Patents

Literature

199results about How to "Reduce storage area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Document processing utilizing a version managing part

InactiveUS7134071B2Eliminate the problemReduce storage areaDigital computer detailsNatural language data processingDatabaseDocument processing

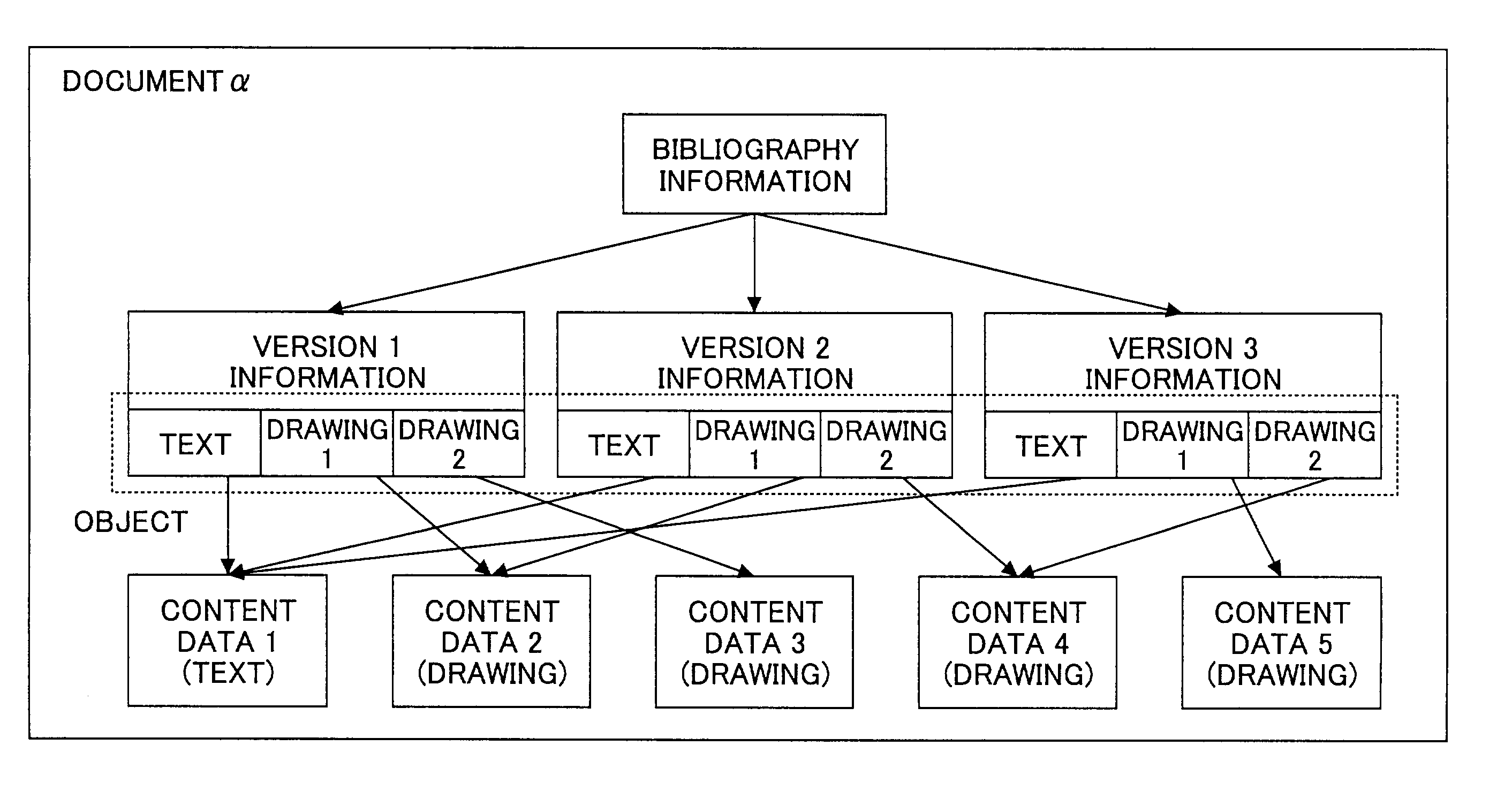

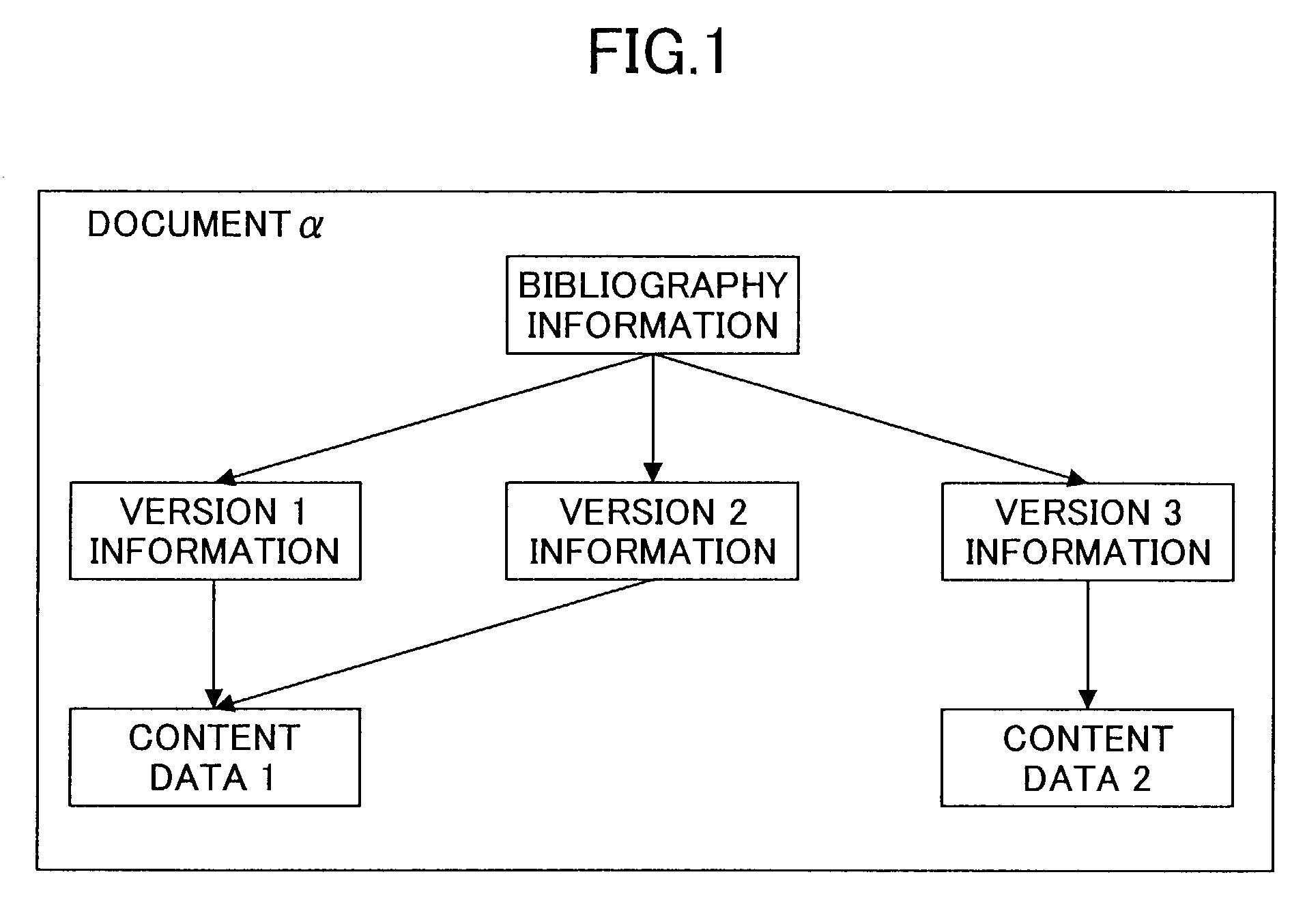

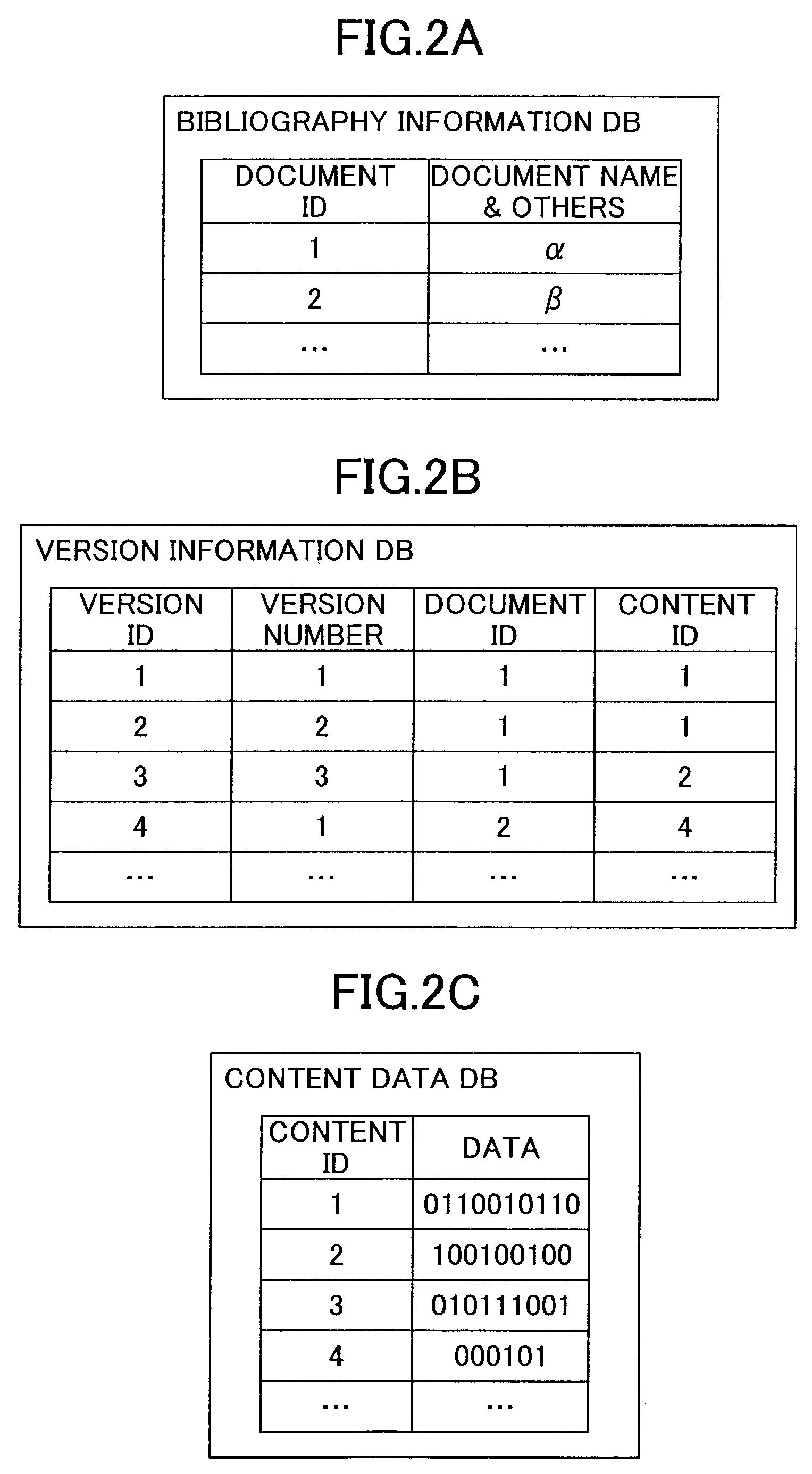

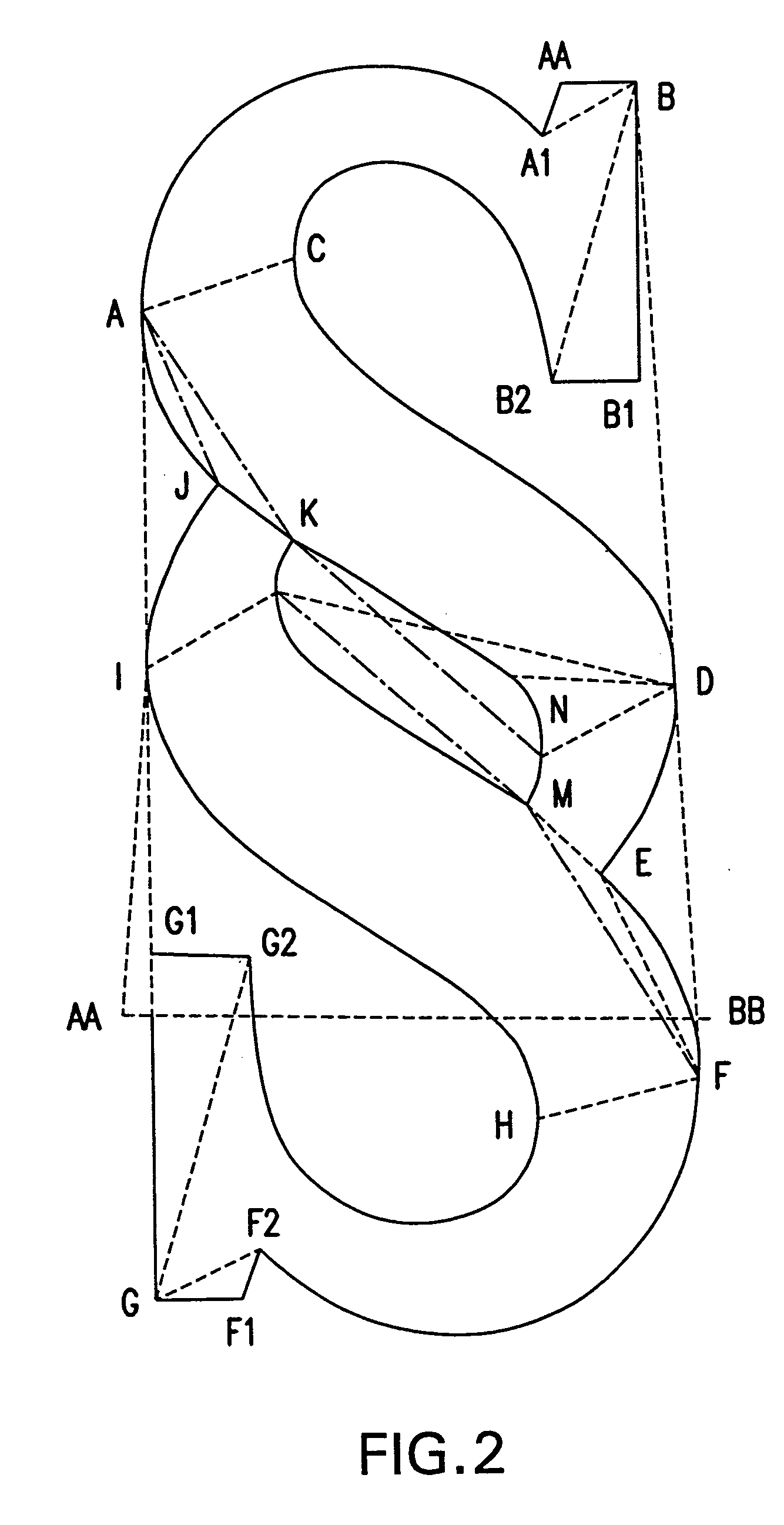

When there are the same contents (content data) of a document among versions, the contents of the document are shared so as to reduce the storage area. Accordingly, instead of accumulating content data separately for each version, each version is related to the content data accumulated in the storage area shared among the versions. When a document α has versions 1 through 3 and each of versions 1 through 3 has sections 1 and 2, three sections 1 of the versions 1 through 3 share content data 1 and the section 2 of each of the versions 1 through 3 has different content data 2, 3, or 4. The content data 1, 2, 3, or 4 indicated by version information are searched for from a content data DB, to be edited. Only when the content data 1, 2, 3, or 4 are changed, new content data are registered.

Owner:RICOH KK

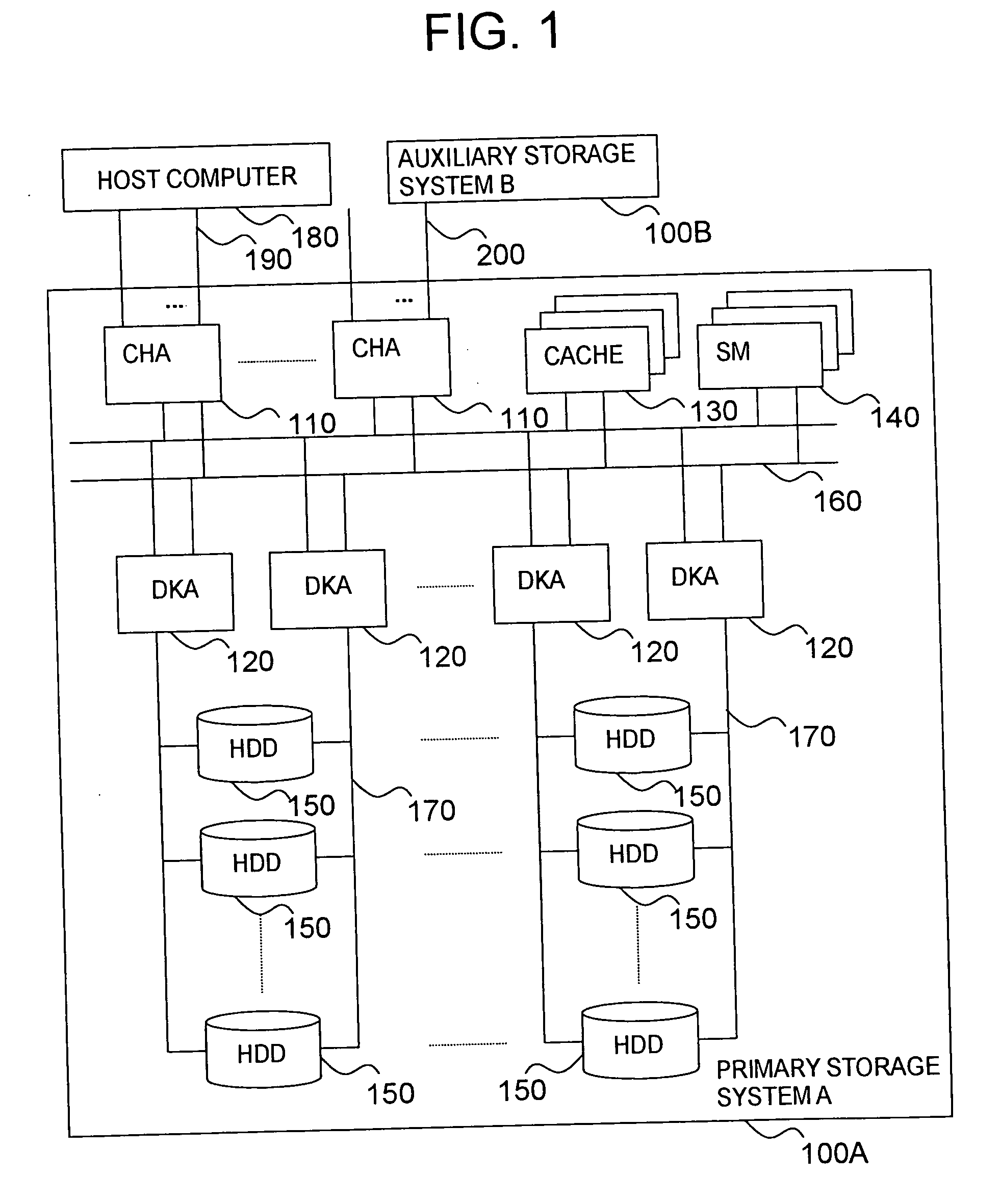

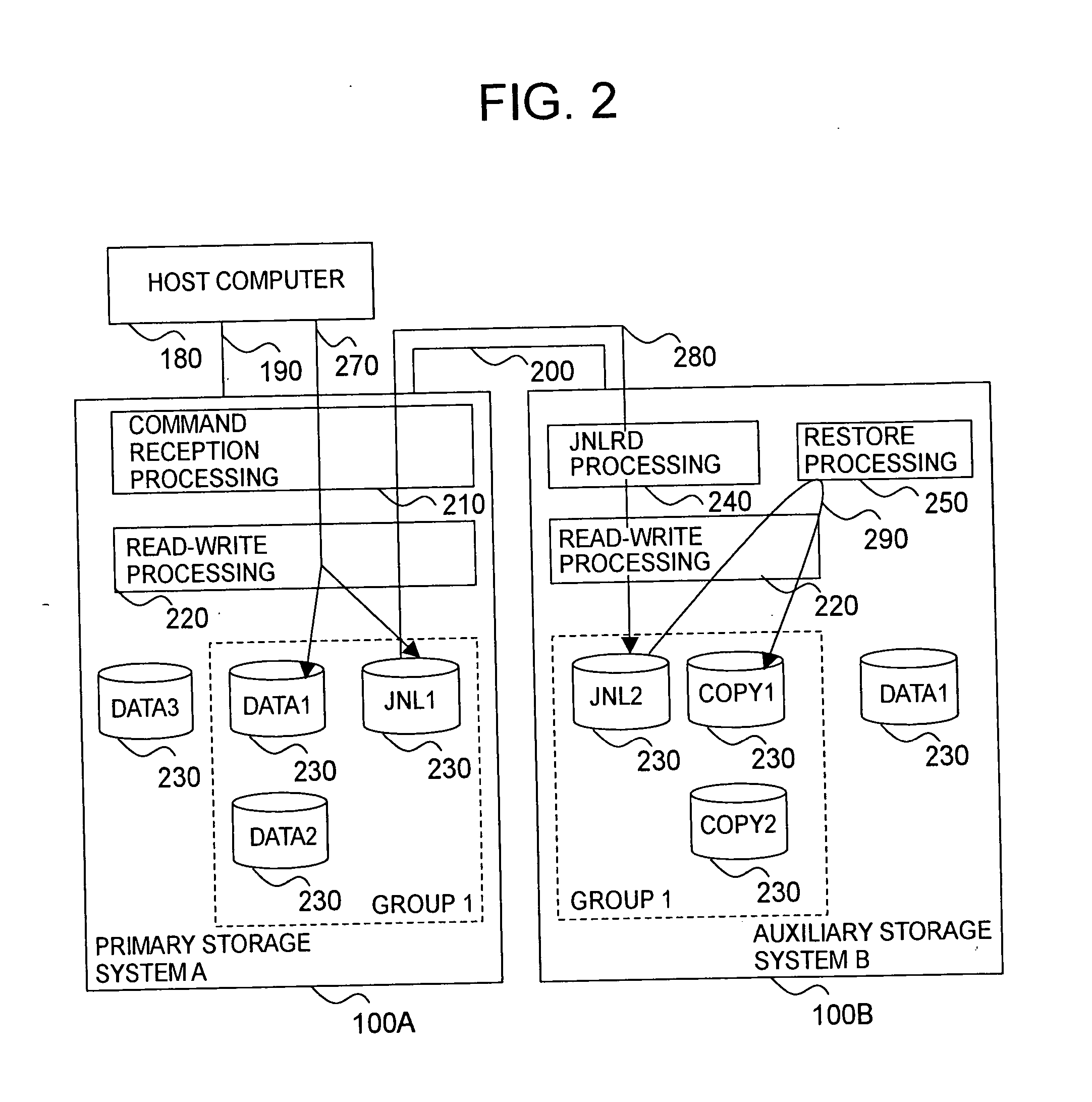

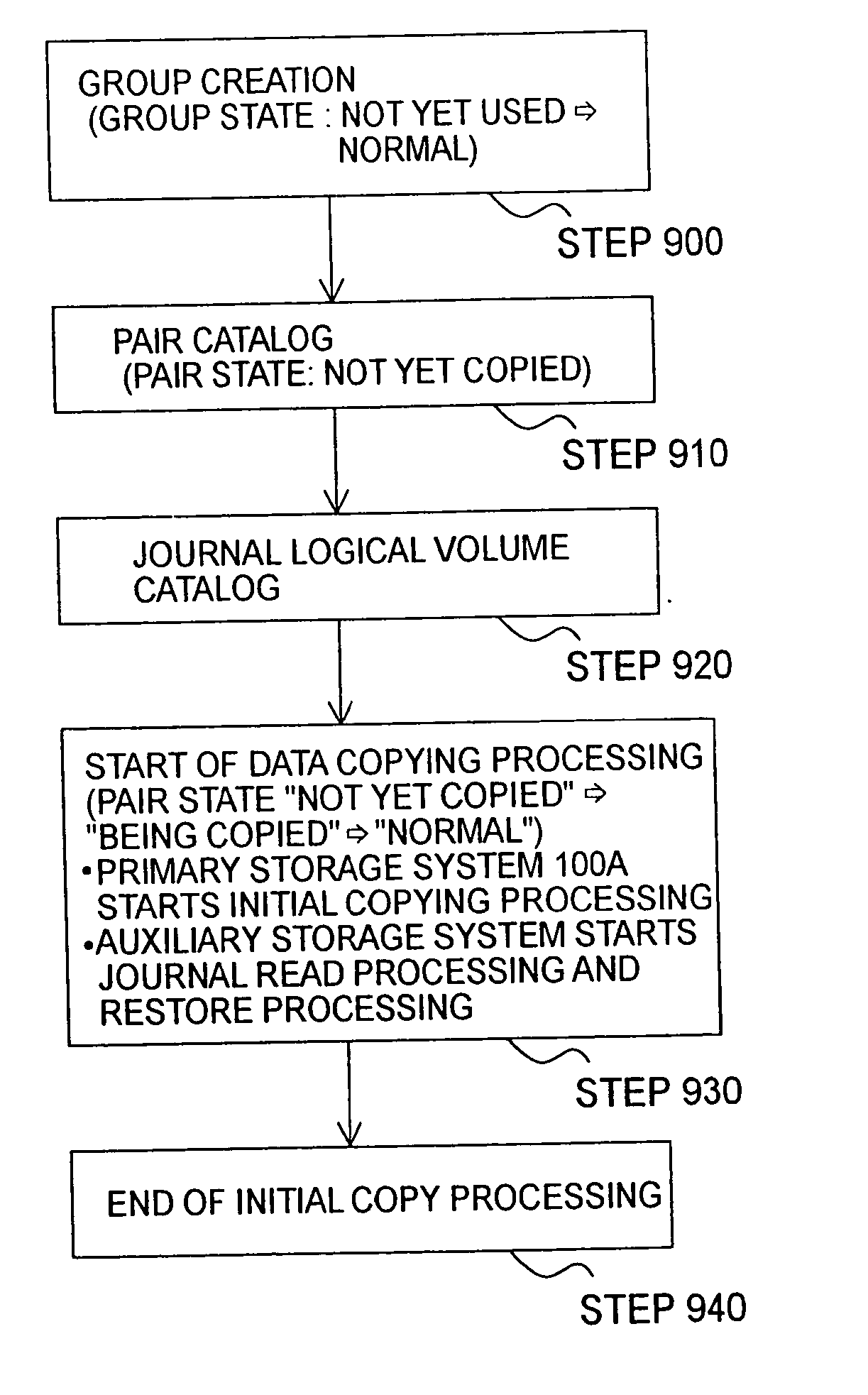

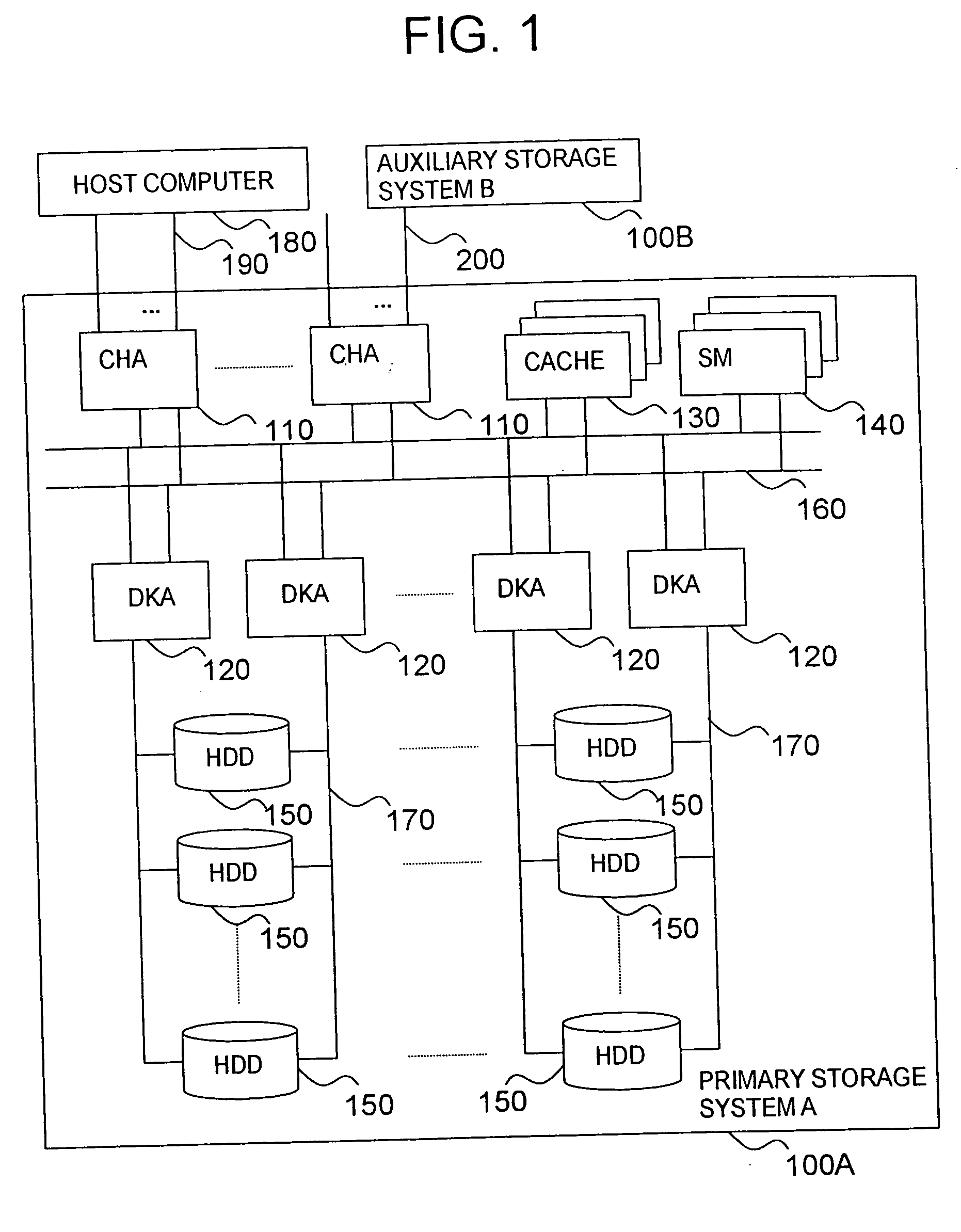

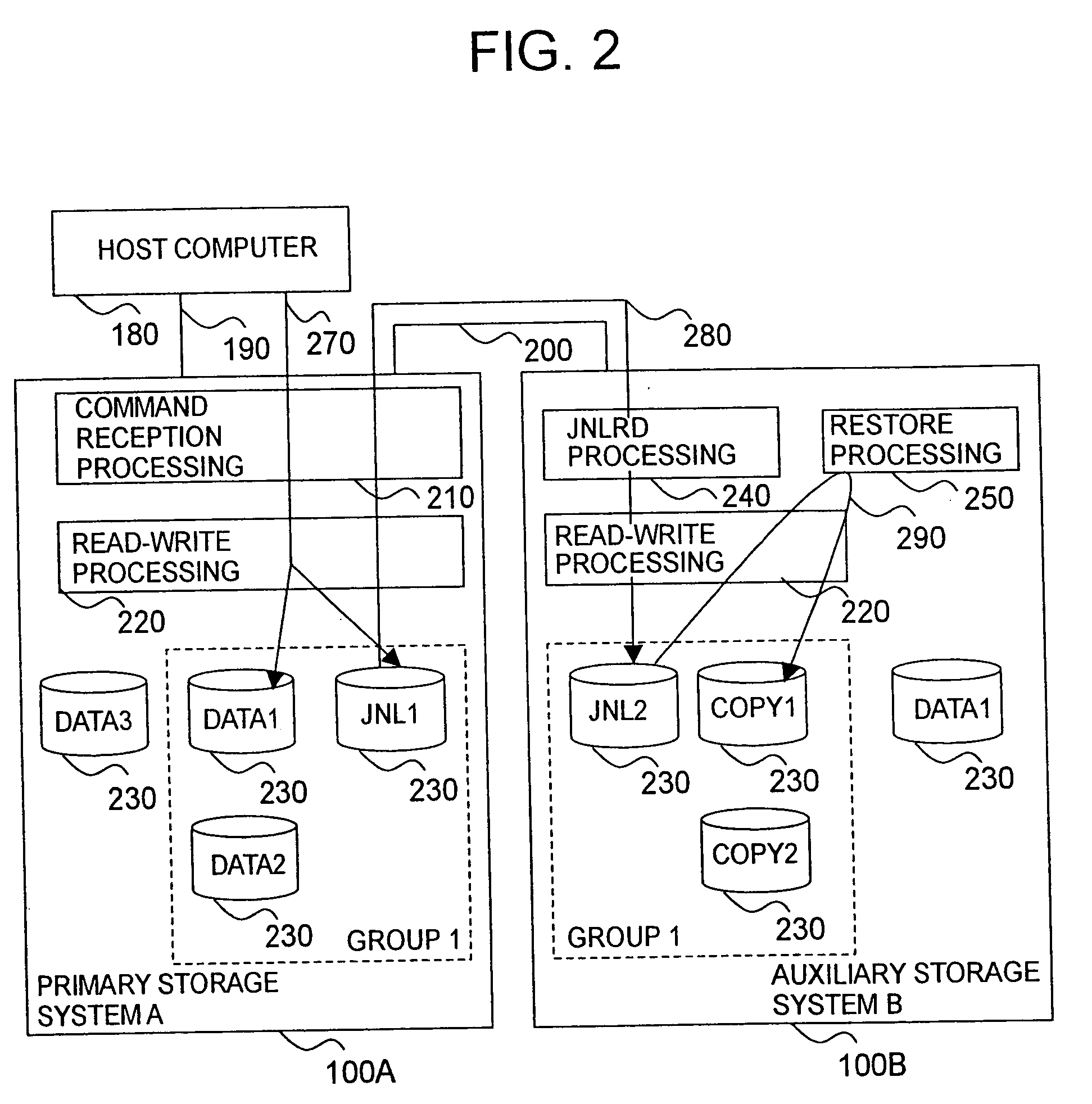

Data processing system having a plurality of storage systems

InactiveUS20050132155A1Reduce decreaseRapidly and effectively data transfer and dataData processing applicationsInput/output to record carriersData processing systemData treatment

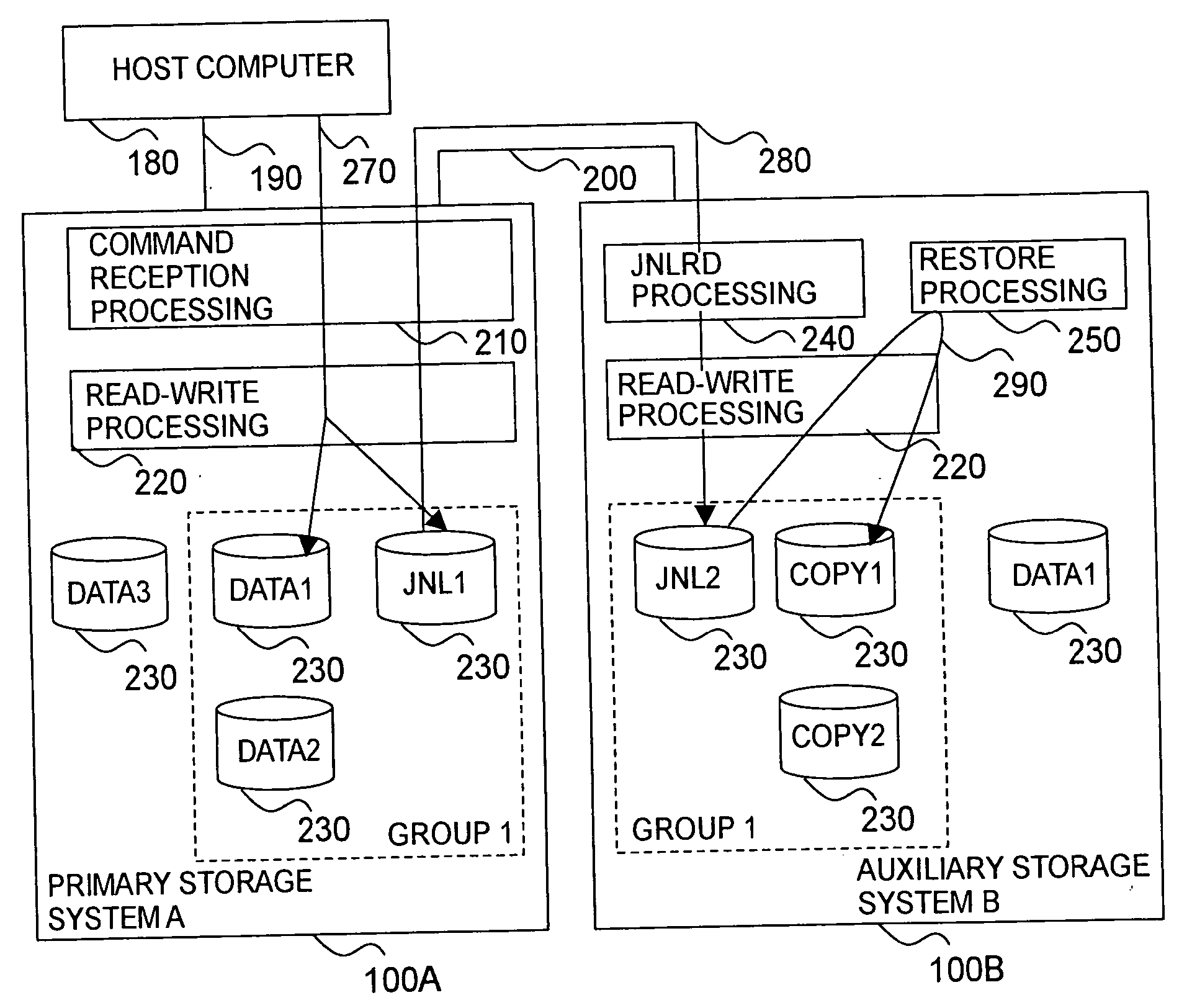

It is an object of the present invention to conduct data transfer or data copying between a plurality of storage systems, without affecting the host computer of the storage systems. Two or more auxiliary storage systems 100B, 100C are connected to a primary storage system 100A connected to a host device 180. The auxiliary storage systems 100B, 100C read journals of data update from the primary storage system 100A at respective independent timings, save the journals in prescribed logical volumes JNL 2, JNL 3, produce copying of the data present in the primary storage system 100A based on the journals present in the logical volumes JNL 2, JNL 3 at the independent timings, and save the copies in auxiliary logical volumes COPY 1, COPY 3. The primary storage system 100A holds the journals till both auxiliary storage systems 100B, 100C read the journals and restore. The timing of journal read can be controlled according to the journal quantity, processing load, and the like.

Owner:HITACHI LTD

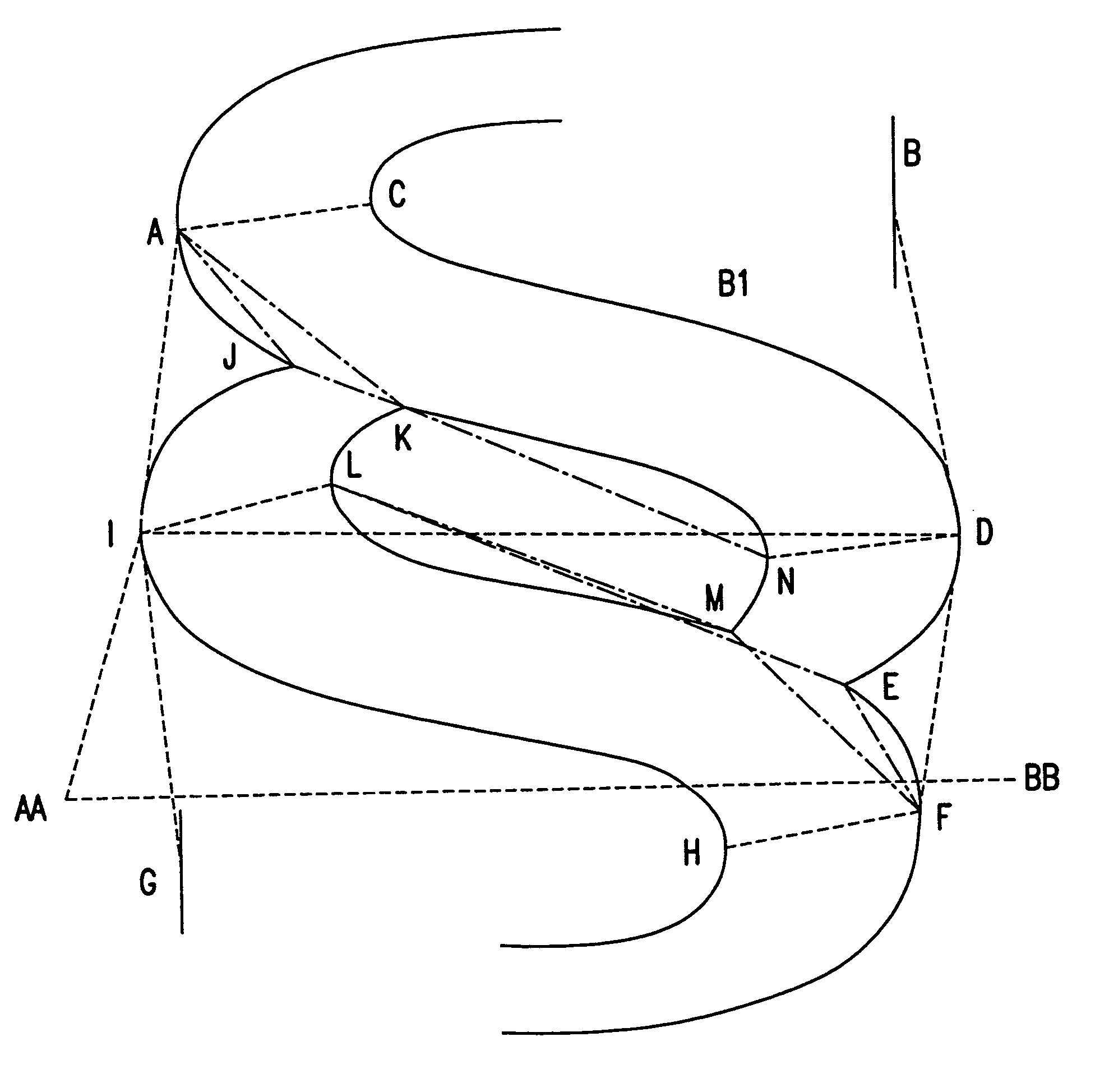

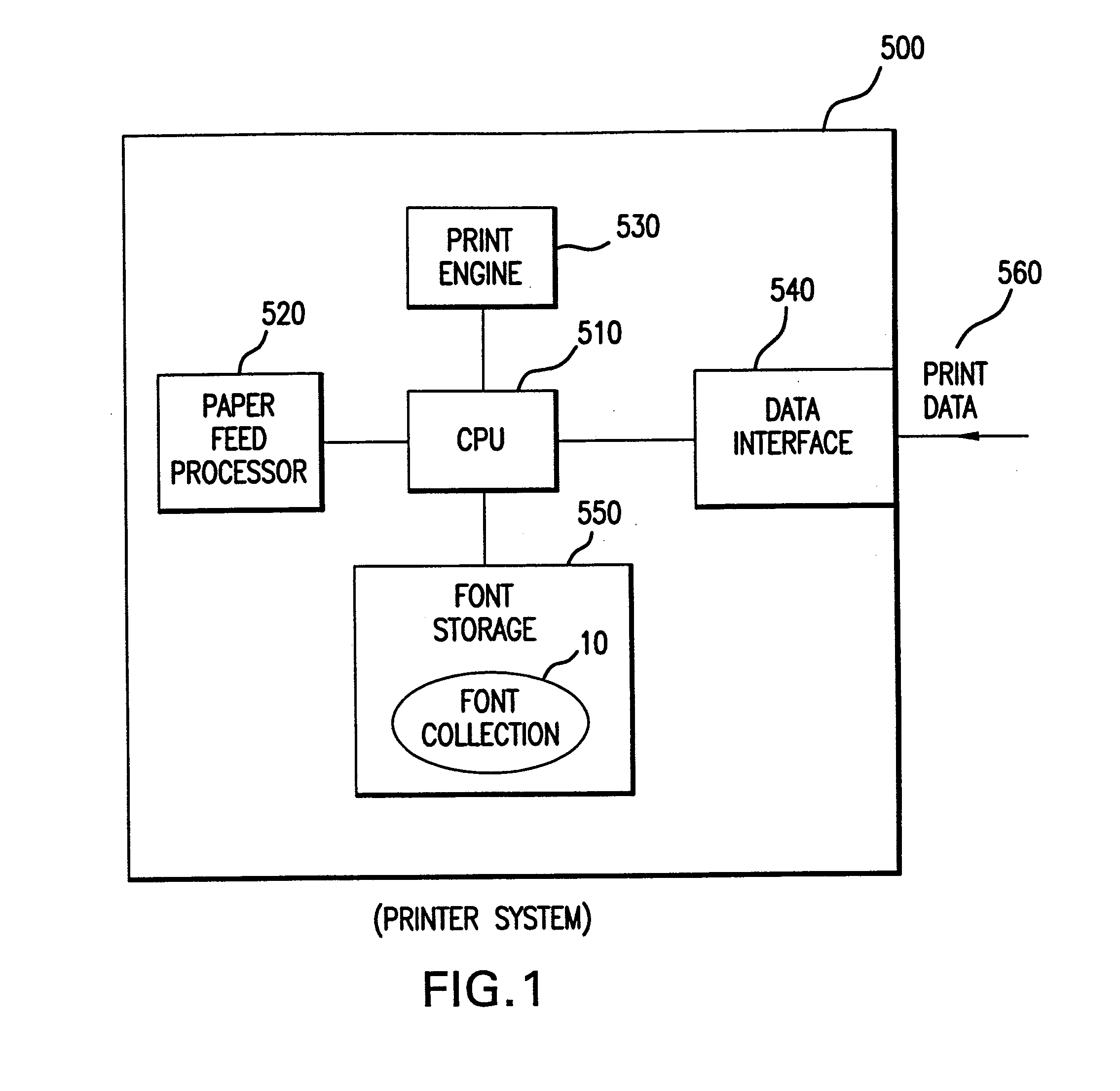

Method and apparatus for font storage reduction

The present invention is aimed at three specific data areas of font compression, each of whose size has become significant as other data areas have been compressed. The three data areas include model factoring, character level feature measurement (local dimensions) factoring, and typeface level feature measurement (global dimensions) factoring. In general, the invention in each area is an apparatus and method used in font compression to reduce redundant information, thereby allowing a reduction in data format (e.g., words to bytes and bytes to bits) resulting in an overall reduction in storage area for a given font collection.

Owner:MONOTYPE IMAGING INC

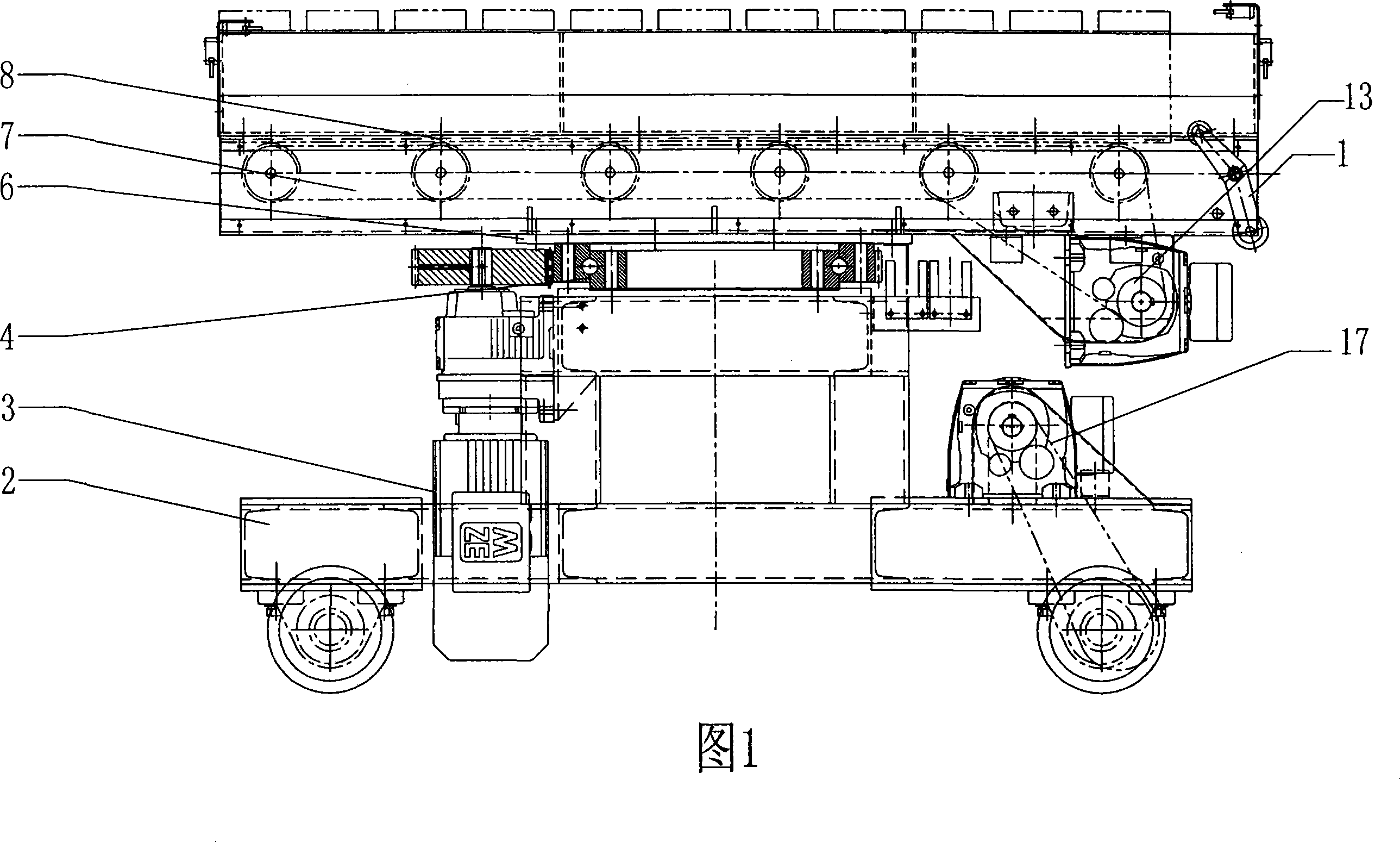

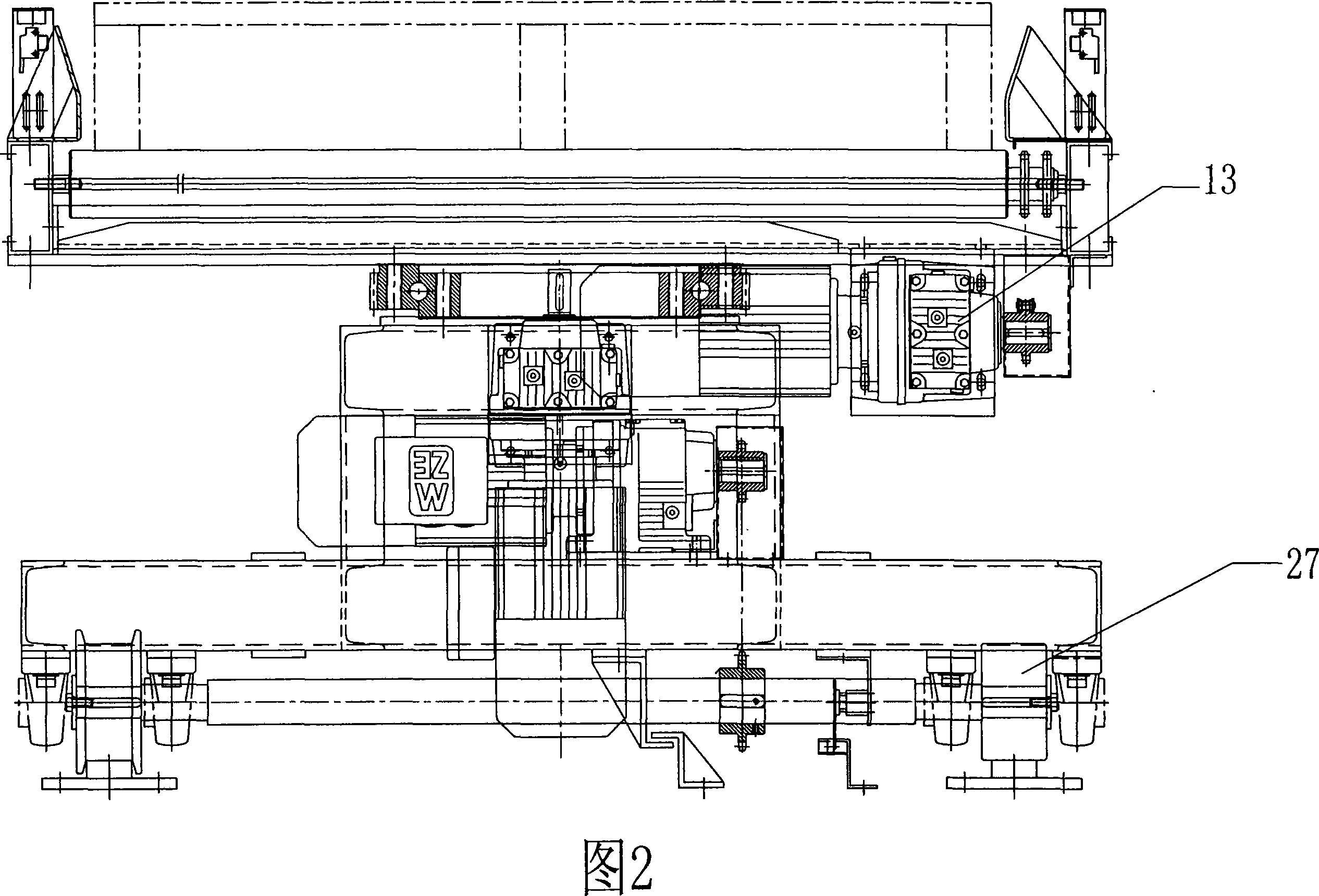

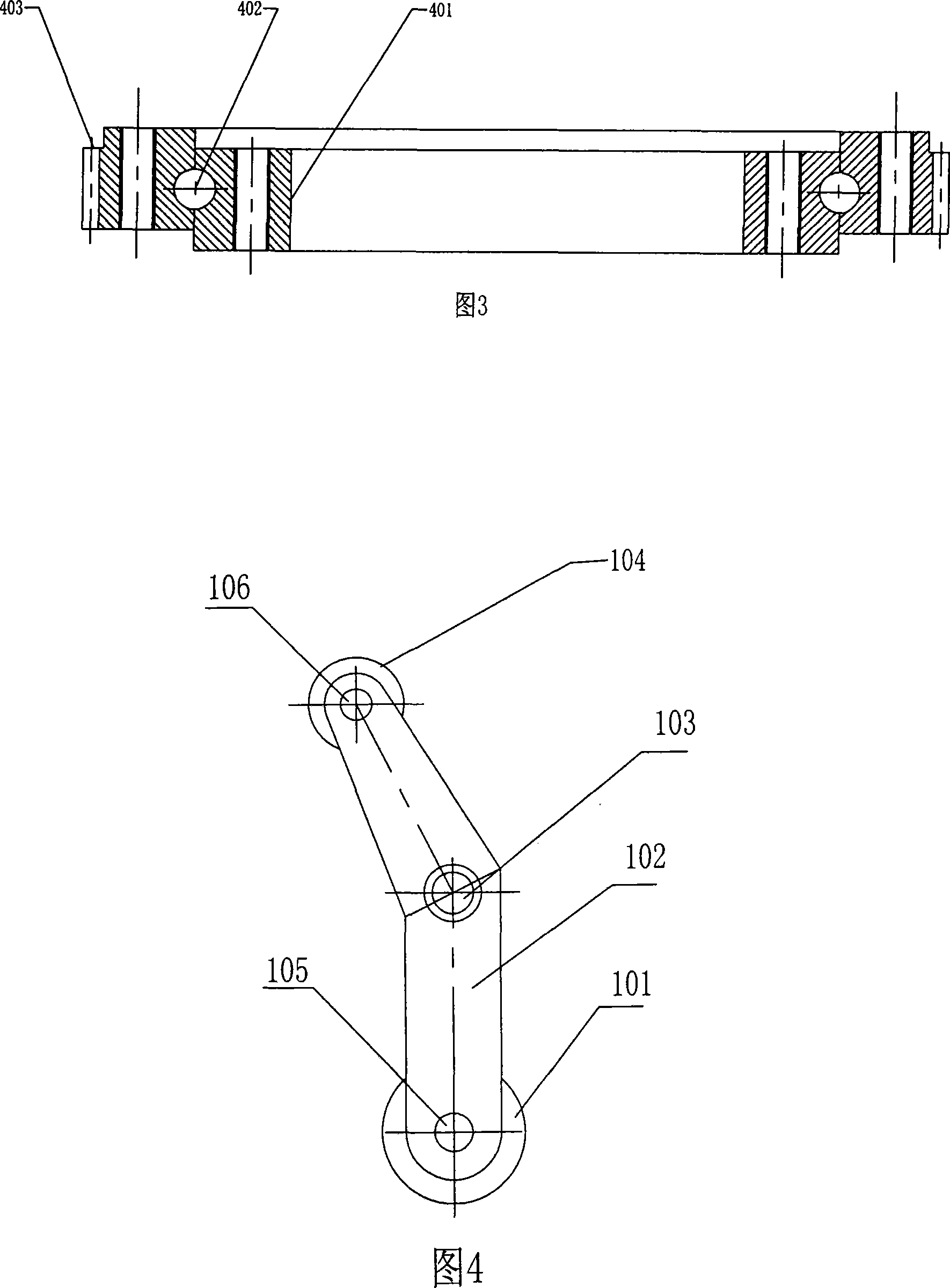

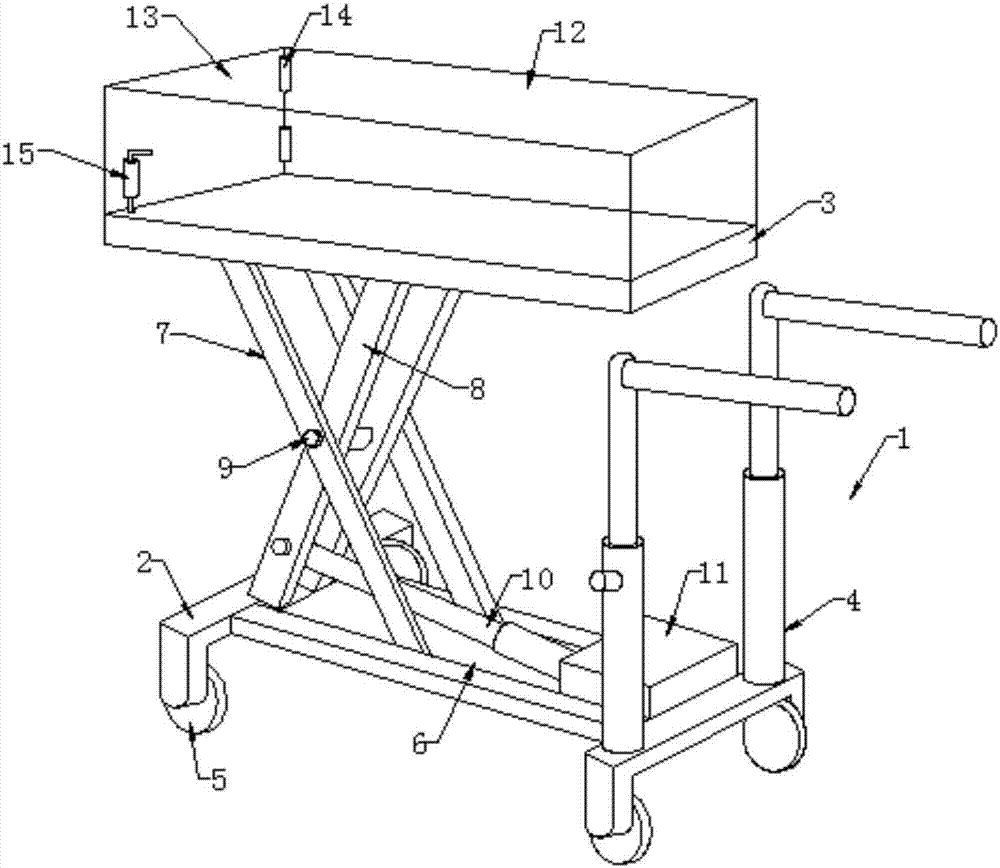

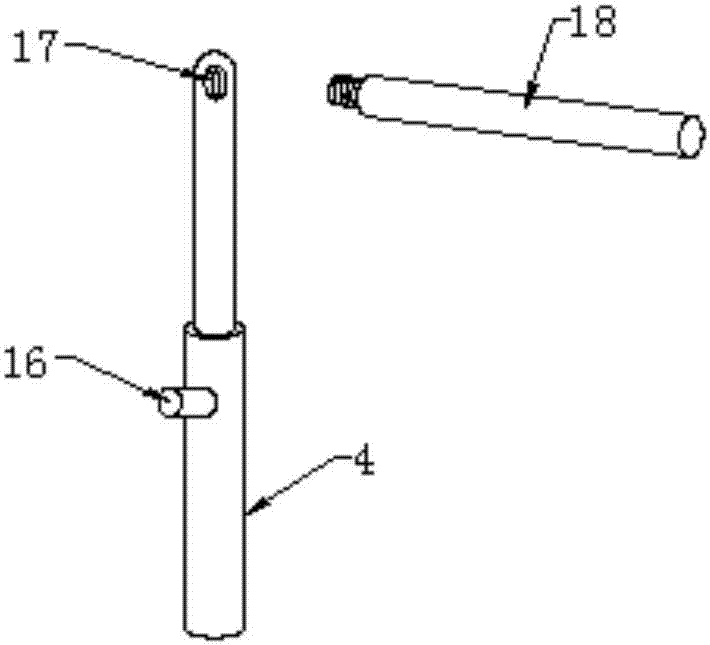

Rotary drum delivering platform vehicle

ActiveCN101024443ASimple structureReduce utilizationElectric locomotivesSupporting framesDrive wheelDrive motor

Owner:JIANGSU LIUWEI LOGISTIC EQUIP INDAL

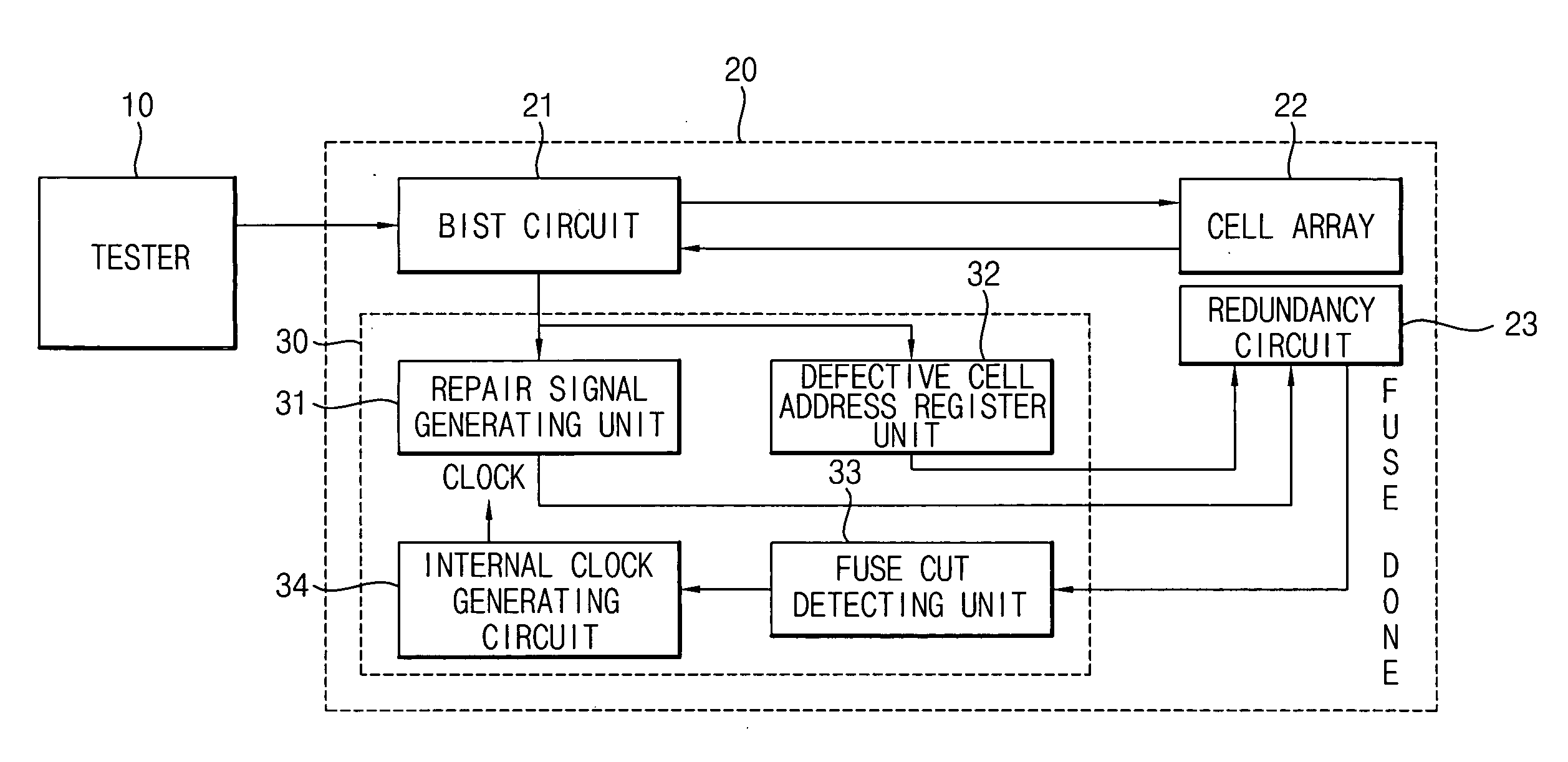

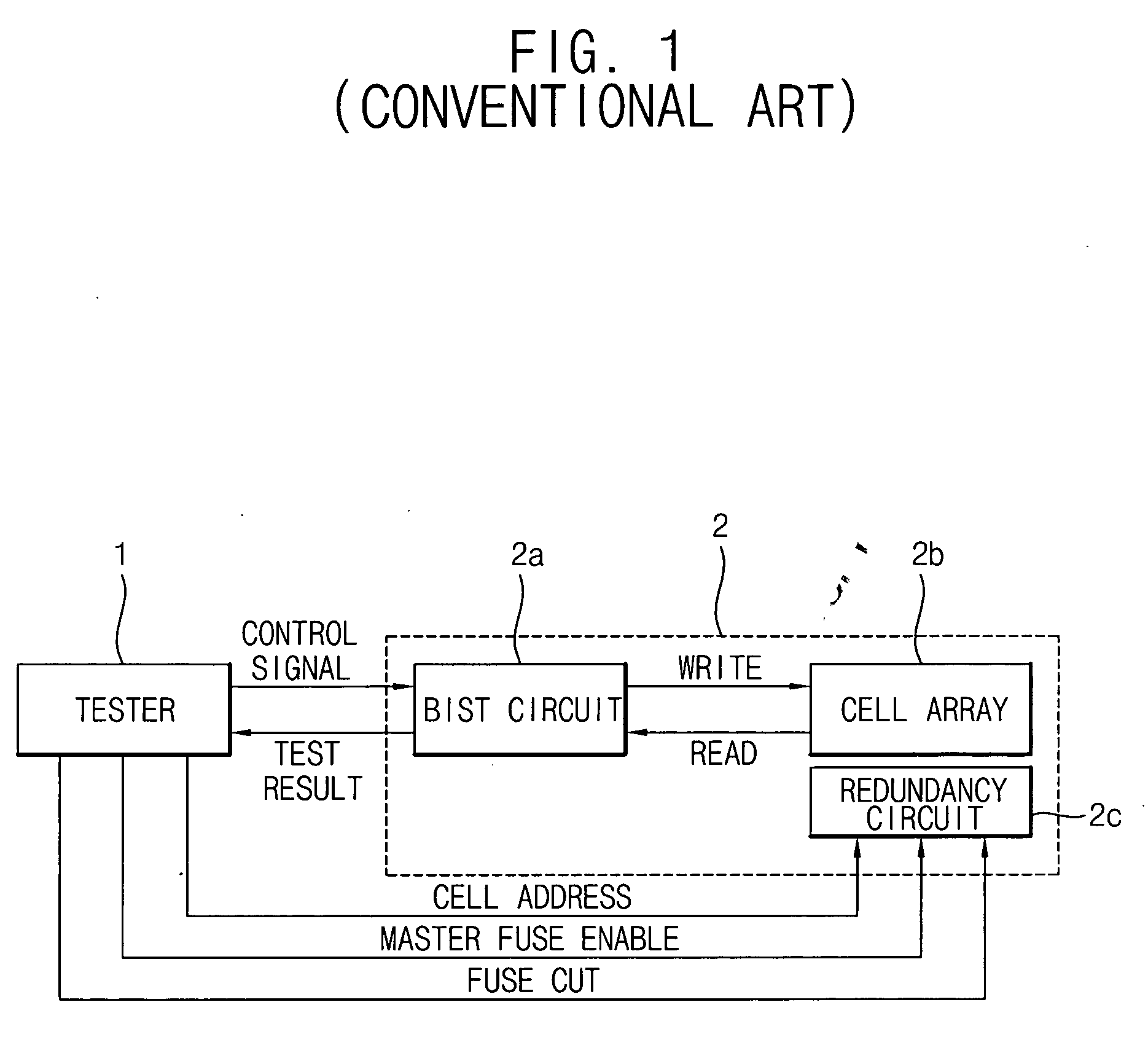

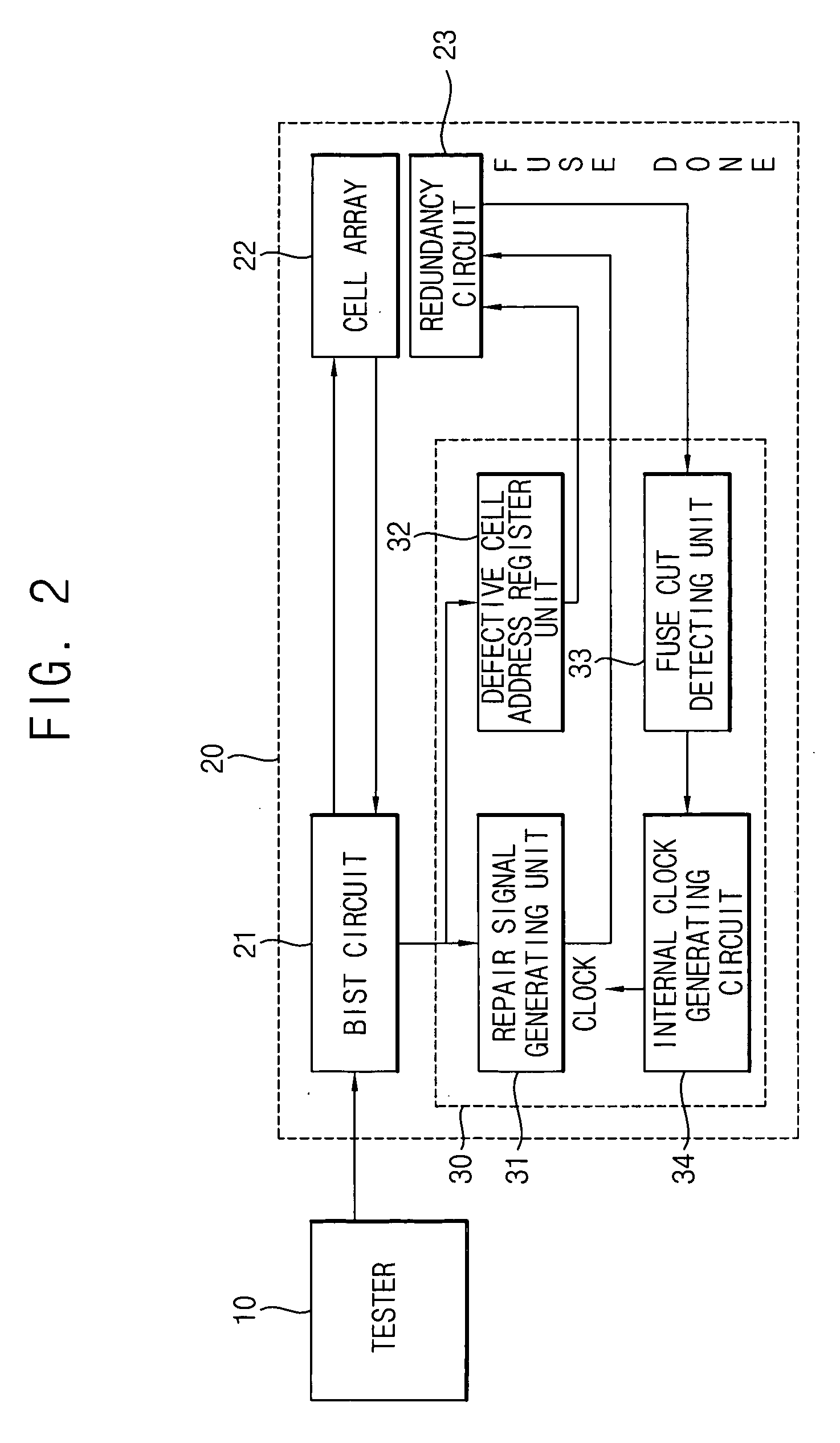

Semiconductor memory devices and a method thereof

InactiveUS20070047347A1Shorten test timeReduce storage areaDigital storageControl circuitComputer science

A semiconductor memory device and a method thereof are provided. The example method may include determining whether a currently tested cell is defective and repairing the currently tested cell, if the currently tested cell is determined to be defective, before determining whether a next tested cell is defective. The example method may be performed by a semiconductor memory device including a built-in self-test (BIST) circuit and a repair control circuit. Alternatively, the example method may be performed by a semiconductor memory device including a BIST circuit, a repair control circuit and a storage device.

Owner:SAMSUNG ELECTRONICS CO LTD

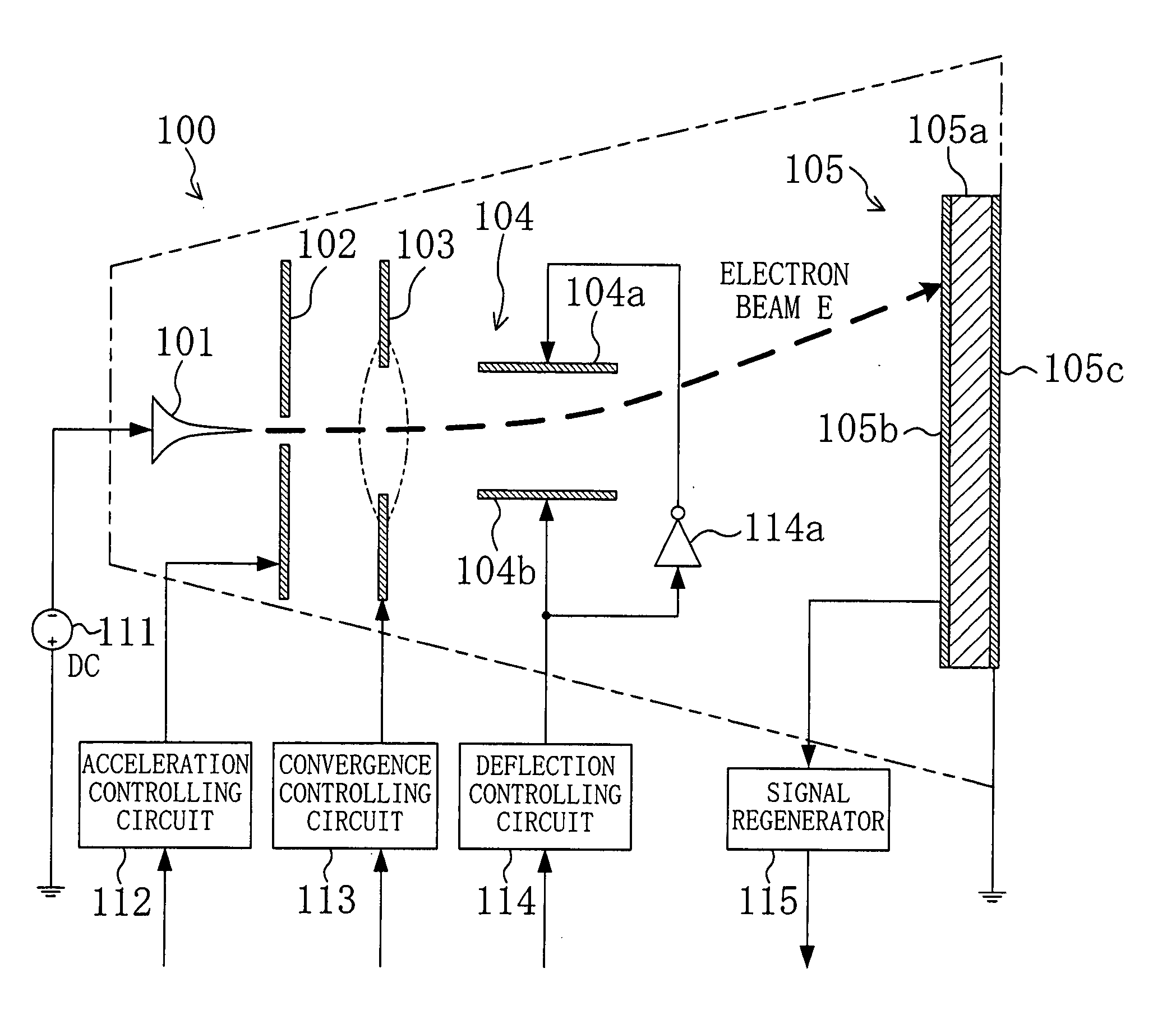

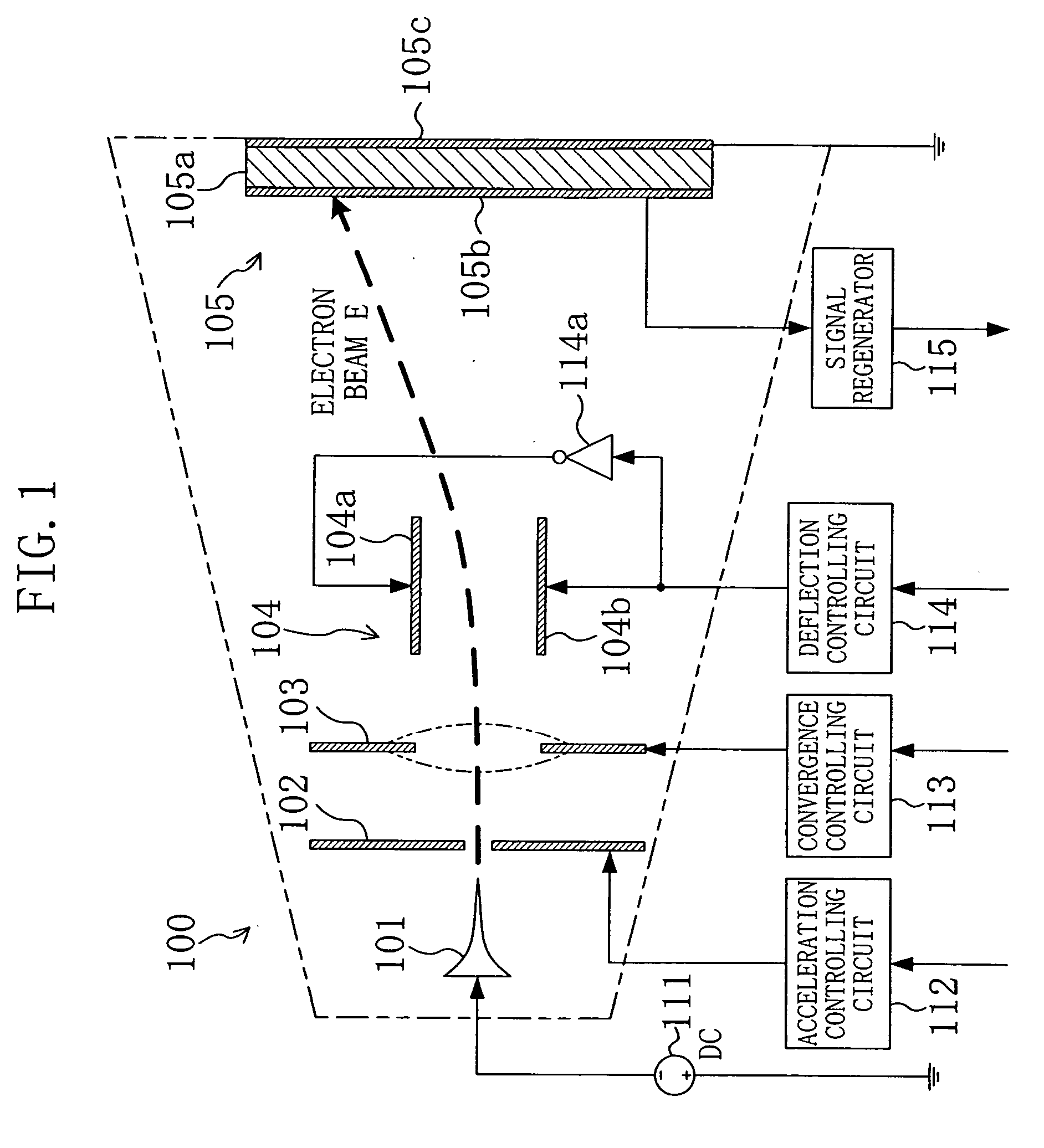

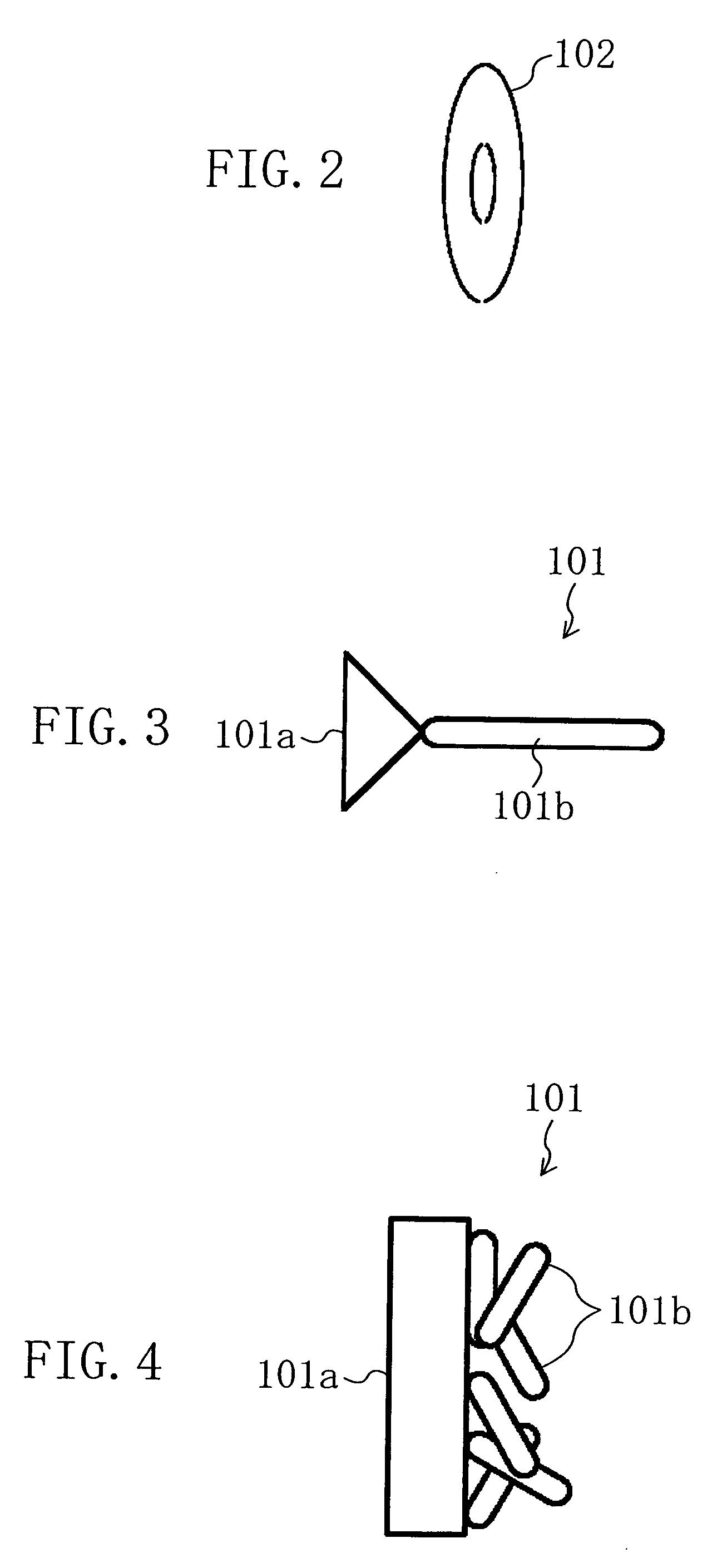

Information storage

InactiveUS20060072427A1Increase speedImprove accuracyRead-only memoriesRecord information storageHigh energyPotential difference

To greatly increase the storage density of a storage apparatus, an electron beam E emitted from a cold cathode 101 is accelerated by an accelerating electrode 102, caused to converge by a convergence electrode 103, deflected by a deflection electrode 104 and applied to a minute region of a storage film 105. The storage film 105 includes, for example, a phase change film 105a. The film is rapidly heated and cooled to change into an amorphous state upon irradiation with an electron beam E with high energy, while being gradually cooled to change into a crystallized state upon irradiation with an electron beam E with approximately intermediate energy, thereby storing data. Upon irradiation with an electron beam E with low energy, the potential difference between a detection electrode 105b and an anode 105c is detected depending on the state, i.e., the amorphous or crystallized state, thereby reading stored data.

Owner:PANASONIC CORP

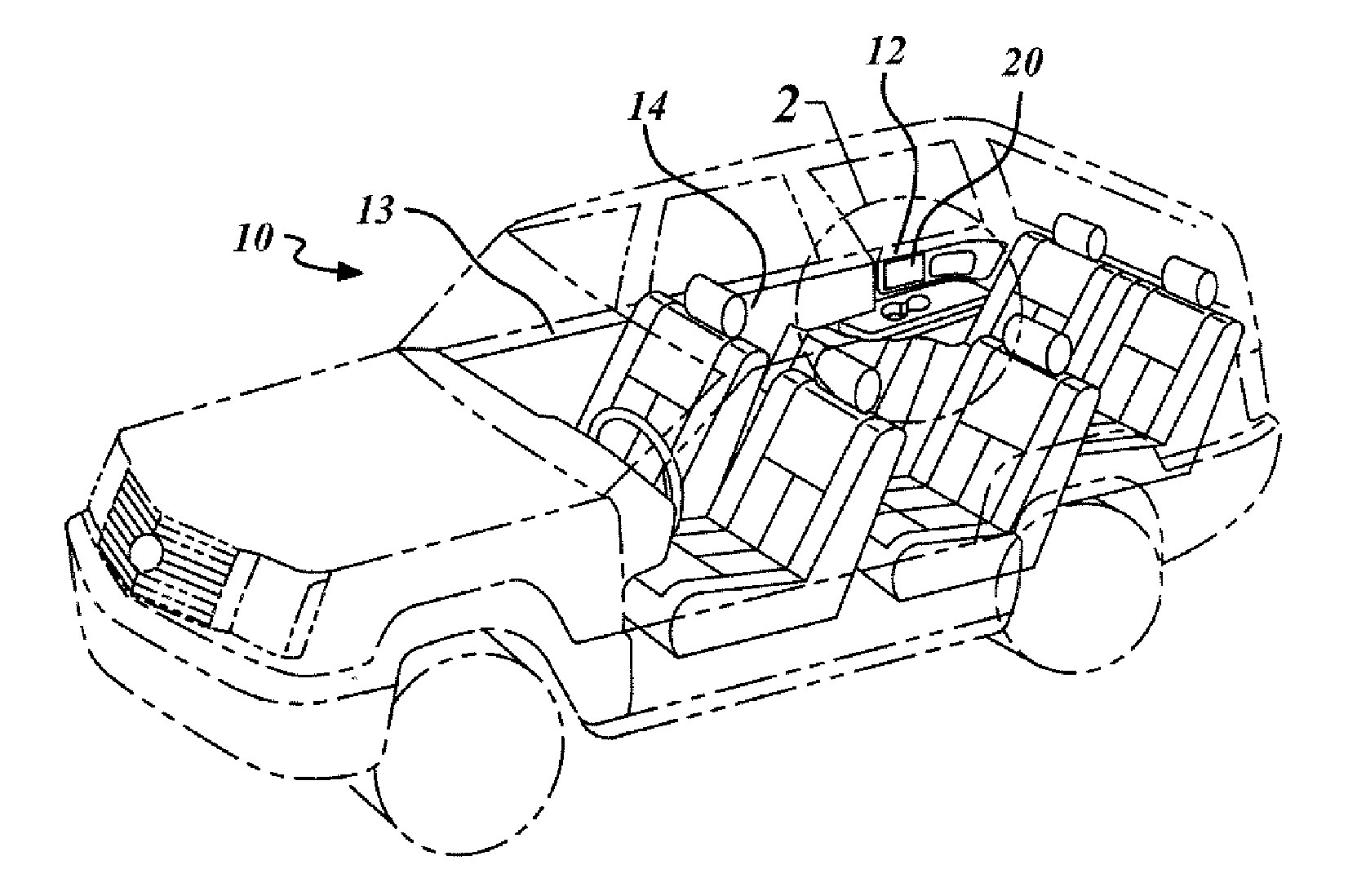

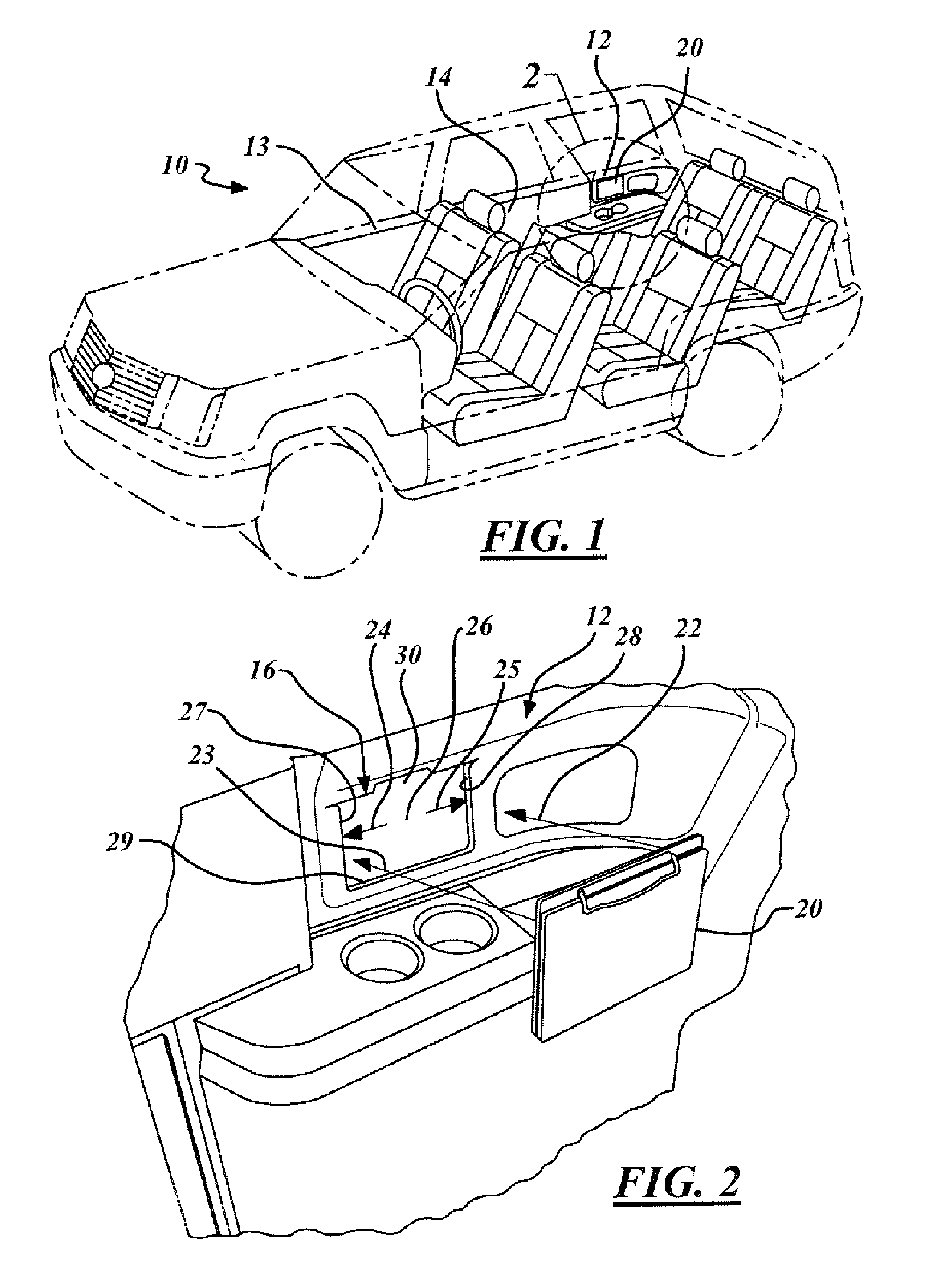

Fold-up tray

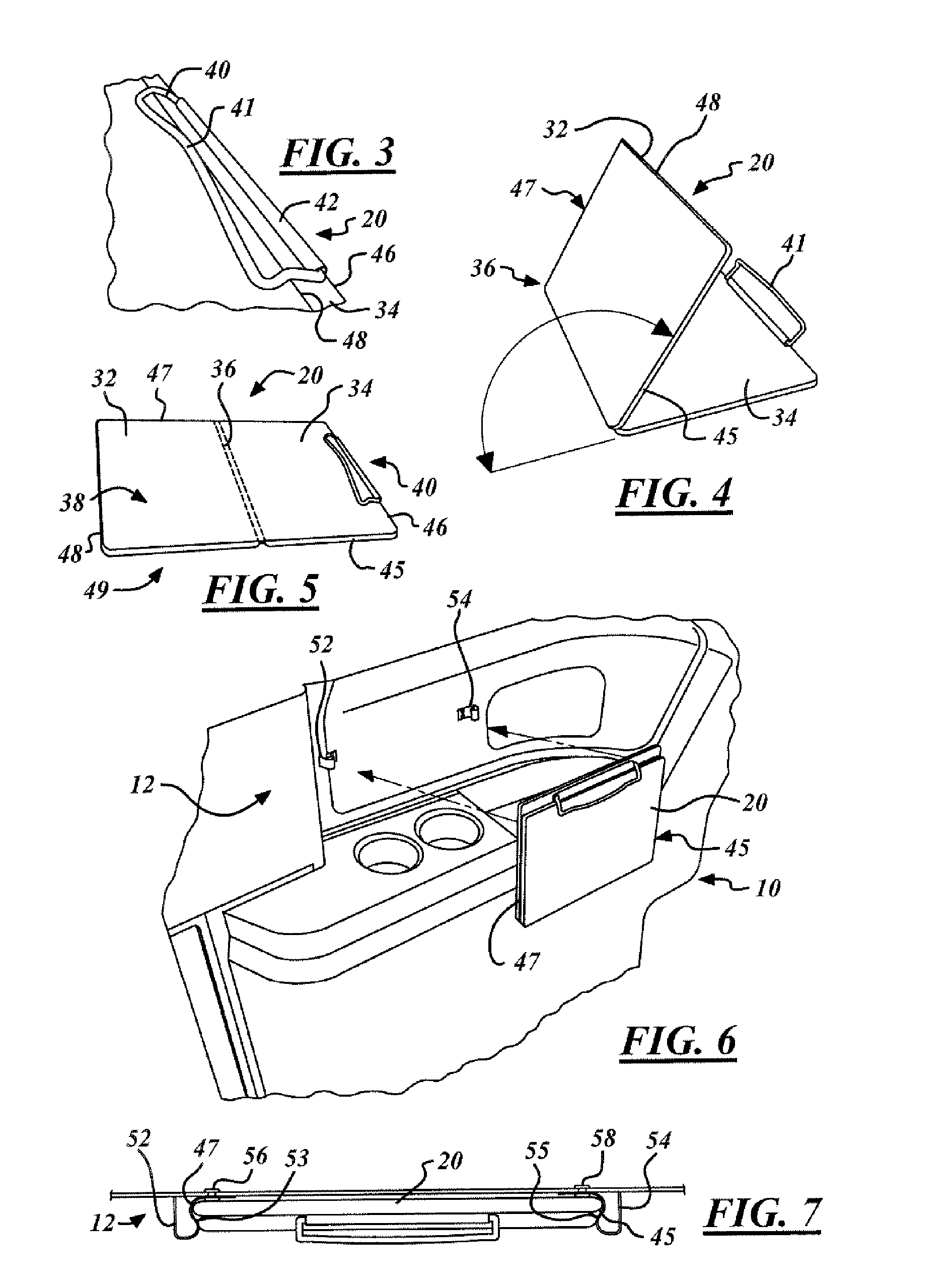

InactiveUS20060266779A1Expand the working areaReduce storage areaVehicle arrangementsSupplementary fittingsEngineeringMechanical engineering

A fold-up tray for use in a vehicle is provided. The tray includes a top surface, a first section, a second section and a hinge. The first section includes a first portion of the top surface. The second section includes a second portion of the top surface. The hinge connects the first section and the second section, thereby affording an increased working surface when both portions of the tray are unfolded while also providing a stowable working surface when both portions of the tray are folded. In one embodiment, the hinge is a living hinge.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

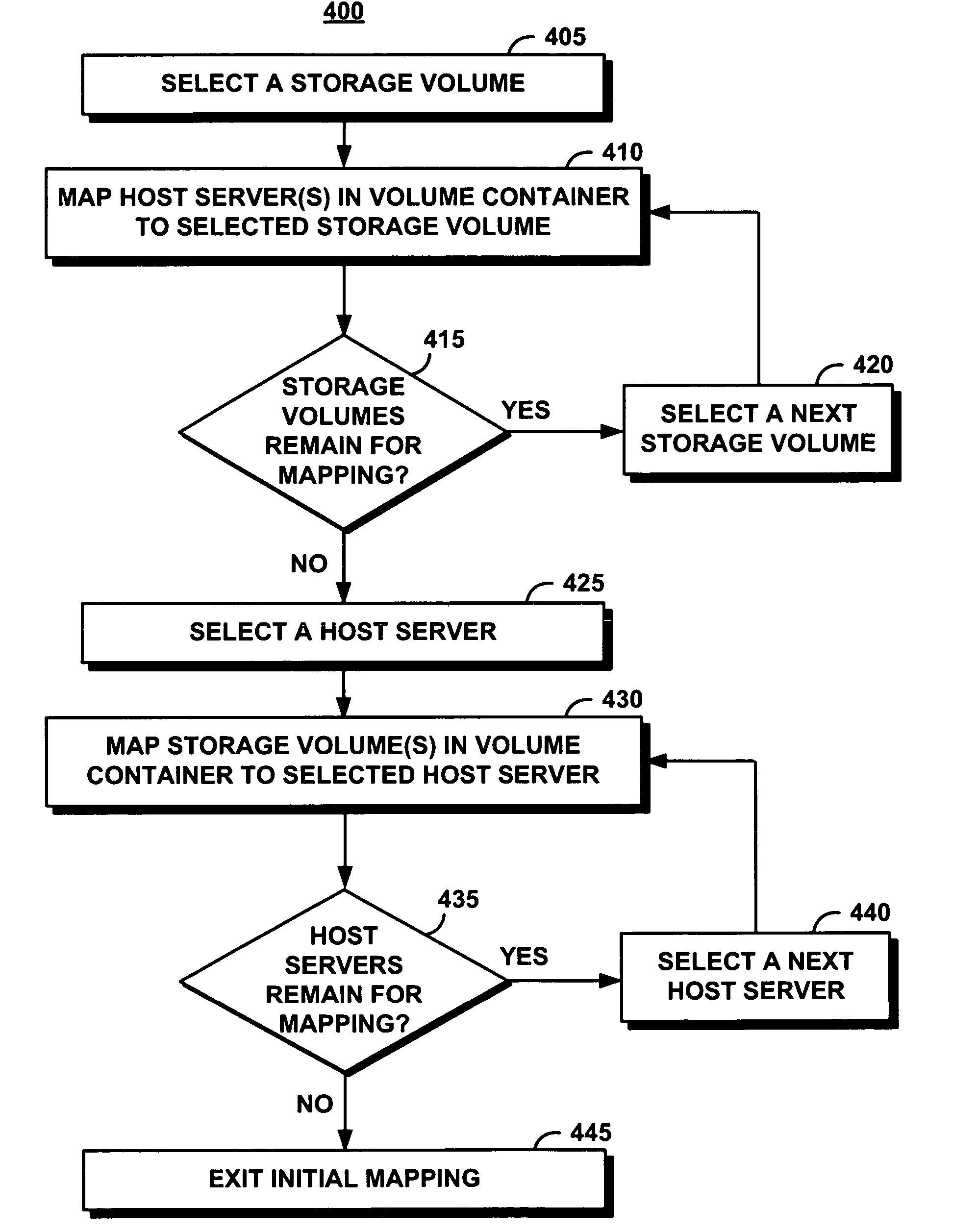

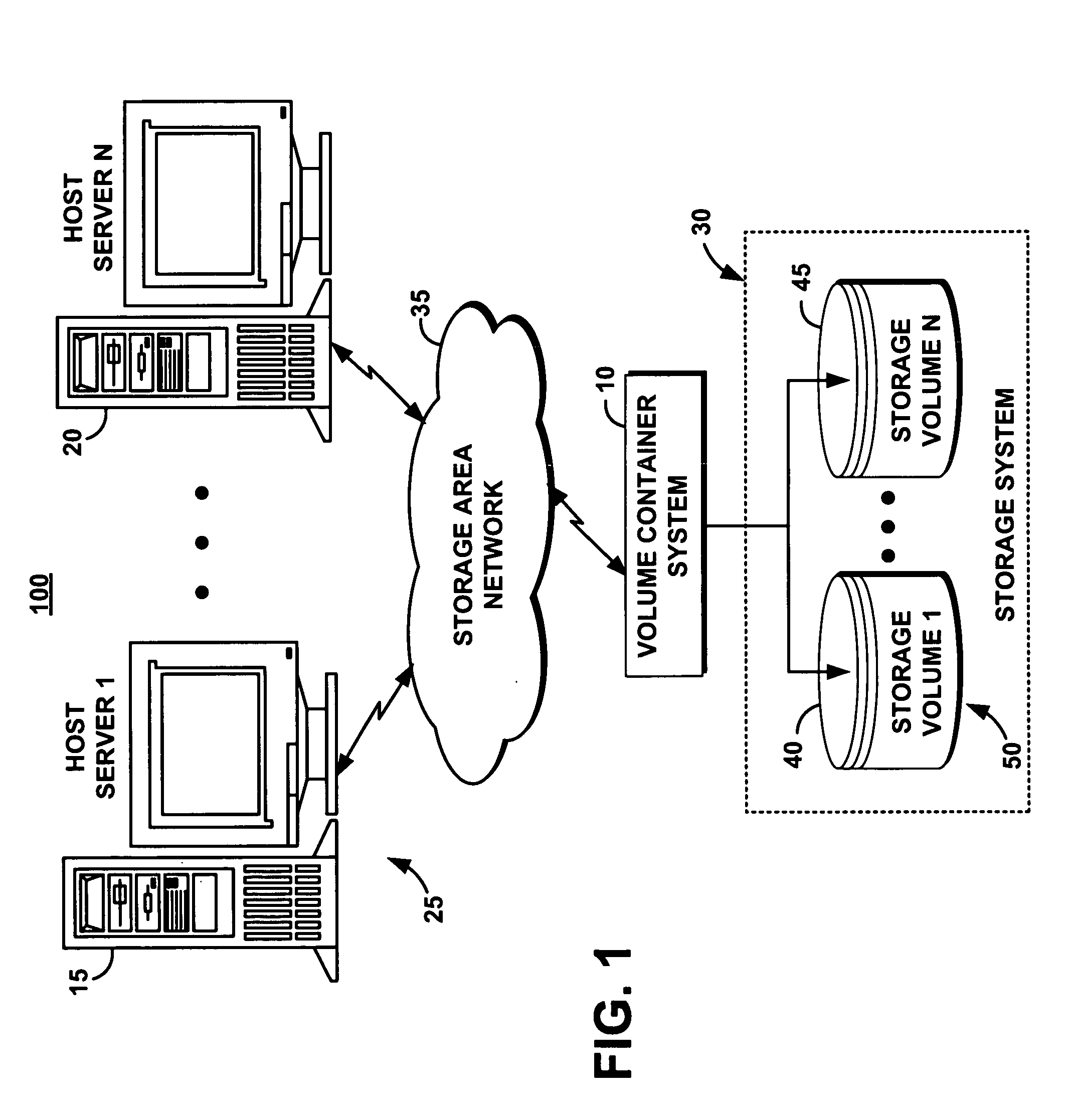

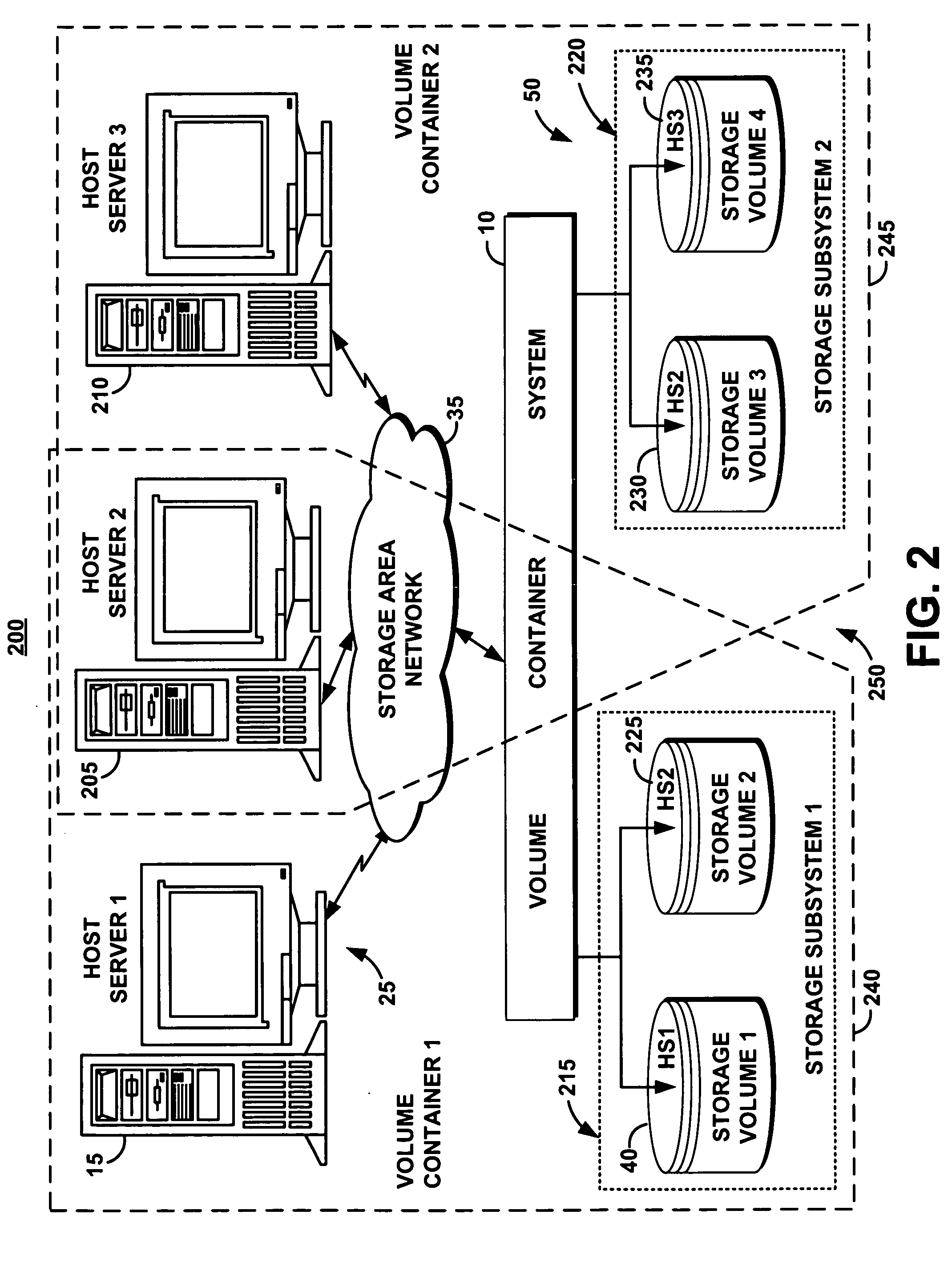

System and method for automatically relating components of a storage area network in a volume container

InactiveUS20070028069A1Improve scalabilityReduce storage areaMemory systemsInput/output processes for data processingStorage area networkNetwork Access Control

A volume container system automatically relates components of a storage area network in membership association of a volume container. The volume container is an abstract entity that maps a relationship between servers and storage devices. The entity captures network access control between servers and storage subsystems such as, for example, security, access, and zoning. Policies of the volume container guide operations in a volume container. The membership associates access and security within the volume container. The volume container reduces administration required for a storage area network, improves consistency in mapping, security, and zoning, and reduces complexity in consistently replicating a logical group of volumes, making failure recovery easier.

Owner:IBM CORP

High-speed decoder based on non-binary LDPC code and decoding method thereof

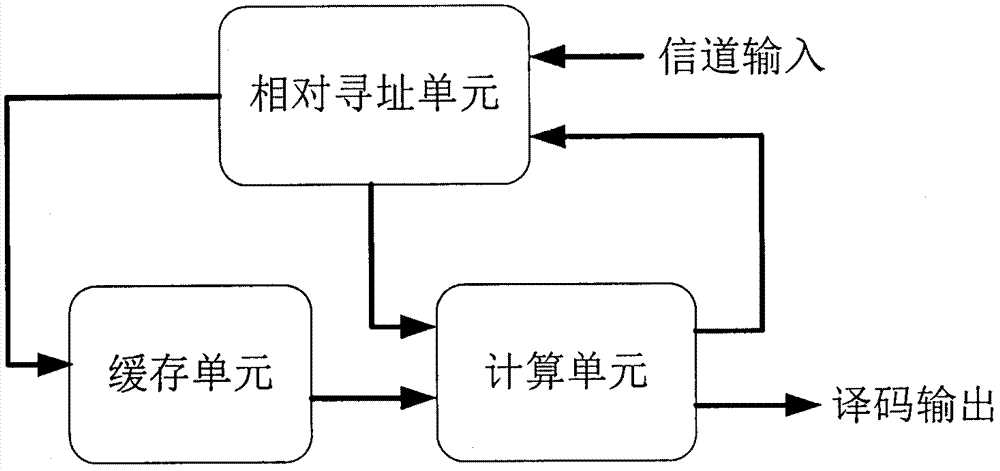

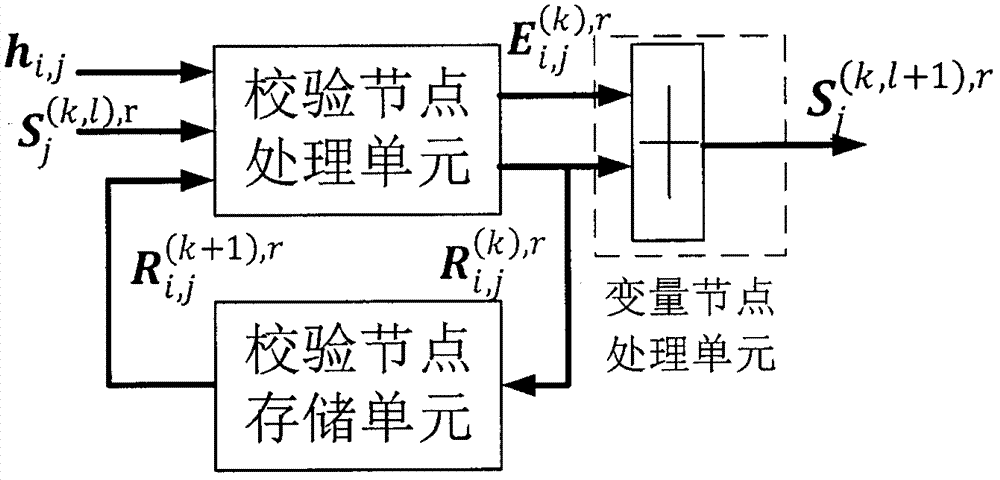

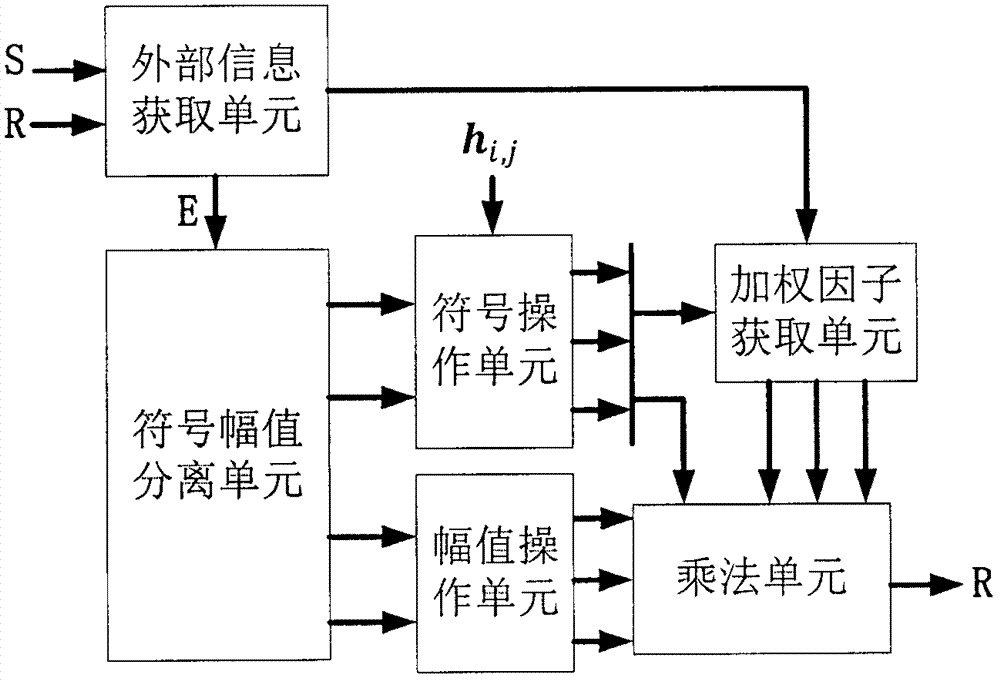

InactiveCN106936446AImprove data throughputLower latencyError correction/detection using multiple parity bitsCode conversionDecoding methodsClock rate

The invention discloses a high-throughput and low-complexity hierarchy decoder suitable for a non-binary LDPC code and a decoding method of the decoder. The decoder comprises a relative addressing unit, a caching unit and a computing unit, wherein the relative addressing unit prestores an input address for each of the computing unit and the caching unit so that a redundant clock period is inexistent between tiers; the depth of the caching unit is 1 so that the delay is maximally lowered; the computing unit comprises 2p-1 basic computing units capable of accomplishing the updating of one tire in a clock unit and optimizing a key path of each module so as to improve the clock frequency. Furthermore, the decoding method disclosed by the invention is a hard decoding method based on majority logic so as to take a compromise on the decoding performance and the complexity; a most reliable message and a secondary reliable message are selected in the method, symbols and confidences thereof are input and output in a bit way, 2p messages are converted into the transmission of P messages, and the storage space is greatly lowered.

Owner:NANJING UNIV

Inulin preparing method taking dried jerusalem artichoke as raw material

The invention relates to the technical field of new resource food processing, in particular to an inulin preparing method taking dried jerusalem artichoke as the raw material. The jerusalem artichoke or chicory is taken as the raw material and is subjected sequentially to peeling, dicing and expansion drying, and dried jerusalem artichoke cubes are obtained; then continuous countercurrent extraction is performed; and an extracting solution enters an ion resin-column for desalination after being subjected to impurity removal and activated carbon decoloration, then is concentrated by a nanofiltration membrane, and then is subjected to spray drying, therefore, high-purity inulin is obtained. The countercurrent extraction adopts purified water, the solid-to-liquid ratio is 1:(5-10), the extraction temperature ranges from 80 DEG C to 100 DEG C, and the extraction time is one hour to two hours; in the processes of impurity removal and decoloration, Ca(OH)2 solids are added first, the pH of the system is regulated to be 10 to 12, CO2 gas is introduced after 30 minutes to enable the PH of the system to be 7 to 8, precipitates are filtered, activated carbon is added for 30 minutes of decoloration and then is filtered out, and a filtrate is reserved; and the adding amount of the activated carbon is 1-5 per thousand of the total weight of the system.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

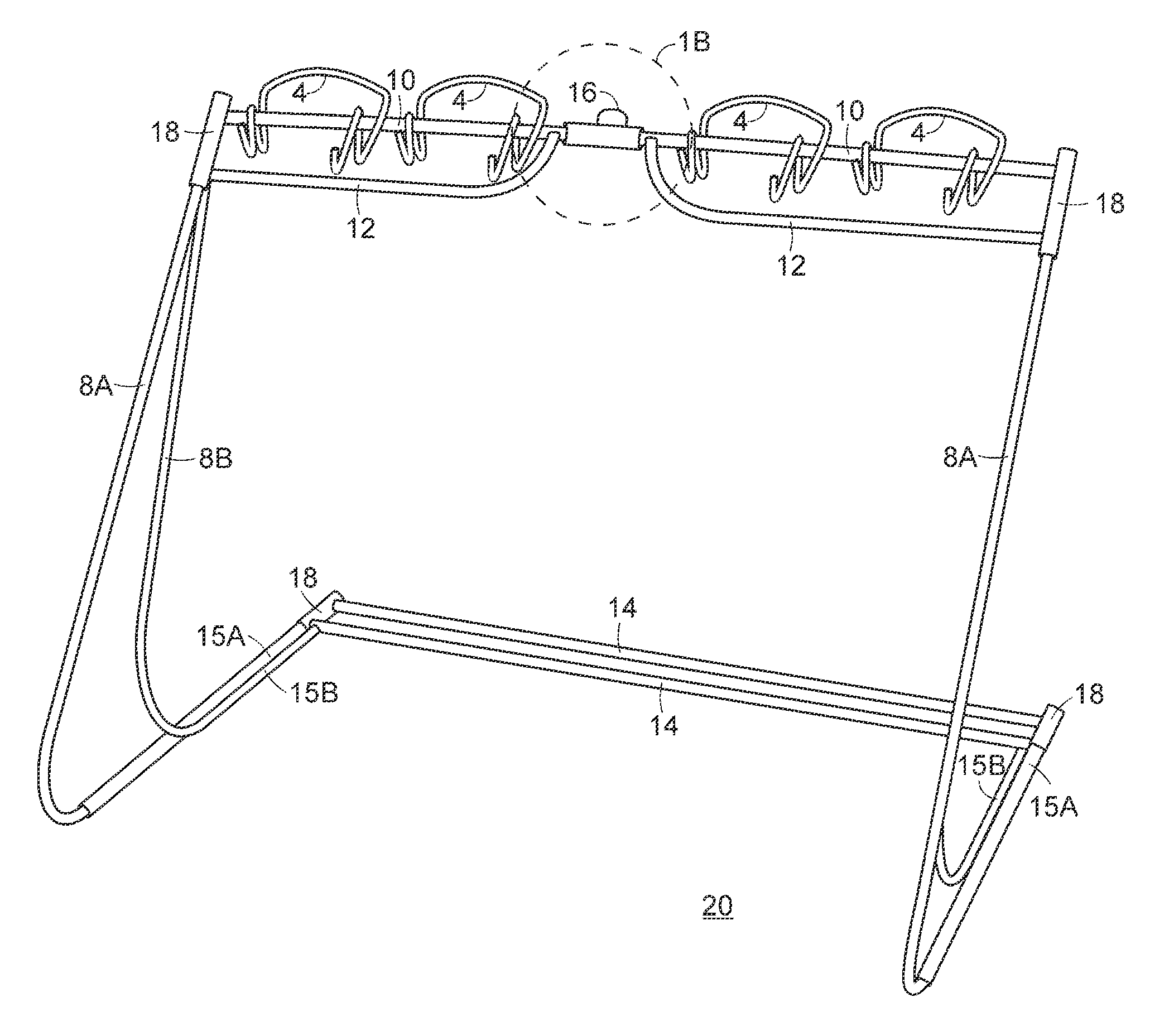

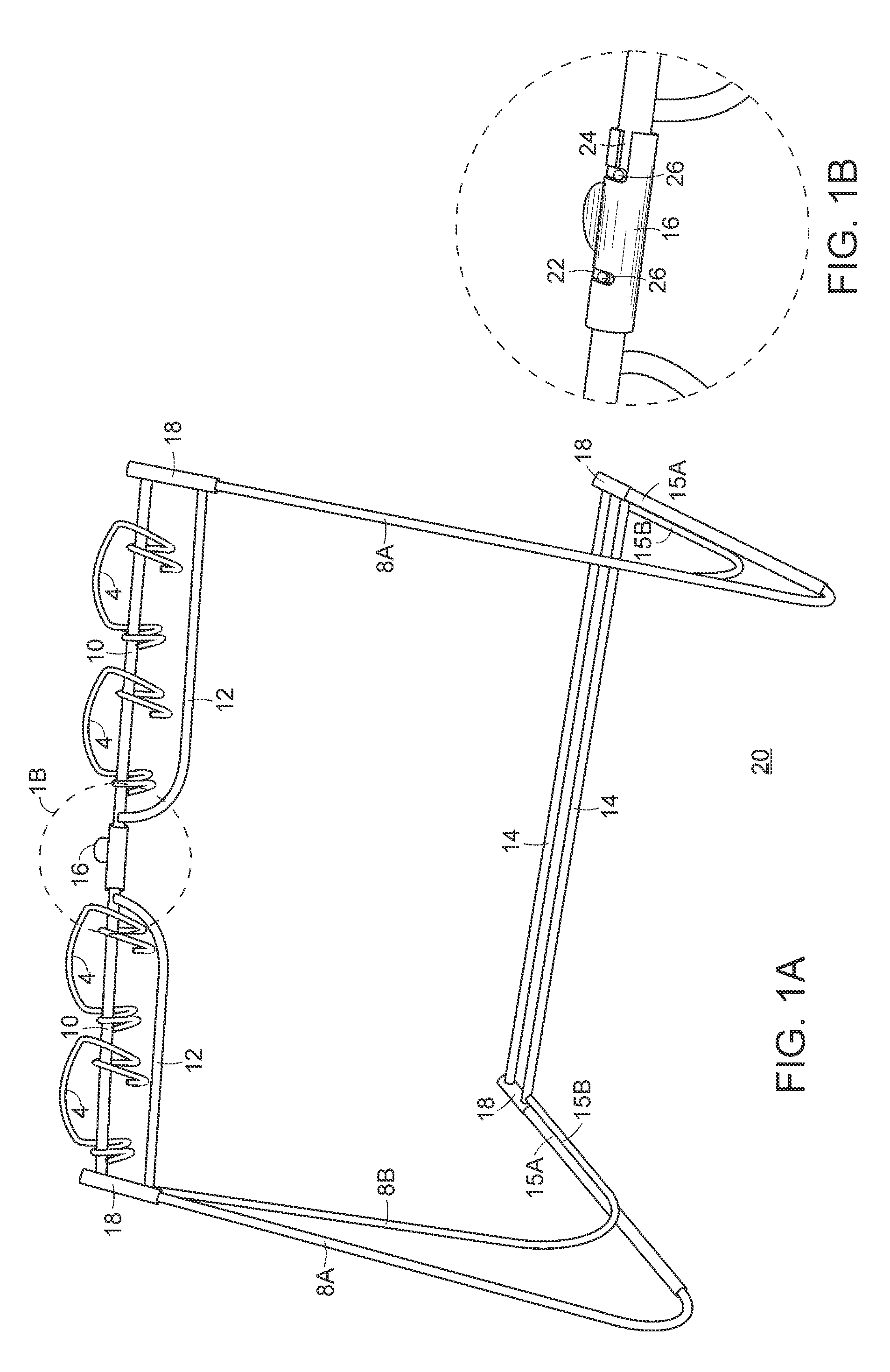

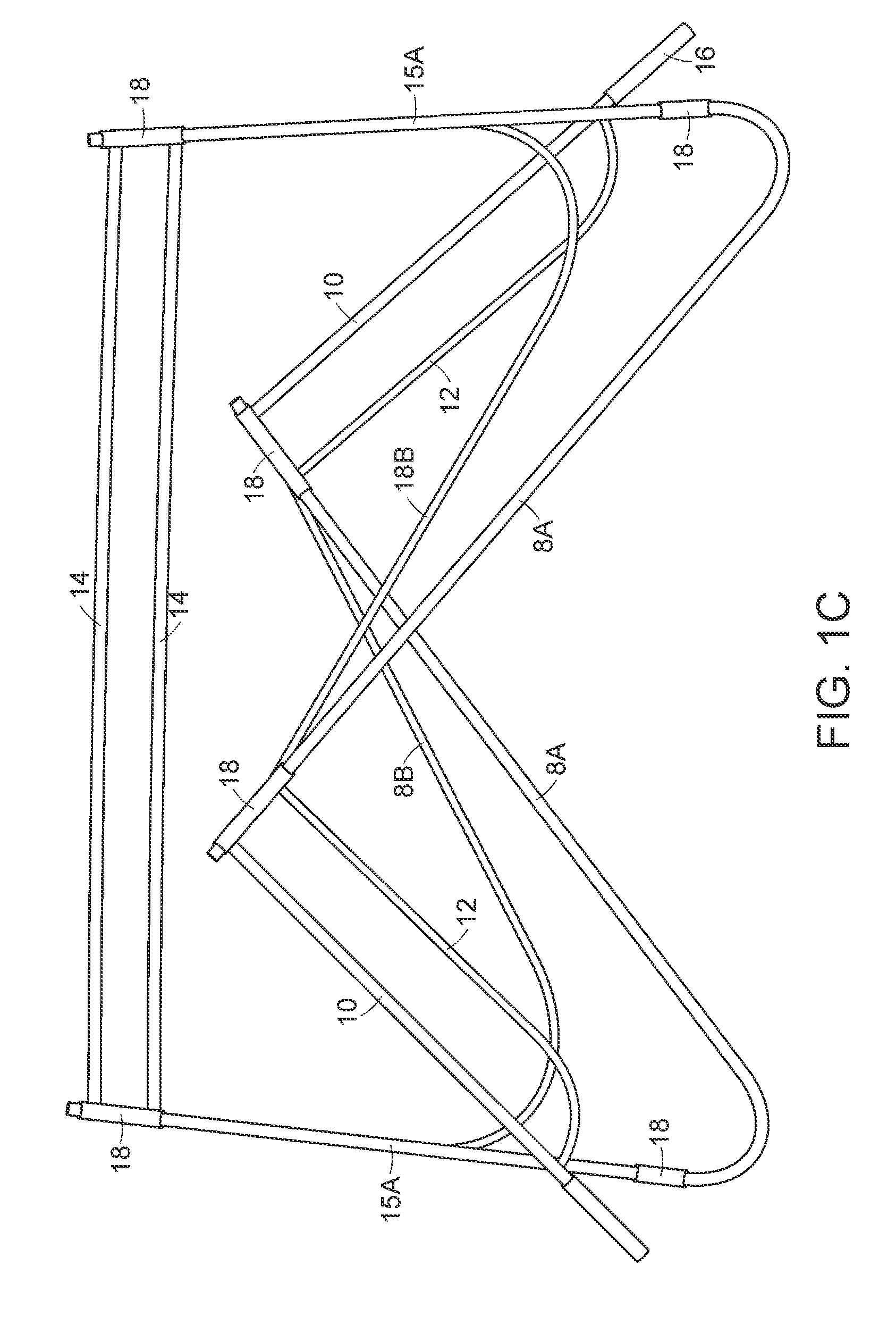

Bag transporting apparatus and methods

InactiveUS20070095989A1Minimize the numberReduce storage areaLuggage compartmentPassenger spaceEngineeringMechanical engineering

The present invention relates to methods, kits and apparatus for storing bags in a vehicle during transportation, or carrying more than one bag simultaneously using removably attached hooks. The apparatus of the present invention includes a frame; and one or more removable attachments having at least one hook, attached at an upper portion of the frame. The frame further includes a base; two legs, attached to the base, at an angle, and an upper portion connecting the two legs; wherein the frame is collapsible. A removable attachment, for attachment to the frame has a recess for receiving the upper portion of the frame, a handle and a least one hook (e.g., 2 hooks).

Owner:RADIO SYST CORP

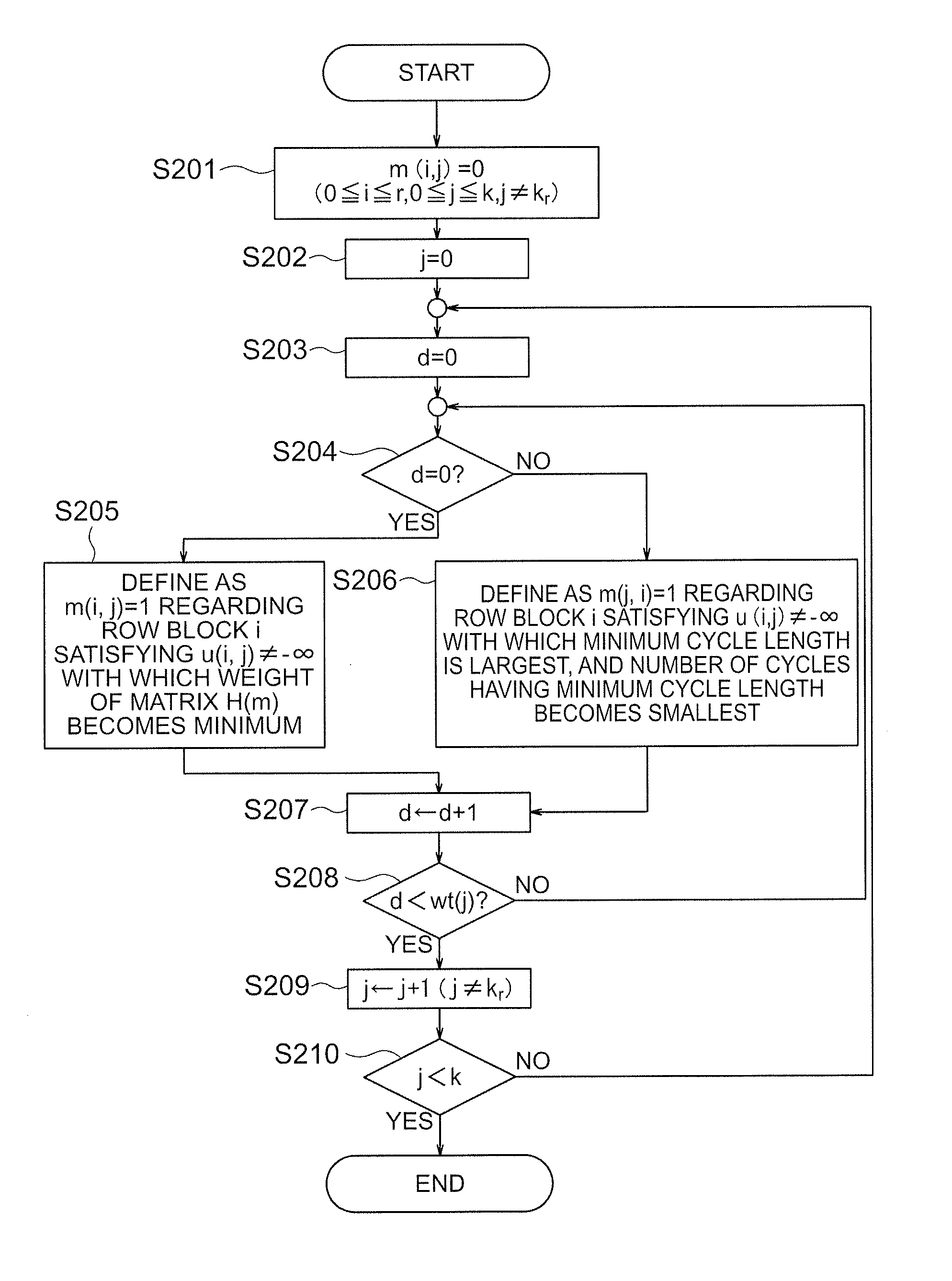

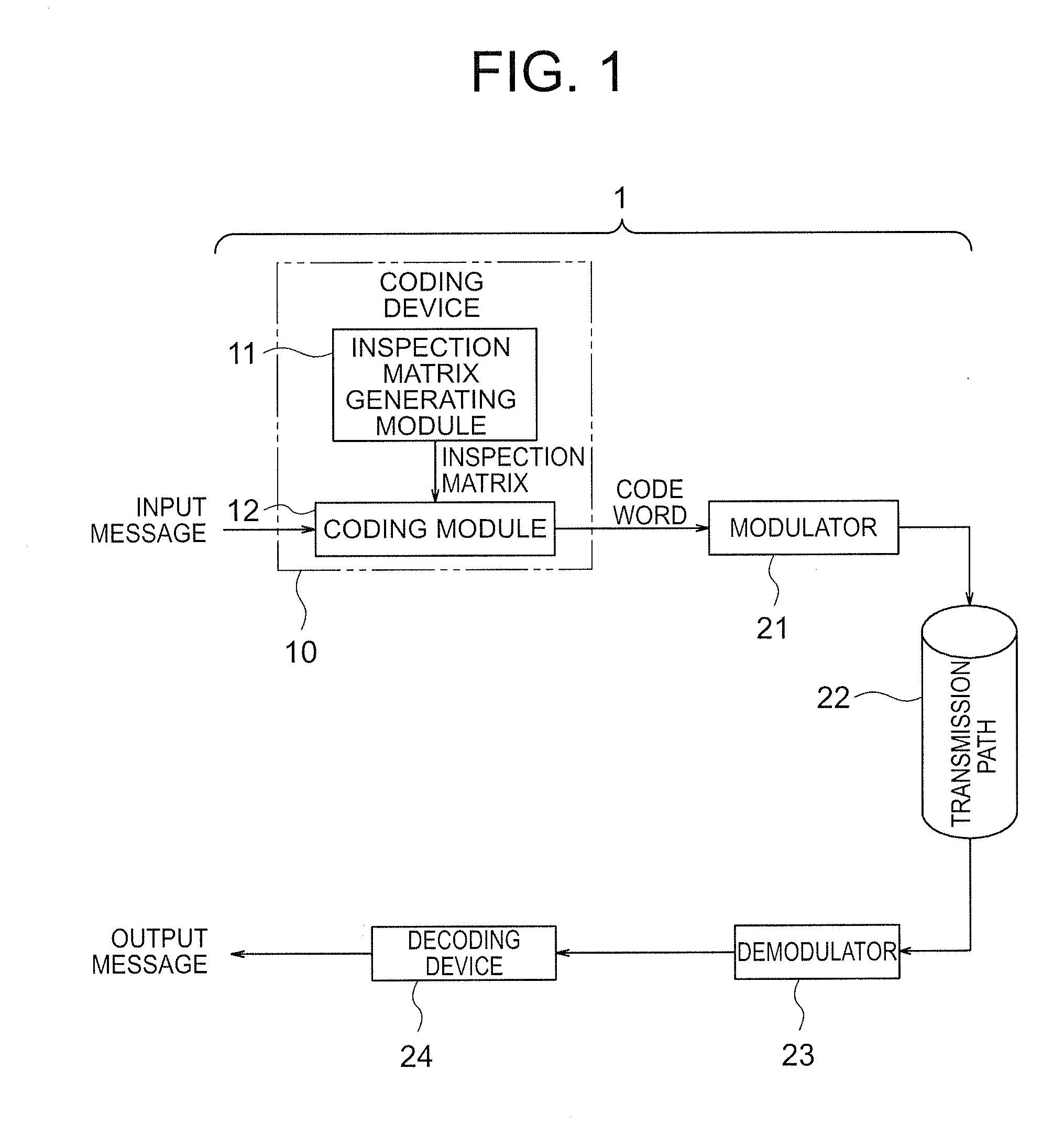

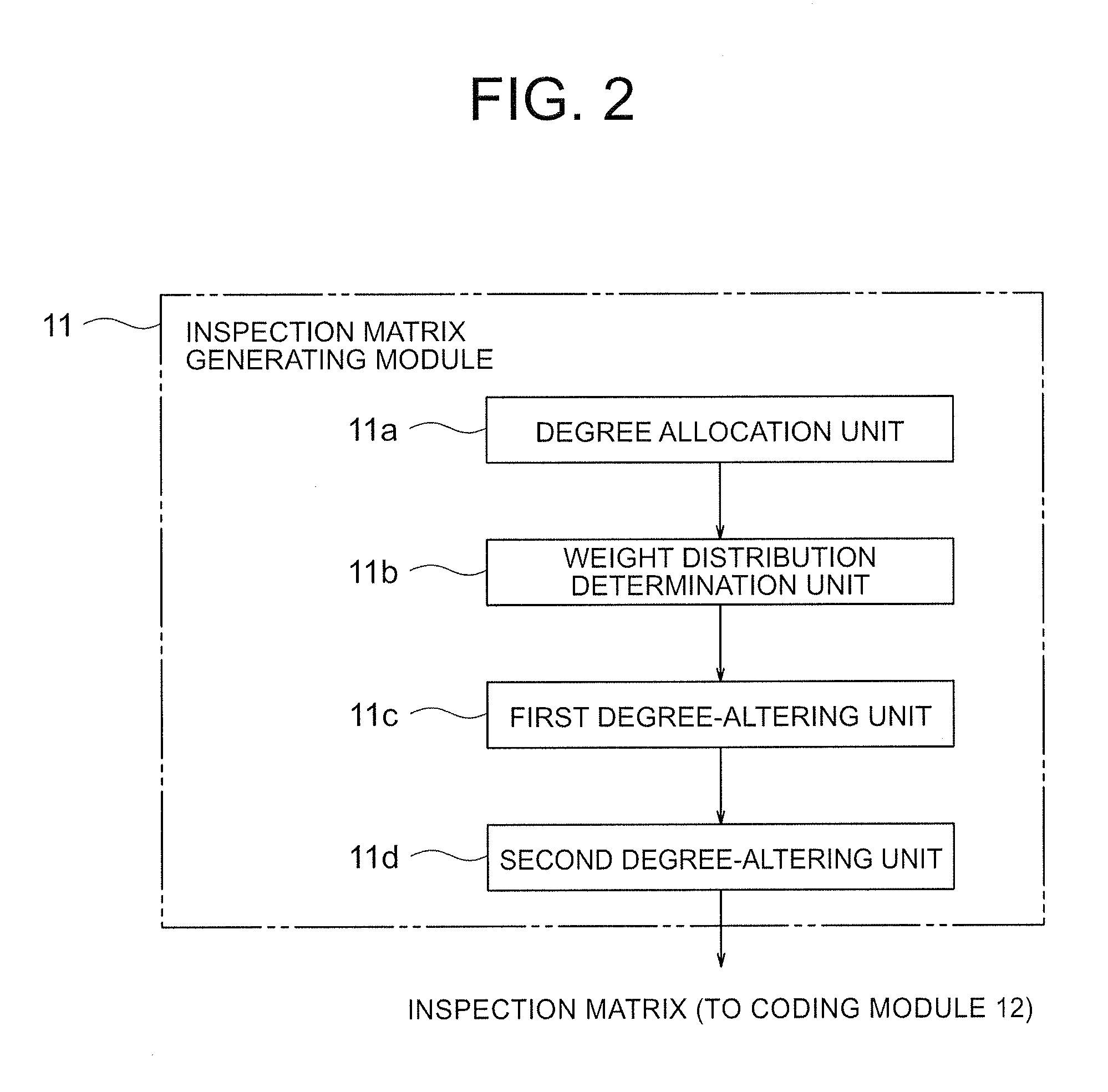

Coding device, error-correction code configuration method, and program thereof

ActiveUS20130031446A1Reduce storage areaReduce switchingCode conversionChecking code calculationsReciprocal polynomialCode module

A coding device includes: an inspection matrix generating module that generates a block inspection matrix; and a coding module that generates and outputs a code word from an input message by the inspection matrix. The inspection matrix generating module includes: a degree-allocation unit that prescribes function values of the block inspection matrix by the coefficients of a self-reciprocal polynomial expression; a weight distribution determination unit that prescribes the number of components that are non-zero matrices among the components of each block of the block inspection matrix using a mask pattern; a first degree-altering unit that considers the sum of the components of the k_r-th row block of the block inspection matrix as a cyclic permutation matrix; and a second degree-altering unit that prescribes the row-block number of components that are non-zero matrices among the components of each row block excluding said k_r-th row block of the clock inspection matrix.

Owner:NEC CORP

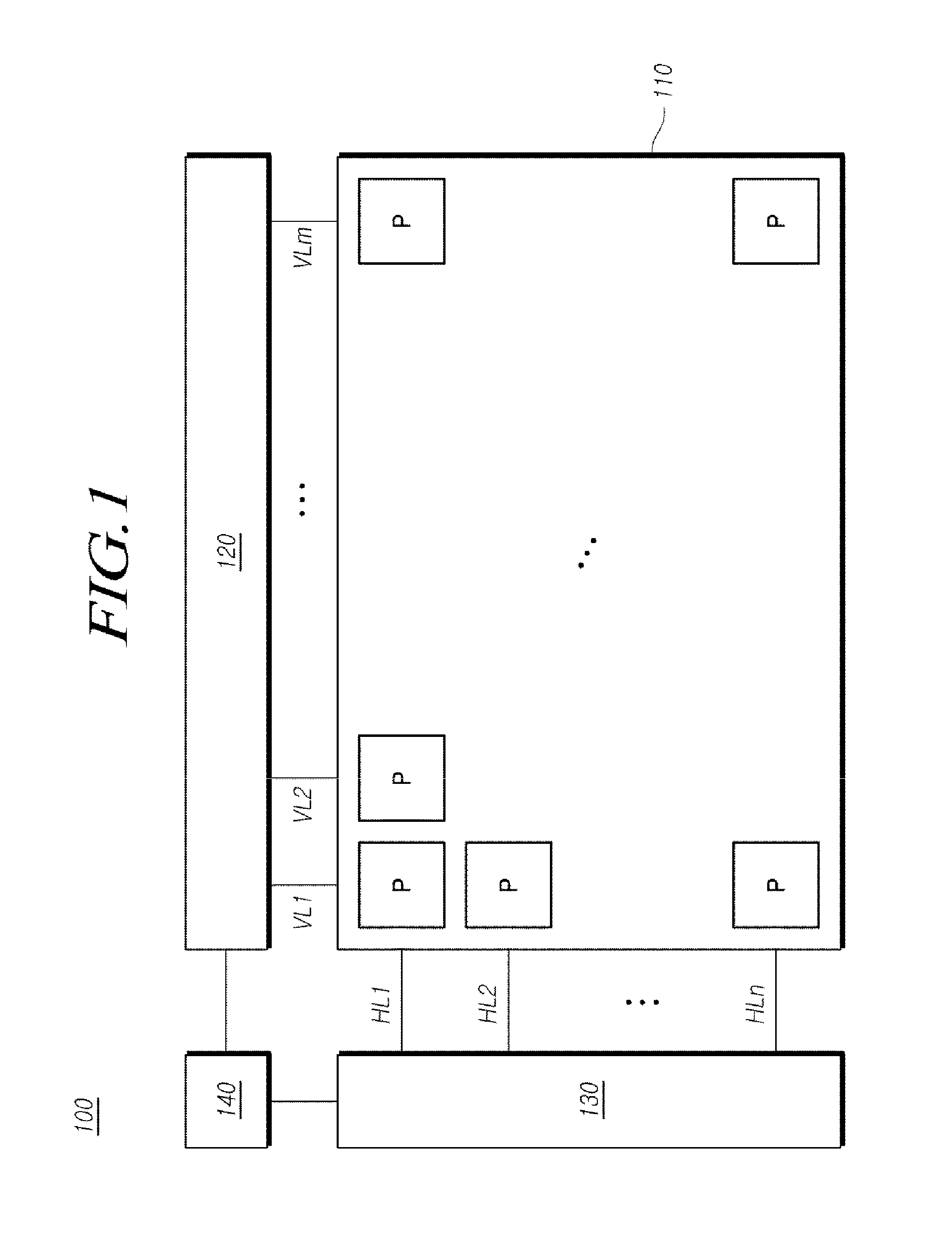

Organic light emitting display panel and method of manufacturing the same

ActiveUS20160071888A1Small sizeIncrease capacitanceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The present invention relates to an organic light emitting display panel and a method of manufacturing the same. In accordance with an aspect of the present invention, there is provided a display panel. The display panel in one example includes a light shielding layer electrically connected to a driving power line on a substrate, and storage capacitors formed on an oxide semiconductor in parallel, insulated from the oxide semiconductor, and overlapped a gate.

Owner:LG DISPLAY CO LTD

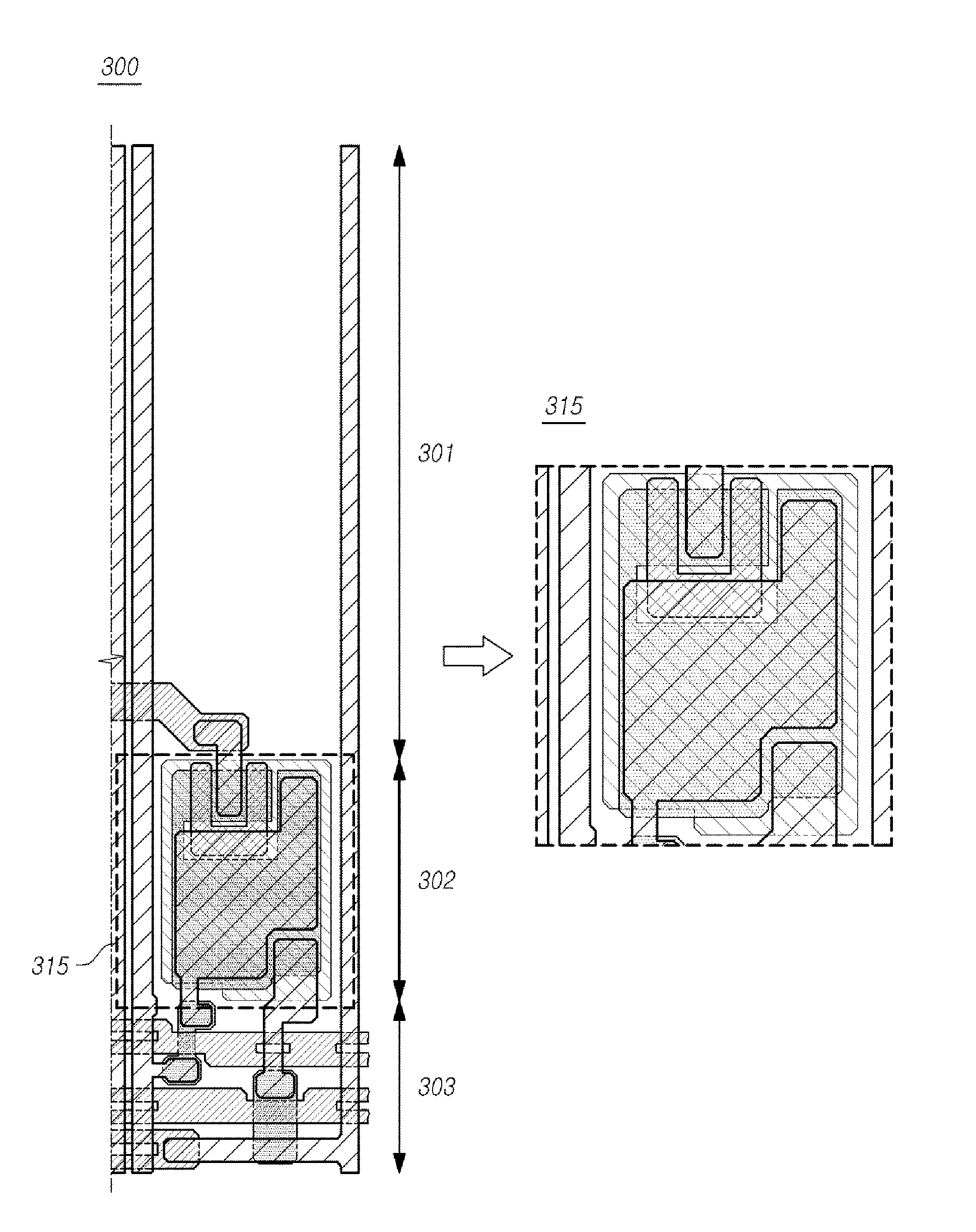

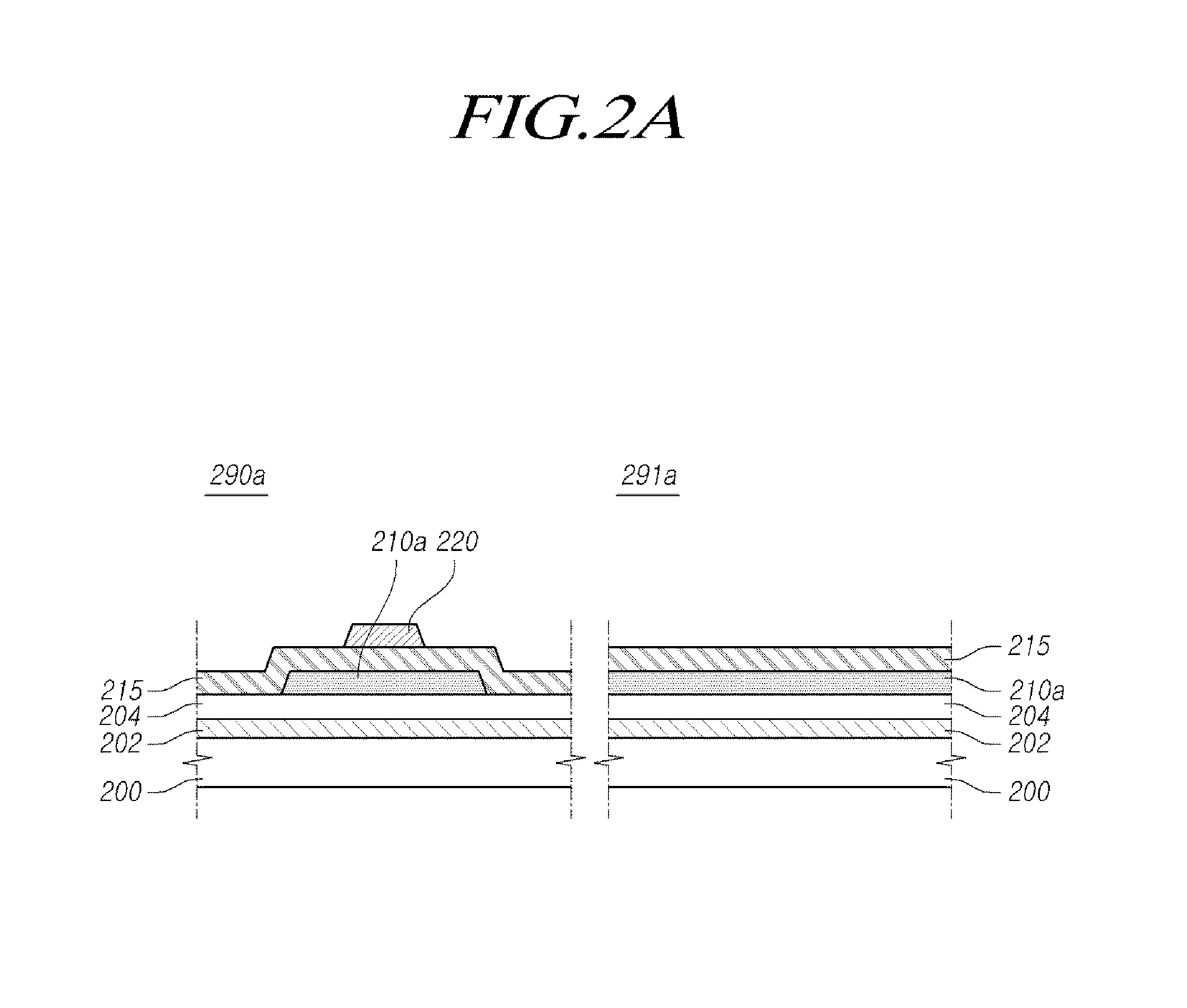

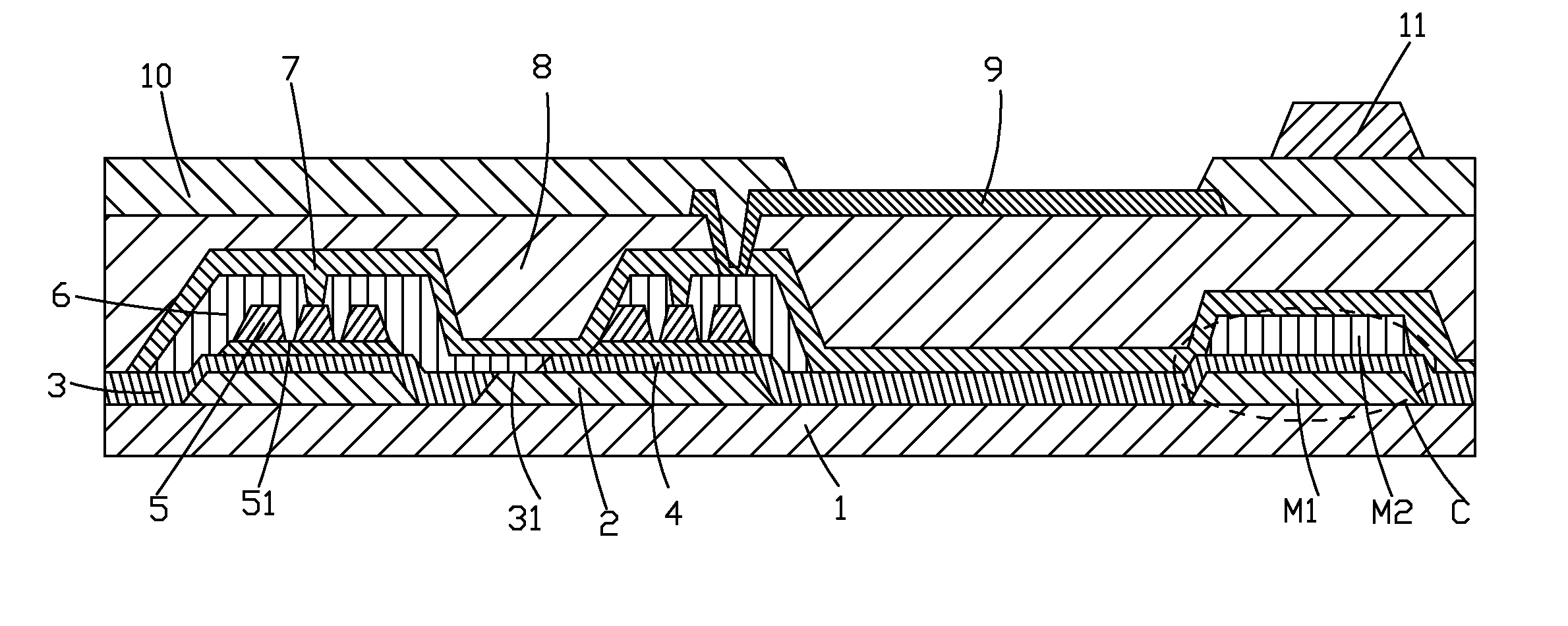

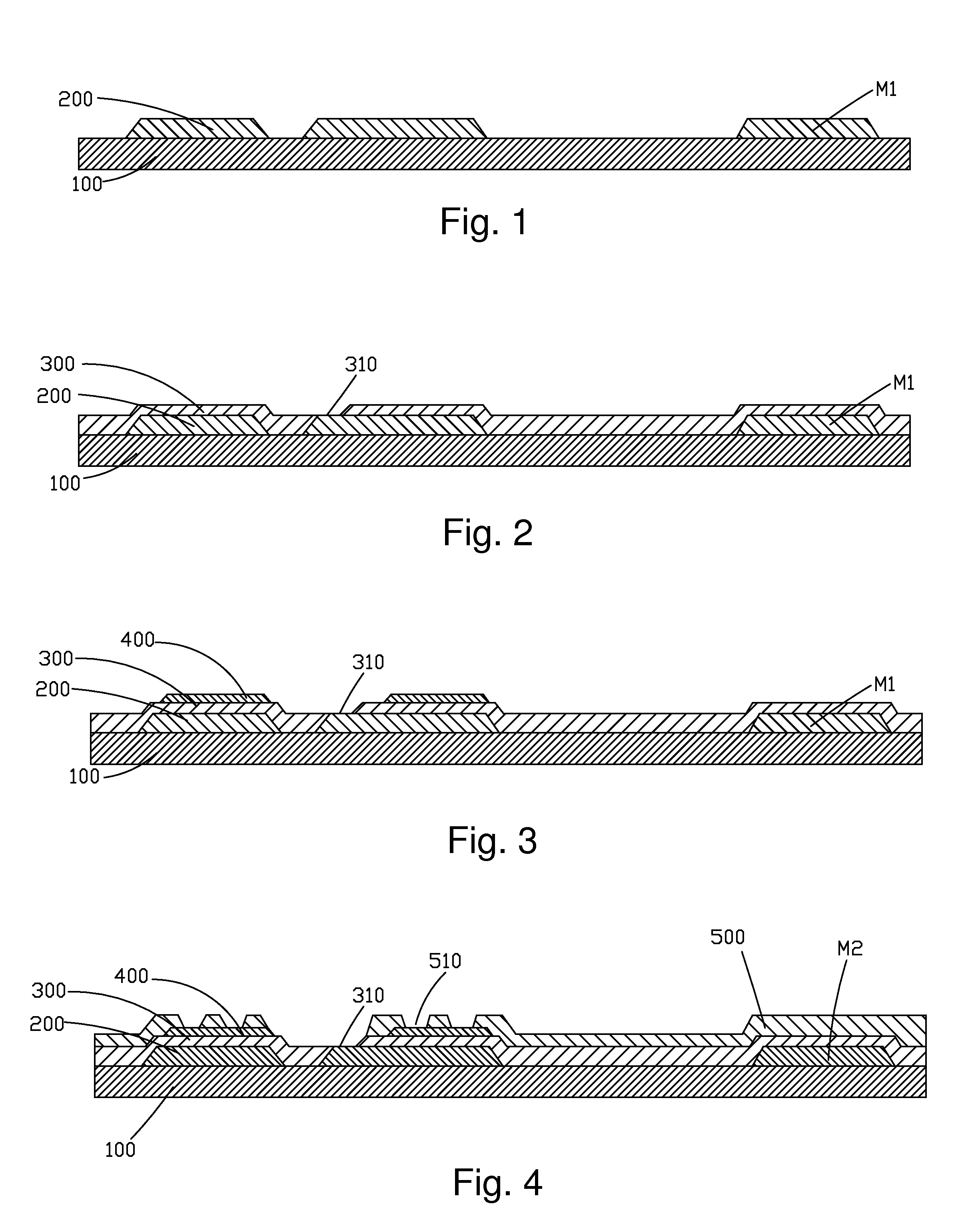

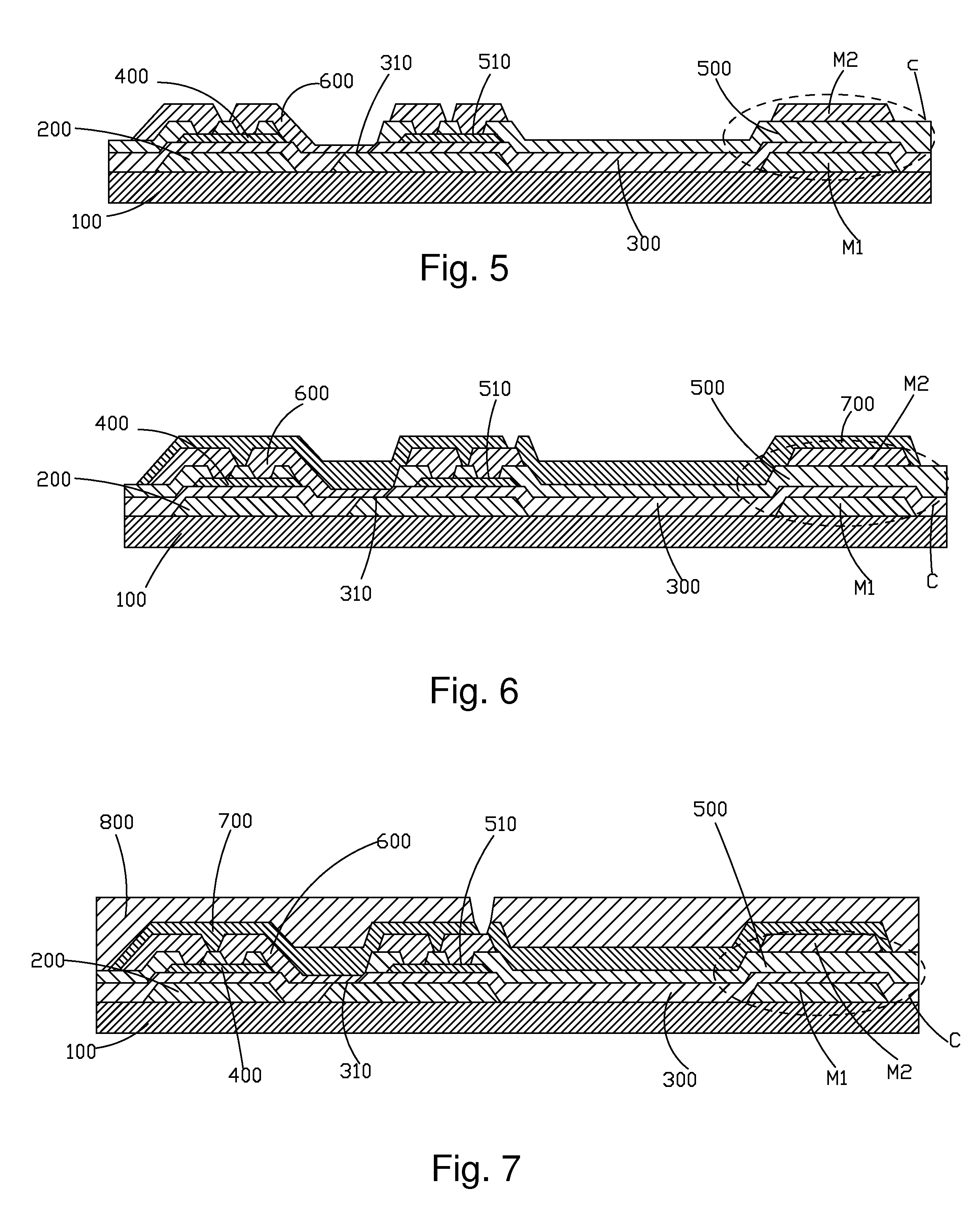

Method for manufacturing TFT backplane and structure of TFT backplane

ActiveUS20160027804A1Manufacturing process be shortenEnhance manufacturing efficiencySolid-state devicesSemiconductor/solid-state device manufacturingPhysicsBackplane

The present invention provides method for manufacturing a TFT backplane and a structure of a TFT backplane. The method includes (1) forming a gate terminal (2) and a first metal electrode M1 on a substrate (1); (2) sequentially forming a gate insulation layer (3), a semiconductor layer, and an etch stop layer on the gate terminal (2), the first metal electrode M1, and the substrate (1) in a successive manner and applying a photolithographic operation to form an island-like semiconductor layer (4) and an island-like etch stop layer (5); (3) applying a photolithographic operation to patternize the island-like etch stop layer (5) and the gate insulation layer (3) to form a plurality of etch stop layer vias (51) and a gate insulation layer via (31); (4) forming source / drain terminals (6) and a second metal electrode M2; (5) forming a passivation protection layer (7); (6) forming a planarization layer (8); (7) forming a pixel electrode layer (9); (8) forming a pixel definition layer (10); and (9) forming a spacer pillar (11).

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Data processing system having a plurality of storage systems

ActiveUS20060123213A1Reduce storage areaFast conductionData processing applicationsInput/output to record carriersData processing systemData treatment

It is an object of the present invention to conduct data transfer or data copying between a plurality of storage systems, without affecting the host computer of the storage systems. Two or more auxiliary storage systems 100B, 100C are connected to a primary storage system 100A connected to a host device 180. The auxiliary storage systems 100B, 100C read journals of data update from the primary storage system 100A at respective independent timings, save the journals in prescribed logical volumes JNL 2, JNL 3, produce copying of the data present in the primary storage system 100A based on the journals present in the logical volumes JNL 2, JNL 3 at the independent timings, and save the copies in auxiliary logical volumes COPY 1, COPY 3. The primary storage system 100A holds the journals till both auxiliary storage systems 100B, 100C read the journals and restore. The timing of journal read can be controlled according to the journal quantity, processing load, and the like.

Owner:HITACHI LTD

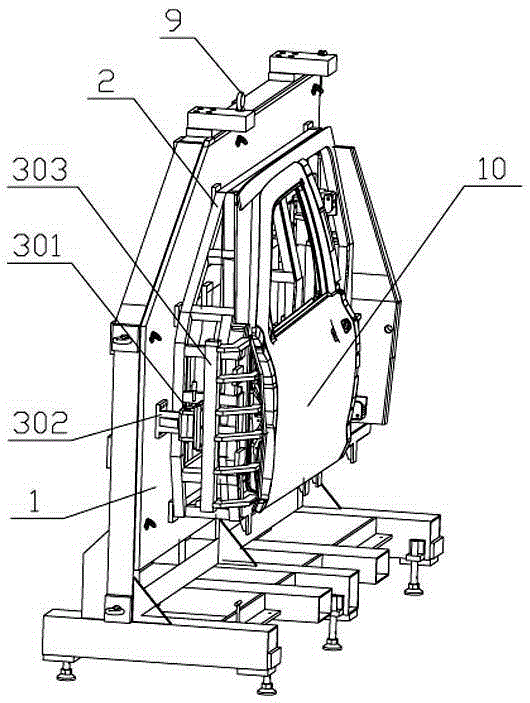

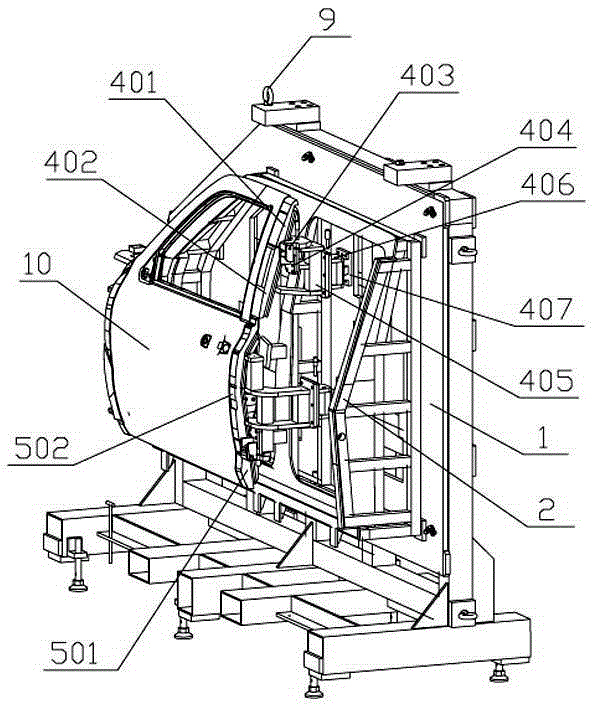

Combined multifunctional vehicle door testing tool

ActiveCN105352390AReduce in quantityEasy to parse and checkMechanical counters/curvatures measurementsBack doorCar door

The invention discloses a combined multifunctional vehicle door testing tool. The combined multifunctional vehicle door testing tool comprises a substrate and a testing tool body arranged on the substrate and matched with a front vehicle door and a rear vehicle door, the front of the outside of the testing tool is provided with a front door front detection unit, the inner side of the testing tool body is provided with a front door rear upper detection unit, a front door rear lower detection unit, a rear door front upper detection unit, and a rear door front lower detection unit, the detection units can rotate and overturn, and the testing tool body is movably provided with a hinge nut detection supporting seat. According to the testing tool, the structure is simple, the usage is convenient, the problem of mutual interference between the detection units and the to-be-tested vehicle doors and between the detection units is overcome, and combined tests of the front vehicle door and the rear vehicle door can be simultaneously conducted; besides, the function of position deviation measurement of the vehicle door hinge nut is additionally provided so that the analysis and test are facilitated during dimension deviation of the vehicle doors.

Owner:郑州日产汽车有限公司

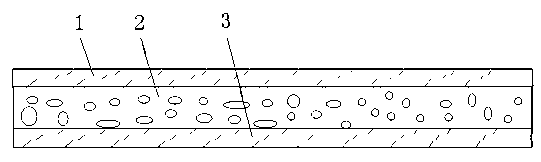

Heat-sealing stone paper

ActiveCN103287036AReduce use costWill not polluteSynthetic resin layered productsBiochemical engineeringMass ratio

The invention provides a piece of heat-sealing stone paper. The heat-sealing stone paper comprises an upper layer, a middle base layer and a lower layer and is once formed in a general three-layer co-extrusion casting combination manner. The heat-sealing stone paper is characterized in that the mass ratio of the upper layer and the lower layer to the middle base layer is (1-20): (99-80); at least one of the upper layer and the lower layer is a heat-sealing layer, and the other layer is a non-heat-sealing layer; and the middle base layer is a foaming layer or a non-foaming layer. According to the heat-sealing stone paper, the processing process is simplified, the production period is shortened, the number of production personnel is reduced, the manufacturing cost is lowered, and the warehouse space is saved. The heat-sealing stone paper has the characteristics of relatively good stiffness and evenness, light specific gravity, high heat-sealing strength, wide heat-sealing range, firm surface printing property and the like and is suitable for packaging products with the heat-sealing strengths required to be lower than 8-10 N / 15 mm.

Owner:KUNMING IRON & STEEL HLDG CO LTD

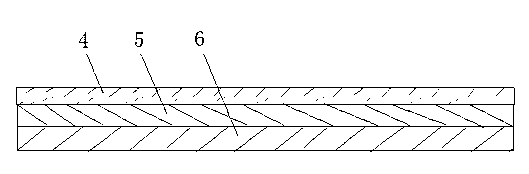

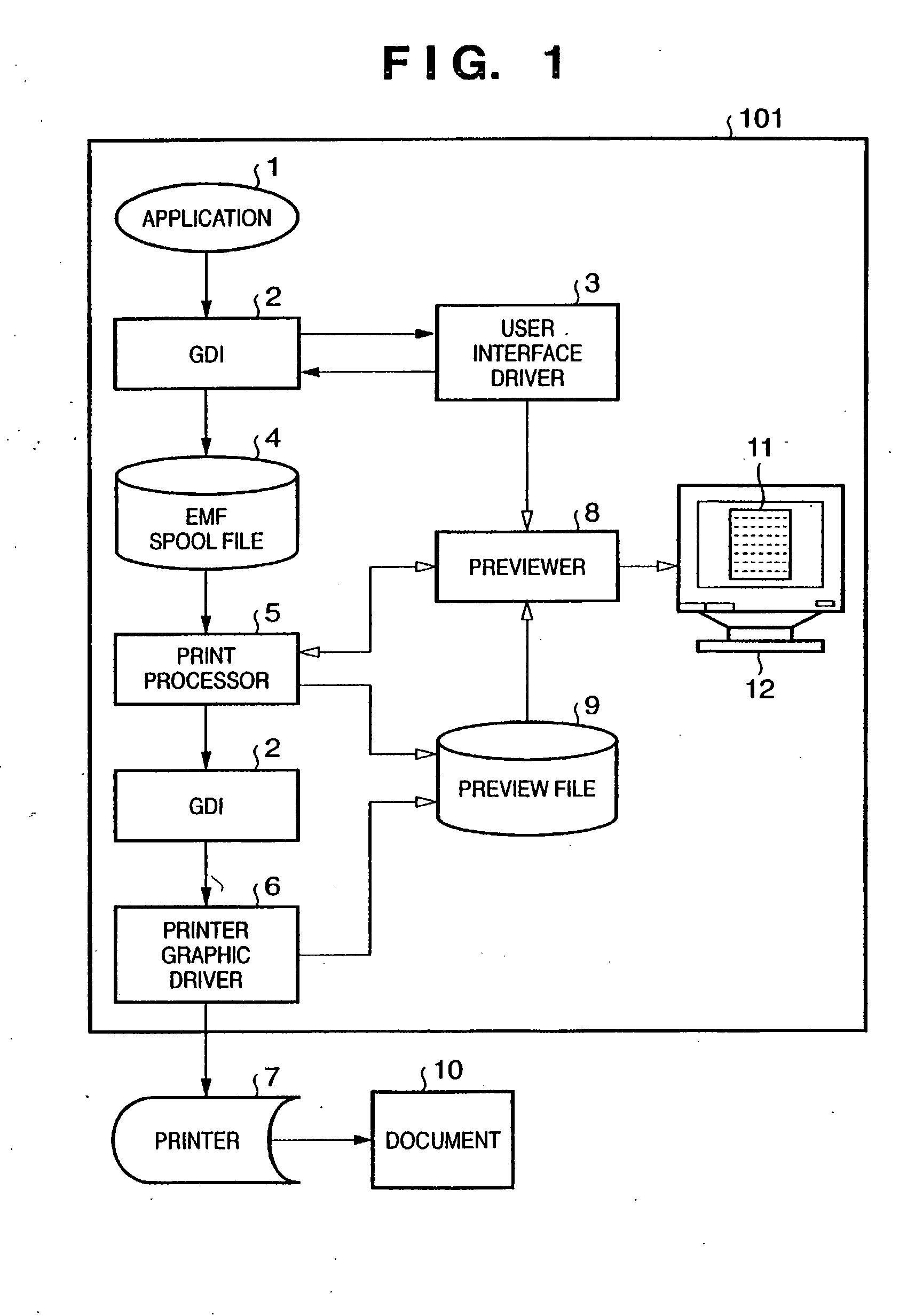

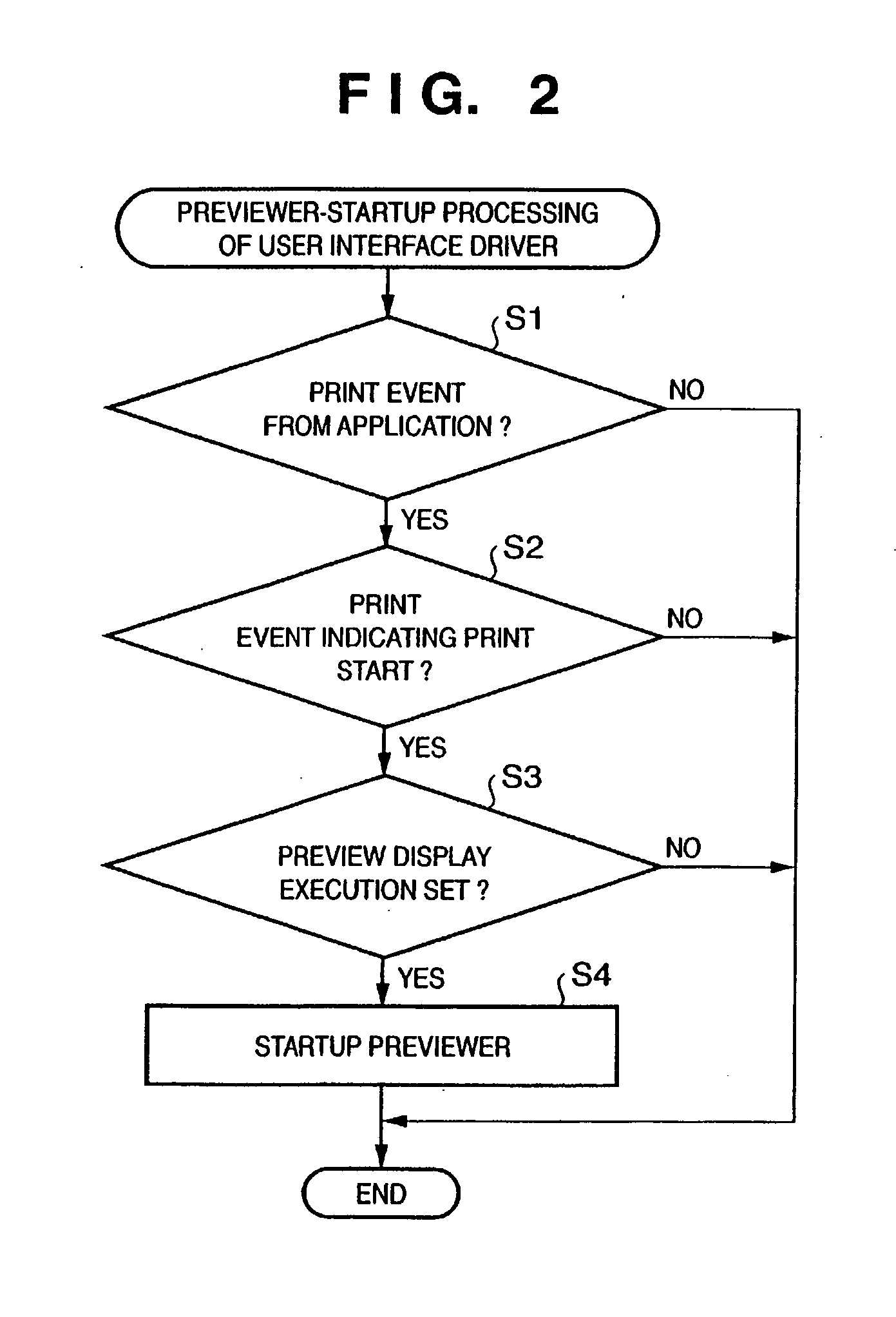

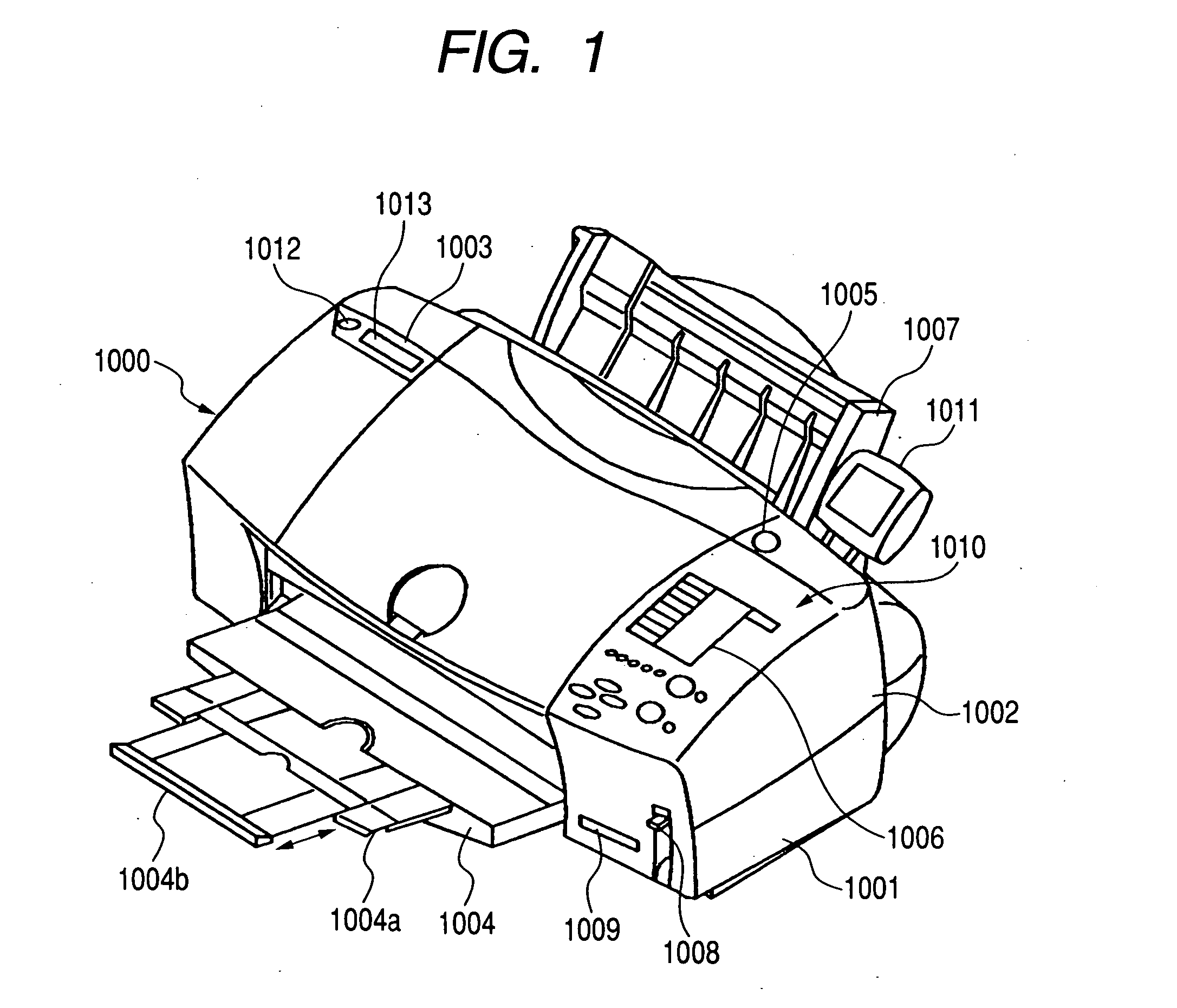

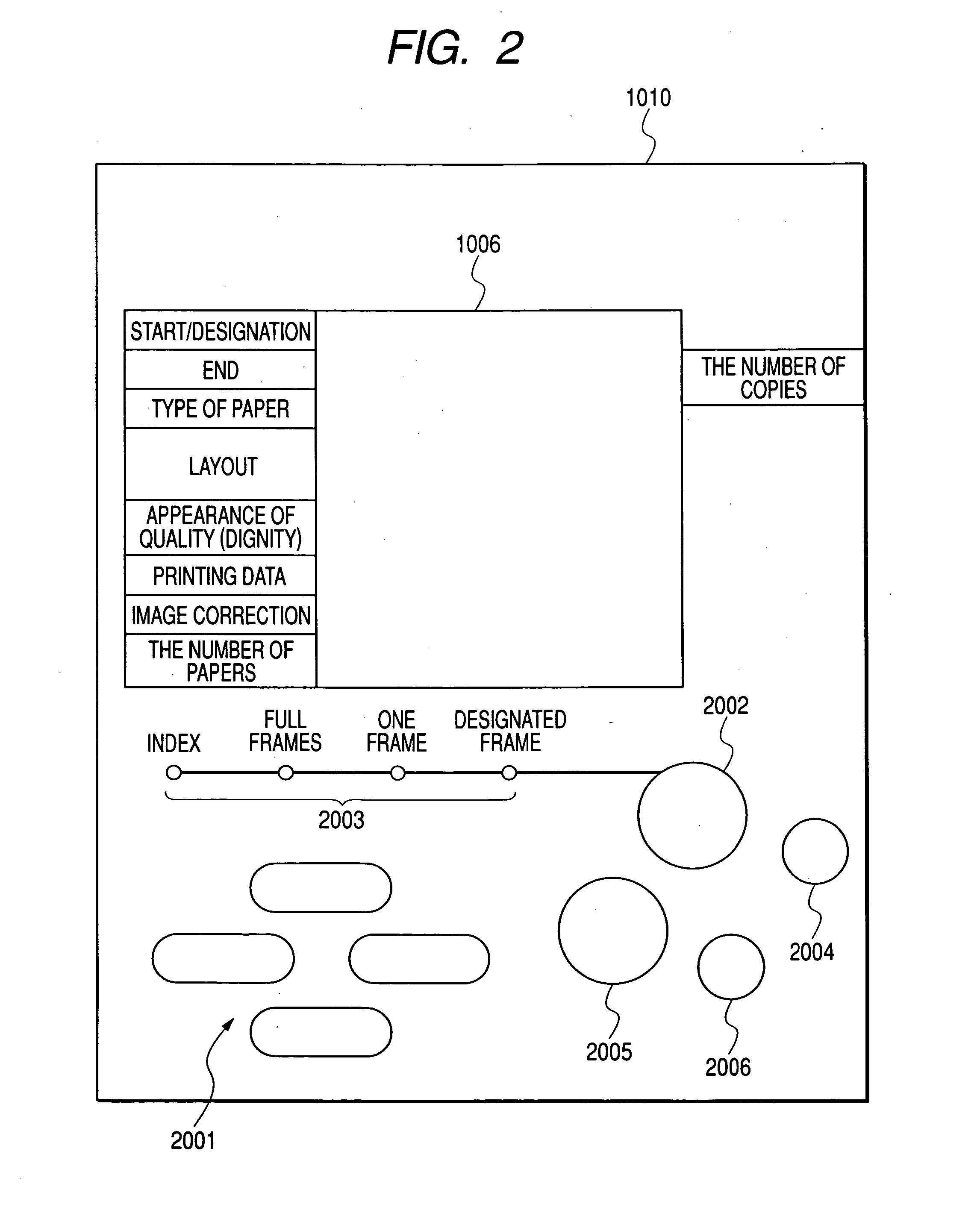

Print control apparatus and method

InactiveUS20080151282A1Effective displayReduce storage areaDigitally marking record carriersDigital computer detailsGraphicsData file

This invention is targeted to realize preview displaying by using a system spooler. In the print system according to this invention, when an application program designates printing of a document, document data is spooled into EMF spool file 4. At the same time, previewer 3 is started to transmit a printing image generation request to print processor 5. The print processor 5 reads the data subjected to preview displaying out of the EMF spool file 4, have printer graphic driver 6 generate image data that has an appropriate display size, and informs the name of the image data file to the previewer 8, which then displays the image data.

Owner:CANON KK

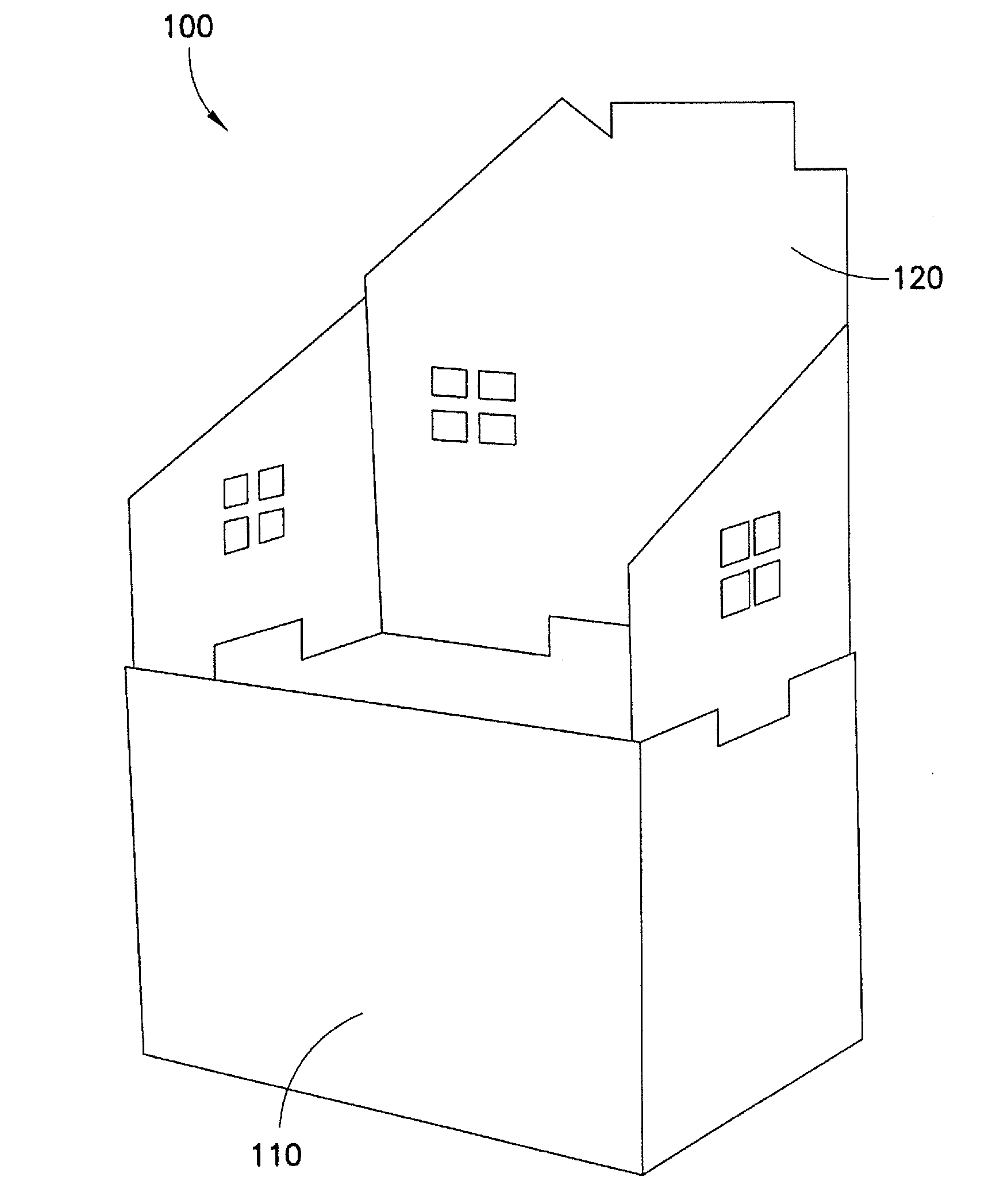

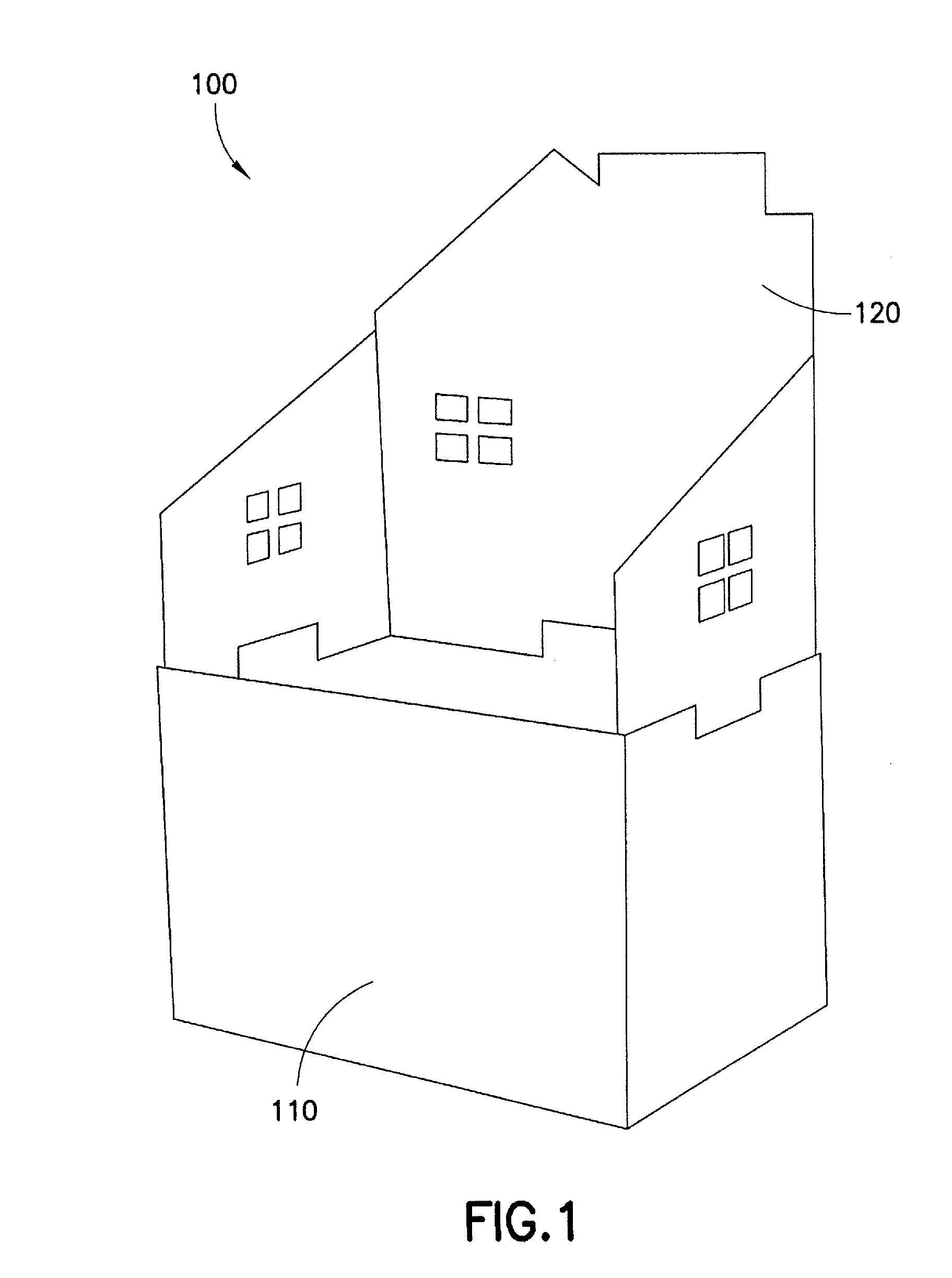

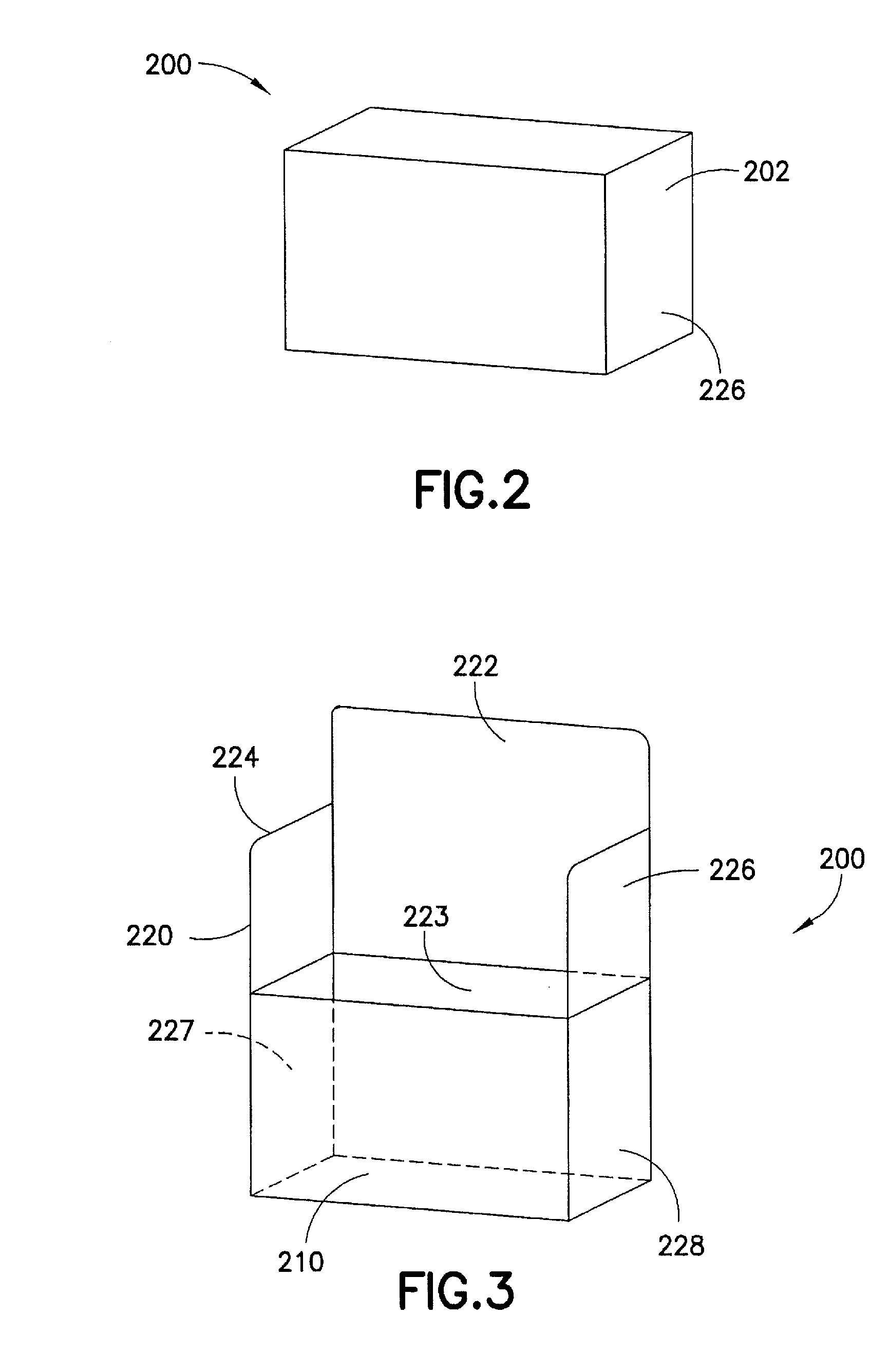

Product display system and method

A display system is provided for shipping products to a retail location and displaying those products, such as pet beds. The display system and the products to be displayed can be shipped and displayed in a single container. In a preferred embodiment of the invention, the container can convert from a shipping box to a combined storage and display system. Systems in accordance with the invention help optimize the use of retail floor space. They can also help insure that products are displayed as the manufacturer intended. Systems in accordance with the invention can also reduce waste. In one preferred embodiment of the invention, the container is in the form of a box comprising cardboard, corrugated paper or other relatively inexpensive material that can hold its shape and can be easily disposed of.

Owner:HARTZ MOUNTAIN

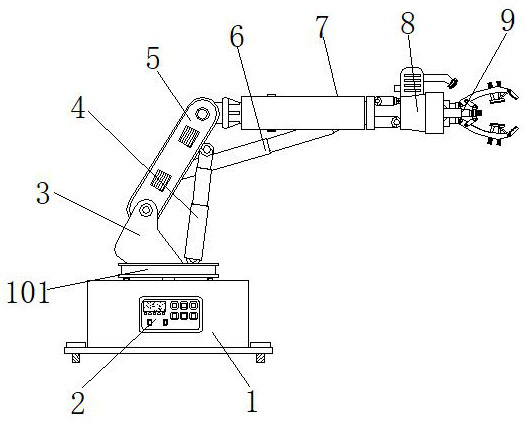

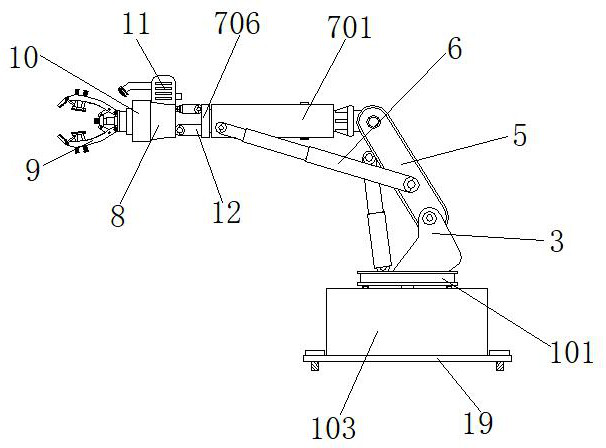

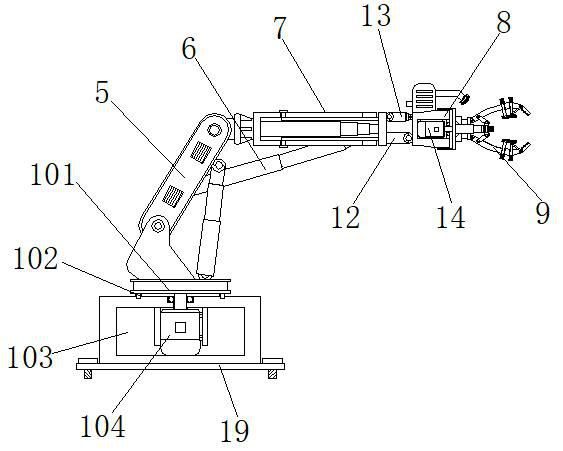

Intelligent multifunctional manipulator

InactiveCN111890347AReduce storage areaEasy to transportProgramme-controlled manipulatorGripping headsControl engineeringManipulator

The invention discloses an intelligent multifunctional manipulator. The intelligent multifunctional manipulator comprises a fixing plate, wherein a rotary base assembly is arranged at the top of the fixing plate, and a mounting bottom frame is arranged at the top of the rotary base assembly; a supporting rod is hinged to the inner side of the top of the mounting bottom frame, and a telescopic assembly is hinged to the top end of the supporting rod; and a pneumatic cylinder D is arranged at the top of the end, away from the supporting rod, of the telescopic assembly, and a connecting plate is arranged at the bottom of the end, away from the supporting rod, of the telescopic assembly. According to the intelligent multifunctional manipulator, the rotary base assembly, the mounting bottom frame, a pneumatic cylinder A, the supporting rod, a pneumatic cylinder B and a mounting pipe are used in cooperation, the supporting rod is supported to be in a vertical state by the pneumatic cylinder A, and then the pneumatic cylinder B is shortened to fold the mounting pipe, so that the mounting pipe and the supporting rod are folded together, the intelligent manipulator can be freely folded whennot in use, the storage area of the whole manipulator is reduced, and the transportation and storage of the manipulator are greatly facilitated.

Owner:杨明清

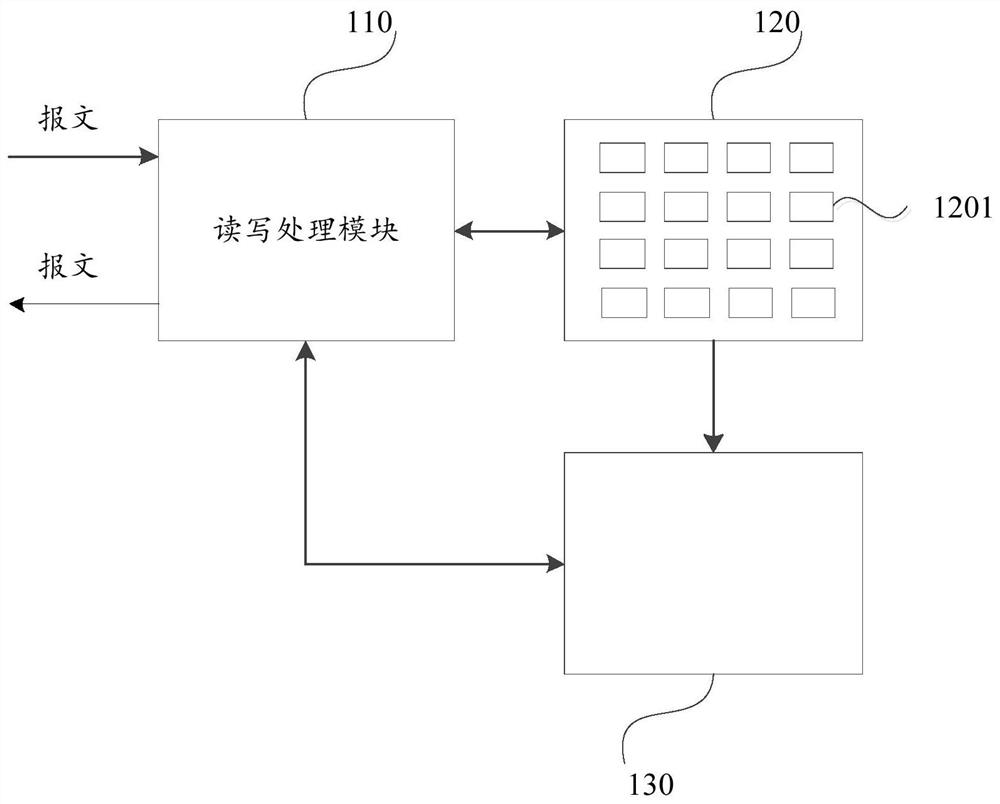

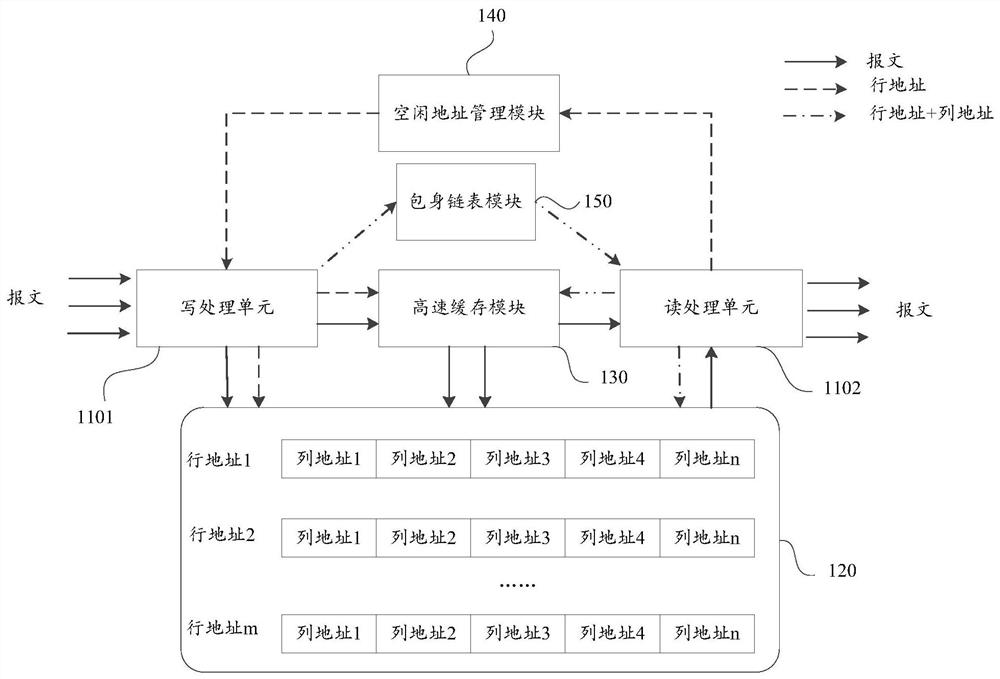

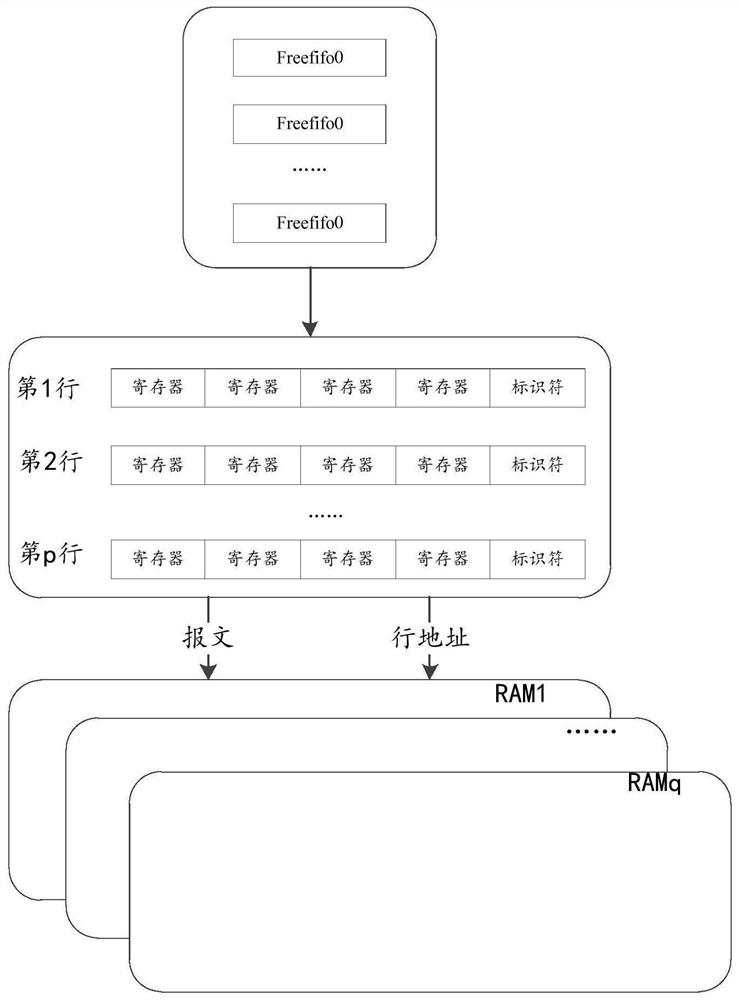

On-chip cache device and read-write method

PendingCN113535633AReduce storage areaReduce power consumptionInput/output to record carriersDigital storageEngineeringMemory module

The invention provides an on-chip cache device and a read-write method, and the device comprises a read-write processing module, a high-speed cache module and a memory module, wherein the read-write processing module is respectively connected with the cache module and the memory module, and the read-write processing module is used for storing messages in the cache module and the memory module, reading the messages stored in the cache module and the memory module, and transferring the messages cached in the cache module to the memory module; the high-speed cache module is connected with the memory module through the read-write processing module, and the high-speed cache module comprises at least one cache register and is used for temporarily caching messages; and the memory module is connected with the read-write processing module and is used for transferring the message cached by the high-speed cache module. The multiple messages are cached to be written into the buffer at the same time, the chip storage space utilization rate is increased, the storage area is reduced, and chip power consumption is reduced.

Owner:SANECHIPS TECH CO LTD

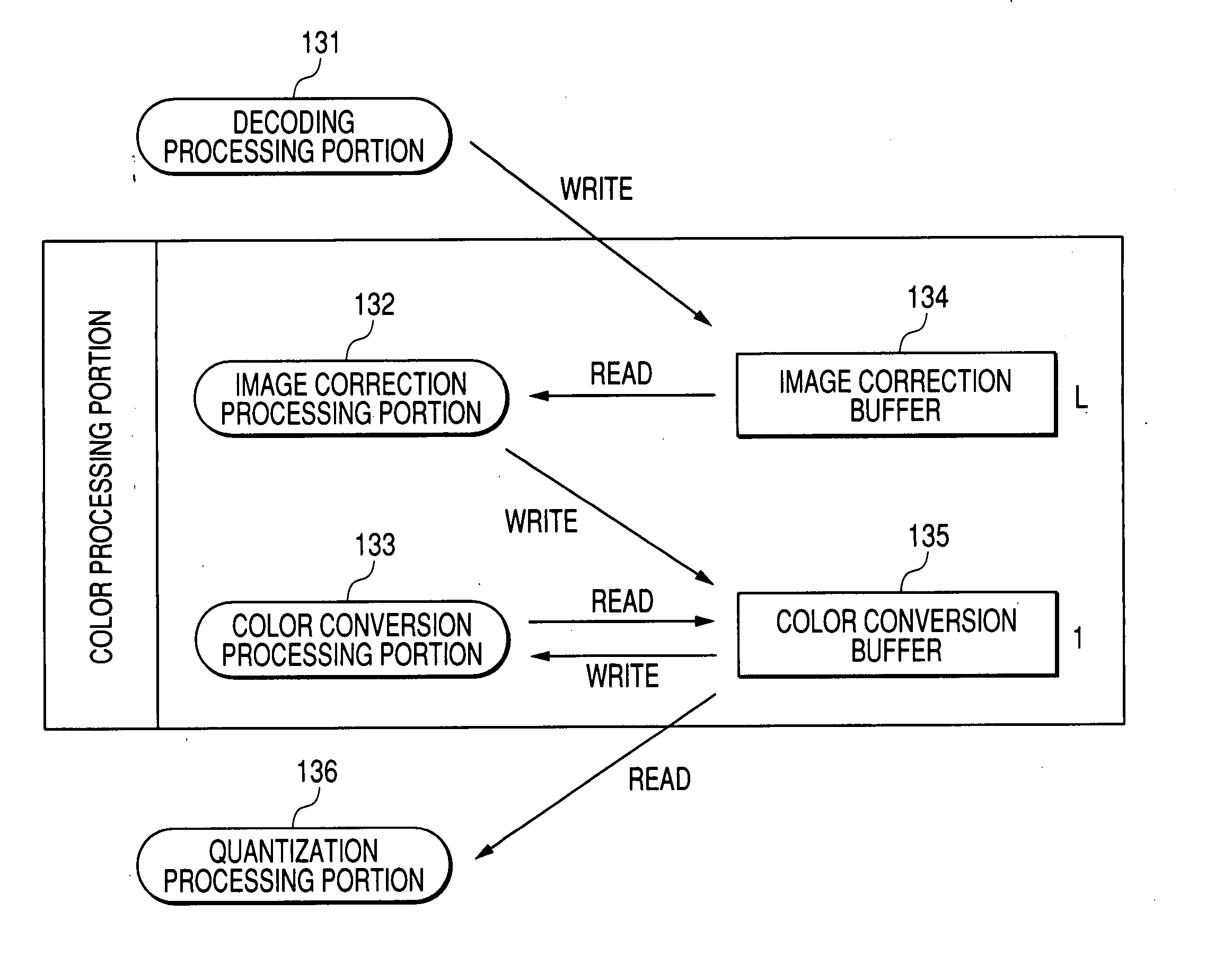

Image processing apparatus, image processing method, storage medium storing a program readable by a computer and program

InactiveUS20050030585A1Reduce memory capacityReduce visitsImage enhancementDigitally marking record carriersImaging processingImage correction

At the image processing time for an image data, a storage area to be secured is reduced, and moreover, the number of access processing times for the storage area which is required until the image processing result is obtained is sharply reduced, thereby shortening the processing time. Consequently, an image correction processing portion is characterized by a configuration wherein the image correction processing portion secures an image correction buffer to store the image data for at least M+(N−1) lines, and when it is determined that an image correction processing requires decoding processing, the address of an image correction buffer is set as a decoding destination, and the image correction processing for the image data is performed within the set storage area.

Owner:CANON KK

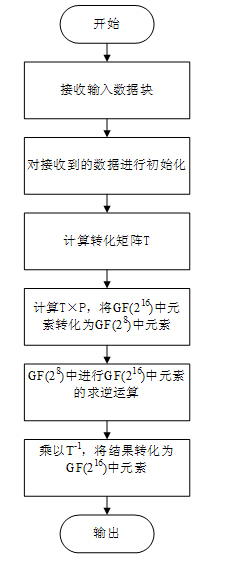

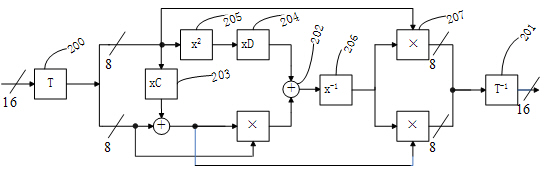

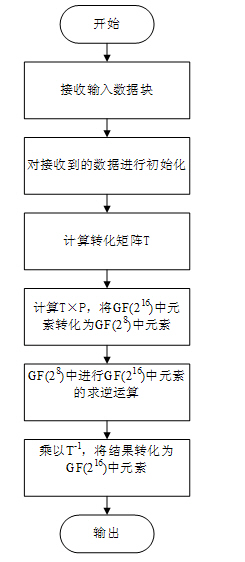

Method for realizing confusing layer in block cipher algorithm

InactiveCN101969374AReduce storage areaReduce areaEncryption apparatus with shift registers/memoriesS-boxTheoretical computer science

The invention provides a method for realizing a confusing layer in a block cipher algorithm. A novel method for realizing an S box based on GF(2<16>) inversion is realized; and by converting a finite field GF(2<16>) and a composite domain GF ((2<8>)<2>), the method reduces storage amount and calculation amount brought by the traditional table look-up method, saves the hardware realizing cost and improves the operation efficiency of the S box based on GF(2<16>) inversion. The method comprises the following steps of: initializing data needing inversion operation on the GF(2<16>); selecting a primitive polynomial on GF (2<8>) for solving a converting matrix of the finite field GF(2<16>) and the composite domain GF ((2<8>)<2>); expressing an initialized element in the GF(2<16>) in the GF (2<8>) by utilizing the converting matrix and carrying out inversion operation in the GF (2<8>); and finally converting an operation result into an element form in the GF(2<16>) by the converting matrix and outputting. Compared with the traditional table look-up algorithm, the scheme provided by the invention has the storage area being only 1 / 512 of the original technology, at least saves 98.57 percent of hardware realizing area and improves speed by 32.96 percent.

Owner:BEIHANG UNIV

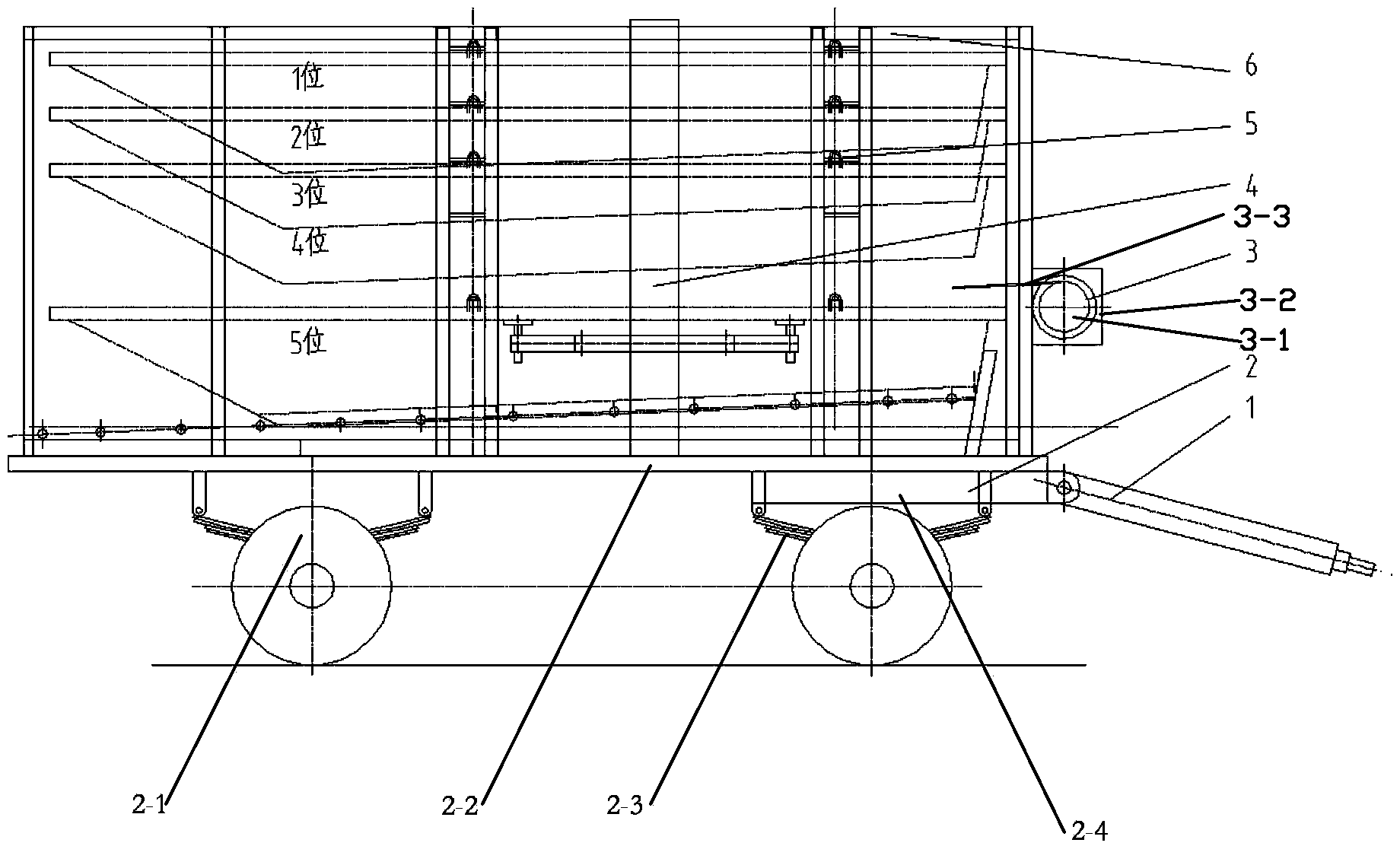

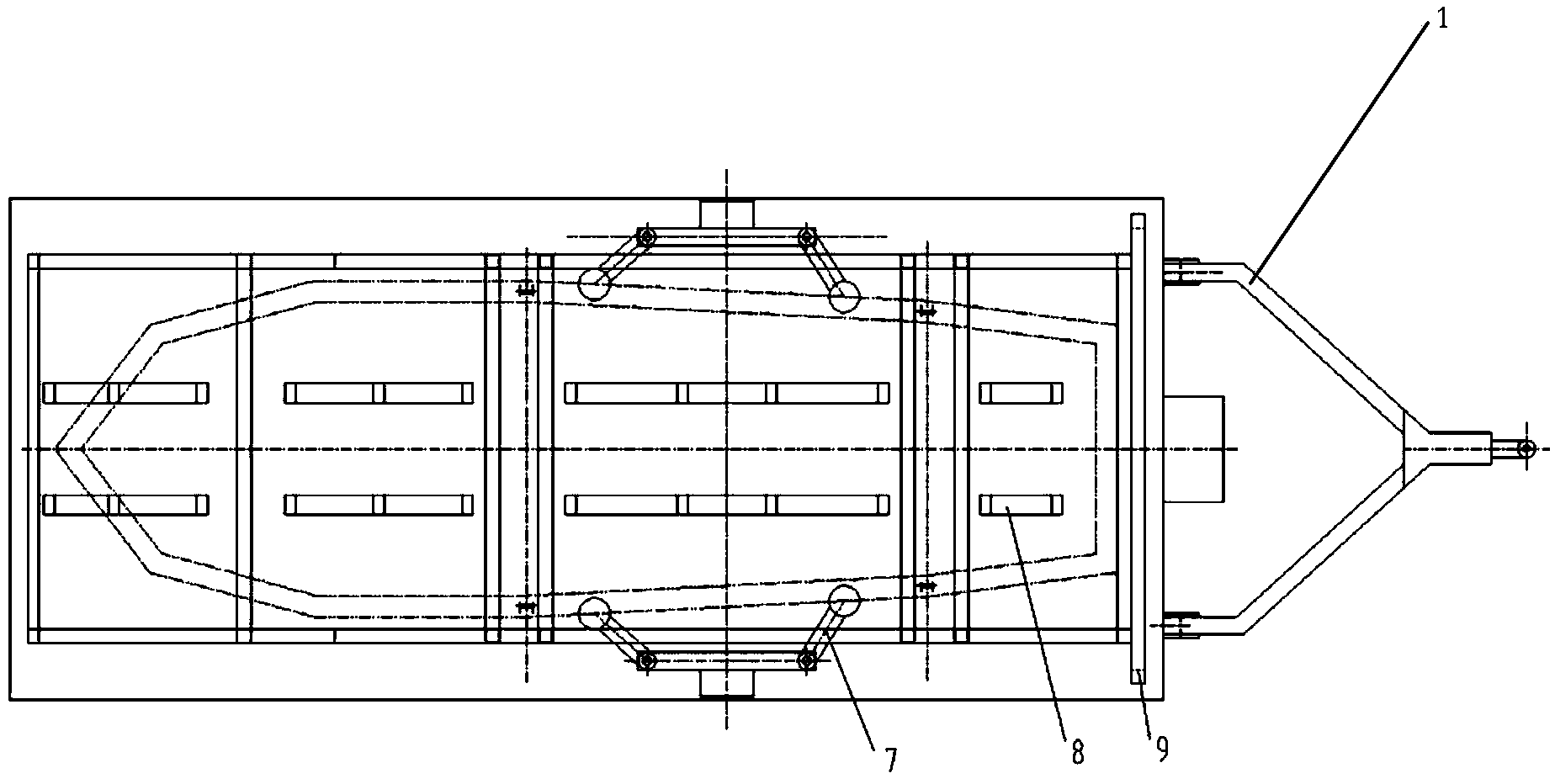

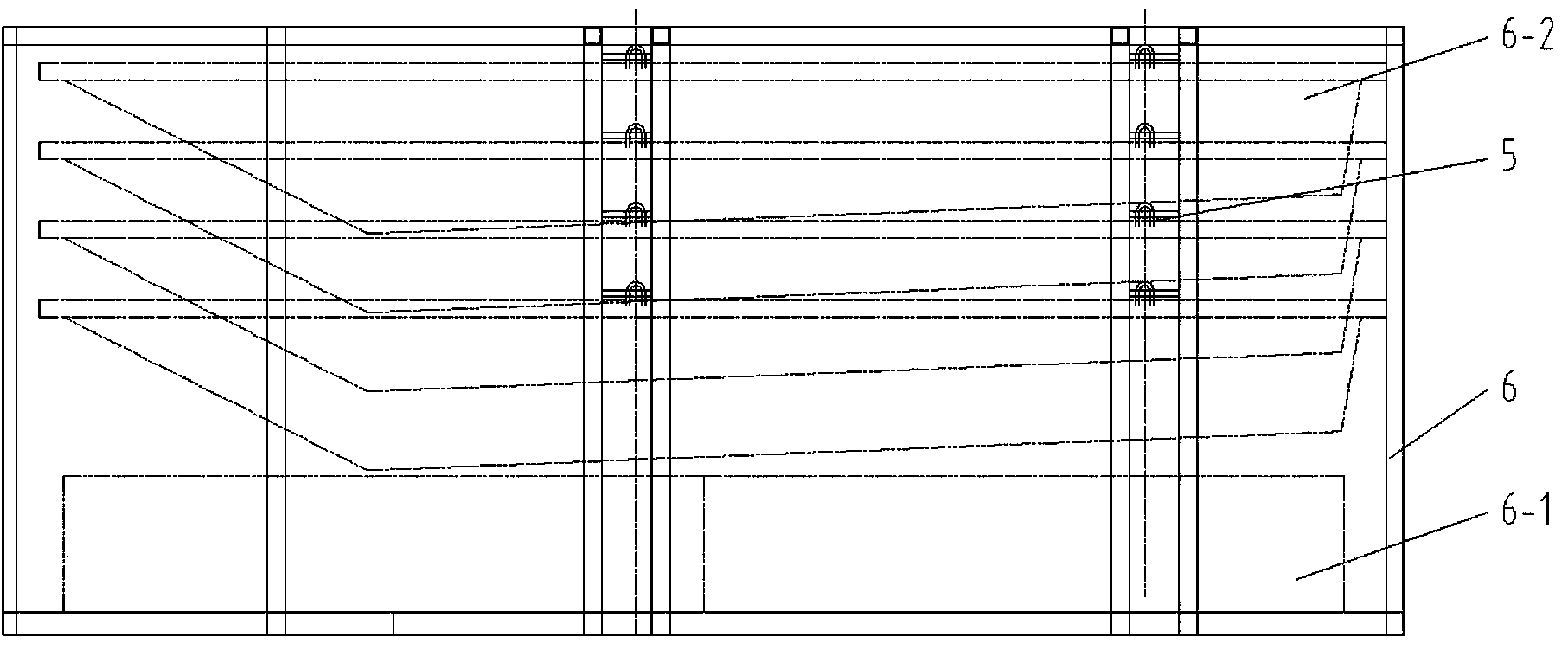

Container type storage vehicle for storing multiple inflatable boats

InactiveCN103522933AReduce storage areaAchieve transshipmentLoading/unloading vehicle arrangmentLoad securingInflatable boatTraction frame

The invention relates to a container type storage vehicle for storing multiple inflatable boats and aims to solve the problem that a trailer is used to transport one or more inflatable boats, related works of a hanging manner, lifting manner and a manual loading and unloading manner are completed by the assistance of a large amount manpower and material resources, and loading and unloading efficiency is low in the prior art. A traction frame (1) is hinged to the front end of a trailer (2). A limit plate (9) is vertically disposed in the front of the trailer (2). A traction winch (3) is disposed on the front end face of the limit plate (9). A lifting mechanism (4) is disposed on the trailer (2). A slideway system (8) is disposed on the trailer (2) from left to right. The included angle between the slideway system (8) and the horizontal plane ranges from 10 degrees to 30 degrees. A container frame (6) is disposed on the trailer (2). A inflatable boat fixing mechanism (5) is disposed on the container frame (6). The container type storage vehicle is applicable to storage and transportation of inflatable boats.

Owner:李伟明

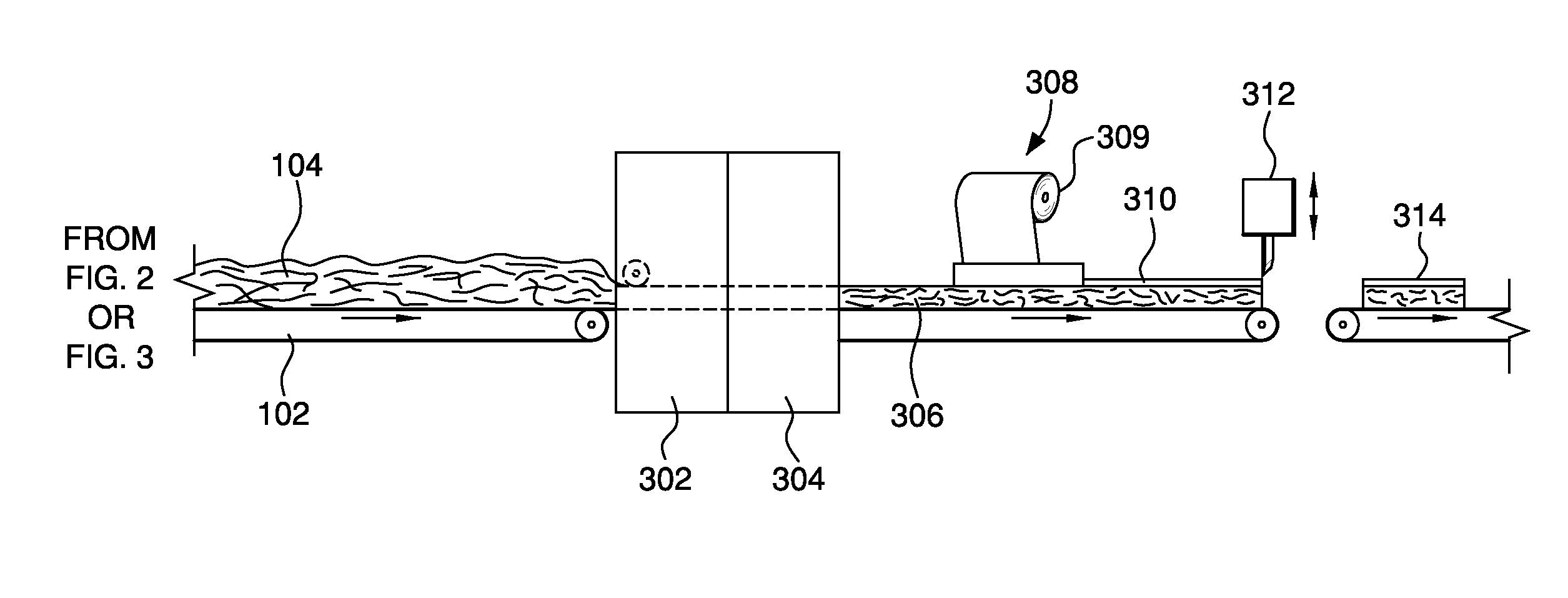

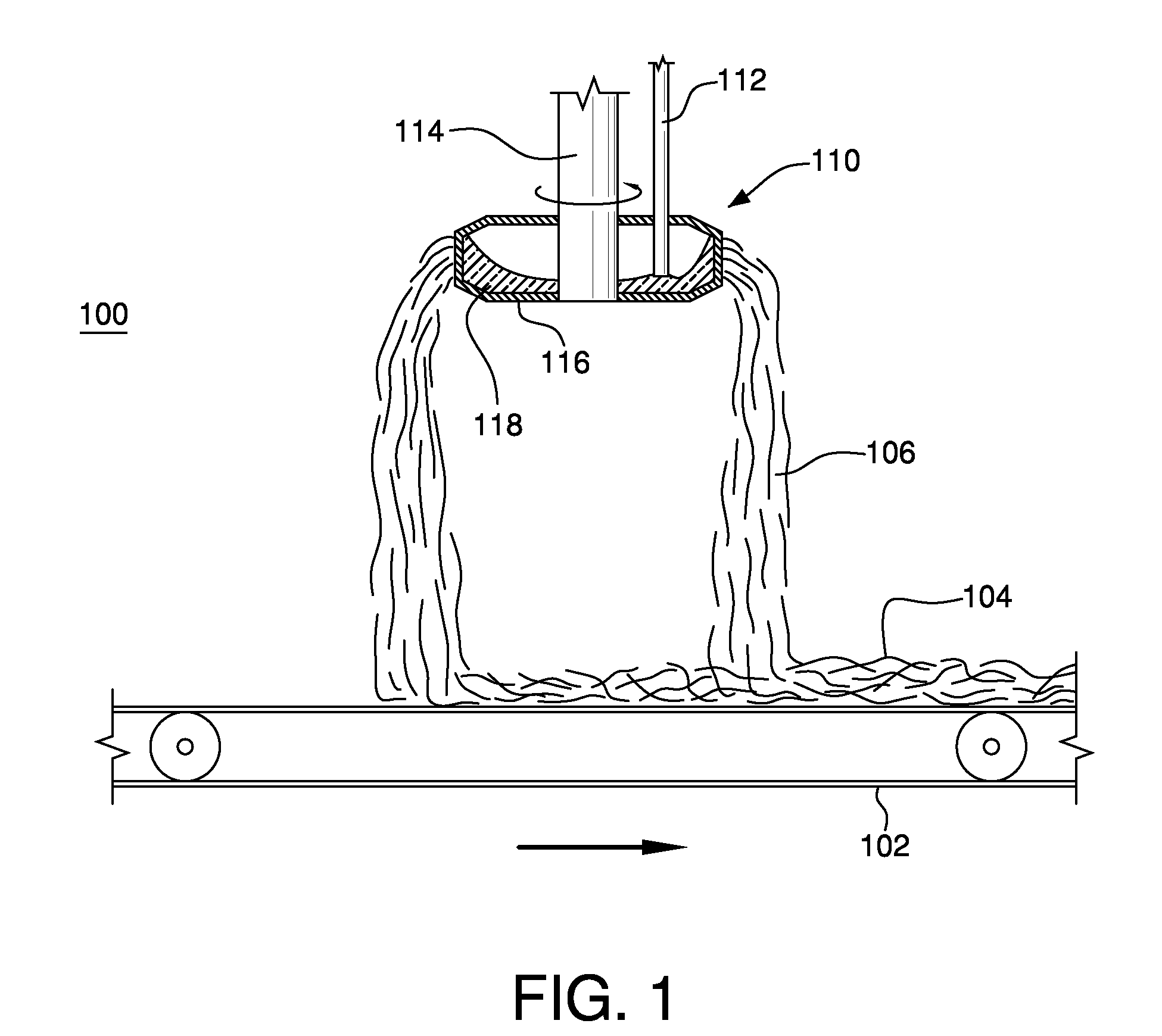

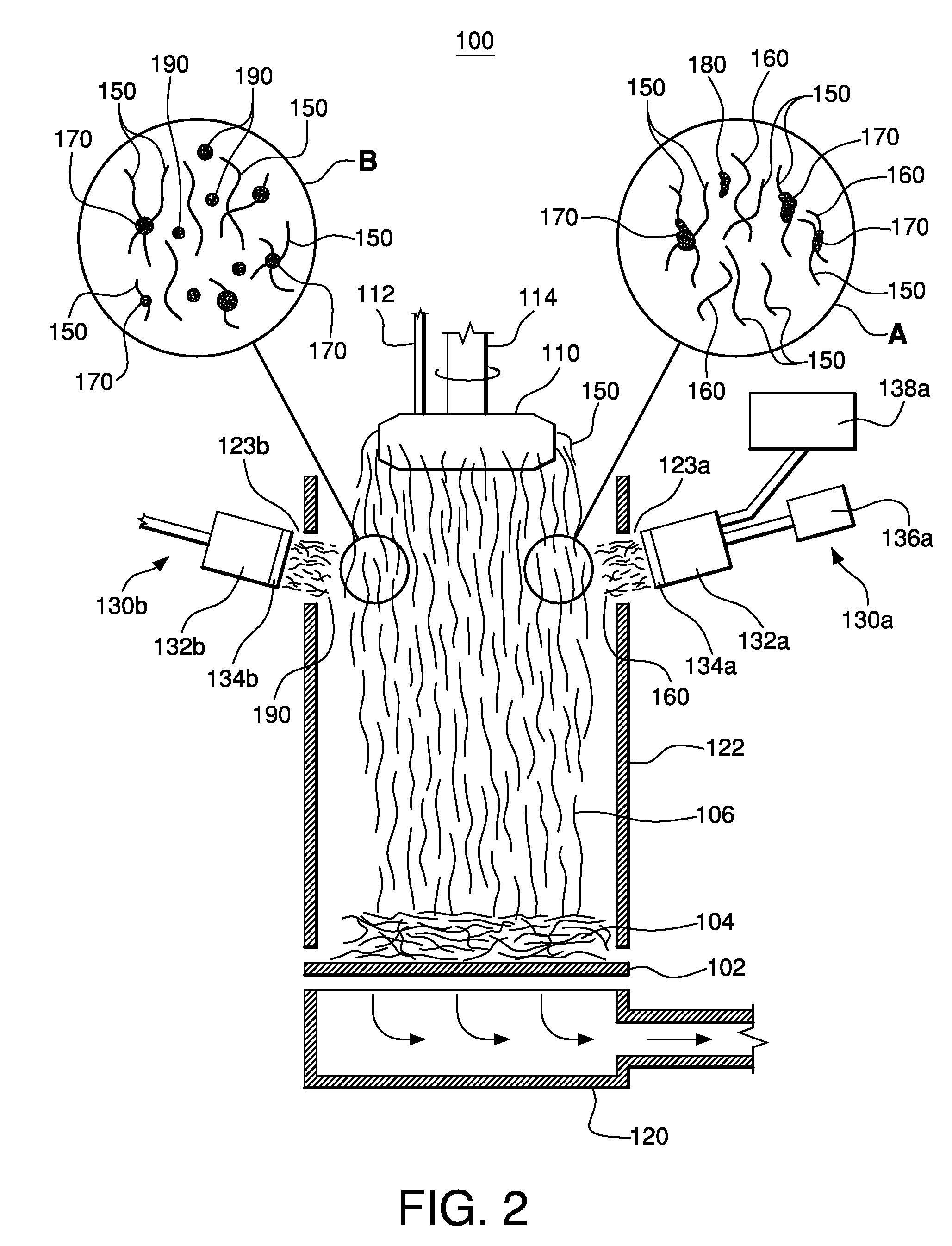

Mineral fiber insulation having thermoplastic polymer binder and method of making the same

InactiveUS20080197316A1Avoids and reduces contaminationAvoids and reduces and other problemBuilding constructionsNon-woven fabricsFiberPolymer science

A method of forming a fibrous insulation product includes forming at least one fibrous veil including first fibers and blowing a non-aqueous, formaldehyde-free, thermoplastic binder in powder, liquid or fibrous form into said veil during said forming step to form a mixture of the binder and the first fibers. When in fibrous form, the binder fibers have average length of less than or equal to about 15 mm. The mixture is collected on the forming belt and formed into an insulation batt, board or molding media.

Owner:CERTAINTEED CORP

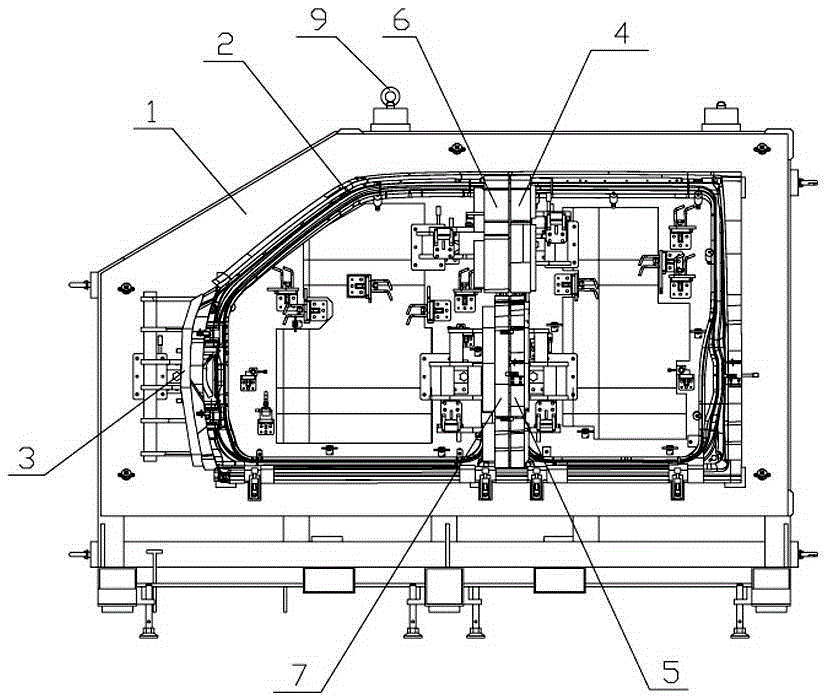

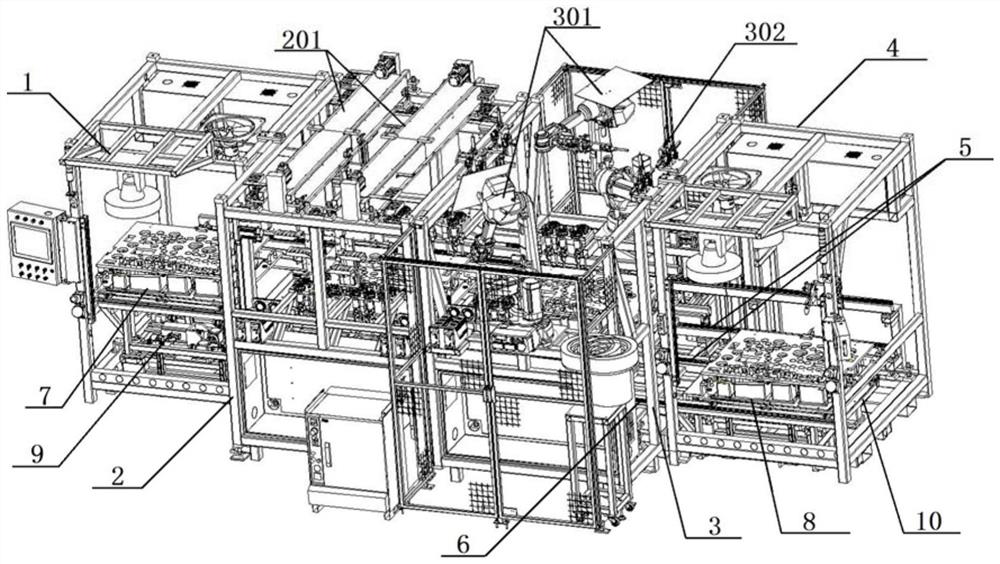

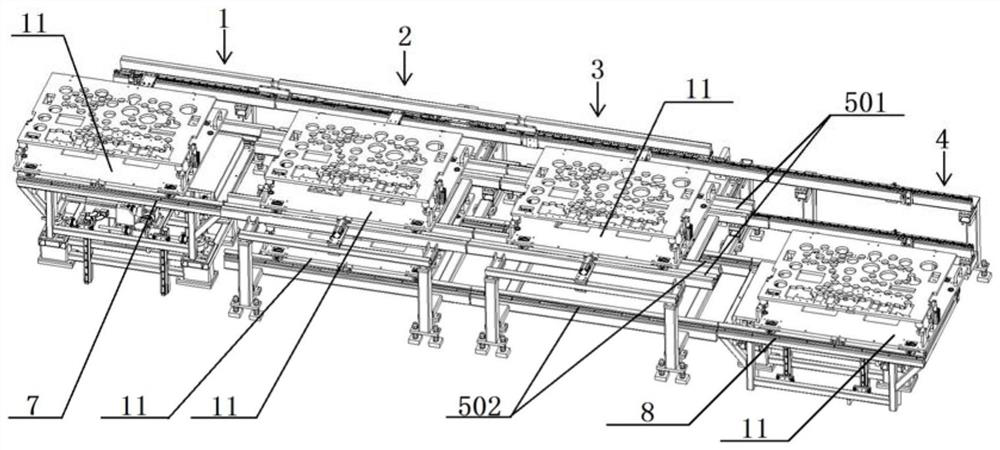

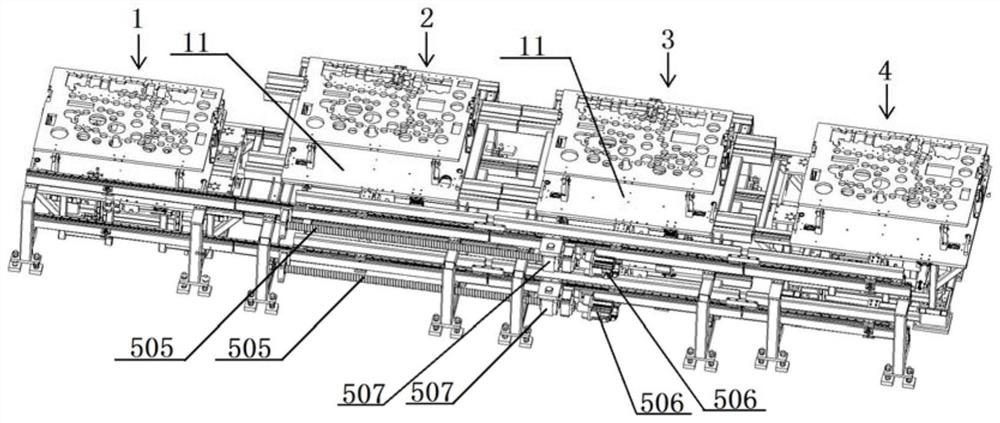

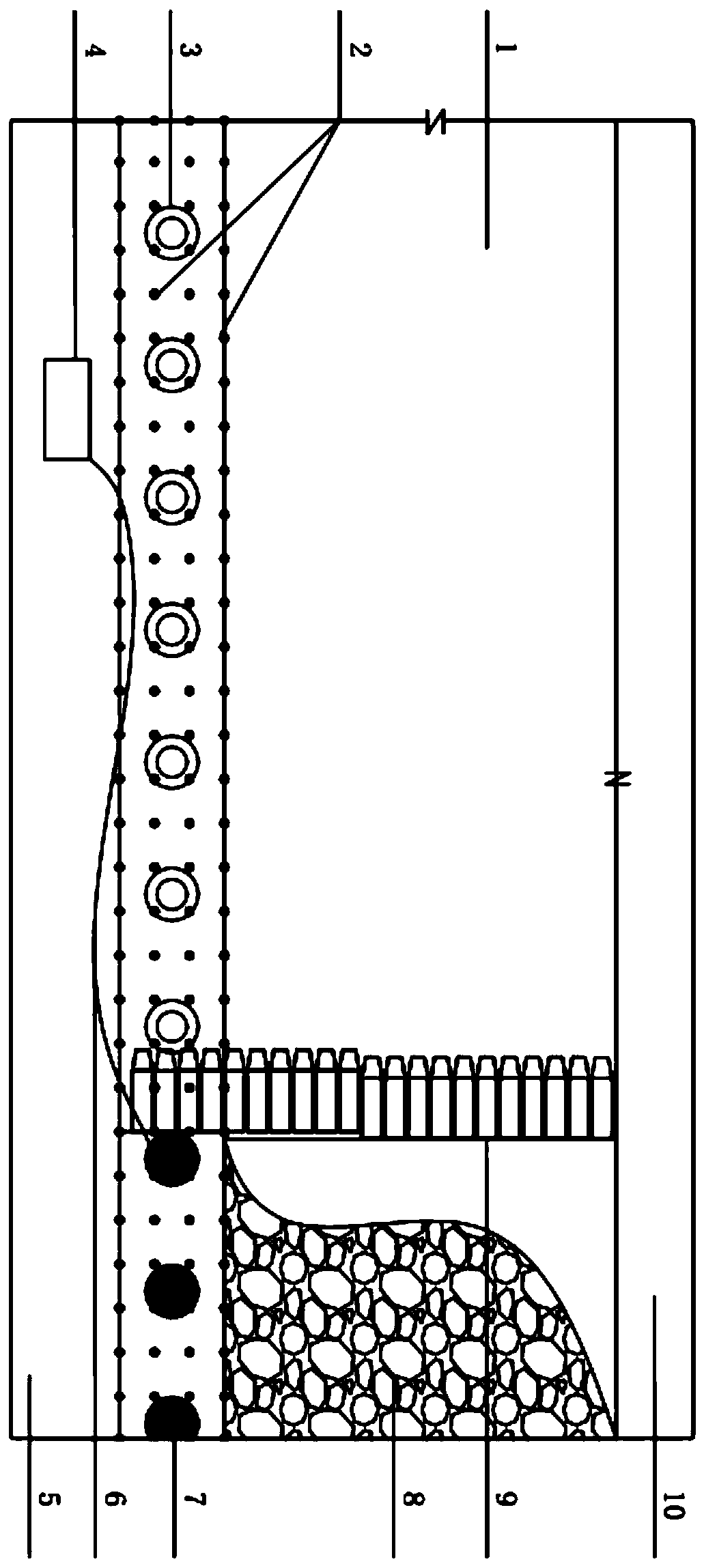

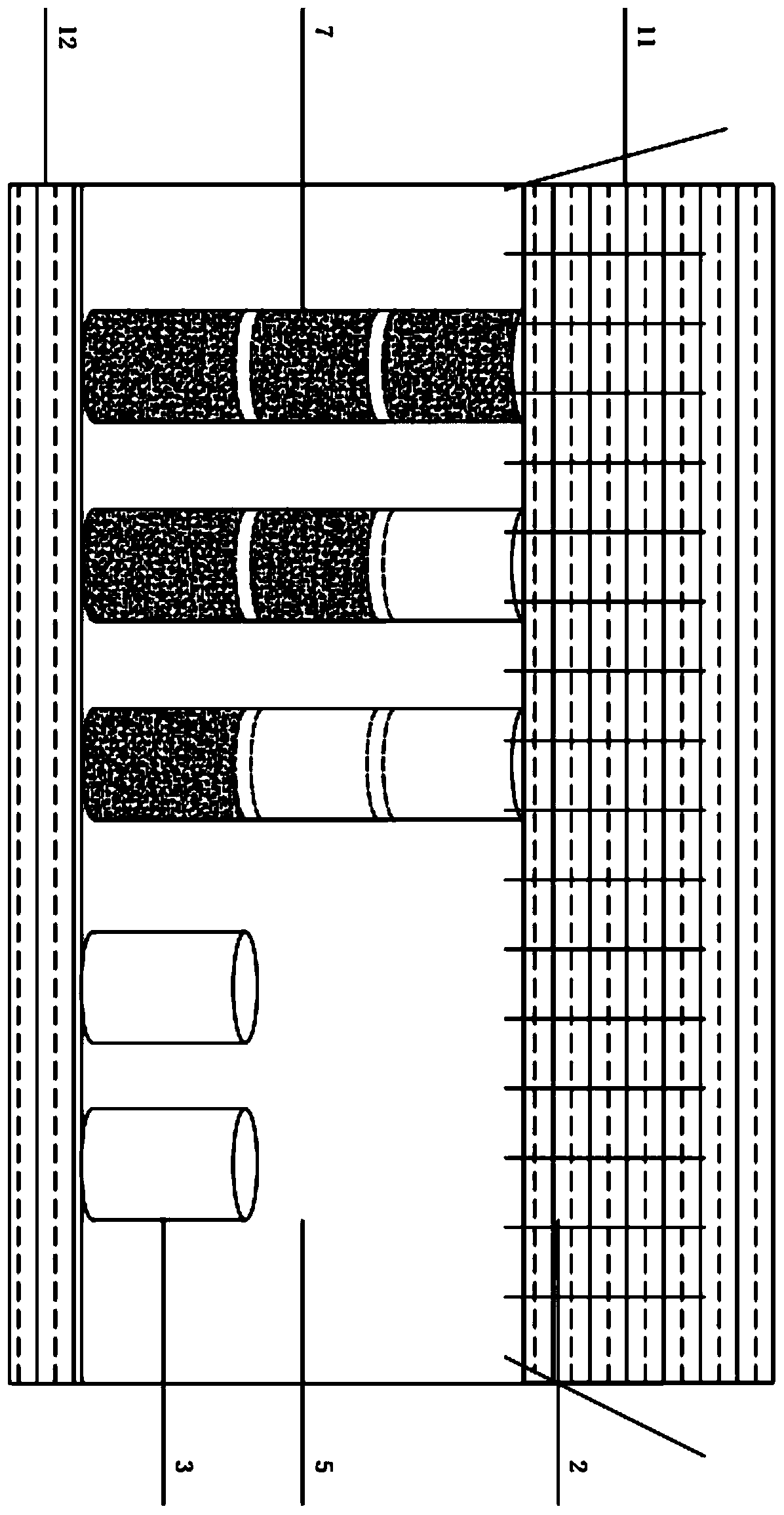

Flexible welding production line for automobile door trim panel

PendingCN112339277ARealize flexible collinear productionFlexible welding realizedDomestic articlesManufacturing lineIndustrial engineering

The invention relates to a flexible welding production line for an automobile door trim panel. The flexible welding production line comprises a workpiece placing station frame, two sets of flexible welding station frames, a workpiece taking station frame, an upper-layer tool conveying rail, a lower-layer tool return rail and two sets of transfer guide rails, wherein the workpiece placing station frame serves as a workpiece placing station, a first forming die lifting mechanism is arranged on the workpiece placing station frame, one set of transfer guide rails are installed on the first formingdie lifting mechanism in the horizontal direction, and the first forming die lifting mechanism is used for transferring a forming die located on the lower-layer tool return rail to the upper-layer tool conveying rail; and a second forming die lifting mechanism is arranged on the workpiece taking station frame, the other set of transfer guide rails are installed on the second forming die lifting mechanism in the horizontal direction, and the second forming die lifting mechanism is used for transferring the forming die located on the upper-layer tool conveying rail to the lower-layer tool return rail. The flexible welding production line has the advantages of being suitable for various small-batch automobile door trim panel projects and capable of realizing flexible collinear production ofvarious products.

Owner:CHANGCHUN FAWAY ADIENT AUTOMOTIVE SYST CO LTD

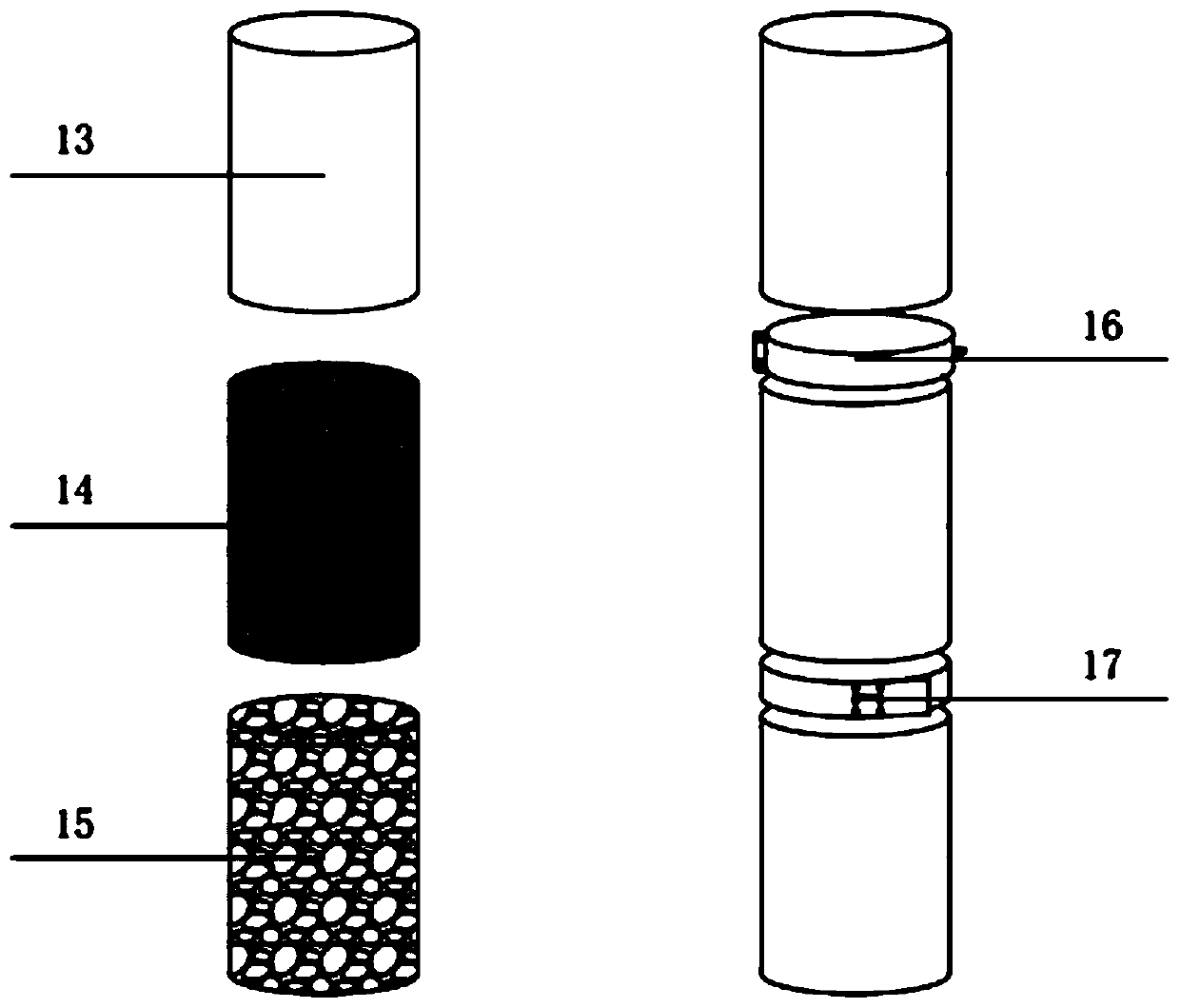

Assembled FRP high-water-material mining combined pillar and construction method

ActiveCN110242334APrevent bucklingImprove longitudinal bearing capacityProps/chocksSupporting systemEngineering

The invention discloses an assembled FRP high-water-material mining combined pillar and a construction method. The assembled FRP high-water-material mining combined pillar comprises prefabricated FRP pipes, fastening devices and internal filling bodies. The FRP pipes with different heights and thicknesses are prefabricated in advance according to the actual height of an underground roadway, the FRP pipes are connected through the rigid semicircular fastening devices or the rubber buckle type rectangular fastening devices or mining flame-retardant adhesive tape, and then the FRP pipes are filled with high-water materials or gangue to form an integral supporting structure. The assembled FRP high-water-material mining combined pillar and the construction method have the beneficial effects that the reciprocating operation mode is carried out in the pouring process, the pillar adapts to the height of the roadway to the largest extent by erecting wood boards at the connecting positions of all the FRP pipes, and the supporting system integrates the dual advantages of FRP and the high-water materials, is high in resistance increasing speed, high in system reliability, simple in construction process and low in production cost and has good application prospects.

Owner:XINJIANG UNIVERSITY

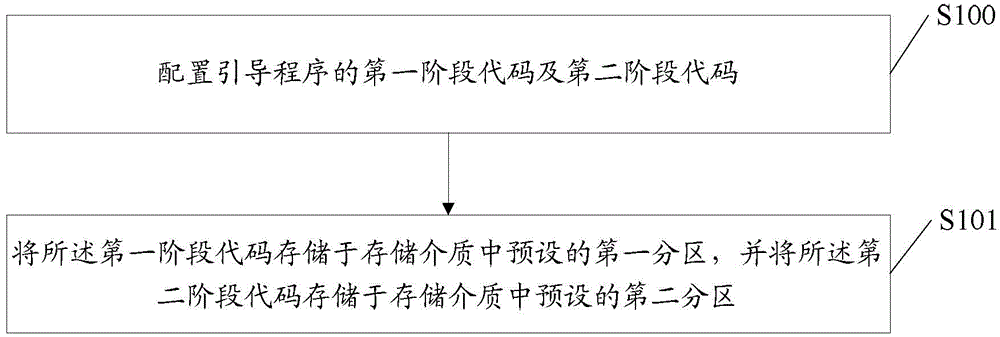

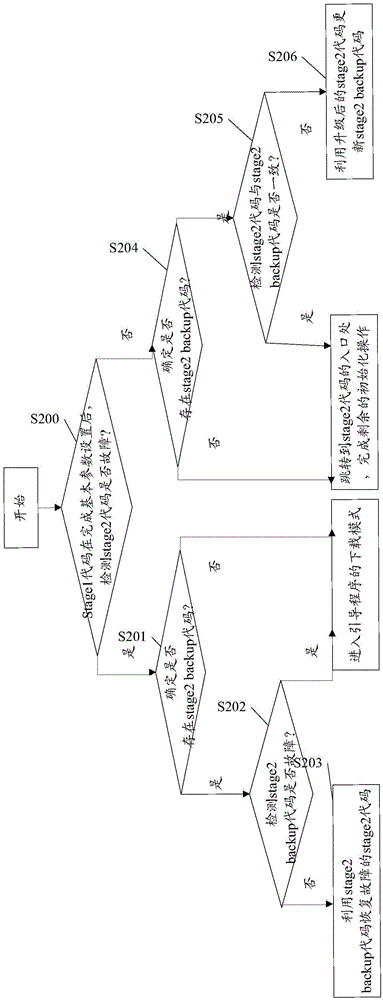

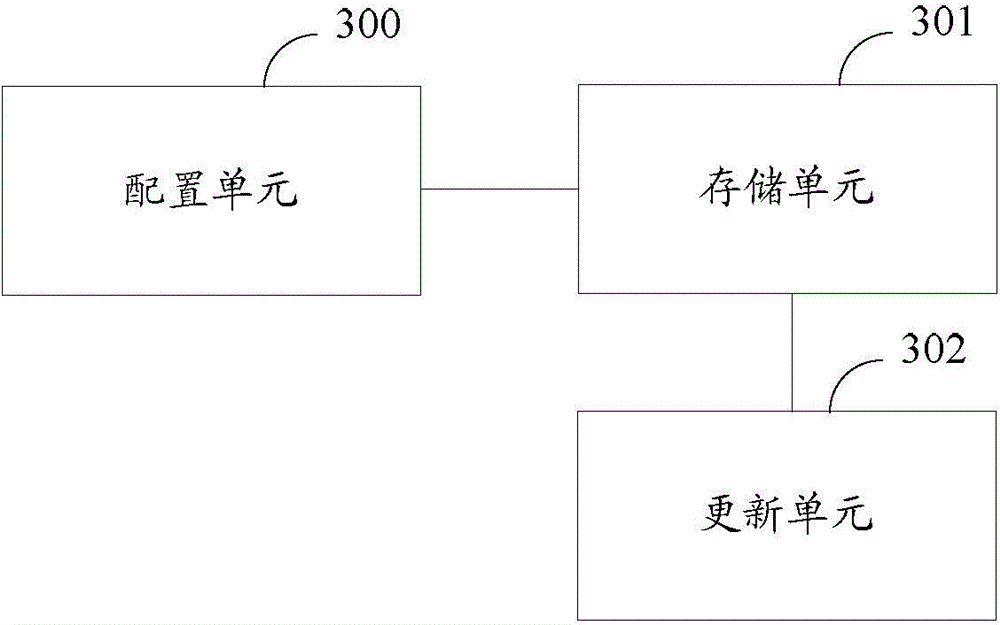

Storage method and fault recovery method for bootstrap program, and devices

InactiveCN105183580AExtended service lifeReduce storage areaInput/output to record carriersProgram loading/initiatingRecovery methodRestoration method

The invention discloses a storage method for bootstrap program. The method comprises: configuring first stage codes and second stage codes of the bootstrap program, wherein the first stage codes are used to complete setting of basic parameters, detect faults of the second stage codes, and execute corresponding operation according to the detection results, and the second stage codes are used to load core to memory and operate the core; storing the first stage codes in a first partition preset in a storage medium, and storing the second stage codes in a second partition preset in the storage medium. The invention also discloses a fault recovery method for the bootstrap program, and a storage device, and an embedded device.

Owner:XIAN ZHONGXING NEW SOFTWARE

Method for improving hydration activity of waste glass powder

The invention discloses a method for improving the hydration activity of waste glass powder. The method comprises the following steps: carrying out cleaning, airing, preliminary crushing and jaw crushing on waste glass having different colors and kinds, collected from salvage stations, and carrying out ball milling by a ball mill for 60-120 min to obtain the waste glass powder; carrying out dry screening, wet screening and a settlement process on the waste glass powder to obtain waste glass powder with the particle size range of 10-75 [mu]m and the particle specific surface area being greater than 400 m<2> / kg; and adding cement and a composite exciter to the waste glass powder, carrying out mixing milling treatment for 30 min, adding water, pouring the obtained mixture into a cement neat paste stirrer, and stirring the mixture for 2-3 min to obtain a composite gelling material. The composite gelling material prepared in the invention is a waste glass recycled product, waste glass has a high utilization rate, wide sources and easiness in obtaining, and the composite gelling material has the advantages of quickness in setting, quickness in hardening, high early stage strength, and great increase of the later strength.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Small hydraulic lifting platform

InactiveCN107265367AIncrease loading capacityImprove the safety of useLifting devicesHydraulic cylinderSurface mounting

The invention discloses a small hydraulic lifting platform, which comprises a body, the body includes a base and a bearing platform, a telescopic rod is fixedly installed on one side of the top of the base, a limit nut is installed on the side end surface of the telescopic rod, and the telescopic A threaded hole is provided at the top of one side of the rod, and the telescopic rod is threadedly connected with a handrail through the threaded hole. A hydraulic cylinder is provided on one side of the telescopic rod, and a hydraulic rod is connected to the output end of the hydraulic cylinder. The middle part of the base There are installation grooves, and the first support rods are movably connected to the inner walls on both sides of the installation grooves. In the present invention, by setting telescopic rods, the side ends of the telescopic rods are provided with limit nuts. When the loading platform is lifted to the highest position, the telescopic rods The length of the telescopic rod makes the top of the telescopic rod against the bottom of the bearing platform, which effectively improves the load-bearing capacity of the bearing platform; the safety of the bearing platform is improved by installing a guardrail and a movable door on the bearing platform.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com