Dust-free environment-friendly architectural decorative stone polishing device

It is a technology for architectural decoration and environmental protection, which is applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine, etc. It can solve problems such as poor grinding effect, personal health injury of operators, and poor grinding accuracy, so as to improve grinding accuracy, Good vacuuming effect and precise grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

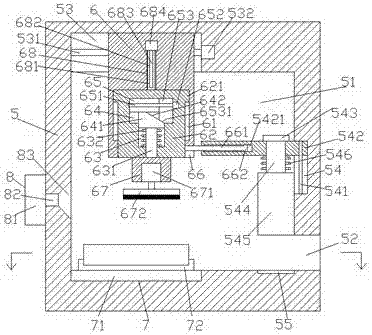

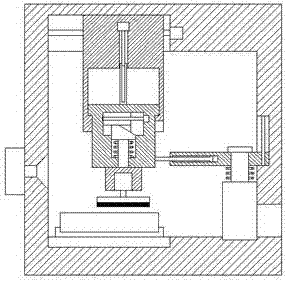

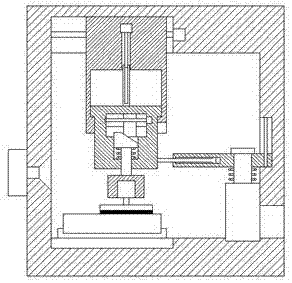

[0024] Such as Figure 1-Figure 5 As shown, a dust-free and environmentally friendly building decoration stone grinding device of the present invention includes a housing 5, a grinding chamber 51 is provided in the housing 5, and a first A chute 53, the inner wall on the right side of the grinding chamber 51 is provided with a second chute 54 extending longitudinally, the right side wall of the housing 5 below the second chute 54 is provided with a left end and a The grinding chamber 51 is connected to the opening 52 provided. The left and right sides of the bottom wall of the grinding chamber 51 are respectively provided with a fixed assembly 7 and a sinking groove 55. The first chute 53 is provided with a left and right extending first A threaded rod 531, the first threaded rod 531 is threadedly connected with a moving block 6 whose bottom extends into the grinding chamber 51, the moving block 6 is provided with a first sliding chamber 61, and the first sliding Inside the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com