L-shaped connecting member for solar cell sheet and use thereof

A technology of solar cells and cells, applied in electrical components, circuits, photovoltaic power generation, etc., can solve problems such as tearing, virtual connection between conductive connectors and cells, and increased probability of hidden cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

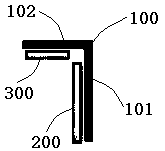

[0103] Such as figure 1 As shown, the present invention provides an L-shaped connector for solar cells, including an L-shaped conductive substrate 100, and the L-shaped conductive substrate 100 includes a first side extending in the same direction for abutting against the side of the cell 101, and a second side 102 for abutting against the front (or front electrode) or back (or back electrode) of the cell; the first side 101 and the second side 102 are integrally connected to form an L-shape;

[0104] The inner surface of the first side 101 is covered with insulating glue 200;

[0105] The inner surface of the second side 102 is covered with solder 300 or conductive glue 300 .

[0106] Preferably, the insulating adhesive 200 is acrylic pressure sensitive adhesive, epoxy adhesive, silica gel, acrylic resin, hot melt adhesive, silicone resin, polyurethane, phenolic resin, polyamide resin, polyimide resin or polycarbonate.

[0107] The L-shaped connector of the present inventio...

Embodiment 2

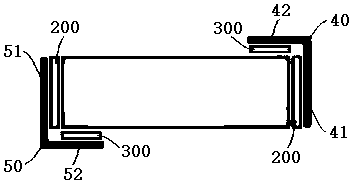

[0109] Such as figure 2 As shown, the present invention provides a solar battery sheet, which includes: a front surface, a back surface, and a pair of opposite sides; the battery sheet is also provided with a pair of L-shaped connectors, and the pair of L-shaped connectors is used to implement The L-shaped connector provided in Example 1;

[0110] The above-mentioned pair of sides includes a first side and a second side;

[0111] The pair of L-shaped connectors includes a first L-shaped connector 40 and a second L-shaped connector 50;

[0112] The inner surface of the first side 41 on the first L-shaped connector 40 is in contact with the first side of the battery sheet, and the inner surface of the first side 41 is fixed to the first side of the battery sheet by the insulating glue 200 covered by itself. catch;

[0113] The inner surface of the second side 42 on the first L-shaped connector 40 is in contact with the front electrode of the cell (the front electrode is not ...

Embodiment 3

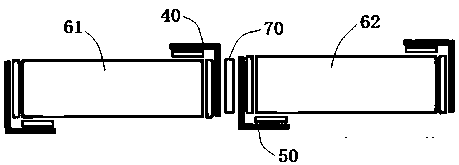

[0121] Such as image 3 As shown, instead of using conductive connectors (such as welding wire, welding strip, conductive tape, etc.), only using externally coated conductive glue 70, and using the battery sheets provided in Example 2 to tile and connect in series to prepare battery strings is as follows:

[0122] A plurality of battery slices are tiled sequentially along a certain arrangement direction, the front of each battery slice is set upward, the second side of the latter battery slice 62 is opposite to the first side of the previous battery slice 61, and the latter battery slice The outer surface of the first side of the second L-shaped connector 50 on 62 is bonded to the outer surface of the first side of the first L-shaped connector 40 on the previous cell 61 through the externally coated conductive glue 70 .

[0123] Apparently, the fronts of the battery slices are arranged facing downwards, and can also be connected in series accordingly, so details will not be re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com