Solid energy saving screw cleaning agent

A screw cleaning agent and cleaning agent technology, applied in the field of polymer materials, can solve problems such as unsatisfactory cleaning effect, consumption of manpower and material resources, mechanical surface wear, etc., to achieve convenient and fast cleaning, save time, and improve production efficiency. Effect

Inactive Publication Date: 2010-09-22

彭超

View PDF5 Cites 44 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The cleaning effect of the previous cleaning methods is not very satisfactory, especially the cleaning of carbon deposits is even more powerless, and at the same time, it consumes a lot of manpower and material resources

At present, the commonly used solid screw cleaning agents on the Chinese market have certain limitations in terms of cleaning efficiency, environmental protection, and cost. For example, more environmentally friendly resin cleaning agents are difficult to clean the dead corners and gaps of the screw barrel, and the cleaning efficiency is low. ; and the screw cleaning agent added with organic solvent, although it improves the cleaning efficiency, there is a problem of environmental pollution; those screw cleaning agents that add abrasives also cause the corresponding mechanical surface to wear while cleaning the screw barrel

At present, there are almost no effective solid screw cleaning agents in China, and the solid screw cleaning agents used are mainly imported products.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Login to View More

Abstract

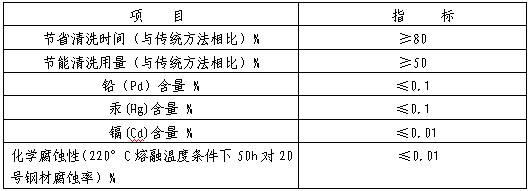

The invention provides a solid energy saving screw cleaning agent which can prepare non-corrosive and non-abrasive energy saving screw cleaning material. The raw material formula of the cleaning agent is as follows by weight percentage: 40-60% of matrix resin, 30%-40% of modified powder and 10-20% of auxiliary agent, and the sum of the weight percentage of all the components is 100%; the auxiliary agent is a cleaning surface, a surface active agent, a lubricating agent, a forming agent and a blowing activator; the raw material formula of the modified powder is as follows by weight percentage: 83-97% of inorganic powder, 2.0-8.0% of dispersing agent and 1.0-5.0% of coupling agent. According to the proportion of the formula, the matrix resin, the prepared modified powder, the cleaning agent, the surface active agent, the lubricating agent, the forming agent and the blowing activator are added into a high-speed mixer, and then are extruded and formed by an extruder to obtain the solid screen cleaning agent.

Description

technical field [0001] The invention relates to the technical field of polymer materials, in particular to the development of a solid energy-saving screw cleaning agent. Background technique [0002] Plastic products are light in weight, cheap, easy to process, good in performance, and various in variety. They are one of the most important materials in modern society. In the plastic processing process, there will be more or less raw materials accumulated in the processing machinery, which will cause waste of raw materials and environmental pollution during operations such as color change and refueling. As the output of plastic products increases year by year, this situation becomes more and more serious. The cleaning effect of the previous cleaning methods is not very satisfactory, especially the cleaning of carbon deposits is even more powerless, and at the same time, it consumes a lot of manpower and material resources. At present, the commonly used solid screw cleaning ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/12C08L23/06C08L55/02C08K13/06C08K9/04C08K9/06C08K3/26C08K3/22C08K3/36C08K3/32C08K5/42C08K5/098C08K5/23C08K3/30C08K3/34B29B9/06

Inventor 彭超吴惠民郑海玲

Owner 彭超

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com