Patents

Literature

50results about How to "Simple variety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antenna steering and hidden node recognition for an access point

InactiveUS7103386B2Facilitate communicationImprove throughputSpatial transmit diversitySubstation equipmentSignal qualityTelecommunications

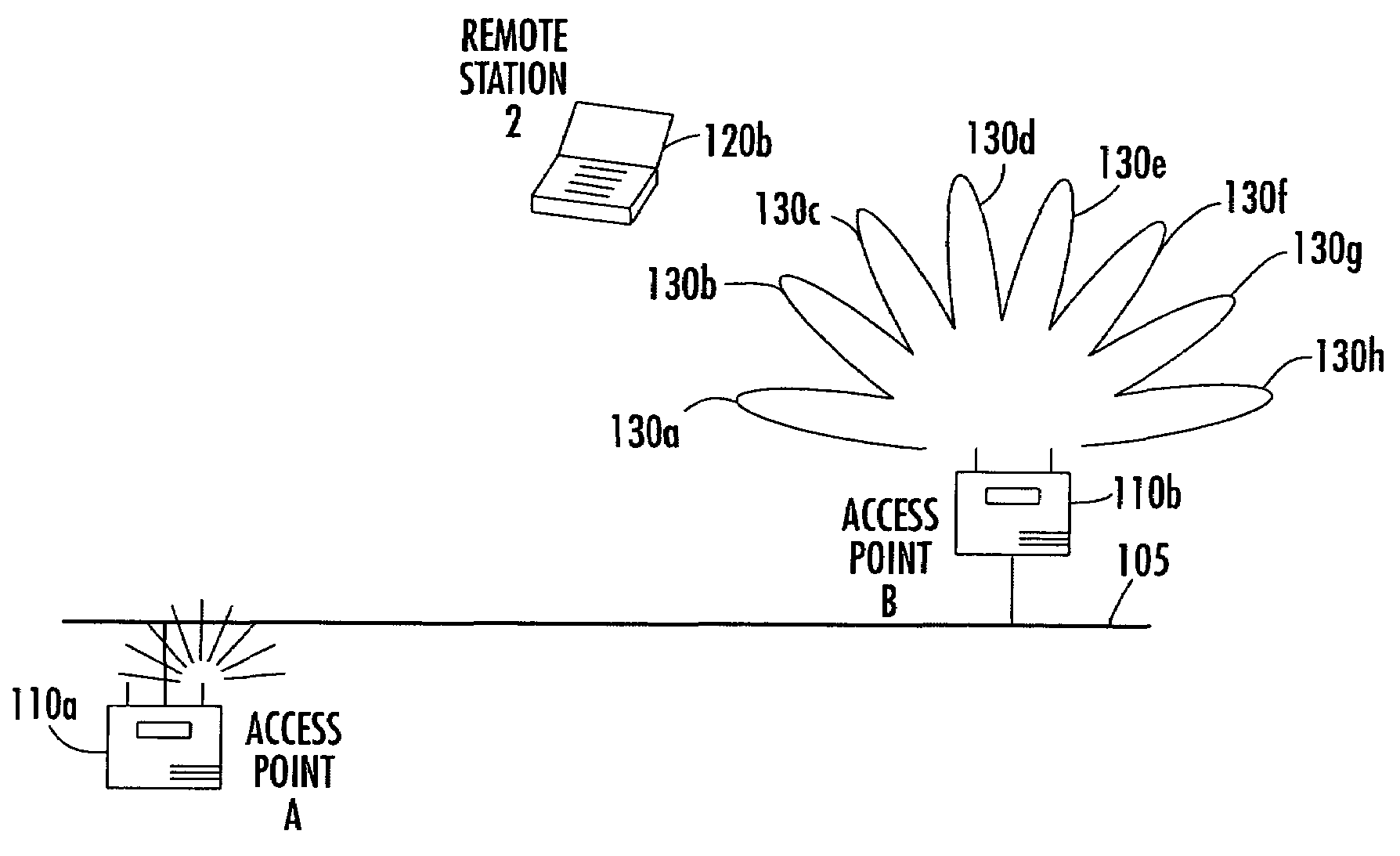

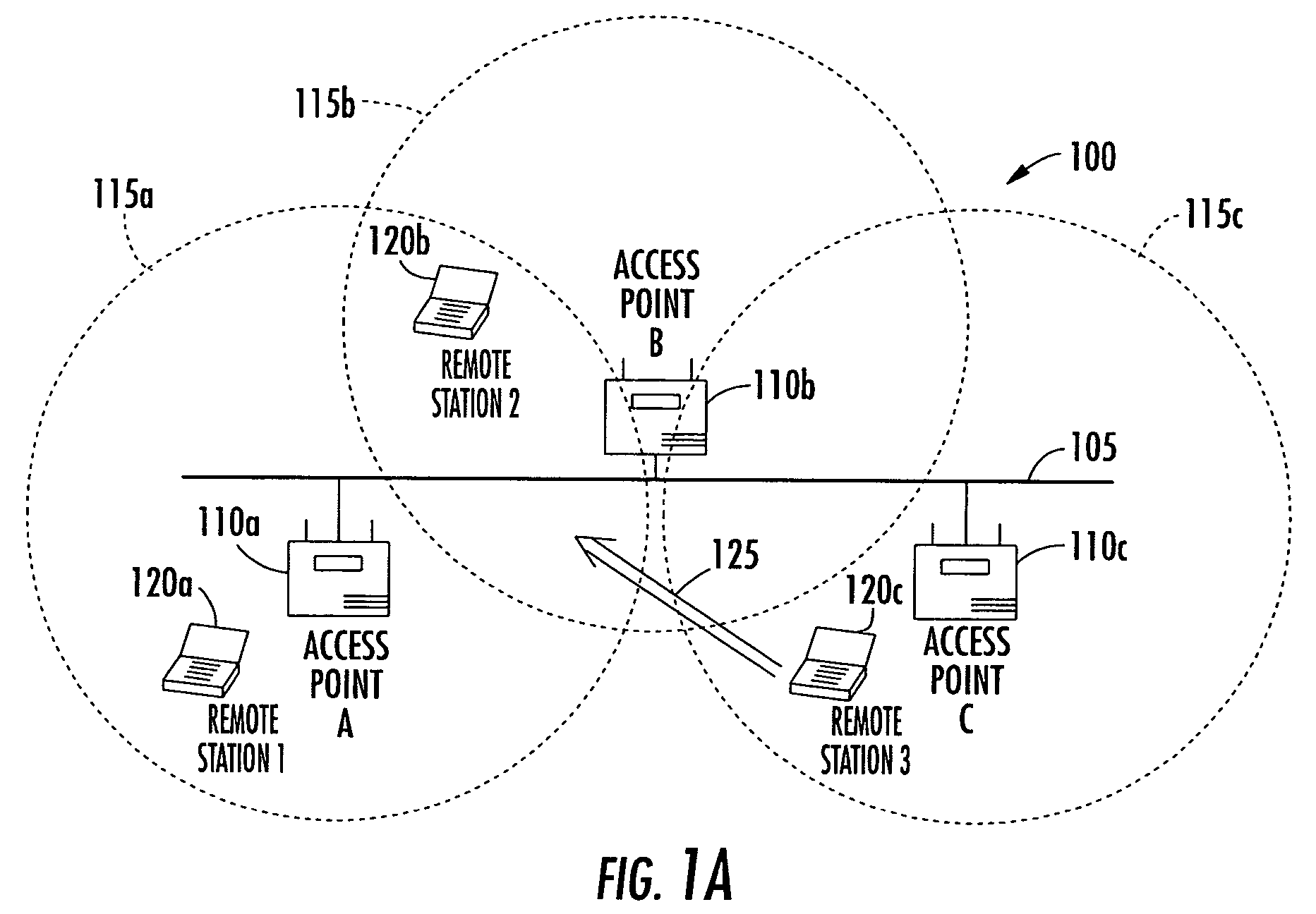

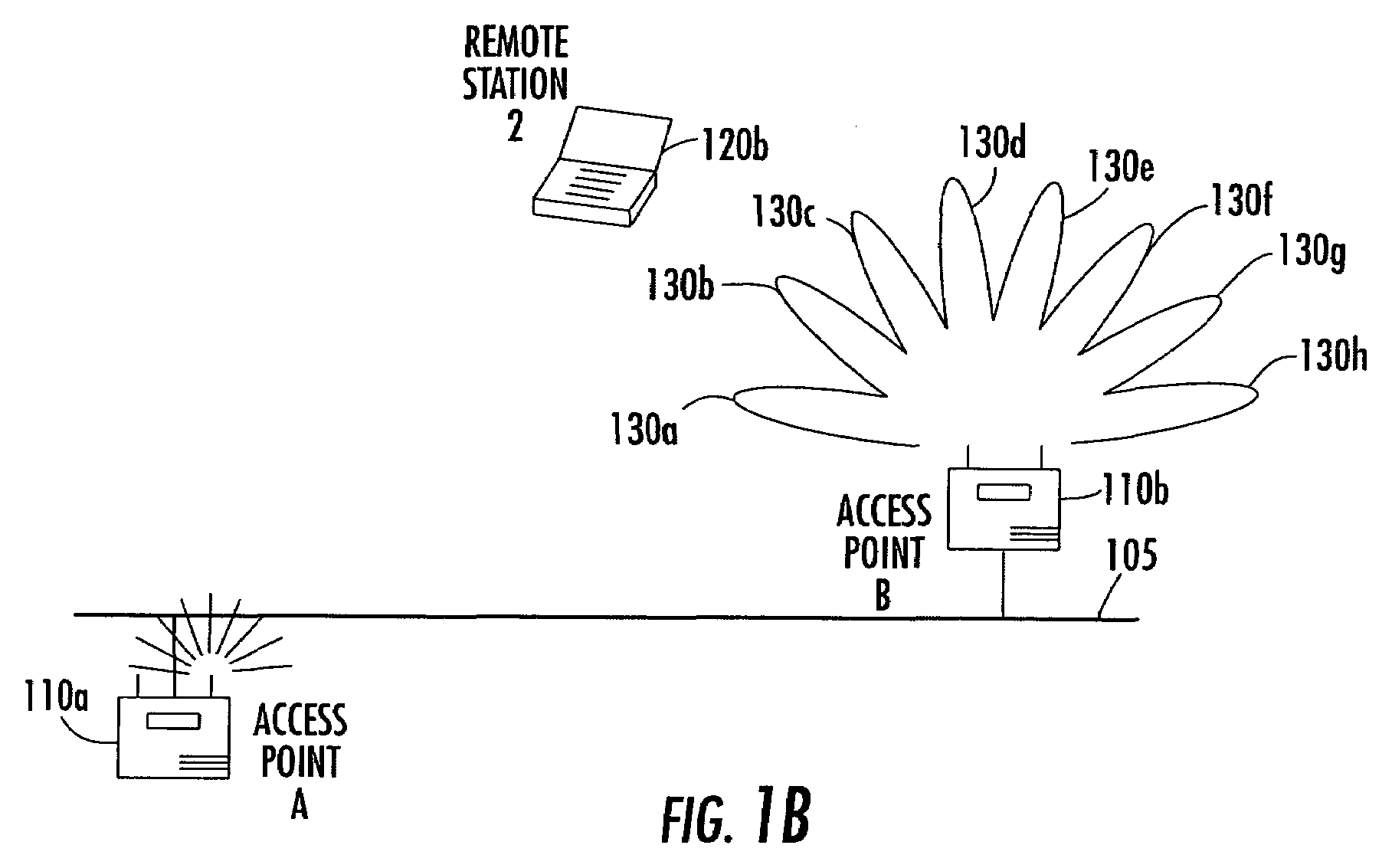

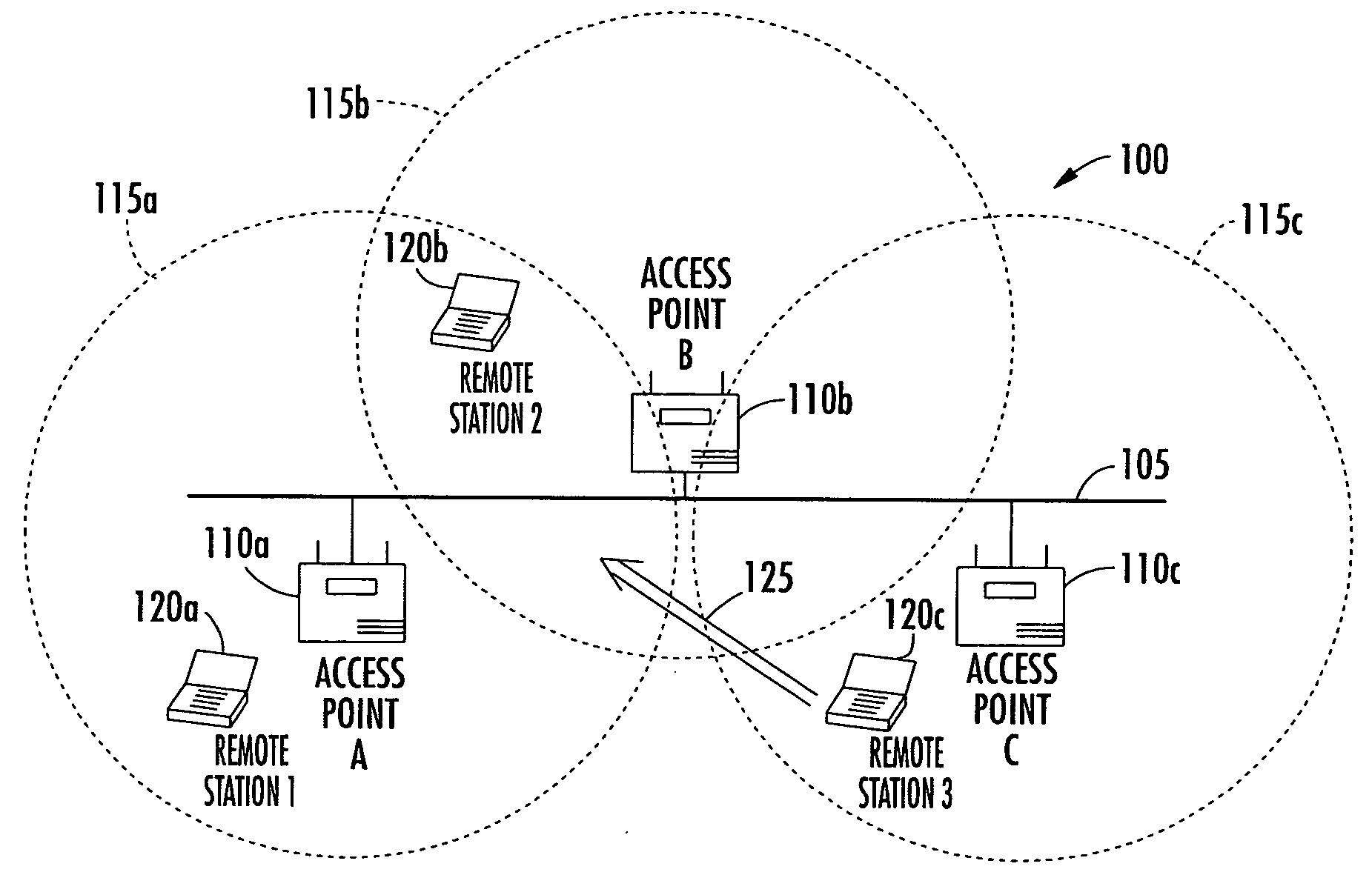

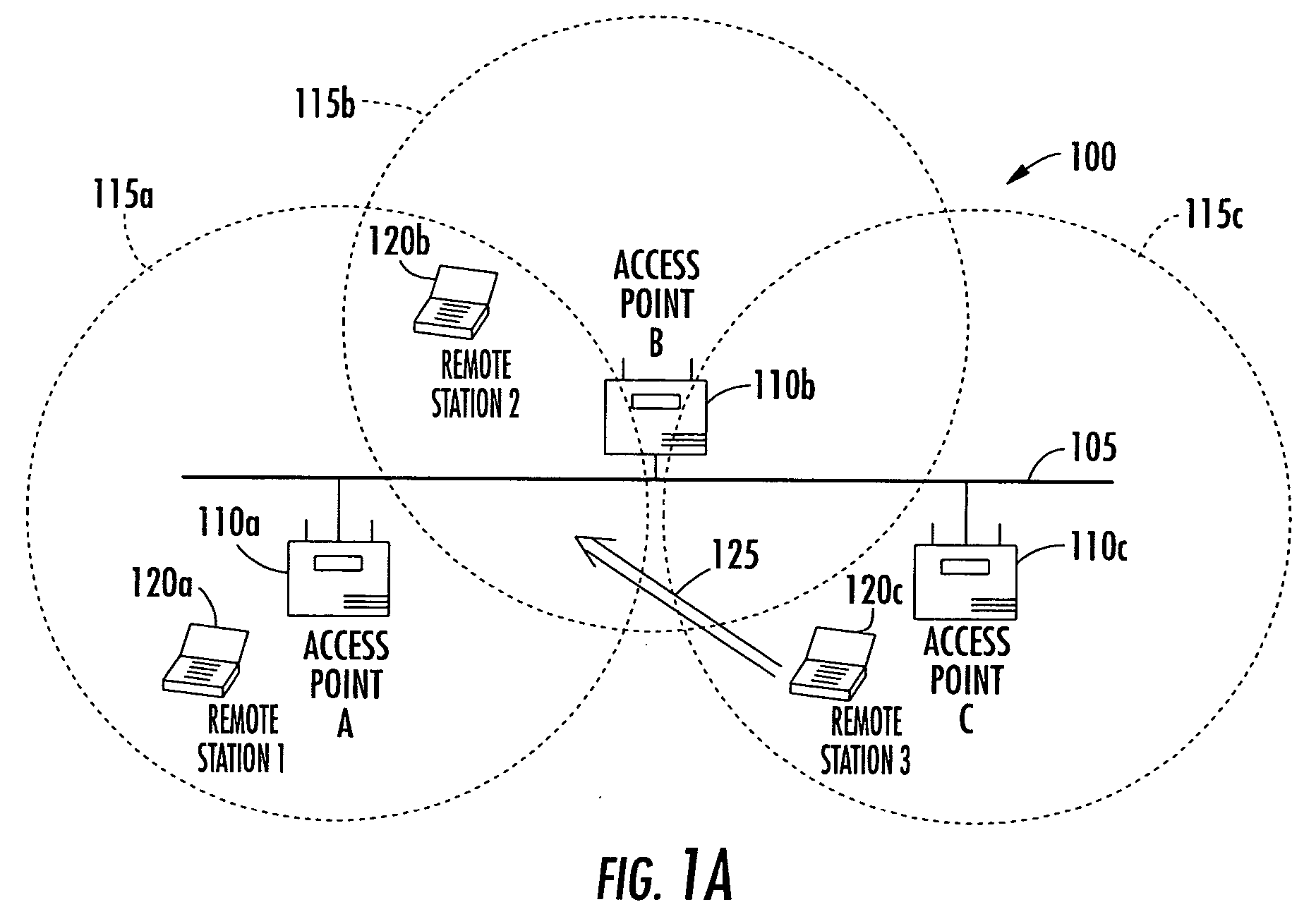

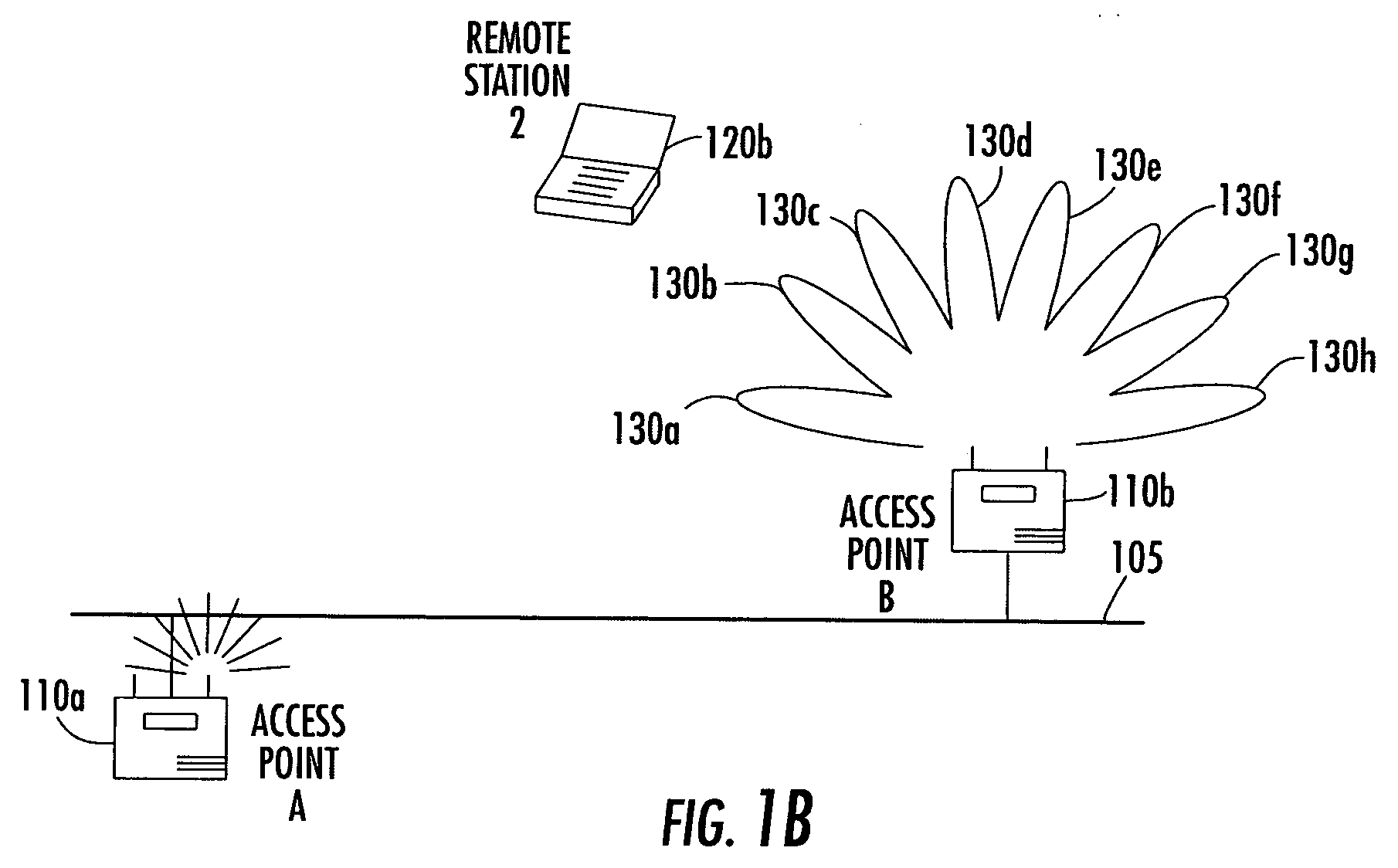

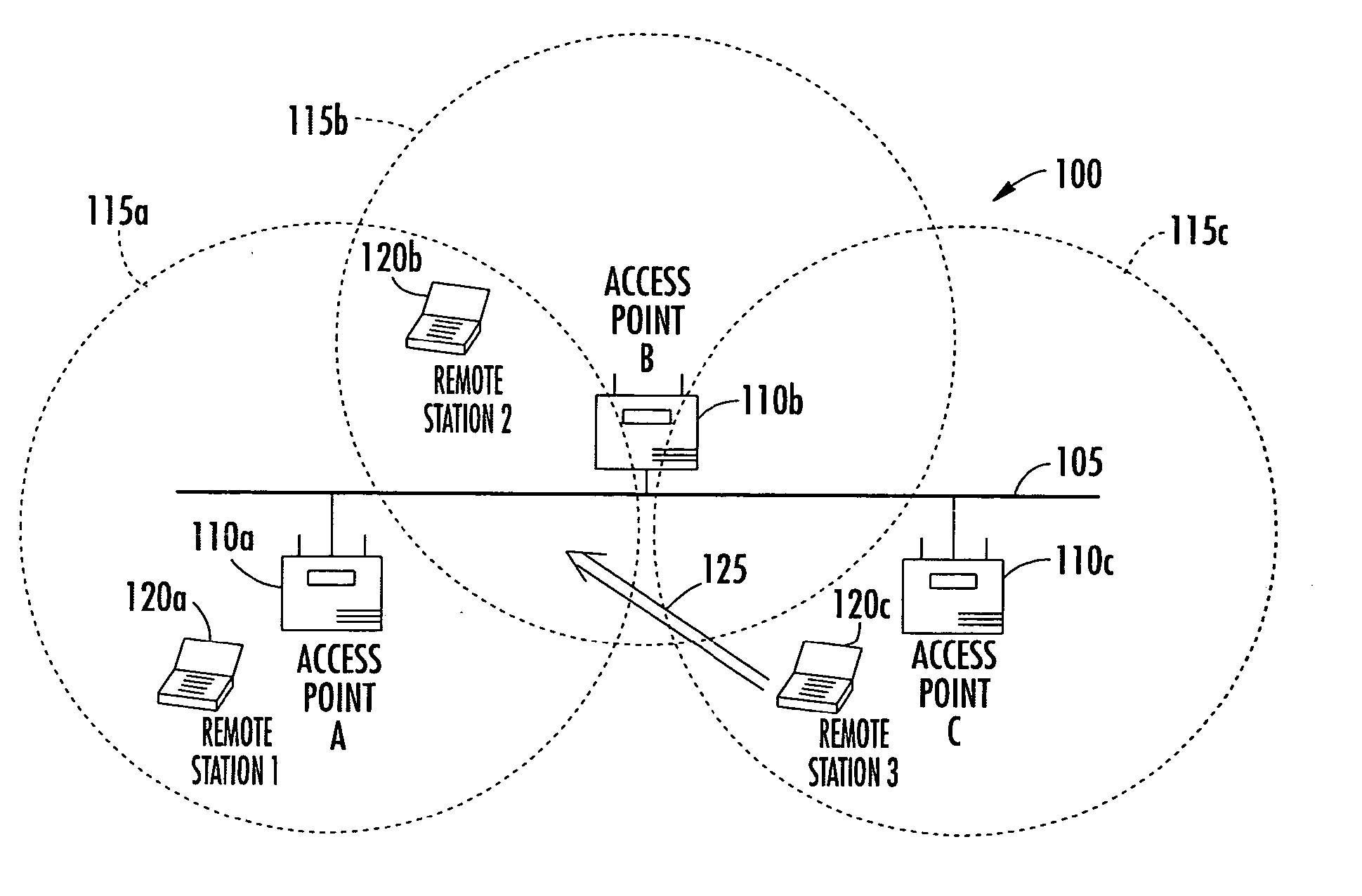

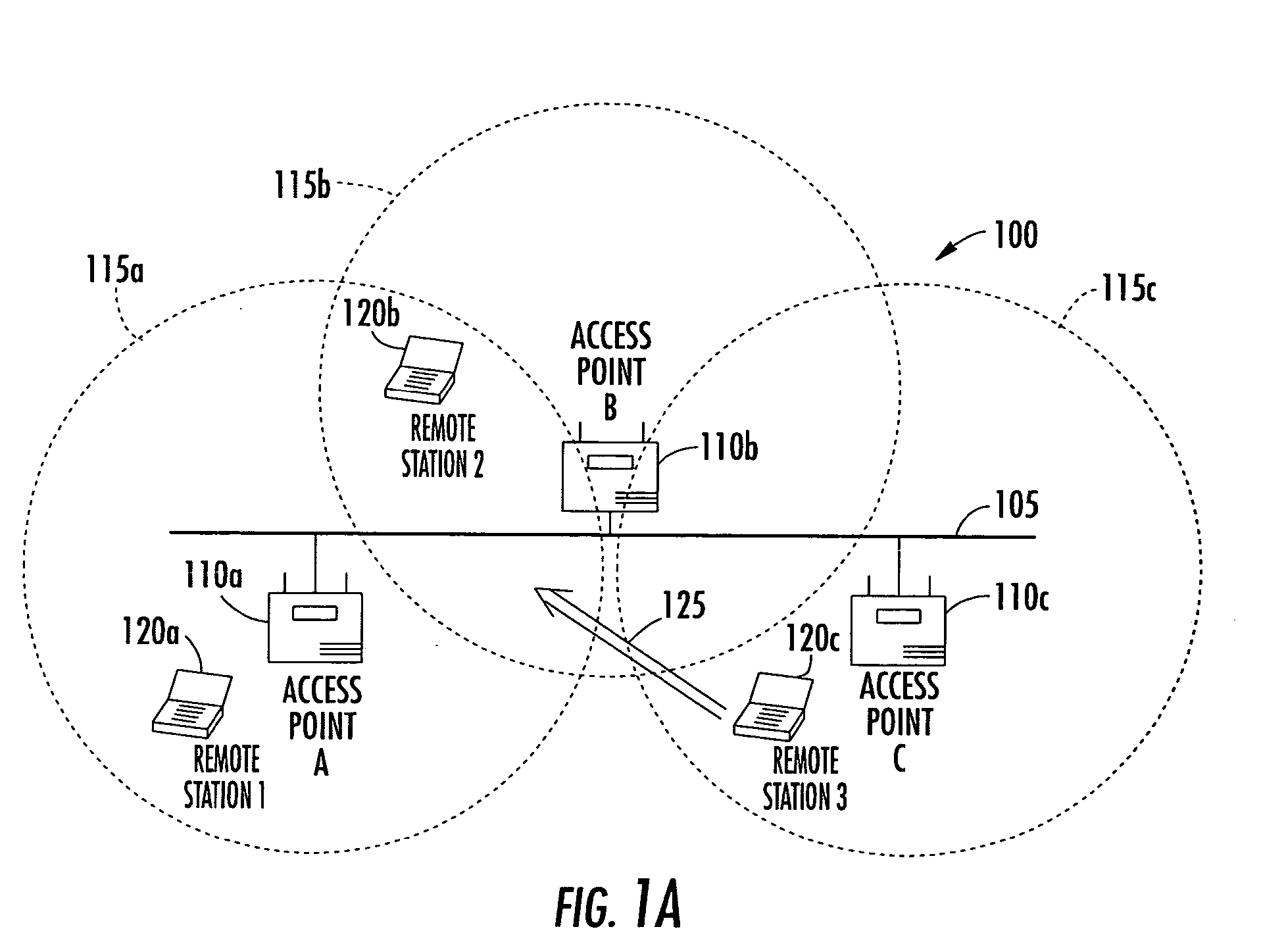

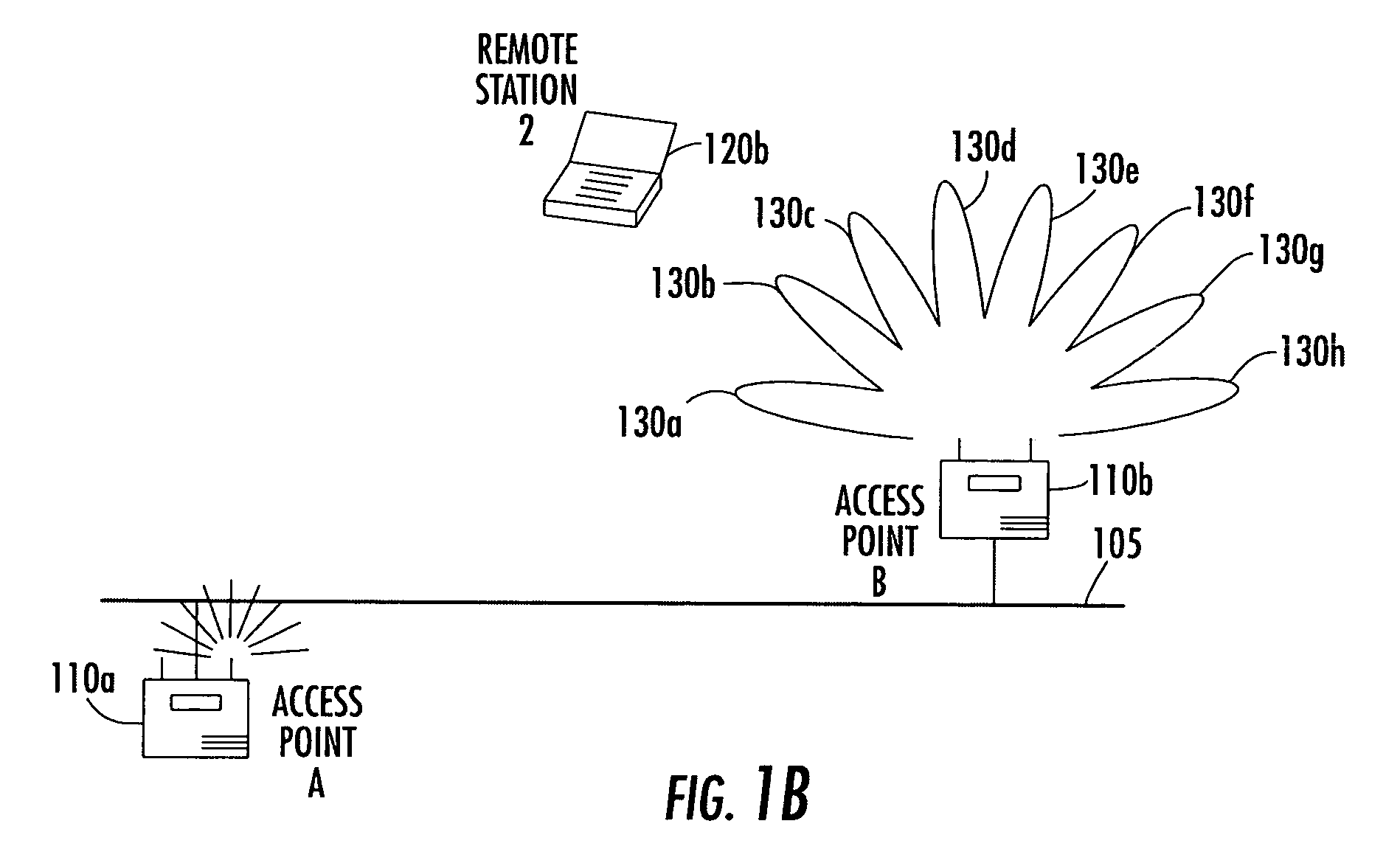

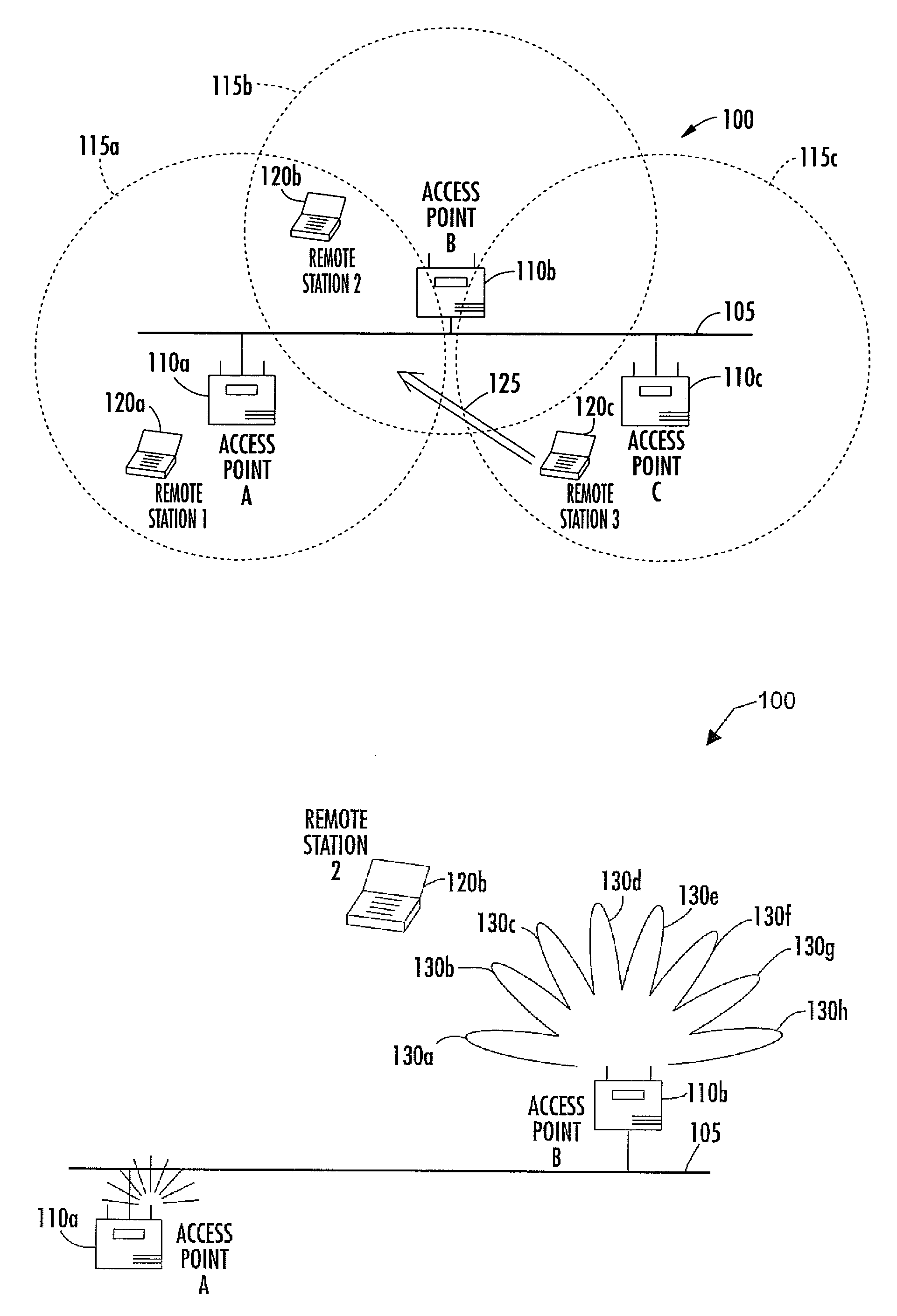

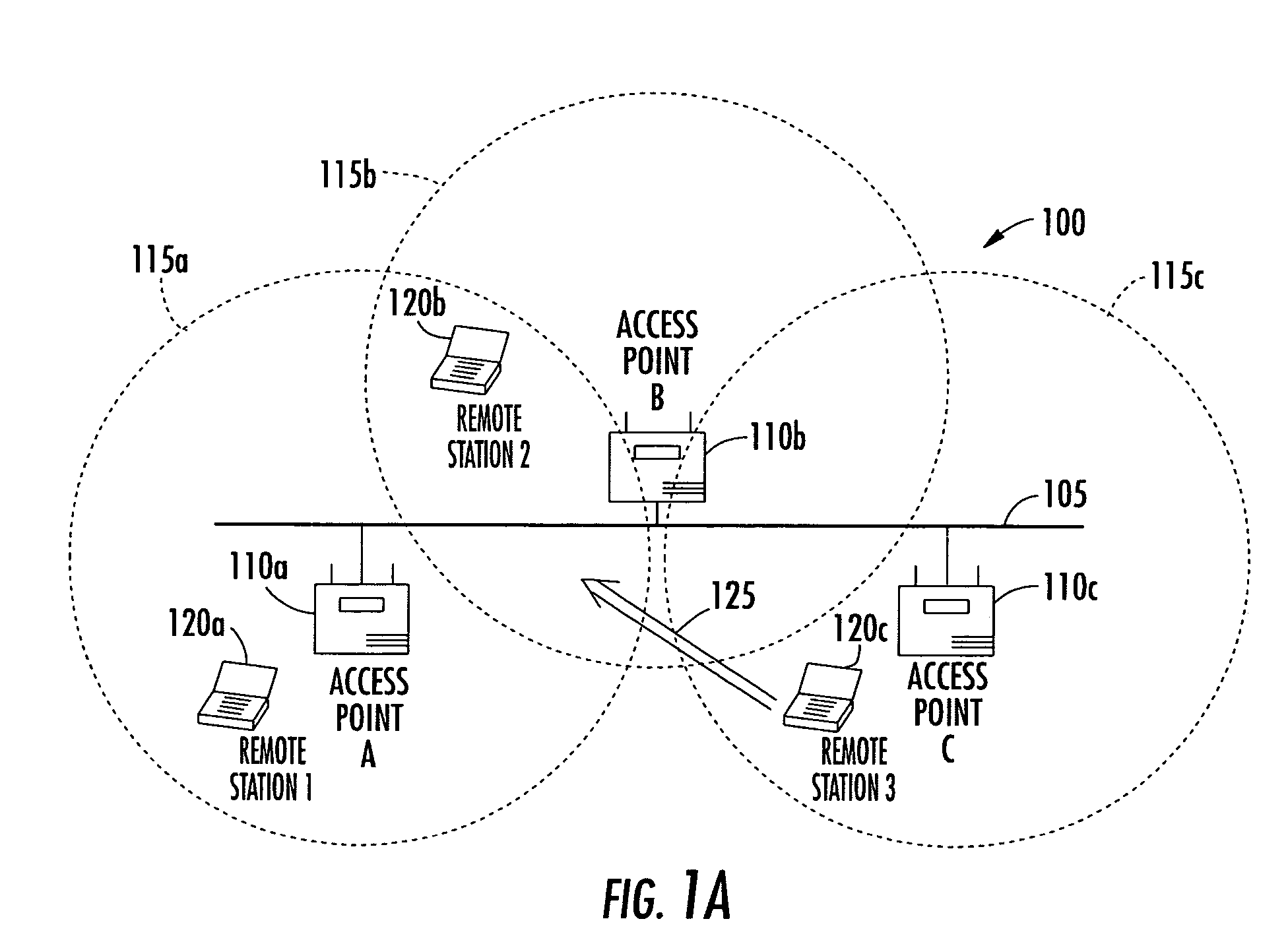

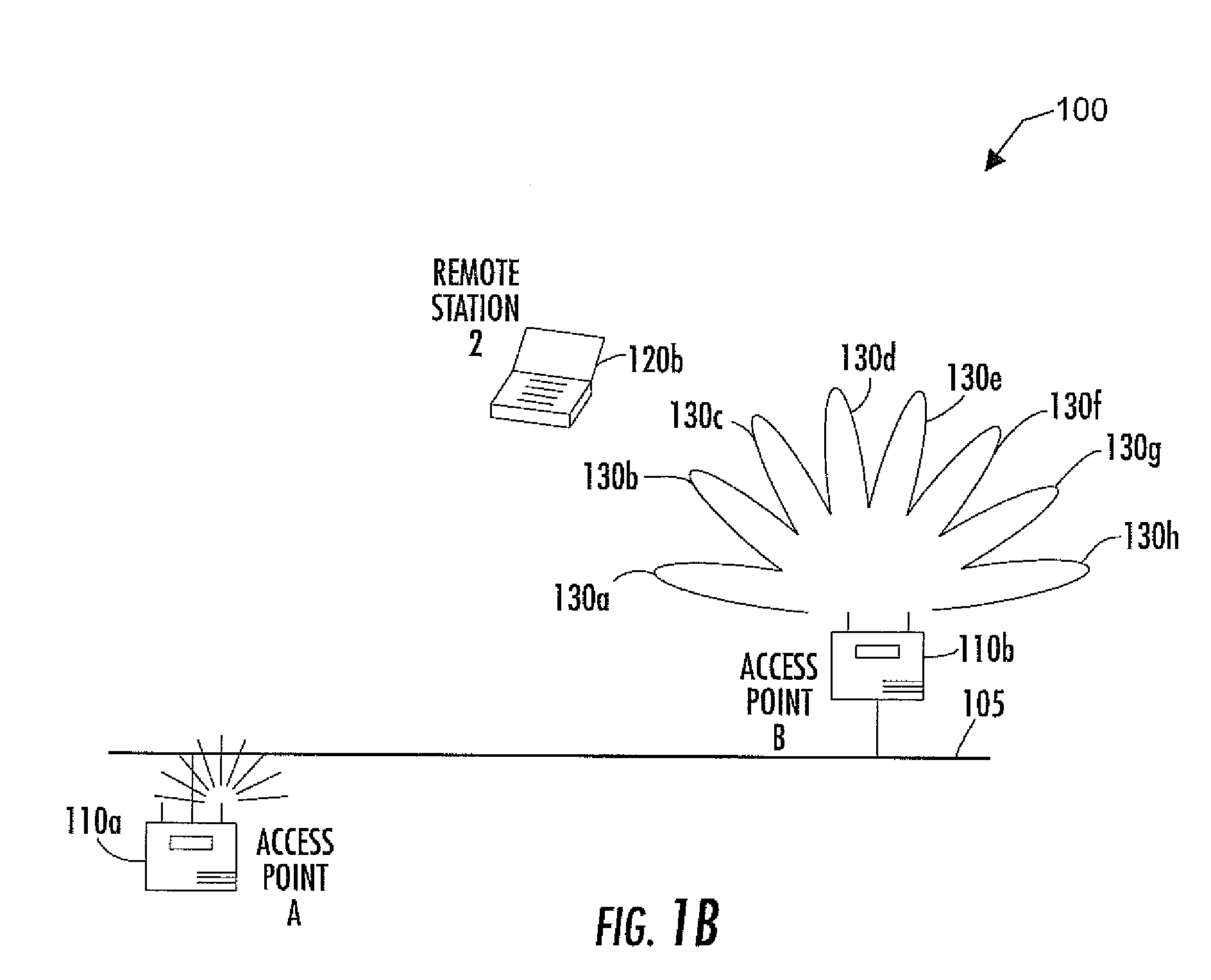

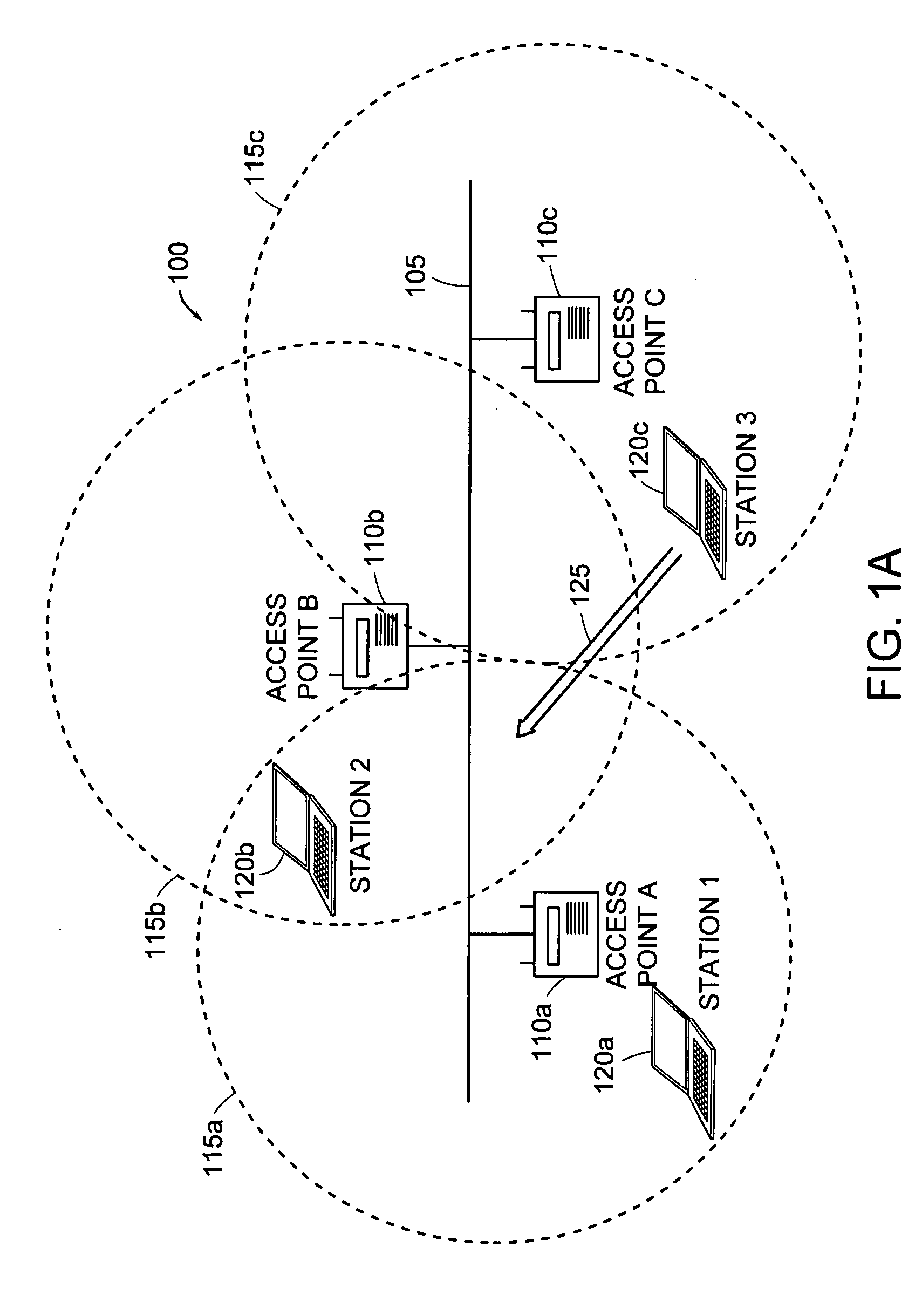

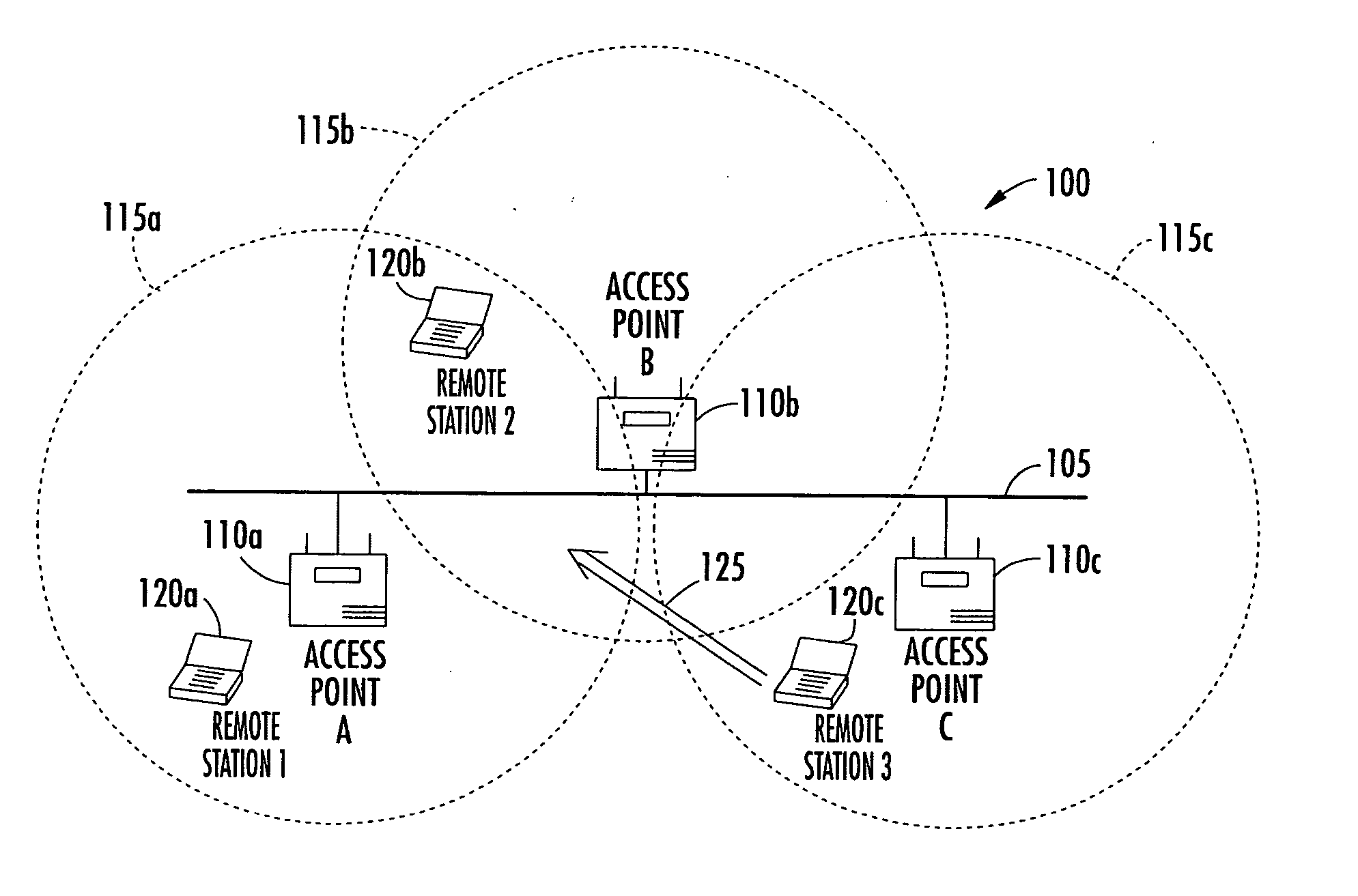

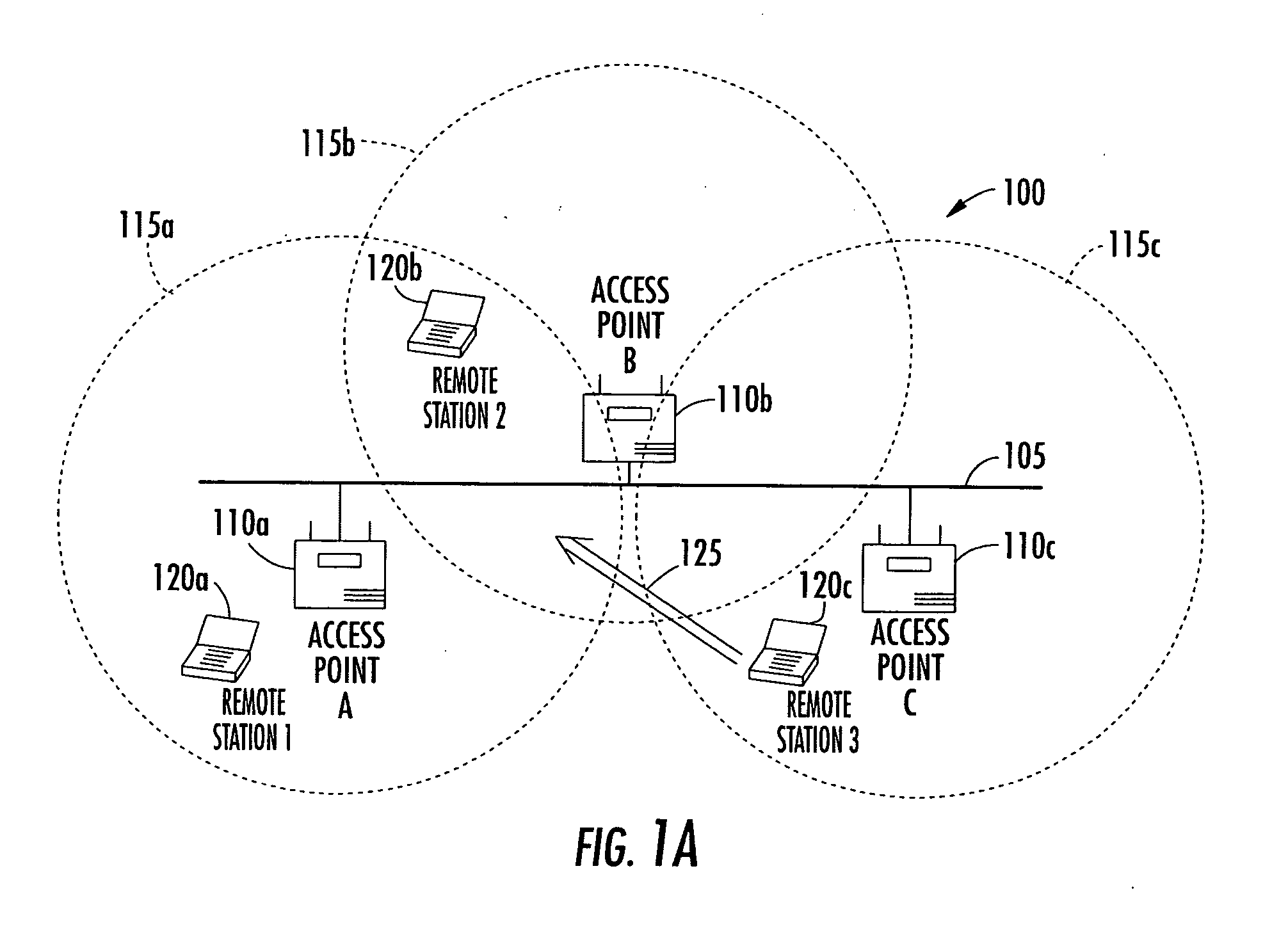

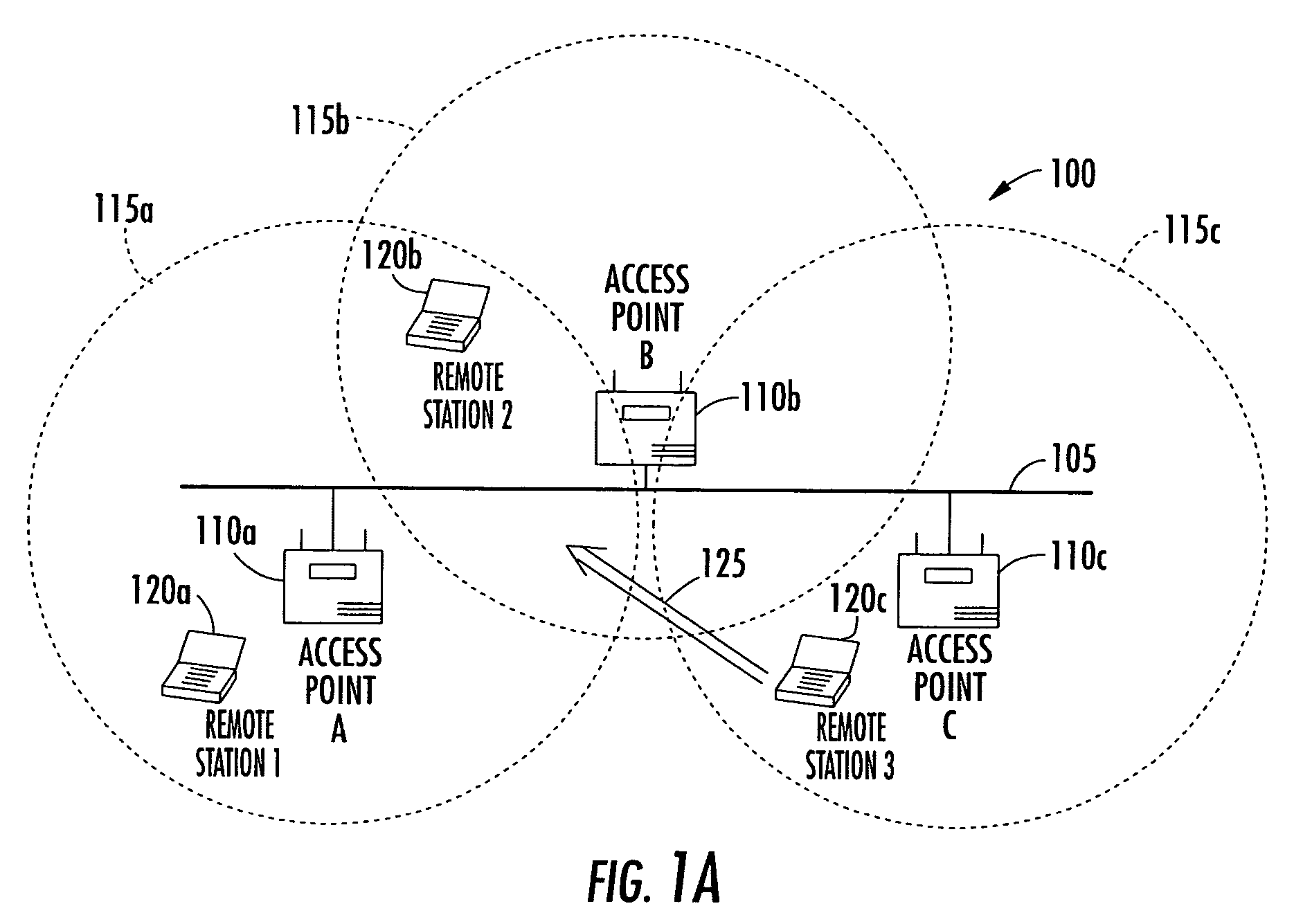

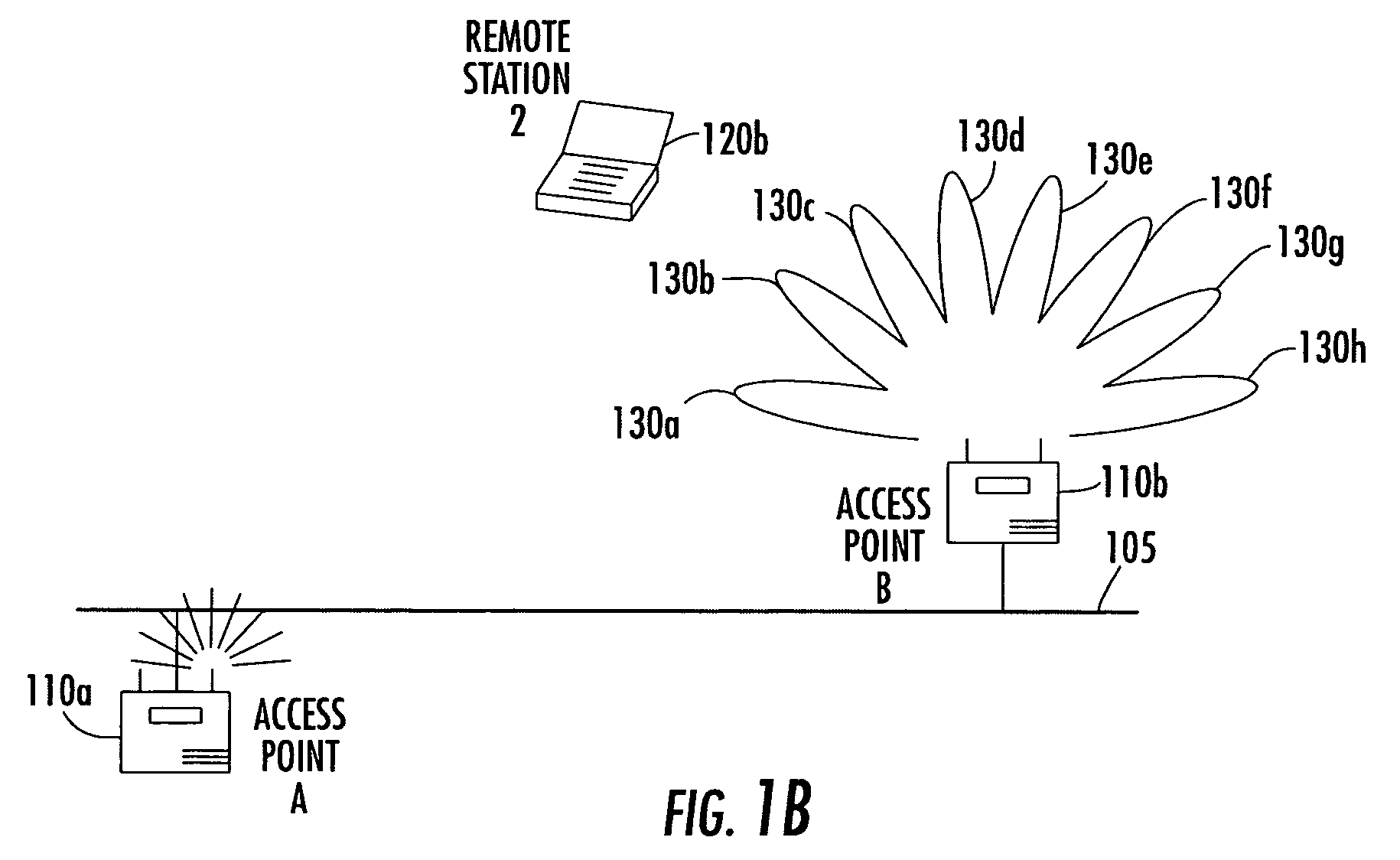

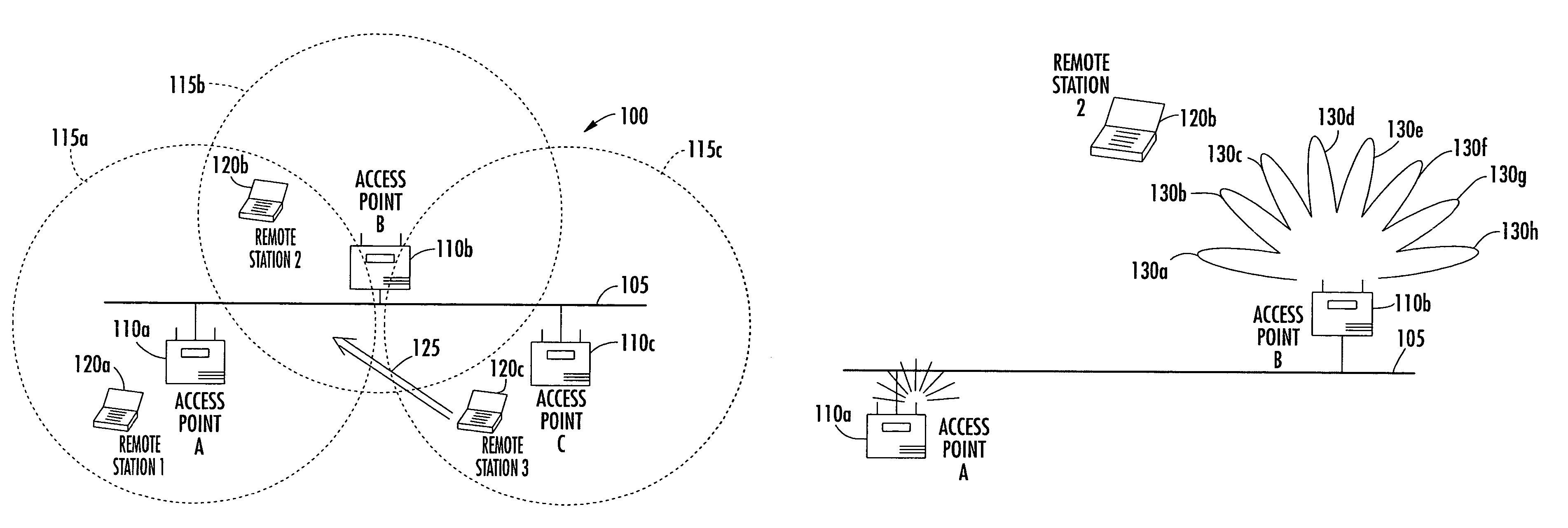

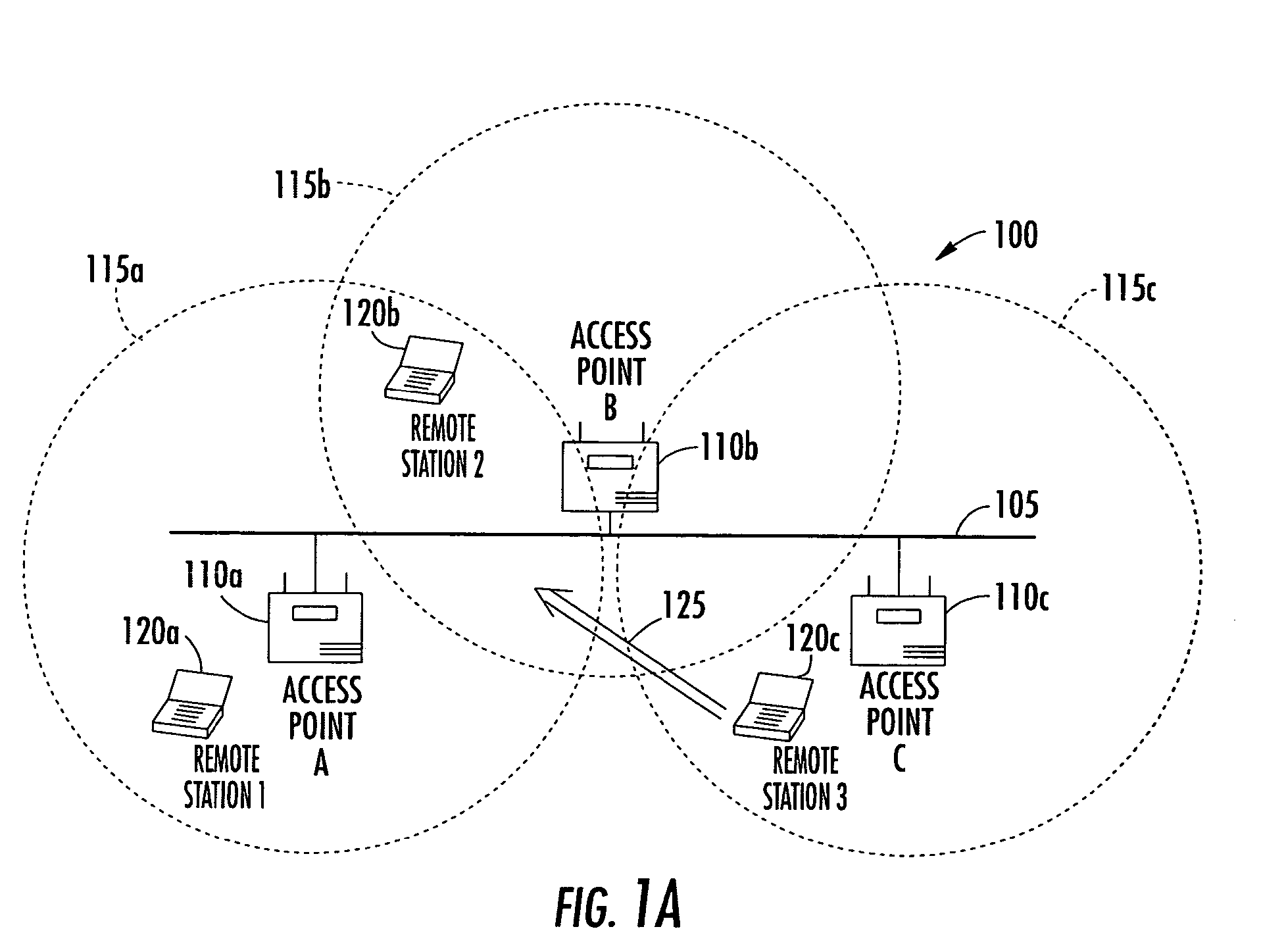

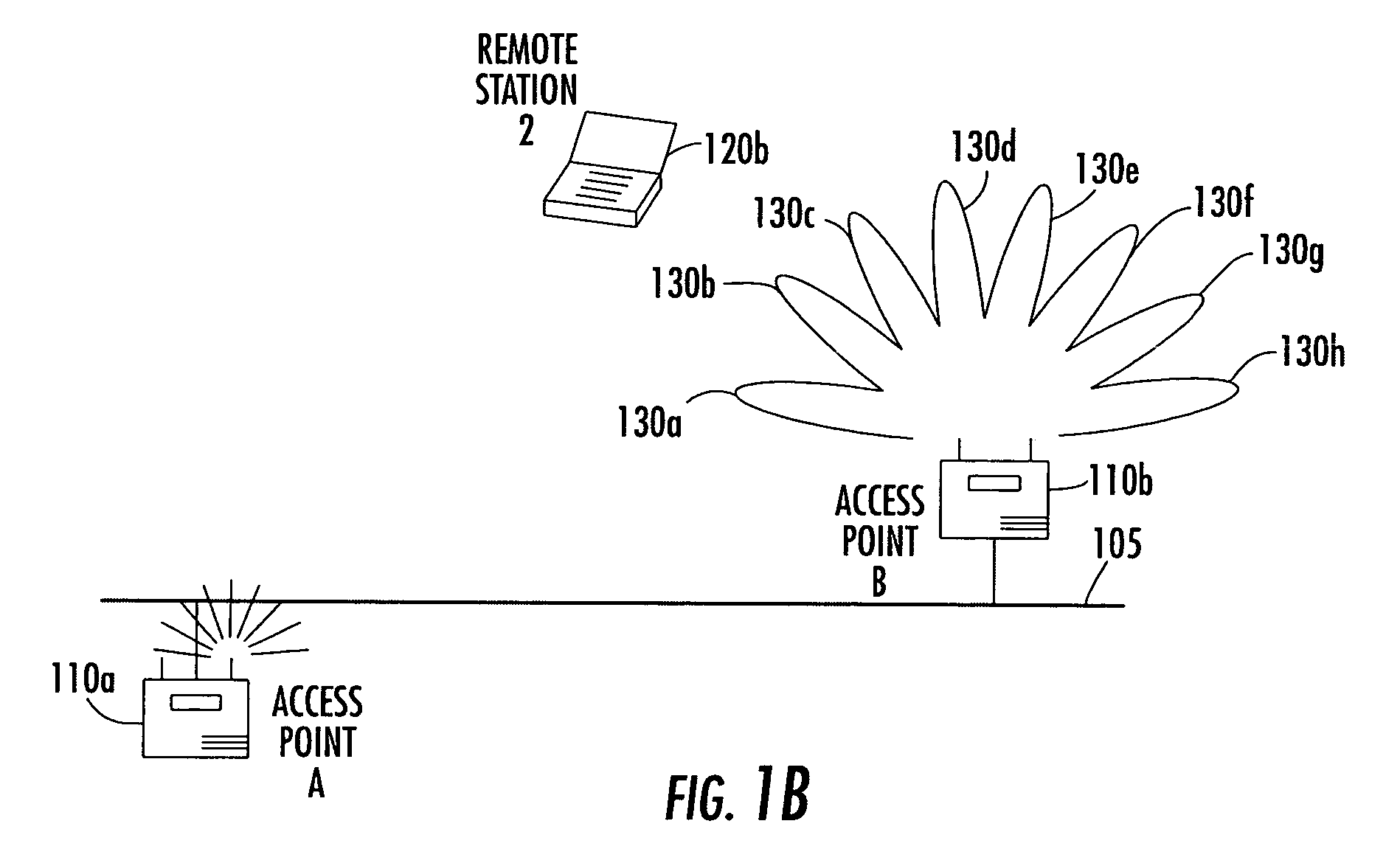

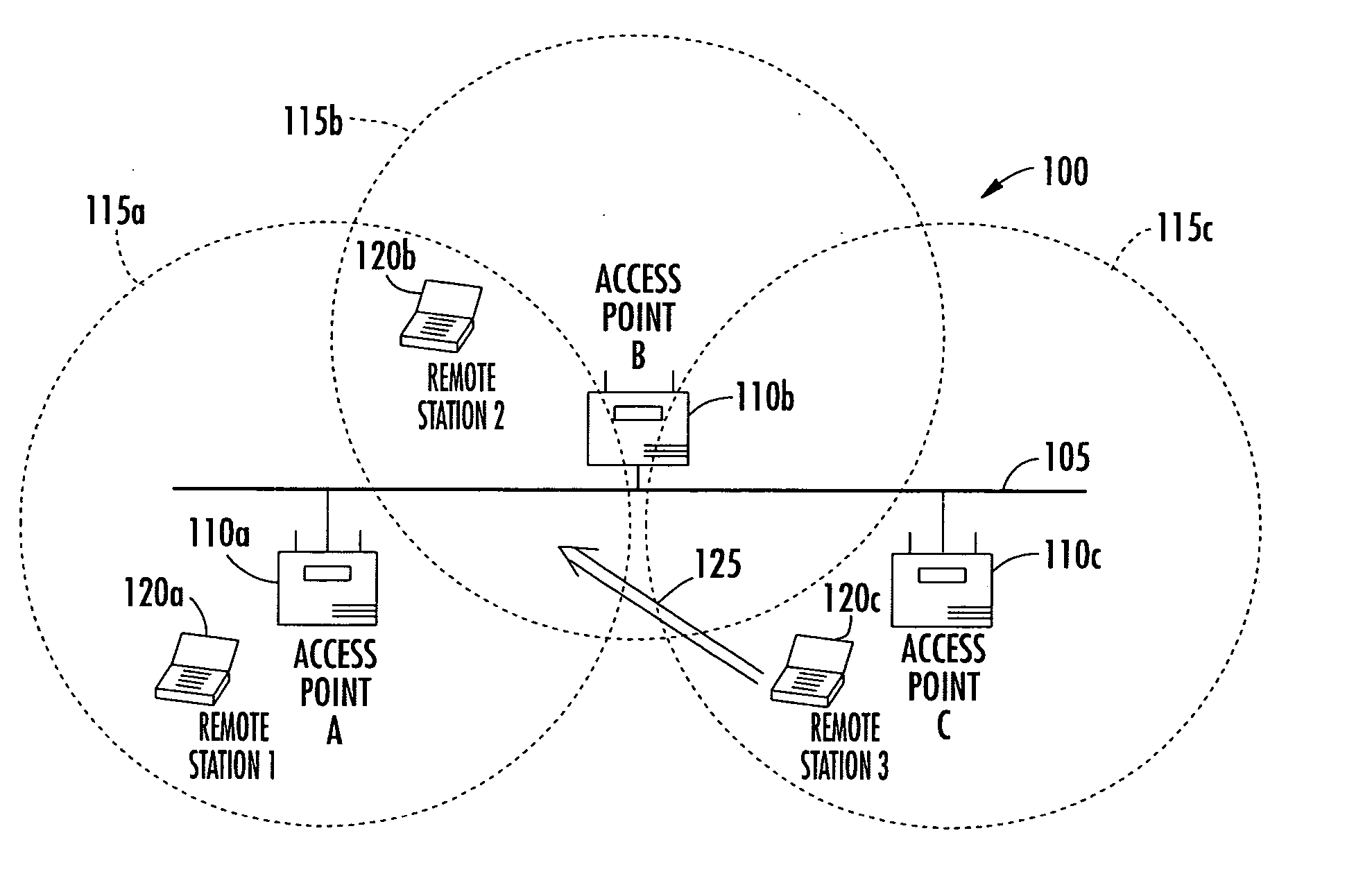

A method for operating an access point in a wireless local area network (WLAN) is provided. The access point includes a directional antenna for communicating with a plurality of remote stations, and the directional antenna includes a plurality of antenna patterns. The method includes creating an antenna database by associating between the access point and each remote station a respective measured signal quality corresponding to the plurality of antenna patterns. The respective measured signal qualities are determined by the access point based upon communications with each remote station. The method further includes determining for each remote station a preferred antenna pattern based upon the antenna database, and selecting a remote station and the corresponding preferred antenna pattern to communicate with. It is also determined based upon the antenna database and prior to communicating with the selected remote station, if any non-selected remote stations have the potential of not being aware when such communications actually occurs.

Owner:IPR LICENSING INC

Antenna steering and hidden node recognition for an access point

InactiveUS20050075142A1Facilitate communicationImprove throughputSpatial transmit diversitySubstation equipmentTelecommunicationsSignal quality

A method for operating an access point in a wireless local area network (WLAN) is provided. The access point includes a directional antenna for communicating with a plurality of remote stations, and the directional antenna includes a plurality of antenna patterns. The method includes creating an antenna database by associating between the access point and each remote station a respective measured signal quality corresponding to the plurality of antenna patterns. The respective measured signal qualities are determined by the access point based upon communications with each remote station. The method further includes determining for each remote station a preferred antenna pattern based upon the antenna database, and selecting a remote station and the corresponding preferred antenna pattern to communicate with. It is also determined based upon the antenna database and prior to communicating with the selected remote station, if any non-selected remote stations have the potential of not being aware when such communications actually occurs.

Owner:IPR LICENSING INC

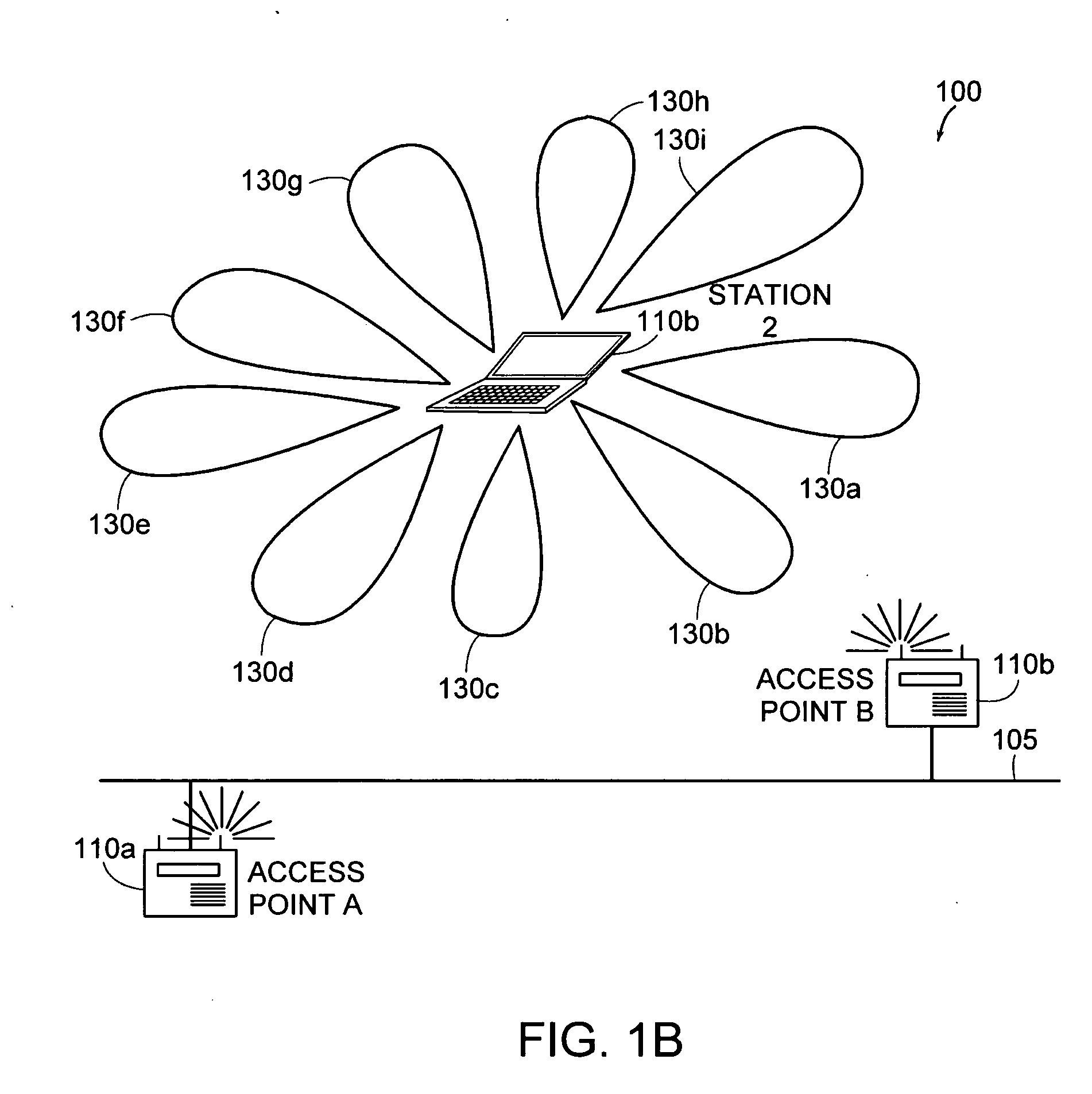

Antenna steering for an access point based upon spatial diversity

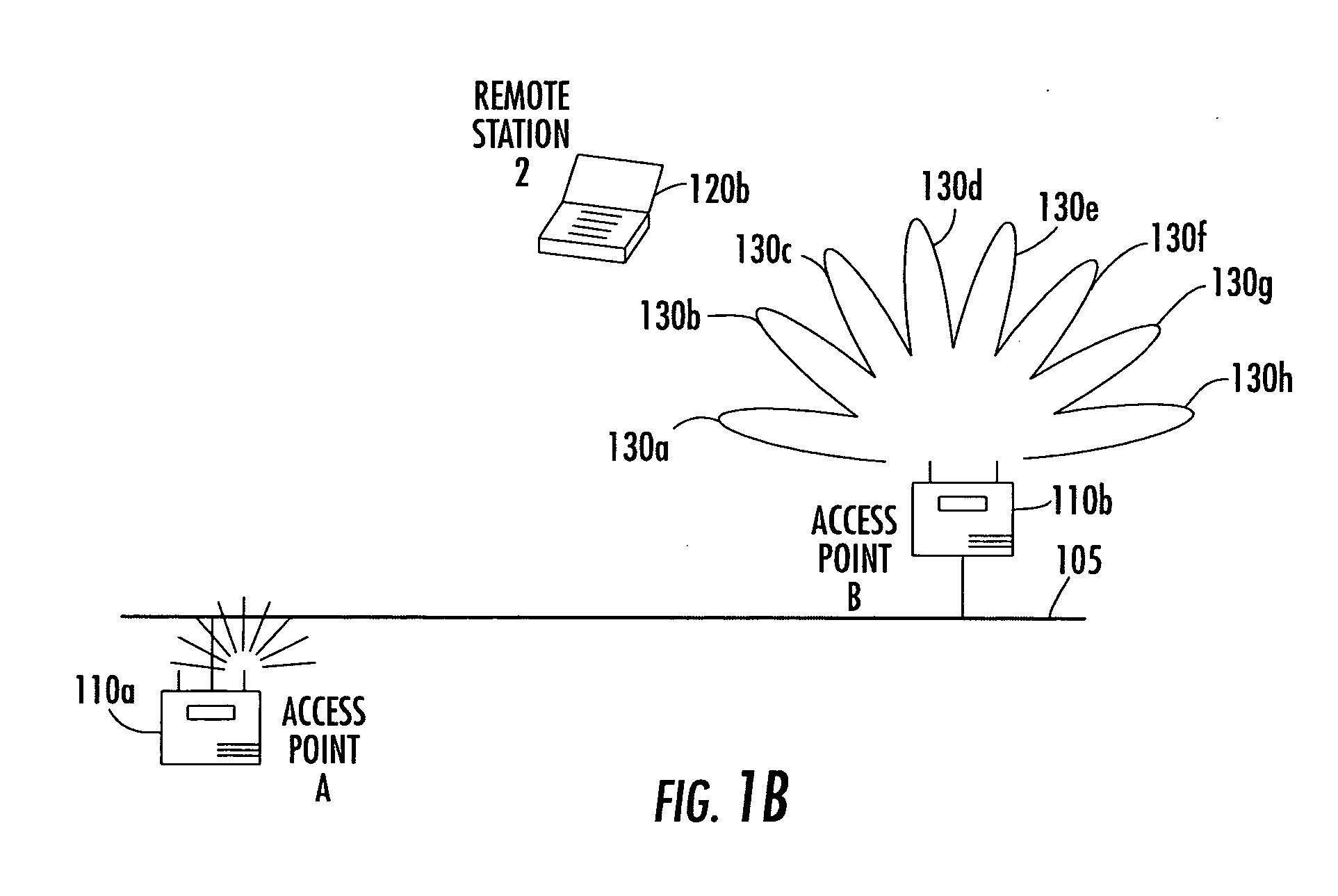

InactiveUS20050063340A1Facilitate communicationImprove throughputSpatial transmit diversityNetwork topologiesDirectional antennaEngineering

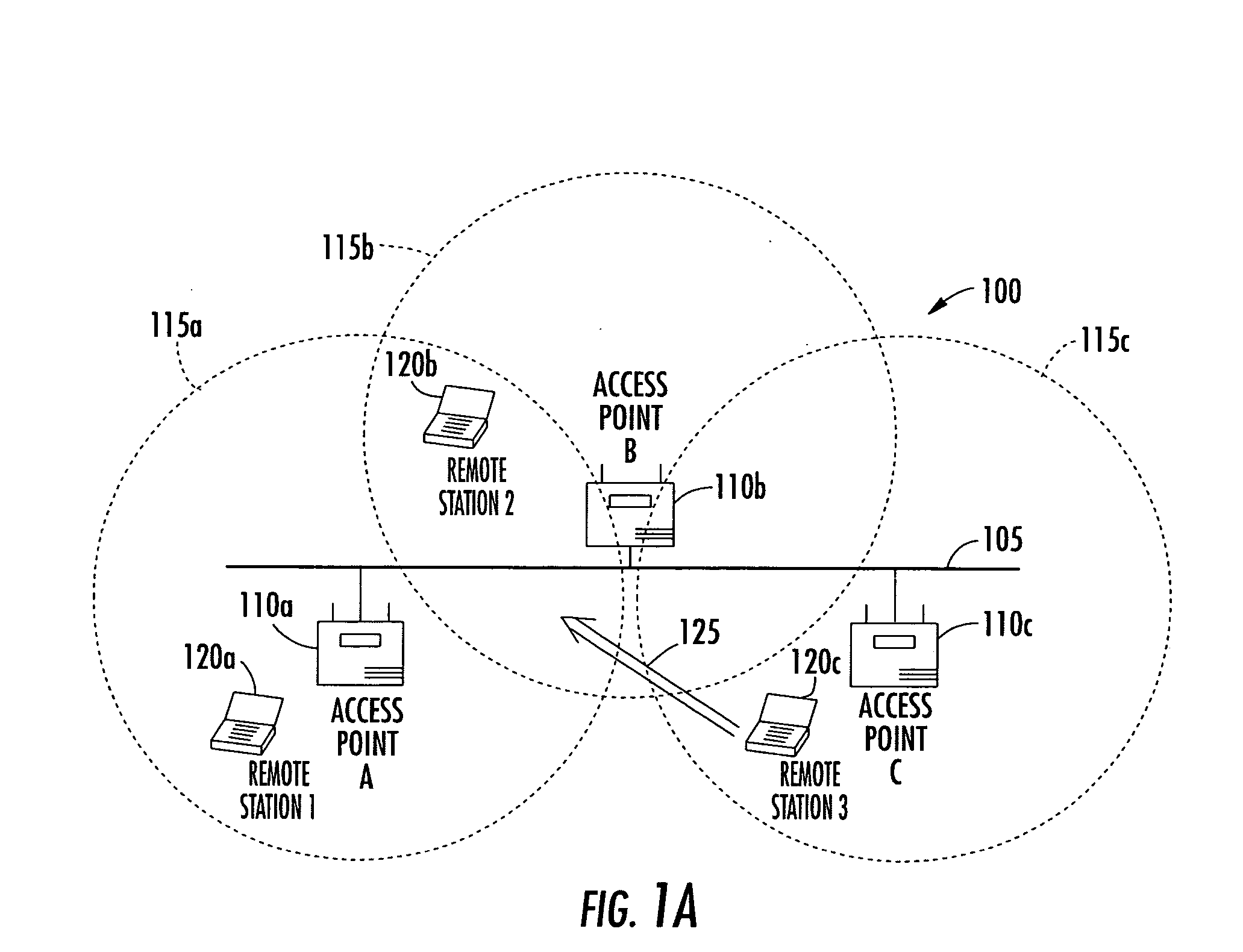

A method for operating an access point in a wireless local area network is provided, wherein the access point includes a directional antenna for communicating with at least one remote station. The method includes communicating with a selected remote station using a current angle of the directional antenna, and scanning an alternate angle from a plurality of alternate angles of the directional antenna for communicating with the selected remote station. Respective signals received via the current angle and the alternate angle from the selected remote station are measured. The current angle or the alternate angle is selected as a preferred angle based upon the measured signals for continuing communications with the selected remote station.

Owner:IPR LICENSING INC

Antenna steering for an access point based upon control frames

InactiveUS7609648B2Improve throughputIncrease rangeSpatial transmit diversityError preventionSignal qualityDirectional antenna

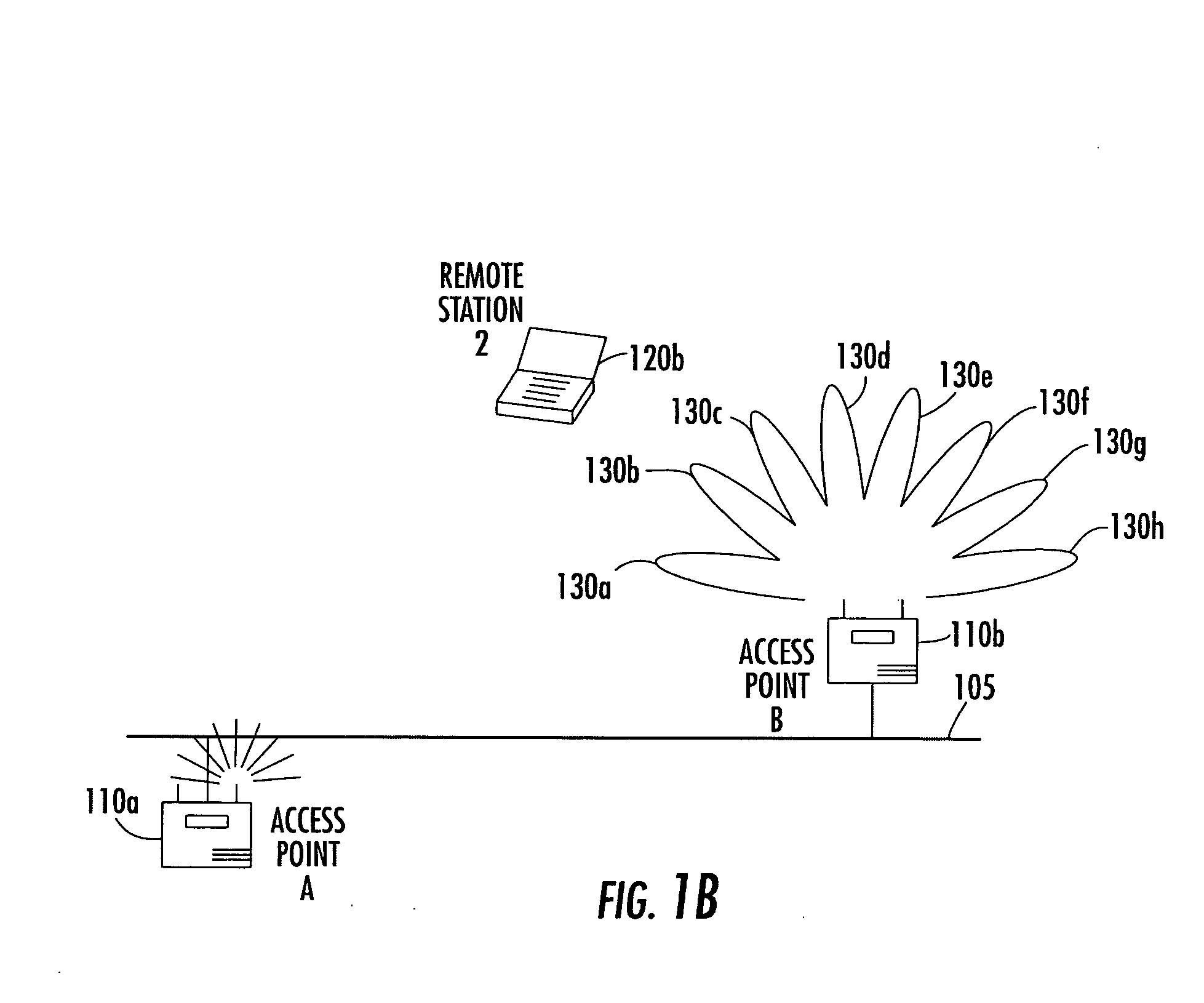

A method for operating an access point in a wireless local area network (WLAN) is provided. The access point includes a directional antenna for communicating with at least one remote station in a forward link based upon an exchange of packet data comprising a plurality of control frames and a data frame. The directional antenna includes a plurality of antenna patterns. The method includes receiving a first control frame via a first antenna pattern of the directional antenna from the remote station, transmitting a first data frame to the remote station, and receiving a second control frame via a second antenna pattern of the directional antenna from the remote station. A signal quality of the first control frame received via the first antenna pattern and a signal quality of the second control frame received via the second antenna pattern are measured. The respective measured signal qualities associated with the first and second antenna patterns are compared.

Owner:IPR LICENSING INC

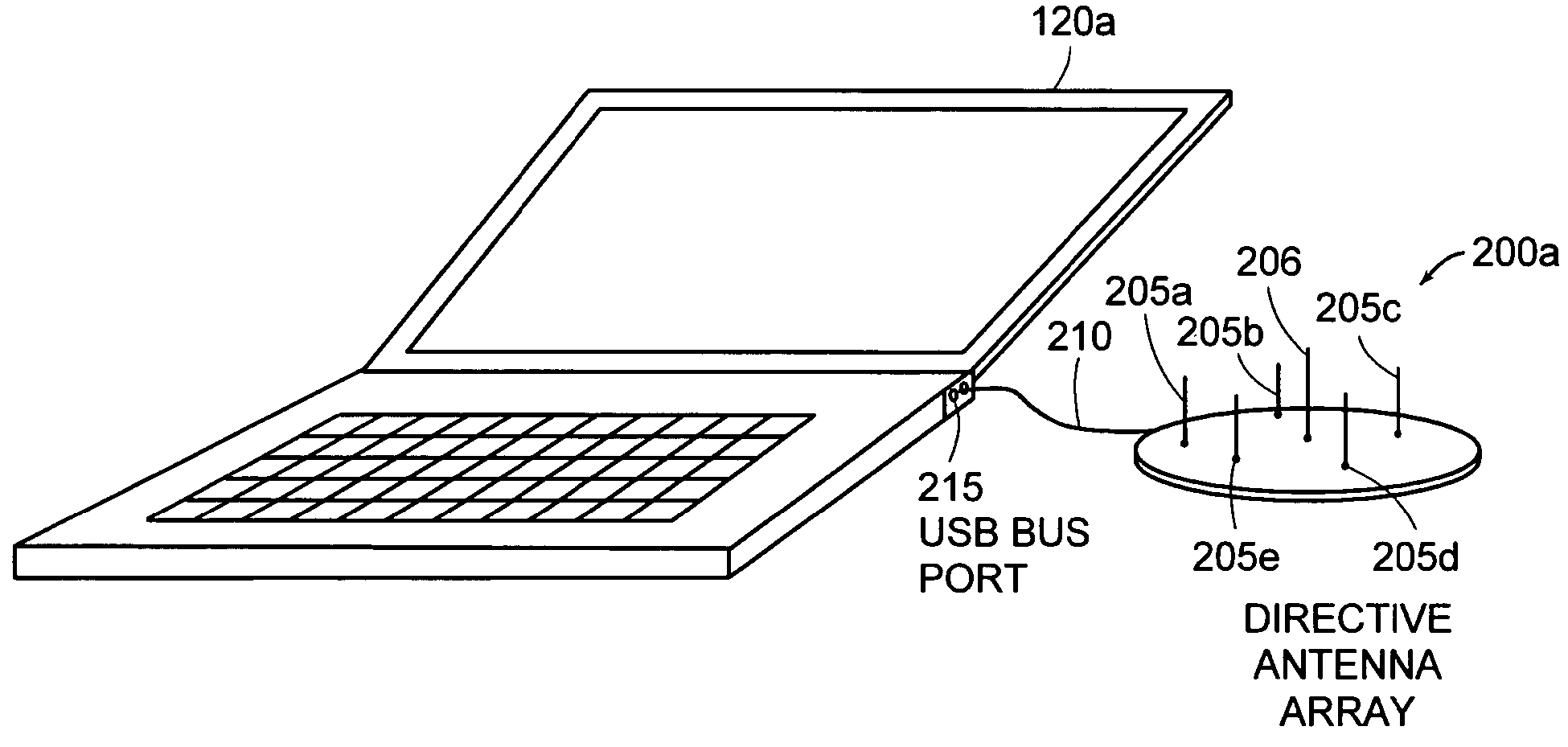

Antenna steering method and apparatus for an 802.11 station

InactiveUS20050037822A1Improves diversityImprove signal qualityAntenna supports/mountingsSubstation equipmentSignal-to-noise ratio (imaging)Media access control

A method or apparatus steers a directional antenna for a station to communicate with an Access Point (AP) in an 802.11 protocol system. The method or apparatus may include setting the directional antenna in an omni-directional pattern during a Beacon scan. After authentication with a selected AP, the method or apparatus conducts an antenna beam selection process to determine a “best” direction for communicating with the selected AP based on a metric, such as Signal-to-Noise Ratio (SNR), of the Beacon frames received on each of the directional antenna scan angles. The method or apparatus may be integrated into or associated with a Medium Access Control (MAC) layer and receive signal quality metrics from the Physical (PHY) layer.

Owner:IPR LICENSING INC

Antenna steering for an access point based upon probe signals

InactiveUS20050075141A1Facilitate communicationImprove throughputSpatial transmit diversityData switching by path configurationDirectional antennaEngineering

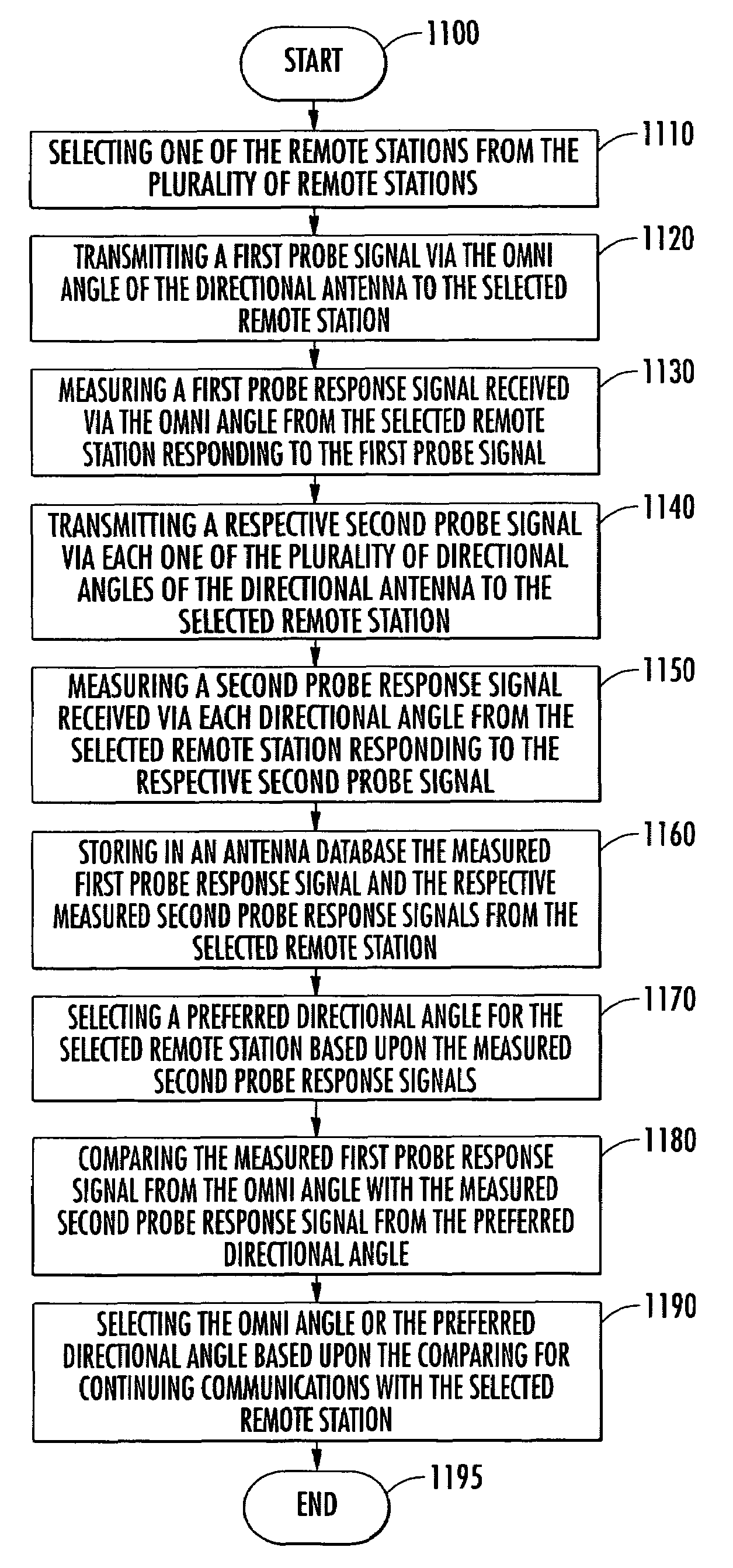

A method for operating an access point in a wireless local area network (WLAN) is provided. The access point includes a directional antenna for communicating with a plurality of remote stations, and the directional antenna includes an omni angle and a plurality of directional angles. The method includes selecting one of the remote stations from the plurality of remote stations, transmitting a first probe signal via the omni angle of the directional antenna to the selected remote station, and measuring a first probe response signal received via the omni angle from the selected remote station responding to the first probe signal. A respective second probe signal is transmitted via each one of the plurality of directional angles of the directional antenna to the selected remote station, and a second probe response signal received via each directional angle from the selected remote station responding to the respective second probe signal is measured. The measured first probe response signal and the respective measured second probe response signals from the selected remote station are stored in an antenna database.

Owner:IPR LICENSING INC

Antenna steering for an access point based upon probe signals

InactiveUS7047046B2Improve throughputIncrease rangeSpatial transmit diversityData switching by path configurationDirectional antennaEngineering

Owner:IPR LICENSING INC

Antenna steering for an access point based upon spatial diversity

InactiveUS7587173B2Improve throughputIncrease rangeSpatial transmit diversityNetwork topologiesDirectional antennaEngineering

A method for operating an access point in a wireless local area network is provided, wherein the access point includes a directional antenna for communicating with at least one remote station. The method includes communicating with a selected remote station using a current angle of the directional antenna, and scanning an alternate angle from a plurality of alternate angles of the directional antenna for communicating with the selected remote station. Respective signals received via the current angle and the alternate angle from the selected remote station are measured. The current angle or the alternate angle is selected as a preferred angle based upon the measured signals for continuing communications with the selected remote station.

Owner:IPR LICENSING INC

Antenna steering for an access point based upon control frames

InactiveUS20050063343A1Facilitate communicationImprove throughputSpatial transmit diversityError preventionSignal qualityDirectional antenna

A method for operating an access point in a wireless local area network (WLAN) is provided. The access point includes a directional antenna for communicating with at least one remote station in a forward link based upon an exchange of packet data comprising a plurality of control frames and a data frame. The directional antenna includes a plurality of antenna patterns. The method includes receiving a first control frame via a first antenna pattern of the directional antenna from the remote station, transmitting a first data frame to the remote station, and receiving a second control frame via a second antenna pattern of the directional antenna from the remote station. A signal quality of the first control frame received via the first antenna pattern and a signal quality of the second control frame received via the second antenna pattern are measured. The respective measured signal qualities associated with the first and second antenna patterns are compared.

Owner:IPR LICENSING INC

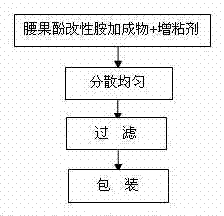

High-performance high-solid general modified epoxy antirust paint and preparation method thereof

ActiveCN102363690AHas acid and alkali resistanceNo acid and alkali resistanceAnti-corrosive paintsEpoxy resin coatingsLife ProlongationSlurry

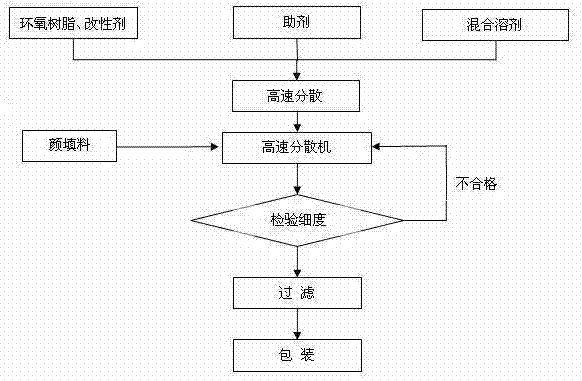

The invention discloses a general modified epoxy antirust paint with high performances and high solids and a preparation method thereof. The paint comprises a component A and a component B, wherein the component A comprises 10-20 parts of an E44 epoxy resin, 10-20 parts of an NPPN-631 epoxy resin, 5-15 parts of a terpene resin, 4-18 parts of a cumarone resin, 0.1-1.0 parts of a BYK antifoaming agent, 0.1-1.0 part of an HX leveling agent, 0.1-1.5 parts of a rheological assistant, 5-20 parts of active silica, 10-20 parts of a mixed solvent and 10-30 parts of a pigment-filler; and the component B comprises 10-40 parts of cardanol modified amine and 0.5-3 parts of a modified silane coupling agent. The antirust paint of the invention has the advantages of compact coating, low viscosity, good compatibility and fast curing of a curing agent, high tough strength and strong adhesion of the coating, coating number reduction during the thick slurry curing, construction efficiency improvement, construction cost reduction, and anticorrosion life prolongation.

Owner:XIAMEN SUNRUI SHIP COATING

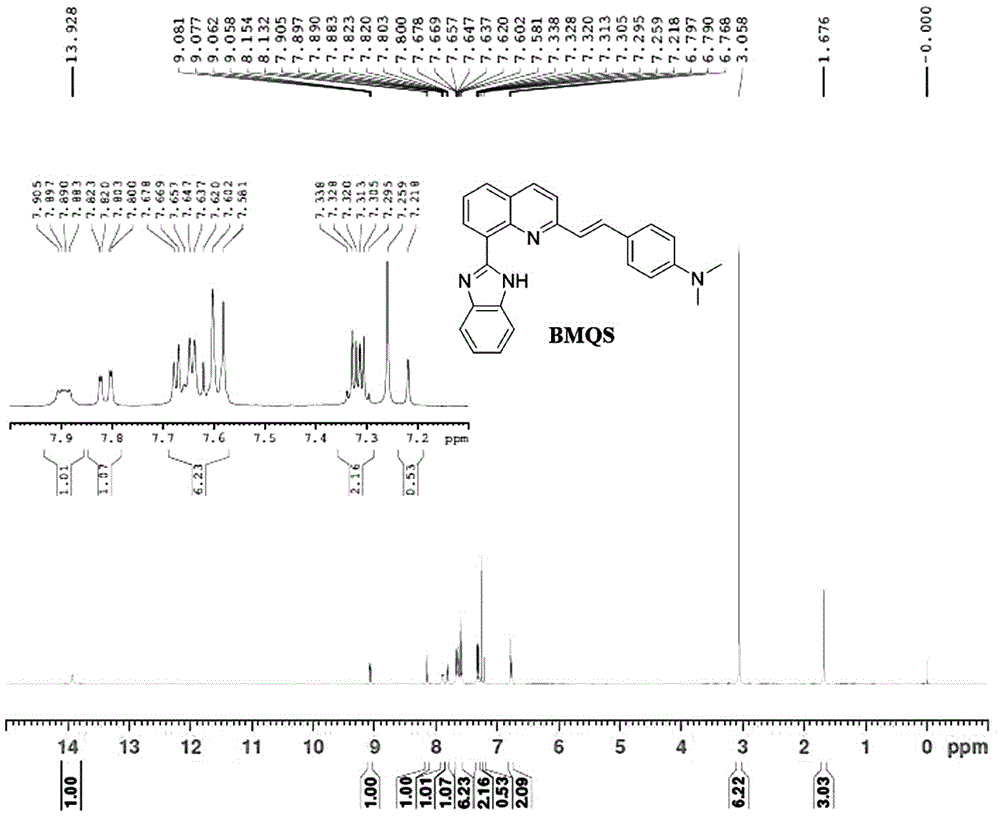

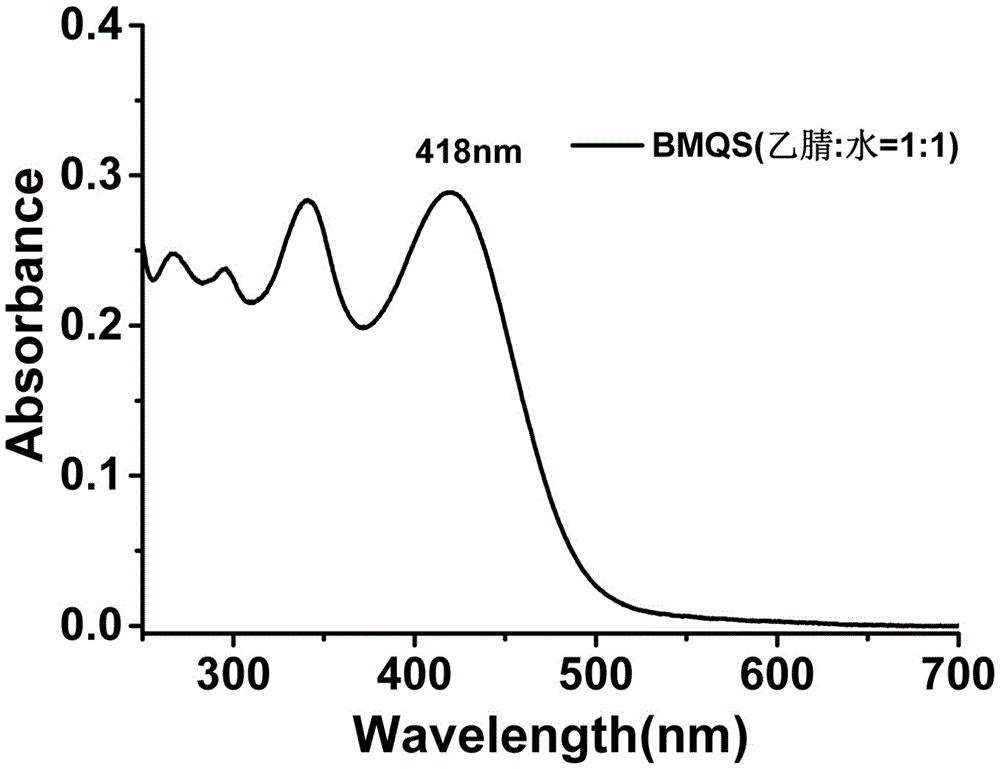

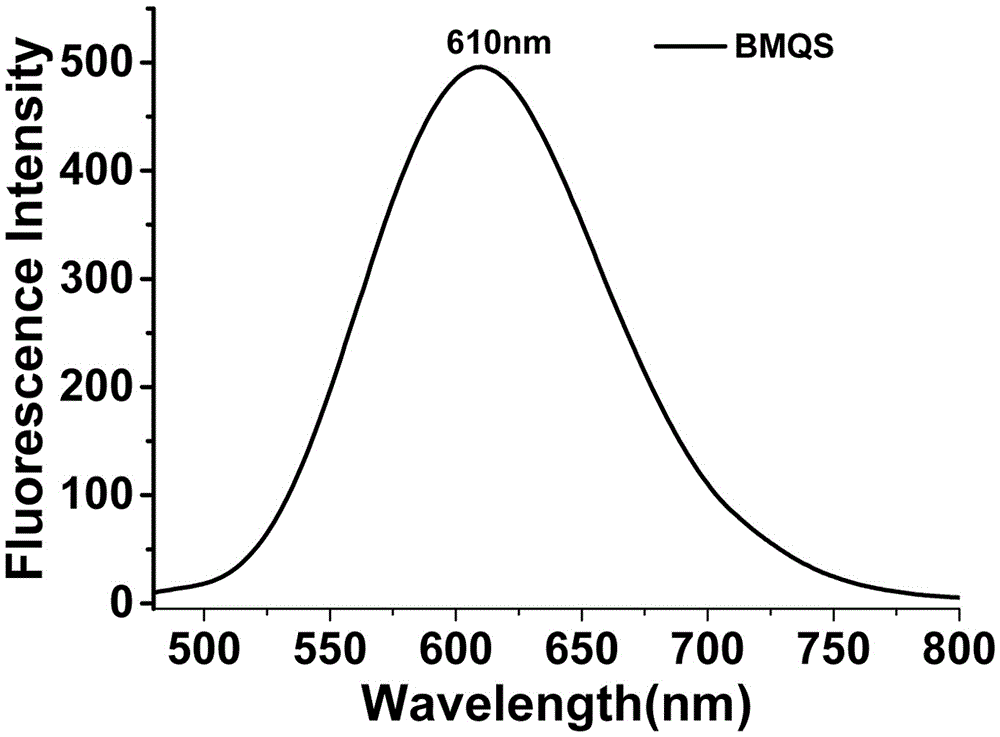

Benzimidazole quinoline derivative and preparation method and application

ActiveCN105669644AImprove complexation effectQuick responseOrganic chemistryColor/spectral properties measurementsBenzaldehydeQuinoline

The invention provides a benzimidazole quinoline derivative, a preparation method and application in copper ion detection, and particularly relates to a 2-(4-N,N-bis-substituted styryl)-8-1H-benzimidazole) quinoline derivative. Particularly, 2-aminobenzoic acid is used for preparing 2-methylquinoline-8-carboxylic acid, then the 2-methylquinoline-8-carboxylic acid and o-phenylenediamine are subjected to condensation to obtain 2-methyl-8-(2-benzimidazolyl) quinoline, the 2-methyl-8-(2-benzimidazolyl) quinoline and N,N-bis-substituted benzaldehyde are subjected to condensation to obtain the benzimidazole quinoline derivative. A probe has the good complexation with copper ions, when the copper ions exist, derivation of the solution is observed with naked eyes, and the solution is changed from yellow to purple, absorption at the 418 nm position on an ultraviolet visible absorption spectrum is weakened, and a novel absorption peak appears at the 550 nm and gradually increases when the concentration of the copper ions is increased; the benzimidazole quinoline derivative can be used for real-time and rapid measurement of complex samples and can also be used for semiquantitative detection of micro / trace Cu2+ of environment samples from different sources.

Owner:CHINA THREE GORGES UNIV

Super environmental protection latex paint with zero VOC

An environment protection type emulsoid paint without VOC is prepared from water, sodium polyacrylate "5040", hydroxyethyl cellulose "250HBR", mineral oil modified silicone BYK-003, titanium white powder, filming agent and assistant. Its advantages are high hardness and adhesion, high resistance to dirt, zero VOC and no poison and harm.

Owner:FOSHAN FEIHONG COATING

Aqueous metal latex paint

A water emulsoid paint for metal is prepared from nacreous pigment, filming agent, sodium polyacrylate "5040", mineral oil modified silicone, filming assistant, and hydroxyethyl cellulose. Its advantages are no pollution, low cost, high decorative effect and high dirt resistance.

Owner:FOSHAN FEIHONG COATING

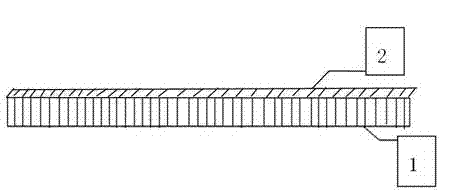

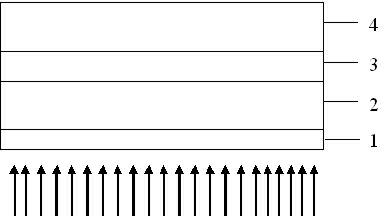

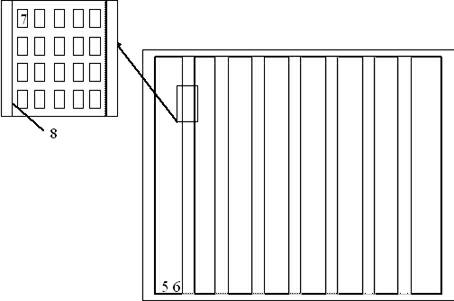

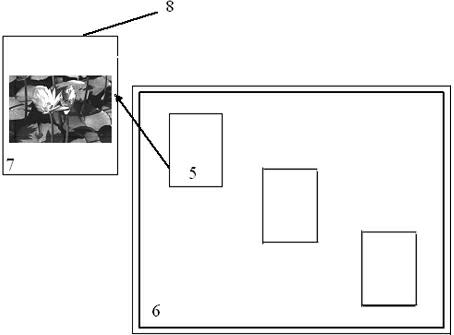

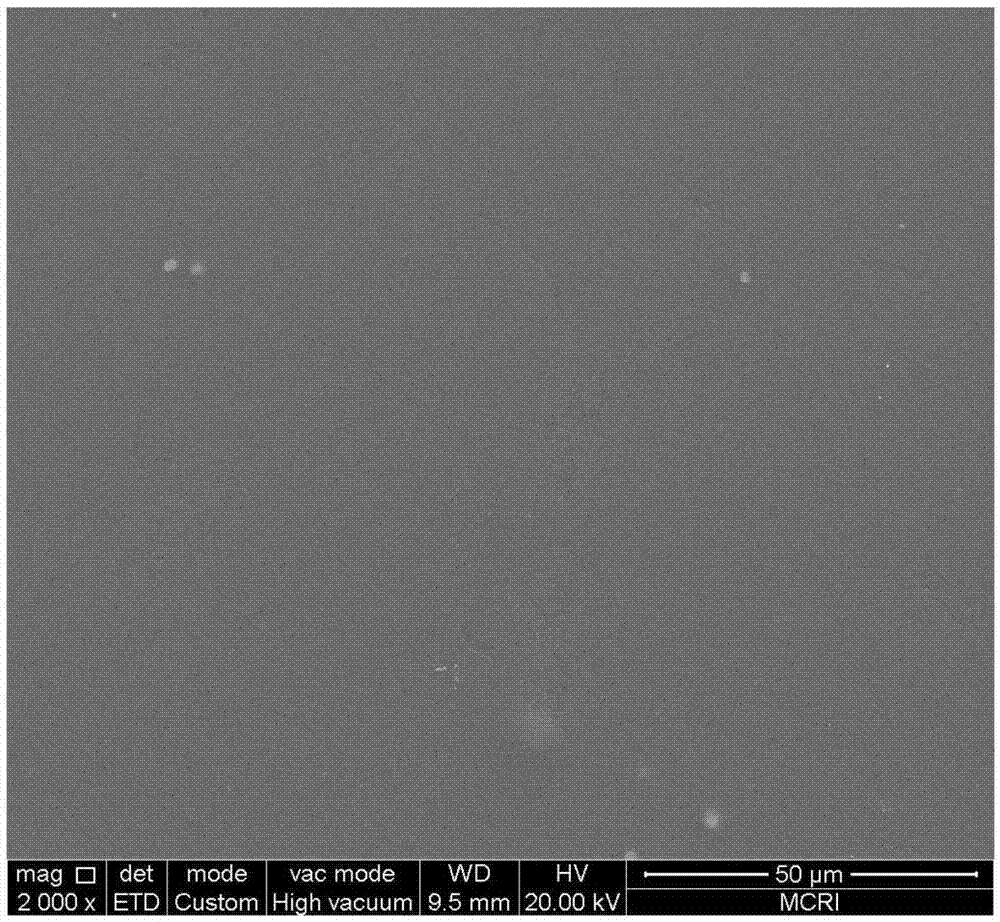

Method for realizing light transmission of thin film solar module by using vibrating mirror laser equipment

InactiveCN102237441ARealize the function of power generationRealize point-by-point scanning and scribingFinal product manufactureLaser beam welding apparatusElectrical batteryEngineering

The invention relates to a method for realizing the light transmission of a thin film solar module by using vibrating mirror laser equipment and belongs to the technical field of thin film solar batteries. The technical scheme is that: the method comprises the following steps of: depositing a front transparent conductive electrode, a thin film photoelectric conversion layer and a back conductive electrode on an insulation light transmission substrate; cutting off the three layers of thin films by adopting laser devices having different wavelengths so as to form insulation regions having different sizes and length-to-width ratios; and removing the three layers of thin films from the insulation regions by using laser scribing equipment with a vibrating mirror system, and scribing a pattern by changing an angle of a vibrating mirror and the magnitude of laser energy and switching laser on / off in real time, wherein film layers outside the insulation regions can realize a power generation function; at positions, where front glass is exposed out of, inside the insulation regions, light rays can be transmitted through the battery directly, so that a light transmission function of the module is realized. By the method, the preparation of a novel light transmission solar module is realized; the output electric performance and the light transmission performance of the thin film solar module are higher than those of the thin film solar module prepared in the prior art; and the method has the characteristics of low cost, high working efficiency, simple operation, diversified light transmission images, simple implementation and the like.

Owner:BAODING TIANWEI GRP CO LTD +1

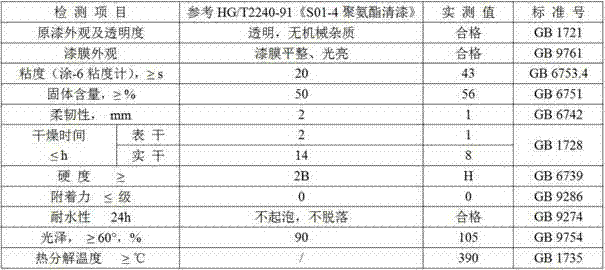

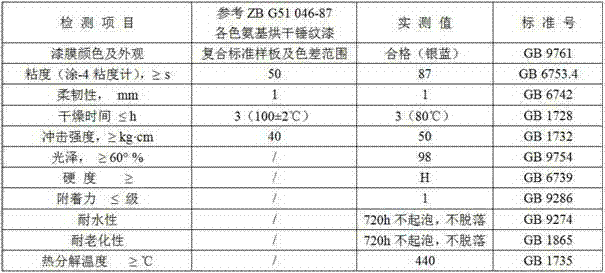

High-hydroxy phenolic resin prepared by using phenols residues as raw material, and application of high-hydroxy phenolic resin to production of high-temperature-resistant paint

InactiveCN102757544AAchieve emissionsSolve pollutionPolyurea/polyurethane coatingsChemical reactionSolvent

The invention provides a high-hydroxy phenolic resin. Phenols residues and aldehydes compounds are used as main raw materials and are subjected to function modification by using an unsaturated compound or polymer, the high-hydroxy phenolic resin is obtained through a series of chemical reactions, then the high-hydroxy phenolic resin is used as a main film forming material, is compounded with laminar inorganic mineral materials such as glass flakes, and then crosslinked and cured by using polyurethane resin or amino resin to prepare the high-temperature-resistant paint which has the advantages of high drying speed, good adhering force, large hardness, high gloss, good heat resistance, water resistance, strong solvent resistance and the like, and is suitable for heat-resistant corrosion-proof coatings with high decoration on the surface of devices such as a chemical machinery device, a pipeline, a flue, a storage tank and a heat radiator. According to the invention, zero emission of the phenols residues is realized, the problem of environment pollution caused by the phenols residues is radically solved, and the effects of comprehensive treatment and waste material recycling is achieved. Meanwhile, a new variety of coating products is increased, the application range of phenolic coatings is enlarged, and the cost of corresponding coatings is lowered.

Owner:LANZHOU PETROCHEM COLLEGE OF VOCATIONAL TECH

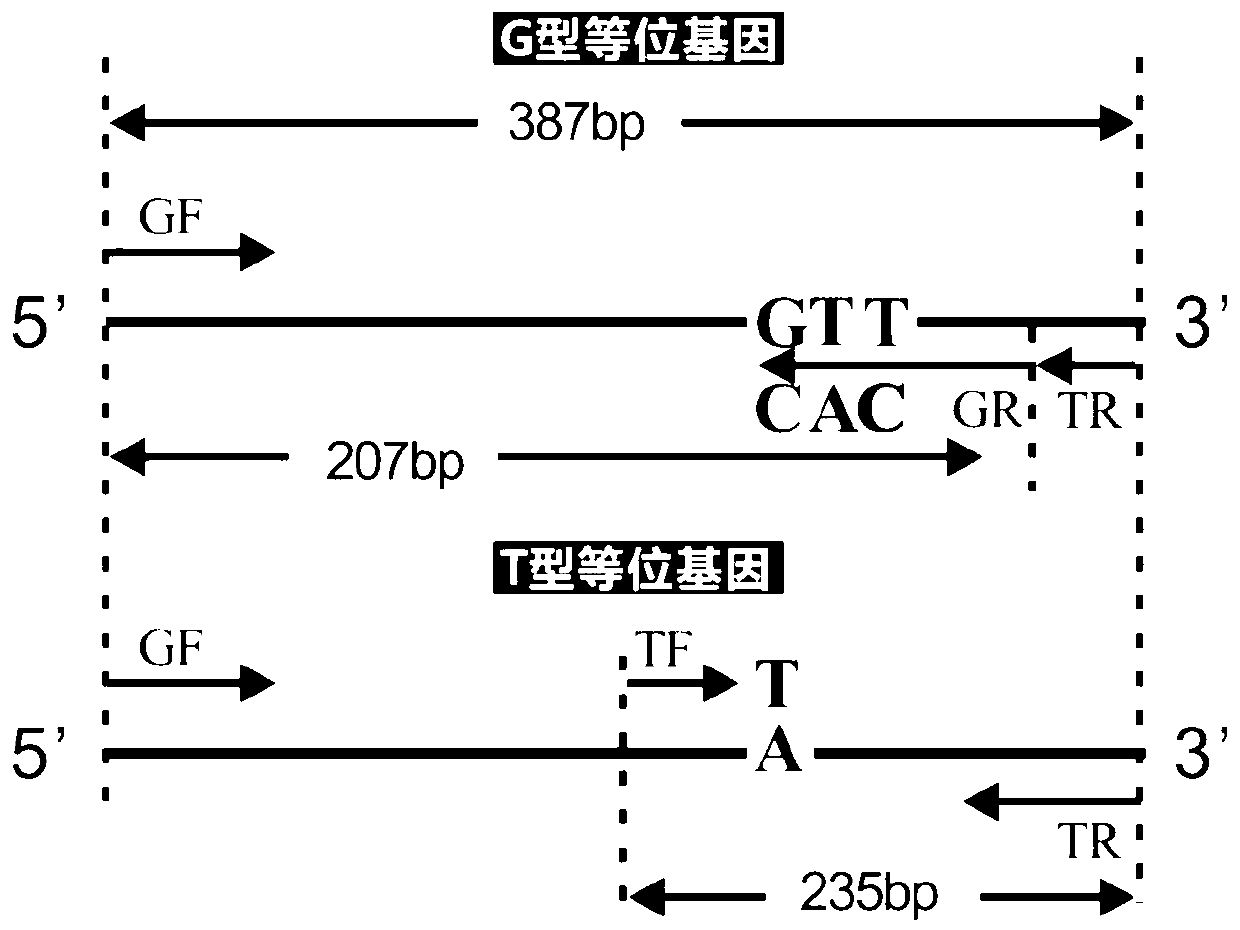

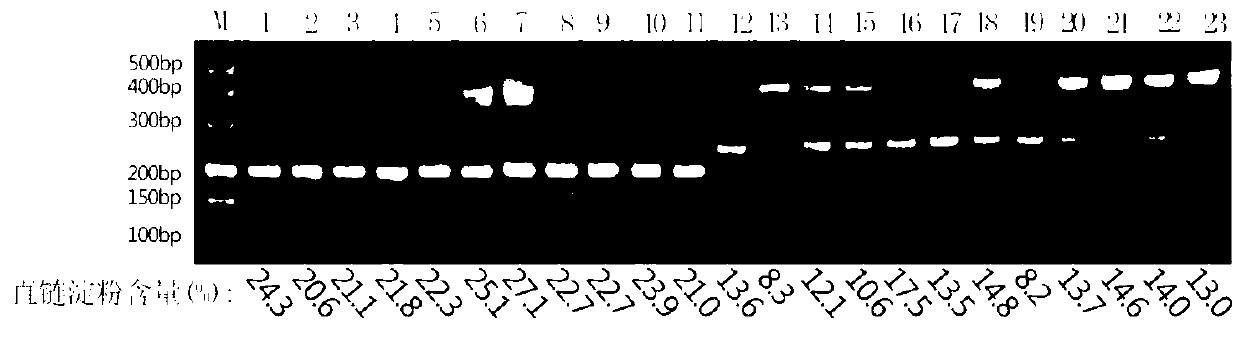

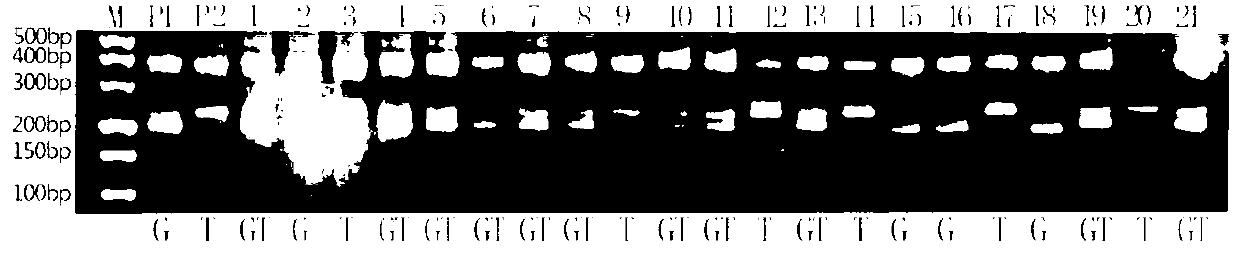

Genotype identification primer and method of rice amylose content control gene Wx and identification method

ActiveCN103276071ASimple methodIncrease varietyMicrobiological testing/measurementDNA/RNA fragmentationAgricultural scienceGenomic DNA

The invention discloses a genotype identification primer and method of a rice amylose content control gene Wx. The level of AC (amylose content) depends on a basic group type of a first intron+1(Inl) site of the Wx gene. According to the genotype identification primer and method, a set of functional markers for identifying different basic group types at a WxInl site is developed. The method comprises the following steps of: carrying out PCR (Polymerase Chain Reaction) amplification by means of the markers and genomic DNA (Deoxyribonucleic Acid) of a rice variety to be detected; respectively amplifying 207bp or 235bp special stripes by using the Inl site as an isozygotic G or T basic group genotype material, wherein GT heterozygotic material has the two strips at the same time. The three strips share one 387bp stripe which can be used as reference of the existing Wx gene. Therefore, the Wx genotype identification method is simple and rapid and low in cost, and can be widely applied to molecular marker-assisted selection to cultivate varieties with different ACs applied to different industrial applications or assistant selection of moderate AC varieties applied to quality breeding of rice.

Owner:INST OF FOOD CROPS HUBEI ACAD OF AGRI SCI

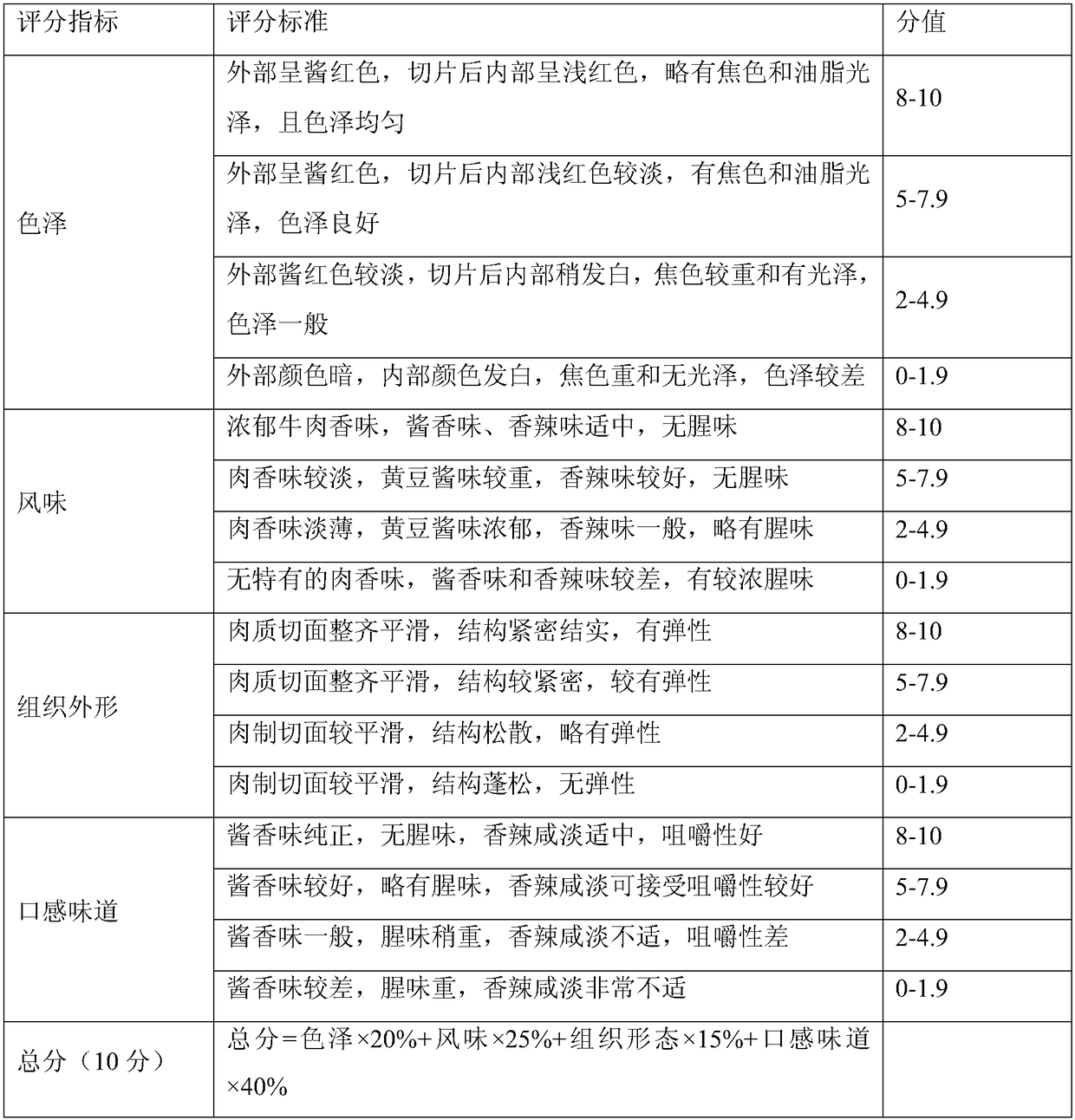

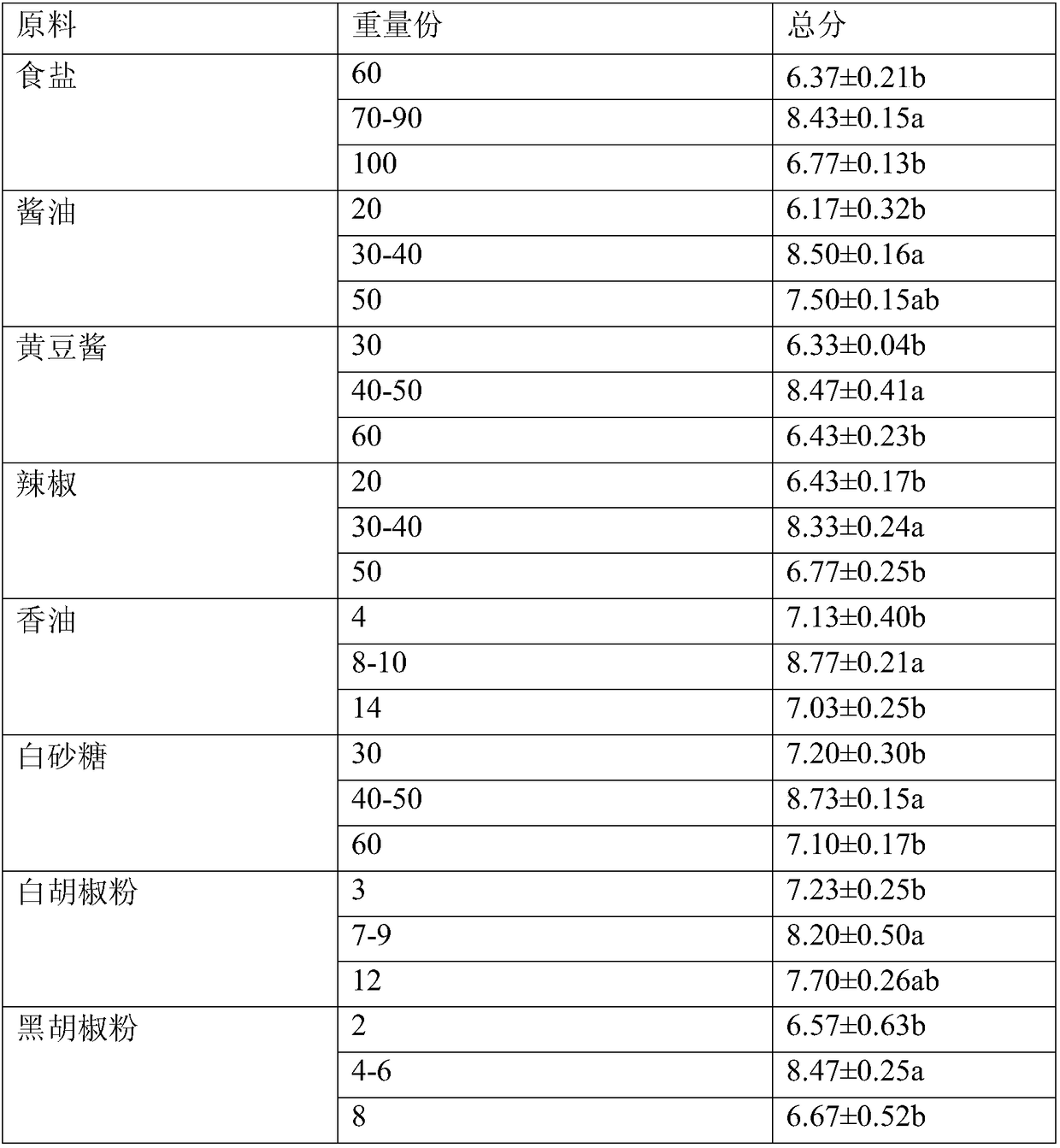

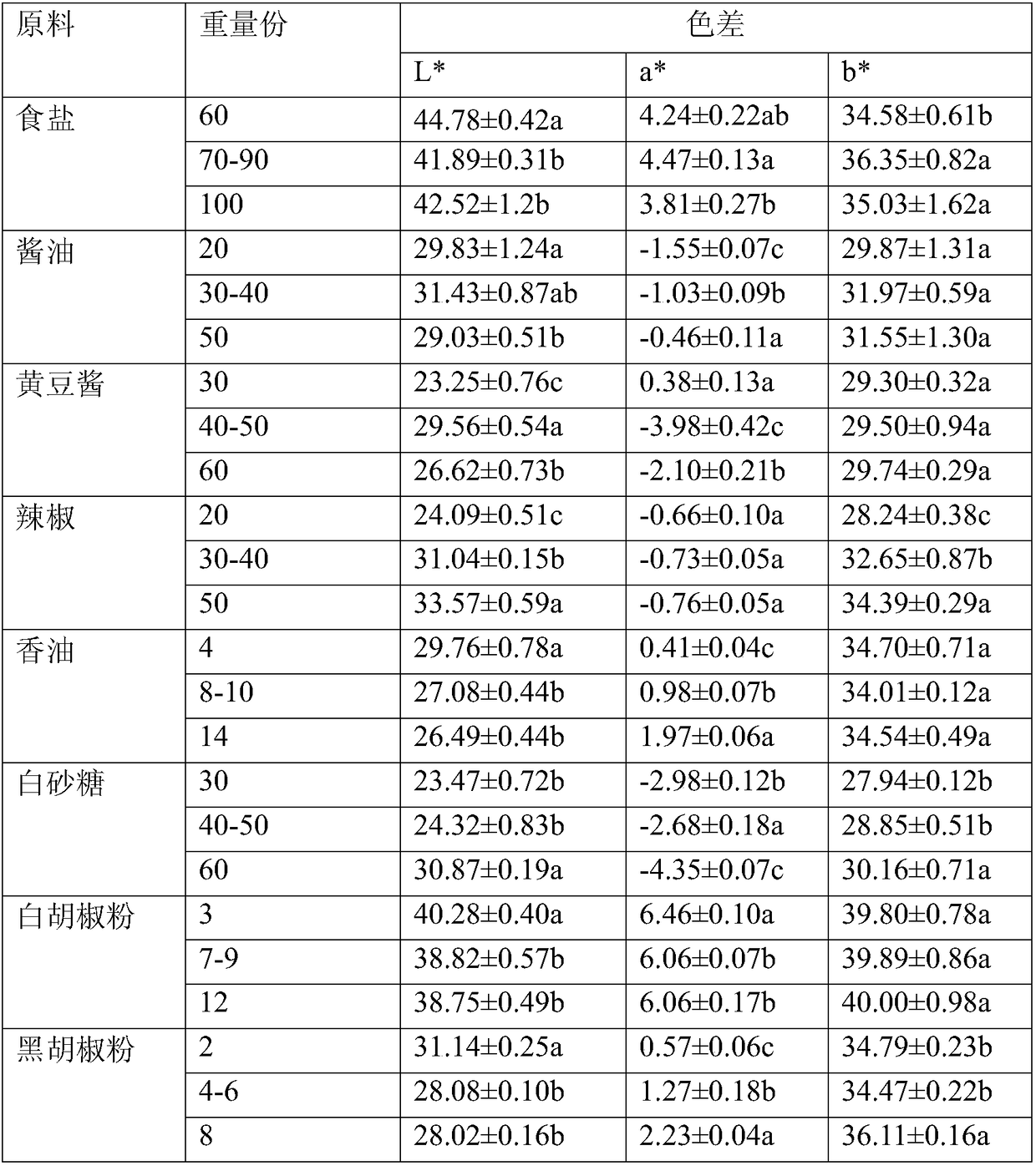

Making method of spicy beef seasoned with soy sauce

InactiveCN108142839ARich varietySimple varietyFood ingredient as taste affecting agentFood ingredient as flavour affecting agentFlavorSoya sauce

The invention relates to a making method of spicy beef seasoned with soy sauce. The method is used for solving the problems that existing beef seasoned with soy sauce is single in flavor, the flavor of spices is strong, taste is various, and the making technology is complex. The making method includes the detailed steps that material selecting and arranging are performed, material liquor is made,pickling is performed, boiling is performed, and standing soaking and cooling making are performed. The spicy beef seasoned with soy sauce which is made through the method has a special flavor, and fills up a market blank, the variety of the beef seasoned with soy sauce is enriched, and the demands for spicy foods of consumers are met; according to scientific experiments, the reasonable usage quantities of food raw materials of all varieties are determined, while the appropriate taste of the beef seasoned with soy sauce is ensured, the hardness, the elasticity and the chewiness of the beef seasoned with soy sauce are improved, and the beef is spicy, delicious, and good in color, aroma and taste.

Owner:JILIN UNIV

Method and module for building basic furniture component

InactiveCN101498331AImprove efficiencyExtended service lifeFurniture joiningThree-dimensional spaceMechanical engineering

Owner:LONGYAN UNIV

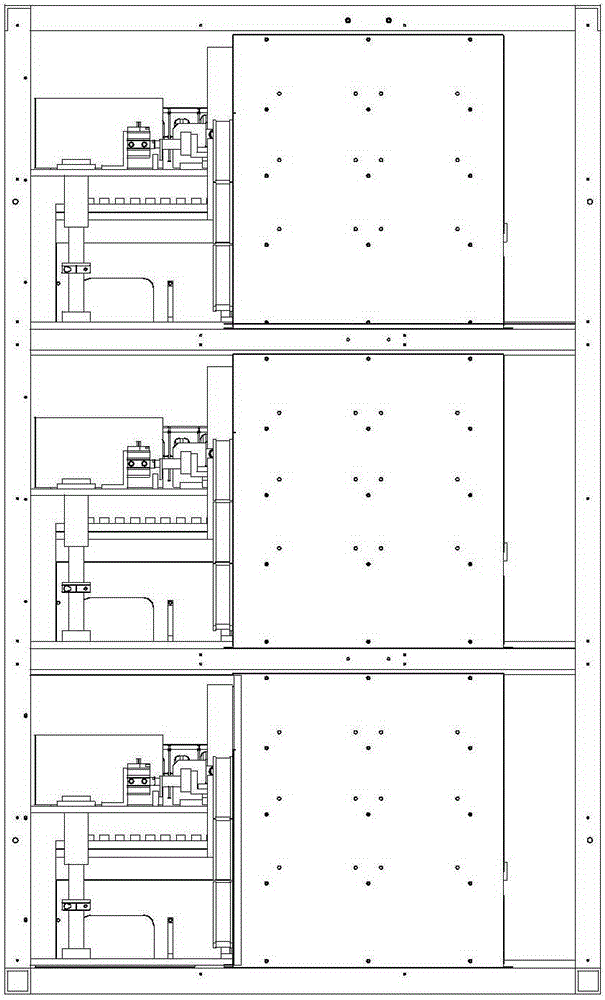

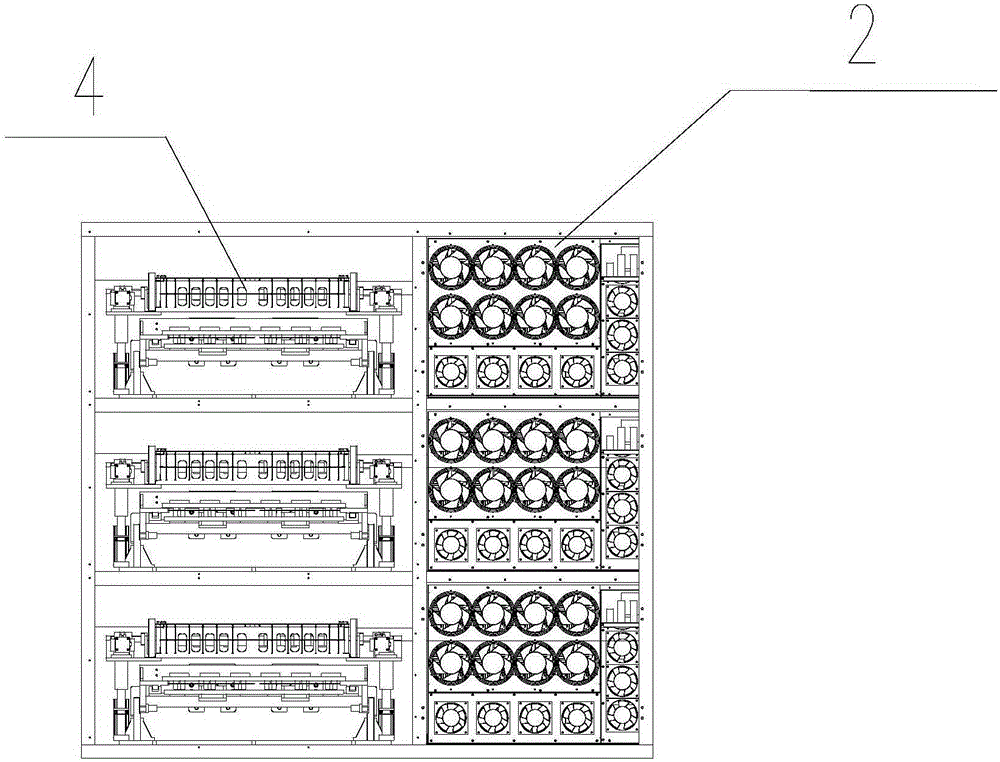

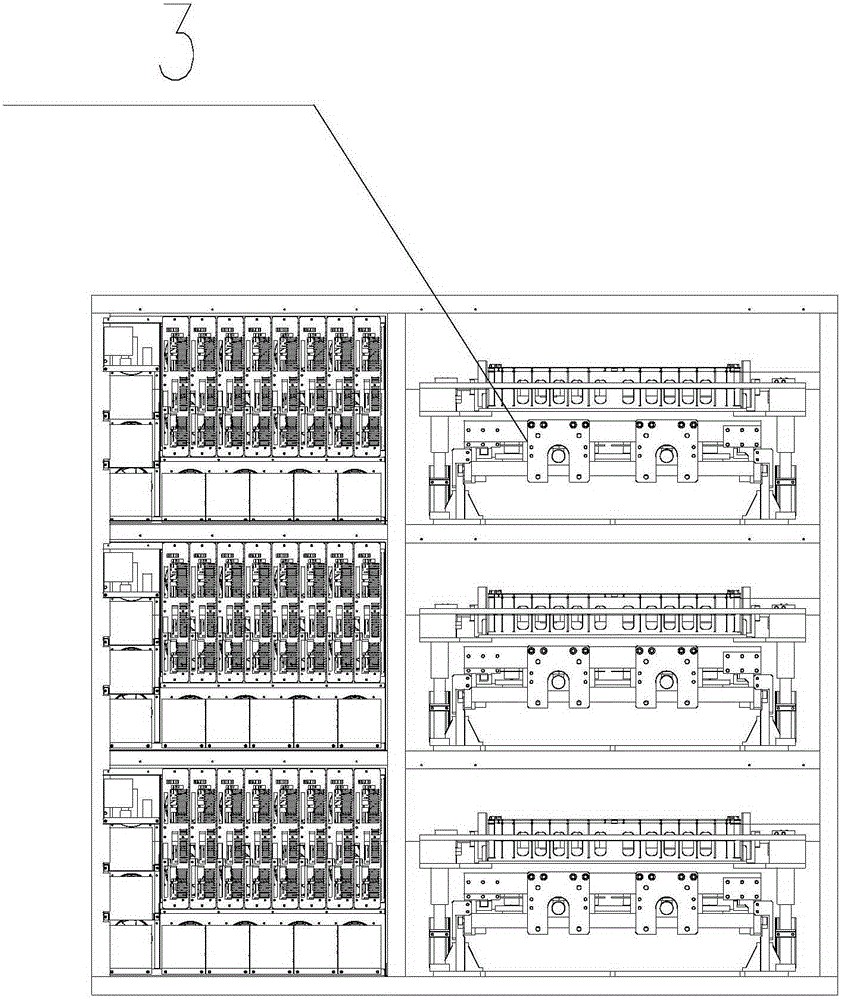

Cylindrical lithium-ion battery forming and capacity-grading equipment

InactiveCN105186041ASo as not to damageHigh profileFinal product manufactureElectrolyte accumulators manufactureElectrical batteryPersonal computer

The invention discloses cylindrical lithium-ion battery forming and capacity-grading equipment, which comprises a rack, a charge-discharge power box, a battery clamping movement mechanism, a battery tray and a control mechanism, wherein the charge-discharge power box with a variable condition is arranged on the rack; the battery clamping movement mechanism is used for clamping positive and negative electrode tabs of a cylindrical lithium-ion battery; the battery tray is arranged in the battery clamping movement mechanism; the control mechanism is arranged in a personal computer (PC) outside a rack; the charge-discharge power box with the variable condition is electrically connected with the battery clamping movement mechanism; and the charge-discharge power box and the battery clamping movement mechanism are in control connection with the control mechanism respectively. According to the cylindrical lithium-ion battery forming and capacity-grading equipment, two procedures of forming and capacity-grading of the cylindrical lithium-ion battery can be finished; the equipment variety is simplified; and the production efficiency is improved, so that high quality, high efficiency and traceability of the cylindrical lithium-ion battery in the manufacturing process are achieved.

Owner:ZHEJIANG HANGKE TECH

Pear grafting method

The invention discloses a grafting method of a pear tree. The main stem or main branch of pear tree with deterioration of strains and low quality is cut at the place 1 m away from the ground as a stock A branch of the good-quality pear tree with the length less than 15 cm and 2 to 3 sprouts is used, wherein, the bottom of the branch is cut into wedge shape. A slit with the same width as that of a graft is cut on the pear tree as stock. The graft is stably and tightly inserted into the slit of stock. And then a ventilated plastic film is tightly tightened at the grafting place. 2 to 4 grafts are grafted in the four directions according to the size of the stock. The survival rate of grafts grafted by aforementioned method is over 90% the operation is simple and needs no special trainer; and the method can quickly improve variety and has high economic benefit.

Owner:李巧英

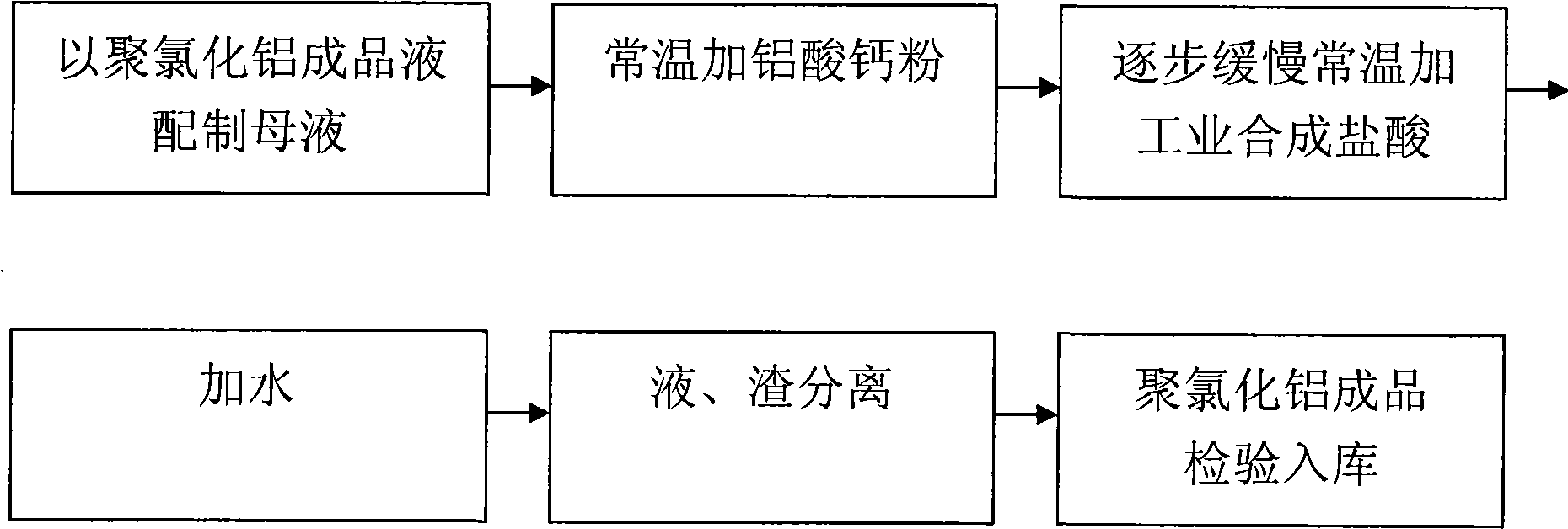

Method for producing polyaluminium chloride

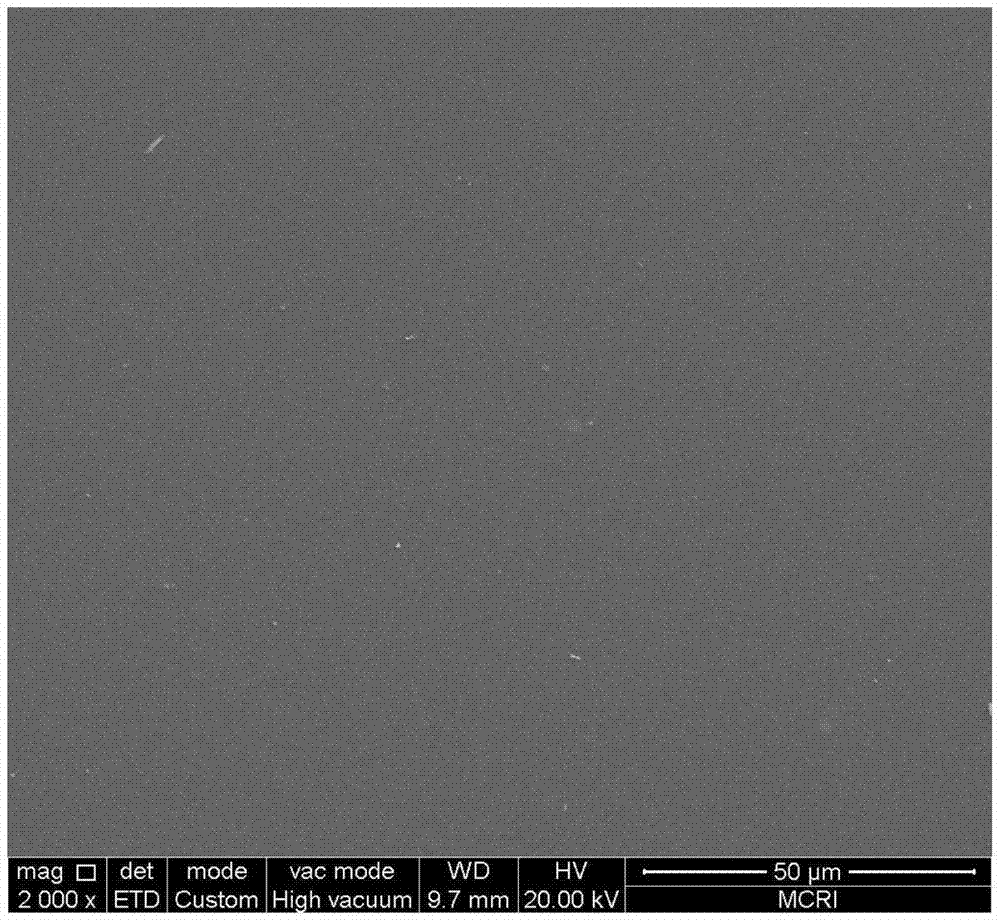

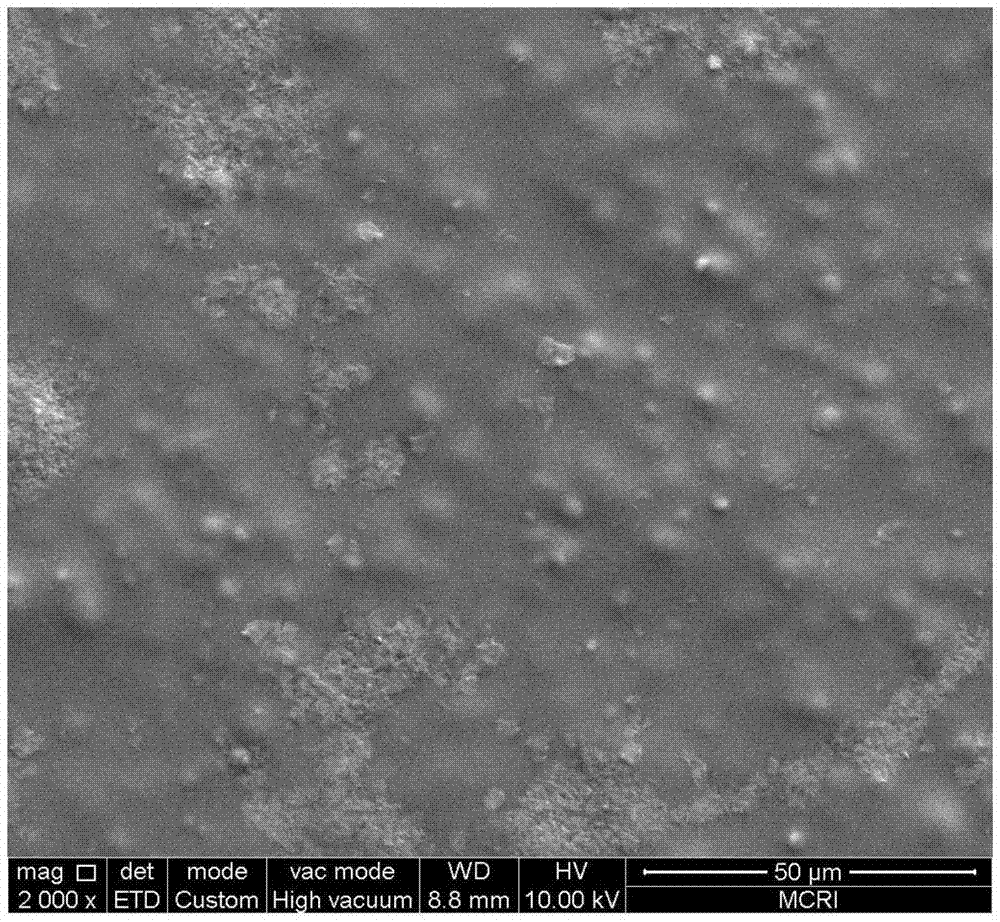

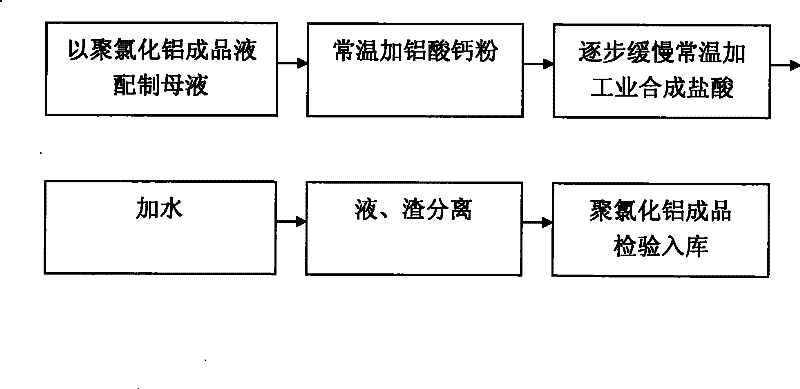

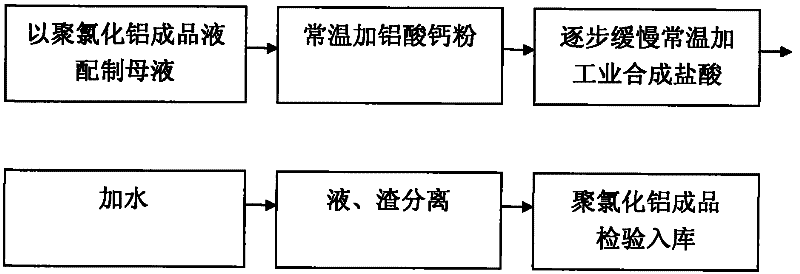

ActiveCN101531389AEasy to manageEasy to separateAluminium chloridesWater/sewage treatment by flocculation/precipitationLiquid productSlag

The invention relates to a method for producing polyaluminium chloride as a drinking water treating agent, which uses 1 ton of liquid product which contains 10 percent of Al2O3 in mass content as a mother solution of which total output is 15 to 40 percent in percentage by mass. The mother solution is added with 200 to 210 kilograms of calcium aluminate powder in one step under a stirring state, wherein the content of the Al2O3 is 51 to 52 percent. Under normal temperature, industrial synthetic hydrochloric acid with 100 percent of mass concentration is added into the mother solution, and the weight of the industrial synthetic hydrochloric acid is 0.65 to 0.83 of the calcium aluminate powder. When the temperature is raised to 55 DEG C, 661.8 to 624.9 kilograms of water is added into the mother solution, and the flow is controlled within a reaction temperature of between 87 and 100 DEG C. When the temperature finally does not reach 87 DEG C, steam is supplemented, and water quantity is deducted. When the reaction is carried out for 2 to 3 hours, liquid and slag are separated. The raw material variety of the invention is little, the process flow is short, the reaction is shortened by one third, the harmful substances are controlled in a standard range, the cost is lowered, the waste slag is little, and the obtained product has clear color and good quality.

Owner:浙江嘉灵环保科技有限公司

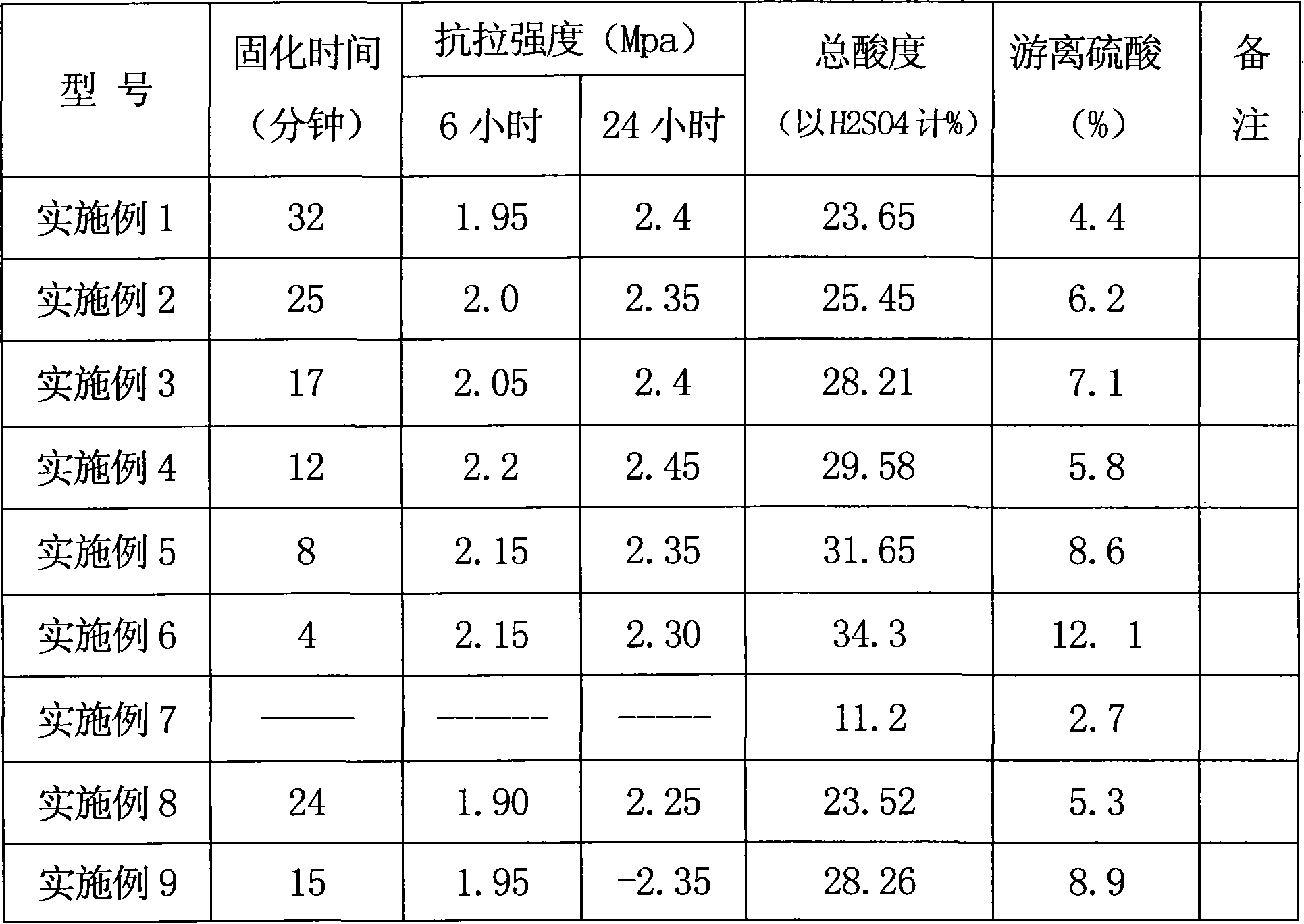

Technique for producing sulfonic acid firming agent for foundry by industry waste material-sulfonic acid mother liquor

InactiveCN101249544AReduce manufacturing costSimple varietyFoundry mouldsFoundry coresFoundryFirming agent

The invention discloses a process for preparing a sulfonic acid curing agent for casting from industrial waste, i.e. sulfonic acid mother liquor, which comprises the following steps of: pre-treating the sulfonic acid mother liquor, adding 98% concentrated sulfuric acid 175 to 250 parts in dimethylbenzene 100 parts, stirring, heating to 110 to 140 DEG C, keeping the temperature and reacting for 1 to 3 h, decreasing the temperature below 70 DEG C, adding water and alcohol solvent 40 to 105 parts slowly, adding the pre-treated sulfonic acid mother liquor 70 to 350 parts, stirring for 0.5 to 1 h, decreasing the temperature below 40 DEG C, adding hydrogen peroxide 2 to 3 per mill, and stirring uniformly to obtain the final product. The sulfonic acid curing agent prepared by the process keeps the excellent performance of original curing agent, and is improved in the selection of use range, cured strength, viscosity, odor, decrease of production cost, etc. by different degrees. Particularly, the sulfonic acid curing agent has very strong competition advantages in environment protection, low viscosity and low cost.

Owner:昌乐恒昌化工有限公司

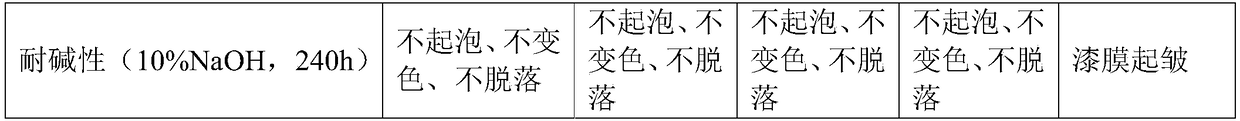

Aqueous epoxy terrace paint and preparation method thereof

ActiveCN105482618AGood emulsification and dispersionModerate concentrationEpoxy resin coatingsWorking lifeReactive diluent

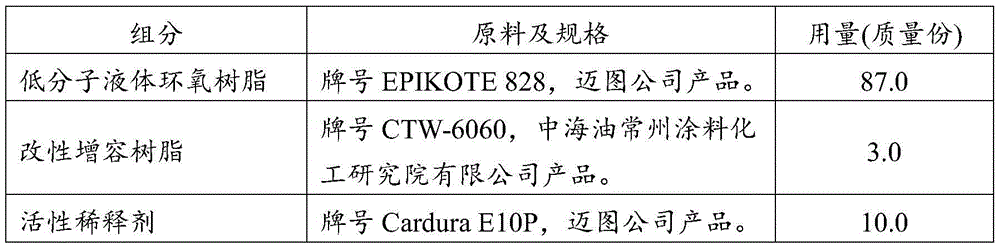

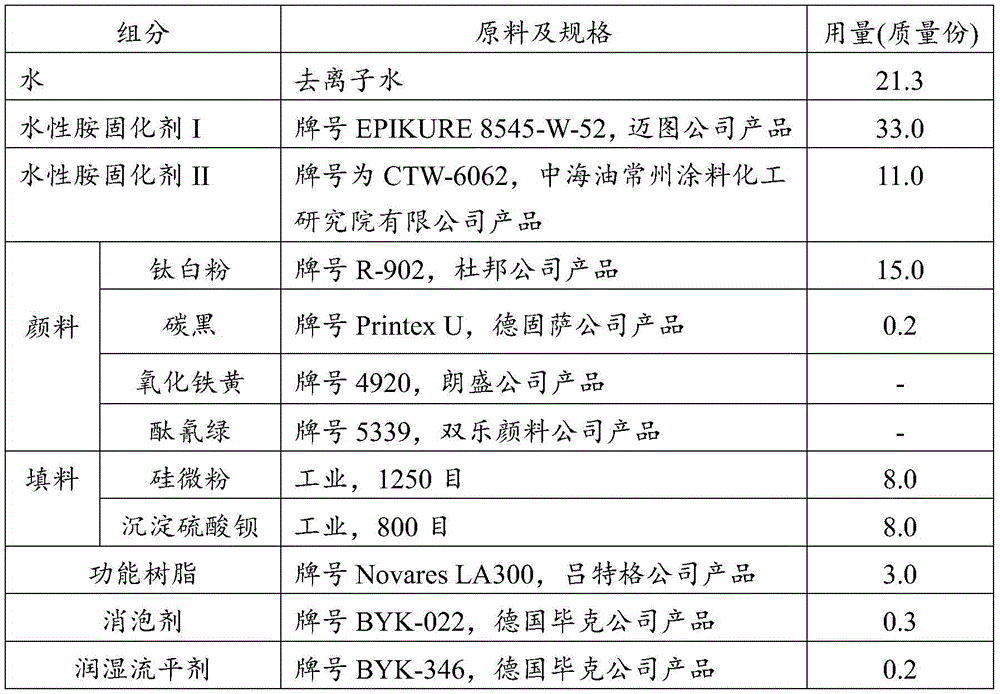

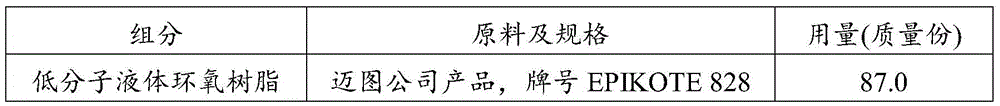

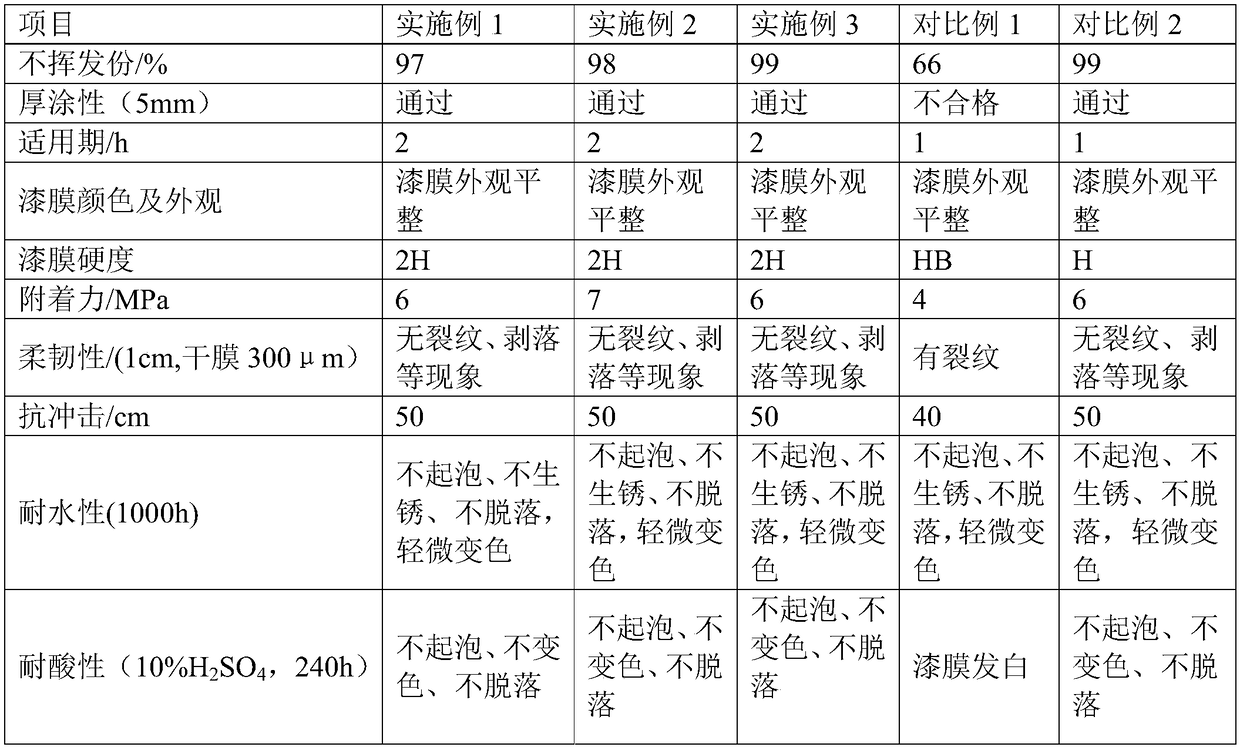

The present invention provides an aqueous epoxy terrace paint, comprising a component A and a component B. The component A comprises 80-90 parts of low molecular weight liquid epoxy resin,2-4 parts of a modified resin compatibilizer and 5-15 parts of a reactive diluent. The component B comprises 20-0 parts of water, 40-45 parts of an aqueous amine curing agent, 3-5 parts of a functional resin, 3-18 parts of a pigment, 10-25 parts of a filler, 0.1-0.5 part of a defoamer and 0.1-0.3 part of a wetting leveling agent. The components A and component B of the aqueous epoxy terrace paint are mixed according to a certain proportion to form a film with suitable working life and good workability. The film has good hardness, wear resistance, flexibility, impact resistance and other physical and mechanical properties and chemical resistance. The invention also provides a preparation method of the aqueous epoxy terrace paint.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Heavy-load resistance and corrosion-resistance waterborne polyurethane floor coating and preparation method thereof

InactiveCN109401600AHigh tensile strengthHigh compressive strengthAnti-corrosive paintsPolyurea/polyurethane coatingsSodium metasilicatePolyol

The invention discloses a heavy-load resistance and corrosion-resistance waterborne polyurethane floor coating and a preparation method thereof. The waterborne polyurethane floor coating comprises acomponent A, a component B and a component C, wherein the component A comprises polyol, an emulsifier, a defoaming agent, a flatting agent and water; the component B comprises polyisocyanate; and thecomponent C comprises white cement, toner, sodium metasilicate, a water reducing agent and quartz sand. The preparation method comprises the following steps that firstly, the component A and the component C are separately prepared, and then the three components A, B and C are mixed during use. The coating has low viscosity, high solid content, no solvent volatilization, rapid drying and long recoating time, can realize thick-film formation, and has high adaptability to coating environment, so that the requirements of various factories on rapid and environment-friendly coating are met.

Owner:JIANGSU HUAXIA PAINT MAKING

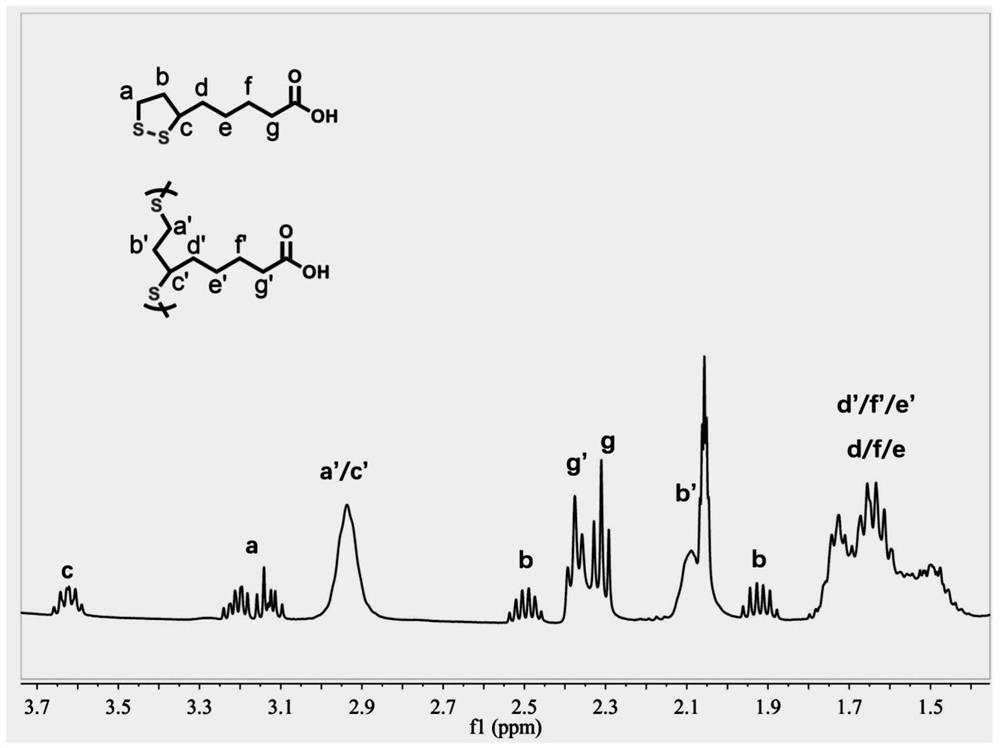

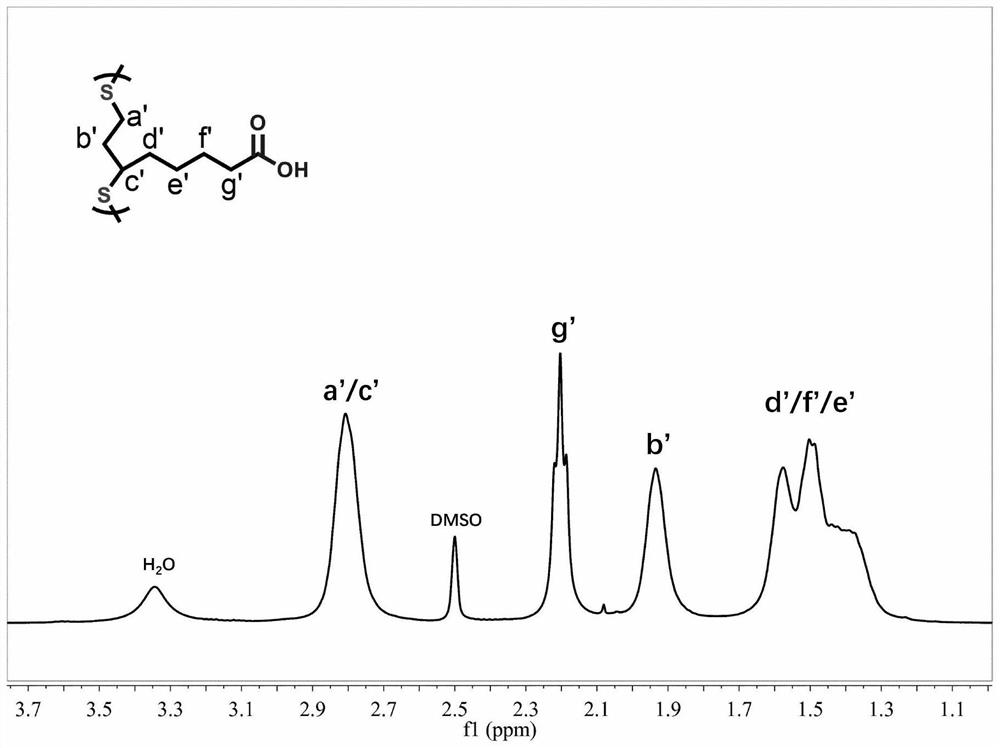

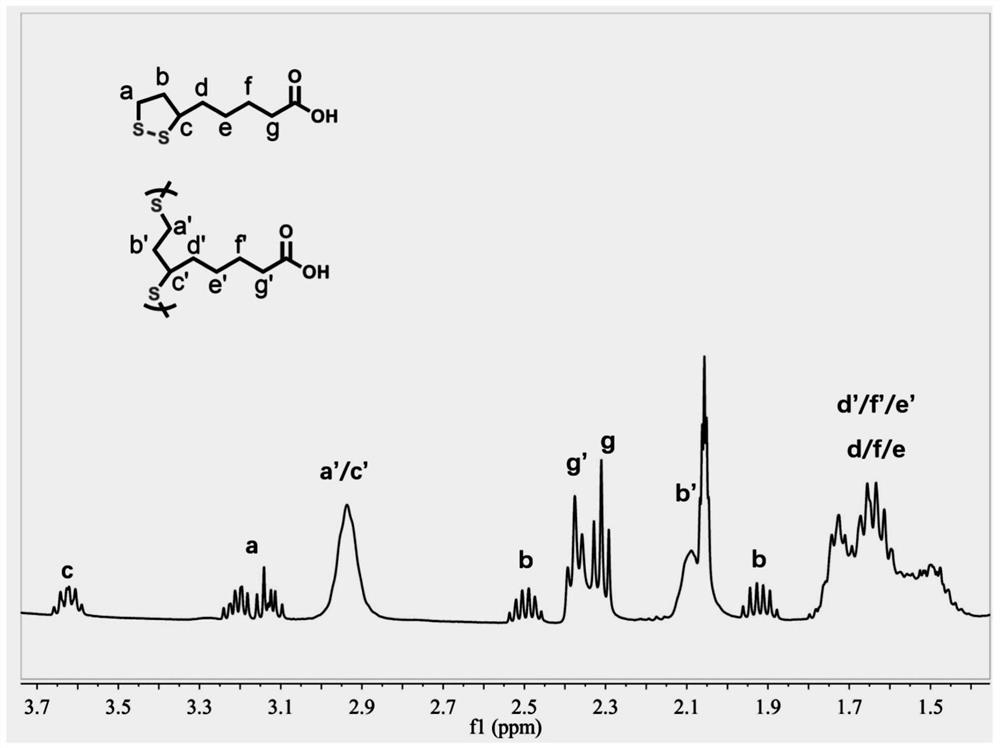

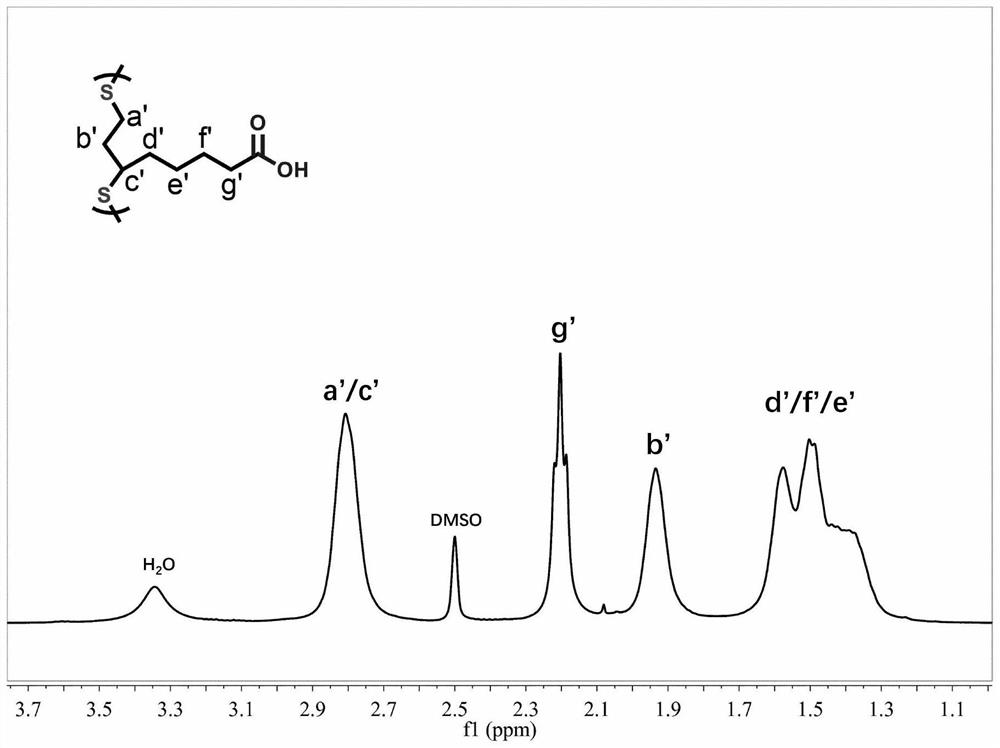

Preparation method of polymer of lipoic acid compound

ActiveCN113214482AFast and efficient ring-opening polymerizationMild reaction conditionsOrganic solventCatalytic method

The invention discloses a preparation method of a polymer of a lipoic acid compound. The preparation method is selected from a solvent-free direct hot-melting catalytic polymerization method or a room-temperature solution catalytic polymerization method. The catalyst used in the method is wide in source, easy to prepare and low in price, catalysis methods are diversified, the process is simple, metal ions are not contained, efficient catalysis can be achieved only through a trace amount of catalyst, and practical industrial feasibility is achieved; catalytic polymerization can be carried out under the condition that no solvent is directly heated and melted, and catalytic polymerization can also be carried out in a solution under the room temperature condition; the direct hot melting catalysis method does not need any organic solvent, has the advantages of rapid catalysis process, mild conditions, simple and safe operation, high atom utilization rate and no three wastes, and meets the green chemical requirements; according to the room-temperature solution catalysis method, heating and complex conditions are not needed, and efficient catalytic polymerization under the room-temperature condition can be achieved by adding a trace amount of catalyst into a monomer solution.

Owner:EAST CHINA UNIV OF SCI & TECH

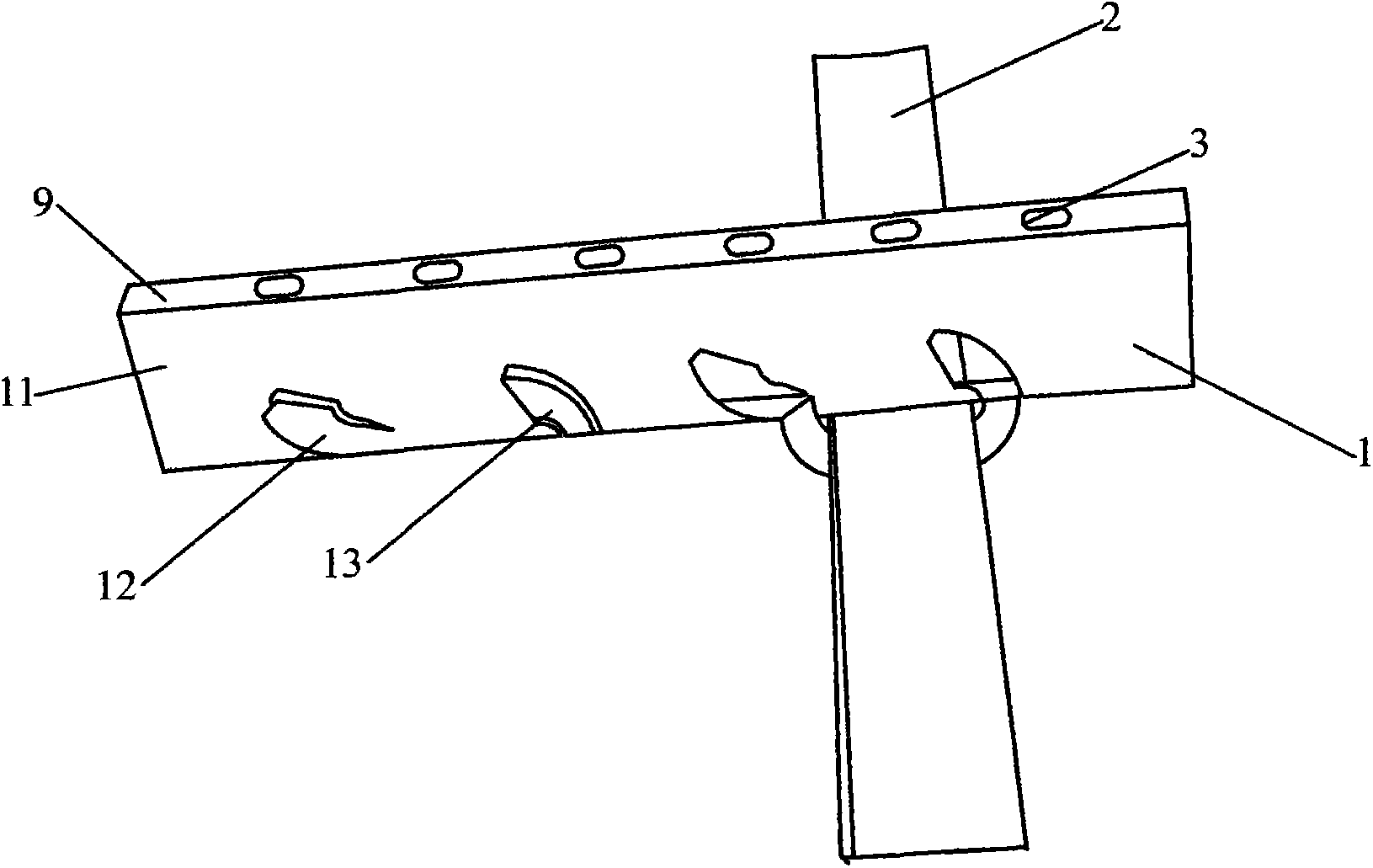

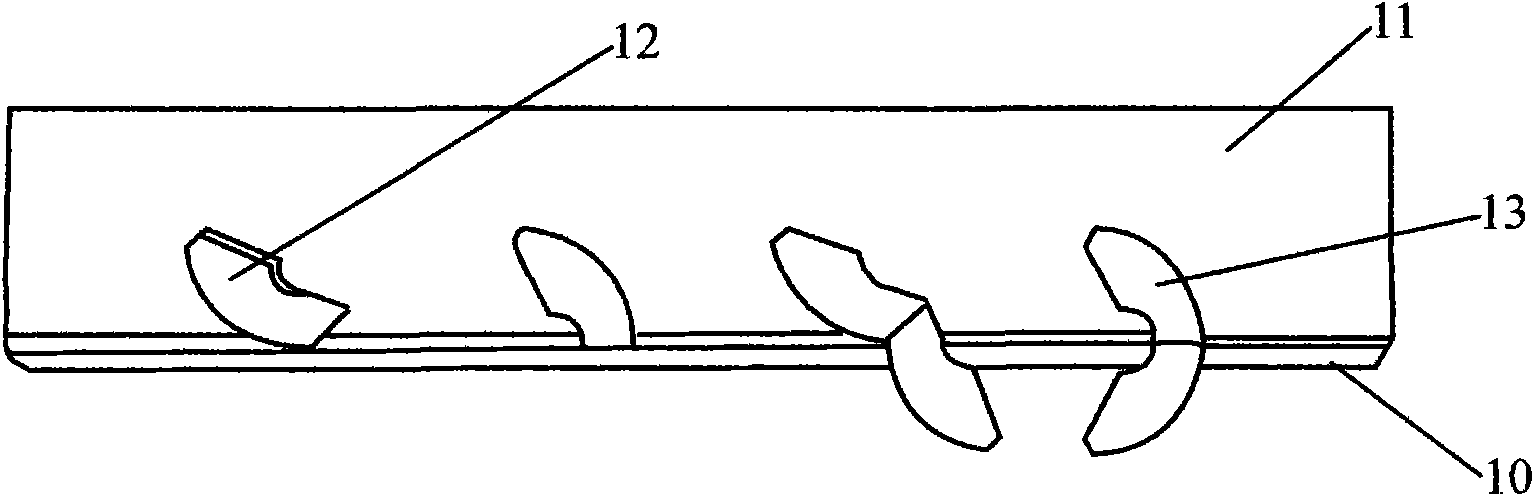

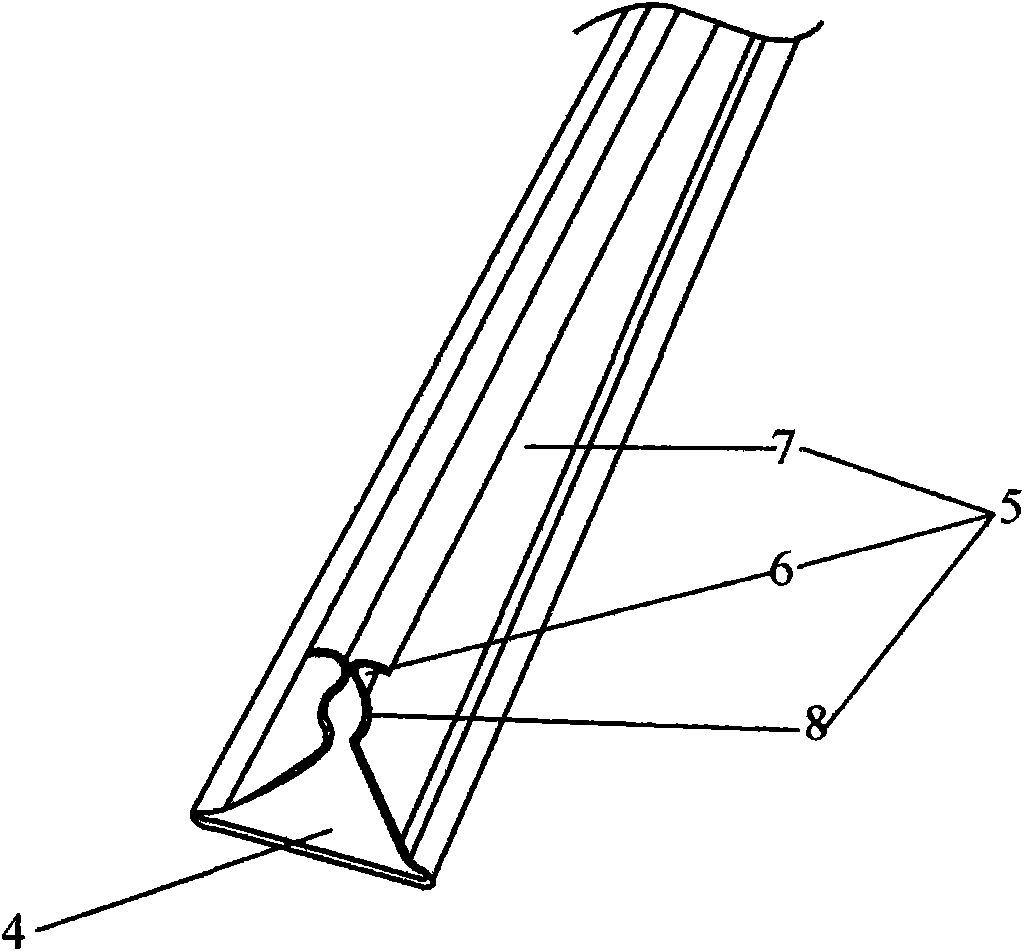

Ceiling joist assembly

The invention belongs to the field of indoor integrated ceiling decoration, and particularly relates to a ceiling joist assembly. The ceiling joist assembly comprises a main joist, a triangular joist and hanging rod installation holes, and is characterized in that the triangular joist is composed of a triangular joist top plane, two symmetrical triangular joist side faces and a bottom groove, the main joist comprises an upper plate, a lower plate and a middle plate, the hanging rod installation holes are formed in the upper plate of the main joist, 45-degree overturn hanging buckles and perpendicular overturn hanging buckles are arranged on the middle plate and are arranged in an alternate mode, the arc-shaped bending direction of each 45-degree overturn hanging buckle and the arc-shaped bending direction of the adjacent perpendicular overturn hanging buckle are opposite, and every two adjacent 45-degree overturn hanging buckles or every two adjacent perpendicular overturn hanging buckles are in the same shape. The ceiling joist assembly has the advantages that the varieties of installation materials are reduced, installation can be conveniently achieved, various hanging pieces and the main joist are integrated, and the situation that the hanging pieces are pulled straight when bearing too large force or bearing force for a long time can not occur.

Owner:王德路

Formula of slurry capable of being applied to weaving under low sizing rate and sizing method thereof

ActiveCN105442317ASimple varietyIn line with the development trend of "less components"Fibre typesSizingDyeing

The invention discloses a formula of a slurry capable of being applied to weaving under a low sizing rate. The slurry comprises polyvinyl alcohol (PVA), modified starch, and dimethyl sulfoxide. The invention also discloses a sizing method capable of being applied to weaving under a low sizing rate. The method comprises the following steps: weighing slurry, blending slurry, pumping slurry into the slurry tank of a sizing machine, and carrying out sizing on warp yarns through a double-soaking double-pressing mode. The slurry formula is simple. The slurry only comprises PVA and etherified potato starch, the error of slurry blending can be reduced, moreover, the storage management becomes convenient, and the formula is accord with development trend of less components of slurry. DMSO is taken as the compatibilizer to solve the problem that the performance of slurry is influenced by the different thermodynamic compatibilities of different slurries. The yarns produced by the provided sizing technology can meet the requirements of weaving under the condition of low sizing rate, the using amount of slurry is largely reduced, the production cost for the textile enterprises is reduced, the pollution generated by pretreatment of printing and dyeing is reduced, and thus the formula and method have a good market prospect.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Environment-friendly polyaluminum chloride water purifying agent and preparation method thereof

InactiveCN109293005ASimplify the variety of raw materialsShort processBiological water/sewage treatmentParacoccus aminovoransChemistry

The invention discloses an environment-friendly polyaluminum chloride water purifying agent, which comprises the following components by weight: 30-42 parts of polyaluminum chloride, 9-15 parts of activated carbon, 13-20 parts of aluminum sulfate, 6-9 parts of ferric chloride, 8-11 parts of ferric sulfate, 4-7 parts of bentonite, 15-18 parts of a shell filter material, 1-3 parts of paracoccus aminovorans powder, and 0.9-1.5 parts of nitrobacteria powder. The purified water quality is superior to that purified by an aluminum sulfate flocculant, and the water purification cost is about 20% lowerthan that adopting aluminum sulfate flocculant; the consumption of alkalinity in the water is lower than that of various inorganic flocculants, therefore no or a small amount of alkaline agent can beapplied. And the polyaluminum chloride water purifying agent has a wide PH application range. Only two main raw materials are used in production, the raw material variety is simplified, the technological process is shortened, and the reaction is accelerated. The product is clear, the quality and performance are improved, the basicity is increased by about 10% than that of products adopting aluminum hydroxide as the raw material, and the production cost is reduced by 20% or more, and compared with products adopting bauxite as the raw material, the waste residue is reduced by 20-30%, thus beingconducive to environmental control.

Owner:湖南贵友新材料科技股份有限公司

Method for producing polyaluminium chloride

ActiveCN101531389BEasy to manageEasy to separateAluminium chloridesWater/sewage treatment by flocculation/precipitationLiquid productSlag

The invention relates to a method for producing polyaluminium chloride as a drinking water treating agent, which uses 1 ton of liquid product which contains 10 percent of Al2O3 in mass content as a mother solution of which total output is 15 to 40 percent in percentage by mass. The mother solution is added with 200 to 210 kilograms of calcium aluminate powder in one step under a stirring state, wherein the content of the Al2O3 is 51 to 52 percent. Under normal temperature, industrial synthetic hydrochloric acid with 100 percent of mass concentration is added into the mother solution, and the weight of the industrial synthetic hydrochloric acid is 0.65 to 0.83 of the calcium aluminate powder. When the temperature is raised to 55 DEG C, 661.8 to 624.9 kilograms of water is added into the mother solution, and the flow is controlled within a reaction temperature of between 87 and 100 DEG C. When the temperature finally does not reach 87 DEG C, steam is supplemented, and water quantity is deducted. When the reaction is carried out for 2 to 3 hours, liquid and slag are separated. The raw material variety of the invention is little, the process flow is short, the reaction is shortened by one third, the harmful substances are controlled in a standard range, the cost is lowered, the waste slag is little, and the obtained product has clear color and good quality.

Owner:浙江嘉灵环保科技有限公司

A kind of preparation method of the polymer of lipoic acid compound

ActiveCN113214482BFast and efficient ring-opening polymerizationMild reaction conditionsOrganic solventCatalytic method

The invention discloses a method for preparing a polymer of lipoic acid compounds, which is selected from solvent-free direct hot-melt catalytic polymerization or room temperature solution catalytic polymerization; the catalyst used in the method of the invention has a wide range of sources, is easy to prepare, and is inexpensive. Inexpensive, diverse catalytic methods and simple process, no metal ions, only a small amount of catalyst is needed to achieve high-efficiency catalysis, and has practical industrial feasibility; it can catalyze polymerization under the condition of direct heating and melting without solvent, or at room temperature Catalytic polymerization in the solution under the environment; the direct hot melt catalytic method does not need any organic solvent, the catalytic process is rapid, the conditions are mild, the operation is simple and safe, the utilization rate of atoms is high, and there is no three wastes, which meets the requirements of green chemistry; the room temperature solution catalytic method does not need heating and complicated High-efficiency catalytic polymerization at room temperature can be achieved by adding a small amount of catalyst to the monomer solution.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com