Mechanism for mechanical steering control of steering gear

A rudder control and mechanical technology, applied in manipulators, program control manipulators, manufacturing tools, etc., can solve the problems of rudder shaking easily, rudder and chip damage, etc., to avoid rudder shaking, simple operation and control, The effect that the base part is flexible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

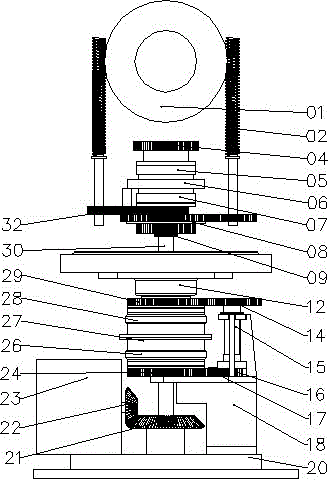

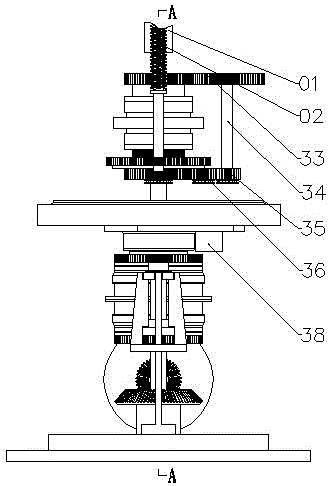

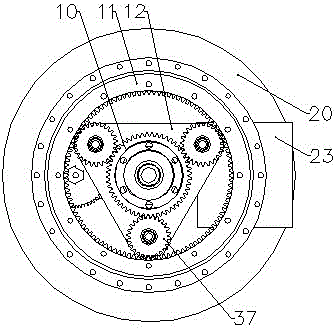

[0007] like Figure 1~Figure 5 As shown, the present invention is a mechanism for mechanically controlling steering gear steering, a mechanically controlling forward and reverse base mechanism for a mechanical arm, including a housing 19, a motor 23 that can be fixedly mounted on a base 20, and the base 20 can be fixed Installed on the shell 19. The reduction bevel gear 21 is fixedly connected on the main shaft 30, and the reversing gear bracket 18 is fixedly connected on the base 20, and the reversing gear bracket 18 is equipped with a reversing bull gear 14, a reversing gear shaft 15, a first reversing gear The gear reversing system that pinion 16, the second reversing pinion 17 form. The reversing bull gear 14, the first reversing pinion 16 are fixedly connected with the reversing gear shaft 15, and the second reversing pinion 17 is then vacantly sleeved on an axle at its position. The first clutch electromagnet 27 of dual-clutch device is installed on the shell 19, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com