Patents

Literature

39results about How to "Compact performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

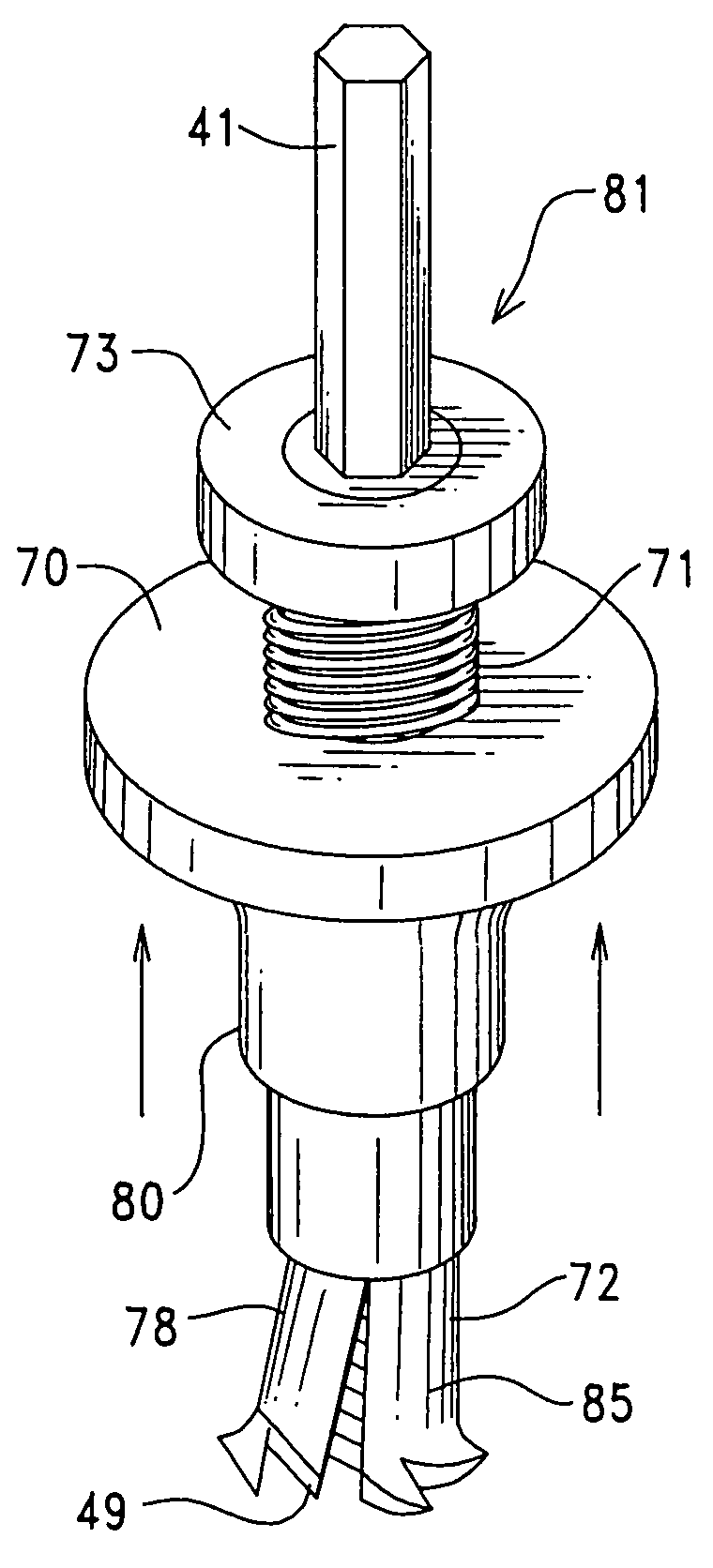

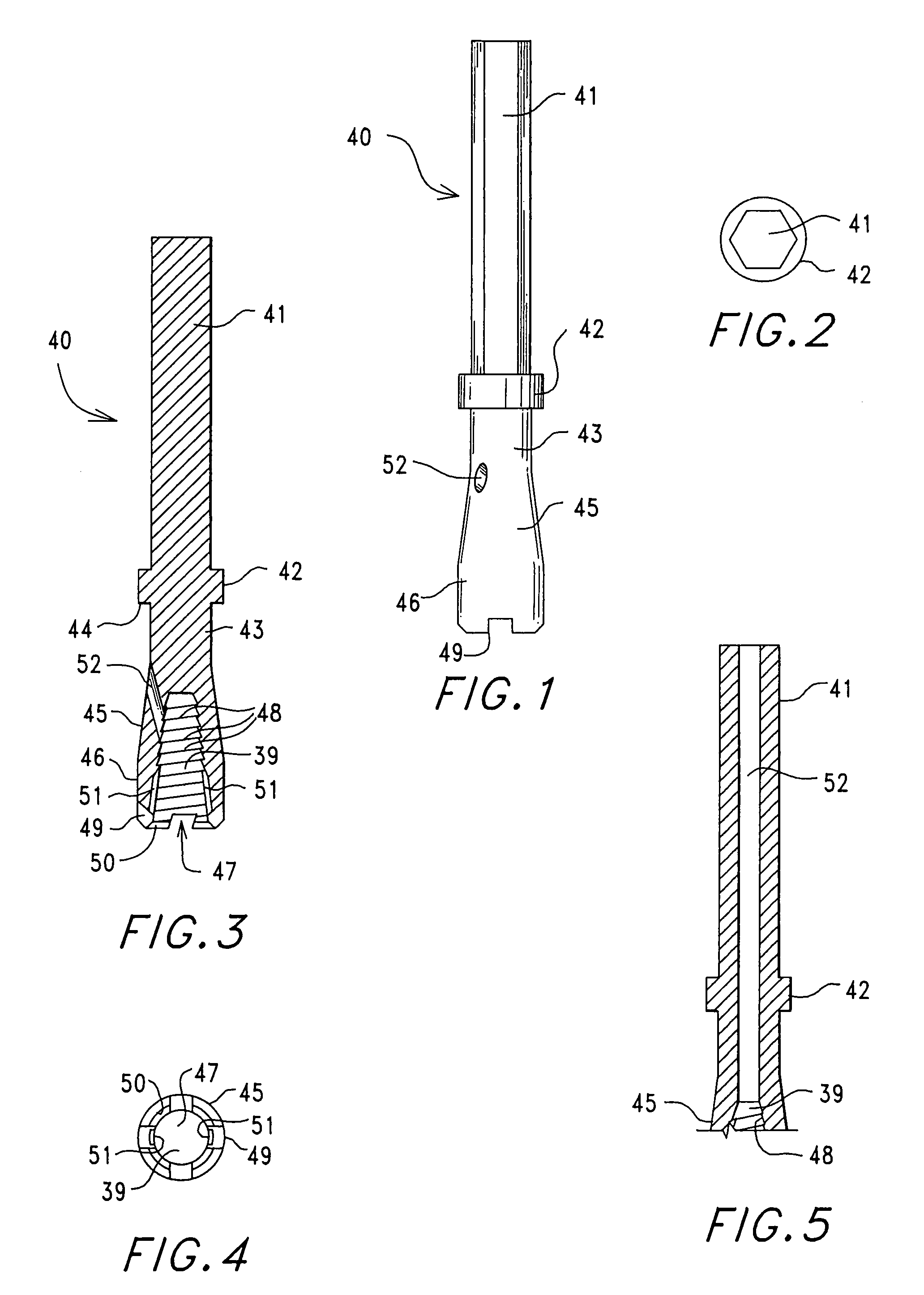

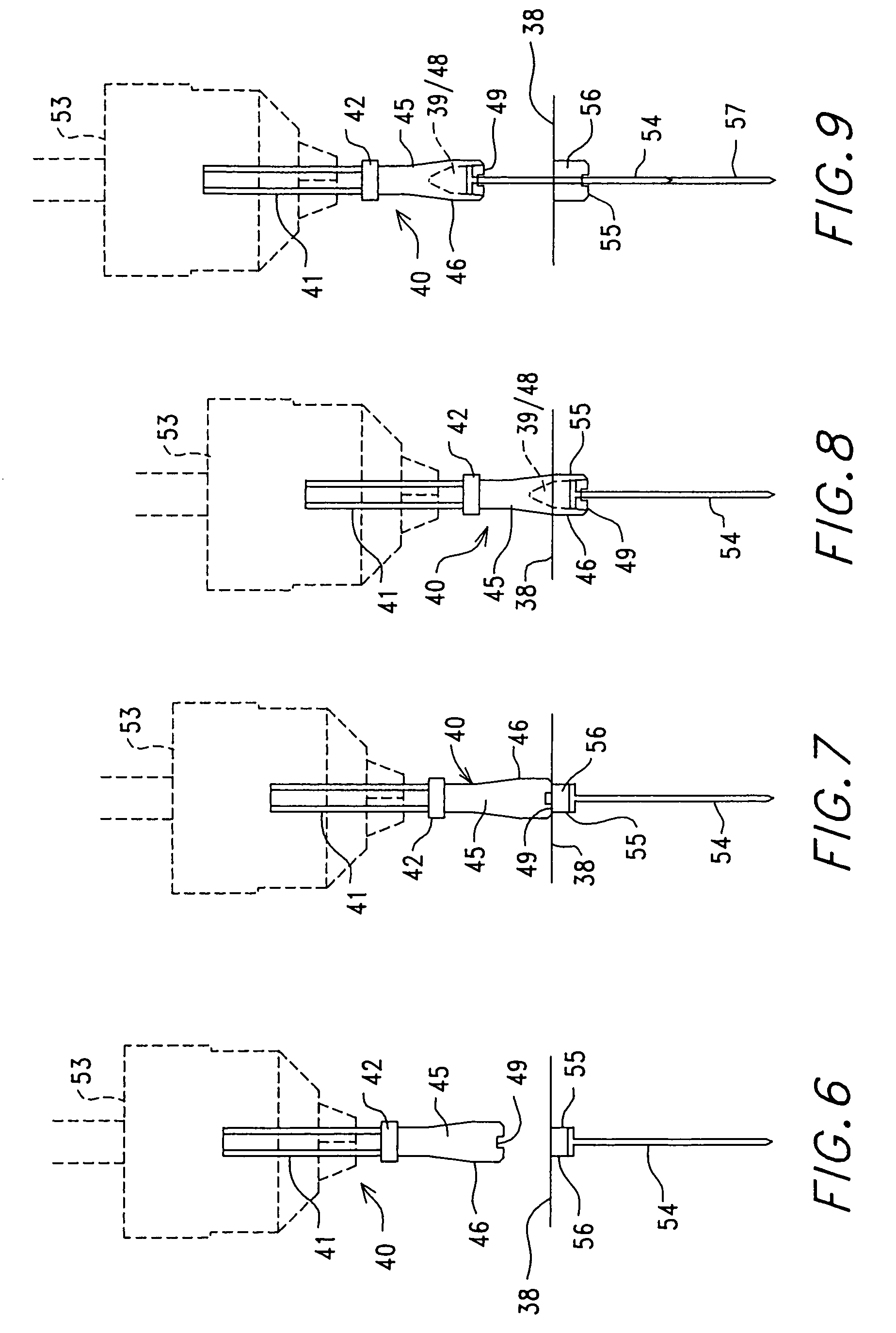

Methods for extracting fasteners from a host material

InactiveUS7140087B1Rapid and repeated utilizationLabor savingCrowbarsNail extractorsHost materialEngineering

Apparatus and methods for extraction of nails, screws and other such fasteners from wood or other host materials are disclosed. One embodiment of the apparatus includes a shank adapted for application at a rotational drive source, a two-part engaging member at one end of the shank having a cavity extending thereinto for receiving therein a fastener to be extracted and openable to release the fastener after extraction. A cutting component is defined at a bottom edge of the engaging member adjacent to an opening to the cavity for cleanly removing host material from around the fastener. A gripping surface formation comprising a spiraling striation is formed at a surface of the cavity for threadably engaging the fastener to be removed.

Owner:RECONNX

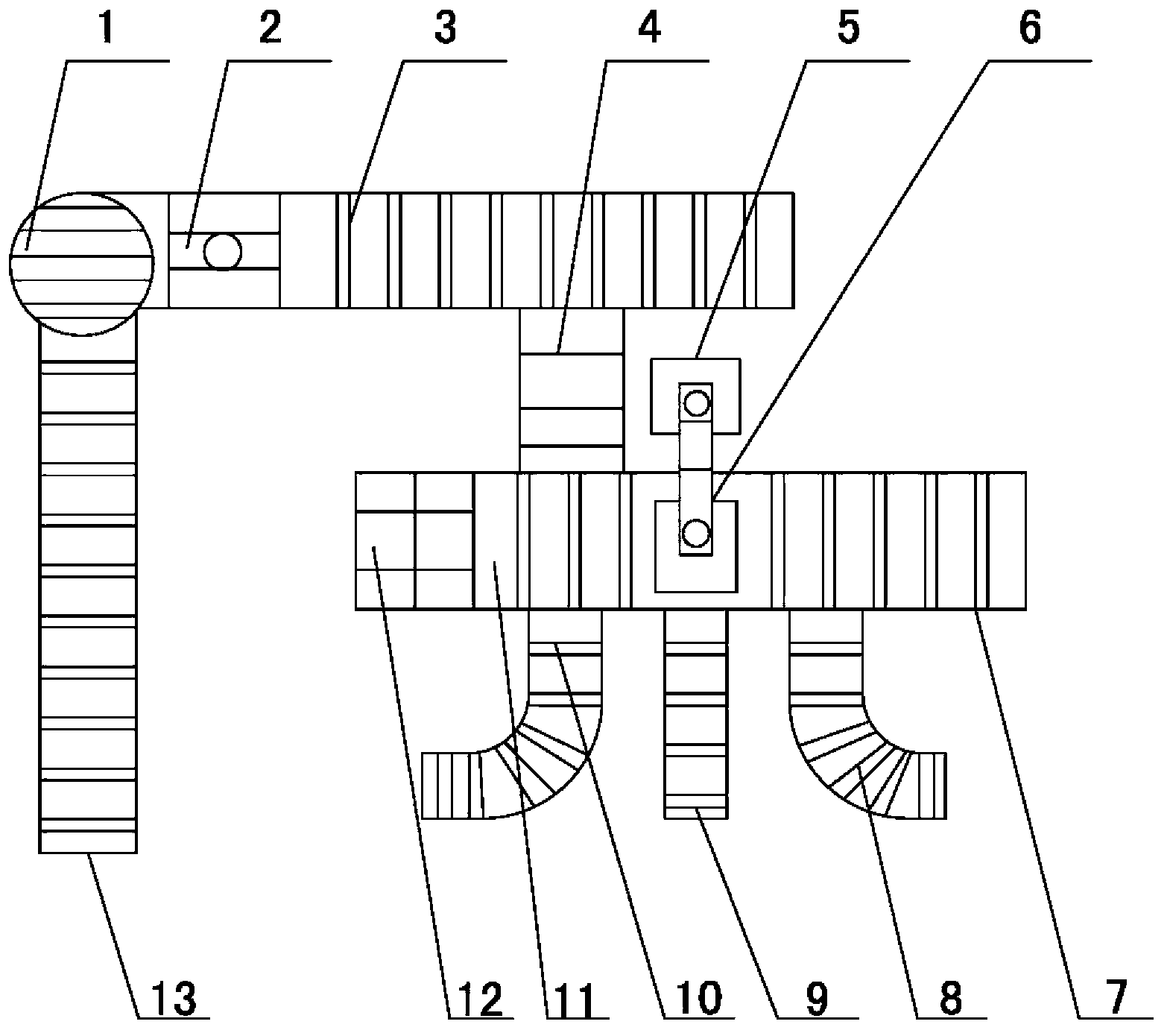

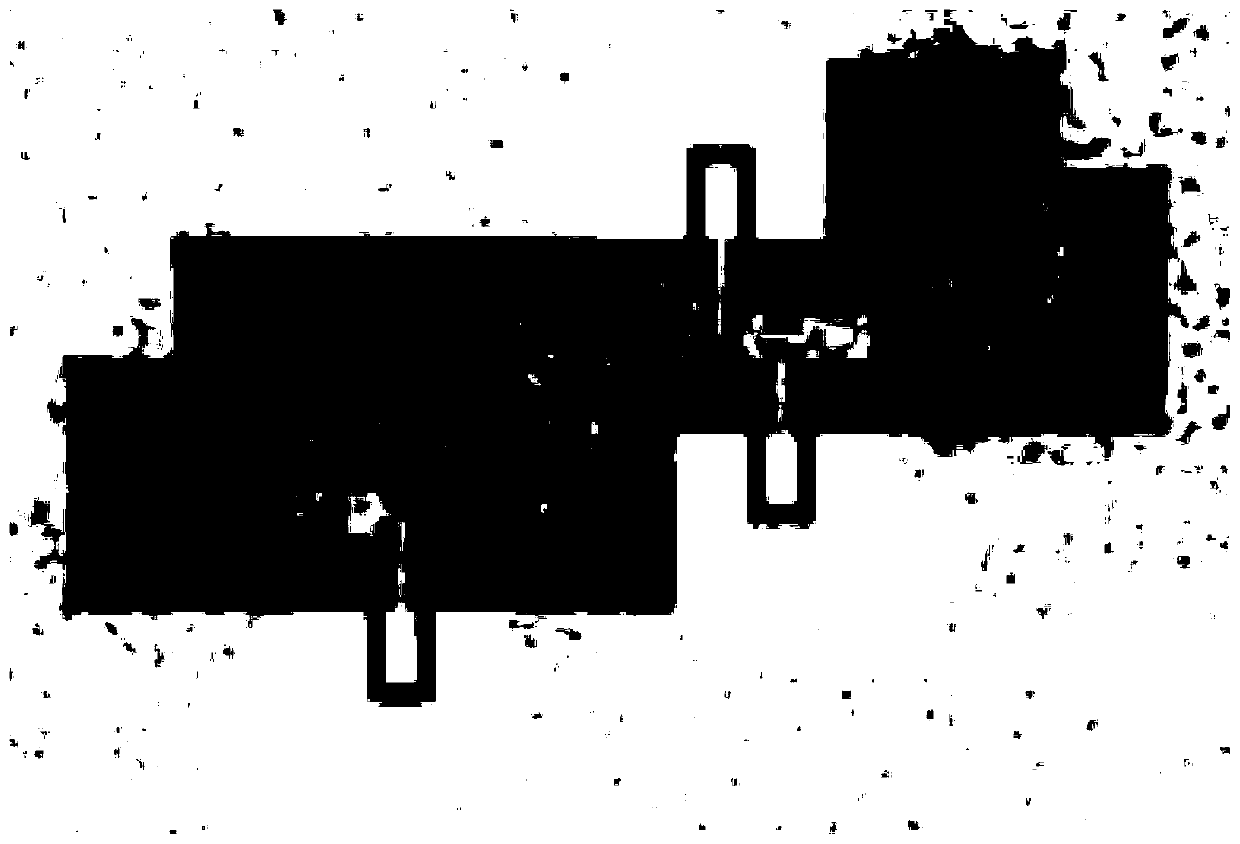

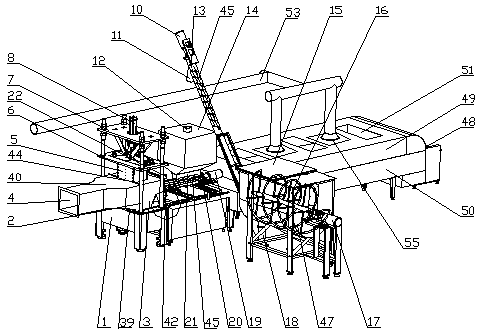

Automatic pharmaceutical glass packaging and integrating system

ActiveCN103057770ACompact and reasonable structureLess investmentStacking articlesDe-stacking articlesProgrammable logic controllerMechanical equipment

The invention belongs to the field of mechanical equipment and particularly relates to an automatic pharmaceutical glass packaging and integrating system. The automatic pharmaceutical glass packaging and integrating system is characterized by comprising a transfer robot, a pallet conveying line, a backing plate conveying line, a cover plate conveying line, a capturing line, a heavy tray conveying line and a stacking area, wherein the pallet conveying line, the backing plate conveying line, the cover plate conveying line, the capturing line, the heavy tray conveying line and the stacking area are distributed around the transfer robot. The pallet conveying line is connected with a pallet supply machine, the capturing line is connected with a hot pack conveying line, a full-automatic rotary packing machine is arranged on the heavy tray conveying line, and a composite manipulator is mounted on the mechanical arm of the transfer robot and is connected with a PLC (programmable logic controller) system. The integral automatic pharmaceutical glass packaging and integrating system can be monitored in all around by the PLC system during running. Hot packs can be conveyed and stacked automatically, backing plates can be added automatically, cover plates can be automatically captured and placed, and trays can be automatically packed. The automatic pharmaceutical glass packaging and integrating system is convenient and quick to operate, labor intensity is reduced, extra equipment investment is reduced and economic and practical purposes are achieved. The conveying lines distributed within a circumference taking the gravity center of the transfer robot as a circle center are reasonable and compact in arrangement.

Owner:SHANDONG PHARMA GLASS

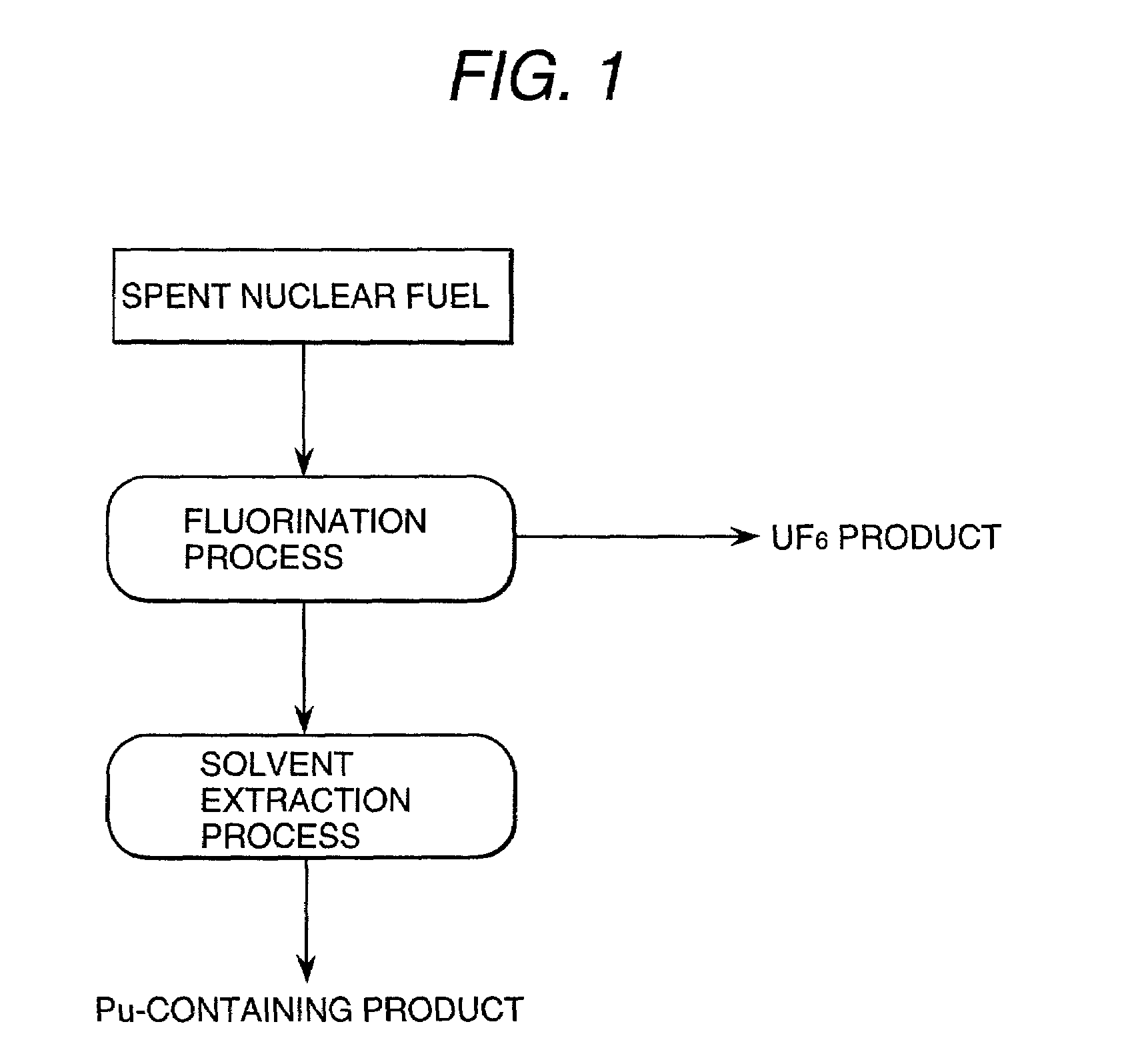

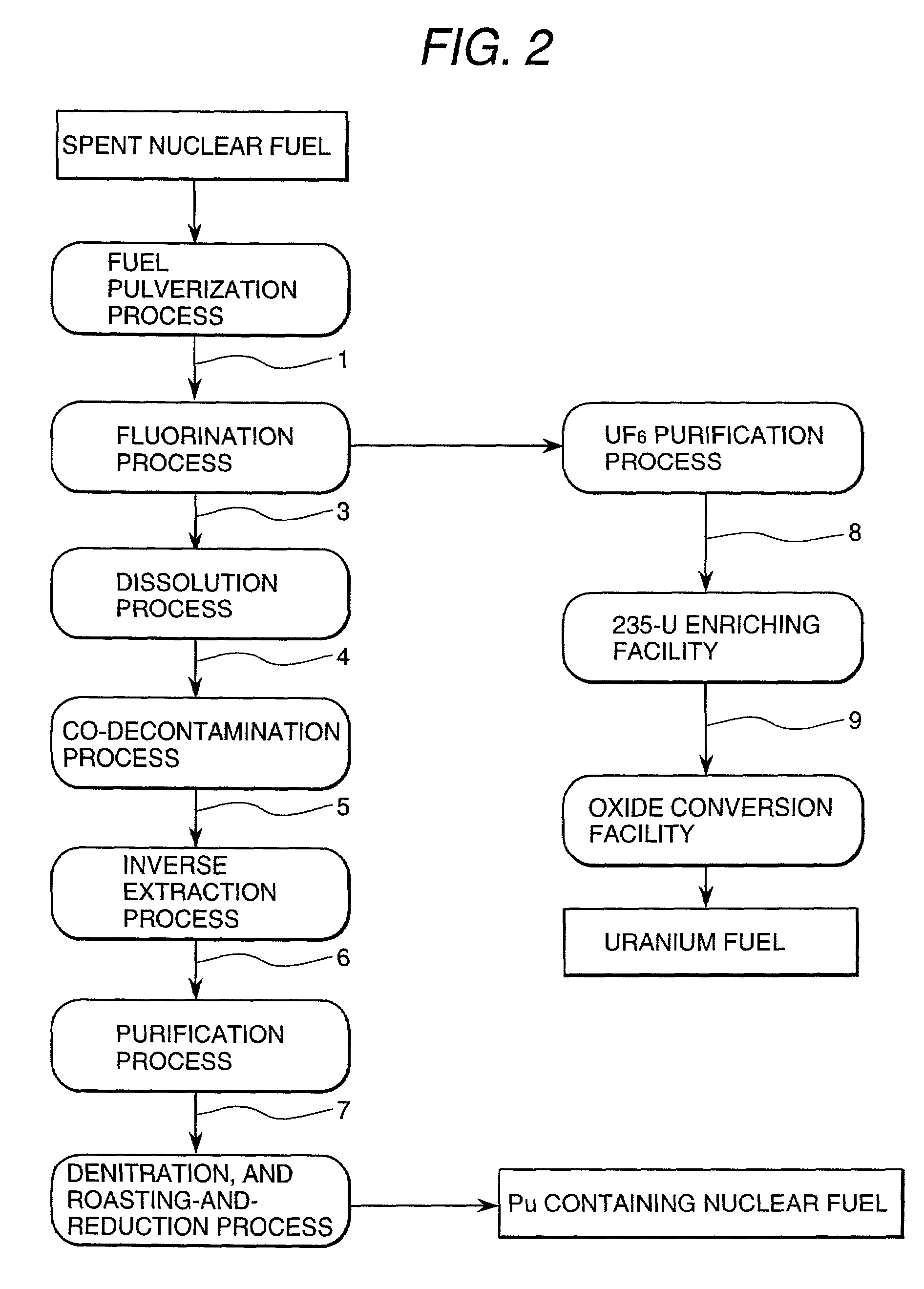

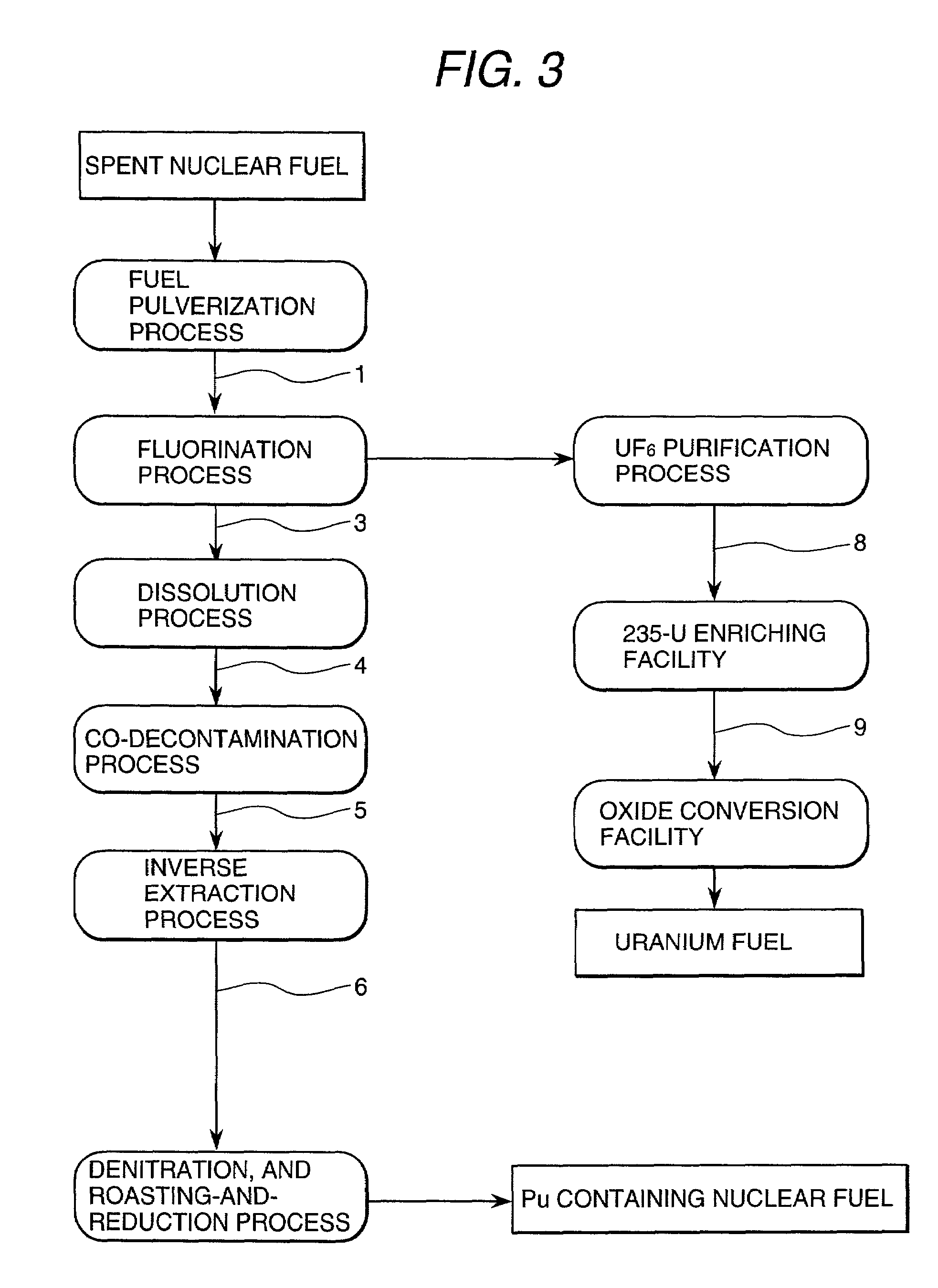

Method of reprocessing spent nuclear fuel

InactiveUS7445760B2Excellent decontaminationDownsizing of facilityPhosphorus halides/oxyhalidesTransuranic element compoundsEngineeringPu element

Most part of an amount of uranium contained in the spent nuclear fuel is removed by making fluorine or a fluorochemical act on the spent nuclear fuel to convert the uranium into UF6, and the uranium is purified through a simple method of distilling the UF6 together with a absorbent. After removing the most part of the amount of uranium, the remaining nuclear fuel material is dissolved and then transferred to an extraction process to recover plutonium. By doing so, a small sized dry process can be employed as a uranium purification process. Since the nuclear fuel material is dissolved and extracted after removing most part of an amount of uranium, a volume of processing solution can be reduced and the machine installation scale can be made small. Accordingly, the reprocessing facility can be extremely downsized.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

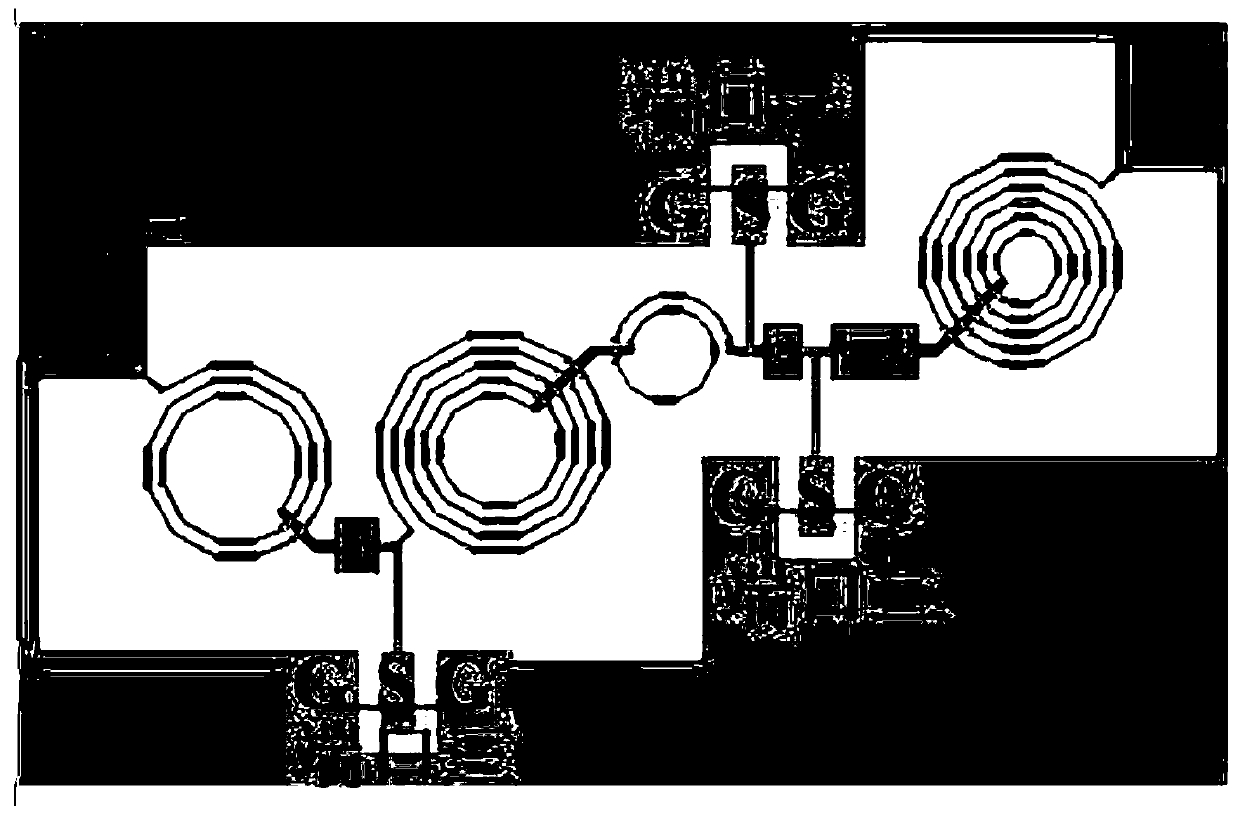

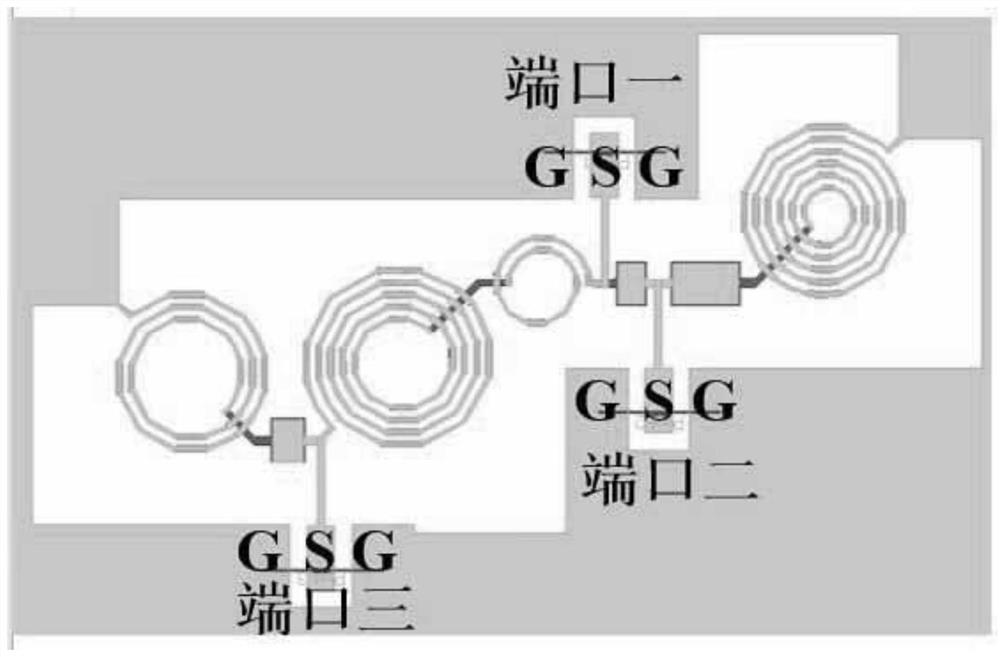

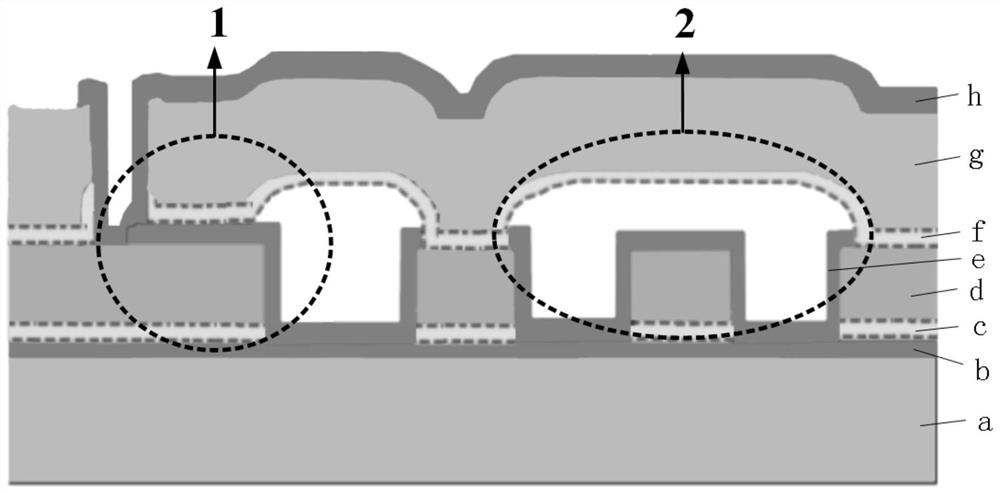

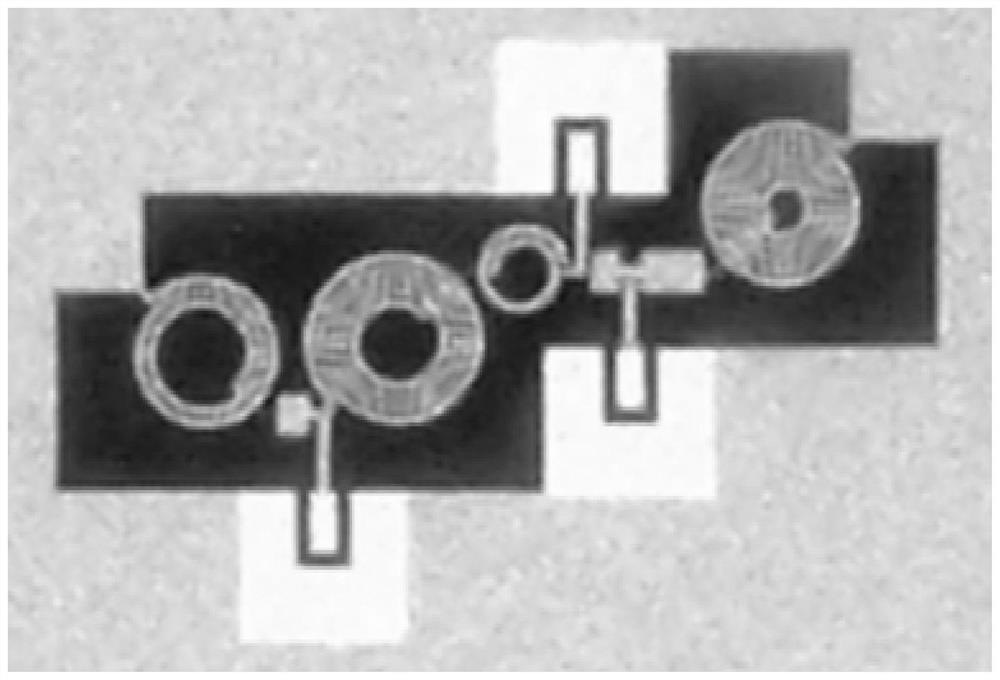

Miniaturized compact duplexer based on thin film integrated passive device technology

ActiveCN109962324AImprove performancePerformance improvements and optimizationsCoupling devicesCapacitanceMicrowave

The invention discloses a miniaturized compact duplexer based on a thin film integrated passive device technology, belongs to the field of microwave devices, particularly relates to a miniaturized duplexer, and aims to solve the problems that an existing duplexer with a planar cascade structure is large in size and unstable in performance in the working process. The compact duplexer comprises a high-pass filter and a low-pass filter, wherein the high-pass filter is coupled to a first signal port and a second signal port, and the low-pass filter is coupled to the first signal port and a third signal port. The high-pass filter is formed by the parallel connection of a second capacitor with a first capacitor and inductor resonance circuit, and the low-pass filter is formed by the parallel connection of two series inductors with a second capacitor and inductor resonance circuit. The miniaturized compact duplexer is manufactured into a multi-layer structure through the thin film integratedpassive device technology. The size of the compact diplexer is only 1.9 mm*0.8 mm, and the thickness of the compact diplexer is 0.2 mm. Moreover, the manufacturing process of the compact diplexer is high in precision and the performance of the compact diplexer is stable.

Owner:HARBIN INST OF TECH

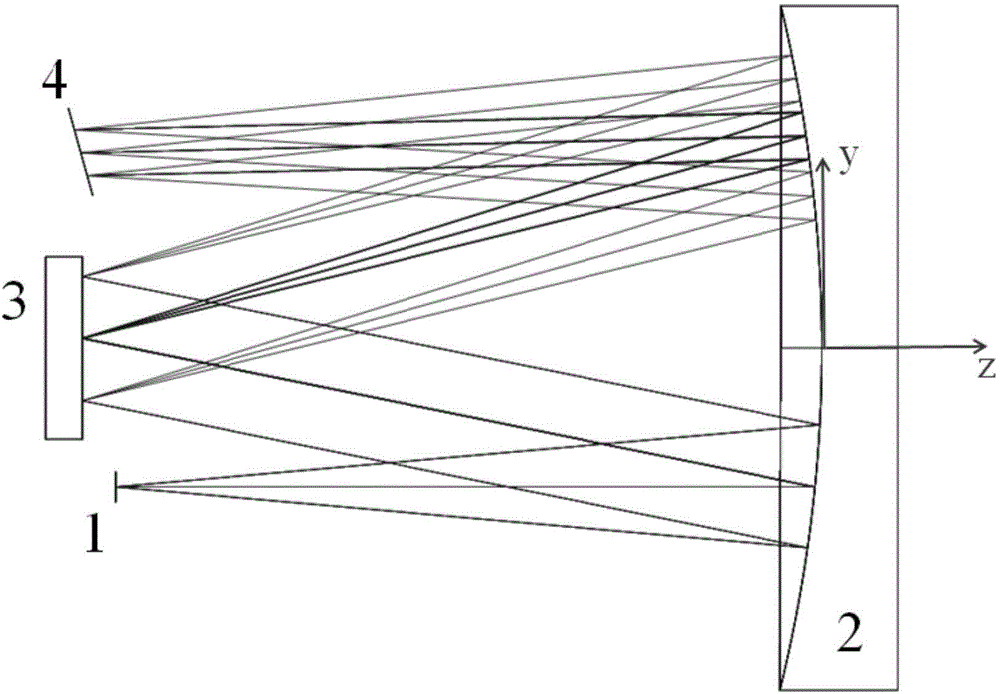

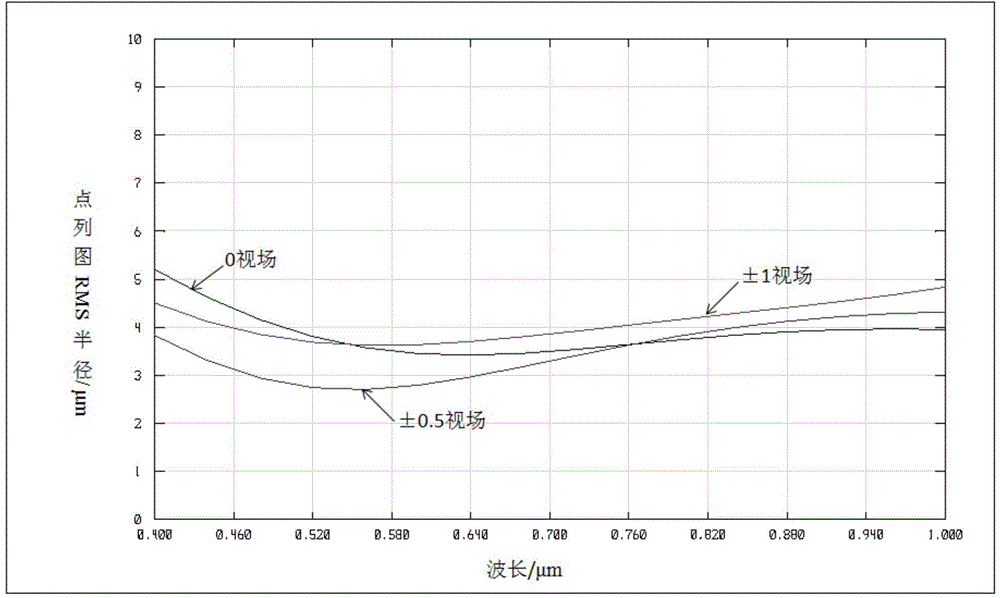

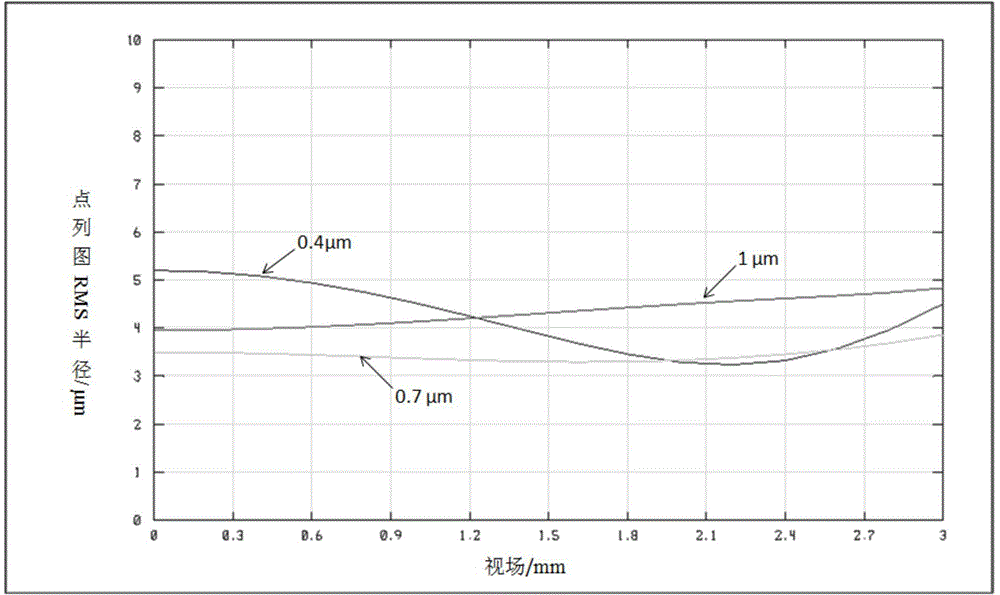

Imaging spectrometer optical splitting system based on single free curved surface

ActiveCN104406691ASmall distortionReduce aberrationRadiation pyrometrySpectrometry/spectrophotometry/monochromatorsAviationGrating

The invention discloses an imaging spectrometer optical splitting system based on a single free curved surface. The system is composed of an entrance slit, a free curved surface reflecting mirror, plane blazed grating and an image surface. The system is characterized in that one non-rotational symmetric free curved surface reflecting mirror is used for two times to act as a collimating mirror and an imaging mirror respectively, and plane blazed grating which is high in performance and mature in processing technology is used cooperatively so that the spectrometer optical splitting system which is simple and compact in structure, small in aberration, low in distortion and high in efficiency is realized. According to the embodiment of the imaging spectrometer optical splitting system based on the single free curved surface, great spectral imaging is realized in 400-1000nm visible near-infrared spectrum so that spherical aberration, coma aberration, astigmatism, spectral distortion and spectral line bending are greatly corrected under the premise that the system is ensued to be simple and compact. The imaging spectrometer optical splitting system based on the single free curved surface can be applied to the field of hyper-spectral imaging of spaceflight and aviation.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Photocuring aluminum oxide ceramic paste and atomization cavity integrated forming method thereof

PendingCN112919887AHigh solid contentImprove uniformityAdditive manufacturing apparatusOxide ceramicStearic acid

The invention discloses a photocuring aluminum oxide ceramic paste and an atomization cavity integrated forming method thereof. The paste comprises ceramic powder, stearic acid powder, premixed liquid and a dispersing agent. The forming method comprises the following steps: printing the photo-cured aluminum oxide ceramic paste into an atomization cavity structure, and then performing degreasing and sintering; and adjusting atomization cavity structure parameters, printing process parameters and degreasing sintering process parameters. The atomization cavity structure parameters comprise the overall wall thickness and the connecting fillet radius of an atomization cavity; the printing process parameters comprise a printing support gap, printing laser power, layer thickness and curing depth; and the degreasing sintering process parameters comprise heating rate, powder burying amount, pre-sintering temperature, degreasing temperature point and heat preservation time. By optimizing the components of the photocuring aluminum oxide ceramic paste, the structure of the atomization cavity and the post-treatment process, the performance (strength, corrosion resistance and the like) of the aluminum oxide atomization cavity is improved, the cracking deformation of the atomization cavity in the preparation process is reduced, and the preparation yield of the atomization cavity is further improved.

Owner:XI AN JIAOTONG UNIV

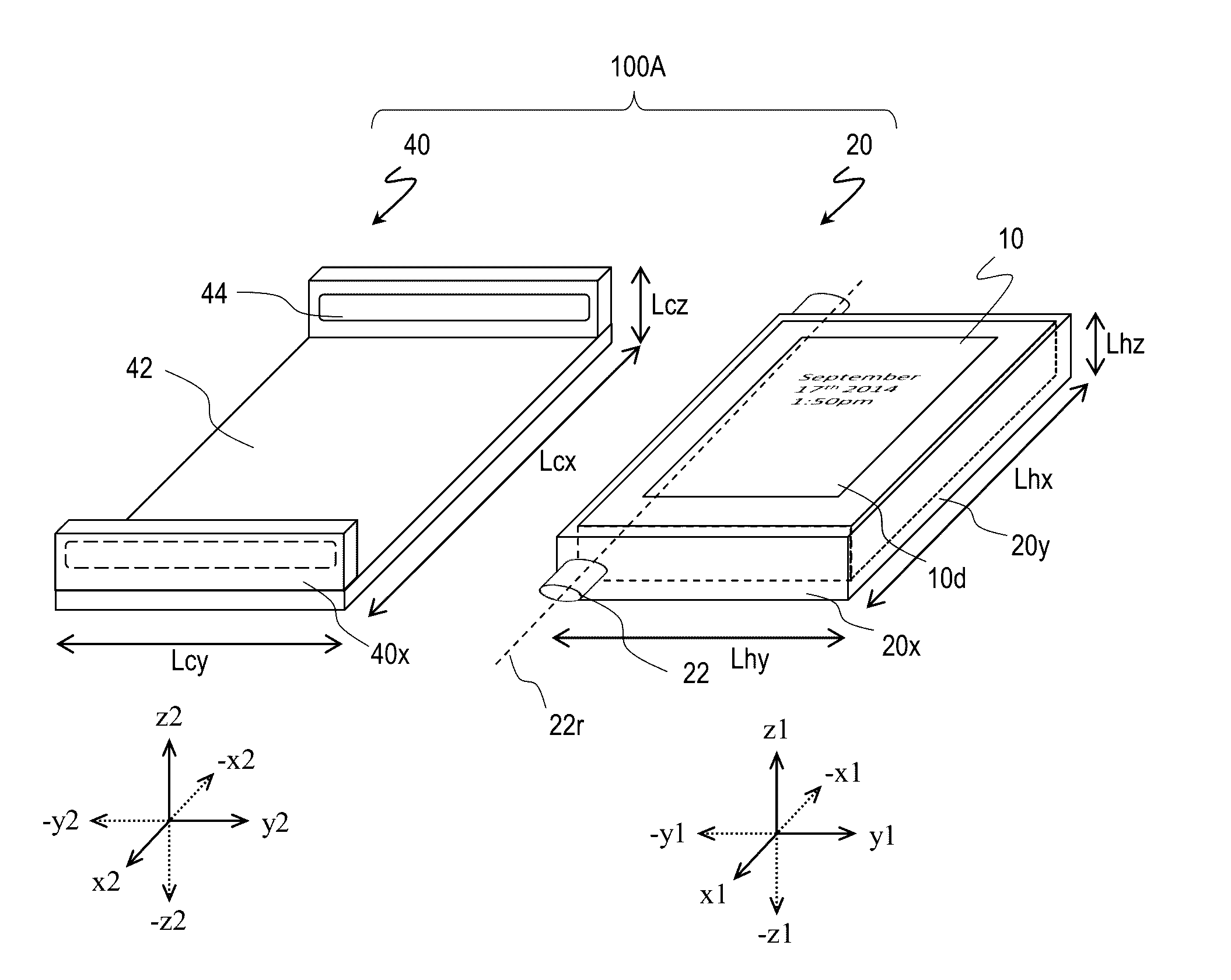

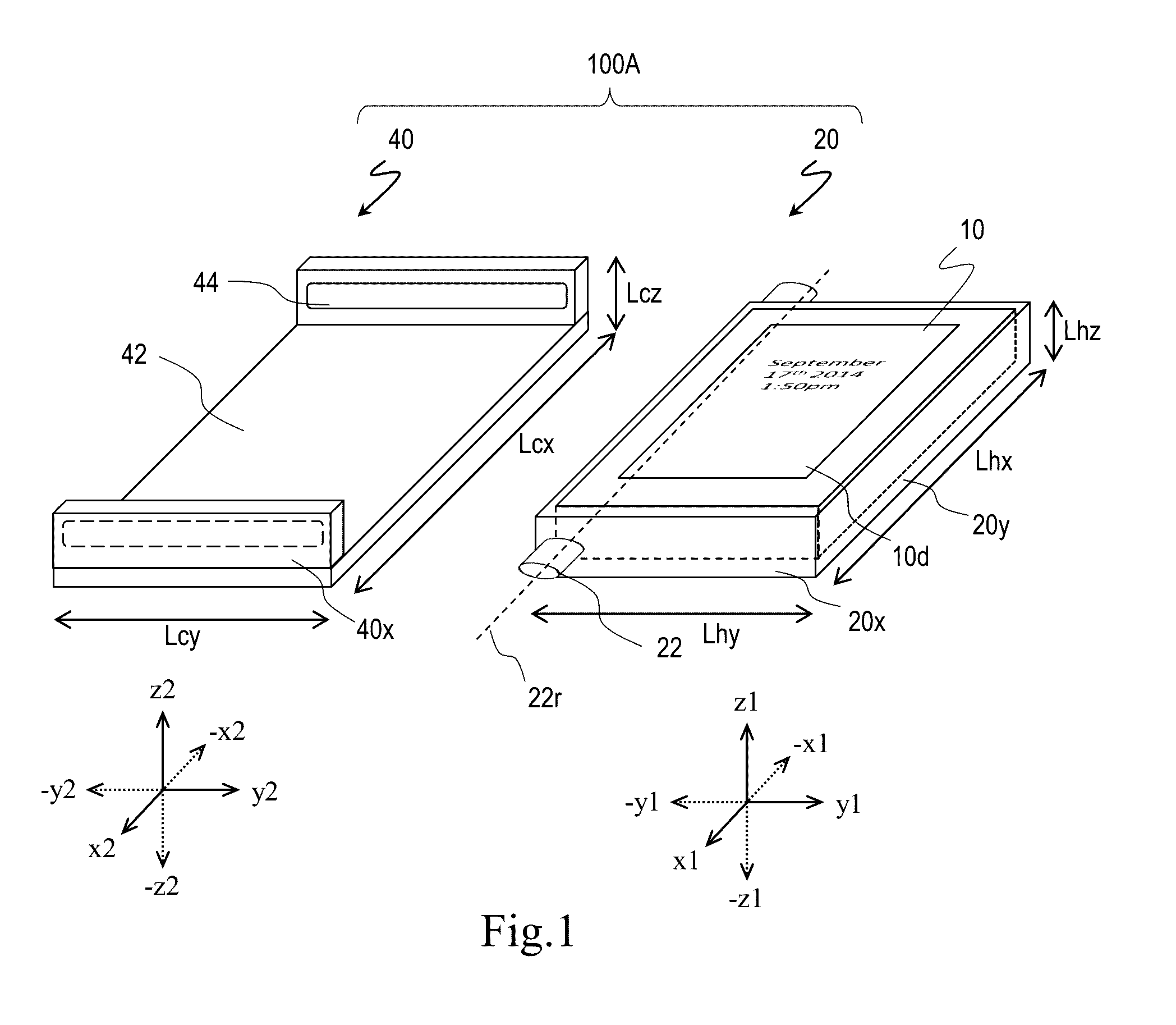

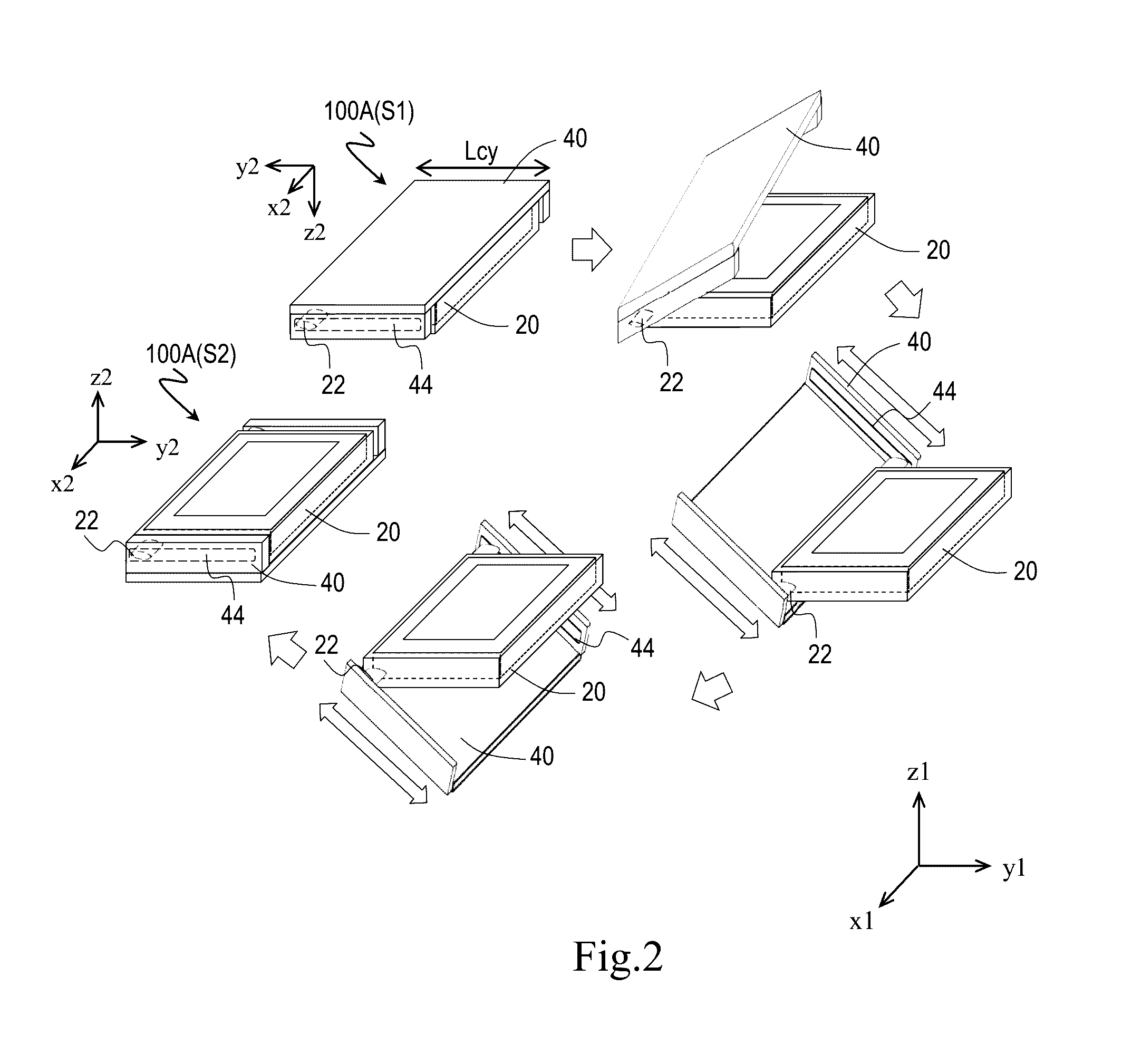

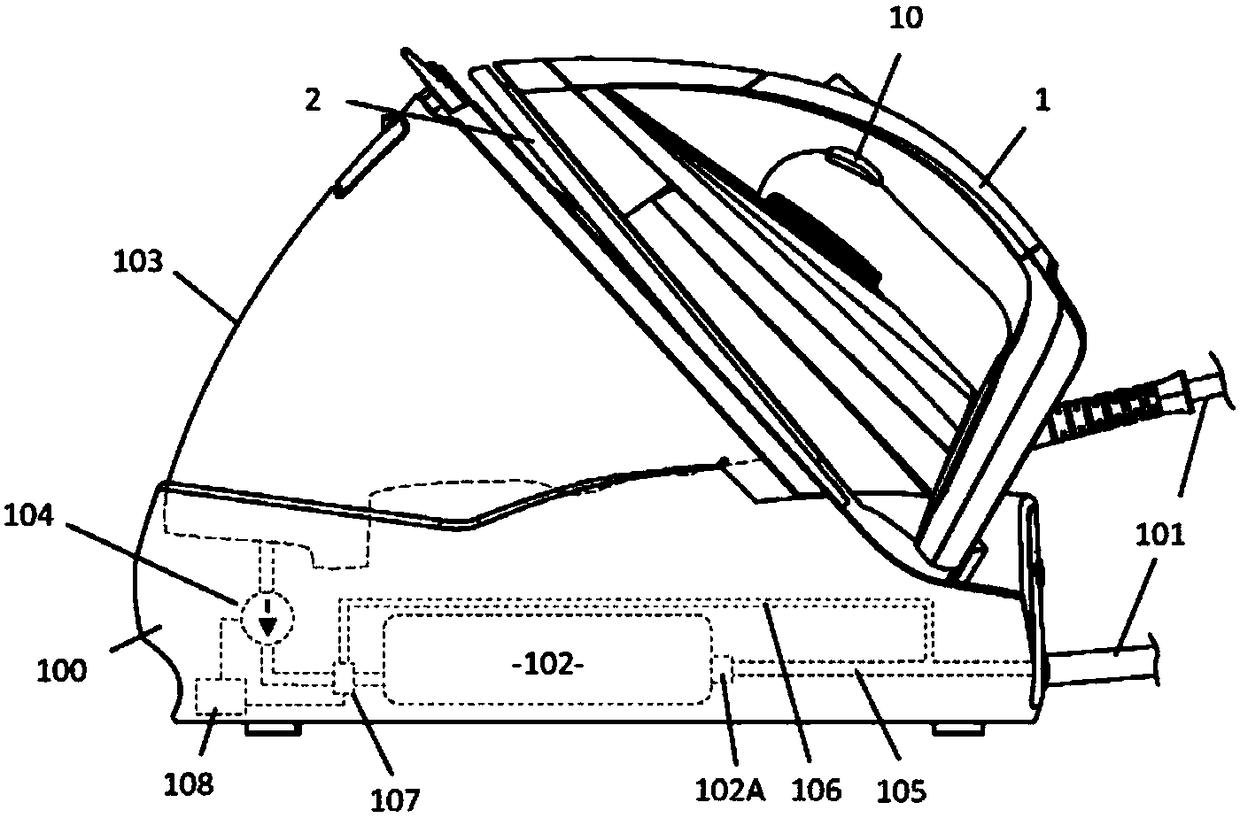

Electronic apparatus case

InactiveUS20160278493A1Compact performanceTravelling carriersHoldersOrthogonal coordinatesDisplay device

An electronic apparatus case includes a holder holding an electronic apparatus and a cover covering a display. In the holder, when taking an x1y1z1 orthogonal coordinate system where a direction orthogonal to and away from the display surface is a z1 axis, and a direction parallel to a side of the display is a y1 axis. In the cover, when taking an x2y2z2 orthogonal coordinate system where a direction coinciding with the x1 axis is an x2 axis, and a direction orthogonal to the cover, and away from an inner surface of the cover is a z2 axis, the z1 axis coincides with the −z2 axis when the display is covered by the cover. The holder has a convex defining a rotation axis in the x1 axis direction and the cover has a track defining a gap extending in the y2 axis direction and storing the convex.

Owner:SHARP KK

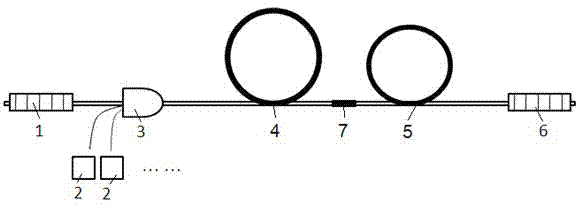

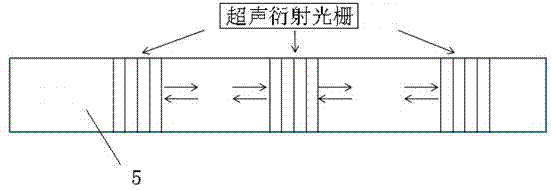

All-fiber Q-switched fiber laser based on stimulated Brillouin scattering

InactiveCN103500912AFully embodies the advantages of maintenance-freeReduce manufacturing costActive medium materialActive medium shape and constructionGratingFiber disk laser

The invention discloses an all-fiber Q-switched fiber laser based on stimulated Brillouin scattering, which comprises a low-reflectivity fiber Bragg grating, a laser beam combiner, ytterbium-doped doubly-clad active optical fibers, Sm3+-doped single-mode optical fibers, a high-reflectively fiber Bragg grating and a plurality of pumping sources. The core diameter of the Sm3+-doped single-mode optical fibers is smaller than the core diameter of the ytterbium-doped doubly-clad active optical fibers. The laser beam combiner is provided with a first beam combining connecting end, a second beam combining connecting end and a pumping input end. The first beam combining connecting end is connected with the low-reflectivity fiber Bragg grating. The pumping input end is respectively connected with the input ends of the plurality of pumping sources. The second beam combining connecting end is connected with one end of the ytterbium-doped doubly-clad active optical fibers. The other end of the ytterbium-doped doubly-clad active optical fibers is fused with one end of the Sm3+-doped single-mode optical fibers. The other end of the Sm3+-doped single-mode optical fibers is connected with the high-reflectively fiber Bragg grating. The all-fiber Q-switched fiber laser based on stimulated Brillouin scattering has a passive Q switching function, the automatic Q switching stability is good, the pulse peak power is improved and the pulse width is reduced.

Owner:JIANGSU SKYERALASER TECH +1

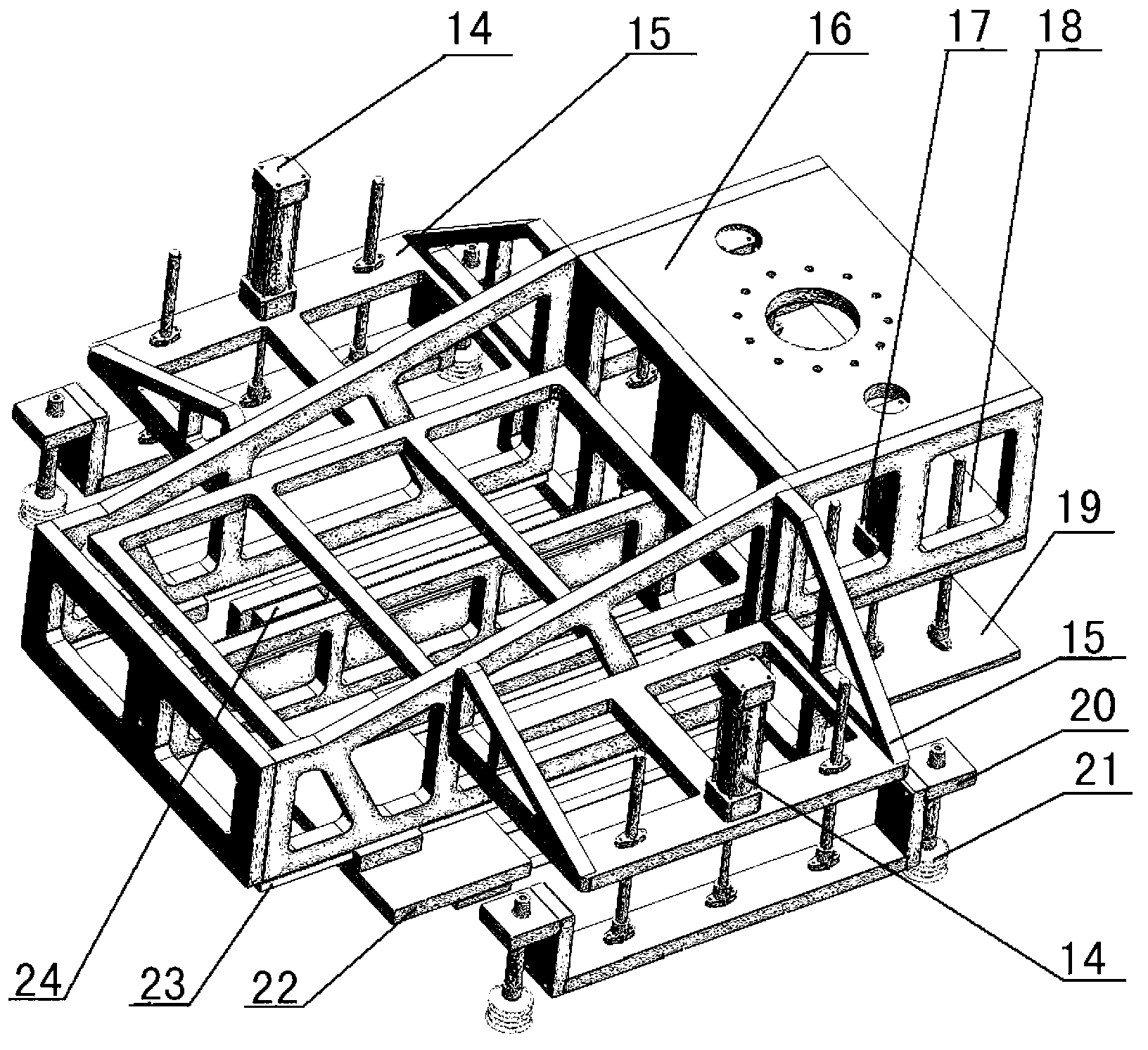

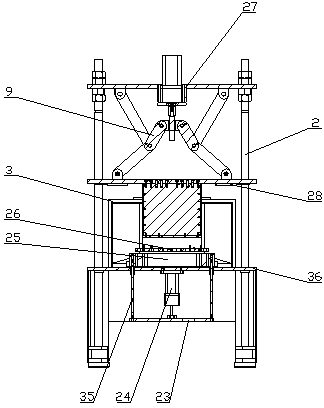

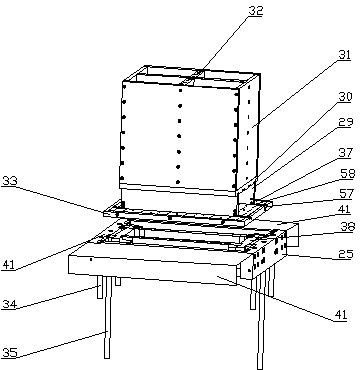

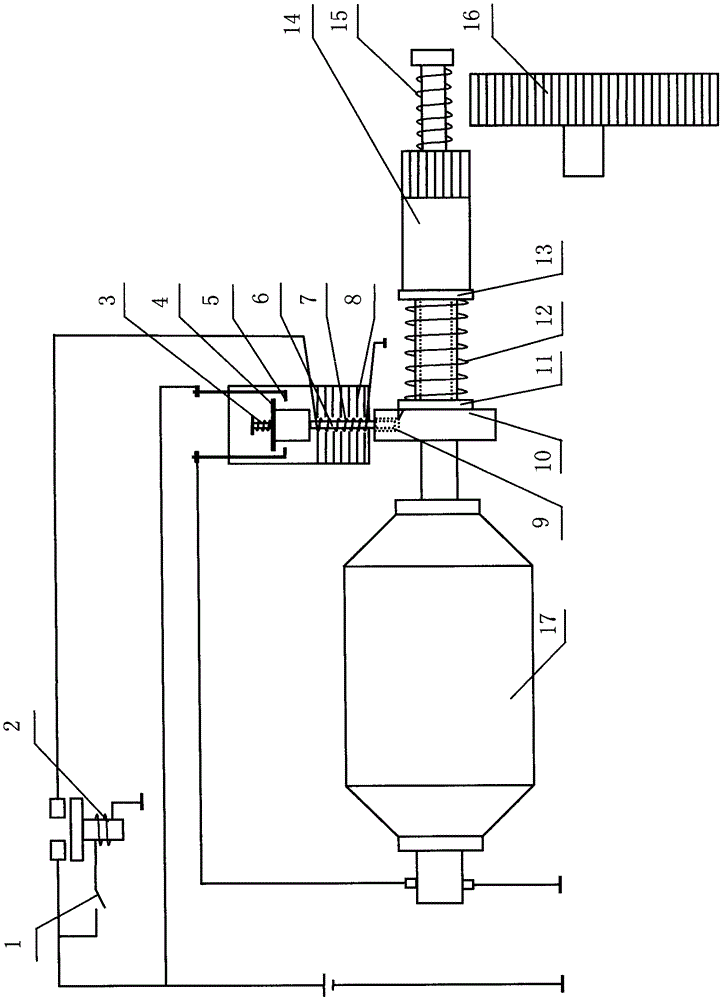

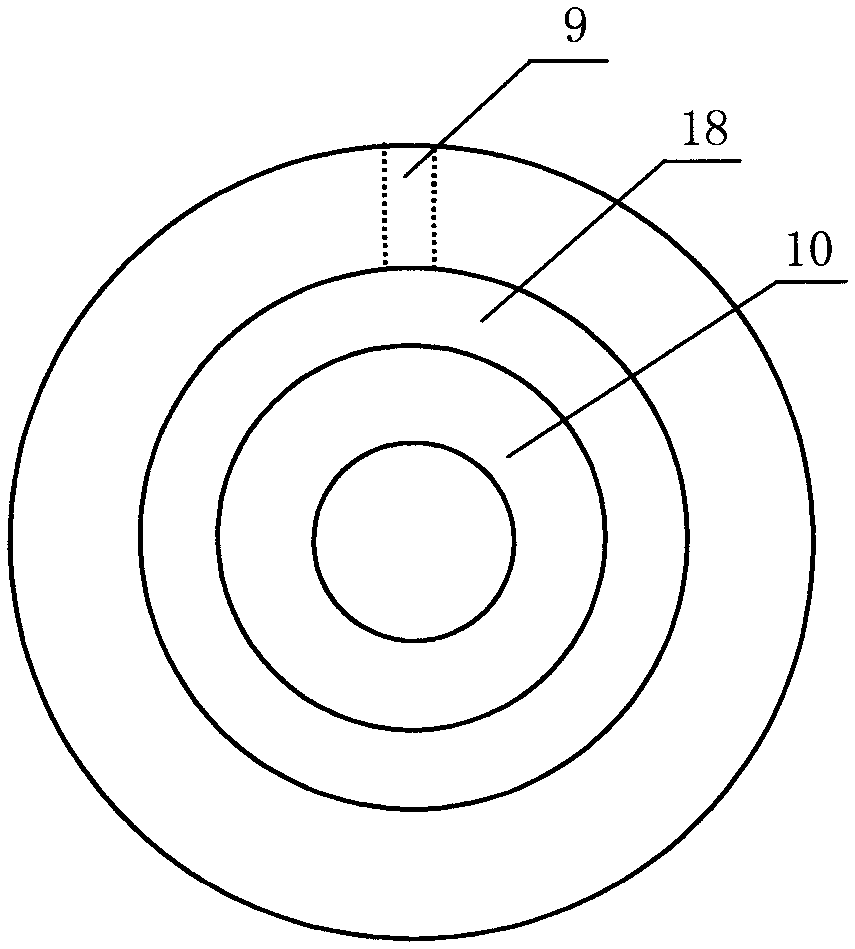

Efficient compression molding system for vacuum insulated panel

InactiveCN103991125AShorten the overall lengthHigh-speed and smooth loading and unloadingAuxillary shaping apparatusShaping press ramFrequency changerElectric devices

The invention discloses an efficient compression molding system for a vacuum insulated panel and relates to the field of green building energy conservation. The compression molding system is mainly composed of a main machine frame, a die, a driving device, a transmission mechanism, a dust hood, an injection system assembly, a feeding device, a mixing device and a conveying and setting device. Due to the digital intelligent control of input and output of electric devices such as a PLC and a frequency converter, compression molding speed is high, operation is steady, clamping force is large, high-density homogeneous core materials and non-homogeneous core materials can be produced, one device can be adapted to production of plates in various specifications, the utilization rate is high, repeated investment is avoided, resources are saved, driving force is provided by pure electric energy, the problems of high hydraulic energy consumption and pollution are solved, dust-free and waste gas-free production is realized in the compression molding and setting process, the working environment is good, equipment performance is stable, service life is long, mixing, feeding, injection, compression molding, setting and conveying are conducted continuously, the mechanical structure is compact, the appearance is attractive, manufacturing is convenient, labor and cost are saved, and energy conservation, environment protection and efficient production are realized in the true sense.

Owner:KUNSHAN YUANHAI PLASTIC PROD +1

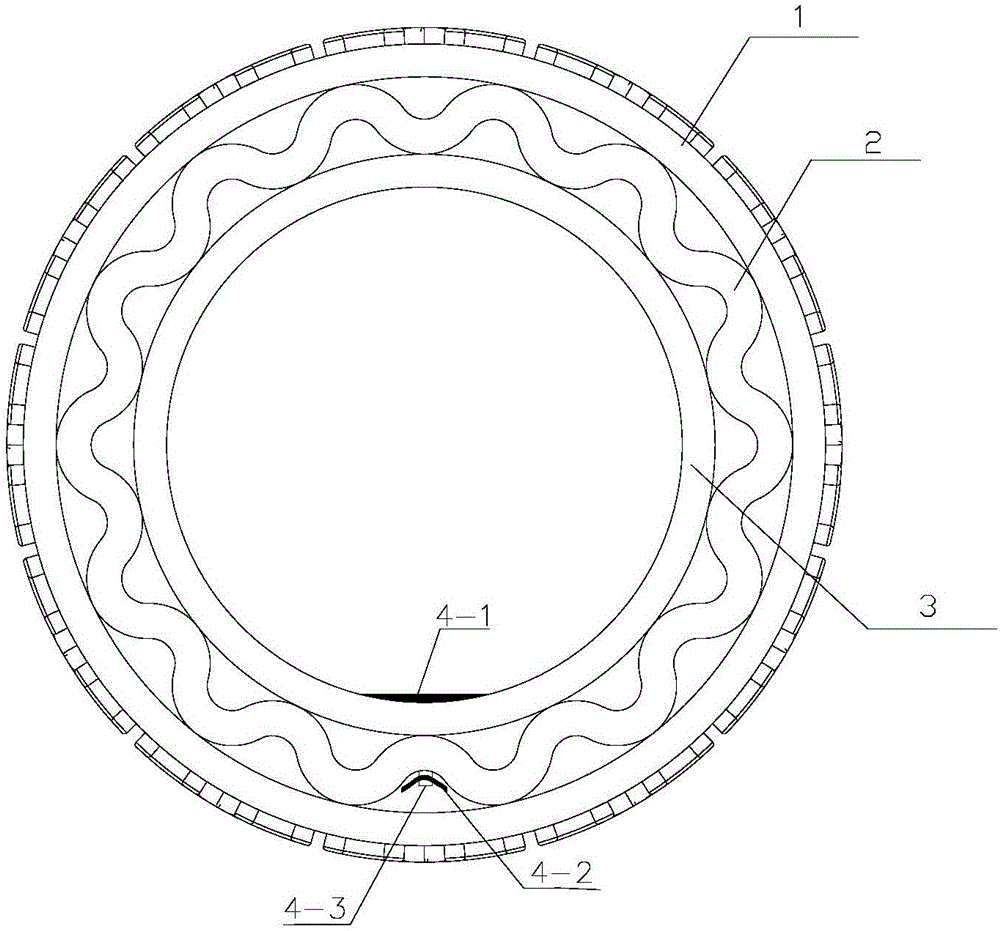

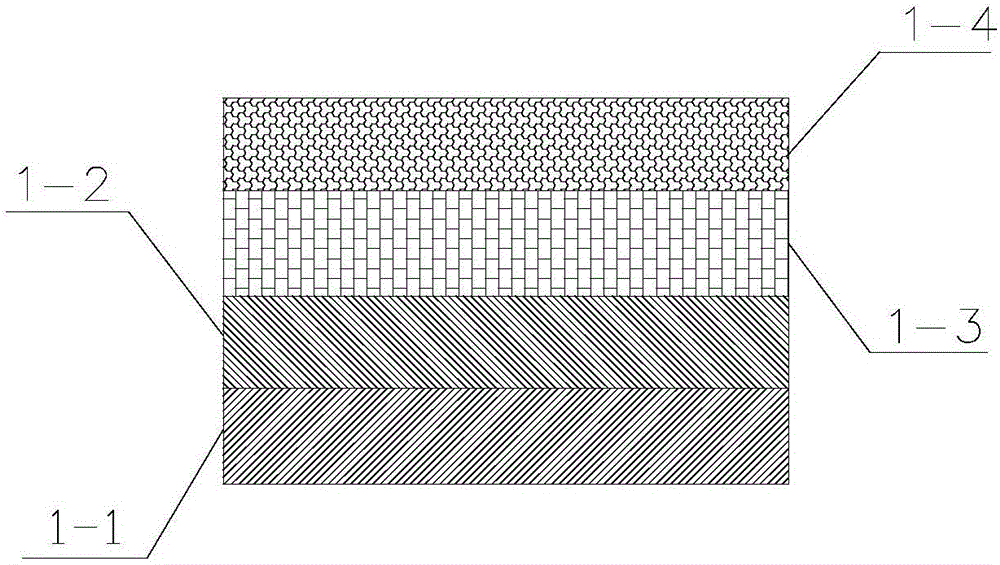

Non-pneumatic tire

ActiveCN105856971AGuaranteed service lifeIncreased durabilityNon-inflatable tyresTyresTweelManufacturing technology

The invention belongs to the technical field of tires and specifically relates to a non-pneumatic tire, in particular to the non-pneumatic tire of an annular corrugated structure. The non-pneumatic tire comprises a rim. A tread, a buffer layer and a rim matching component are sequentially arranged on the rim from outside to inside. The tread is sequentially composed of tread rubber, a transitional rubber sheet I, all-steel cords and a transitional rubber sheet II from outside to inside. The buffer layer is of an annular corrugated structure. Wave crests of the buffer layer are tightly attached to the inner side of the tread. Wave troughs of the buffer layer are tightly attached to the outer side of the rim matching component. A Reuleaux triangle space is formed between the buffer layer and the tread, and a Reuleaux triangle space is formed between the buffer layer and the rim matching component. The buffer layer and the rim matching component are fixed through a U-shaped buckle. By the adoption of the non-pneumatic tire, the flat tire problem of a pneumatic tire is solved, the buffer performance is good, and a manufacturing technology is simple.

Owner:DEZHOU LINGLONG TIRE

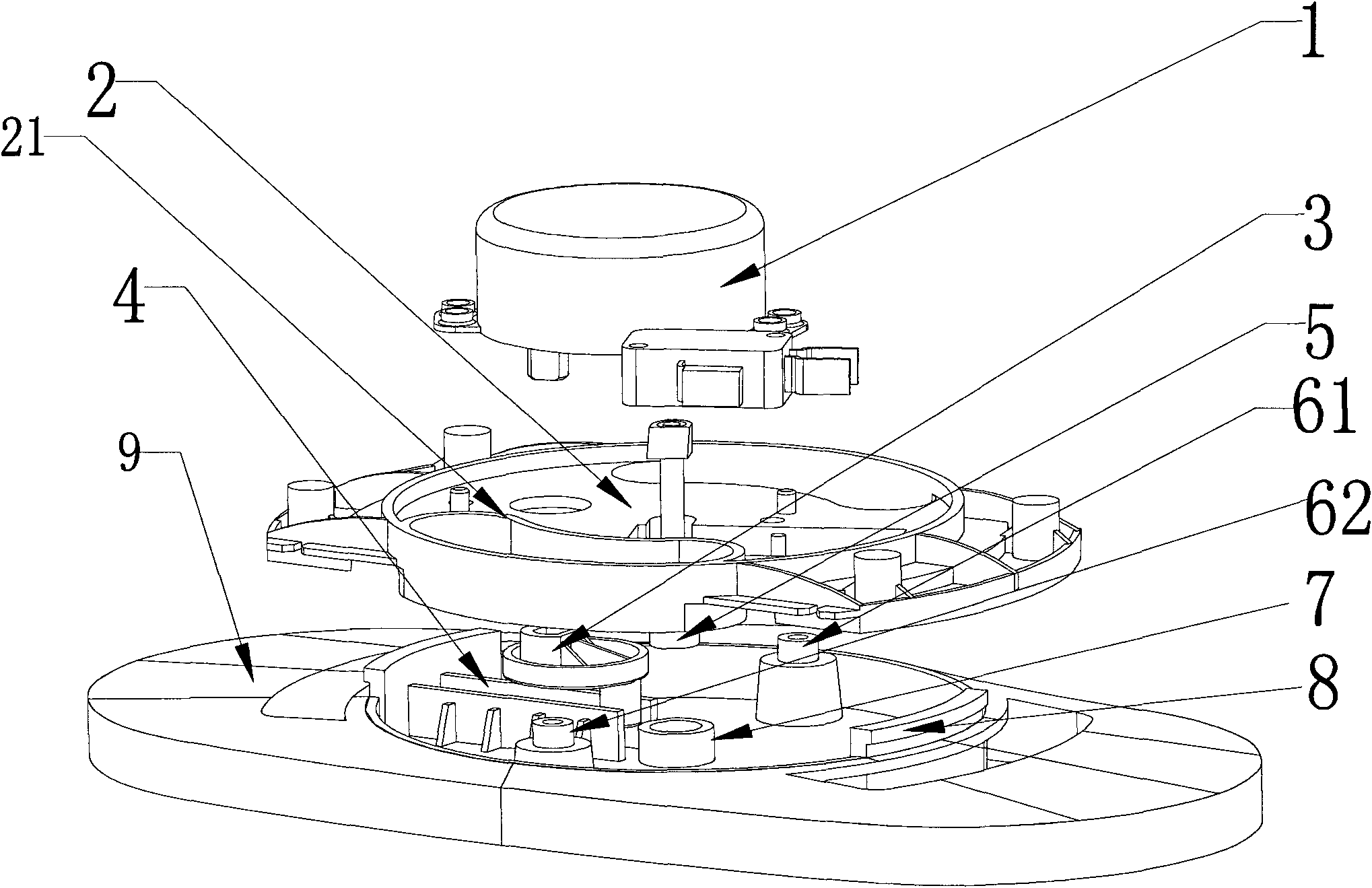

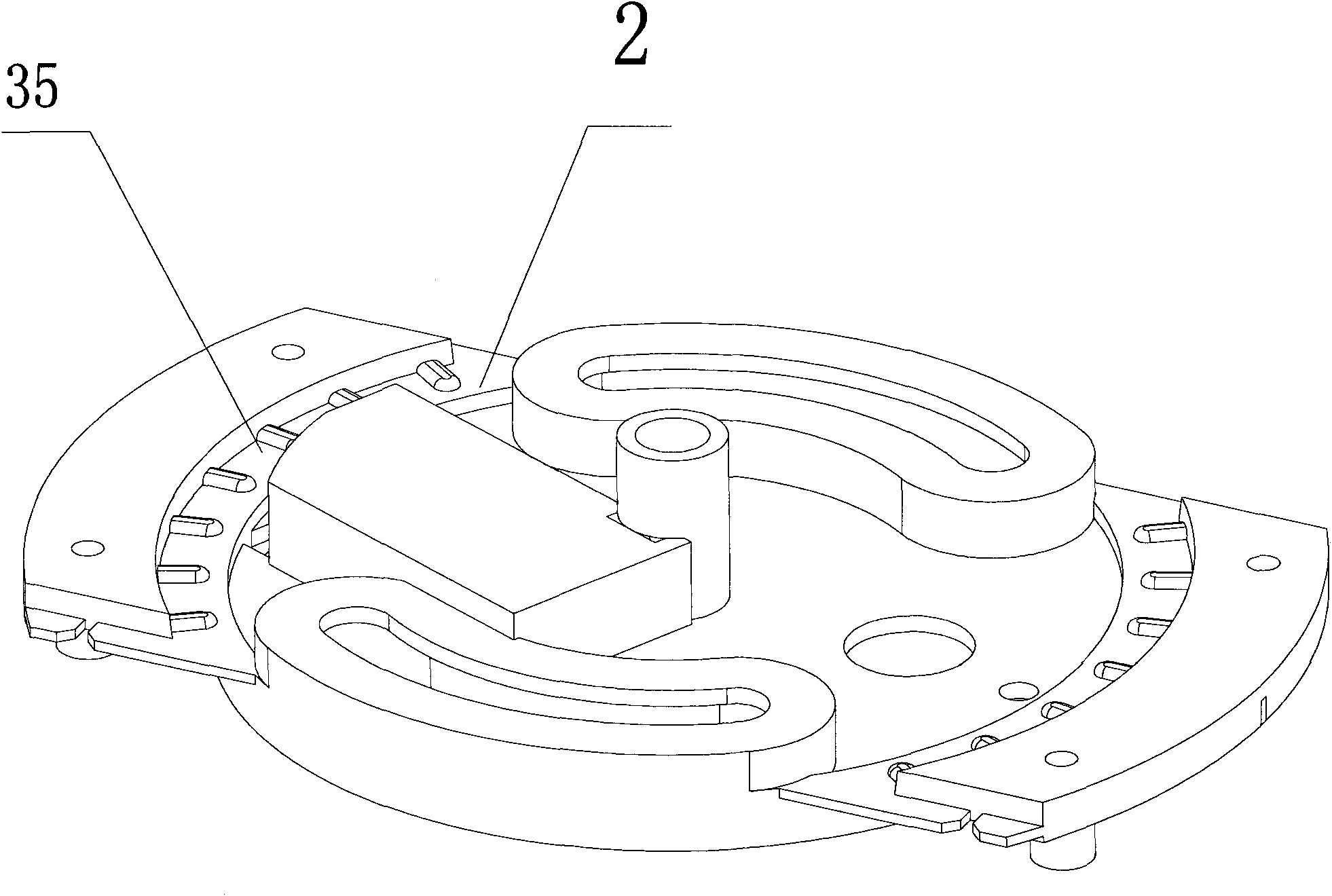

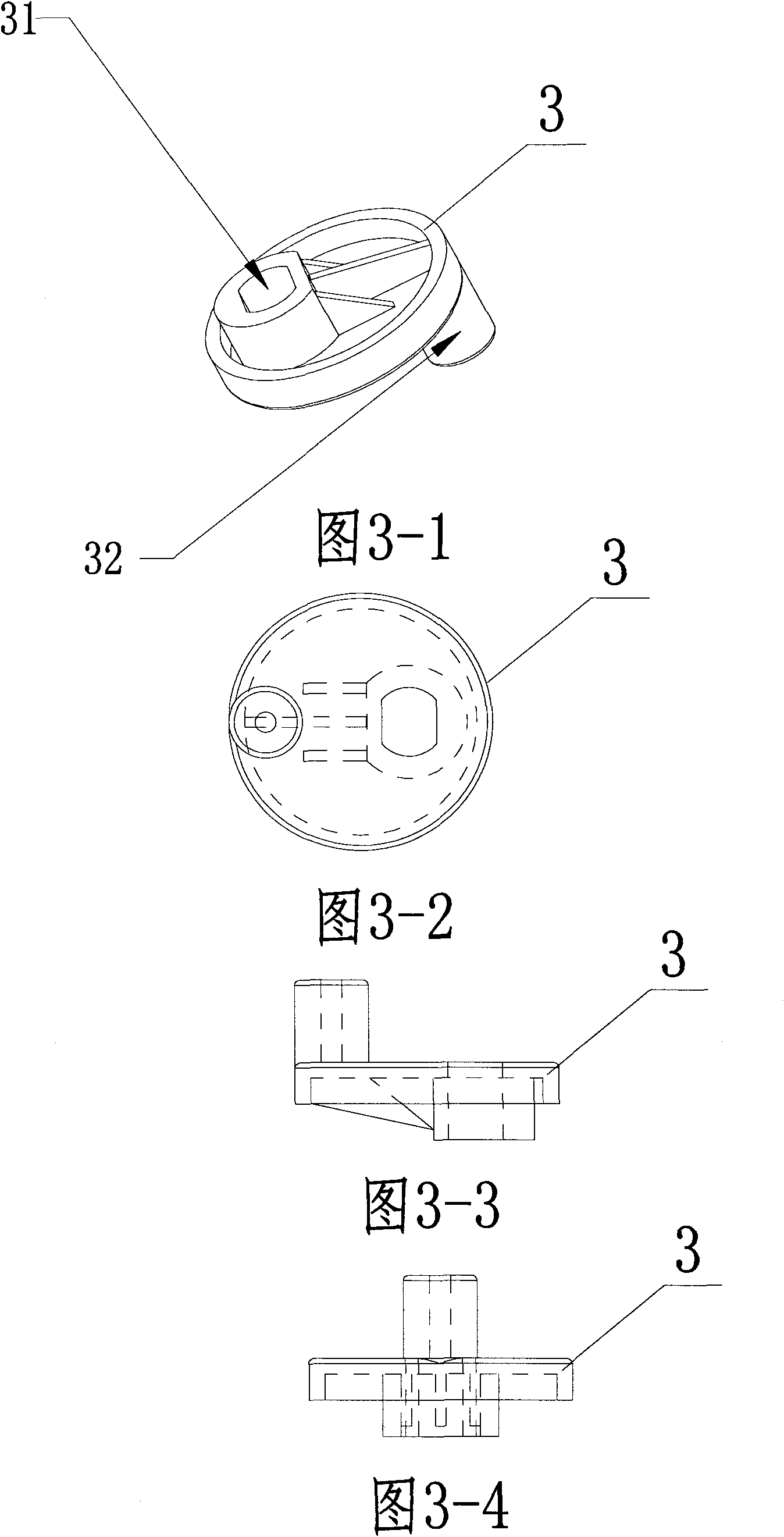

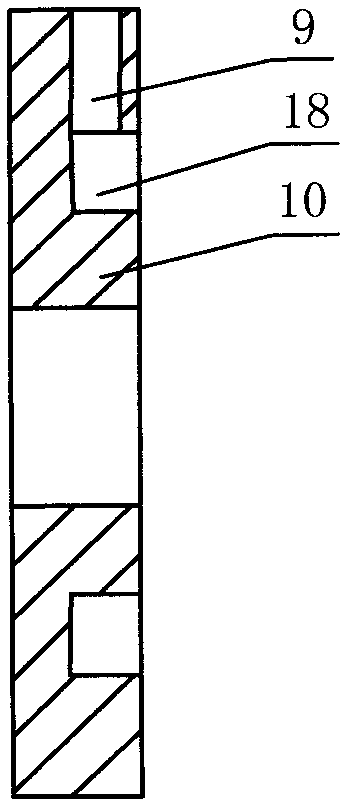

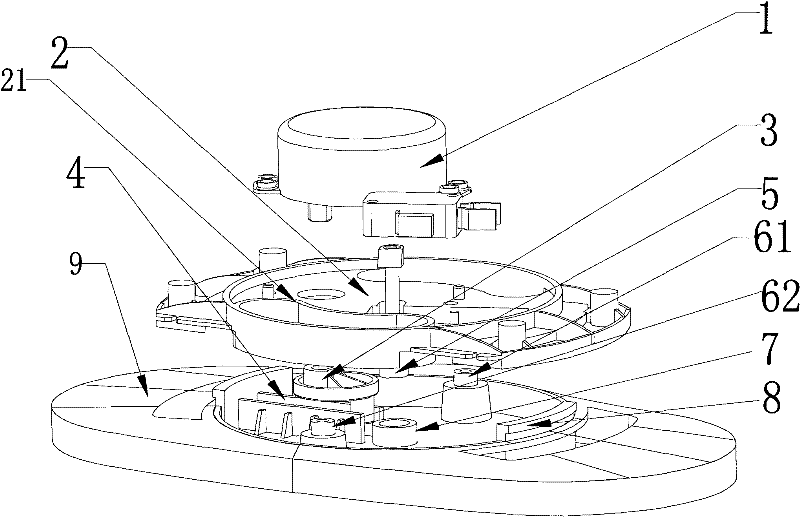

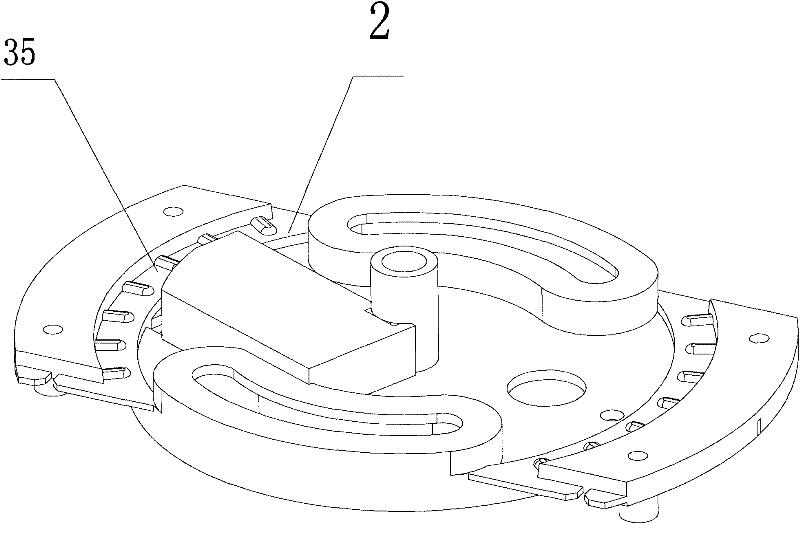

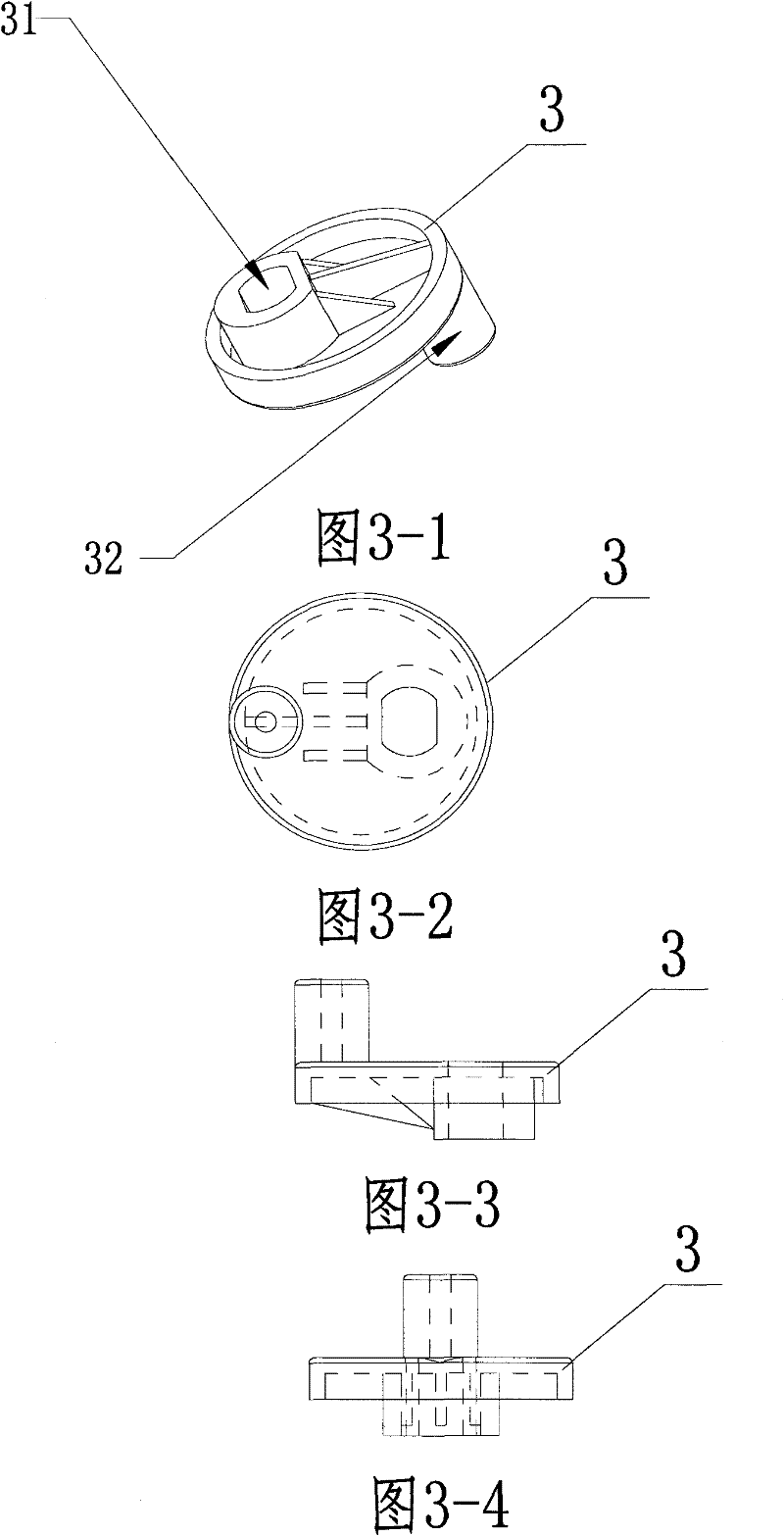

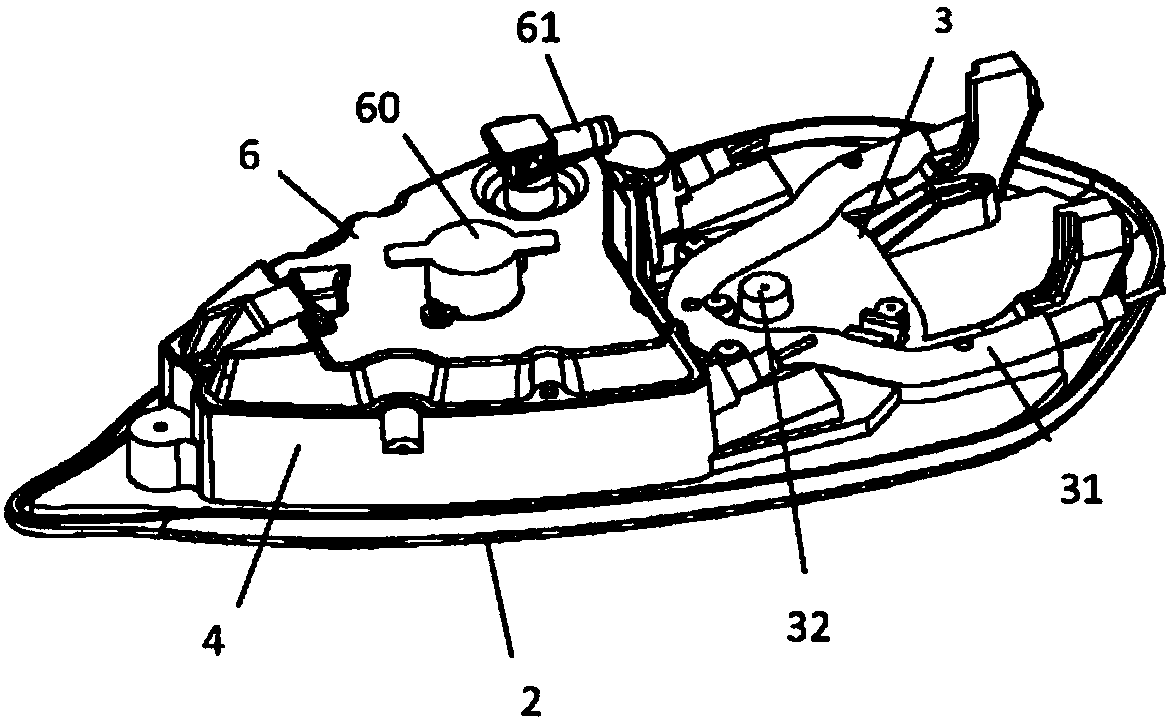

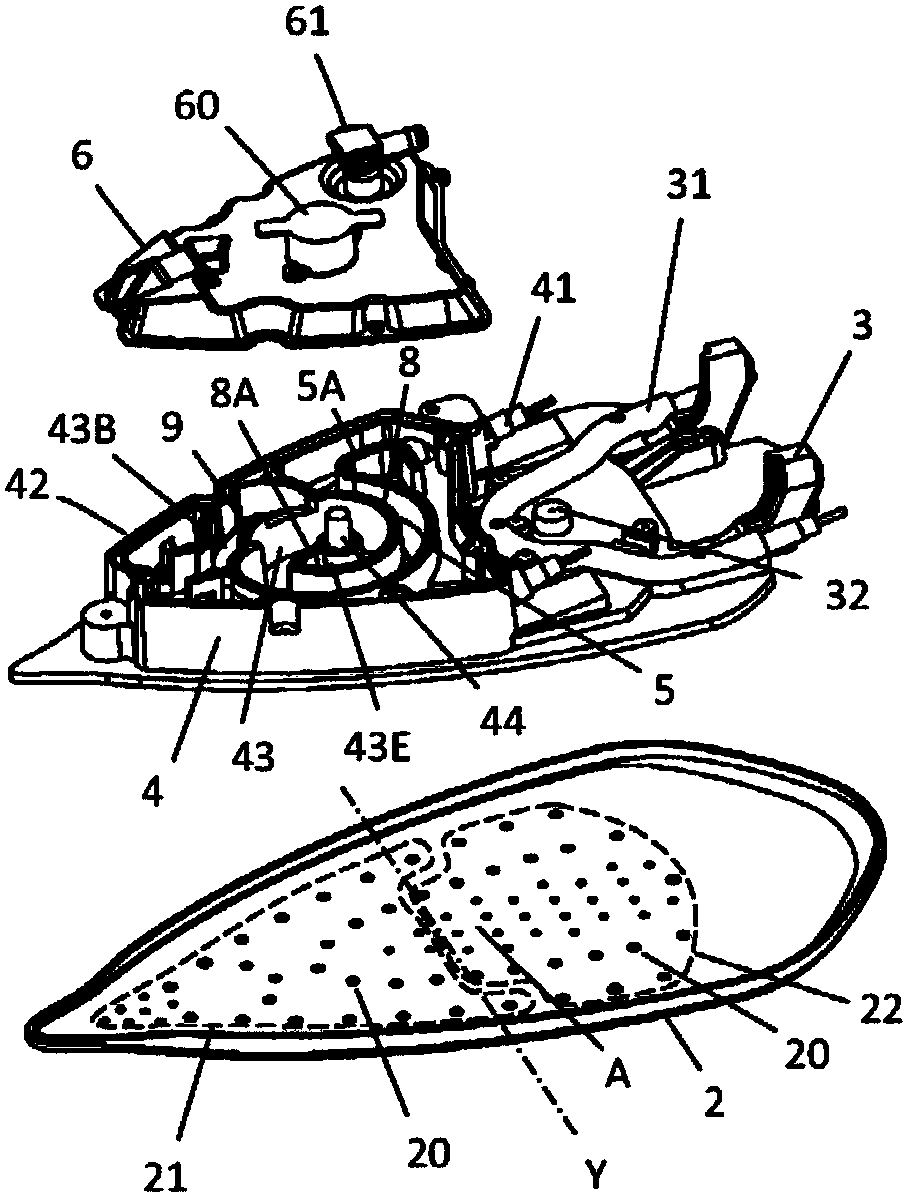

Head oscillating structure of warmer

ActiveCN101776307ACompact performanceImprove performanceLighting and heating apparatusSpace heating and ventilation detailsDrive shaftDrive motor

The invention relates to a head oscillating structure of a warmer. The head oscillating structure comprises a warmer base, a rotating part, a driving cam and a driving motor, wherein the driving cam is arranged between the warmer base and the rotating part, the driving motor is arranged at the top of the rotating part, the output shaft of the driving motor penetrates through the rotating part and is inserted into the installation hole of the driving cam, the driving shaft of the driving cam is arranged in a slide rail arranged on the base, a sliding positioning column arranged on the base is installed in the rotating slide rail arranged at the rotating part, and a rotating central shaft arranged at the rotating part is sheathed on a rotating central sleeve arranged on the base. By adopting the structure that the cam drives the rotating part to move, the space dimension of the product is reduced, the exterior smallness and exquisiteness are improved, the stability is improved and the head oscillating structure passes 750 thousand of times of head oscillation tests. Moreover, screws are not used for the fixation between the cam and the rotating part and between the rotating part and the base slide rail, the assembling efficiency is improved and the cost is reduced.

Owner:MIDEA GRP CO LTD

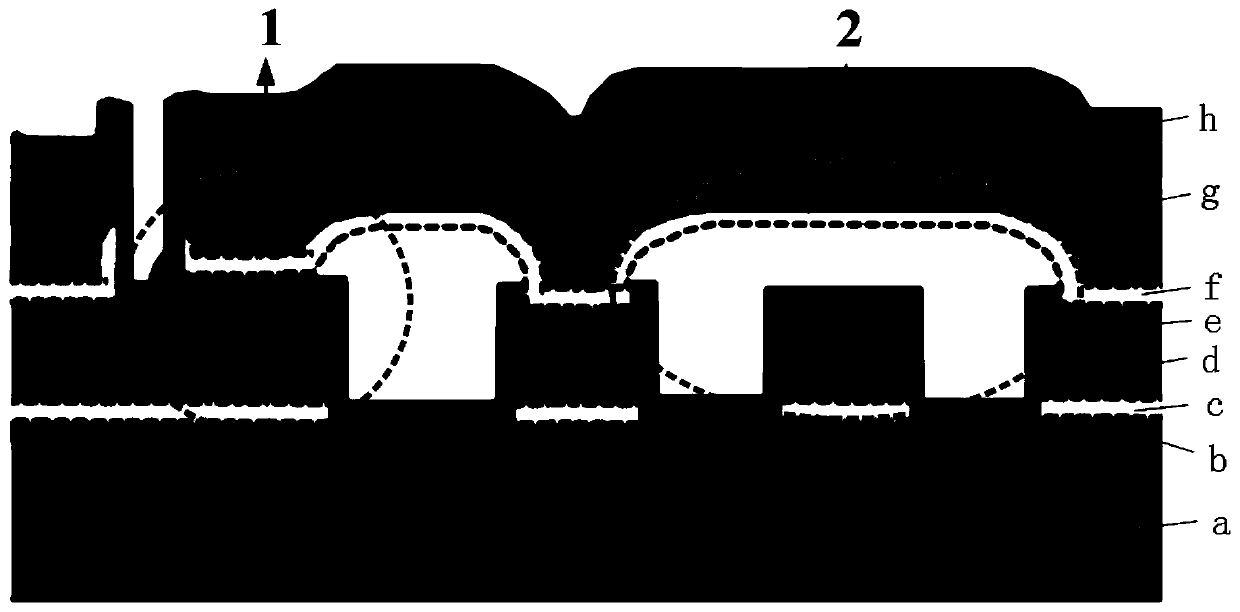

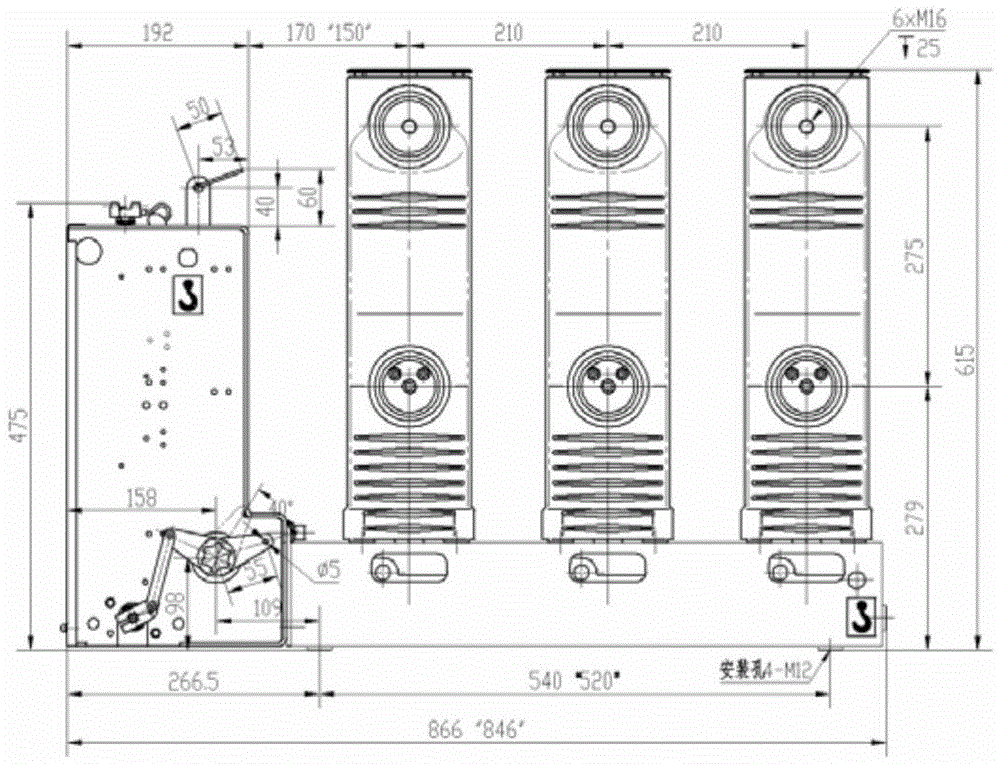

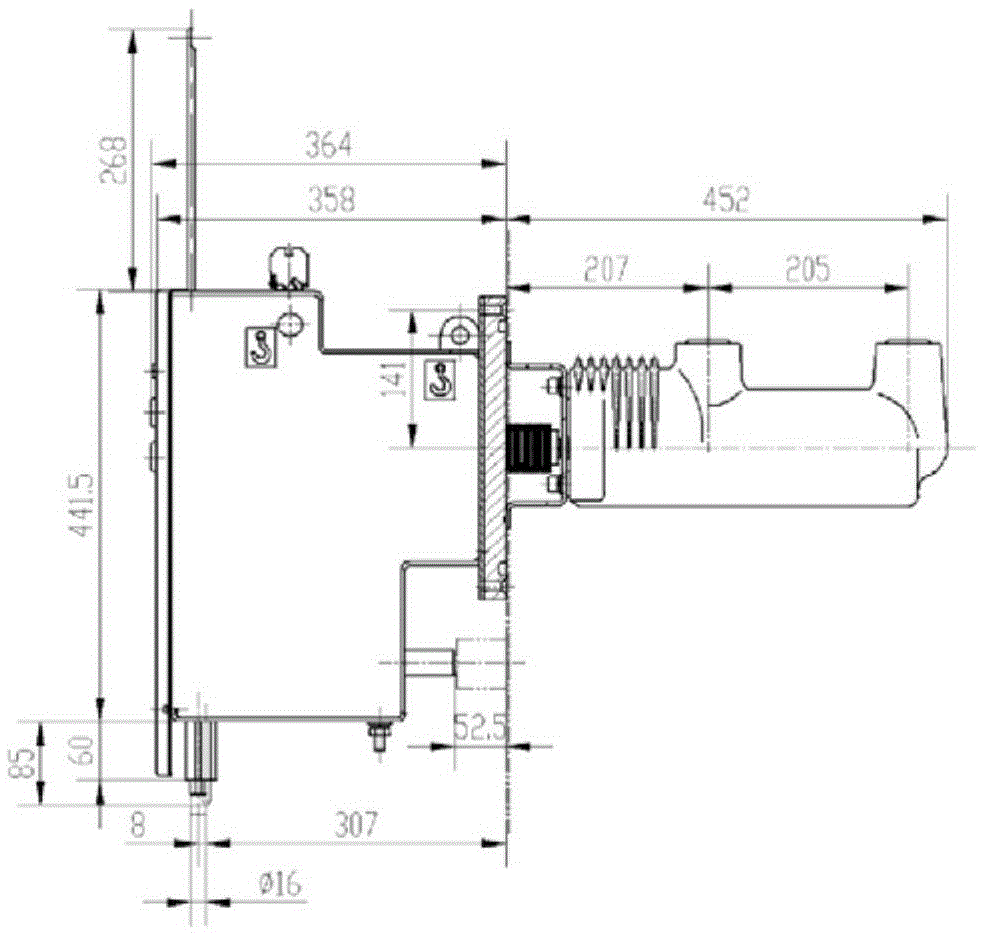

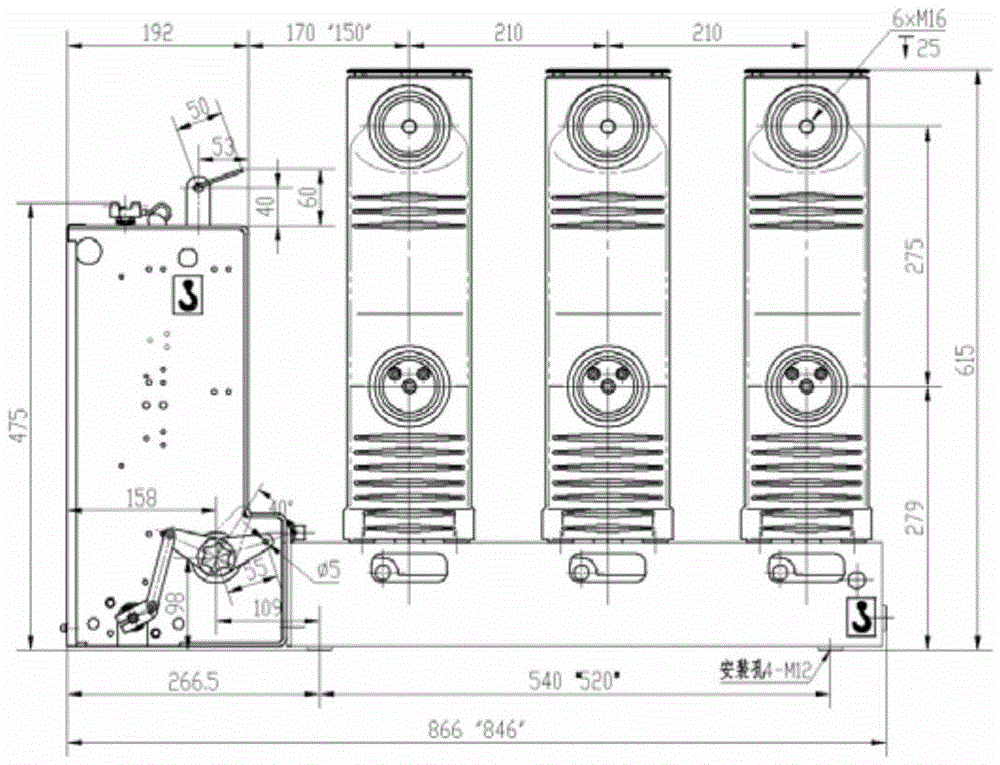

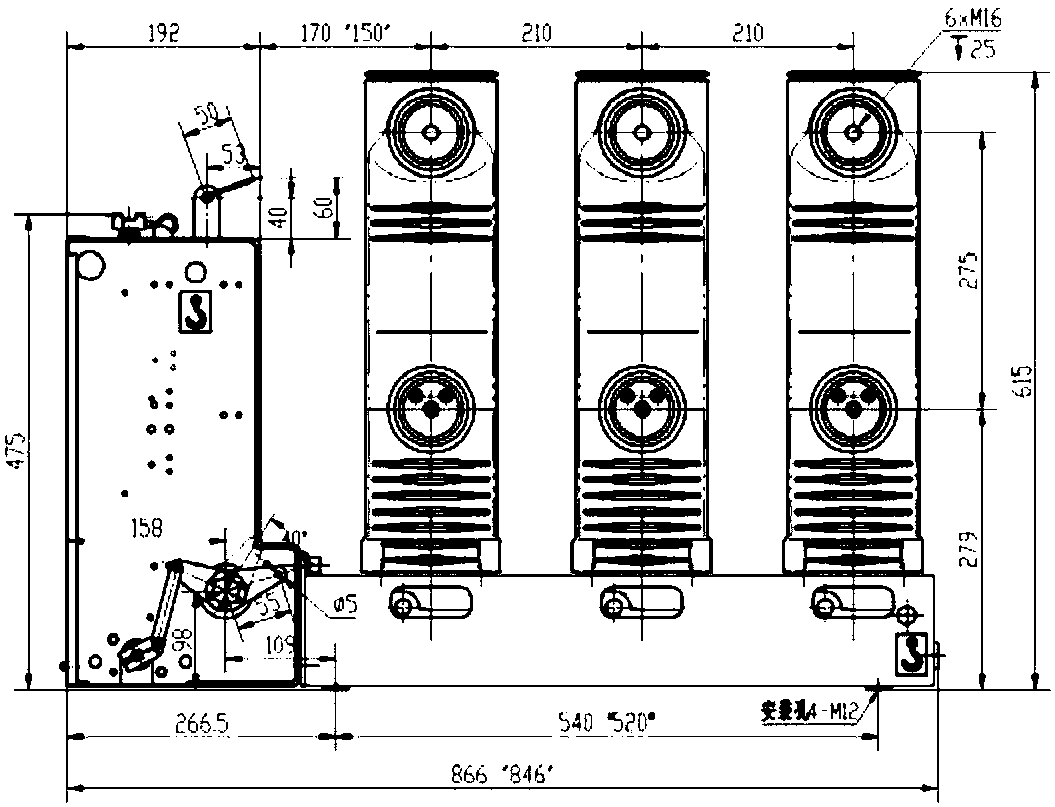

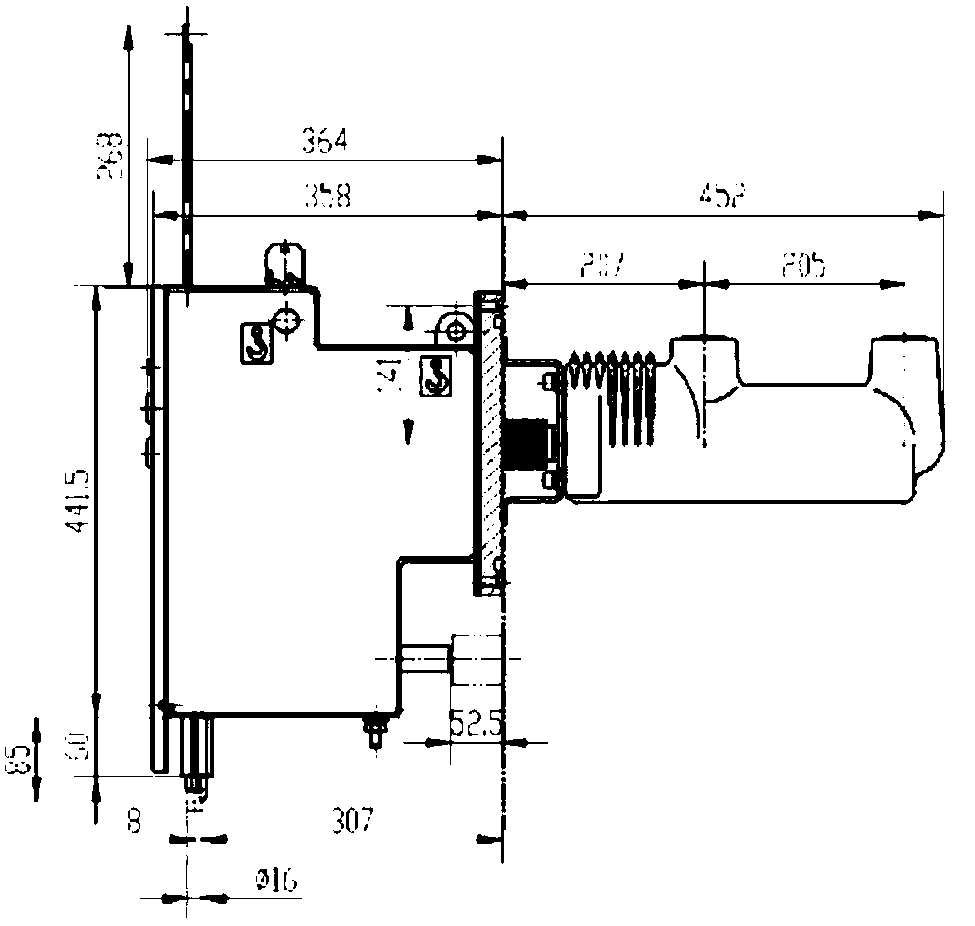

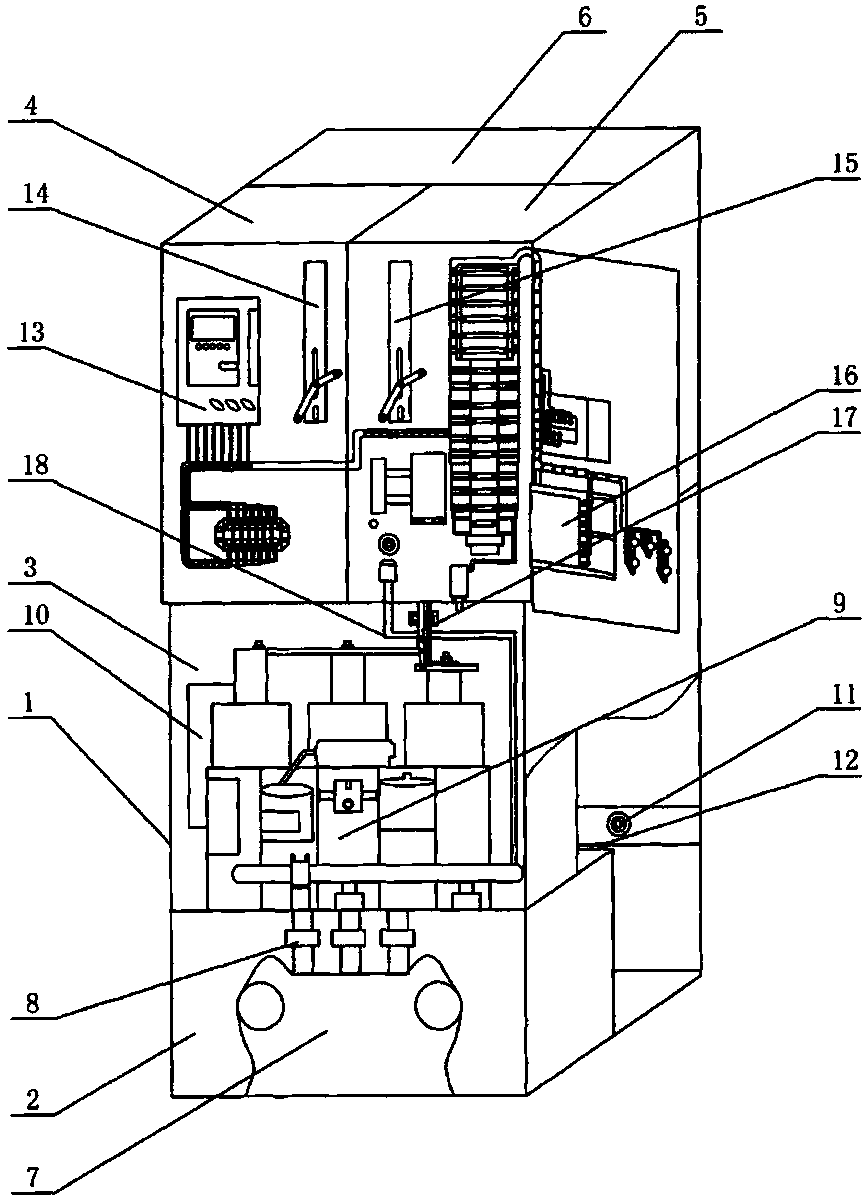

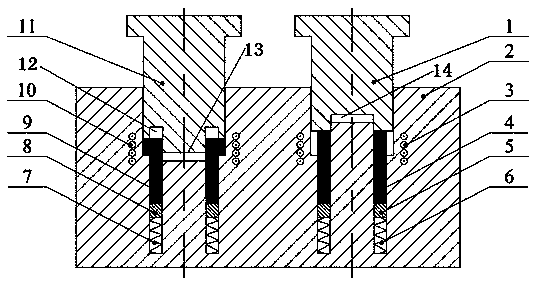

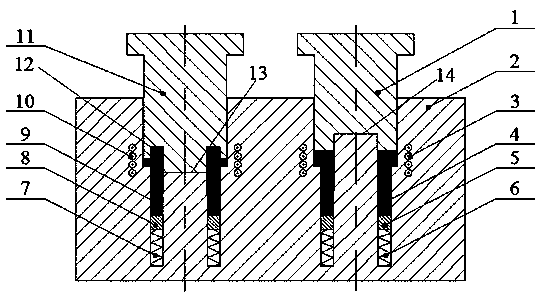

Insulating embedded vacuum circuit breaker for gas-filled tank

ActiveCN105609362AMeet application needsReasonable space arrangementSwitchgear arrangementsSwitchgear with withdrawable carriageHeat sinkVacuum arc

The invention relates to a circuit breaker, in particular to an insulating embedded vacuum circuit breaker for a gas-filled tank. The insulating embedded vacuum circuit breaker comprises a circuit breaker shell, a circuit breaker body, an operating mechanism and a circuit control module, wherein a circuit breaker operating mechanism and an embedded pole are arranged in a box body; the embedded pole is connected with the breaker circuit operating mechanism; the embedded pole comprises an upper conductive frame and a lower conductive frame; a vacuum arc-extinguishing chamber and a fixed contact are arranged between the upper conductive frame and the lower conductive frame; the fixed contact is located in the vacuum arc-extinguishing chamber and is connected with the upper conductive frame; a moving contact capable of moving up and down is arranged in the vacuum arc-extinguishing chamber; the moving contact and the lower conductive frame are kept in connection; an embedded casting body coats the upper conductive frame, the lower conductive frame and the outer wall of the vacuum arc-extinguishing chamber; an air flow channel is arranged in the embedded casting body on the periphery of the vacuum arc-extinguishing chamber; and a cooling fin is arranged on the upper conductive frame. The embedded pole is modified through powder, so that the embedded pole has relatively good sealing stability; and the stability performance of the pole is improved.

Owner:BEST ELECTRICAL

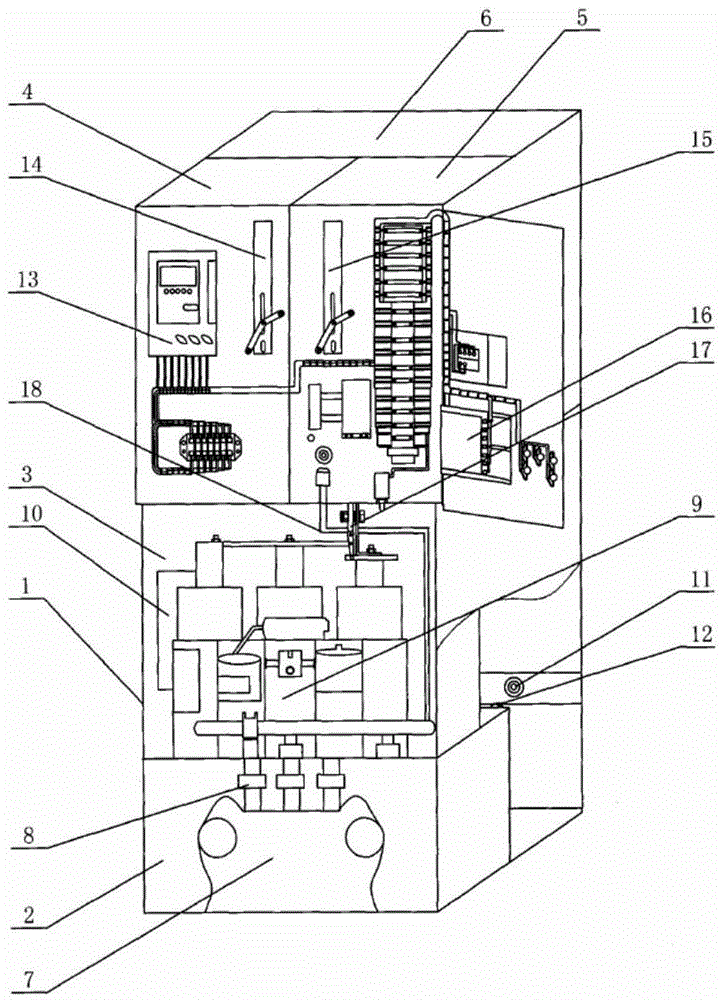

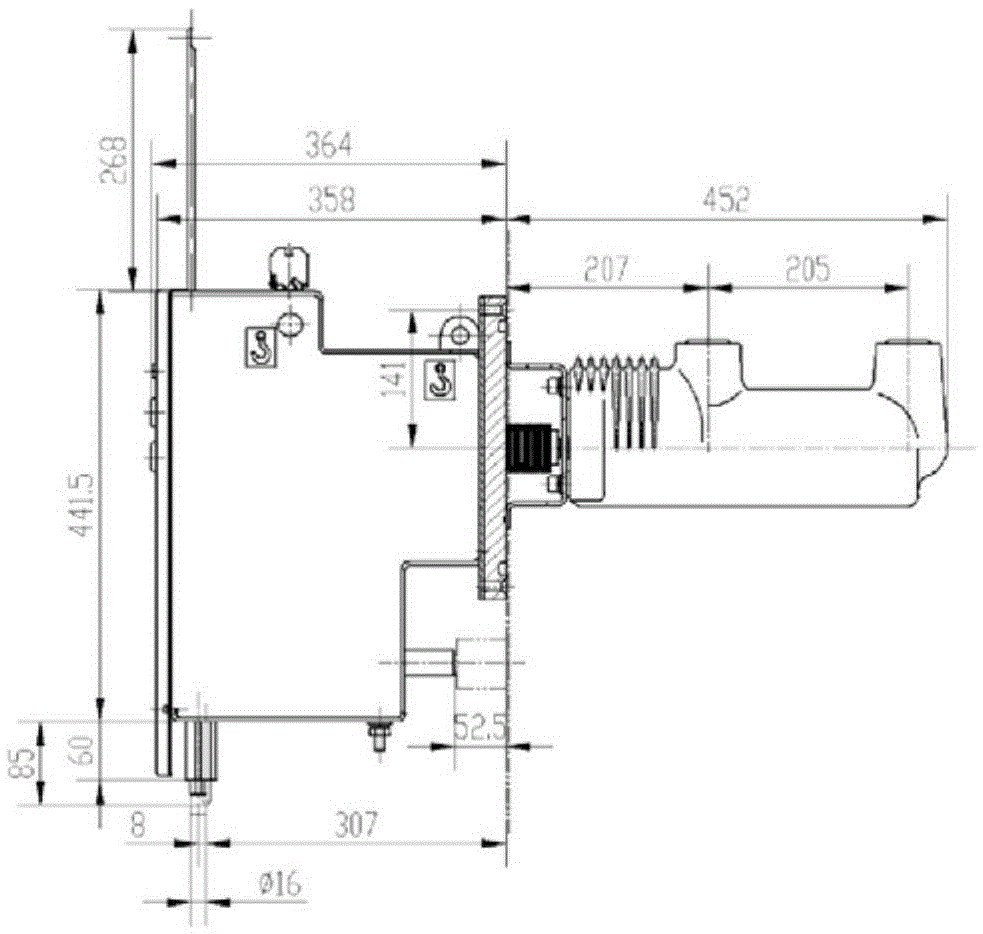

Permanent magnet vacuum circuit breaker

ActiveCN105680362AMeet application needsReasonable space arrangementSwitchgear arrangementsHigh-tension/heavy-dress switchesBusbarEngineering

The invention discloses a sealed insulating vacuum circuit breaker for an inflating cabinet, and belongs to the field of vacuum high-voltage circuit breakers. The circuit breaker comprises a circuit breaker shell, a circuit breaker body, an operating mechanism and a control module, and also comprises a wire incoming room, a circuit breaker room, a metering room, an instrument room and a busbar room, wherein the wire incoming room and the circuit breaker room are positioned at the lower part and the middle part of a wire incoming cabinet respectively, the metering room and the instrument room are positioned in the front of the upper part of the wire incoming cabinet, and the busbar room is positioned at the back of the upper part of the wire incoming cabinet; a double-winding double-ratio voltage transformer and a high-voltage fuse are mounted in the wire incoming room; a circuit breaker, a three-winding current transformer, a lightning arrester and a sensor are mounted in the circuit breaker room; a loss-voltage timing instrument and a multifunctional metering instrument are mounted in the metering room; an electric energy prepaying device and a protection control device are mounted in the instrument room; and an isolating switch and busbars are mounted in the busbar room. According to the circuit breaker, an auxiliary positioning device and a chassis truck adjusting device are further specially designed, so that the performance of the circuit breaker is superior.

Owner:BEST ELECTRICAL

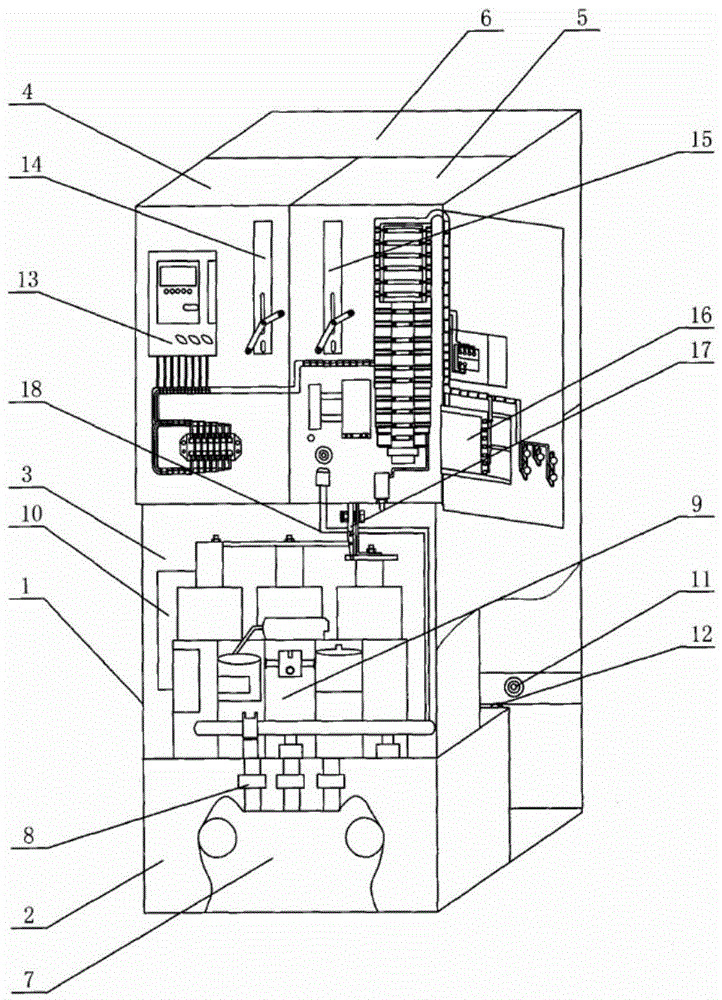

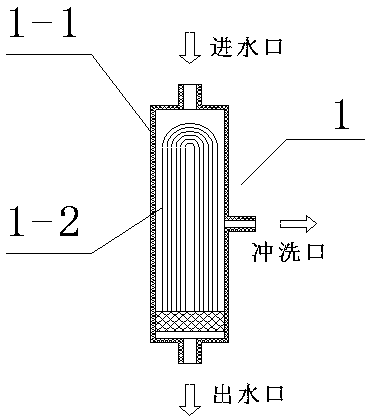

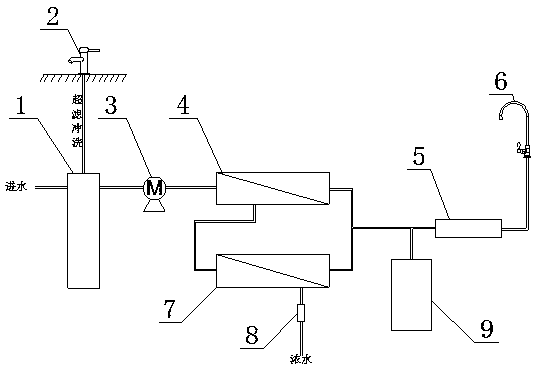

Full-membrane micro-concentrated water nanofiltration machine

PendingCN109987734AReasonable designCompact structureWater contaminantsTreatment involving filtrationActivated carbonUltrafiltration

The invention discloses a full-membrane micro-concentrated water nanofiltration machine, and relates to the novel nanofiltration machine which is suitable for reducing replacement frequency of a pretreatment filter element. Pretreatment is carried out by adopting ultrafiltration, so that a sterile state is kept in a machine, discharge of concentrated water is reduced, and the recovery rate of purewater is increased. The nanofiltration machine comprises an ultrafiltration filter element, a vegetable washing basin faucet, a booster pump, a first-stage nanofiltration membrane, a second-stage nanofiltration membrane, a rear activated carbon filter element, a purified water faucet, a concentrated water proportioning device and a water storage barrel; a water inlet of the ultrafiltration filterelement is connected with a tap water pipeline through a water inlet pipe; a water outlet of the ultrafiltration filter element is connected with a water inlet of the booster pump through a pipeline;a water outlet of the booster pump is connected with a water inlet of the first-stage nanofiltration membrane through a pipeline; a concentrated water outlet of the first-stage nanofiltration membrane is connected with a water inlet of the second-stage nanofiltration membrane through a pipeline; a pure water outlet of the first-stage nanofiltration membrane and a pure water outlet of the second-stage nanofiltration membrane are connected with the water storage barrel through pipelines; a water outlet of the water storage barrel is connected with a water inlet of the rear activated carbon filter element through a pipeline; and a water outlet of the rear activated carbon filter element is connected with the purified water faucet through a pipeline.

Owner:世保康环境电器(南京)有限公司

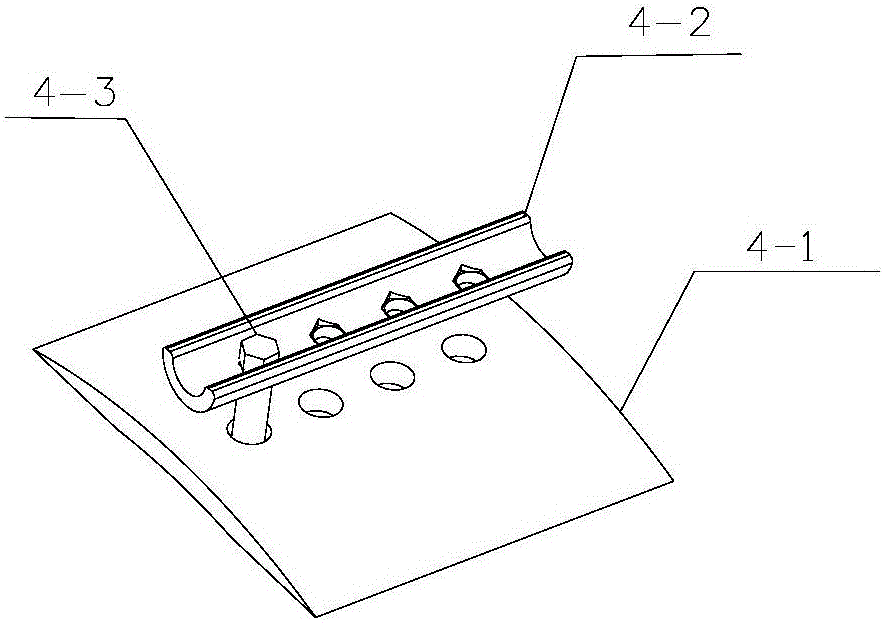

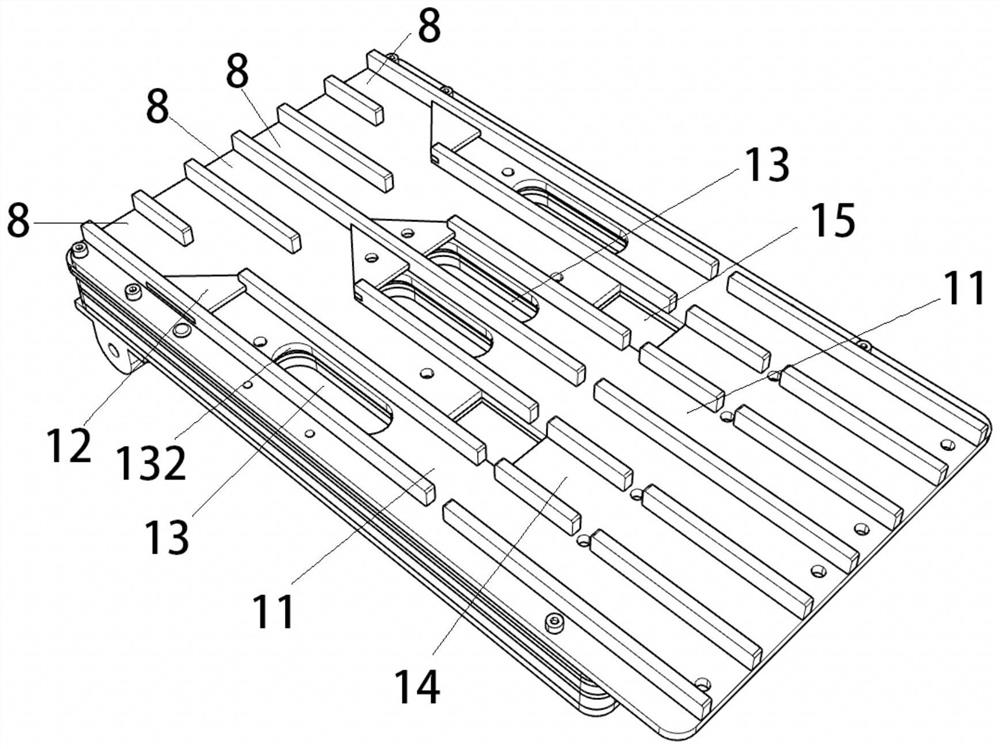

Coin separating and metering device

The invention discloses a coin separating and metering device which comprises a one-yuan coin separating layer, a fourth-version one-jiao coin separating layer, a fifth-jiao coin separating layer and a fifth-version one-jiao separating layer. The one-yuan coin separating layer is provided with a one-yuan coin channel, the one-yuan coin channel is provided with a first separating groove for separating one-yuan coins, the five-jiao coin separating layer is provided with a five-jiao coin channel, the five-jiao coin channel comprises an inclined section, and the inclined section is provided with a second separating groove for separating five-jiao coins; the fifth-version one-jiao separation layer is provided with a fifth-version one-jiao coin channel communicated with the second separation groove; the one-yuan coin separating layer is further provided with a fourth-version one-jiao coin separating channel communicated with the one-yuan coin channel, and a height limiting plate for separating fourth-version one-jiao coins is arranged at the communication position of the fourth-version one-jiao coin separating channel. The functions of separating, classifying, metering, collecting and the like of coins can be integrated on one composite board, meanwhile, energy consumption is reduced by adopting an unpowered separation technology depending on gravity, performance is stable, efficiency is high, and energy conservation and environmental protection are achieved.

Owner:ZHEJIANG UNIV OF TECH

Functional master batch for strengthening tensile strength of polypropylene

The present invention relates to the field of functional master batches, and specifically discloses a functional master batch for strengthening the tensile strength of polypropylene. The functional master batch is prepared from a carrier resin, an alicyclic epoxy resin, a cross-linking agent, nanometer alumina powder, nano-scale porcelain powder, glass fiber, nanometer graphene, nano-scale wood powder, a coupling agent and a dispersant, wherein the carrier resin is a polypropylene resin, the cross-linking agent is preferably one selected from diisopropylbenzene hydroperoxide, triethylenetetramine, diethylenetriamine and diethylaminopropylamine, the coupling agent is preferably one selected from a vinyl silane coupling agent, an aminosilane coupling agent and an epoxy silane coupling agent, and the dispersant is preferably one selected from lignin fiber, bamboo pulp fiber and zinc stearate. According to the present invention, the cross-linking compactness of polypropylene is synergistically improved by cross-linking polypropylene with the alicyclic epoxy resin and by using nanometer alumina powder, porcelain powder and wood powder as the composite nucleating agent, the tensile strength is improved, and the mechanical property of the polypropylene resin is further improved through glass fiber and nano-graphene.

Owner:长兴天晟能源科技有限公司

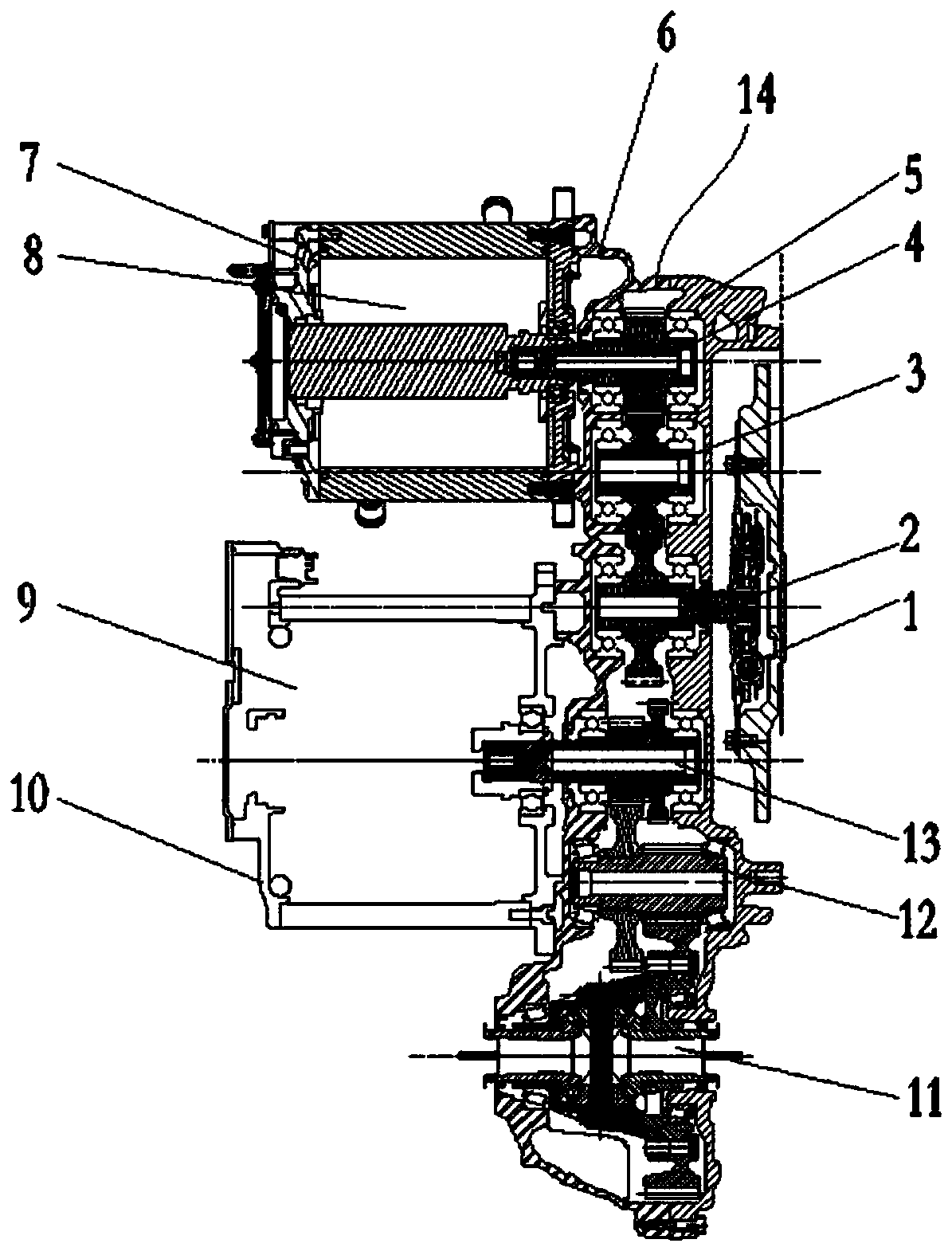

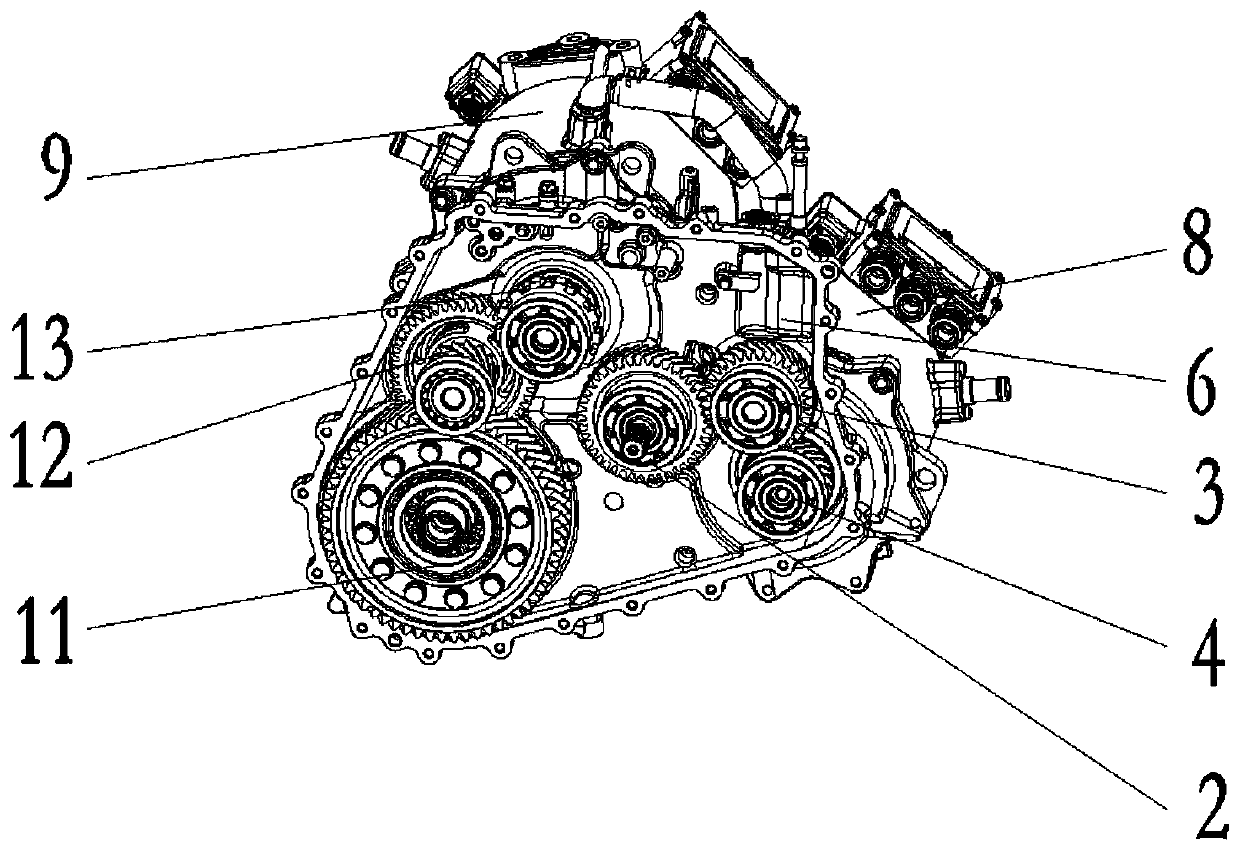

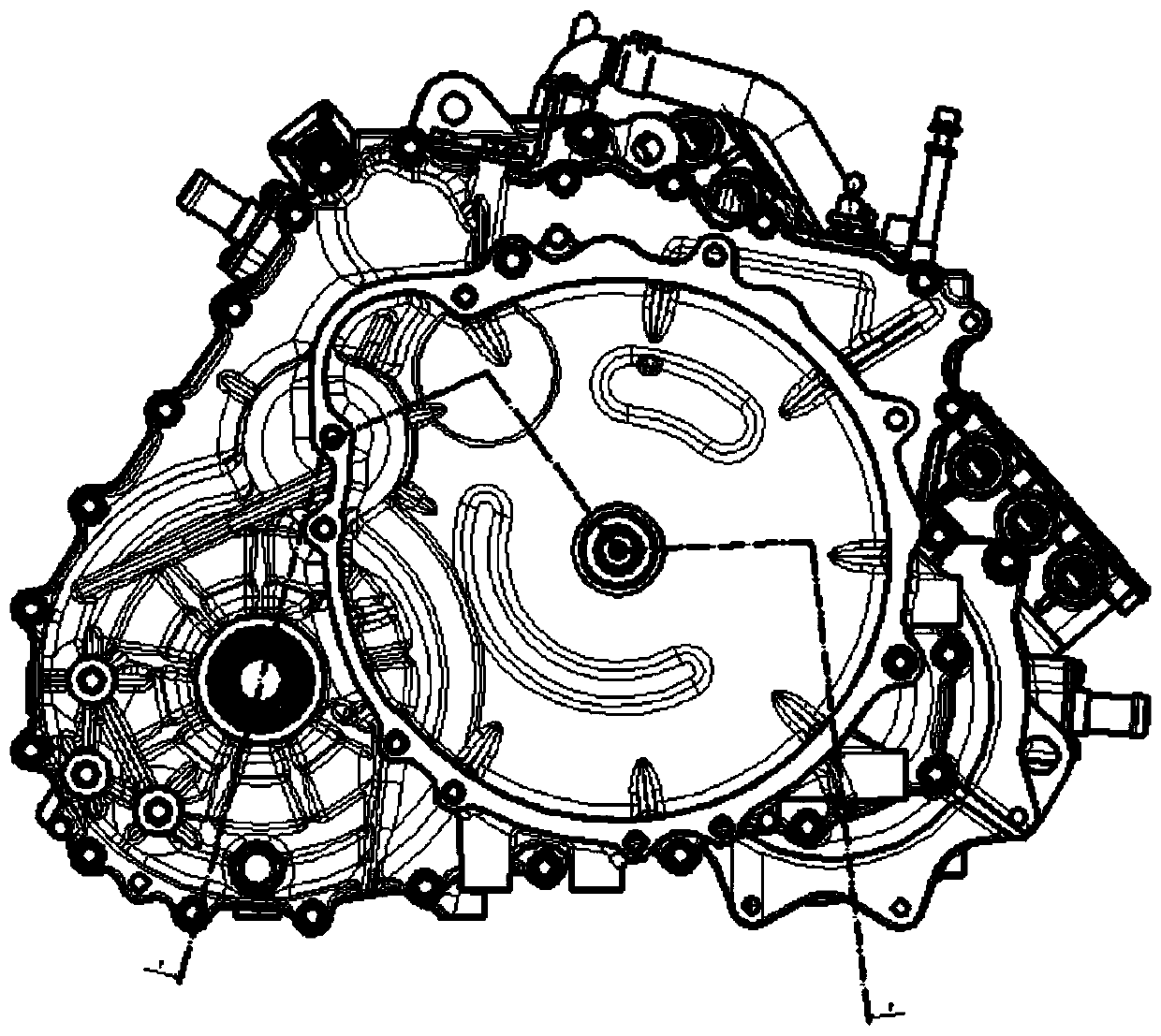

Speed reducer layout structure used for range-extending type electric vehicle

InactiveCN110435420ACompact structureShort axial lengthElectric propulsion mountingControl devicesElectric generatorSpeed reduction

The invention discloses a speed reducer layout structure used for a range-extending type electric vehicle, and belongs to the technical field of electric vehicle speed reducers. The speed reducer layout structure comprises a power generation transmission mechanism, a drive transmission mechanism and a differential mechanism, wherein the power generation transmission mechanism comprises a power generation input shaft, an idle wheel shaft and a power generation output shaft; the drive transmission mechanism comprises a drive input shaft and a drive output shaft; power output by an engine is transmitted into the power generation transmission mechanism through dual mass flying wheels, and rotation speed is increased by the power generation transmission mechanism through a gear wheel of each axle, so that a power generator is driven to generate power in a high-efficiency area, and therefore, electric power is provided to a whole vehicle power battery and a drive motor; power generated by the drive motor is transmitted to the differential mechanism through secondary speed reduction of the drive transmission mechanism, and the differential mechanism is used for transmitting power to wheels to drive the whole vehicle to travel. The power transmission mechanism is more compact and simpler in structure, is convenient in assembly, and effectively overcomes the defects that an existing electric vehicle is low in endurance mileage and is high in cost due a too great power battery.

Owner:HARBIN DONGAN AUTOMOTIVE ENGINE MFG

A rotary damping buffer tooth-mesh automobile motor

InactiveCN102352809BLow costLow failure ratePower operated startersElectric motor startersFailure rateElectricity

The invention discloses a rotary damping buffering meshed type automobile motor, aiming to solve the problems of easy gear milling and complicated structure of the existing motor. The automobile motor disclosed by the invention comprises a driving device, an electromagnetic switch and an electric driver and the like, wherein the driving device comprises a pusher dog, a one-way device spring, a round iron plate, a one-way clutch and a return hairspring; and the electromagnetic switch also comprises a spring, a movable tactile disk, a tactile point, a tactile rod, a tactile rod return spring and a holding electromagnetic coil. According to the invention, a backspring is used and the principle that the backspring becomes more and more tight along with screwing due to the reverse acting force is also used to form a buffering and fastening machine element, thus the meshing can be realized fully and lightly without damaging gear rings and producing gear milling. By adopting the motor disclosed by the invention, the cost can be reduced, partial motor cast iron components can be saved, the weight can be lightened and the energy-saving effect can be more obvious; as the lever mechanism of the traditional motor can be omitted, the size can be reduced, the structure can be more compact, the materials can be saved and the motor is lighter and smaller; and besides, the product has excellent performance, extremely low failure rate, faster startup and no rigid frictions, thus the service life of the motor gear rings can be prolonged. Therefore, the motor disclosed by the invention can be used for replacing any existing starting motor in the market.

Owner:王振营

Head oscillating structure of warmer

ActiveCN101776307BCompact performanceImprove performanceLighting and heating apparatusSpace heating and ventilation detailsDrive shaftDrive motor

The invention relates to a head oscillating structure of a warmer. The head oscillating structure comprises a warmer base, a rotating part, a driving cam and a driving motor, wherein the driving cam is arranged between the warmer base and the rotating part, the driving motor is arranged at the top of the rotating part, the output shaft of the driving motor penetrates through the rotating part andis inserted into the installation hole of the driving cam, the driving shaft of the driving cam is arranged in a slide rail arranged on the base, a sliding positioning column arranged on the base is installed in the rotating slide rail arranged at the rotating part, and a rotating central shaft arranged at the rotating part is sheathed on a rotating central sleeve arranged on the base. By adopting the structure that the cam drives the rotating part to move, the space dimension of the product is reduced, the exterior smallness and exquisiteness are improved, the stability is improved and the head oscillating structure passes 750 thousand of times of head oscillation tests. Moreover, screws are not used for the fixation between the cam and the rotating part and between the rotating part andthe base slide rail, the assembling efficiency is improved and the cost is reduced.

Owner:MIDEA GRP CO LTD

A solid-sealed insulated vacuum circuit breaker for an inflatable cabinet

ActiveCN105609362BMeet application needsReasonable space arrangementSwitchgear arrangementsSwitchgear with withdrawable carriageEngineeringHeat sink

The invention relates to a circuit breaker, in particular to an insulating embedded vacuum circuit breaker for a gas-filled tank. The insulating embedded vacuum circuit breaker comprises a circuit breaker shell, a circuit breaker body, an operating mechanism and a circuit control module, wherein a circuit breaker operating mechanism and an embedded pole are arranged in a box body; the embedded pole is connected with the breaker circuit operating mechanism; the embedded pole comprises an upper conductive frame and a lower conductive frame; a vacuum arc-extinguishing chamber and a fixed contact are arranged between the upper conductive frame and the lower conductive frame; the fixed contact is located in the vacuum arc-extinguishing chamber and is connected with the upper conductive frame; a moving contact capable of moving up and down is arranged in the vacuum arc-extinguishing chamber; the moving contact and the lower conductive frame are kept in connection; an embedded casting body coats the upper conductive frame, the lower conductive frame and the outer wall of the vacuum arc-extinguishing chamber; an air flow channel is arranged in the embedded casting body on the periphery of the vacuum arc-extinguishing chamber; and a cooling fin is arranged on the upper conductive frame. The embedded pole is modified through powder, so that the embedded pole has relatively good sealing stability; and the stability performance of the pole is improved.

Owner:BEST ELECTRICAL

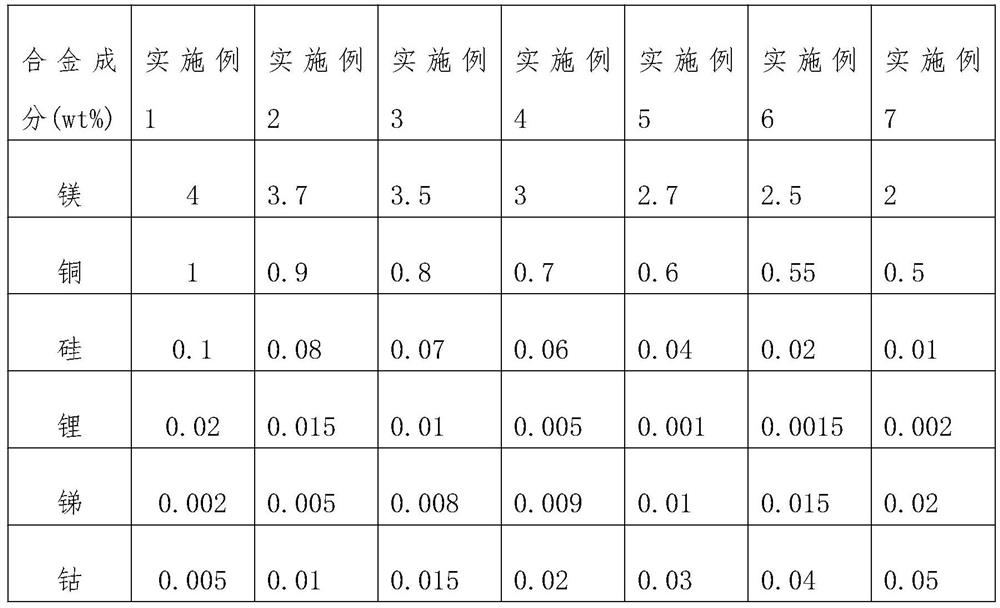

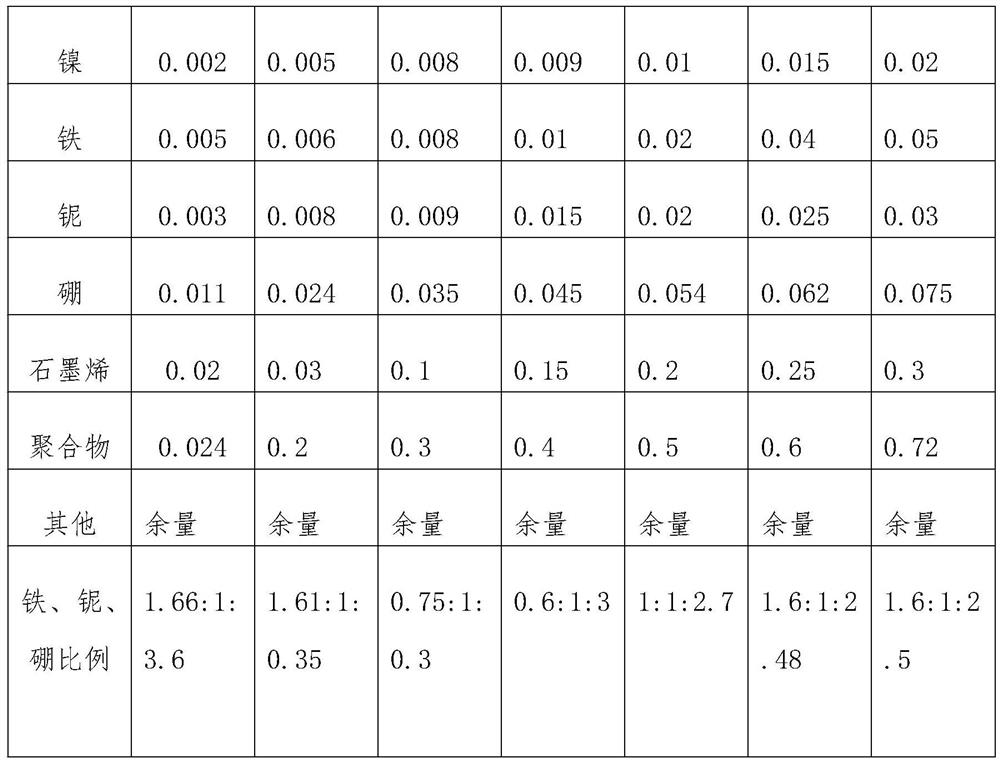

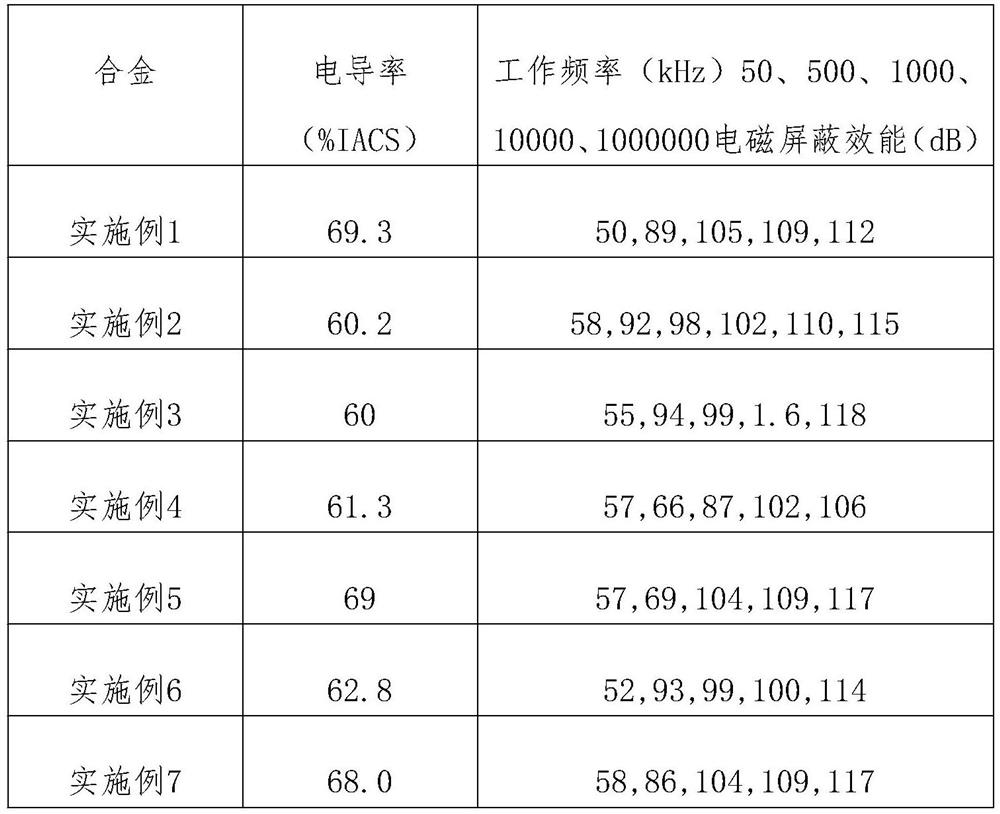

A kind of aluminum alloy with electromagnetic shielding function and processing method thereof

The invention relates to the field of material processing, in particular to aluminum alloy with an electromagnetic shielding function and a processing method thereof. The aluminum alloy comprises thefollowing components in percent by mass: 2-4% of magnesium, 0.5-1% of copper, 0.01-0.1% of silicon, 0.002-0.02% of lithium, 0.002-0.02% of antimony, 0.005-0.05% of iron, 0.002-0.02% of nickel, 0.011-0.075% of boron, 0.005-0.05% of cobalt, 0.003-0.03% of niobium, 0.02-0.3% of graphene, 0.024-0.72% of a conductive polymer, and the balance of aluminum and inevitable impurities. The material comprising iron, niobium and boron has strong capability of absorbing and consuming electromagnetic waves, and can absorb the electromagnetic waves outside an object so as to achieve a shielding effect; testsshow that the electromagnetic shielding performance of the material is 50-120 dB.

Owner:贵州航天风华精密设备有限公司

Fluorine-containing drainage aid for fracturing

The invention provides a fluorine-containing drainage aid for fracturing, which belongs to the technical field of oilfield chemical additives. The drainage aid is composed of sodium perfluorononenyloxybenzene sulfonate with a mass content of 0.1%-0.25%, coconut oil fatty acid diethanolamide with a mass content of 10%-37.5% and the balance of water. The drainage aid has good compatibility with the fracturing fluid, and will not affect the performance of the fracturing fluid itself after compounding, and the surface tension of the fracturing fluid breaking fluid is less than or equal to 28mN / m, and the fracturing fluid breaking fluid and kerosene The interfacial tension is less than 2mN / m.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

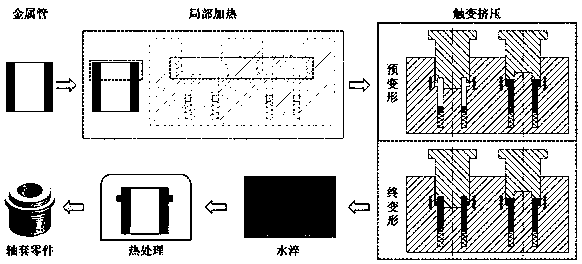

A kind of thixotropic forming method for pipe parts with shoulders

ActiveCN109092958BReduce transfer stepsShorten the manufacturing cycleShaping toolsFurnace typesSemi solidHeat conservation

The invention discloses a contact forming method of a pipe with a shoulder, and belongs to the field of semi-solid forming. The method comprises the following steps that firstly, a metal pipe is conducted local induction heating to a solidus temperature or above, and heat preservation is carried out; and then the metal pipe is put into a preheated progressive mold to carry out first pass extrusiondeformation and pressure maintaining is carried out; then the metal pipe is rapidly taken out, and put into the preheated progressive mold to carry out second pass extrusion deformation and pressuremaintaining is carried out so as to obtain a pipe part with the shoulder; then rapid water quenching is carried out on the pipe part with the shoulder, and finally T6 heat treatment is carried out. According to the method, progressive mold two-step local contact extrusion forming is adopted to prepare the pipe part with the shoulder, the mold is simple in structure, production efficiency is high,cost is low, product quality is high, a material utilization rate is high, and mechanization and automatic production are realized conveniently.

Owner:KUNMING UNIV OF SCI & TECH

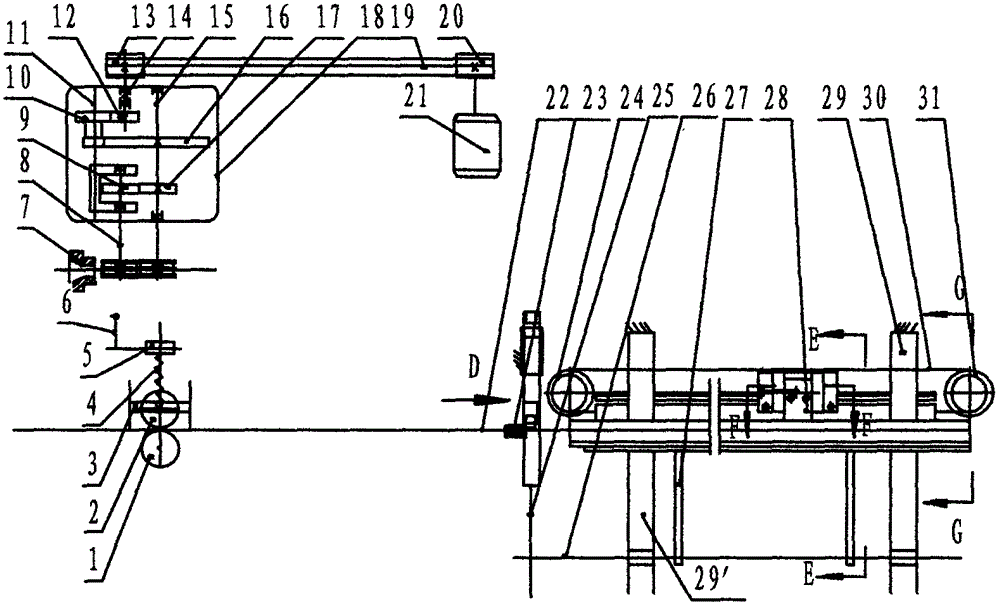

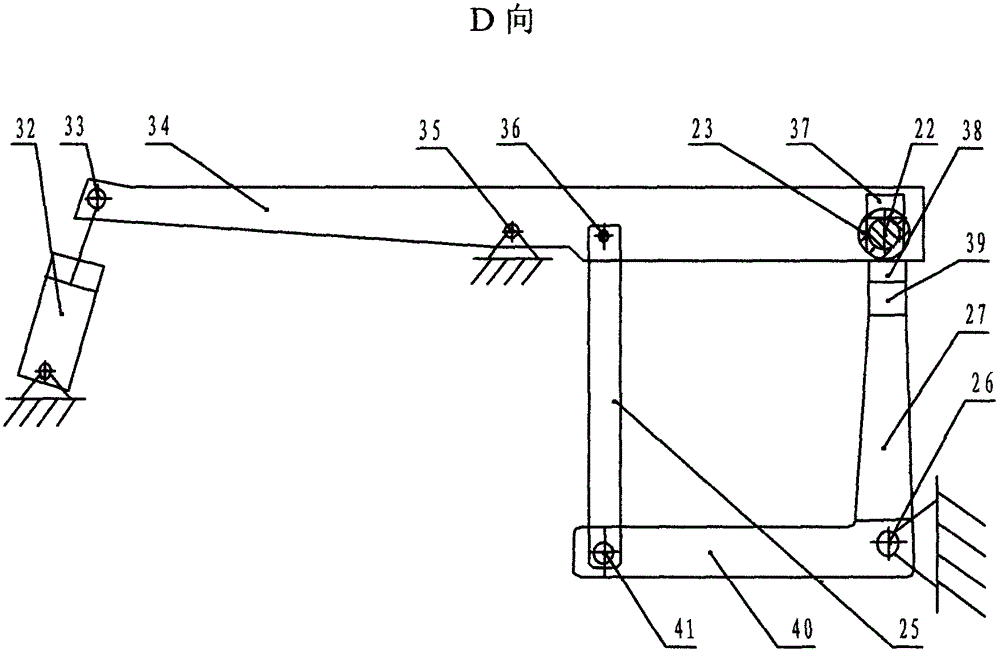

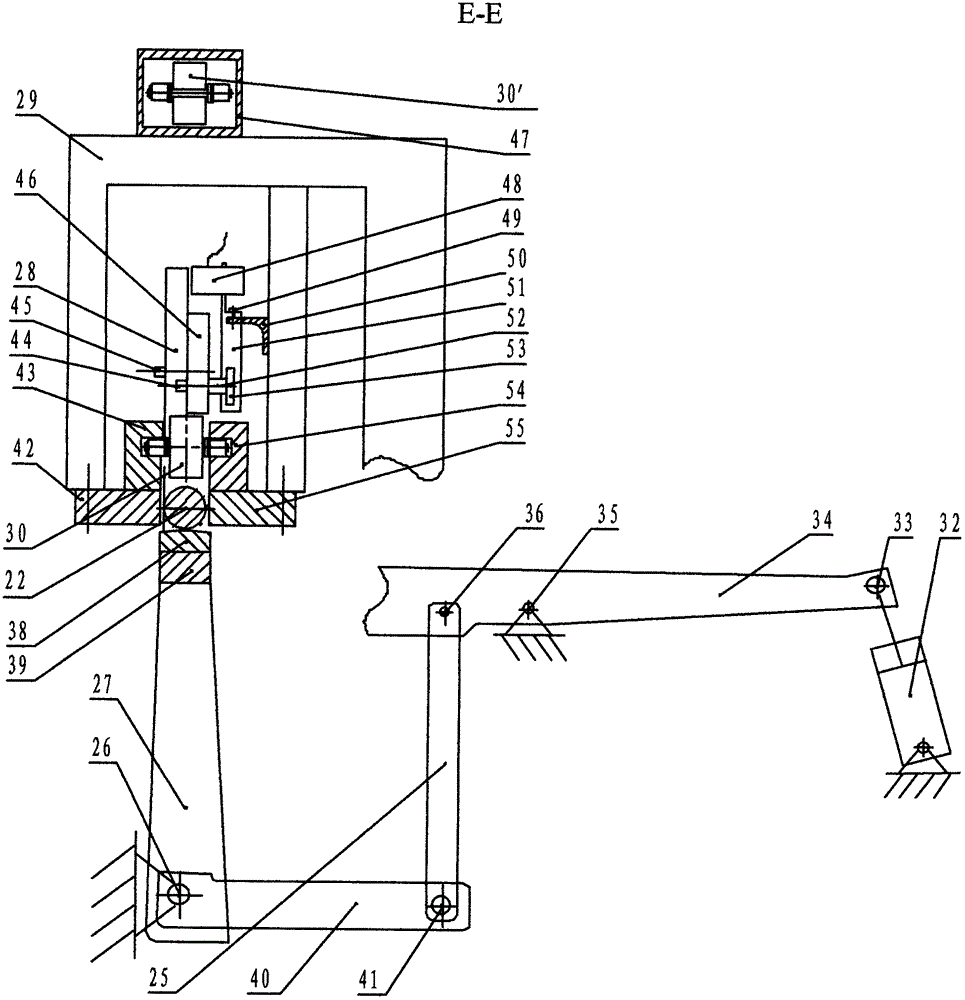

Prestressed steel bar cutting machine

The invention discloses a pre-stressed steel bar shearing machine, which comprises a driving mechanism, a feeding mechanism, a receptacle trough and a sizing mechanism, and a hydraulic shearing and blanking mechanism. The upper part of a vertical cantilever support (29) is provided with a trough front side plate (42) and a trough rear side plate (55); the trough front side plate (42) is provided with a chain front guide rail (43); the trough rear side plate (55) is provided with a chain rear guide rail (54); a piston rod on the hydraulic cylinder I (32) is hinged with a lever (34) by a shaft I (33); a bearing shaft II (35) is hinged with the lever (34); and the other end of the lever (34) is provided with a movable knife I(37) corresponding to a fixed knife I (23). The pre-stressed steel bar shearing machine has the advantages of reliable performance, full function, simple and compact structure, and saved time, labor, and resource, in this way, the pre-stressed steel bar shearing machine products with high shearing quality and perfect function are provided to users.

Owner:曲海涛

Miniaturized and compact duplexer based on thin film integrated passive device technology

ActiveCN109962324BImprove performancePerformance improvements and optimizationsCoupling devicesCapacitanceMicrowave

A miniaturized and compact duplexer based on thin-film integrated passive device technology, the invention belongs to the field of microwave devices, and in particular relates to a miniaturized duplexer, which solves the problem that the size of the existing planar cascaded duplexer is relatively large. The problem of performance instability during the work process. The compact duplexer of the present invention includes a high-pass filter and a low-pass filter, the high-pass filter is coupled to signal port one and signal port two, and the low-pass filter is coupled to signal port one and signal port three, wherein the high-pass filter consists of two No. capacitor in parallel with the first capacitor-inductance resonant circuit, and the low-pass filter is composed of two serial inductors in parallel with the second capacitor-inductor resonant circuit; the miniaturized and compact duplexer is made into a multi-layer structure through thin film integrated passive device technology. The size of the compact duplexer of the present invention is only 1.9mm×0.8mm, and the thickness is 0.2mm, and the manufacturing process of the present invention has high precision and stable device performance.

Owner:HARBIN INST OF TECH

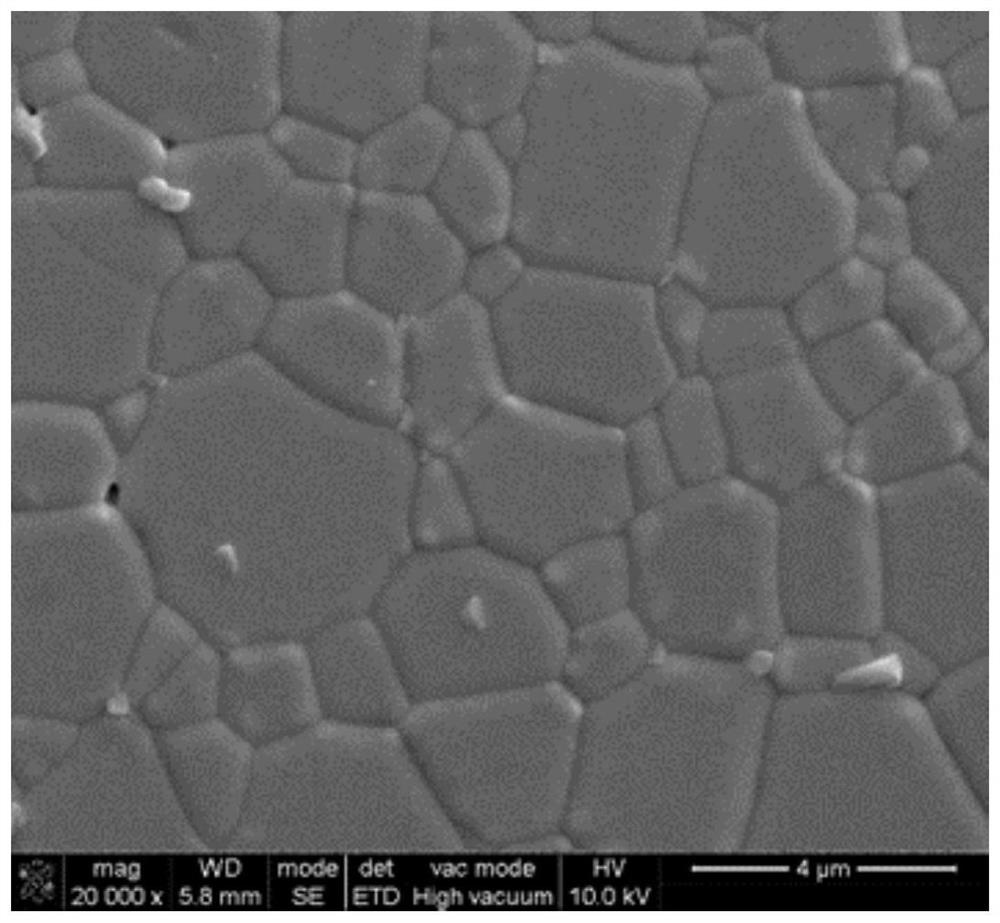

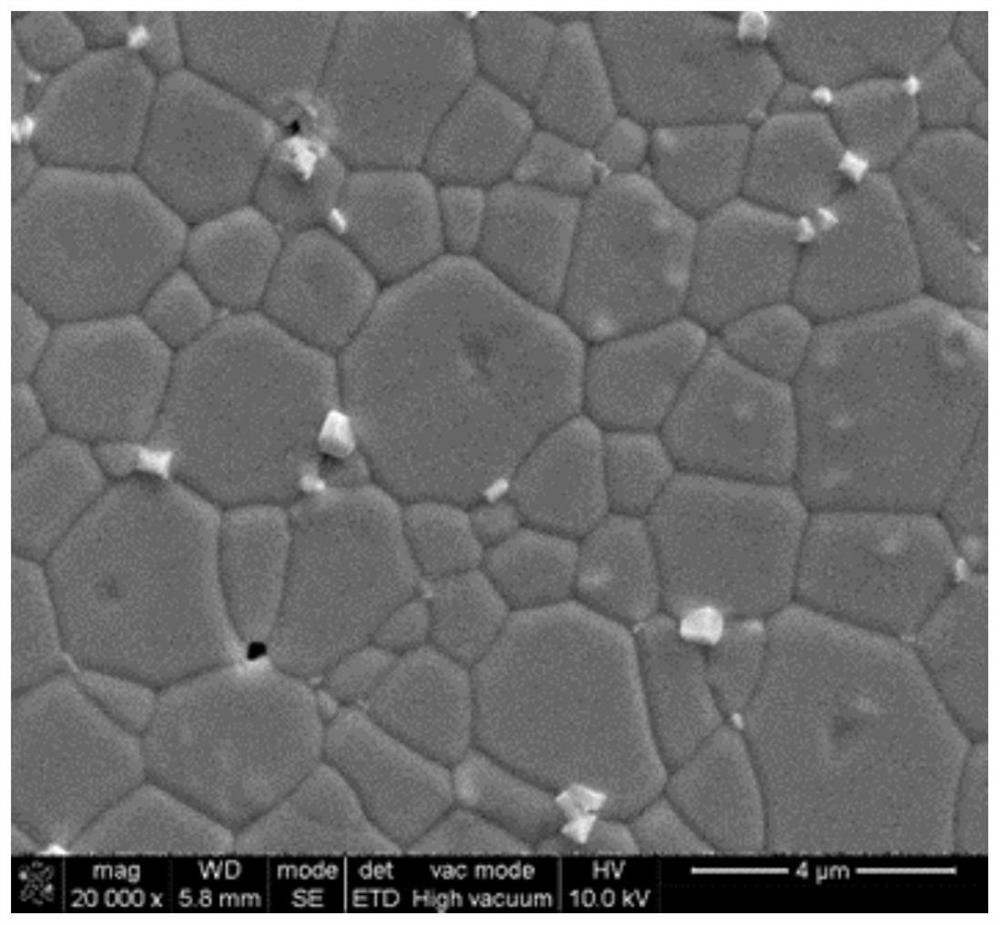

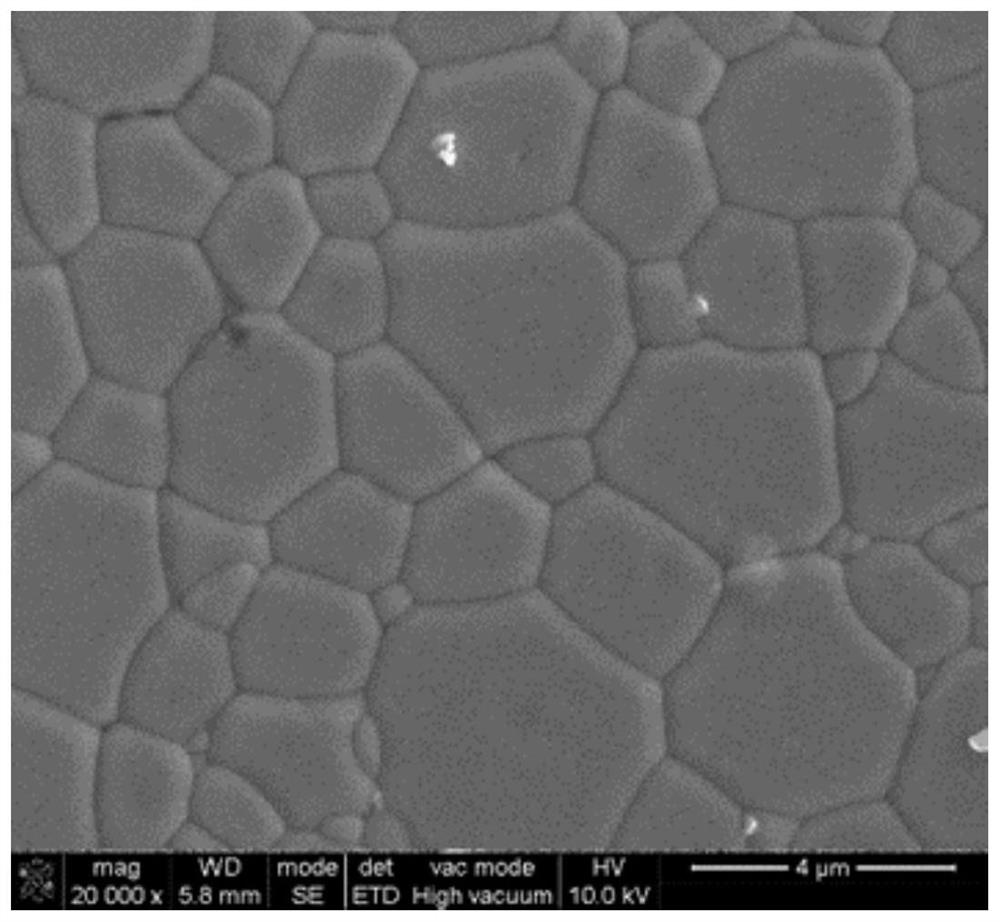

Plasma-etching-resistant ceramics, preparation method thereof, and plasma-etching equipment

ActiveCN111620692BImprove corrosion resistancePerformance impactElectric discharge tubesHigh densityPhysical chemistry

The invention relates to a plasma etching resistant ceramic, a preparation method thereof and plasma etching equipment. The preparation method of the above-mentioned plasma etching-resistant ceramics includes the following steps: by mass percentage, the following raw materials are weighed: 64.7% to 100% of nanoscale yttrium oxide powder and 0% to 35.3% of nanoscale zirconia powder, and the nanoscale oxidized The purity of the yttrium powder is not lower than 90.0%; the raw materials are sintered to obtain plasma-etching resistant ceramics, wherein the sintering temperature is 1600°C-2000°C, and the sintering time is 1h-2h. The preparation method of the above-mentioned plasma etching-resistant ceramics can make the prepared ceramics have good etching resistance, high density and good mechanical properties.

Owner:SHENZHEN SUNTECH ADVANCED CERAMICS

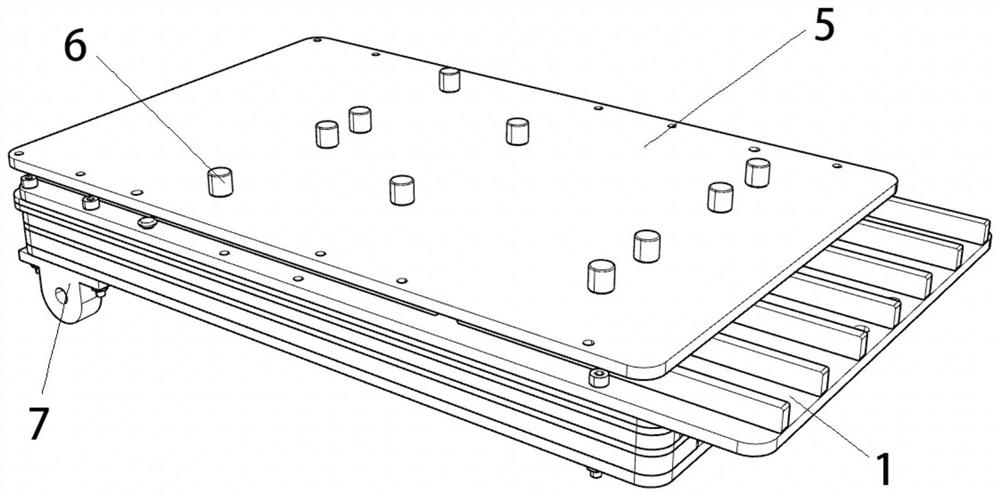

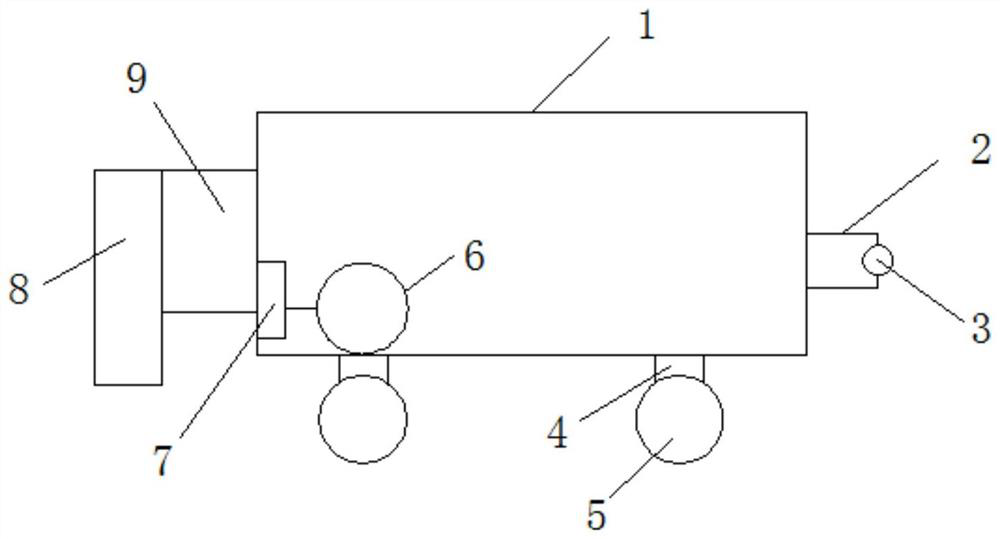

Amusement vehicle parking device capable of storing different types of amusement vehicles

The invention discloses an amusement vehicle parking device capable of placing different types of amusement vehicles. The amusement vehicle parking device comprises a vehicle body, a tail rod, a hanging ring, supports, trundles, a motor, a controller, a pushing plate and a lifting rod. The lifting rod is arranged at one end of the vehicle body, a pushing plate is fixed to the front end of the lifting rod, the controller is arranged in the vehicle body, the controller is connected with the motor, the trundles are connected to the bottom end of the motor, the supports are arranged at the bottomend of the vehicle body, the trundles are arranged at the bottom ends of the supports, the tail rod is arranged at one end of the vehicle body, and the hanging ring is arranged at one end of the tailrod. Lifting of the device is achieved through the lifting rod and the pushing plate which are arranged at the front end of the vehicle body, the device can adapt to amusement vehicles with differentheights, the controller is arranged to control a remote controller directly, some amusement vehicles can be pulled conveniently through the tail rod and the hanging ring, the controller directly controls the motor in the vehicle body to operate, and the motor controls rotation of the trundles.

Owner:庞宝娟

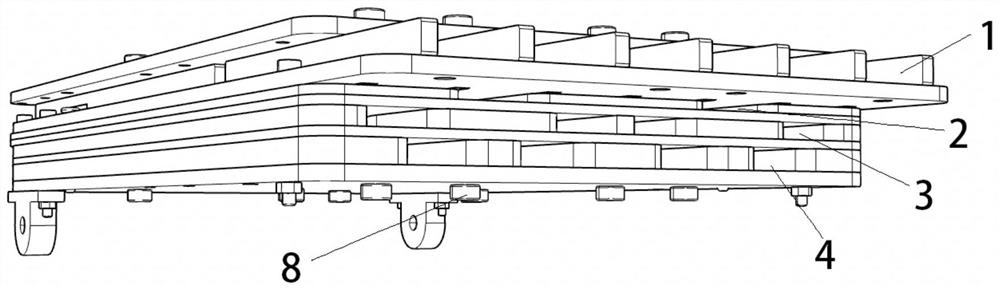

Wood block pretreatment method for bed boards

InactiveCN109016006ALow costEasy splicing of wooden blocksWood treatment detailsPretreatment apparatusCorrosion resistantBed boards

The invention discloses a wood block pretreatment method for bed boards, and relates to the technical field of bed board manufacturing. The method is characterized by comprising the operation steps ofmaterial selection, flushing, baking, dipping, dipping again and drying. The method is reasonable, convenient to operate, waterproof and corrosion-resistant.

Owner:聚宝实木家私

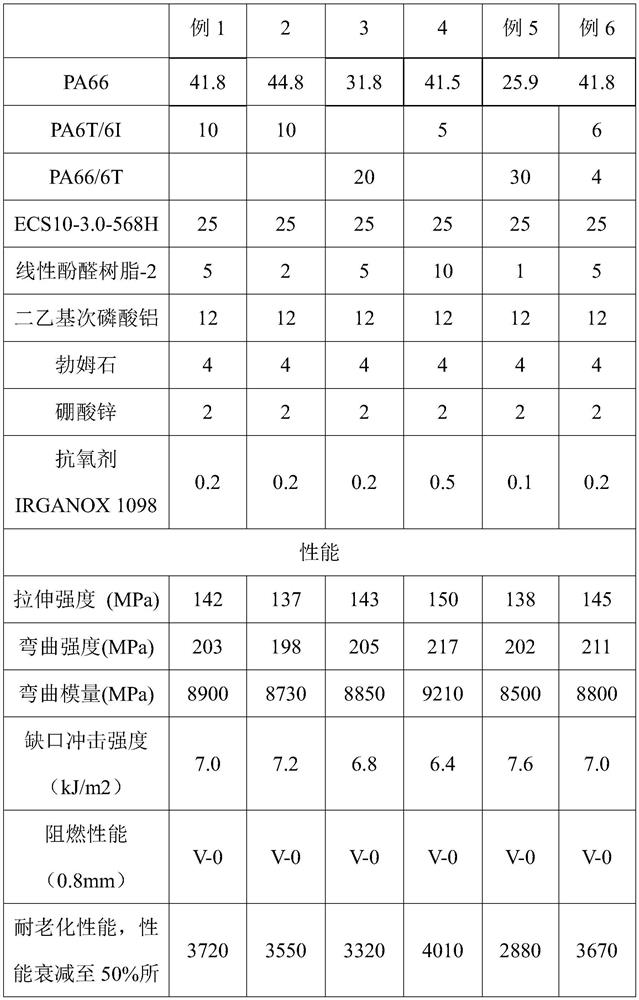

High-heat-resistance halogen-free flame-retardant polyamide compound and preparation method thereof

The invention provides a high-heat-resistance halogen-free flame-retardant polyamide compound. The high-heat-resistance halogen-free flame-retardant polyamide compound is characterized by being prepared from the following raw materials, by weight: 10 to 60 parts of aliphatic polyamide, 5 to 30 parts of aromatic polyamide, 10 to 30 parts of a halogen-free flame retardant, 1 to 10 parts of phenolicresin, 10 to 50 parts of a glass fiber, and 0.1 to 0.5 part of an antioxidant; the phenolic resin is linear phenolic resin, and the molecular weight of the phenolic resin is 1000-4000 g / mol. Accordingto the high-heat-resistance halogen-free flame-retardant polyamide compound and the preparation method thereof disclosed by the invention, the halogen-free flame-retardant polyamide compound is endowed with excellent ageing resistance, flame retardance and mechanical property through the combined synergistic effect of multiple components including the phenolic resin, the antioxidant, the aromaticnylon and the halogen-free flame retardant.

Owner:TIANJIN KINGFA NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com