Dust removing device for copper plate of integrated circuit

A technology of integrated circuit and dust removal device, which is applied in the field of integrated circuit copper plate dust removal device, can solve the problems of secondary dust and other problems, achieve the effect of comprehensive dust removal, avoid copper plate wear, and reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

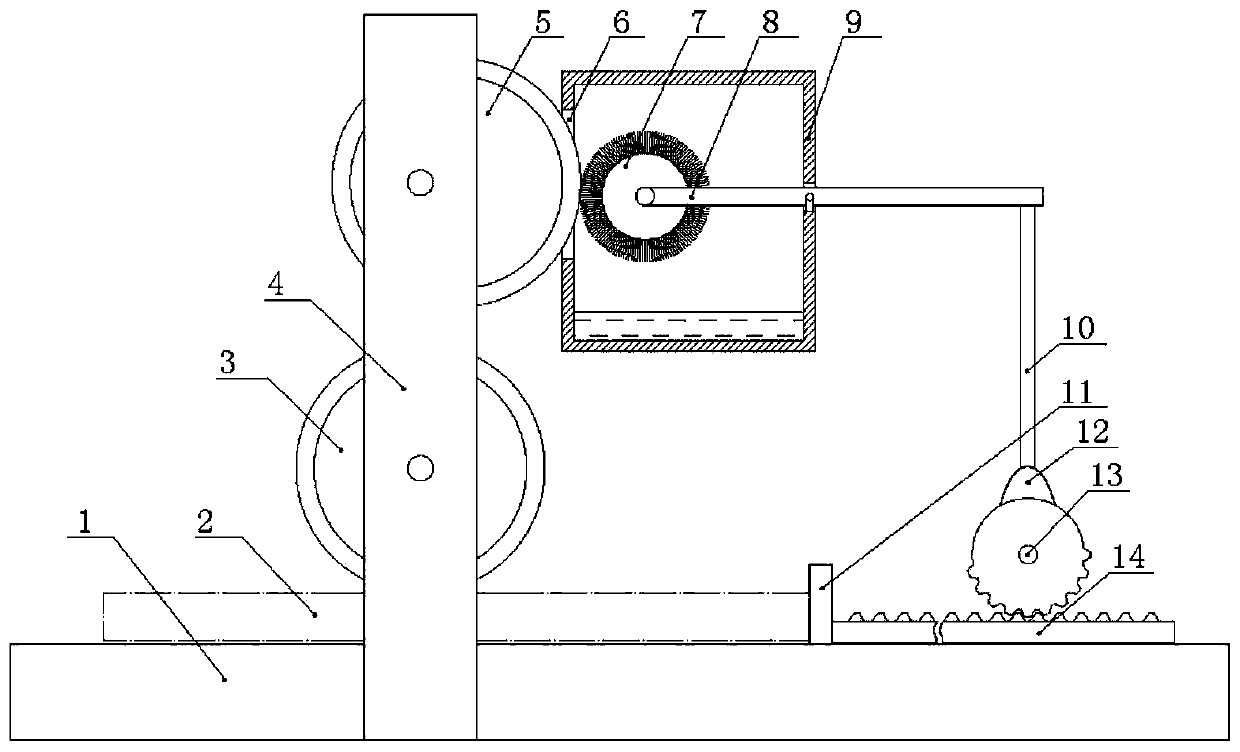

[0032] Such as figure 1 As shown, the integrated circuit copper plate dedusting device includes a frame on which a processing table 1 is horizontally installed, and a mounting frame 4 is vertically welded on both sides of the processing table 1. Symmetric centerline symmetrical setting. The mounting frame 4 is rotatably connected with a spiral dust removal roller 3, and the dust removal roller 3 is made of silica gel. The space between the bottom of the dust removal roller 3 and the processing table 1 is the space for placing the copper plate 2. After the copper plate 2 is put into the space, the dust removal roller 3 can be in contact with the copper plate 2. The top of the cleaning roller 3 is equipped with a spiral dust-staining roller 5 that can mesh with the cleaning roller 3. The dust-staining roller 5 is rotatably connected to the installation frame 4. The surface of the dust-staining roller 5 is provided with an adhesive layer. Shaft eccentric setting. The dust-clea...

Embodiment 2

[0044] The difference between this embodiment and Embodiment 1 is that several feeding rollers (not shown) are rotatably installed on the processing table 1, the surfaces of the feeding rollers are flush, and each feeding roller is covered with a silicone sleeve. In this way, when the copper plate 2 slides on the processing table 1, it can push the feed roller to rotate, thereby changing the sliding friction between the copper plate 2 and the processing table 1 to the rolling friction between the copper plate 2 and the feed roller, reducing the friction force and avoiding Copper plate 2 is worn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com