Preparation method of degradable nano bacteriostatic thin film

A nano-film technology, applied in the field of nano-antibacterial film preparation, can solve the problem of no antibacterial and other problems, and achieve the effect of easy promotion, simple process steps, and low permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

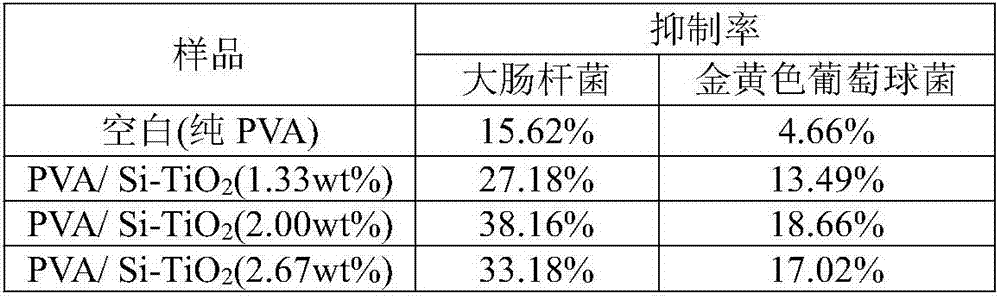

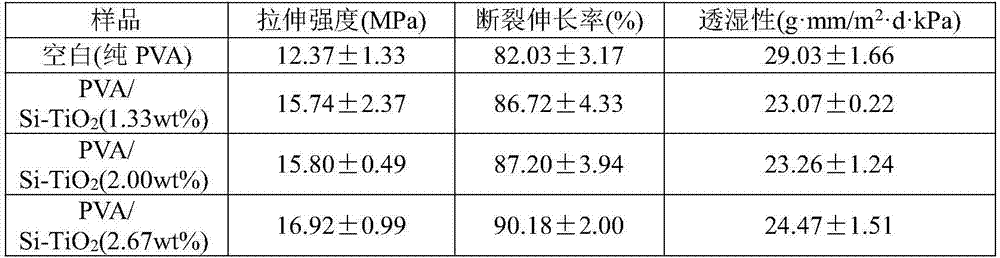

Embodiment 1

[0027] The present embodiment relates to a kind of preparation method of degradable nano antibacterial film, and it comprises the steps:

[0028] Nano-TiO Modified by Silane Coupling Agent 2 : 0.1g nano-TiO 2 (particle size of 100nm) and 0.01g of silane coupling agent (aminopropyltriethoxysilane, APS) were added to 10mL of acetone solution, ultrasonically coupled under the condition of ultrasonic power of 600W for 30 minutes, washed with pure water for 2 times, filtered, vacuum dried for 4h, and the dried product was ground into modified nano-TiO 2 (Si-TiO 2 ). Polyvinyl alcohol / nano Si-TiO 2 Preparation of packaging materials: Add 3 g of polyvinyl alcohol (type 1797) powder into 97 mL of pure water, heat and stir at 95° C. for 2 hours, and cool to obtain a 3% polyvinyl alcohol aqueous solution. 0.06g nano-Si-TiO 2 Add 0.06g dispersant polyethylene glycol 400 (PEG400) into the above-mentioned polyvinyl alcohol (PVA) aqueous solution and blend (Si-TiO 2 / PVA=2.00wt%), so...

Embodiment 2

[0030] The present embodiment relates to a kind of preparation method of degradable nano antibacterial film, and it comprises the steps:

[0031] Nano-TiO Modified by Silane Coupling Agent 2 : 0.1g nano-TiO 2 (particle size of 100nm) and 0.02g of silane coupling agent (aminopropyltriethoxysilane, APS) were added to 10mL of acetone solution, ultrasonically coupled for 30 minutes under the condition of ultrasonic power of 500W, and washed with pure water for 2 times, filtered, vacuum dried for 4h, and the dried product was ground into modified nano-TiO 2 (Si-TiO 2 ). Polyvinyl alcohol / nano Si-TiO 2 Preparation of packaging materials: Add 3 g of polyvinyl alcohol (type 1797) powder into 97 mL of pure water, heat and stir at 95° C. for 2 hours, and cool to obtain a 3% polyvinyl alcohol aqueous solution. 0.04g nano-Si-TiO 2 And 0.08g dispersant polyethylene glycol 400 (PEG400) adds in the above-mentioned polyvinyl alcohol (PVA) aqueous solution and blends (Si-TiO 2 / PVA=2.67...

Embodiment 3

[0033] The present embodiment relates to a kind of preparation method of degradable nano antibacterial film, and it comprises the steps:

[0034] Nano-TiO Modified by Silane Coupling Agent 2 : 0.1g nano-TiO 2 (particle size of 100nm) and 0.01g of silane coupling agent (aminopropyltriethoxysilane, APS) were added to 10mL of acetone solution, ultrasonically coupled under the condition of ultrasonic power of 600W for 30 minutes, washed with pure water for 2 times, filtered, vacuum dried for 4h, and the dried product was ground into modified nano-TiO 2(Si-TiO 2 ). Polyvinyl alcohol / nano Si-TiO 2 Preparation of packaging materials: Add 3 g of polyvinyl alcohol (type 1797) powder into 97 mL of pure water, heat and stir at 95° C. for 2 hours, and cool to obtain a 3% polyvinyl alcohol aqueous solution. 0.04g nano-Si-TiO 2 Add 0.04g dispersant polyethylene glycol 400 (PEG400) into the above-mentioned polyvinyl alcohol (PVA) aqueous solution and blend (Si-TiO 2 / PVA=1.33wt%), und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com