Truss type garbage compression station

A garbage compression station and garbage compressor technology, applied in the direction of presses, manufacturing tools, etc., can solve the problem of high cost of compressed garbage bins, garbage compressors cannot use multiple garbage bins, garbage compressors and garbage bins cannot be separated, etc. problems, to achieve the effect of reducing waste disposal costs, low cost, and reduced transshipment steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

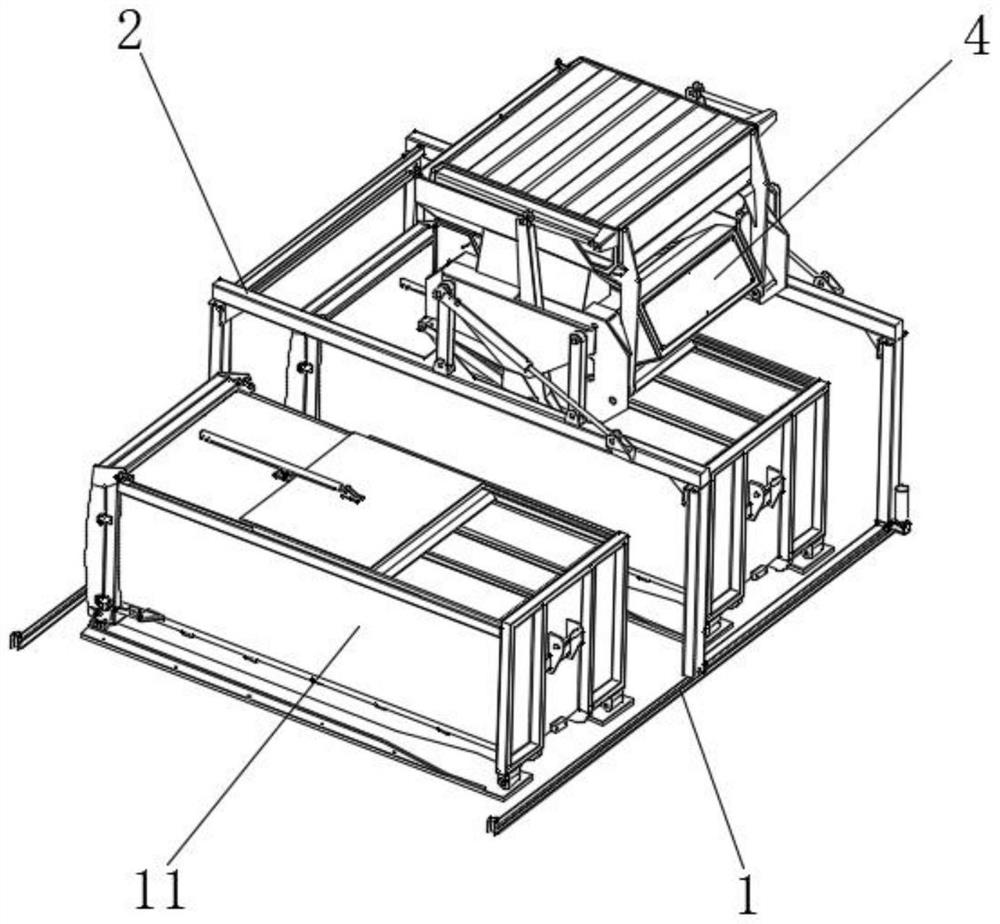

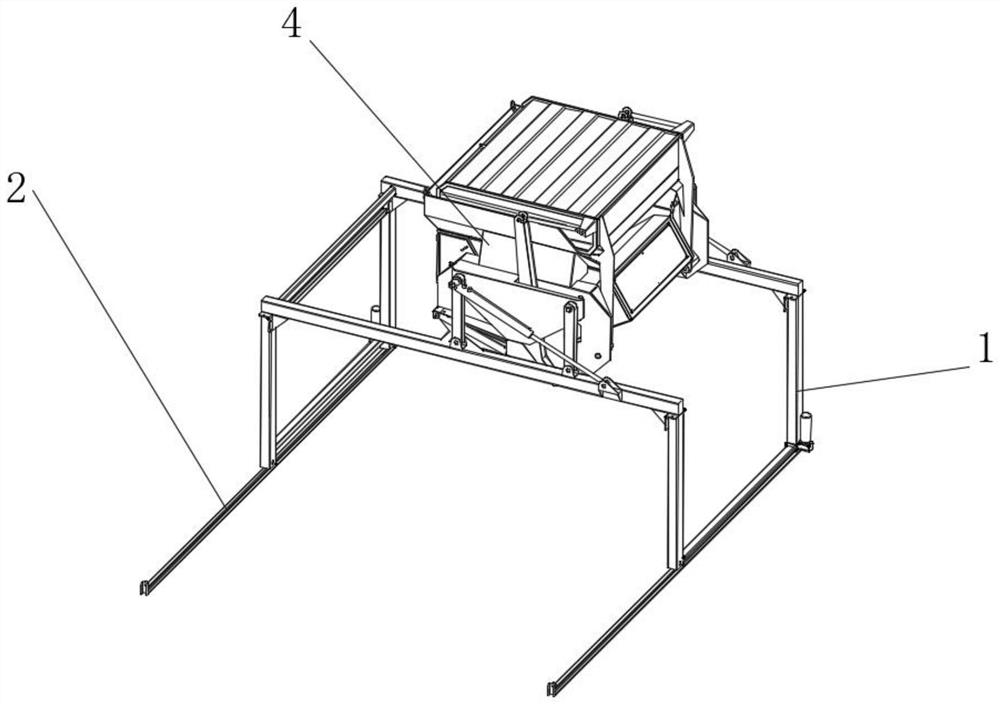

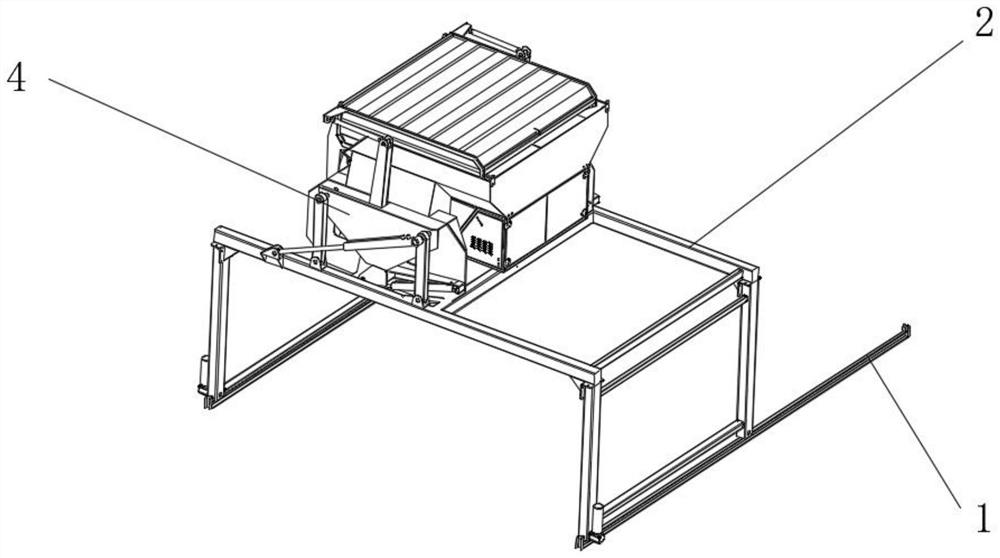

[0036] Such as figure 1 , 2 As shown in and 3, the device includes two parallel guide rails 1 fixed on the ground, two mobile trusses 2 installed on the two parallel guide rails 1, and a garbage compressor 4 installed on the mobile truss 2, and the mobile truss 2 is an upside-down "U" shape, and at least one reinforcing beam is arranged between two moving trusses 2, and the reinforcing beam is located on the other side of the loading direction of the garbage compressor 4, and the moving truss 2 is provided at the bottom with the guide rail 1 Cooperating driving wheel, the driving wheel is driven by a hydraulic motor or an electric motor, the driving wheel is a chute or a rack, and the guide rail 1 is correspondingly provided with a chute or a rack, preferably the guide rail 1 is a raised slide rail, and the driving wheel is The grooved wheel that cooperates with the guide rail 1, the two sides of the guide rail 1 are provided with bars to prevent the driving wheel from fallin...

Embodiment 2

[0042] The difference between Embodiment 2 and Embodiment 1 is that the guide rail 1 is installed on the wall or the roof, the guide rail 1 is installed on the wall, beam or roof through a plurality of fixed brackets, and the driving wheels on the truss 2 are suspended on the guide rail 1 , the driving wheel is hung on the inside or outside of the two guide rails, and a fixed beam is provided on the moving truss 2 to fix the distance between the driving wheels, making it easier to hang the driving wheels on the guide rails, and it can also be used in the movement of the driving wheels Barriers are set on both sides of the direction, which are used to guide and limit the movement of the drive wheel. When the guide rail 1 is hung on the roof and the wall, the guide rail 1 is fixed by a plurality of vertical beams, and a fixed base and reinforcement ribs are provided at the fixed connection between the vertical beam and the roof. , increase the triangular oblique tension rod to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com