Patents

Literature

1003results about How to "Improve vacuuming effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

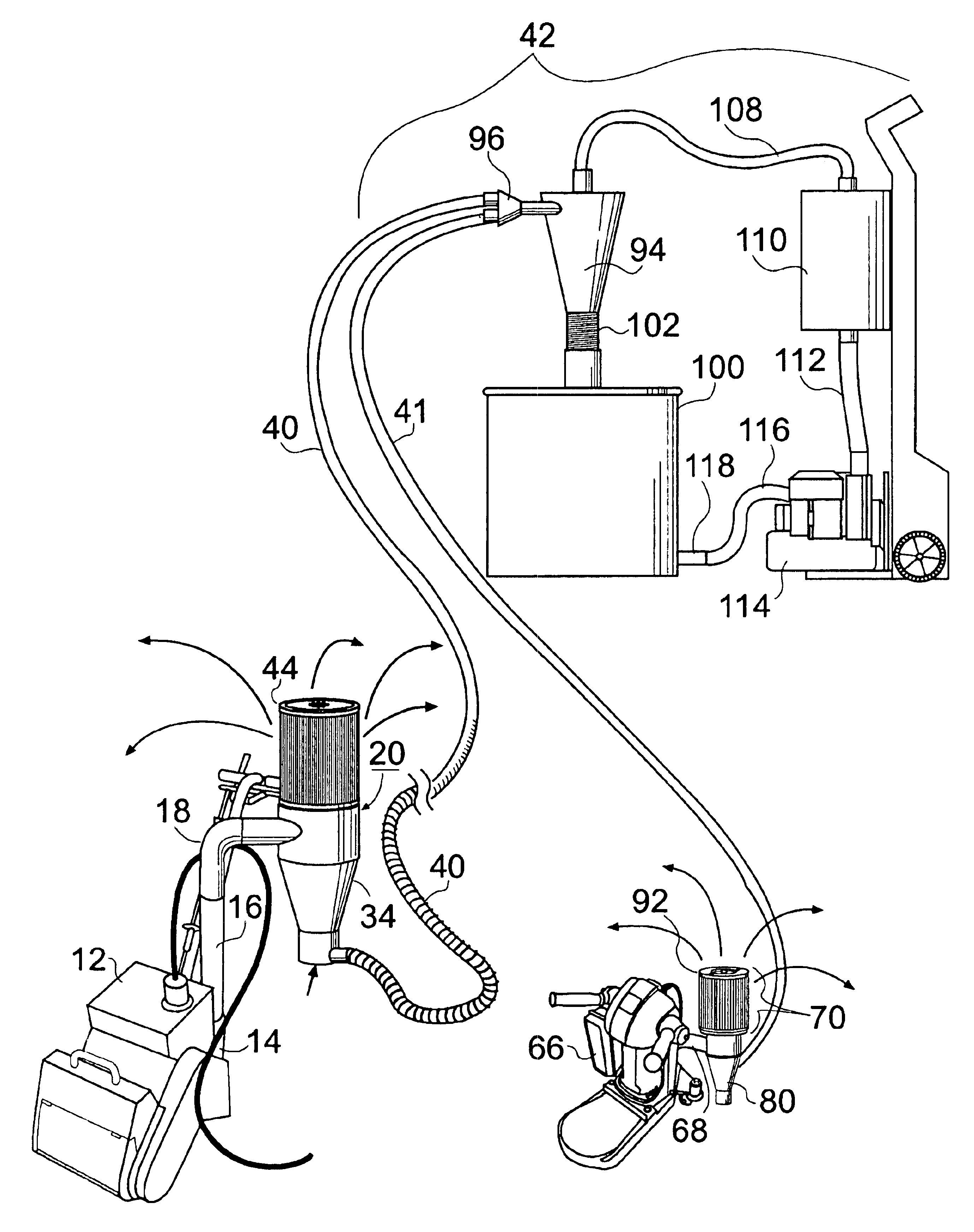

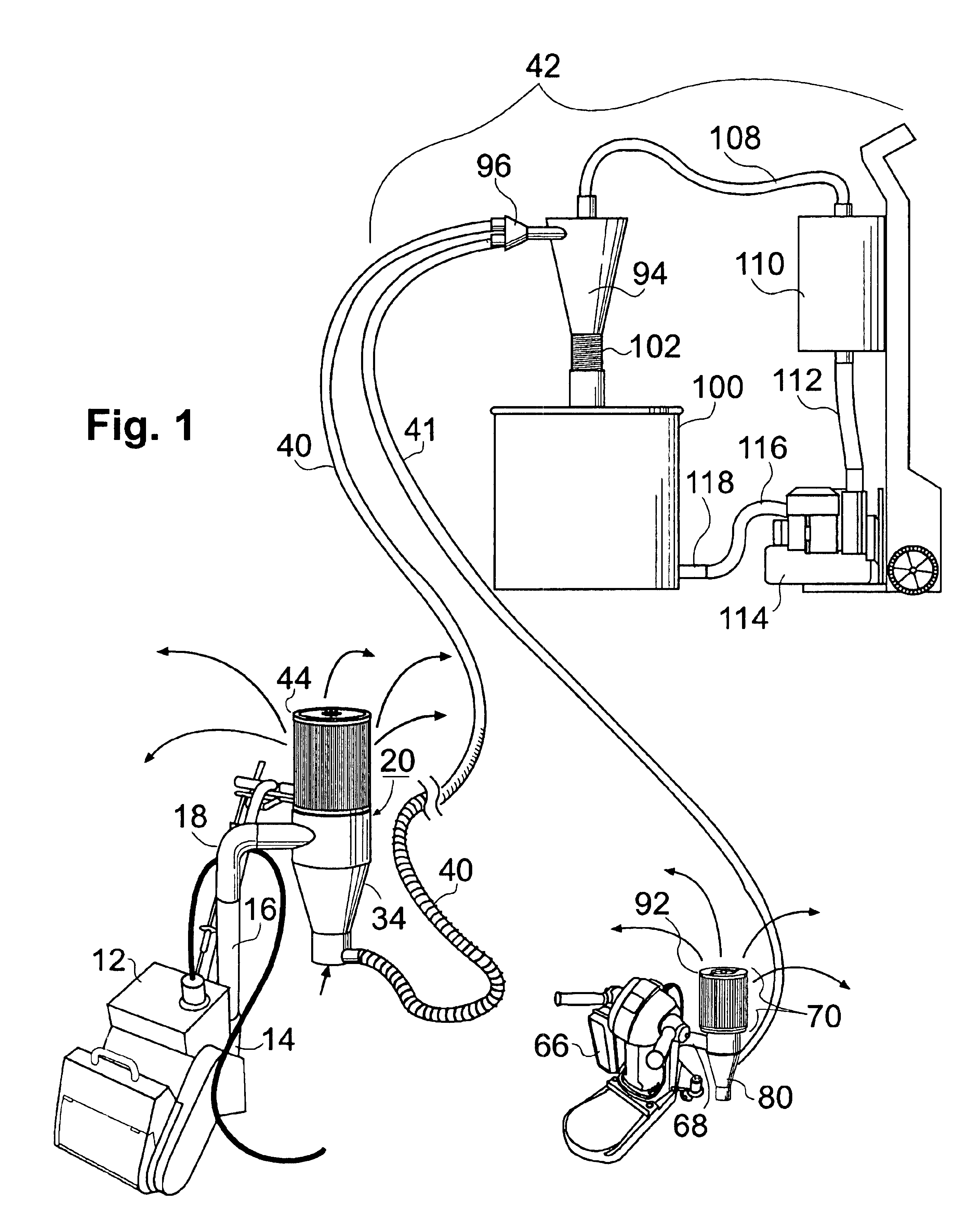

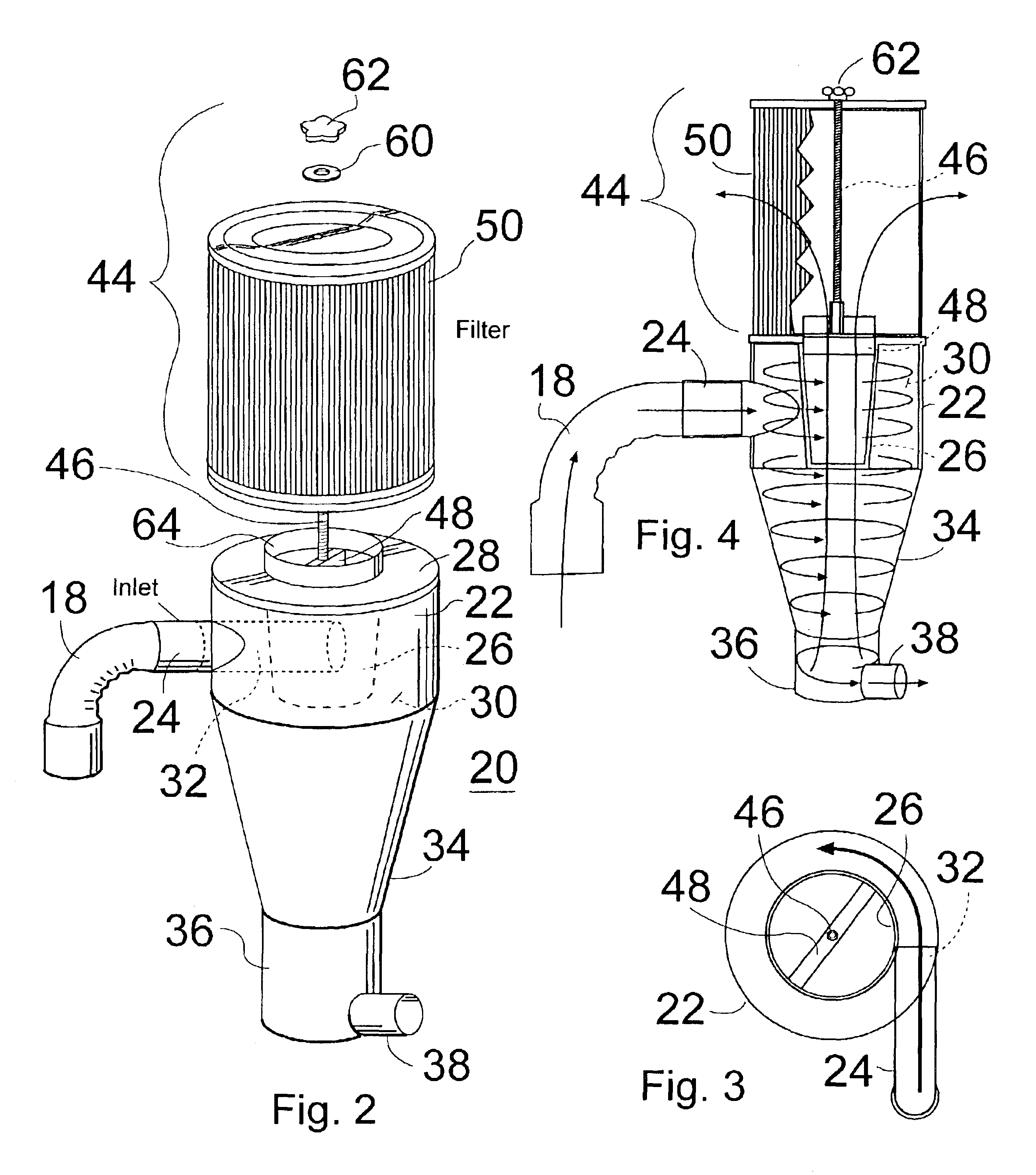

Dust collection system

InactiveUS6833016B2Reduced Power RequirementsReduce the risk of explosionCombination devicesReversed direction vortexCycloneCollection system

Owner:WITTER ROBERT M

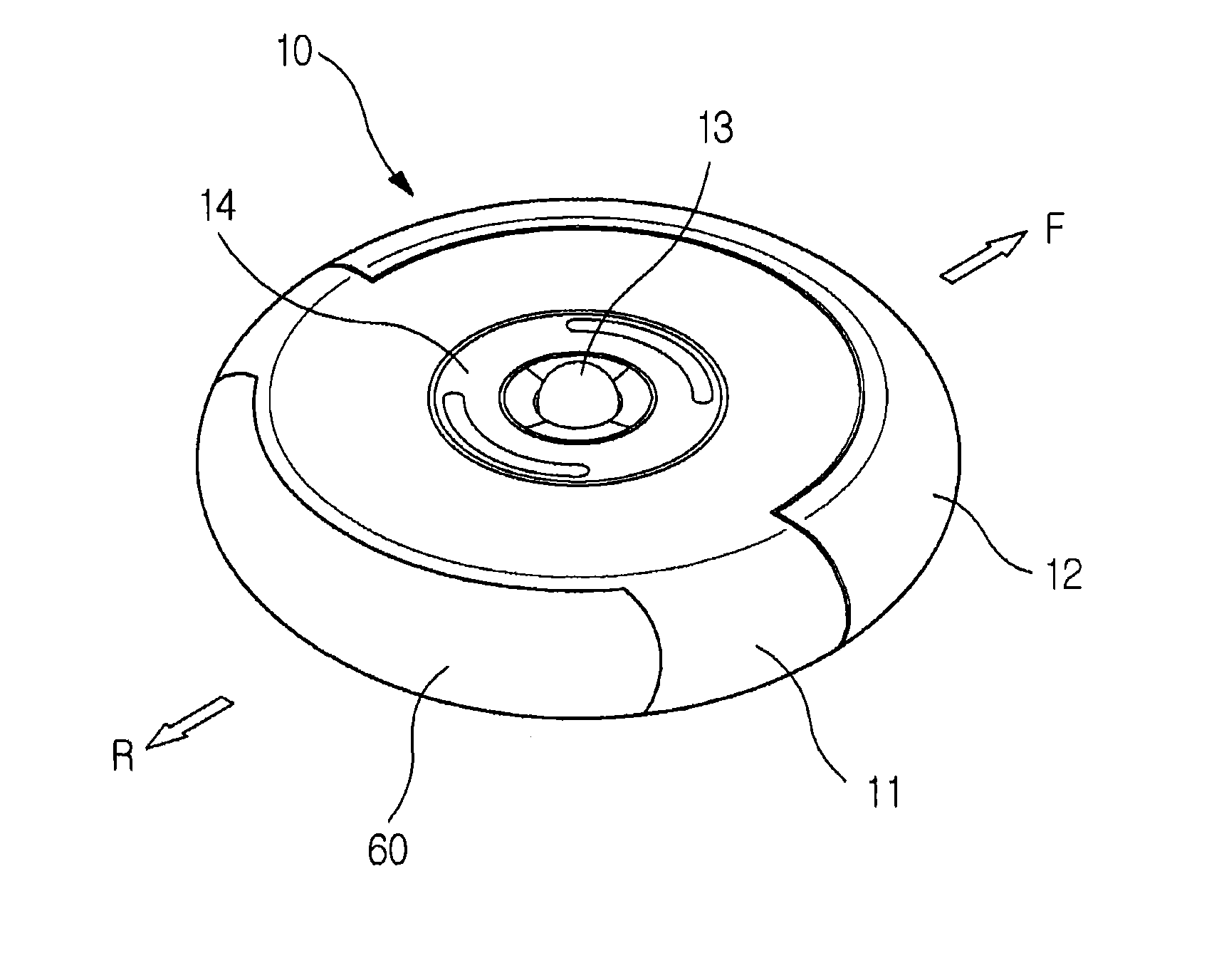

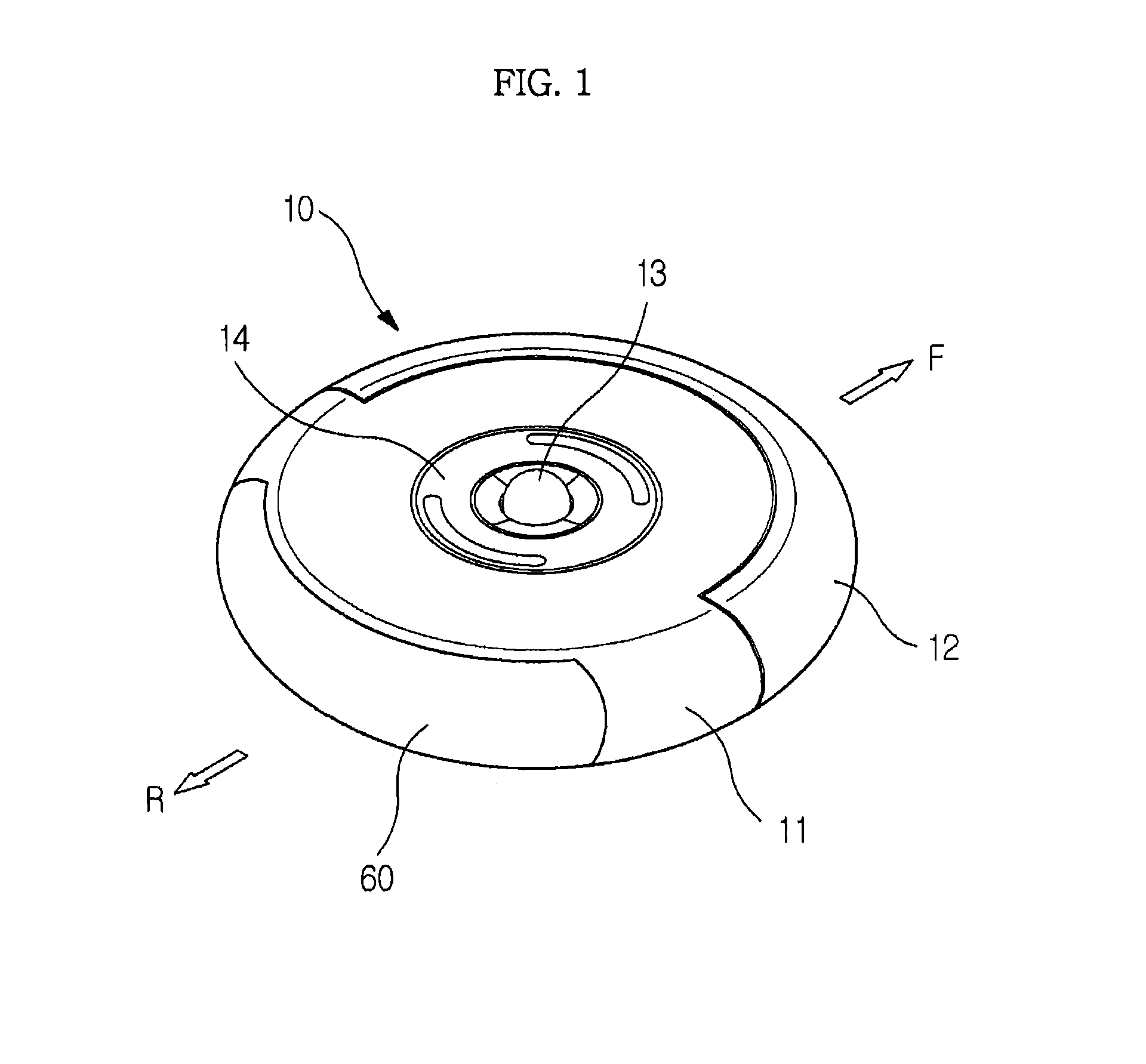

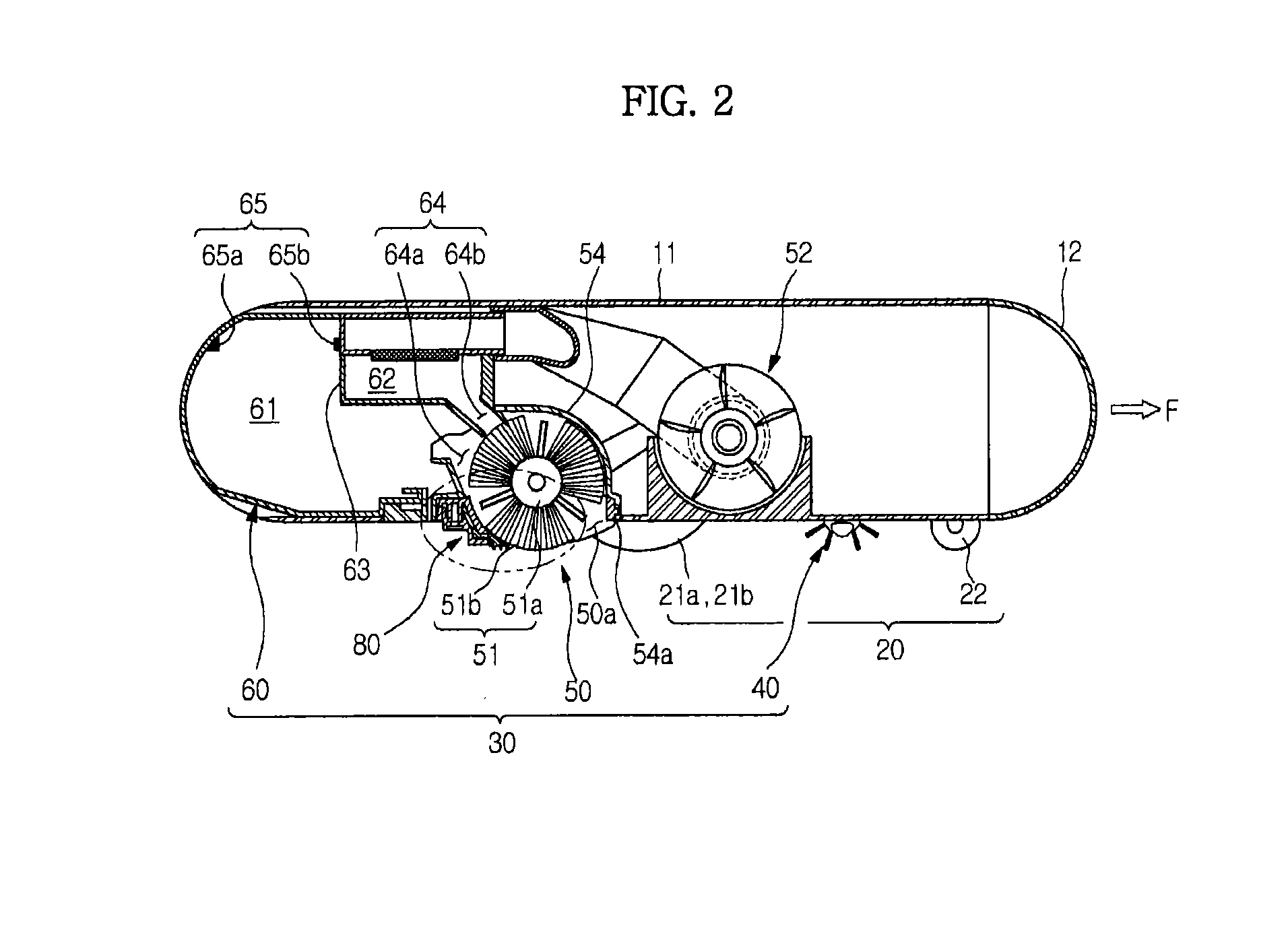

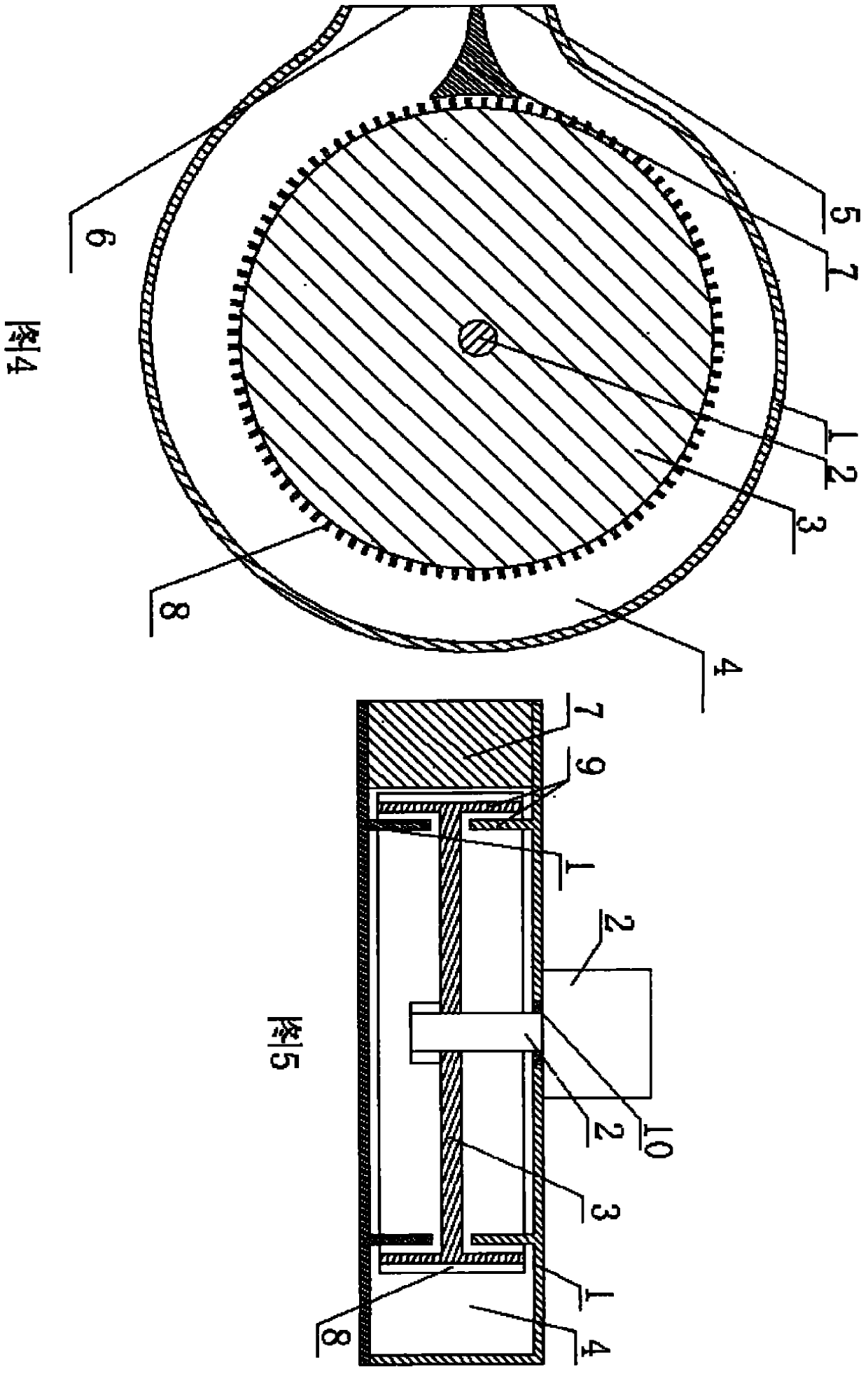

Autonomous cleaning device

ActiveUS20120317745A1Improve vacuuming effectSecures travel performance and cleaning performanceCarpet cleanersFloor cleanersBiomedical engineering

A blade assembly of an autonomous cleaning device. The blade assembly includes a blade having a first part fixed to the main body and a second part extended from the first part toward a floor and a support member having at least a portion disposed adjacent to the second part of the blade to restrict movement of the second part of the blade to within a predetermined range.

Owner:SAMSUNG ELECTRONICS CO LTD

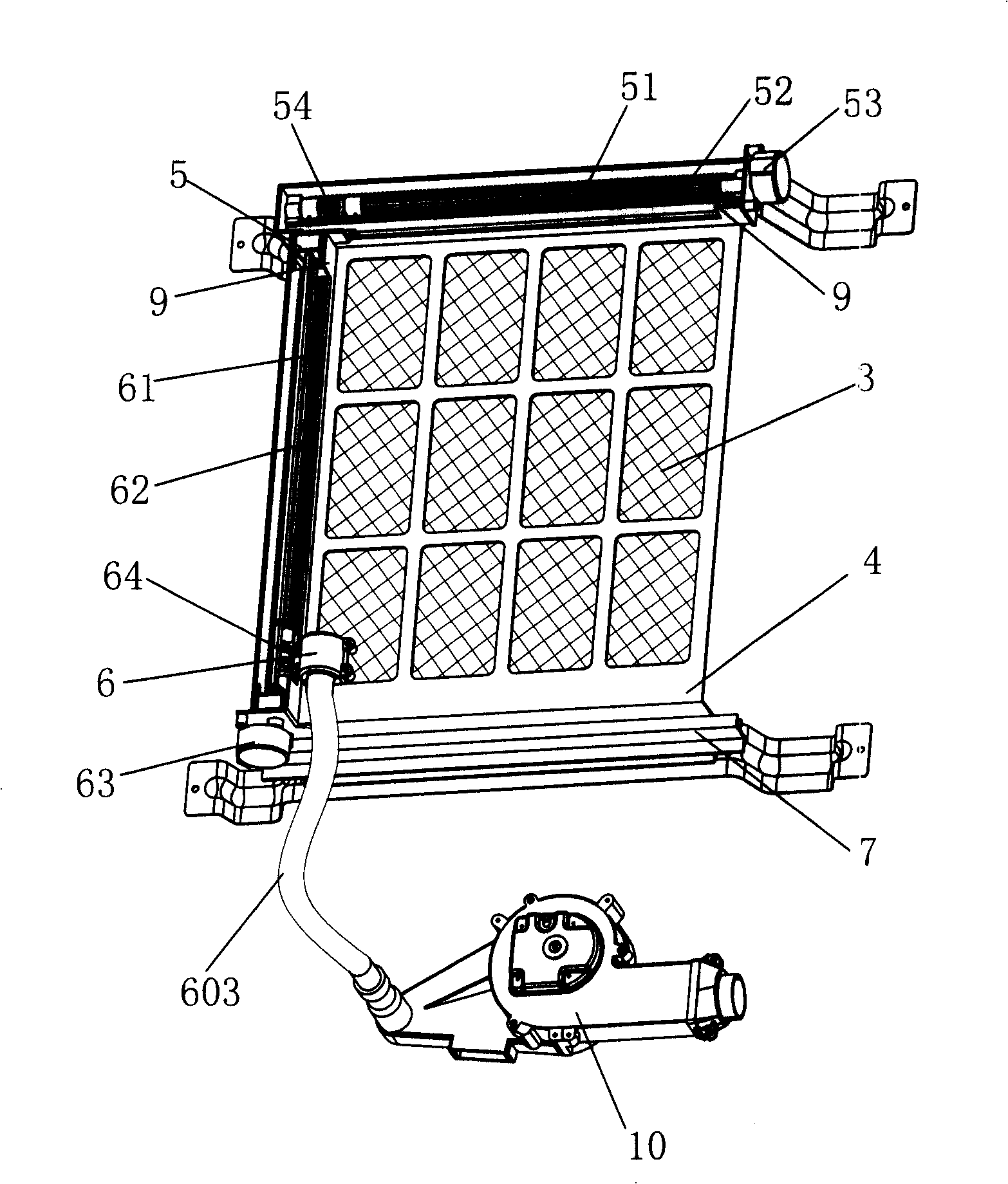

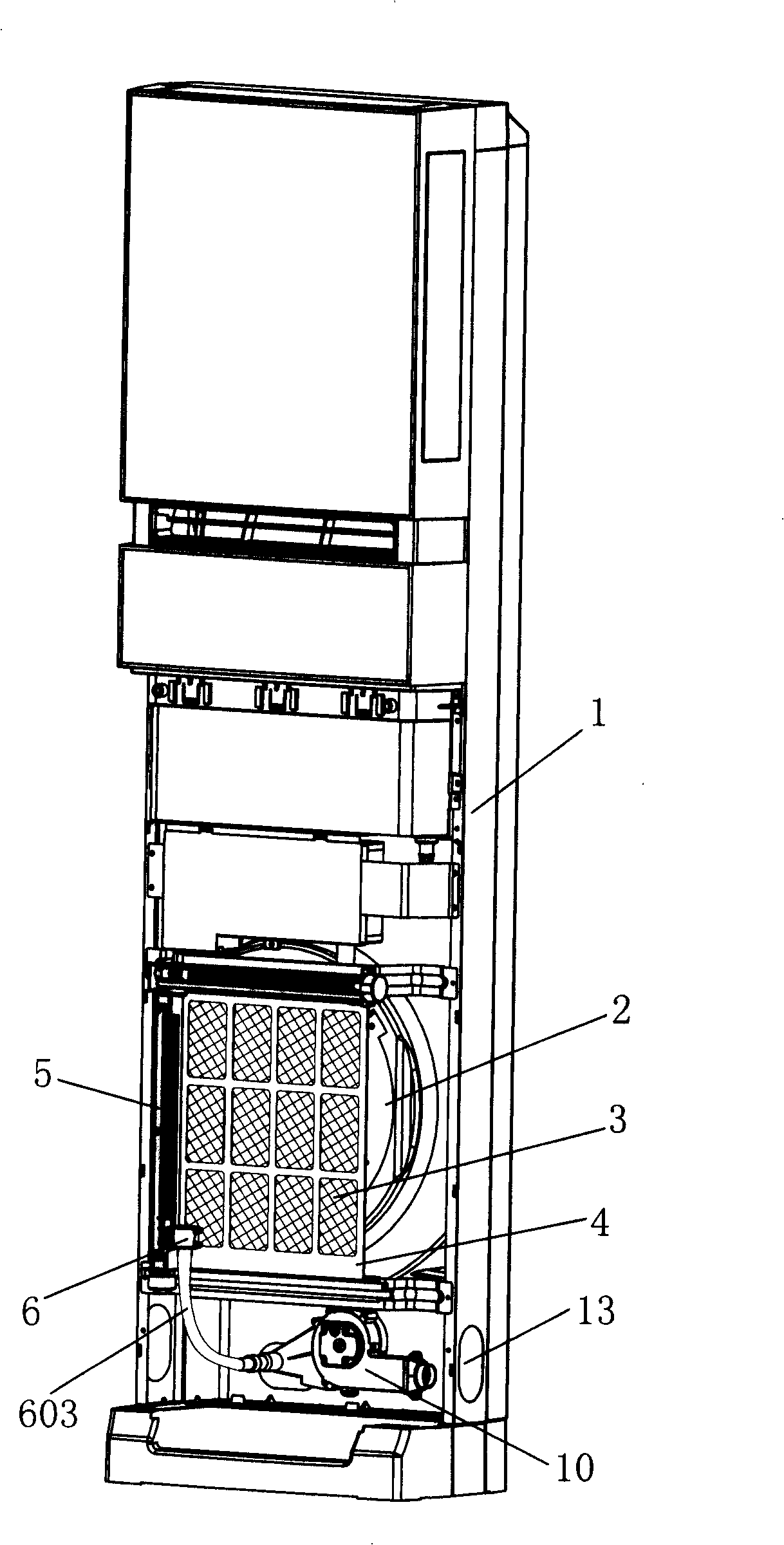

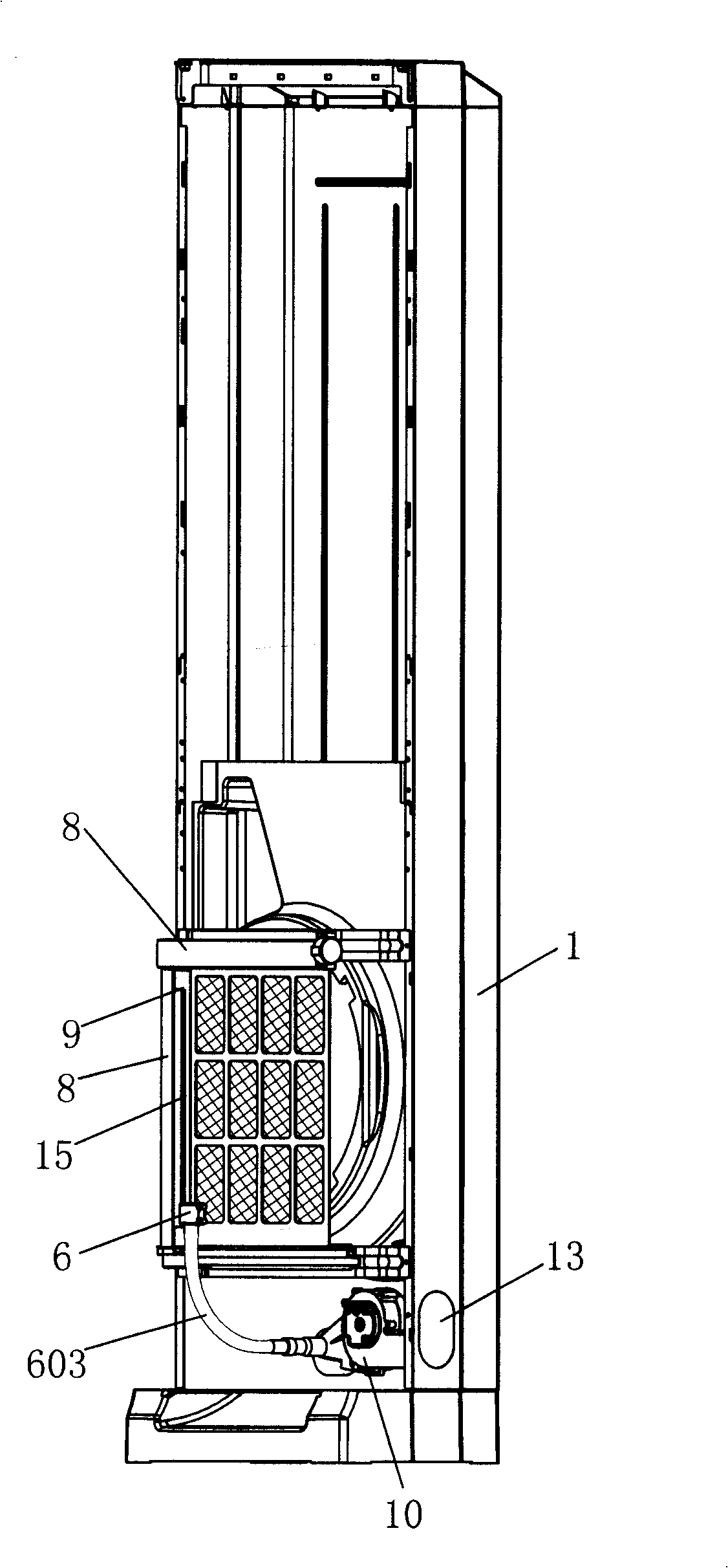

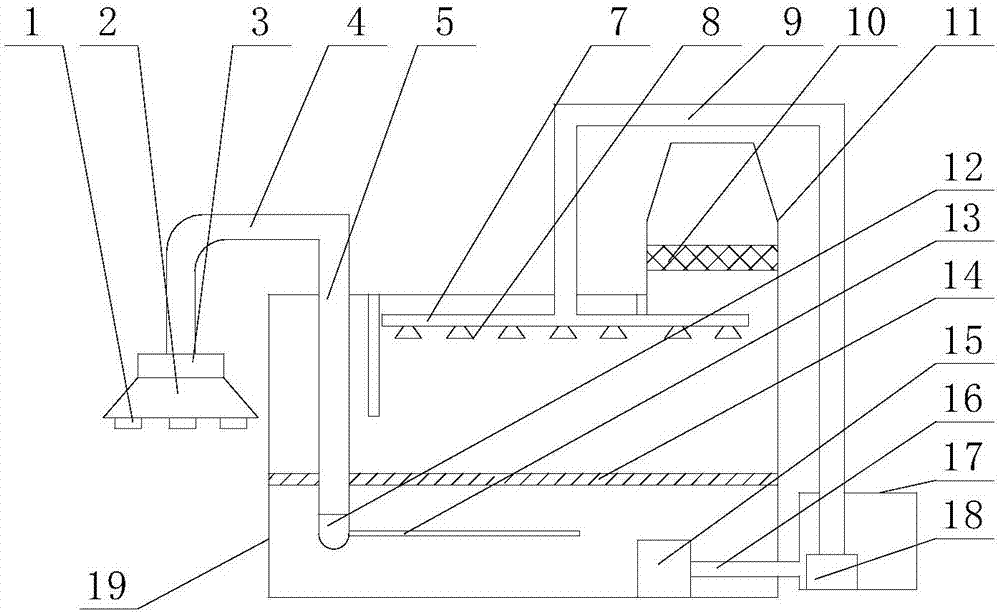

Cabinet air-conditioner dust gauze self-cleaning device and operation method thereof

ActiveCN101270913ASports reliableLow costLighting and heating apparatusSpace heating and ventilation detailsAirflowEngineering

The invention discloses a cabinet-type air-conditioning strainer mesh self-cleaning device and the working methods, wherein the device consists of a suction nozzle mechanism and a strainer mesh mechanism; the strainer mesh mechanism is fixed outside the scroll casing of the air passage and consists of a strainer mesh and a strainer mesh frame; the suction nozzle mechanism is attached to the side of the strainer mesh facing outward, and consists of main body arranged on the strainer mesh and a suction nozzle arranged on the main body, wherein the main body is driven by a drive mechanism to slide between the left and the right sides of the strainer mesh along the track, and the suction nozzle is driven by another drive mechanism to slide between the top and bottom sides of the strainer mesh along the main body; the suction nozzle is provided with a dust absorption port and a brush, and is connected with the vacuum cleaner arranged in the air-conditioning through a connecting passage; the brush adjacent to the dust absorption port cleans the strainer mesh first, and then the connecting passage of the vacuum cleaner produces negative pressure high speed air flow by way of the suction nozzle, and the air flow keeps sucking the dust at the dust absorption port. The invention is characterized by reliable operation, low costs, wide ranged of dust absorption and good effect of dust cleaning.

Owner:HAIER GRP CORP +1

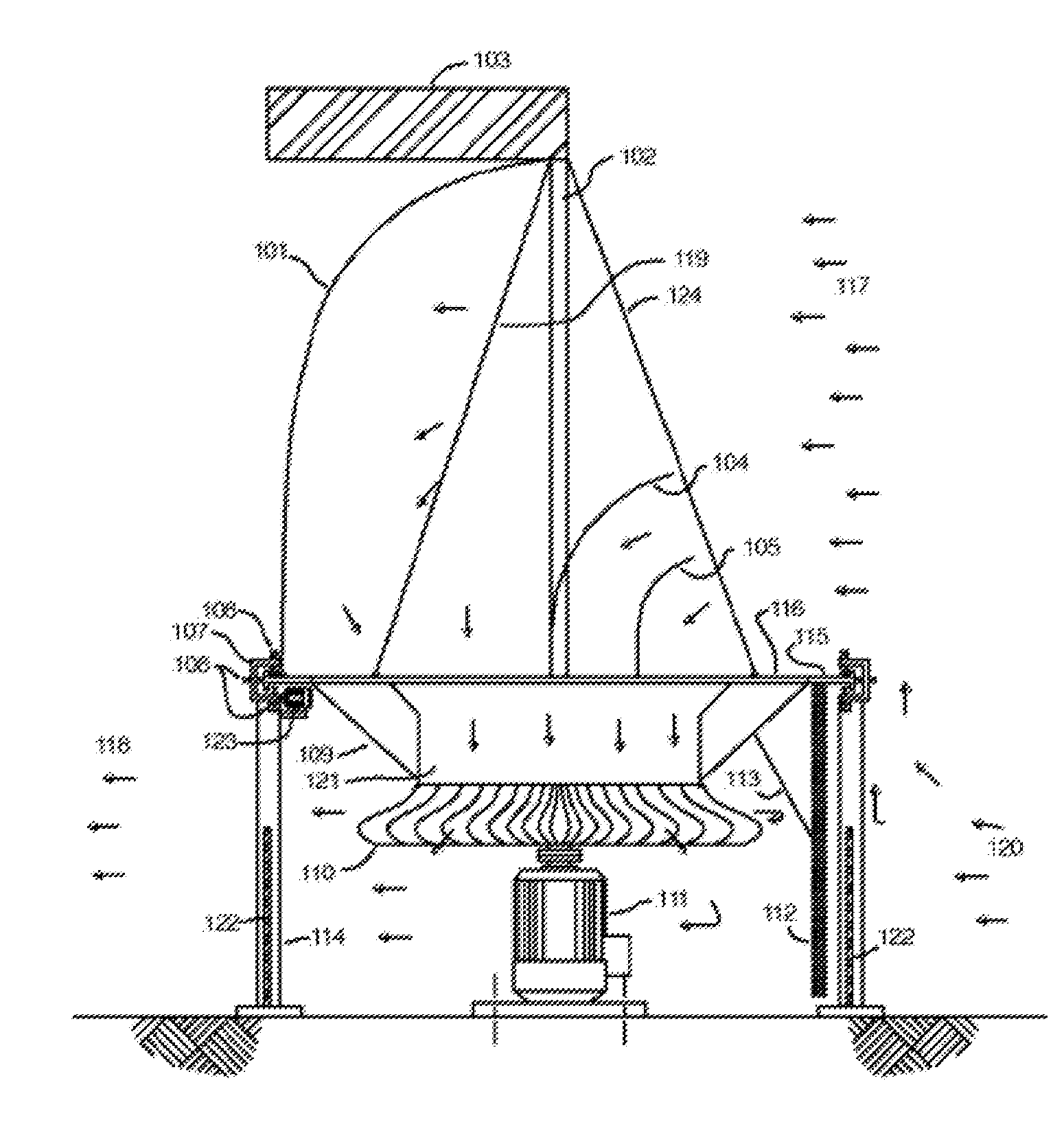

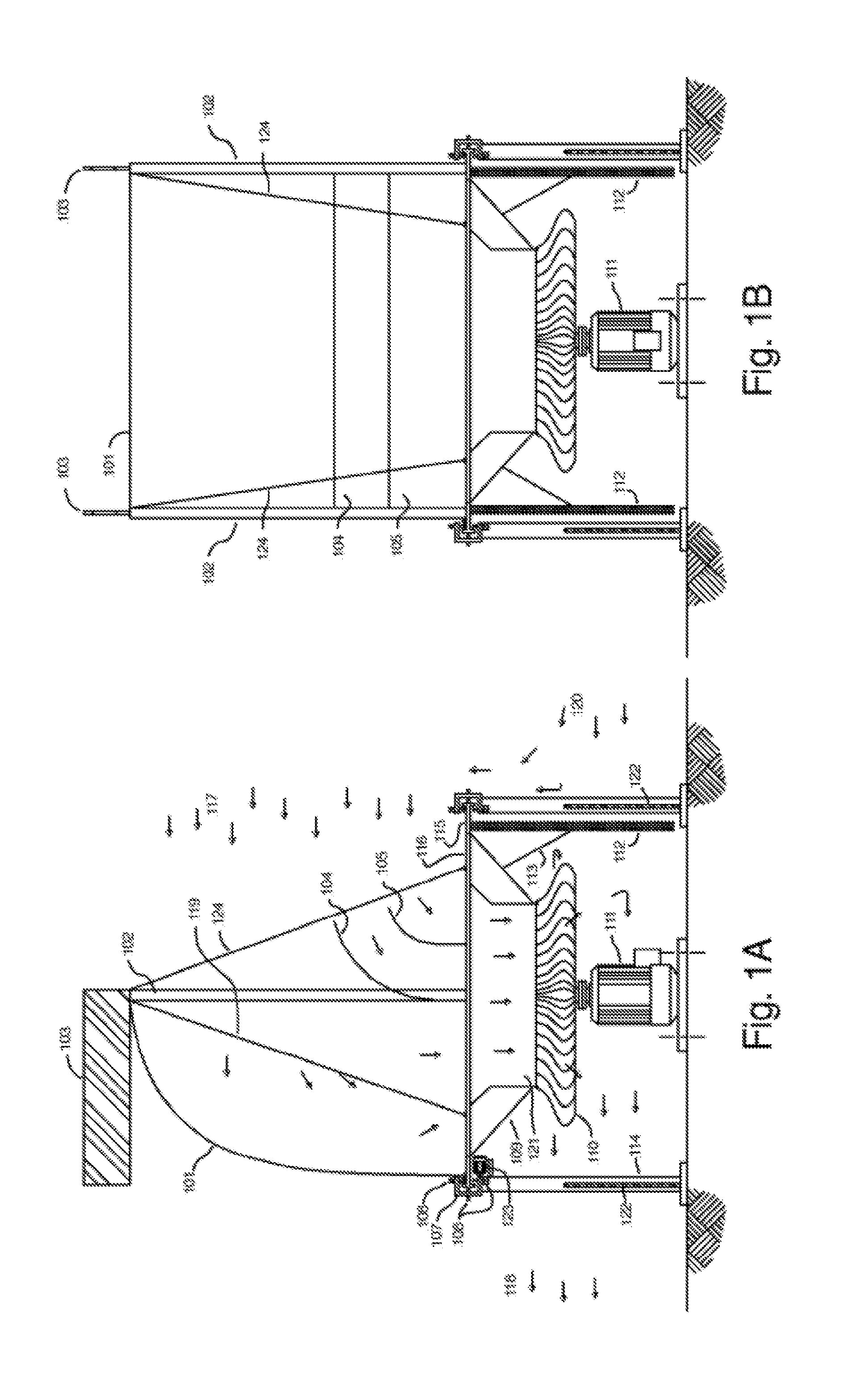

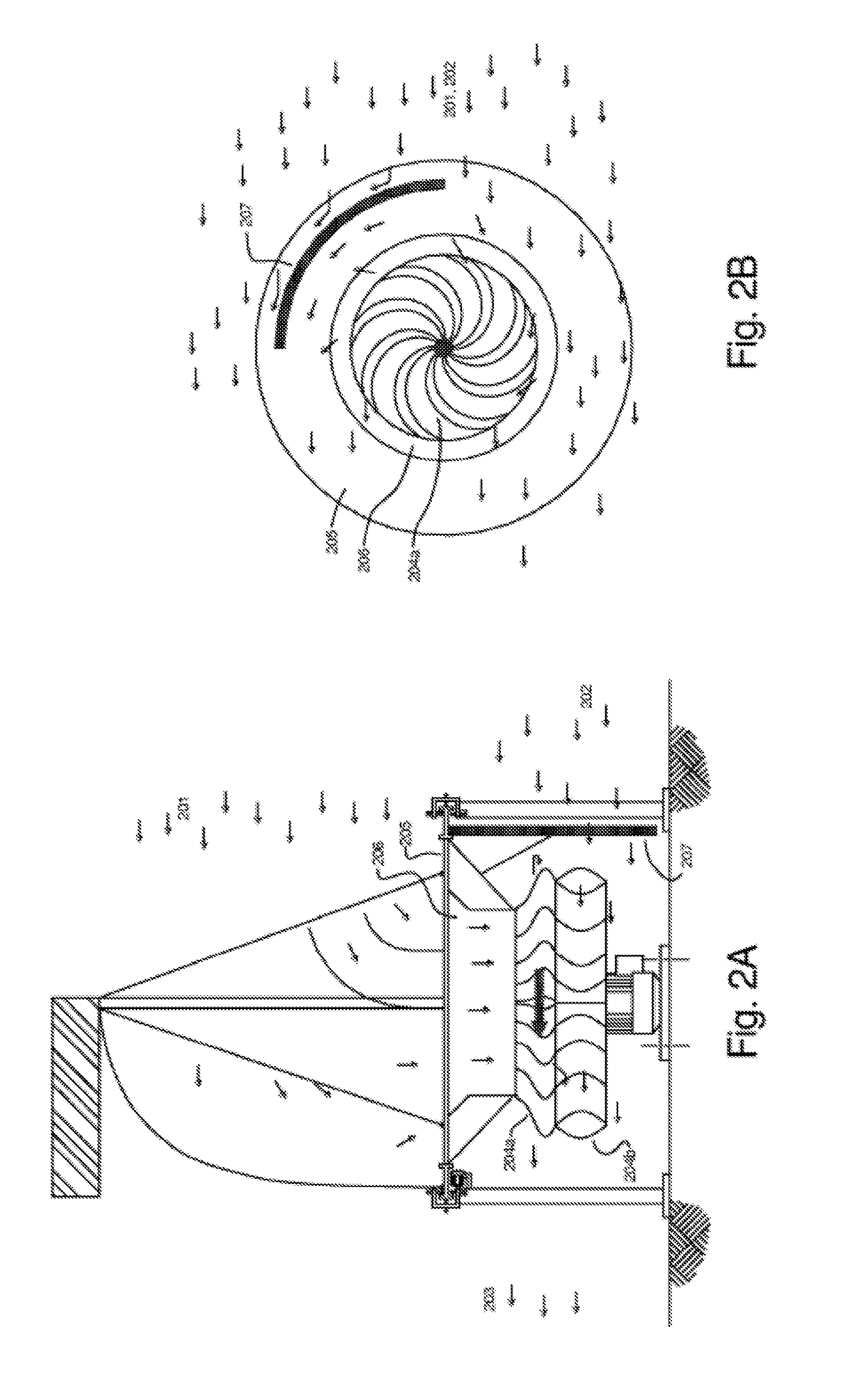

Building integrated wind energy power enhancer system

ActiveUS20160084227A1Efficient and effectiveHigh possible pressure differentialPump componentsRotary non-positive displacement pumpsGlobal wind patternsEngineering

An omnidirectional building integrated wind energy power enhancer system is configured to produce electrical power from a wind turbine(s) concealed within and / or on top of a building by means of a flow of pressurized air from the prevailing wind that enters and flows through a portion of a building. A building may provide large exterior surface areas for receiving and directing airflow to the turbine(s). At least a portion of the wind energy power enhancer system is configured within a building, such as between floors, on a single floor, and / or a roof structure. The wind turbine(s) may be configured to receive airflow directly from an inflow chamber that is configured with a building, or from a flow tube coupled with the inflow chamber. Air deflectors may be fixed or dynamic to direct air flow into a flow tube regardless of the direction of the incoming airflow relative to the building.

Owner:AEROMINE TECH

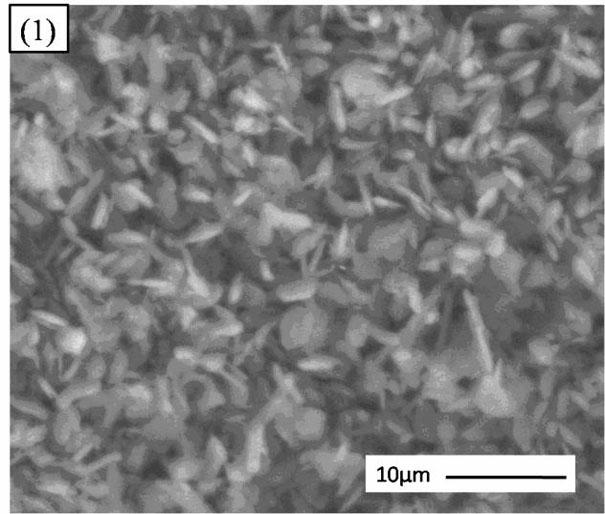

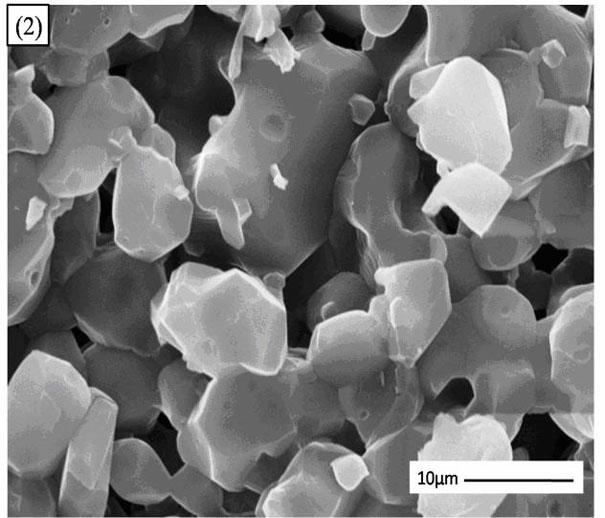

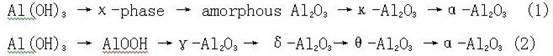

Machinable aluminium oxide ceramics and preparation method of machinable aluminium oxide ceramics

The invention discloses machinable aluminium oxide ceramics which is characterized in that the machinable aluminium oxide ceramics comprises the following components in percentage by mass: 60 percent to 68 percent of nano alumina, 30 percent to 36 percent of tabular alumina, 0.5 percent to 1.5 percent of magnesium oxide and 1 percent to 3 percent of titanium dioxide. A preparation method of the ceramics comprises the following steps of: preparing the nano alumina; after carrying out mixing and ball milling on the nano alumina, alumina, the magnesium oxide, titanium dioxide and absolute ethyl alcohol, drying the mixture, removing zirconium oxide grinding balls, and carrying out roasting, washing, filtering and drying on the obtained product to obtain composite powder; and after uniformly mixing the composite powder and a polyvinyl alcohol 1799 binder and pelleting the obtained mixture, carrying out dry-pressing forming to obtain a green body and placing the formed green body into a high temperature furnace to carry out sintering so as to obtain the ceramics. The bending strength of the ceramics reaches 526MPa. The fracture toughness of the ceramics reaches 6.4MPa.m1 / 2. The ceramicshave excellent machinable performance. The problems of complex structure and high cost and difficultly-controlled preparation process of the existing machinable ceramics are effectively solved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

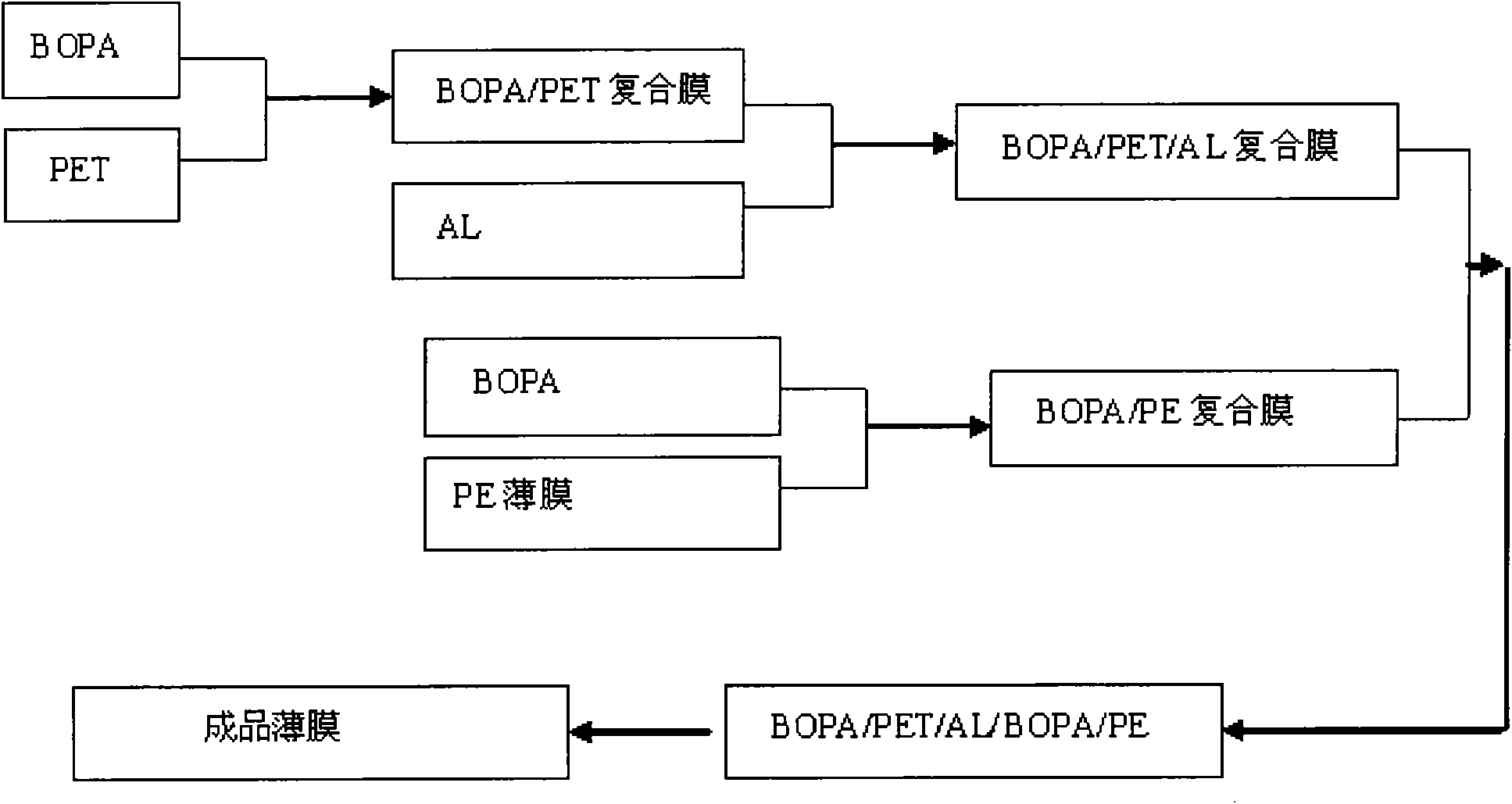

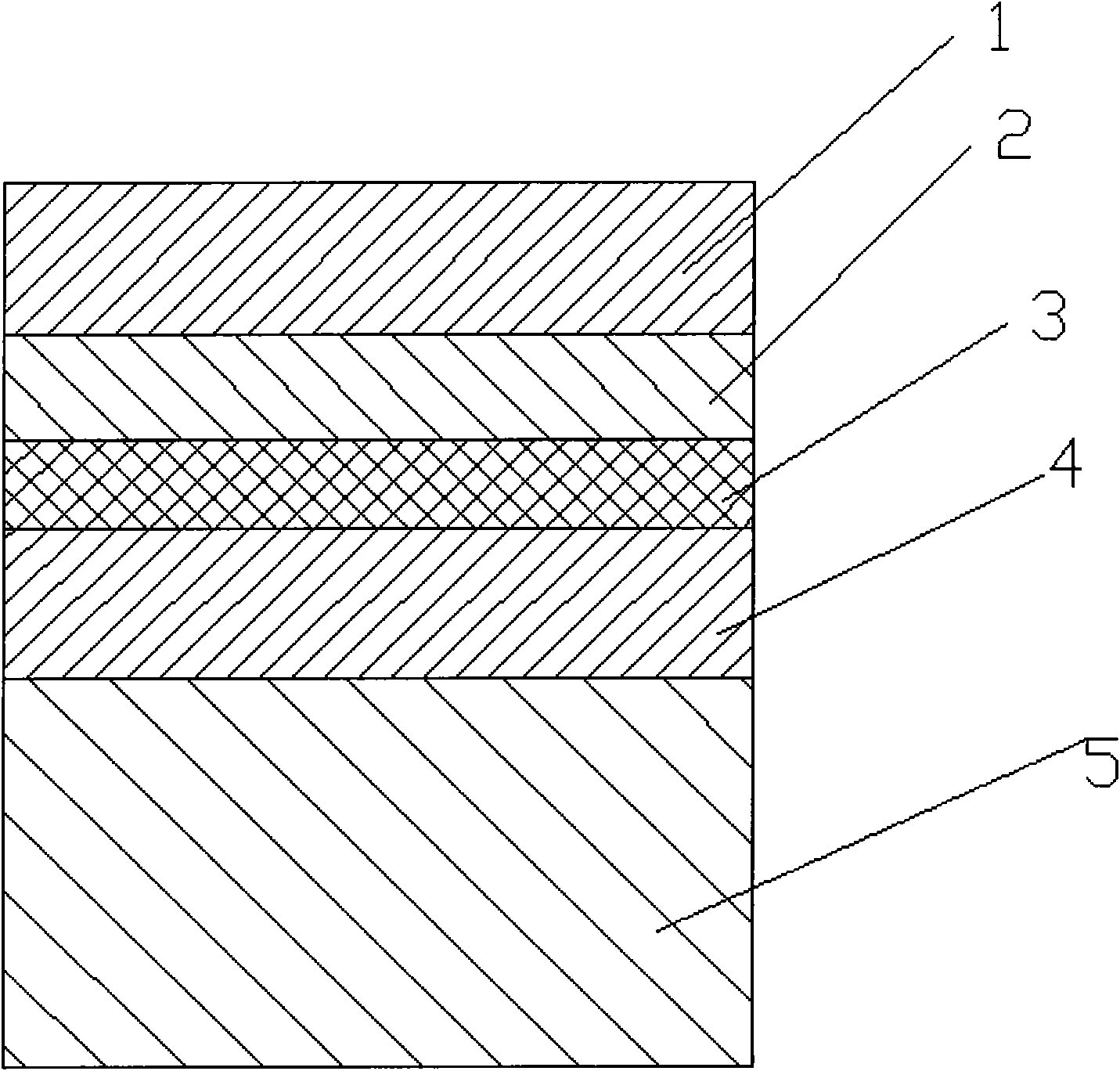

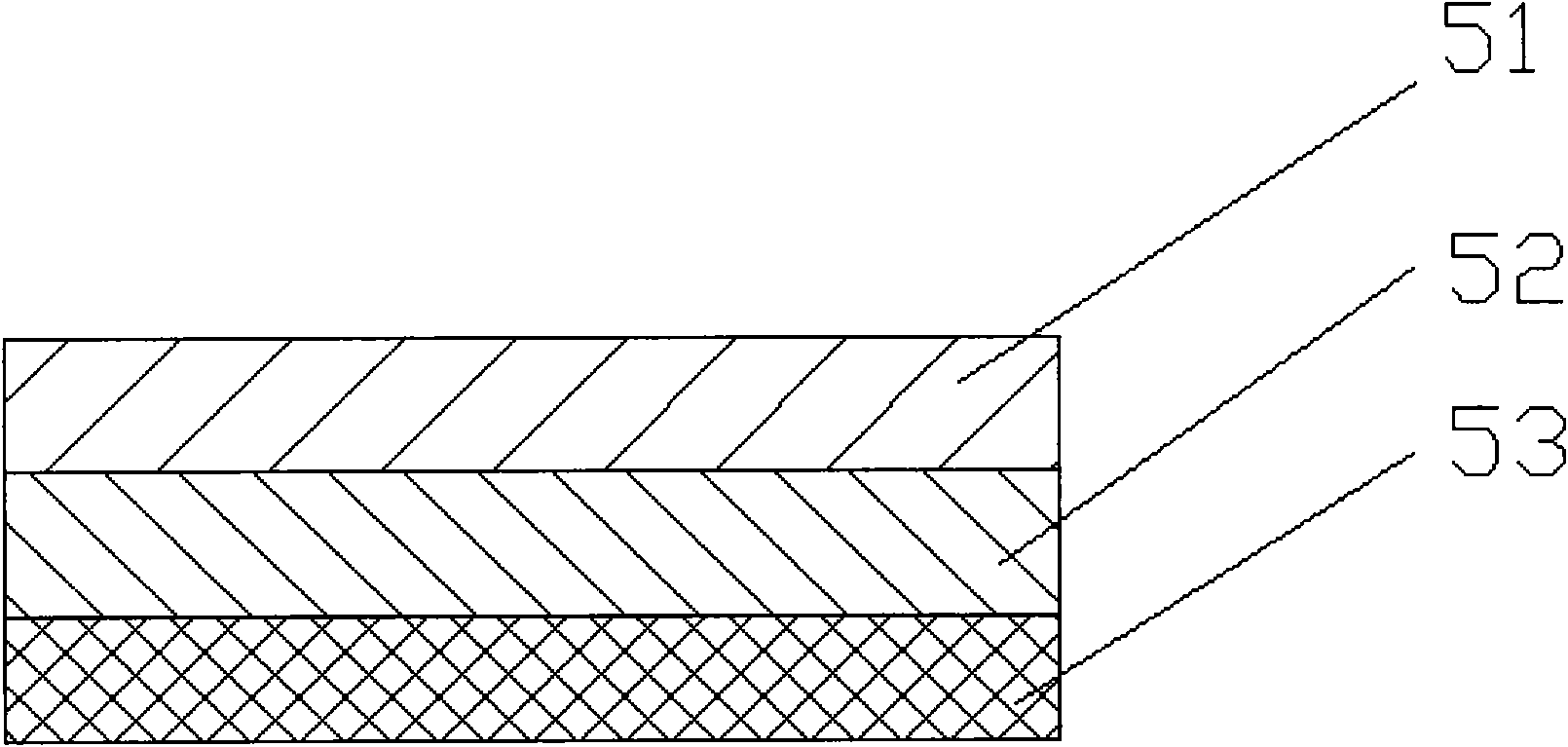

Vacuum thermal baffle packaging film and preparation method thereof

ActiveCN101844642AGood hot tack propertiesGood aging resistanceFlexible coversWrappersWrinklePolyethylene glycol

The invention discloses a vacuum thermal baffle packaging film and a preparation method thereof. The vacuum thermal baffle packaging film comprises a biaxially oriented nylon layer, a polyethylene glycol terephthalate layer, an aluminum foil layer, a biaxially oriented nylon layer and a composite polyethylene layer sequentially from inside to outside. Compared with the prior art, the vacuum thermal baffle packaging film has the characteristics of smooth appearance of bag bodies (+ / -5 percent of limit deviation), no phenomena of wrinkles, crystal points, PE coke buttons and the like, high barrier properties of packaging bags and good vacuumizing effect, peel strength, temperature tolerance and anti-aging effect.

Owner:HUANGSHAN NOVEL

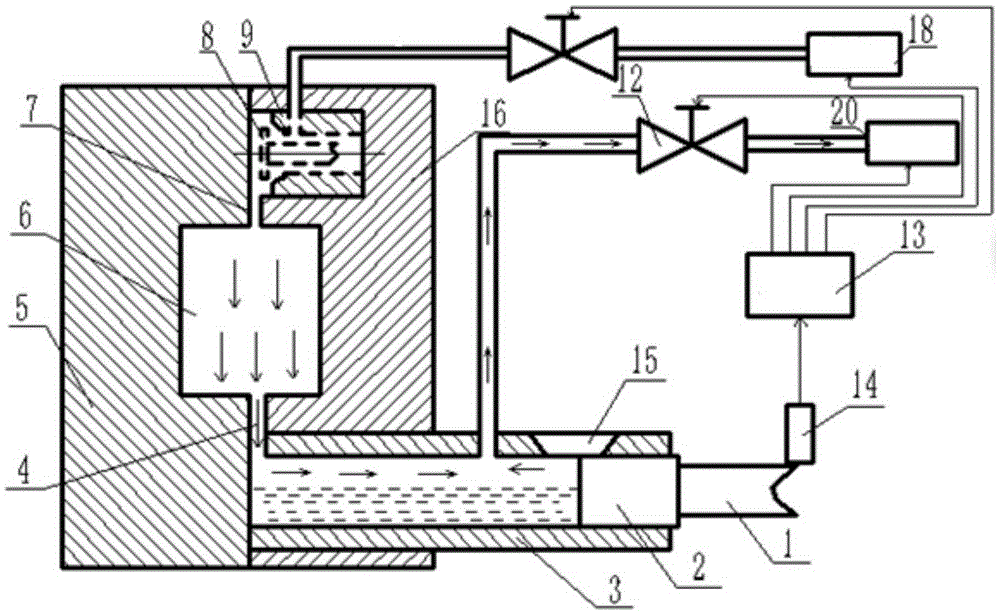

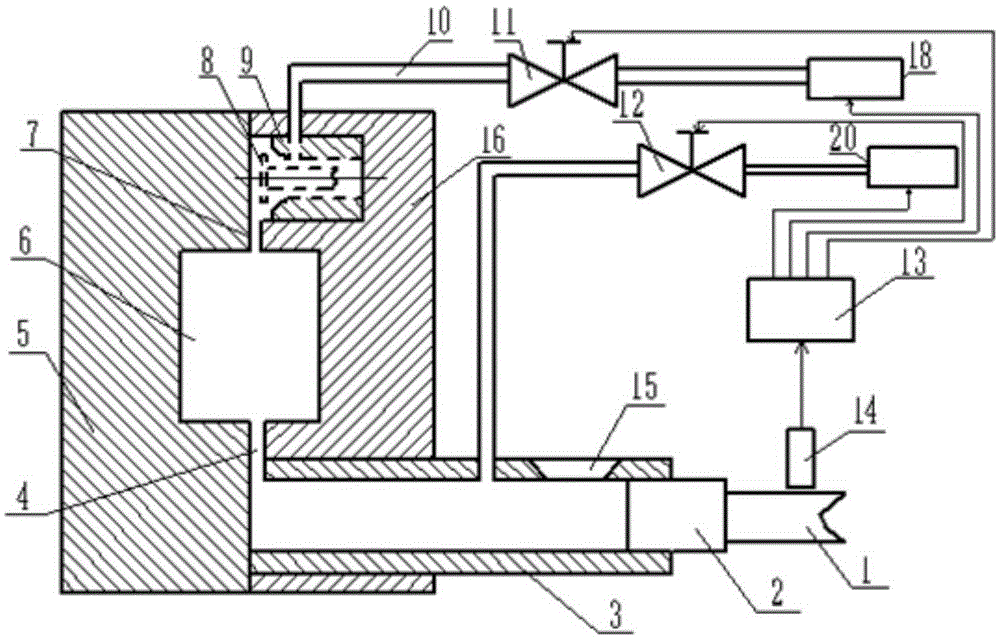

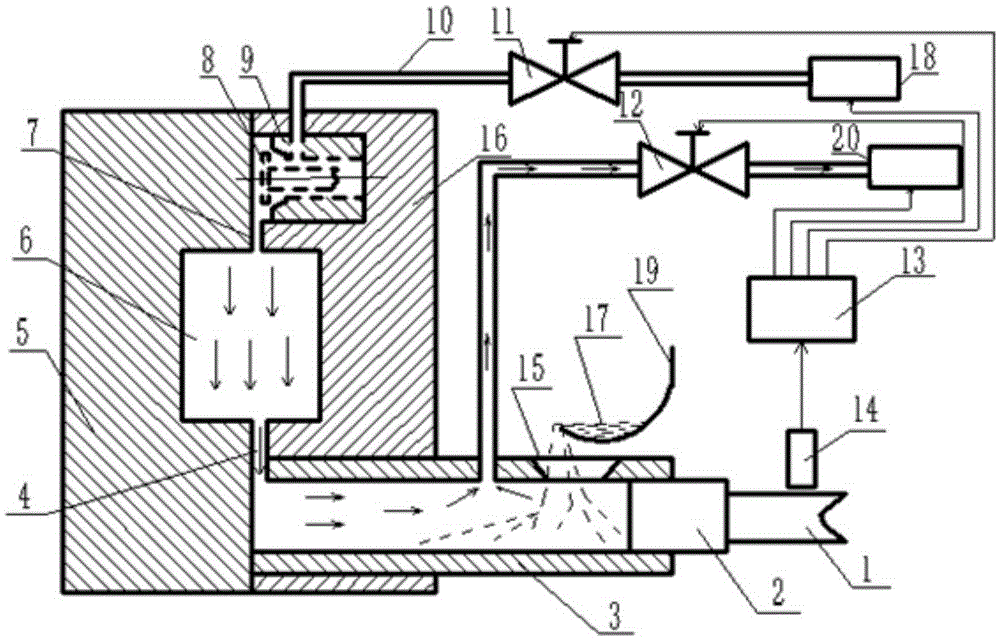

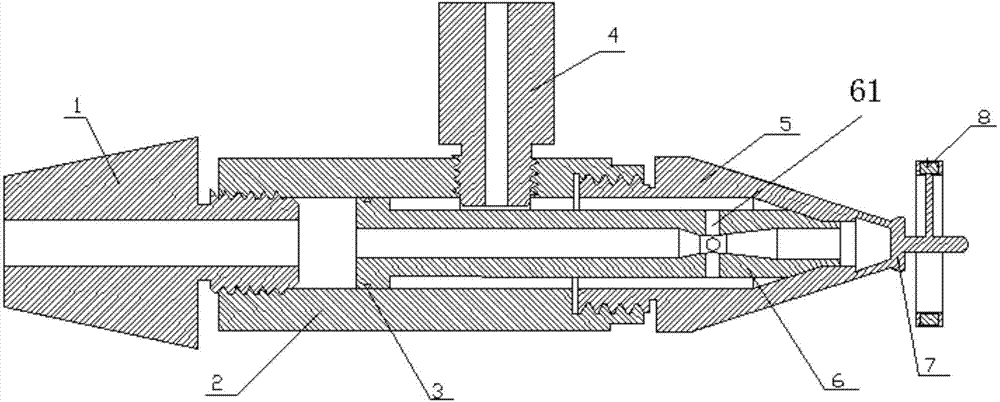

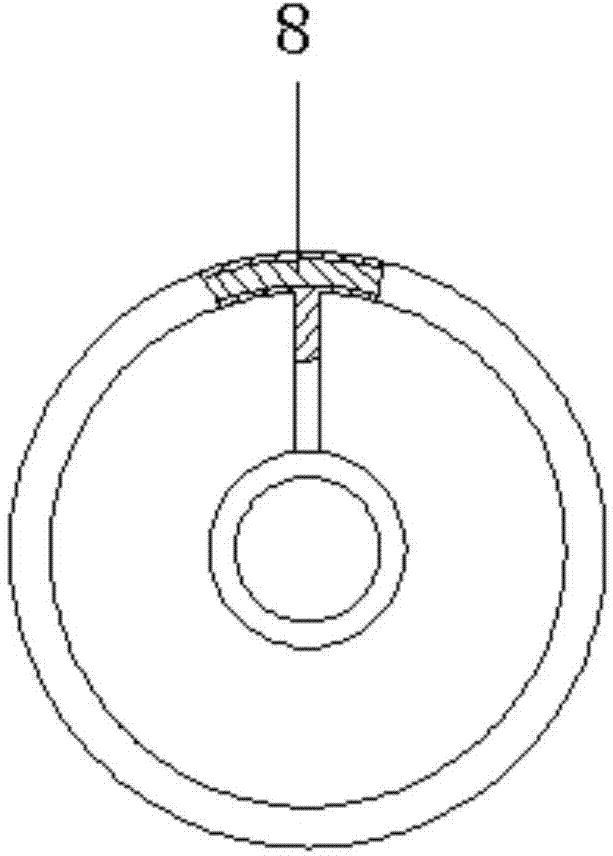

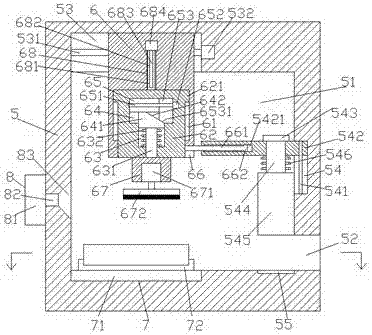

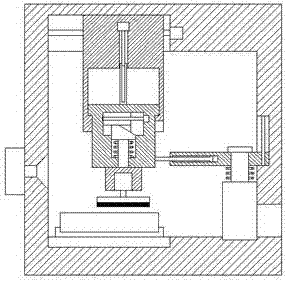

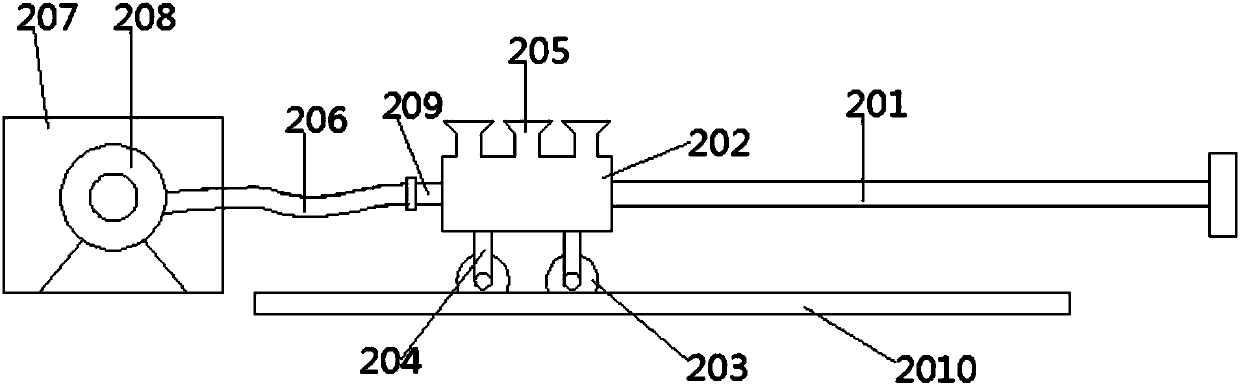

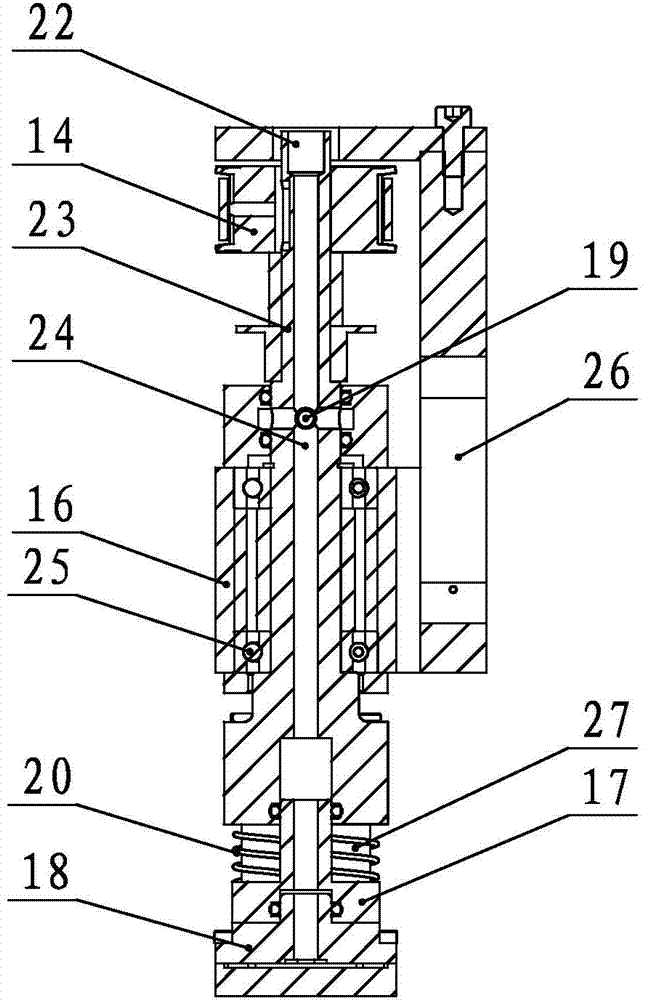

Die-casting mechanism of horizontal freezing chamber vacuum die-casting machine and method for using die-casting mechanism for die-casting operation

ActiveCN105414515AReduces chances of getting into cavitiesEliminate the effects ofDie castingEngineering

The invention discloses a die-casting mechanism of a horizontal freezing chamber vacuum die-casting machine. The die-casting mechanism comprises a pressure chamber, a die-casting die, a vacuum valve, a punch, an injection rod, a first stop valve, a first vacuum system, a second stop valve, a second vacuum system, a control device and a displacement sensor. The die-casting die comprises a fixed die body and a movable die body, the movable die body and the fixed die body are matched, and therefore a cavity, an inner gate and an exhausting way are formed. The vacuum valve is arranged in a valve cavity in the fixed die body. The punch is fixedly connected with the injection rod. The pressure chamber is provided with a casting gate and a pipe connecting joint, the pipe connecting joint is connected with a second vacuum pipe, the other end of the second vacuum pipe is connected with the second stop valve, and the second stop valve is connected with the second vacuum system. The control device is used for controlling operation of the first vacuum system and the second vacuum system and controlling opening and closing of the first stop valve and the second stop valve. The die-casting mechanism has the beneficial effects of being good in vacuumizing effect, easy and convenient to arrange and maintain, low in fault rate and long in service life.

Owner:GUANGDONG HONGTU TECHNOLOGY (HOLDINGS) CO LTD

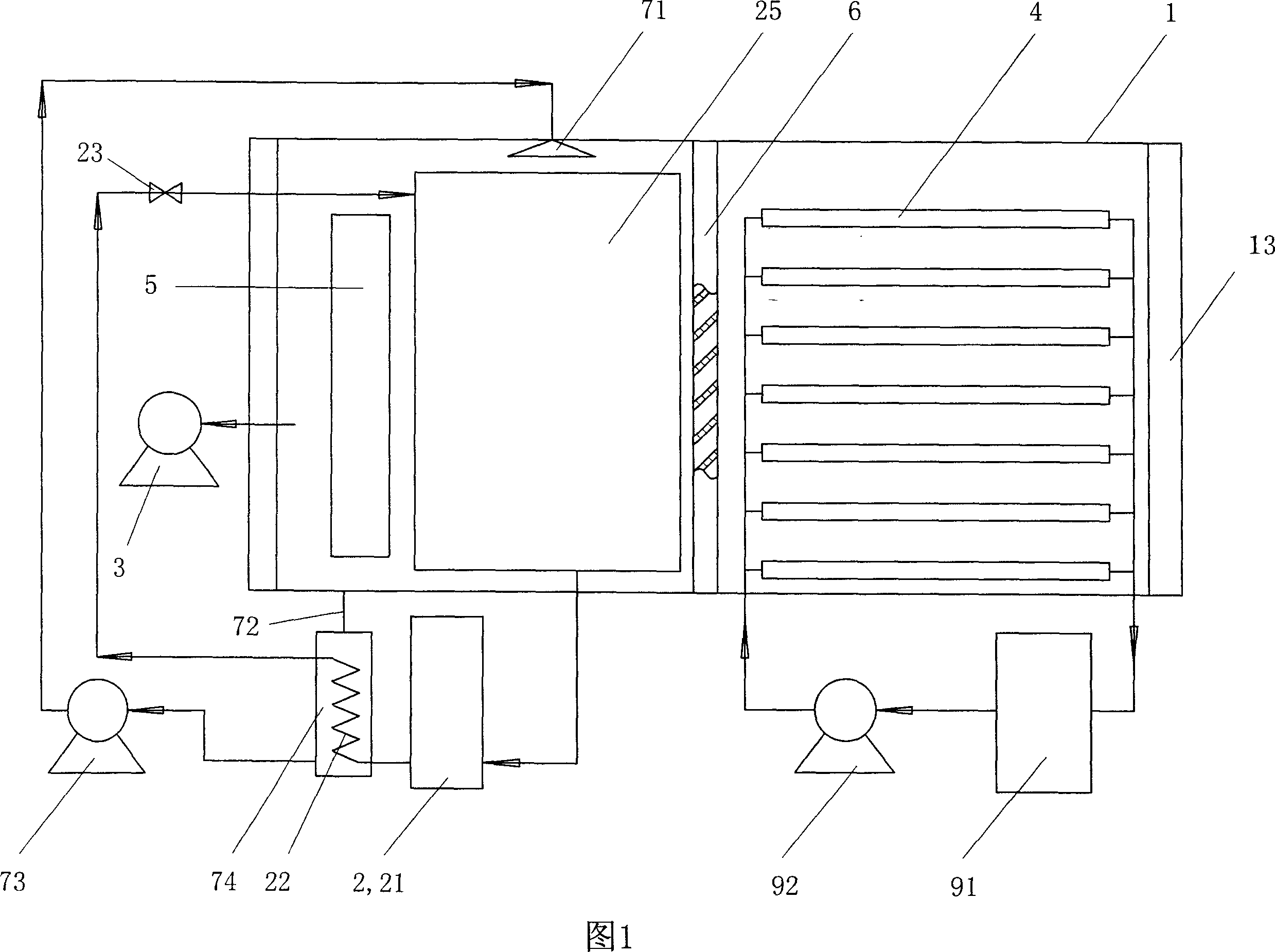

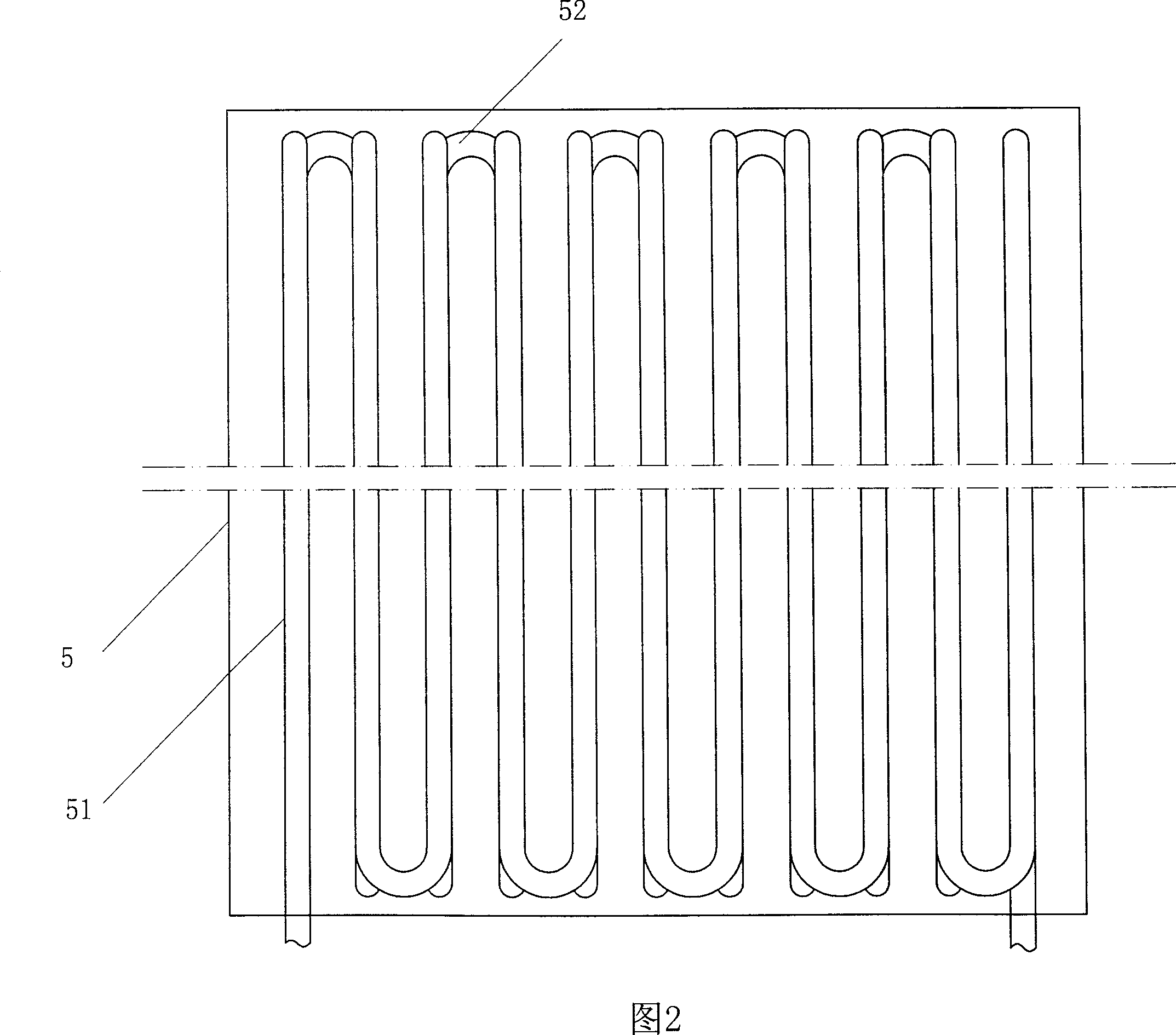

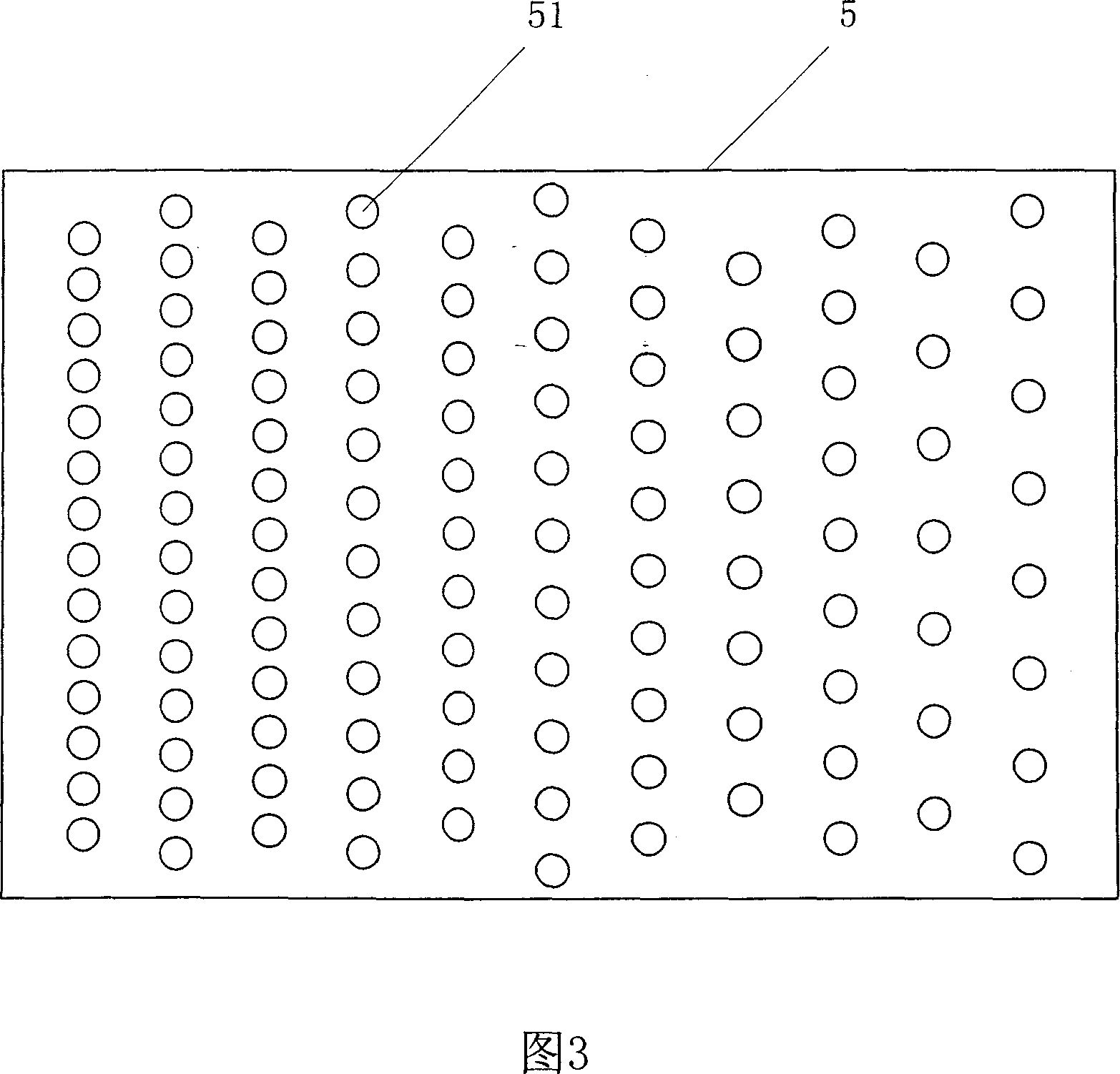

Freezing drying machine

InactiveCN101025329ADoes not affect circulationIncrease contact areaDrying solid materials without heatDrying machines with local agitationFreeze-dryingEngineering

This invention is about a kind of freeze-drying set, composing of case; freezing engine set vacuum pump and hot plate. The freezing engine set composes of compressor, heat exchanger, expansion valve and evaporator; the hot plate is set in front of the case, and the evaporator of the freezing engine set is set in rear of the case; there are louver interboards between the evaporator and hot plate, and fan in rear of the evaporator. The invention consumes less energy and be manipulated conveniently.

Owner:李志平 +1

Atomization spray nozzle

ActiveCN104772242AImprove vacuuming effectRapid coagulation and sedimentationLiquid spraying apparatusSpray discharge apparatusGas phasePulp and paper industry

The invention discloses an atomization spray nozzle, which comprises a spray nozzle body, a Venturi air pipe, an air inlet, a liquid inlet and a spray head, wherein the Venturi air pipe is arranged in the spray nozzle body; a liquid-phase suck-in hole is formed in a throat passage section of the Venturi air pipe; the air inlet is connected onto the spray nozzle main body, and is connected with an inlet of the Venturi air pipe; the liquid inlet is also connected onto the spray nozzle main body, in addition, the liquid inlet is also communicated with the liquid-phase suck-in hole of the Venturi air pipe; the front end of the spray head is provided with a scattering head, in addition, an atomization spraying passage is formed between an outlet of the spray head and the scattering head; the spaying head is connected onto the spray nozzle body, in addition, the spray head is communicated with an outlet of the Venturi air pipe, and the front end of the scattering head is provided with an annular electrification coil. The atomization spray nozzle has the advantages that a gas phase and a liquid phase can be sufficiently mixed, meanwhile, the atomization fineness and the fog drop distribution uniformity are greatly improved, the structure is simple, and the cost is low.

Owner:扬州博泰冶金设备制造有限公司

Dust-free environment-friendly architectural decorative stone polishing device

InactiveCN107088799AAutomatically control the left and right movement of the grinding workImprove grinding accuracyGrinding carriagesGrinding drivesAutomatic controlEngineering

The invention discloses a dust-free environment-friendly architectural decorative stone polishing device. The dust-free environment-friendly architectural decorative stone polishing device comprises a shell, a polishing cavity is formed in the shell, a first sliding groove is formed in the left side of the top wall in the polishing cavity, a second sliding groove arranged in a longitudinal extension manner is formed in the inner wall of the right side of the polishing cavity, and an opening with the left side end communicated with the polishing cavity is formed in the position, below the second sliding groove, of the right side wall of the shell in a penetrating manner; a fixed connection assembly and a sinking groove are arranged on the left and right sides of the bottom wall in the polishing cavity correspondingly, a first threaded rod extending left and right is arranged in the first sliding groove, and a movement block with the bottom extending into the polishing cavity is connected to the first threaded rod in a threaded fit manner; and a first sliding cavity is formed in the movement block, a lifting sliding block is connected into the first sliding cavity in a slide fit manner, and protruding sliding blocks connected with the inner walls of the two sides of the first sliding cavity in a slide fit manner are arranged at the edges of the tops of the two sides of the lifting sliding block. The dust-free environment-friendly architectural decorative stone polishing device is simple in structure, convenient to operate and high in safety, opening and closing of a separating plate can be automatically controlled, the dust suction effect is good, the polishing is accurate, and the stability is high.

Owner:徐州惠泉新型建材有限公司

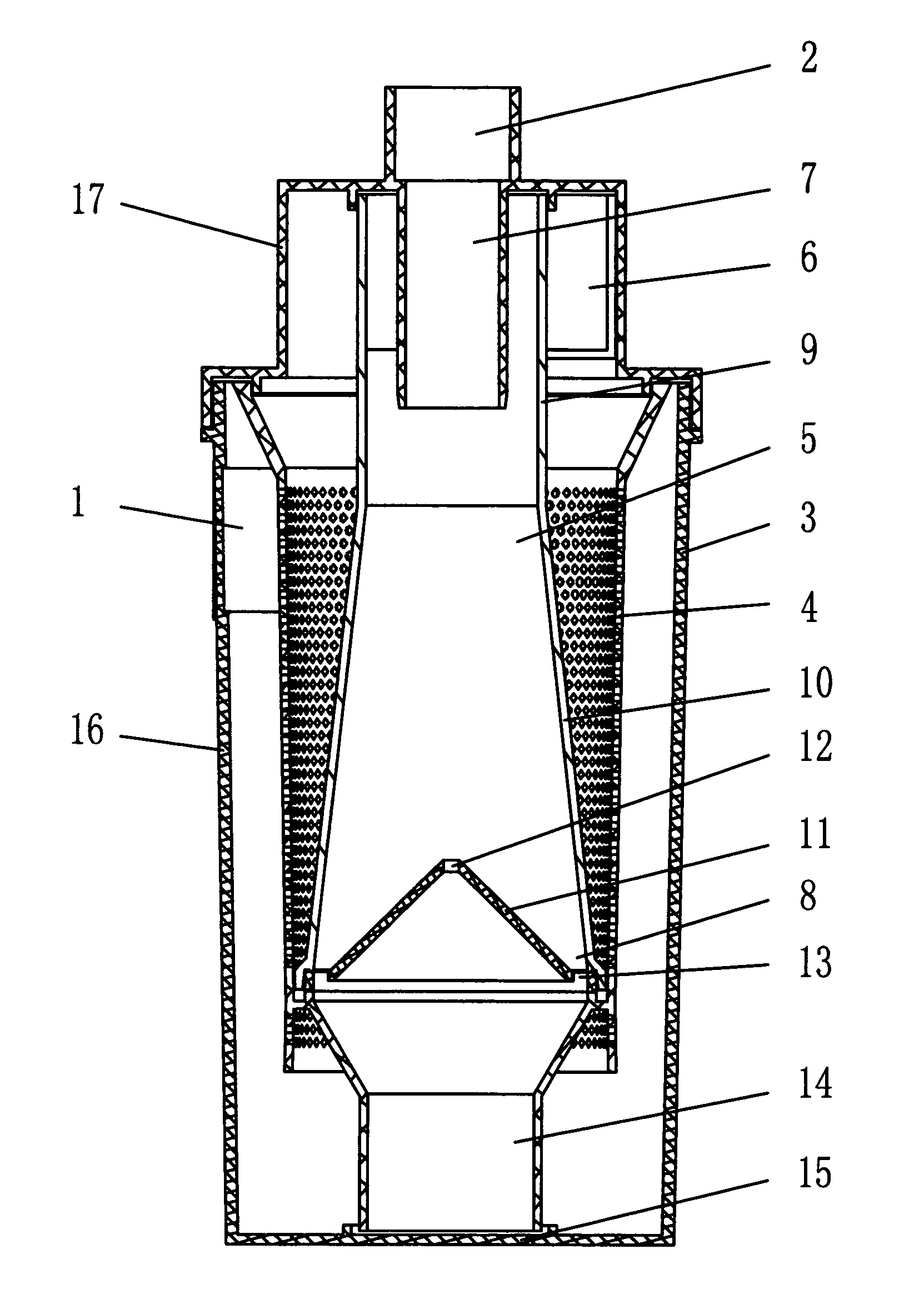

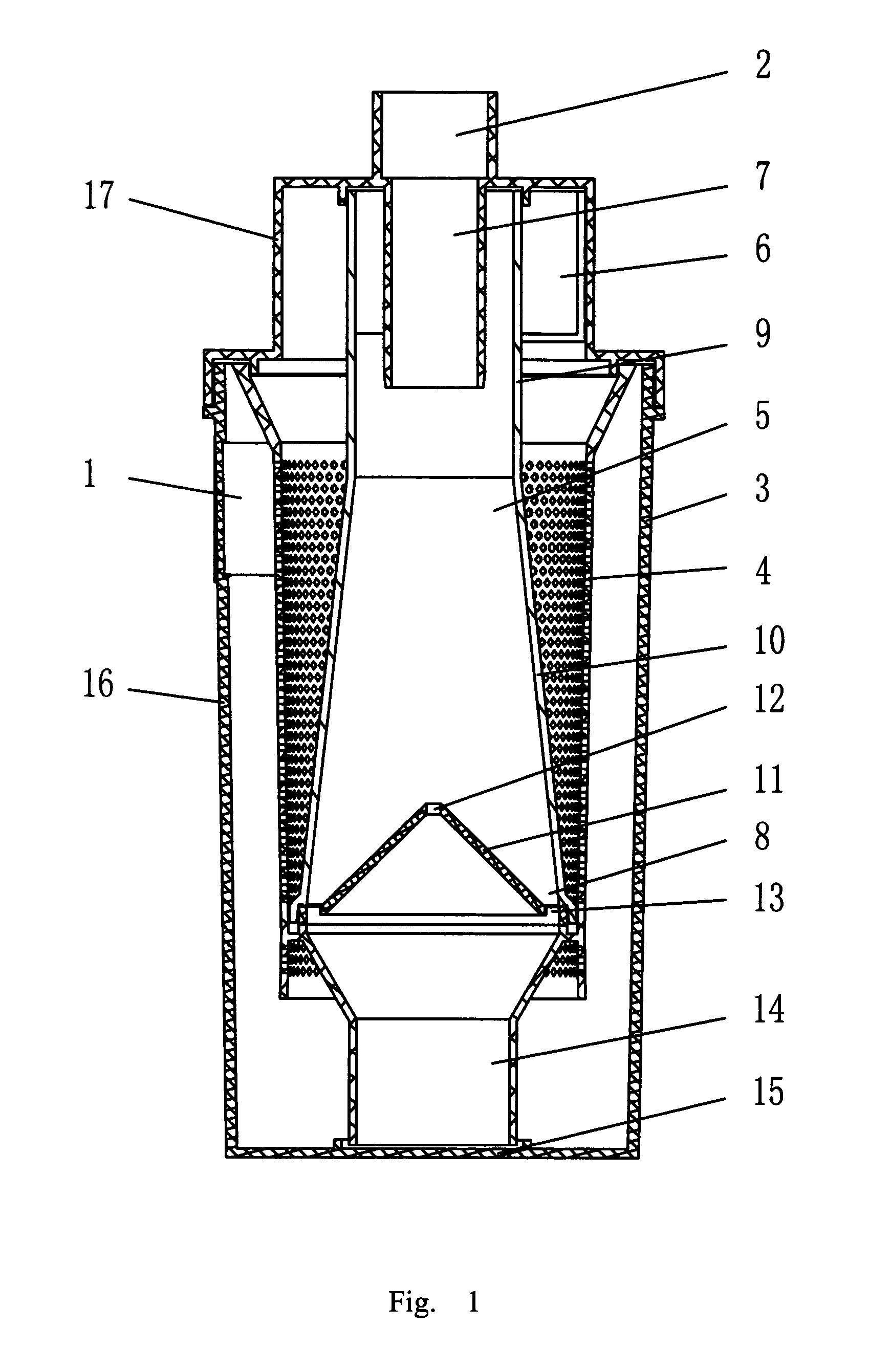

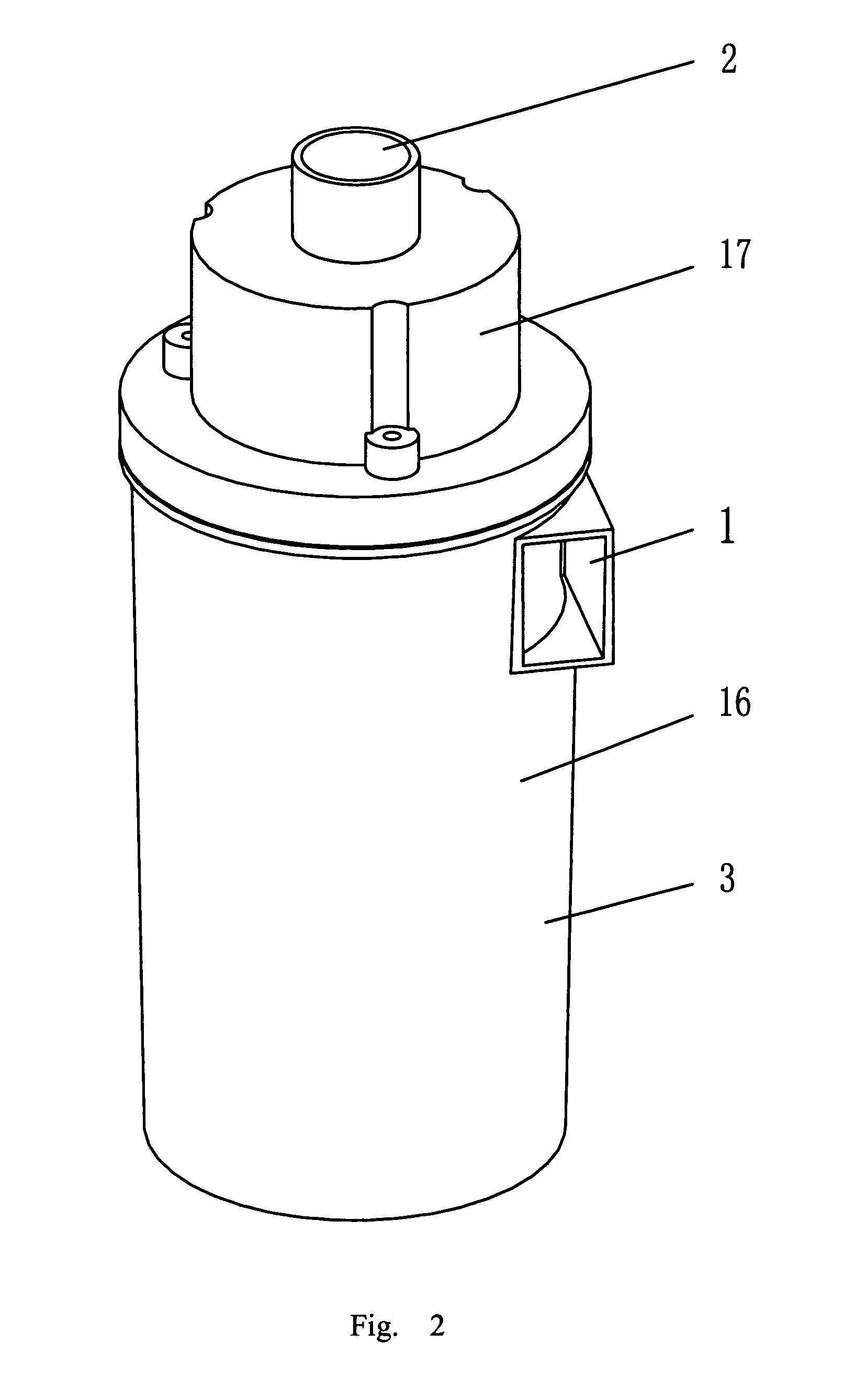

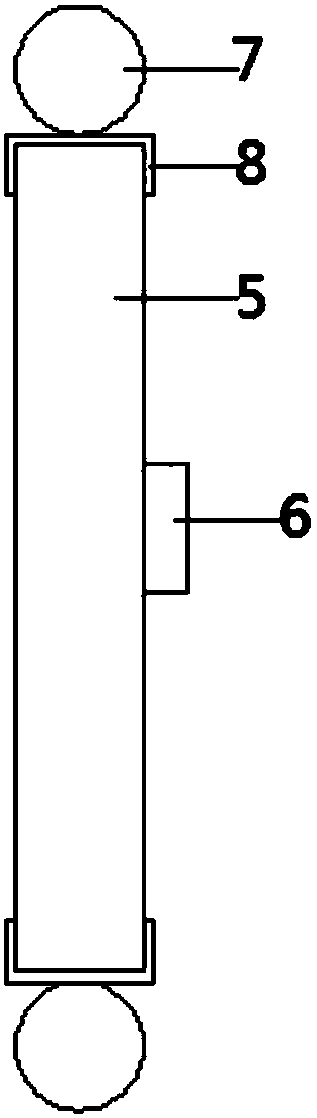

Pervasive dedusting device for a vacuum cleaner

InactiveUS7563296B2Low air flow pressure lossImprove vacuuming effectCleaning filter meansCombination devicesPollutionVacuum cleaner

Owner:SUZHOU KINGCLEAN FLOORCARE

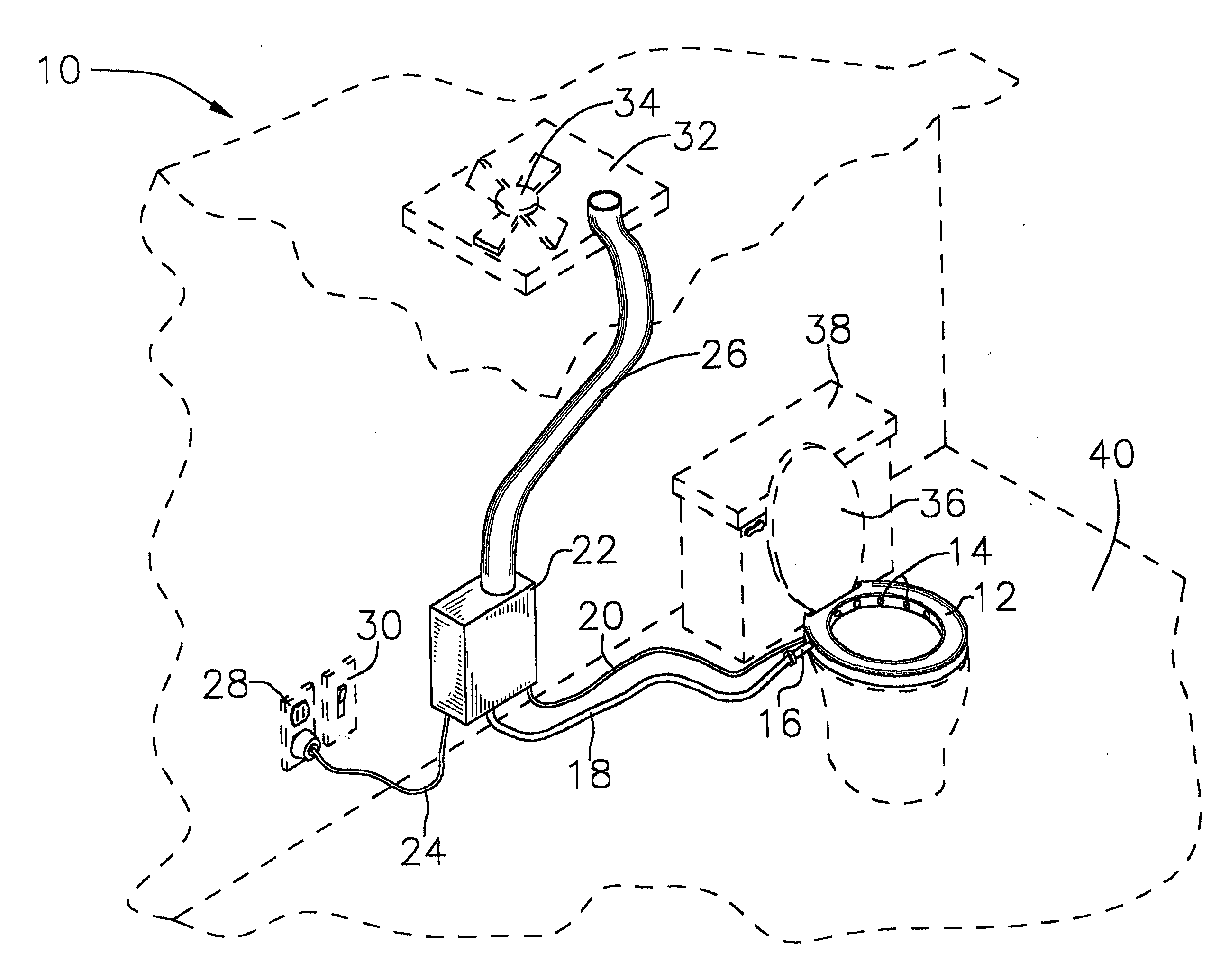

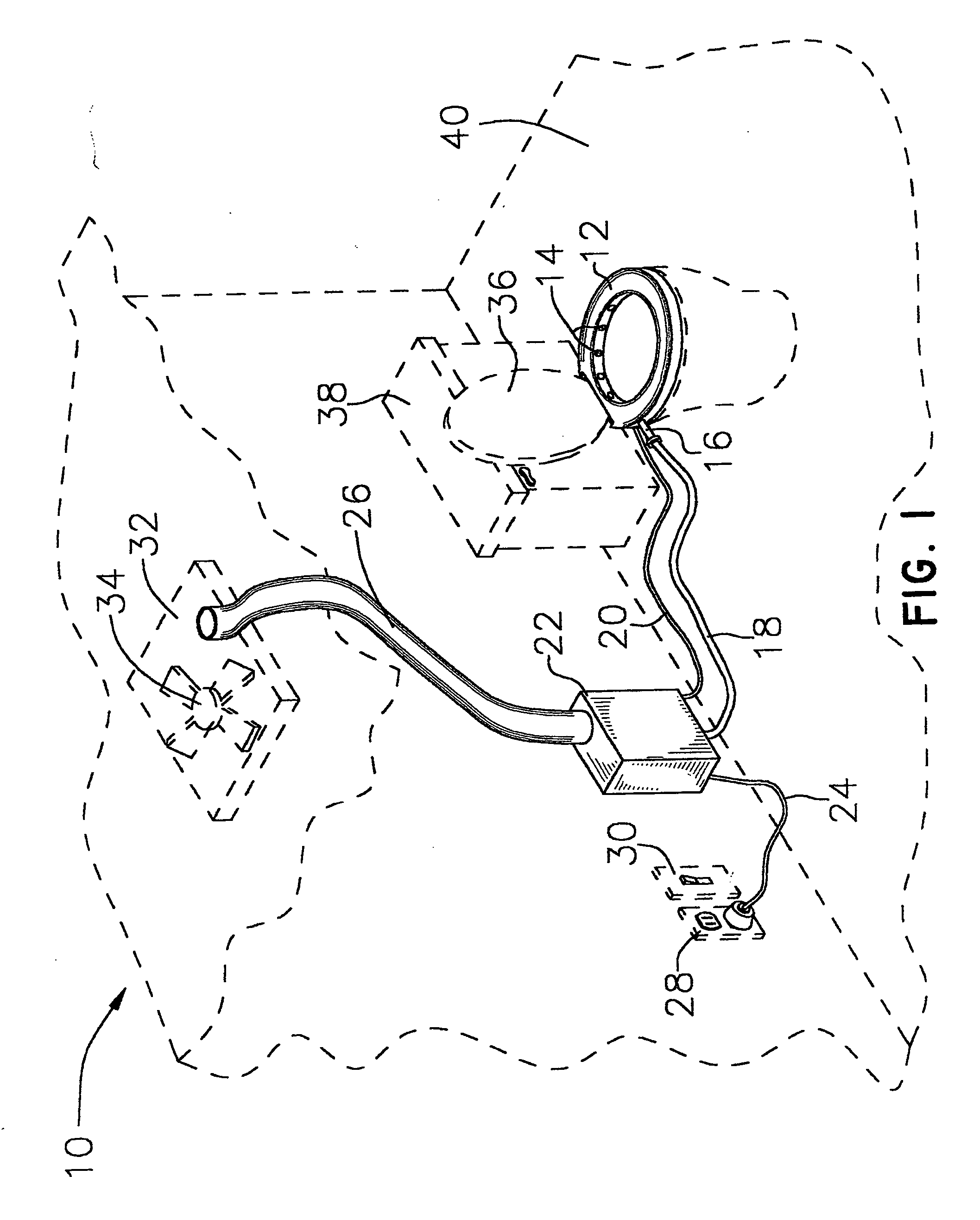

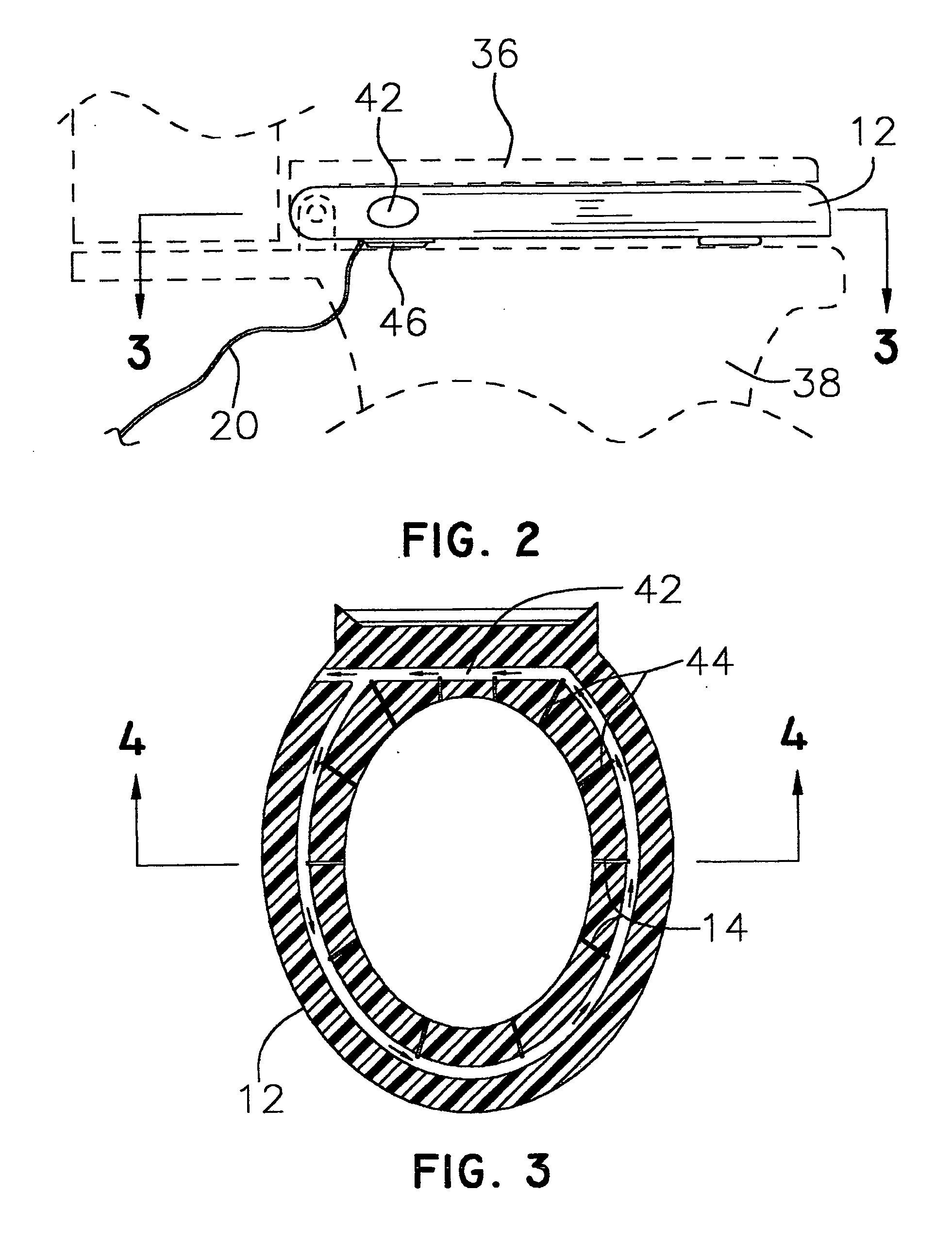

Ventilating apparatus for a toilet

InactiveUS20070186334A1RemovingIncrease speedBathroom coversLavatory sanitoryPrimary channelCeiling fan

Ventilating apparatuses for a toilet remove objectionable odors. Instead of allowing toilet odors to diffuse into the bathroom atmosphere, the ventilating apparatus for a toilet draws toilet odors out of the toilet bowl and exhausts them outside of the house. The ventilating apparatus for a toilet has first inlet channels piercing the interior surface of the toilet seat and second inlet channels piercing the bottom surface of the toilet seat. The opposite ends of the first inlet channels and the second inlet channels protrude into a primary channel, thereby creating a partial air blockage and an enhanced vacuum effect through the first inlet channels and the second inlet channels. A vacuum motor controlled by a pressure-activated switch on the bottom of the toilet seat extracts air from the toilet through the first inlet channels and second inlet channels and exhausts it through a ceiling fan vent.

Owner:CARTER WILBERT L +2

Efficient and energy-saving dust removing device for crusher

InactiveCN107511022AImprove vacuuming effectImprove absorption efficiencyCombination devicesUsing liquid separation agentWater sourceWater storage tank

Provided is an efficient and energy-saving dust removing device for a crusher. The dust removing device includes a dust suction cover, a dust removing box and a water storage tank, wherein an air inlet is formed in the upper side of the left end of the dust removing box, and a dust removing pipe is connected to the air inlet; an air outlet end of the dust removing pipe is arranged below the liquid surface of the dust removing box and connected with an air venting and collecting pipe connected with a plurality of branched venting pipes, and the branched venting pipes are arranged transversely and provided with a plurality of venting holes; the right side of the dust removing box is provided with a venting pipe, the venting pipe is communicated with the interior of the dust removing box, and a filter is arranged in the venting pipe; the dust removing box internally contains water, and a filtering screen is horizontally arranged in the dust removing box; the water storage tank is arranged on the exterior of the right side of the dust removing box; the efficient and energy-saving dust removing device for the crusher is high in dust absorption rate, saves water resources and is worth popularizing in a large-scale mode.

Owner:宝鸡市泰得电子信息有限公司

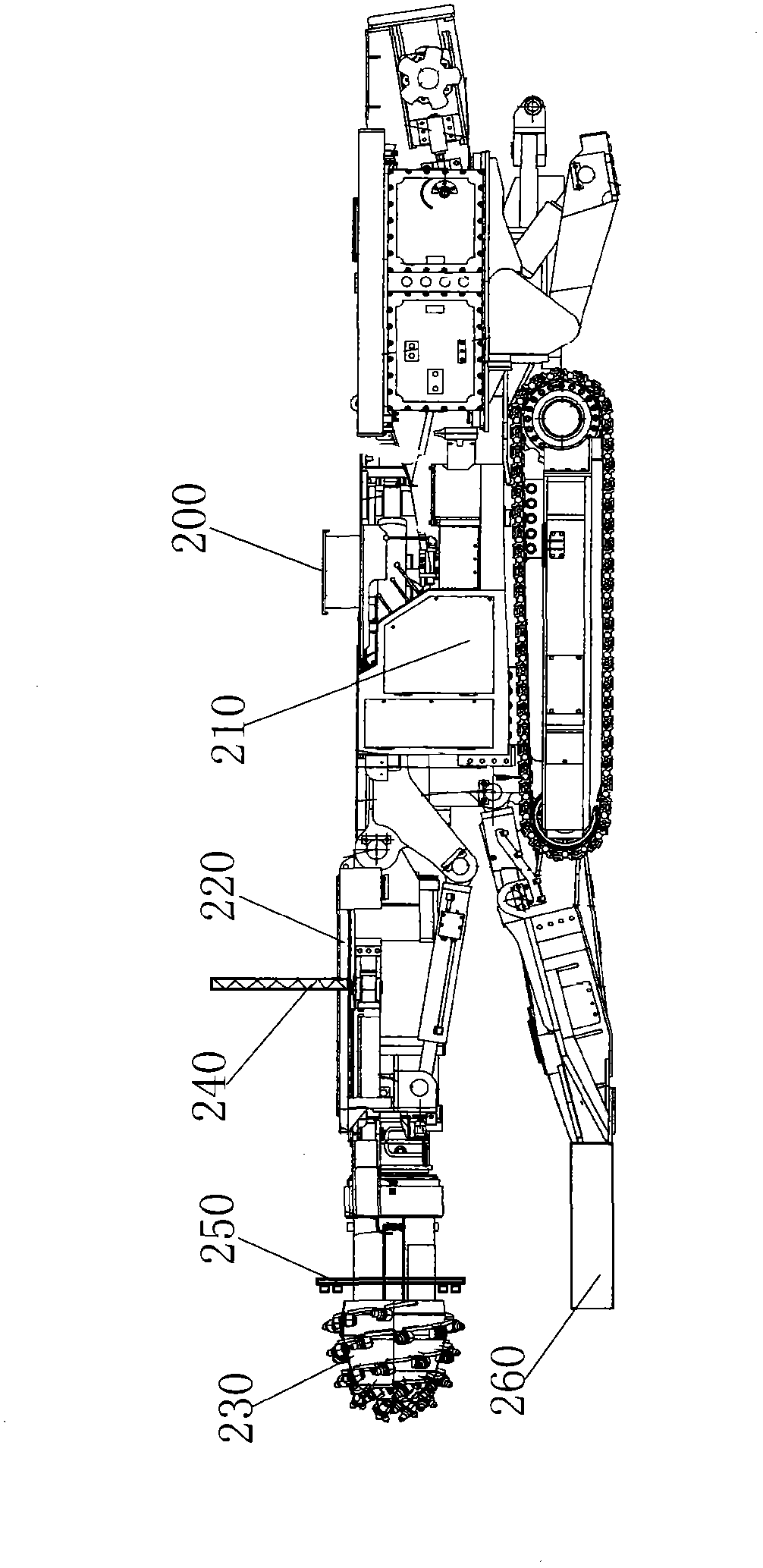

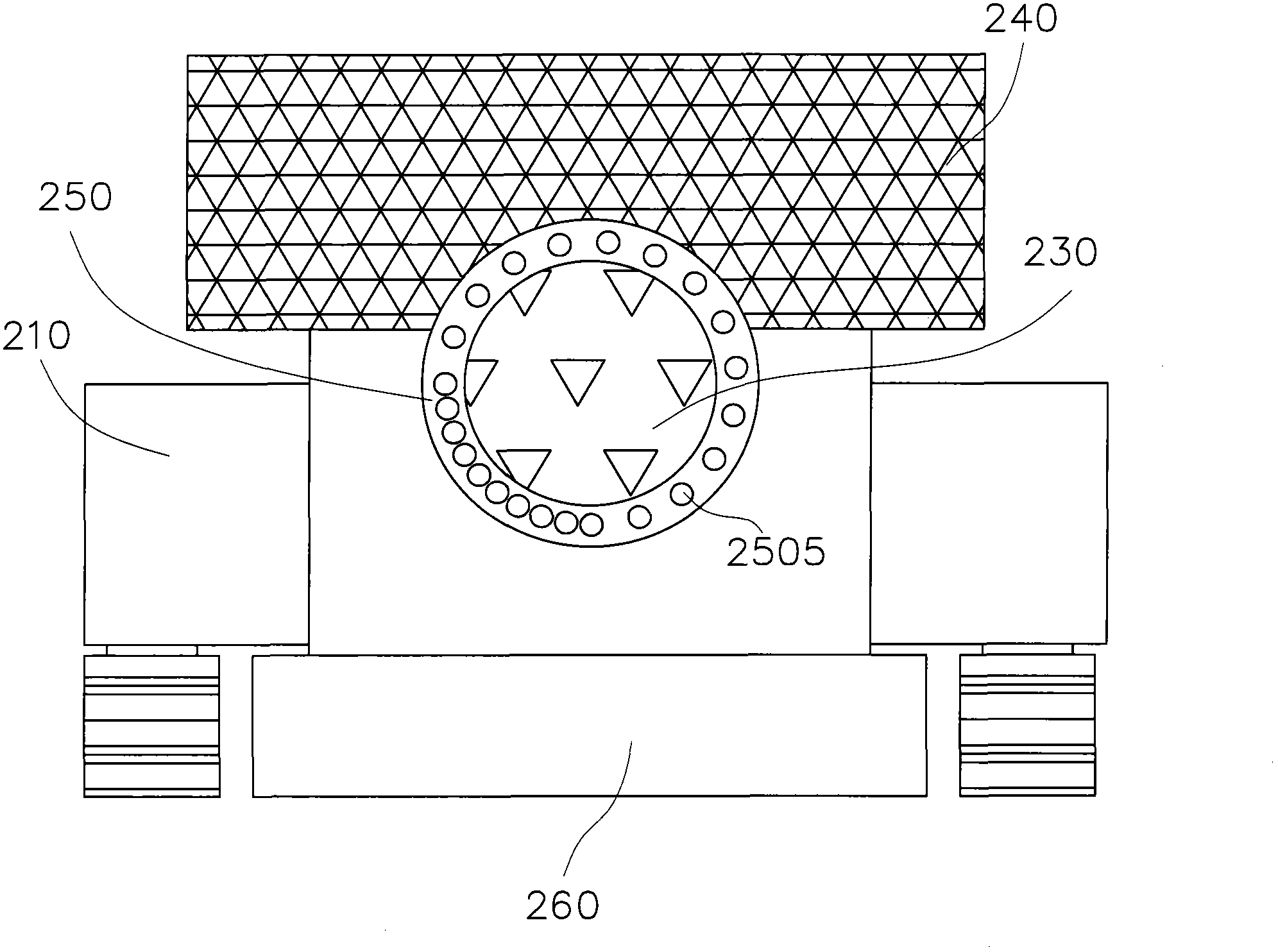

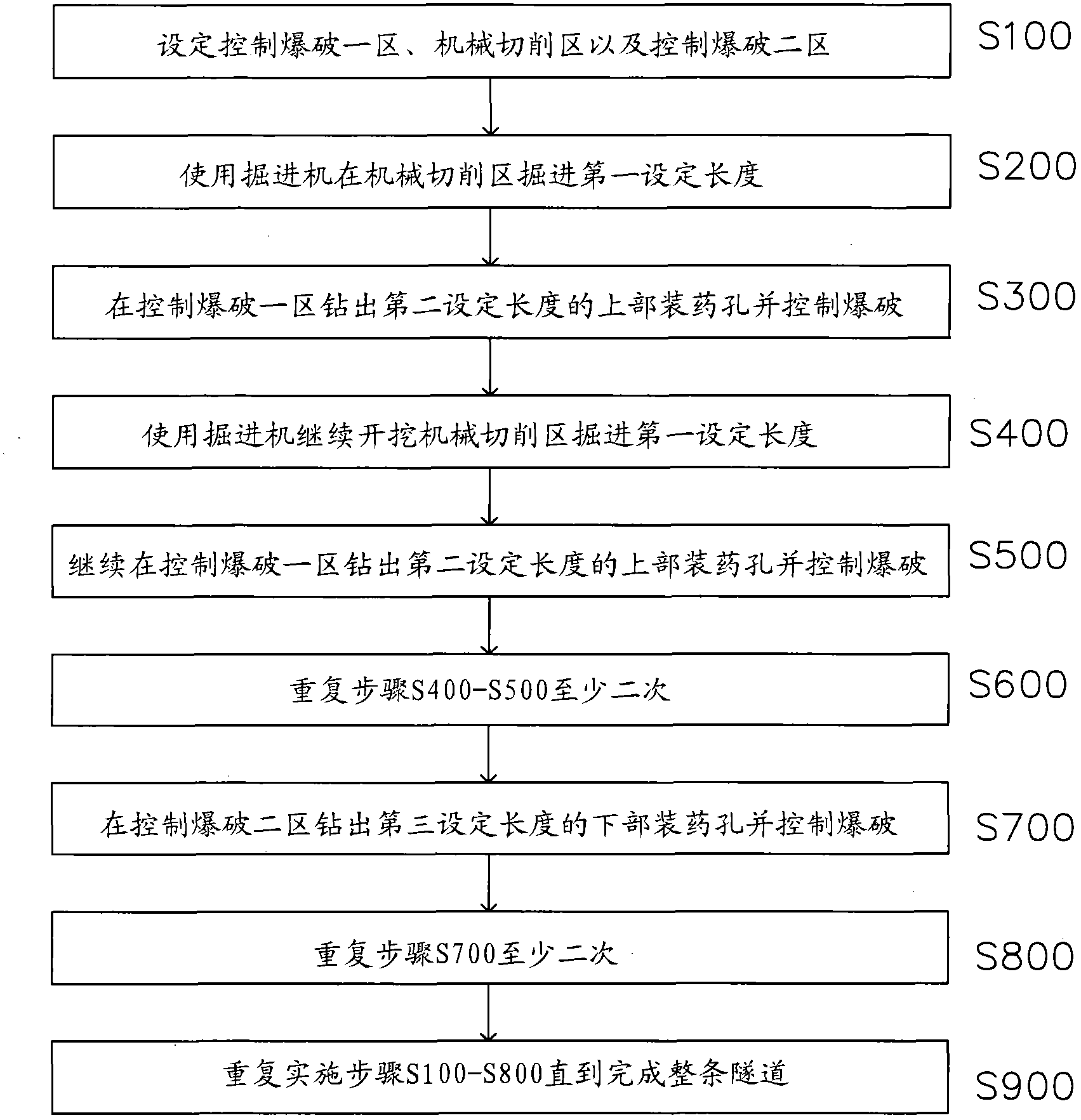

Boom-type roadheader for tunnel construction and tunnel construction method

InactiveCN103291308AAvoid influenceSettlement controlDust removalFire preventionArchitectural engineeringCantilever

The invention discloses a boom-type roadheader for tunnel construction and a tunnel construction method. The boom-type roadheader comprises an engine-driven body, a boom, a milling and excavating head and a water spraying and dust removing device, wherein the boom is connected to the engine-driven body in an extensible and / or swingable manner, and the milling and excavating head is mounted at the free end of the boom in a rotatable manner. The water spraying and dust removing device comprises a plurality of nozzles around the boom and adjacent to the milling and excavating head, and the nozzles are in non-uniform distribution in the circumferential direction. When the boom-type roadheader is used for excavating and milling the cross section of a tunnel, segments and segment strips are set for milling and excavation. When each strip of each segment is excavated and milled, and when the distribution density of the nozzles on the bottom right of the milling and excavating head is set to be higher than that of the nozzles in other regions, the milling and excavating head is driven by the boom to move from left to right; when the distribution density of the nozzles on the bottom left of the milling and excavating head is set to be higher than that of the nozzles in the other regions, the milling and excavating head is driven by the boom to move from right to left.

Owner:北京中铁瑞威基础工程有限公司

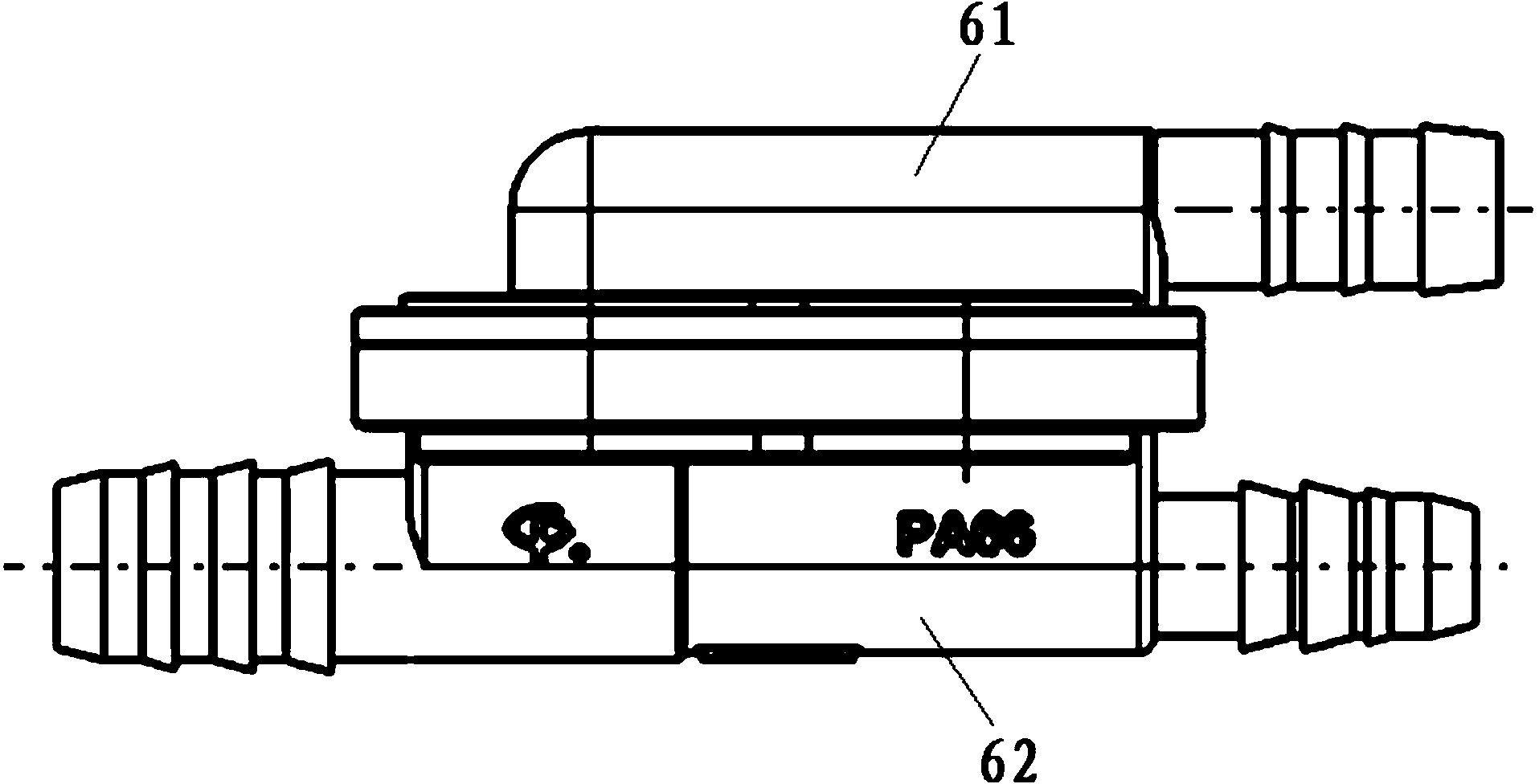

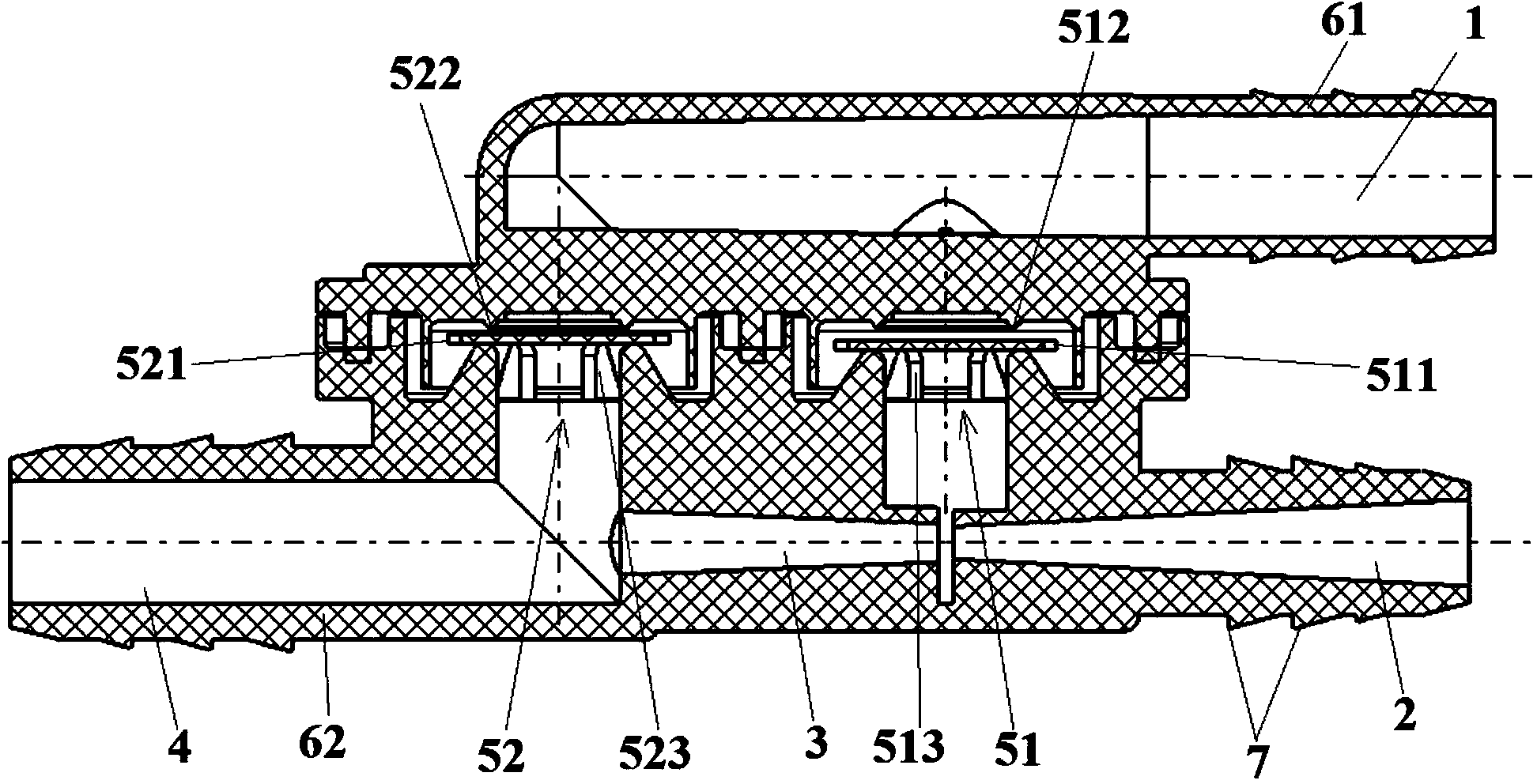

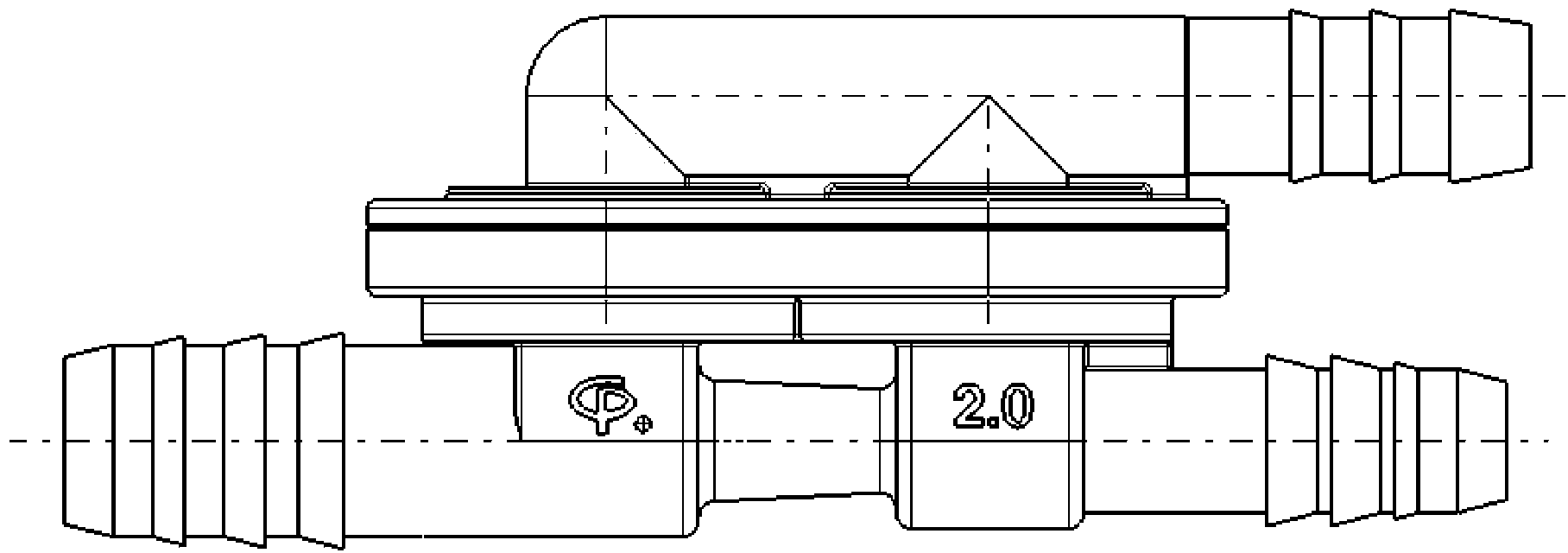

Venturi valve and vacuum power assisting device

InactiveCN103407441AImprove stabilityImprove securityBraking action transmissionPiping arrangementsAir filterEngineering

The invention discloses a venturi valve and a vacuum power assisting device, which relates to the technical field of automobiles, and aims for solving the technical problem in the prior art that people feel hard to stamp down a pedal when an automobile is braked as the vacuum degree inside a vacuum power assisting device is low. The venture valve comprises a suction tube, a venturi tube, a connecting tube body, an exhaust tube, a first check valve and at least one second check valve, wherein the air inlets of the first check valve and the second check valve are both communicated with the air outlet of the suction tube; the air outlet of the first check valve is communicated with the small-diameter port of the venturi tube; the air outlet of the second check valve and the air inlet of the exhaust tube are both communicated with the small-diameter port of the venturi tube through the connecting tube body. The vacuum power assisting device comprises a vacuum source, an air filter, a vacuum power assistor and the venturi valve provided by any technical scheme of the invention. The venturi valve is used for improving the vacuum degree of the vacuum power assisting device.

Owner:HEBEI CHINAUST AUTOMOTIVE PLASTICS CORP LTD

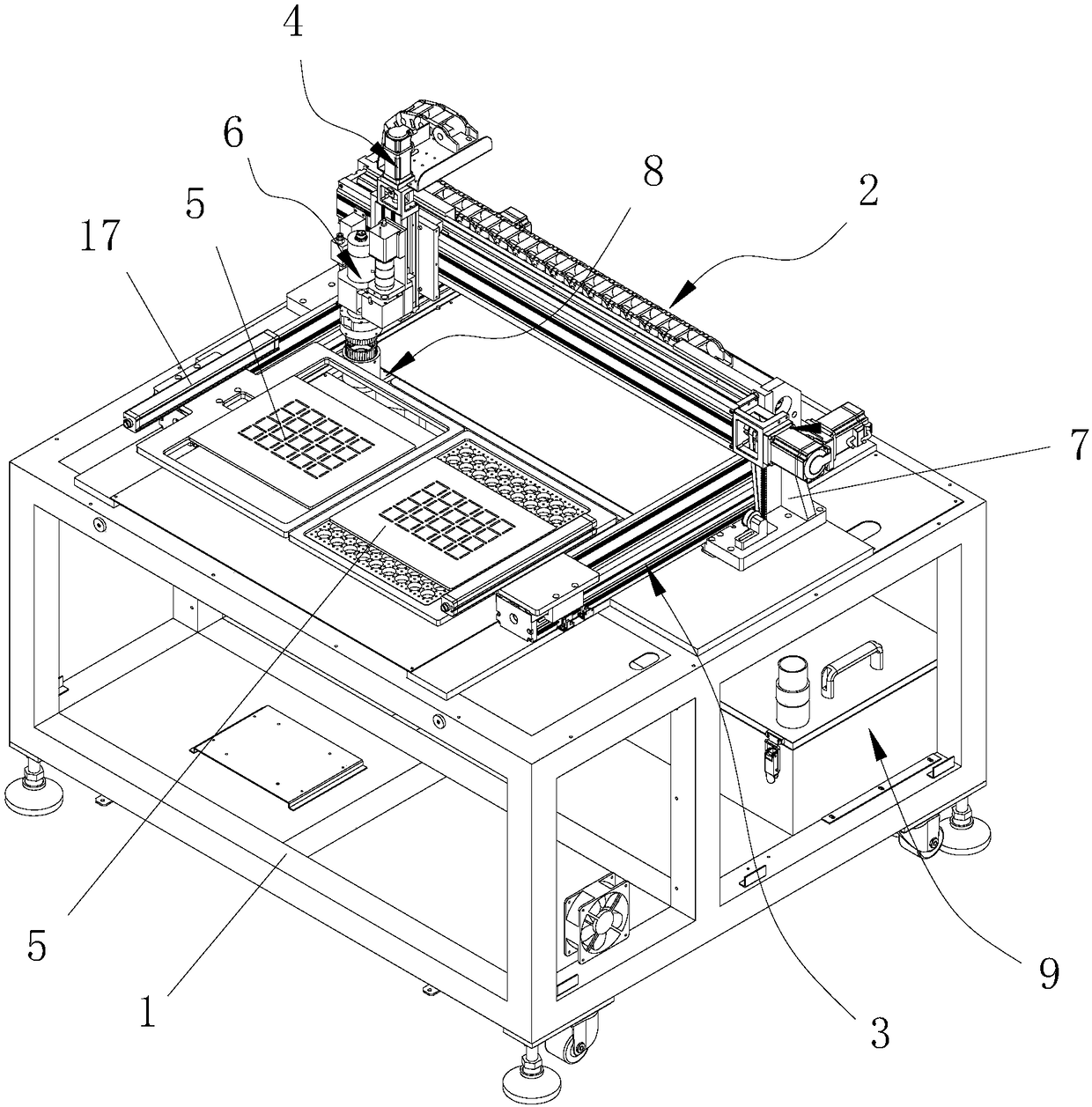

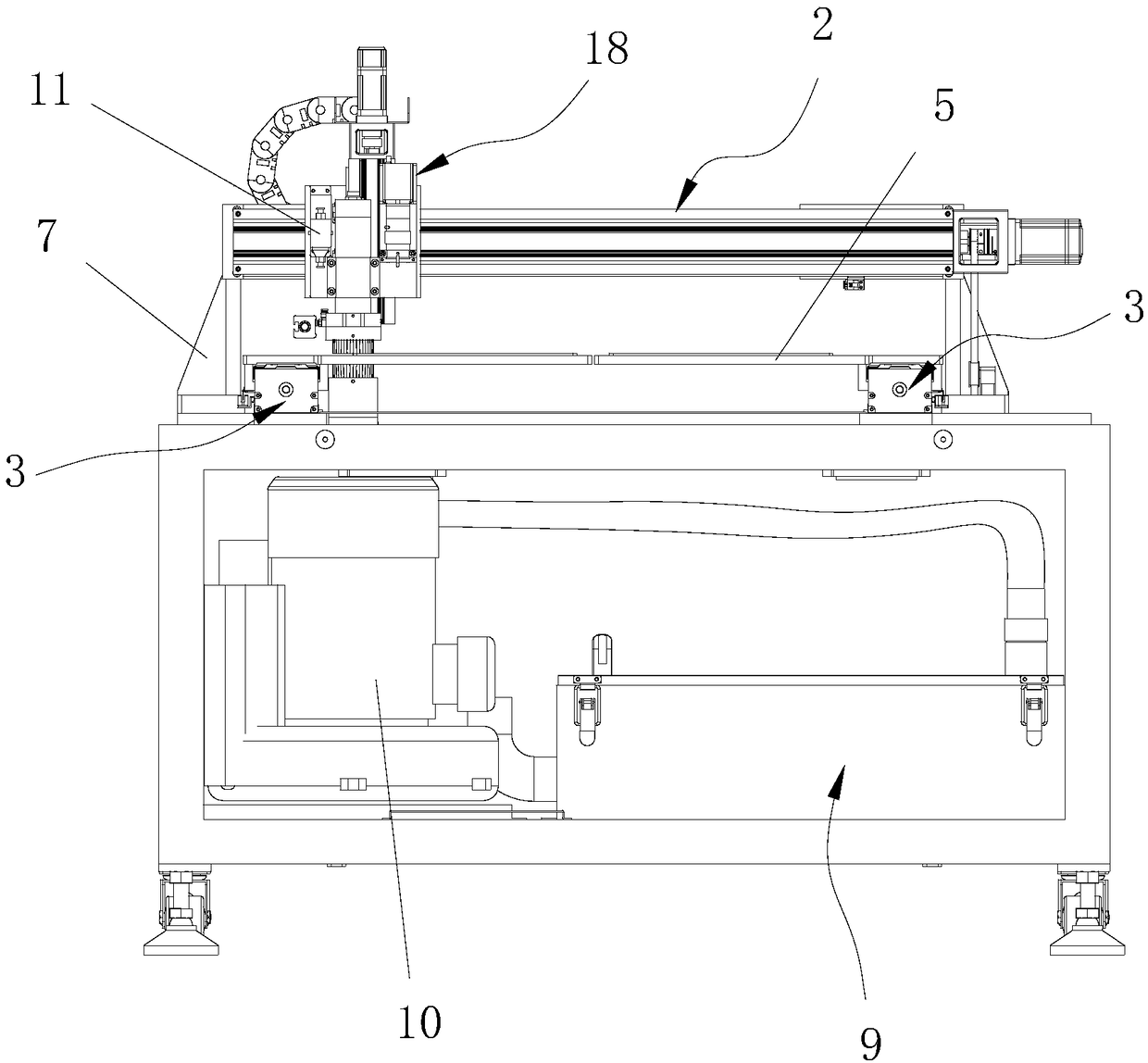

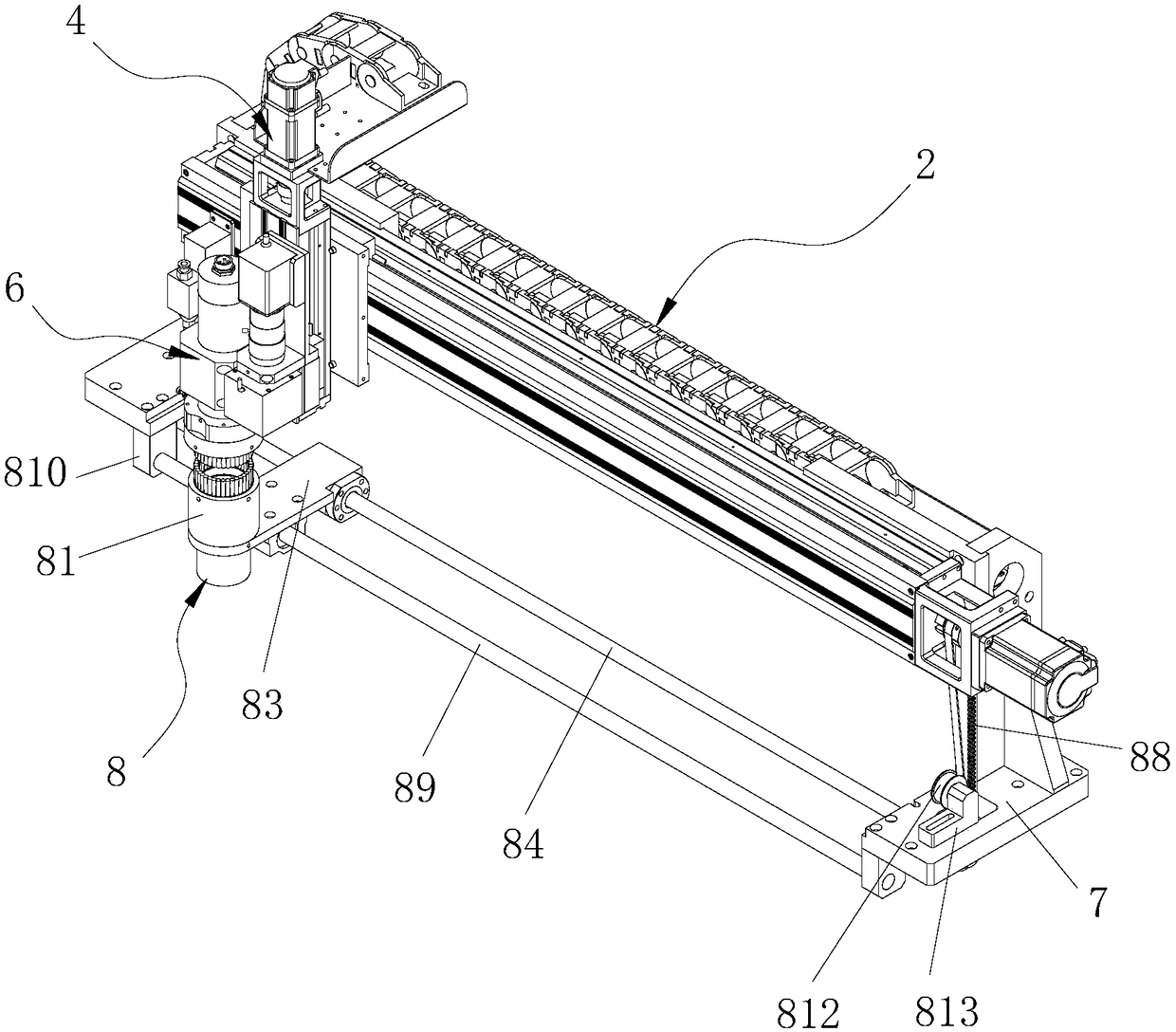

Novel PCB separator

InactiveCN108262779AClean up thoroughlyReduce manufacturing costDispersed particle filtrationTransportation and packagingDepanelingFilter effect

The invention discloses a novel PCB separator. The novel PCB separator comprises a frame, an X-axle moving mechanism, a Y-axle moving mechanism, a Z-axle moving mechanism, a tool tray, a main shaft cutting mechanism, a linked dust sucking mechanism and a dust collection and filter mechanism; the linked dust sucking mechanism is in transmission connection with the X-axle moving mechanism, and can synchronously move along with the main shaft cutting mechanism on the X-axle moving mechanism to suck dust on PCBs on the tool tray; a dust sucking part of the linked dust sucking mechanism is connected with an inlet of the dust collection and filter mechanism through a pipe; and an outlet of the dust collection and filter mechanism is connected with an air sucker through another pipe. The novel PCB separator is reasonable in structural design, stable and reliable in operation, convenient to operate, high in machining precision, excellent in dust sucking effect and high in efficiency, can thoroughly remove the dust, and can realize linear and curve trajectory cutting. In addition, the dust collection and filter mechanism needs no disposable dust collection bag, can achieve recycling after cleaning to prevent the resource waste, and is low in cost and excellent in dust collection and filter effect.

Owner:东莞市手拉手电子科技有限公司

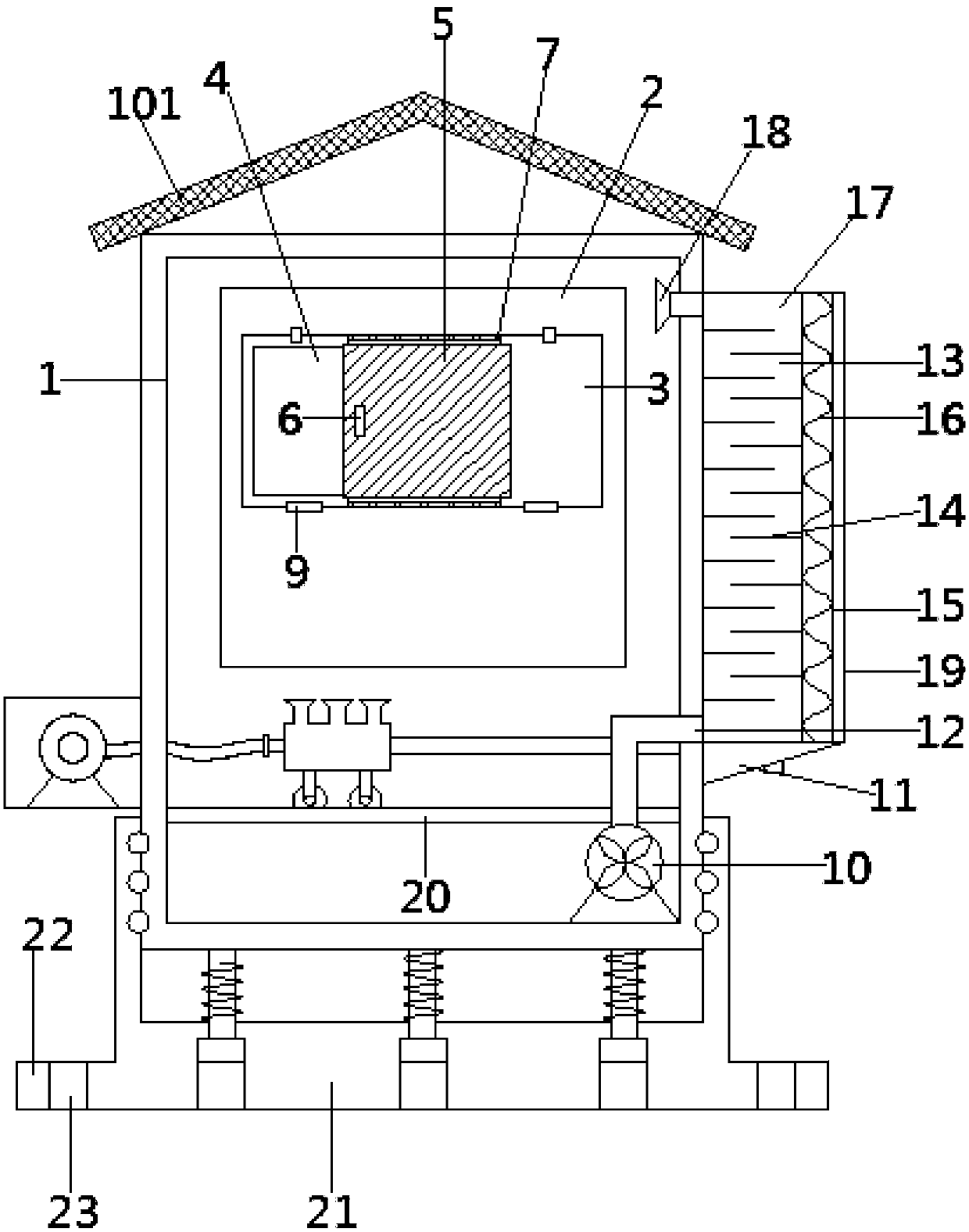

Damping power cabinet capable of effective dehumidification

InactiveCN107706756AMove quicklySmooth movementSubstation/switching arrangement casingsAnti-seismic devicesEngineeringMoisture

The invention discloses a damping power cabinet capable of effective dehumidification. The damping power cabinet comprises a cabinet body and a rainproof top arranged on the top of the cabinet body. Acabinet door is arranged on the front side of the cabinet body. A storage cavity is opened in the cabinet door. An observation window is arranged in the storage cavity area on the cabinet door. Observation glass for opening or closing the observation window is movably arranged in the storage cavity. The lower end of the side wall of the cabinet body is fixedly connected with a support seat. The support seat is welded on the side wall of the cabinet body. The upper end of the support seat is fixedly connected with a heat exchange box. The damping power cabinet capable of effective dehumidification in the invention can effectively reduce a gap between the observation glass and the cabinet door, can effectively prevent the outside dust and impurities from entering the power cabinet, can collect dust inside the cabinet body and absorb the dust thoroughly, is easy to use, can quickly and efficiently remove moisture inside the power cabinet, thereby extending the service life of electricalcomponents, and in addition, is capable of effective damping to prevent damage of a base to the cabinet body, thereby prolonging the service life of the power cabinet.

Owner:合肥名龙电子科技有限公司

Smelting method for vulcanization easy cutting plastic mold steel

The invention provides a smelting method for plastic die steel which is added with sulphur and easily cut; the materials after being smelted by an electric furnace is fed into a refining process; the content of the sulphur in the molten steel is controlled less than 0.005 percent during the refining process; the weight percentage of the steel slag in the molten steel is adjusted between 0.8 and 1.2 percent through slagging off; then the molten steel is fed into a vacuum furnace; an aluminum wire is fed into the molten steel; the weight of the fed aluminum wire is 0.08 to 0.10 percent of the weight of the molten steel; then the steel slag is added; the weight percentage of the steel slag in the molten steel is adjusted between 1.5 to 2 percent; then the molten steel is maintained for 15 to 30 minutes under the pressure of 60 to 70Pa; then the vacuum is released; a sulfurous iron wires are fed in and a calcium silicon block is added to finish smelting. In the invention, the occluded foreignsubstance in the molten steel can be mostly removed; the purify of the molten steel is improved to a large extent; the molten steel smelt after the invention can obtain the plastic die steel which is added with sulphur and easily cut through casting; the inspection grade of the die steel accords with requirments through detection; each property is further improved.

Owner:WUYANG IRON & STEEL

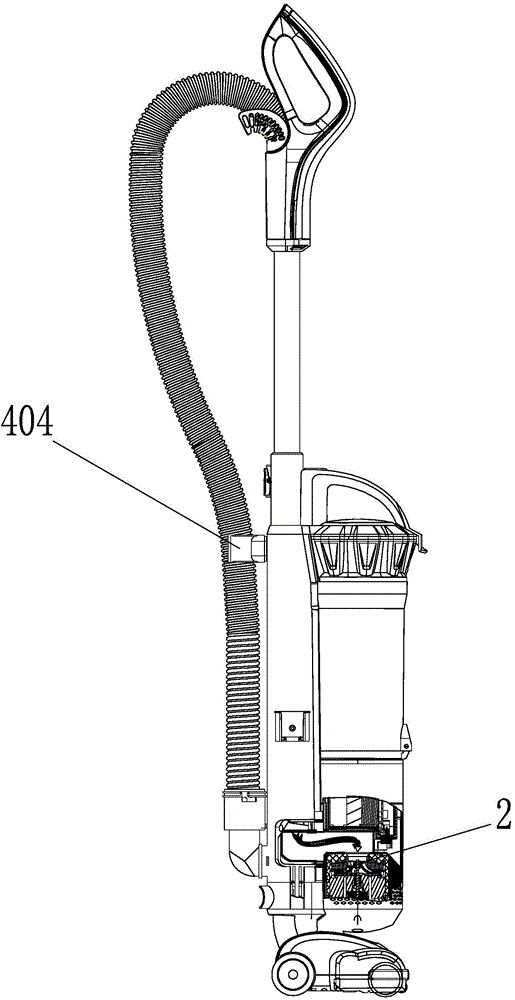

Chargeable stick type dust collector and machine body structure applied to same

The invention discloses a machine body structure applied to a chargeable stick type dust collector and the chargeable stick type dust collector with the machine body structure. The machine body structure comprises a machine body, a ground brush, a multistage cyclone device, a battery pack and a motor. The multistage cyclone device is located above the motor or the battery pack. The battery pack on the machine body structure can directly provide working power for the pole type dust collector so that dust collection can be more convenient, and the battery pack is convenient to disassemble and assemble so that users can replace the battery pack conveniently.

Owner:KINGCLEAN ELECTRIC

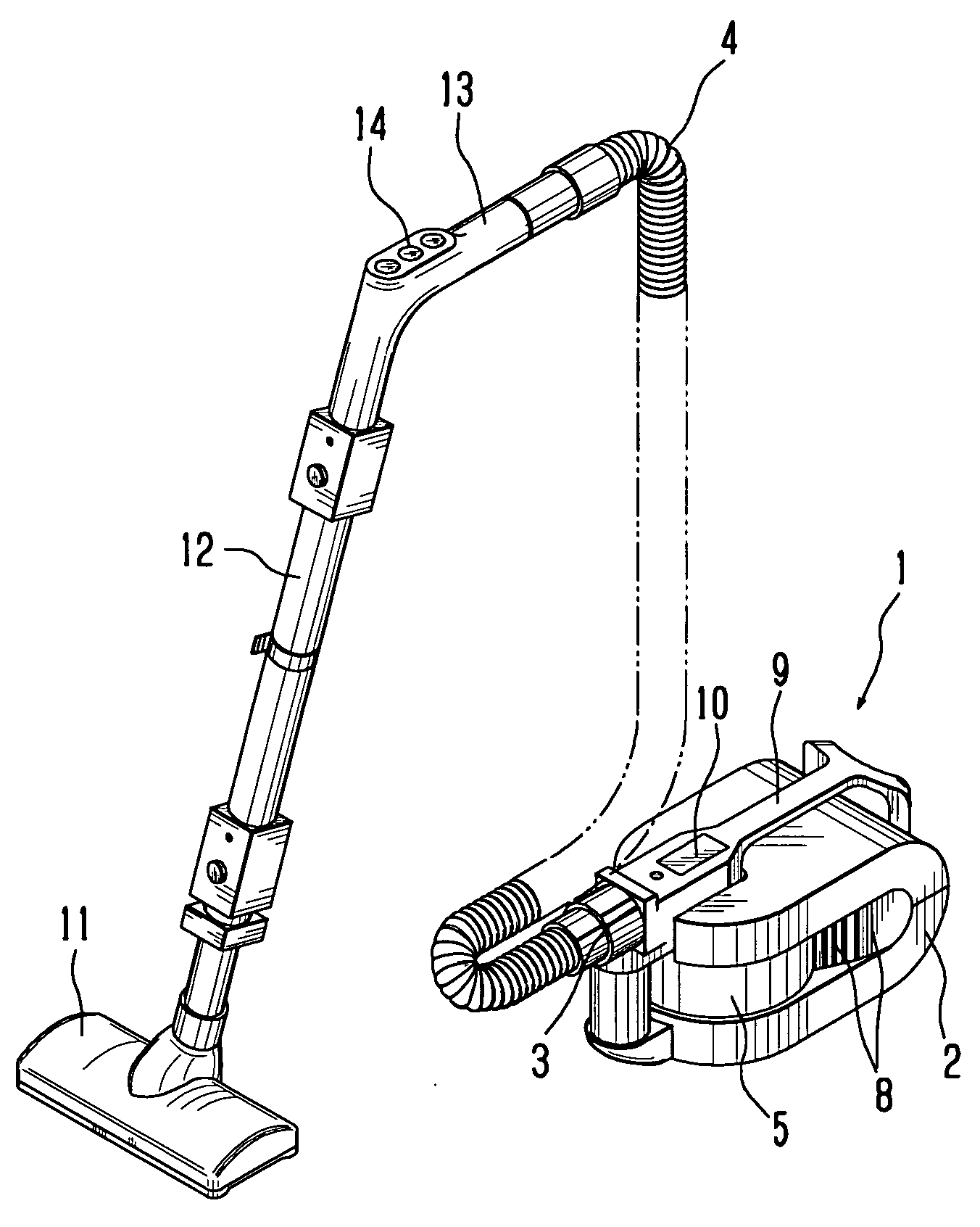

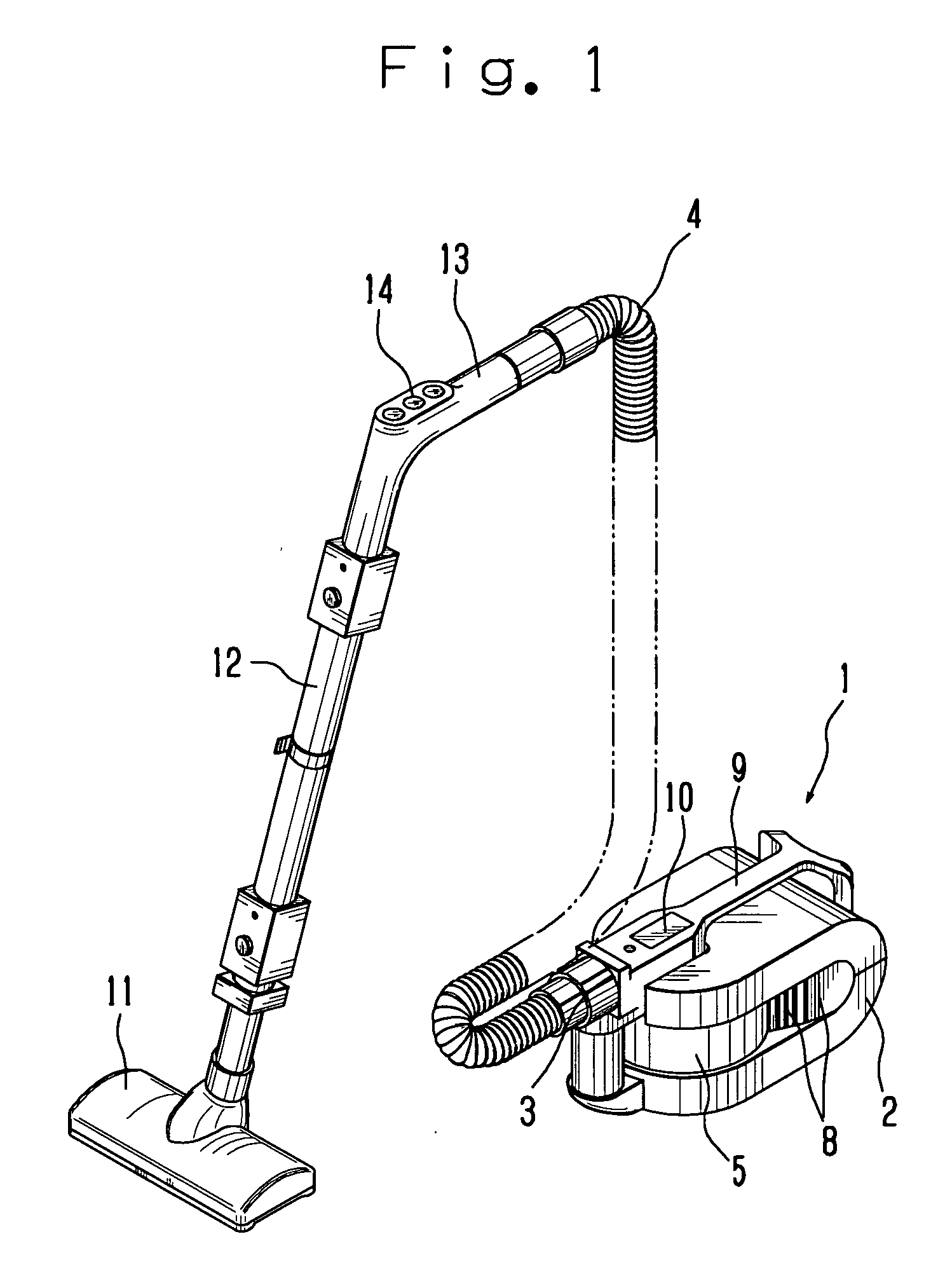

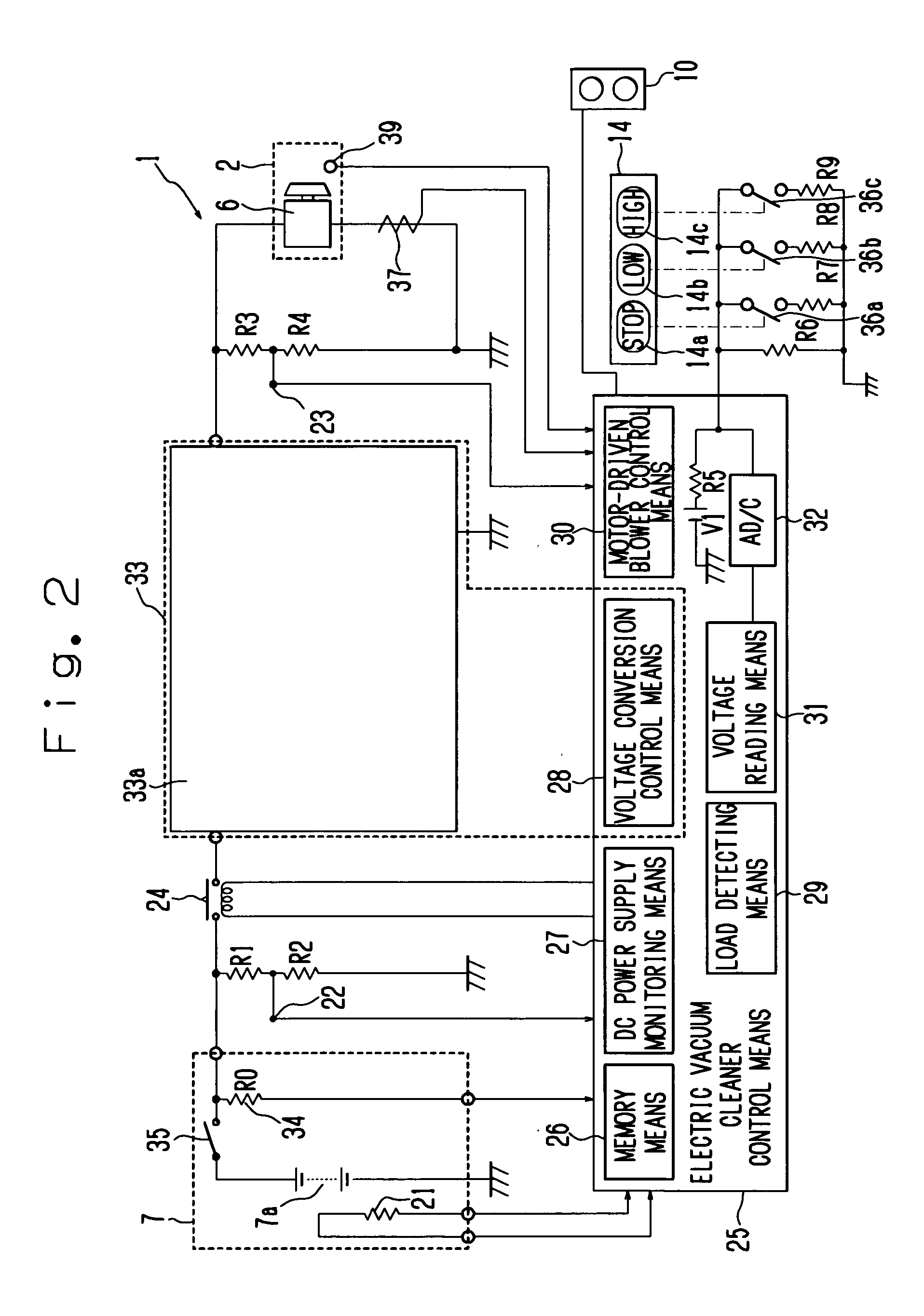

Electric vacuum cleaner

InactiveUS20050097701A1Decrease variationSatisfactory efficiencyDC motor speed/torque controlElectric equipment installationElectrical batteryEngineering

The present invention provides an electric vacuum cleaner equipped with a step-up converter circuit with a DC power supply as a drive source, which drives and controls the step-up converter circuit so as to refer to such a relationship as to decrease a variation in dust suction capability, determine an output voltage to be boosted according to the state of a load on a motor-driven blower, boost the output voltage, based on the result of determination and supply power to the motor-driven blower, thereby activating the step-up converter circuit with satisfactory efficiency. Thus, the dust suction performance of the electric vacuum cleaner is enhanced and the usage time of a battery per charge is lengthened.

Owner:TOSHIBA TEC KK

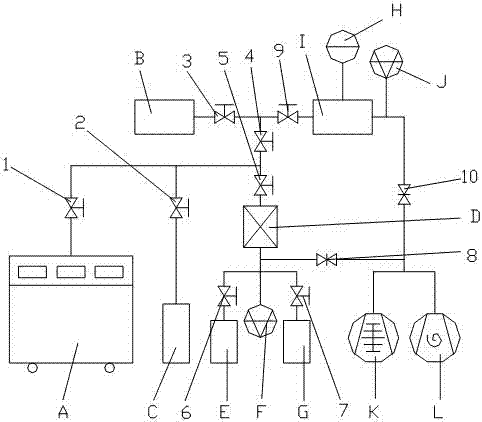

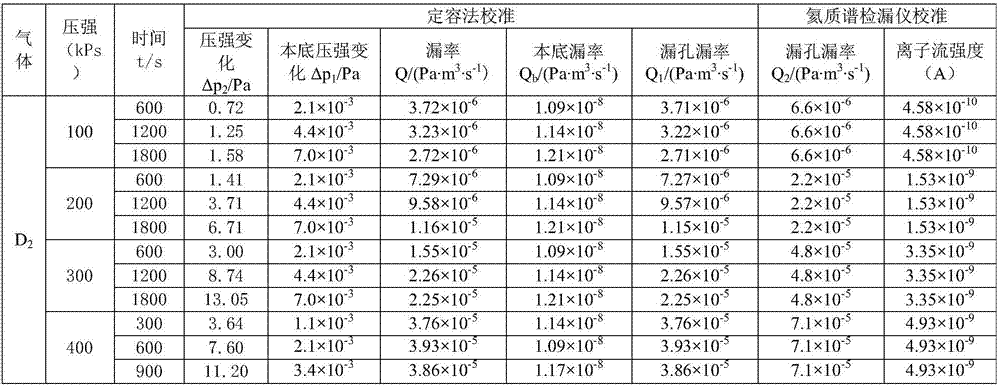

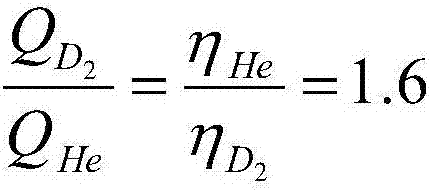

System and method for calibrating leak rates of vacuum leak holes of different leak indication gases

ActiveCN107036769ACalibration works efficientlyEasy calibration workDetection of fluid at leakage pointMeasurement of fluid loss/gain rateSystems designEngineering

The invention discloses a system for calibrating the leak rates of vacuum leak holes of different leak indication gases. The system comprises a helium mass spectrum leak detector, a standard container, an argon source, a vacuum leak hole to be calibrated, a leak indication gas source, a constant volume chamber, a vortex molecular pump and a turbine mechanical pump; the vortex molecular pump and the turbine mechanical pump are connected with the constant volume chamber and the standard container by pipelines in sequence; one end of the vacuum leak hole to be calibrated is connected with the leak indication gas source by a pipeline, the other end is connected between the standard container and the constant volume chamber, and the helium mass spectrum leak detector and the argon source are respectively connected to the connecting pipeline. Besides, the system can obtain a conversion relation between leak rates when different leak indication gas media are quickly measured using the helium mass spectrum leak detector, via the magnitude of the leak rate of the leak hole measured by a constant volume method and in combination with the leak rates, measured by the helium mass spectrum leak detector, of vacuum leak holes of different leak indication gas media. The system is reasonable in design, simple in structure and convenient to operate, and can be used for calibrating the leak rates of vacuum leak holes of different leak indication gases.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Rotatable label sucking head for labeler

The invention discloses a rotatable label sucking head for a labeler. The rotatable label sucking head comprises a rotating motor, a small synchronous wheel driven by the rotating motor, a large synchronous wheel connected to the small synchronous wheel via a synchronous belt, a rotating shaft driven by the large synchronous wheel, and a sucker connected to one end of the rotating shaft. The rotating shaft has a hollow structure of a through hole; one end of the through hole of the rotating shaft is provided with a vacuum suction nozzle; and the other end of the through hole of the rotating shaft is provided with the sucker. A sucker mounting plate sleeves one end, connected to the sucker, of the rotating shaft; the sucker is arranged on the sucker mounting plate via a hook; one end of the hook is arranged on the sucker mounting plate through the rotating shaft; and the other end of the hook is locked in a slot formed in the sucker via a bended hook. The rotatable label sucking head in the invention can rotate through 360 degrees; the sucker is convenient to change and has a buffering function; and the sucker can prevent a labeled product against damage due to pressing while the product is labeled.

Owner:博宸睿(苏州)智能科技有限公司

Vacuum drying apparatus

InactiveCN101025330AImprove protectionIncrease contact areaDrying using combination processesDrying machines with local agitationThermal energyOrganic solvent

The invention is about a kind of Minton dryer, composing of case vacuum pump and heating groupware. The heating groupware composes of hot plate set in the case and heater offering heat energy to the hot plate out of the case; the vacuum is made up of Roots pump and rotary vane pump, concatenating refrigerating catcher between the Roots pump and rotary vane pump. The refrigerating catcher, expansion valve and heat exchanger build up refrigeration circular system. The invention can recover organic solvent, benefit lowering production costs and environmental protection, reduce pressure quickly, keep vacuum effectiveness good, dries quickly under the low temperature and consume less energy.

Owner:李志平 +1

Vacuum sweeper sucker structure with automatic avoiding function

Owner:HUBEI JULI AUTOMOTIVE TECH CO LTD

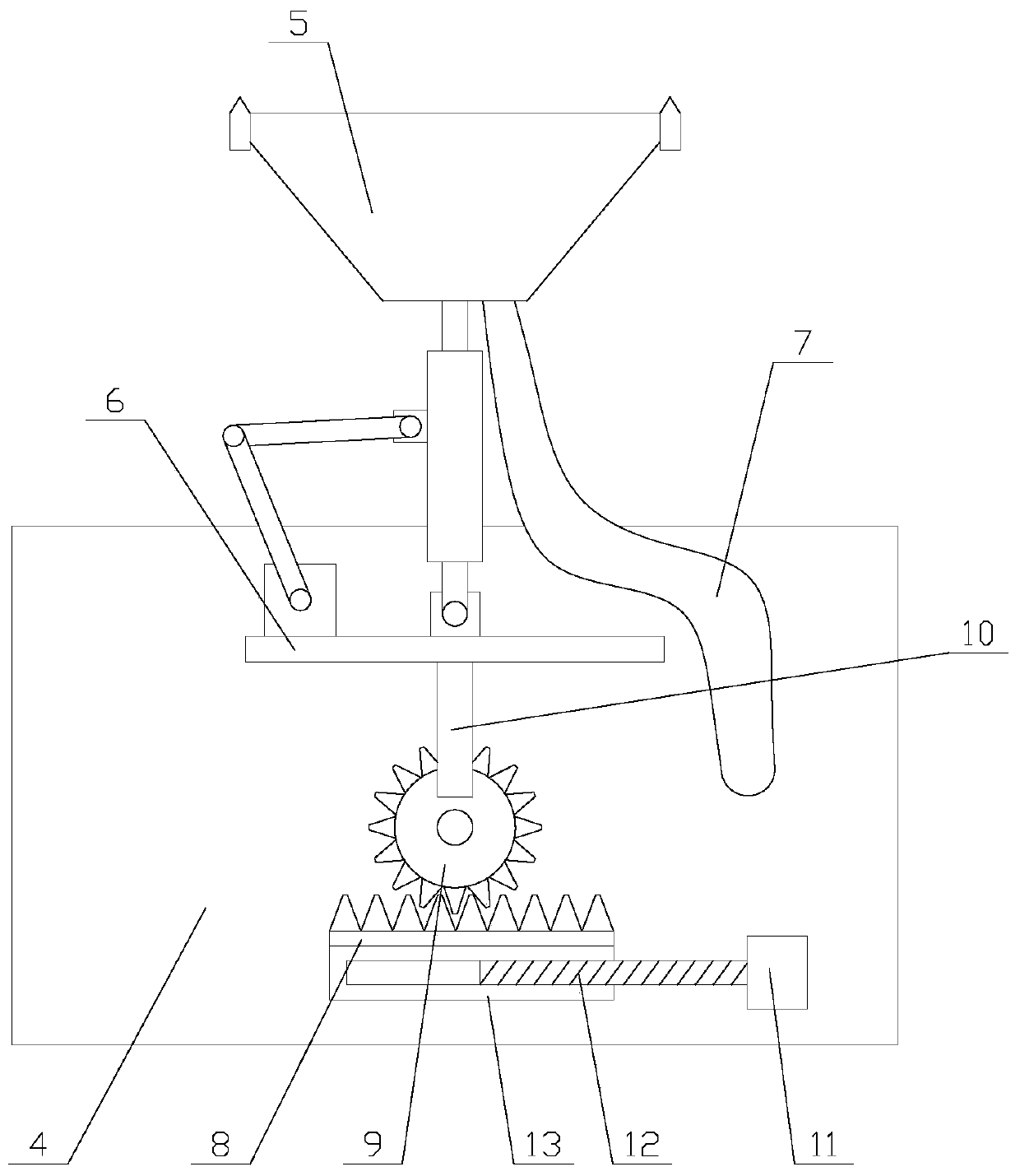

Industrial ventilation and dust removal equipment with adjusting function

ActiveCN110899286AExpand the vacuum rangeImprove vacuuming effectDirt cleaningGear wheelDust control

The invention relates to industrial ventilation and dust removal equipment with an adjusting function. The equipment comprises a base, a host, a controller, a lifting mechanism, a platform, a dust hood, a swing mechanism, a swing plate, a connecting pipe and an adjusting mechanism. The swing mechanism comprises a translation component, a rack, a gear, a supporting component and a connecting rod. The translation component comprises a first motor, a screw rod and a translation block. The adjusting mechanism comprises a hinge component, a direction adjusting component and an air cylinder. By using the industrial ventilation and dust removal equipment with the adjusting function, the swing plate is driven by the swing mechanism to swing so that the dust hood swings at a dust source and a dustsuction range is expanded; and in addition, the adjusting mechanism is used for driving the dust hood to rotate and move so that the dust hood and the dust source keep a specific distance and angle, adust suction effect is improved, and practicability of the equipment is improved.

Owner:福建兴万祥建设集团有限公司

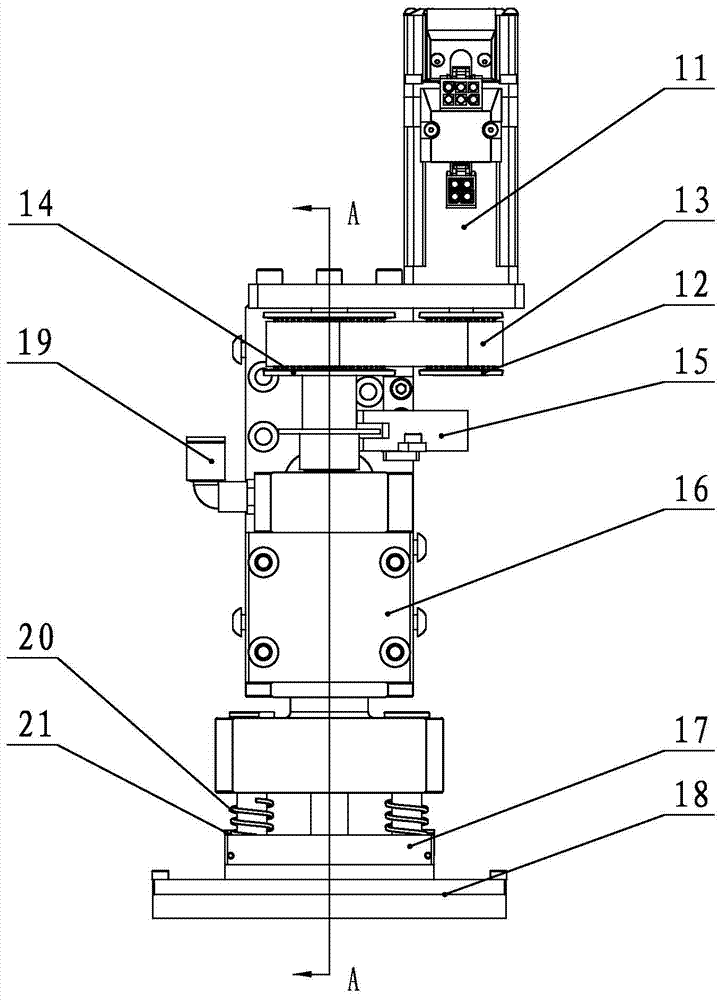

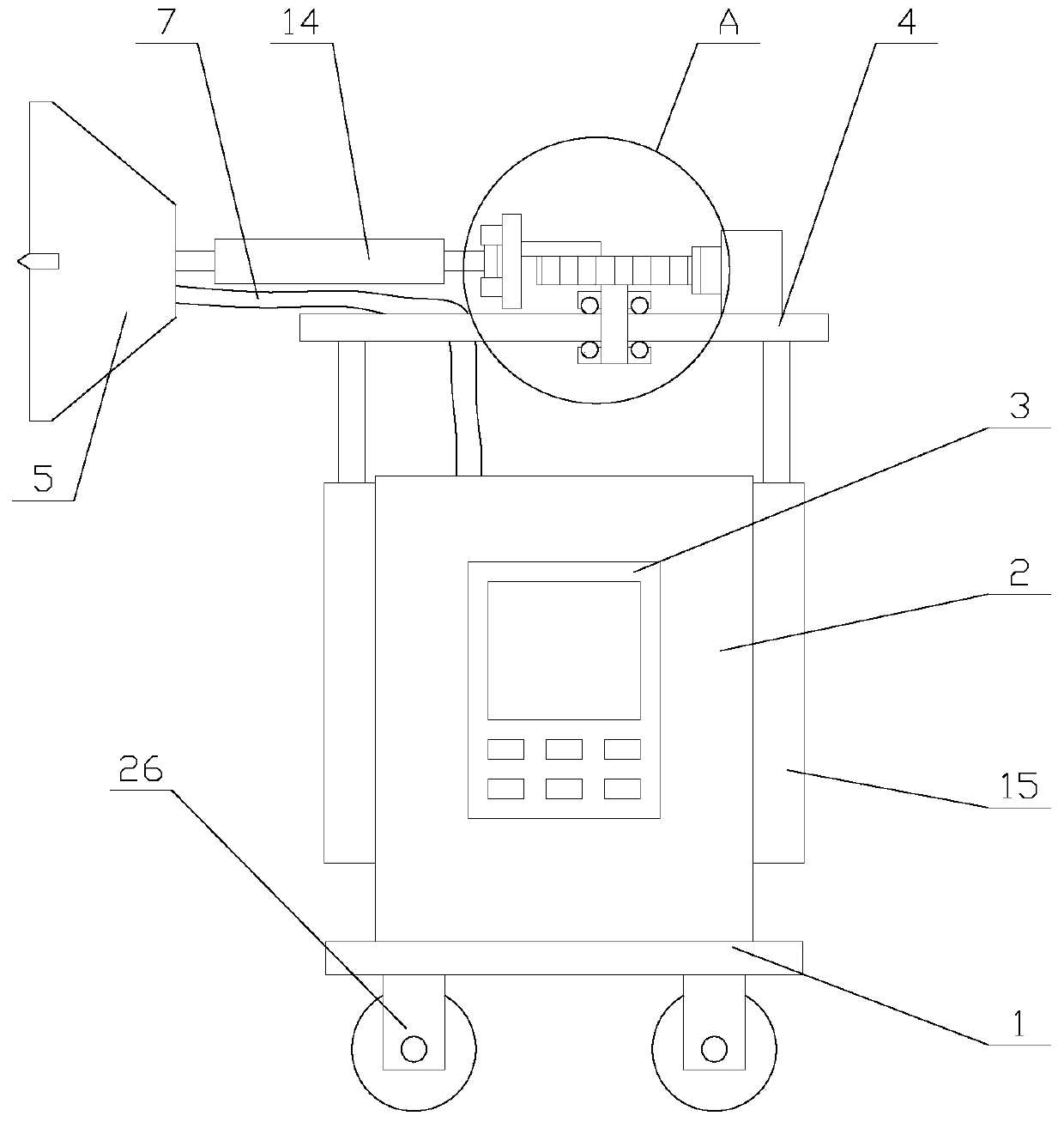

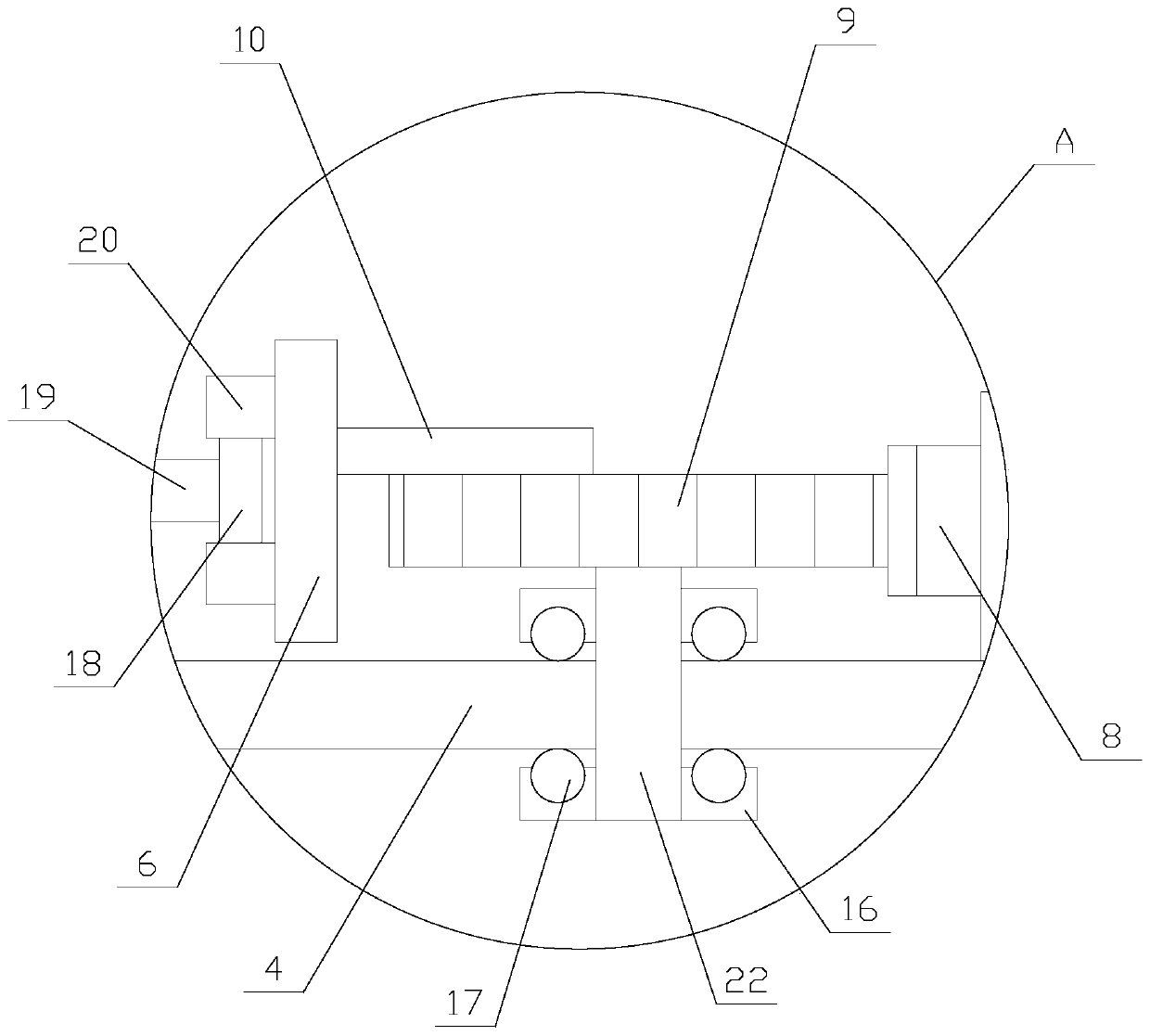

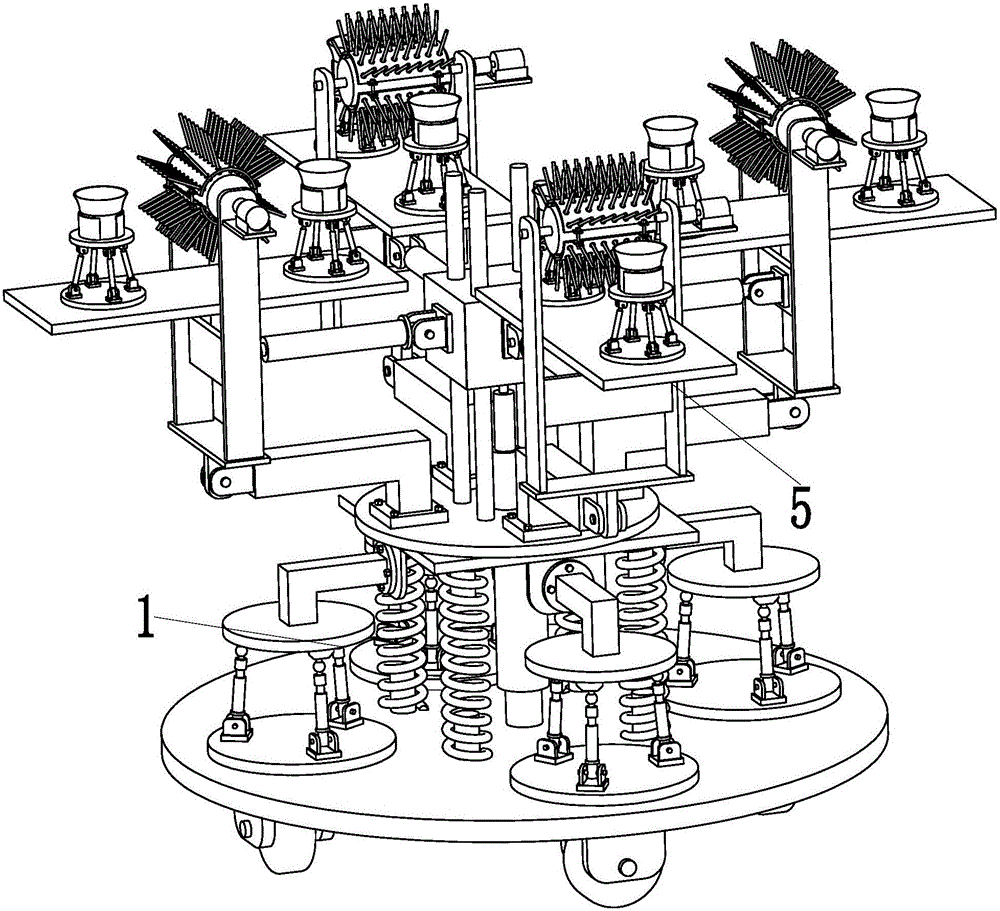

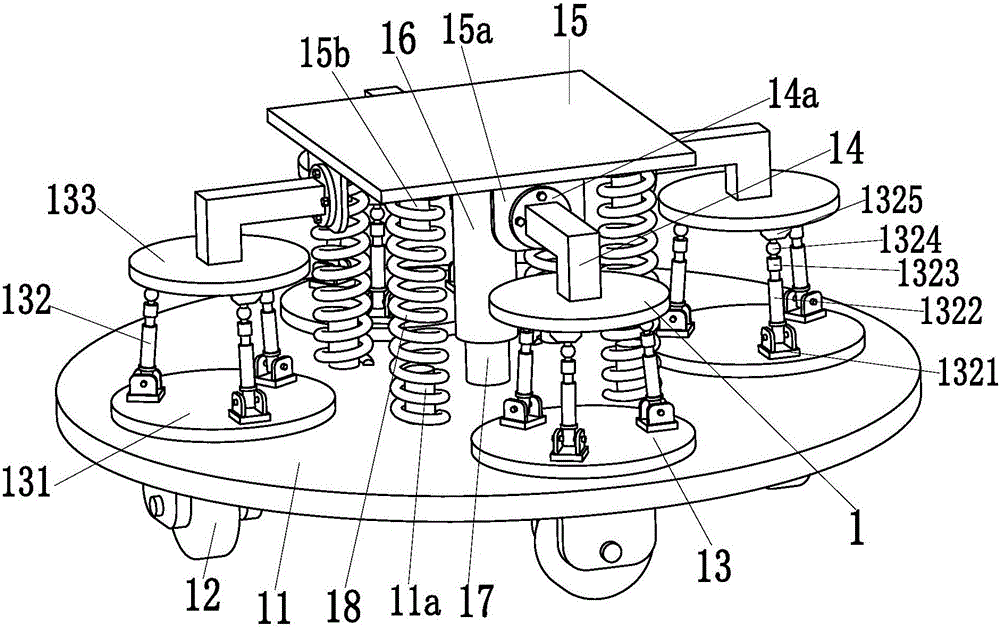

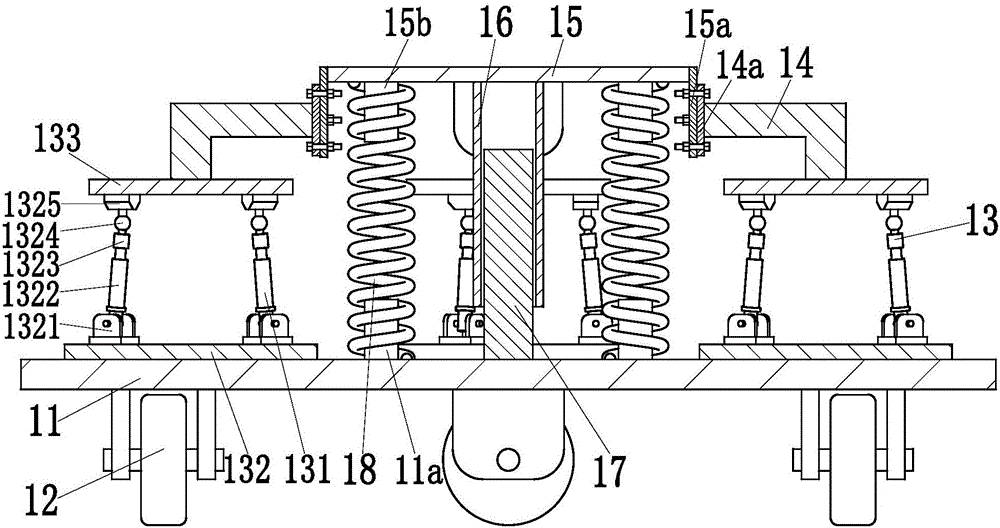

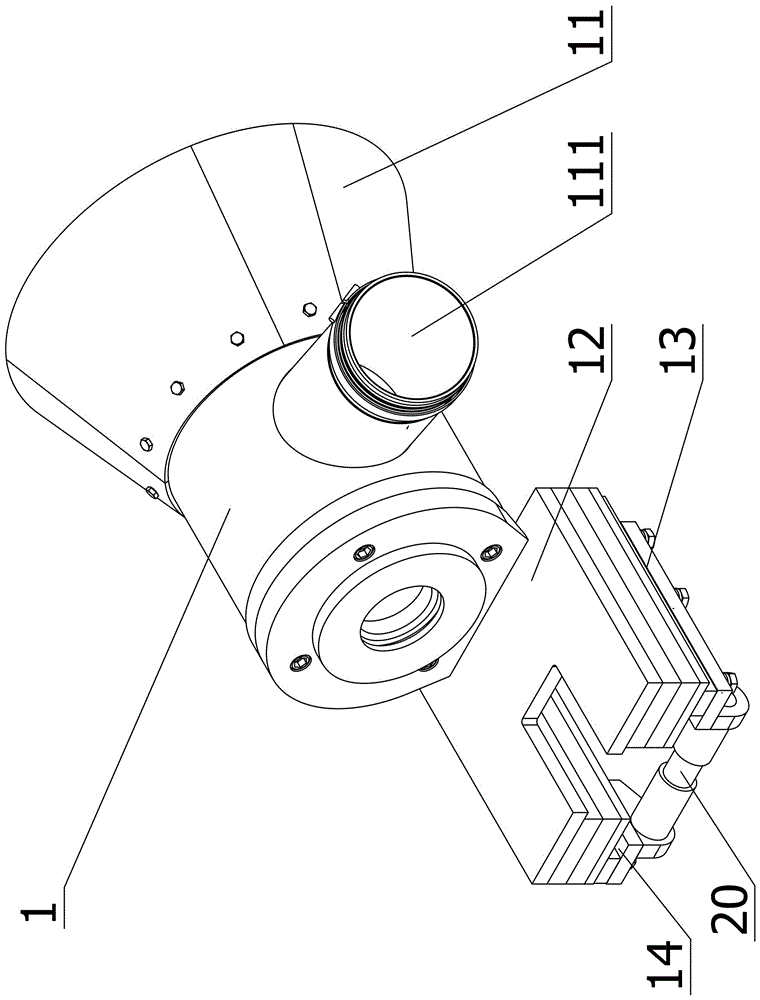

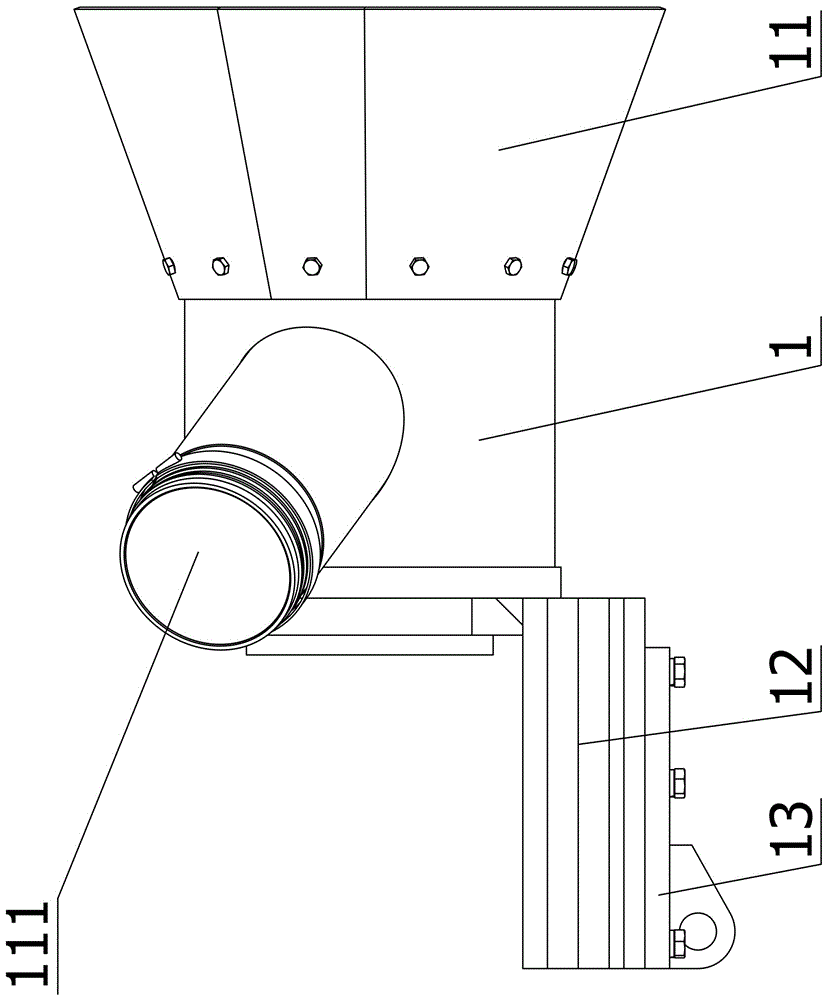

Robot for cleaning interior architecture based on parallel mechanism

ActiveCN105773638AImprove carrying capacityImprove stabilityProgramme-controlled manipulatorCarpet cleanersSelf-stabilizationEngineering

The invention relates to a robot for cleaning an interior architecture based on a parallel mechanism. The robot comprises a self-stabilization supporting device, wherein the self-stabilization supporting device has good rigid supporting performance, stable performance and vibration reducing performance; a cleaning manipulator is arranged in the middle of the upper end face of the self-stabilization supporting device; the cleaning manipulator is adjustable in cleaning angle and wide in application range, can realize the functions of automatically cleaning a ceiling, and spider webs and dust on the ceiling and the like; the interior architecture is automatically cleaned by the cleaning manipulator; the self-stabilization supporting device comprises a fixed circular table; and four universal wheels are symmetrically arranged on the lower end face of the fixed circular table. The robot disclosed by the invention is moved to a place required to be cleaned, of the interior architecture through the four universal wheels; and four parallel supporting branched chains are uniformly arranged on the upper end face of the fixed circular table along the axial direction. According to the robot disclosed by the invention, a function of automatically cleaning the interior architecture can be realized, and a new path for automatically cleaning the interior architecture is provided.

Owner:XUZHOU NAILI MACROMOLECULE TECH CO LTD

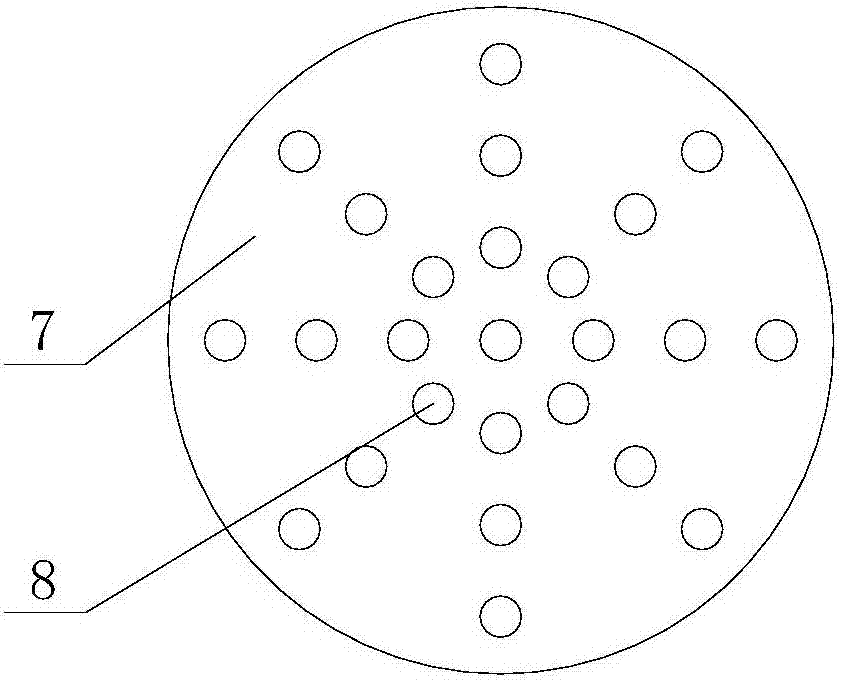

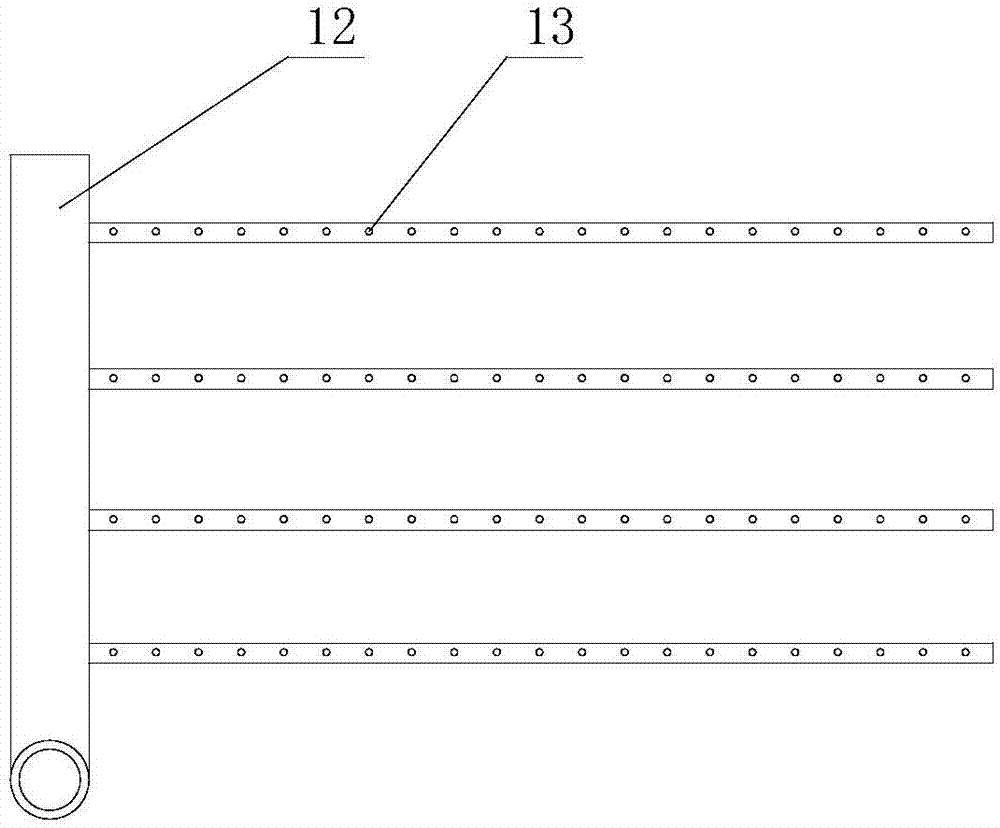

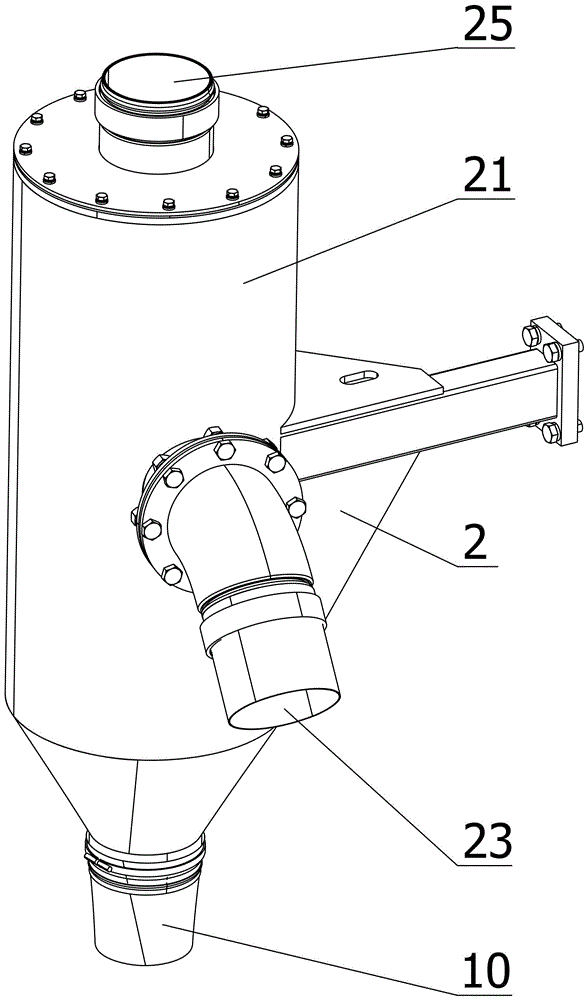

Two-stage dry dust cleaning device and down-hole drilling machine including same

The invention provides a two-stage dry dust cleaning device and a down-hole drilling machine including the same. The two-stage dry dust cleaning device comprises a dust catching part, a first stage dust cleaning part and a second stage dust cleaning part. The dust catching part, the first stage dust cleaning part and the second stage dust cleaning part are connected with flow guiding pipes sequentially; and a centrifugal exhaust fan with an air outlet is installed on the second stage dust cleaning part. According to the down-hole drilling machine provided with the two-stage dry dust cleaning device, rock dust generated from drilling operation is sequentially sucked into the dust catching part, the first stage dust cleaning part and the second stage dust cleaning part from the drilling positions through the sucking power of the centrifugal exhaust fan, and the rock dust is collected into the first stage dust cleaning part and the second stage dust cleaning part according the sizes of the dust particles; and tilting baffles are arranged on air flow paths in the first stage dust cleaning part and the second stage dust cleaning part, and a filtering element capable of adsorbing the light dust is arranged in the second stage dust cleaning part, so that dust sucking effect is improved, working environment and human health are protected, damage to the centrifugal exhaust fan is reduced, and using quality of the down-hole drilling machine is ensured.

Owner:广东孔山重工机械有限公司

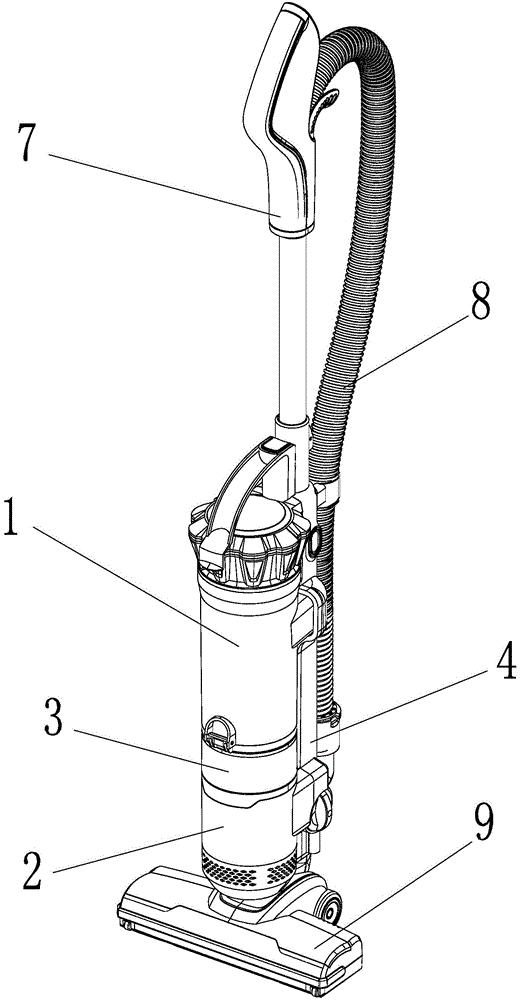

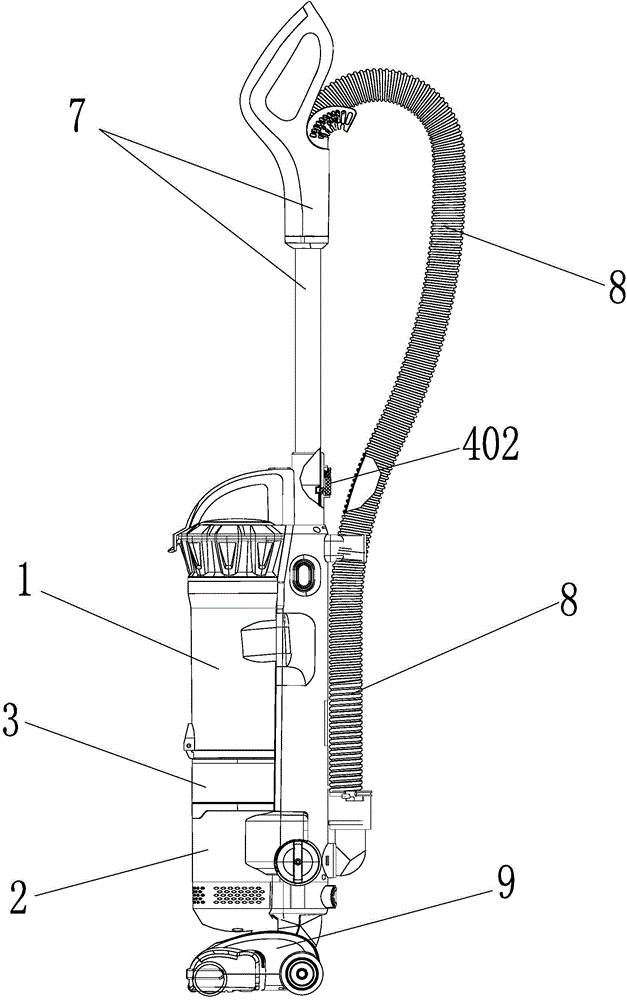

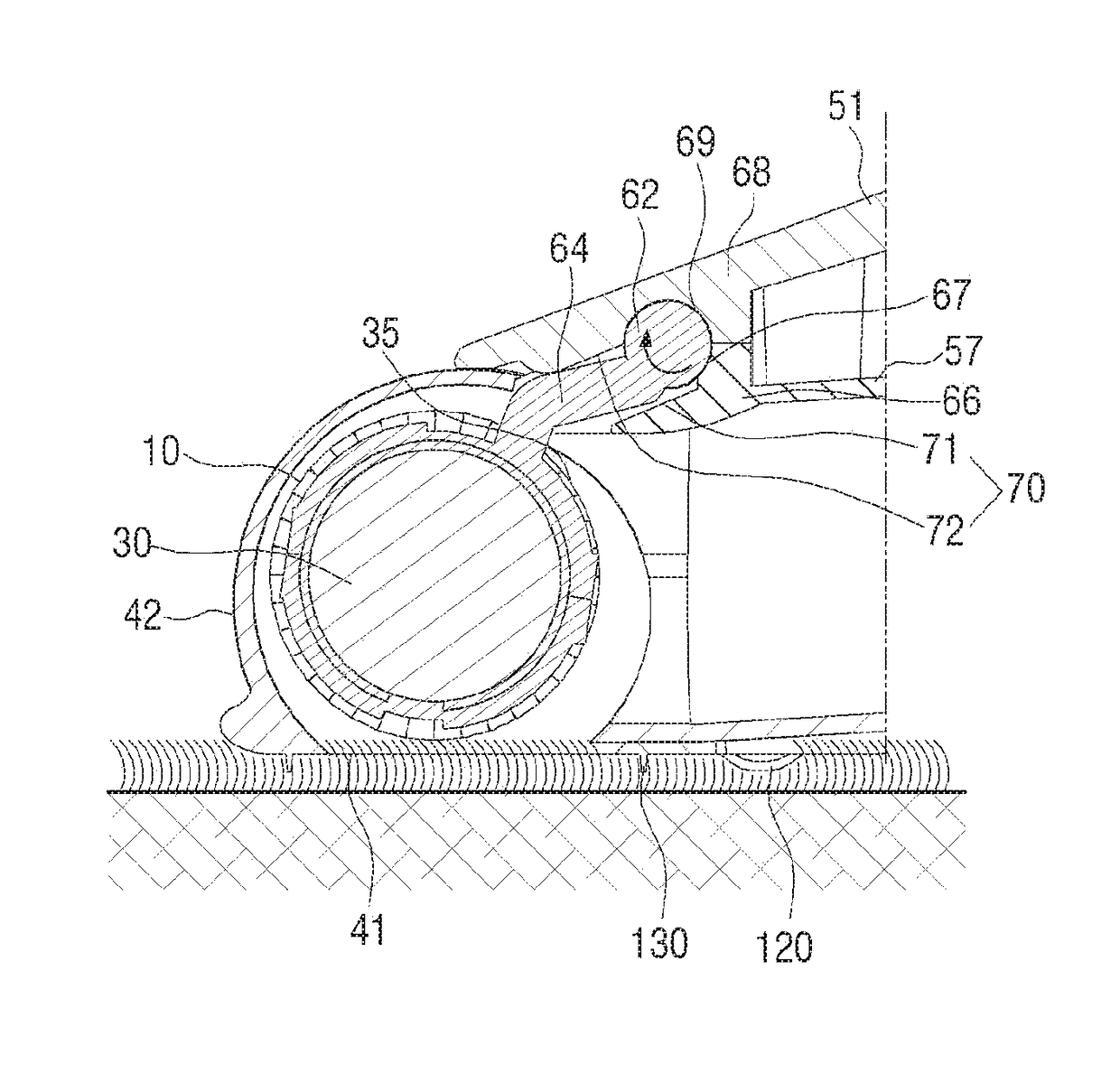

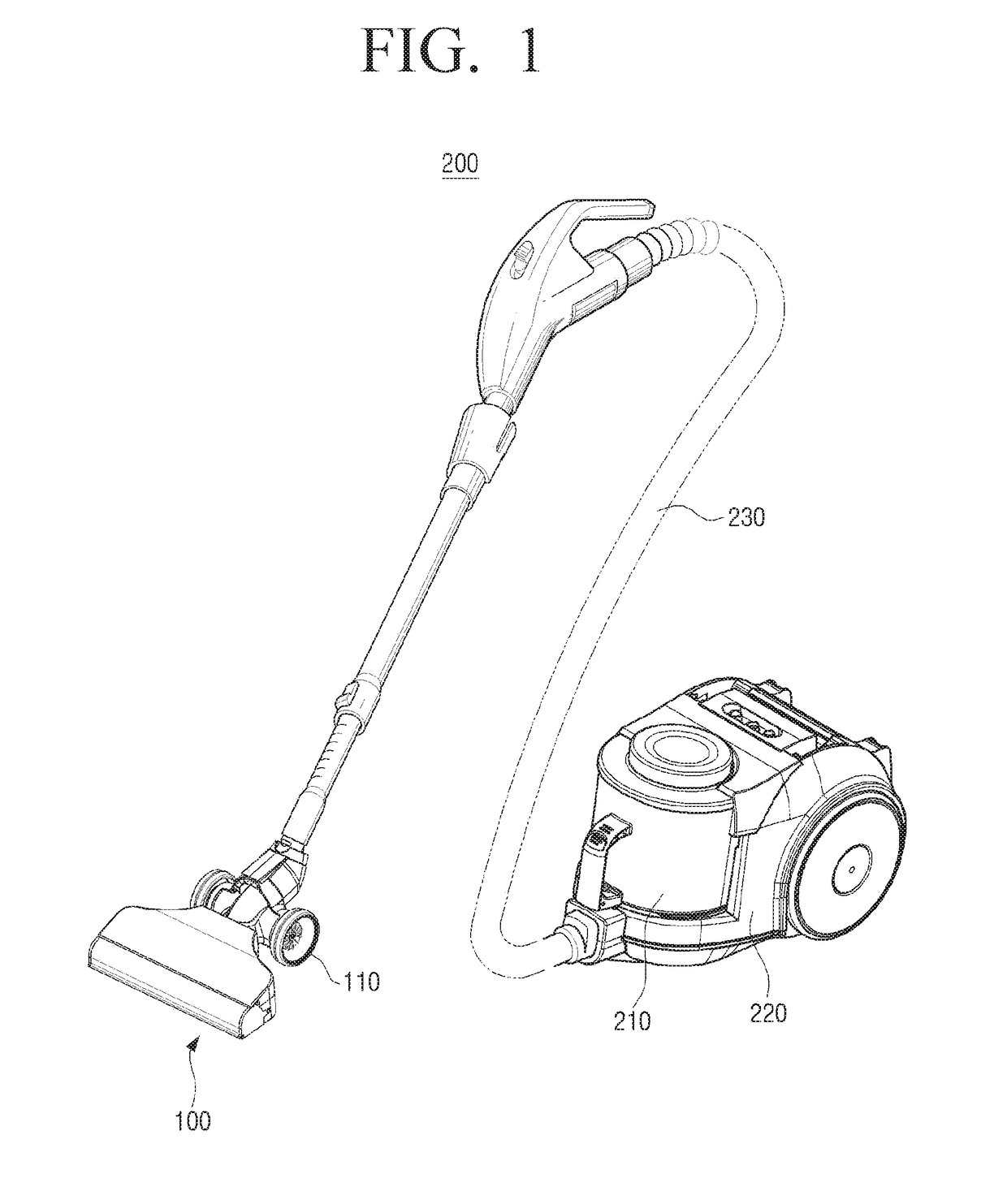

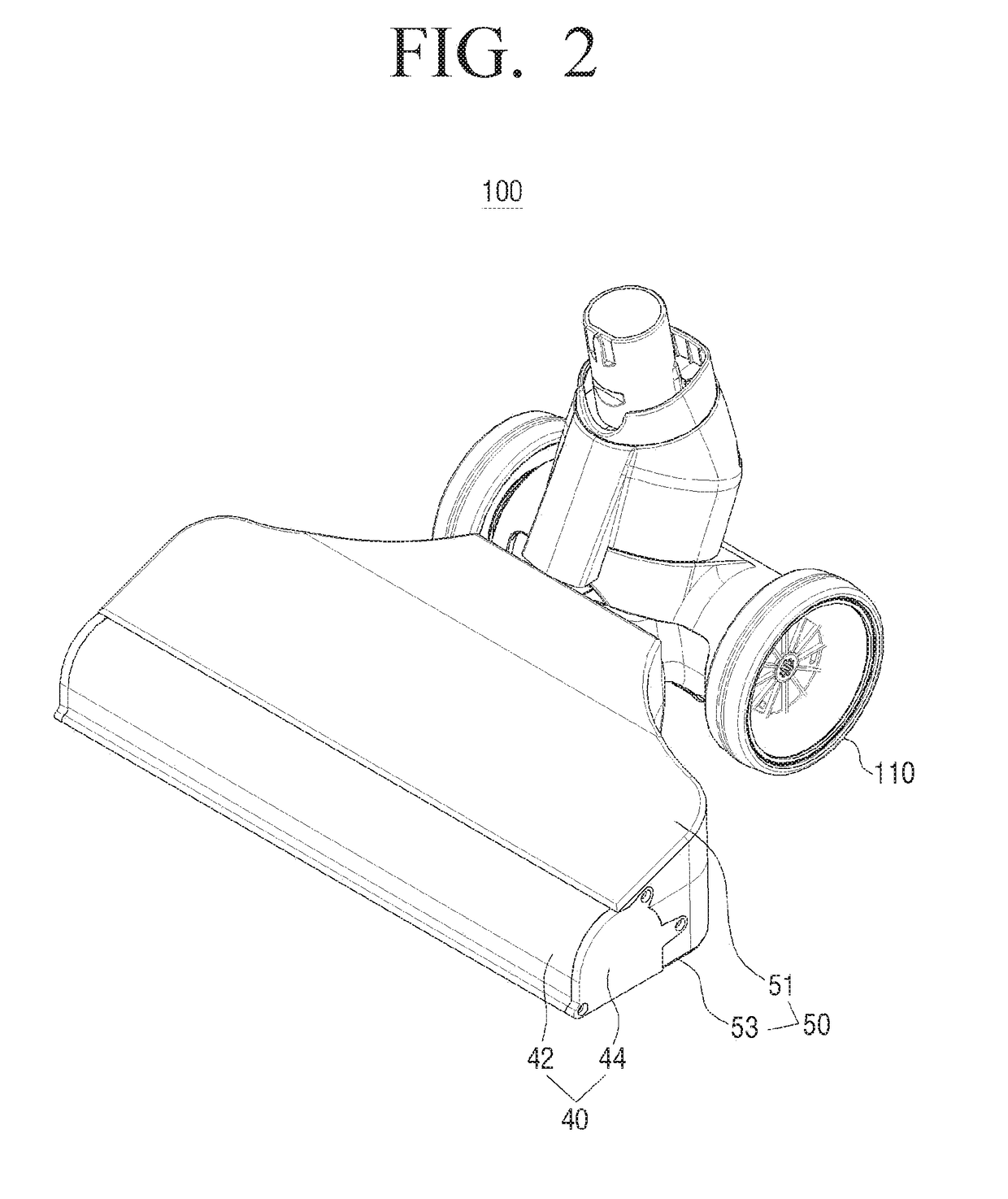

Vacuum cleaner

ActiveUS20170143175A1Minimizing torque loss of a main brushImprove vacuuming effectSuction nozzlesEngineeringVacuum cleaner

A nozzle assembly for a vacuum cleaner includes a driving member including a first driving shaft and a second driving shaft in both sides thereof, a first drum of which one end is coupled to the first driving shaft to be driven by directly receiving driving force of the first driving shaft, and a second drum of which one end is coupled to the second driving shaft to be driven by directly receiving driving force of the second driving shaft.

Owner:SAMSUNG ELECTRONICS CO LTD

Circulator

InactiveCN103216450AWonder Material PropertiesAchieve separationCircumferential flow pumpsPump componentsDust controlEngineering

The invention relates to a circulator. The circulator comprises a shell body and a transmission device, wherein the transmission device is mounted on the shell body, a rotary wheel is mounted on the transmission device, a plurality of vanes are arranged on the periphery of the rotary wheel, the rotary wheel is arranged in the shell body, a circulation cavity is formed in the inner wall of the shell body at the periphery of the rotary wheel, a circulation cavity port A is formed in one end of the circulation cavity, a circulation cavity port B is formed in the other end of the circulation cavity, and an isolating body is arranged on the inner wall of the shell body between the circulation cavity port A and the circulation cavity port B. According to the circulator provided by the invention, circular motion and fluid motion are used sufficiently; torsion is better converted into pressure through fluid; pressure is better converted into torsion through the fluid; and the fluid separation is realized by using vortex. The circulator provided by the invention can serve as a water pump, a slurry pump, a sewage pump, a blower, a compressor, spray equipment, a reactor, a steam turbine, vacuum equipment or a separator and be applied to wastewater treatment, seawater desalination, marine chemical engineering, mineral processing, waste disposal, hydrogen production, carbon dioxide decomposition, harmful gas decomposition, air purification, dedusting, dust absorption, refrigeration, oxygen production, oil refining and the like; and the blue sky and water can be completely realized, and foamed materials can be produced so as to bring a material revolution.

Owner:陈久斌

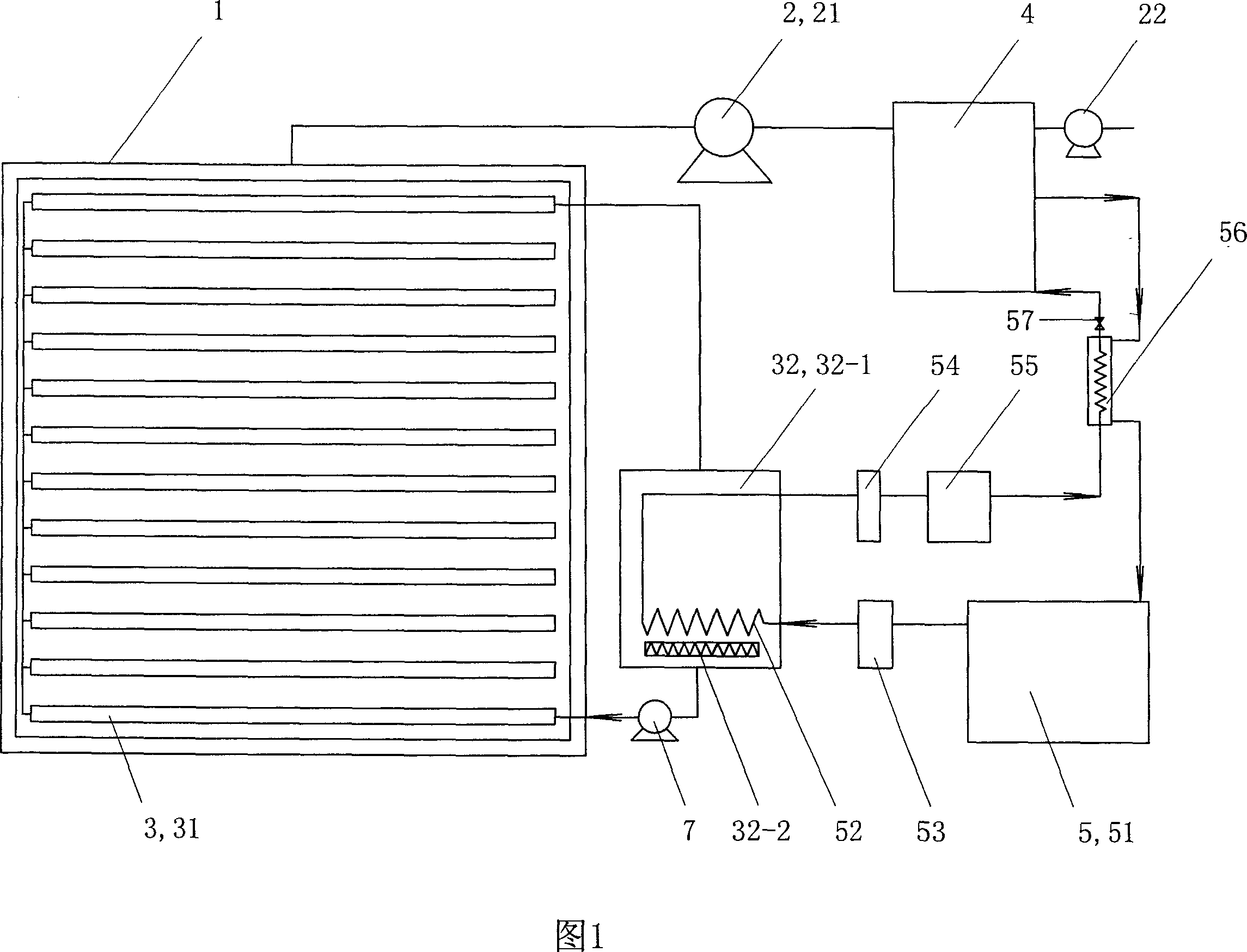

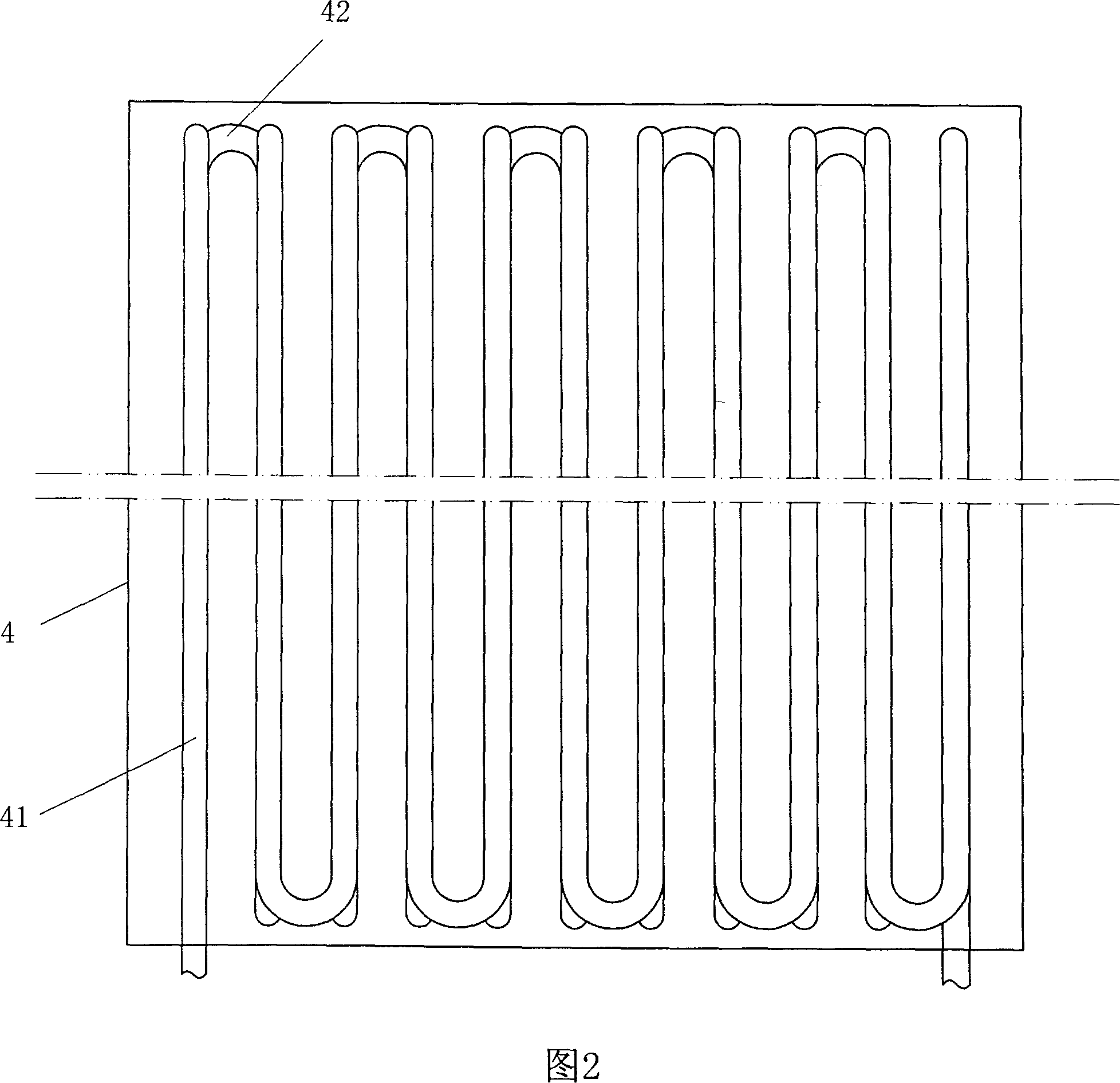

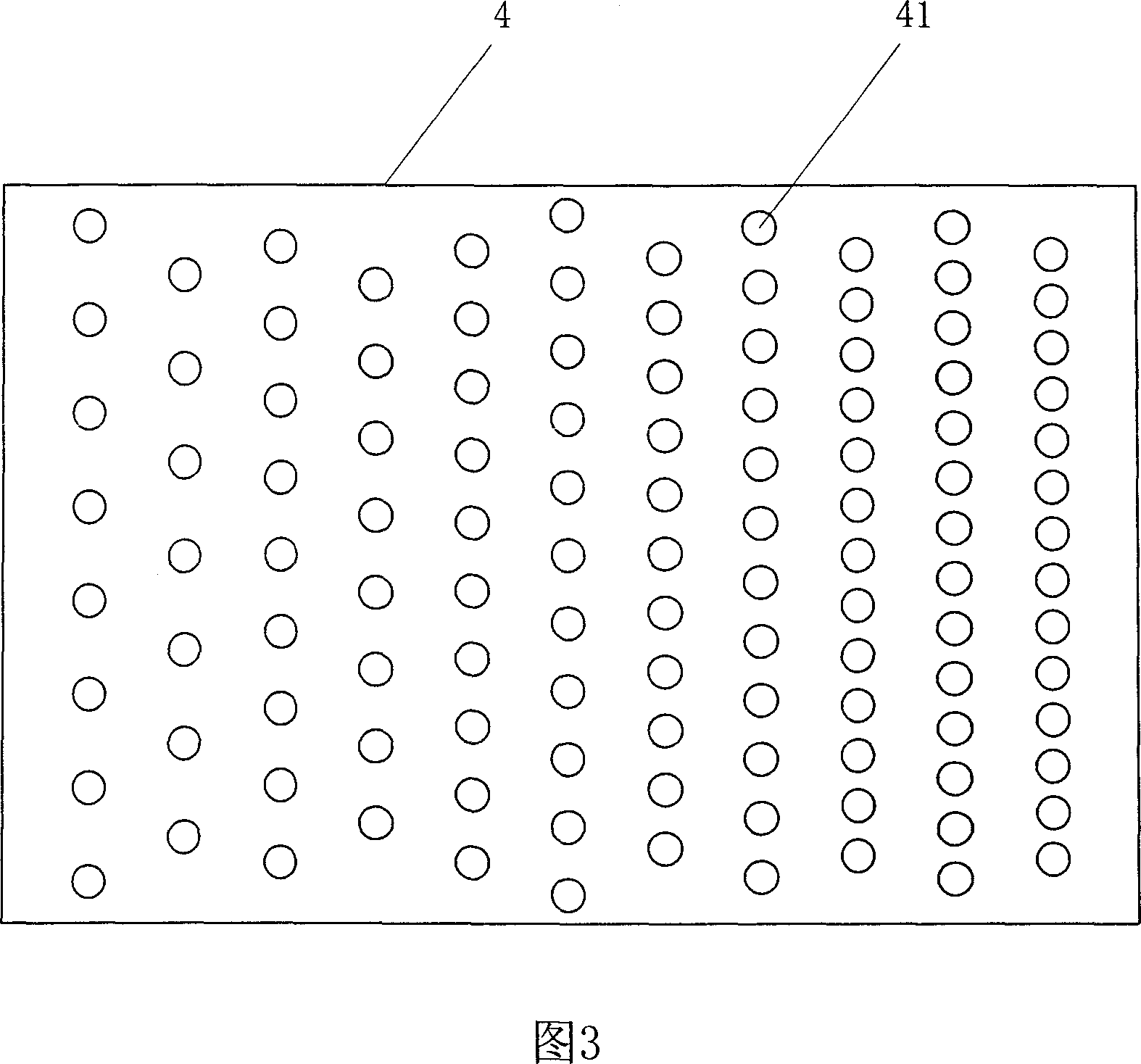

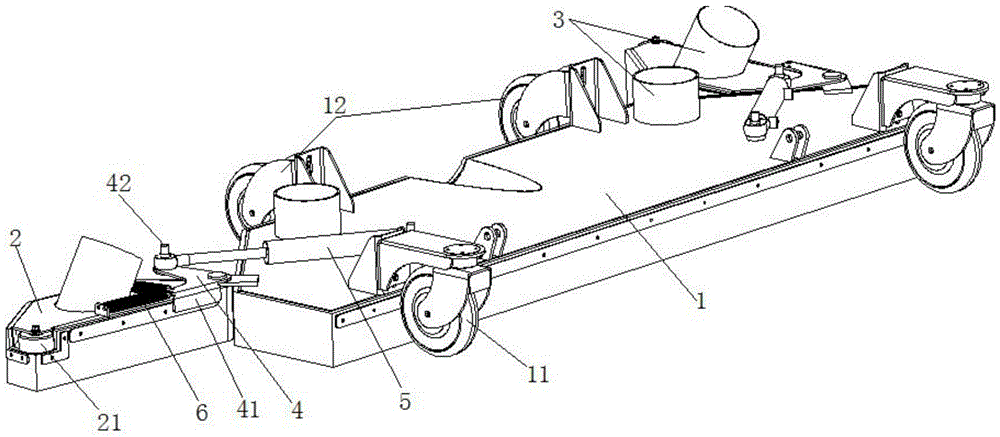

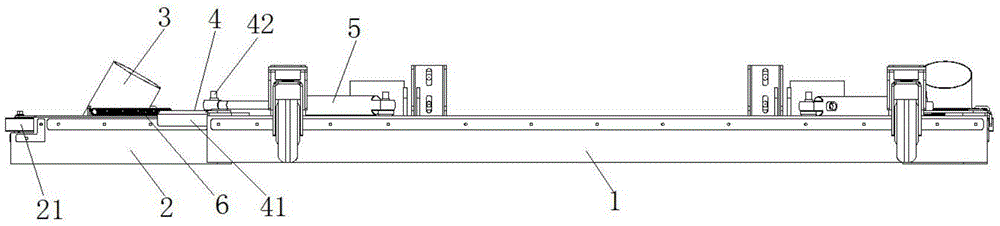

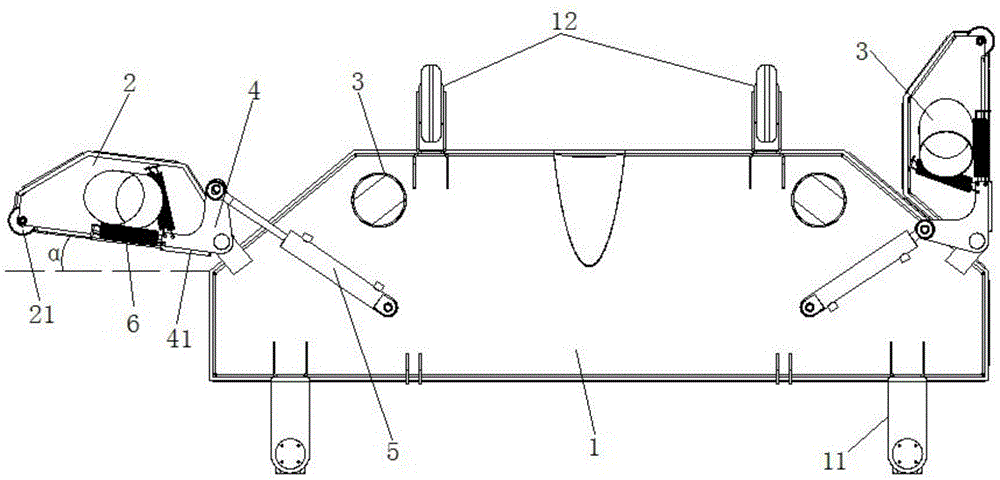

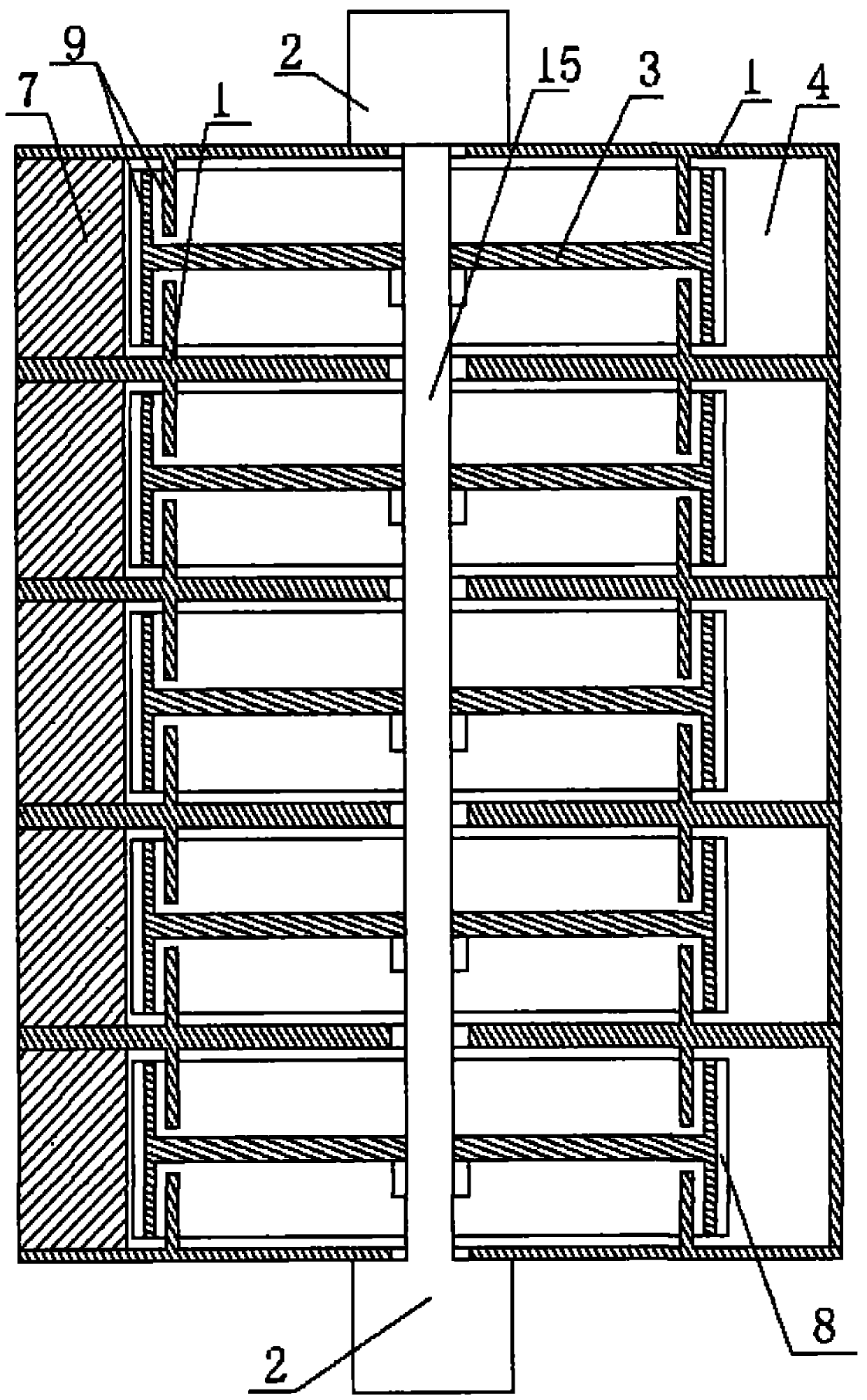

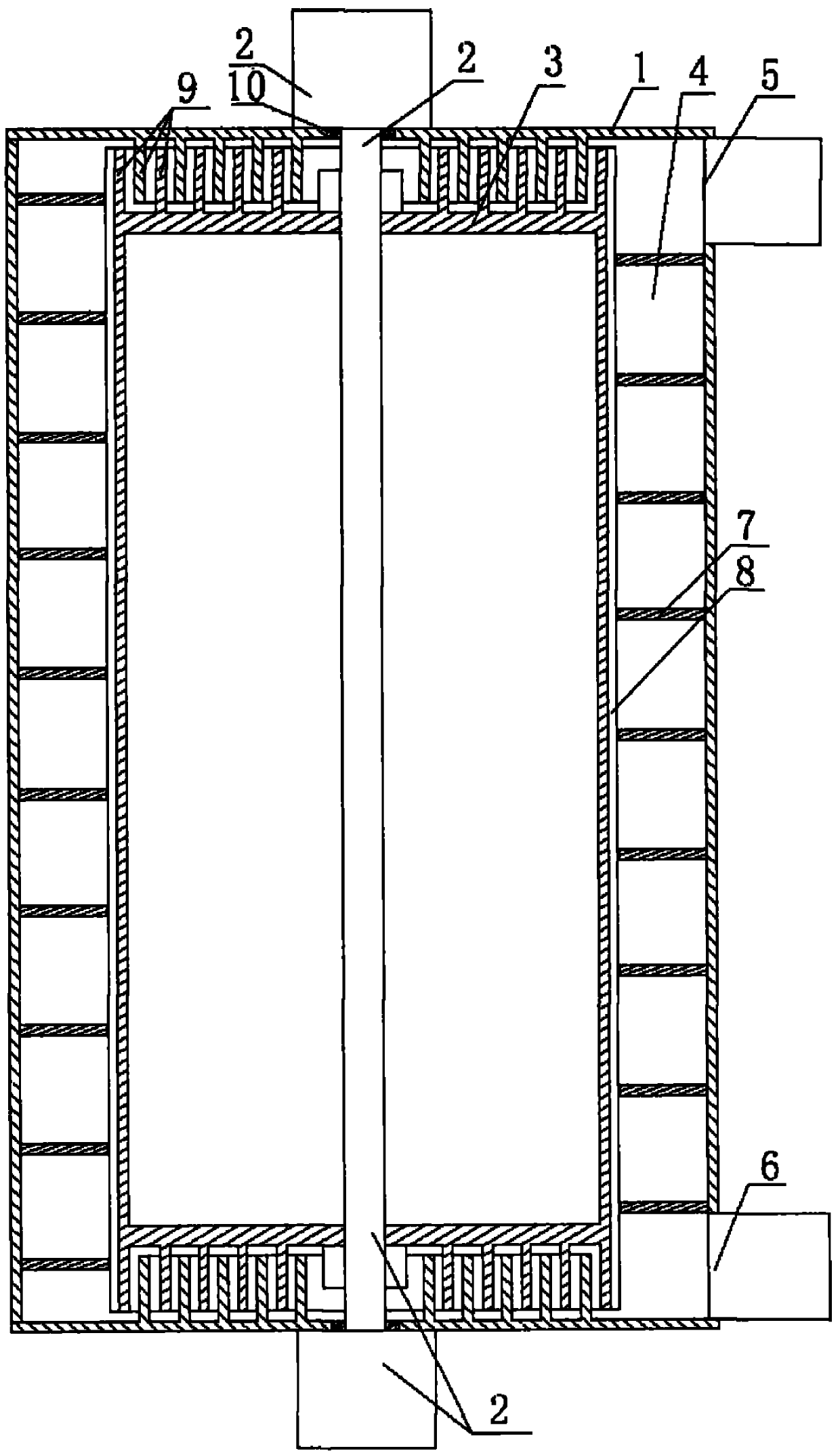

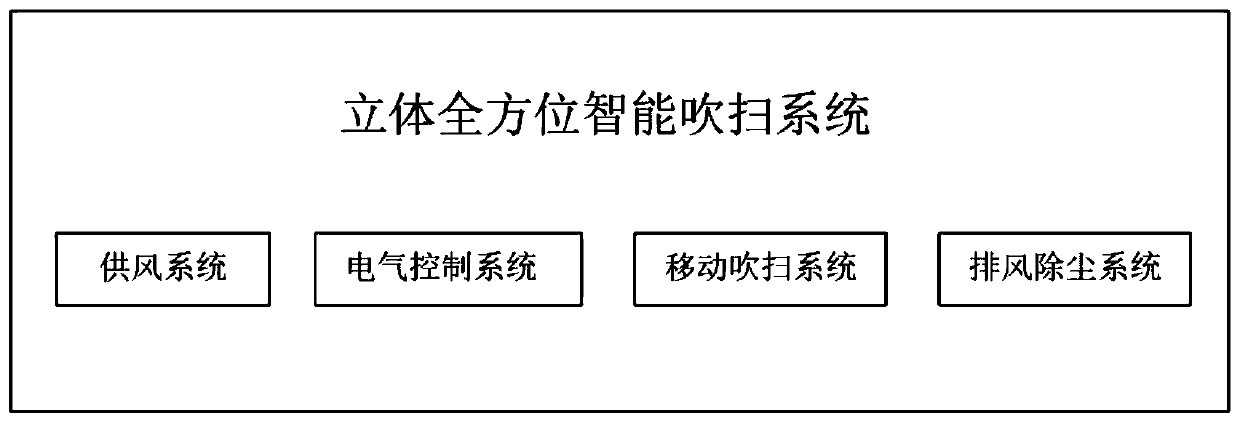

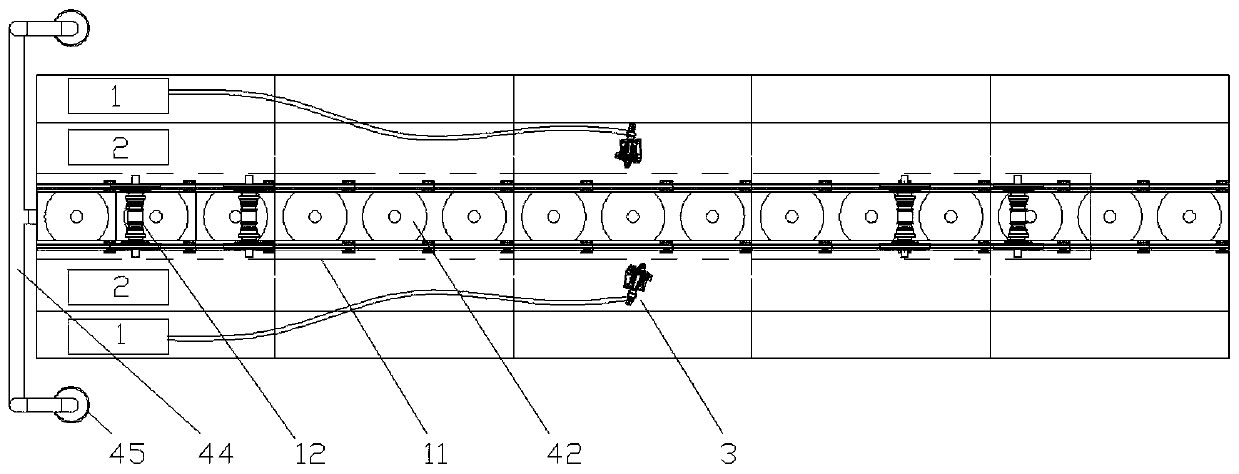

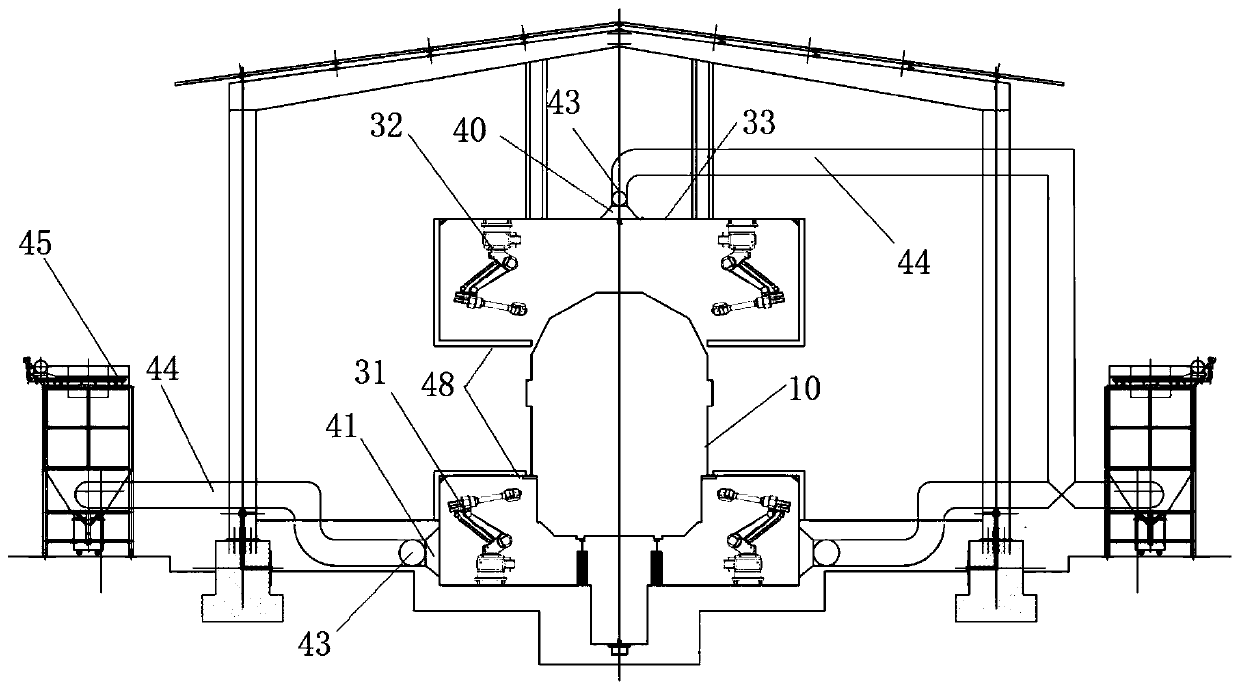

Three-dimensional omnibearing intelligent purging system and method for rail transit vehicle

PendingCN109733333AEfficient removalImprove working environmentVehicle cleaning apparatusWorking environmentElectrical control

The invention discloses a three-dimensional omnibearing intelligent purging system for a rail transit vehicle. The three-dimensional omnibearing intelligent purging system is characterized by comprising an air supply system (1), an electrical control system (2), a moving purging system (3) and an air exhaust and dust removal system (4). The moving purging system (3) comprises a bottom moving purging robot (31) and a top moving purging robot (32); the air exhaust and dust removal system (4) is respectively connected to the operation areas through pipelines; the air supply system (1) is connected with the bottom moving purging robot (31) and the top moving purging robot (32) through flexible pipelines to provide high-pressure air for the bottom moving purging robot (31) and the top moving purging robot (32); and the electric control system (2) is used for monitoring environmental parameters in a rail transit vehicle purging workshop. Dust of the vehicle can be quickly and efficiently removed, the working environment in the purging warehouse is improved, and three-dimensional omnibearing purging of the bottom, the sides and the top of the rail transit vehicle is achieved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com