Patents

Literature

124results about How to "Transport impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

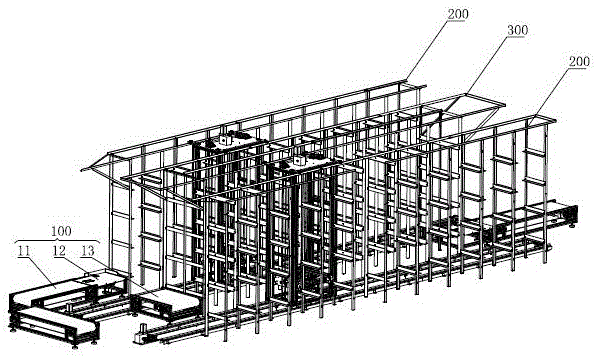

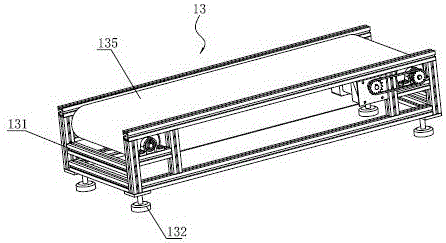

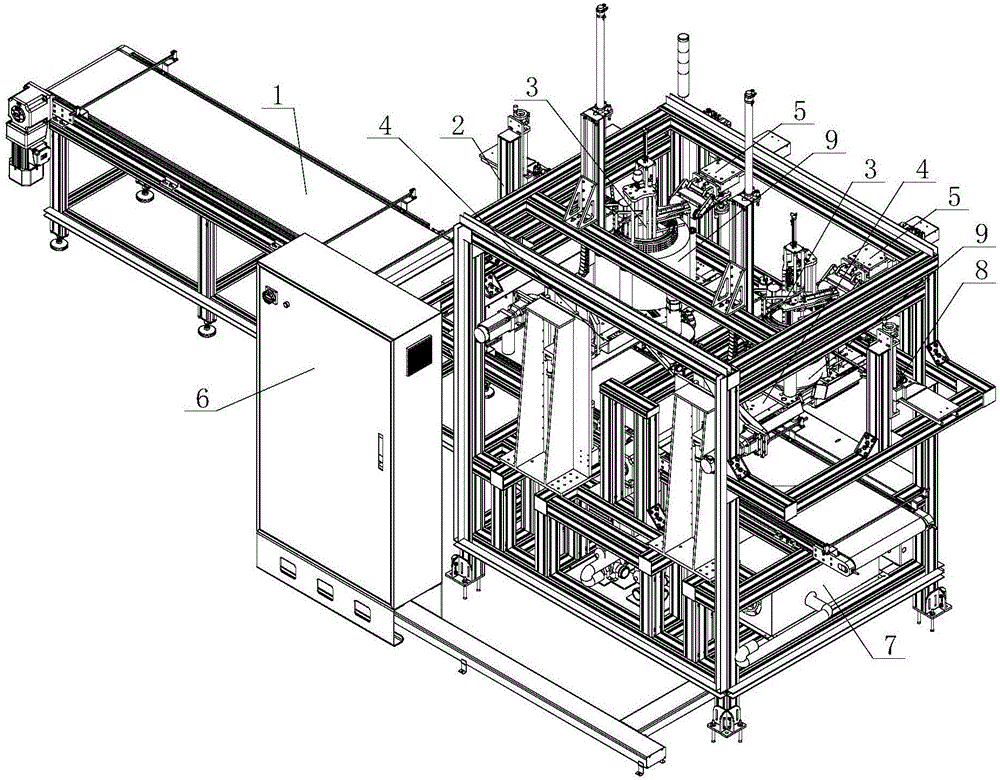

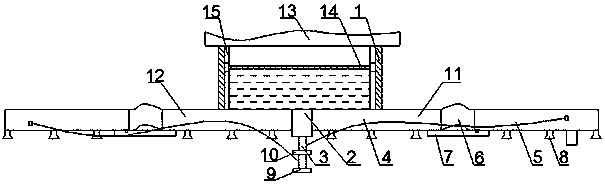

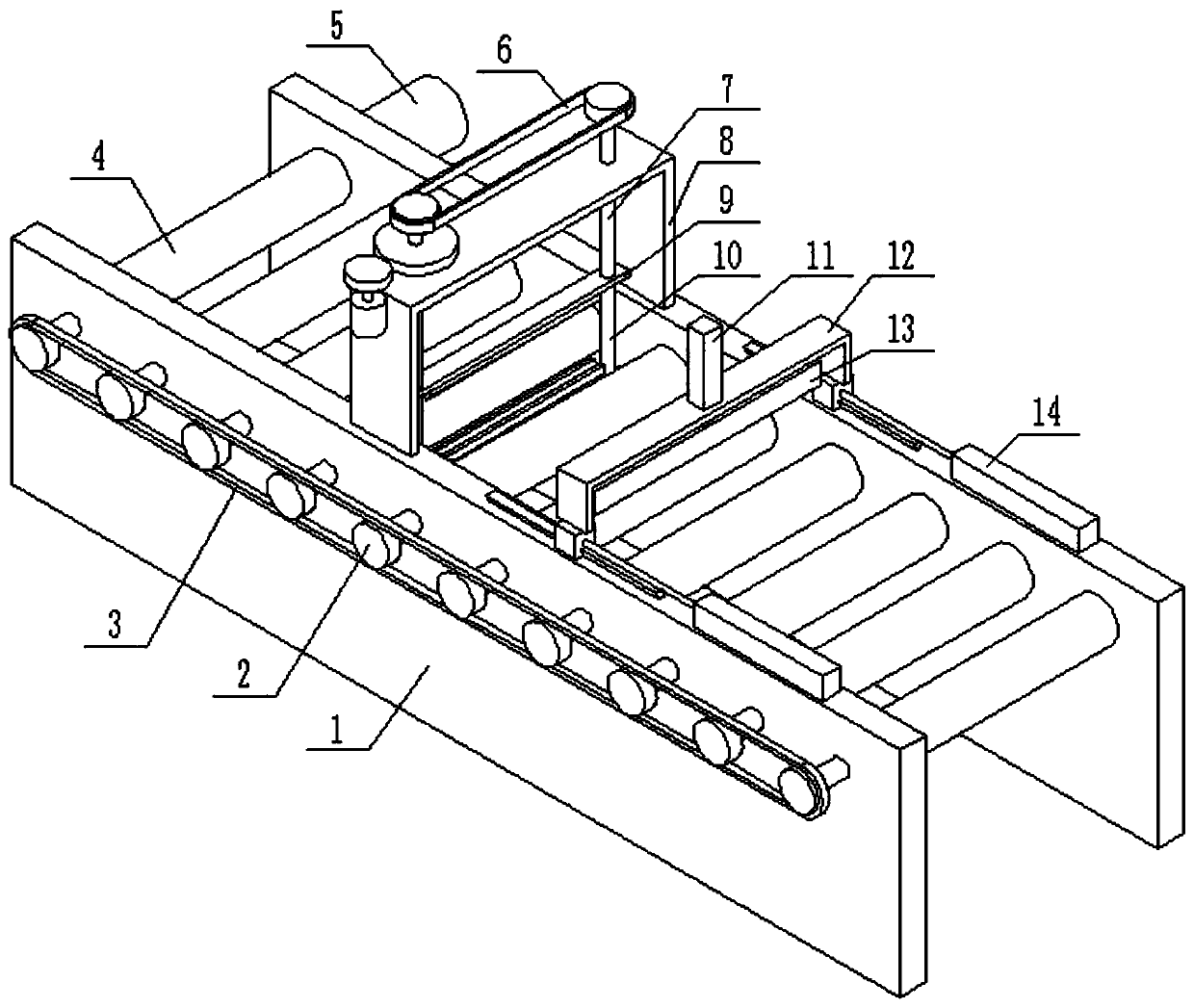

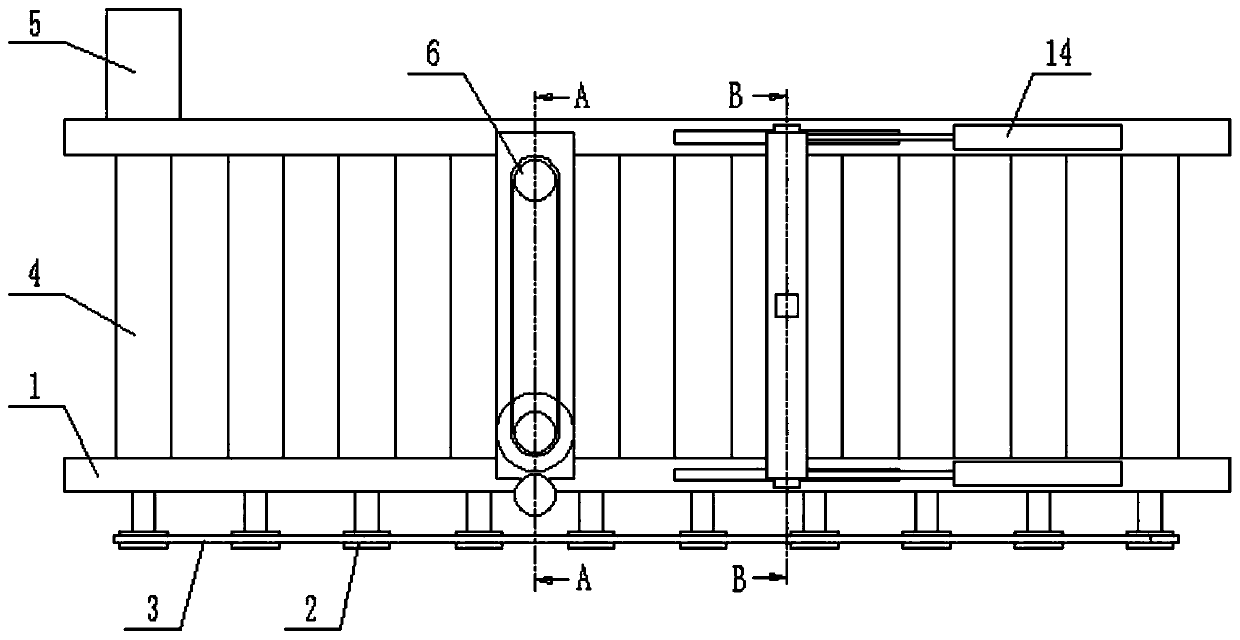

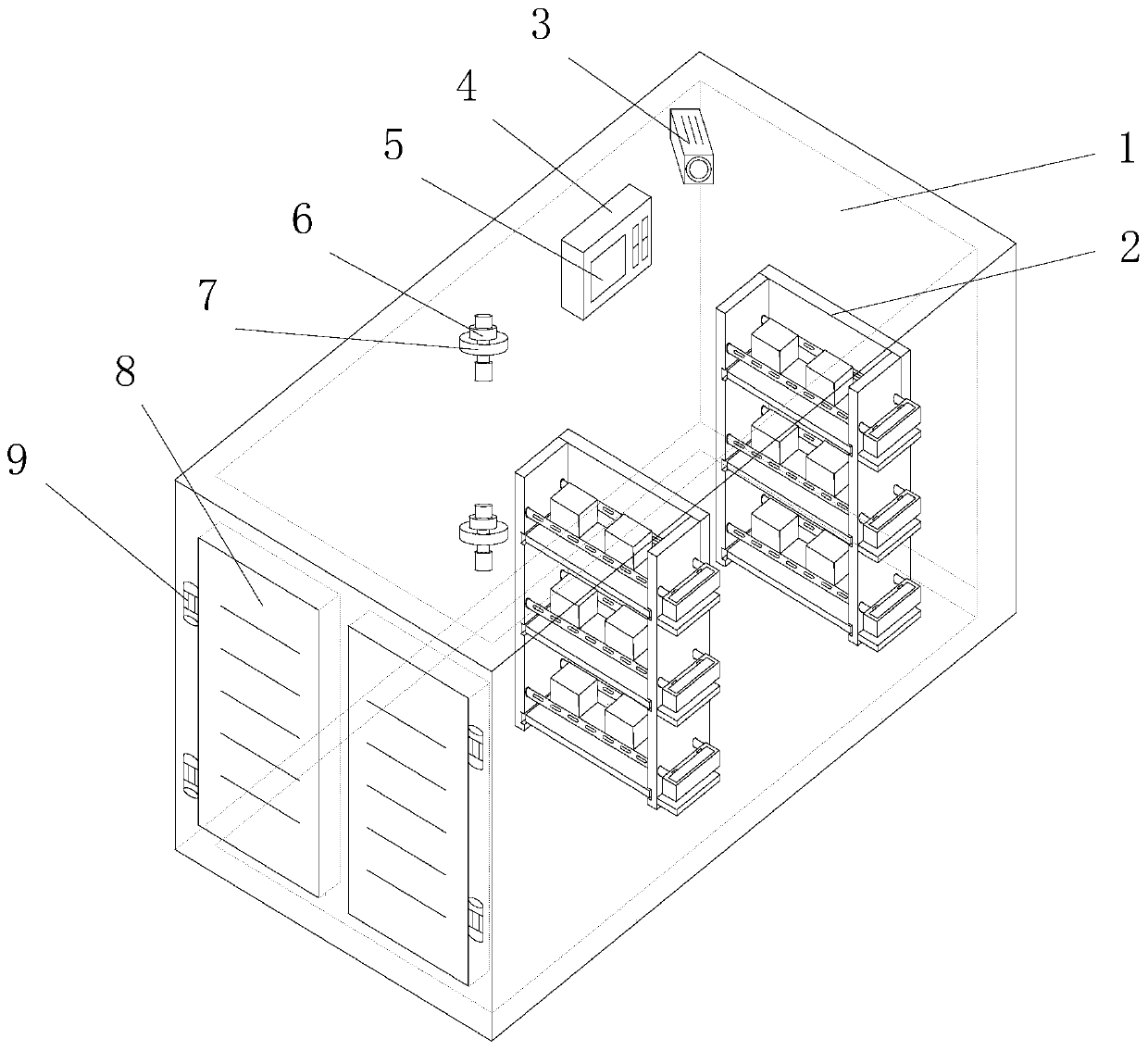

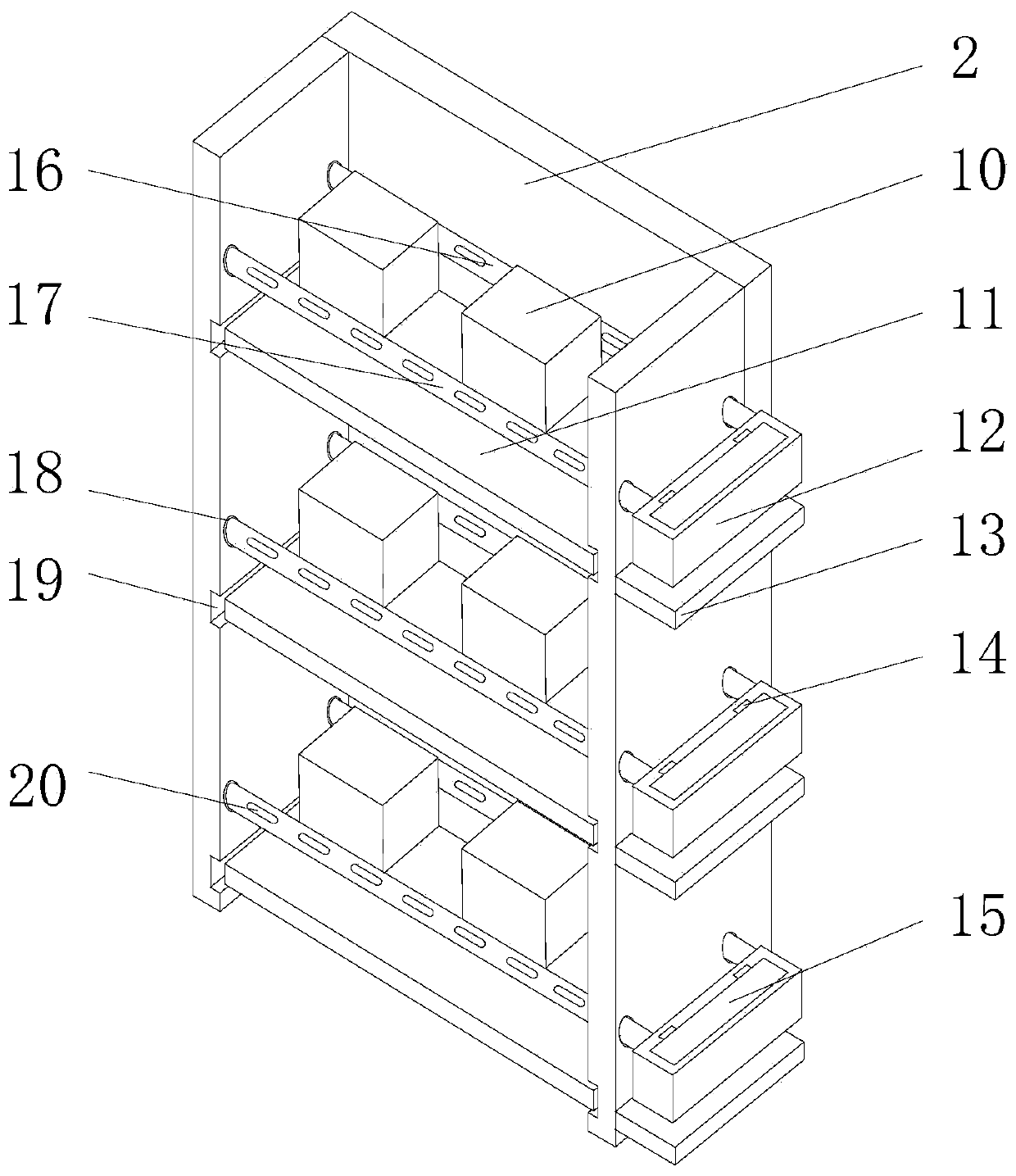

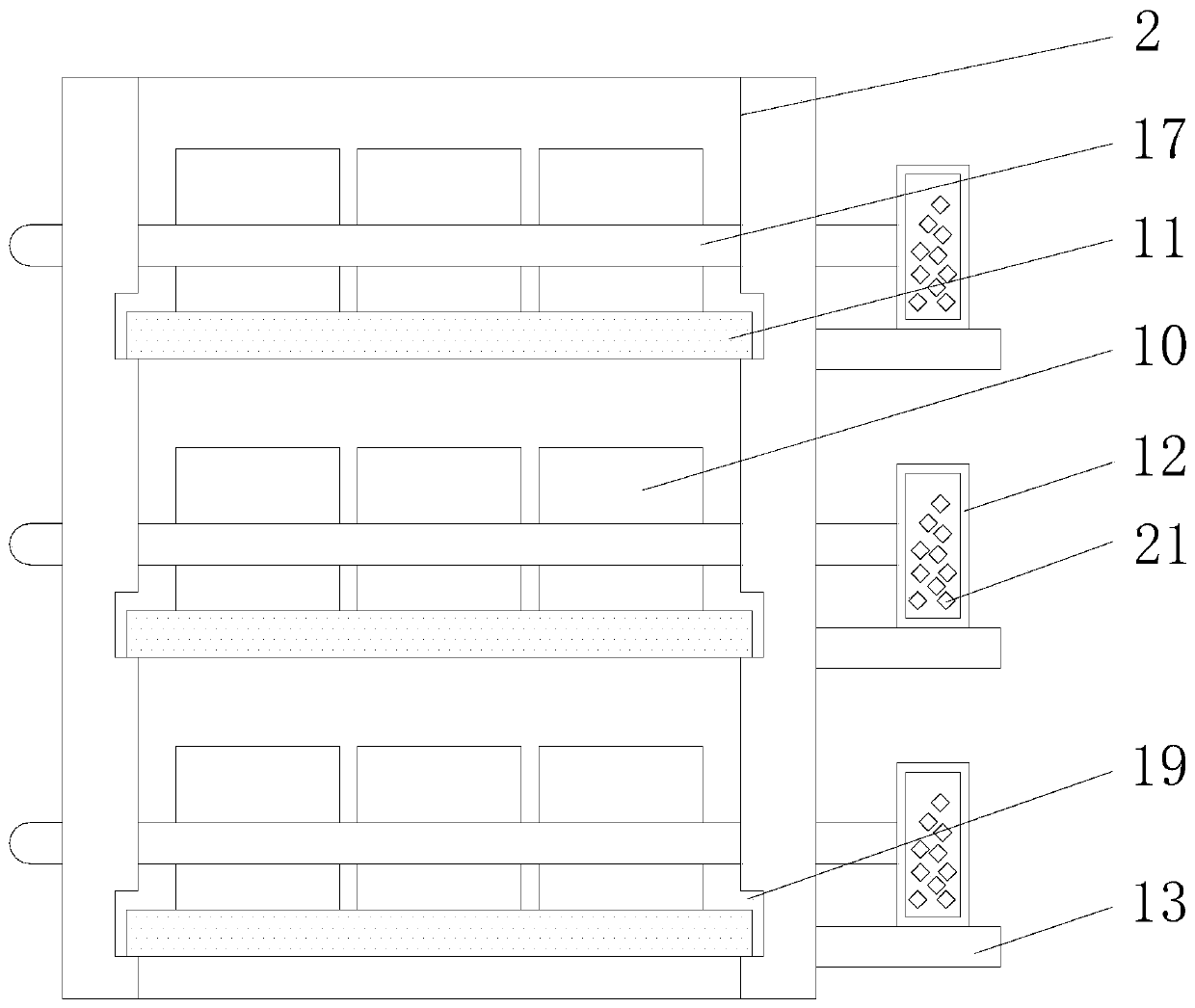

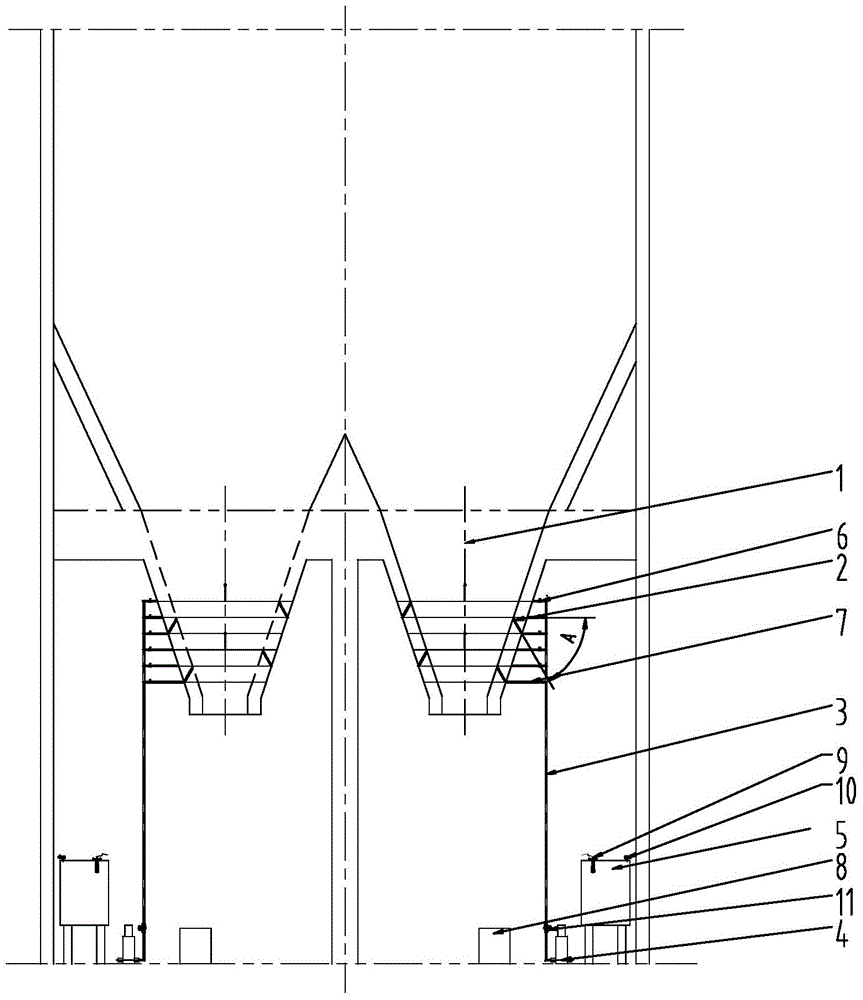

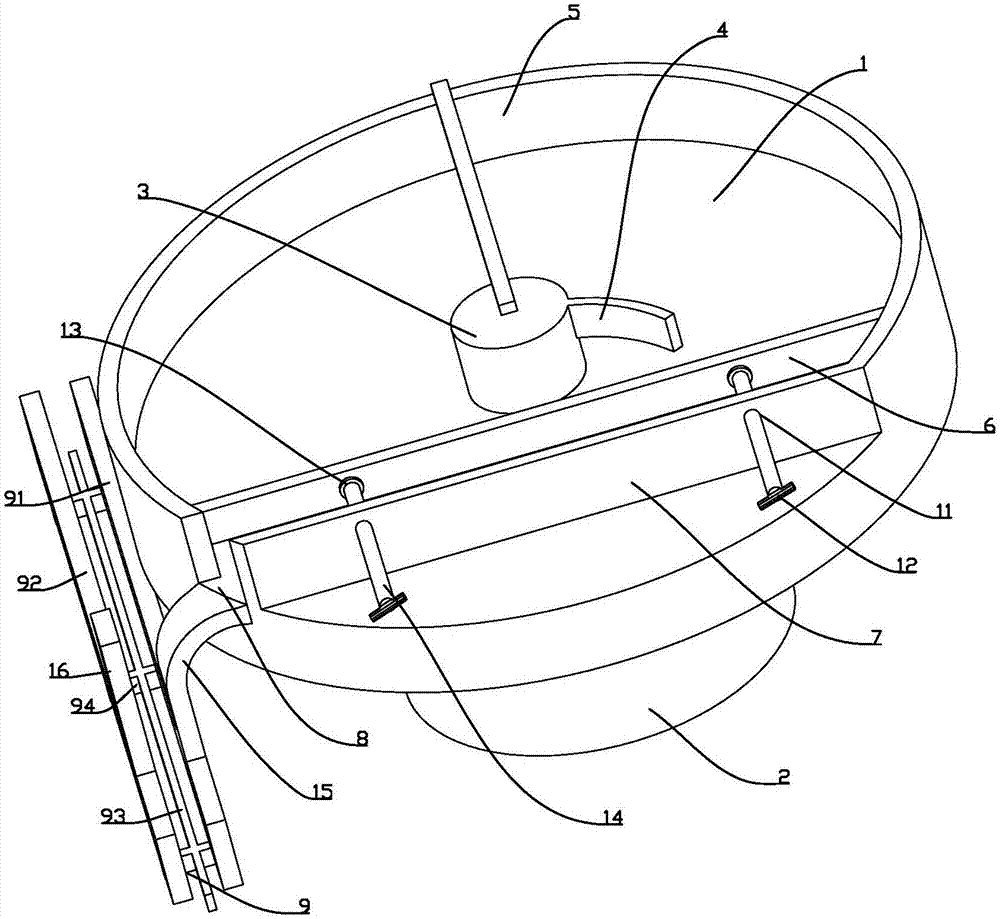

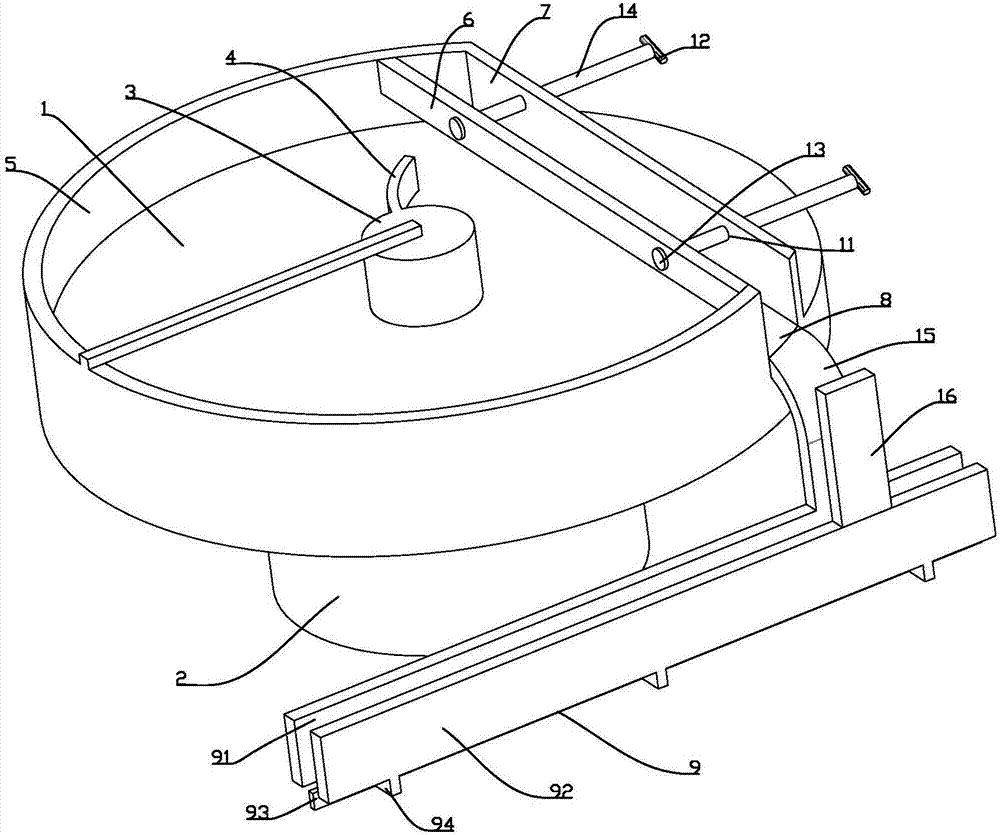

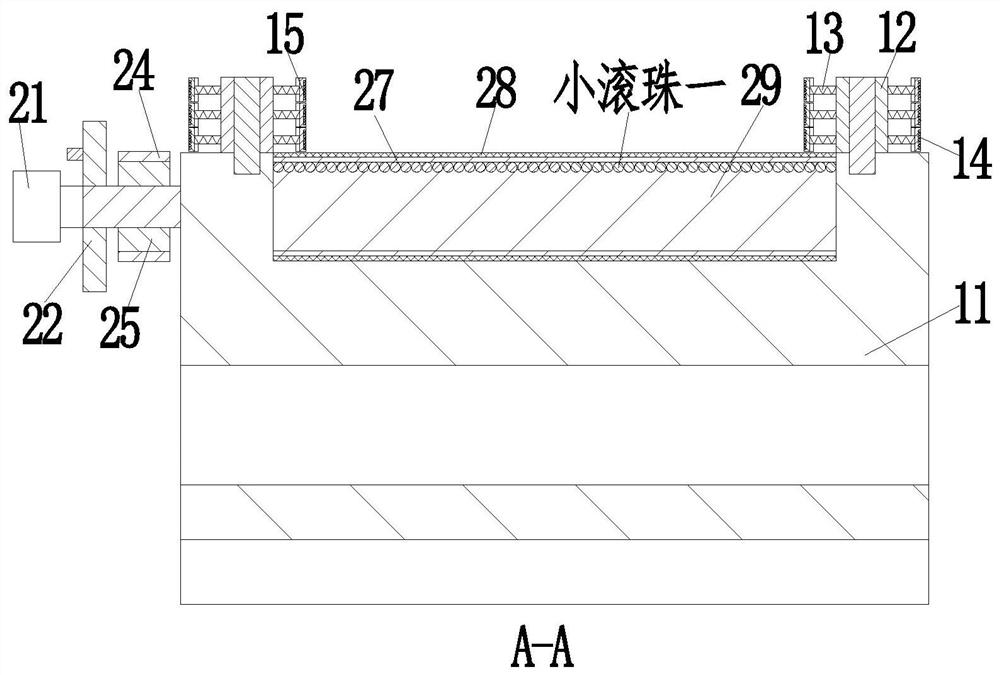

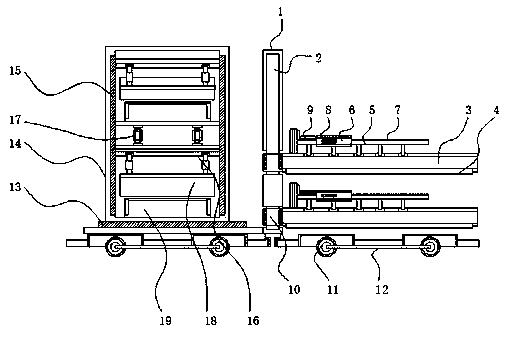

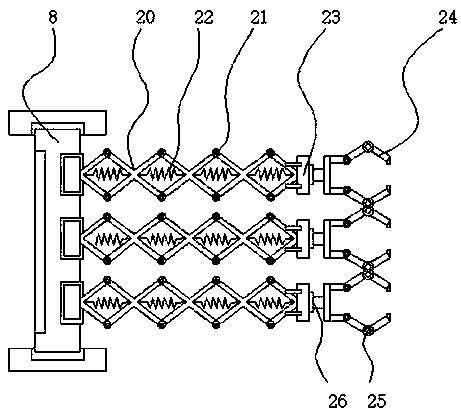

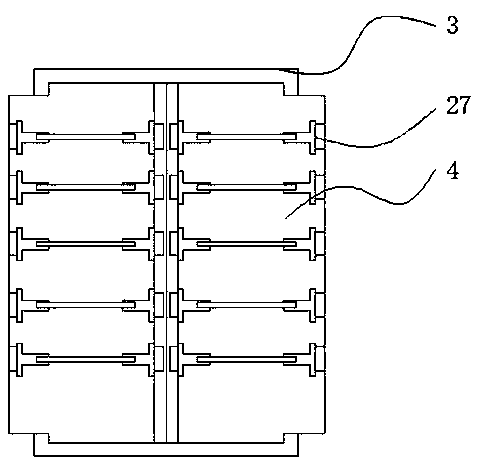

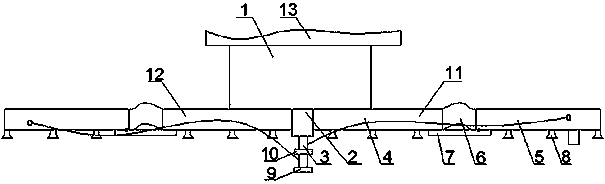

Automatic warehousing system of baby garment dehumidifying room

InactiveCN106429147ATransport impactIt has the function of limiting and resistingStorage devicesOutput deviceAutomatic testing

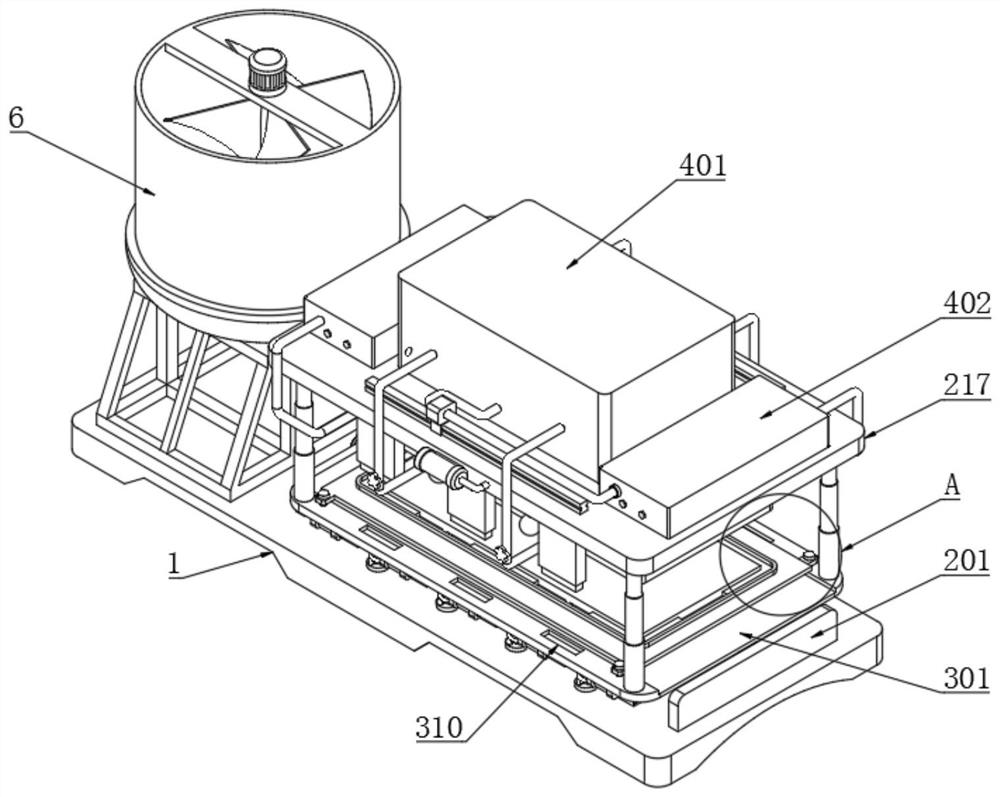

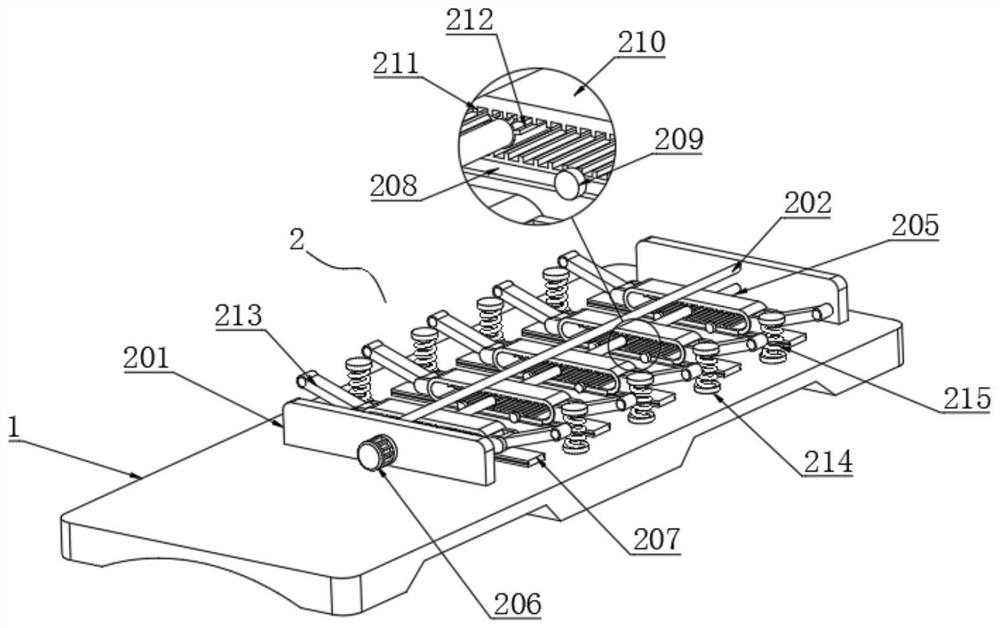

The invention discloses an automatic warehousing system of a baby garment dehumidifying room. The system comprises a rack automatic rotating device, a first shelf, a second shelf, an automatic feeding and discharging device and an automatic output device; the automatic rotating device comprises a first conveying device, a pushing device and a second conveying device; the automatic feeding and discharging device is arranged between the first shelf and the second shelf, and comprises a ground rail, a vehicle bottom assembly, a rack, a rack top, a feeding and discharging conveying device, a fork, a first feeding and discharging drive mechanism and a second feeding and discharging drive mechanism; the automatic output device comprises a discharging through-connection device and an output device, the discharging through-connection device is arranged at the output end of the ground rail, and the output device is arranged at the output end of the discharging through-connection device. The system can achieve automatic conveying and automatic dehumidifying work, efficiency is improved, and manual cost is reduced.

Owner:广州市杰兴制衣有限公司

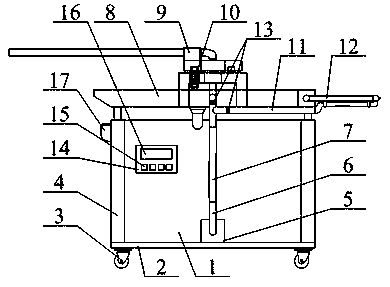

Film-coating method for glass fiber yarn cluster

ActiveCN106586060ATransport impactImprove coating efficiencyWrapper folding/bending apparatusWrapping with article rotationGlass fiberYarn

The invention discloses a film-coating method for a glass fiber yarn cluster, and belongs to the technical field of glass fiber production equipment. The invention aims to provide the film-coating method for the glass fiber yarn cluster, and the coating method is relatively good in coating effect and is high in film-coating efficiency. The film-coating method comprises the following steps: step I: conveying yarn clusters; step II: grabbing the yarn clusters; step III: pressing the yarn clusters; step IV: coating a film, wherein a coating film is pushed to a specific position through a film feeding device, a gas blowing tube of a film cutting mechanism of the film feeding device works to blow the coating film; and the coating is adhered on the yarn cluster in a sticky mode, and the coating film is pressed onto the yarn cluster through a film-pressing thin sheet of the film pressing device; a clamping rotating device drives the yarn cluster to rotate, the coating film is continuously guided out and is coated on the cluster yarn; and the film is cut off through a blade of a film cutting mechanism; step V: pushing a film, wherein the film pressing device moves upwards and the film pressing device works to level the coating film exceeding the upper end surface of the yarn cluster to the upper end surface of the yarn cluster; and step VI: outputting finished products. The film-coating method is a film-coating method suitable for coating a layer of film outside the glass fiber yarn cluster.

Owner:福德机器人(成都)有限责任公司

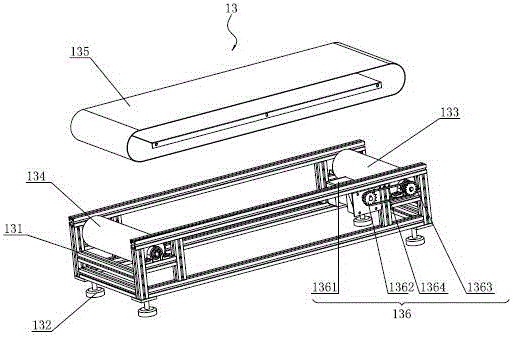

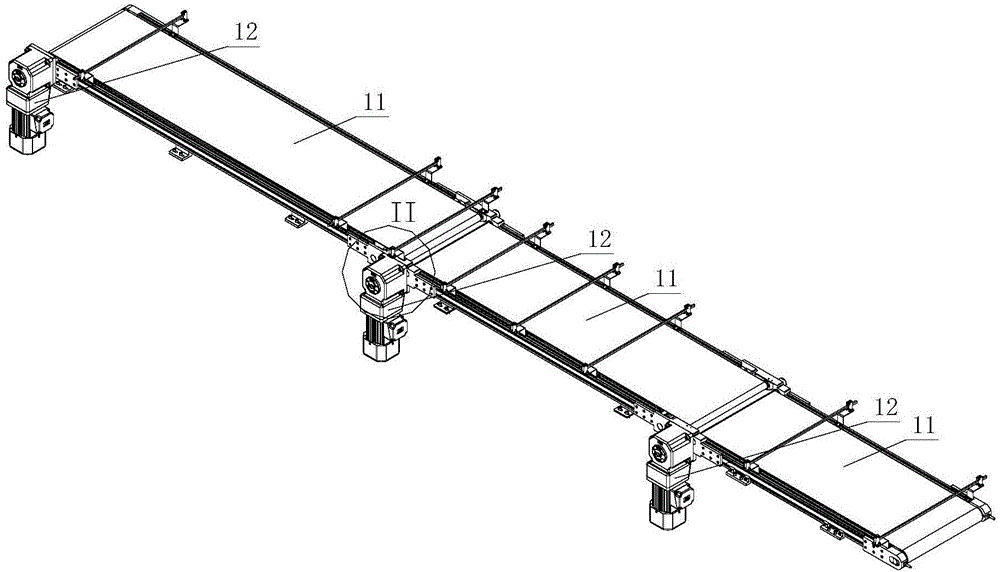

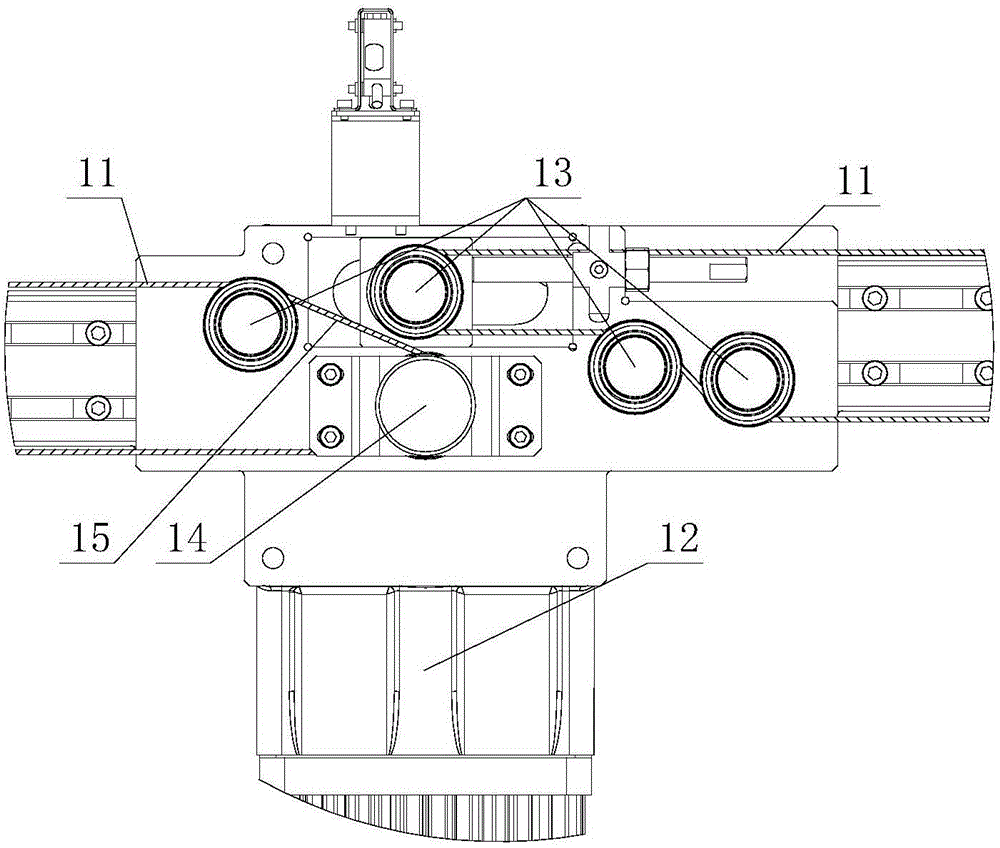

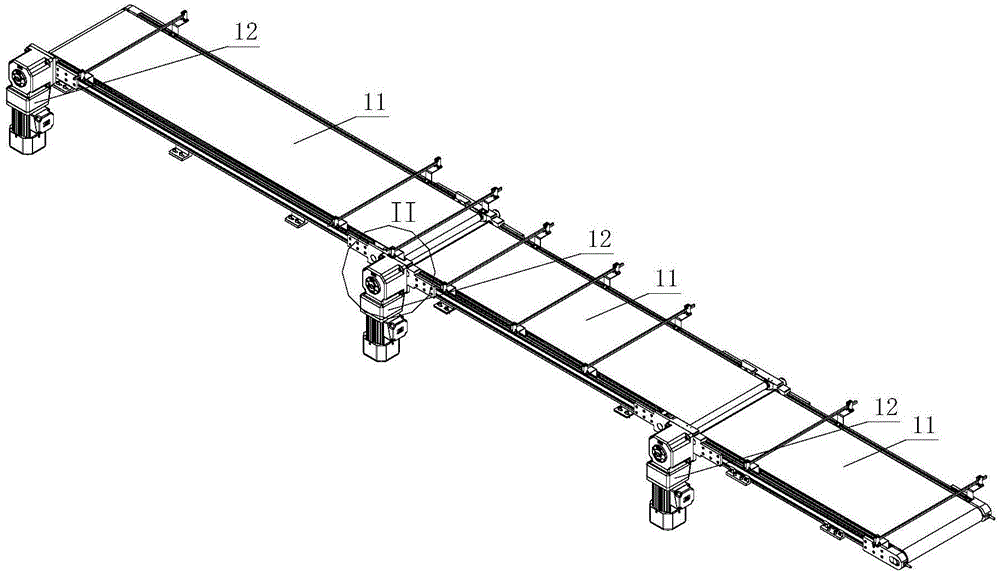

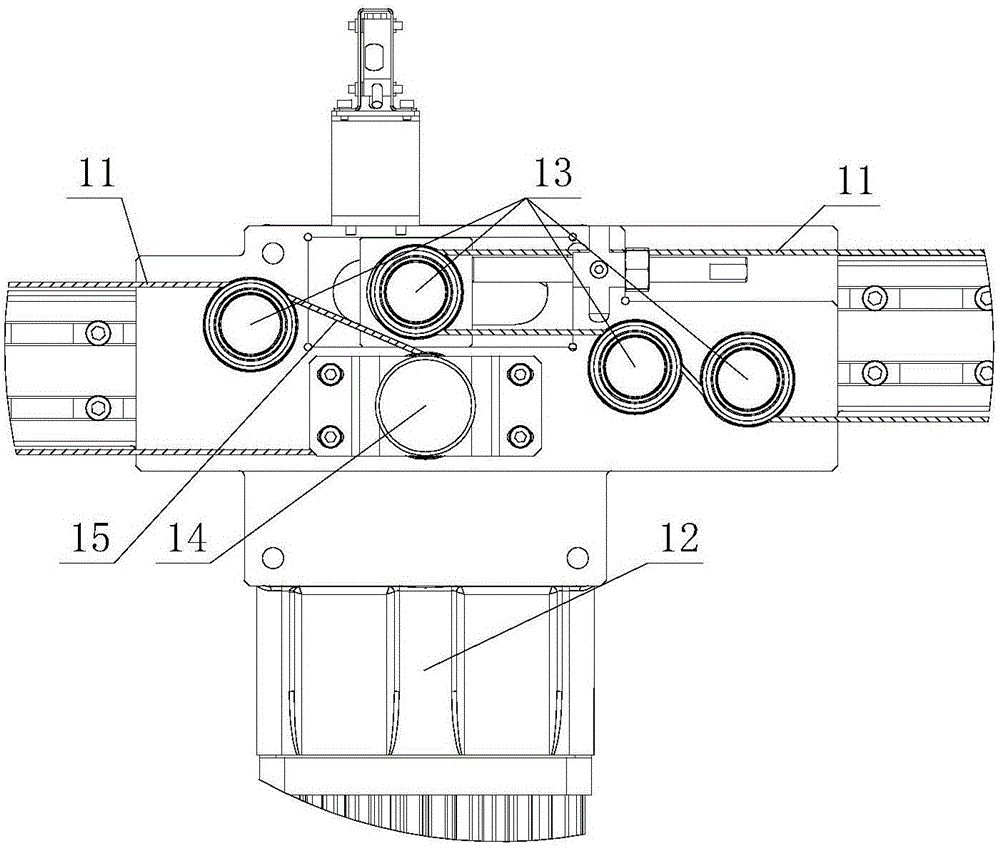

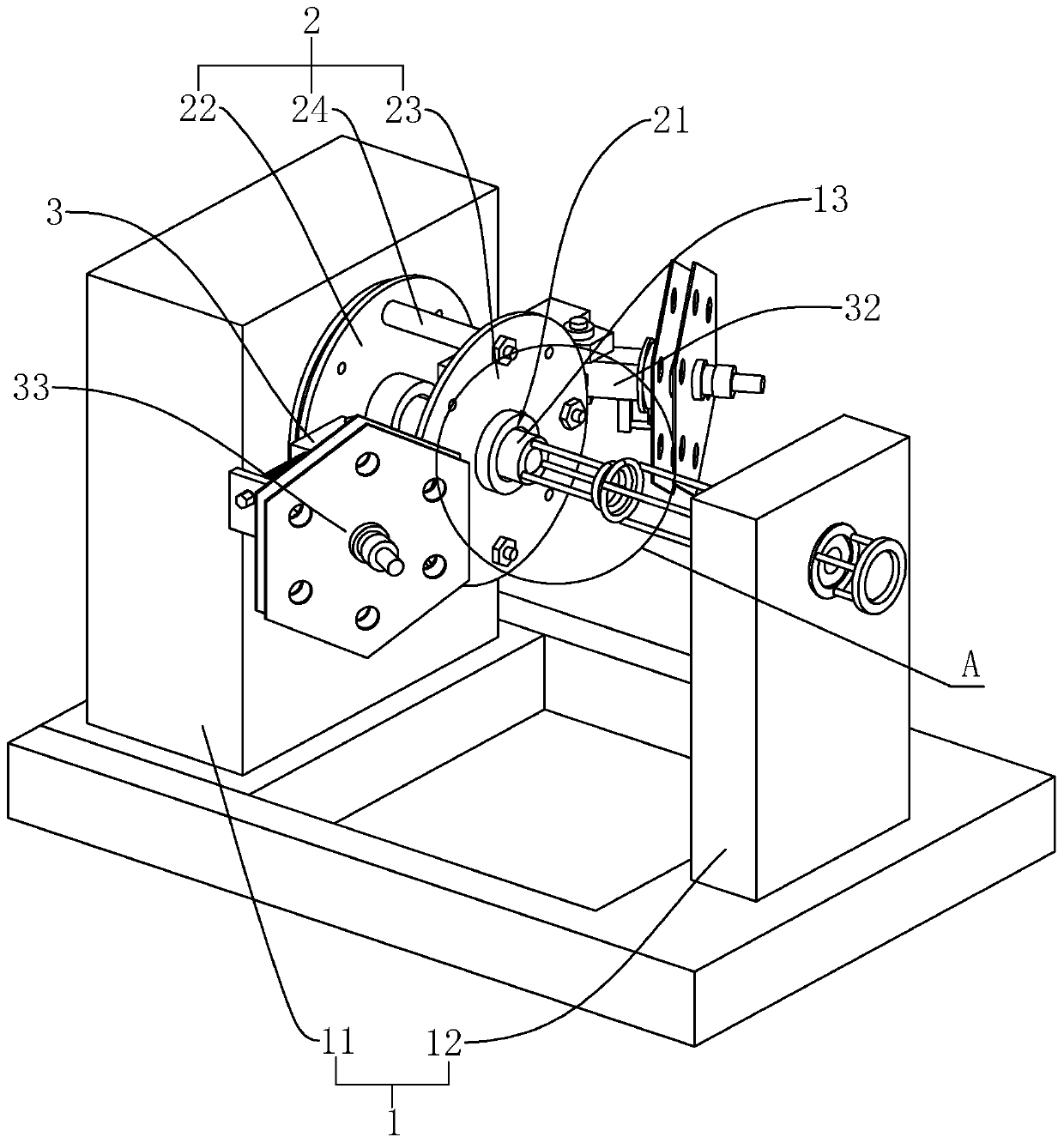

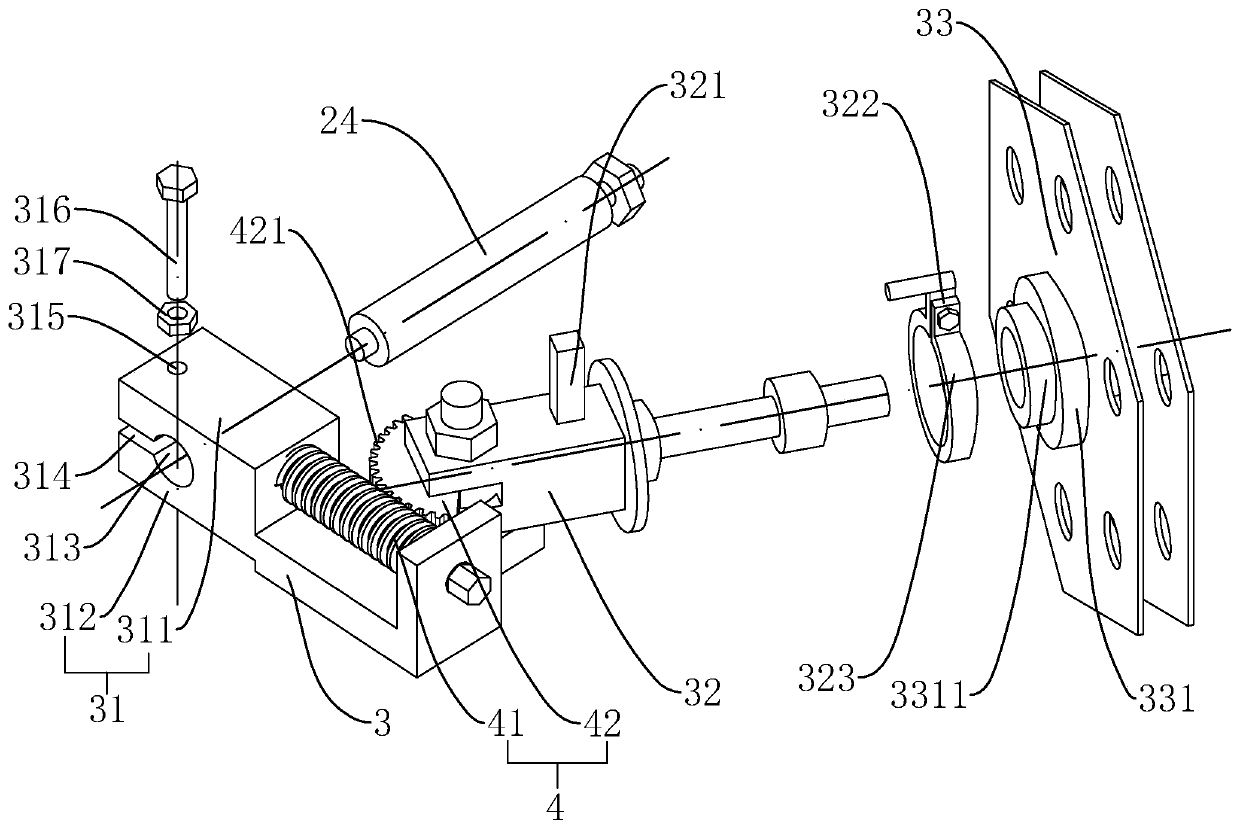

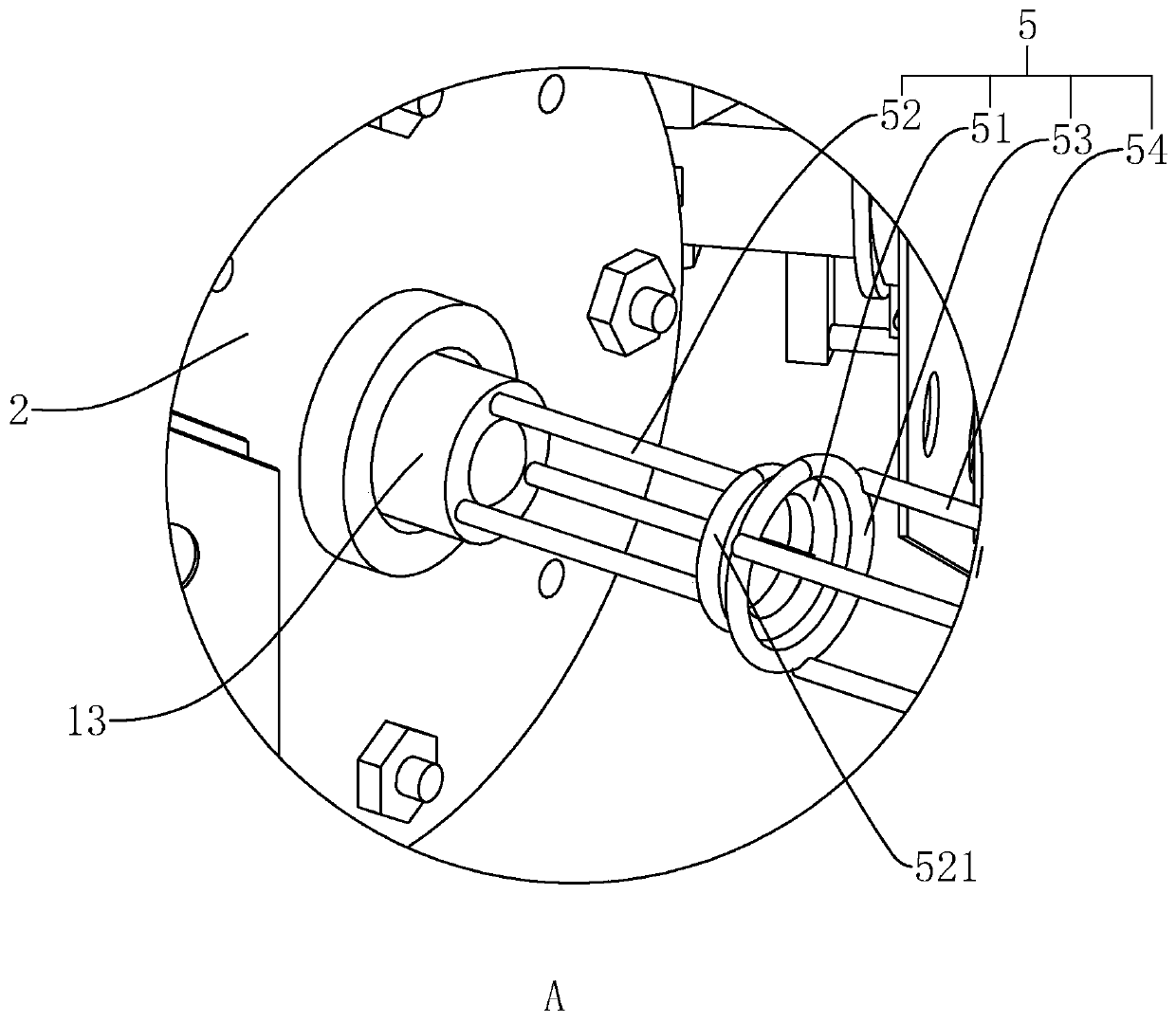

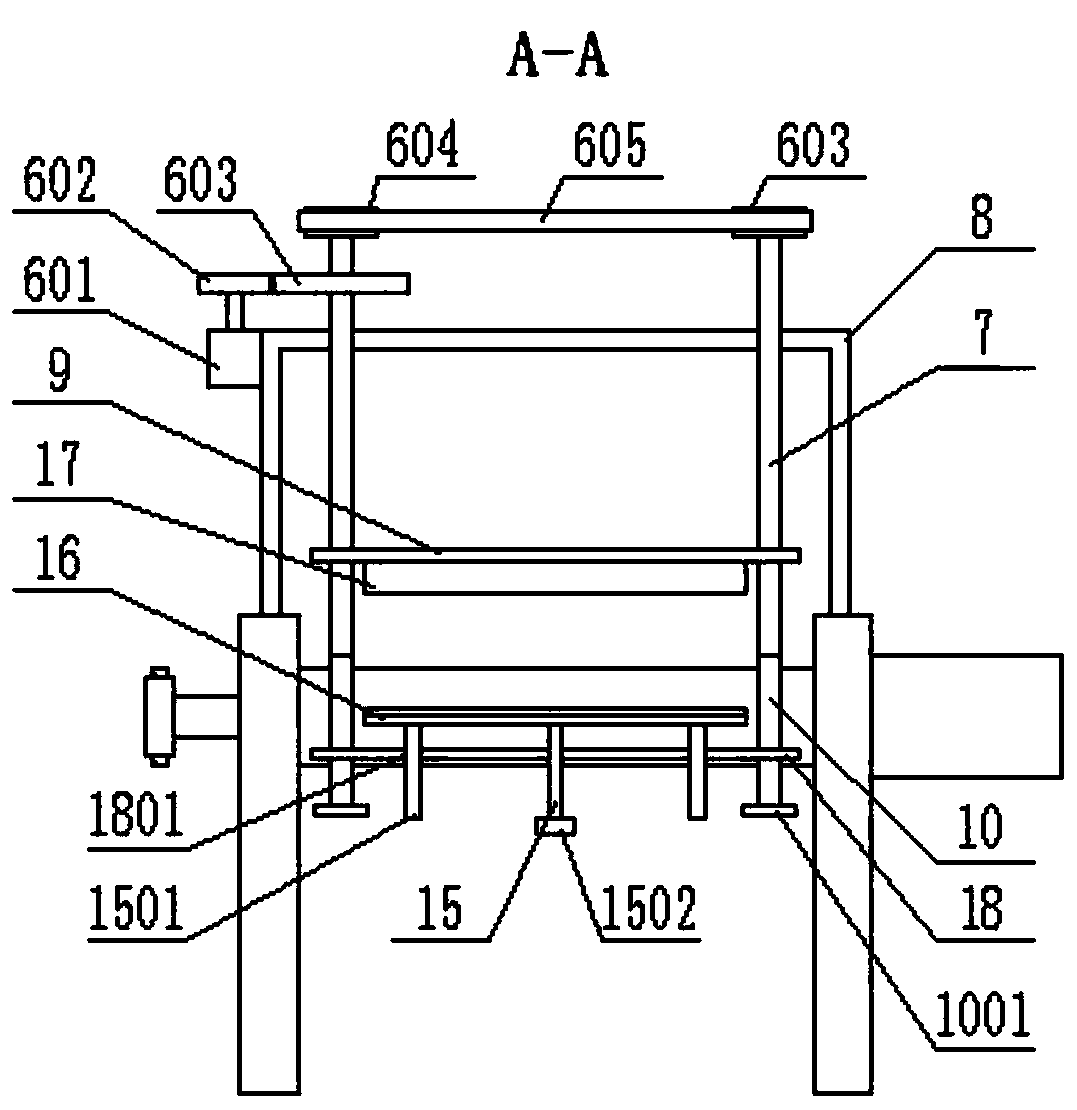

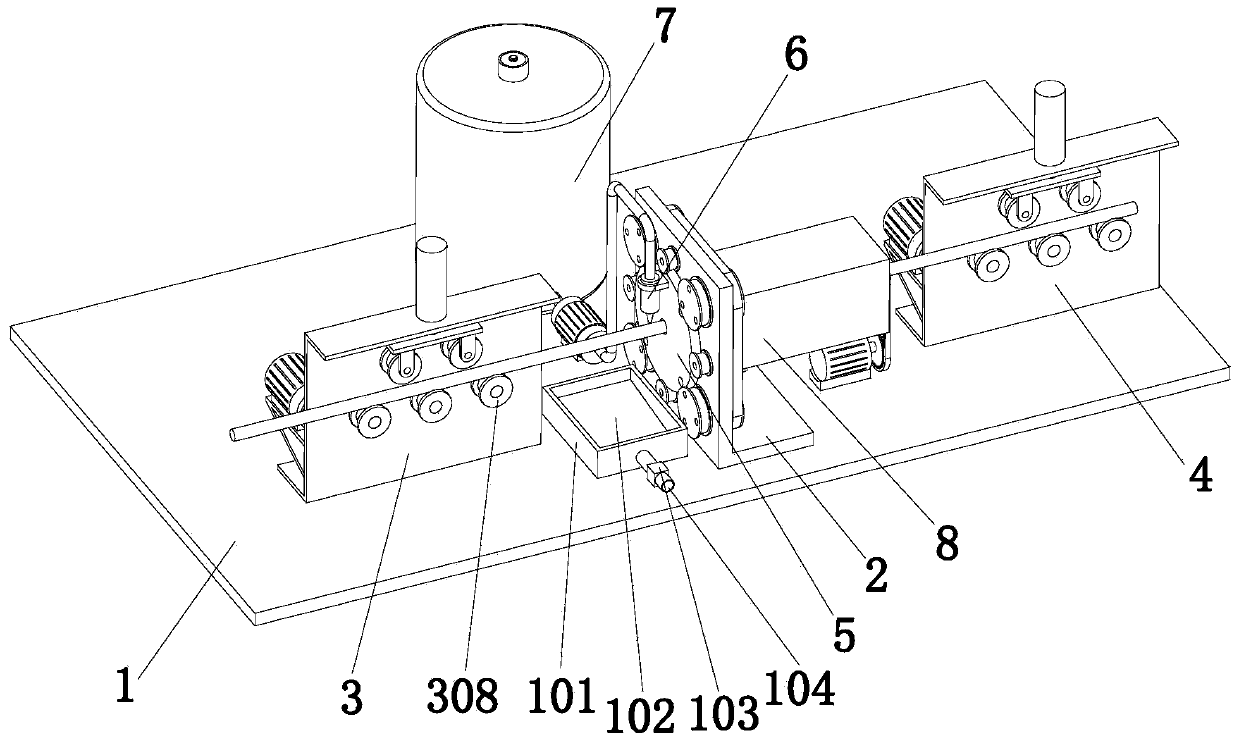

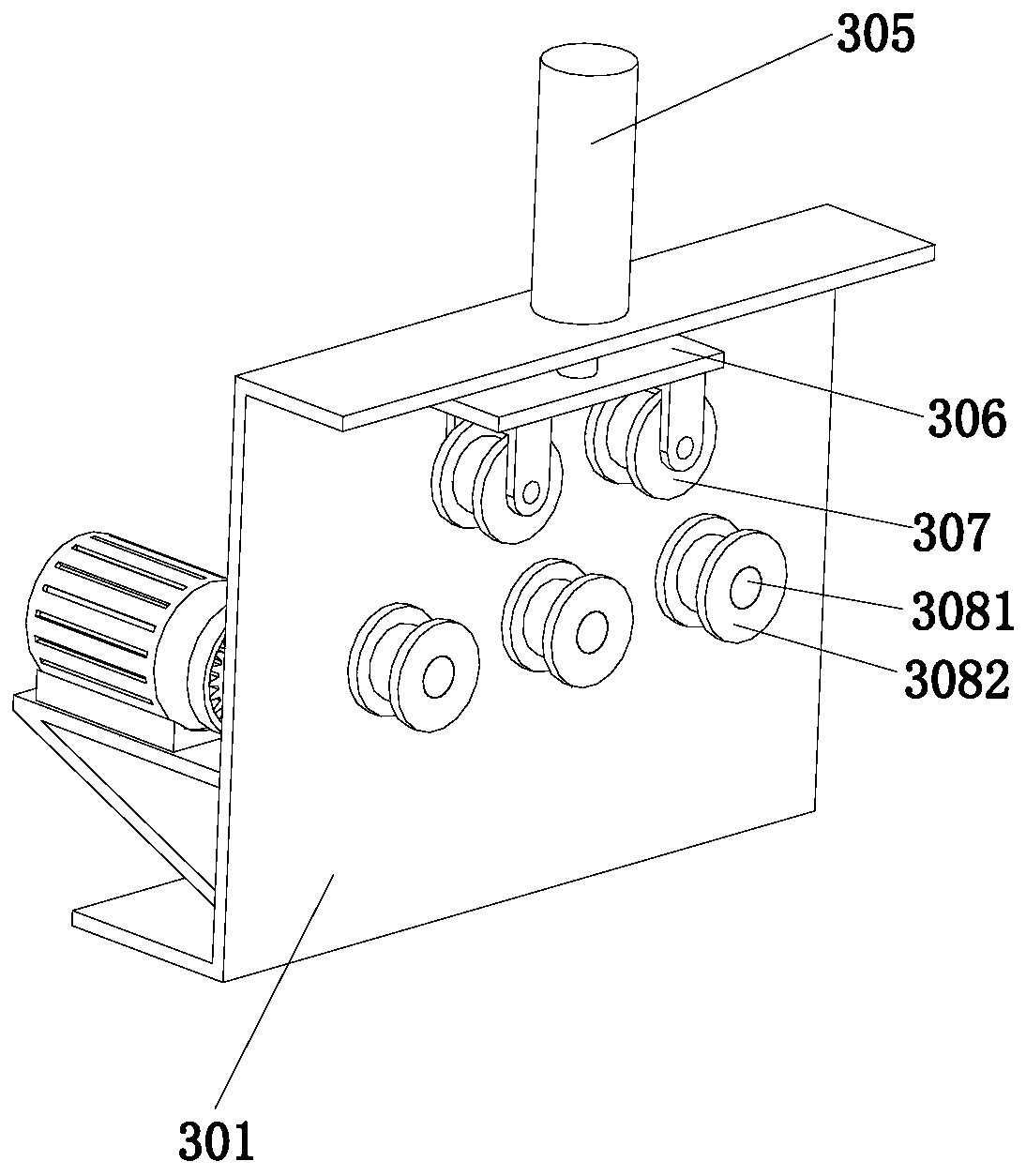

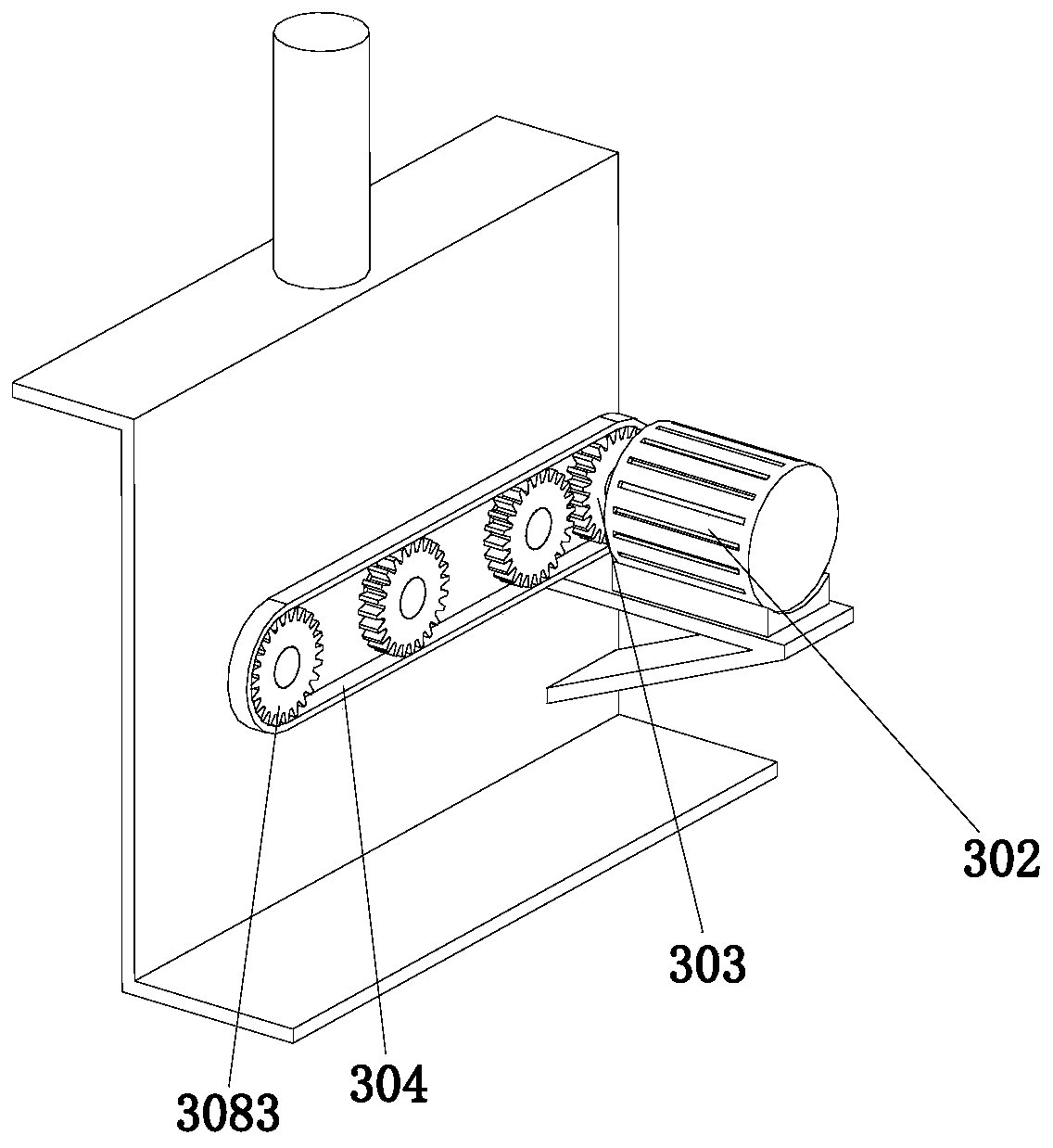

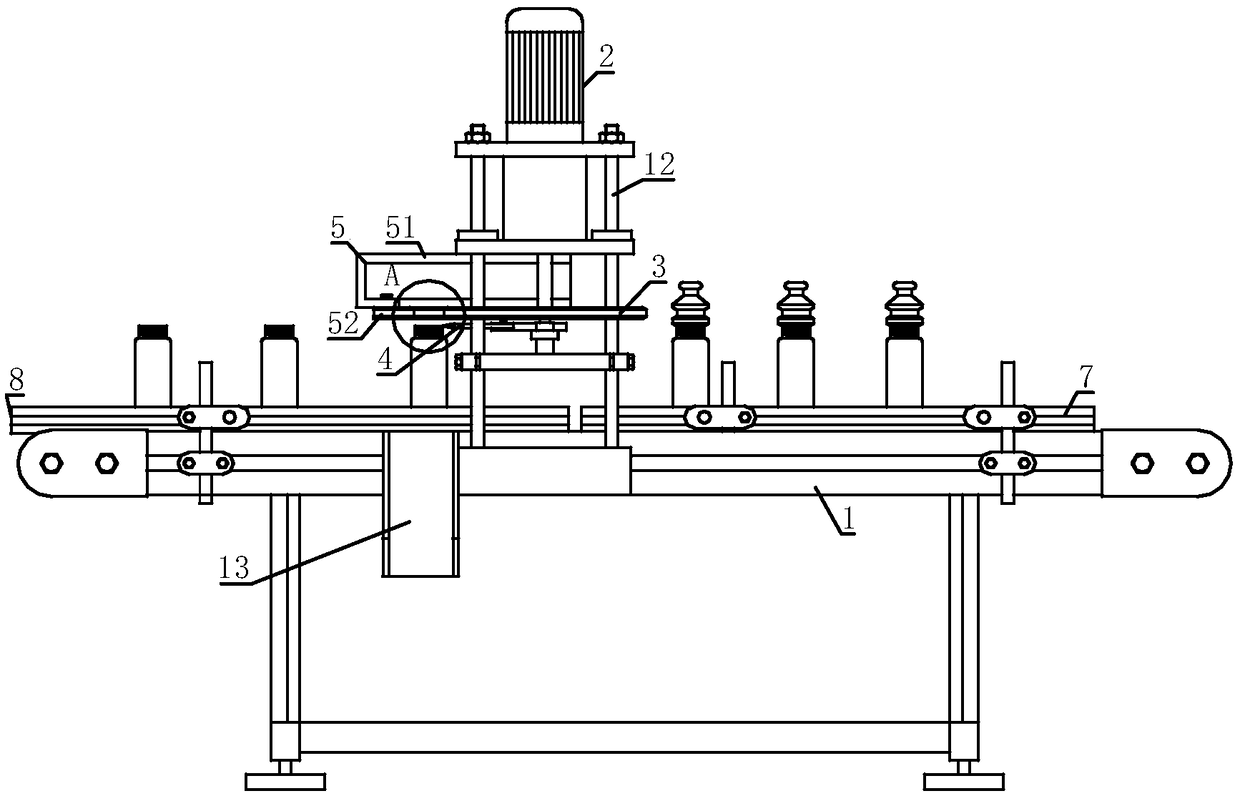

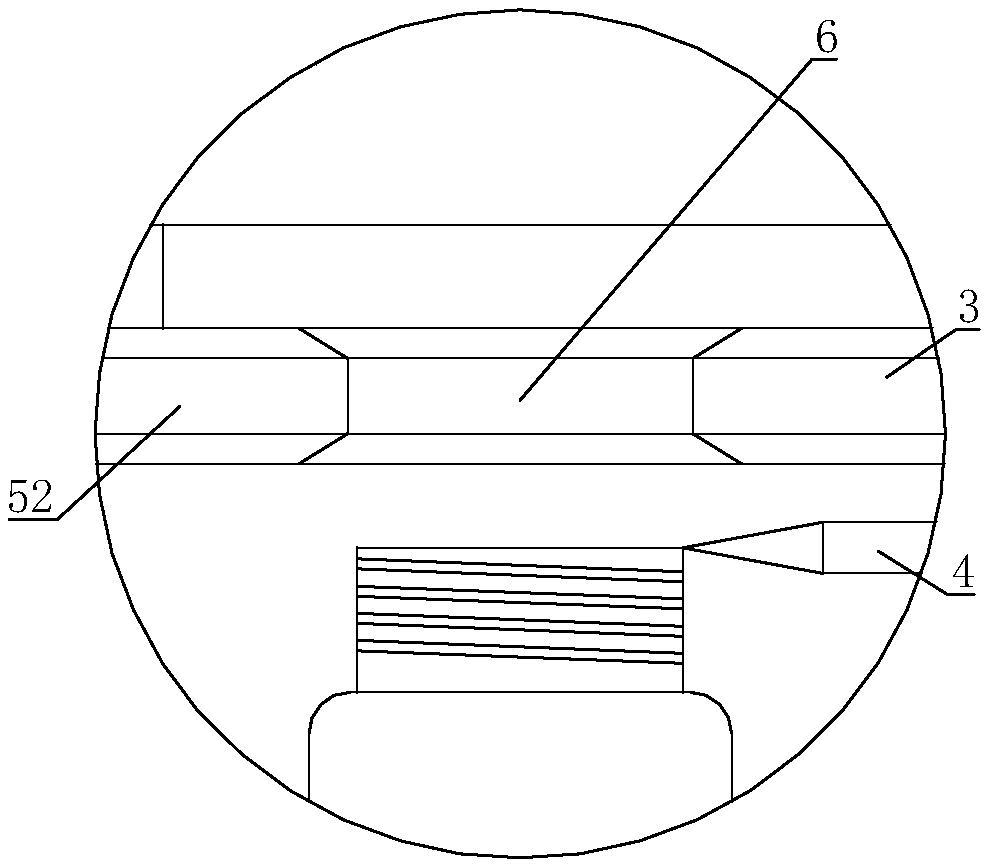

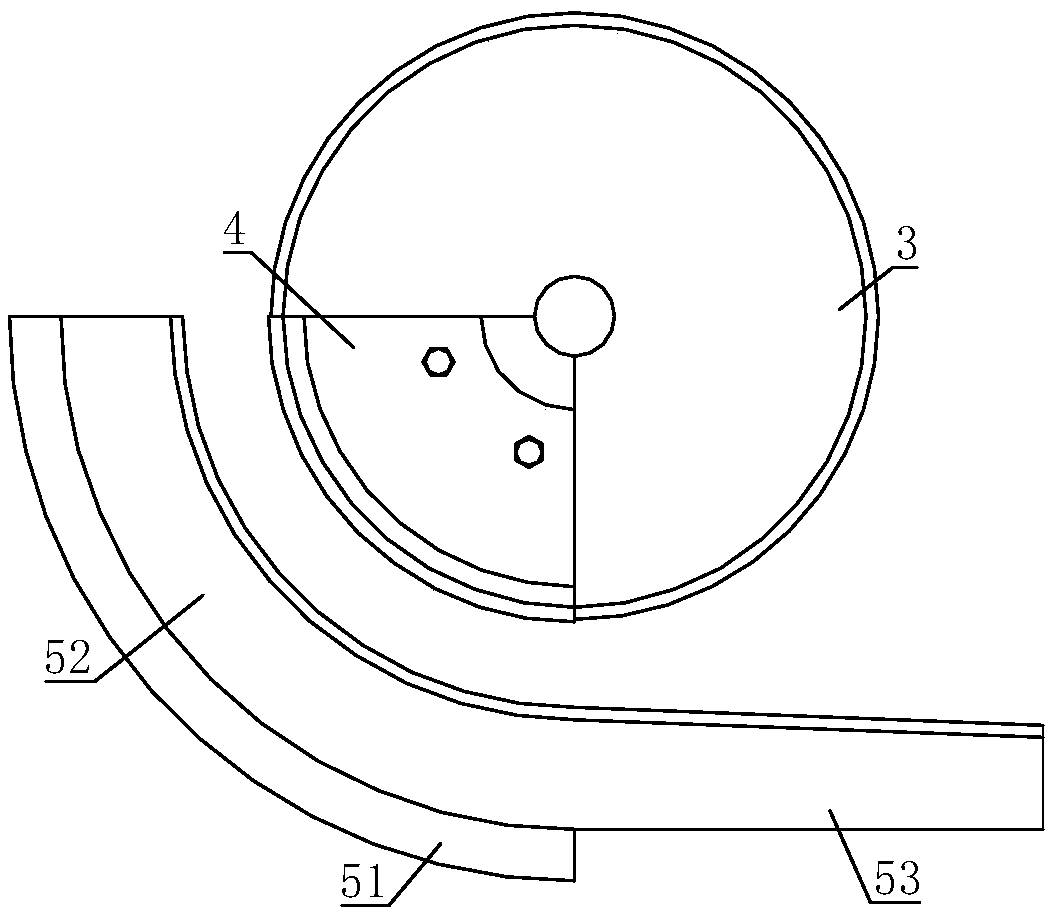

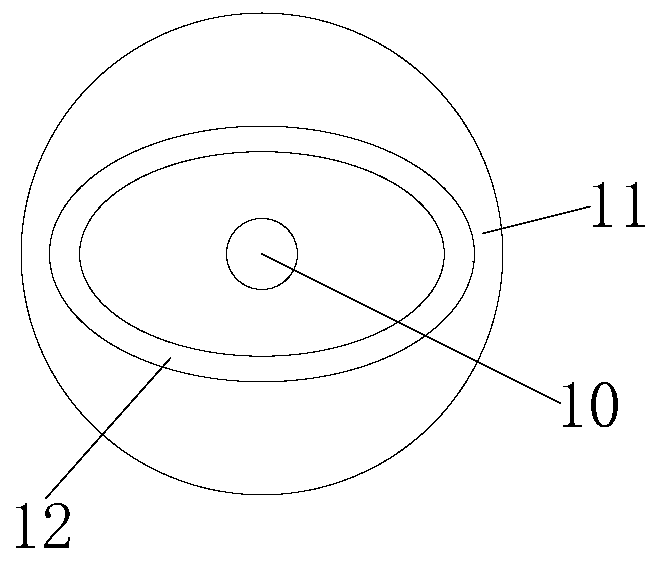

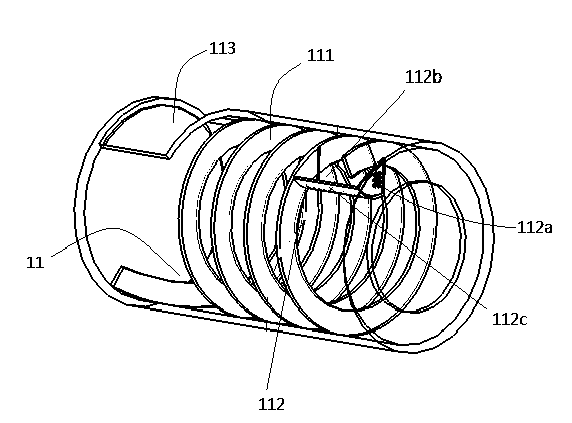

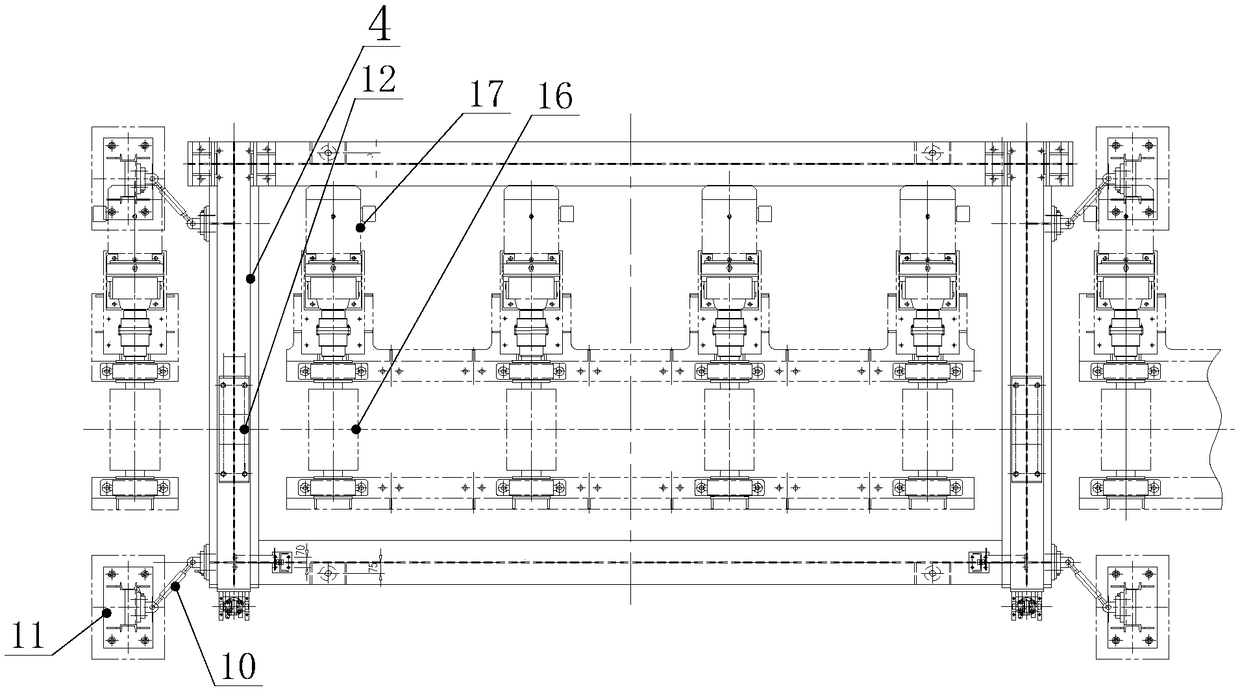

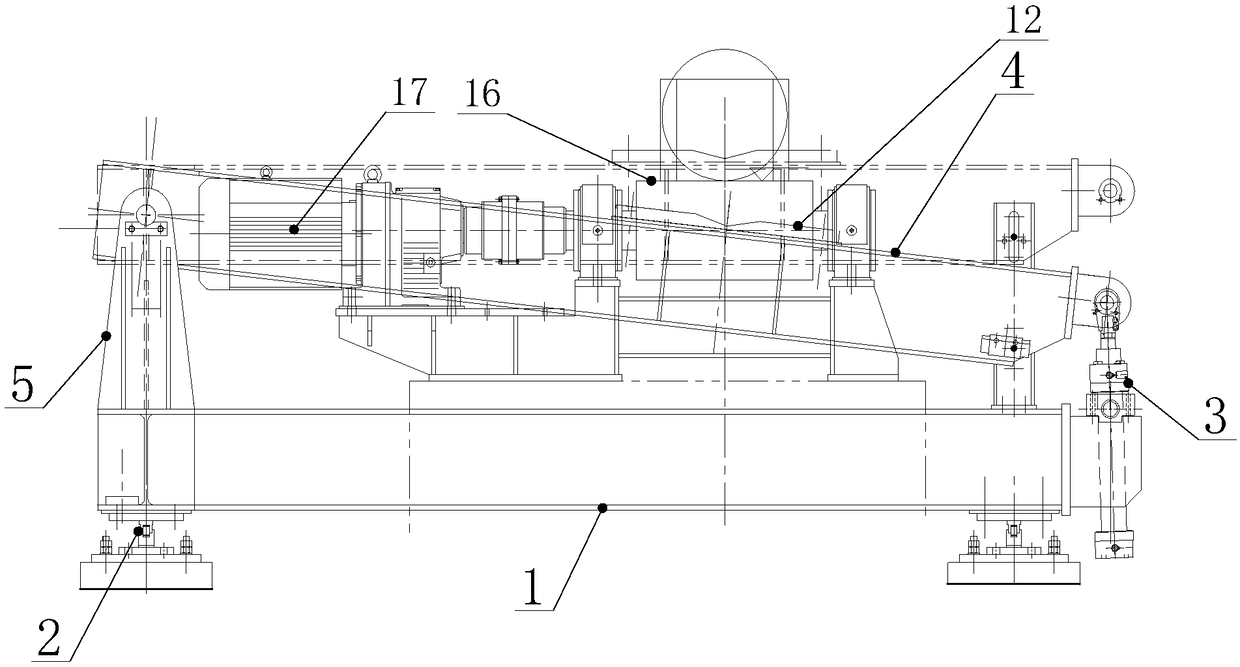

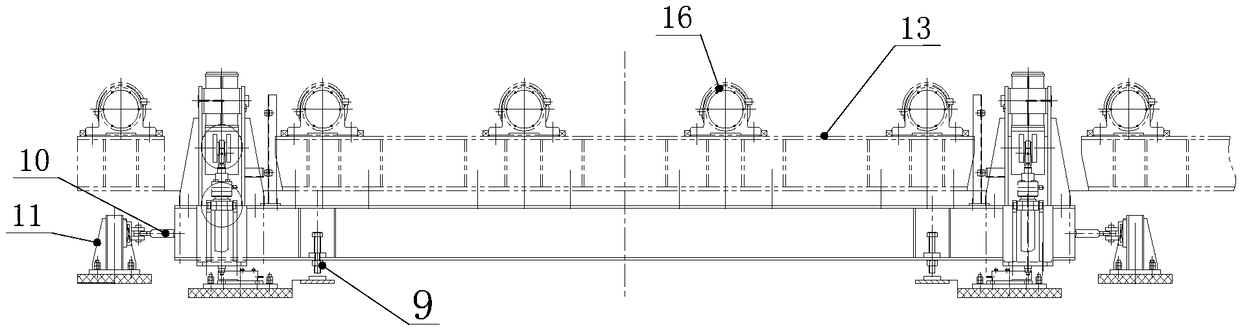

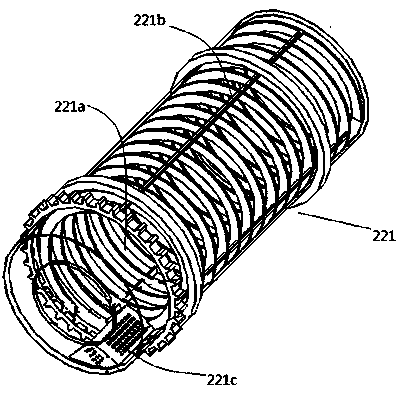

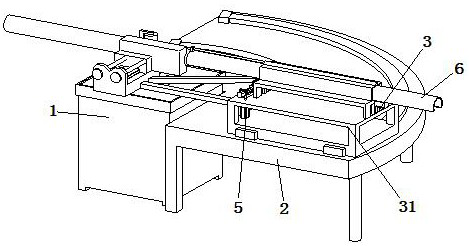

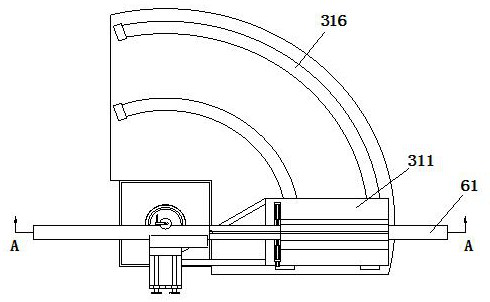

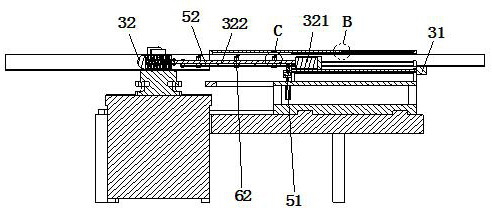

Glass fiber yarn roll membrane coating machine

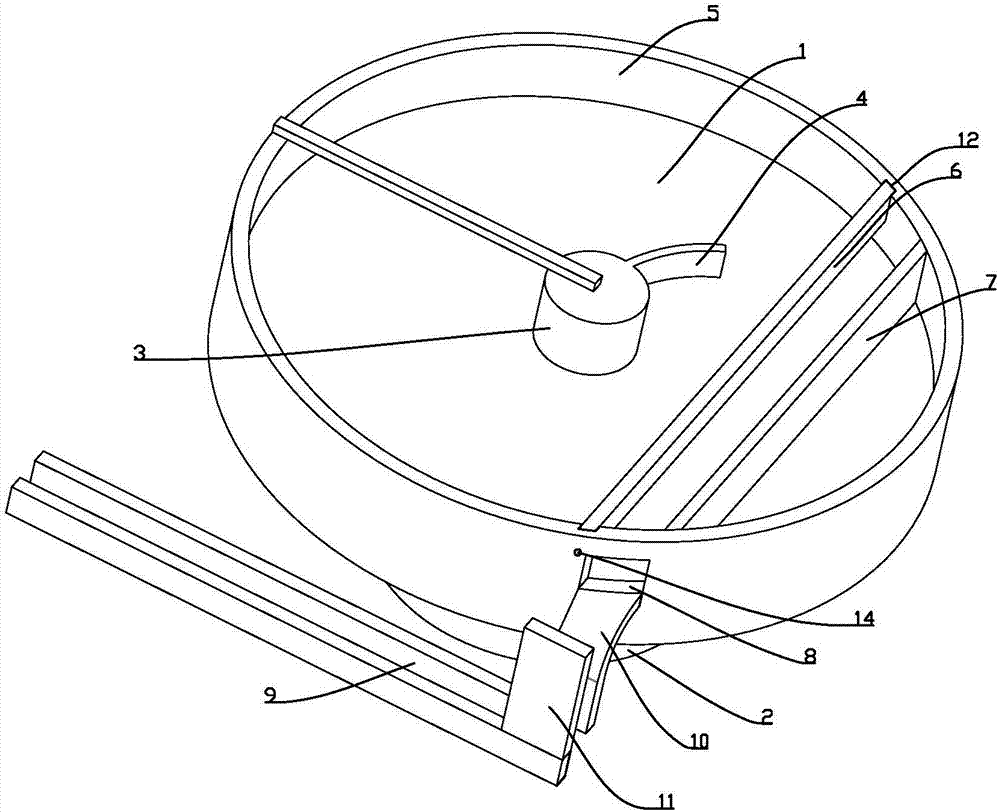

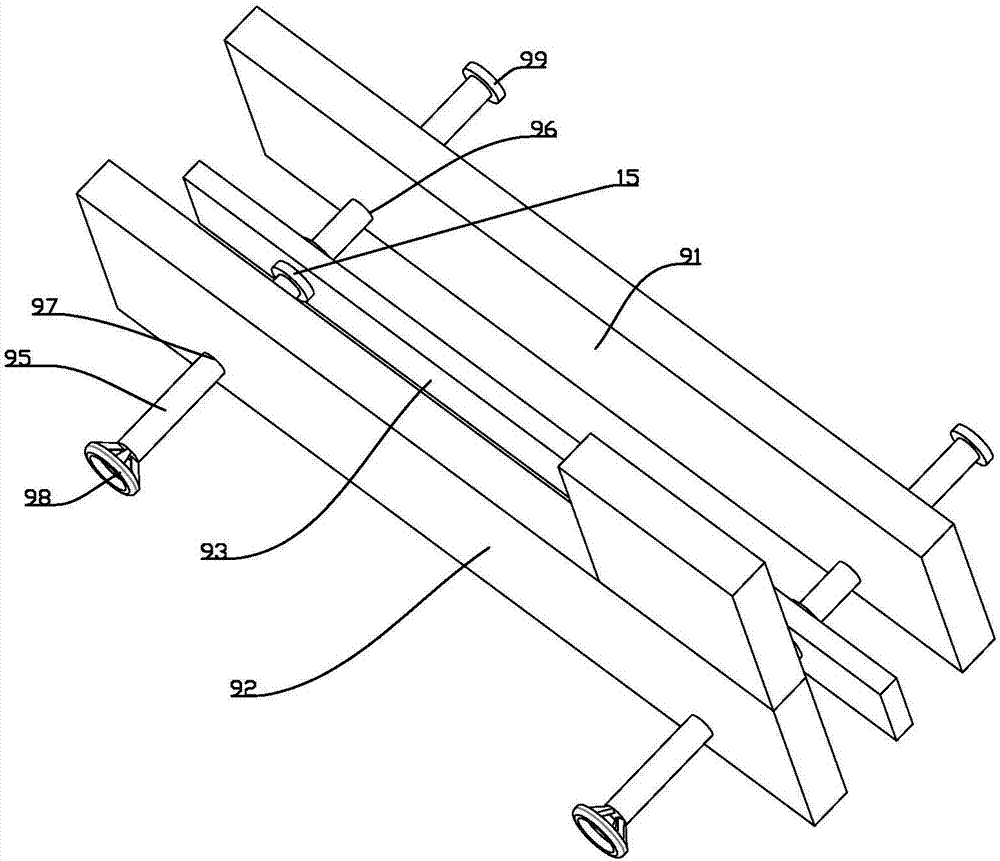

ActiveCN106697366ATransport impactImprove coating efficiencyPackaging by pressurising/gasifyingWrapping with article rotationYarnGlass fiber

The invention discloses a glass fiber yarn roll membrane coating machine, and belongs to the technical field of glass fiber production equipment. The glass fiber yarn roll membrane coating machine is good in coating effect and high in membrane coating efficiency. The glass fiber yarn roll membrane coating machine comprises a conveying device used for conveying yarn rolls and preventing scattered yarns of the yarn rolls from getting stuck, clamping turnover devices used for grabbing, overturning, lifting and rotating the yarn rolls, a membrane conveying device used for placing coating membranes, attaching the coating membranes onto the yarn rolls and cutting off the coating membranes, a membrane pressing device used for tightly pressing the yarn rolls, membrane pushing devices used for pushing level the coating membranes exceeding the end faces of the yarn rolls onto the end faces of the yarn rolls, and a control system used for controlling the clamping turnover devices, the membrane conveying device, the membrane pressing device and the membrane pushing devices to achieve linkage. The glass fiber yarn roll membrane coating machine is suitable for a membrane coating machine coating a layer of membrane outside glass fiber yarn rolls.

Owner:福德机器人(成都)有限责任公司

Intelligent segmental box girder spraying maintenance system

PendingCN111360995APlay the function of tightening upEasy to fixCeramic shaping apparatusLiquid spraying apparatusInterference fitBall bearing

The invention provides an intelligent segmental box girder spraying maintenance system which comprises a liquid storage tank, a transverse bottom plate, moving wheels, a telescopic air cylinder, a water suction pump, a water suction pipe, a telescopic corrugated pipe, a water liquid collection frame structure, a rotary water outlet frame structure, an auxiliary positioning frame structure, a transverse water guide pipe, an electromagnetic valve, a mounting frame, a controller and a power switch. The transverse bottom plate is mounted at the lower part of the liquid storage tank through bolts;the water suction pump is mounted at the lower middle part of the front side of the liquid storage tank through bolts, and meanwhile, a water inlet is communicated with the liquid storage tank; and the water suction pipe is in threaded connection with a water outlet of the water suction pump. A fixed pipe is inserted into the upper middle part of a U-shaped mounting frame and is in interference fit with an inner ring of a ball bearing, so that the ball bearing can better rotate a connecting disc and a top spraying pipe on the fixed pipe by a certain angle; and a jacking spring is connected tothe outer side of the positioning rod in a sleeving mode and arranged on the inner sides of a limiting plate and a limiting ring at the same time, and fixing of the connecting disc after angle adjustment is facilitated.

Owner:山东博远重工有限公司

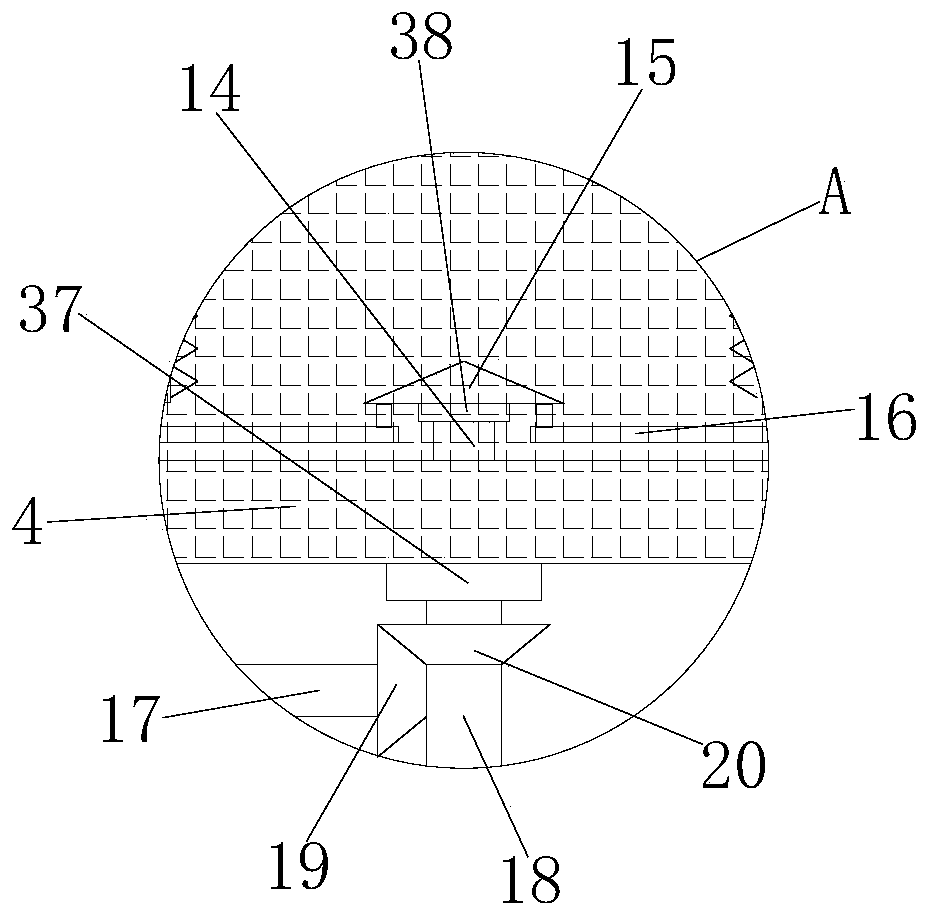

Anti-sloshing spraying unmanned aerial vehicle

InactiveCN108275276AGood for transportationExpand the scope ofAircraft componentsInsect catchers and killersEngineeringMechanical engineering

The invention discloses an anti-sloshing spraying unmanned aerial vehicle. The anti-sloshing spraying unmanned aerial vehicle comprises a containing box used for containing medicine, a first sprayingassembly and a second spraying assembly, wherein the containing box is detachably arranged on an unmanned aerial vehicle body, the bottom of the containing box is fixedly provided with a motor, a shaft front end of the motor is connected to a rotating shaft, the structure of the first spraying assembly is same as that of the second spraying assembly, the first spraying assembly and the second spraying assembly are arranged symmetrically, the first spraying assembly comprises a first spraying rod, a second spraying rod, a hose, a supporting part and a rope, a cavity penetrating through one sideend face of the first spraying rod is formed into an opening A, a cavity penetrating through one side end face of the second spraying rod is formed into an opening B, the containing box is communicated with the cavity of the first spraying rod, one end, close to the opening A, of the first spraying rod is fixedly connected to the supporting part, the supporting part is hinged with the second spraying rod, the two ends of the hose are respectively communicated with the opening A and the opening B, and the two ends of the rope are respectively and fixedly connected with the second spraying rodand the rotating shaft. The anti-sloshing spraying unmanned aerial vehicle has the advantages that the structure is simple, the parking is convenient, and the spraying range is increased.

Owner:CHENGDU RAINPOO TECH CO LTD

Cable wrapping device

ActiveCN110600204AWide range of anglesAccurate angleInsulating conductors/cablesEngineeringMechanical engineering

The invention relates to the technical field of wrapping devices, and aims at providing a cable wrapping device. The device comprises a rack, a wrapping disc rotationally connected to the rack, and adriving motor used for driving the wrapping disc to rotate. A through hole for a cable to pass is formed at the central position of the wrapping disc; an adjusting seat is fixedly connected to the eccentric position of the wrapping disc, and a wrapping rod is hinged to the adjusting seat through a hinge shaft; a wrapping barrel is rotatably connected to the wrapping rod along the axis, and a wrapping tape is wound on the wrapping barrel; and an adjusting device for adjusting the rotating angle of the wrapping rod is arranged on an adjusting seat. The wrapping rod can rotate relative to the wrapping disc, and the adjusting device is used for carrying out adaptive adjustment according to the winding angle of the wrapping tape, so the winding angle range of the wrapping barrel is enlarged, the wrapping disc does not need to be replaced or the installation position of the wrapping barrel does not need to be changed, and the operation is easier and more convenient.

Owner:上海祥龙电缆制造有限公司

Cutting device for package printing and using method thereof

The invention discloses a cutting device for package printing and a using method thereof. The cutting device comprises a rack; a fixed frame and a sliding frame capable of moving on the upper surfaceon the rack are arranged on the upper surface of the rack; an electric positioning cylinder is mounted on the upper surface of the sliding frame; a positioning plate is connected with an output end ofthe electric positioning cylinder; a vertical first screw rod is rotationally mounted on the upper surface of the fixed frame; a second screw rod is coaxially connected with the bottom end of the first screw rod; a first lifting plate and a second lifting plate are separately mounted on the outer sides of the first screw rod and the second screw rod through threads; a cutting knife is connected to the bottom surface of the first lifting plate; and a cutting bottom plate is arranged on the upper surface of the second lifting plate. The cutting device has the benefits that the lifting of the cutting bottom plate can be realized, and the cutting bottom plate assists the cutting knife in cutting, so that the influence on paperboard transporting can be prevented, and the cutting quality is ensured; and the sliding frame is driven by a positioning driving piece to move to adjust the position of the positioning plate, so that the positioning requirements on different cutting lengths can be met, and the application range is wide.

Owner:重庆市永川区华泰印务有限公司

Special damping device used for elbow pipe of petroleum delivering pipeline

The invention discloses a special damping device used for an elbow pipe of a petroleum delivering pipeline, and relates to the technical field of delivering pipelines. The special damping device comprises a filtering device arranged in a straight pipe section of a petroleum pipeline, a fixed rod set is arranged on the filtering device and comprises a first fixed rod and a second fixed rod, a first spring sleeves the first fixed rod, a second spring sleeves the second fixed rod, one ends of the first spring and the second spring are fixed on the filtering device, an arc sliding sleeve is arranged at the position of the elbow pipe, the other end of the first fixed rod is arranged inside the arc sliding sleeve, the other end of the first spring is connected with an opening of the arc sliding sleeve, the other end of the second fixed rod is embedded in an outer wall of the arc sliding sleeve, the other end of the second spring is connected with an opening of the outer wall of the arc sliding sleeve, and buffering stop pieces are symmetrically arranged on an inner wall of the straight pipe section of the petroleum pipeline. The special damping device has the advantages that impact force on the elbow pipe of the petroleum pipeline can be reduced, and petroleum impurities in the pipeline can be recycled effectively.

Owner:弘毅天承知识产权股份有限公司

Cold-chain transportation device capable of measuring and monitoring in real time

InactiveCN109850384ASolve the problem of missing temperature detection functionAffect food qualityLiving organism packagingDomestic cooling apparatusMicrocomputerCold chain

The invention discloses a cold-chain transportation device capable of measuring and monitoring in real time. The device comprises a box body, storing racks, a first temperature sensor, a storing box and a second temperature sensor, wherein the first temperature sensor is clamped at the inner side of a fixing rack; a camera is mounted on the inner wall of the box body at one side of the control box; the storing rack is stored in the box body; the storing boxes are positioned at the upper part of the supporting plate; a second cold air pipe is mounted at the inner side of the storing rack at thefront side of the storing box; a first cold air pipe is mounted at the inner side of the storing rack at the rear side of the storing box; the second temperature sensor is mounted at the inner side of a cover plate; and a buzzer is mounted on the surface of the storing box. According to the device, the storing box, the second temperature sensor, the buzzers, the storing rack, a cold air box, thefirst cold air pipe, the second cold air pipe, the box body, the camera, the first temperature sensor and a single-chip microcomputer structure are arranged, so that the problems that a cold fresh product storing box cannot perform temperature detecting function, a support for storing cold fresh products is not provided with an external cooling structure, and the inner condition of a cold fresh product conveying device cannot be monitored, can be solved.

Owner:XINJIANG SHIHEZI VOCATIONAL TECHN COLLEGE

Full-automatic coal bunker water cannon dredging device

InactiveCN104085625AReduce fuel self-injectionAvoid running unsafe factorsLarge containersElectricitySpray nozzle

The invention relates to a full-automatic coal bunker water cannon dredging device which is particularly used for dredging blockage inside a coal bunker through pressurized water, and belongs to the technical field of coal bunker devices. The full-automatic coal bunker water cannon dredging device comprises a plurality of spray nozzles, a water conveying pipeline, a water tank and a control cabinet. All the spray nozzles are connected with a main water conveying pipe through branch water conveying pipes. The main water conveying pipe is connected with the water tank. An electromagnetic valve is arranged on each branch water conveying pipe. A pressurization pump is arranged between the water tank and the water conveying pipeline. A water level indicator is arranged in the water tank. A water supplementation valve is arranged on the water inlet of the water tank. A PLC and a time relay are arranged in the control cabinet. The PLC is electrically connected with the water supplementation valve, the water level indicator, the pressurization pump and the electromagnetic valve. By means of the full-automatic coal bunker water cannon dredging device, potential safety hazards caused by blockage and coal shortage in running of a mill can be eliminated, the fuel oil self-injection situation which is caused by coal shortage to the mill is reduced, unsafe factors can be avoided as much as possible for running of a unit, and therefore safety, reliability and economical efficiency of running of the unit are greatly improved; the advantages of being safe, saving energy and being low in cost and good in dredging effect are achieved, and no influence on coal conveying is produced.

Owner:WUXI HUATONG ENVIRONMENTAL PROTECTION EQUIP CO LTD

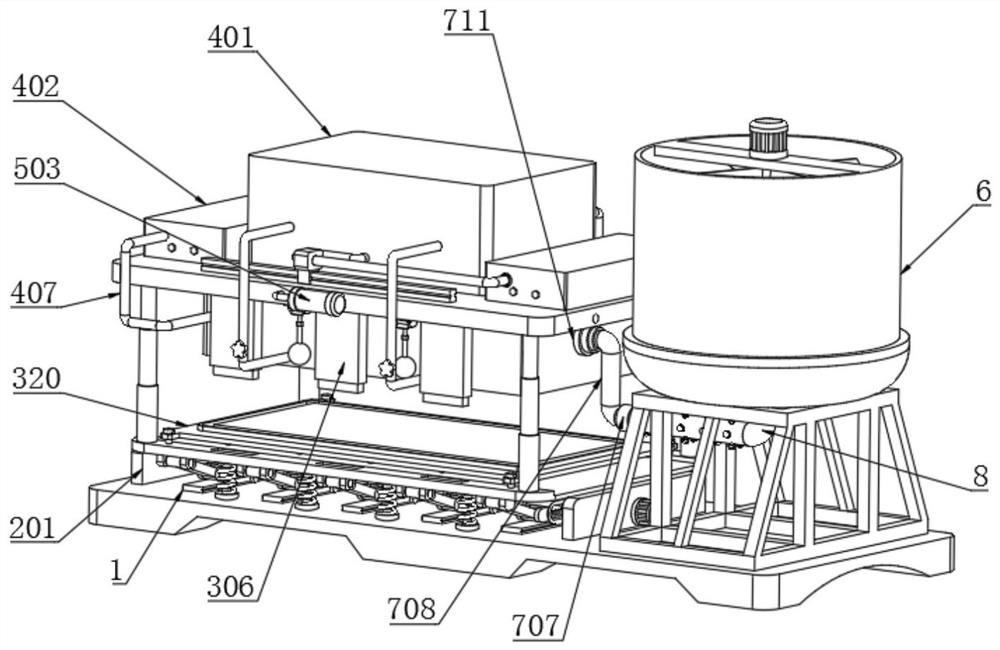

Spraying device for optical cable gel

ActiveCN110918291AQuality improvementTransport impactPretreated surfacesFibre mechanical structuresStructural engineeringMechanical engineering

The invention discloses a spraying device for optical cable gel, and belongs to the technical field of optical fiber manufacturing equipment. The spraying device comprises a bearing plate, a fixing plate, a feeding assembly, a discharging assembly, a rotating assembly, a spraying assembly, a gel supply assembly and a heating assembly, wherein the bearing plate is arranged on the ground, the fixingplate is arranged on the bearing plate, the feeding assembly and the discharging assembly are of the same structure and are separately arranged on the two sides of the fixing plate, the rotating assembly is mounted on the fixing plate, the spraying assembly is mounted on the rotating assembly, the gel supply assembly is arranged beside the fixing plate, and the heating assembly is mounted on thefixing plate. By the adoption of the spraying device, the problem when an existing spraying device for optical cable gel is used for spraying cable gel on the surfaces of optical fibers, a fixed sprayhead cannot uniformly spray the cable gel on the surfaces of the round optical cables, and consequentially, the spraying quality is affected is solved.

Owner:山东鹰联光电科技股份有限公司

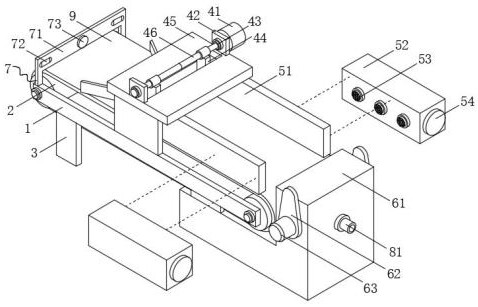

Automatic cutting device for plastic bottle opening residues

PendingCN109352962AGuaranteed smoothImprove cutting efficiencyDomestic articlesEngineeringConveyor belt

The invention relates to the field of polyurethane bottle production equipment, in particular to an automatic cutting device for plastic bottle opening residues. The invention provides the technical scheme that the automatic cutting device for the plastic bottle opening residues comprises a rack, wherein a conveyor belt and a support are arranged on the rack; a drive mechanism is arranged on the support; an output shaft of the drive mechanism is connected with a rotating plate; a cutting knife is fixed onto the support and is located under the rotating plate; a clamping mechanism is further fixed onto the support and is located beside the rotating plate; a rotating and clamping slot for clamping and rotating a plastic bottle is formed in the area between the clamping mechanism and the rotating plate. The automatic cutting device for automatically cutting the plastic bottle opening residues provided by the invention solves the problem that the residues of the clamping part of the bottlebody can be only cut manually.

Owner:成都伟福实业有限公司

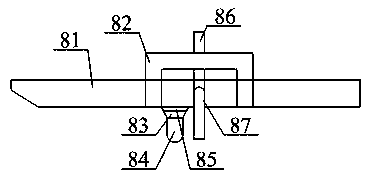

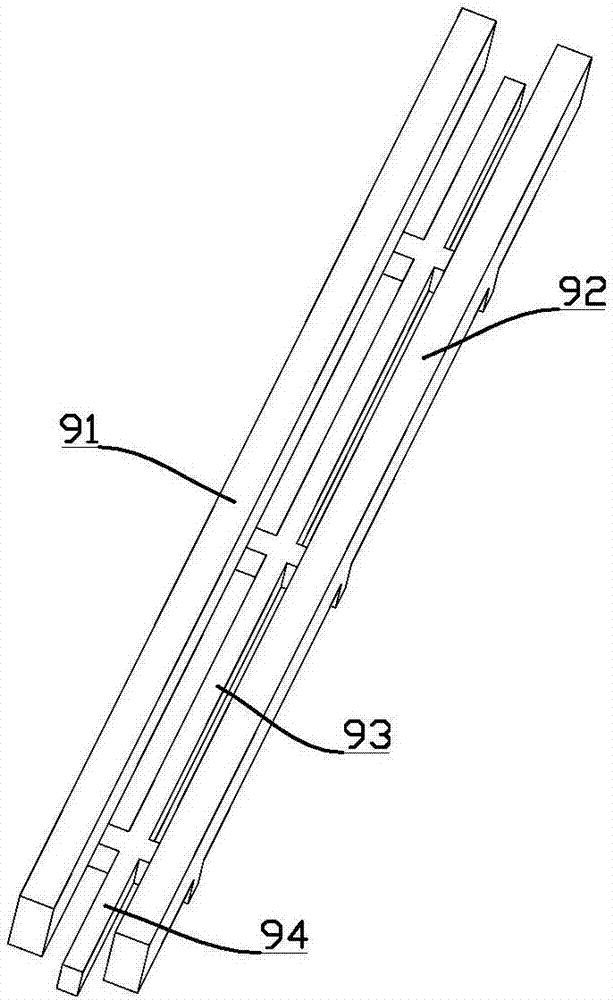

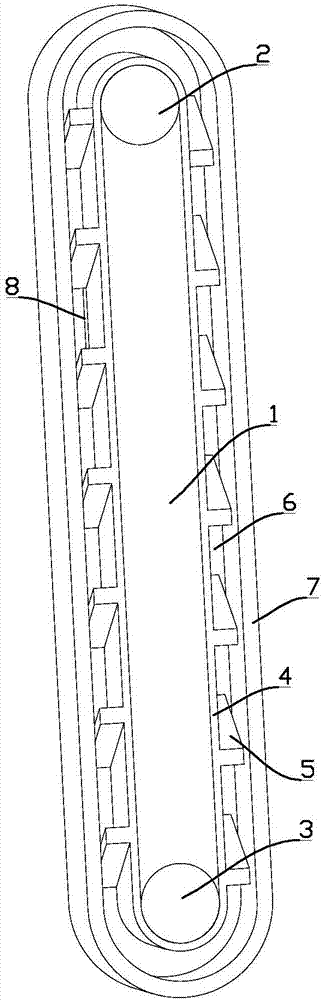

Bearing conveying and lifting device

PendingCN107458814ASimple structureEasy to useConveyorsMetal working apparatusEngineeringStructural engineering

The invention discloses a bearing conveying and lifting device. The bearing conveying and lifting device comprises a conveying groove and a lifting device; a discharge port of the conveying groove is positioned at the lower part of the lifting device; one end of the discharge port of the conveying groove is lower than the other end; the conveying groove comprises a left baffle plate, a right baffle plate, and a support rod at the middle part between the left baffle plate and the right baffle plate; the left baffle plate, the right baffle plate and the support rod are fixed through connecting rods; the lifting device comprises a bracket vertically fixed; a driving roller and a driven roller are respectively fixed at the top and the bottom of the bracket; a lap of conveying belt coats the bracket; the conveying belt is driven through the driving roller; multiple inclined stoppers are uniformly fixed on the outer surface of the conveying belt; the heights of two ends of the inclined stoppers are different; a back baffle plate integrated with the bracket is fixed at the back part of the bracket; side retainer rings are fixed at the side parts; gaps are formed between the side retainer rings and the inclined stoppers; and the back baffle plate is provided with discharge ports in the upper parts of operation trajectories of the inclined stoppers. The bearing conveying and lifting device realizes automatic conveying and lifting of bearing blanks.

Owner:长兴三通机械有限公司

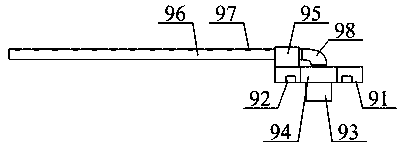

Bearing machining feeding and conveying device capable of being adjusted

PendingCN107499871ARealize automatic feedingImplement preprocessingConveyorsConveyor partsElectric machineryStructural engineering

The invention discloses a bearing machining feeding and conveying device capable of being adjusted. The bearing machining feeding and conveying device capable of being adjusted comprises a rotary disc, a motor, a rotating block, a cleaning rod, a baffle ring, a first baffle, a second baffle, an adjusting rod and a conveying trough. The conveying trough comprises a left baffle, a right baffle and a supporting rod, and the left baffle, the right baffle and the supporting rod are mutually fixed through connecting rods. According to the bearing machining feeding and conveying device capable of being adjusted, automatic feeding and conveying of bearing green bodies are achieved, and adjustment can be conducted on bearings according to the different sizes of the outer diameters of the bearings.

Owner:长兴三通机械有限公司

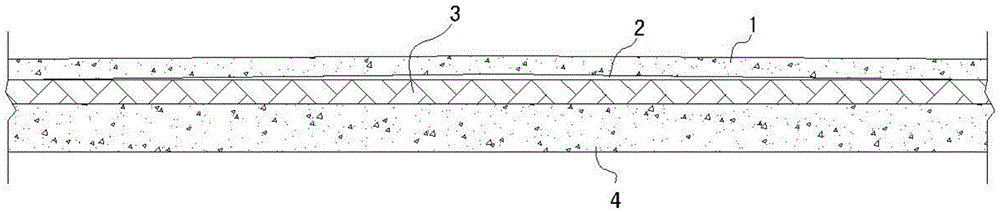

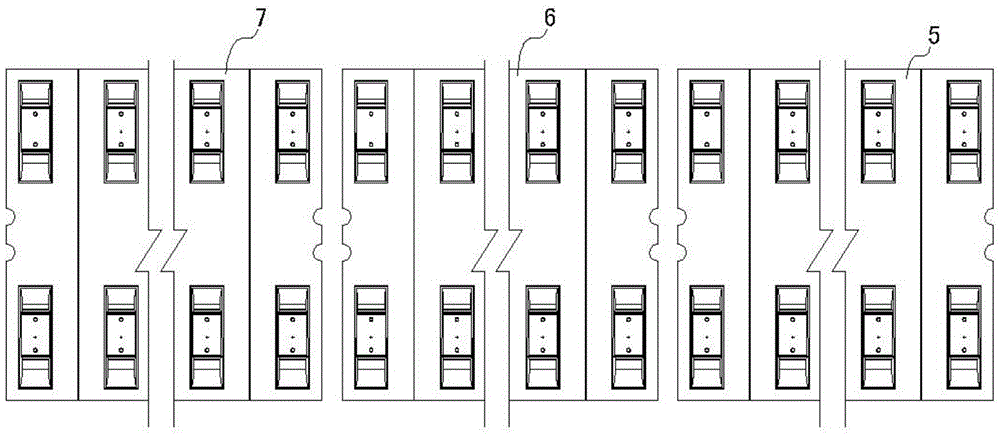

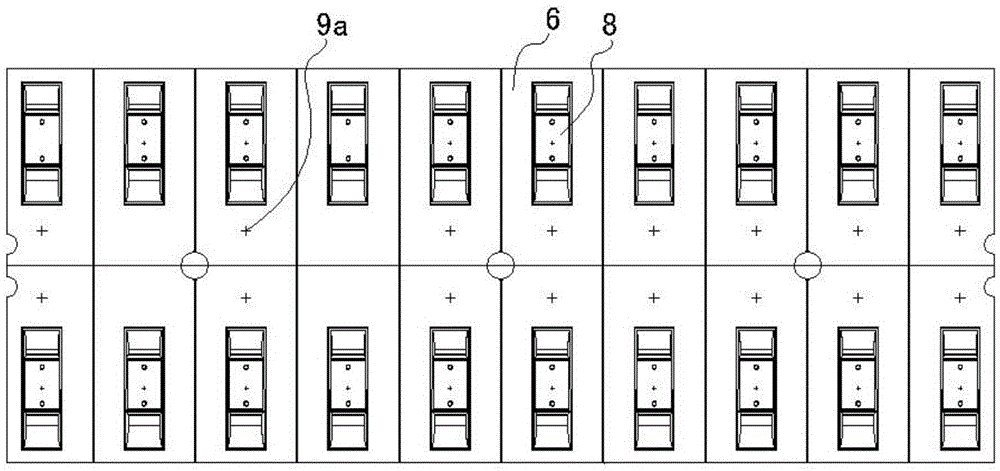

High-speed rail crts Ⅱ type slab ballastless track track slab gap adjustment method

InactiveCN103952952BAvoid expansionPrevent lateral movementRailway track constructionEngineeringSteel bar

Owner:中铁二十四局集团安徽工程有限公司 +1

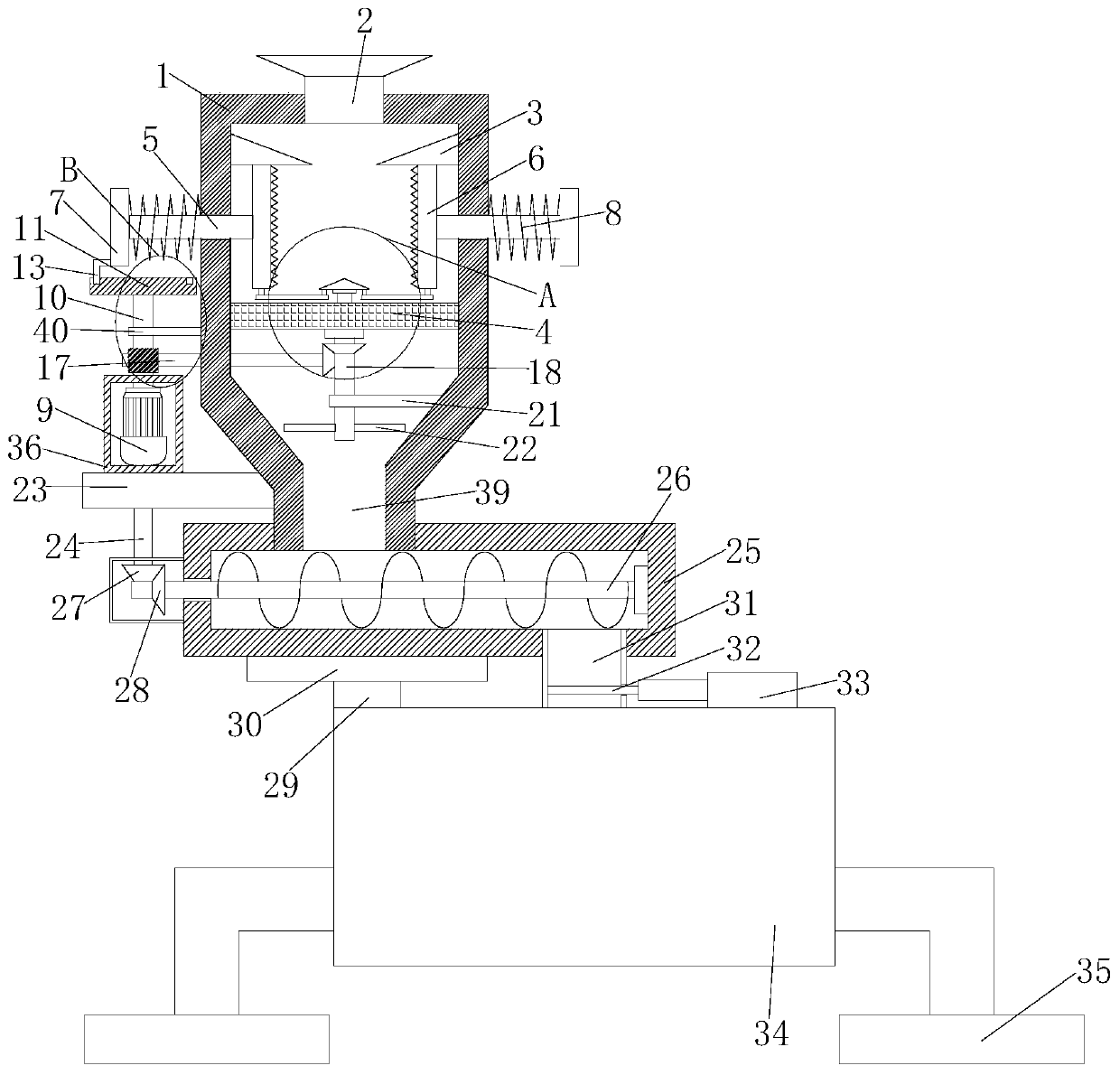

Quantitative feeding system for anode casting machine

InactiveCN111390147ATransport impactPrevent affecting casting efficiencyMolten metal supplying equipmentsElectric machineryStructural engineering

The invention belongs to the technical field of anode casting equipment, and particularly discloses a quantitative feeding system for an anode casting machine. The quantitative feeding system comprises a processing box and the casting machine; a feeding port is formed in the top of the processing box, and a discharging port is formed in the bottom of the processing box; two inclined plates are symmetrically installed on the inner walls of two sides of the processing box; a filtering plate is fixed in the processing box; supporting rods are slidably installed on two sides of the processing box,crushing plates are fixedly installed on one sides of the two supporting rods, the two crushing plates are matched with each other, and fixing plates are fixedly installed on the other sides of the two supporting rods; and a mounting plate is fixedly installed on one side of the processing box, a mounting box is fixedly installed at the top of the mounting plate, a double-shaft motor is fixedly installed in the mounting box, and the bottom end of a first driving shaft is fixedly installed on one output shaft of the double-shaft motor. The quantitative feeding system can control the conveyingquantity of raw materials, also can prevent hard objects from being mixed into the raw materials and affecting the casting effect through crushing and stirring, greatly increases the utilization rateof the raw materials, and reduces environmental pollution.

Owner:罗峰

Energy-saving and heat-preservation type preparation equipment for concrete blocks

InactiveCN112692957AImprove uniformityReduce gapDischarging arrangementFeeding arrangmentsElectric machineGear wheel

The invention discloses energy-saving heat preservation type preparation equipment for concrete blocks. The equipment comprises a bottom plate, wherein a stirring tank is fixedly connected to the side position of the top end of the bottom plate, a discharging pipe is fixedly connected to the bottom end of the stirring tank, a vibration stirring mechanism is fixedly connected to the position, corresponding to one side of the stirring tank, of the top end of the bottom plate, and the vibration stirring mechanism comprises a fixed plate, a rotating rod, a rotating block, a shaking plate, a rotating shaft, a rotating motor, a sliding plate and a limit plate. The equipment is scientific and reasonable in structure and safe and convenient in use; the vibration stirring mechanism is arranged, and the rotating shaft is driven by the rotating motor to rotate, so that the rotating shaft drives a gear to rotate, and the gear is matched with a cam through the arrangement of a sector gear; and an incomplete gear mechanism is formed to drive a moving frame to repeatedly slide, the shaking plate is pushed through cooperation of a rotating plate and rotates and swings along the rotating rod, concrete in a mold is stirred, and the uniformity of the concrete in the mold is improved.

Owner:韦海强

Bearing feeding and conveying device capable of adjusting

PendingCN107458849ARealize automatic feedingImplement preprocessingPackagingConveyor partsElectric machineryEngineering

The invention discloses a bearing feeding and conveying device capable of adjusting. The device comprises a turntable, a motor, a rotating block, a cleaning rod, a retainer ring, a first baffle plate, a second baffle plate and a conveying groove; and the conveying groove comprises a left baffle plate, a right baffle plate, a support rod, an adjusting rod, a hand wheel and a retainer ring. The device realizes automatic feeding and conveying of bearing blanks, and can be adjusted when conveying bearings with different thicknesses.

Owner:长兴三通机械有限公司

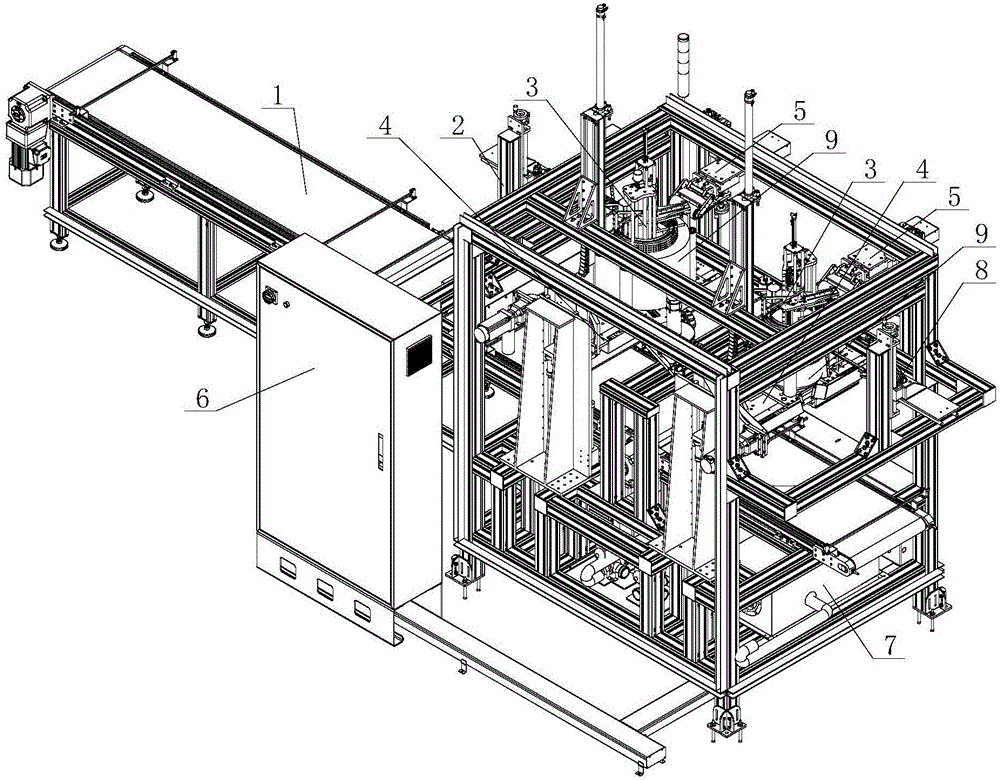

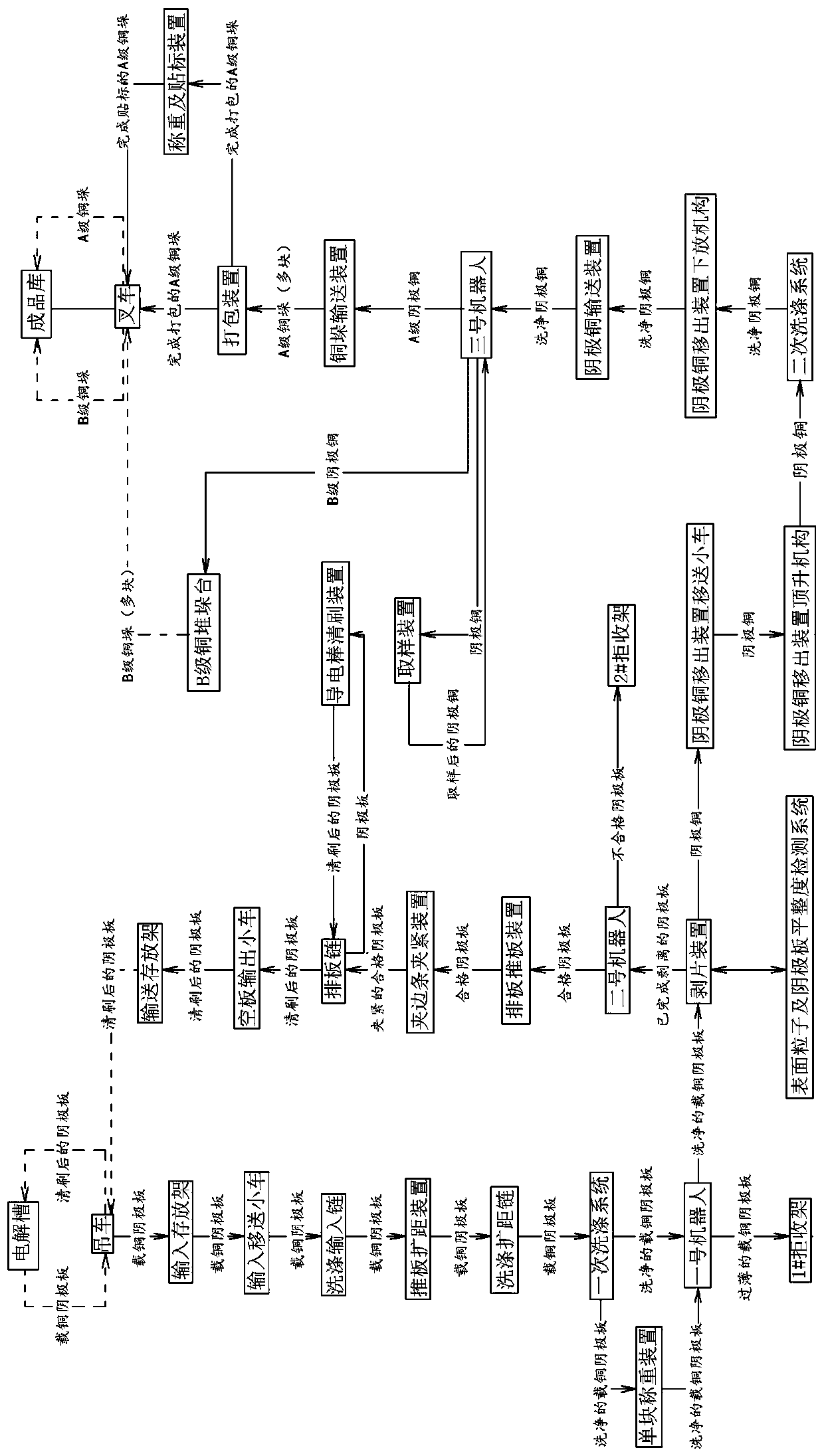

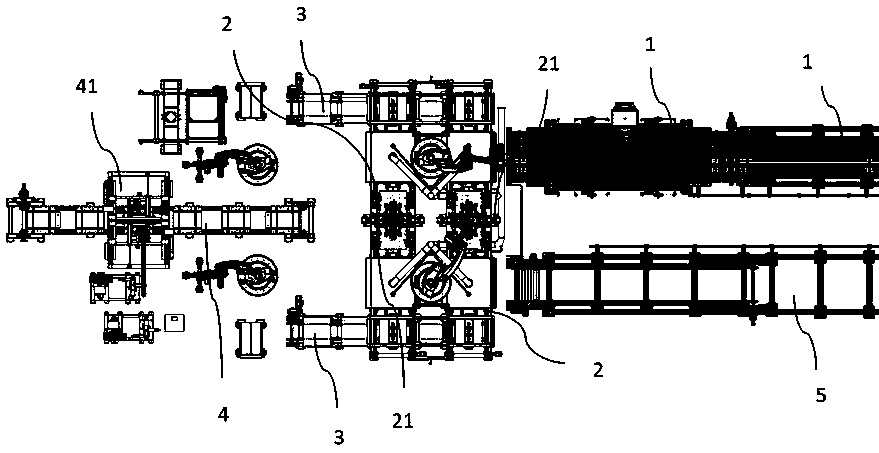

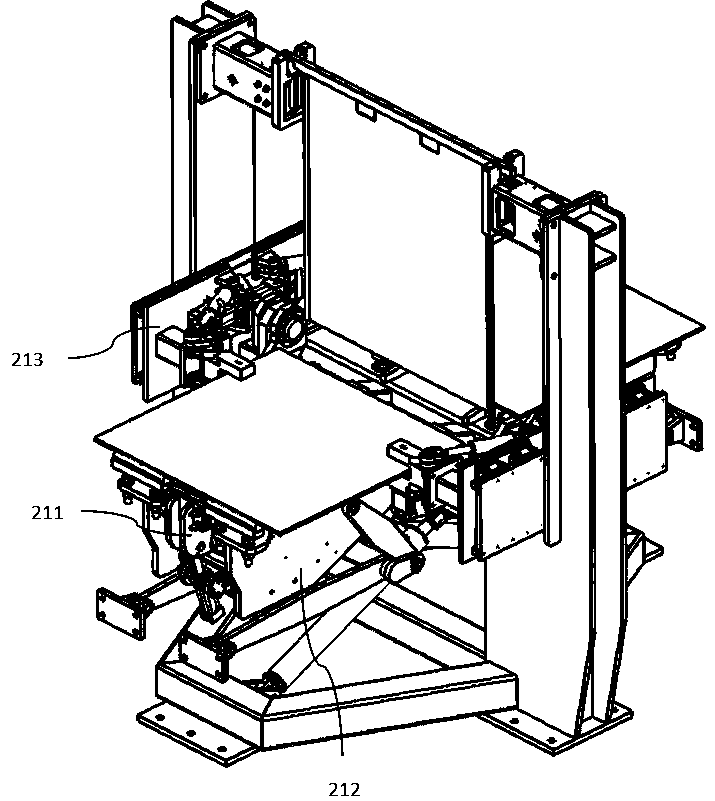

Copper electrolysis cathode washing and stripping process and cathode washing and stripping unit thereof

ActiveCN111424292AIncrease valueEasy to check instantlyElectrolysis componentsProcess efficiency improvementElectrolysisCopper

The invention belongs to the technical field of electrolytic smelting, and discloses a copper electrolysis cathode washing and stripping process and a cathode washing and stripping unit thereof. The process comprises the following steps of S1, carrying out first-time washing on a cathode plate attached with cathode copper through plate pushing and distance expanding; S2, feeding the cathode plateattached with the cathode copper and obtained after the first-time washing into a stripping system for stripping of the cathode copper; S3, flatly laying two pieces of mutually-connected cathode copper which are stripped from the surfaces of the two sides of the cathode plate; S4, tearing and separating the two pieces of mutually-connected cathode copper; S5, removing the cathode copper from the torn part, and carrying out second-time washing on the smooth face of the cathode copper; and S6, transferring the cathode copper obtained after the second-time washing to a conveying chain, and transferring the qualified cathode copper to a packaging chain by the conveying chain for packaging. According to the copper electrolysis cathode washing and stripping process and the cathode washing and stripping unit thereof, the two pieces of cathode copper on the two sides of the cathode plate are creatively turned, torn and separated during stripping, the situation that the smooth face of the cathode copper cannot be exposed to the outside due to continuous adhesion of the two pieces of cathode copper is avoided, and then the cathode copper with the smooth face facing upwards undergoes second-time washing, and then impurities on the smooth face of the cathode copper can be removed to the maximum extent.

Owner:株洲优瑞科有色装备有限公司

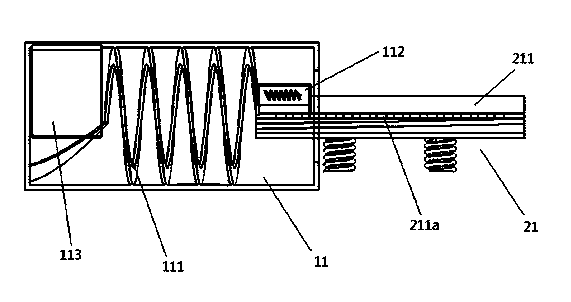

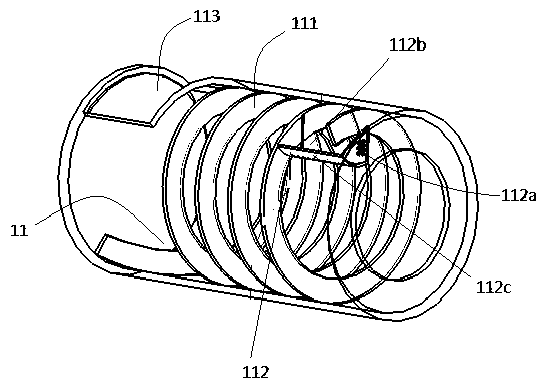

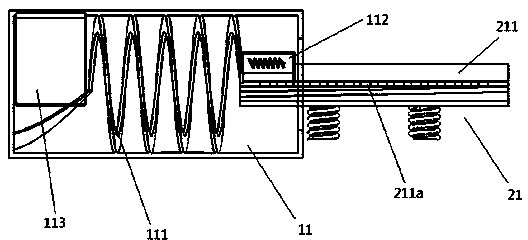

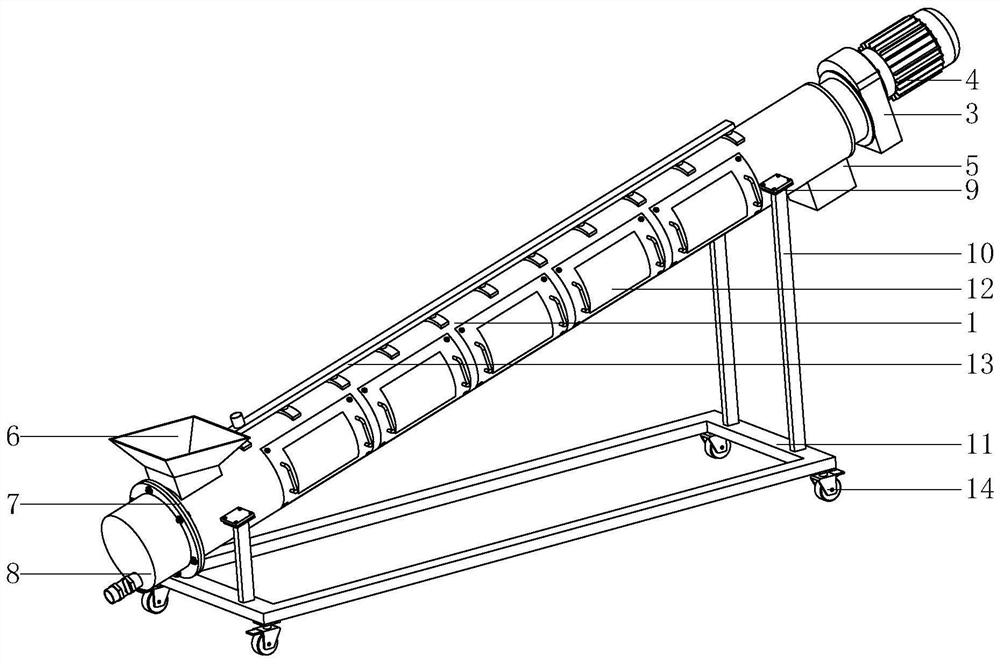

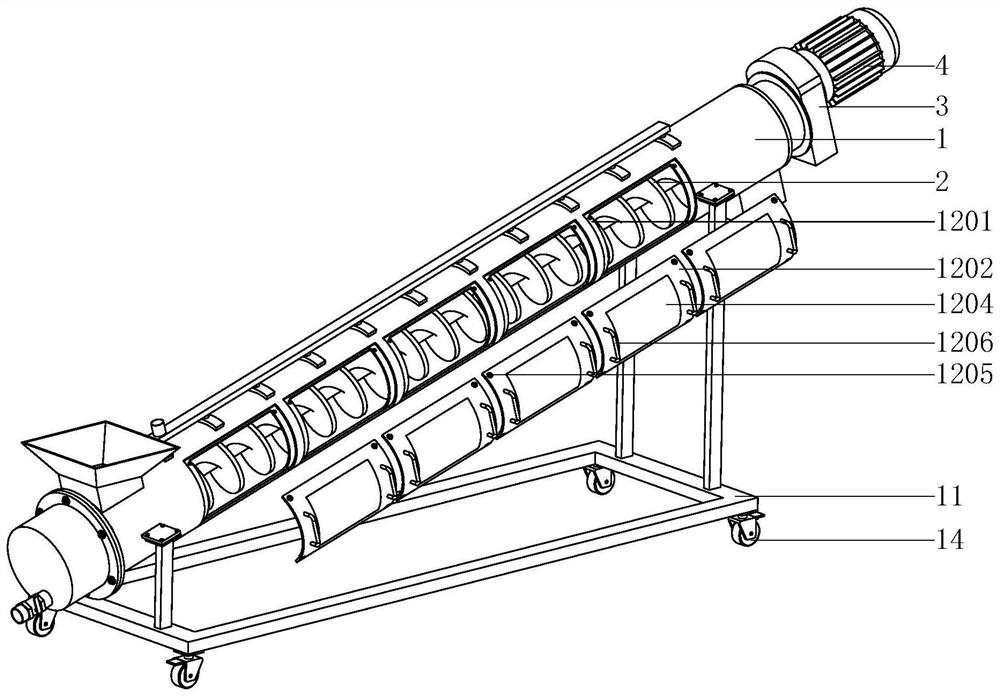

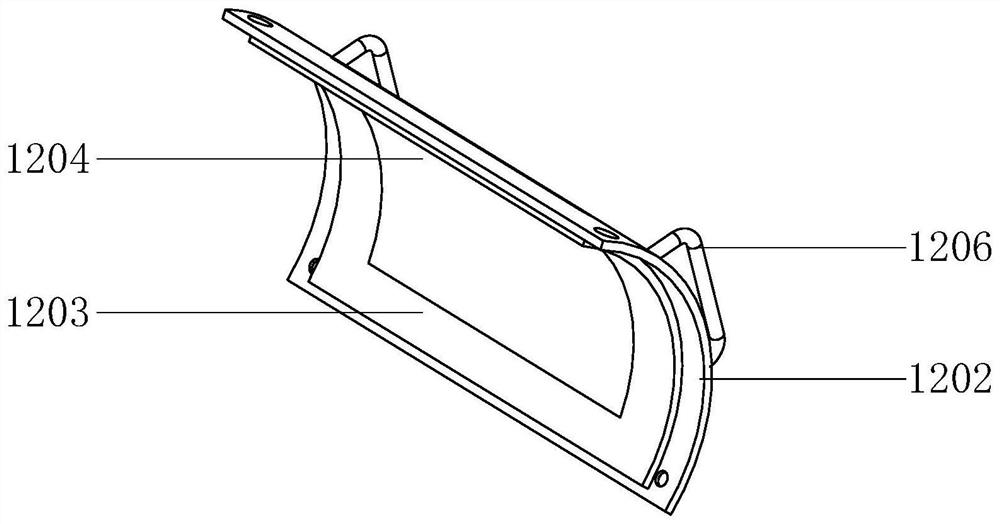

Spiral conveying and drying device

ActiveCN104121765ARealize the conveying effectPlay a water removal effectDrying machines with progressive movementsHeating arrangementEngineeringMechanical engineering

The invention provides a spiral conveying and drying device. The spiral conveying and drying device comprises a feeding assembly and a drying assembly, wherein the feeding assembly is used for receiving materials cleaned in a cleaning section and conveying the materials to a drying section; the drying assembly is used for receiving the materials sent by the feeding assembly and drying the materials; the feeding assembly comprises a circulation roller, and one end of the circulation roller is suitable for being connected to a material outlet of the cleaning section and receiving the cleaned materials; the inner wall of the circulation roller is provided with a spiral conveying channel and a bucket, a drainage port and a bucket opening are formed in the bucket, and the bucket opening corresponds to a discharge port of the spiral conveying channel; in the rotating process of the circulation roller, the bucket opening receives the materials from the discharge port and dumps the materials into the drying assembly. The spiral conveying and drying device achieves the conveying function and has a good drying effect.

Owner:SHENZHEN KAIZHONG PRECISION TECH CO LTD

Industrial workshop assembly line conveying equipment based on automatic deviation rectifying mechanism

InactiveCN113479553ATransport impactPrevent agingConveyorsCleaningTransmission beltElectric machinery

The invention discloses industrial workshop assembly line conveying equipment based on an automatic deviation rectifying mechanism, and belongs to the technical field of assembly line conveying equipment. The industrial workshop assembly line conveying equipment comprises two side plates, two transmission rollers, the automatic deviation rectifying mechanism, a clearing mechanism and an infrared detection mechanism, wherein the two transmission rollers are rotationally connected between the two side plates, the outer sides of the two transmission rollers are sleeved with a conveying belt, the lower surfaces of the side plates are fixedly connected to supporting legs, and the upper surfaces of the two side plates are fixedly connected to the automatic deviation rectifying mechanism. According to the industrial workshop assembly line conveying equipment, by arranging the automatic deviation rectifying mechanism, when a first motor works, threaded columns are driven to rotate through a first rotating shaft, threaded caps can stably move front and back along a track under the action of the automatic deviation rectifying mechanism, the thread directions of the two threaded columns are opposite, and on the contrary, two deviation rectifying plates are away from each other, the positions of parts are limited according to the actual situation, the parts deviating from the track are moved to the normal track, and transportation of the parts is not affected.

Owner:马鞍山市数知物联科技有限公司

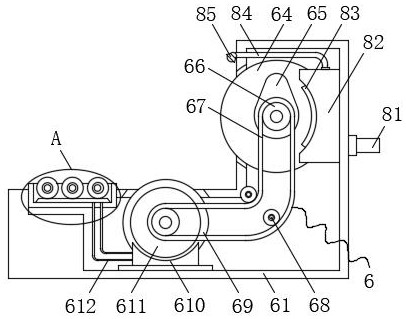

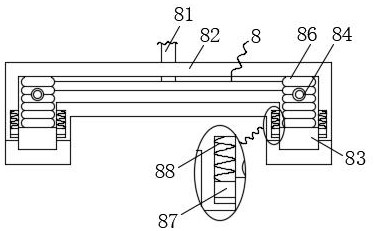

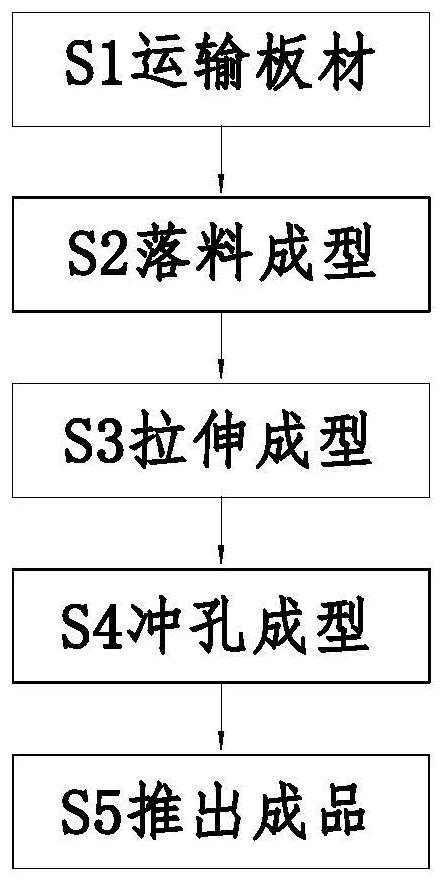

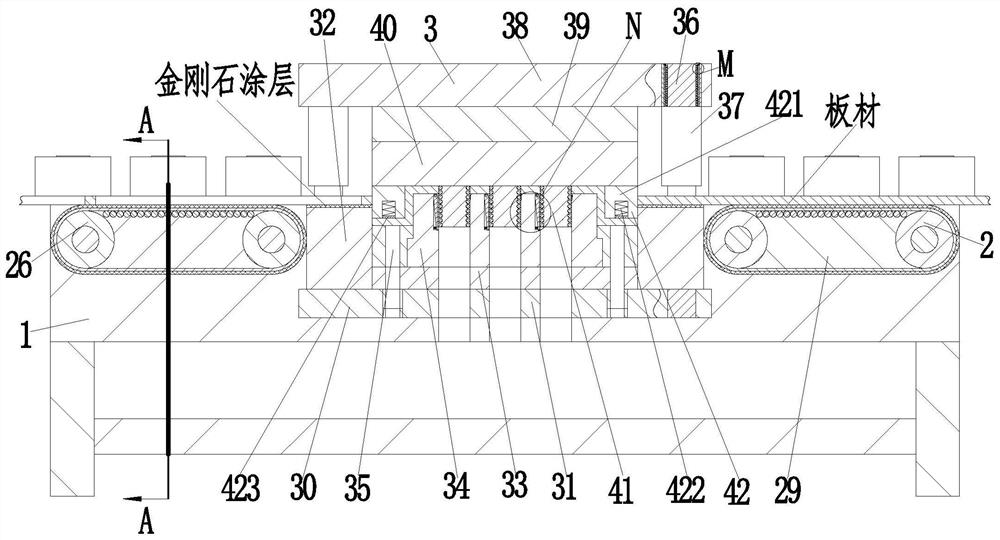

Electric appliance cabinet metal plate punch forming machining method

The invention relates to an electric appliance cabinet metal plate punch forming machining method. A workbench, a conveying device and a punching device are included, wherein the conveying device is fixedly installed at the front end of the left side of the workbench, and the punching device is fixedly installed in the middle of the upper end of the workbench. The conveying device comprises a first motor, a first gear, a second gear, a first chain wheel, a first toothed chain belt, a second chain wheel, a second toothed chain belt, a belt and a supporting plate. Plates are positioned and intermittently conveyed through the conveying device, manual control is not needed in the whole process, blanking, stretching and punching are conducted on the plates through the punching device, and in the whole process, a first male die provided with a waste falling hole makes complete contact with the surfaces of the plates, so that the surfaces of the plates are completely stressed, meanwhile, holes in the plates are ground in the punching process, and subsequent machining is not needed.

Owner:南京皮斯特新能源科技有限公司

Soft robot having transport function for material transport

InactiveCN109352622AIncrease flexibilityIncrease the number of bearersProgramme-controlled manipulatorGripping headsControl theoryMaterial transport

The invention discloses a soft robot having a transport function for material transport, and relates to the technical field of soft machines for material transport. The soft robot comprises an outer rod and a transport box; an inner rod is arranged in the outer rod; the right side of the outer rod is provided with bearing plates; a shaft sleeve is arranged between each bearing plate and the outerrod; a clamping slot is formed in the bottom part of the transport box; and the transport box is located at the left side of the outer rod. According to the soft robot having the transport function for material transport, by installation of the outer rod, the whole robot can be supported directly; the inner rod is arranged in the outer rod; on one hand, the inner rod cooperates with the outer rodto support the robot, so that stability is increased; on the other hand, the inner rod can cooperate with a size between the shaft sleeves, and thus, the inner rod and the shaft sleeves cooperate witheach other to form a rotating structure; thus, flexibility of the bearing plates can be increased; and the bearing plates are arranged in parallel in the vertical direction of the outer rod by two groups, thus being in favor of increasing bearing capacity of each bearing plate.

Owner:DONGGUAN UNIV OF TECH

Supporting fin type automatic roller way scale and rolling material conveying roller way

PendingCN108820693APrecise deliveryTransport impactConveyorsControl devices for conveyorsEngineeringMechanical engineering

Owner:DAYE SPECIAL STEEL CO LTD

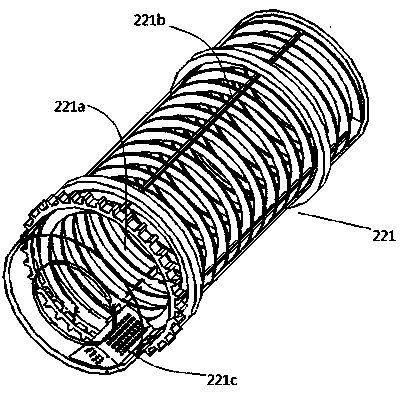

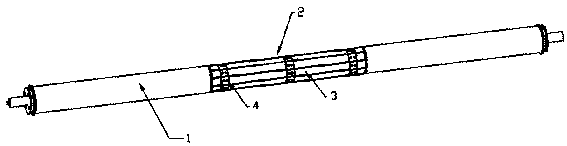

Expansion and contraction type wire drawing machine conveying roller

PendingCN109576402AEnsure the soft effectKeep it flatSkins/hides/leather/fur manufacturing apparatusLeather softeningEngineeringWire drawing

The invention relates to an expansion and contraction type wire drawing machine conveying roller. The expansion and contraction type wire drawing machine conveying roller comprises a conveying rollerbody, the conveying roller body is provided with at least one expansion section, the expansion section is provided with a plurality of expansion pieces which are annularly distributed, an expansion driving mechanism which is internally arranged in an annular inner ring formed by the multiple expansion pieces, and the expansion driving mechanism drives the expansion pieces to move in the radial direction of the annular radial direction. The conveying roller has the advantages that the expansion section is arranged on the conveying roller body, and the expansion pieces are used for moving in a radial direction, so that the caliber of the expansion section changes, and then the whole conveying roller body forms a state which is high in middle and low in two sides; and when the conveying roller is used for conveying a conveying belt of a tensioning soft machine, the conveying belt forms the state which is high in middle and low in two sides, so that when leather is conveyed from the conveying belt, the leather is prevented from getting close to the middle position of the conveying belt to be stacked, the phenomenon of wrinkling is avoided, and the soft effect of the leather is ensured.

Owner:NANTONG SIRUI ENG

Spiral conveying and drying process

ActiveCN104121764ARealize the conveying effectPlay a water removal effectDrying machines with progressive movementsDrying solid materialsEngineeringMechanical engineering

The invention provides a spiral conveying and drying process. The spiral conveying and drying process comprises the first step that a feeding assembly is adopted to convey materials cleaned in a cleaning section to a drying section, and the second step that a drying assembly is adopted to dry and then output the materials from the feeding assembly, wherein the feeding assembly comprises a circulation roller, and one end of the circulation roller is suitable for being connected to a material outlet of the cleaning section and receiving the cleaned materials; the inner wall of the circulation roller is provided with a spiral conveying channel and a bucket, a drainage port and a bucket opening are formed in the bucket, and the bucket opening corresponds to a discharge port of the spiral conveying channel; in the rotating process of the circulation roller, the bucket opening receives the materials from the discharge port and dumps the materials into the drying assembly. By the adoption of the spiral conveying and drying process, the materials are dumped into the drying assembly through the bucket opening after moisture in the materials is fully filtered out, and consequently the conveying function and a good drying effect are simultaneously achieved.

Owner:SHENZHEN KAIZHONG PRECISION TECH CO LTD

Auxiliary mechanism for bending petroleum pipeline

ActiveCN111922811AEasy to operateImprove machining accuracyGrinding carriagesRevolution surface grinding machinesPhysicsMechanical engineering

The invention discloses an auxiliary mechanism for bending a petroleum pipeline, and belongs to the technical field of petroleum pipeline processing. The auxiliary mechanism includes a pipeline bending device, an auxiliary table, a polishing device, an auxiliary device, a fixing device, and a limiting device. The polishing device includes an adjustment assembly and a polishing assembly. The auxiliary device is arranged at the front end of the polishing device, the fixing device includes a driving assembly and a fixing assembly, the fixing assembly is installed at the front end of the polishingdevice, the driving assembly is arranged on the adjusting assembly, and the driving assembly is matched with the fixing assembly. The limiting device includes a restricting assembly and a plurality of limiting assemblies. The limiting assemblies are distributed at the front of the polishing assembly at equally intervals. The restricting assembly is installed above the adjusting assembly and the restricting assembly is matched with all the limiting assemblies. The deformation of the pipeline bending positions at the time of bending the pipeline can be reduced or even prevented through the auxiliary device, the pipeline bending position can be polished by the polishing device, and the quality of the pipeline is improved.

Owner:烟台云汇智能科技有限公司

Unmanned-aerial-vehicle spraying device

InactiveCN108157337ATransport impactFlight impactAircraft componentsInsect catchers and killersEngineeringMechanical engineering

The invention discloses an unmanned-aerial-vehicle spraying device. The unmanned-aerial-vehicle spraying device comprises a containing box for containing pesticide, a first spraying assembly and a second spraying assembly. The containing box is detachably installed on an unmanned-aerial-vehicle body, a motor is fixed at the bottom of the containing box, a winding shaft is connected to the shaft front end of the motor, and the first spraying assembly and the second spraying assembly are same in structure and are symmetrically arranged; the first spraying assembly comprises a first spraying rod,a second spraying rod, a flexible pipe, a supporting piece and a rope, both the first spraying rod and the second spraying rod comprise cavities penetrating through one side end faces of the first spraying rod and the second spraying rod to form an opening A and an opening B respectively, the containing box is communicated with a cavity of the first spraying rod, the supporting piece is fixedly connected to the end, close to the opening A, of the first spraying rod, and is hinged to the second spraying rod, the two ends of the flexible pipe are communicated with the opening A and the openingB respectively, and the two ends of the rope are fixedly connected with the second spraying rod and the winding shaft respectively. According to the unmanned-aerial-vehicle spraying device, the structure is simple, parking is convenient, and the spraying range is widened.

Owner:CHENGDU RAINPOO TECH CO LTD

Tubular spiral conveyor for kitchen garbage

PendingCN113772360AImprove work efficiency andImprove the delivery effectCleaningRefuse gatheringElectric machineryScrew conveyor

The invention belongs to the technical field of kitchen garbage treatment, and particularly relates to a tubular spiral conveyor for kitchen garbage. The tubular spiral conveyor comprises a conveying shell, a spiral body is rotatably connected in the conveying shell, the upper side shaft end of the spiral body penetrates through the conveying shell and is connected with a speed reducer, and a motor is mounted on the speed reducer; and a discharging port is fixed to the lower side wall of the upper end of the conveying shell, a feeding port is fixed to the upper side wall of the lower end of the conveying shell, a flange is fixed to the side wall of the periphery of the bottom end of the conveying shell, a liquid filtering structure is arranged on one side of the flange, fixing blocks are fixed to the front side wall and the rear side wall of the conveying shell, and the fixing blocks are connected with supporting legs through fixing bolts. The blocked part of the tubular spiral conveyor is checked through a transparent plate, then a screw at the corresponding position is unscrewed, a dredging cover at the corresponding position is taken down, so that the blocked part of the tubular spiral conveyor can be quickly dredged by an operator conveniently, the whole shell does not need to be disassembled, and the working efficiency of the operator is improved.

Owner:镇江天韵德环境工程有限公司

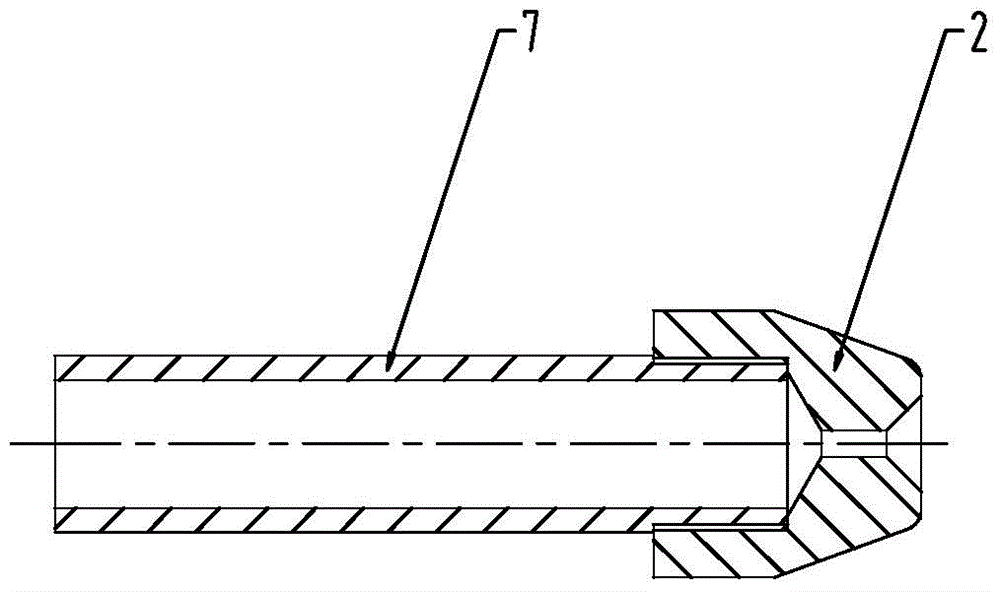

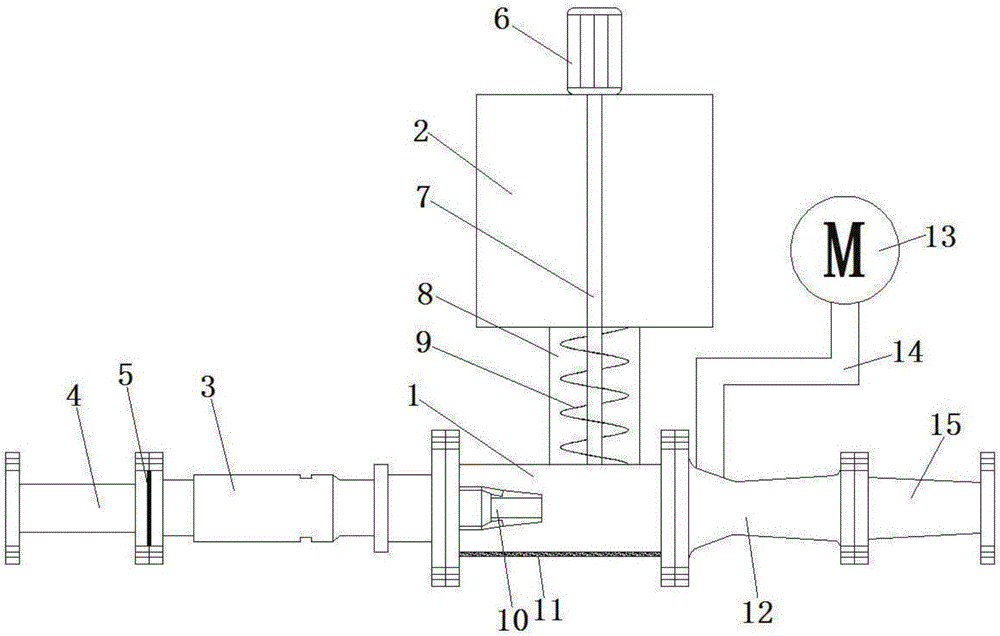

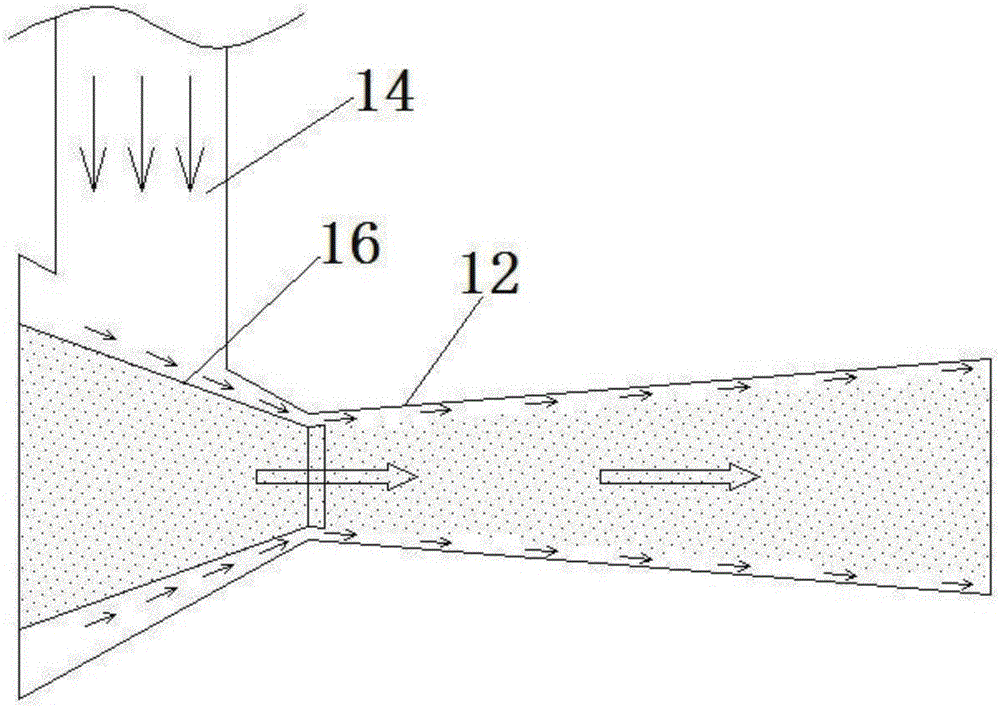

Structurally improved continuous material delivery pump

The invention discloses a structurally improved continuous material delivery pump. The structurally improved continuous material delivery pump comprises a storage silo, a pump body, an adjustable ejector and a Venturi tube, wherein the storage silo is connected to the pump body by a material inlet pipe, an annular jet nozzle is arranged in the pump body, the gas inlet end of the pump body is connected with the adjustable ejector, a first pipe casing is additionally arranged at the gas inlet end of the adjustable ejector, and a dust gauze is arranged between the adjustable ejector and the first pipe casing; the discharge end of the pump body is connected with the Venturi tube; an auger is arranged in the material inlet pipe, a main shaft is fixedly arranged at the center of the auger in a penetrating manner and penetrates the storage silo to be in transmission connection with a motor arranged at the top of the storage silo; a discharge nozzle is arranged at the discharge end of the pump body and extends into the Venturi tube, and a slit ring is formed between the discharge nozzle and the Venturi tube; and the side surface of the Venturi tube is connected with a high-pressure blower by a high-pressure air pipe.

Owner:TIANJIN SHIDA ELECTRIC POWER EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com