Air gun for removing dust in hole

An air gun and gun body technology, applied in the field of air guns, can solve the problems of insufficient dust removal through small-caliber through holes, affecting the sealing of valves, etc., and achieves the effect of strong practicability and high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

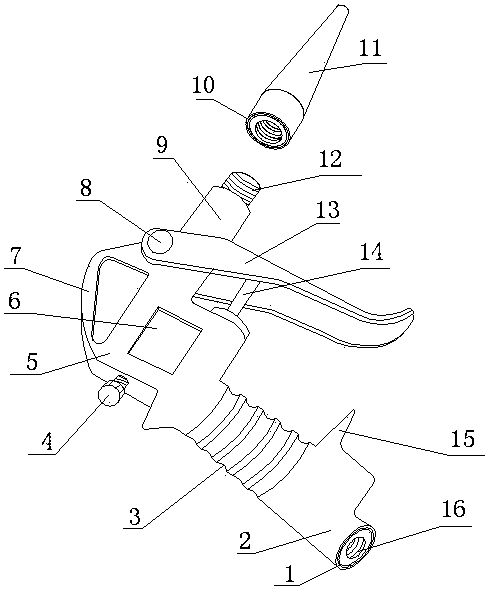

[0018] like figure 1 The air gun of dust removal in the hole shown, comprises gun body 5 and nozzle 11, and the gun handle end of gun body 5 is air inlet end 2, and air inlet end 2 is provided with internally threaded hole 16, and the gun handle circumference of described gun body 5 A plurality of anti-slip grooves 3 are arranged on the surface, and the front end of the gun body of the gun body 5 is an air outlet 9, and the air outlet 9 is provided with a threaded joint 12, and the threaded joint 12 is connected to the nozzle 11, and the nozzle 11) is a cone with a large end and a small end. Shaped structure, the gun body of described gun body 5 is also provided with rotating shaft 8, and rotating shaft 8 connects wrench 13, and the inner side of spanner 13 is connected with return spring bar 14, constitutes the rotating structure that wrench 13 rotates with rotating shaft 8 as an axis.

[0019] A sealing groove I10 is provided on the end surface where the nozzle 11 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com