Method for constructing extra-large variable cross section tunnel

A technology of tunnel construction and variable cross-section, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve problems such as uneconomical construction operations, unguaranteed construction schedules, and limited distance between one-time dismantling and support, and achieve good coordination and stability. efficiency, orderly and flexible process conversion, and good construction flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing of description and specific embodiment:

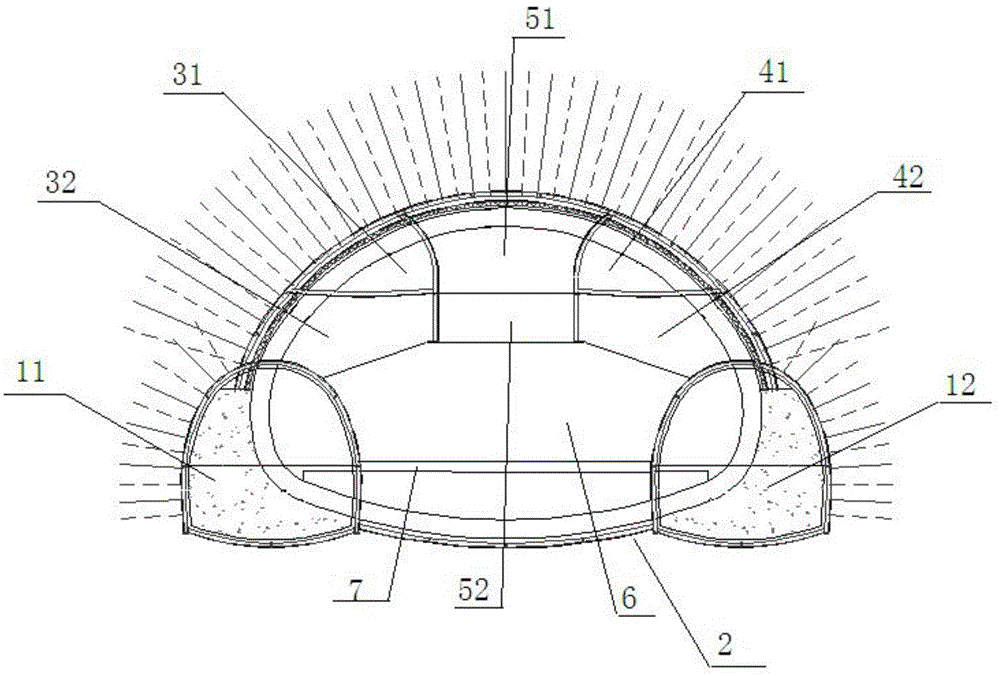

[0042] The invention provides a construction method for super-large variable-section tunnels, comprising the following steps:

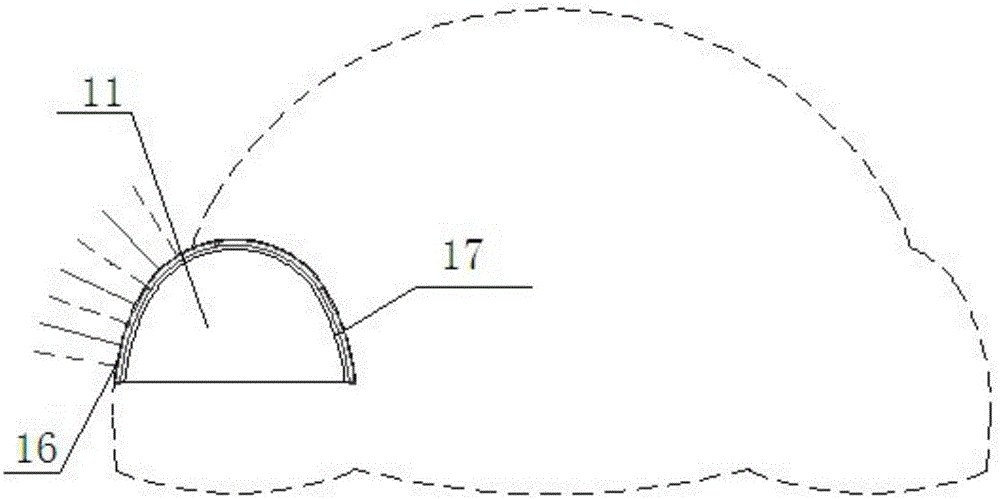

[0043] A. Use the upper and lower step method to excavate the upper half of the left pilot tunnel 11, such as figure 2 As shown, the corresponding initial support of the pilot tunnel arch wall composed of mortar anchor, I-shaped steel frame and shotcrete, and the temporary support of the pilot tunnel composed of I-shaped steel frame and shotcrete 17 were implemented in time. ;

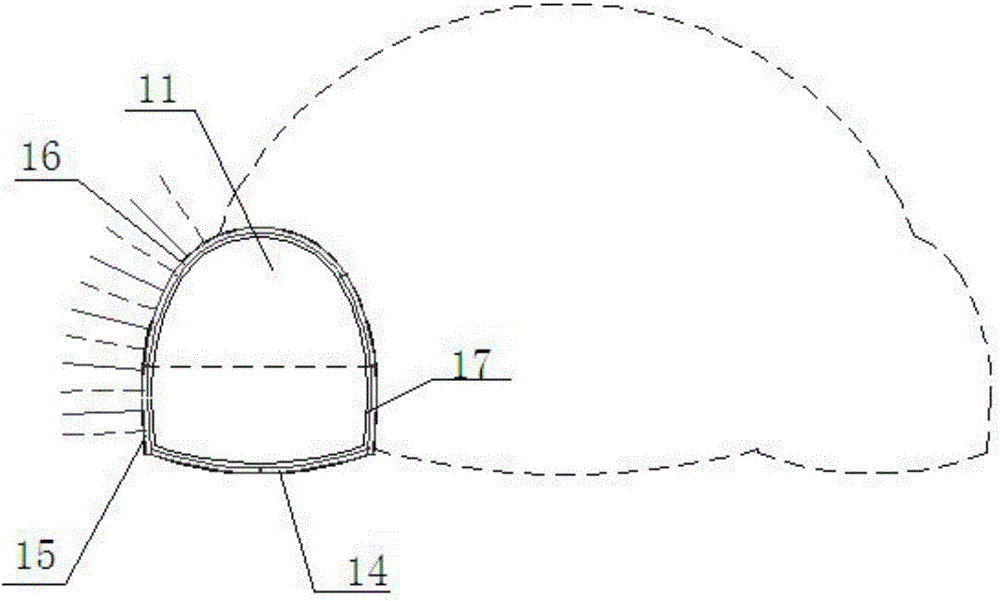

[0044] B. Use the upper and lower step method to excavate the lower half of the left pilot tunnel 11, such as image 3 As shown, the corresponding pilot tunnel extension initial support 15, pilot tunnel inverted arch initial support 14 and pilot tunnel temporary support 17 are implemented in time to make the pilot tunnel arch wall i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com