Patents

Literature

240results about How to "Achieve rotary motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

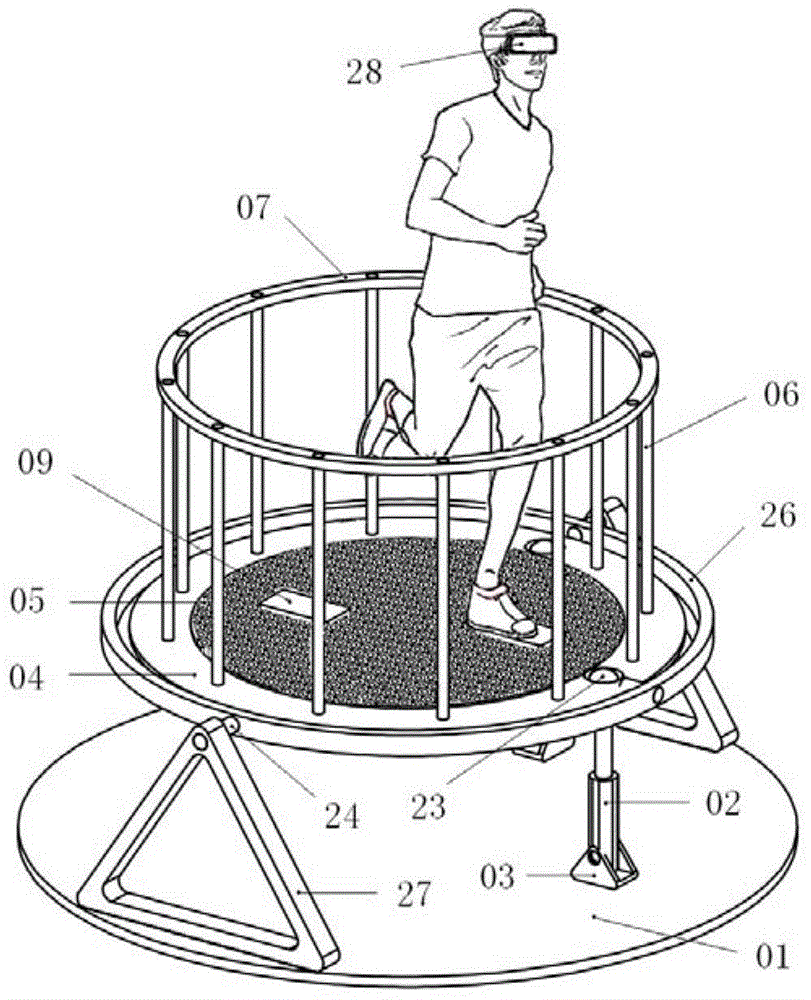

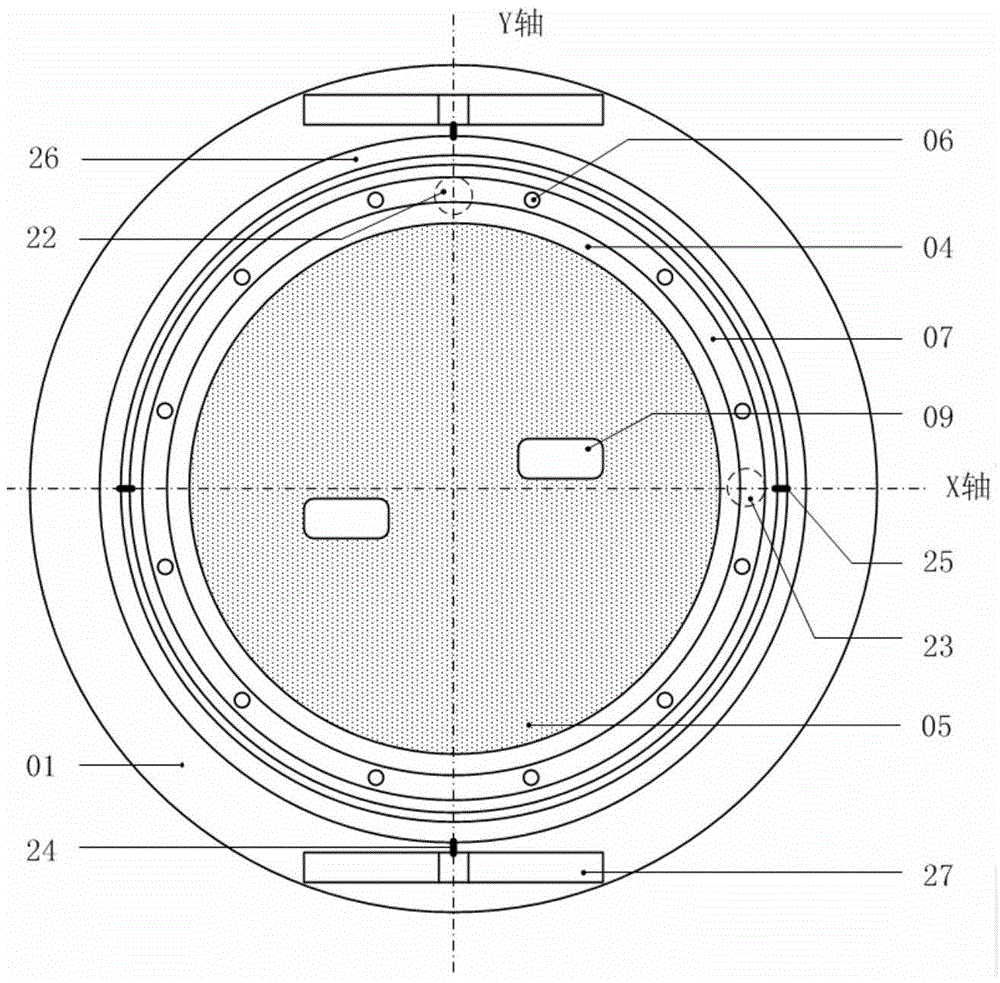

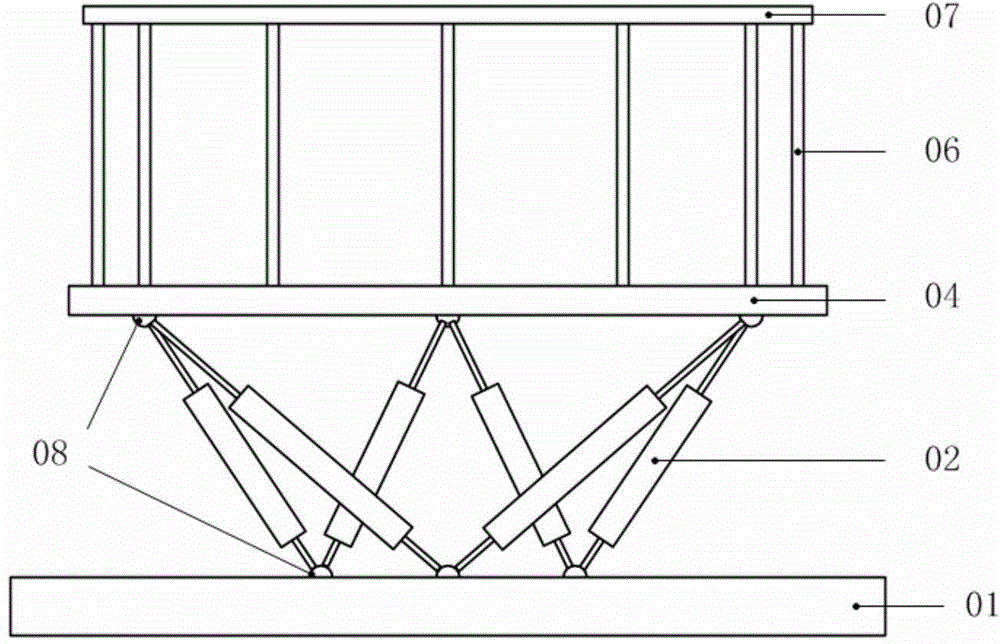

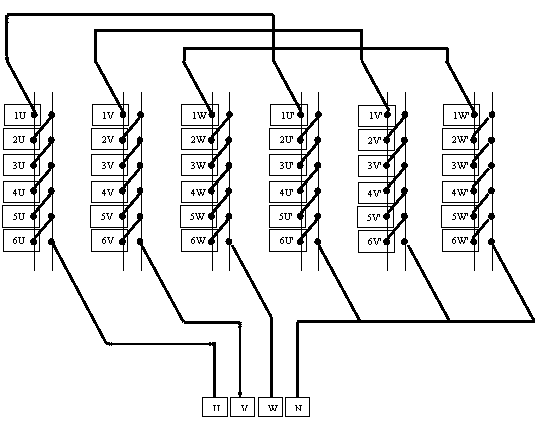

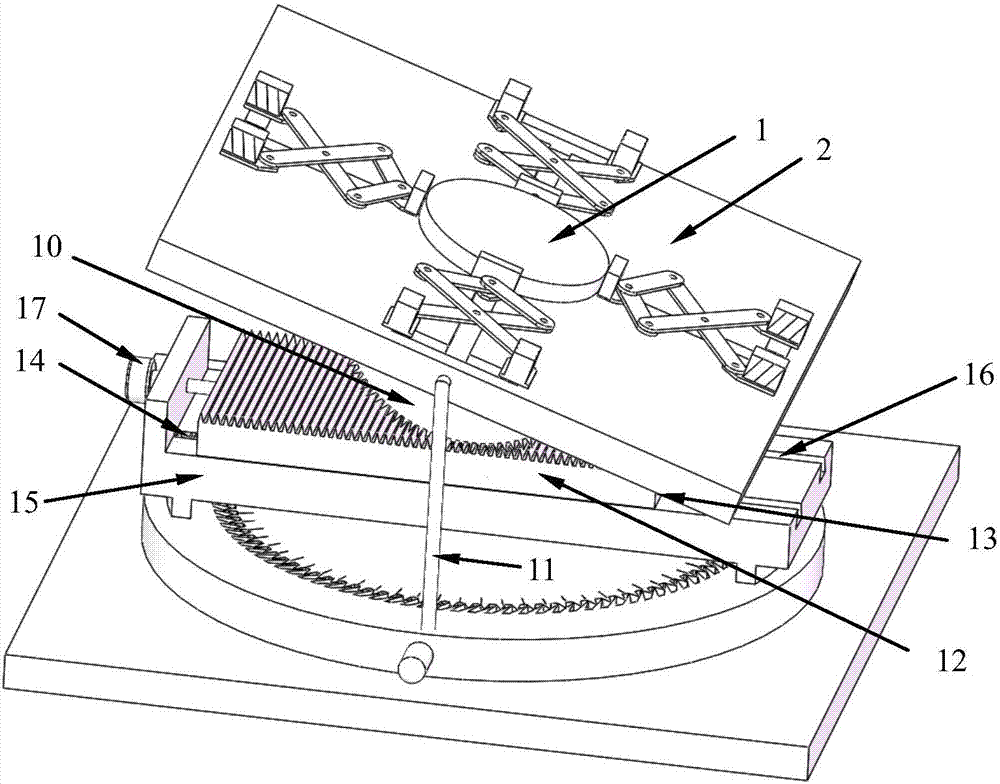

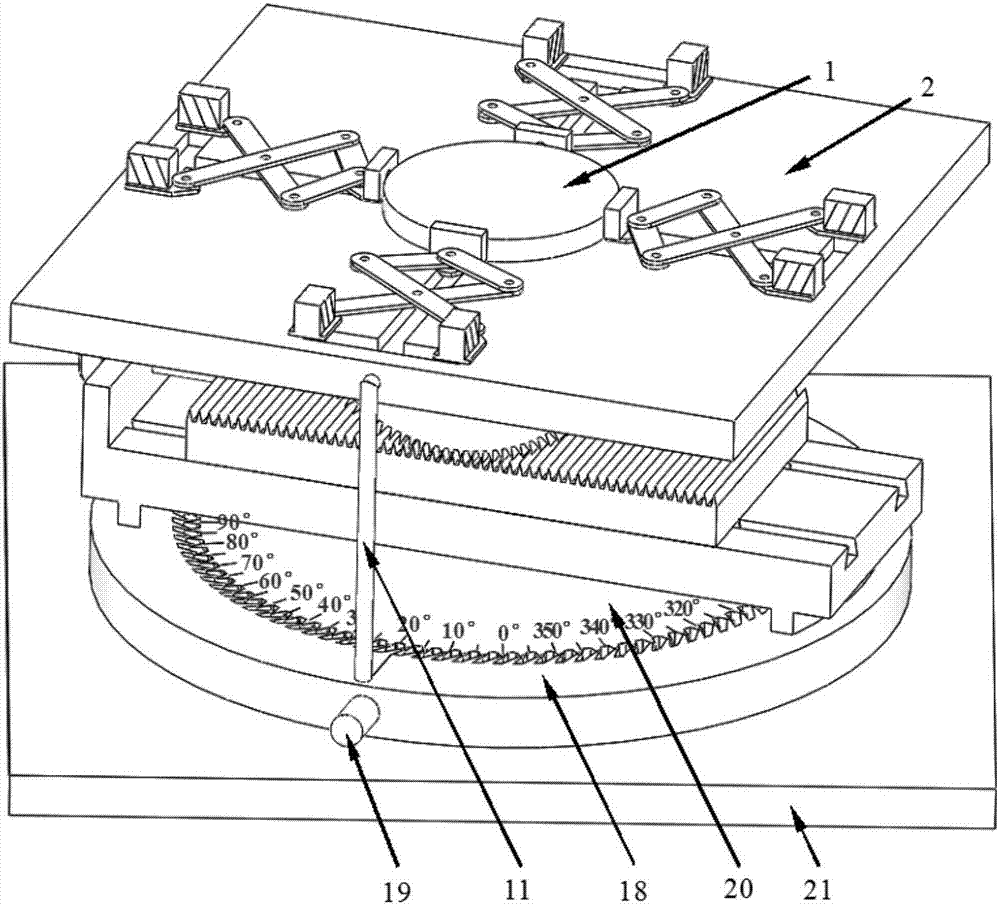

Electromagnetic type multi-degree of freedom virtual roaming platform

ActiveCN104461018AAchieve rotary motionRealize planar driveInput/output for user-computer interactionGraph readingControl systemEyewear

An electromagnetic type multi-degree of freedom virtual roaming platform comprises a moving platform, a platform tilt actuating mechanism, a platform tilt perception system, two mats, a foot motion perception system, a corresponding flotation structure, a pressure sensor and the like, wherein the moving platform is composed of an array magnetic-driven unit, and the two mats are suspended on the platform and allow a user to directly tread. By means of the virtual reality technology, forward road situations and surrounding panoramic environments are displayed in real time on a helmet displayer or specific glasses of the user, and the user can select and move forward according to the situation. A control system can precisely control the mats so that the mats can bear the feet of the user to equivalently finish walking, running and other motions in the range of the platform, corresponding virtual scenes are changed synchronously according to the specific forwarding situations of the user to achieve the roaming effect. The user can move linearly on site on the platform and can turn left and right, particularly, real ground slope experience can be obtained through proper tilt of the platform.

Owner:河北腾云信息技术有限公司

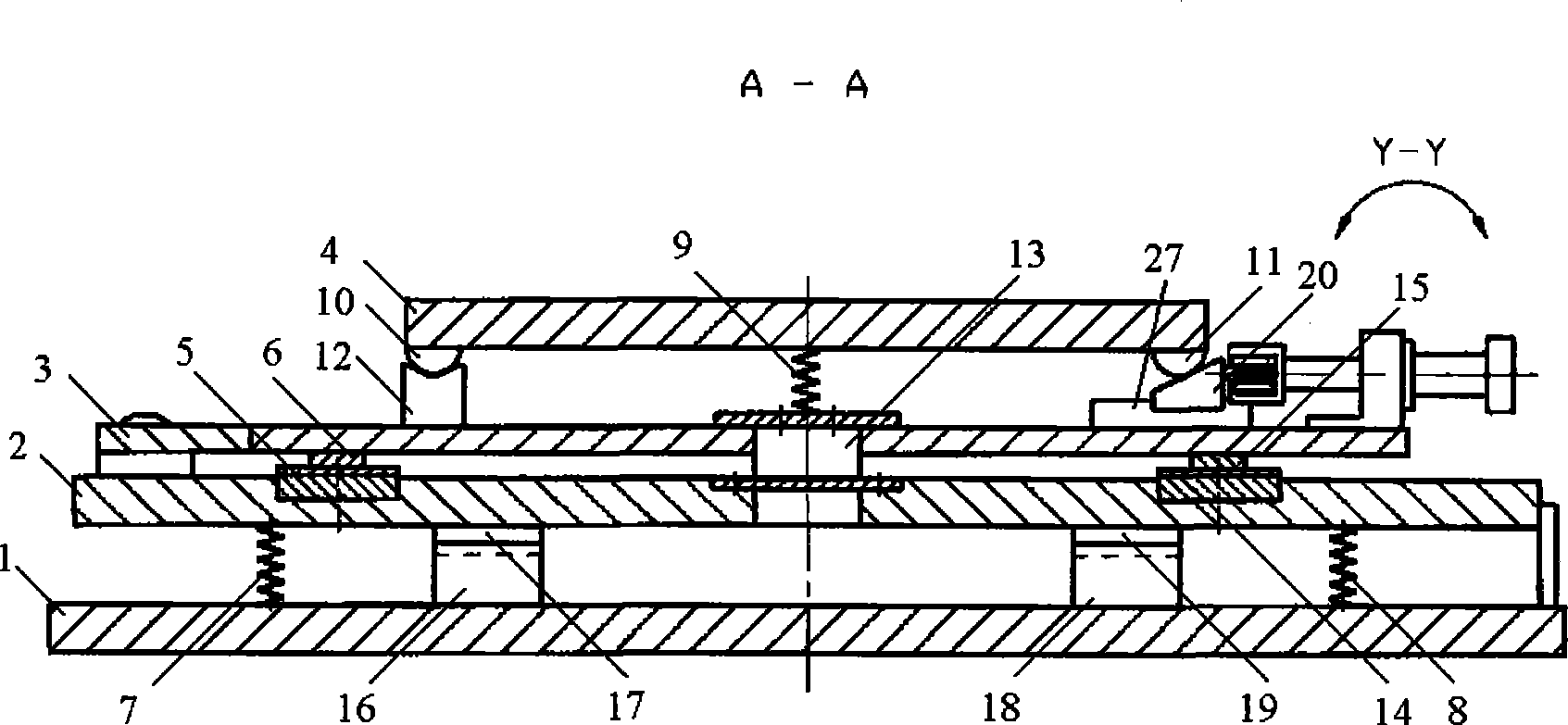

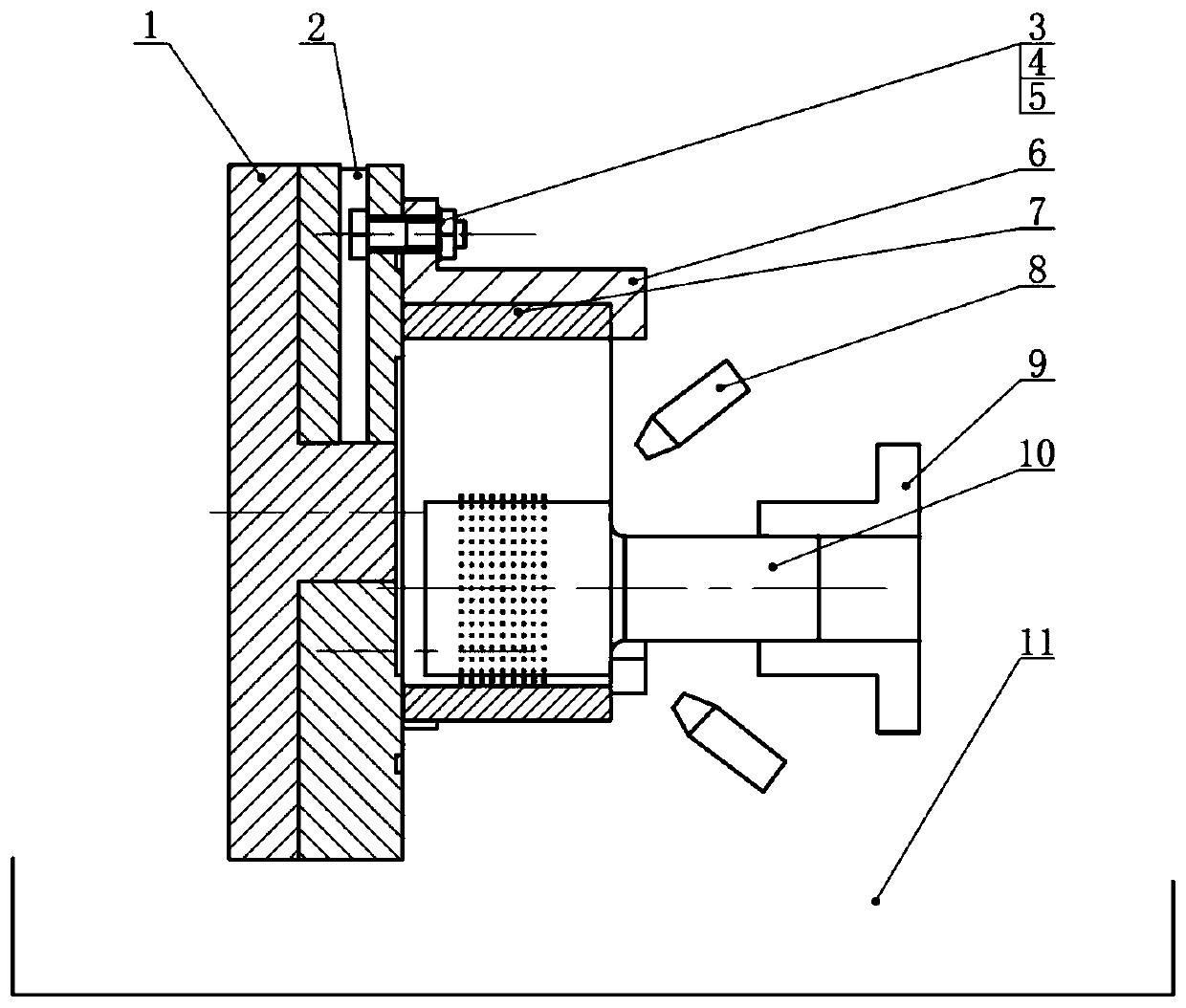

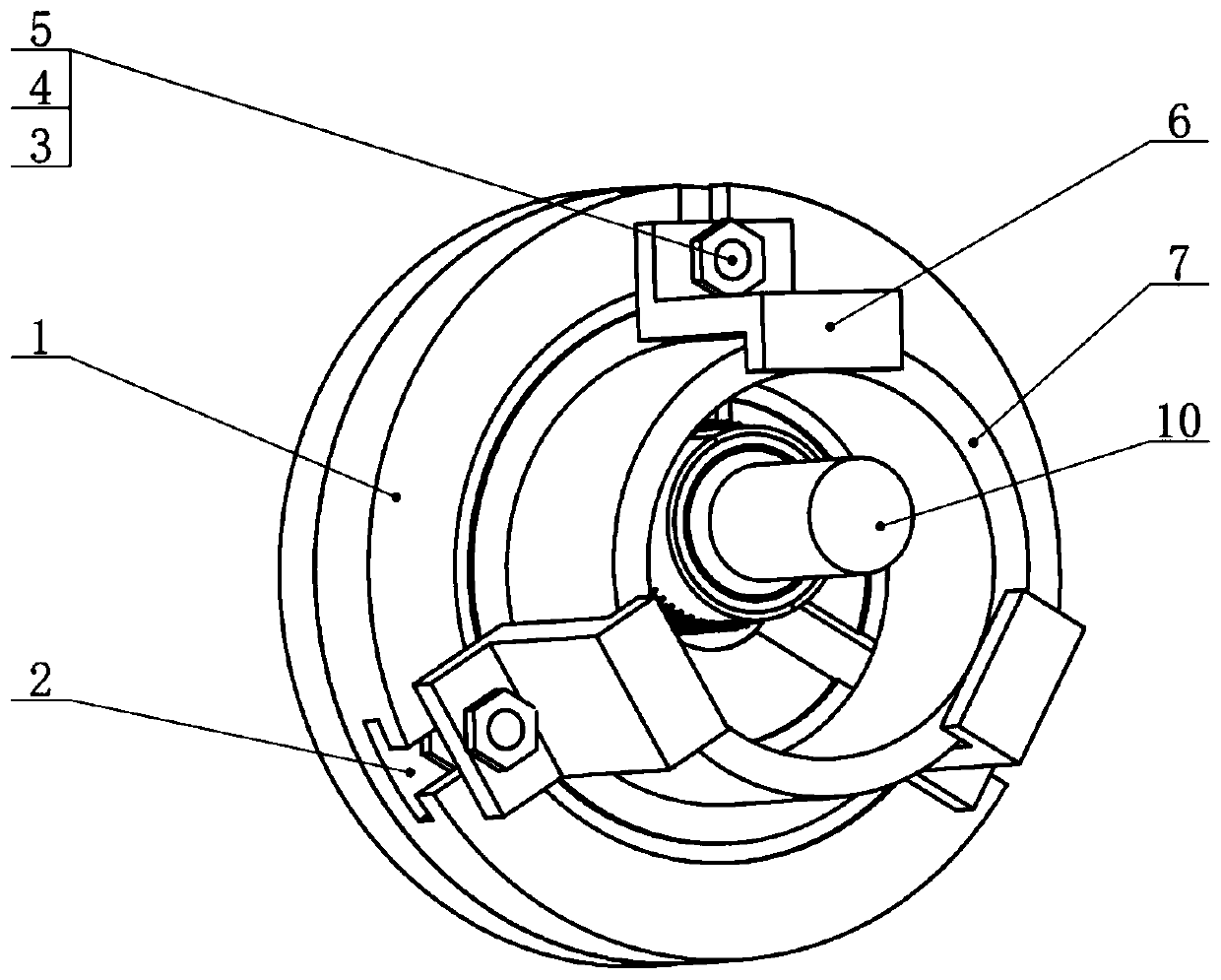

Accurate one-dimensional rotary and two-dimensional tilting table

InactiveCN101436436AImprove carrying capacityHigh adjustment accuracyInstrumental componentsPosition/direction controlEngineeringWork demand

Owner:TONGJI UNIV

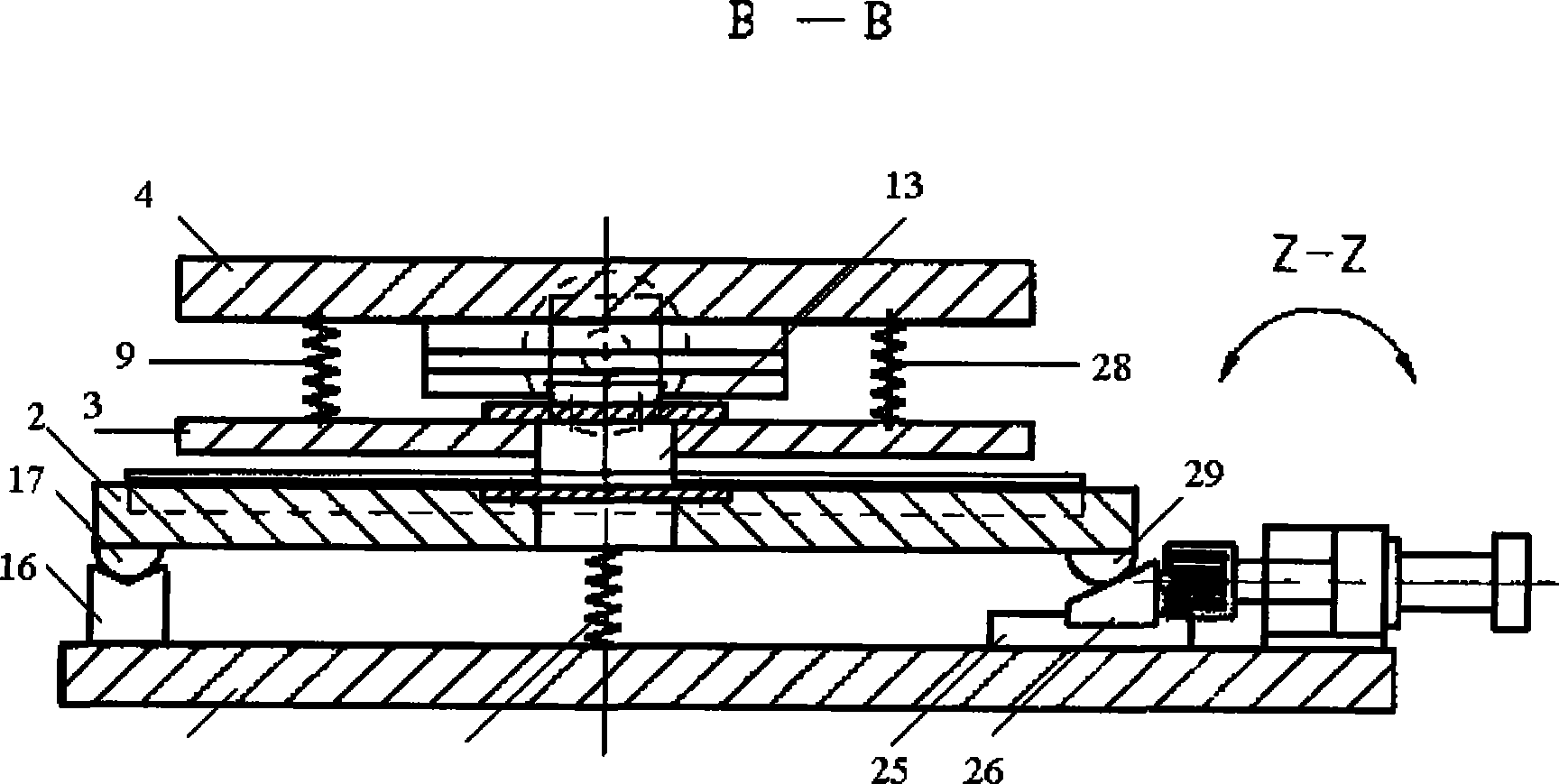

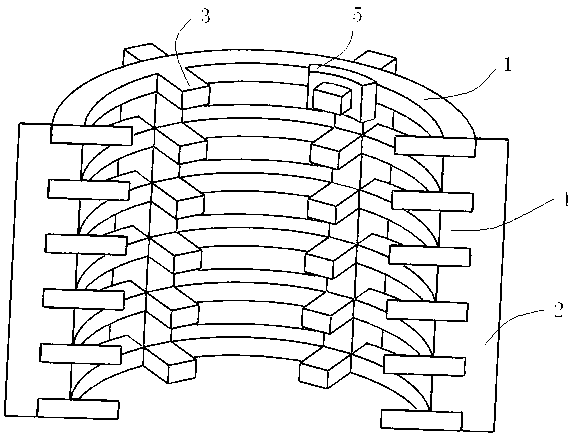

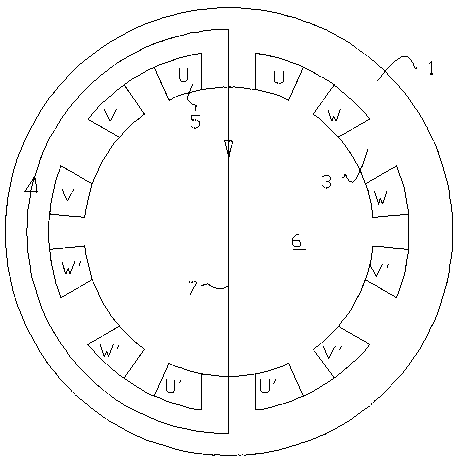

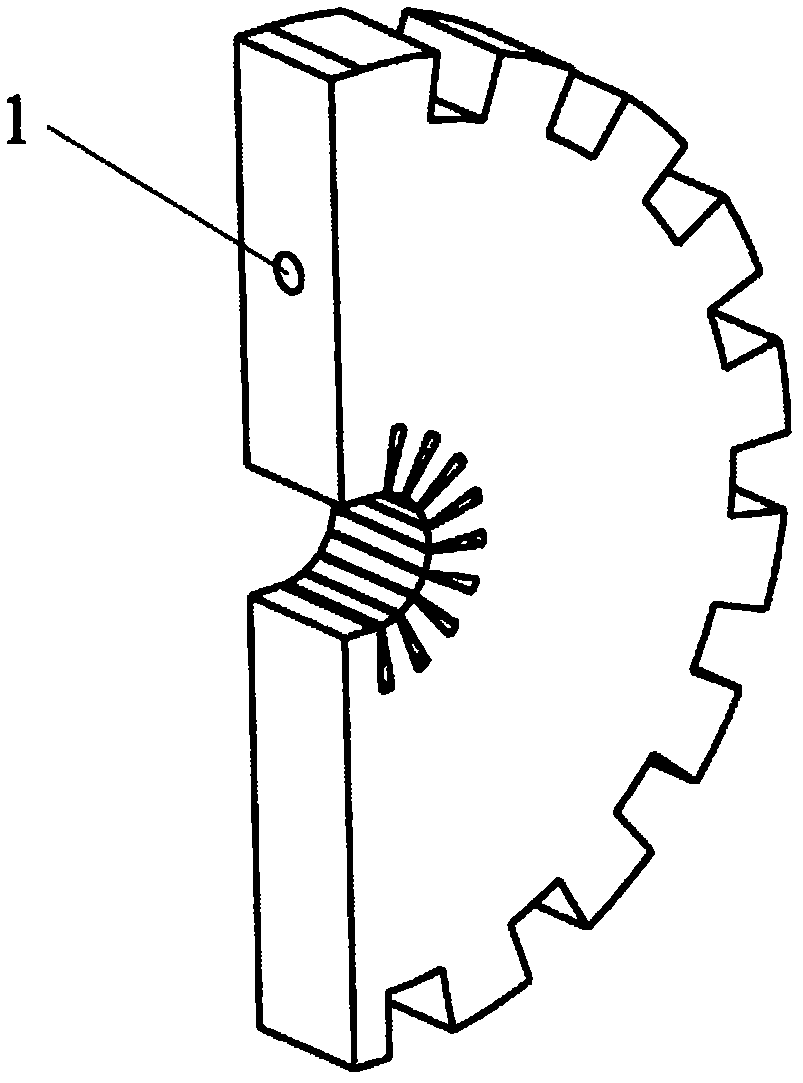

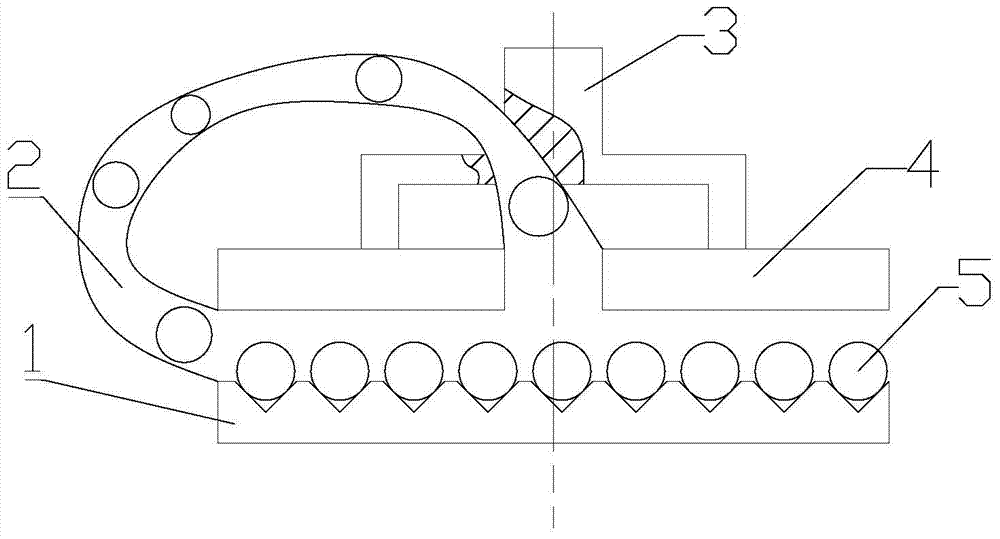

Multifunctional electromagnetic stirrer

The invention discloses a multifunctional electromagnetic stirrer, comprising six layers of annular cores (1) which are horizontally arranged, six rack cores (2) which are vertically arranged and thirty-six identical solenoid coil windings (5); the six layers of annular cores are mutually independent layer by layer, are aligned vertically and are separated at intervals; the inner wall of each layer of annular core is provided with six salient poles (3); the six rack cores are uniformly distributed on the outer walls of the annular cores; each rack core is provided with five salient poles (4); the salient poles of the rack cores are inserted into the intervals, which are vertically separated, of the annular poles; the salient poles of each rack core and the salient poles of the six layers of annular cores are located on the same circumference; the top surfaces of the salient poles of each rack core are inserted into the inner walls between the salient poles of the annular cores; the thirty-six solenoid coil windings are respectively sleeved on each salient pole of the annular cores; and three-phase low-frequency alternating current is supplied by a variable-frequency power source. According to the multifunctional electromagnetic stirrer, the structure is simple, the size is small, magnetic leakage is small, and the working efficiency is high.

Owner:BAOSHAN IRON & STEEL CO LTD

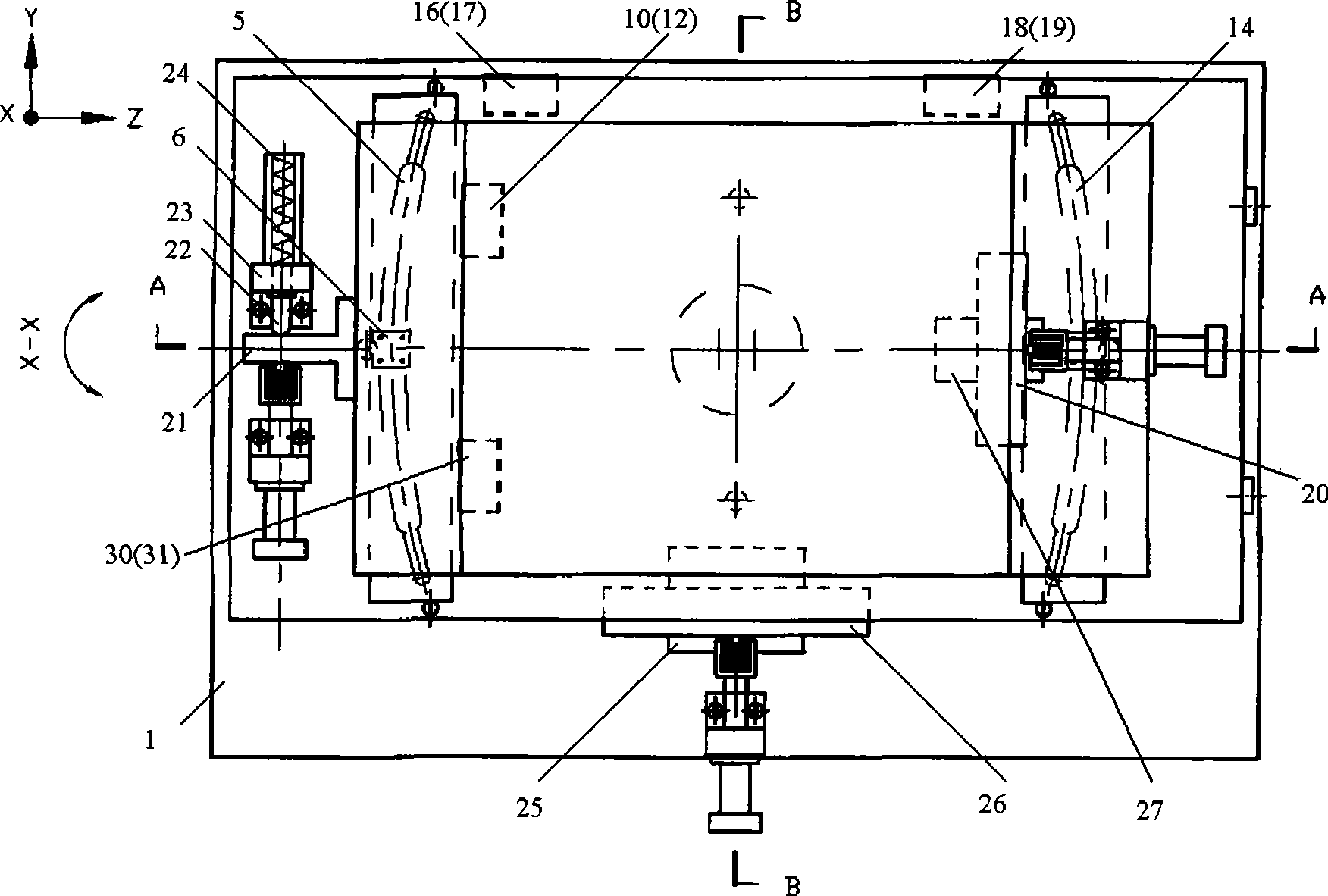

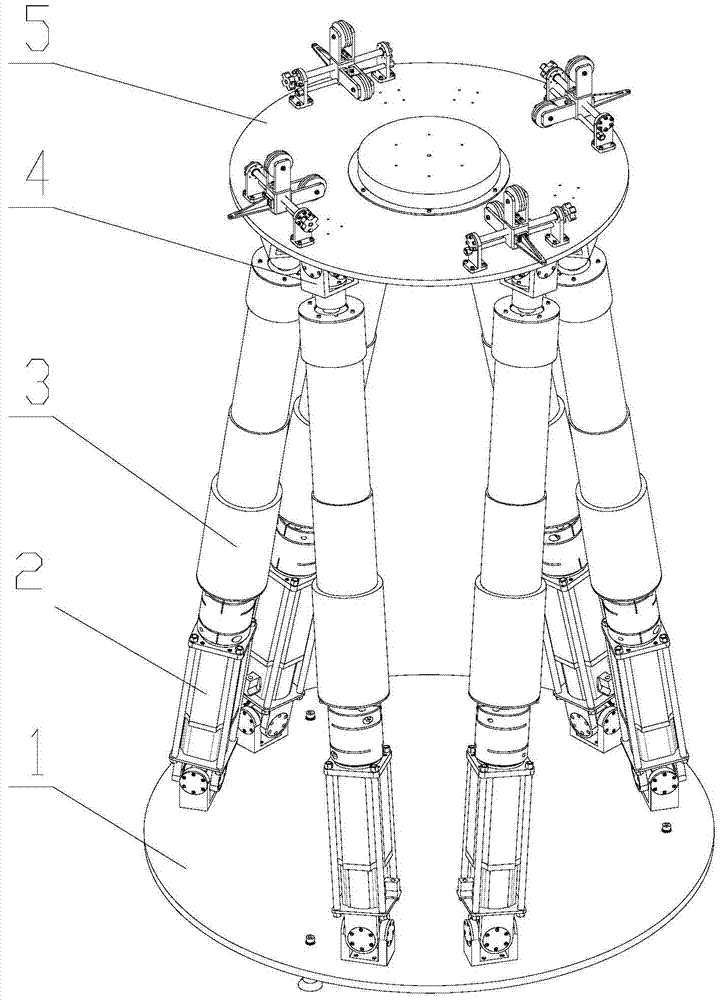

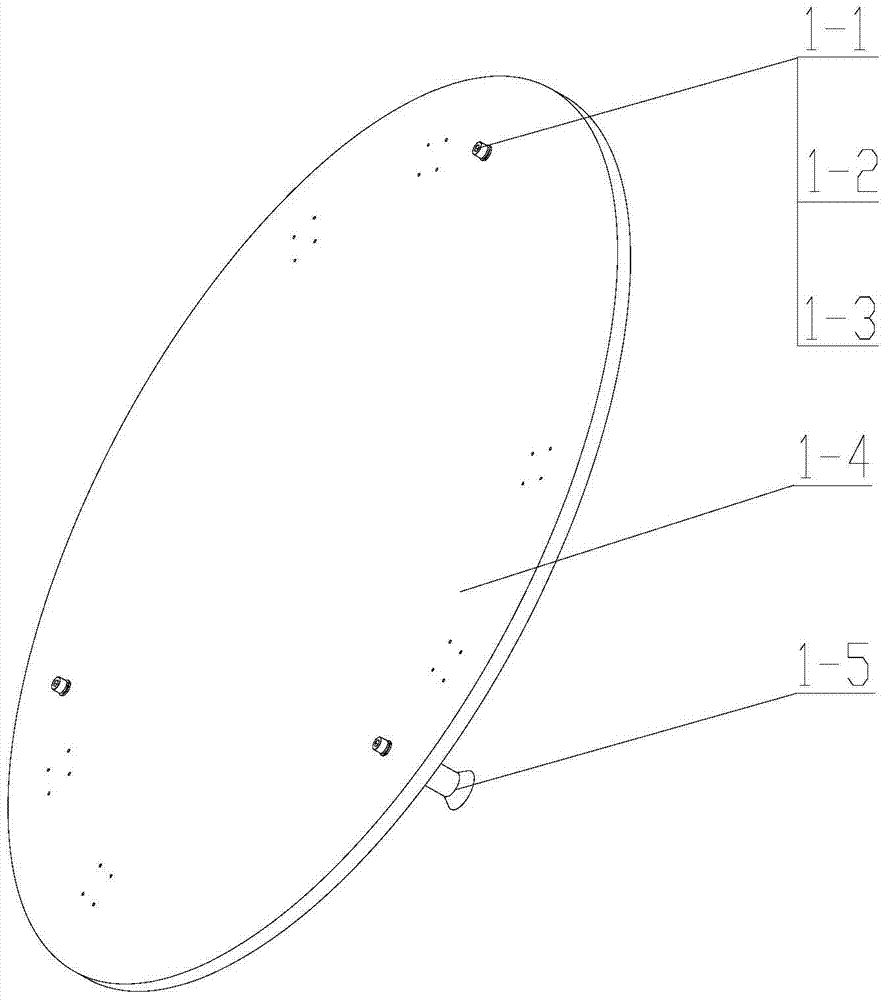

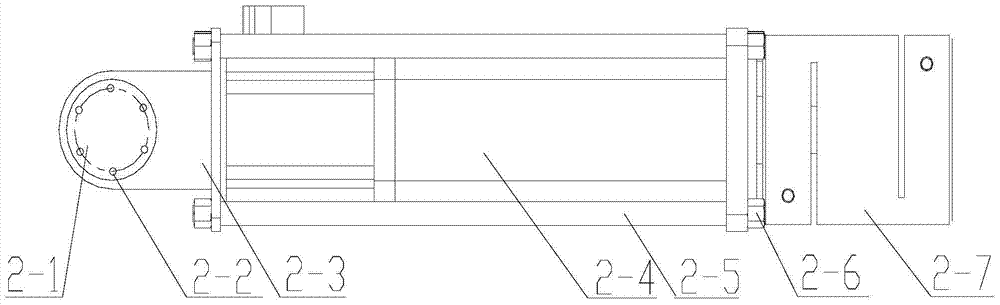

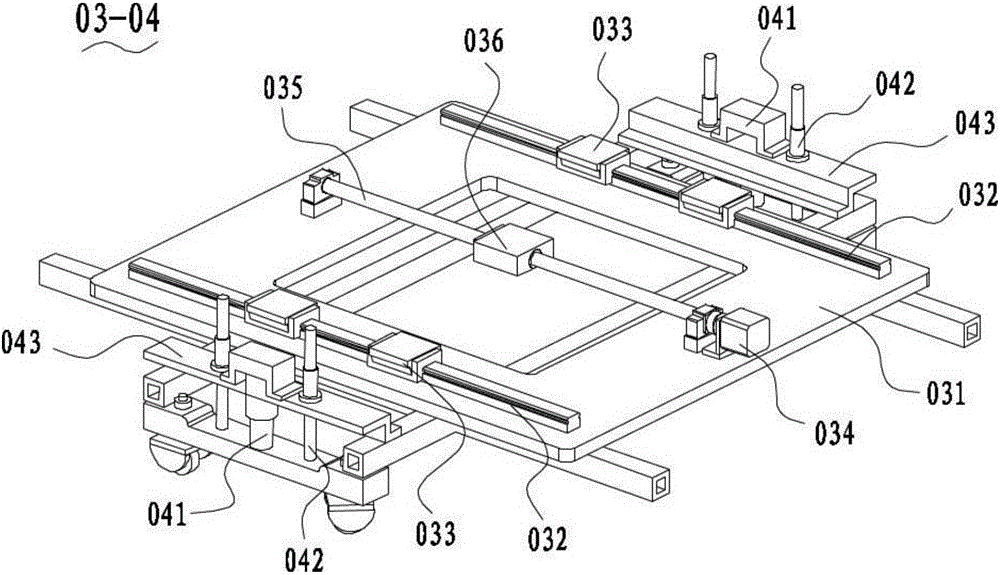

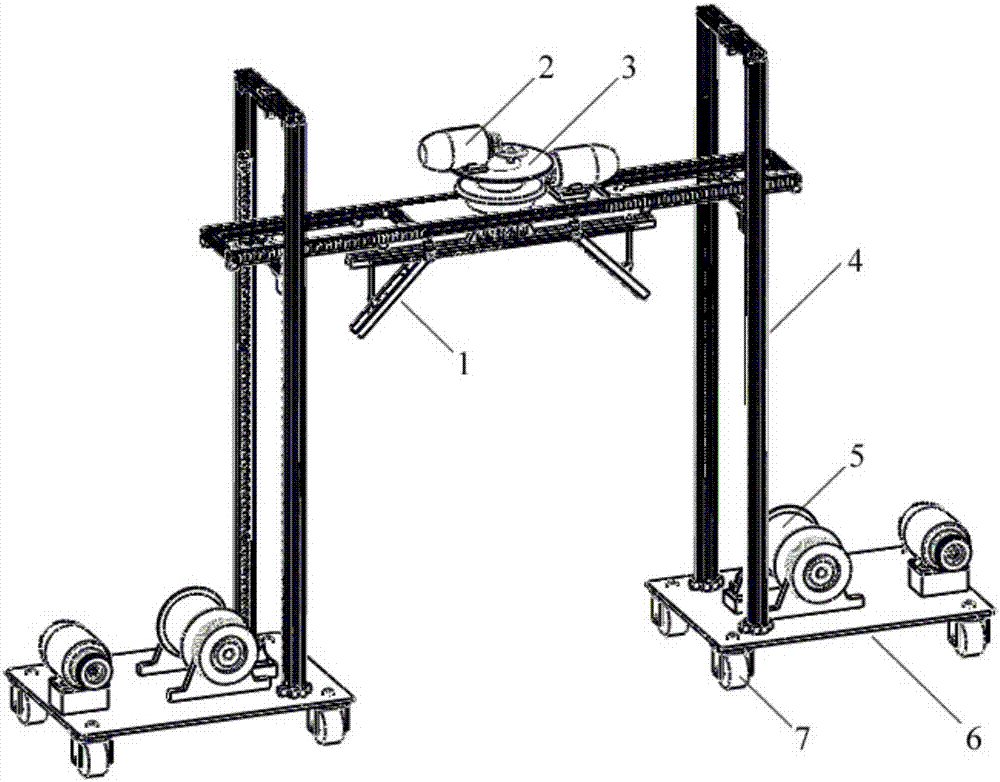

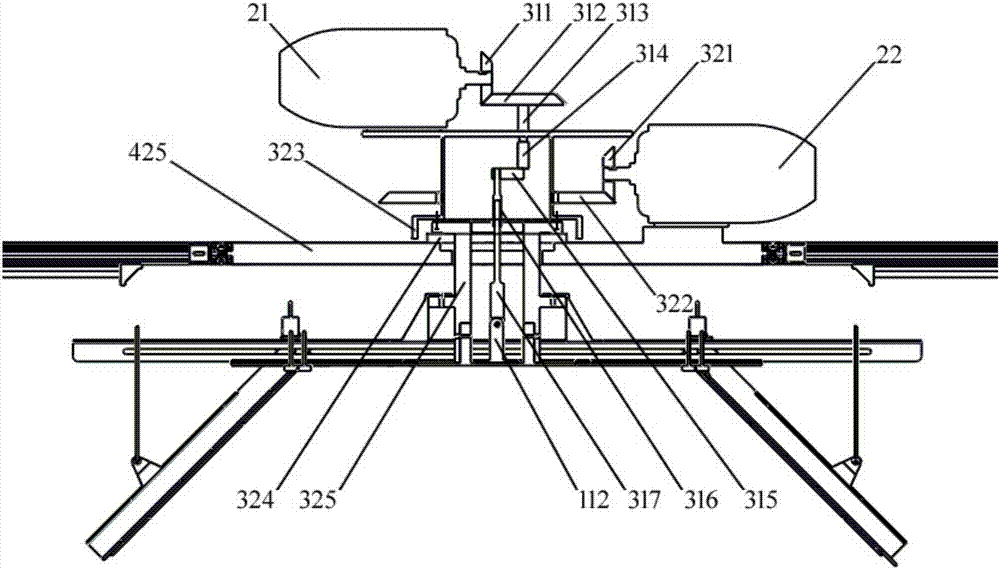

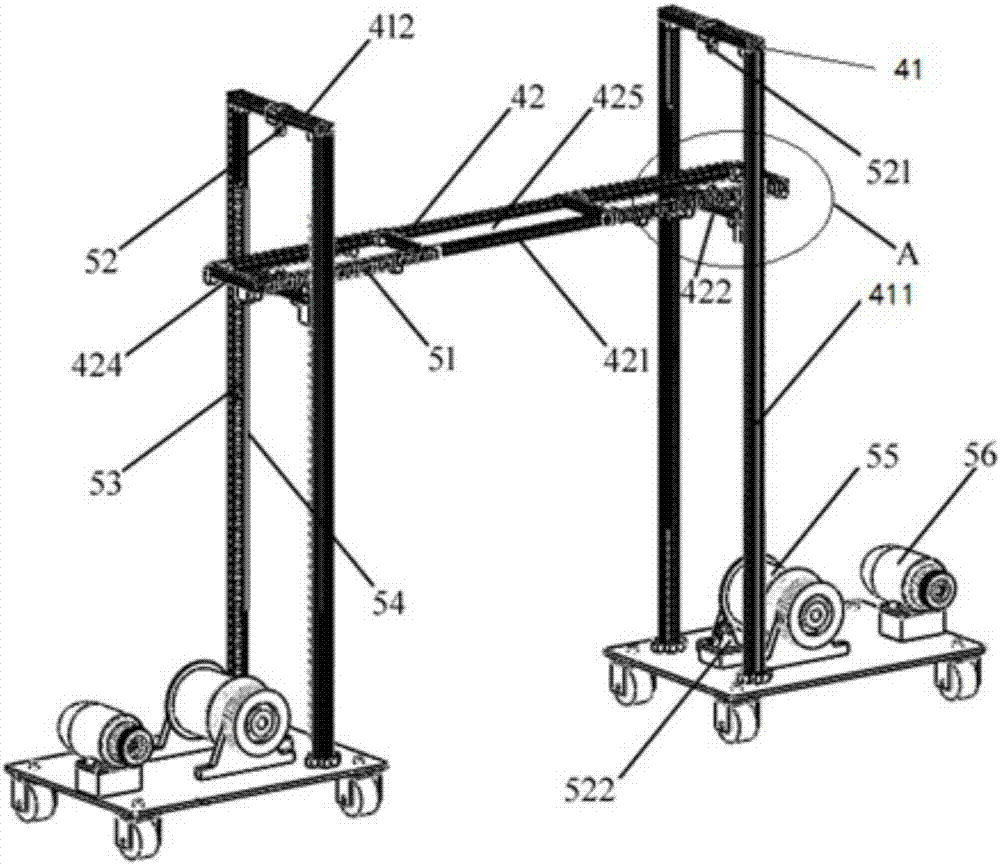

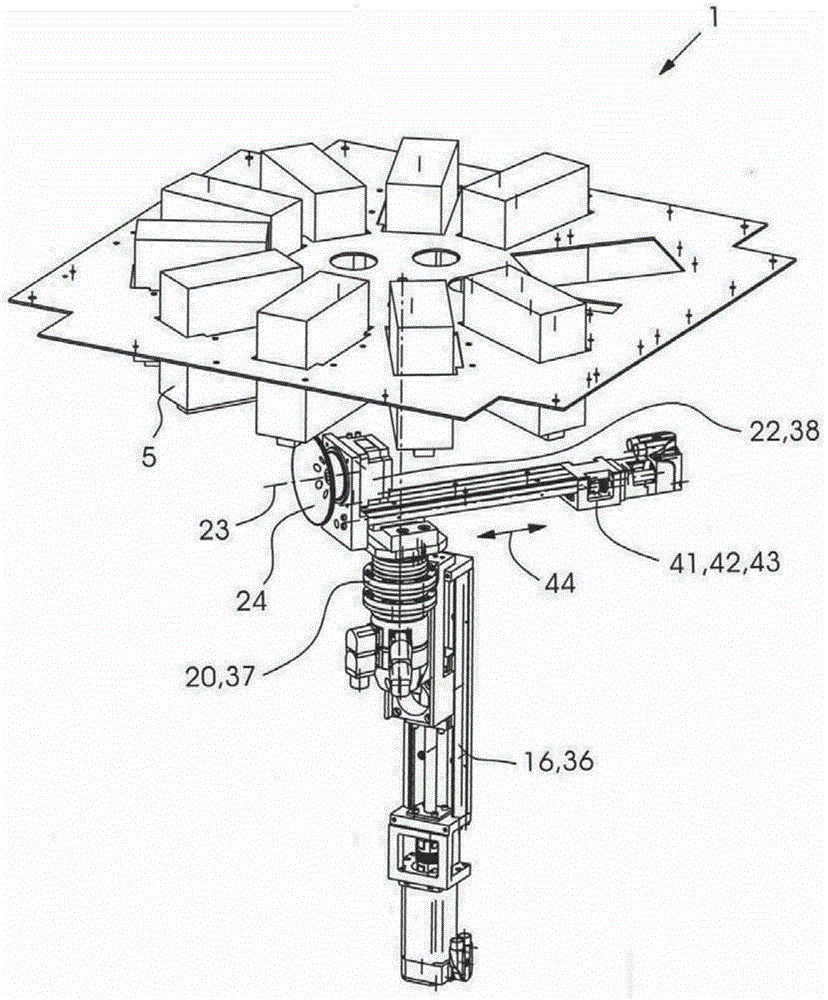

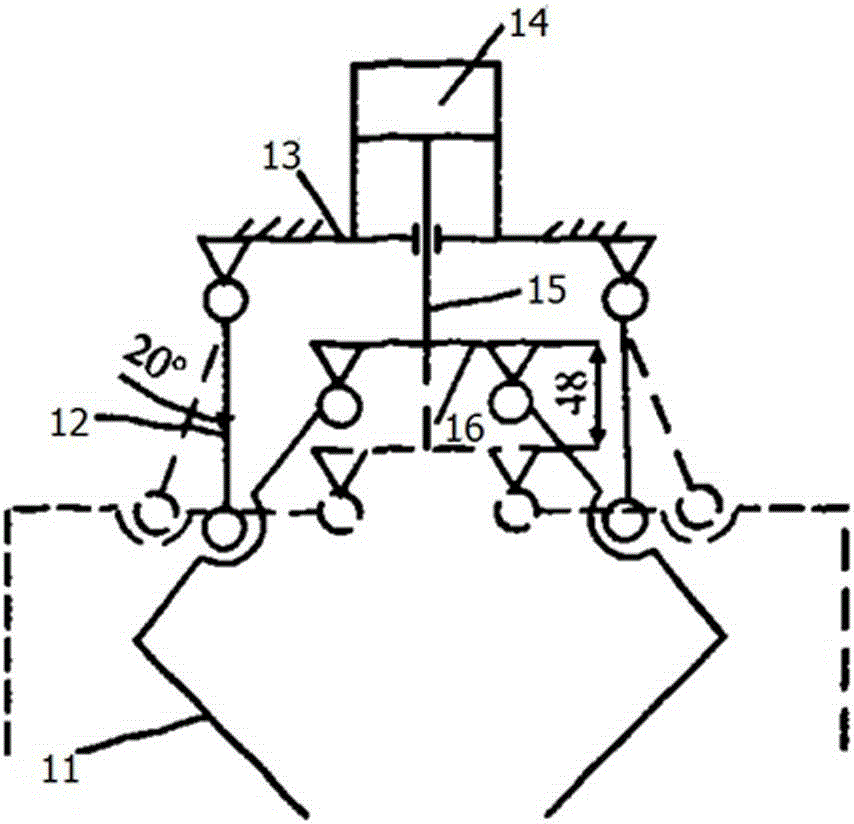

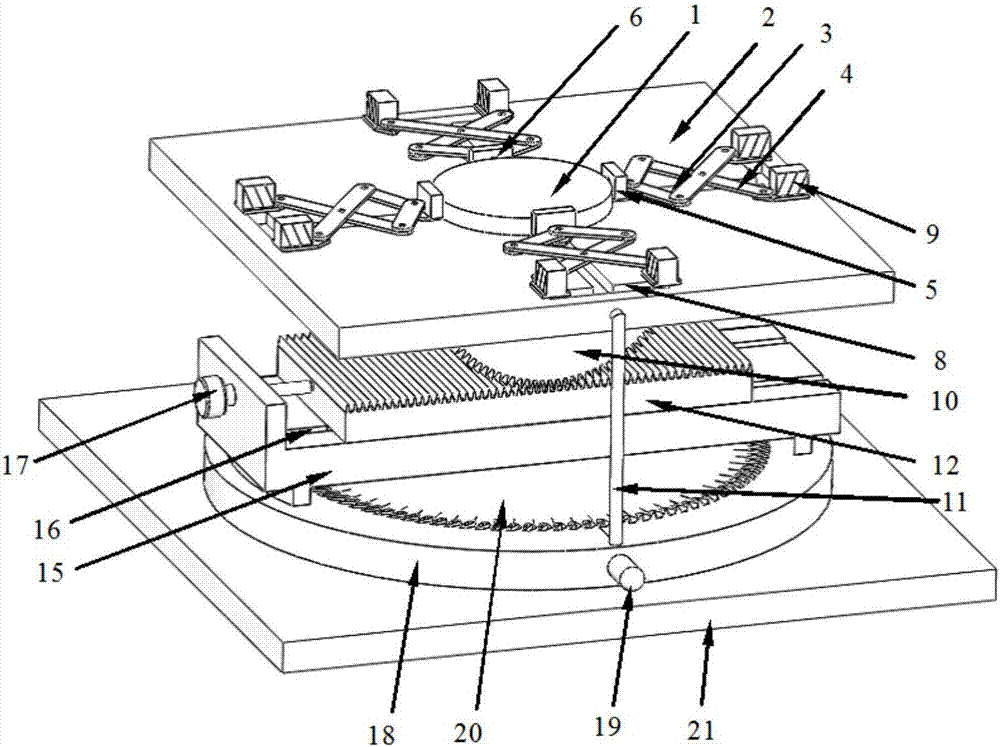

Multi-dimensional force sensor calibration device with controllable poses

InactiveCN103926038ARealize dynamic calibrationRealize functionForce/torque/work measurement apparatus calibration/testingChinese charactersEngineering

The invention provides a multi-dimensional force sensor calibration device with controllable poses. The multi-dimensional force sensor calibration device comprises a fixing platform, drive mechanisms, connecting rod mechanisms and a moving platform. The upper ends of the drive mechanisms and the lower ends of the connecting rod mechanisms are connected to form drive connecting rod mechanisms. The upper ends of the six drive connecting rod mechanisms are hinged to the moving platform through universal hinges, and the lower ends of the six drive connecting rod mechanisms are hinged to a fixed platform to form a six-freedom-degree parallel mechanism. The six drive connecting rod mechanisms are divided into three groups. Every two adjacent drive connecting rod mechanisms form one group and are arranged in the mode shaped like a Chinese character 'ba'. The poses of a calibration platform can be controlled and changed, and the calibration device has the function of calibrating a sensor dynamically and statically, and is complete in function, convenient to operate, high in calibration precision and capable of being well applied to practical engineering.

Owner:HARBIN ENG UNIV

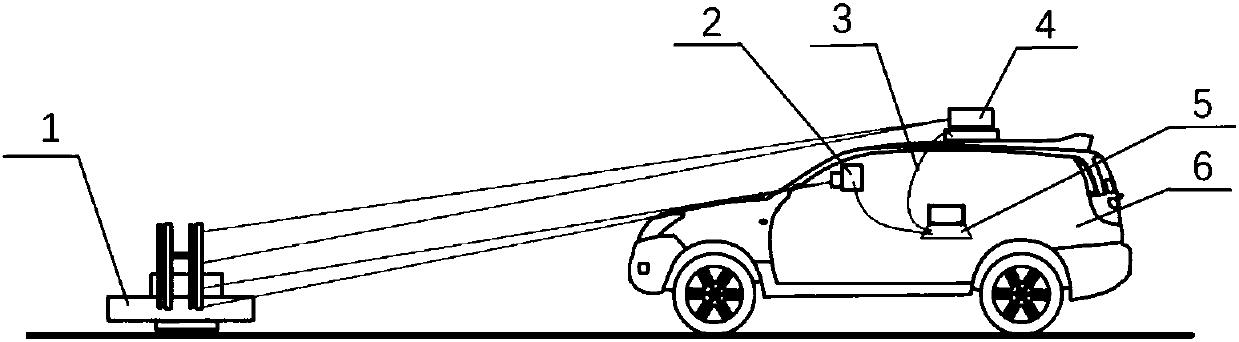

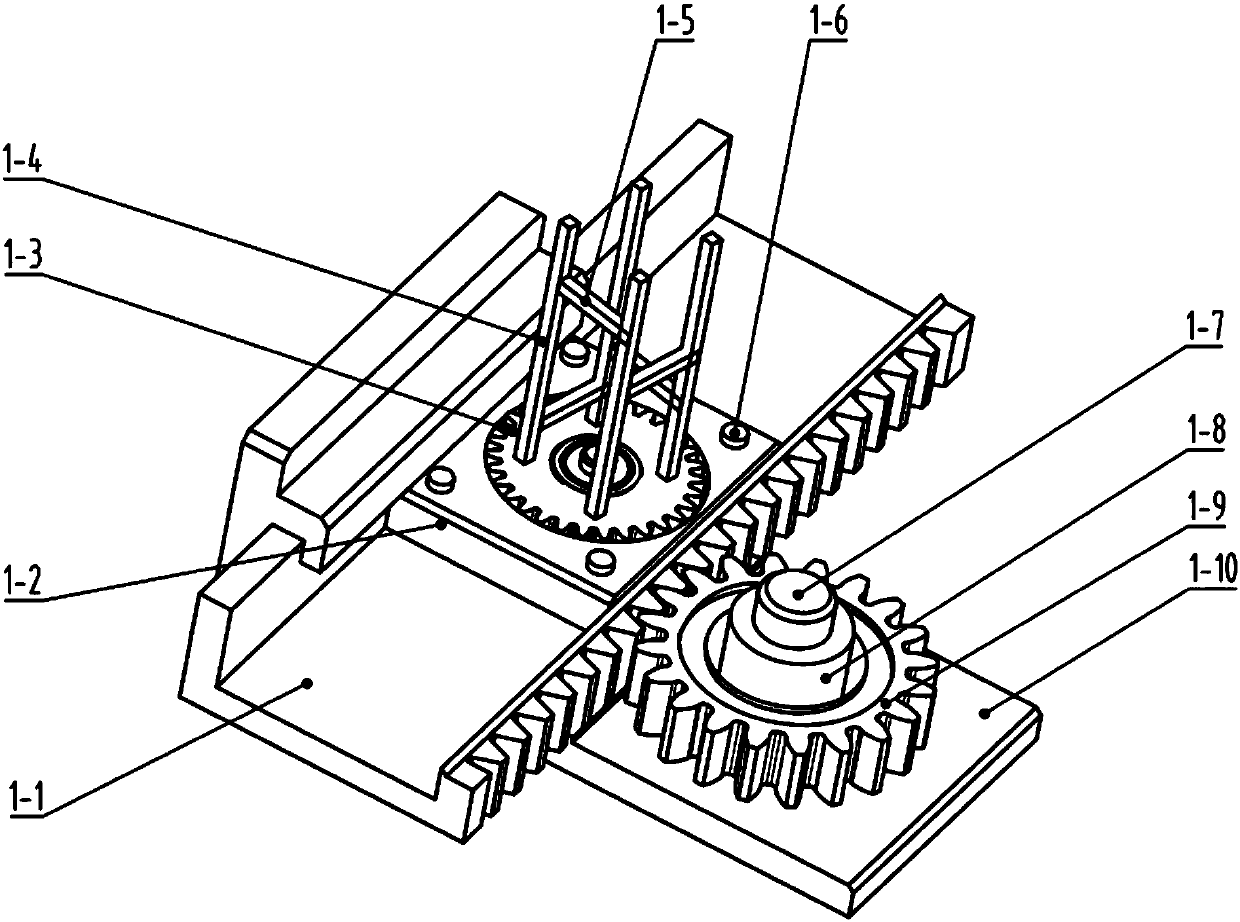

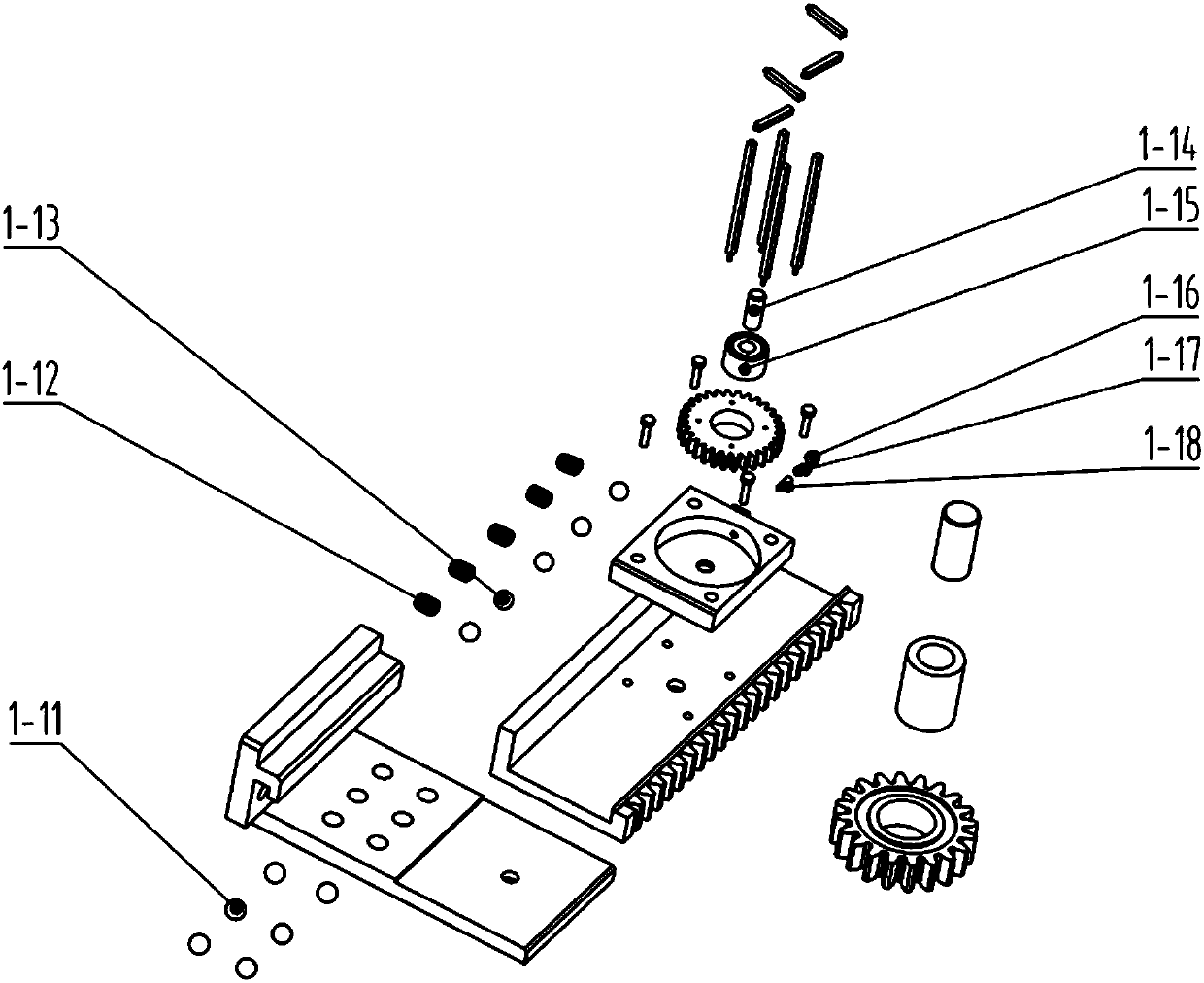

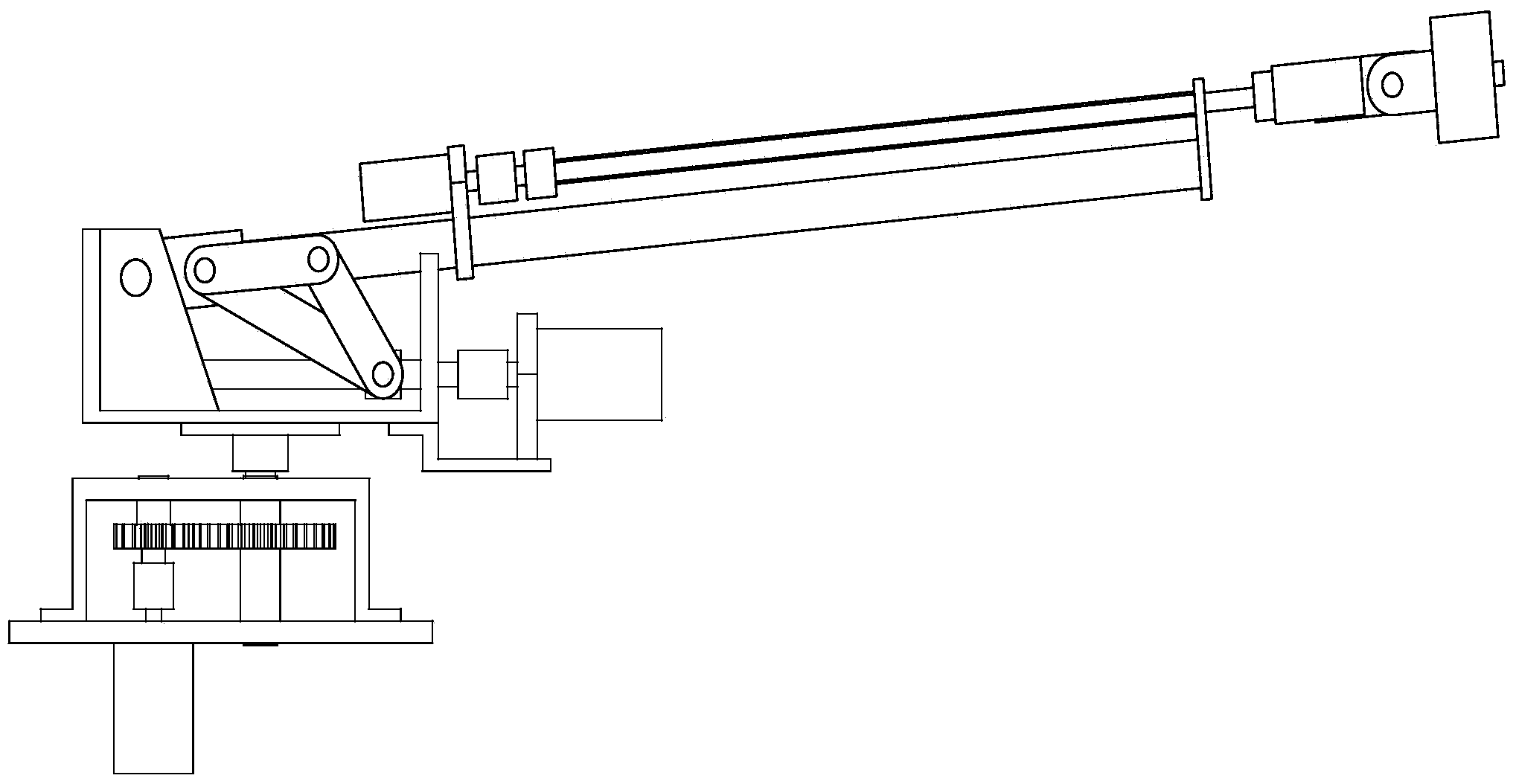

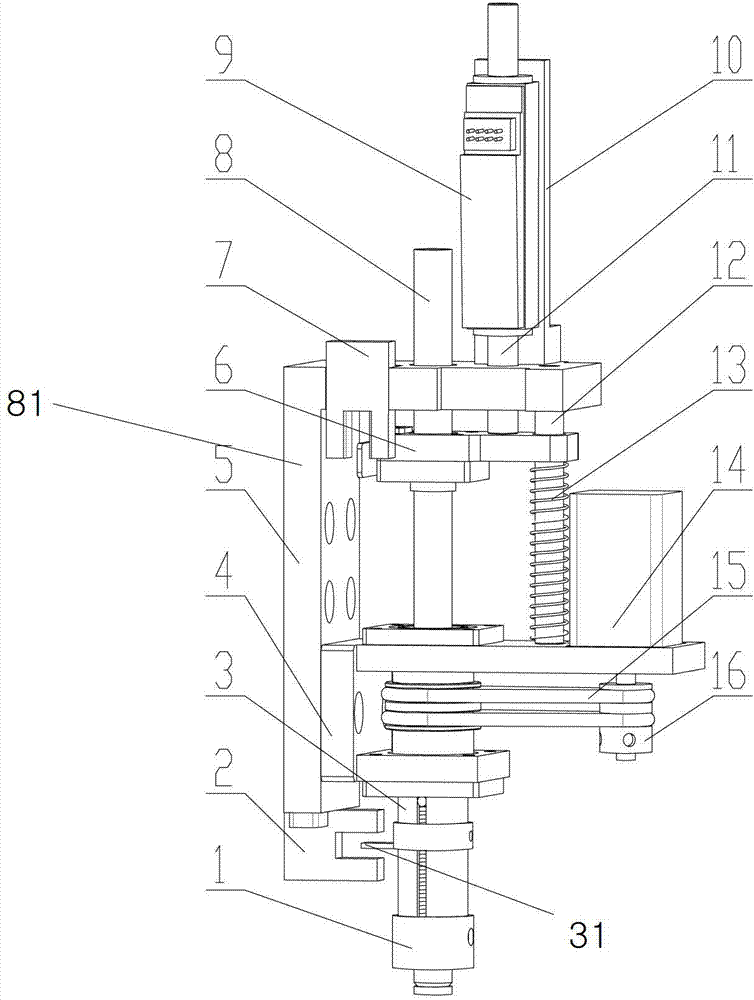

Calibration device based on laser radar and camera fusion as well as calibration method thereof

PendingCN108564630ASimple structureRealize linear motionImage analysisWave based measurement systemsRadarMaterials science

The invention belongs to the technical field of intelligent automobile environmental perception and particularly relates to a calibration device based on laser radar and camera fusion as well as a calibration method thereof. The calibration device comprises a rack, a base plate, a turnplate, a calibration long rod, a calibration short rod, a screw, a gear shaft, a gear bearing, a gear, a bottom plate, a bottom plate steel ball, a limiting spring, a limiting steel ball, a turnplate shaft, a turnplate bearing and a spring locking mechanism. According to the calibration device based on laser radar and camera fusion as well as the calibration method thereof, which are provided by the invention, the calibration device is simple in structure, can be operated manually, can move and rotate in a two-dimensional plane and can calibrate the three-dimensional coordinates of a scanning point. The defect that the single sensor cannot acquire environmental information accurately and integrally is overcome, and a series of difficulties that the position of the scanning points is difficult to determine, the calibration process is tedious and the scanning points are discrete and discontinuous are overcome.

Owner:JILIN UNIV

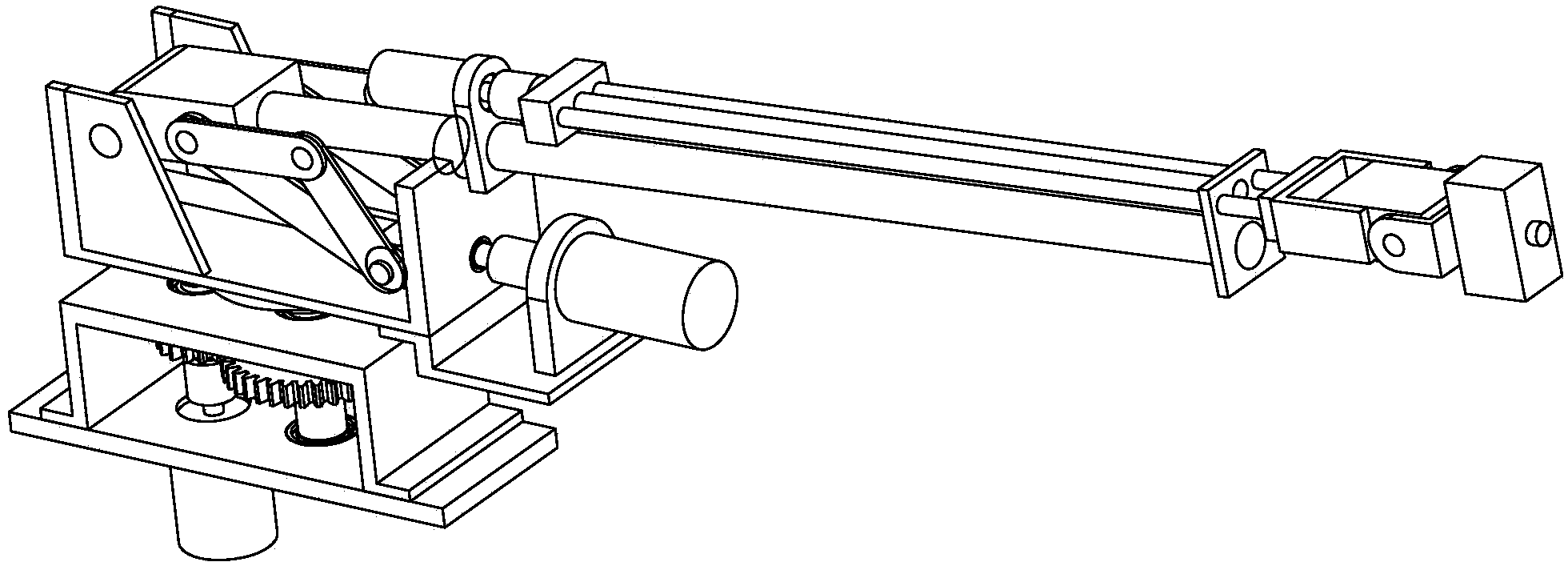

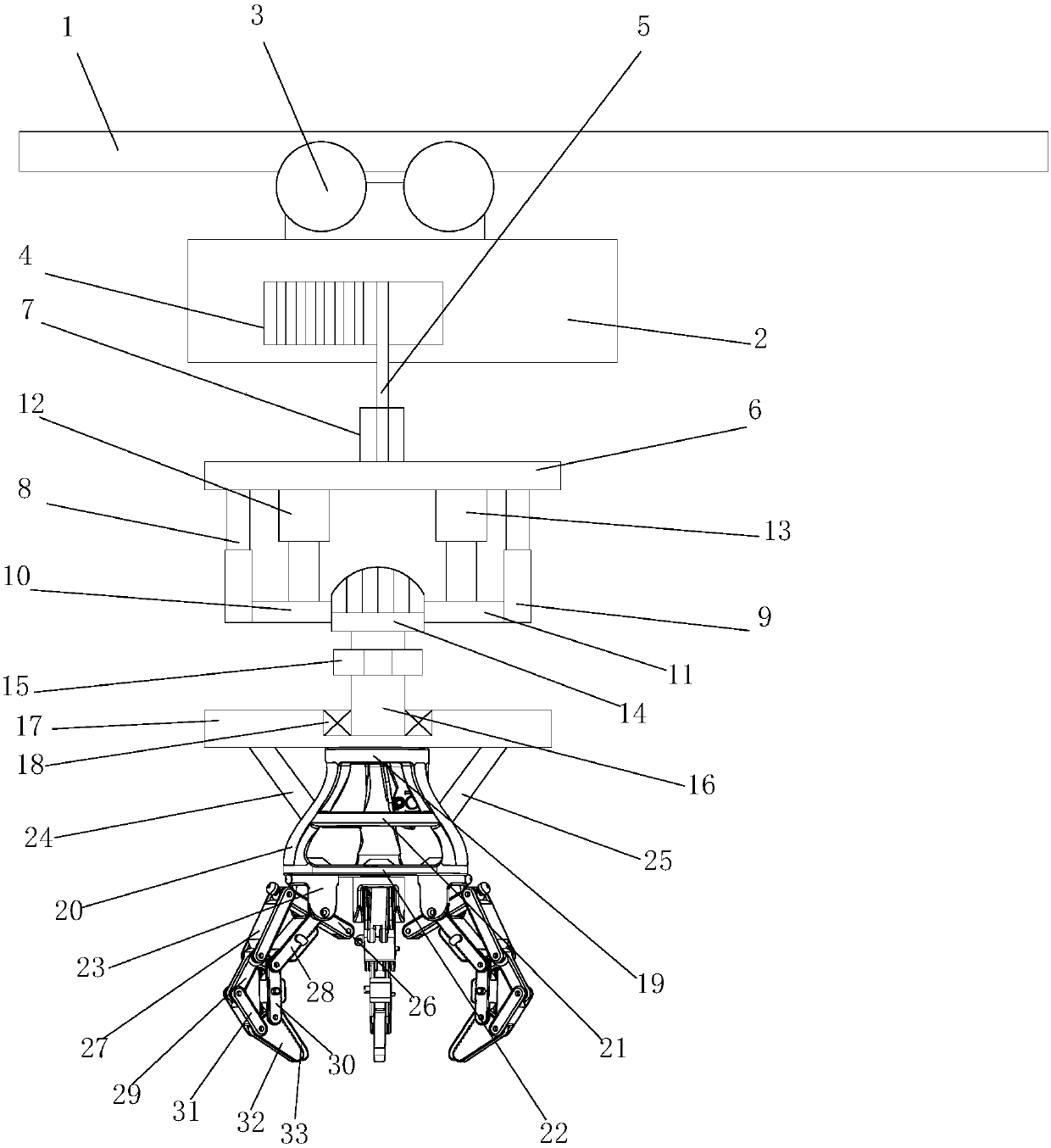

Folding type probing mechanical arm based on triangular configured connecting rod transmission

The invention aims to provide a folding type probing mechanical arm based on triangular configured connecting rod transmission. The folding type probing mechanical arm comprises a telescopic mechanism, a pitching mechanism and a rotating mechanism. The telescopic mechanism comprises a telescopic motor, a telescopic lead screw, a telescopic lead screw slider, a telescopic rod and a telescopic bracket, and the telescopic motor is controlled to realize relative sliding of the telescopic rod and the telescopic bracket. The pitching mechanism comprises a pitching motor, a pitching lead screw slider, a pitching lead screw, a pitching frame, a pitching rod, a pitching rod connecting frame and a triangular configured connecting rod. The rotating mechanism comprises a rotating motor, a gearbox, a main gear and a pinion. When a robot cannot move due to spatial limit, the tail-end implementing mechanism of the robot still can stably reach any point in space coordinates within a controllable range, the tail-end implementing mechanism can be equipped with a CCD (charge coupled device) camera to observe the internal condition of a closed space and also can be equipped with a clamping mechanism. When vital signals in the closed space is observed, food, water and medicine and the like can be correspondingly provided for the first time, and search and rescue and detection task can be completed well.

Owner:三亚哈尔滨工程大学南海创新发展基地

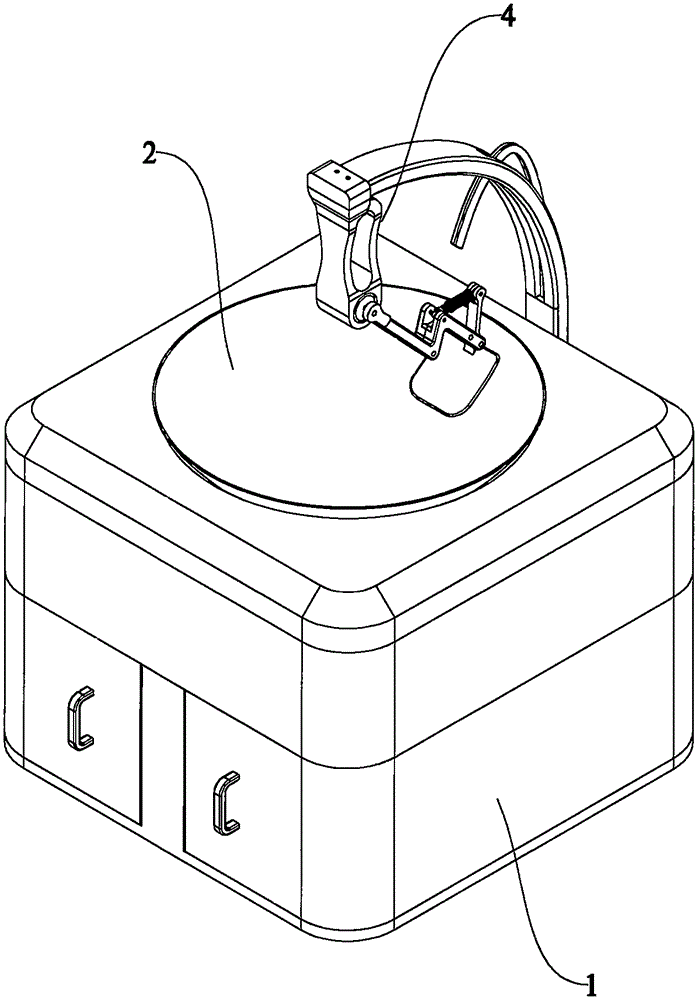

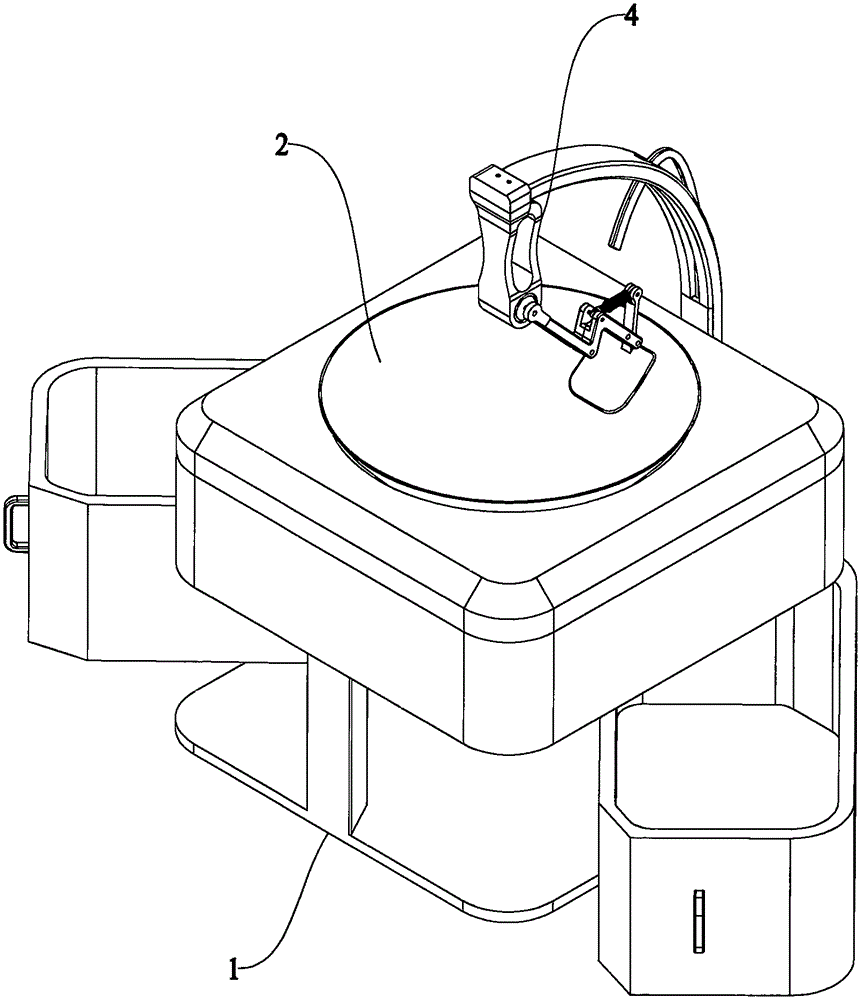

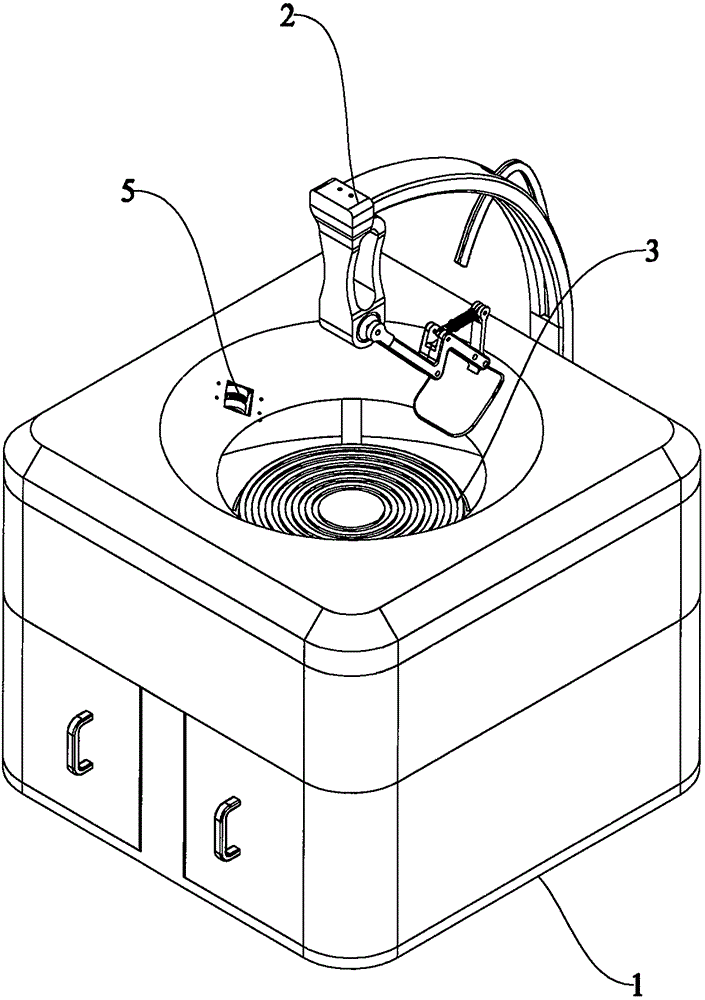

Novel automatic rotation stir-frying induction cooker

ActiveCN105640303AAchieve rotary motionSimple structureCooking insertsVessels with intergral heatingElectric machineryDrive motor

The invention discloses a novel automatic rotation stir-frying induction cooker. The novel automatic rotation stir-frying induction cooker comprises a shell, a pot and a heating coil and is characterized by further comprising a scooping mechanism and a power mechanism, wherein the scooping mechanism conducts stir-frying close to the pot body, and the power mechanism can drive the pot body to rotate or swing. Due to the fact that automatic stir-frying can be conducted simply under power provided by a scoop motor and a driving motor, multiple stir-frying modes can be realized simply through the rotation of the motors, and no complicated mechanical arm structure is adopted, the structure is simple, it can be guaranteed that a scoop makes contact with the pot body all through the stir-frying process, stir-frying efficiency is improved, and the pot can rotate, swing in one direction or swing in any direction through different movement states of the power mechanism.

Owner:广东顺德伊派餐饮设备有限公司

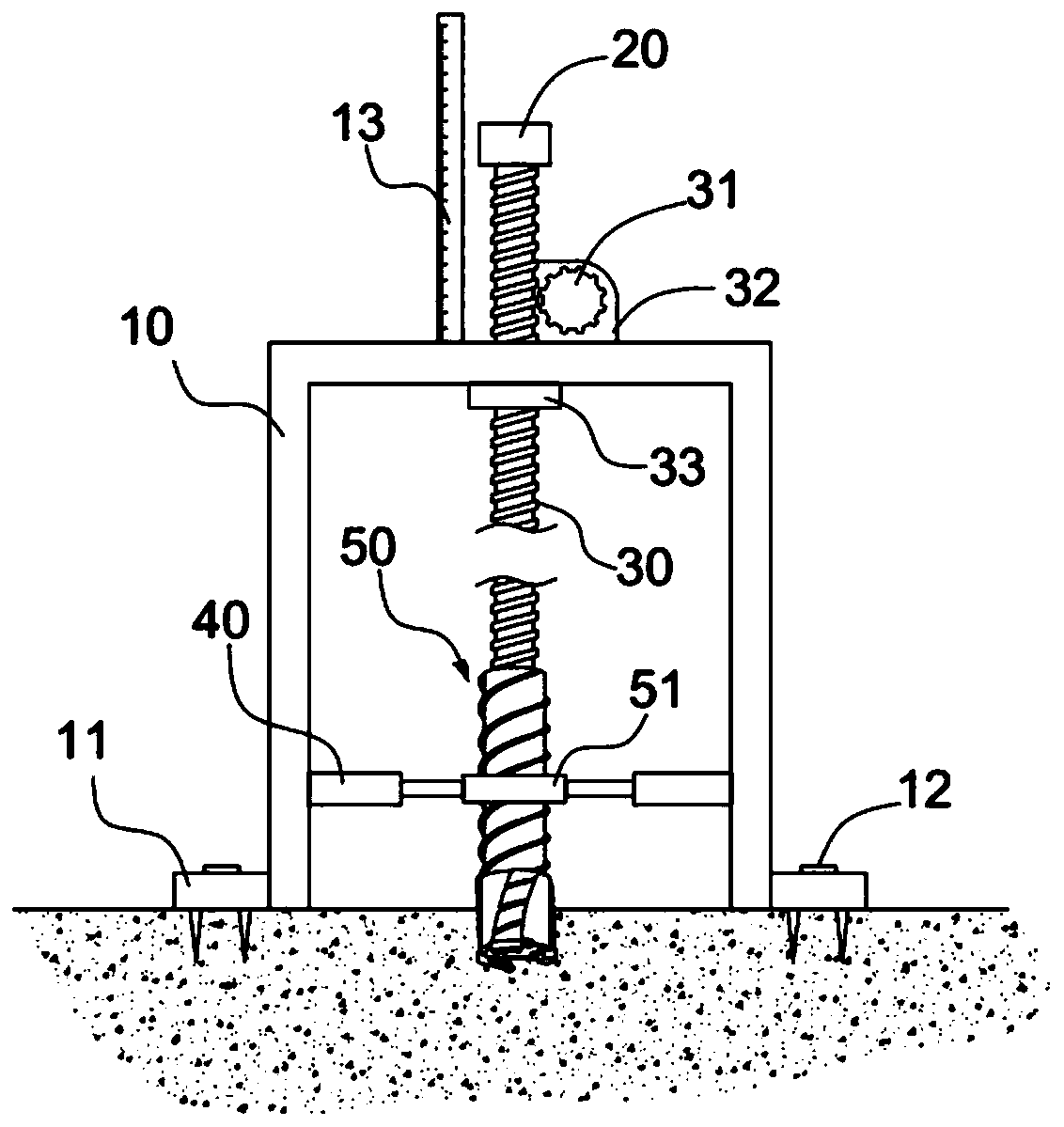

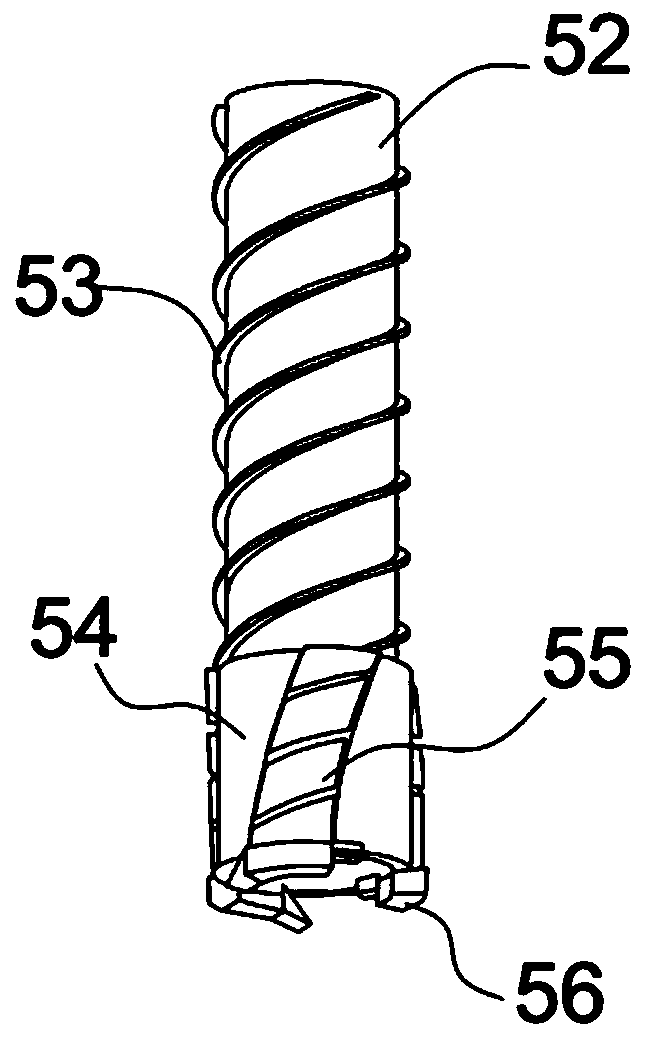

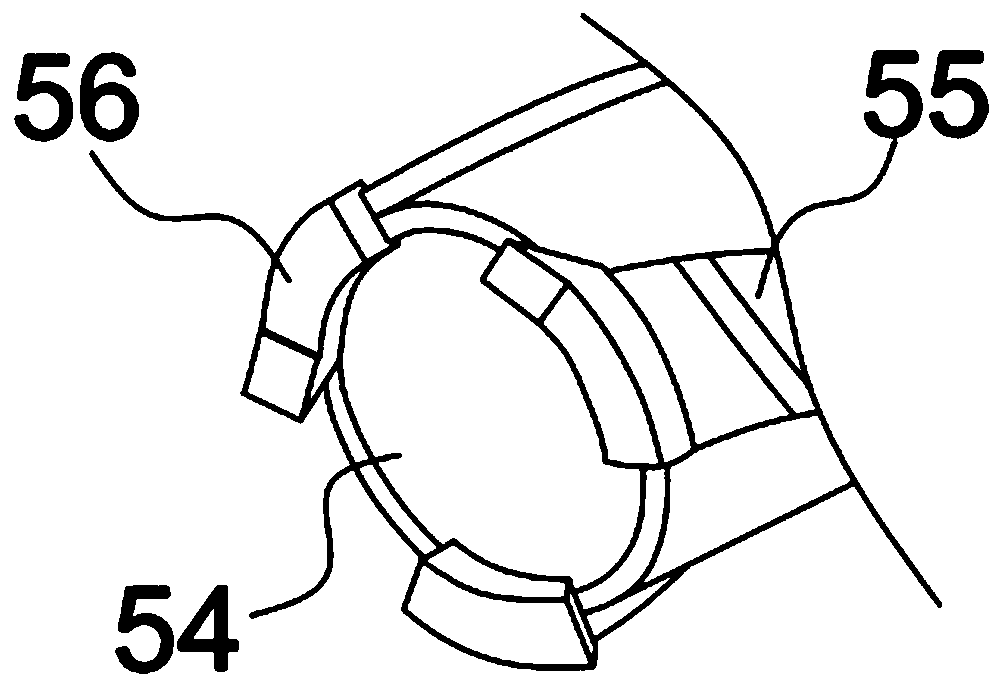

Soil sampler for soil remediation

ActiveCN110426235AAvoid disturbanceAvoid destructionWithdrawing sample devicesSoil remediationEngineering

The invention discloses a soil sampler for soil remediation, and belongs to the technical field of soil sampling. The soil sampler comprises a frame body, a lifting assembly and a sampling assembly, wherein the lifting assembly comprises a worm rod perpendicular to the horizontal plane and arranged on the frame body; the frame body is provided with a first sleeve matched with the worm rod and a worm wheel used for driving the worm rod to move up and down; the sampling assembly is perpendicular to the horizontal plane; the sampling assembly is driven by the lifting assembly to rotate and move up and down for sampling a soil body; the sampling assembly comprises a sampling cylinder; a columnar hollow sampling cavity is formed in the sampling cylinder; a memory alloy wire is arranged on the inner wall of the sampling cavity in a surrounding manner; the memory alloy wire is in a linear shape and is parallel to the central axis of the sampling cylinder; and the memory alloy wire is heated to be deformed in a zigzag shape. According to the soil sampler, soil sampling is controlled through mechanical control, so that the sampling efficiency is effectively improved; an obtained soil sampleis close to an undisturbed soil sample of the natural structure; and the soil sample is effectively prevented from being separated during the extraction process of the soil sample.

Owner:ZHEJIANG OCEAN UNIV

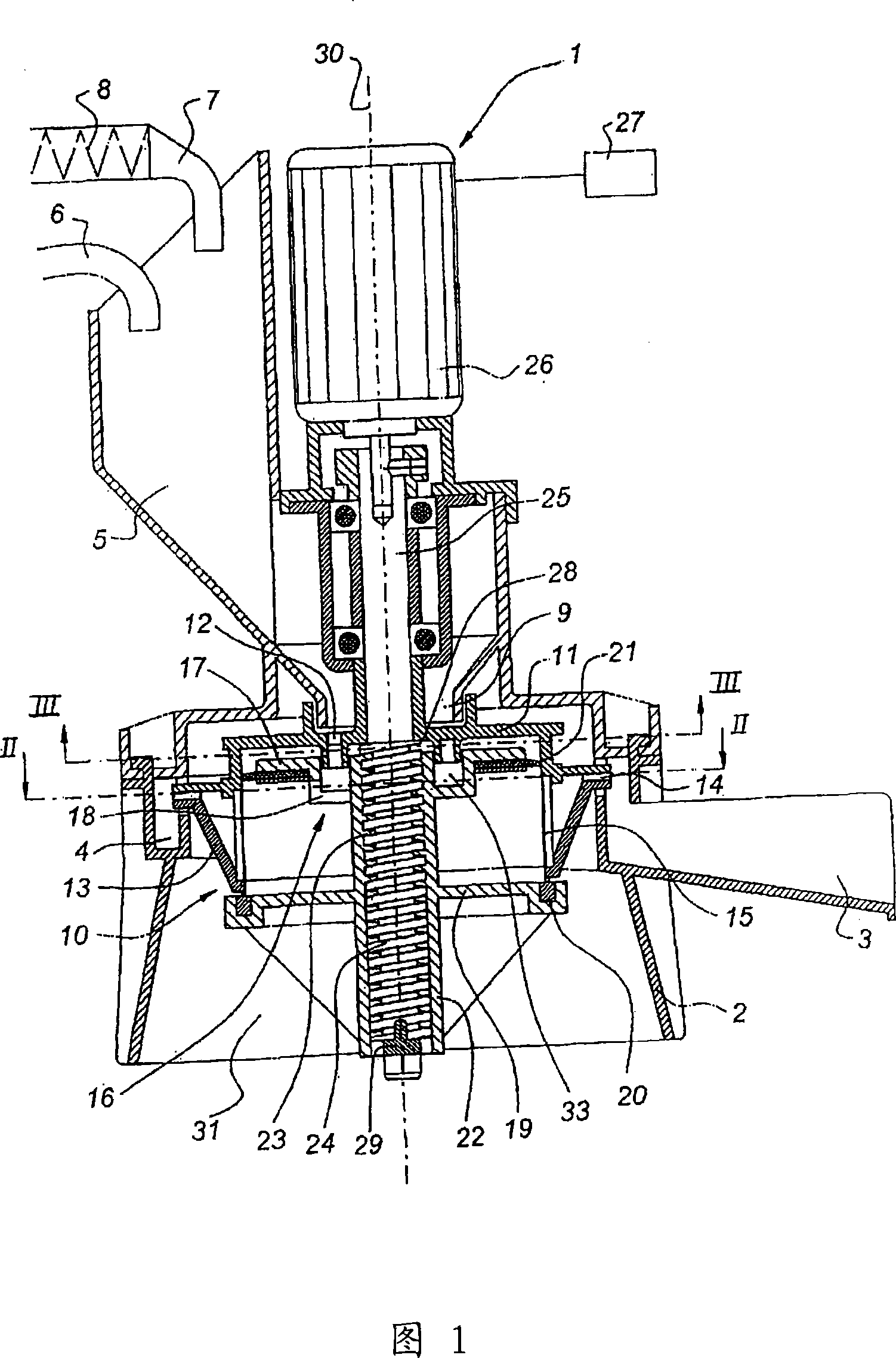

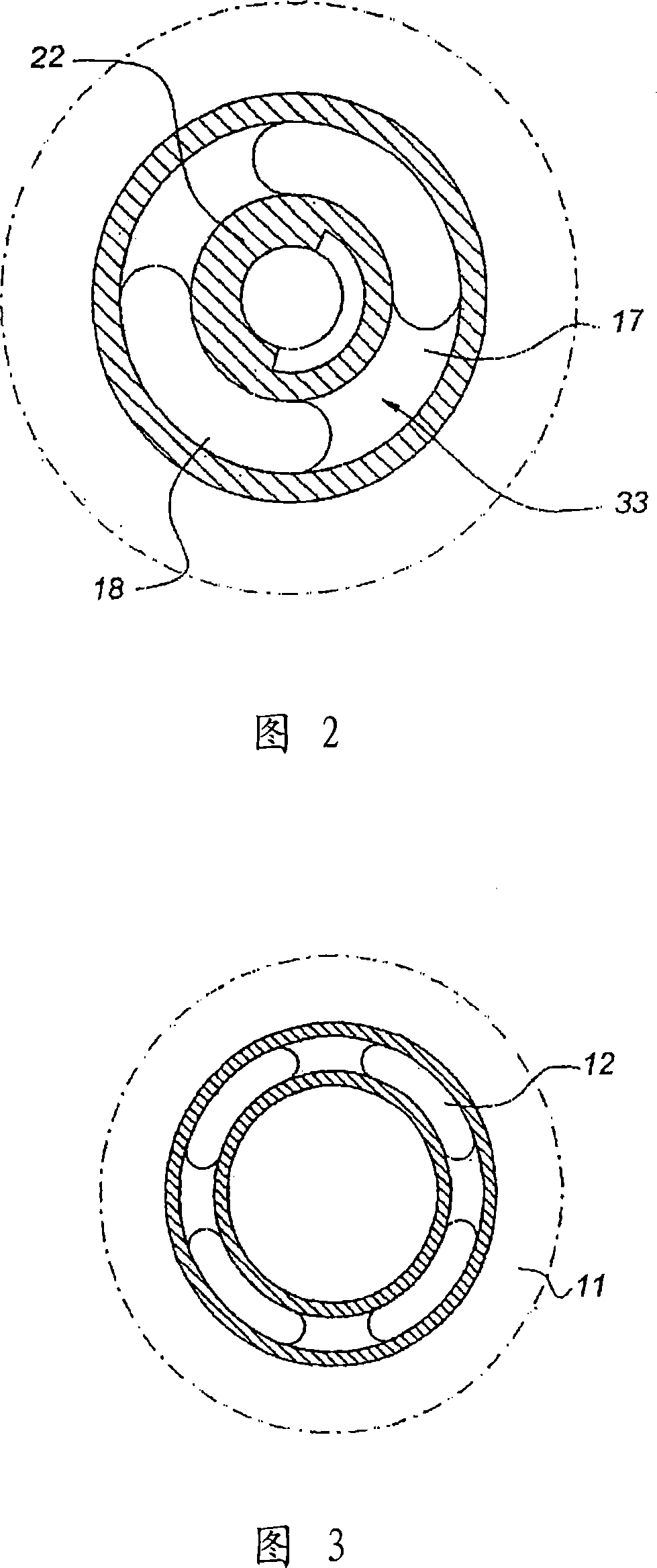

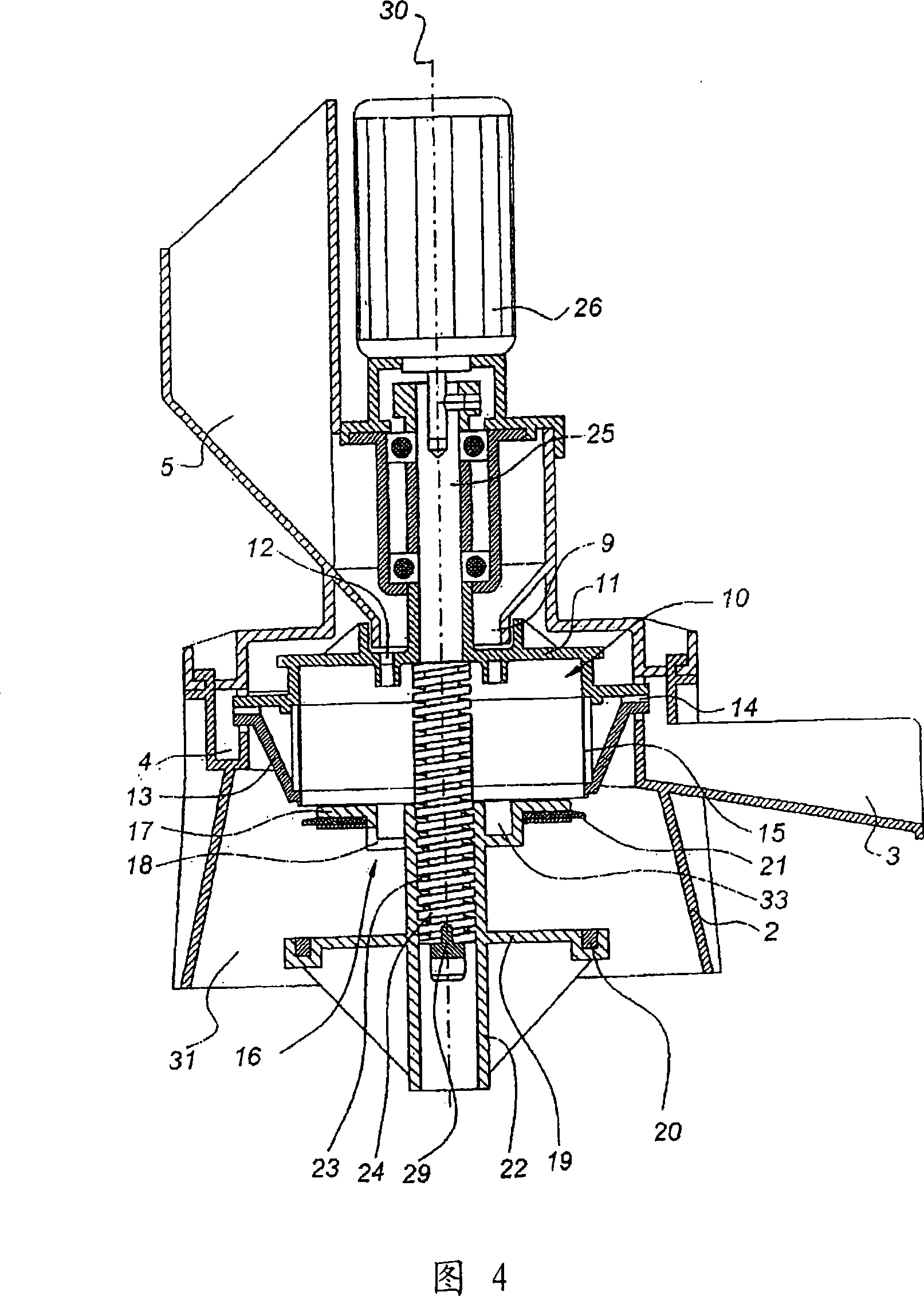

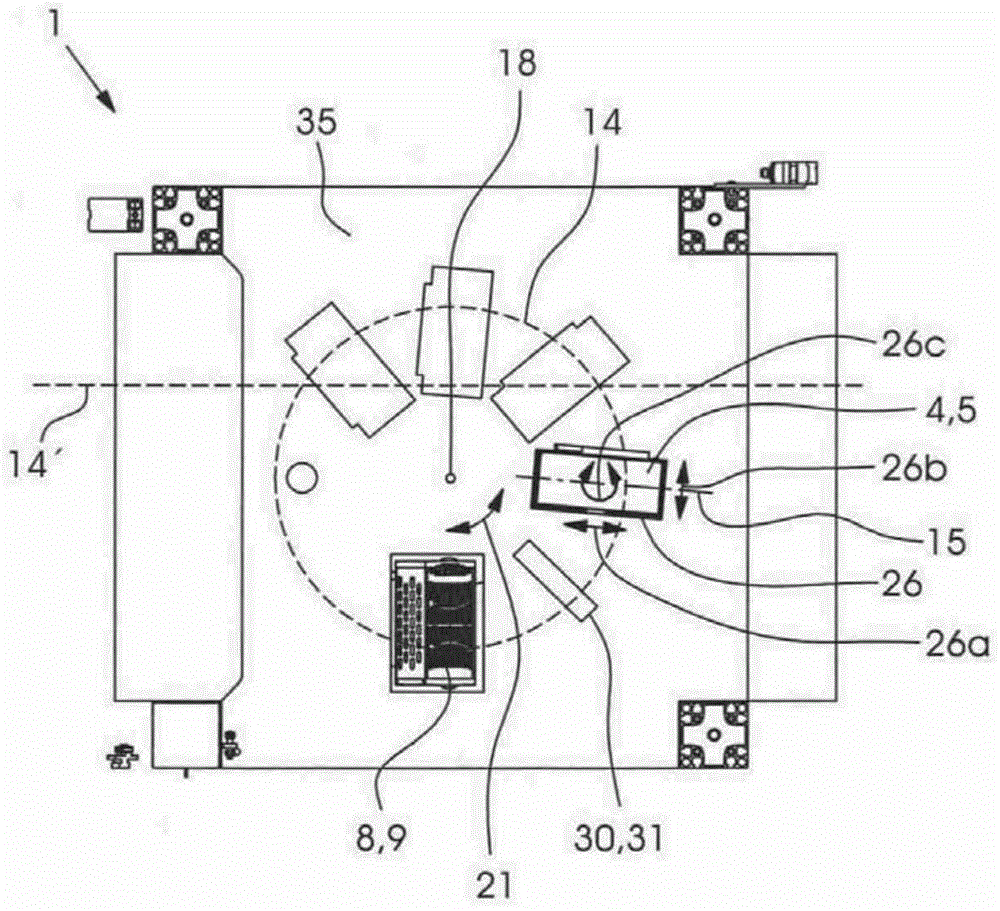

Device for preparing coffee

Device (1) for the preparation of coffee, wherein a water / coffee powder mixture is introduced into a cylindrical space (10). The cylindrical peripheral wall (15) is made as a vertical screen and by rotation / centrifugation the prepared beverage is forced through the filter to the outside, whilst granular coffee material remains behind. The top part (17) and the bottom part (19) of the holder (16) are made such they can be moved with respect to the cylinder wall. The motor (26) for rotation is above or below the top part or, alternatively, bottom part. Furthermore, there is a construction for producing the displacement of the top part or bottom part of the holder with the same motor.

Owner:SPINN HLDG

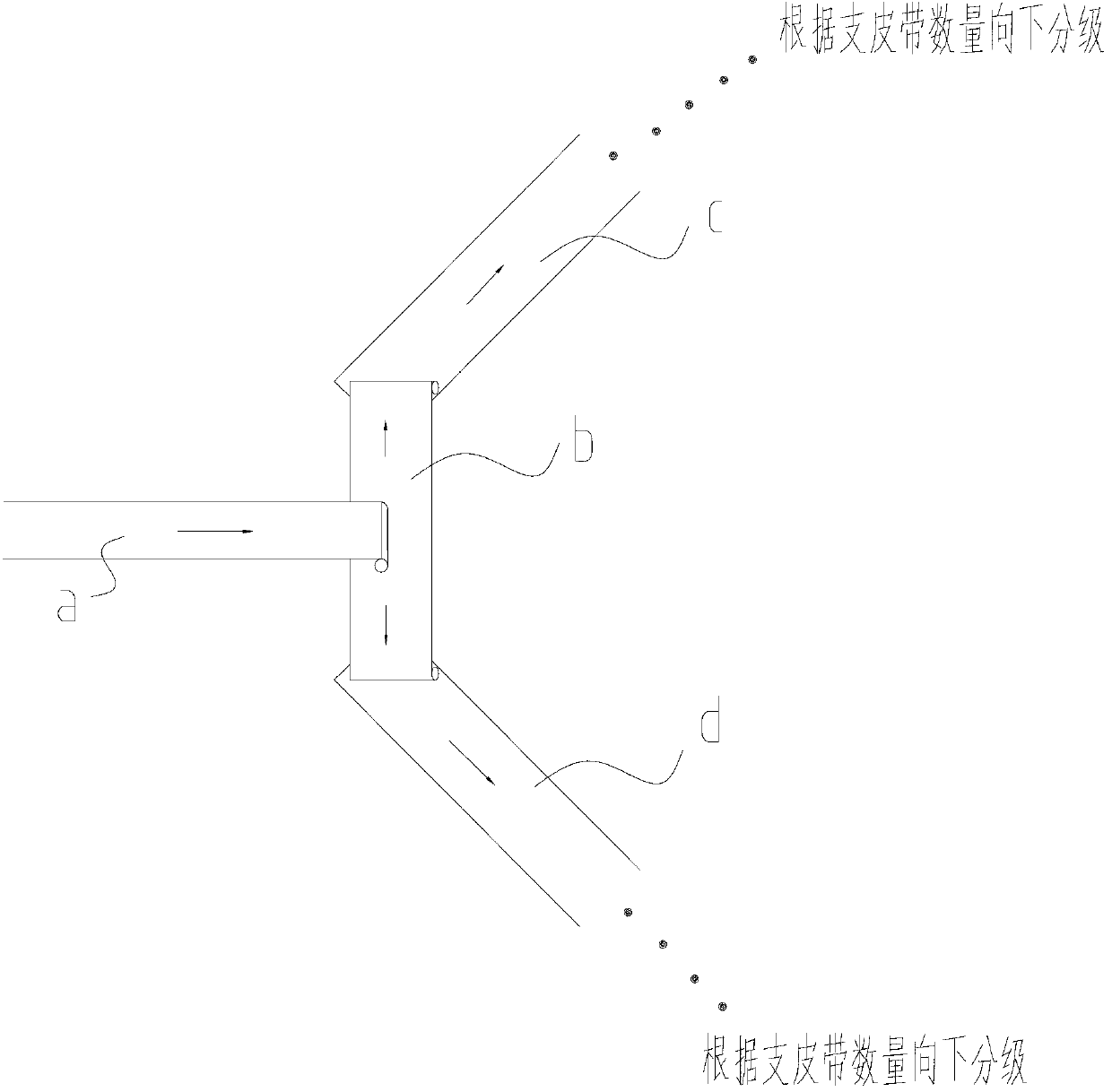

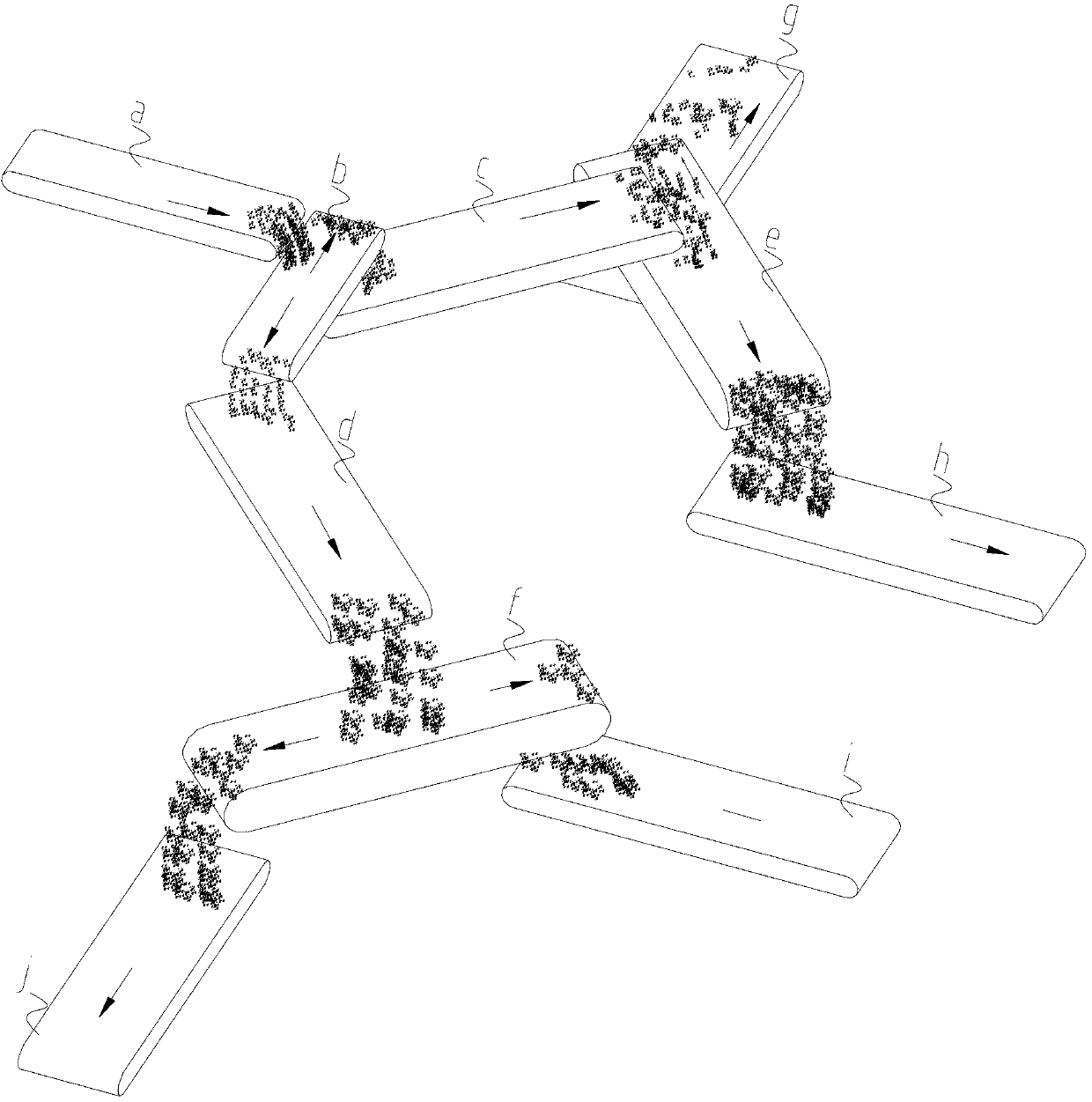

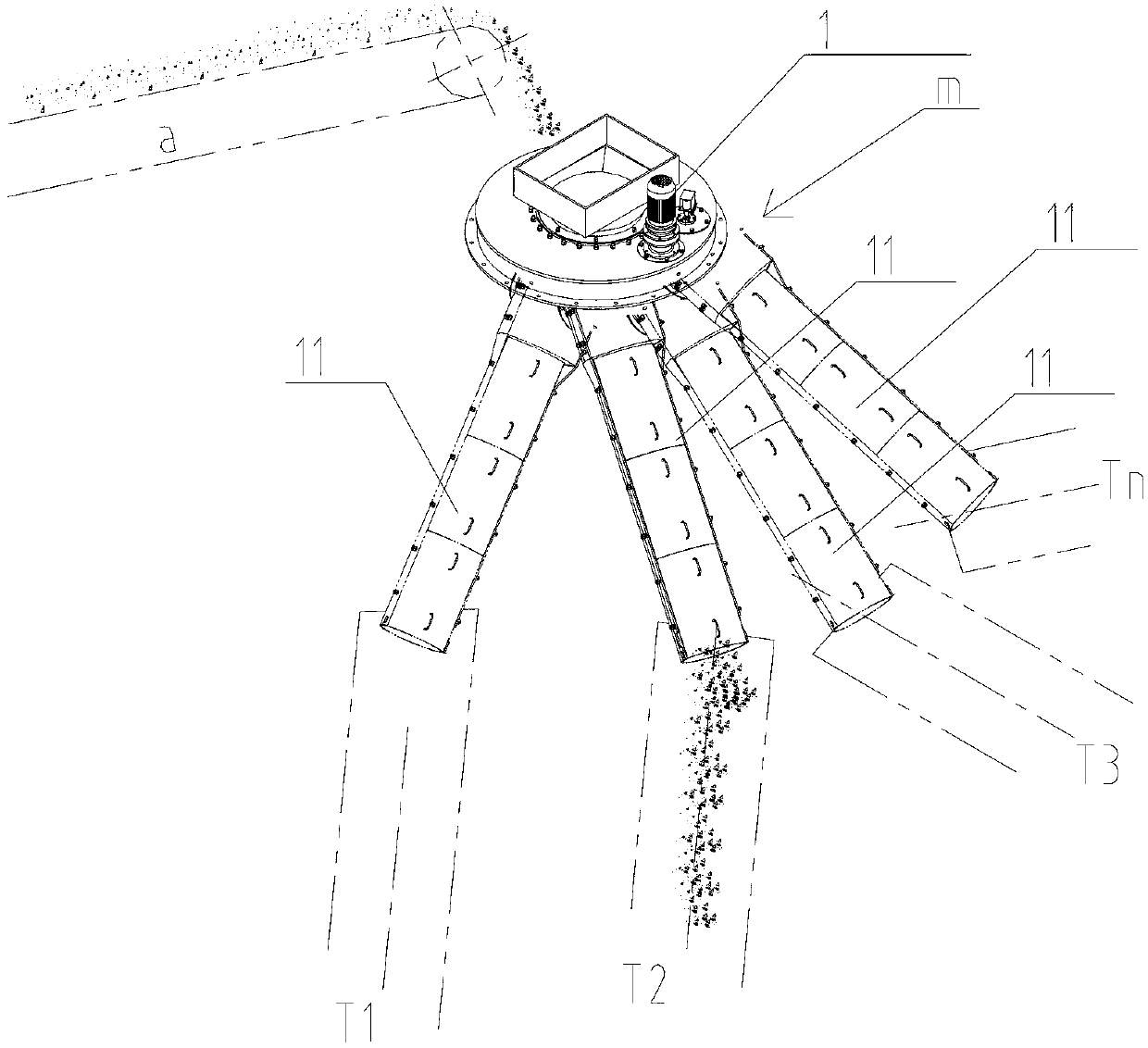

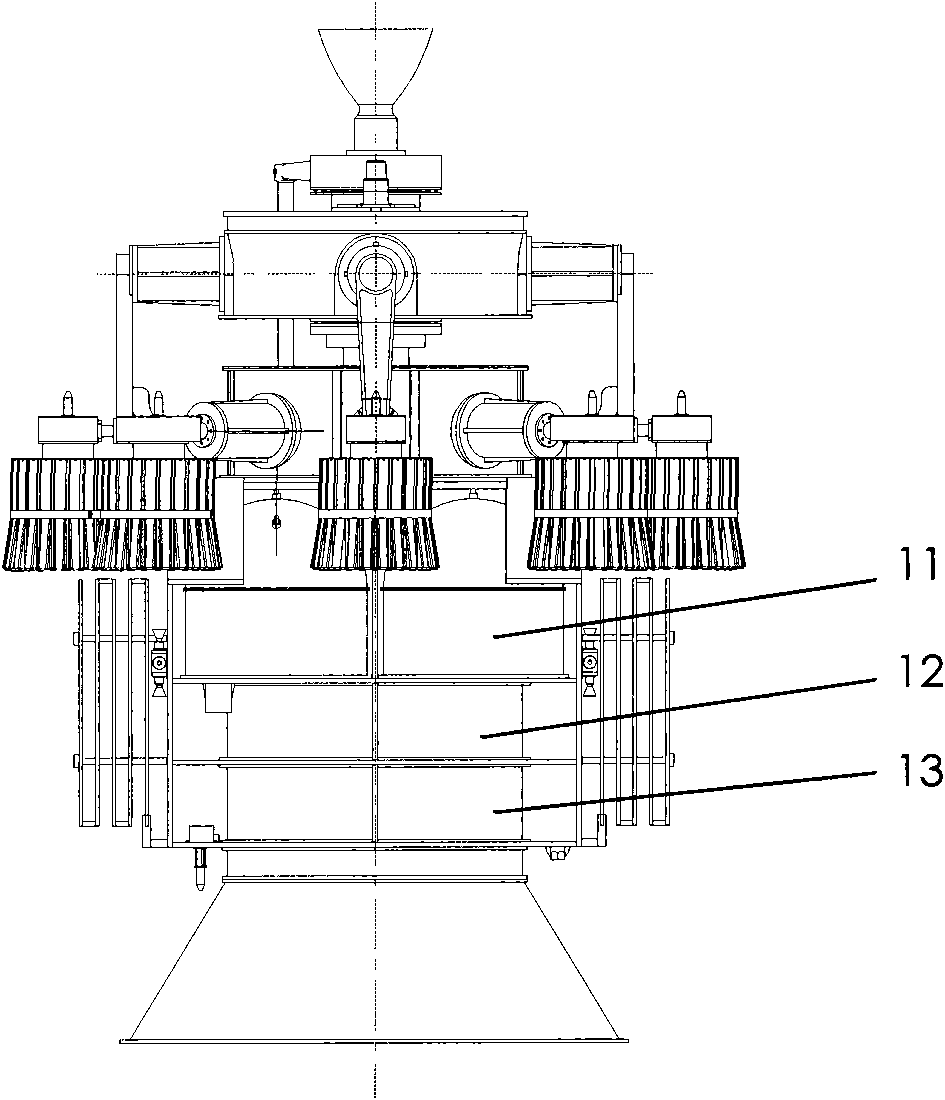

Rotary dividing device

ActiveCN103342230AAchieve rotary motionEasy to controlConveyor partsEngineeringMaterial distribution

The invention discloses a rotary dividing device. The rotary dividing device is used for being matched with a main belt conveyor to distribute materials to a plurality of lowest-stage belt conveyors, and is provided with a box body, wherein a receiving hopper is arranged on the box body. The rotary dividing device further comprises a rotary motor connected on the box body and sliding pipes connected with the outer side of the box body, wherein the sliding pipes can move around the box body for circular motion under the driving of the rotary motor, and the lower ends of the sliding pipes are left on the lowest-stage belt conveyors to distribute material in a fixed point mode and in a quantitative mode. The rotary dividing device is small in occupied space, and can better achieve material distribution in a fixed point mode and in a quantitative mode.

Owner:BERIS ENG & RES CORP

Telescopic mechanical hand

The invention discloses a telescopic mechanical hand which comprises a sliding track, an electric hoist, a rotating rod, an annular groove, a steel wire, a supporting top plate, a first guiding telescopic rod, a second guiding telescopic rod, a first supporting square rod, a second supporting square rod, a first driver, a second driver, a motor and a rotating plate, wherein a mechanical hand support is mounted at the lower end of the rotating plate, an arc-shaped bracket is mounted outside the mechanical hand support, a middle supporting rod and a bottom supporting part are installed in the arc-shaped bracket, a plurality of hinged seats are mounted at the lower end of the bottom supporting part, and one mechanical clamping jaw is mounted on each hinged seat. By utilizing the sliding track, the horizontal position adjustment of the whole telescopic mechanical hand is achieved; by arrangement of the first driver and the second driver, the whole telescopic mechanical hand can rise and fall; by arrangement of the motor, the rotary motion of the telescopic mechanical hand can be implemented, and a workpiece is captured conveniently by utilizing the mechanical clamping jaw.

Owner:苏州浩迈凌环境工程有限公司

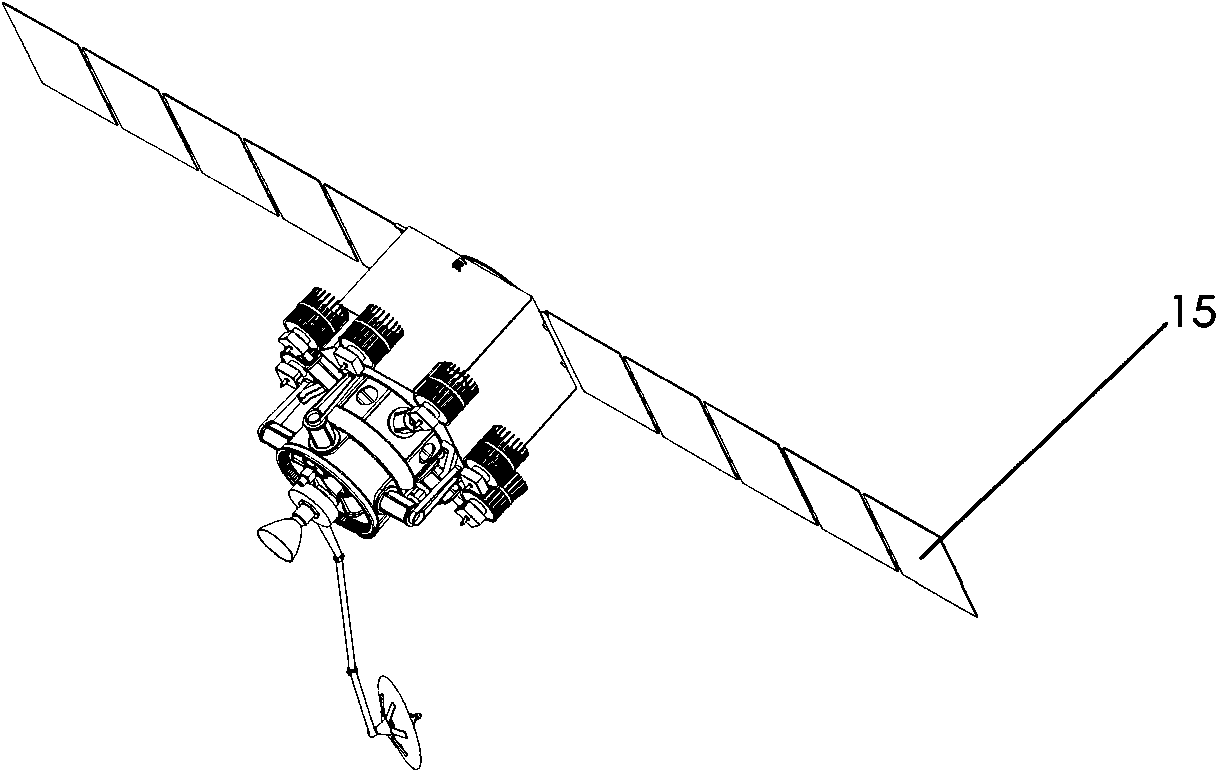

SPORT (Solar Polar Orbit Radio Telescope) clock scanning satellite

InactiveCN101850852AThe power transmission link is clear and conciseConfiguration layout is conducive toArtificial satellitesTransfer orbitEnvironmental geology

The invention relates to an SPORT (Solar Polar Orbit Radio Telescope) clock scanning satellite comprising a satellite body, a subsatellite, a stretching arm, a solar cell paddle, a butt-joint ring, a geosynchronous communication antenna and an orbit control engine. The SPORT clock scanning satellite is characterized in that the satellite body is in a cuboid shape and has a three-cabin internal structure; and the subsatellite concretely comprises a subsatellite body, a helical antenna, a reflecting plate, a reflecting plate support frame, a flexible solar paddle, a helical antenna unfolding guide mechanism, a guide unfolding drive motor, a speed reducer, an S wave-band digital antenna, a receiver and a power module. The SPORT clock scanning satellite adopts a main force-bearing structure which is a central force-bearing drum and a radial partition board force-transferring path, has a clear and concise force-transferring link, and is beneficial to the design of structure strength and rigidity through configuration distribution; the SPORT clock scanning satellite is provided with an orbit maneuver motor so as to transfer orbits per se when flying during a cruise phase, thereby reducing the requirements on a carrying upper stage; in addition, the SPORT clock scanning satellite ensures the stability of a better satellite attitude through the distribution position of a propelling module of the satellite body.

Owner:NAT SPACE SCI CENT CAS

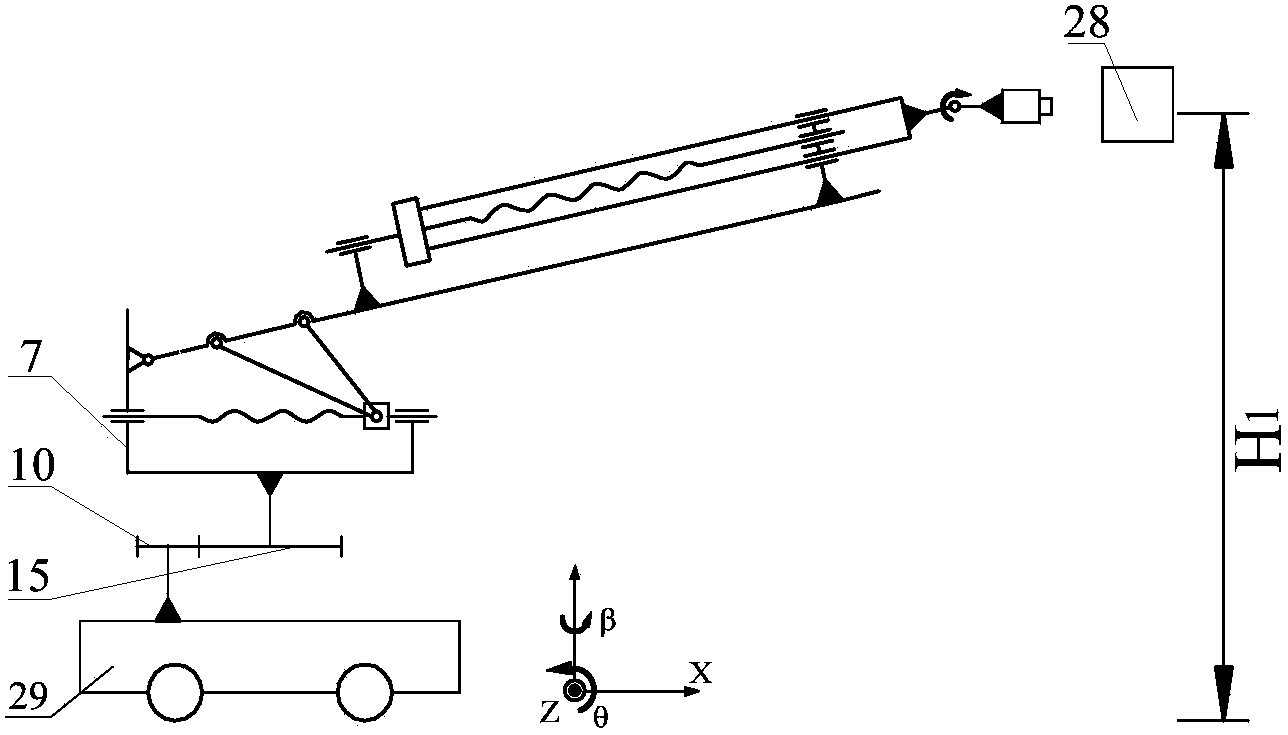

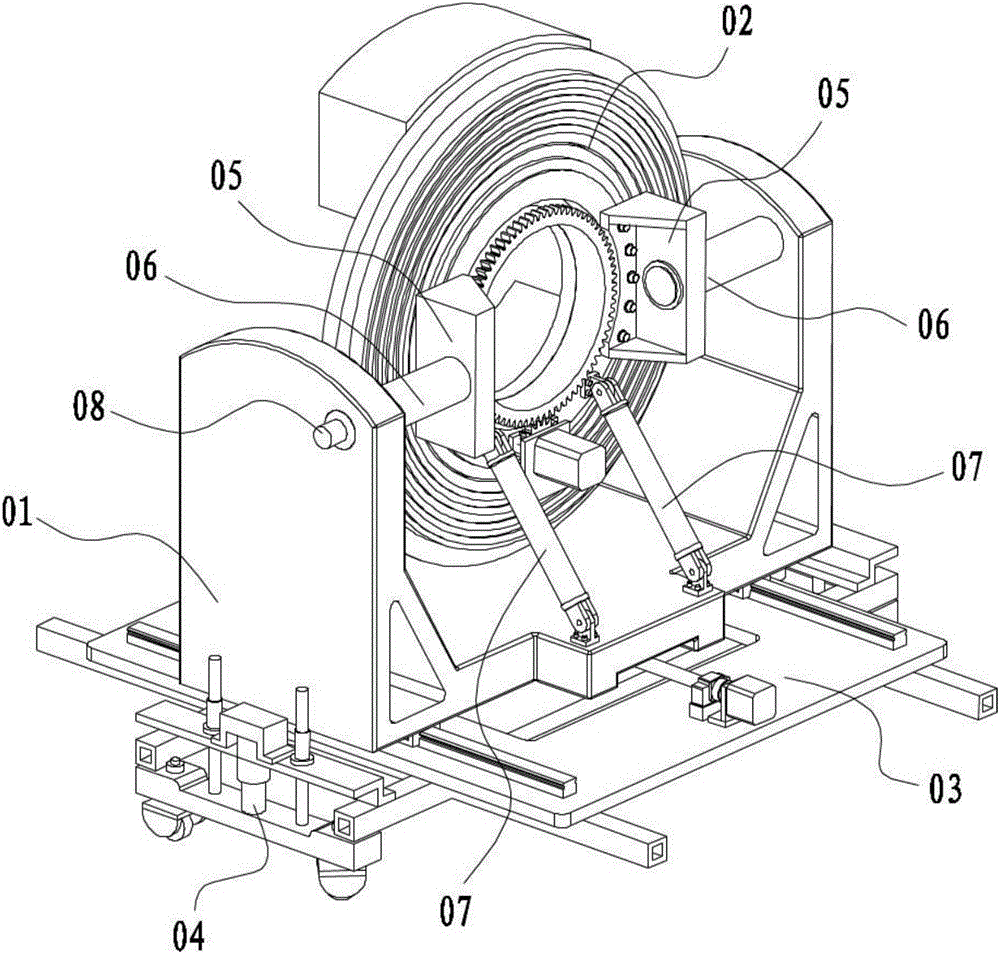

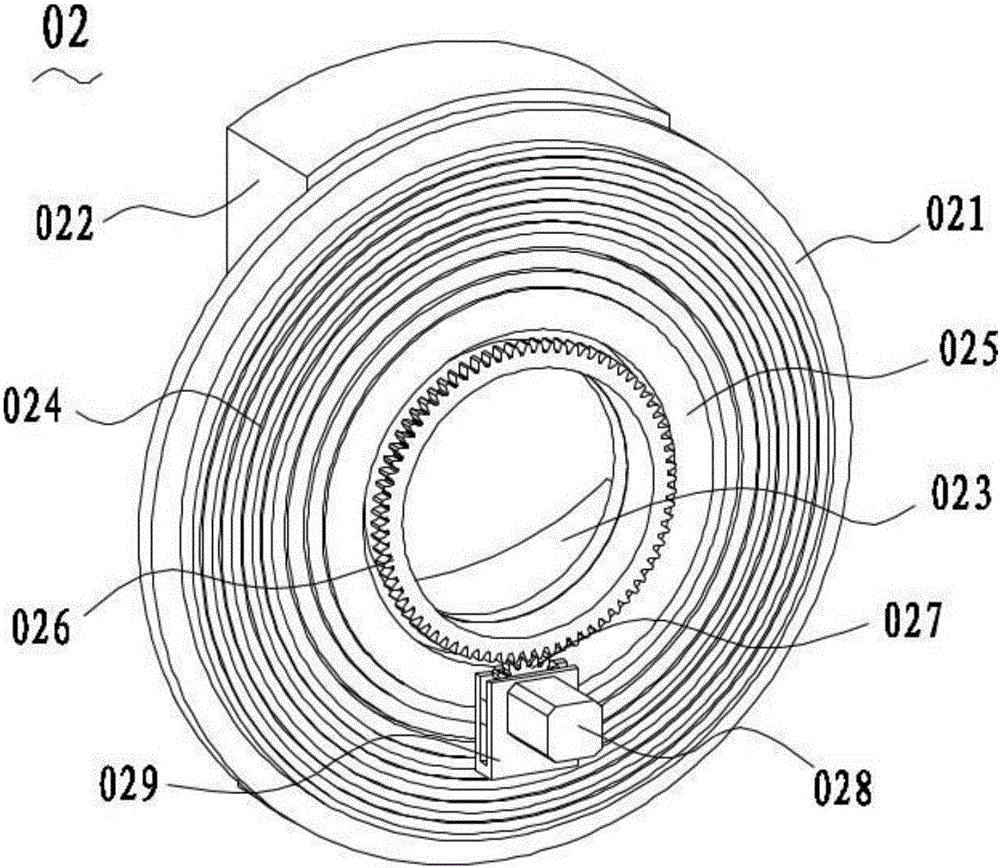

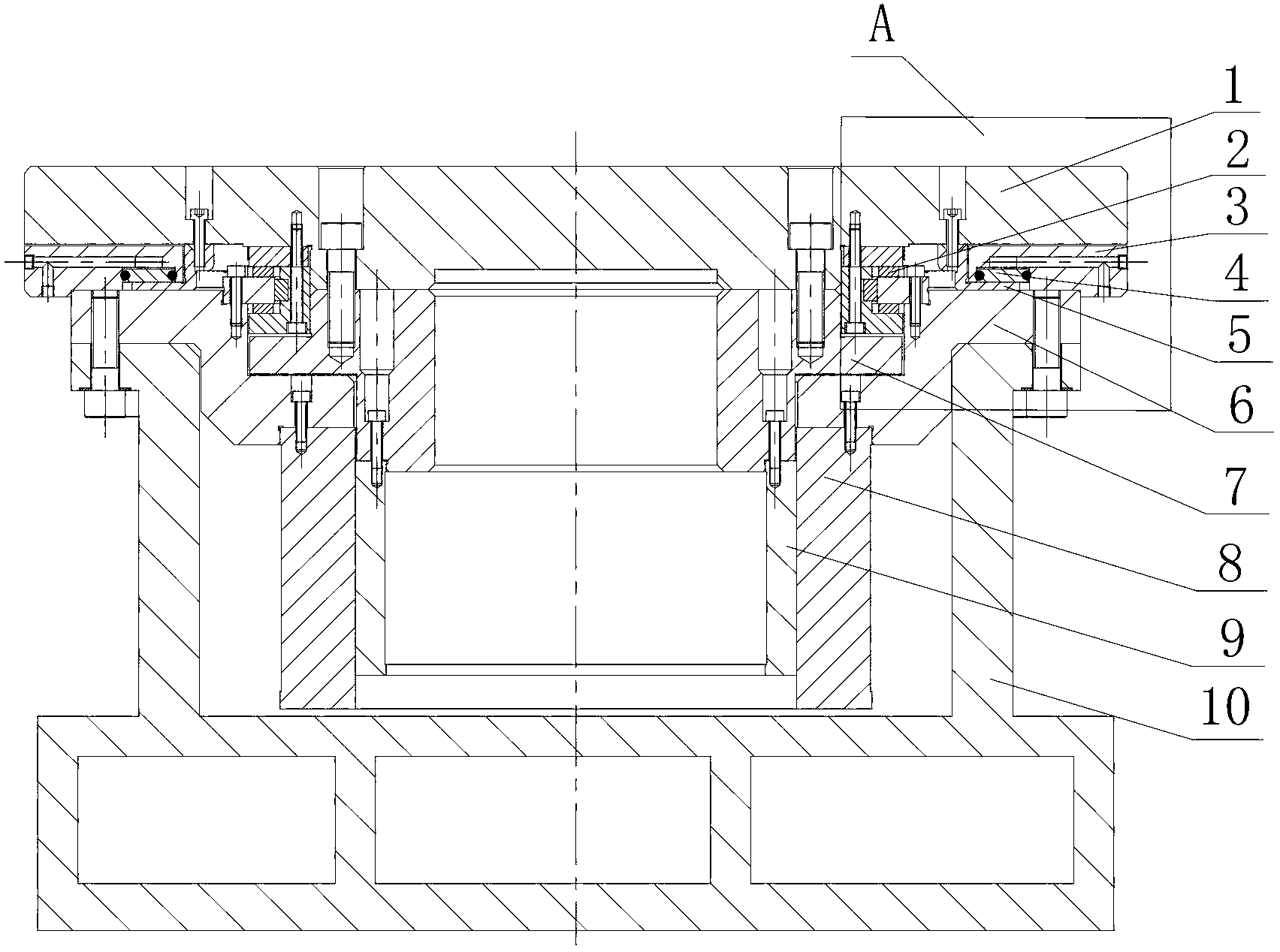

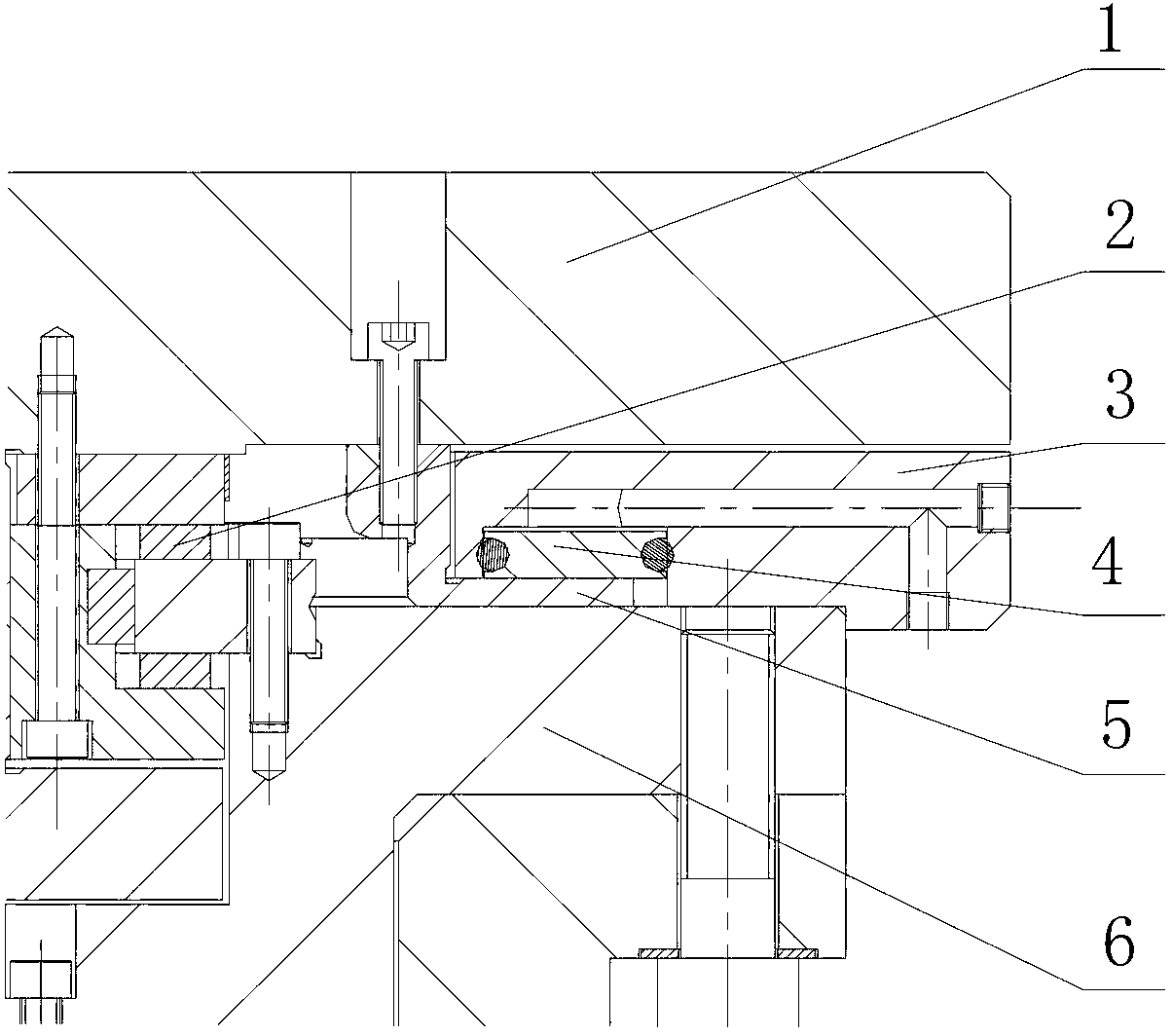

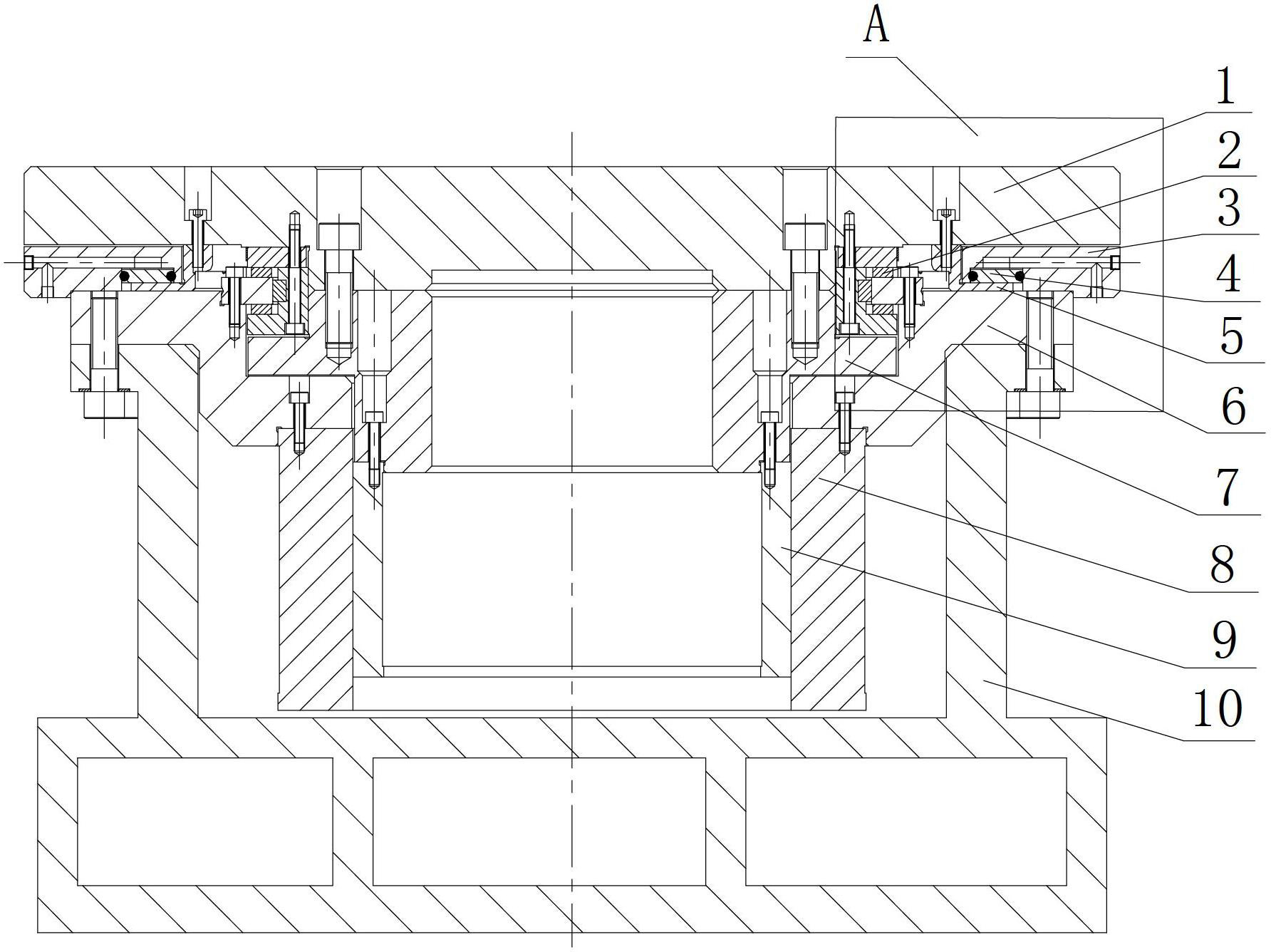

Movable computer tomography device

InactiveCN105877771AAchieve rotary motionSuitable for scanning imagingComputerised tomographsTomographyMotor driveTomography

The invention discloses a movable computer tomography device which comprises a supporting base, a scanning system, a linear driver and a connection shaft. The scanning system comprises a rotary plate, a bulb tube, a detector, a sliding ring, a driven gear, a driving gear and a rotary motor, the bulb tube and the detector are fixed to the rear portion of the rotary plate, the sliding ring and the driven gear are fixed to the front portion of the rotary plate, the driving gear is in transmission with the driven gear in a matched mode, the rotary motor drives the driving gear to rotate, and a bearing is further arranged on the front portion of the rotary plate; one end of the linear driver is hinged to the supporting base, and the other end of the linear driver is hinged to the inner ring of the bearing; one end of the connection shaft is fixedly connected with an angle block, the angle block is fixedly connected to the inner ring of the bearing, the other end of the connection shaft is in pivot connection with the side of the supporting base, and the other end of the connection shaft is connected with an encoder. The movable computer tomography device is safe, reliable and high in transmission precision, and the scanning system can work in a certain dip angle state.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

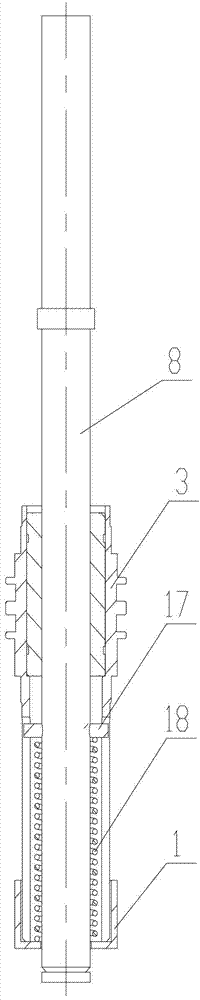

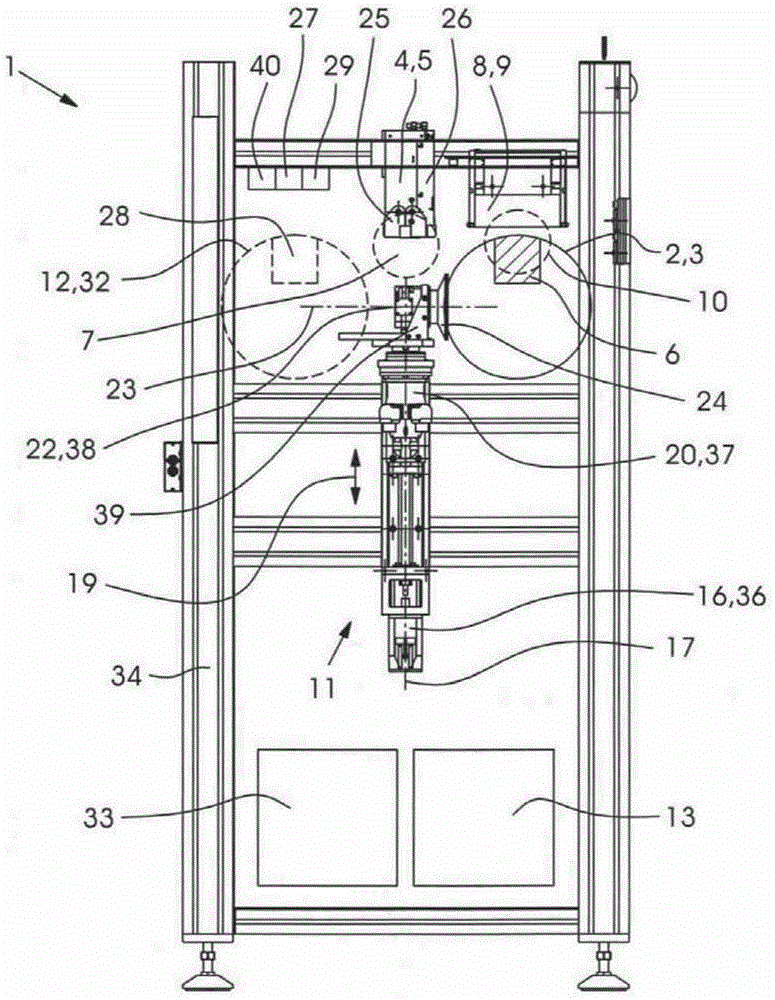

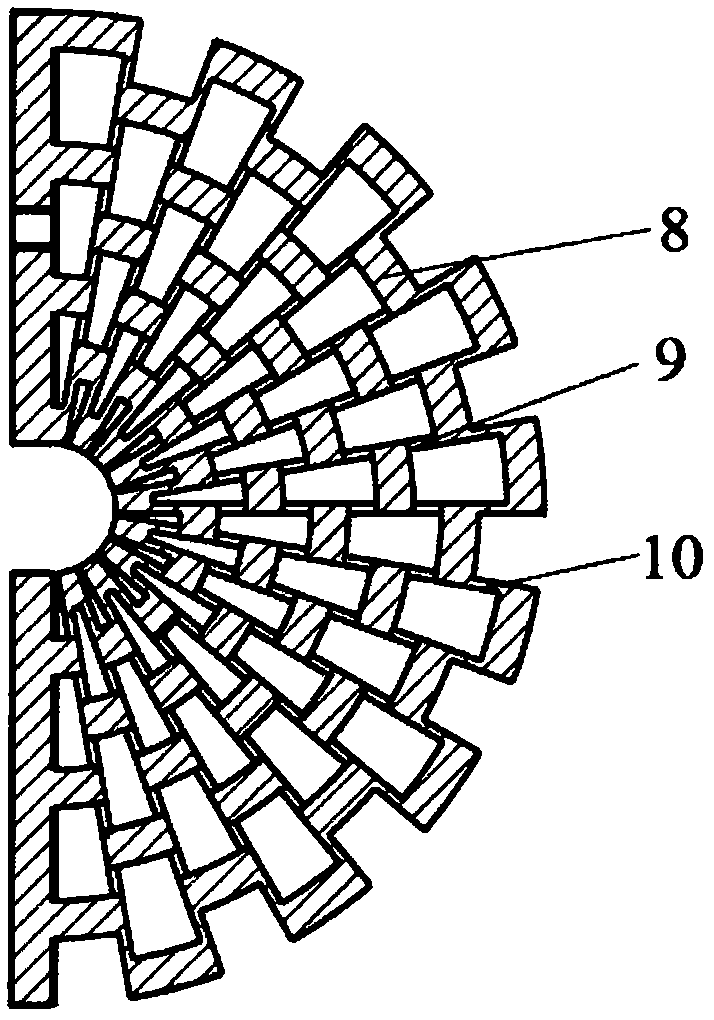

Module type high-speed mounting head for chip mounter

ActiveCN102869201ASimple structureCompact structurePrinted circuit assemblingElectric machineSurface mounting

The invention discloses a module type high-speed sticking head for a chip mounter and relates to the field of chip mounters of electronic surface mount, aiming at providing a module type high-speed sticking head which is simple in overall structure, small in size, light in weight, high in mounting efficiency, good in precision, flexible to integrate, easy to control and convenient to maintain. The module type high-speed sticking head comprises a mounting head fixing bracket, a belt wheel bracket, a mounting main shaft, an elevating mechanism and a rotating mechanism, wherein the belt wheel bracket, the mounting main shaft, the elevating mechanism and the rotating mechanism are connected with the mounting head fixing bracket; the elevating mechanism comprises a servo linear motor, a linear motor push rod and a pressing block, wherein the servo linear motor is installed on the mounting head fixing bracket; the pressing block is connected with the linear motor push rod; and the rotating mechanism comprises a stepper motor, a small belt wheel, an O-shaped belt and a belt wheel shaft, wherein the stepper motor is installed on the belt wheel bracket; and the belt wheel shaft is elastically connected with the mounting main shaft longitudinally.

Owner:JIANGSU NANJIXING TECH +1

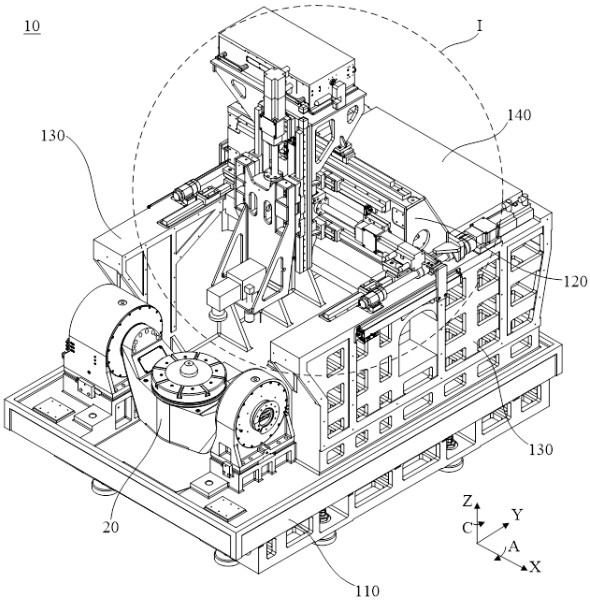

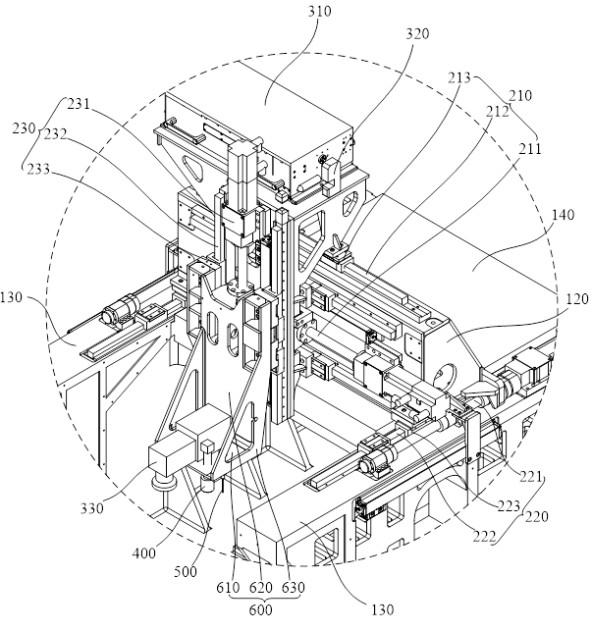

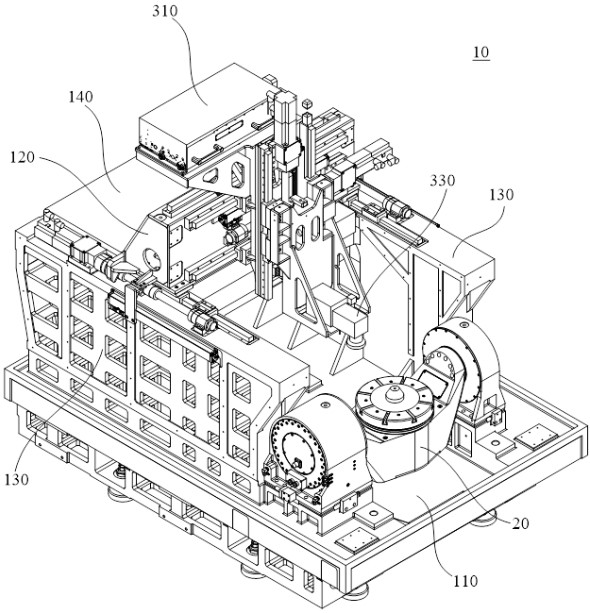

Five-axis laser milling machine tool

PendingCN112207430ASolve processing and manufacturing problemsSmooth machining processLaser beam welding apparatusLinear motionLaser processing

The invention relates to a five-axis laser milling machine tool. The five-axis laser milling machine tool comprises a rack, a mechanical motion assembly and a laser machining assembly; the rack comprises a base, an X-axis mounting frame and two Y-axis mounting frames; the mechanical motion assembly comprises an X-axis motion assembly, a Y-axis motion assembly and a Z-axis motion assembly; the laser machining assembly comprises a laser device, a light path system and a three-dimensional scanning galvanometer module; the X-axis motion assembly, the Y-axis motion assembly and the Z-axis motion assembly are used for carrying the laser machining assembly to conduct linear motion in the X-axis direction, the Y-axis direction and the Z-axis direction correspondingly; the X-axis motion assembly, the Z-axis motion assembly and the Y-axis motion assembly are installed on the Y-axis mounting frames to form a portal frame structure machine body, and stability is achieved in the machining motion process to improve machining precision; the X-axis motion assembly, the Y-axis motion assembly, the Z-axis motion assembly, an AC-axis rotary table and a three-dimensional scanning galvanometer are adopted for conducting linkage motion control over the laser machining assembly, the machined tool and the laser beams correspondingly, one-time laser machining forming of the tool is achieved, the machining efficiency and the machining quality are effectively improved, and the machining and manufacturing problems of high-end tools can be solved.

Owner:CONPROFE TECH GRP CO LTD +2

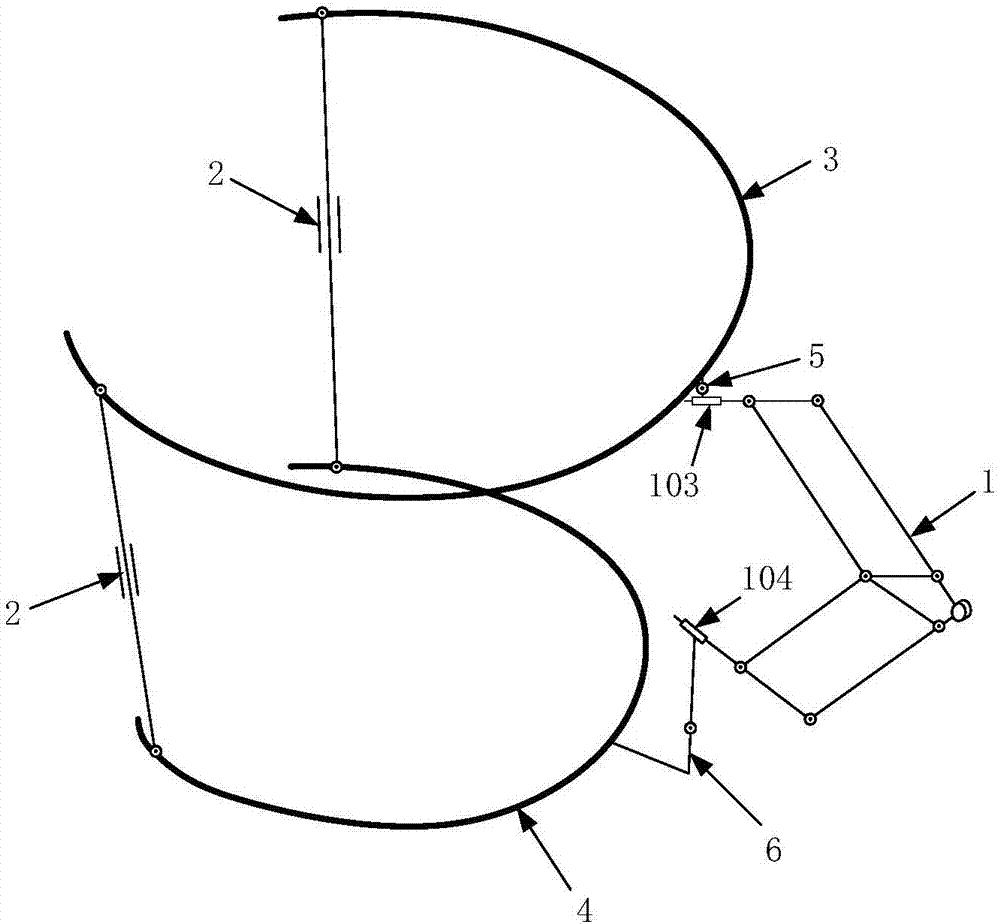

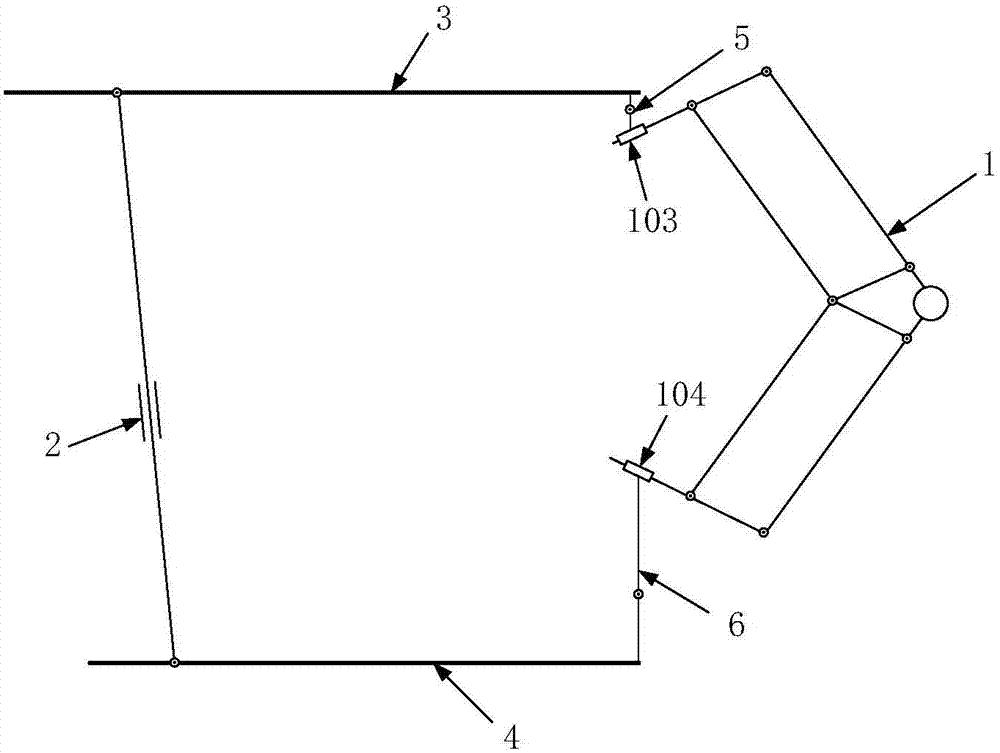

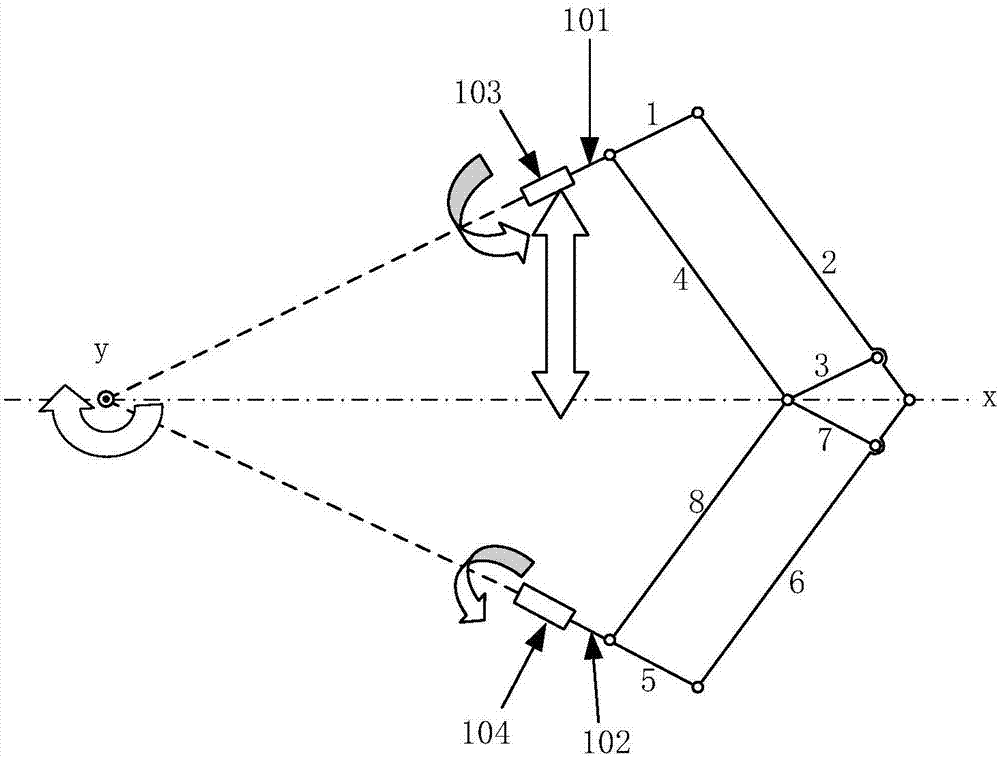

Human body hip joint wearable type assisting device with RCM three-freedom-degree rotation

ActiveCN106926220AAnatomical fitAchieve rotary motionProgramme-controlled manipulatorHuman bodyMain branch

The invention discloses a human body hip joint wearable type assisting device with RCM three-freedom-degree rotation. Three multi-connecting-rod mechanisms restraining the three rotating freedom degrees are used as main branch chains, and two auxiliary driving branch chains are used. The main branch chains and the auxiliary driving branch chains are both connected with a waist bracket and leg brackets. Each main branch chain is composed of two adjacent parallelogram mechanisms coinciding at one point, and a rotating shaft 1 virtually perpendicular to the paper face, a rotating shaft 2 and a rotating shaft 3 jointly form a decoupling three-freedom-degree rotating mechanism rotating around an intersection point, wherein the rotating shaft 2 and the rotating shaft 3 intersect with the rotating shaft 1. The other two freedom degrees of each main branch chain are retrained by the other two auxiliary driving branch chains in the UPS structural type. According to the human body hip joint wearable type assisting device with RCM three-freedom-degree rotation, the waist bracket and the leg brackets are installed on the waist and the legs of a human body correspondingly, a user can adopt two using manners of a push-pull using manner and a carrying-on-the-back manner as required, influences of the load of a function driving system on the user are reduced, and the limitation of the load factor on the size and the weight of the energy system is avoided.

Owner:BEIHANG UNIV

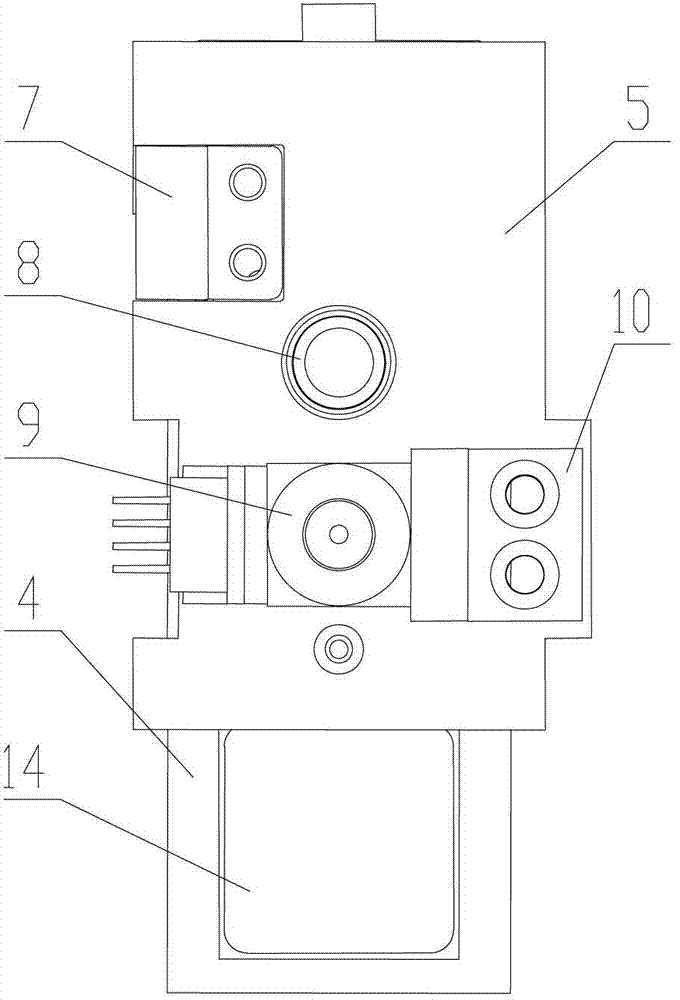

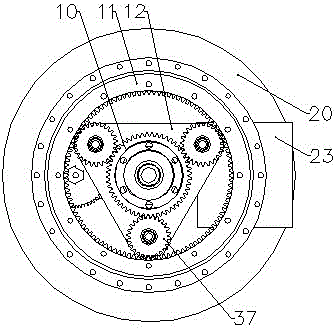

Mechanism for mechanical steering control of steering gear

InactiveCN104440912ASimple operation and controlThe base part is flexibleProgramme-controlled manipulatorClutchMagnet

Disclosed is a mechanism for mechanical steering control of a steering gear. A reversing gear bracket (18) is fixedly connected on a base (20), and a gear reversing system composed of a reversing gear wheel (14), a reversing gear shaft (15), a reversing pinion (16) and a reversing pinion (17) is mounted on the reversing gear bracket (18); a tooth coupling (13) is nested in an unthreaded hole of a sun gear bracket (12) and connected with a sun gear (10); the sun gear (10) forms a sun gear train with a turntable bearing ring gear (11) through three planet gears (37); two worm shafts (2), a clutch magnet (6), a worm reversing gear wheel (33), a worm reversing gear shaft (34), a worm reversing pinion (35), a worm reversing pinion (36) and a thrust bearing (9) are mounted on a rotary support (3); a clutch gear (8), the clutch magnet (6) and a clutch gear (4) sleeve a spindle (30).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Wheel-leg composite driving mechanism for amphibious spherical robot

The invention discloses a wheel-leg composite driving mechanism for an amphibious spherical robot, and belongs to the technical field of underwater robots. The wheel-leg composite driving mechanism comprises two or more mechanical legs distributed along the bottom of the spherical robot and a liftable sliding joint located at the bottom center of the spherical robot; when the liftable sliding joint rises, universal wheels at the bottom do not make contact with the ground, when the liftable sliding joint falls, the universal wheels at the bottom make contact with the ground, and the spherical robot is lifted to the preset height; and the four mechanical legs can move in the circumferential direction of the spherical robot and matched with the liftable sliding joint in a falling state to achieve sliding of the spherical robot, in addition, the four mechanical legs are matched with the liftable sliding joint in a rising state to achieve crawling of the spherical robot. The wheel-leg composite driving mechanism adopts different movement modes aiming at different terrain, and movement in the underwater environment, crawling of rugged road surfaces and sliding on flat road surfaces are achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Shrub pruning machine

PendingCN107242035AImplement pruning workAchieve rotary motionHedge trimming apparatusCuttersEngineeringShrub

The invention discloses a shrub pruning machine, comprising a bottom plate; a support and a support adjuster are mounted on the bottom plate; a pruning driving device and a pruning transmission device are mounted on the support; the pruning driving device is connected with the pruning transmission device; the pruning transmission device is connected with a pruning device. The problem that existing manual shrub pruning has high cost and low efficiency is solved, and the shrub pruning machine having high efficiency and suitable for pruning shrubs of different sizes into various styles is provided.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

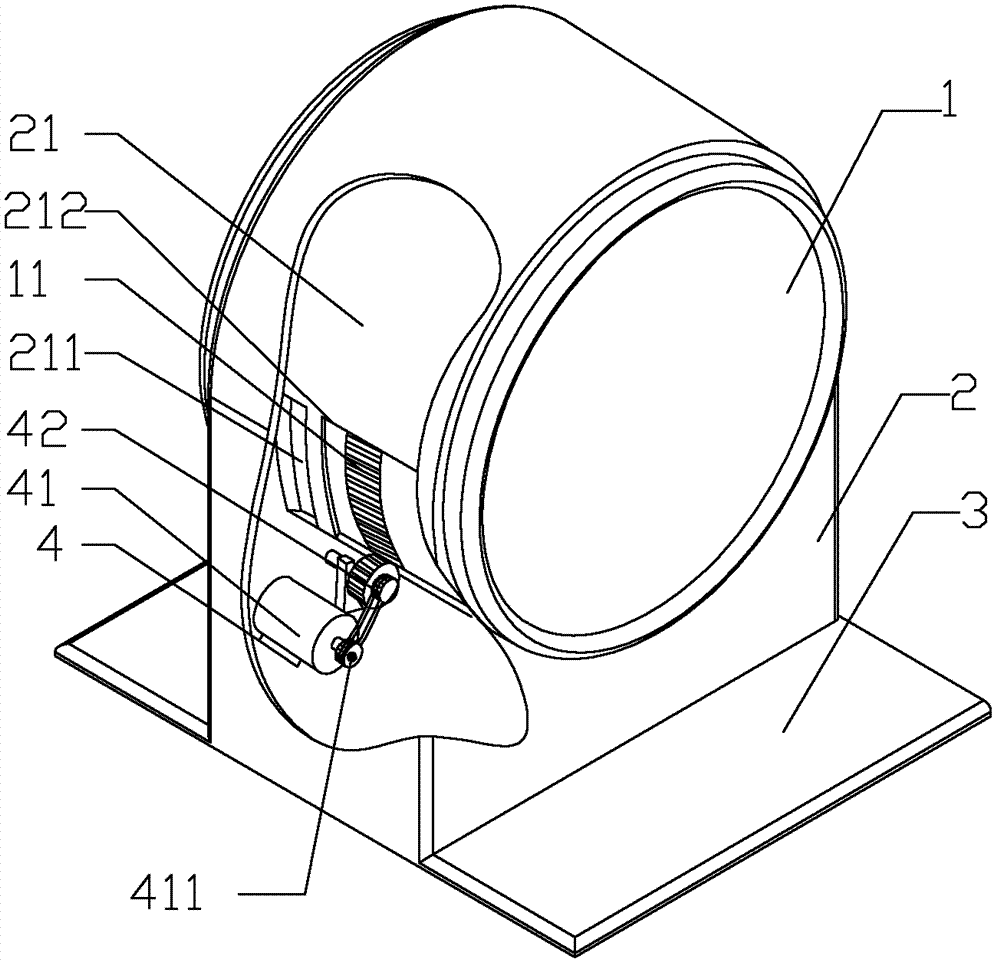

Rolling tube amusement tool

InactiveCN102784481ASimple but strong connection structureSimple but solid operationRolling drumsEngineeringMechanical engineering

Owner:ZHEJIANG DONGYANG DONGYA TOOLS

Precision numerical control rotary workbench

InactiveCN102699691AAdd positioning functionLarge transmission torqueLarge fixed membersNumerical controlTorque motor

The invention relates to a precision numerical control rotary workbench which comprises a workbench base, a workbench spindle and a spindle mandrel fixedly connected with the workbench spindle, wherein a support sleeve is fixedly connected on the workbench base, a rotary workbench bearing outer race and a hydraulic clamping cylinder are installed on the support sleeve, a torque motor stator is fixedly connected on the bottom of the support sleeve, the workbench spindle is installed on the inner race of the rotary workbench bearing, a torque motor rotor is connected below the spindle mandrel, a hydraulic clamping cylinder spring compaction sheet is installed below the workbench spindle, a hydraulic clamping cylinder piston is assembled in a groove of the hydraulic clamping cylinder, and the hydraulic clamping cylinder piston is in contact with the hydraulic clamping cylinder spring compaction sheet. The precision numerical control rotary workbench has the advantages of increasing the bench surface precision and the positioning precision of the workbench under the action of unbalance load impact force, the transmission torque is large, and the assembly is simple and reliable; and the precision numerical control rotary workbench has self-locking function, so that the torque motor can work discontinuously, and the electric energy is saved.

Owner:TIANJIN NO 1 MACHINE TOOL WORKS

Apparatus for printing a curved surface of an object

InactiveCN104943404ARealize linear motionAchieve rotary motionTypewritersOther printing apparatusRadiant heaterControl cell

An apparatus for printing a curved surface of an object, for example a ball includes a stationary printing unit for printing the object, the printing unit including an inkjet print head producing a print on the object surface in an active region of the print head, a curing unit for curing the print, the curing unit including a radiant heater curing the print in an active region of the radiant heater, a movable holding unit for receiving the object in a receiving region, moving the object from the receiving region into the active region of the print head, moving the object in the active region of the print head during production of the print and moving the object into the active region of the curing unit, and a control unit for controlling the movements of the holding unit, the production of the print and the curing of the print.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

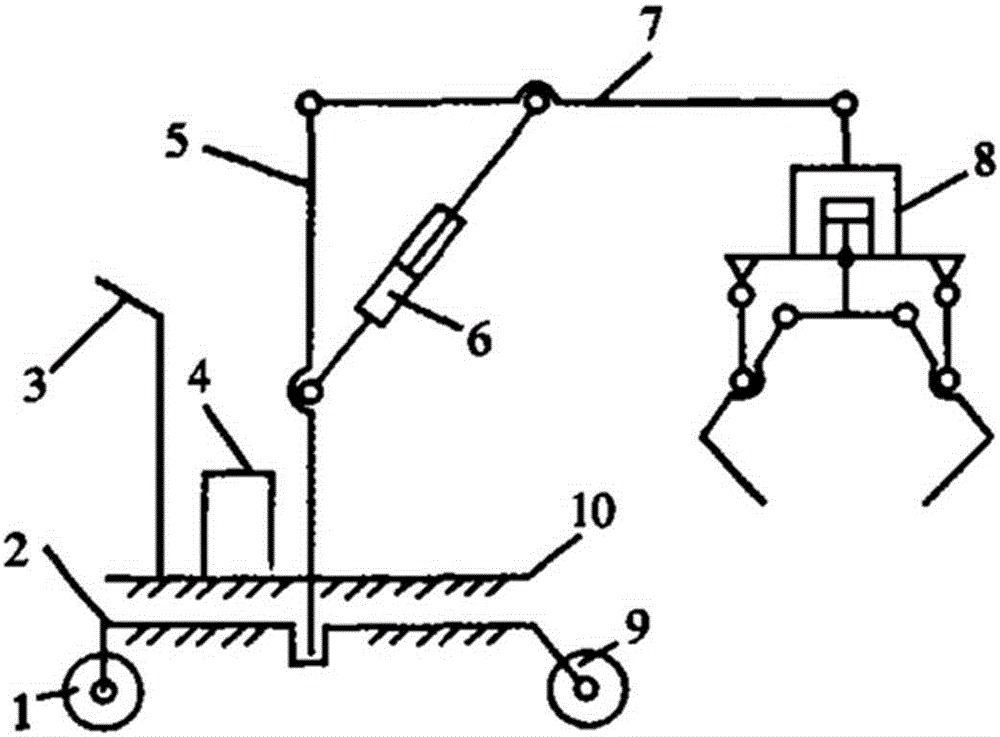

Garbage removal mechanical arm

InactiveCN106607863ASimple structureEasy to operateProgramme-controlled manipulatorHydraulic cylinderHand parts

A garbage removal mechanical arm is mainly composed of a hand part, a rocker, a stand column, a manual hydraulic pump assembly, a lifting hydraulic cylinder, a rotary disc, a base and the like. The body movement includes up-down swinging of the rocker, clockwise and anticlockwise rotation of the rotary disc and movement of wheels in any direction in the horizontal plane. The mechanical arm is used for grabbing, conveying and unloading garbage, and mechanical garbage removal is achieved. According to the mechanical arm, the labor load of operators can be relieved, the production efficiency is improved as well, and high application and popularization value is achieved.

Owner:张桂春

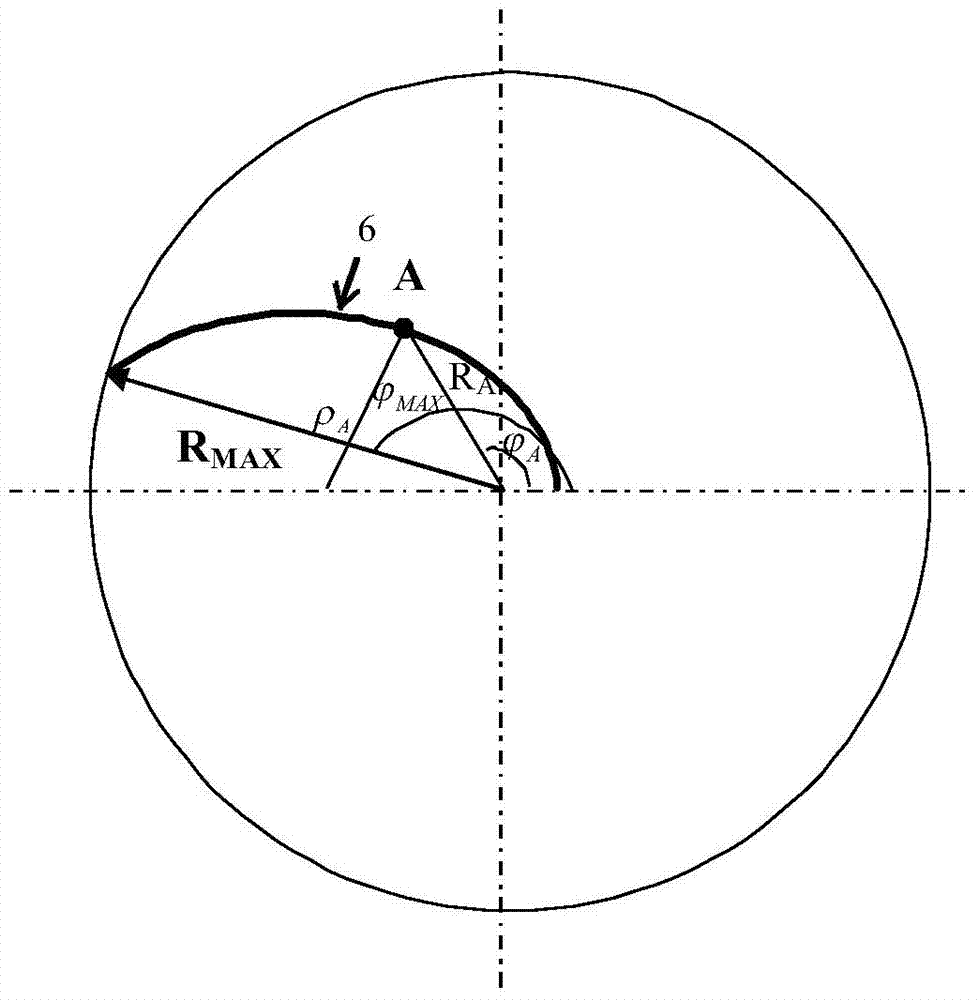

Negative pressure rotating type artificial muscle

InactiveCN108582058ANo explosionAchieve rotary motionProgramme-controlled manipulatorEngineeringPneumatic artificial muscles

The invention discloses a negative pressure rotating type artificial muscle. The negative pressure rotating type artificial muscle is made of elastic materials and is overall of a fan-shaped structure, internal air chambers and supporting columns are arrayed in a staggered mode, and the more the air chamber is away from the circle center, the larger the size of the air chambers is; and when the interior of the artificial muscle is vacuum, the circumferential supporting columns of the pneumatic artificial muscle are inserted into the adjacent air chambers, finally, the whole artificial muscle generates the fan-closing movement along the circle center, and the rotating moment is provided. The negative pressure rotating type artificial muscle can be applied to the field, such as medical rehabilitation, software robots, and bionic robots, needing flexible driving.

Owner:黄郁惠 +1

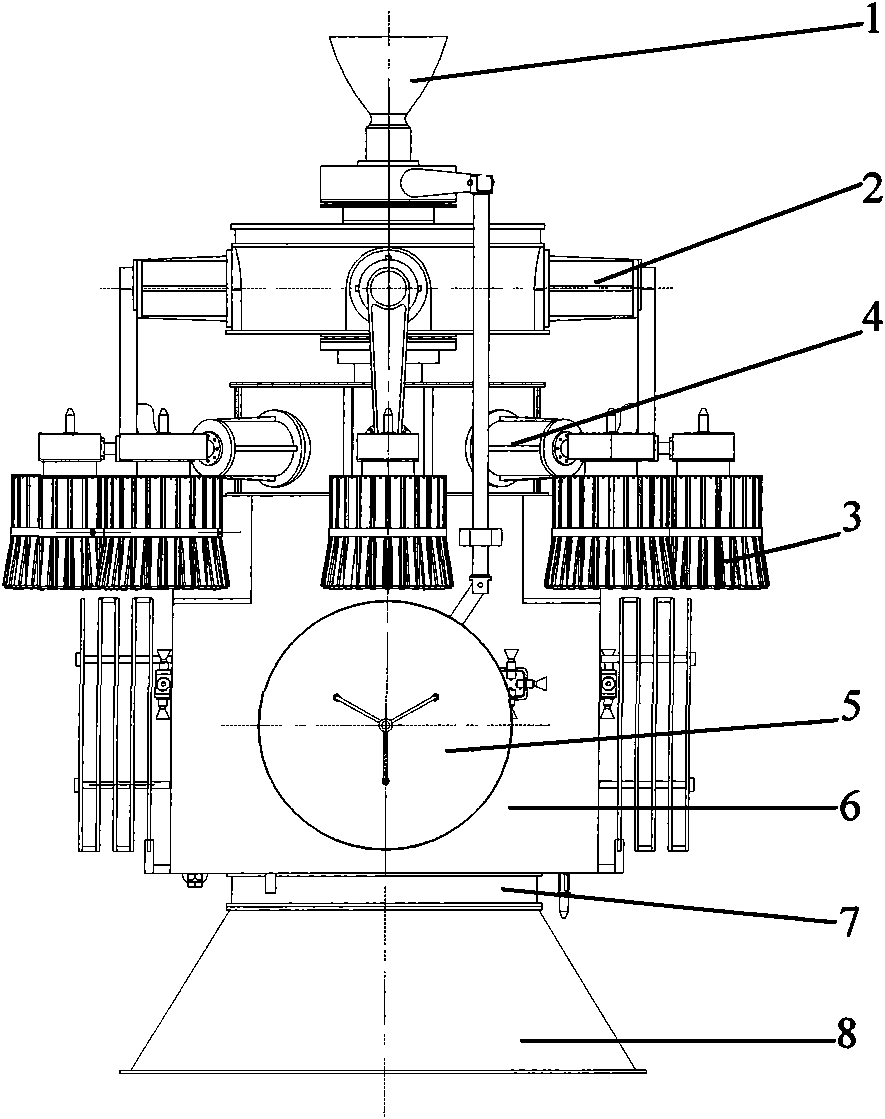

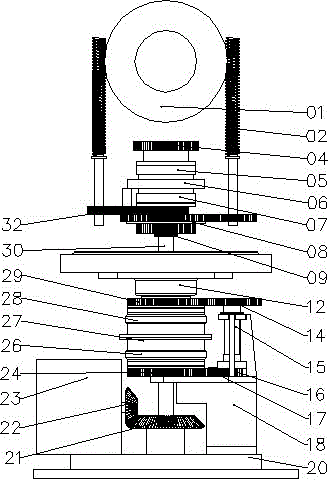

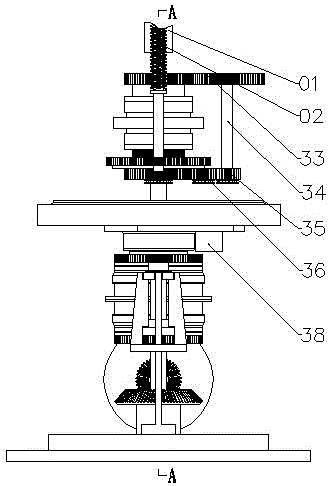

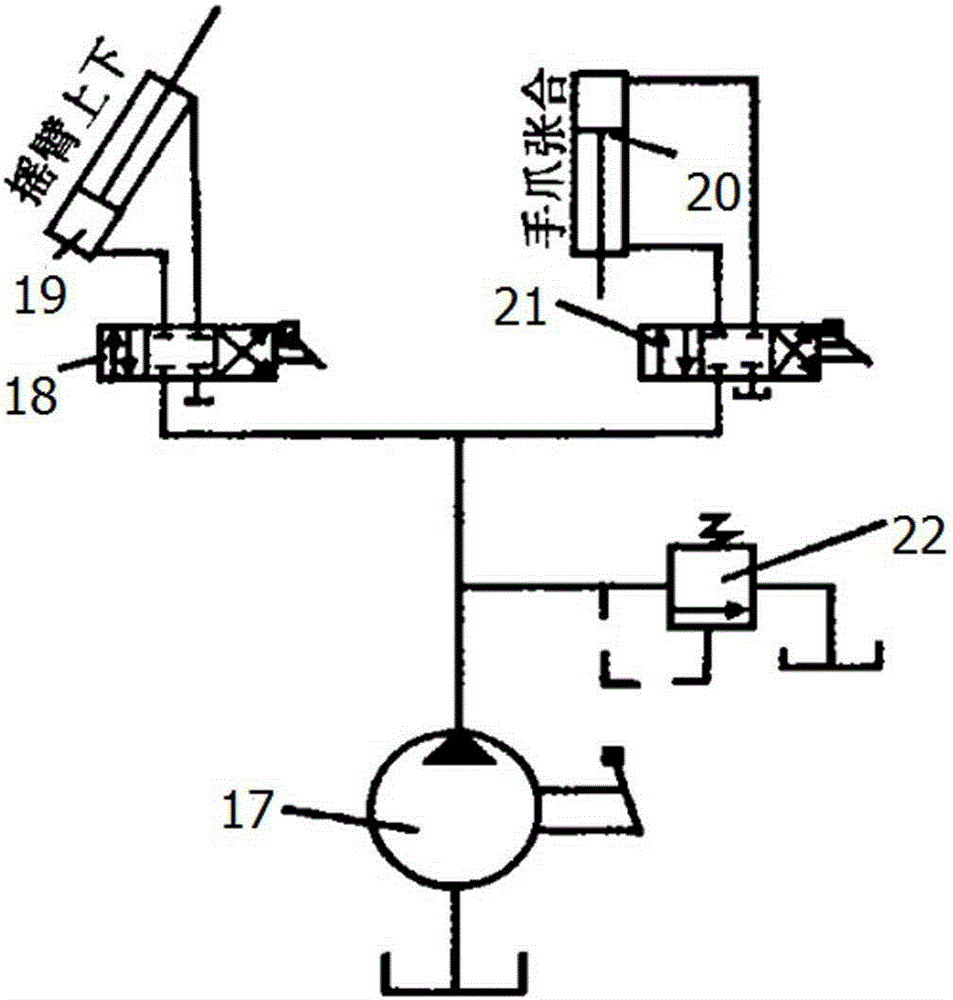

Variable camber groove grinding-based high-precision ceramic ball machining equipment

InactiveCN103567855AHigh precisionImprove consistencyLapping machinesWork carriersMachiningEngineering

Variable camber groove grinding-based high-precision ceramic ball machining equipment comprises a loading system, an upper grinding disc and a lower grinding disc; the upper and lower grinding discs are respectively connected with a driving device; the loading device is positioned on the upper grinding disc; a variable camber groove is formed in the lower grinding disc; the groove structure and the other grinding disc jointly form three machining contact points for grinding a ball blank to be machined; the equipment also comprises a workpiece circulation system; the inlet of the variable camber groove is connected with the outlet of the workpiece circulation system of which the inlet is connected with the outlet of the variable camber grove; the inlet of the variable camber groove is positioned in the center of the lower grinding disc. The variable camber groove grinding-based high-precision ceramic ball machining equipment can realize the higher machining precision and machining efficiency and demands on the equipment are lower.

Owner:ZHEJIANG UNIV OF TECH

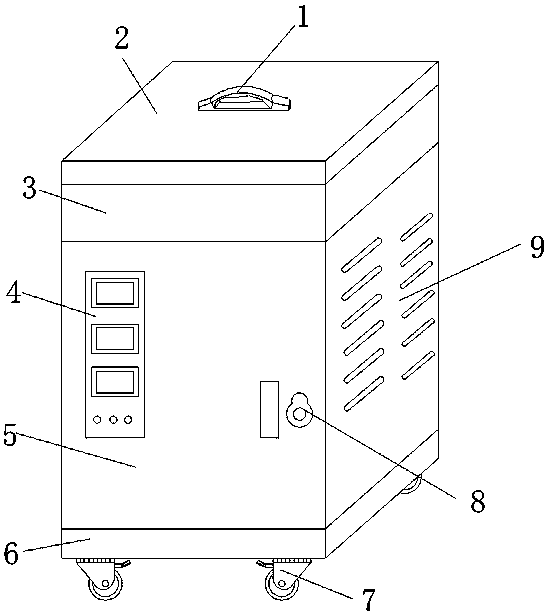

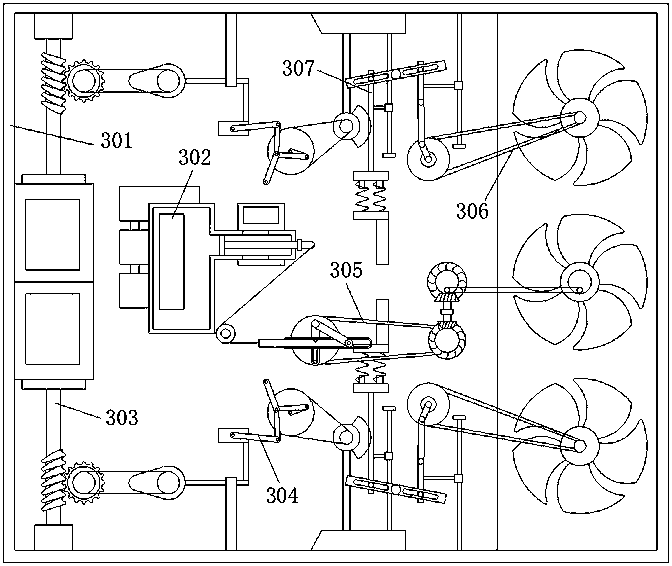

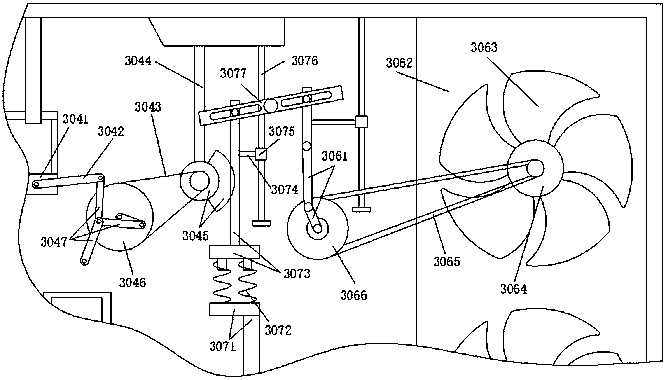

Portable agriculture power distribution device with heat radiation device

InactiveCN108400541AHeat dissipation fastImprove cooling effectSubstation/switching arrangement cooling/ventilationEngineeringAtmospheric pressure

The invention discloses a portable agriculture power distribution device with a heat radiation device. The portable agriculture power distribution device with the heat radiation device structurally comprises a handle, a box cover, a novel heat radiation device, a pressure display control board, a power distribution box, a support base, a universal wheel, a key hole and a ventilation board. The portable agriculture power distribution device with the heat radiation device drives a drive rod mechanism and a matching mechanism by controlling a motor brake device and realizes heat radiation of thepower distribution box through rotation of a radiating fan device; a person can control the work states of an upper draught fan and a lower draught fan based on the temperature condition of the powerdistribution box; and when the temperature is over-high and the two draught fans radiate heat slowly, an air brake device is driven based on an air pressure principle so as to realize rotation of a middle draught fan through a rotation mechanism. The heat radiation effect is enhanced, heat radiation can be carried out based on the actual condition of the power distribution device, a plenty of electric energy can be prevented from being wasted for heat radiation, rapid heat radiation of the power distribution box can be carried out in time, and the device is better protected.

Owner:李士钢 +2

Clamp special for nanoindenter

The invention relates to a clamp special for a nanoindenter. The clamp comprises the following components: four telescoping racks and workpiece clamping blocks are arranged on the upper surface of a workpiece supporting plate, the bottom parts of the telescoping racks are provided with telescoping slide blocks, and the workpiece supporting blocks and the telescoping slide blocks are embedded in atelescoping slide way; the tail ends of the telescoping racks are provided with electromagnets, an inclined gear is arranged below the workpiece supporting plate, and rotation supporting racks are arranged at the side of the workpiece supporting plate; the inclined gear and an inclined tooth bar are connected in engagement, the bottom of the inclined tooth bar is connected to a movable slide way by a movable slide bar, the slide bar is internally provided with a spring, and the end of a micrometer is connected to an inclined tooth bar in contact connection; the rotation supporting rack bottompart and a tooth bar rack are fixed at a rotating disk at the lower part; the inner side of the rotating disk is provided with gear teeth with inclination angles, the outside of a fixed disk is provided with uniformly distributed gear teeth, and the rotating disk is connected to the fixed disk in engagement connection through gear teeth. The clamp has simple operation, can realize multi-freedom motion of the workpiece, and ensures good contact between a pressure head and a workpiece to be measured in the working process of the nanoindenter with accurate and reliable experiment results.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

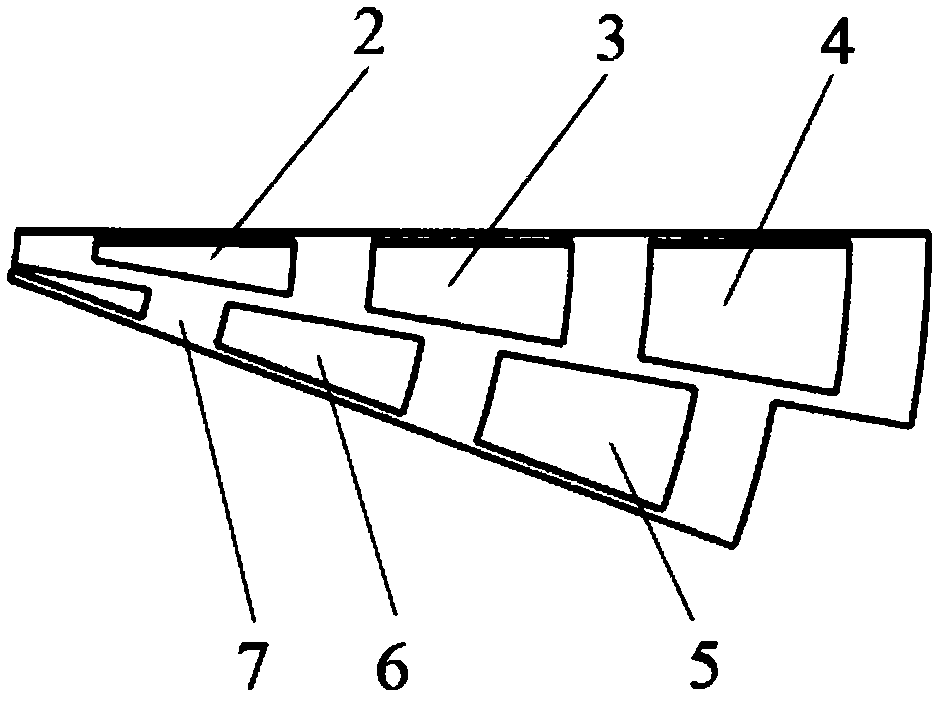

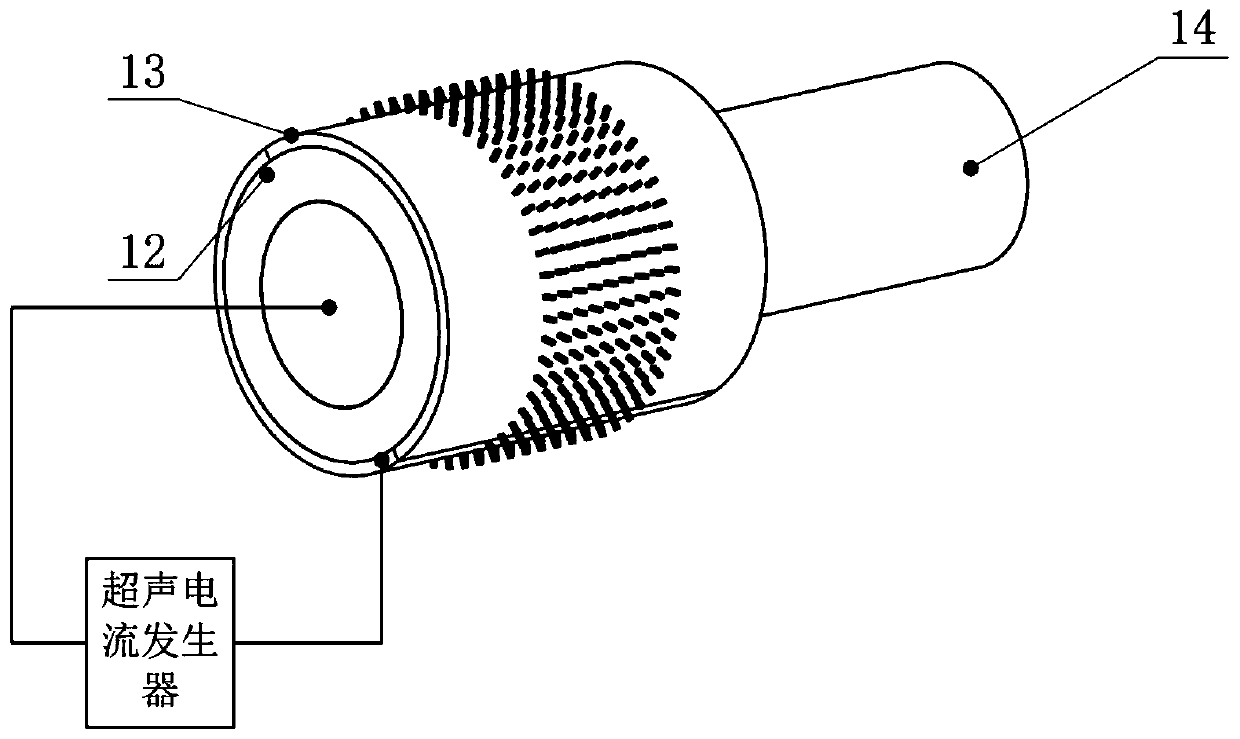

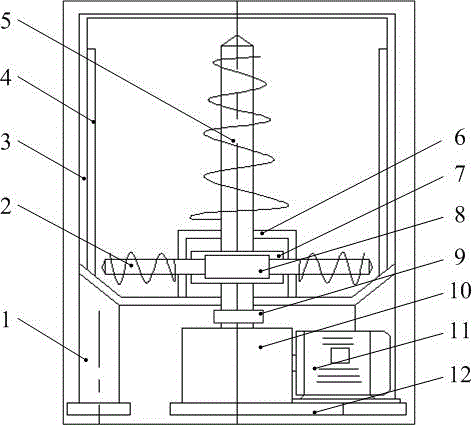

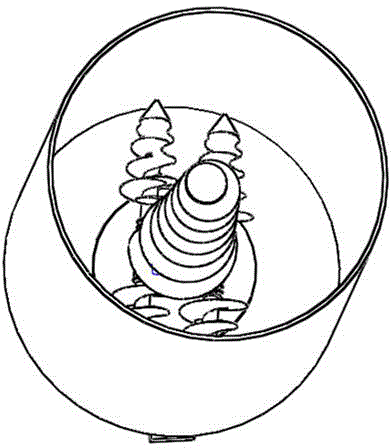

Micro-texture radial vibration auxiliary electrolytic machining method and device for inner wall of rotary body of thin-wall part

PendingCN110102846ASimple structureShort preparation cycleElectrochemical machining apparatusElectrical-based auxillary apparatusElectrolysisEngineering

The invention relates to a micro-texture radial vibration auxiliary electrolytic machining method for the inner wall of a rotary body of a thin-wall part. The method is characterized in that a tool cathode with a micro-boss texture on the surface and capable of doing radial vibration is connected with a negative electrode of the power supply, the tool cathode is connected with an ultrasonic current generator, a thin-wall rotary body workpiece is connected with a positive electrode of the power supply, and the columnar electrode on the tool cathode is arranged in a linear array mode; an electrolyte enters a reaction area between the tool cathode and the workpiece through a liquid supply pipe; a machine tool spindle drives the tool cathode to horizontally move in the peripheral direction according to a preset trajectory, a certain machining gap is reserved between the workpiece and the columnar electrodes on the tool cathode, the machine tool spindle drives the tool cathode to do autorotation motion, and the tool cathode connected with the ultrasonic current generator is used for constructing an ultrasonic energy field; the electrolyte flowing out at a high speed is sprayed onto theworkpiece to obtain the required machining morphology. The invention further provides an micro-texture radial vibration auxiliary electrolytic machining device for the inner wall of the rotary body ofthe thin-wall part. According to the method and the device, the centering property, the stability, the precision and the efficiency for machining the micro-texture of the inner wall of the rotary body are improved.

Owner:ZHEJIANG UNIV OF TECH

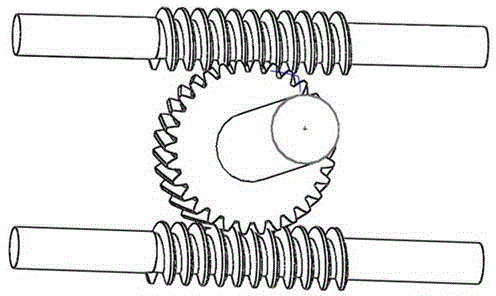

Vertical and horizontal double type efficient pulp shredder driven by single motor and without blind region

The invention provides a vertical and horizontal double type efficient pulp shredder driven by a single motor and without a blind region. The vertical and horizontal double type efficient pulp shredder mainly comprises a shell structure, a driving device, a transmission device and a pulp shredding device, and is characterized in that a vertical pulp shredder rotor and a horizontal pulp shredder rotor are driven by the single motor, and a worm wheel and worm rod transmission mechanism is used for realizing synchronous movement of the vertical pulp shredder rotor and the horizontal pulp shredder rotor, so that all-directional pulp shredding of the pulp shredder is realized, and a bottom pulp shredding blind region is eliminated. By the aid of the vertical and horizontal double type efficient pulp shredder, the whole pulp shredding of shredded materials is realized by the vertical pulp shredder rotor, and the pulp shredding of a bottom working blind region is realized by the horizontal pulp shredder rotor; the supporting of the vertical pulp shredder rotor and the horizontal pulp shredder rotor, and the sealing of the worm wheel and worm rod transmission mechanism are realized by a protection cover with a bearing hole; a fluid 'rotary cake' is eliminated by a convex baffle with a sector-shaped structure and the crushing efficiency is increased; the equipment has high efficiency and low energy consumption.

Owner:UNIV OF JINAN

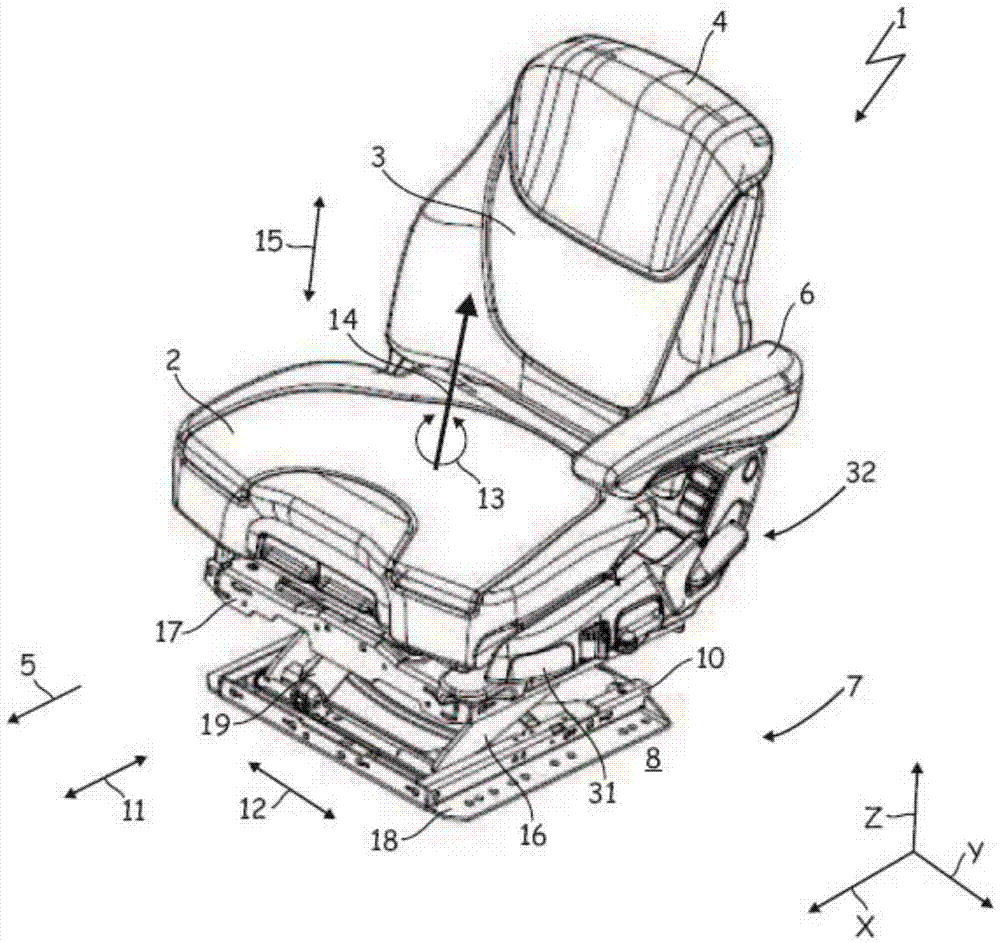

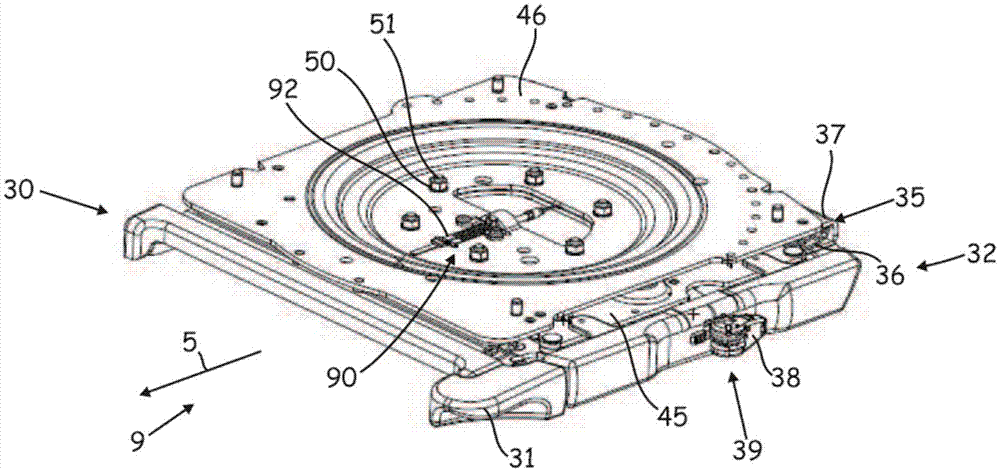

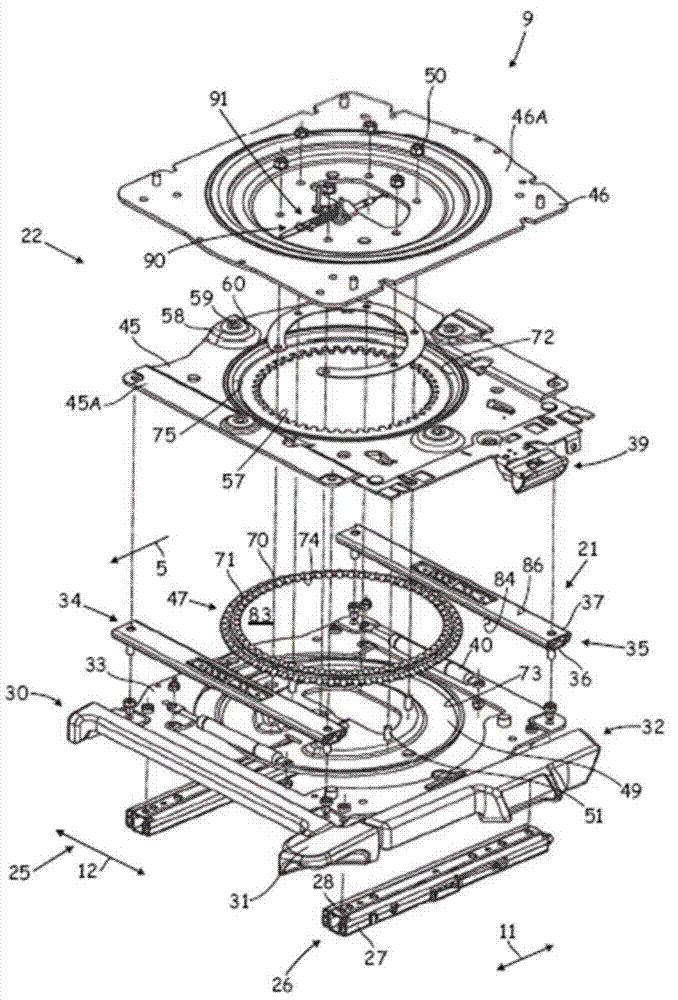

Utility vehicle seat with integrated rotation adjustment device

ActiveCN103863149AReduce design heightReduce the height of the structureMovable seatsBall bearingEngineering

The invention relates to a utility vehicle seat with a seat part, with a backrest part and with a seat substructure for arrangement on a bodywork part of a utility vehicle. The seat substructure including a rotation adjustment device having a roller body bearing unit for rotating at least the seat part about a vertical axis, a longitudinal adjustment device and a transverse adjustment device. The rotation adjustment apparatus is arranged between two longitudinal rail units or transverse rail units, in such a way that a vertical extension of the rotation adjustment apparatus amounts to a maximum of 150% or 100% of a vertical extension of the longitudinal rail units or the transverse rail units.

Owner:GRAMMER AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com