Numerical control machine for lapping spiral bevel gear

A technology of spiral bevel gears and gear grinding machines, which is applied to belts/chains/gears, gear teeth, mechanical equipment, etc., can solve the problems of easy failure, complex machine tool structure, low degree of automation, etc., to maintain dynamic stability. , The compact structure of the machine tool and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

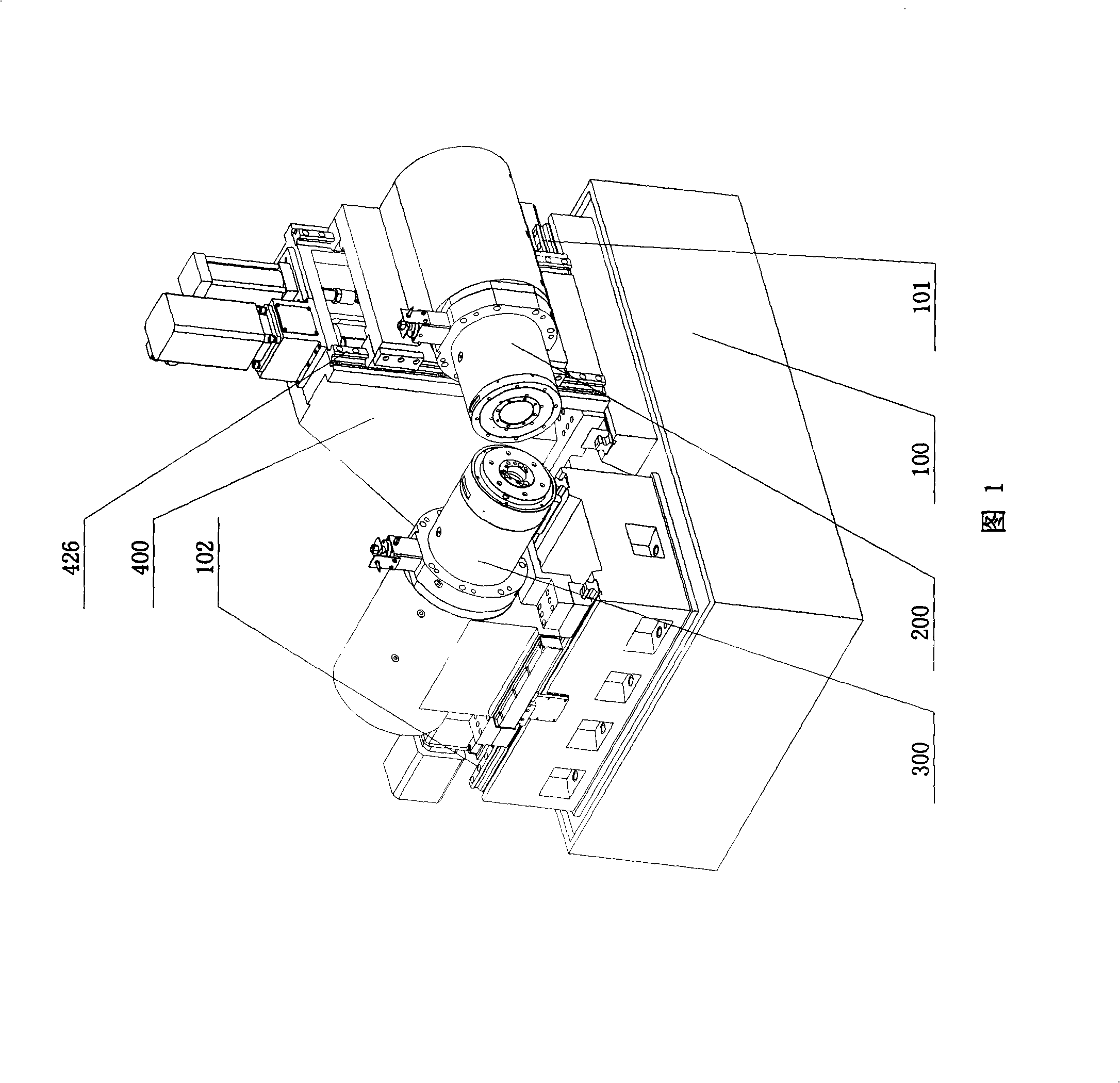

[0058] As shown in Figure 1, the present invention provides a CNC spiral bevel gear grinding machine, the CNC bevel gear grinding machine includes: a bed 100, a column 400, a driving box 200, a driven box 300, a numerical control system (not shown in the figure) shown); on the bed 100, a driving guide rail 101 and a driven guide rail 102 which are 90° to each other are arranged.

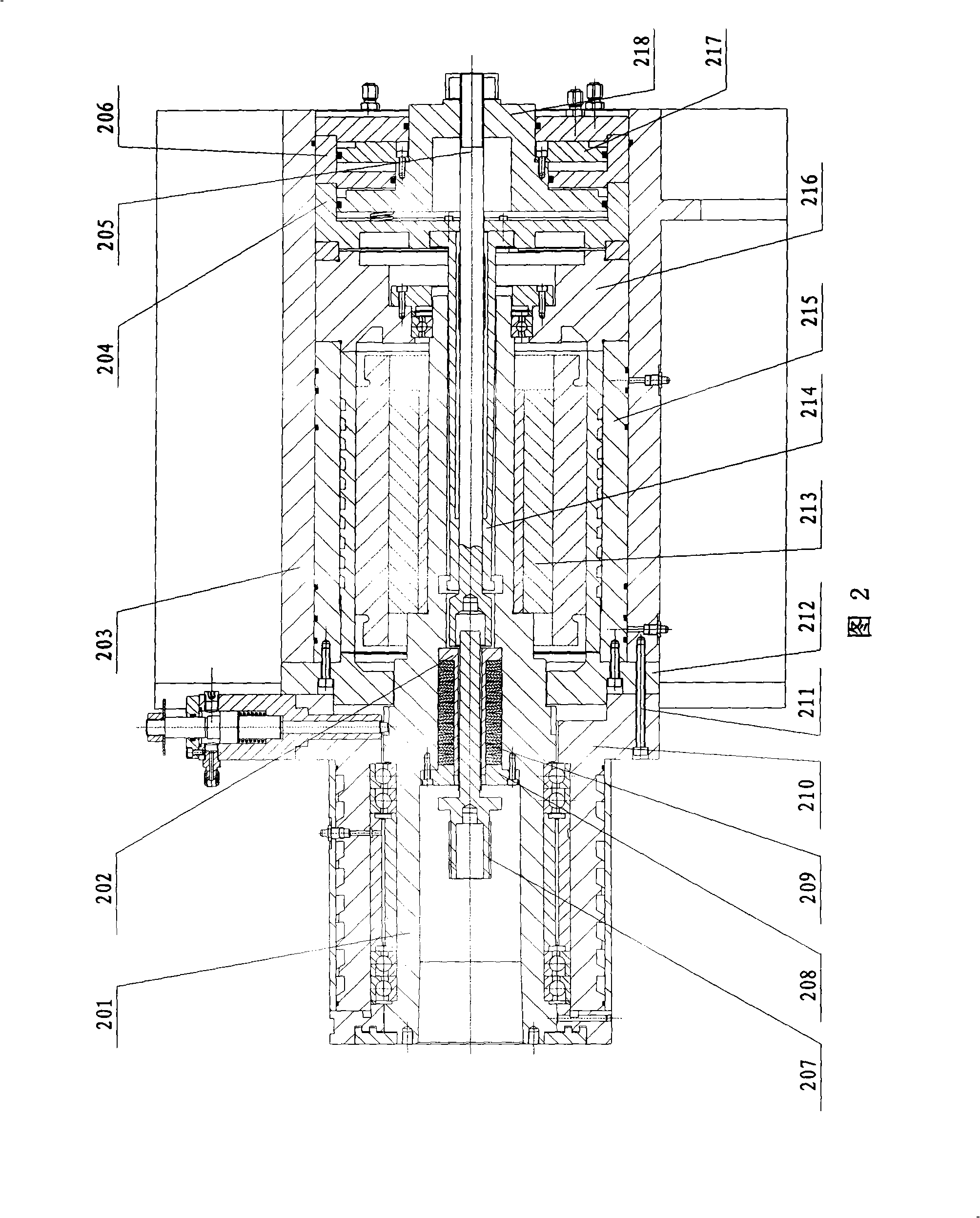

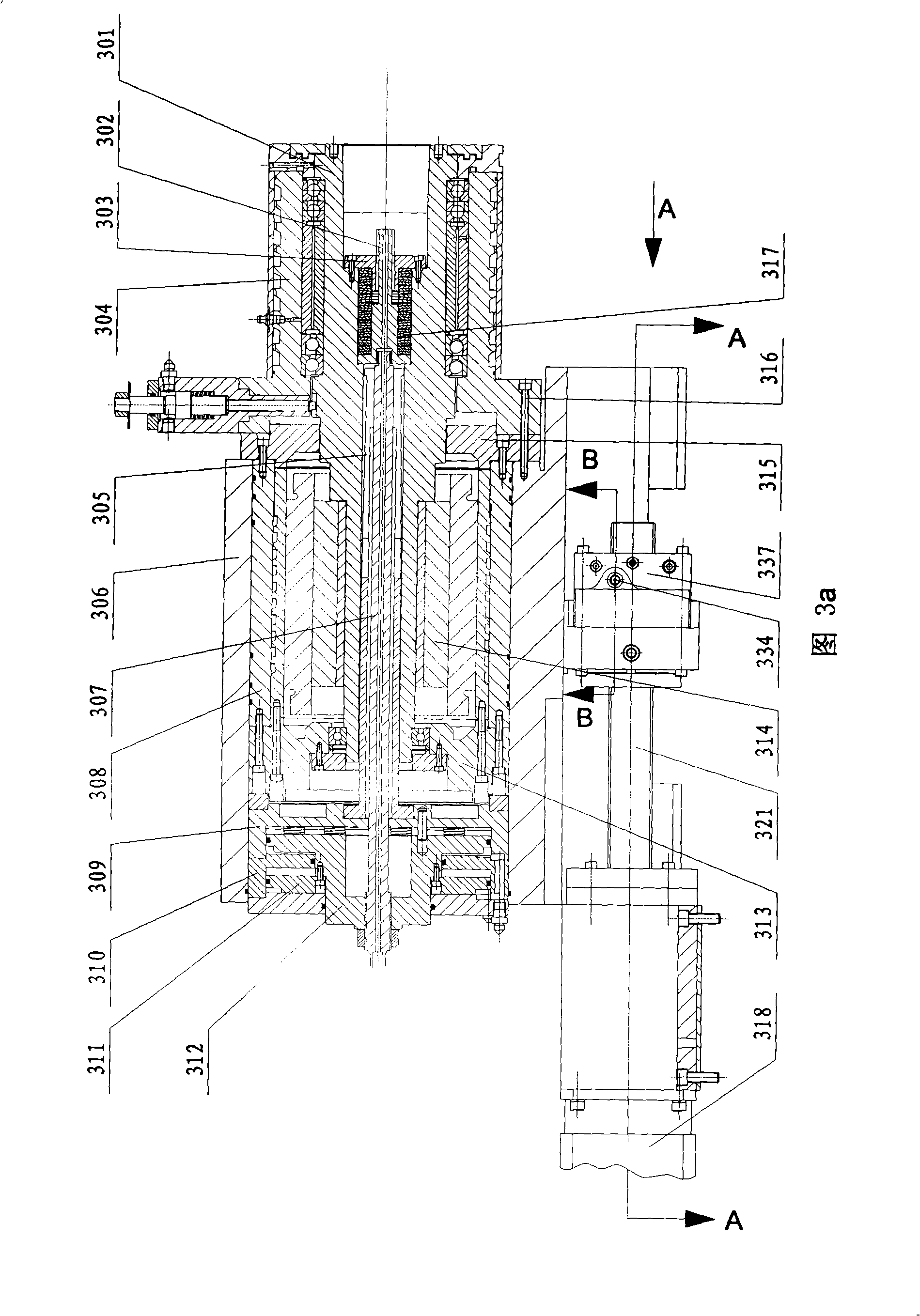

[0059]The column 400 is arranged on the active guide rail 101 on the bed 100, and an automatic movement mechanism that moves along the active guide rail 101 is arranged between the bottom of the column 400 and the bed 100; the active box 200 is hung on the side of the column 400, and the active box The bottom of the 200 is provided with an automatic movement mechanism that can move vertically along the side of the column 400; the driven box 300 is arranged on the driven guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com