Negative pressure rotating type artificial muscle

An artificial muscle and rotary technology, applied in the field of pneumatic muscles, can solve the problems of difficulty in precise control of artificial muscles, increased space occupied by actuators, and high working pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The negative pressure rotating artificial muscle of the present invention will be further described in detail below, and the described embodiment is only one of all embodiments of the present invention, but not all embodiments. Any other embodiments closely related to the embodiments of the present invention belong to the protection scope of the present invention.

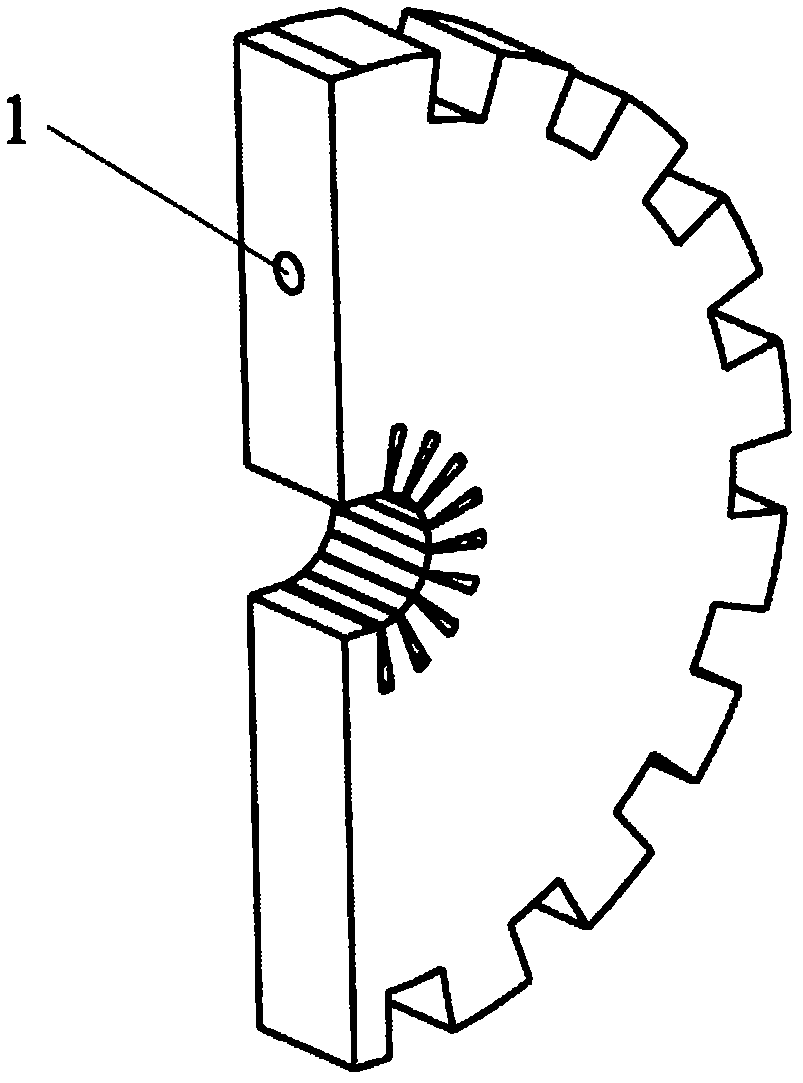

[0037] The artificial muscle according to the present invention includes a main body made of elastic material extending along an arc axis, and an air inlet 1 for fluid communication with an external negative pressure source is provided on the end of the main body.

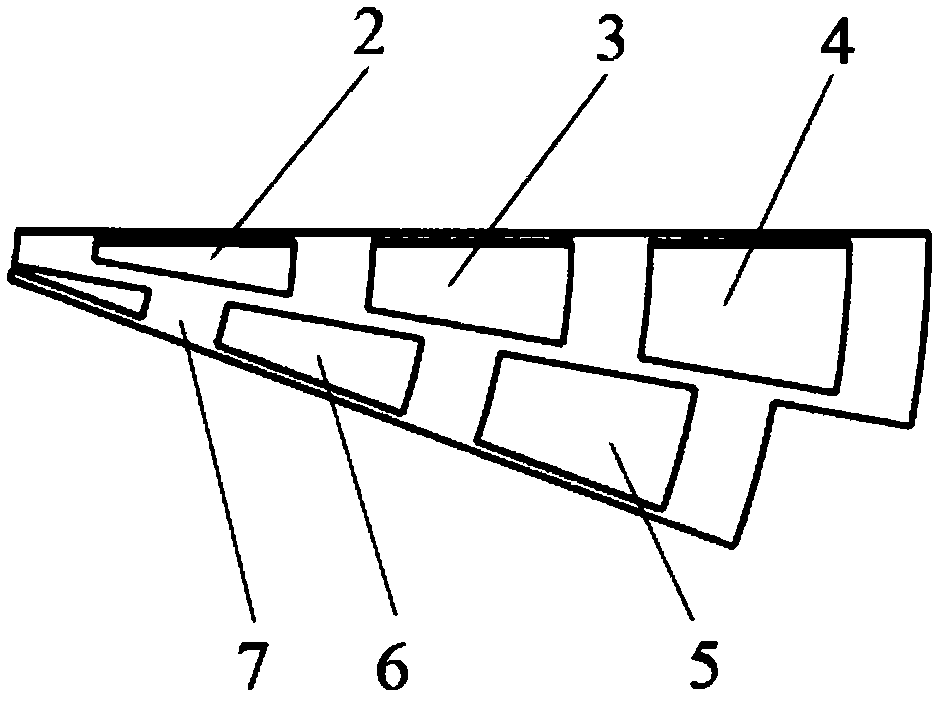

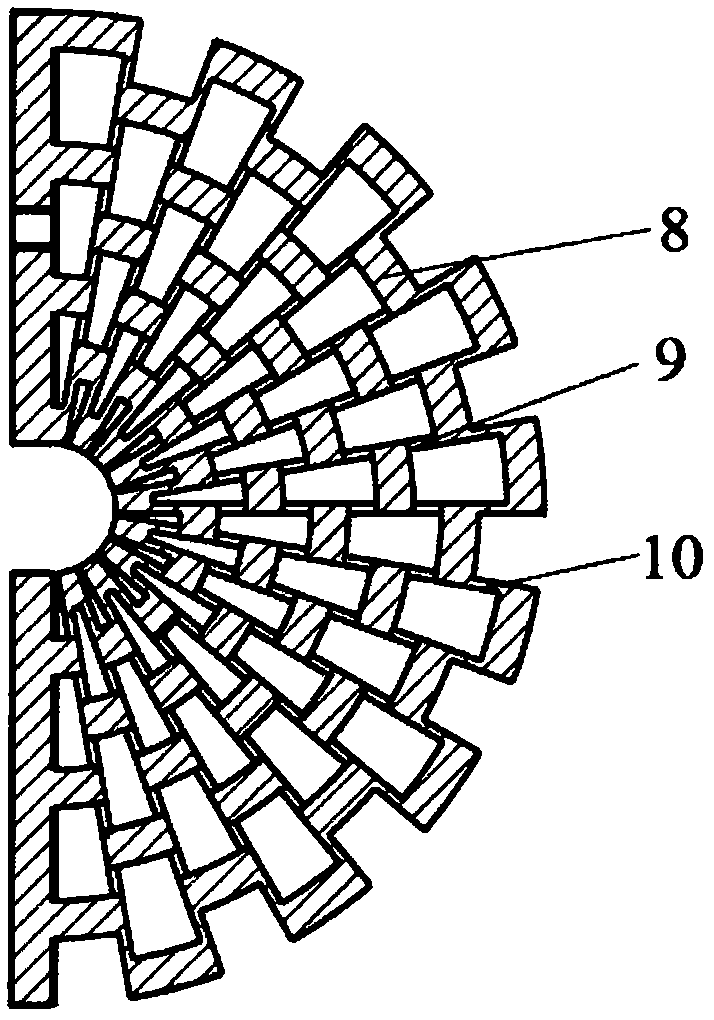

[0038] Such as Figure 1-3As shown, the main body of the negative pressure rotary artificial muscle of the present invention is a fan-shaped structure, which can be divided into a plurality of fan-shaped module units 7 along a straight line passing through the center of the circle, and each fan-shaped module unit 7 is composed of three air chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com