Patents

Literature

77results about How to "Reduce transfer steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

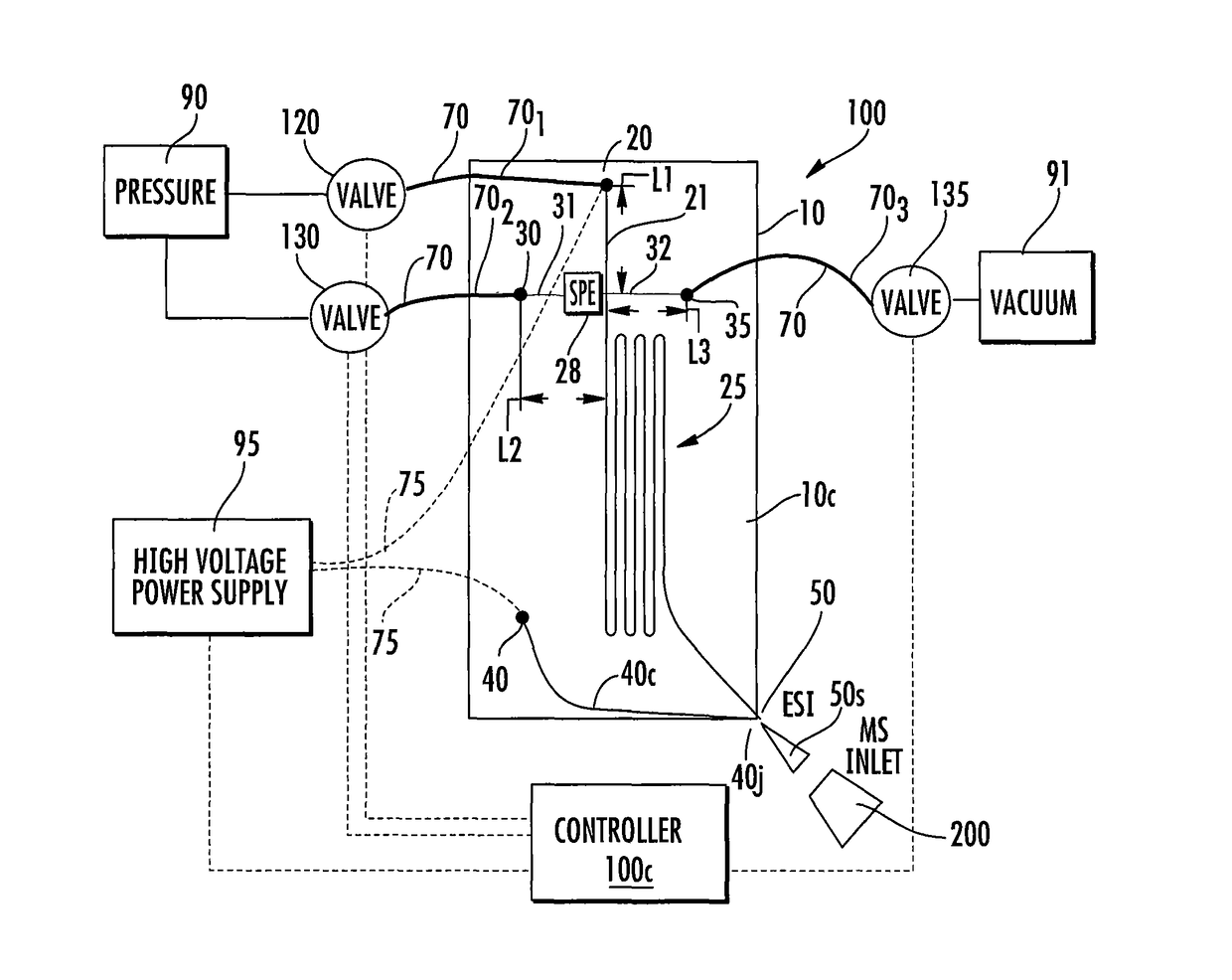

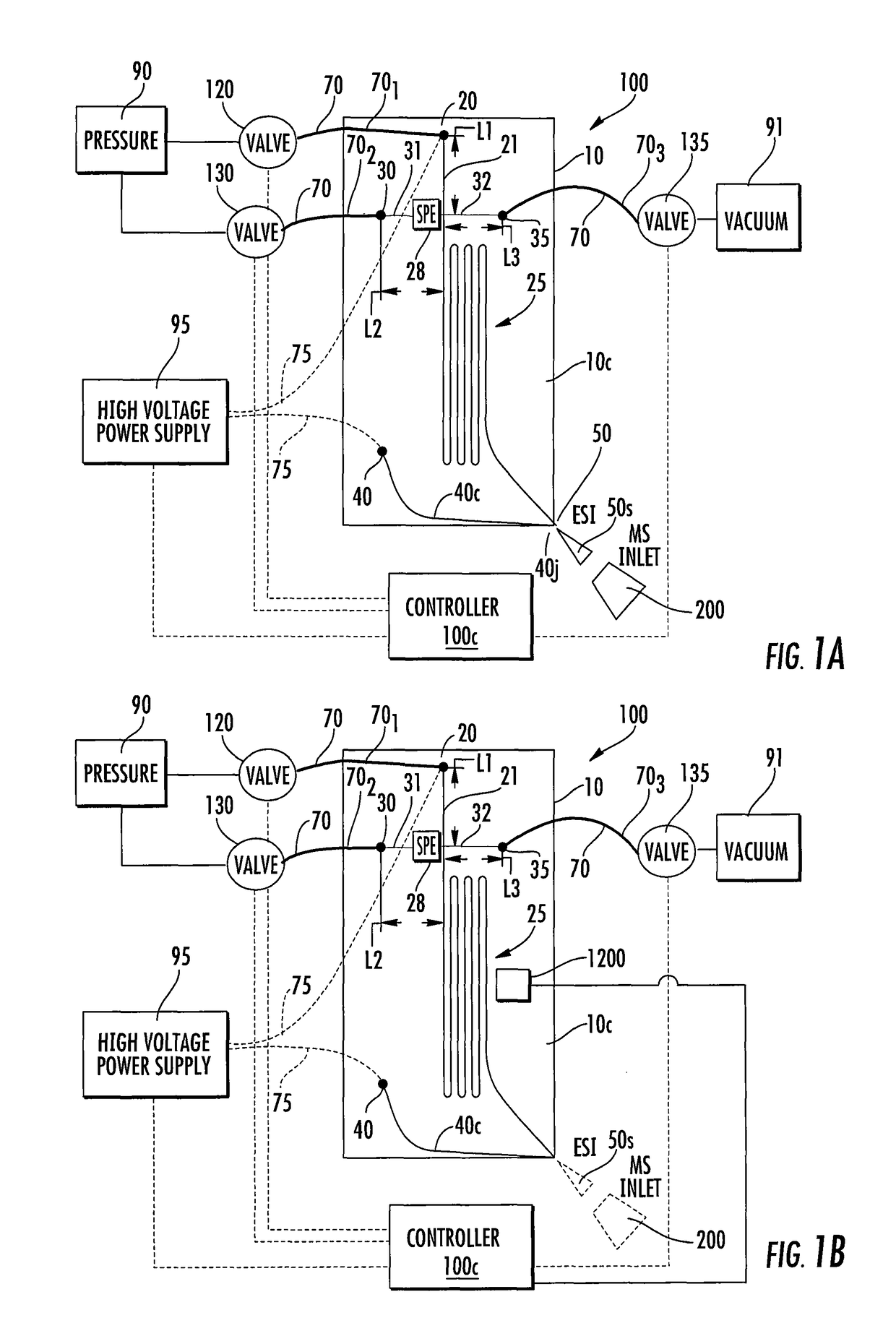

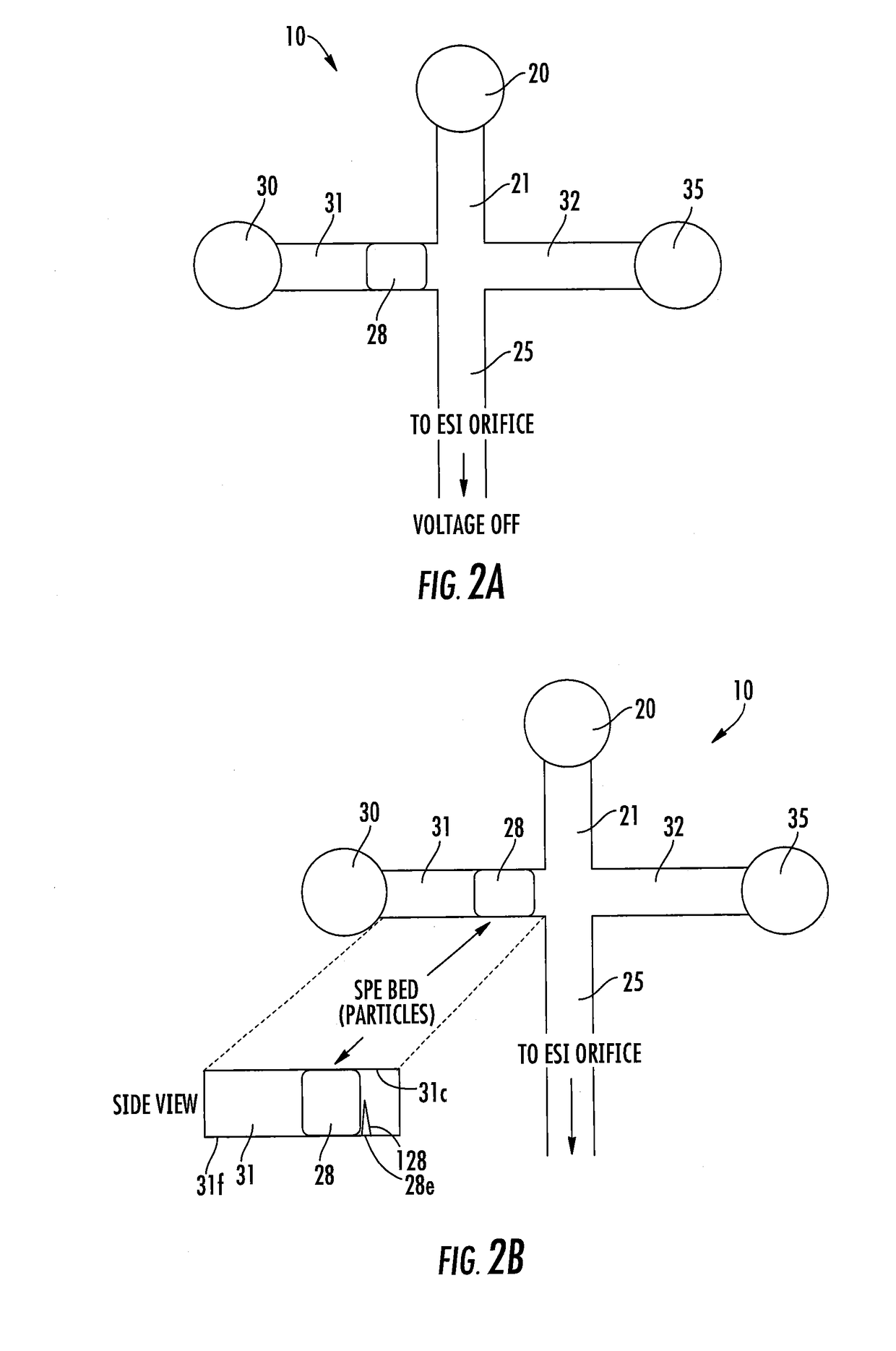

Solid phase extraction with capillary electrophoresis

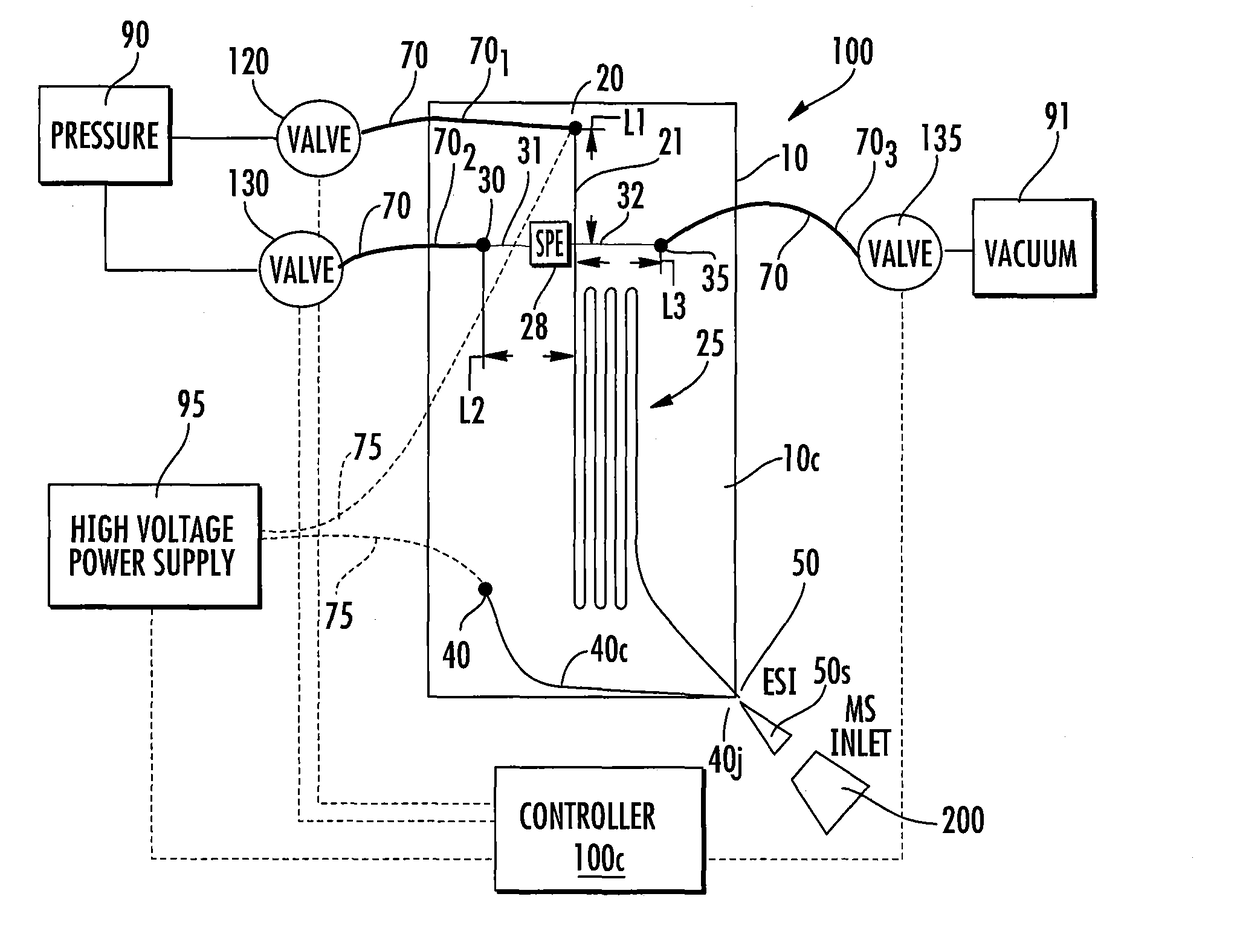

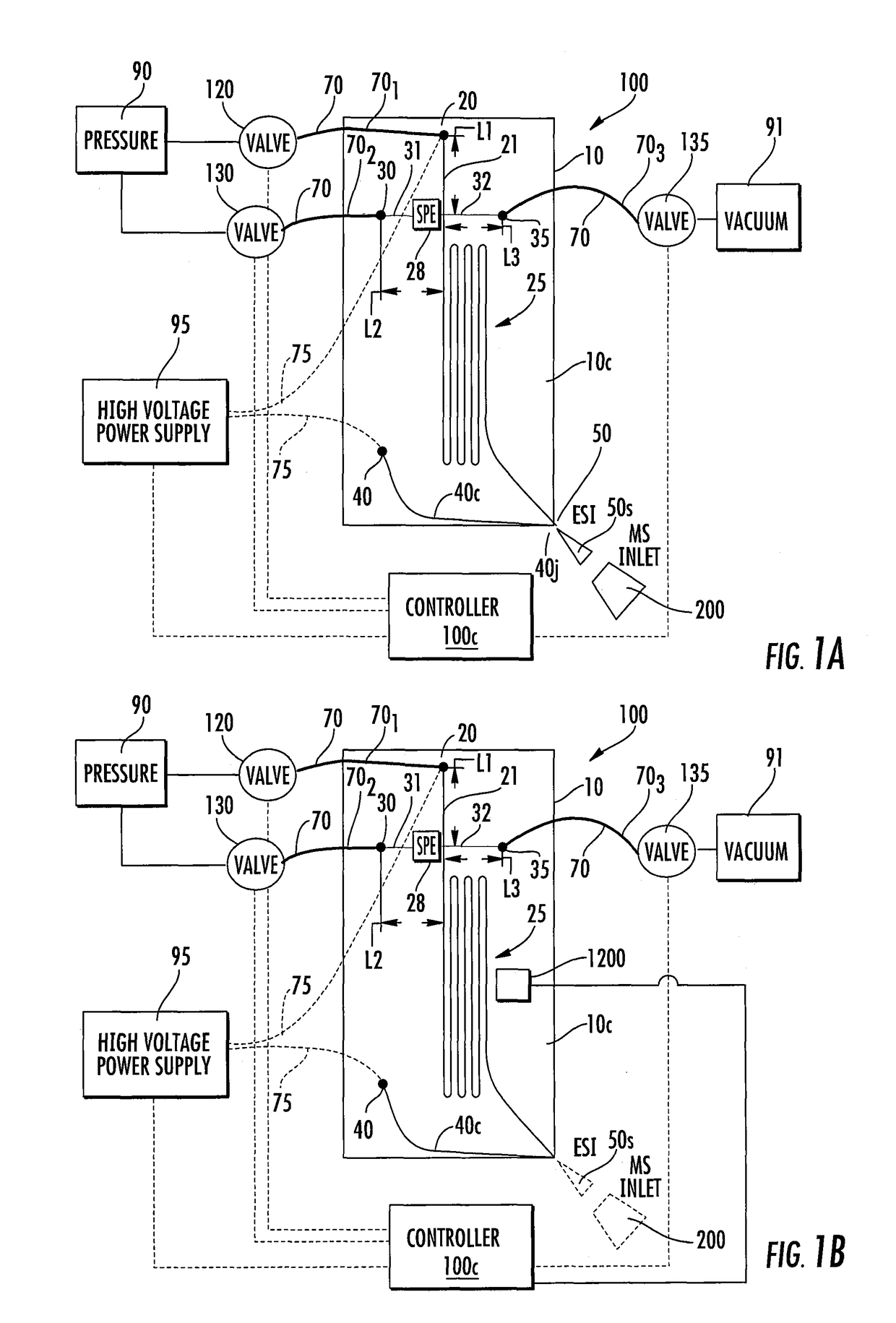

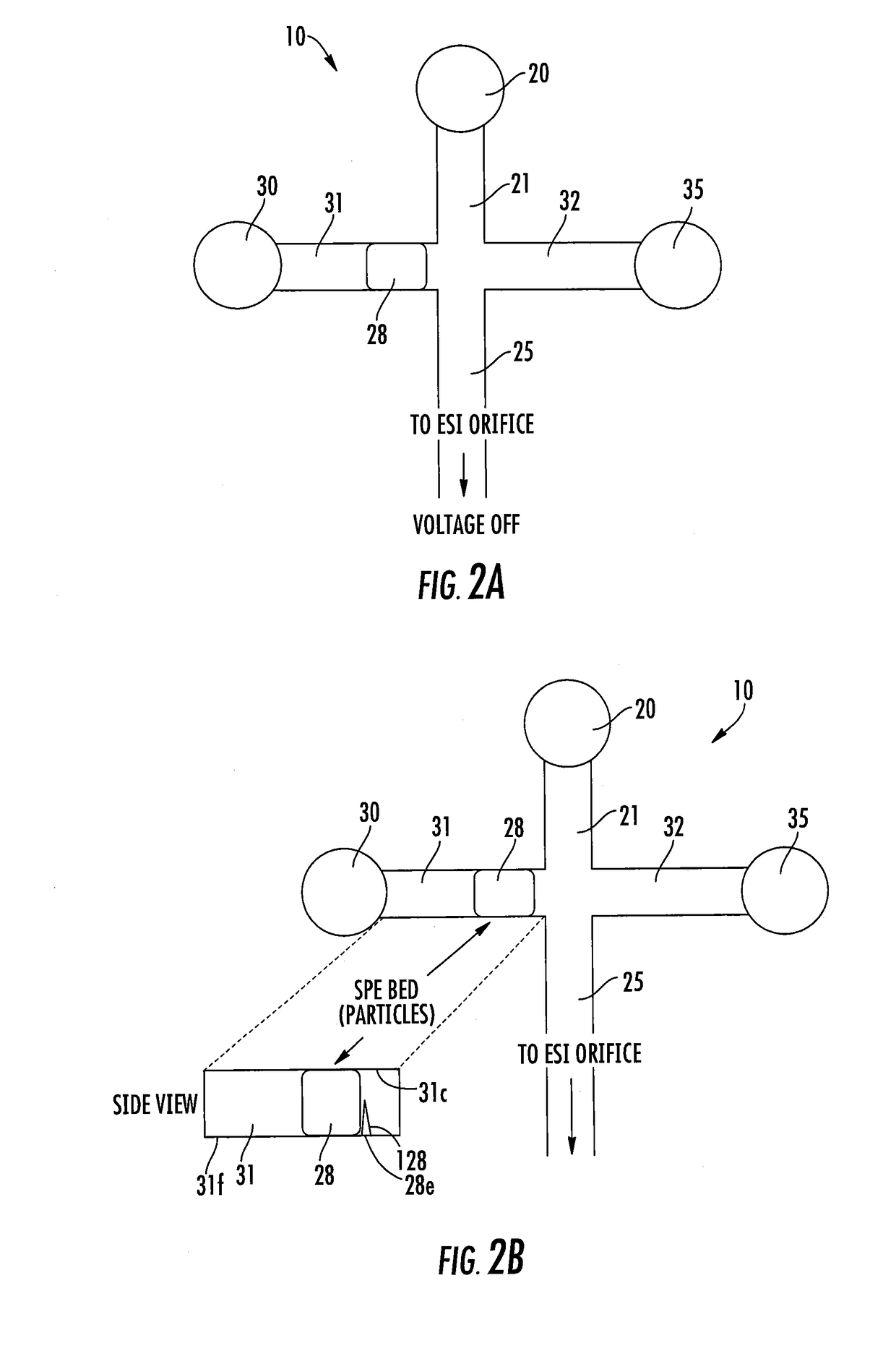

ActiveUS20170110307A1Eliminate and reduce band broadeningHigh performance separationSamples introduction/extractionMaterial analysis by electric/magnetic meansCapillary electrophoresisElectrophoresis

Methods, systems and devices that provide fluid devices with at least one SPE bed adjacent (upstream of) a separation channel which may be in communication with an inlet of a Mass Spectrometer. The fluid device can be configured to operate using independently applied pressures to a BGE reservoir and a sample reservoir for pressure-driven injection that can inject a discrete sample plug into a separation channel that does not require voltage applied to the sample reservoir and can allow for in-channel focusing methods to be used. The methods, systems and devices are particularly suitable for use with a mass spectrometer but optical or other electronic detectors may also be used with the fluidic devices.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

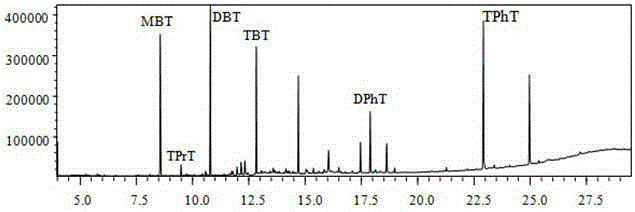

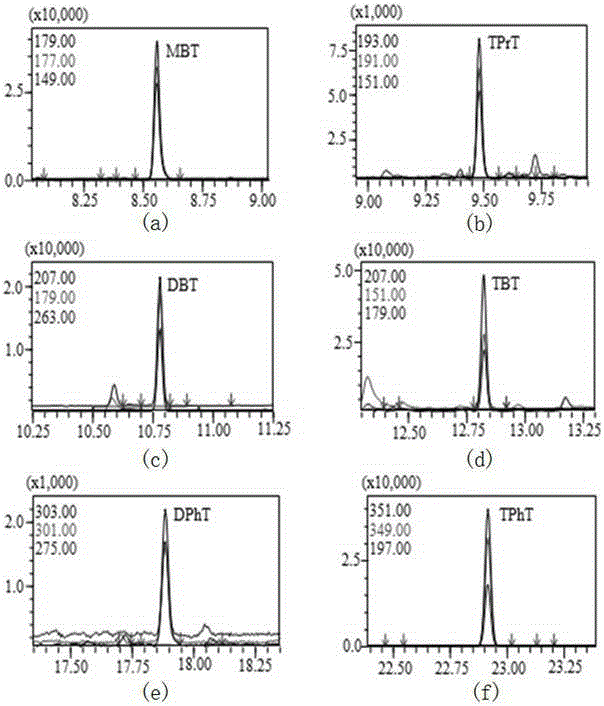

Detection method for trace amount of organic tin in marine products

InactiveCN105181874AImprove extraction efficiencyImprove derivation efficiencyComponent separationPre treatmentPeak area

The invention belongs to the technical field of marine product detection, and particularly relates to a method for determining the trace amount of organic tin in marine products. The method comprises the steps that a to-be-determined sample is ground into powder after being preprocessed, the powder is soaked, extracted, frozen, purified, derived, processed through a cleanert florisil column and concentrated to obtain a to-be-determined sample solution; series of different-concentration organic tin mixed standard solutions are added in equivalent blank matrixes same as a sample matrix, soaked for a certain time and then processed through the mode same as the sample; a gas chromatography-tandem mass spectrum detection system is adopted to determine the standard mixed solutions, and a working curve is drawn; the to-be-determined sample solution is determined, the peak area ratio is obtained from a chromatogram chart of the to-be-determined sample solution, regression is performed on the working curve to obtain regression values, and then the concentration of all target objects in the to-be-determined sample can be calculated. The detection method can determine the concentration of butyltin and triphyltin simultaneously, is sensitive, accurate, rapid, simple and convenient and can be applied to detection of the organic tin in the marine products.

Owner:TONGJI UNIV

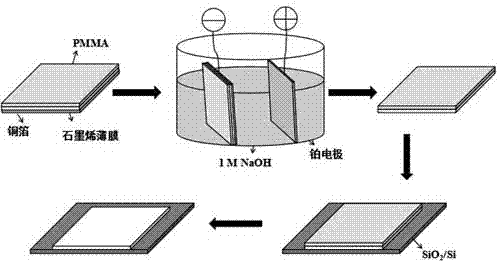

Method for transferring graphene

The invention discloses a method for transferring graphene. The method comprises four steps: preparing a graphene film on an initial substrate; coating the surface of graphene with a conductive adhesive; peeling the graphene film from the initial substrate through an electrochemical method, and attaching the peeled graphene film to a target substrate; and finally cleaning the target substrate with a graphene film attached to complete graphene transfer. Through an electrochemical bubbling transferring method, a graphene film is peeled from the initial substrate. A metal corrosion method for transferring is avoided, pollution of a corrosion product to a graphene film is prevented, the production cost and time are effectively reduced, and damage and wrinkle of the graphene film are reduced. The method is simple to operate and is convenient to be used in the graphene field.

Owner:国成仪器(常州)有限公司

Solid phase extraction with capillary electrophoresis

ActiveUS9728387B2Lower performance requirementsEliminate or reduce band broadeningSamples introduction/extractionMaterial analysis by electric/magnetic meansCapillary electrophoresisElectrophoresis

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

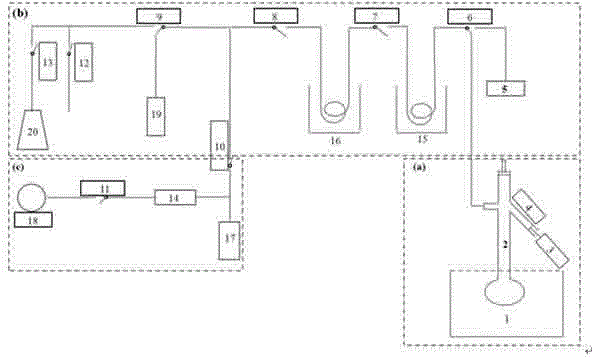

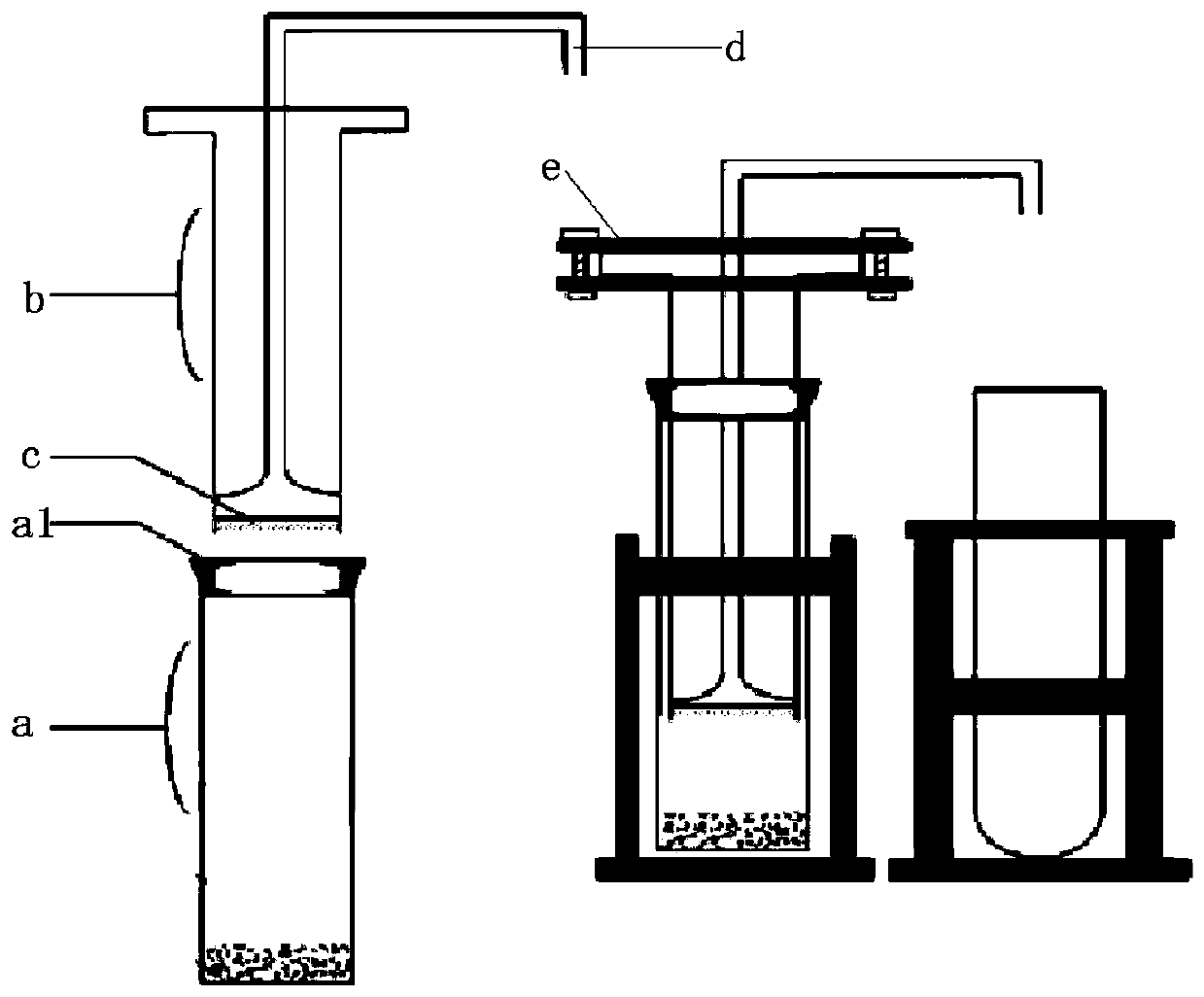

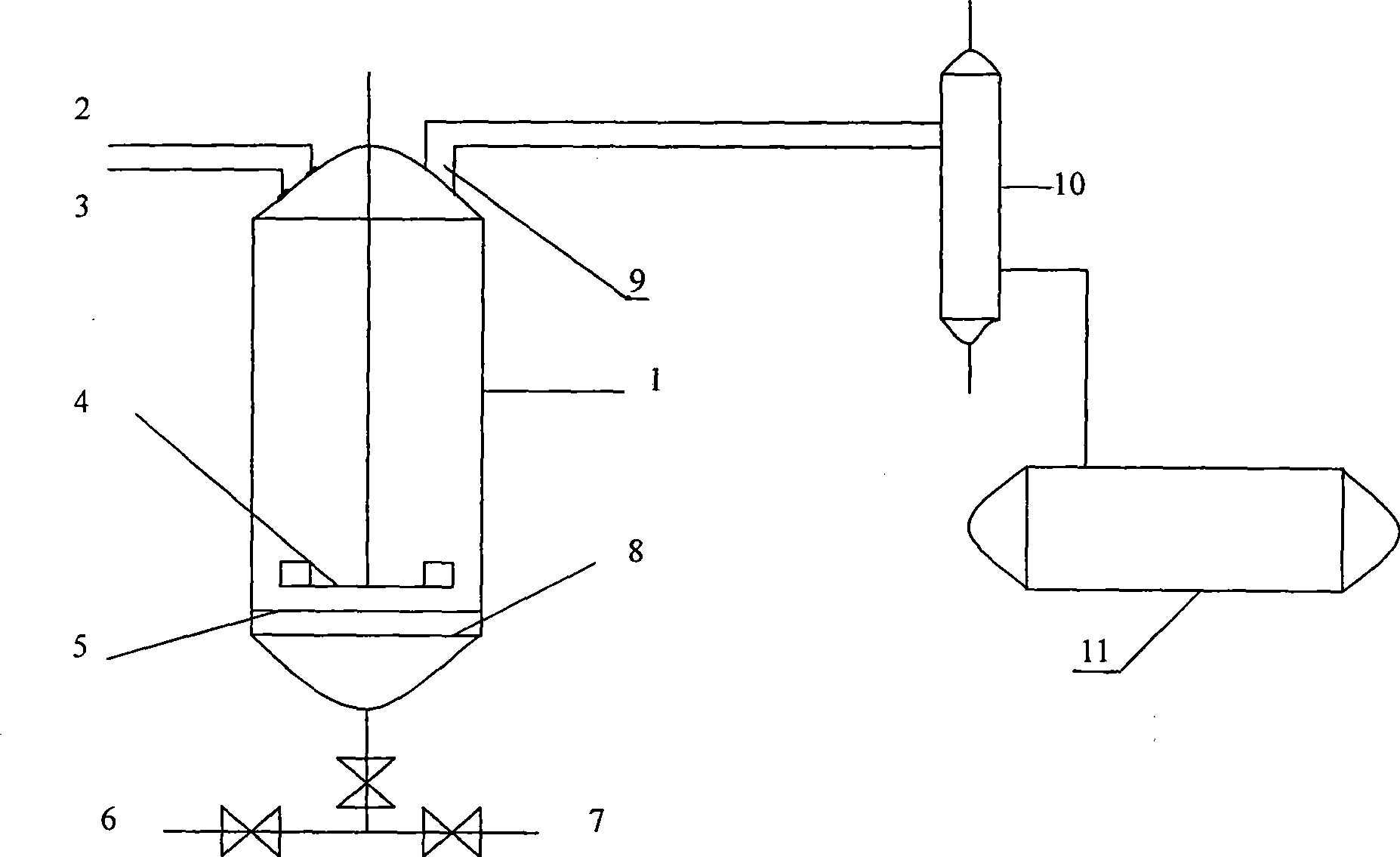

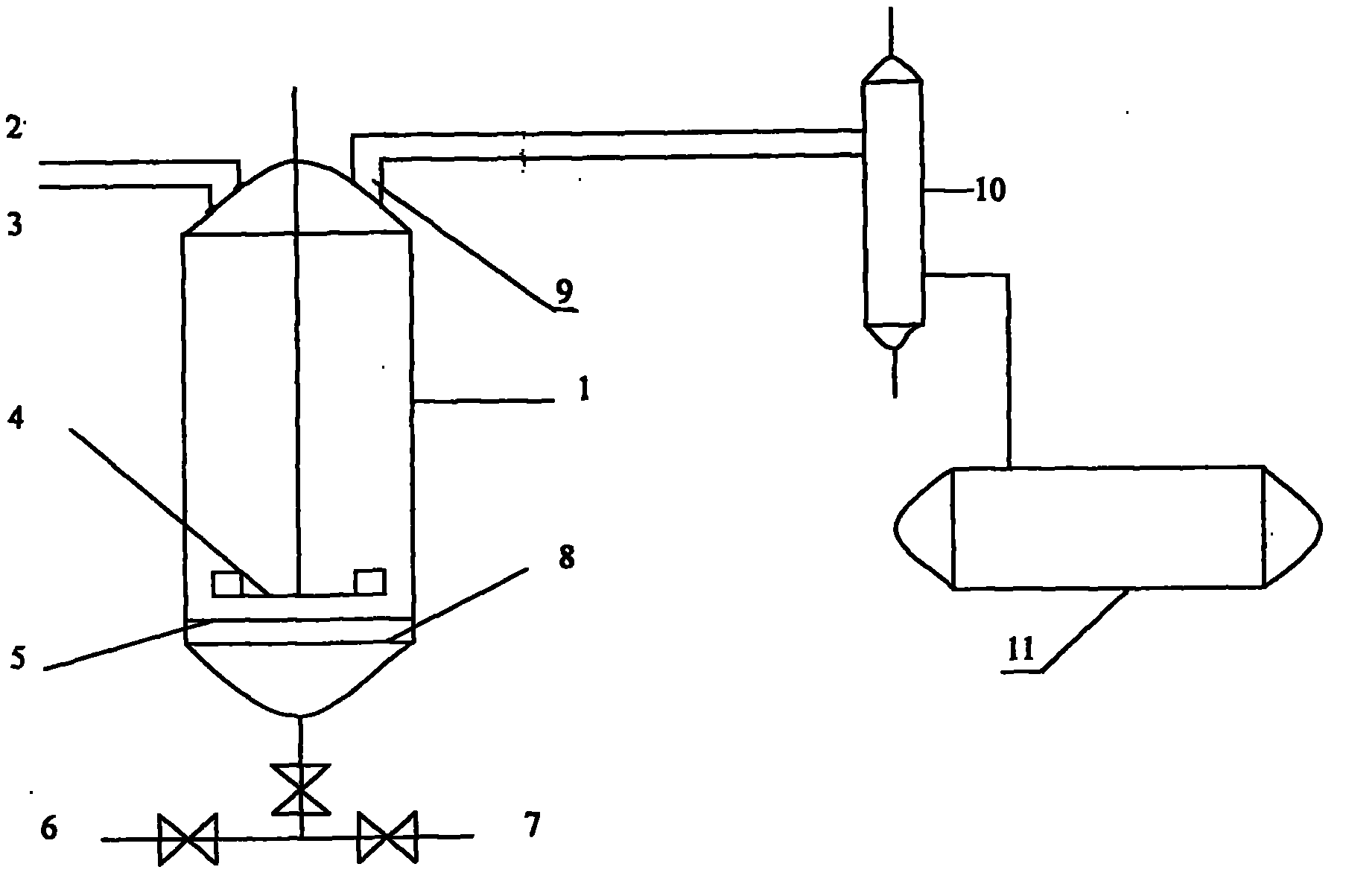

Novel sample preparation system for carbon and oxygen isotopes of carbonate and sample preparation method thereof

ActiveCN105277401AHigh degree of automationGuaranteed normal injectionPreparing sample for investigationWater bathsAutosampler

The invention provides a novel sample preparation system for carbon and oxygen isotopes of carbonate and a sample preparation method thereof. The sample preparation system comprises an original sample reaction device, a finished sample extraction device and a system vacuum degree controlling device, wherein the original sample reaction device is connected with an autoinjection device. The sample preparation system employs the autoinjection device, so the automation degree of the sample preparation system is increased, and it is guaranteed that all the saturated phosphoric acid solution enters the bottom of a reaction tube and participates in a reaction; a touch button type vacuum valve is used to replace a conventional turn button type vacuum valve, so service life is prolonged, simplicity of usage of devices is improved, and operation time is shortened in preparation; and a constant temperature water-bath is added, vacuum-pumping and reaction can be completed in the devices in the same time, so a transfer step between vacuum-pumping and sample reaction is reduced. Moreover, the invention provides the sample preparation method of the novel sample preparation system. According to the invention, accuracy and the automation degree in preparation of a test sample are effectively improved, and standardized operational process is formed.

Owner:CHINA PETROLEUM & CHEM CORP +1

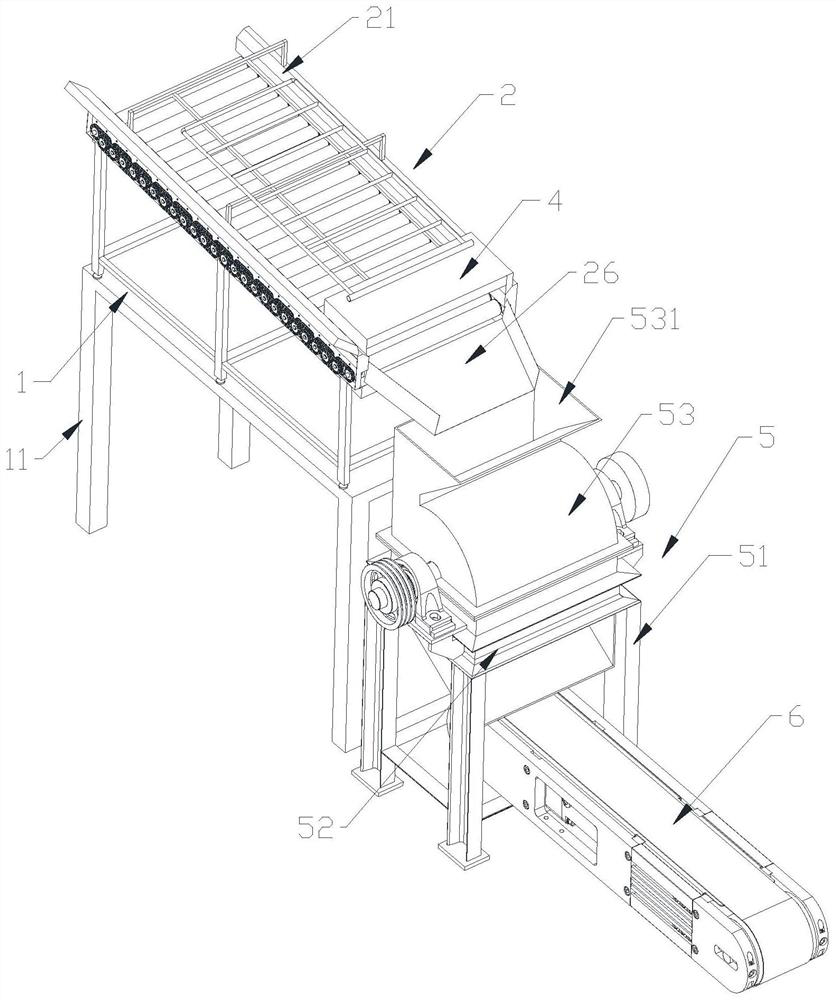

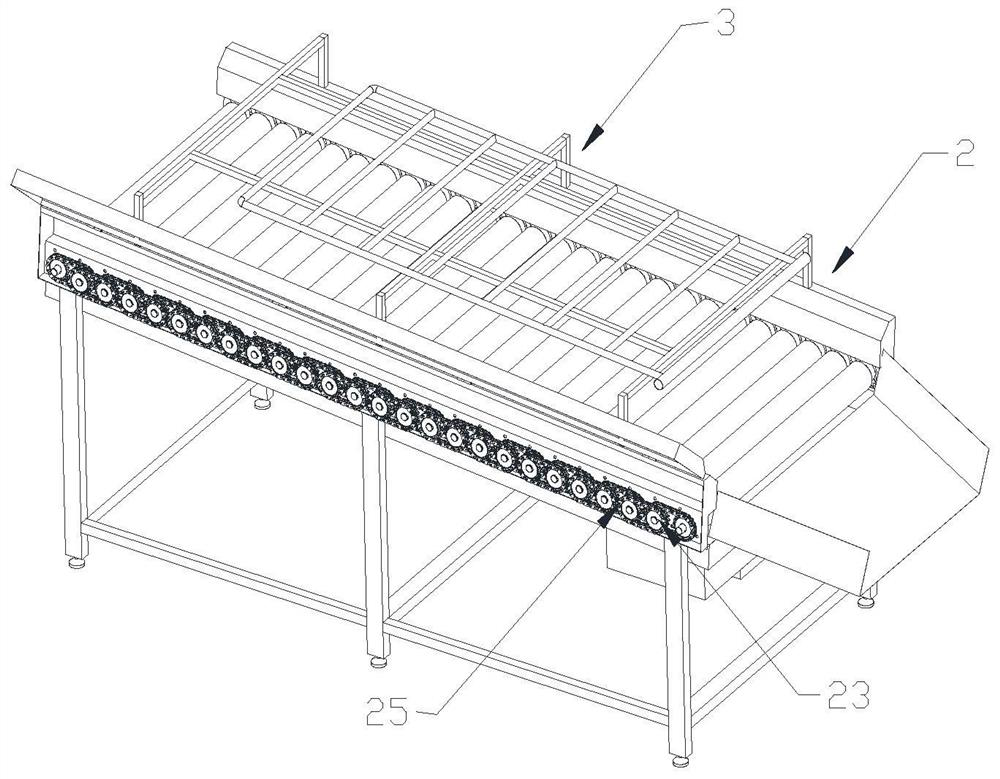

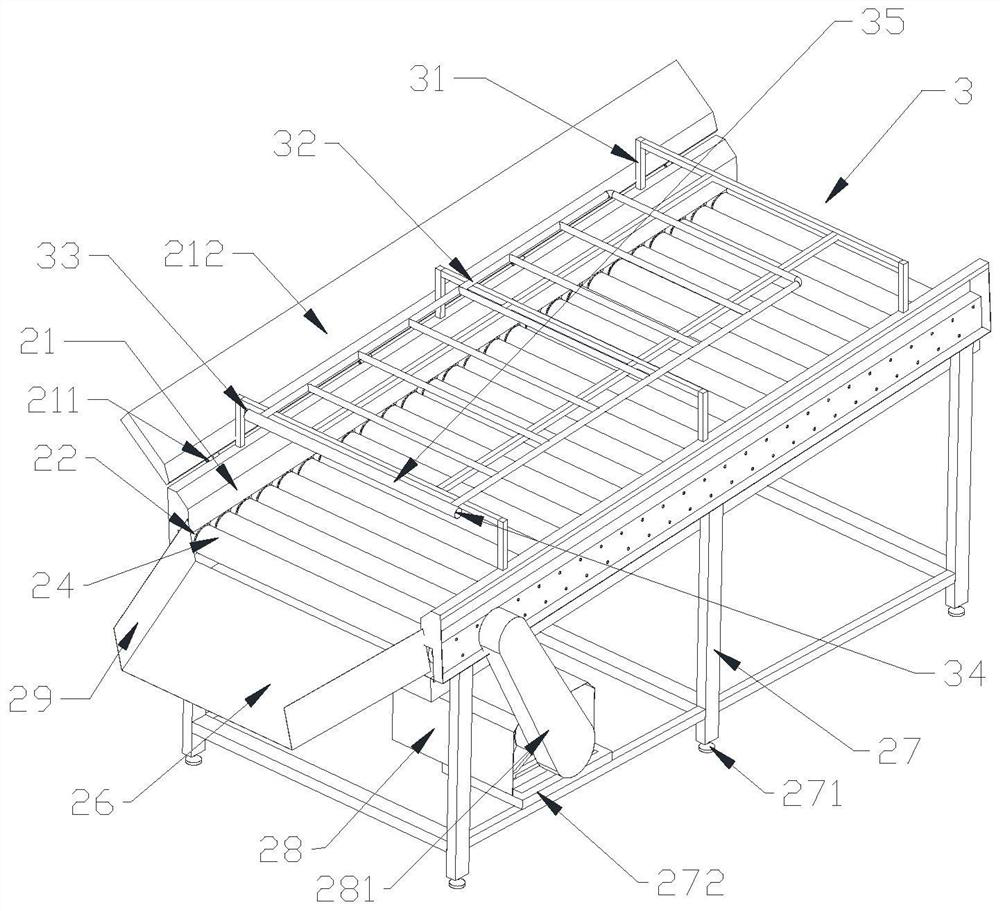

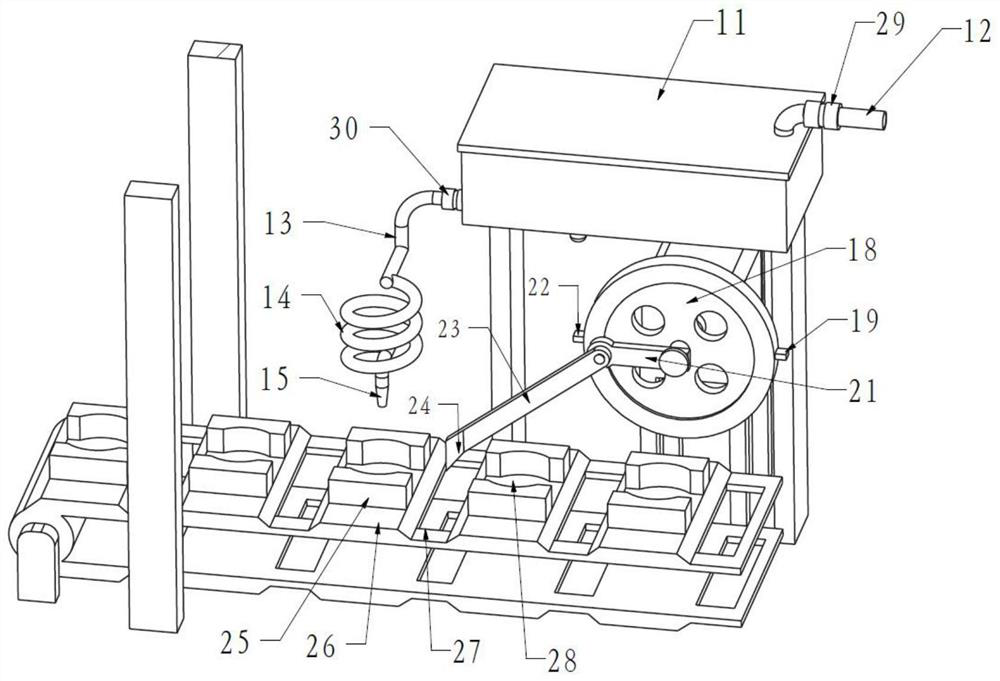

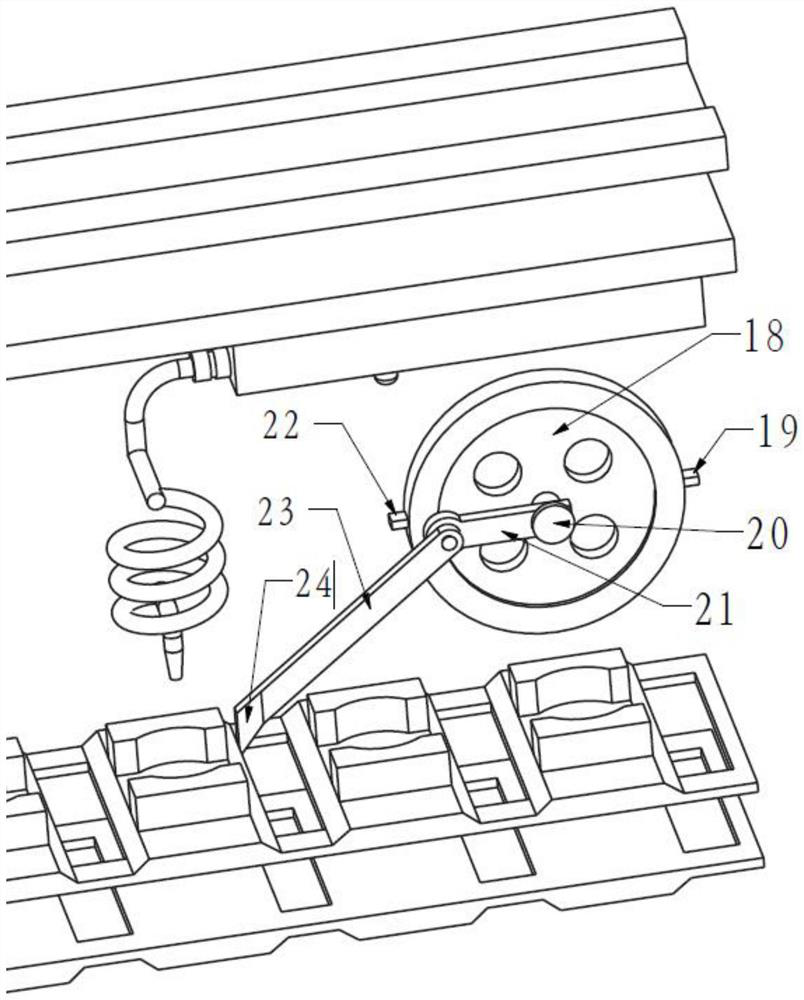

Special integrated production device for furniture parts

ActiveCN105057150AReduce transfer stepsSuitable for mechanized productionLiquid surface applicatorsCoatingsEngineeringMechanical engineering

A special integrated production device for furniture parts comprises a machine frame and a feeding rack arranged on the machine frame. One end of the feeding rack is a feeding end, the other end of the feeding rack is a discharging end, and a first automatic dust removal device, a embellishing device, a drying device, a paint spraying device and an airing bin are arranged on the feeding rack sequentially from the feeding end to the discharging end at intervals. The embellishing device and the paint spraying device each comprises a paint spraying chamber with a paint spraying platform and two groups of spraying guns arranged in the paint spraying chamber, wherein each group comprises two spraying guns, a conveying belt is laid horizontally on the paint spraying platform, a transverse sliding rail is arranged above a feeding end and a discharging end of the conveying belt, and a movable seat is installed on the transverse sliding rail. The two spraying guns in each group are installed on the same movable seat and are arranged in the mode of inclining downwards towards the two outer sides of the corresponding paint spraying platform. The transverse sliding rails and the movable seats are arranged, uniform paint spraying on the furniture parts is realized through transverse and reciprocating swinging of the spraying guns. The special integrated production device is suitable for embellishing and paint spraying of various furniture parts, and improves the production and quality.

Owner:LIANYUNGANG MOBO HOUSEHOLD

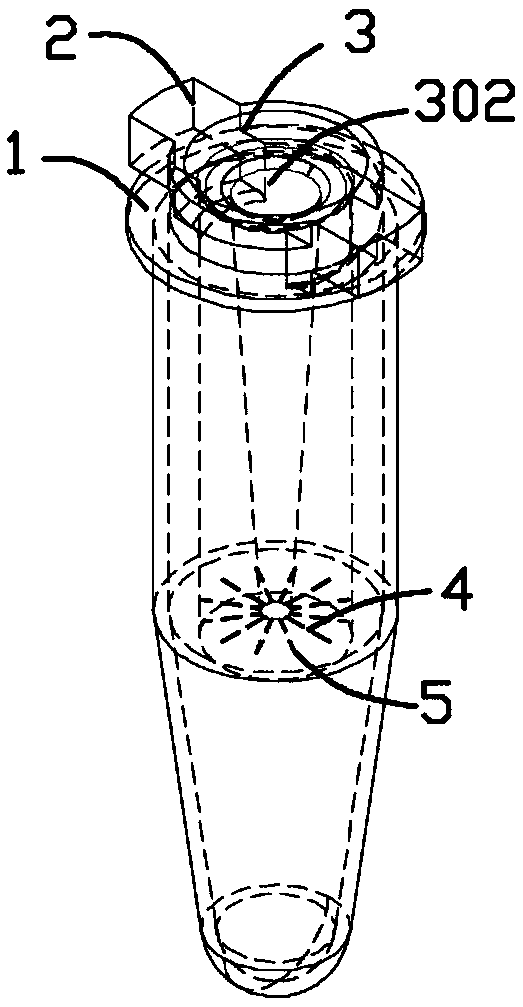

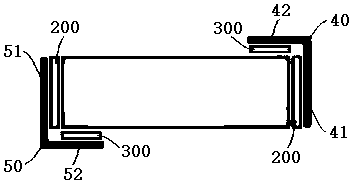

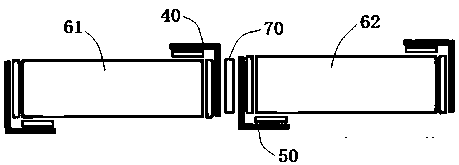

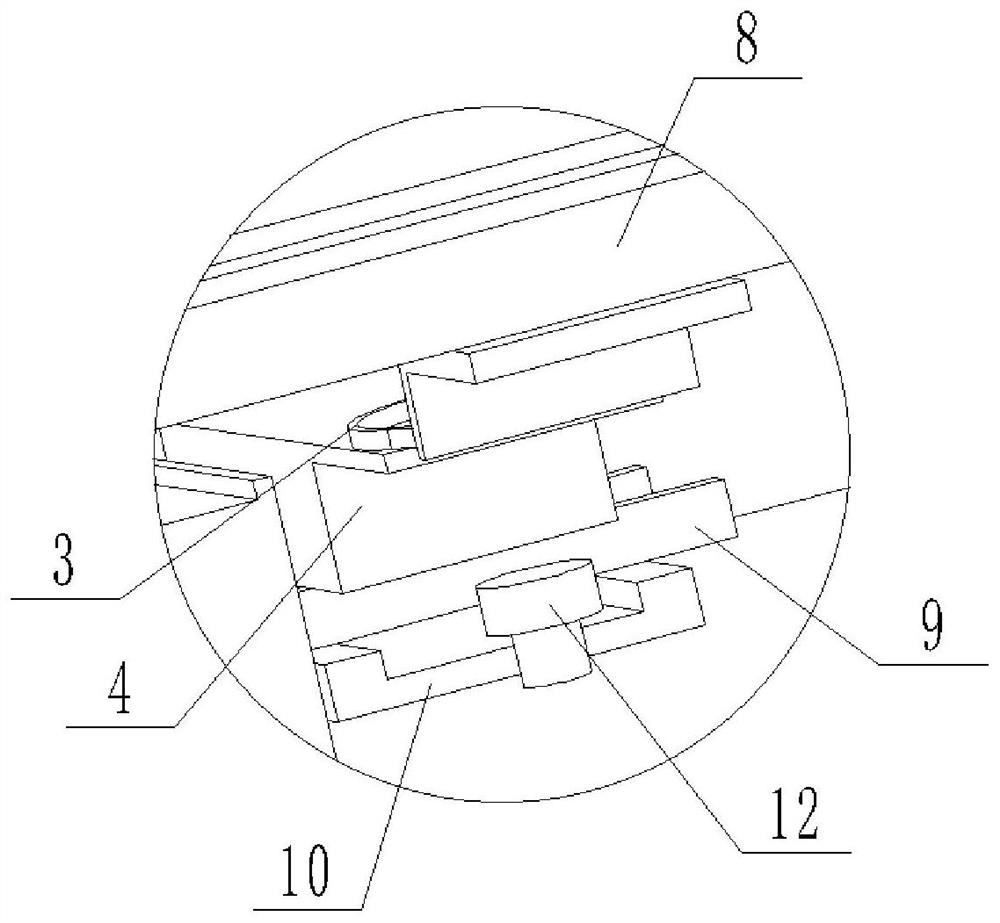

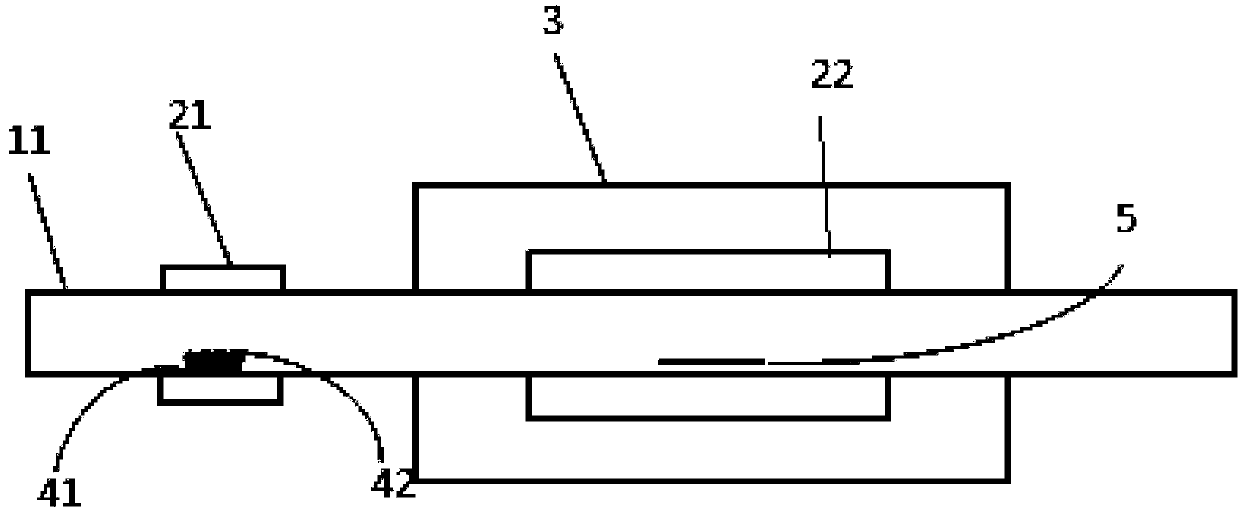

In-tube liquid drop preparing chip device

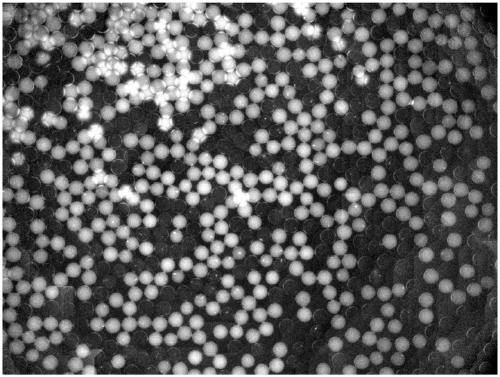

PendingCN109395788AReduce consumptionReduce complexityLaboratory glasswaresGeneration processControl system

An in-tube liquid drop preparing chip device comprises a reaction tube and a liquid drop generation chip, wherein the liquid drop generation chip comprises a reagent inlet and a plurality of branch micro-channels with the consistent sizes and structures; the branch micro-channels are connected with the reagent inlet; the branch micro-channels are parallel to the bottom of the liquid drop generation chip and are distributed in an outwards scattered manner from the center of the chip; outlets of the branch micro-channels are positioned at the outer edge of the side wall of the liquid drop generation chip, and a spraying opening structure is formed to be used for preparing liquid drops; the reaction tube is loaded with a continuous phase reagent during preparation of the liquid drops; in a whole liquid drop preparation process, the continuous phase reagent fully submerges and soaks the branch micro-channels and the spraying opening structure of the liquid drop generation chip, and a dispersion phase reagent is loaded through a reagent inlet, arrives at the position of the spraying opening structure via the branch micro-channels under the effect of pressure and then is broken to form liquid drops; and the integration performance of the device is improved, a liquid drop generation process is simplified, external pressure drive is relieved, the cost and complexity of the system are controlled, the liquid drop preparation frequency is increased to a maximum extent, and analysis requirements of different applications are met.

Owner:XI AN JIAOTONG UNIV

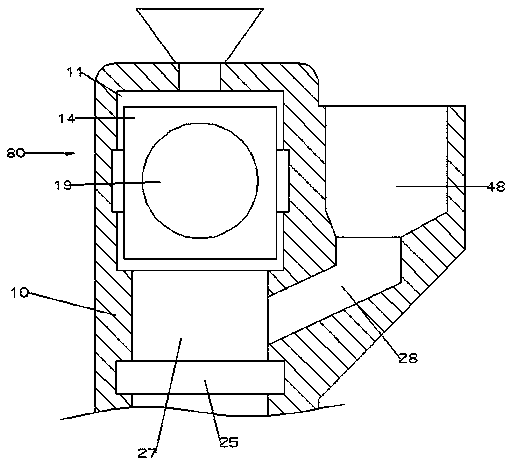

Rapeseed oil extracting machine ensuring low impurity content and high oil yield

InactiveCN110257164AImprove oil yieldNo wasteFatty-oils/fats refiningFatty-oils/fats productionHydraulic cylinderMotor drive

The invention discloses a rapeseed oil extracting machine ensuring low impurity content and high oil yield. The rapeseed oil extracting machine comprises a device cabinet. A hopper is fixedly arranged on the top surface of a gear cavity, a rotating table is rotatably mounted in a stir-frying chamber, a stir-frying cylinder is rotatably mounted in the rotating table, and a heating component is fixedly mounted in the rotating table. When a regulating motor is started up, the regulating motor drives a first gear to rotate, and the first gear rotates to drive the rotating table to rotate; when the rotating table rotates to enable an opening of the stir-frying cylinder to face upwardly, rapeseeds are poured into the stir-frying cylinder; when the rotating table rotates to drive the opening of the stir-frying cylinder to face rightwards, stir-frying is carried out. The rapeseeds for oil manufacture can be heated and stir-fried, halfway device transfer steps can be reduced, heat of the stir-fried rapeseeds is not lost, and the oil yield of the rapeseeds is increased; a hydraulic cylinder is used for oil manufacture of the rapeseeds, and accordingly, the oil yield is increased; filtered oil is subjected to static settlement, and accordingly, the impurity content of the obtained rapeseed oil is greatly reduced.

Owner:SHENGZHOU PANCHEN MASCH TECH CO LTD

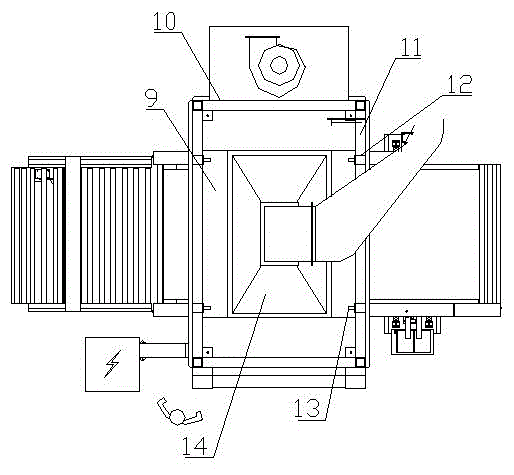

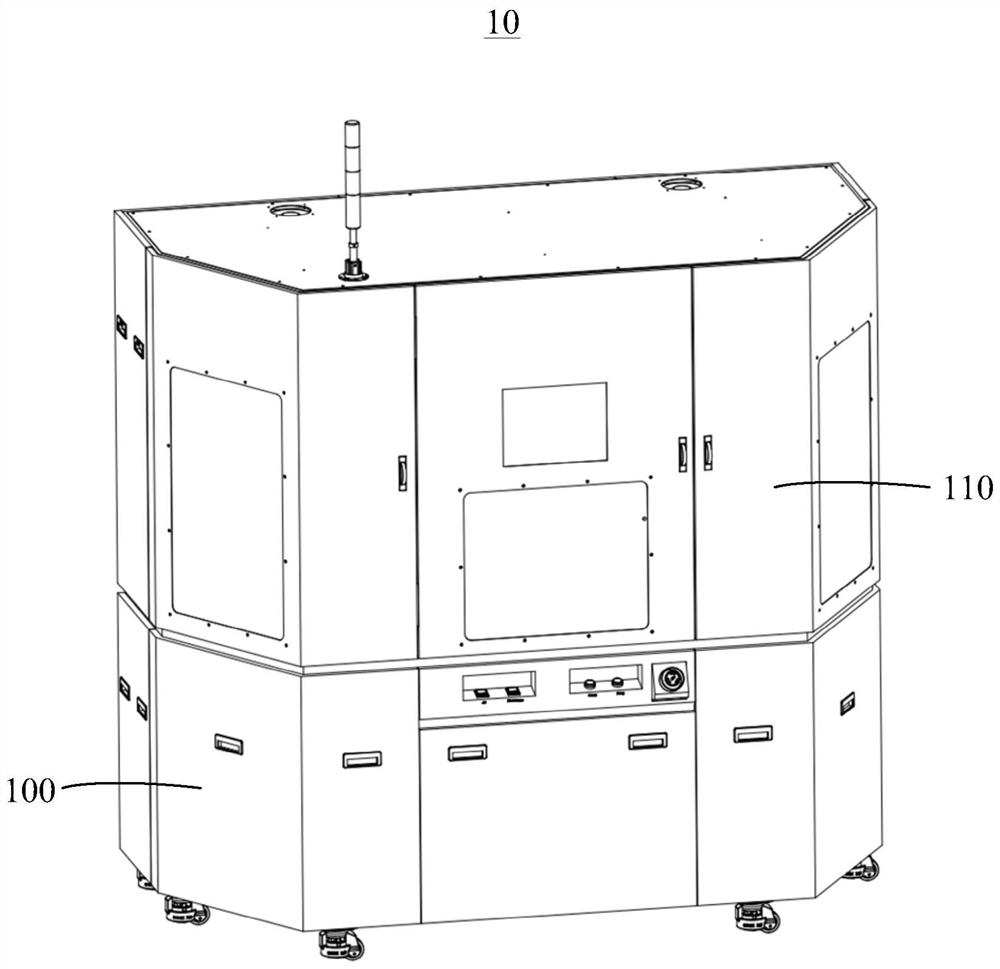

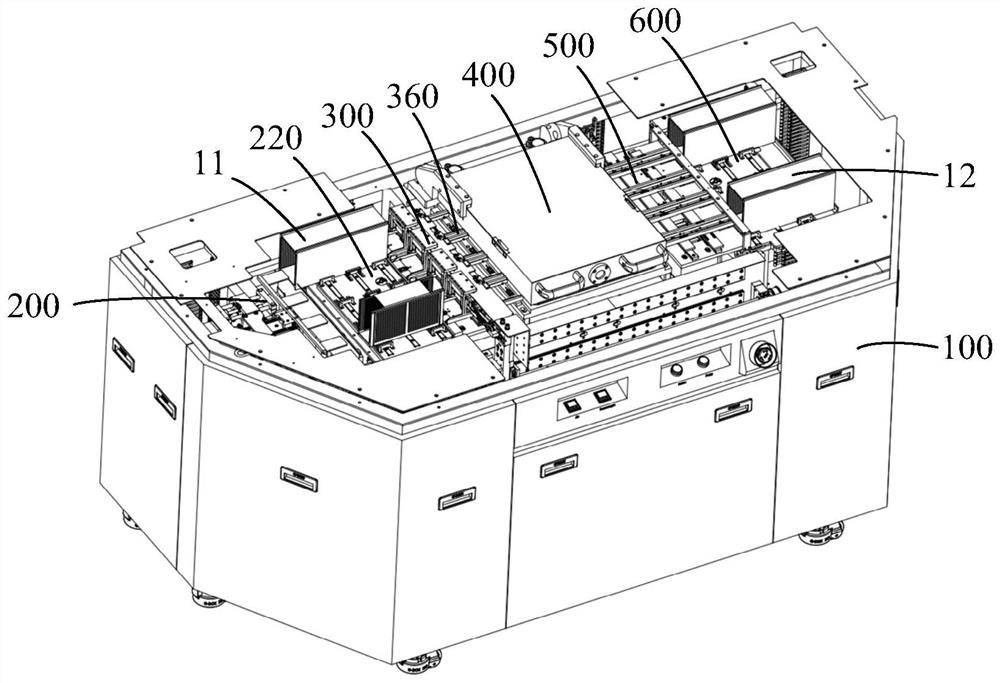

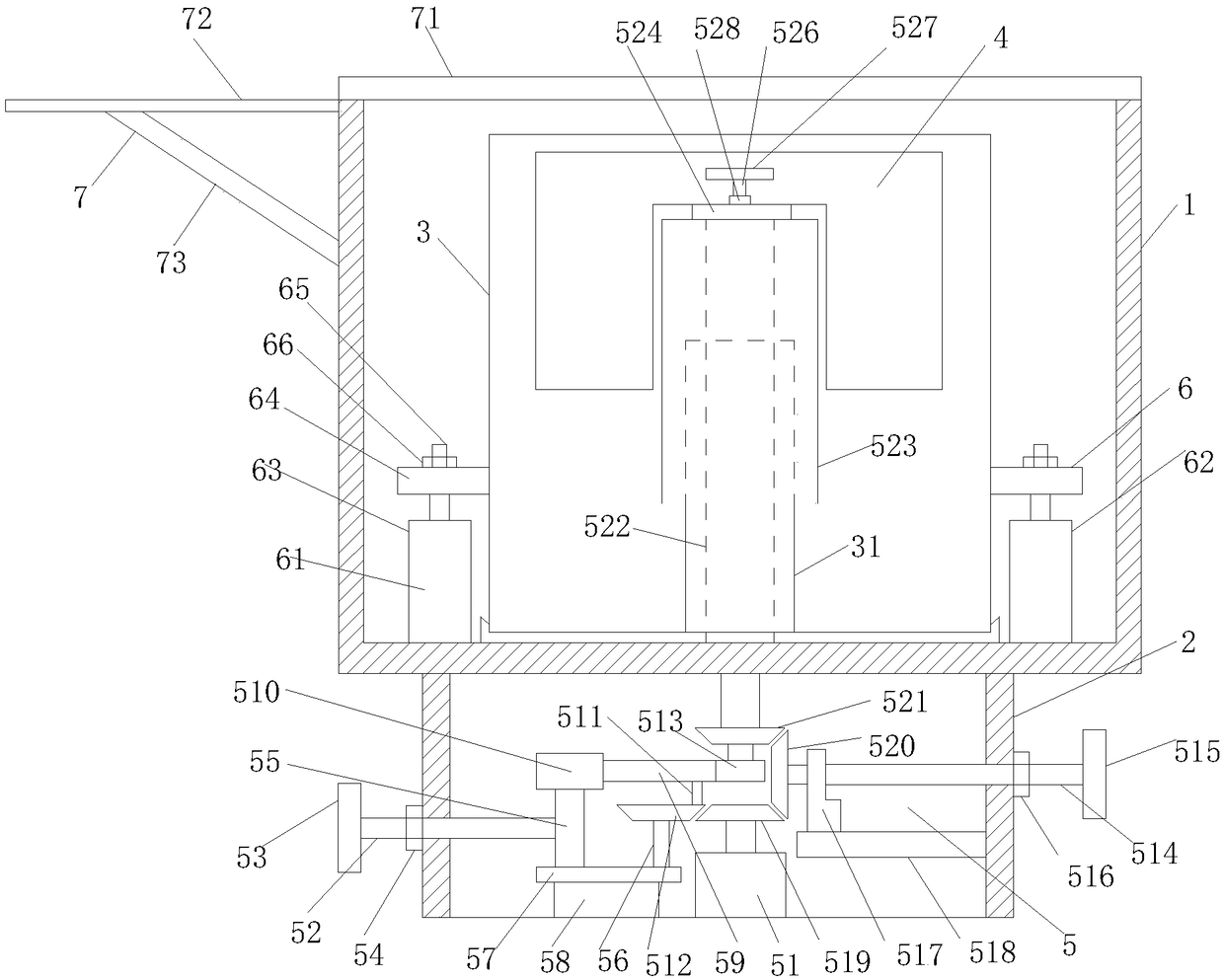

Plasma cleaning machine

PendingCN113770121AEasy transferReduce transfer stepsCleaning processes and apparatusTransfer mechanismIndustrial engineering

The invention provides a plasma cleaning machine. The plasma cleaning machine comprises a material pushing mechanism, a transferring mechanism, a cleaning mechanism, a temporary storage mechanism and a material receiving mechanism, wherein the material pushing mechanism is used for pushing out material strips in a discharging box; the transferring mechanism comprises a transferring assembly and a pushing assembly arranged on the transferring assembly, the transferring assembly is movably arranged on the rack so that the transferring assembly can do rotary motion among the pushing mechanism, the cleaning mechanism and the temporary storage mechanism, and the transferring assembly is used for transferring the pushed-out material strips to the cleaning mechanism and transferring the cleaned material strips to the temporary storage mechanism; the cleaning mechanism is used for cleaning the material strips transferred to the cleaning mechanism; the pushing assembly is used for pushing the material strips transferred to the temporary storage mechanism to the material receiving mechanism; and the material receiving mechanism is used for receiving the material strips pushed to the material receiving mechanism. According to the plasma cleaning machine provided by the invention, the problem that the material strip cleaning efficiency is low due to the fact that an existing plasma cleaning machine is unreasonable in structural arrangement can be solved.

Owner:SHENZHEN TETE SEMICON EQUIP CO LTD

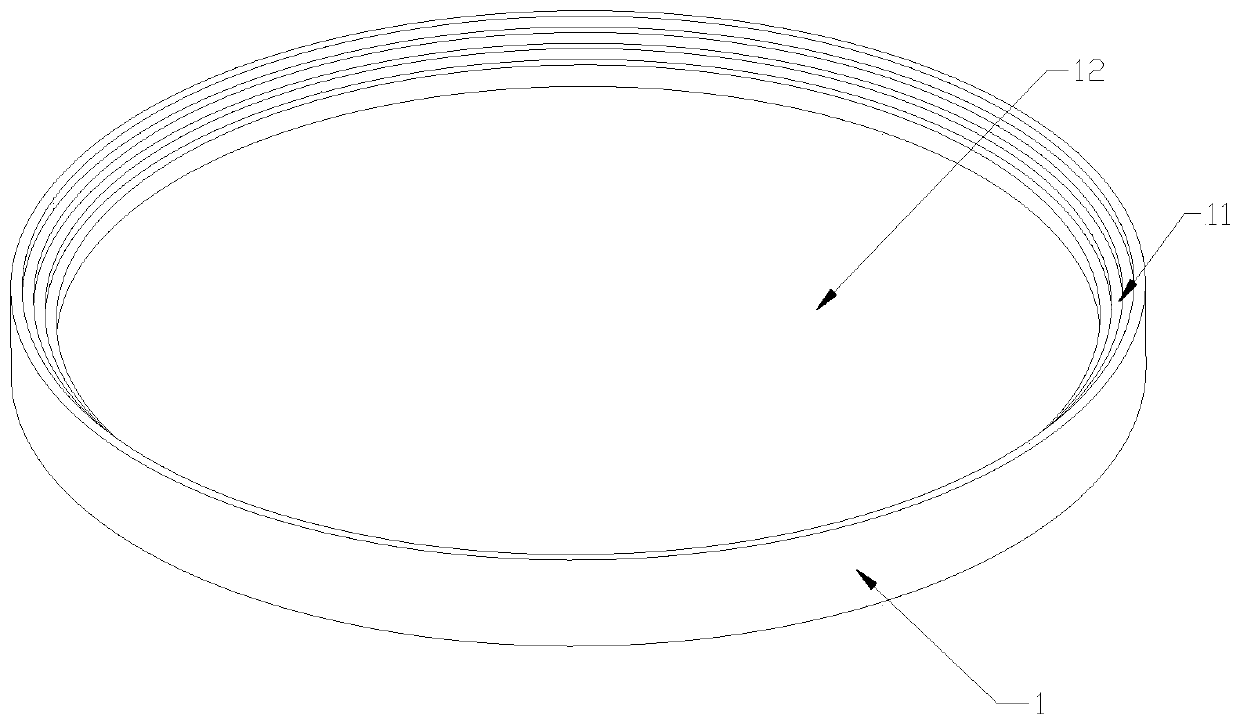

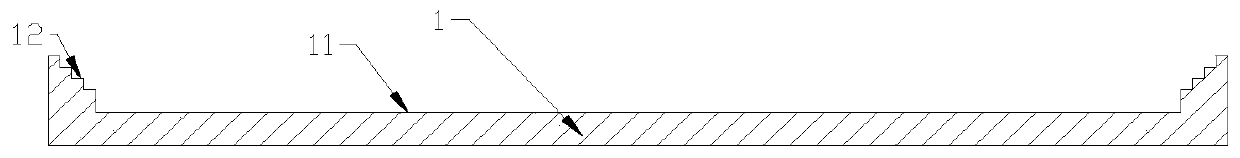

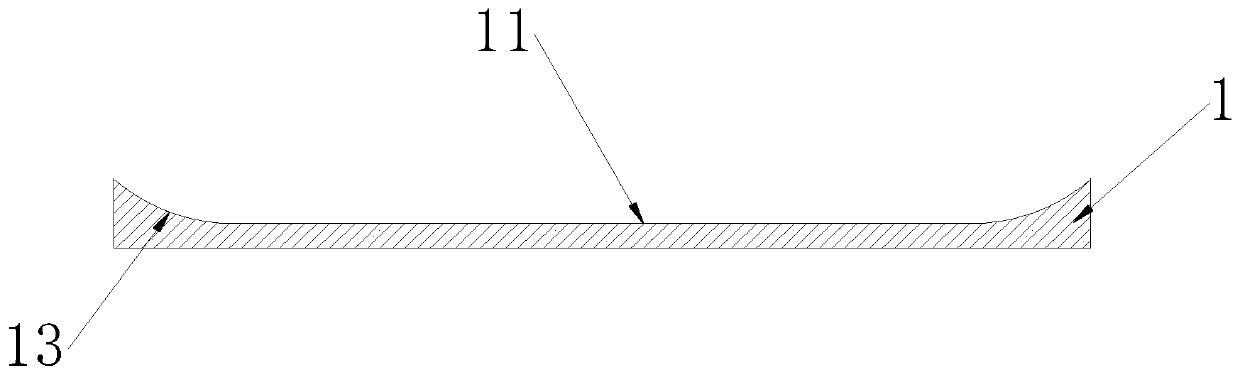

Wafer with edge stepped/gentle slope type protection ring and manufacturing method thereof

InactiveCN111446163AReduce the area of lossReduce transfer stepsSemiconductor/solid-state device manufacturingSemiconductor devicesEtchingWafer

The invention discloses a wafer with an edge stepped / gentle slope type protection ring and a manufacturing method of the wafer. The wafer with the edge stepped protection ring comprises a wafer body,and the wafer body is provided with a grinding front surface. The periphery of the wafer body is provided with a step protection ring / slope protection ring. The preparation method comprises the stepsof pasting a grinding pasting film on the front surface of the wafer; and grinding the back surface of the wafer, using etching equipment, automatically measuring the configuration thickness by an etching process, controlling the concentration and flow of etching liquid, automatically controlling the scaling of a blocking agent by a program to protect the edge shielding ring / edge configuration inert fluid nozzle to dilute and reduce the edge etching amount, etching the back surface of the wafer, and gradually reducing the height of the protection ring from outside to inside. The ultrathin wafer structure with the protection ring is used for subsequent ion implantation, yellow light and double-sided simultaneous metal deposition processes. The front side and back side processes can be carried out at the same time in one time of production, so that the process time is saved. The ultrathin wafer structure with the protection ring reduces the lost area of an edge wafer.

Owner:绍兴同芯成集成电路有限公司

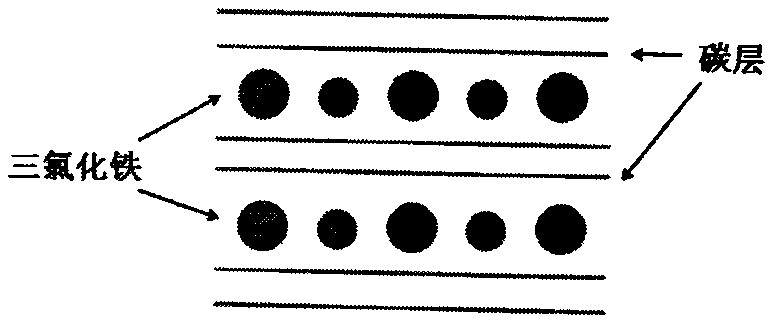

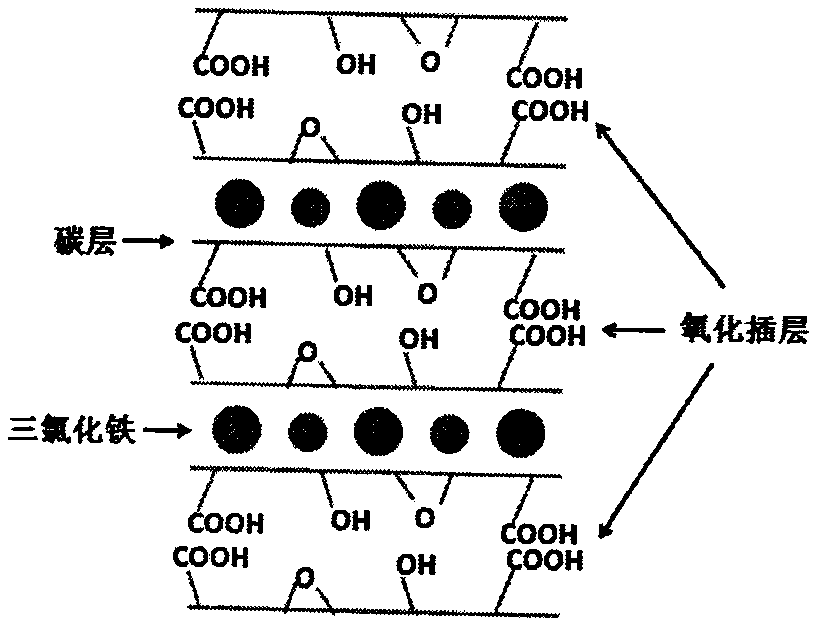

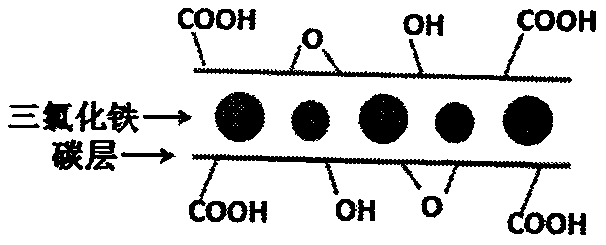

Graphene transparent electrode and work function regulation and control method thereof

InactiveCN109817828AGood stabilityReduce transfer stepsSolid-state devicesSemiconductor/solid-state device manufacturingCvd grapheneTransmittance

The invention relates to a graphene transparent electrode and a work function regulation and control method thereof, and belongs to the technical field of materials. The method comprises the followingsteps: pre-treating a transparent substrate; plating an ultrathin copper layer on the transparent substrate; growing a graphene layer on the surface of the ultrathin copper layer through a CVD method; forming a metal film layer on the graphene layer by using an ion sputtering method; and finally depositing an anti-reflection layer. According to the invention, the graphene is directly grown by using the ultrathin copper foil, so that the transfer step of the graphene is omitted; on the basis, the work function of the metal thin film layer is selectively regulated and controlled to be smaller than or larger than that of the graphene, and the anti-reflection layer is matched, so that the two key problems of the work function and the surface resistance of the graphene transparent electrode are solved on the premise that the transmittance is ensured. The graphene transparent electrode is good in stability and can be widely applied to the field of electronic information such as electroluminescent devices, solar cells and photoelectric detectors.

Owner:重庆石墨烯研究院有限公司 +1

PET solid hard sheet processing device and using method

InactiveCN111730782AImprove front-end processing efficiencyImprove securityPlastic recyclingProcess engineeringMaterial transfer

The invention discloses a PET solid hard sheet processing device. The PET solid hard sheet processing device comprises an equipment platform, wherein extension supporting legs distributed in an arraymode are arranged at the lower end of the equipment platform, a cleaning and conveying device is arranged on the equipment platform, and a crushing device is arranged on one side of the equipment platform; a cleaning and disinfection device is arranged on the cleaning and conveying device, the cleaning and disinfection device comprises cleaning supports distributed in an array mode, and a sprayingframe is jointly arranged on the cleaning supports; the cleaning and conveying device comprises conveying frames distributed in an array mode, cleaning rollers distributed in an array mode are arranged between the conveying frames, and a drying box is further jointly arranged on one sides of the conveying frames; and a conveying belt is further arranged on one side of the crushing device. According to the PET solid hard sheet processing device, the pre-pass processing efficiency of a PET material is effectively improved, and the disinfection, cleaning and drying for material recovery are facilitated, so that the safety of PET material recovery is improved, the packaging production cost is reduced, and the environment is protected; and meanwhile, the material transfer steps are reduced, sothat the material is prevented from being polluted in the transfer process, and meanwhile, the labor intensity of operating personnel is also reduced.

Owner:安徽普瑞康医药包装科技有限公司

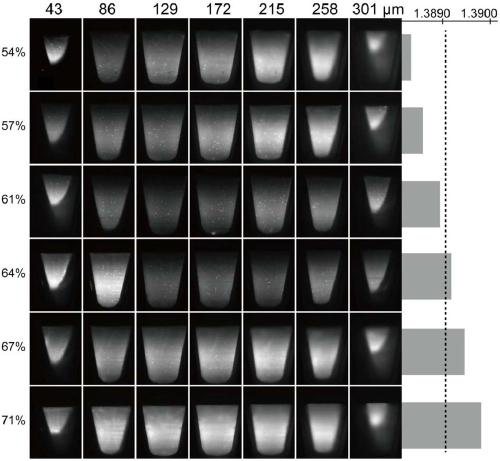

Water-in-oil transparent crude emulsion with phase separation and application thereof

InactiveCN109234363AImprove mechanical stabilityImprove thermal stabilityMicrobiological testing/measurementWater in oilChemistry

Provided are a water-in-oil transparent crude emulsion with phase separation and application thereof. The transparent crude emulsion isobtained by emulsifying and dispersing an aqueous phase and an oil phase, wherein the aqueous phase liquid droplets dispersed in the oil phase have an average diameter of not less than 0.2 [mu]m, and an application thereof; And a refractive index reinforcing agentis also dissolved in the aqueous phase, and the refractive index reinforcing agent component accounts for not less than 20% by mass in the whole aqueous phase; And a surfactant with HBL value not greater than 8 is also dissolved in the oil phase; Furthermore, the absolute value of the difference in refractive index between the aqueous phase and the oil phase does not exceed 0.1. By controlling thecomposition of both the water phase and the liquid phase of the water-in-oil coarse emulsion used for phase separation, in particular by adjusting the refractive index of the water phase in the coarse emulsion droplets, the coarse emulsion droplets are transparent, so that light rays can pass through the shallow transparent droplets to reach the deep droplets, thereby realizing in-situ sealed imaging detection of the deep droplets of the coarse emulsion.

Owner:因纽美瑞克斯公司

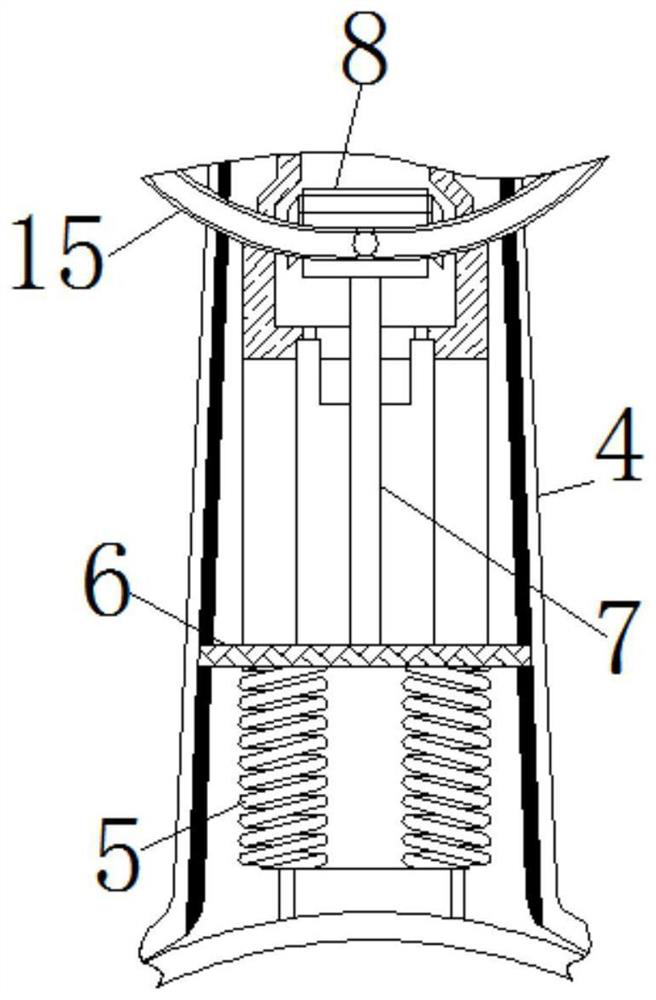

Core clamping device

ActiveCN109365755ALow costHigh versatilityFoundry mouldsFoundry coresEngineeringBiomedical engineering

Owner:KOCEL EQUIP

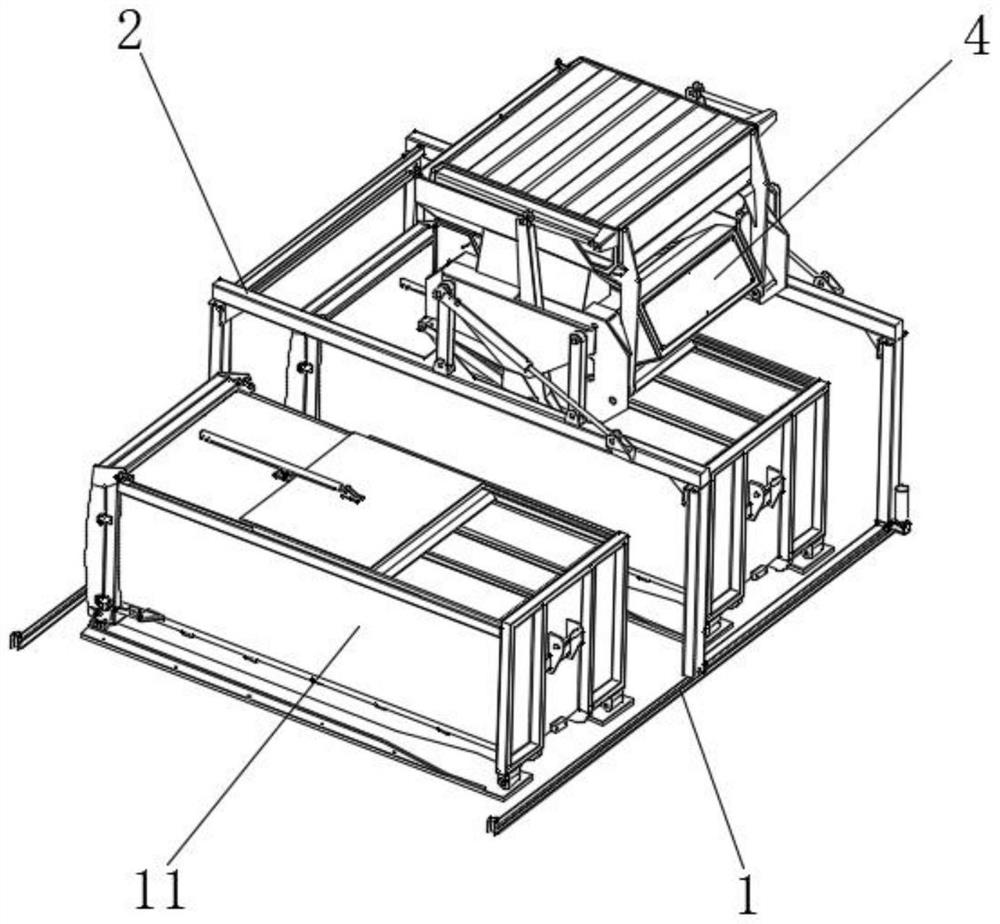

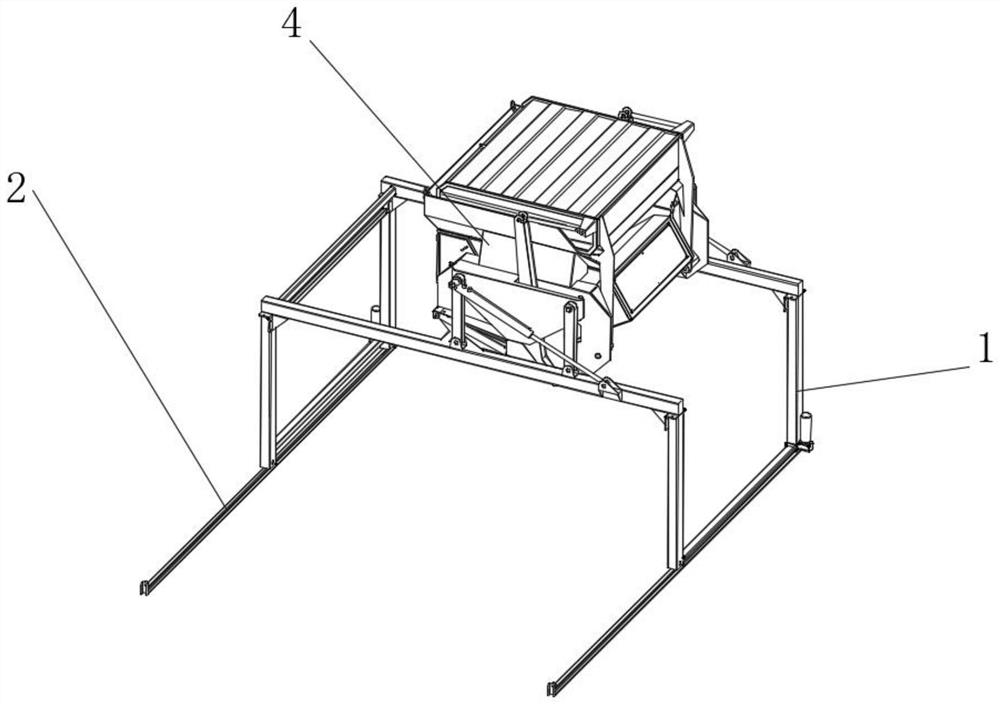

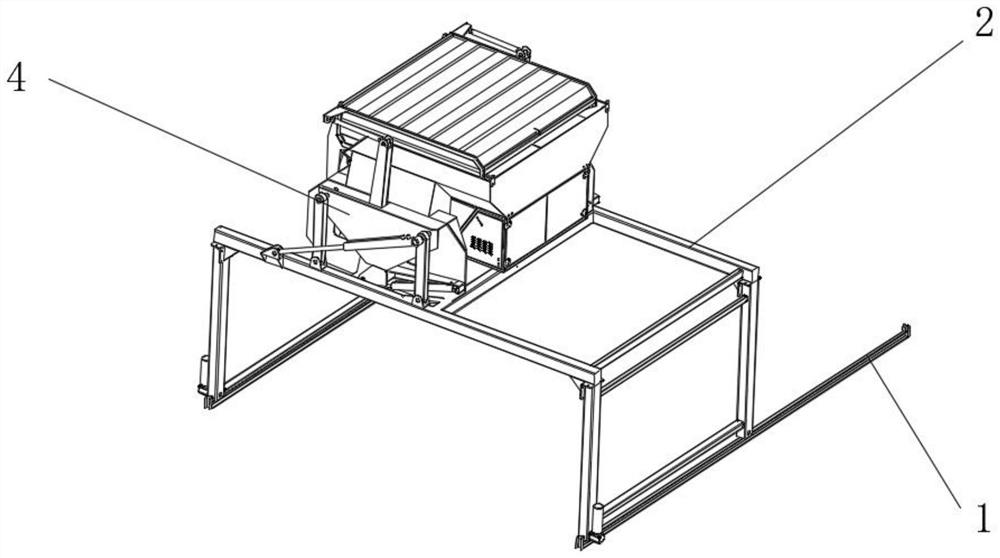

Truss type garbage compression station

The invention relates to the field of garbage treatment, in particular to a truss type garbage compression station. The truss type garbage compression station comprises at least one guide rail, at least two movable trusses installed on the guide rail and a garbage compressor installed on the movable trusses, wherein the garbage compressor is connected to the movable truss through a plurality of connecting rods; a lifting hydraulic cylinder is arranged at the end, hinged to one connecting rod, of the garbage compressor, the other end of the lifting hydraulic cylinder is fixed to the movable truss, and the lifting hydraulic cylinder drives the connecting rods to swing to achieve lifting of the lifting garbage compressor; and the end, connected with the guide rail, of the movable truss is provided with a driving wheel, and the driving wheel drives the movable truss to move on the guide rail. The garbage compressor is separated from garbage cans, one garbage compressor can be used for garbage compression of the multiple garbage cans, compared with a compression type garbage can, the cost is greatly reduced, the garbage compressor does not need to be transferred when the garbage cans are transferred, and the garbage treatment cost is indirectly reduced.

Owner:重庆捌拾玖度环保科技有限公司

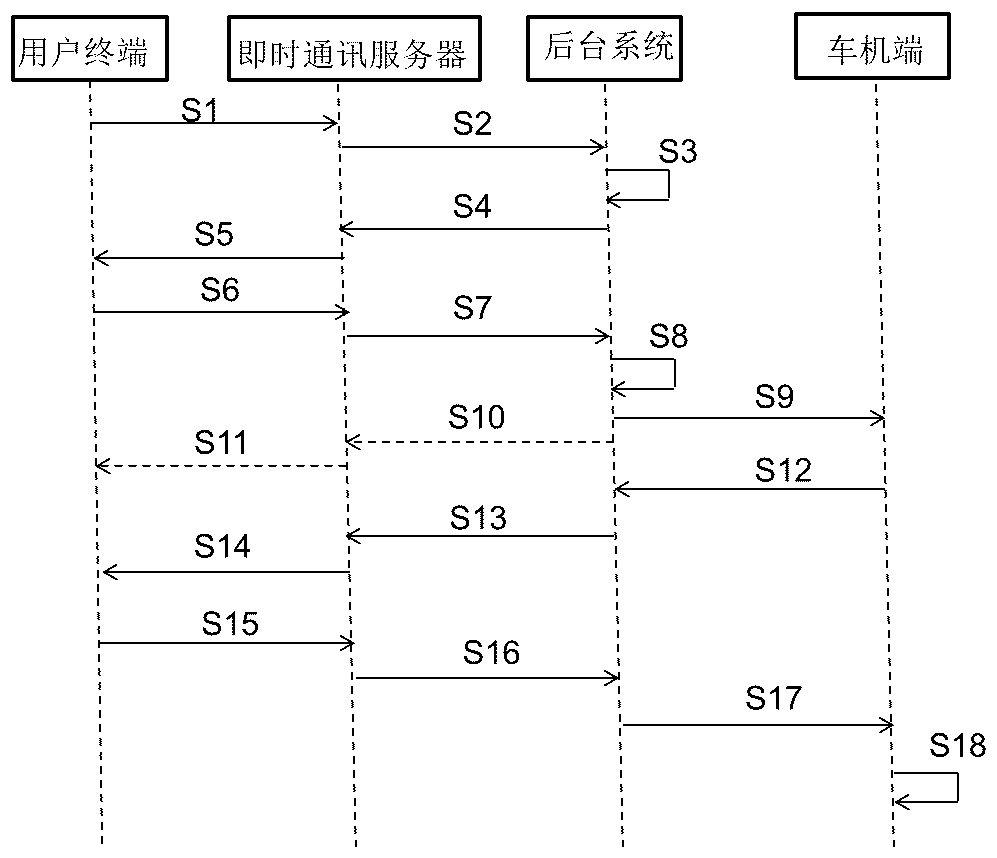

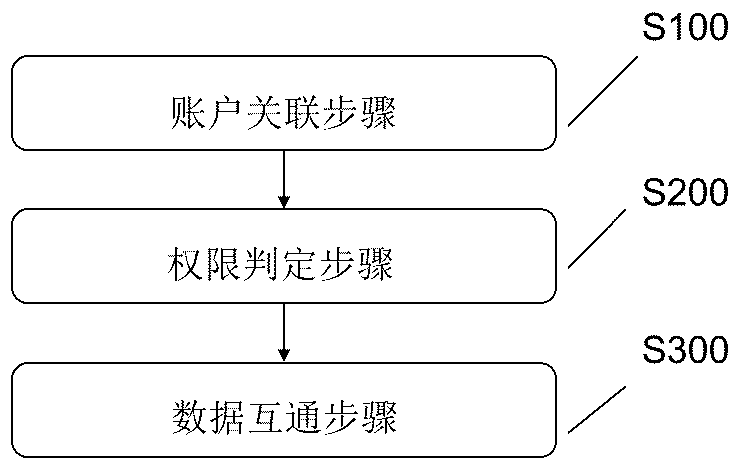

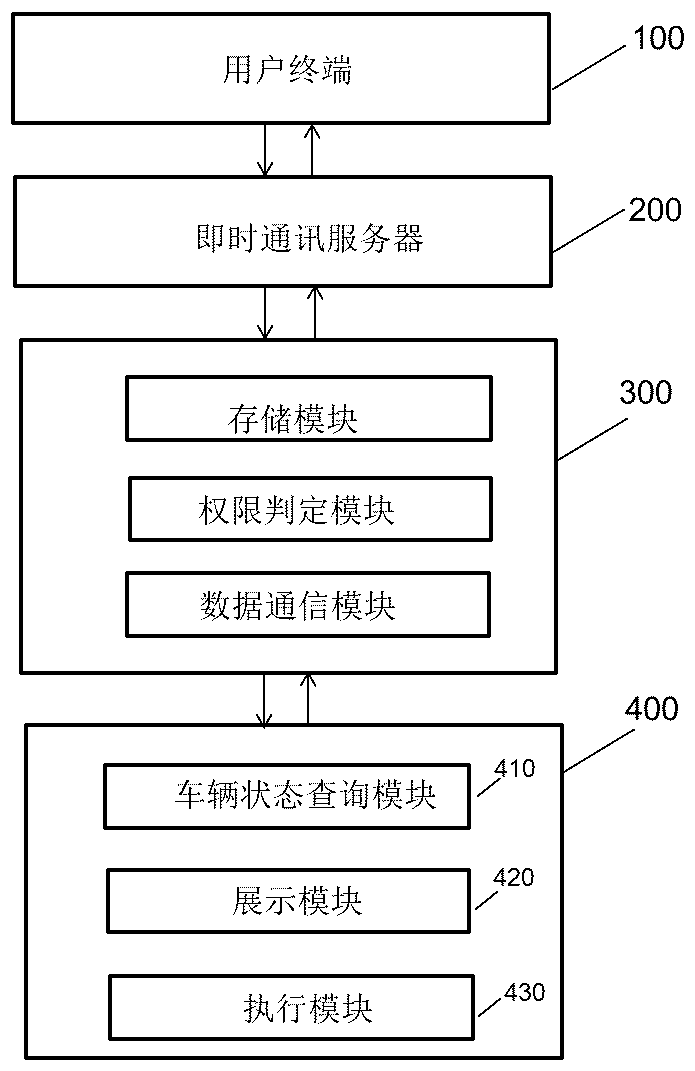

A vehicle-mounted instant messaging method and a vehicle-mounted instant messaging system

InactiveCN109936497AImprove convenienceEfficiencyParticular environment based servicesMessaging/mailboxes/announcementsComputer terminalInstant messaging

The invention relates to a vehicle-mounted instant messaging method and system. The method comprises the following steps: associating an instant messaging user with a vehicle, and storing an association relationship in a background system; sending a permission judgment request from the user terminal to the instant messaging server, forwarding the permission judgment request to a background systemthrough the instant messaging server, carrying out permission judgment by the background system based on the association relationship, if the permission judgment is successful, continuing the following data intercommunication step, and otherwise, ending the process; And sending the communication data or the user instruction from the user terminal to the background system through the instant messaging server, and forwarding the communication data or the user instruction to the vehicle-mounted terminal through the background system. According to the invention, the instant messaging and the vehicle-mounted system can be better fused, so that the user can use the instant messaging on the vehicle more conveniently.

Owner:NIO ANHUI HLDG CO LTD

L-shaped connecting member for solar cell sheet and use thereof

ActiveCN109801981AReduce overall man-hoursLow costPhotovoltaic energy generationSemiconductor devicesAdhesiveEngineering

The invention provides an L-shaped connecting member for a solar cell sheet. The L-shaped connecting member comprises an L-shaped conductive substrate. The L-shaped conductive substrate comprises a first side and a second side which extend in the same direction, wherein the first side is attached to the side surface of the solar cell sheet, and the second side is attached to the front surface or the back surface of the solar cell sheet. The first side and the second side are integrally connected with each other to form an L shape. The inner side surface of the first side is covered with insulating glue. The inner side surface of the second side is covered with solder tin or a conductive adhesive. The invention also provides the use of the L-shaped connecting member. The L-shaped connectingmember of the present invention has a specially designed three-dimensional structure such that the front electrode and the back electrode of the solar cell sheet can extend to the side surface of thesolar cell sheet, which facilitates the serial connection of the solar cell sheets and the close arrangement of the solar cell sheets.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

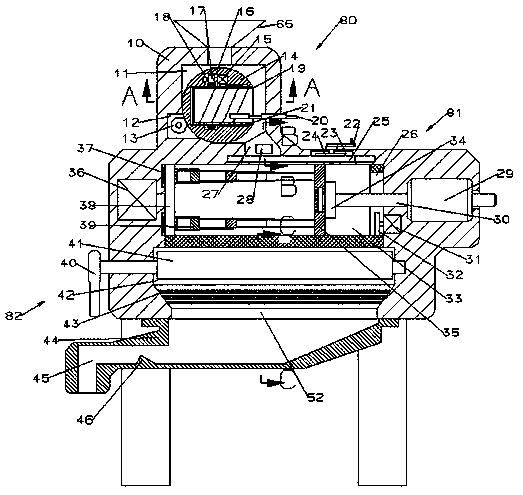

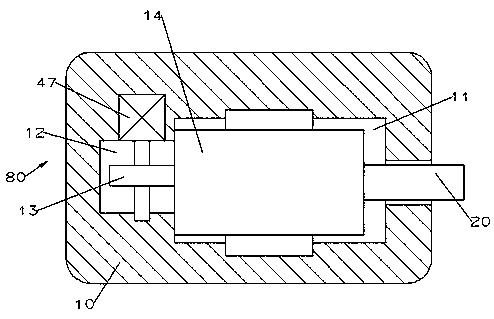

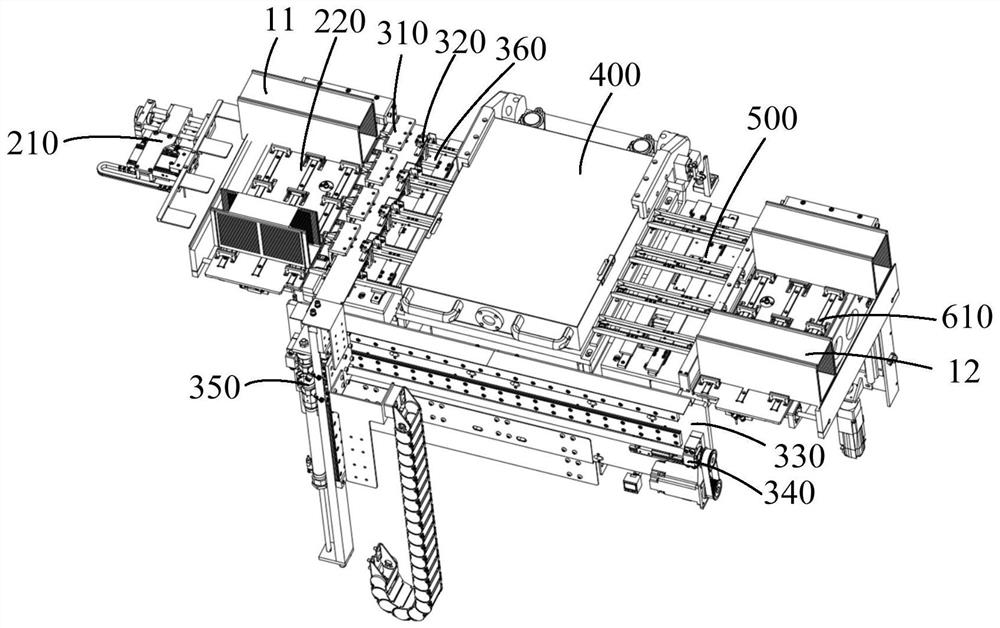

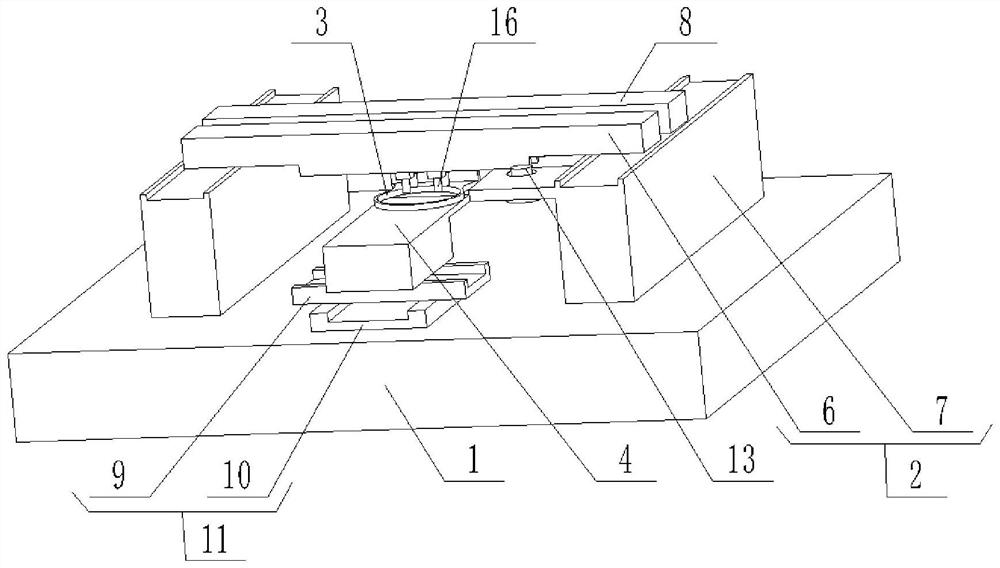

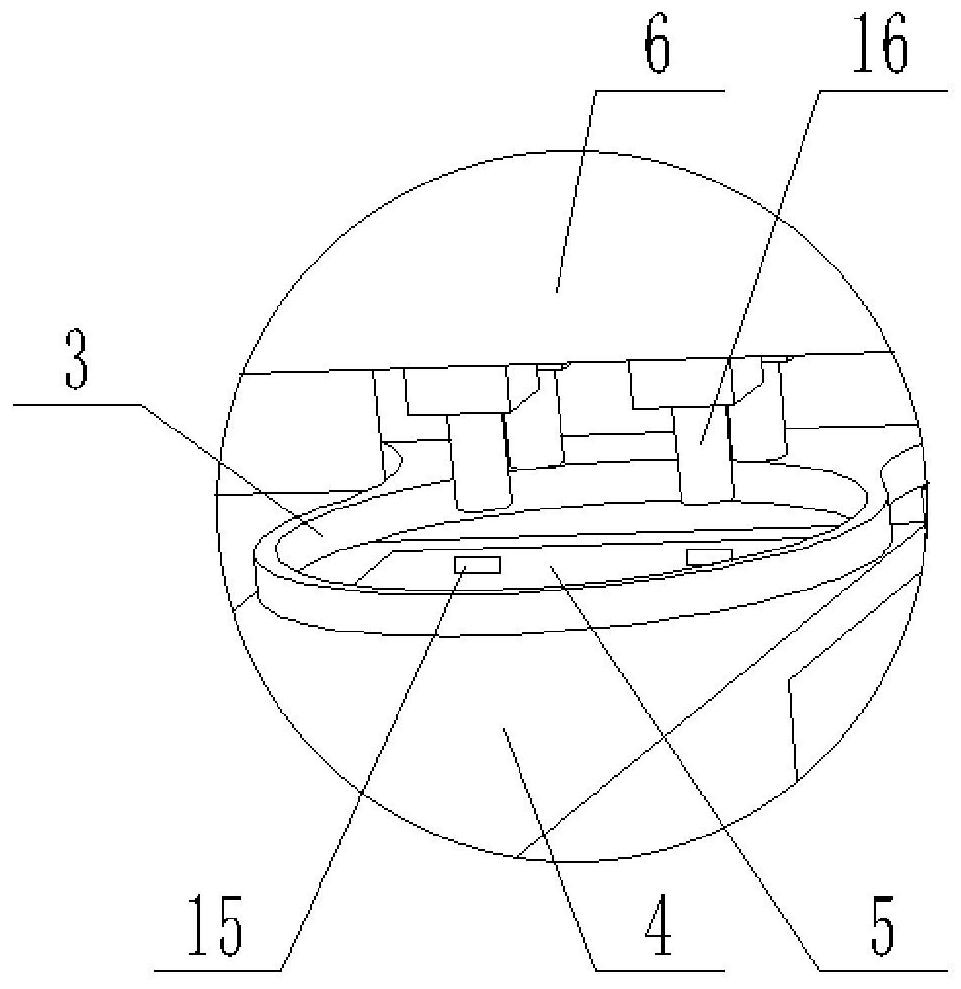

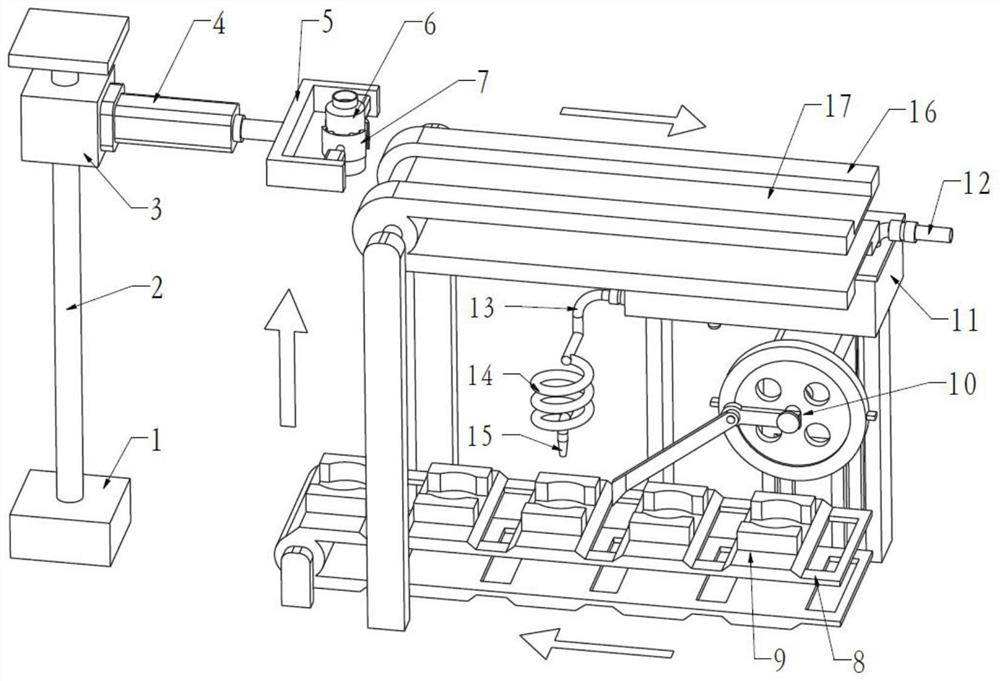

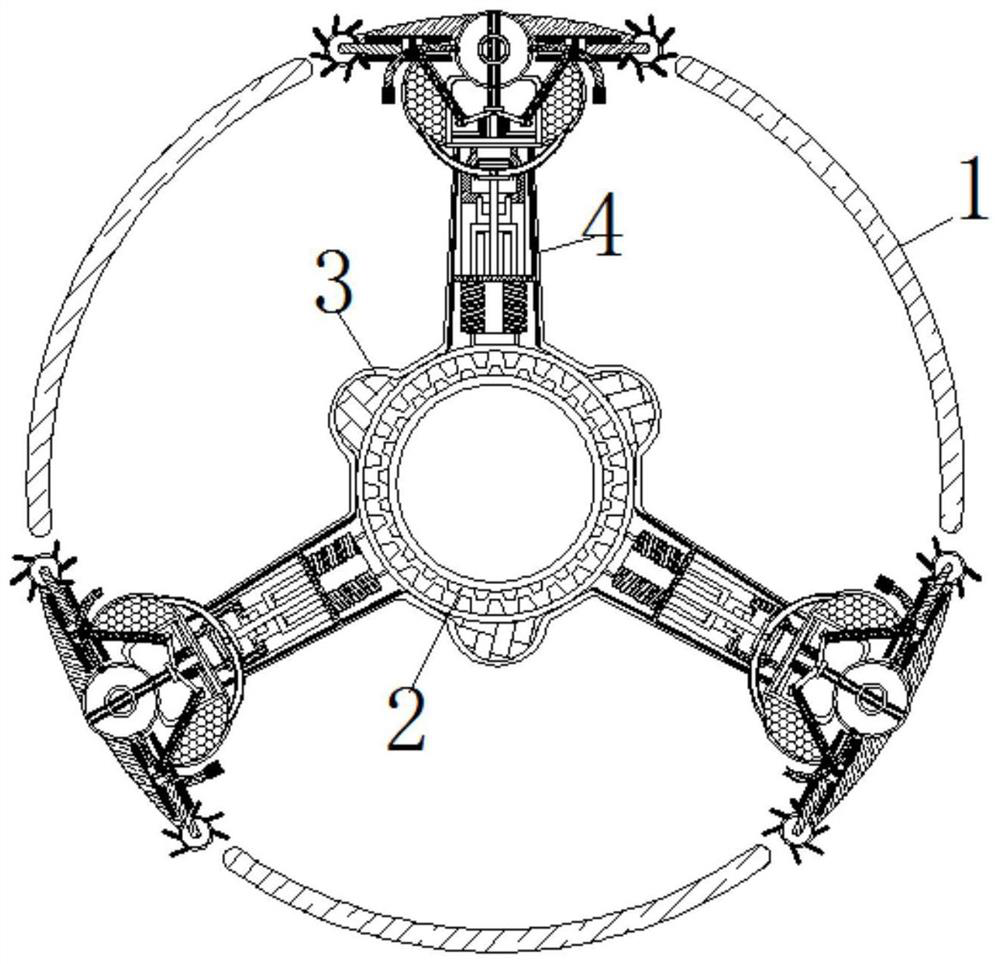

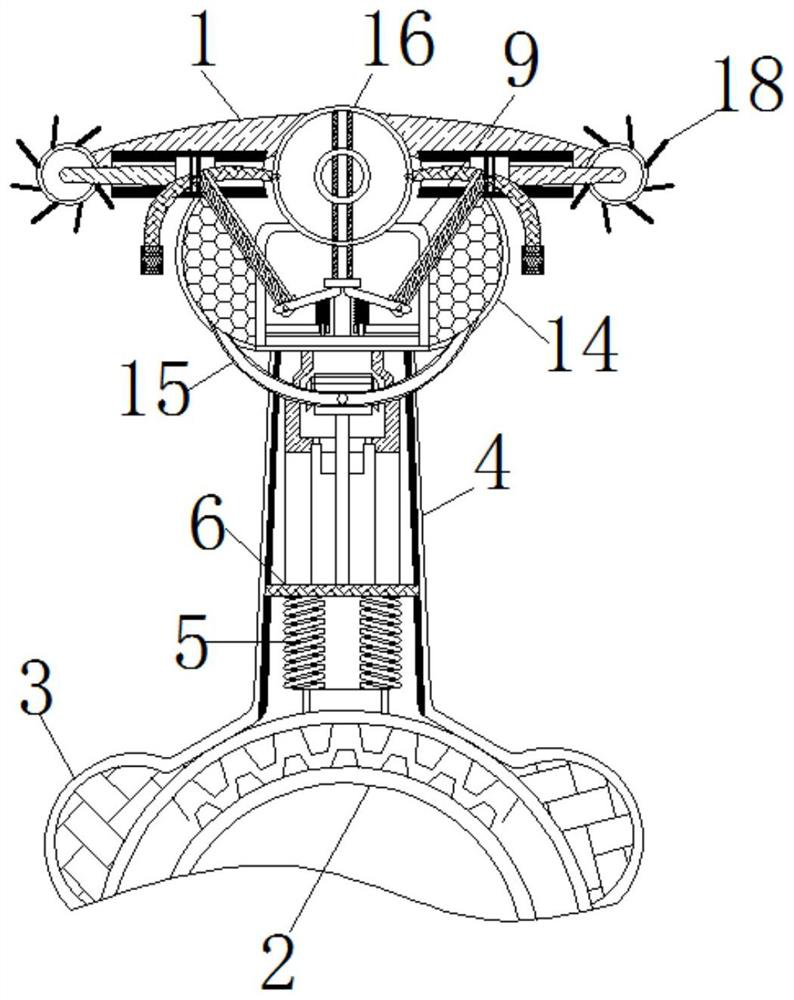

Needling type die bonder

PendingCN113539935AReduce manufacturing costReduce transfer stepsSemiconductor/solid-state device manufacturingSemiconductor devicesManufacturing cost reductionCircular disc

The invention relates to the technical field of die bonding, in particular to a needling type die bonder which comprises a base, wherein a needling device is arranged above the base through a first gantry assembly, and the needling device is provided with a plurality of needling heads; a wafer disc which is used for bearing a wafer and is movably mounted below the plurality of needling heads through a first linear driving mechanism; a carrying table, which is used for carrying a substrate and is movably mounted below the wafer disc through a second linear driving mechanism, so that any one of the needling heads, an LED wafer in the wafer and a wafer fixing point in the substrate are located on the same straight line. In conclusion, by adopting the design of the invention, on one hand, the manufacturing cost can be reduced and the transfer steps can be reduced by omitting the structure of a suction nozzle, and on the other hand, the transfer of a plurality of LED wafers can be realized at one time through the design of a plurality of needling heads, so that the transfer efficiency is improved.

Owner:SHEN ZHEN TALUER TECH CO LTD

A new type of carbonate carbon and oxygen isotope sample preparation system and sample preparation method

ActiveCN105277401BHigh degree of automationGuaranteed normal injectionPreparing sample for investigationWater bathsAutosampler

The invention provides a novel sample preparation system for carbon and oxygen isotopes of carbonate and a sample preparation method thereof. The sample preparation system comprises an original sample reaction device, a finished sample extraction device and a system vacuum degree controlling device, wherein the original sample reaction device is connected with an autoinjection device. The sample preparation system employs the autoinjection device, so the automation degree of the sample preparation system is increased, and it is guaranteed that all the saturated phosphoric acid solution enters the bottom of a reaction tube and participates in a reaction; a touch button type vacuum valve is used to replace a conventional turn button type vacuum valve, so service life is prolonged, simplicity of usage of devices is improved, and operation time is shortened in preparation; and a constant temperature water-bath is added, vacuum-pumping and reaction can be completed in the devices in the same time, so a transfer step between vacuum-pumping and sample reaction is reduced. Moreover, the invention provides the sample preparation method of the novel sample preparation system. According to the invention, accuracy and the automation degree in preparation of a test sample are effectively improved, and standardized operational process is formed.

Owner:CHINA PETROLEUM & CHEM CORP +1

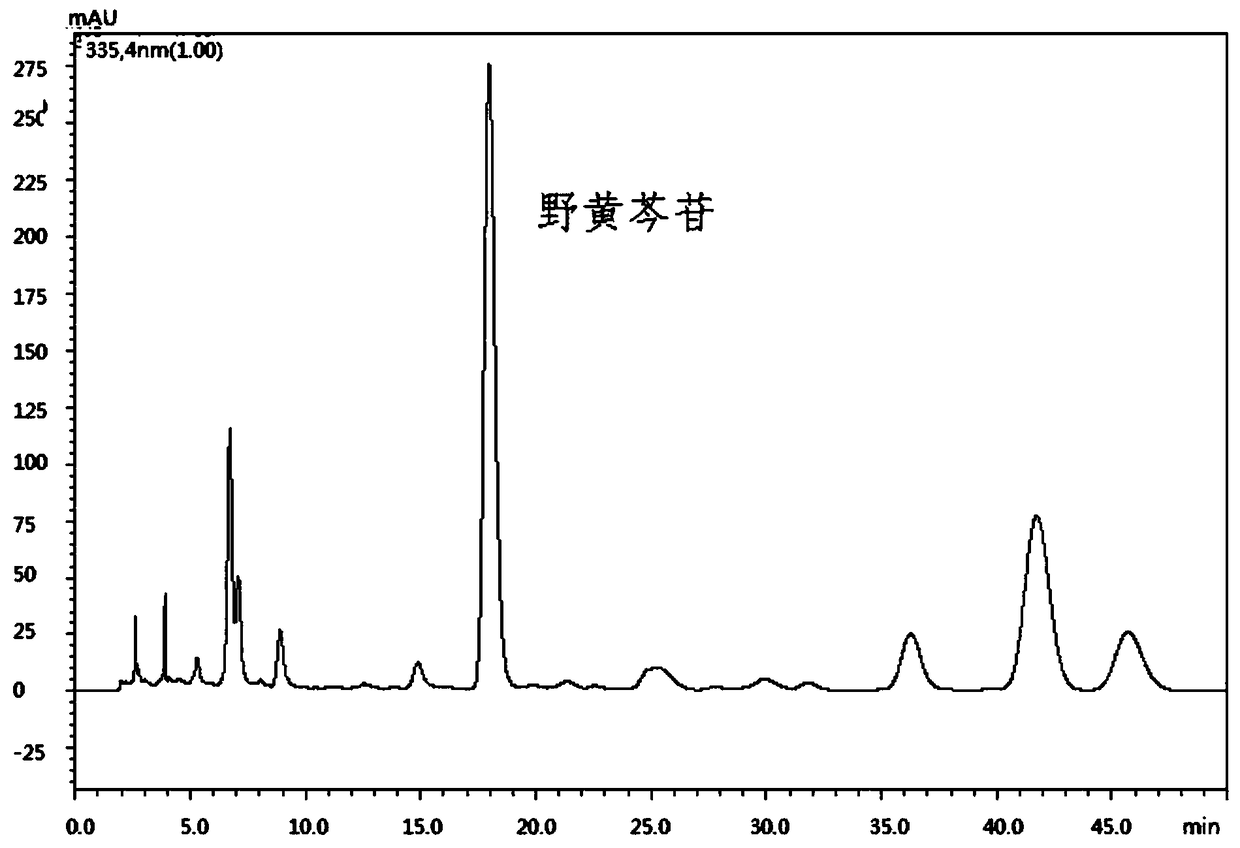

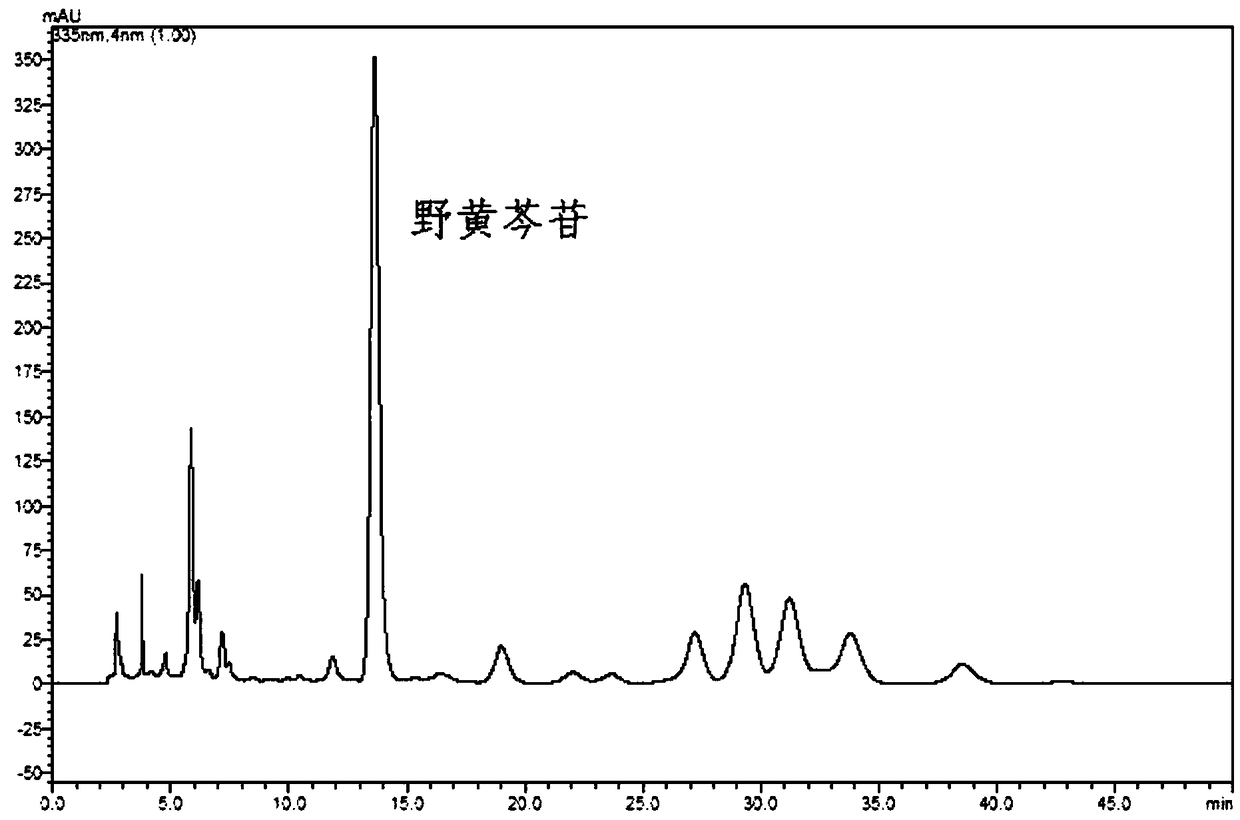

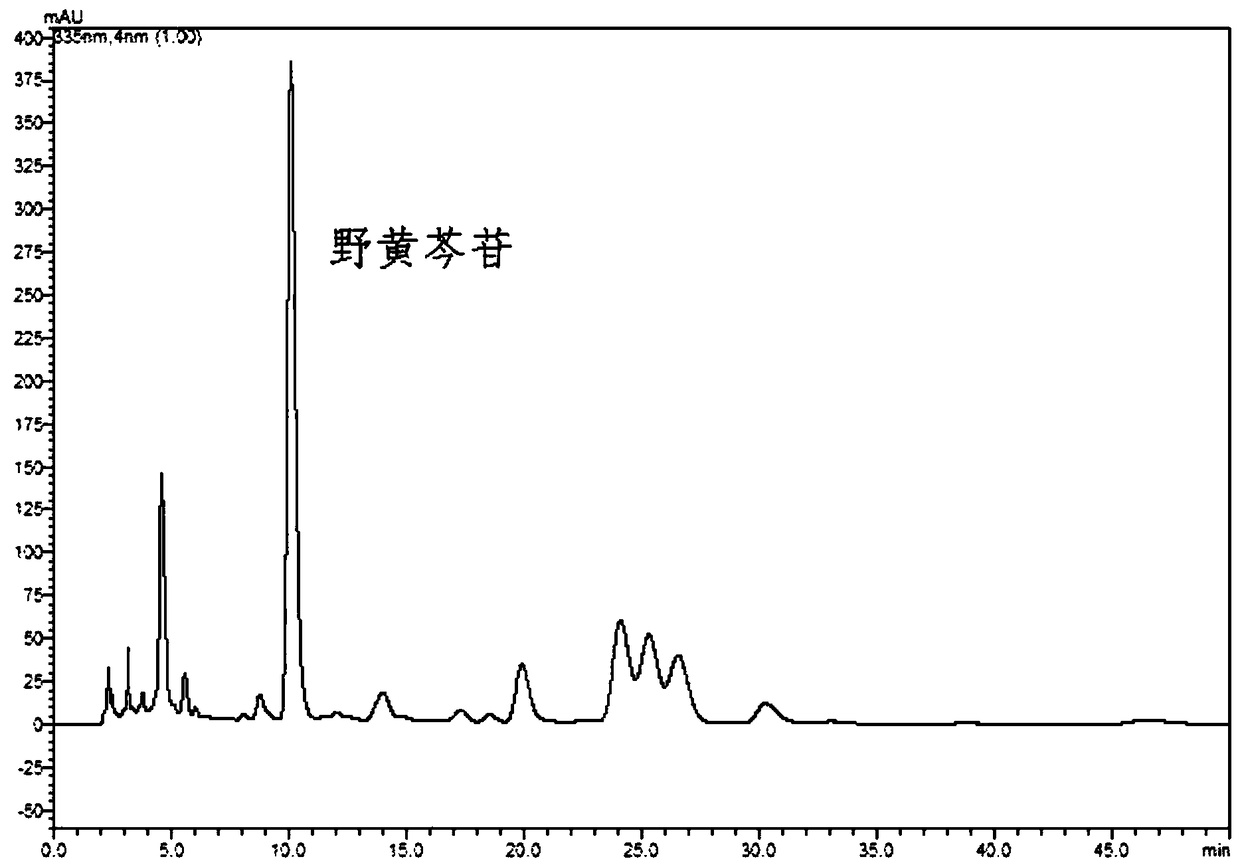

Detection method of content of wild baicalin in traditional Chinese medicine

InactiveCN109470795AEasy to handleExtract completelyComponent separationMedicinal herbsPhosphoric acid

The invention provides a detection method of the content of wild baicalin in a traditional Chinese medicine, and belongs to the field of traditional Chinese medicines. The detection method comprises astep of preprocessing a sample and a step of injecting and detecting the sample, wherein the sample is herba erigerontis preferably; ethanol is adopted for extraction in preprocessing of the sample;the sample is injected in the conditions as follows: a C18-bonded packed column is adopted, a mobile phase comprises acetonitrile, tetrahydrofuran and 0.1%-0.2% phosphoric acid at a ratio of 7:14:79,the flow rate is 1.0 ml / min, and the column temperature is 40 DEG C. The detection method has the advantages of being stronger in adaptability, reducing the preprocessing step of the sample and more accurately reflecting the content of the wild baicalin in the traditional Chinese medicine.

Owner:YUNNAN BIOVALLEY PHARMA CO LTD

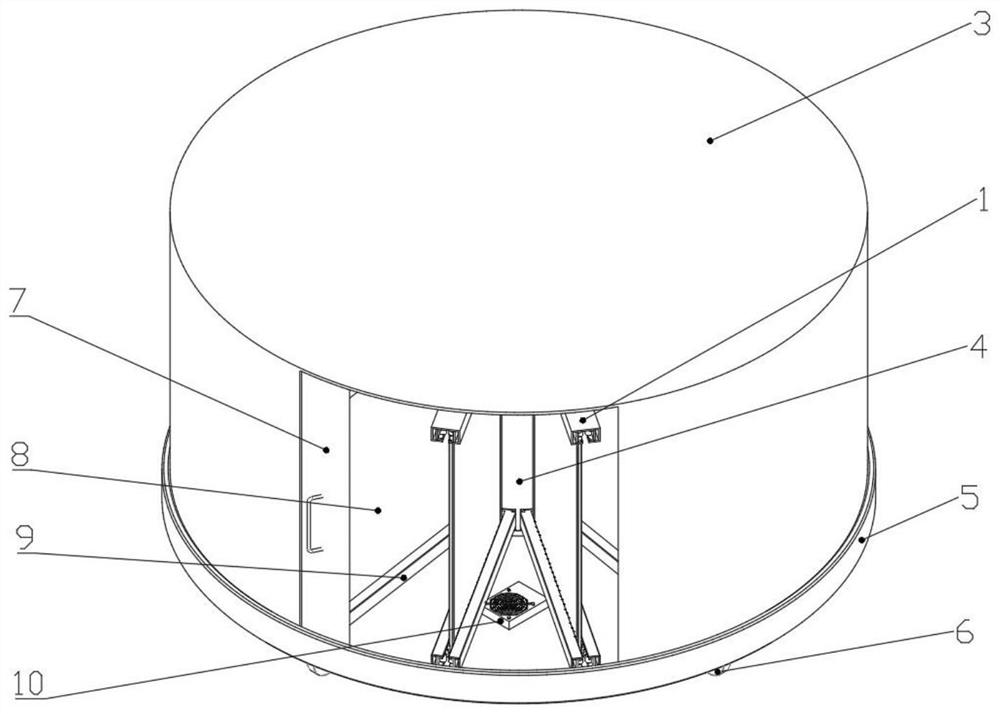

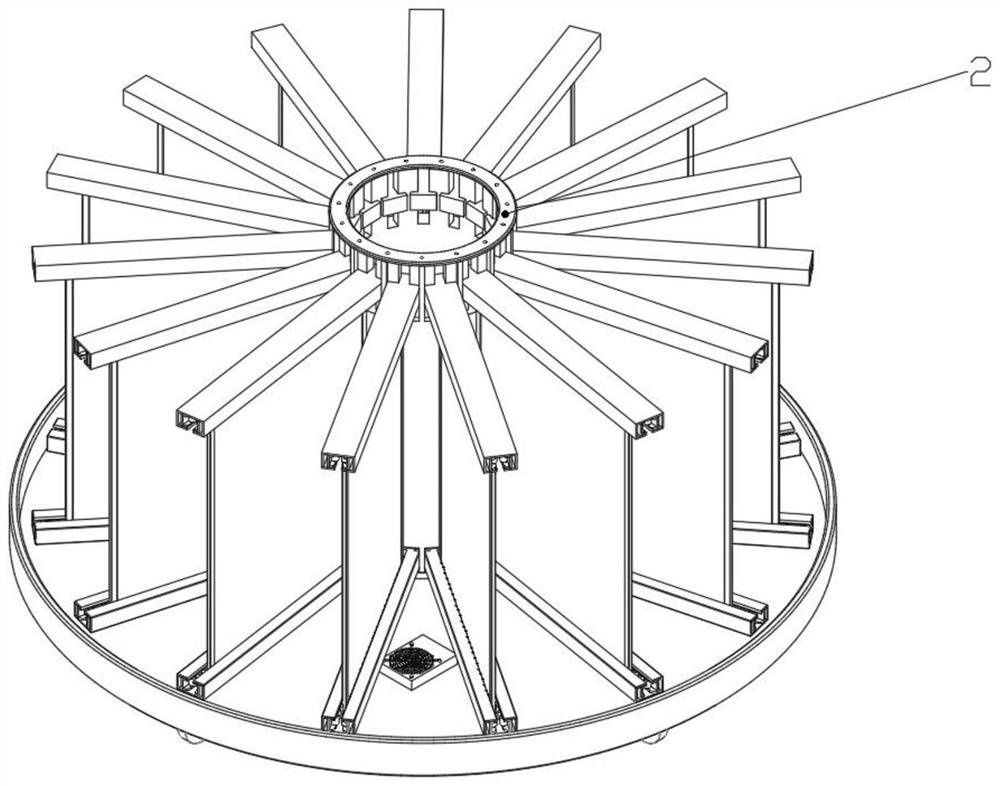

Drying and storing integrated device for screen printing plate

PendingCN114166000ARealize storageEfficient dryingDrying gas arrangementsDrying chambers/containersScreen printingMechanical engineering

The invention discloses a drying and storing integrated device for a screen printing plate. The drying and storing integrated device comprises an upper clamping body, a top cover, a protective cover, a base column, a base, a lower clamping body and an air blowing device. Wherein the base and the base column are matched through a hole shaft, the base column can rotate around the shaft, one or more upper clamping bodies and one or more lower clamping bodies are correspondingly installed at the upper end and the lower end of the base column respectively, the top cover is fixed to the upper portion of the base column, and the air blowing device is fixedly installed on the base and used for drying a screen printing plate 8. A protective cover matched with the base in shape is arranged on the base and used for opening and closing the base. By assembling the upper clamping body capable of moving up and down and moving the clamping plates in the upper clamping body and the lower clamping body in the horizontal direction, storage of silk-screen printing plates with different length, width and thickness directions can be achieved, and the silk-screen printing plates can be comprehensively and effectively dried by further matching with an air blowing device.

Owner:KUNMING UNIV OF SCI & TECH +1

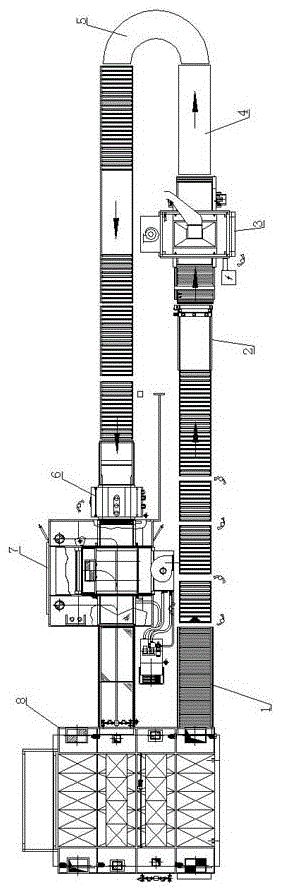

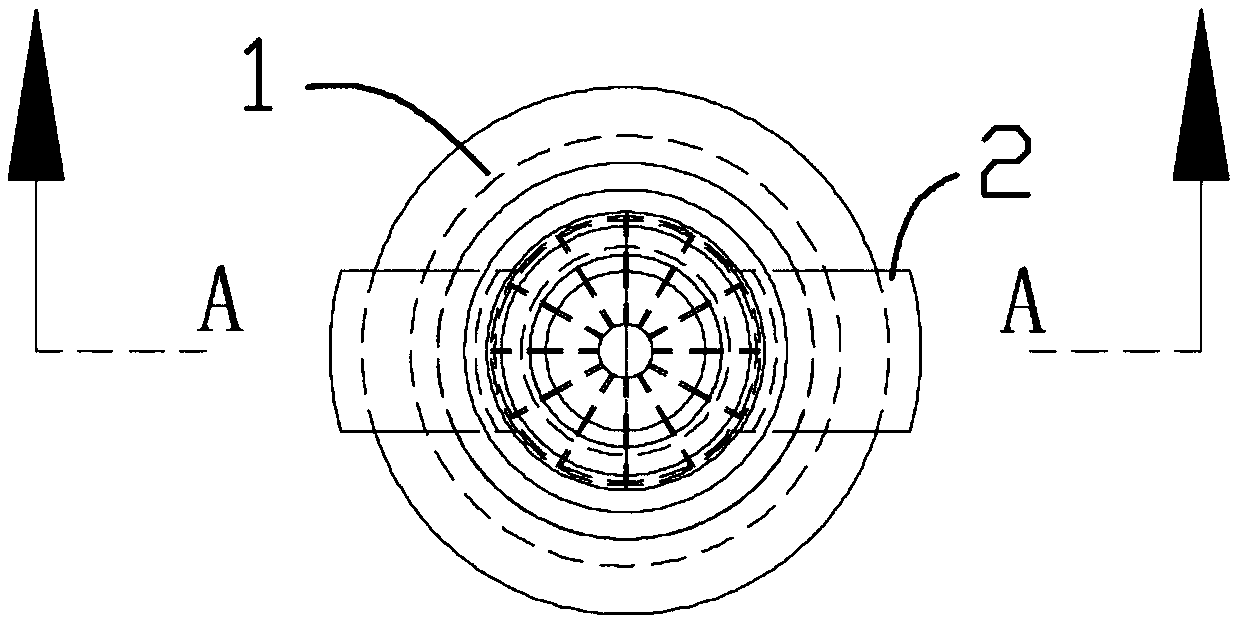

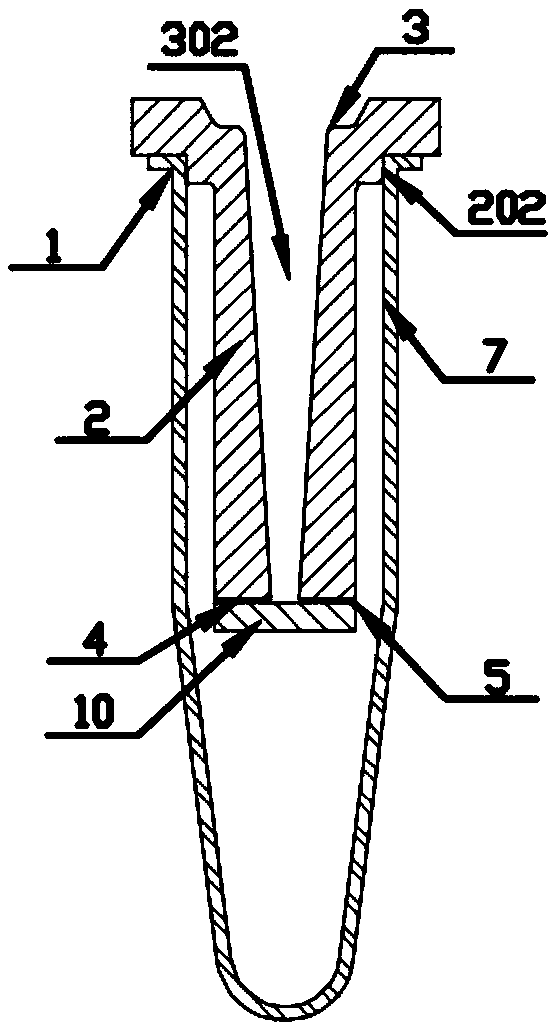

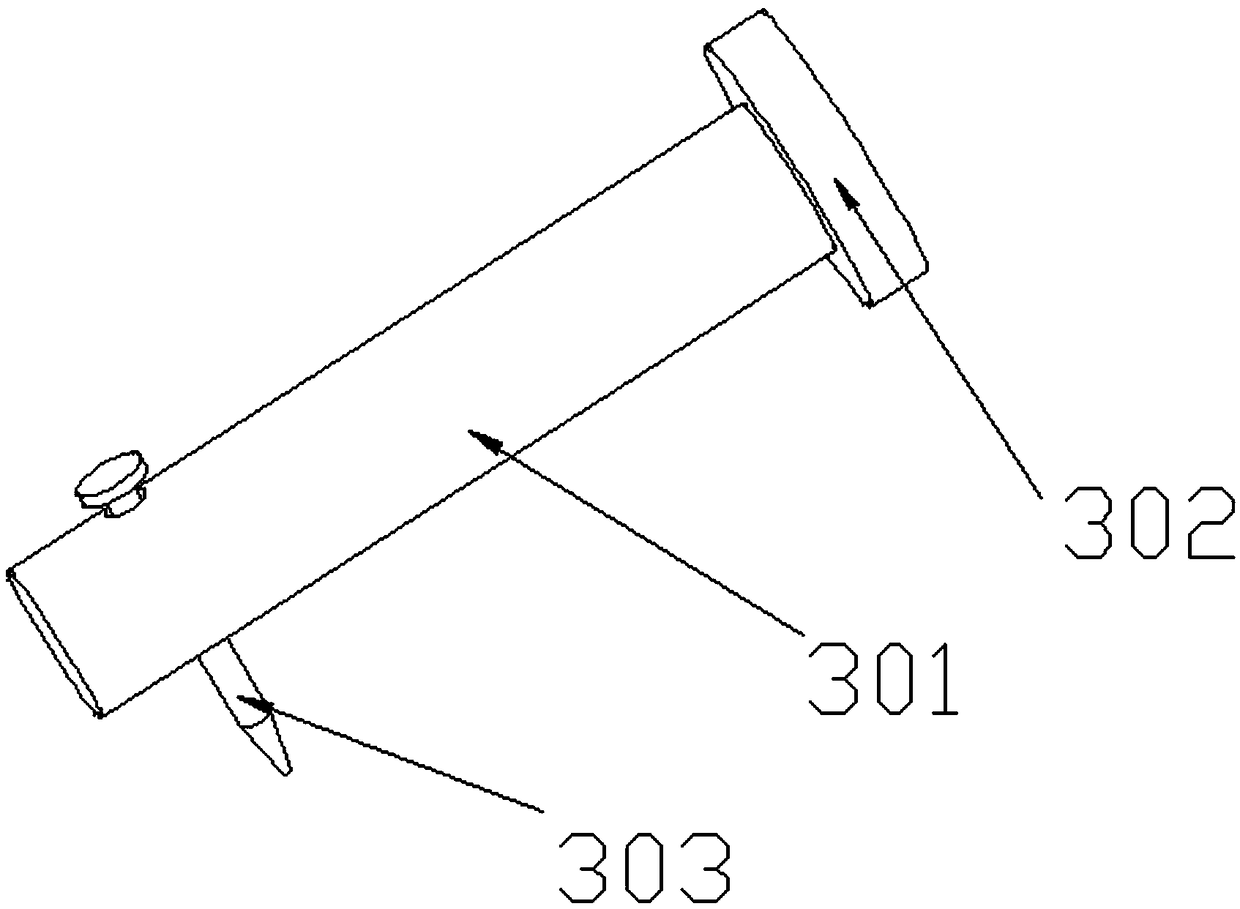

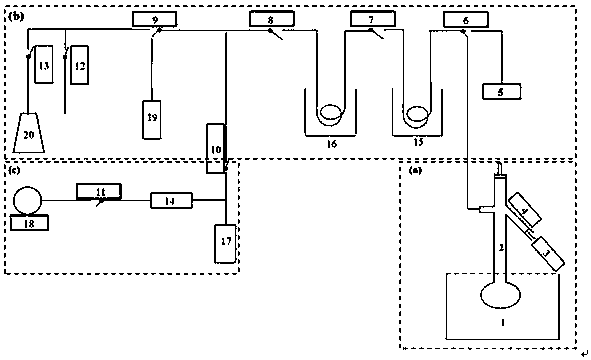

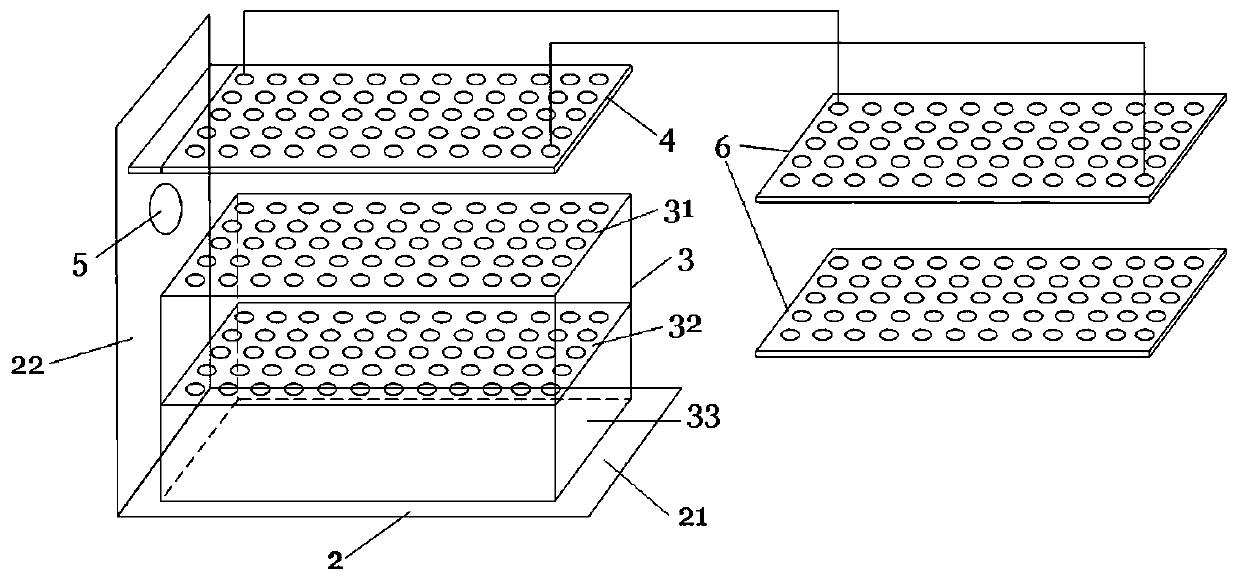

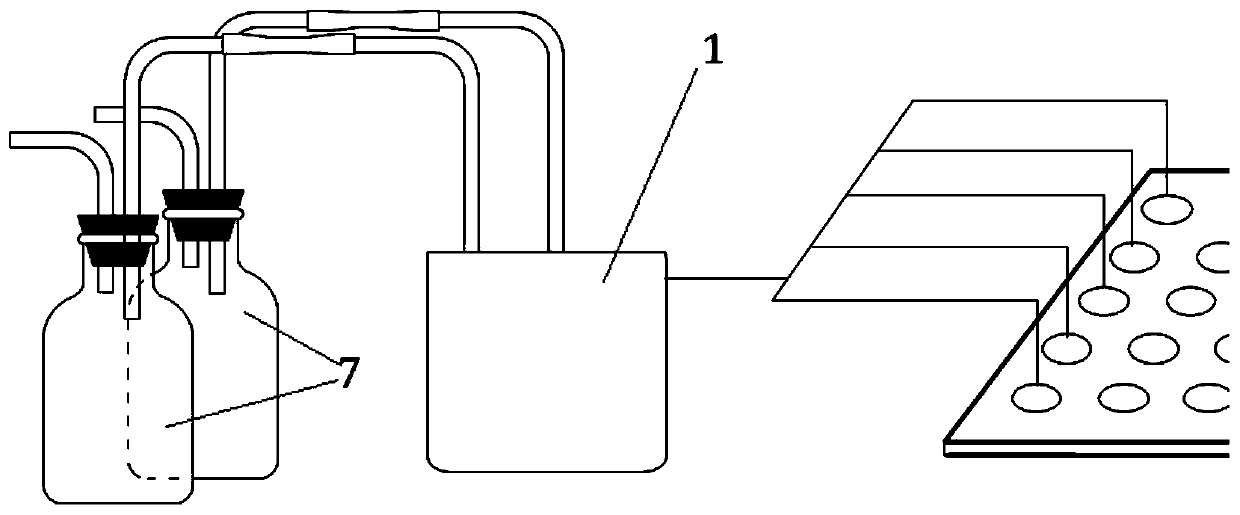

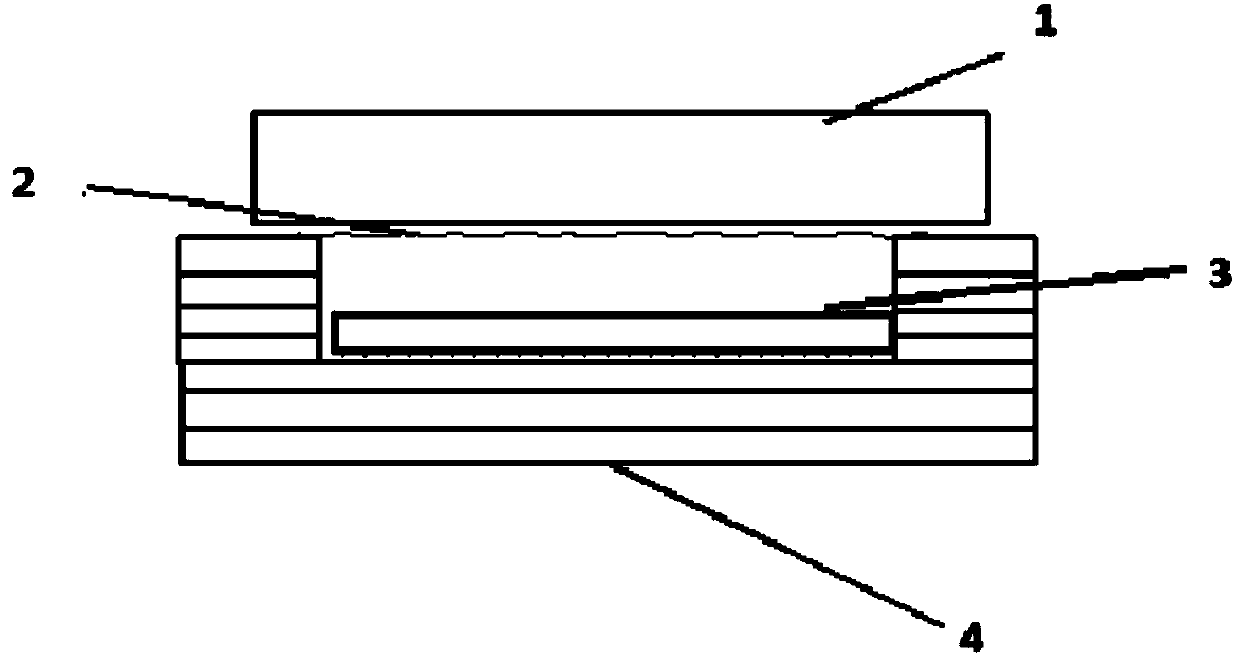

Pretreatment device for multiple samples for continuous flow analysis and application method of device

PendingCN110398606AThe pre-processing process is simpleEasy to handlePreparing sample for investigationEngineeringContinuous flow

The invention discloses an automatic sample pretreatment device for continuous flow analysis. The device comprises the following components of a support (2), an extraction pipe (a), an extraction pipeframe (3), a filter pipe (b), a filter pipe frame (4) and a lifting handle (5). The invention further discloses an application method of the device. By using the device disclosed by the invention, the sample analysis efficiency can be increased by several times.

Owner:CHINA TOBACCO YUNNAN IND

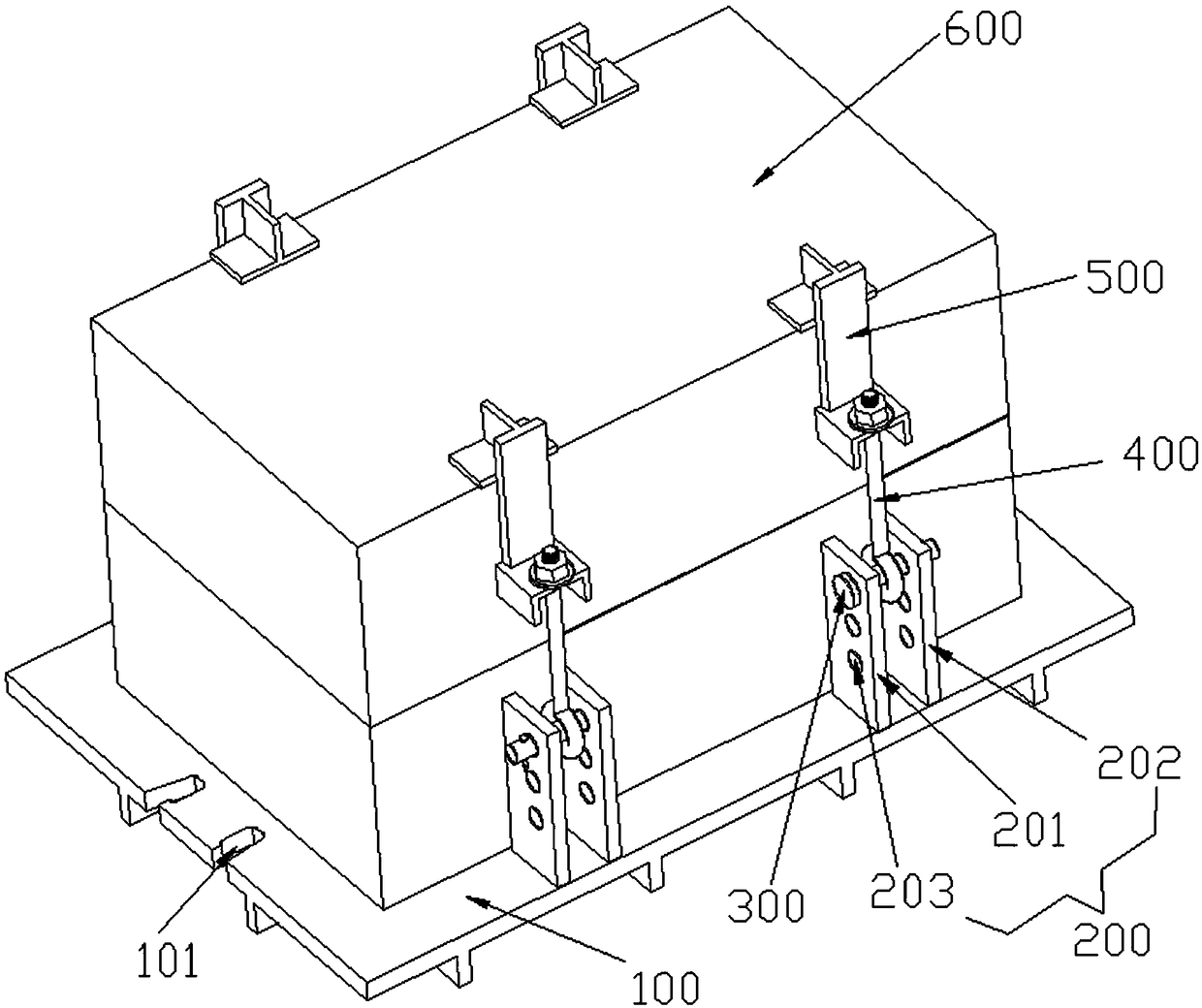

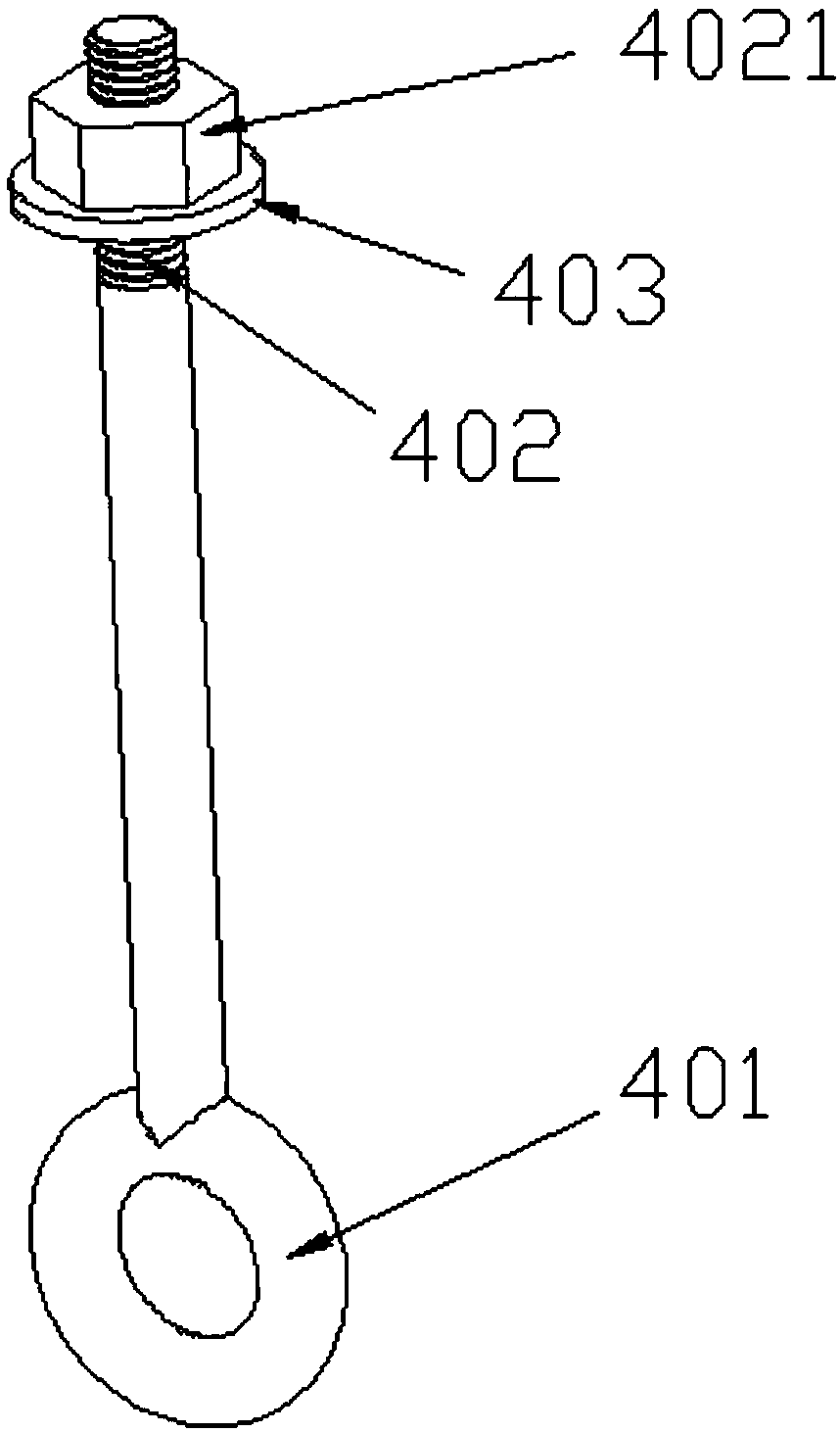

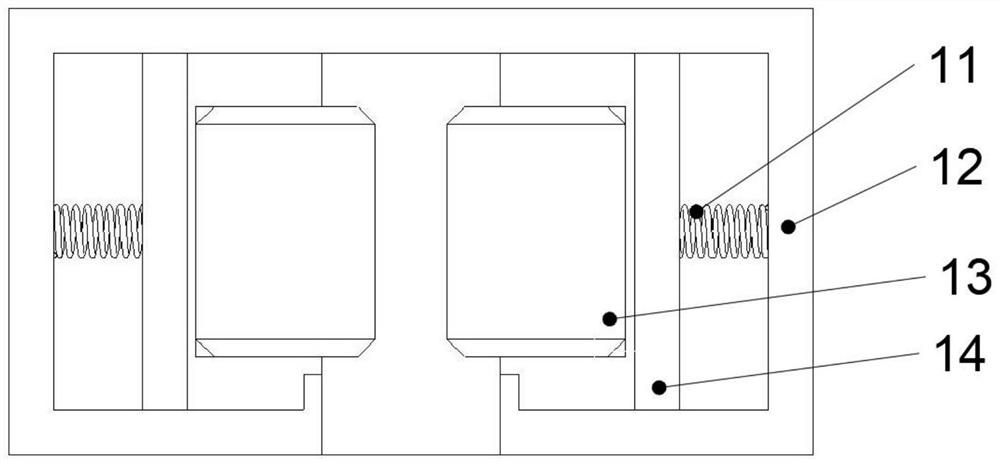

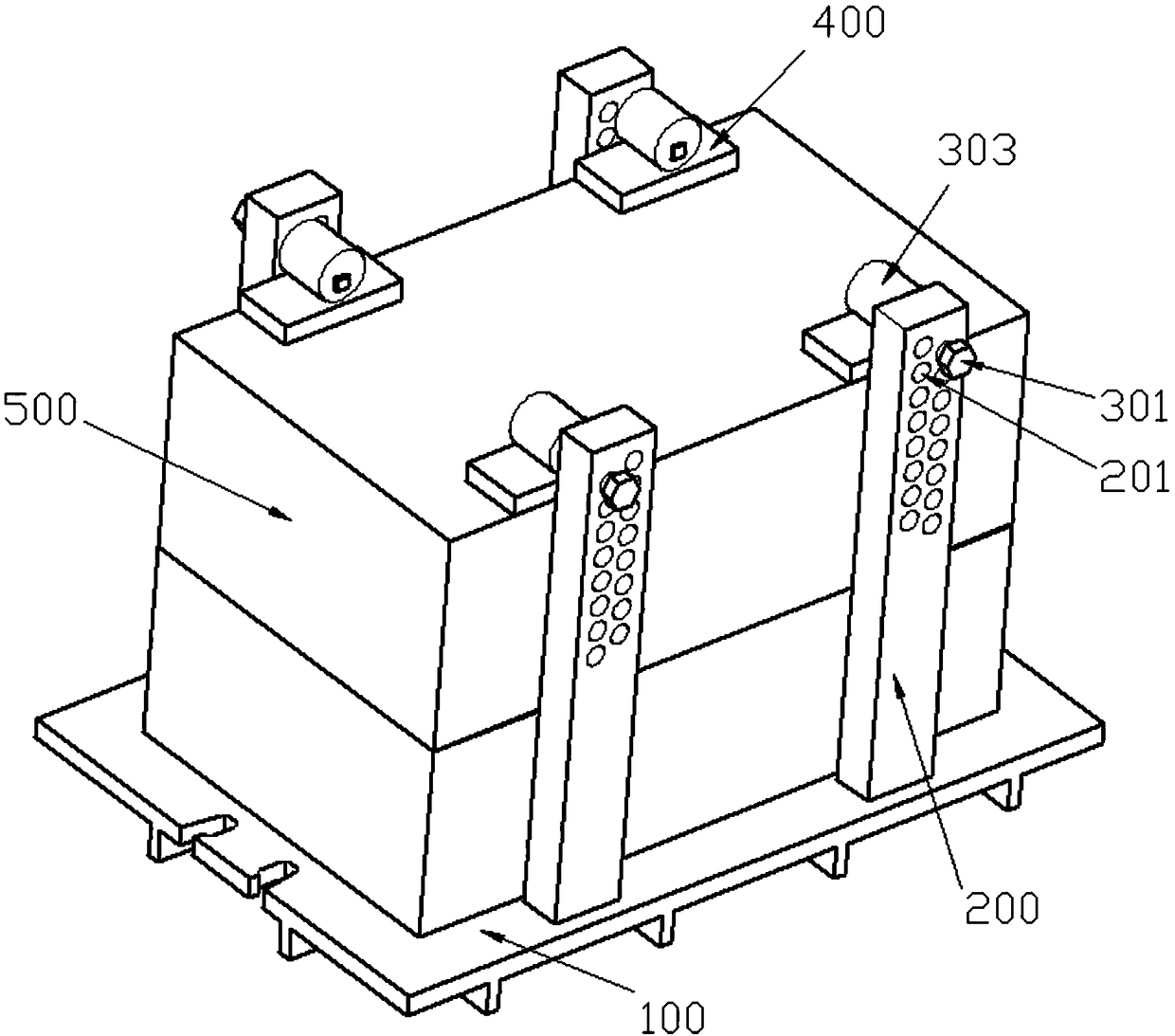

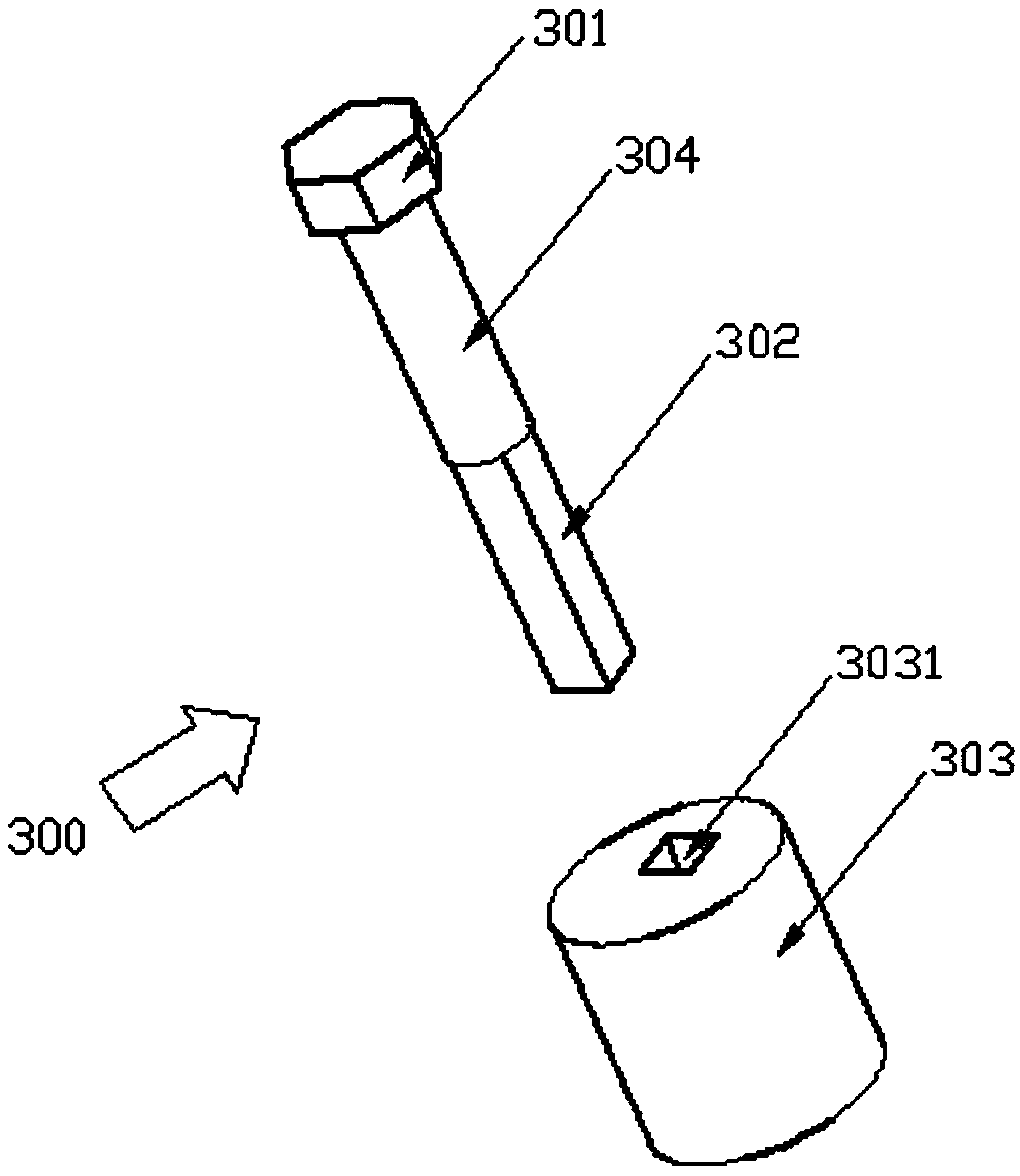

Mold core clamping device

InactiveCN109290521AGuaranteed snap-in strengthReduce transfer stepsFoundry mouldsFoundry coresIndustrial engineeringType selection

The invention relates to a mold core clamping device comprising a mold plate, fixed support seats, fixed holes and clamping-connecting mechanisms. The mold plate is a flat plate with a horizontal topface. The fixed support seats are arranged on the top face of the mold plate and are provided with at least one fixed hole. The clamping-connecting mechanisms penetrate in the fixed holes rotationally. One end of each clamping-connecting mechanism is provided with a baffle, and the other end of each clamping-connecting mechanism is provided with a clamping head, wherein a clamping cap matched withthe clamping head is fixed to the clamping head detachably and is a cylinder provided with an eccentric hole axially. The fixed support seats of the mold core clamping device are provided with the multiple fixed holes, the fixed holes are mutually staggered, type selection requirements of different-height mold cores can be met, with matching of ingenious design of the eccentric clamping caps of the clamping-connecting mechanisms, clamping-connecting requirements of different-height different-size mold core can be met, and the generality is high.

Owner:KOCEL EQUIP

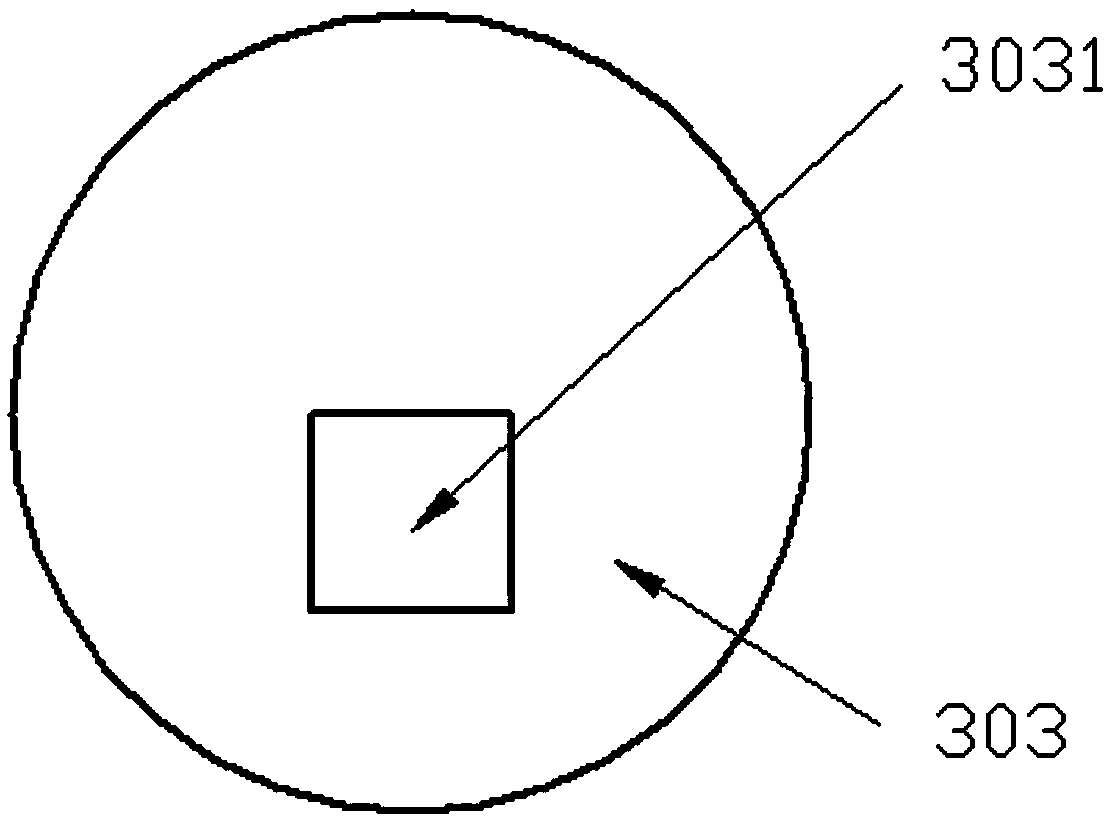

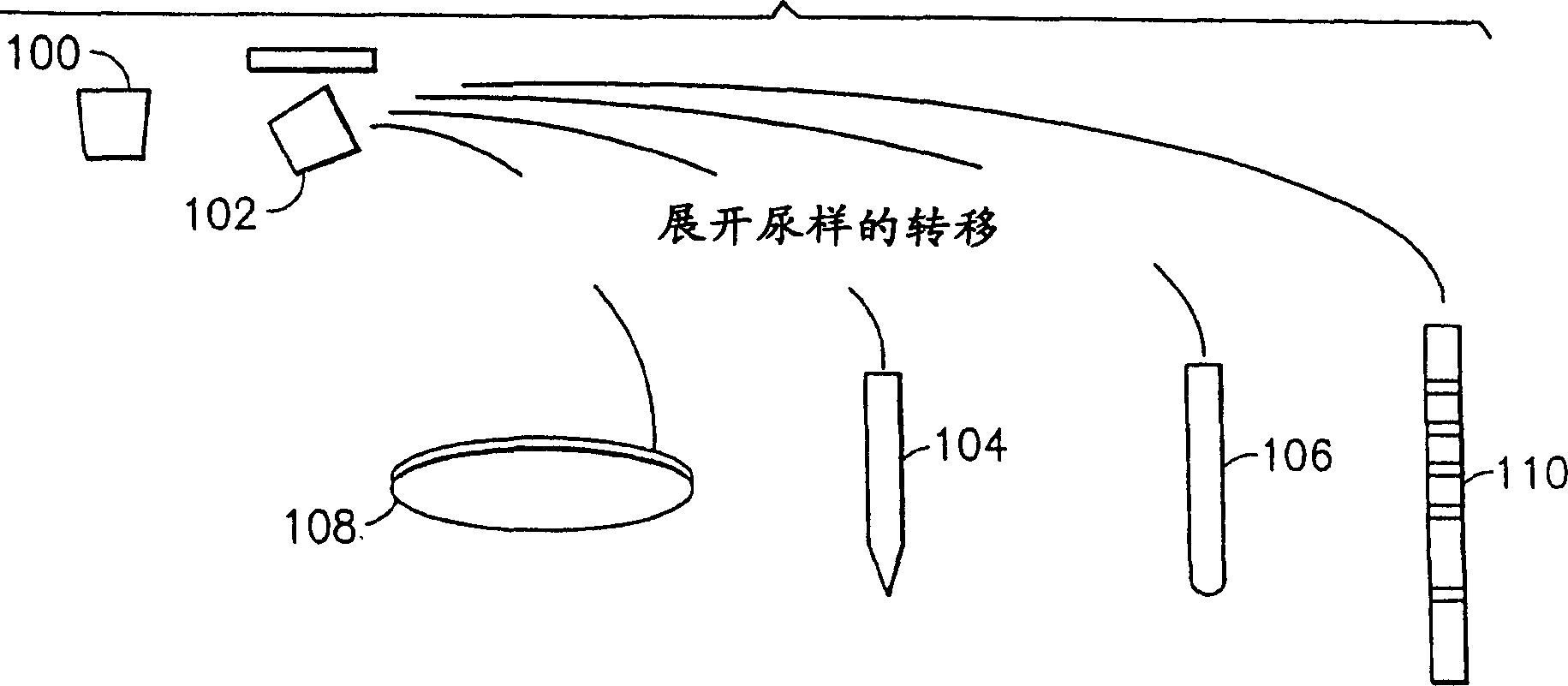

Vacuum tube and microscope inspection, chemical treatment and microbe determination method of urine precipitate

InactiveCN1384347AReduce in quantityReduce dumpingWithdrawing sample devicesPreparing sample for investigationChemical treatmentEngineering

A urine sample container assembly is provided. The assembly includes a vacuum tube and a cap for maintaining a vacuum condition in the tube and sealing the tube after a urine sample is placed therein. The tube includes an open top end engaging the shroud and a cylindrical interface extending from the open top end. A conical base extends from the lower end of the cylindrical interface to the bottom end of the tube. The fin extends outwardly from the conical base and defines a profile substantially the same as that of the round bottom tube. In this way, the tube can be used in chemical analyzers constructed for round-bottomed tubes and in centrifuges so that the sediment is retained in the conical bottom.

Owner:BECTON DICKINSON & CO

Preparation method of graphene-coated atomic force microscope probe

InactiveCN110514875AReduce rapid wearExtended service lifeScanning probe microscopySingle layer grapheneCvd graphene

The invention provides a preparation method of a graphene-coated atomic force microscope probe. The preparation method comprises the following steps of preparing a single-sided selective graphene oxide material, and preparing a single-layer graphene film on a gas-liquid interface in a self-assembly manner; placing the atomic force microscope probe to be coated below the liquid level, and enablingthe atomic force microscope probe to be at a positive potential; slowly pumping the liquid to descend the liquid level, and covering the tip of the atomic force microscope probe with the single-layergraphene; and implementing microwave treatment, so that a metal layer can effectively absorb microwave energy, and internal oxygen-containing functional groups are decomposed. According to the method,the single-layer graphene film is prepared at the gas-liquid interface in the self-assembly manner, the film can be controlled at the thickness of a monatomic layer, graphene is firmly attached to the surface of the atomic force microscope probe, coating is tight and uniform, the service life of the probe is prolonged, the preparation process is simple, used materials are easy to obtain, the requirement for equipment is low, large-scale and batch coating can be achieved, and the production efficiency is greatly improved.

Owner:YANCHENG TEACHERS UNIV

Centrifugal equipment for dacromet treatment

PendingCN109174552AReduce transfer stepsImprove dip coating effectLiquid surface applicatorsCoatingsEngineeringDip-coating

The invention discloses centrifugal equipment for dacromet treatment. The centrifugal equipment comprises a first frame, a second frame, a liquid storage box, a material storage box, a centrifugal mechanism and a lifting mechanism, wherein the material storage box is of a mesh structure; the liquid storage box is connected with the lifting mechanism; the material storage box is connected with thecentrifugal mechanism; the liquid storage box is arranged inside the first frame; the material storage box is arranged inside the liquid storage box; the centrifugal mechanism is arranged inside the second frame; and the first frame is welded on the top of the second frame. According to the design of the lifting mechanism and the centrifugal mechanism, after workpiece dip-coating is completed, dacromet coating liquid is separated from the workpiece, and the workpiece is subjected to centrifugal treatment by the centrifugal mechanism. The centrifugal equipment disclosed by the invention is simple in structure and convenient to use, the workpiece transfer step is saved, the working efficiency is improved, the rotary column can rotate back and forth, and the dip-coating effect of the workpiece is improved.

Owner:芜湖聚鑫涂装有限公司

Avermectin extraction technology and apparatus

ActiveCN101362785BReduce dosageShorten the production cycleSugar derivativesArthropodicidesAlcoholAvermectin

The invention relates to an extraction technique for avermectin and a device thereof. Mycelia of the avermectin after being dried is put into a leaching column and is soaked statically in alcohol for 1 hour to 2 hours firstly; then methanol or ethanol is continuously added from the top end of the leaching column for dynamic elution; leaching liquid is continuously collected from a liquid outlet at the lower part of the leaching column; when avermectin residues in the effluent liquid after elution is less than 100u / mg, the adding of alcohol is stopped; nitrogen is pumped from the top end of the leaching column to extrude all rest leaching liquid in the leaching column; steam enters from a sieve plate of the leaching column; by connecting a condenser with a gas collection opening at the upper part of the leaching column, the recycling and utilization of the methanol or the ethanol are carried out. The dynamic elution and a closed leaching and filtering system of the technique of the invention overcome the defects of a plate filtration production technique, can reduce the leakage and use amount of menstruum and can shorten production period and lower production cost.

Owner:山东齐发药业有限公司

Filling system for preassembled module type flusher

InactiveCN113942672ARealize the collectionReduce occupancyConveyorsPackaging automatic controlTubular linear motorElectric machine

The invention discloses a filling system for a preassembled module type flusher, and belongs to the technical field of flusher processing. The system comprises a feeding conveying belt and a discharging conveying belt, wherein the feeding conveying belt is positioned below the discharging conveying belt, a vertically arranged tubular linear motor is arranged beside the feeding conveying belt and the discharging conveying belt, a bottle clamping mechanism is connected to a rotor of the tubular linear motor, bottle limiting portions are arranged on the feeding conveying belt in an array mode, and slotted holes are formed in the positions, between the bottle limiting portions, of the feeding conveying belt; an interval pushing device is arranged above one side of the feeding conveying belt, the interval pushing device comprises a rotating disc, and a rotating shaft of the rotating disc is connected to a swing rod pushing mechanism to match the slotted holes to push the feeding conveying belt at intervals; a liquid storage tank is arranged above the feeding conveying belt, one end of the liquid storage tank is connected to a liquid inlet pipe, the other end thereof is provided with a liquid outlet pipe, and a liquid inlet valve and a liquid outlet valve are arranged on the liquid inlet pipe and the liquid outlet pipe respectively; and the bottle clamping mechanism comprises bottle clamping members which are symmetrically arranged.

Owner:岳阳职业技术学院

Equipment for manufacturing knitwear raw materials by rotary centrifugal force

InactiveCN111691016AReduced spinning transfer stepsReduce transfer stepsFibre cleaning/opening machinesYarnSpinning

The invention relates to the technical field of knitwear raw material silk yarn manufacturing, and discloses equipment for manufacturing knitwear raw materials by rotary centrifugal force. The equipment comprises a shell, a gear is movably connected into the shell, an observation sleeve is movably connected to the surface of the gear, a guiding plate is fixedly connected to the surface of the observation sleeve, a compression spring is movably connected into the guiding plate, a sliding plate is movably connected to the end, away from the guiding plate, of the compression spring, a push rod ismovably connected to the side, away from the compression spring, of the sliding plate, a piston is movably connected to the upper end of the push rod, a carding plate is fixedly connected to the end,away from the observation sleeve, of the guiding plate, a roller rod is movably connected to the end, away from a spring rod, of a lifting rod, and a knocking rod is movably connected to the joint ofthe roller rod and the lifting rod. The centrifugal force generated by rotating of the observation sleeve is gradually greater than the elastic force of the spring rod, rollers rotate to enable shortfiber to be in touch with a winding rod, and thus the effects that reducing the silk yarn spinning and transferring steps and completing spinning and cleaning are achieved.

Owner:海宁王骏新材料有限公司

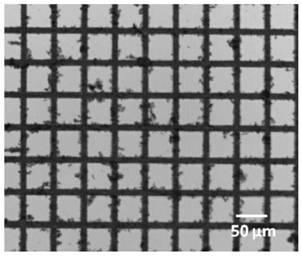

Preparation method of carbon nanometer film/nano-micrometer network composite film

InactiveCN109536917AShorten the timeControl reaction rateChemical vapor deposition coatingComposite filmMicrometer

The invention provides preparation method of a carbon nanometer film / a nano-micrometer network composite film, and relates to technical field of nanometer materials and preparation of the nanometer materials. A carbon source is subjected to chemical gaseous phase pyrolysis, holes of a nano-micrometer network are filled with the carbon nanometer film grown at the low temperature, and the surface ofthe nano-micrometer network is not covered, and the composite film is formed. The holes of the nano-micrometer network on a catalyst substrate are filled with the carbon nanometer film grown at the low temperature, and the self-supporting composite film can be formed through separation. The preparation method of the carbon nanometer film / the nano-micrometer network composite film comprises a carbon source and nano-micrometer network in-situ contact method, a carbon source and nano-micrometer network in-situ non-contact method and a carbon source and nano-micrometer network non-in-situ low-temperature transmission method. According to the preparation method, production steps are simplified, the production cost is greatly lowered, and the preparation method has industrialization prospects.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com