Prestressed steel bar cutting machine

A prestressed steel bar and cutting machine technology, applied in the field of wire rod processing and processing, can solve the problems of many wearing parts, high power of cutting mechanism, no labor saving, etc., and achieve the effect of simple and compact structure, high cutting quality and simple adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

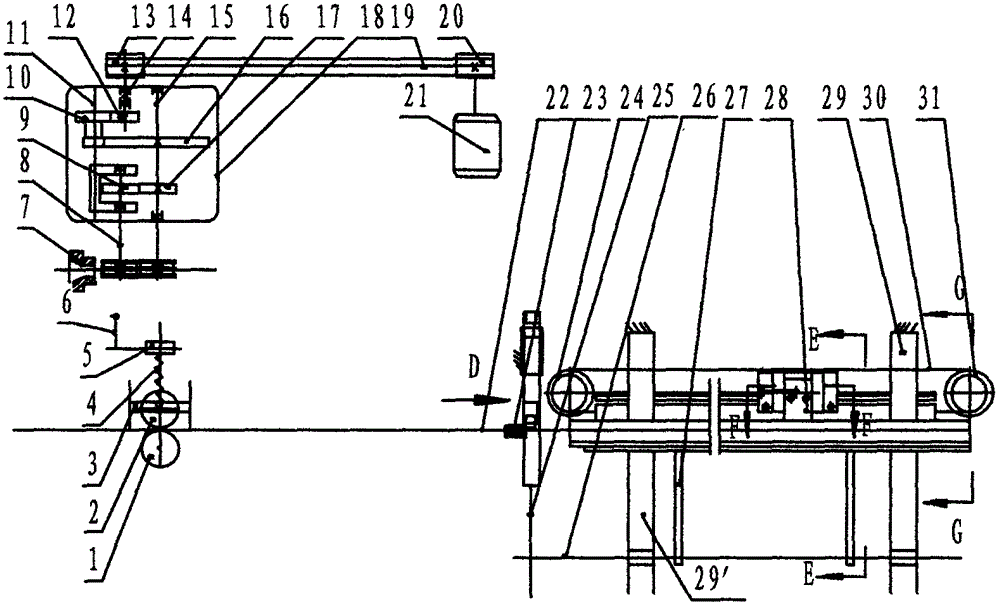

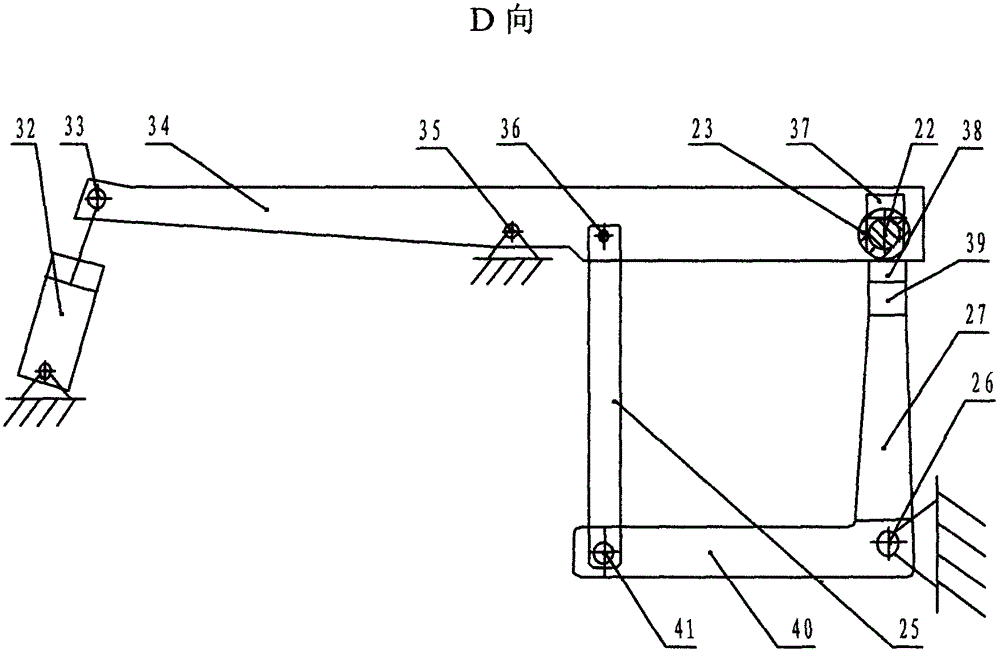

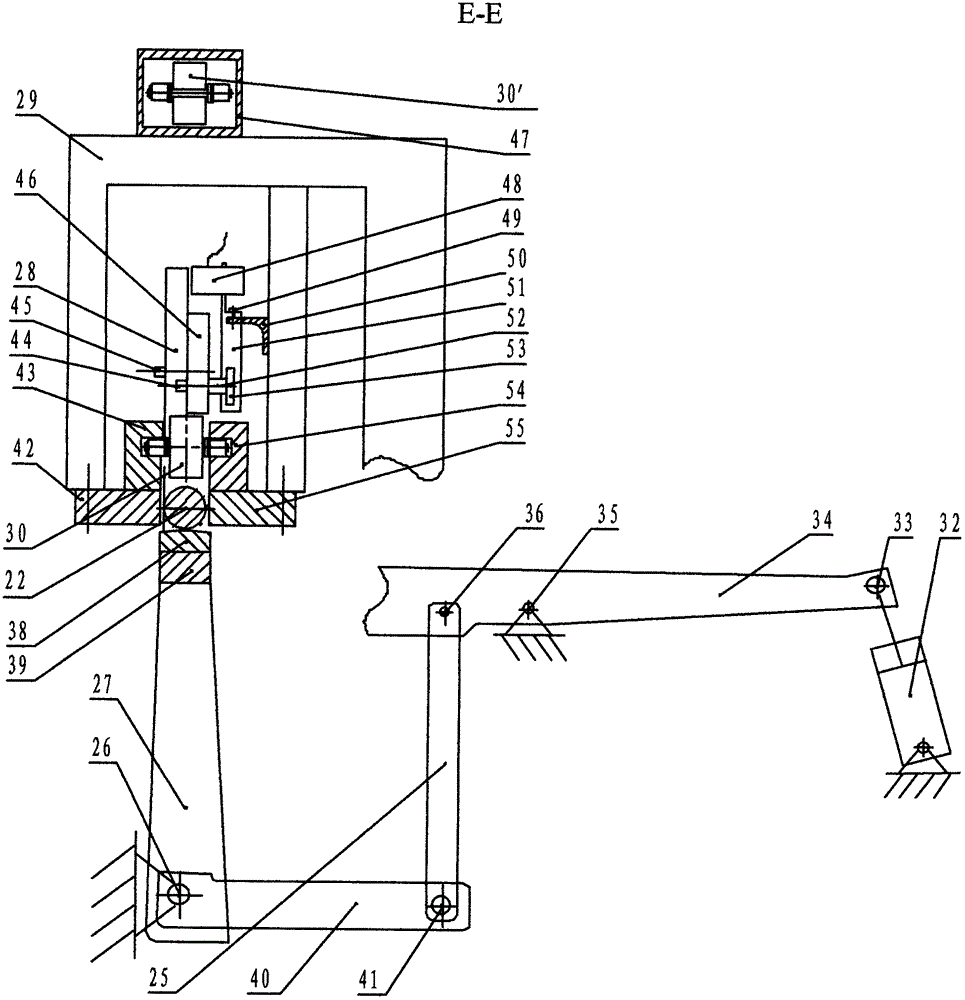

[0020] attached Figure 1-5 The first embodiment of the present invention is disclosed. A prestressed steel bar cutting machine includes a driving mechanism, a feeding mechanism, a material receiving trough and a length-setting mechanism, and a hydraulic cutting and blanking mechanism. The pulley II20 of the drive motor 21 of the driving mechanism is connected with the pulley I13 on the transmission shaft 14 through the belt 19, the pinion 12 installed on the transmission shaft 14 is engaged with the large gear on the double gear 10 installed on the support shaft I11, and the double gear The pinion gear on the gear 10 meshes with the large gear 16 installed on the lower pressure roller shaft 15, and the lower pressure roller shaft gear 17 installed on the lower pressure roller shaft 15 meshes with the upper pressure roller shaft gear 9 installed on the upper pressure roller shaft 8 , the lower pressure roller 1 is installed on the outer end of the lower pressure roller shaft ...

Embodiment 2

[0031] In embodiment two, the hydraulic cylinder II66 is set in the cutting and blanking mechanism, and the piston rod on the hydraulic cylinder II66 is hinged with the lower end of the upper connecting rod 67, the upper end of the lower connecting rod 71, and the upper end of the long connecting rod 65 with the shaft V70, and the long connecting rod 65 is hinged with horizontal connecting rod II80 with shaft VII79, the upper end of upper connecting rod 67 is hinged with shaft IV68 and cutter body seat 69, the lower end of lower connecting rod 71 is hinged with the upper end of moving knife bar 75 with shaft VI72, and the middle part of moving knife bar 75 is installed on the knife body. In the hole of bar seat 74, knife bar seat 74 is installed on the cutter body seat 69, and moving knife II76 is installed at the lower end of moving knife bar 75, and moving knife II76 is corresponding to fixed knife II77, and back-moving spring II73 is installed on moving knife bar 75 tops. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com