Variable-frequency vibration dust removal device based on energy converters

A technology of variable frequency vibration and dust removal device, which is applied in the direction of fluid, chemical instruments and methods, cleaning methods and utensils using vibration, can solve problems such as high energy consumption and funnel damage, achieve low energy consumption, comprehensive dust removal, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

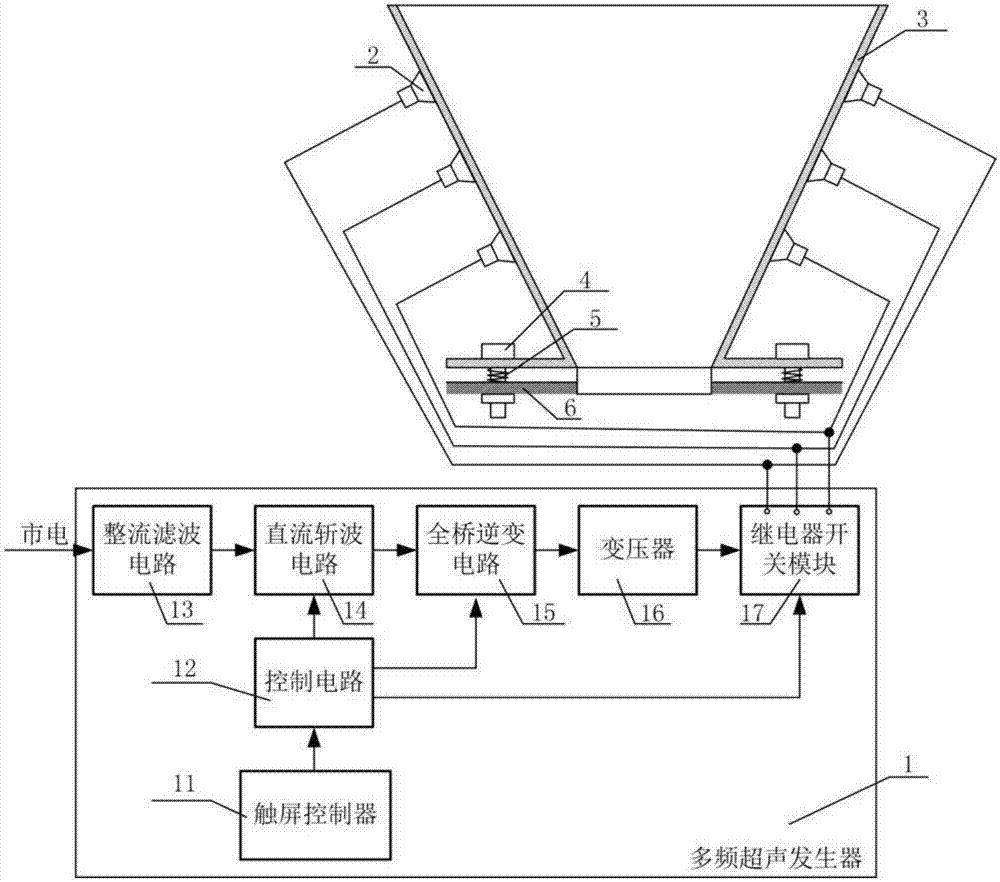

[0039] combine figure 1 According to an embodiment of the present invention, a frequency conversion vibration dust removal device based on a transducer 2, a multi-frequency ultrasonic generator 1, a funnel 3 and more than two groups of transducers 2, wherein the multi-frequency ultrasonic generator 1 output port and The input port of the transducer 2 is electrically connected, each group of transducers 2 includes two transducers 2 with the same center frequency and symmetrically distributed on the surface of the funnel 3, and the center frequencies of different groups of transducers 2 are different from top to bottom. The bottoms are evenly spaced on the surface of the funnel 3, and the funnel 3 is elastically connected to the fixed support 6.

[0040] In this embodiment, the number of groups of transducers 2 is three groups, and the center frequencies of the three groups of transducers 2 from top to bottom are respectively f 1 , f 2 , f 3 , and satisfy f 1 2 3 .

[0041]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com