Quantitative canning machine for irregular materials

A quantitative tank and irregular technology, applied in the field of material canning, can solve the problems that are not suitable for large-scale production, difficult to meet the canning requirements, and inaccurate canning volume, etc., to achieve the advantages of overall layout, high degree of automation, The effect of compact structure arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

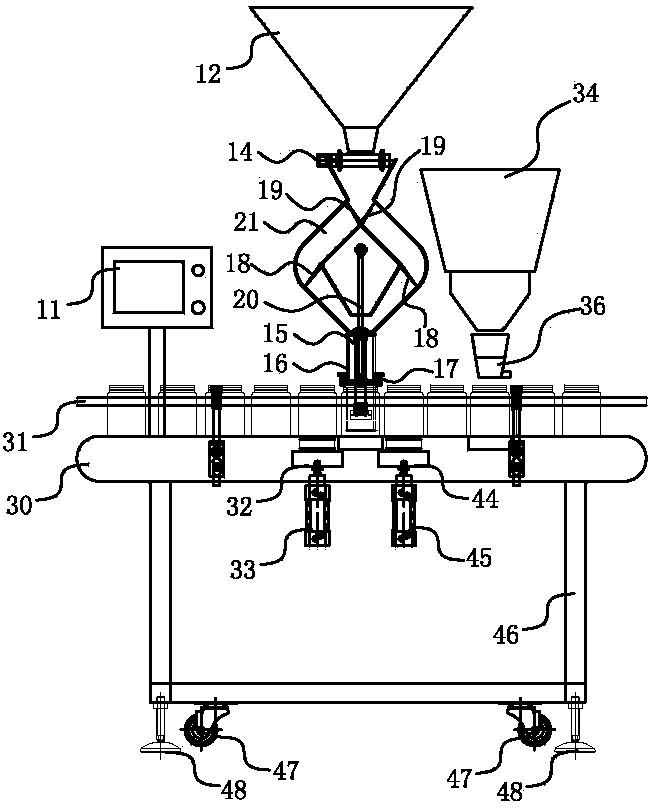

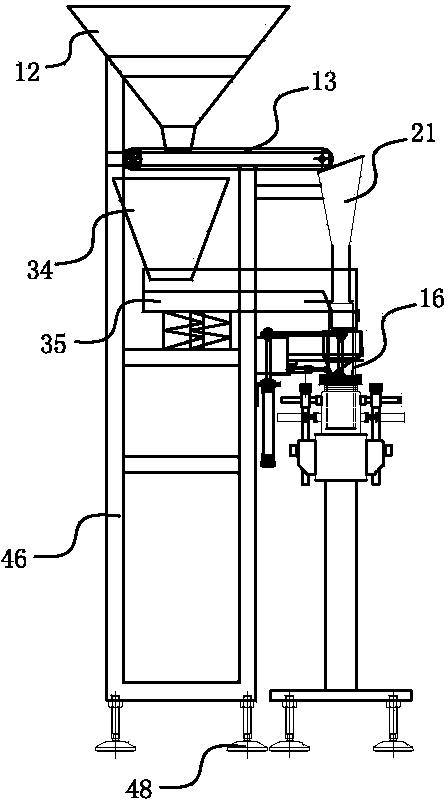

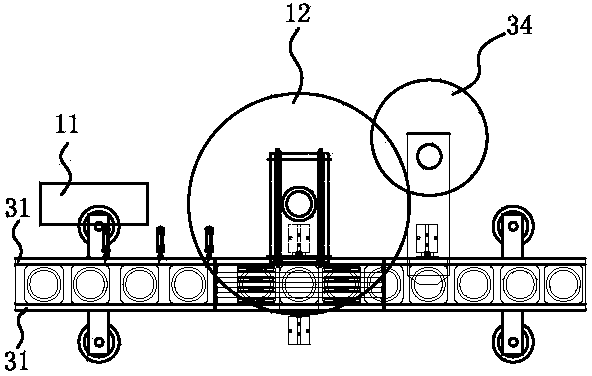

[0060] See Figure 1 to Figure 5 As shown, it shows the structure and working principle of the first irregular material quantitative filling machine of the present invention. The irregular material quantitative filling machine of this kind of structure is especially suitable for the canning of granular and fragile materials. For example, irregular granular Chinese patent medicines, etc., which can be packed in bags or bottles;

[0061] Here, take bottled Chinese patent medicine granules as an example:

[0062] One end of this irregular material quantitative canning machine is connected with a bottle unscrambler, and the other end is connected with a capping machine; The secondary weighing device, the main feeding device, the second weighing device and the compensation blanking device, the programmable controller is respectively connected with the aforementioned conveying device, the first weighing device, the main feeding device, and the second weighing device. The device an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com