Facer beam barrier system

a technology of facer beams and barriers, applied in the field of facer beam barrier systems, can solve the problems of bowdens system not teaching a method of ease and efficiency for collateral extension in a vertical direction, bowdens and chapmans both lack the ability to remove plywood modules, and the barrier installation process is not complete. the effect of man-hours and dramatic reduction of variable costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The description provided herein explains the manufacture, assembly, disassembly and storage of the components of the Facer Beam Barrier System. Its versatile nature in meeting barrier requirements will be obvious to those schooled in the construction and use of barriers. As shown in the drawings like numerals represent like parts throughout the various views and the following description will be clear with reference to the drawing figures and views as numbered in the description.

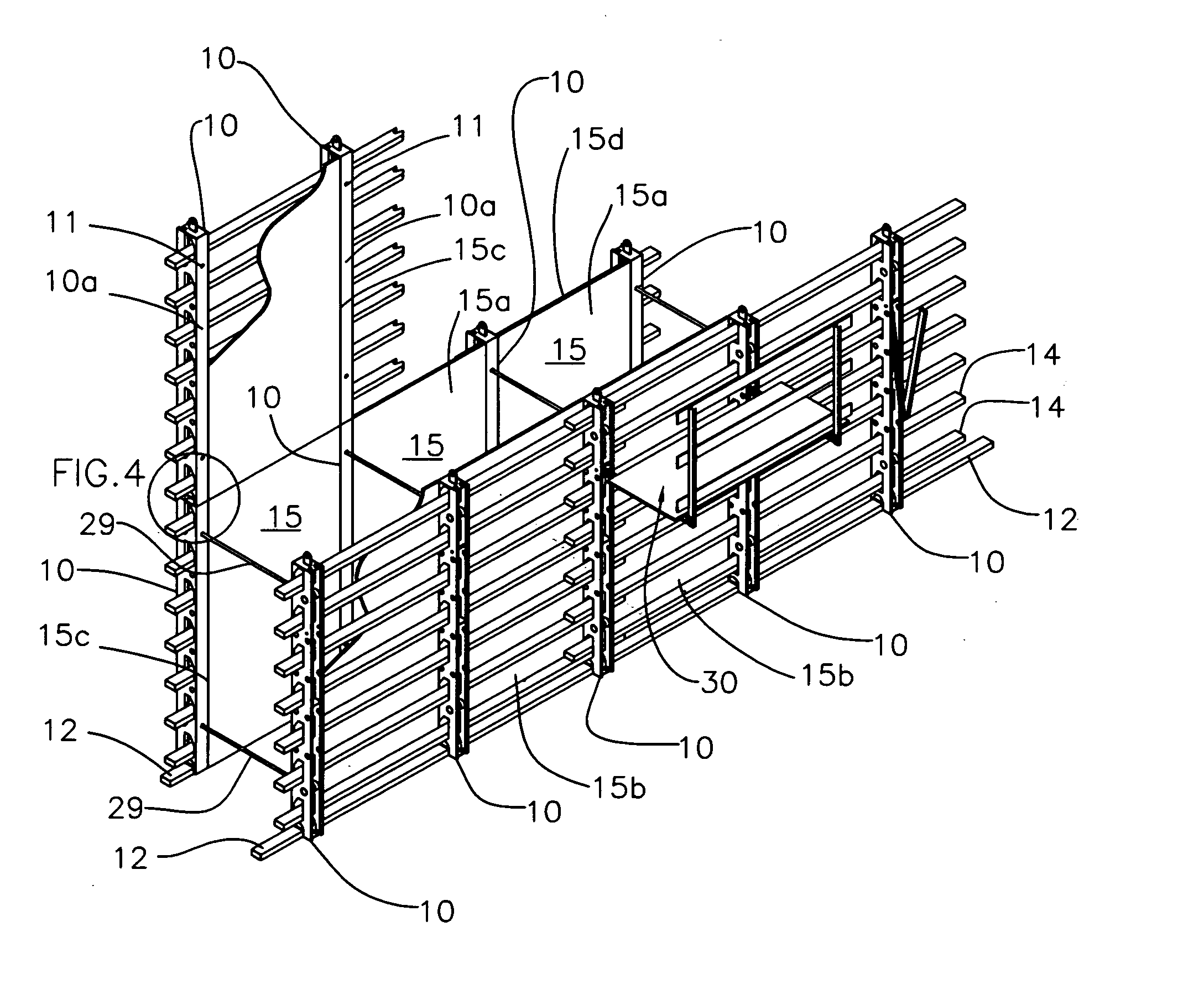

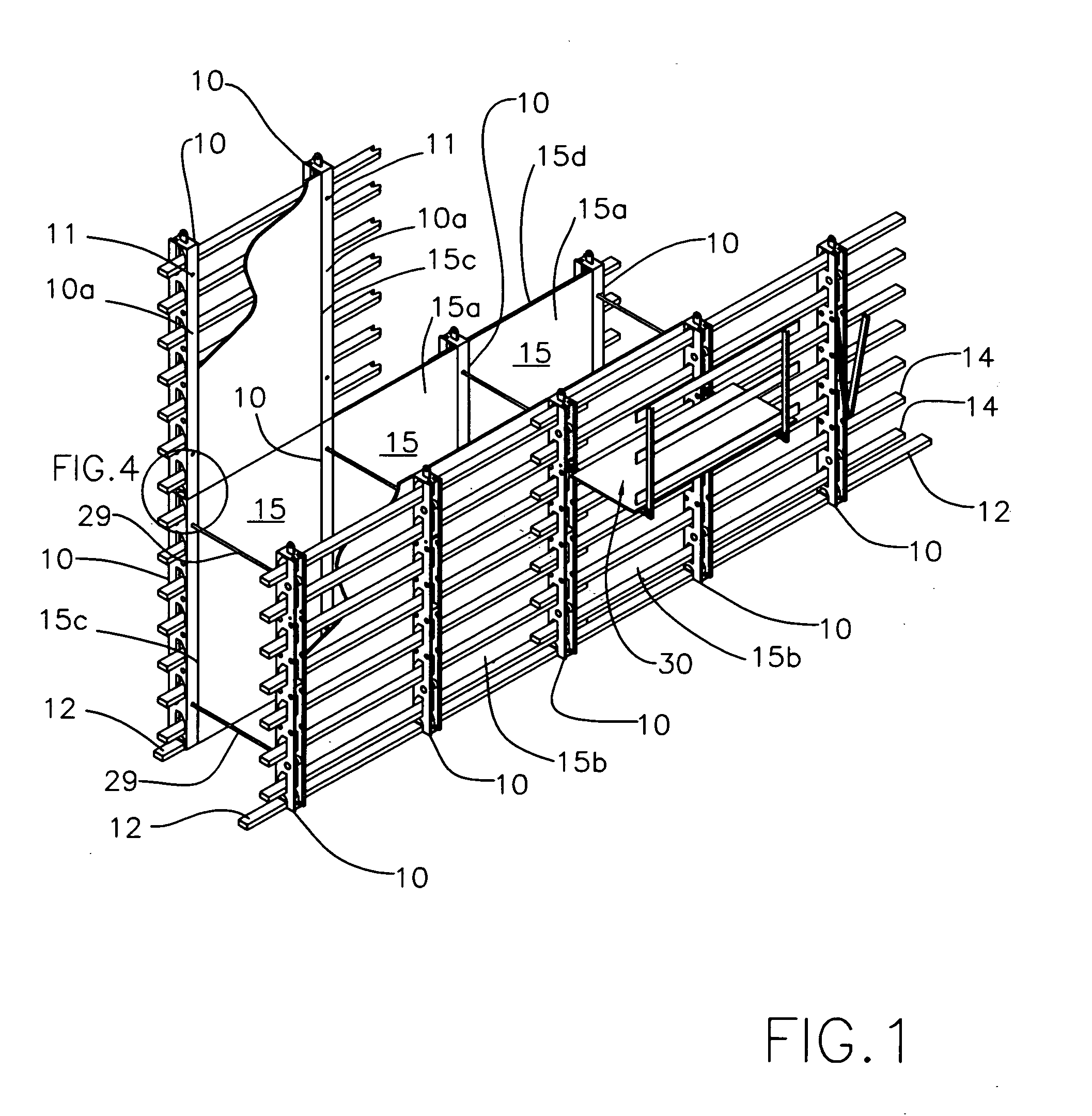

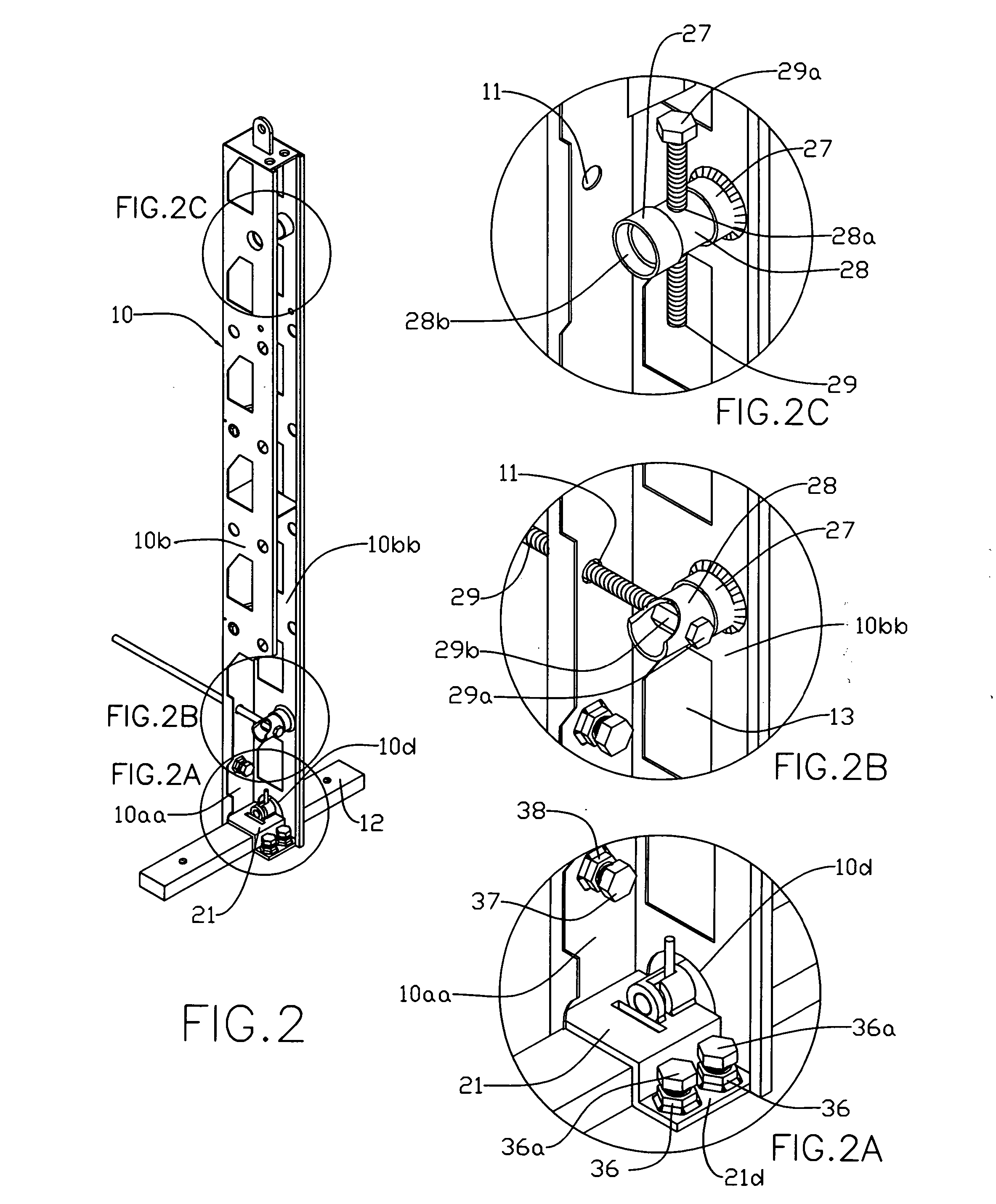

[0076]FIG. 1 displays erected barriers used as concrete formwork and further displays a plurality of identical, elongated, multi-functional, super-ordinate, opened back box type ┌┐-facer beams 10 (FIGS. 1 and 2) arranged in parallel segments, with side webs 10b (FIG. 2) of box beams 10 generally wider than the face 10a (FIG. 1) and the open back of box beams 10, webs 10b are shaped by bending 90 degrees back and away from face 10a, webs 10b also have a deformed return lip 10c (FIG. 3) located at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com