Patents

Literature

121results about How to "Increase the station" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

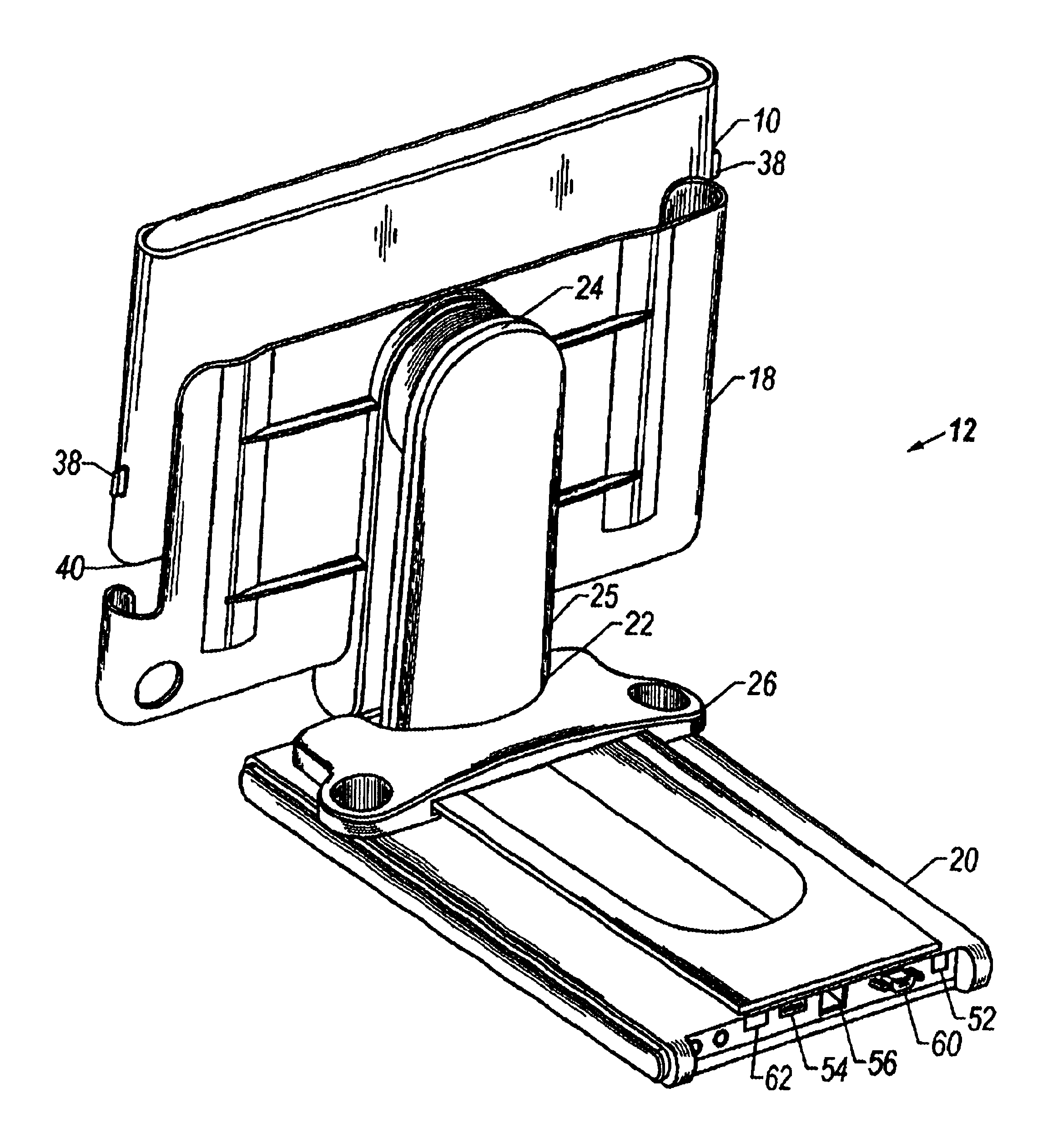

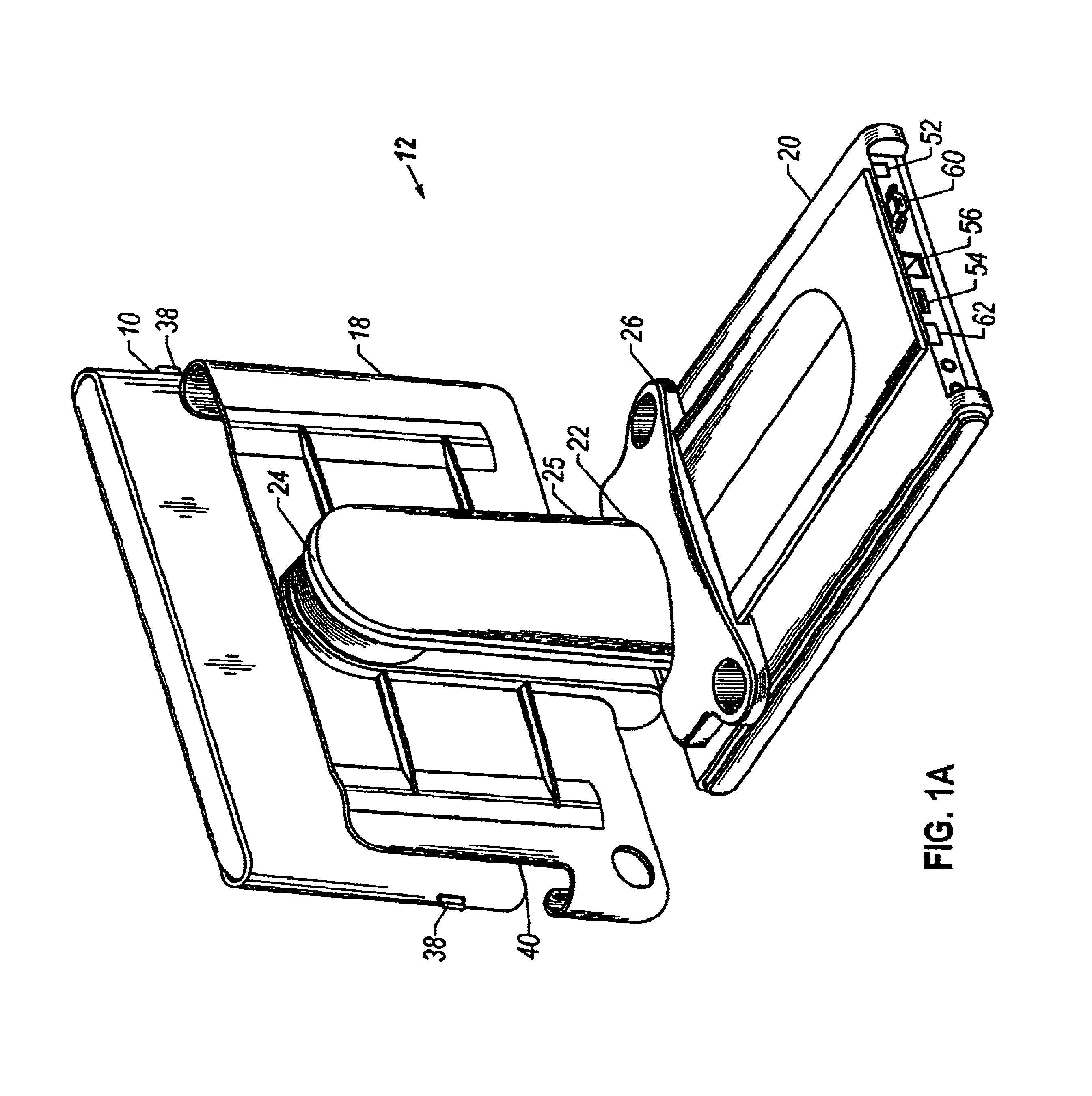

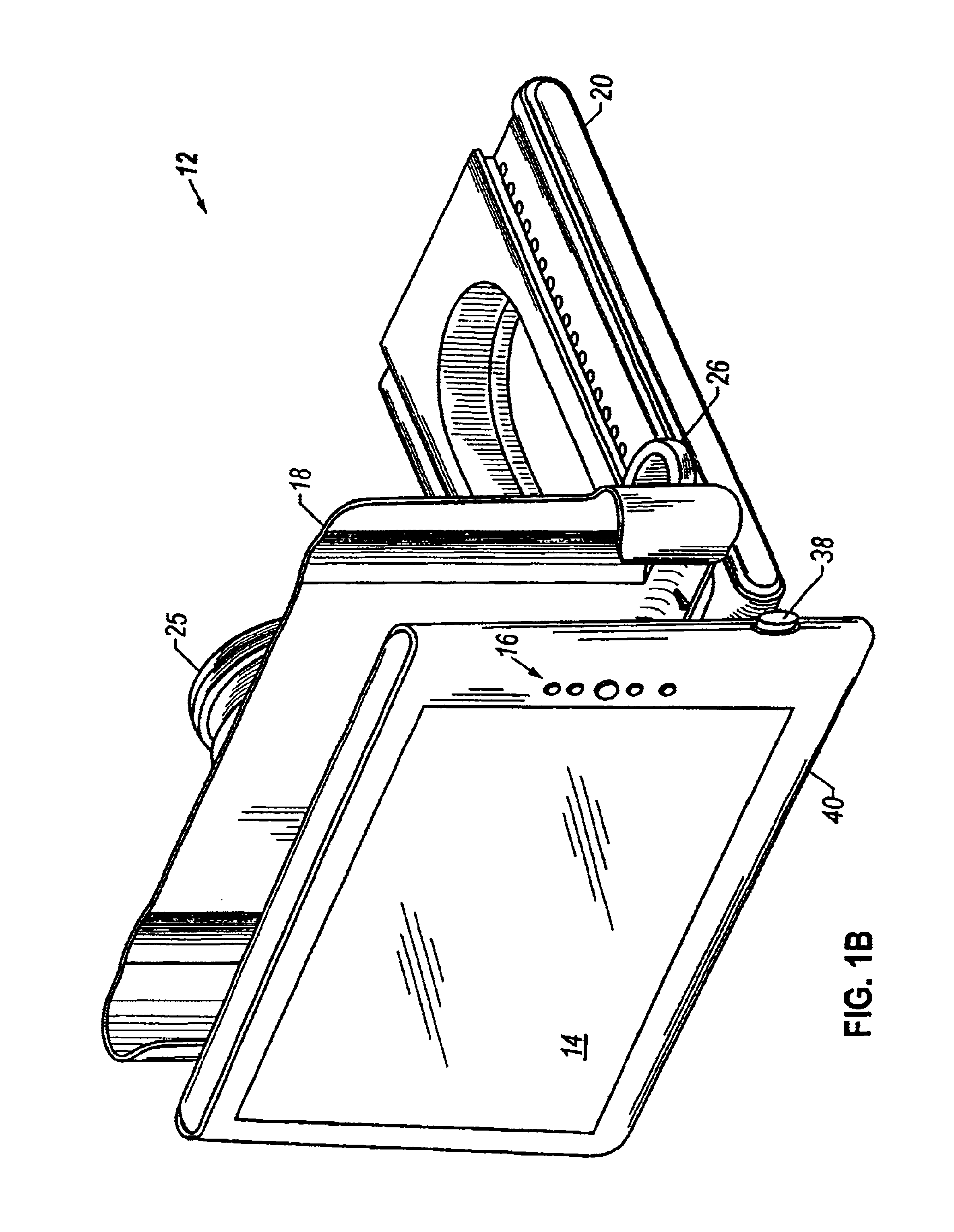

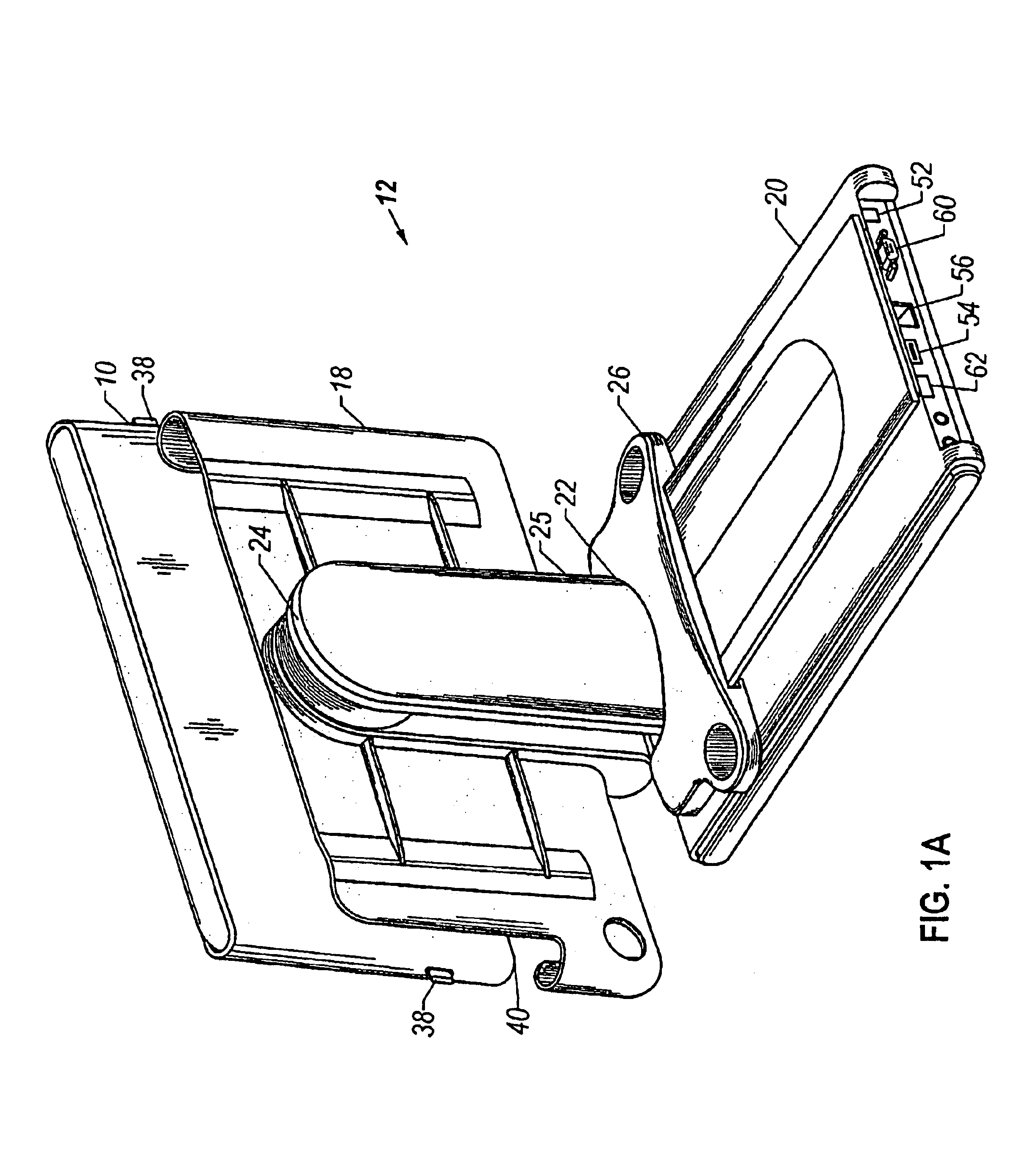

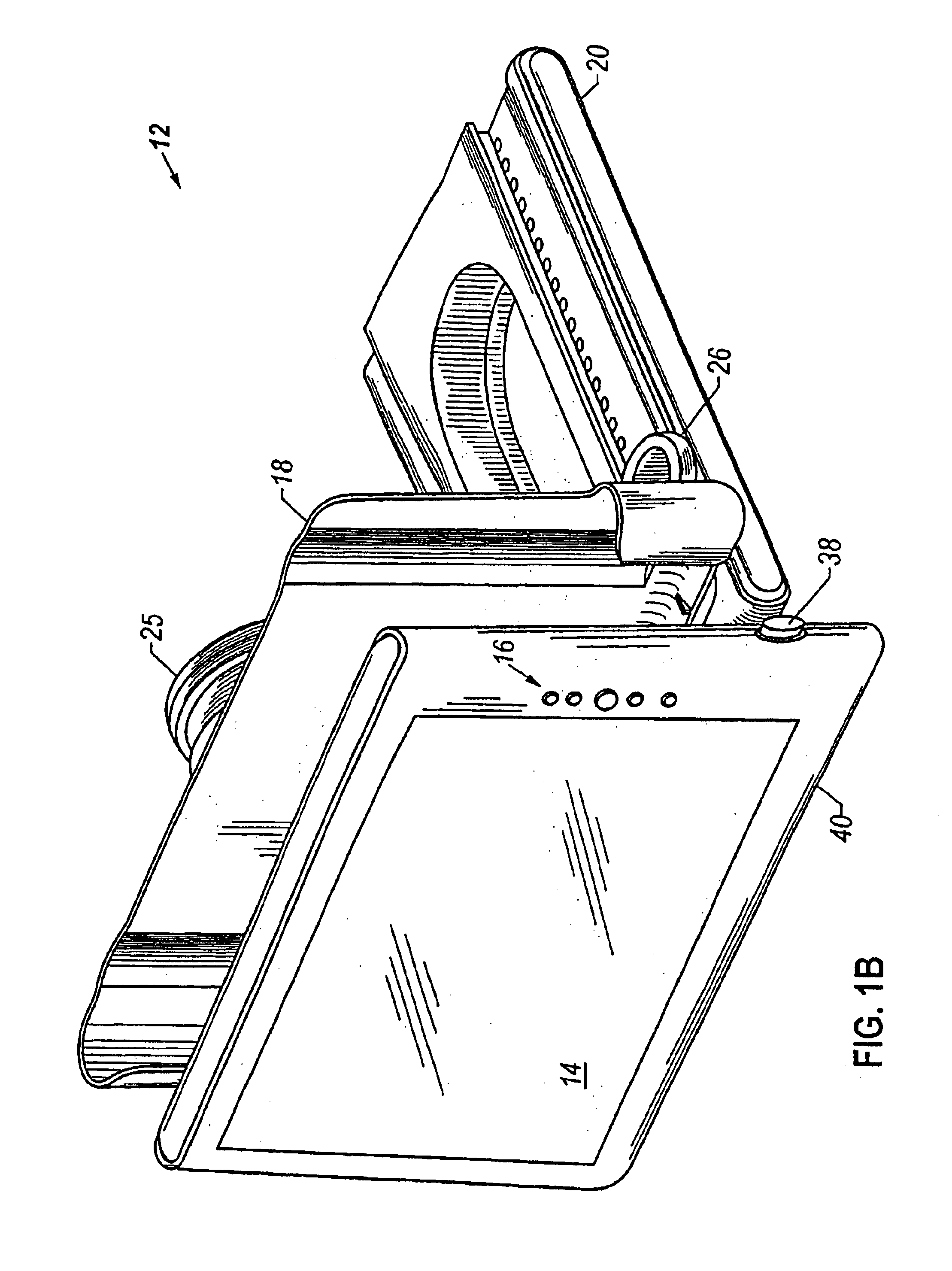

Tablet computing device with three-dimensional docking support

InactiveUS6856506B2Improved expansion baseImproved docking stationInput/output for user-computer interactionCoupling device connectionsTablet computerData connection

The present invention provides a tablet computer and a docking station assembly. This docking station comprises a docking assembly for positioning with three degrees of freedom and having a data connector for mechanically supporting and interfacing with the tablet computer. A support member couples the docking assembly to an expansion base. The base includes a number of ports for interfacing with a variety of peripheral devices or power supplies. These varieties of ports mount to a printed circuit board contained within the expansion base. A flexible printed circuit (FPC) combines the signal pathways for the variety of ports, allowing the signal pathways to travel from the printed circuit board and to the data connector. The tablet computing device has a plurality of contact or touch points positioned on the right and left edges of the tablet to facilitate aligning the tablet to the docking assembly in either a landscape or portrait mode.

Owner:ZEBRA TECH CORP

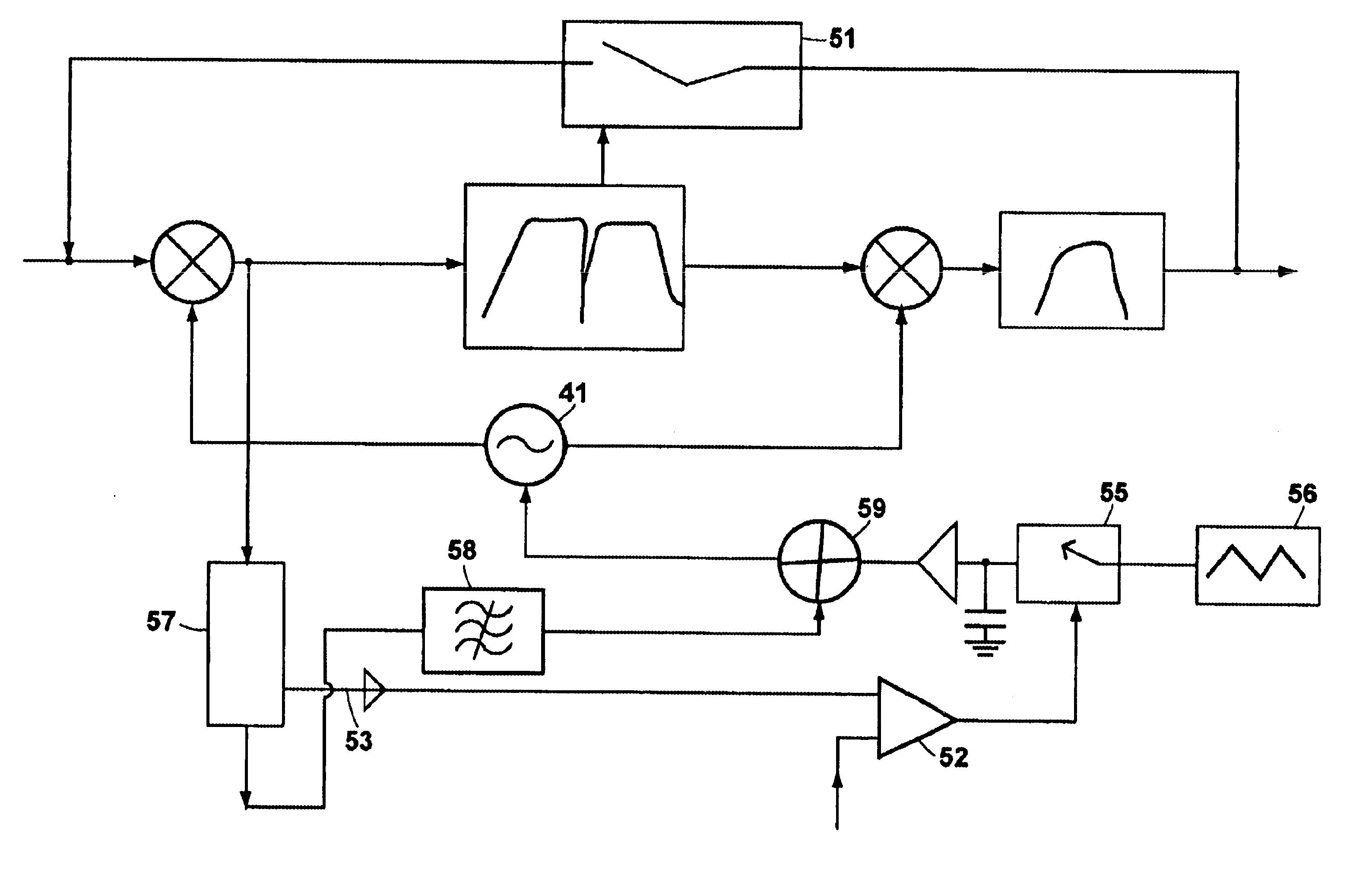

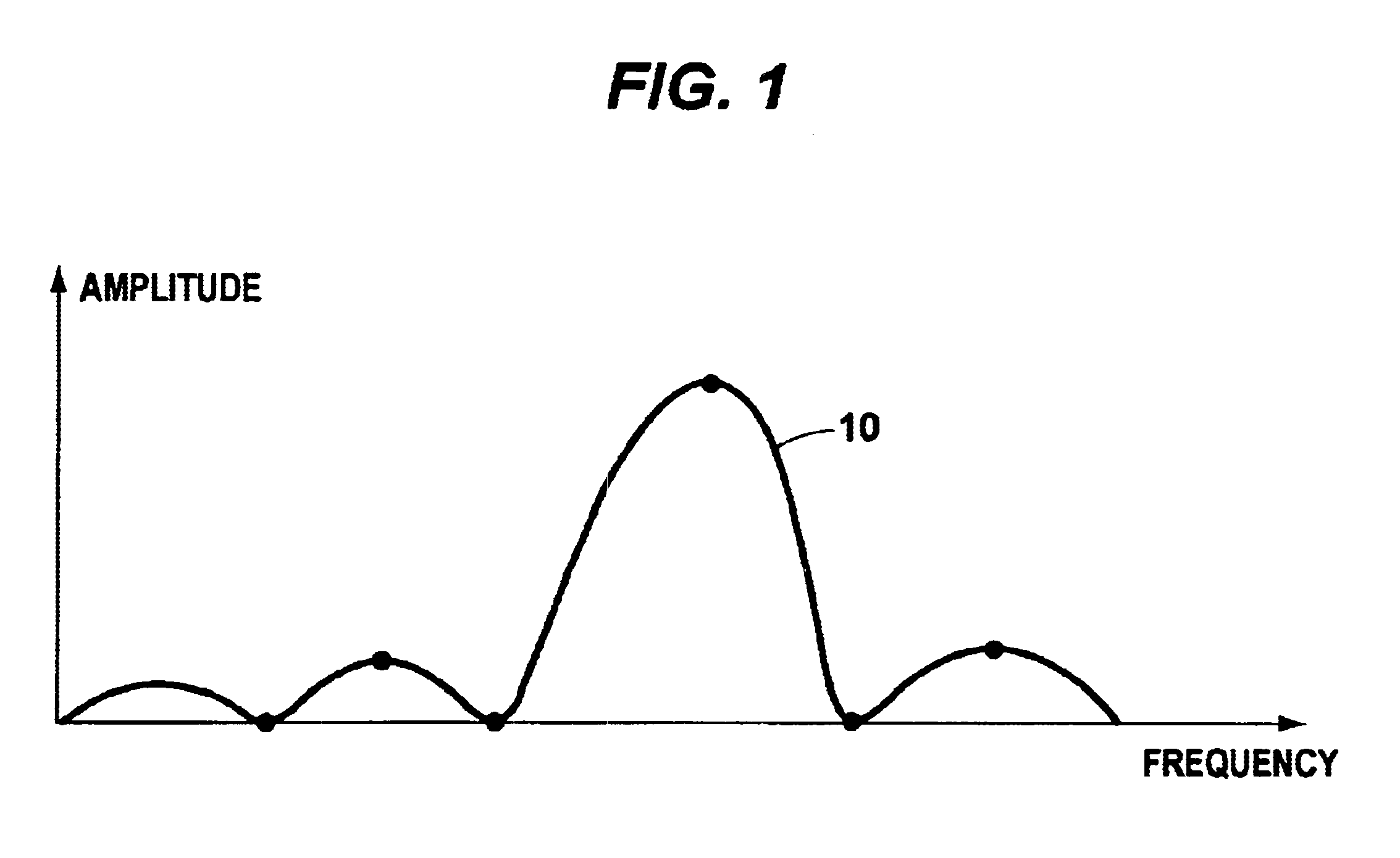

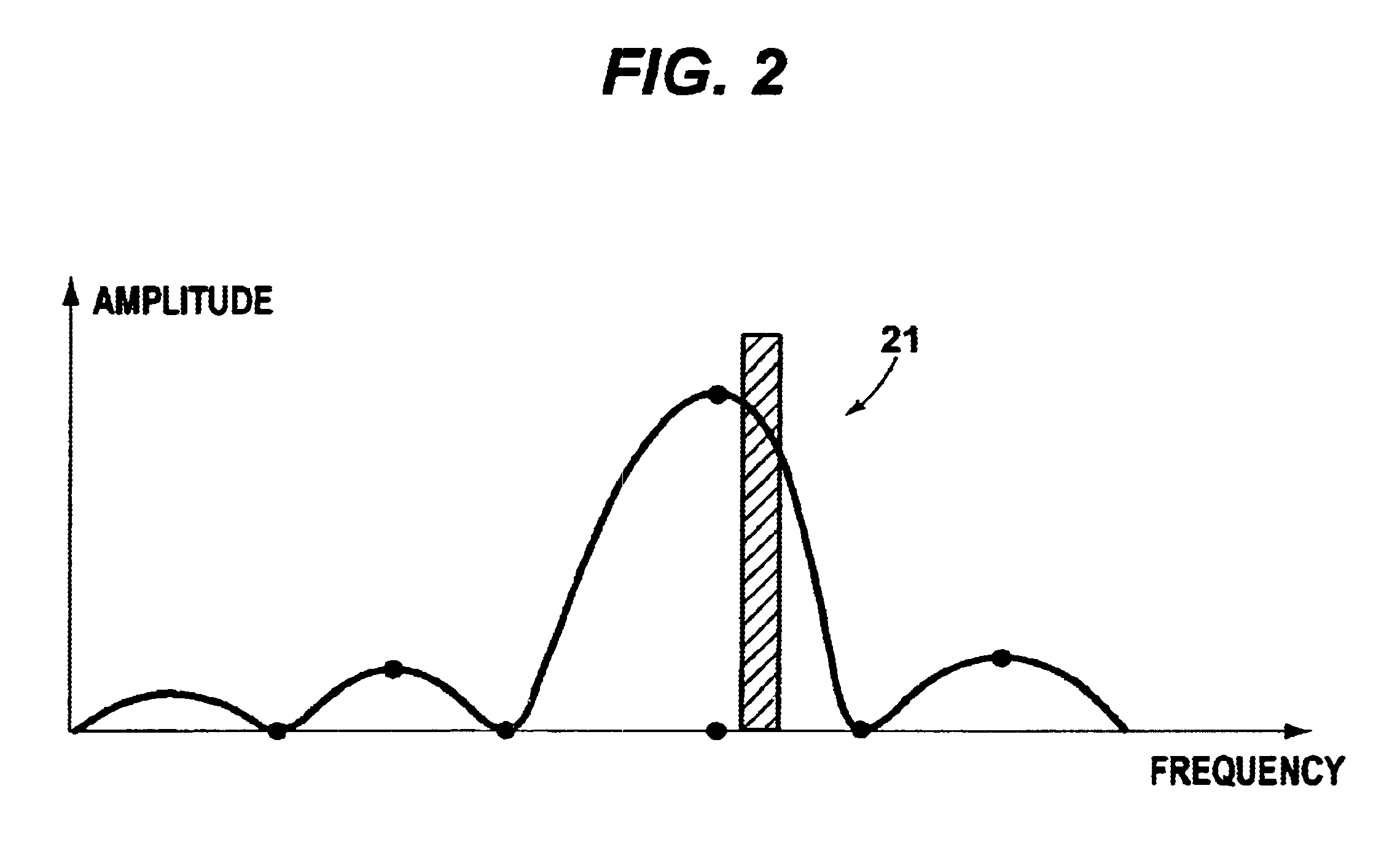

Method and a device for maintaining the performance quality of a code-division multiple access system in the presence of narrow band interference

InactiveUS6807405B1Reduce adverse effectsReducing and eliminating disruptionPower managementNetwork traffic/resource managementContinuous scanningTime division multiple access

A method and device which dynamically detects, tracks and filters interfering signals with sufficient speed (i.e. within one IS-95 CDMA data frame period, or 20ms and fidelity to eliminate or greatly reduce the deleterious effects of narrow band interferor signals on a CDMA link. When inserted in an RF signal path an Adaptive Notch Filter (ANF) detects narrow band interferors above a threshold level within the CDMA signal. Detection is accomplished by continuous scanning of a preset excision band, e.g. a specified narrow band associated with an AMPS system. Detected interferors are then automatically acquired and suppressed. This is achieved by electronically placing a rejection notch at the frequency of the interferors. Multiple notch filters may be used to simultaneously suppress multiple interferors. In the absence of interferors a bypass mode is selected allowing the RF signal to bypass the notch. Upon detection of an interferor, a switch is made to a suppression mode where the interferor is steered through a first notch section and suppressed. Alternatively, an external control line may be used to select the bypass mode so that the signal is allowed to pass the notch section, regardless of interferer content.

Owner:ILLINOIS SUPER CONDUCTOR CANADA CORP A CO INC UNDER THE LAWS OF CANADA +1

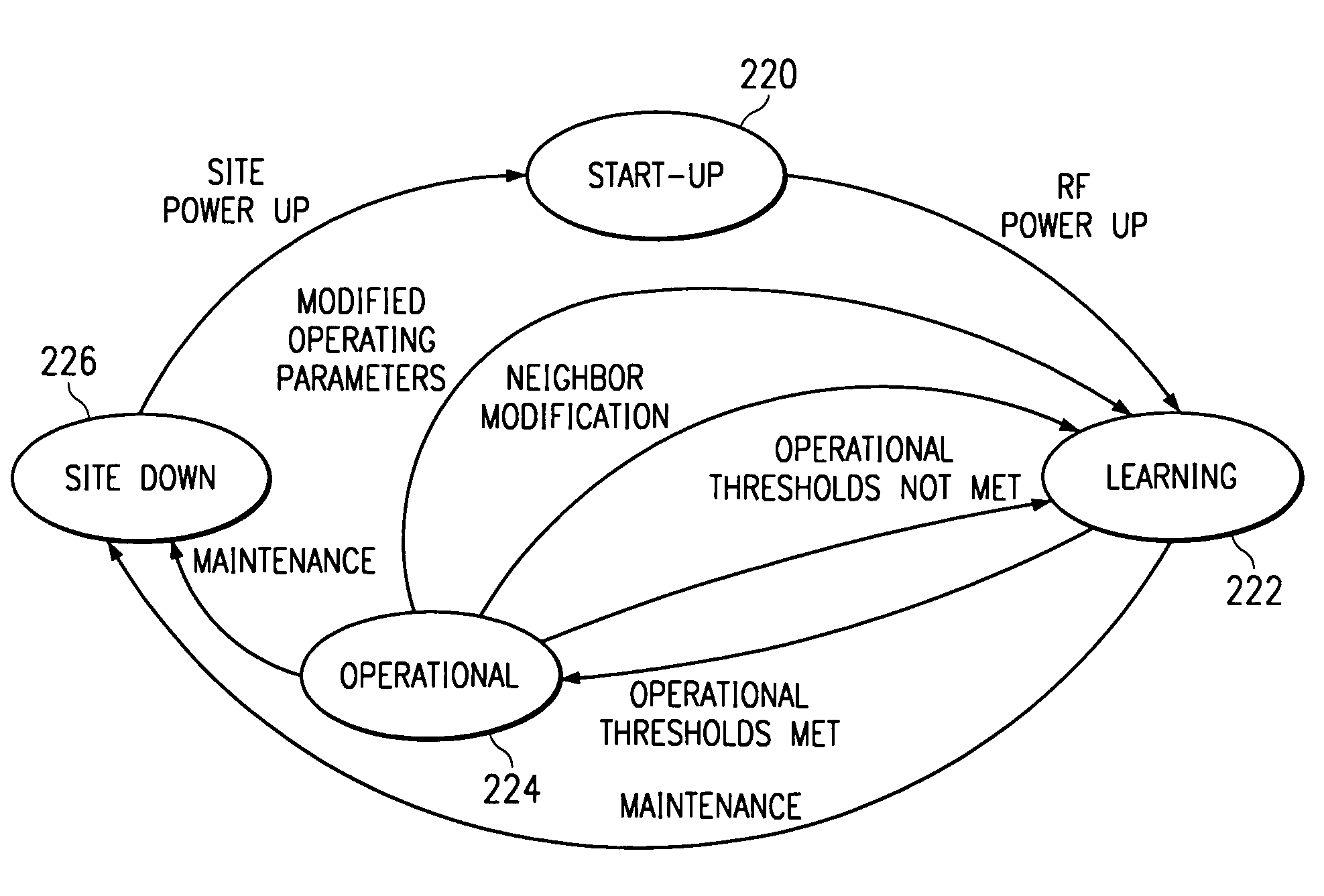

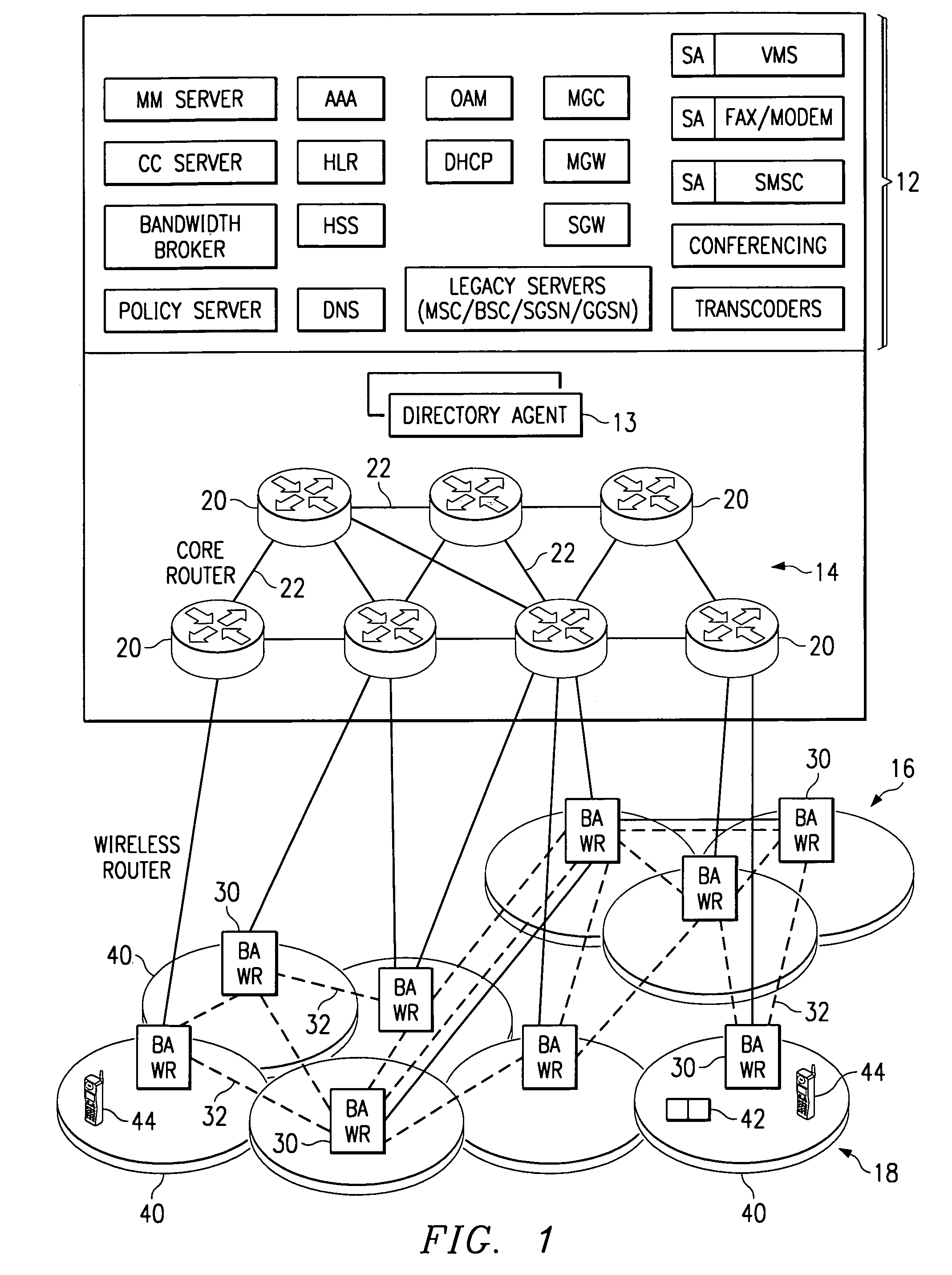

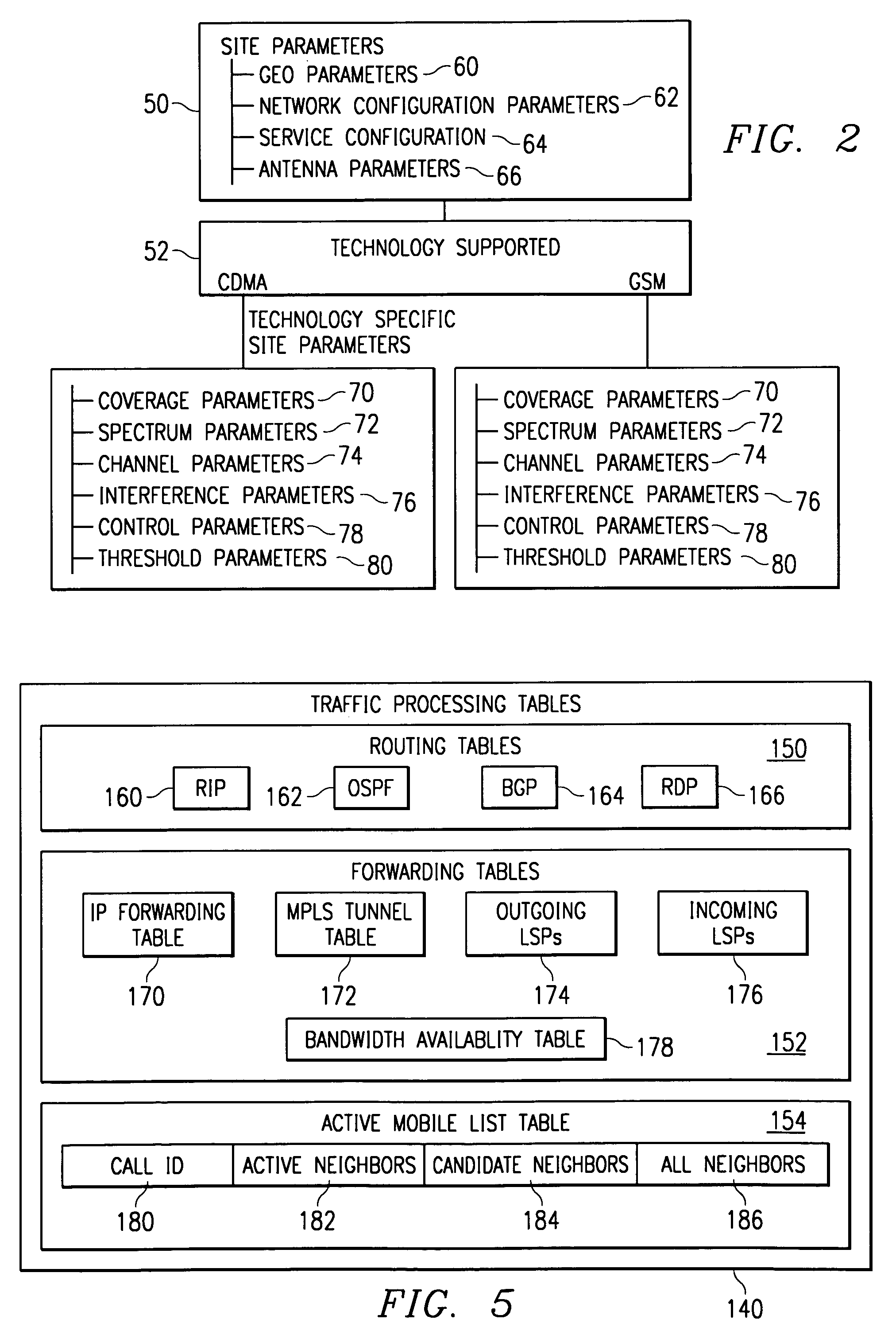

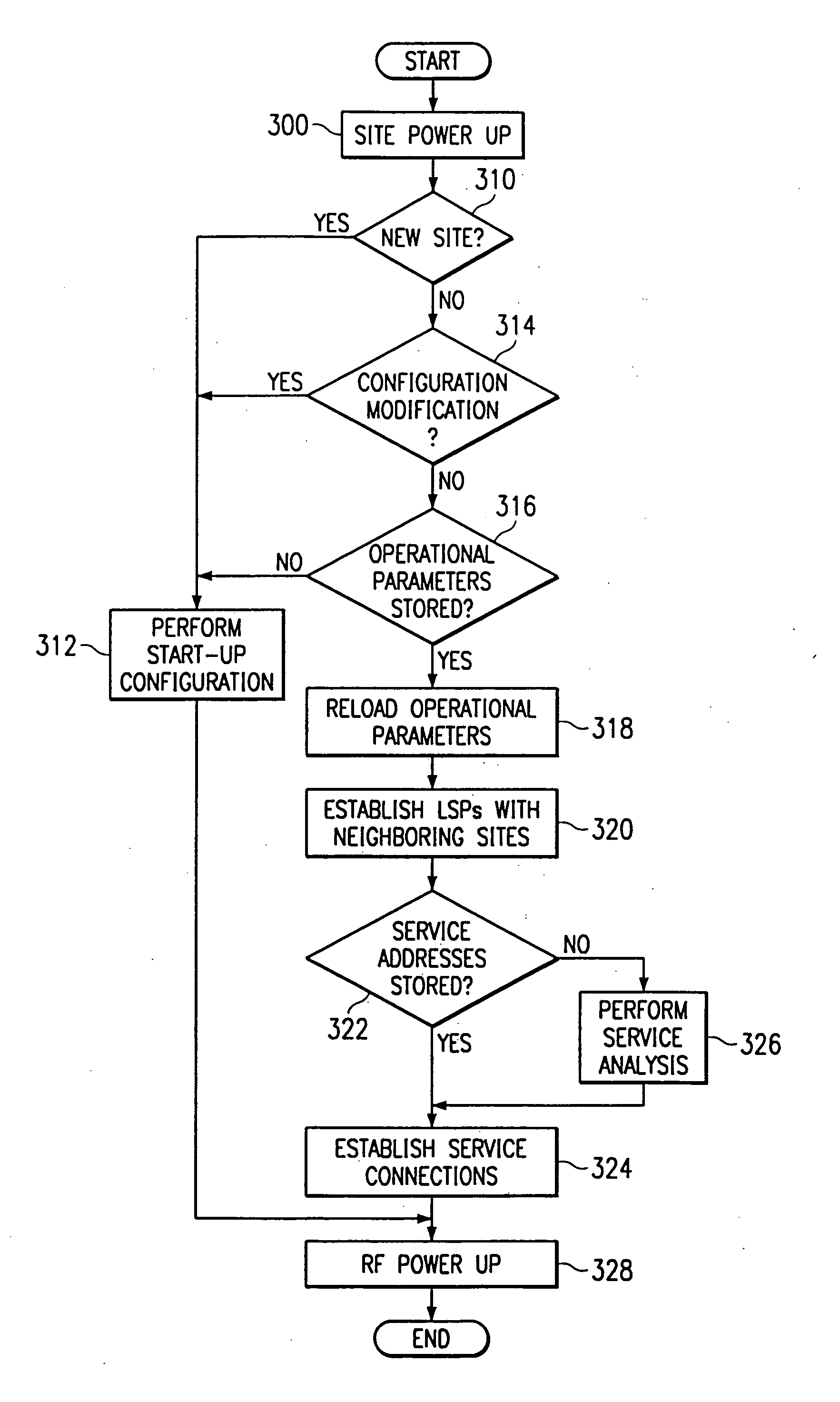

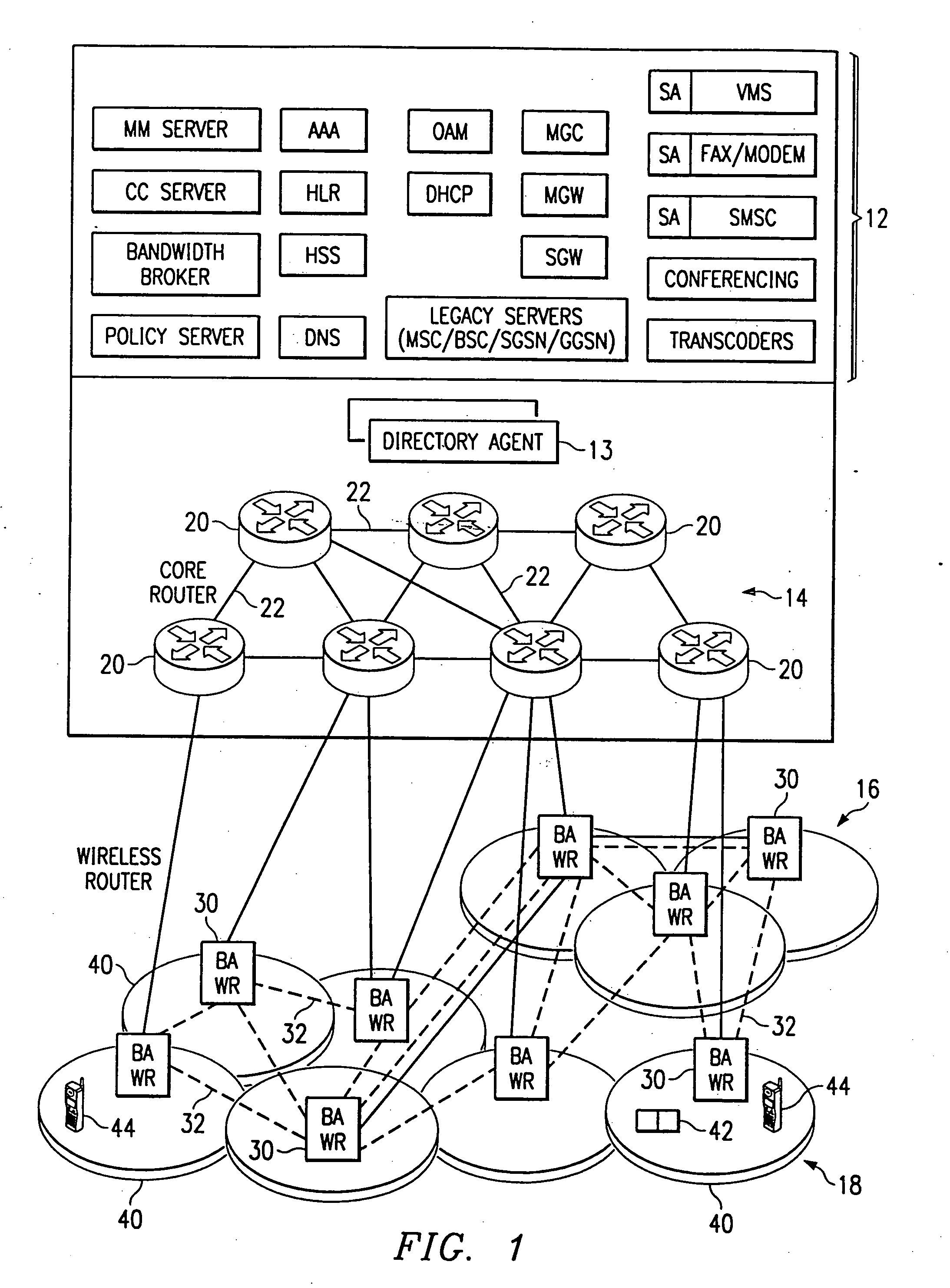

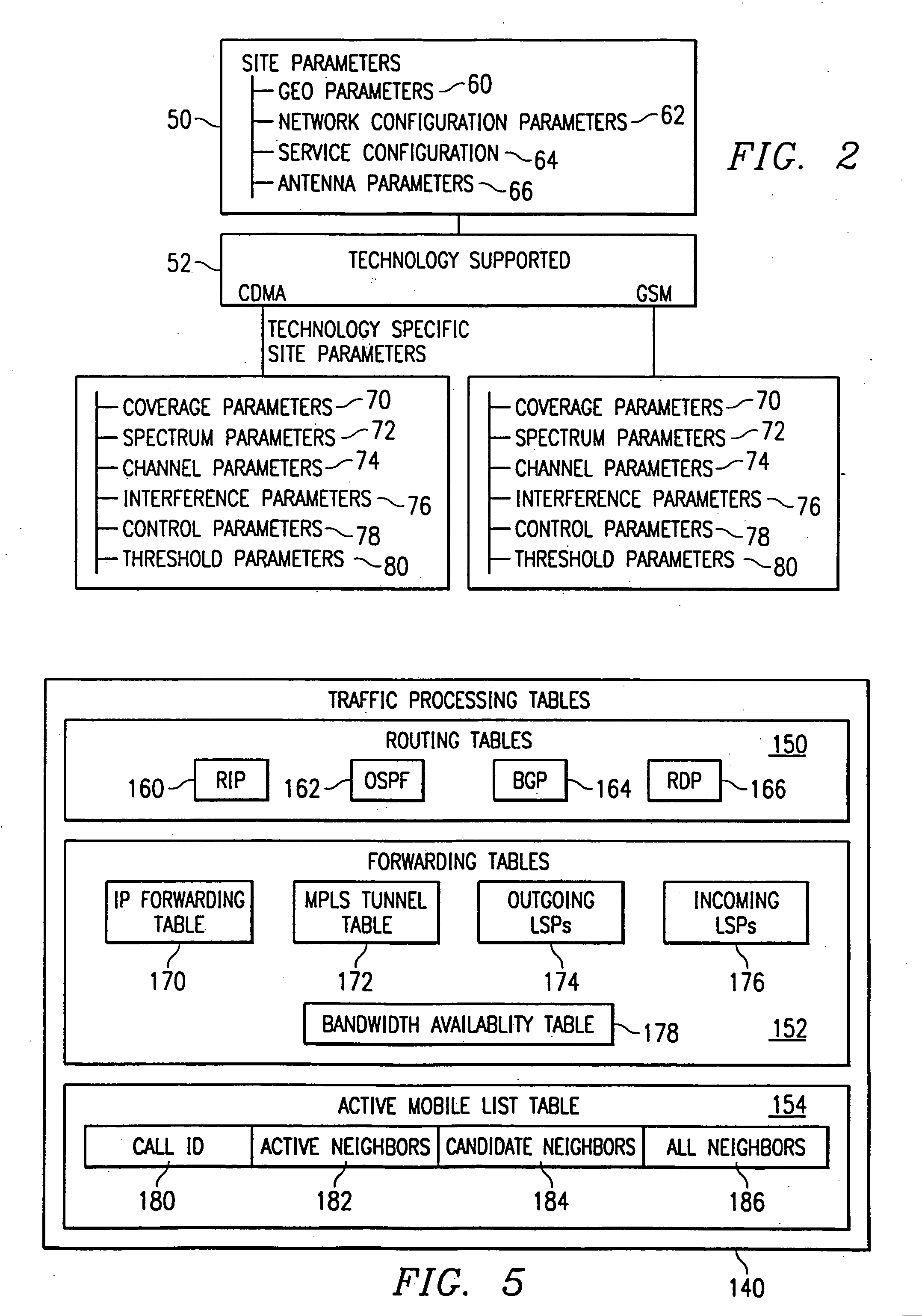

Method and system for configuring wireless routers and networks

InactiveUS7031266B1Easy to deployAutomatically configurablePower managementNetwork traffic/resource managementWireless routerComputer network

A method and system for configuring a wireless router and a wireless communications network includes establishing connectivity between a wireless router and at least one wireline router. Connectivity between the wireless router and a plurality of neighboring wireless routers is established through the wireline router. The wireless router is configured based on information exchanged with the neighboring wireless routers through the wireline router.

Owner:CISCO TECH INC

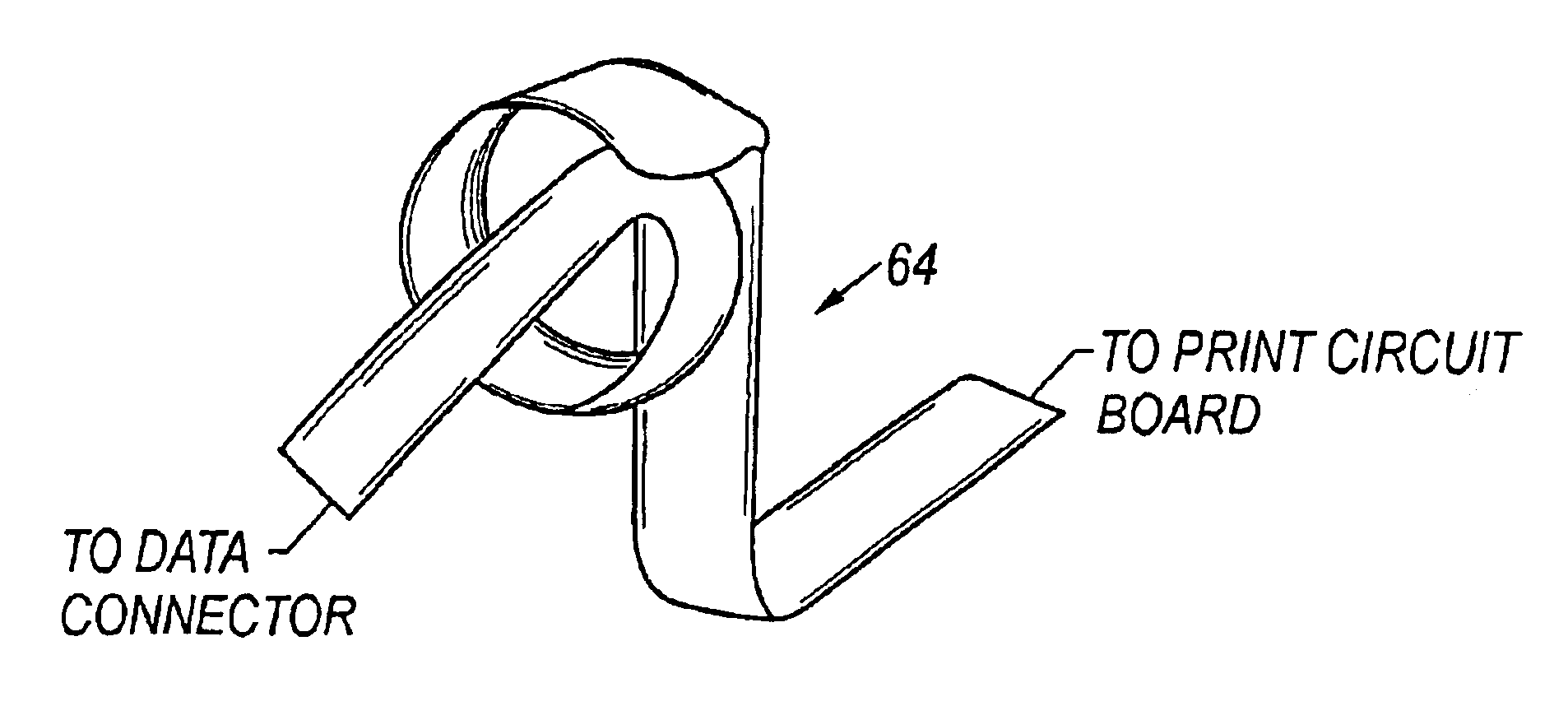

Flexible circuit board for tablet computing device

InactiveUS6914197B2Easy constructionReduce manufacturing costCoupling device connectionsDigital data processing detailsTablet computerDocking station

Owner:ZEBRA TECH CORP

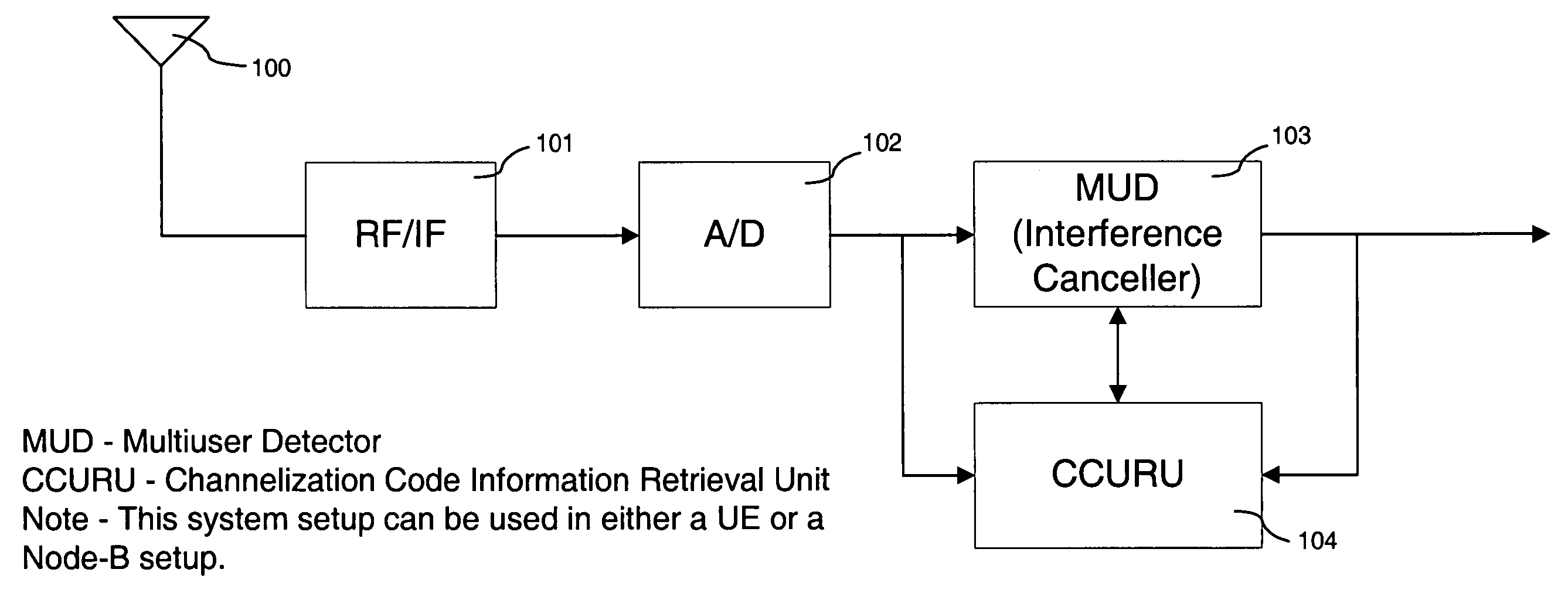

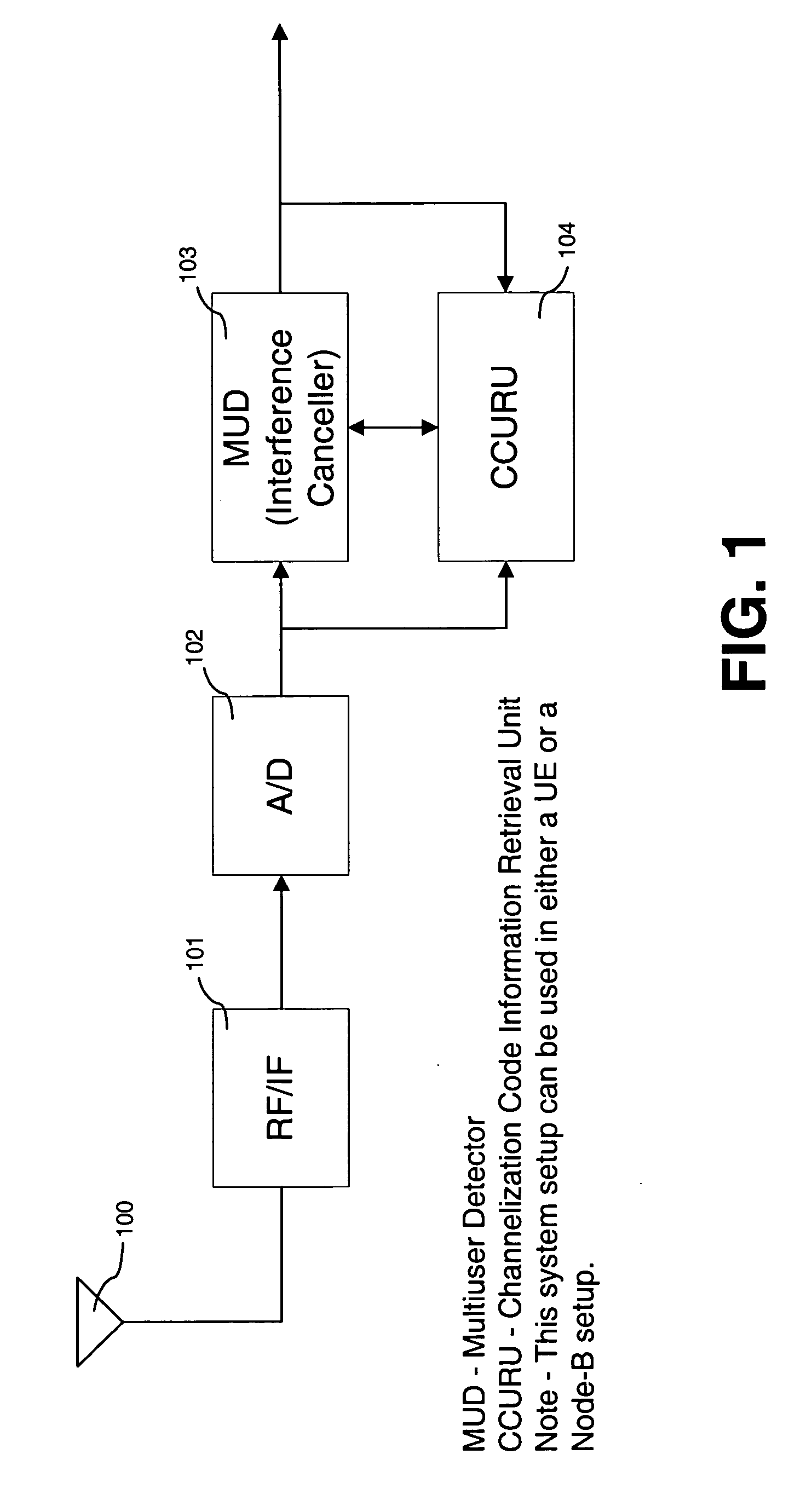

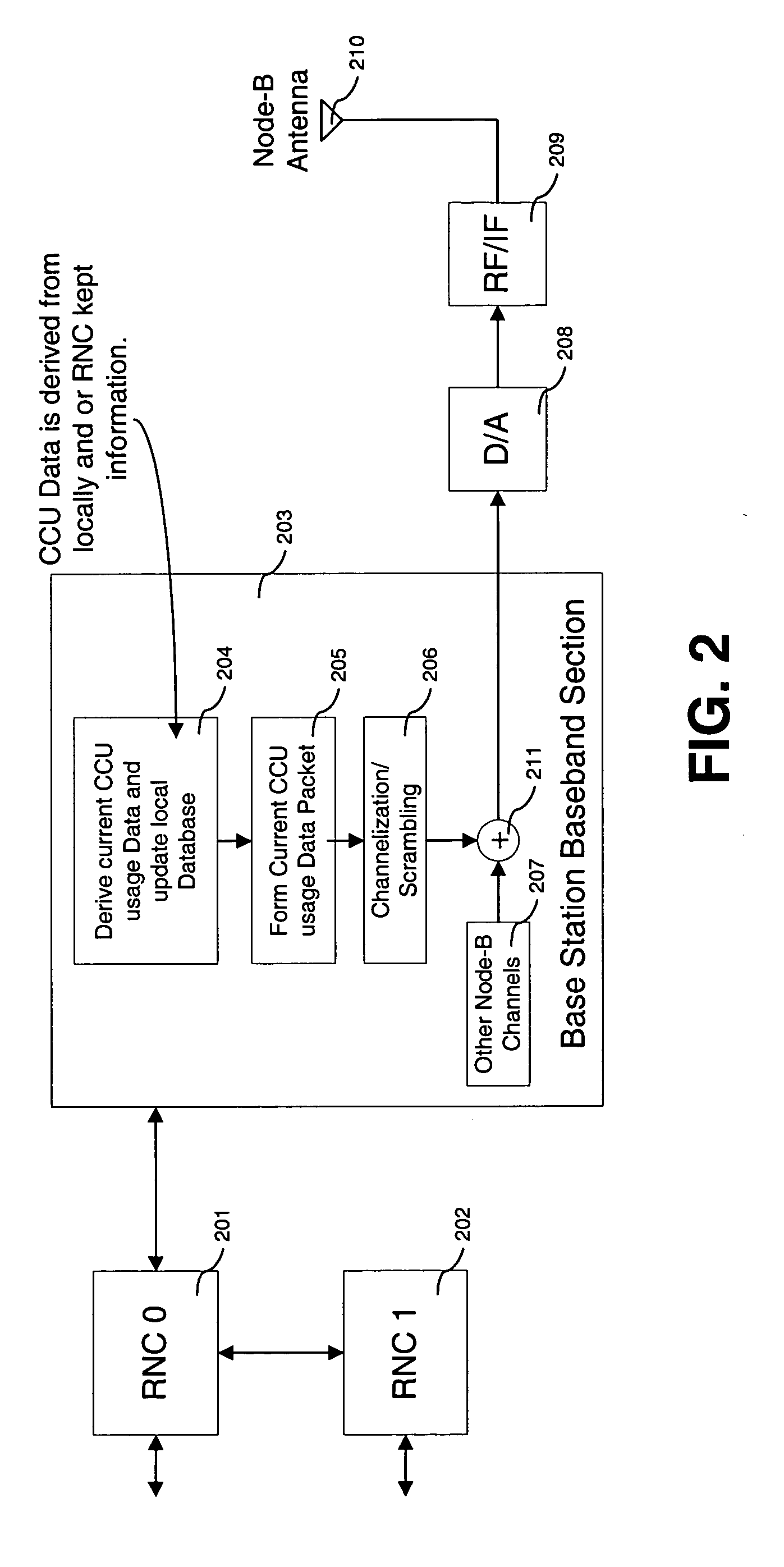

Interference cancellation method and apparatus

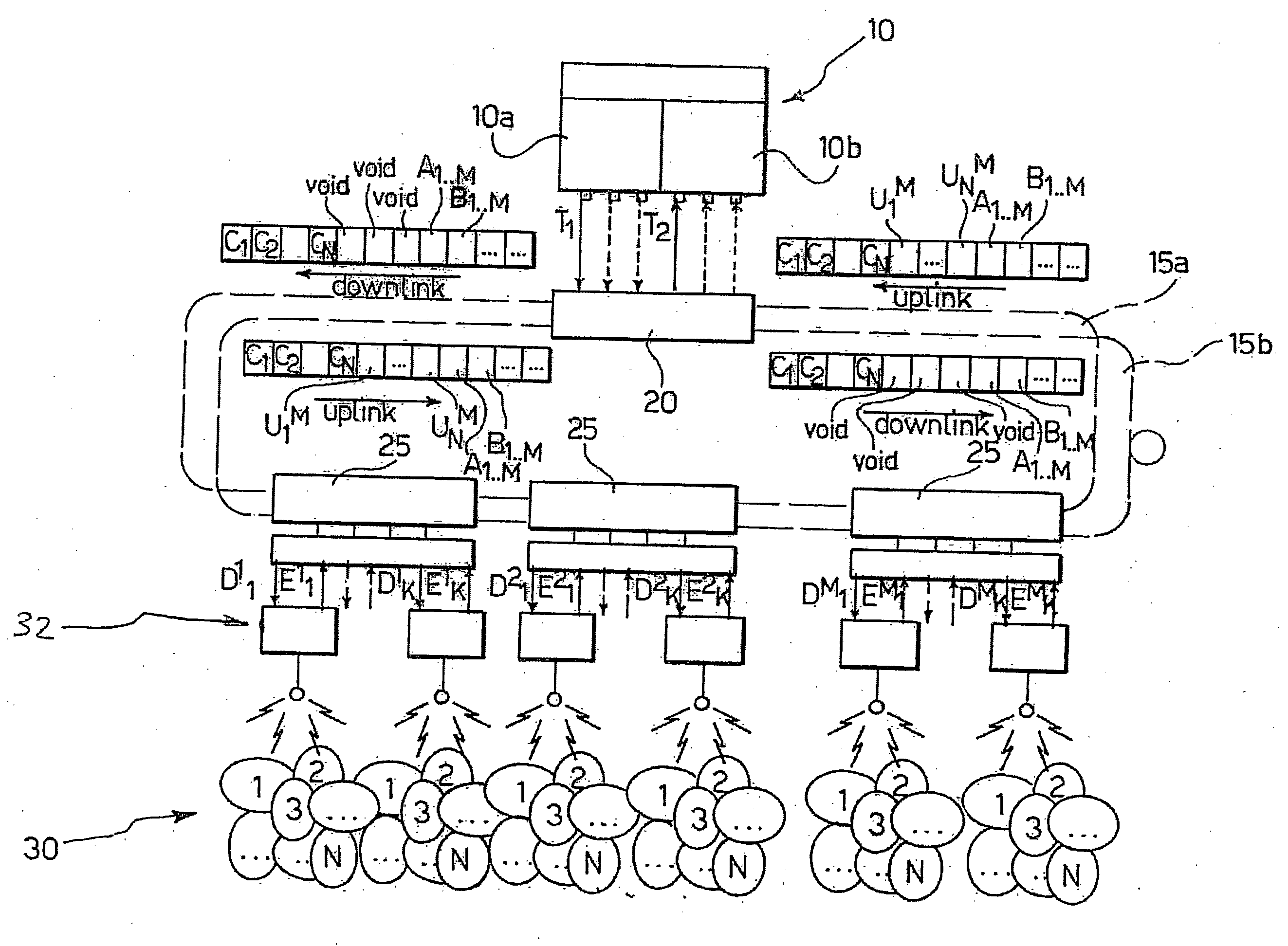

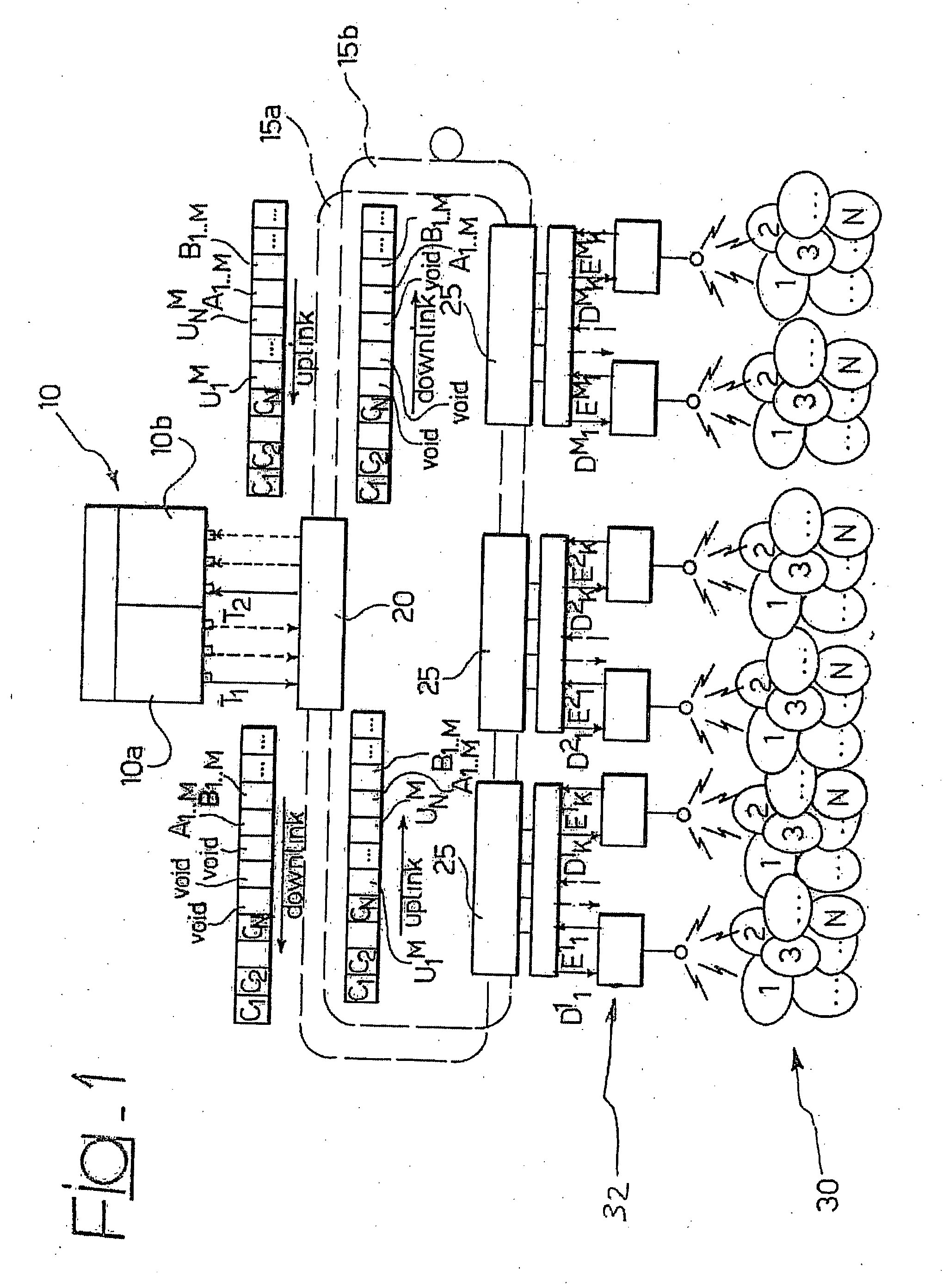

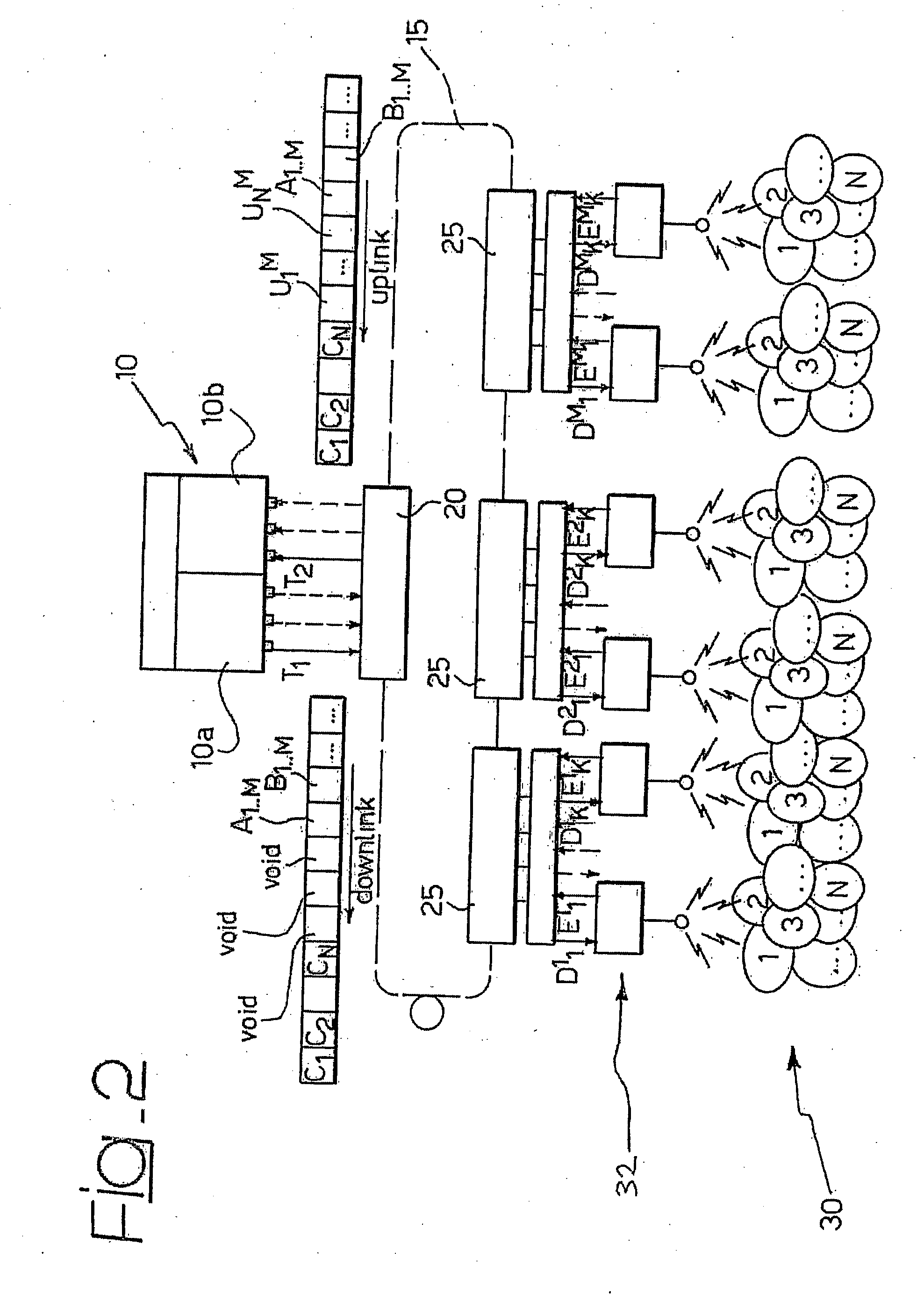

InactiveUS20050111405A1Increase the stationImprove abilitiesRadio/inductive link selection arrangementsWireless commuication servicesMulti user interferenceInterference cancelation

A Multi-User Detection device and method for DS-CDMA to allow enhanced signal reception under Multi-User Interference (MUI) at either the Remote Station or the Base Station is disclosed. The method includes the steps of relaying current channelization code use at Base Stations to Remote Stations operating in the vicinity of the Base Stations. This information is used by an MUD device at the Remote Station, to improve its ability to separate signals transmitted from different Base Stations. The downlink channelization code information is used to recreate the interference received by all neighboring Base Stations transmissions at the Remote Station. The same method can be applied at the Base Station side. The Uplink Channelization Code Usage information is relayed to each Base Station from its neighboring Base Stations. Recreating the total Remote Station interference at the Base Station allows a multistage interference cancellation based MUD to enhance its capability of receiving Remote Stations in its coverage area.

Owner:DESIGN STANDARDS CORP

Method and system for configuring wireless routers and networks

InactiveUS20060126536A1Easy to deployAutomatically configurablePower managementNetwork traffic/resource managementWireless routerComputer network

A method and system for configuring a wireless router and a wireless communications network includes establishing connectivity between a wireless router and at least one wireline router. Connectivity between the wireless router and a plurality of neighboring wireless routers is established through the wireline router. The wireless router is configured based on information exchanged with the neighboring wireless routers through the wireline router.

Owner:CISCO TECH INC

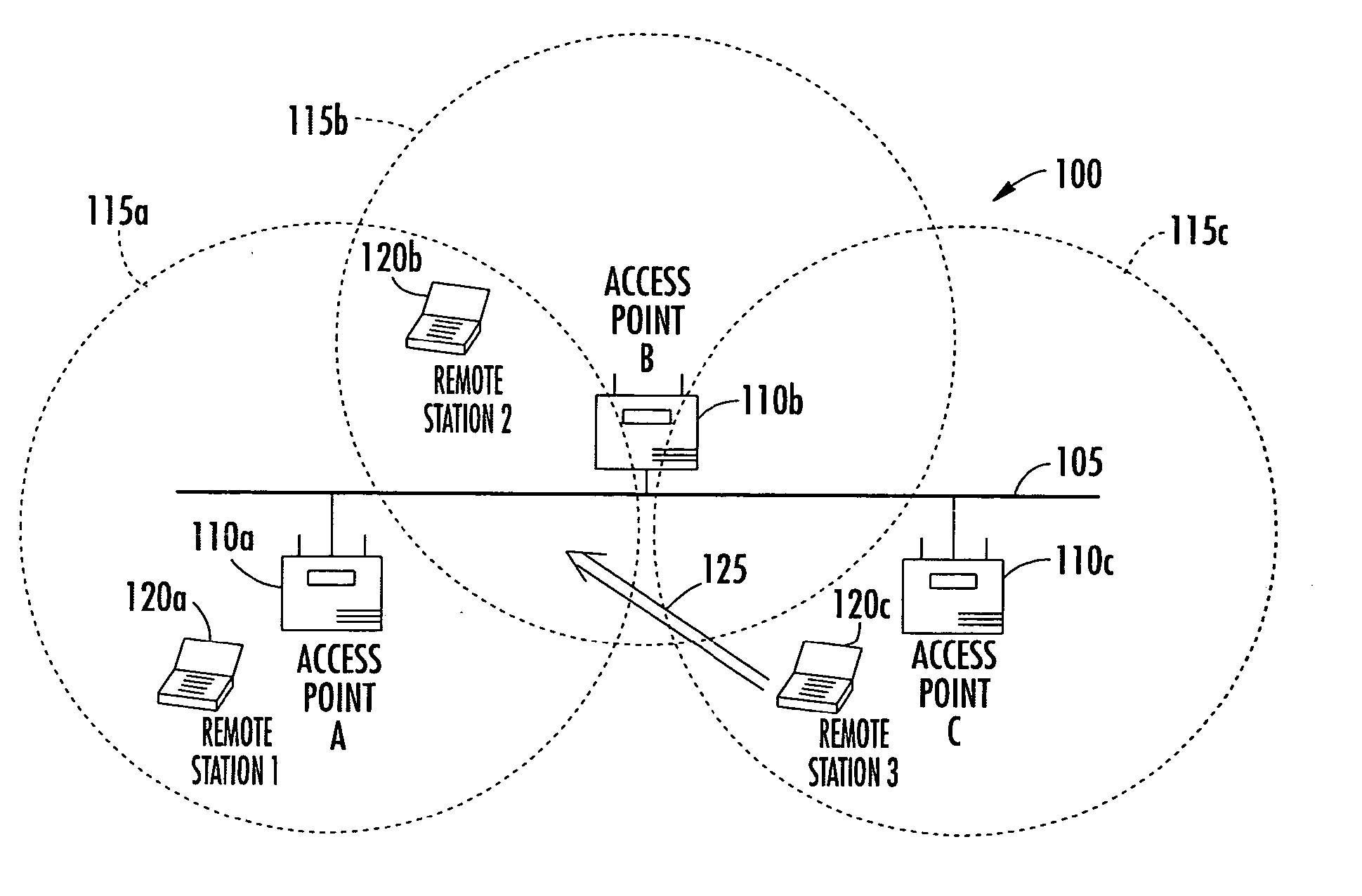

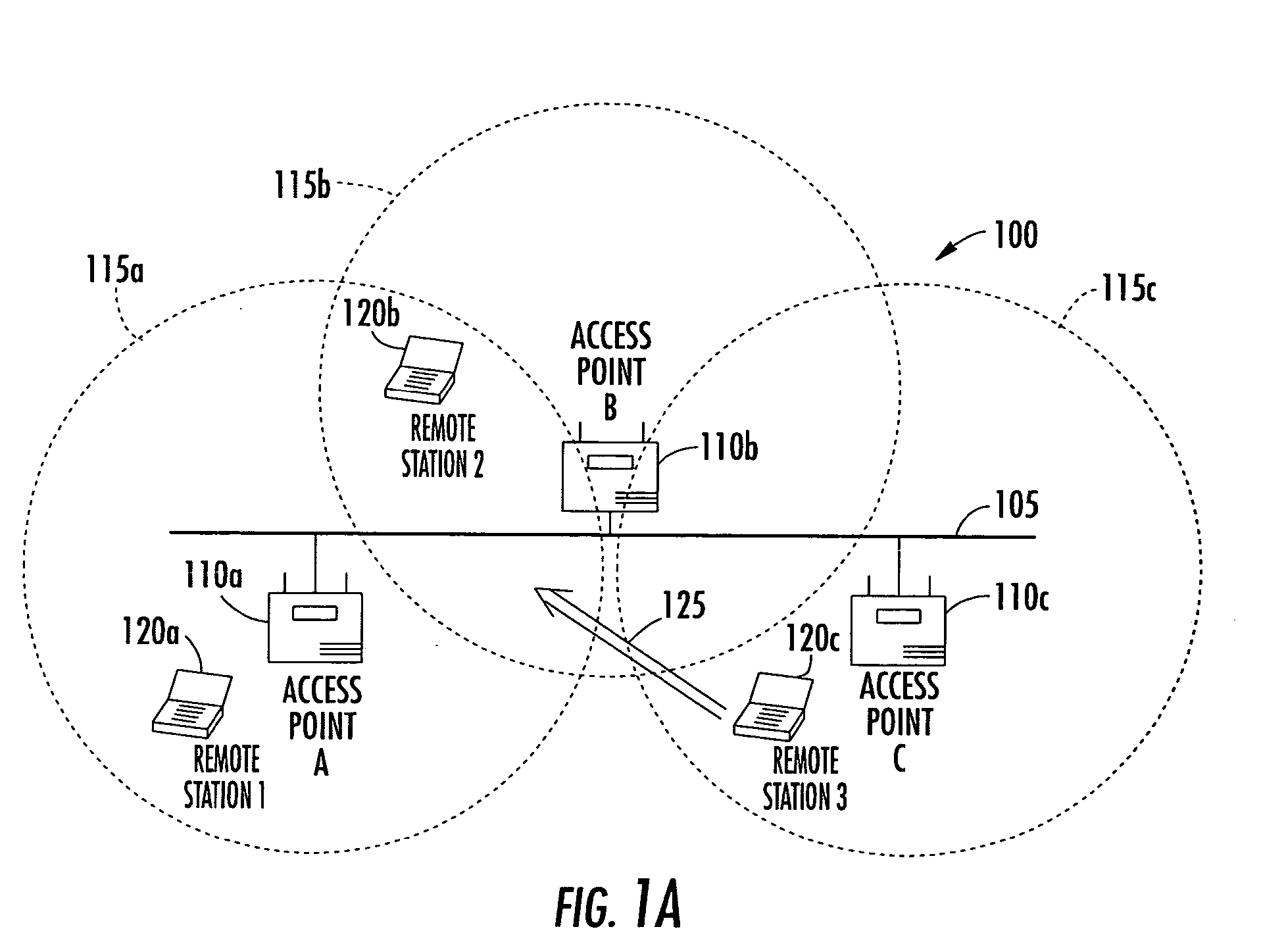

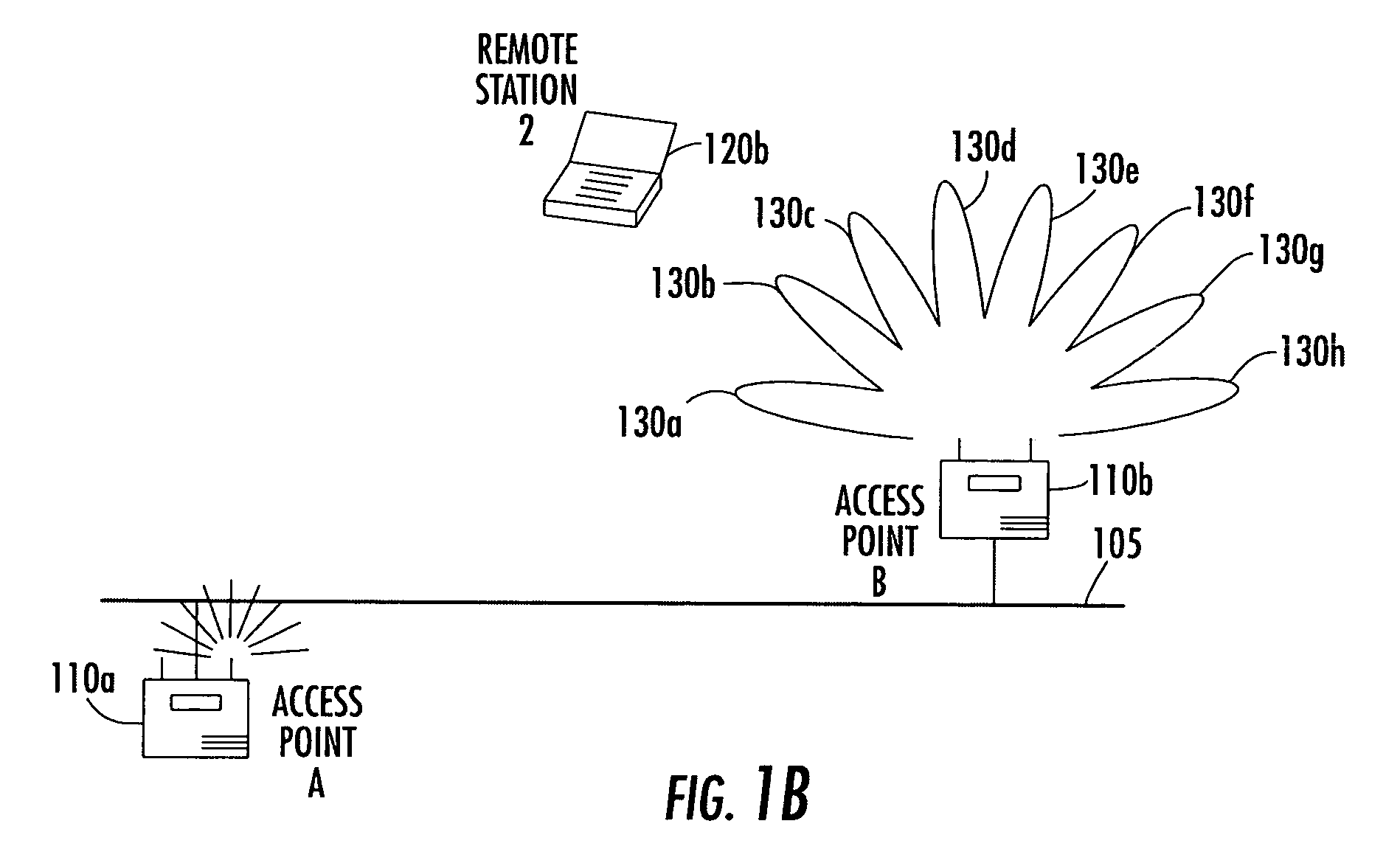

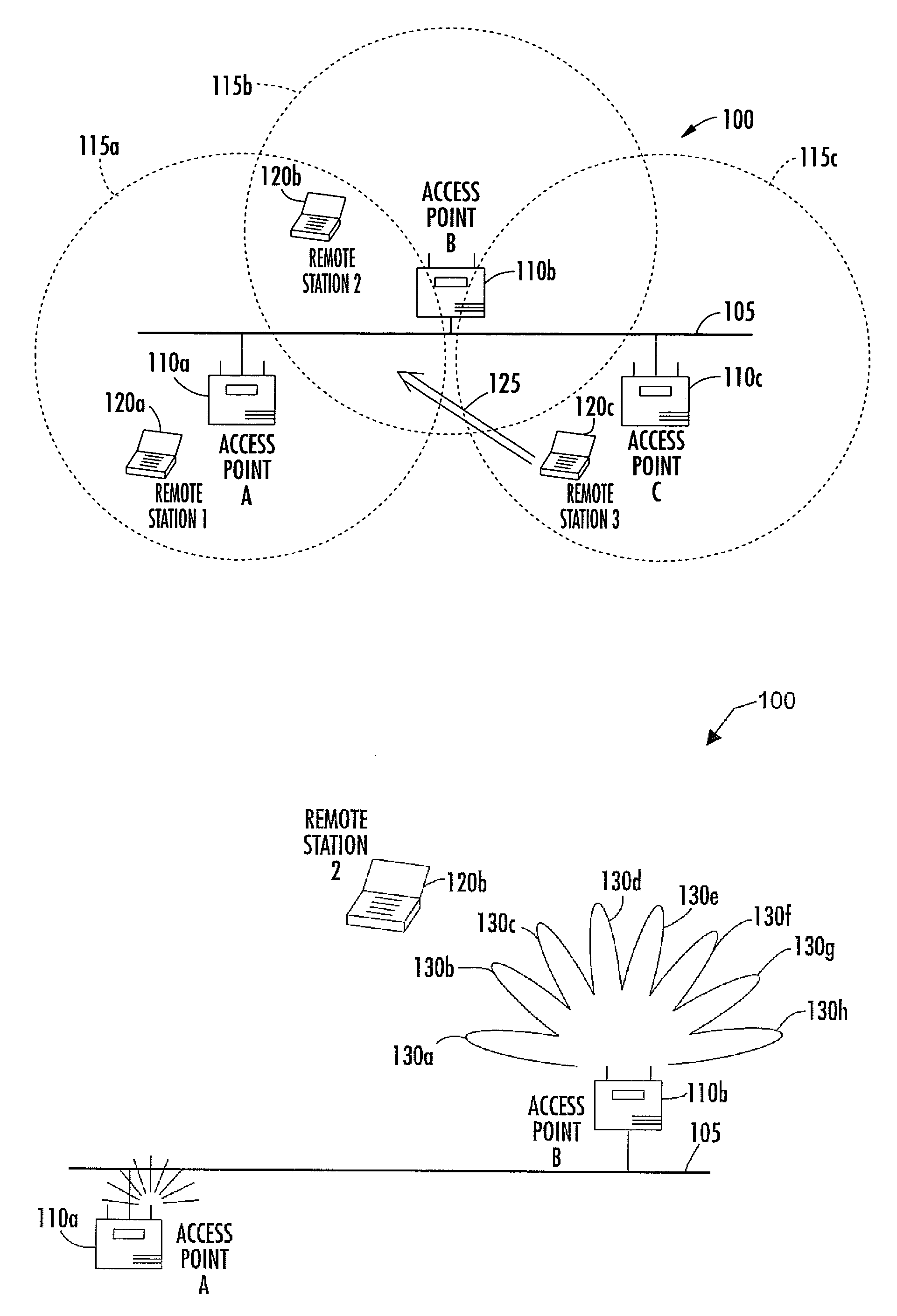

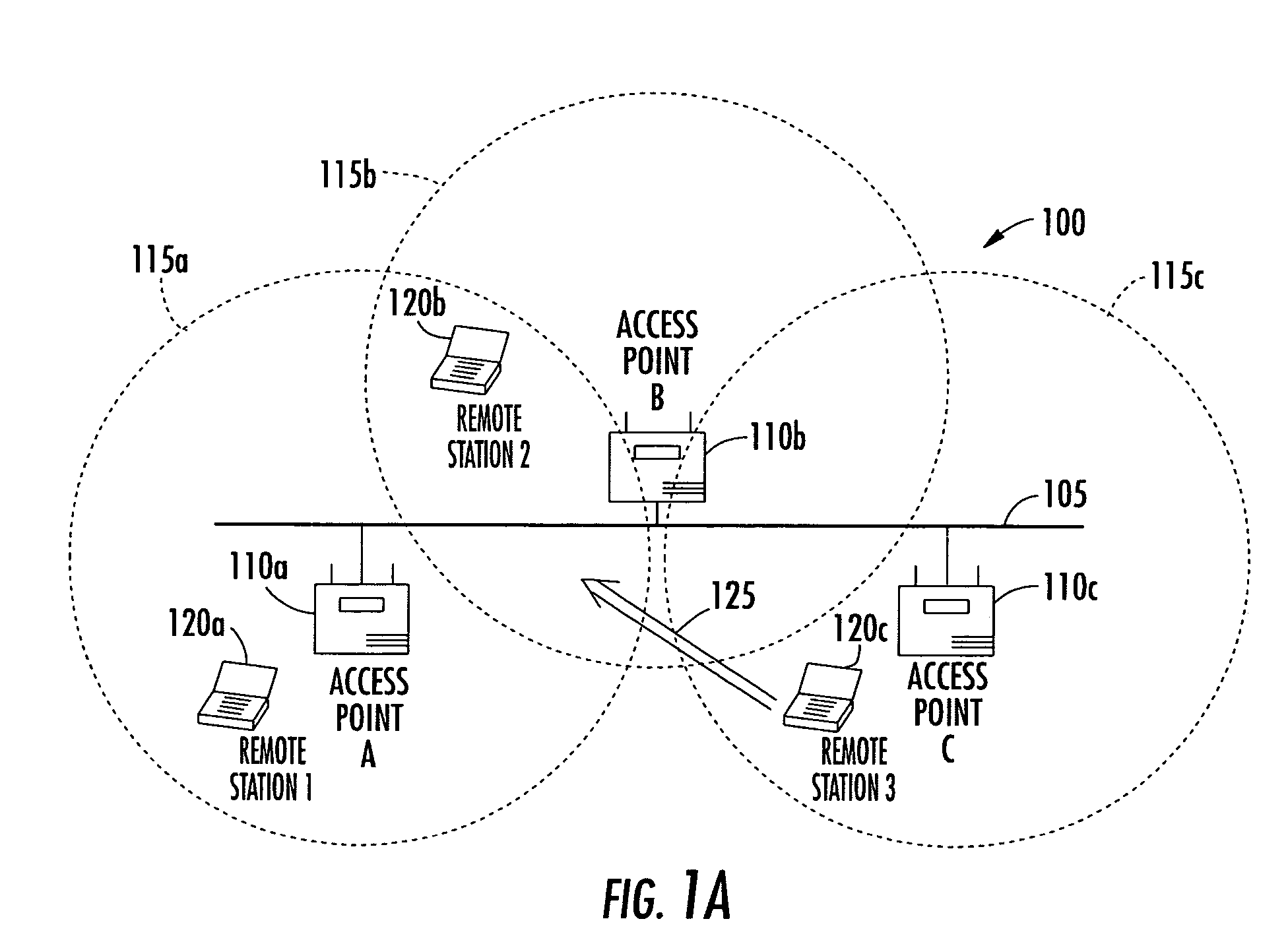

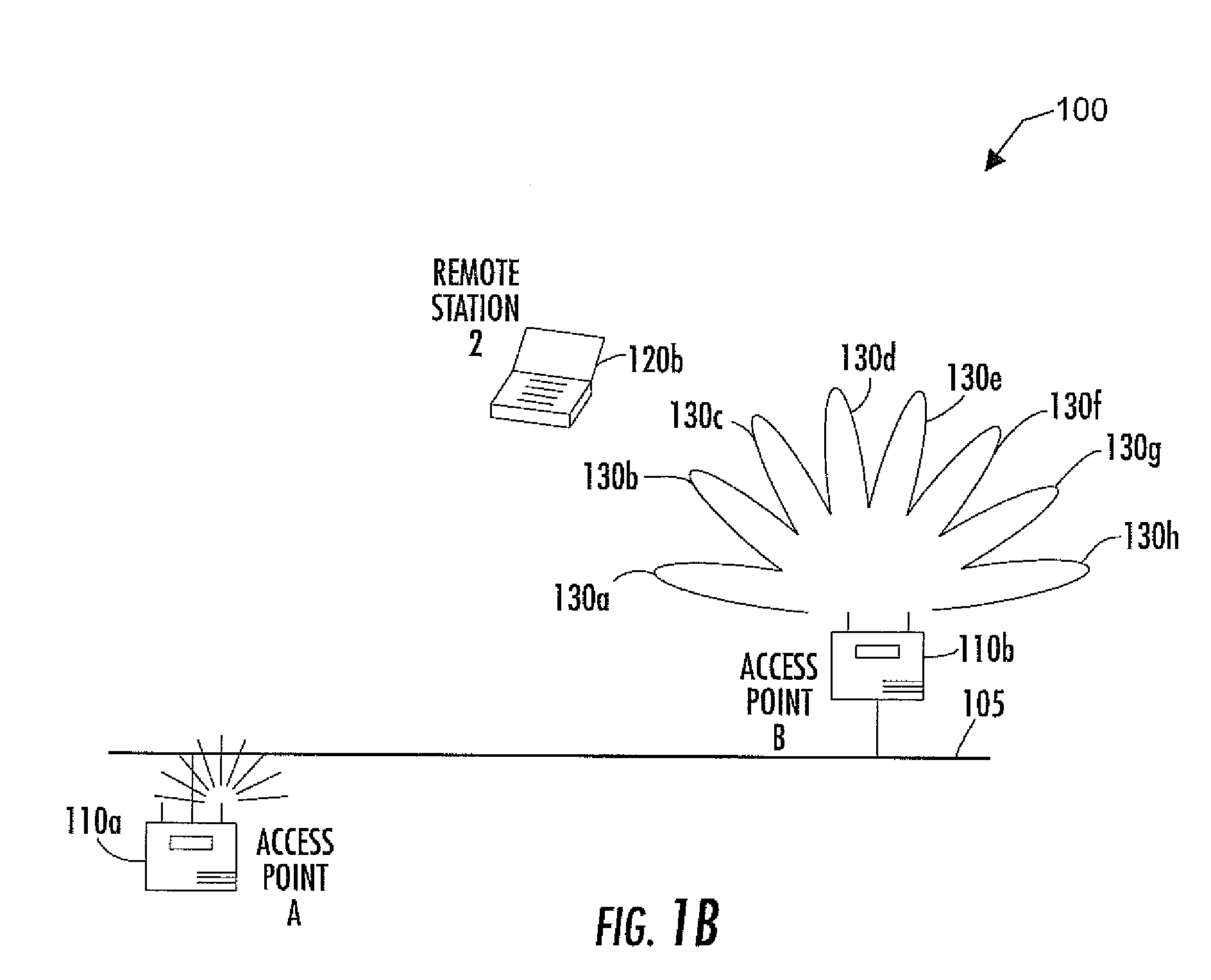

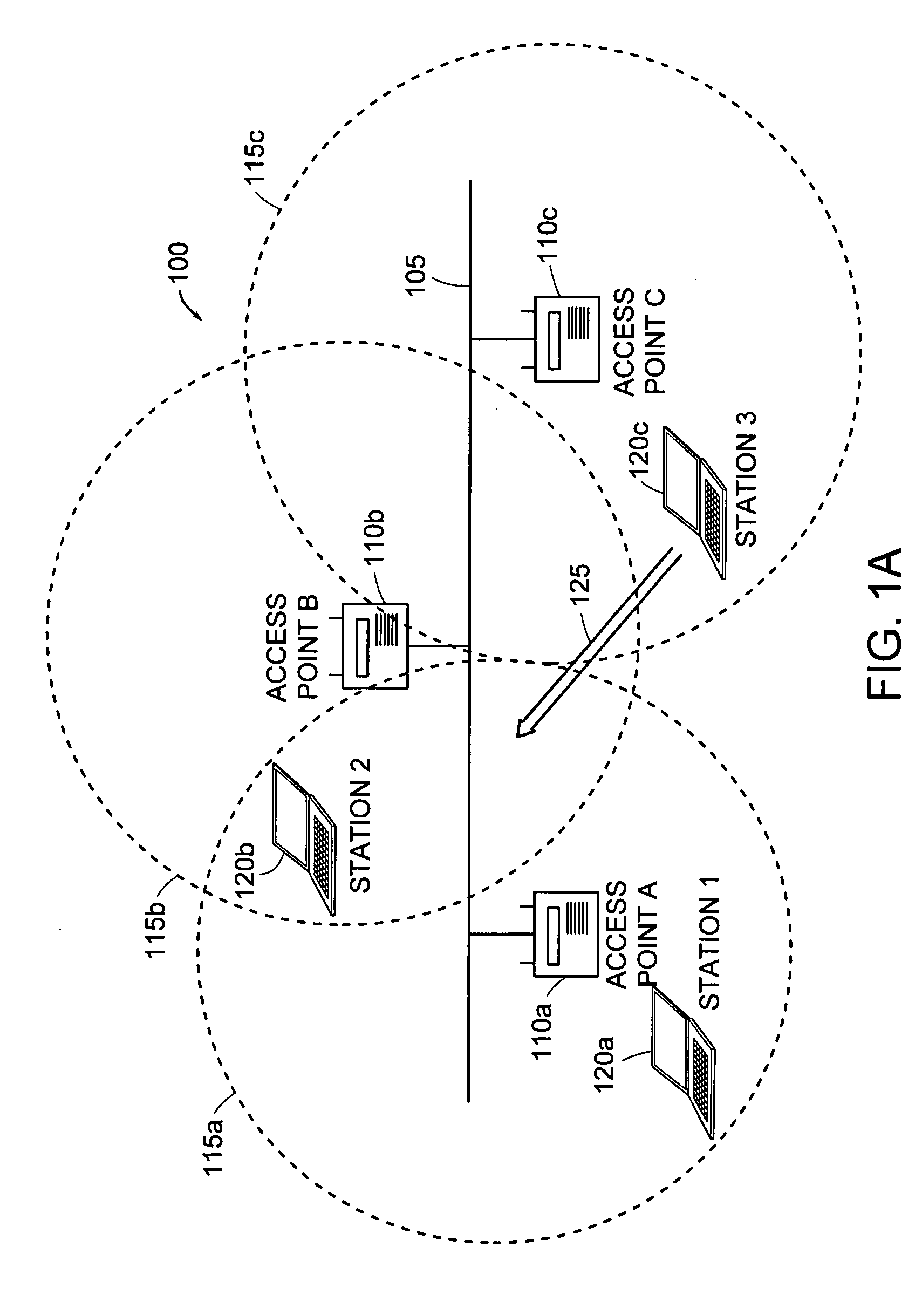

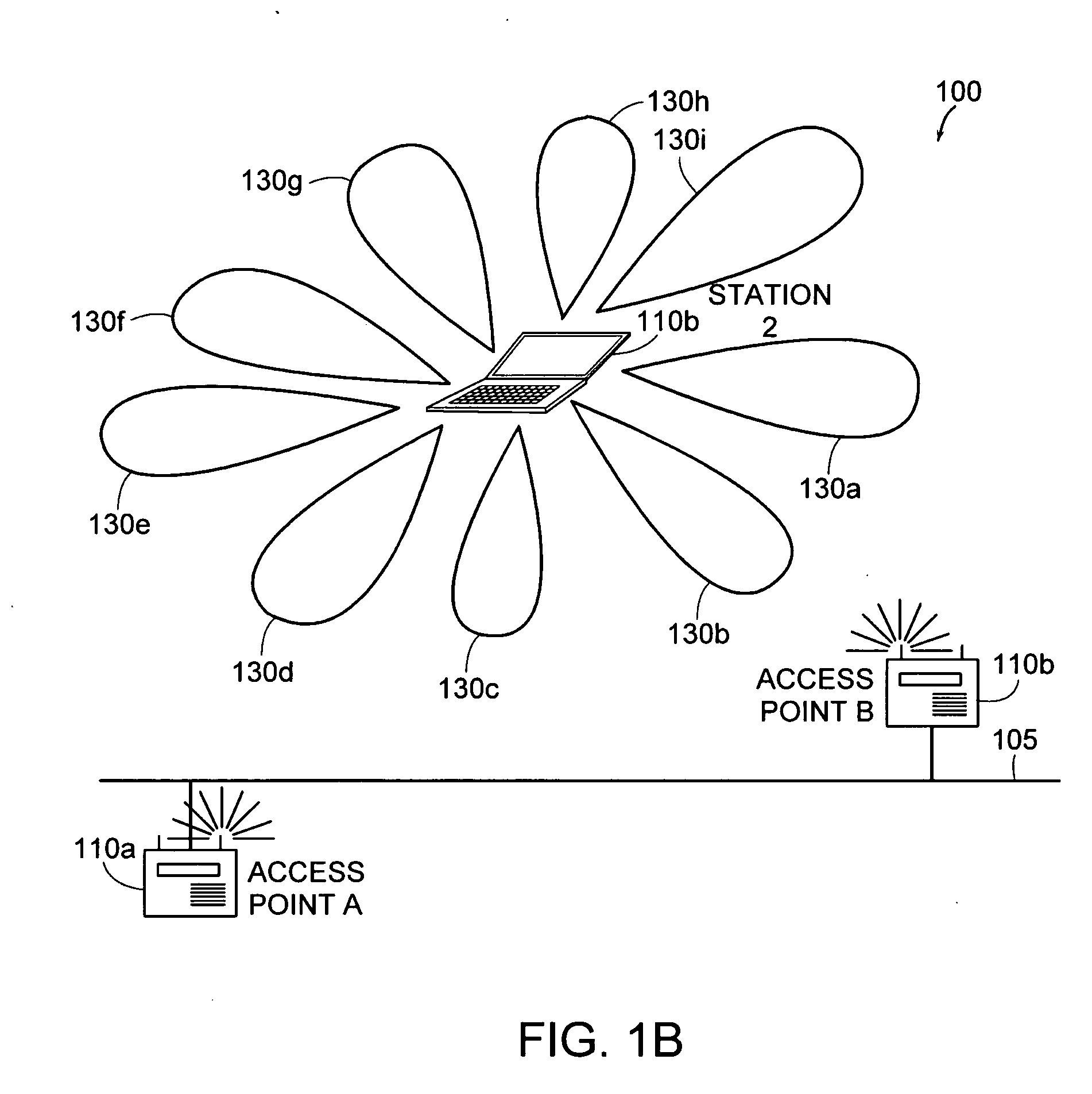

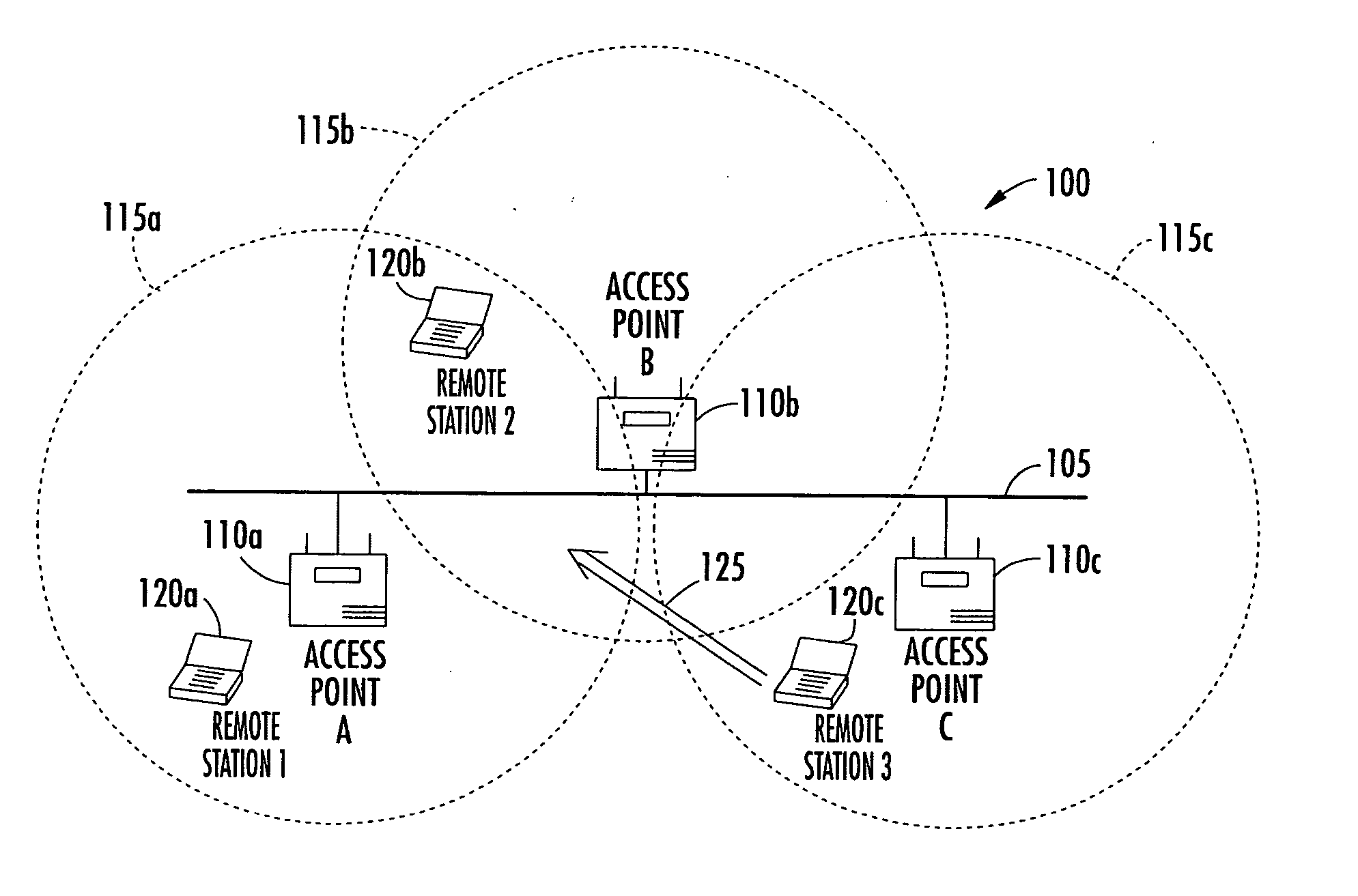

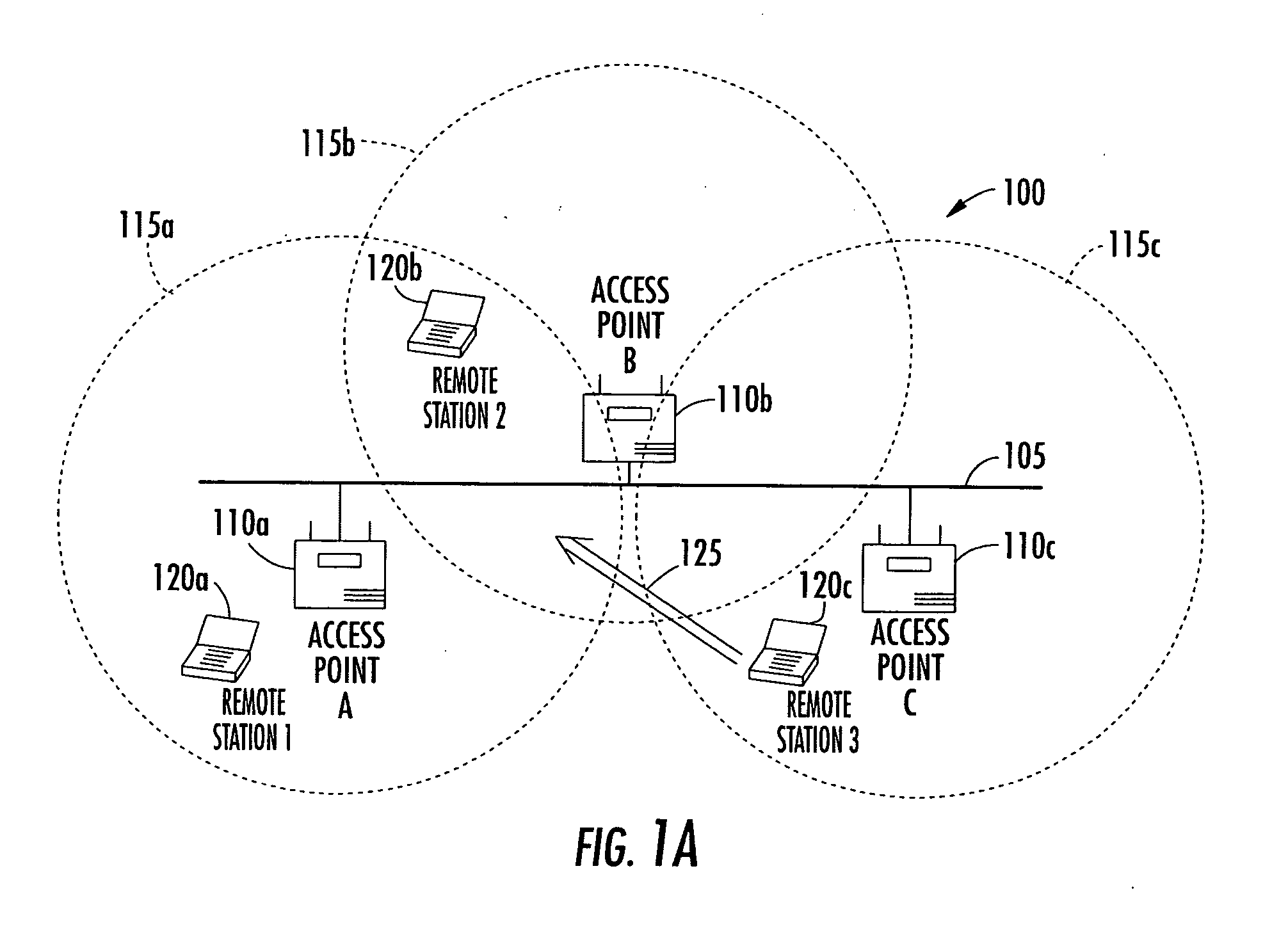

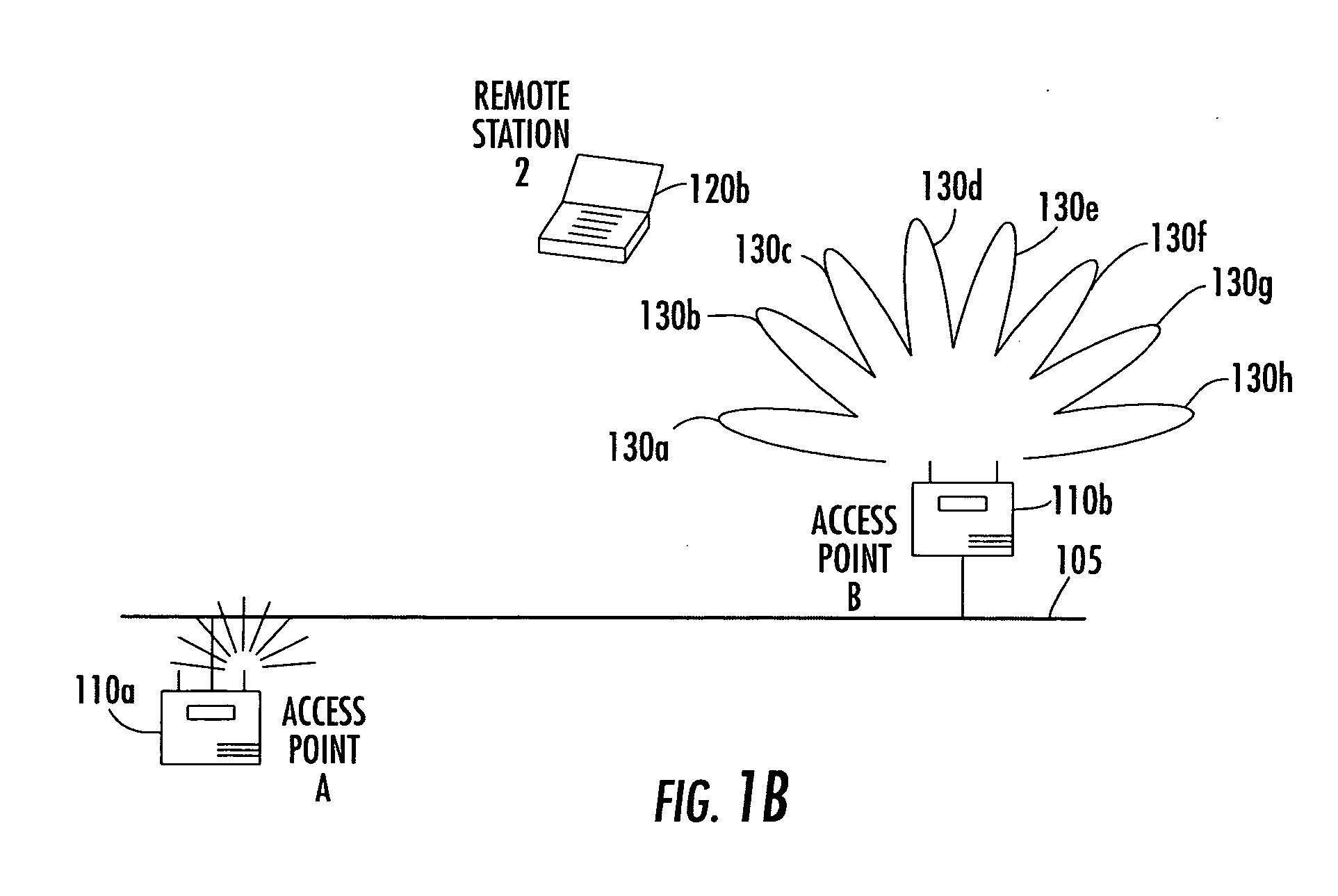

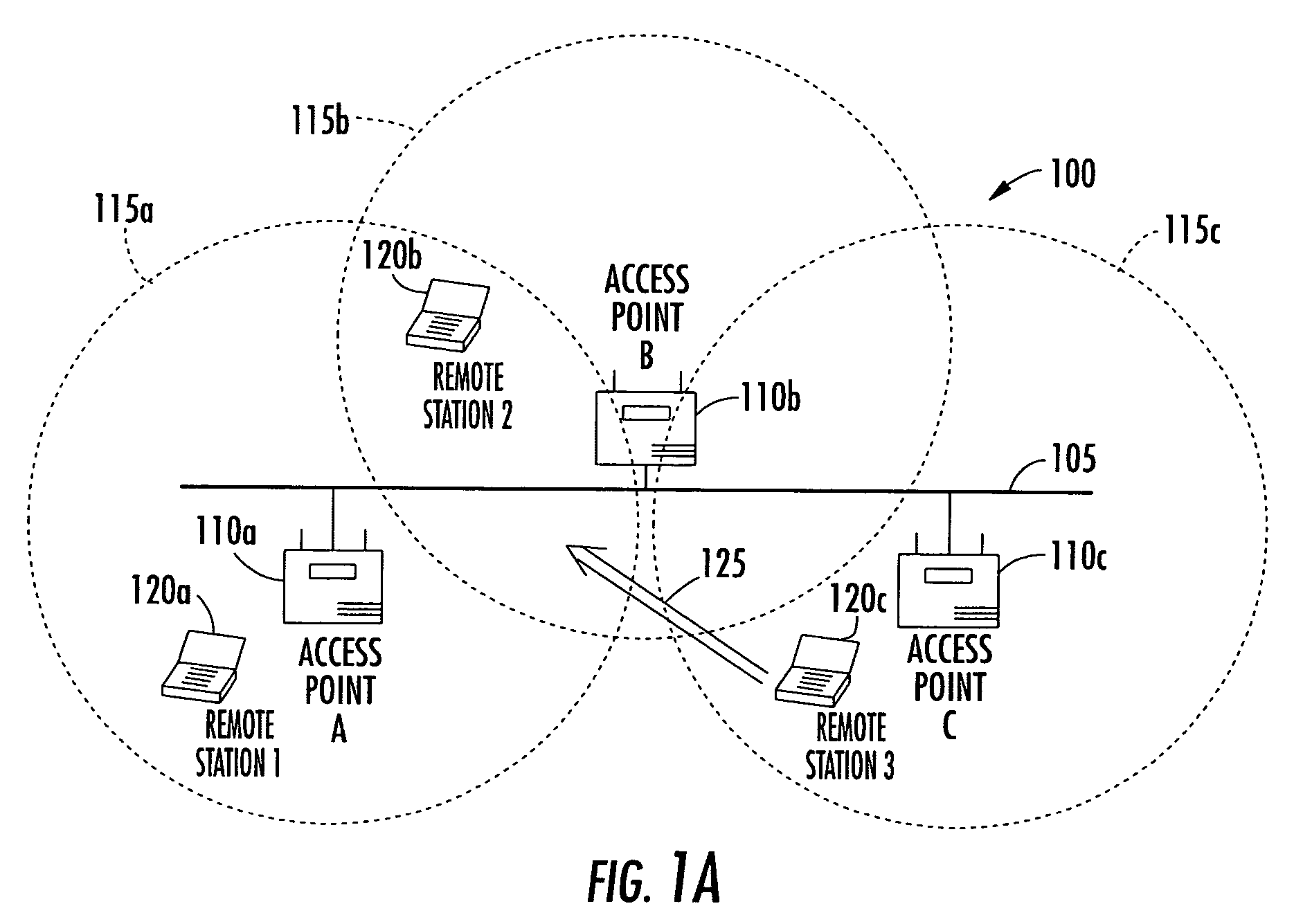

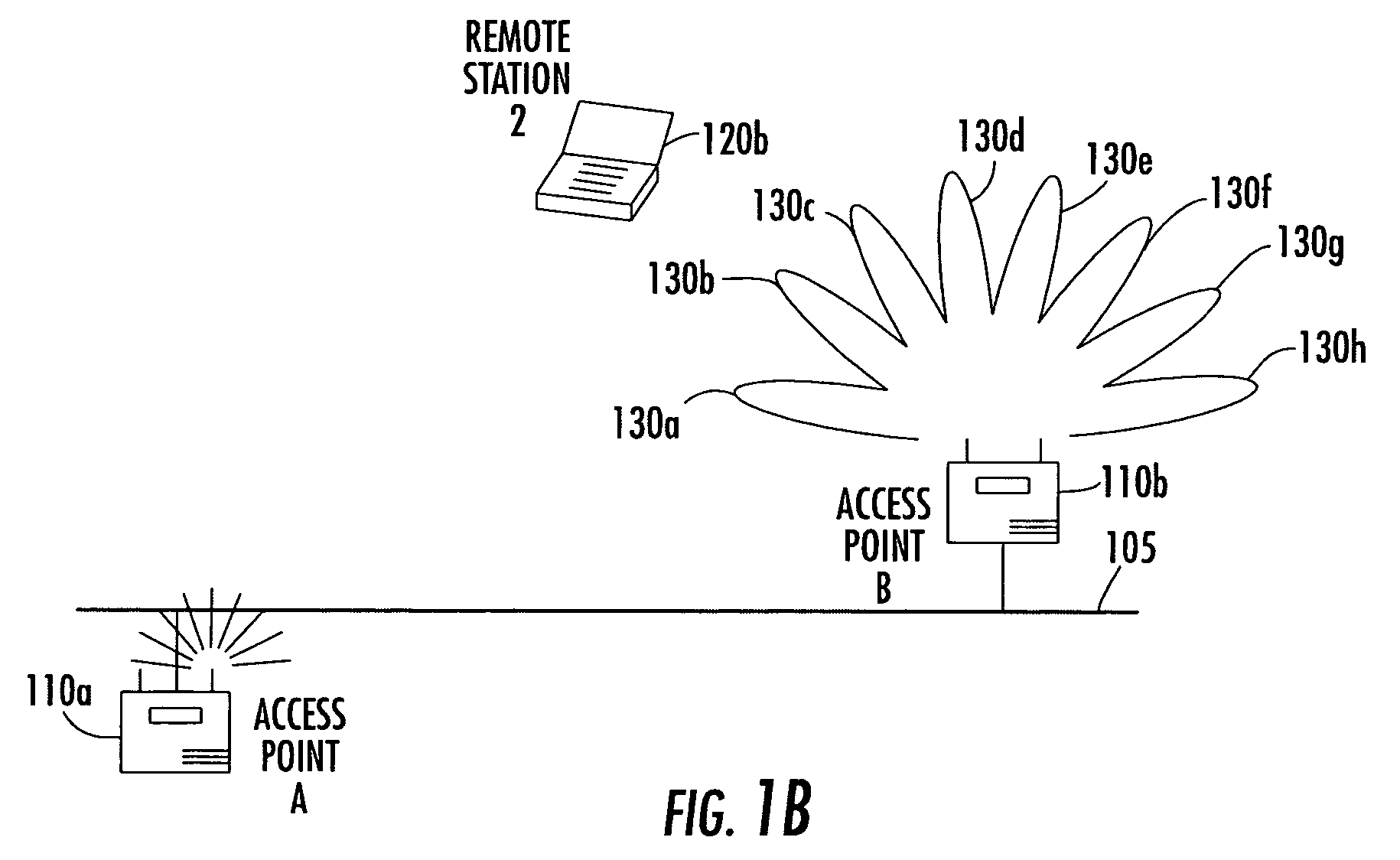

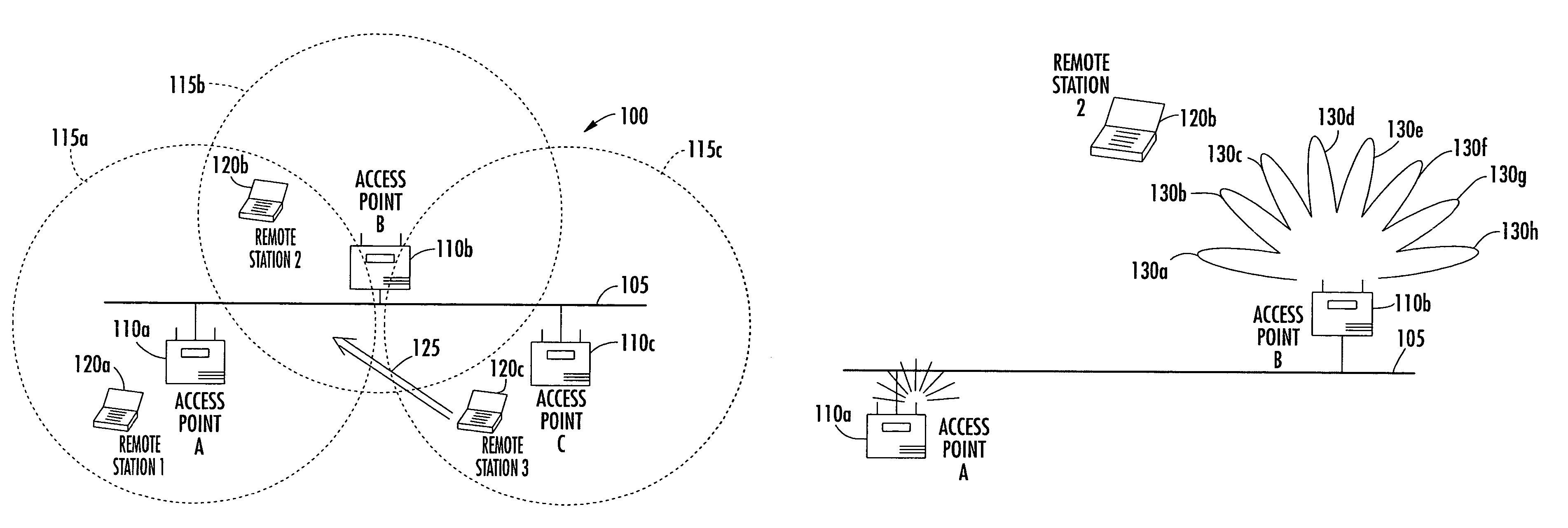

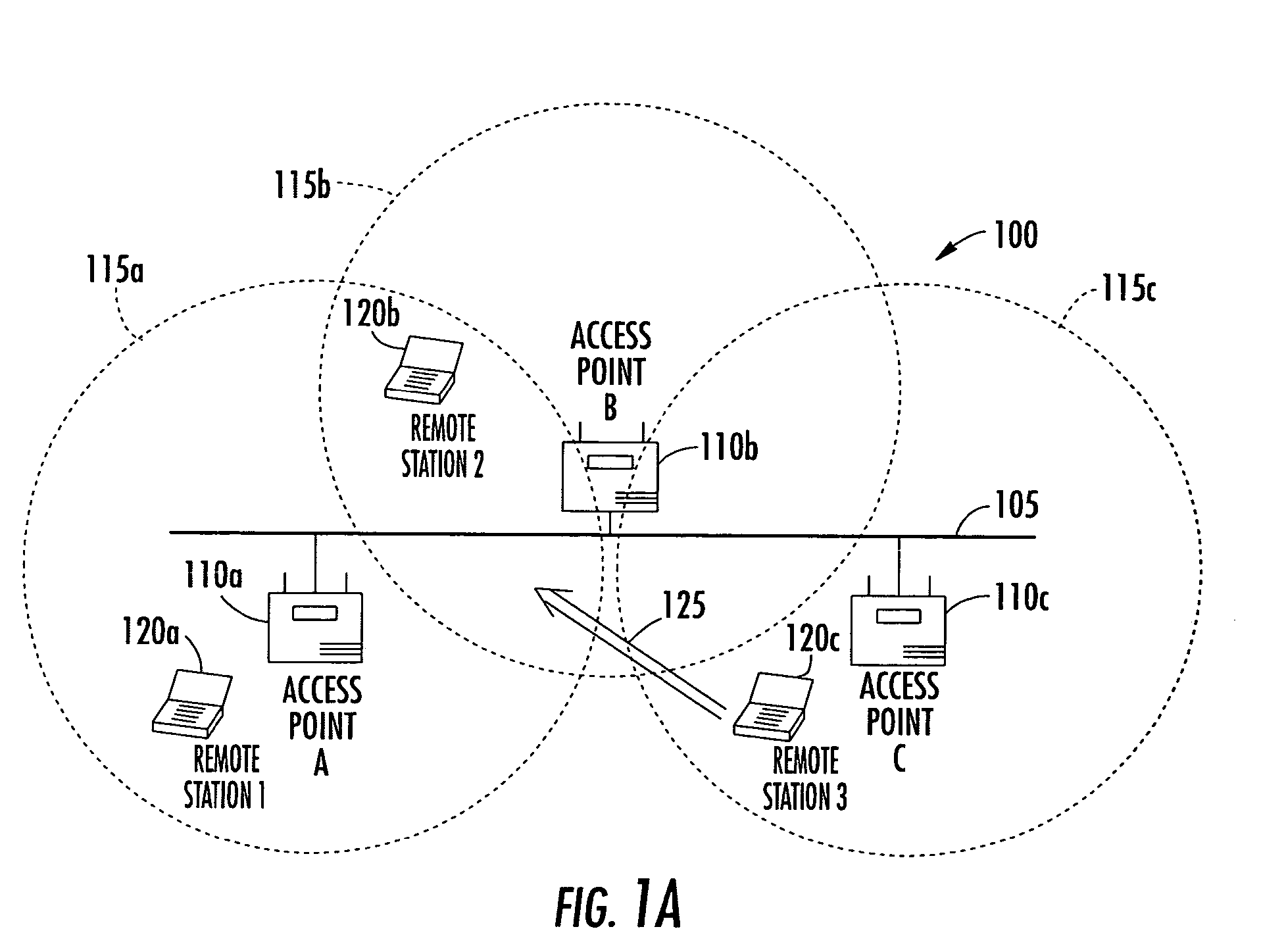

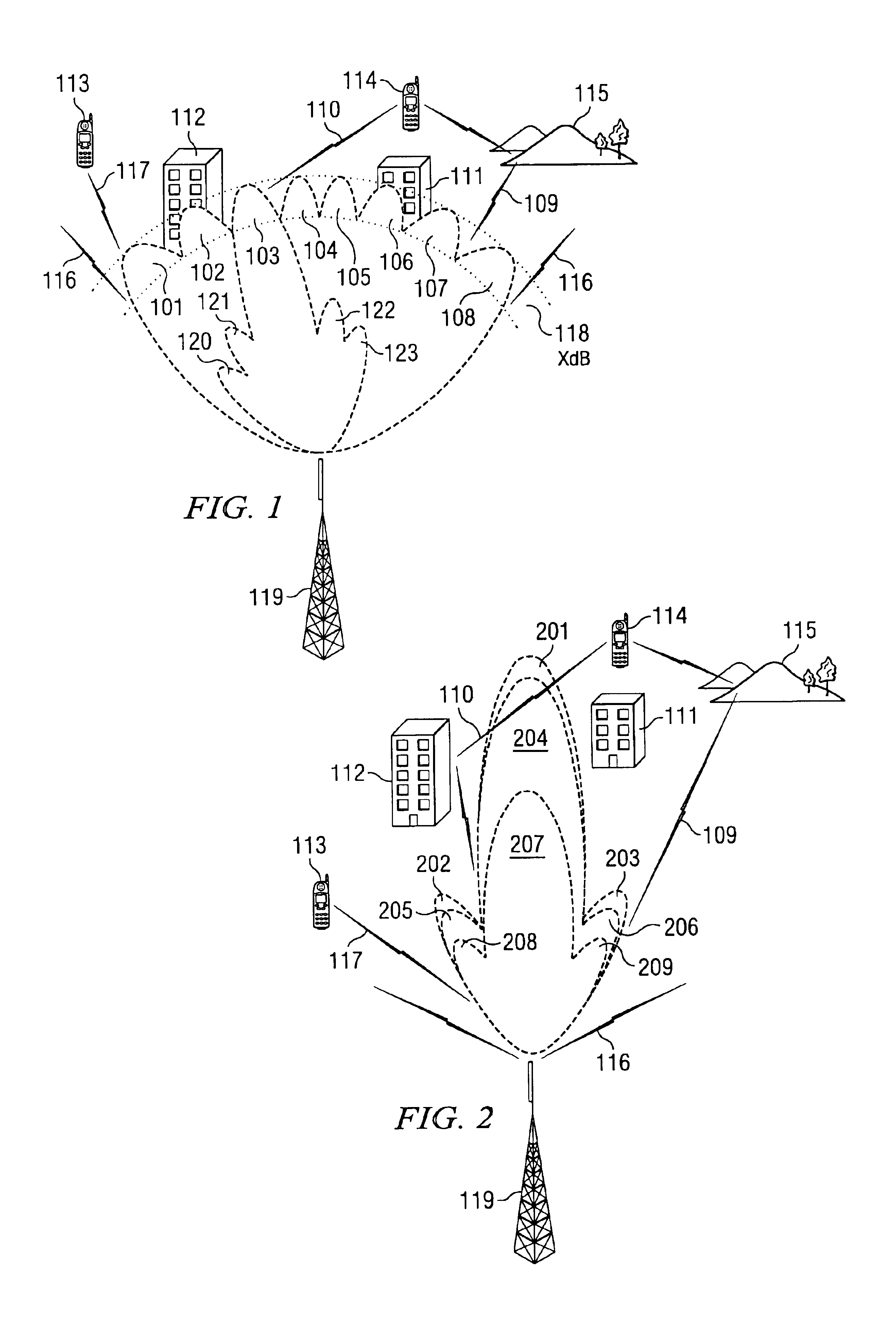

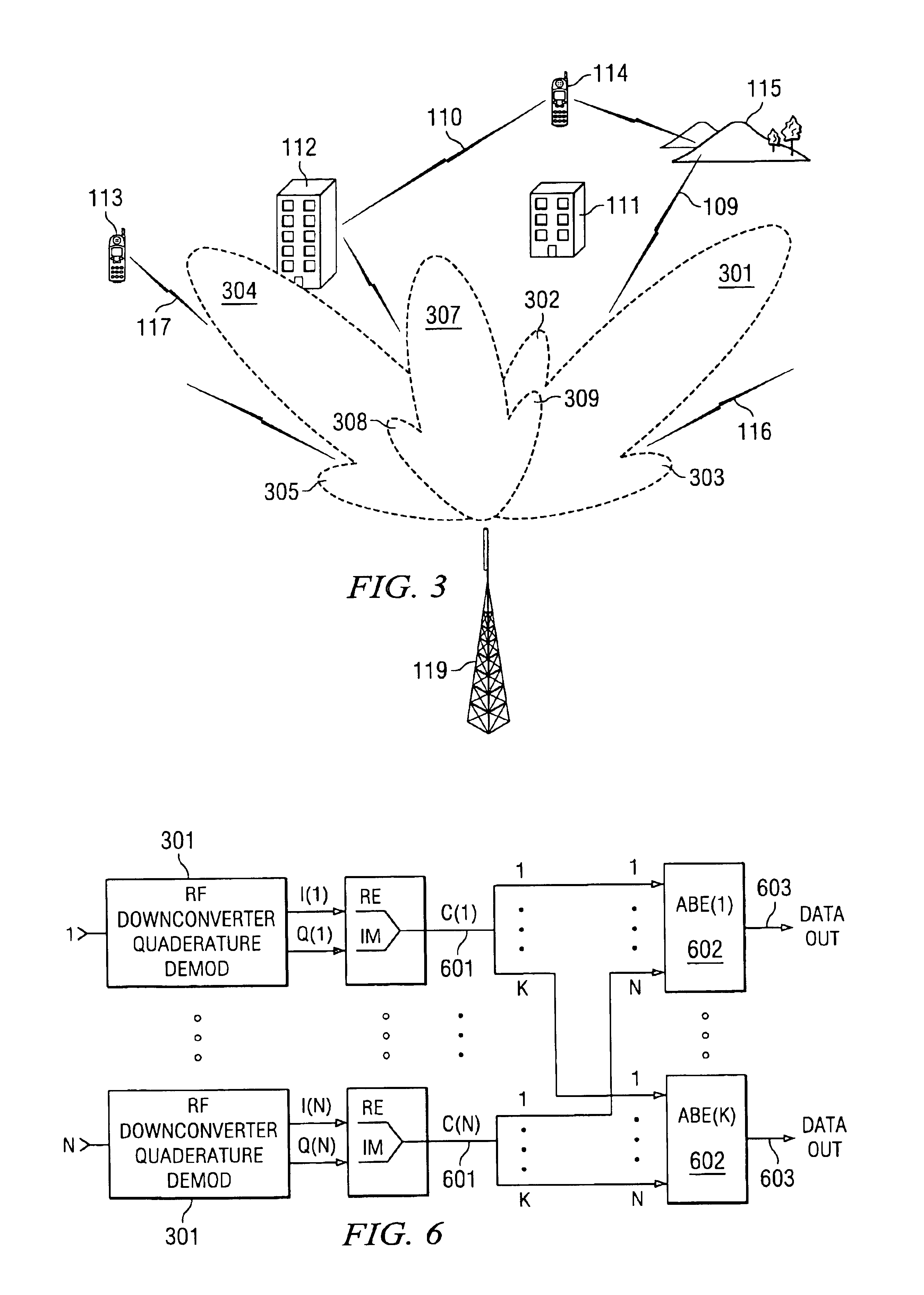

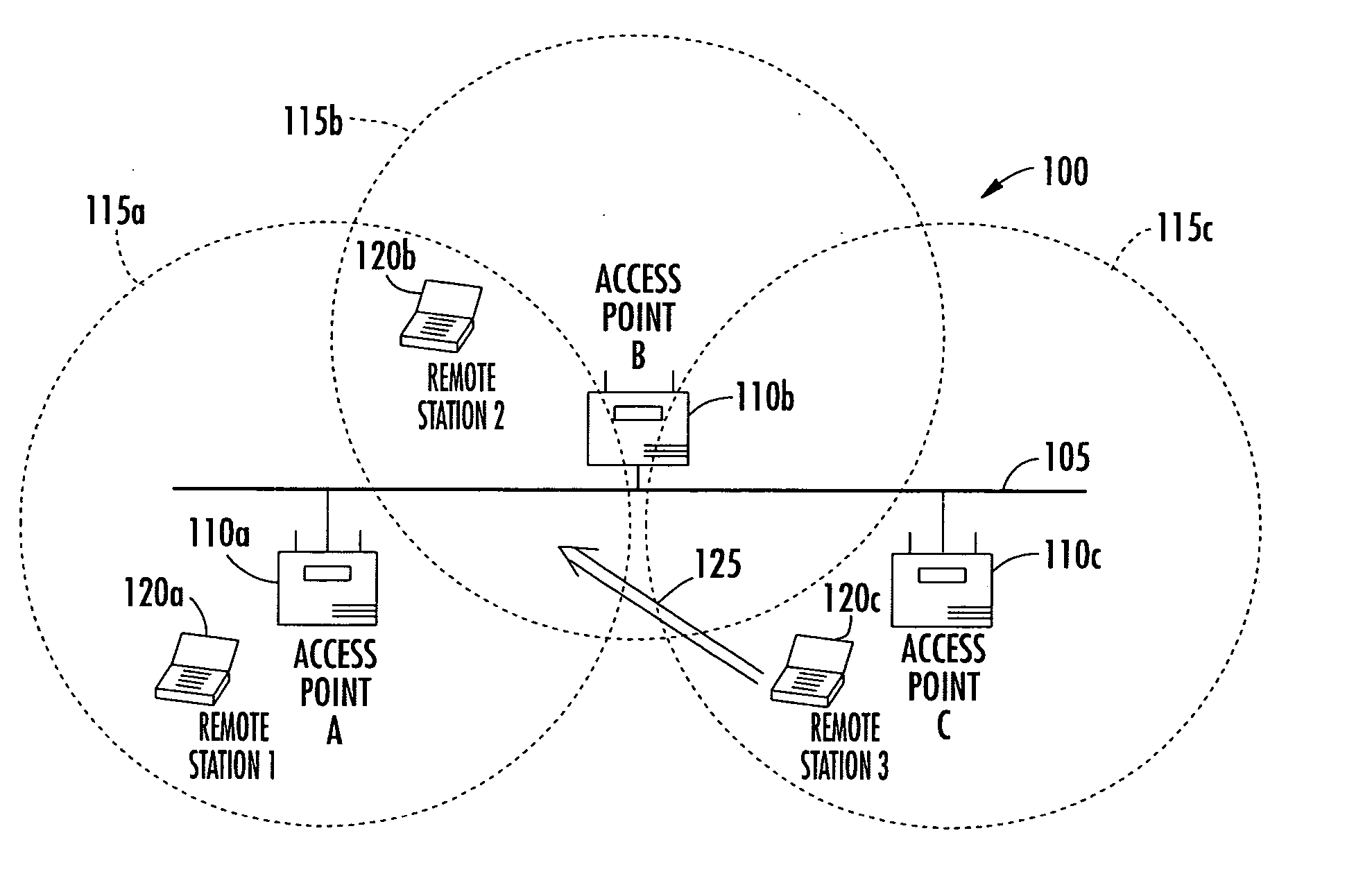

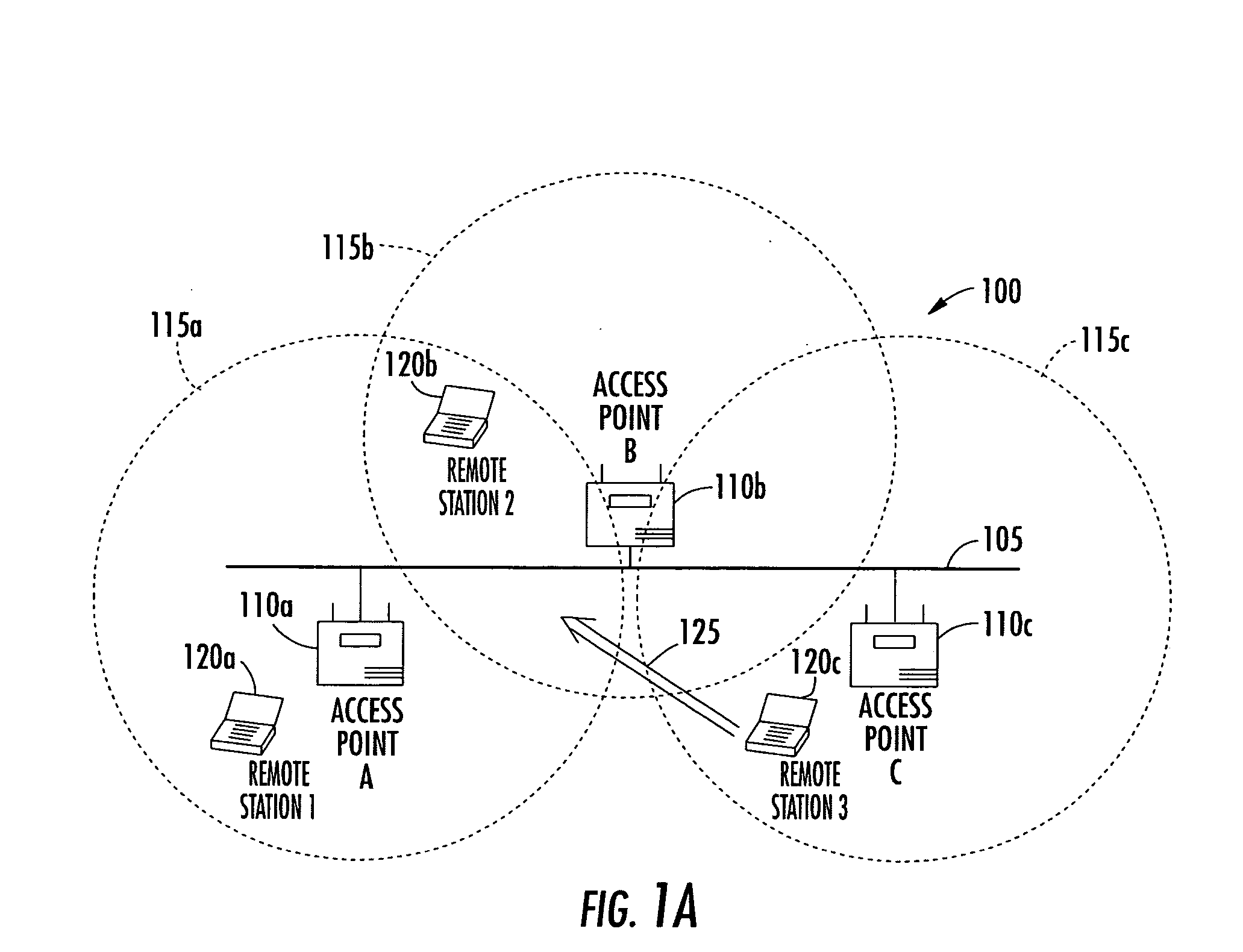

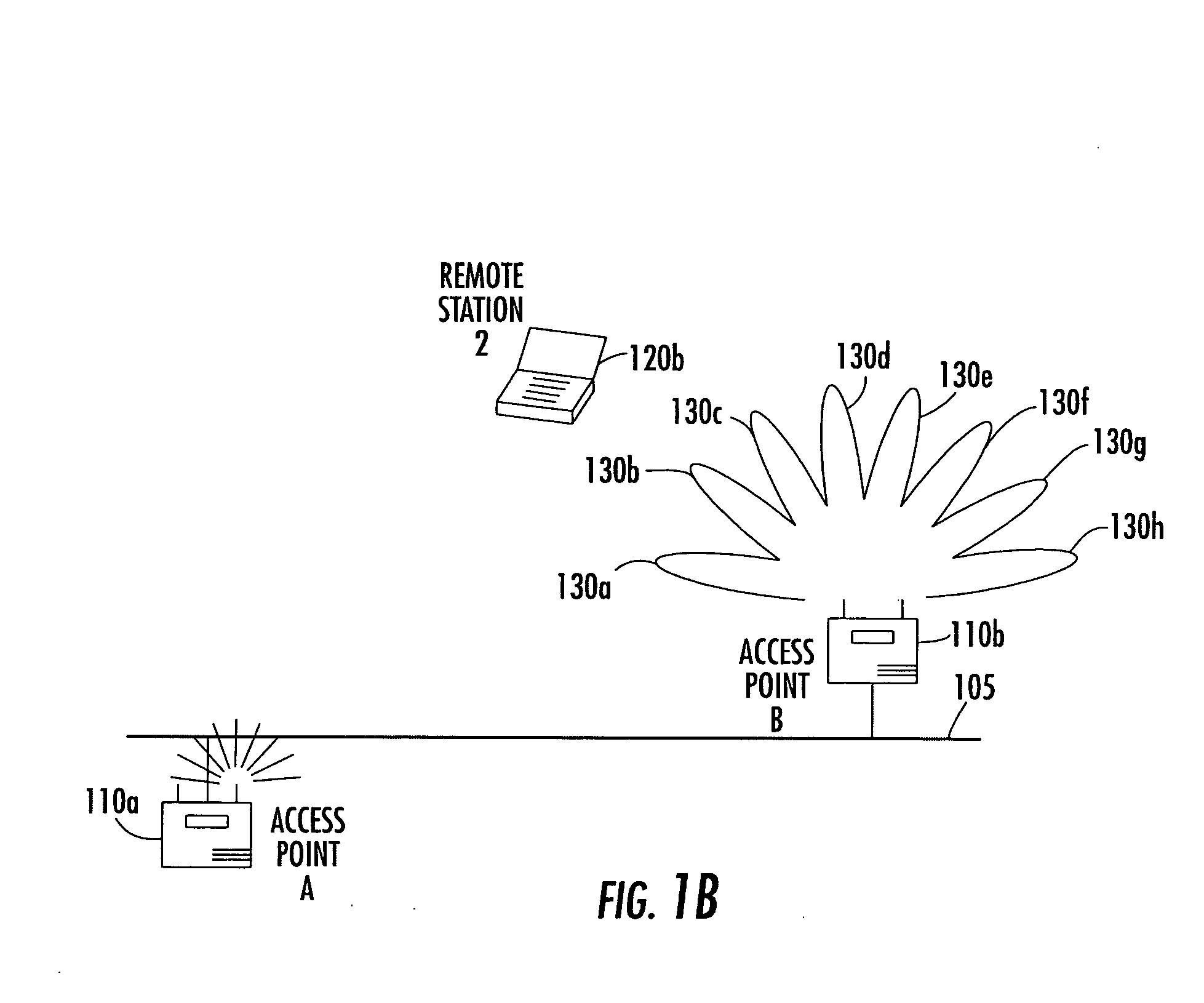

Antenna steering for an access point based upon spatial diversity

InactiveUS20050063340A1Facilitate communicationImprove throughputSpatial transmit diversityNetwork topologiesDirectional antennaEngineering

A method for operating an access point in a wireless local area network is provided, wherein the access point includes a directional antenna for communicating with at least one remote station. The method includes communicating with a selected remote station using a current angle of the directional antenna, and scanning an alternate angle from a plurality of alternate angles of the directional antenna for communicating with the selected remote station. Respective signals received via the current angle and the alternate angle from the selected remote station are measured. The current angle or the alternate angle is selected as a preferred angle based upon the measured signals for continuing communications with the selected remote station.

Owner:IPR LICENSING INC

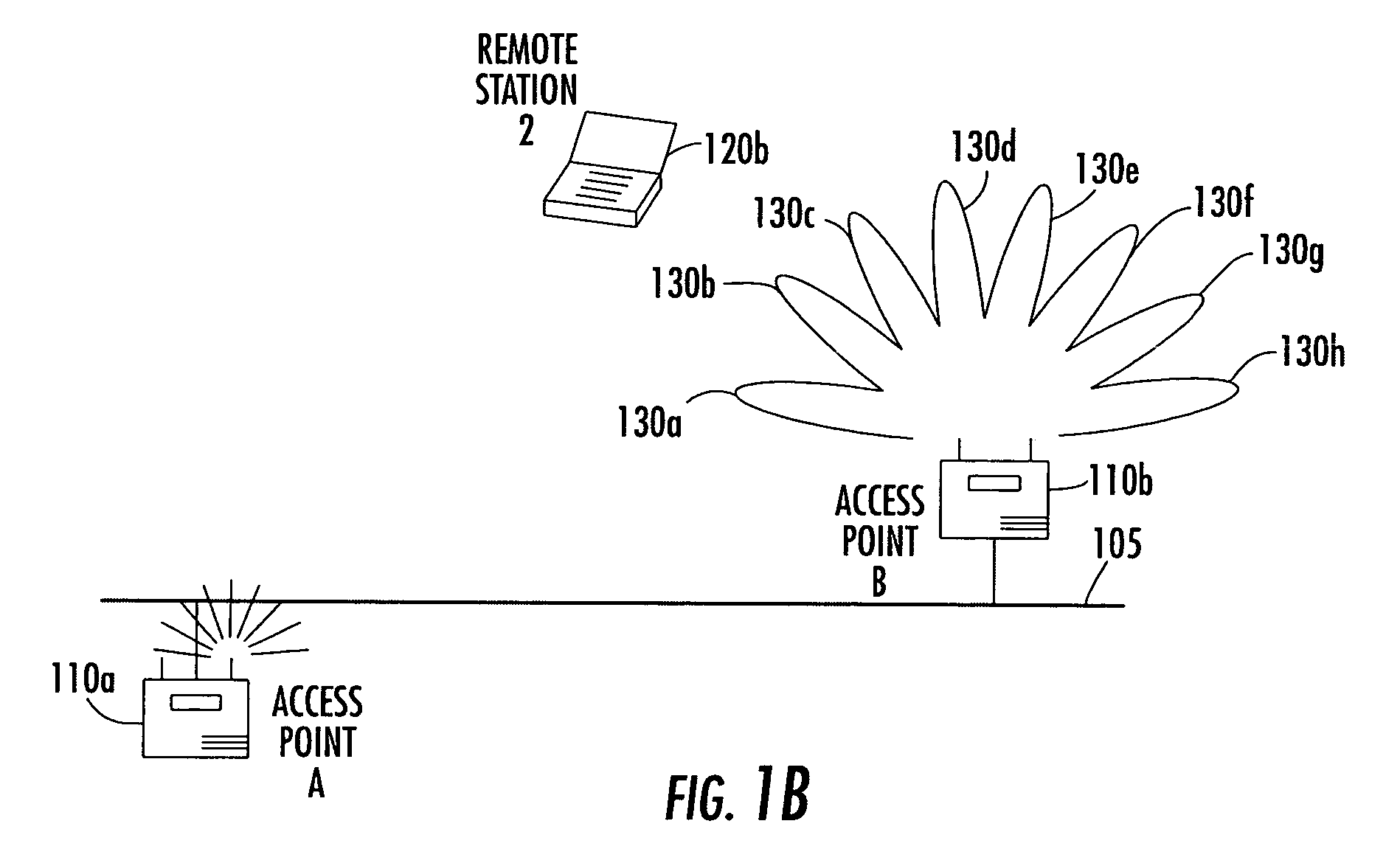

Antenna steering for an access point based upon control frames

InactiveUS7609648B2Improve throughputIncrease rangeSpatial transmit diversityError preventionSignal qualityDirectional antenna

A method for operating an access point in a wireless local area network (WLAN) is provided. The access point includes a directional antenna for communicating with at least one remote station in a forward link based upon an exchange of packet data comprising a plurality of control frames and a data frame. The directional antenna includes a plurality of antenna patterns. The method includes receiving a first control frame via a first antenna pattern of the directional antenna from the remote station, transmitting a first data frame to the remote station, and receiving a second control frame via a second antenna pattern of the directional antenna from the remote station. A signal quality of the first control frame received via the first antenna pattern and a signal quality of the second control frame received via the second antenna pattern are measured. The respective measured signal qualities associated with the first and second antenna patterns are compared.

Owner:IPR LICENSING INC

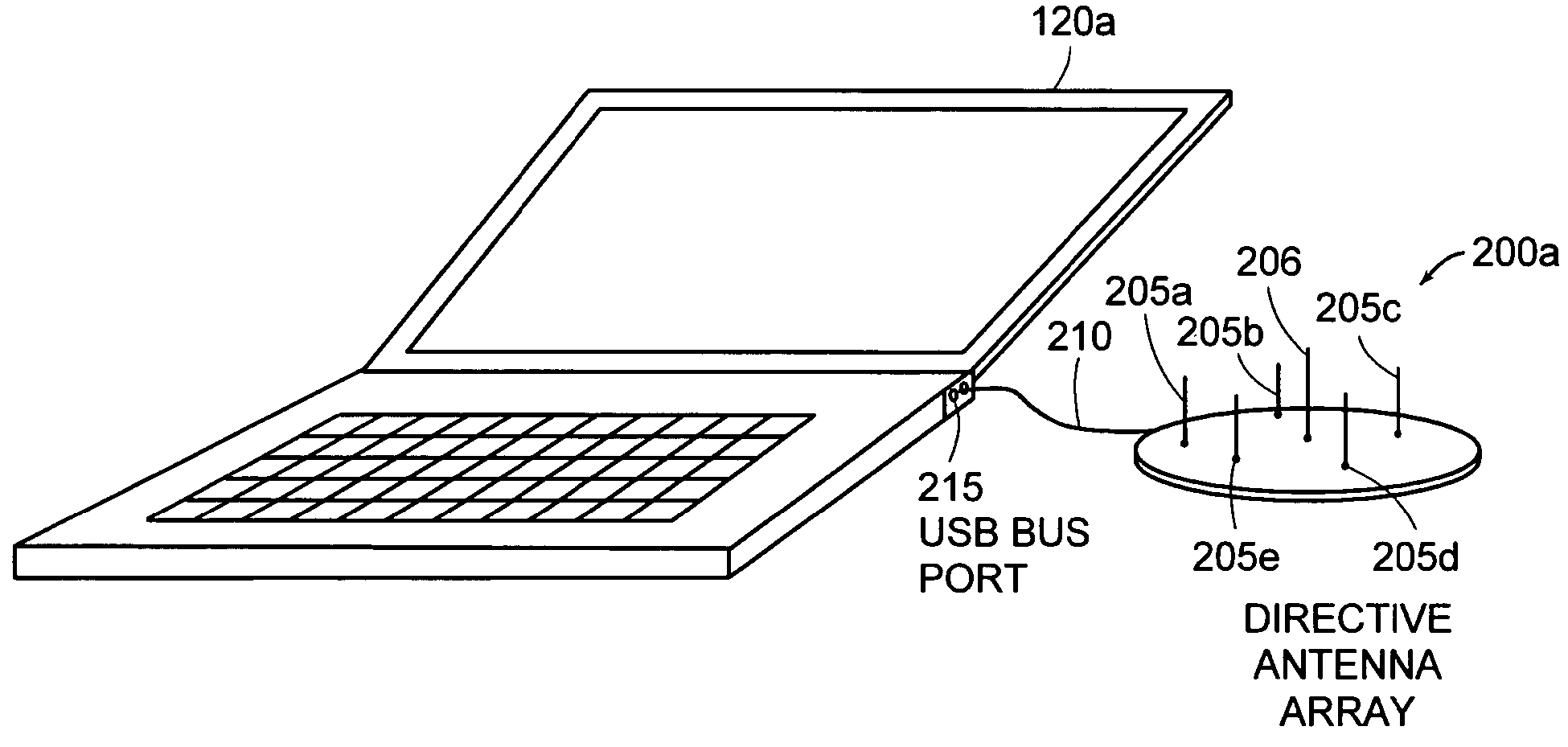

Antenna steering method and apparatus for an 802.11 station

InactiveUS20050037822A1Improves diversityImprove signal qualityAntenna supports/mountingsSubstation equipmentSignal-to-noise ratio (imaging)Media access control

A method or apparatus steers a directional antenna for a station to communicate with an Access Point (AP) in an 802.11 protocol system. The method or apparatus may include setting the directional antenna in an omni-directional pattern during a Beacon scan. After authentication with a selected AP, the method or apparatus conducts an antenna beam selection process to determine a “best” direction for communicating with the selected AP based on a metric, such as Signal-to-Noise Ratio (SNR), of the Beacon frames received on each of the directional antenna scan angles. The method or apparatus may be integrated into or associated with a Medium Access Control (MAC) layer and receive signal quality metrics from the Physical (PHY) layer.

Owner:IPR LICENSING INC

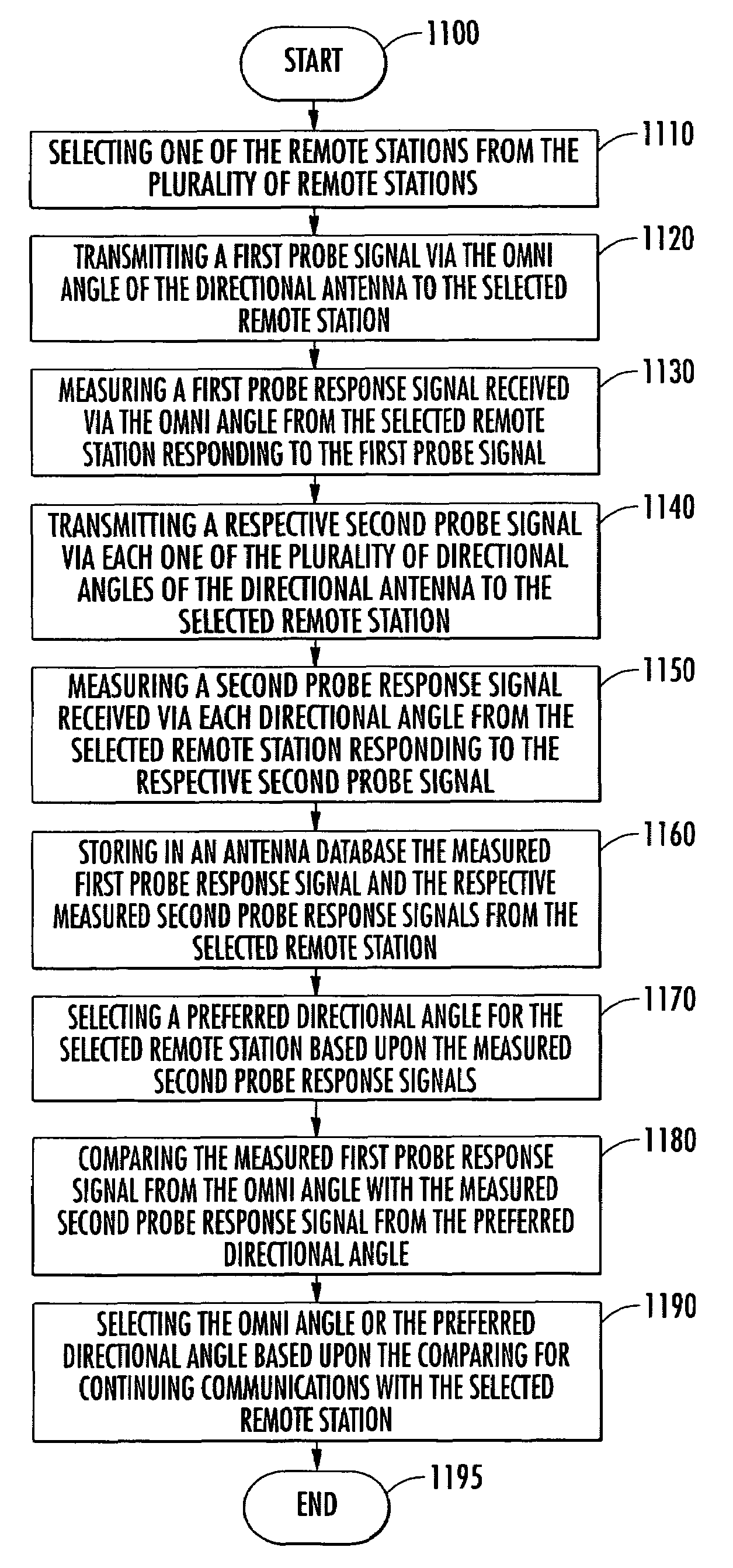

Antenna steering for an access point based upon probe signals

InactiveUS20050075141A1Facilitate communicationImprove throughputSpatial transmit diversityData switching by path configurationDirectional antennaEngineering

A method for operating an access point in a wireless local area network (WLAN) is provided. The access point includes a directional antenna for communicating with a plurality of remote stations, and the directional antenna includes an omni angle and a plurality of directional angles. The method includes selecting one of the remote stations from the plurality of remote stations, transmitting a first probe signal via the omni angle of the directional antenna to the selected remote station, and measuring a first probe response signal received via the omni angle from the selected remote station responding to the first probe signal. A respective second probe signal is transmitted via each one of the plurality of directional angles of the directional antenna to the selected remote station, and a second probe response signal received via each directional angle from the selected remote station responding to the respective second probe signal is measured. The measured first probe response signal and the respective measured second probe response signals from the selected remote station are stored in an antenna database.

Owner:IPR LICENSING INC

Antenna steering for an access point based upon probe signals

InactiveUS7047046B2Improve throughputIncrease rangeSpatial transmit diversityData switching by path configurationDirectional antennaEngineering

Owner:IPR LICENSING INC

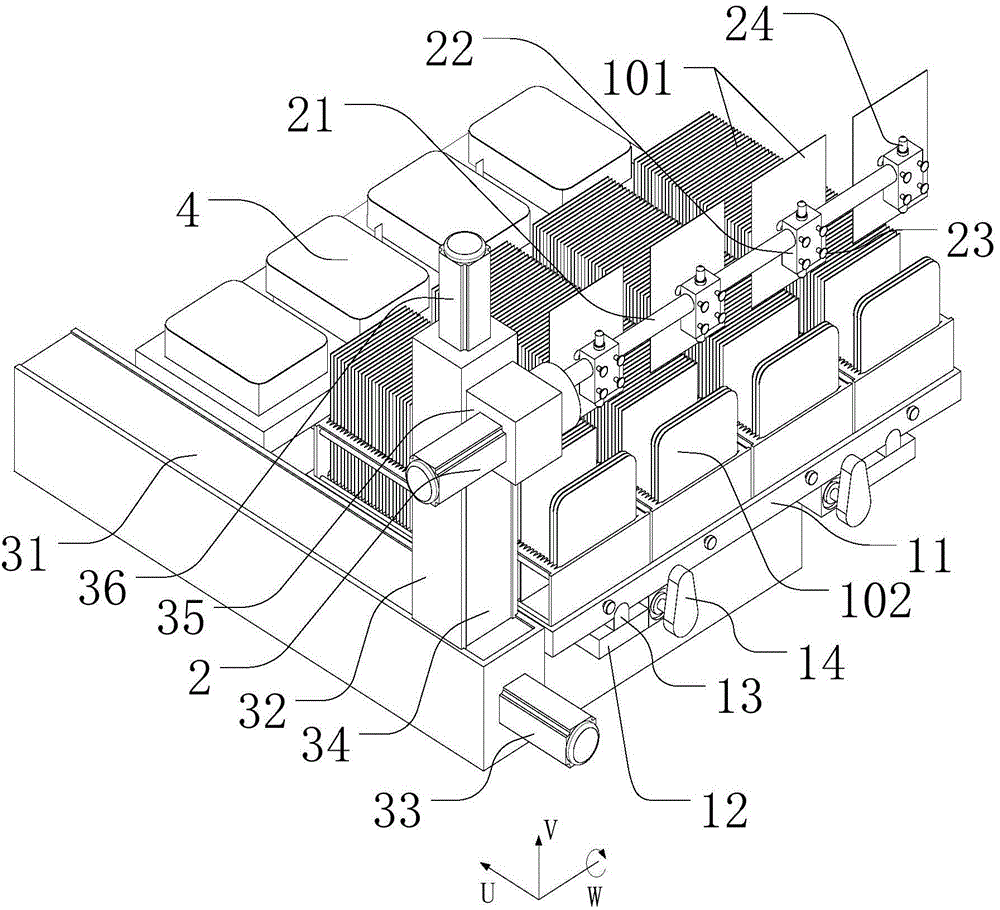

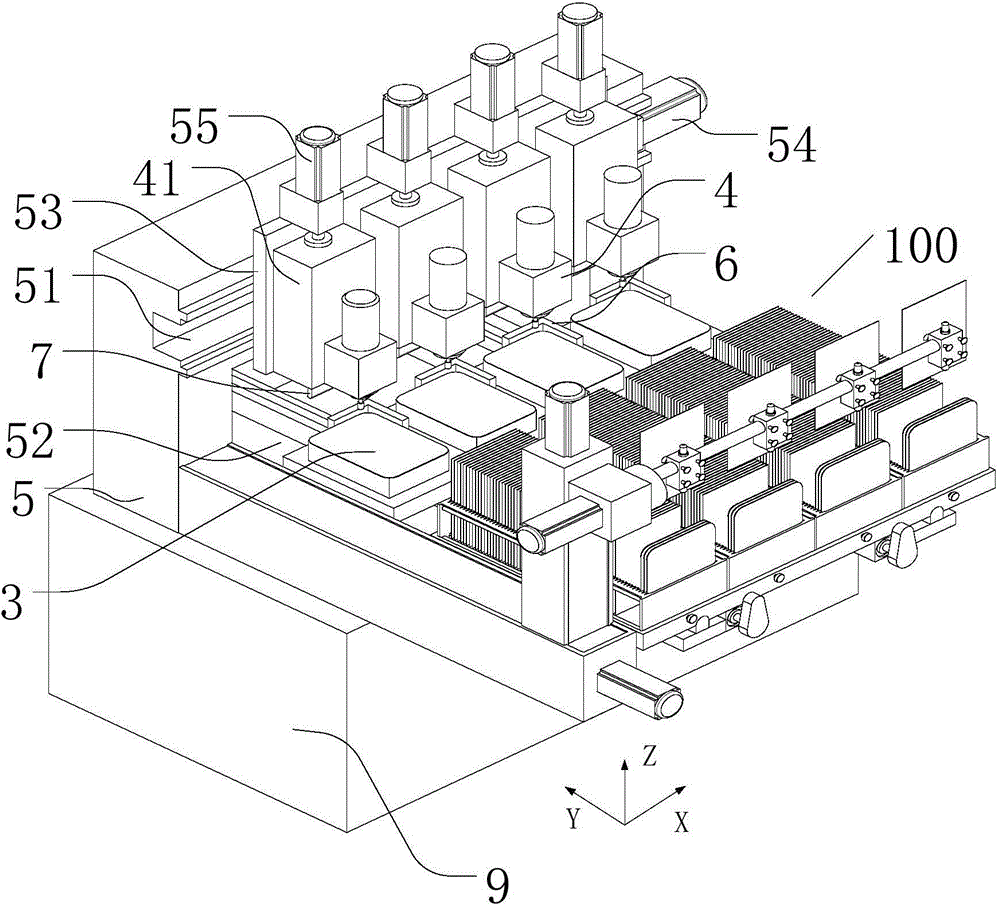

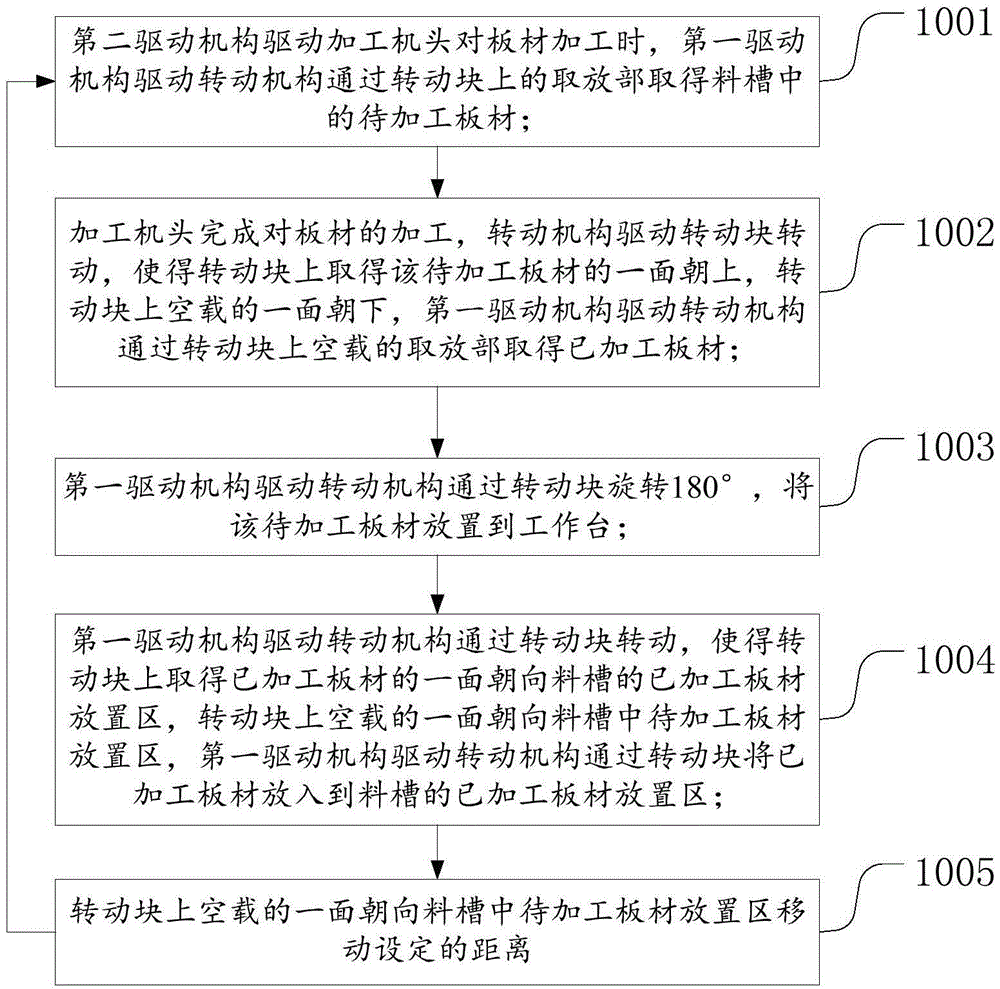

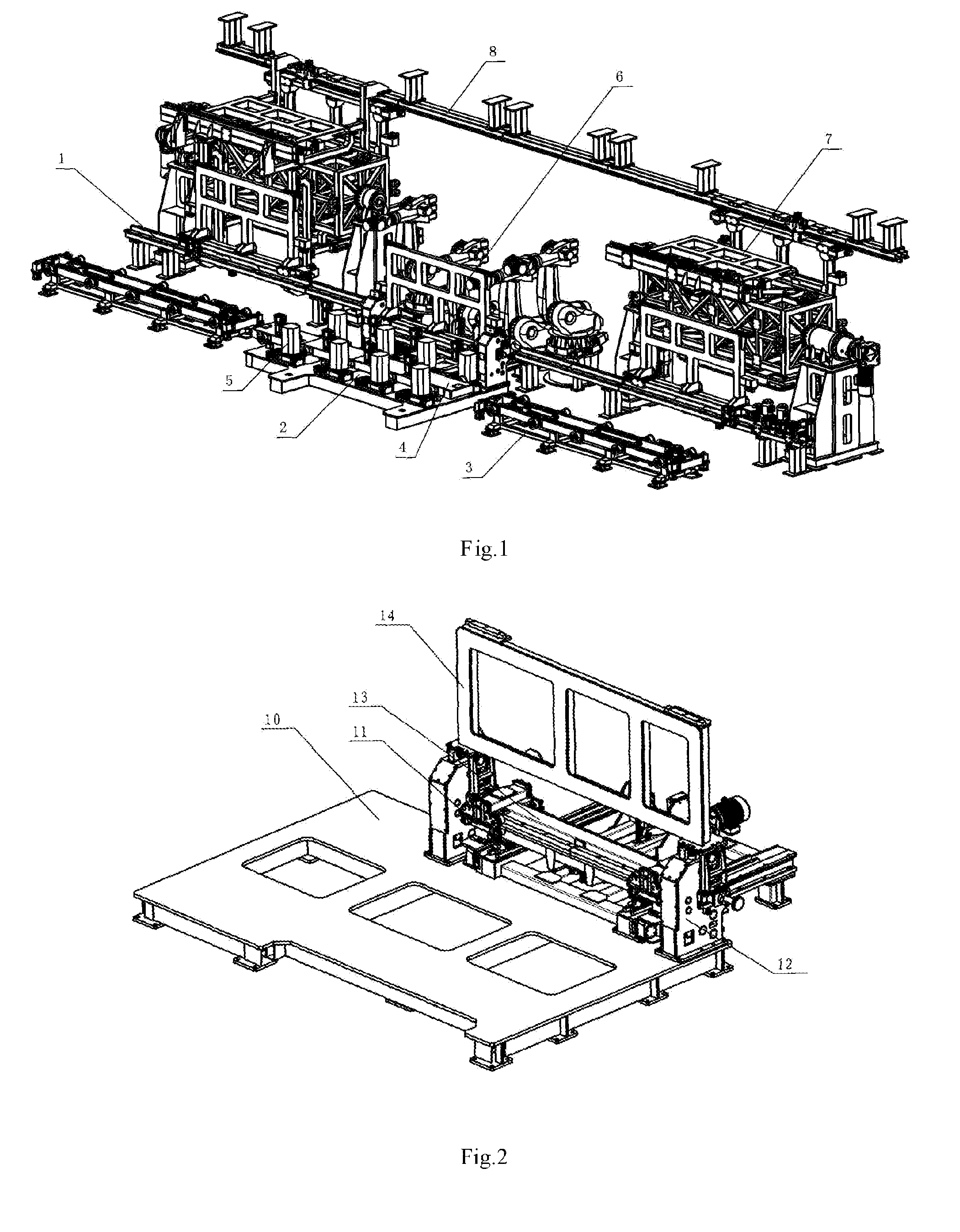

Sheet material feeding and discharging device, mobile phone glass machining center and machining method

ActiveCN104890422AFlexible loading and unloading methodsImprove the efficiency of picking and unloadingGrinding feedersOther artistic work equipmentsEngineeringMachine tool

The invention discloses a sheet material feeding and discharging device, a mobile phone glass machining center and a machining method. The device comprises a material groove, a rotating mechanism provided with a rotating rod, a first drive mechanism and rotating blocks installed on the rotating rod; and taking and placing parts are respectively installed on the front and rear sides of each rotating block, the rotating mechanism is installed on the first drive mechanism, and the rotating blocks are located over the material groove. Two faces of the rotating blocks are provided with the taking and placing parts, the rotating mechanism can drive the rotating blocks to perform 360-degree rotation, a feeding and discharging mode is more flexible, and taking and placing efficiency is greatly improved. After the sheet material feeding and discharging device is applied to the mobile phone glass machining center, a mode that the rotating blocks are fixed to the rotating rod is adopted, and the rotating rod extends to the other side to form a gantry crane type structure, so the rotating blocks can be unlimitedly expanded on the rotating rod, a machining table and the material groove can be correspondingly increased, a plurality of working positions can be increased on one machine tool to the maximum extent, and machining efficiency is greatly improved.

Owner:苏州恒远精密数控设备有限公司

Radio-Access Method, Related Radio Base Station, Mobile-Radio Network and Computer-Program Product Using an Assignment Scheme for Antennas' Sectors

ActiveUS20090238566A1Increase flexibilityImproving degree of reconfigurabilityOptical multiplexElectromagnetic transmissionRadio over fiberMobile radio

A radio base station for a mobile radio network, includes a set of remote units connected with the radio base station, preferably via a radio over fibre arrangement. Each remote unit provides radio cell coverage by means of a set of communication channels, and is equipped with a respective set of antenna elements. The communication channels are distributed over the antenna elements according to an assignment scheme that is dynamically variable.

Owner:TELECOM ITALIA SPA

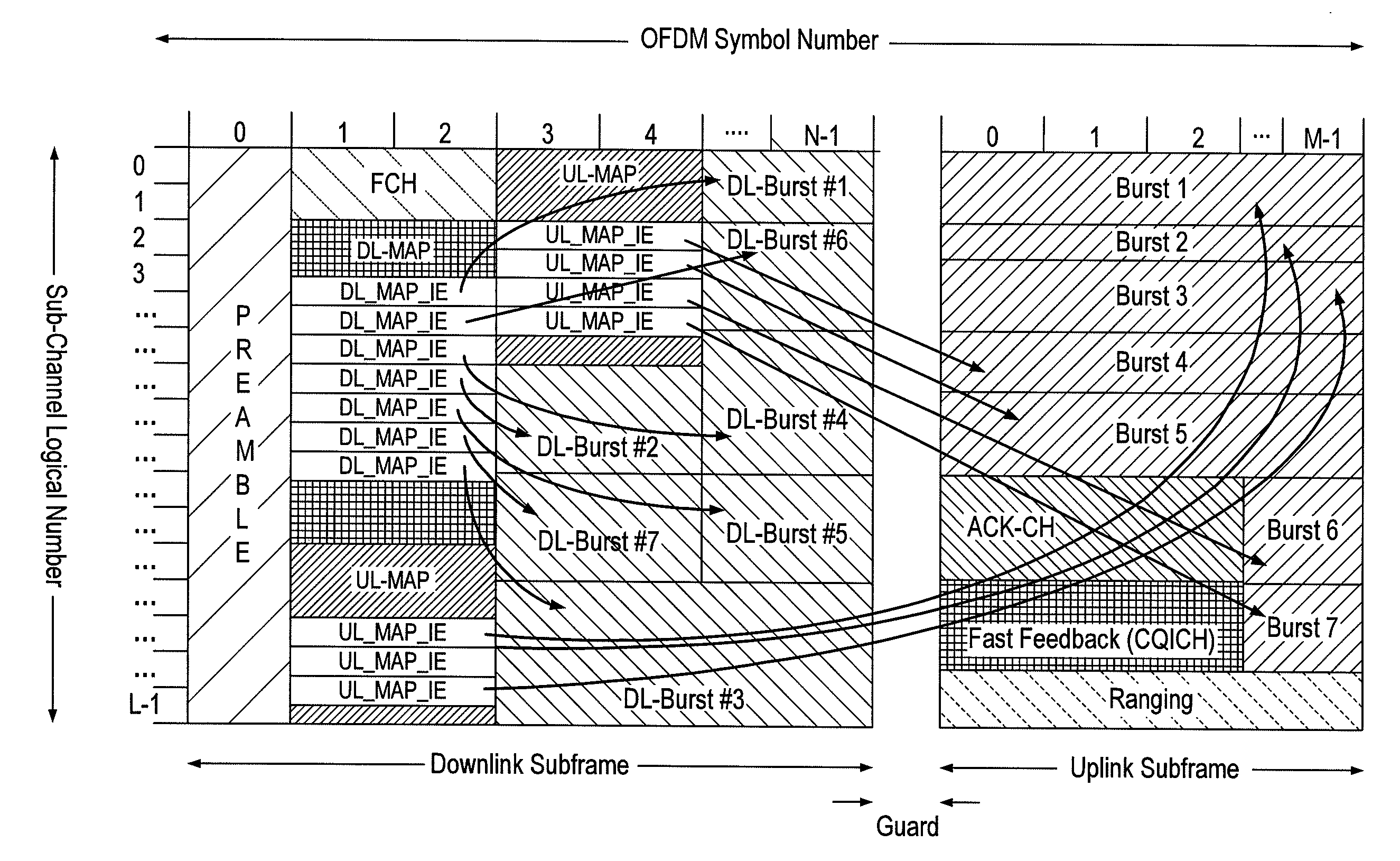

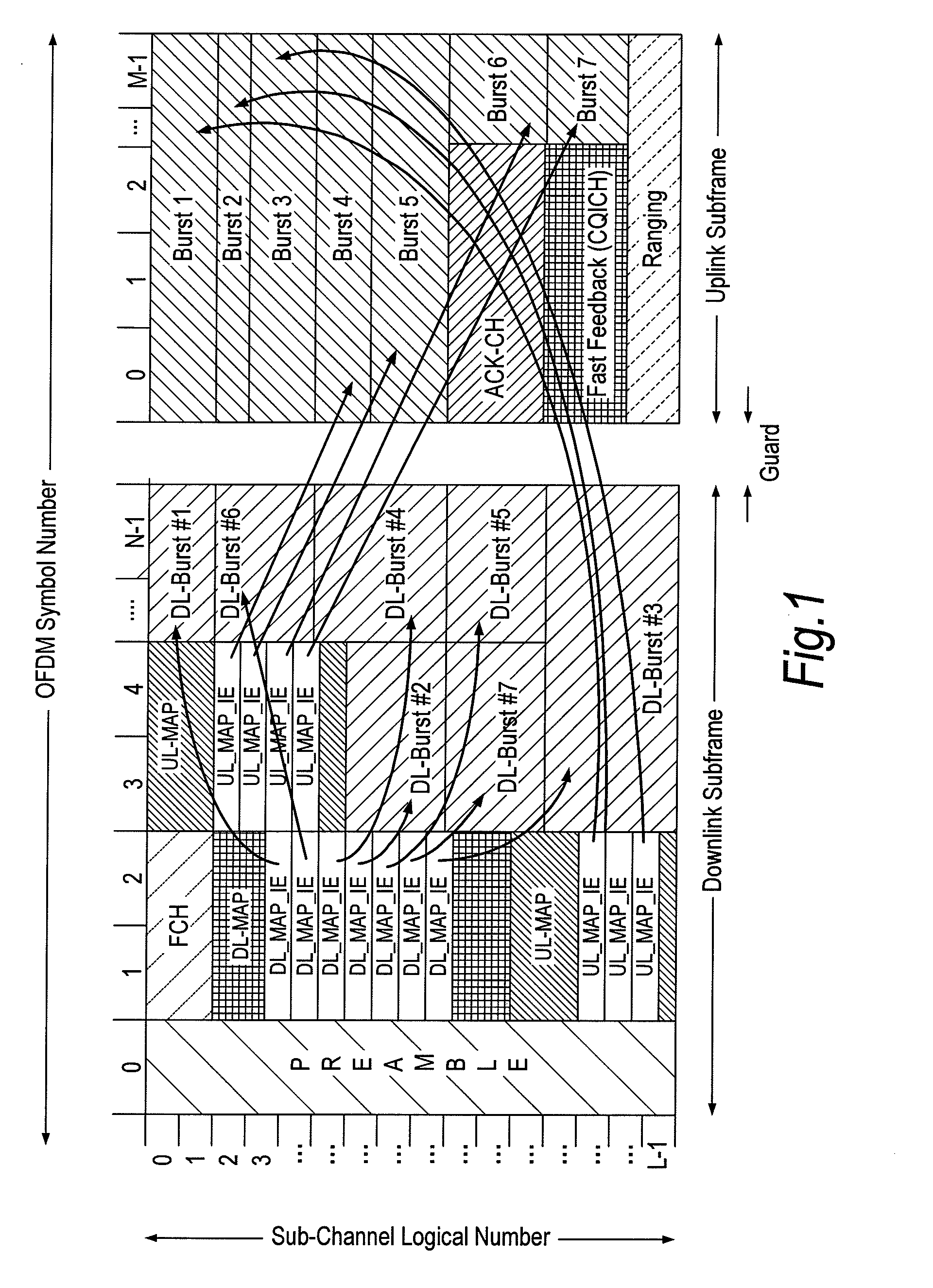

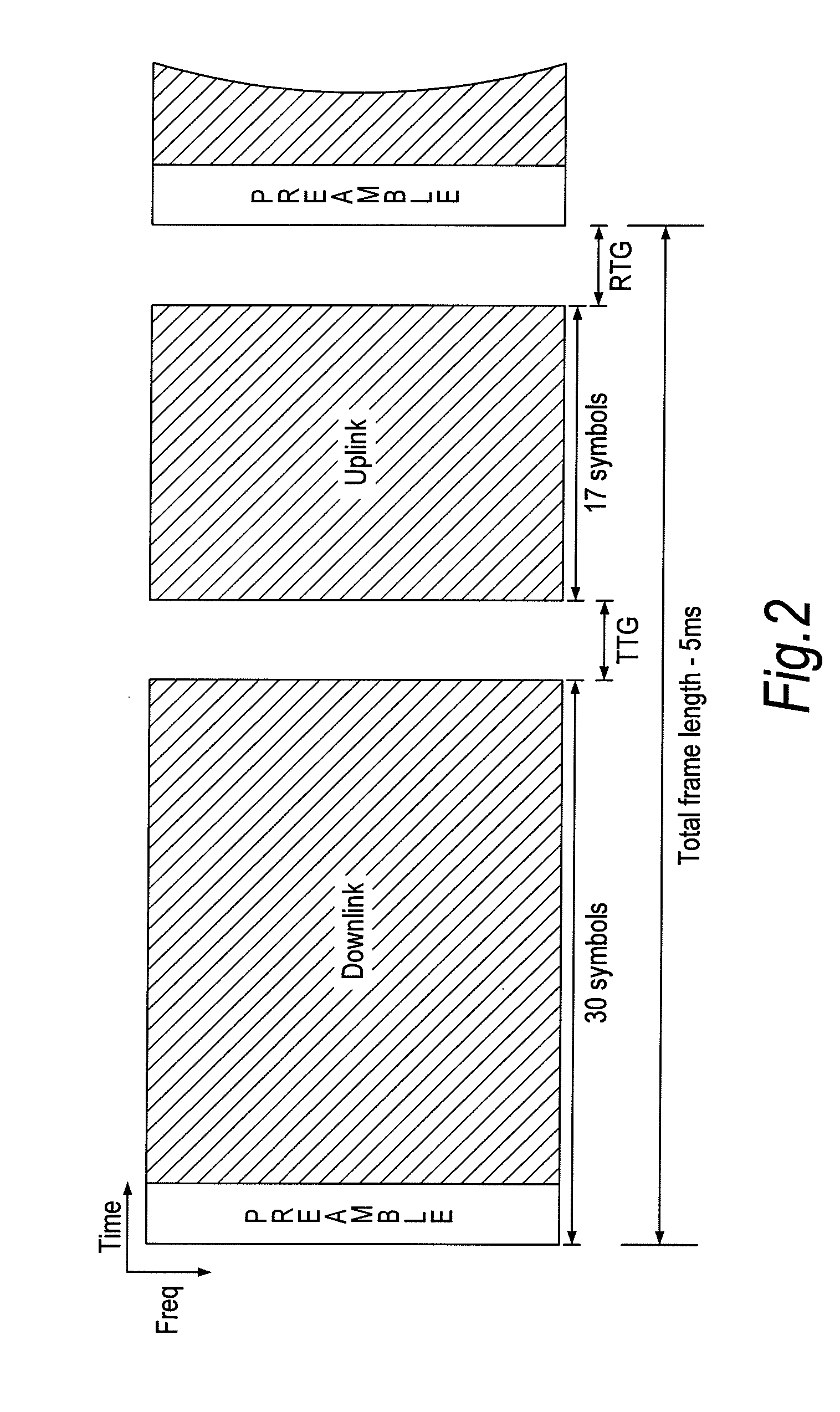

Frame structure for a wireless communication system

ActiveUS20090257366A1Improve latencyFully compatibleTime-division multiplexSecret communicationCommunications systemFeature set

A frame format used in a wireless communication system, more particularly an OFDMA TDD wireless communication system, of the kind comprising a base station and a plurality of fixed or mobile subscriber stations, the base station maintaining connections with each of the subscriber stations by performing wireless communication in units of frames having said frame format, and within each frame, allocating resources for data transmission and signalling.Each frame has a plurality of downlink subframes and a plurality of uplink subframes including, in time order, a first downlink subframe, a first uplink subframe, a final downlink subframe and a final uplink subframe. One or more further downlink subframe / uplink subframe pairs may be interposed between the first and final subframes as desired, and the configuration can be changed dynamically.The frame structure is capable of adapting to a system that is evolving from supporting predominantly legacy terminals to one which will be supporting an increasing number of enhanced terminals. The coexistence of both legacy and enhanced terminals within the proposed frame structure will have minimal impact of the performance of legacy subscriber stations. Depending on the required number of either legacy or enhanced terminals that need to be supported, the base station has the ability to define a frame configuration where the number of subframes per frame is configured based on the feature set of the operational subscriber stations and the mobility requirements of enhanced subscriber stations such that the frame structure at all times retains sufficient features to support the attachment of legacy stations that do not support the enhanced features.

Owner:FUJITSU LTD

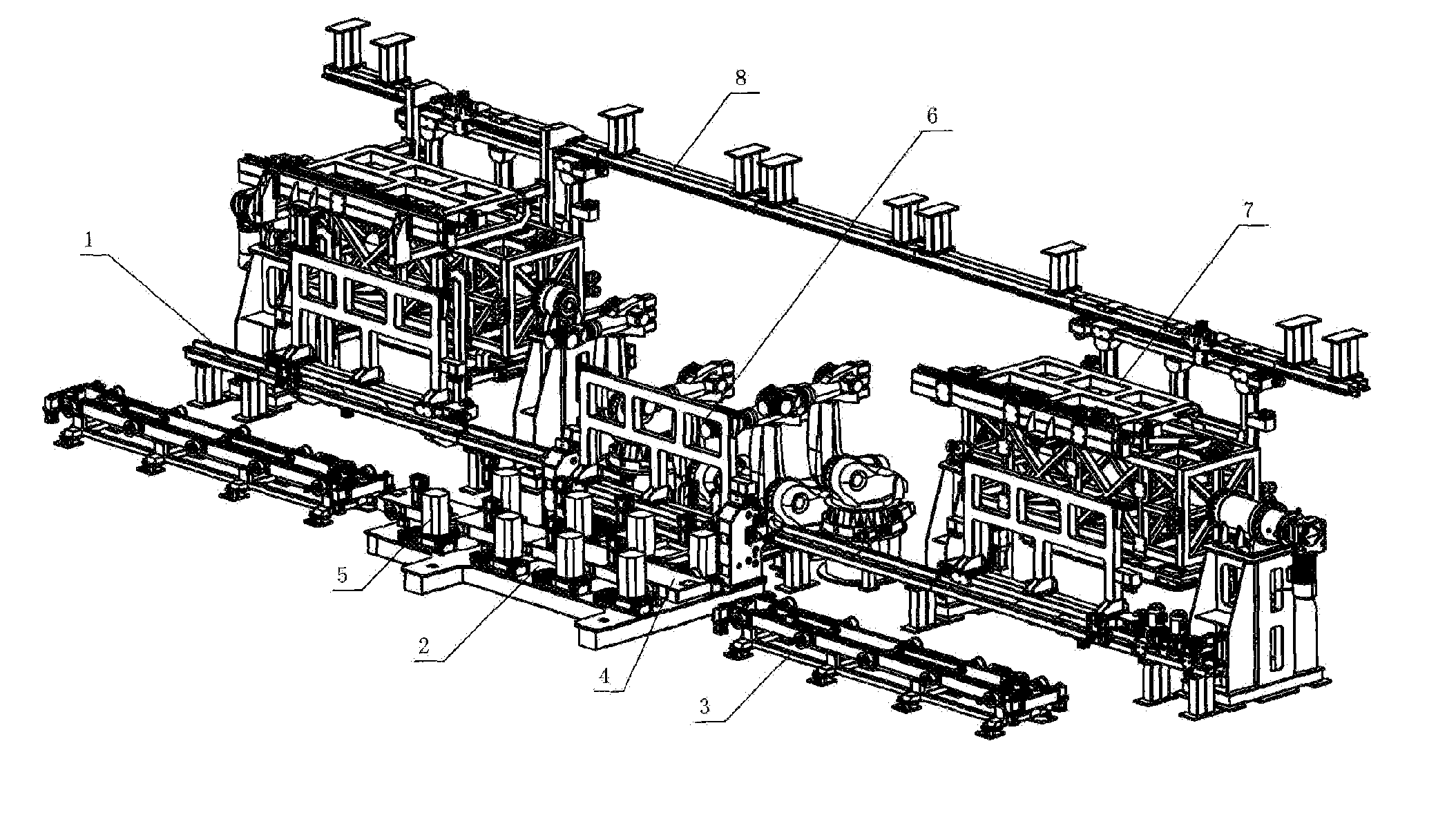

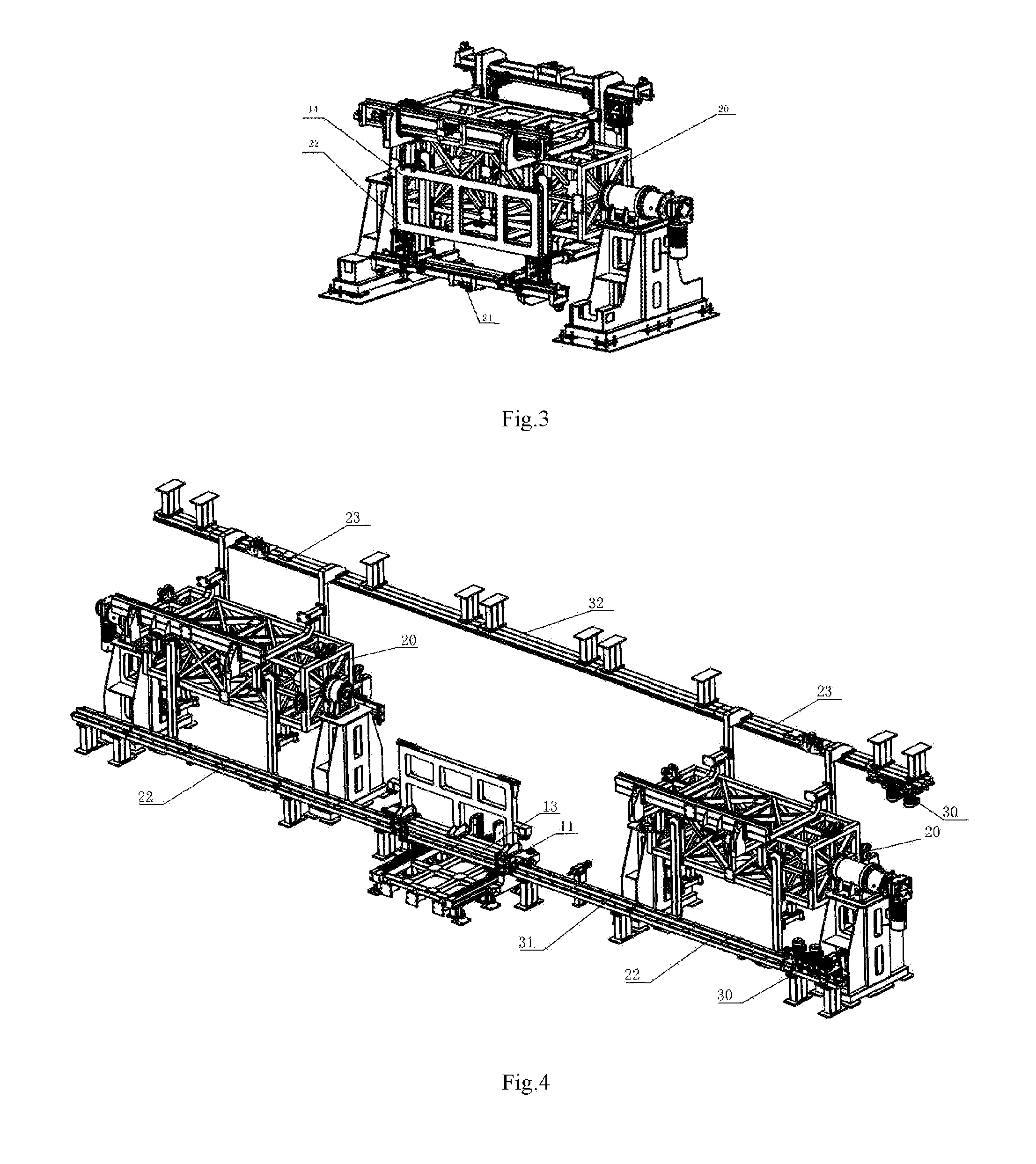

Multi-vehicle model collinear flexible framing system

ActiveUS20150001279A1Improve production efficiencyRapid paceWelding/cutting auxillary devicesAuxillary welding devicesProduction lineTransport system

A multi-vehicle type co-production line flexible framing is disclosed, comprising a robot welding system, a high speed transport system, a floor panel intelligent flexible positioning system, and a side panel flexible positioning and switching system. The floor panel intelligent flexible positioning system is correspondingly connected to a transfer rail of the high speed transport system. The side panel flexible positioning and switching system comprises a side panel fixture consolidation system, a fixture storage system, and a fixture switching and rail system. The side panel fixture consolidation system corresponds to the side of the floor panel intelligent flexible positioning system. The fixture storage system is arranged on two sides of the side panel fixture consolidation system in the transfer direction of the high speed transport system. The fixture switching and rail system is connected between the side panel fixture consolidation system and the fixture storage system. The improved structure is relatively compact and practical, has a short switching time, a high production efficiency, and a small floor area, and may use a large number of welding robots, fully satisfying the capacity requirement of 60JPH of the automobile factory.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD

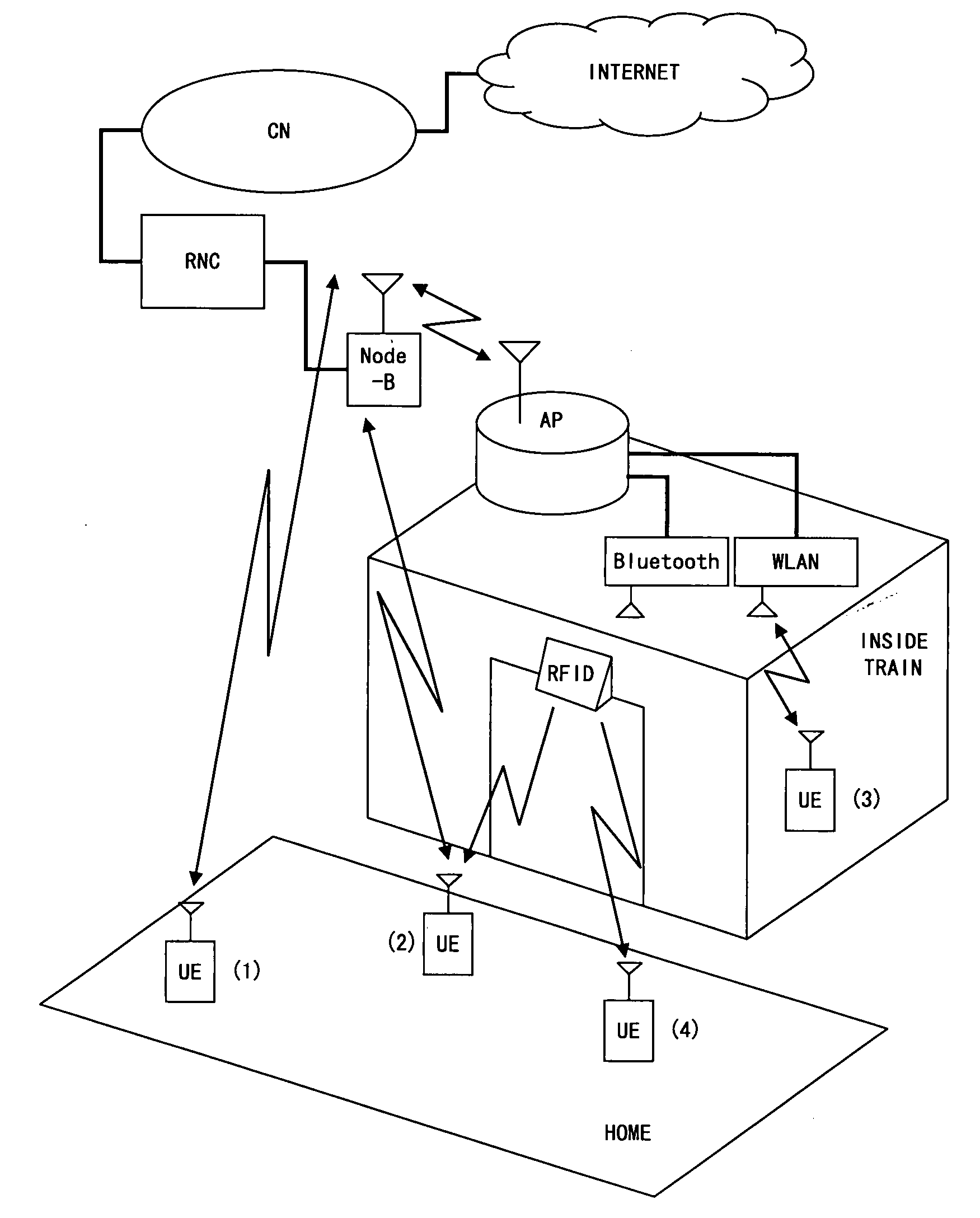

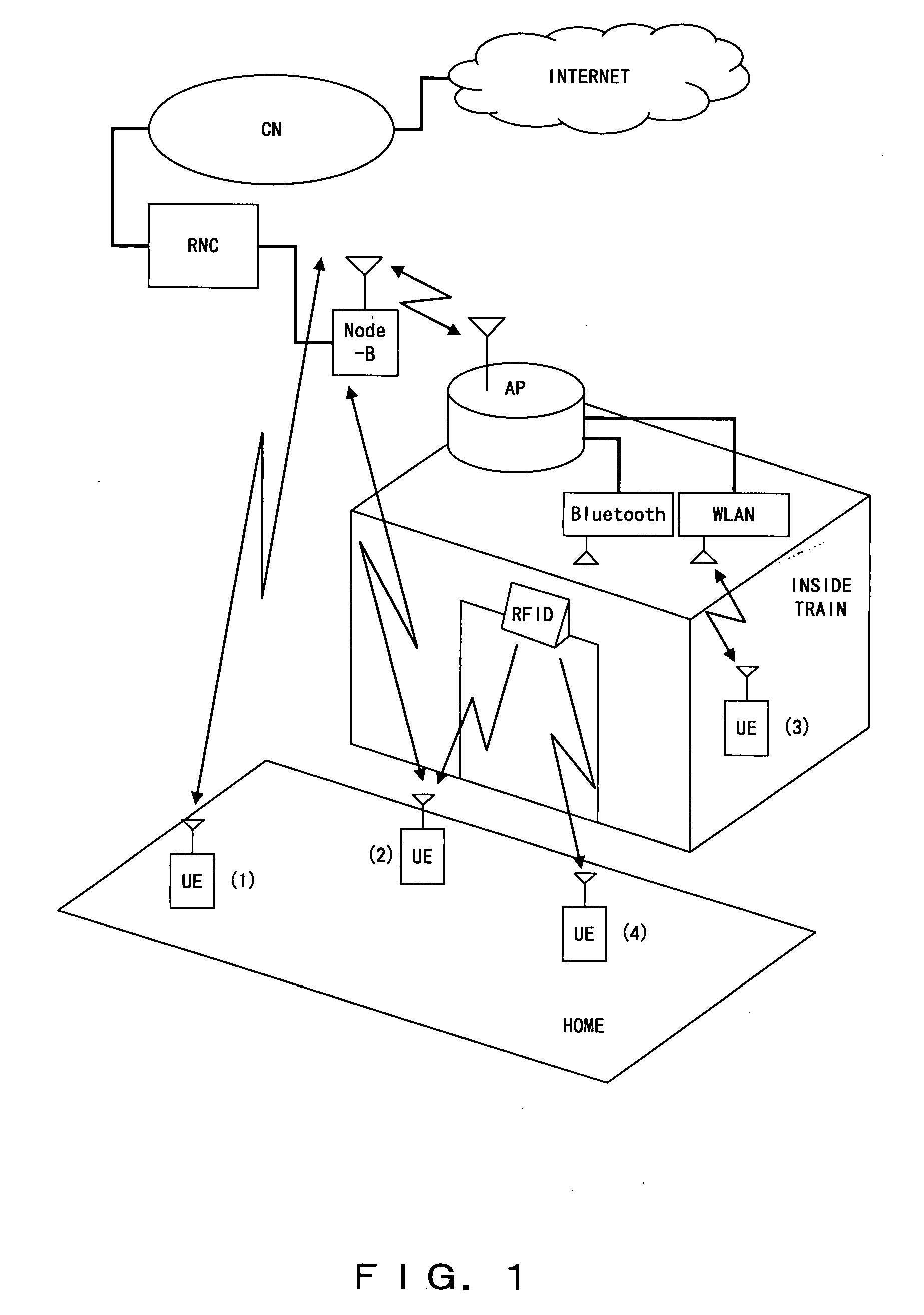

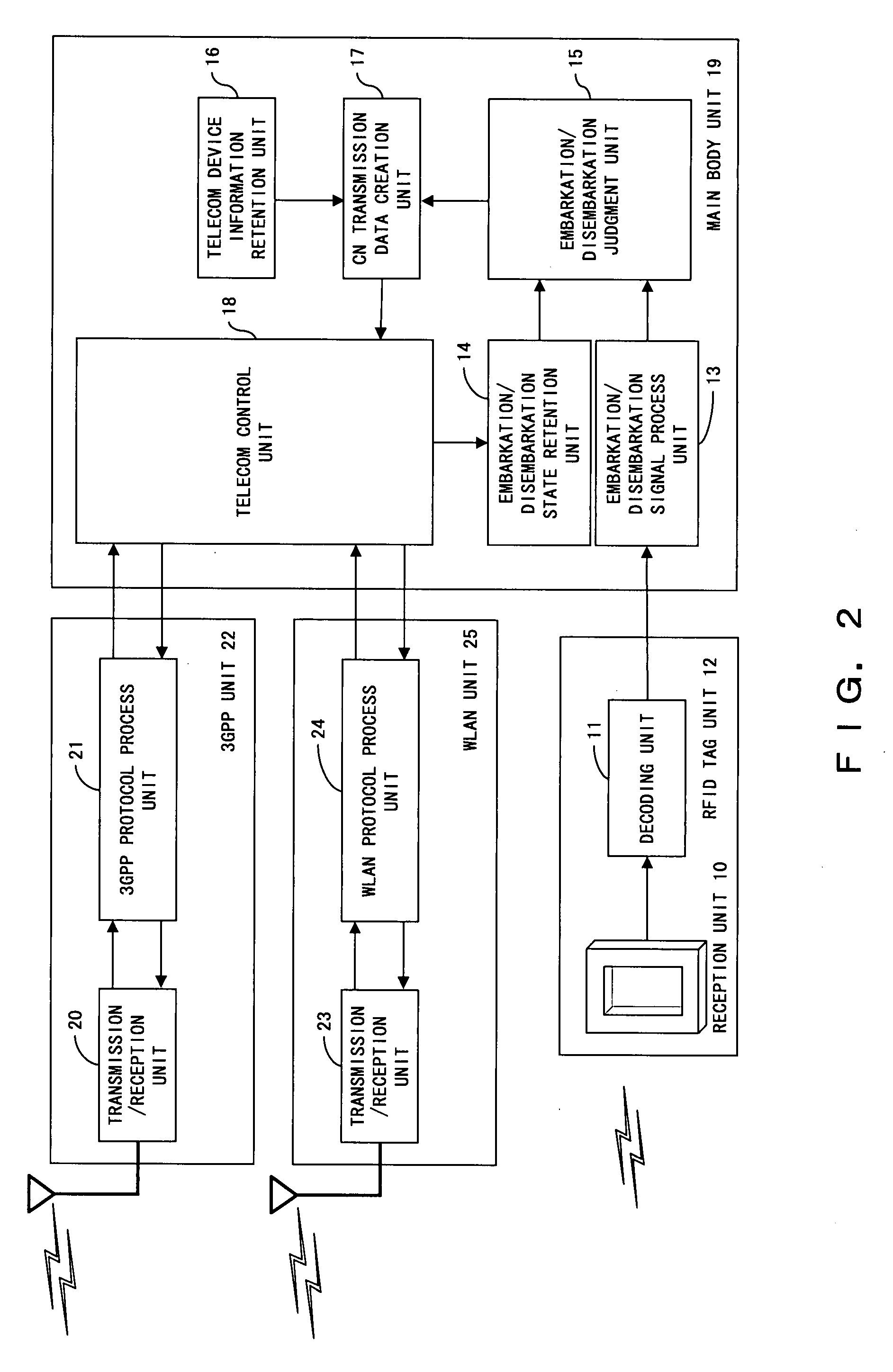

Telecommunication system used with a means for transporting passengers and cargo

InactiveUS20080227434A1Suppress increases in hardware resources and power consumption on a wireless networkIncrease the stationNetwork topologiesSpecial service for subscribersOn boardIn vehicle

A mobile terminal UE accesses a CN and utilizes the Internet via a base station Node-B. When riding an electric train, the mobile terminal UE receives a disembarkation notification and an embarkation notification from a RFID tag writer equipped on a train, and notifies the base station Node-B that the terminal is on-board the train. While on-board the train, the terminal accesses an in-vehicle AP by employing a WLAN, Bluetooth, or similar system, and the in-vehicle AP communicates with the base station Node-B. This configuration enables the in-vehicle AP to handle all of the mobile devices existing on a train in a centralized manner, thereby eliminating the need for each of the mobile devices to individually access the base station Node-B.

Owner:FUJITSU LTD

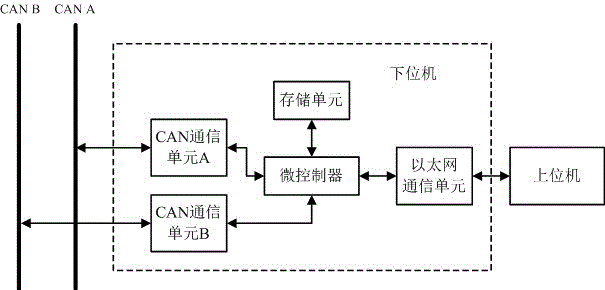

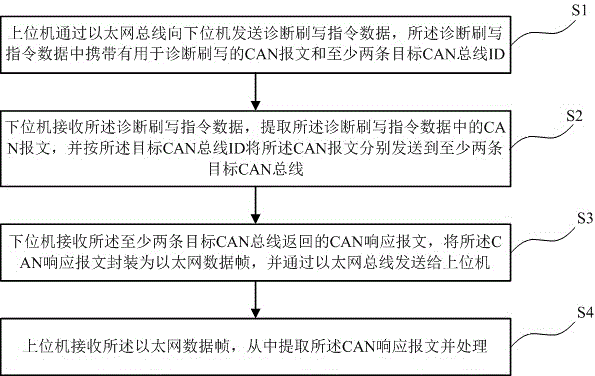

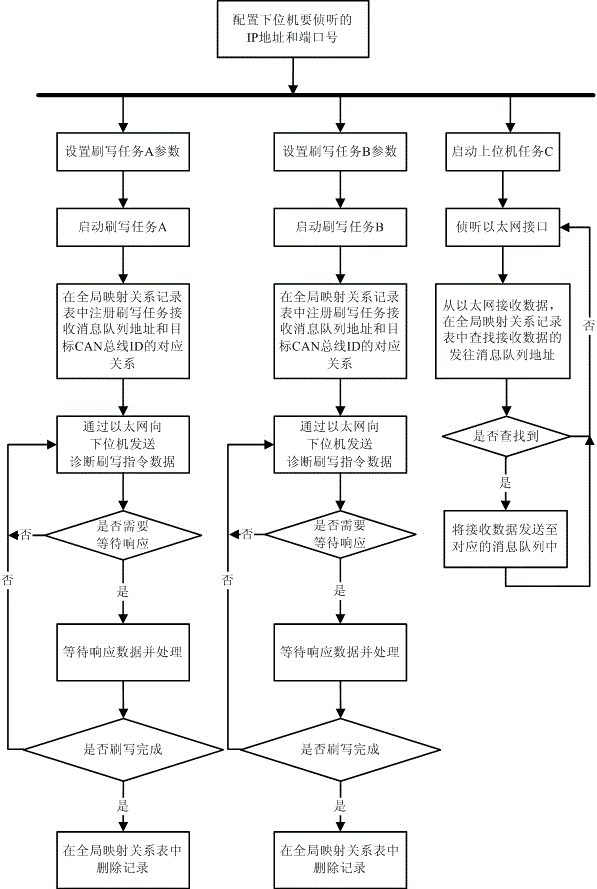

Method and system for diagnosing and flashing electronic control unit of vehicle

ActiveCN106375175AImprove offline production efficiencyIncrease productivityBus networksUser Datagram ProtocolEthernet

The invention provides a method and a system for diagnosing and flashing the electronic control unit of a vehicle. The method comprises the following steps: an upper computer sends diagnosing and flashing instruction data to a lower computer via an Ethernet bus, wherein the diagnosing and flashing instruction data carries a CAN message for diagnosing and flashing and at least two target CAN bus IDs; the lower computer receives the diagnosing and flashing instruction data, extracts a CAN message in the data, and sends the CAN message to at least two target CAN buses according to the target CAN bus IDs; the lower computer receives a returned CAN response message, packages the CAN response message into an Ethernet data frame, and sends the Ethernet data frame to the upper computer via the Ethernet bus; the upper computer receives the Ethernet data frame, extracts the CAN response message from the Ethernet data frame, and processes the CAN response message; and the upper computer and the lower computer communicate via a user datagram protocol UDP. The electronic control units on multiple CAN buses can be flushed at the same time, and thus, the production efficiency is improved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

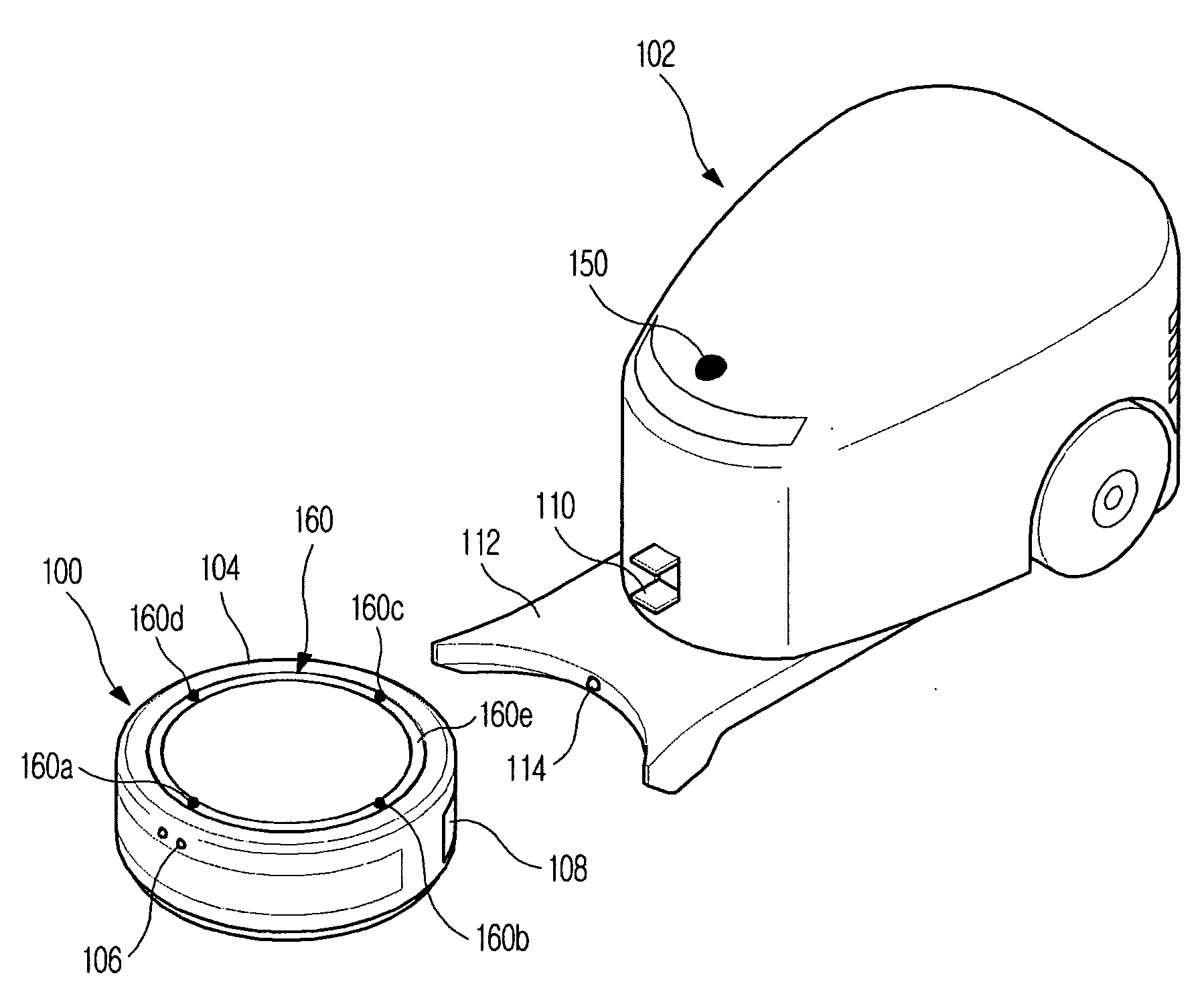

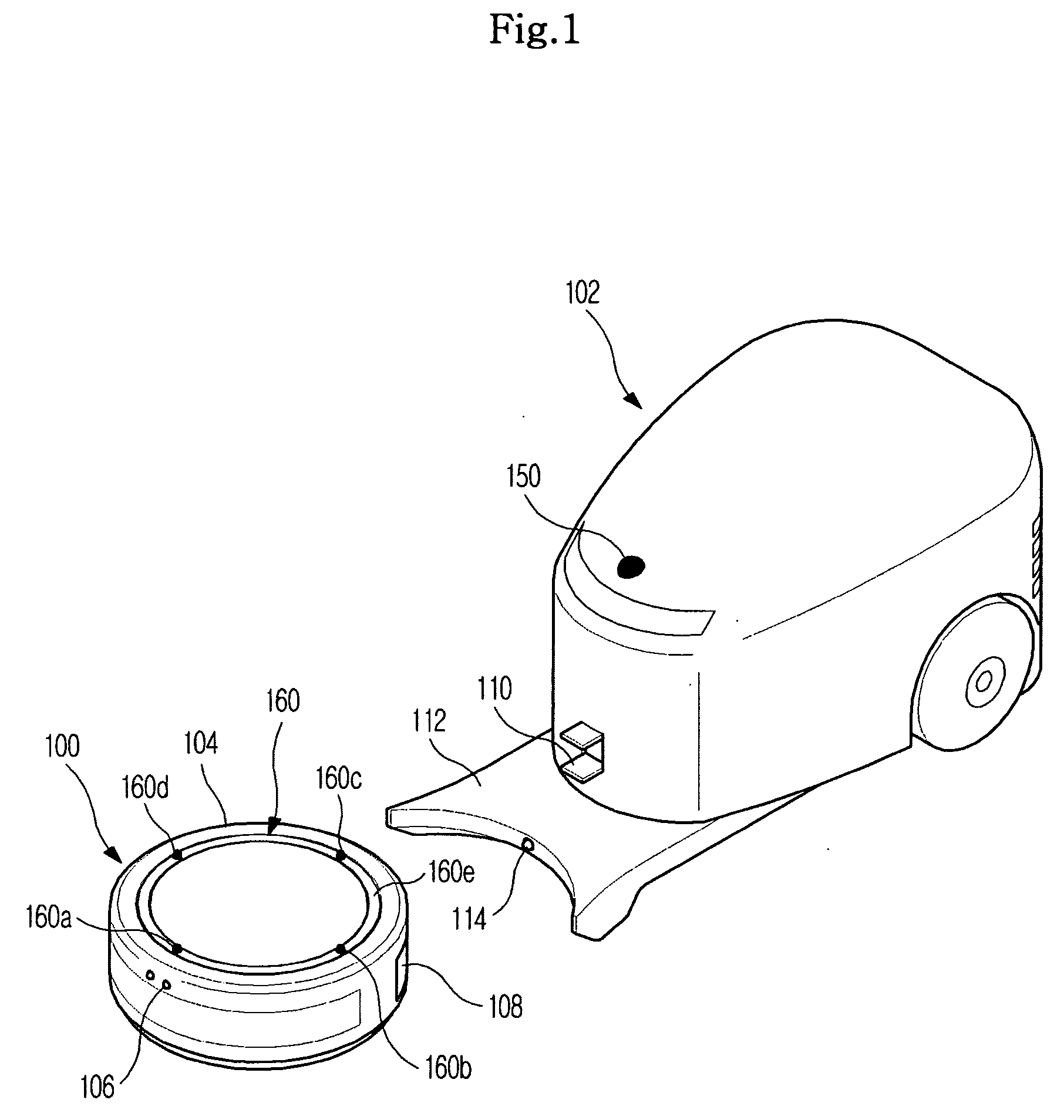

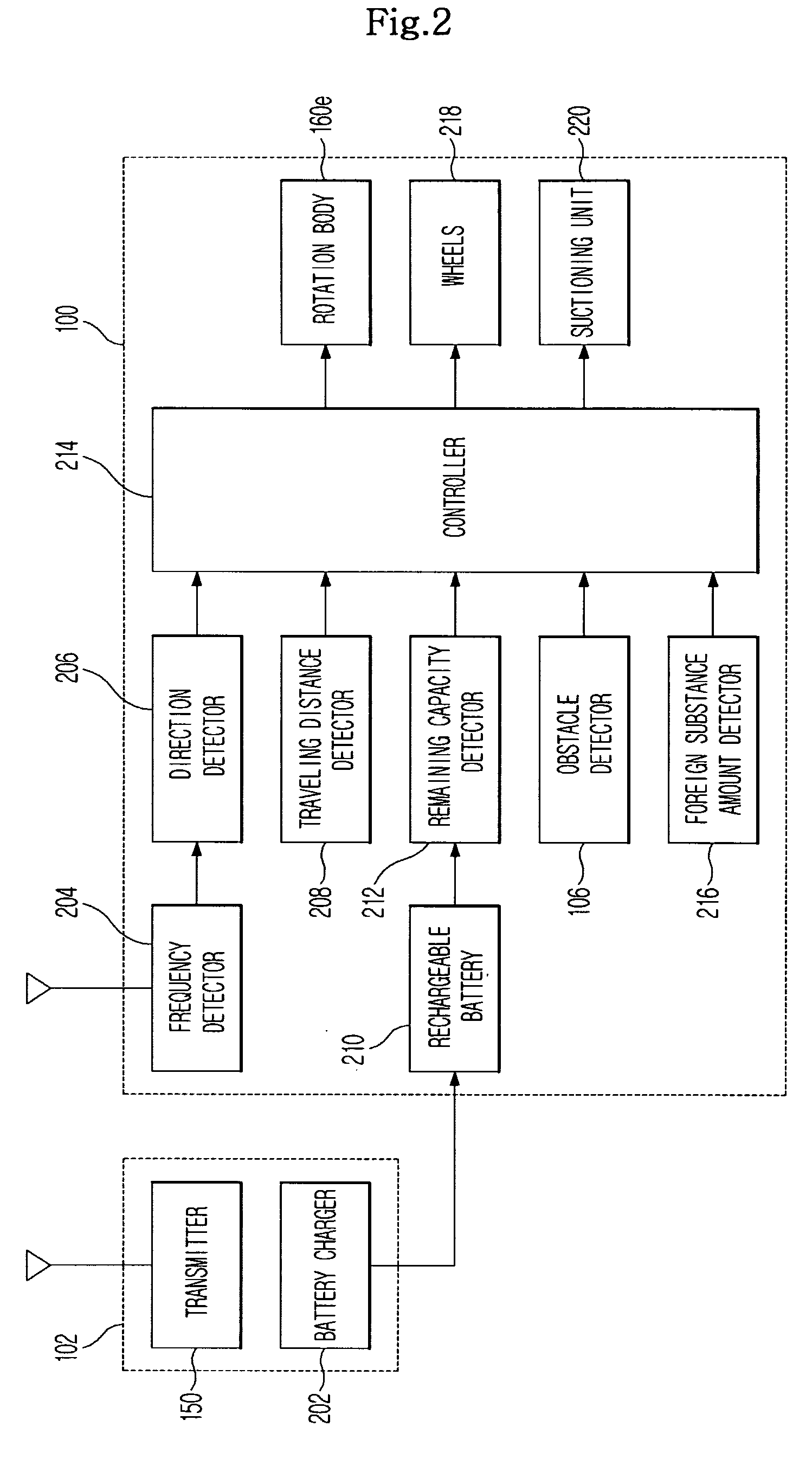

Robot cleaner system and method of controlling the same

InactiveUS20080004751A1Reduce manufacturing costLow costProgramme controlComputer controlRobotic systemsEngineering

A robot cleaner system and a control method thereof reduce manufacturing costs, expand a detected distance, and precisely control a movement and positioning of a robot cleaner. The robot cleaner system includes a robot cleaner and a station. One of the robot cleaner and the station transmits a signal of a predetermined frequency and the other receives the signal so that a direction toward the transmitting side for transmitting the signal is detected based on a Doppler shift observed by the receiving side that receives the signal.

Owner:SAMSUNG ELECTRONICS CO LTD

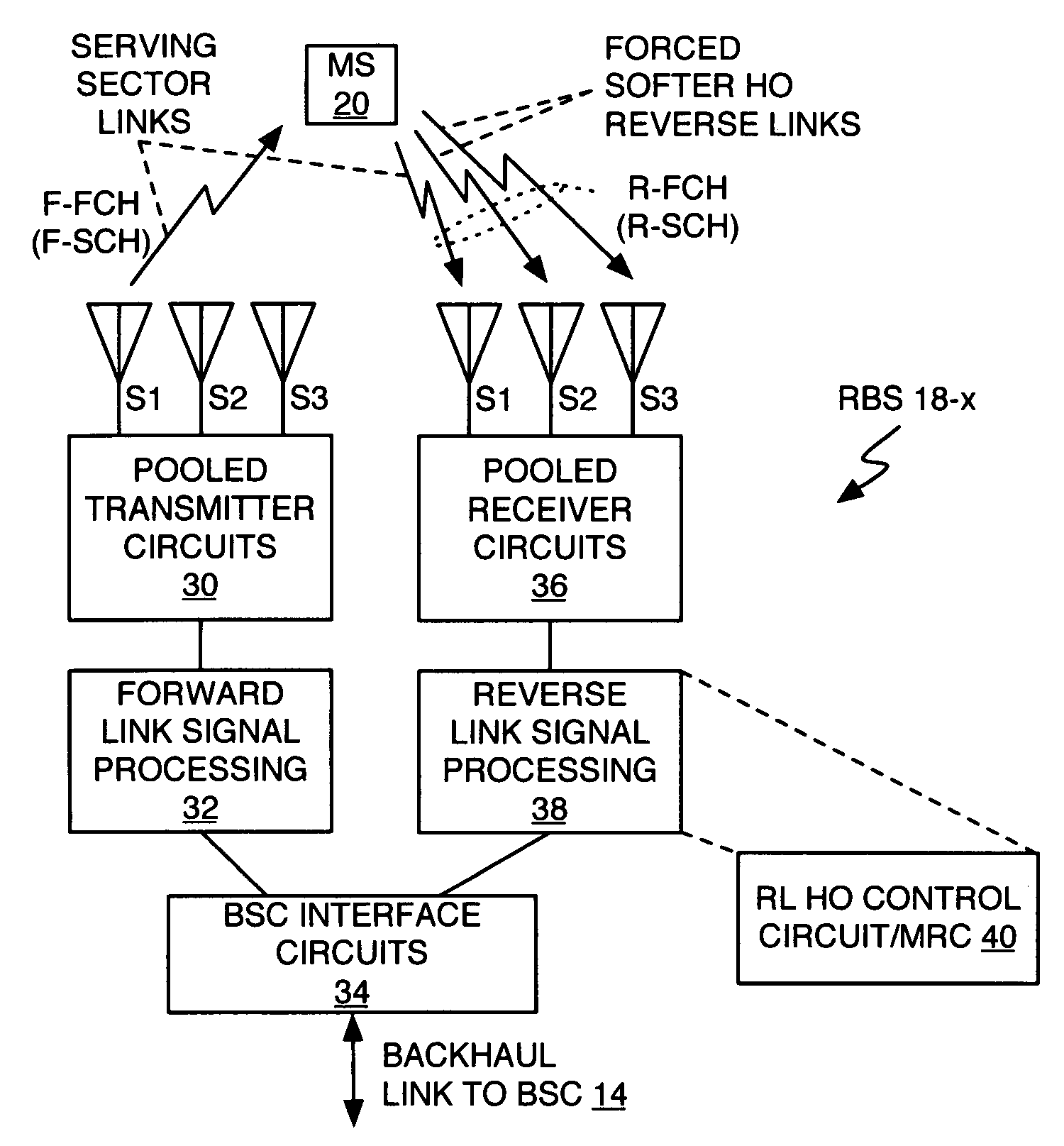

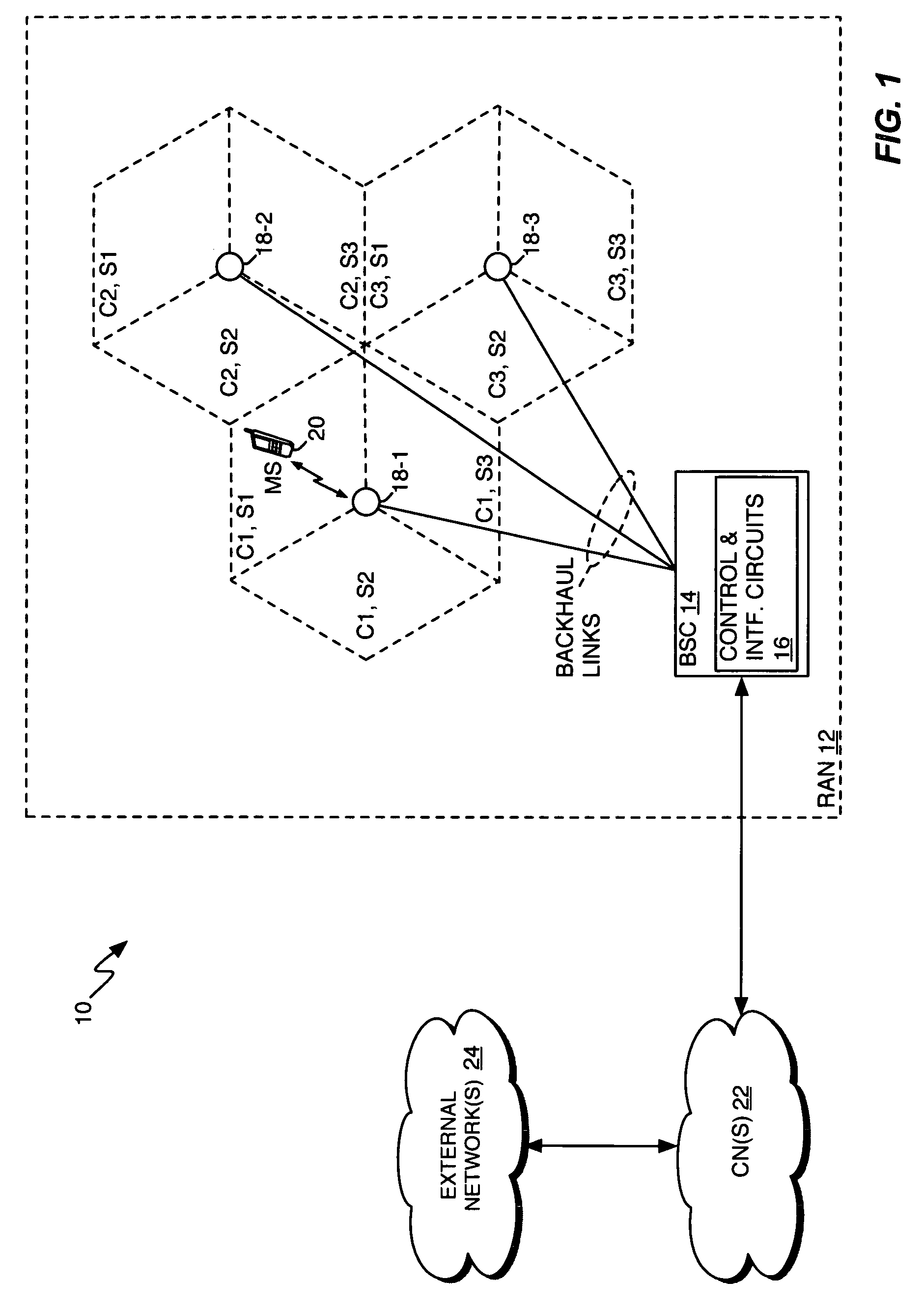

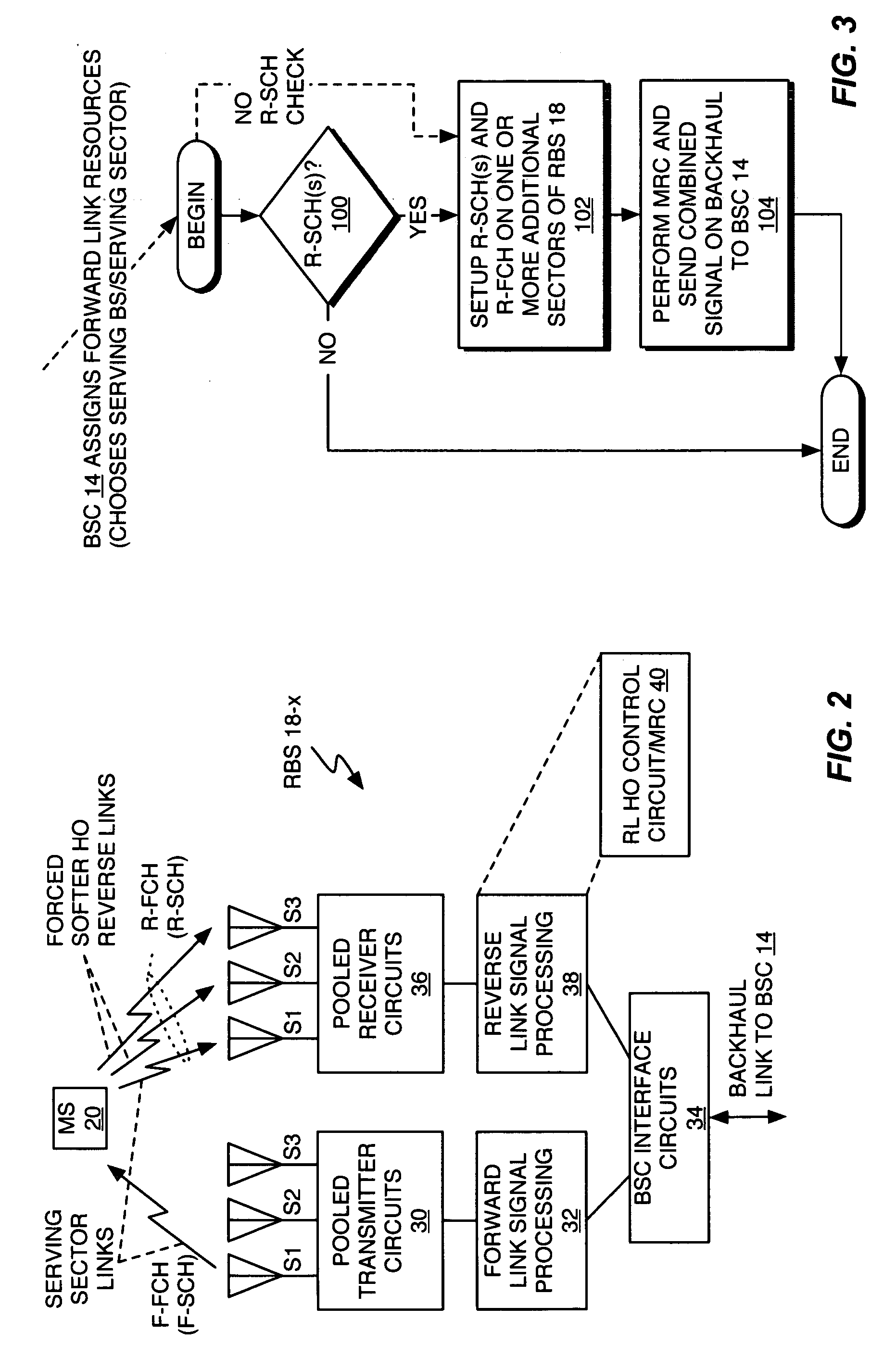

Method and apparatus to improve CDMA reverse link performance

ActiveUS20050073975A1Improve link performanceImprove receptionPower managementSpatial transmit diversityTransmitted powerRadio Base Station

Reverse link reception and reverse link capacity are improved at a multi-sector radio base station (RBS) by forcing always-softer reverse link handoff conditions for mobile stations served by the RBS. Whenever a serving sector reverse link is assigned to a mobile station at the RBS, one or more additional reverse links are assigned to it from remaining sectors of the RBS. Such assignments are made irrespective of whether those sectors are, or could be, used to serve the mobile station on the forward link. The RBS improves its reception of the mobile station's reverse link transmissions by combining signals from all of the assigned reverse links. With improved reception, mobile stations can be commanded or configured to reduce their reverse link transmit power, thereby reducing reverse link interference and increasing reverse link capacity. Always-softer handoff may not be forced unless the mobile station has a reverse supplemental channel, since the use of such channels makes interference reduction particularly beneficial.

Owner:TELEFON AB LM ERICSSON (PUBL)

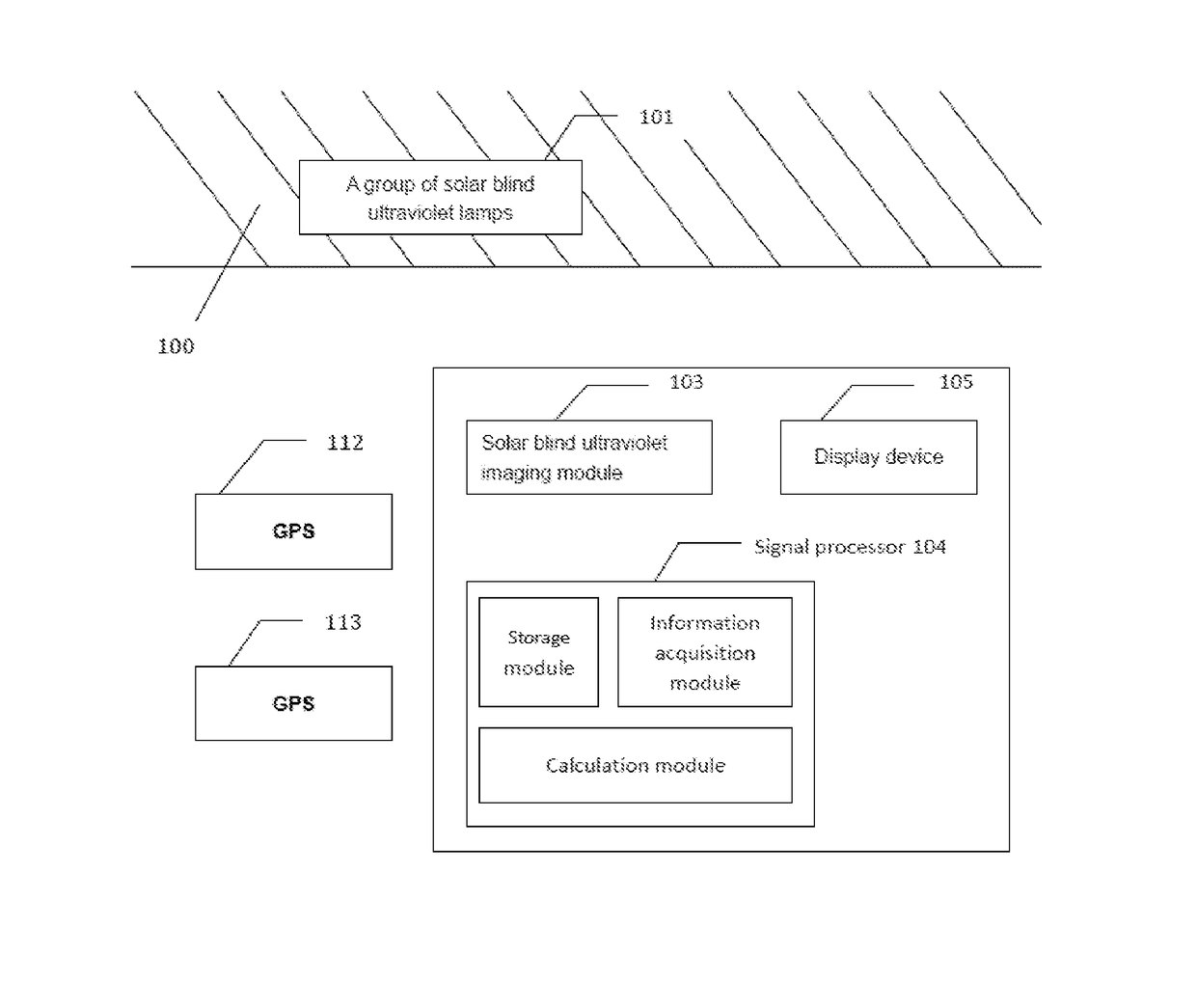

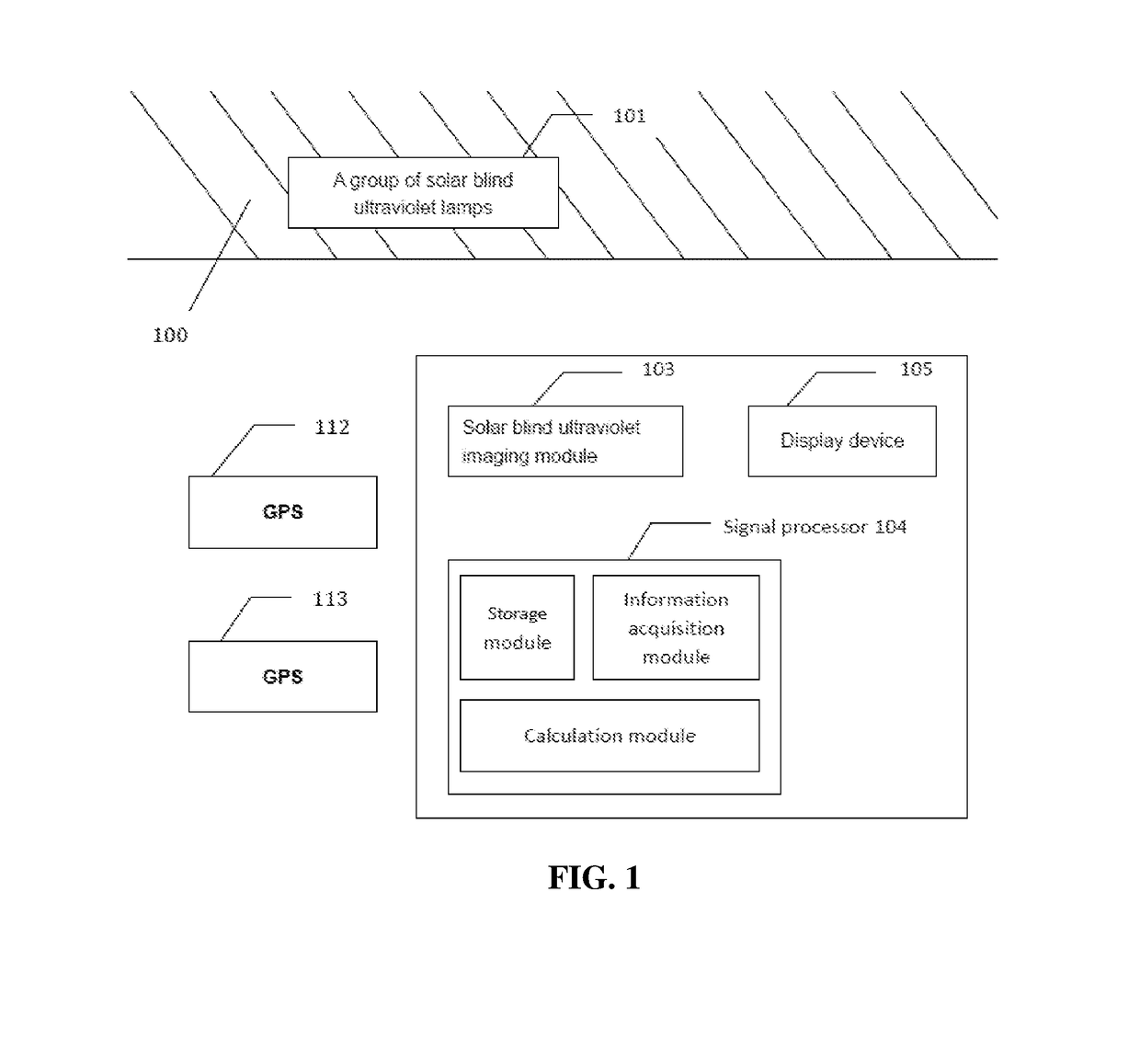

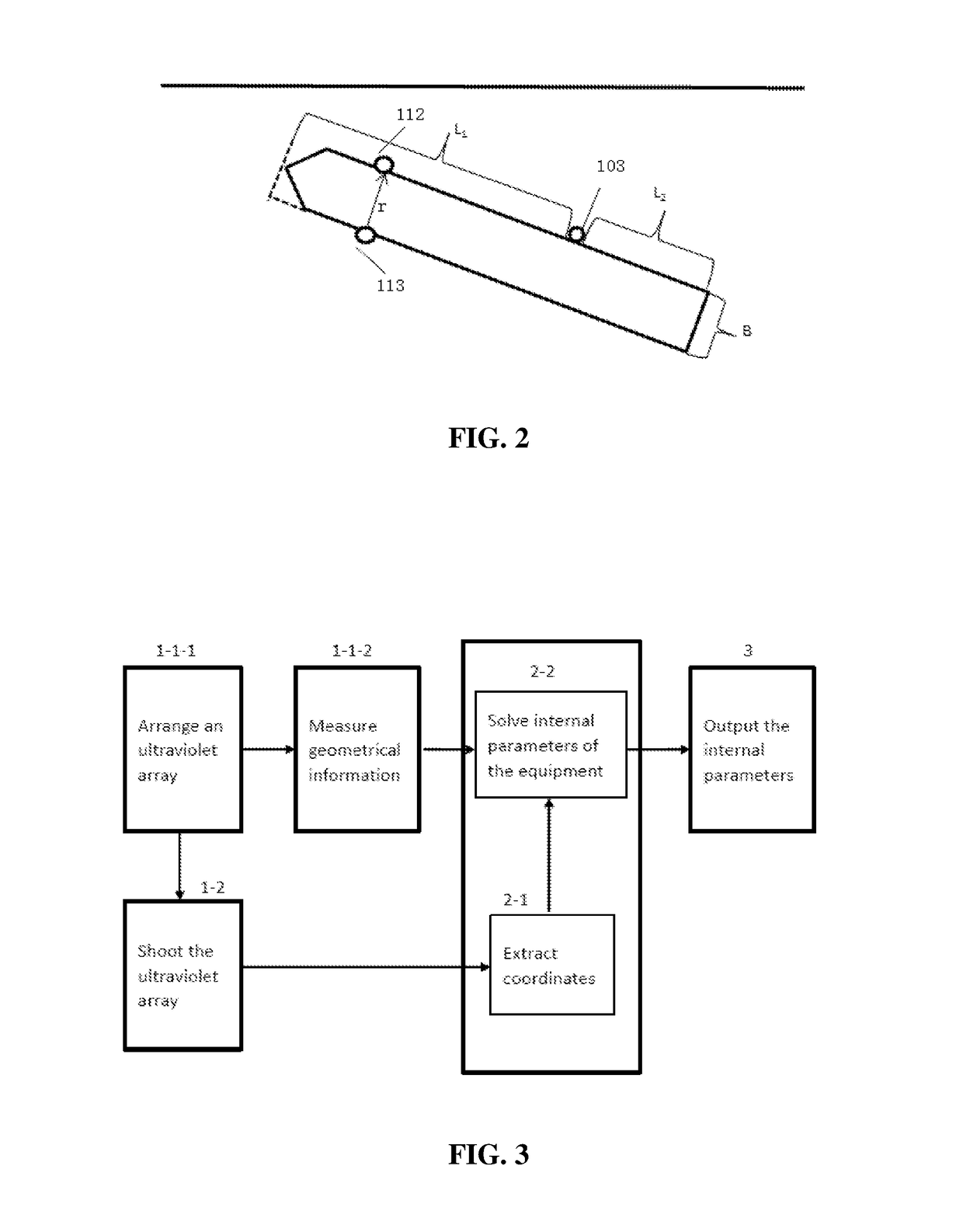

Auxiliary berthing method and system for vessel

ActiveUS20180012498A1High positioning accuracyGuaranteed smoothImage enhancementImage analysisVisibilityGps receiver

The present invention provides an auxiliary berthing method and system for a vessel. Position information of a vessel relative to a berth is determined by a solar blind ultraviolet imaging method; meanwhile, by a GPS method, an attitude angle of the vessel relative to the berth is determined by at least two GPS receivers. Thus, the vessel can be berthed safely when getting close to the shore at low visibility. Further, in the method and device of the present invention, it can be preferable to integrate coordinate data and angle data received by a solar blind ultraviolet imaging module and GPS signal receiving modules by a normalized correlation algorithm and a data fusion algorithm, so as to improve the positioning accuracy.

Owner:NANJING UNIV 5D TECH

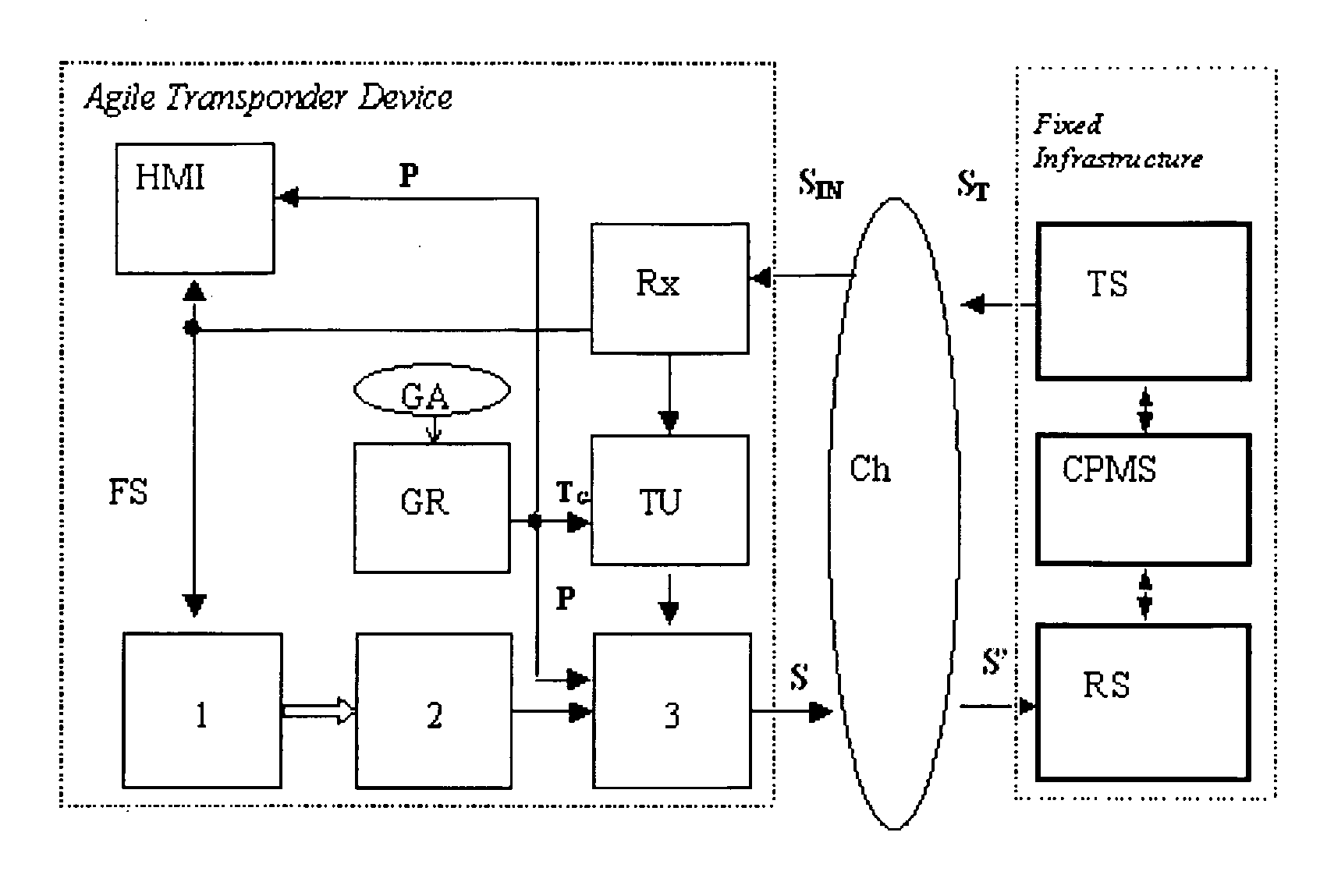

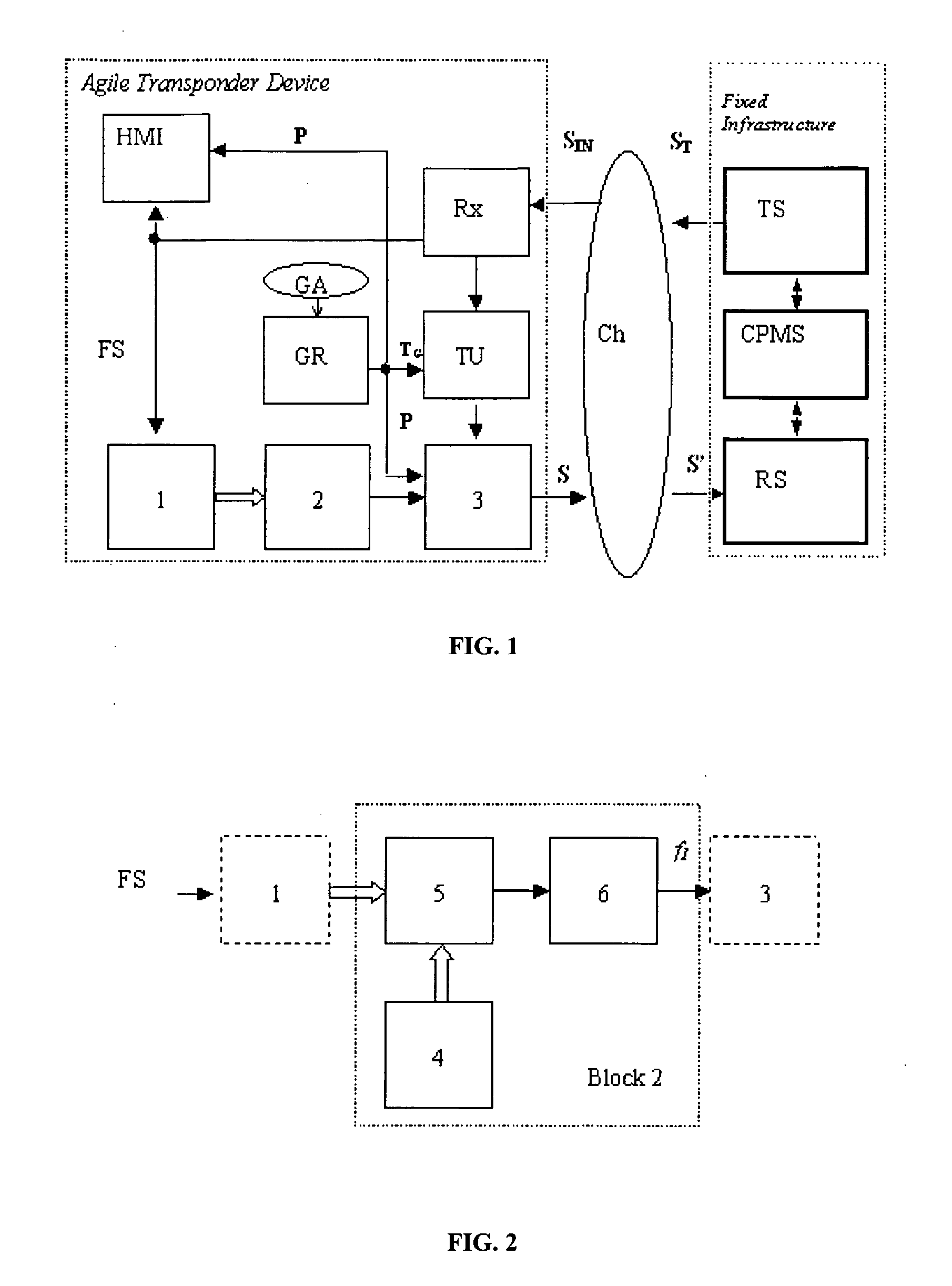

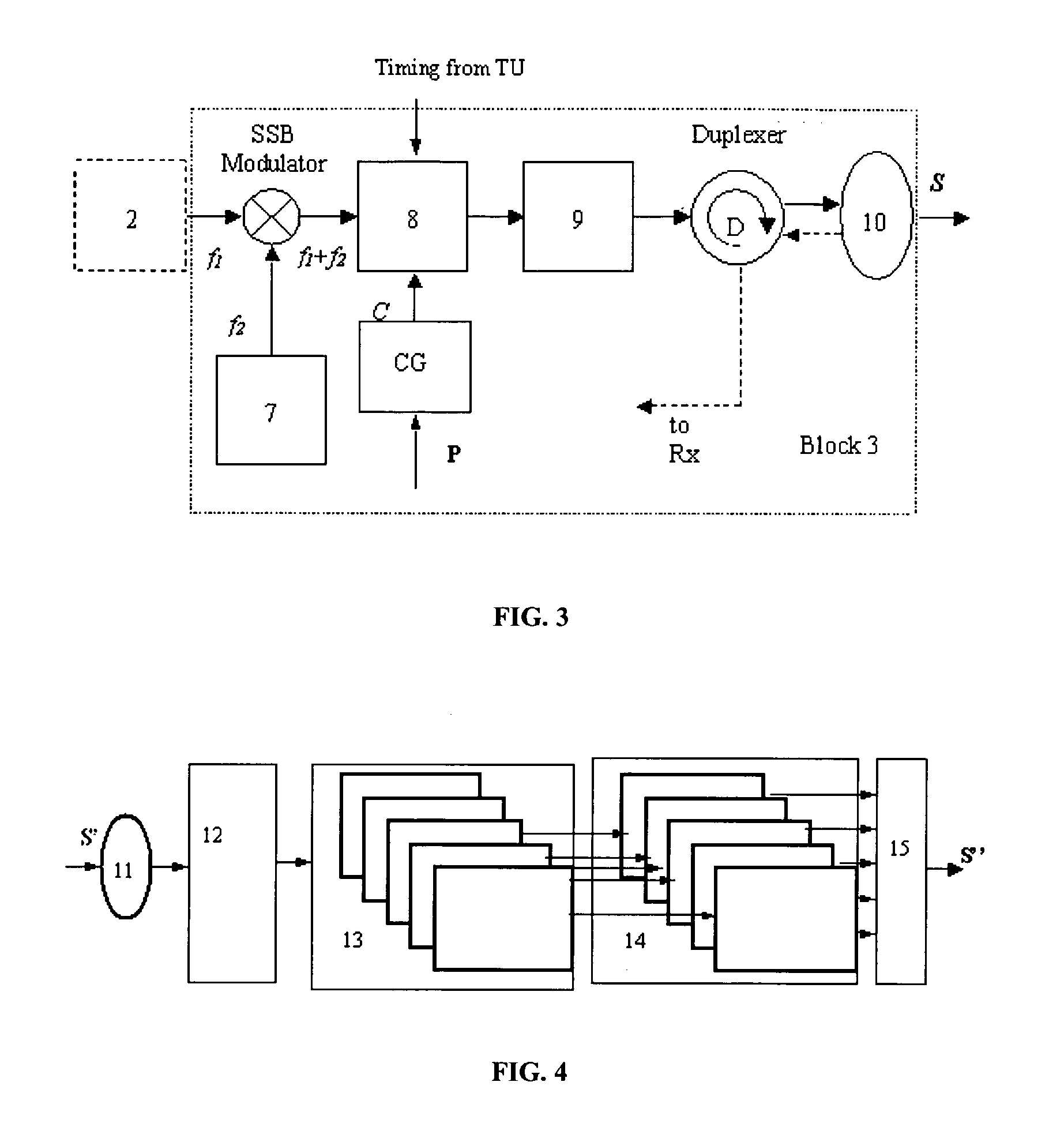

High-Capacity Location and Identification System for Cooperating Mobiles With Frequency Agile and Time Division Transponder Device on Board

InactiveUS20080106457A1Easy to operateOvercome limitationsRadio wave reradiation/reflectionOn boardGround vehicles

Cooperating mobiles (ground vehicles, aircraft) are located and identified by Multilateration and Automatic Dependent Surveillance-Broadcast (ADS-B) techniques using the frequency band and the format of the Secondary Surveillance Radar (SSR) signals in high traffic situations. Standard messages, transmitted by the mobile on the downlink channel, i.e. to a set of fixed receiving stations, and including the identification code, permit the location of the mobile by multiple time measurements (Multilateration) from a subset of the set of fixed receiving stations; when the message contains the position (GPS and, later, Galileo datum) the mobile may be located with the ADS-B when in view even of a few stations or of a single station. In order to overcome the problem that arises with high traffic, i.e. the superimposition of signals, called garbling.

Owner:UNIVERSITY OF ROME TOR VERGATA

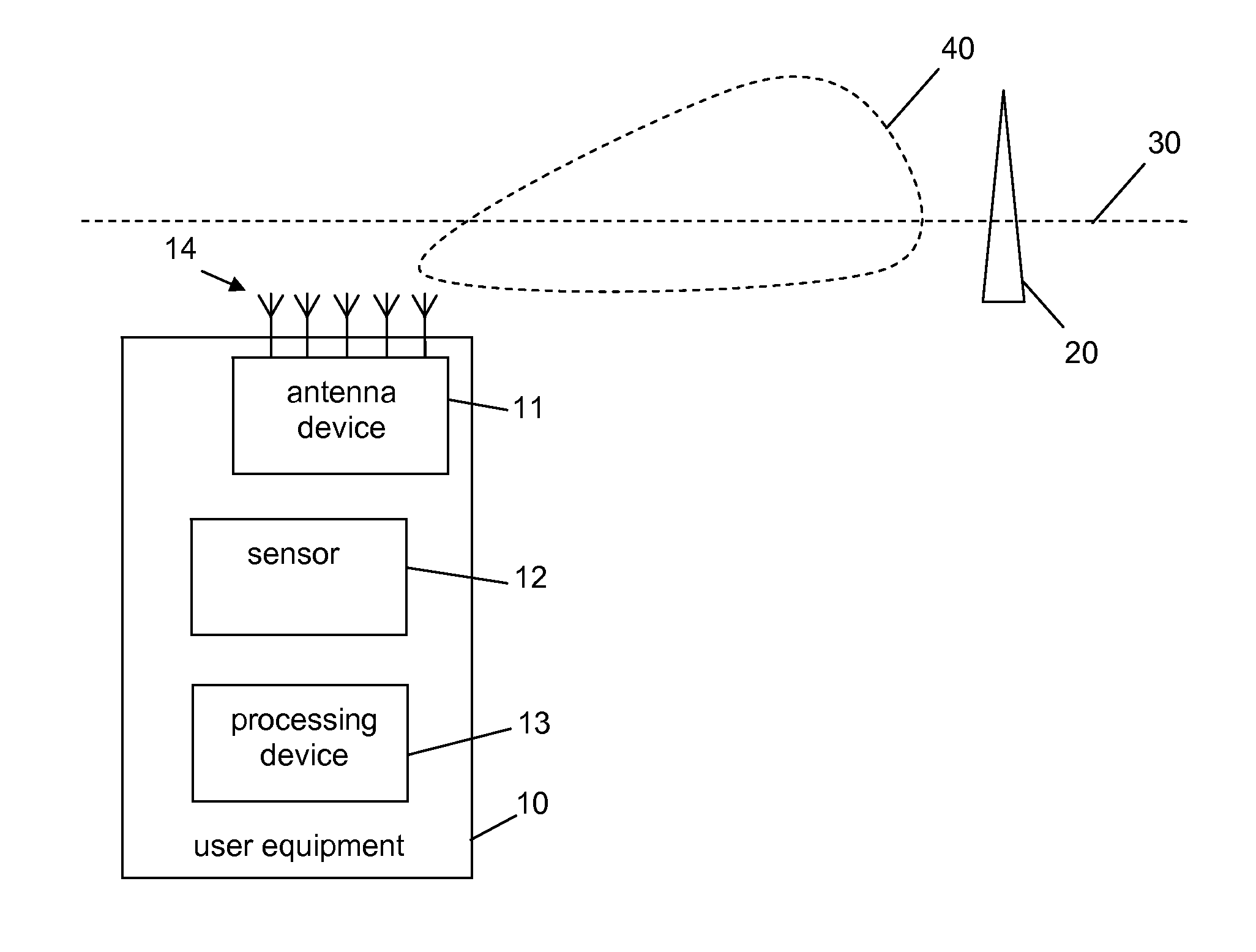

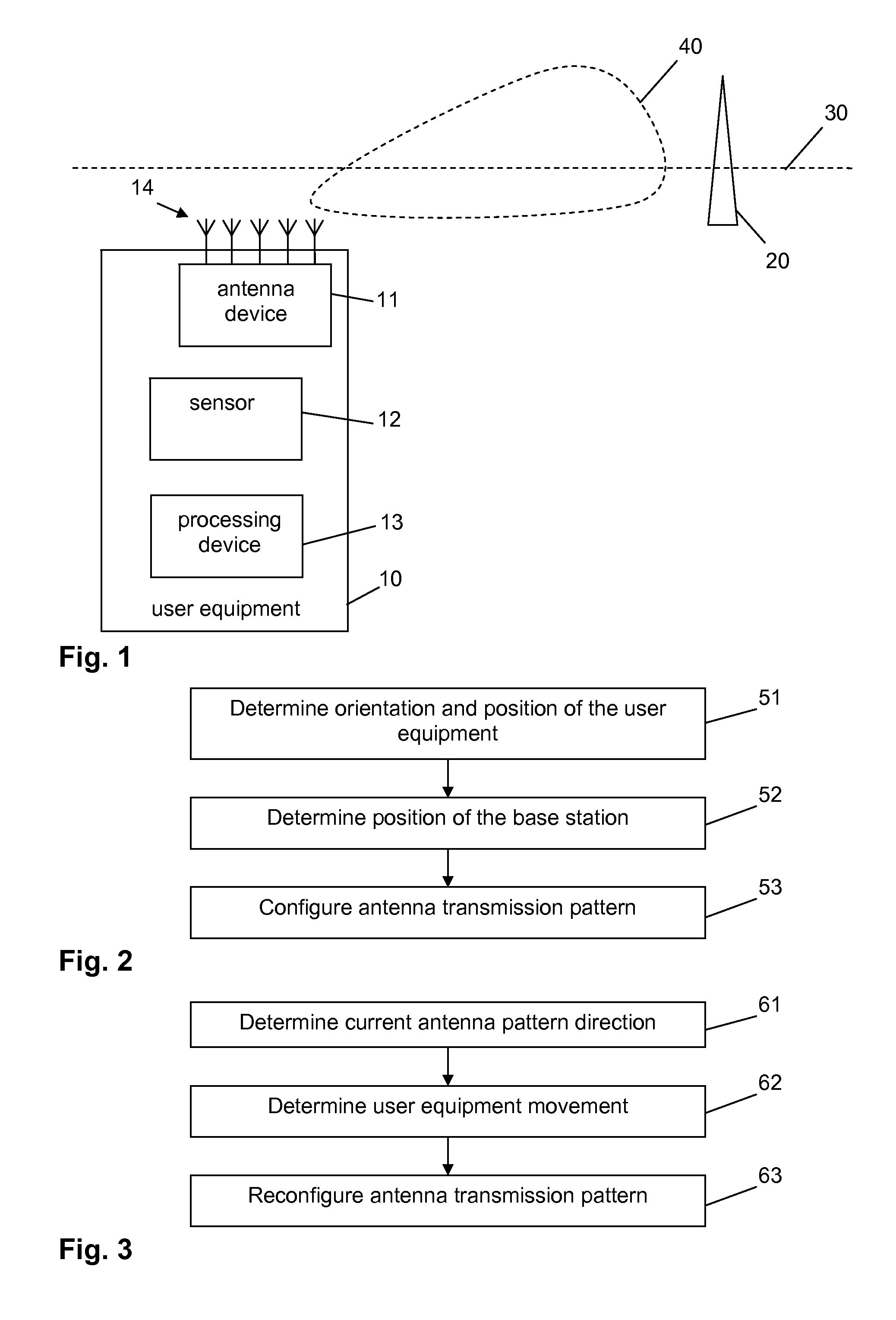

Operating a User Equipment in a Wireless Communication Network

ActiveUS20160014566A1Raise the possibilityImprove directivitySite diversitySubstation equipmentTelecommunicationsUser equipment

The present invention relates to methods for operating a user equipment in a wireless communication network and user equipments for a wireless communication network.

Owner:SONY CORP

Antenna steering for an access point based upon spatial diversity

InactiveUS7587173B2Improve throughputIncrease rangeSpatial transmit diversityNetwork topologiesDirectional antennaEngineering

A method for operating an access point in a wireless local area network is provided, wherein the access point includes a directional antenna for communicating with at least one remote station. The method includes communicating with a selected remote station using a current angle of the directional antenna, and scanning an alternate angle from a plurality of alternate angles of the directional antenna for communicating with the selected remote station. Respective signals received via the current angle and the alternate angle from the selected remote station are measured. The current angle or the alternate angle is selected as a preferred angle based upon the measured signals for continuing communications with the selected remote station.

Owner:IPR LICENSING INC

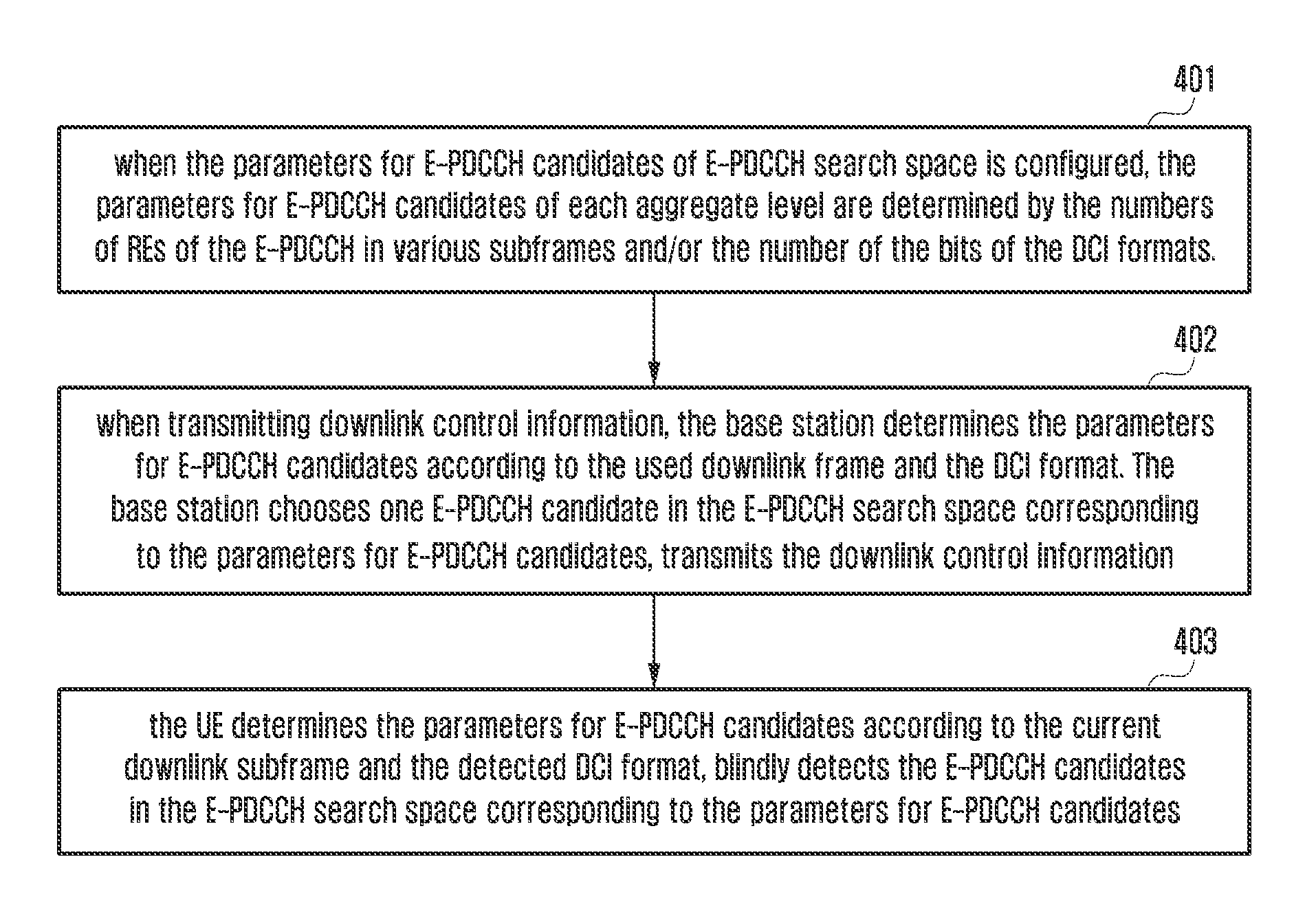

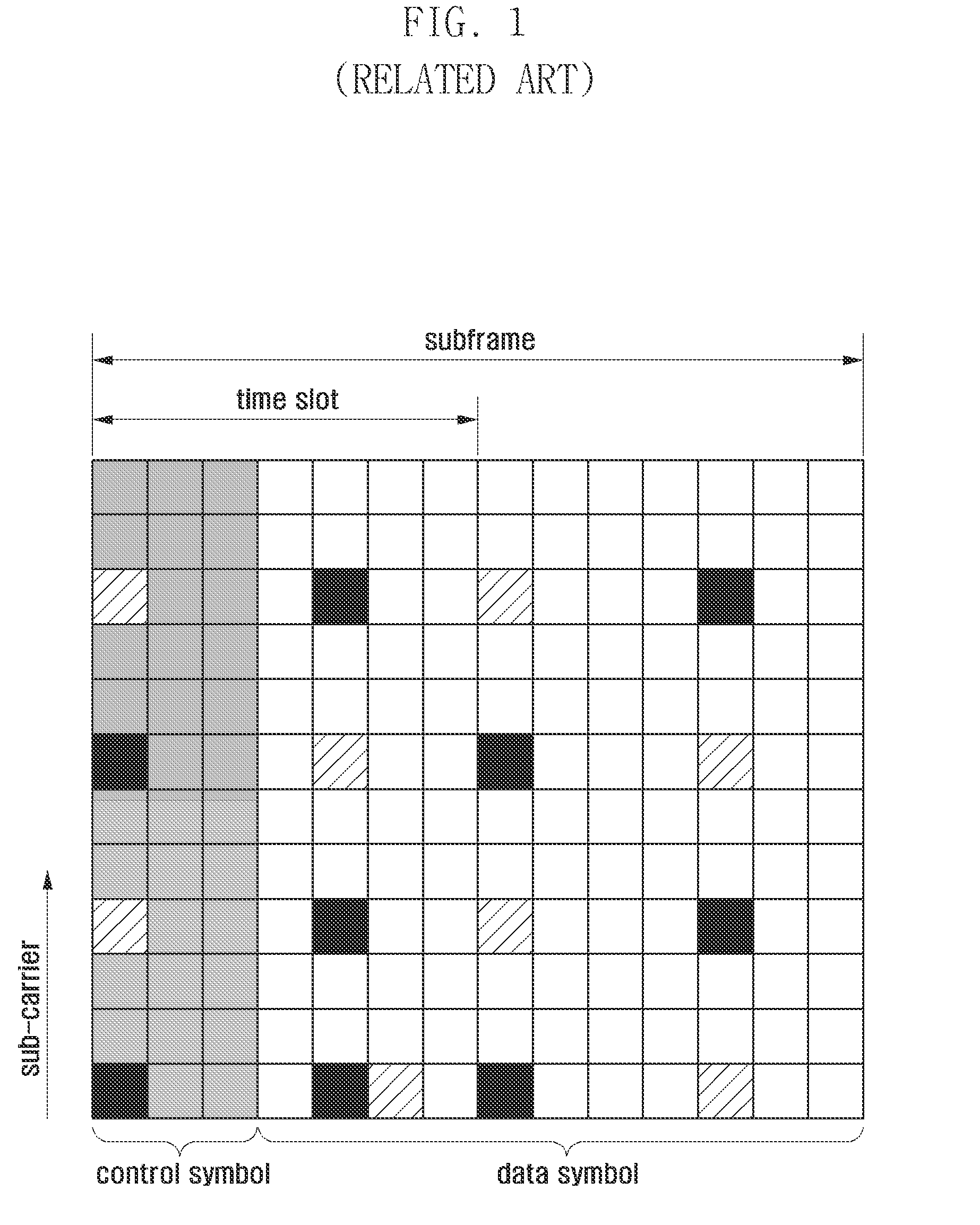

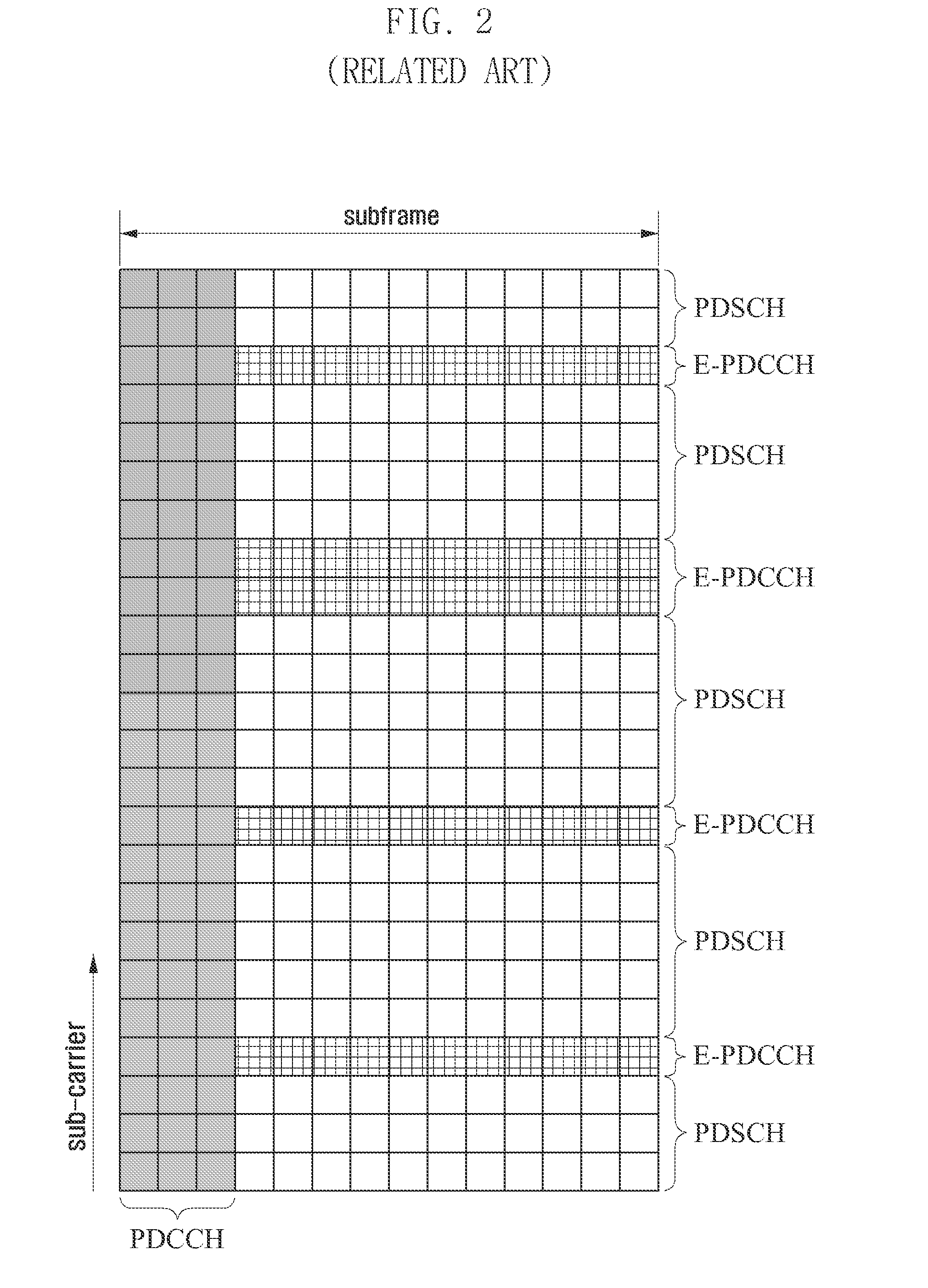

Method and apparatus for configuring search space of a downlink control channel

ActiveUS20130242906A1Increase flexibilityIncrease the stationError preventionSignal allocationResource elementAggregate level

A method for configuring a search space of a downlink control channel is provided. The method includes determining the parameters for Enhanced Physical Downlink Control Channel (E-PDCCH) candidates of each aggregate level according to the number of Resource Elements (RE) in a subframe and / or the number of bits of Downlink Control Information (DCI) formats, when the parameters for E-PDCCH candidates of E-PDCCH search space is configured, determining, by a User Equipment (UE), the parameters for E-PDCCH candidates according to a current downlink subframe and a detected DCI format, and detecting blindly, by the UE, the E-PDCCH candidates in the E-PDCCH search space corresponding to the parameters for E-PDCCH candidates. The present invention also provides a UE and a base station. Application of the present invention can improve the flexibility of the base station scheduling, and reduce the possibility that the E-PDCCHs of different UEs block each other.

Owner:SAMSUNG ELECTRONICS CO LTD

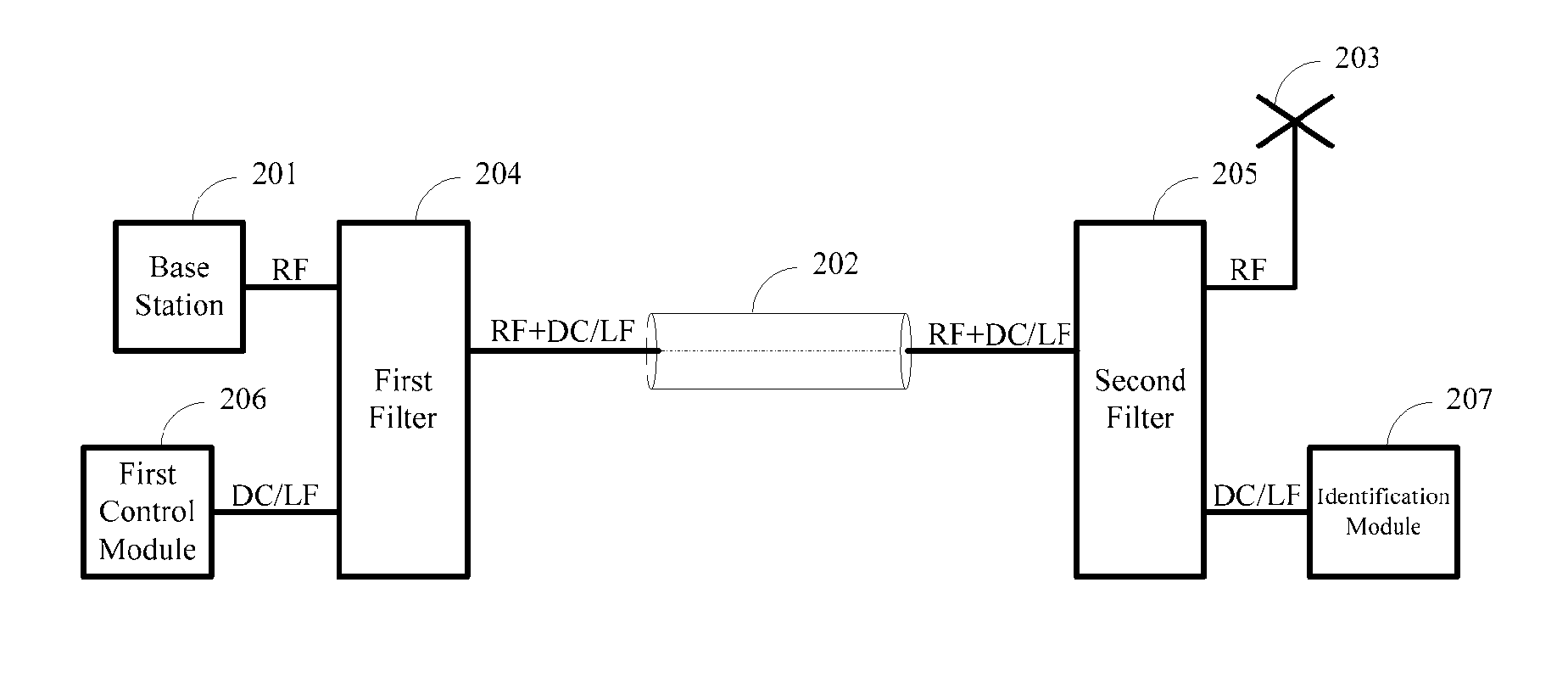

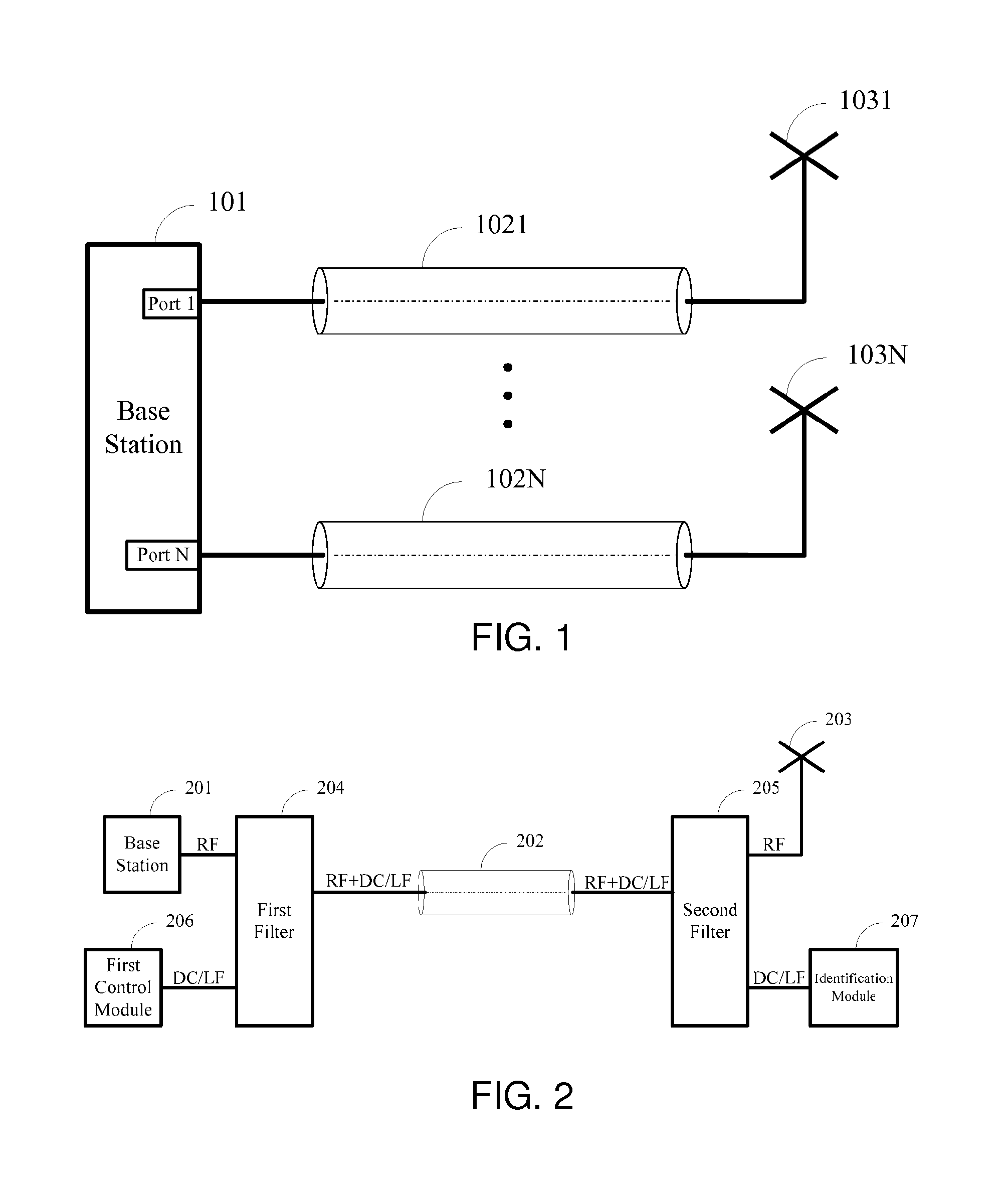

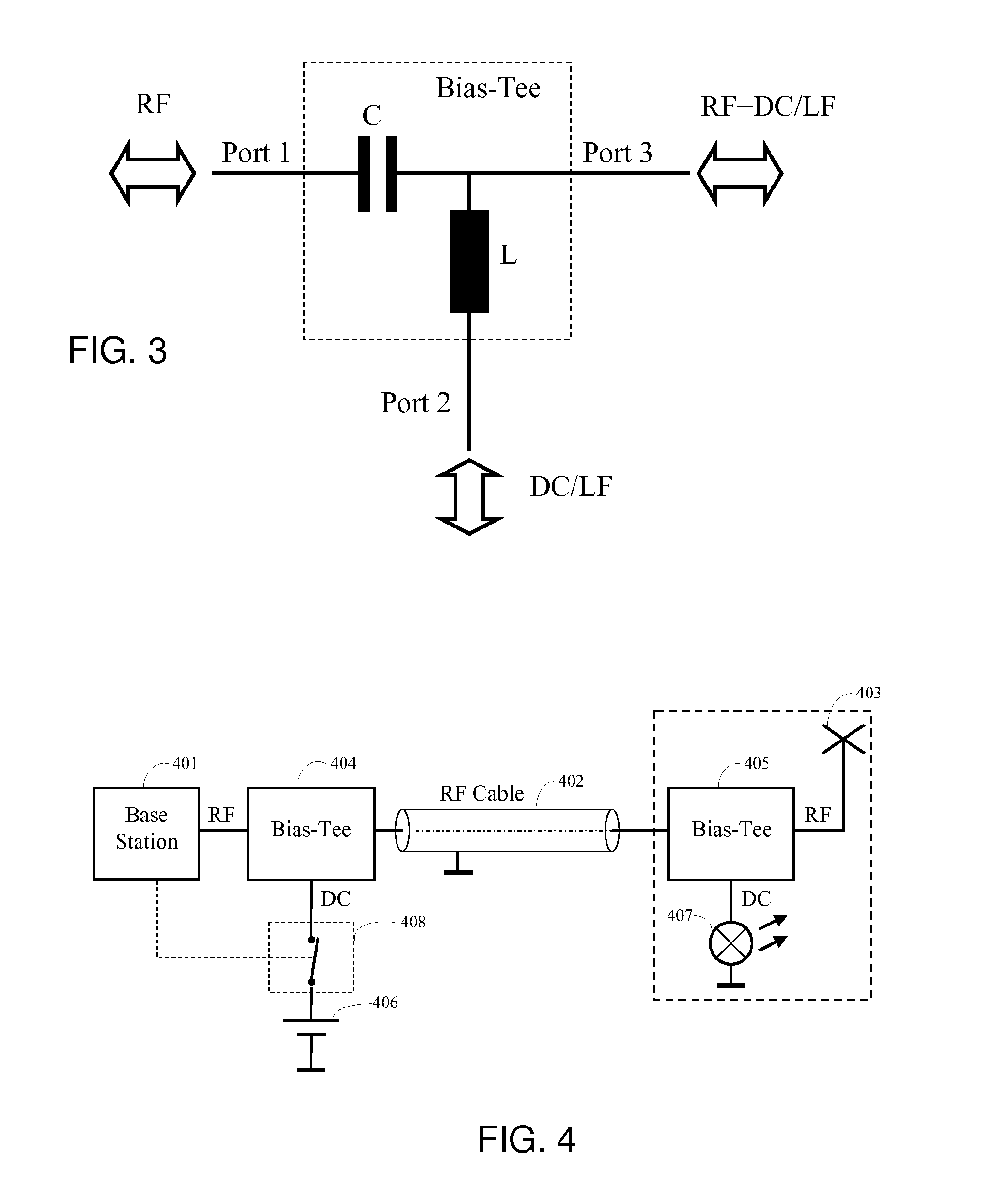

Radio communication system and method for communication between base station and antenna

InactiveUS20120021790A1Simplifying maintenance taskEasy to integrateRadio transmission for post communicationWireless communicationCommunications systemRadio frequency

A radio communication system has a base station and one or more antennas, each of the one or more antennas connects with a radio frequency port of the base station through an RF connection. Direct current and / or low frequency (DC / LF) signals are transmitted to an antenna via the RF connection corresponding to the antenna. The radio communication system further has an identification module at the antenna side, adapted to give an indication for identification of the antenna when receiving the DC / LF signals from the RF connection. Accordingly, the information exchange between the base station and a more or less intelligent “identification unit” in the antenna is performed to allow identification of the antenna from the base station side and further allow diagnosis of the cable link.

Owner:SIEMENS AG

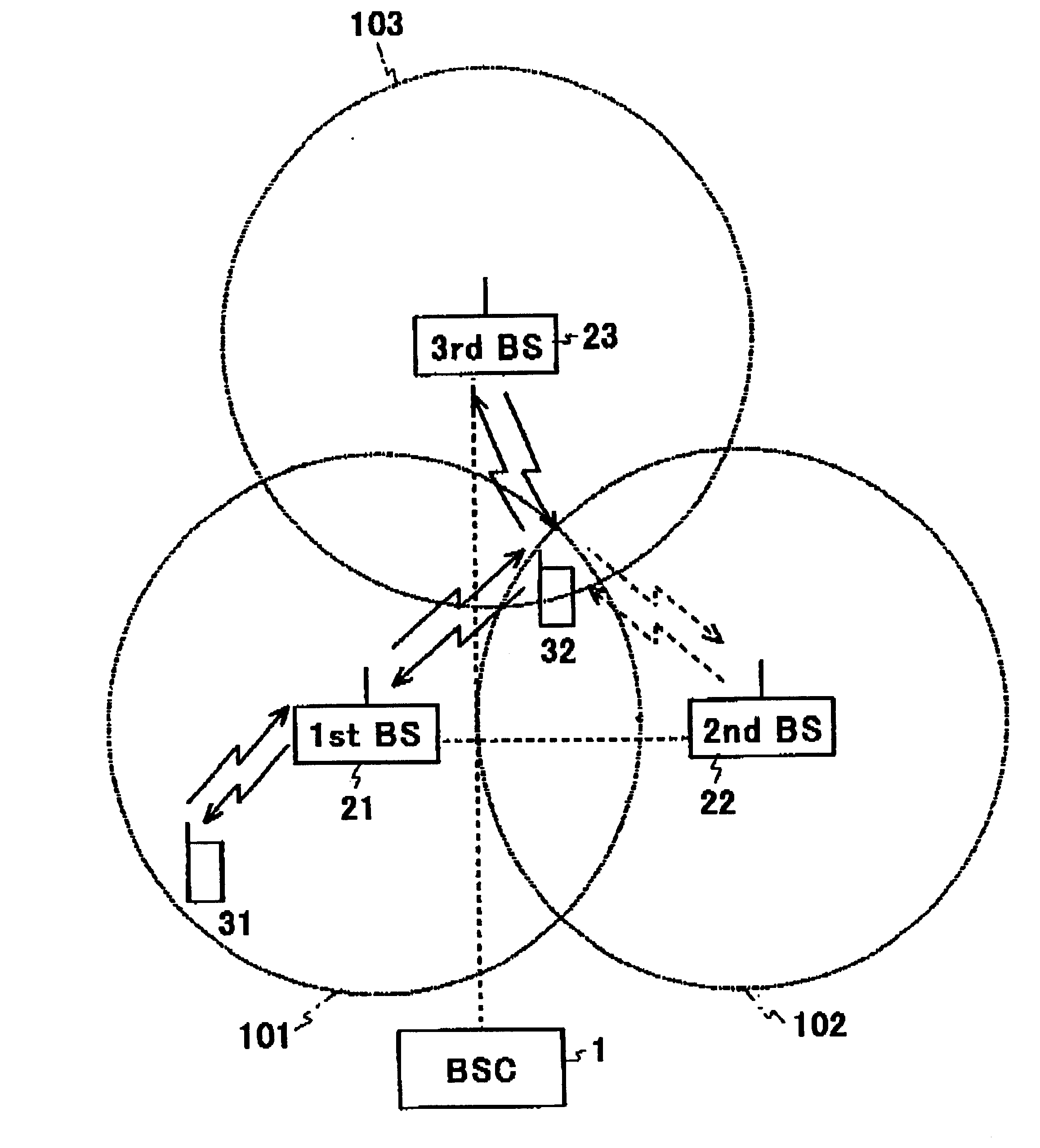

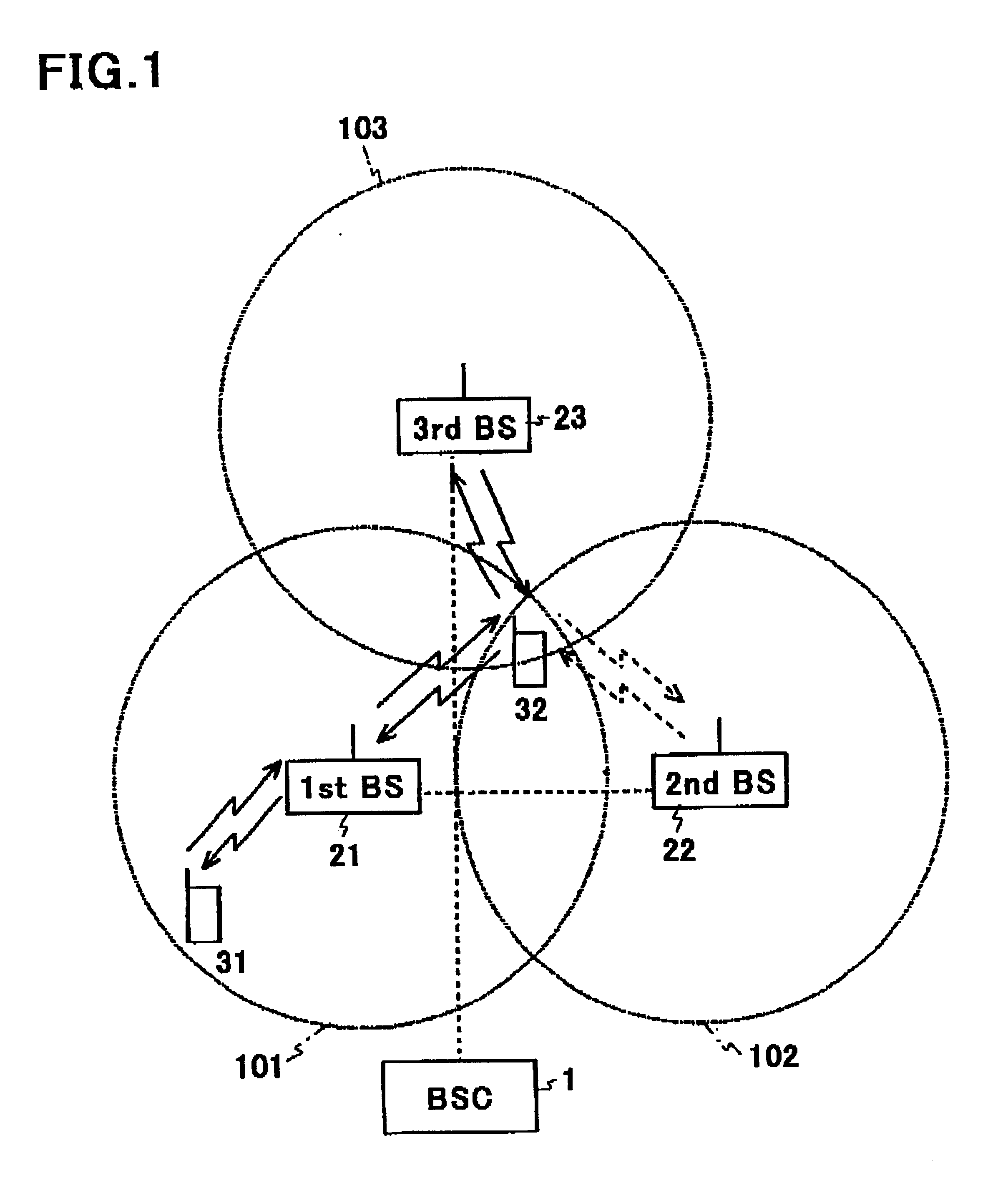

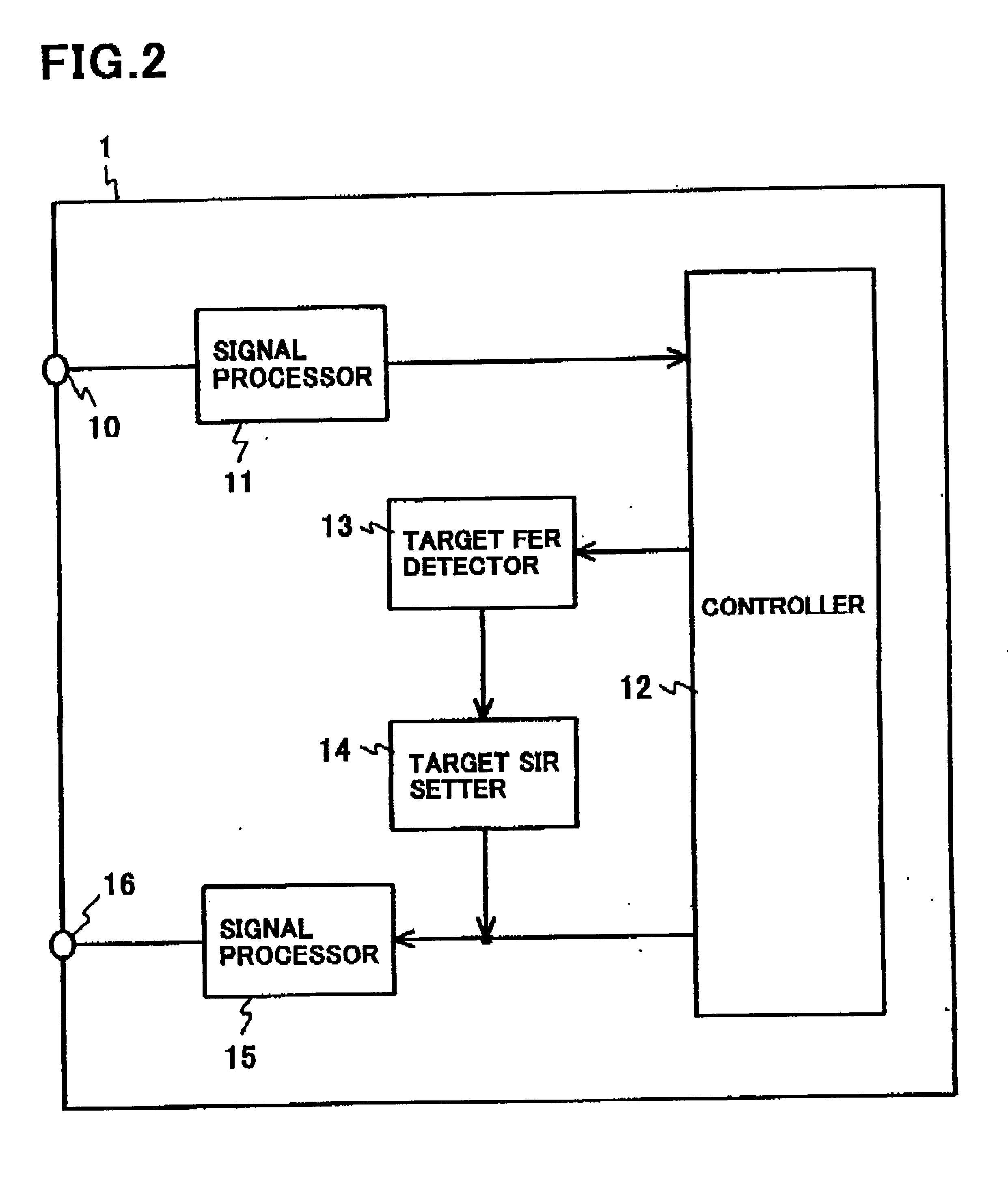

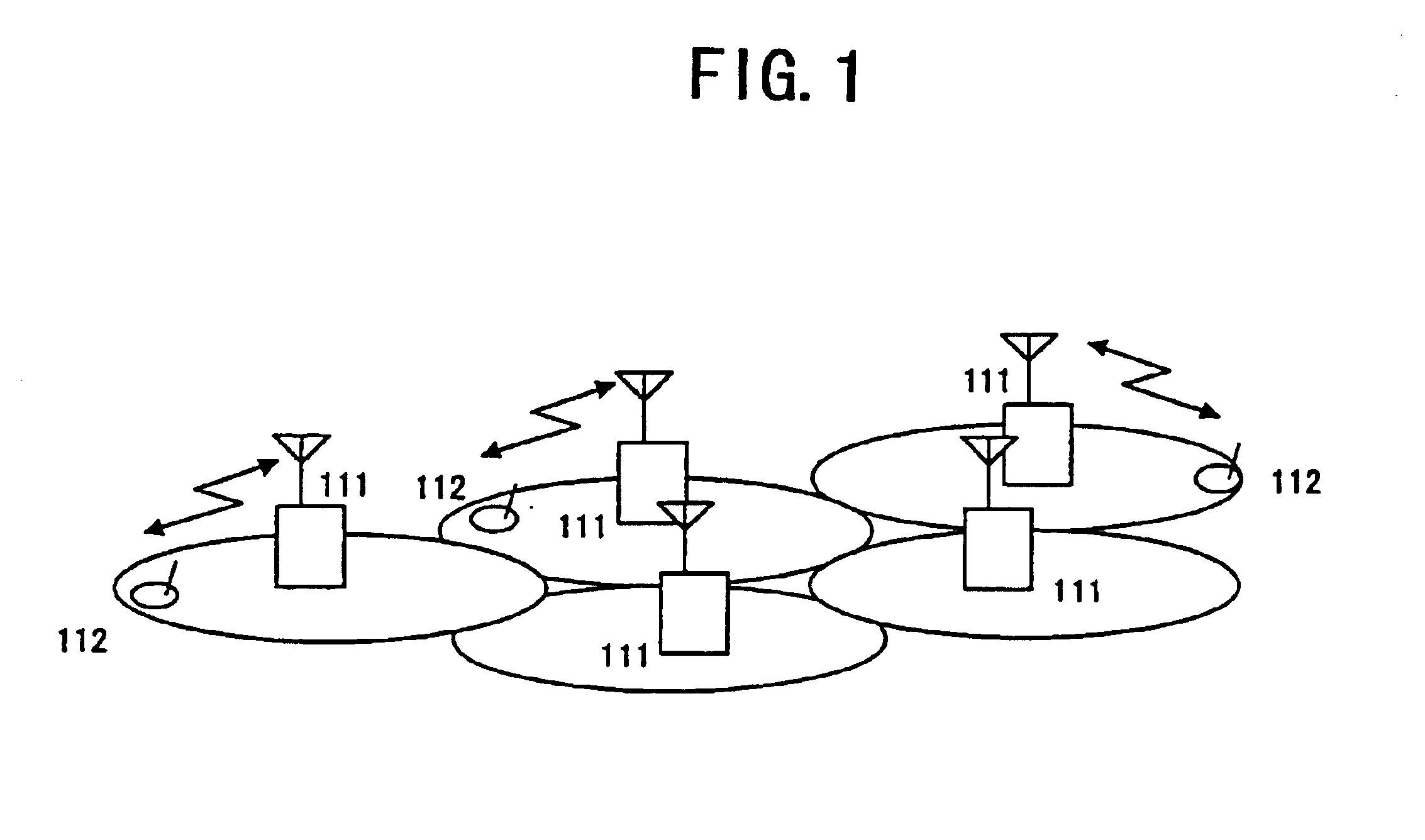

Cellular system

InactiveUS6842616B2Minimize impactImproved base stationPower managementTransmission control/equalisingTarget signalMobile station

A cellular system includes a mobile station and base stations, wherein the mobile station establishes a communication line with N first base stations wherein N is an integer (1≦N), measures receipt quality in pilot signals transmitted from the N first base stations, determines M second base stations to make communication therethrough among the N first base stations, based on measurement results of the receipt quality, wherein M is an integer (1≦M≦N), and transmits an designation signal to the M second base stations through upward line to designate the M second base stations as a base station through which the mobile station makes communication, and each of the base stations makes communication with the mobile station, if designated by the designation signal, and does not make communication with the mobile station, if not designated. The cellular system further includes a first apparatus for varying a signal-receipt error rate in the designation signal to be transmitted through upward line in accordance with a target signal-receipt error rate in downward line.

Owner:NEC CORP

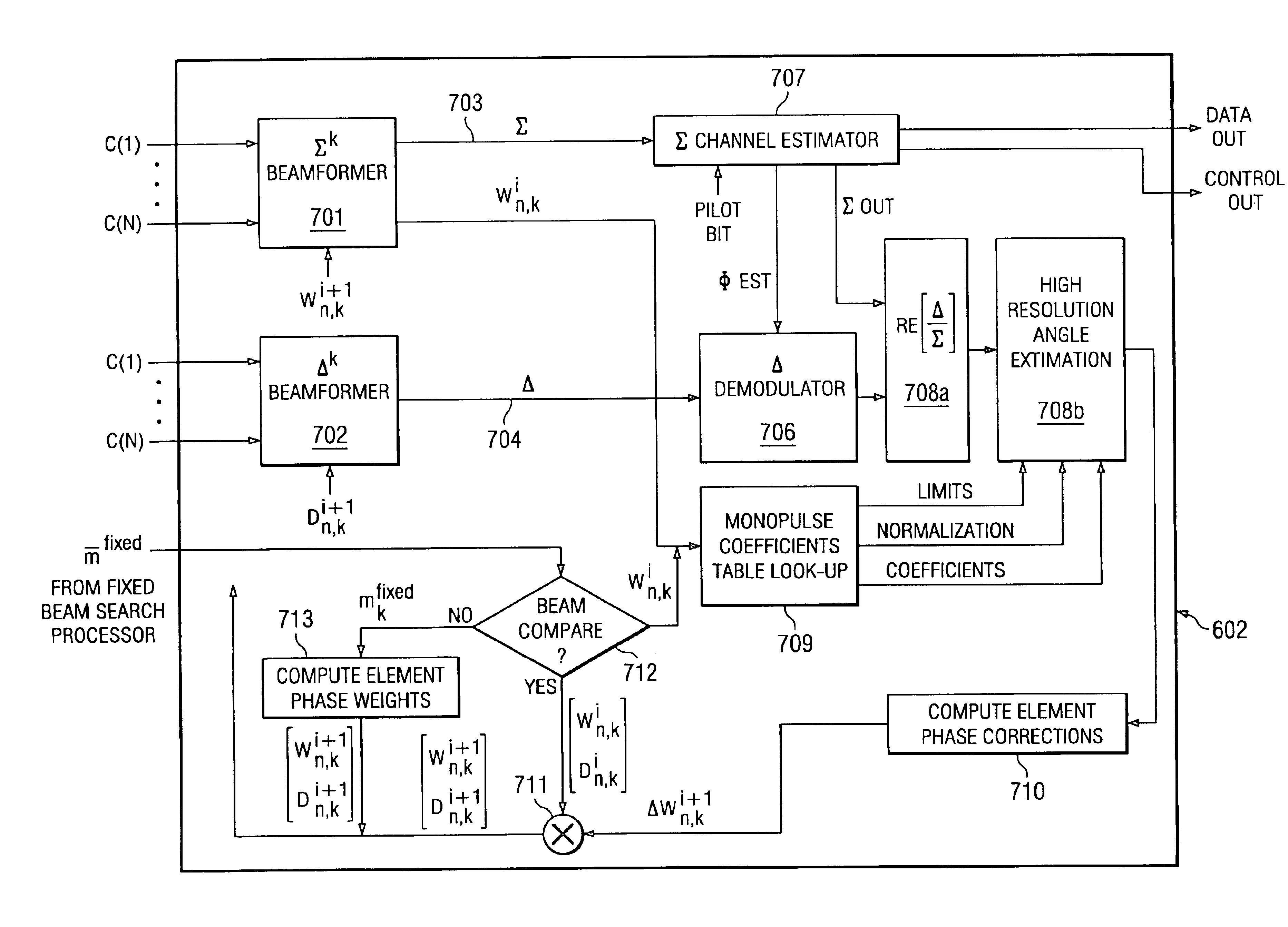

Method and apparatus for high resolution tracking via mono-pulse beam-forming in a communication system

InactiveUS6930637B2Increase capacityIncrease rangeSpatial transmit diversityRadio wave direction/deviation determination systemsPulse beamCommunications system

Method and apparatus for high resolution tracking via mono-pulse beam-forming in a communication system in which the capacity and range of mobile or fixed wireless communication base stations are improved by implementing a single or multiple antenna beam per signal path. Adaptive beam-forming based on up-link direction-of arrival estimation can be performed without using the above-mentioned computationally intensive techniques.

Owner:TEXAS INSTR INC

Antenna steering for an access point based upon control frames

InactiveUS20050063343A1Facilitate communicationImprove throughputSpatial transmit diversityError preventionSignal qualityDirectional antenna

A method for operating an access point in a wireless local area network (WLAN) is provided. The access point includes a directional antenna for communicating with at least one remote station in a forward link based upon an exchange of packet data comprising a plurality of control frames and a data frame. The directional antenna includes a plurality of antenna patterns. The method includes receiving a first control frame via a first antenna pattern of the directional antenna from the remote station, transmitting a first data frame to the remote station, and receiving a second control frame via a second antenna pattern of the directional antenna from the remote station. A signal quality of the first control frame received via the first antenna pattern and a signal quality of the second control frame received via the second antenna pattern are measured. The respective measured signal qualities associated with the first and second antenna patterns are compared.

Owner:IPR LICENSING INC

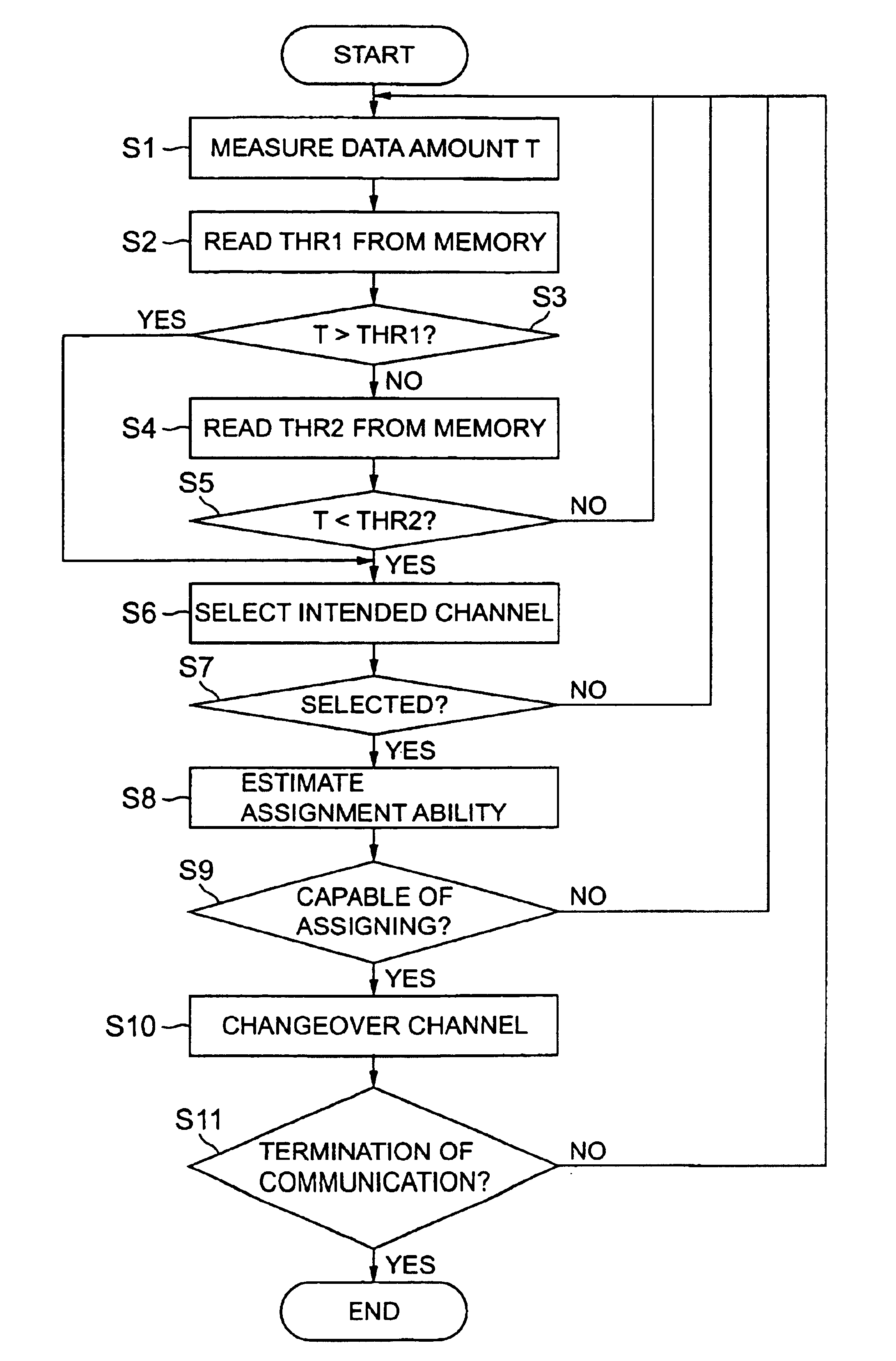

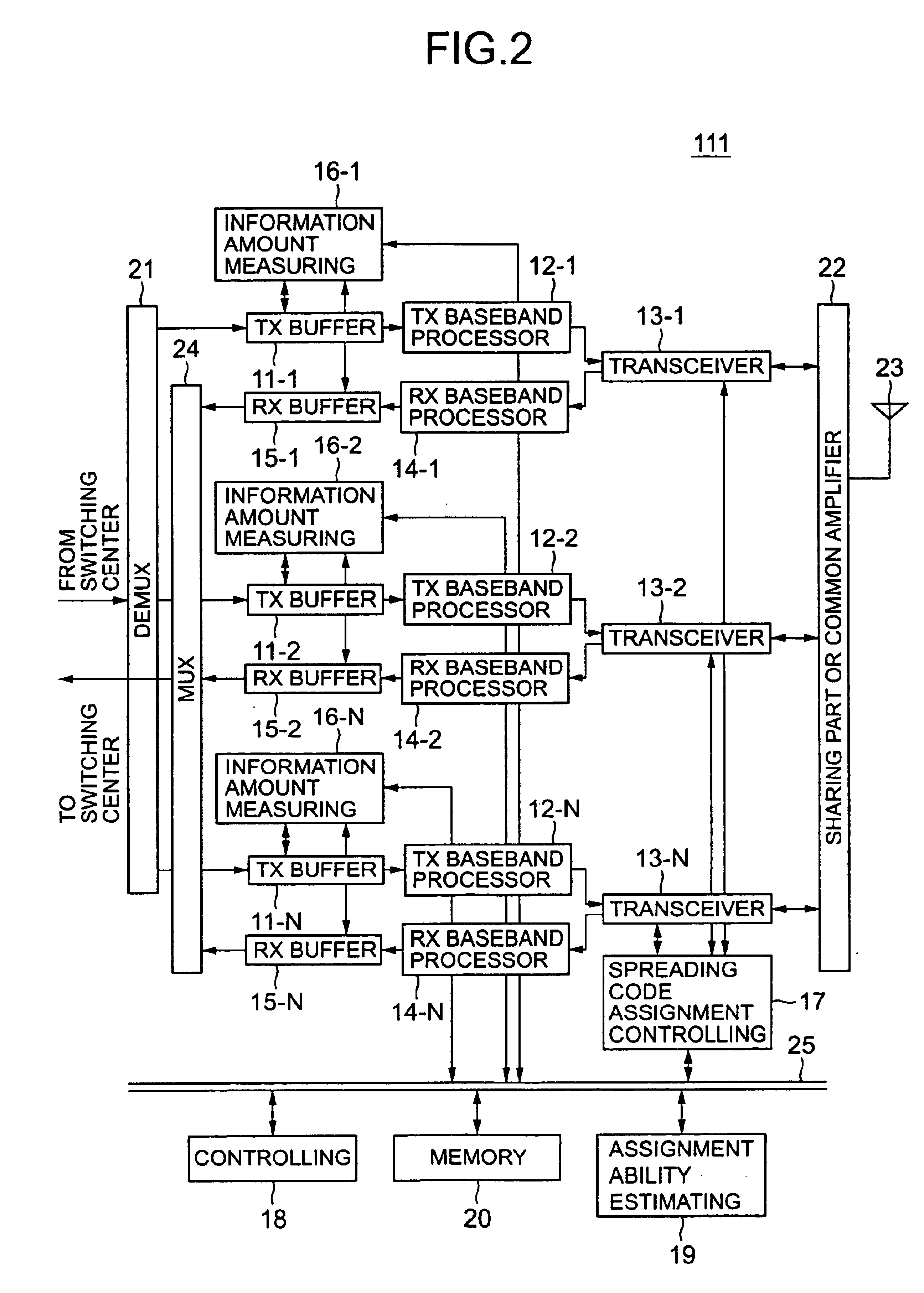

Wireless channel changeover method and mobile communication system

InactiveUS6907250B2Improve transmission efficiencyImprove efficiencyNetwork traffic/resource managementNetwork topologiesMobile communication systemsMobile station

A mobile communication system includes a plurality of base stations and a mobile station communicating with the base station through a wireless channel. The system comprises a part which measures an amount of information transferred between the base station and the mobile station and a comparator which compares the measured amount of information with first and second threshold values corresponding to a currently used wireless channel. A wireless channel changeover part changes the current wireless channel to a wireless channel with a transmission capability higher or lower than that of the current wireless channel when the measured amount of information is above the first threshold value or below the second threshold value, respectively.

Owner:NTT DOCOMO INC

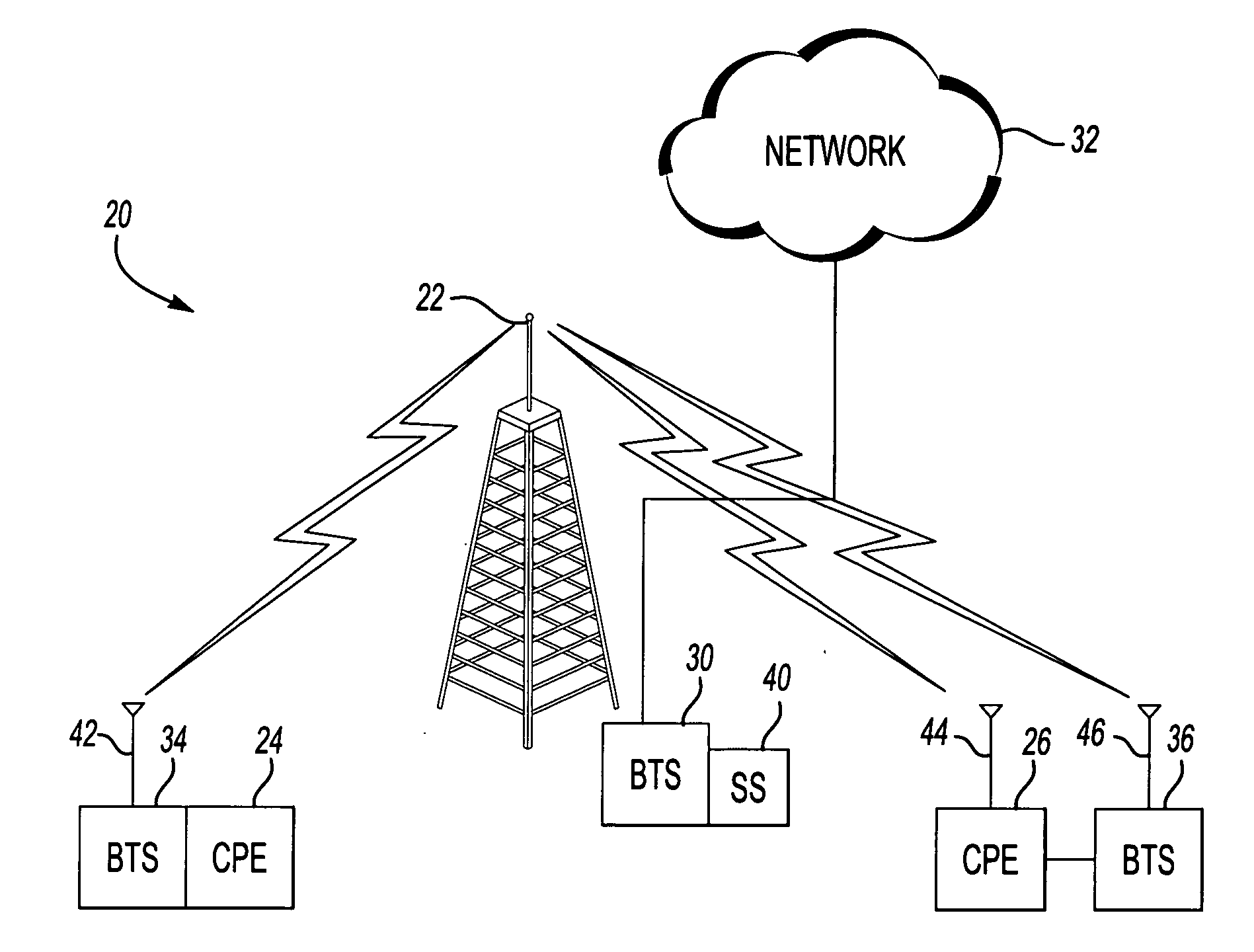

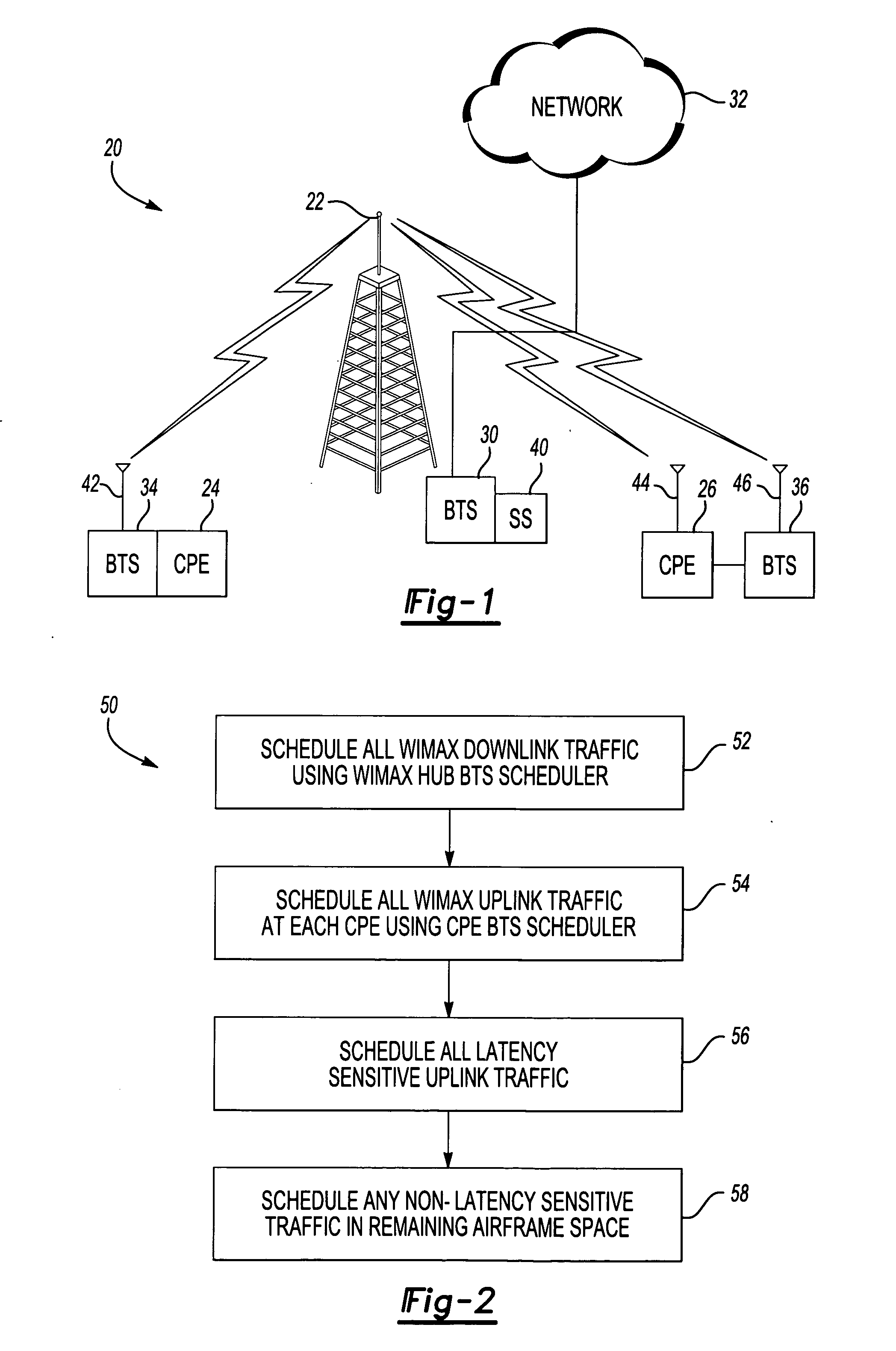

Managing wireless backhaul communications

InactiveUS20070298808A1Delay minimizationImprove usabilityRadio/inductive link selection arrangementsWireless communicationCommunications systemCustomer-premises equipment

A wireless communication system is disclosed where a hub base station has an associated scheduler. Remotely located subscriber stations such as customer premises equipment devices each have their own associated scheduler in the vicinity of each device. The hub base station scheduler is responsible for scheduling communications in a first direction between the hub base station and the subscriber stations. Each subscriber station scheduler is responsible for scheduling communications in a second, opposite direction between the corresponding subscriber station and the hub base station. In one example, the schedulers associated with the subscriber stations are responsible for scheduling all backhaul or uplink communications from the subscriber station to the base station. A disclosed example is useful for WiMax communications.

Owner:LUCENT TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com