Load box for self-balanced method testing of concrete pipe pile

A technology of concrete pipe piles and load boxes, which is applied in the test of infrastructure, construction, infrastructure engineering, etc., can solve the problems of difficult load boxes, high costs, and many processes, and achieves reduction in design height, saving steel, and ensuring The effect of a solid connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further specifically described below in conjunction with the embodiments and the accompanying drawings.

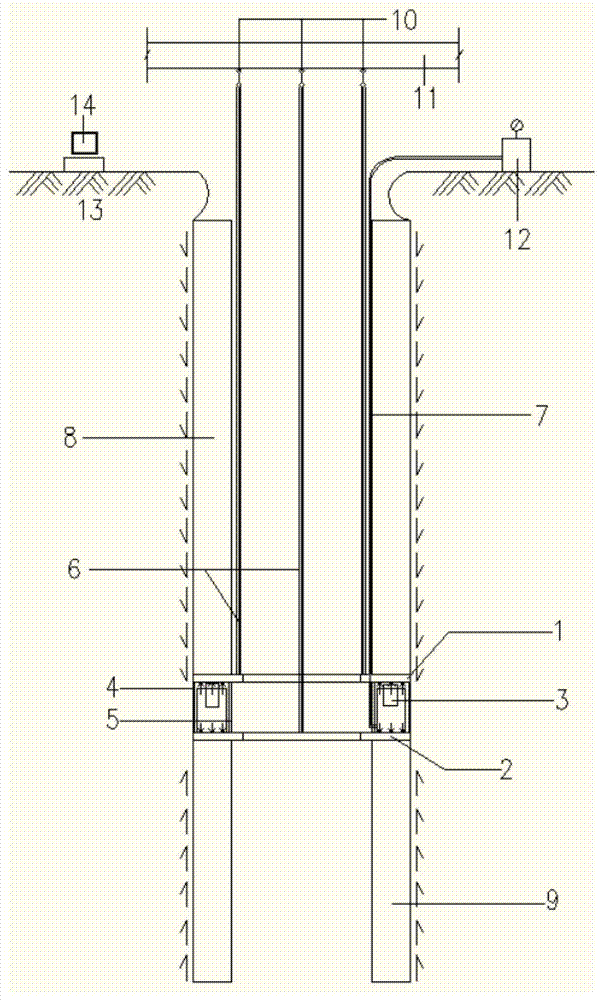

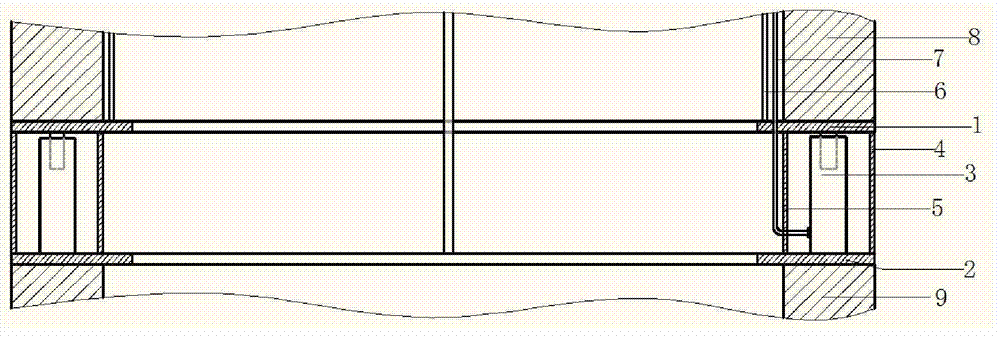

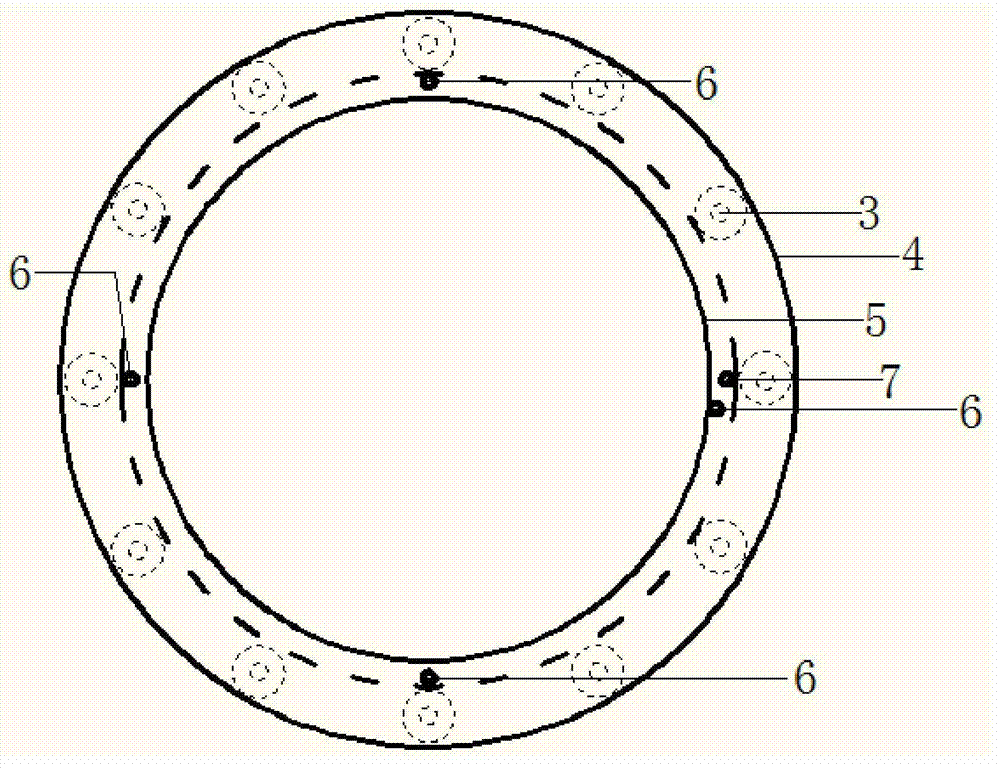

[0020] The load cell used for testing the self-balancing method of concrete pipe piles of the present invention includes an upper annular steel plate 1 and a lower annular steel plate 2 arranged symmetrically up and down, a hydraulic cylinder 3 arranged between the upper annular steel plate 1 and the lower annular steel plate 2, an outer The ring baffle 4 and the inner ring baffle 5, the number of hydraulic cylinders 3 is at least four, and the ring center of the upper annular steel plate 1 and the lower annular steel plate 2 is symmetrically distributed, and the bottom of the hydraulic cylinder 3 is connected by bolts. On the upper surface of the lower annular steel plate 2, the piston of the hydraulic cylinder 3 is connected to the bottom surface of the upper annular steel plate 1, the outer ring baffle 4 is located at the outer edge o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com