Thickened frame type ballastless track plate

A ballastless track and frame-type technology, which is applied in the direction of track, road, ballast layer, etc., can solve the problems of track slab and mortar layer separation, small effective prestress, track slab cracking, etc., and achieve enhanced lateral stability The effect of reducing tensile and compressive stress and reducing warping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

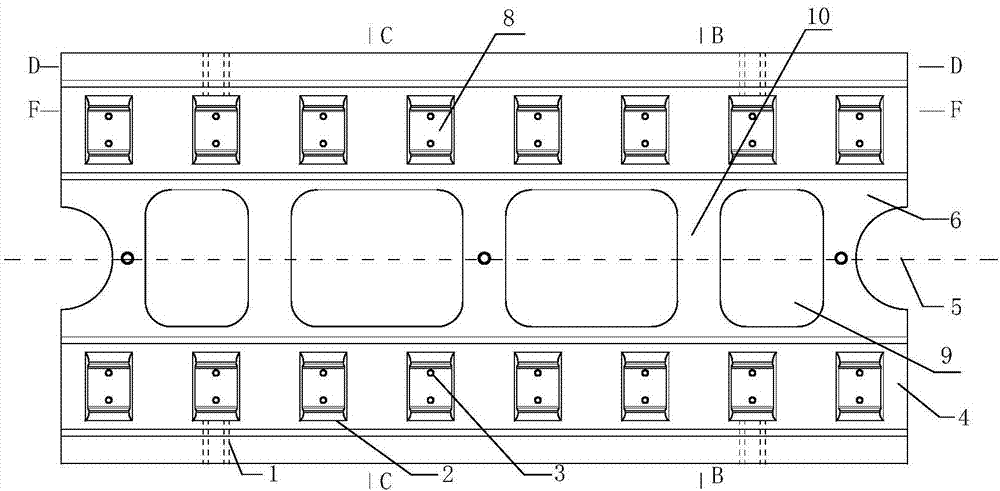

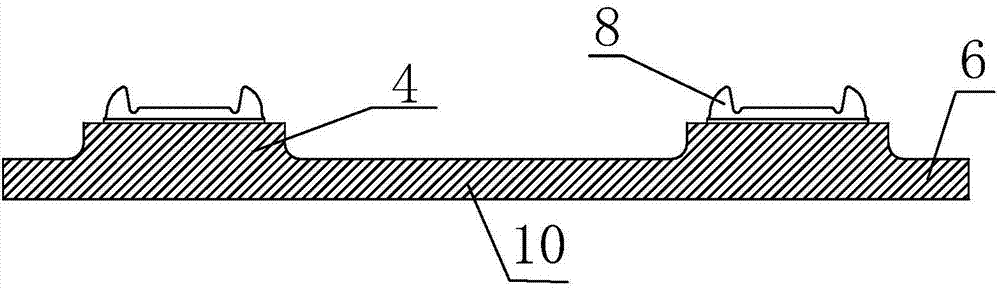

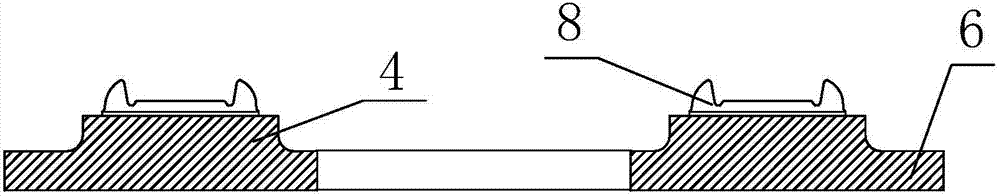

[0048] See attached figure 1 , 2 , 3, 4, 5, a thickened frame type ballastless track slab of the present invention, the track slab includes a base plate 6, a boss 4, and a rail support platform 8, the base plate 6 is a cuboid, and one of the base plates 6 On the surface, a pair of bosses 4 are arranged symmetrically along the axis 5 in the length direction of the cuboid, and rail bearing platforms 8 are evenly distributed along the length direction of the upper surface of the bosses 4; the bottom plate 6 is provided with a through hole 9, and the through hole 9 is located between a pair of bosses 4 symmetrically arranged on the bottom plate 6, forming a frame structure connected by a transversely reinforced concrete 10 between the pair of bosses 4; the shape of the through hole 9 provided on the bottom plate 6 is rectangular The ratio of the height of the base plate 6 to the height of the boss 4 is 10:9; the sum of the height of the base plate, the boss, and the rail platform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com