A kind of processing method of polymetallic dust

A process method and technology of metal dust, applied in metal processing equipment, manufacturing tools, grinding/polishing safety devices, etc., can solve problems such as health threats, dust pollution, difficult discharge, etc., to prevent inhalation hazards and improve safety , the effect of comprehensive dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the A component of the dust remover is as follows: mixing and stirring sodium lauryl sulfate, lauryl glucoside, potassium perfluorobutane sulfonate, polyanionic cellulose, and water evenly to obtain the product.

[0040]The inventor believes that the metal dust is sucked into the dust collection tower by a negative pressure fan, and after being washed and settled by component A of the dedusting agent, the metal dust is captured and settled to ensure that there is no suspended metal dust in the dust collection tower and avoid excessively high Hazards caused by high concentrations of metal dust. The inventor speculates that the possible reason is that during the spraying and falling process of the dust remover component A solution, as the air in the solution enters, the sodium lauryl sulfate and lauryl glucoside molecules will automatically shrink in volume and form a hydrophilic group. Facing the water, the hydrophobic base faces the spherical c...

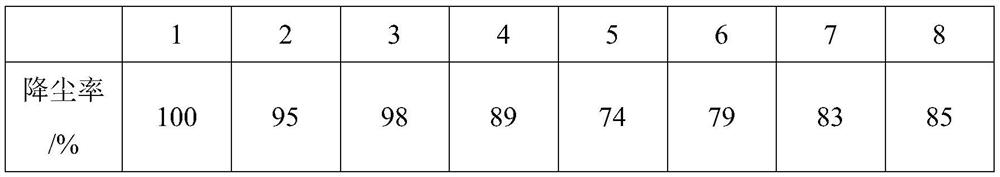

Embodiment 1

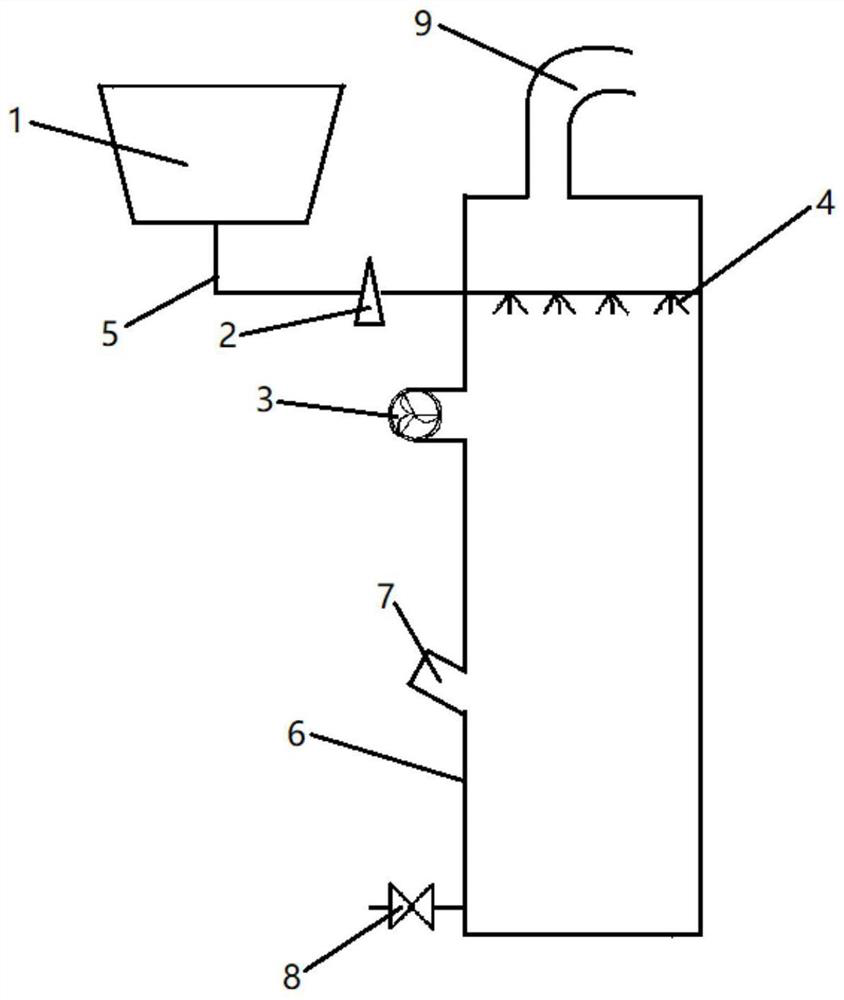

[0062] Embodiment 1 provides a kind of processing method of polymetallic dust, comprises the following steps:

[0063] (1) The metal dust is sucked into the dust collection tower body through the negative pressure fan, the water diversion valve is opened, and the component A of the dust remover is sprayed out through the nozzle to wash and settle the metal dust;

[0064] (2) The metal dust and the solution of component A of dust remover fall into the solution of component B of dust remover at the bottom of the dust collection tower together under the action of gravity;

[0065] (3) After dust removal, open the drain valve to discharge the liquid in the dust collection tower.

[0066] The dust remover component A includes sodium lauryl sulfate, lauryl glucoside, potassium perfluorobutanesulfonate, polyanion cellulose, and water in a weight ratio of 18:27:10:8:100.

[0067] The preparation method of the A component of the dust remover is as follows: mixing and stirring sodium l...

Embodiment 2

[0072] Embodiment 2 provides a kind of processing method of polymetallic dust, comprises the following steps:

[0073] (1) The metal dust is sucked into the dust collection tower body through the negative pressure fan, the water diversion valve is opened, and the component A of the dust remover is sprayed out through the nozzle to wash and settle the metal dust;

[0074] (2) The metal dust and the solution of component A of dust remover fall into the solution of component B of dust remover at the bottom of the dust collection tower together under the action of gravity;

[0075] (3) After dust removal, open the drain valve to discharge the liquid in the dust collection tower.

[0076] The dust remover component A includes sodium lauryl sulfate, lauryl glucoside, potassium perfluorobutane sulfonate, polyanion cellulose, and water in a weight ratio of 15:30:5:6:100.

[0077] The preparation method of the A component of the dust remover is as follows: mixing and stirring sodium l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com