Patents

Literature

90results about How to "Reduce design height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

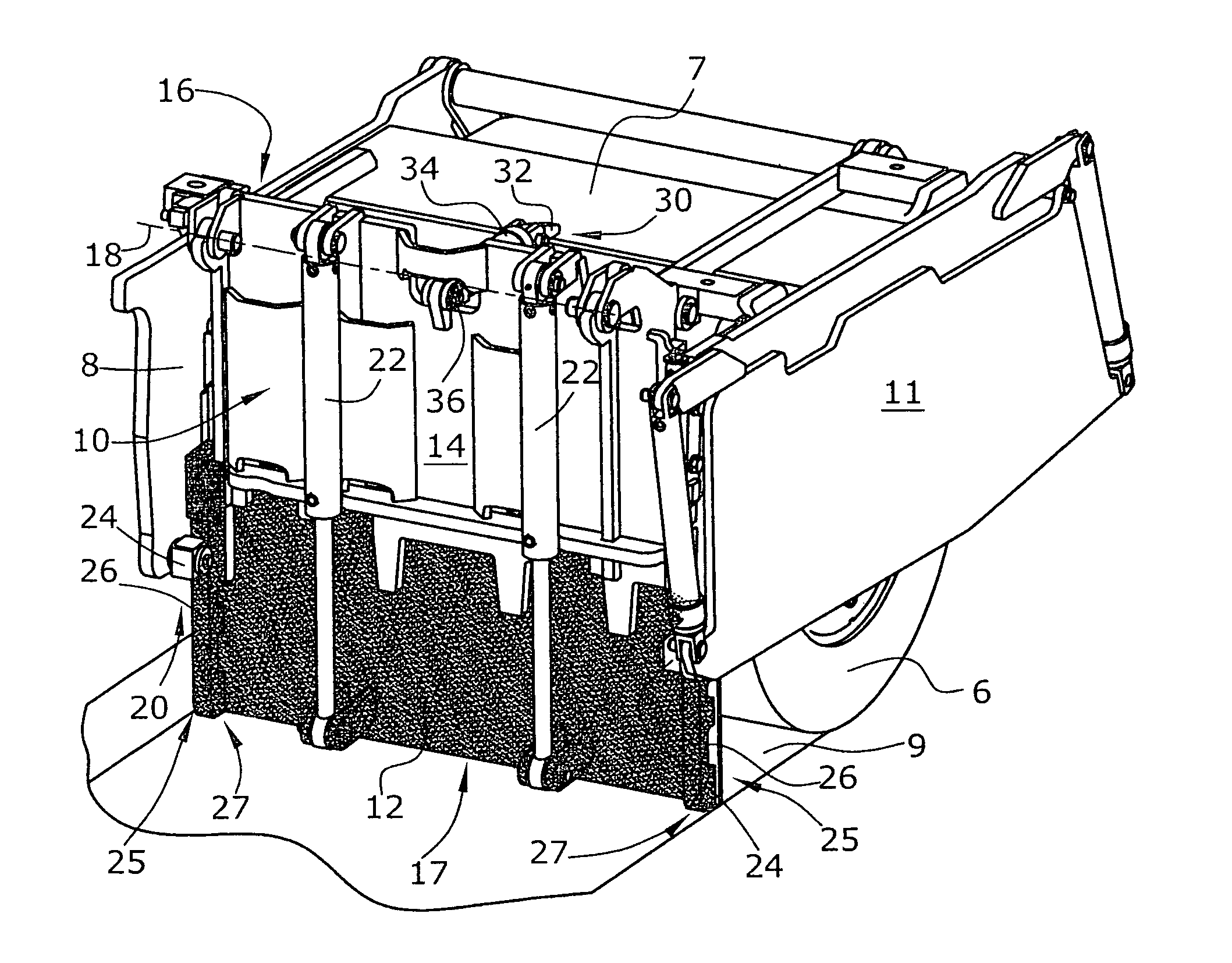

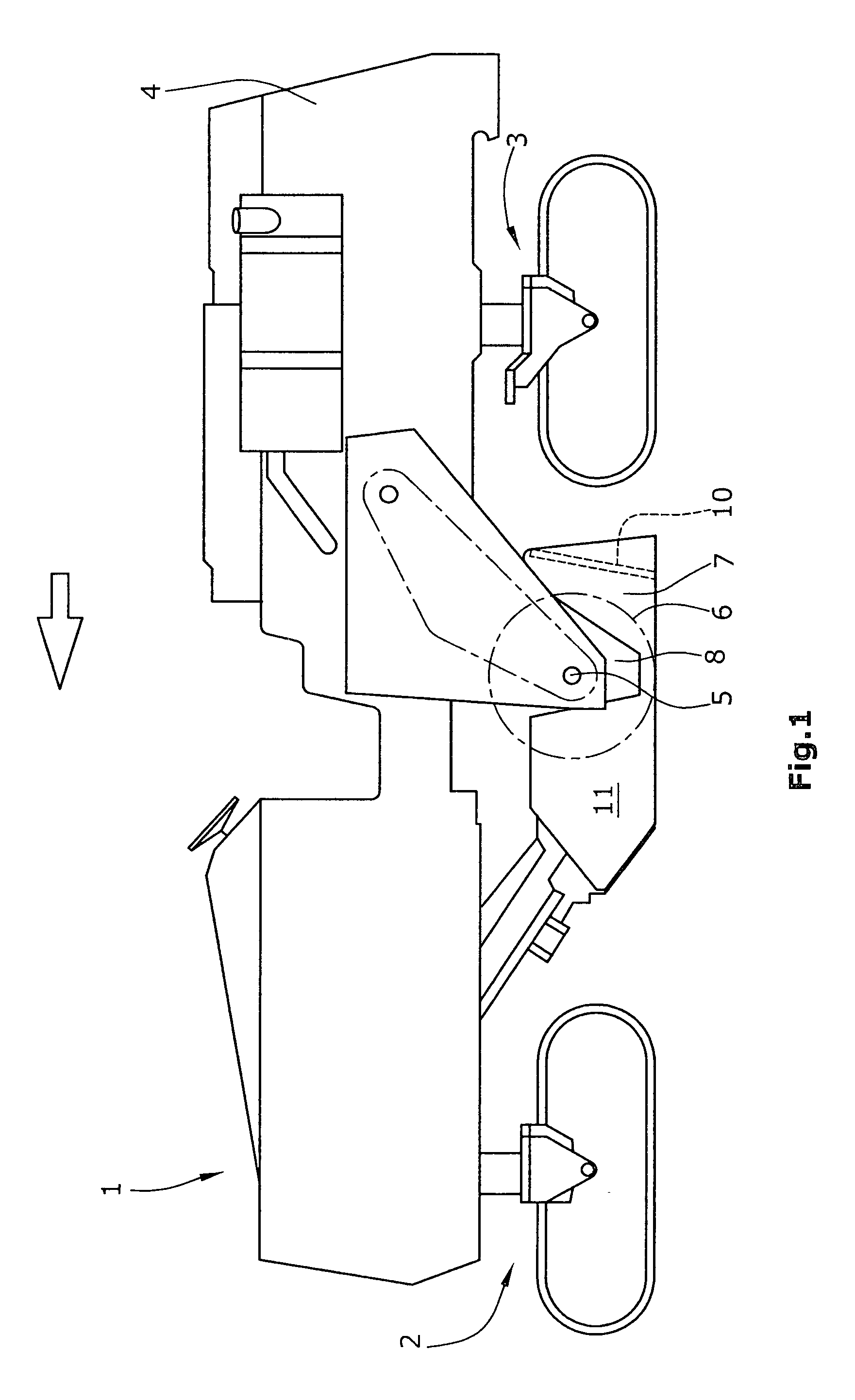

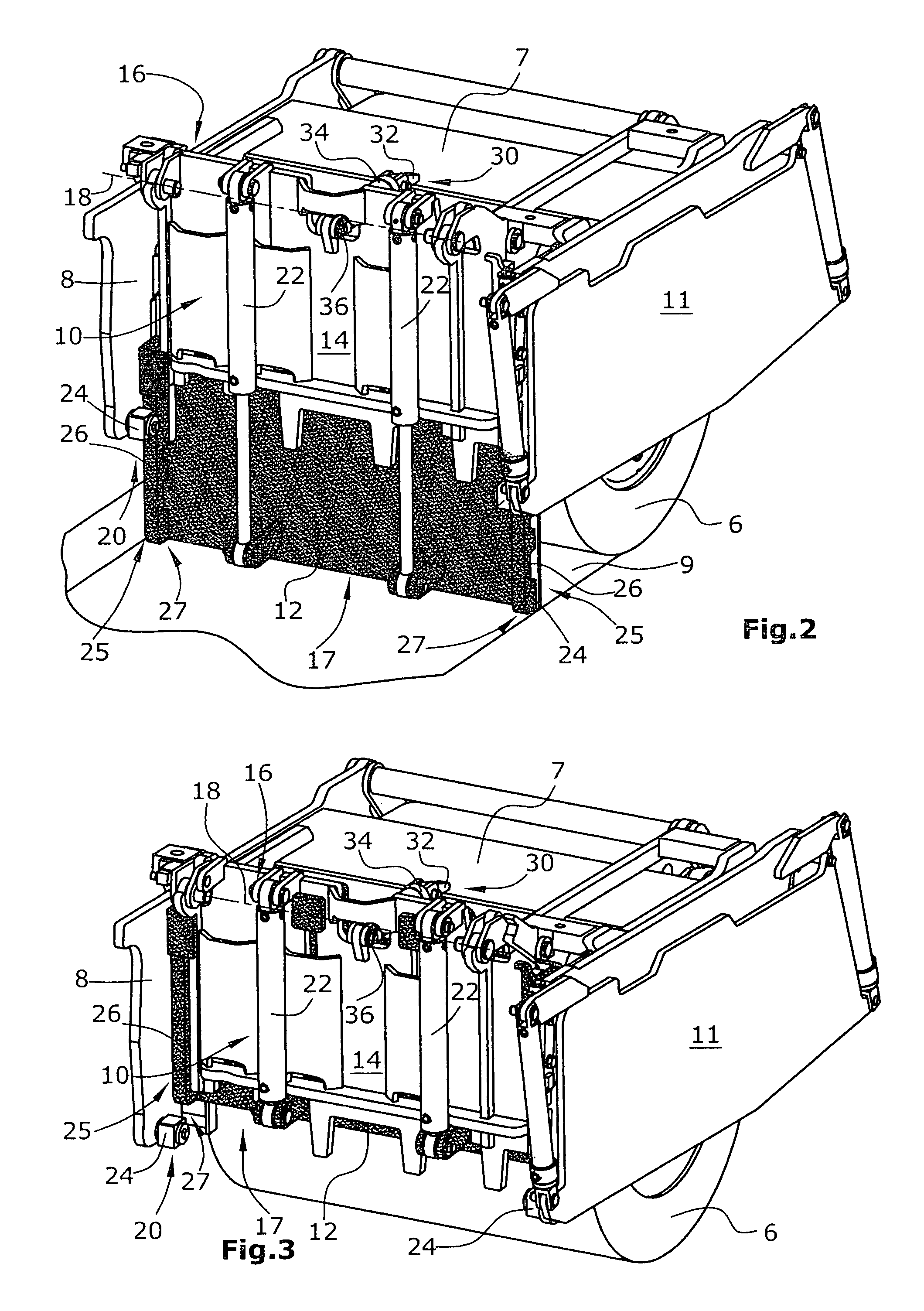

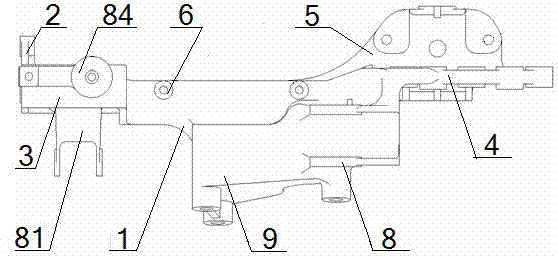

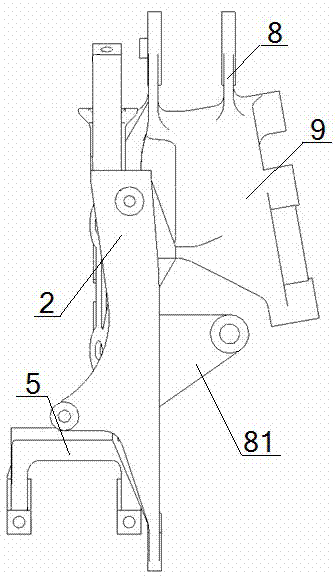

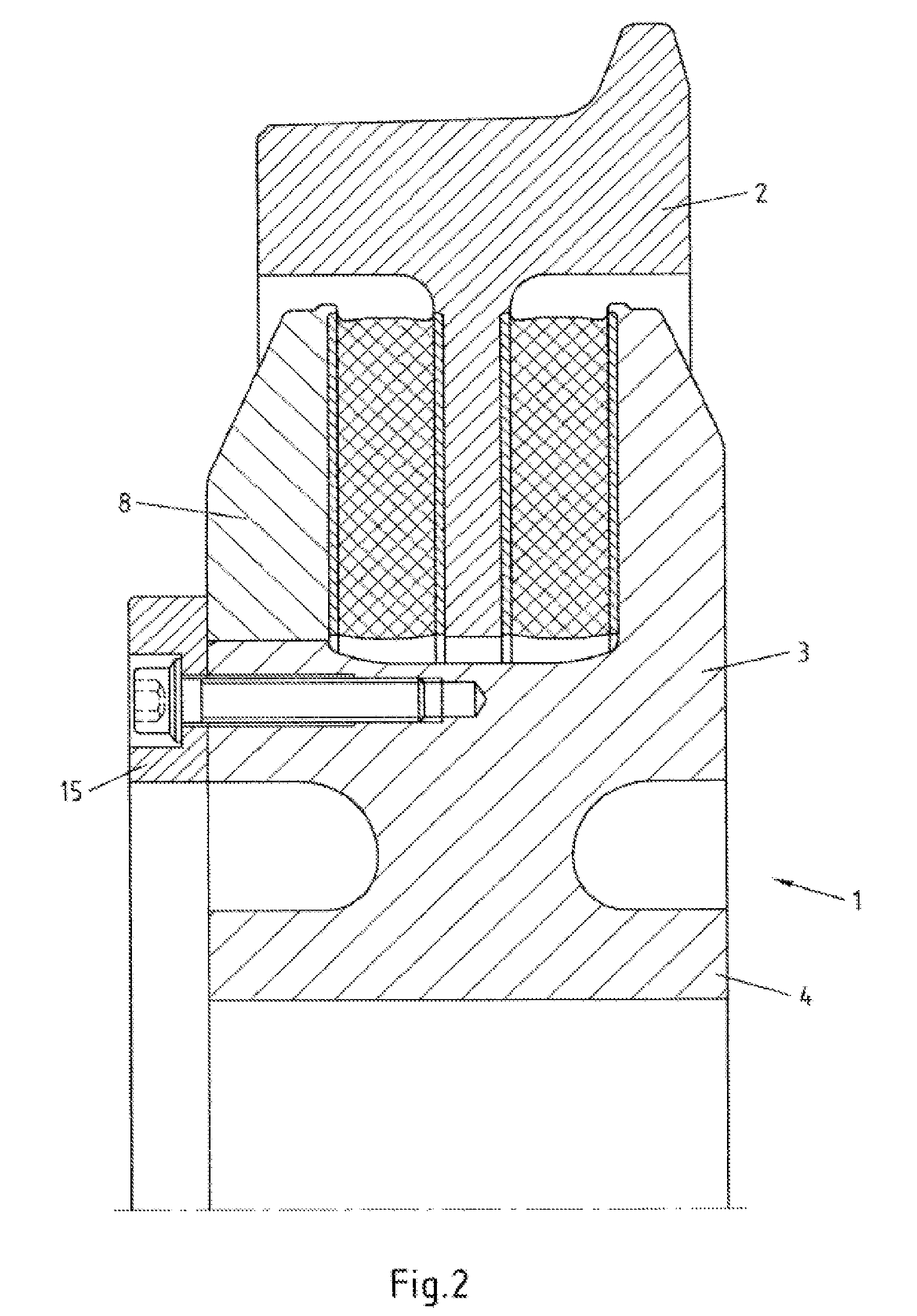

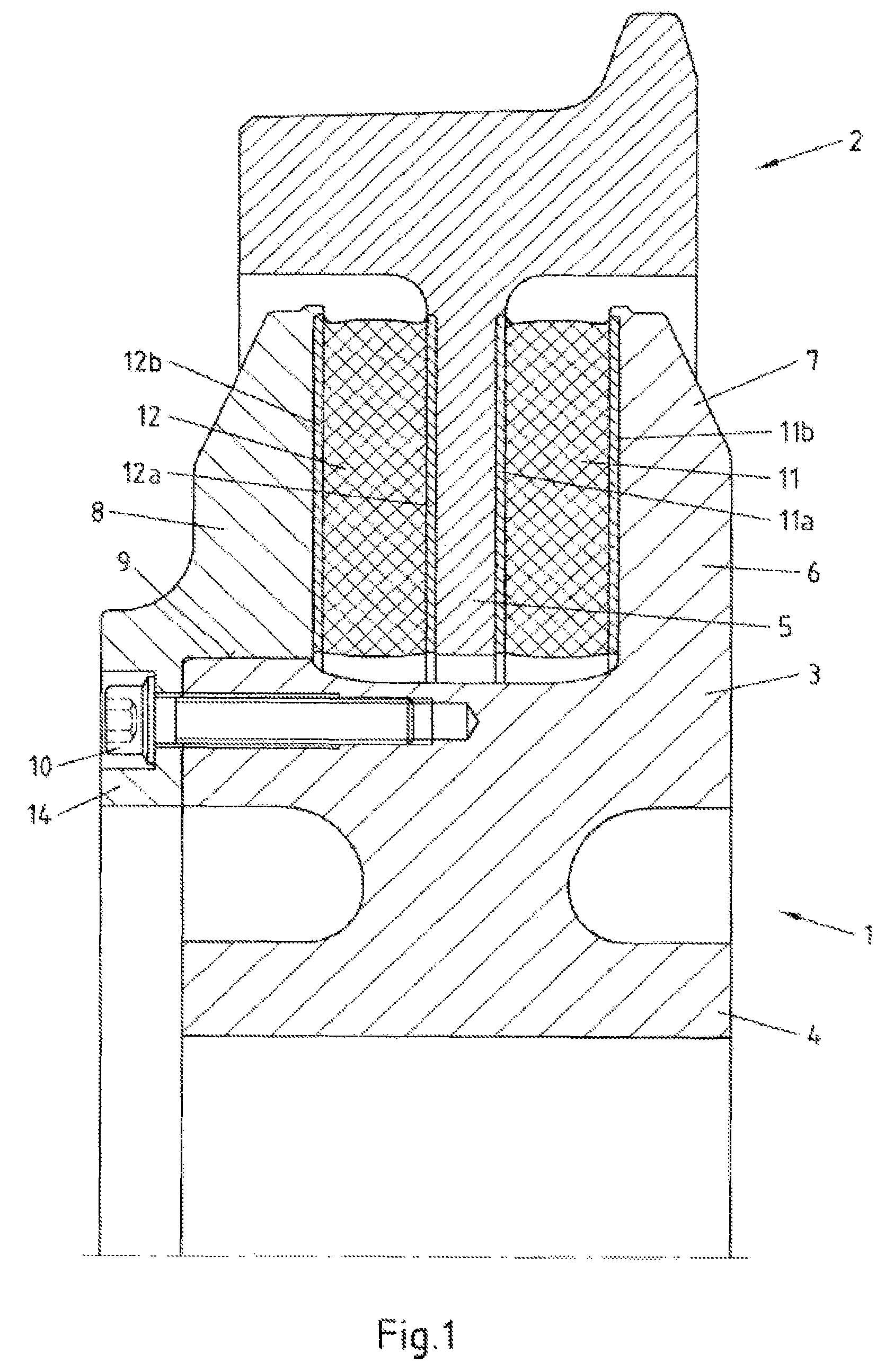

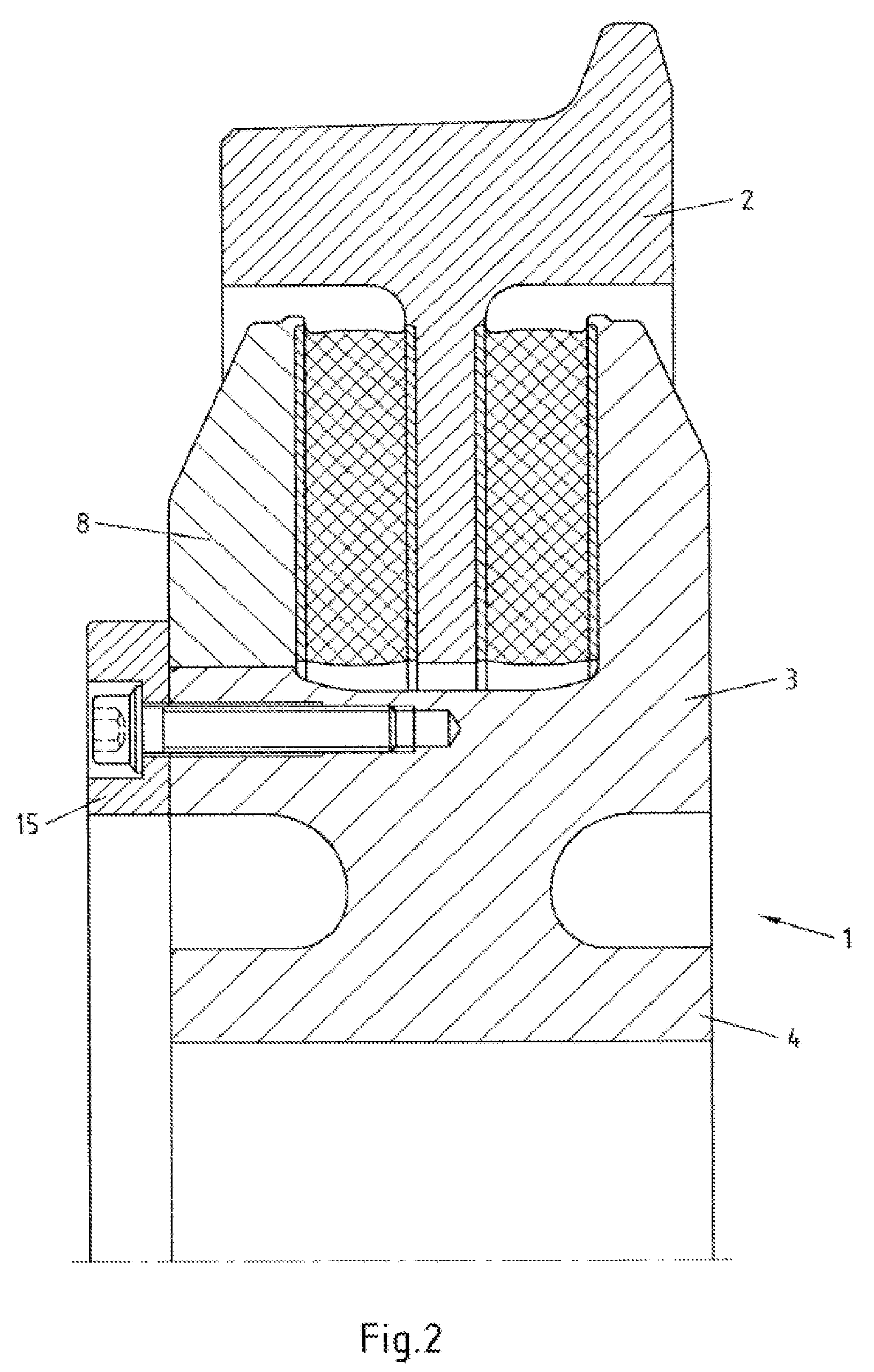

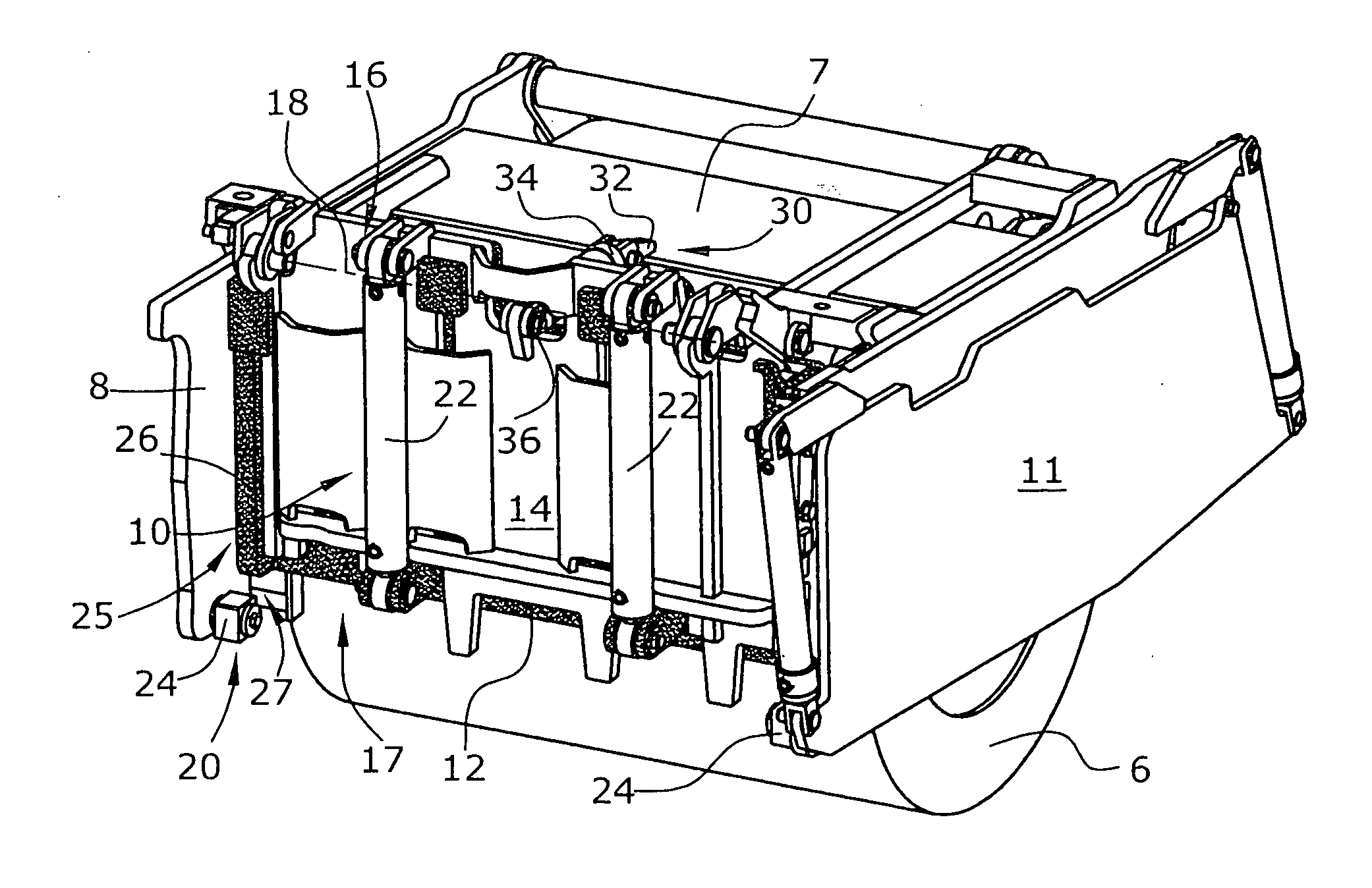

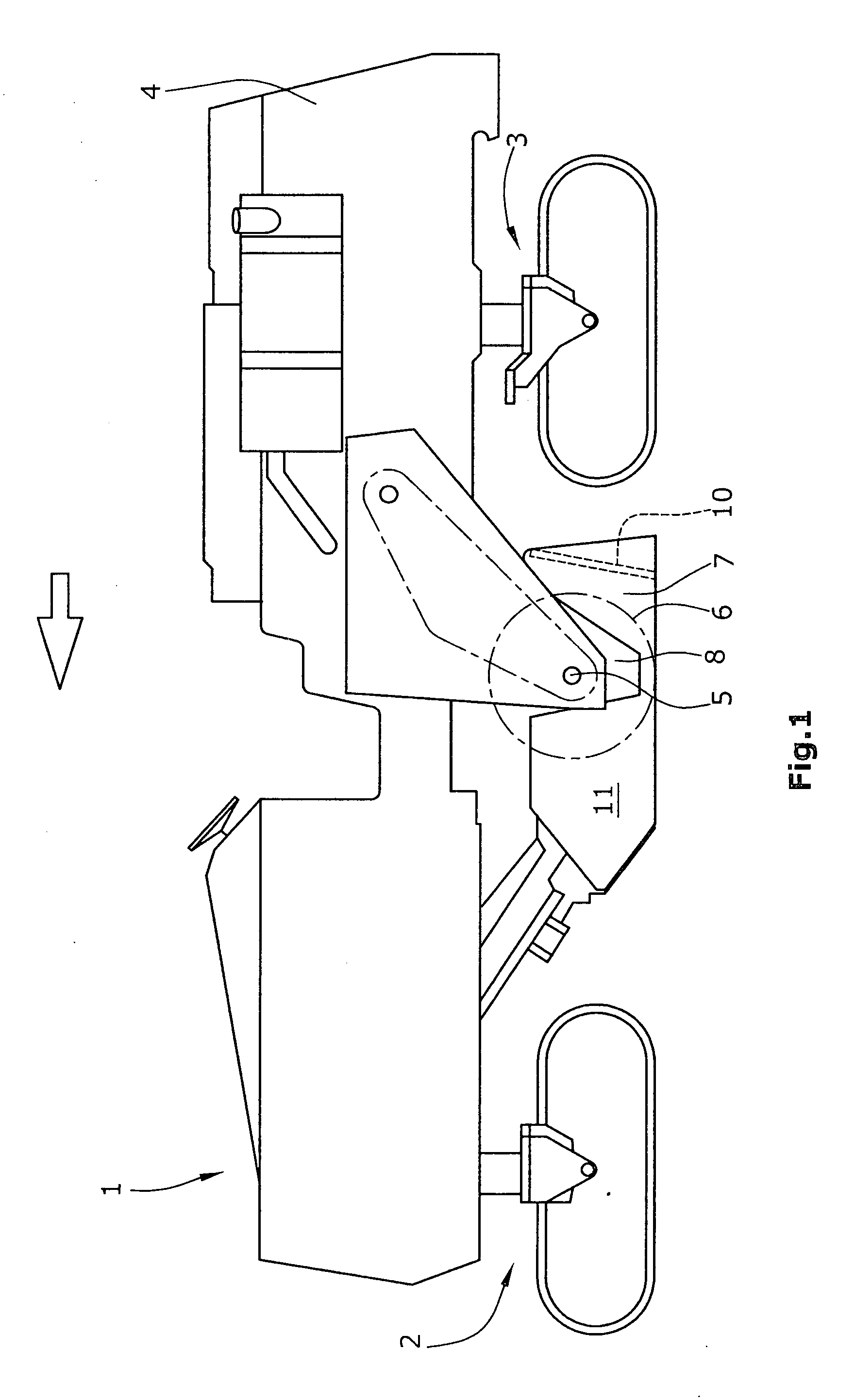

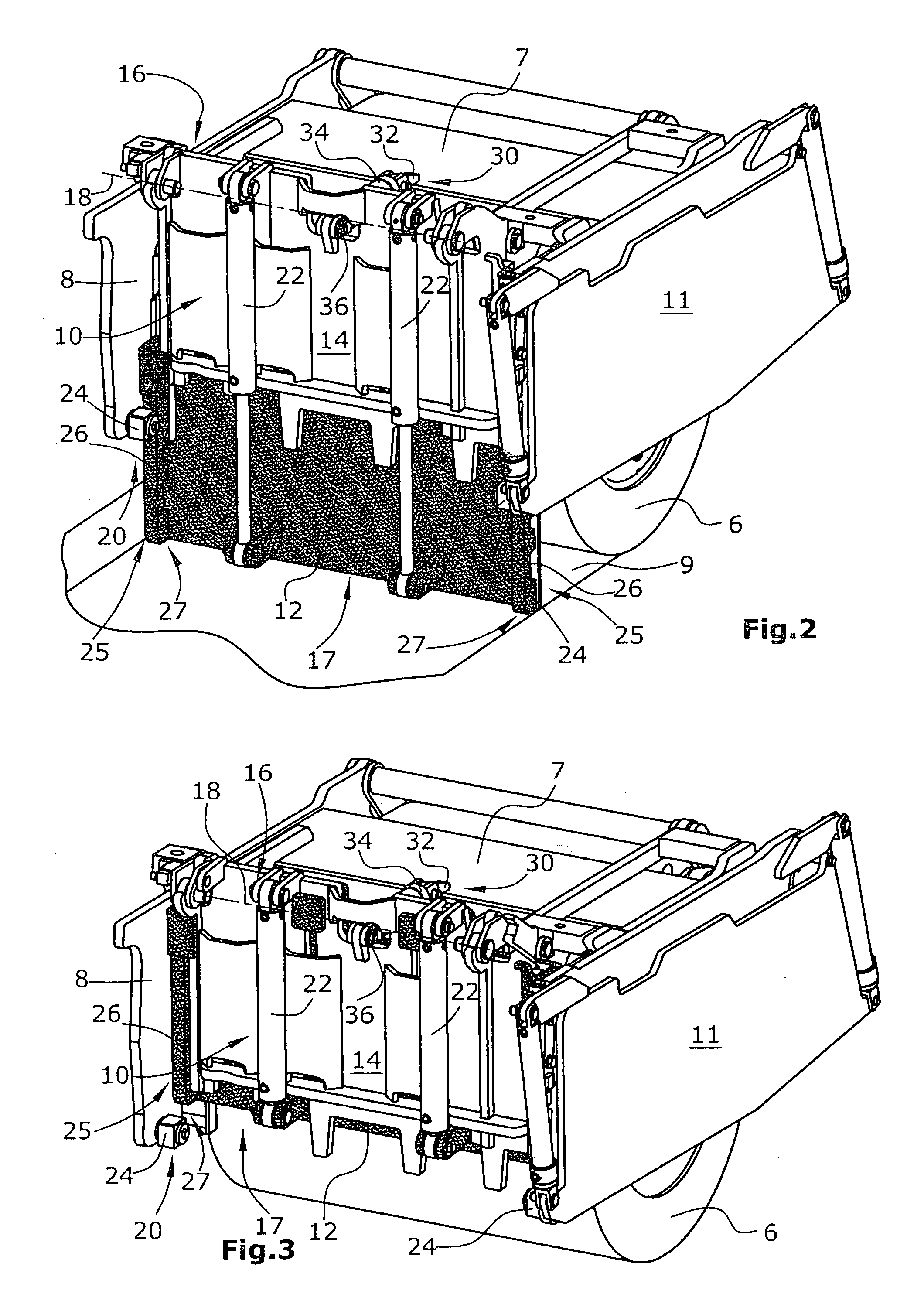

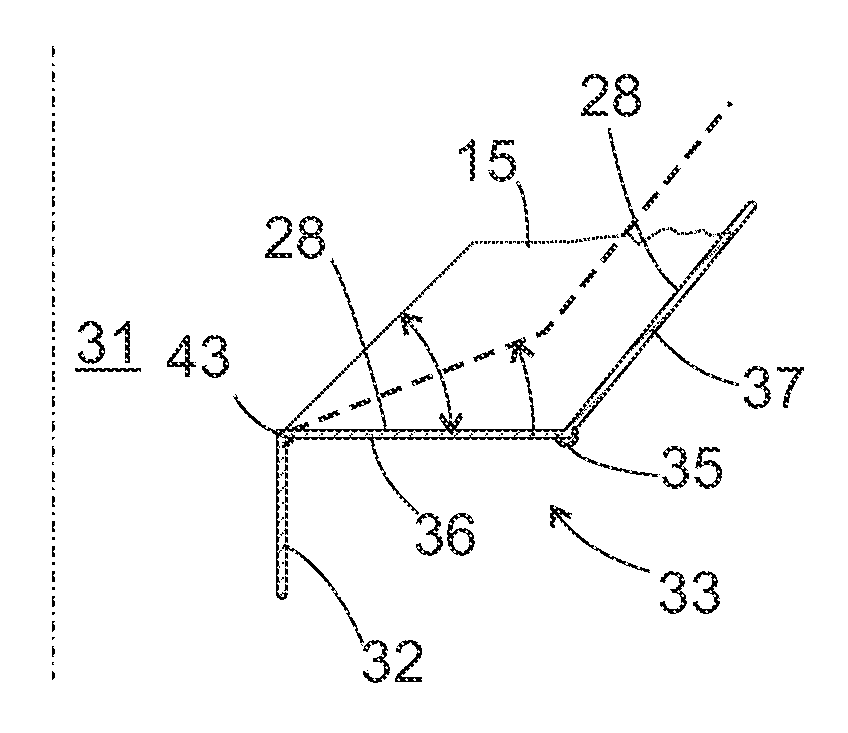

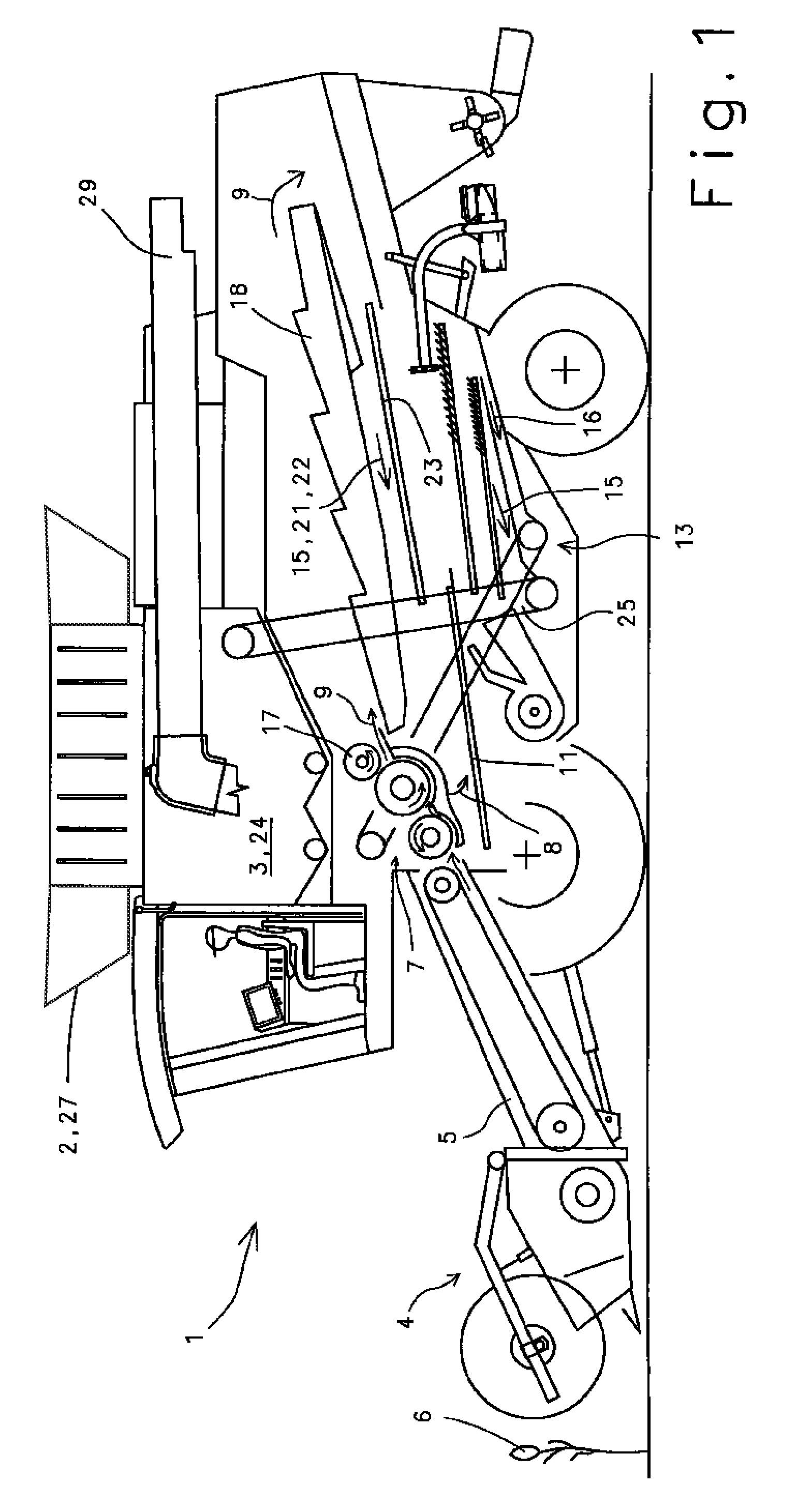

Scraper device, as well as construction machine

ActiveUS8100480B2Small contact surfaceImprove pressure resistanceBrushesWork treatment devicesEngineeringMechanical engineering

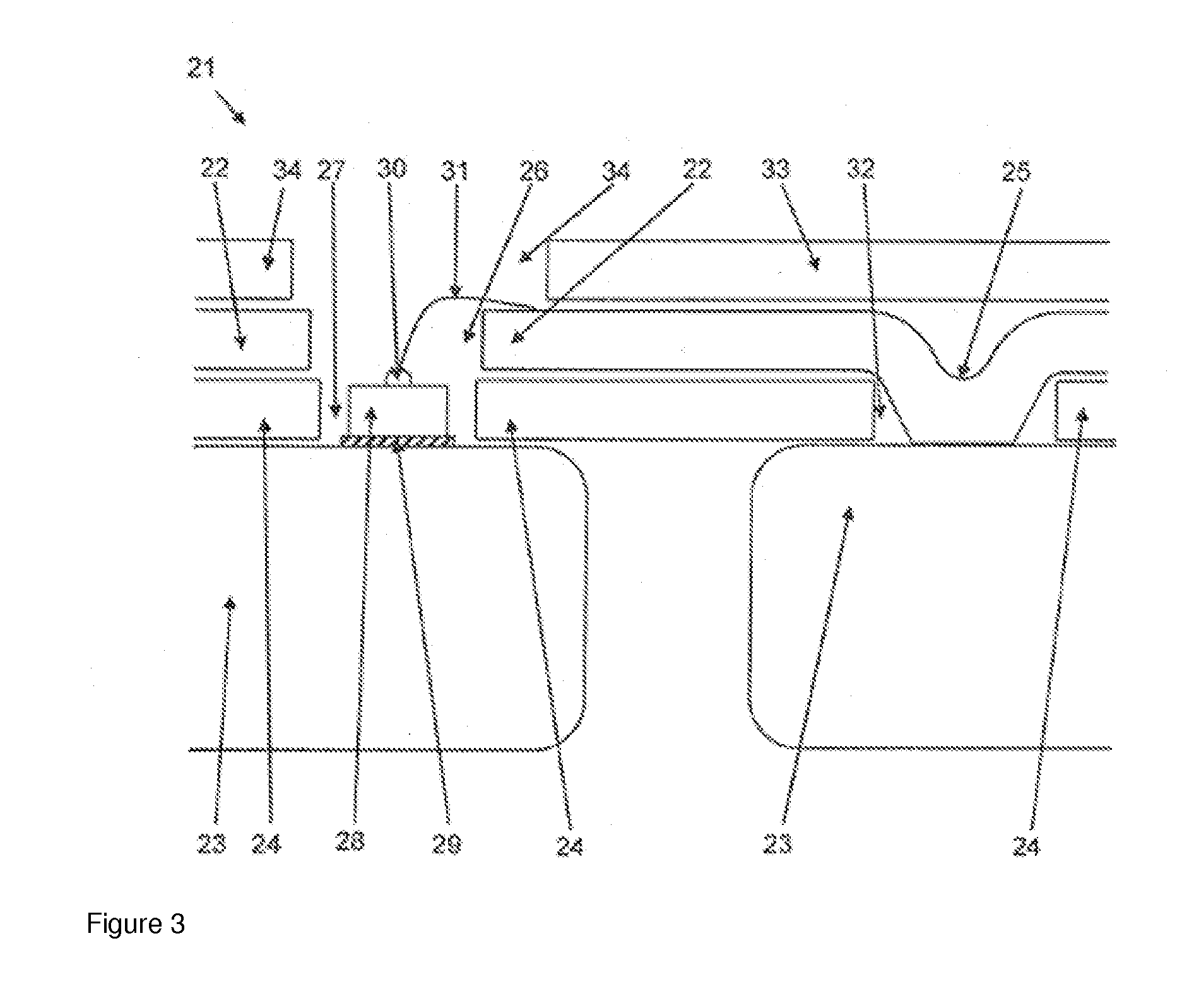

A scraper device for a milling drum mounted in a construction machine at a machine frame between lateral walls with a milling drum axis, with a two-part scraper blade arranged in a height-adjustable fashion behind the milling drum when seen in the direction of travel, the lower part of which can glide over the ground surface milled off by the milling drum, where the lower part of the scraper blade is adjustable in height when in operating position, it is provided that the upper part of the scraper blade is attached, at the upper end, to swivel about a swivelling axis parallel to the axis of the milling drum, that the scraper blade, when in operating position, is engaged with lateral retaining devices at the lateral walls, which retain the scraper blade in a position running essentially orthogonally to the ground surface, that a swivelling device is capable of swivelling the scraper blade about the swivelling axis when the scraper blade is disengaged from the lateral retaining devices, and that the swivelling device is provided, at the upper end of the upper part of the scraper blade, with an operating device articulated between a permanently installed part of the construction machine and the upper part of the scraper blade.

Owner:WIRTGEN AMERICA

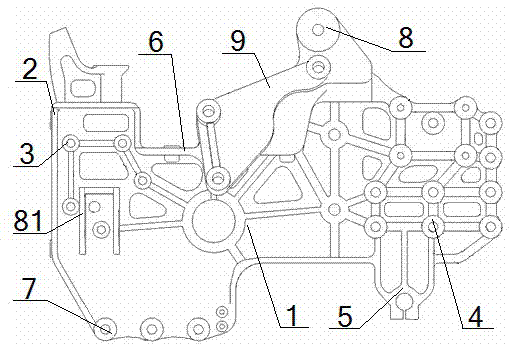

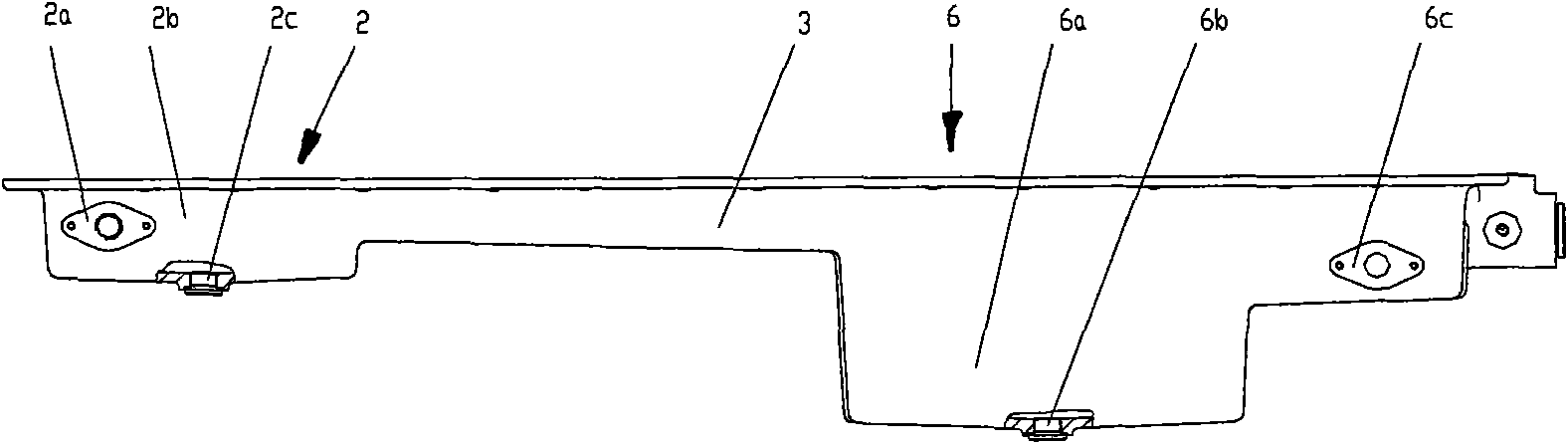

Integrated frame longitudinal beam connecting support

ActiveCN103921842AHigh mechanical strengthReduce in quantityUnderstructuresLoading-carrying vehicle superstructuresVehicle frameEngineering

An integrated frame longitudinal beam connecting support comprises a base and a bumper mounting portion, a beam assembly mounting portion, a frame fixing portion and a plate spring mounting portion which are arranged on the base. The back of the bumper mounting portion is fixedly connected to the front end of the frame fixing portion through the beam assembly mounting portion, the bottom of the frame fixing portion is fixedly connected to the plate spring mounting portion, a sunken water tank mounting portion and a cab front suspension turning arm mounting portion are arranged between the beam assembly mounting portion and the frame fixing portion, a front-lower protective supporting base fixing portion is fixedly connected to the lower portion of the beam assembly mounting portion, and a front suspension vibration absorber mounting support is fixedly connected to the side of the beam assembly mounting portion; the base is integrated with the bumper mounting portion, the beam assembly mounting portion, the frame fixing portion, the plate spring mounting portion, the sunken water tank mounting portion, the front-lower protective supporting base fixing portion, the cab front suspension turning arm mounting portion and the front suspension vibration absorber mounting support. The support is in high integrated level, is reasonable in structure and has high mechanical strengthen.

Owner:DONGFENG COMML VEHICLE CO LTD

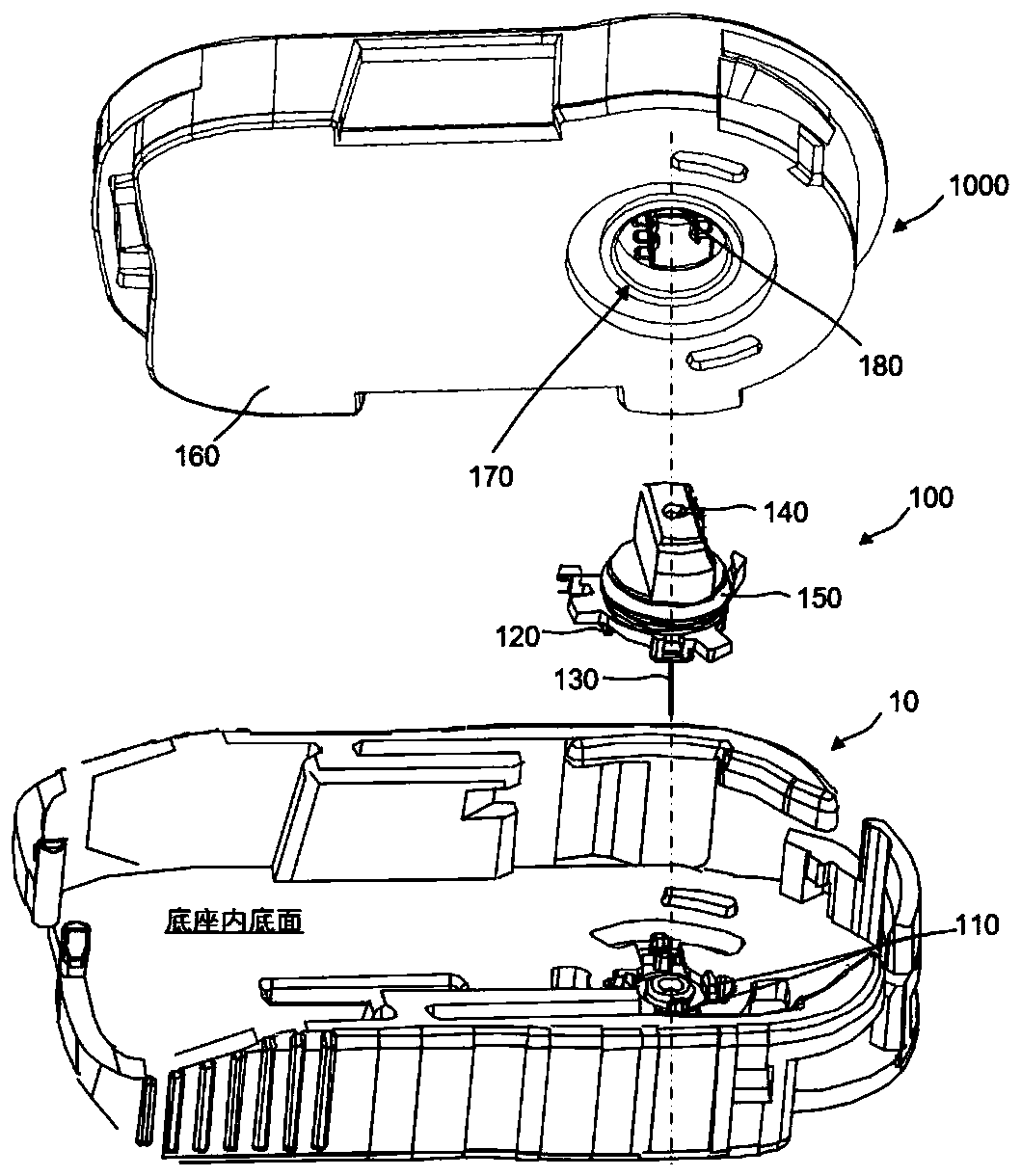

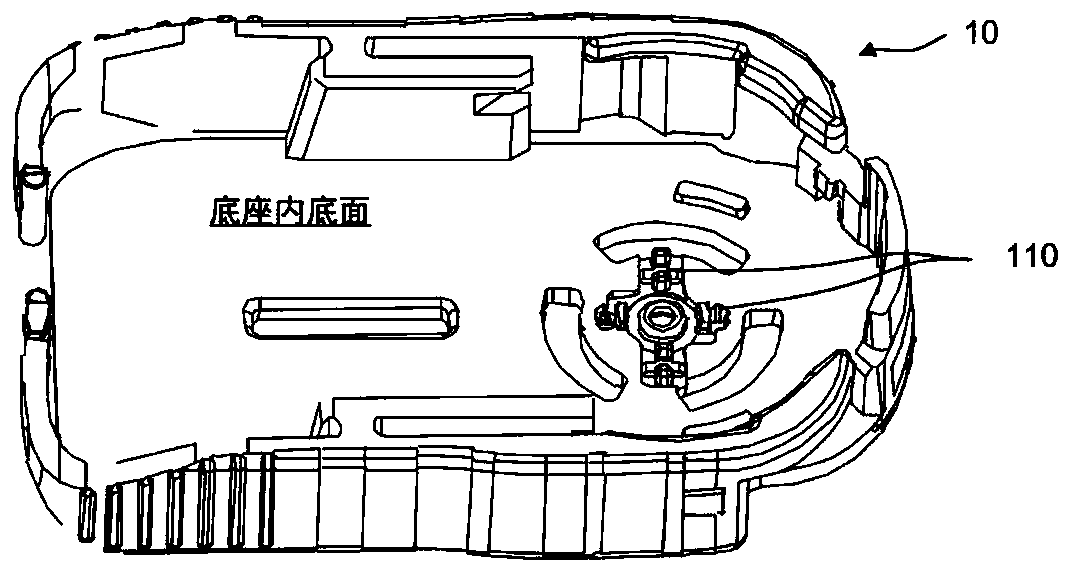

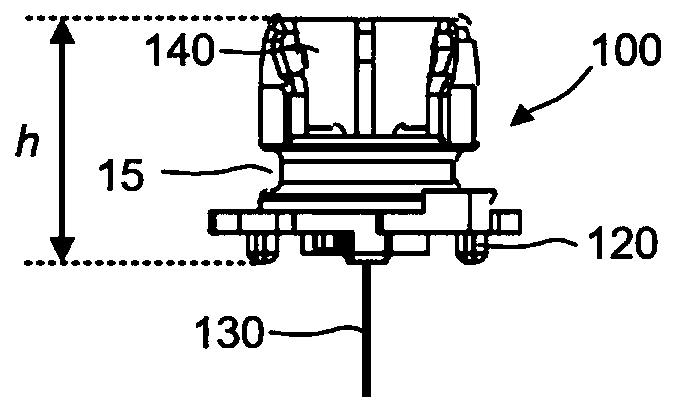

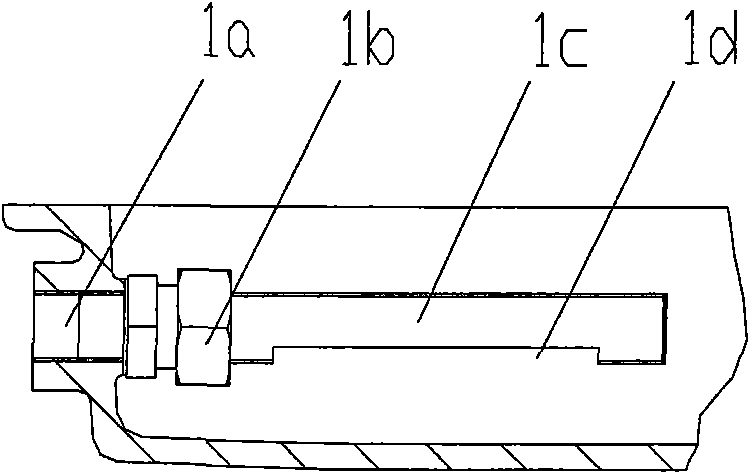

Sensing device

InactiveCN110584676AReduced Thickness DimensionsReduce complexitySensorsBlood characterising devicesAnalyteBody fluid

The invention discloses a sensing device, and the device comprises the following parts: a pedestal which is provided with a first clamping part; a probe structure which comprises a second clamping part capable of being clamped with the first clamping part, a probe used for detecting body fluid analyte parameters and a connecting area electrically connected with the probe, wherein the second clamping part is arranged at one end of the probe structure, and the second clamping part and the first clamping part are clamped with each other so that the probe structure can be installed on the pedestal; and a transmitter structure, which comprises an emitter shell and an emitter arranged in the emitter shell, wherein the emitter shell is provided with a connecting hole, the connecting hole is matched with the probe structure in shape and structure, when the emitter structure is installed on the pedestal, the probe structure is located in the connecting hole, and the emitter is electrically connected with the connecting area so as to receive signals generated by the probe. Due to the design, the thickness of the sensing device is reduced, and the user experience is enhanced.

Owner:MEDTRUM TECH

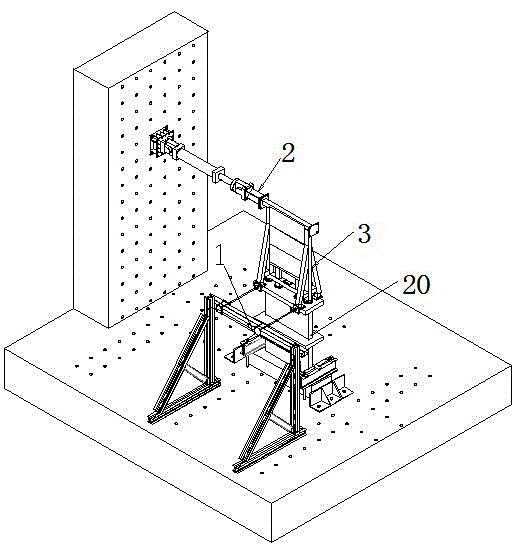

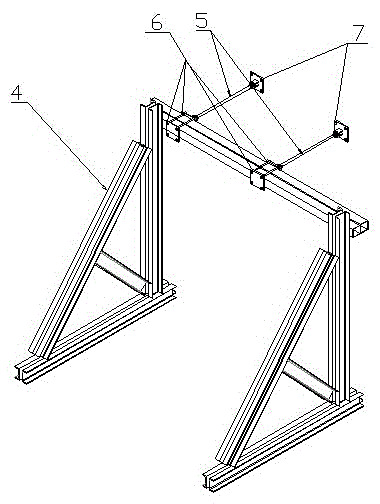

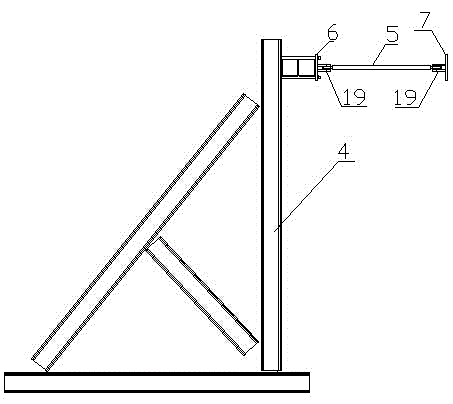

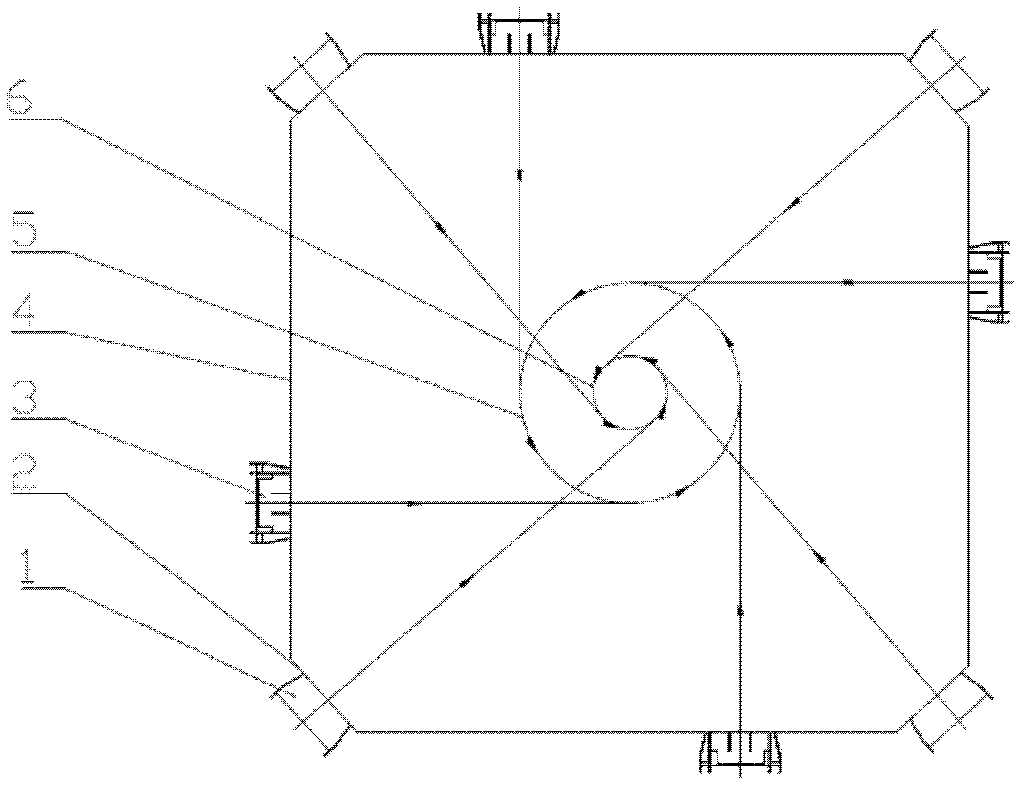

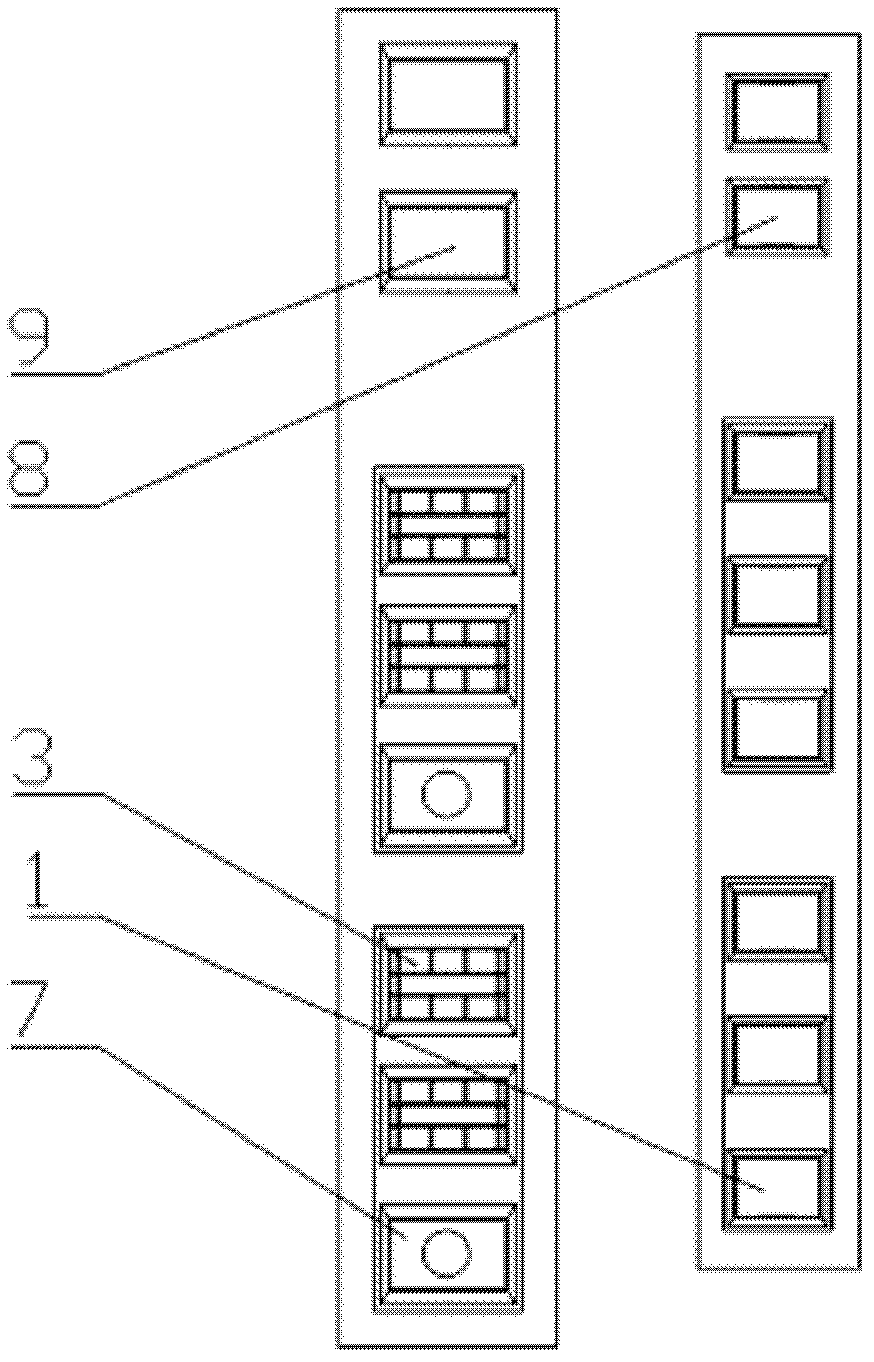

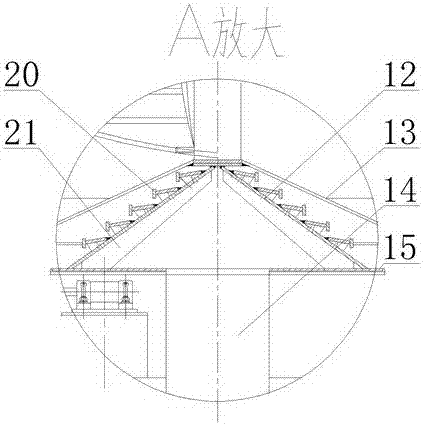

Detachable and reusable shear wall earthquake-proof performance test loading rack and test method

InactiveCN105067211AReduce design heightLight in massVibration testingAxial pressureAxial compression

The invention relates to a detachable and reusable shear wall earthquake-proof performance test loading rack and a test method. The test loading rack comprises a wall steel frame apparatus, a loading connecting apparatus, and an anti-sidesway module, wherein the wall steel frame apparatus comprises a loading beam, a steel frame wall, and steel frame wall fulcrum bars; two sides of the steel frame wall are provided with inclined strut type wall fulcrum bars; the wall fulcrum bars are in fixed connection with the bottom of the steel frame wall and a shear wall test piece floor; a jack is arranged on the square steel tube frame of a hollow part on the steel frame wall; the loading beam is fixed on the upper part of the steel frame wall, and is in connection with the loading connecting apparatus through loading terminals at ends of the loading beam; the anti-sidesway module comprises fixed steel frames and anti-sidesway pull rods; two ends of the anti-sidesway pull rods are respectively hinged to the fixed steel frames and the steel frame wall fulcrum bars in the wall steel frame apparatus. The loading rack can increase the shear span ratio of a shear wall test piece, meet the requirement that the shear span ratio is greater than 3 in an earthquake-proof performance test, apply axial pressure to the shear wall test piece, and meet requirements for different axial compression ratios required by a shear wall test.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

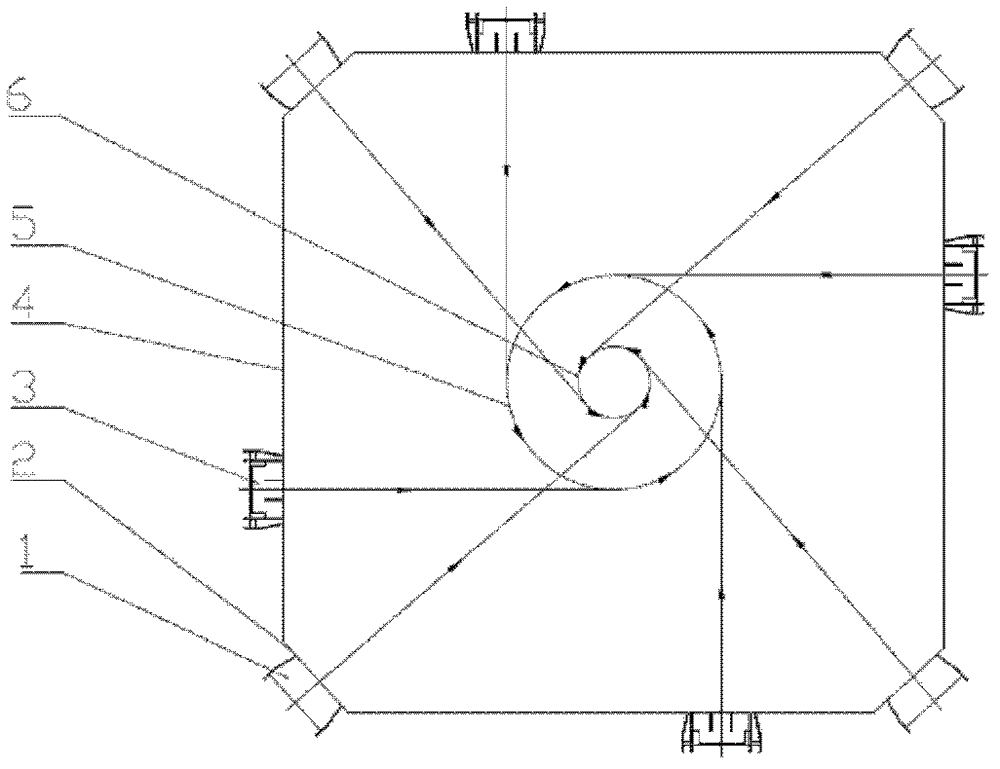

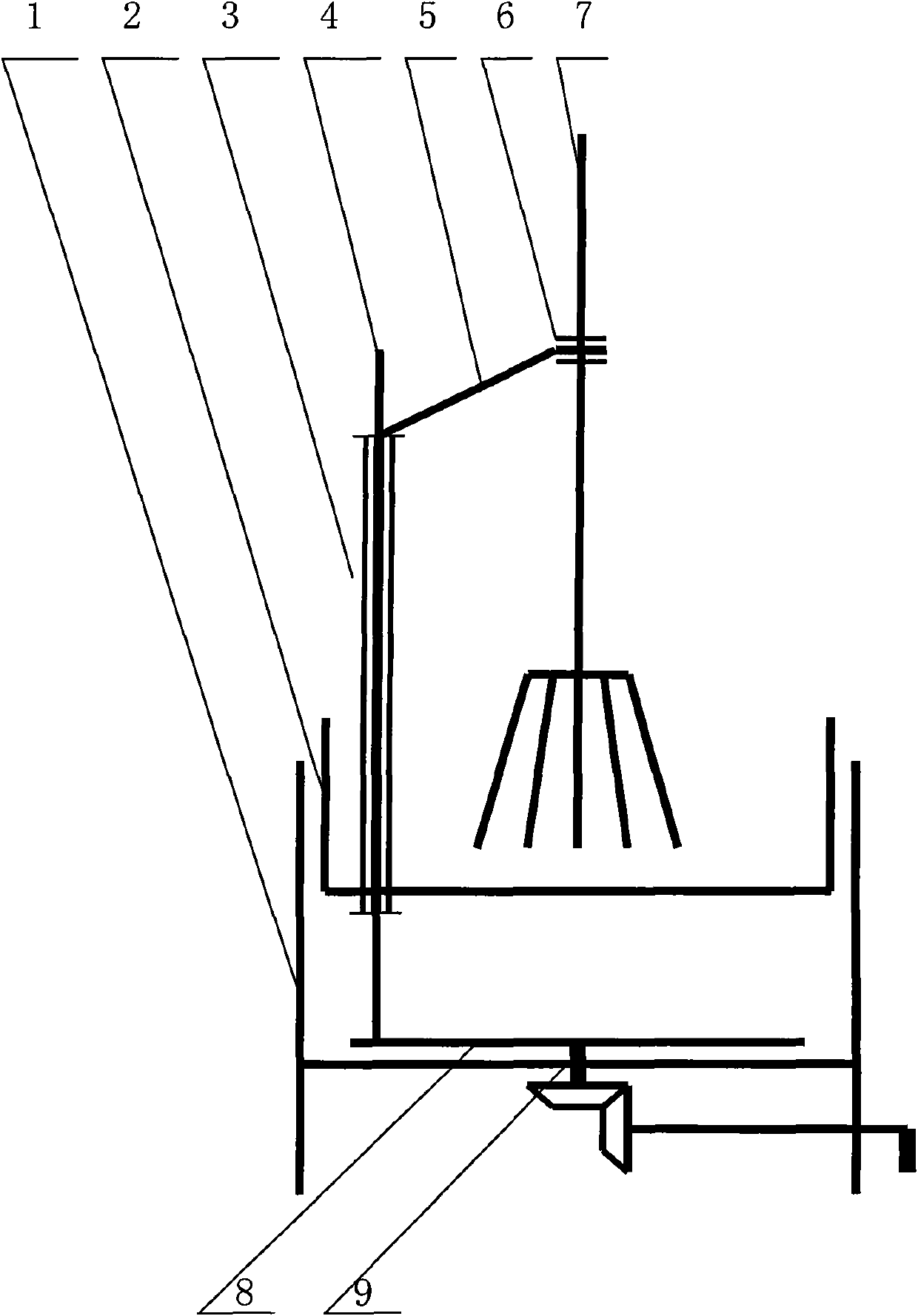

Multi-corner tangential multi-scale pulverized coal decoupling combustion device and decoupling combustion method thereof

InactiveCN103134049AOvercoming the Persistent Problem of Combustion-Coupled EmissionsDecoupled combustion reducesCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCENBOLCombustion

The invention relates to a multi-corner tangential multi-scale pulverized coal decoupling combustion device and a decoupling combustion method thereof; based on pulverized coal combustion characteristics and substance transformation rules, in a microcosmic scale, each column of primary air nozzles (3) on a multi-corner tangential combustion furnace hearth is arranged in a manner that at least 2 or more than 2 nozzles are centralized and adjacent to each other up and down, and the nozzles (3) are relatively centralized at an area in the hearth close to the flame center and with a very high temperature, so multi-area horizontal front-and-back fractional combustion is realized; in a medium scale, second-stage secondary air nozzles (1) are arranged in a local centralization mannerto form a strong reducibility area and a weak reducibility area or a weak oxidability area respectively before and after mixing with the primary air nozzles (3), so multi-area horizontal left-and-right fractional combustion is realized; in a macroscopic scale, peripheral over-fire air nozzles (8) and center over-fire air nozzles (9) are disposed to respectively form a reducibility area and an oxidability area at the lower and upper parts of the hearth, so vertical up-and-down air fractional combustion is realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

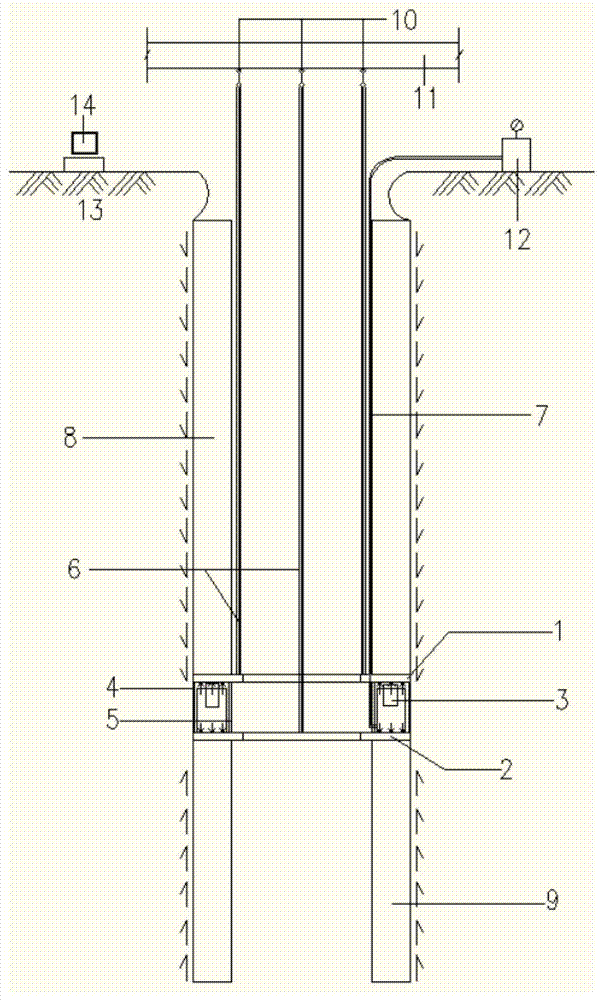

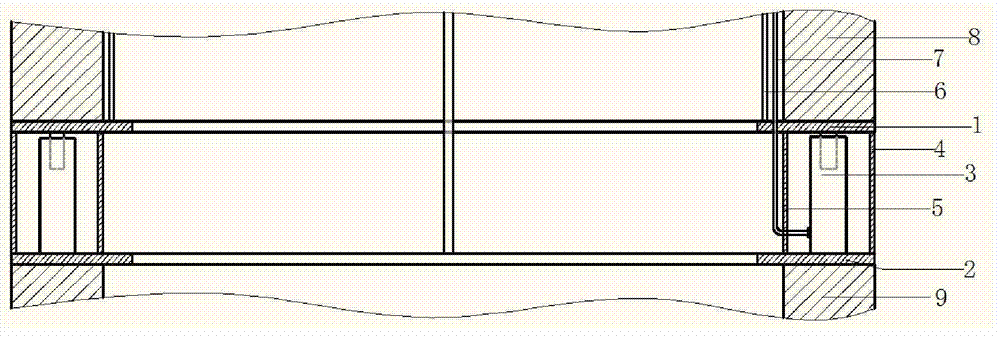

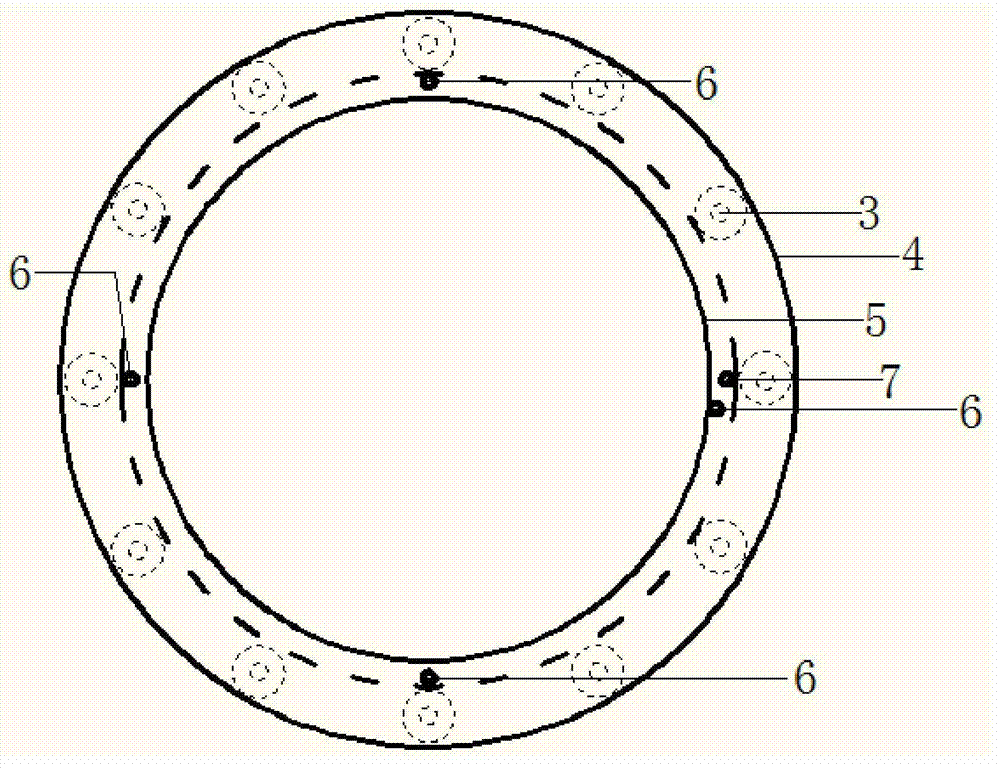

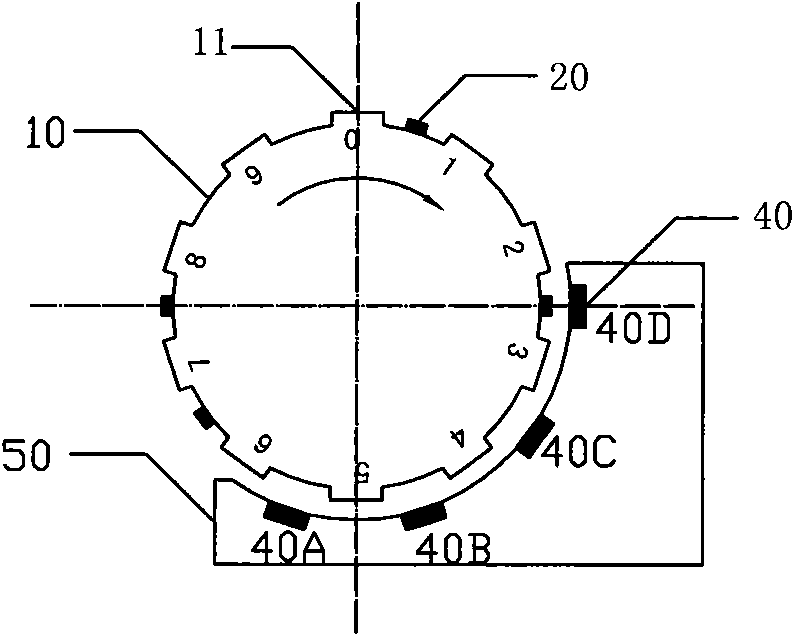

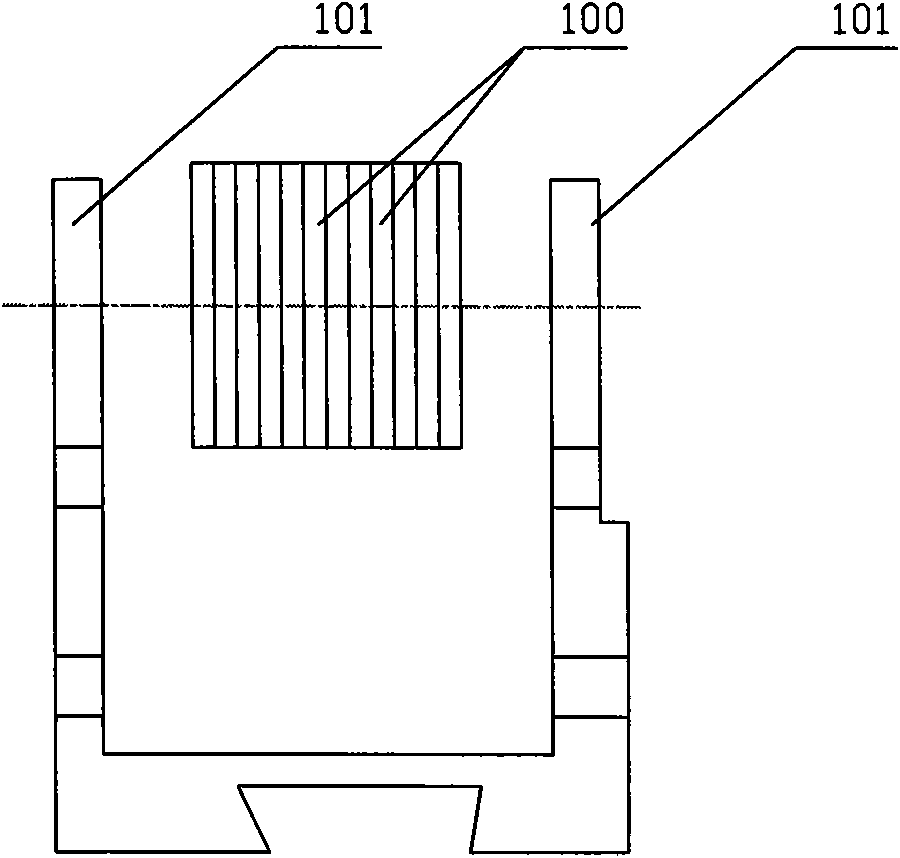

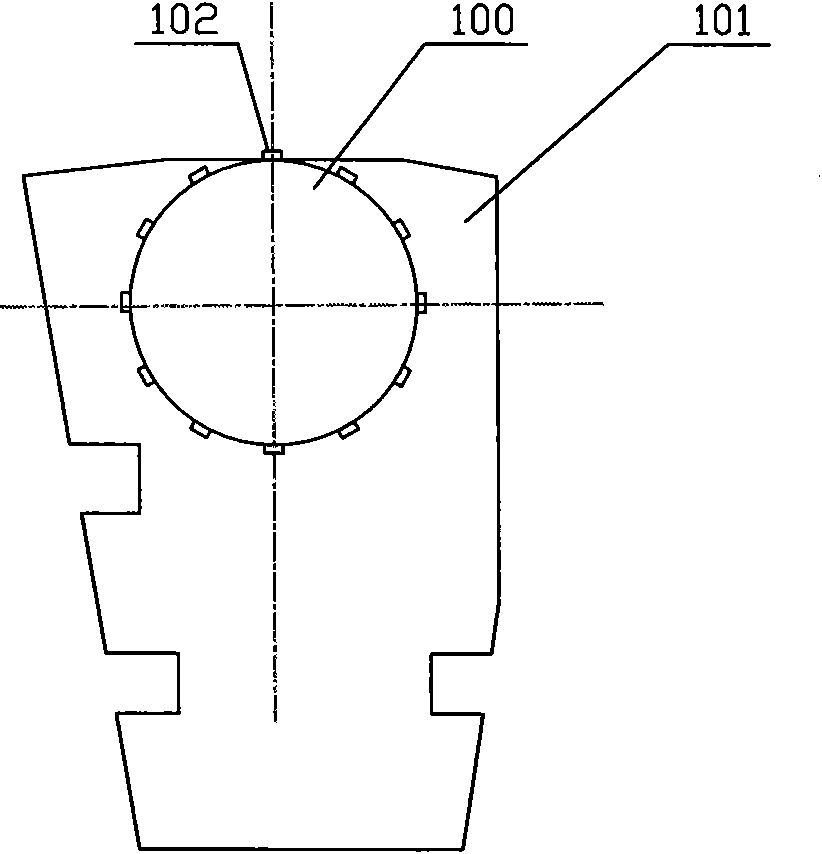

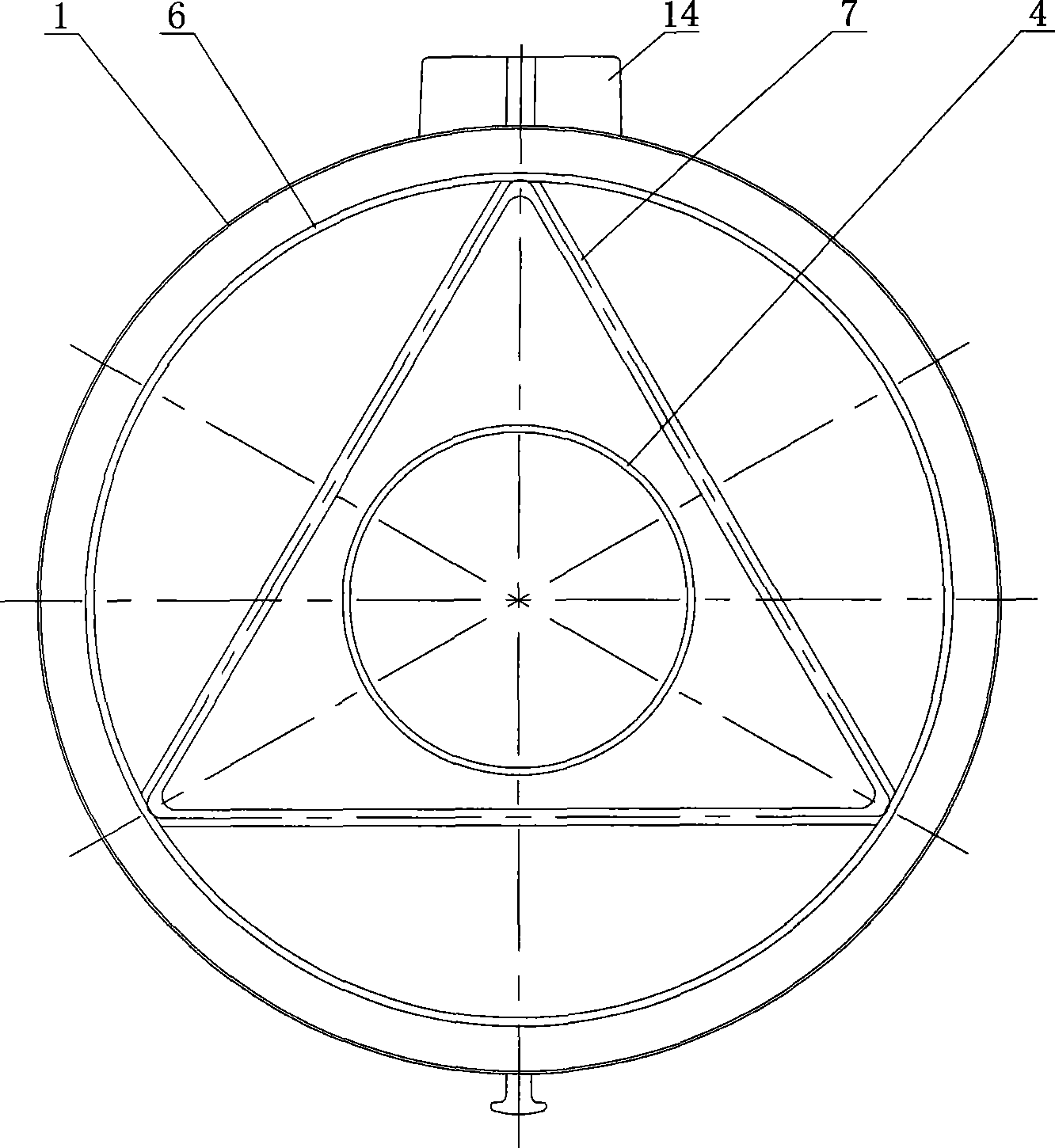

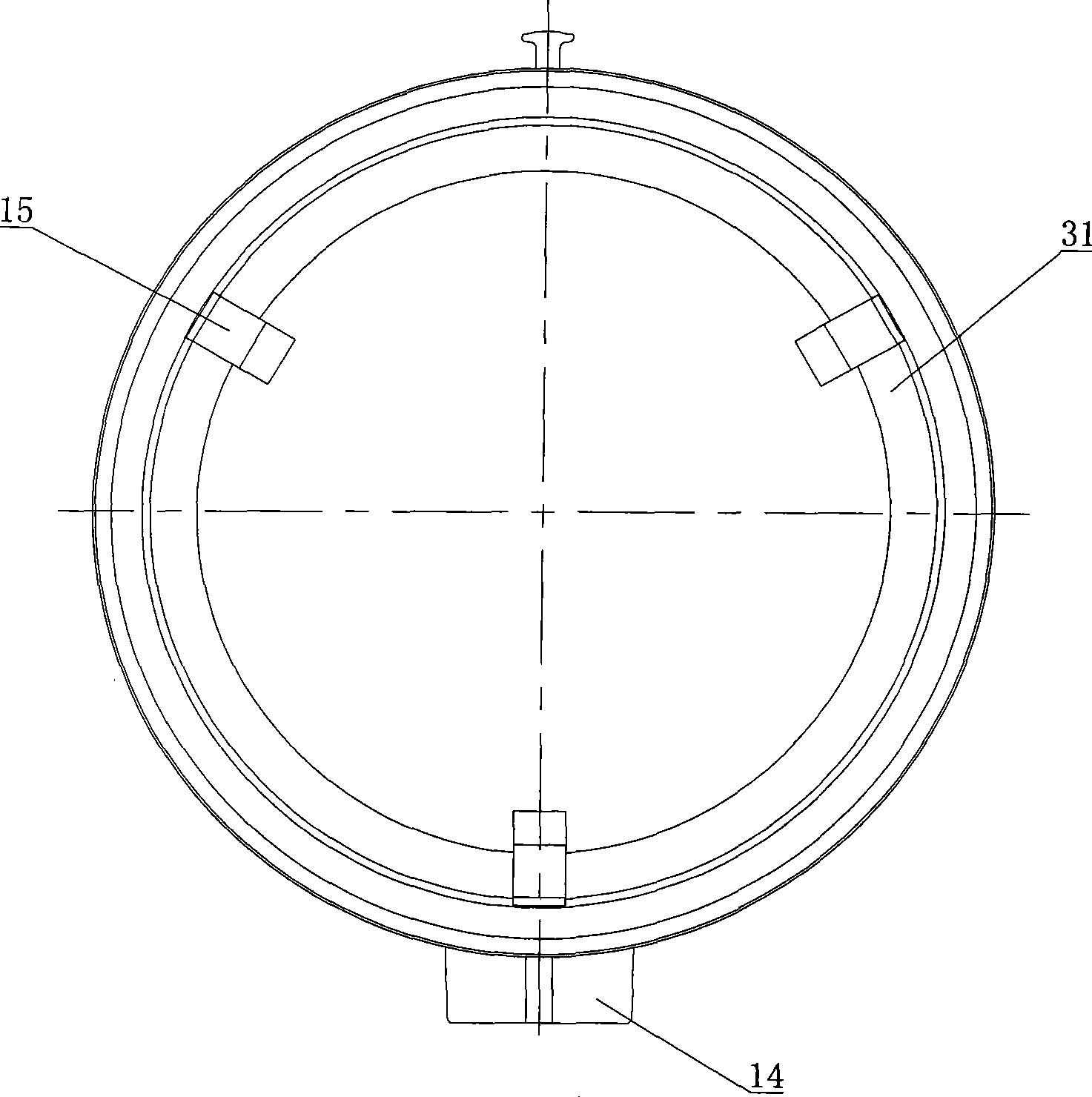

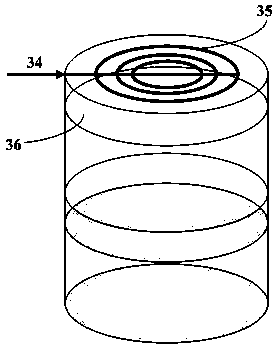

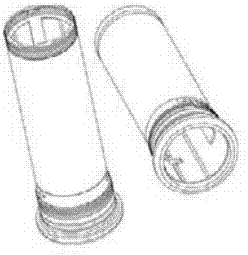

Load box for self-balanced method testing of concrete pipe pile

The invention discloses a load box for self-balanced method testing of a concrete pipe pile. The load box comprises an upper annular steel plate, a lower annular steel plate, hydraulic oil cylinders, an outer ring baffle plate and an inner ring baffle plate, wherein the upper annular steel plate and the lower annular steel plate are arranged symmetrically one above the other; the hydraulic oil cylinders are arranged between the upper annular steel plate and the lower annular steel plate; at least four the quantity of the hydraulic oil cylinders is at least four; the hydraulic oil cylinders are distributed symmetrically by taking the ring centers of the upper annular steel plate and the lower annular steel plate as the ring centers; the bottoms of the cylinder bodies of the hydraulic oil cylinders are connected to and arranged on the upper surface of the lower annular steel plate by adopting bolts; pistons of the hydraulic oil cylinders are connected with the bottom surface of the upper annular steel plate; the outer ring baffle plate is positioned on the outer edges of the upper annular steel plate and the lower annular steel plate; the upper end of the outer ring baffle plate is connected with the lower side of the upper annular steel plate by spot welding, and the lower end of the outer ring baffle plate is completely welded with the upper side of the lower annular steel plate; the inner ring baffle plate is positioned on the inner edges of the upper annular steel plate and the lower annular steel plate which are close to the hydraulic oil cylinders, and is kept consistent with the inner diameter of the pipe pile; and the upper end of the inner ring baffle plate is connected with the lower side of the upper annular steel plate by spot welding, and the lower end of the inner ring baffle plate is completely welded with the upper side of the lower annular steel plate.

Owner:SOUTHEAST UNIV

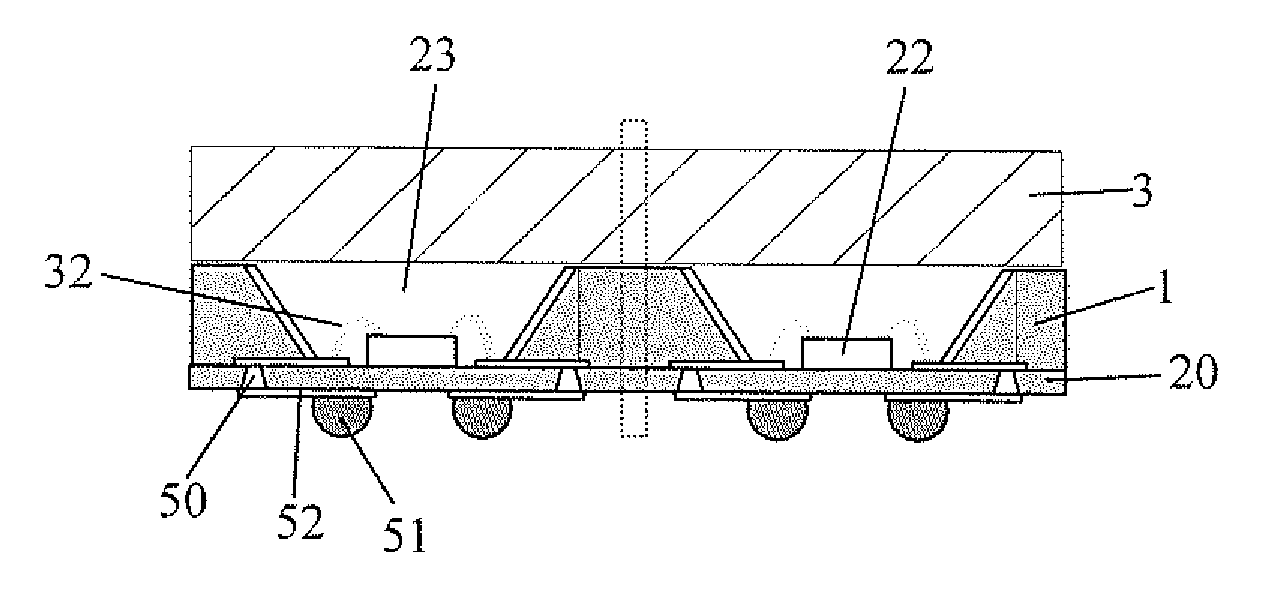

Method for manufacturing an arrangement with a component on a carrier substrate, an arrangement and method for manufacturing a semi-finished product, and a semi-finished product

ActiveUS20120314393A1Efficient use ofCost effective productionWave amplification devicesSolid-state devicesManufacturing engineering

Owner:MSG LITHOGLAS AG

Method for manufacturing an arrangement with a component on a carrier substrate and a method for manufacturing a semi-finished product

ActiveUS8966748B2Efficient use ofCost effective productionLiquid surface applicatorsWave amplification devicesWork in processManufacturing engineering

Owner:MSG LITHOGLAS AG

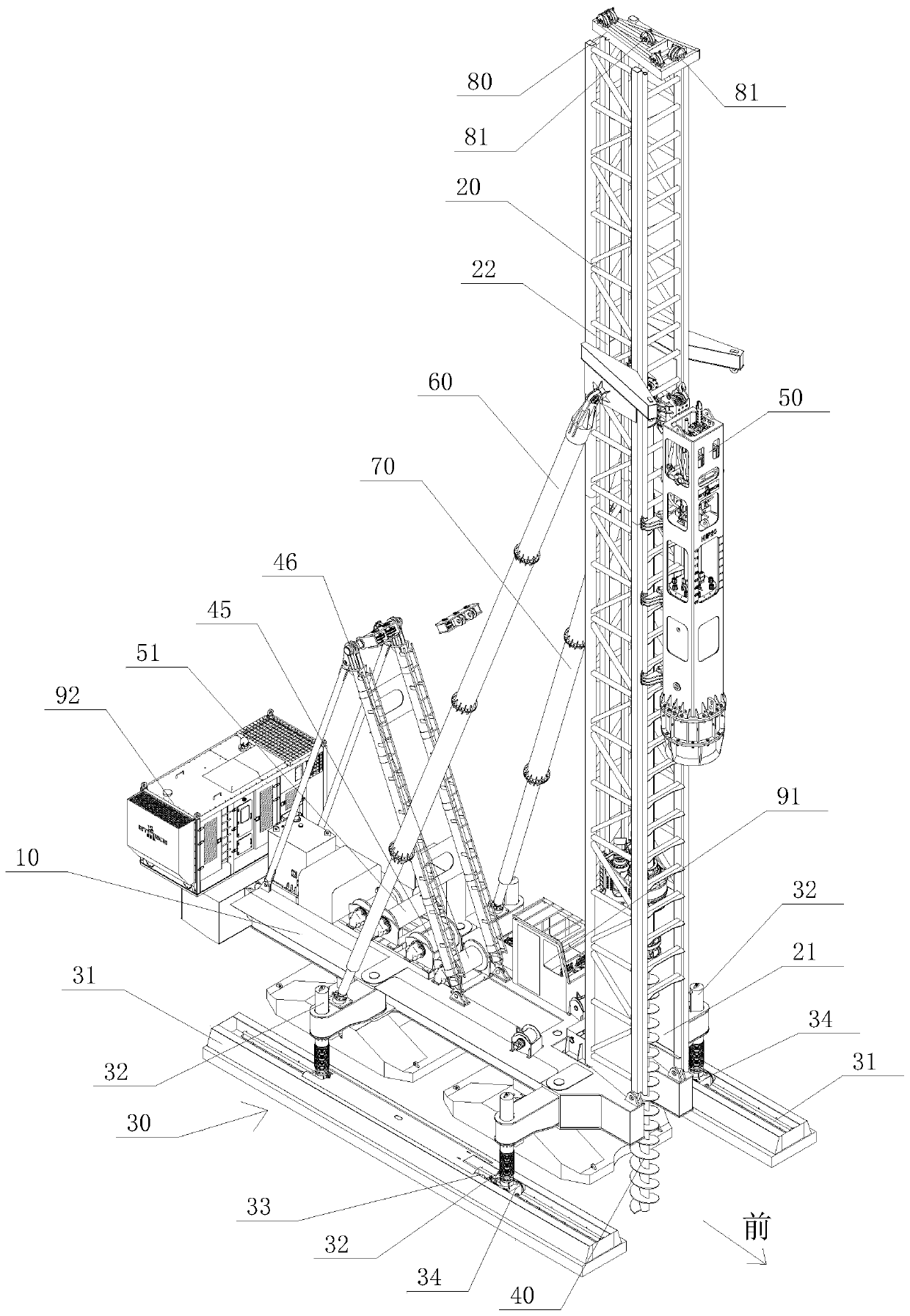

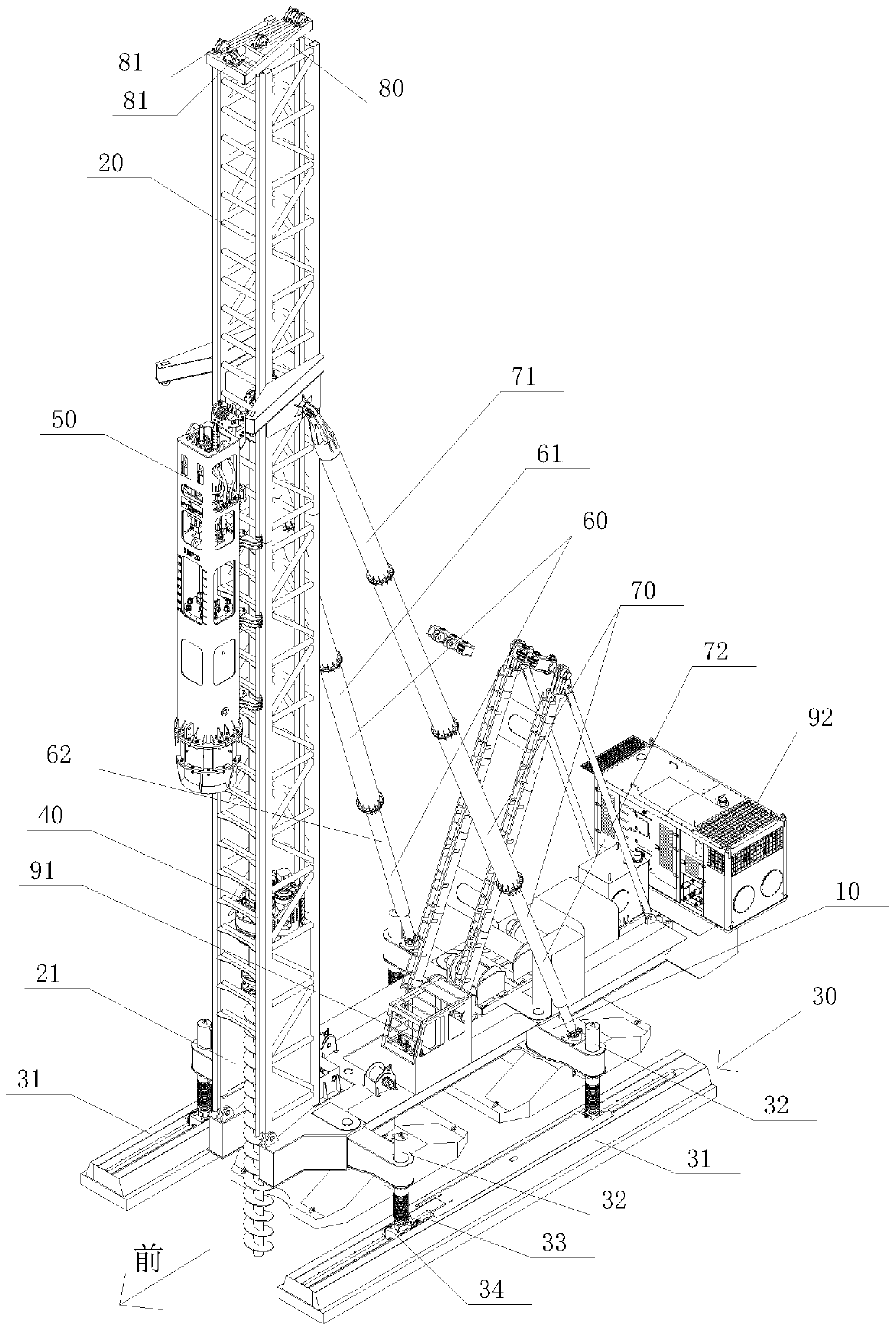

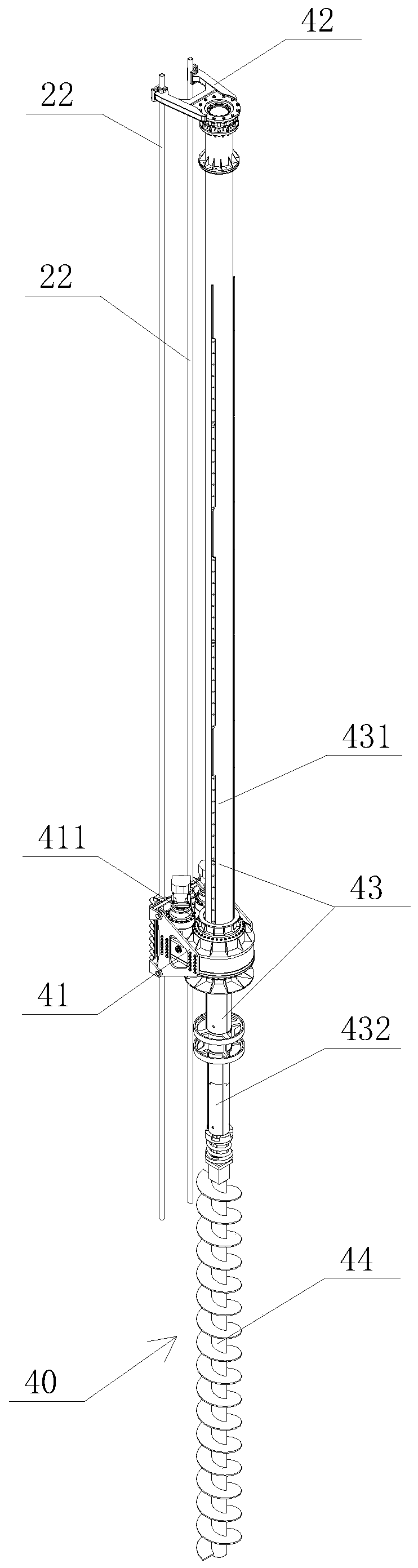

Construction method of big-diameter PHC prefabricated pipe pile and piling machine for implementing method

PendingCN110952552APrecise control of tilt angleSolve difficult-to-sink problemsBulkheads/pilesTowerPipe

The invention discloses a construction method of a large-diameter PHC prefabricated pipe pile. The method comprises the following steps of putting the piling machine in place; regulating an inclination angle; mounting the large-diameter PHC prefabricated pipe pile; performing hammering pile conveyance through a soft soil layer; aligning a guide hole; internally drilling the guide hole; performinghammering alignment; and performing hammering pile conveyance to a hard soil layer. The invention also discloses piling equipment for implementing the method. A hammering mode is used for pile foundation construction in the soft soil layer of a foundation; a large-diameter PHC pipe pile is sunk into the soft soil layer; the lateral friction resistance between the upper part of the pile foundationand the soft soil layer is ensured; the bearing force of the pile foundation is improved; a mode of firstly forming the guide hole and then performing hammering is used on the hard soil layer of the foundation; the problem of a plugging effect of the hard soil layer on the large-diameter PHC pipe file is solved, so that the large-diameter PHC pipe pile can be smoothly sunk into the hard soil layer; by regulating the inclination angle of a tower frame, the inclination angle of the large-diameter PHC pipe file is accurately controlled; and the precise and high-efficiency construction of the large-diameter PHC pipe file with the set inclination angle is realized.

Owner:GUANGDONG LIYUAN HYDRAULIC MACHINERY

Coding device and coding method of print wheel of numbering machine

InactiveCN101524929AReduces chances of smudgingGuaranteed StrengthCharacter printing data arrangement from carrierStampingElectrical polarityEngineering

The invention discloses a coding device of a print wheel of a numbering machine, which comprises one or more print wheels around the circumference of which more than 2<n-1> and less than or equal to 2<n> print characters are distributed, wherein the print wheels are provided with a plurality of magnetic elements for transmitting magnetic signals to sensor units and the sensor units are arranged close to the circumferences of the print wheels; each sensor unit corresponding to each print wheel comprises n-1 sensor elements continuously arranged according to the angle intervals of the print characters on each print wheel; the magnetic elements include magnetic elements of positive and negative two polarities; the sensor elements comprises two kinds of effective sensor elements triggered by the magnetic elements of positive and negative two polarities; a computer processor superposes the former character codes and the character codes after jump of sensor elements, the magnetic elements and the sensor elements are distributed in a mode that when the codes of a plurality of print characters detected by the n-1 sensor elements are the same, the codes of print characters before the characters having the same code are different. The device solves the problems of the prior coding device such as a large number of sensor elements required for the realization of full codes of the characters and consequent small spatial place of the numbering machine.

Owner:CHINA BANKNOTE PRINTING & MINTING

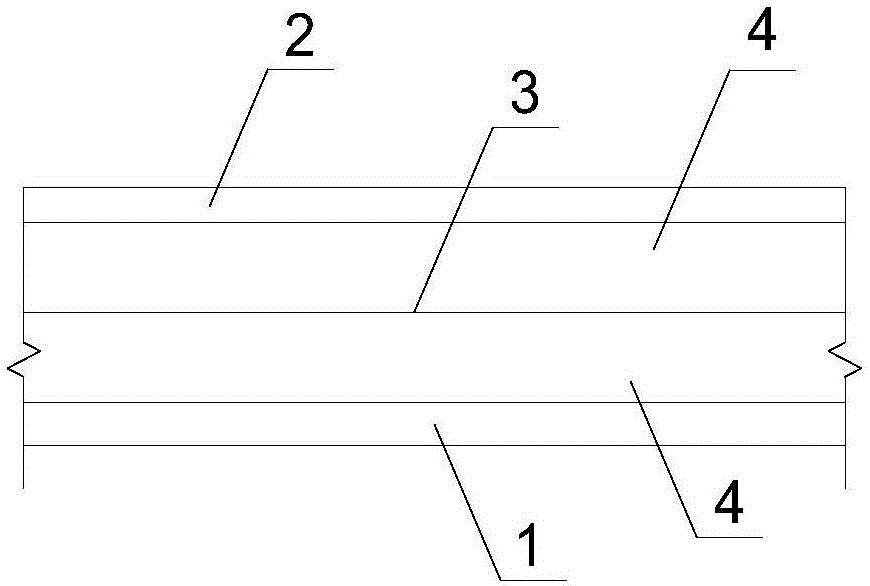

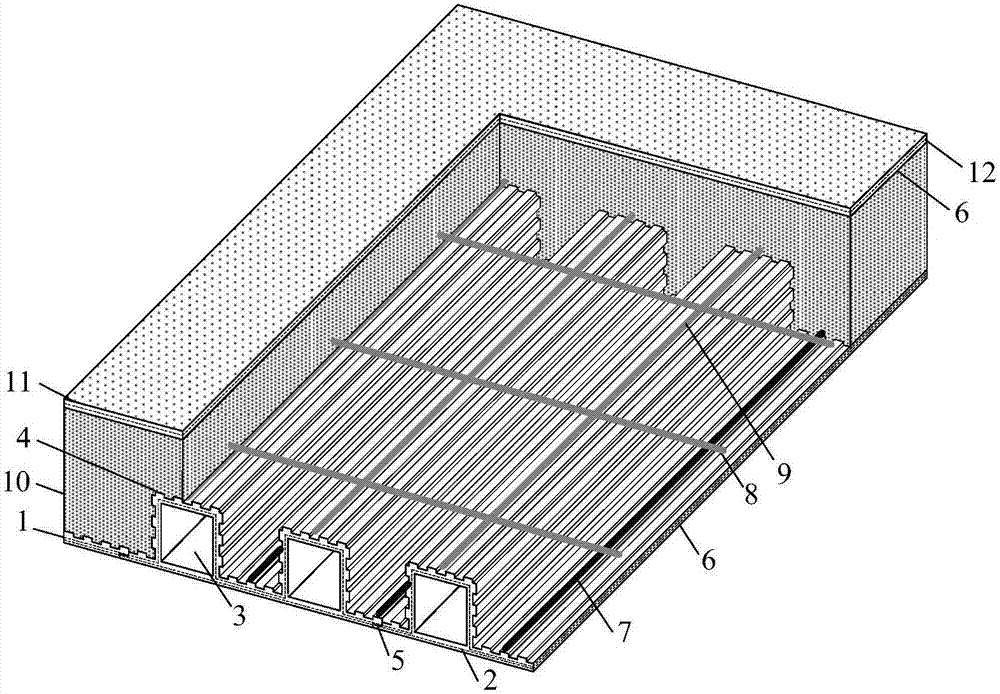

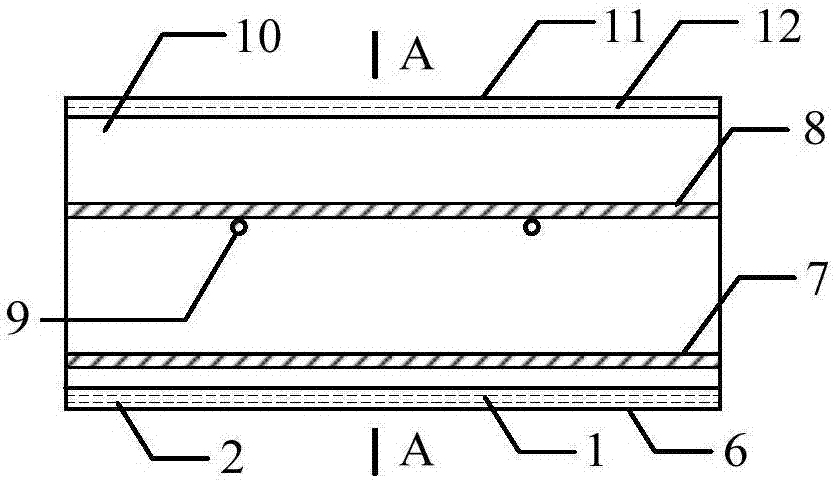

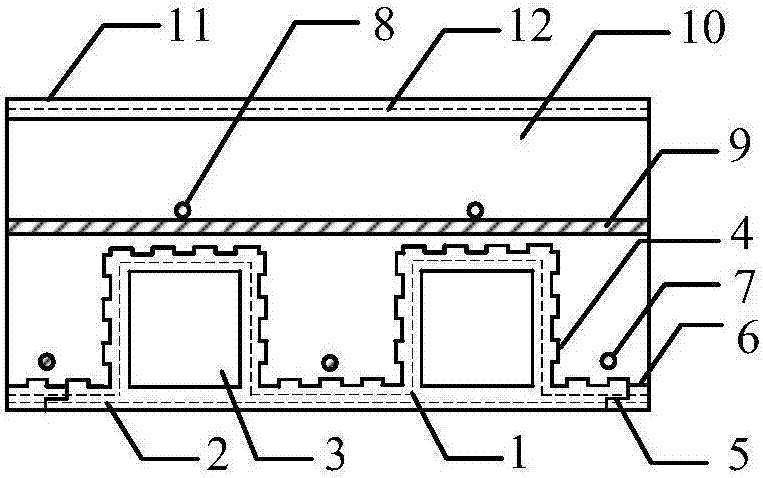

Fiber net-ultra high toughness cementitious compound material composite bridge deck structure and method

ActiveCN106835973AImprove patencyImprove comfortClimate change adaptationBridge structural detailsBridge deckMaterials science

The invention discloses a fiber net-ultra high toughness cementitious compound material composite bridge deck structure and a method. The fiber net-ultra high toughness cementitious compound material composite bridge deck structure comprises a bridge deck plate and a fiber net-reinforced ultra high toughness cementitious compound material pavement layer poured onto the bridge deck plate, wherein an asphalt concrete wearing layer is paved on the fiber net-reinforced ultra high toughness cementitious compound material pavement layer. In the fiber net-ultra high toughness cementitious compound material composite bridge deck structure, due to the adoption of the fiber net-reinforced ultra high toughness cementitious compound material pavement layer, damages, such as longitudinal cracks and wave pass which are caused by repeated action of temperature and vehicle load, local upheaval and comminuted racks of the traditional asphalt concrete paving method are avoided; patency and comfort of vehicles are improved; the durability of a bridge structure is also improved.

Owner:SHANDONG UNIV

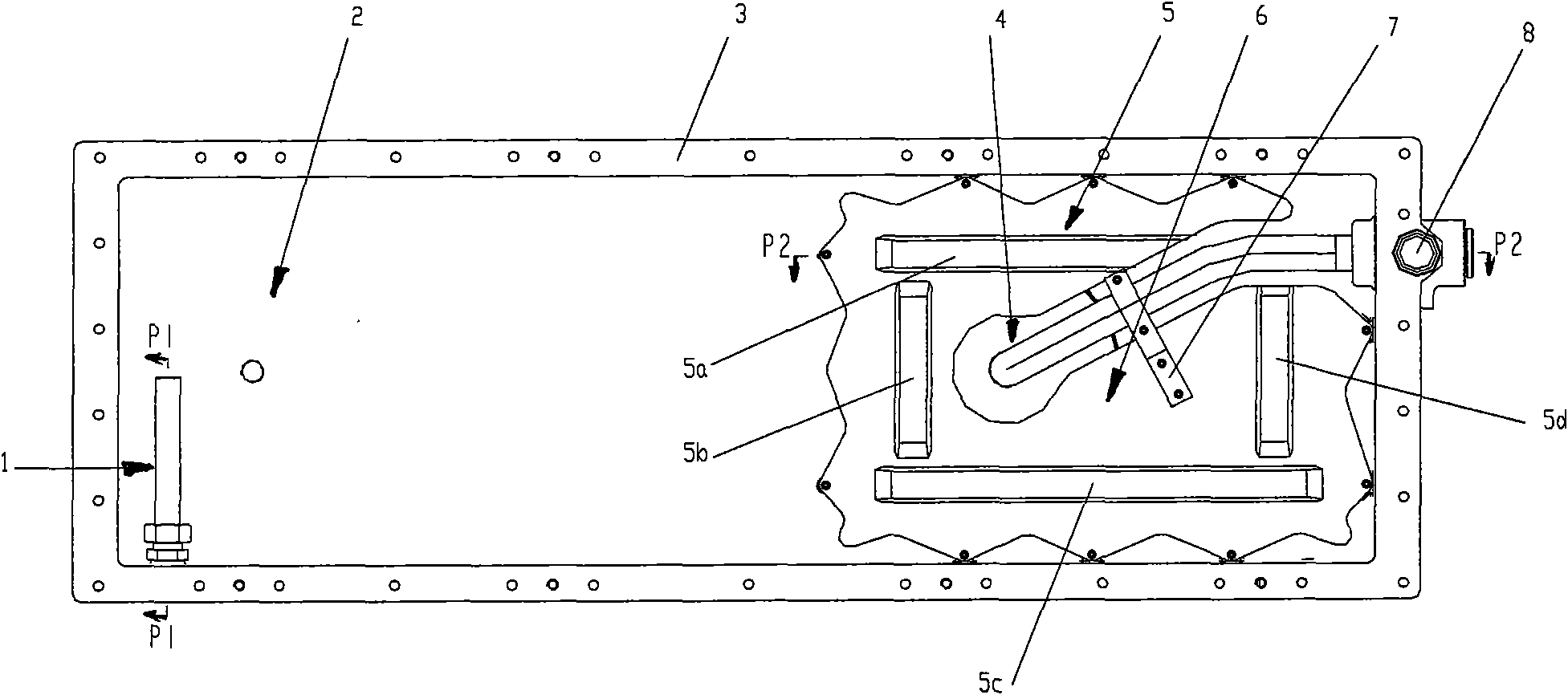

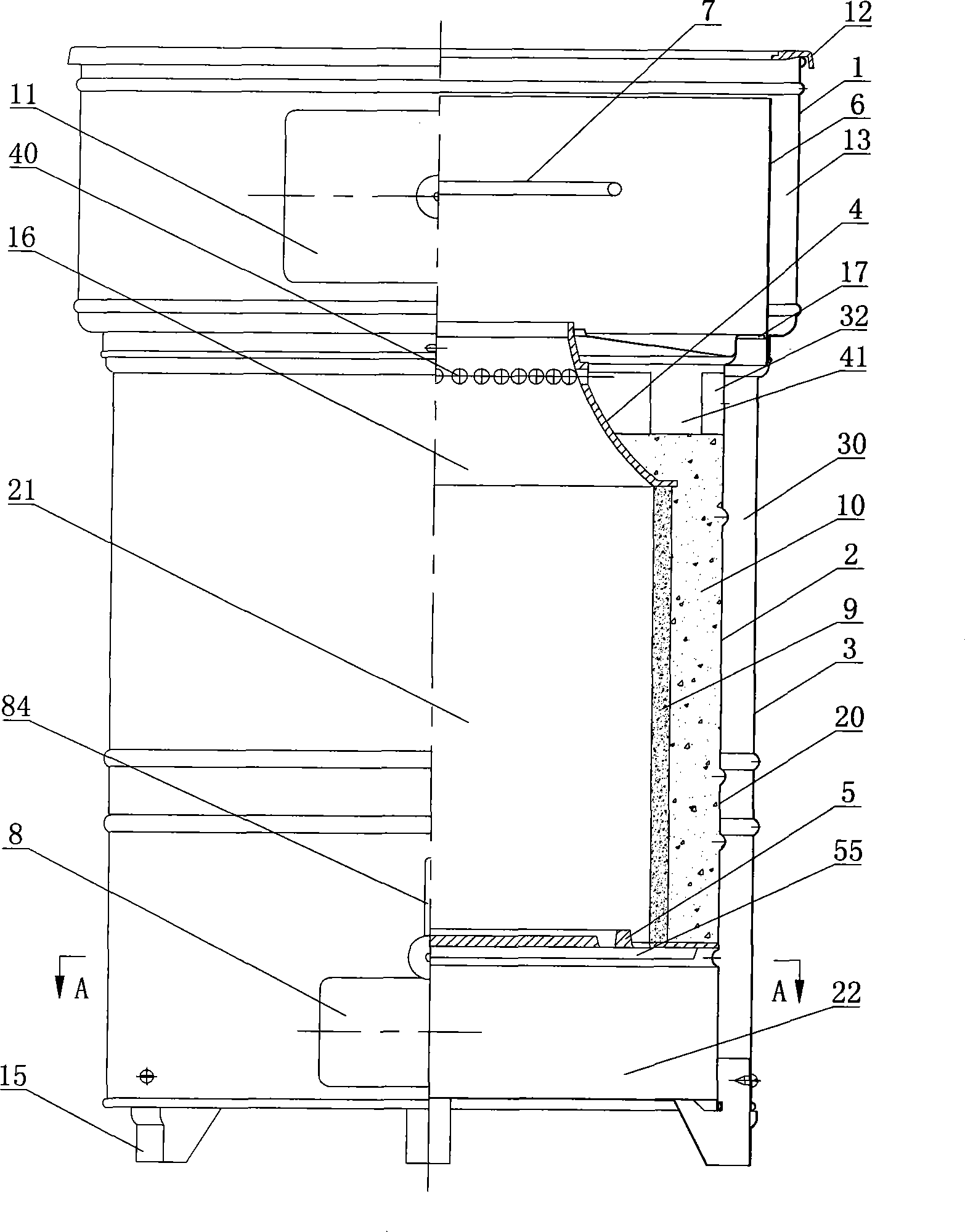

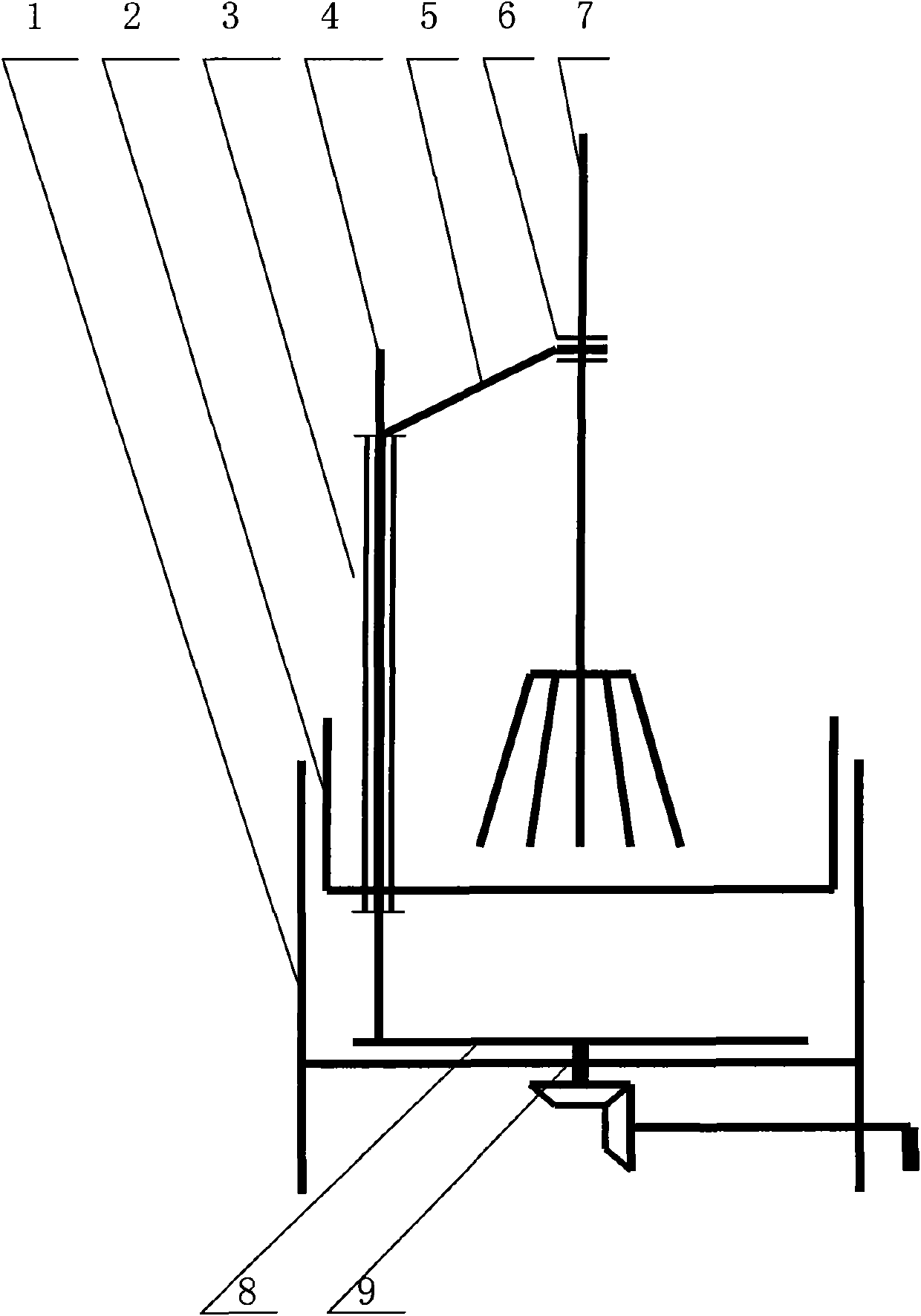

Inclination-resistant oil sump for engine

ActiveCN101660436AReduce design heightFlexible layoutPressure lubrication with lubrication pumpLubricationOil storage

The invention discloses an inclination-resistant oil sump for an engine, which is arranged on the lower part of the engine and comprises an oil sump body, an oil absorbing pipe module, an oil storagechamber, a deep oil storage chamber, a shallow oil storage chamber, an oil pumping pipe module and an oil pump module, wherein the deep oil storage chamber and the shallow oil storage chamber are arranged on the oil sump body; two oil storage chambers are arranged along the length direction of the oil sump at certain distance, the shallow oil storage chamber is an oil pumping cavity, the deep oilstorage chamber is an oil absorbing cavity which is internally provided with an oil absorbing pipe module, and the oil absorbing pipe module is communicated with an oil pump of the engine and conveysengine oil to the oil pump; the oil pumping module is arranged in the oil pumping cavity; and the oil pump module, two ends of which are connected with the oil pumping cavity and the oil absorbing cavity, conveys the engine oil in the oil pumping cavity to the oil absorbing cavity. The invention can ensure that a lubrication system reliably works under the condition of high inclination of the engine, obviously reduce the height size of the oil sump of the engine and has compact structure and convenient arrangement.

Owner:SHANGHAI MICROPOWERS

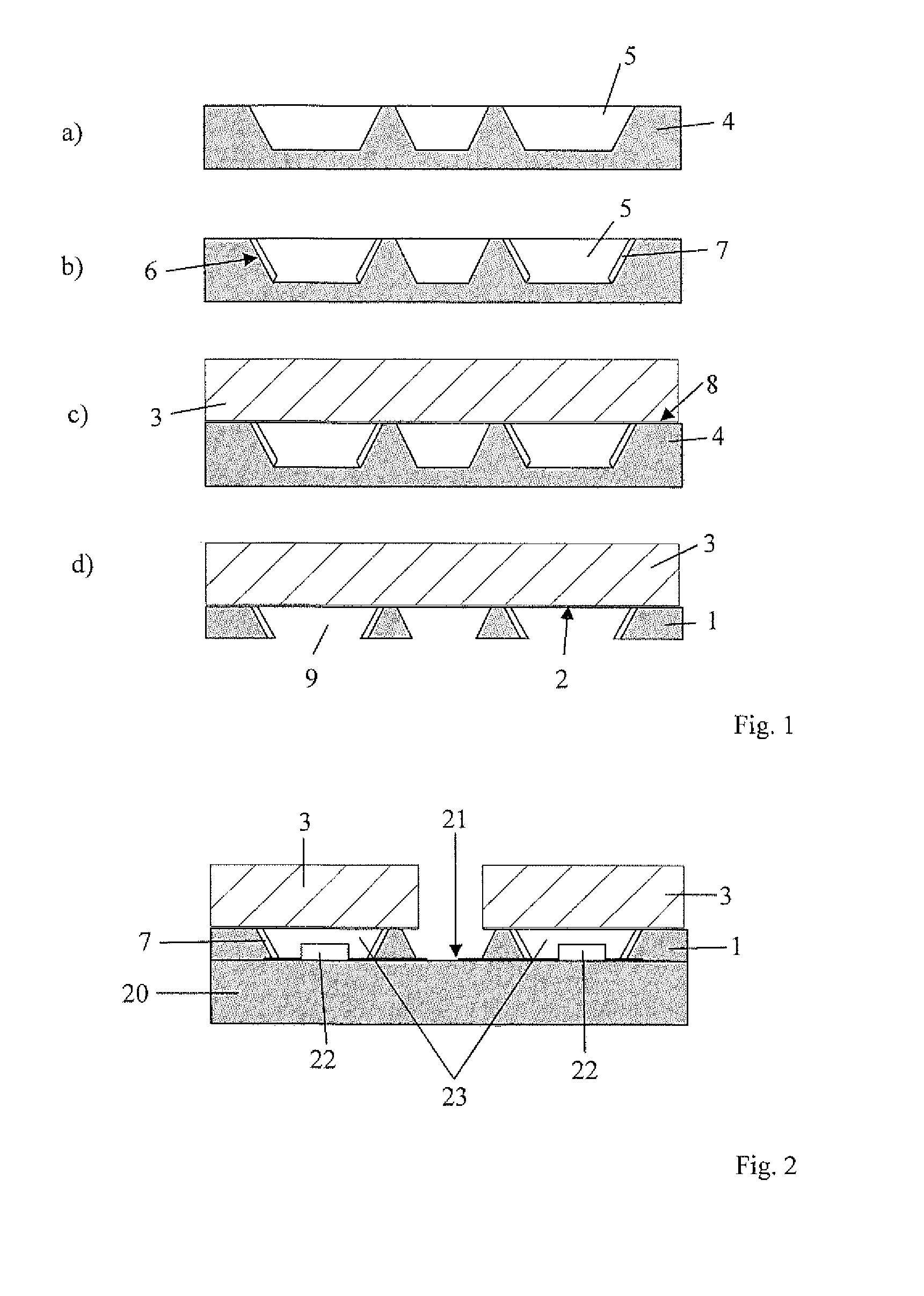

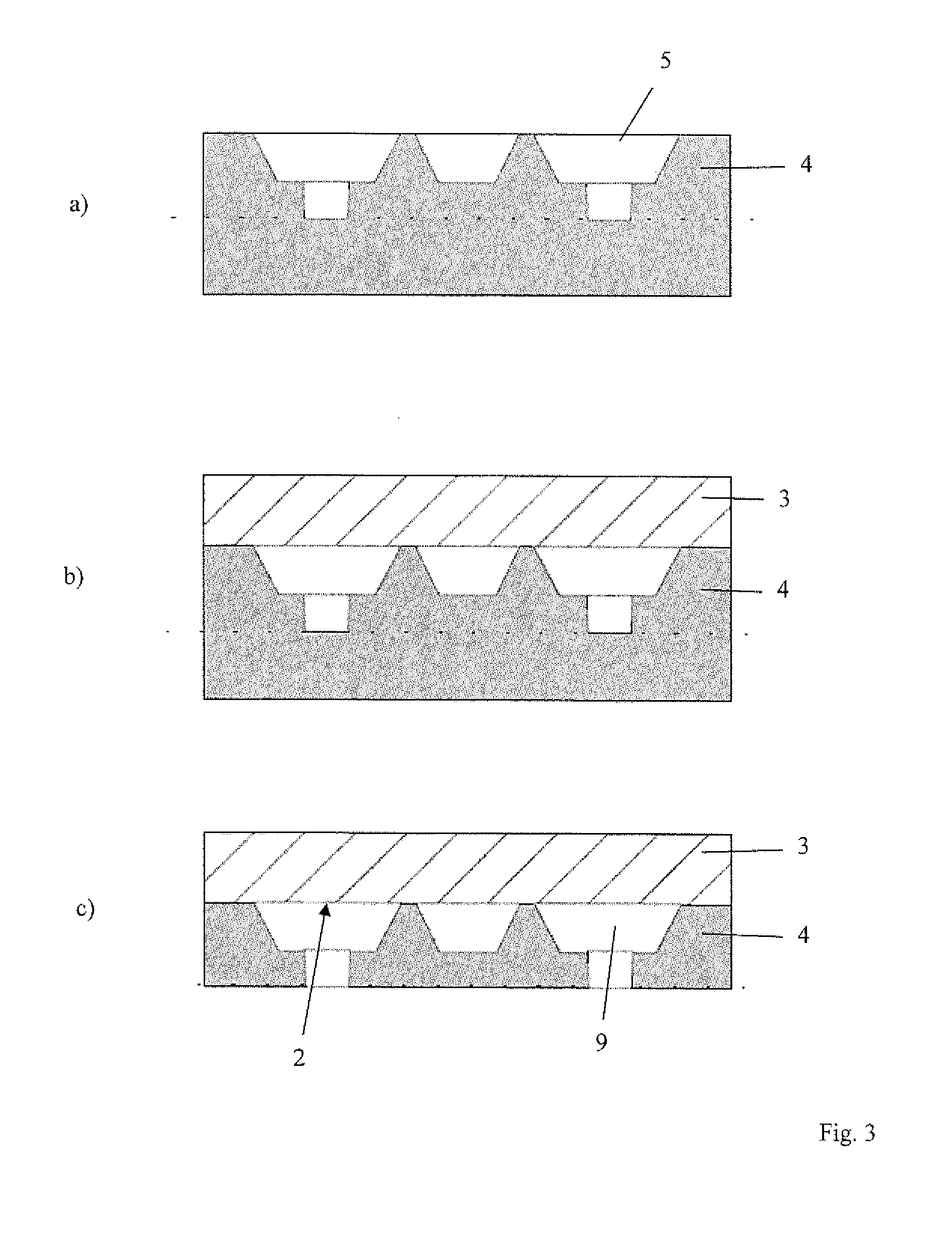

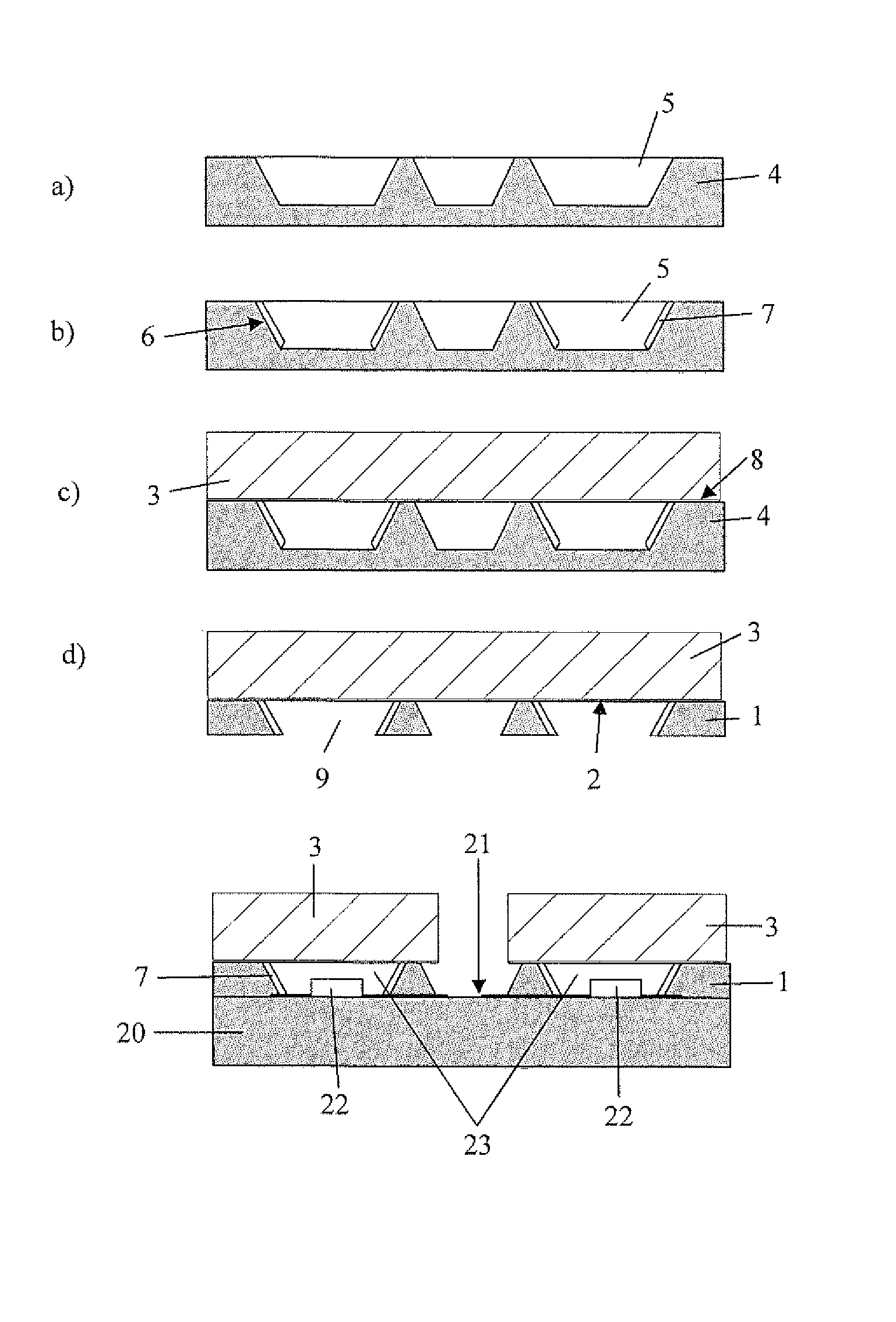

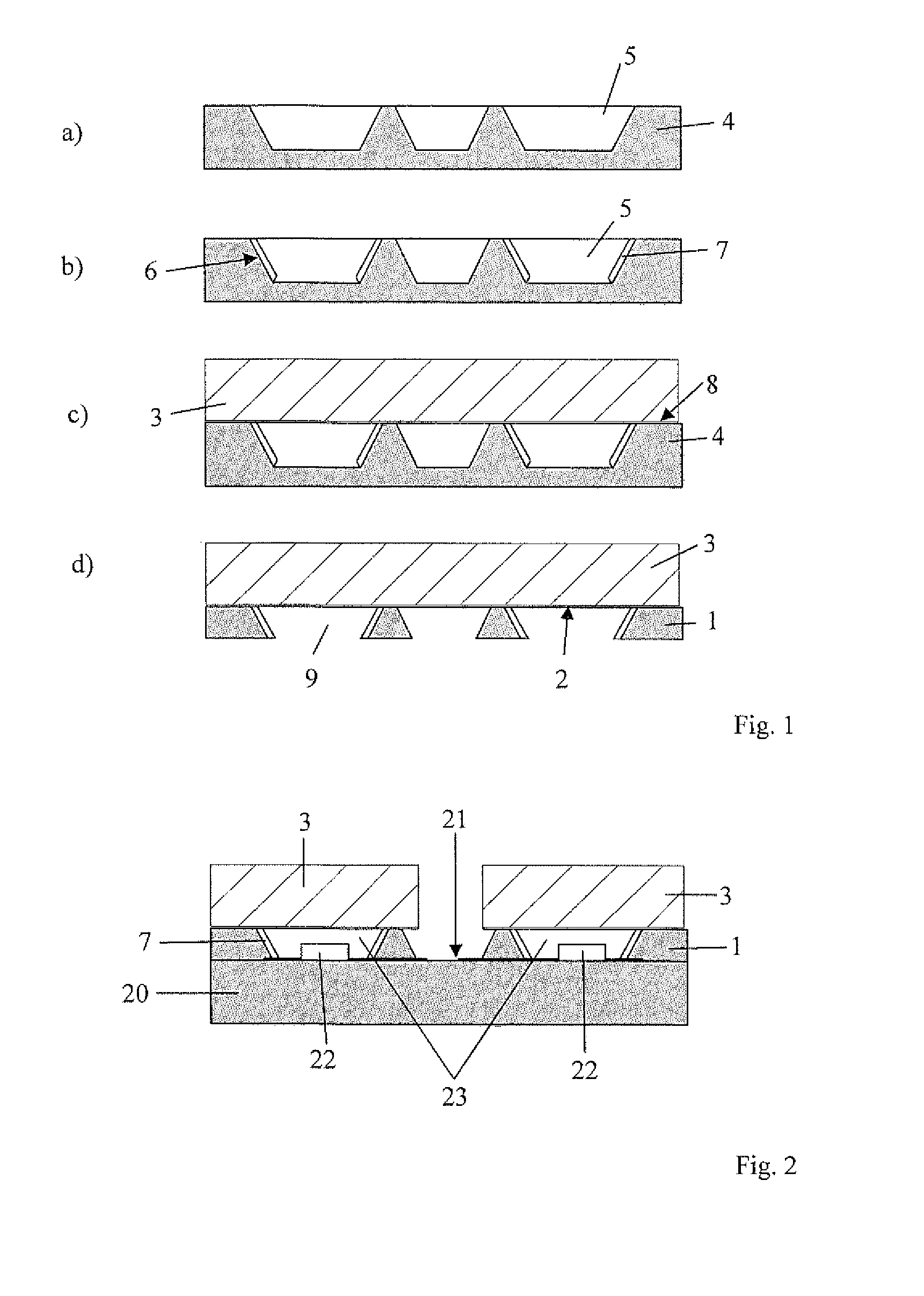

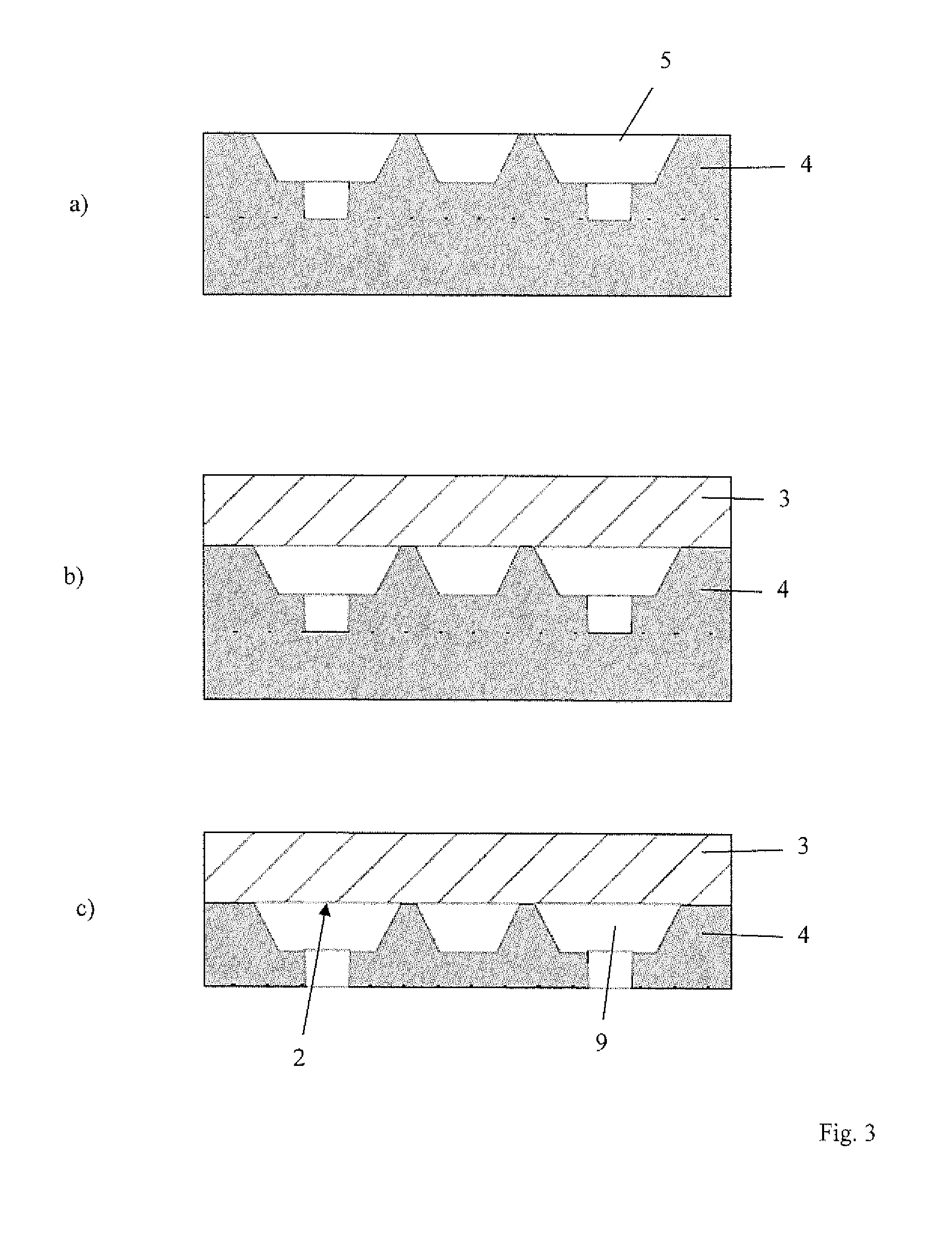

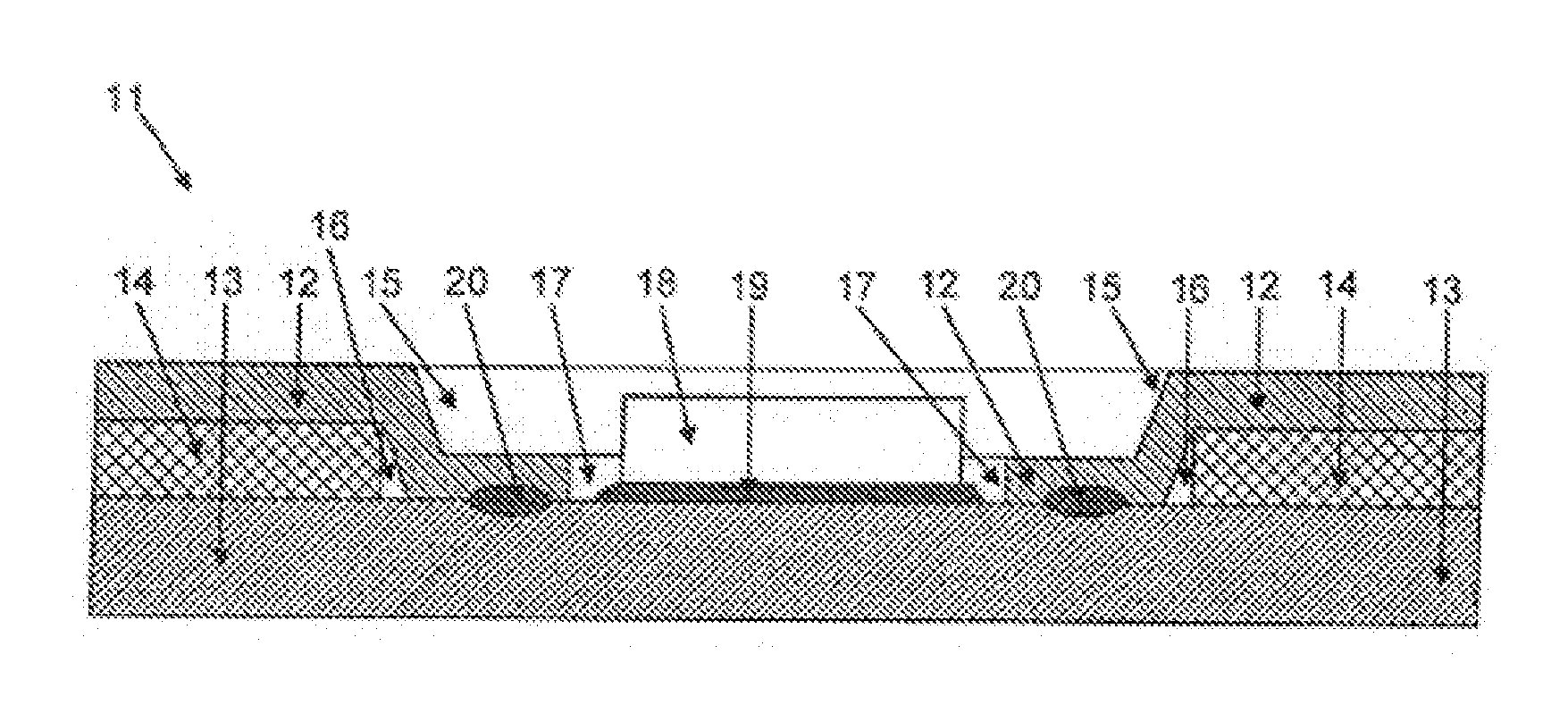

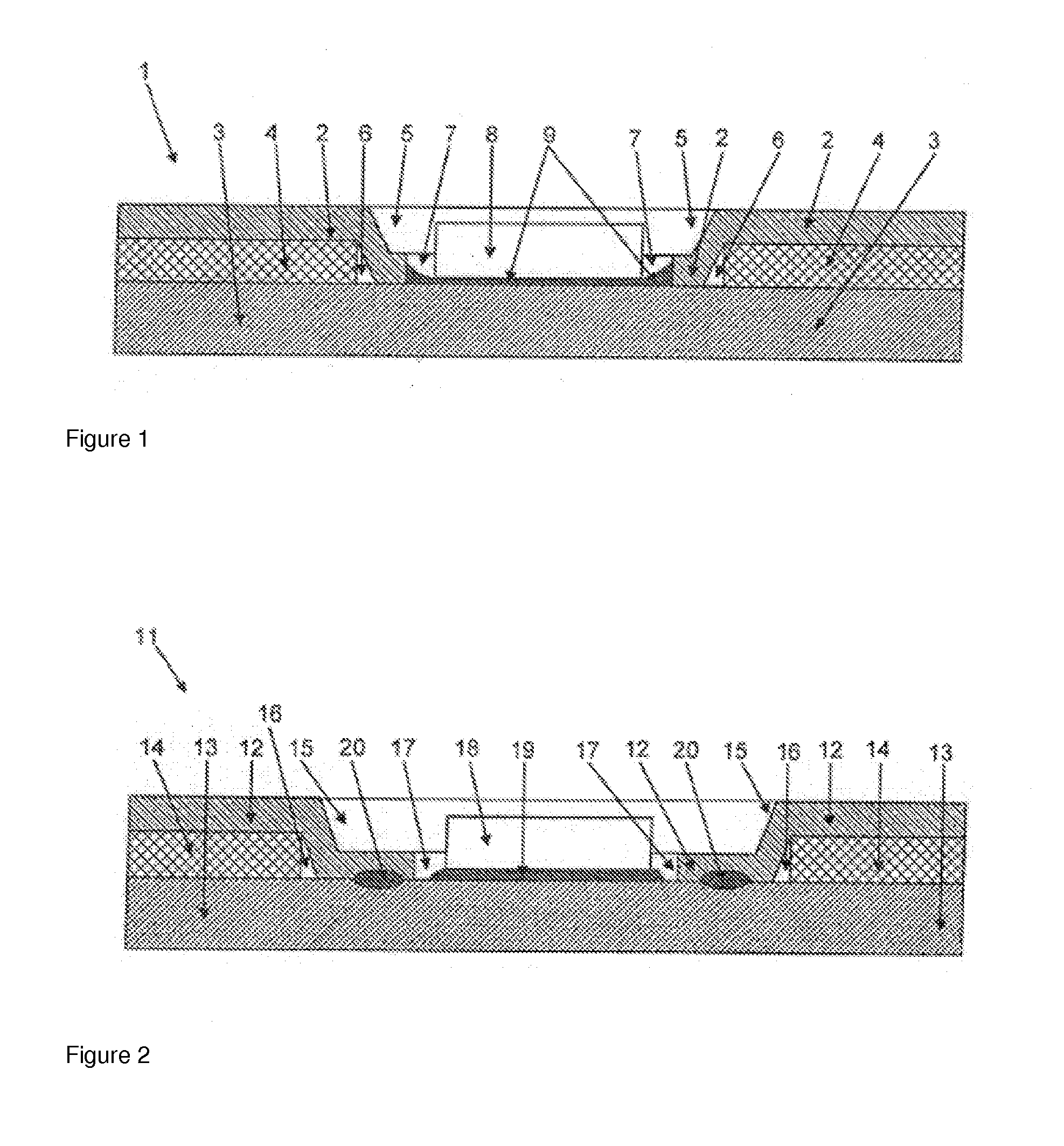

Laminate with integrated electronic component

InactiveUS20130215584A1Low design heightImprove heat dissipationSemiconductor/solid-state device detailsSolid-state devicesMetalContact region

The invention relates to methods for producing a laminate for contacting an electronic component, in which an insulating layer is arranged between first and second metal layers. The method includes contacting the metal layers to each other in a contact region, generating a recess in the insulating layer, laminating the metal layers to the insulating layer, generating a notch for accommodating the electronic component in the contact region in the first metal layer, inserting the electronic component in a depression in the laminate formed through a notch and recess. The electronic component is connected in a conductive manner to the second metal layer, such that an entire circumference of the electronic component is accommodated in the recess and / or notch, and at least part of the height of the electronic component is accommodated in the notch and / or recess. The invention also relates to such a laminate for contacting an electronic component.

Owner:HERAEUS MATERIALS TECH

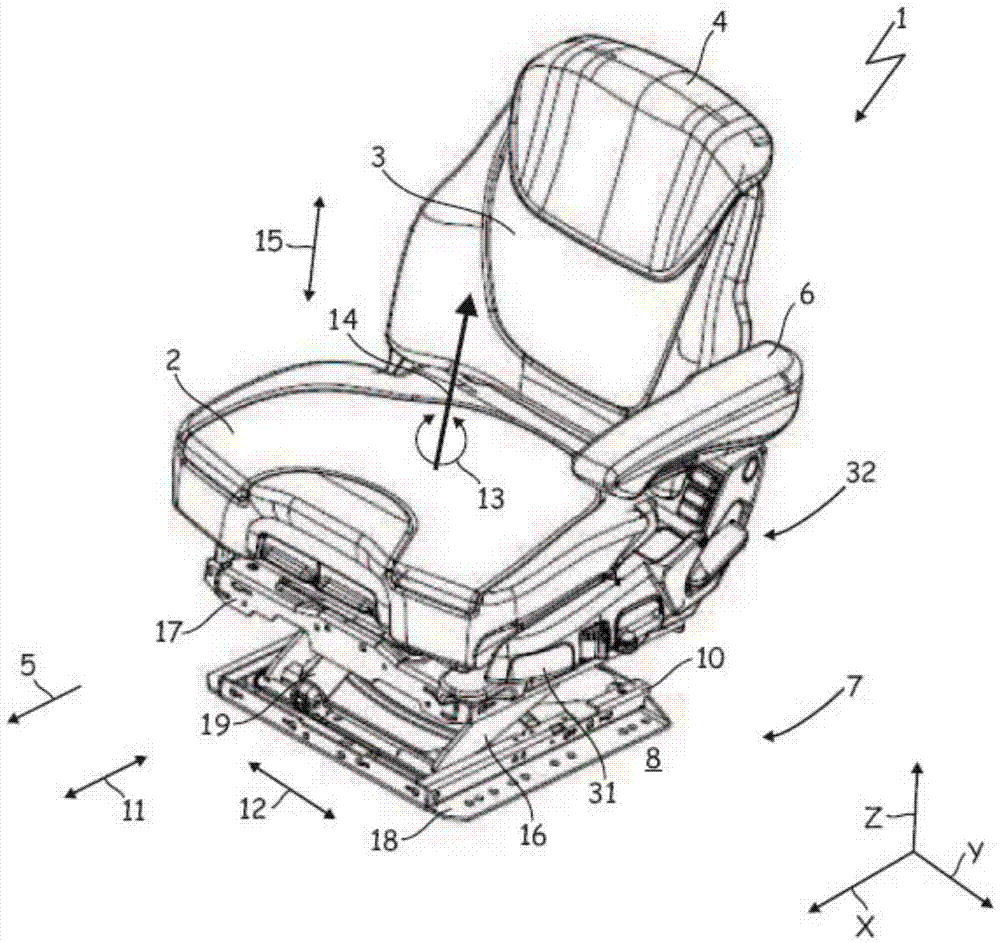

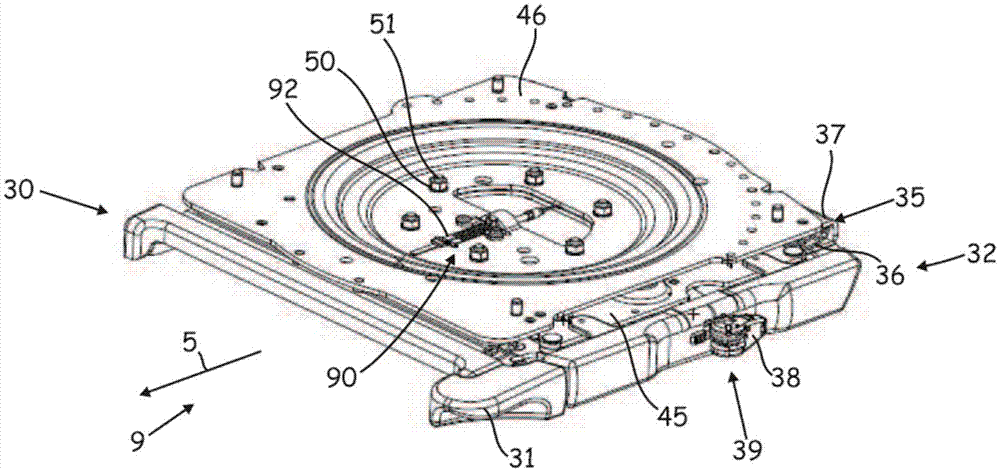

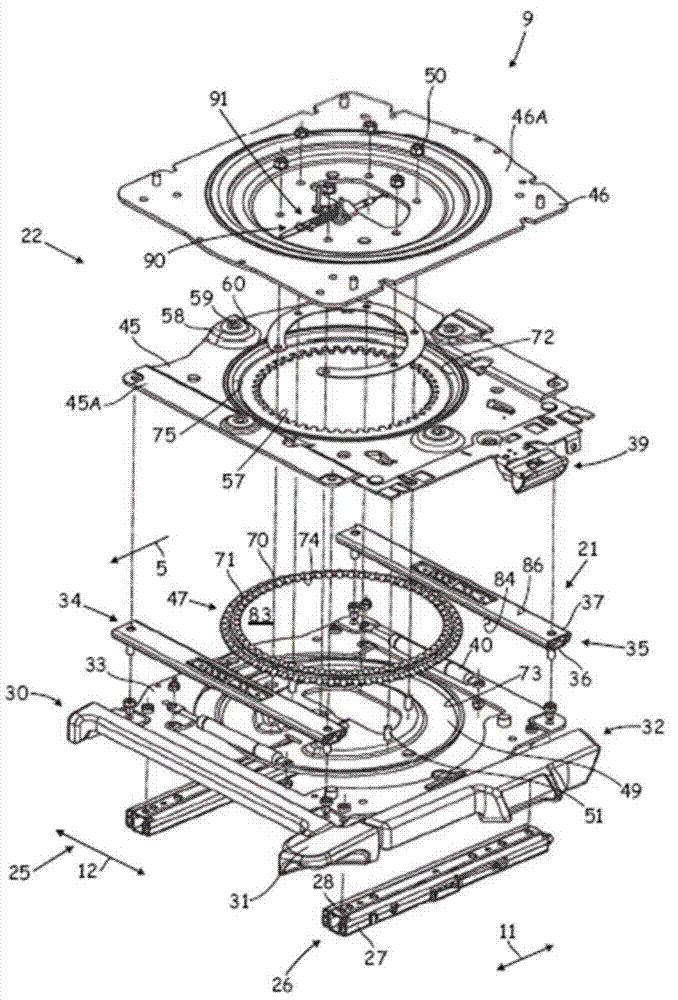

Utility vehicle seat with integrated rotation adjustment device

ActiveCN103863149AReduce design heightReduce the height of the structureMovable seatsBall bearingEngineering

The invention relates to a utility vehicle seat with a seat part, with a backrest part and with a seat substructure for arrangement on a bodywork part of a utility vehicle. The seat substructure including a rotation adjustment device having a roller body bearing unit for rotating at least the seat part about a vertical axis, a longitudinal adjustment device and a transverse adjustment device. The rotation adjustment apparatus is arranged between two longitudinal rail units or transverse rail units, in such a way that a vertical extension of the rotation adjustment apparatus amounts to a maximum of 150% or 100% of a vertical extension of the longitudinal rail units or the transverse rail units.

Owner:GRAMMER AG

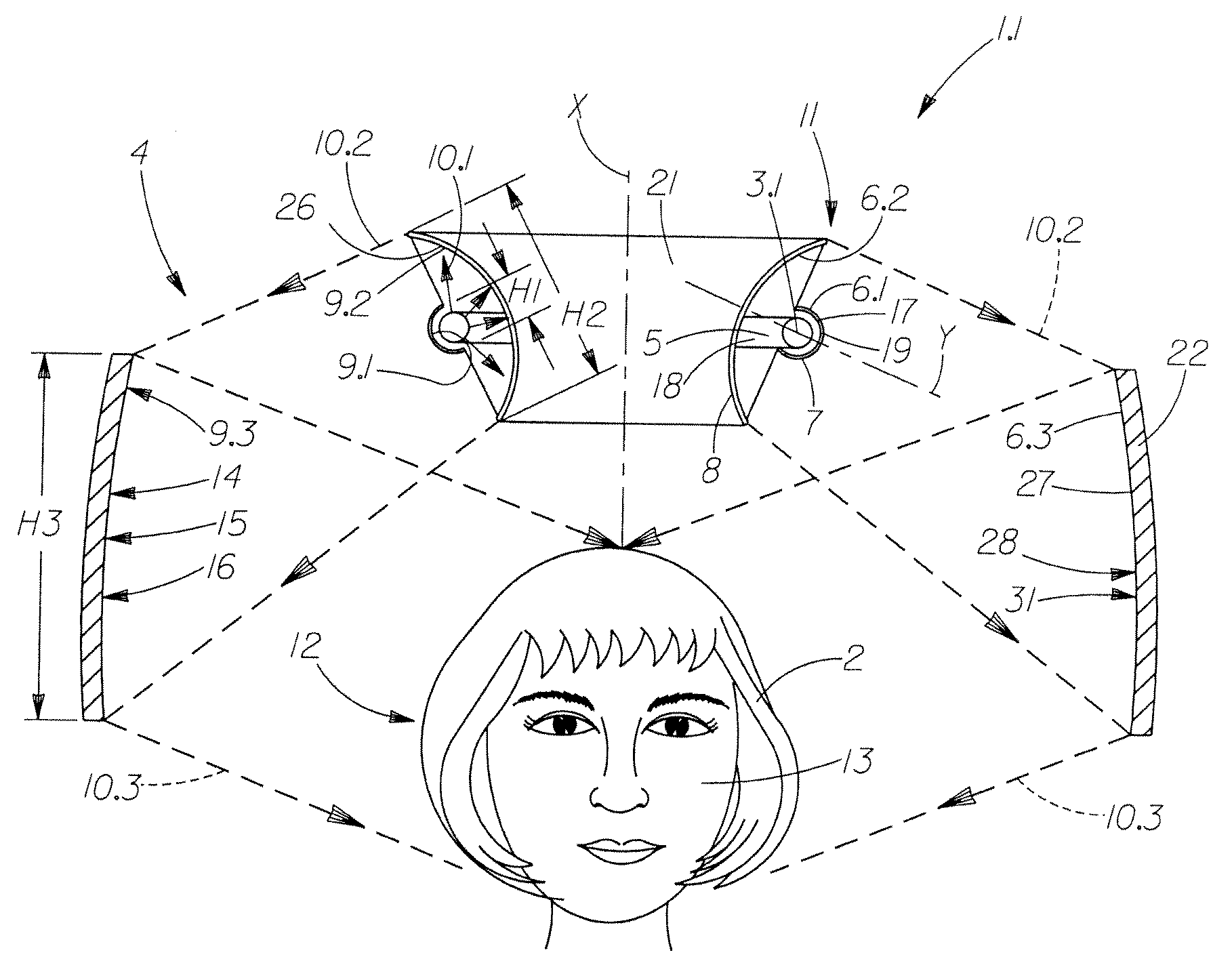

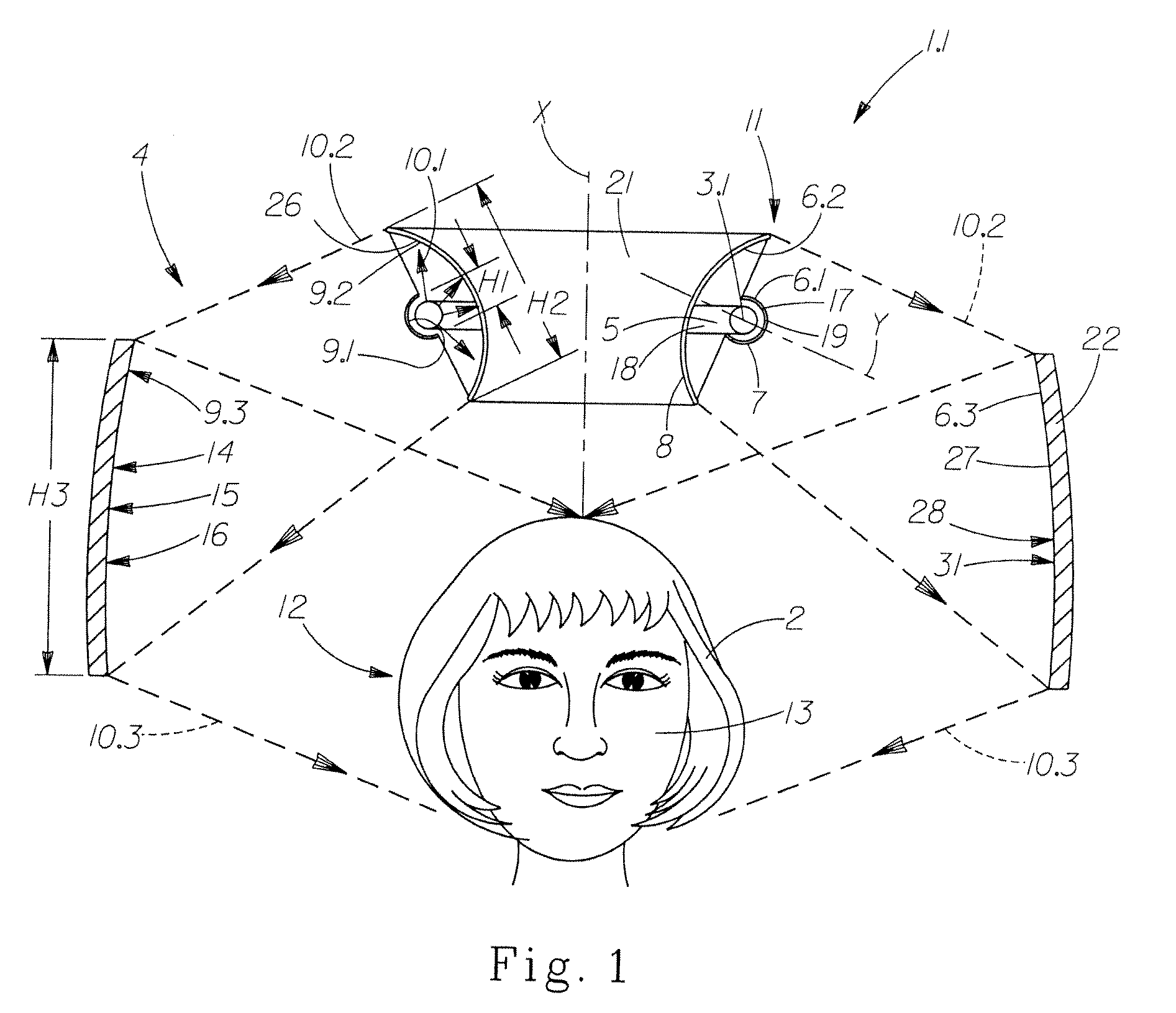

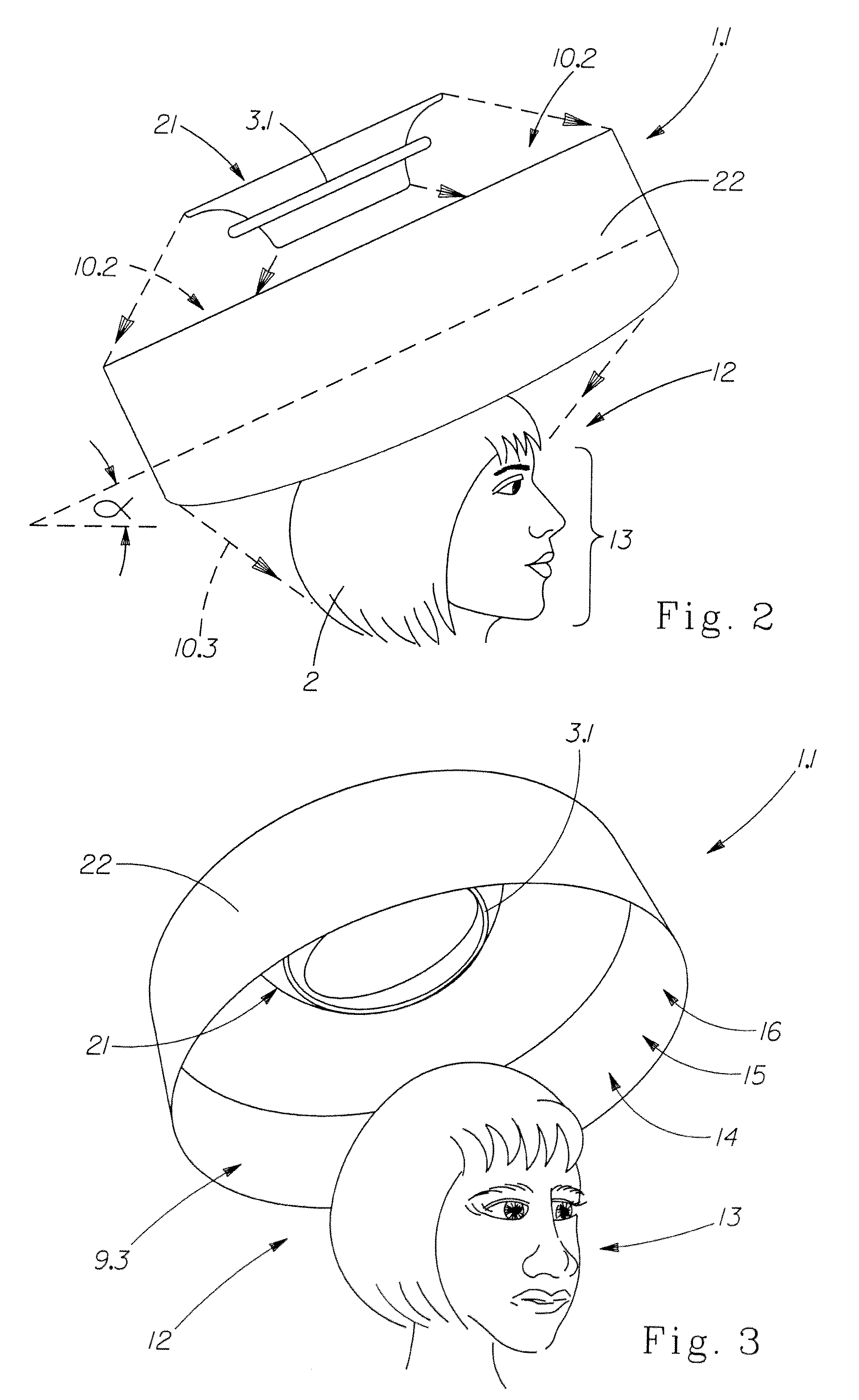

Device for the Infrared Radiation of Scalp Hair

ActiveUS20090062889A1Easy and inexpensive actuationSimple mechanical structureCurling-ironsCurling-tongsInfrared lampOptoelectronics

A device (1.1) for the radiation of scalp hair (2) using infrared radiation (10.3), wherein the infrared radiation (10.3) is generated by at least one linear-shaped infrared lamp (3.1) with a reflector system (4). In a first exemplary embodiment, a first reflector (6.1) is allocated to the infrared lamp (3.1) on the longitudinal side, wherein the infrared lamp (3.1) basically forms an optical collection line of the first reflector (6.1). The first reflector (6.1) with a first reflection side (9.1) and a second reflector (6.2) with a second reflection side (9.2) are placed facing each other, wherein the infrared lamp (3.1) is enclosed by the first and the second reflector (6.1, 6.2), by at least 360° altogether.

Owner:WELLA OPERATIONS US LLC

Biomass semi-gasification stove

ActiveCN101487597AIncrease the ventilation areaImprove combustion efficiencyDomestic stoves or rangesSpecial form destructive distillationCombustion chamberCombustor

The invention discloses a biomass semi-gasification furnace which comprises a panel fire surrounding cover and an internal furnace, wherein, an inflamer is arranged at the upper part of the internal furnace, a combustion chamber is surrounded by the inflamer, the panel fire surrounding cover is arranged above the internal furnace and covered at the periphery of the inflamer, a secondary fan housing is sheathed outside the internal furnace, a ring-shaped secondary air channel is encircled by an inner shell of the internal furnace and the secondary fan housing, a ring-shaped secondary air chamber is encircled by the inflamer, the panel fire surrounding cover and the inner shell of the internal furnace, the lower end of the secondary air channel is provided with a secondary air inlet communicated with the outside, the upper end of the secondary air channel is provided with a secondary air outlet communicated with the secondary air chamber, and a plurality of secondary air holes that are communicated with the secondary air chamber and the combustion chamber are evenly arranged at the upper edge of the inflamer along the ring direction. The biomass semi-gasification furnace has the advantages of even secondary air intake, improved combustion-supporting efficiency, simple and ingenious structure, small occupying space, low manufacturing cost and convenient installation.

Owner:湖南万家工贸实业有限公司

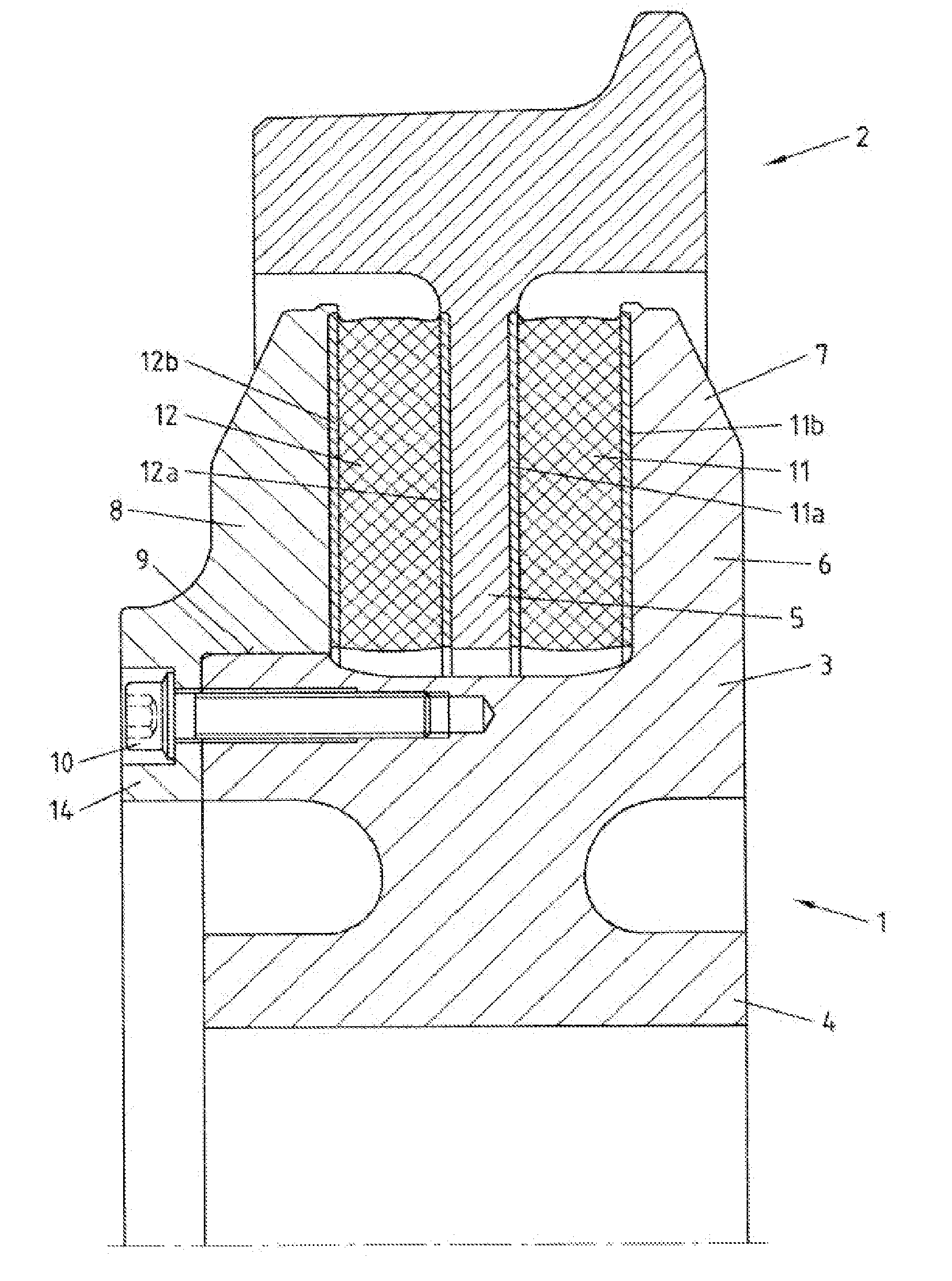

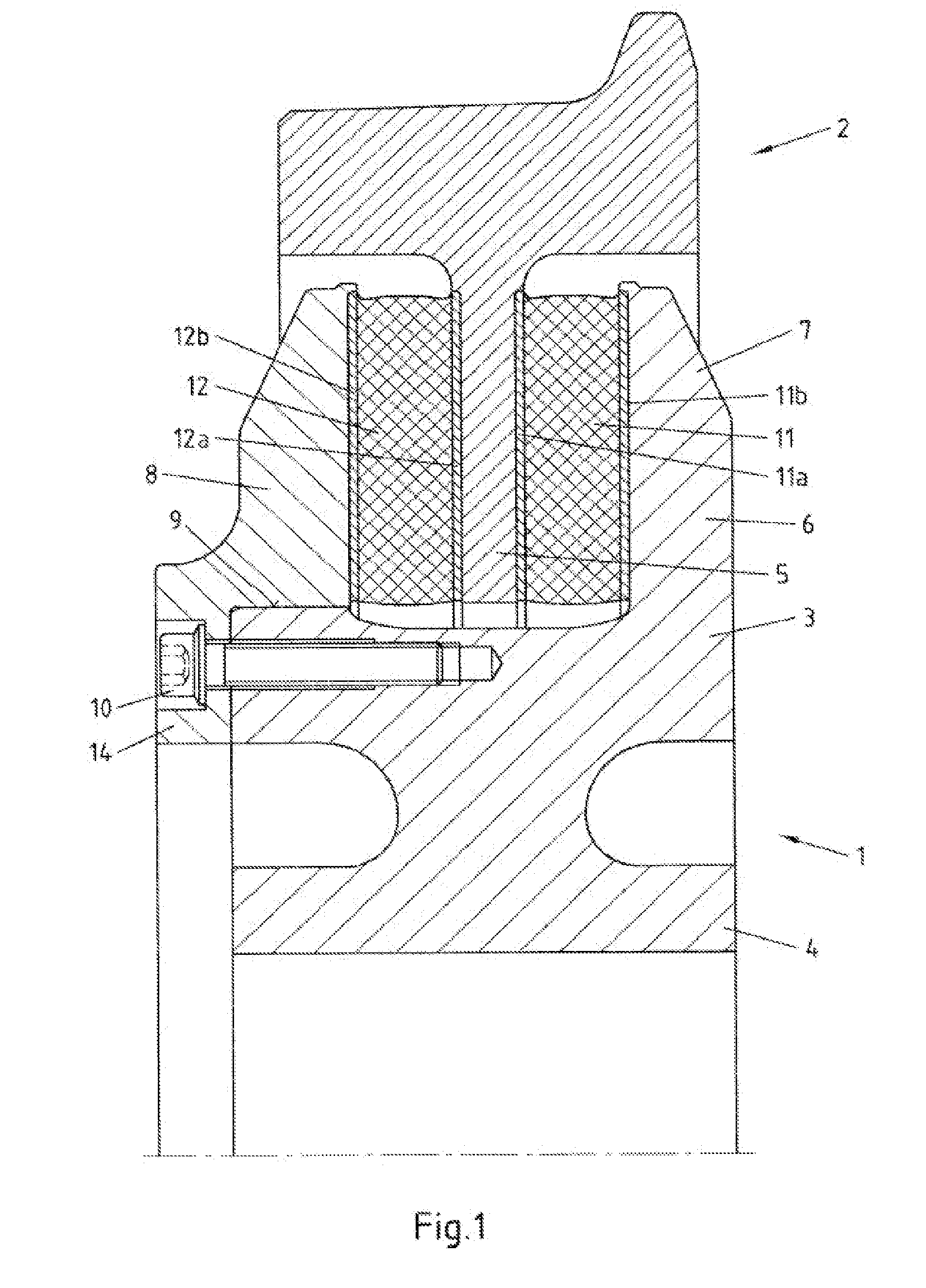

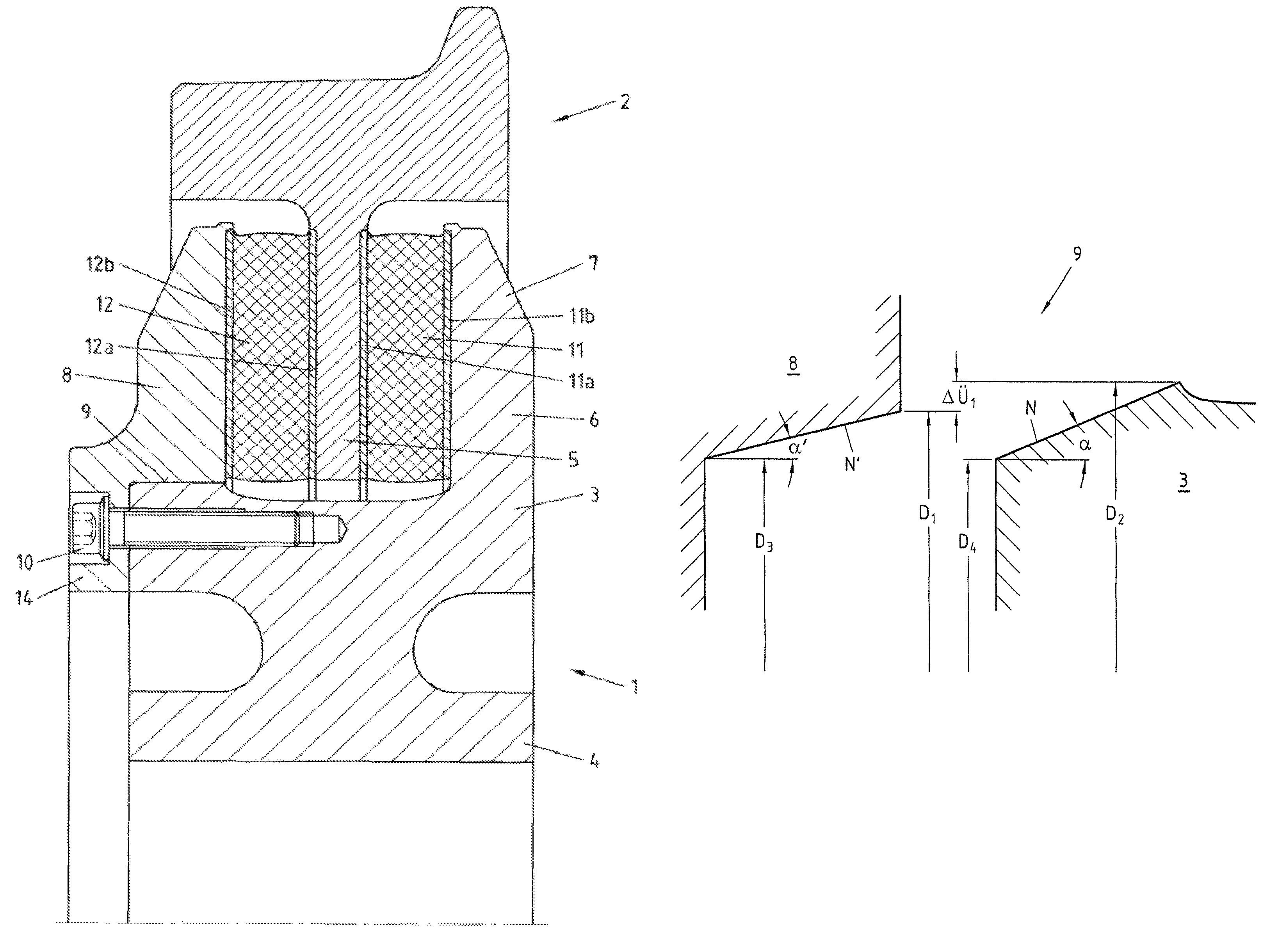

Railway Vehicle Wheel with Elastic Rubber Suspension

ActiveUS20080217940A1Sufficient clearanceAvoid stress concentrationRail-engaging wheelsNon-inflatable tyresInterference fitSuspension (vehicle)

A rubber-sprung rail vehicle wheel which is designed in particular, but not exclusively, for rail vehicles with a low design height is described. In this rail vehicle wheel, the wheel tire (2) is connected to the wheel rim (3) by way of a rubber insert that is formed by two flat rings (11, 12) that are arranged so as to be essentially vertical in relation to the wheel axle. The rings (11, 12) are held, under very considerable axial prestress, between an inner circumferential middle web (5) of the wheel tire (2) and two outer flanges (6, 8) of the wheel rim (3). At least one of the flanges (8) is seated on the wheel rim (3) with an interference fit (9) that is designed as a conical press fit. The interference fit (9) is designed such that the cone of the flange (8) in the stress-free state has a lesser conicity than does the cone of the wheel rim (3), and in the pressed-on state rests on the entire surface against the cone of the wheel rim (3), as far as possible at an even surface pressure across the entire width of the interference fit (9). This provides a secure hold for the flange (8). There is no need to provide additional screw bolts (10) in the region of the rings (11, 12) of the rubber insert, so that the space between the web (5) and the flanges (6, 8) can be utilised entirely for the rubber insert.

Owner:BOCHUMER VER VERKEHRSTECHNIK GMBH

Reinforcement type textile concrete floor and manufacturing method and installing method thereof

The invention provides a reinforcement type textile concrete floor and a manufacturing method and an installing method thereof. The reinforcement type textile concrete floor comprises a prefabricated multi-cavity textile concrete sheet, a fine stone reinforced concrete reinforcing layer and a waterproof leveling layer. The prefabricated multi-cavity textile concrete sheet is composed of textiles, chopped fibers and mortar. In the installation process, the short span direction of the floor is used as the length direction of the prefabricated multi-cavity textile concrete sheet, the prefabricated multi-cavity textile concrete sheet serves as a floor formwork and can also serve as a lower protection layer and a tension layer of the floor after being subjected to casting molding, the thickness of the protection layer is not limited, the story height is reduced, corresponding loads are borne, the construction cost can be reduced, and the construction progress is accelerated. The floor is high in bearing force, good in durability, good in crack resistance, low in amount of needed concrete and low in cost. The floor casting process is simple, and the construction efficiency is high.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Railway vehicle wheel with elastic rubber suspension

ActiveUS7735888B2Improve rigidityImprove featuresRail-engaging wheelsNon-inflatable tyresInterference fitRailroad wheel

Owner:BOCHUMER VER VERKEHRSTECHNIK GMBH

Scraper device, as well as construction machine

ActiveUS20090044366A1Small contact surfaceImprove pressure resistanceBrushesWork treatment devicesRotational axisClassical mechanics

A scraper device for a milling drum mounted in a construction machine at a machine frame between lateral walls with a milling drum axis, with a two-part scraper blade arranged in a height-adjustable fashion behind the milling drum when seen in the direction of travel, the lower part of which can glide over the ground surface milled off by the milling drum, where the lower part of the scraper blade is adjustable in height when in operating position, it is provided that the upper part of the scraper blade is attached, at the upper end, to swivel about a swivelling axis parallel to the axis of the milling drum, that the scraper blade, when in operating position, is engaged with lateral retaining devices at the lateral walls, which retain the scraper blade in a position running essentially orthogonally to the ground surface, that a swivelling device is capable of swivelling the scraper blade about the swivelling axis when the scraper blade is disengaged from the lateral retaining devices, and that the swivelling device is provided, at the upper end of the upper part of the scraper blade, with an operating device articulated between a permanently installed part of the construction machine and the upper part of the scraper blade.

Owner:WIRTGEN AMERICA

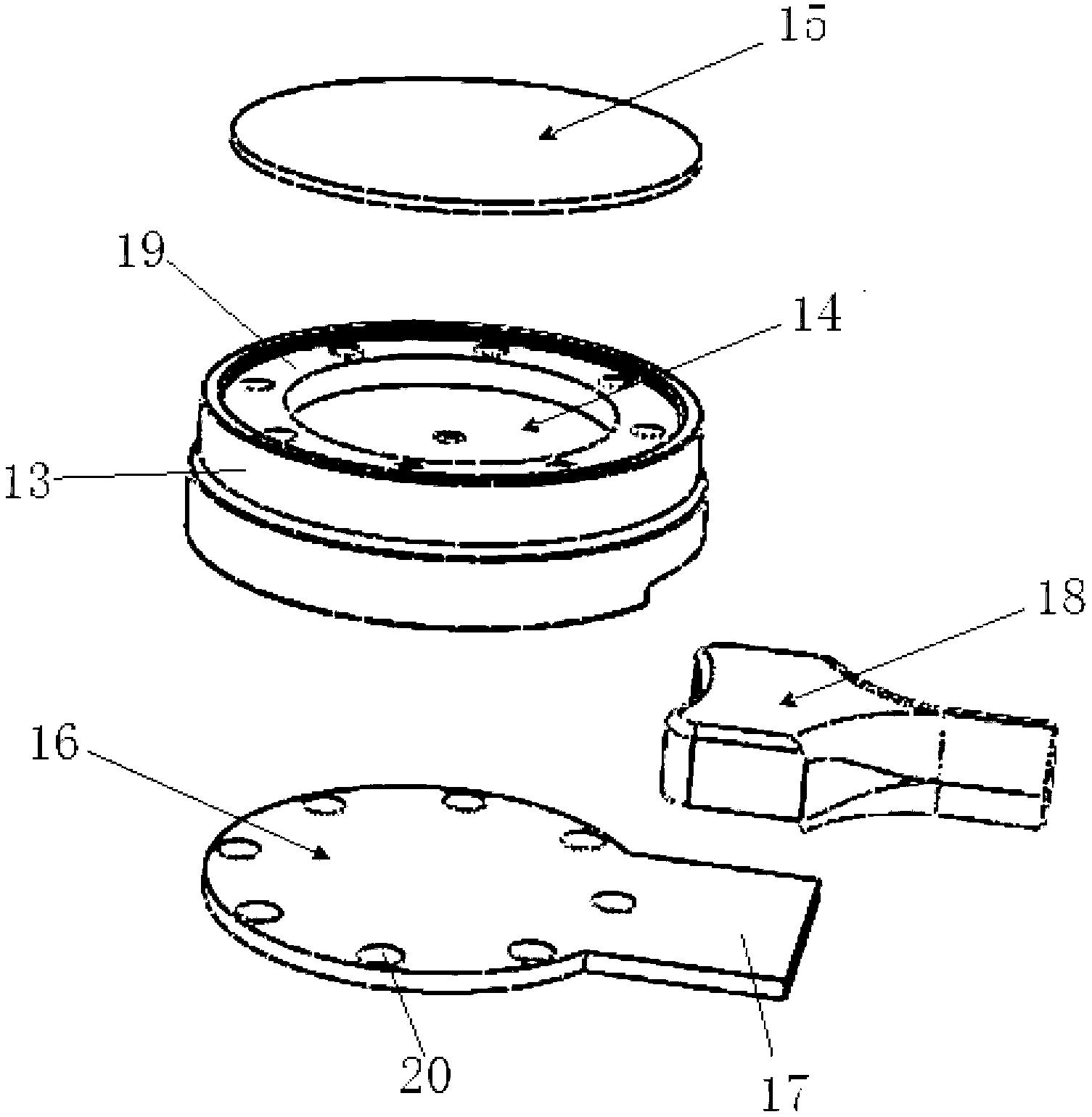

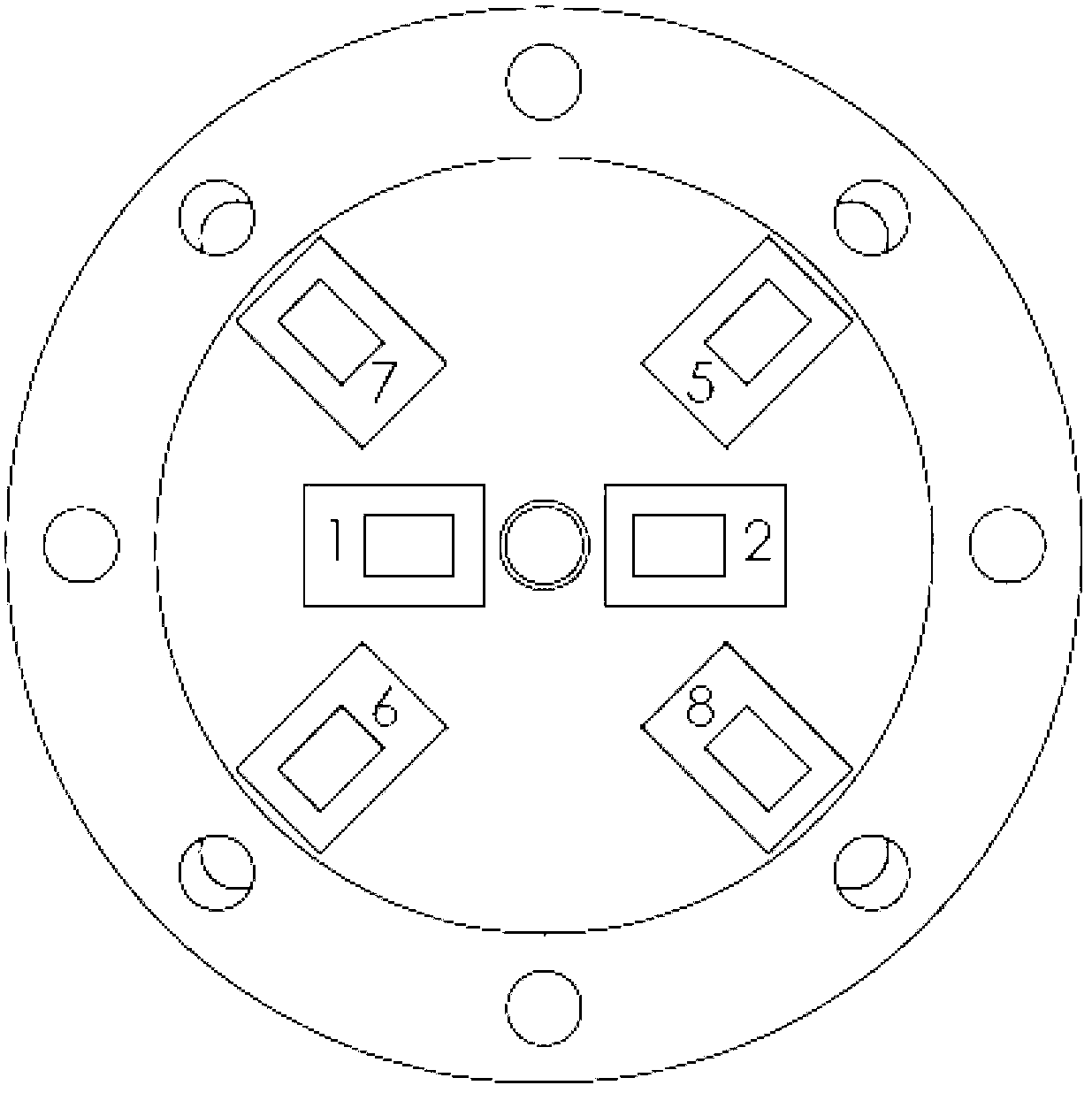

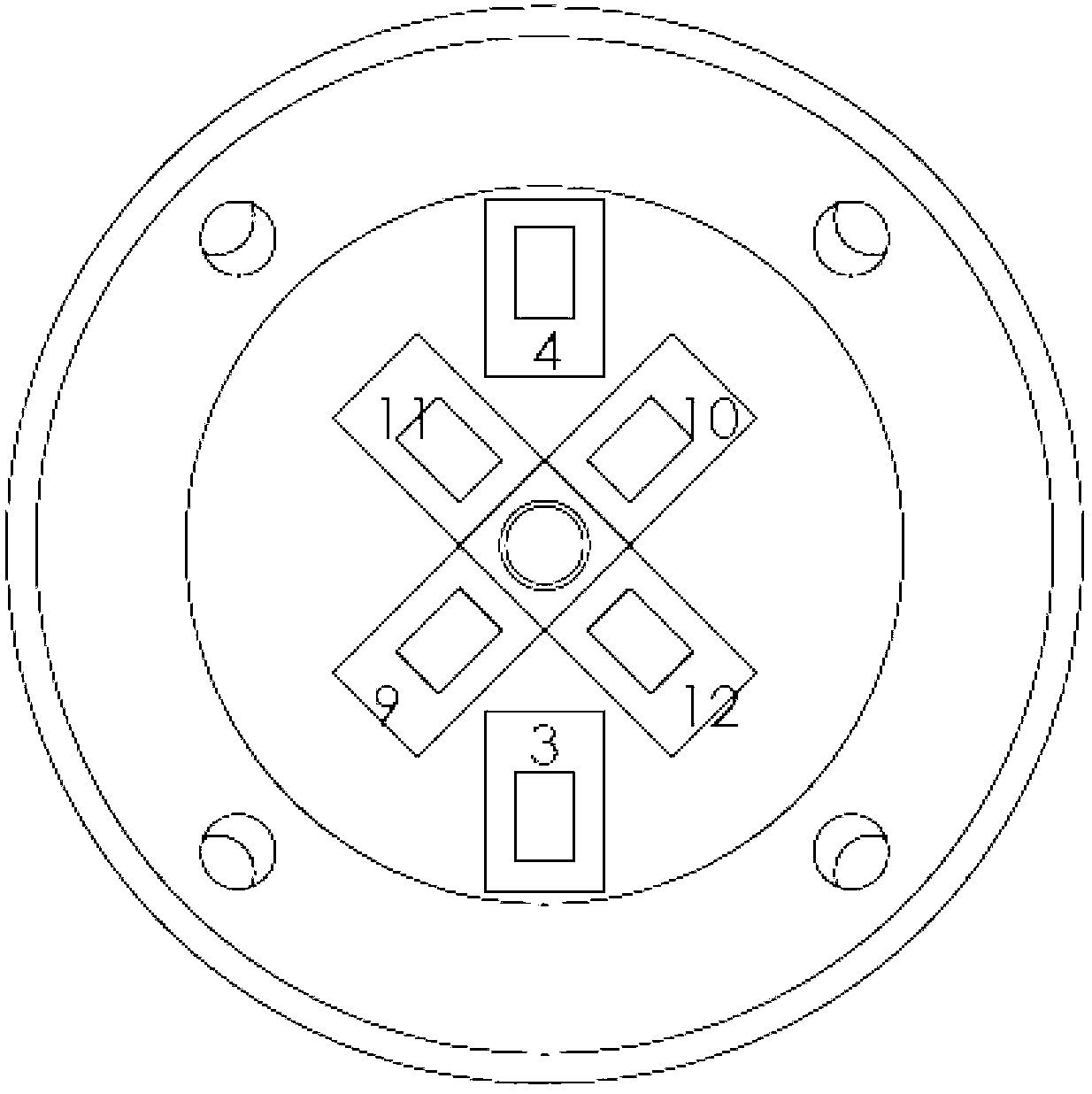

Button-type five-dimensional force sensor

InactiveCN102840940ASmall diameterLead to reliableForce measurementWork measurementEngineeringStrain gauge

The invention discloses a button-type five-dimensional force sensor which comprises a cylindrical base, wherein a base plate is arranged in the cylindrical base; a circular covering plate is arranged at the upper end of the cylindrical base; a junction circuit board is arranged at the lower end of the cylindrical base; a handle is arranged at one side of the junction circuit board; an outgoing line encapsulation head is arranged at one side of the cylindrical base; one side of the outgoing line encapsulation head is adhered to a side wall of the cylindrical base; the bottom of the outgoing line encapsulation head is fixed on the handle of the junction circuit board; six strain gauges are respectively adhered to the upper and lower end faces of the base plate; and terminals of the strain gauges are all welded on the junction circuit board and subsequently led into the outgoing line encapsulation head together. By adopting a double-end circular membrane sheet structure, design height of the sensor can be reduced greatly, and at the same time, height of the sensor is further reduced by adopting a novel machining process; for material selection, a group bridge is designed by adopting ultra-small strain gauges, so that diameter is reduced greatly; and by adopting a mode of an outgoing line of the junction circuit board, the height is not increased, and at the same time, signal lines are reliably led out.

Owner:ANHUI BIOFORCEN INTELLIGENT TECH

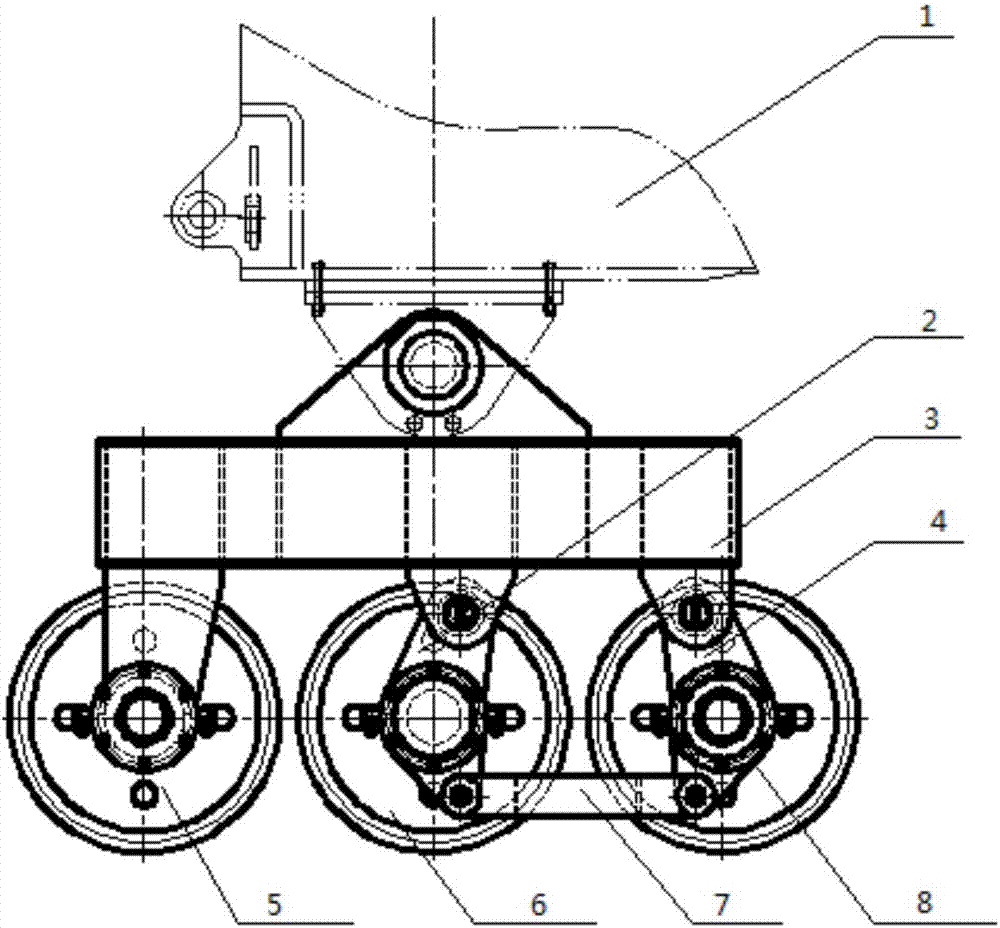

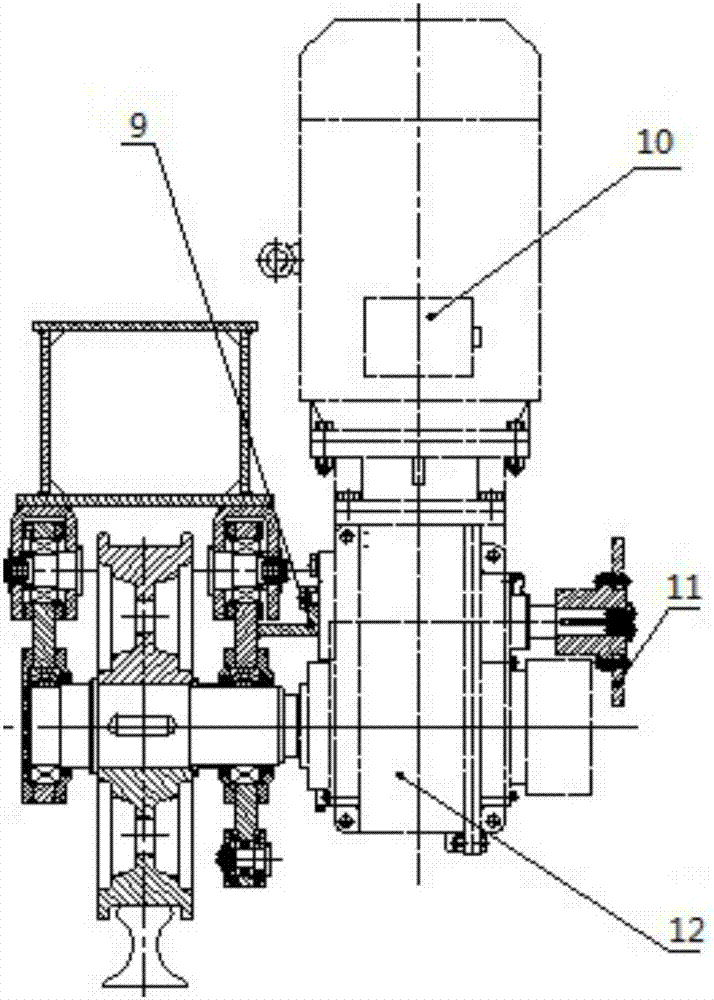

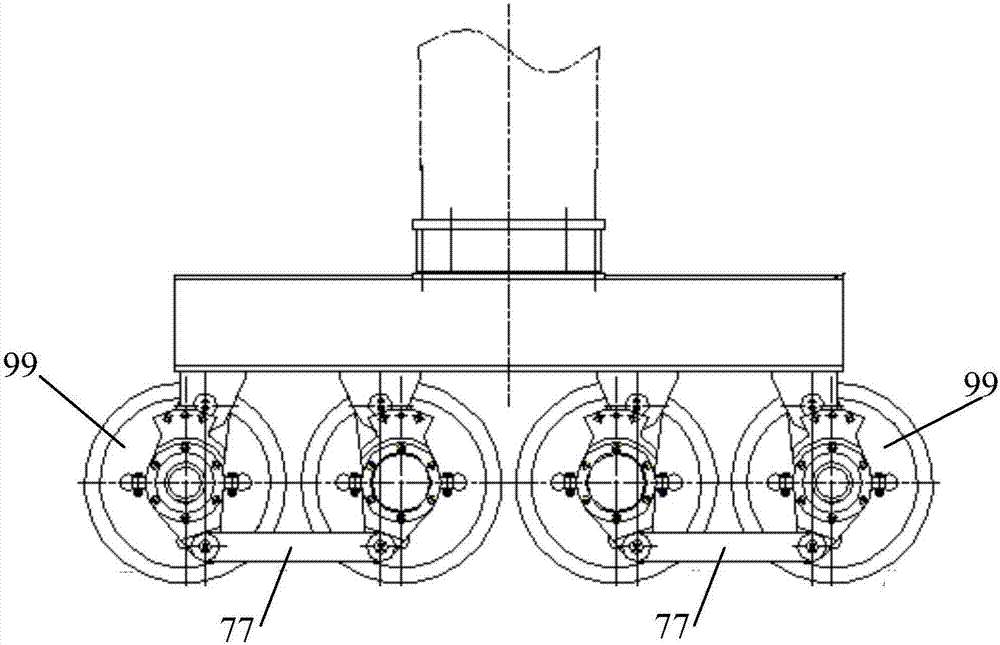

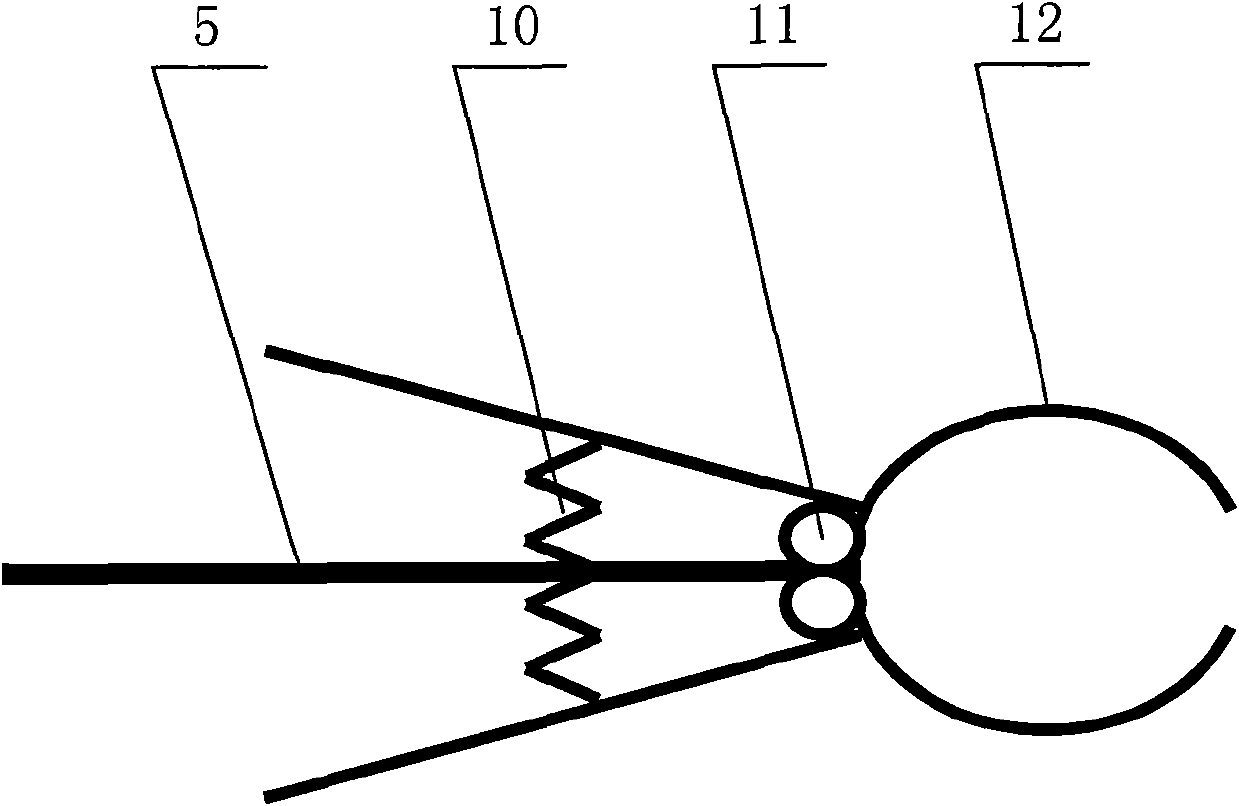

Cart traveling mechanism

ActiveCN107161853AReduce design heightReduce quality problemsTravelling gearVehicle frameEngineering

The invention provides a cart traveling mechanism. The cart traveling mechanism comprises a cart frame and a plurality of wheels, and is characterized in that a wheel support is hinged between the cart frame and each corresponding wheel, the centers of the wheels and corresponding hinged points on the cart frame are deviated in the vertical direction, and every two adjacent wheel supports are connected through a balancing link. According to the cart traveling mechanism, the dead weight and the height of a cart mechanism are reduced to the utmost extent, and further, the running stability and the driving capability are improved.

Owner:TONGJI UNIV

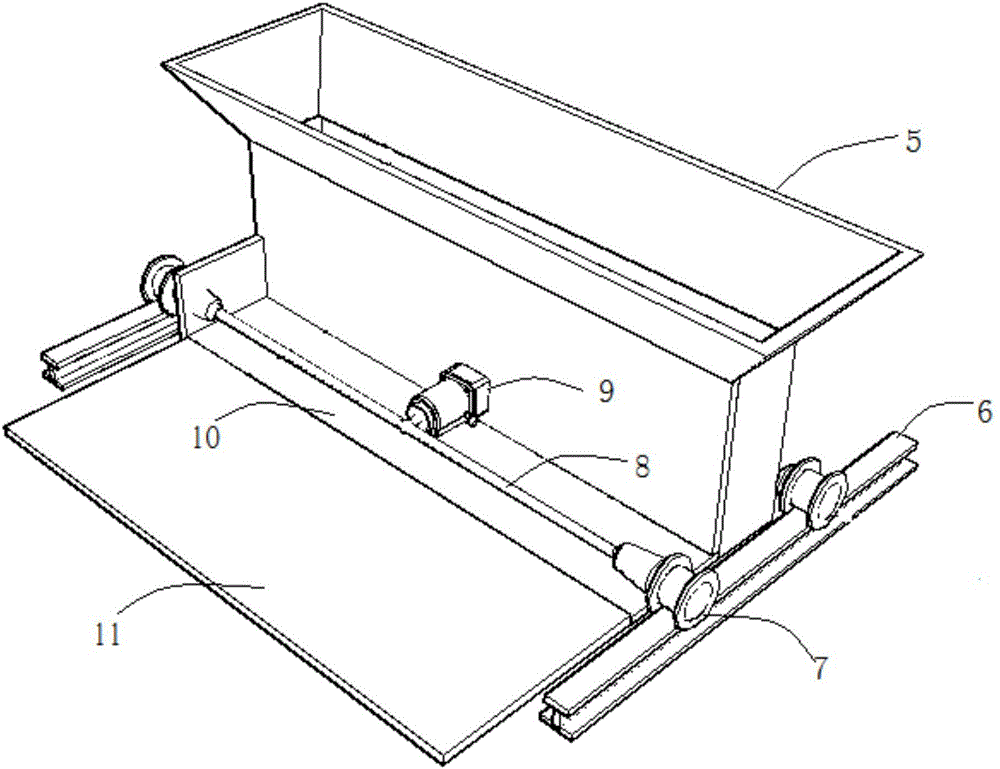

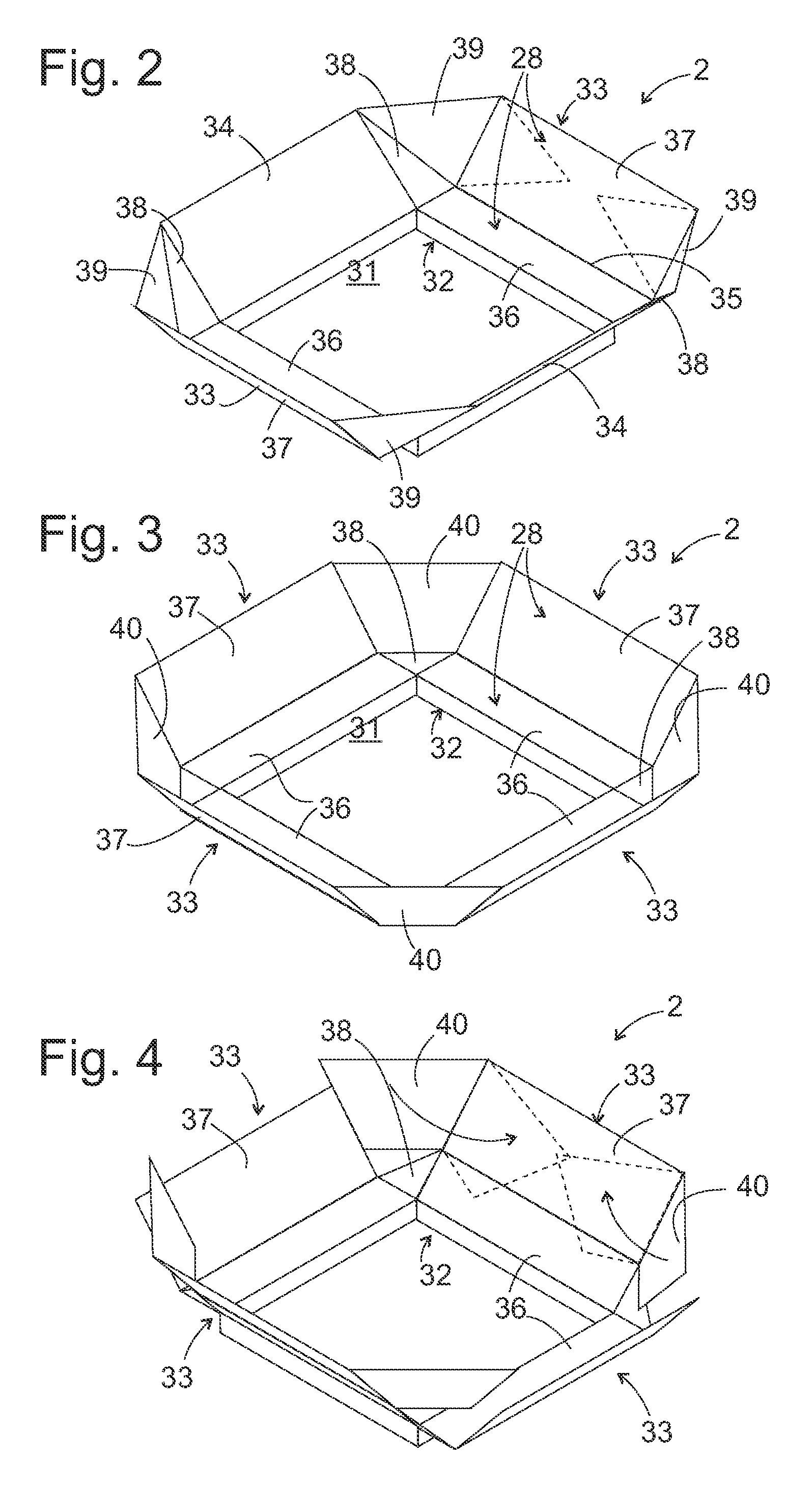

Extension attachment for a bulk material container

Owner:MOHR JAN HENDRIK +2

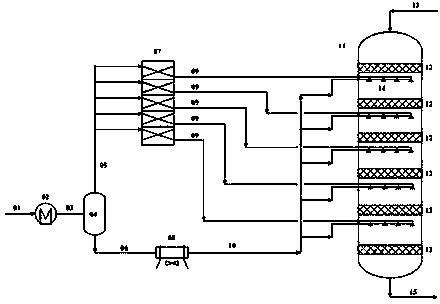

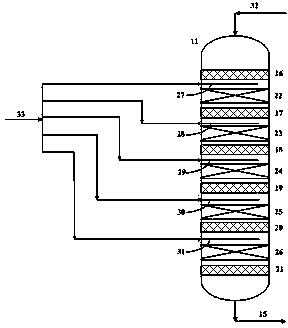

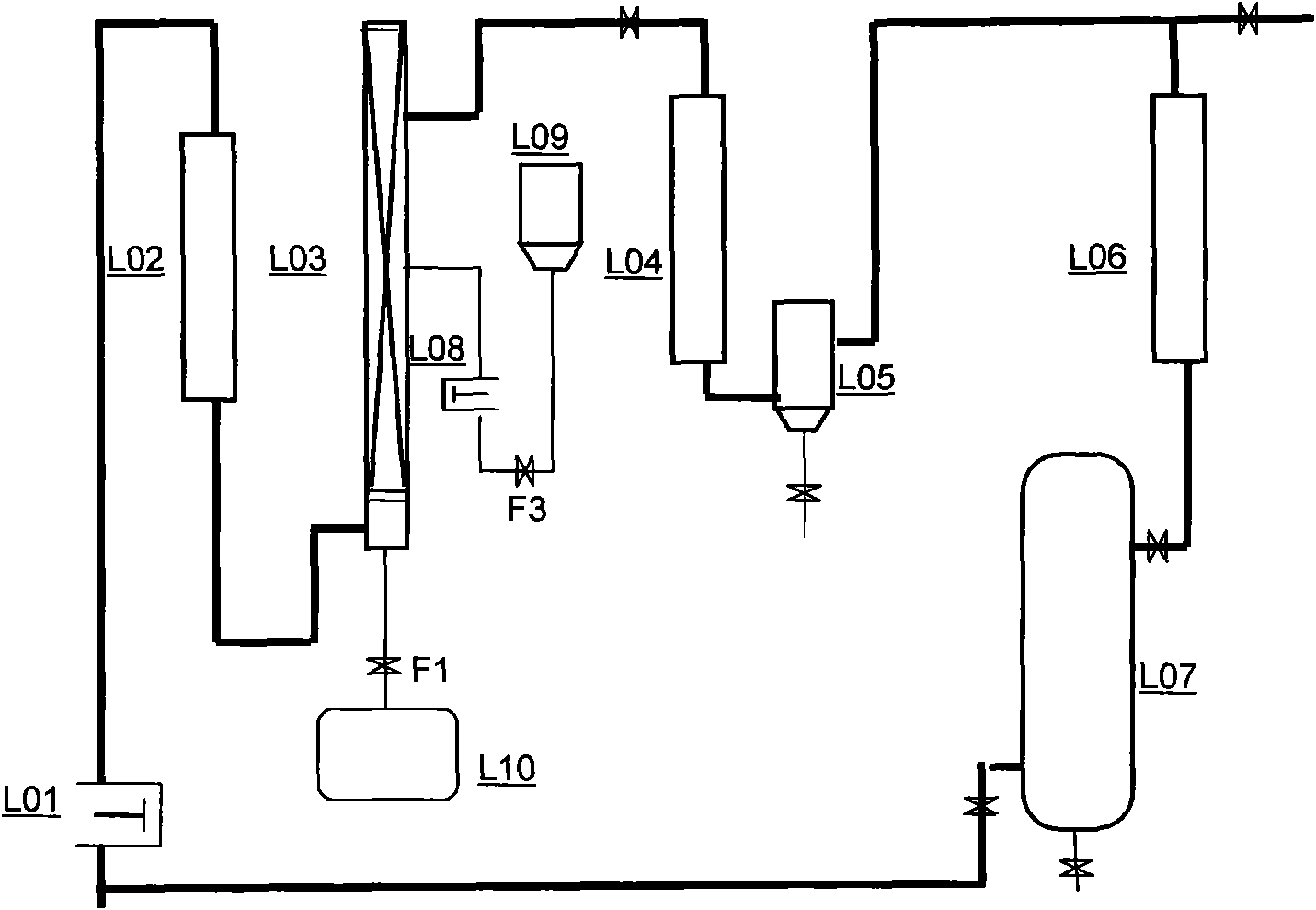

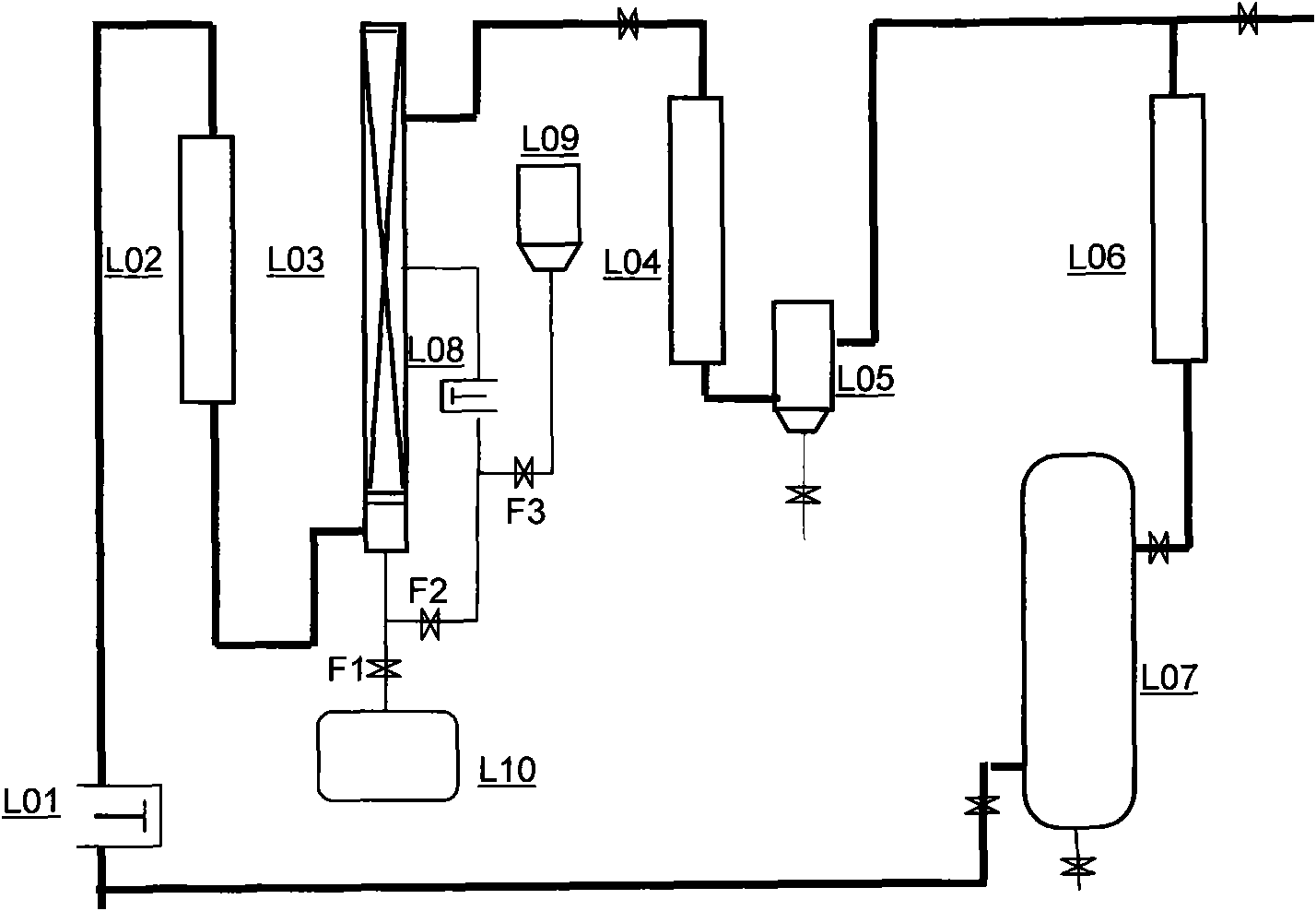

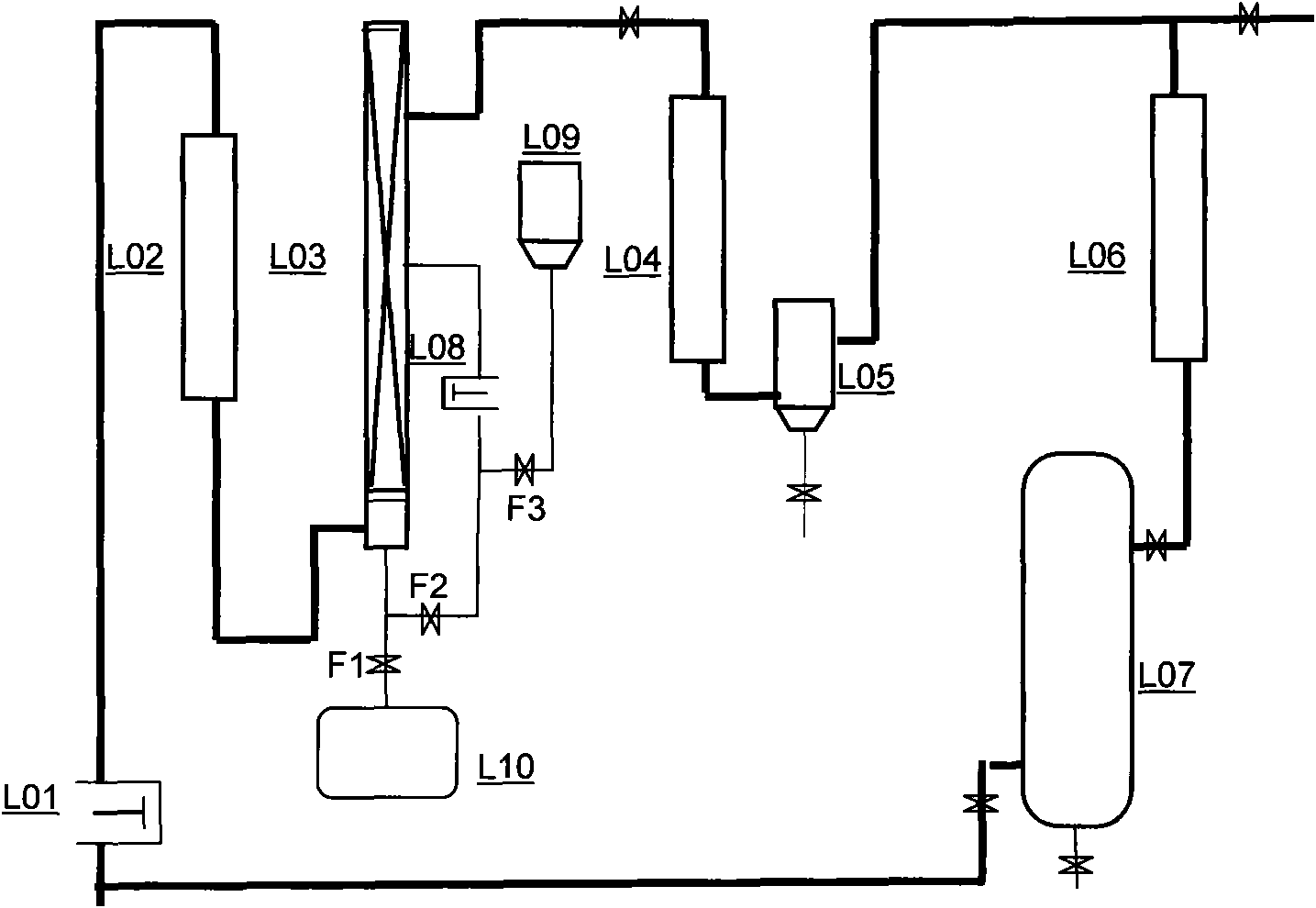

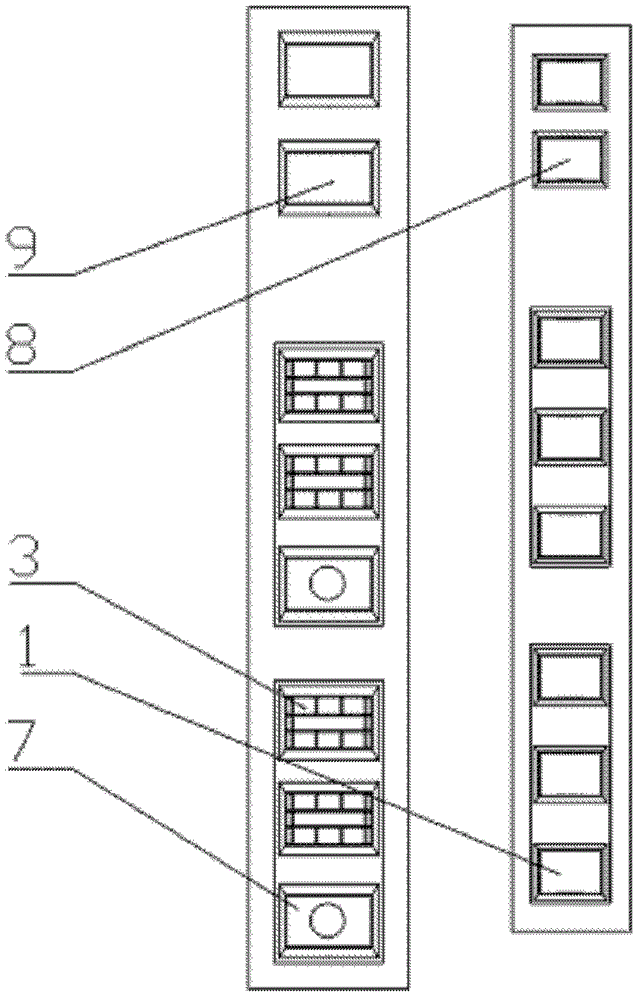

Methanol-to-olefin reaction apparatus and application thereof

ActiveCN104109072AHigh yieldImprove protectionHydrocarbon from oxygen organic compoundsReaction temperatureVaporization

The invention relates to a methanol-to-olefin reaction apparatus and an application thereof. The technical problems of high requirements and easy obstruction of chilled liquid phase nozzle equipment of a methanol-to-olefin multistage fixed bed reactor, mutual influences of the reaction temperature and the reaction air speed of the fixed bed reactor and low utilization rate of an intersegmental chilled liquid phase vaporization space existing in the prior art are mainly solved. The methanol-to-olefin reaction apparatus mainly comprises catalyst bed layers (16-21), distributors (27-31) and filler layers (22-26); and the top layer in the apparatus is the catalyst bed layer (16), the lower portion of the catalyst bed layer (16)is the distributor (27), the lower portion of the distributor (27)is the filler layer (22), the lower portion of the filler layer (22) is the catalyst bed layer (17), the bottom layer in the apparatus is the catalyst bed layer (21) in a same arrangement mode, a feed inlet is arranged between two adjacent bed layers, and the distributors are distributor pipe bustle pipe structures. The apparatus well solves the problems, and can be used in the industrial production of methanol-to-olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

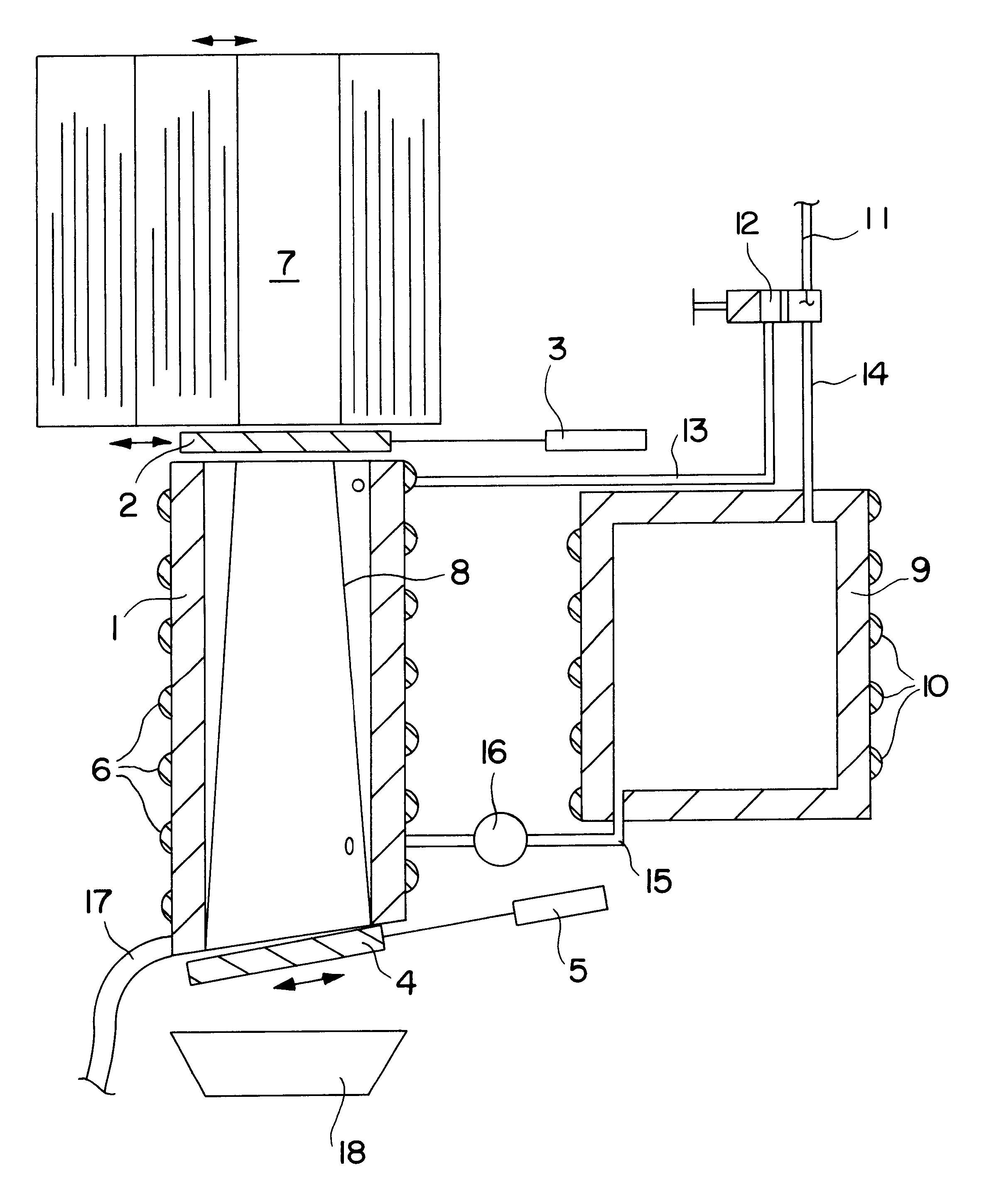

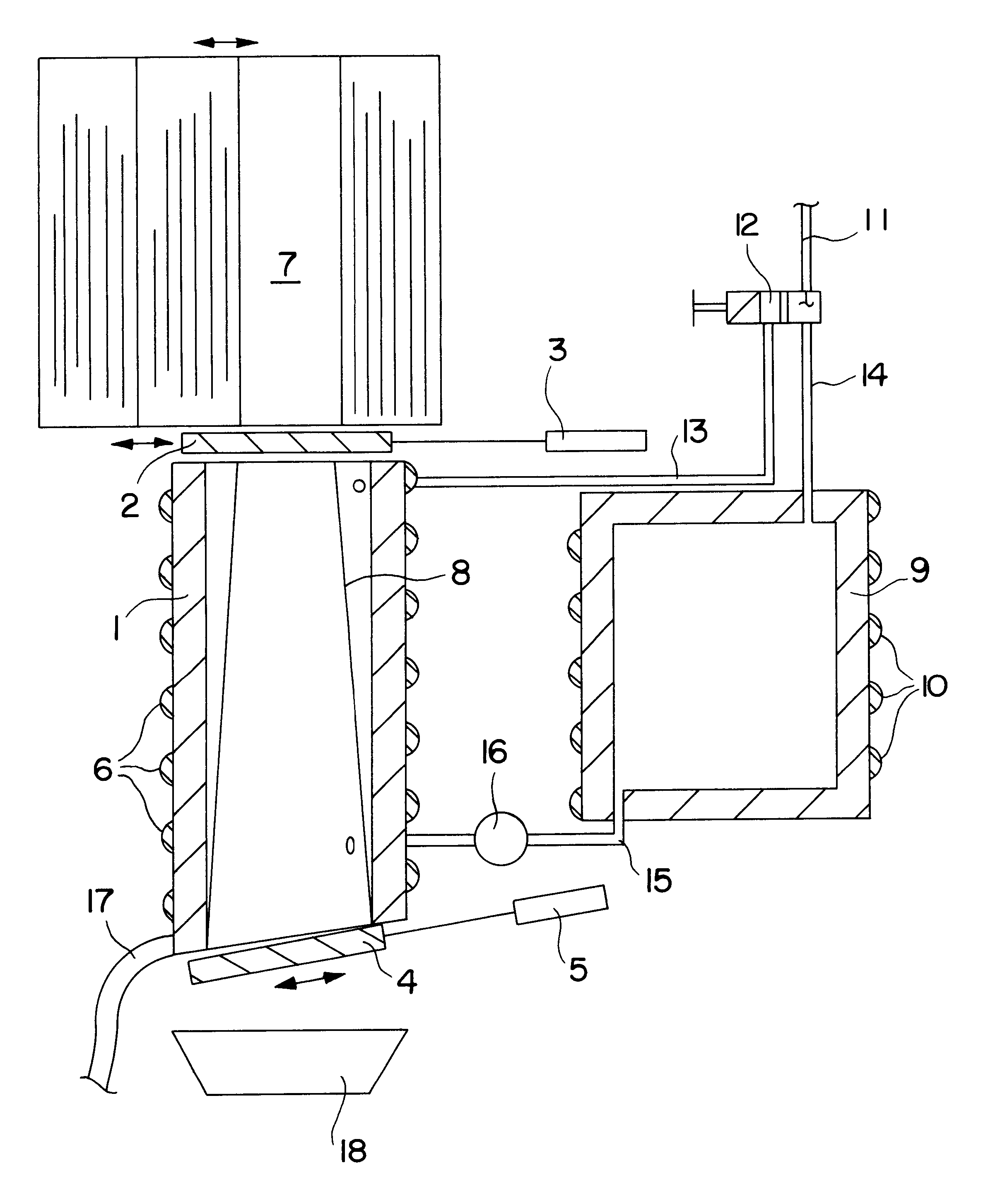

Device for the discontinued preparation of pasta

InactiveUS6176174B1Reduce design heightReduce preparation timeCooking vesselsDeep fat fryersSingle chamberWaste management

Shown and described is a device for the discontinuous preparation of pasta such as spaghetti or similar, comprising a pasta supply unit (7); a pasta preparation unit closed off by inlet shutters (2) and outlet shutters (4), for cooking and draining the pasta; and a pasta dispenser unit where the design height has been reduced in that the pasta preparation unit comprises only a single chamber (1) which is used both for cooking and rinsing with cold water and draining the cooked pasta.

Owner:STEIN HANS ULRICH

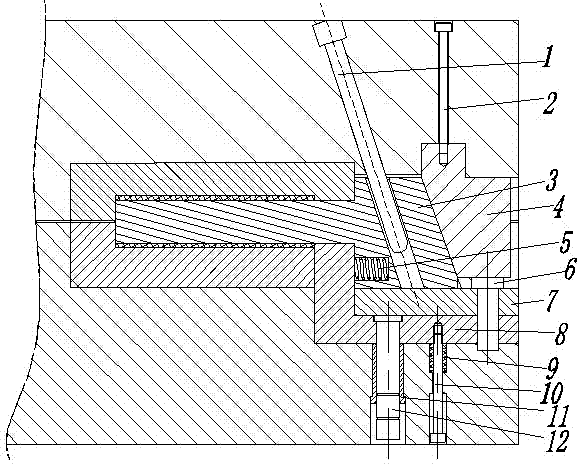

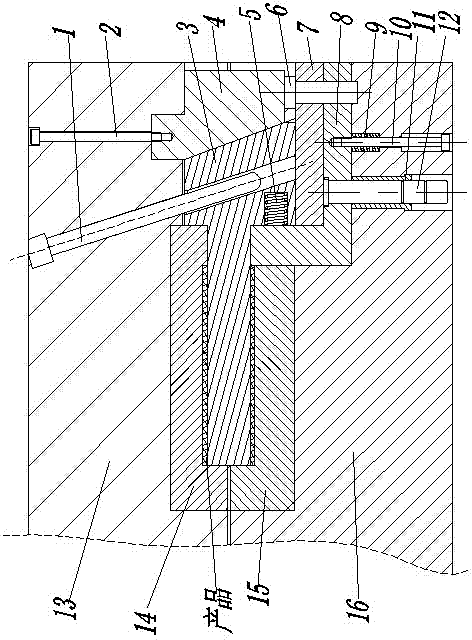

Floating type sliding block core pulling and demoulding mechanism

InactiveCN104760225AReduce design heightReduce manufacturing costTubular articlesShell moldingMechanical engineering

The invention provides a floating type sliding block core pulling and demoulding mechanism. The floating type sliding block core pulling and demoulding mechanism comprises a slider angle pin, a compressing block screw, a long core sliding block body, a compressing block, a sliding block body spring, a sliding block body limiting pin, a sliding block body sliding groove plate, a blocking floating plate, a floating plate spring, a floating plate pull rod, a guide sleeve and a floating plate guide column. According to the floating type sliding block core pulling and demoulding mechanism in the technical scheme, in the mould shaping process of tubular plastic products with the small circular tube diameter and large length, mould design height can be effectively reduced, it can be guaranteed that ejection marks are not reserved on the products in the ejection process, the forming quality of the products is effectively guaranteed, and mould production and manufacturing cost and product injection molding cost are lowered. The mould structural design is reasonable, the structure is compact, work is stable, safety and reliability are achieved, and use is convenient.

Owner:耿晓冬

Continuous countercurrent supercritical fluid extraction equipment and method applied to materials

InactiveCN101987255AHigh theoretical plate numberReduce design heightLiquid solutions solvent extractionTheoretical plateEngineering

The invention discloses continuous countercurrent supercritical fluid extraction equipment applied to a plurality of materials and a continuous countercurrent supercritical fluid extraction method applied to the plurality of materials, which aim to solve the problems of high equipment cost and inconvenience of operation and maintenance caused by the excessive height of an extraction tower. A pressurizing pump is communicated with the bottom of the extraction tower by a pipeline. A raw material pump is communicated with a feeding pipeline and a feeding valve, and is communicated with the upper part of the extraction tower by the pipeline. A material outlet at the top of the tower is communicated with a separator by the pipeline. The bottom end of the extraction tower is divided into two parallel pipelines which are provided with a discharge valve and a raw material circulating valve respectively. The pipeline with the raw material circulating valve is communicated with the intake end of the raw material pump. Materials to be extracted flow through the extraction tower from the top down, and are discharged from the bottom of the extraction tower and pumped into the extraction tower again by the raw material pump for cyclic extraction, and the extracted raw materials are discharged from a discharge pipeline at the bottom of the extraction tower. The raw materials are cyclically extracted for twice or more than twice, so the number of theoretical plates of the conventional extraction tower is multiplied, and the height of the extraction tower is greatly reduced.

Owner:大连卓尔高科技有限公司

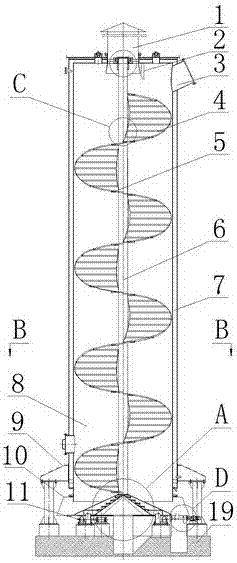

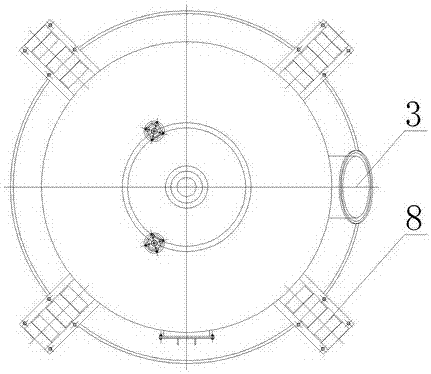

Use method of spiral step fin tower for purifying VOCs (volatile organic compounds) waste gas

ActiveCN106861363AEfficient use ofImprove mass transfer efficiencyGas treatmentDispersed particle separationSorbentSlag

The invention relates to the technical field of control on VOCs (volatile organic compounds) waste gas, in particular to a use method of a spiral step fin tower for purifying the VOCs waste gas. The use method is characterized by comprising use methods of a tower body assembly, a slag discharge rotary disc assembly, a support roll assembly and a support table. The use method has the advantages that the spiral conveying is effectively combined with a tower reaction working principle, and the spiral conveying is utilized, so that the sustained moving of an adsorbent under the sealing condition is realized, the interphase contact area with a tower reactor is large, and the mass transfer efficiency is high; the adsorbent filler can continuously maintain interphase contact with the VOCs waste gas; under the saturation condition, the contact is timely disengaged, and the technical problem of difficulty in realizing continuous purifying of the VOCs waste gas under the condition of continuous production is solved.

Owner:SHENZHEN YUANTONG ROBOT AUTOMATION CO LTD

A multi-angle tangential circle multi-scale pulverized coal decoupling combustion device and its decoupling combustion method

InactiveCN103134049BOvercoming the Persistent Problem of Combustion-Coupled EmissionsDecoupled combustion reducesCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustionEngineering

The invention relates to a multi-corner tangential multi-scale pulverized coal decoupling combustion device and a decoupling combustion method thereof; based on pulverized coal combustion characteristics and substance transformation rules, in a microcosmic scale, each column of primary air nozzles (3) on a multi-corner tangential combustion furnace hearth is arranged in a manner that at least 2 or more than 2 nozzles are centralized and adjacent to each other up and down, and the nozzles (3) are relatively centralized at an area in the hearth close to the flame center and with a very high temperature, so multi-area horizontal front-and-back fractional combustion is realized; in a medium scale, second-stage secondary air nozzles (1) are arranged in a local centralization mannerto form a strong reducibility area and a weak reducibility area or a weak oxidability area respectively before and after mixing with the primary air nozzles (3), so multi-area horizontal left-and-right fractional combustion is realized; in a macroscopic scale, peripheral over-fire air nozzles (8) and center over-fire air nozzles (9) are disposed to respectively form a reducibility area and an oxidability area at the lower and upper parts of the hearth, so vertical up-and-down air fractional combustion is realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Mop washing/dehydrating device

InactiveCN101766467AReduce design heightSimple and efficient operationCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention discloses a mop washing / dehydrating device, relates to a wringer of a washing pad, a mop, and the like combined with a bucket, and mainly solves the problem that the bucket body is designed to be higher, the washing space in the bucket is segmented, and the operation for fixing the mop is complex in the prior art. The mop washing / dehydrating device comprises a framework for supporting the mop, and is characterized in that: a vertical seat rod deviating from a central axis of a seat wheel is fixedly connected to the seat wheel which is horizontally arranged at the bottom of the bucket and of which the center is connected with a rotating shaft; a movable rod which is higher than the bucket body and can slide up and down is connected with the seat rod, and a basket is fixedly connected to the lower end of the movable rod; and a support rod extending towards the central axis of the seat wheel is fixedly connected to the upper end of the movable rod or the seat rod, and a clamping head is connected to the tail end of the support rod for clamping the mop to rotate. The mop washing / dehydrating device is suitable for washing / dehydrating various mops.

Owner:高玉见

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com