Gas soot blower

A soot blower and gas technology, applied in the field of gas soot blowers, can solve the problems of soot blowing dead angle and poor soot blowing effect, and achieve the effect of eliminating soot blowing dead angle, improving soot blowing effect and improving soot blowing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

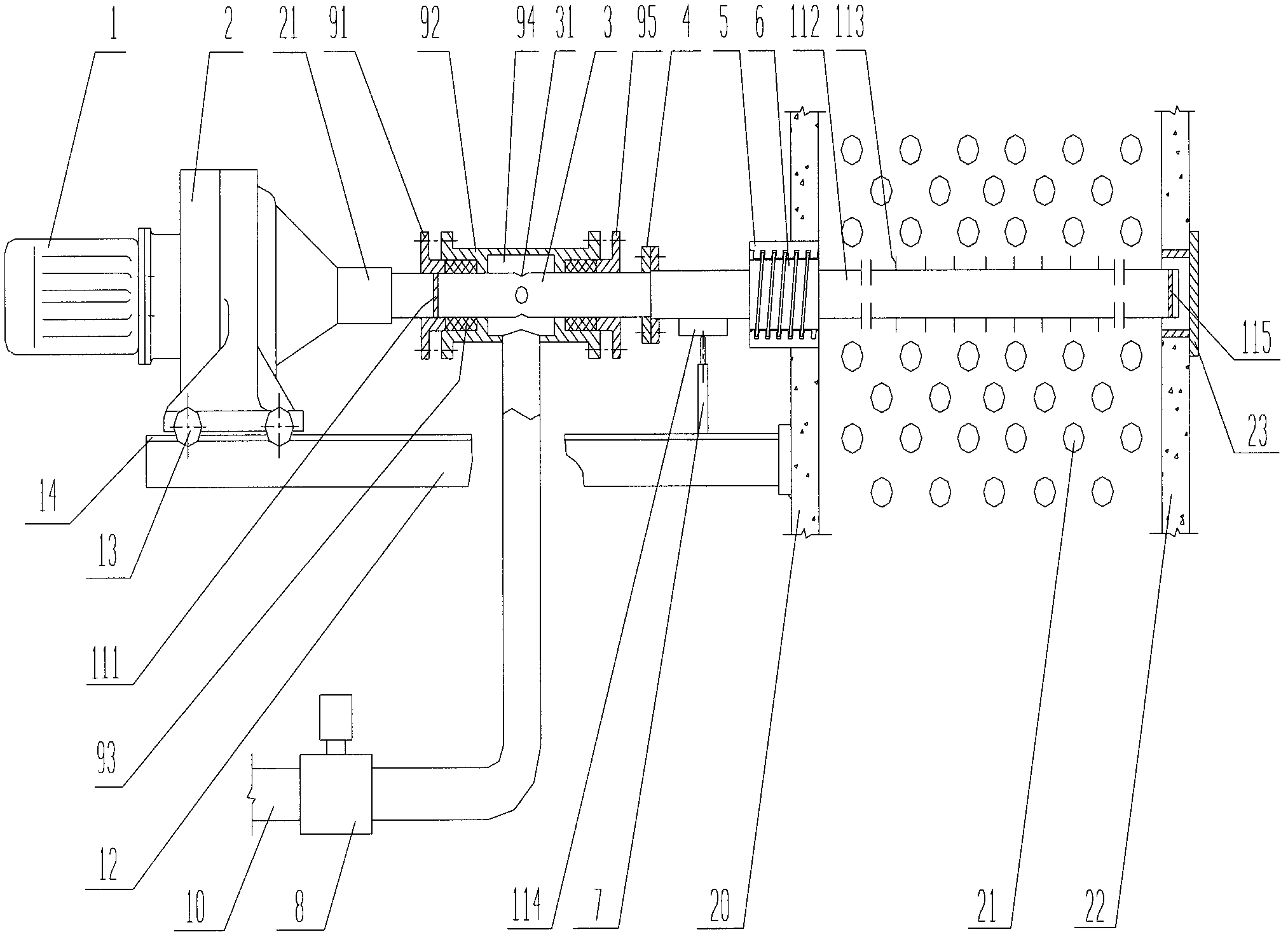

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The drawings and specific embodiments do not limit the scope of protection claimed by the present invention.

[0011] figure 1 It is a specific embodiment of the gas soot blower used in the tubular heating furnace of the present invention. It is equipped with a transmission system, an air intake system, a limit system, a feed system, a soot blowing tube assembly, and a bracket 12 . The transmission system is provided with a motor 1, a reducer 2, a shaft coupling 21, and a pulley 13. The reducer 2 of the soot blower is a cycloid reducer, which can be various commonly used types in industry. The present invention adopts the cycloid reducer, because its deceleration ratio is relatively large (can reach 700~1500).

[0012] The feeding system of the soot blower is a lead screw and nut auxiliary mechanism, which is provided with a hollow le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com