Copper electrolysis cathode washing and stripping process and cathode washing and stripping unit thereof

A technology of copper electrolysis and cathode, applied in electrolysis components, electrolysis process, etc., can solve the problems of price reduction, low recovery rate, affecting factory income, etc., and achieve the effect of increasing value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

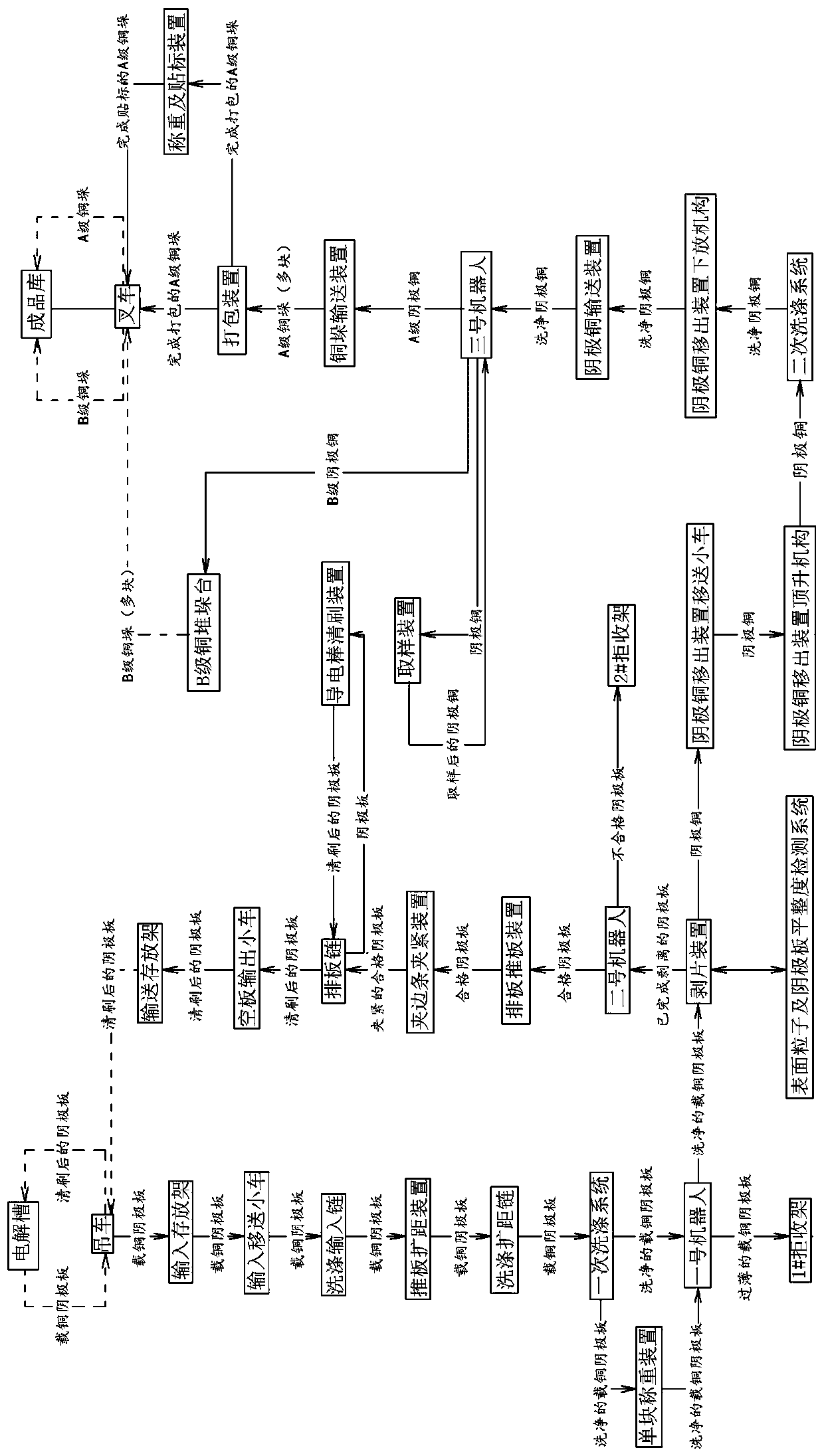

[0045] Such as figure 1As shown, a copper electrolytic cathode washing and stripping process, the copper-loaded cathode plate is transported to the input storage rack by a crane after it comes out of the electrolytic cell, and the input transfer trolley gradually sends the copper-loaded cathode plate on the input storage rack to the washing input chain to Prepare for washing before stripping. The push plate distance expansion device on the washing conveyor chain can expand the distance between the plates to ensure a good washing effect. Then, the following cathode washing and stripping steps are formally started, including:

[0046] S1. The copper-loaded cathode plate is washed for the first time in the first washing system after the distance is extended by the washing chain.

[0047] S2. After the first washing, the copper-loaded cathode plate is sent to the stripping system by the No. 1 robot for cathode copper stripping.

[0048] Copper-loaded plates will be weighed indivi...

Embodiment 2

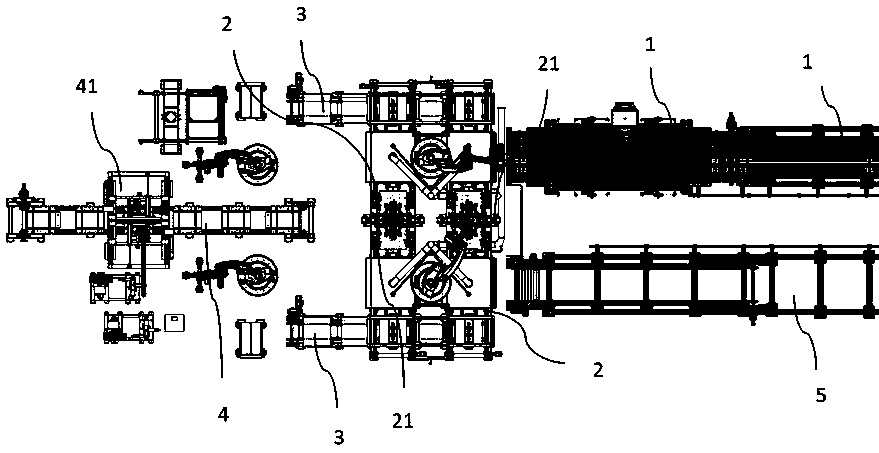

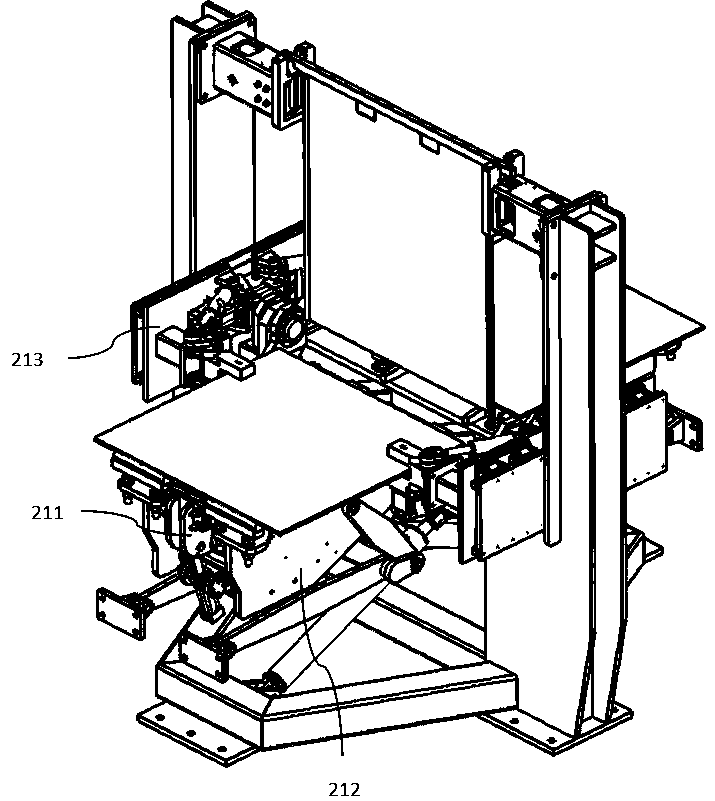

[0058] Such as figure 2 As shown, there is provided a cathode washing and stripping unit that realizes the copper electrolysis cathode washing and stripping process described in Embodiment 1, which includes a cathode input system 1 before the S1 step starts, a stripping conveyor chain 2 that receives a copper cathode plate on the cathode input system, The stripping system 21 set on the stripping conveyor chain 2, the finished product conveyor chain 3 vertically connected to the stripping conveyor chain, the transfer device 22 for moving cathode copper from the stripping system to the finished product conveyor chain and the end of the finished product conveyor chain The stacking conveyor chain 4 is provided with a packing device 41 at the end of the stacking conveyor chain, and a cathode output system 5 parallel to the cathode input system is also arranged at the stripping conveyor chain 2. The cathode output system is used to output the cathode plate after stripping the cathod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com