Apparatus for printing a curved surface of an object

A technology of curved surfaces and objects, applied in printing, printing devices, typewriters, etc., which can solve problems such as collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

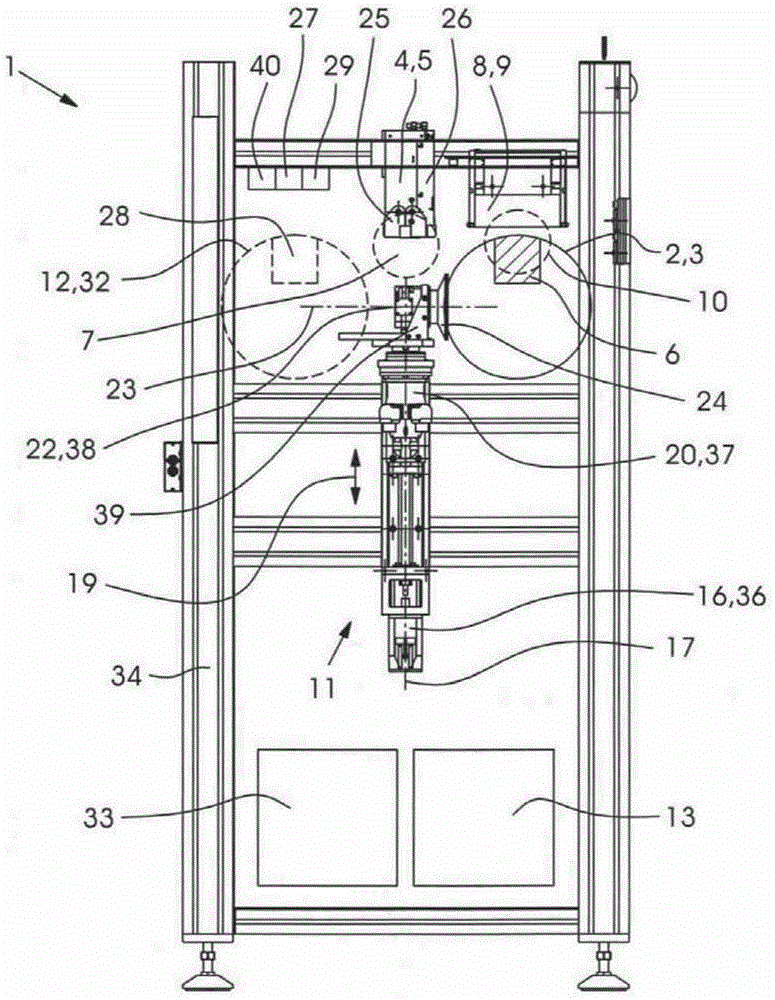

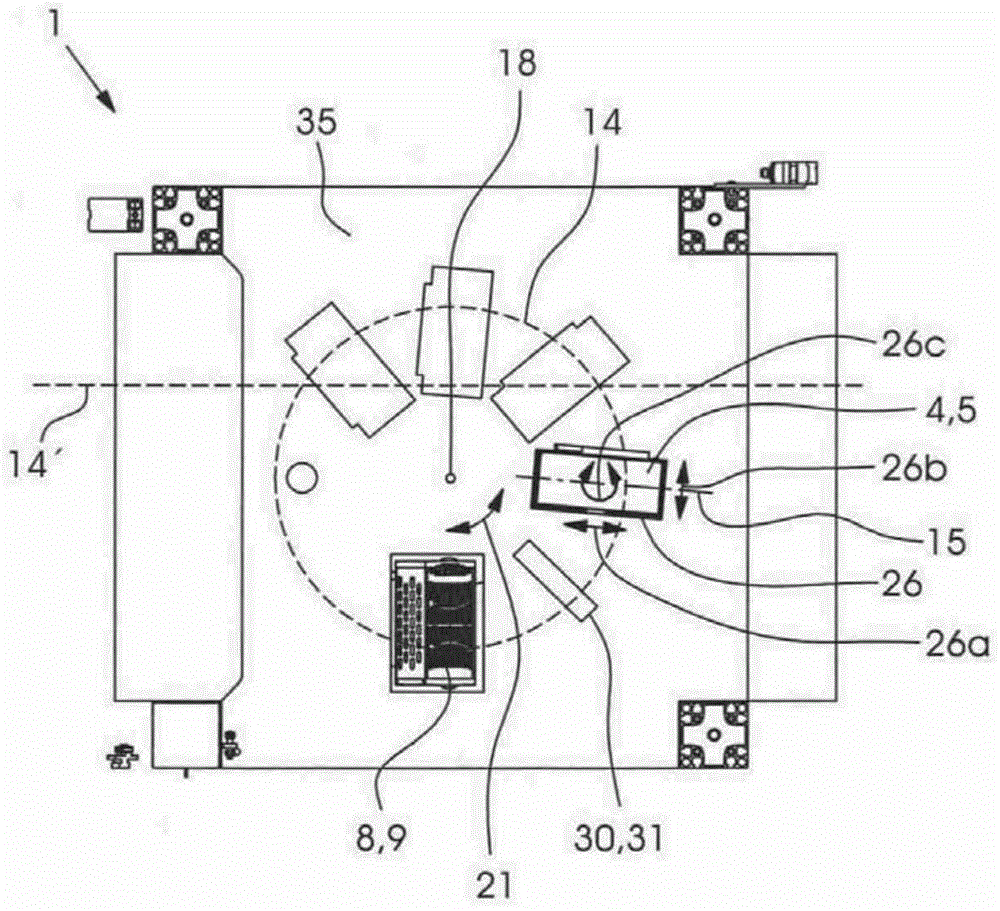

[0028] figure 1 A side view of a preferred embodiment of the device 1 according to the invention for the individual printing of surfaces 3 curved in any direction of a three-dimensional moving object 2 is shown. The object may for example be a ball. figure 2 A plan view of the same preferred embodiment of the device 1 according to the invention is shown. Mutually corresponding elements are provided with the same reference numerals in both figures.

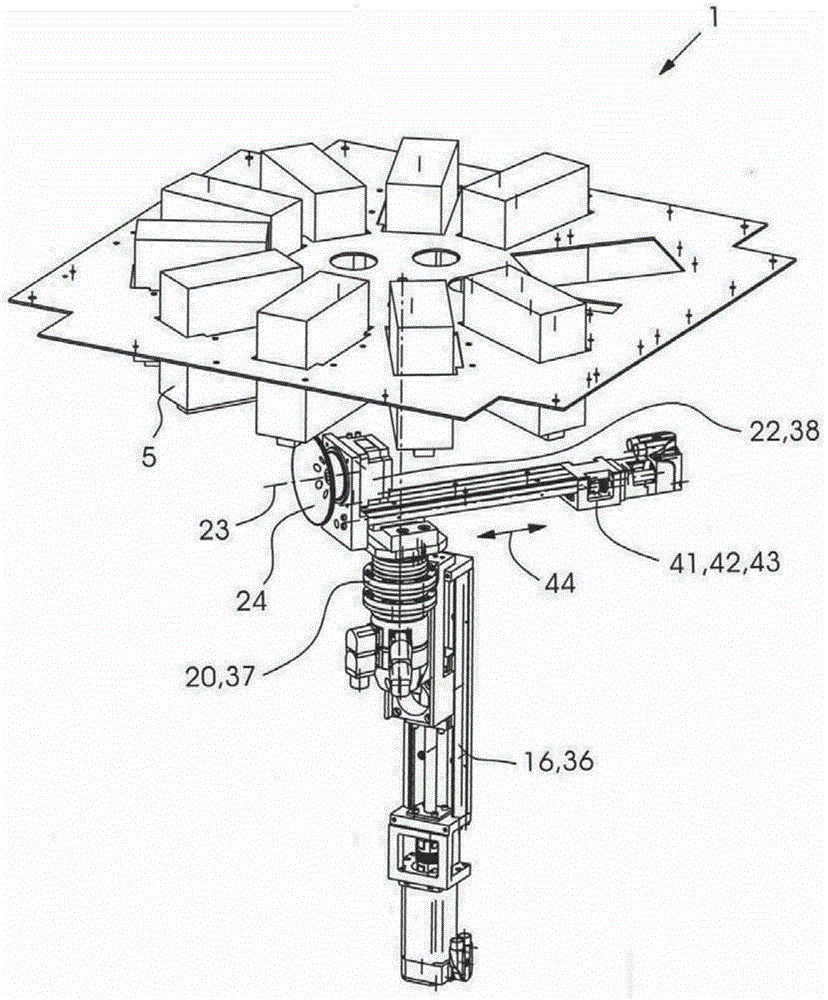

[0029] The device 1 comprises a printing unit 4 . The printing unit is arranged stationary in the upper region of the device. The printing unit includes an inkjet printing head 5 . The print head is received in an orientation unit 26 of the printing unit. The orientation unit is arranged in an opening of a horizontally arranged plate 35 of the frame 34 of the device 1 . The plate has multiple openings, so multiple print head arrangements are possible. The openings and the plurality of print heads are located on a circle 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com