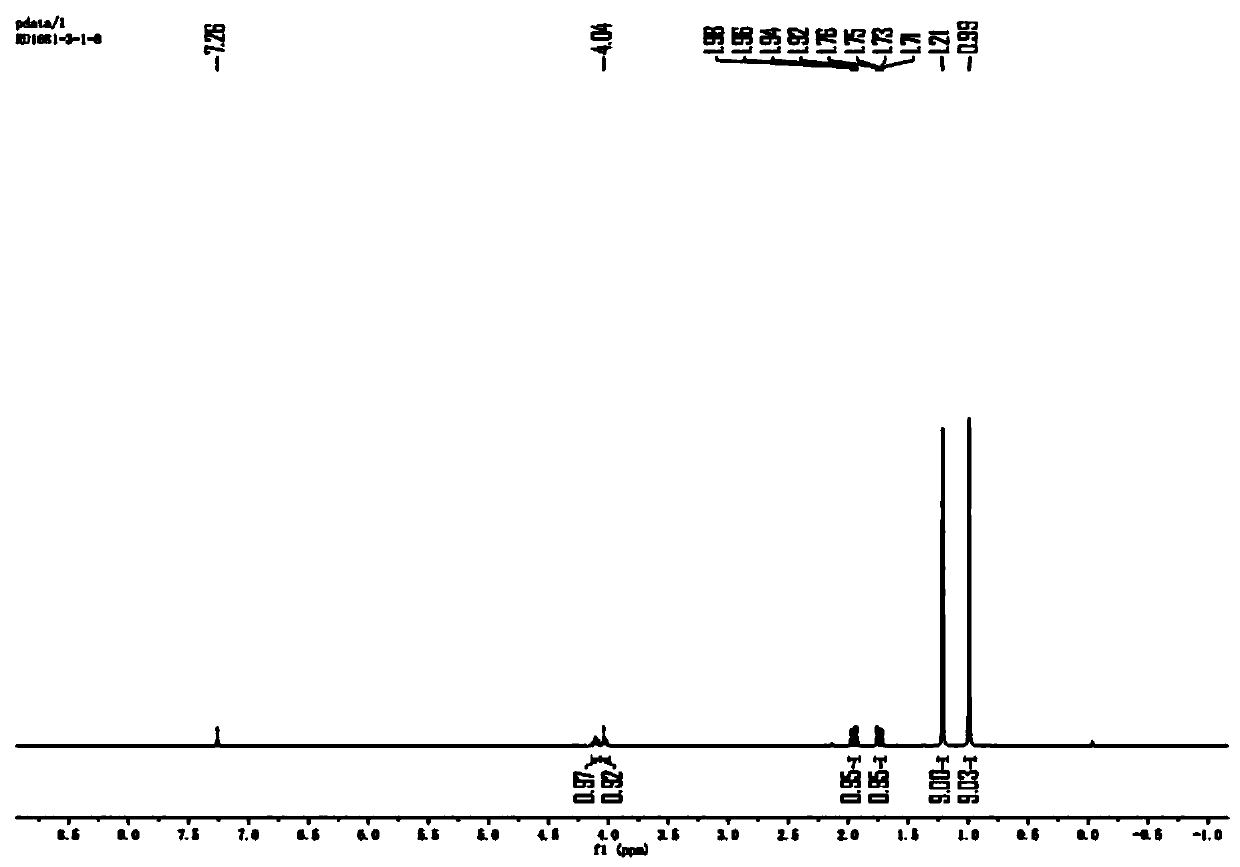

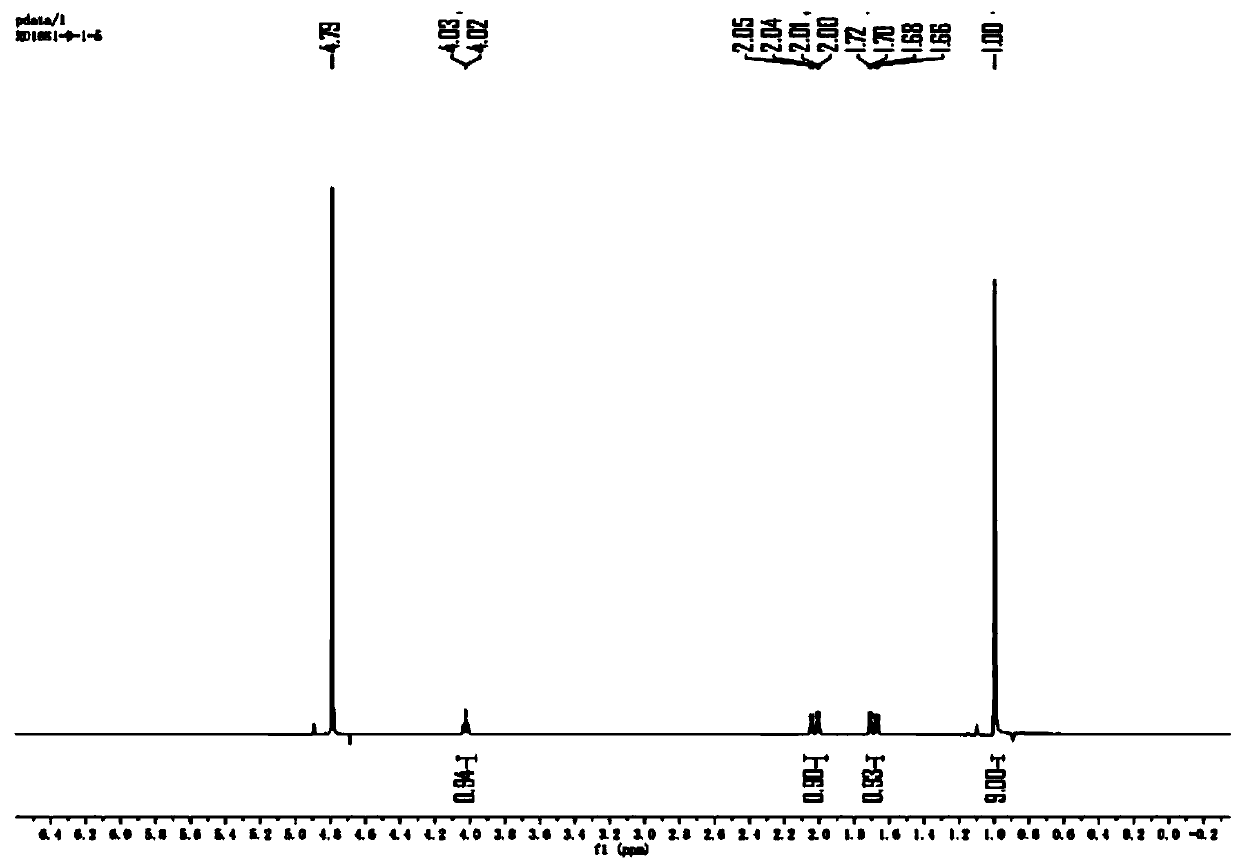

Method for synthesizing DL-alpha-amino caprolactam

ActiveCN102093292AEasy to separateOperation process securityOrganic chemistryTwo stepAlkyl substitution

The invention discloses a method for synthesizing DL-alpha-amino caprolactam. The method for synthesizing the DL-alpha-amino caprolactam comprises the following two steps of: 1, performing nucleophilic substitution reaction on alpha-halogenated caprolactam and benzyl amine under a certain condition; and 2, performing hydrogenolysis to remove benzyl and generate the required DL-alpha-amino caprolactam. In the method for synthesizing the DL-alpha-amino caprolactam, virulent, flammable and combustible NaN3 is avoided; the whole process is safe, simple and convenient in operation; an intermediate and a product are convenient to separate; the yield is high; and the method is suitable for industrialized large-scale production.

Owner:NANJING UNIV OF TECH +1

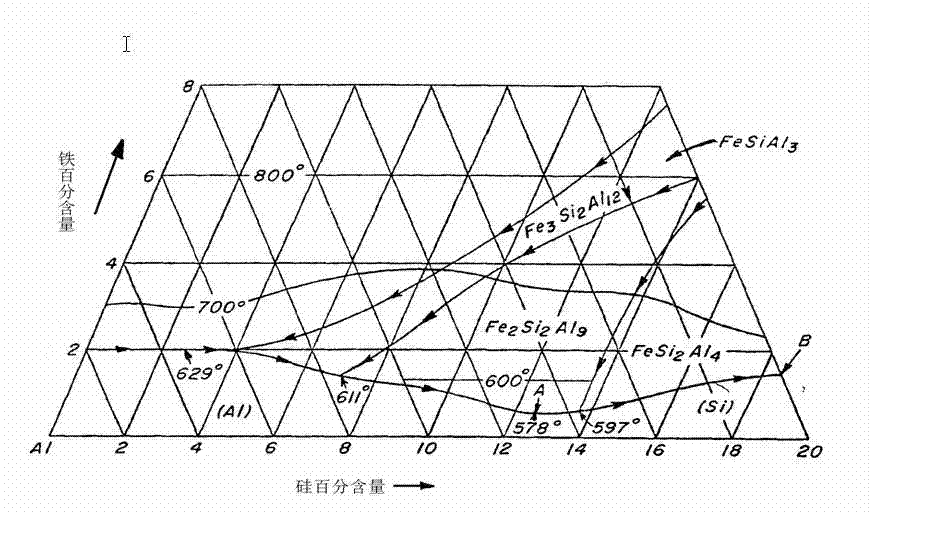

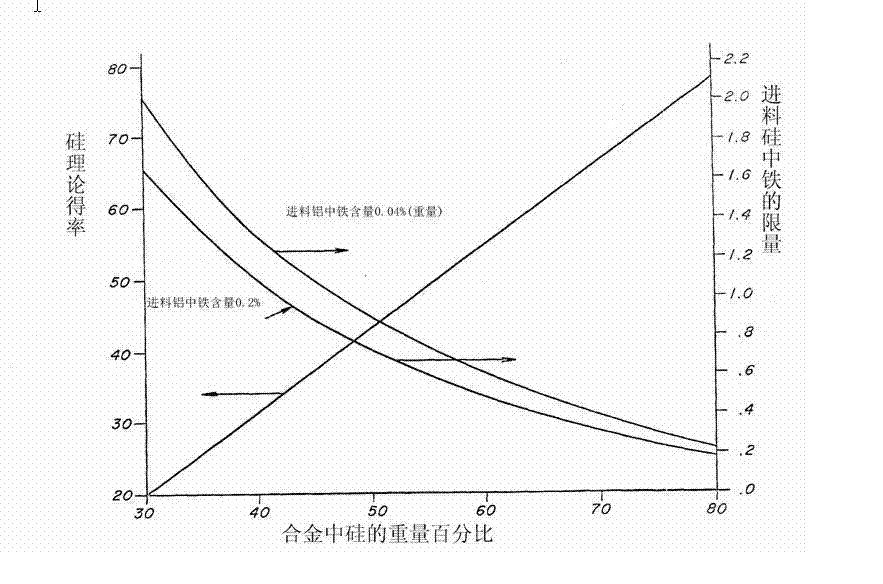

Method for purifying solar grade polysilicon

InactiveCN102815703ALow costLess investment in equipmentSilicon compoundsSolid phasesPolycrystalline silicon

A method for purifying solar grade polysilicon. The method comprises the key points of: using silicon containing 99 wt% of silicon as a raw material; adding at least one flux selected from tin, zinc, aluminum, silver and lead into the silicon, with a weight ratio of silicon raw material to metal flux being 20-30:80-70; meanwhile adding no more than 0.2 wt% of titanium and heating to prepare a melt containing a large amount of silicon and metal; standing for 1-4 h and separating out boron; introducing chlorine gas to the bottom of the melt and blowing upwards for 10-40 min to concentrate phosphorus on the surface of the melt; removing the phosphorus by a traditional method; cooling to a freezing point of an eutectic, and keeping the temperature at the freezing point to form a solid phase containing crystalline; concentrating impurities in the melt phase; separating the melt phase metal flux with the solid phase; reheating part or all the solid phase to a melting state; and repeating the above cooling step to obtain purer crystalline silicon. The invention has advantages of low cost, low equipment investment, and simple and safe operation process.

Owner:叶文胜

Process for refined production of stevioside

InactiveCN105061527AAvoid damageImprove securitySugar derivativesSugar derivatives preparationSolubilityFiltration

A process for refined production of stevioside comprises the following steps: (1) mixing stevioside raw sugar and edible ethanol solution and performing stirring backflow until the stevioside raw sugar is fully dissolved; (2) performing immediate filtration of the obtained solution and crystallizing filtrate obtained after the filtration; performing refiltration after the crystallization and obtaining crystal I and filtrate I; (3) after the obtained crystal I is dried, mixing the obtained crystal I and the edible ethanol solution, and performing stirring backflow until the crystal I is fully dissolved; (4) performing immediate filtration of the obtained solution and crystallizing the filtrate obtained after the filtration; performing refiltration after the crystallization and obtaining crystal II and filtrate II; (5) performing concentration and drying of the obtained filtrate II; (6) drying the crystal II obtained through the step (4), and obtaining the product. By utilizing the fact that components of stevioside are different in solubility in the edible ethanol solution, rebaudioside A is separated and extracted, stevioside with the purity of rebaudioside A over 97% is obtained, and the use of solvents class 2 such as methanol and isopropanol is avoided.

Owner:湖南威嘉生物科技有限公司

Buckwheat jelly fresh-keeping process

The invention relates to a buckwheat jelly fresh-keeping process. With the process, a product shelf life can reach 6 moths, and the product has the advantages of simple application, good taste, convenient carrying, and good toughness, such that modern people requirements of convenient and fast product are satisfied. The operation of the process is reliable and safe. The process belongs to the field of food processing. The process is characterized in comprising the steps that: 1, potatoes are washed and peeled; the potatoes are steamed; potato fine powder and buckwheat powder are added, and the mixture is well mixed; 2, the mixture is steamed in a steam heating pot; 3, cooling and shaping are carried out; and 4, the material obtained in the step 3 is steamed for 20min in a high-temperature-resistant steaming bag with a mold; and 5, vacuuming and sterilization are carried out.

Owner:毛秋生

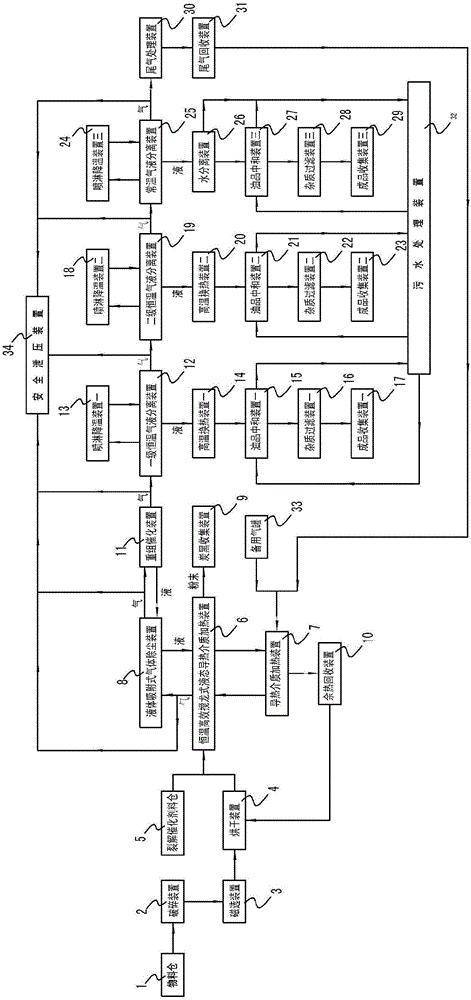

Safe and environment-friendly oil refining technology achieving cracking recycling of waste organic matter by means of continuous feeding and slag discharging

ActiveCN105778970ANo secondary pollutionGuaranteed uptimePigmenting treatmentTransportation and packagingEnvironmental resistanceHeat conducting

The invention discloses a safe and environment-friendly oil refining technology achieving cracking recycling of waste organic matter by means of continuous feeding and slag discharging.The waste organic matter is sequentially treated with a stock bin, a crushing device, a magnetic separator, a drying device, a cracking catalyst stock bin, a constant-temperature efficient auger-type liquid heat-conducting medium heating device, a heat-conducting medium heating device, a liquid adsorption-type gas dedusting device, a carbon black collecting device, a catalytic restructuring device, a first-stage constant-temperature gas-liquid separation device, spray devices, high-temperature heat exchange devices, oil product neutralization devices, impurity filtering devices, finished product collecting devices, a second-stage gas-liquid separation device, a room-temperature gas-liquid separation device, an oil-water separation device, a tail gas treatment device, a tail gas recycling device, a waste water treatment device and a safety pressure relief device.By means of the safe and environment-friendly oil refining technology, the full set of functions from recycling to production oil refining of the waste organic matter can be achieved, continuous operating of the whole set of the functions is guaranteed, and therefore the production efficiency is greatly improved, and the production technology is optimized.

Owner:ZHEJIANG KEMAO ENERGY TECH CO LTD

RNC binding agent and method for extracting RNC-RNA (ribosome nascent-chain complex and ribonucleic acid) from blood

ActiveCN106047864AInhibitory activityAntioxidant inhibitionMicrobiological testing/measurementDNA preparationEthylene glycol bisRed blood cell

The invention relates to an RNC binding agent and method for extracting RNC-RNA (ribosome nascent-chain complex and ribonucleic acid) from blood, wherein the RNC binding agent comprises the following components by content: 120-180 Mug / ml of cycloheximide, 25-35 mM of dithiothreitol, 0.45-0.65 M of ammonium chloride, 25-35 mM of sodium citrate, 25-35 mM of ethylene diamine tetraacetic acid, 10-20 mM of ethylene glycol bis(2-aminoethyl ether)tetraacetic acid, 15-25 MuM of 1,2,3,4,6-O-pentagalloylglucose, 0.005-0.015% of glycerol, and the balance of water. The RNC binding agent (RNC blood binding solution) of the invention is a multifunctional reagent integrating translation extension inhibitor, RNA protectant and red blood cell lysate and may serve as an RNA protectant for use in the collection of conventional samples.

Owner:GUANGZHOU SAGENE BIOTECH

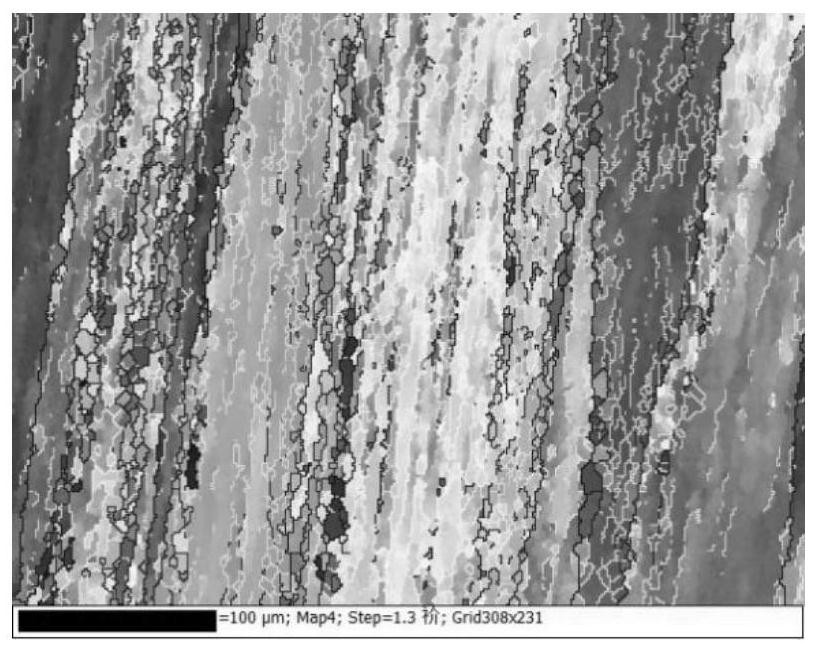

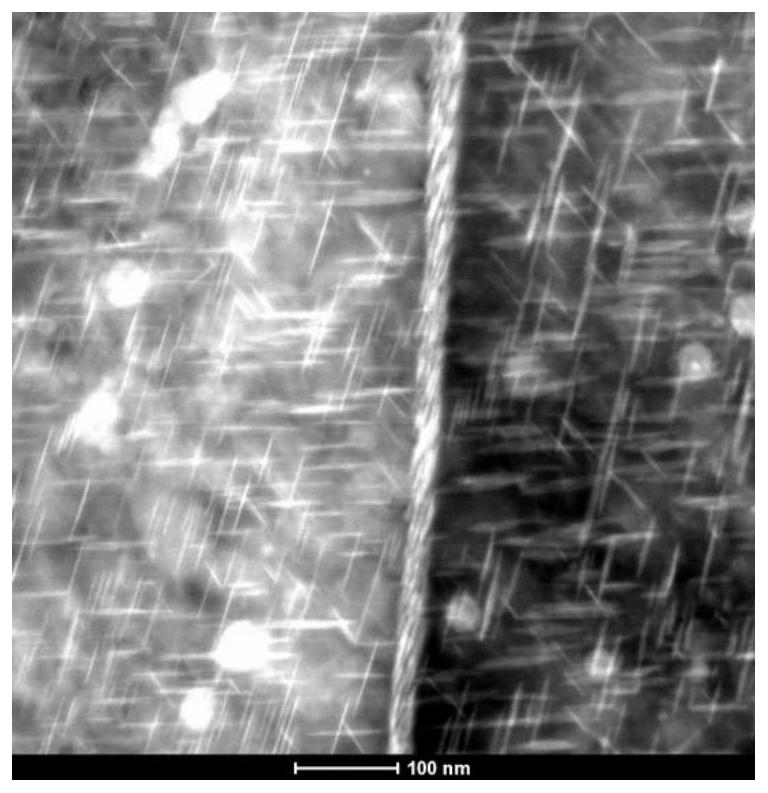

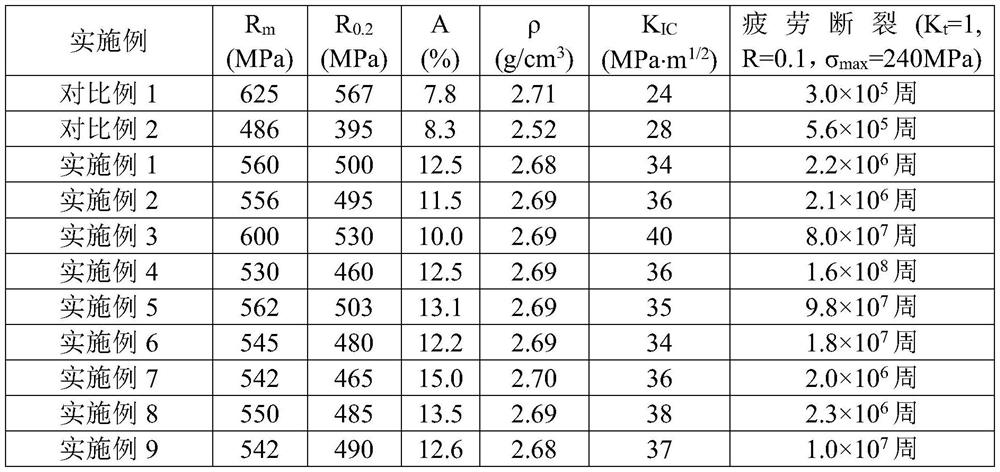

Low-density high-strength damage-resistant aluminum-lithium alloy hot-rolled plate and preparation method thereof

PendingCN113215460AHigh strengthImprove fracture toughnessUltimate tensile strengthAluminium-lithium alloy

The invention discloses a low-density high-strength damage-resistant aluminum-lithium alloy hot-rolled plate and a preparation method thereof. The aluminum-lithium alloy hot-rolled plate comprises the following components in percentage, by mass, 3.5-4.0% of Cu, 0.7-1.1% of Li, 0.5-1.0% of Mg, 0.2-0.5% of Ag, 0.25-0.5% of Zn, 0.1-0.2% of Zr, 0.1-0.3% of Mn, 0-0.1% of Ti, 0-0.08% of Sc, less than or equal to 0.05% of Fe, less than or equal to 0.05% of Si and the balance of Al, the total amount of Cu and Li is 4.0-5.5, and the mass ratio of Cu to Li is 3.0-5.0. The low-density aluminum alloy with excellent mechanical properties is obtained by regulating and controlling the mass fraction proportion of the main alloy elements and the process conditions of deformation heat treatment and the like, and the prepared aluminum alloy has excellent comprehensive mechanical properties such as room temperature strength, plane fracture toughness and fatigue fracture resistance.

Owner:CENT SOUTH UNIV

Downward full waste boiler entrained-flow bed gasification device for superheated steam and coal chemical industry system

ActiveCN113072980AHigh online operation rateEasy to operate and maintainEnergy inputGranular/pulverulent flues gasificationSyngasThermodynamics

The embodiment of the invention provides a downstream full waste heat boiler entrained-flow bed gasification device for superheated steam and a coal chemical industry system, and relates to the field of coal chemical industry. According to the downstream full waste heat boiler entrained-flow bed gasification devicefor superheated steam, a radiation waste boiler and a convection waste boiler are connected by arranging an ash falling waste boiler, so that synthesis gas is turned back upwards, ash entrained by the synthesis gas flows into a chilling chamber by virtue of gravity, the height of the whole equipment is reduced, and sensible heat recovery of the synthesis gas is realized. The overall height of the frame is relatively low, the device has the remarkable advantages of safe and reliable process operation, high online operation rate, convenience in operation and maintenance, low operation economic cost, low comprehensive energy consumption and the like, and the economic value is greatly improved. The problems of transportation overrun and inconvenience in operation and maintenance of a large gasification furnace with a full waste heat boiler are solved, the recovery rate of sensible heat in recovered synthesis gas is high, and the quality of steam generated by heat recovery is high.

Owner:宁夏神耀科技有限责任公司

Method for preparing 2,3,5,6-tetramethylpyrazine

PendingCN107879987ASave raw materialsRaw materials are easy to getOrganic chemistryPhosphoric acidChemistry

The invention discloses a method for preparing 2,3,5,6-tetramethylpyrazine. The method comprises the following steps: adding industrial phosphoric acid and process water into a three-necked flask having a volume of 1000ml, and uniformly stirring; controlling temperature to be 20-40 DEG C, introducing ammonia gas into the flask until the pH of the system is 7.8-8.2; controlling the temperature to be 30-40 DEG C, dropwise adding acetoin for about 30 minutes, and insulating to react for 2 hours; heating to 90-100 DEG C to react for 1 hour; heating and distilling to obtain fraction at 100 DEG C, and completing distillation when the temperature is 103 DEG C to obtain distillate; adding a small amount of phosphoric acid into the distillate to regulate the pH to be 6-7, cooling to 0-5 DEG C, standing for 4 hours or more, and extracting and filtering the mixture to obtain a crude product; recrystallizing the crude product with water, separating to obtain a wet product, and drying in vacuum toobtain the product. The 2,3,5,6-tetramethylpyrazine has the benefcial effects that the raw materials are low in price and easily available, the reaction stock solution can be recycled, the process operation is safe and environmentally friendly, the product has relatively good quality and relatively low cost and is suitable for large-scale production.

Owner:SHANDONG JITIAN AROMA CHEM CO LTD

Method for purifying dye wastewater containing high-concentration cyanide

InactiveCN107954547AHigh removal rateRemovalWater contaminantsMultistage water/sewage treatmentHigh concentrationEnvironmental issue

The invention discloses a method for purifying dye wastewater containing high-concentration cyanide. According to the specific pollutants of dye wastewater containing high-concentration cyanide in theprinting and dyeing industry, i.e., cyanide and the like, an appropriate process route is chosen, a technical route of acidification, stripping and ozone oxidation is adopted, and thereby the objective of removing and recovering cyanide is achieved. As a cyanide purification technique, the method reduces the concentration of cyanide, so that highly poisonous dye wastewater becomes slightly poisonous, and thereby a foundation is laid for the subsequent biological treatment process. The method has the advantages of simple process flow, safe process operation, stable treatment effect, high pollutant removal rate, no secondary pollution and low operation cost. The invention solves the major environmental issue for the printing and dyeing industry, and also solves the problem of safety in theprocess of wastewater treatment, and environmental benefit, economic benefit and social benefit are remarkable.

Owner:CHANGCHUN GOLD RES INST

Preparation method of N-Boc-(R)-2-amino-4, 4-dimethylvaleric acid

ActiveCN110256297ARaw materials are cheap and easy to getLow costCarbamic acid derivatives preparationOrganic compound preparationOrganic synthesisMedicinal chemistry

Belonging to the field of organic synthesis, the invention discloses a preparation method of N-Boc-(R)-2-amino-4, 4-dimethylvaleric acid. The preparation method of N-Boc-(R)-2-amino-4, 4-dimethylvaleric acid includes a synthetic route shown as the specification. The preparation method of N-Boc-(R)-2-amino-4, 4-dimethylvaleric acid provided by the invention has the advantages of cheap and easily available raw materials, low cost, convenient process operation, safety and high product yield, is suitable for industrial production, and has broad application prospects.

Owner:ASTATECH CHENGDU BIOPHARM CORP

Method for preparing functional nourishment by using deep-processed sweet potatoes

InactiveCN104366356AHigh clarityImprove stabilityNatural extract food ingredientsFood preparationUltra high pressurePressure cell

The invention relates to a method for preparing functional nourishment by using deep-processed sweet potatoes. The method comprises the following steps of (1) smashing canes, leaves and tuberous roots of sweet potatoes to pulp and separating the pulp to obtain clear liquid and dregs; (2) adding molecular complexing agents to the clear liquid which is obtained from the step (1) and performing ultrahigh pressure cell-breaking extraction and sterilization on the clear liquid; (3) performing membrane separation and low-temperature drying on the clear liquid which is obtained by extraction and sterilization from the step (2) so that the water content of the material reaches 5 to 10 in percentage by weight; and (4) smashing the material which is obtained by drying from the step (3) to obtain dry powder of sweet potato extracts which can pass through a sieve with meshes of 40 to 80 and preparing the dry power to formulation which is acceptable in nourishment processing according to the conventional method. By the method for preparing the functional nourishment by using the deep-processed sweet potatoes, the whole process can be completed at low temperatures, the specific processes of molecular complexing, ultrahigh pressure cell-breaking extraction and sterilization, membrane separation concentration and low-temperature drying are fully utilized, a new deep-processing technology of the sweet potatoes is formed, and the technology is remarkably improved as a whole.

Owner:台建祥 +5

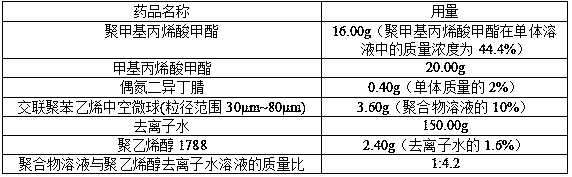

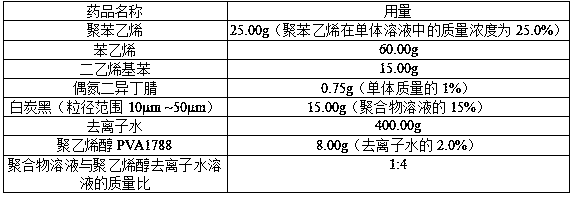

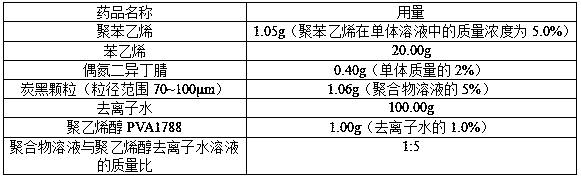

Method for preparing millimeter-scale polymer composite microsphere

InactiveCN108948274AGood versatilityVersatile and easyMicroballoon preparationMicrocapsule preparationSolubilityPolymer composites

The invention discloses a method for preparing a millimeter-scale polymer composite microsphere, and the method comprises dissolving a non-crosslinked polymer in a monomer to obtain a polymer monomersolution, then adding an oil-soluble initiator, finally adding an organic microsphere or inorganic particle, after thorough stirring and even mixing, performing polymerization in an aqueous phase system by suspension polymerization to prepare the millimeter-scale polymer composite microsphere. By selecting of specific polymers and corresponding monomers and adjusting of types or amounts of the specific polymers and the corresponding monomers and types or amounts of coated organic microspheres or inorganic particles, millimeter-scale polymer composite microspheres having different solubility properties, adjustable densities, controllable particle sizes, controllable mechanical strengths, adjustable hydrophilic and hydrophobic properties and controllable diameter ranges of 0.5-2.0mm can be prepared; and the millimeter-scale polymer composite microspheres can be widely used in acid mist suppression, drug carriers, catalyst loading and other fields.

Owner:KUNMING UNIV OF SCI & TECH

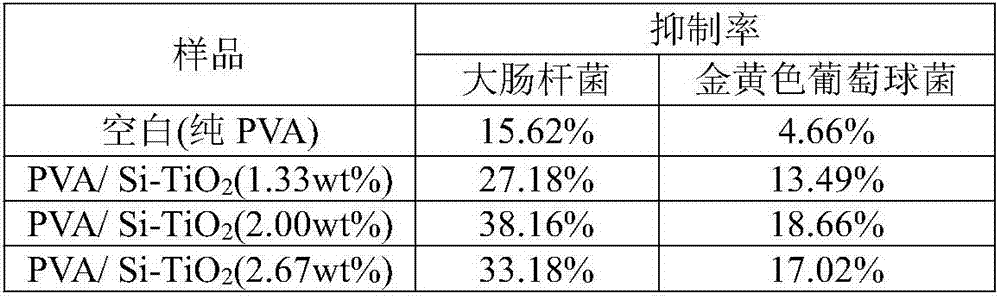

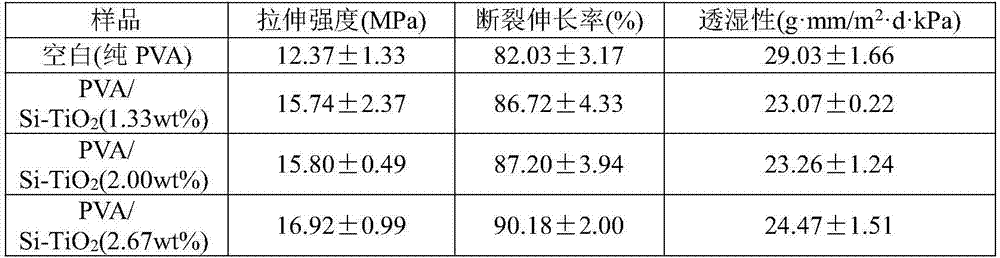

Preparation method of degradable nano bacteriostatic thin film

InactiveCN107082895ASignificant antibacterialSignificant Staphylococcus aureus) effectFlexible coversWrappersEscherichia coliStaphylococcus aureus

The invention provides a preparation method of a degradable nano bacteriostatic thin film. The preparation method comprises the following steps: preparing nano Si-TiO2; adding the nano Si-TiO2 and a dispersant into a degradable polymer water solution; uniformly mixing and degassing to obtain a film forming solution; carrying out film casting on the film forming solution to obtain the degradable nano bacteriostatic thin film. A preparation method of the nano Si-TiO2 comprises the following steps: dispersing nano TiO2 and a silane coupling agent into acetone; coupling under an ultrasonic condition; filtering, washing with water, drying in vacuum and grinding to prepare the nano Si-TiO2. Compared with the prior art, the preparation method of the degradable nano bacteriostatic thin film has the following beneficial effects that process steps are simple and the bacteriostatic (escherichia coli and staphylococcus aureus) effect of a packaging material is remarkable; the packaging material provided by the invention has the advantages of strong mechanical properties, small permeability and the like; the preparation method has the advantages of safe process operation, high efficiency and no toxin, greenness and environmental friendliness, easiness for popularization and the like.

Owner:SHANGHAI JIAO TONG UNIV

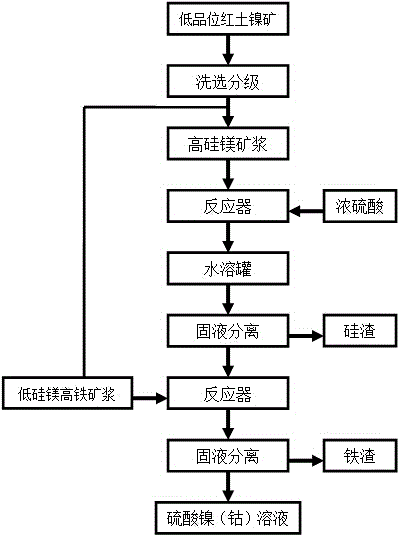

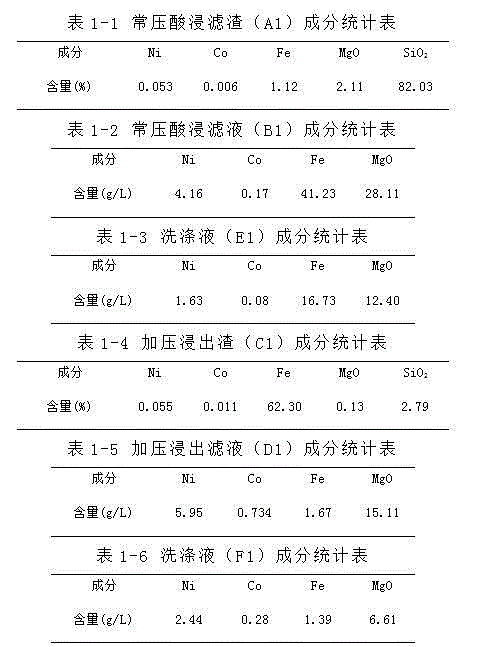

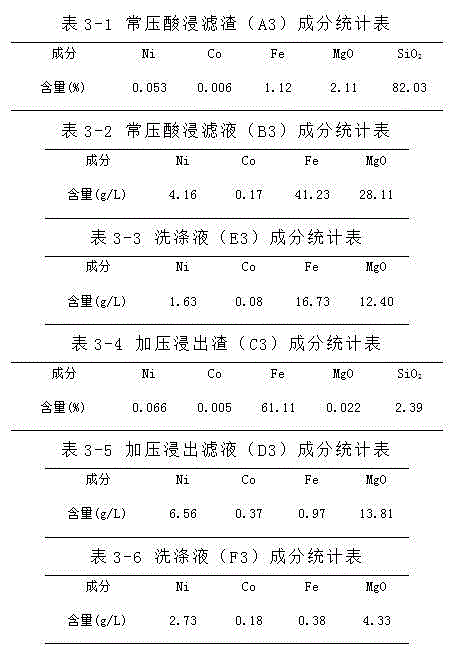

Method for treating low-grade nickel laterite ore

InactiveCN104611580AReduce consumptionEasy to separateProcess efficiency improvementSlagHydrometallurgy

The invention relates to the field of wet metallurgy, in particular to a method for extracting nickel and cobalt by using wet processing from low-grade nickel laterite ore. Brown iron ore and transitional ore can be treated at the same time, and sulfuric acid does not need to be added additionally in the pressure leaching stage of high-silica magnesite ore. Fe<3+> in atmospheric pressure leaching liquid is hydrolyzed to form sediment, protons are released and then low-silica magnesite high iron ore is leached, and then Fe<3+> is further hydrolyzed to form sediment to be filtered out under the conditions of pressurization and heating, so that the consumption of sulfuric acid is reduced, and the content of iron in pressure leaching slag after solid-liquid separation is higher and can reach 58-65%; pressure leaching is realized by medium and low pressure equipment, so that the defects that high-pressure autoclave equipment is expensive and easy to scale are avoided. According to the method, iron slag and silicon slag can be naturally and conveniently separated in the technological process, and the content of silicon dioxide in the pressure leaching slag reaches 65-90%, so that leached slag can be effectively utilized, and efficient development and utilization for low-grade nickel laterite ore are realized; the method is simple in technological operation, safe, short in technological time and high in efficiency.

Owner:JINCHUAN GROUP LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com