Expansion and contraction type wire drawing machine conveying roller

A technology of conveying rollers and softening machines, applied in the field of softening machines, can solve the problems of close stacking, pleating, affecting the softening effect of leather, etc., and achieve the effect of ensuring the softening effect and keeping the smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following embodiments can make those skilled in the art understand the present invention more comprehensively, but do not limit the present invention to the scope of the described embodiments.

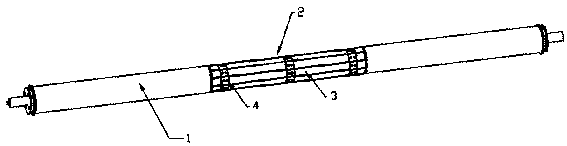

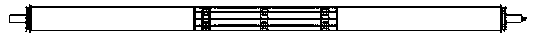

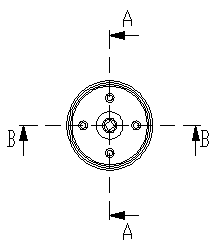

[0031] like Figure 1-Figure 10 The shown conveying roller of an expansion-contraction softener includes a conveying roller body 1, the conveying roller body 1 has at least one expansion-contraction section 2, and the expansion-contraction section 2 has a plurality of annularly distributed expansion pieces 3, and a built-in The expansion drive mechanism in the ring formed by the plurality of expansion pieces 3 drives each expansion piece 3 to move synchronously in a radial shape along the radial direction of the ring.

[0032] Each expansion piece 3 constituting the same expansion and contraction section is held tightly by a holding mechanism. As for the setting of the holding mechanism, each expansion piece 3 constituting the same expansion and contraction section is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com