Patents

Literature

275results about How to "Effective connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

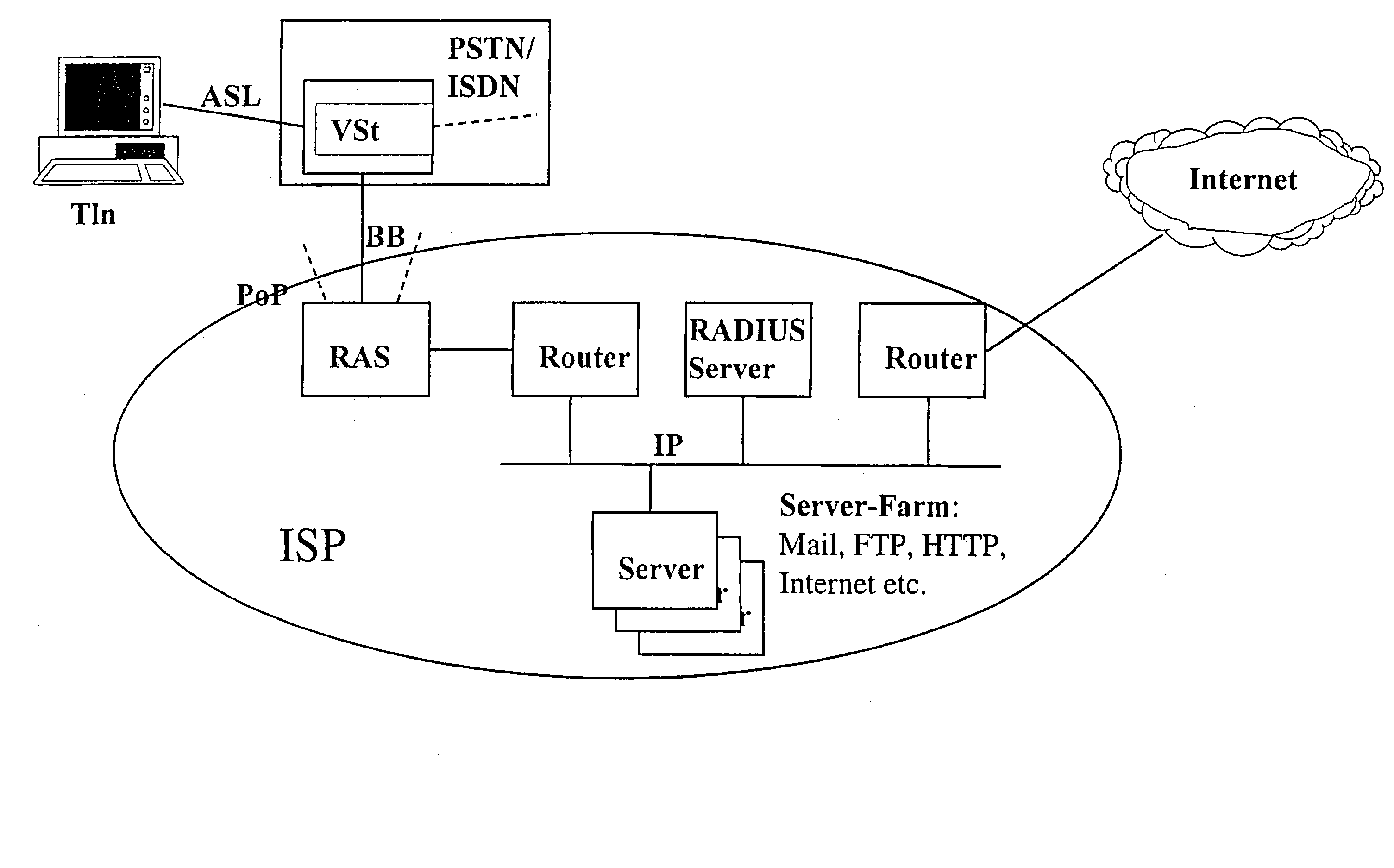

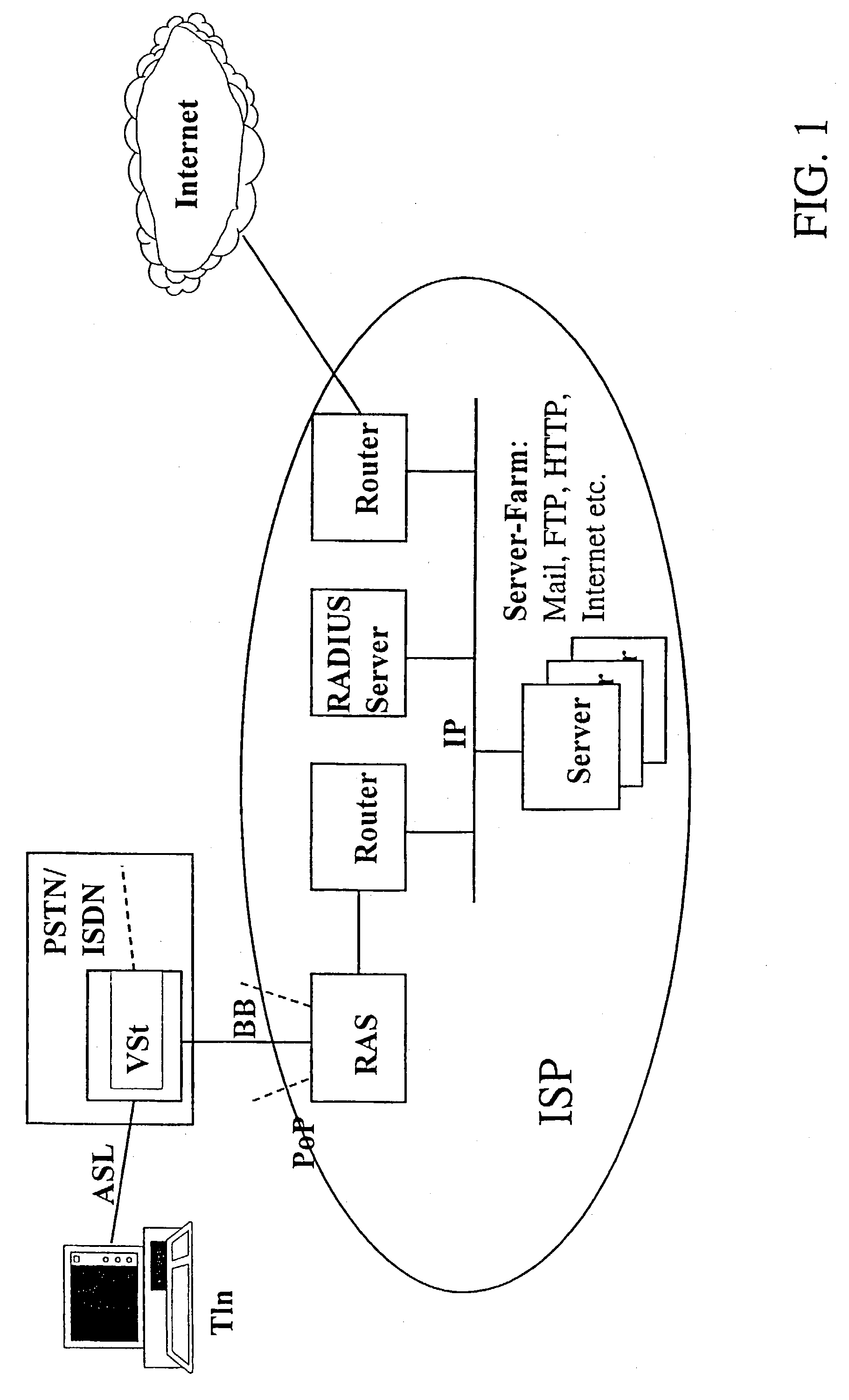

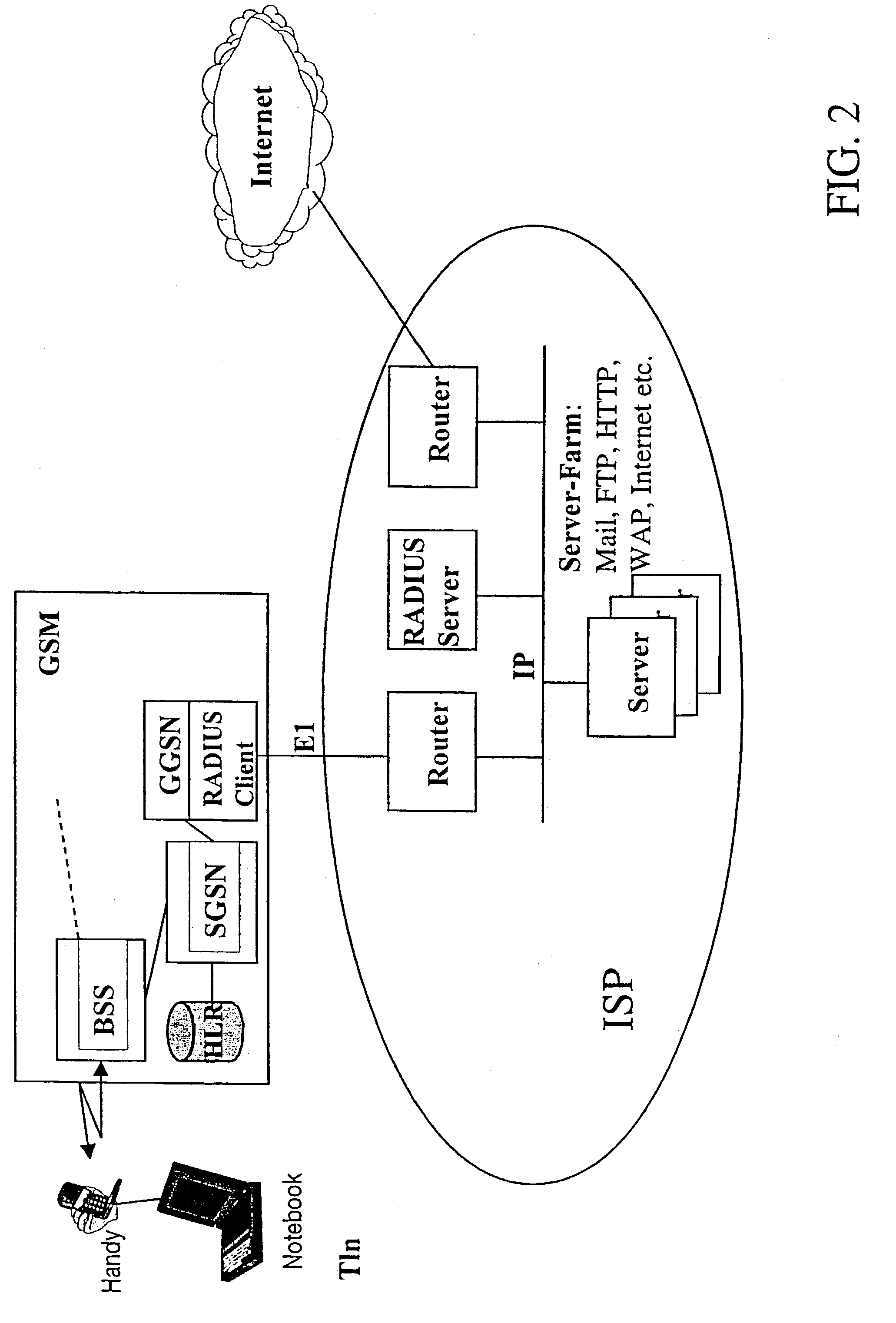

Method and arrangement for the improved exploitation of technical resources between telecommunications networks and ip-networks

InactiveUS20030103506A1Effective connectionTime-division multiplexData switching by path configurationRADIUSTelecommunications link

The invention relates to a method for the improved exploitation of resources between telecommunications networks and IP networks (for example, corporate LANs or the public Internet), for reducing the costs of permanent connections (always-on connections) and for optimsing IP address economy. According to said method an access, authentication and multiplex device ("RAMSES-client") replaces the usual RADIUS client. Said RC has an authentication device (RAC) which is connected to the ISP-specific authentication device and authenticates the ISP access of the subscriber. During the periods when there is no traffic, the RC deactivates the connection between the telecommunications network and the IP network, while the subscriber-side connection is maintained. When the subscriber has new data traffic, the RC automatically activates the IP connection concerned to the ISP with reversion to the stored authentication data. This makes a static use of the limited resources between the telecommunications and IP networks, such as dynamic IP addresses, PVCs, transmission channels, lines etc, possible. Additional RAMSES protocol elements allow the ISP-side activation of the partial connection for ISP-initiated e-mail delivery.

Owner:T-MOBILE DEUTSCHLAND

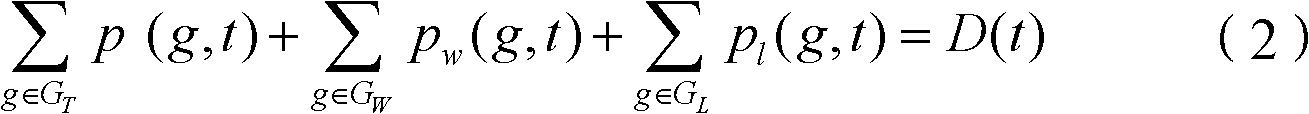

Optimal evaluation method of wind power capacity based on sced

ActiveCN102280878AGuaranteed uptimeWind power capacity is reasonableAc network circuit arrangementsElectricityWind power penetration

The invention discloses a wind power penetration optimization evaluation method based on SCED. The method comprises the following steps: based on a physical model and an economic model of an evaluation power grid and under a condition of knowing a turn on / turn off scheme of a routine unit, establishing a safety constraint economy scheduling model; taking a wind power station in an area as a concrete evaluation target, setting an optimization object of the safety constraint economy scheduling model to be a maximized total wind power output and acquiring an optimization model of wind power penetration evaluation; linearizing non-linear factors in the evaluation model; solving the evaluation model by adopting a linear programming method, calculating an active curve of the accepted wind powerin the research area, acquiring a wind power penetration ability of the power grid and acquiring a maximized grid-connected generation capacity of the each wind power station in an evaluation period.By using the method of the invention, carrying out precontrol to a risk of accessing large scale wind power into the power grid can be easily achieved, and security of power grid operation can be raised.

Owner:NARI TECH CO LTD +1

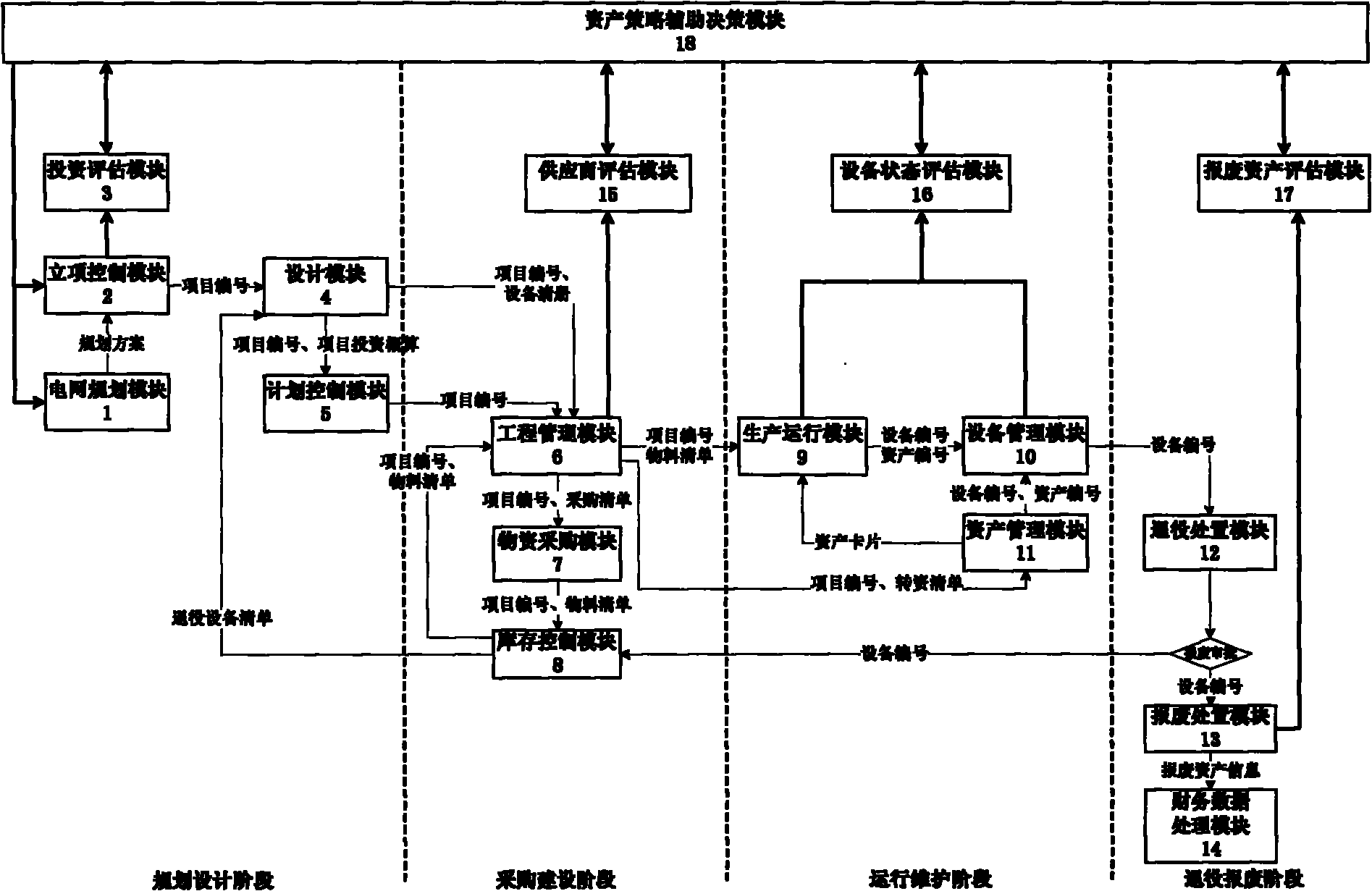

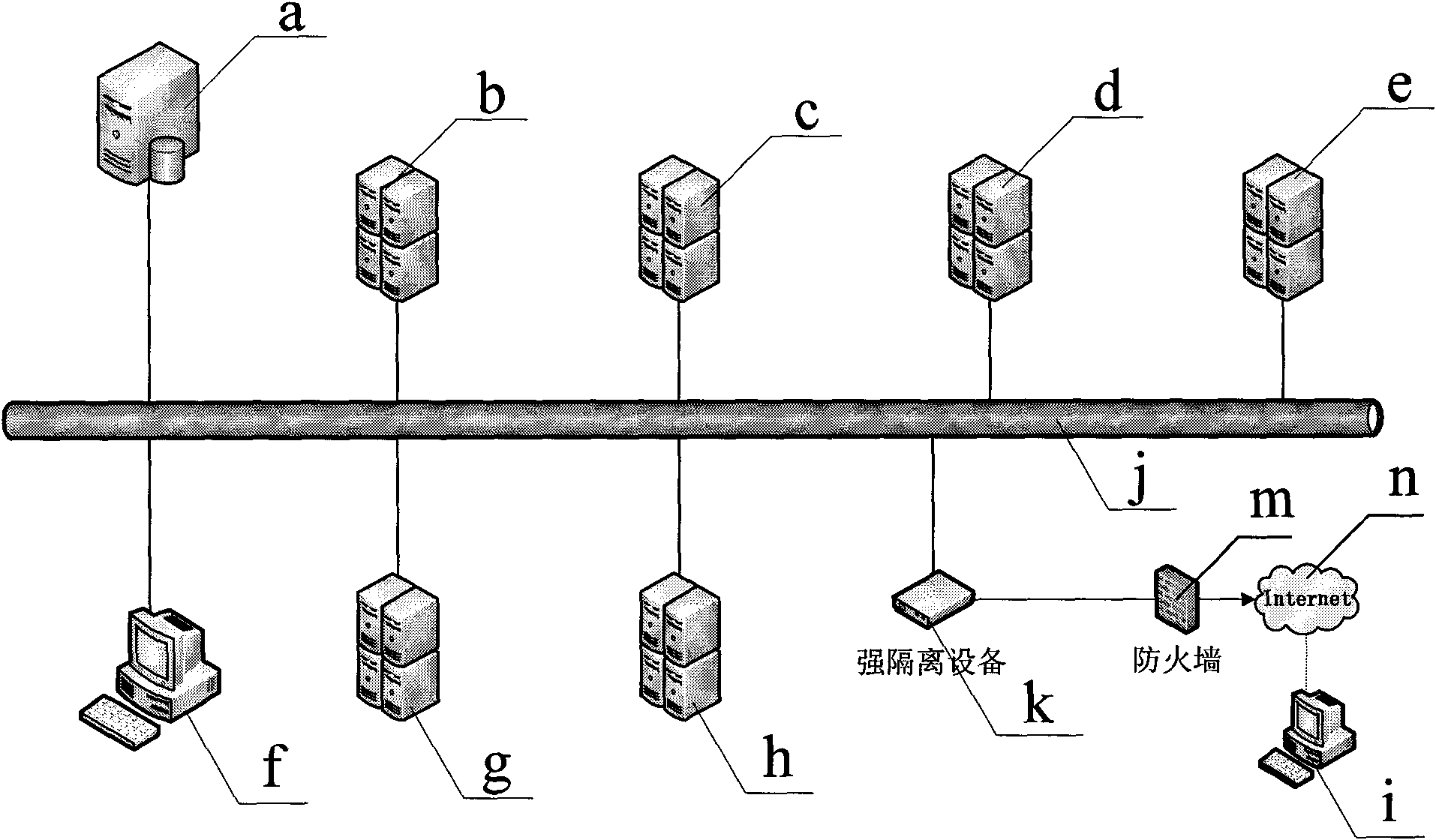

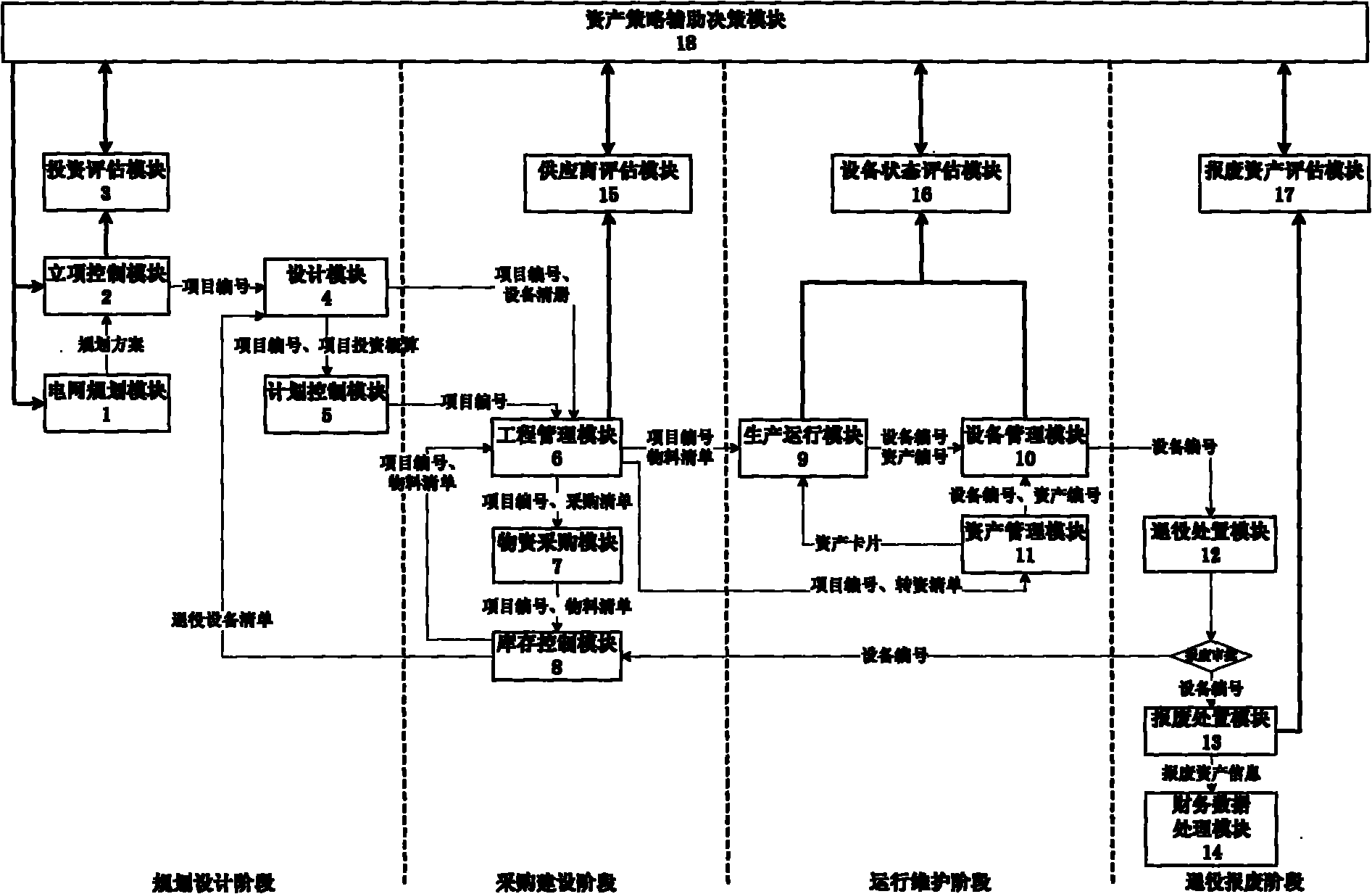

Asset life information integrated control method and device suitable for power system

InactiveCN102142111AAchieve horizontal penetrationEffective connectionData processing applicationsPagerElectric power system

The invention relates to an asset life information integrated control method and a device suitable for a power system. The method comprises the following steps: an asset strategy auxiliary decision module is used for controlling a power grid planning module according to life cycle cost evaluation results of the existing equipment to select a corresponding planning scheme from a database server and sending the life cycle cost evaluation results to a project control module. The asset life information integrated control device suitable for the power system comprises the database server, a PSP (Python Server Pagers) application server, a BW (Band Width) application server, a BPS (Basic Programming System) application server, an SRM (Storage Resource Management) application server, a PMS (Purchase Management System) application server, a WRP (Wireless Routing Protocol) application server, an internal client, an external client, an internal bus and an Internet. Compared with the prior art, the asset life information integrated control method and the device suitable for the power system have the advantages of forming the evaluation decision of closed-loop linkage, optimizing the life cycle cost of the equipment and the like.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

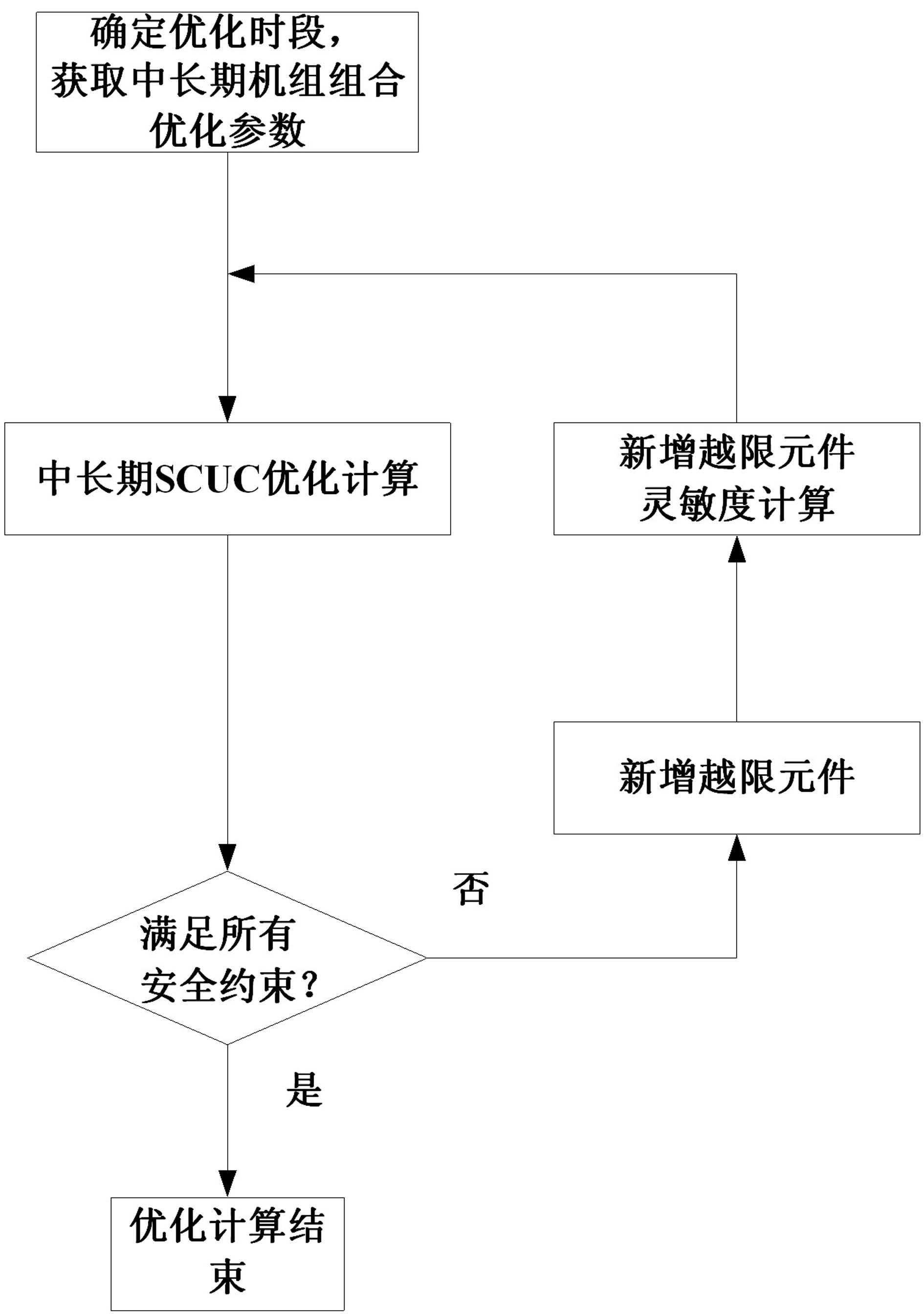

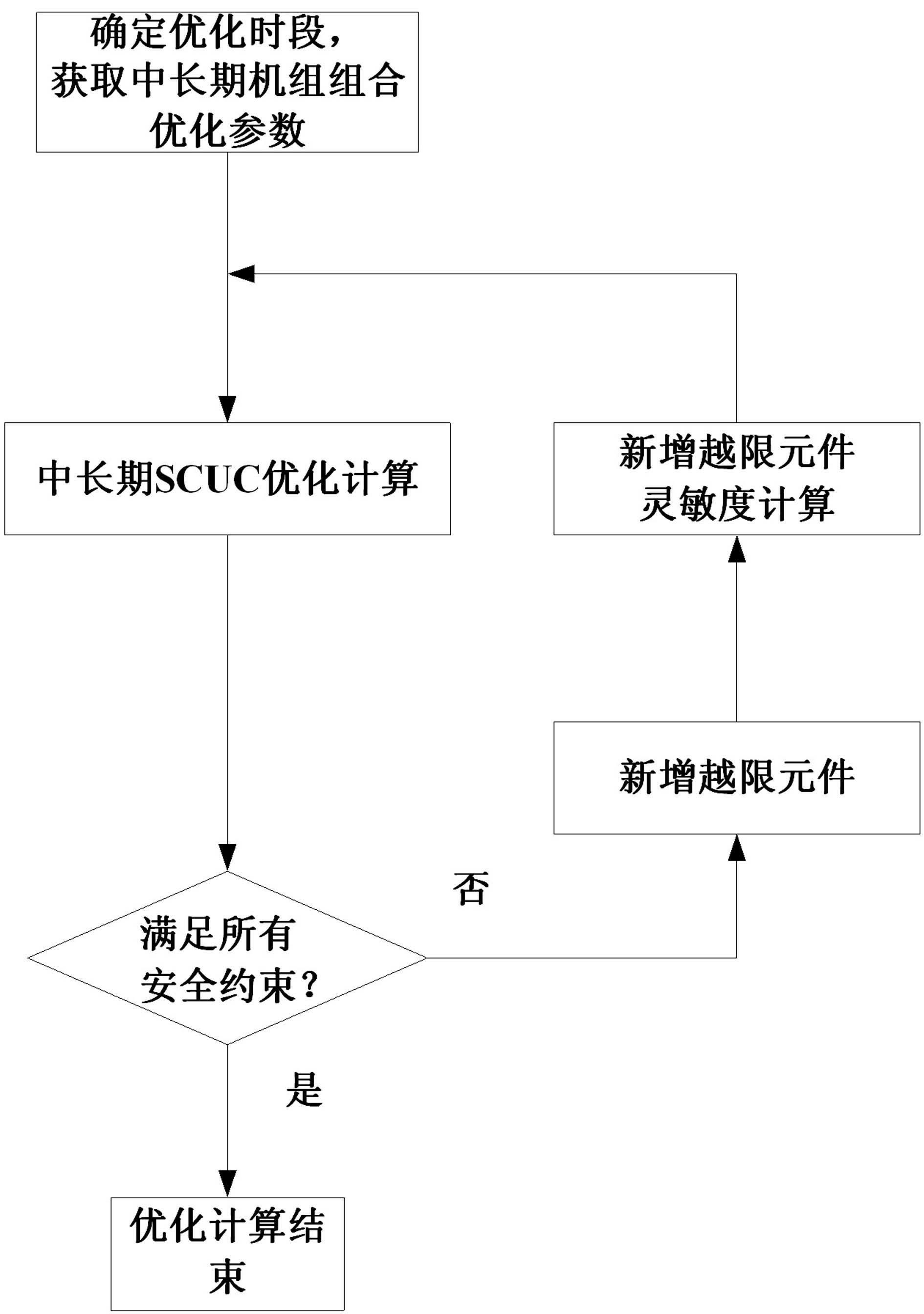

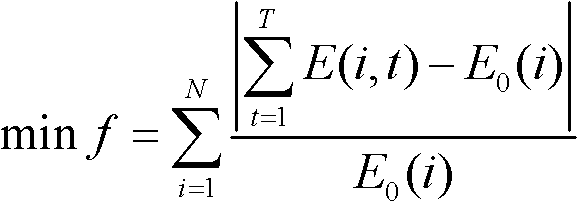

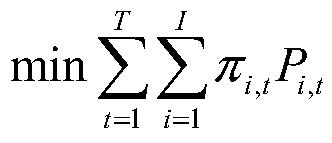

Mid-long-term unit commitment optimizing method

ActiveCN102097866AImprove driving abilityIncrease resourcesCircuit arrangementsMinimum deviationCommitment scheme

The invention discloses a mid-long-term unit commitment optimizing method. The method comprises the following steps: acquiring various optimized data to determine the optimal space of mid-long-term unit commitment; then establishing a mid-long-term security constrained unit commitment model with minimum deviation between the generated energy of the unit and the expected electric quantity as the target according to the practical power grid model; adopting the mixed integer programming approach to compute the starting / stopping state, load factor and active power output in the peak load period of the unit in each day in the dispatching period; considering all the network monitoring components and adopting the daily maximum load point to carry out security check according to the starting / stopping state and power output in the peak load period of the unit which are obtained through optimization; and finally acquiring the mid-long-term unit commitment scheme satisfying the power grid security through the optimization technology and iteration of security check. The large power grid steering capability and the power resource optimal allocation capability are greatly improved by adopting the method.

Owner:NARI TECH CO LTD +1

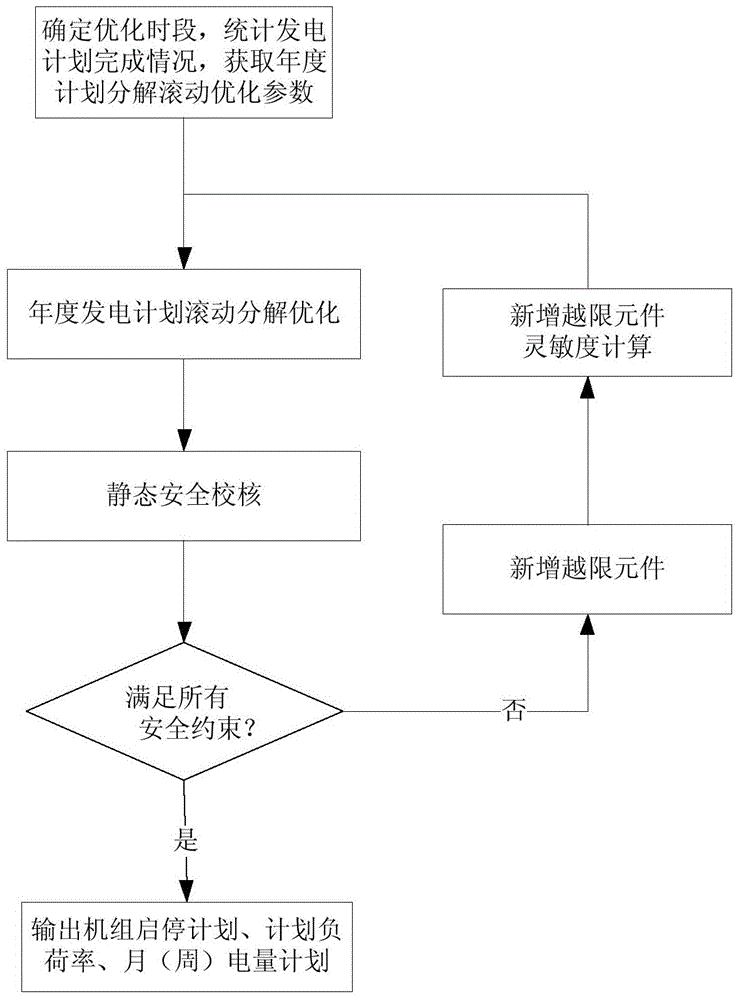

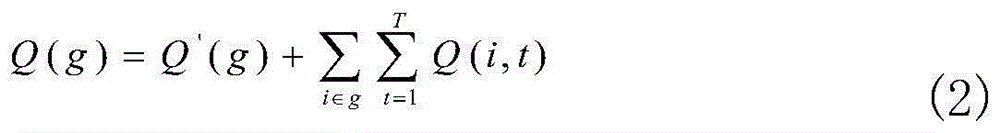

Annual power generation plan rolled decomposition optimization method taking balance between plan finishing rate and load rate into consideration

ActiveCN104616069AImplement trackingRealize regulationForecastingInformation technology support systemLinear programming algorithmDecomposition

The invention discloses an annual power generation plan rolled decomposition optimization method taking balance between plan finishing rate and load rate into consideration; the method comprises the following steps: (1) determining a plan period and a plan parameter requiring the annual power generation plan rolled decomposition optimization; (2) establishing a security constraint machine set combined optimization model applicable to the annual power generation plan rolled decomposition; (3) using a mixed integer linear planning algorithm to calculate start and stop states, the plan load rate and the peak and valley active outputs of the machine set at each plan period; (4) implementing the security check, judging if all security constraints are satisfied; if all the security constraints are satisfied, going to step (5); if not all the security constraints are satisfied, adding a new out-of-limit element, and calculating sensitivity information of the newly added out-of-limit element, going to step (2). The disclosed method circularly optimizes and drafts the machine set start and stop plan as well as the machine set average plan load rate, drafts monthly, weekly and daily power generation amount plans of the power plant; the disclosed method ensures the execution of the annual power generation amount plant, and achieves the purpose of saving energy and reducing emission.

Owner:NARI TECH CO LTD +2

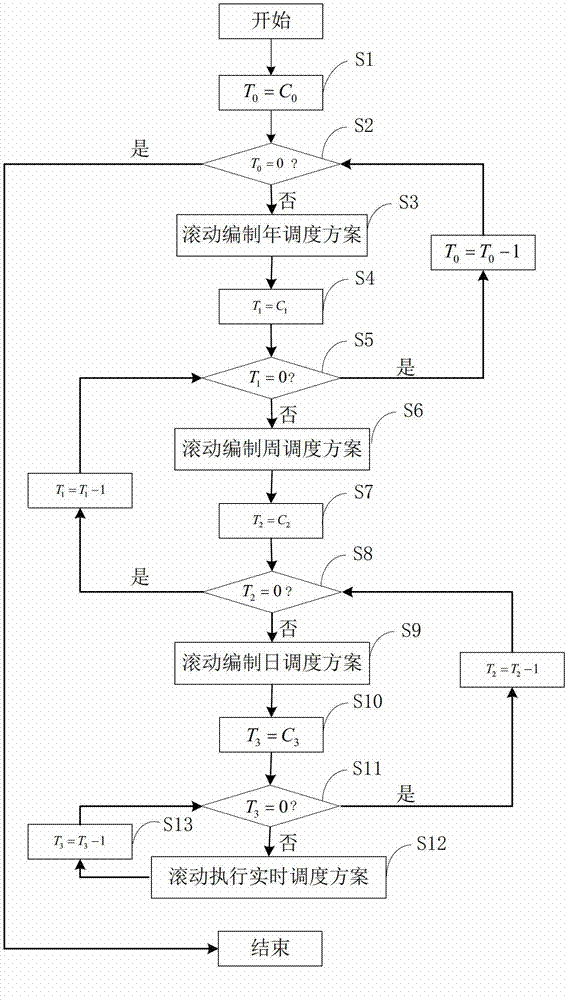

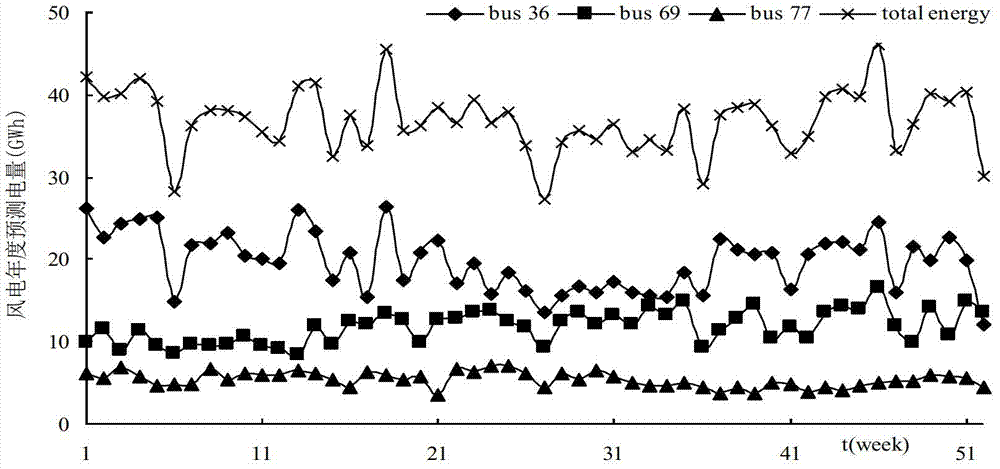

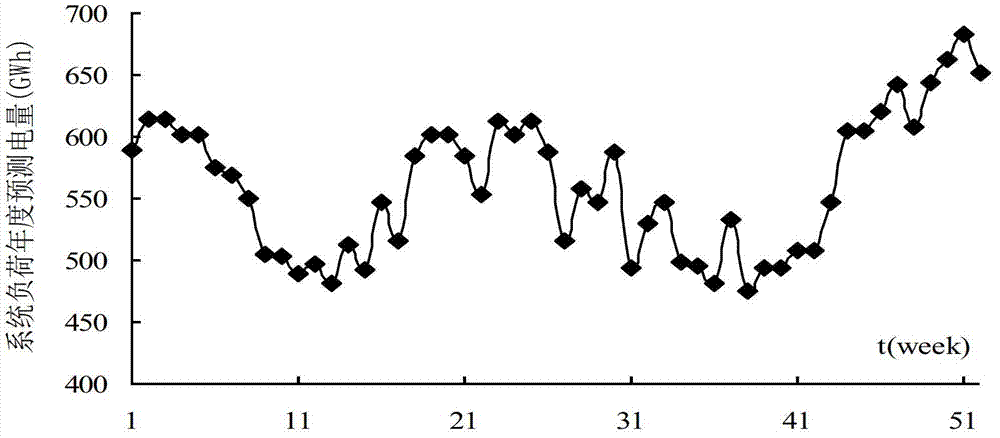

Multi-time-scale rolling coordination scheduling method for electric power system with wind power

InactiveCN102738833AEffective connectionSmooth transitionSingle network parallel feeding arrangementsWind energy generationElectricityNetwork connection

The invention discloses a multi-time-scale rolling coordination scheduling method for an electric power system with wind power. The method comprises the following steps of: calculating a thermal power unit overhauling plan and an annual electric quantity plan according to annual prediction and thermal power unit overhauling data, and working out an annual scheduling scheme in a rolling mode; discomposing the annual power generation quantity of a thermal power unit into weeks; calculating a thermal power unit starting and stopping plan and a weekly contribution plan according to weekly prediction data and the weekly power generation quantity of the thermal power unit; decomposing the weekly power generation quantity of the thermal power unit into days; calculating a daily contribution plan of the thermal power unit according to short-period prediction data and the daily power generation quantity of the thermal power unit, and working out a daily scheduling scheme in the rolling mode; calculating a thermal power unit contribution adjustment quantity according to ultrashort-period prediction data and the daily contribution plan of the thermal power unit, and executing a real-time scheduling scheme in the rolling mode; and correcting the annual scheduling scheme, the weekly scheduling scheme and the daily scheduling scheme in the rolling mode according to updated prediction data and an actual executing condition. By the method, uncertain influence caused by large-scale wind power network connection can be well handled.

Owner:STATE GRID HUBEI ELECTRIC POWER COMPANY +1

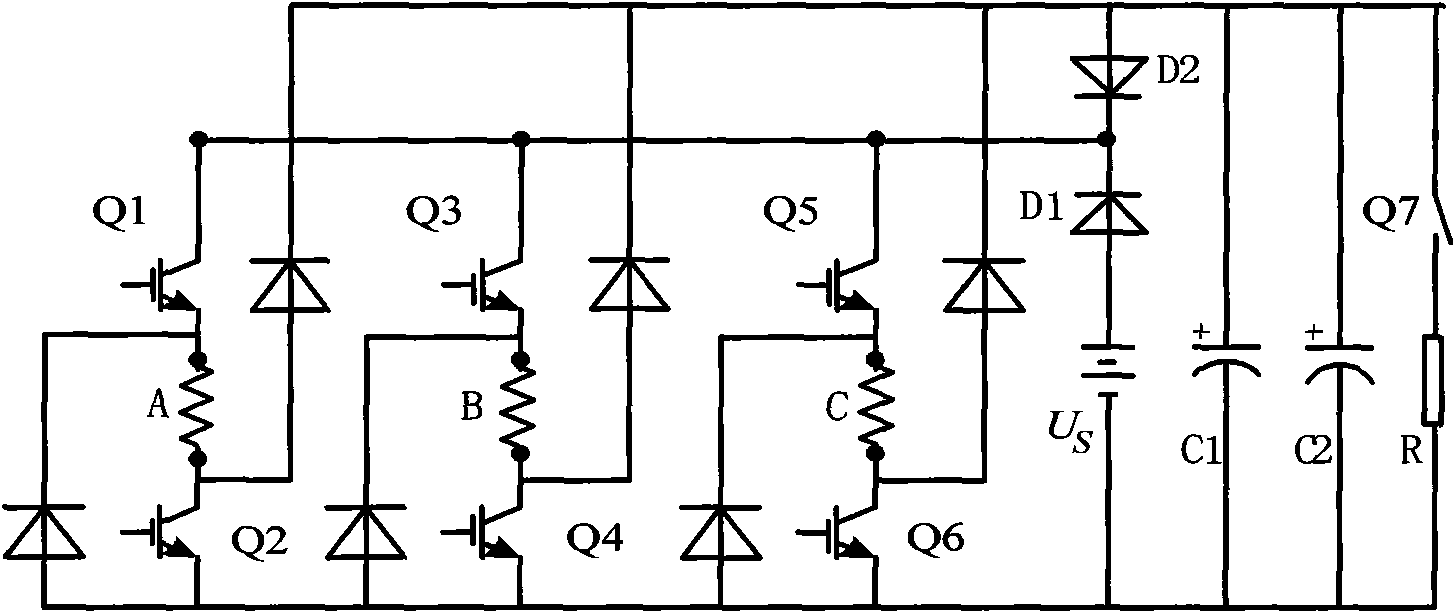

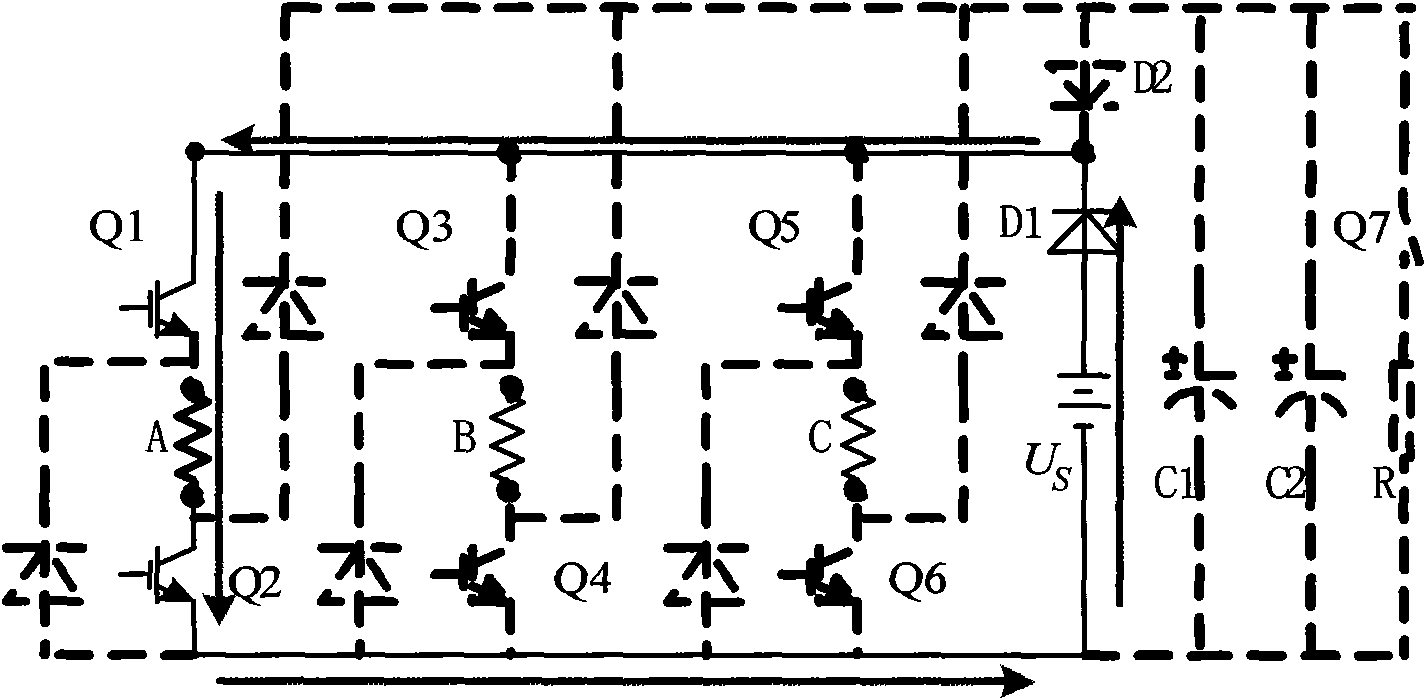

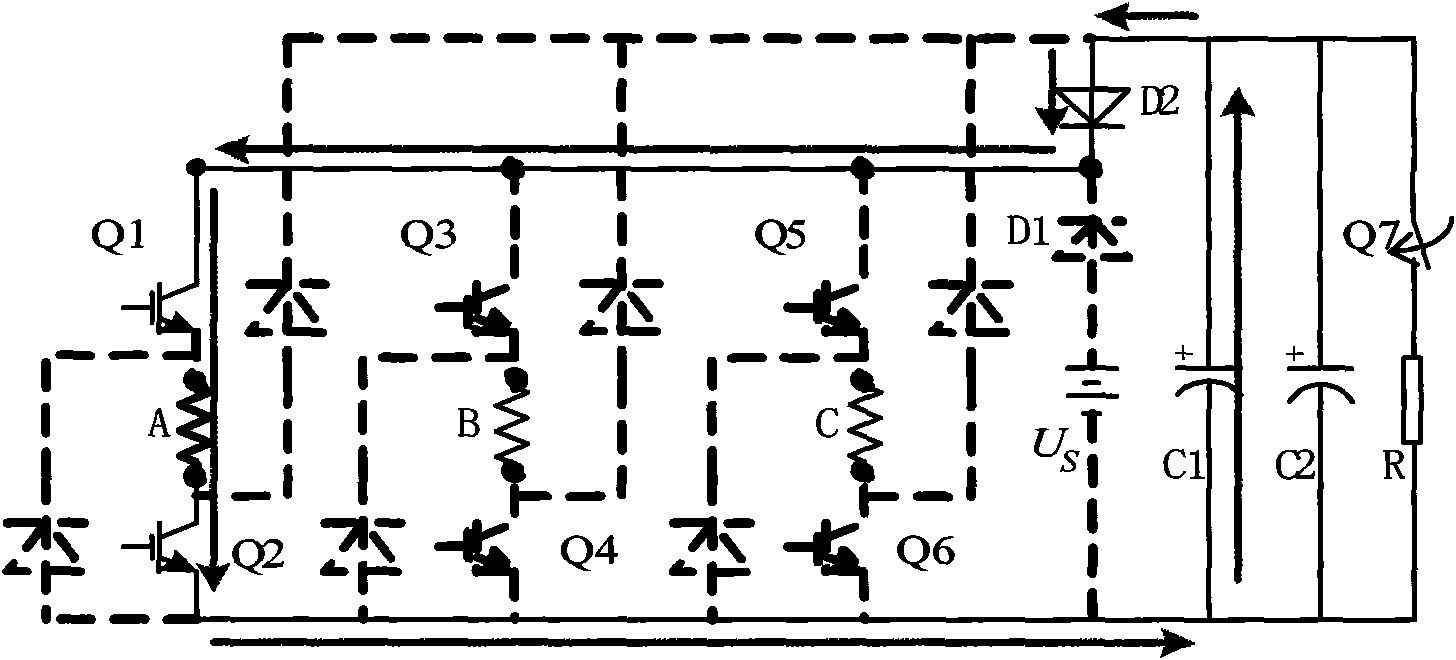

Power converter for switch reluctance starter/generator

InactiveCN101582671AEffective connectionAchieve redundancyElectric generator controlMagnetic reluctanceEngineering

The invention discloses a power converter for a switch reluctance starter / generator, and belongs to the technical field of fault tolerant control of switch reluctance generators and design of power converters. The power converter adopts a power converter topology, and effectively combines a switching tube and a load switching tube of each bridge arm by adding six auxiliary switching tubes S1-S6 in the conventional asymmetrical semi-bridge power converter topology of the self-excitation mode so as to realize redundancy when any switching tube of each bridge arm fails; and the switching tube has high utilization rate and strong reliability. Aiming at different fault modes, the power converter can be applied to various different control strategies, realizes fault tolerant operation, greatly improves the generating property and reliability of a generating system, and is quite applicable to fault tolerant control for the switch reluctance starter / generator.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Flux-cored wire for fusion welding butt joint of titanium-steel composite board and preparation method of flux-cored wire

InactiveCN104028917ASmall diameterEffective connectionArc welding apparatusWelding/cutting media/materialsFilling rateMaterials science

A flux-cored wire for fusion welding butt joint of a titanium-steel composite board comprises the components in percentage by mass as follows: 80-81% of vanadium powder and 19-20% of chromium powder, and the sum of the mass percentageof the components is 100%. The invention further discloses a preparation method of the flux-cored wire. The preparation method comprises the steps as follows: the vanadium powder and the chromium powder are dry-mixed to obtain flux core powder, the flux core powder is placed on a charging machine of flux-cored wire production equipment, a copper belt is placed on a belt unwinding machine, ultrasonic cleaning is performed, then U-shaped groove rolling and powder adding operations are performed, the powder filling rate is controlled, sealing of the copper belt is performed through a forming machine, and a wire with the diameter of 3.8 mm is formed; then the flux-cored wire is obtained through six reducing treatment processes and a nine-stage reducing finish drawing treatment process sequentially. By means of the flux-cored wire, a titanium layer and a steel layer weld structure of the composite board can be effectively joined together, and the fusion welding butt joint of the titanium-steel composite board is realized; an obtained weld joint has excellent toughness; and the preparation process is simple, and mass production is facilitated.

Owner:XIAN UNIV OF TECH

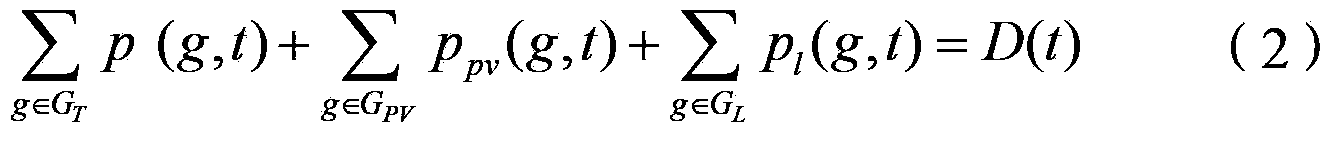

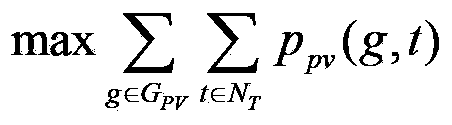

Day-ahead power generation plan photovoltaic power generation receiving capability analysis method based on SCED

InactiveCN103441535APrevent risks brought about by safe operation in advancePrevent risks from safe operationSingle network parallel feeding arrangementsPhotovoltaic energy generationPower gridPhysical model

The invention discloses a day-ahead power generation plan photovoltaic power generation receiving capability analysis method based on SCED. The day-ahead power generation plan photovoltaic power generation receiving capability analysis method based on SCED includes the following steps that based on a physical model and an economic model which access a power grid, under the condition that a regular unit booting and shutting scheme is known, an SCED model is set up; photovoltaic power stations in a zone serve as a specific analysis target, an optimized target of the SCED model is set to be maximum photovoltaic power generation total output power and an optimized model of photovoltaic power generation receiving capability analysis is obtained; non-linear factors in the model undergo linearization; the linear programming method is used for solving the model to calculate out an active power curve of receiving photovoltaic generation of a study area, the photovoltaic generation receiving capability of the power grid is obtained and the maximum grid connection power generating capability in an analysis period of all photovoltaic power stations is obtained. The day-ahead power generation plan photovoltaic power generation receiving capability analysis method based on SCED facilitates pre-control on risks generated after the power grid accesses large-scale photovoltaic power generation and improves safety of operation of the power grid.

Owner:NARI TECH CO LTD

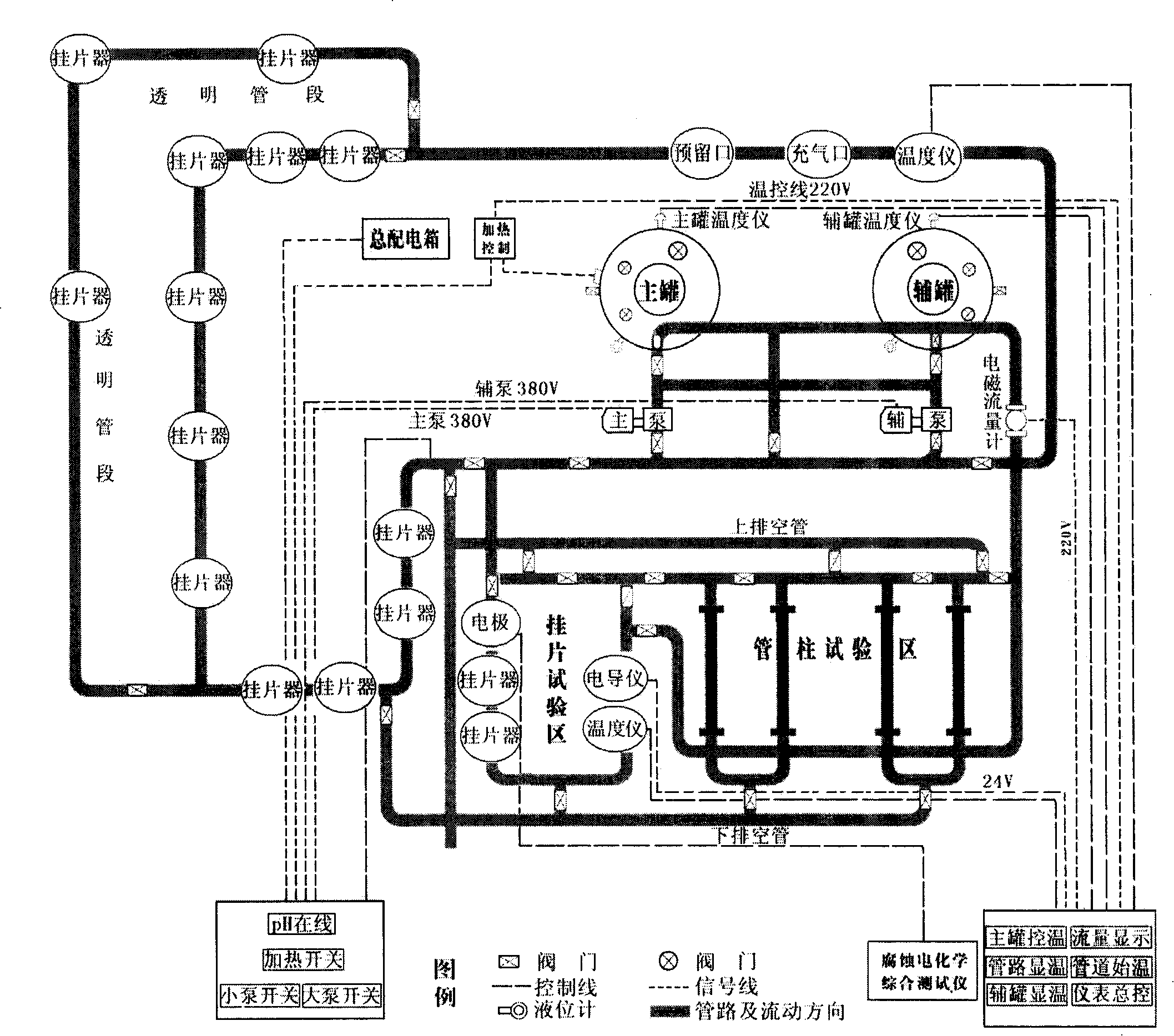

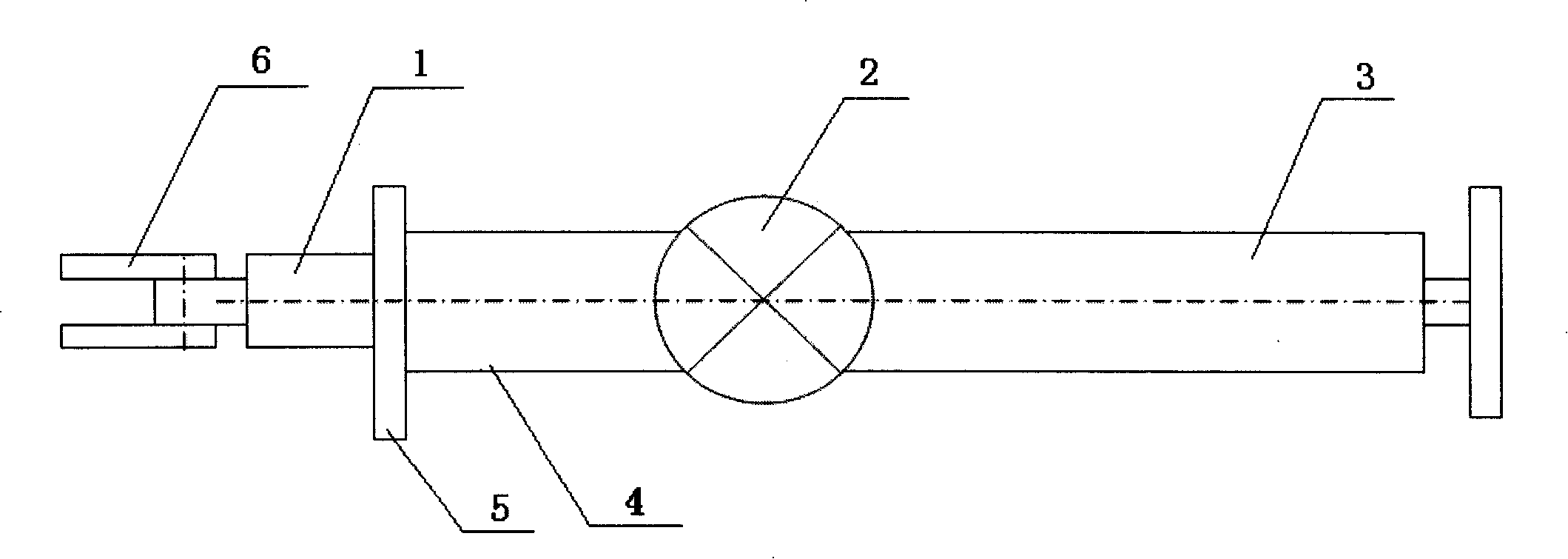

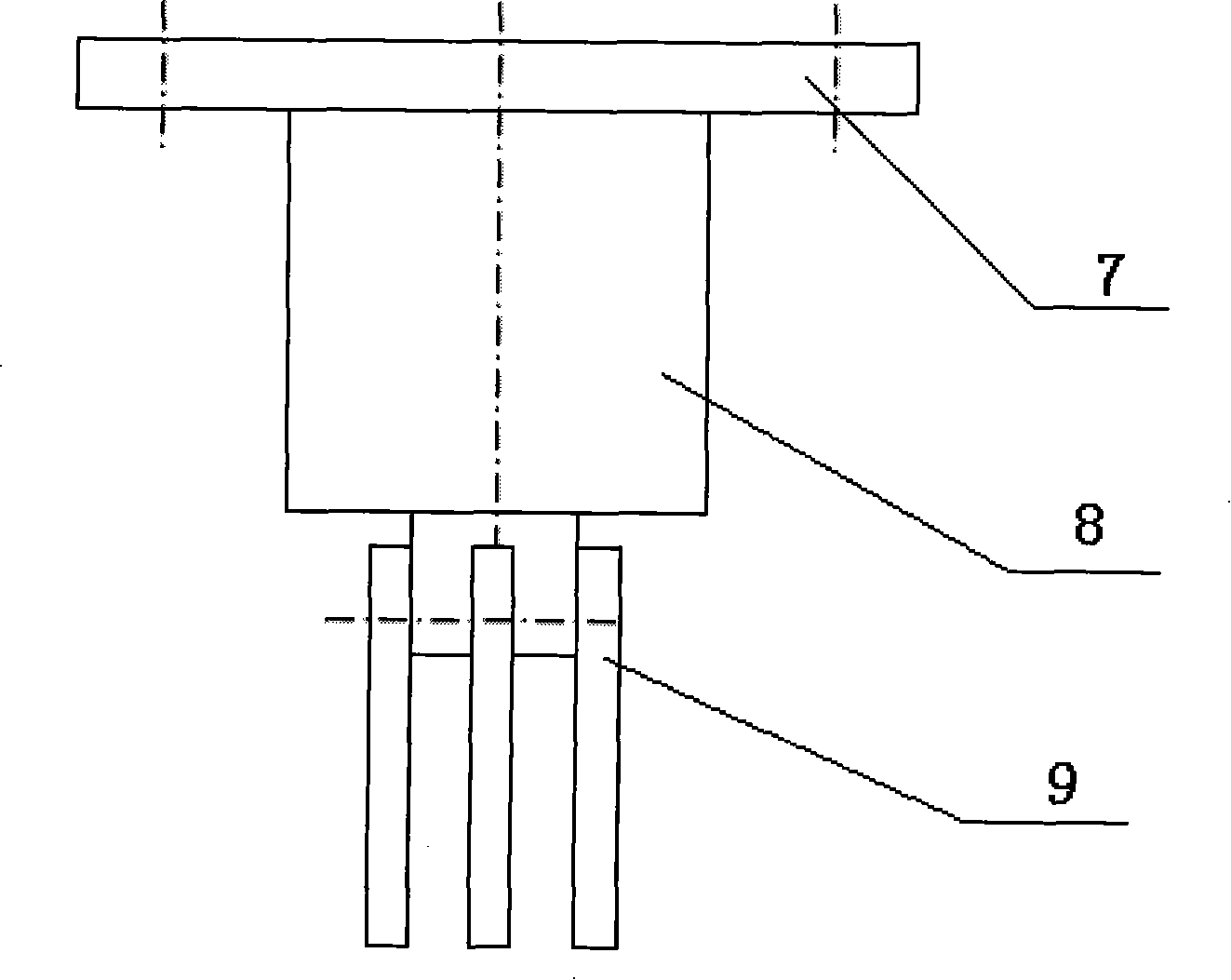

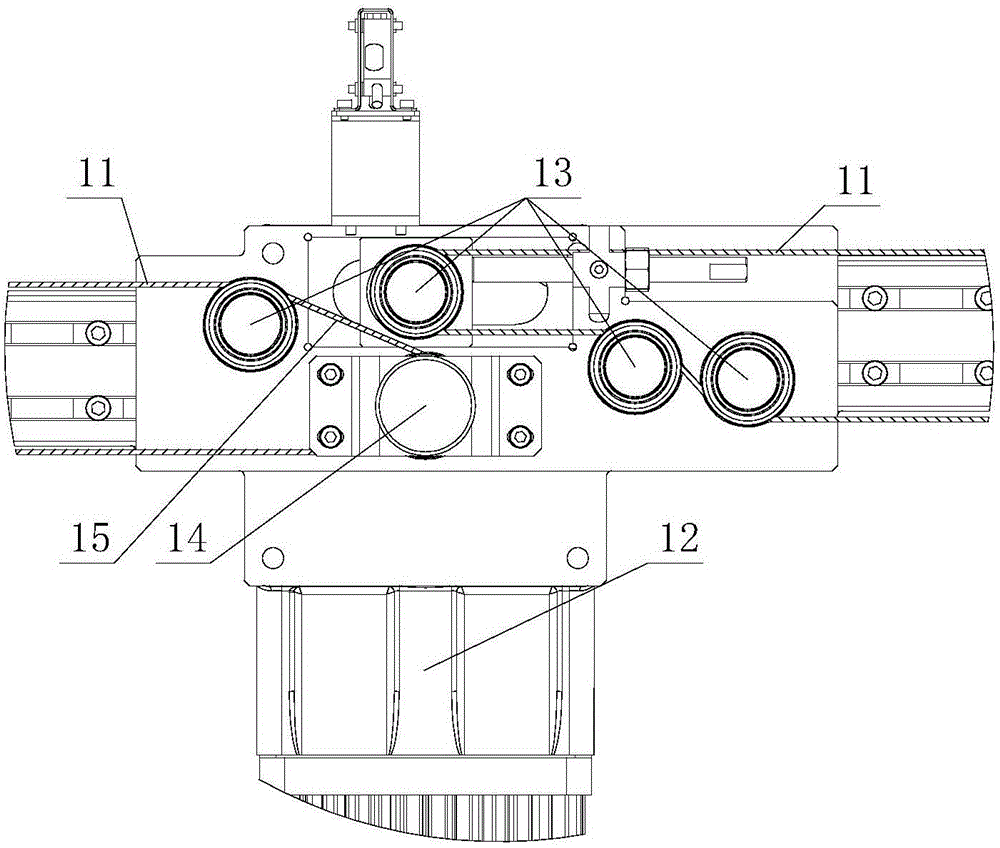

Dynamic simulation tester in erosion chamber

InactiveCN101226134AEffective connectionWeather/light/corrosion resistanceTemperature controlOil field

The invention relates to a dynamic analogue test device in corrosion room, which technical scheme is composed of a pipeline system, a temperature control system, a detection system, a corrosion-resistance circulating pump, a corrosion-resistance tank and a control valve, wherein the pipeline system has two lines to realize the corrosion tests at two flow speeds and online flow state detection on the corrosion medium and coupon, while the pipeline is preformed with a plurality of test ports, the invention uses at least one corrosion-resistance circulating pump as power supply to feed and circulate the site water in the corrosion-resistance tank or prepared analogue water in the pipeline, the detection system is provided with a column test device and a coupon test device. The invention has the advantages that the invention can effectively abut lab and site to realize successful transition from indoor corrosion-resistance technique to worksite application and can evaluate and screen oil field prior or novel anti-corrosion technique, anti-corrosion art and anti-corrosion material, while the result is matched with practical application.

Owner:中国石化股份胜利油田分公司技术检测中心

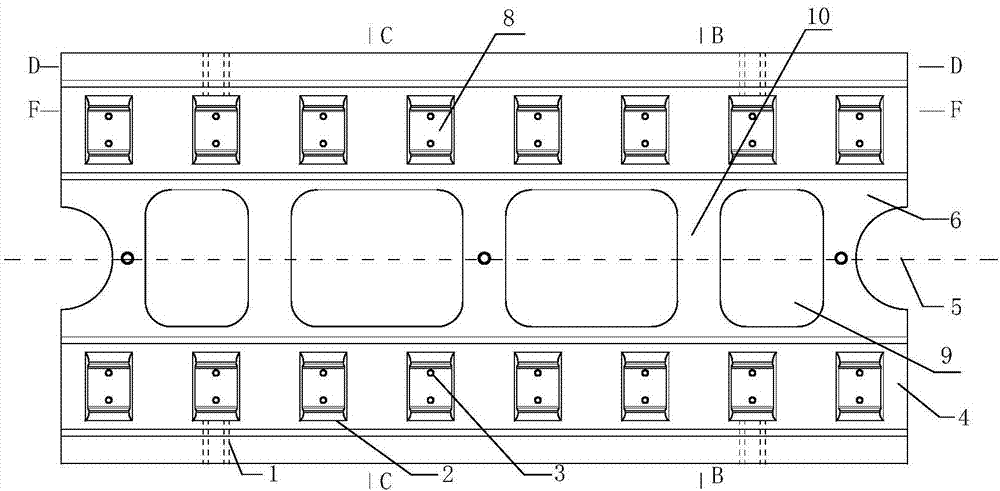

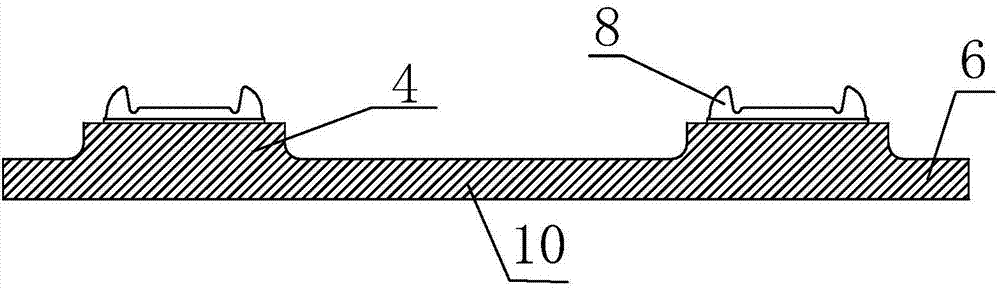

Thickened frame type ballastless track plate

Provided is a thickened frame type ballastless track plate. The track plate comprises a base plate, bosses and track bearing tables. The base plate is of a cuboid, the two bosses are symmetrically arranged on one face of the base plate along the axis of the cuboid in the length direction, and the track bearing tables are evenly distributed in the length direction of the upper surfaces of the bosses. A through hole is formed in the base plate and is located between the two bosses symmetrically arranged on the base plate, and a frame structure connected between the two bosses through a transverse reinforcement concrete structure is formed. The thickened frame type ballastless track plate can effectively reduce track plate warping caused by temperature stress, eliminate a pull cracking phenomenon, and enhance running safety and comfort. The thickened frame type ballastless track plate is reasonable in structural stress, light, high in structural strength and capable of effectively improving the stress condition of a sleeper structural system, prolonging the service life of the structure and optimizing rack circuit parameters, improves the circuit transmission characteristic of a resonant track, can be directly and effectively connected with a current high-speed railway CRTS-I ballastless track plate, and is suitable for industrial production.

Owner:CENT SOUTH UNIV

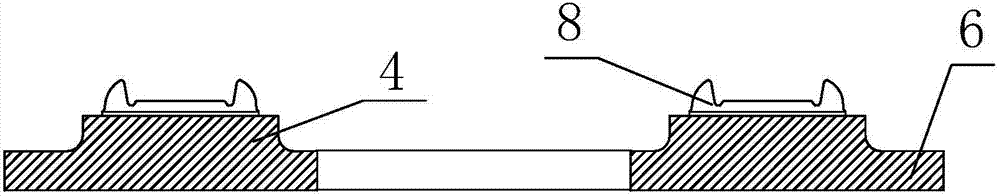

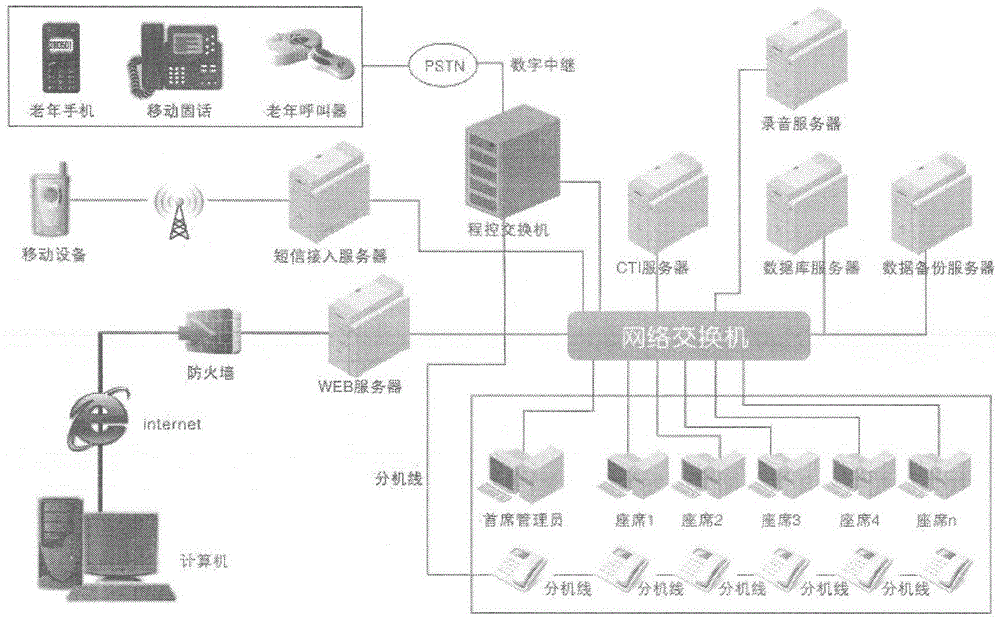

Home-based care for the aged intelligent service system

InactiveCN103942632AImprove service typesWide coverage areaResourcesTransmissionInformatizationMarket place

The invention discloses a home-based care for the aged intelligent service system. Based on a system platform, four service modes of emergency rescue, medical service, life help and active care are constructed on the basis of an elder database, a call center, a community medical center and an emergency call terminal. Relying on an intelligent service system with integration of social service resources, home-based medical care together with elderly care services including emergency rescue, medical service and life help are comprehensively provided for the aged. An informatization and intellectualization virtual nursing home operation mode with "public welfare as the premise, socialization as the basis and marketization as the supplement" is established so that continuous, healthy and rapid development of home-based medical care together with elderly care service industry is promoted.

Owner:YIHE HOUSING & PENSION SERVICE BEIJING

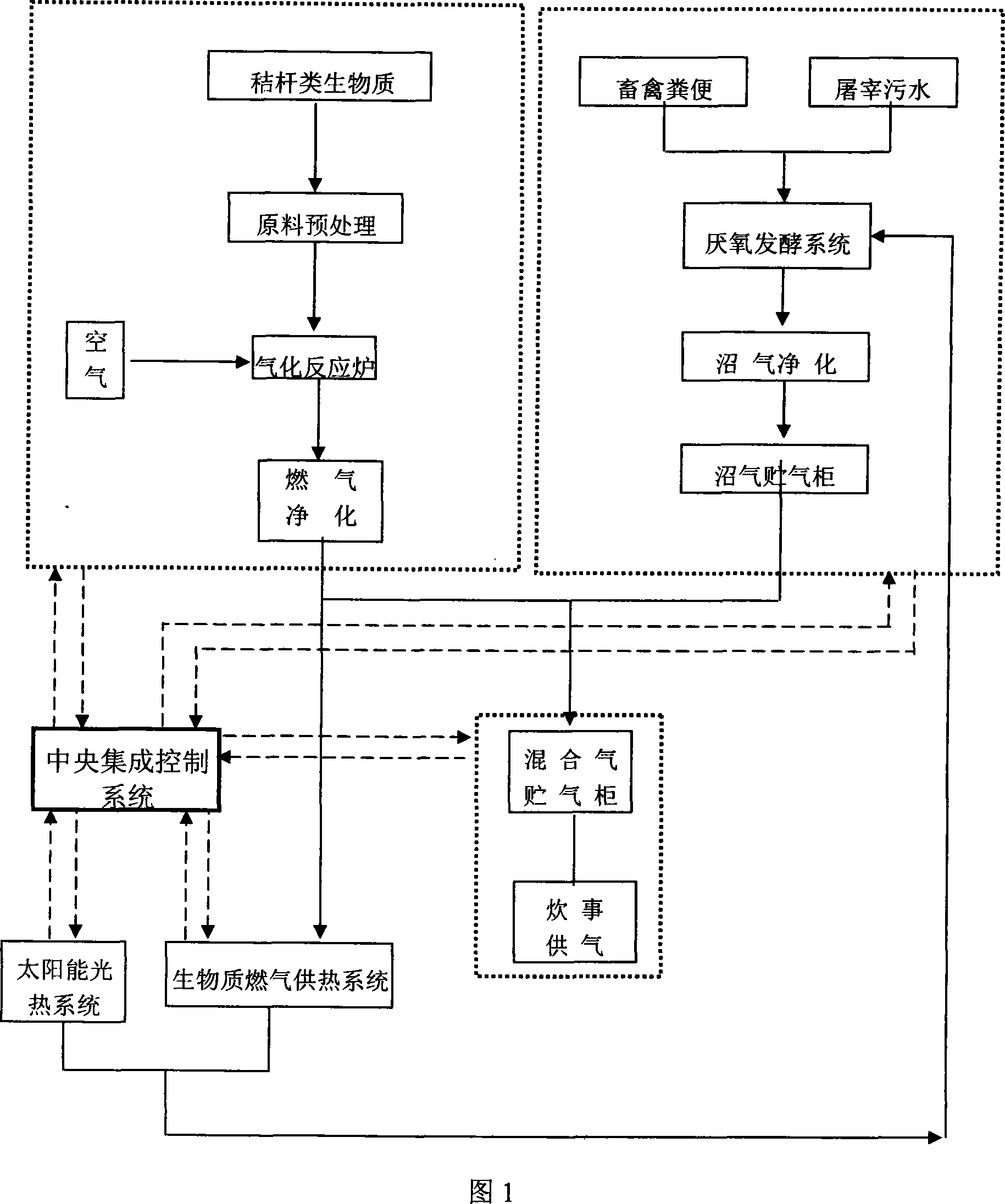

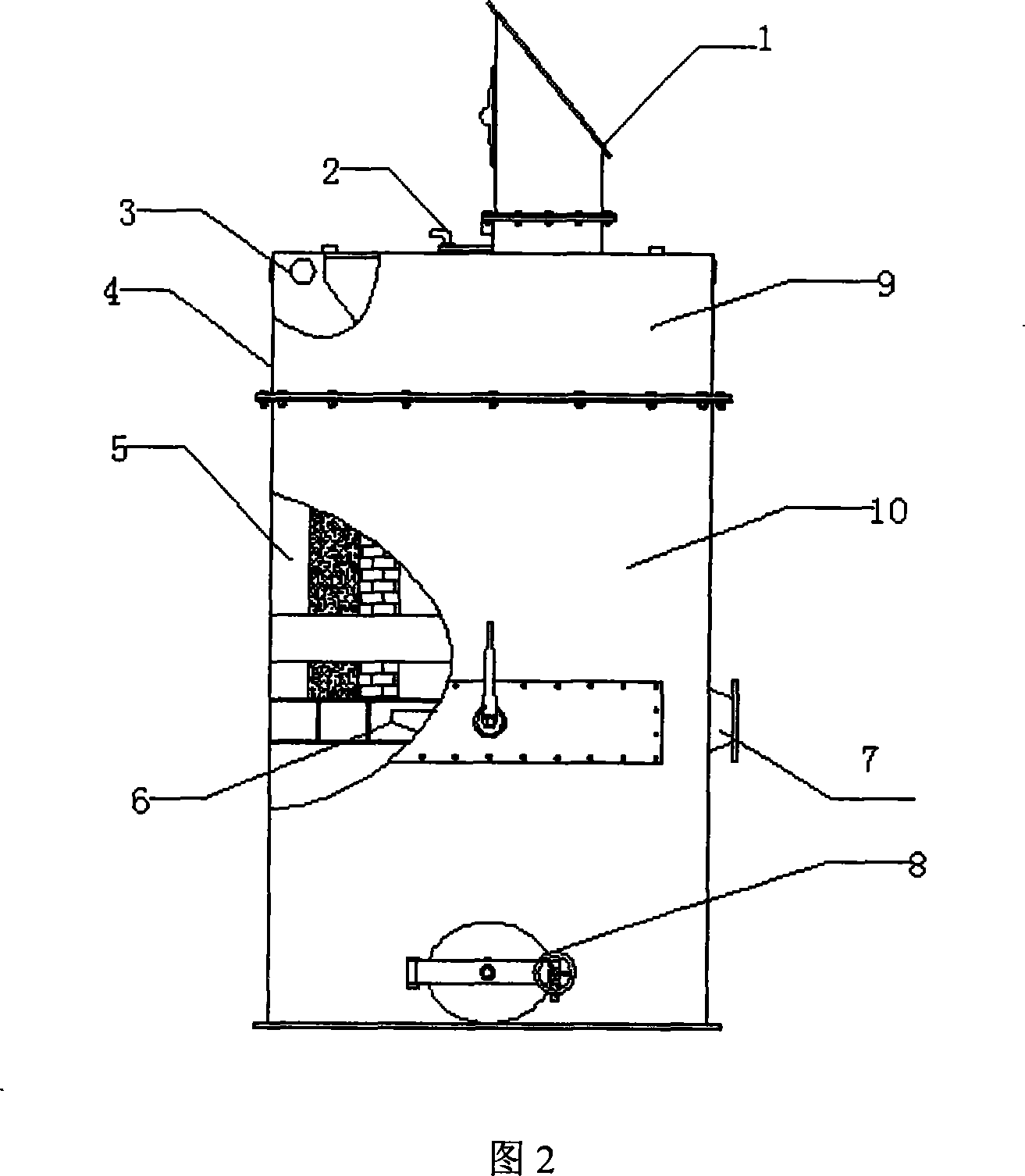

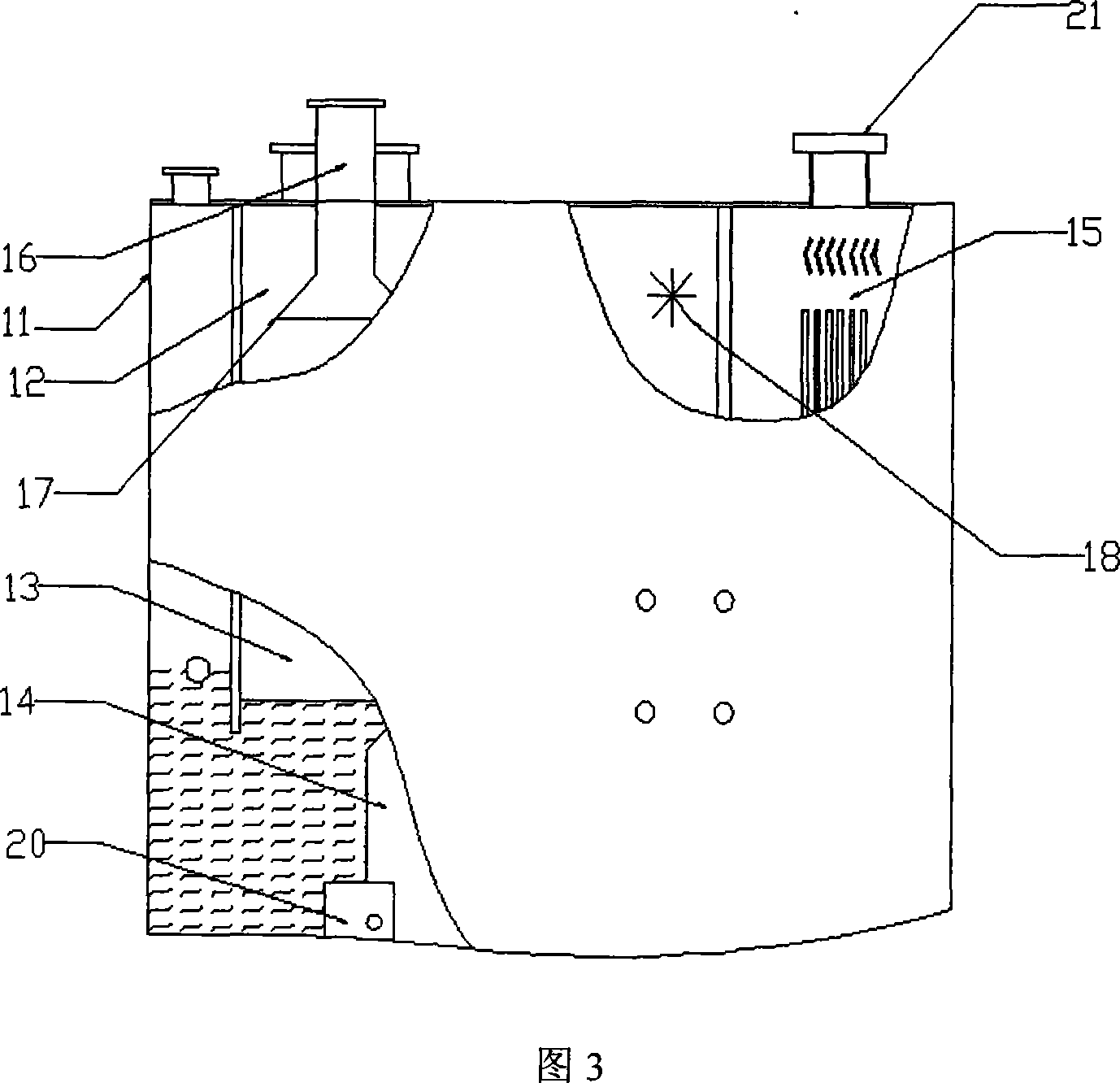

Biological energy-marsh gas fermentation-solar energy integrated utilization system

InactiveCN101063080AEfficient use ofAvoid corrosionSolar heat devicesGas production bioreactorsMarshFermentation

The invention discloses a biological mass energy-marsh gas fermentation-solar energy integrated usage system, which is characterized by the following: comprising biomass evaporated unit, marsh gas anaerobic fermentation unit, central integrated control unit, solar energy light hot unit, biomass gas heat supply unit, biomass fuel and marsh gas automatic mixed unit, fuel transmitting and distributing and user unit; connecting the central control unit and the other units separately; connecting the biomass gasifying unit with the biomass fuel heat supply unit, biomass fuel and marsh gas automatic mixed unit separately; connecting the marsh gas anaerobic fermentation unit with the biomass fuel and marsh automatic mixed unit; connecting the biomass fuel and marsh automatic mixed unit with fuel transmitting and distributing and user unit; connecting the solar energy light hot unit and biomass gas heat supply unit with the marsh gas anaerobic fermentation unit separately. This invention can transform the pollution as marsh gas source.

Owner:浙江网新百川环境科技有限公司

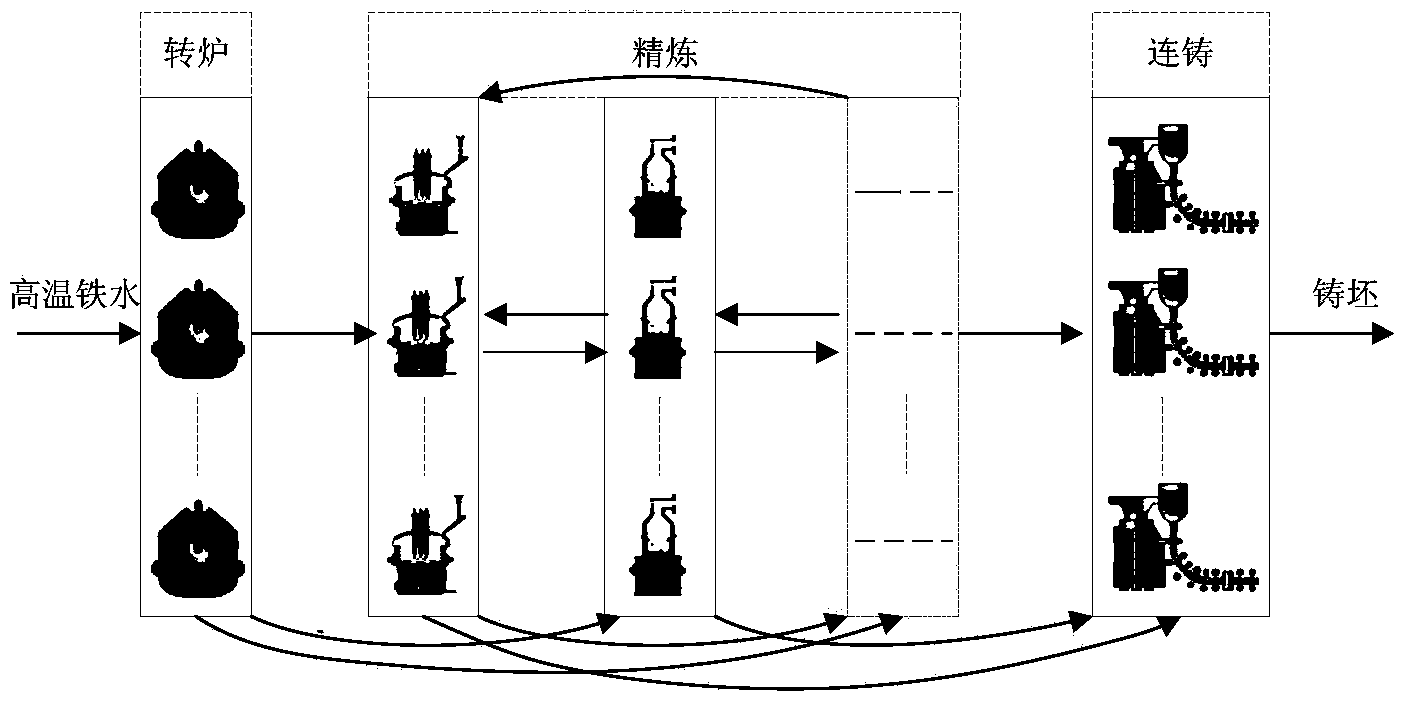

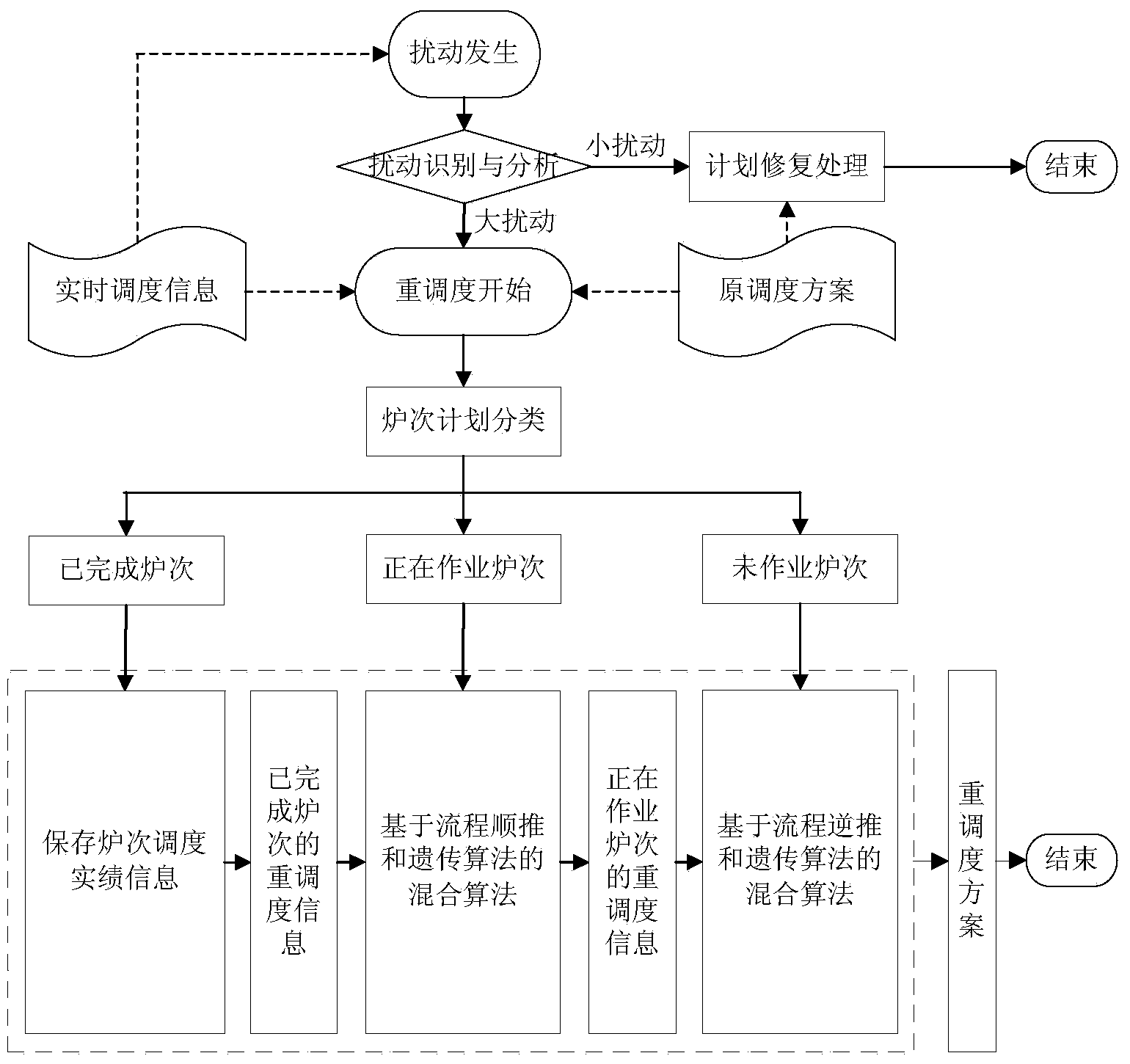

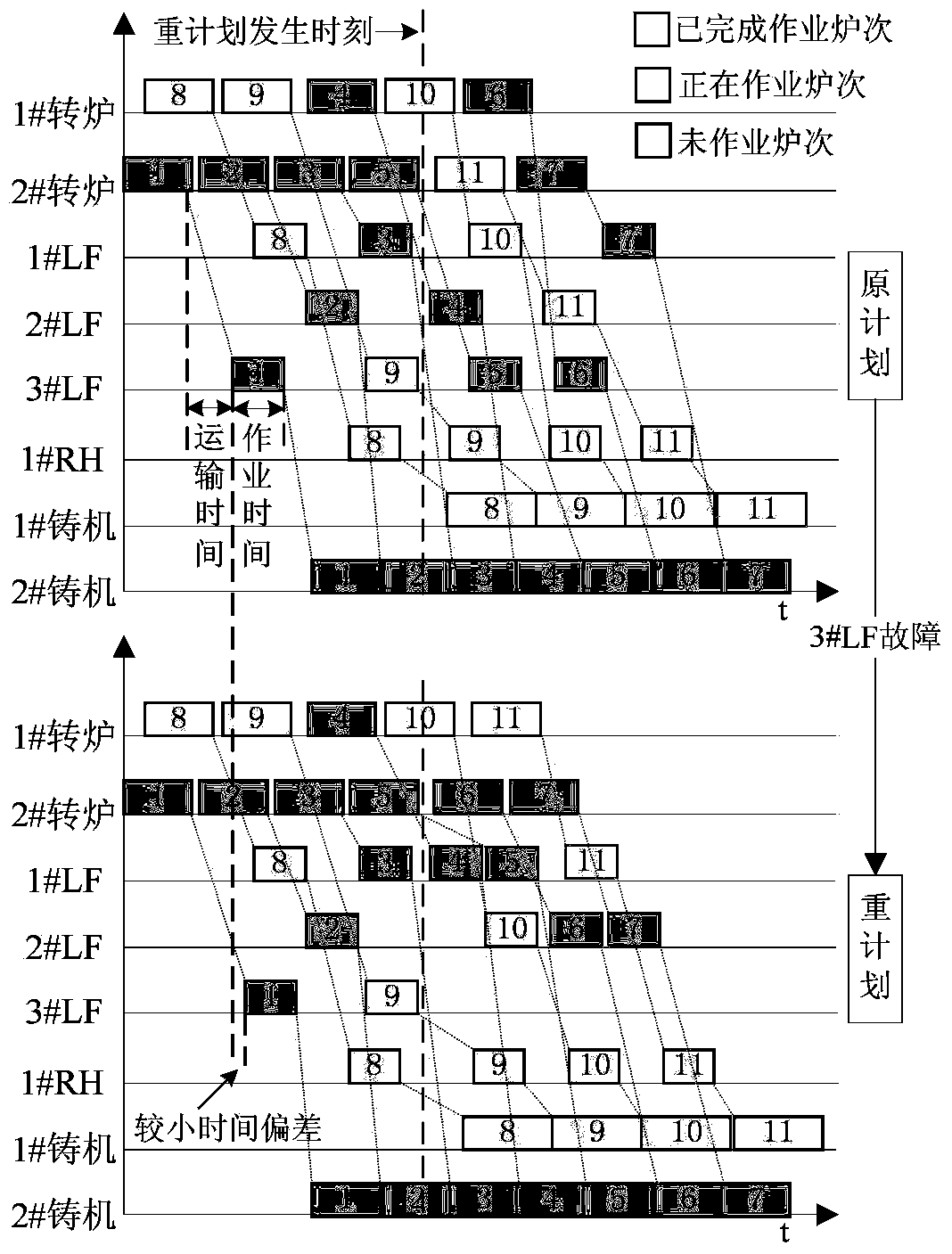

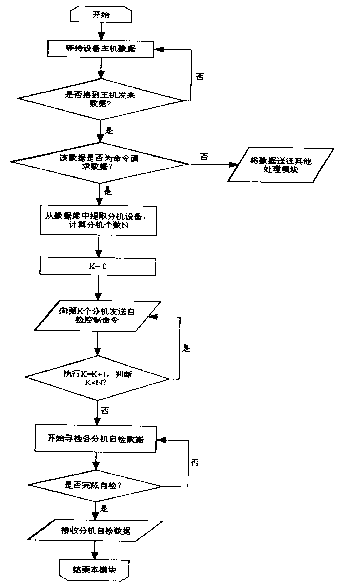

Rescheduling method and rescheduling system of steel making and continuous casting on basis of genetic algorithm

ActiveCN103631243AGuaranteed reasonablenessEffective connectionTotal factory controlProgramme total factory controlTime scheduleMetallurgy

The invention provides a rescheduling method and a rescheduling system of steel making and continuous casting on the basis of a genetic algorithm. The rescheduling method comprises the following steps: by virtue of the rescheduling system, acquiring a production batch plan, the current scheduling scheme and real-time scheduling data of a steel making and continuous casting system, carrying out disturbance identification and analysis, adjusting the current scheduling scheme in small disturbance, carrying out rescheduling in large disturbance; for all furnaces in the operation-finished furnace set, adopting actual scheduling information as a rescheduling subscheme of all the furnaces in the set; for all the furnaces in an operating-furnace set, on the basis of the actual scheduling information and a rescheduling target of the operation-finished furnace set, solving according to a hybrid algorithm of flow direct and a genetic algorithm; for all the furnaces in a stopped-furnace set, on the basis of the rescheduling subscheme of the operation-finished furnace set and the rescheduling subscheme of the operating-furnace set, solving according to the hybrid algorithm of the flow direct and the genetic algorithm. The rescheduling method and rescheduling system provided by the invention have the advantages that the problem of rescheduling under random disturbance in the process of steel making and continuous casting production can be solved.

Owner:CHONGQING UNIV

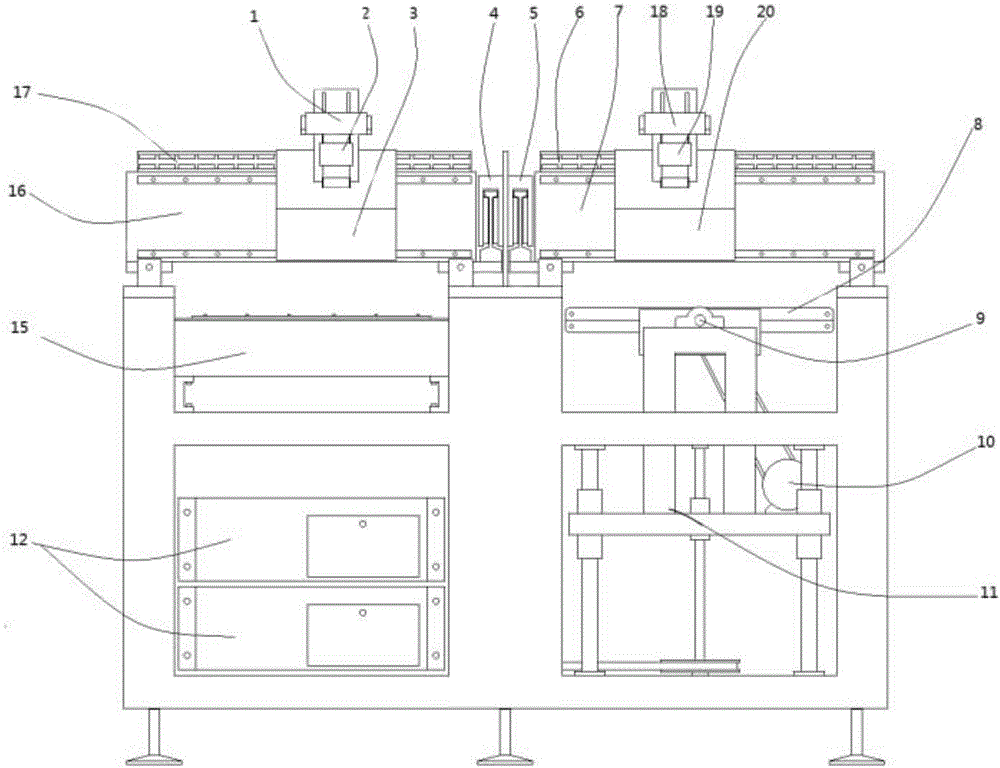

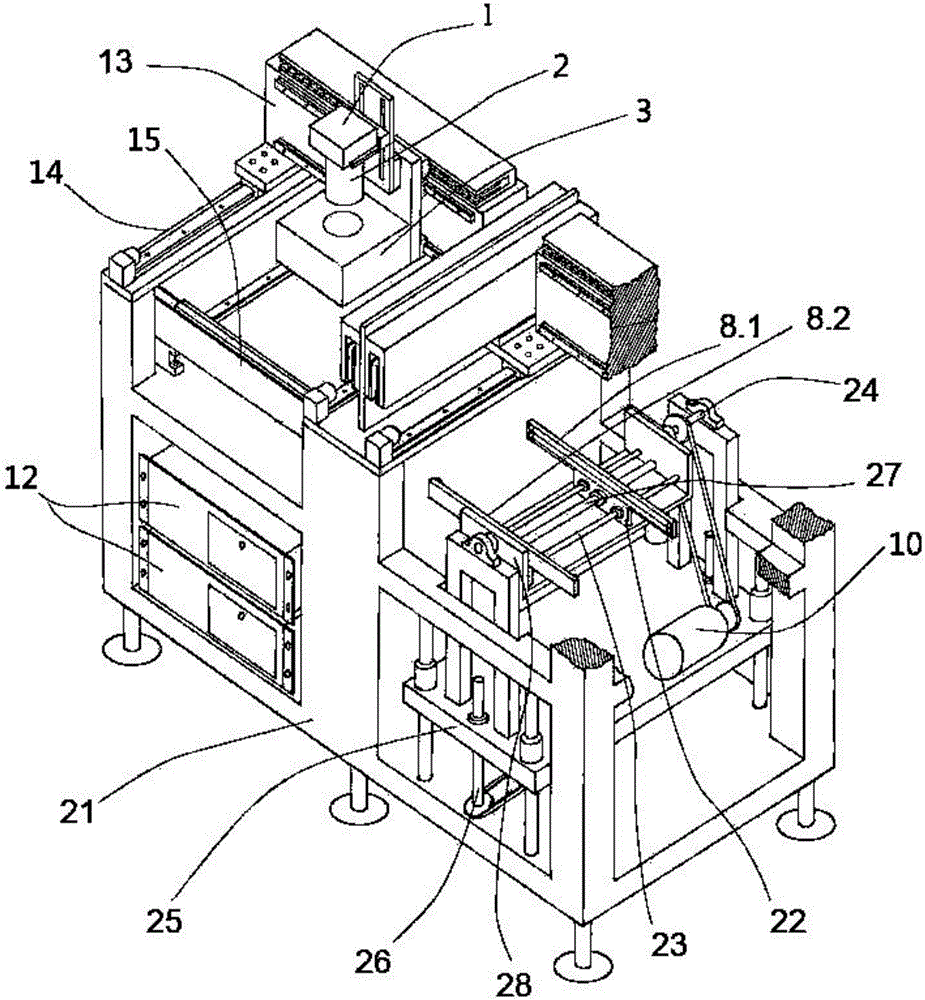

Circuit board double-face detection equipment

ActiveCN104990934AEffective detection distanceEffective connectionOptically investigating flaws/contaminationFace detectionImage detection

The invention provides circuit board double-face detection equipment. The equipment comprises a front transmission mechanism, a rear transmission mechanism, and a plate turnover mechanism; the front transmission mechanism is connected to the rear transmission mechanism; an image detection mechanism is arranged above the front transmission mechanism and the rear transmission mechanism respectively; the rear transmission mechanism is provided with a clamping device, the plate turnover mechanism is connected to the rear transmission mechanism and is used to turn over the top surface and bottom surface of the rear transmission mechanism; the equipment also comprises an elevating device, and the elevating device is connected to the rear transmission mechanism. The provided plate turnover mechanism is used to turn over the rear transmission mechanism so as to turn over a circuit board, and thus the other side of the circuit board can be detected by the image detection mechanism. The elevating device can guarantee that the space is enough to turn over the circuit board, and at the same time can adjust the distance between the image detection mechanism and the circuit board so as to achieve an effective detection distance.

Owner:深圳市凌志锐科技有限公司

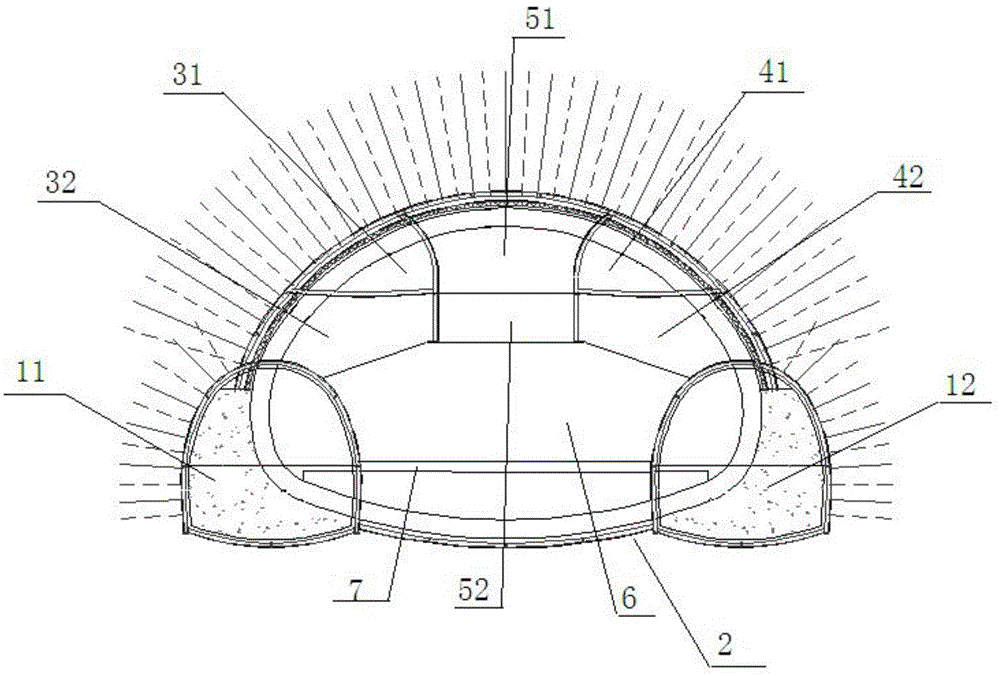

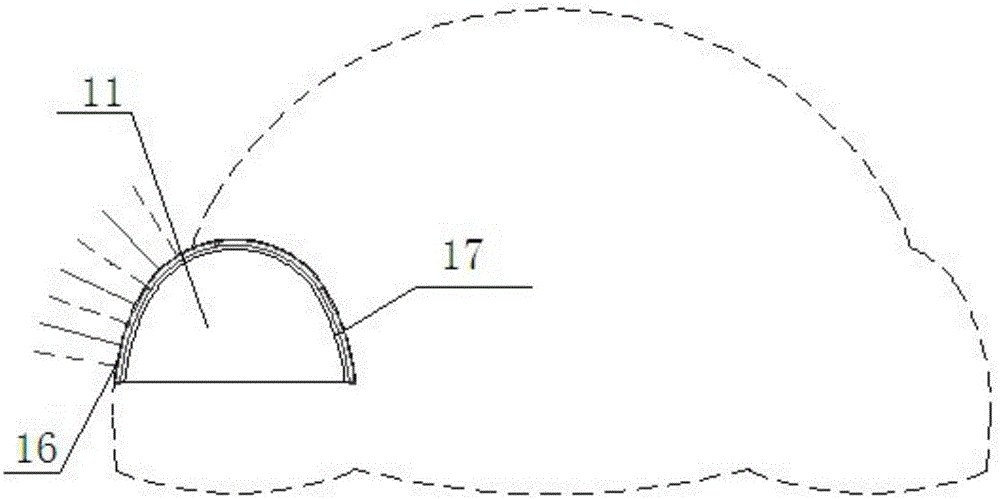

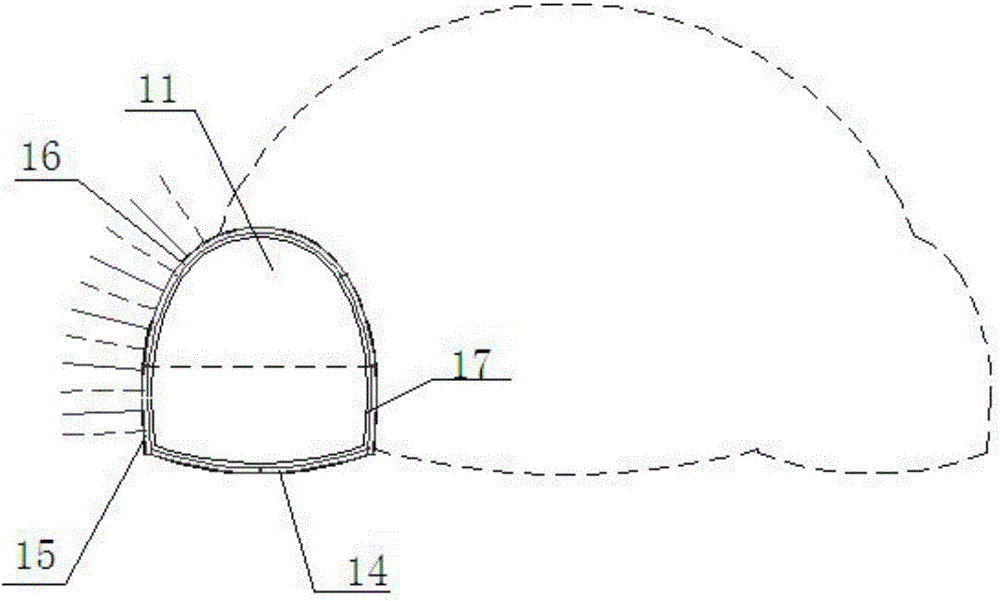

Method for constructing extra-large variable cross section tunnel

ActiveCN104653197AMeet complex force requirementsMeet the construction stability requirementsUnderground chambersTunnel liningSecondary layerSafety risk

The invention discloses a method for constructing an extra-large variable cross section tunnel. The method comprises the following steps: firstly excavating left pilot tunnels and timely constructing primary supports and temporary supports; packing large boot-shaped wall feet and constructing right pilot tunnels by the same process; excavating the upper half part of the left side of the main tunnel and timely constructing first-layer primary supports, temporary vertical braces and temporary inverted arches; excavating the lower half part and timely constructing first-layer primary supports and temporary vertical braces; constructing the upper half part of the right side of the main tunnel by the same process and excavating a middle arch part and timely constructing first-layer primary supports; constructing second-layer primary supports and removing the temporary braces and temporary inverted arches of the arch part; excavating a central part and timely constructing the primary supports of the inverted arches; removing the temporary supports of the left and right lower pilot tunnels, packing the secondary lining of the inverted arch, and filling the bottom of the tunnel; finally once packing the secondary lining of the arch wall by a model board trolley. According to the method, the safety risk for removing the temporary supports can be effectively reduced, the operation freedom degree is increased and the construction schedule is quickened.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

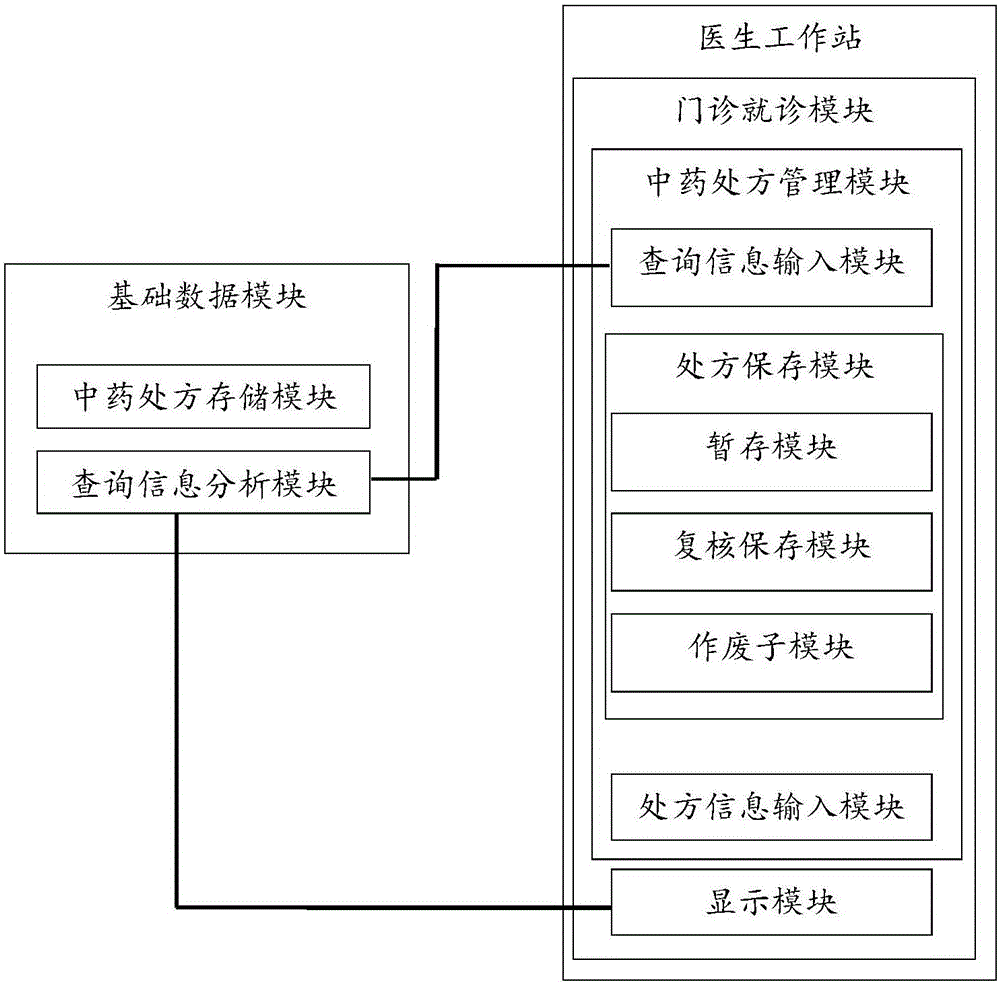

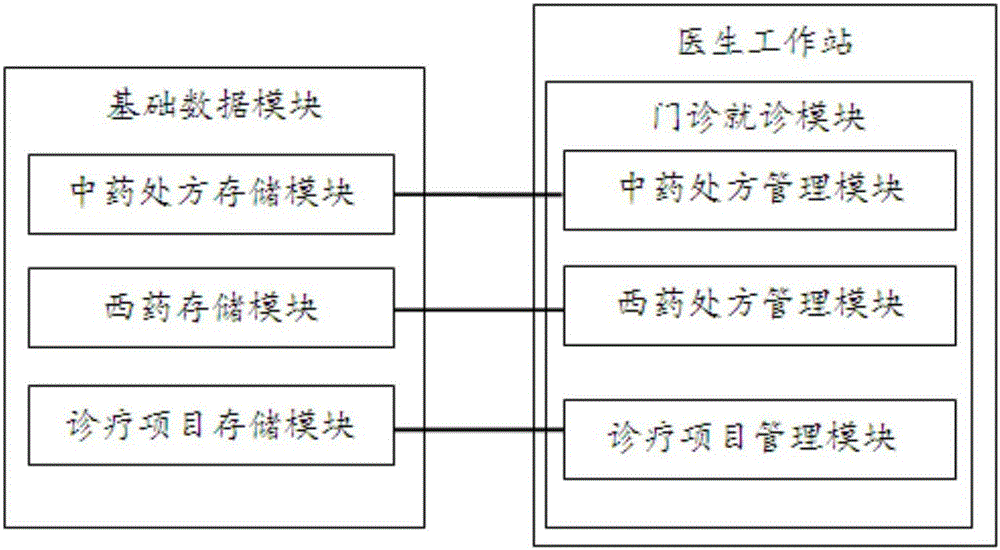

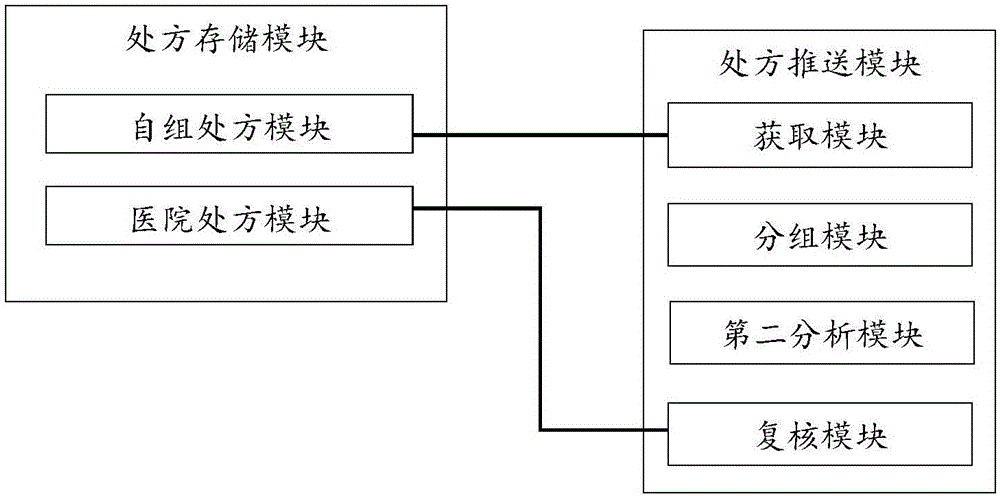

Prescription management application system

InactiveCN106096319AQuickly locate TCM diagnosisAccurate positioning of TCM diagnosisMedical data managementSpecial data processing applicationsPrescription dataMedical treatment

The invention provides a prescription management application system which comprises a basic data module and a doctor workstation, wherein the basic data module comprises a traditional Chinese medicine prescription storage module and a Western medicine storage module. In the prescription management application system provided by the invention, by efficiently combining the traditional Chinese medicine prescription storage module with the Western medicine storage module, a comprehensive and standard prescription data source is provided for doctors, and the grass-roots doctors can locate traditional Chinese medicine diagnosis and corresponding Western medicine diagnosis more quickly and accurately to find out corresponding prescription, thereby improving the diagnosis level and working efficiency; the promotion and implementation of the prescription management application system provided by the invention in hospitals can sufficiently realize networked, electronic and paperless office work of medical office work and facilitate effective connection of medical treatment flows among departments as well as the standardized management of hospitals.

Owner:智慧中医科技(广东)有限公司

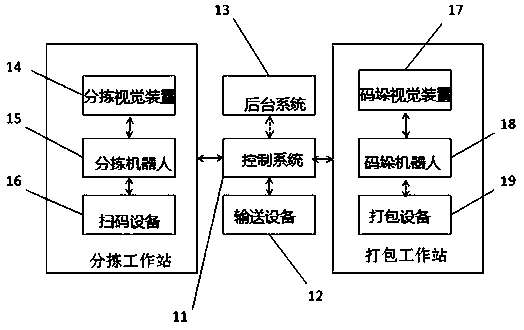

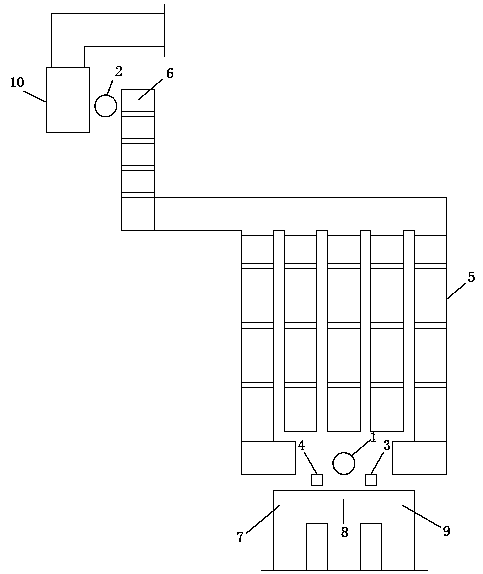

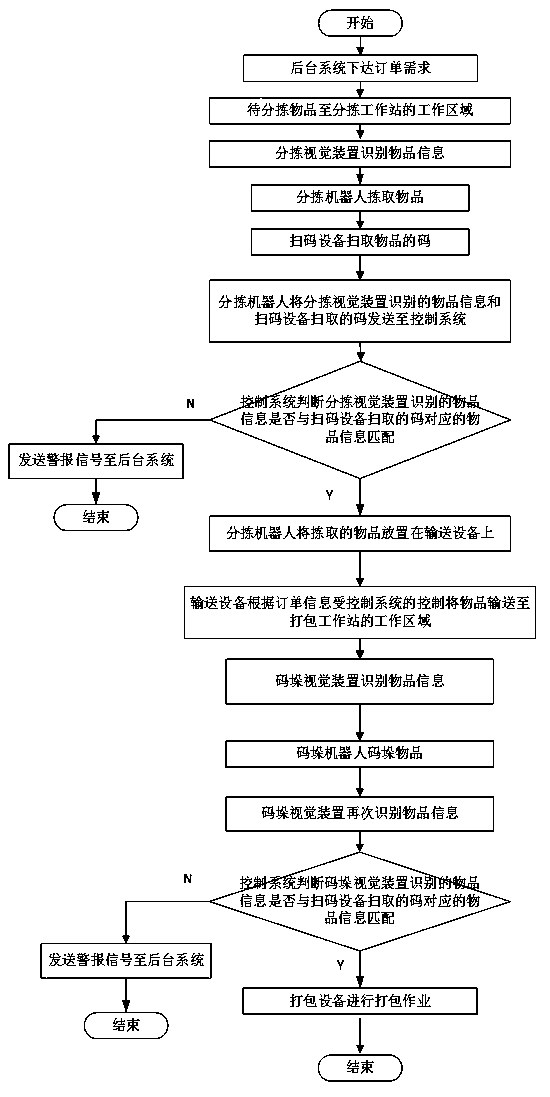

Intelligent sorting and packing system and sorting and packing method thereof

ActiveCN108722882AImprove work efficiencyReduce error rateCo-operative working arrangementsStacking articlesControl systemSimulation

The invention provides an intelligent sorting and packing system. The intelligent sorting and packing system comprises a sorting work station, a packing work station and a control system electricallyconnected with the sorting work station and the packing work station. The sorting work station comprises a sorting visual device, a sorting robot and a code scanning device. The sorting visual deviceand the code scanning device are both electrically connected with the sorting robot. The control system comprises a database module and a controller. The controller is arranged to judge whether objectinformation identified by the sorting visual device is matched with object information corresponding to the code scanned by the code scanning device or not, when the object information identified bythe sorting visual device is matched with the object information corresponding to the code scanned by the code scanning device, the controller sends a sorting signal to the sorting robot, and when theobject information identified by the sorting visual device is not matched with the object information corresponding to the code scanned by the code scanning device, the controller generates an alarmsignal to a background system. The packing work station is arranged to conduct stacking and packing operation. A sorting and packing method of the intelligent sorting and packing system achieve unmanned sorting and packing operation of objects, the operation efficiency is improved, and the error rate and the labor cost are lowered.

Owner:JIANGSU HUAZHANG LOGISTICS TECH CO LTD

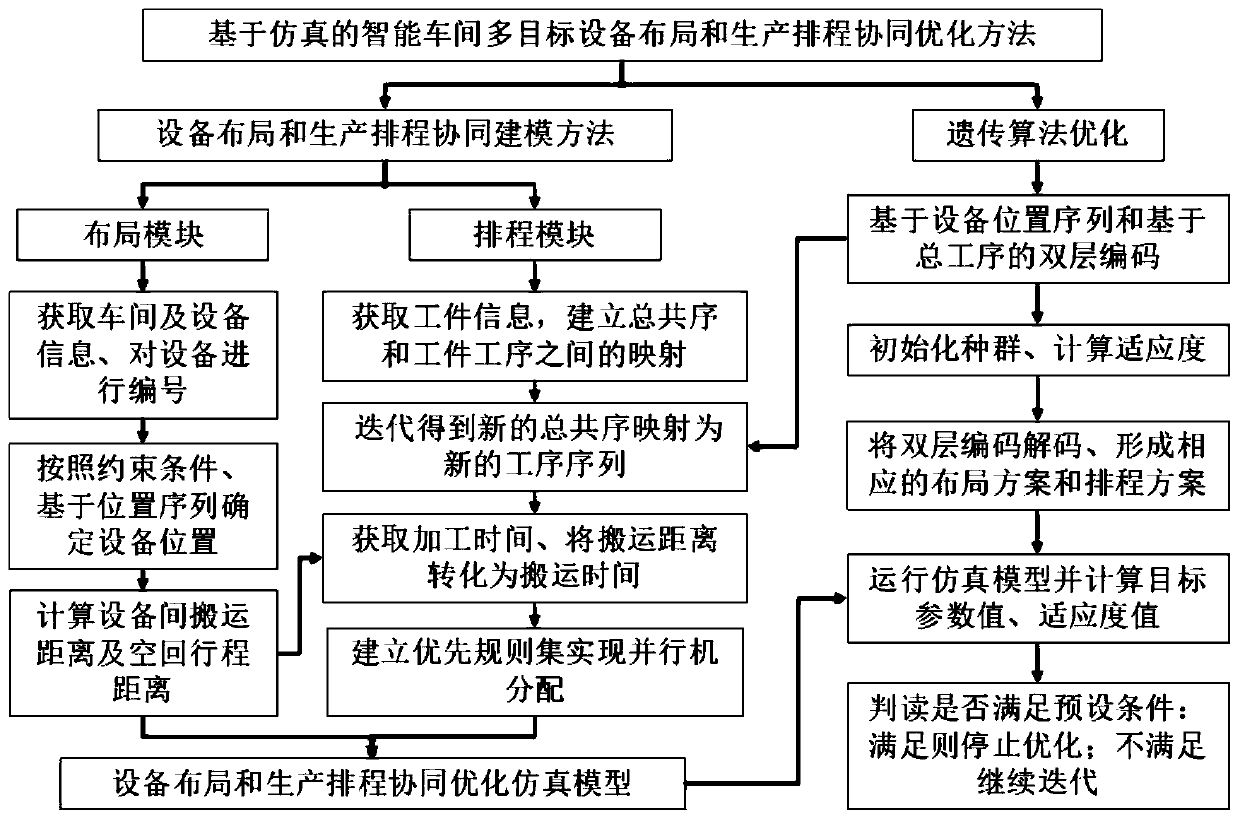

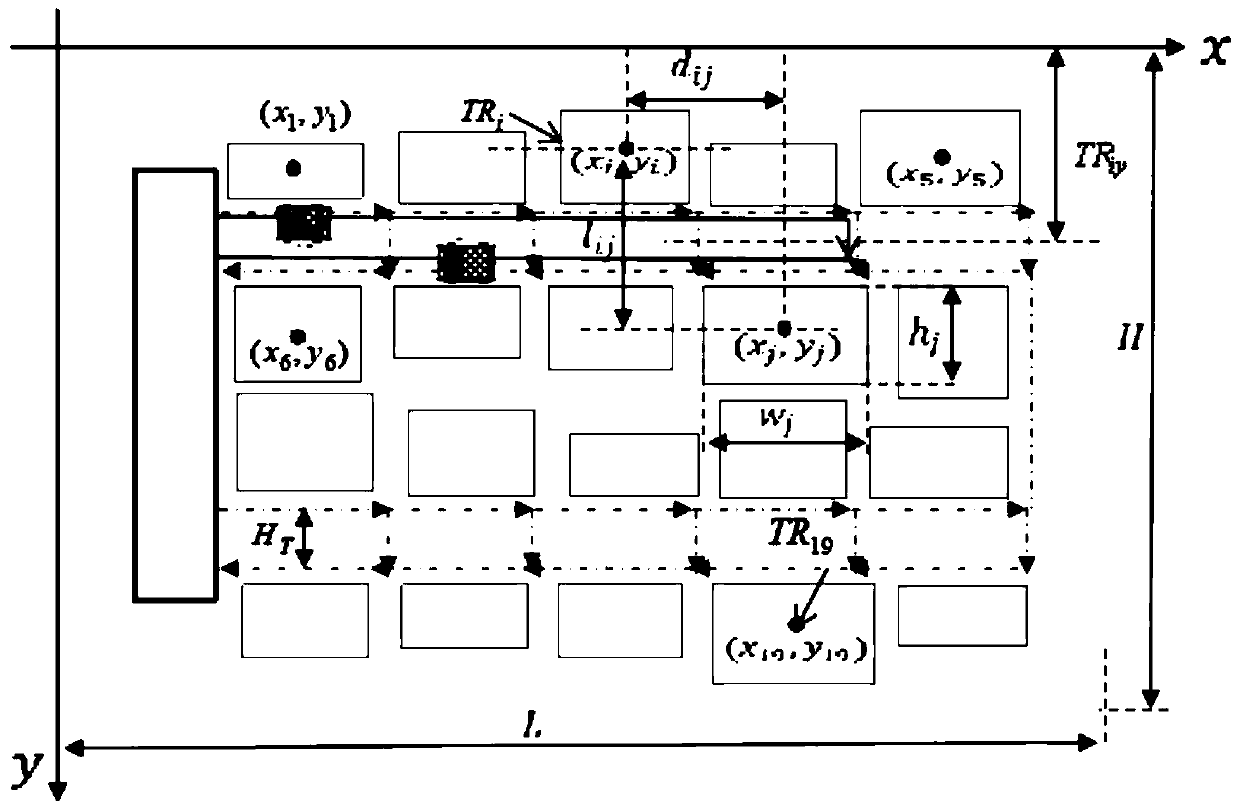

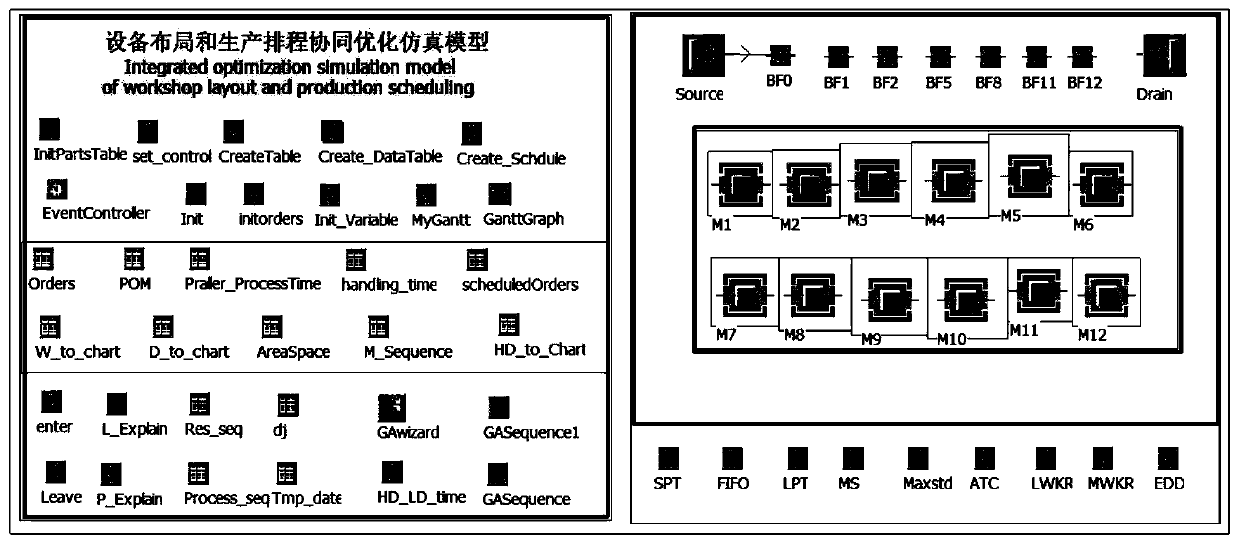

Multi-target equipment layout and production scheduling collaborative optimization method based on simulation

ActiveCN110069880AImprove practicalityIn line with the actual processing situationDesign optimisation/simulationResourcesProduction lineGenetic algorithm

The invention discloses a multi-target equipment layout and production scheduling collaborative optimization method based on simulation, which comprises the following steps: acquiring plant, equipmentand workpiece information, performing collaborative modeling on equipment layout and production scheduling, and constructing an intelligent workshop equipment layout and production scheduling collaborative optimization simulation model; operating the intelligent workshop equipment layout and production scheduling co-simulation model and calculating corresponding target parameter values; constructing a double-layer genetic algorithm based on an equipment position sequence and a total consensus sequence to optimize a simulation model of intelligent workshop equipment layout and production scheduling collaborative optimization, and when an optimization algorithm is a genetic algorithm, according to the performance value of a current target parameter, continuously iterating and finding the optimal equipment layout and scheduling scheme meeting the target parameter. By means of the simulation technology, the machining process of each workpiece in the production line is dynamically simulated, real-time calculation of relevant data is achieved, the equipment layout and production scheduling scheme of the production line can be provided for an enterprise when the enterprise builds a factory, and the production cost of the enterprise is reduced.

Owner:XI AN JIAOTONG UNIV

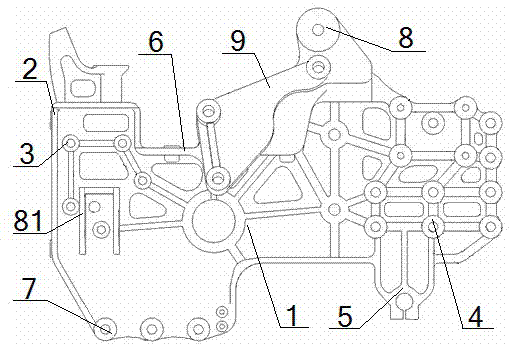

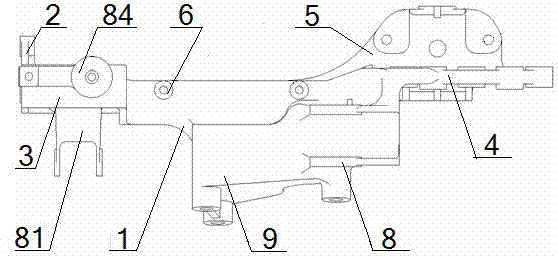

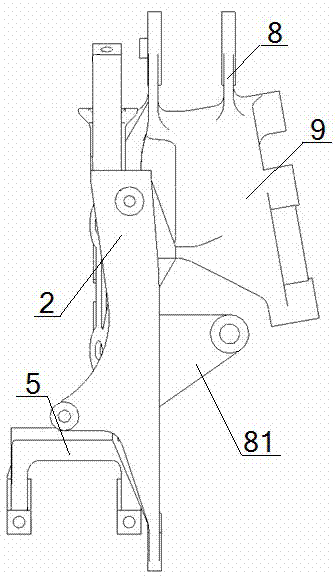

Integrated frame longitudinal beam connecting support

ActiveCN103921842AHigh mechanical strengthReduce in quantityUnderstructuresLoading-carrying vehicle superstructuresVehicle frameEngineering

An integrated frame longitudinal beam connecting support comprises a base and a bumper mounting portion, a beam assembly mounting portion, a frame fixing portion and a plate spring mounting portion which are arranged on the base. The back of the bumper mounting portion is fixedly connected to the front end of the frame fixing portion through the beam assembly mounting portion, the bottom of the frame fixing portion is fixedly connected to the plate spring mounting portion, a sunken water tank mounting portion and a cab front suspension turning arm mounting portion are arranged between the beam assembly mounting portion and the frame fixing portion, a front-lower protective supporting base fixing portion is fixedly connected to the lower portion of the beam assembly mounting portion, and a front suspension vibration absorber mounting support is fixedly connected to the side of the beam assembly mounting portion; the base is integrated with the bumper mounting portion, the beam assembly mounting portion, the frame fixing portion, the plate spring mounting portion, the sunken water tank mounting portion, the front-lower protective supporting base fixing portion, the cab front suspension turning arm mounting portion and the front suspension vibration absorber mounting support. The support is in high integrated level, is reasonable in structure and has high mechanical strengthen.

Owner:DONGFENG COMML VEHICLE CO LTD

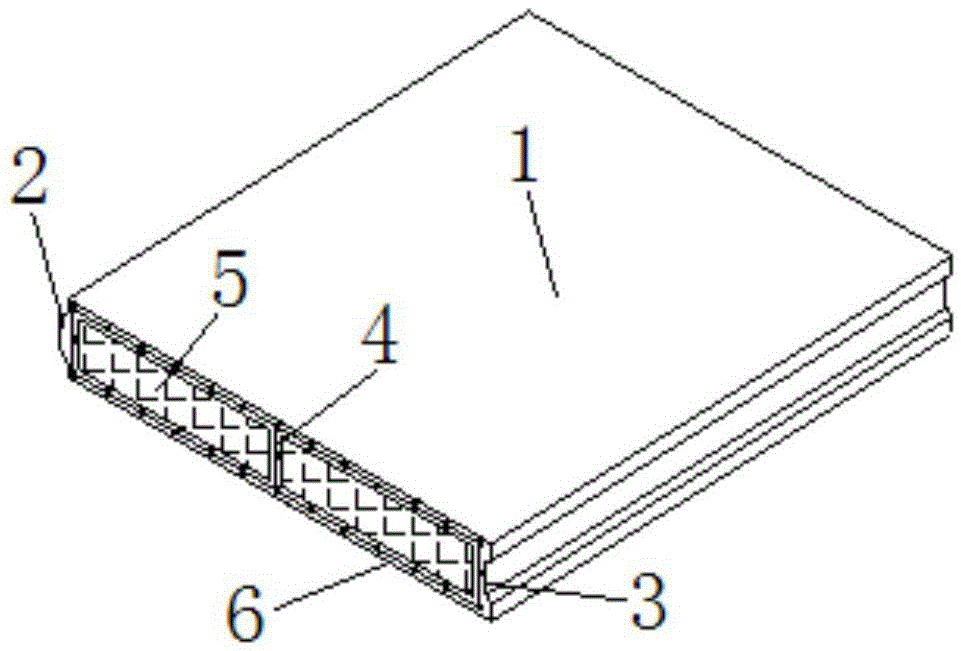

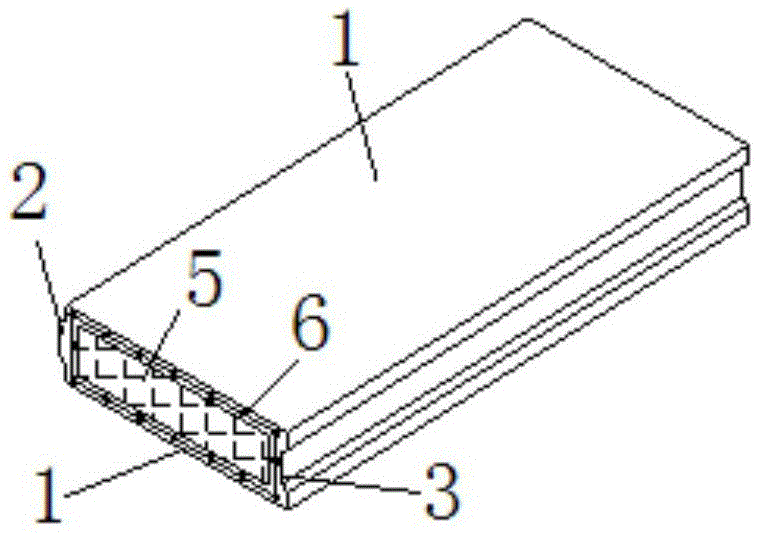

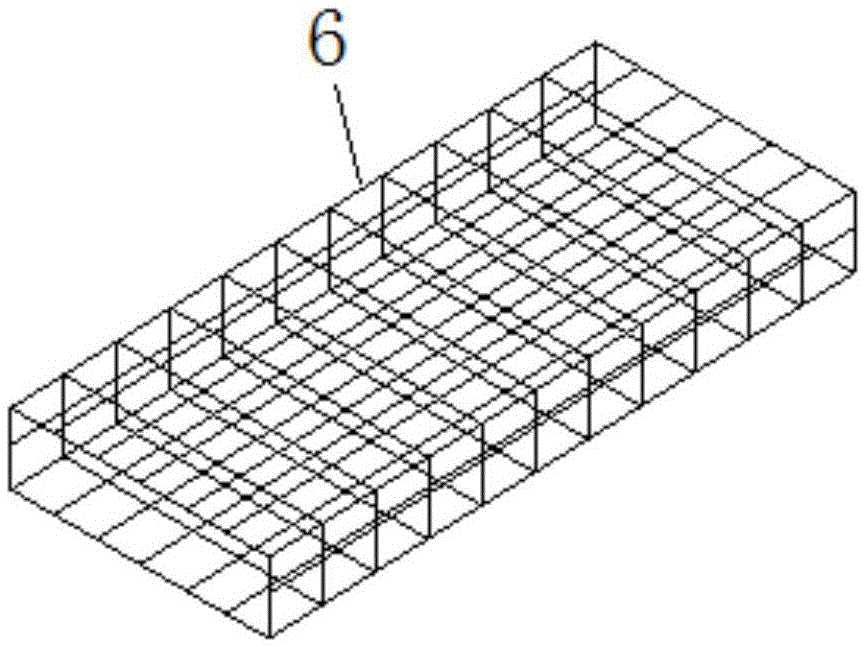

Composite heat-preserving wallboard

ActiveCN105421652AImprove carrying capacityImprove stabilityCeramic shaping apparatusBuilding componentsCrack resistanceEngineering

The invention discloses a composite heat-preserving wallboard which is composed of panels, rib plates, a core material and reinforcing materials. The panels comprise an upper panel and a lower panel. The rib plates comprise an outside rib plate A and an outside rib plate B. The panels and the rib plates form a cross section in a closed geometry form. The core material is placed into the cross section. The reinforcing materials are placed in the panels and the rib plates. The panels and the rib plates are made of concrete. A heat preserving core material is adopted as the core material. Meshed prestress long-fiber reinforcing grids are adopted as the reinforcing materials and compounded with the panels and the rib plates made of the concrete. According to the composite heat-preserving wallboard, as the meshed prestress long-fiber reinforcing grids are compounded, on the premise of hardly increasing the mass additionally, the panels and the rib plates are reinforced, it is ensured that the rib plates are effectively connected with the panels at the two sides, the fracture surface in the closed geometry form is formed, and crack resistance and ultimate bearing capacity of the composite heat-preserving wallboard are greatly improved.

Owner:NANTONG SUDONG NEW EXTERNAL WALL INSULATION BOARDCO

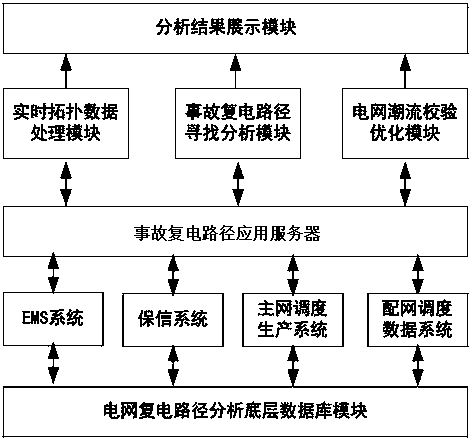

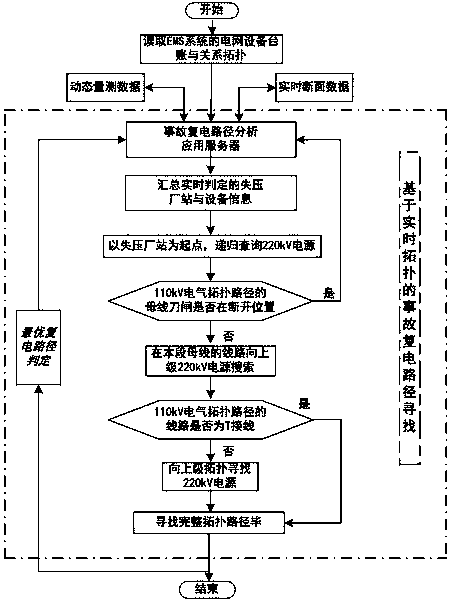

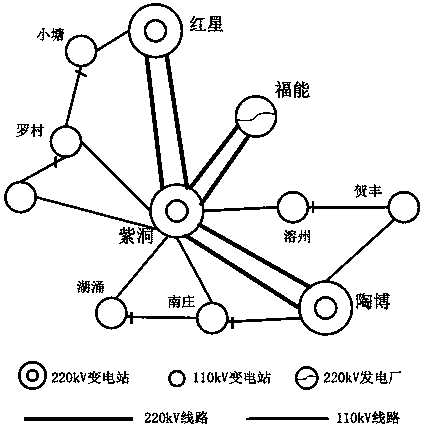

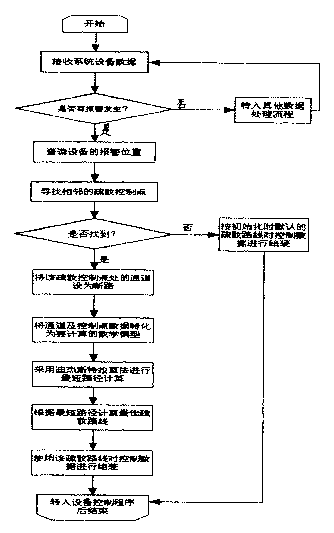

System and method for power restoration path in power grid accidents

The invention relates to a system and a method for power restoration path in power grid accidents. The system comprises a power grid power restoration path analysis bottom layer database module, an EMS system, a credit preservation system, a main network dispatching production system, a distribution network dispatching data system, an accident power restoration path application server, a real-timetopological data processing module, an accident power restoration path finding and analyzing module, a power grid power flow verification optimization module and an analysis result display module, wherein the EMS system, the credit preservation system, the main network dispatching production system and the distribution network dispatching data system are respectively connected with the power gridpower restoration path analysis bottom layer database module and also connected with the accident power restoration path application server, and the real-time topological data processing module, theaccident power restoration path finding and analyzing module and the power grid power flow verification optimization module are respectively connected with the power grid power restoration path analysis bottom layer database module and the analysis result display module. According to the invention, the overall situation of the power grid accident and the accident occurrence can be comprehensivelymonitored, and a control strategy for power restoration and switching supply can be automatically generated.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID

Film-coating method for glass fiber yarn cluster

ActiveCN106586060ATransport impactImprove coating efficiencyWrapper folding/bending apparatusWrapping with article rotationGlass fiberYarn

The invention discloses a film-coating method for a glass fiber yarn cluster, and belongs to the technical field of glass fiber production equipment. The invention aims to provide the film-coating method for the glass fiber yarn cluster, and the coating method is relatively good in coating effect and is high in film-coating efficiency. The film-coating method comprises the following steps: step I: conveying yarn clusters; step II: grabbing the yarn clusters; step III: pressing the yarn clusters; step IV: coating a film, wherein a coating film is pushed to a specific position through a film feeding device, a gas blowing tube of a film cutting mechanism of the film feeding device works to blow the coating film; and the coating is adhered on the yarn cluster in a sticky mode, and the coating film is pressed onto the yarn cluster through a film-pressing thin sheet of the film pressing device; a clamping rotating device drives the yarn cluster to rotate, the coating film is continuously guided out and is coated on the cluster yarn; and the film is cut off through a blade of a film cutting mechanism; step V: pushing a film, wherein the film pressing device moves upwards and the film pressing device works to level the coating film exceeding the upper end surface of the yarn cluster to the upper end surface of the yarn cluster; and step VI: outputting finished products. The film-coating method is a film-coating method suitable for coating a layer of film outside the glass fiber yarn cluster.

Owner:福德机器人(成都)有限责任公司

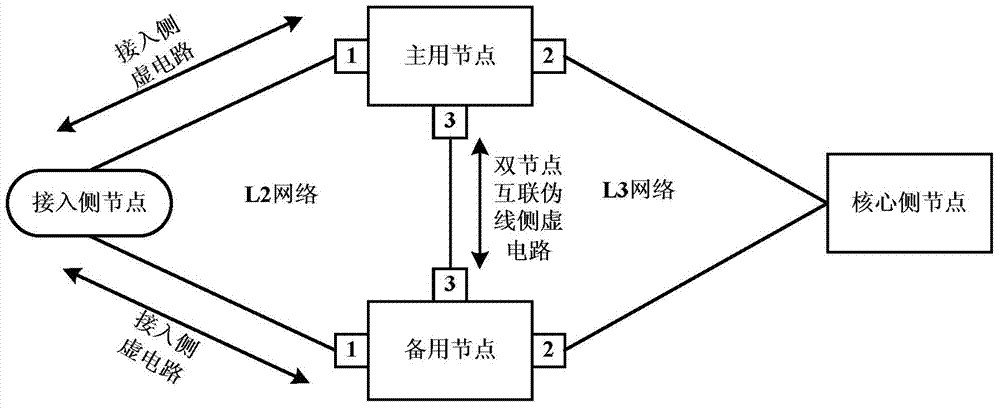

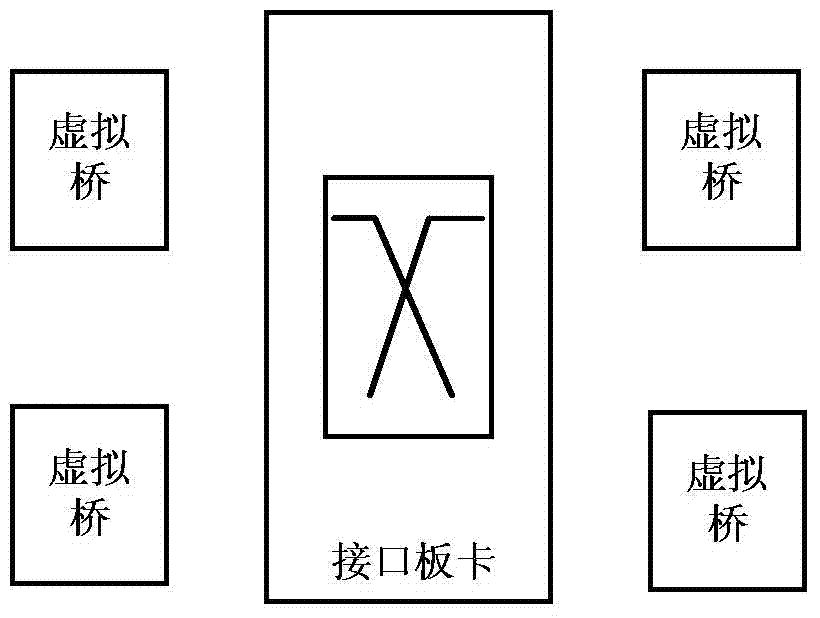

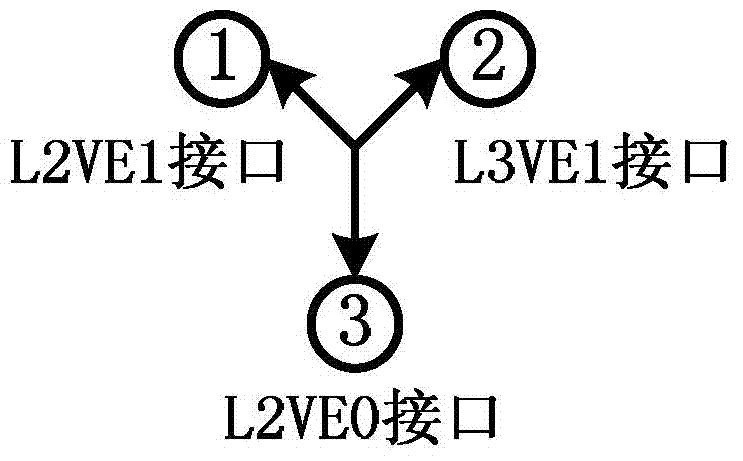

System and method for realizing double-node interconnected pseudo-wire

ActiveCN104270231AImprove stabilityImprove reliabilityError preventionNetworks interconnectionPseudo-wireComputer science

The invention discloses a system and a method for realizing a double-node interconnected pseudo-wire, and relates to the technical field of application of wireless backhaul networks. The system comprises two bridge nodes, at least one access side node and at least one core side node, wherein the two bridge nodes are connected with each access side node and each core side node respectively; the two bridge nodes are taken as a master node and a standby node; both the master node and the standby node are provided with access side interfaces, double-node interconnected pseudo-wire side interfaces and core side interfaces; any two interfaces on the same bridge node are communicated with each other; a double-node interconnected pseudo-wire side virtual circuit is arranged between the master node and the standby node; access side virtual circuits are arranged between the access side node and the master node as well as between the access side node and the standby node respectively; the double-node interconnected pseudo-wire side virtual circuit and the access side virtual circuits are bound in one double-node interconnected pseudo-wire group; and automatic protection changeover signaling channels are overlapped on the double-node interconnected pseudo-wire side virtual circuit and the access side virtual circuits respectively.

Owner:FENGHUO COMM SCI & TECH CO LTD

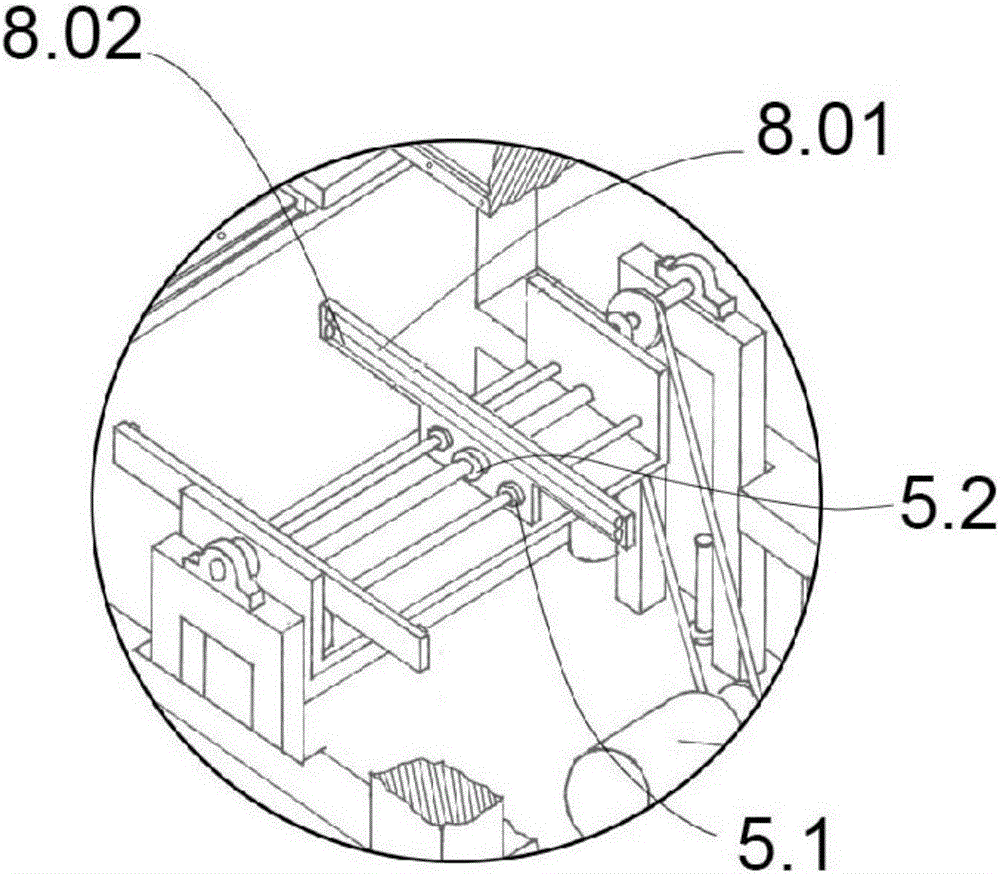

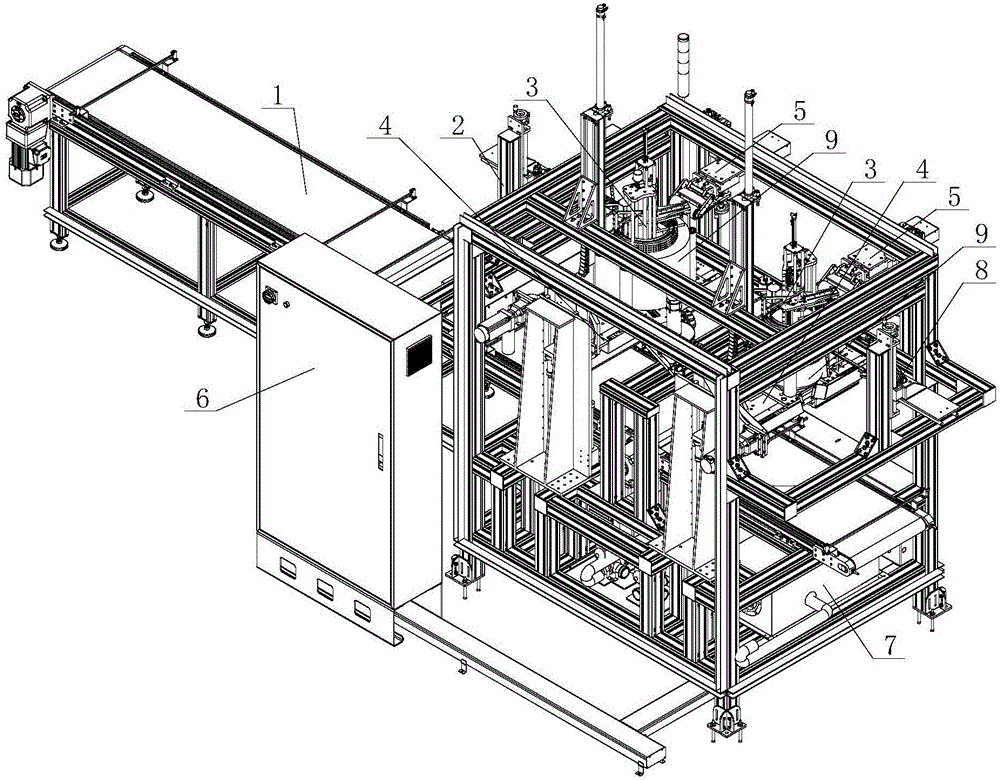

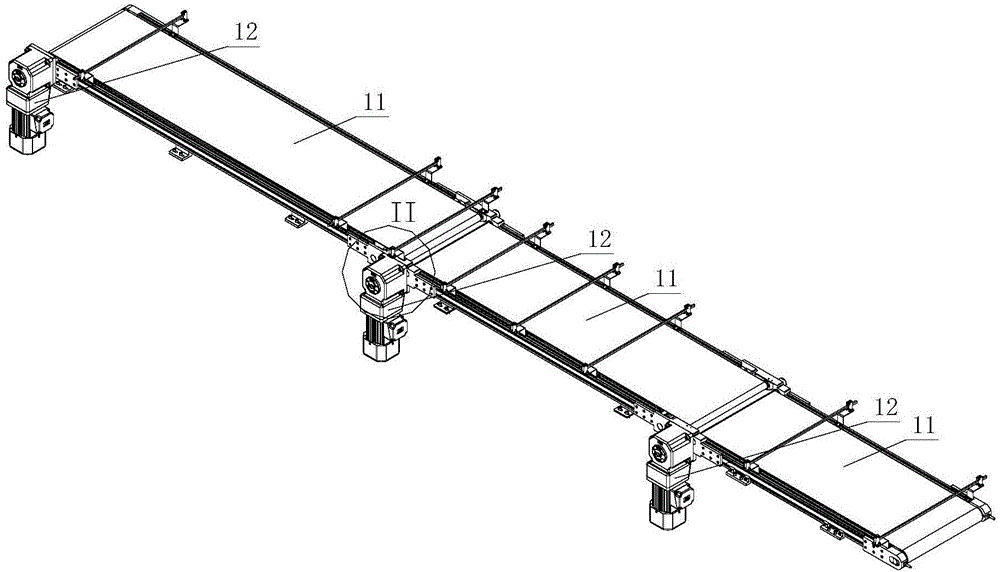

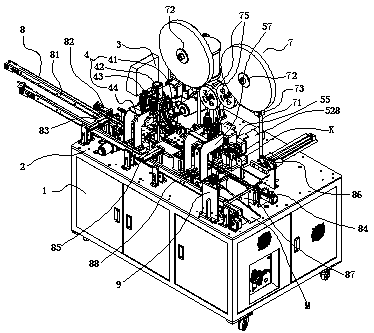

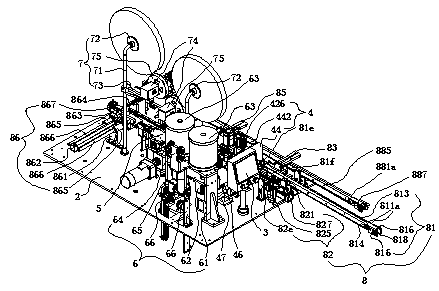

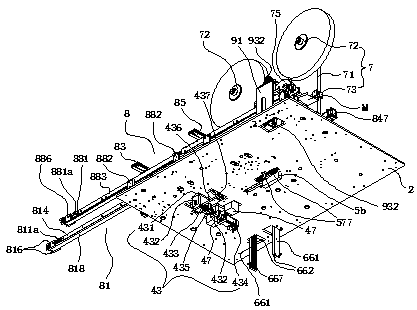

Fully-automatic relay terminal welding wire machine

PendingCN110289194AFully automatedGuaranteed accuracyLine/current collector detailsWelding/cutting auxillary devicesEngineeringFully automatic

The invention discloses a fully-automatic relay terminal welding wire machine, which comprises a frame, a workbench arranged on the frame and a control box arranged on the workbench, wherein the workbench is sequentially provided with a cutting and stripping wire feeding and welding device and a cutting and feeding material comb wire welding device; the wire feeding end of the cutting and stripping wire feeding and welding device is provided with a setting-out unit; the terminal feeding direction of the cutting and feeding material comb wire welding device is provided with a terminal placing unit; the cutting and stripping wire feeding and welding device and the cutting and feeding material comb wire welding device are connected through a conveying and recycling device; and one side of the conveying and recycling device is also provided with a blanking unit. Automation of the welding work of the relay is realized, the wire and the terminal welding position are accurately positioned, the processing precision of each station is improved, the consumed time between the stations is greatly reduced, the stations are effectively connected, the product welding quality is ensured, the yield of the product is improved, time and labor are saved, the production efficiency is greatly improved, and the automatic degree is high.

Owner:东莞市蓝斯自动化设备有限公司

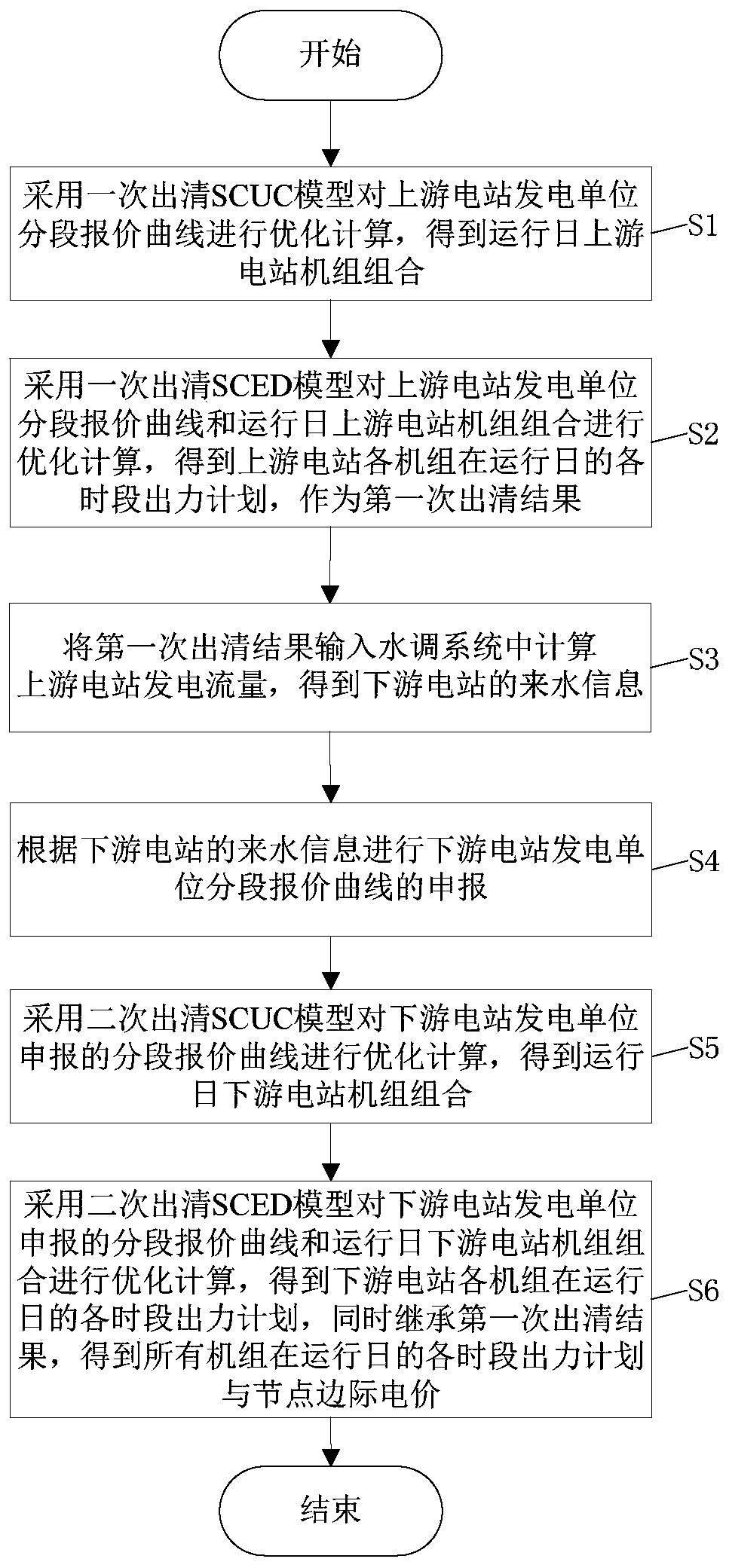

Basin cascade upstream and downstream power station participation electric power spot market secondary clearing method

ActiveCN110555590AFull participationEnsure market transaction balanceMarket predictionsResourcesElectricityPower station

The invention discloses a basin cascade upstream and downstream power station participation electric power spot market secondary clearing method. Compared with the prior art, the agent mechanism and the water and electricity benefit compensation mechanism are provided; the secondary clearing mode can ensure that the cascade hydropower upstream and downstream power stations have sufficient participation degree in the spot market as power generators, the bid winning amount and the actual distribution amount of the downstream power stations are kept consistent without joint bidding, and market transaction balance is ensured.

Owner:YUNNAN POWER GRID

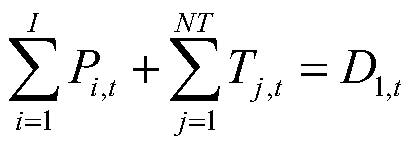

Method for making brocade single-pattern garment imitating plain embroidery

ActiveCN103938371AEffective connectionSolve the problem of not connectingProgramme-controlled sewing machinesWork-feeding meansEngineeringDesign pattern

The invention discloses a method for making a brocade single-pattern garment imitating plain embroidery. According to the style and the type of a designed finished garment, designed patterns are accurately located on the positions of the garment, so that a special pattern of a set type is formed, type setting is conducted on the pattern of the set type on a corresponding single-pattern brocade fabric designing system, a final pattern formed on the surface of the fabric serves as a dermatoglyphic pattern of the fabric after type setting is conducted, the fabric is woven according to the breadth and the dermatoglyphic pattern of the fabric after type setting is conducted, and after the fabric is taken out of a device, the fabric is cut and sewn. The method comprises the following steps that firstly, the style, the pattern and the type of the single-pattern garment are designed; secondly, the specification, the texture and a pattern card of the brocade single-pattern garment imitating the plain embroidery are designed and made; thirdly, a weaving machine is prepared; fourthly, the fabric is woven by the weaving machine; fifthly, the fabric is cut and sewn. The method solves the problem that patterns of a traditional embroidery garment cannot be well spliced.

Owner:李加林

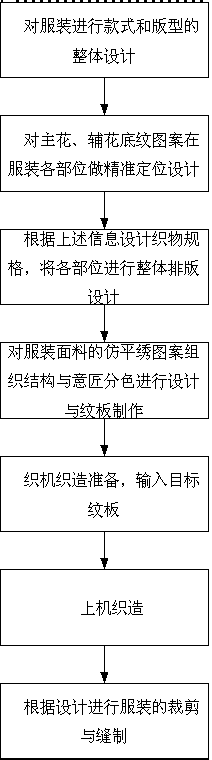

Intelligent emergency evacuation control system and implementing method thereof

InactiveCN103035097AKnow in timeEffective controlBuilding rescueFire alarm smoke/gas actuationSmoke detectorsControl signal

The invention discloses an intelligent emergency evacuation control system and an implementing method of the intelligent emergency evacuation control system. The system comprises a photoelectric indication board with a direction indicating function, a remote control warning and receiving device, a fire source smoke detector, an alarm broadcasting device, a control center and a control cabinet, wherein the fire source smoke detector is used for detecting fire alarm signals and transmitting the fire alarm signals to the control cabinet. The fire alarm signals are processed by the control cabinet and are transformed into warning signals transmitted to the control center. The control center receives fire alarm confirmation signals through the remote control warning and receiving device, confirms the warning position, and calculates the best evacuation route. The control center sends control signals to the photoelectric indication board to indicate the evacuation direction. According to the intelligent emergency evacuation control system and the implementing method of the intelligent emergency evacuation control system, an existing fire alarm monitoring device is fully utilized, the intelligent emergency evacuation control system and the implementing method of the intelligent emergency evacuation control system are high in degree of automation, have a fire alarm prompting function with the integration of sound, light and electricity, and have various alarm notifying modes, so that fire caused by carelessness of operators on duty is effectively prevented, and manual warning and automatic prewarning are realized.

Owner:上海日浦信息技术有限公司

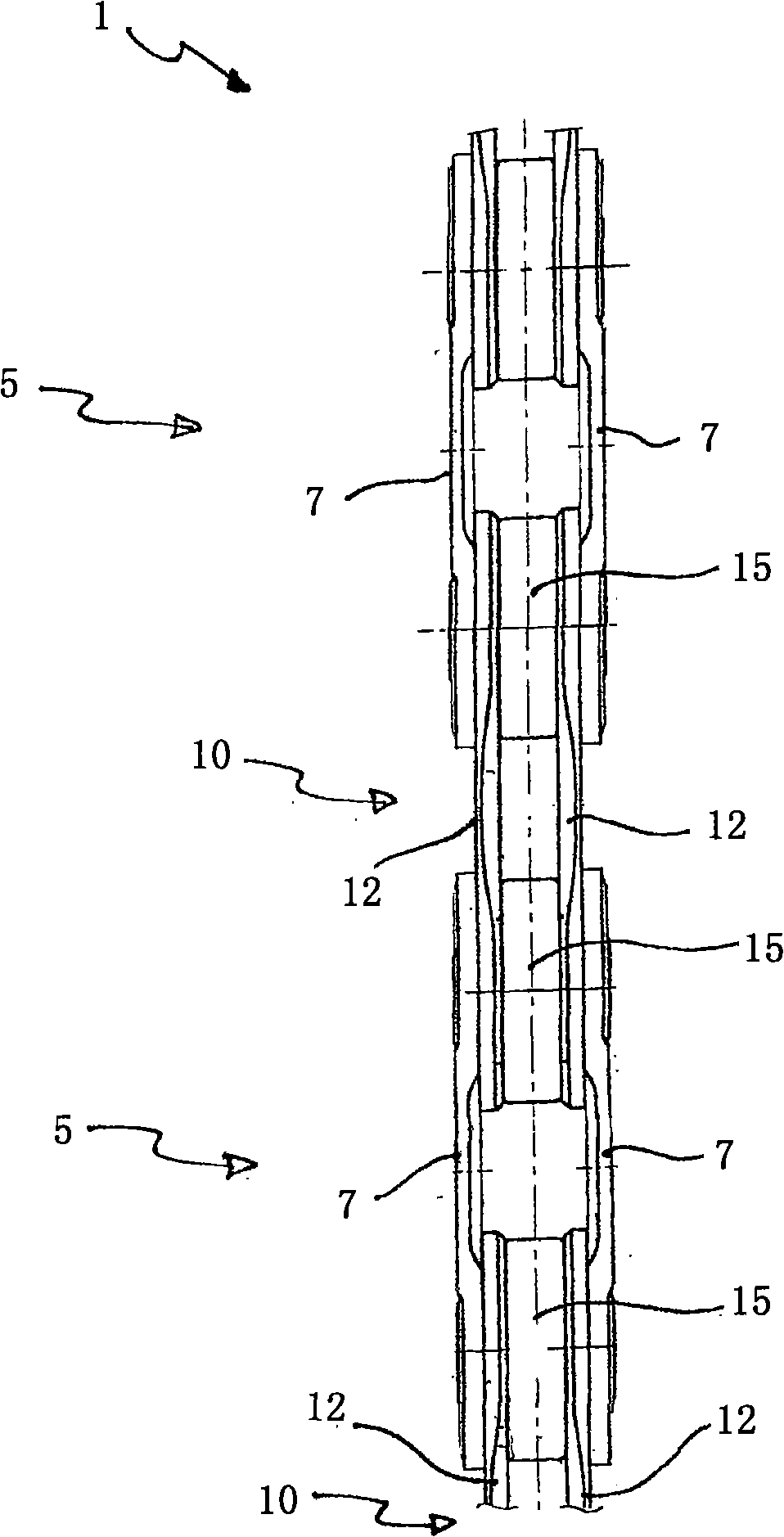

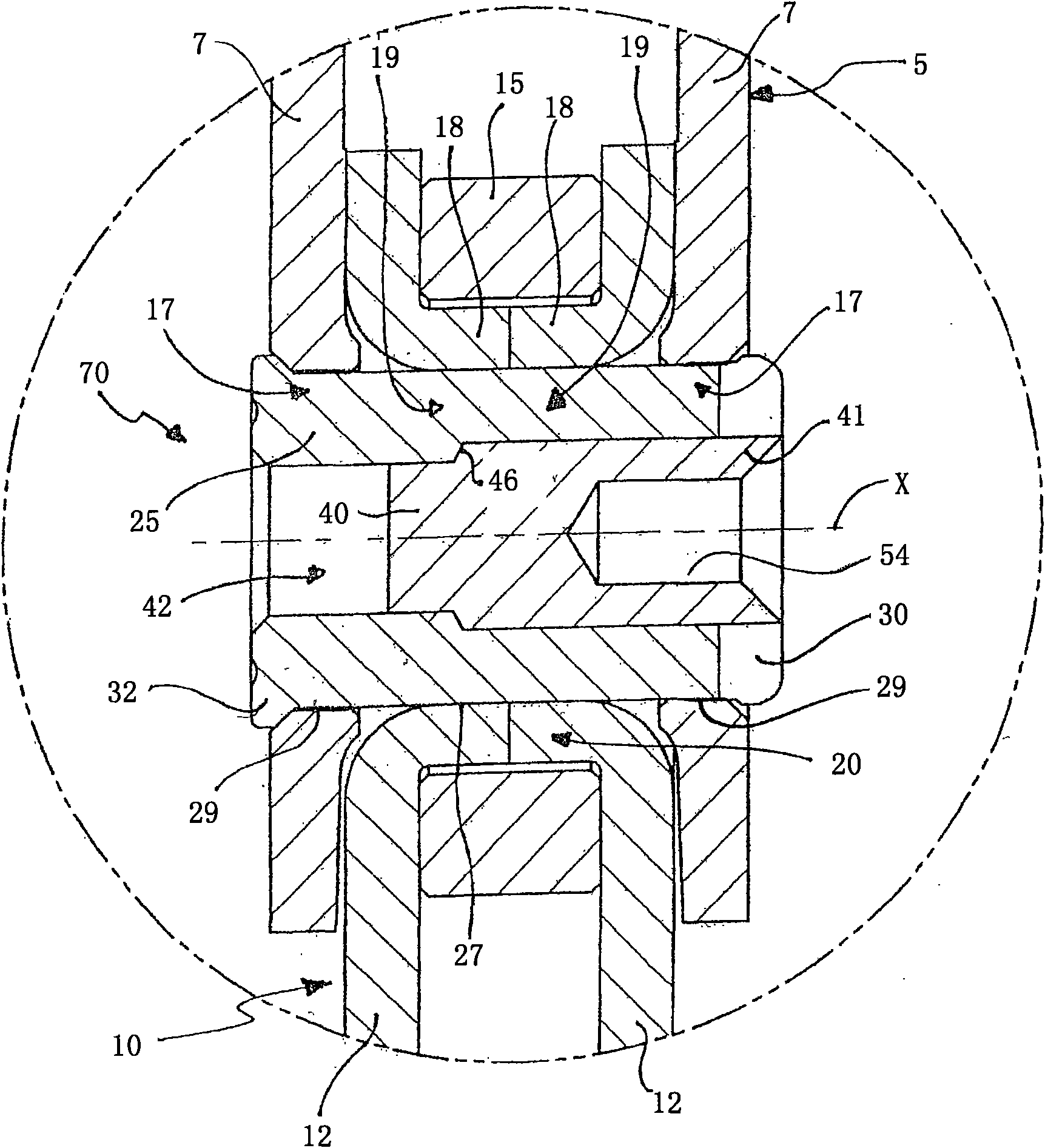

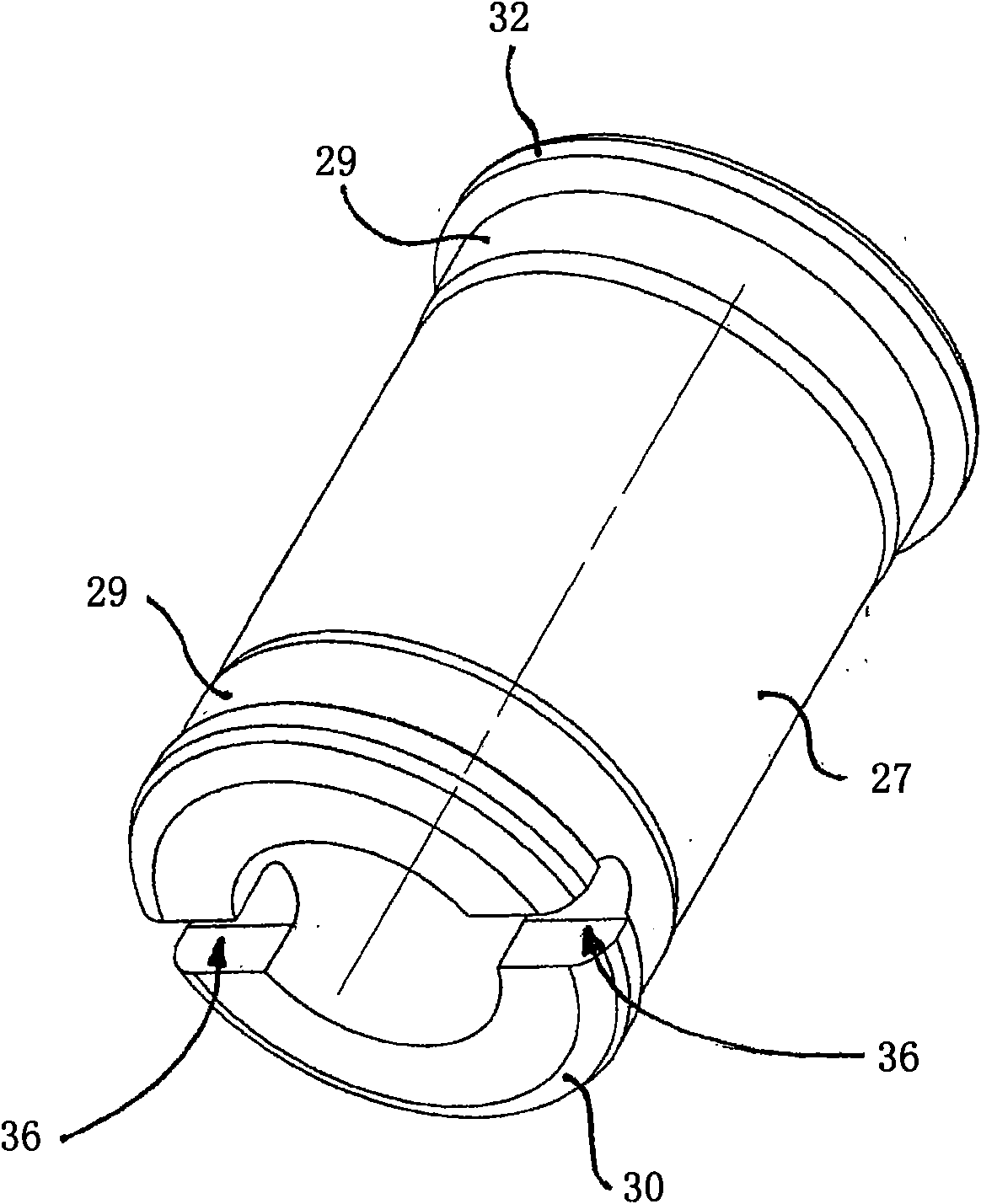

Articulating pin for bicycle chains and relative chain

ActiveCN101561027AMinimize the risk of damageEffective connectionDriving chainsMetal chainsClassical mechanicsEngineering

The invention relates to an articulating pin for bicycle chains and relative chain. Concretely, the articulating pin for bicycle chains, of the type capable to be inserted in aligned holes of an outerlink and of the corresponding inner link of the chain, to hinge the links to one another, has a central portion and a distal portion. The distal portion is elastically deformable for the insertion th rough the holes. The invention also discloses a lock button for bicycle chains, which is characterized in that the lock button can deform plasticly to prevent the wall of the pin from deforming or moving along the related lognitudinal axes. The invention also discloses a lock assembly for chains including the said articulating pin and the corresponding lock button, a bicycle drive chain including the said assembly and tools for assembling the bicycle chain.

Owner:CAMPAGNOLO SRL

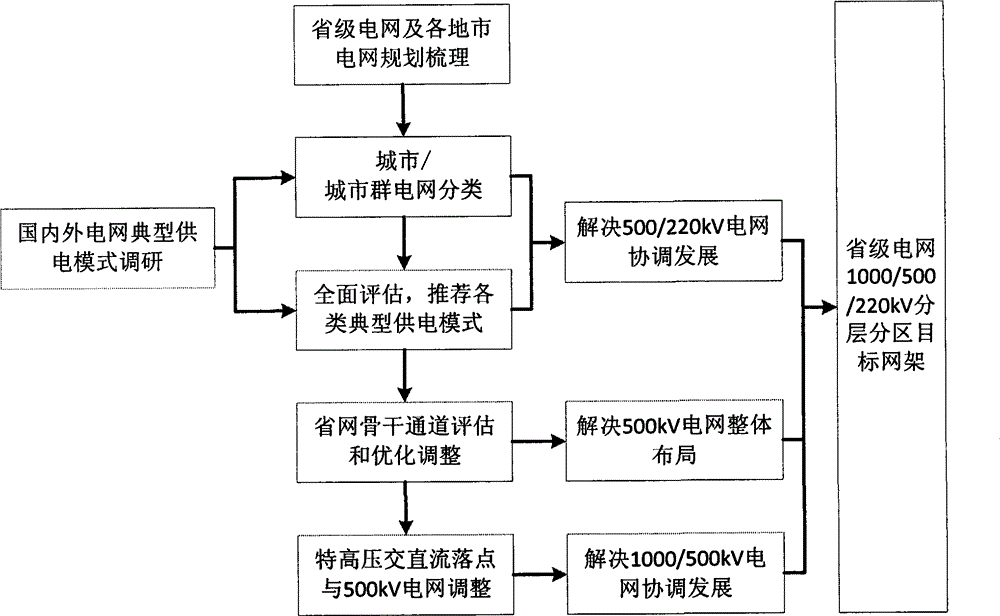

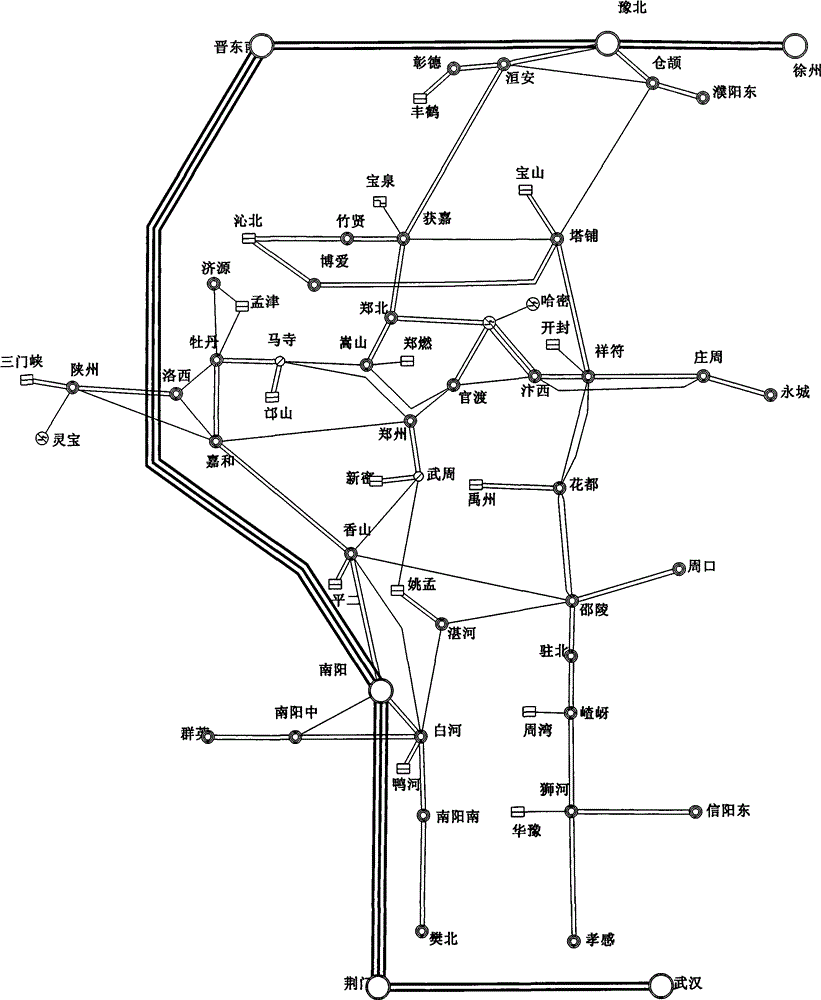

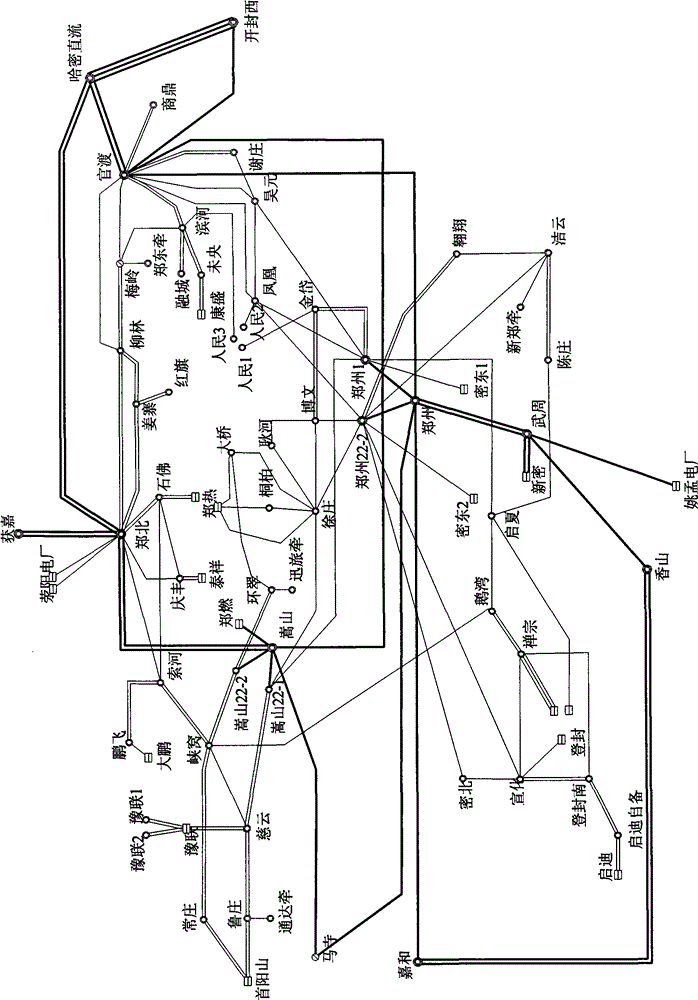

Provincial level power grid layering and partitioning typical power supply mode planning method

ActiveCN105096019ARealize Hierarchical PlanningImproving the flexible transshipment capacity of the tideResourcesThree levelElectricity

The invention provides a provincial level power grid laying and partitioning grid structure planning method, and includes the steps of: calculating power supply demand evaluation indexes of a power grid of each city or a city group, and performing city power grid development goal classification; evaluating a typical power supply mode of each city or the city group; evaluating adaptation of transmission channels among the cities or the city group; evaluating a capacity requirement of a provincial level power grid for external electricity, and judging whether to adopt other power supply mode according to the capacity requirement; and combing an analysis result, and forming a provincial level power grid layering and partitioning grid structure planning recommendation scheme. The method can realize effective layering planning of a city / city group power supply network, a 500kV provincial network backbone power grid and an ultrahigh-voltage direct current drop-point power grid, and can also realize comprehensive coordinated planning of 1000 / 500 / 220kV three-level power grids, thereby realizing comprehensive optimization of a layering objective and an overall objective.

Owner:STATE GRID CORP OF CHINA +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com