Patents

Literature

46results about How to "No secondary dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

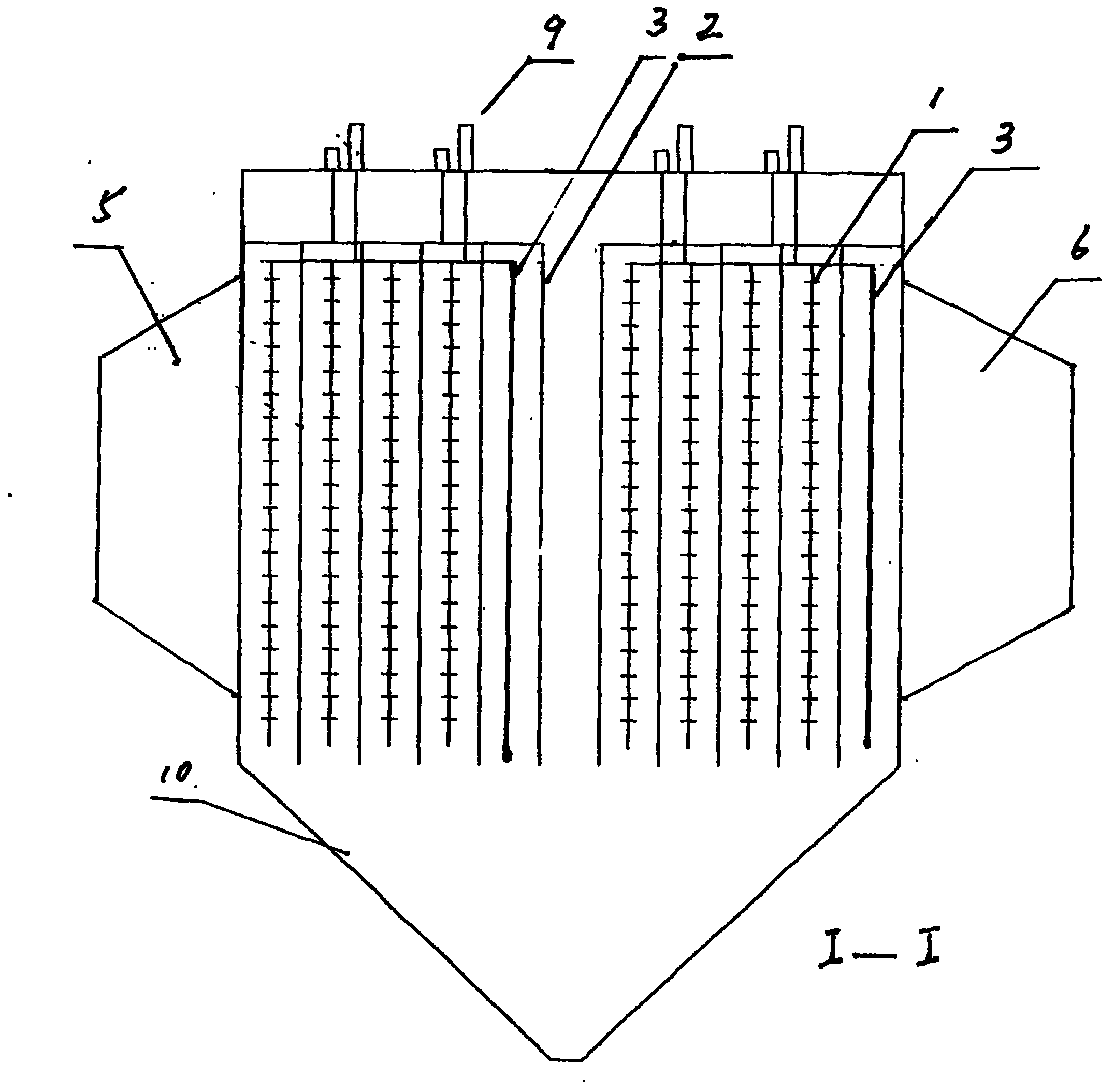

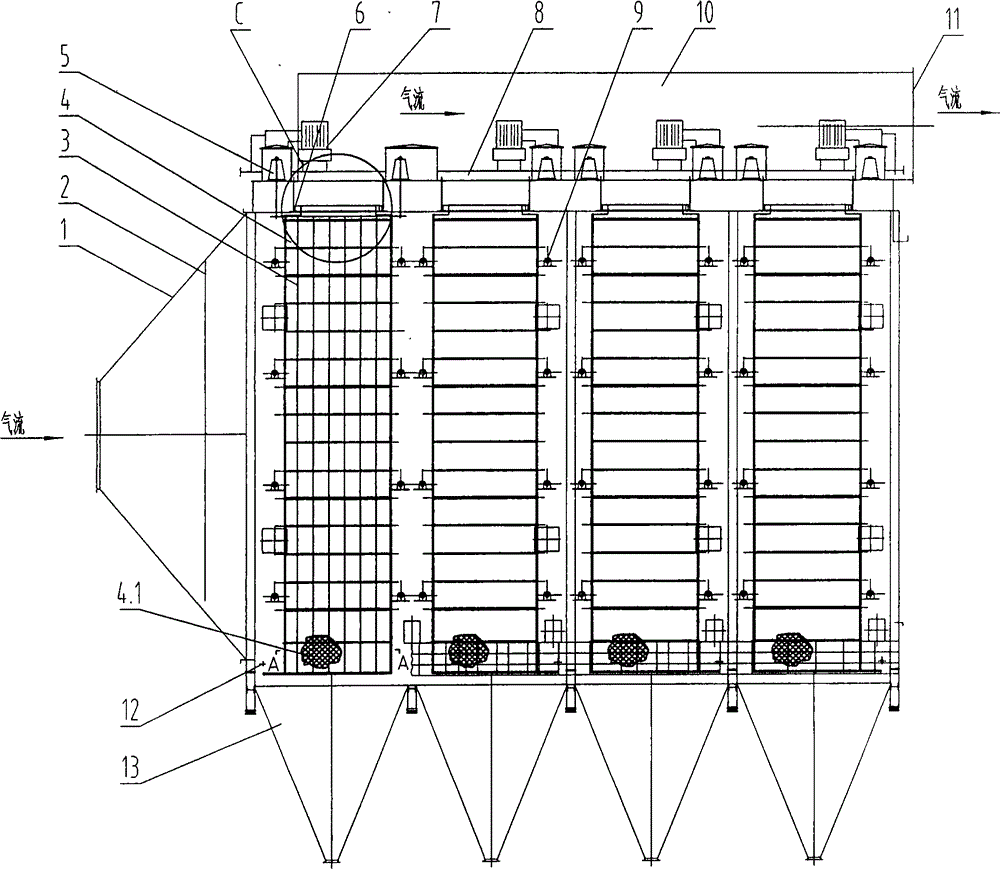

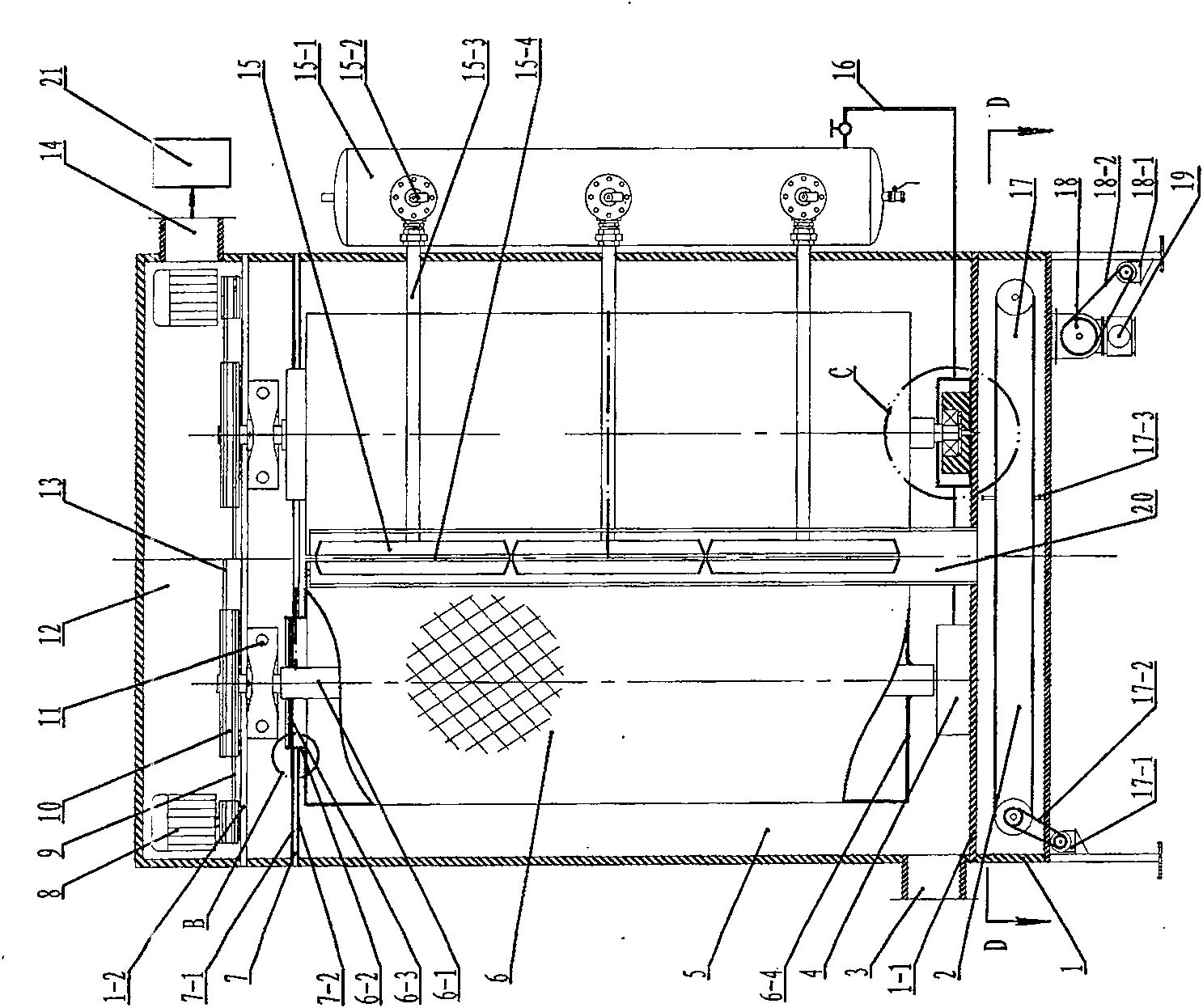

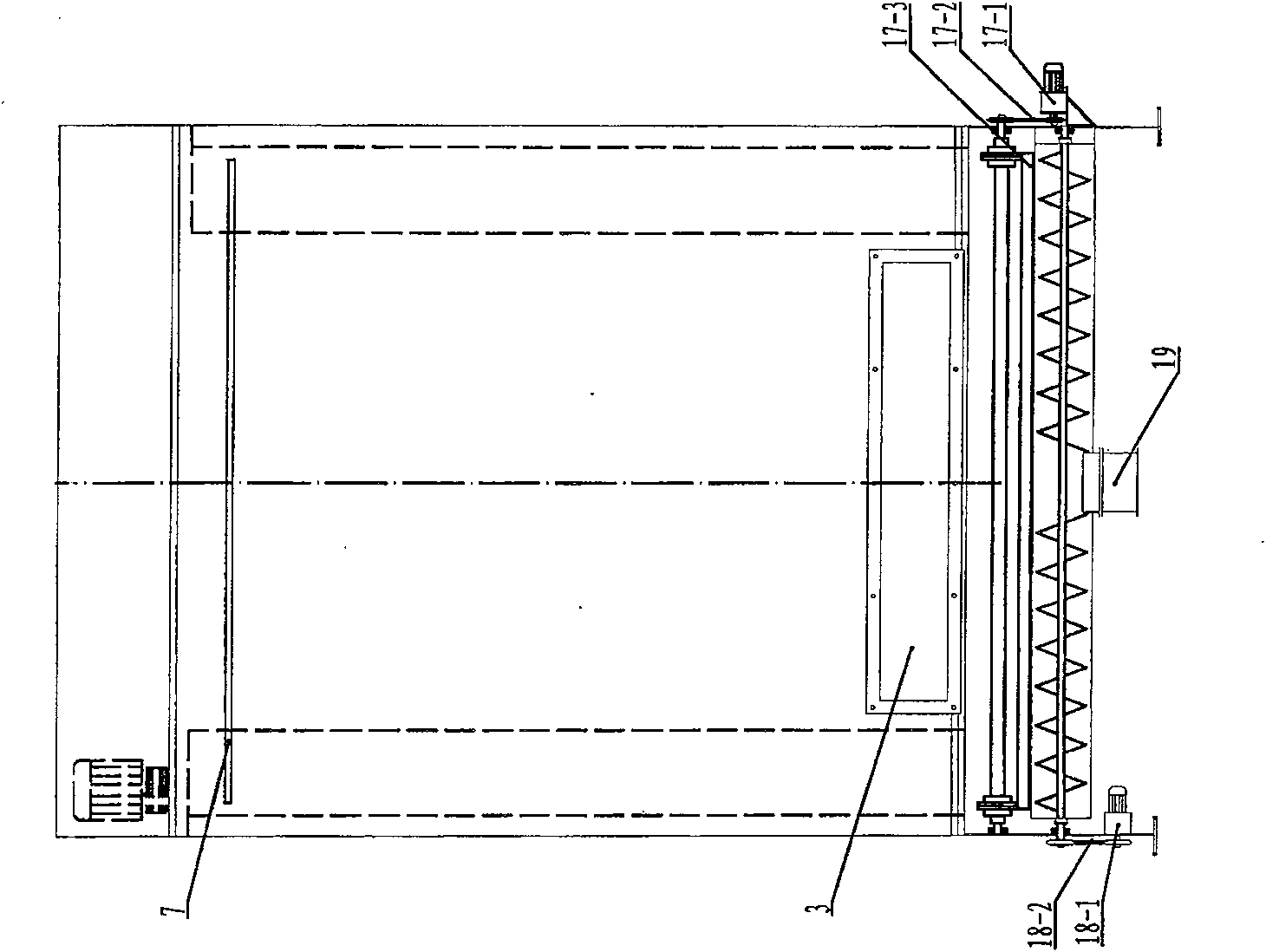

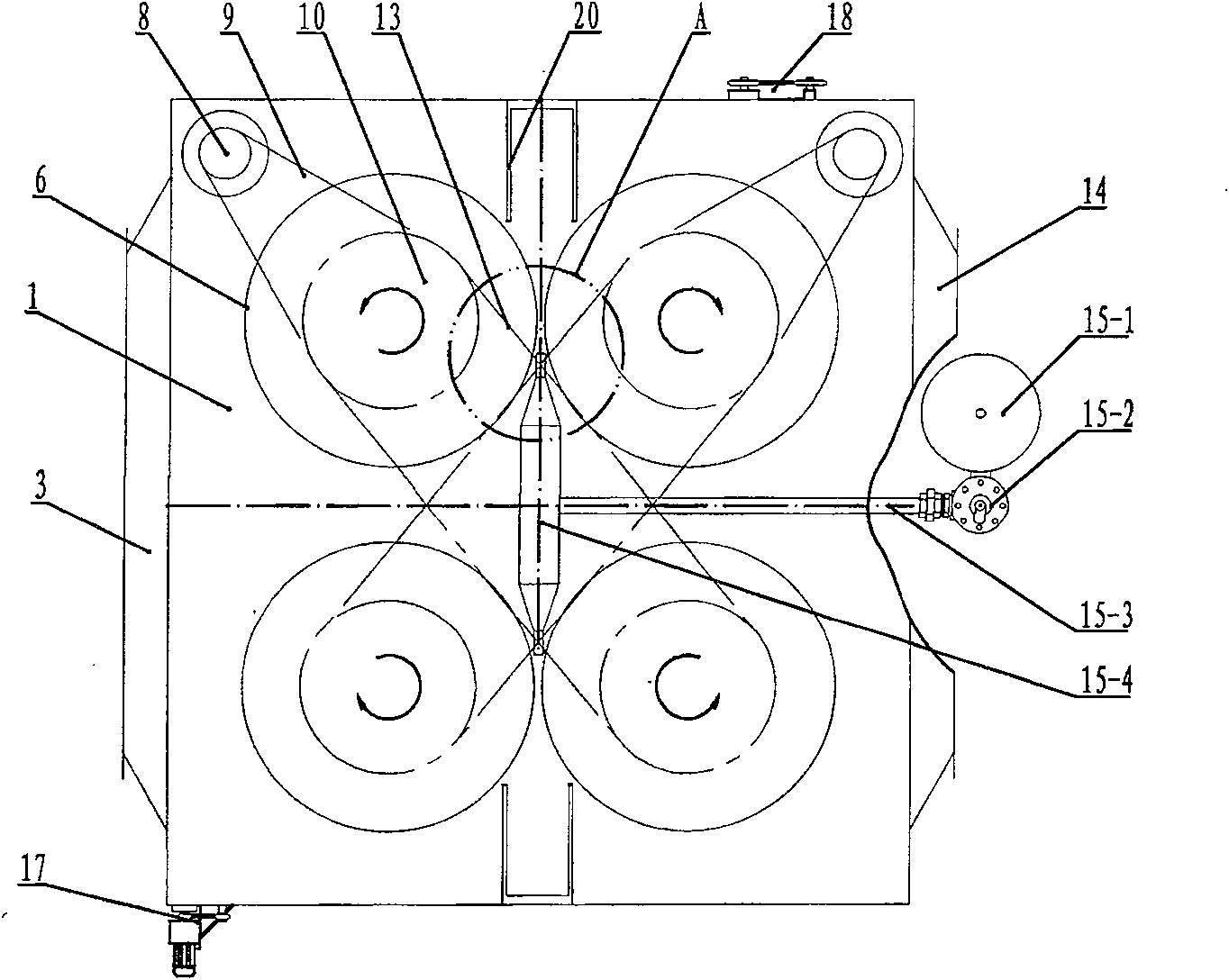

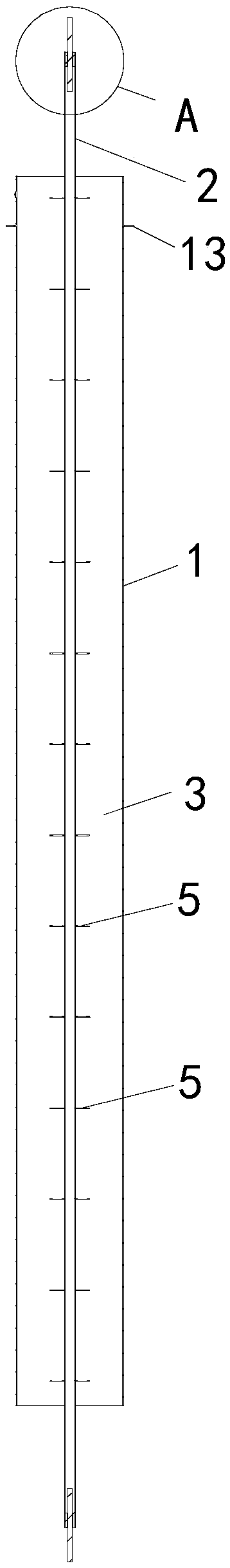

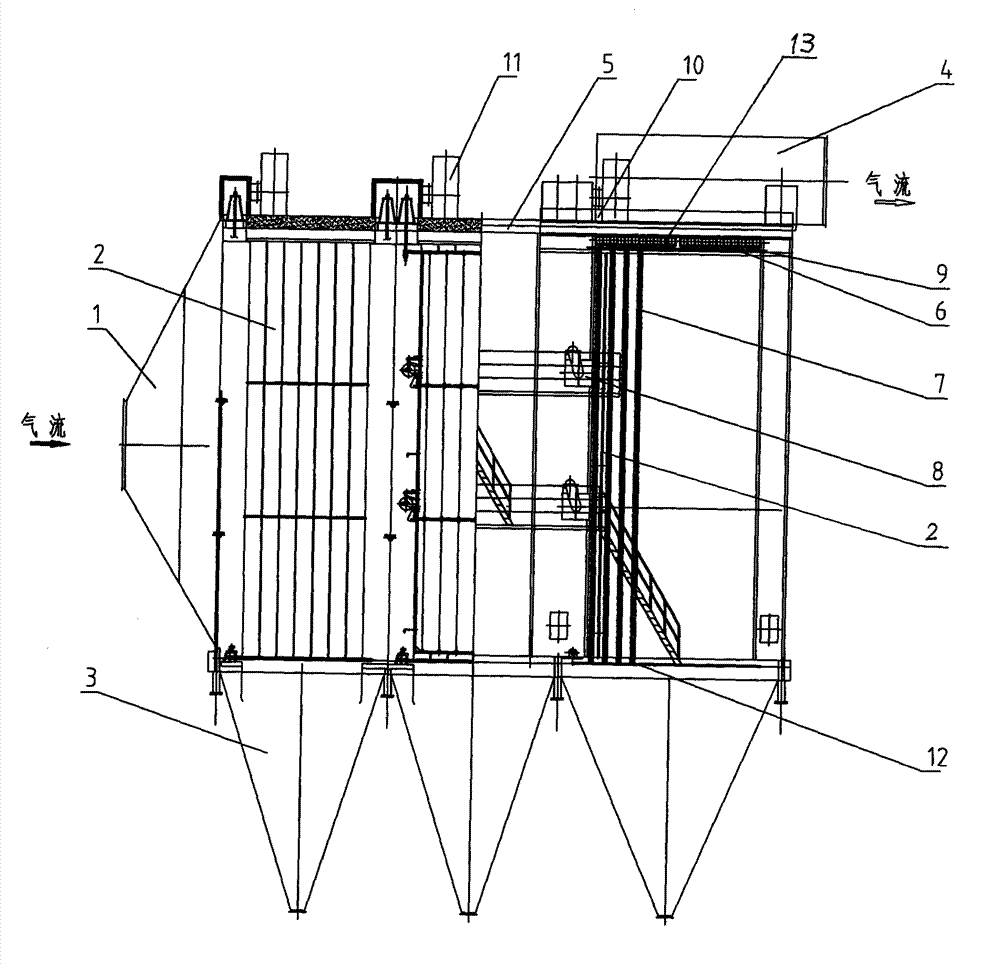

Rotating filter cartridge type air dust remover

InactiveCN101264406AEfficient removalConstant dust removal effectDispersed particle filtrationHigh humidityChain type

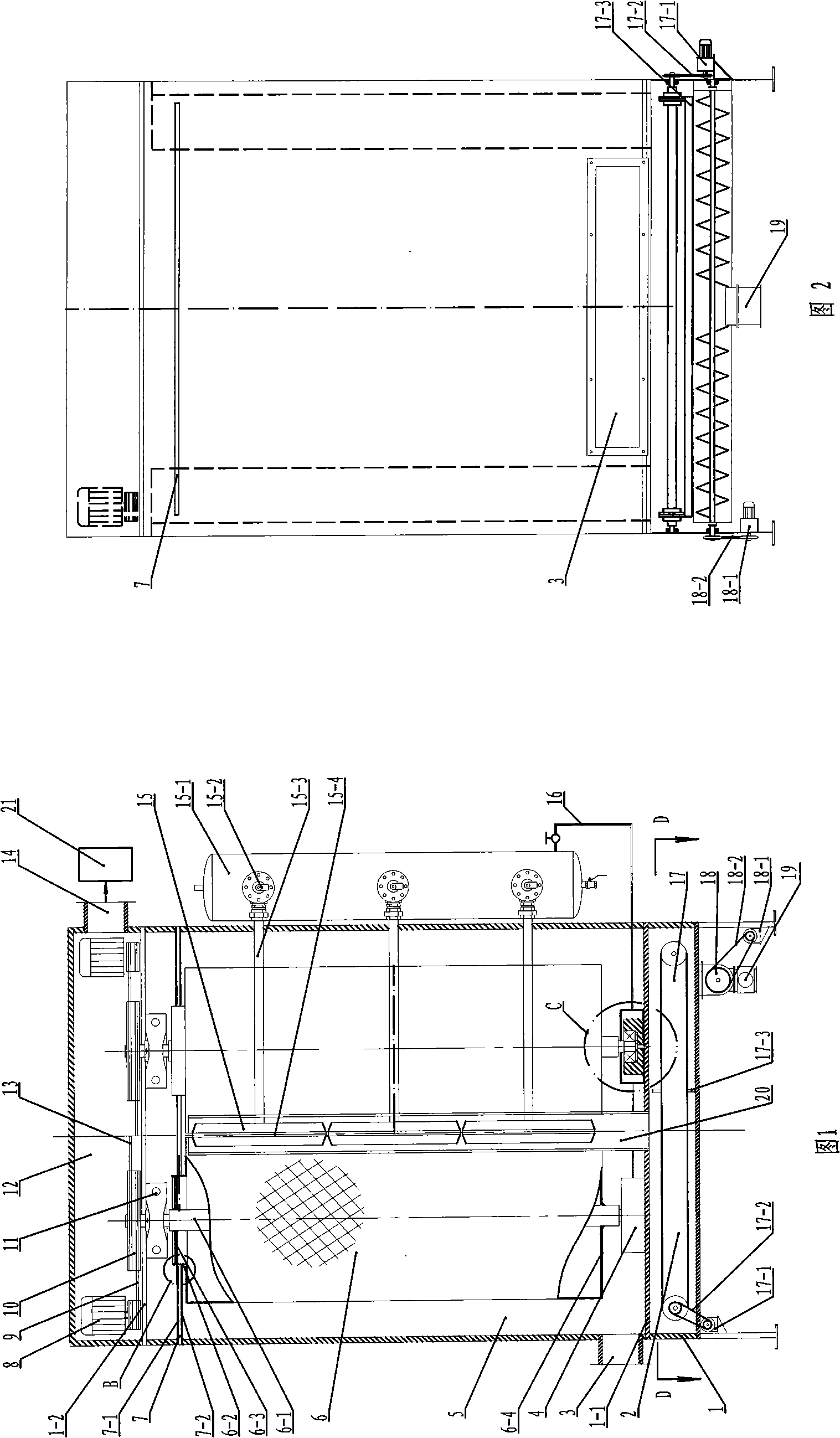

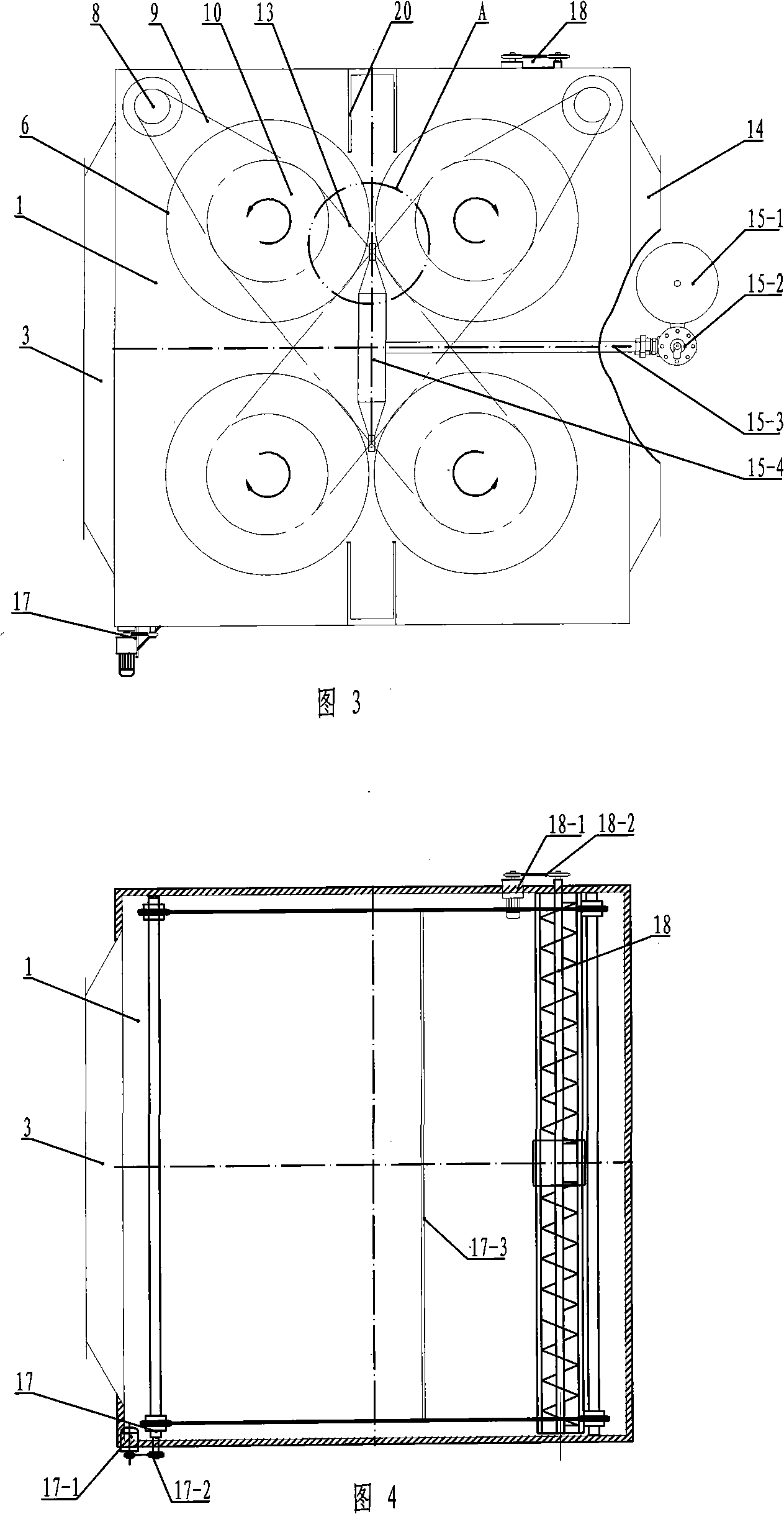

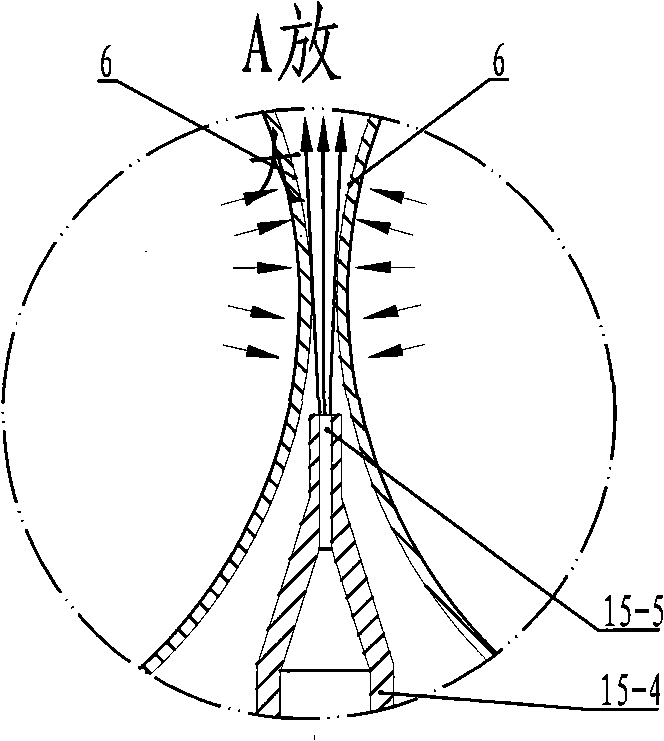

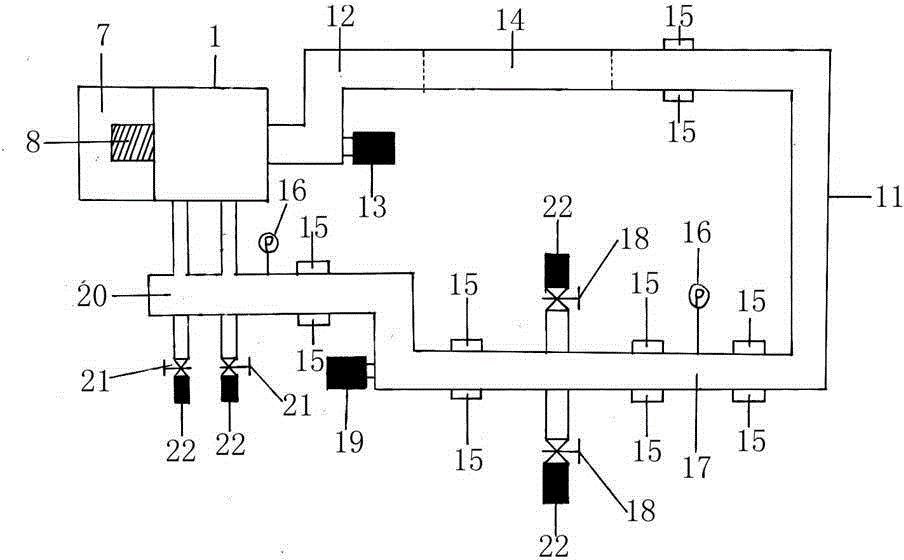

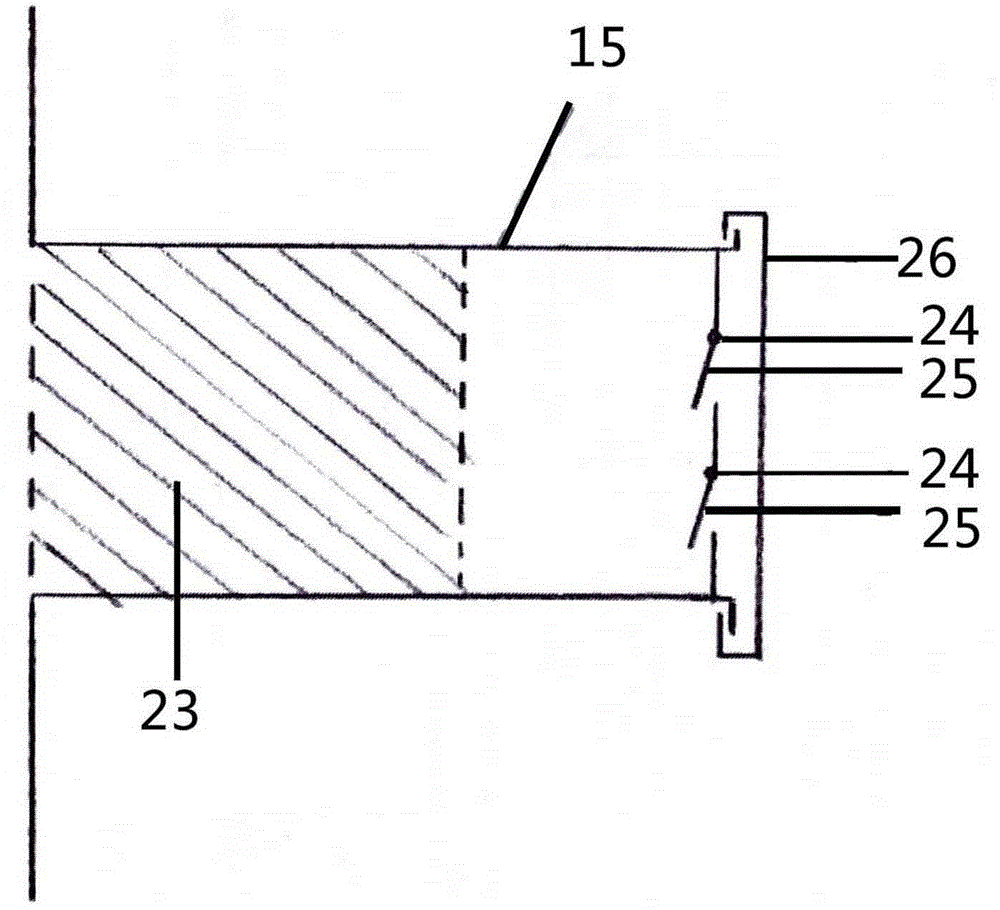

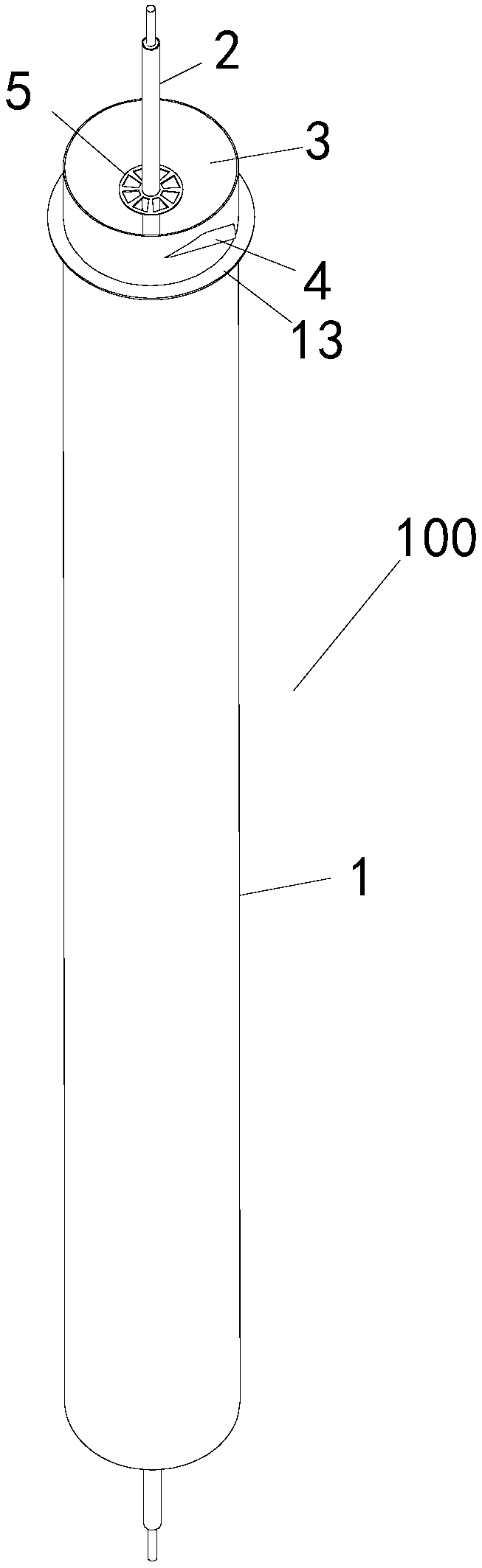

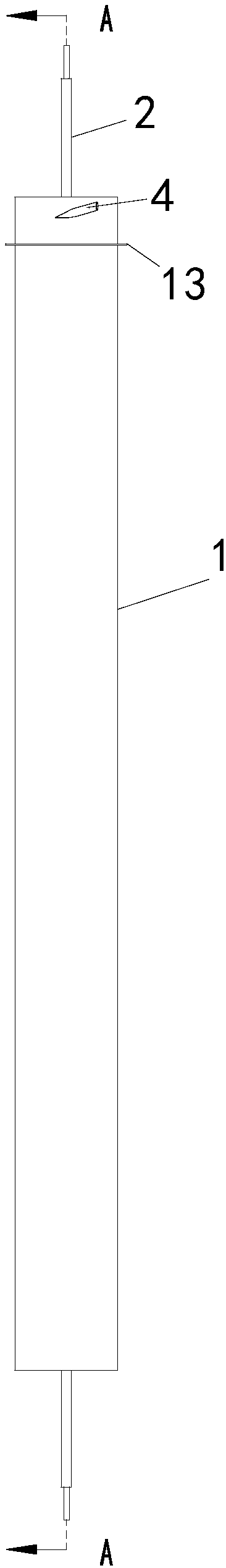

The invention discloses a rotary drum type dust remover, comprising a housing, a plurality of filter cylinders arranged in the intracavity of the housing for isolating dust, a main motor for driving filter cylinders, an impulse sweep system for cleaning the deposit dust on the surface of the filter cylinder, a chain typed scraper chain conveyor for cleaning dust, a spiral ash transportor and a dust discharge valve. The dust remover has the advantages of low dust concentration requirement for the air to be purified, ability to remove dust in various environments, and stable dust removal efficiency; and high temperature resistance, high humidity resistance, acid and alkaline corrosion resistance, electrostatic prevention as the filtered cloth material is stainless steel material; and ability to be used independently, also to be used multi-parallelly, and to select the number of single machine in an unit according to different discharge standard.

Owner:JIANGSU HUAZHENG ENVIRONMENTAL PROTECTION TECH CO LTD

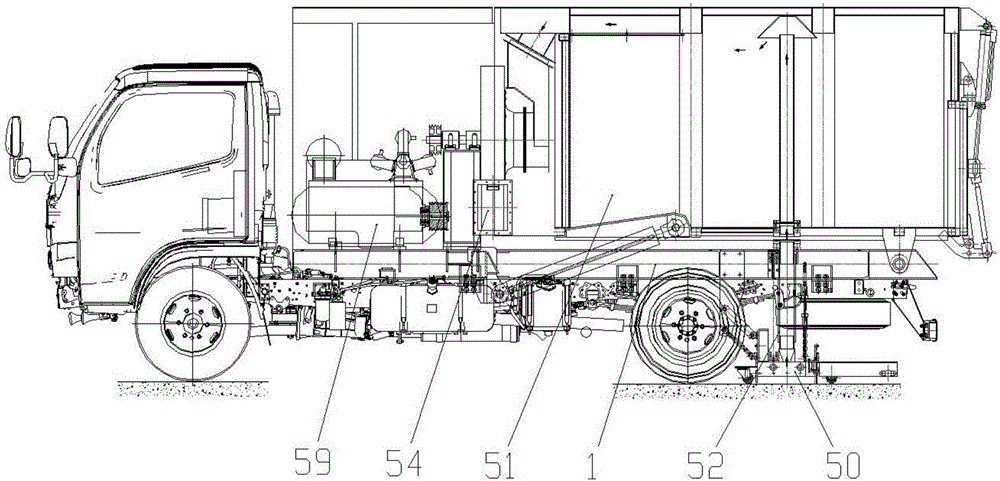

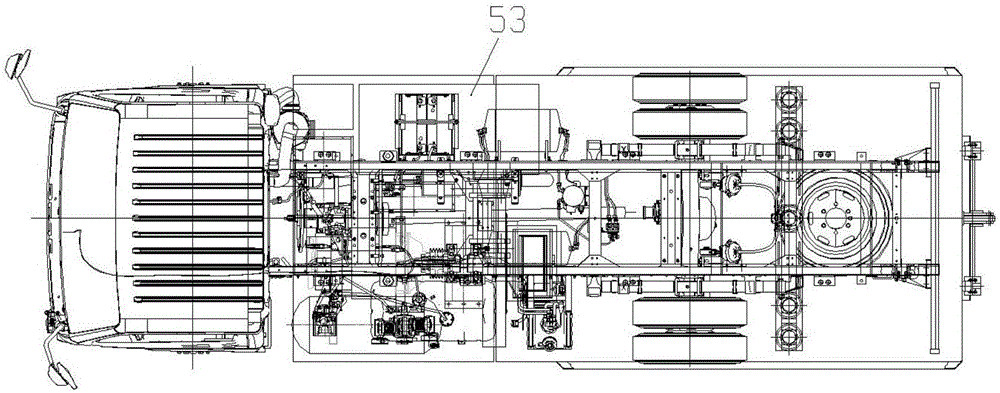

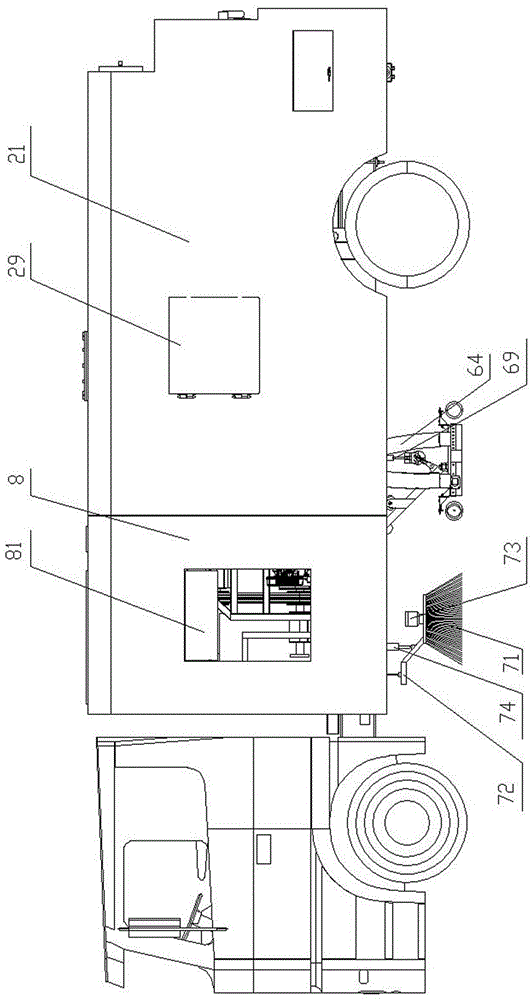

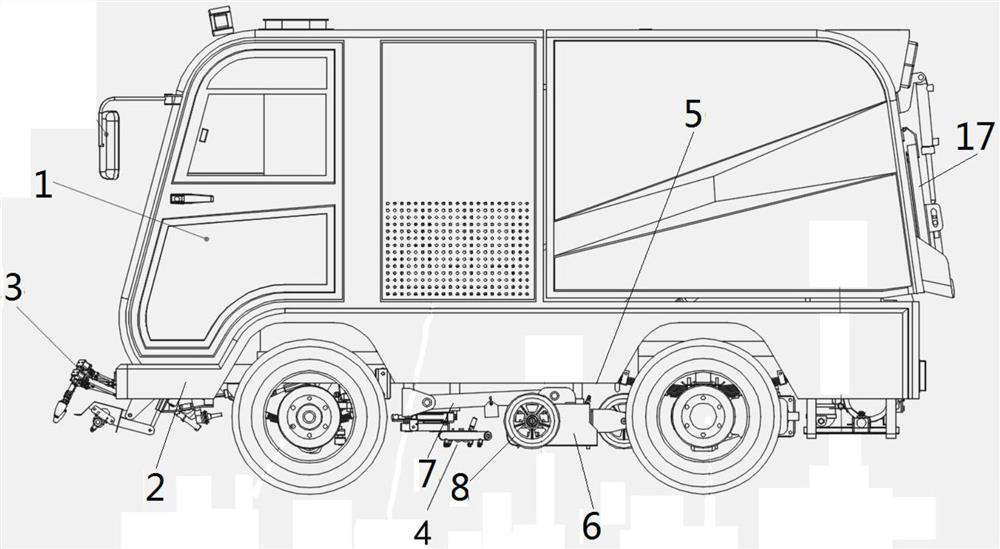

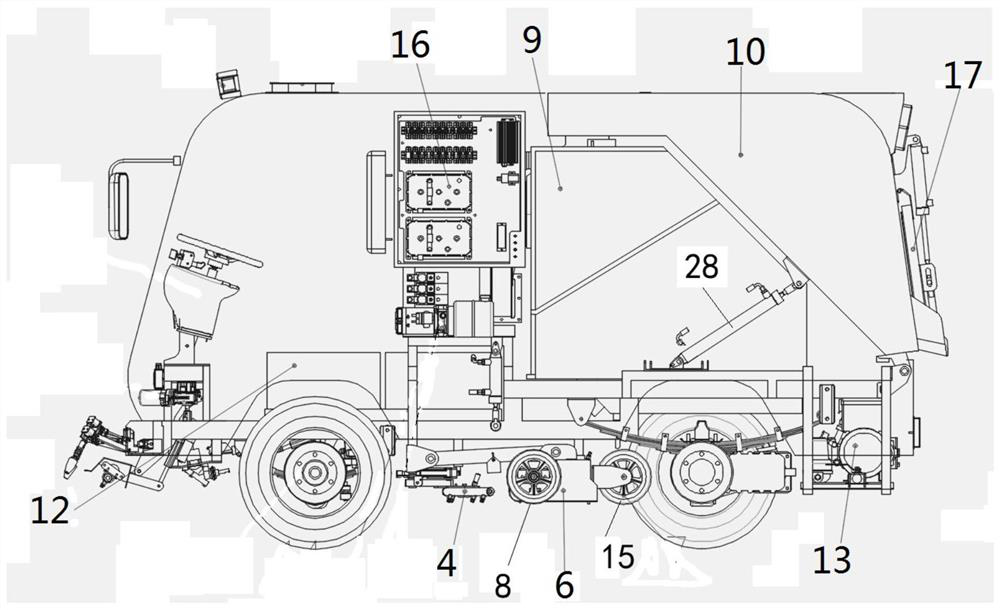

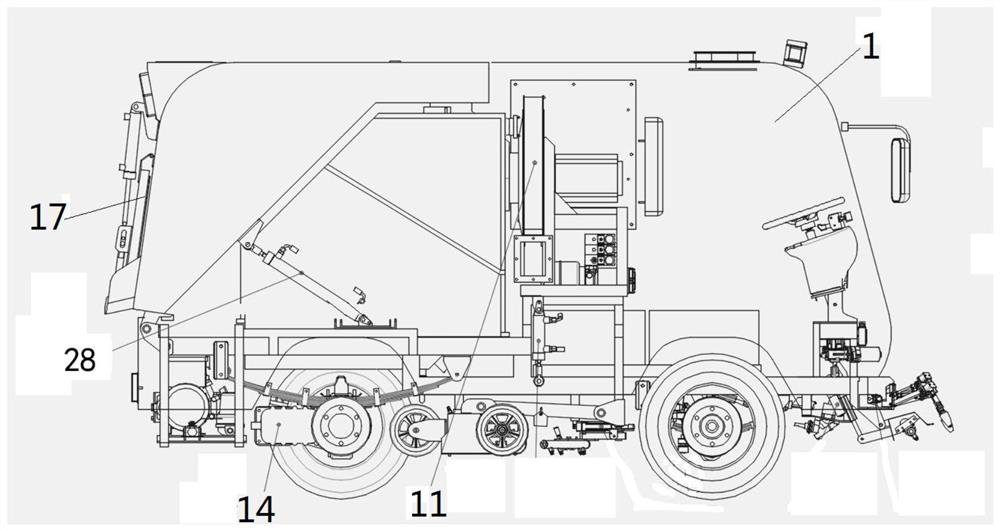

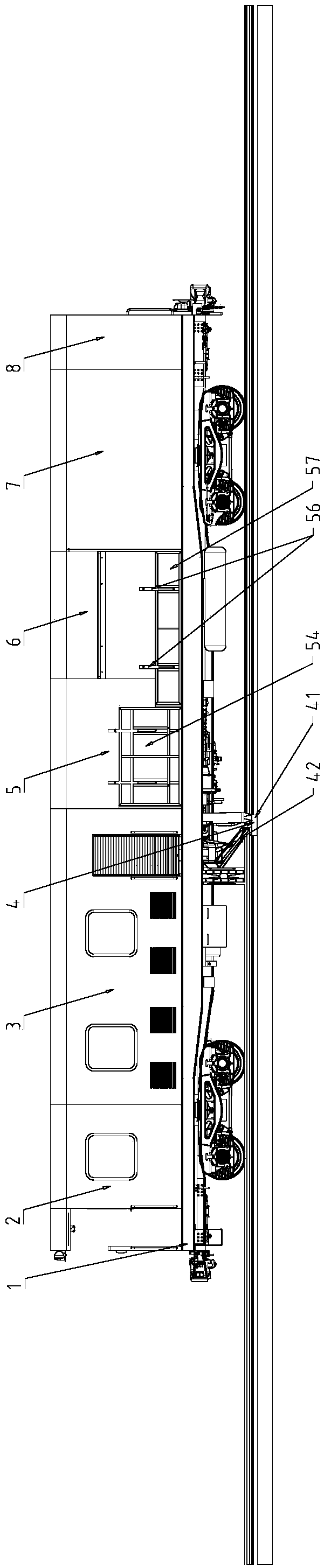

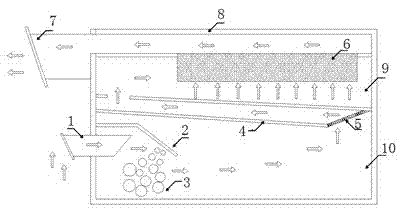

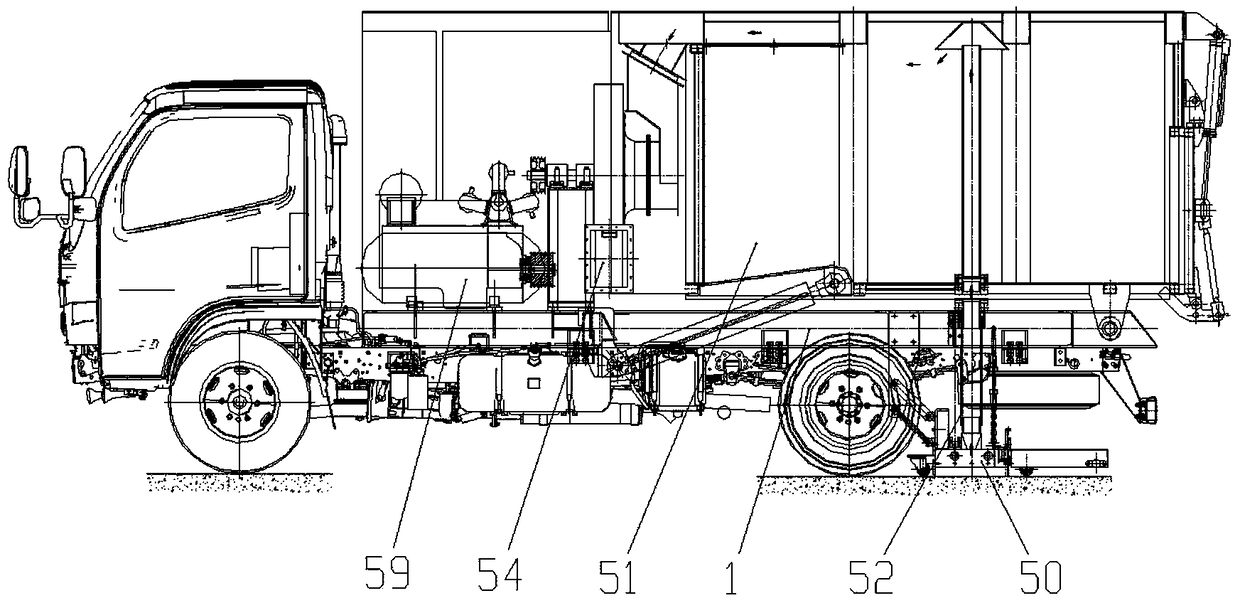

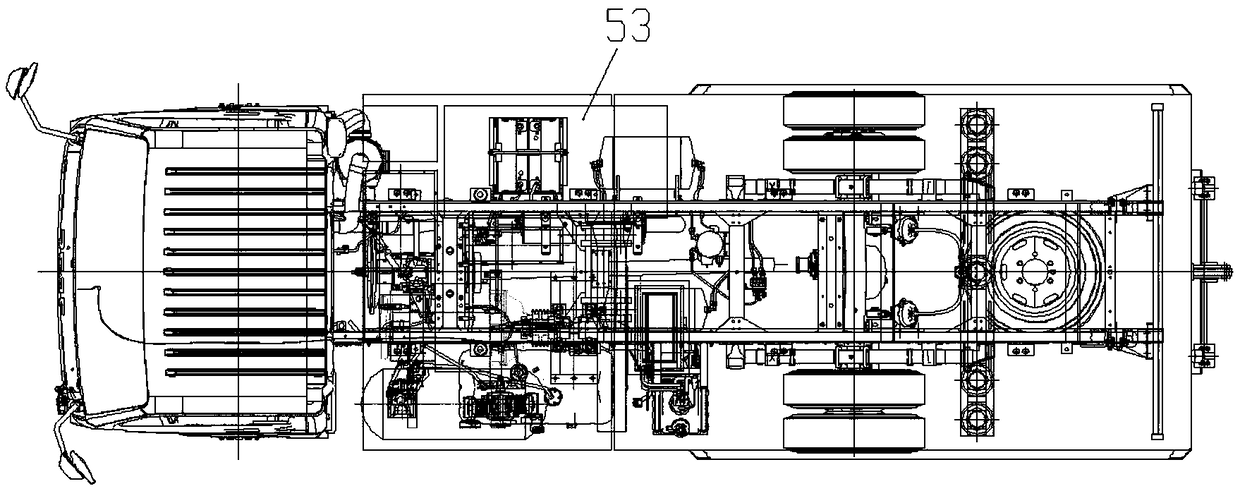

Road surface vacuum sweeper

The invention relates to a road surface cleaning device, in particular to a road surface vacuum sweeper. The vacuum sweeper comprises a vice vehicle frame, a suction nozzle assembly, a dust collecting box and a dust removing box, wherein the suction nozzle assembly, the dust collecting box and the dust removing box are installed on the vice vehicle frame cprrespondingly, the suction nozzle assembly is used for absorbing dust on the ground, the dust collecting box is connected with the suction nozzle assembly and used for collecting the partial dust, and the dust removing box is connected with the dust collecting box. According to the road surface vacuum sweeper, the dust absorbing rate is high, dust and particulate matter absorbing, separating and conveying are integrated.

Owner:CHANGSHA WEINUO ELECTROMECHANICAL

Dust-containing gas treatment device

PendingCN110604990ALow costReduce energy consumptionCombination devicesUsing liquid separation agentWater pipeProduct gas

The invention discloses a dust-containing gas treatment device, which includes a housing; a mixed air inlet pipeline is arranged on one side of the shell; a clear water atomization electromagnetic valve is arranged on the mixed air inlet pipeline; a spiral water spraying pipeline electromagnetic valve is further arranged on the mixed air inlet pipeline; a sewage flow guide groove and a spiral flowguide plate are arranged in the shell; capillary holes are further formed in the spiral water spraying pipe; the water outlet direction of the capillary holes points to the inner wall of the shell; an inner cylinder is further arranged in the center of the shell; the shell is also provided with a combination part; a blow-off water pipe is also arranged at the lowermost part of the shell; and theblow-off water pipe is fixedly connected with the shell through a flange. The device has the advantages that: the blow-off water pipe and the shell are fixedly connected together; the dust remover ishigh in efficiency, simple to operate, low in manufacturing cost, low in energy consumption, free of moving parts, free of secondary dust, low in maintenance cost, compact in structure and capable ofonly consuming a small amount of water, the part can be recycled, and available components contained in recycled sewage are convenient to comprehensively utilize.

Owner:BENGANG STEEL PLATES +1

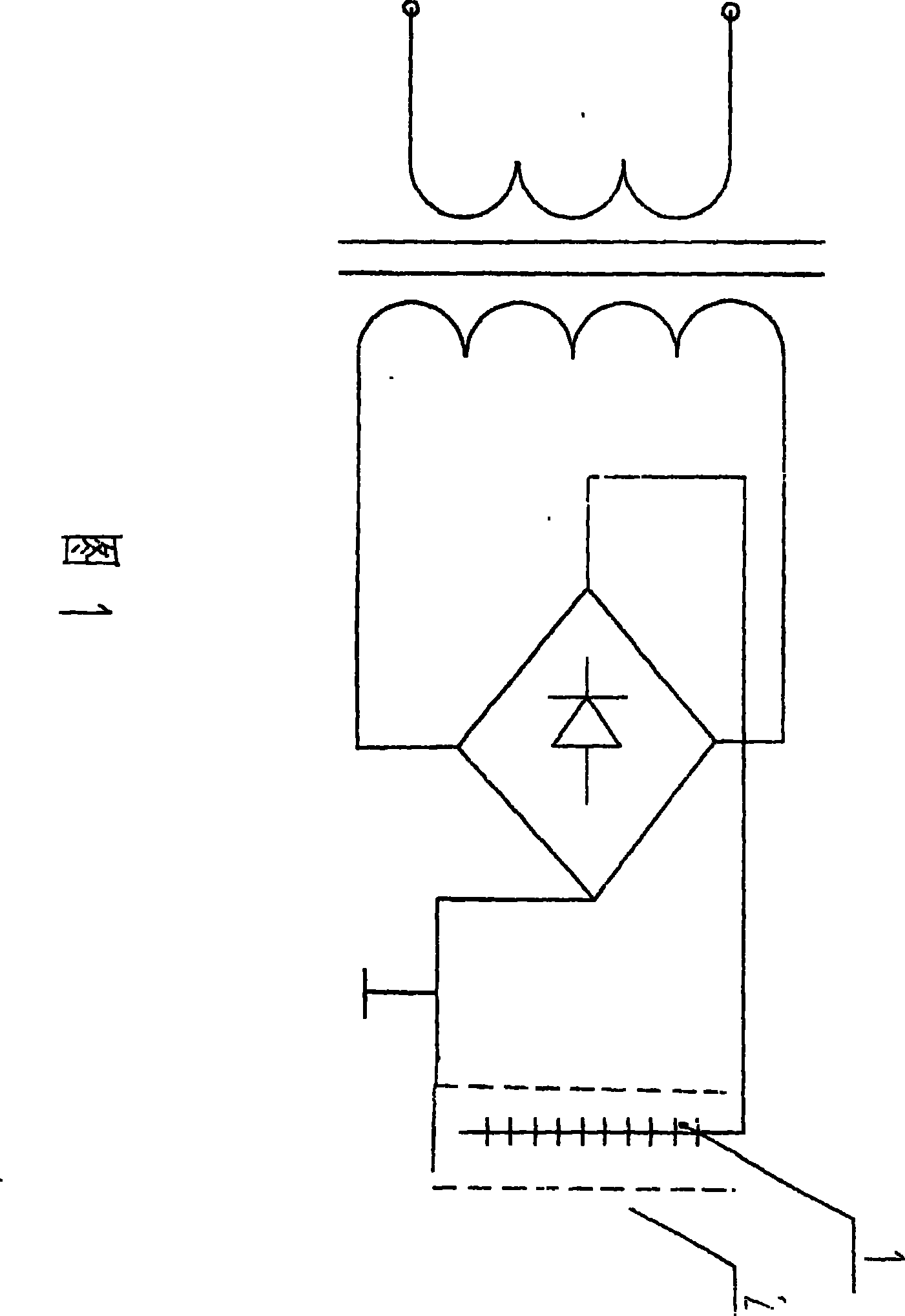

Electric dust collector with ultra- low concentration discharge

InactiveCN101130180BSimple structureLower internal resistanceExternal electric electrostatic seperatorElectrode constructionsElectricityCorona discharge

The invention discloses a hyperlow density discharge electric dedusting device of industrial smoke, which comprises the following parts: box body, intake box and ventilating box at two ends of box, ash bucket at lower part of the box, permeability dust collection block and corona discharge wire in the box body, absorbent electric field with multiple transverse dust collection grids in perpendicular to flow moving direction with equal distance and paralleling alternatively, deashing beating device on the corona discharge wire and dust collection board separately, wherein the dust collection board has multiple ventilation holes; one or more block grid net is set in each block grid of absorbent electric field with damper to seal air-out end at air-out position. The invention eliminates sub-micron graded smoke particle effectively to avoid secondary dust to reduce bulk and cost.

Owner:SHENYANG LONGDA ENVIRONMENTAL PROTECTION

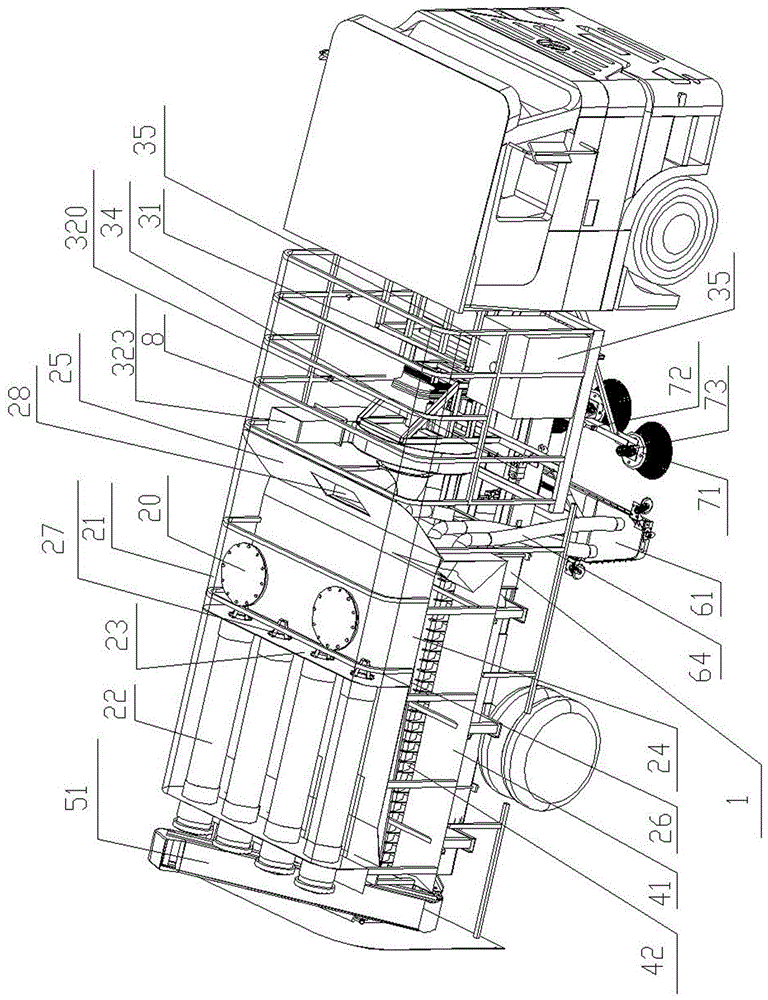

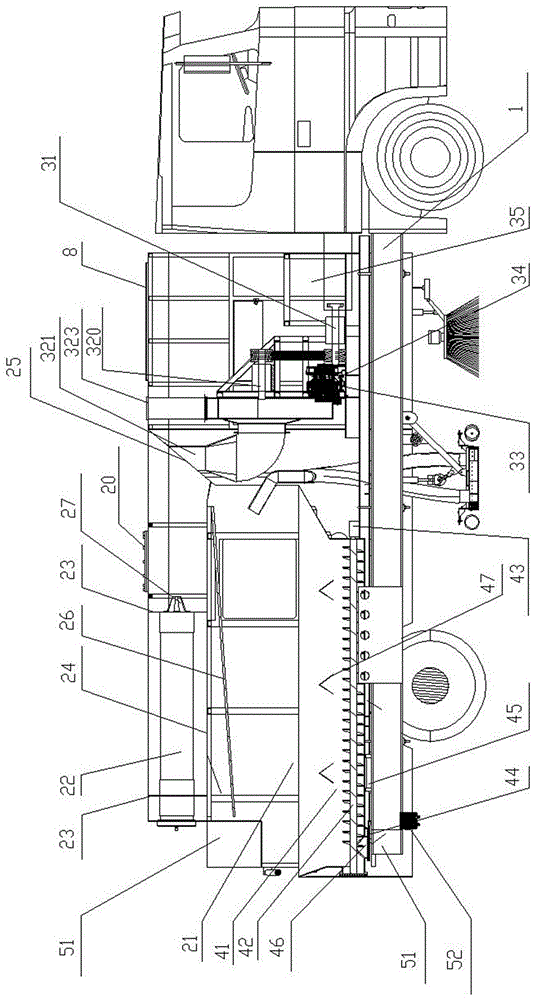

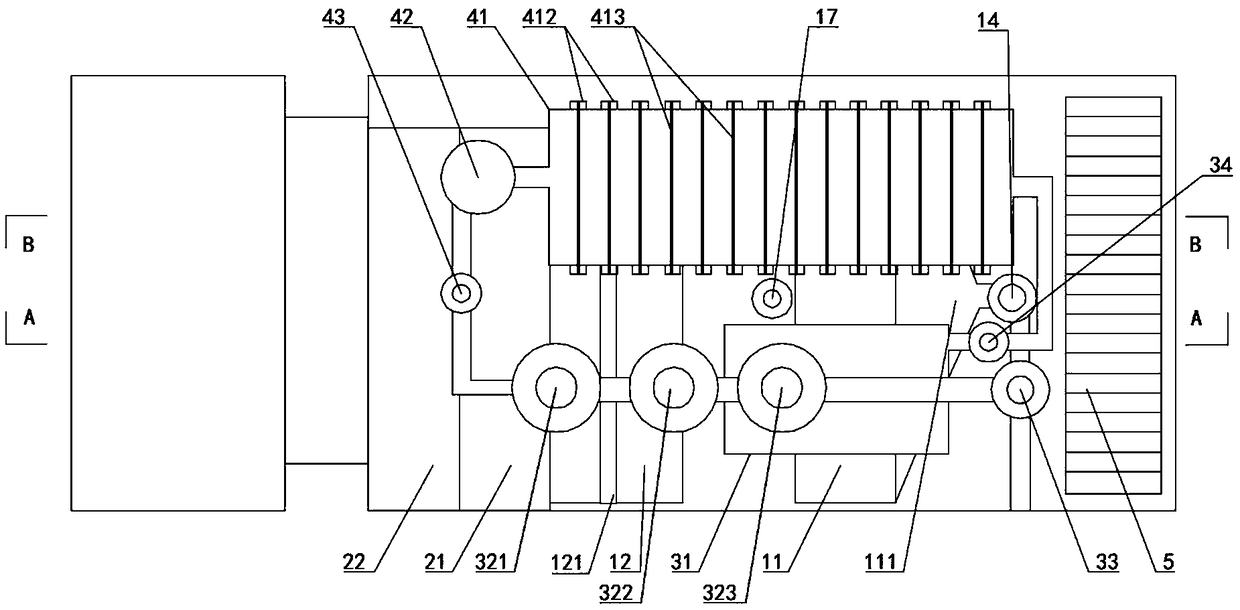

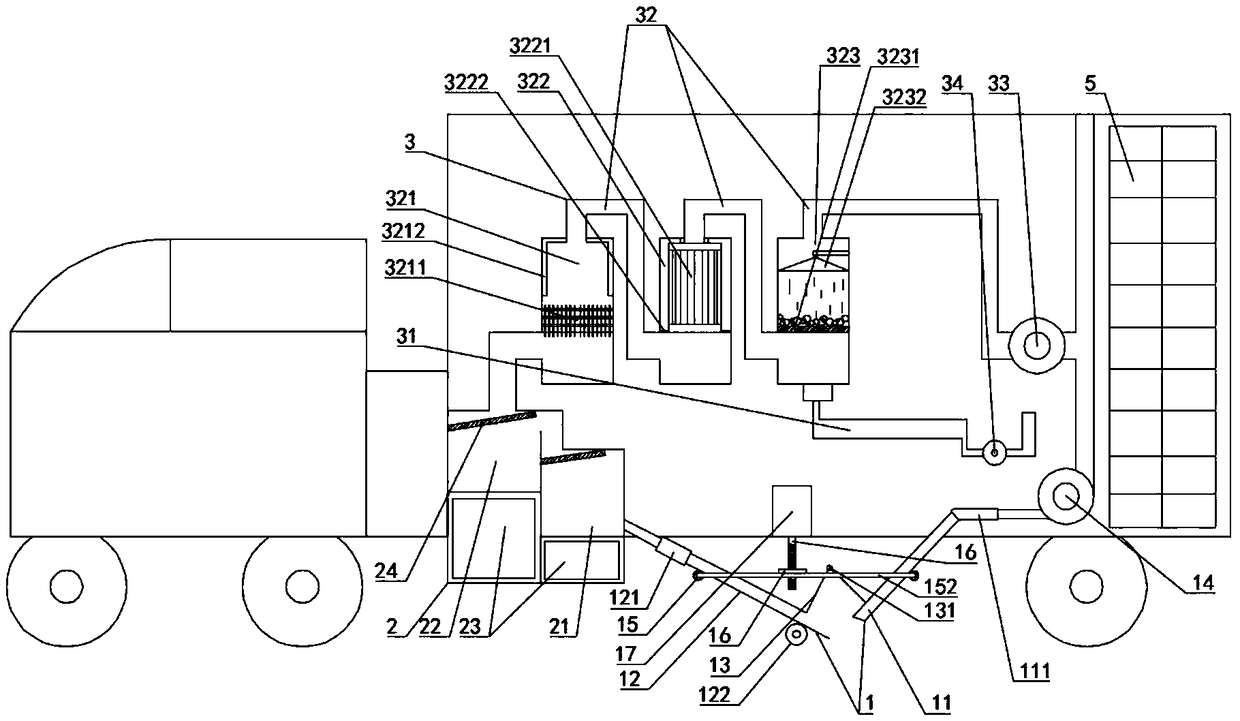

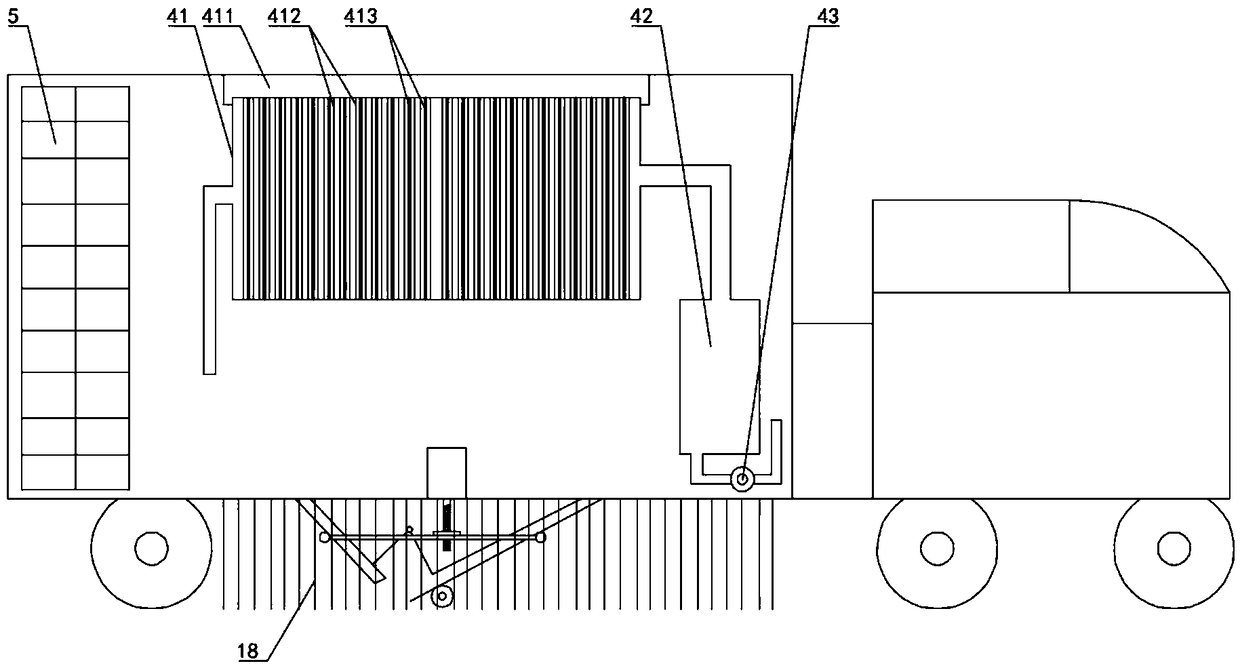

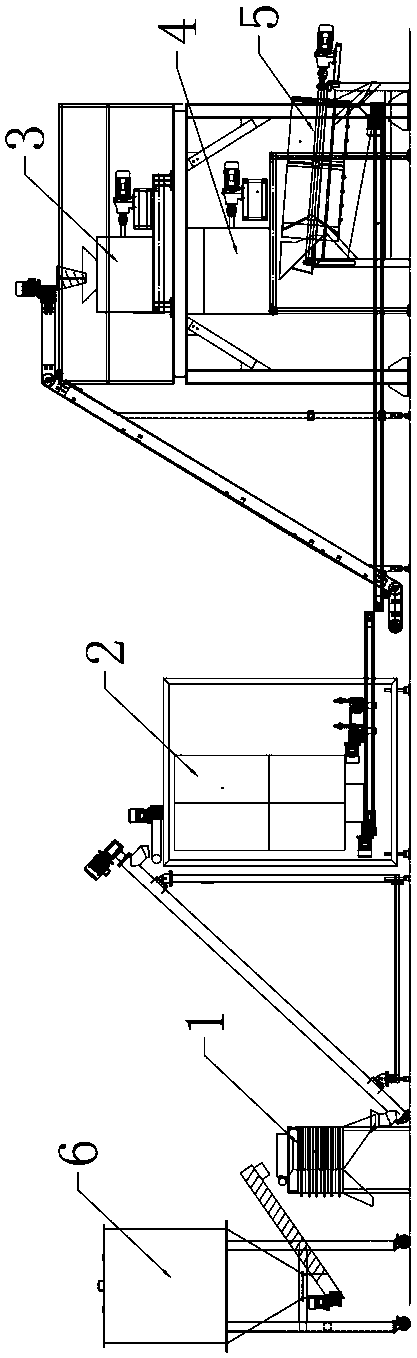

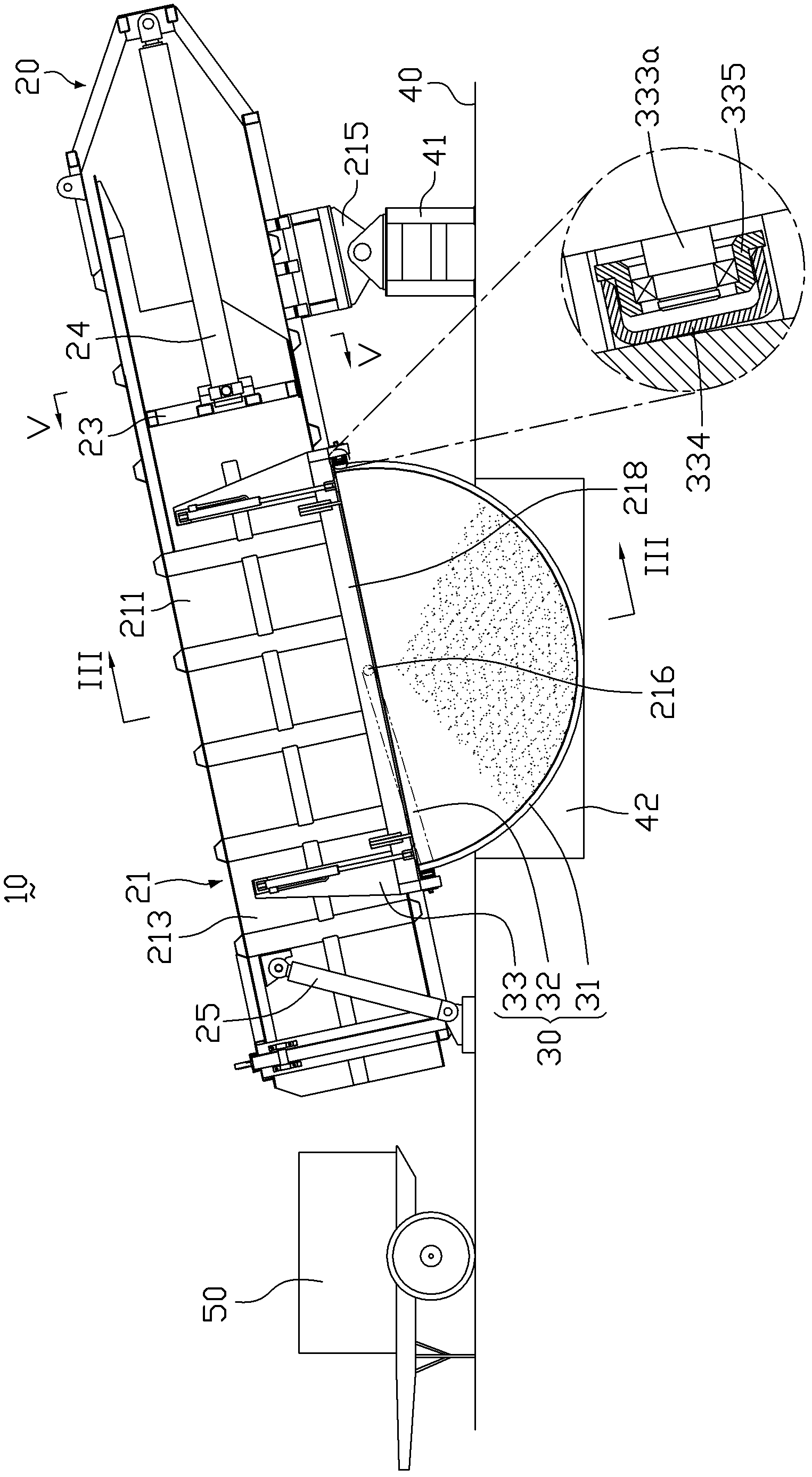

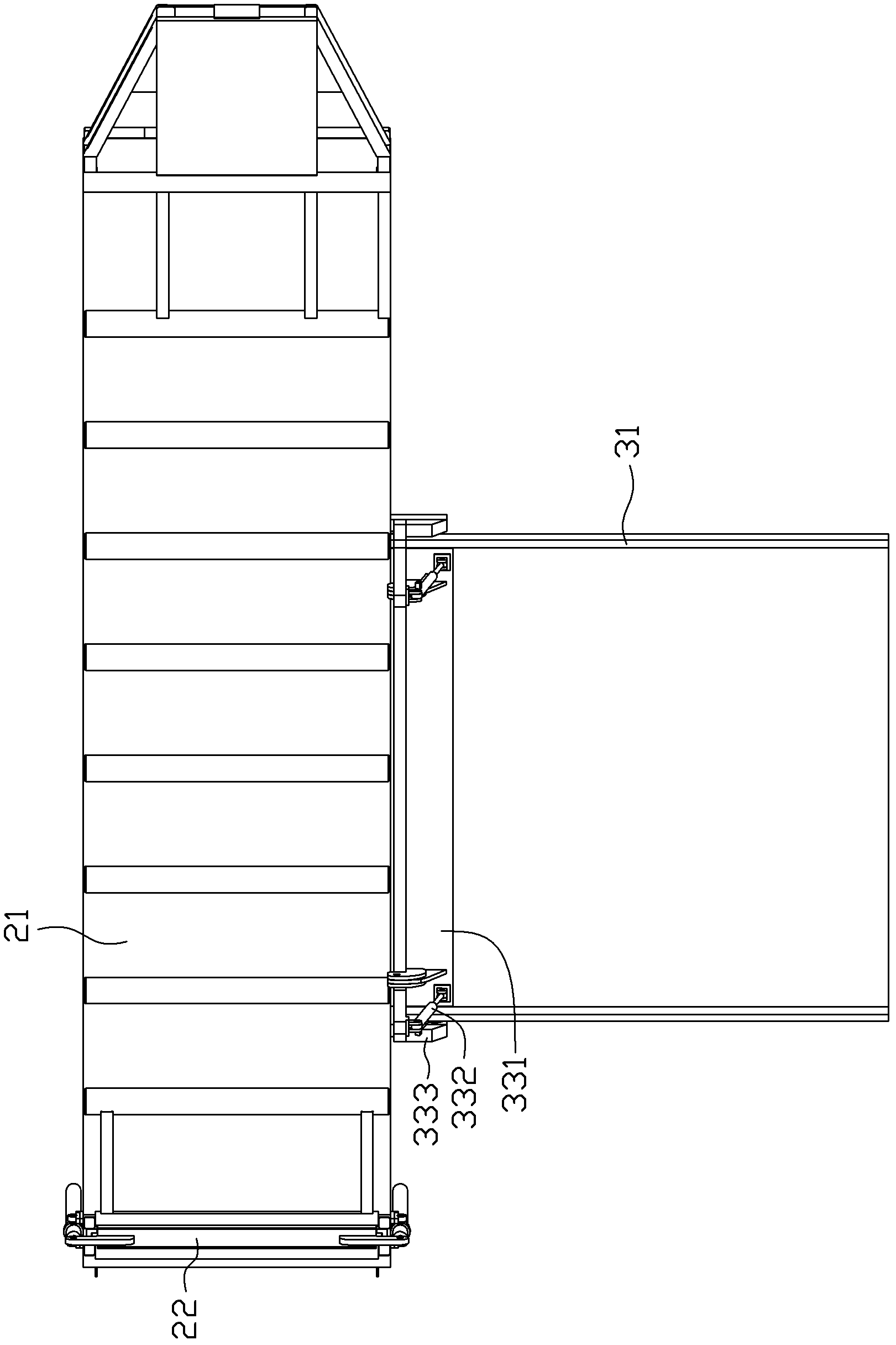

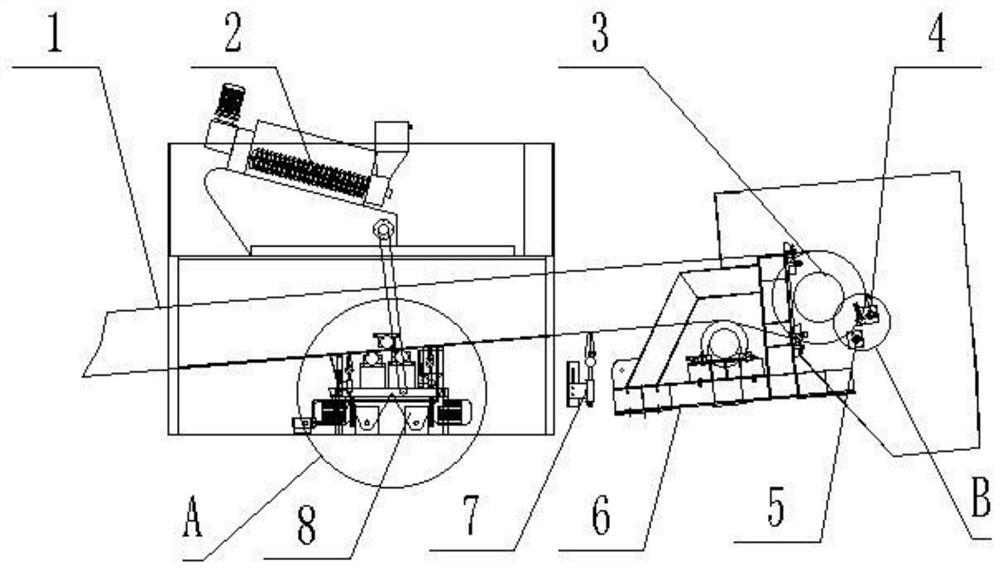

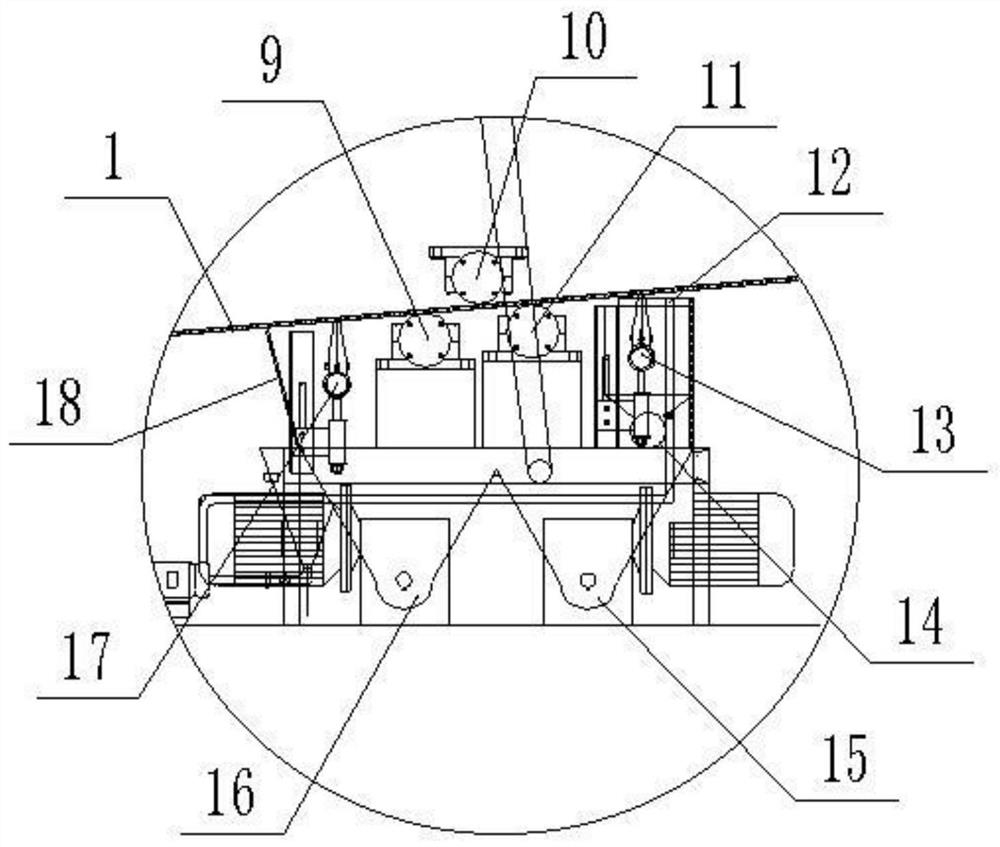

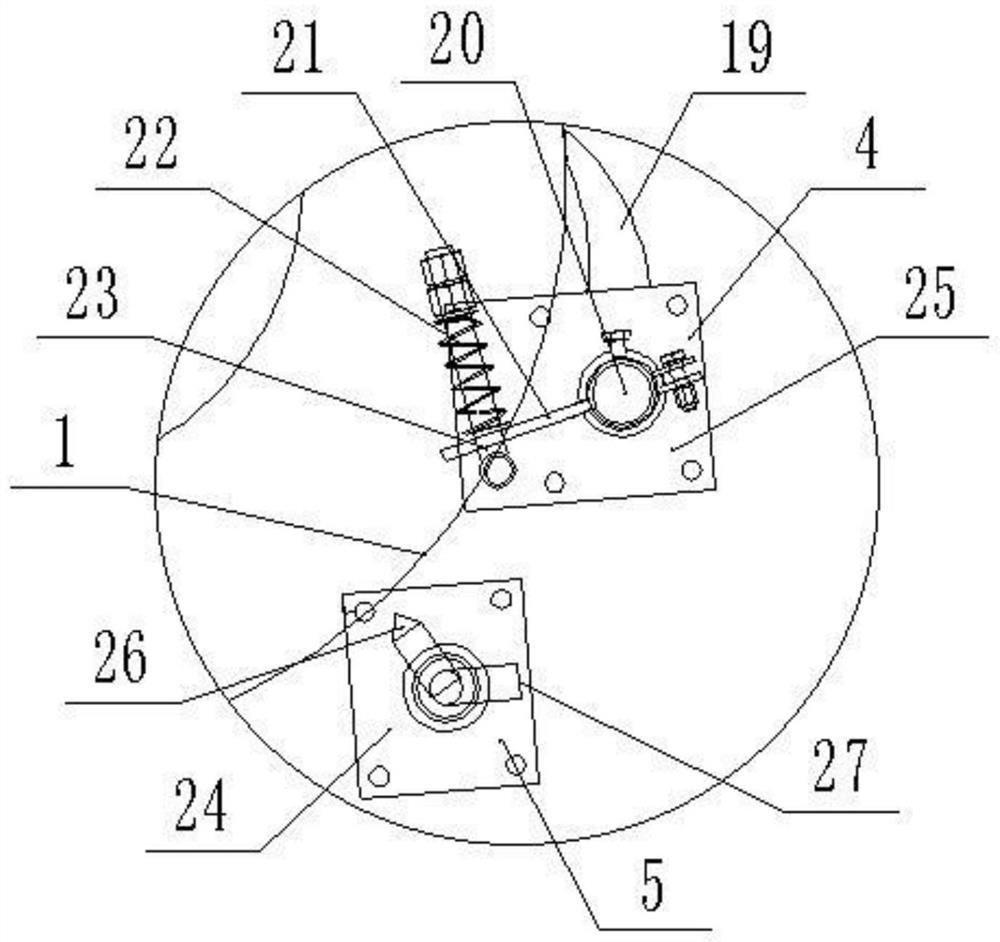

Auxiliary-power-free sweeper

The invention discloses an auxiliary-power-free sweeper. The auxiliary-power-free sweeper comprises an automobile chassis, a power part, a garbage box part, a hopper part, a folding belt conveying part, a suction nozzle part and a sweeping plate part, wherein the automobile chassis extracts force at full power, and the garbage box part, the hopper part, the folding belt conveying part, the suction nozzle part and the sweeping plate part are connected with the power part. The power part, the hopper part, the folding belt conveying part and the sweeping plate part are arranged on the automobile chassis. The garbage box part is arranged on the top of the hopper part and communicated with the hopper part. The suction nozzle part is arranged at the bottom of the automobile chassis and connected with the garbage box part. The auxiliary-power-free sweeper is high in efficiency, low in cost, large in suction, good in cleaning effect and high in safety performance, and energy saving and environmental friendliness are achieved; no secondary pollution exists; the auxiliary-power-free sweeper is suitable for multiple occasions including urban road environmental sanitation, harbor districts, wharfs, production factories, coal mines, chemical industry, iron and steel enterprises and the like and especially suitable for high-speed milling-planing road surface suction sweeping work.

Owner:HUNAN XINYONGLI JIAOTONG KEGONG MAO CO LTD

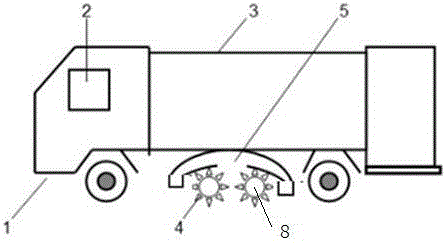

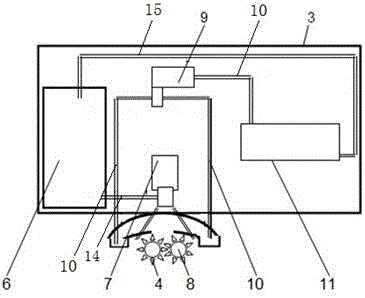

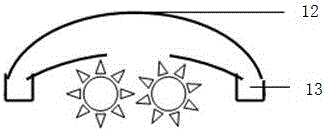

Road cleaning vehicle and road surface cleaning method thereof

InactiveCN106049324AHigh cleaning efficiencyReduce PM2.5 contentRoad cleaningSludgeWater storage tank

The invention relates to a road cleaning vehicle and a road surface cleaning method thereof. The road cleaning vehicle is characterized in that the vehicle comprises a road brushing and sweeping engineering working vehicle, a console, an outer cover, a rotary cleaning brush, a muddy water collection tank, a water storage tank, a water pump, a drive motor, a mud pump, a mud conveying pipeline, a filter press unit, and a water pipe. The console is arranged in a cab of the road brushing and sweeping engineering working vehicle; the outer cover covers on the road brushing and sweeping engineering working vehicle in an inverted mode; the rotary cleaning brush is arranged below the road brushing and sweeping engineering working vehicle; the muddy water collection tank is arranged above the rotary cleaning brush in an inverted covering mode; and the water storage tank, the water pump, the drive motor, the mud pump, the mud conveying pipeline, and the filter press unit are arranged in the space that is formed by inverted covering of the outer cover. The road cleaning vehicle has the following advantages: firstly, the cleaning efficiency is high; secondly, cleaning can be carried out completely; no secondary dust floating is caused; fourthly, no muddy water flowing into a sewer, so that pollution is avoided and sewer blocking is also prevented; and fifthly, mud and water separation is carried out on sludge by the filter press unit, so that water saving and energy conservation are realized.

Owner:JIANGSU ZHUODIAN DRILLING & TUNNELING TECH CO LTD

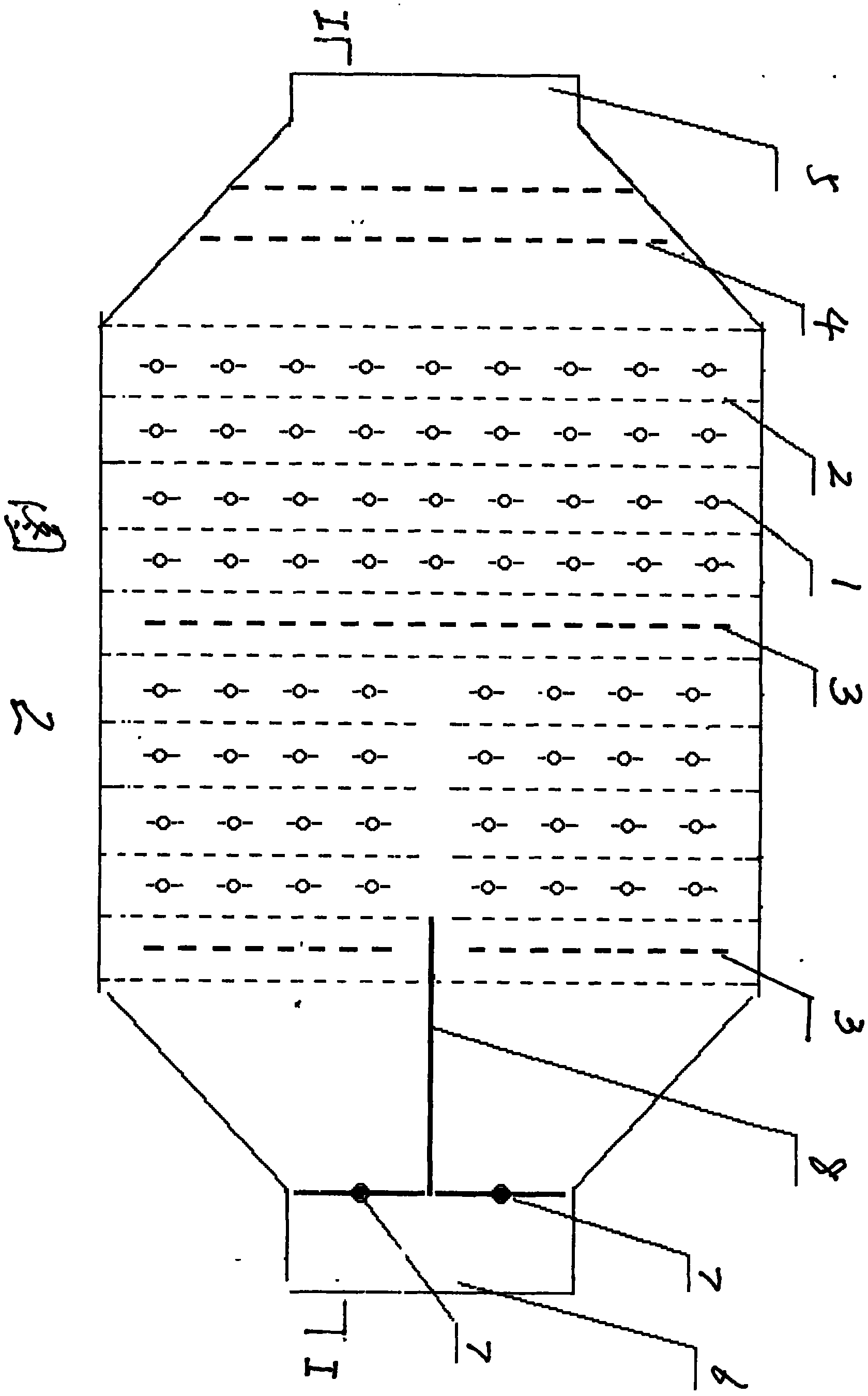

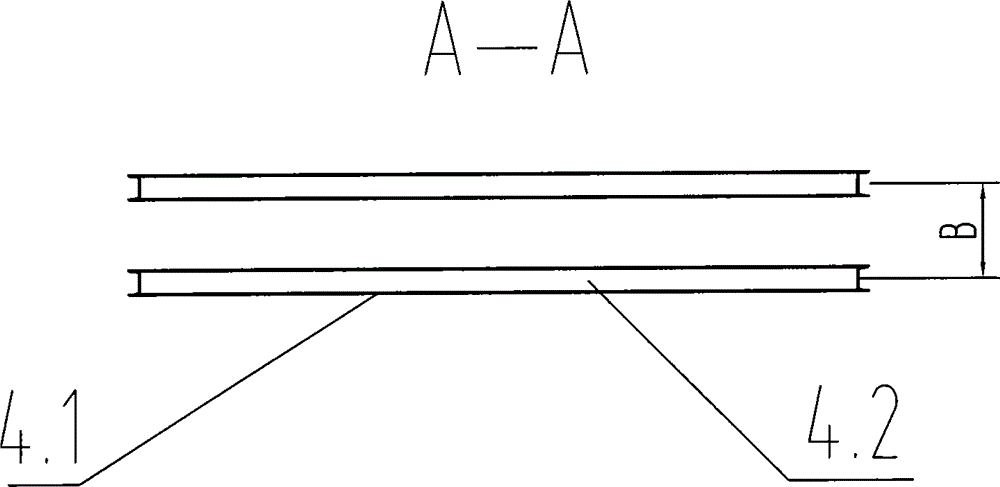

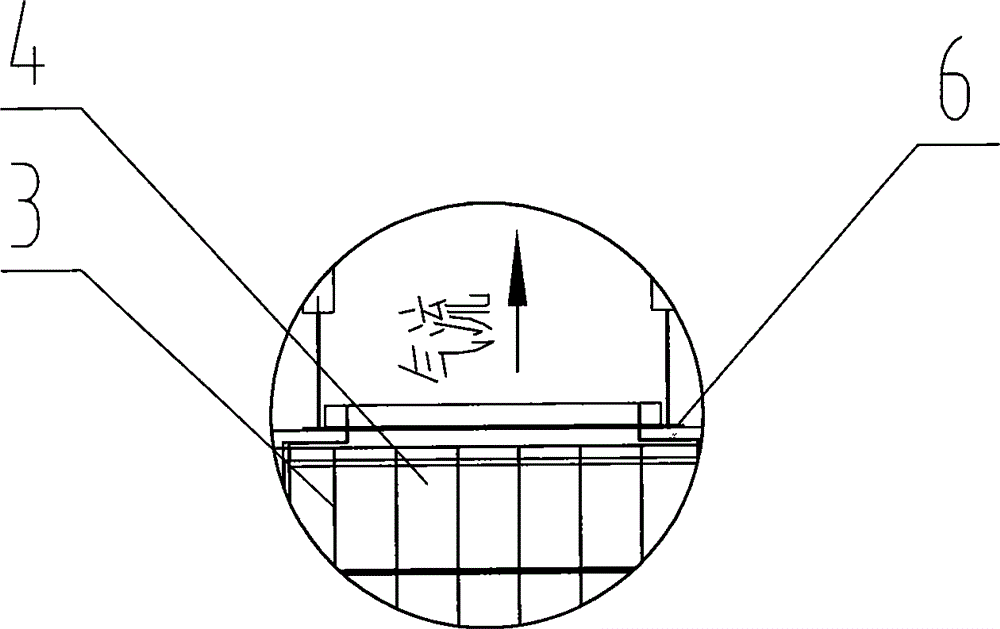

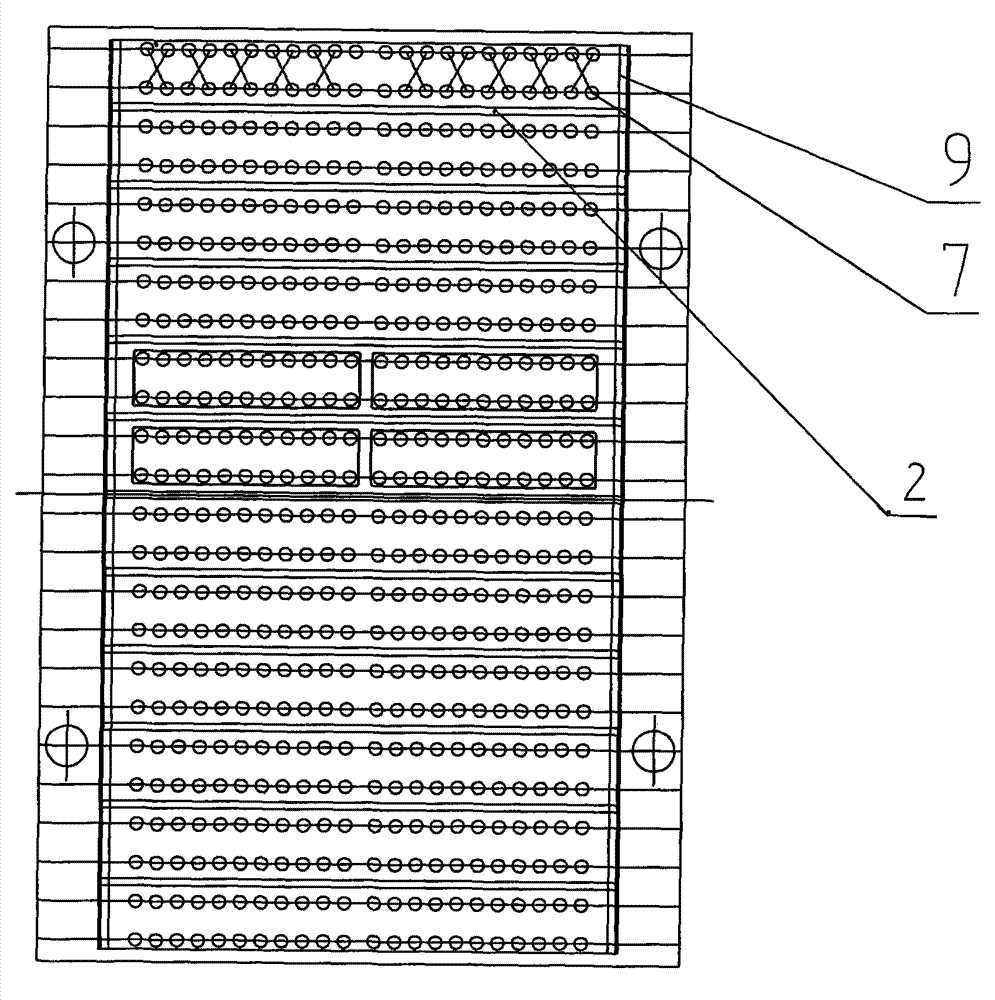

Filter plate type electrostatic precipitator

InactiveCN104668096APlay a filtering roleIncrease collection speedElectrode constructionsElectrodes cleaningElectric fieldAirflow

The invention relates to a filter plate type electrostatic precipitator. An anode row of the precipitator consists of a plurality of parallelly arranged box type filter plates; the box type filter plates are suspended on a suspending beam in a precipitator shell and are in alternative arrangement with a discharge electrode row, so that the filter plate box bodies configured in the shell and the discharge electrode row suspended among the filter plates form positive and negative electrode systems of the electrostatic precipitator; rapping devices are arranged at two sides of the cathode row and the anode row for rapping the cathode row configured at the electrode interval B and the filter plate box bodies periodically; upper opening ends of the filter plate air ducts are communicated with the air exhaust channels at the top of the precipitator; an electric field and a metal filter plate form a composite dust precipitation chamber, and dust attached to the outer surface of the filter plate falls into a dust hopper. According to the invention, the bidirectional dust precipitation under the action of electric field power and air flow power does not generate secondary dust flying; the system resistance is relatively low, and is less than or equal to 500Pa; the dust filtering and precipitation speed is improved by 60 times; the service life of a filter cartridge can reach 10 years; the dust precipitation efficiency Eta is greater than or equal to 99.95%; the absorption of fine dust (not greater than 1 micron) can meet the PM2.5 emission requirement.

Owner:BODI WEAPON MAKES

Pure electric washing and sweeping vehicle

InactiveCN111691342AStrengthenAvoid the disadvantages of suspended depressionRoad cleaningControl systemHigh pressure water

The invention relates to a pure electric washing and sweeping vehicle. The vehicle comprises: a driving and braking system used for driving and braking the washing and sweeping vehicle; a chassis system used for assembling equipment of the washing and sweeping vehicle and a washing and sweeping assembly thereof; a power supply power system used for storing and conveying a power source required bythe washing and sweeping vehicle; a washing and sweeping system used for washing, sweeping and cleaning the road surface; a high-pressure water pump power system used for pumping out water conveyed ina water path in the washing and sweeping vehicle, connected with a waterway control system and providing waterway power required by the waterway control system; the waterway control system used for controlling a flushing function; and a sewage recycling and dumping system used for recycling sewage and garbage and dumping garbage. The pure electric washing and sweeping vehicle is designed in a pure electric mode, no tail gas is discharged, and the vehicle is more environmentally friendly; and due to the modular design, daily maintenance is facilitated. And the vehicle body is variable in size,low in noise and suitable for communities and lanes. And the cleaning and sweeping system is flexible, and multiple functional purposes such as curbstone flushing, road surface oil stain cleaning, green belt watering and advertising board cleaning can be achieved.

Owner:ANHUI NANBO ROBOT CO LTD

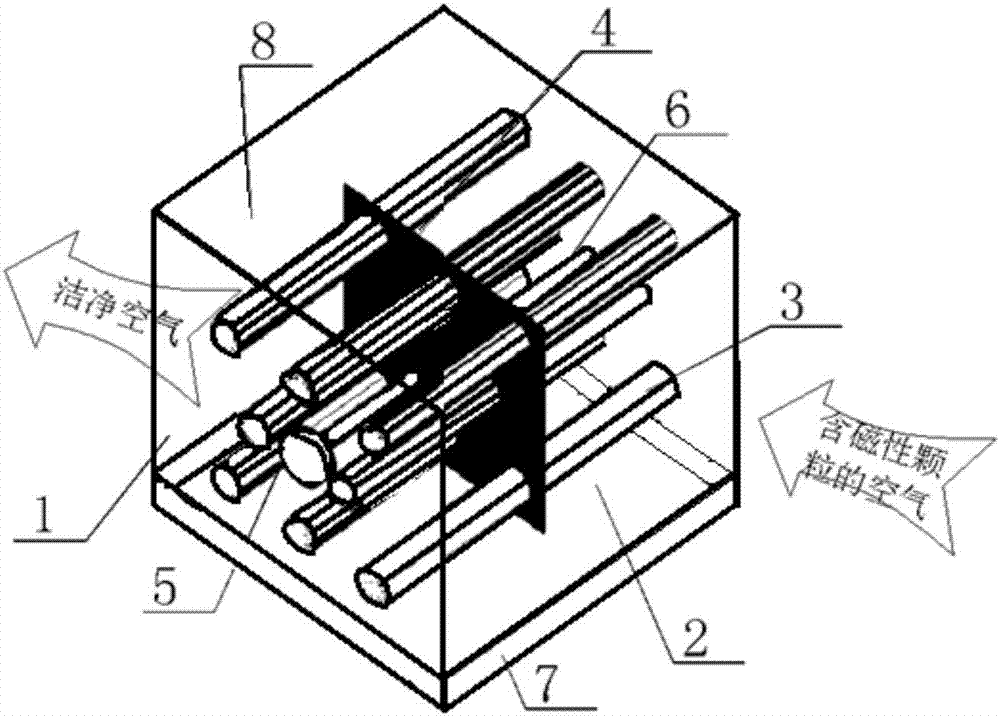

Self-cleaning type magnetic particle separating device

PendingCN107497596AExtended cleaning cycleLow maintenanceCleaning using toolsMagnetic separationMotor driveMagnetic poles

The invention relates to a self-cleaning type magnetic particle separating device. The self-cleaning type magnetic particle separating device comprises a shell, an air inlet, magnetic bodies, a dust extraction plate, a motor, a rotating shaft, a dust raise preventing dust collecting box and an air outlet, the air inlet is formed in one end of the shell, the air outlet is formed in the other end of the shell, the dust raise preventing dust collecting box is arranged at the bottom of the shell, all magnetic bodies are transversely arranged in an air runner in an arrayed manner, and the dust extraction plate is arranged on multiple magnetic poles in a sliding and penetrating manner. According to the self-cleaning type magnetic particle separating device, in the dust extraction manner, air containing magnetic particles enters the self-cleaning type magnetic particle separating device through the air inlet to be attracted to the magnetic bodies, and clean air flows out from the air outlet; under the self-cleaning mode, the motor drives the dust extraction plate to move along the magnetic bodies, the particles are separated from the magnetic bodies, the separated particles sink into the dust raise preventing dust collecting box under the action of gravity, a surface magnetic plate and a middle magnetic plate are arranged inside the dust raise preventing dust collecting box, and therefore the sinking magnetic particles can be effectively attracted, and reentrainment of dust is avoided. The self-cleaning type magnetic particle separating device has the beneficial effects of being long in cleaning period, low in maintaining cost, free of reentrainment of dust and the like.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO

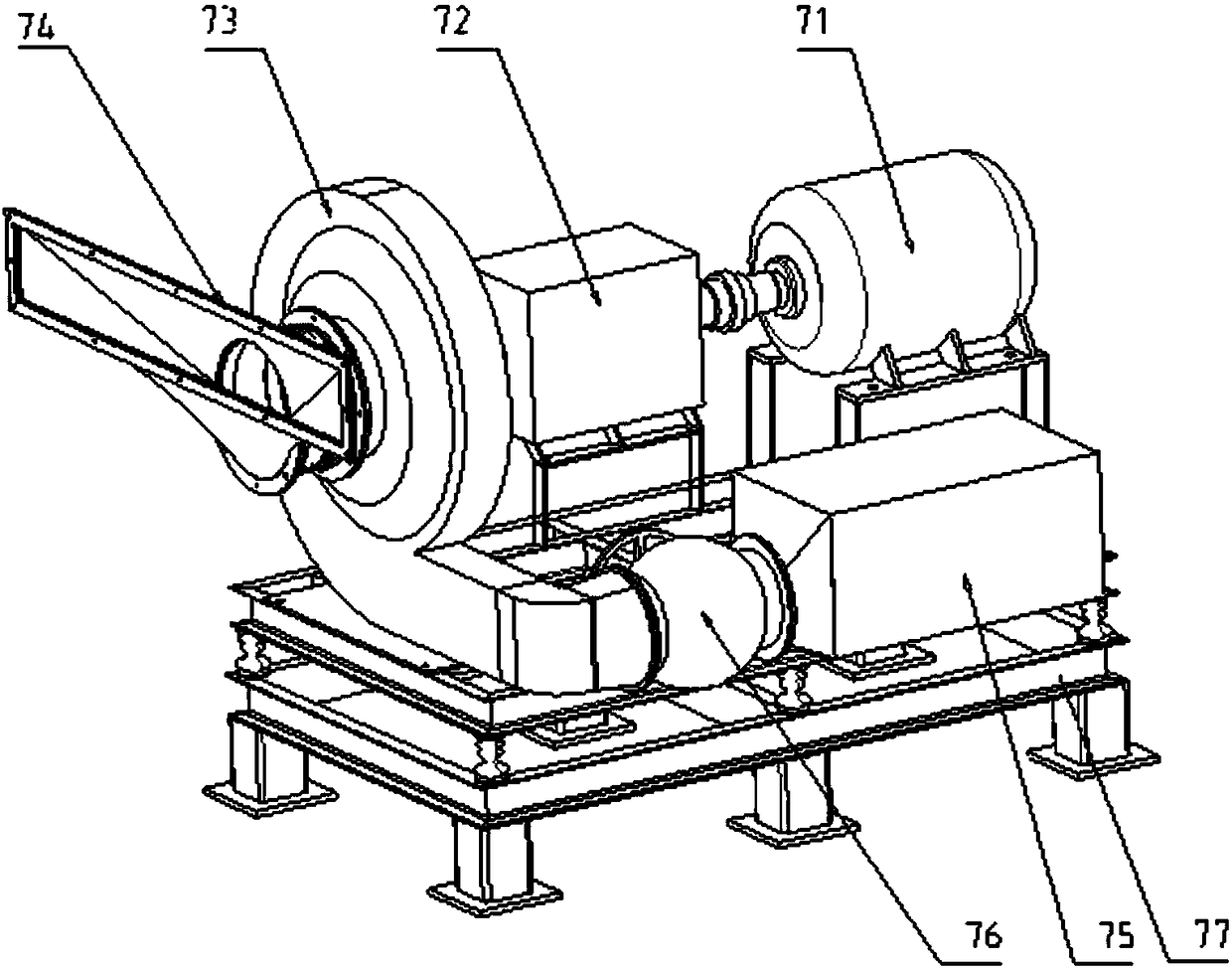

Novel efficient air-flowing type floor cleaning vehicle

PendingCN108824312APrevent overflowImprove work efficiencyCombination devicesElectrostatic separationWater storage tankRechargeable cell

The invention relates to a novel efficient air-flowing type floor cleaning vehicle. The novel efficient air-flowing type floor cleaning vehicle comprises a blowing-sucking device, a settling device, an air purifying mechanism, a water purifying mechanism and a rechargeable battery pack, wherein the blowing-sucking device comprises an air blowing passage plate and an air sucking passage plate, theair blowing passage plate and the air sucking passage plate are in V-shaped arrangement, the air blowing passage plate and the air sucking passage plate are fixedly connected with sealing plates, thebottom of the air sucking passage plate is provided with a roller, the air blowing passage plate is connected with a high pressure draught fan, the settling device is connected with the air sucking passage plate and the air purifying mechanism respectively, the air purifying mechanism comprises a sewage collection tank and an air purifying device, the sewage collection tank is communicated with the air purifying device, the air purifying device is connected with the settling device, the air purifying device is connected with an exhaust fan, the sewage collection tank is connected with a firstwater pump, the water purifying mechanism comprises a sewage filtering device, a clear water storage tank and a second water pump, the sewage filtering device is connected with the first water pump, the second water pump is connected with the air purifying device, and the rechargeable battery pack provides powder for the high pressure draught fan, the exhaust fan , the first water pump and the second water pump.

Owner:曹梅君

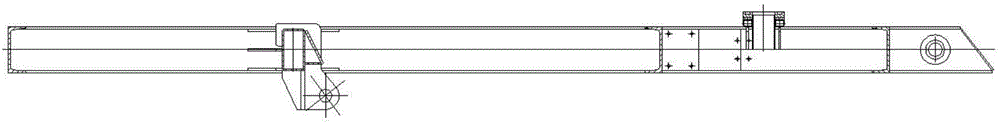

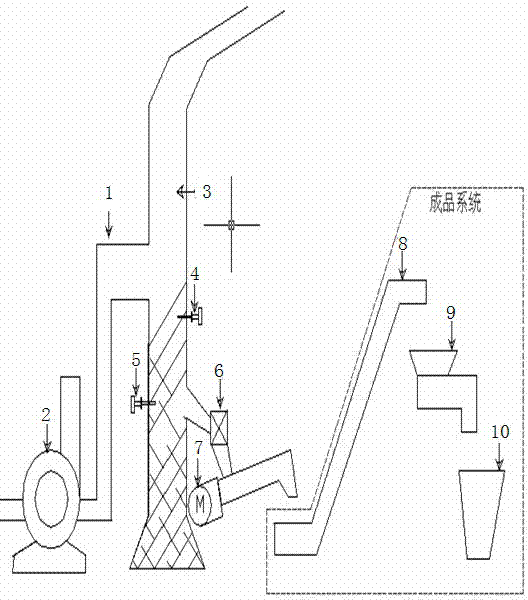

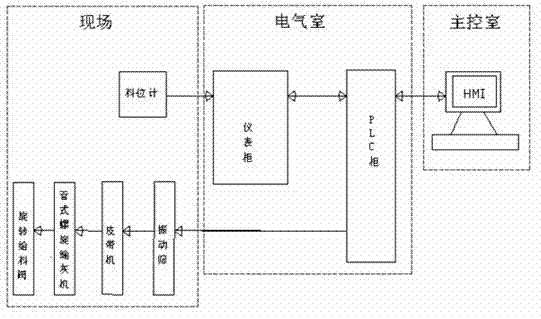

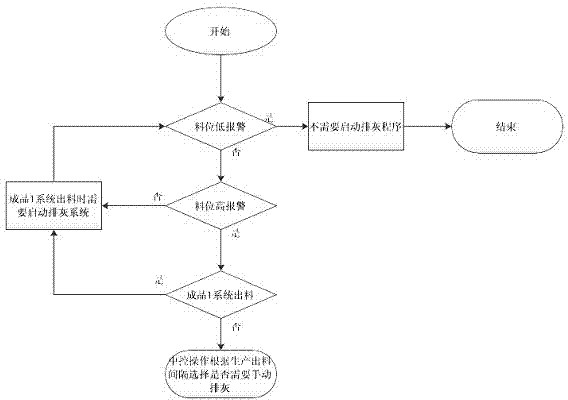

Sleeve kiln exhaust gas flue ash discharge system and control method thereof

ActiveCN103939926AGuarantee unimpededAvoid heavy duty operationControl devices for furnacesSolid removalProduct systemEngineering

The invention provides a sleeve kiln exhaust gas flue ash discharge system and a control method thereof. The sleeve kiln exhaust gas flue ash discharge system comprises a level gauge, a rotary feeding valve, a pipe-type screw conveyer and a finished product system. The level gauge is arranged in a kiln body exhaust gas pipe; one end of the rotary feeding valve is connected with the kiln body exhaust gas pipe, and the other end of the rotary feeding valve is connected with the pipe-type screw conveyer; the finished product system comprises a belt conveyer, a vibrating screen and an ash storage bin, and one end of the belt conveyer is arranged at an outlet of the pipe-type screw conveyer; an inlet of the vibrating screen is arranged at the position of an outlet of the belt conveyer; the ash storage bin is arranged at the position of an outlet of the vibrating screen. The sleeve kiln exhaust gas flue ash discharge system further comprises an instrument cabinet, a PLC cabinet and an HMI, and the PLC cabinet is connected with the instrument cabinet and the HMI. When accumulated ash in a waste gas flue reaches a value at which ash needs to be discharged, the level gauge sends out a signal, the accumulated ash is conveyed to the ash storage bin through the rotary feeding valve and the pipe-type screw conveyer, therefore, it is guaranteed that the flue is kept smooth at any time, normal negative pressure in a sleeve kiln can be guaranteed, and meanwhile safe and environment-friendly production can be guaranteed.

Owner:NANJING MEISHAN METALLURGY DEV +1

Steelmaking slag treatment dust removing system of AOD furnace

InactiveCN105749686AReduce resistanceHandling large air volumeCombination devicesSteelmakingCyclonic spray scrubber

The invention relates to a steelmaking slag treatment dust removing system of an AOD furnace.The steelmaking slag treatment dust removing system comprises a hopper dust suction hood and a discharging port dust suction hood, and is characterized in that the hopper dust suction hood is arranged on a slag feeding hopper and connected with a hopper dust removing pipeline, the discharging port dust suction hood is arranged at a slag discharging port and connected with a discharging port dust removing pipeline, the discharging port dust removing pipeline is communicated with the hopper dust removing pipeline, the hopper dust removing pipeline is connected with a concentration main pipeline, and the concentration main pipeline is communicated with an air inlet of a cyclone dust remover.An air outlet of the cyclone dust remover is communicated with a draught fan.An air outlet of the draught fan is provided with a water membrane dust remover.The steelmaking slag treatment dust removing system of the AOD furnace is compact in designed structure, capable of saving ground, and high in stability, reliability and dust removing efficiency due to the fact that the unique smoke dust purifying system is arranged oriented to slag features of the AOD furnace.

Owner:WUXI SANDA ENVIRONMENTAL PROTECTION TECH CO LTD

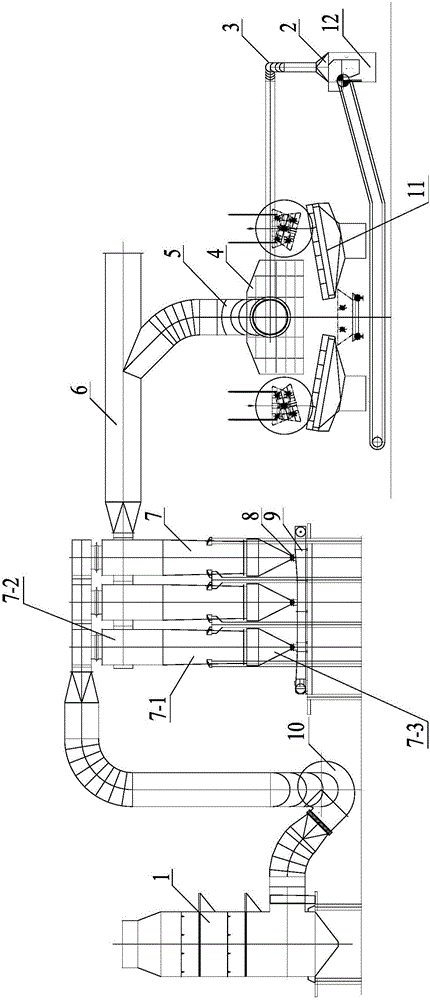

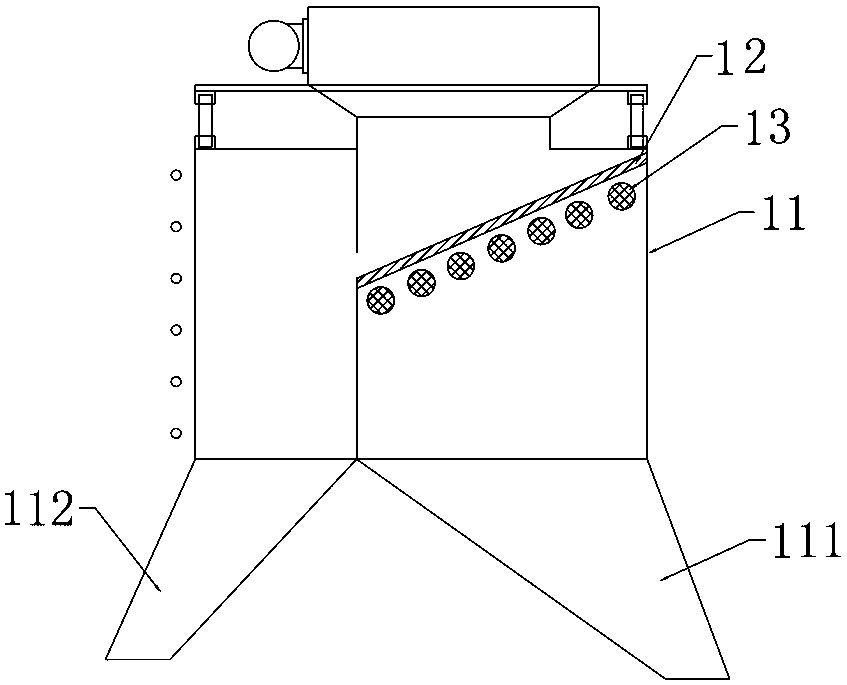

Ceramic tail powder material recycling treatment process and system

PendingCN108705657AFacilitation of the recycling processMeet production needsSievingScreeningMaterials preparationHardness

The invention discloses a ceramic tail powder material recycling treatment system. A sieving station, a humidifying station, an extruding station, a crushing and pelletizing station and a screening station are sequentially arranged along a tail powder material recycling treatment path, wherein tail powder materials are fed into the sieving station to be subjected to sieving and iron removing treatment so that sieved powder materials can be obtained; the humidifying station is provided with a humidifying device used for performing quantitative humidifying on the sieved powder materials, and therefore humidified powder materials with a preset water content are formed; the extruding station is provided with an extruding mechanism used for extruding the humidified powder materials to form blocky materials with proper hardness; the crushing and pelletizing station is provided with a crushing device used for performing crushing treatment on the blocky materials to form particle powder materials; and the screening station is provided with a device used for separating finished powder materials meeting the particle size requirement in the particle powder materials. The tail powder materialrecycling procedure is effectively improved, the production cost is greatly lowered, the finished powder materials meet the discharging requirement conforming to powder material preparation, and the characteristics that reentrainment of dust is avoided, cost is low, and direst inputting for production is achieved are achieved.

Owner:FOSHAN LANZHIJING SCI & TECH CO LTD

Dust removing device for copper plate of integrated circuit

InactiveCN111185414AImprove efficiencyComprehensive dust removalCleaning using toolsChemistryIntegrated circuit

The invention relates to the technical field of circuit board processing, in particular to a dust removing device for a copper plate of an integrated circuit. The dust removing device comprises a processing table, wherein a spiral dust removing roller made of silica gel is rotationally arranged above the processing table, the dust removing roller can be in contact with the copper plate, a spiral dust sticking roller capable of being engaged with the dust removing roller is arranged above the dust removing roller, an adhesive layer is arranged on the surface of the dust sticking roller, and a pushing mechanism for intermittently pushing the copper plate is arranged on the processing table. The dust removing device can solve the problem that in the prior art, secondary flying dust is easy togenerate due to brush dust removal and wind dust removal.

Owner:重庆市和鑫达电子有限公司

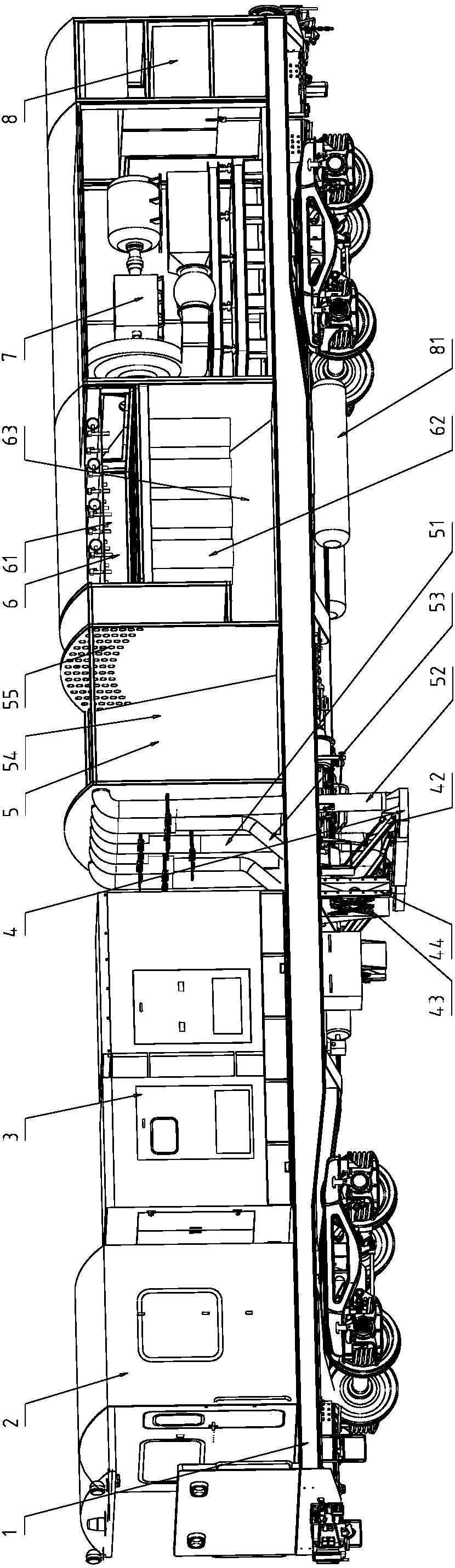

Suction-type track cleaning vehicle, method and application

ActiveCN106759057BProduce damageEasy to cleanRoad cleaningRailway cleaningPositive pressureEngineering

The invention relates to a blowing and suction type rail cleaning vehicle and method and application. The problem that in the prior art, a railway track bed and a railway culvert are hard to clean is solved, and the technical effect that a railway culvert wall and the track bed can be efficiently cleaned is achieved. The cleaning vehicle part mainly comprises a vehicle body, an operation room and a power room are arranged on the vehicle body, and a dust collection system, a garbage bin, a filtering room, a vacuum fan room and an air compressor room are further arranged on the vehicle body. The dust collection system comprises a track bed blowing and suction mechanism located below the vehicle body and tunnel wall suction mechanisms located on the two sides of the track bed blowing and suction mechanism; the track bed blowing and suction mechanism is driven by a lifting mechanism to vertically move; the tunnel wall suction mechanisms are driven by a telescopic mechanism to move left and right. The negative pressure air of the track bed blowing and suction mechanism and the tunnel wall suction mechanisms is from the vacuum fan room, and the positive pressure air of the track bed blowing and suction mechanism is from the air compressor room. The track bed blowing and suction mechanism and the tunnel wall suction mechanisms are all communicated with the garbage bin.

Owner:CRRC SHANDONG CO LTD

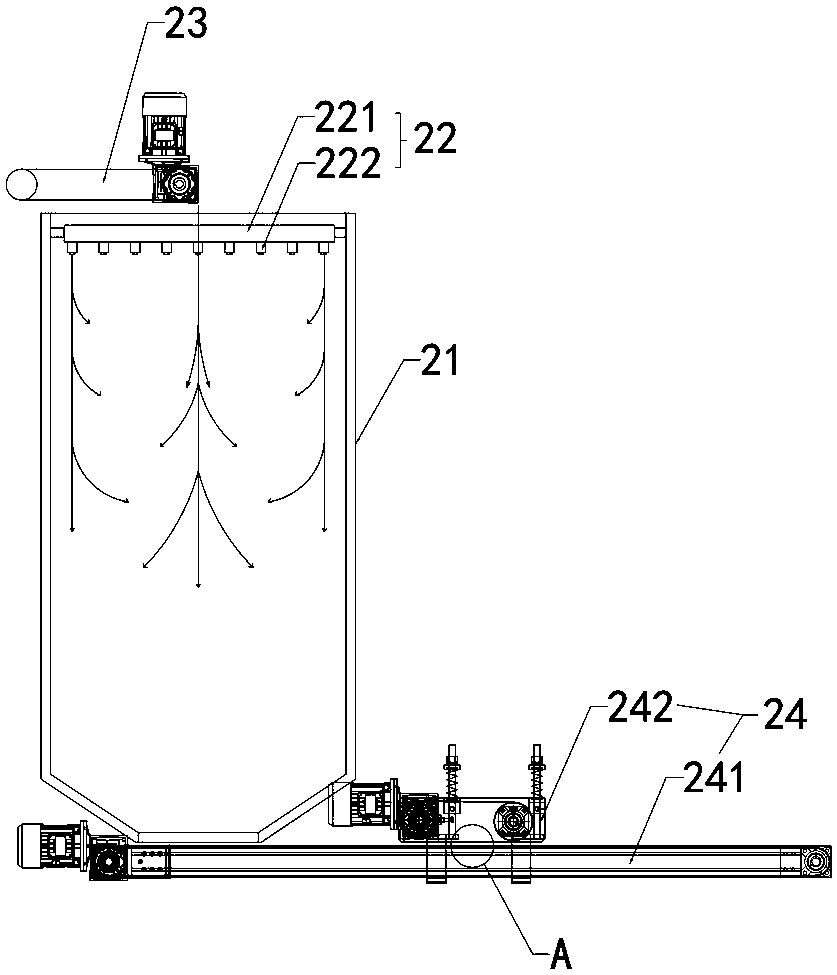

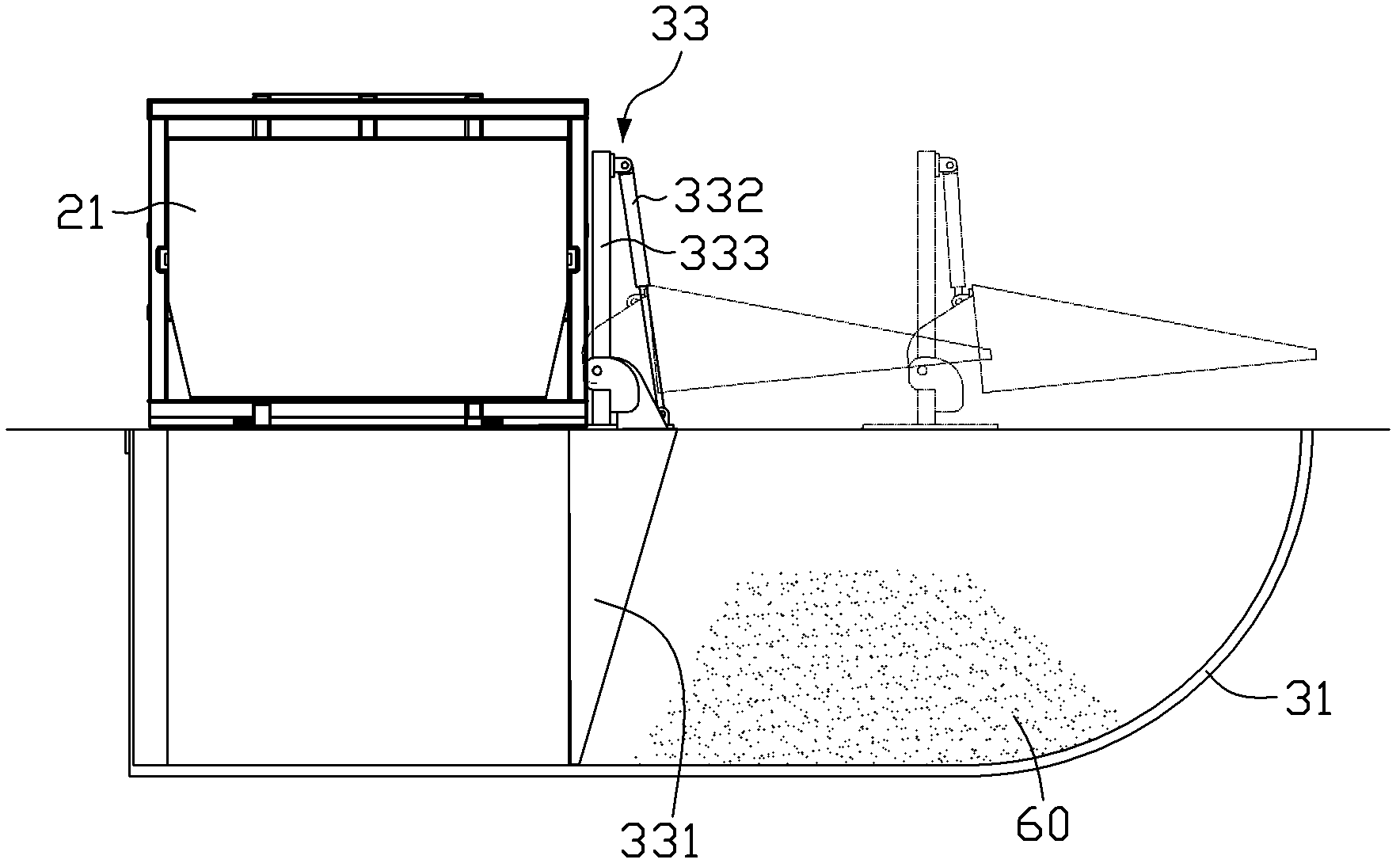

Garbage compressor

ActiveCN102424225BCompact structureEasy loadingRefuse transferringStorage devicesLand acquisitionGas compressor

The invention relates to a garbage compressor, which comprises a compression mechanism and a feeding mechanism, wherein the compression mechanism comprises a box body, the bottom of the box body is provided with a material inlet, the feeding mechanism comprises a bottom scraper, one end of the bottom scraper is hinged with the bottom of the box body, when the garbage is unloaded into the bottom of the box body, the bottom scraper rotates around the hinging part with the box body, the other end of the bottom scraper scraps garbage and scrapes the garbage into the box body from the material inlet, and simultaneously, the material inlet is sealed by the bottom scraper. The garbage compressor adopts the bottom scraper arranged at the bottom of the box body for feeding from the bottom of the box body, and the whole body has the characteristics that the structure is compact, the feeding is convenient, no odor exists, the secondary fly dust and the secondary pollution are avoided, the occupied area is small, the civil engineering cost is low, the flexibility is realized, and the like. The garbage compressor is particularly applicable to old station modification and new transfer station construction under the conditions of difficult urban area land acquisition and small sites.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

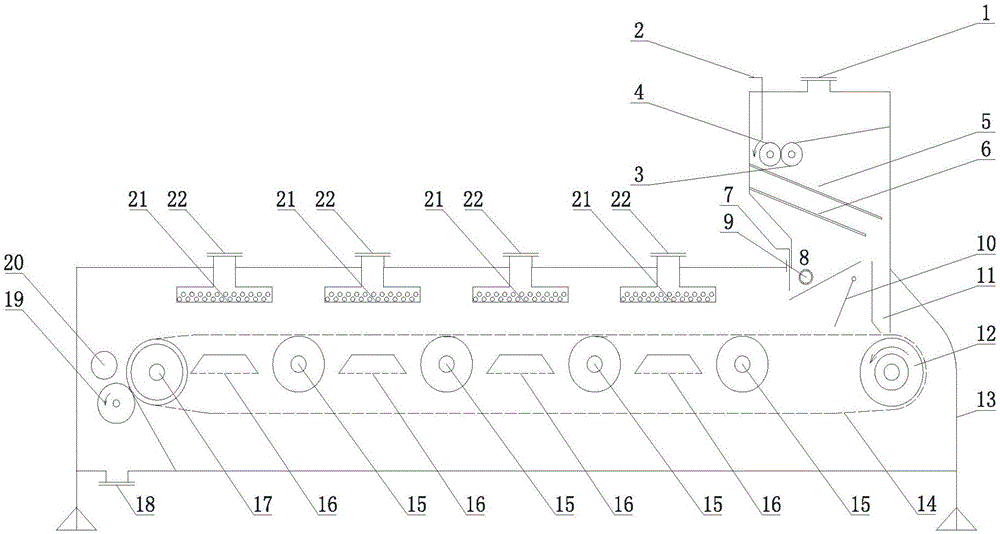

Rotating filter cartridge type air dust remover

InactiveCN100571844CEfficient removalConstant dust removal effectDispersed particle filtrationHigh humidityAir filter

The invention discloses a rotary filter cartridge type air dust collector, which consists of a box body, a plurality of filter cartridges installed in the inner cavity of the box for isolating dust, a main motor driving the rotation of the filter cartridges, and removing dust sticking on the surface of the filter cartridges. It is composed of advanced pulse blowing system, chain scraper machine for cleaning dust, screw ash conveyor and ash discharge valve. The dust collector has low requirements on the dust concentration of the air to be purified, can be adapted to dust removal in various environments, and has stable dust removal efficiency. The filter cloth is made of stainless steel, which can withstand high temperature, high humidity, acid and alkali corrosion, and anti-static. The dust collector can be used independently, or multiple machines can be connected in parallel, and the number of single units can be selected according to different emission standards.

Owner:JIANGSU HUAZHENG ENVIRONMENTAL PROTECTION TECH CO LTD

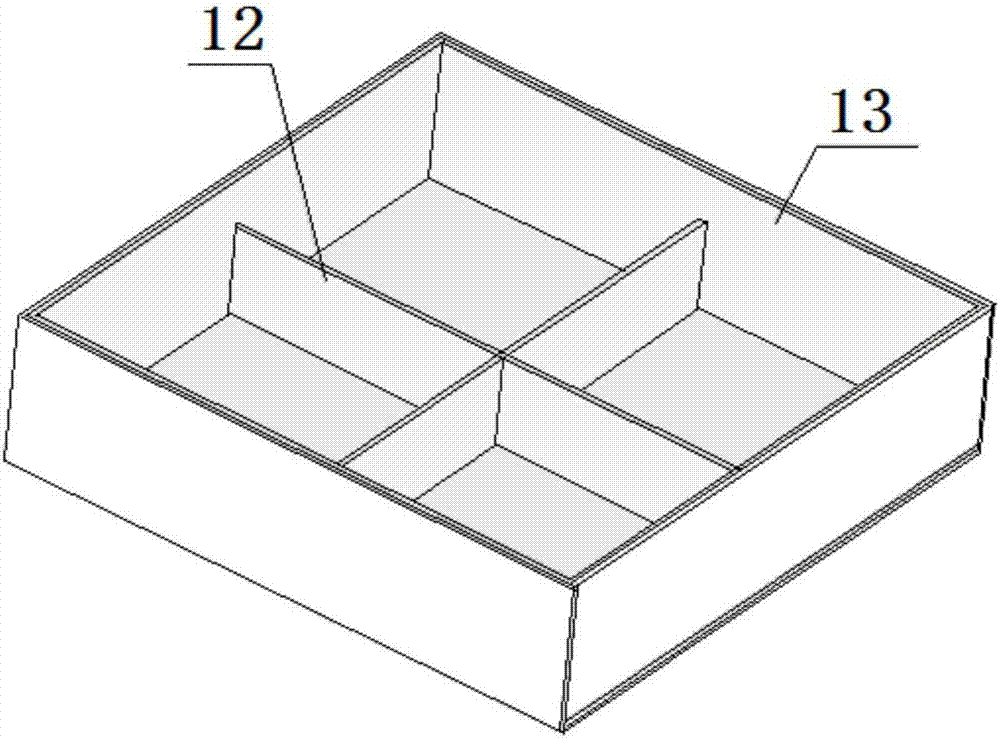

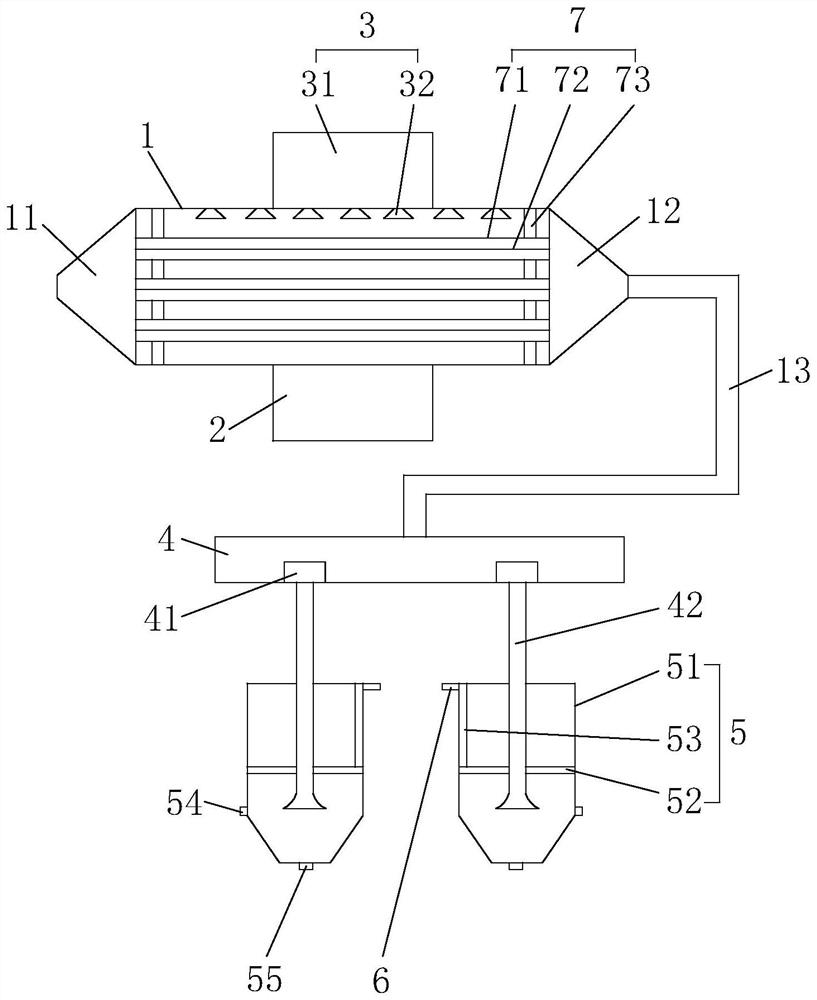

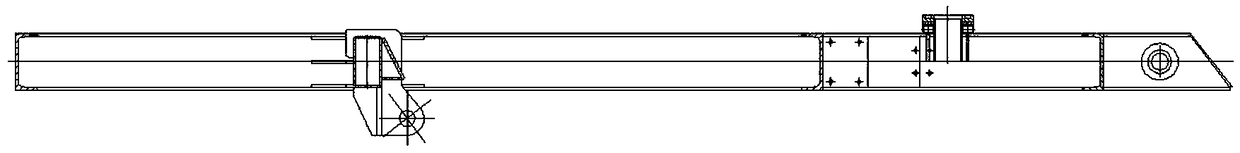

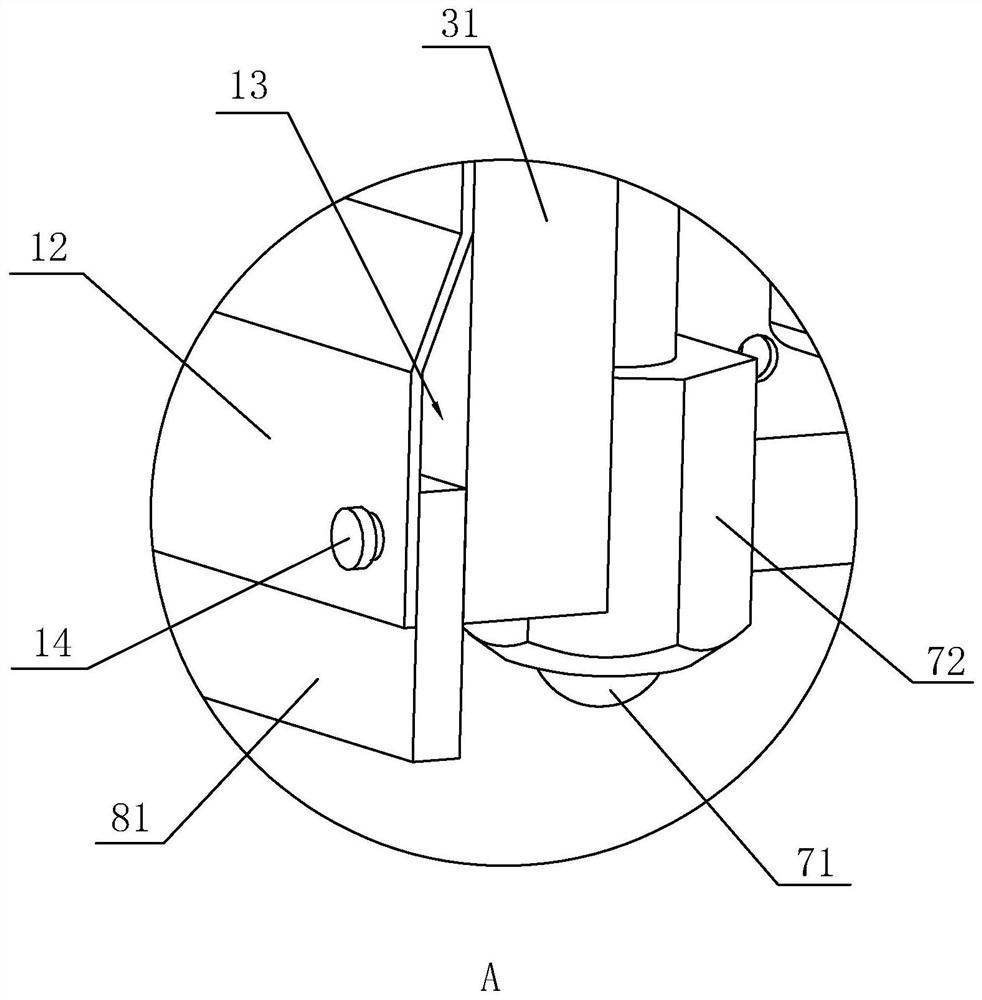

Multi-functional filtering and dust falling box

InactiveCN105442481ANo emissionsWide range of vacuumingCombination devicesGas treatmentEngineeringRoad surface

The invention discloses a multi-functional filtering and dust falling box which comprises a dust box main body (8), a dust falling plate (2), a separating hole plate (5), a one-time dust separating box (10), a second-time dust separating box (4), a third-time dust separating box (9) and an air steam filtering device (6). The dust box main body (8) is of a multi-layer box-type structure, the one-time dust separating box is located on the bottommost layer and communicated with a dust inlet, and the dust falling plate (2) is located on the upper portion of the dust inlet formed in the one-time dust separating box; the second-time dust separating box is located on the one-time dust separating box, and the separating hole plate (5) is arranged in the second-time dust separating box; the third-time dust separating box is located on the second-time dust separating box, the air steam filtering device is arranged in the third-time dust separating box, and an outlet of the air steam filtering device is communicated with an air inlet interface (7) of a draught fan. The multi-functional filtering and dust falling box integrates dust sucking, dust falling and dehumidifying into a whole. The problems that a traditional pure-suction-type dust suction vehicle is low in dust suction efficiency and cannot be operated in a humid environment and on a rainwater road surface for a long time are solved, and the purpose of improving the operation efficiency and being free of secondary flowing dust pollution, simple in structure, few in wear-out parts, convenient to use and maintain and easy to operate are achieved.

Owner:LUOYANG ZHONGZHONG SPECIAL VEHICLE CO LTD

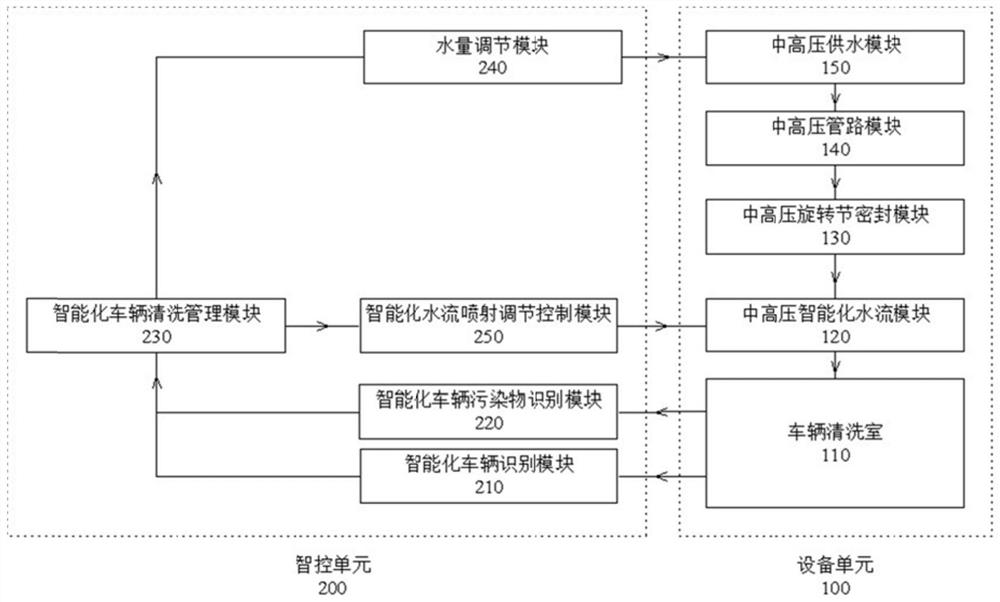

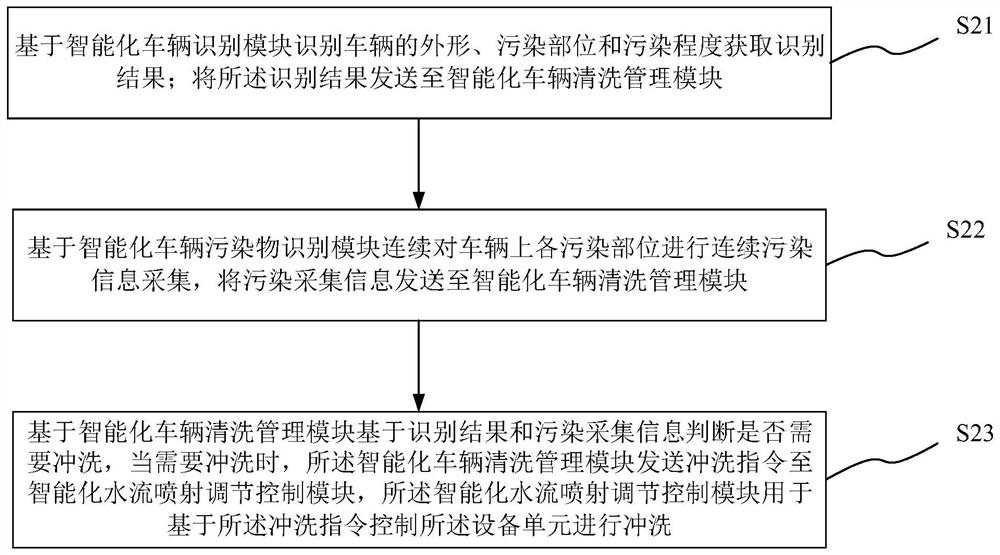

Middle-high pressure intelligent freight vehicle sludge flushing system and method

InactiveCN112677934AEffective flushingThe situation of poor cleaning effect is solvedInternal combustion piston enginesCleaning apparatus for vehicle exteriorsSludgeVehicular pollution

The invention provides a middle-high pressure intelligent freight vehicle sludge flushing system and method. The system comprises an intelligent control unit and an equipment unit, wherein an intelligent vehicle identification module is used for identifying the shape, the pollution part and the pollution degree of the vehicle to obtain an identification result; the identification result is sent to an intelligent vehicle cleaning management module; an intelligent vehicle pollutant identification module is used for continuously acquiring pollution information of each polluted part on the vehicle and sending the acquired pollution information to the intelligent vehicle cleaning management module; the intelligent vehicle cleaning management module is used for judging whether flushing is needed or not based on the identification result and the acquired pollution information, and when flushing is needed, the intelligent vehicle cleaning management module sends a flushing instruction to an intelligent water flow jetting adjustment control module; and the intelligent water flow jetting adjustment control module is used for controlling the equipment unit to flush based on the flushing instruction. The system and the method are used for intelligently identifying the polluted part of the vehicle and cleaning the vehicle according to the vehicle pollution condition.

Owner:BIOMINTEC ENVIRONMENT (SHANGHAI) CO LTD

Cleaning device for return rubber belt of belt conveyor

PendingCN113602770AGood cleaning effectEliminate backhaul build-up problemsConveyorsCleaningPhysicsEngineering

The invention particularly relates to a cleaning device for a return rubber belt of a belt conveyor, belongs to the technical field of belt cleaning, and aims to provide the cleaning device for the return rubber belt of the belt conveyor, which can improve the field working environment. According to the scheme, a stock bin for receiving unloaded material is fixed to an unloading roller of the belt conveyor; a first sweeper is installed at the unloading roller and used for sweeping materials remaining on the surface of the belt and falling into the stock bin, and a wet type belt sweeping component for further cleaning the materials remaining on the belt is installed on the return stroke section of the belt; and a spraying pipe, a third sweeper, a roller set and a fourth sweeper of the wet type belt sweeping component are sequentially arranged in the running direction of the return stroke section of the belt. Fine materials attached to the surface of the belt are cleaned in time, and the situation that the fine materials float in the air is avoided.

Owner:山西敬天瑞德冶金设备有限公司

Low-altitude electrostatic oil fume purifier and purification method thereof

PendingCN113000209AEasy to cleanQuality improvementFire rescueExternal electric electrostatic seperatorPurification methodsElectric machine

A low-altitude electrostatic oil fume purifier of the present invention comprises a wet-type electrostatic purification system and an adsorption purification mechanism connected with the wet-type electrostatic purification system. The wet-type electrostatic purification system comprises a shell, a control electric box and a fire extinguishing system which are installed at the two sides of the shell respectively, a direct-current high-voltage power source is arranged in the control electric box, and a cylindrical honeycomb electric field electrically connected with the direct-current high-voltage power supply is arranged in the shell. The adsorption purification mechanism comprises an exhaust fume collecting hood and a plurality of filter units connected with the exhaust fume collecting hood, a plurality of oil fume extraction motors are arranged in the exhaust fume collecting hood, the bottoms of the oil fume extraction motors are connected with filter pipelines, and each filter unit comprises a water tank containing oil absorption alkali liquor, a filter material layer and a vertical filter material net which are arranged in the water tank. One end, far away from the oil smoke exhaust motor, of each filter pipeline penetrates through the filter material layer and extends into the oil absorption alkali liquor of the water tank box, the vertical filter material net is fixed on the inner wall of the water tank box above the filter material layer, and an exhaust port connected with the vertical filter material net is formed at the edge, close to the opening, of the water tank box.

Owner:福建南粤厨具股份有限公司

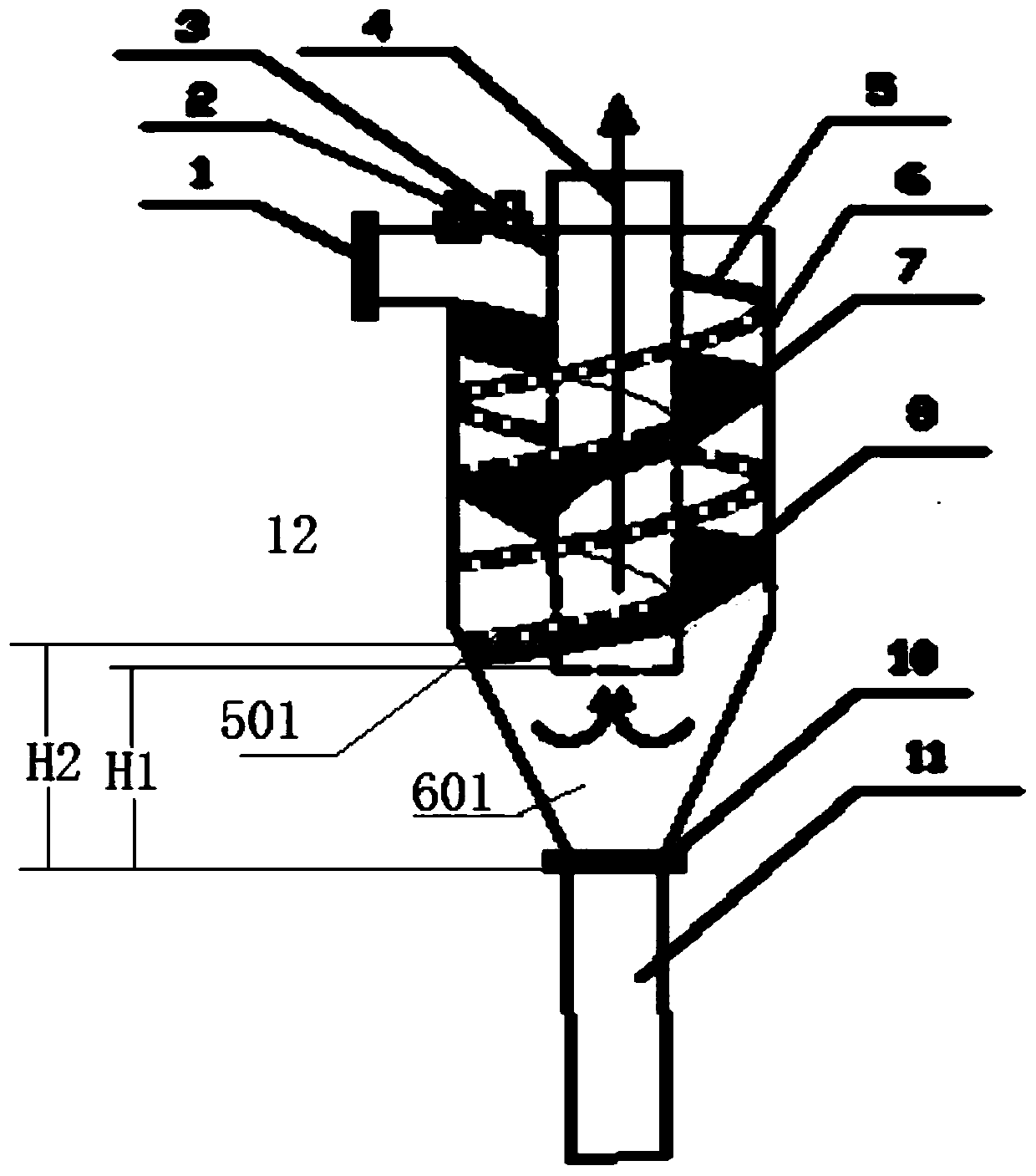

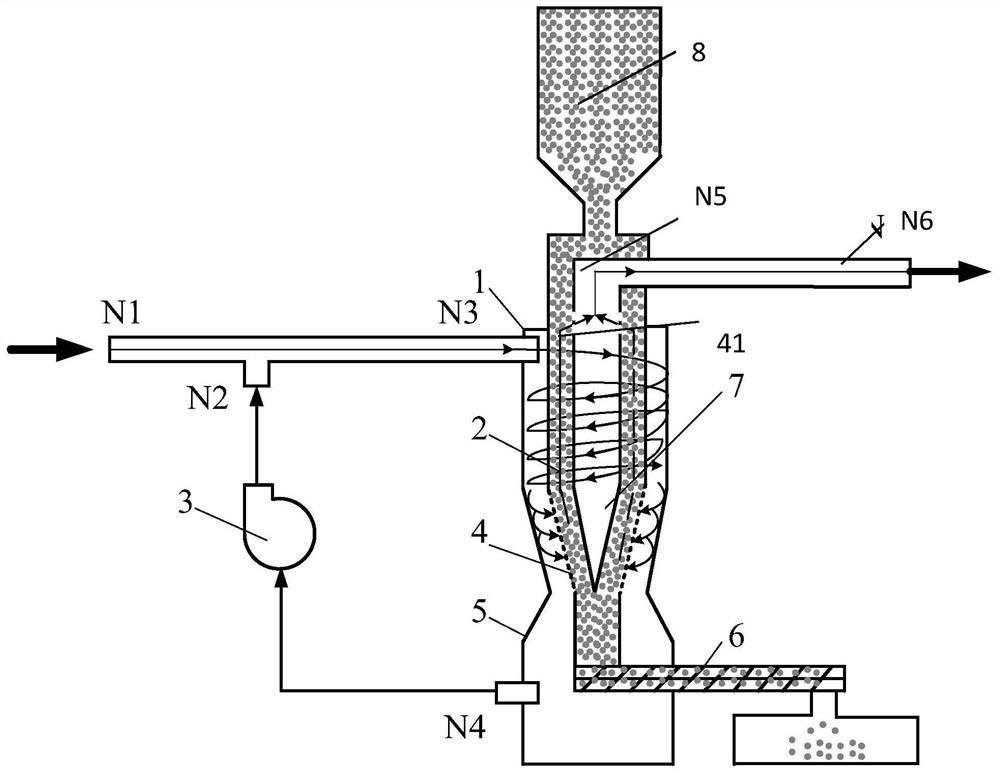

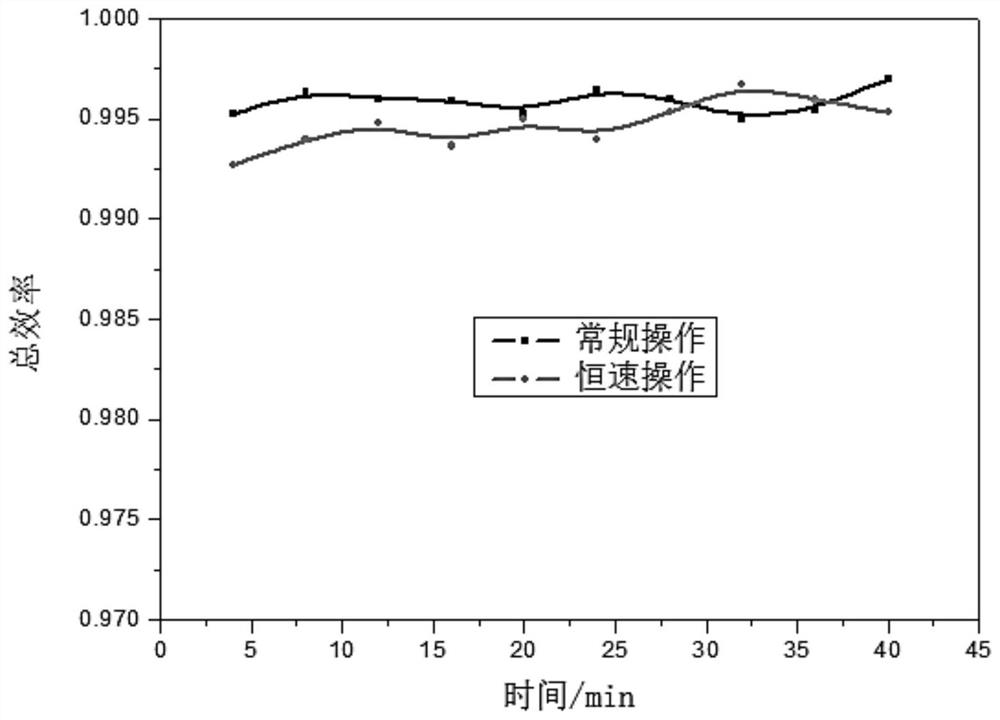

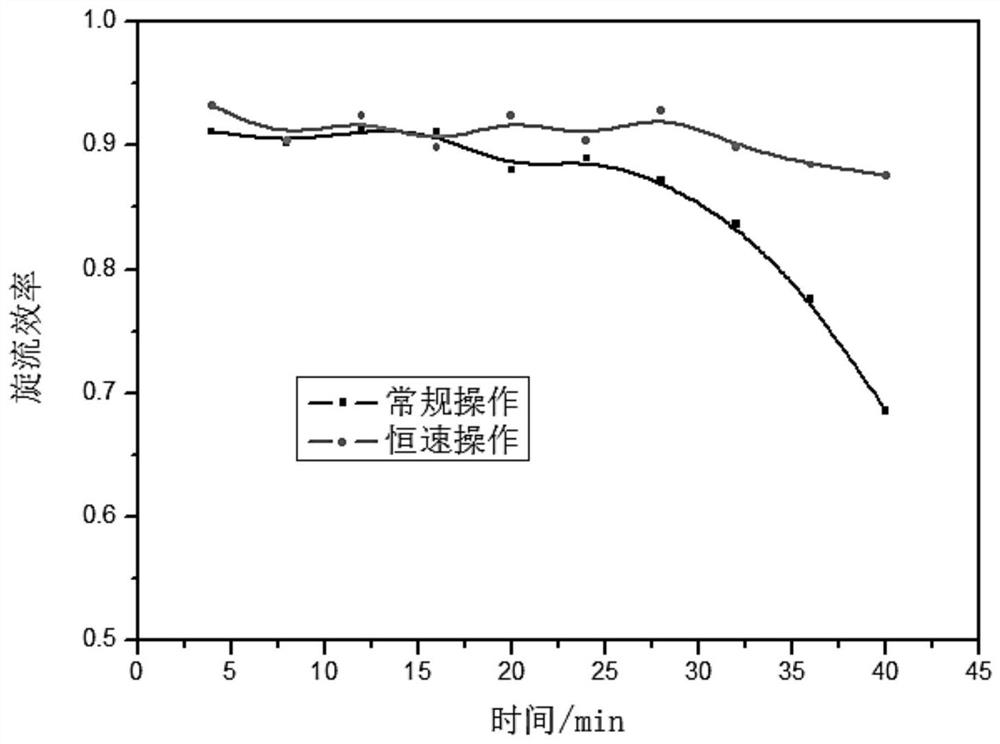

A swirl filter combined pyrolysis gas dedusting device and method with adjustable flow rate

ActiveCN110899008BShort stayMinimized secondary cracking reactionsReversed direction vortexFrequency changerCyclone

The invention discloses a cyclone filter combined pyrolysis gas dedusting device and method with adjustable flow velocity, belonging to the field of high temperature dedusting. It includes a cyclone separator, a granular bed filter and a frequency conversion fan. The cyclone separator adopts a tangential flow reversal type cylindrical cone structure. It is used on the outside of the cyclone separator for suction circulation and the circulating air volume is adjusted by the frequency converter to control the cyclone air velocity and filter air velocity. The invention keeps the gas velocity constant during the operation process, not only makes full use of the centrifugal separation effect of the downward external swirling flow, but also enables the incoming dust-laden gas to pass through the particle bed for fine filtration.

Owner:INST FOR PROCESS MODELING & OPTIMIZATION JITRI

Efficient combining integration module

The invention provides an improvement on electric precipitator polar plate and polar line design and relates to an efficient combining integration module which is applied to a device for collecting electrical charge smoke particles in an electric precipitator. The efficient combining integration module is characterized by being different from various airstream shield type dust collecting polar plates formed by rolling metal plates in the past. The efficient combining integration module has high airflow permeability and can provide enough sedimentation area for electrical charge smoke particles, and especially has a high ability to adsorb the submicron-order electrical charge smoke particles. The electric precipitator adopting the efficient combining integration module has high strength and high stability, and can greatly increase the wind speed of an electric field, shorten the length of a sedimentation channel in the electric field and effectively reduce secondary flying dust, equipment transportation, installation and adjustment are easy and convenient, operation is efficient, the investment and operation cost of the electric precipitator is reduced substantially, and the emission concentration technical performance index is lower than that of a bag type dust collector.

Owner:中电国核(北京)节能环保科技有限公司

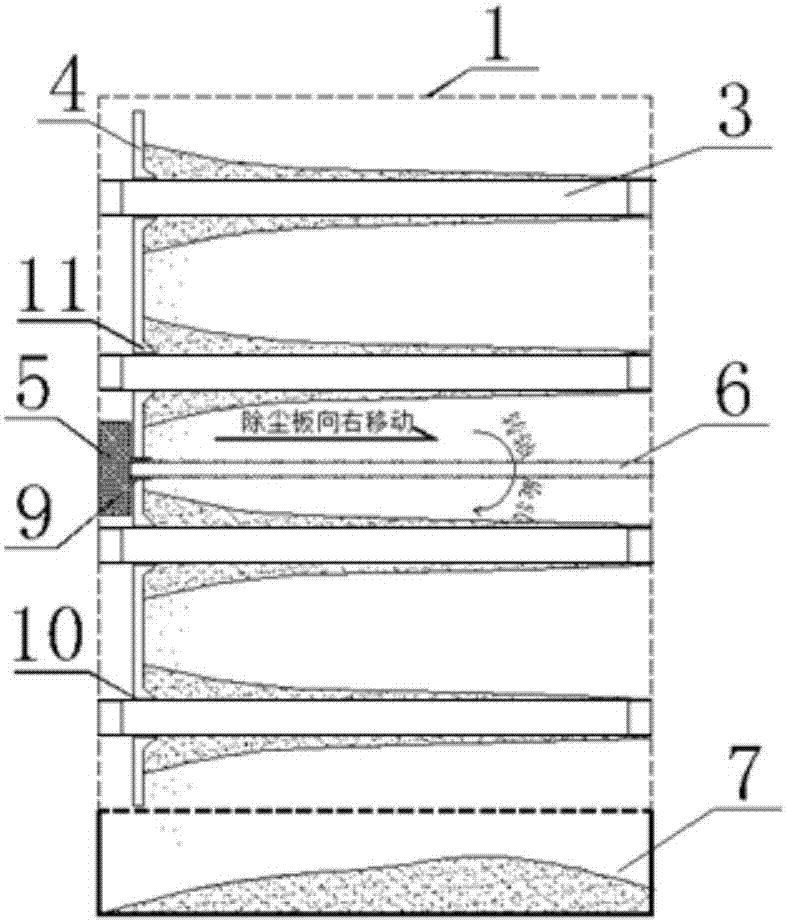

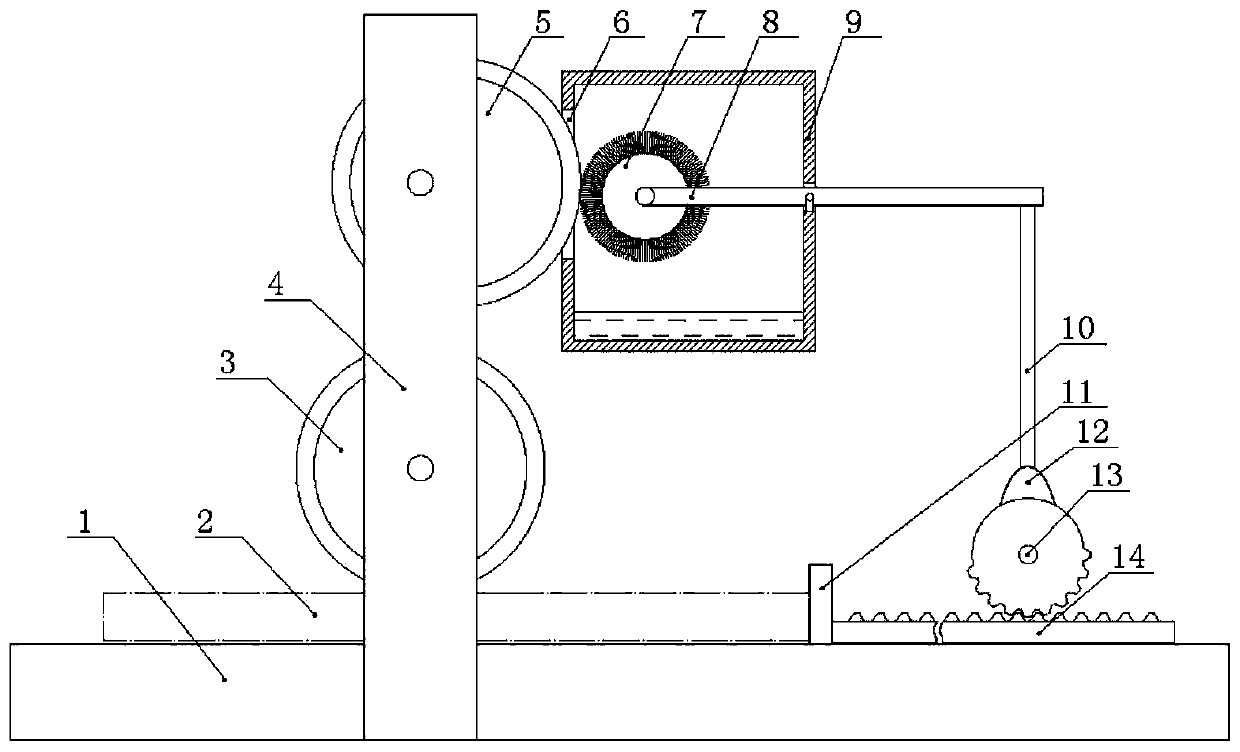

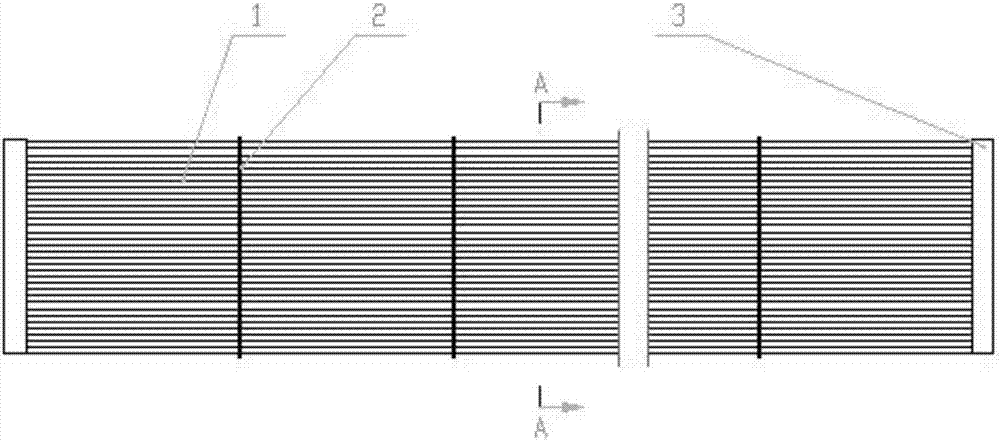

Horizontal type moving bed particle layer filtration high-temperature oil gas dedusting technology and device

InactiveCN105032078ANo secondary dustEasy to operateDispersed particle filtrationRotational axisDrive wheel

The invention discloses a horizontal type moving bed particle layer filtration high-temperature oil gas dedusting technology and device. The device comprises a shell, a material filtering bin and a plurality of gas inlet pipes are arranged on the upper portion of the shell, and distributing pipes are arranged in the gas inlet pipes. A hot semicoke inlet is formed in the upper end of the material filtering bin. Feeding rollers are arranged in the material filtering bin, and a feeding gate plate is vertically mounted at the front end tangent line position in the rotating direction of the feeding rollers. A bar grating type screener is obliquely mounted below the feeding rollers. A tooth rake device with the top being provided with a rotating shaft is mounted below the bar grating type screener. A driving wheel and a driven wheel are arranged in the shell, a conveying belt is arranged between the driving wheel and the driven wheel, and cold purification high-temperature oil gas outlets are formed below the conveying belt. A material stopping tube and a sealing roller which is tangent to the material stopping tube are arranged beside the driving wheel. A shell segregation board is arranged between the axis of the driving wheel and the axis of the sealing roller. A particle filtering layer is formed on the conveying belt. High-dust semicoke discharging outlets are formed below the shell. The technology and device overcome the defects that the particle layer of an existing fixed bed particle layer filtration high-temperature oil gas dedusting device is backwashed and is difficult to regenerate, and the operating period is short.

Owner:SHAANXI MEISILIN ENERGY SCI & TECH RES INST

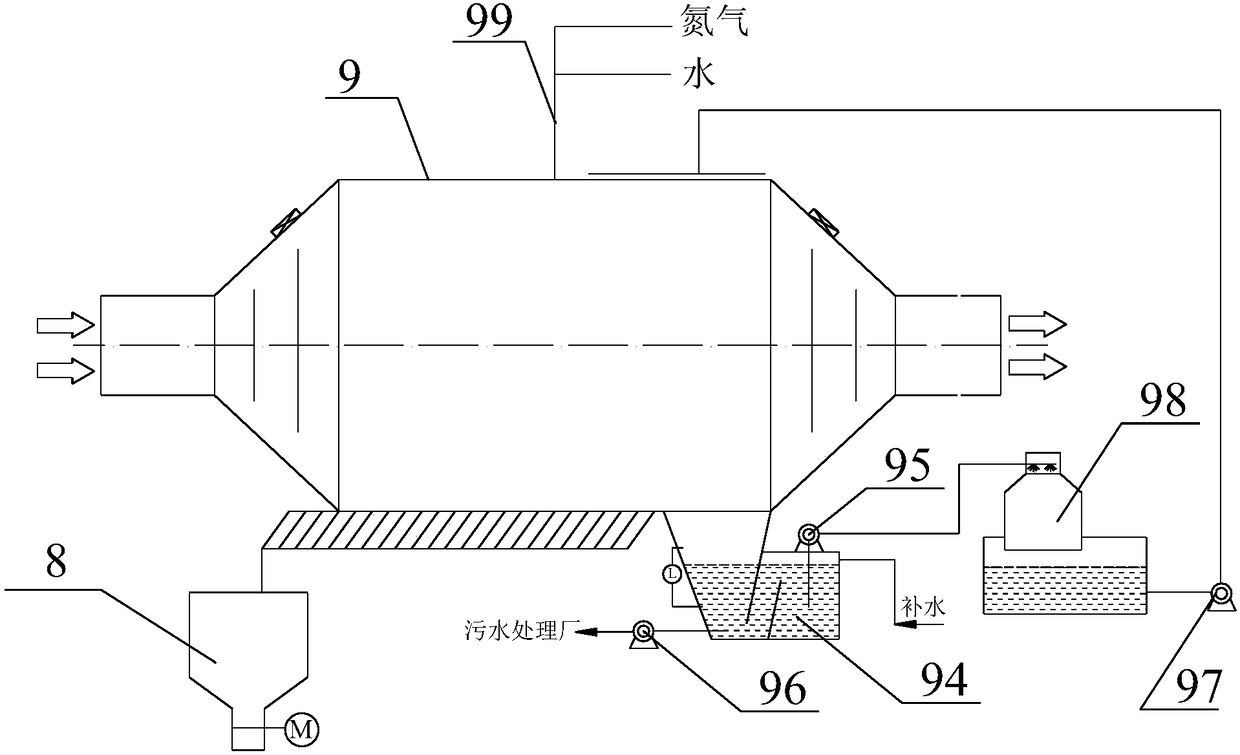

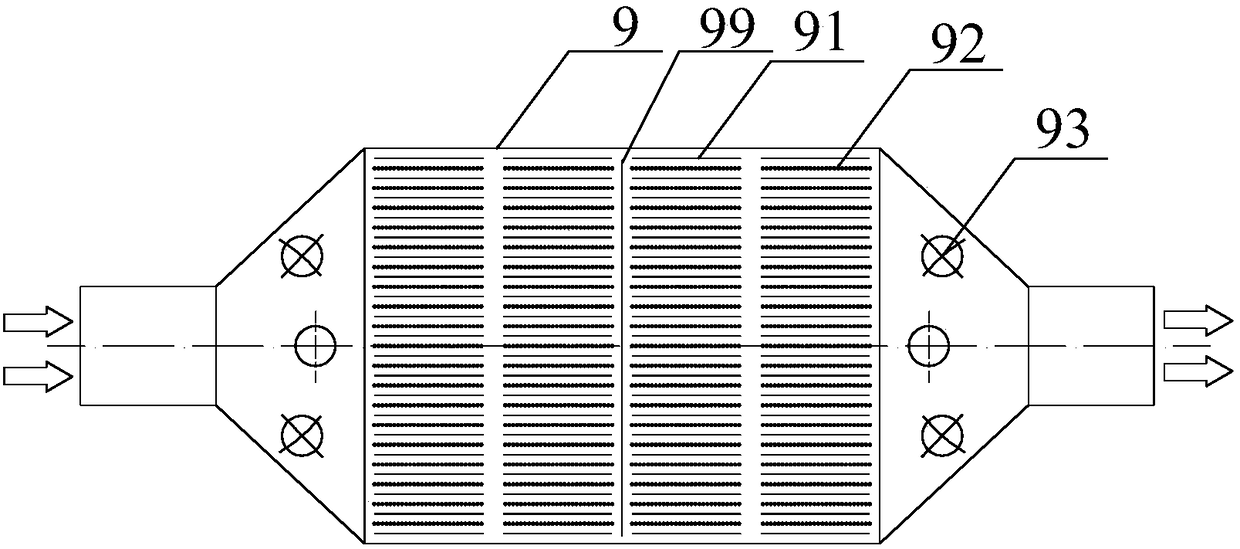

Converter gas electrostatic precipitator and control method thereof

PendingCN108531682AImprove dust removal efficiencyGuaranteed stabilityIncreasing energy efficiencyManufacturing convertersThermal sprayingWater flow

The invention discloses a converter gas electrostatic precipitator which comprises a cylindrical shell, and a first electric field, a second electric field, a third electric field and a fourth electric field located in the shell. An explosion venting valve communicating with an explosion venting device is arranged on the shell; a spraying device is arranged in front of the third electric field; the third electric field and the fourth electric field are wet type polar plates; and the spraying device is used for forming a layer of water film on each of the polar plates of the third electric field and the fourth electric field, so that dust attached onto the water films flows into a water collecting tank through the actions of a water flow and a gravitational force, and no reentrainment of dust is caused. According to the converter gas electrostatic precipitator provided by the invention, the dust content of a gas at an outlet of the electrostatic precipitator can be reduced, meanwhile, the water spraying amount is controlled to achieve the aim of gas cooling, and the gas can be fed into a gas chamber without the need to be further cooled.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

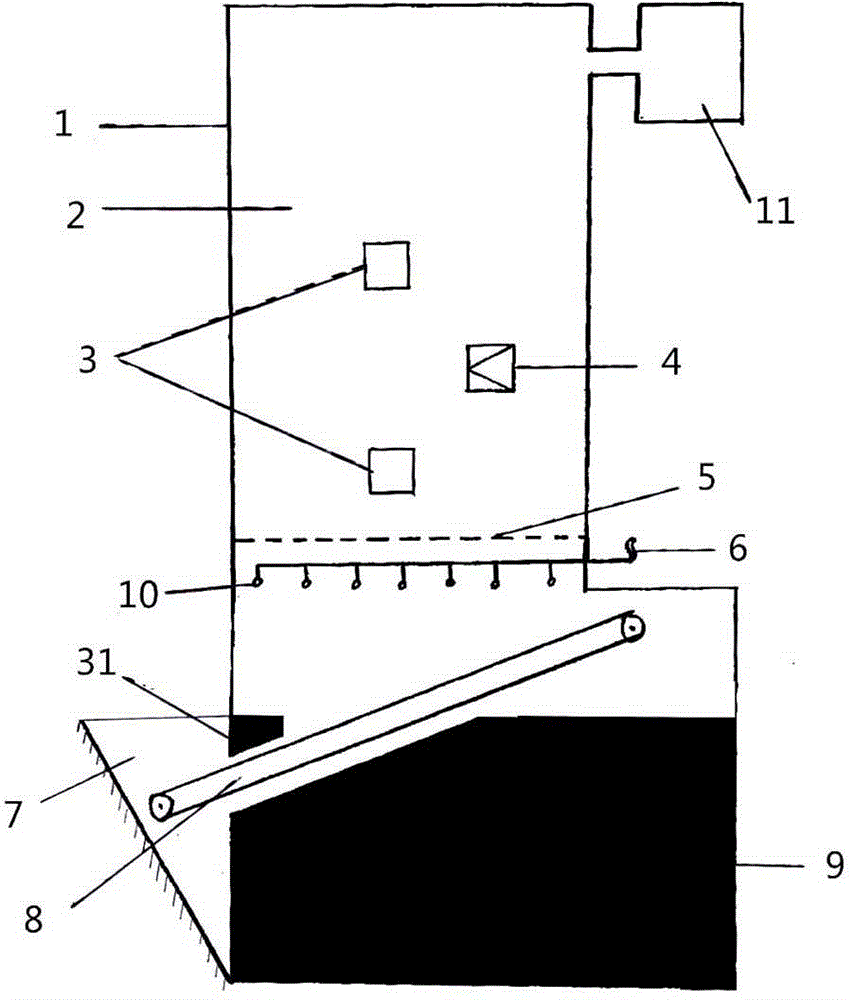

Novel smokeless boiler

ActiveCN106032897AAvoid dustNo secondary dustSolid fuel combustionCombustion apparatusCombustion chamberEngineering

The invention relates to a new type of smokeless boiler, which includes a combustion chamber, a damper, an ash conveyor belt, a water pool and a flue, and is characterized in that a water level liquid sealing wall is provided on the outer wall of the furnace pit enclosure above the ash conveyor belt, and a smoke extinguishing wall is arranged in the flue Compared with the existing technology, when the ash falls, there is no dust, and the fly ash in the smoke eliminator can be dust-free collected, suppressed, and re-sent into the combustion chamber, which greatly improves the combustion efficiency and realizes smoke-free chemical treatment, the present invention can be widely used in industrial production and household heating direction.

Owner:曹登林

Liquid film plasma deduster

InactiveCN107648967ANo back coronaAchieve dust removal effectCombination devicesElectrical and Electronics engineeringElectrode

The invention relates to a liquid film plasma deduster. The liquid film plasma deduster comprises a metal tube body with two penetrating ends, one end of the metal tube body is an air inlet end, and the other end is an air outlet end. The deduster also comprises: a discharge electrode stretching into the tube body and arranged along the axis direction of the tube body, wherein the discharge electrode is not in contact with the tube body; a liquid conveyer for inputting a liquid into the tube body to make the liquid form a liquid film on the inner wall of the tube body; and a plasma power supply, wherein the positive electrode of the plasma power supply is electrically connected with the discharge electrode, the negative electrode of the plasma power supply is electrically connected with the tube body, and a plasma dedusting channel is formed between the outer wall of the discharge electrode and the inner wall of the tube body after the power supply is switched on. The liquid film plasma deduster has the advantages of reasonable structure design, good dedusting effect, and no individual cleaning of dusts in a striking hammering manner.

Owner:JIANGSU HEHAI NEW ENERGY

A road vacuum cleaner

The invention relates to a road surface cleaning device, in particular to a road surface vacuum sweeper. The vacuum sweeper comprises a vice vehicle frame, a suction nozzle assembly, a dust collecting box and a dust removing box, wherein the suction nozzle assembly, the dust collecting box and the dust removing box are installed on the vice vehicle frame cprrespondingly, the suction nozzle assembly is used for absorbing dust on the ground, the dust collecting box is connected with the suction nozzle assembly and used for collecting the partial dust, and the dust removing box is connected with the dust collecting box. According to the road surface vacuum sweeper, the dust absorbing rate is high, dust and particulate matter absorbing, separating and conveying are integrated.

Owner:CHANGSHA WEINUO ELECTROMECHANICAL

Electro-filtration duplex double-phase dust remover

InactiveCN104740963AIncrease collection speedImprove collection efficiencyCombination devicesFiltrationDouble phase

The invention relates to an electro-filtration duplex double-phase dust remover. An anode bar of the dust remover is composed of a plurality of metal filter cartridges which are arrayed in parallel; the metal filter cartridges are correspondingly suspended on ceiling holes in a dust remover shell; a ceiling is fixed on a top beam of the shell; the metal filter cartridges are used for replacing an anode plate of an electrostatic dust remover to serve as an anode system of an electrostatic dust remover and a duplex dust collection chamber is composed of an electric field and the metal filter cartridges; a blowing pipe, which is mounted at the top of the dust remover and is provided with air holes, is used for blowing back the metal filter cartridges under the blowing pipe so that dust attached on the outer surfaces of the filter cartridges falls into a dust bucket; vibration and striking rods connected with the filter cartridges are mounted on the side face of the anode bar; and vibration and striking mechanisms corresponding to the filter cartridges are used for vibrating and striking. By virtue of the electro-filtration duplex double-phase dust remover, double-phase dust removal is realized by the action of an electric field force and airflow power, and secondary dust raising is not generated; the system resistance is relatively low and is less than or equal to 500Pa; the dust filtering and collection speed is improved by 60 times, the service life of the filter cartridges can reach 10 years and the dust removing efficiency eta is more than or equal to 99.95%; and the absorption (less than or equal to 1u) for fine dust can meet the emission requirements of PM2.5.

Owner:BODI WEAPON MAKES

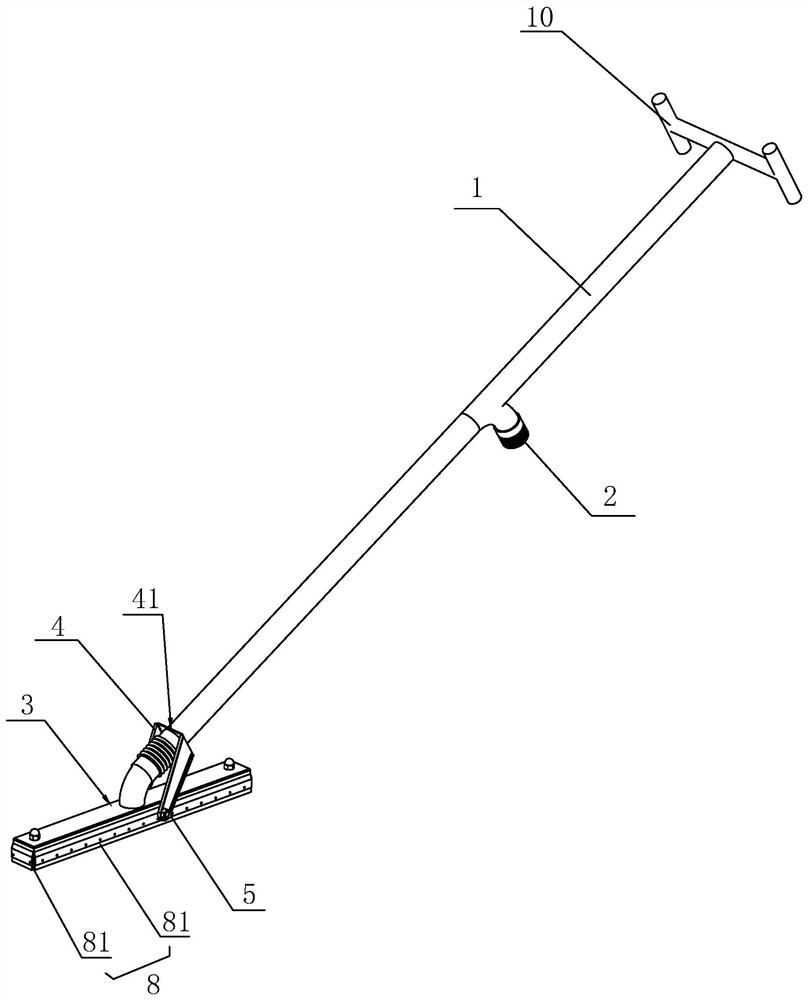

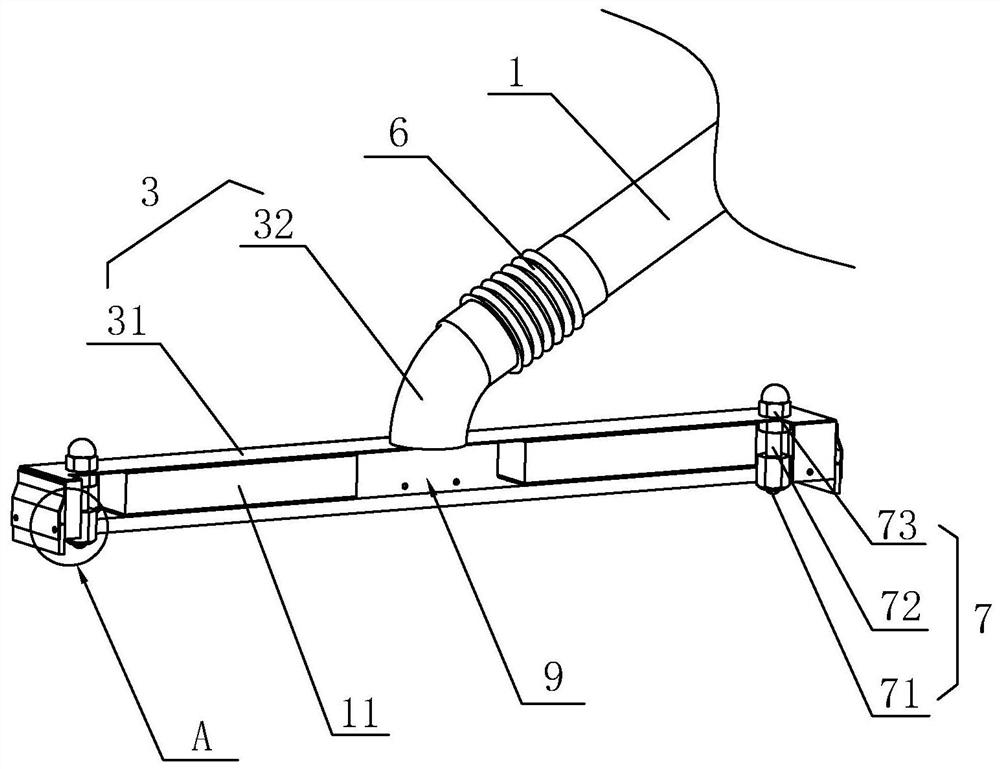

Handheld transverse sweeping type universal double-supporting-wheel vacuum suction head

PendingCN111616642AReduce labor intensityReduce labor costsSuction hosesSuction nozzlesEngineeringIndustrial premises

The invention discloses a handheld transverse sweeping type universal double-supporting-wheel vacuum suction head, and relates to the technical field of vacuum negative-pressure dust collection devices. The suction head comprises a handle rod, a negative pressure connector, a transverse sweeping suction head assembly, a hinge lug, a hinge shaft, a telescopic connecting hose, a supporting structureand a sealing plate. The transverse sweeping suction head assembly comprises an adsorption block and a flow guide pipe. An adsorption cavity is formed in the adsorption block, the flow guide pipe iscommunicated with the adsorption cavity, limiting holes are formed in the hinge lug, two ends of the hinge lug are hinged with the adsorption block, a negative pressure hole is formed in the handle rod, the negative pressure connector is communicated with the negative pressure hole, the telescopic connecting hose is communicated with the flow guide pipe and the handle rod, the supporting structurecomprises a supporting ball and a ball support, the ball support is connected with the adsorption block, the supporting ball is in rolling connection with the ball support, and the sealing plate is arranged on the outer wall of the adsorption block. By using the suction head, the labor intensity of manual operation is reduced, the dust suction operation efficiency is improved, and the suction head is particularly suitable for sweeping dust on the ground inside and outside a large-area industrial factory building.

Owner:上海宇源机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com