Patents

Literature

57results about How to "Realize the grinding function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

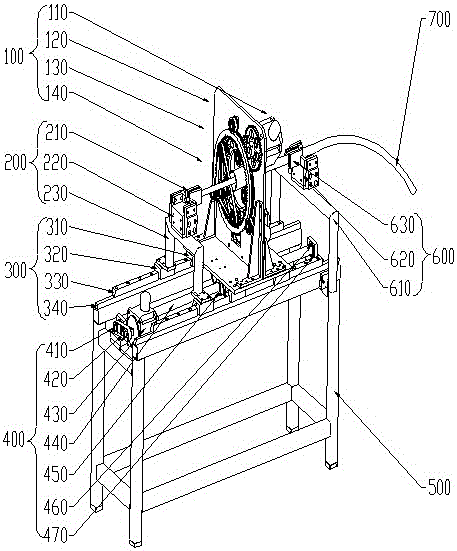

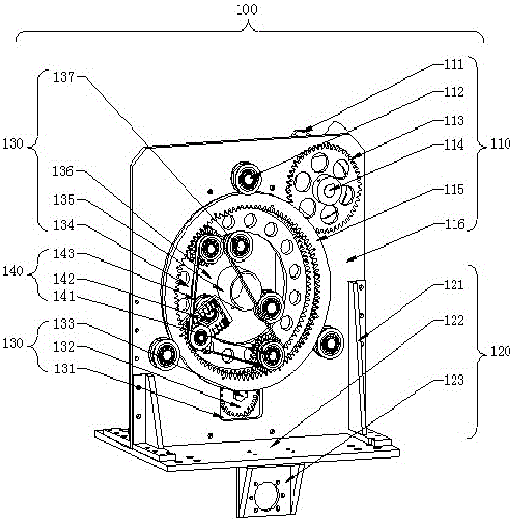

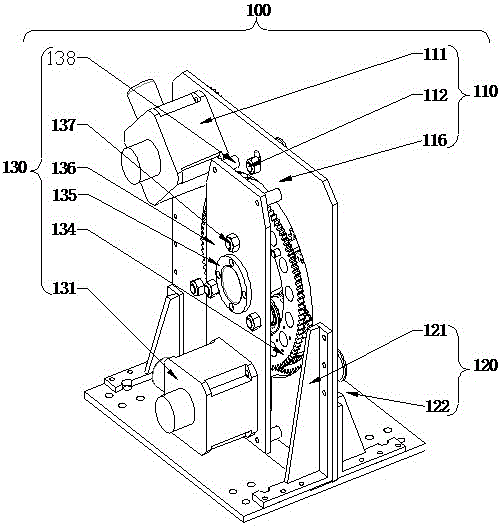

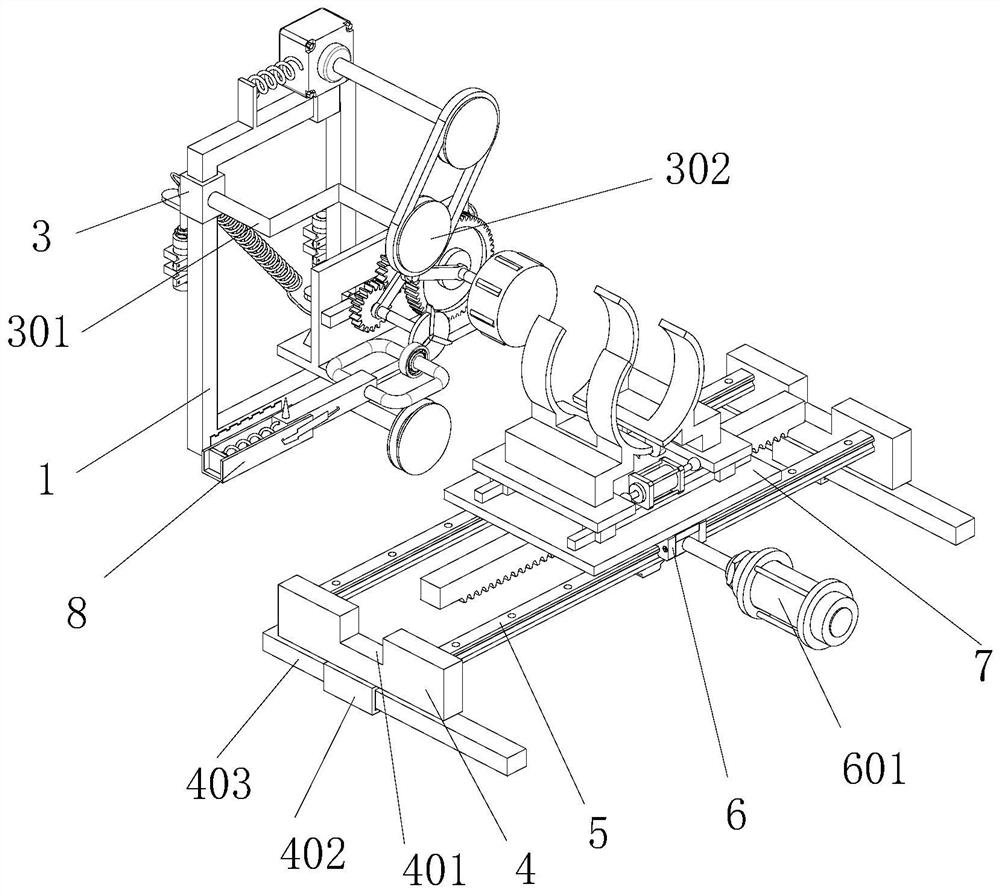

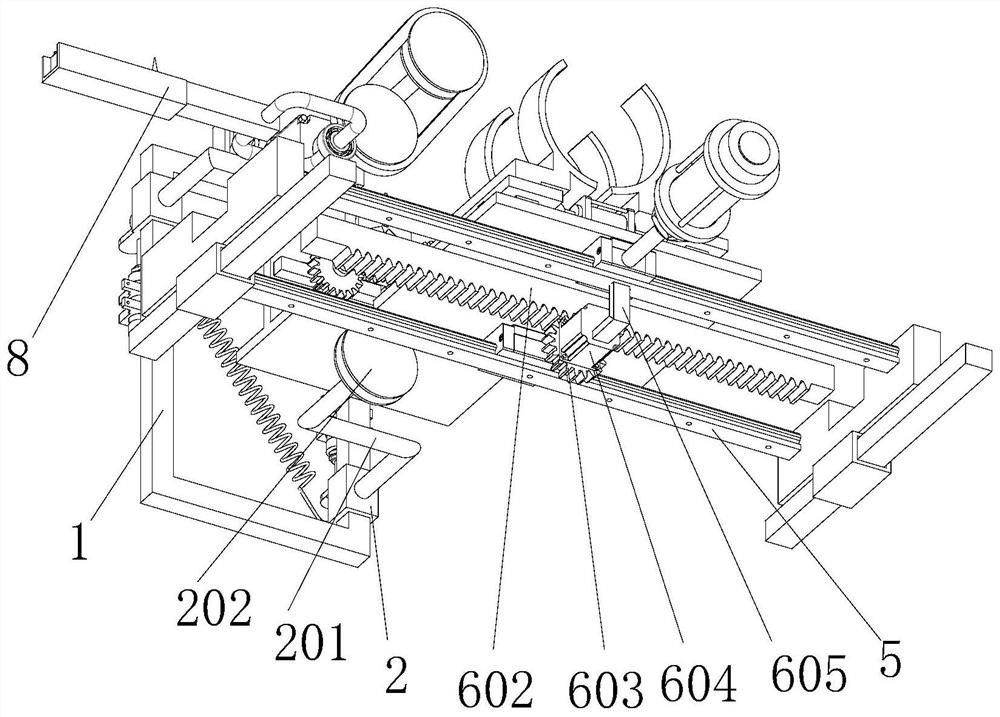

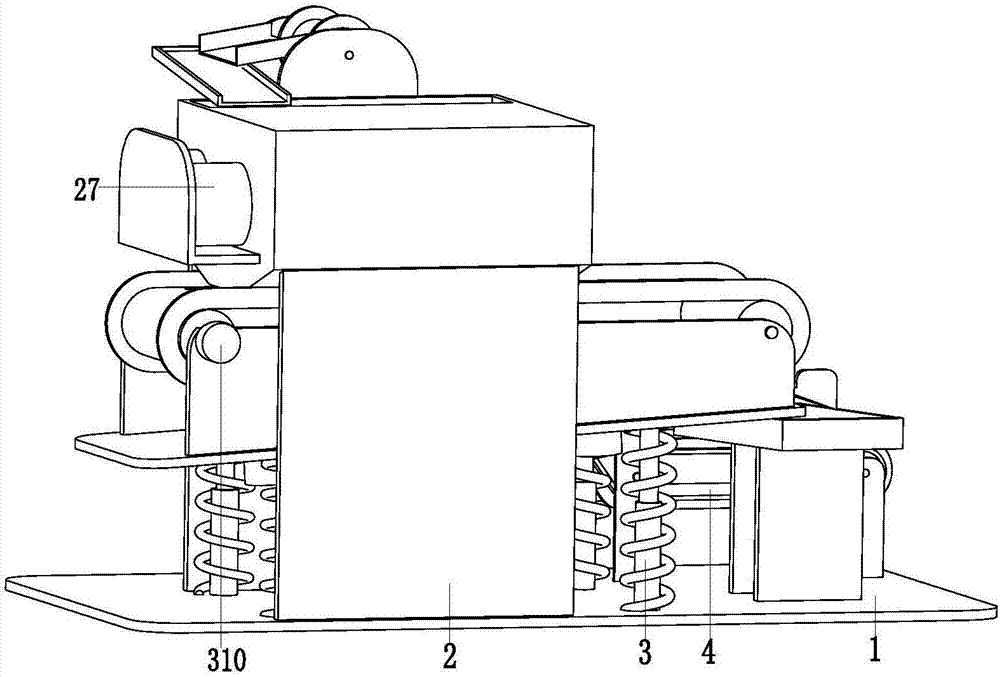

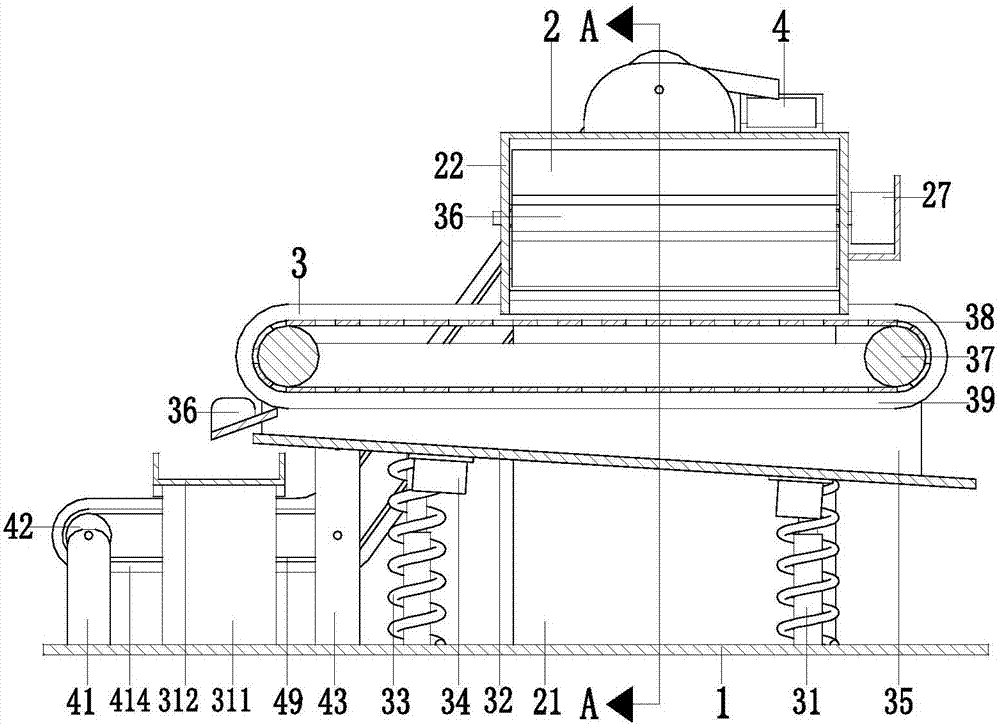

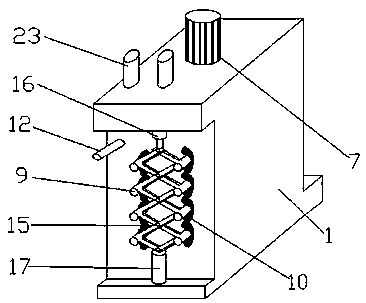

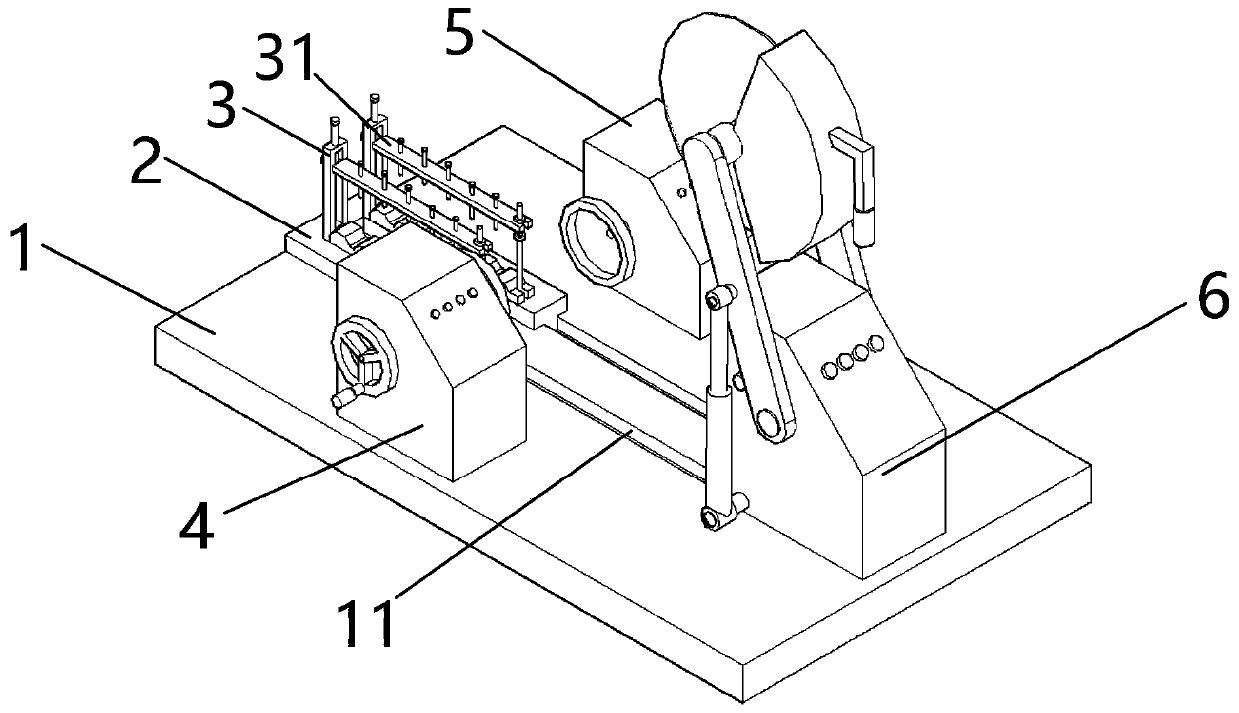

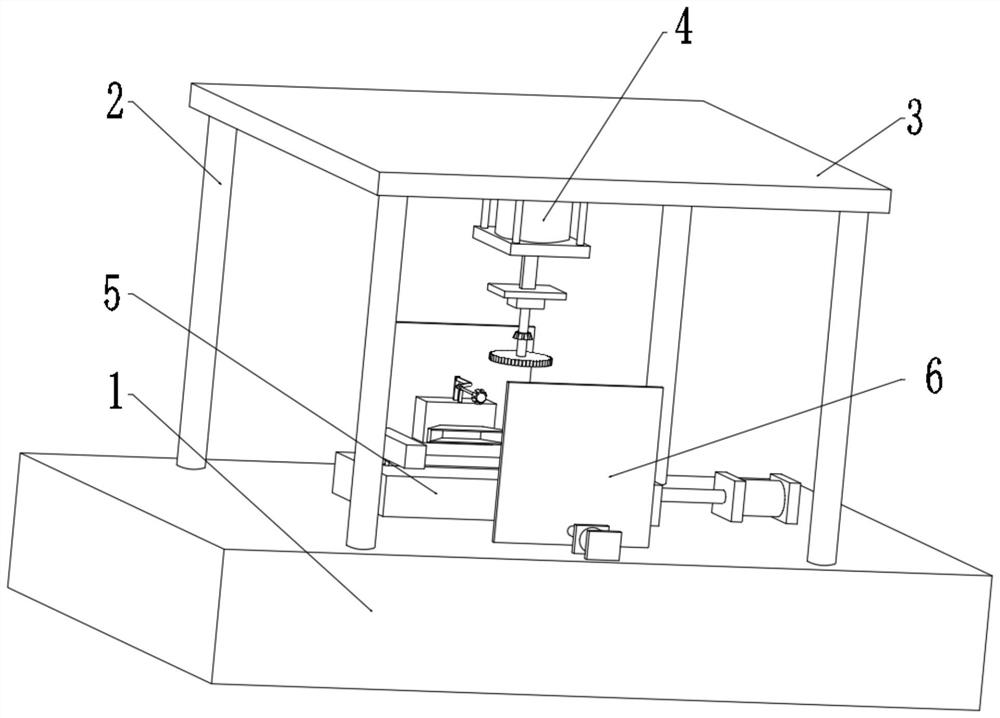

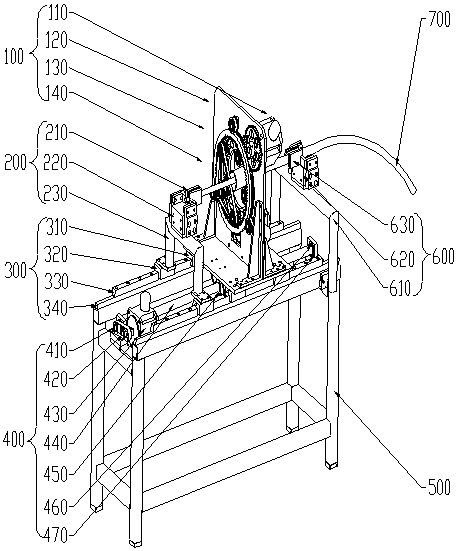

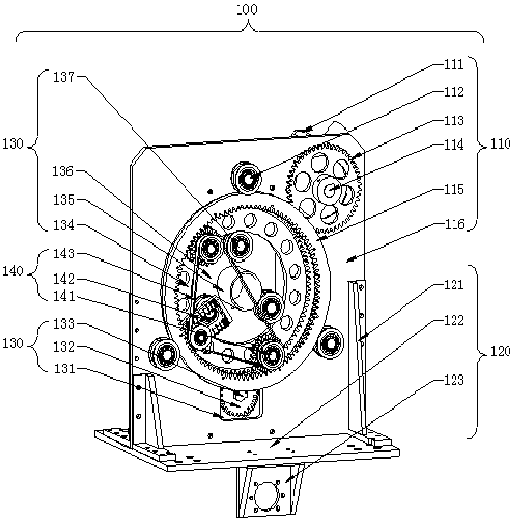

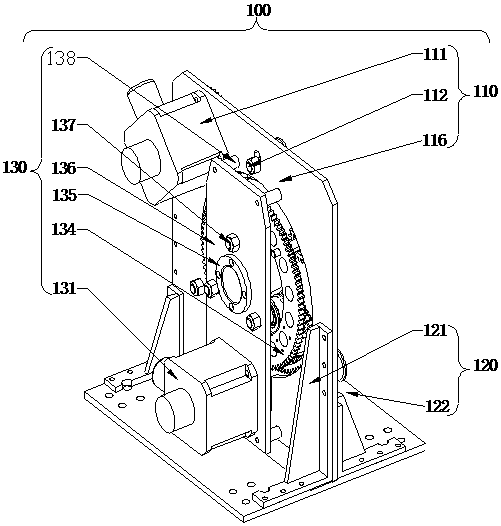

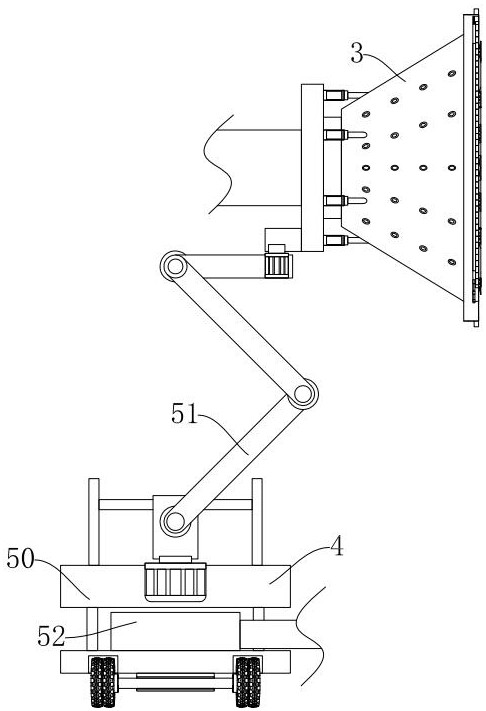

Circular revolution grinding equipment

ActiveCN105945689ARealize the grinding functionReduce labor intensityGrinding drivesBelt grinding machinesBall screwEngineering

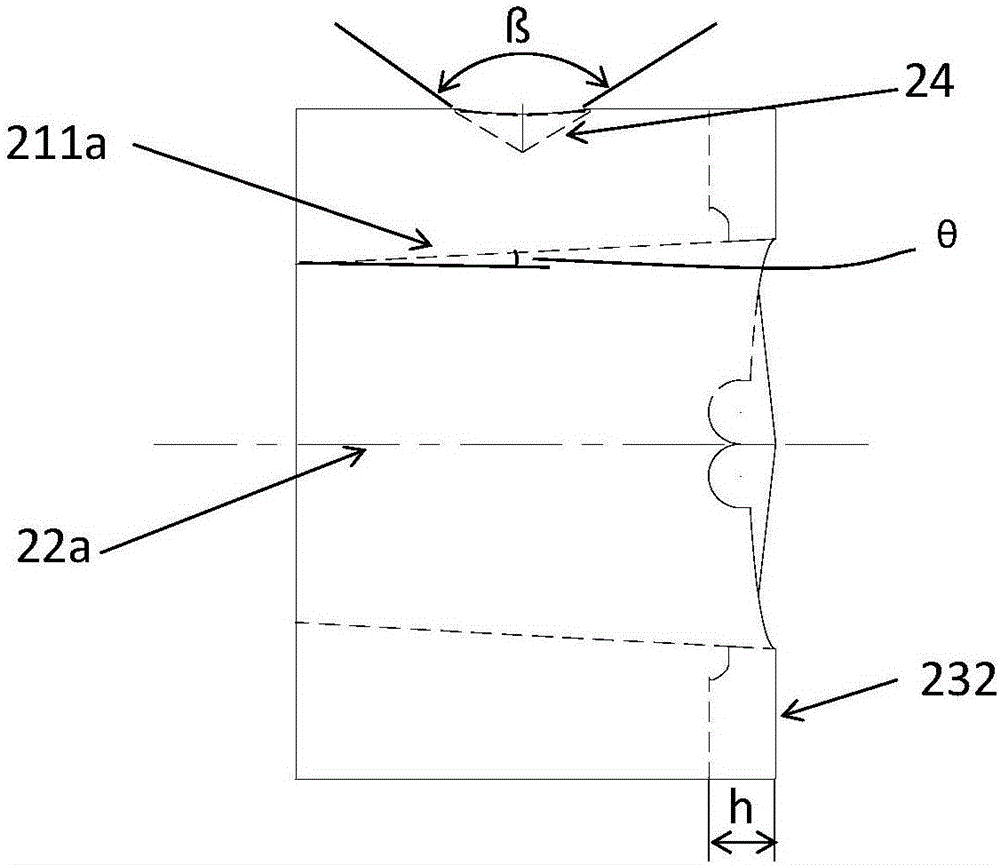

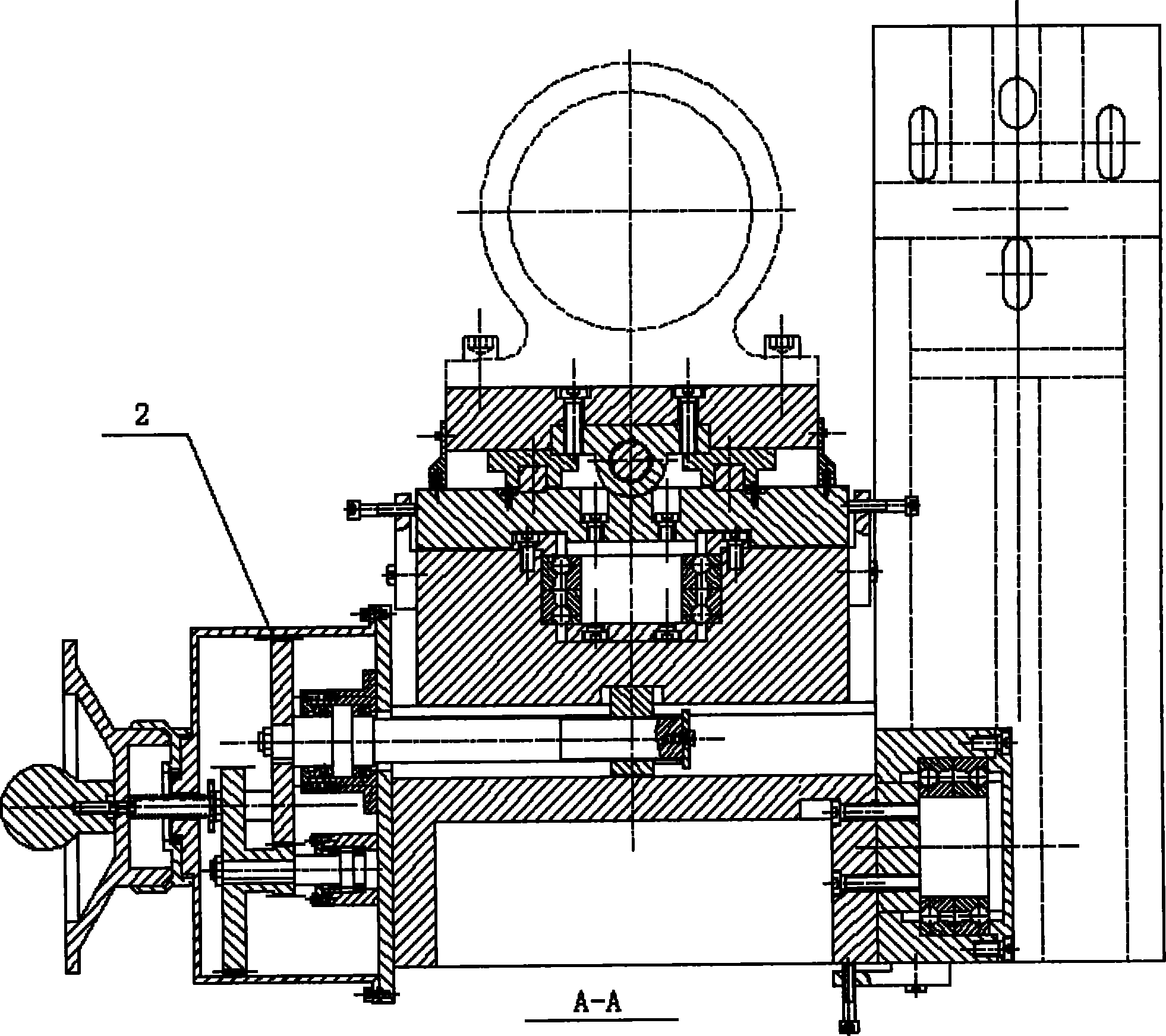

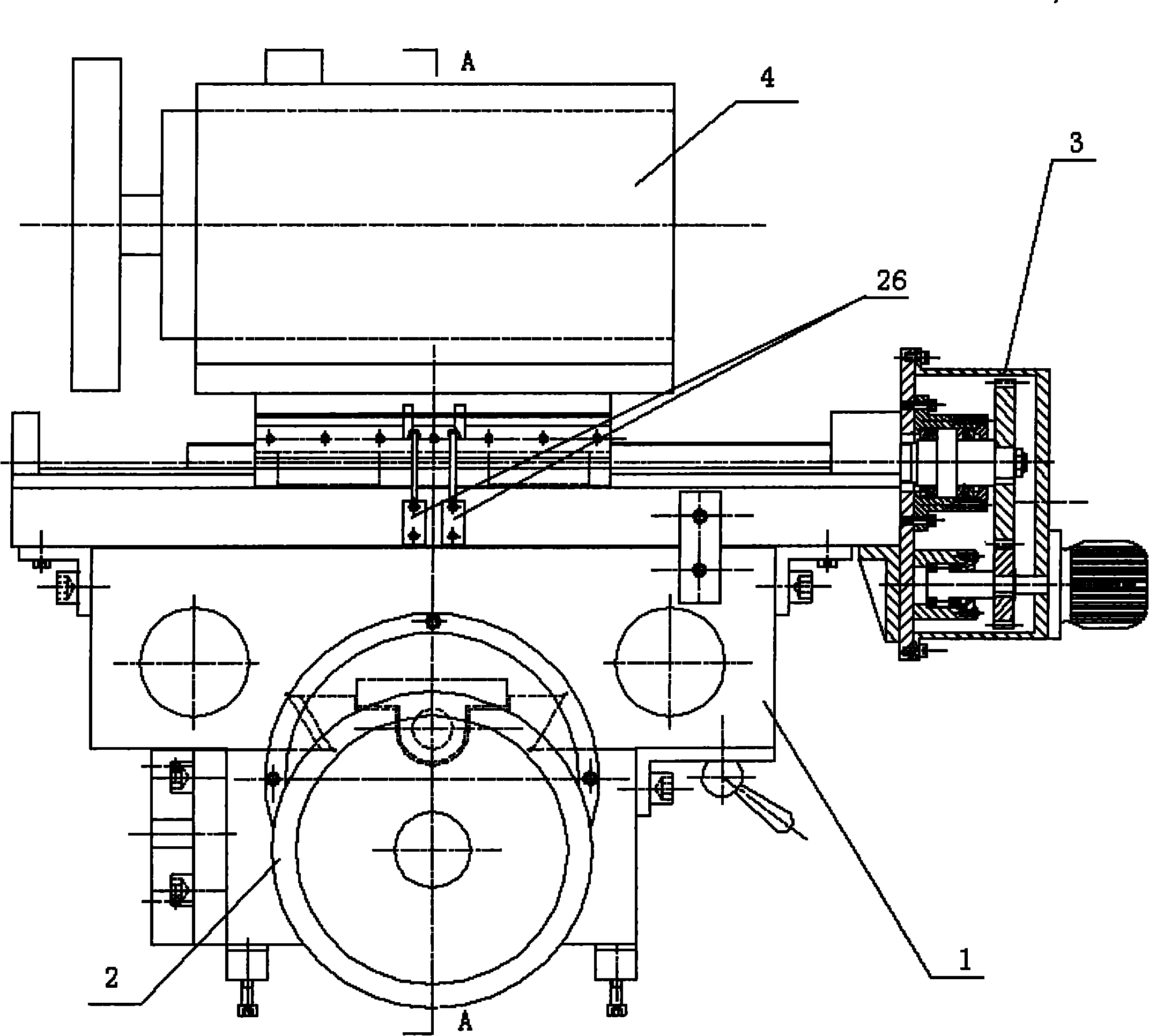

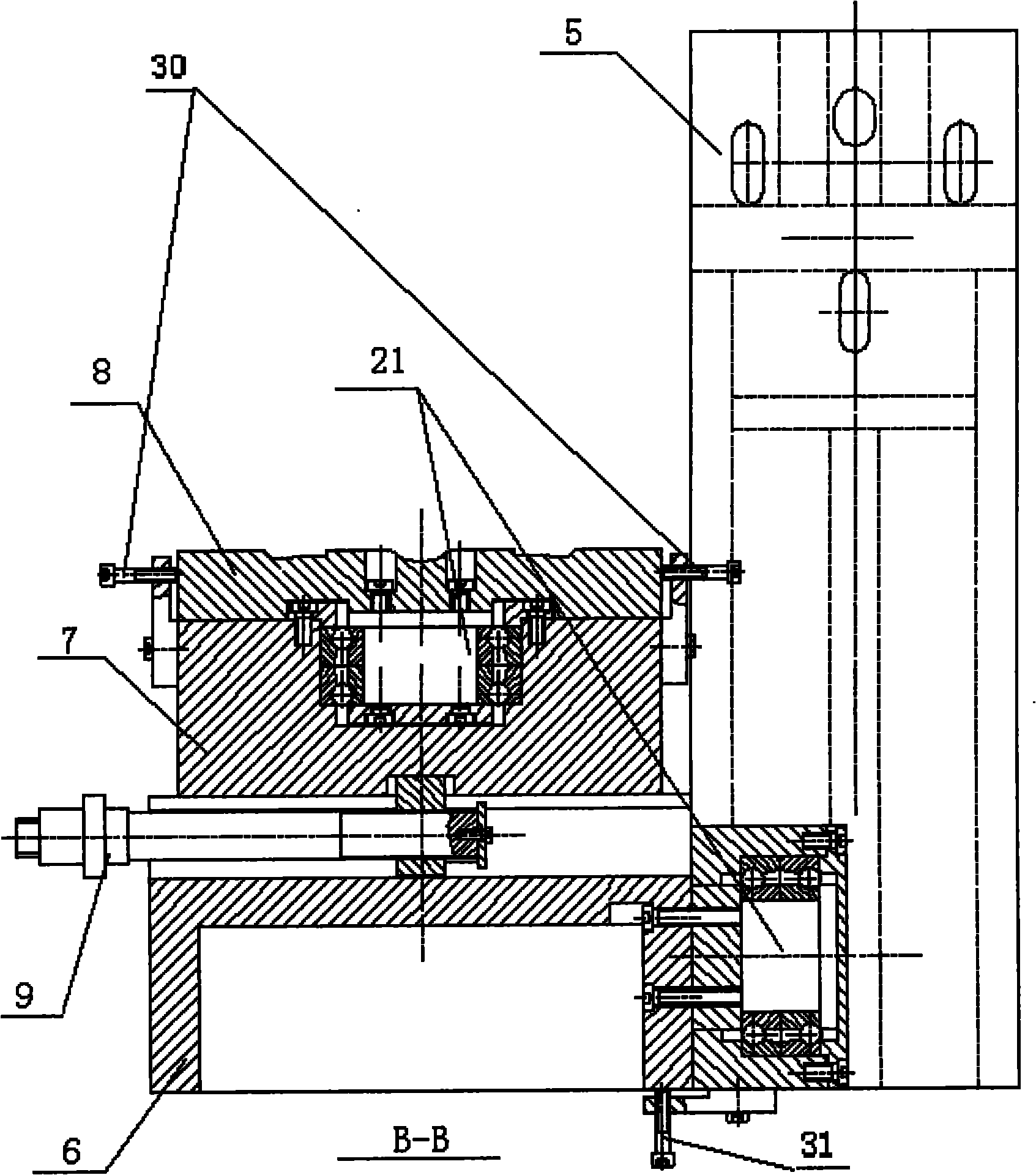

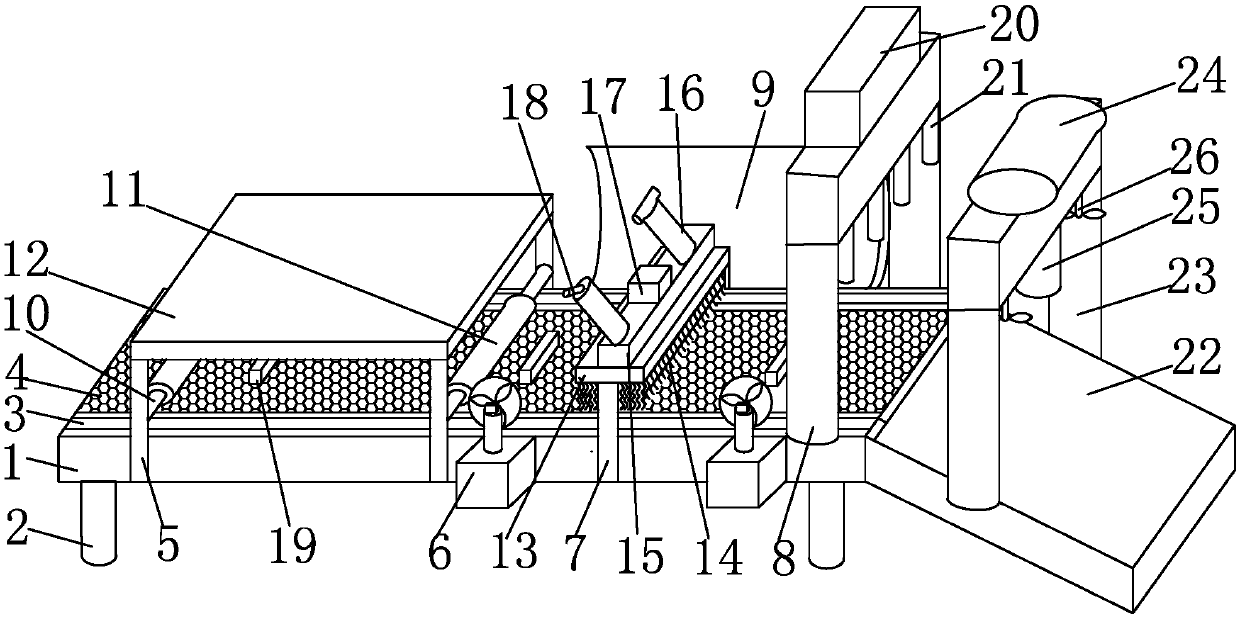

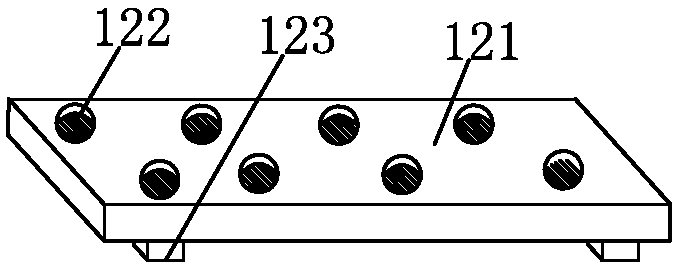

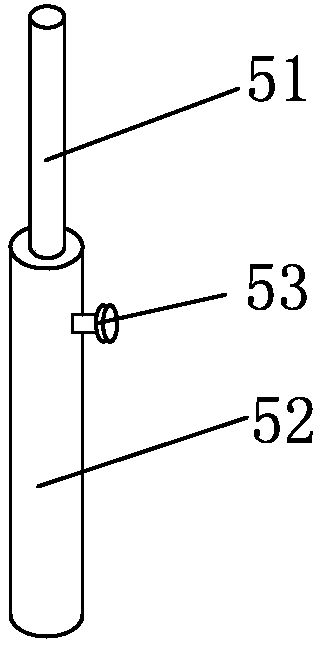

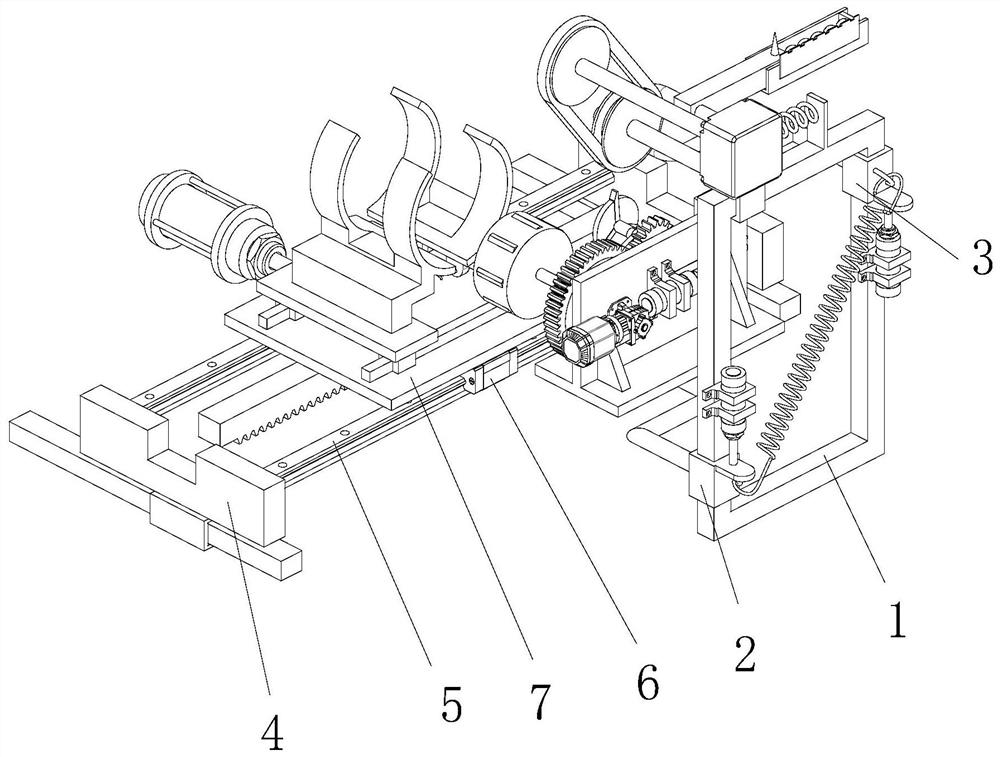

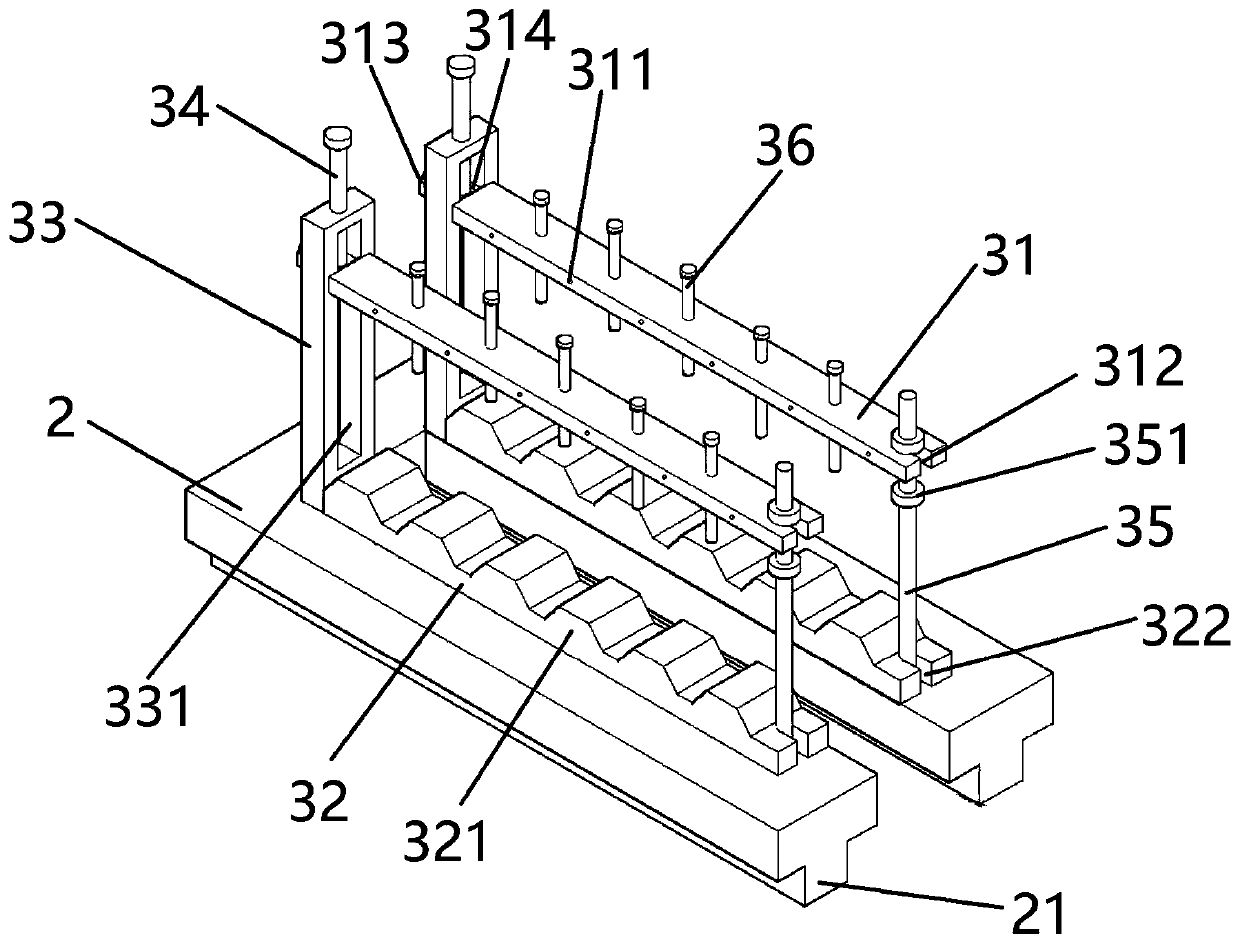

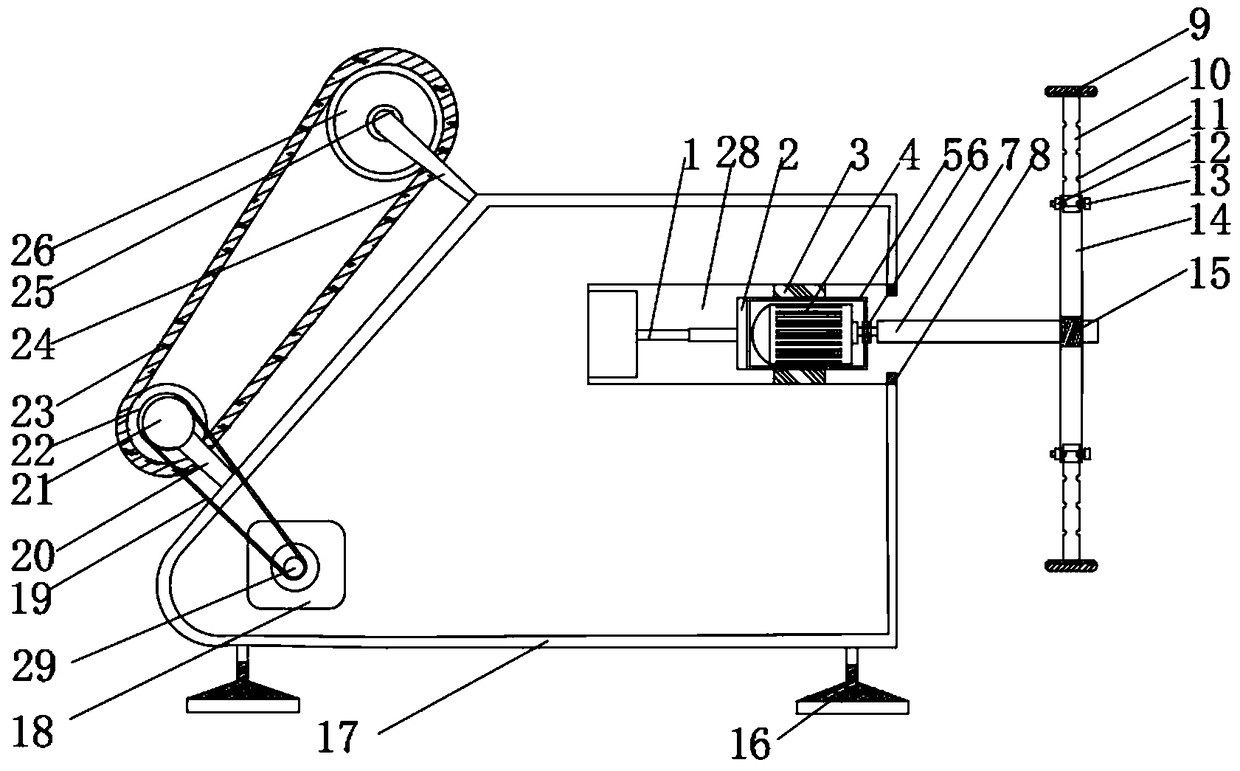

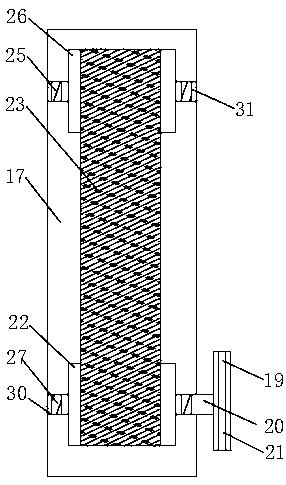

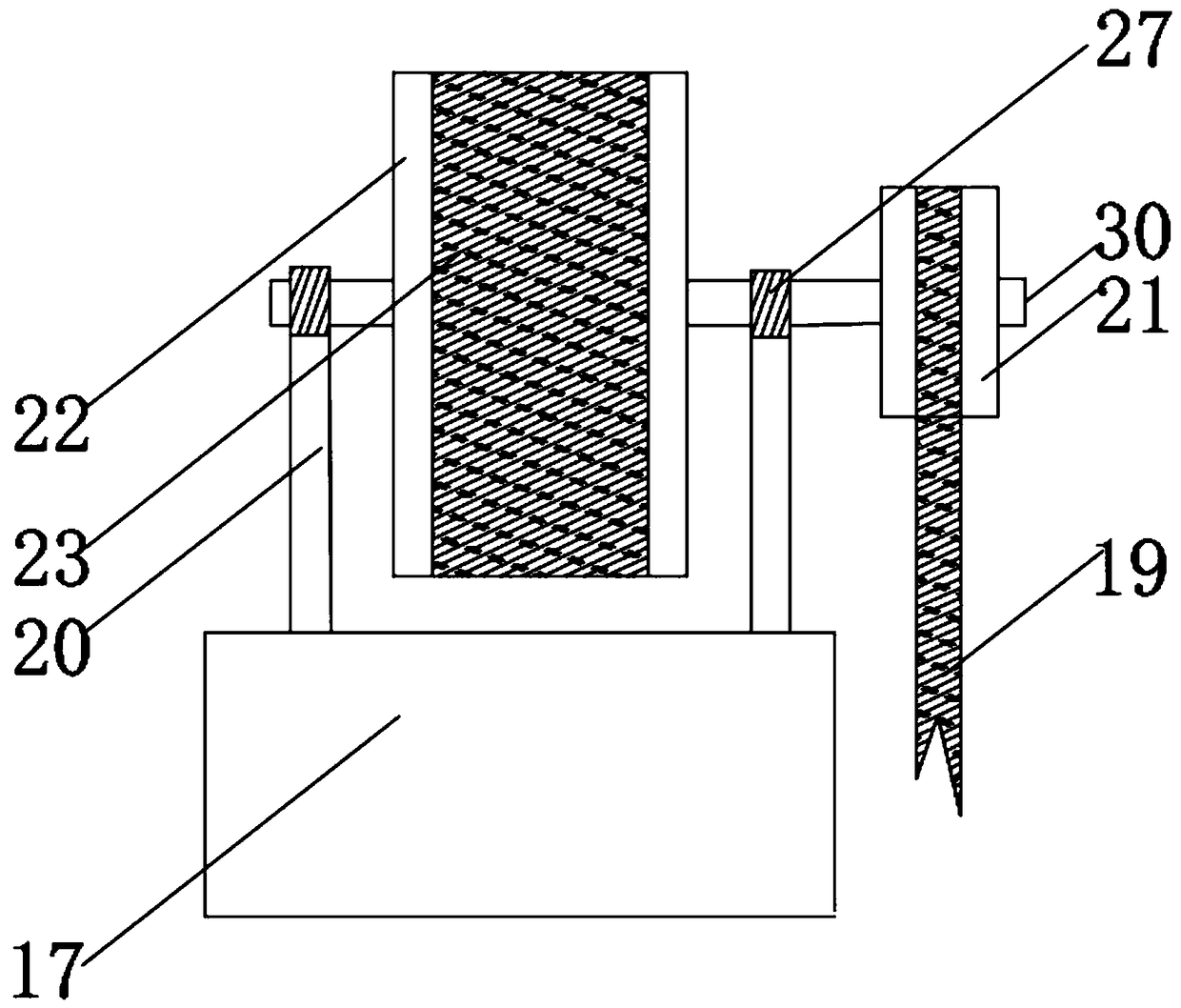

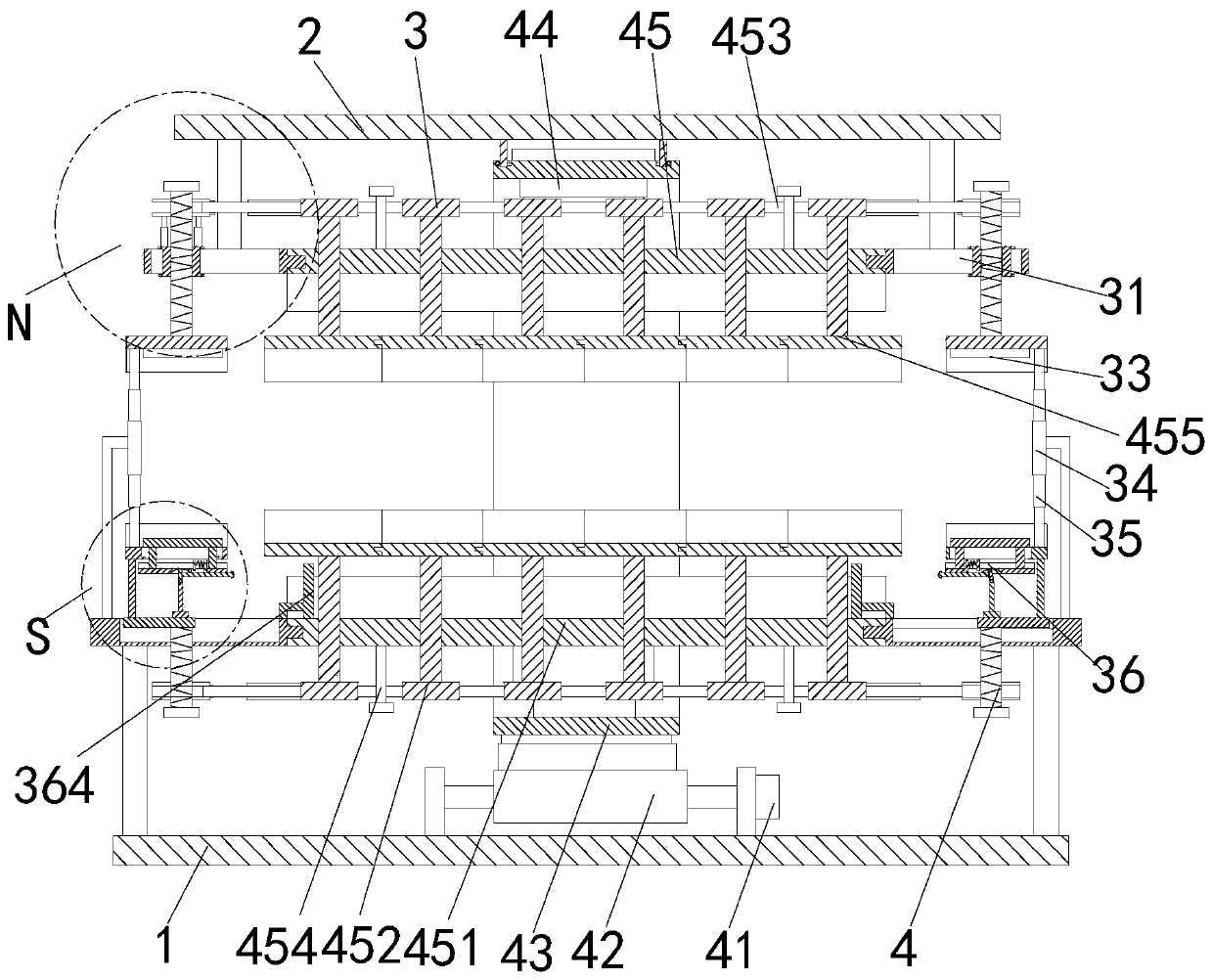

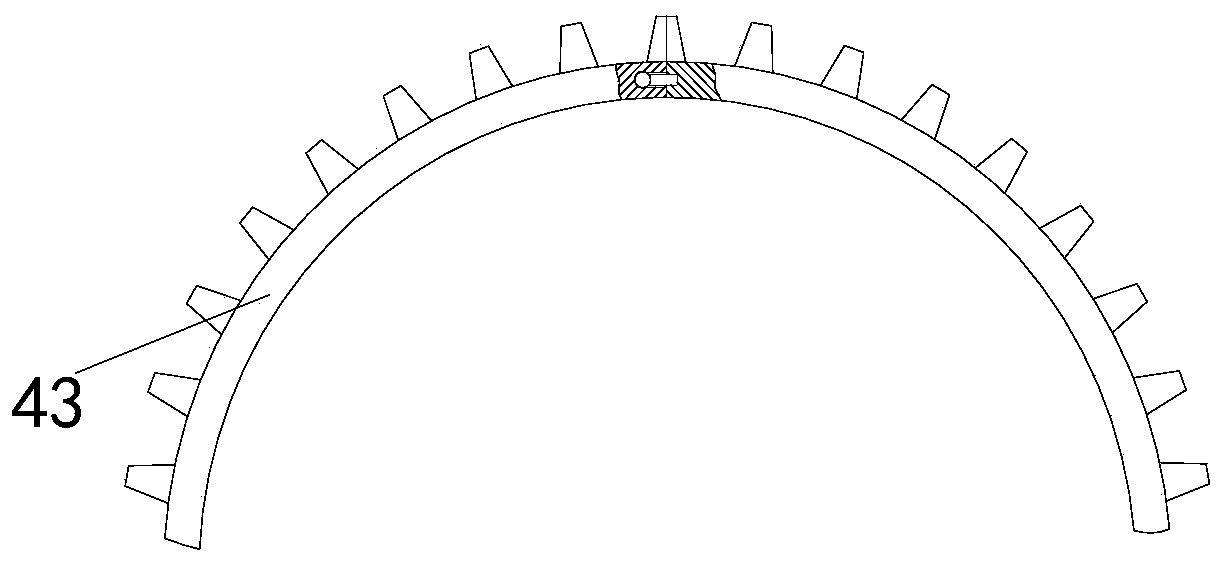

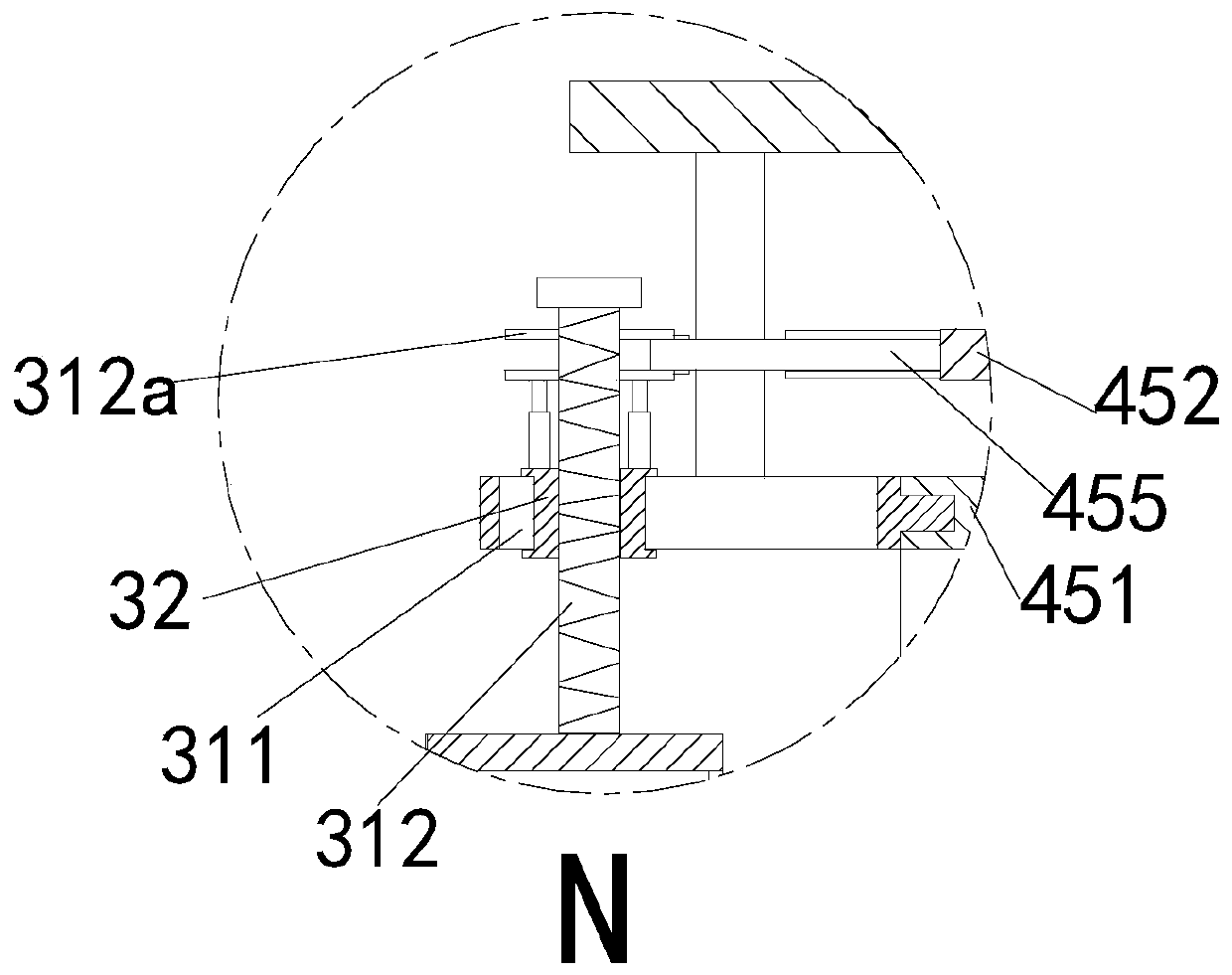

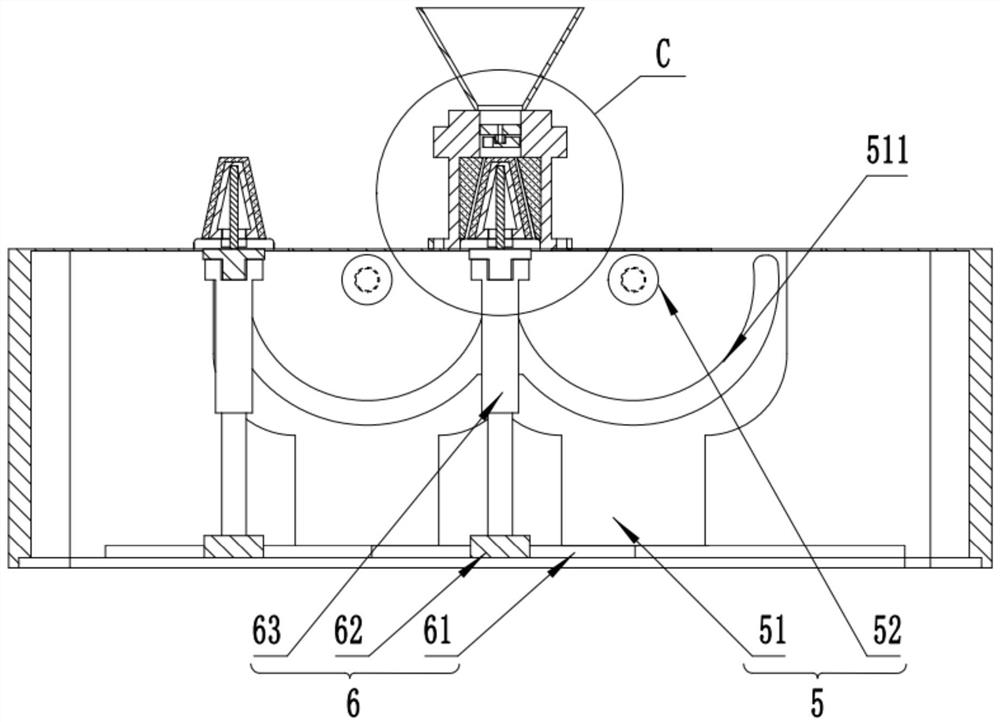

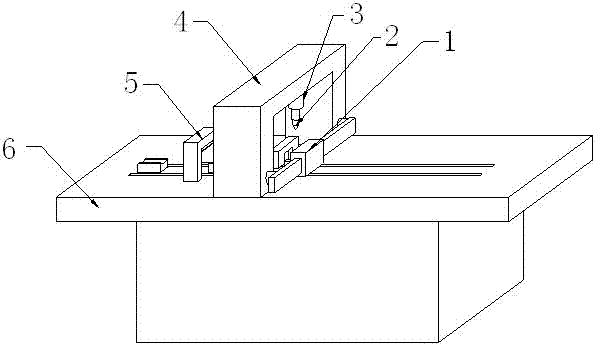

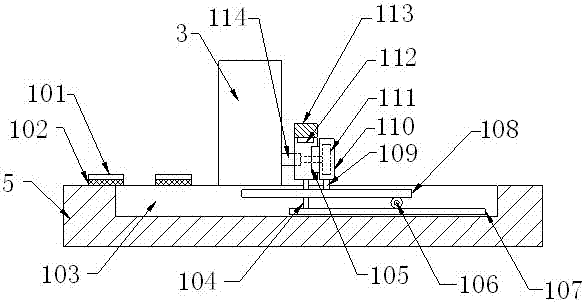

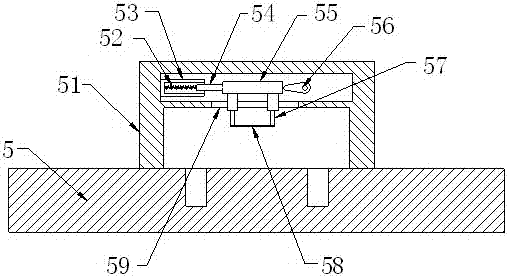

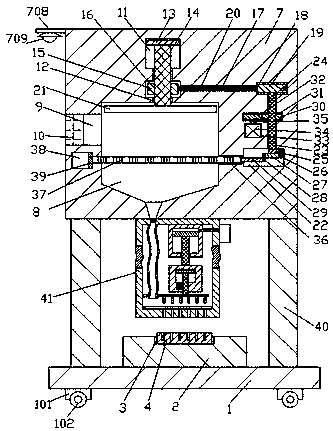

The invention discloses circular revolution grinding equipment. The circular revolution grinding equipment comprises a grinding device, a clamping device I, a sliding device, a moving device, a support mechanism and a clamping device II, wherein the grinding device is connected with a ball screw nut through a screw nut seat, a moving base plate is in coupling contact with a sliding rail through a base plate slider, the two ends of a ground object are clamped by pneumatic jaws of the clamping device I and the clamping device II, the sliding device is connected with the support mechanism through a sliding rail support plate, bearings IV at the two ends of a ball screw of the moving device are separately mounted in screw bearing pedestals, and the screw bearing pedestals are fixedly connected with the support mechanism. Through enabling an abrasive belt to revolve and rotate, a function of grinding superlong objects is realized. Labor intensity is obviously reduced, cost is saved, and grinding efficiency and precision are improved.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

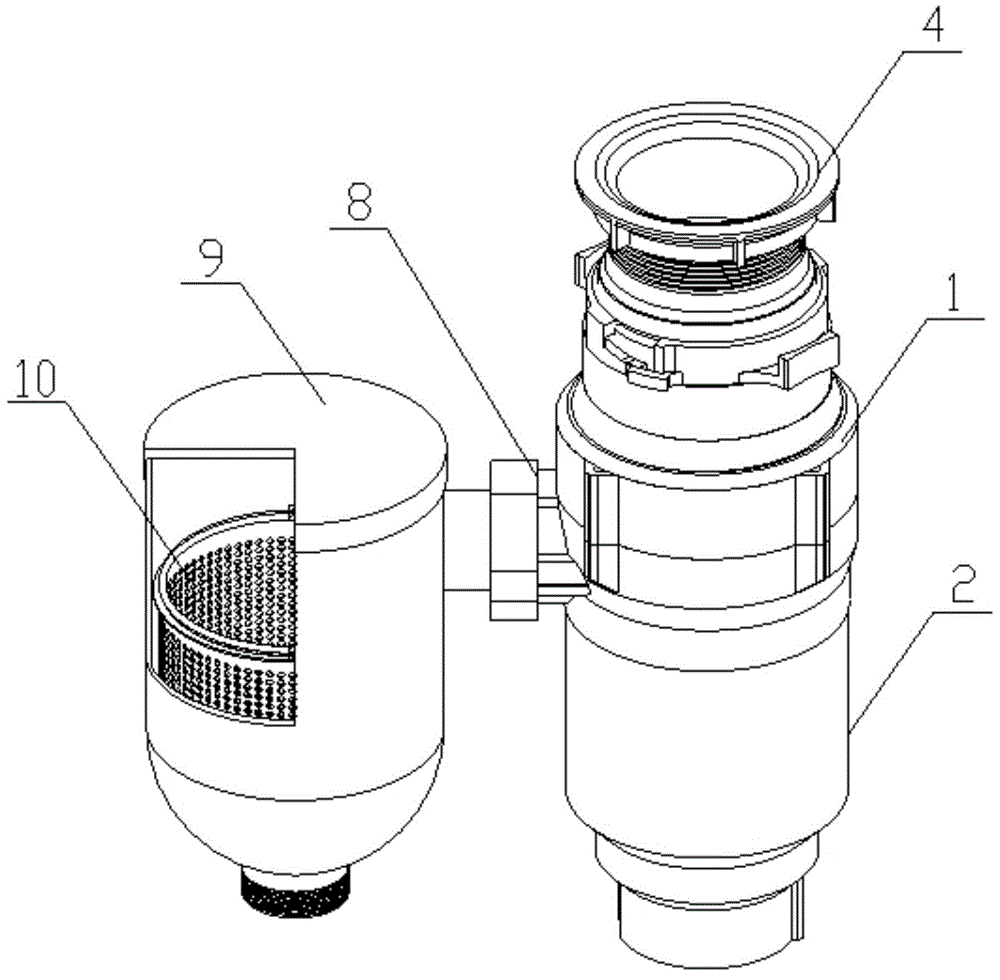

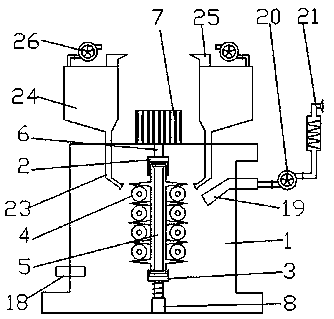

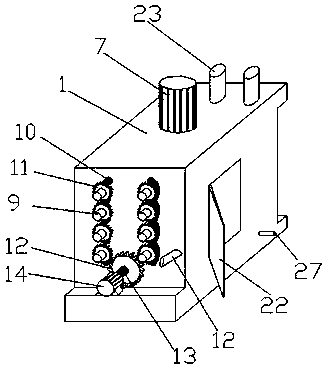

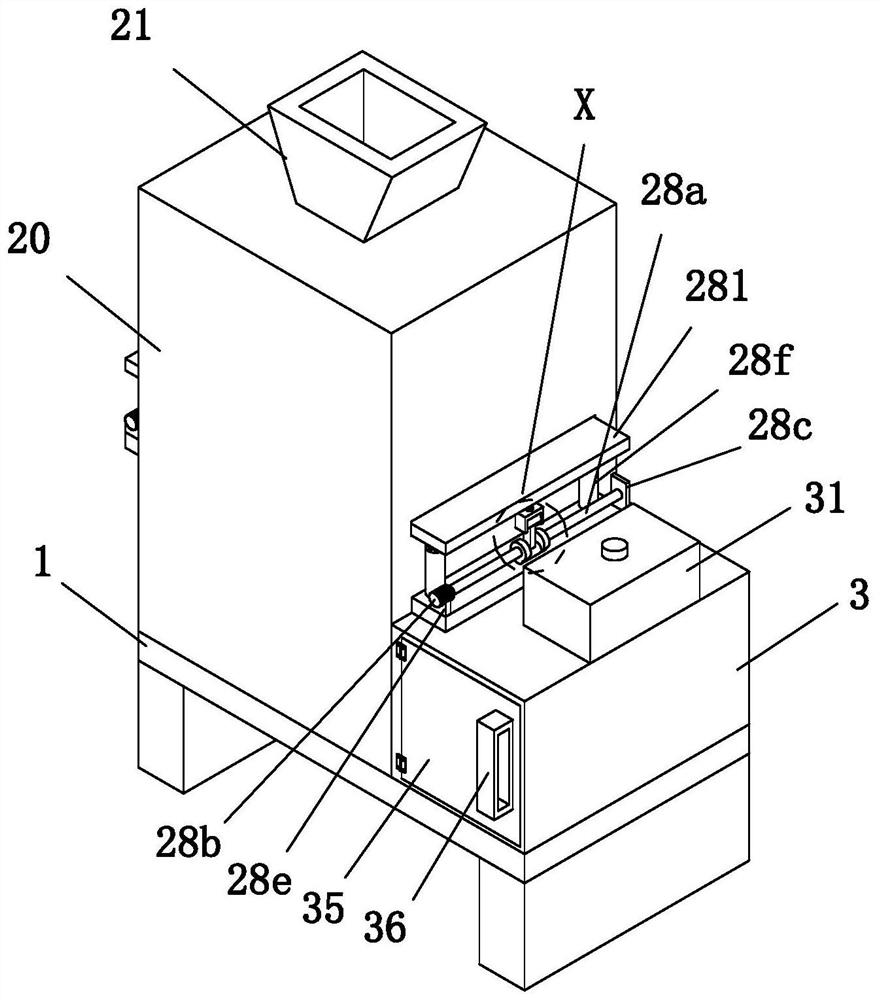

Miniature domestic garbage disposer

InactiveCN103599919AReduce volumeAchieve reuseSolid waste disposalCocoaElectric machineProcess engineering

The invention provides a miniature domestic garbage disposer, which comprises a grinding chamber and a motor mounted in a housing; the motor drives a crushing cutterhead in the grinding chamber to rotate so as to crush garbage; a feed inlet at the upper end of the grinding chamber is movably connected with a water outlet; a secondary grinding cutterhead is disposed in the grinding chamber; the secondary grinding cutterhead is located below the crushing cutterhead and is mounted on a rotating shaft of the motor in a coaxial manner with the crushing cutterhead; the secondary grinding cutterhead is provided with a cutter groove which can cooperate with the chamber wall of the grinding chamber to perform secondary grinding of garbage. With the above mode, garbage disposers with 'crushing' as a main concept are improved, and both crushing and grinding functions are realized. Garbage primarily crushed by the crushing cutterhead is further grinded by the secondary grinding cutterhead, which obtains garbage debris with smaller sizes, and enables garbage debris to be easier to discharge. Meanwhile, a series of apparatus for garbage waste residue collection and post processing are designed to realize the energy saving idea of waste recycle.

Owner:HANBOK KITCHEN ELECTRIC APPLIANCE TECH

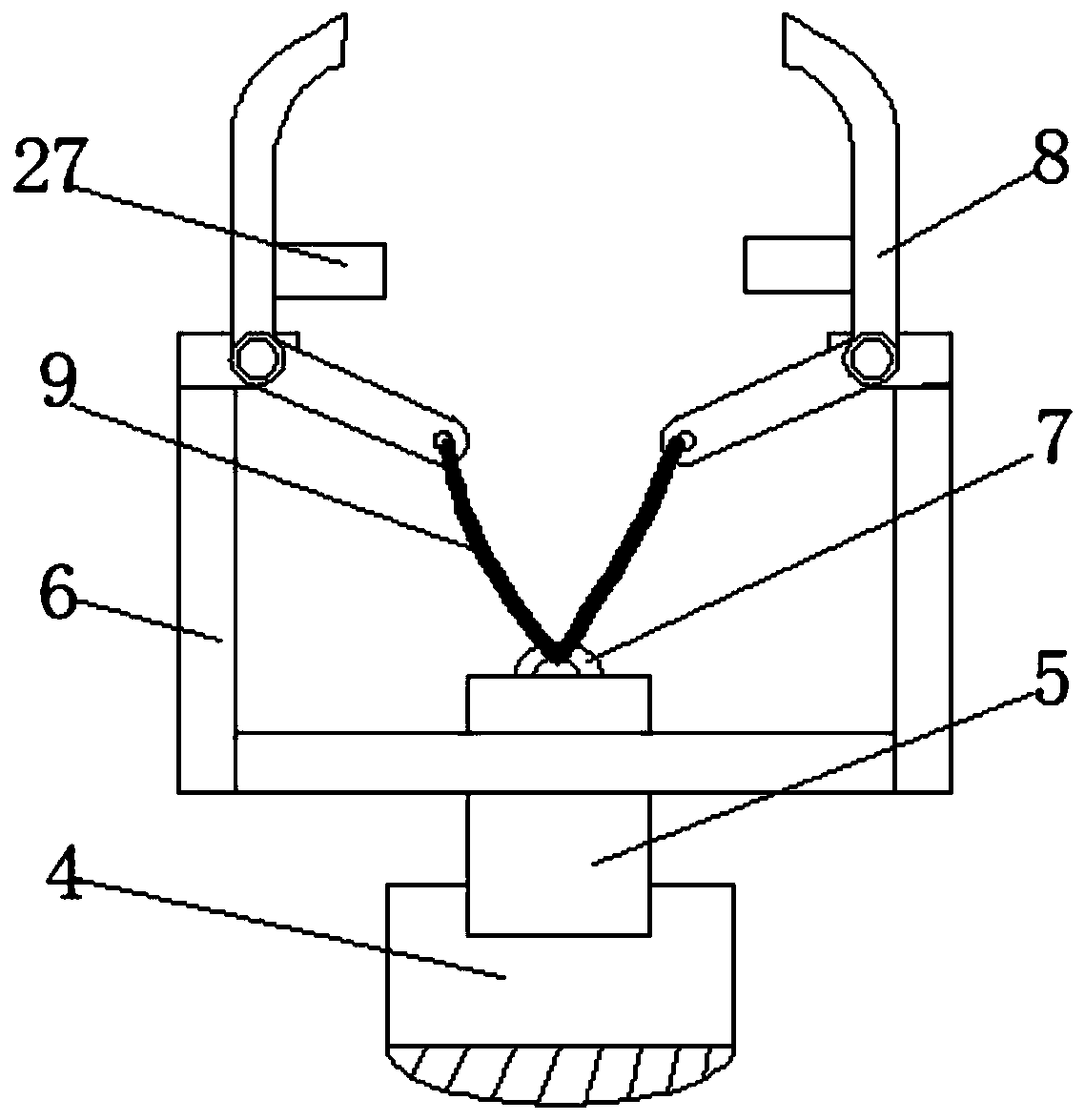

Grinding device of welding gun electrode rod

ActiveCN106624592ARealize the grinding functionSolve resource problemsElectrode maintenanceEngineeringElectrode

The invention relates to the technical field of grinding, and discloses a grinding device of a welding gun electrode rod. The grinding device includes a tool apron and a tool; a tool installation groove is formed in one end of the tool apron; the tool is fixedly arranged in the tool installation groove; the tool includes a plurality of arc blades; and the plurality of arc blades are distributed around the center of the tool to form an electrode rod grinding hole, and in this way, the grinding function is achieved. The grinding device can effectively solve the problem of resource waste and increased cost due to direct scraping of broken electrode rods; and compared with the conventional grinding tools, the grinding device can improve the grinding efficiency, is simple in structure, and can be widely applied.

Owner:GUANGQI HONDA

Micro-motion stepless speed regulation grinding device for common big vertical lathe

InactiveCN101804599AEasy loading and unloadingFlexible adjustmentGrinding carriagesGrinding drivesMicro motionMorse taper

The invention relates to a micro-motion stepless speed regulation grinding device for a common big vertical lathe, which comprises a two-dimensional regulation mechanism, a hand feeding mechanism, a lifting mechanism of a grinding head and a grinding head of an electric main shaft. The two-dimensional regulation mechanism connects a support body, a first connector, a second connector and a mounting plate of a guide rail sequentially by two pairs of swivel bearing pairs and one pair of dovetail pairs and realizes the two-dimensional regulation of the entire device; the hand feeding mechanism realizes microfeed by the transmission of the two pairs of gear pairs; the lifting mechanism of the grinding head drives one pair of gear pairs by a motor, and then the gear pairs push a lead screw thread pair with a linear guide rail, thereby realizing the up-and-down lifting of the mounting plate of the electric main shaft; and the grinding head of the electric main shaft is formed by sequentially connecting an electric main shaft seat, the electric main shaft, an Morse taper shank and a grinding wheel. The invention realizes that a grinding function is realized on the common big vertical lathe, the grinding range is 0 to 10000rpm, and the minimum feed amount of the hand feeding mechanism is 0.0005mm.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Automobile baffle grinding apparatus production device

PendingCN109940487ARealize the cleaning functionRealize centralized recyclingGrinding machine componentsElectrostatic cleaningBristleEngineering

The invention discloses an automobile baffle grinding apparatus production device. A first base is included, and the bottom four corner positions of the first base are fixedly connected with supporting columns; the top of the first base is sequentially provided with a water draining groove and a conveying belt in the width direction; the side wall of the first base is sequentially connected with first supporting rods, air blowers, second supporting rods and a first support in the horizontal direction; the side wall of the other side of the first base is sequentially connected with the first supporting rods, the second supporting rods and an adsorbing plate in the horizontal direction; the first supporting rods are symmetrically arranged into two sets; a roller shaft is rotationally connected between each set of the first supporting rods through a rotating shaft; a first bristle layer is fixedly connected to the outer wall of each roller shaft; the top ends of the first supporting rodsare fixedly connected with an electrostatic dust sucking plate; and the top ends of the second supporting rods are fixedly connected with a second base. The automobile baffle grinding apparatus production device is simple in structure, convenient to operate and capable of effectively preventing secondary pollution caused by scraps in the grinding process.

Owner:ZHEJIANG SHUNSHI AUTOMOBILE TECH

Steel pipe machining mechanism

InactiveCN112846790ARealize automatic feeding functionRealize the grinding functionOther manufacturing equipments/toolsPositioning apparatusPipe fittingMachining

The invention discloses a steel pipe machining mechanism, and belongs to the field of pipe fitting machining. The steel pipe machining mechanism comprises a square frame, the square frame is fixedly installed, a bottom square sleeve and a top square sleeve are installed on the square frame and are both in sliding connection with the square frame, and a zigzag arm is arranged on one side of the bottom square sleeve. A balance weight roller is arranged at the end of the zigzag arm, and the balance weight roller is rotationally connected with the zigzag arm. An extension arm is installed on one side of the top square sleeve, and a pressing roller is installed at the end of the extension arm. The steel pipe machining mechanism integrates grooving and polishing functions.

Owner:苏州市佳信美智能装备有限公司

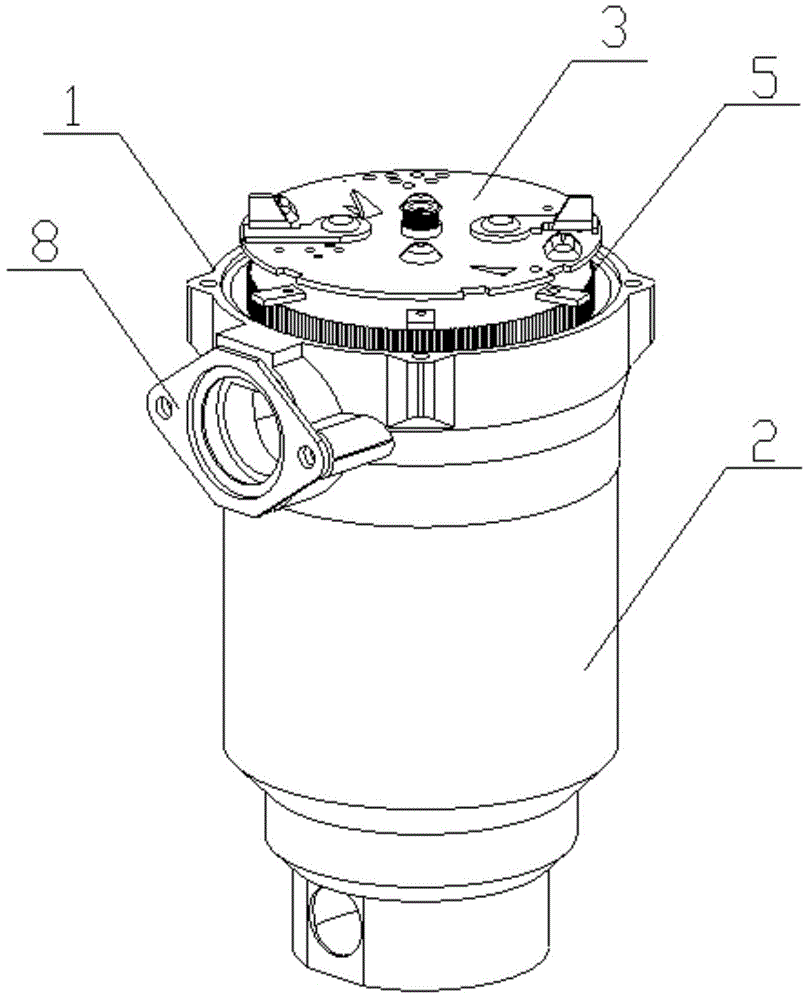

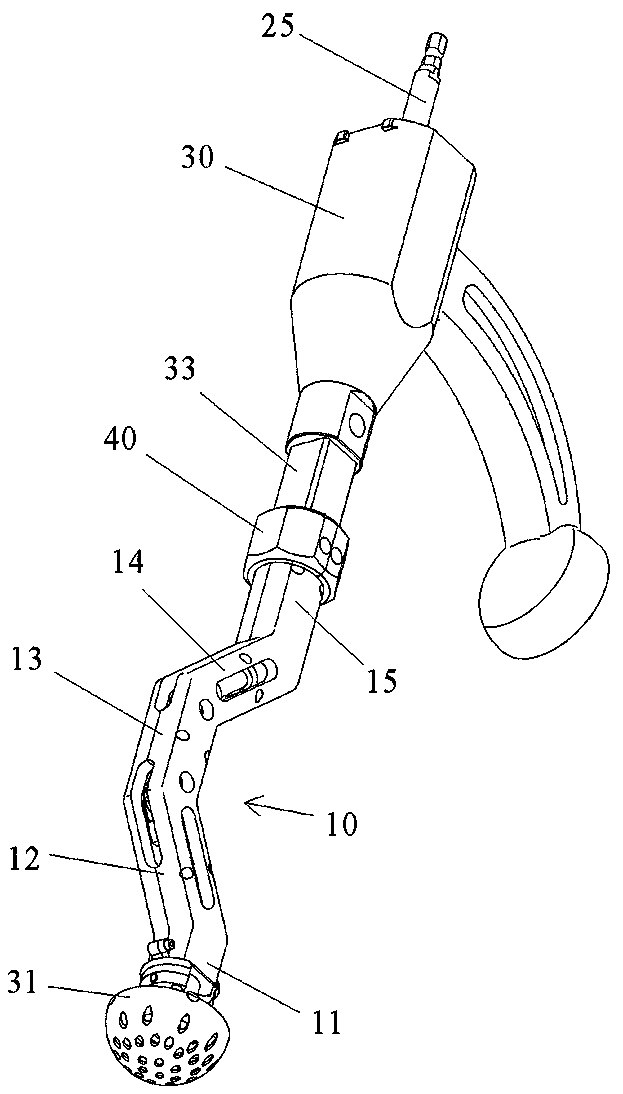

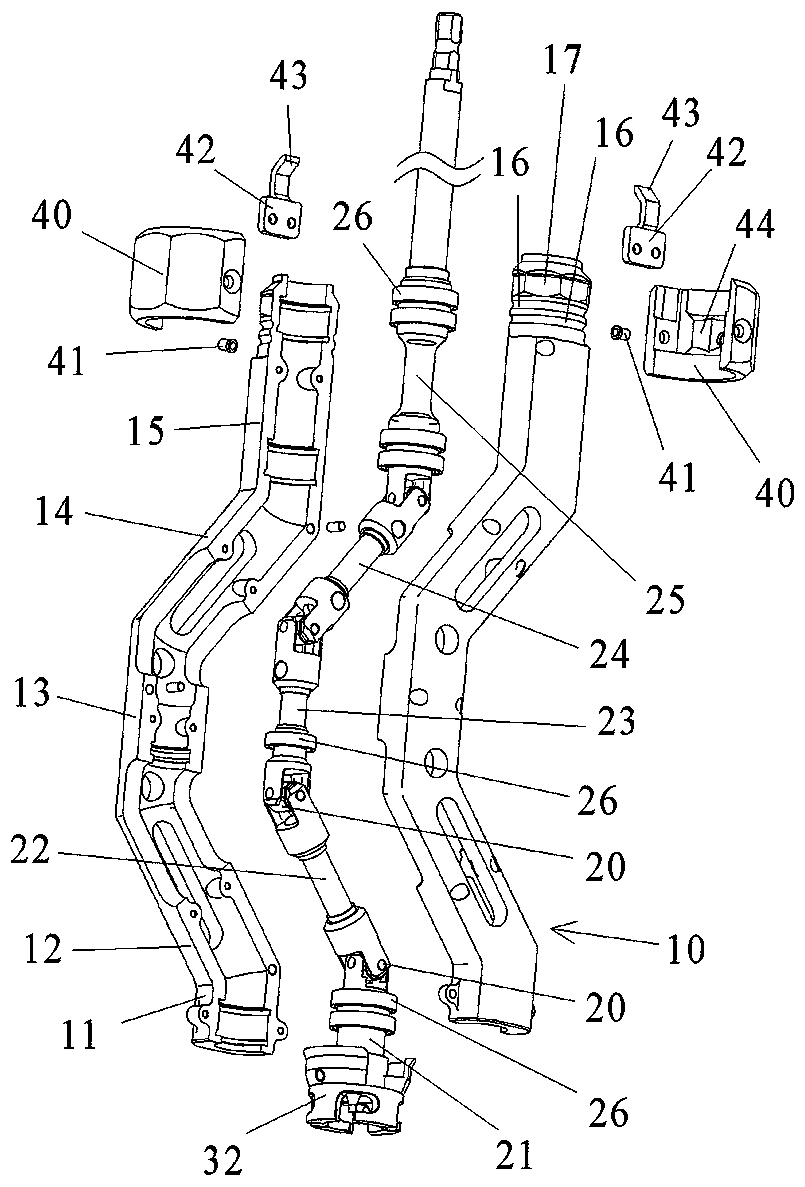

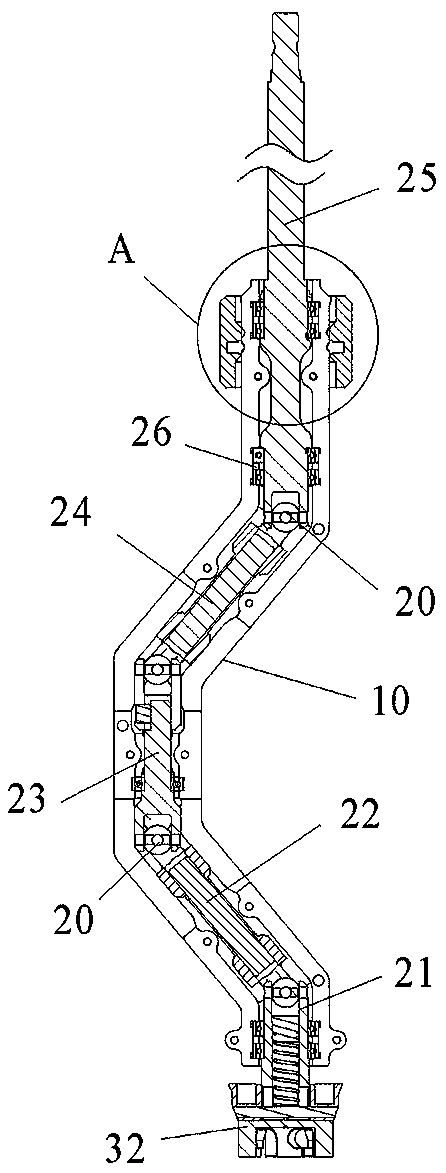

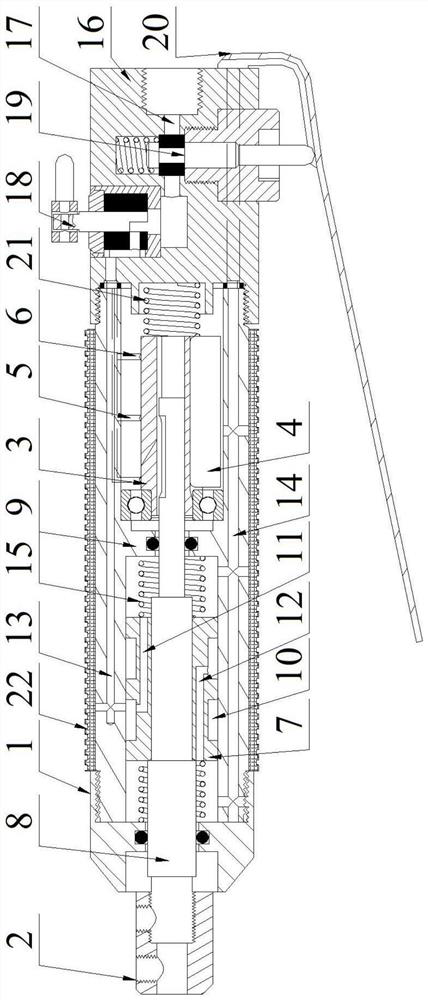

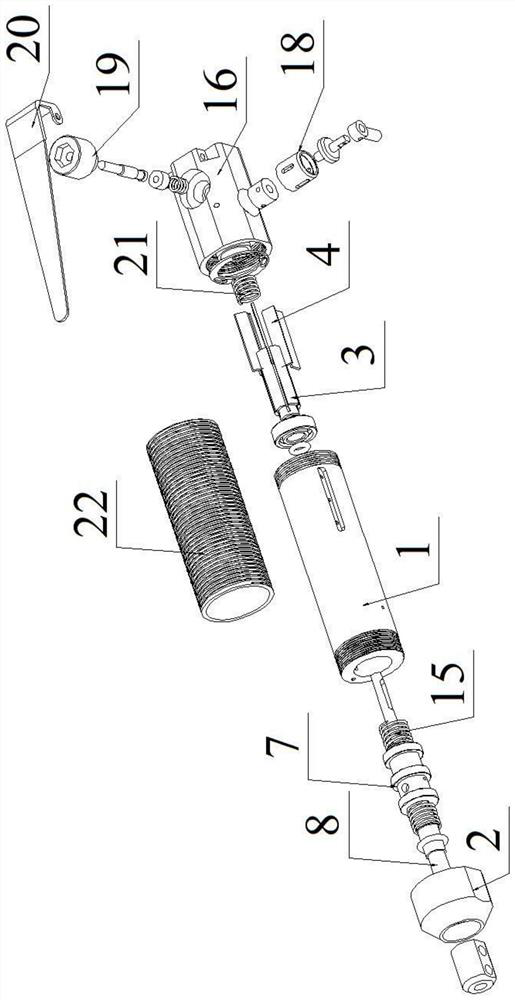

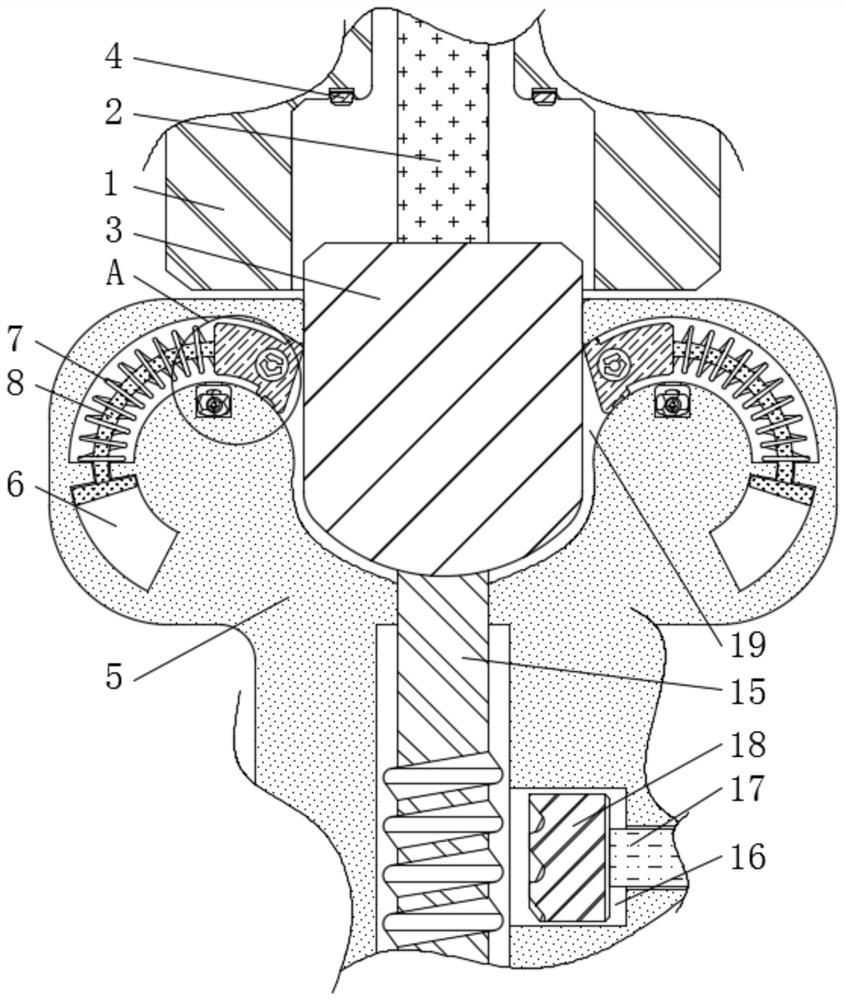

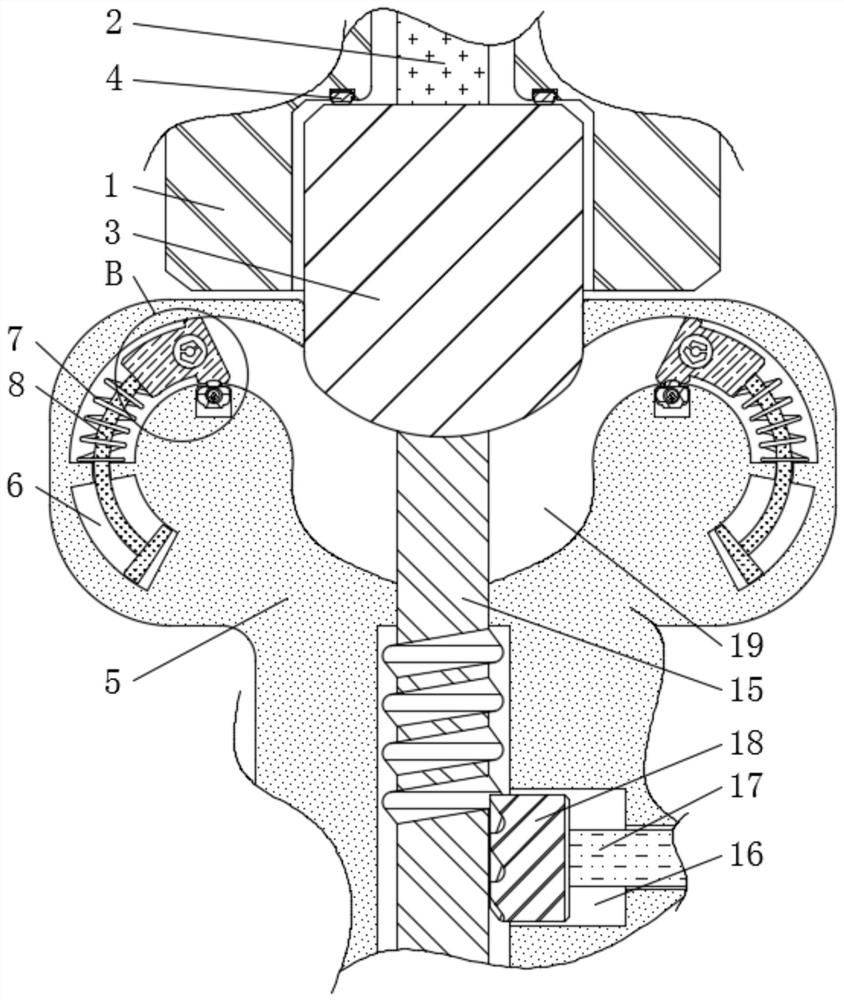

Gear type universal shaft connection anti-blocking acetabulum filing and cup placing self-locking mechanism rod

The invention discloses a gear type universal shaft connection anti-blocking acetabulum filing and cup placing self-locking mechanism rod. The gear type universal shaft connection anti-blocking acetabulum filing and cup placing self-locking mechanism rod comprises a tubular shell, wherein the shell comprises a first shell section, a second shell section, a third shell section, a fourth shell section and a fifth shell section; the first shell section and the fifth shell section are vertically distributed, and the second shell section, the third shell section and the fourth shell section are located on the same side of the fifth shell section; the second shell section is obliquely distributed upwards, and the fourth shell section is obliquely distributed downwards; a first shaft section is arranged in an inner cavity of the first shell section, and a second shaft section is arranged in an inner cavity of the second shell section; the first shaft section and the second shaft section are connected through a universal coupling; a fifth shaft section is arranged in an inner cavity of the fifth shell section; the first shaft section and the fifth shaft section extend to the outside of theshell; and the fifth shaft section is used for being connected with an axial stabilizing mechanism; and the fifth shell section is sleeved with a check ring. According to the gear type universal shaft connection anti-blocking acetabulum filing and cup placing self-locking mechanism rod, the shell is provided with a bent part, so that the shell can avoid the human body part during an operation, and the normal operation of the hip joint operation is not influenced.

Owner:上海龙慧医疗科技有限公司

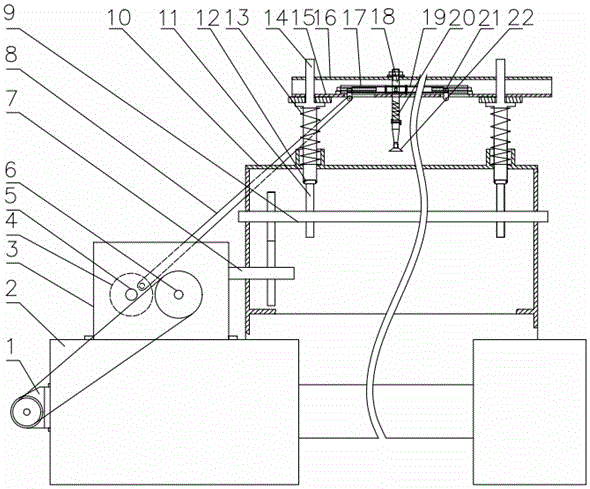

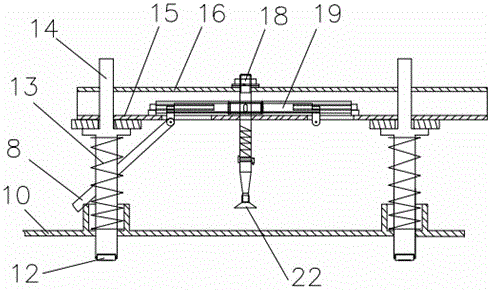

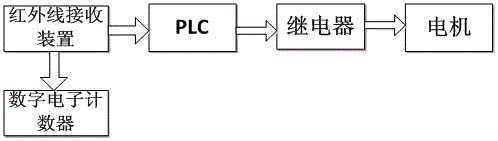

Valve grinder with limited processing capacity

ActiveCN105773394AGuaranteed assembly qualityGuaranteed mass productionGrinding drivesLapping machinesAutomatic controlHigh volume manufacturing

The invention discloses a valve grinder with the limited processing capacity. The valve grinder comprises a grinding device, wherein the grinding device is arranged on a groove beam which can lift up and down and is horizontally arranged; a rack plate which slides left and right along the groove beam is arranged at the middle part of the groove beam and is matched with a small gear on the grinding device; one end of the rack plate is connected with a crank-guide rod-sliding block mechanism on a stand; the stand is also provided with a control system which limits the grinding processing capacity; and the control system is composed of an infrared transmitting and receiving device, a counter, a PLC, a relay and a motor and controls the grinding capacity by controlling the running state of the motor according to the number of round trips. According to the valve grinder, the grinding capacity of a valve seat can be automatically controlled, the use of manpower resources is reduced when high grinding accuracy and production efficiency are ensured, and the cost of processing the valve seat is lowered, so that the assembly quality of an engine is ensured, and the need of mass production is met.

Owner:SHAOYANG UNIV

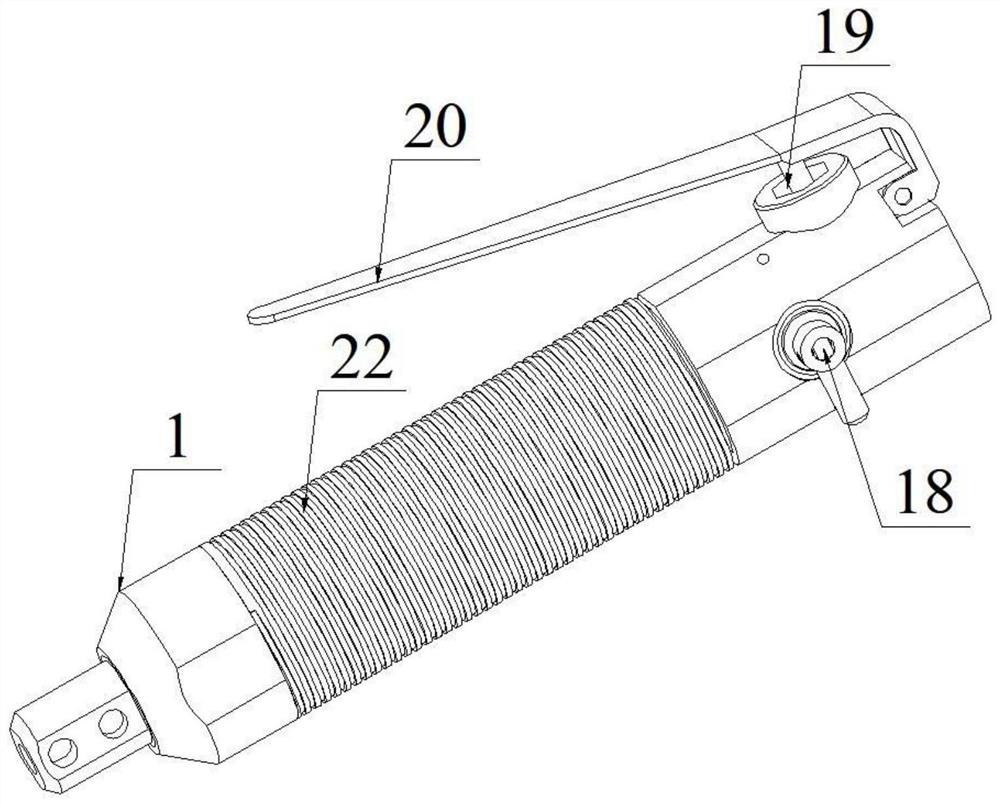

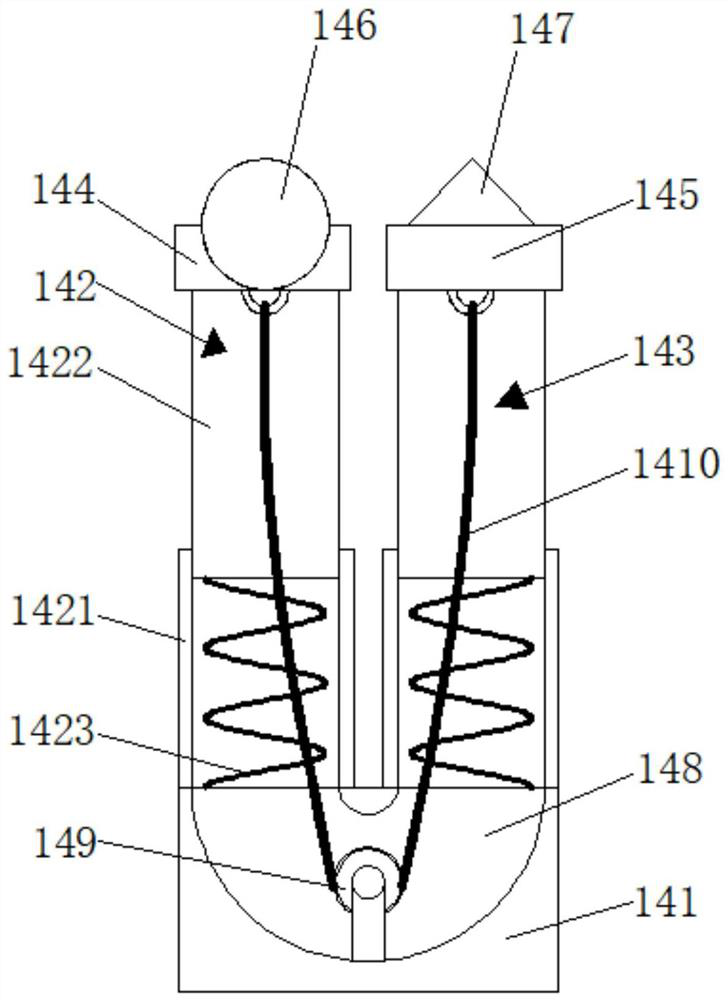

Multi-functional pneumatic file device

ActiveCN111941086AAchieve rotary motionRealize the grinding functionOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention relates to the technical field of machining device structures, in particular to a multi-functional pneumatic file device. The multi-functional pneumatic file device comprises a shell anda clamping sleeve, and is characterized in that a reciprocating driving structure for driving the clamping sleeve to move in an axial direction of the shell and a rotating driving structure for driving the reciprocating driving structure and the clamping sleeve to rotatably move around the axis of the shell are arranged in the shell; the clamping sleeve and the rotating driving structure are fixed to the two ends of the reciprocating driving structure respectively; and the shell is provided with an air channel respectively communicating with the reciprocating driving structure and the rotating driving structure. The multi-functional pneumatic file device comprises a shell and a clamping sleeve, and is characterized in that a reciprocating driving structure for driving the clamping sleeveto move in an axial direction of the shell and a rotating driving structure for driving the reciprocating driving structure and the clamping sleeve to rotatably move around the axis of the shell are arranged in the shell; the clamping sleeve and the rotating driving structure are fixed to the two ends of the reciprocating driving structure respectively; and the shell is provided with an air channel respectively communicating with the reciprocating driving structure and the rotating driving structure.

Owner:东风汽车动力零部件有限公司

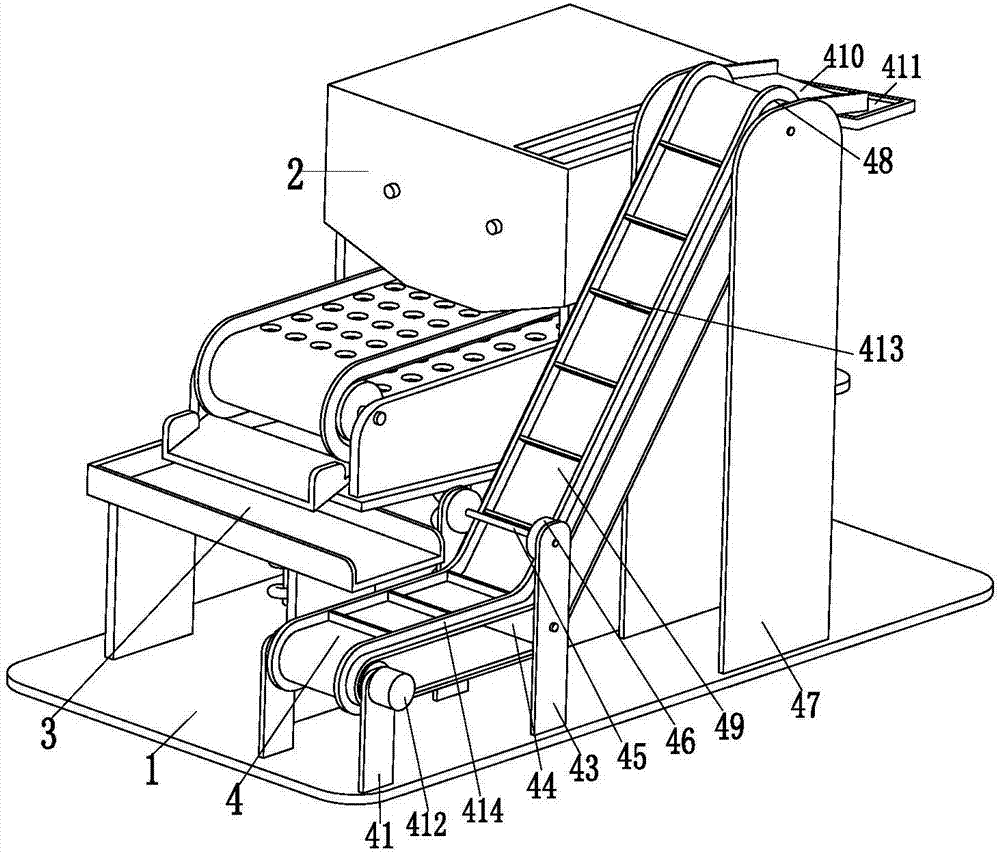

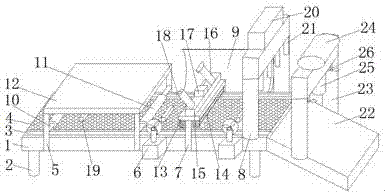

Automatic raw material grinding equipment special for building decoration material marble tiles

InactiveCN107365157AQuality will not affectRealize the grinding functionRaw materialGrinding process

The invention relates to automatic raw material grinding equipment special for building decoration material marble tiles. The automatic raw material grinding equipment comprises a bottom plate and is characterized in that a grinding device and a conveying and sieving device are mounted on the bottom plate, a feeding device is mounted at the right end of the bottom plate, the feeding device is located on the lower side of the right end of the conveying and sieving device, and the grinding device, the conveying and sieving device and the feeding device are coordinated to complete the automatic and repeated grinding process of marble tile raw materials. The automatic raw material grinding equipment has the advantages that the problems that an existing marble tile raw material grinding process is insufficient in grinding, the quality of the marble tiles is affected, marble tile raw materials which do not meet the requirements after sieving needs to be collected manually, the marble tile raw materials which do not meet the requirements needs to be manually re-conveyed into the grinding equipment for repeated processing, operation is complex, labor intensity is high, work efficiency is low, and the like can be solved, and functions of marble tile raw material automatic and repeated grinding and sieving can be achieved.

Owner:合肥集知网信息技术有限公司

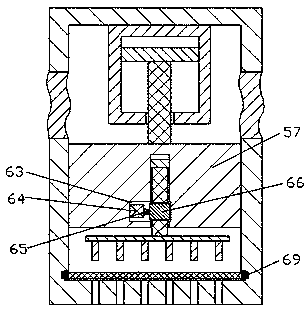

Roller paint device for organic composite insulator and roller paint process of organic composite insulator

ActiveCN110400664ARealize the grinding functionImprove adsorption capacityInsulatorsComposite insulatorsSurface layer

The invention discloses a roller paint device for an organic composite insulator. The roller paint device comprises a spray paint box body, the spray paint box body is used for erecting an insulator core boy through a rotary sleeve and a lifting sliding sleeve, the rotary sleeve is connected with a first rotating shaft, the lifting sliding sleeve is connected with a first hydraulic rod, one end ofa brush roller is sleeved with a driven gear, the driven gear is engaged with a driving gear and a third rotating shaft, the other end of the brush roller is connected with a hinging rack, the hinging rack is connected with a second hydraulic rod and a connection elastic rod; a spray paint box is provided with an air outlet pipe, an air inlet pipe, a seal door and a spray paint pipe, the air inlet pipe is connected with an air pump and an air heater, and the spray paint pipe is connected with a feeding box and a pressing pump. The present invention further provides a roller paint process of an organic composite insulator. The process comprises polishing, ash blowing, dual-shaft roller paint, surface leveling, preliminary drying, roll coating surface coating and high temperature baking. The roll paint of the invention has the high efficiency, the adhesion of the insulation paint at the surface of the core body is high, the insulation structure of the insulator is stable, the insulationperformance is high, the creepage distance is large, and the porcelain surface of the surface layer is favorable for dust prevention and decontamination.

Owner:安徽东盾电力有限公司

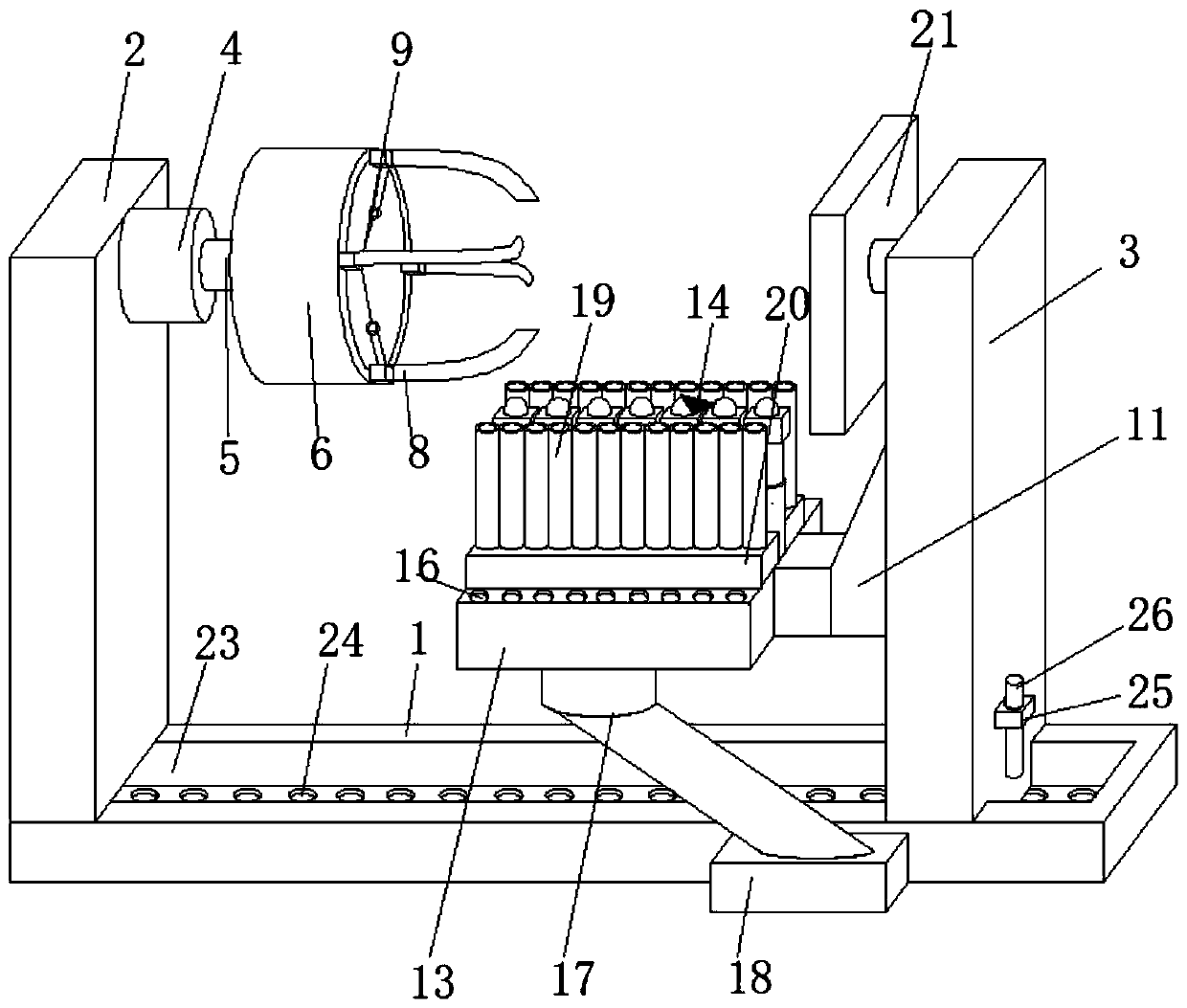

Automobile metal pipe mold smoothening and grinding device

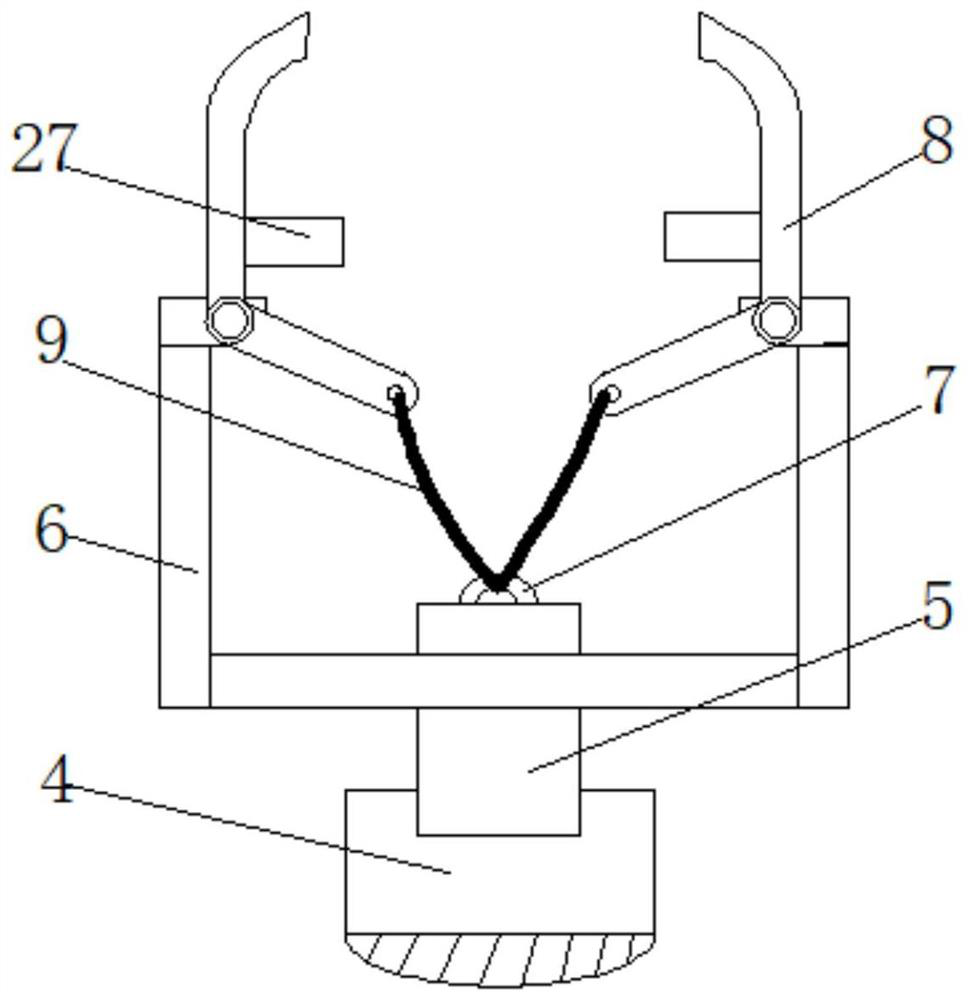

ActiveCN110509153ARealize the clamping functionRealize the grinding functionGrinding machinesGrinding work supportsEngineeringMachining

The invention discloses an automobile metal pipe mold smoothening and grinding device and belongs to the technical field of automobile part machining equipment. The automobile metal pipe mold smoothening and grinding device comprises a base. The top of the base is connected with a first fixed plate and a second fixed plate in the horizontal direction. The side, close to the second fixed plate, ofthe top end of the first fixed plate is connected with a rotation motor. The output end of the rotation motor is connected with a horizontal rotary shaft. The end, far away from the rotation motor, ofthe horizontal rotary shaft is connected with a sleeve through a bearing. The end, penetrating through the bearing, of the horizontal rotary shaft is connected with a tying ring. Four fixed jaws symmetrically distributed are hinged to the end, far away from the horizontal rotary shaft, of the sleeve. An adjusting steel rope is connected between the two opposite fixed jaws. The center of the adjusting steel rope is connected to the tying ring. The automobile metal pipe mold smoothening and grinding device achieves the treatment function on the surface smoothness of an automobile metal pipe mold, effectively collects scraps produced in the mold surface treatment process to prevent secondary pollution and improves the mold surface treatment stability and accuracy.

Owner:安徽中运智能科技有限公司

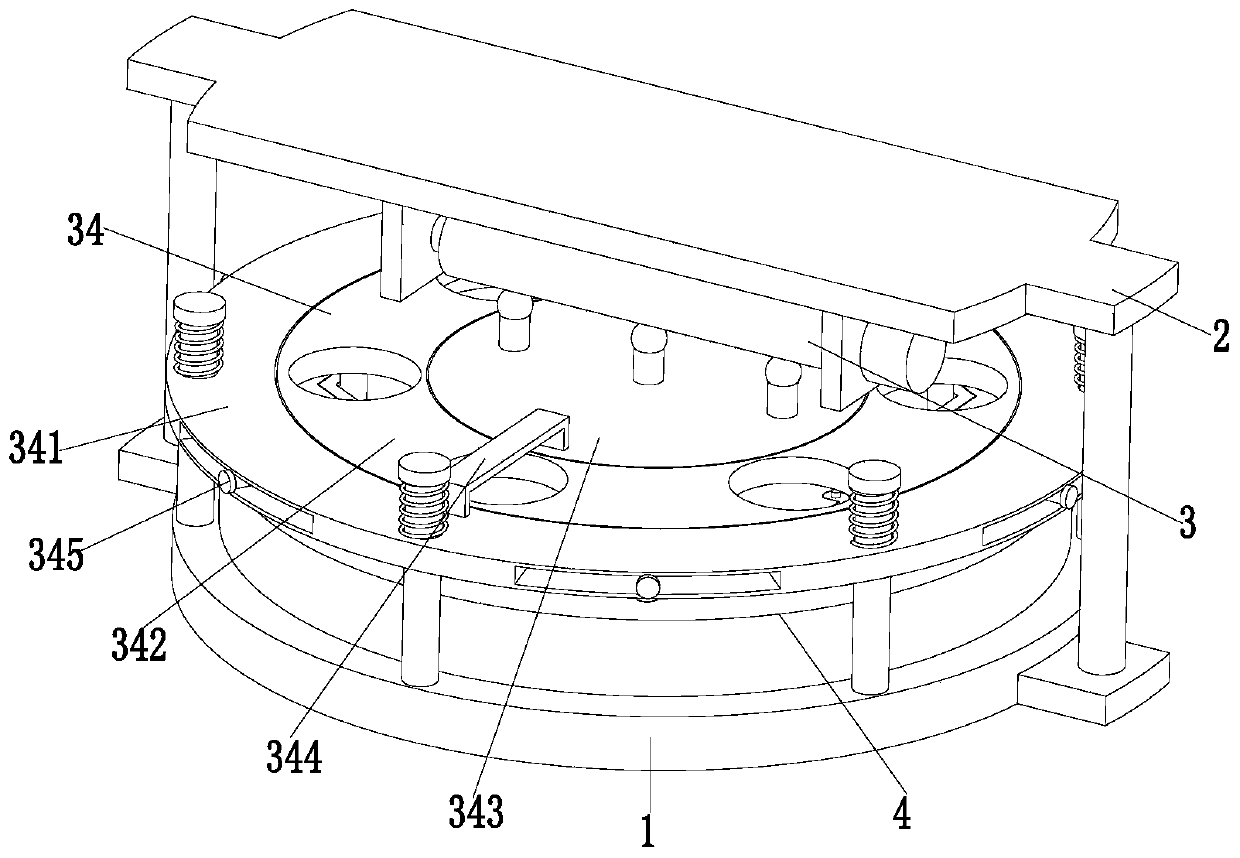

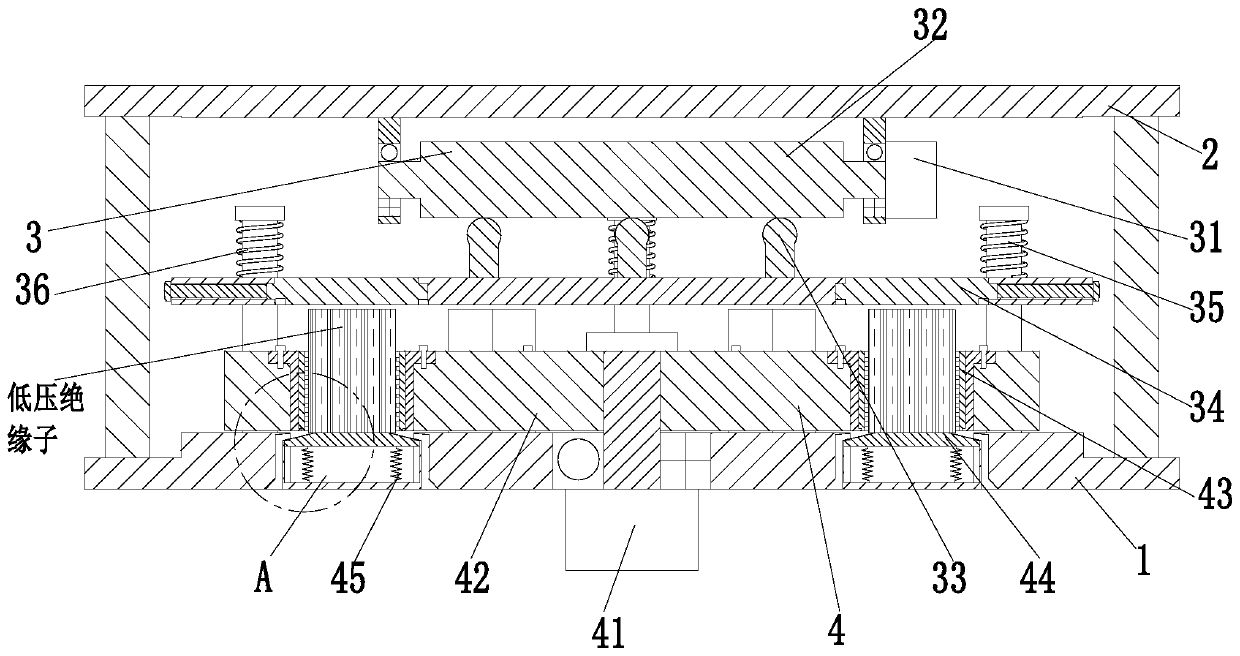

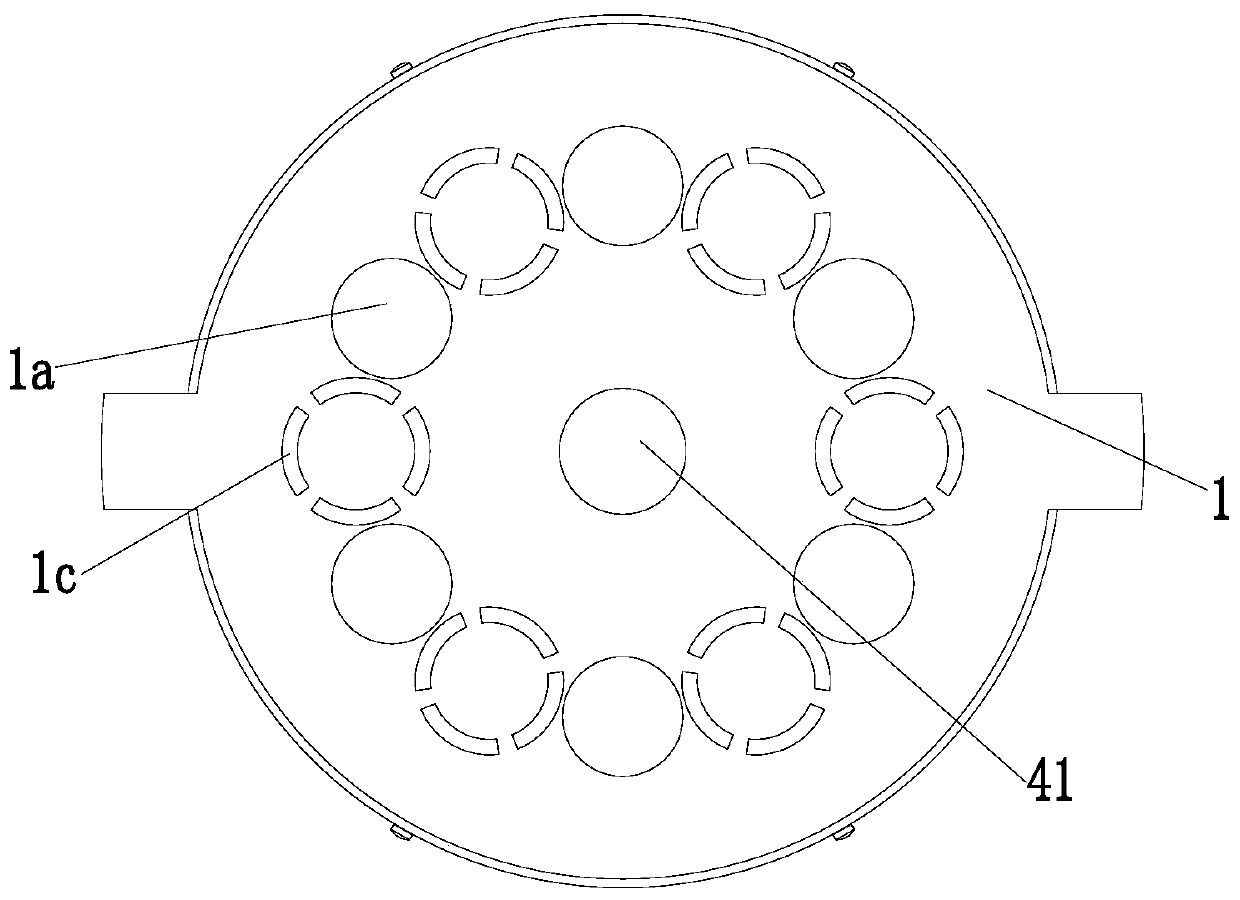

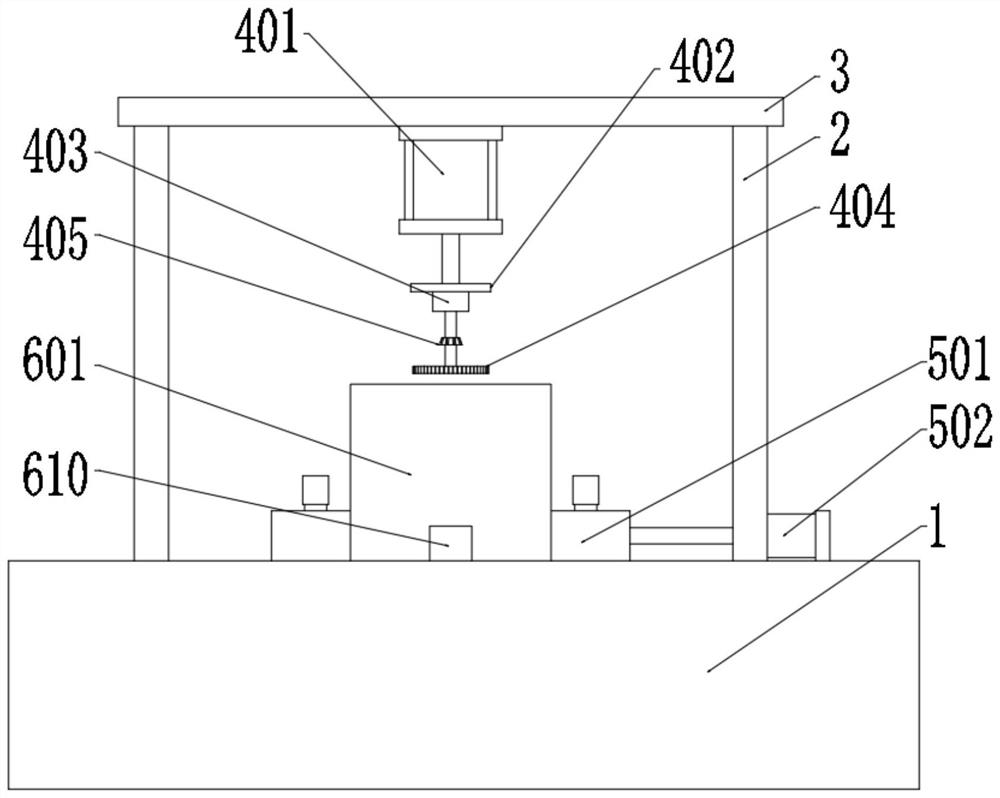

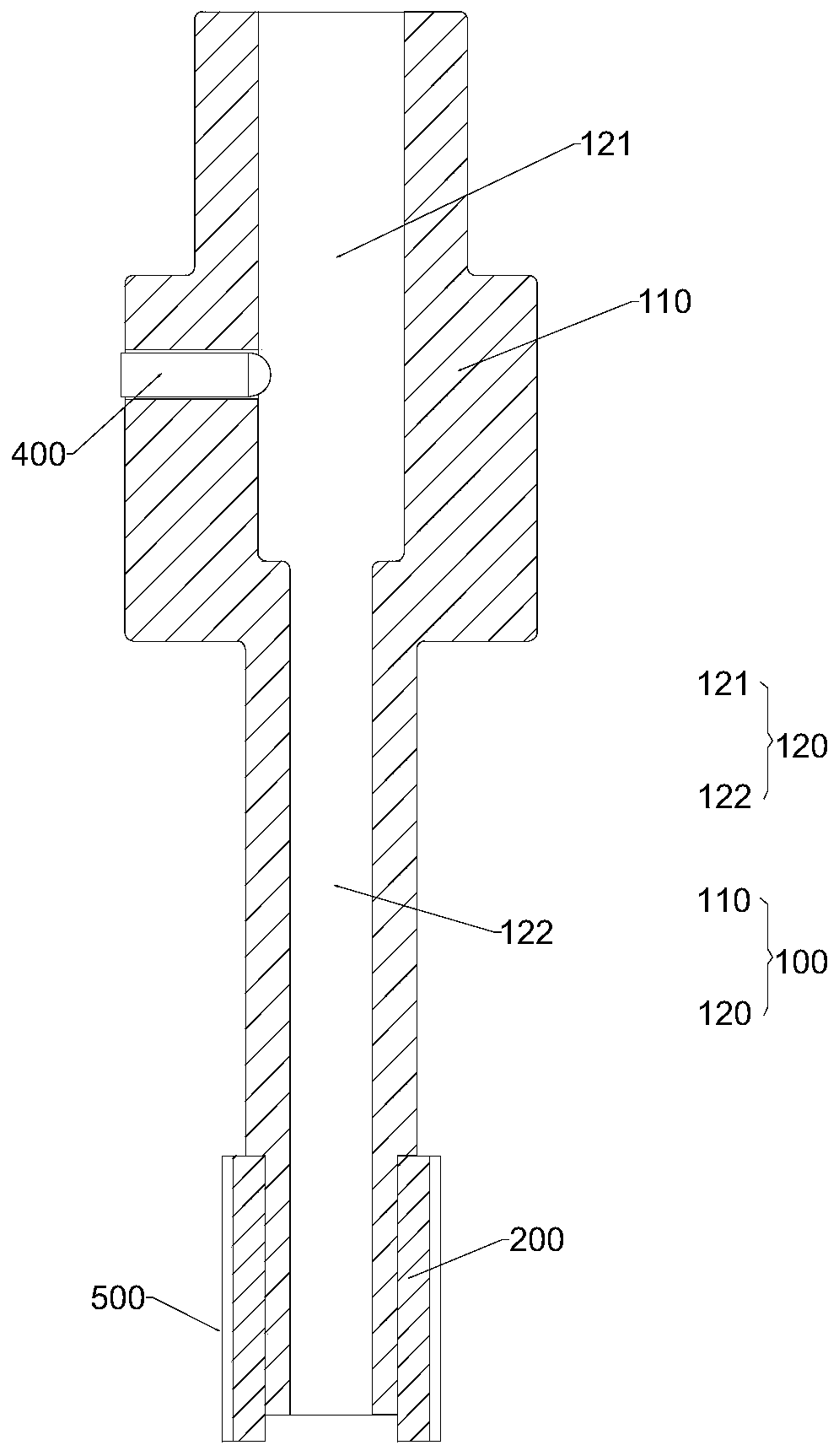

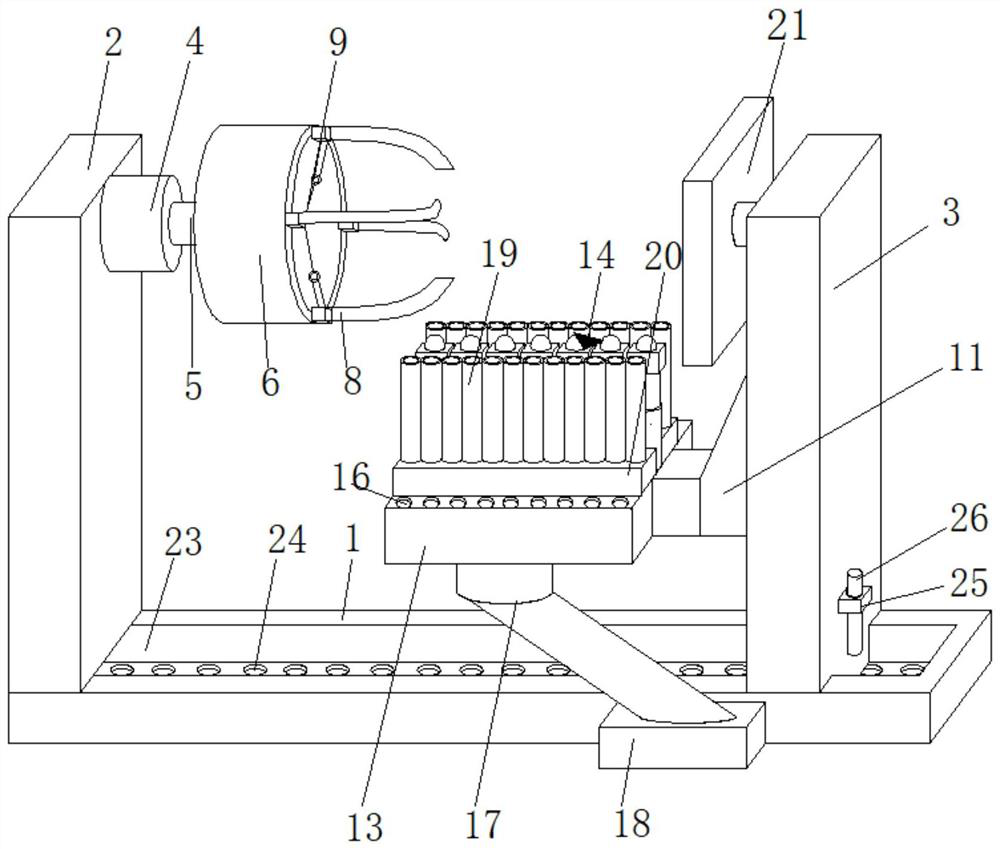

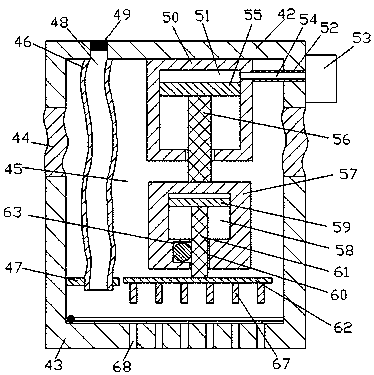

Forming manufacturing machining machine and machining method for low-voltage insulator

ActiveCN111531444AReduce fixation stepsImprove grinding efficiencyGrinding machinesGrinding work supportsStructural engineeringManufacturing engineering

The invention relates to a forming manufacturing machining machine and a machining method for a low-voltage insulator. The forming manufacturing machining machine comprises a fixing table board, a mounting frame, a pushing pressing mechanism and a material placing mechanism, wherein the upper end of the fixing table board is provided with the mounting frame, the lower end of the mounting frame isprovided with the pushing pressing mechanism, the lower end of the pushing pressing mechanism is tightly attached to the upper end of the material placing mechanism, the material placing mechanism ismounted on the fixing table board, blanking openings and material placing grooves are uniformly formed in the fixing table board in the circumferential direction of the fixing table board, the blanking openings and the material placing grooves are arranged at intervals, and the blanking openings and the material placing grooves each are of a circular structure. According to the forming manufacturing machining machine, through the common cooperation of the pushing pressing mechanism and the material placing mechanism, the operation of grinding the outer surface of the hexagonal low-voltage insulator is completed; and a grinding frame matched with the shape of the low-voltage insulator is arranged on the material placing mechanism in advance, so that it is guaranteed that the grinding frameis attached to the surface of the low-voltage insulator without repeated position adjustment of the material placing mechanism before grinding, the grinding efficiency is effectively improved, and thegrinding effect is guaranteed.

Owner:永州捷宝电讯塑胶五金有限公司

Cutting and grinding integration device

ActiveCN110181695AAvoid damageOvercome the cumbersome process of traditional sample preparationGrinding drivesWorking accessoriesParallel plateEngineering

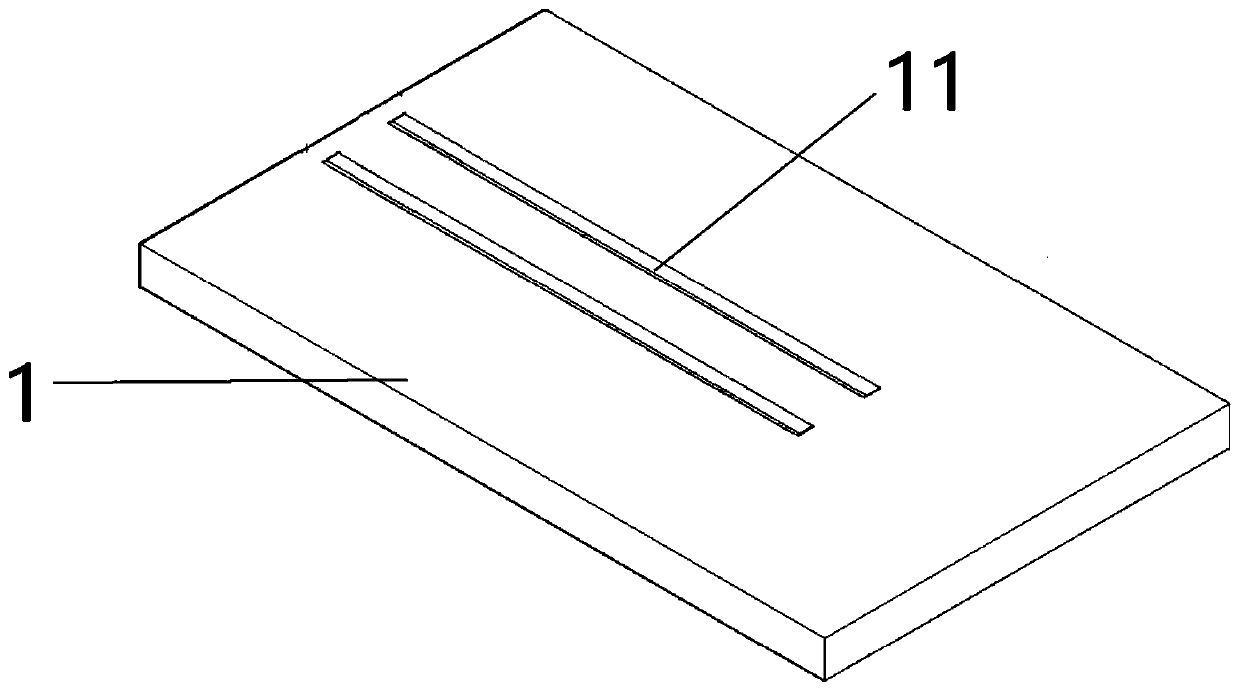

The invention relates to a cutting and grinding integration device which comprises a working table. Two moving grooves are formed in the surface of the working table; a basic movement plate can be slidably connected into the moving grooves and is in a U shape; a horizontal structure of the basic movement plate is far away from a cutting structure; rectangular moving lugs are arranged on the bottomparts of two parallel plates of the basic movement plate; the moving grooves are matched with the rectangular moving lugs; fixing structures are arranged on the two parallel plates of the basic movement plate so as to form a fixing structure group; and a space between the two moving grooves is equal to a space between the two parallel plates. The cutting structure for cutting a sample is arrangedon the working table in a parallel plate extending direction, and grinding structures with same structures are arranged on two sides of the fixing structure group. The cutting and grinding integration device provided by the invention overcomes the defects that a traditional sample preparation process is tedious, sample fixing and transferring cause scrappage and the inner part of the sample is damaged; the sample preparation process is simplified; and the frequency of sample fixing and transferring and the damage probably caused on the sample are reduced.

Owner:HOHAI UNIV

Grinding device for petroleum pipeline end openings

InactiveCN108214222APolished evenlyEliminates the hassle of changing grinding wheelsGrinding carriagesGrinding drivesSlagSurface grinding

The invention discloses a grinding device for petroleum pipeline end openings. The grinding device comprises an electric push rod, a pushing plate, a sliding block, a first motor, a motor shell, a first bearing, a first rotating shaft, a limiting block, a friction block, an adjusting rod, limiting holes, a limiting nut, a limiting bolt, a supporting rod, a second bearing, fixing supporting feet, agrinding machine shell, a second motor, a belt, a first fixing rod, a first rotary table, second rotary tables, a grinding belt, second fixing rods, third bearings, third rotary tables, fourth bearings, a moving cavity, a fourth rotary table, a second rotating shaft and a third rotating shaft. The grinding device is designed for grinding the petroleum pipeline end openings and has the functions of surface grinding and inner cavity side wall grinding, and welding slag, gaps and uneven places of the surface and the inner wall of a petroleum pipeline can be uniformly eliminated.

Owner:洛阳高昌机电科技有限公司

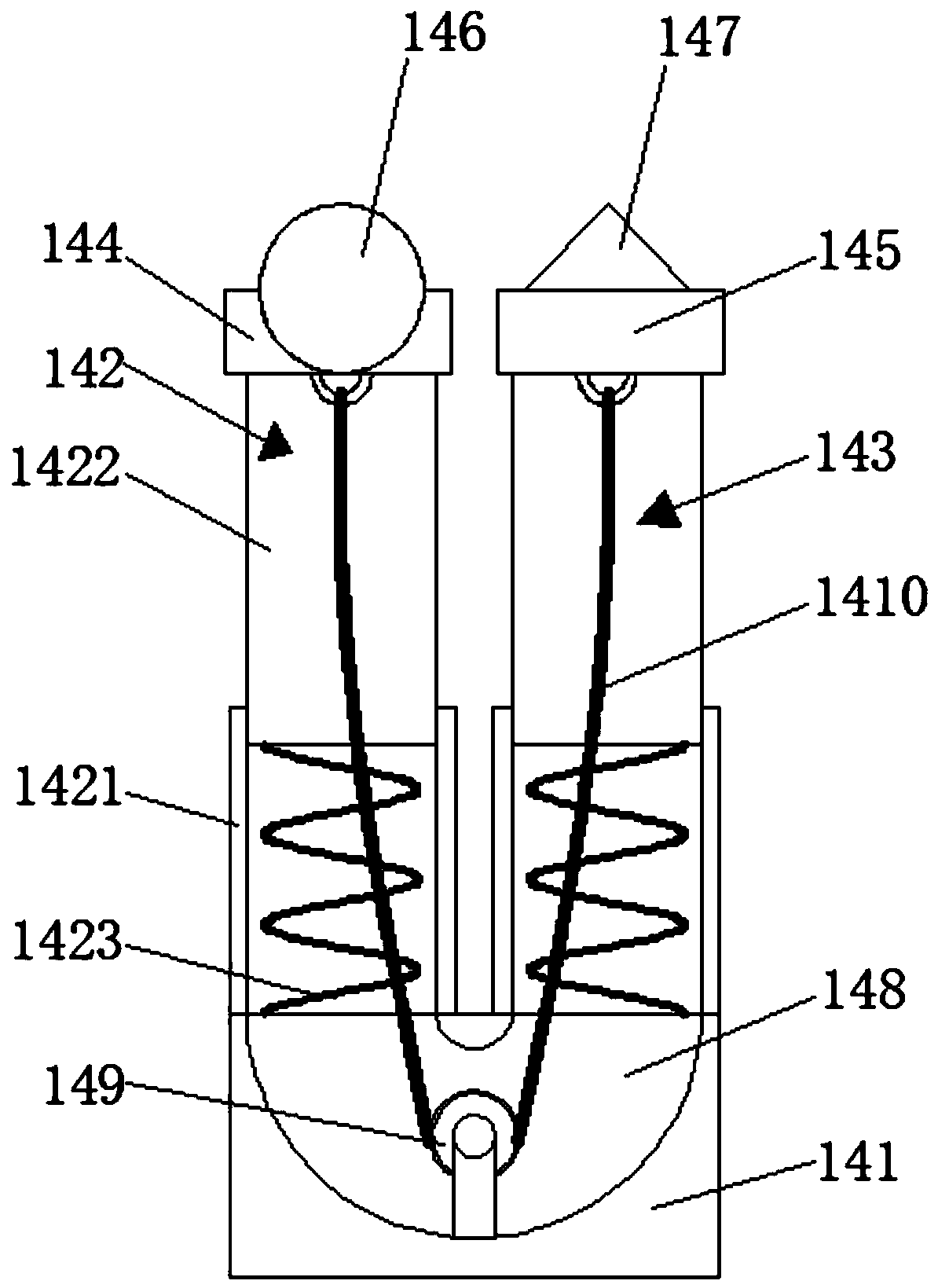

Crystal rod outer diameter grinding equipment for semiconductor devices

ActiveCN110561264AReduce stepsImprove grinding precisionLapping machinesWork carriersPower semiconductor deviceButt joint

The invention relates to crystal rod outer diameter grinding equipment for semiconductor devices. The equipment comprises a worktable, a mounting frame, a support mechanism and a grinding mechanism; the support mechanism is mounted at the upper end of the worktable; the mounting frame is arranged at the upper end of the support mechanism; the grinding mechanism is mounted at the lower end of the mounting frame, and comprises a driving motor, a driving gear, a driven gear, a connecting plate and a grinding support chain; the support mechanism comprises a butt joint branch chain, a slide block,a pressing plate, a fixed plate, an extension plate, a support branch chain and an electric slide block; and the grinding support chain comprises a working plate, an adjusting rod, a transverse plate,an adjusting bolt and a grinding plate. Through cooperation of the support mechanism and the grinding mechanism during working, the equipment achieves the purpose of alternately clamping the left andright ends of crystal rods, so that the overall grinding work of the crystal rods is once finished, the operation steps are reduced, the grinding precision is improved, the clamping of the crystal rods by a manual mode is not needed, and the centering precision is improved.

Owner:奥准企业发展上海有限公司

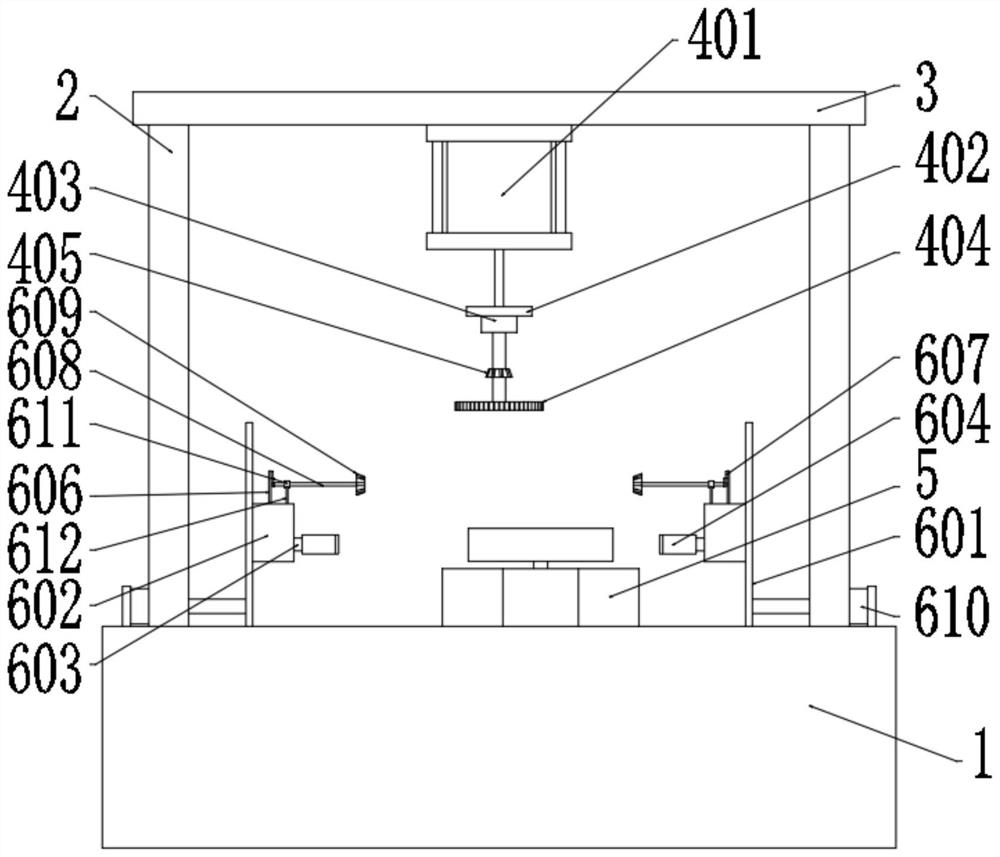

Machining device and technological method for high-precision sheet metal part of medical equipment

InactiveCN114367904ASolve the troublesome problem of subsequent processing of debrisGuaranteed fixed effectGrinding drivesGrinding machinesMedical equipmentReciprocating motion

The invention relates to the technical field of medical equipment, and discloses a medical equipment high-precision sheet metal part machining device and technological method.The medical equipment high-precision sheet metal part machining device comprises a machining base, supporting columns are fixedly installed on the periphery of the top end of the machining base, the other ends of the supporting columns are fixedly connected with a top plate, and a grinding mechanism is arranged at the bottom end of the top plate; a clamping mechanism is arranged at the top end of the machining base. According to the high-precision sheet metal part machining device for the medical equipment and the technological method, by arranging an adsorption mechanism, during grinding and when a synchronous bevel gear rotates, a transmission shaft can be driven to rotate, so that a connecting rod is driven to move, a synchronous rod is driven to do up-down reciprocating motion, and a piston is driven to do up-down reciprocating suction; and due to the arrangement of the one-way valve, continuous suction is started at the adsorption pipeline, so that chippings generated in the polishing process are sucked to the adsorption hopper, the beneficial effects that the chippings can be synchronously adsorbed and the like are achieved, and the existing problem that follow-up chipping treatment is troublesome is solved.

Owner:南京翼之锋机电制造有限公司

Automobile baffle grinding tool production equipment

InactiveCN107971890ARealize the cleaning functionRealize centralized recyclingGrinding machinesGrinding feedersEngineeringAir blower

The invention discloses automobile baffle grinding tool production equipment. The automobile baffle grinding tool production equipment comprises a first base, supporting columns are fixedly connectedto the four corners of the bottom of the first base, a water draining channel and a conveying belt are sequentially mounted at the top of the first base in the width direction of the first base a setof,first supporting rods, air blowers, a second supporting rod and a first support are sequentially connected to the side wall of the first base in the horizontal direction, and the other set of firstsupporting rods, another second supporting rod and an adsorption plate are sequentially connected to the other side wall of the first base in the horizontal direction. The two sets of first supporting rods are symmetrically arranged, a roller shaft is rotatably connected to the position between each set of first supporting rods through a rotary shaft, and first brush layers are fixedly connectedto the outer walls of the roller shafts. An electrostatic dust suction plate is fixedly connected to the top ends of the first supporting rods, and a second base is fixedly connected to the top ends of the second supporting rods. The automobile baffle grinding tool production equipment is simple in structure and convenient to operate, and effectively prevents secondary pollution from being generated by chippings in the grinding process.

Owner:郑宾玲

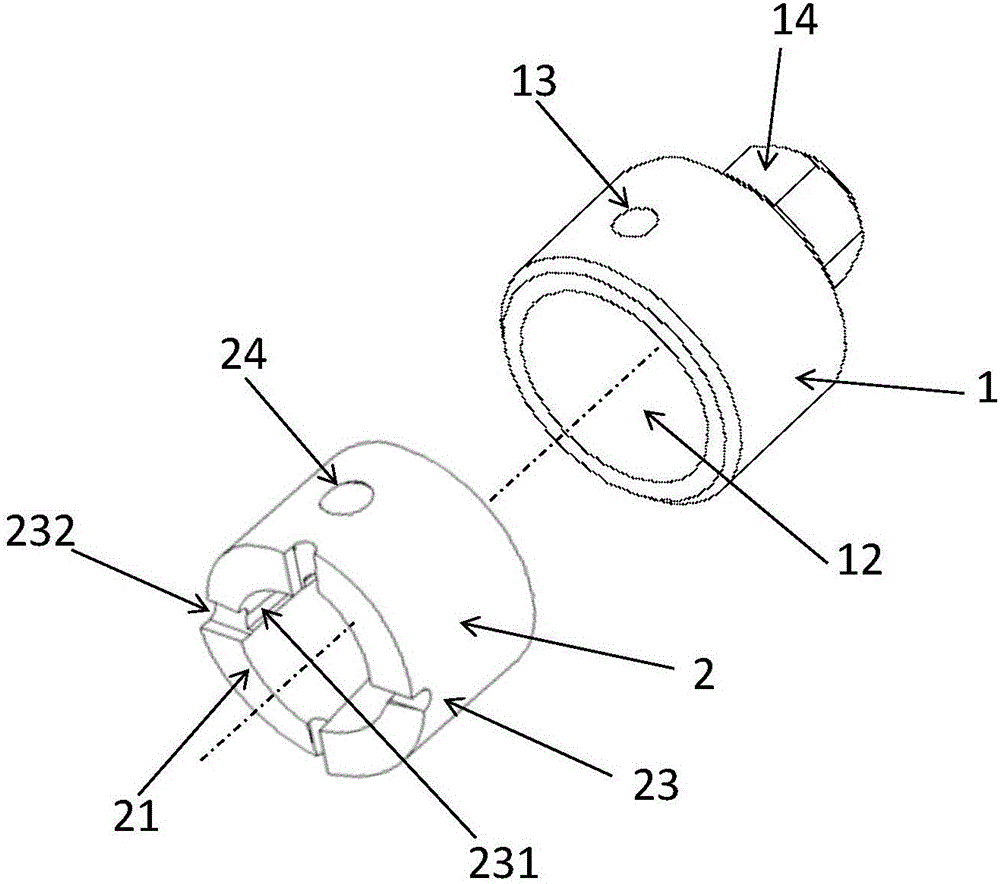

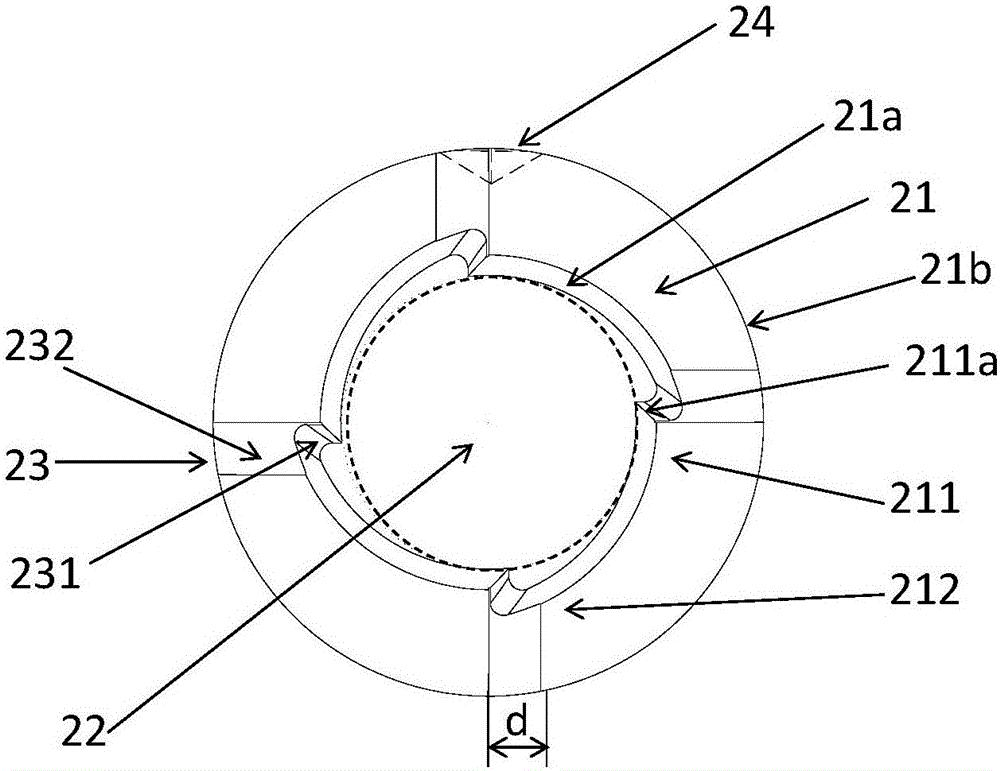

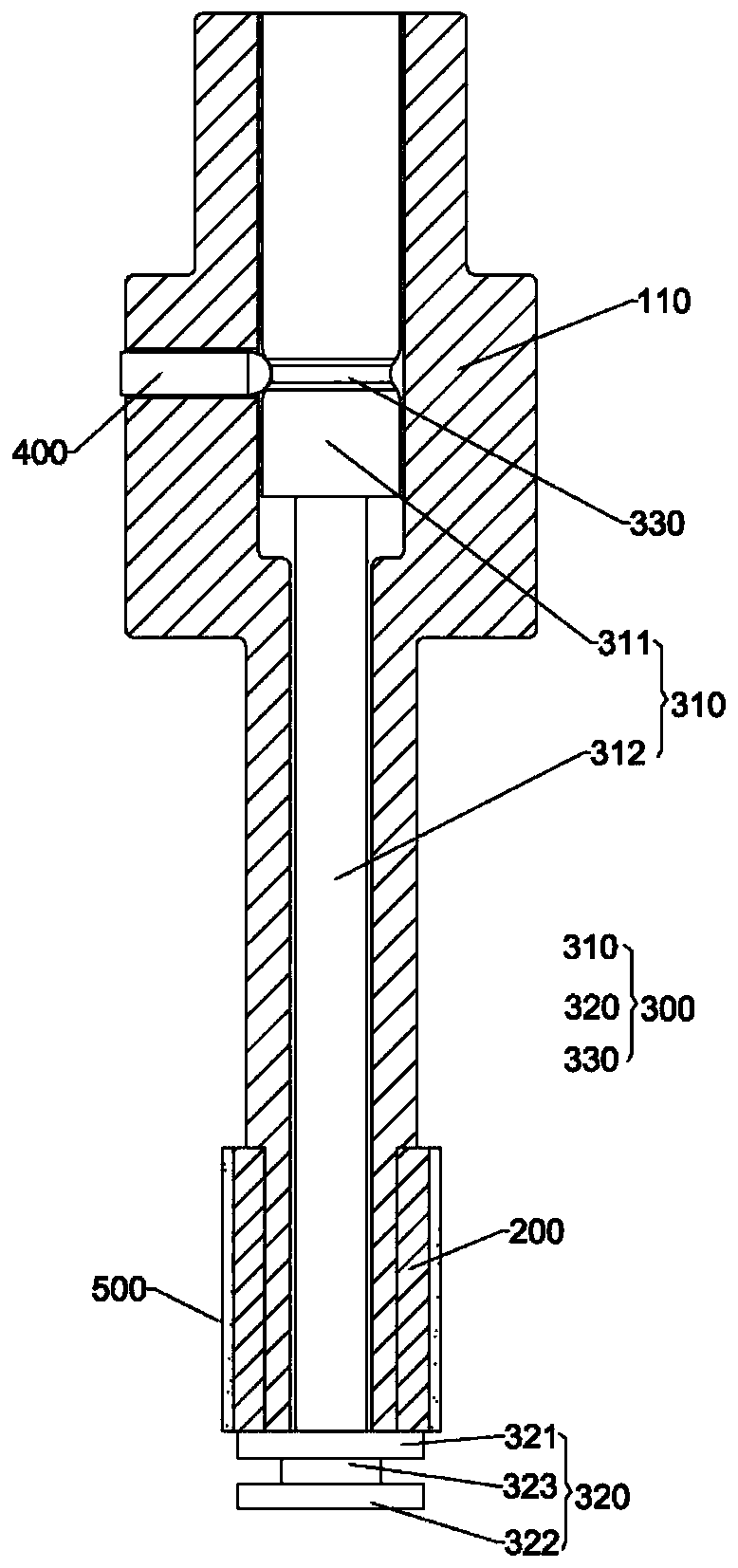

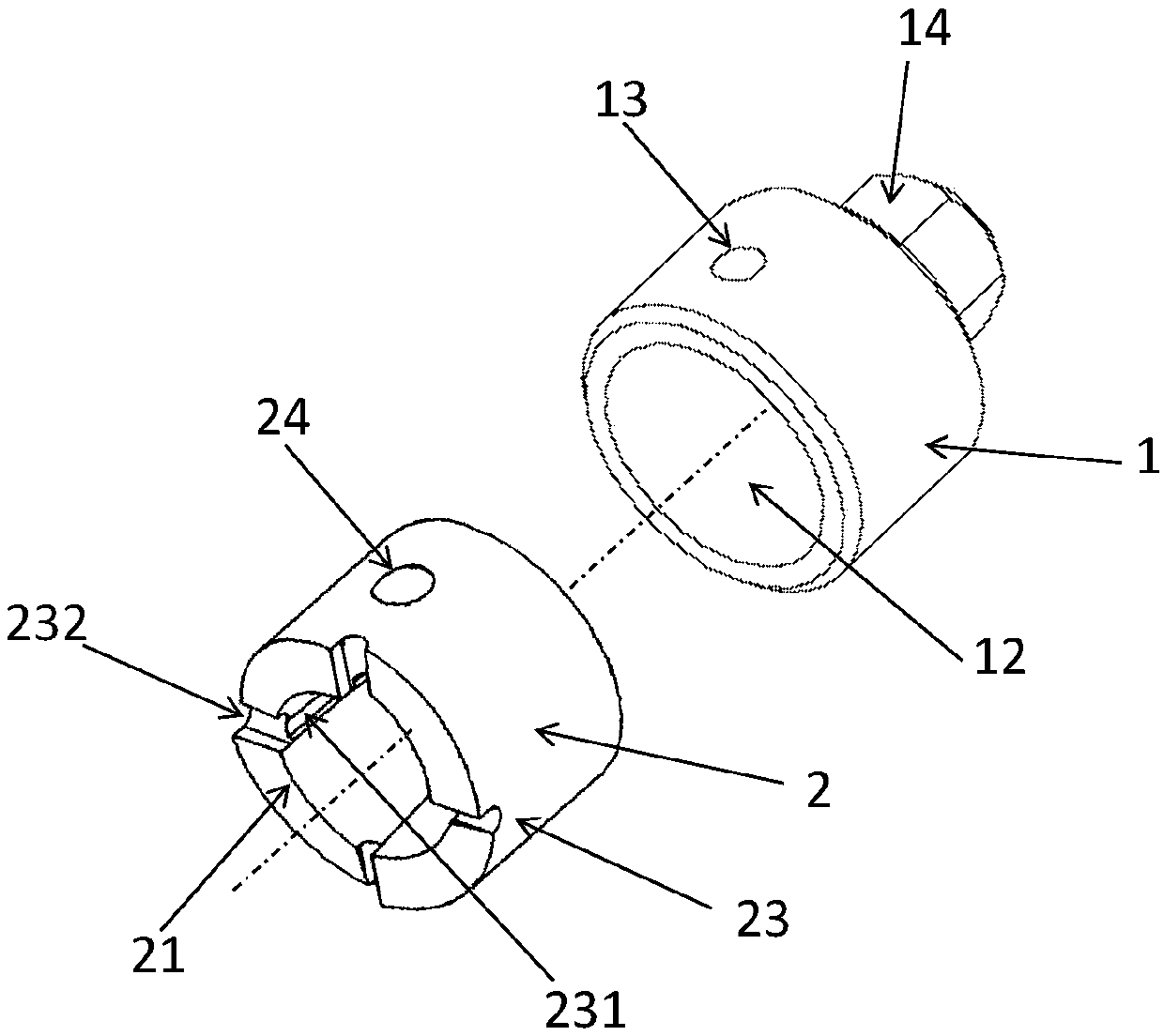

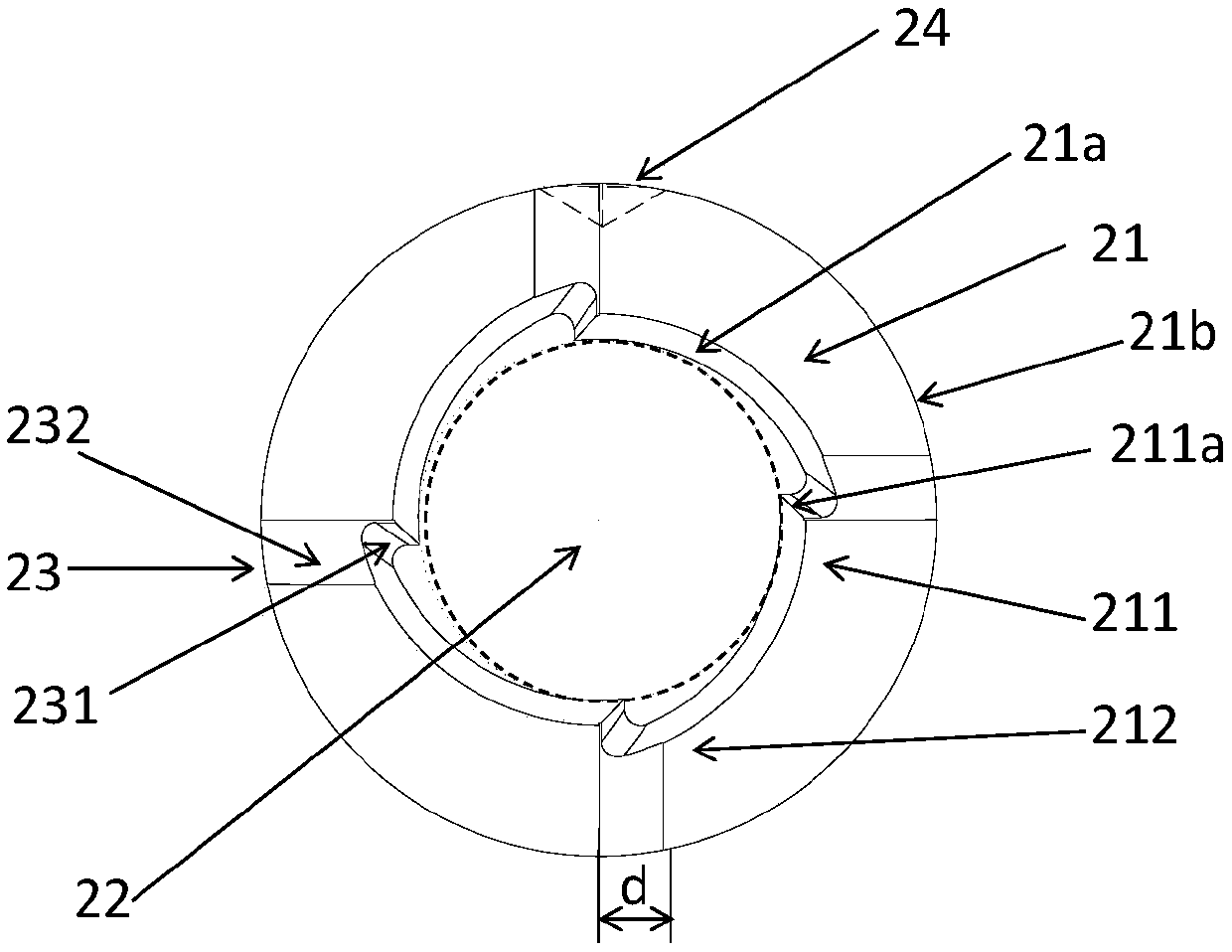

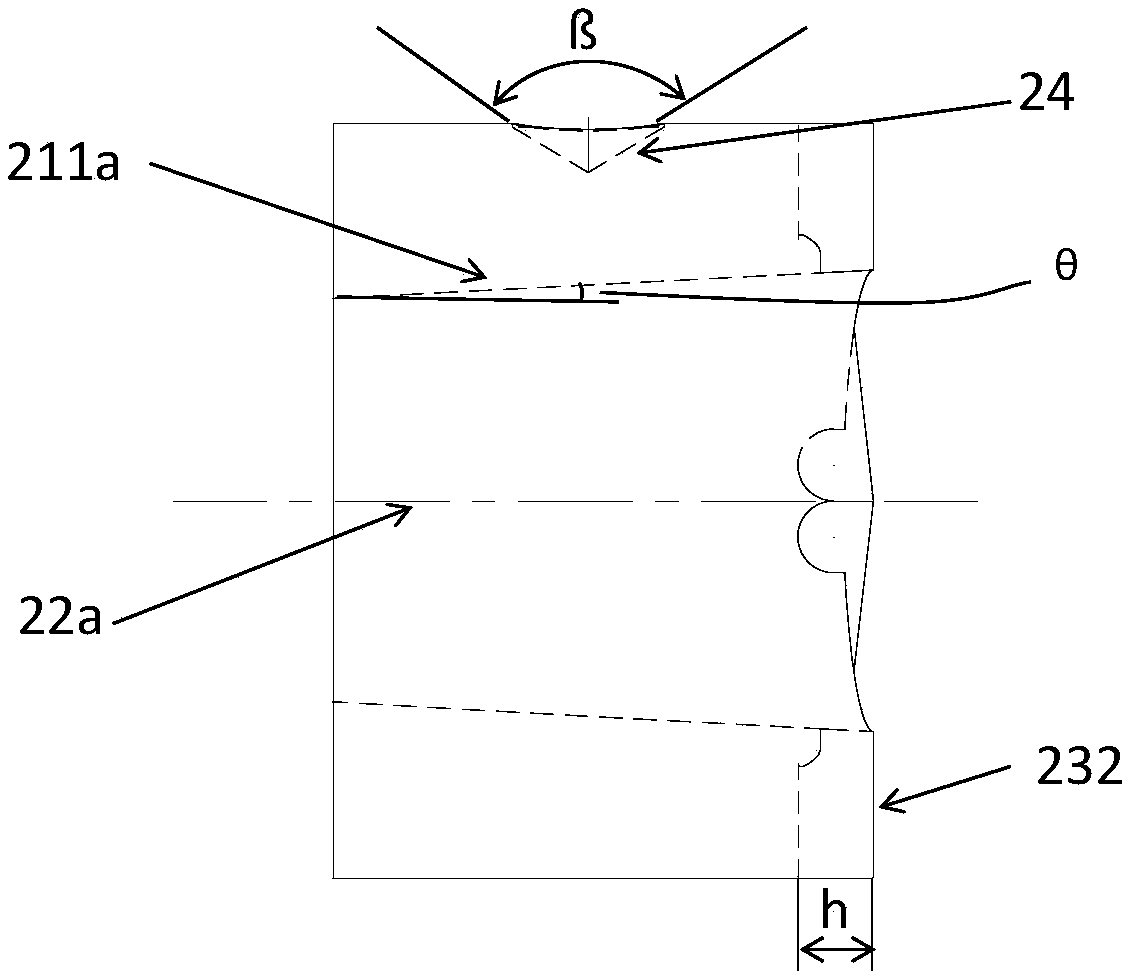

Grinding head and grinding tool

PendingCN110539248AExtend working hoursAvoid scrappingGrinding machine componentsLocking mechanismEngineering

The invention relates to a grinding head and a grinding tool. The grinding head comprises a clamping body, an elastic supporting ring, a core bar and a locking mechanism. The clamping body is providedwith the elastic supporting ring, the core bar is arranged in the clamping body and used for abutting against and pushing the elastic supporting ring so that the elastic supporting ring can be expanded in the radial direction, and the locking mechanism is arranged on the clamping body and locks the core bar through the elastic action so that the elastic supporting ring can be kept in an expansionstate. Elastic force generated by the locking mechanism is utilized for fixing the position of the core bar, elastic force is overcome so that the core bar can be made to move, the relative positionbetween the core bar and the elastic supporting ring is adjusted, and replacement of an abrasive paper ring can be achieved. Control over the relative position between the core bar and the elastic supporting ring through manual screw screwing is not needed, and the labor intensity of manual replacement of the abrasive paper ring is lowered.

Owner:SUZHOU MICROPORT ORTHORECON CO LTD

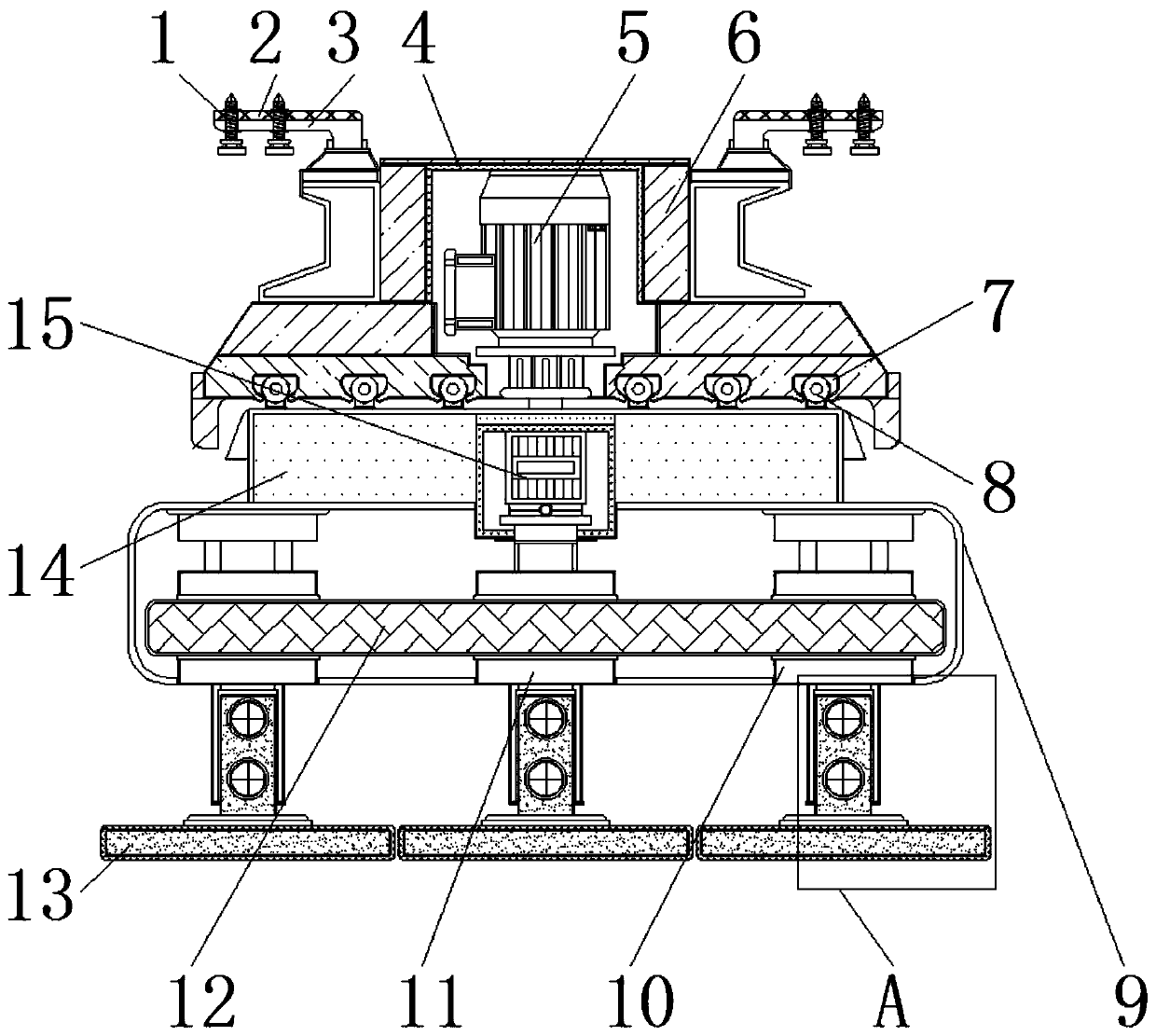

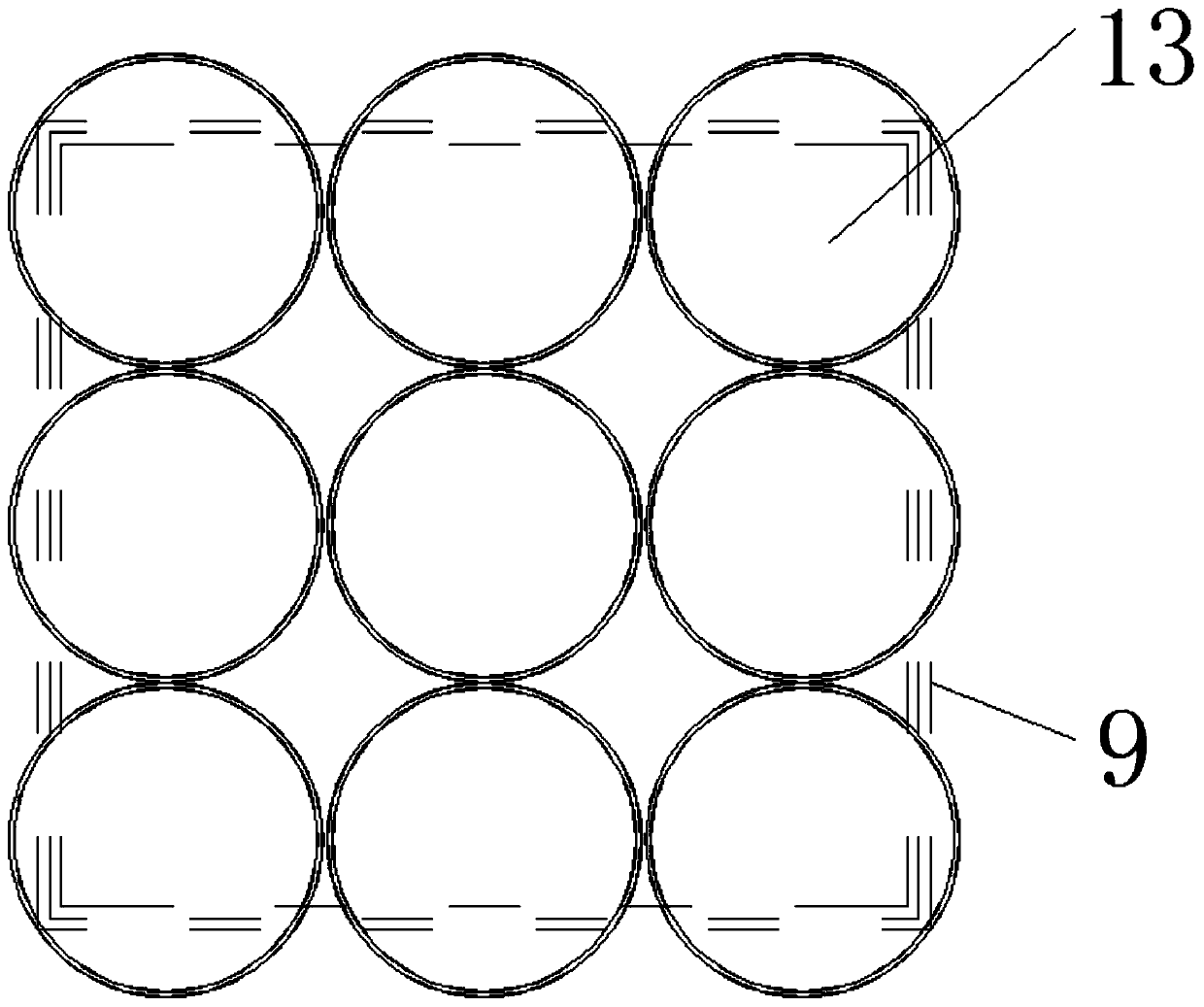

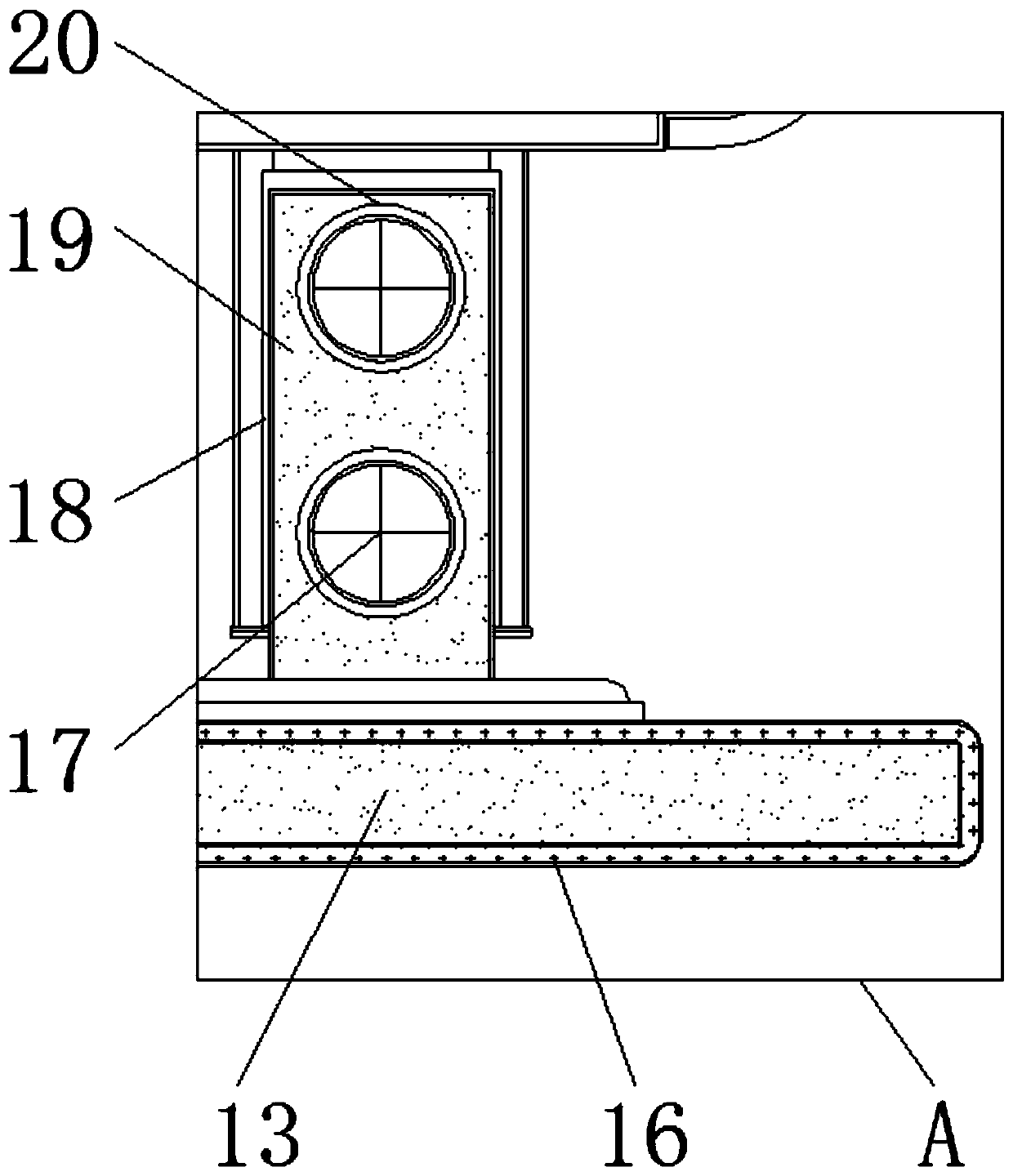

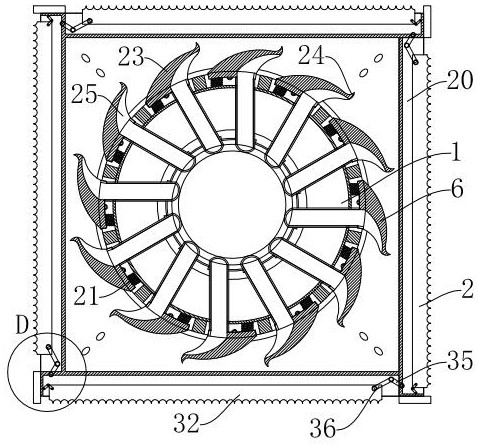

Dust removal adsorption type building block wall surface grinding device based on Bernoulli's law

ActiveCN113681377ARealize the function of one-way transportationRealize the grinding functionPlane surface grinding machinesGrinding/polishing safety devicesPhysicsSurface grinding

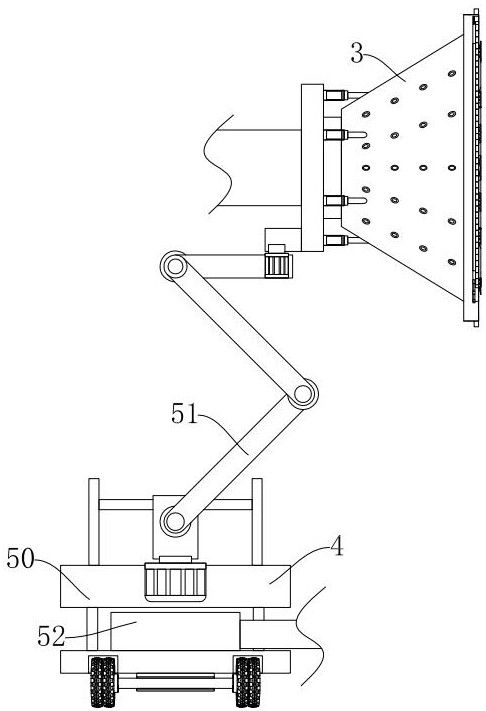

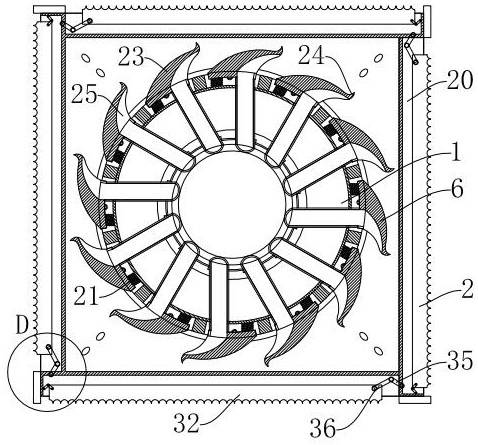

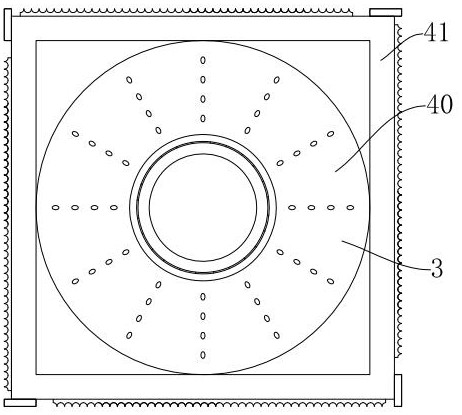

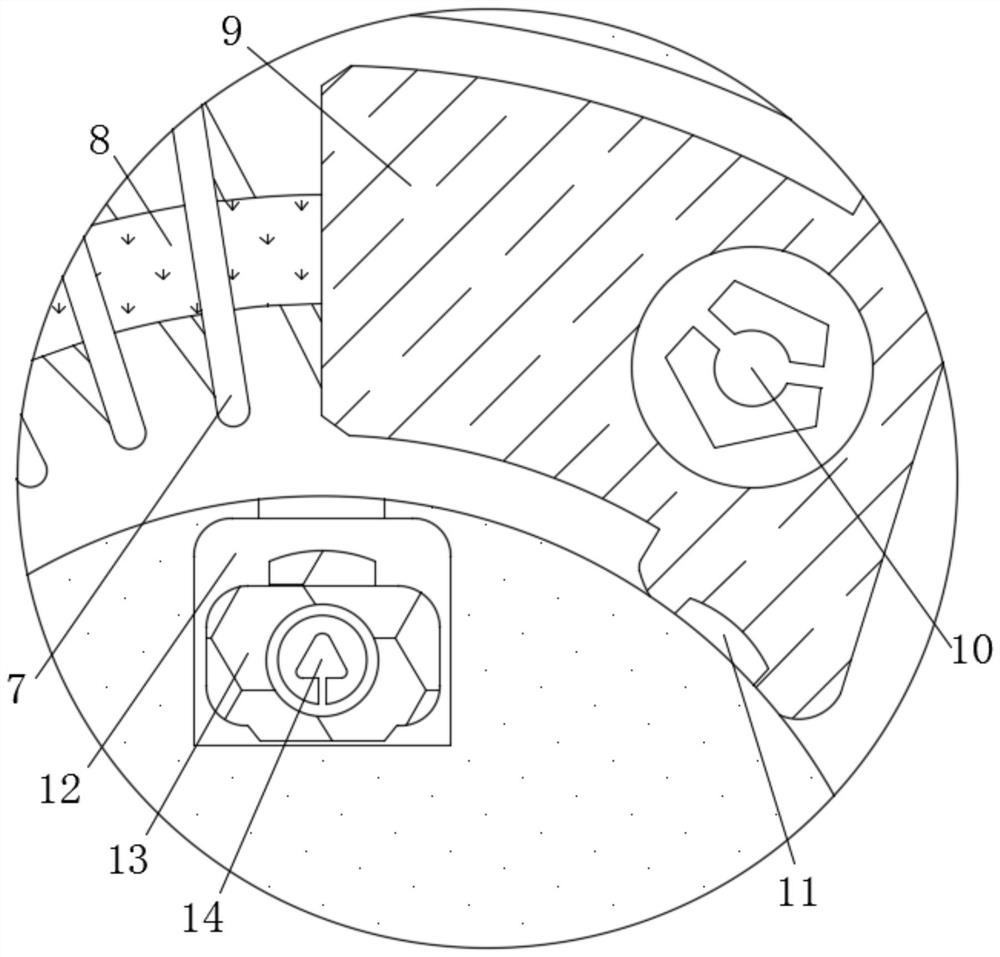

The invention discloses a dust removal adsorption type building block wall surface grinding device based on the Bernoulli's law. The dust removal adsorption type building block wall surface grinding device comprises a Bernoulli's type centripetal rotation dust collection grinding device, a right-angle side grinding device, a dust prevention and noise reduction partition device and a five-axis mechanical arm moving vehicle. The invention belongs to the technical field of concrete inner wall building block grinding devices, and particularly relates to the dust removal adsorption type building block wall surface grinding device based on the Bernoulli's law. Centripetal acting force generated in the rotating process, the Bernoulli's law and the law that the air flow direction is changed due to the pressure intensity change in the environment are creatively combined, and limiting of grinding dust in an arc-shaped grinding tool is effectively achieved; meanwhile, a dust collection glue connecting plate on a wing-like arc-shaped protrusion is matched to achieve adhesion of dust outside the arc-shaped grinding tool, and the multi-angle and multi-direction dust removal function during building block surface grinding is effectively achieved; and in order to reduce noise and prevent the grinding dust from entering a noise reduction groove hole, an anti-deposition flow guide opening is in tangent connection with a noise reduction circular groove, dust accumulation is avoided, and the noise reduction effect is guaranteed.

Owner:江苏华兮网络科技工程有限公司

Saline-alkali soil improvement and restoration method

InactiveCN112121898AImprove soil crushing rateImprove soil improvement and restoration rate and utilization rateSoil lifting machinesSievingAgricultural engineeringAlkali soil

The invention relates to a saline-alkali soil improvement and restoration method. A base, a grinding device and a chemical box are included, the grinding device is installed at the left end of the upper end face of the base, the chemical box is installed at the lower end of the left end face of the grinding device, and the lower end face of the chemical box is connected with the upper end face ofthe base. Saline-alkali soil is fully crushed by adopting a design concept of grinding, and the arranged grinding device can achieve a function of fully grinding the soil, so that the soil crushing rate is increased, and the subsequent soil improvement and restoration rate and utilization rate are further increased.

Owner:合肥品瞻环保科技有限公司

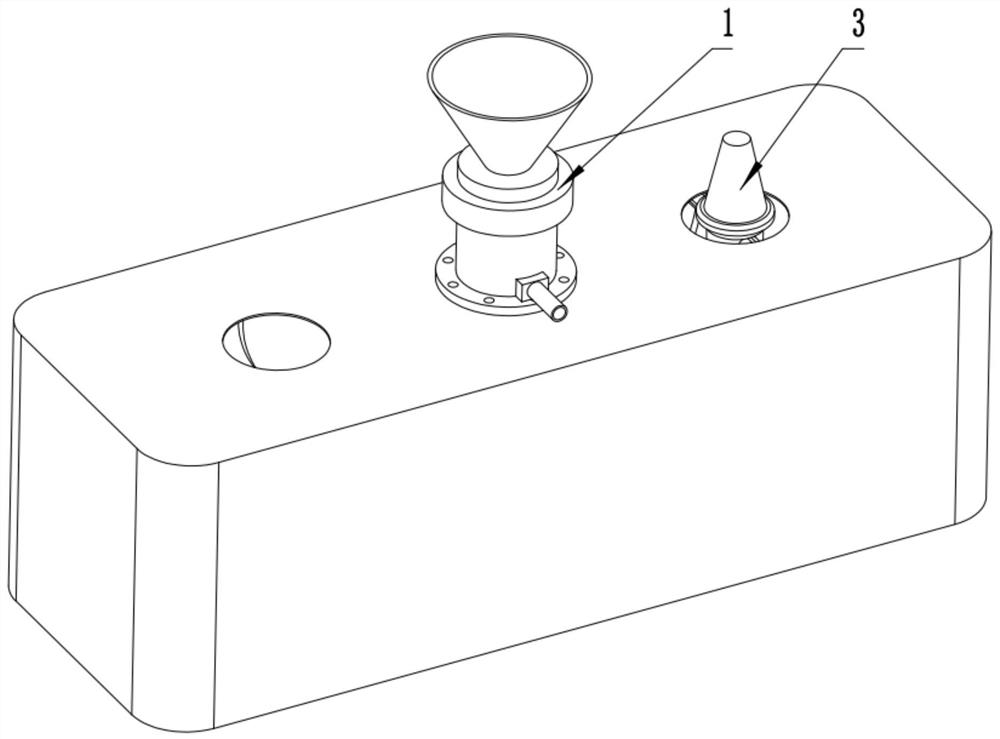

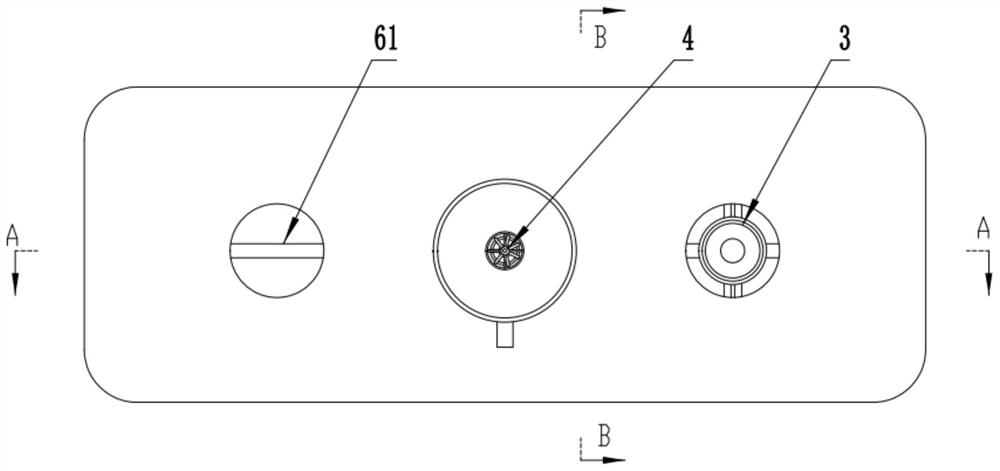

Colloid mill and production line

ActiveCN112246352ATimely detection of sheddingRealize the grinding functionOptical detectionGrain treatmentsProduction lineInfrared

The invention discloses a colloid mill and a production line which are capable of finding abrasive falling in time. The colloid mill comprises a colloid mill fixing seat, wherein a static abrasive disc and a movable abrasive disc are arranged in an accommodating cavity of the colloid mill fixing seat, and a grinding cavity is arranged between the static abrasive disc and the movable abrasive disc;the movable abrasive disc comprises a grinding base, and a driving piece and an infrared distance measuring device are fixedly connected to the grinding base; a rotating part of the driving piece isfixedly connected to a hollow abrasive supporting seat; the infrared distance measuring device is arranged in the abrasive supporting base, and a grinding layer is arranged outside the abrasive supporting seat; and the infrared distance measuring device is electrically connected to an alarm device. The production line comprises the colloid mill. When the abrasive falls off from the grinding layer,infrared rays emitted by the infrared distance measuring device can penetrate through the falling position of the grinding layer to be emitted outwards, so that the distance measured by the infrareddistance measuring device is increased, the colloid mill can give an alarm in time through the alarm device, the falling of the movable abrasive disc can be found in time, the production quality of products is improved, and the production efficiency is improved.

Owner:广州市爱百伊生物技术有限公司

Steel pipe locating and welding device for industrial machine

InactiveCN107877088ARealize quick positioning functionRealize the grinding functionWelding/cutting auxillary devicesAuxillary welding devicesSteel tubeCam

The invention provides a steel pipe positioning welding device for industrial machinery, which includes a welding head, a lifting cylinder, a bracket, a workbench, a steel pipe positioning mechanism and a weld grinding mechanism. The welding head is installed on the lower surface of the lifting cylinder, and the lifting cylinder The lifting cylinder is fixed on the inner upper end surface of the bracket, and the bracket is installed on the upper end surface of the workbench. The steel pipe positioning mechanism includes an arc groove, a support seat, a guide groove, a connecting rod one, a steel pipe splint, a gear, a lower rack, The upper rack, the second connecting rod, the top seat, the connecting plate, the dryer, the shell and the electric telescopic rod one. Compared with the prior art, the telescopic rod 2, emery cloth and opening, the present invention has the following beneficial effects: the quick positioning function of the welding position of the steel pipe is realized, and the grinding function of the welding seam position of the steel pipe is also realized.

Owner:陈美赞

A kind of circular revolution grinding equipment

ActiveCN105945689BRealize the grinding functionReduce labor intensityGrinding drivesBelt grinding machinesBall screwEngineering

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

A flat grinding device for automobile metal pipe mold

ActiveCN110509153BRealize the clamping functionRealize the grinding functionGrinding machinesGrinding work supportsElectric machineStructural engineering

The invention discloses an automobile metal pipe mold leveling and grinding device, which belongs to the technical field of automobile parts processing equipment; an automobile metal pipe mold smoothing and grinding device comprises a base, and the top of the base is connected with a first fixing plate and a second fixing plate along the horizontal direction Two fixing plates, the top of the first fixing plate close to the side of the second fixing plate is connected with a rotating motor, the output end of the rotating motor is connected with a horizontal rotating shaft, and the end of the horizontal rotating shaft away from the rotating motor is connected with a bushing through a bearing, and the horizontal rotating shaft passes through One end of the bearing is connected with a tie ring, and the end of the casing away from the horizontal shaft is hinged with four symmetrically distributed fixed claws, and an adjustment steel rope is connected between the two opposite fixed claws, and the center of the adjustment steel rope is connected to the system. On the ring; the invention realizes the processing function of the surface flatness of the automobile metal pipe mold, and at the same time effectively collects the debris generated in the mold surface treatment process, prevents secondary pollution, and improves the stability and accuracy of the mold surface treatment.

Owner:安徽中运智能科技有限公司

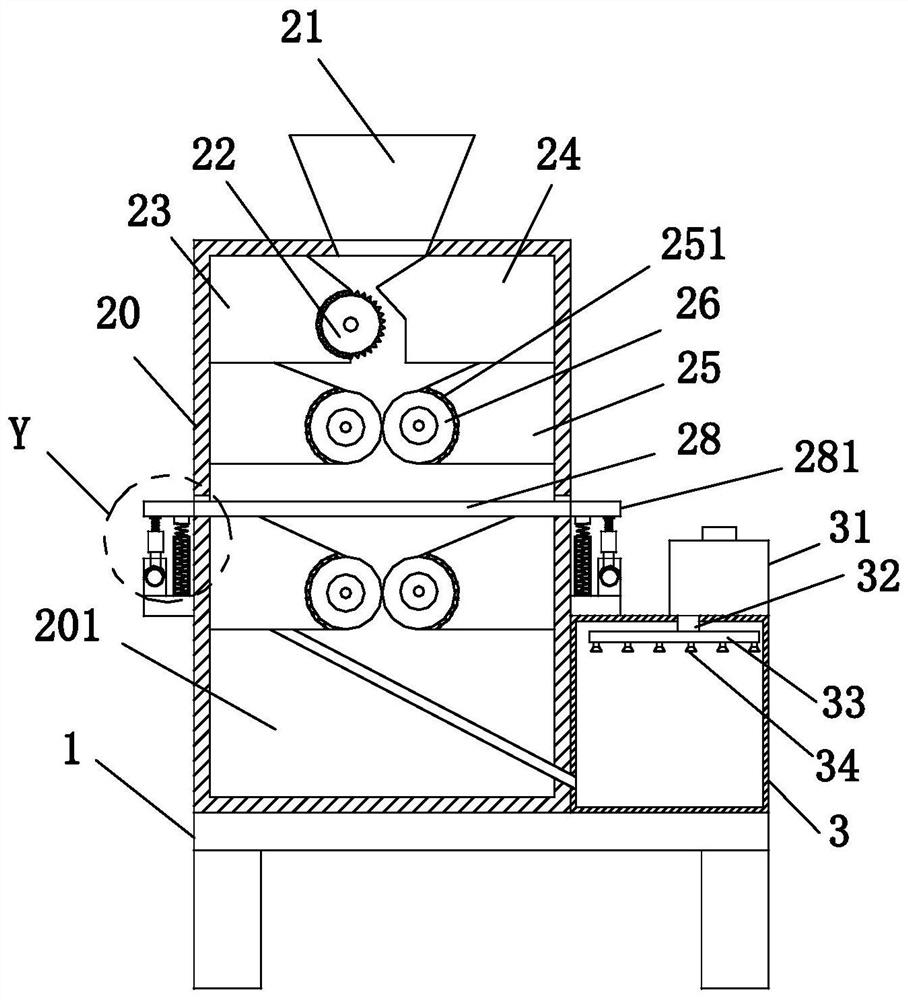

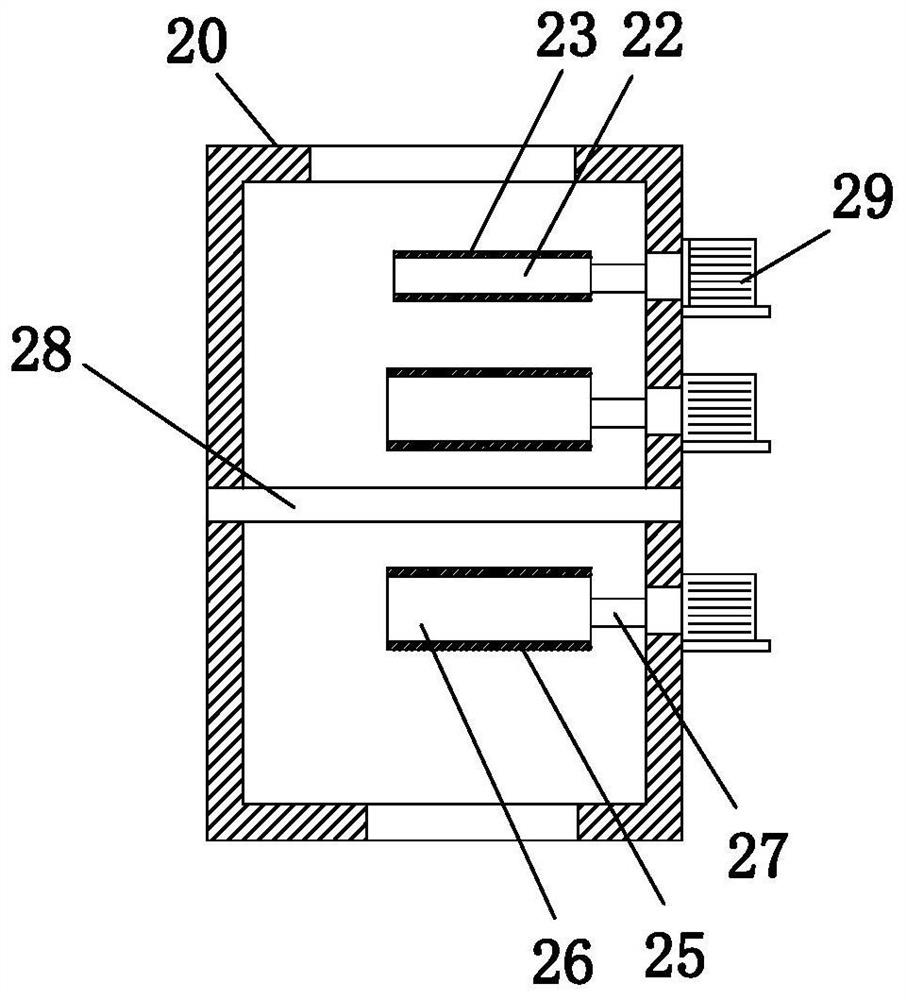

Improved nonferrous metal prealloy powder preparation technology equipment

InactiveCN108543949APromote lowerRealize the grinding functionManufacturing technologyNonferrous metal

The invention discloses improved nonferrous metal prealloy powder preparation technology equipment. The improved nonferrous metal prealloy powder preparation technology equipment comprises a base, a conveying platform which extends front and back is arranged in the middle of the upper end face of the base, a grinding box is arranged over the base, a grinding cavity is formed in the grinding box, afilling device is arranged on the lower end face of the grinding box and comprises a fixed shell which is fixedly connected with the grinding box, a movable shell is arranged at the lower end of thefixed shell, the fixed shell and the movable shell are fixedly connected through an annular telescopic sleeve, the fixed shell, the movable shell and the telescopic sleeve jointly form an internal inner cavity, and a propelling device is arranged at the lower end of the interior of the inner cavity.

Owner:韦德远

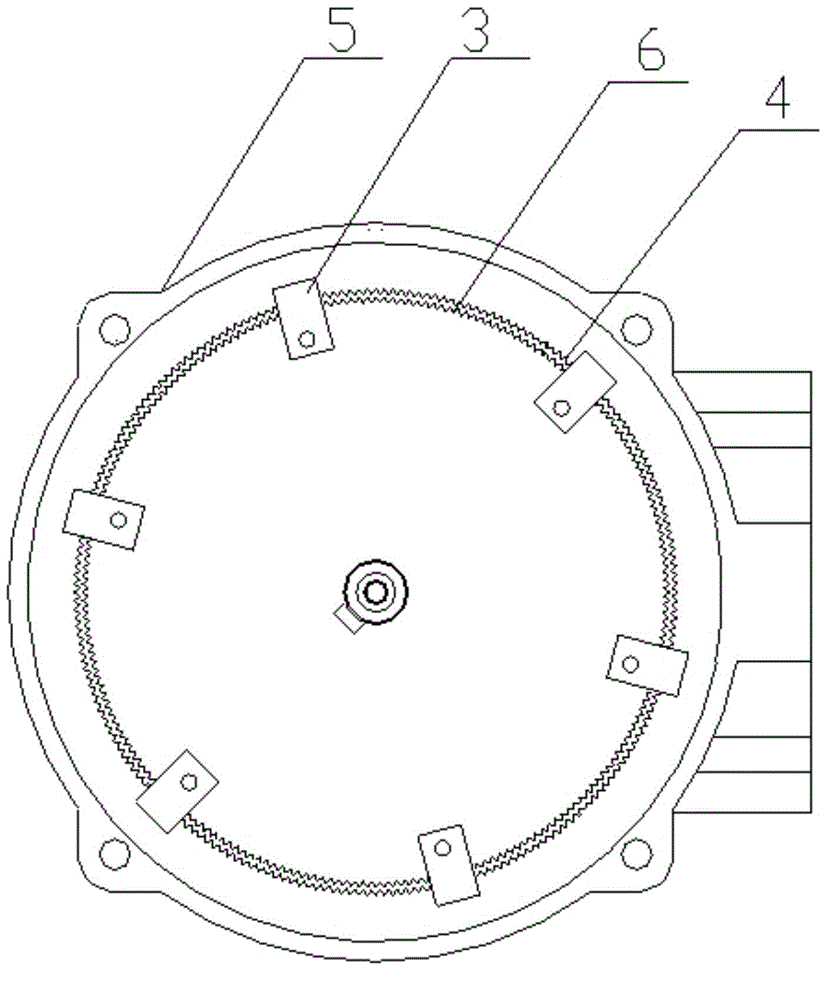

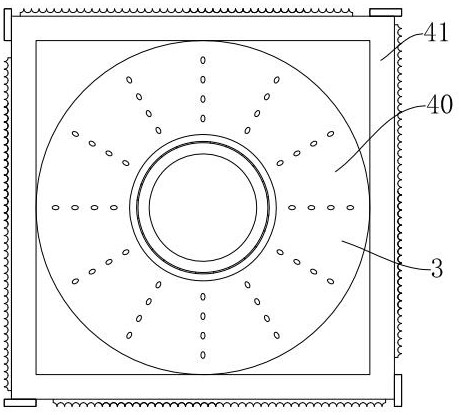

Chuck polishing device with revolving and rotation

InactiveCN110712112ARealization of revolutionRealize the grinding functionGrinding wheel securing apparatusGrinding carriagesDrive wheelPolishing

The invention discloses a chuck polishing device with revolving and rotation. The device comprises a silencing cover, a first driving motor, a first fixed frame and a second fixed frame; and mountingfeet are uniformly arranged at the bottom end of the first fixed frame. As the device is provided with the first driving motor, the second fixed frame, a second driving motor, a belt, a driving wheel,a driven wheel and polishing plates, on the one hand, the first driving motor drives the second fixed frame to rotate to realize revolving of multiple polishing plates to achieve a polishing function; and on the other hand, the second driving motor drives the driving wheel to rotate, and the driven wheel is driven to rotate by using the effect of the belt to realize rotation of the multiple polishing plates to further achieve the polishing function; and the revolving and the rotation are synchronously realized through control of the polishing plates to achieve no-dead-angle polishing, so thatthe product polishing uniformity is guaranteed, and the use effect of the device is improved.

Owner:常州明全机械有限公司

Grinder for electrode rod of welding torch

ActiveCN106624592BRealize the grinding functionSolve resource problemsElectrode maintenanceEngineeringKnife blades

Owner:GAC HONDA AUTOMOBILE CO LTD

Automatically-controlled grinding device for folium artemisiae argyi grinding

InactiveCN112892811ARealize automatic controlRealize repeated grindingGrain treatmentsAutomatic controlEngineering

The invention relates to the technical field of folium artemisiae argyi grinding equipment, and discloses an automatically-controlled grinding device for folium artemisiae argyi grinding. The automatically-controlled grinding device comprises a cover body, wherein a main rotating shaft is movably connected in the cover body, a grinding block is fixedly connected to the bottom of the main rotating shaft, two symmetrical trigger blocks are movably connected to the top of the cover body, and a base is movably connected to the bottom of the cover body; and movable grooves are formed in the two sides of the base, a spring is fixedly connected into each movable groove, and a movable rod is movably connected into each movable groove. According to the automatically-controlled grinding device for folium artemisiae argyi grinding, through mutual cooperation of the main rotating shaft and the grinding block, when the main rotating shaft rotates and moves, a grinding body is driven to extrude folium artemisiae argyi in a grinding groove, the folium artemisiae argyi is ground through mutual cooperation of the grinding block and the grinding groove, and when the volume in the grinding groove is continuously reduced, the pressure of a content in the grinding groove rises and the content moves to the top of the grinding groove to drive starting blocks to overcome the elastic force of the spring to move and trigger control blocks, so that the functions of automatic control and repeated grinding of a product are realized.

Owner:江永光

Dust removal and adsorption block wall grinding device based on Bernoulli's law

ActiveCN113681377BRealize the function of one-way transportationRealize the grinding functionPlane surface grinding machinesGrinding/polishing safety devicesRobotic armDust control

The invention discloses a dust-removing and adsorption-type block wall grinding device based on Bernoulli's law, including a Bernoulli-type centripetal rotating dust-collecting grinding device, a right-angle edge grinding device, a dust-proof and noise-reducing partition device and a five-axis The robotic arm moves the cart. The invention belongs to the technical field of concrete inner wall block grinding device, specifically refers to a dust removal and adsorption block wall grinding device based on Bernoulli's law, which creatively combines the centripetal force generated in the rotation process and Bernoulli's law Combining with the change of air flow direction caused by the change of environmental pressure, it effectively solves the limit of grinding dust in the arc-shaped grinding tool, and cooperates with the dust-collecting adhesive plate on the arc-shaped protrusion of the imitation wing to realize the arc-shaped grinding The adhesion of the external dust of the cutting tool effectively realizes the multi-angle and multi-directional dust removal function when grinding the surface of the block. In order to reduce the noise and prevent the grinding dust from entering the noise-reducing slot The grooves are connected tangentially to avoid dust accumulation and ensure the noise reduction effect.

Owner:江苏华兮网络科技工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com