Formula of slurry capable of being applied to weaving under low sizing rate and sizing method thereof

A sizing method and conditional technology, which is applied in the field of textile sizing, can solve the problems that yarn cannot be weaved under the condition of low sizing rate, complex sizing formula, high sizing rate, etc., achieve good market promotion prospects, reduce sizing rate, and adjust sizing accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

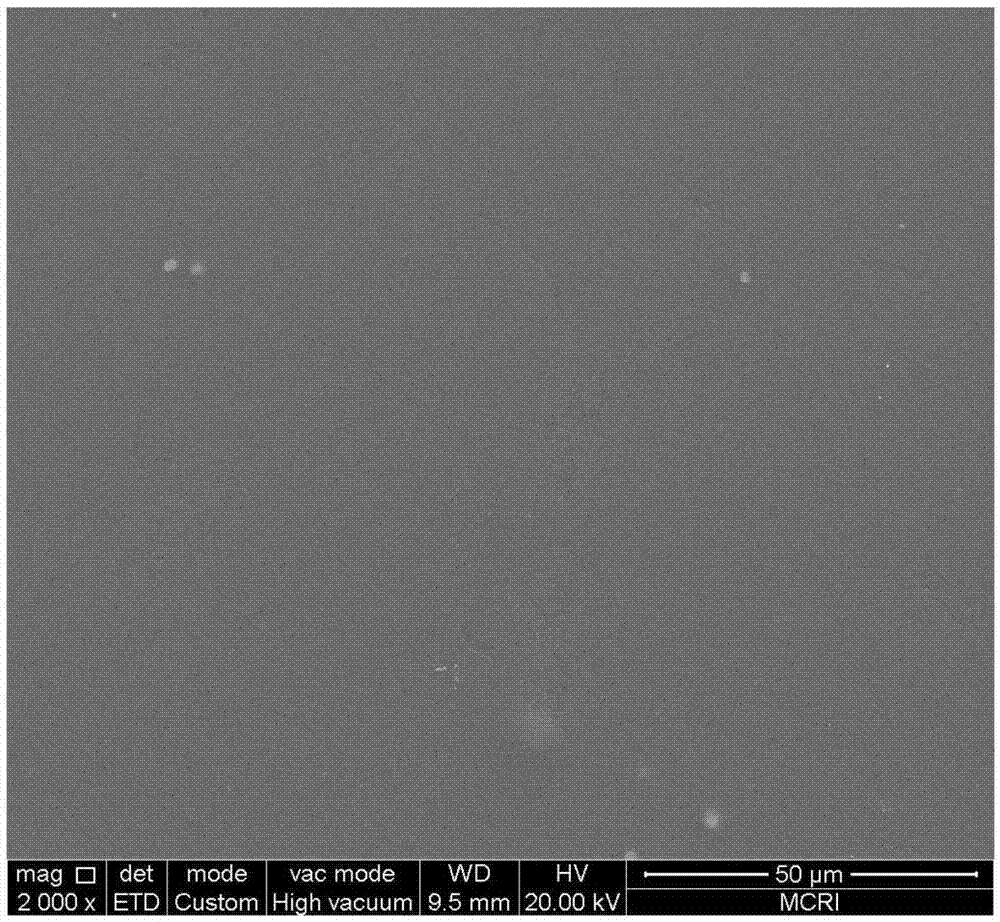

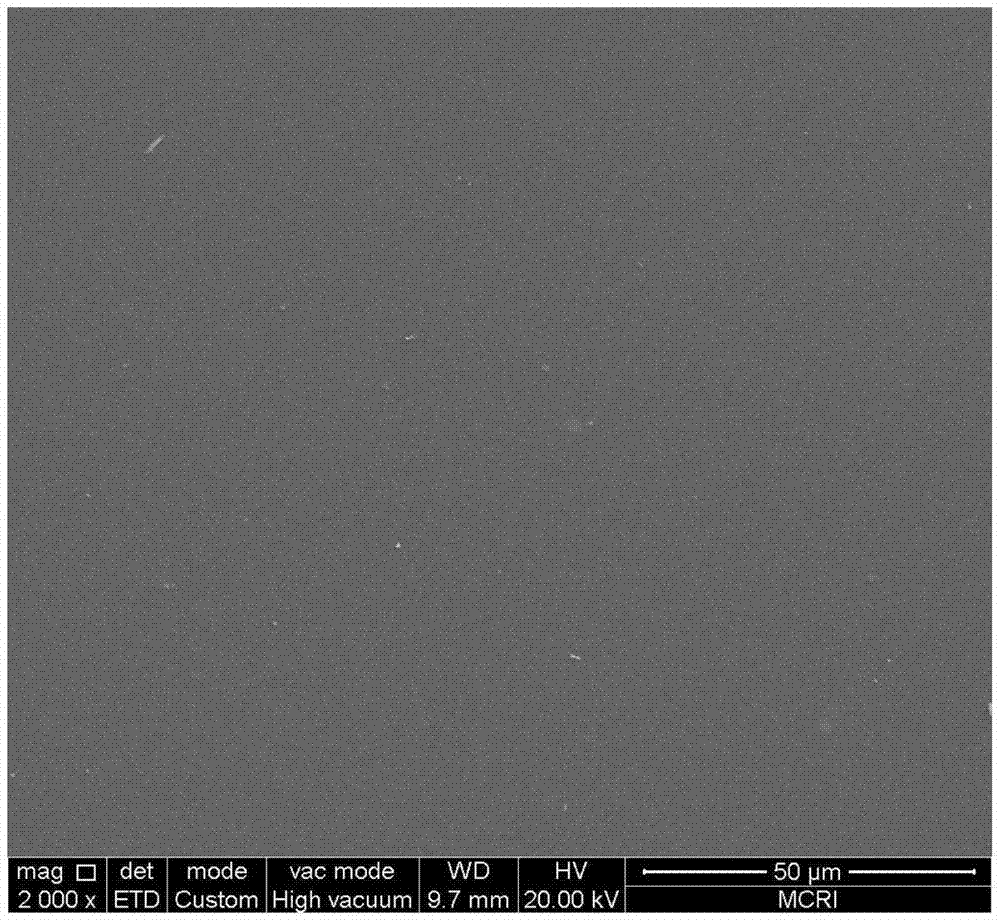

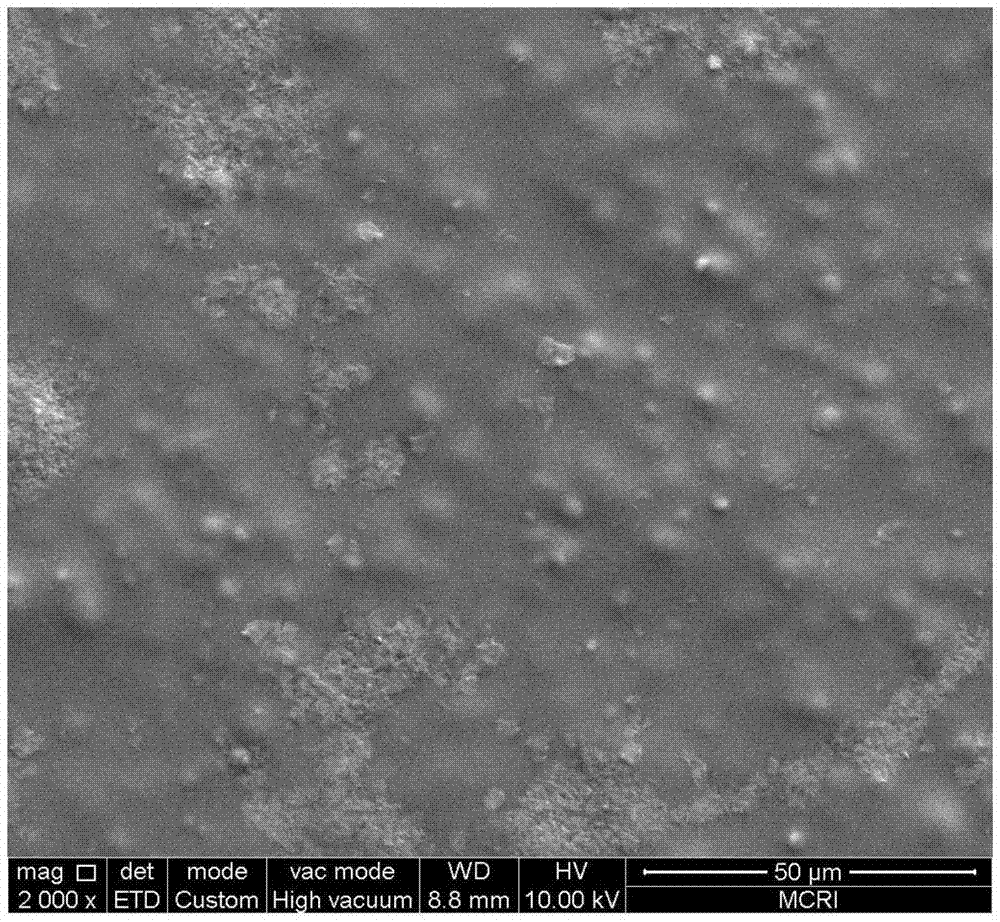

Image

Examples

Embodiment 1

[0047] Fabric specification: MJ60×60×140×12067”1 / 1

[0048] Step 1, take by weighing 1799 type PVA25kg, potato etherified starch 75kg (PVA mass ratio accounts for 28%, 100% potato etherified starch mass ratio accounts for 72%), DMSO0.89kg (1% of PVA and modified starch dry basis weight) , Pour 709L tap water into the mixing tank, stir and add the weighed PVA, modified starch and DMSO into it, set the temperature of the mixing tank at 98°C, when the temperature in the mixing tank rises to 98°C, keep it warm for 45min , use a YT821 funnel-type viscometer to test the viscosity value of the slurry in the mixing tank, the test hole is the No. 3 hole, when the viscosity is 6.0 seconds, the slurry preparation is completed, and the mixed slurry is obtained;

[0049] Step 2, input the mixed slurry obtained in step 1 into the size tank of the Benninger double size tank sizing machine, set the moisture regain of the sizing machine to 7%, the speed of the sizing machine is 75m / min, and the ...

Embodiment 2

[0051] Fabric type: DC60×60×155×12067.4〞Dobby

[0052] Step 1, take by weighing 1799 type PVA31.25kg, potato etherified starch 75kg (PVA mass ratio accounts for 32.8%, 100% potato etherified starch mass ratio accounts for 67.2%), DMSO0.91kg (PVA and modified starch dry basis weight 1 %), put 846L tap water into the slurry tank, stir and add the PVA, starch and DMSO denatured into it, set the temperature of the slurry tank to be 115 °C, when the temperature in the slurry tank rises to 115 °C, Keep warm for 30 minutes, and use a YT821 funnel-type viscometer to test the viscosity value of the slurry in the mixing tank. The test hole is the No. 3 hole. When the viscosity is 6.3 seconds, the slurry preparation is completed, and the mixed slurry is obtained;

[0053] Step 2, input the mixed slurry obtained in step 1 into the size tank of the Benninger double size tank sizing machine, set the moisture regain of the sizing machine to 7%, the speed of the sizing machine is 75m / min, and...

Embodiment 3

[0055] Fabric type: C60S×60S×157×120×180cm dobby

[0056] Step 1, take by weighing 1799 type PVA37.5kg, potato etherified starch 62.5kg (PVA mass ratio accounts for 40%, 100% potato etherified starch mass ratio accounts for 60%), DMSO0.90kg (PVA and modified starch dry basis weight 1%), put 800L tap water into the mixing tank, stir and add the PVA, starch and DMSO denatured into it, set the temperature of the mixing tank to 110 °C, when the temperature in the mixing tank rises to 110 °C , keep warm for 38 minutes, use a YT821 funnel-type viscometer to test the viscosity value of the slurry in the mixing tank, the test hole is No. 3 hole, when the viscosity is 6.5 seconds, the slurry preparation is completed, and the mixed slurry is obtained;

[0057] Step 2, input the mixed slurry obtained in step 1 into the size tank of the Benninger double size tank sizing machine, set the moisture regain of the sizing machine to 7%, the speed of the sizing machine is 75m / min, and the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com