Permanent magnet vacuum circuit breaker

A vacuum circuit breaker and permanent magnet technology, applied in high-voltage air circuit breakers, circuits, switchgear and other directions, can solve problems such as failure, device function failure, circuit breaker instability, etc., to ensure the safety of electricity consumption and ensure effective monitoring , to ensure the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

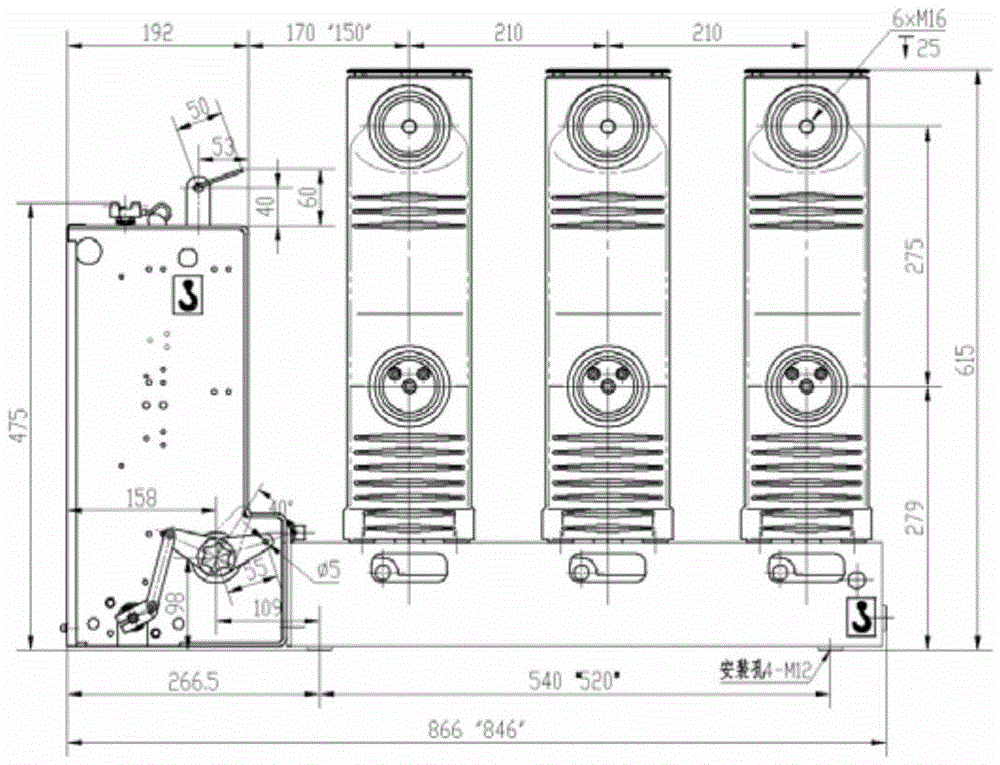

[0047] This embodiment mainly introduces a high-voltage circuit breaker. The high-voltage circuit breaker includes a circuit breaker housing, a circuit breaker body, an operating mechanism and a control module.

[0048] Further, the circuit breaker body is a vacuum circuit breaker body.

[0049] Further, the circuit breaker housing is further provided with a metal shield, and the control module is arranged in the metal shield.

[0050] Further, the control module includes an intelligent control circuit module, an arc extinguishing control module, a power supply protection module, and an opening and closing count monitoring switch module.

[0051] Further, the metal shield is provided with a plurality of cooling holes.

Embodiment 2

[0053] This embodiment is carried out on the basis of the foregoing embodiments. It should be specially stated that this embodiment is not only applicable to the content described in this application, but also applicable to other circuit breakers not described in this application, and has strong versatility.

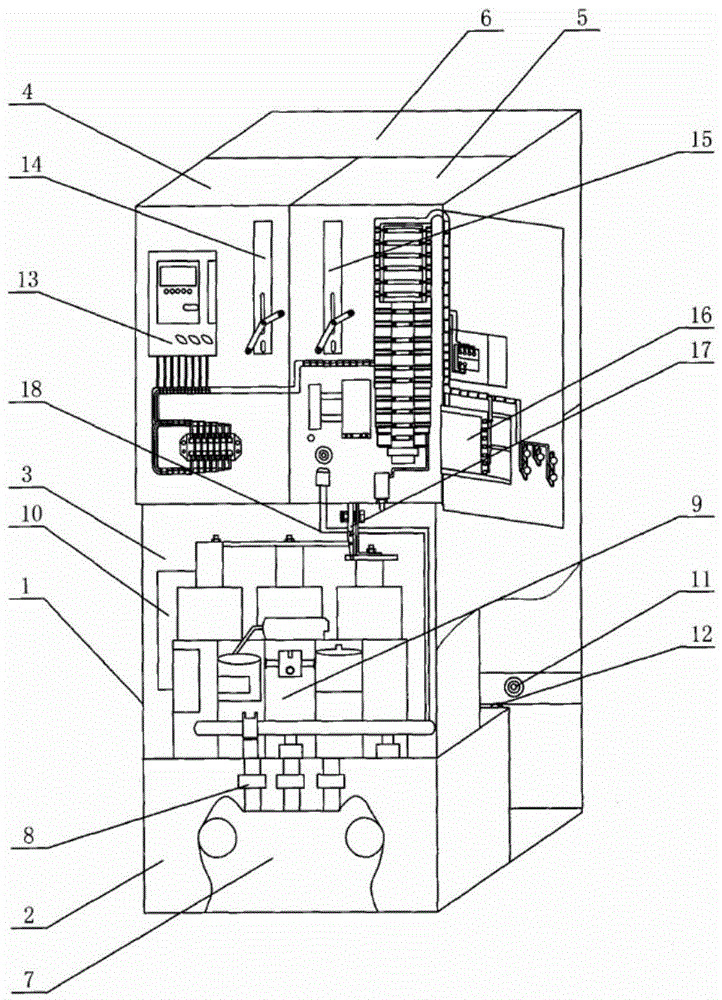

[0054] This embodiment is a combined electrical cabinet, such as image 3 As shown, it includes incoming line cabinet 1, which is subdivided into incoming line room 2, circuit breaker room 3, metering room 4, instrument room 5, and busbar room 6;

[0055] The incoming line room 2 and the circuit breaker room 3 are respectively located in the lower and middle parts of the incoming line cabinet, the metering room 4 and the instrument room 5 are located in front of the upper part of the incoming line cabinet 1, and the busbar room 6 is located in the upper rear of the incoming line cabinet 1;

[0056] A double-winding double-ratio voltage transformer 7 and a high-voltage f...

Embodiment 3

[0065] This embodiment is implemented on the basis of one of the preceding embodiments or on the basis of any combination of two or more embodiments. It should be specially stated that this embodiment is not only applicable to the content described in this application, but also applicable to other circuit breakers not described in this application, and has strong versatility.

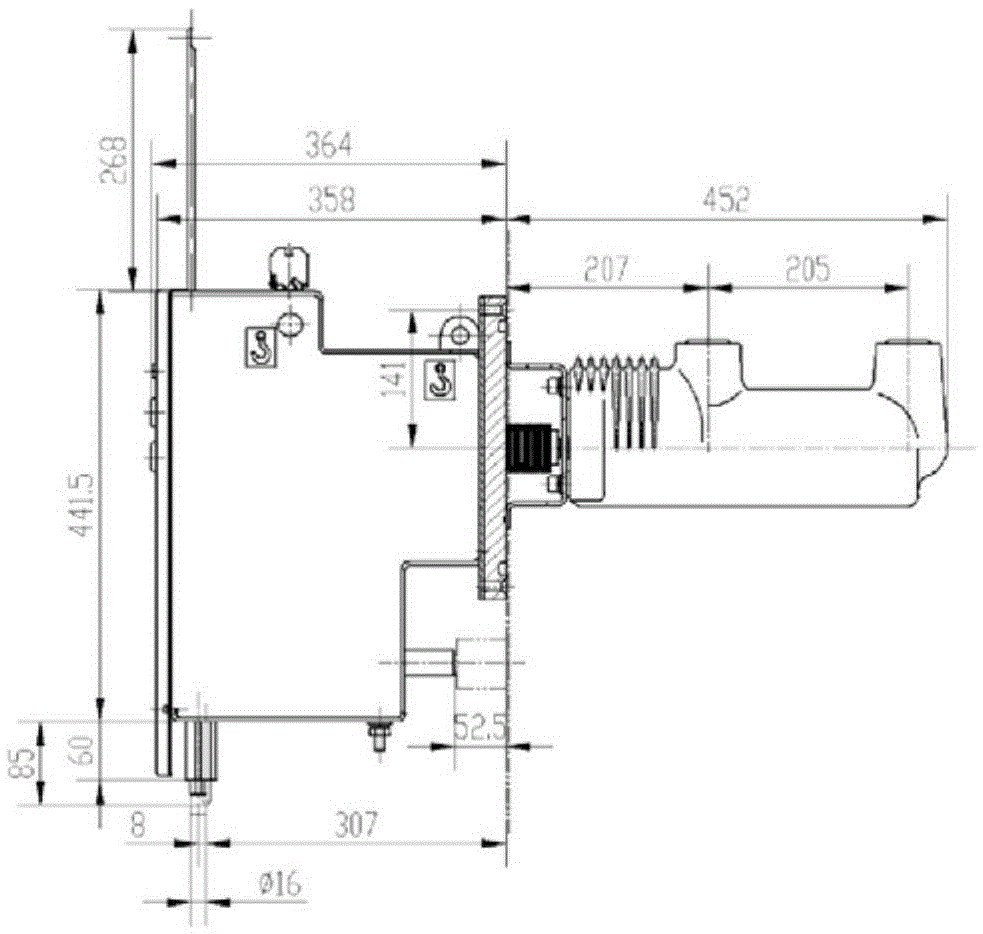

[0066] Such as Figure 4 As shown, a high-voltage vacuum circuit breaker is especially suitable for a fixed gas-filled cabinet, including a box body 19, a circuit breaker operating mechanism 20 is arranged inside the box body 19, and a solid-sealed pole 27 connected to the circuit breaker operating mechanism 20.

[0067] Further, the outside of the box 19 is provided with a mounting plate 24 for mounting the solidified pole, the mounting plate 24 is connected to the fixed inflatable cabinet, and the mounting plate 24 is provided with a mounting hole 23 connected to the fixed inflatable cabinet.

[0068...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com