Patents

Literature

62results about How to "Guaranteed movement track" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

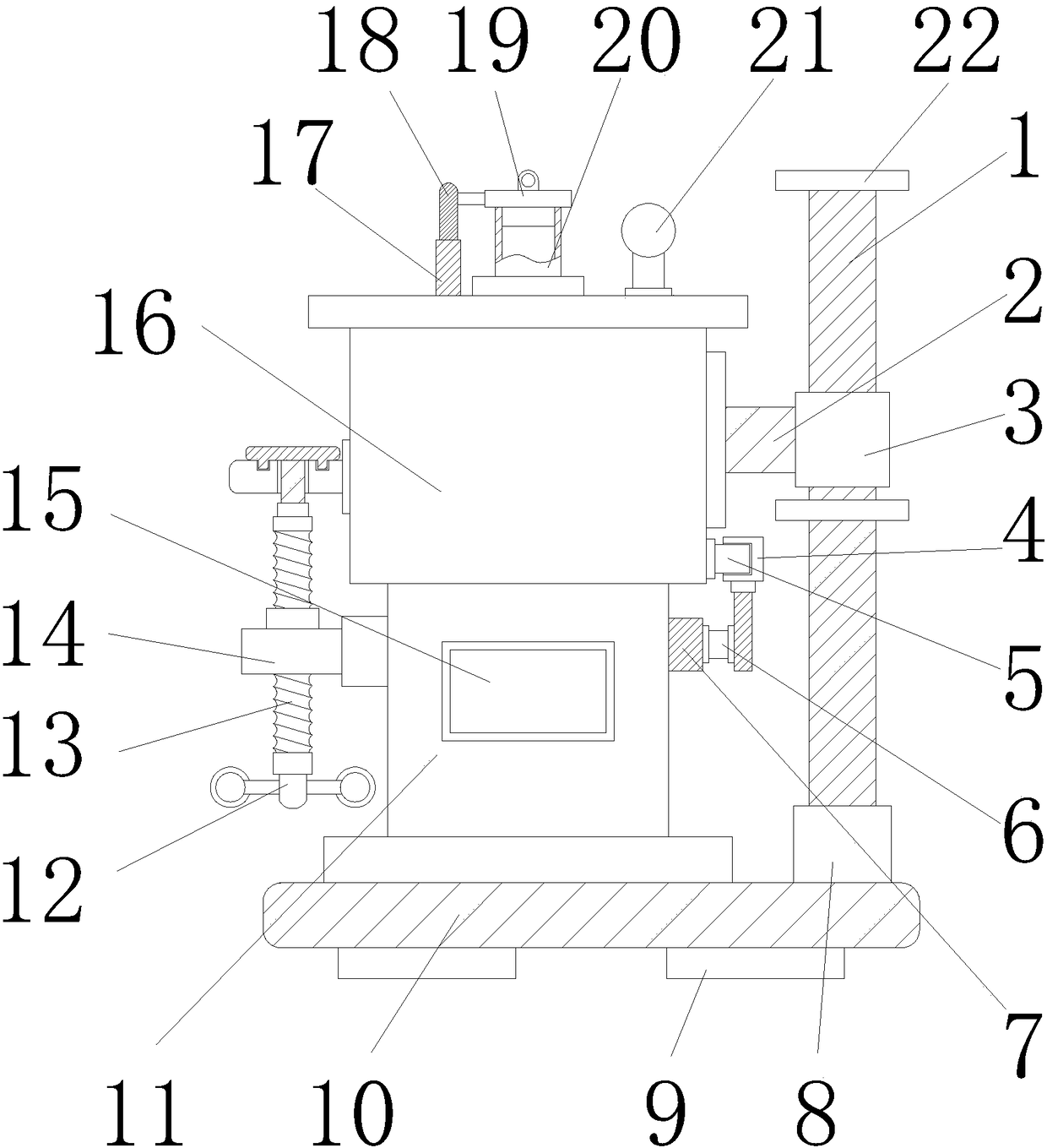

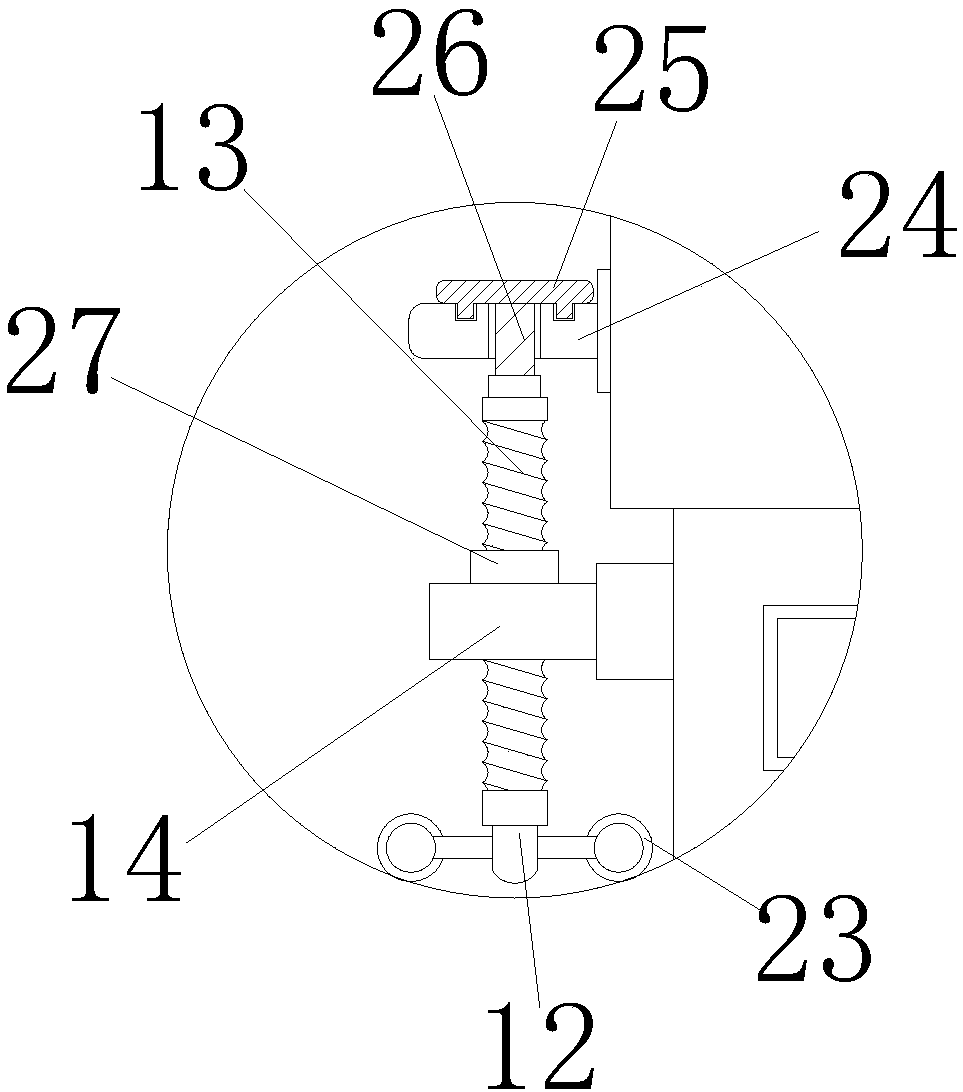

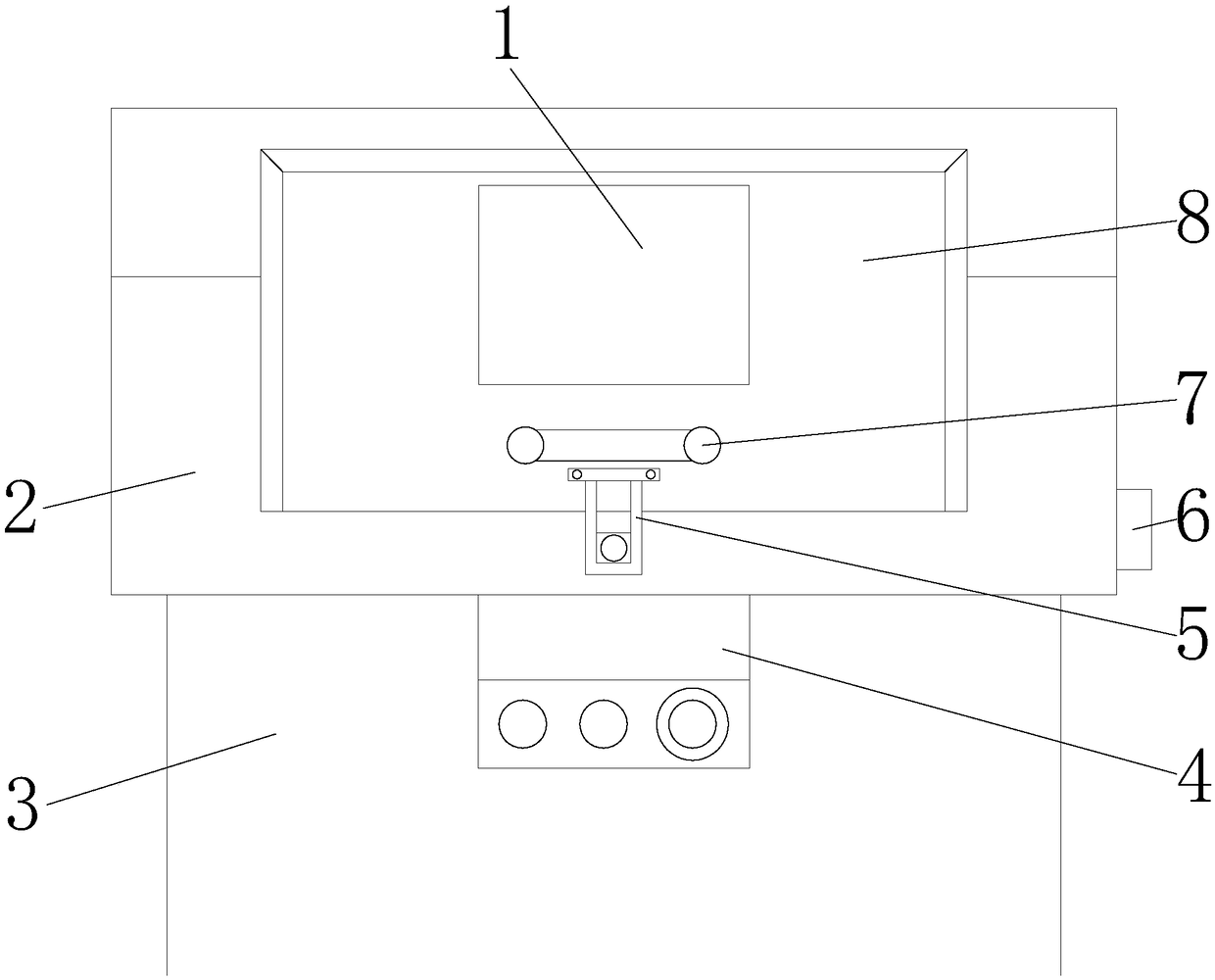

Board coating device

InactiveCN110935588AQuality assuranceGuaranteed movement trackLiquid surface applicatorsCleaning using toolsSurface cleaningEngineering

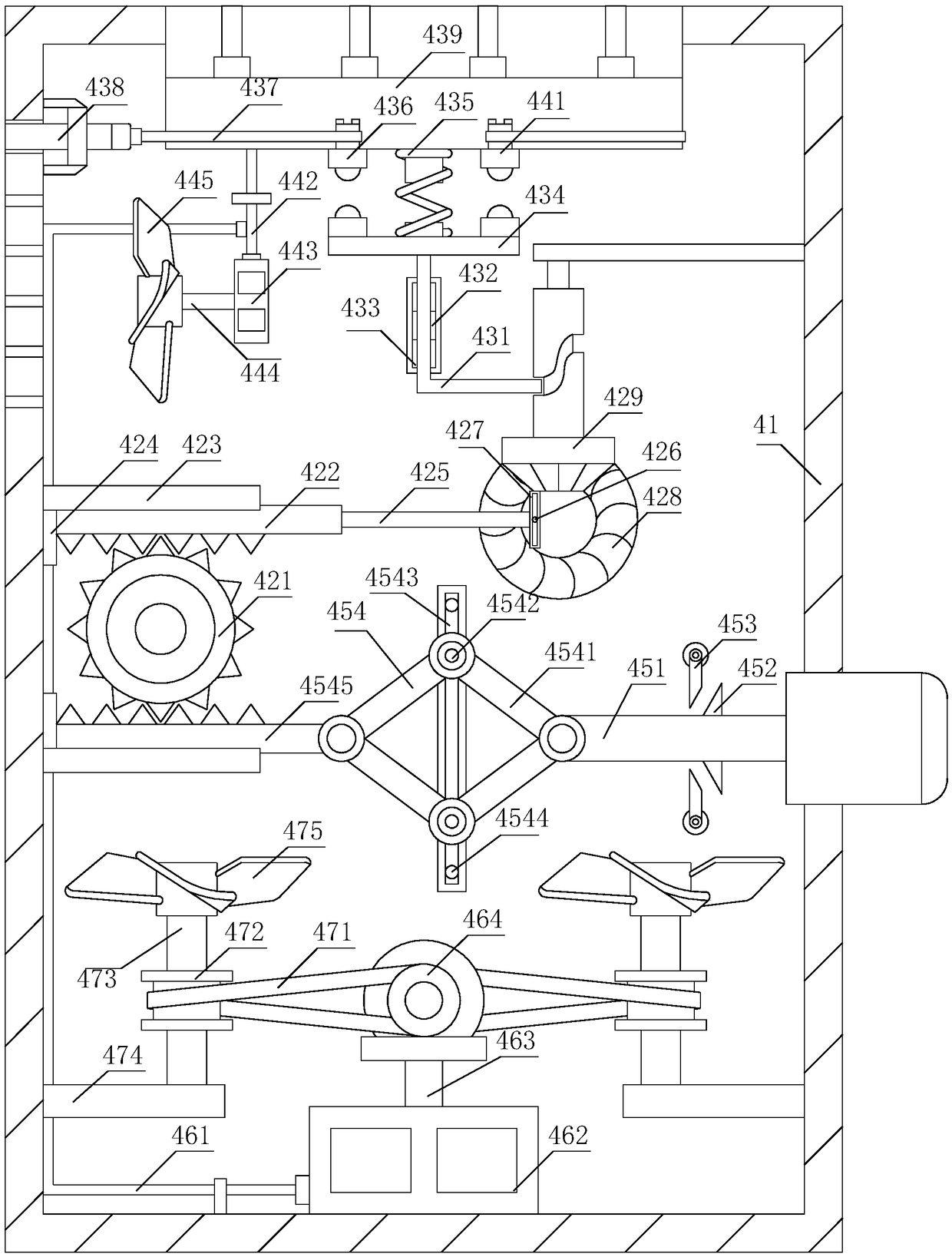

The invention relates to the industrial field, in particular to a board coating device. The device comprises a shell, the shell internally comprises a paint box which is arranged on the right side ofthe shell and attached to the shell, a front handle combined handle is arranged on the upper surface of the shell, and comprises a front handle fixedly mounted on the upper surface of the shell and arear handle fixedly mounted on the upper surface of the paint box, a through work cavity is formed in the rear handle, a through first gear cavity is formed in the paint box, and the first gear cavityand the work cavity are coaxial. According to the board coating device, four steps of board leveling, surface cleaning, painting and primary drying in board coating can be finished, finished productquality is ensured, meanwhile, the device further comprises two detachable flows of board leveling, surface cleaning, painting and primary drying, and the device can be purely used for board grindingor board painting except for joint finishing of the four steps.

Owner:YUYAO FEIGE AUTOMATION TECH CO LTD

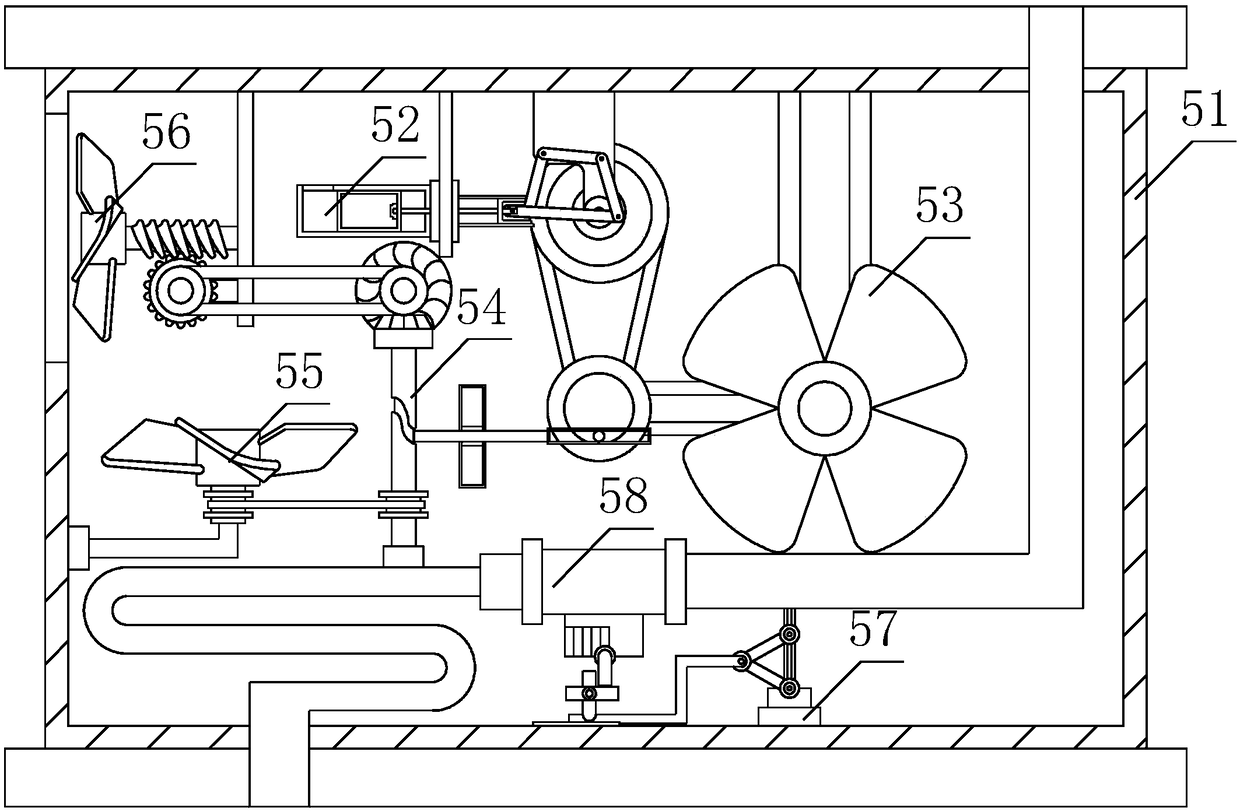

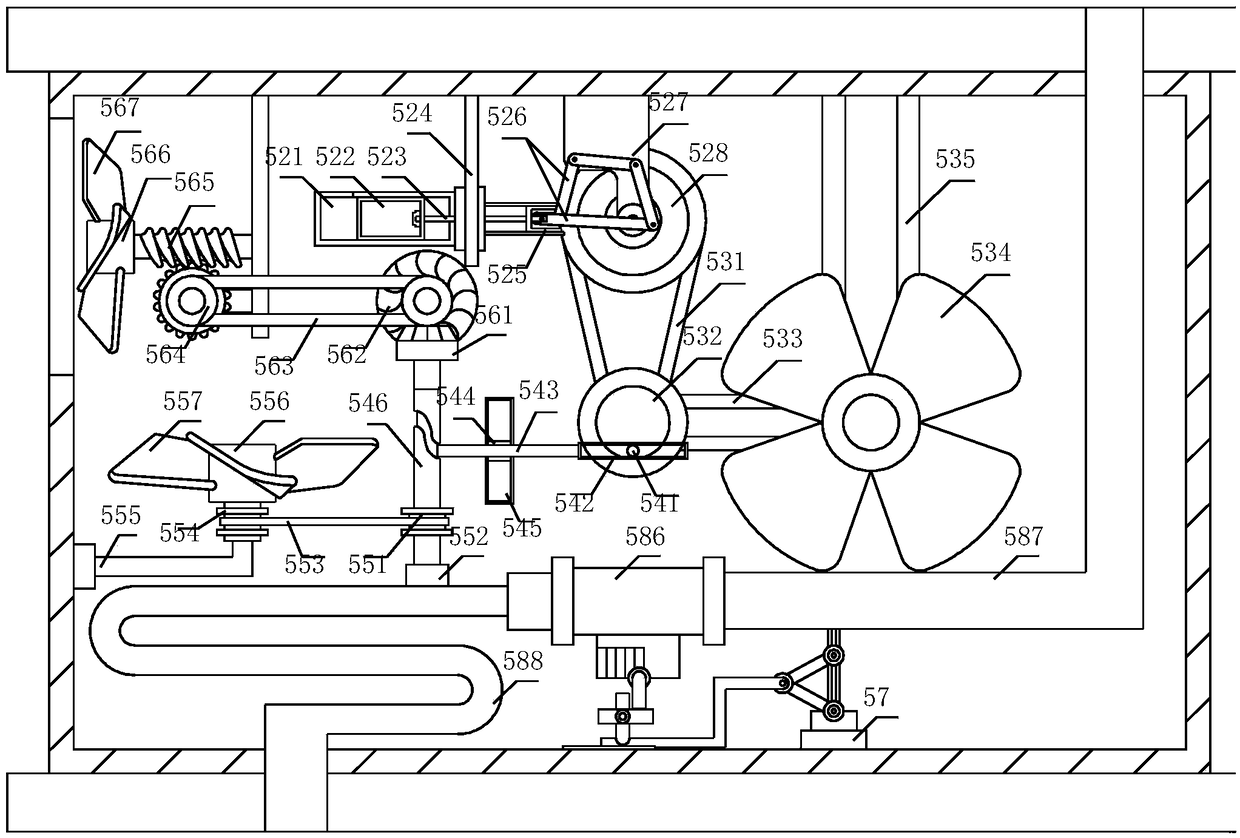

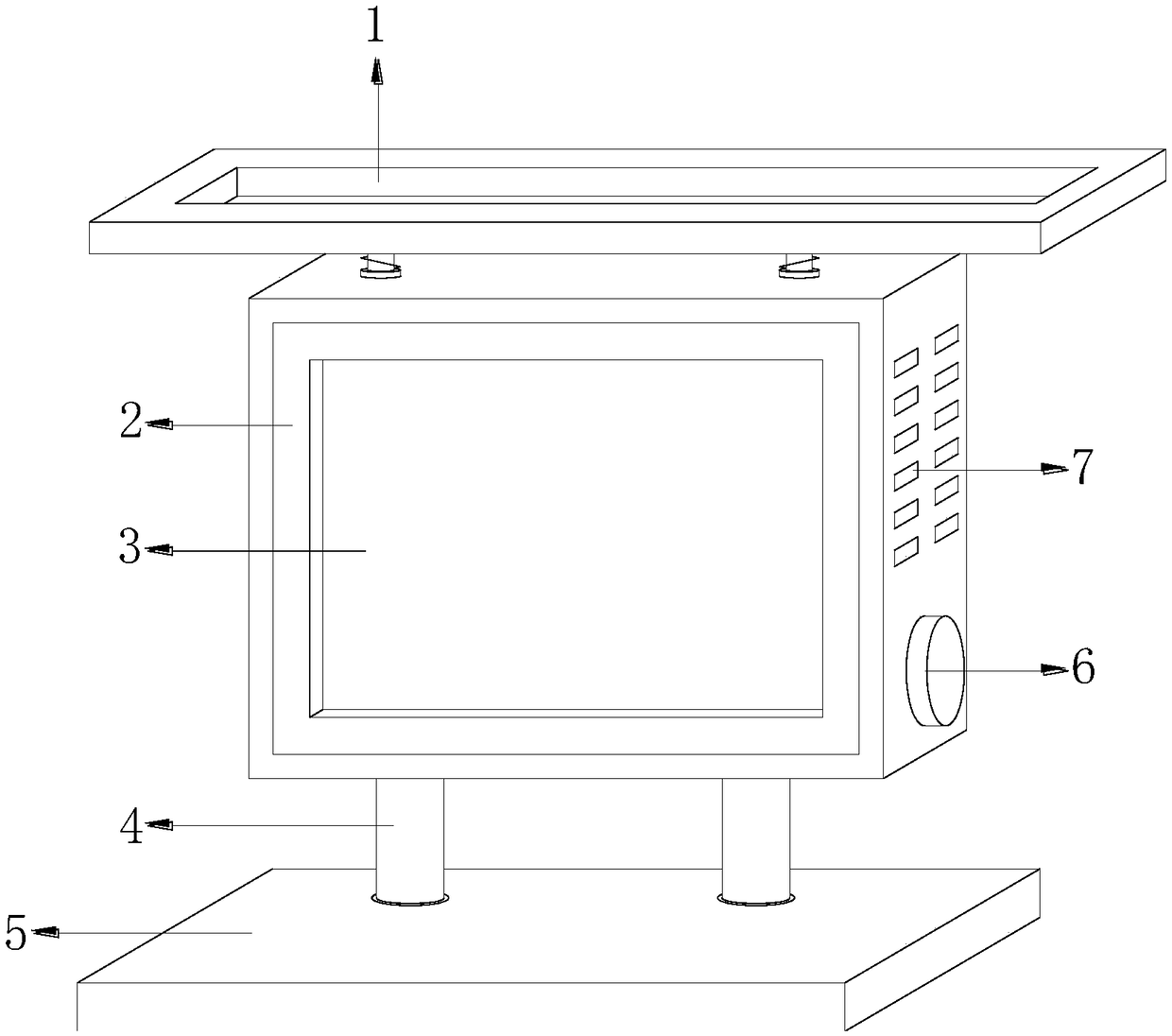

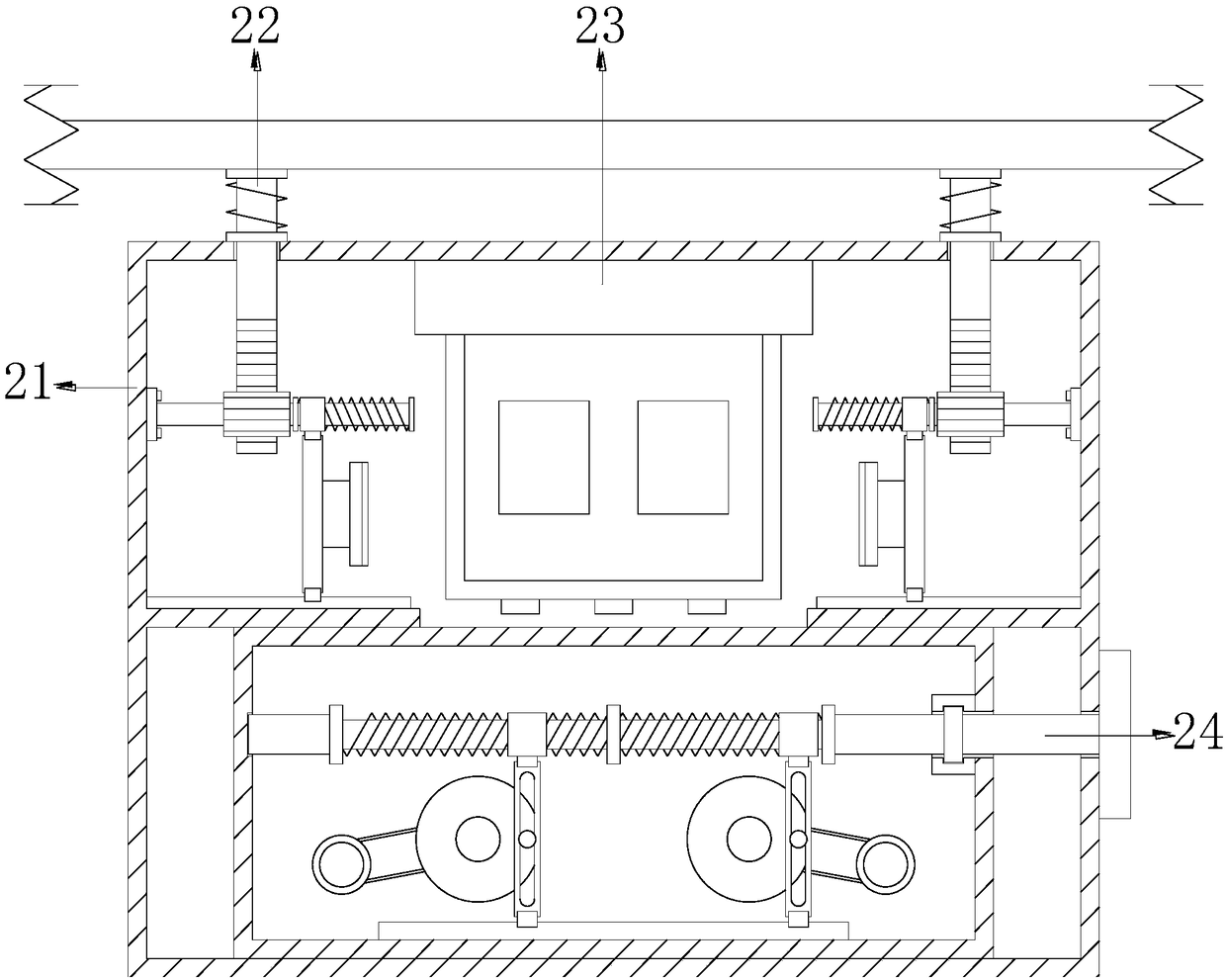

Concrete shrinkage testing device under cold construction conditions

InactiveCN108693338AComprehensive testTo detect contractilityMaterial thermal analysisMaterial testing goodsEngineeringFan blade

The invention discloses a concrete shrinkage testing device under cold construction conditions. The structure comprises a window, a test host, a recycling box, universal wheels, a base and an operation panel. The window is embedded on the left side of the outer surface of the test host, and the lower end of the test host is connected with the recycling box. The test host is mounted on the base. Through transmission of a linkage belt, a linkage spindle rotates to drive a rotating rod to rotate, and then a placement plate on the upper end of the rotating rod also starts to rotate so as to perform more comprehensive testing of concrete. After a compression tube performs air compression, compressed air is blown out through an air outlet to drive rotating fan blades to rotate. Thereby, throughthe simulation testing of the concrete with large cold wind, shrinkage of the concrete under cold conditions can be detected. The left end of a second traction plate is shifted to the right side and the right end is shifted to the left side to touch a power box, and then a water pump works and water inside a water tank is more powerfully discharged to a shower head for cold water spraying testingof the concrete. The test effect is more obvious.

Owner:谢燕玲

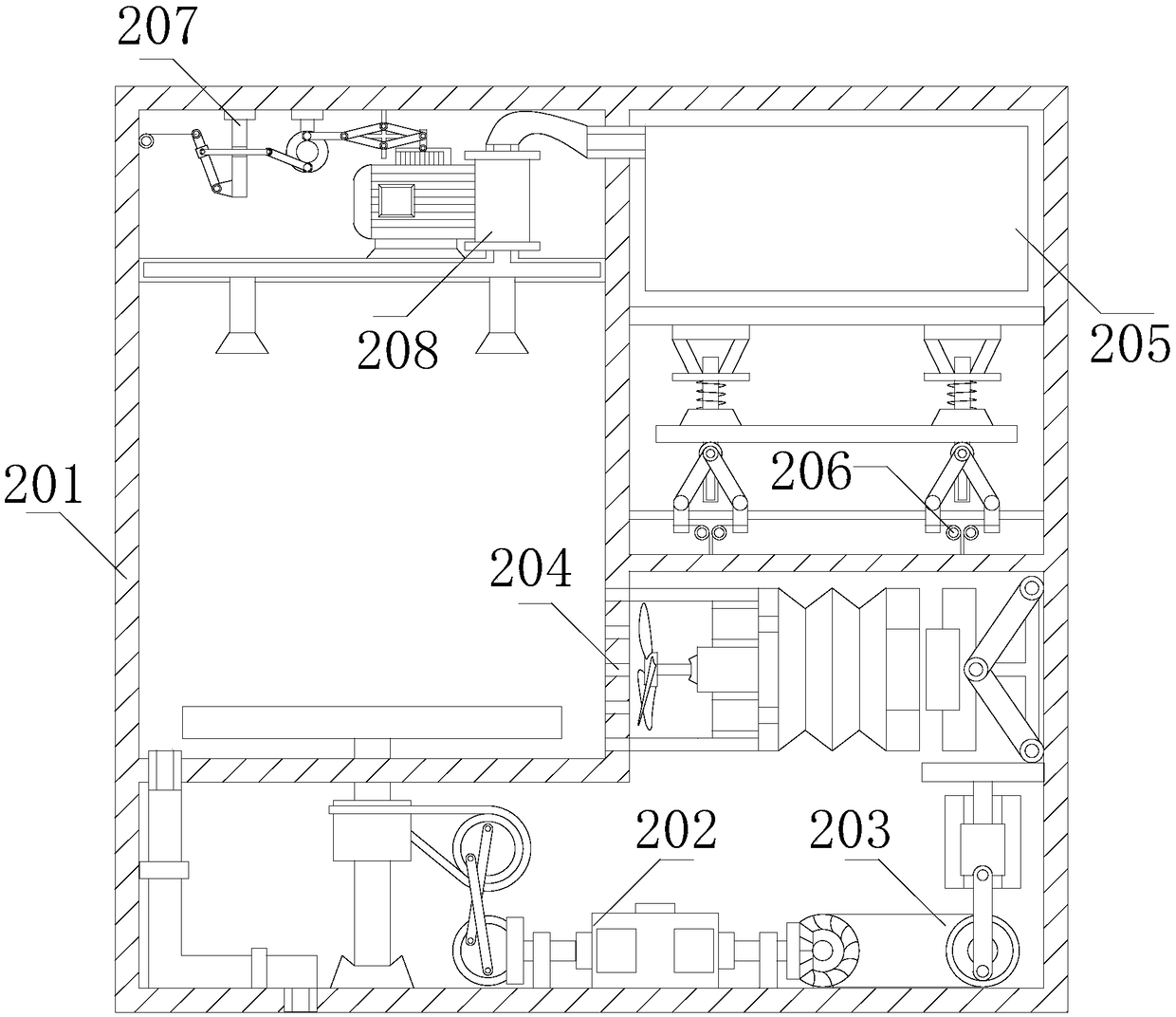

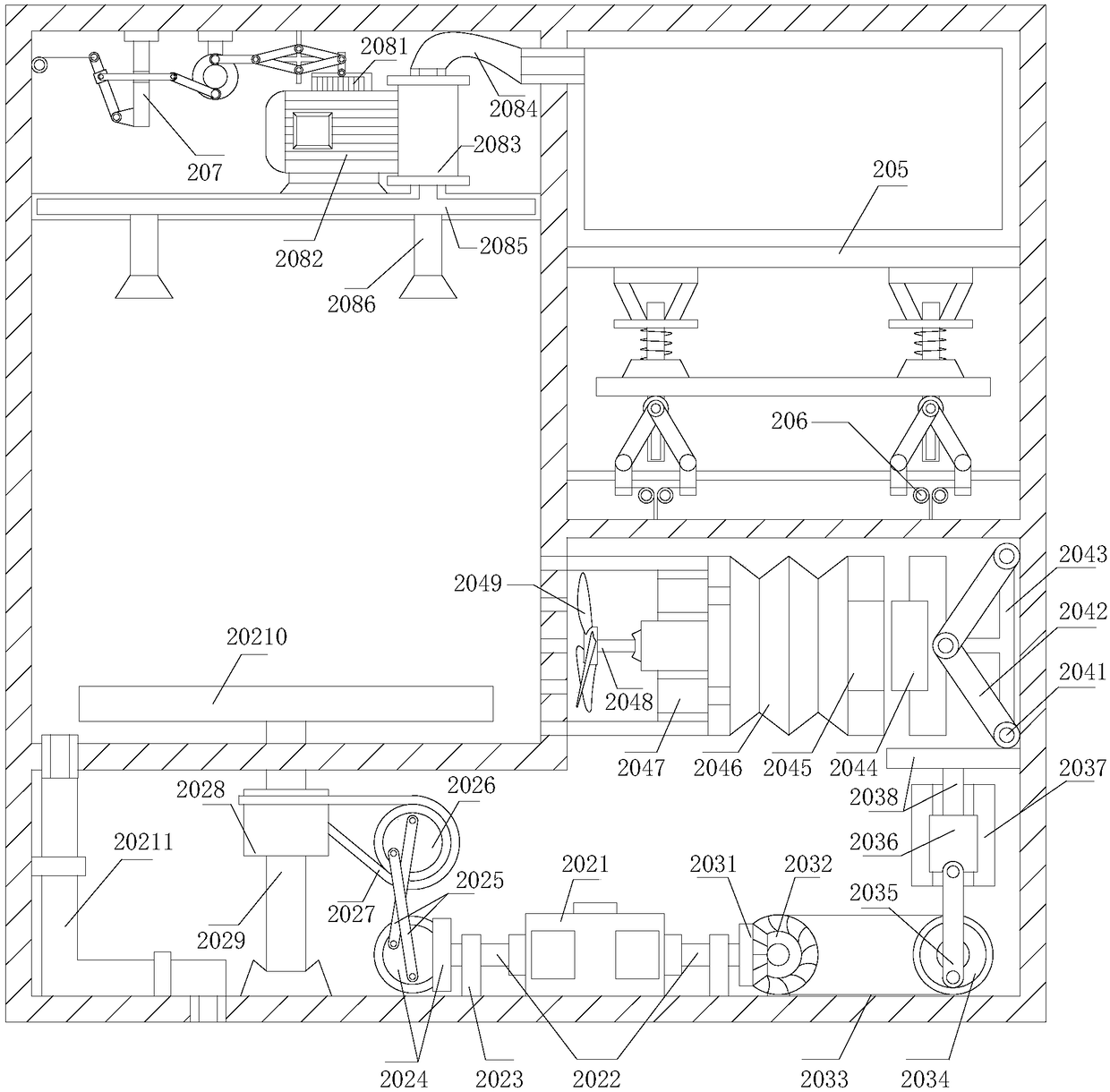

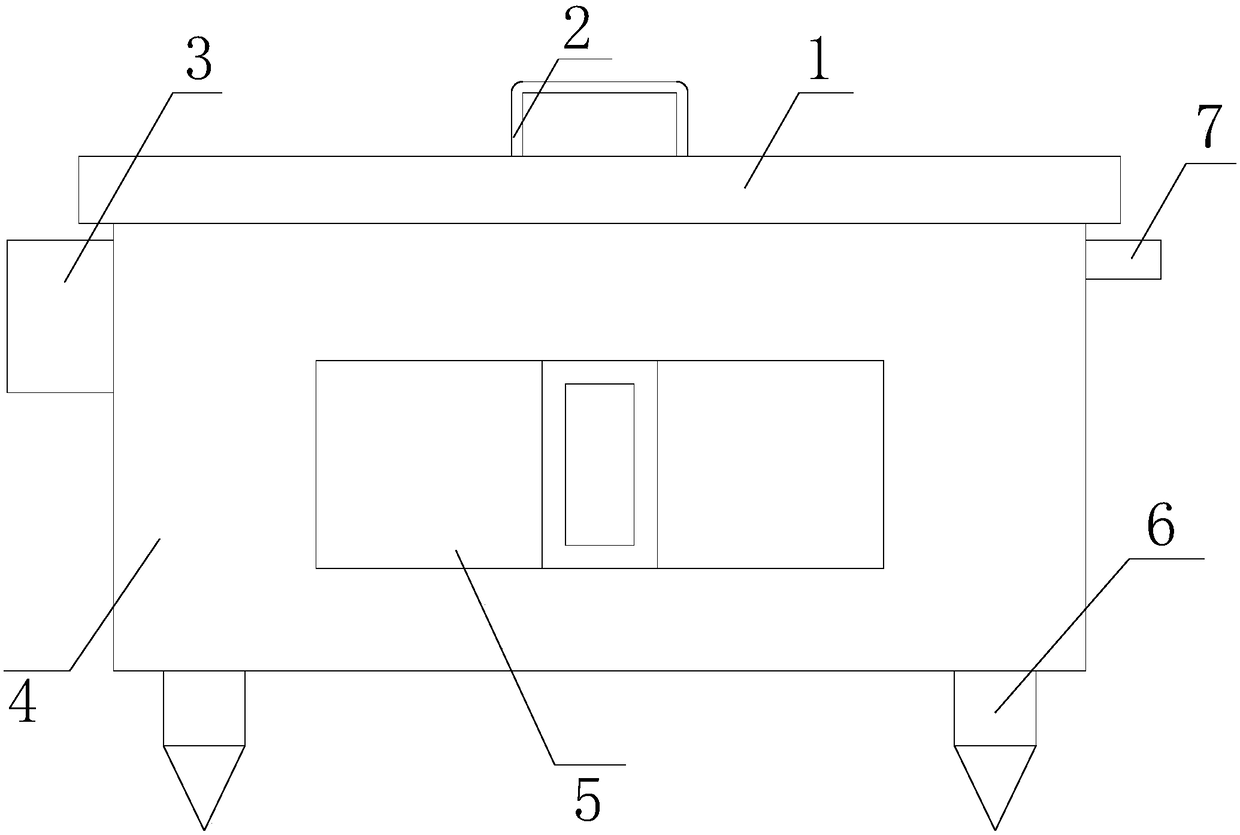

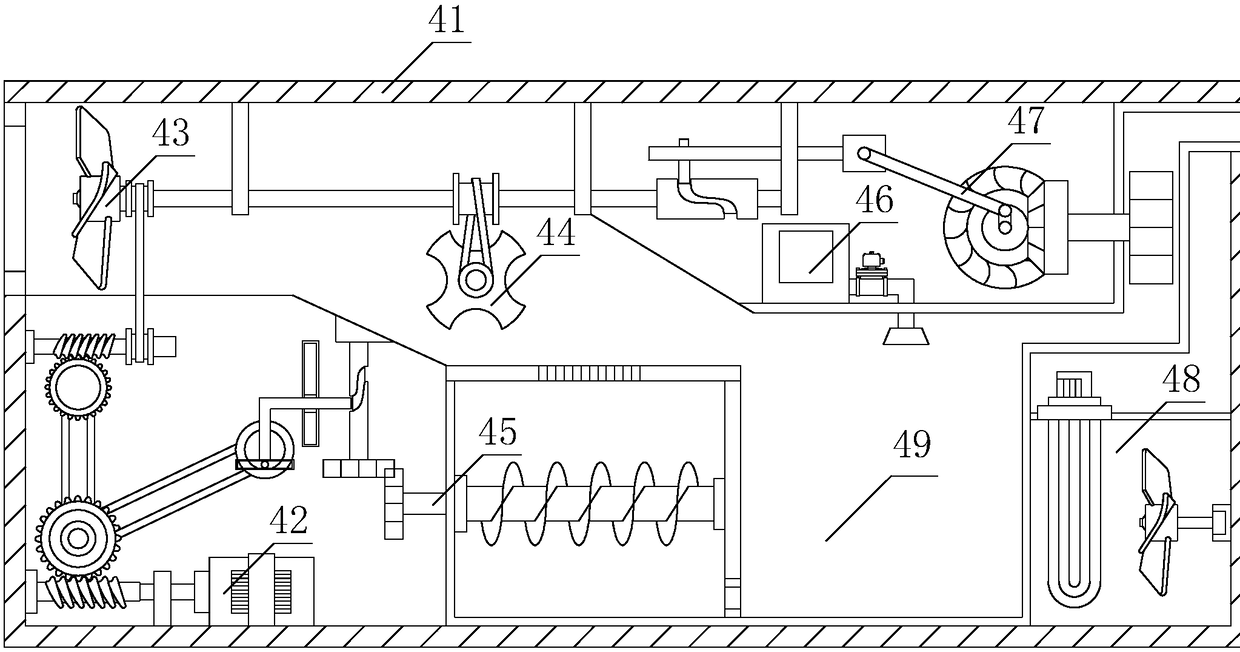

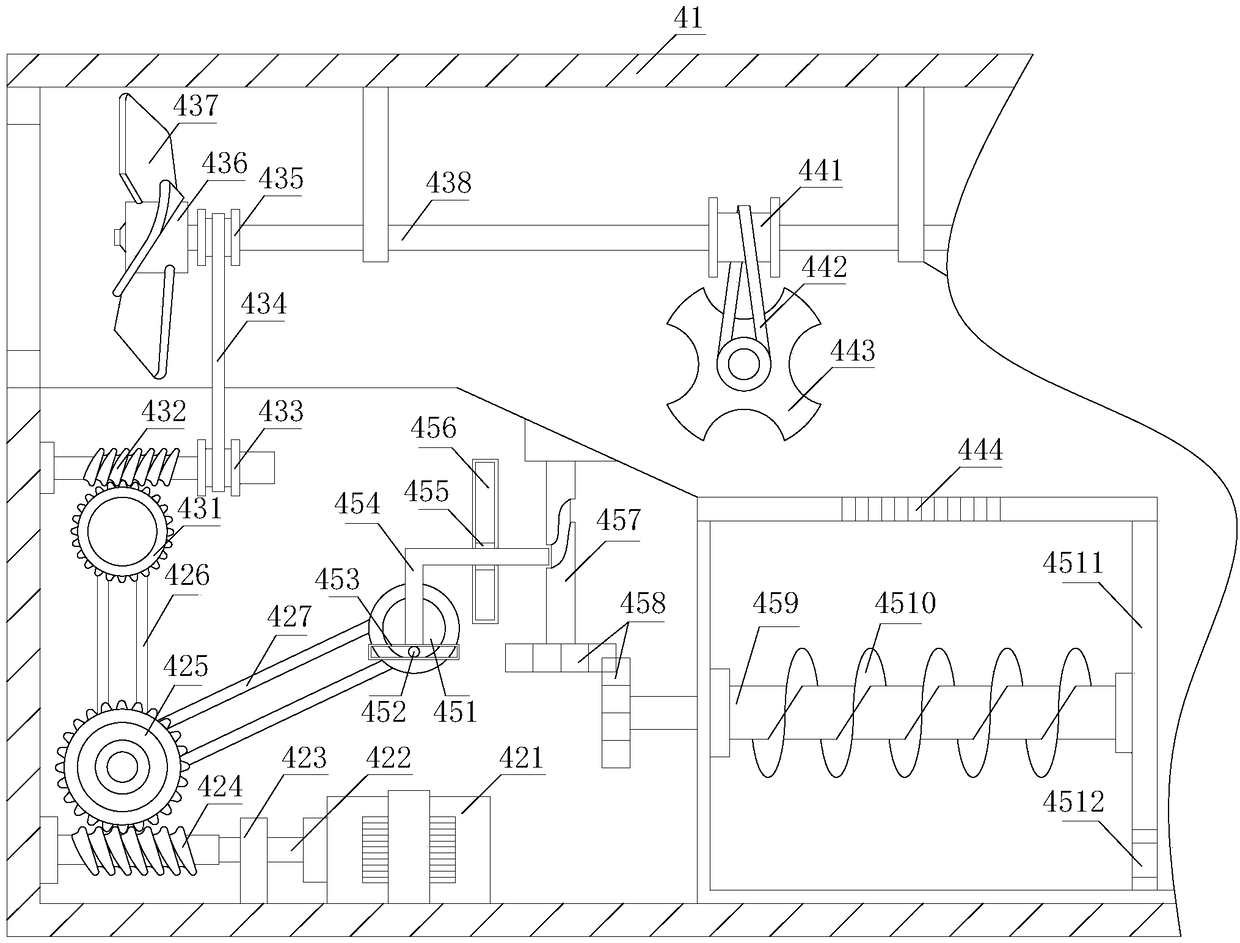

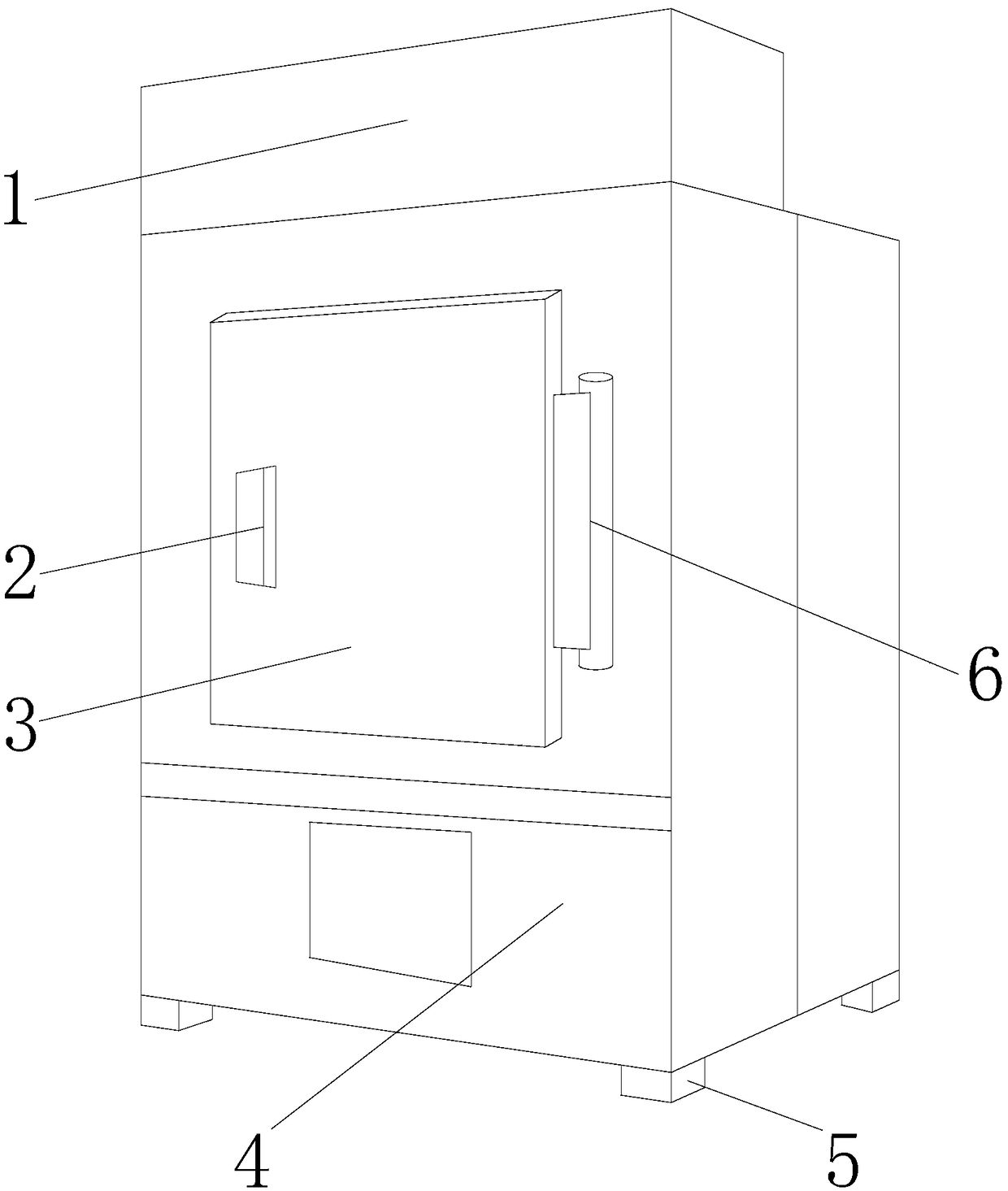

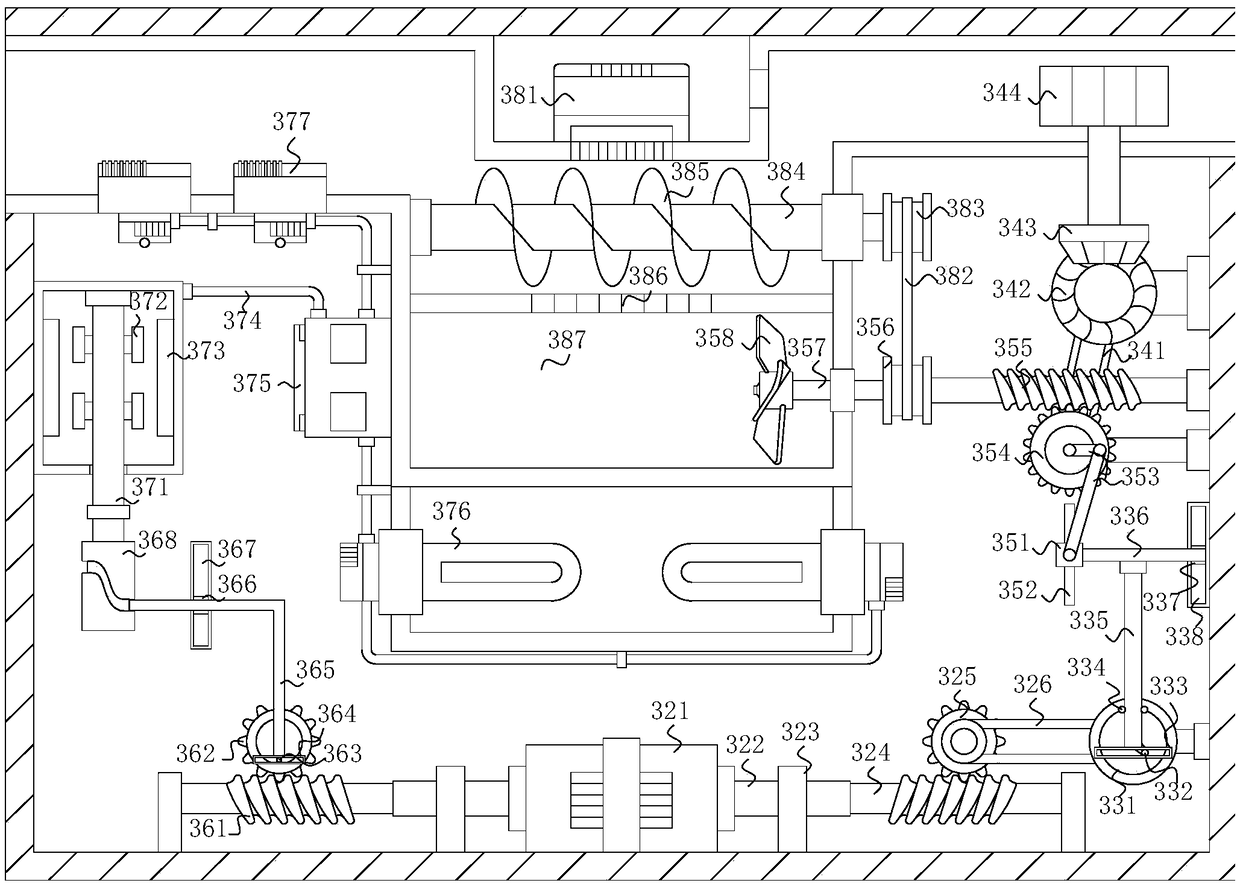

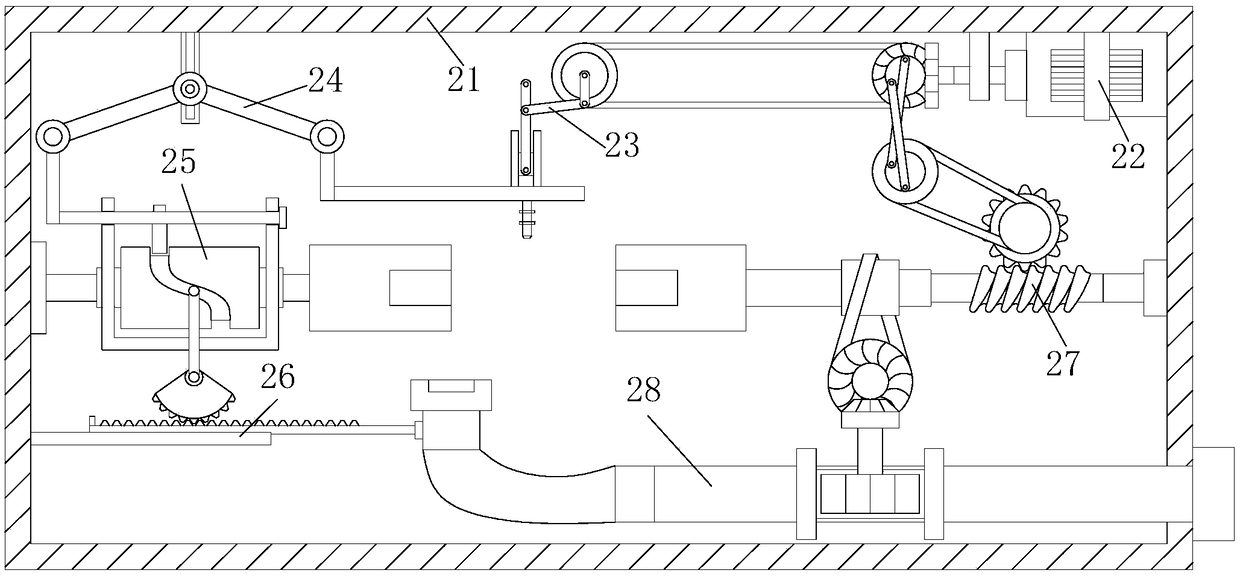

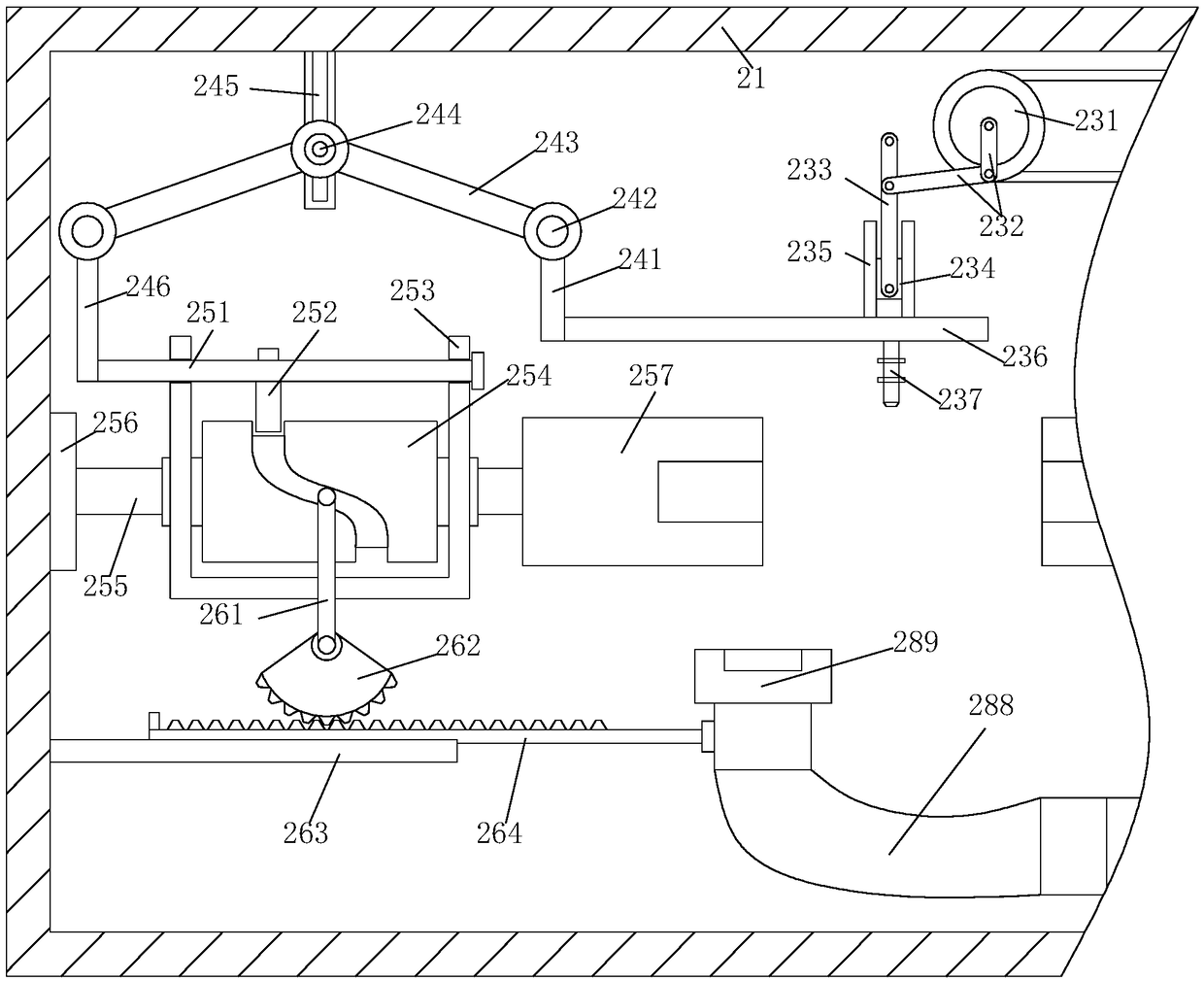

Ecological dredging integrated device

InactiveCN109235520AEasy to handleStir and separate fullySludge treatment by de-watering/drying/thickeningMechanical machines/dredgersEngineeringTherapeutic effect

The invention discloses an ecological dredging integrated device, which structurally comprises a top cover, a handle, a dredging opening, a dredging main machine, a box door and a fixing foot, whereinthe handle is welded at the middle portion of the upper surface of the top cover, the top cover is fixedly arranged at the upper end of the dredging main machine, and the right end of the dredging opening is arranged inside the upper left end of the dredging main machine in an embedding mode; the front surface of the dredging main machine is provided with the box door, four fixing feet are arranged in total and the upper ends of the four fixing feet are welded to the bottom four corners of the dredging main machine, the power generated by power mechanism enables a dredging mechanism to extract silt, and the silt is extracted to a screening mechanism for screening, so that the silt particles are distinguished and the treatment effect is better, while large particles fall into a sedimentation tank, small particles enter the mixing separation mechanism for fully mixing and separating and then enter the sedimentation tank; the silt in the sedimentation tank is precipitated through the dosing treatment by a dosing mechanism and the clear water is discharged through a drainage mechanism, and then the silt is dried through a drying mechanism.

Owner:深圳鑫安满金融服务有限公司

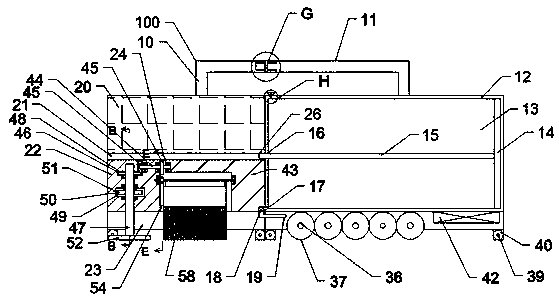

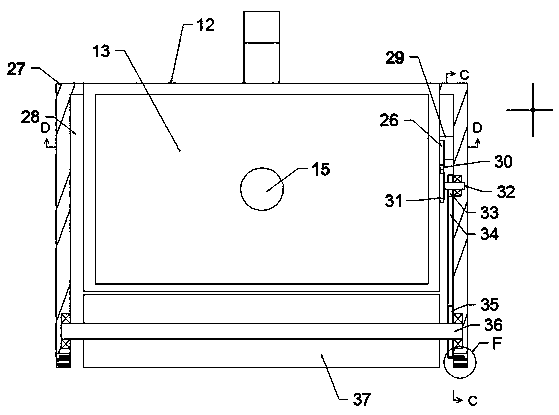

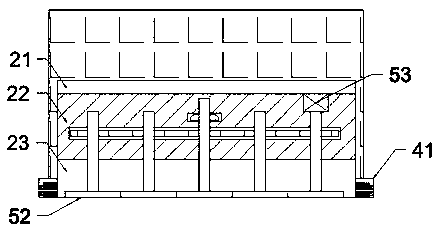

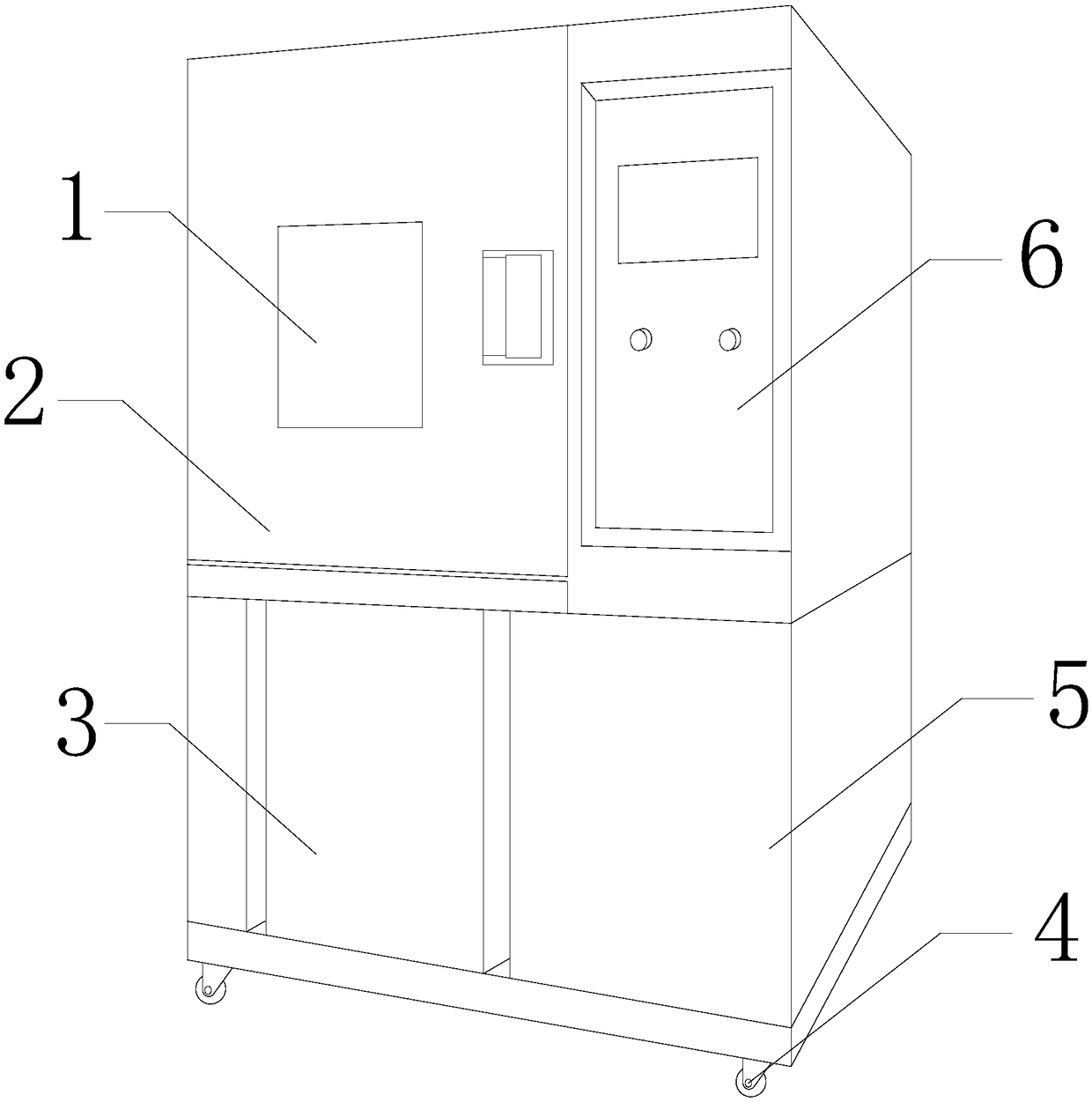

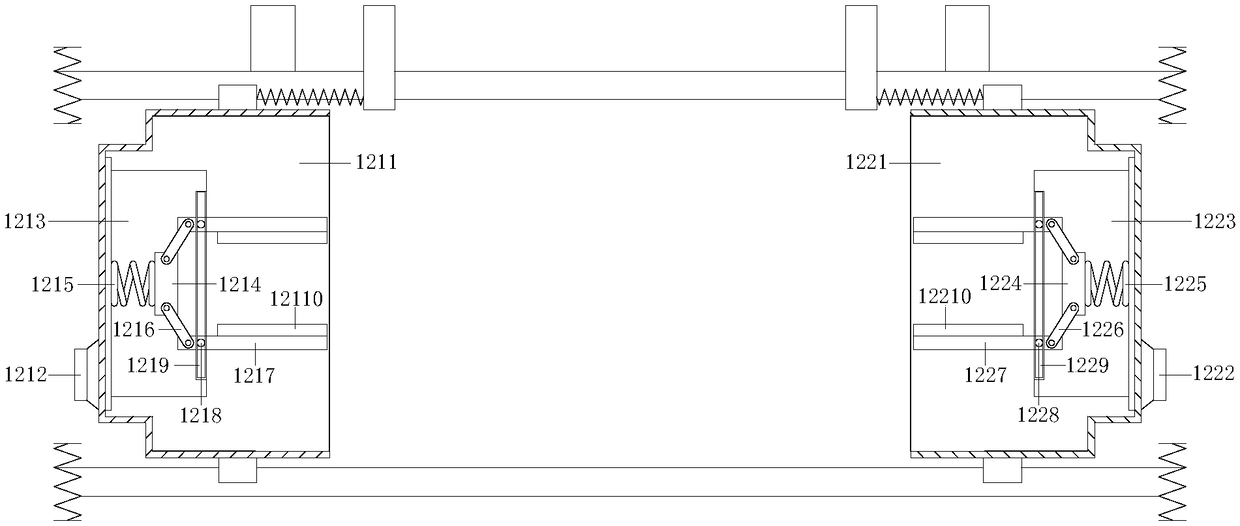

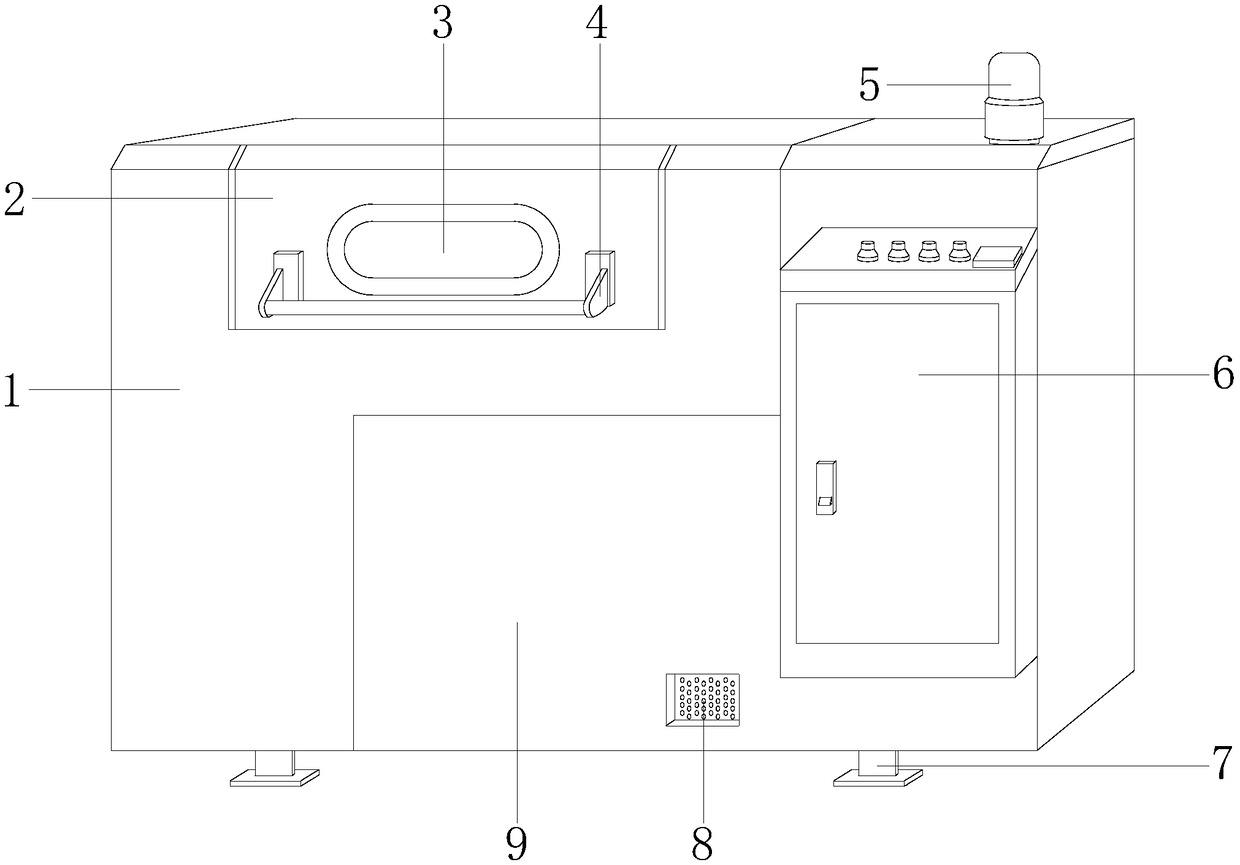

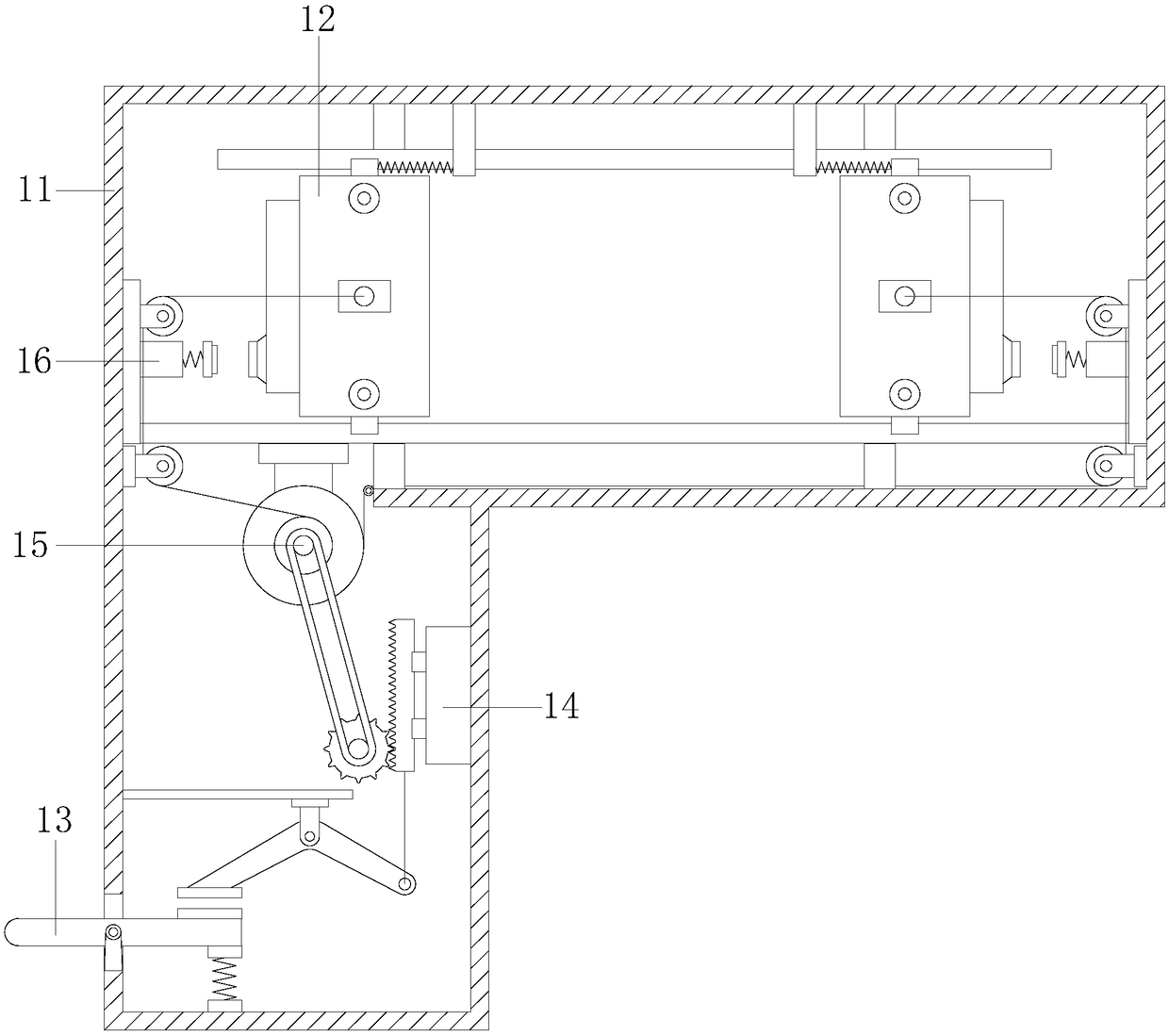

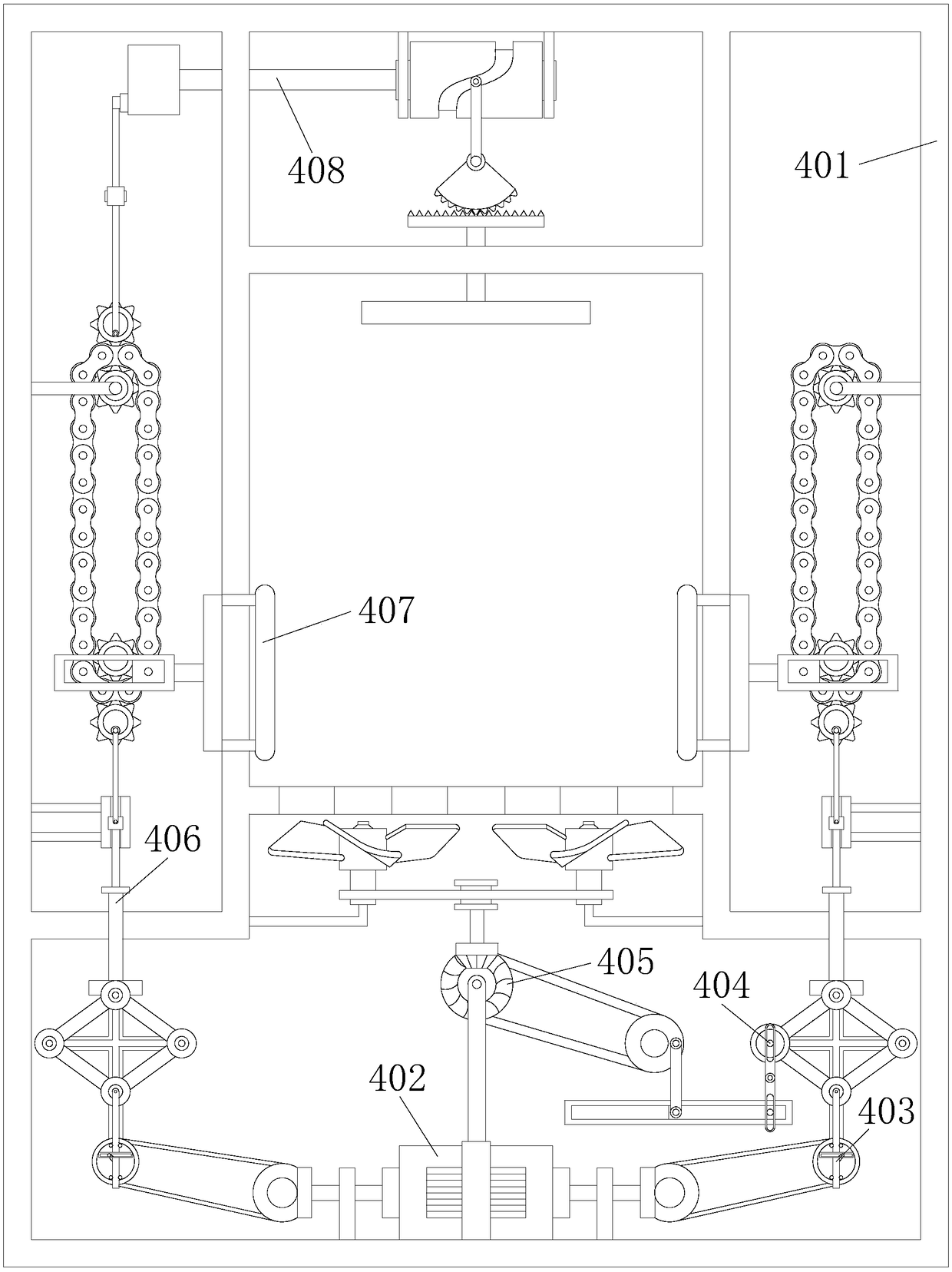

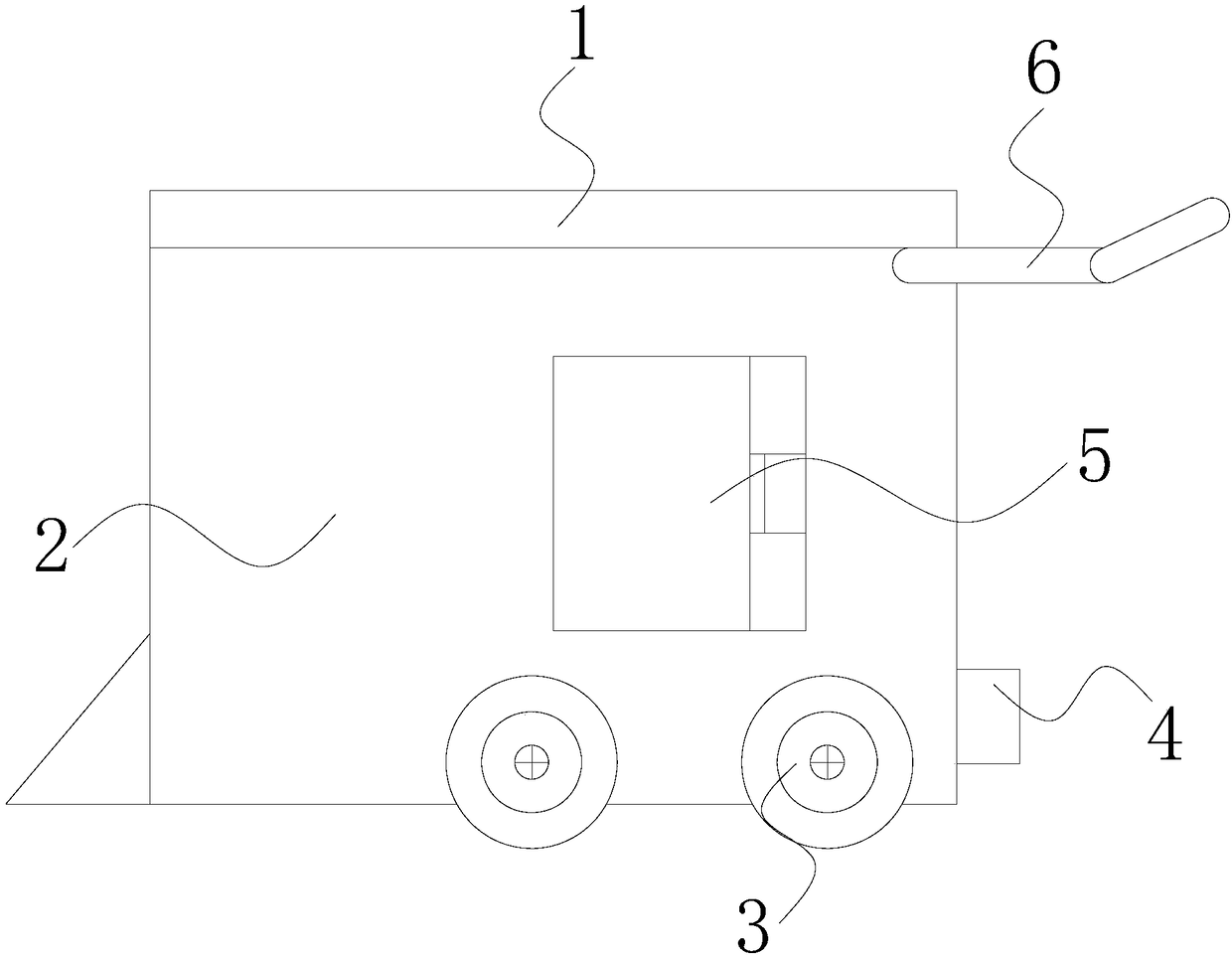

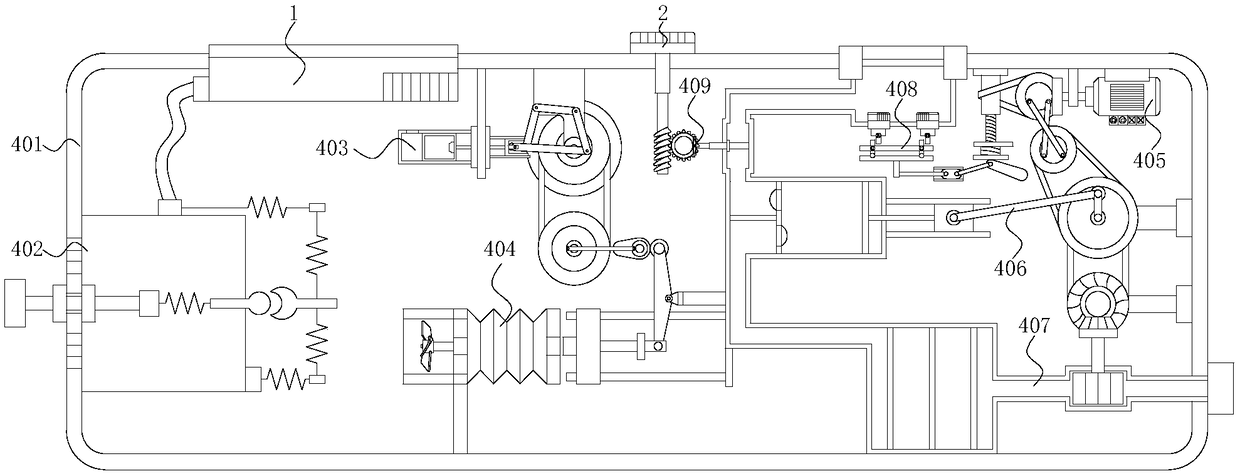

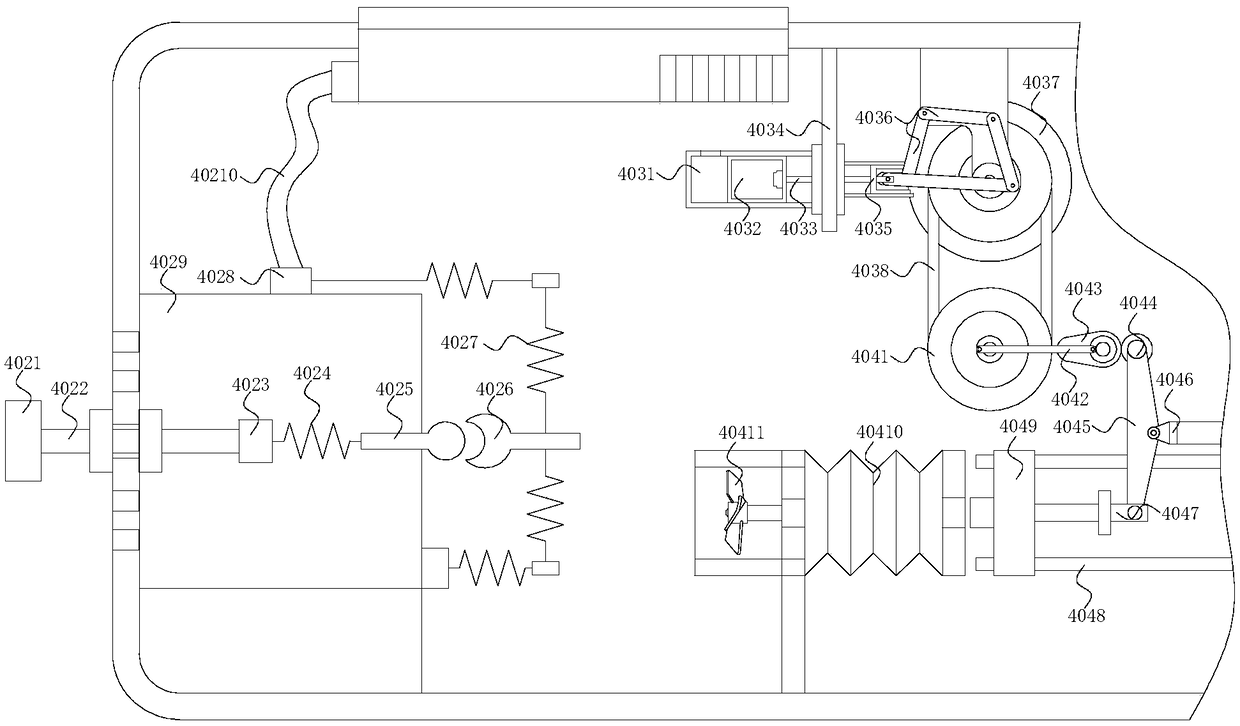

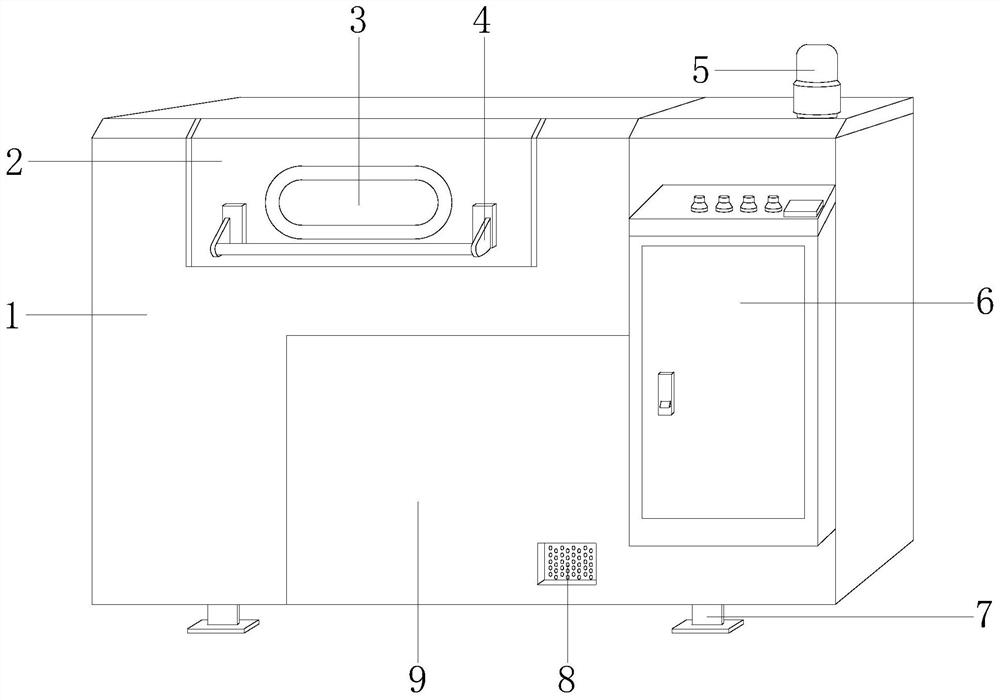

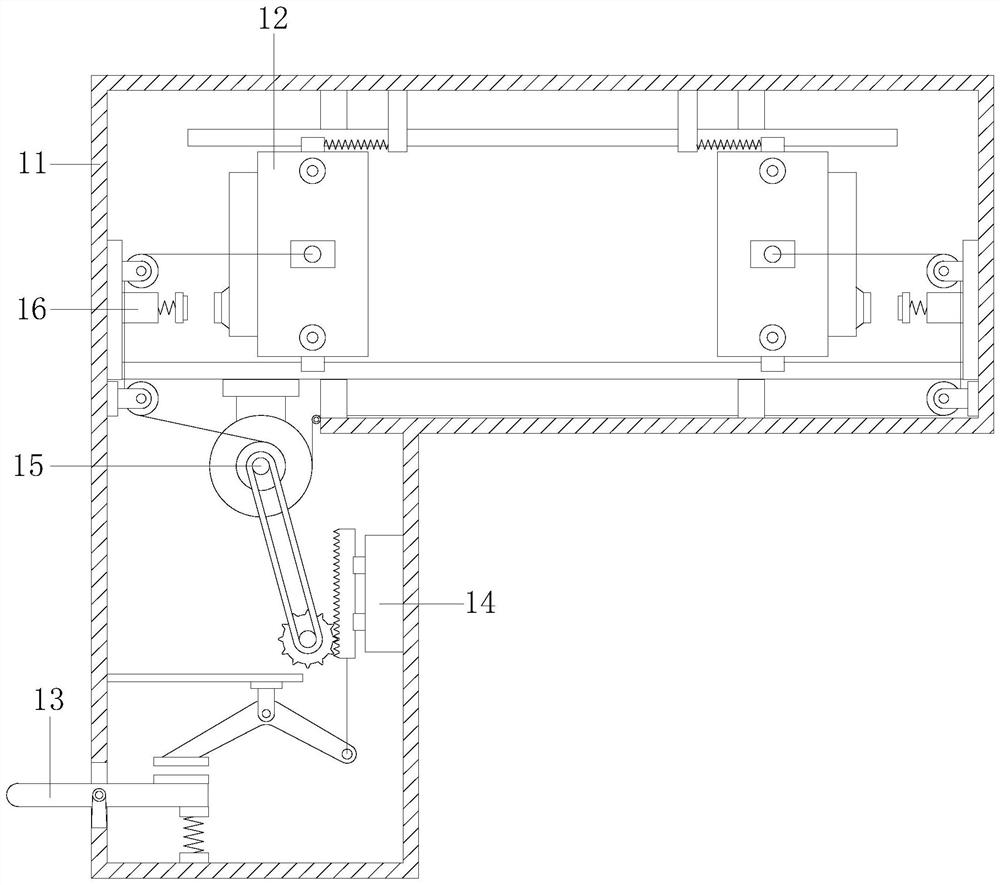

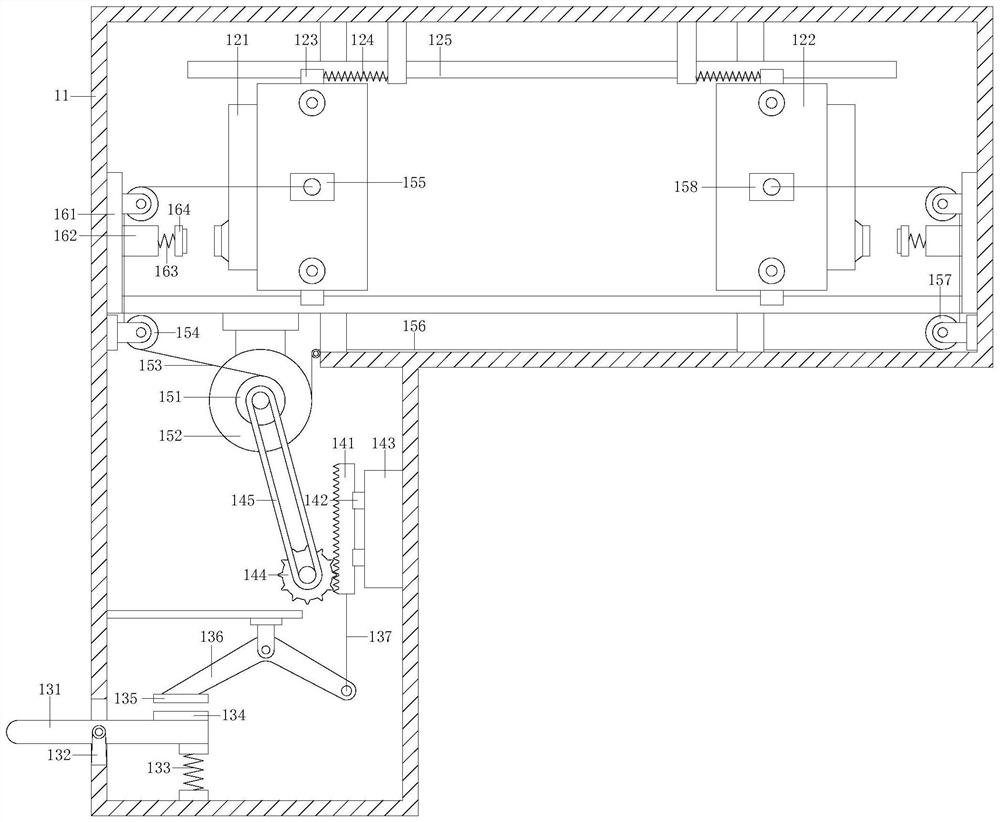

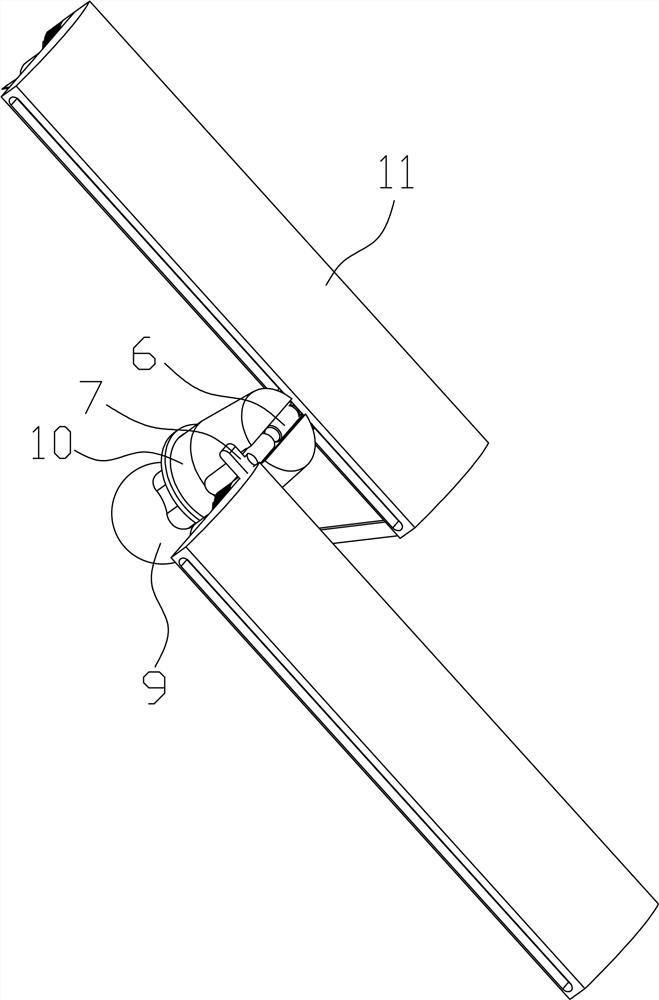

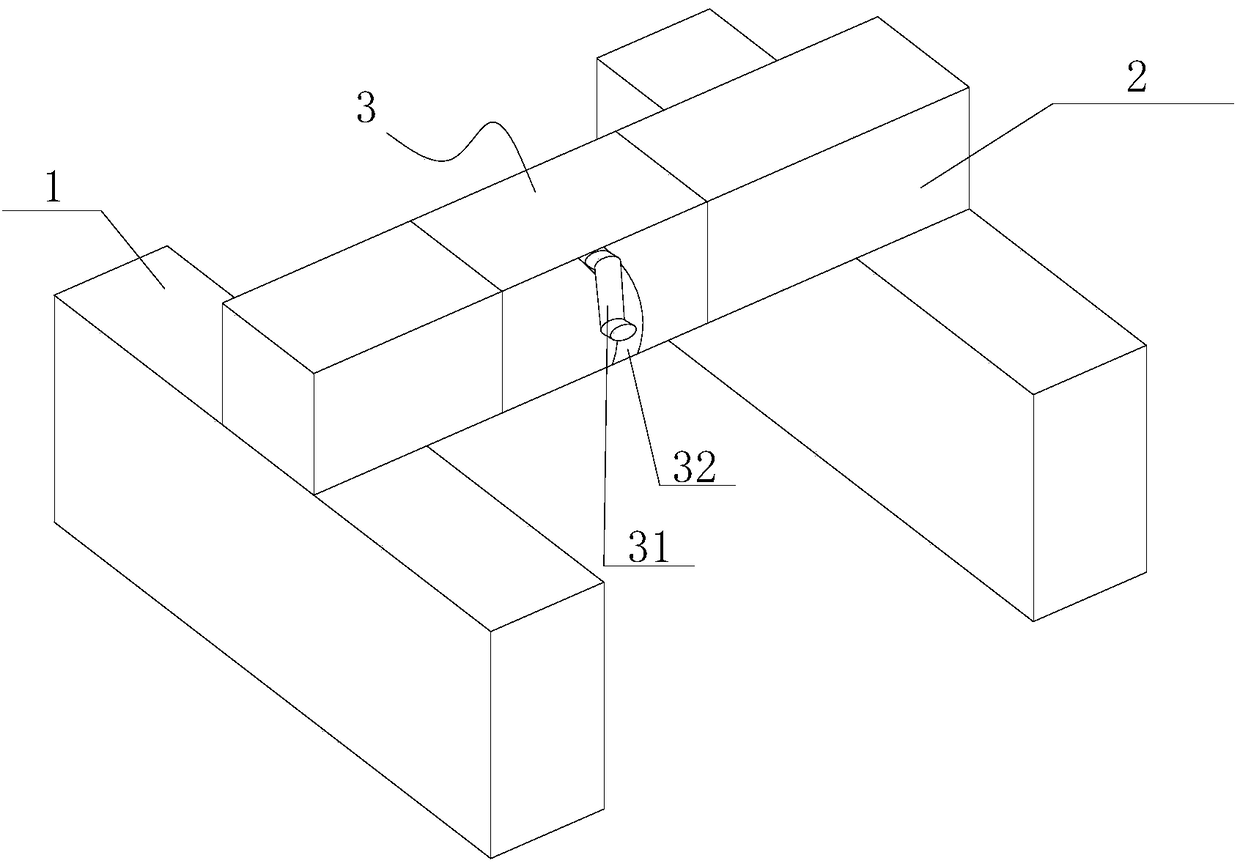

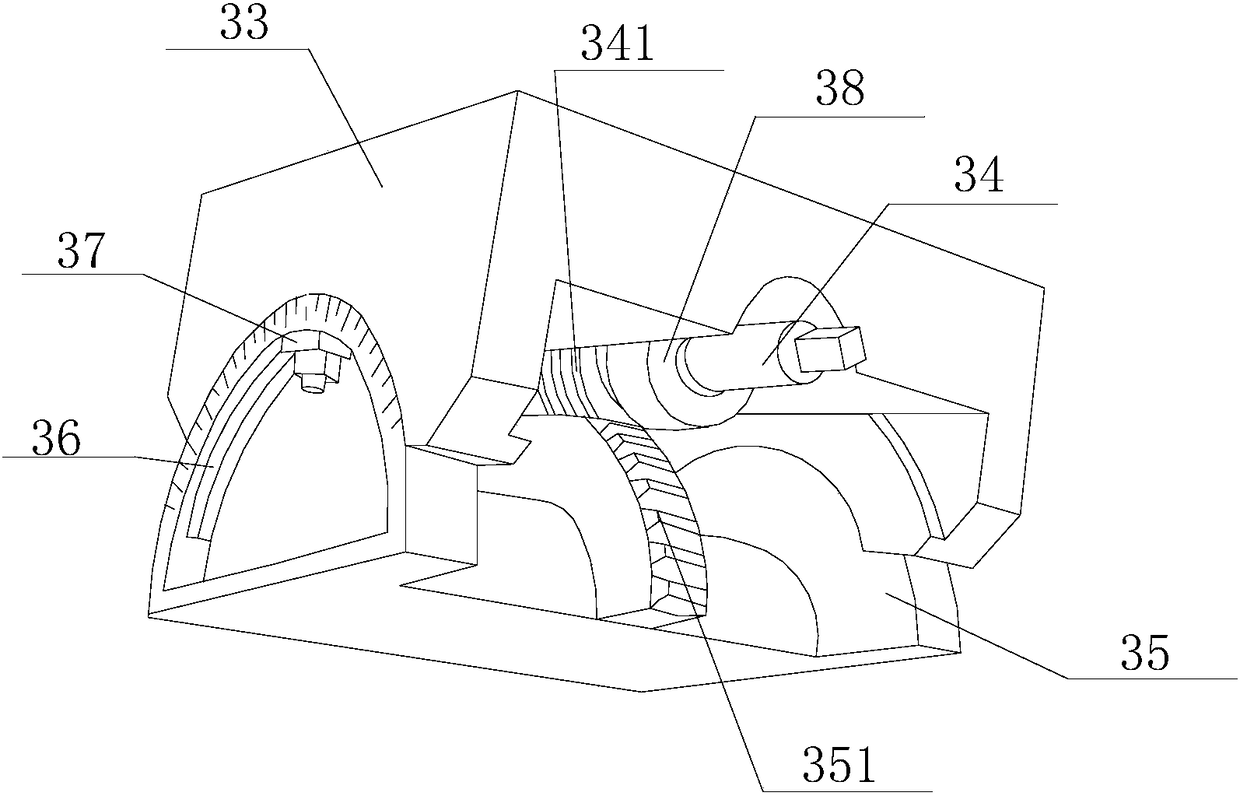

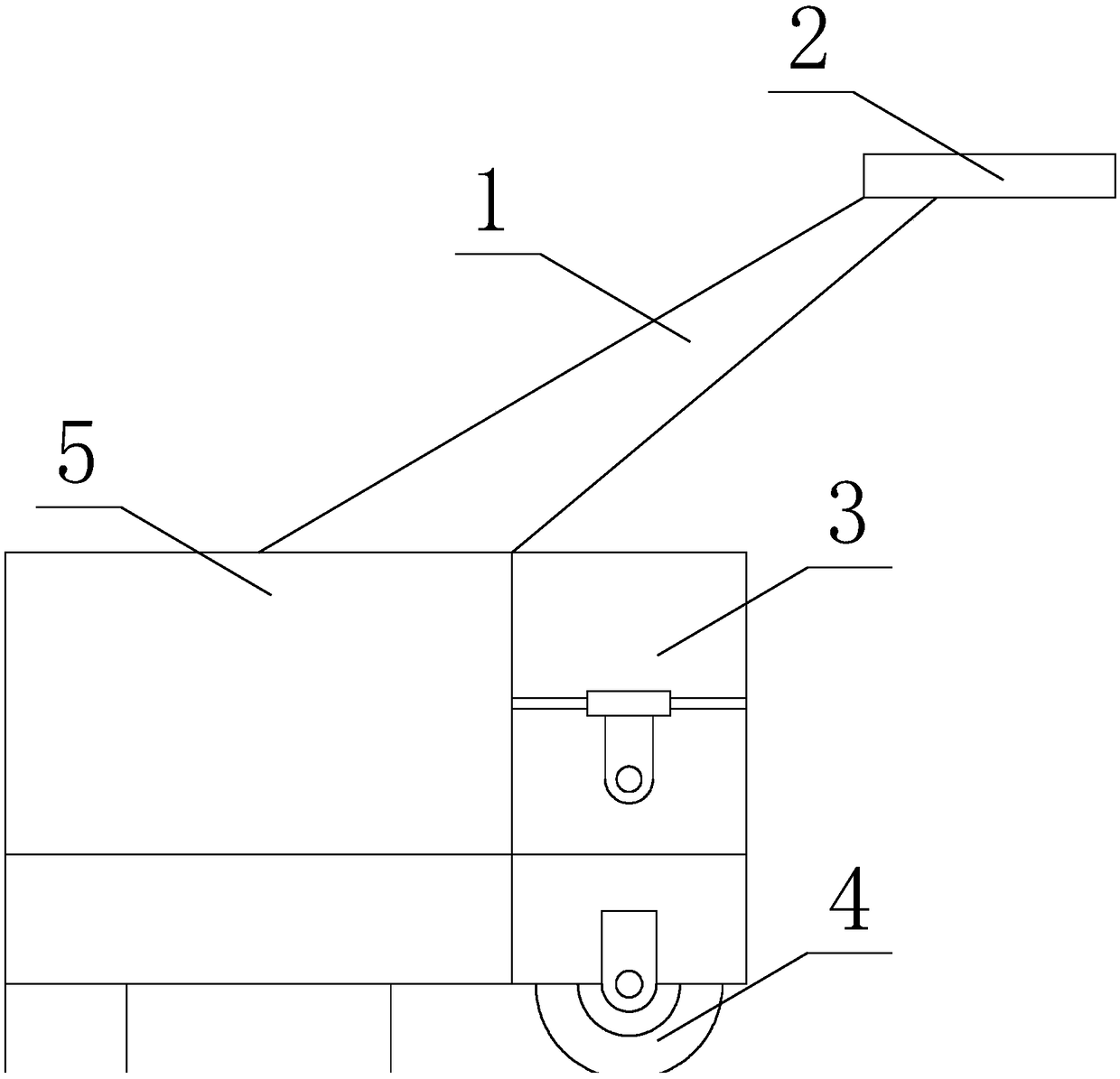

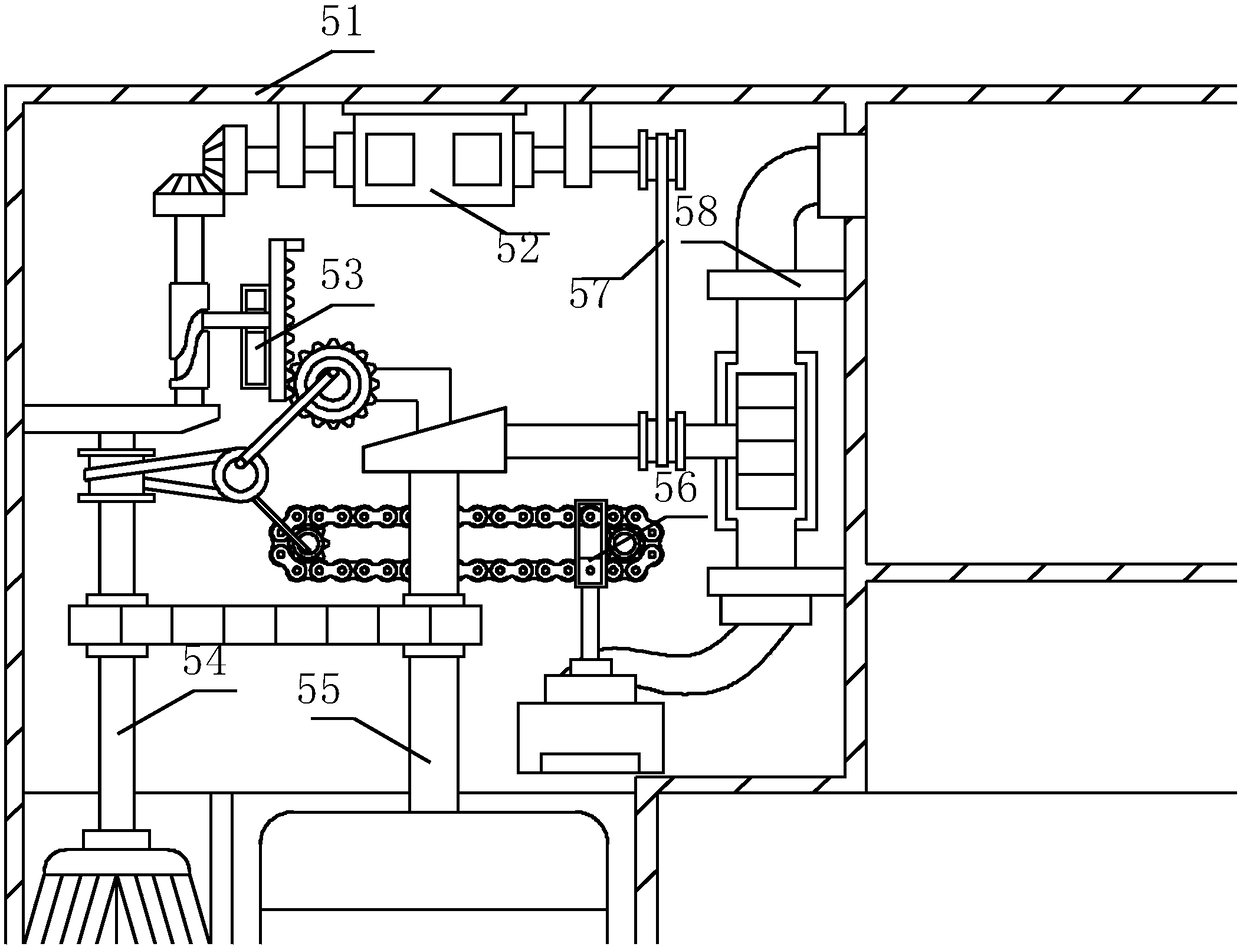

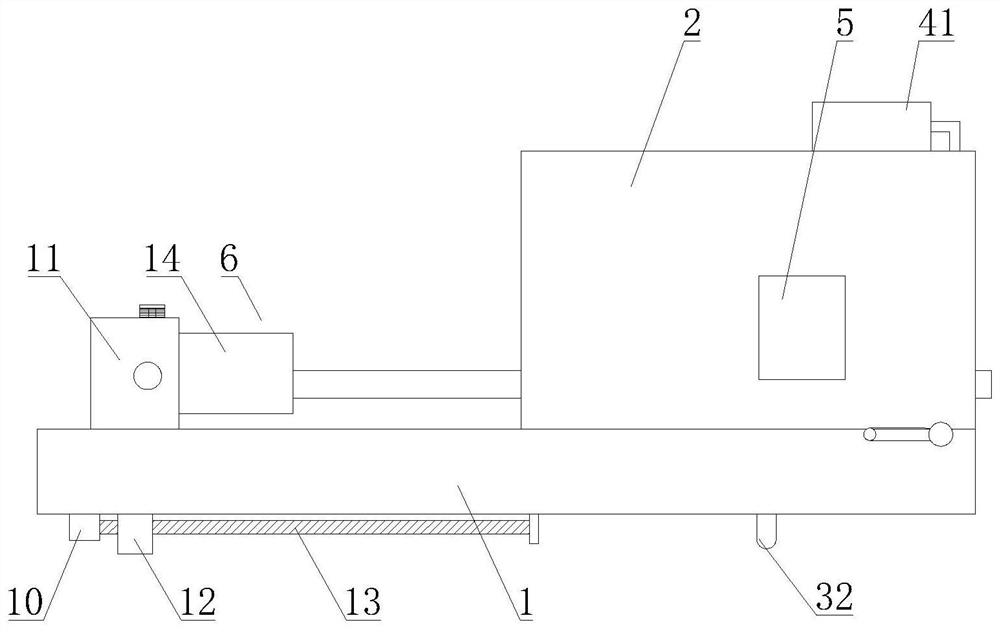

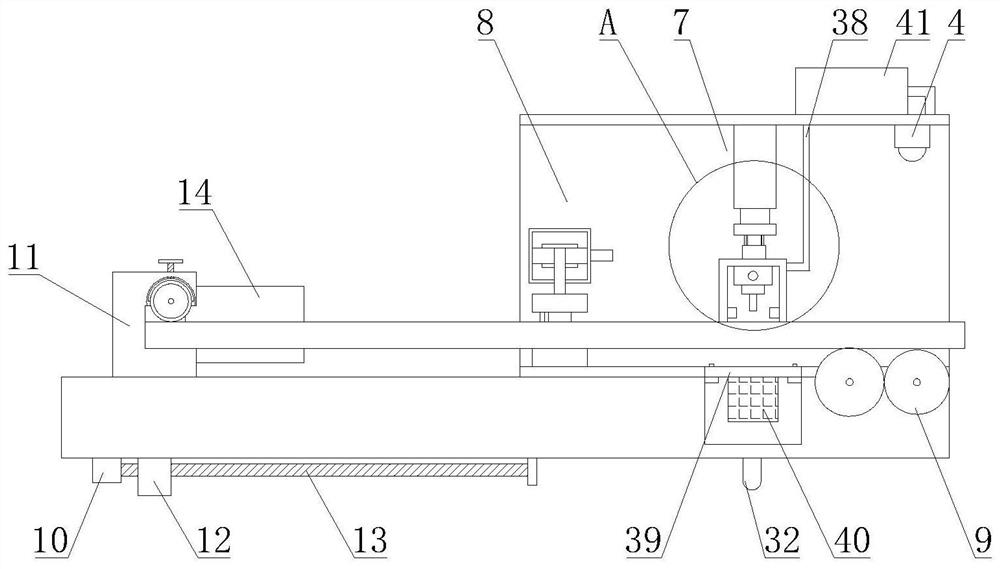

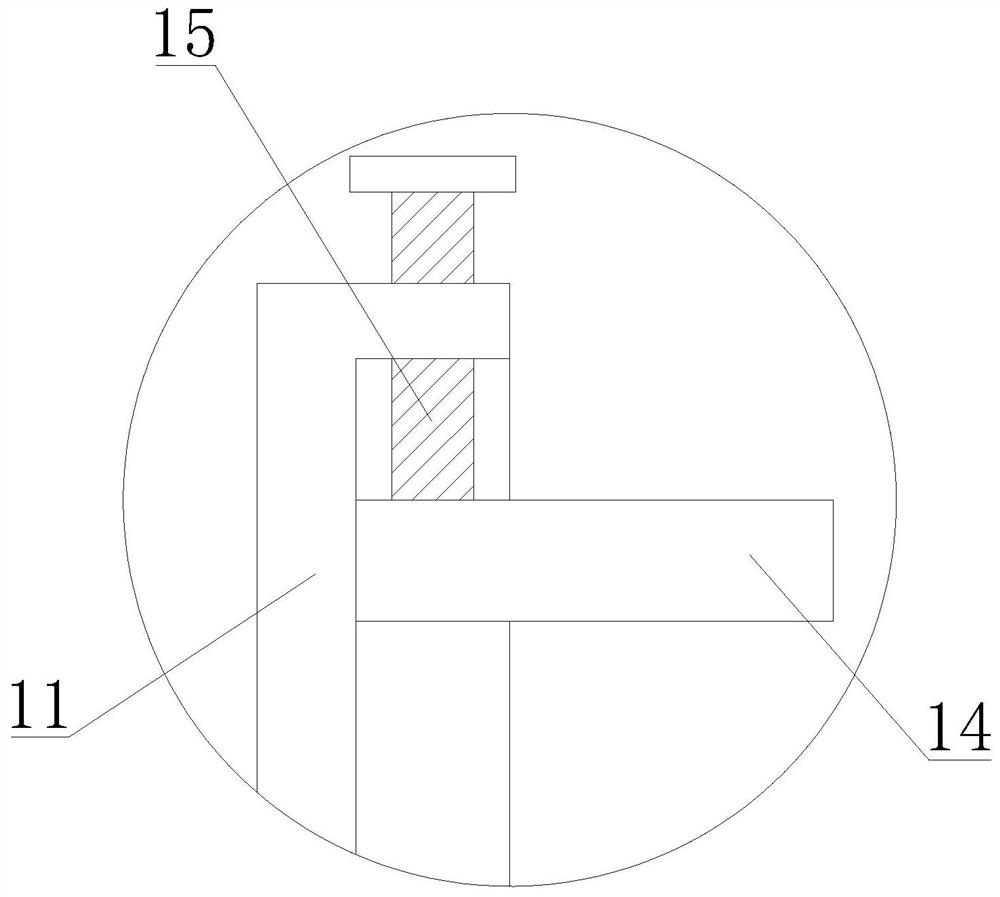

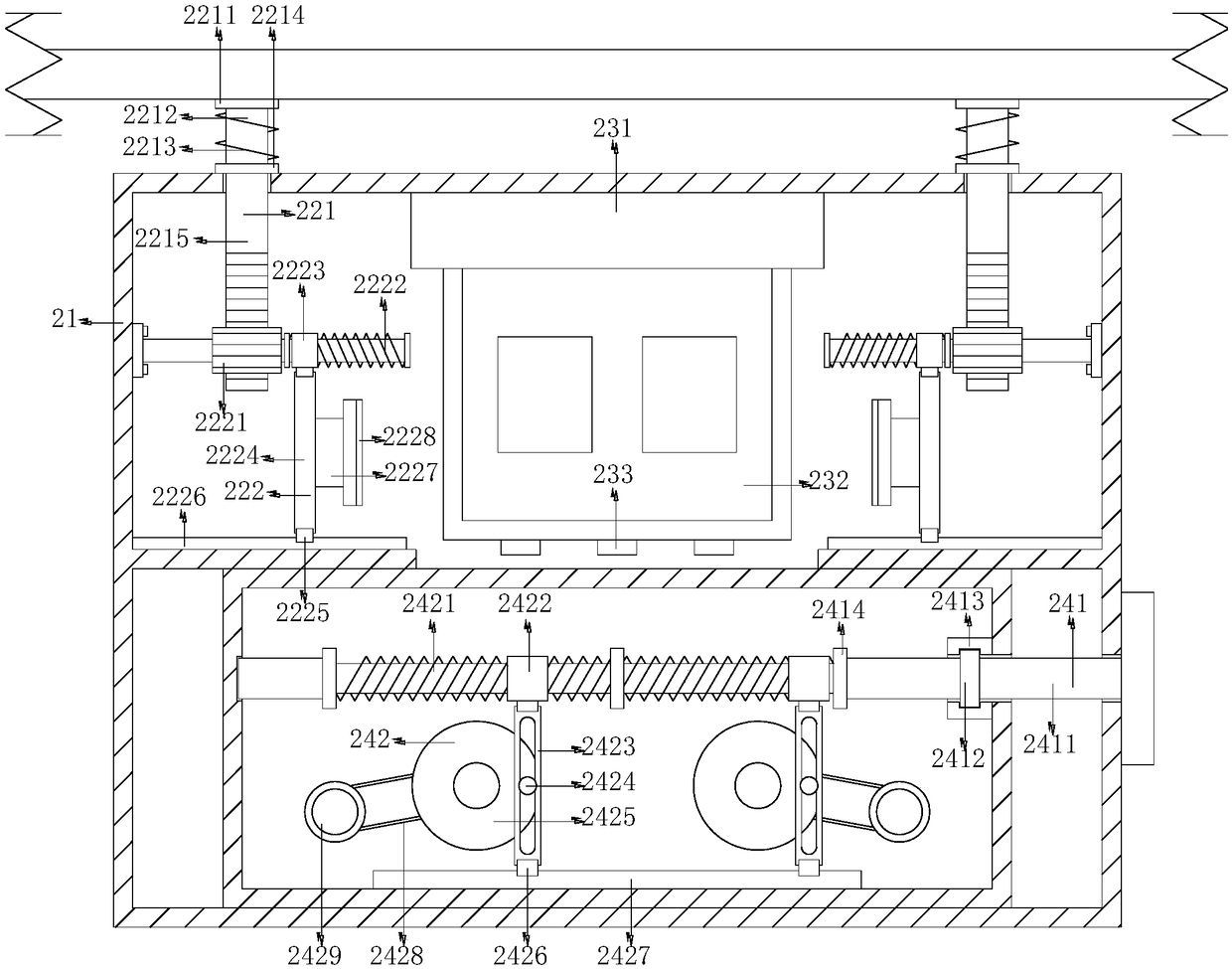

Cable conductor continuous stranding and drawing forming device

ActiveCN109461539AAvoid loweringGuaranteed movement trackCable/conductor manufactureElectrical conductorEngineering

The present invention discloses a cable conductor continuous stranding and drawing forming device. The structure of the device comprises a stranding main body, a box door, a window, a handle, a warning light, a console, a support leg, a heat dissipation hole and a device base. The top of the stranding main body is fixedly provided with the box door; the window is embedded on the front surface of the box door; the handle is fixedly mounted on the box door; the window is located directly above the handle; and the warning light is fixedly mounted on the top of the device base. The first end and the last end of a bare conductor are clamped by using a first fixed stranding mechanism and a tail fixed stranding mechanism, and the clamping force is increased; the first fixed stranding mechanism and the tail fixed stranding mechanism are driven by using a foot mechanism to draw the bare conductor; after drawing, the first fixed stranding mechanism and the tail fixed stranding mechanism are automatically enabled by using a touch mechanism to perform the reverse stranding operation, and the stranding speed is accelerated; and the worker can perform the cable stranding work without opening theswitch on the stranding mechanism, and the operation is more convenient.

Owner:安徽新信电气有限公司

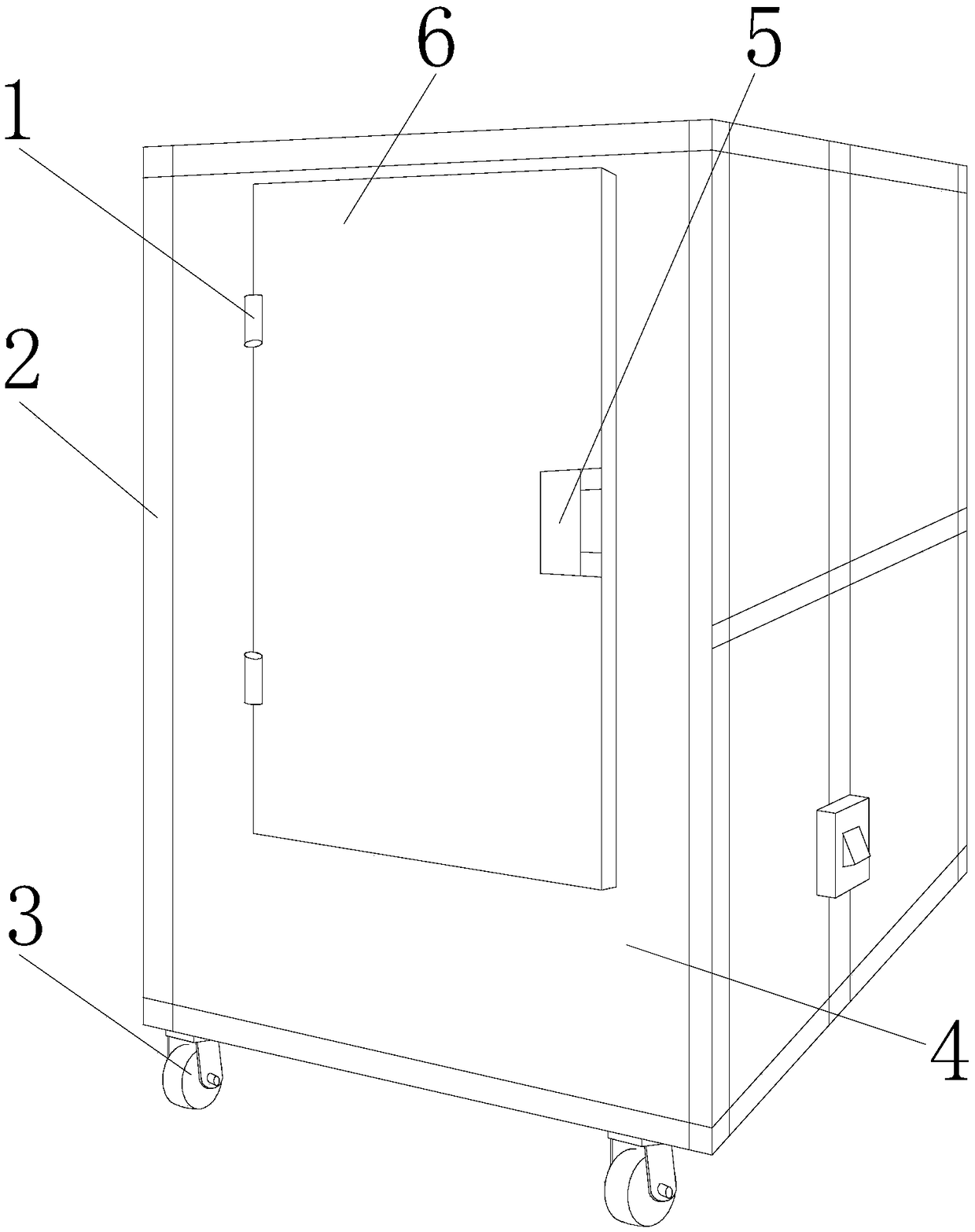

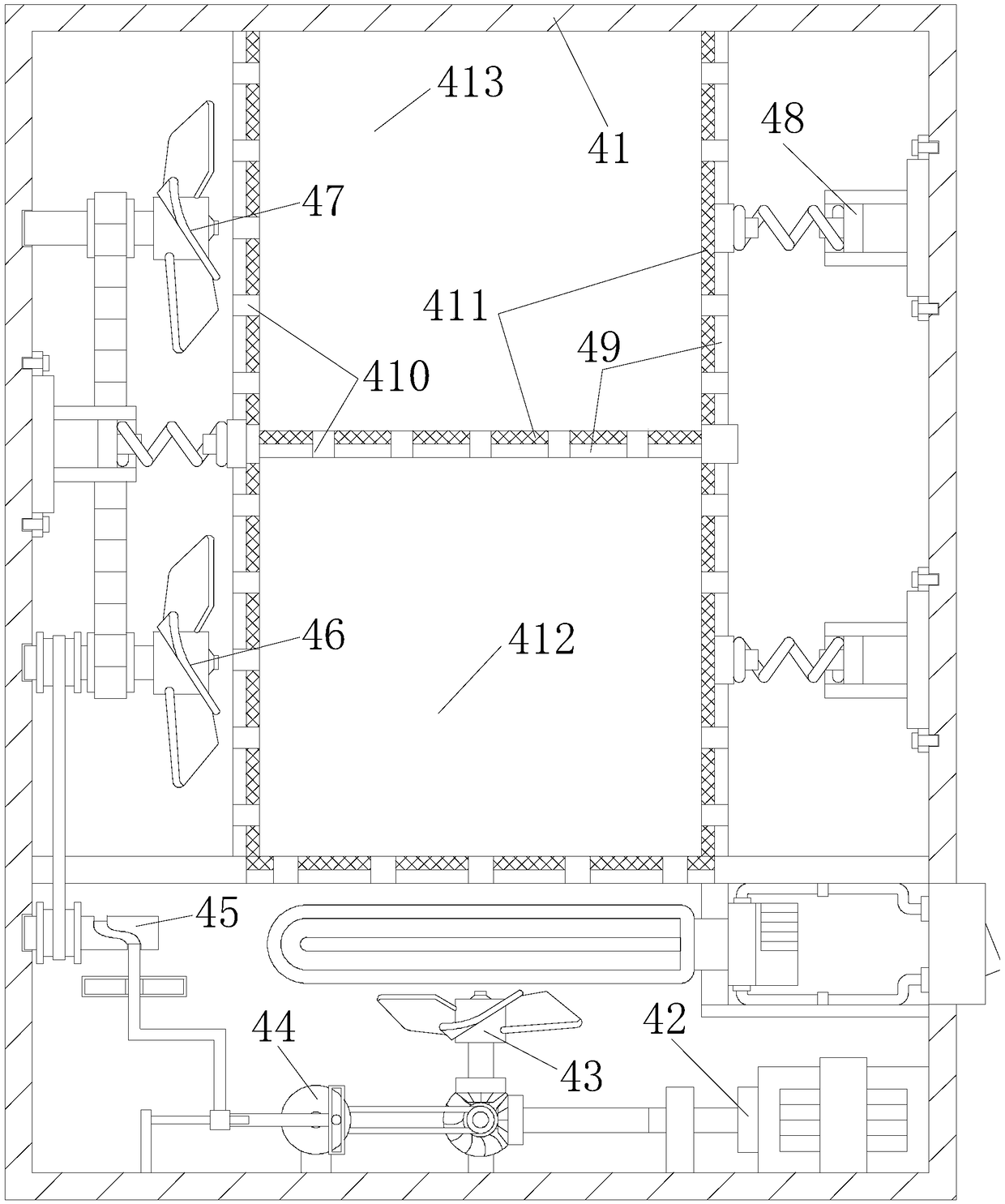

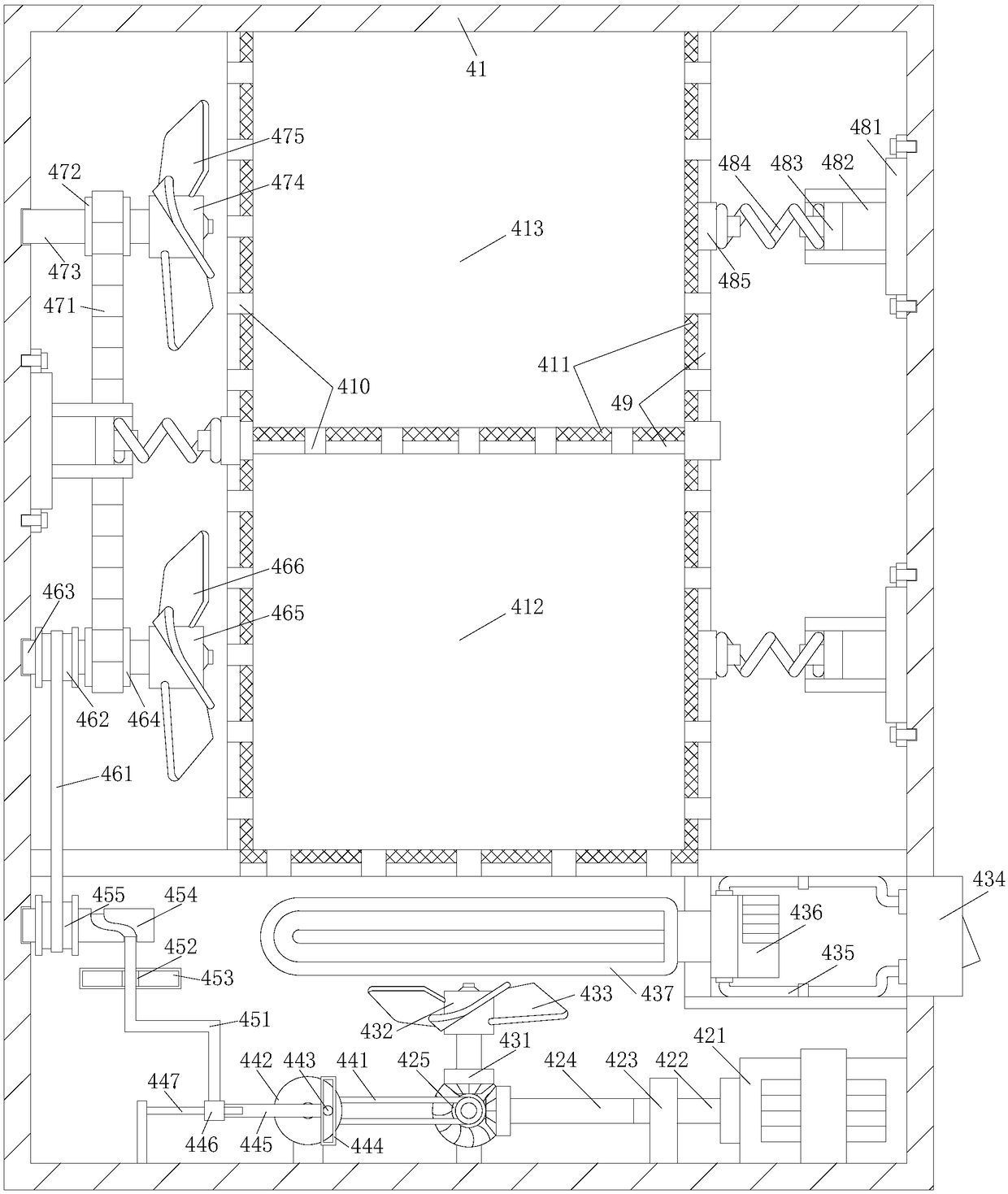

Heat preservation type logistic trolley

InactiveCN109050592AInhibit mildewAvoid spoilageVentilationHand carts with multiple axesEngineeringFan blade

The invention discloses aheat preservation type logistic trolley. , The structure comprises a hinge, Collision strips, moving wheels, trolley body, Handles, case doors, the hinge is weld to that leftend of the front surface of the trolley body, Anti-collision strip are fixedly installed around that trolley body, Four move wheels are arrange in total and fixedly mounted at four corners of that trolley body, in summer, the first heat dissipation mechanism and the second heat dissipation mechanism dissipate the heat of the goods in the first storage chamber and the second storage chamber, Each storage compartment has its own heat dissipation capability, improve cooling effective, to prevent moldy goods, the controller on the blowing mechanism is turned on in winter so that the heating rod isheated, Then, heat energy is transferred to the first storage room and the second storage room through the blowing fan blades to heat preservation of the goods, so as to prevent the goods from deteriorating and achieve the effect of warming in winter and cooling in summer. When collision occurs in the transportation process, the goods are protected by a vibration damping mechanism and an anti-collision cushion to prevent the goods from being damaged.

Owner:吴铁城

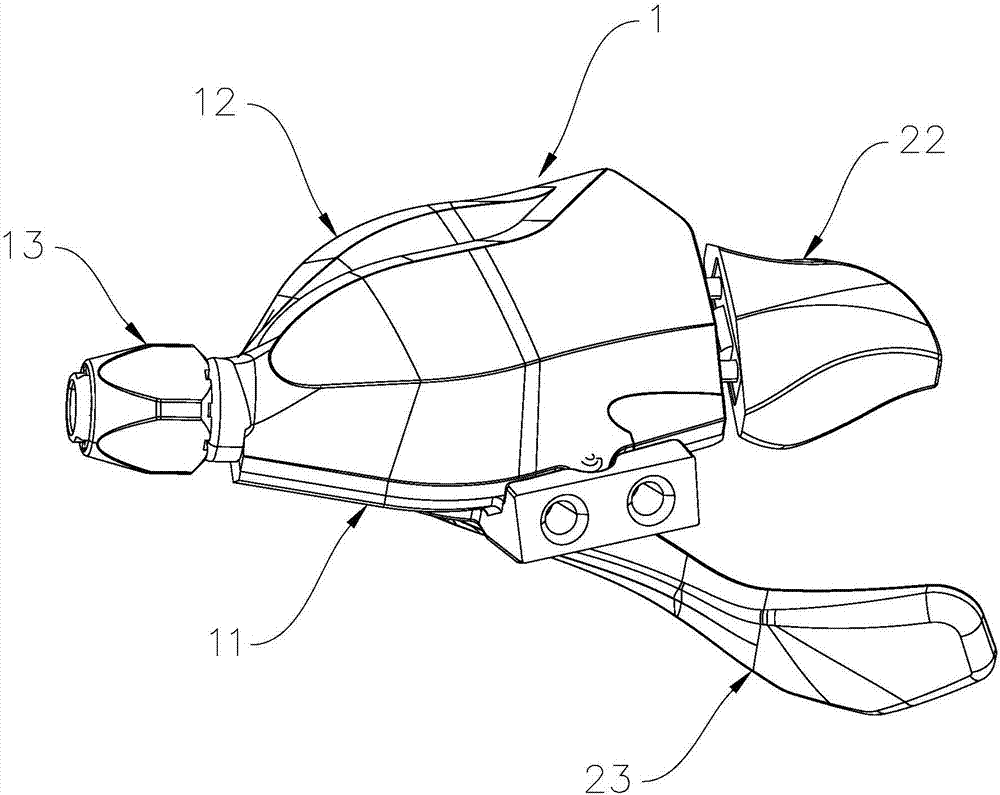

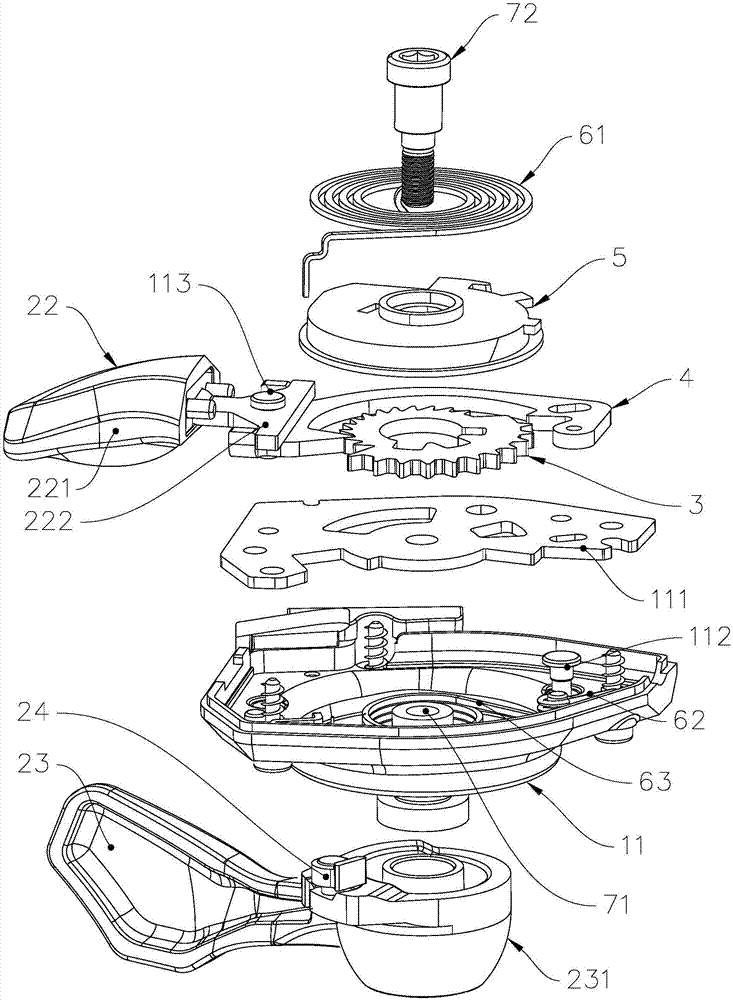

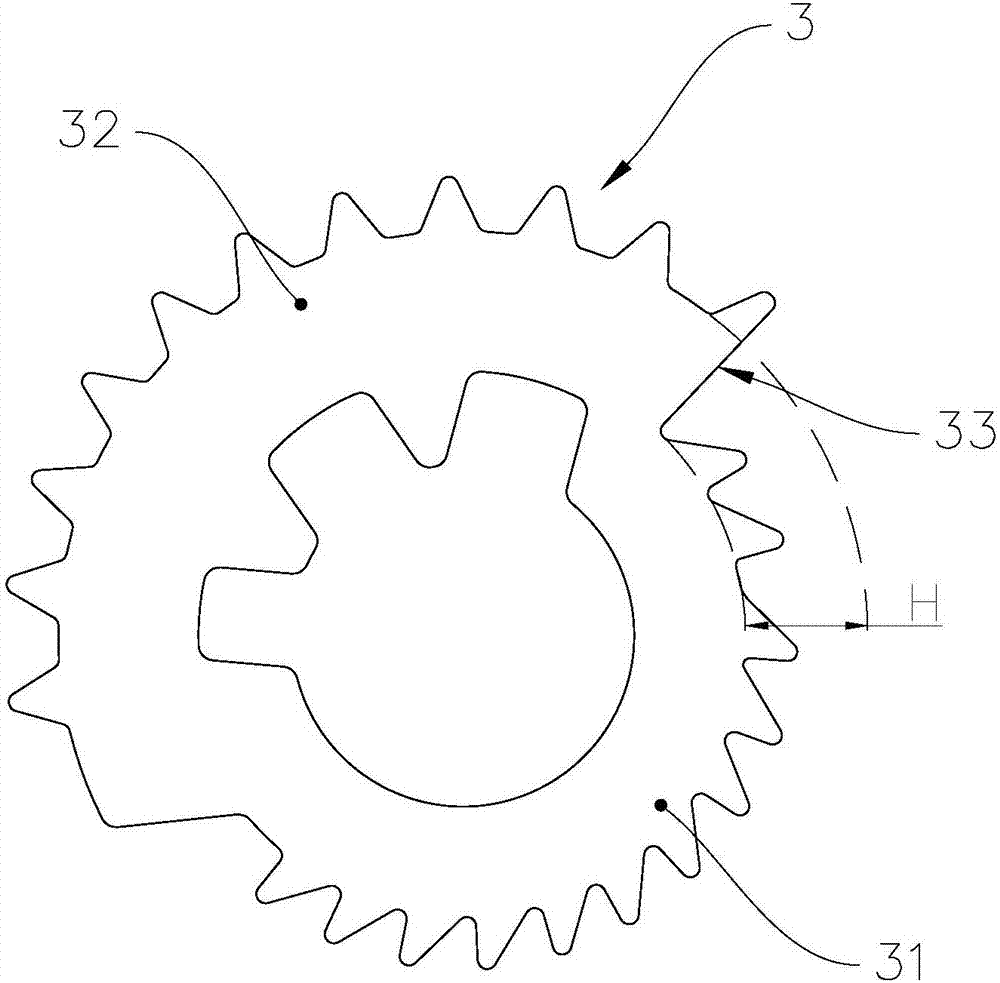

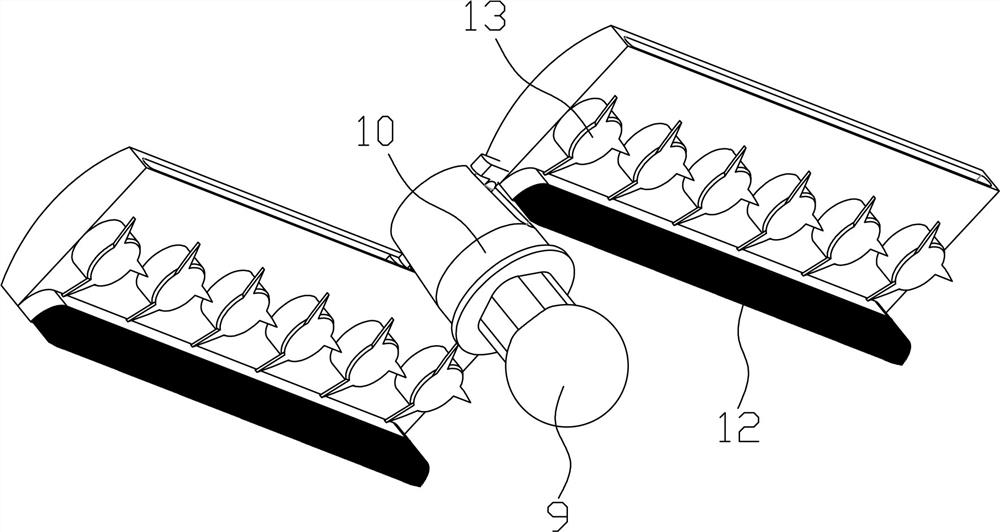

Bicycle shifter

The invention discloses a bicycle shifter. The bicycle shifter comprises a base member, a shift up assembly, a pawl member and a ratchet member; the ratchet member is located on the base member and rotates along a first rotating shaft; the shift up assembly can abut against the ratchet member; the ratchet member is surrounded by a detent ratchet group and an intercept ratchet group; the pawl member comprises a connecting part, a detent pawl and an intercept pawl, and the detent pawl and the intercept pawl are fixed to both ends of the connecting part correspondingly; the pawl member slides between a first position and a second position of the base member, when the pawl member is in the first position, the detent pawl is matched with a shift up ratchet, and the intercept pawl is separated from a shift down ratchet; and when the pawl member is in the second position, the intercept pawl is matched with the shift down ratchet, and the detent pawl is separated from the shift up ratchet, a fracture surface is formed between the detent ratchet group and the intercept ratchet group, and the shift up assembly can abut against the fracture surface. Driving members are fewer, the coordinate precision among the members is improved, the position precision of the members is improved, and the anti-gear slipping effect is better.

Owner:ZHUHAI L-TWOO SPORT TECH CO LTD

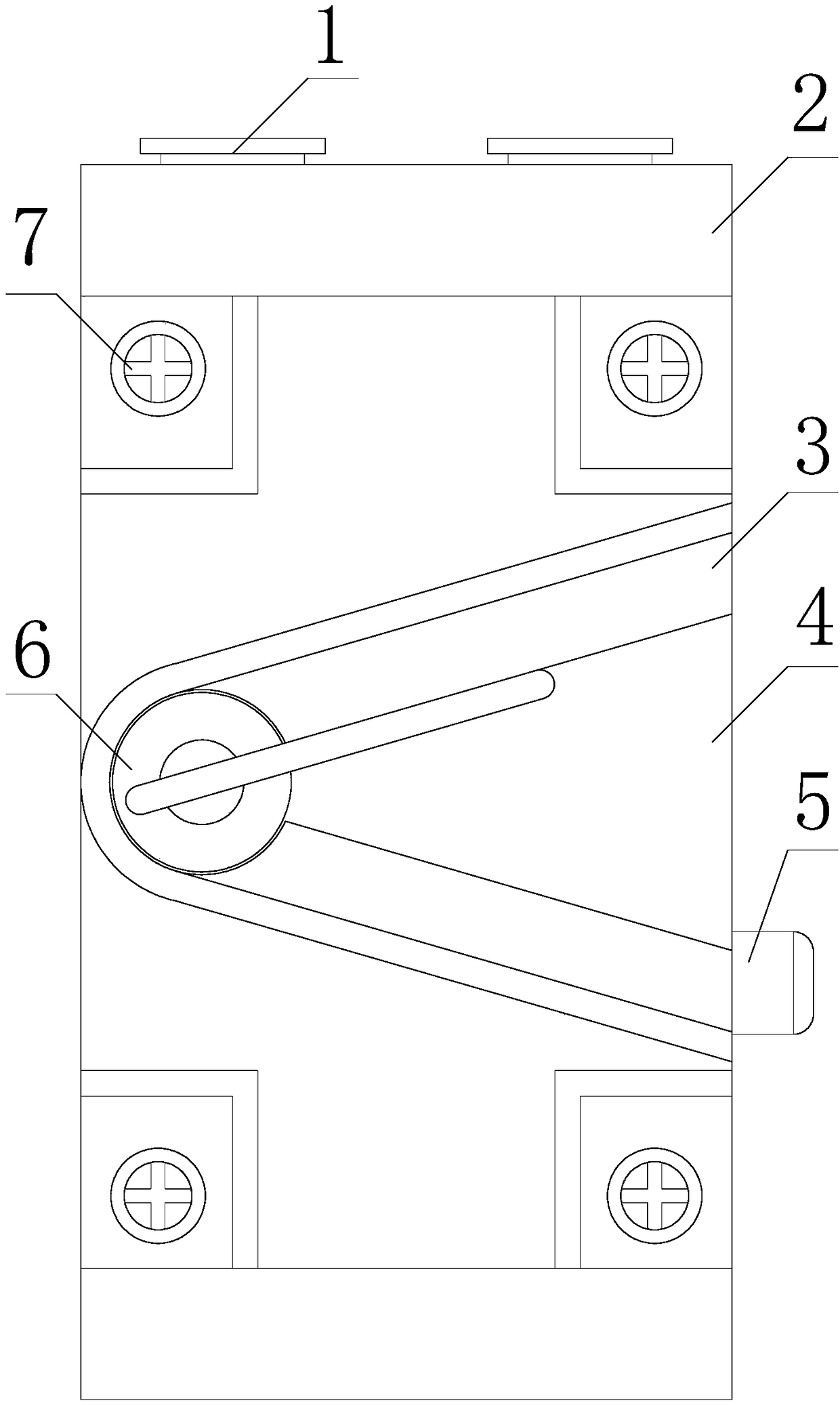

Safety switch device for turning on and safely cutting off electric load

The invention discloses a safety switch device for turning on and safely cutting off an electric load, which comprises a connecting block, a mounting seat, a limit plate, a safety switch main body, anemergency cut button, a turning-on switch and a screw. The lower end of the connecting block is installed inside the mounting seat, the lower surface of the mounting seat is fitted to the upper surface of the safety switch main body, and the limit plate is welded to the front surface of the safety switch main body. The operation of the driving mechanism drives the turning-on mechanism to work, and the turning-on mechanism is responsible for turning on the electric load; at the same time, a heat dissipation mechanism is electrically operated to dissipate the heat of a turning-on element on theturning-on mechanism to ensure the normal operation of the turning-on mechanism; at this time, a power mechanism is also powered, so that a moisture-proof mechanism works to supply air to the structure inside the main body housing and prevent the structure from being damp; the dust inside the structure is also blown away to prevent the dust inside the switch from increasing, so that the safety switch can be used normally.

Owner:中通服节能技术服务有限公司

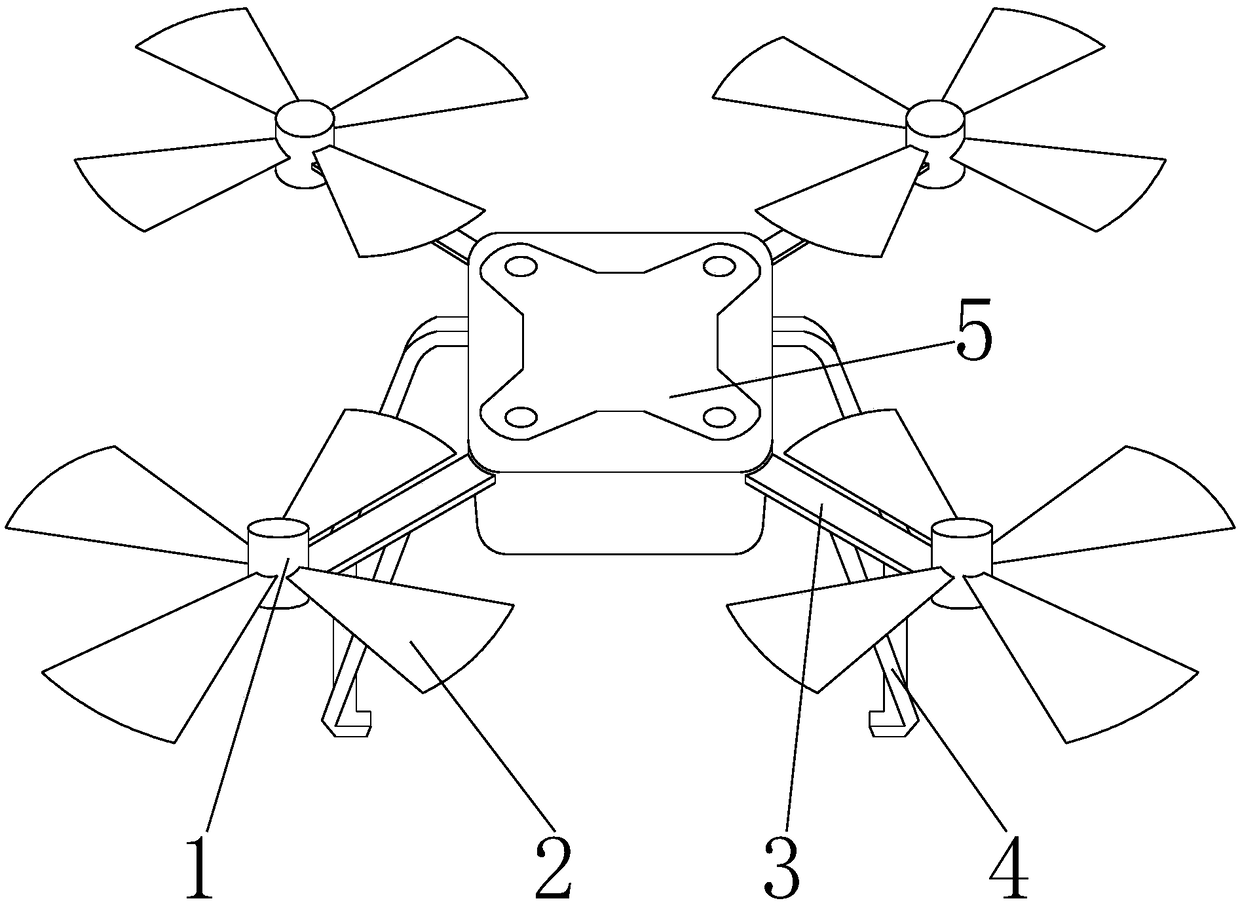

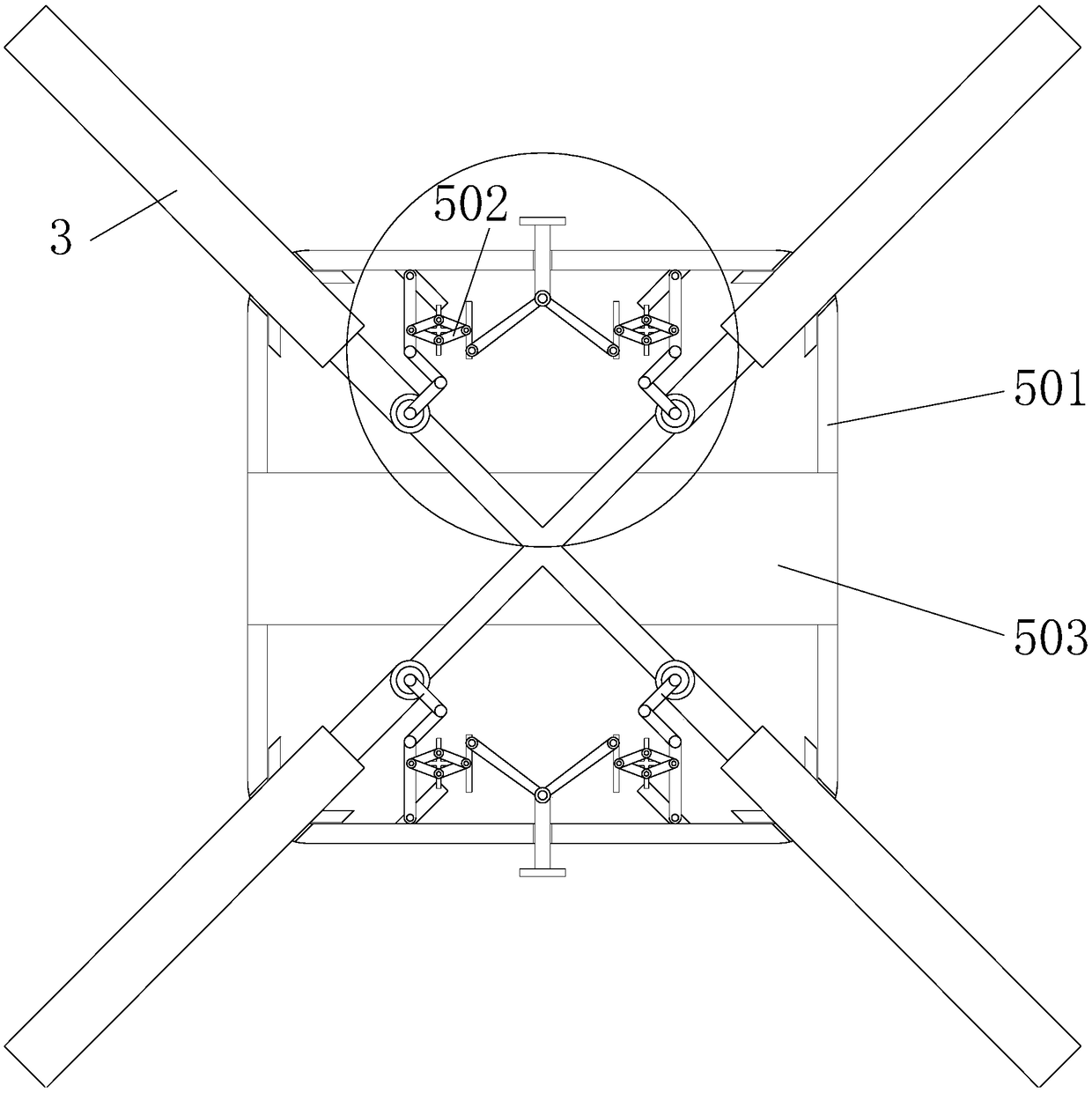

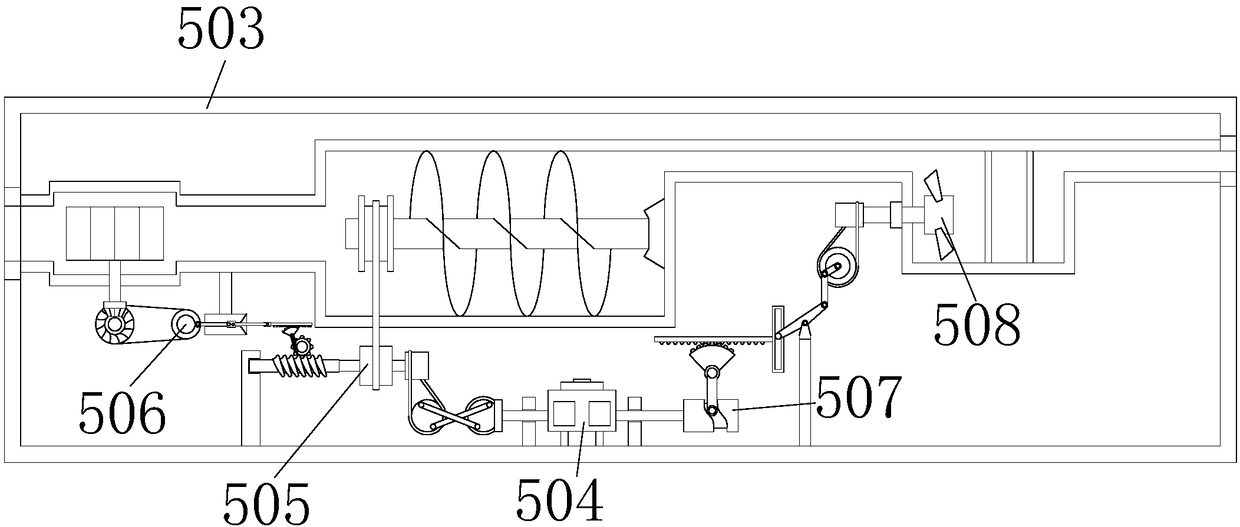

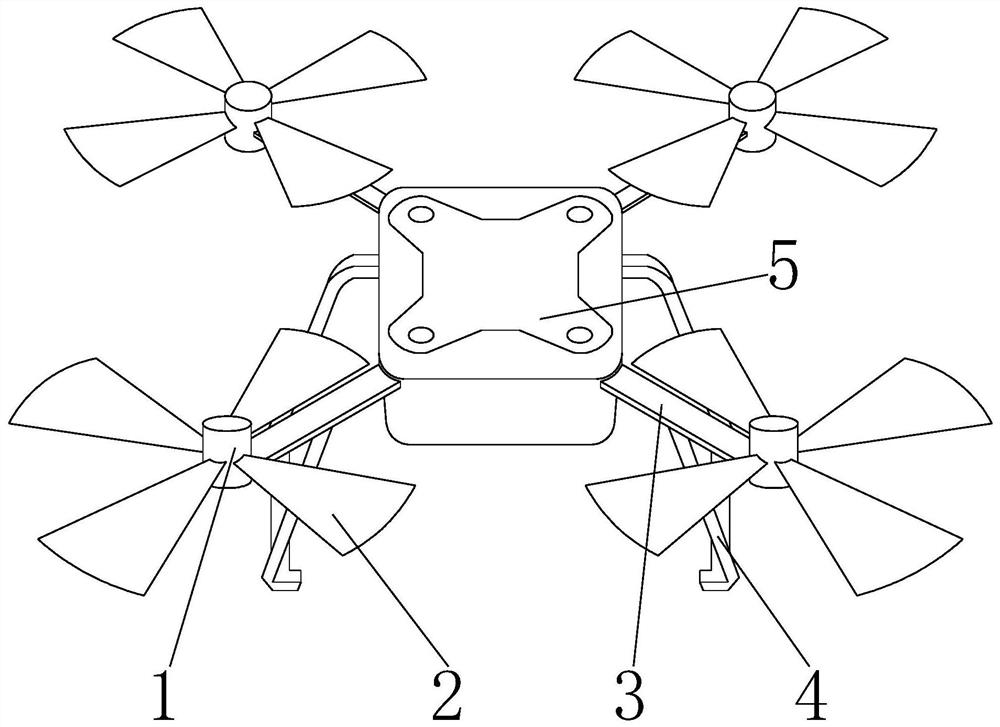

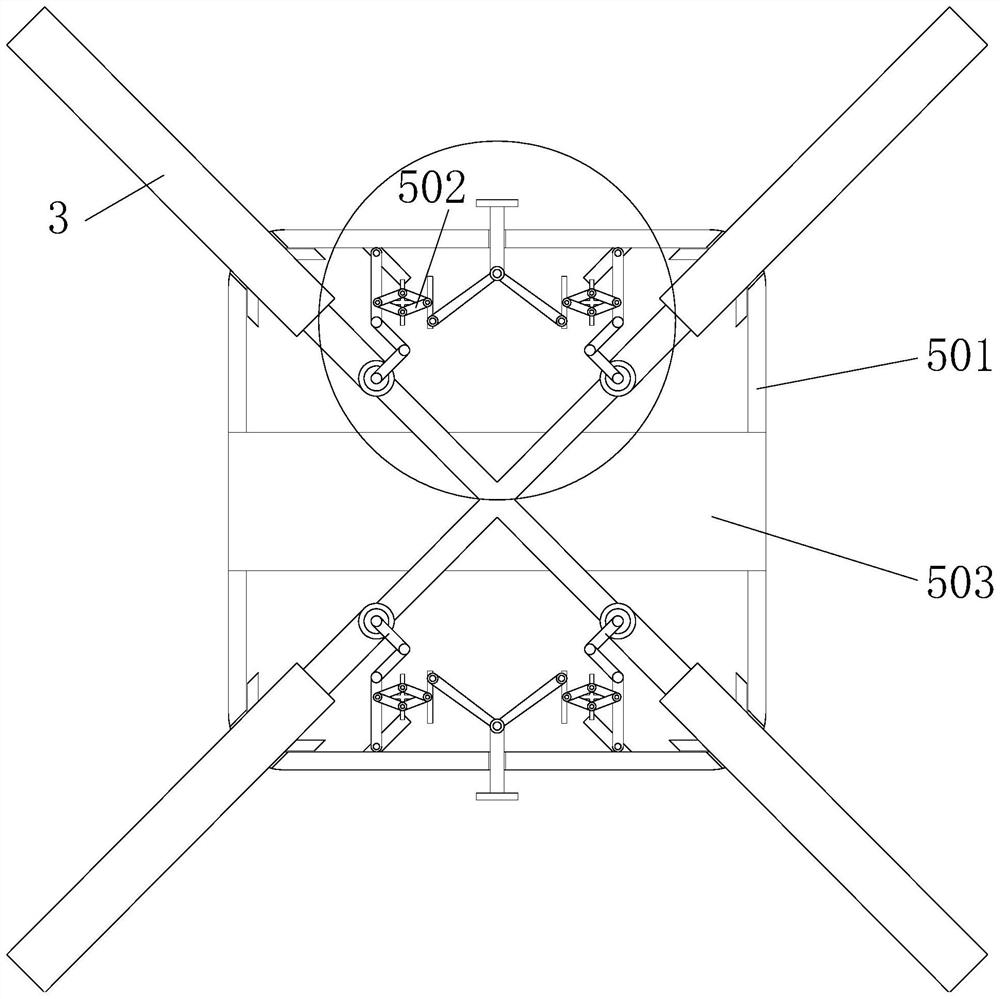

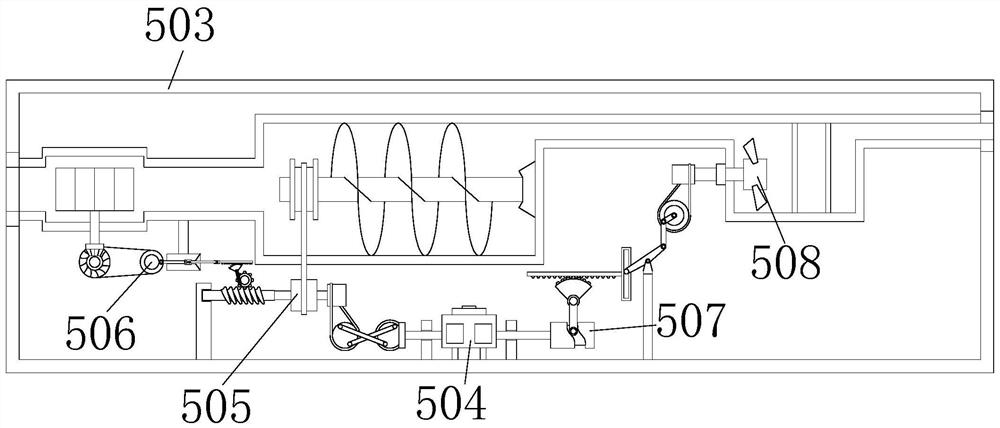

Unmanned aerial vehicle with adsorption function

ActiveCN108820208AImprove purification effectEffective inhalationDispersed particle filtrationFuselagesCircular discFan blade

The invention discloses an unmanned aerial vehicle with an adsorption function. The structure of the unmanned aerial vehicle with the adsorption function comprises a rotation motor, a flying blade, atelescopic arm, a supporting seat and an unmanned aerial vehicle main body; the rotation motor is mounted at the front end of the telescopic arm; the flying blade is mechanically connected with the rotation motor; a spiral rod engaged with a saw tooth circular disc rotates to enable an exhaust fan blade to extract air so as to suck the atmosphere, and therefore, several dust particles are more effectively sucked; the transmission of a second belt drives a second rotating shaft to rotate; at the moment, a second rotating rod rotates to drive the fan blade to rotate so that power assistance is provided for the air to blow the air into an adsorbing carbon plate to adsorb dusts, and therefore, an air purifying effect is better; a downward moving plate moves to the right lower side; a limitingplate has a limiting effect on a moving track of the downward moving plate to guarantee the moving track of the downward moving plate; the downward moving plate pulls a fixed connecting plate to move;the fixed connecting plate pulls a slide block to run on a sliding rod; the slide block drives the telescopic arm to extend into a housing so as to have a protecting effect on the telescopic arm.

Owner:安徽匠桥财务咨询服务有限公司

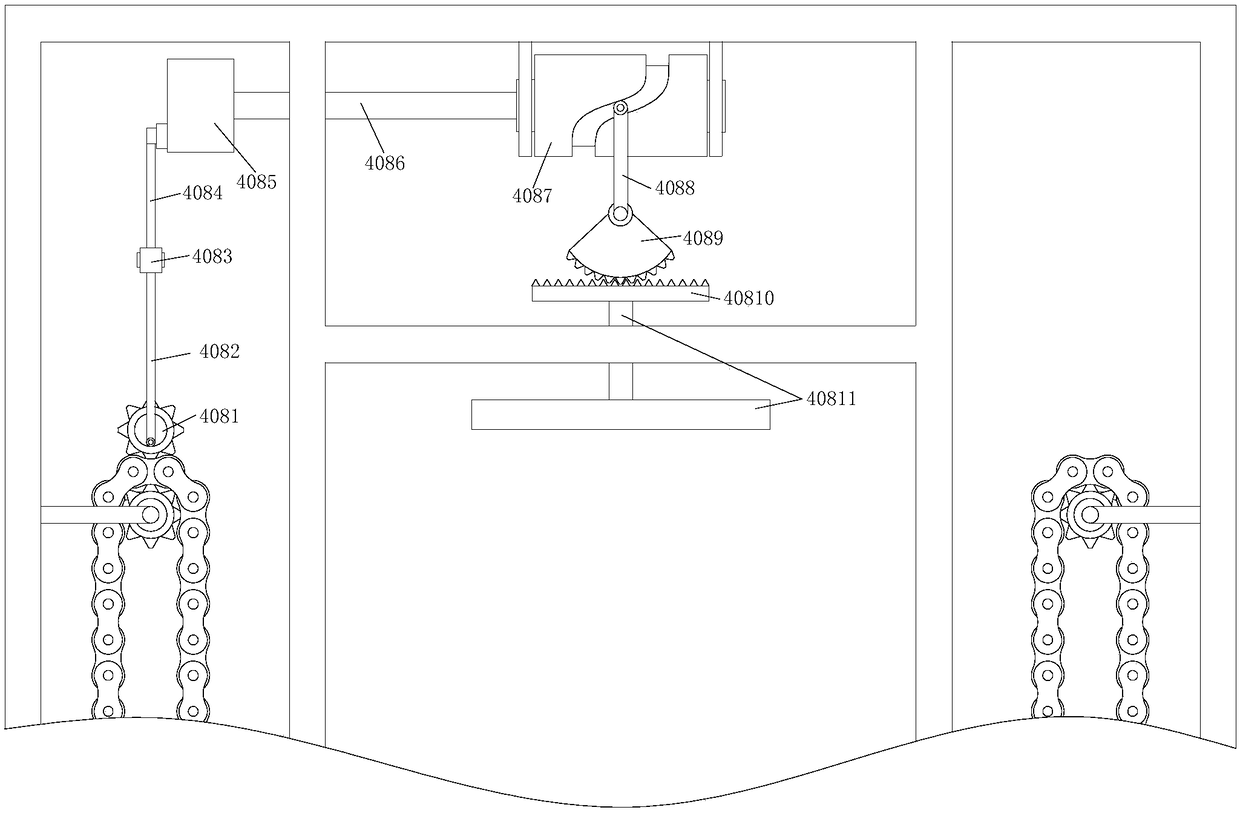

Automatic textile processing and drying device

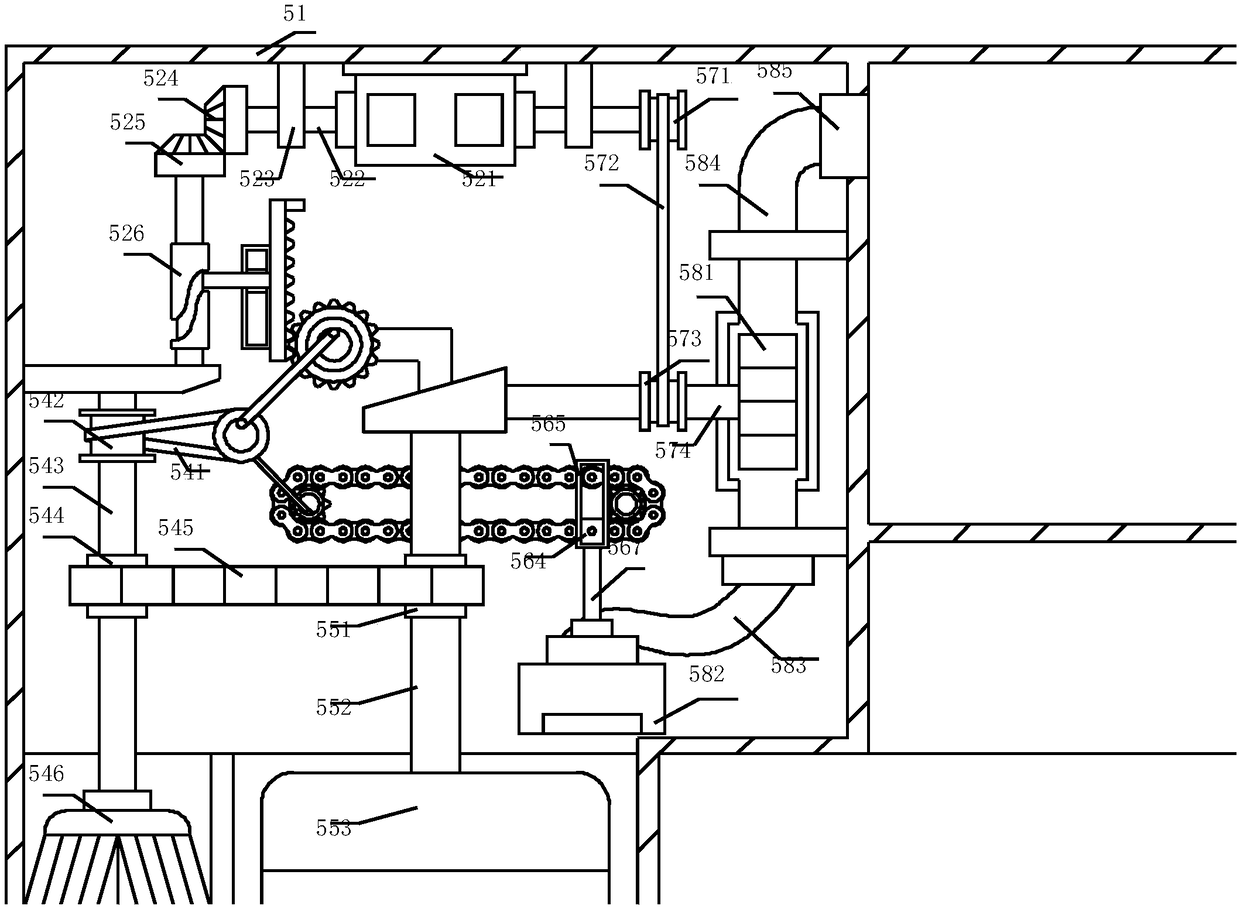

ActiveCN108731446AFully dryGuaranteed movement trackDrying solid materials with heatDrying gas arrangementsFan bladeWind power

The invention discloses an automatic textile processing and drying device which structurally comprises a top box, a handle, a box door, a drying main machine, a supporting leg and a hinge, wherein thelower end of the top box is fixedly mounted at the upper end of the drying main machine; the handle is mounted on the front surface of the box door; the box door is mounted on the front surface of the drying main machine through the hinge; at the moment, a blowing mechanism starts to work, a linking rotary shaft on the blowing mechanism rotates, so that fan blades rotate to manufacture wind energy to dry a textile primarily; a reinforcing block on a chain moves along with the chain, so that a frame moves to drive a connecting rod to move, and at the moment, a drying lamp moves therewith to guarantee that all parts of the textile can be irradiated by the drying lamp, so that the textile is dried comprehensively; a swing rod starts to swing through a track in a track roller, and at the moment, an arc-shaped toothed plate starts to swing and a rack engaged to the arc-shaped toothed plate moves left and right, too, to drive the textile to move left and right, and therefore, the textile isprevented from being damaged as the drying lamp irradiates the same part for a long time.

Owner:山东省科学院高新技术产业(中试)基地

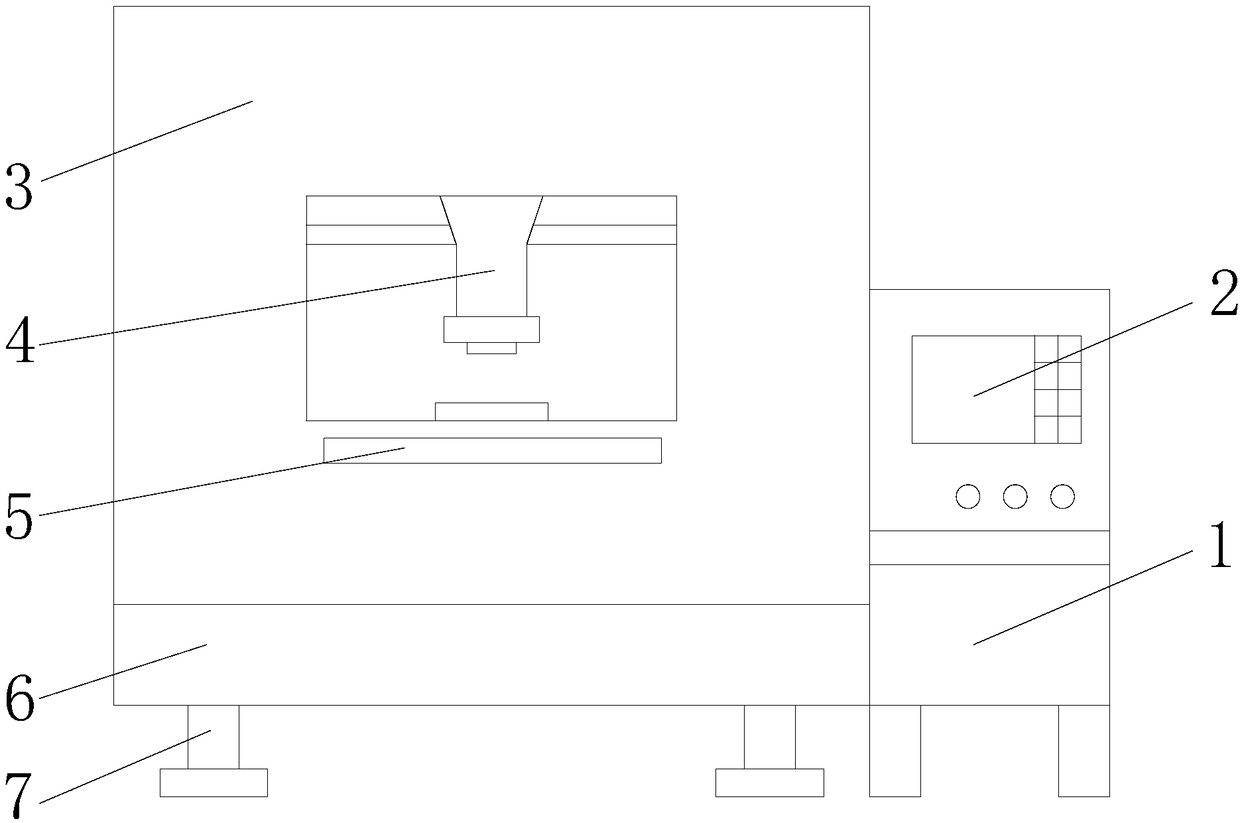

Blanking equipment for wheel core of toy wheel

InactiveCN108714644AAvoid breakingAvoid wastingShaping toolsNon-rotating vibration suppressionEngineeringSlide plate

The invention discloses blanking equipment for a wheel core of a toy wheel. The equipment structurally comprises an operation table, an operation panel, a wheel core blanking main machine, a blankinghead, a handle and a base, the operation table is arranged on the right side surface of the wheel core blanking main machine and is electrically connected with the right side surface of the wheel coreblanking main machine through a wire, a rotating shaft rotates to drive a worm to run and rotate through the transmission of a belt, at the moment, a sliding plate descends, the blanking head is driven to descend, a second fixing round block on a rotating disc drives a moving frame to run, and at the moment, a downward-pressing rod descends, the blanking head is driven to descend so that the blanking head can perform the blanking work on a material more powerfully, and proceeding of the blanking work is guaranteed; upper ends of connecting rods contract towards the two sides, push rods contract towards a blanking die plate, clamping pieces are used for fixing and clamping the blanking die plate, so that the situation that due to the fact that the material is separated in the operation process, the material is damaged is prevented; and a connecting rotating shaft rotates to enable a rotating fan blade to rotate, air is blown out from an air outlet hole to cool the material subjected toblanking, and the situation that due to overheating caused by friction, the material is damaged in the blanking process is prevented.

Owner:孙培宗

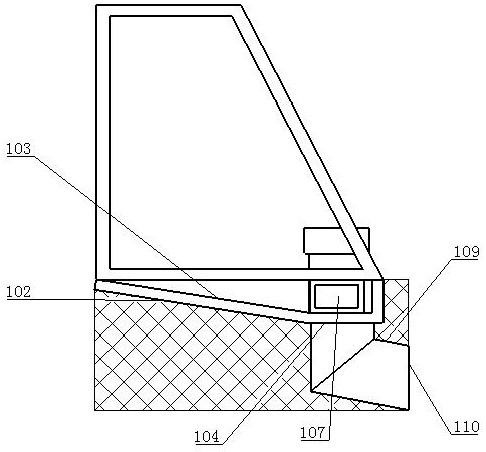

Novel parting face structure of injection mold

The invention discloses a novel parting face structure of an injection mold. The novel parting face structure of the injection mold comprises a supporting rod and a base; the left end of a hinge pin is fixedly connected with a support; a buckle is movably connected with the support through the hinge pin; the left end of the support is fixedly connected with a fixed mold body; the left end of the fixed mold body is fixedly connected with an ejector rod; the upper end of the ejector rod is fixedly connected with a nut, a lead screw is arranged on the inner wall of the nut, and the nut and the lead screw are in threaded connection; and the lower end of the lead screw is fixedly connected with a rotary handle, the upper end of the lead screw is connected with a rotary rod, the upper end of therotary rod is provided with a clamping plate, and the clamping plate is connected with a clamping rod in a clamped mode. According to the novel parting face structure of the injection mold, through cooperation of the fixed mold body and a movable mold body, the attachment effect of the fixed mold body and the movable mold body is ensured, the mold can be fixed better through cooperation of the ejector rod and the nut, cooperation of the nut and the lead screw, cooperation of the lead screw and the rotary handle and the rotary rod and cooperation of the rotary rod and the clamping plate and the clamping rod, the mold casting effect is ensured, the mold casting quality is improved, and high practicability is achieved.

Owner:FANCHANG BEISI PRODIVITY PROMOTION CENT

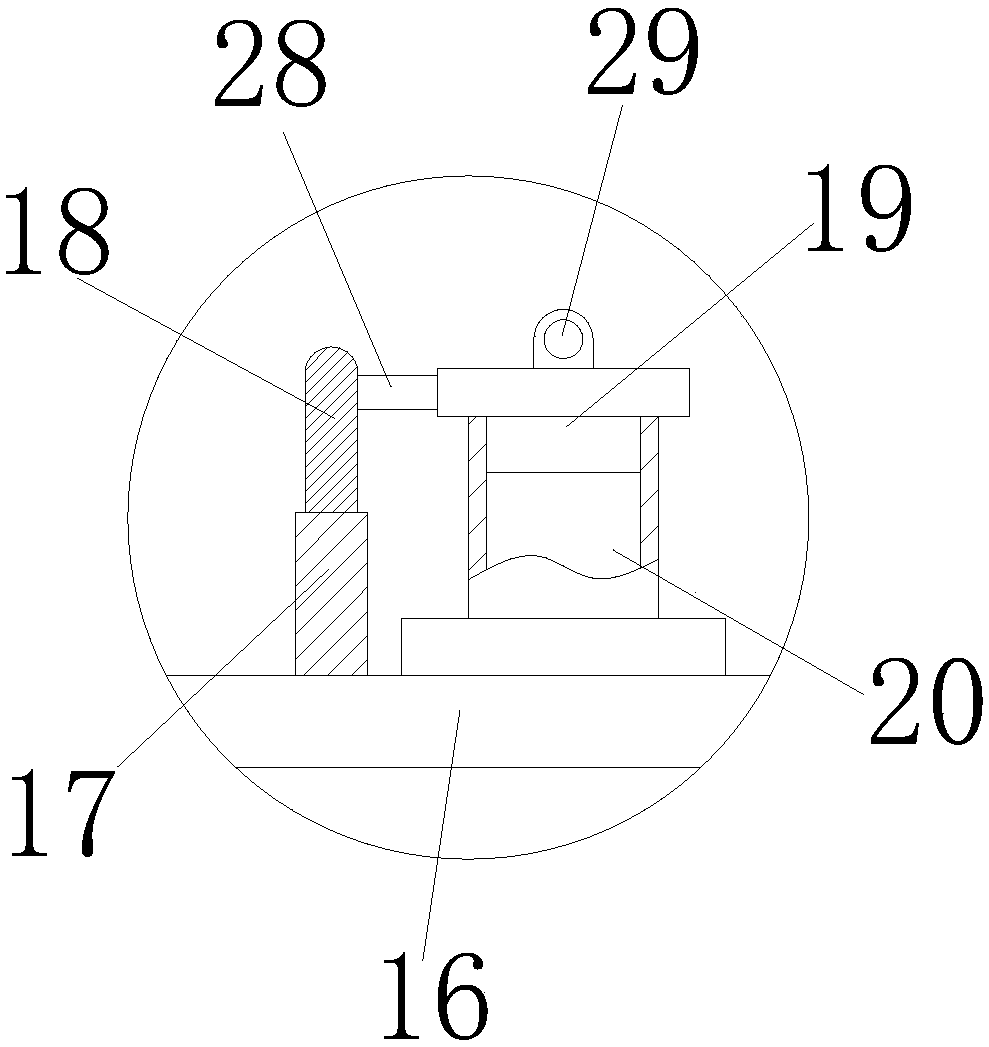

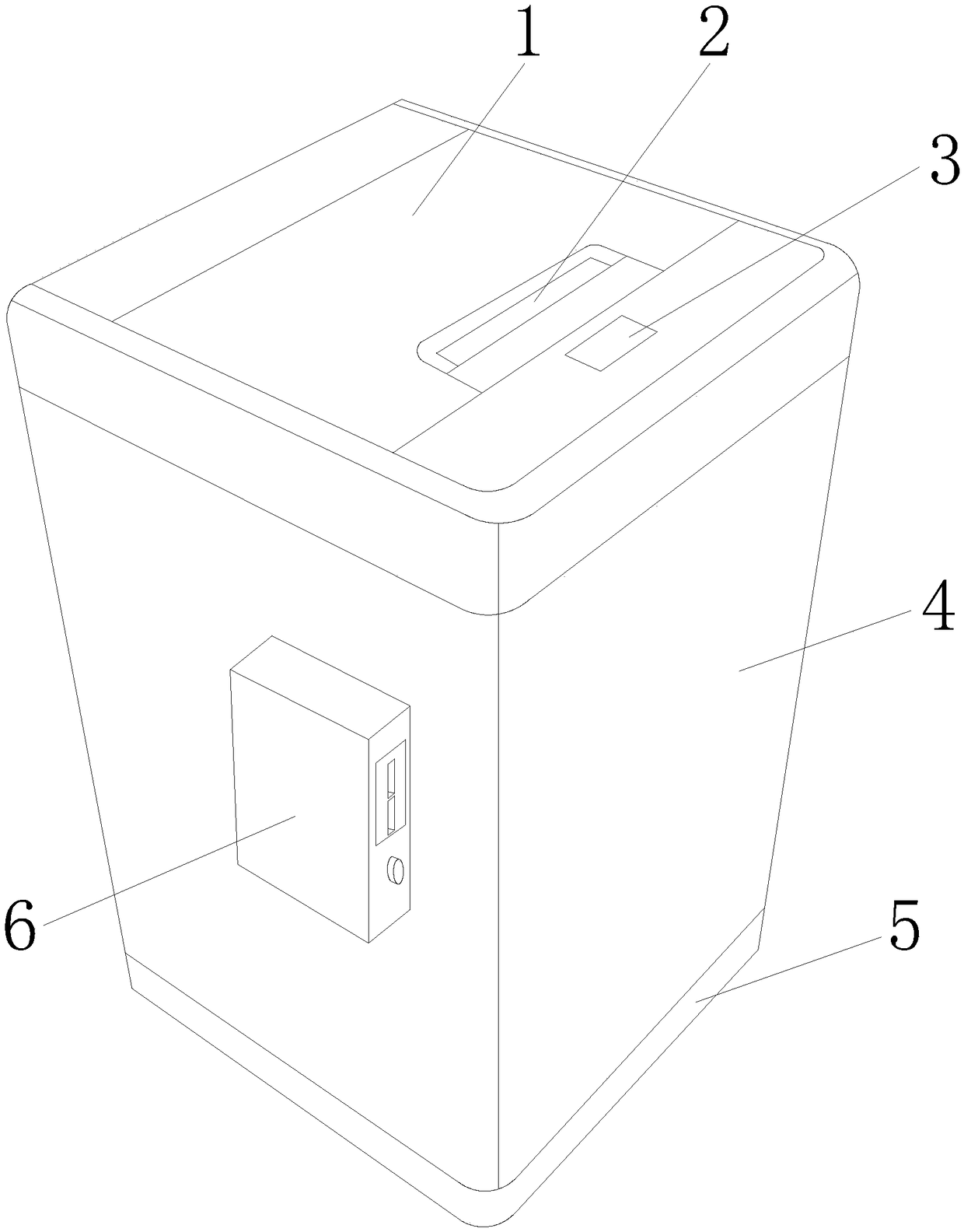

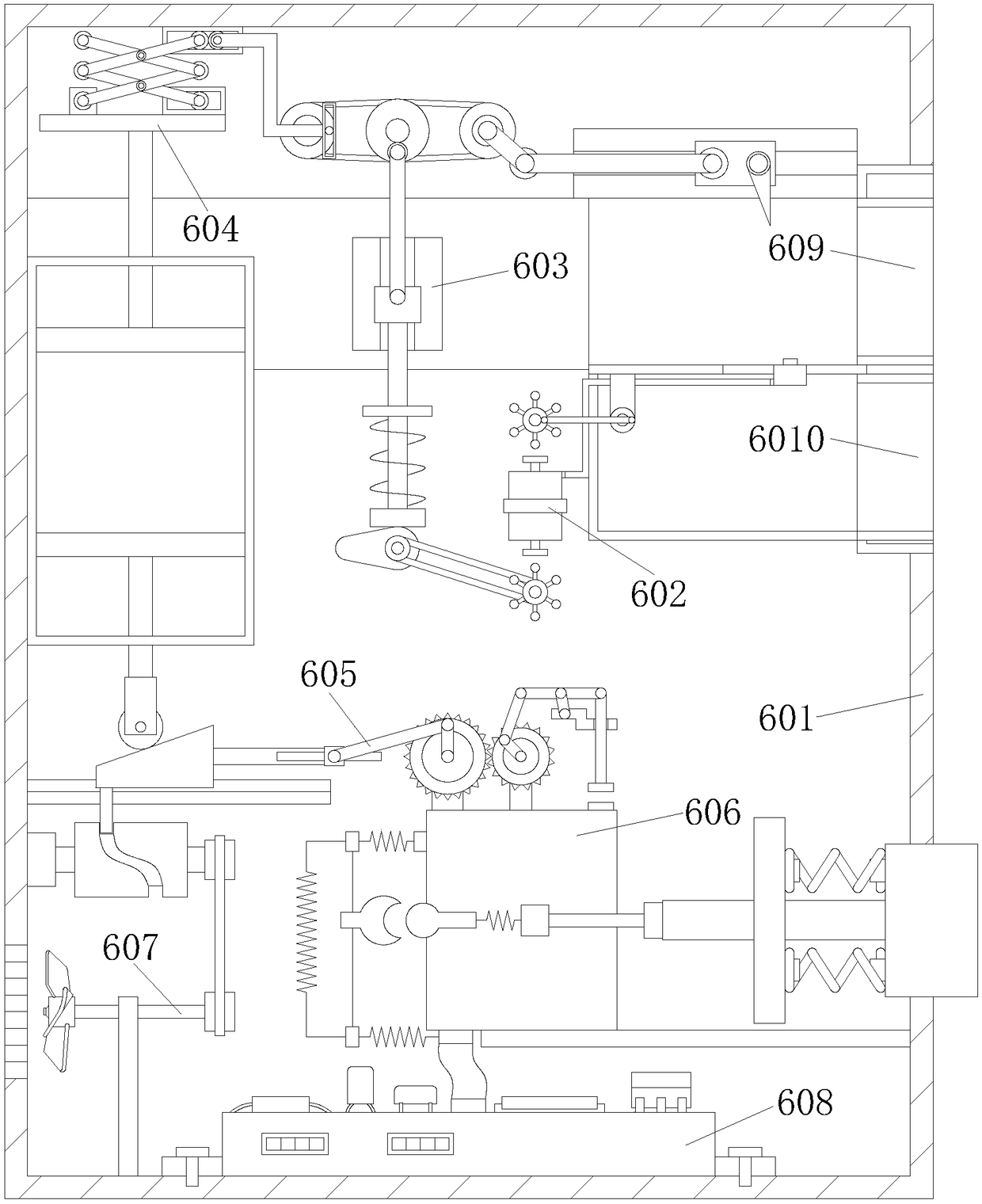

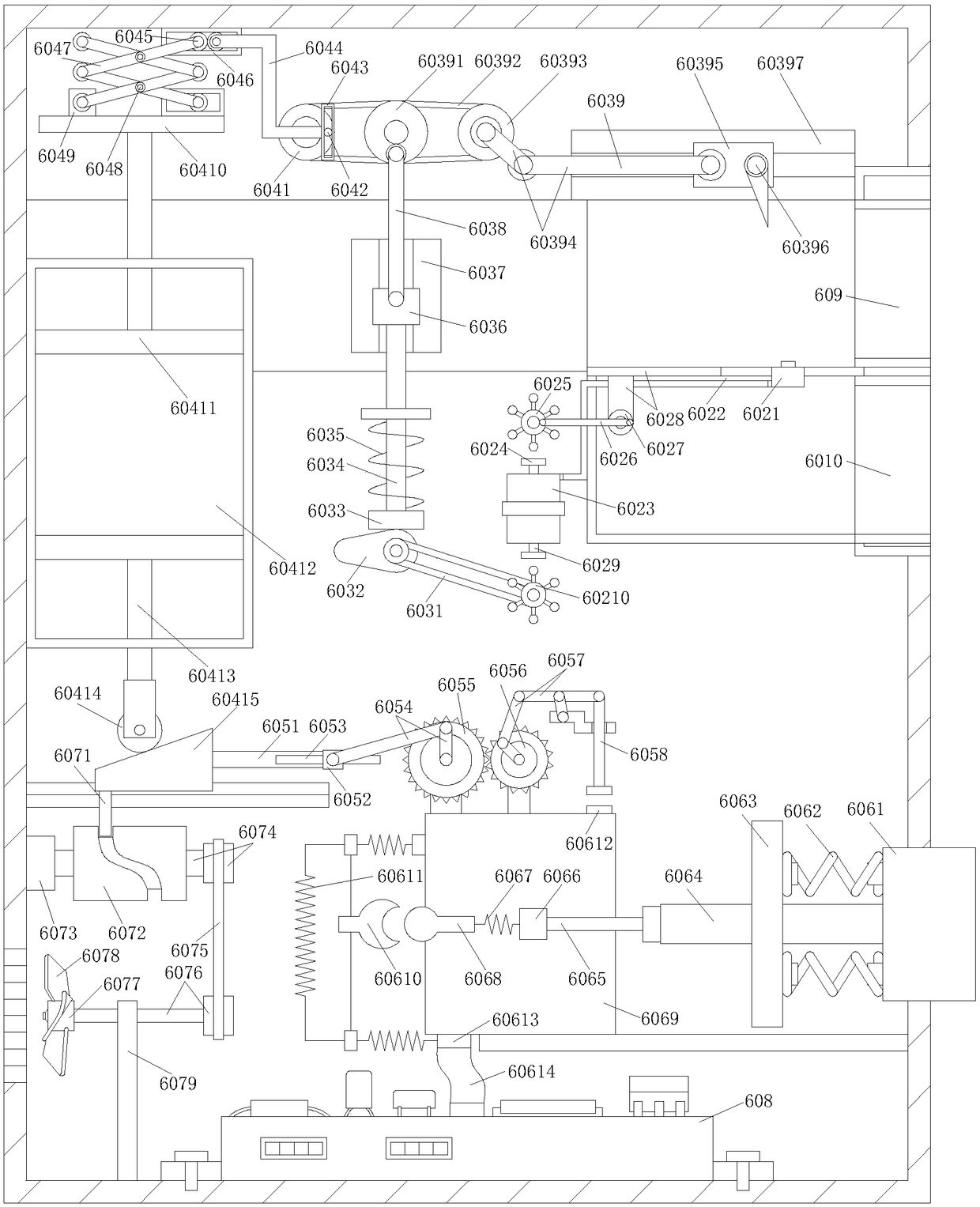

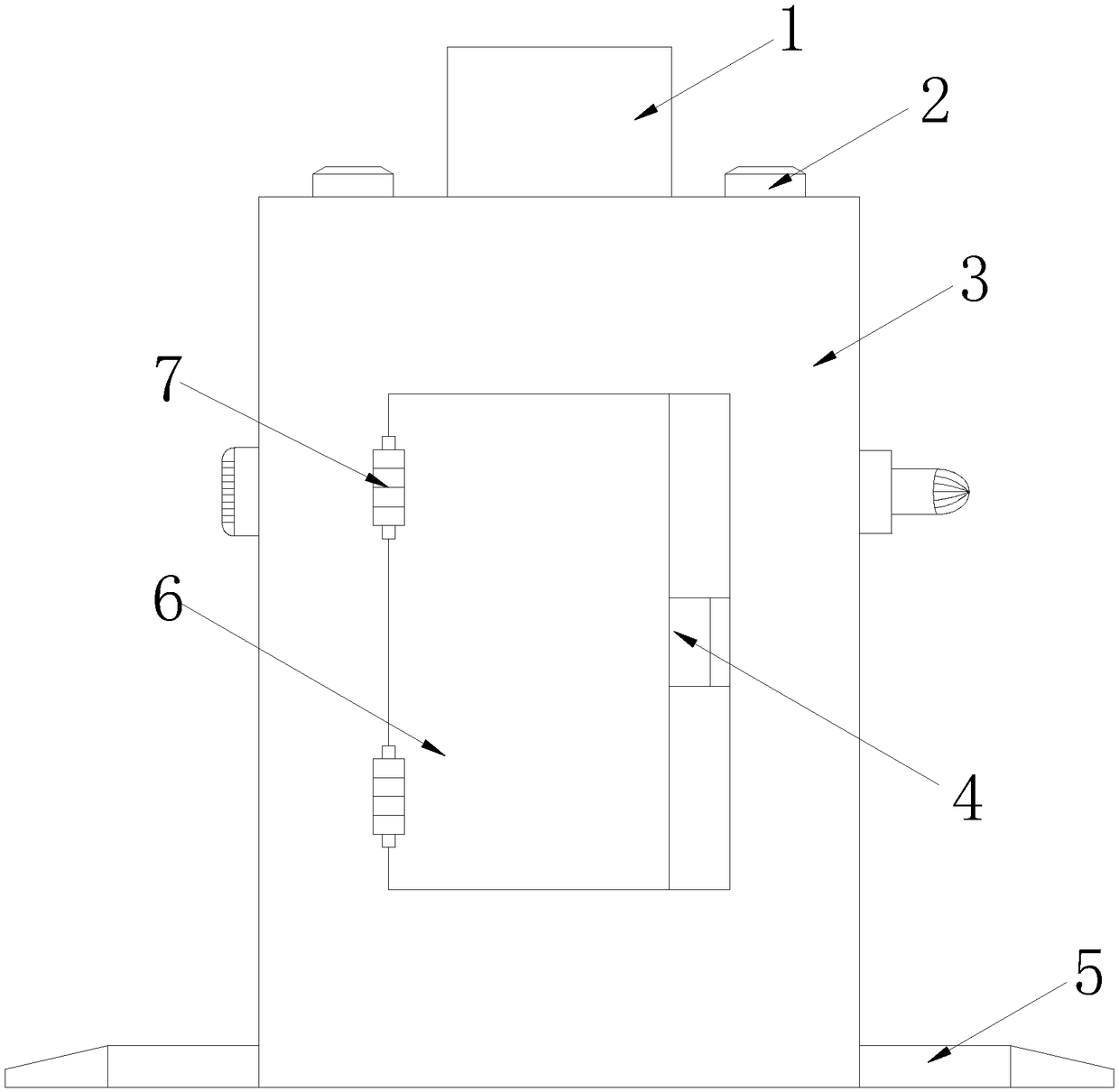

Control device for coin-operated washing machine

InactiveCN108831063APrevent card coinGuaranteed movement trackApparatus for meter-controlled dispensingDisplay deviceEngineering

The invention discloses a control device of a coin-operated washing machine. The device structurally comprises a top cover, a handle, a display device, the washing machine, a cushion, a coin-operatedcontrol box and an anti-theft mechanism. The top cover is installed at the upper end of the washing machine, the handle is arranged on the top cover, the display device is embedded in the upper surface of the washing machine and electrically connected with the coin-operated control box through a wire, the lower end of the washing machine is welded with the upper surface of the cushion, a slider drives a linkage rod to run, a poke mechanism works through the linkage effect of the linkage rod, a poke rod on the poke mechanism is used for poking coins in to prevent the coins from jamming in equipment, and it is ensured that the equipment can normally run. A trapezoidal block moves right and drives a drive block to move, a trajectory drum in clearance fit with the drive block starts rotate anddrives a drive rotating rod to rotate, a linkage rotating rod rotates through drive of a drive belt, a rotating shaft at the left end of the linkage rotating rod follows the rotation so as to drive fan blades to rotate for heat dissipation, and it is guaranteed that a control circuit board works at constant temperature.

Owner:WUHU LINGMENG E COMMERCE CO LTD

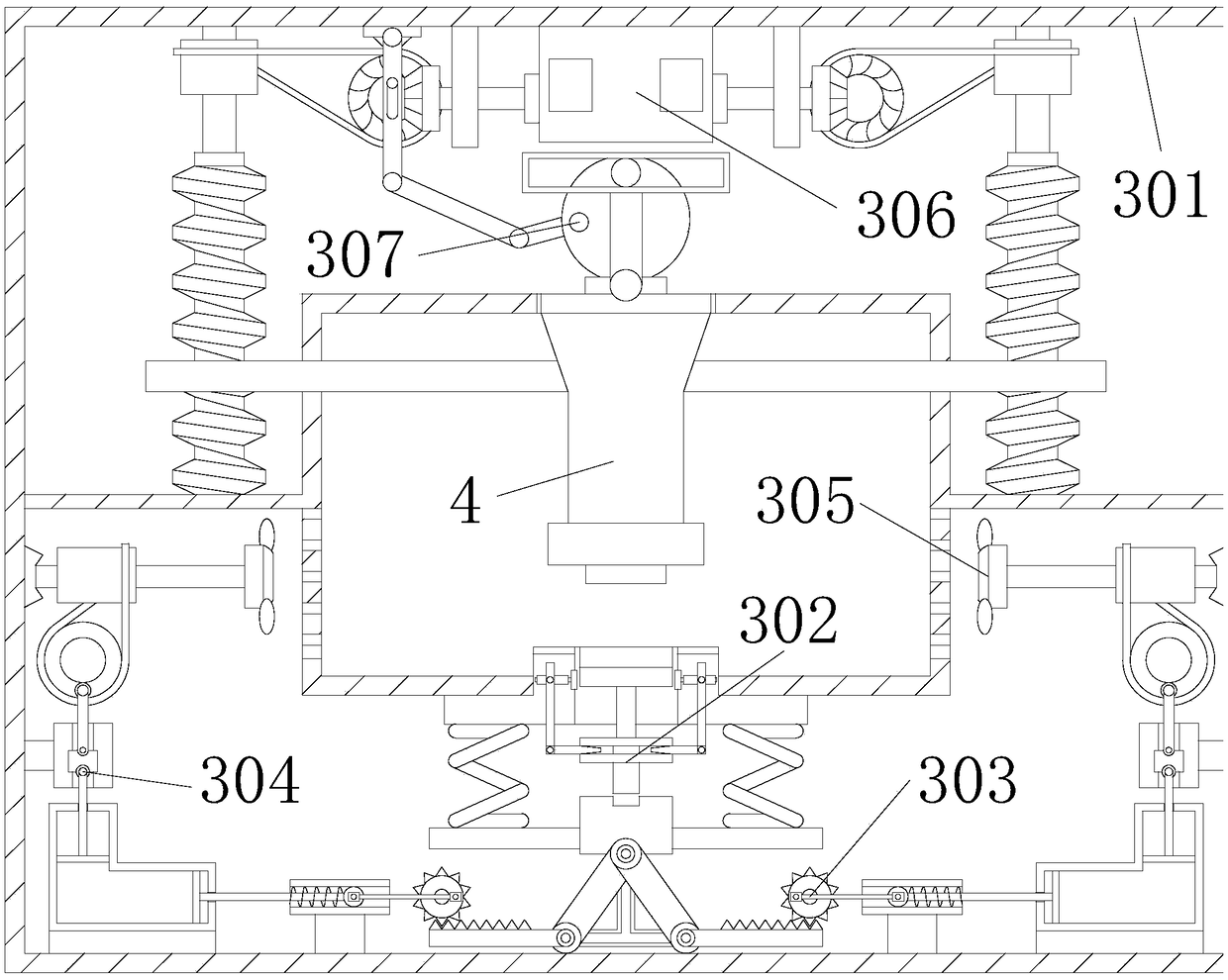

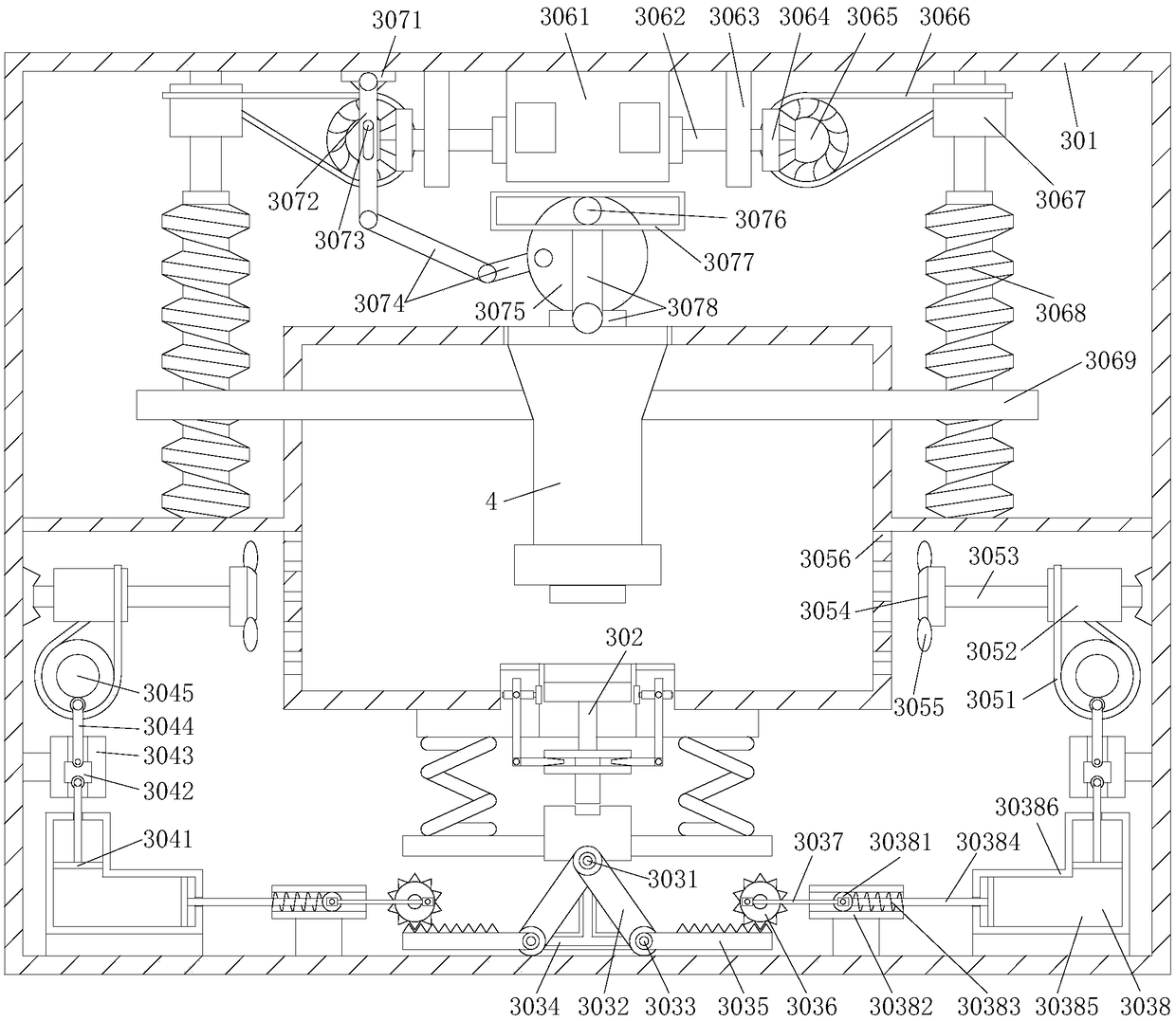

Bumper impact test device based on automobile safety

ActiveCN111551338AIncrease the simulation functionEasy to adjustShock testingVehicle shock testingVehicle frameAutomobile safety

The invention discloses a bumper impact test device based on automobile safety, relates to the technical field of automobile detection, and solves the problems that a bumper detection device used at present mainly detects a bumper through a pressure test, detected data is difficult to simulate real inertia, and the detection effect is common. The bumper impact test device based on automobile safety comprises a bottom plate. Side rails are fixedly connected to the two sides of the top of the bottom plate through stand columns. A front frame and a rear frame are arranged in the side rails in a sliding manner. Pulley frames are fixedly arranged on the two sides of the front frame and the two sides of the rear frame through bolts. By arranging the side rails, the front frame and the rear frame, straight running of an automobile can be simulated for a simulation test, and compared with an original fixed detection compression resistance method, the test conclusion is more direct, operation is convenient, and control is easy. The arrangement of the side rail and the pulley yoke can ensure that the movement tracks of the front frame and the rear frame are straight, and ensure that the testdevice moves linearly along the side rail.

Owner:江苏永成汽车零部件股份有限公司

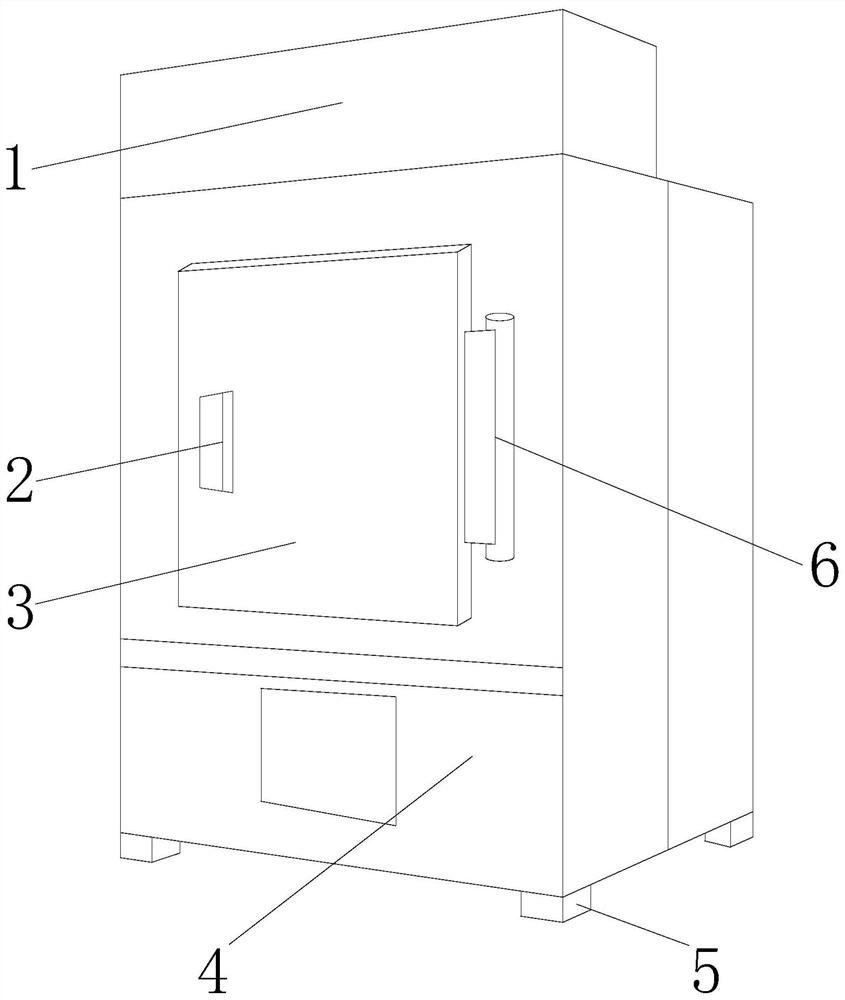

Electric device comprising adsorbent

ActiveCN108963779AAvoid emissionsGuaranteed movement trackDispersed particle separationSubstation/switching arrangement casingsToxic gasElectrical equipment

The invention discloses an electric device comprising an adsorbent. The structure of the electric device comprises an adsorption cover, screws, an electric host, a handle, a fixing seat, a box door and hinges. The lower end of the adsorption cover is installed in an upper end of the electric host by an embedded method, the screws are in threaded connection with the upper end of the electric host,the handle is welded to the front surface of the right end of the box door, and the fixing seat is fixedly mounted on both sides of the lower end of the electric host. When electrical equipment is working, an internal medium leaks to cause toxic gas to be generated. At this time, a blowing mechanism is driven to operate by a power mechanism, and the gas is discharged into an adsorption mechanism,so that the gas is enabled to be fully adsorbed by the adsorbent in the adsorption mechanism. Then, a gas collection mechanism is used for filtering to prevent the toxic gas from being discharged, andthe adsorbed substance has a certain weight and enters into the gas collection mechanism, so that a lowering mechanism is operated, a warning mechanism and a buzzing alarm mechanism are connected toa power supply, and an alarm is issued to promptly remind the management personnel to ensure that the management personnel perform processing at the first time.

Owner:ANHUI KECHUANG NEWENERGY TECH CO LTD

Device for removing water from waste combustion tail gas

InactiveCN109442434AEasy to separateFree dischargeDeodrantsIncinerator apparatusHazardous substanceEnvironmental engineering

The invention discloses a device for removing water from waste combustion tail gas. The device structurally comprises a purification outlet, a box door, a water removal main machine, a tail gas inletand supporting bases. The purification outlet is formed in the upper end inside the left side of the wat removal main machine in an embedding manner. The box door is hinged with the front surface of the water removal main machine. The left end of the tail gas inlet is arranged at the upper end inside the right side of the water removal main machine in an embedding manner. A driving mechanism is operated by opening a power mechanism, then a gas intake mechanism exhausts the tail gas into a water collection mechanism from the tail gas inlet; and through the compression work of the water collection mechanism and the action of a moisture removal box, the liquid is separated from the tail gas, and the liquid separation effect is better; then the liquid is removed through the work of a wind power mechanism; meanwhile a heater on a power supply mechanism carries out high-temperature treatment on the harmful substances in the liquid, the water removal effect is better, and the harmful substances are prevented from being discharged at will and polluting the environment; and the tail gas is exhausted again after the work of a negative ion generator to ensure that the air is not polluted.

Owner:广州顺途信息科技有限公司

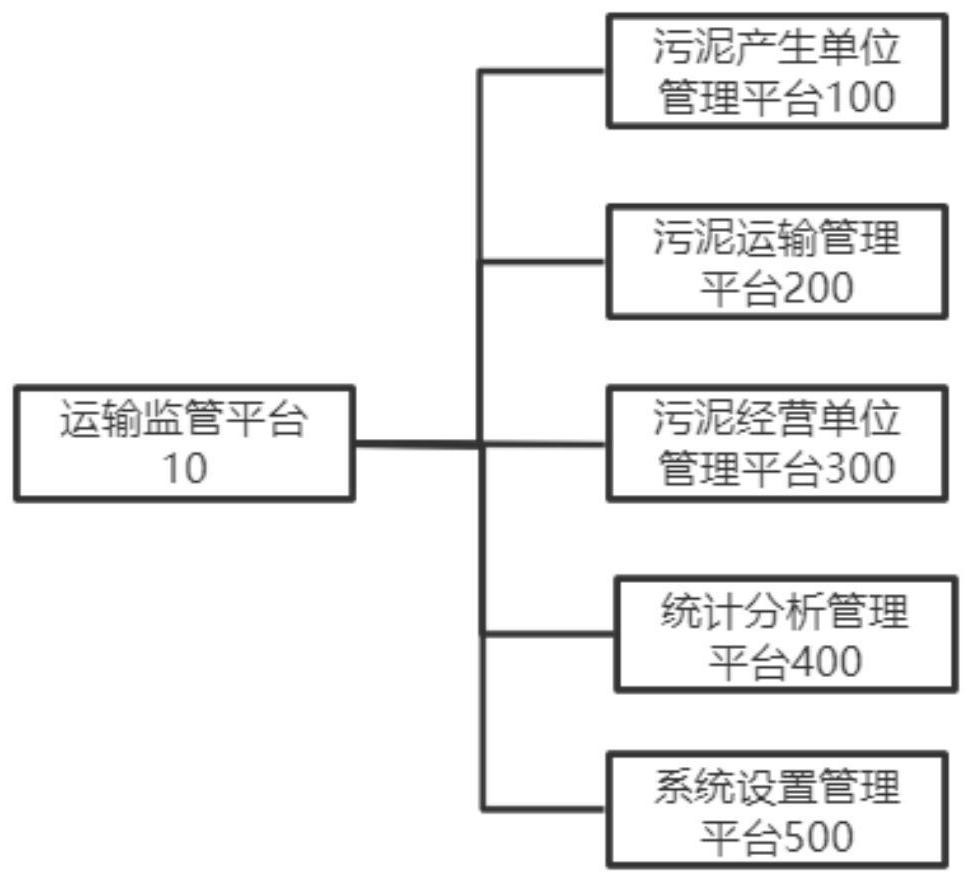

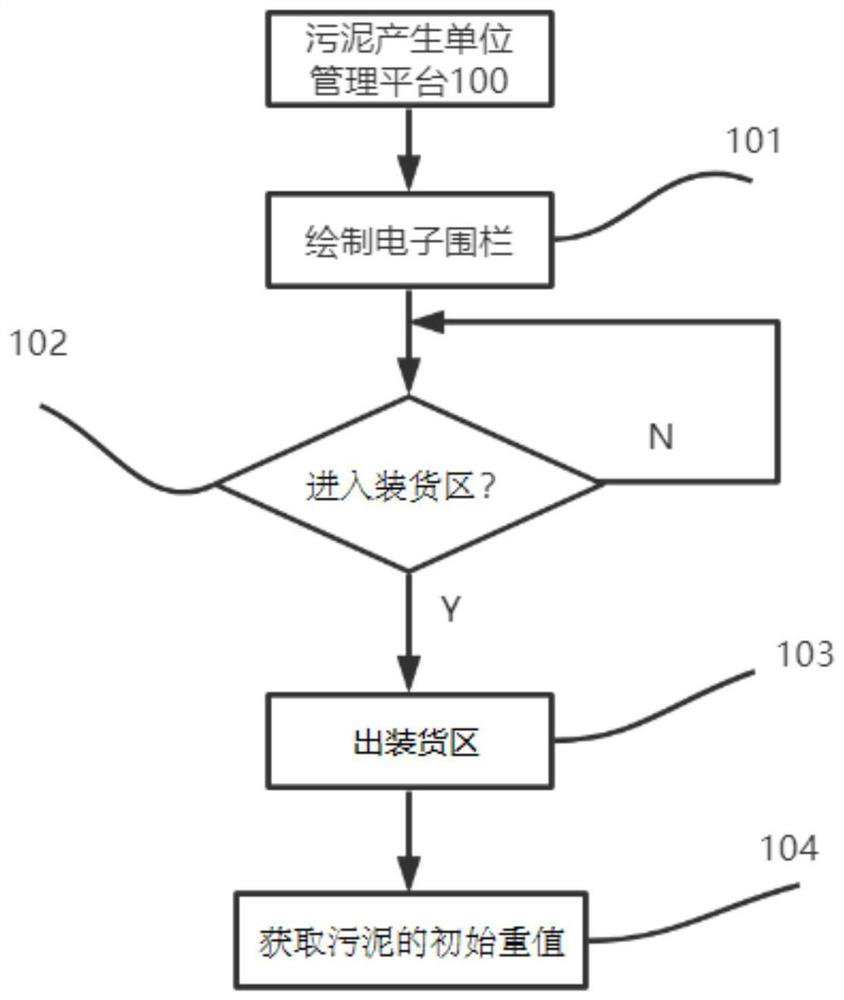

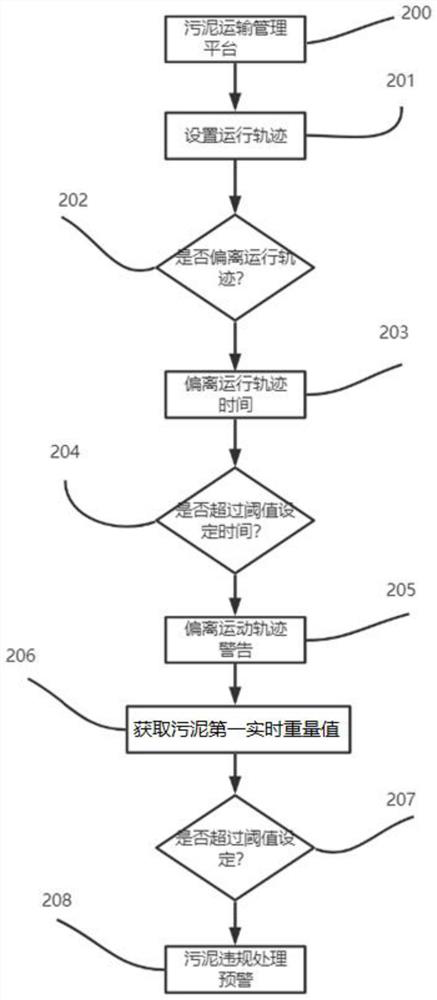

Sludge transportation supervision system and method based on electronic map

PendingCN113888863AImprove intelligenceGuaranteed movement trackDetection of traffic movementGeographical information databasesSludgeStatistical analysis

The invention discloses a sludge transportation supervision system and method based on an electronic map, and the system comprises: a sludge generation unit management platform which is used for drawing and managing an electronic fence of a sludge generation unit loading area; a sludge transportation management platform which is used for configuring and monitoring a running track of a sludge transportation vehicle; a sludge operation unit management platform which is used for drawing an unloading area electronic fence and acquiring sludge transport vehicle operation state information; a statistical analysis management platform which is used for analyzing and managing various data in the transportation process; and a system setting management platform which is used for system configuration, list configuration, rule tracking, message pushing and bulletin board management of system functions. According to the sludge transportation supervision system and method based on the electronic map, the management ledger of sludge transportation is effectively standardized, the sludge transportation link is comprehensively monitored, solid waste standardized management requirements are met, and an environmental protection department is assisted to timely and dynamically master sludge information.

Owner:CHINABATA NANJING TECH

Device for connecting with threaded fastener

InactiveCN108956115AGuaranteed movement trackComprehensive dust removalMachine part testingGeological measurementsEngineeringThreaded fastener

The present invention discloses a device for connecting with a threaded fastener. The structure of the device comprises a window, a detection host, a pedestal, an operation panel, a buckle, an air inlet, a handle and a box cover. The window is inlaid at the front surface of the box cover, the box cover is inlaid at the front surface of the detection host, the lower surface of the detection host iswelded with the upper surface of the pedestal, the operation panel is fixedly installed at the middle portion of the upper end of the front surface of the pedestal and is electrically connected withthe detection host through a wire, the upper end of the buckle is hinged with the lower end of the front surface of the box cover, the lower end of the buckle is connected with the middle portion of the lower end of the front surface of the detection host, and the air inlet is installed at the surface of the right side of the detection host in an embedding mode. A power mechanism drives a mobile detection mechanism to perform mobile detection to allow the detection to be more comprehensive and allow the detection result to be more accurate, a rotation clamping mechanism is employed to performlow-speed rotation of the threaded fastener, and therefore, the detector can perform omnibearing detection for the threaded fastener, a dust collection mechanism can remove other things at the external portion of the threaded fastener so that the detection result is more accurate.

Owner:刘凤红

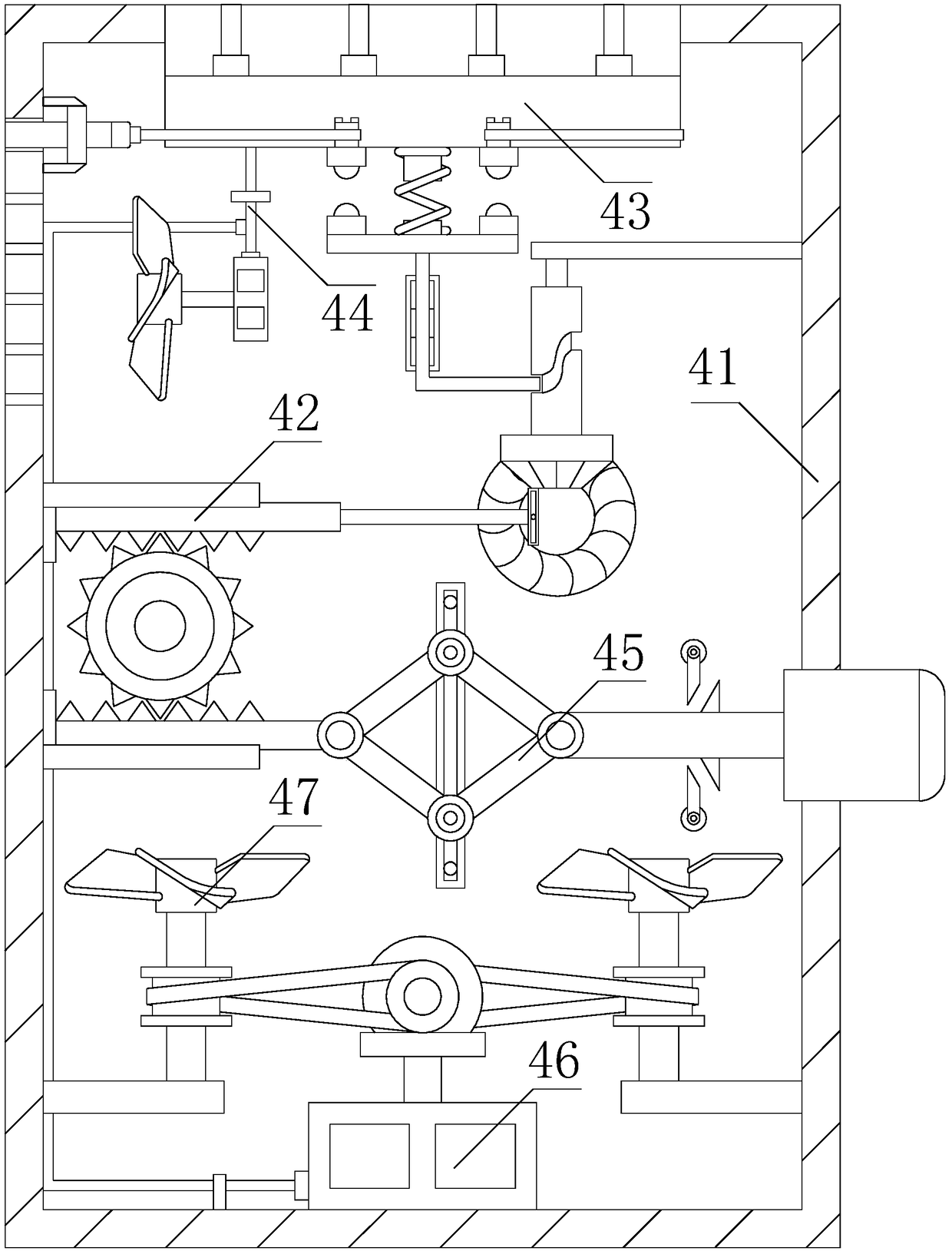

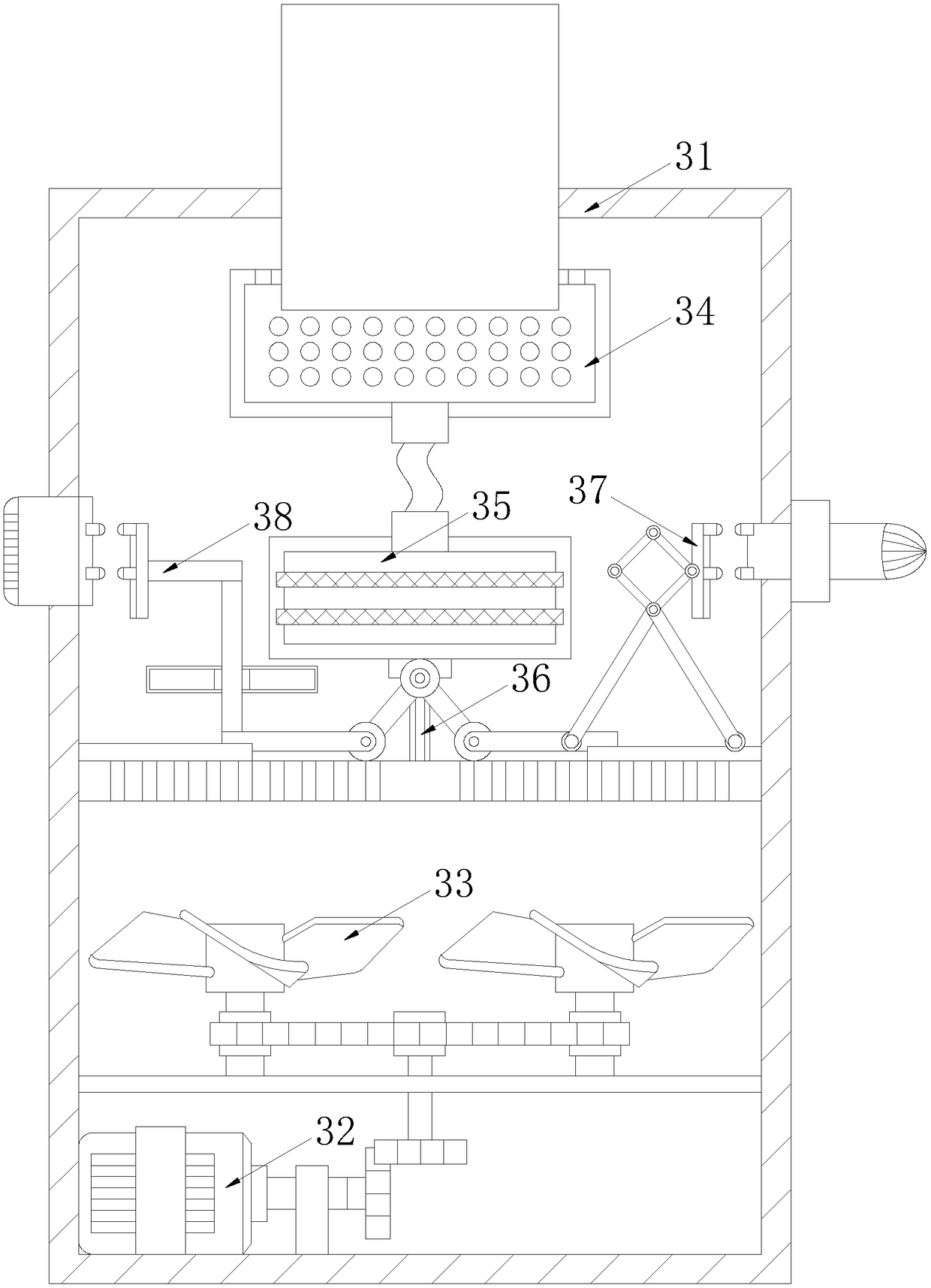

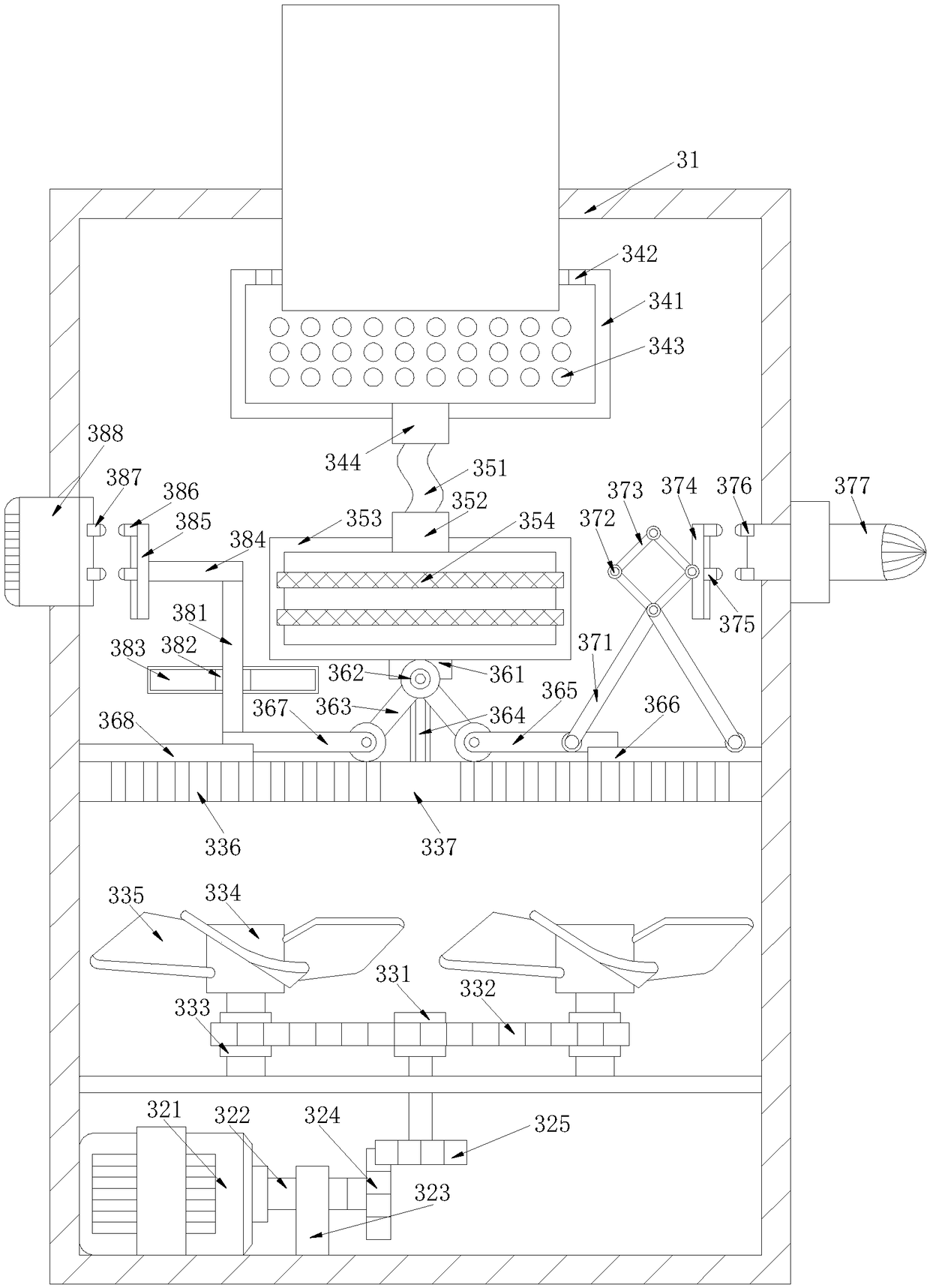

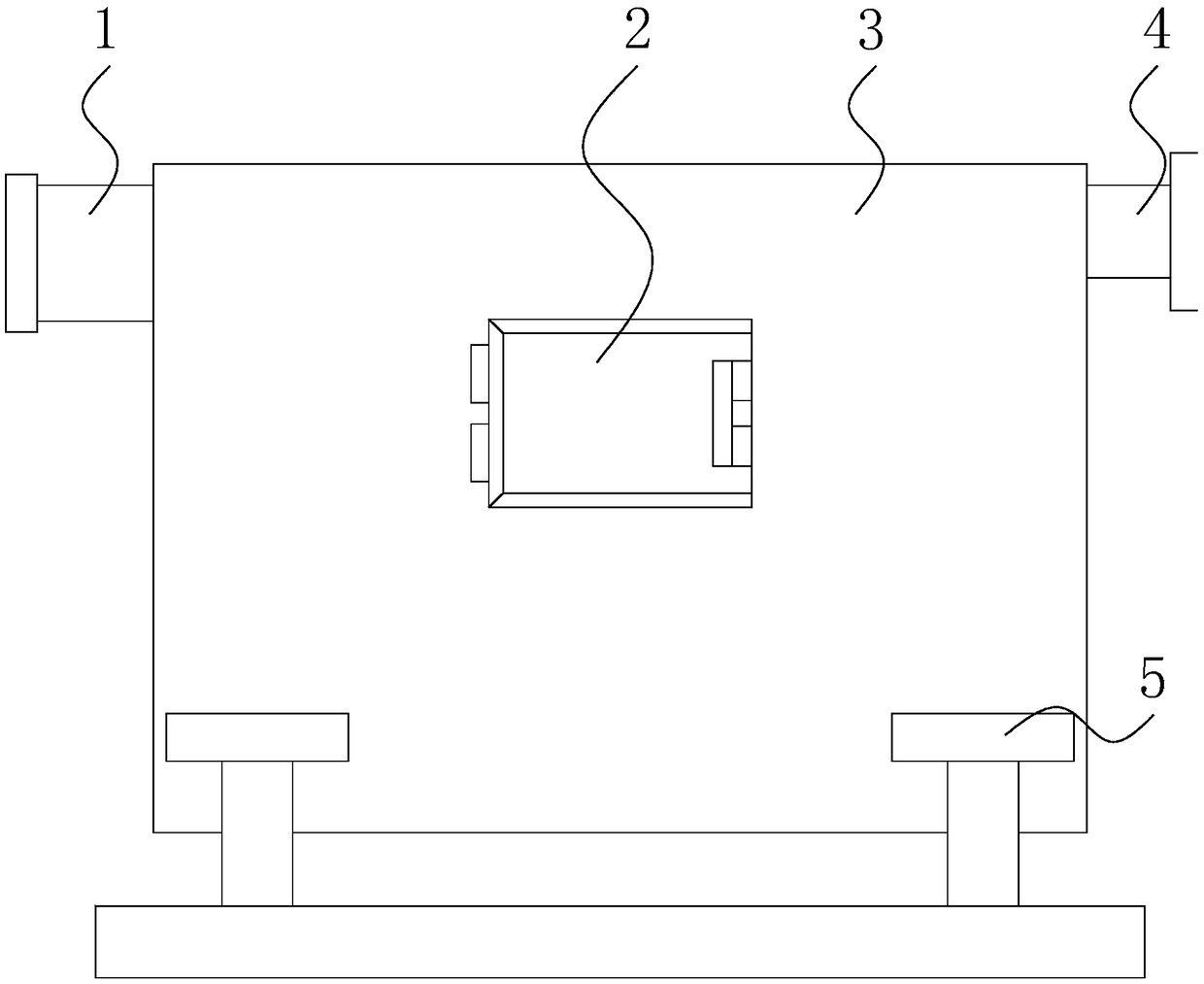

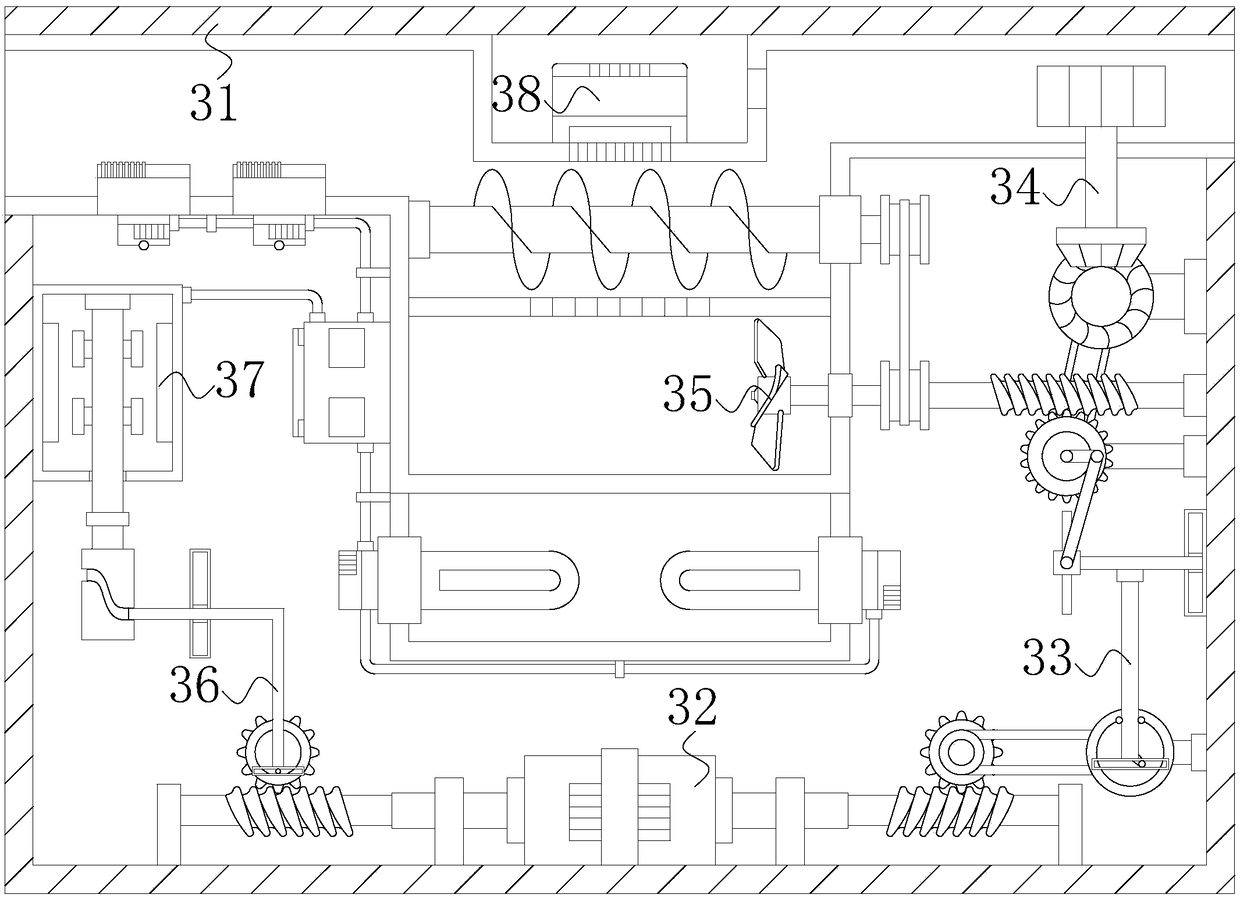

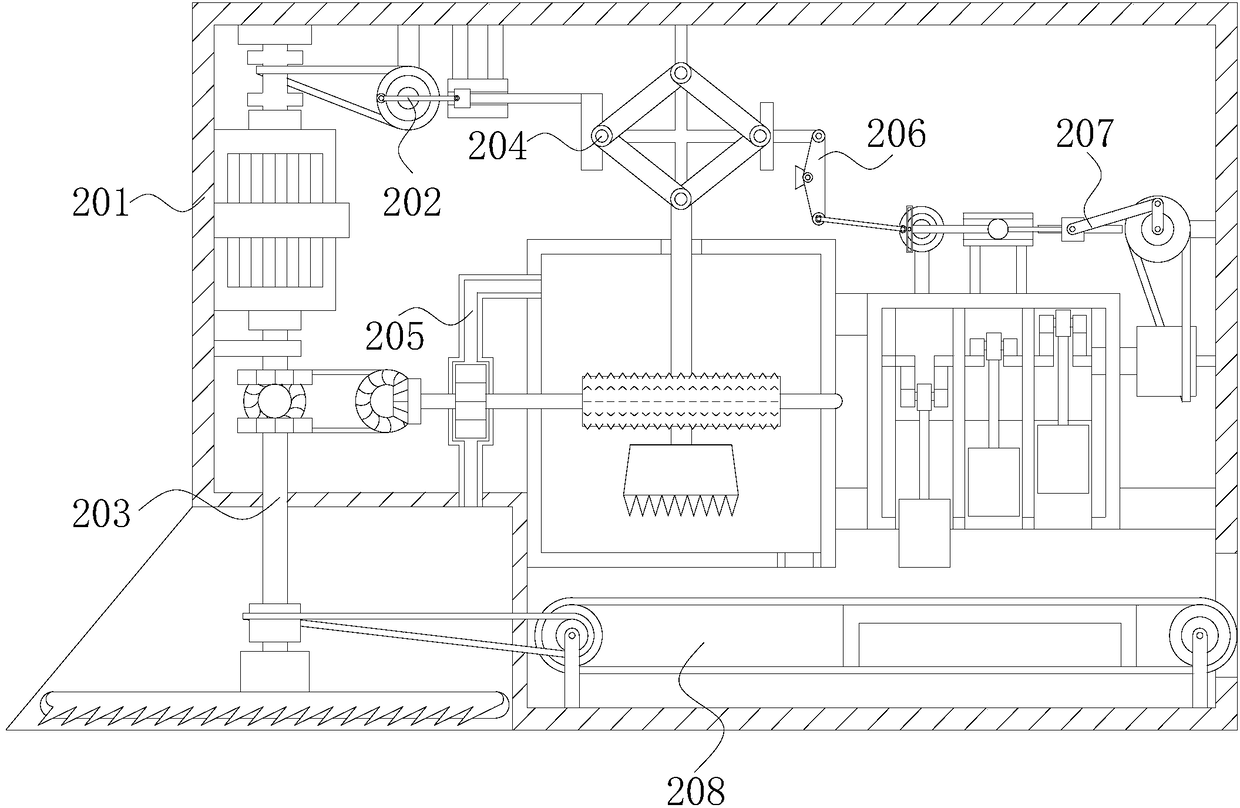

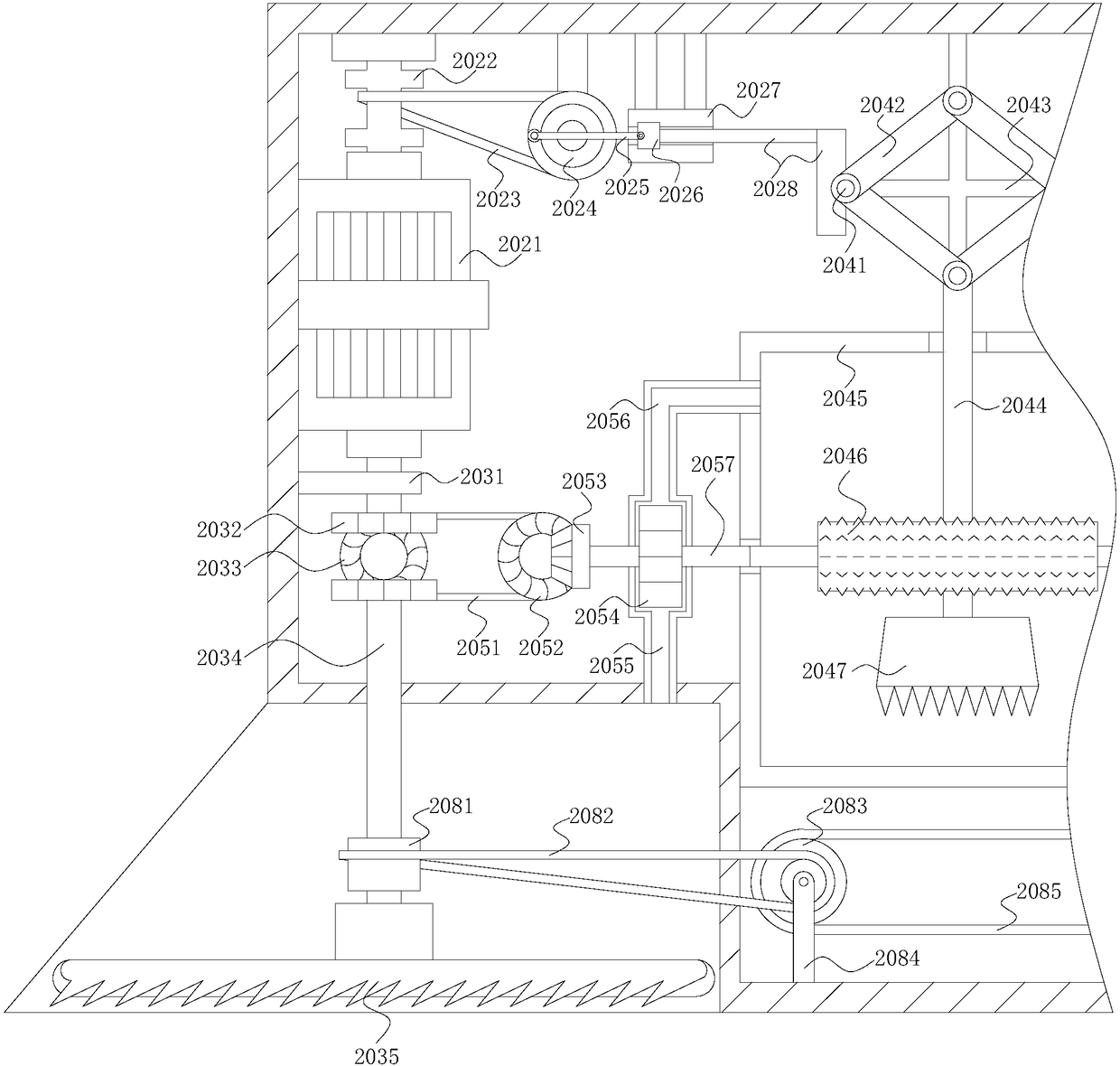

Feeding and compacting device of silage harvester

The invention discloses a feeding and compacting device of a silage harvester. The feeding and compacting device of the silage harvester structurally comprises a top cover, a feeding main unit, four moving wheels, a compacting outlet, a box door and a pushing handle, wherein the top cover is mounted on the upper surface of the feeding main unit; the four moving wheels are fixedly mounted at the lower end of the feeding main unit; the compacting outlet is formed in the lower end of the right side of the feeding main unit; the box door is inlaid in the front surface of the feeding main unit; atthe moment, a screw rod which is engaged with a linkage saw-tooth disc begins to rotate and drives suction fan blades to suck air; the cut silage is sucked to an air outlet from an air inlet and thenis discharged into a chopping box, and thus, the silage can be centralized effectively and then is cut up; and the left end of a traction plate moves rightwards, the lower end of the traction plate moves downwards, a downward pressing rod is driven to press downwards so that the cutting-up knife cuts up the silage, and the cut-up silage can be compacted well; and three piston pressure plates continuously move vertically to compact the silage, and therefore, the silage compacting effect is good.

Owner:福建省莆田市荔城区其乐淘淘电子商务有限公司

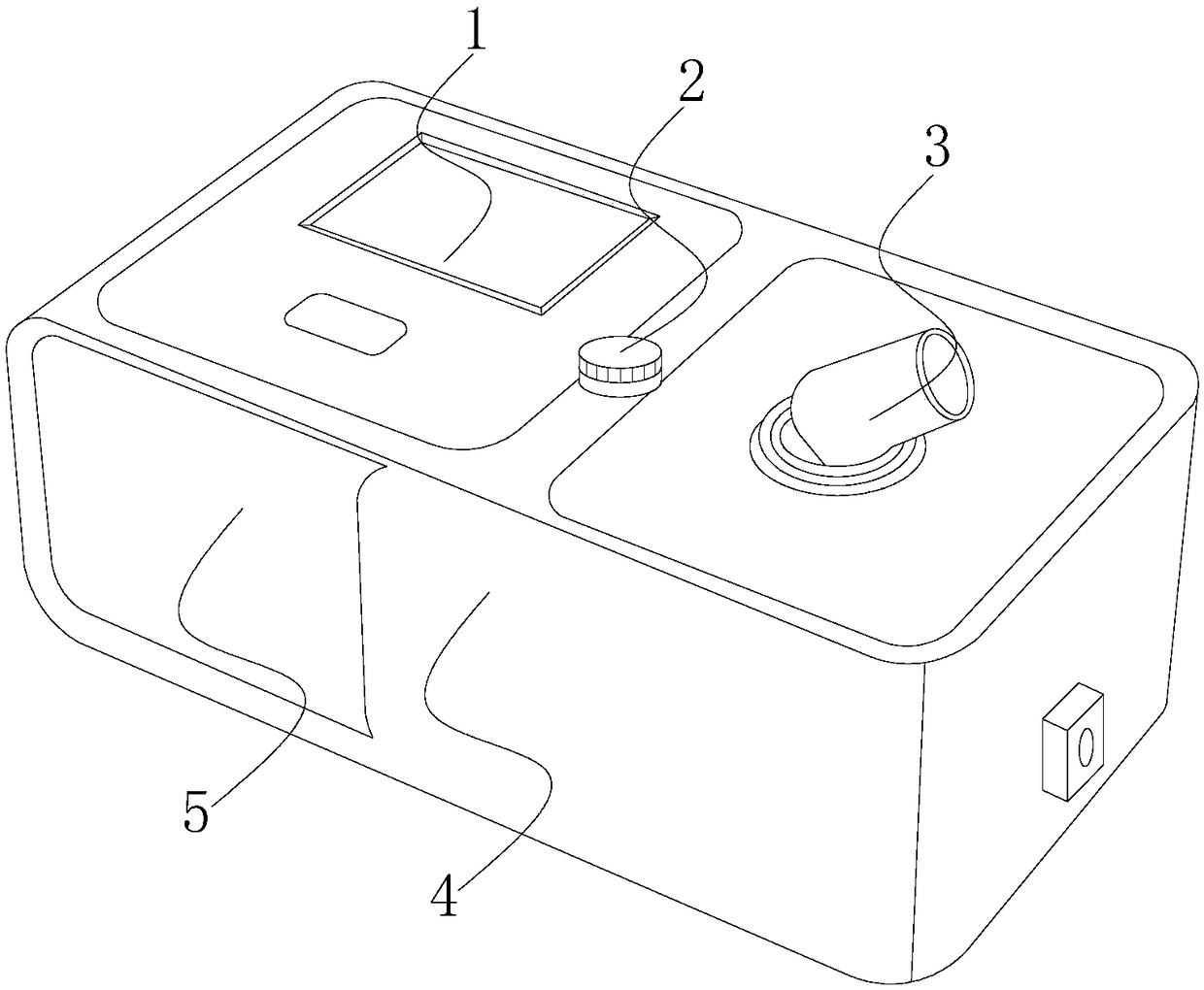

Breathing machine for cardio-pulmonary resuscitation

InactiveCN108853666AIncrease oxygenImprove work efficiencyRespiratorsMedical devicesElectricityMedicine

The invention discloses a breathing machine for cardio-pulmonary resuscitation. The breathing machine structurally comprises a data displayer, an adjusting knob, an oxygen connecting pipe, a breathinghost and a front cover, wherein the data displayer is embedded in the left end of the upper surface of the breathing host and electrically connected with the left end of the upper surface of the breathing host through a wire, the lower end of the adjusting knob is embedded in the middle end of the breathing host and mechanically connected with the inner portion of the middle end of the breathinghost, the oxygen connecting pipe is connected with the inner portion of the right side of the breathing host, and the left end of the front surface of the breathing host is provided with the front cover. The breathing machine for the cardio-pulmonary resuscitation has the advantages that an air inlet mechanism is adopted to make the air amount increase, the oxygen amount increases through the workof a compressing mechanism, so that the oxygen amount of the inner portion of the breathing machine increases, thereby having a very good effect on the cardio-pulmonary resuscitation; a heat transmission mechanism absorbs heat energy in the breathing machine, and heat dissipation is carried out on internal electronic components through the work of an air blast heat dissipation mechanism, therebyimproving the working efficiency of the breathing machine.

Owner:张莹

Cable conductor continuous stranding drawing forming device

ActiveCN109461539BAvoid loweringGuaranteed movement trackCable/conductor manufactureElectrical conductorEngineering

The invention discloses a continuous twisting and drawing forming device for cable conductors, the structure of which comprises a twisting host, a box door, a window, a handle, a warning light, an operating table, supporting feet, heat dissipation holes, and a device base. The top of the twisting host is fixedly installed with The box door has a window embedded in the front surface of the box door, and a handle is fixedly installed on the box door. The window is located directly above the handle, and the warning light is fixedly installed on the top of the device base. Both ends of the head and tail are clamped to increase the clamping force. At the same time, the foot-operated mechanism drives the first fixed twisting mechanism and the tail fixed twisting mechanism to pull the bare conductor. After pulling, the first fixing mechanism is automatically opened by the touch mechanism. The twisting mechanism and the tail fixed twisting mechanism perform reverse twisting work, which speeds up the twisting speed. At the same time, the staff can carry out the cable twisting work without turning on the switch on the twisting mechanism, and the operation is more convenient.

Owner:安徽新信电气有限公司

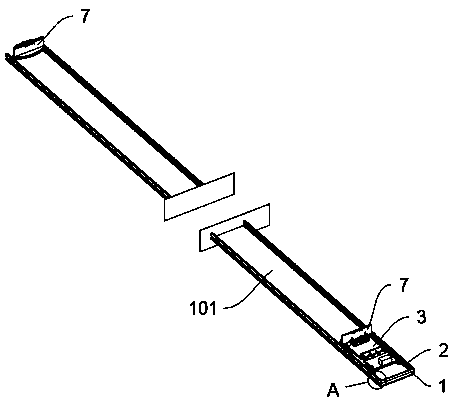

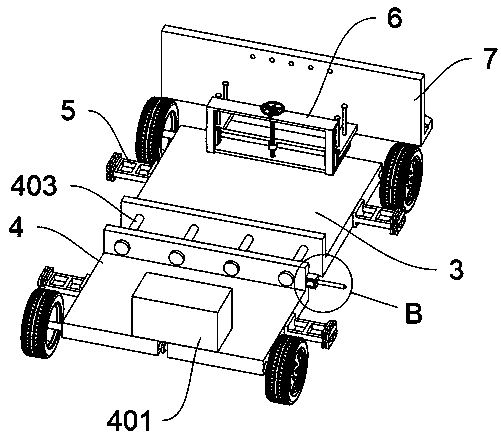

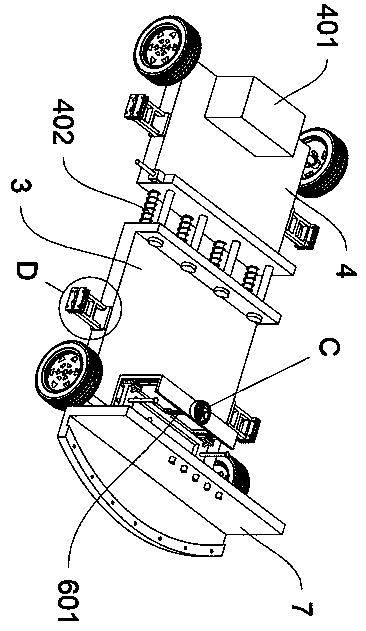

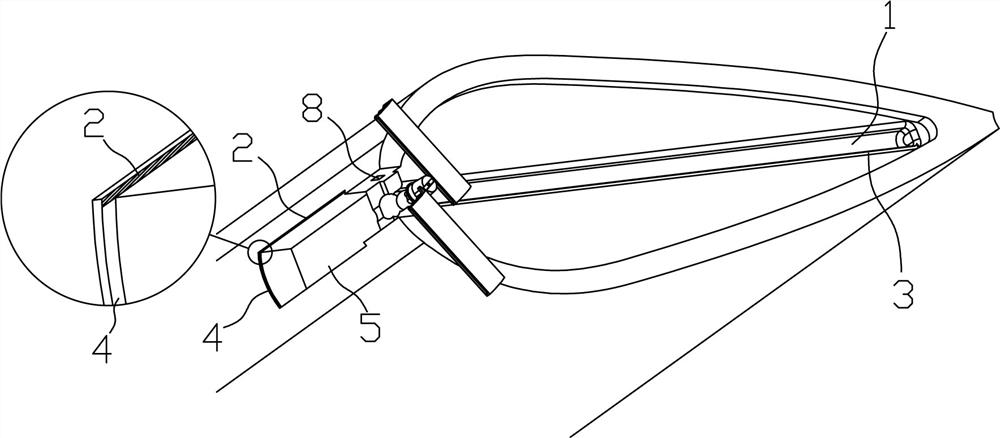

Cleaning device and cleaning method for lifting fins of marine scientific research ship

ActiveCN112758262BGuaranteed movement trackReduce erosionVessel cleaningHydrodynamic/hydrostatic featuresMarine engineeringCrank

A cleaning device and method for lifting and lowering fins of marine scientific research ships, including a moving track, a driving device, a cleaning panel and a general controller, the driving device is driven to move by a cyclical driving motor, and the cyclical driving motor is powered by a battery Thereby driving the driving device to move, the crank connecting rod is connected with the driving device through a wire, thereby driving the crank connecting rod to drive the cleaning panel to move, the brush on the cleaning panel and the double-sided combined rotary blade move to remove the attachment on the fin plate, and The purpose of cleaning the fins of scientific research ships is finally achieved, the manpower, material and financial resources required for fin cleaning are reduced, and the convenience and safety of fin cleaning operations are realized.

Owner:CHINA THREE GORGES UNIV

An automatic textile processing and drying device

ActiveCN108731446BFully dryGuaranteed movement trackDrying solid materials with heatDrying gas arrangementsFan bladeChain link

The invention discloses an automatic textile processing and drying device. Its structure includes a top box, a handle, a box door, a drying host, supporting feet, and a hinge. The lower end of the top box is fixedly installed on the upper end of the drying host, and the handle is installed in front of the box door. On the surface, the box door is installed on the front surface of the drying machine through hinges. At this time, the blowing mechanism starts to work, and the linkage shaft on the blowing mechanism rotates to make the fan blades rotate to generate wind energy and initially dry the textiles; Following the movement of the chain, the frame moves, which drives the connecting rod to move. At this time, the drying lamp moves to ensure that all parts of the textile can be irradiated by the drying lamp, and the textile is fully dried; through the trajectory inside the roller, Make the swing rod start to swing, at this time the arc-shaped tooth plate starts to swing, and the rack meshed with the arc-shaped tooth plate also moves left and right, moving the textiles left and right, so as to prevent the drying lamp from irradiating the same part for a long time and causing the textiles to be damaged .

Owner:山东省科学院高新技术产业(中试)基地

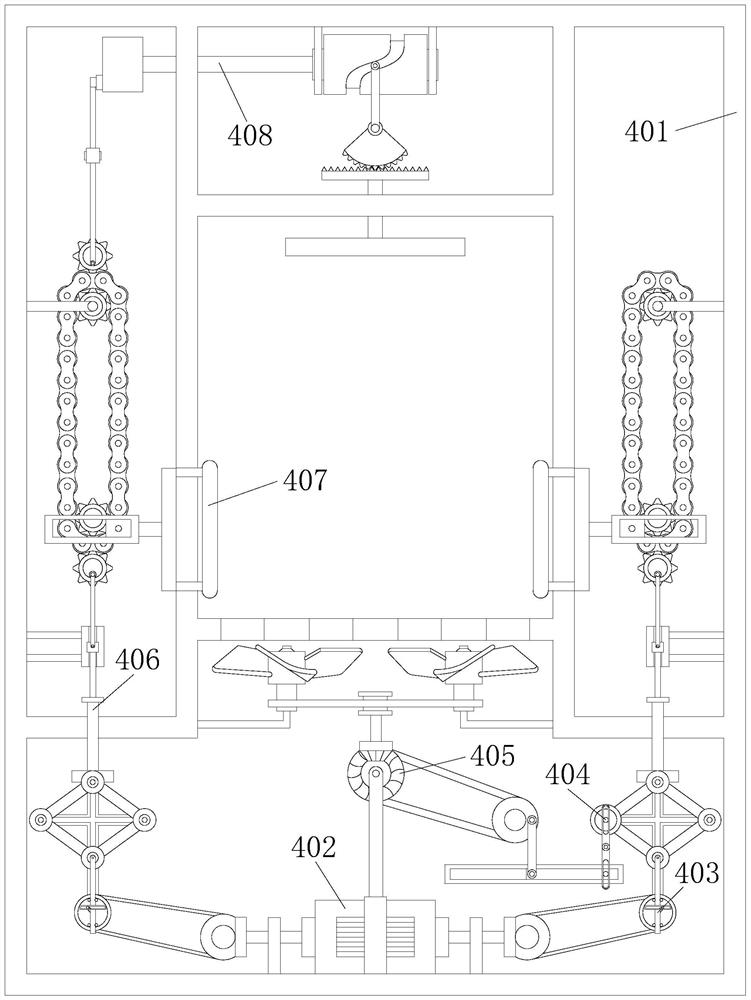

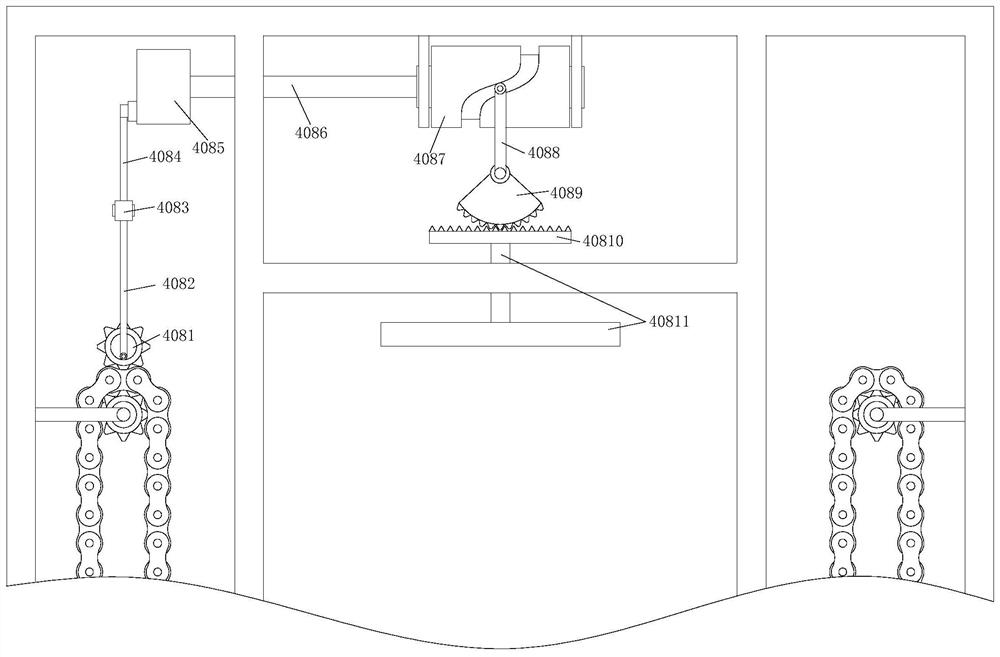

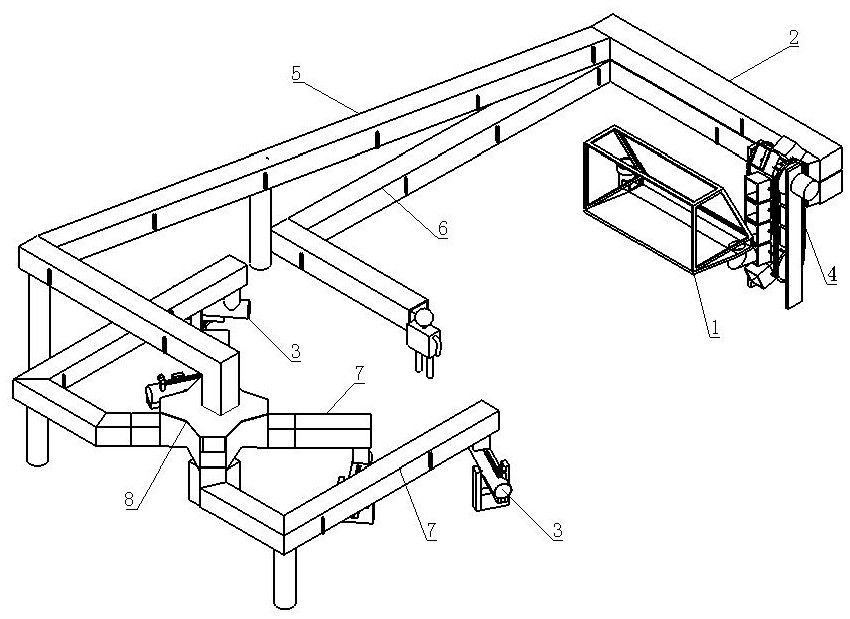

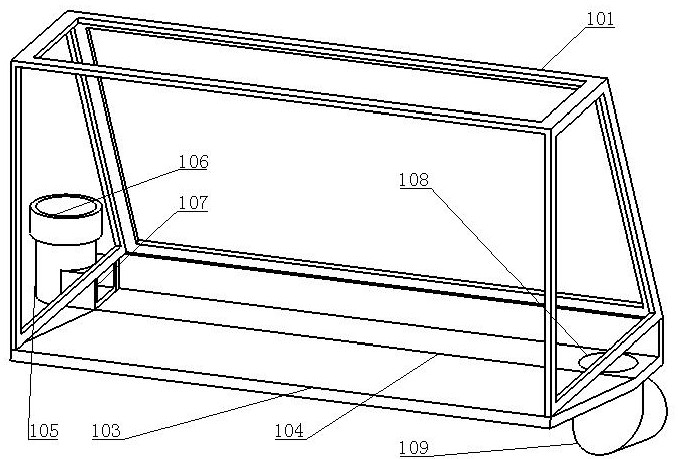

Intelligent football shooting training system

ActiveCN112843640AEasy to movePrevent fallingBall sportsPhysical medicine and rehabilitationControl system

The invention belongs to the technical field of football training equipment, relates to the technical field of intelligent manufacturing, and particularly discloses an intelligent football shooting training system which comprises a shooting training system and a control system matched with the shooting training system, and is characterized in that the shooting training system comprises a collecting device and a conveying device matched with the collecting device; and multiple transmitting devices are arranged at the end, away from the collecting device, of the conveying device. The conveying device comprises a fixed-point conveyor matched with the collecting device and further comprises a first conveying channel and a second conveying channel which are matched with the fixed-point conveyor, a random conveyor is arranged at the end, away from the fixed-point conveyor, of the first conveying channel, and a third conveying channel is arranged between the random conveyor and any transmitting device. Each launching device comprises an ejection mechanism and further comprises a compression mechanism and a locking mechanism which are matched with the ejection mechanism, and a warning lamp is arranged in each launching device.

Owner:HENAN POLYTECHNIC INST

A drone with adsorption function

ActiveCN108820208BImprove purification effectEffective inhalationDispersed particle filtrationFuselagesCircular discAir decontamination

The invention discloses an unmanned aerial vehicle with an adsorption function. The structure of the unmanned aerial vehicle with the adsorption function comprises a rotation motor, a flying blade, atelescopic arm, a supporting seat and an unmanned aerial vehicle main body; the rotation motor is mounted at the front end of the telescopic arm; the flying blade is mechanically connected with the rotation motor; a spiral rod engaged with a saw tooth circular disc rotates to enable an exhaust fan blade to extract air so as to suck the atmosphere, and therefore, several dust particles are more effectively sucked; the transmission of a second belt drives a second rotating shaft to rotate; at the moment, a second rotating rod rotates to drive the fan blade to rotate so that power assistance is provided for the air to blow the air into an adsorbing carbon plate to adsorb dusts, and therefore, an air purifying effect is better; a downward moving plate moves to the right lower side; a limitingplate has a limiting effect on a moving track of the downward moving plate to guarantee the moving track of the downward moving plate; the downward moving plate pulls a fixed connecting plate to move;the fixed connecting plate pulls a slide block to run on a sliding rod; the slide block drives the telescopic arm to extend into a housing so as to have a protecting effect on the telescopic arm.

Owner:安徽匠桥财务咨询服务有限公司

Engine repair auxiliary device

The invention belongs to the technical field of engines and provides an engine repair auxiliary device. The engine repair auxiliary device comprises supporting frames, a fixing frame and an adjustingdevice. The adjusting device is fixedly connected with a supporting device through the fixing frame. The adjusting device comprises an adjusting seat, an adjusting shaft and a fixing seat. Limiting railways are arranged at the two ends of the fixing seat, the adjusting seat is connected with the fixing seat through fixing bolts, and the fixing bolts are positioned in the limiting railways. A firstgear structure is arranged on the fixing seat. A second gear structure meshing with the first gear structure is arranged on the adjusting shaft. A limiting hole is formed in the adjusting seat, one end of the adjusting shaft is in the limiting hole, and the other end of the adjusting shaft penetrates through the limiting hole and is fixedly connected with an adjusting handle. The engine repair auxiliary device enables the engines and other big equipment to rotate fixedly, so that the engines and the other big equipment are convenient to repair.

Owner:SHANDONG VOCATIONAL COLLEGE OF SCI & TECH

Precisely adjustable intelligent road construction equipment

The invention discloses an intelligent road construction device which can be precisely adjusted, A support bar is connected to that support bar, Pusher, dust box, moving wheel, A low end of that connecting support rod is weld to the upper surface of the construction main machine, An upper end of the connection support rod is welded with a push hand, A dust collector is fixedly installed on the right side surface of the construction main machine, At that low end of the dust collector, the moving wheel is arrange to make the main transmission mechanism work through the opening of the power mechanism, This is the sweeping mechanism that sweeps the pavement, sweep away sharp objects, Then, the dust is polished by a polishing mechanism, the polishing process is damaged, and the dust generated during the polishing is sucked into a dust collecting box through a driving mechanism to be processed centrally so as to prevent the dust from floating everywhere, and the dust sucking mechanism is driven to move by a moving mechanism, so that the dust sucking mechanism is omni-directionally sucked, and the dust sucking effect is better.

Owner:浙江金果知识产权有限公司

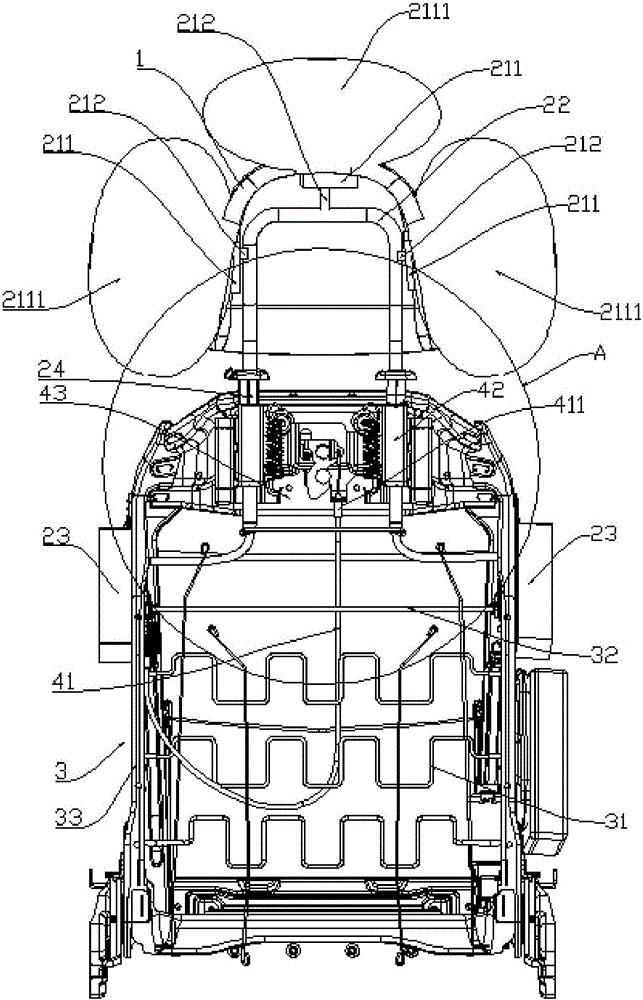

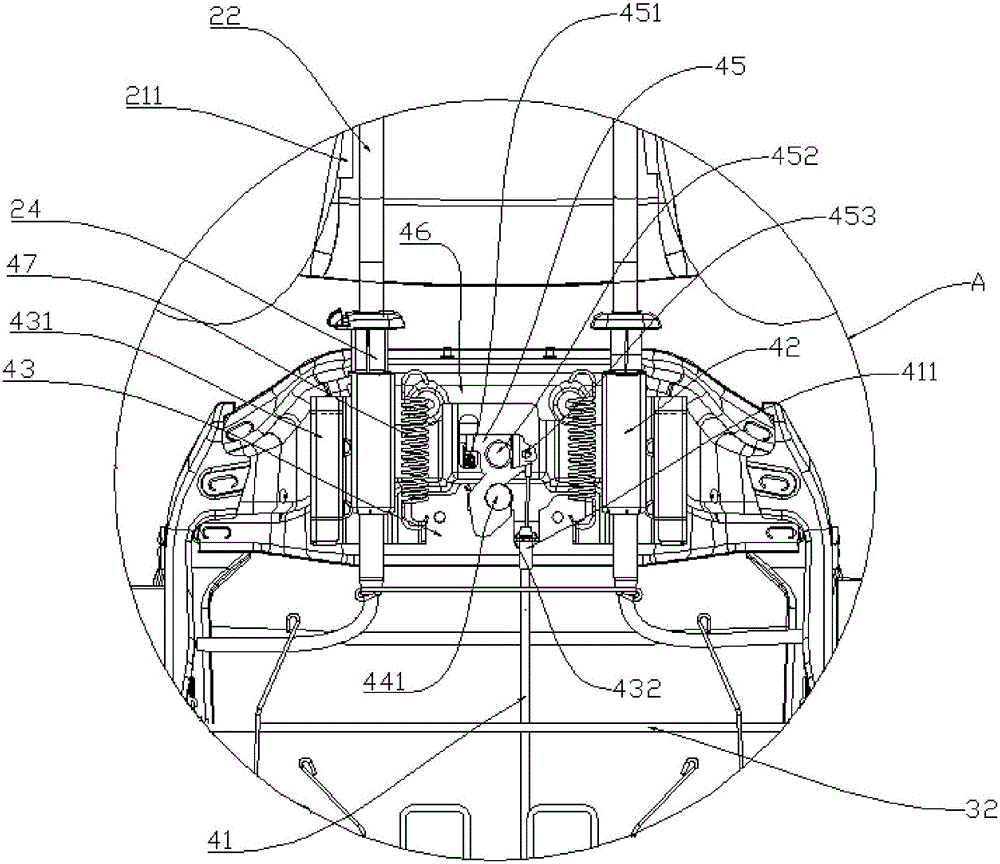

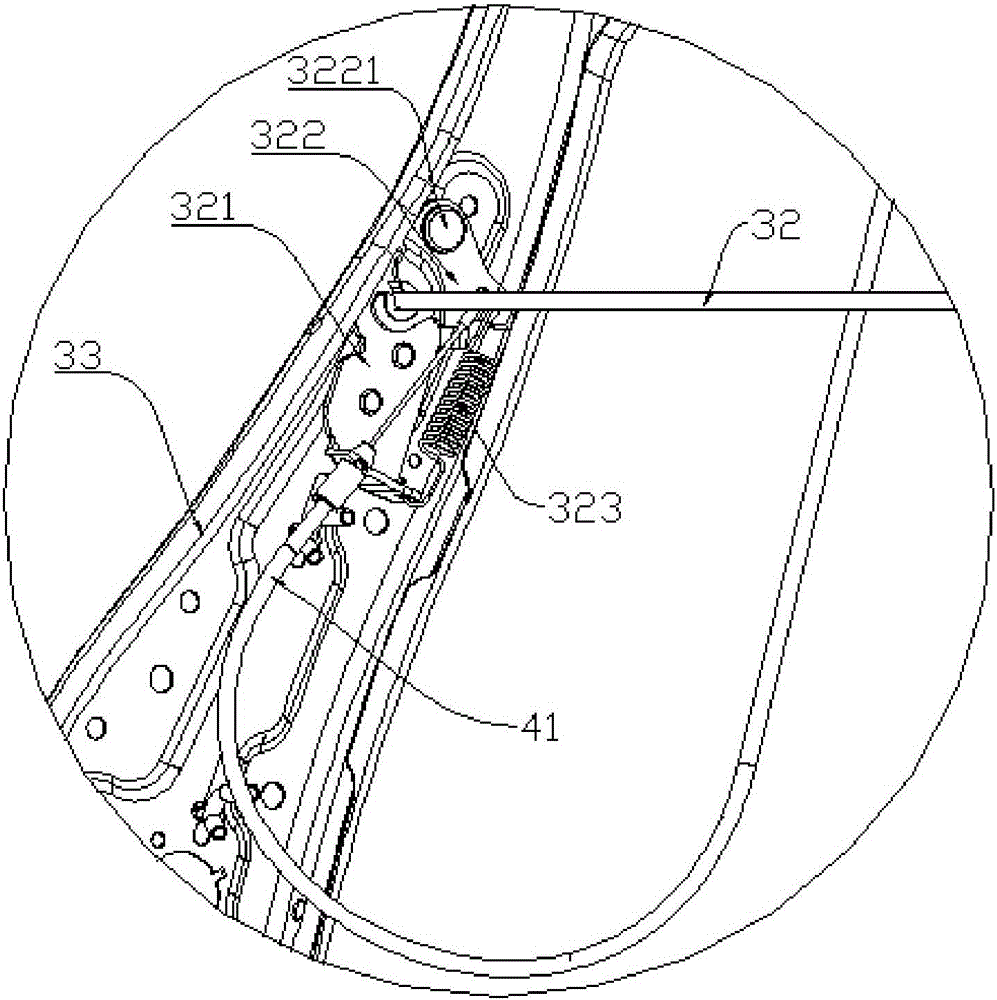

a car seat

ActiveCN104527478BAutomatic and quick adjustmentAvoid dangerVehicle seatsPedestrian/occupant safety arrangementCar seatPull force

The invention provides an automobile seat. The automobile seat comprises a head cushion and a backrest which are configured in a matched manner, wherein the head cushion is connected with the backrest through a head cushion rod, and comprises a head cushion movement mechanism; the head cushion movement mechanism comprises an operation force generating assembly and a movement assembly; the movement assembly comprises a limiting buckle clamping shaft, a movable board and a pull force spring; a clamping shaft through hole is formed in the movable board; the limiting buckle clamping shaft is fixedly connected with the movable board through the clamping shaft through hole; one end of the pull force spring is connected with the movable board; the movable board is further connected with the head cushion rod; the other end of the pull force spring is connected with the backrest. According to the automobile seat, the operation force generating assembly and the movement assembly are configured in the matched manner, so that the height of the head cushion, which is relative to the backrest, is automatically and rapidly realized. Therefore, the damage that the head of a passenger is clamped in the connection of the head cushion and the backrest can be effectively avoided.

Owner:GREAT WALL MOTOR CO LTD

Cutting device for steel plate machining

ActiveCN112792410APrevent slippingGuaranteed steady stateMeasurement/indication equipmentsPositioning apparatusWastewaterStructural engineering

The invention discloses a cutting device for steel plate machining, and relates to the field of steel plate machining. The cutting device for the steel plate machining comprises an operation table, a cutting chamber, a cutter, automatic measuring equipment, a controller, a moving roller, a feeding assembly and a dustproof assembly; the cutting chamber is arranged on the operation table, and a feeding end and a discharging end are open; the moving roller is rotationally arranged on the operation table; the cutter and the automatic measuring equipment are arranged in the cutting chamber; the feeding assembly is arranged on the operation table and is close to the feeding end of the cutting chamber; the dustproof assembly is arranged on the cutter. According to the cutting device for the steel plate machining, the feeding assembly is arranged to fix a steel plate, a stable state of the steel plate in the cutting process is guaranteed, a cutting error is reduced, automatic feeding is achieved, and the working efficiency is improved; the dustproof assembly avoids dust flying, waste water is recycled, and environment-friendly and energy-saving purposes are achieved; a positioning assembly is arranged to position a cutting end of the steel plate, a steel plate moving track is guaranteed, and cutting accuracy is improved.

Owner:浙江天羿钢结构有限公司

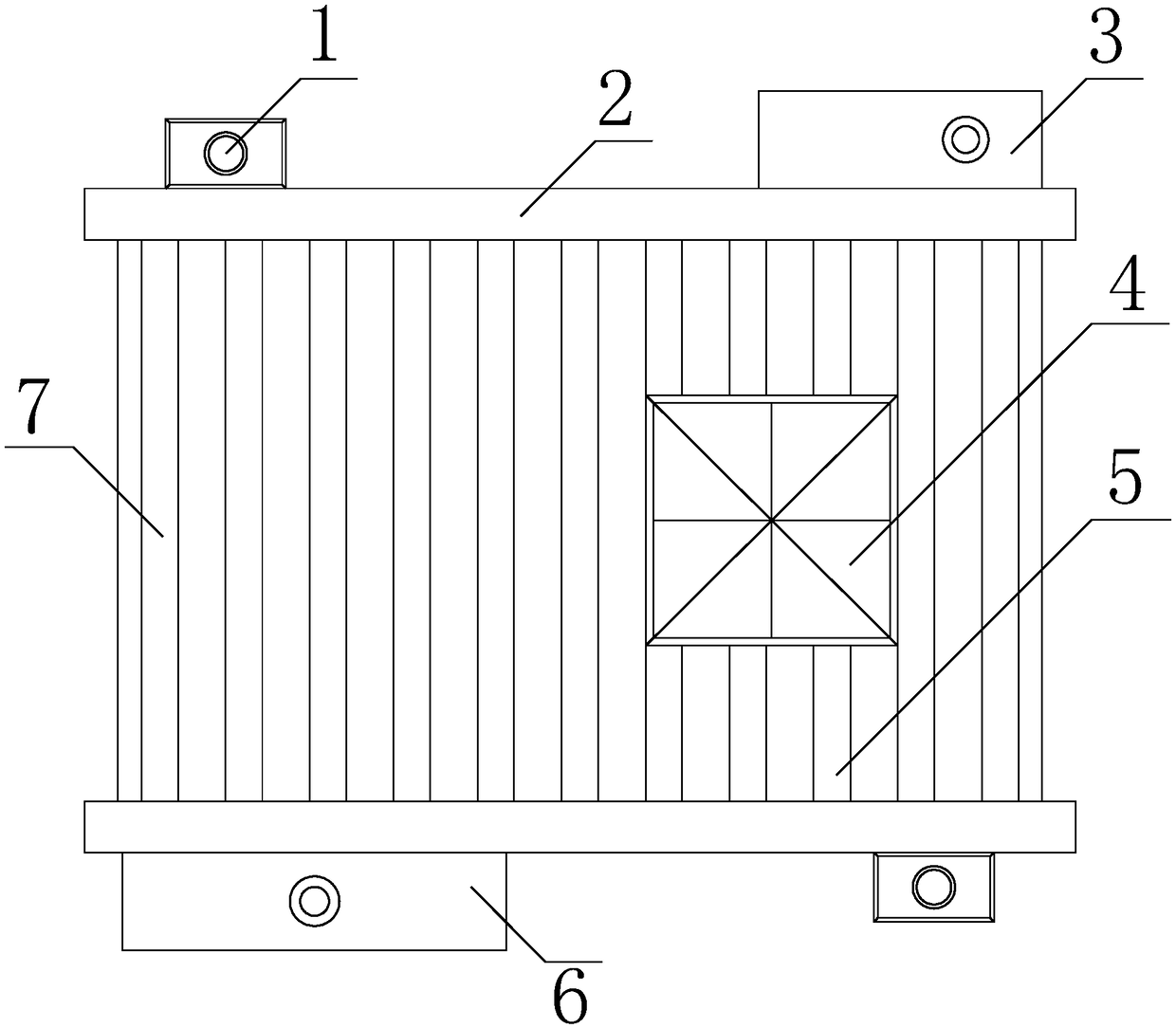

Engine radiator

ActiveCN109296438AImprove cooling effectGood effectLiquid coolingMachines/enginesThermal energyCooling effect

The invention discloses an engine radiator. The engine radiator structurally comprises a lifting lug, a fixing base, a water inlet, an air outlet, a radiator body, a cooling water outlet and cooling fins. The lifting lug is fixedly mounted on the upper surface of the left side of the fixing base. The water inlet is formed in the upper surface of the right side of the fixing base and is connected with the interior of the radiator body. The air outlet is inlaid in the front surface of the right side of the radiator body. The cooling water outlet is formed in the lower end of the left side of theradiator body. The cooling fins are inlaid in the outer surface of the radiator body. A heat transfer mechanism absorbs heat of an engine to work, so that wind energy is generated by a wind mechanismto cool the engine; the engine is correspondingly cooled according to the quantity of heat generated by the engine, so that the cooling effect is better; and a cooling mechanism is driven by a driving mechanism to operate, so that excessive heat in the radiator body is avoided, and the working efficiency of the radiator is ensured; and a circulating water pump mechanism can be automatically started through heat expansion of a heat expansion mechanism so as to spray cooling liquid to the engine to achieve cooling, and thus, the effect is better.

Owner:BOTE HEAT EXCHANGE SYST JIANGSU CO LTD

Safety warning device for bridge construction

ActiveCN109267511AGuaranteed to workAvoid power outagesTraffic signalsBridge erection/assemblyElectricityDisplay device

The invention discloses a safety warning device for bridge construction, the structure comprises a baffle, warning host, warning display, support foot, fixed base, adjusting knob, cooling hole, the baffles are positioned directly above the warning main unit and parallel to each other, a warning display is embedded on the front surface of the warning main unit and is electrically connected throughwires. the support pins are provided with two pins and penetrate the inside of the warning host, the supporting feet are vertically mounted inside the fixed base and are fitted with a clearance fit, asmall falling object is cushioned by a cushioning mechanism, and fixing and clamping the internal electronic mechanism through the fixing and clamping mechanism, a small falling object is prevented from hitting on the warning main unit and causing the electronic mechanism to vibrate and deviate, during the offshore construction, the center of gravity of the warning main engine can be lifted and lowered at will by the center of gravity lifting mechanism, and the center of gravity of the warning main engine can be lowered when the sea breeze is large, so as to ensure that the warning main engine can work normally and will not be blown down by the sea breeze.

Owner:HANGZHOU ZHUILIE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com