Patents

Literature

54results about How to "Comprehensive dust removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

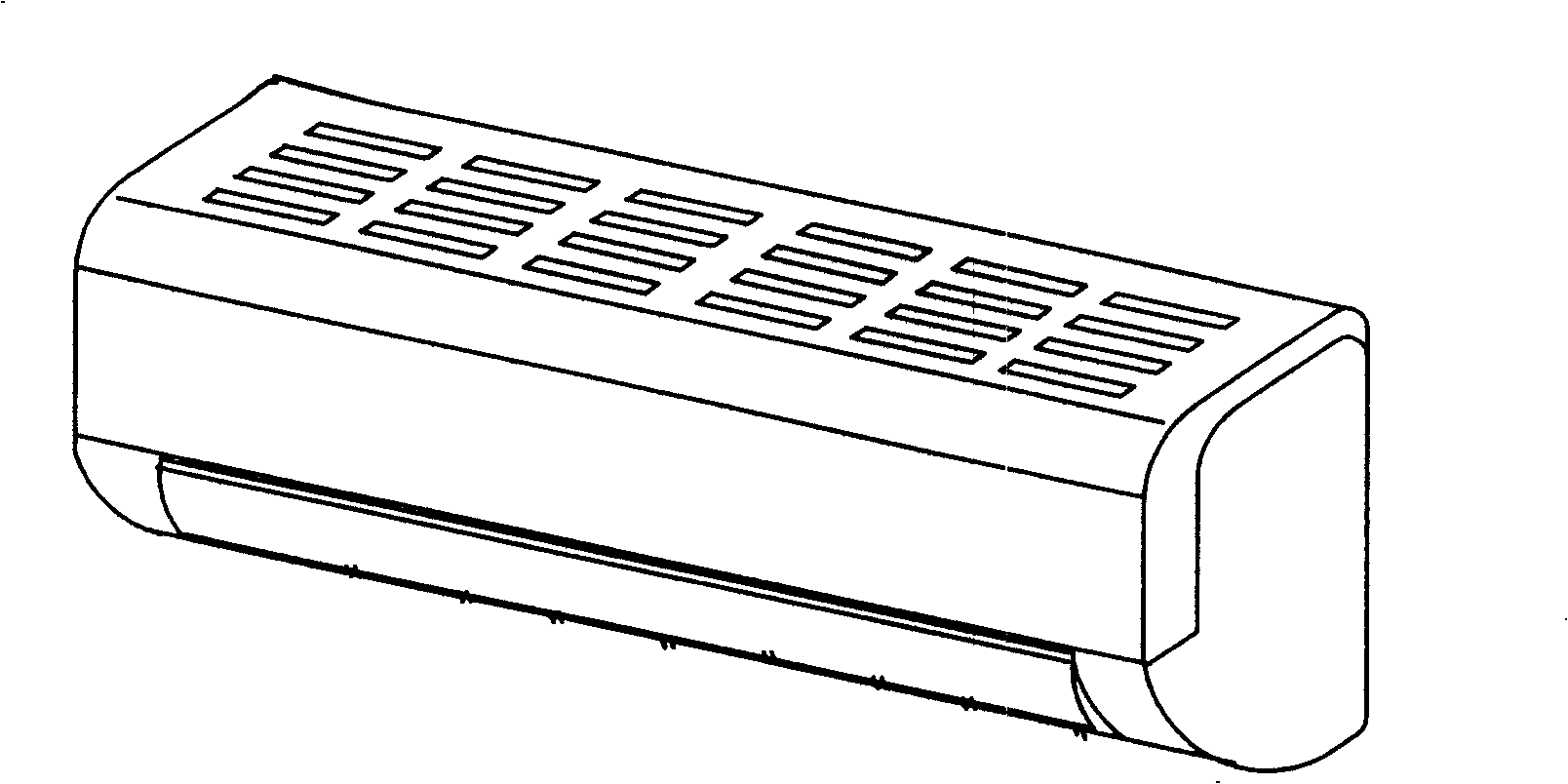

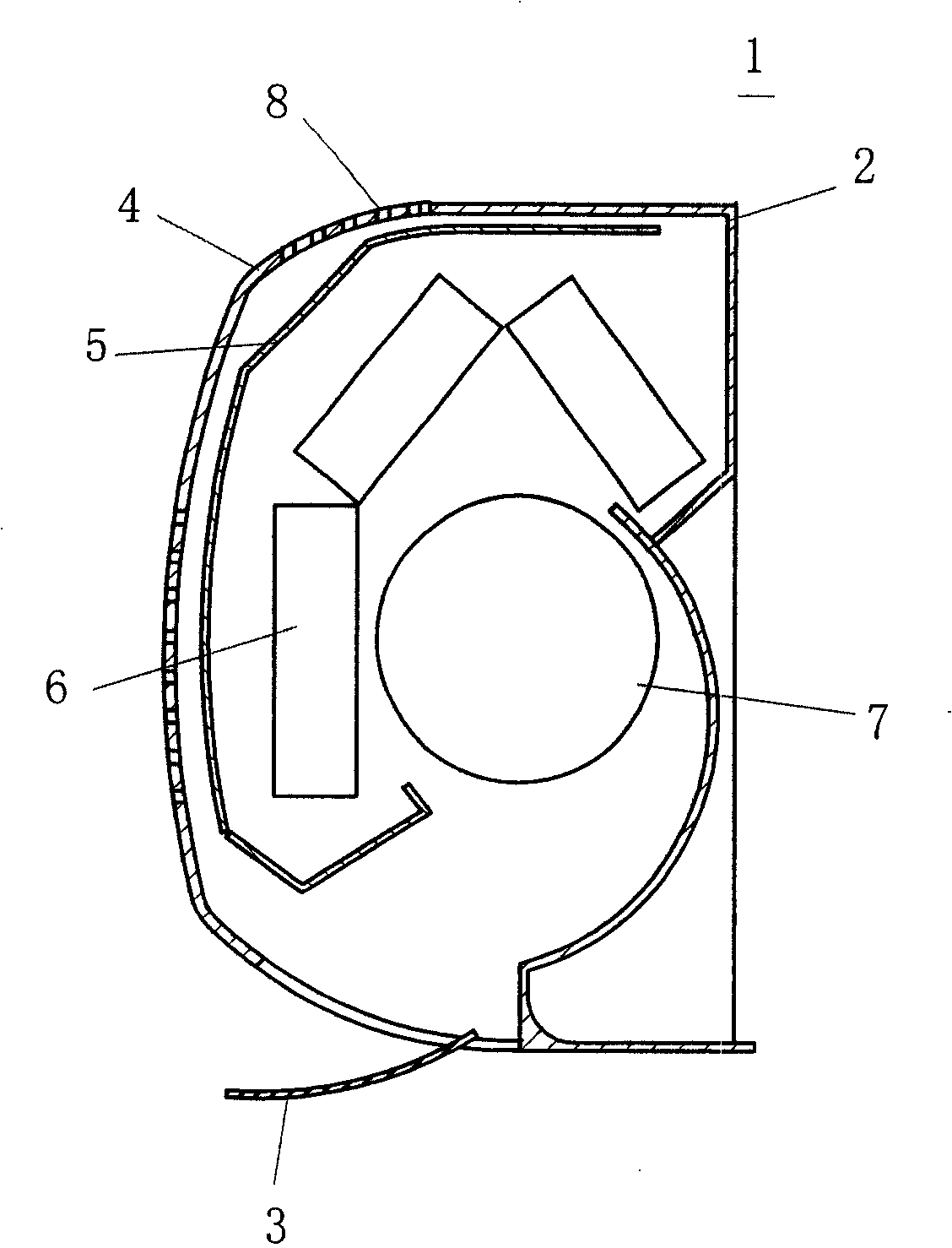

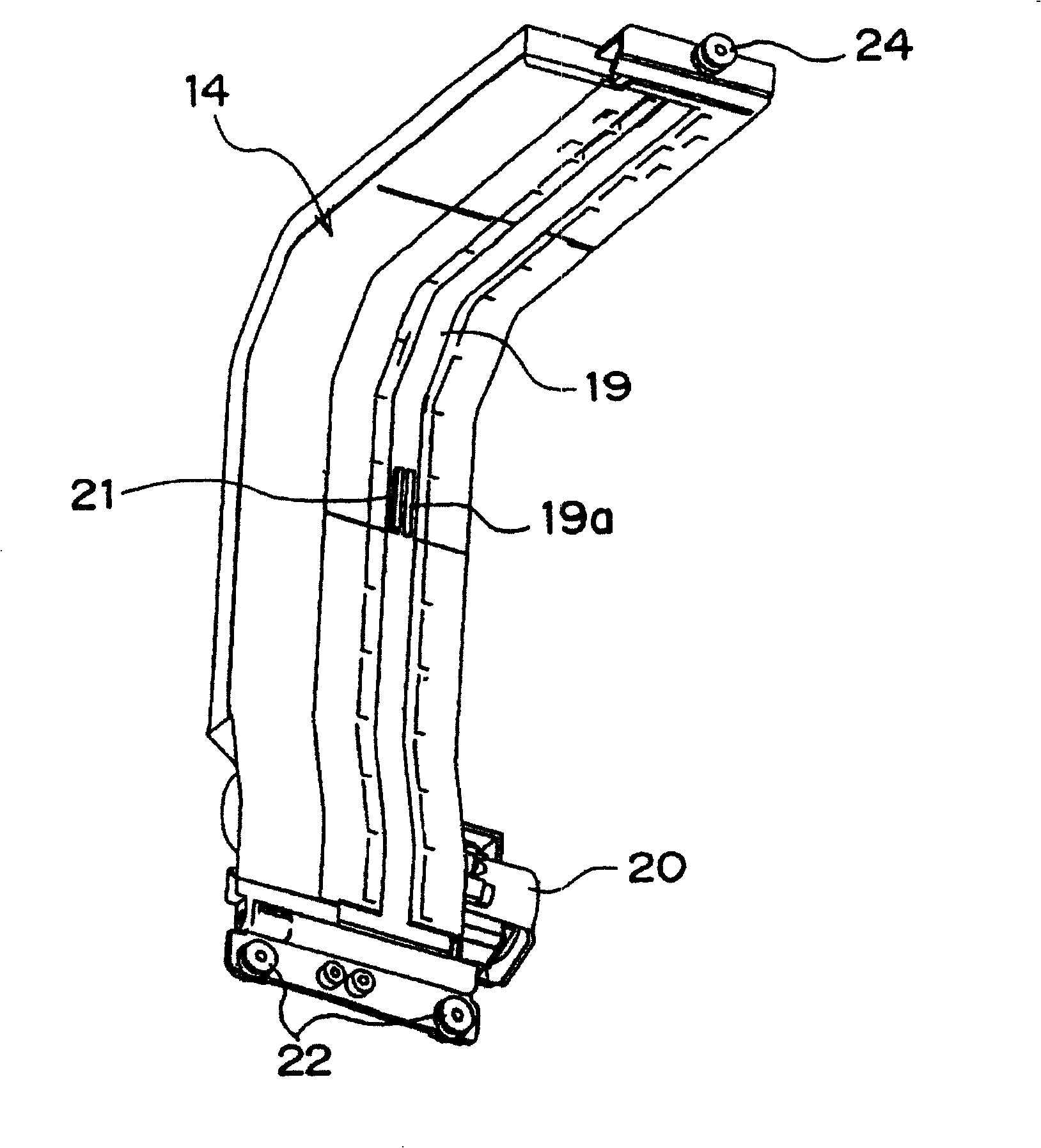

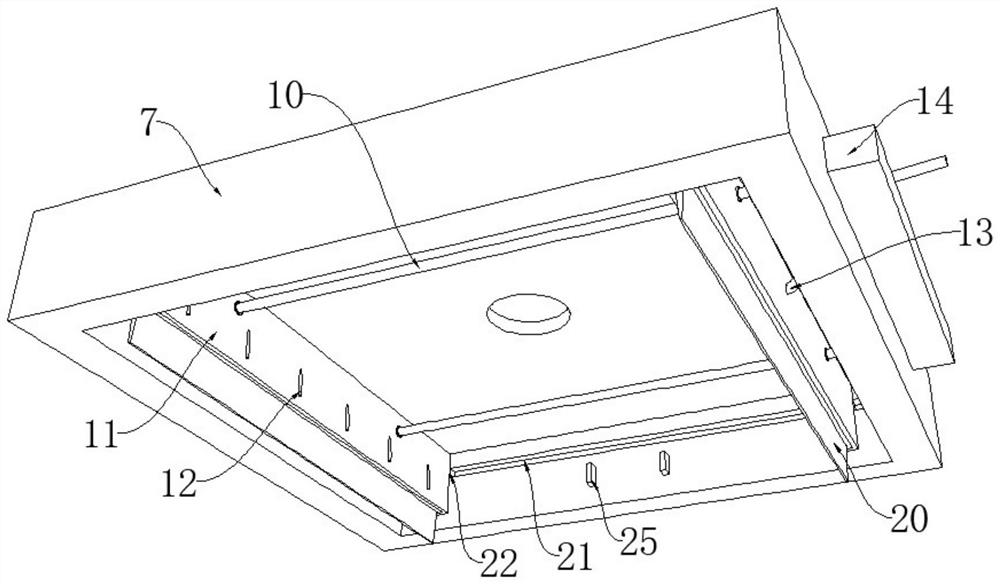

Indoor set of air-conditioner with filtering net dust collector

ActiveCN101256008AAchieve vertical movementEfficient dust removalLighting and heating apparatusSpace heating and ventilation detailsEngineeringAir tightness

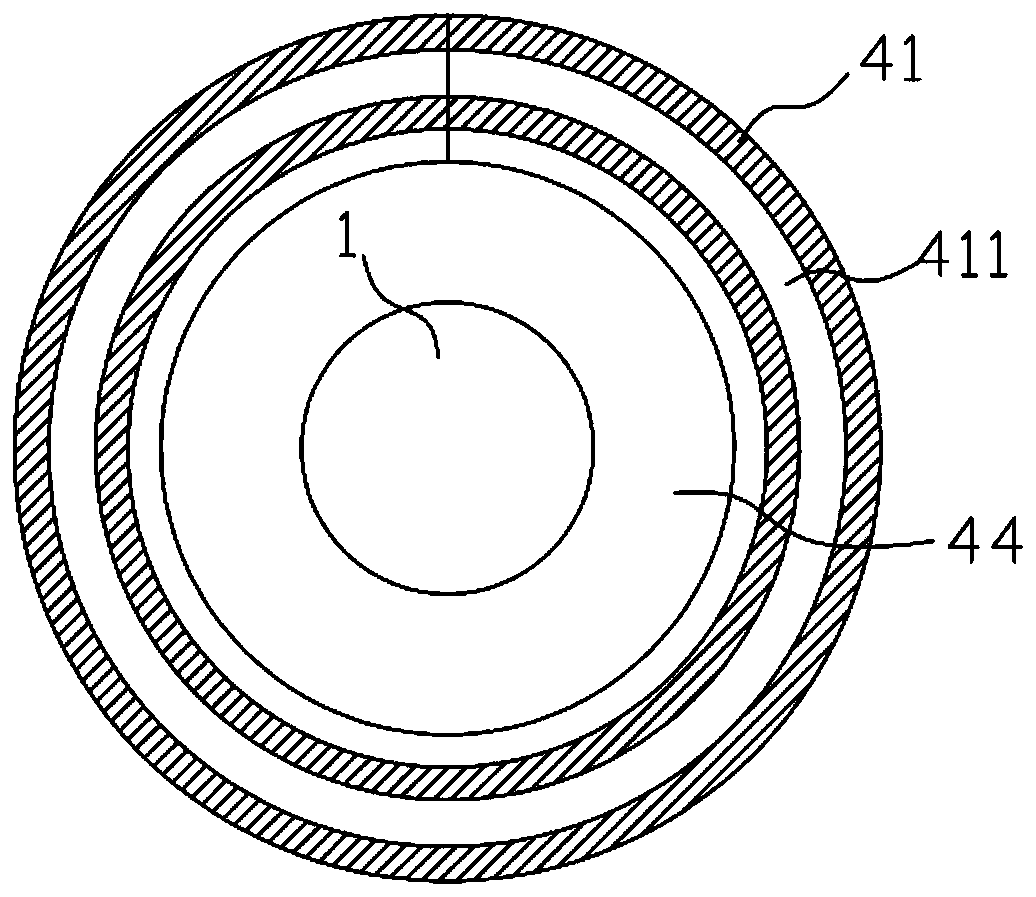

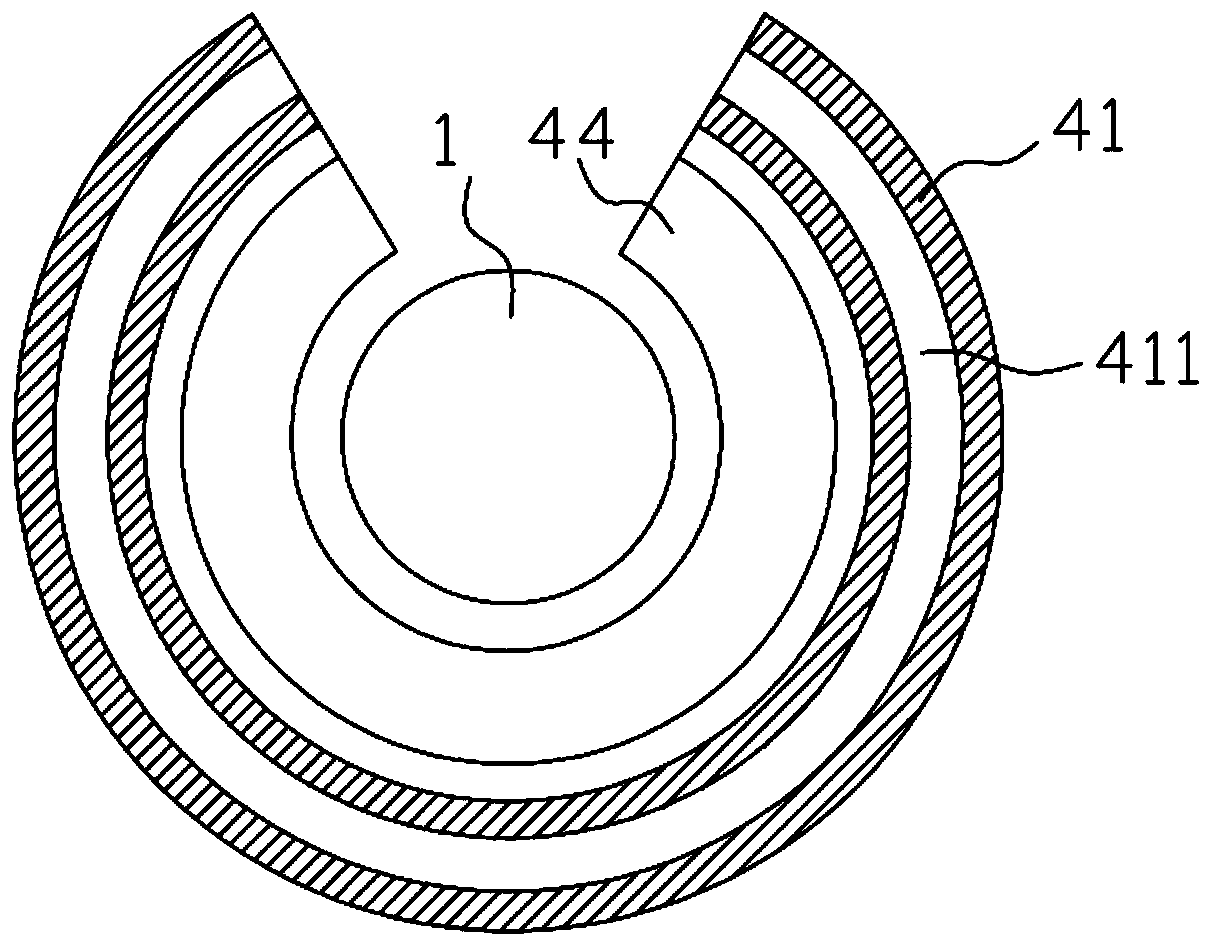

The invention pertains to air conditioner field, and specifically is an air conditioner indoor set with a filter screen dust removing device, comprising a housing, an air inlet and an air outlet disposed on the housing, a circular heat exchanger disposed in the housing, a fan is disposed at the circulating center of the circular heat exchanger, an air outlet of the fan communicating with the air outlet of the housing, and a dust removing filter screen disposed at the outer side of the circular heat exchanger; wherein a rolling shaft activating the filter screen is disposed at the two ends of the filter screen; a dust absorption pipe formed of a helical groove pipe and an axial straight groove pipe sleeving each other is disposed near to the filter screen, a hose communicating with the dust absorption pipe is disposed at the terminal of the straight groove pipe of the dust absorption pipe, and an electric motor rotating the helical groove pipe is disposed at the terminal of the helical groove pipe. An inhalation pore is formed by a straight groove pipe and a helical groove pipe sleeving each other with airtightness, wind power is centralized, and dust is removed with high efficiency; filter screen dust is removed roundly in condition that the indoor set outer cover is not opened.

Owner:HAIER GRP CORP +1

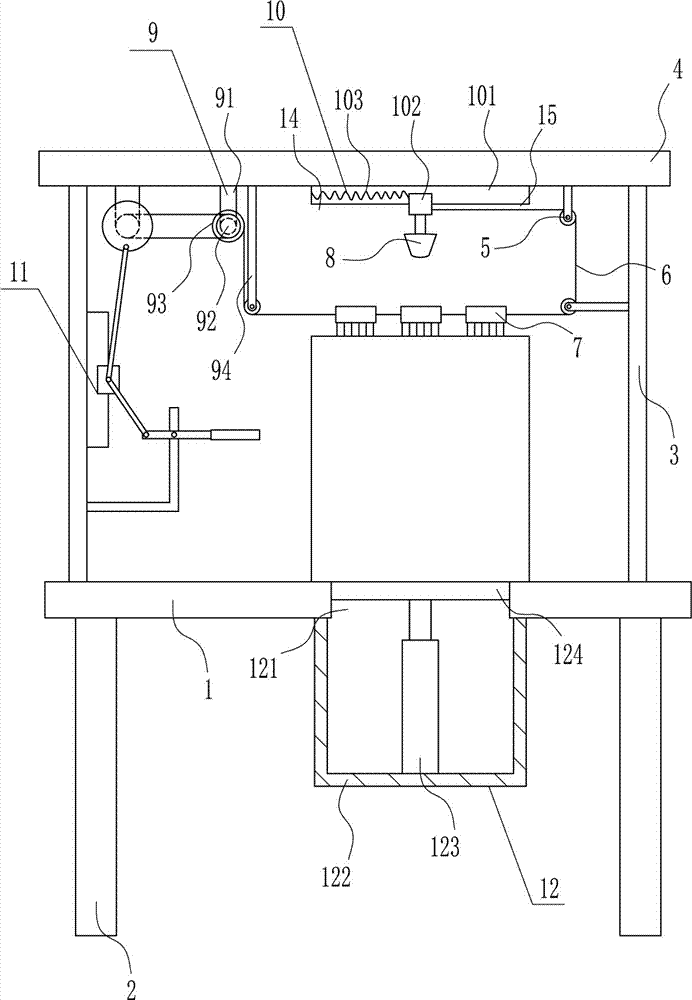

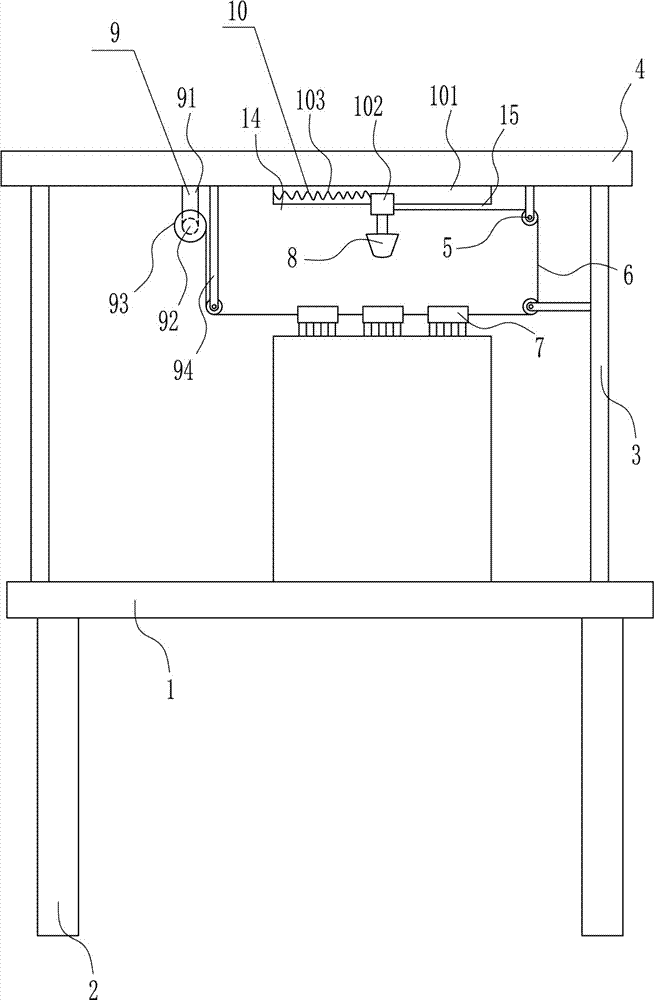

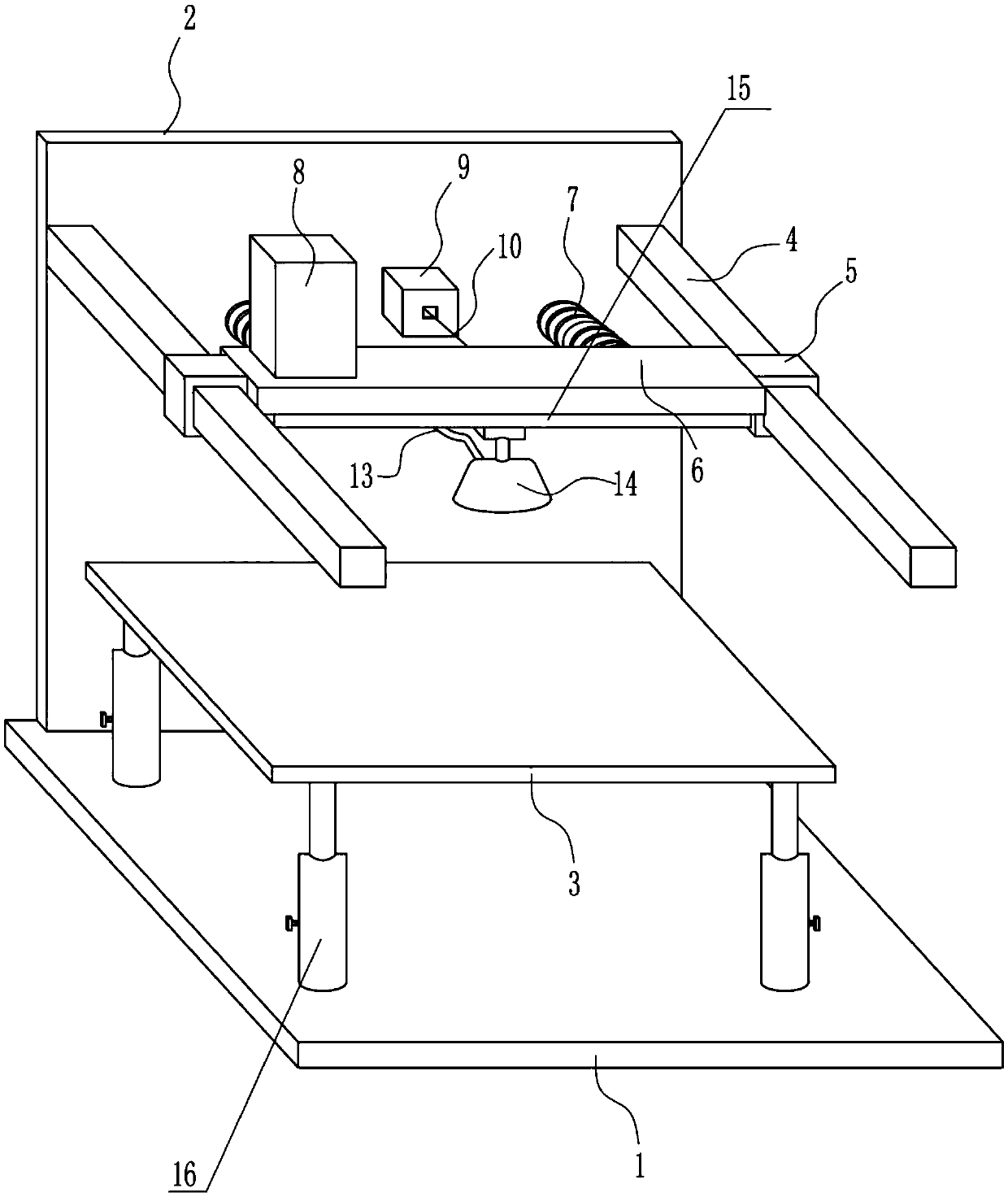

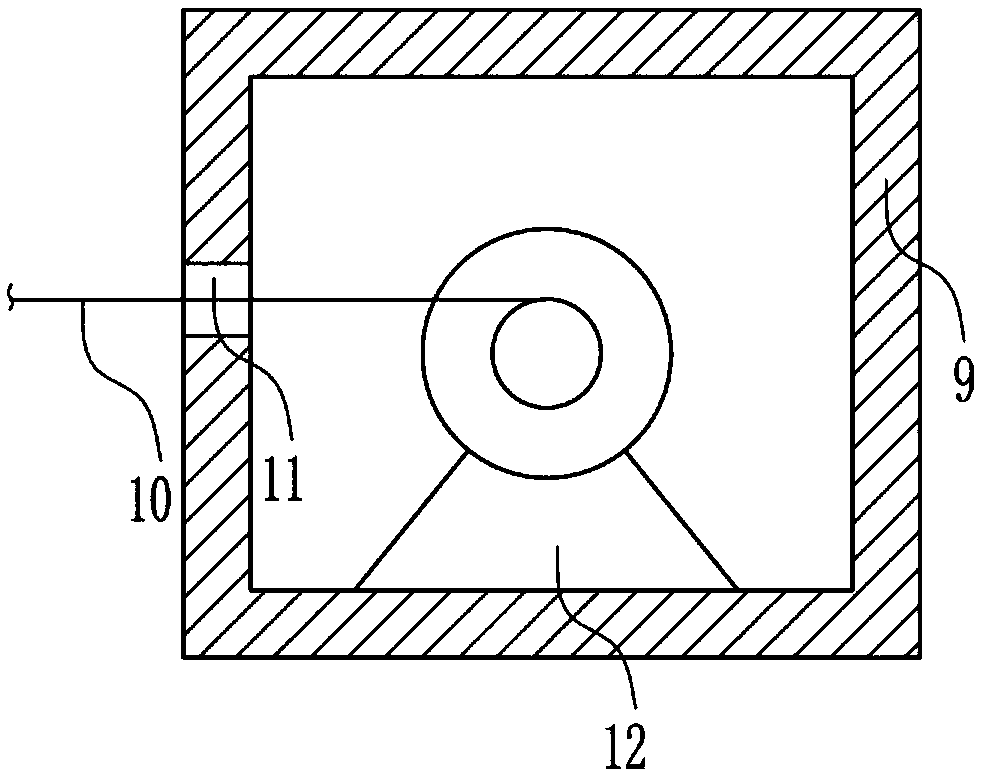

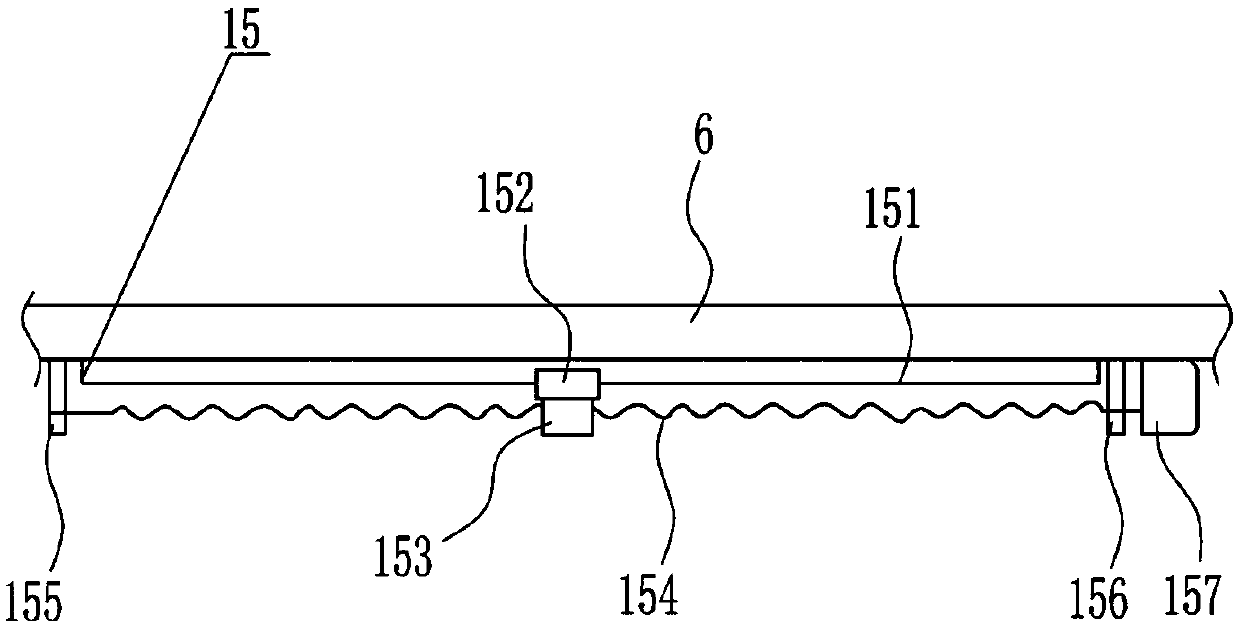

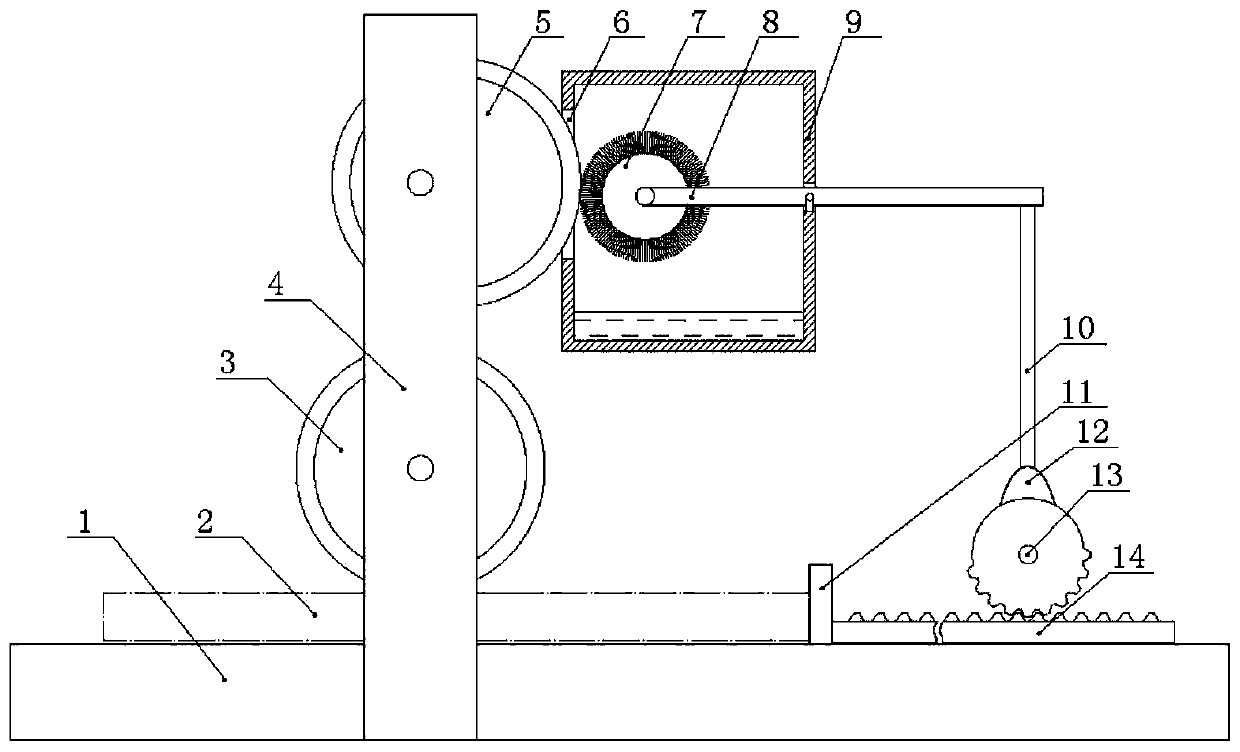

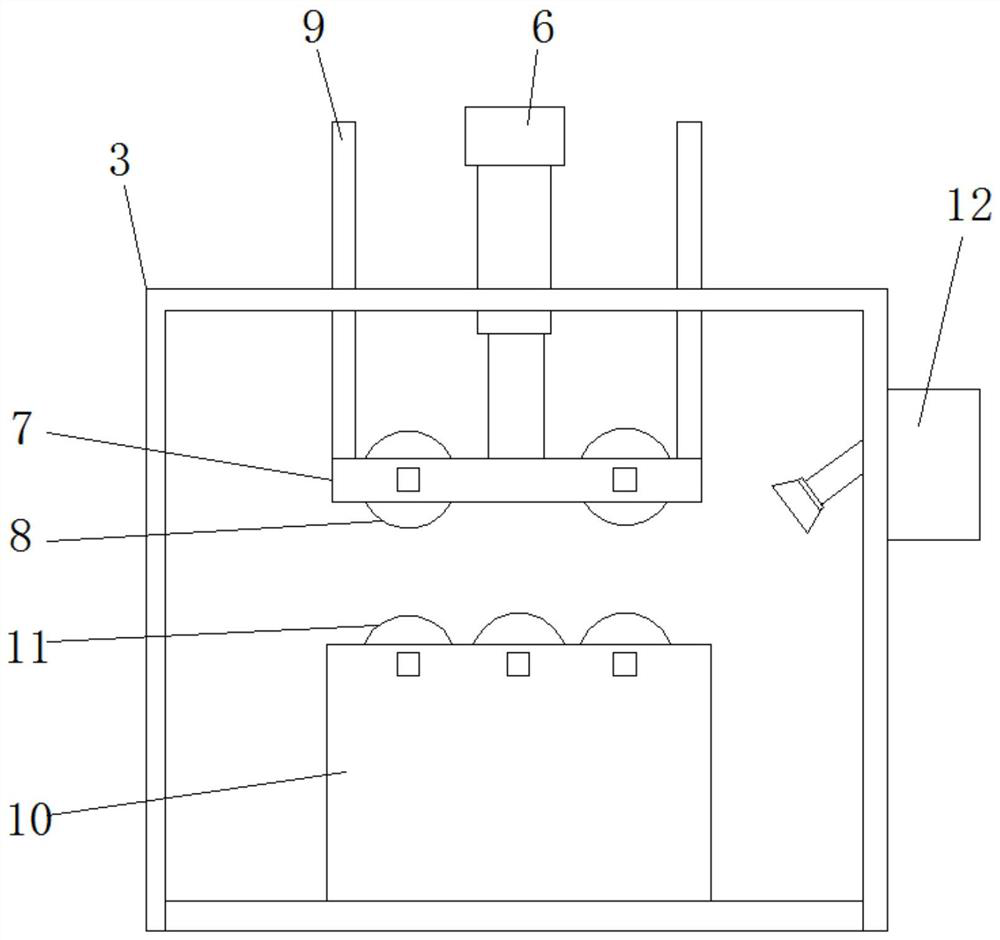

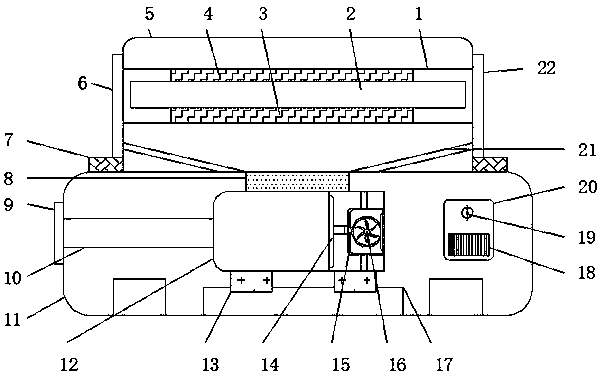

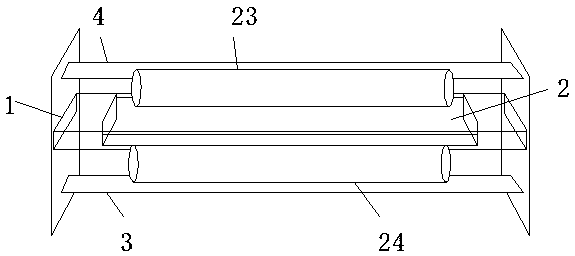

High-efficiency dust removing equipment for electronic product

InactiveCN106964576AComprehensive dust removalAdjustable distanceCleaning using toolsCleaning using gasesBolt connectionPulley

The invention relates to dust removing equipment for an electronic product, in particular to high-efficiency dust removing equipment for the electronic product. The invention aims to solve the technical problem of providing the high-efficiency dust removing equipment for the electronic product, which has the advantages of being time-saving, labor-saving, and high in dust-removing speed, and the electronic product is not liable to damage during dust removal. In order to solve the technical problem, the high-efficiency dust removing equipment for the electronic product, provided by the invention, is characterized by comprising a bottom plate, supporting legs, supporting plates, a top plate, a first pulley, a pull thread, hair brushes, a fan and the like, wherein the supporting legs are respectively mounted on the left side and the right side of the bottom of the bottom plate in a bolted connection manner, and are in symmetrical arrangement; the supporting plates are respectively mounted on the left side and the right side of the top of the bottom plate in a bolted connection manner; and the top plate is mounted at the top of the top plate in a bolted connection manner. According to the high-efficiency dust removing equipment provided by the invention, dust removal can be performed on the electronic product through the fan and the hair brushes, and besides, an arc-shaped plate swings up and down, so that thorough dust removal can be performed for the electronic product; and through a lifting device, the distance between the electronic product and the hair brushes can be adjusted.

Owner:刘养青

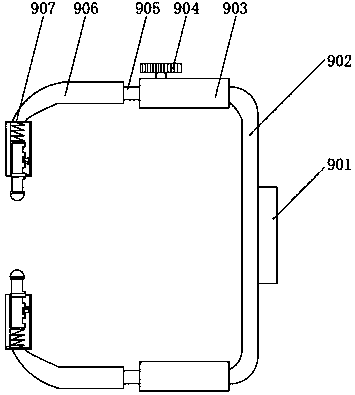

Special frequency converter box for large sound box

PendingCN108401198AGuaranteed working environmentEasy to check for faultsTransducer casings/cabinets/supportsFixed frameOmni directional

The invention discloses a special frequency converter box for a large sound box, which comprises a working box, wherein the two sides of the bottom of the working box are fixedly connected with a cooling liquid storage box; the bottom of the inner wall of the cooling liquid storage box is fixedly connected with a supply cooling pump; the supply cooling pump is communicated with a cooling pipe through an output port; one end, far away from the output port, of the cooling pipe is communicated with a heat dissipation pipe; a fan fixing frame is arranged above the heat dissipation pipe; the bottomof the fan fixing frame is fixedly connected with a head dissipation fan; the heat dissipation fan is rotationally connected with blades through a rotating shaft; and one end, far away from the cooling pipe, of the heat dissipation pipe is communicated with a backflow pipe. The invention relates to the technical field of sound equipment accessories. The special frequency converter box for the large sound box solves the problems of heat dissipation and stable cooling of the working box, and wire arrangement, so that omni-directional dust removal and personnel protection can be achieved, intelligent heat dissipation and dust removal can be realized, and the energy waste is reduced.

Owner:湖州坚美电声元件有限公司

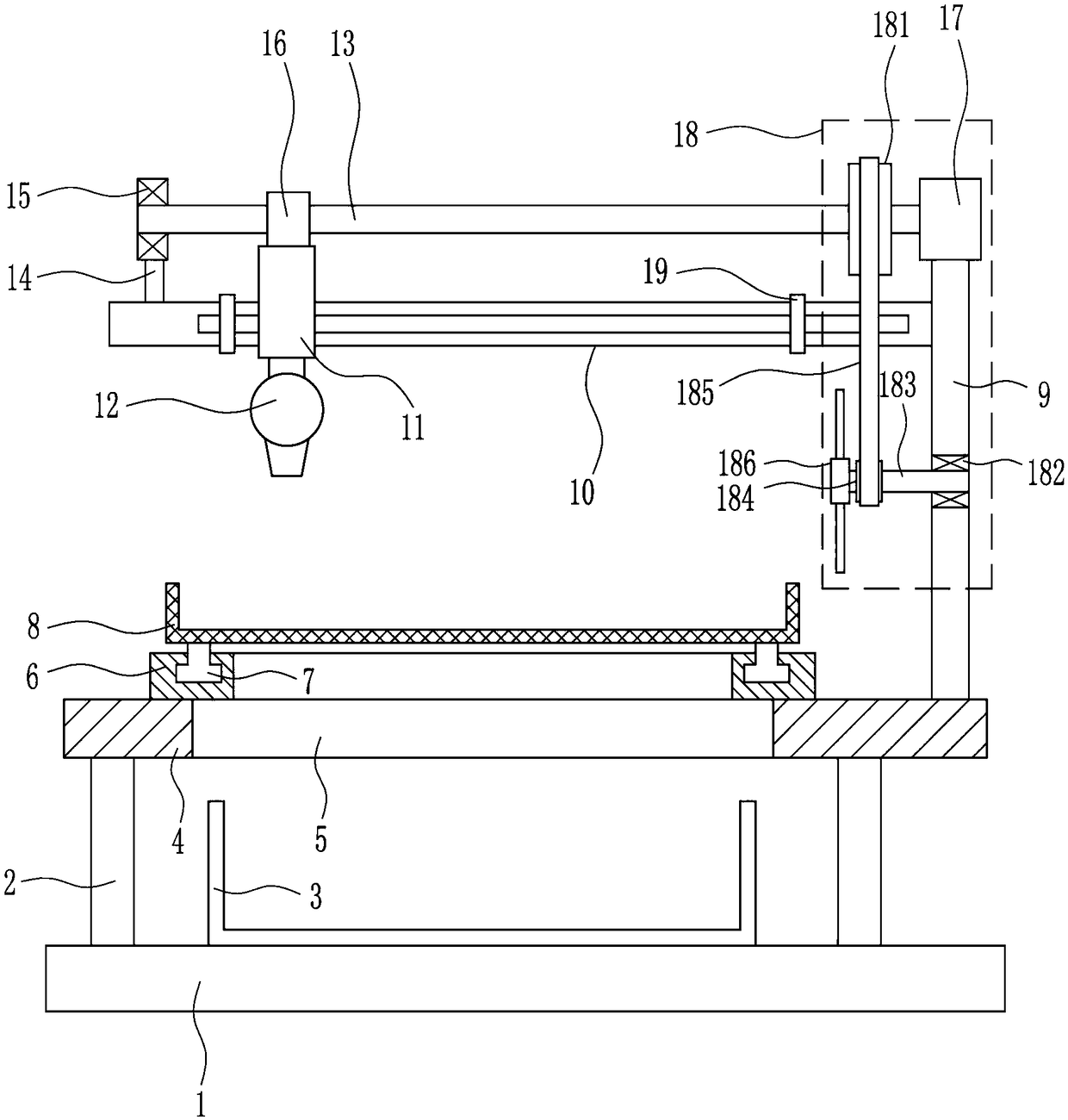

Painting device

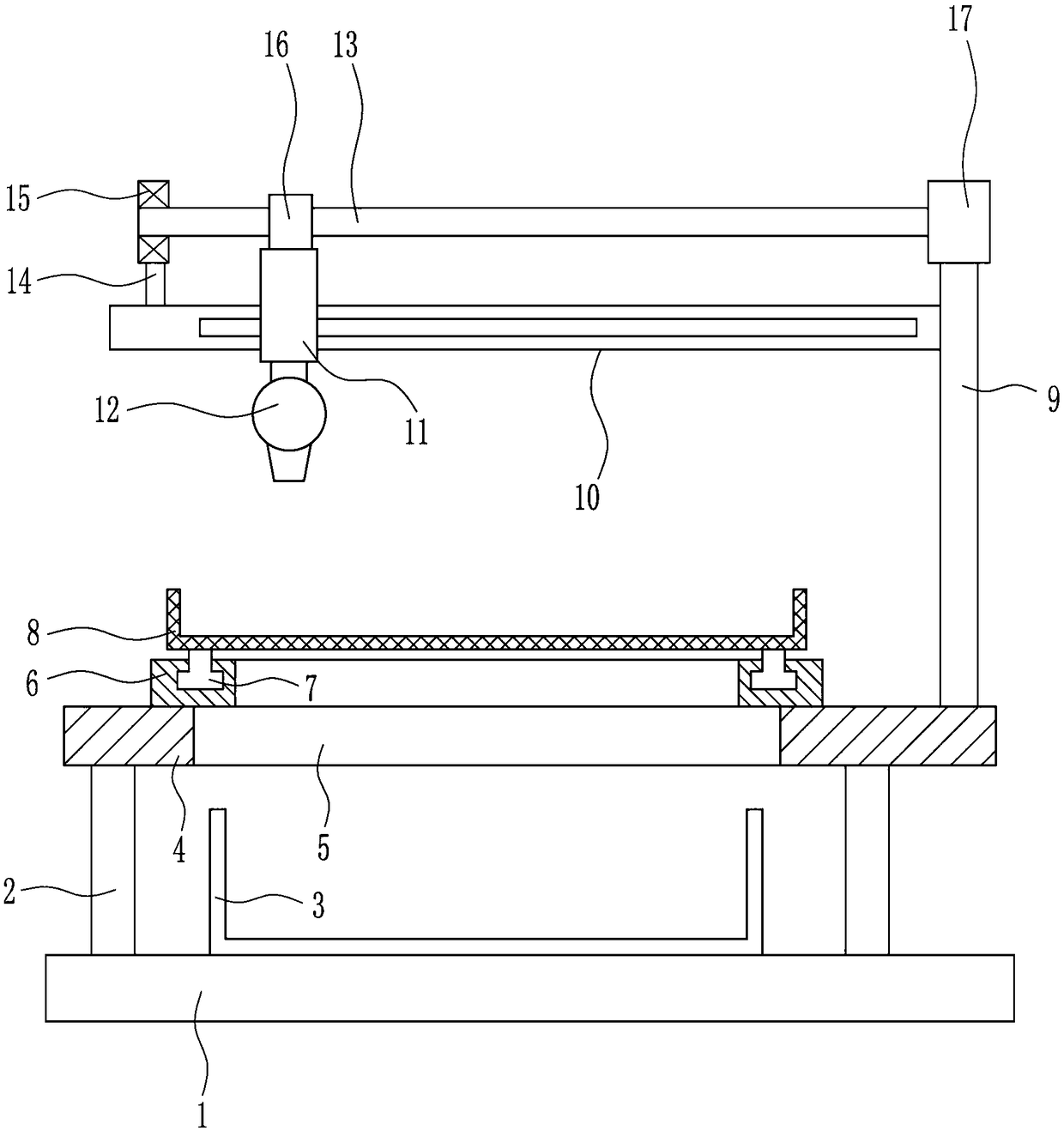

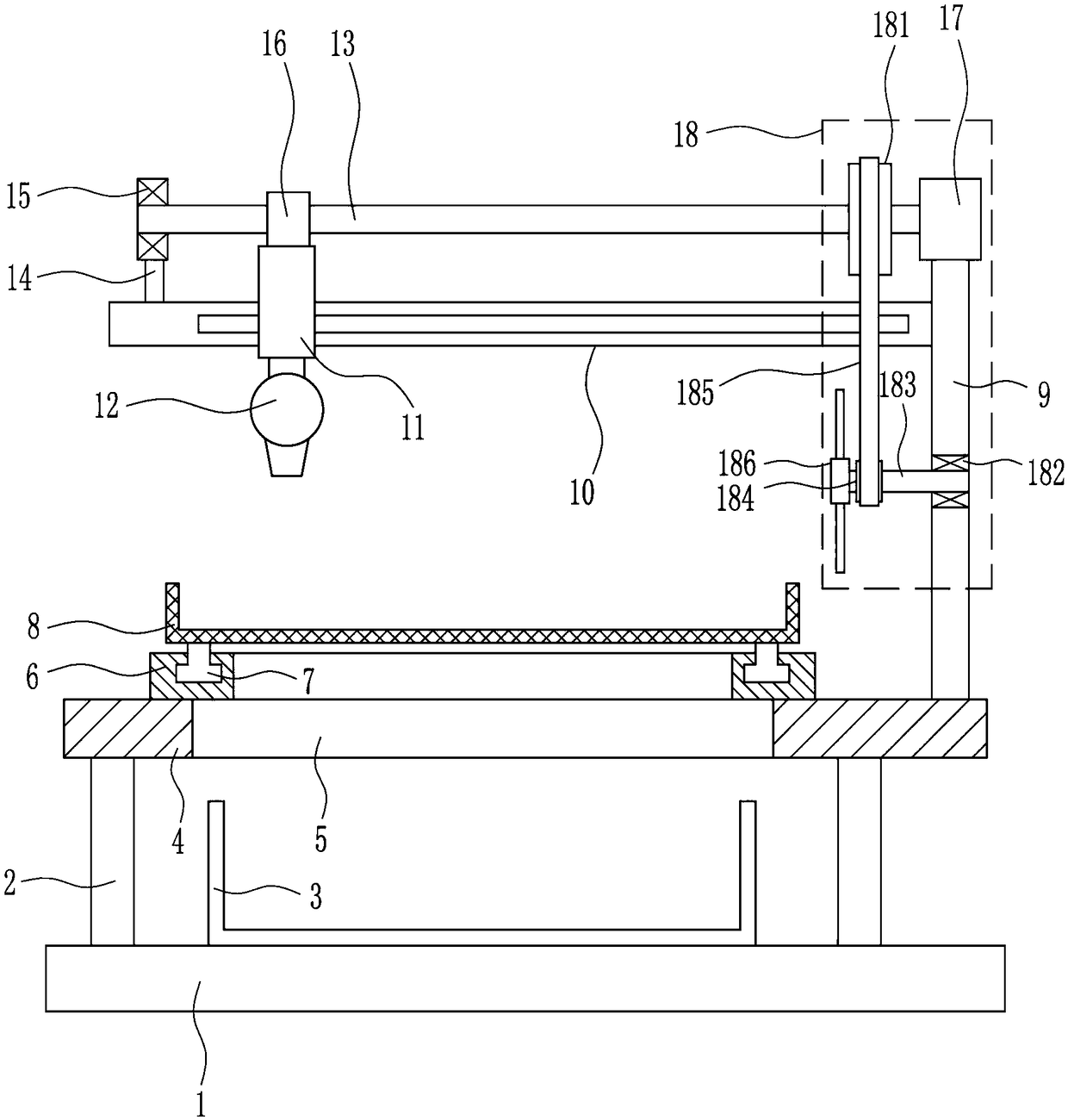

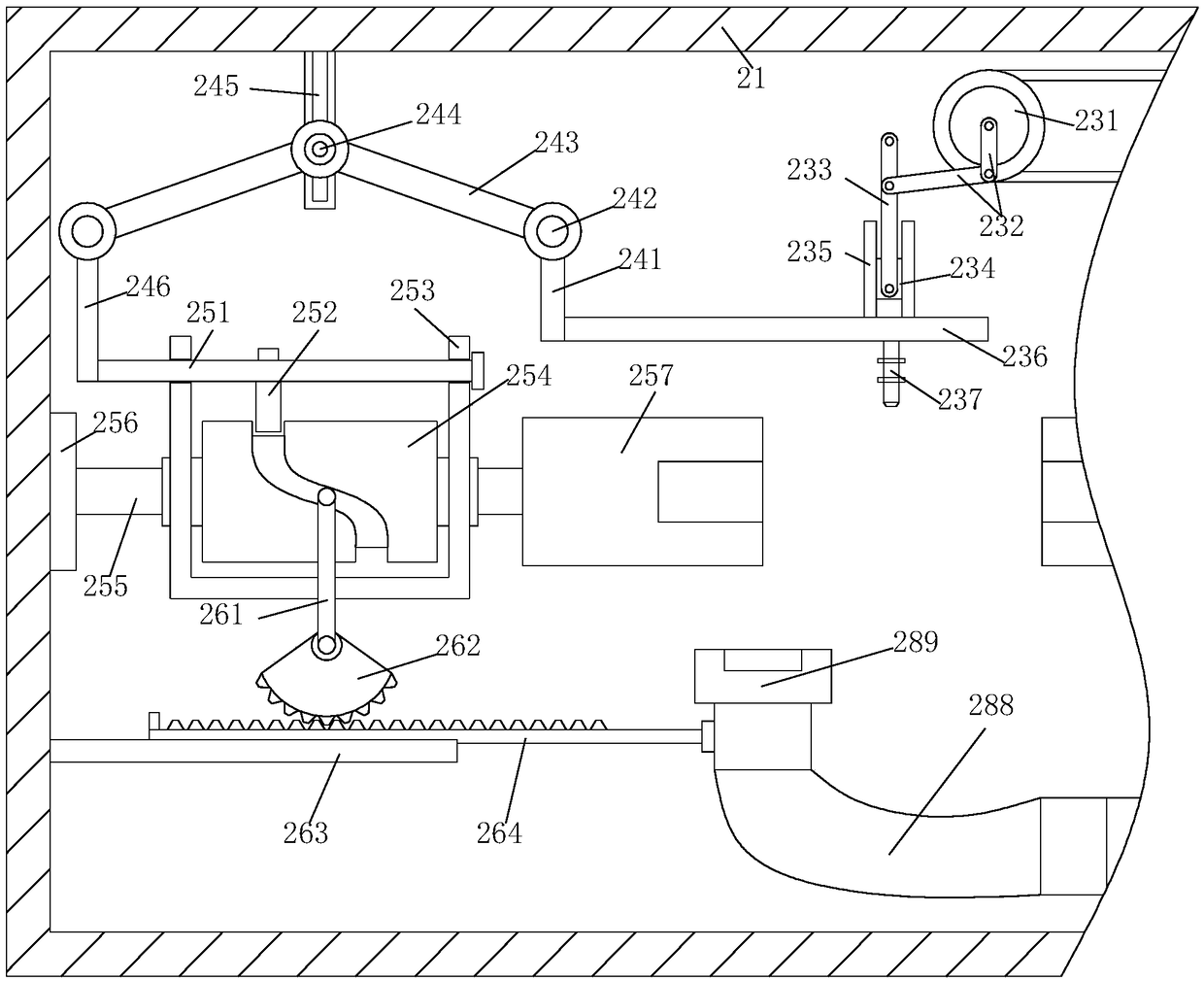

ActiveCN108480158AEfficient dust removalComprehensive dust removalSpraying apparatusPretreated surfacesMechanical engineeringPiston

The invention relates to the field of painting decoration equipment, and discloses a painting device. The painting device comprises a supporting frame and a base, a painting opening is formed in the front end of the supporting frame, an electric air pump, an air conveying pipe and a brush rod are arranged in the supporting frame, the electric air pump comprises an air inlet and an air outlet, oneend of the air conveying pipe is connected with the air outlet of the electric air pump, a piston is arranged in the air conveying pipe, a transmission mechanism is arranged between one end of the brush rod and the piston, a brush head is arranged at the other end of the brush rod, a first rack, a first gear, a second rack and a fixing part capable of clamping a workpiece are further included, thepiston is provided with a swing rod, an opening is formed in the air conveying pipe, the swing rod penetrates the opening and is connected with the first rack, the first rack and the second rack areengaged with the first gear, a first wedge face is arranged at one end of the second rack, and the lower end of the fixing part is provided with a second wedge face matched with the second rack. According to the scheme, a workpiece can move up and down while the brush head rotates for dust removal, and the comprehensive thorough dust removal effect on the workpiece surface can be achieved.

Owner:宁波隆锐机械制造有限公司

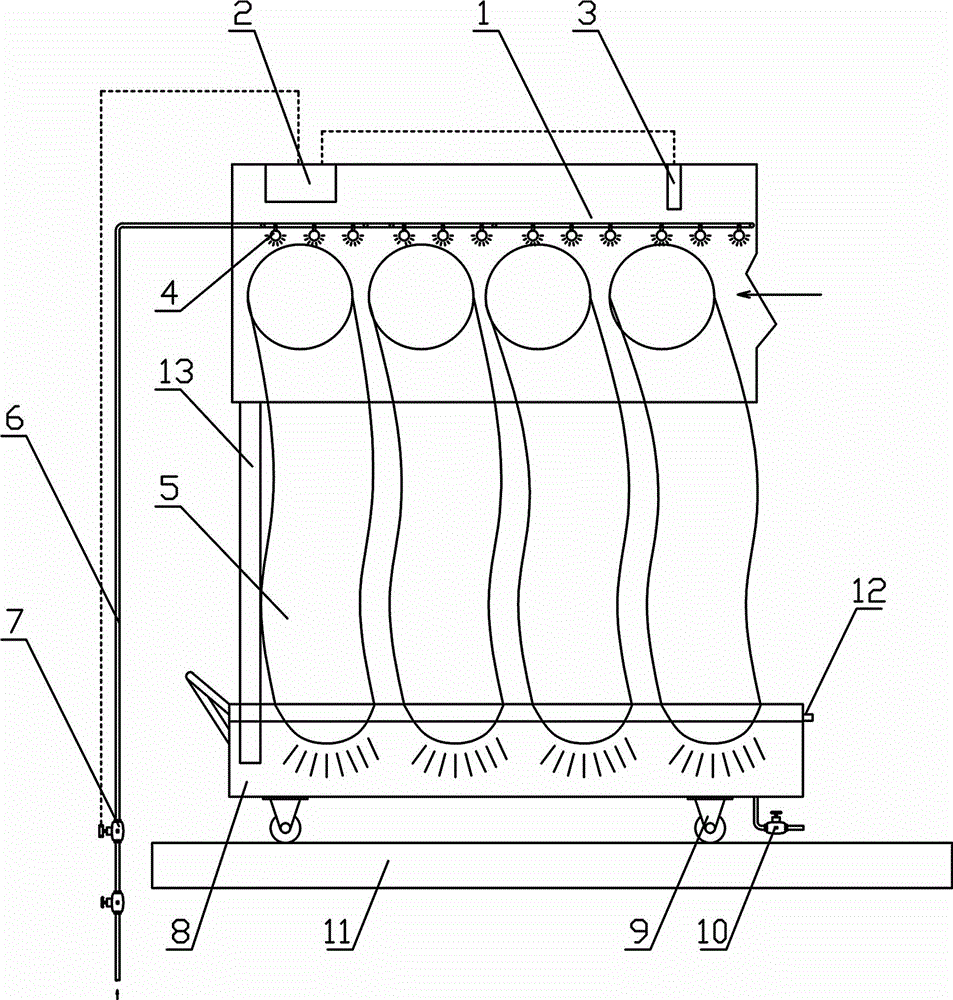

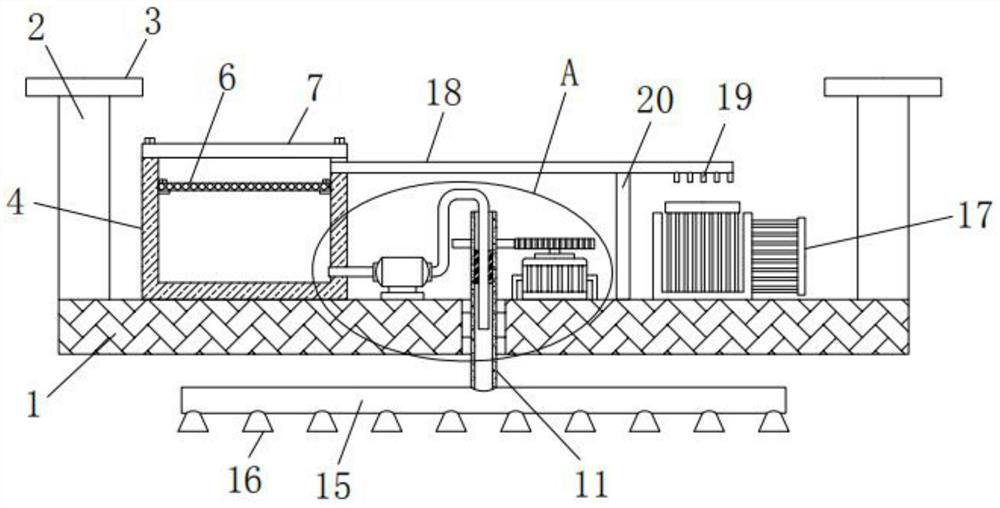

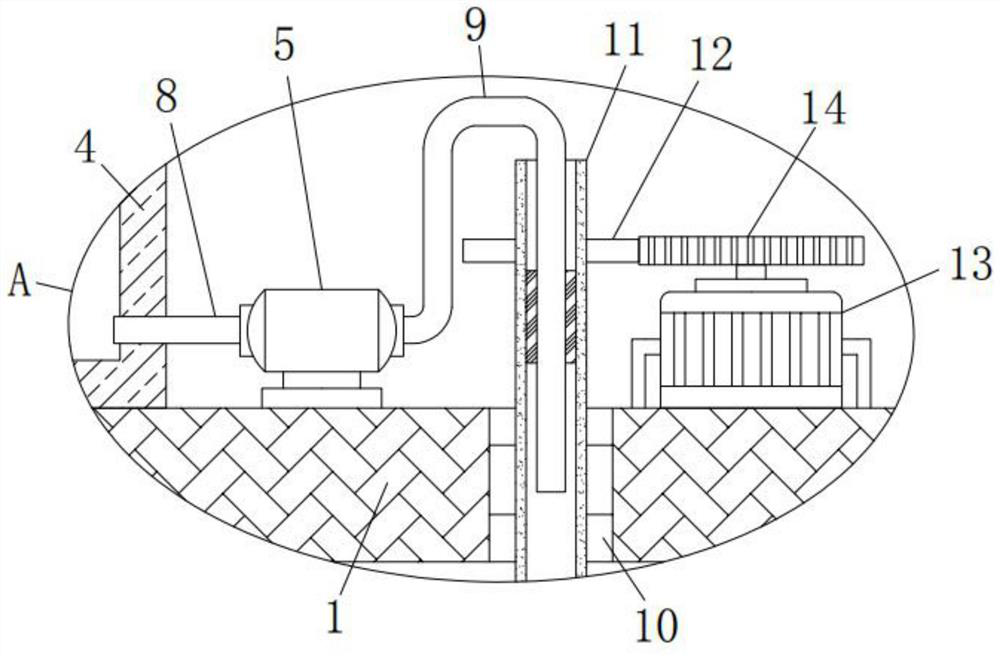

Capacitor shell drying machine

The invention provides a capacitor shell drying machine and relates to the technical field of drying machines. The capacitor shell drying machine comprises a machine housing internally provided with a drying channel, a driving belt passing through the drying channel and a heater arranged in the machine housing. The capacitor shell drying machine is characterized in that a heat insulating layer is arranged inside the machine housing; a hole is formed in the heat insulating layer; a draught fan is arranged outside the machine housing and below the outside of the machine housing and communicated into the top heat insulating layer inside the machine housing; a temperature inductor is arranged above the machine housing; the temperature inductor passes through the heat insulating layer arranged inside the machine housing; and two ends of the machine housing are provided with gates. The capacitor shell drying machine has the beneficial effects that the gates move vertically so as to adjust the sizes and the amount of capacitors entering the inside of the drying channel; and small holes formed in the draught fan and the heat insulating layer can be used for completely removing dust on the shells of the capacitors while drying the shells of the capacitors.

Owner:铜陵麟安生物科技股份有限公司

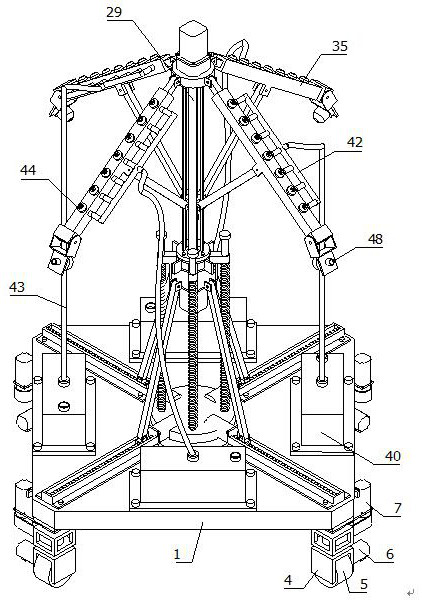

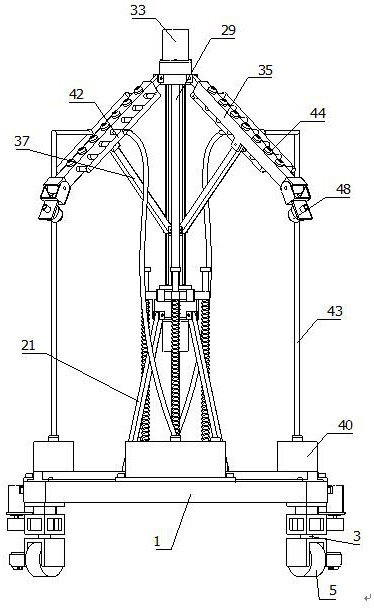

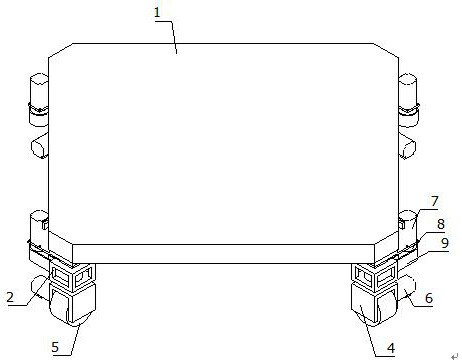

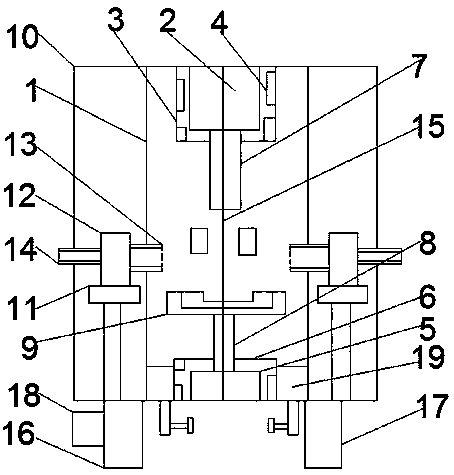

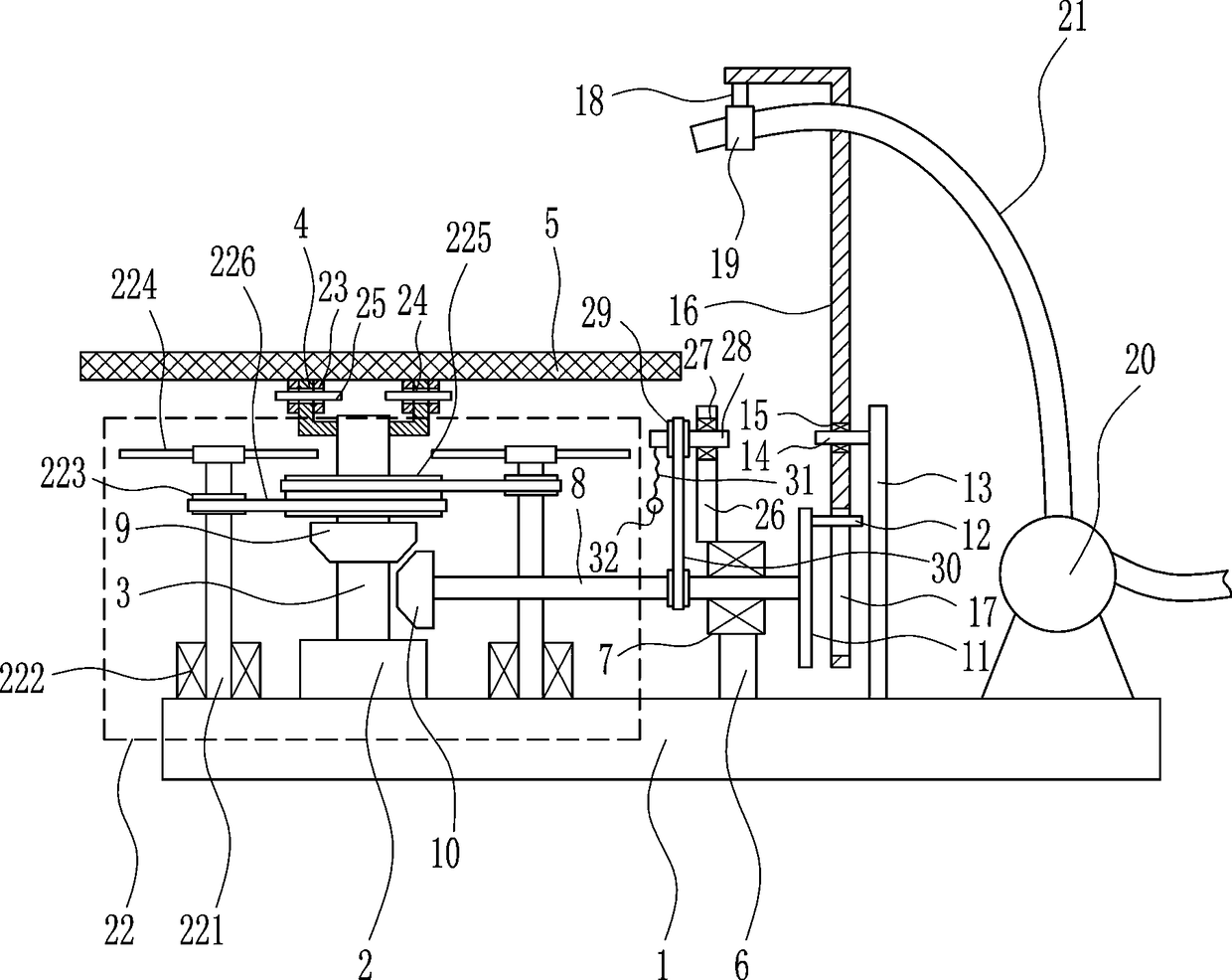

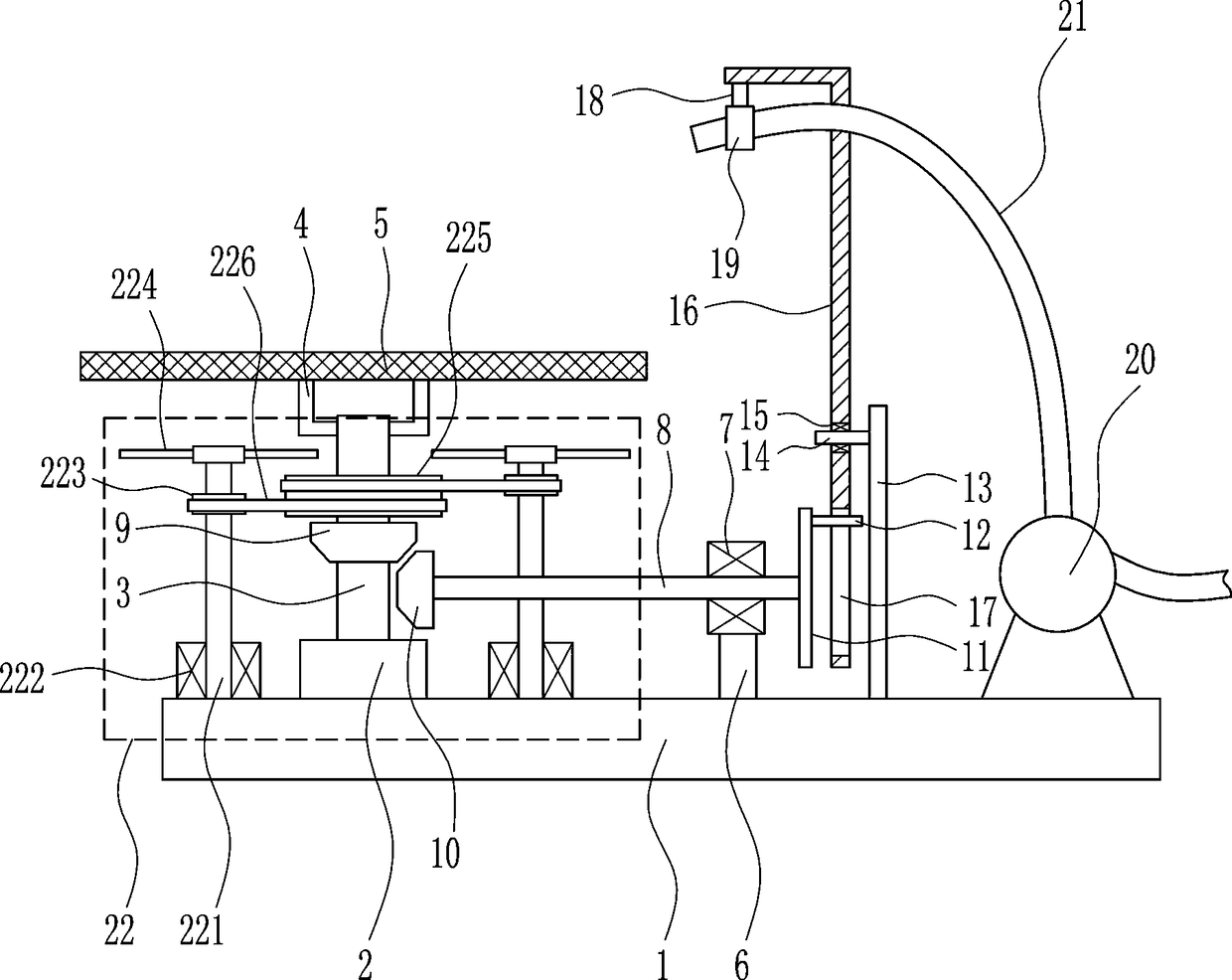

Indoor multidirectional automatic dust removal spraying device for building construction

InactiveCN112206618AImprove dust removal effectKeep healthyUsing liquid separation agentSpraying apparatusDust controlWater resources

The invention relates to the field of building construction, in particular to an indoor multidirectional automatic dust removal spraying device for building construction. The device comprises a saddlefor playing a supporting role, a moving assembly used for driving the saddle to move and arranged at the bottom of the saddle, a height adjusting assembly used for adjusting the spraying height and arranged at the top of the saddle, four water supply mechanisms being same in structure, used for providing spraying water resources and arranged on the periphery of the top of the saddle, an angle adjusting assembly used for adjusting the spraying angle, a rotating assembly used for driving the angle adjusting assembly to rotate, and four water spraying mechanisms used for spraying water for dustremoval and being same in structure. The problems that traditional spraying dust removal equipment cannot move and cannot adjust the spraying range in multiple directions are solved, the indoor dust removal effect is improved, and the health of personnel is guaranteed.

Owner:王富英

Dust removal device of instrument and apparatus

InactiveCN108672410ANot hurtImprove the noise reduction effectDirt cleaningCleaning using gasesEngineeringInstrumentation

Owner:ANHUI MUFAN ELECTRONICS TECH CO LTD

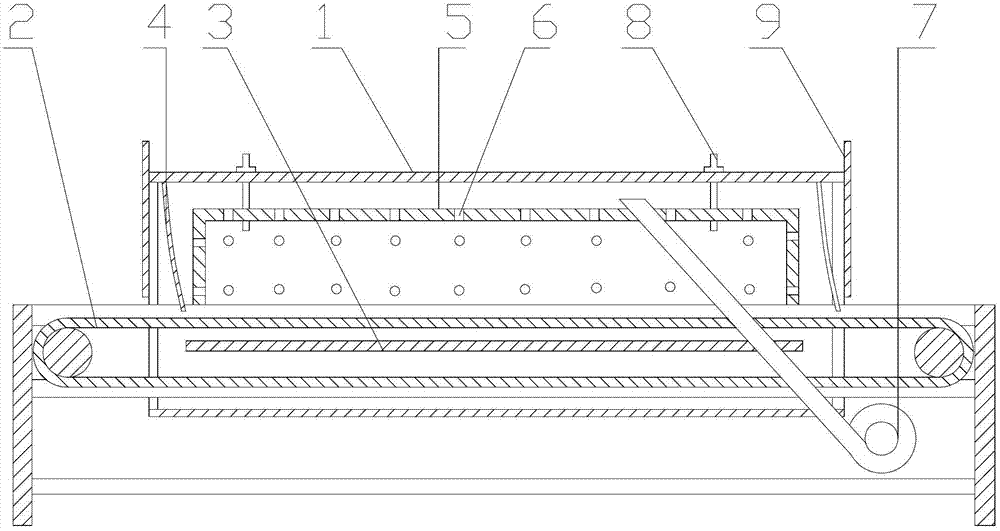

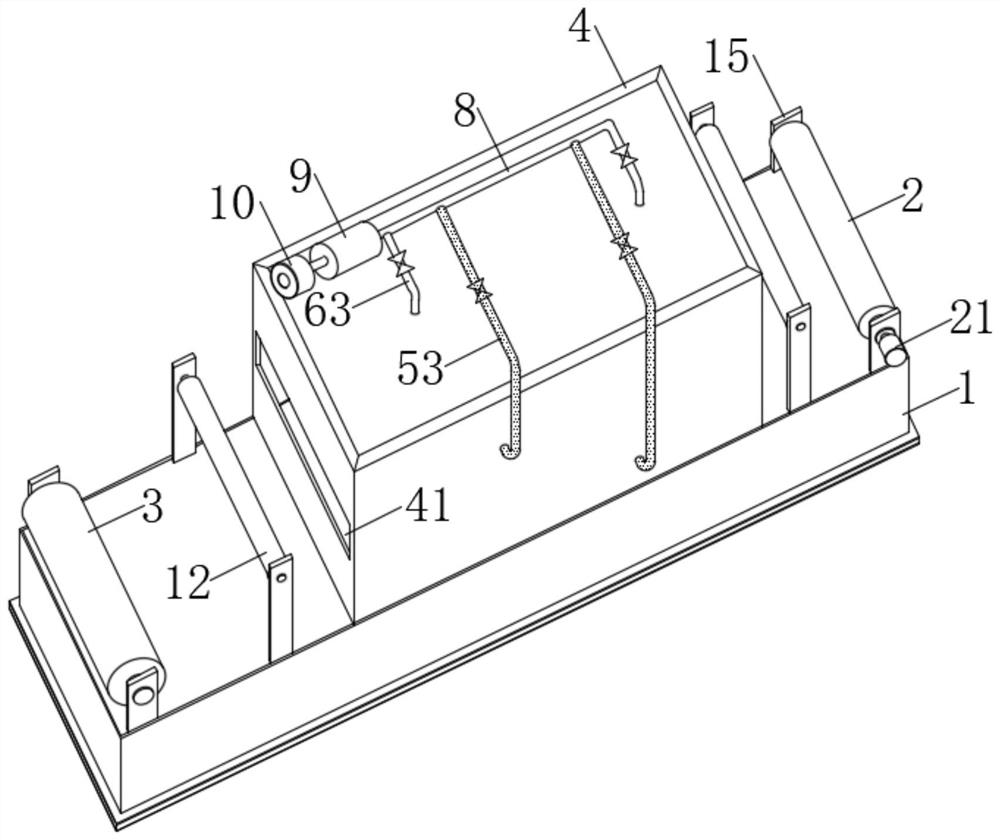

Fabric surface dust removal device for fabric processing

PendingCN112897146AReduce energy consumptionGuaranteed cleanlinessMechanical cleaningPressure cleaningElectric machineDust control

The invention discloses a fabric surface dust removal device for fabric processing. The device comprises a fabric processing table and a wind-up roll, wherein the wind-up roll is rotationally arranged at one side of the top of the fabric processing table through a supporting frame; one side of the wind-up roll and the output end of a winding motor on the supporting frame are fixedly arranged through a coupler; a discharging roller is rotationally arranged at the side, away from the wind-up roll, of the top of the fabric processing table through the supporting frame; a dust removal protective cover is fixedly arranged at the portion, between the wind-up roll and the discharging roller, of the top of the fabric processing table; cloth guide openings are arranged at the two sides, close to the wind-up roll and the discharging roller, of the dust removal protective cover respectively; fabric on the discharging roller penetrates through the dust removal protective cover through the cloth guide opening; a first dust removal component is arranged in the dust removal protective cover; and a second dust removal component is arranged in the position, above the first dust removal component, in the dust removal protective cover through a reciprocating mechanism. The device has the beneficial effects that continuous static electricity elimination and dust removal are conducted at the two sides of the surface of the fabric, the efficiency is higher, the cost is reduced, the effectiveness of dust removal on the surface of the fabric is ensured, and dust removal on the surface of the fabric is thorough and comprehensive.

Owner:戈郁

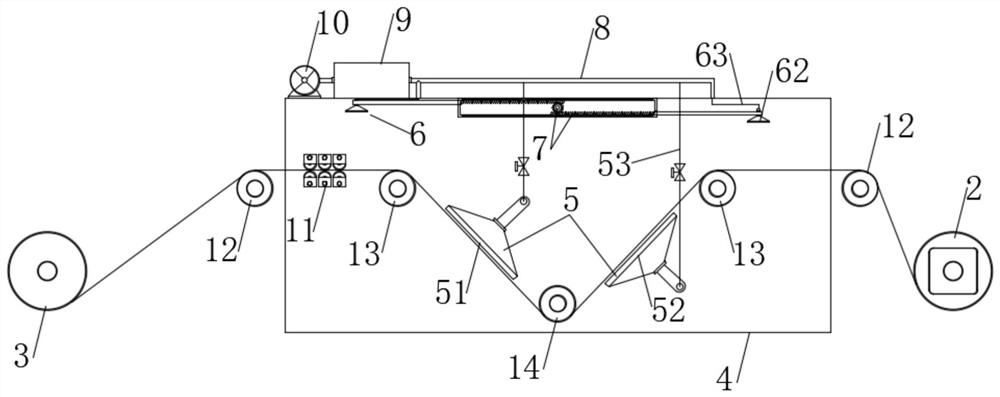

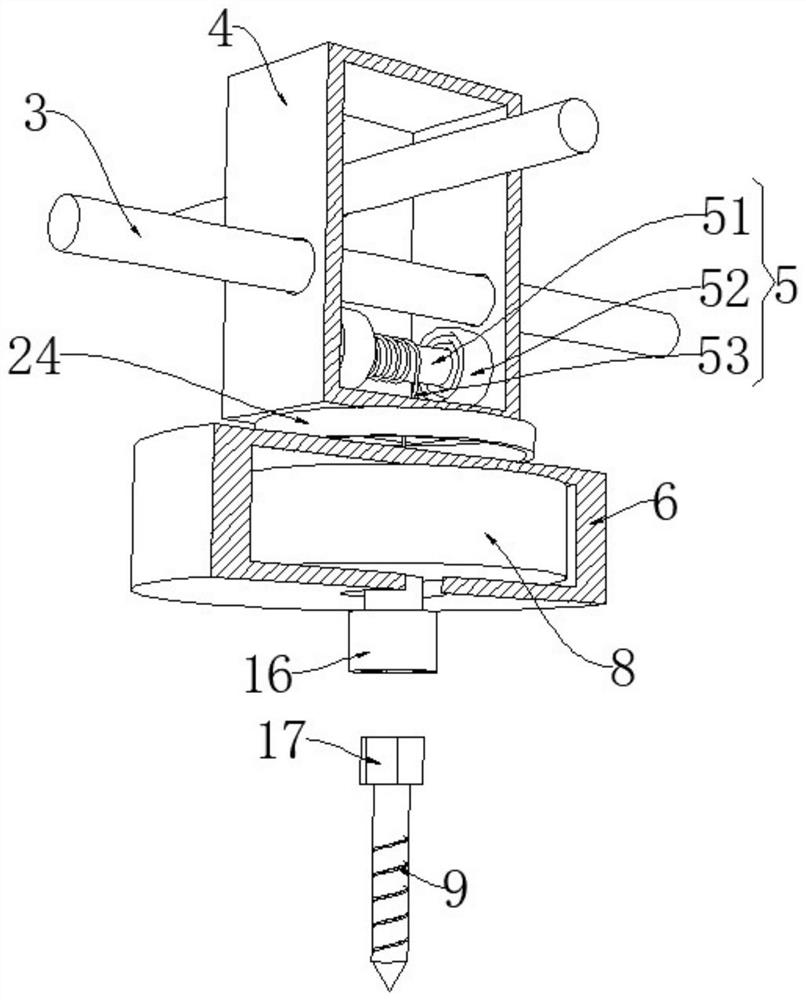

Security monitoring device with function of self-cleaning

InactiveCN111266330AClean and thoroughEasy to cleanCleaning using toolsCleaning using gasesDust controlElectric machinery

The invention discloses a security monitoring device with the function of self-cleaning. The security monitoring device comprises a camera body (1), a frame (2) arranged on the camera body (1), an airblowing device (3) arranged on the frame (2), an elastic frame device (2) arranged below the frame (2) and a motor device (5) arranged outside the frame (2). According to the security monitoring device, a camera can be thoroughly cleaned, and a significant cleaning effect is achieved; moreover, an elastic frame can be elastically deformed, an entire circular truncated cone is constituted when theelastic frame moves to the bottommost position, and can surround the camera by 360 degrees, and then air is blown to the camera centralizedly to achieve comprehensive dust removing treatment on the camera; and in the meanwhile, a centralizing frame is arranged at the lower end of the elastic frame and can blow air to the lower end of the camera to facilitate dust removing on the lower end of thecamera, thus thorough dust removing on the camera is guaranteed, and the dust removing effect on the camera is also ensured.

Owner:李玉盛

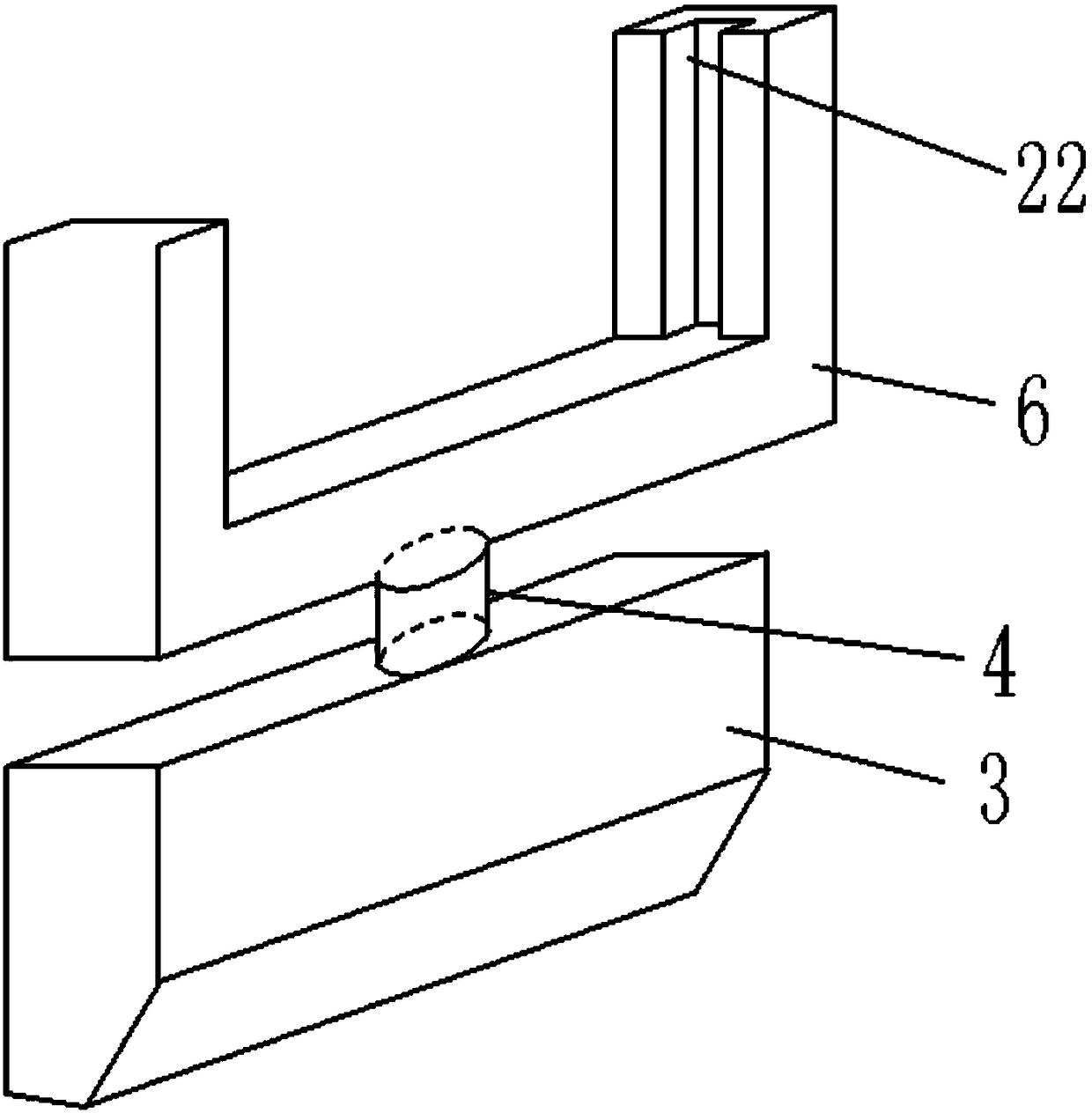

Dust removal device for electronic product recycling

InactiveCN109013555AEasy to remove dustDust removal speed is fastDirt cleaningCleaning using gasesEngineeringMechanical engineering

The invention relates to a dust removal device for electronic product recycling. The dust removal device for electronic product recycling is thorough and comprehensive in dust removal, and cannot hurtthe health of a person. The dust removal device for electronic product recycling comprises a bottom plate, supporting rods, a collection frame, a mounting plate, an annular sliding rail, a first sliding block, a net frame, a support, a straight sliding rail, a second sliding block, a blowing machine, a screw rod, a supporting block and the like; the supporting rods are arranged on the left side and the right side of the top of the bottom plate, the mounting plate is connected to the top ends of the supporting rods, the collection frame is arranged at the position, between the supporting rods,of the top of the bottom plate, and through holes are formed in the mounting plate and formed above the collection frame. Dust removal is thorough and comprehensive, the hurt to the health of the person is avoided, continuous left and right moving of the blowing machine is combined with rotation of the electronic product, and the electronic product can be rapidly and comprehensively subject to dust removal.

Owner:泉州闽字铺食品有限公司

Power control box for corrugated paper production equipment

InactiveCN108521091AGuaranteed working environmentEasy to check for faultsSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsSoftware engineeringPaper production

The invention discloses a power control box for corrugated paper production equipment. The power control box includes a work box. Two coolant storage tanks are fixedly connected on two sides of the bottom of the inner wall in the work box respectively. The bottom of the inner wall of each coolant storage tank is fixedly connected with a supply cooling pump. Each supply cooling pump is communicatedwith a cooling pipe through an output port. One end of each cooling pipe, away from the corresponding output port, is communicated with a heat dissipation pipe. A fan fixing support is arranged aboveeach heat dissipation pipe. The bottom of each fan fixing support is connected with heat dissipation fans, and the heat dissipation fans are rotatably connected with blades through rotary shafts. Oneend of each heat dissipation pipe, away from the corresponding cooling pipe, is communicated with a return pipe. The invention relates to the technical field of power control. The power control box for corrugated paper production equipment enables heat dissipation and steady cooling of the work box to be realized, can arrange conductors, can comprehensively remove dust and protect workers, dissipates heat and removes dust in an intelligent manner, and reduces energy waste.

Owner:东莞顺裕纸业有限公司

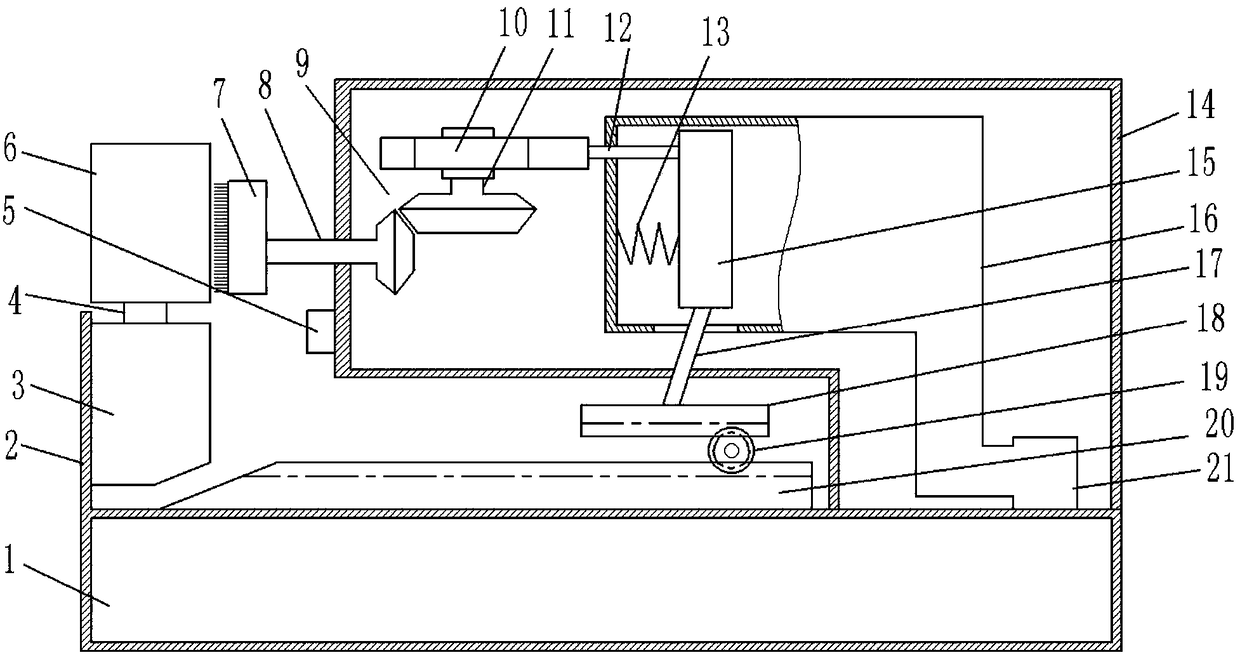

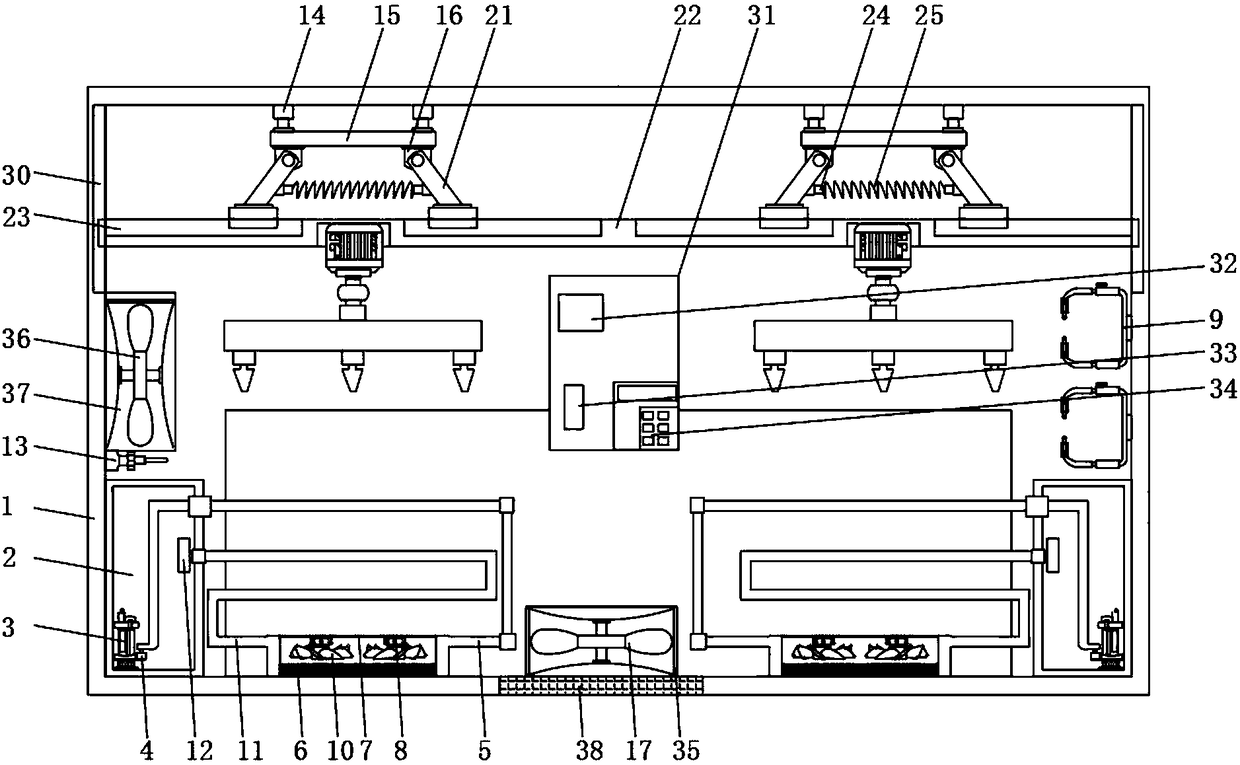

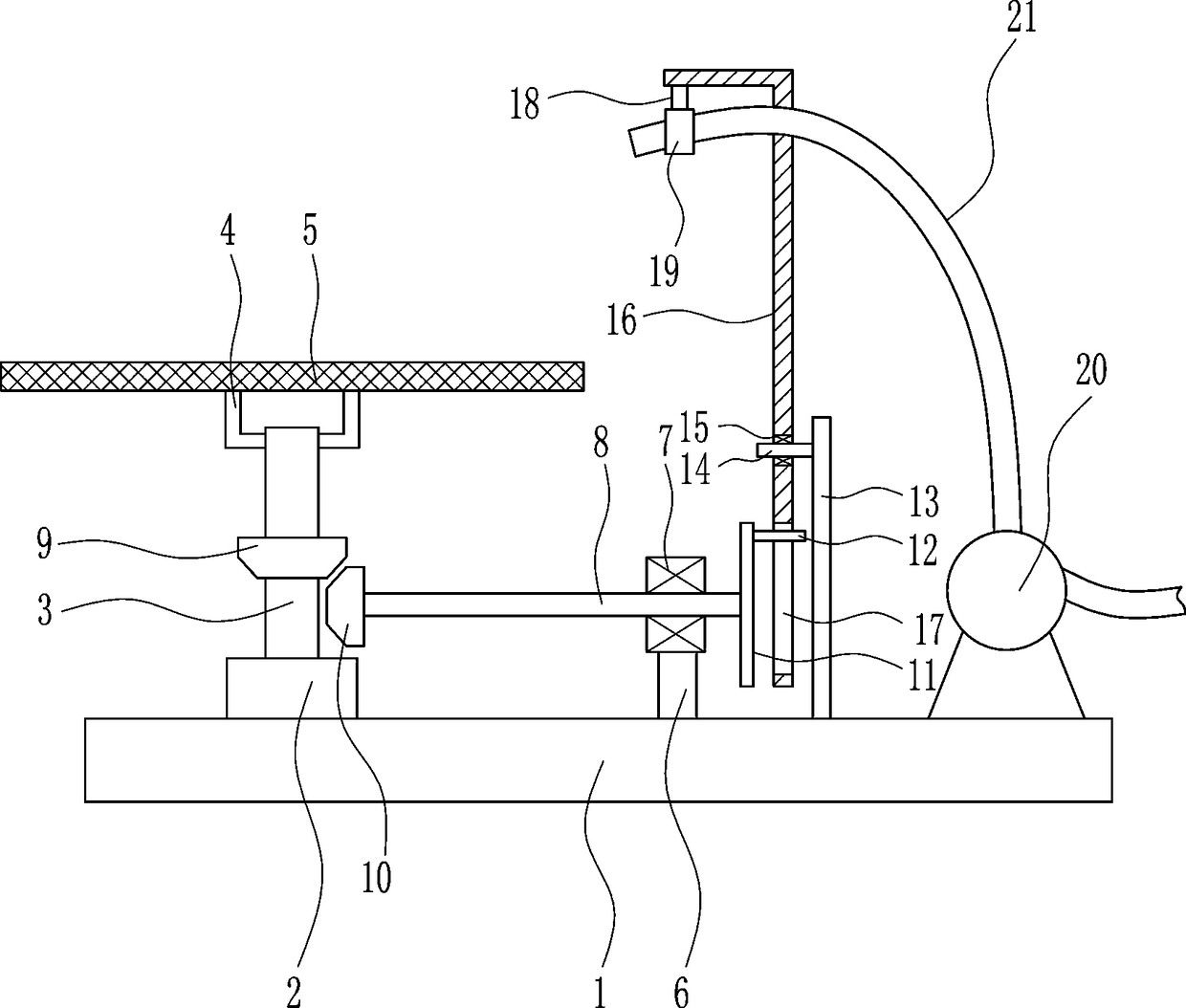

Dust removing equipment for computer host

InactiveCN109622511AComprehensive dust removalDust removal speed is fastCleaning using toolsCleaning using gasesAir pumpEngineering

The invention relates to dust removing equipment, in particular to dust removing equipment for a computer host. According to the technical problem to be solved, the dust removing equipment for the computer host is high in dust removal speed and efficiency, and removes dust on the computer host comprehensively. To solve the technical problem, the dust removing equipment for the computer host comprises a bottom plate, a rear side plate, a first transverse plate, a sliding rod, a sliding sleeve, a second transverse plate, a first spring, an air pump, a small box body, a first drawing line, an electric winding wheel, an air output pipe and the like. A height adjusting device is arranged on the top of the bottom plate. The rear side plate is installed on the rear side of the top of the bottom plate through a bolt connecting manner. The first transverse plate is arranged on the top of the bottom plate. According to the dust removing equipment, by means of moving of an air nozzle and rollingof a rolling brush, the dust on the computer host can be removed comprehensively and fast, the dust removing speed is high, the efficiency is high, and the effect of removing the dust on the computerhost is achieved.

Owner:ZHENGZHOU GUOZHI NETWORK TECH CO LTD

Printing machine dust removal device

InactiveCN105709539AImprove workshop environment quality and product qualityComprehensive dust removalCombination devicesUsing liquid separation agentSpray nozzleWater pipe

A printing machine dust removal device is disclosed, fog water is sprayed to air with dust, the fog water adsorbs smaller dust to avoid the smaller dust from drifting from pores on cloth bags away in the air, and workshop environmental quality can be improved. An air inlet box of the printing machine dust removal device is connected with a plurality of cloth bags, wherein the air inlet box is connected with a printing machine, a water receiving tray is arranged below the cloth bags, the air inlet box is also provided with an atomization spray nozzle, the atomization spray nozzle and a water inlet pipe are in connection, and the water inlet pipe is provided with an electromagnetic valve. The edge of the water receiving tray is provided with an overflow hole. The bottom of the water receiving tray is provided with wheels capable of moving back and forth with the printing machine. The bottom of the air inlet box is provided with a water drain pipe. Through adoption of the above structure, the air with dust can be dedusted comprehensively, and workshop environment and product contamination caused by the smaller dust in ordinary cloth bag filter dust removal methods can be avoided, and workshop environment and product quality are improved.

Owner:HUBEI TAISHENG PACKAGING

Dust removing device for copper plate of integrated circuit

InactiveCN111185414AImprove efficiencyComprehensive dust removalCleaning using toolsChemistryIntegrated circuit

The invention relates to the technical field of circuit board processing, in particular to a dust removing device for a copper plate of an integrated circuit. The dust removing device comprises a processing table, wherein a spiral dust removing roller made of silica gel is rotationally arranged above the processing table, the dust removing roller can be in contact with the copper plate, a spiral dust sticking roller capable of being engaged with the dust removing roller is arranged above the dust removing roller, an adhesive layer is arranged on the surface of the dust sticking roller, and a pushing mechanism for intermittently pushing the copper plate is arranged on the processing table. The dust removing device can solve the problem that in the prior art, secondary flying dust is easy togenerate due to brush dust removal and wind dust removal.

Owner:重庆市和鑫达电子有限公司

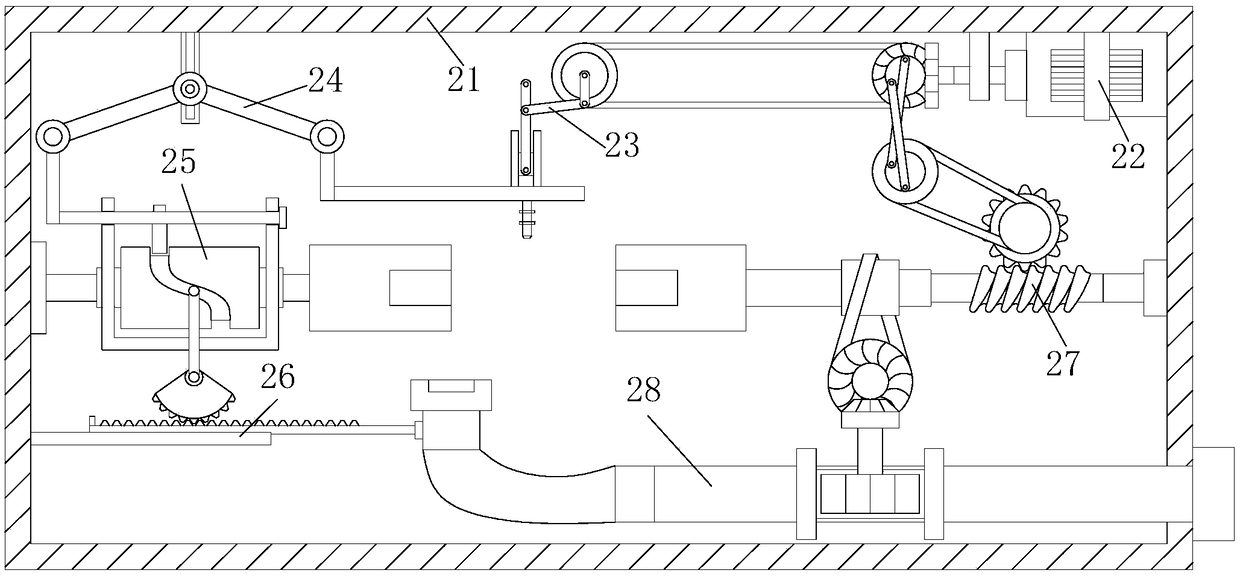

Dust removing device for recycling electronic products

InactiveCN108772377AComprehensive dust removalQuick dust removalCleaning using gasesGear wheelEngineering

The invention relates to a dust removing device, in particular to a dust removing device for recycling electronic products. The dust removal device for recycling the electronic products is not harmfulto human health, convenient to remove dust and comprehensive in dust removal. According to the technical scheme, The dust removal device for recycling the electronic products comprises a bottom plate, a motor, a first rotating shaft, L-shaped supporting rods, mesh plates, a first supporting rod, a first bearing seat, a second rotating shaft and a first bevel gear; the motor is arranged on the left side of the top of the bottom plate, and the first rotating shaft is connected with an output shaft of the top of the motor; and the L-shaped supporting rods are arranged on the upper portions of the left side and the right side of the first rotating shaft, and mesh plates are connected to the top ends of the L-shaped supporting rods. The dust removing device reaches the effects of no harm to human health, convenient dust removal and comprehensive dust removal. The dust removing device does not require people to remove dust beside the electronic products, and the dust cannot cause harm to the health of users. A bottom dust removal device can carry out dust removal of the bottoms of the electronic products, and the dust removal of the electronic products is more comprehensive and more quickly.

Owner:南京六创科技发展有限公司

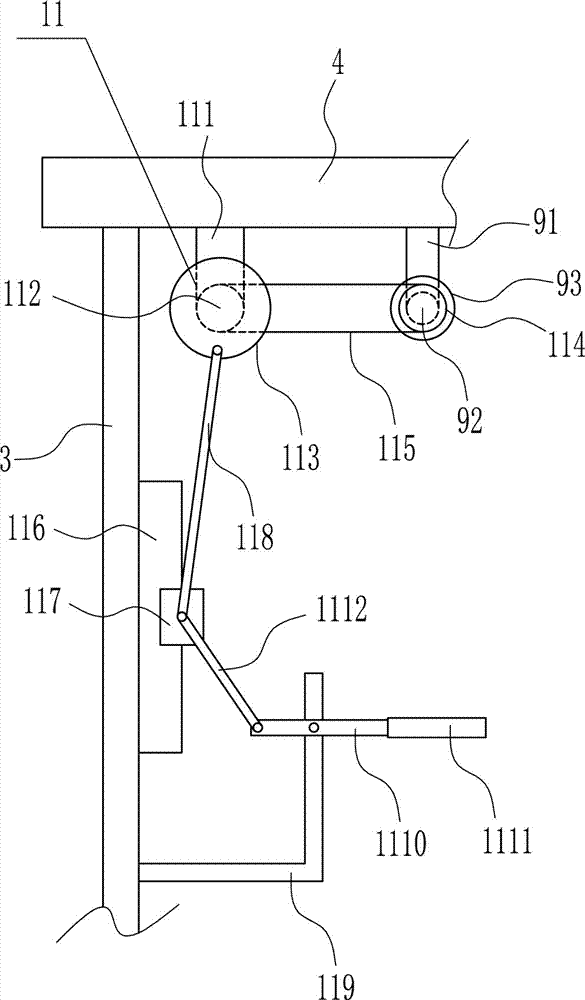

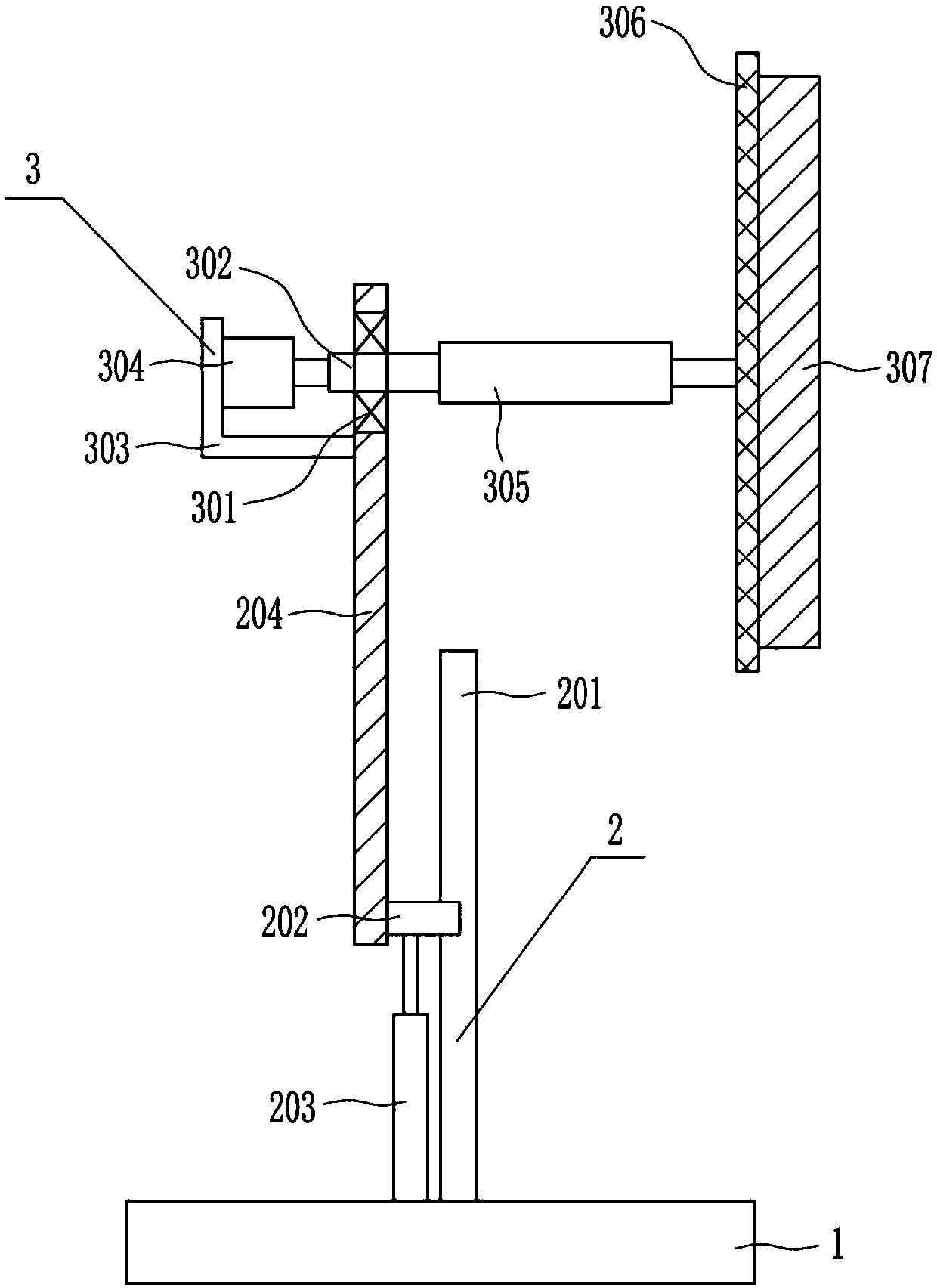

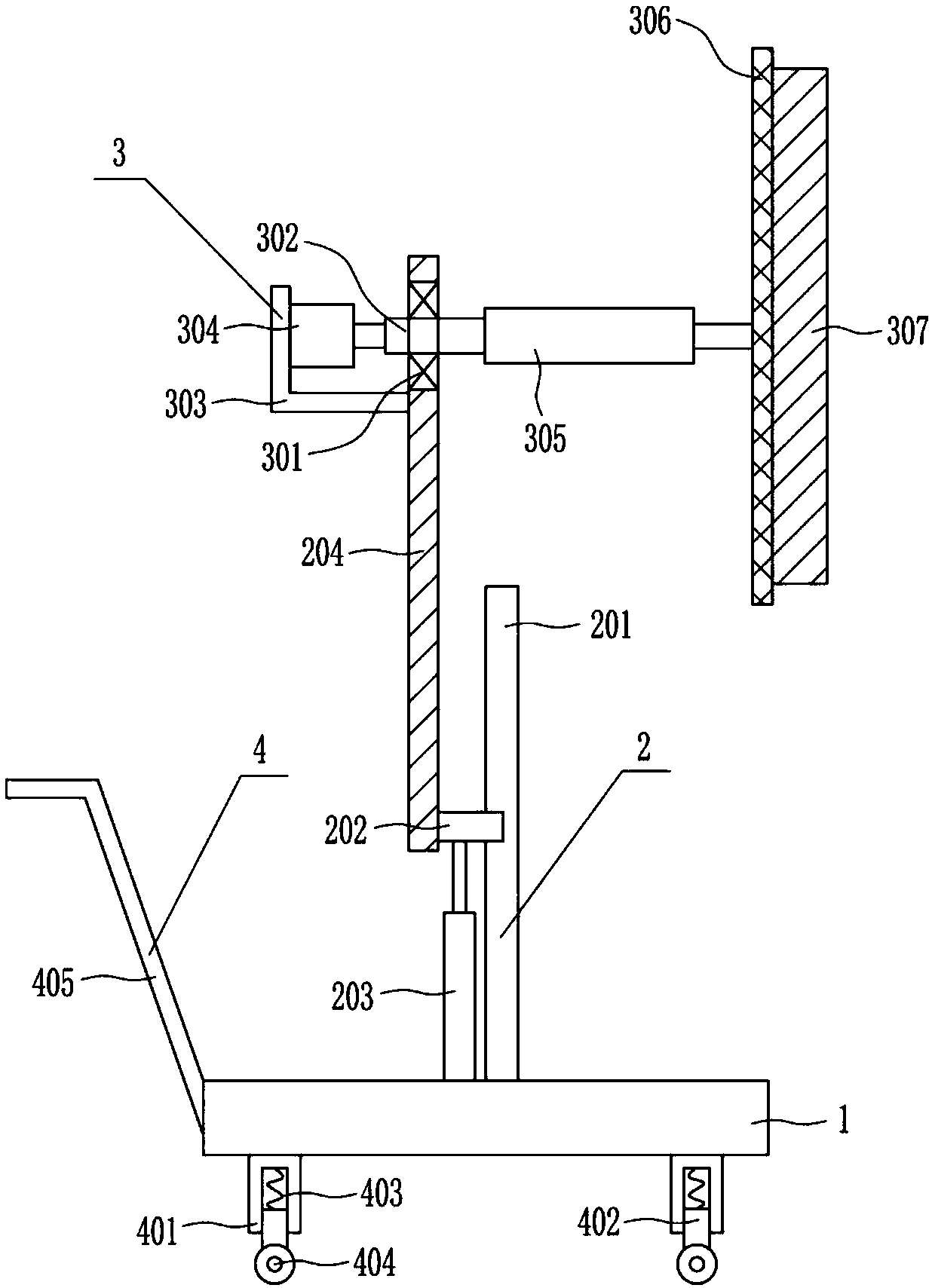

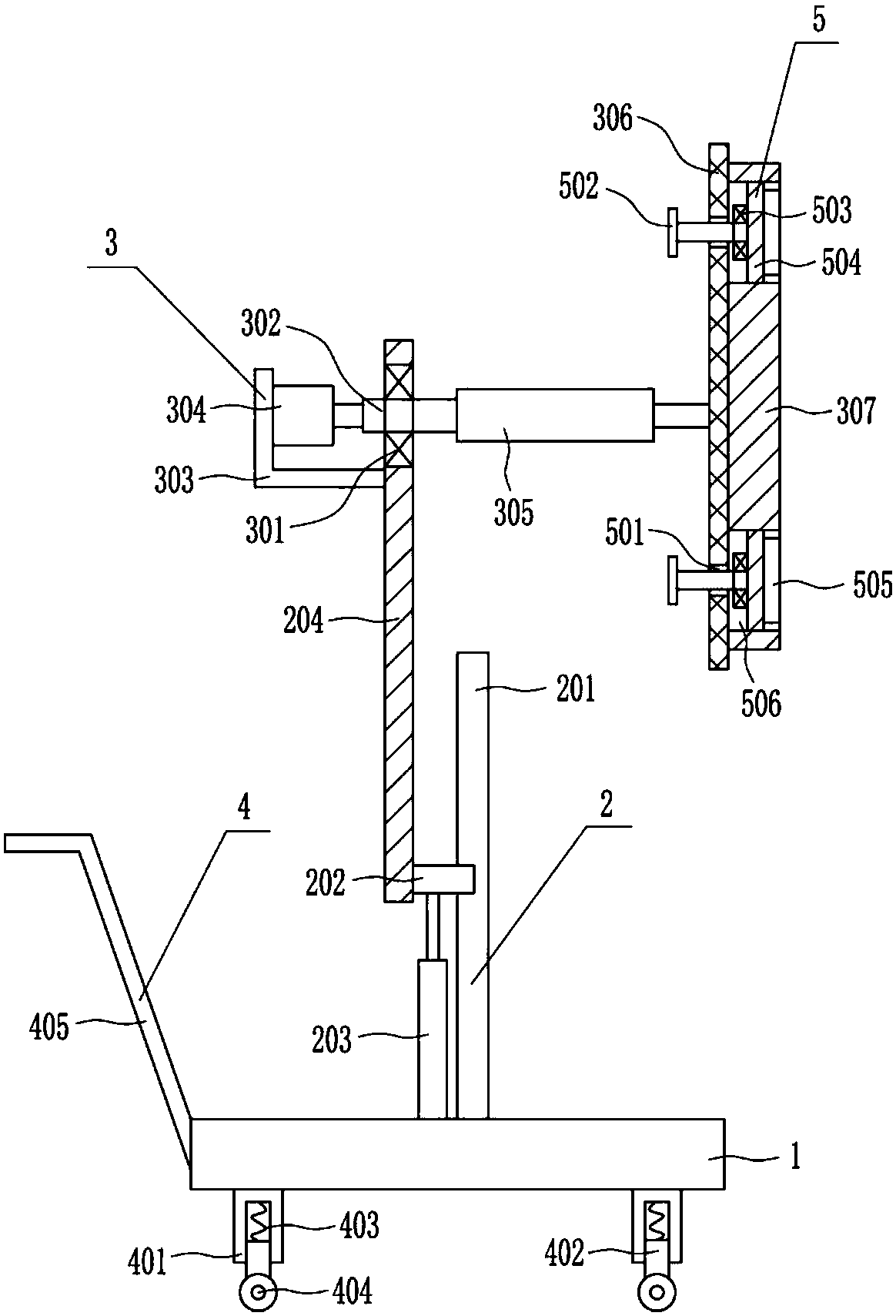

Security door dust collection device for smart home

InactiveCN107811573AComprehensive dust removalNot easy to scratchWindow cleanersPhysical healthEngineering

The invention relates to a dust collection device, in particular to a security door dust collection device for smart home. The technical purpose for providing a security door dust collection device which does not affect the physical health of people or environment and is not likely to scratch hands for the smart home is achieved. In order to achieve the technical purpose, the security door dust collection device for the smart home comprises a base and the like; an up-down moving device is installed on the top of the base, and a dust collection device is installed on the up-down moving device.Accordingly, by controlling the up-down moving device to work, the dust collection device is driven to move up and down; meanwhile, the dust collecting device is started to work, comprehensive dust collection is conducted on a security door, and then the effects of being easy to operate, convenient to use and not likely to scratch the hands are achieved.

Owner:范中麟

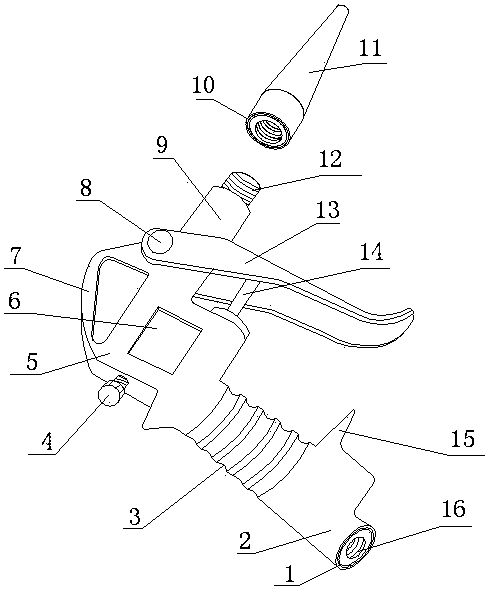

Air gun for removing dust in hole

InactiveCN103831188AComprehensive dust removalImprove dust removal efficiencySpray nozzlesSingle-unit apparatusEngineeringNail gun

The invention discloses an air gun for removing dust in a hole. The air gun for removing the dust in the hole comprises a gun body (5) and a nozzle (11), wherein the end of a gun handle of the gun body (5) is an air inlet end (2), an internal threaded hole (16) is formed in the air inlet end (2), multiple anti-skid grooves (3) are formed in the circumferential surface of the gun body (5), the front end of a gun part of the gun body (5) is an air outlet end (9), a threaded connector (12) is arranged at the air outlet end (9) and is connected with the nozzle (11), the nozzle (11) is of a conical structure with one end big and the other end small, a rotary shaft (8) is further arranged on the gun part of the gun body (5), the rotary shaft (8) is connected with a spanner (13), the inner side of the spanner (13) is connected with a reset spring rod (14), and the rotating structure that the spanner (13) rotates with the rotary shaft (8) as the axis is formed. According to the air gun for removing the dust in the hole, comprehensive dedusting of a valve can be achieved, the dust removal efficiency is high, and the practicability is high.

Owner:CHENGDU DAMO PETROLEUM MACHINERY GRP

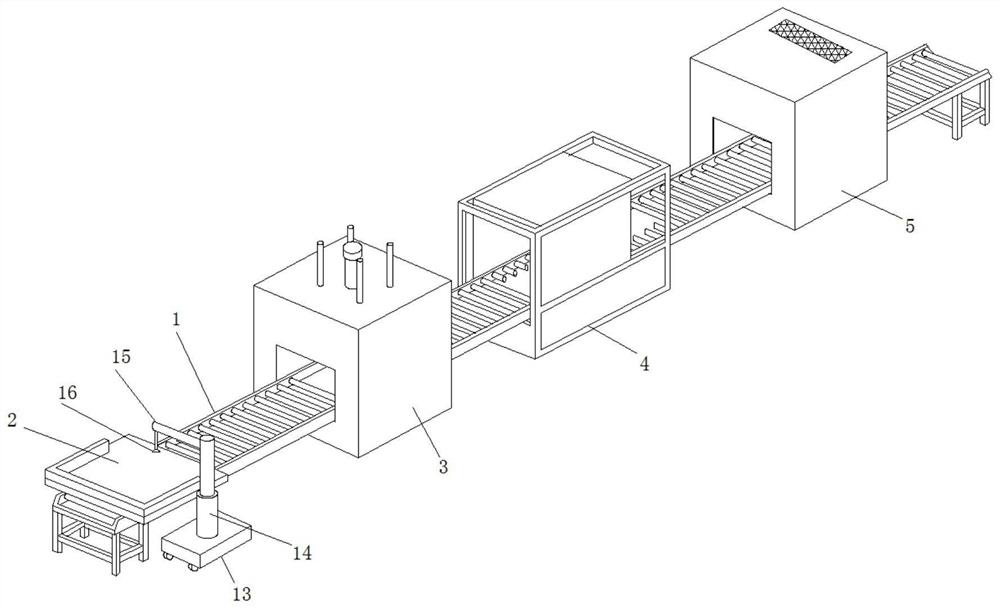

Dust removal device for aluminum alloy door and window production

PendingCN112170293ANo health hazardResidue reductionDrying gas arrangementsCleaning using toolsMetallurgyDust control

The invention discloses a dust removal device for aluminum alloy door and window production. The dust removal device comprises a conveying rack, a stacking tray, a feeding assembly, a floating ash treatment bin, a stain treatment bin and an air drying bin, wherein the stacking tray is arranged at one end of the conveying rack, and the feeding assembly is arranged at one side of the stacking tray;the floating ash treatment bin, the stain treatment bin and the air drying bin are sequentially arranged from front to back on the conveying rack; and a pneumatic cylinder is arranged in the middle ofthe top of the floating ash treatment bin, the output end of the pneumatic cylinder extends into the floating ash treatment bin, and a mounting frame is arranged at the output end of the pneumatic cylinder. According to the dust removal device, aluminum alloy doors and windows are stacked through the stacking tray, the feeding assembly is utilized to sequentially grab the aluminum alloy doors andwindows and movably placing the aluminum alloy doors and windows on the conveying rack, the conveying rack conveys the aluminum alloy doors and windows to the floating ash treatment bin, the stain treatment bin and the air drying bin for air drying, and one process of dust removal treatment is completed; and in the whole process, manpower is not needed, automatic conveying and automatic dust removal are realized, and the efficiency is high.

Owner:ANHUI PROVINCE JINPENG ENERGY SAVING TECH CO LTD

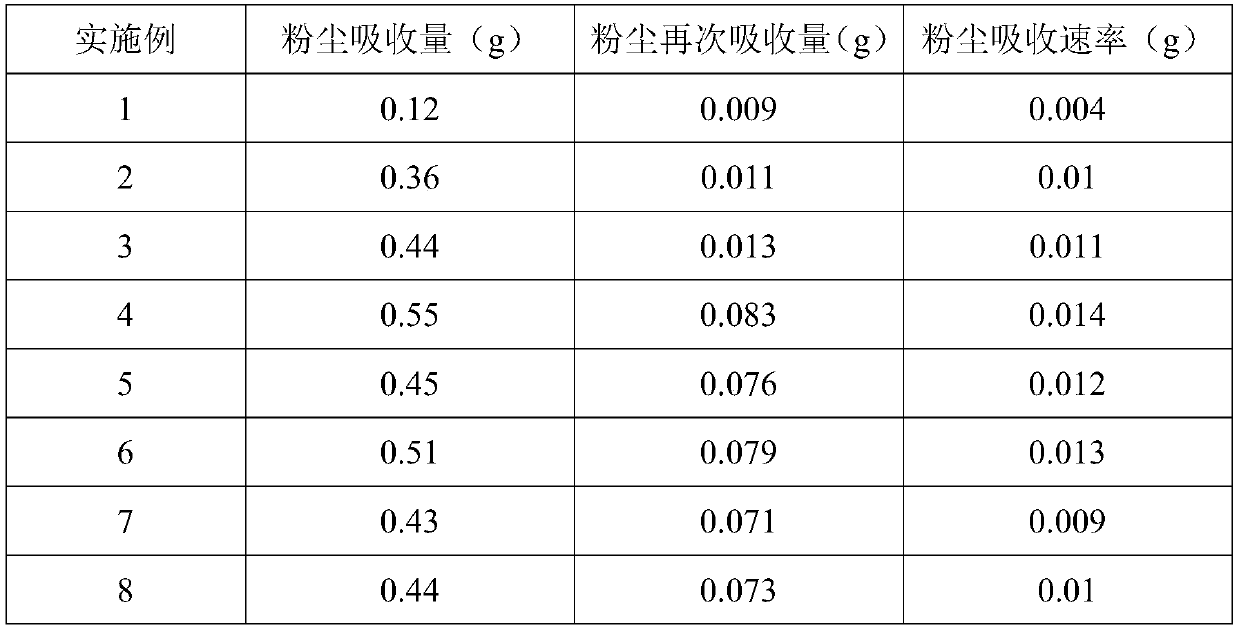

Polishing dust removal agent and dust removal process

ActiveCN110524424AFast absorptionAvoid residueCombination devicesUsing liquid separation agentCombustionTrifluoroacetic acid

The invention relates to the field of dust removal processes, in particular to a polishing dust removal agent and a dust removal process. The dust removal process comprises the polishing dust removalagent dust removal and the dust collection tower dust removal. The dust removal process provided by the present invention can be used for rapidly and comprehensively removing the dust and preventing the dust residues. By discharging the dust generated during the polishing process, the phenomena of combustion, explosion and the like caused by the dust enrichment are prevented, and the environmentalpollution and the inhalation danger of a human body are prevented. In addition, the polishing dust removal agent for the dust removal process can rapidly absorb the dust, the volatilization of an acidic dust removal agent can be reduced by adding the trifluoroacetic acid and thep-toluenesulfonic acid, so that safety is improved. The polishing dust removal agent can be repeatedly used by adding the ionic liquid.

Owner:江苏汉隆环保有限公司

Cable bridge with dedusting cleaning effect

InactiveCN107952745AEasy to remove dustTo achieve the purpose of dust removalElectrical apparatusDirt cleaningCable trayEngineering

The invention discloses a cable bridge with dust removal and cleaning effect. The cable bridge includes a fan arranged on one side plate of the wire groove of the bridge, and an exhaust fan arranged on the other side plate of the wire groove of the bridge. The position of the fan is There is an air collection box installed on the inner side of the side plate of the wire slot of the bridge frame, and an air collection port installed on the inner side of the side plate of the wire slot of the bridge frame is arranged at the position where the exhaust fan is located. Several air nozzles are arranged on the air collection box. The inner sides of the air collecting port and the air nozzle are respectively provided with mesh partitions installed vertically on the bottom of the wire groove of the bridge, and the mesh partition is arranged along the direction of the wire groove of the bridge. The present invention can realize the cleaning and discharge of the accumulated dust in the cable tray of the cable tray through the blower fan and the exhaust fan, can thoroughly and effectively clean the cable tray, and ensures that the cables in the cable tray will not cause problems such as heating due to dust accumulation, and its structure Simple and practical.

Owner:SICHUAN LIZHI JIUCHUANG INTPROP OPERATION CO LTD

Cooling and dust removing device for electronic components

InactiveCN112384043AEffective coolingAvoid damageDispersed particle filtrationCooling/ventilation/heating modificationsDust controlStructural engineering

The invention discloses a cooling and dust removing device for electronic components. The device comprises a transverse plate, four supporting columns are fixedly installed at the top of the transverse plate, every two of the four supporting columns are symmetrically arranged, an installation plate is fixedly installed at the top of each supporting column, and a dust collection box and a dust suction fan are fixedly installed at the top of the transverse plate. A filter screen is fixedly installed in each dust collection box through screws, the top of each dust collection box is of an openingstructure, a cover plate is fixedly installed at the top of each dust collection box through screws, the discharging end of the dust suction fan is fixedly connected with a dust discharging pipe, andthe end, away from the dust suction fan, of the dust discharging pipe extends into the dust collection boxes and is located below the filter screens. The suction end of the dust suction fan is fixedlyconnected with a first conveying pipe, and a mounting hole is formed in the top of the transverse plate. The device is reasonable in design and good in practicability, electronic components can be well dedusted, cooled and cooled, and the phenomena that the electronic components are damaged due to high temperature and short circuit occurs are avoided.

Owner:HANGZHOU KUANFU TECH

Dust removal device for zinc oxide powder production

InactiveCN108097619AEasy to handleImprove dust removal effectCleaning using toolsEngineeringBlock structure

The invention discloses a dust removal device for zinc oxide powder production. The dust removal device comprises a base, wherein a power supply box is arranged on one side of the front surface of thebase, a main shell is fixed at the top end of the base, and a feeding opening and a discharging opening are formed in the two sides of the main shell respectively. A mounting plate is arranged between the feeding hole of the main shell and the side wall of the discharging hole, a fixing groove is formed in the center of the top of the mounting plate, an upper sliding groove and a lower sliding groove which are fixed at the upper end and the lower end of the fixing groove are cooperatively used with the fixing groove, an inclined plate is arranged on the side wall of the bottom end of the inner part of the main shell, a first dust outlet arranged at the position of the inner top end of the base is cooperatively used with the inclined plate, and a dust collecting box is fixed below the first dust outlet through a sliding block installed on a sliding rail. An upper dust removal brush, a lower dust removal brush, the dust collection box, the sliding rail and a sliding block structure arearranged, so that the dust removal device has the advantages that the dust removal efficiency is high, dust is properly treated, and the device for treating the dust is convenient and fast to mount and dismount.

Owner:XINGHUA SANYUAN ZINC

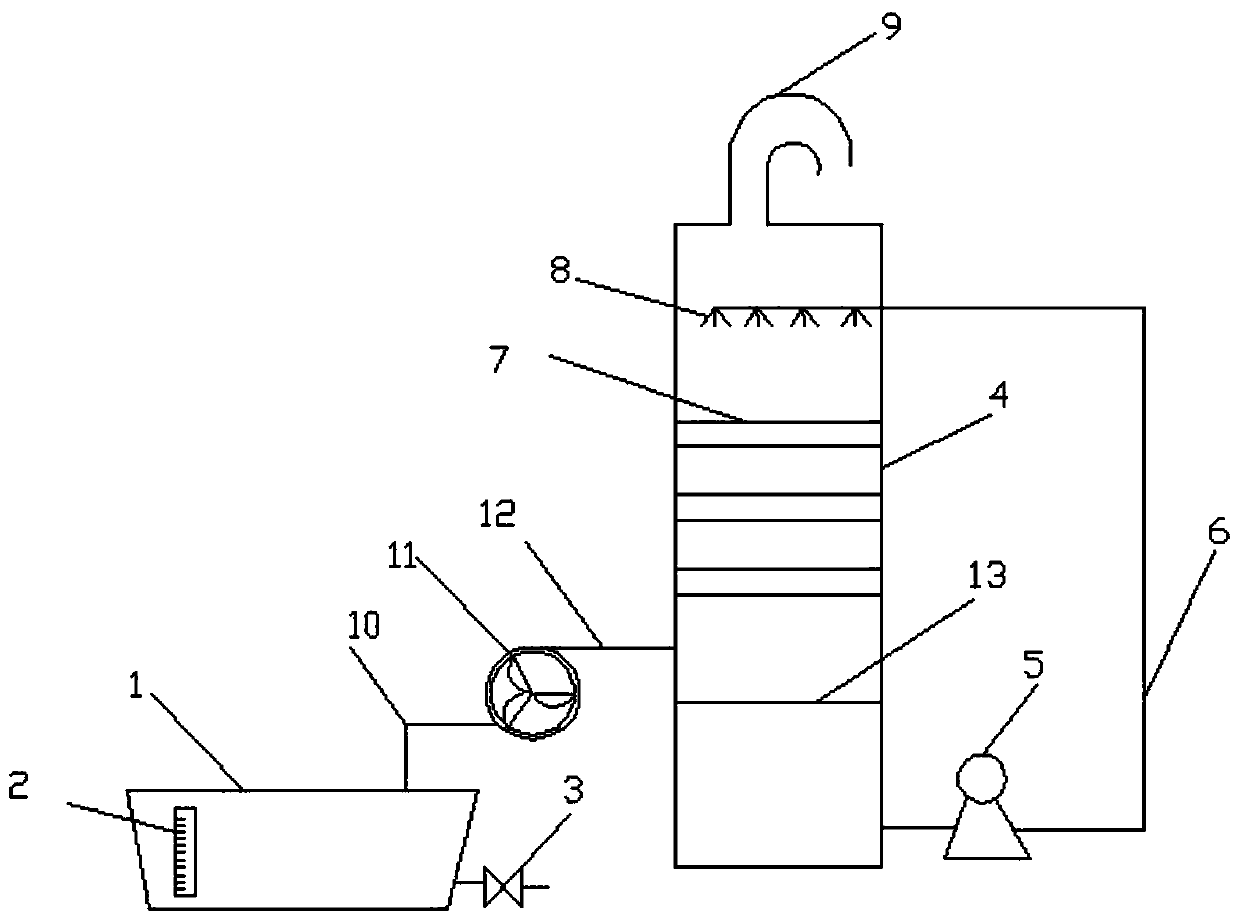

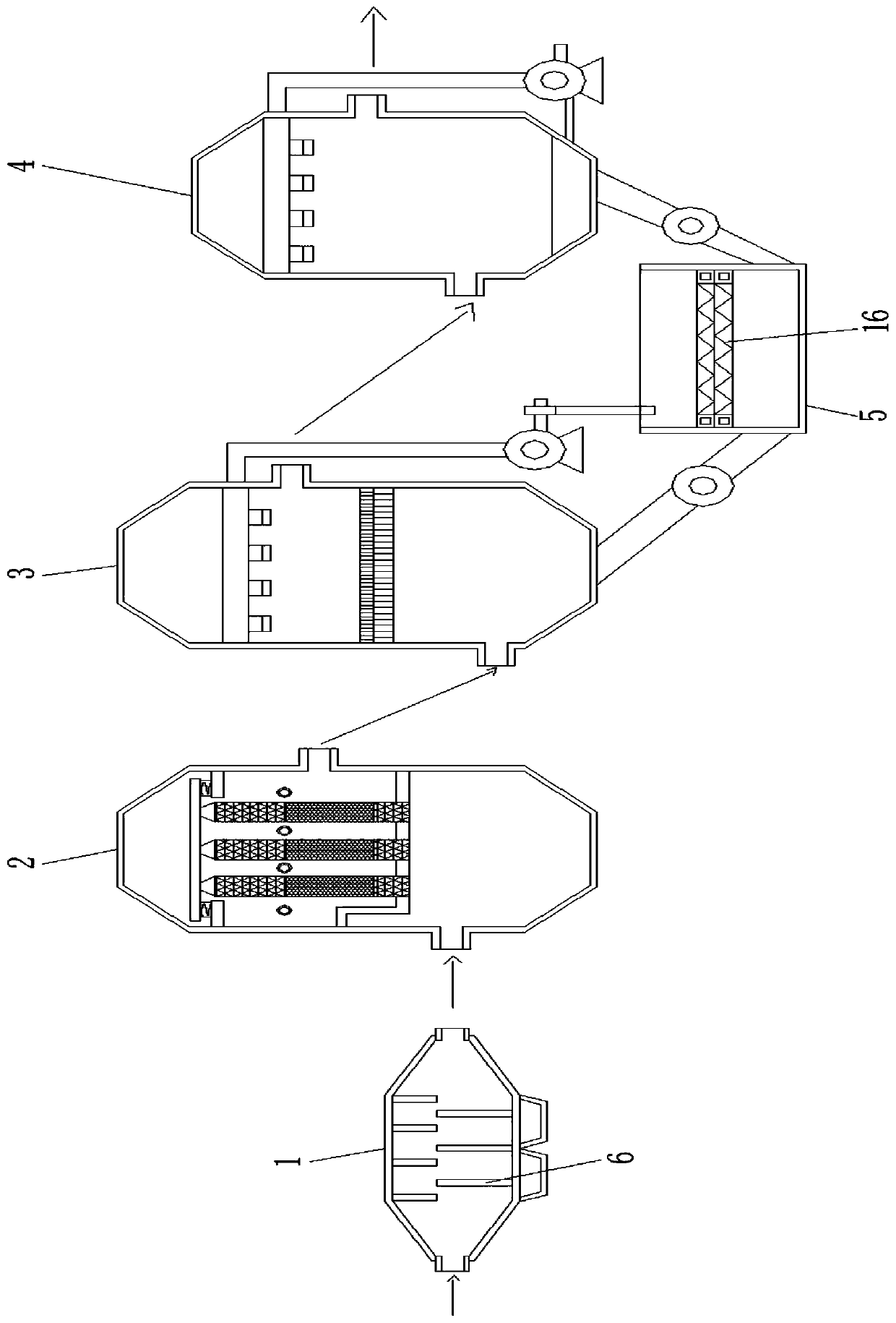

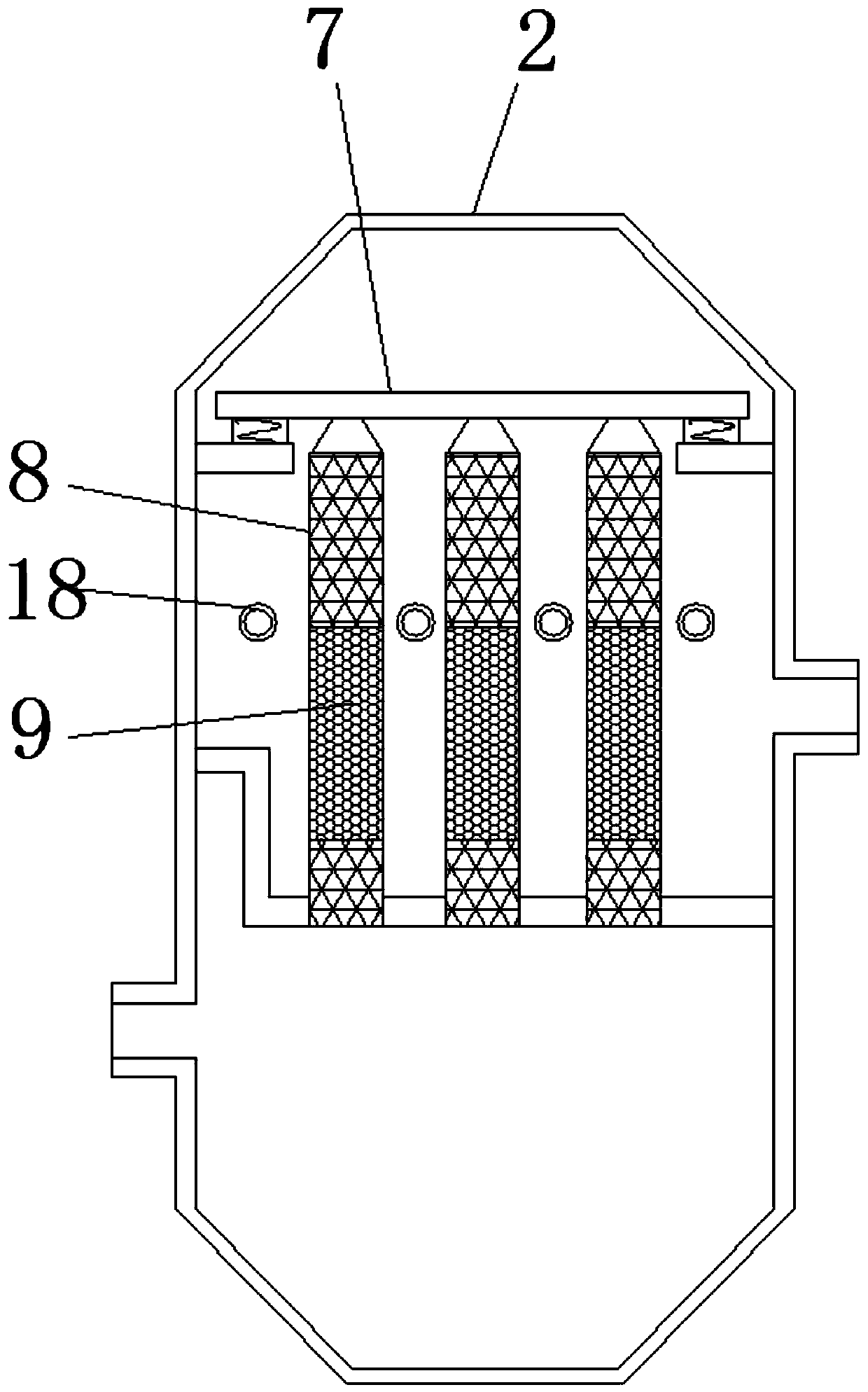

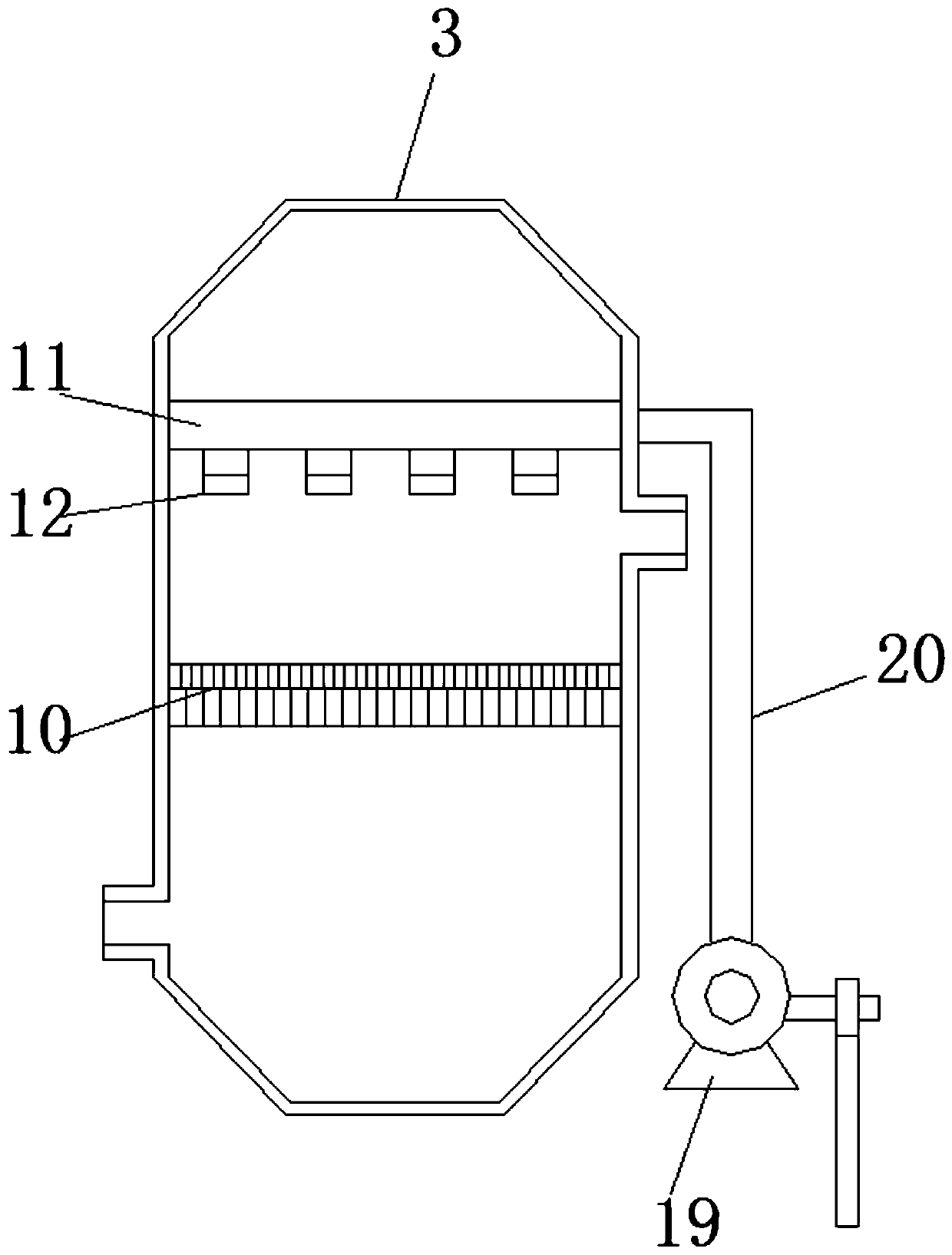

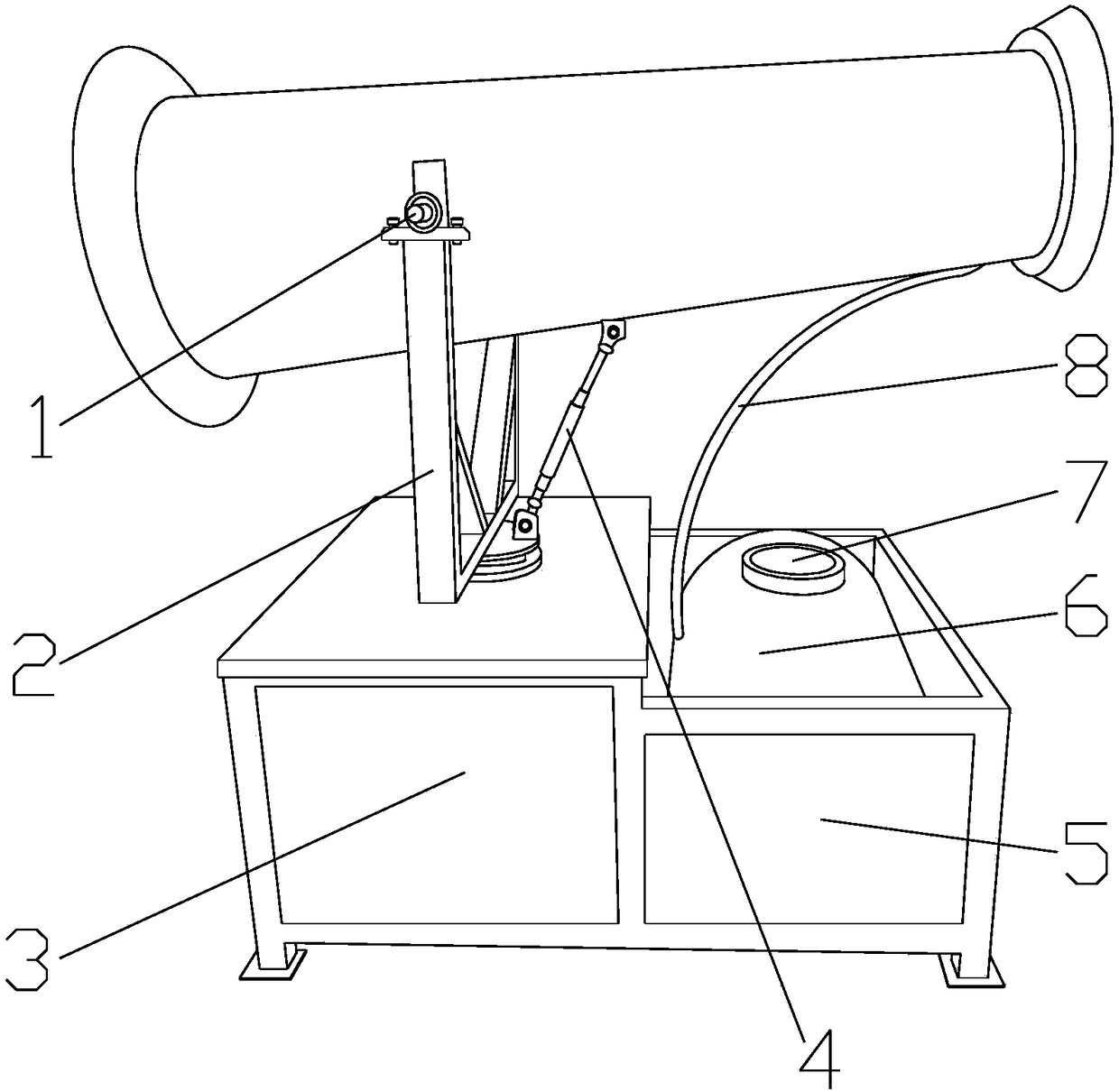

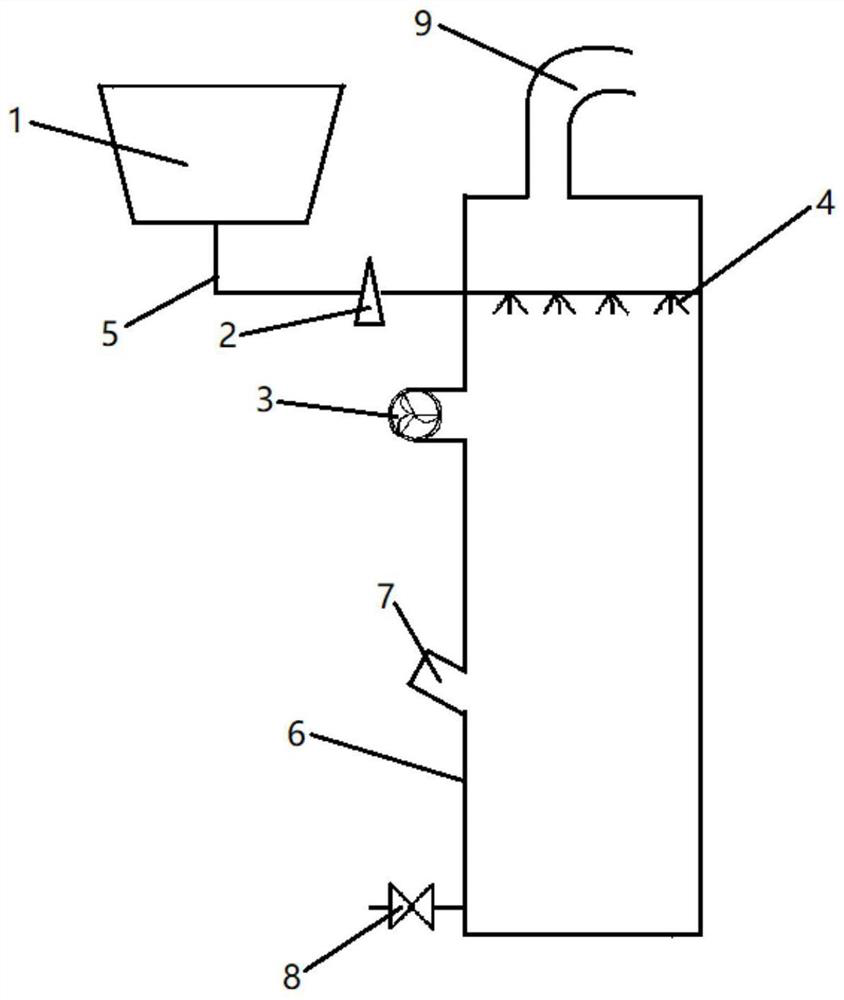

Coal-fired boiler smoke efficient desulfurization and dedusting purification system for steam production

InactiveCN110801699AComprehensive dust removalEasy to desulfurizeCombination devicesGas treatmentProcess engineeringEnvironmentally friendly

The invention discloses a coal-fired boiler smoke efficient desulfurization and dedusting purification system for steam production. The system comprises a gravity sedimentation chamber, a filtering dedusting tower, a water bath dedusting tower, a desulfurization tower and a sedimentation filtering pond, wherein dust baffles are arranged on the inner wall of the gravity sedimentation chamber, and the dust baffles are arranged in multiple groups in a staggered mode; and a filtering cavity is formed inside the filtering dedusting tower, an installing plate is flexibly installed on the upper portion inside the filtering cavity, a dedusting cloth bag is arranged below the installing plate, the bottom end of the dedusting cloth bag communicates with the filtering cavity, and an activated carbonadsorption sleeve is arranged in the middle of the dedusting cloth bag. According to the system, through four-step dedusting and desulfurization treatment, the smoke purification effect is better; anda water source after water bath dedusting and slurry prepared from limestone powder after desulfurization are guided into the bottom of the sedimentation filtering pond, and sedimentation and filtration are performed. The system is used for recovery, brings convenience to resource saving and is environmentally friendly and sustainable.

Owner:亿利洁能科技(乐陵)有限公司

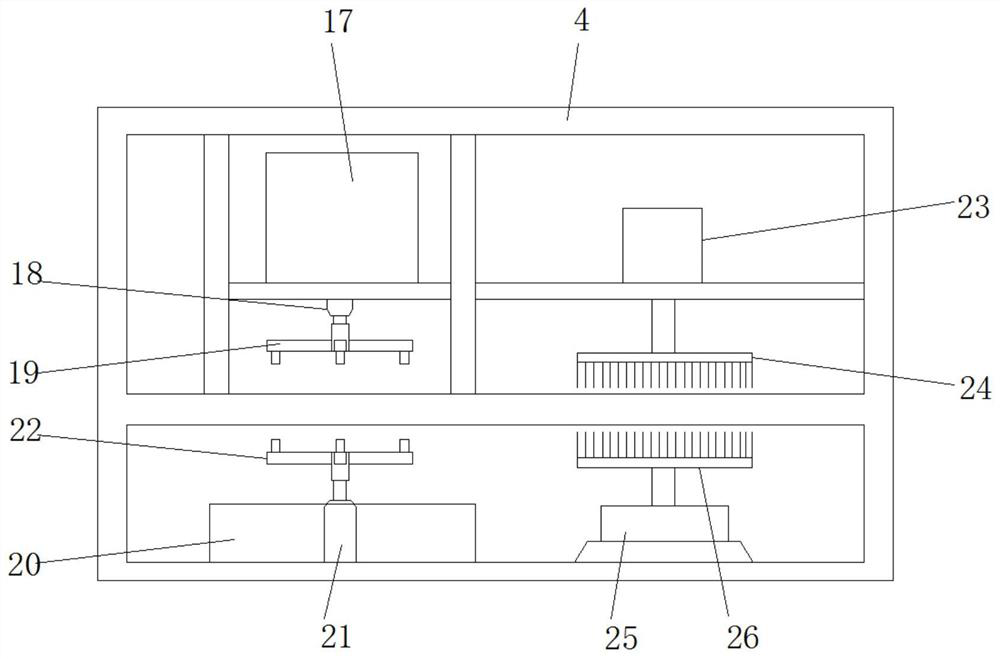

Drilling device with cleaning function for circuit board processing and using method

PendingCN114800685AEasy to moveEasy drillingDirt cleaningPrinted circuit manufactureDust controlThreaded rod

The invention discloses a circuit board processing drilling device with a cleaning function and a using method, and belongs to the technical field of drilling, the circuit board processing drilling device comprises a working box, guide grooves are formed in the periphery of an inner cavity of the working box, sliding rods are slidably connected to inner cavities of the guide grooves, and the surfaces of the sliding rods are sleeved with box bodies; through cooperation of a sliding rod and a box body, the box body can move freely in the working box in the horizontal direction, meanwhile, through cooperation of a traction shrinkage assembly, a drill bit is moved up and down, drilling treatment can be conveniently conducted on circuit boards at different positions in the working box, and then through a dust collection pipe and a hose, the dust collection efficiency is improved. Chippings generated by drilling of a drill bit are conveniently discharged out of a working box, the surface of a circuit board is smooth and clean during drilling, meanwhile, a driving assembly is used for driving a positive and negative threaded rod to rotate, a movable frame is conveniently moved during drilling, comprehensive dust removal is conducted on the top of the circuit board, and the working efficiency is improved. The problem that a traditional drilling device for circuit board machining cannot synchronously remove dust is solved.

Owner:SHENZHEN BOMIN ELECTRONICS

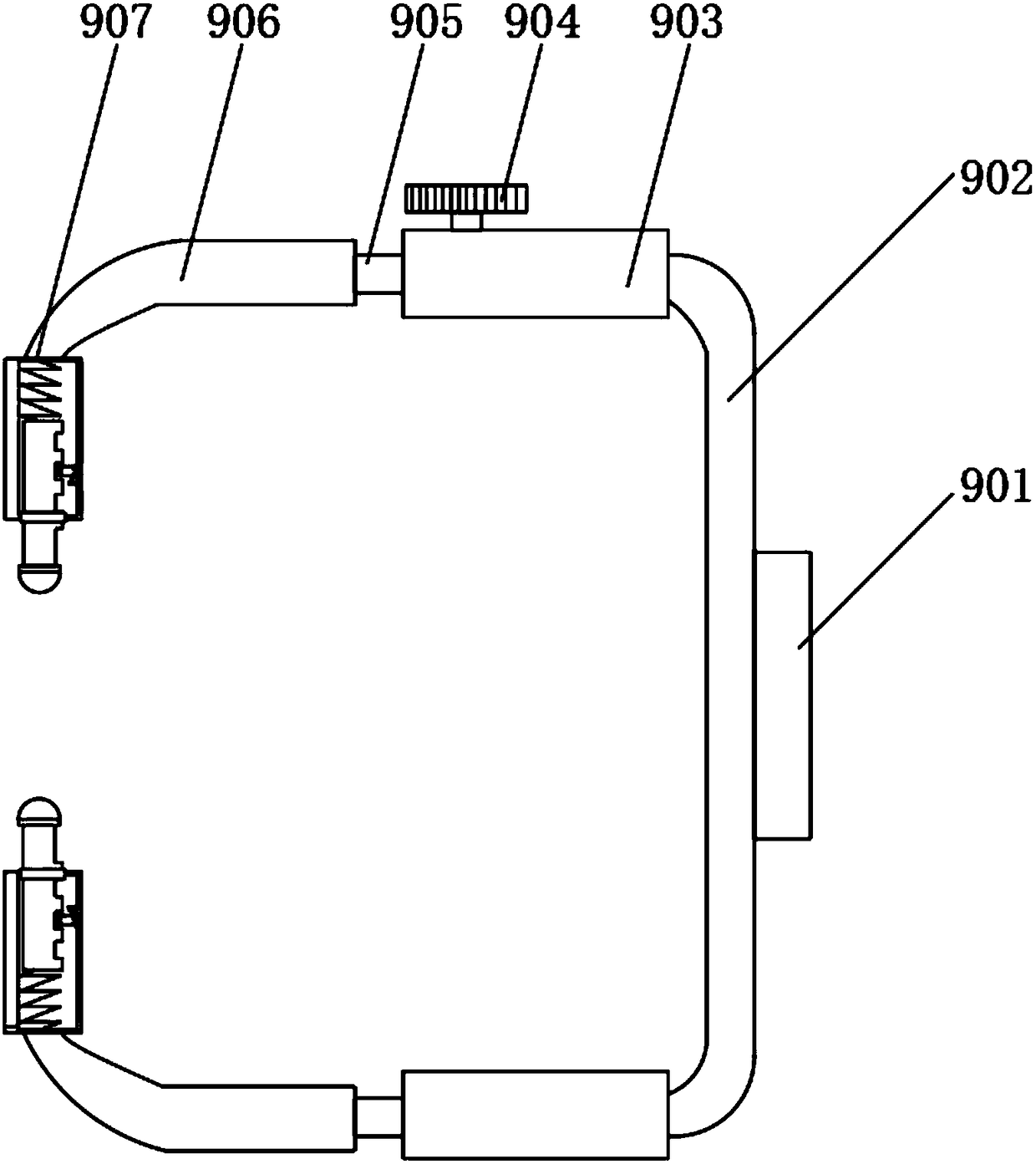

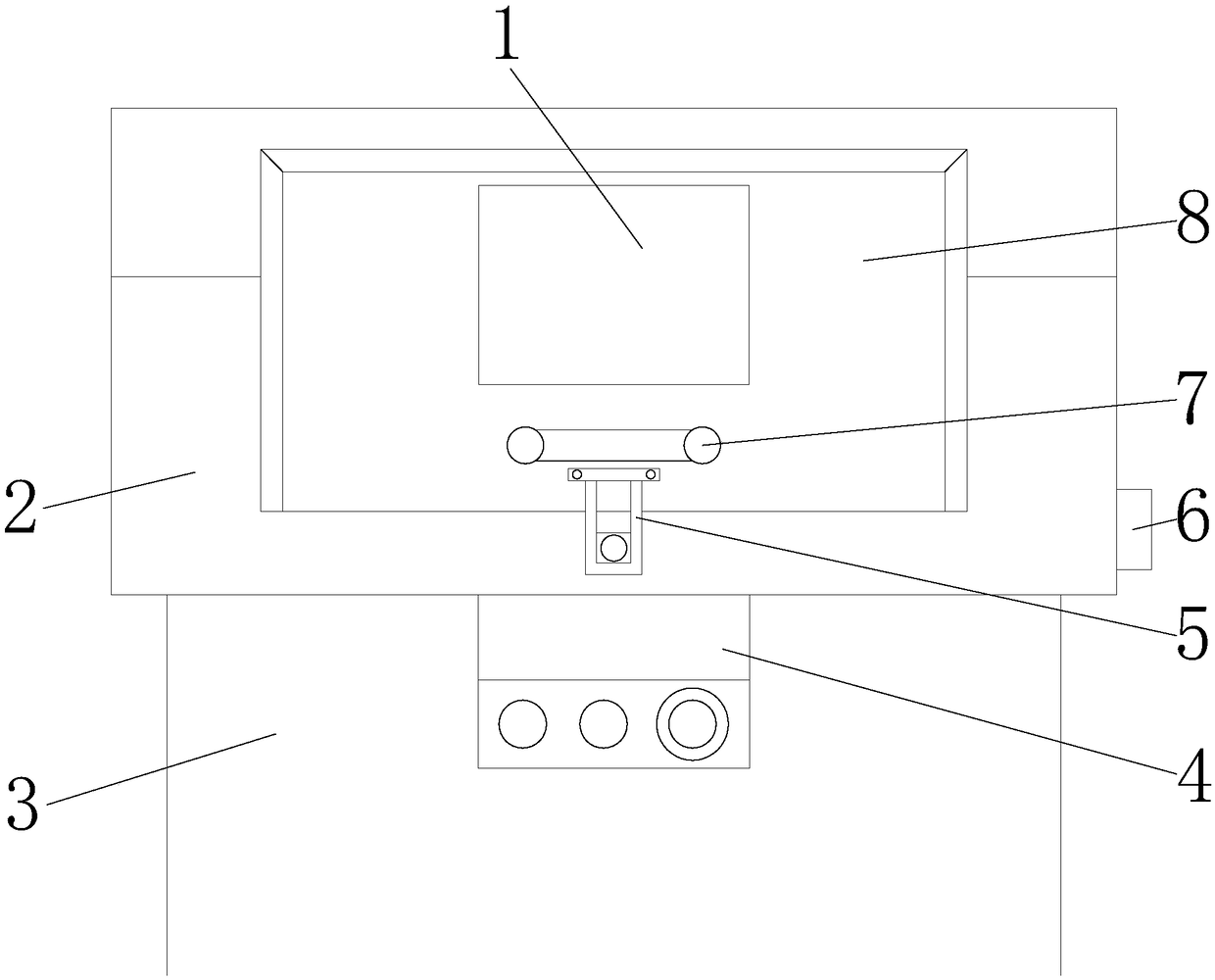

Device for connecting with threaded fastener

InactiveCN108956115AGuaranteed movement trackComprehensive dust removalMachine part testingGeological measurementsEngineeringThreaded fastener

The present invention discloses a device for connecting with a threaded fastener. The structure of the device comprises a window, a detection host, a pedestal, an operation panel, a buckle, an air inlet, a handle and a box cover. The window is inlaid at the front surface of the box cover, the box cover is inlaid at the front surface of the detection host, the lower surface of the detection host iswelded with the upper surface of the pedestal, the operation panel is fixedly installed at the middle portion of the upper end of the front surface of the pedestal and is electrically connected withthe detection host through a wire, the upper end of the buckle is hinged with the lower end of the front surface of the box cover, the lower end of the buckle is connected with the middle portion of the lower end of the front surface of the detection host, and the air inlet is installed at the surface of the right side of the detection host in an embedding mode. A power mechanism drives a mobile detection mechanism to perform mobile detection to allow the detection to be more comprehensive and allow the detection result to be more accurate, a rotation clamping mechanism is employed to performlow-speed rotation of the threaded fastener, and therefore, the detector can perform omnibearing detection for the threaded fastener, a dust collection mechanism can remove other things at the external portion of the threaded fastener so that the detection result is more accurate.

Owner:刘凤红

Dust prevention and removal device for agricultural equipment

The invention discloses a dust prevention and removal device for agricultural equipment. The device structurally comprises a fixed screw rod, a connection frame, a dust removal device, a hydraulic adjusting rod, a placing tank, a water tank, a tank cover and a drainage pipe. The fixed screw rod is in threaded connection with the upper end of the connection frame, the connection frame is in threaded connection and welded connection with the dust removal device through the fixed screw rod, the lower end of the dust removal device is connected with the placing tank, the lower end of the hydraulicadjusting rod is installed on the surface of the lower end of the dust removal device, a third saw tooth rod is rotated to drive a rotating disc to rotate, the rotating disc is rotated to enable theconnection frame to be rotated around the rotating disc, and at the moment, the upper end of the dust removal device can be rotated. A second worm gear lever is rotated through electricity supplied bya power mechanism, at the moment, a connection rotating shaft is rotated, rotating fan blades are rotated, wind energy is supplied, a rotating pipeline and a spray head in a water spraying mechanismare rotated through rotation of a wind power mechanism, and water flow is rotationally sprayed to removal dust on the agricultural equipment more comprehensively.

Owner:JIANGXI DONGJIAN AGRI DEV CO LTD

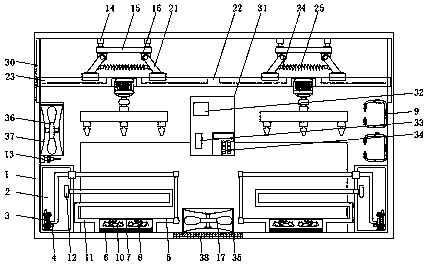

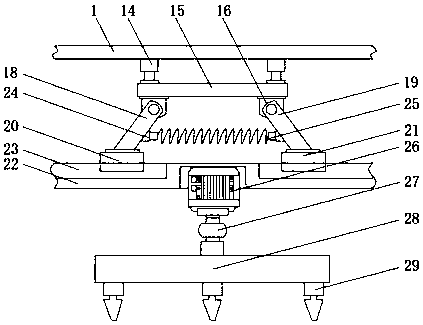

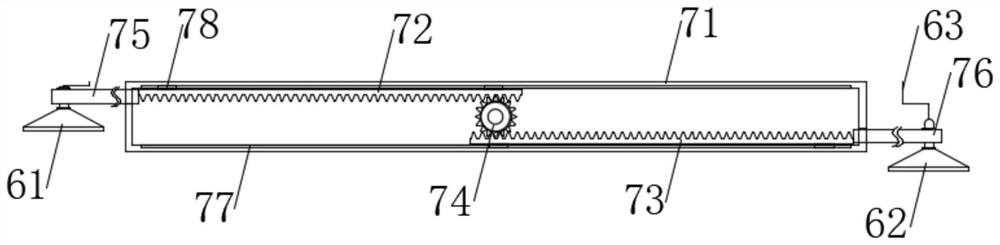

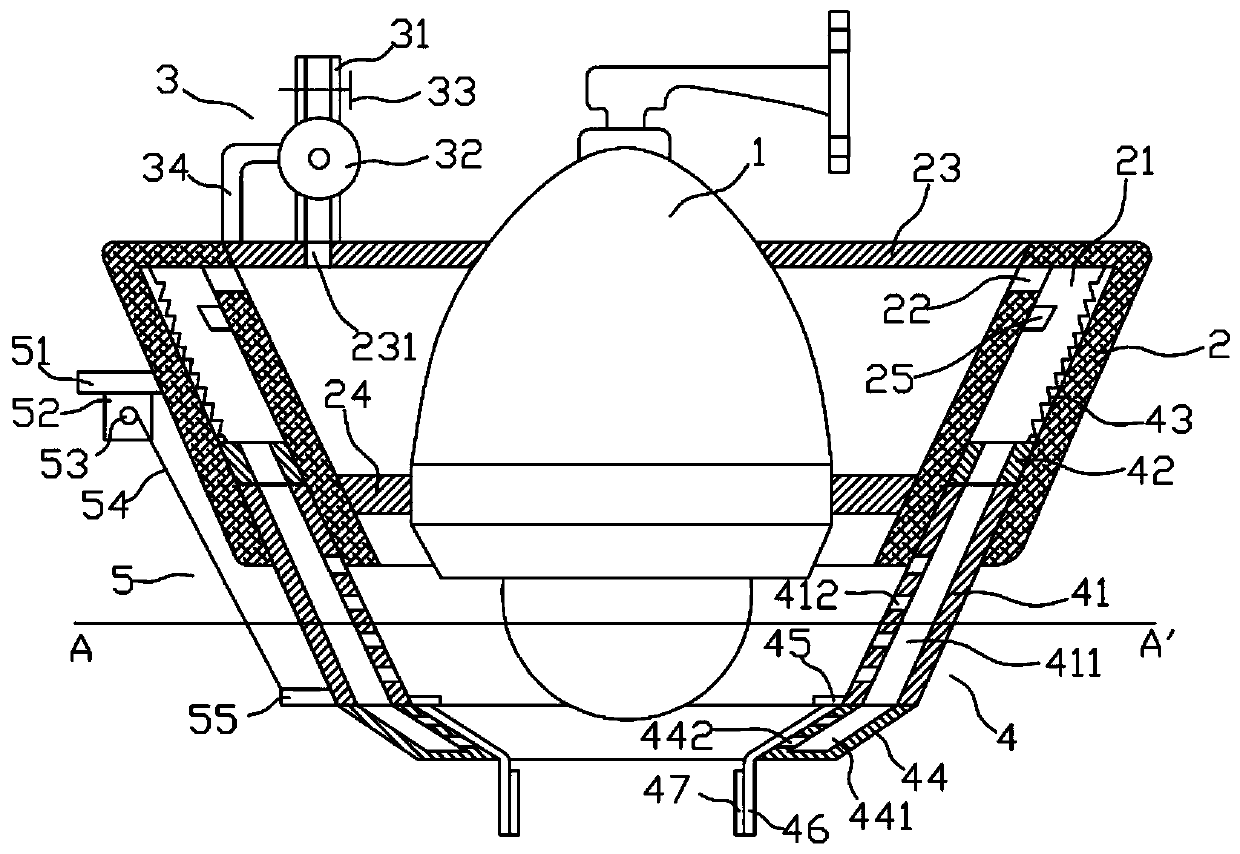

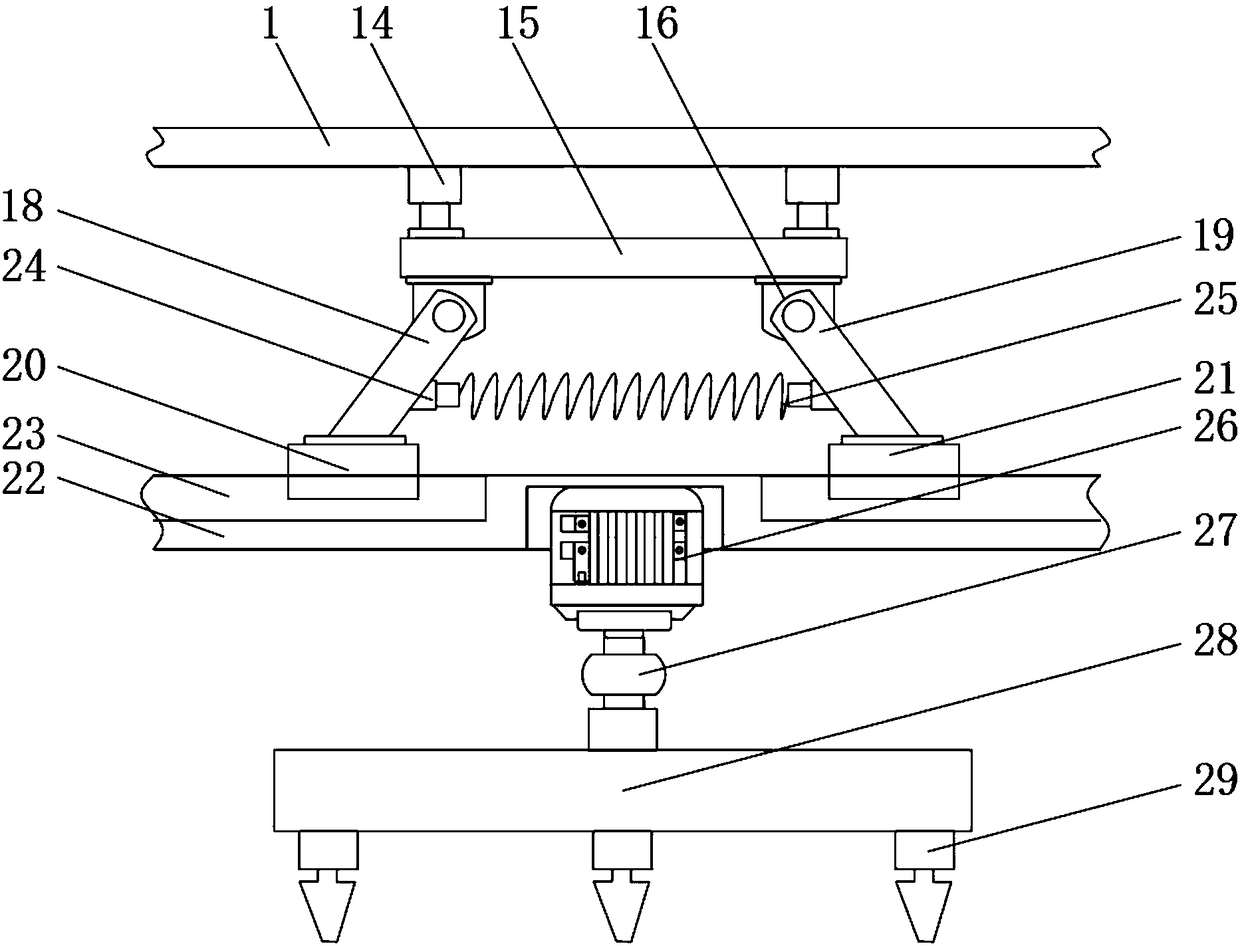

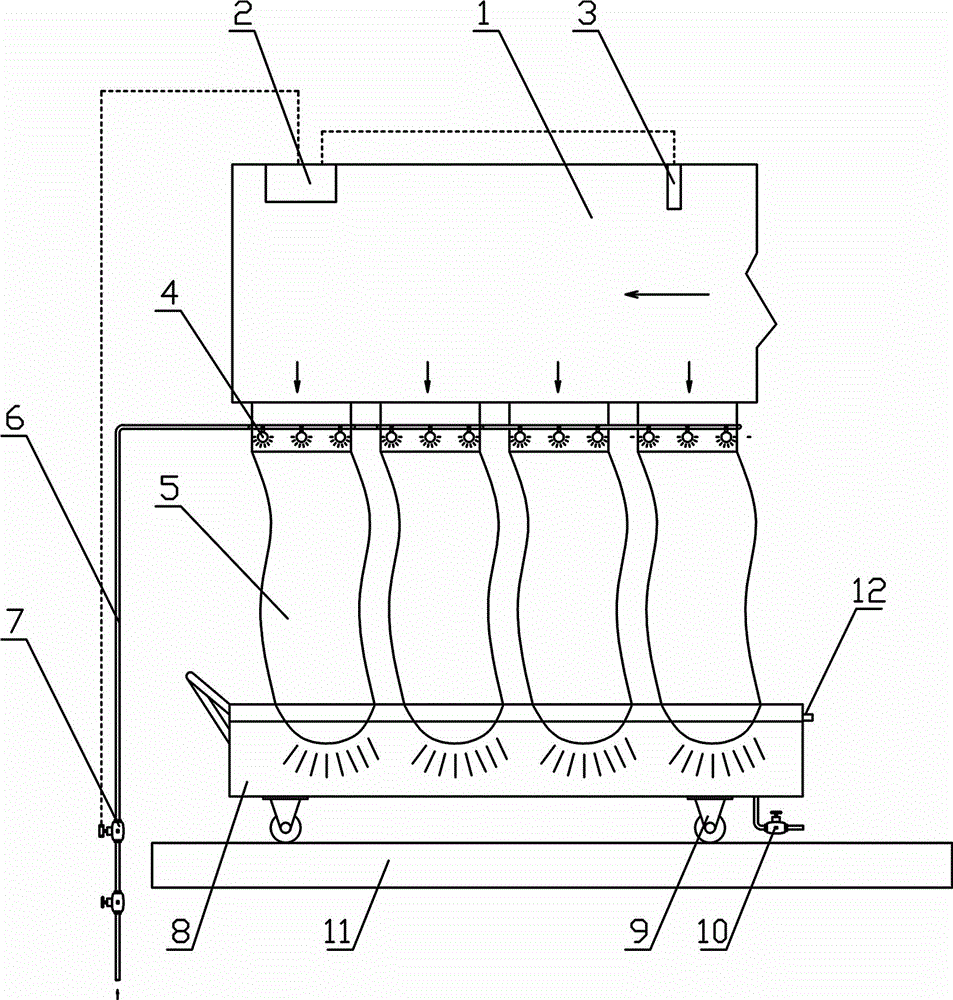

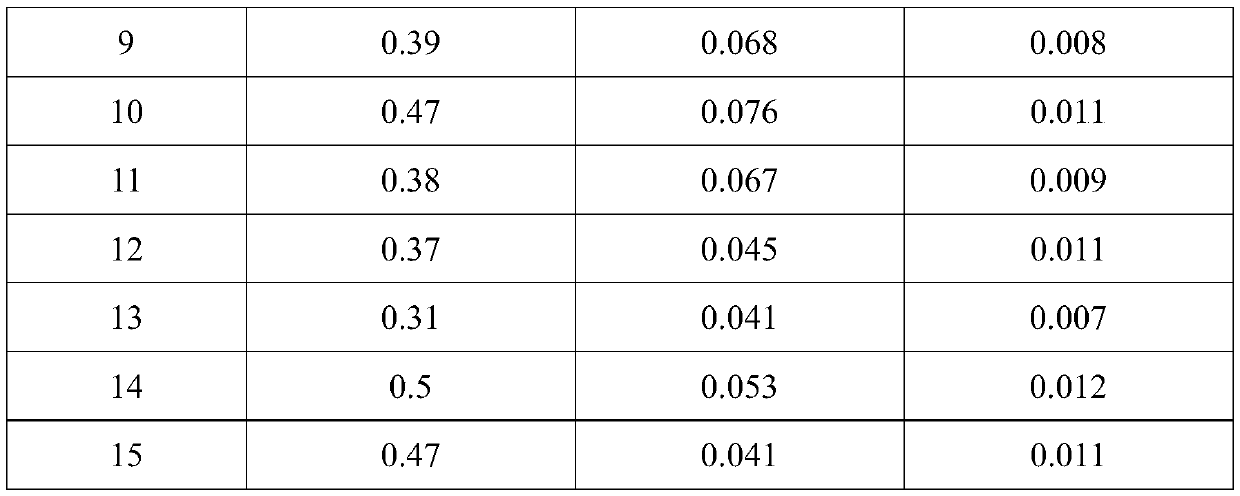

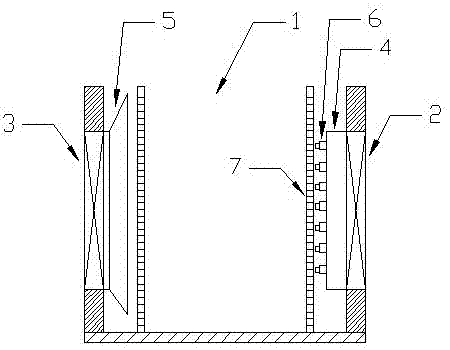

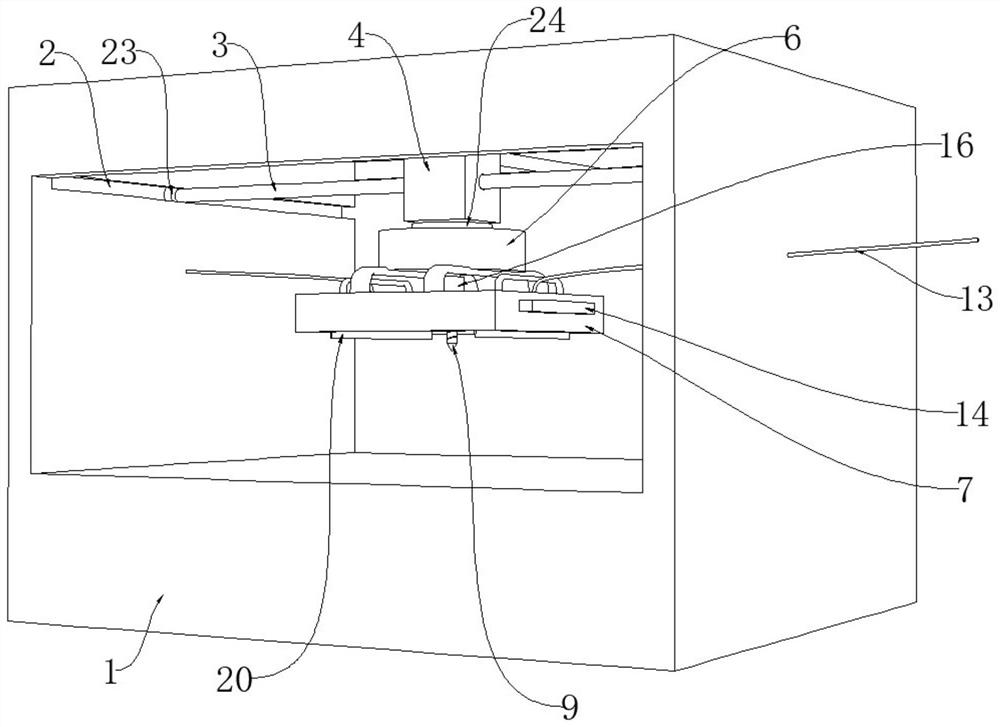

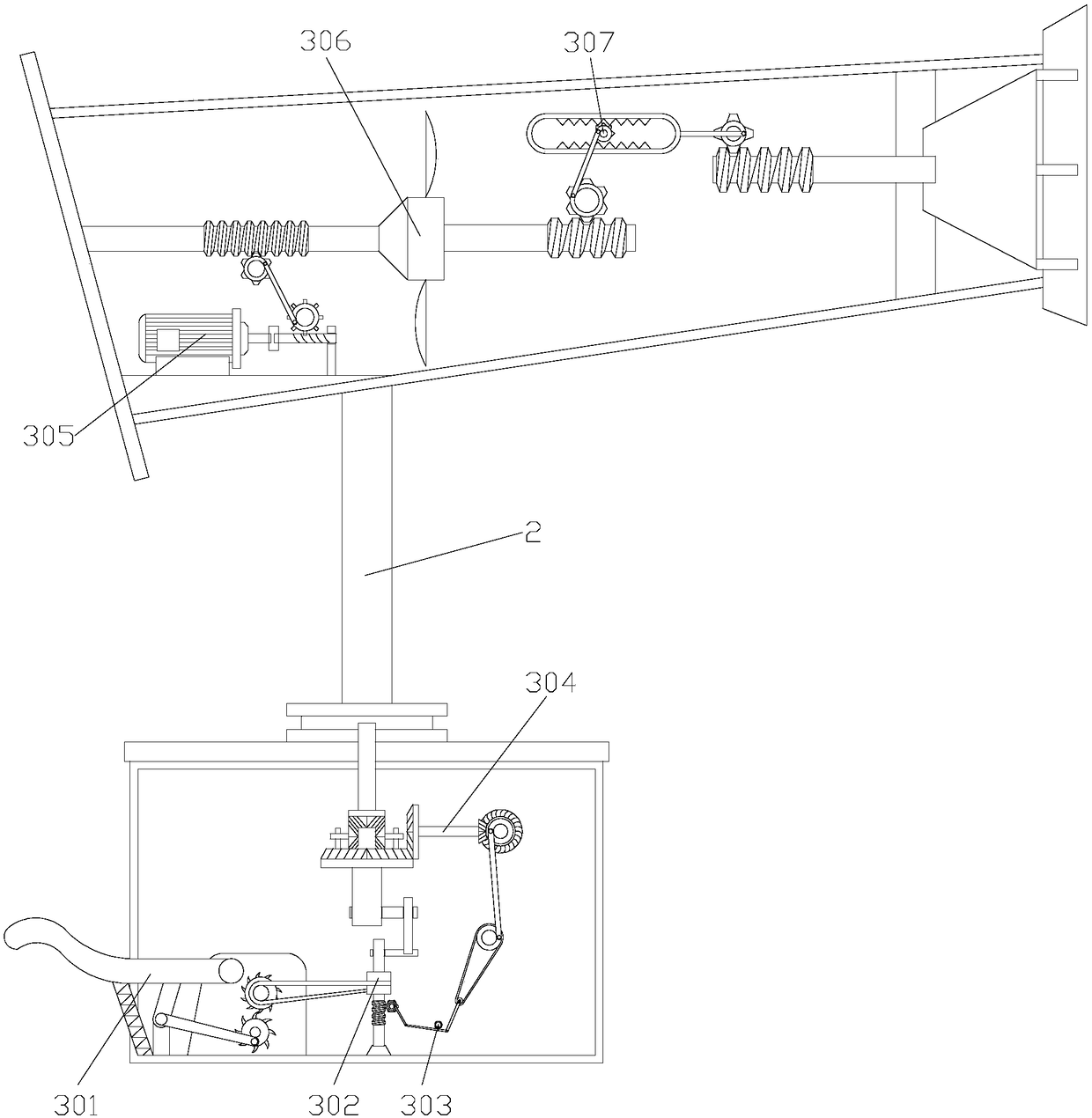

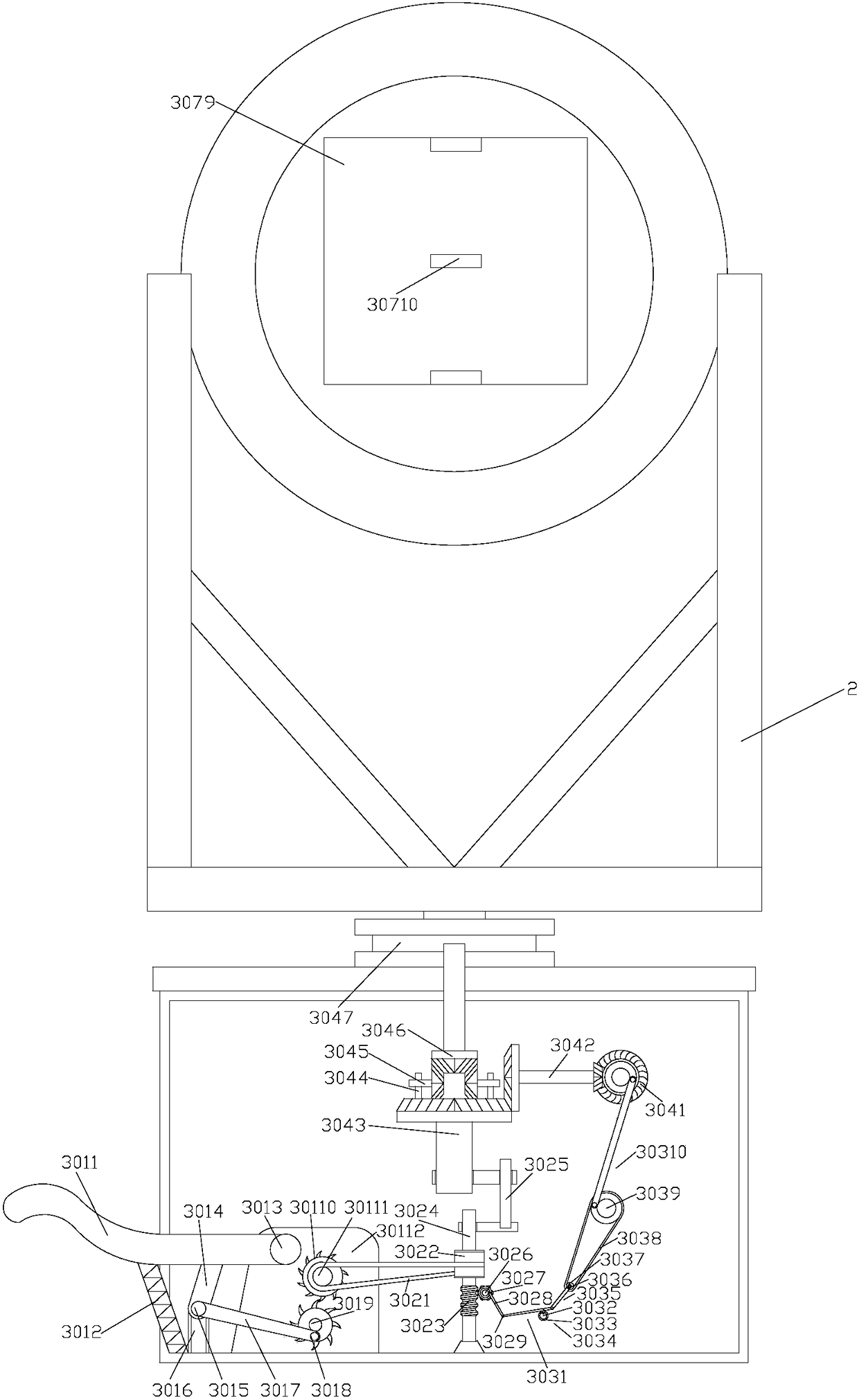

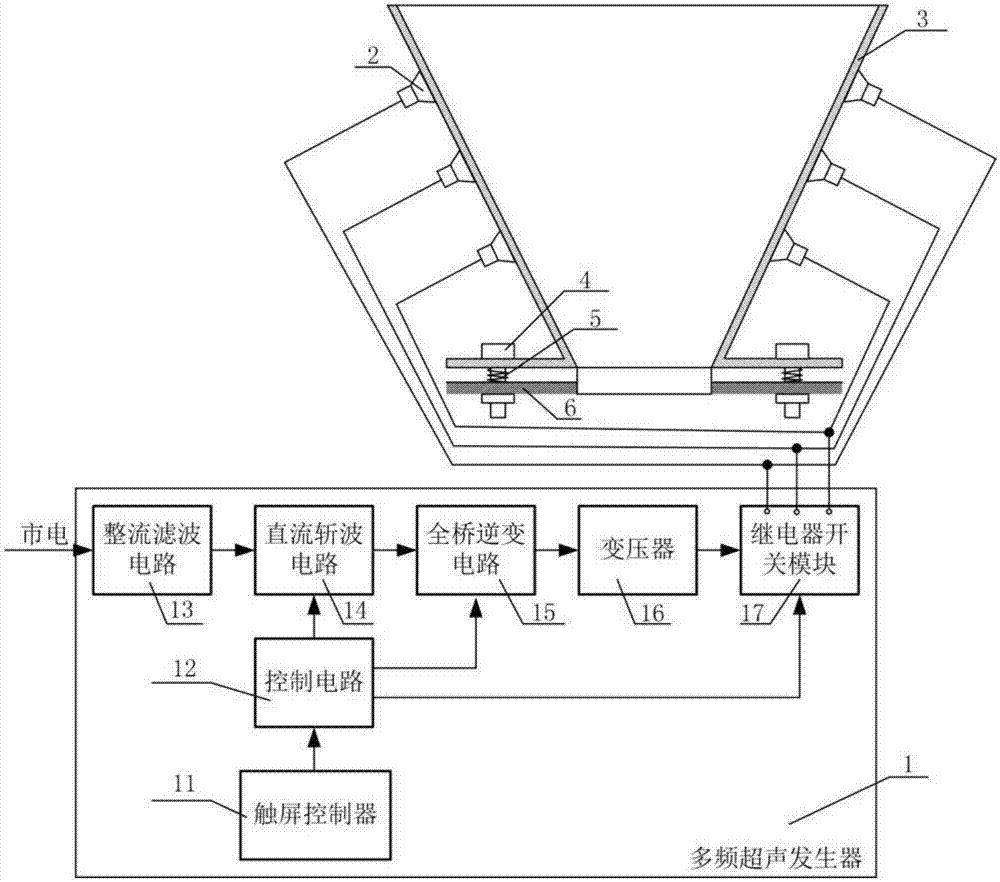

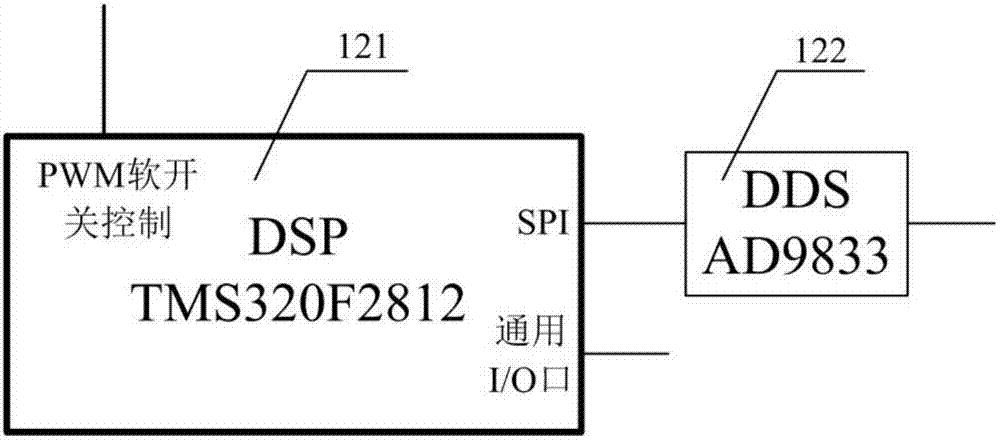

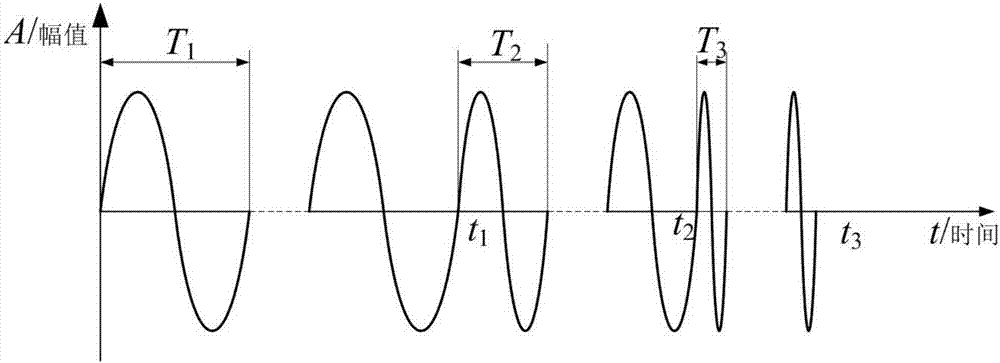

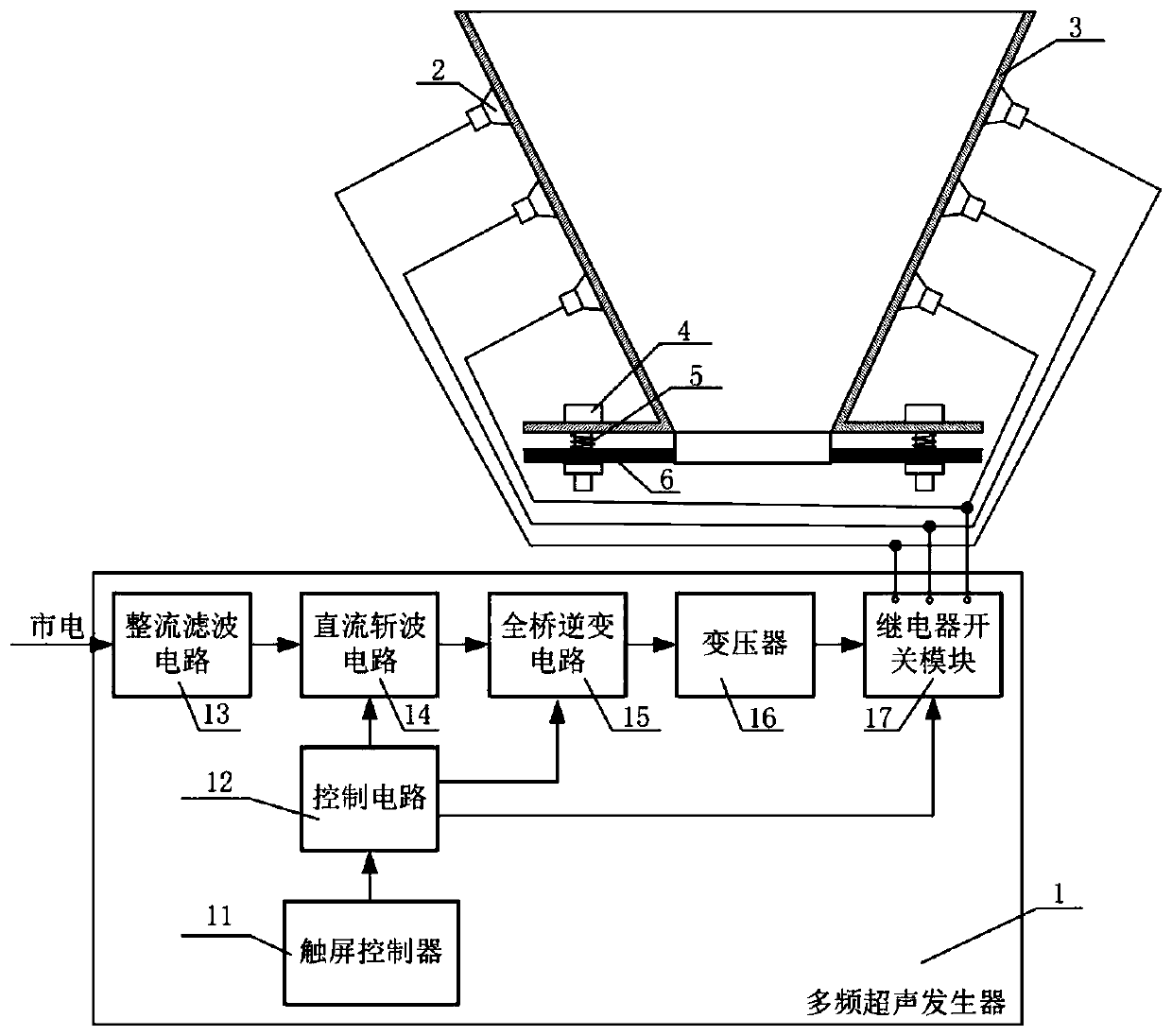

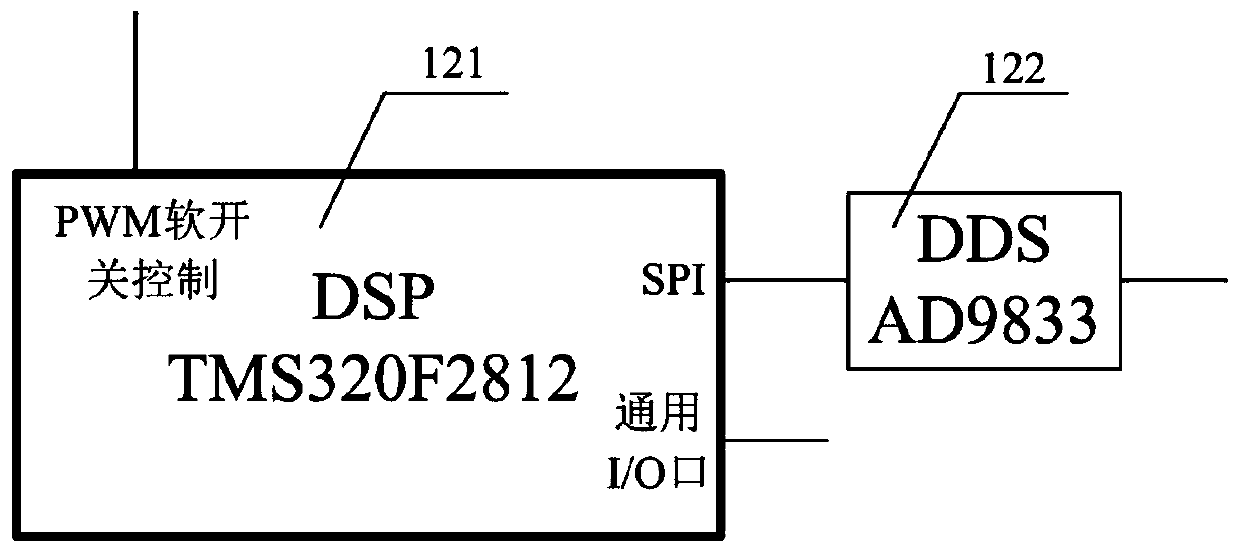

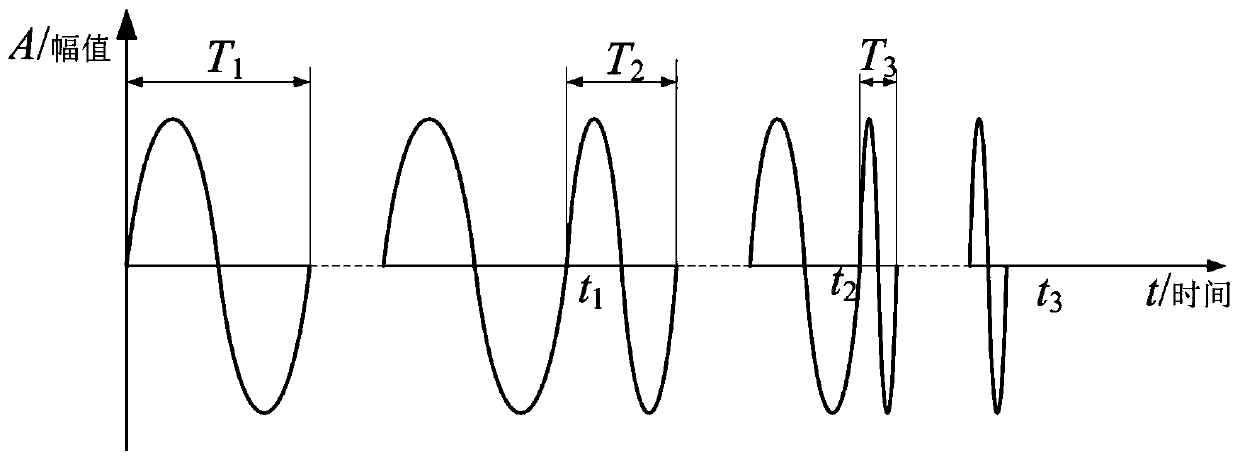

Variable-frequency vibration dust removal device based on energy converters

ActiveCN107377534AReduce labor intensityComprehensive dust removalHollow article cleaningMechanical vibrations separationEngineeringCenter frequency

The invention provides a variable-frequency vibration dust removal device based on energy converters. The variable-frequency vibration dust removal device comprises a multi-frequency ultrasonic generator, a funnel and two or more sets of the energy converters. The funnel is elastically connected to a fixing supporting seat, the funnel is provided with the two or more sets of energy converters, each set of energy converters comprise two energy converters, wherein the center frequency of the energy converters is the same, the energy converters are distributed on the surface of the funnel in a transversely symmetrical manner, the center frequency of different sets of energy converters is different, and the energy converters are distributed on the surface of the funnel from top to bottom at an equal interval. The input port of each energy converter is connected with the output port of the multi-frequency ultrasonic generator, and the energy converters work under the control of the multi-frequency ultrasonic generator. The variable-frequency vibration dust removal device has the advantages of being good in dust removal effect, high in automated degree, low in power consumption and the like.

Owner:NANJING UNIV OF SCI & TECH

A transducer-based frequency conversion vibration dust removal device

ActiveCN107377534BReduce labor intensityComprehensive dust removalHollow article cleaningMechanical vibrations separationConvertersFrequency conversion

The invention provides a variable-frequency vibration dust removal device based on energy converters. The variable-frequency vibration dust removal device comprises a multi-frequency ultrasonic generator, a funnel and two or more sets of the energy converters. The funnel is elastically connected to a fixing supporting seat, the funnel is provided with the two or more sets of energy converters, each set of energy converters comprise two energy converters, wherein the center frequency of the energy converters is the same, the energy converters are distributed on the surface of the funnel in a transversely symmetrical manner, the center frequency of different sets of energy converters is different, and the energy converters are distributed on the surface of the funnel from top to bottom at an equal interval. The input port of each energy converter is connected with the output port of the multi-frequency ultrasonic generator, and the energy converters work under the control of the multi-frequency ultrasonic generator. The variable-frequency vibration dust removal device has the advantages of being good in dust removal effect, high in automated degree, low in power consumption and the like.

Owner:NANJING UNIV OF SCI & TECH

A kind of processing method of polymetallic dust

ActiveCN111015519BAvoid residueAvoid Aspiration HazardsGrinding/polishing safety devicesEnvironmental engineeringPolluted environment

The invention relates to the technical field of dust removal technology, in particular to a process method for processing polymetallic dust. A process method for processing polymetallic dust, at least comprising the following steps: (1) metal dust is sucked into the body of the dust collection tower by a negative pressure fan, the water diversion valve is opened, and component A of the dedusting agent is sprayed out through the nozzle, washed, Settling metal dust; (2) Metal dust and dedusting agent A component solution fall together into the dedusting agent B component solution at the bottom of the dust collection tower under the action of gravity; (3) After dust removal, open the drain valve to discharge from the dust collection tower liquid in. The invention provides a process method for processing polymetallic dust, which can quickly and comprehensively remove dust, especially the metal dust generated during the polishing process, prevent the residue of metal dust, prevent the phenomenon of combustion and explosion caused by dust enrichment, and prevent pollution of the environment and Inhalation hazard occurs to the human body, improving safety.

Owner:上海御镐实业发展有限公司

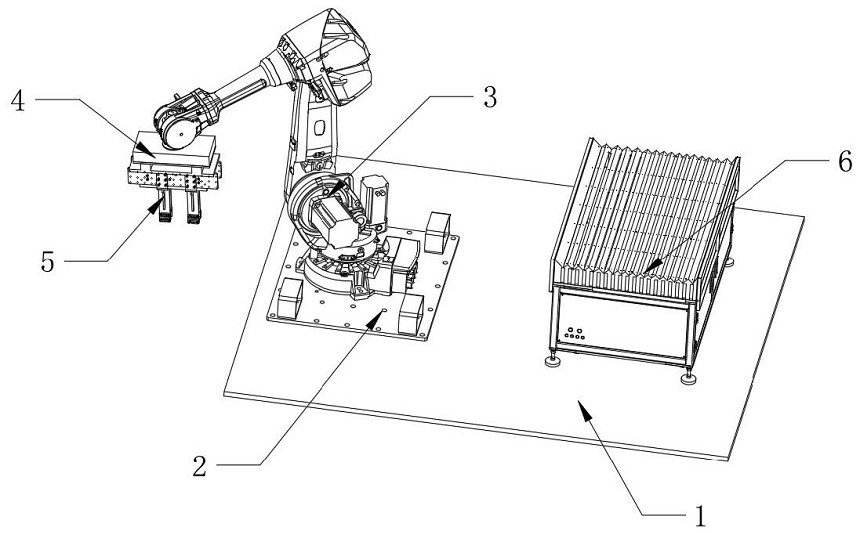

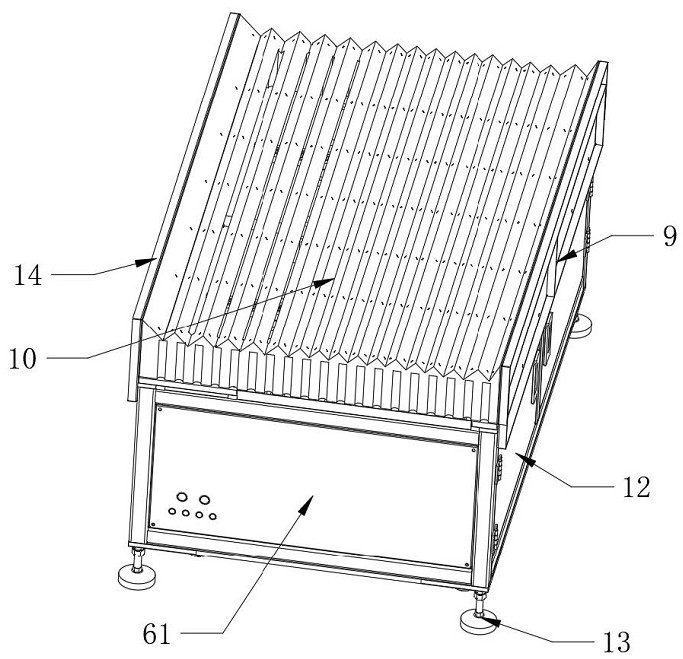

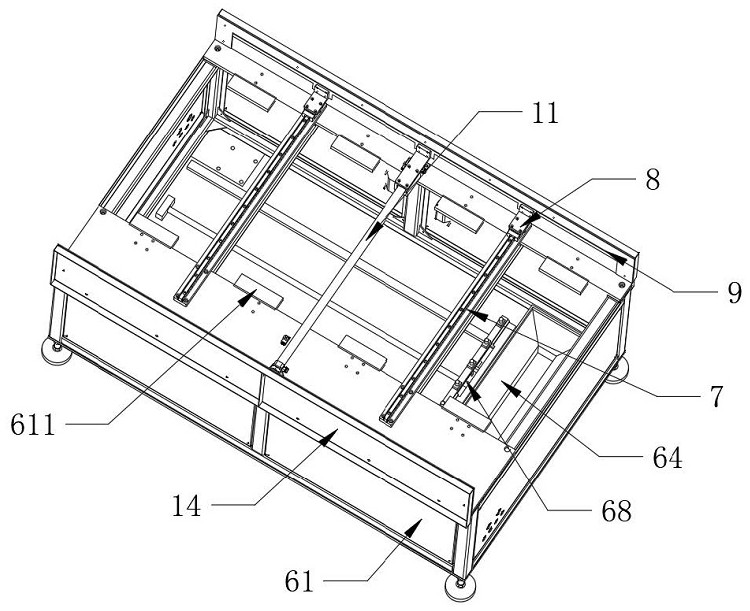

A device and method for automatically changing manipulators

ActiveCN112677164BAchieve replacementReduce labor intensityGripping headsControl engineeringDust control

The invention provides a device and method for automatically replacing a manipulator, which includes a bottom plate, a mounting plate, a mechanical arm and a gripping manipulator. The utility model sets a temporary storage platform in the grinding room, so that the clamping manipulator can temporarily store on the temporary storage platform, realizes the connection and disconnection of the mechanical arm and the clamping manipulator through the replacement device, realizes the replacement of the clamping manipulator, and reduces people's labor Intensity, to avoid the danger caused by manual replacement, by setting a bag filter and ash hopper in the temporary storage box, and blowing off the dust adhering to the clamping manipulator through the destatic ion air gun in the soot blowing mechanism, through The ash collecting hopper and bag filter are used to collect and remove dust, so that the surface of the clamping manipulator to be replaced is kept clean, and the driving rod in the soot blowing mechanism cooperates with the driving frame to make the rotary block swing back and forth, so that the destatic ion air gun can swing and blow , making dust removal more comprehensive.

Owner:升励五金(深圳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com